Group control device and method for multi-robot welding system

A welding system and multi-robot technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as low efficiency, and achieve the effects of strong scalability, good fault protection and processing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

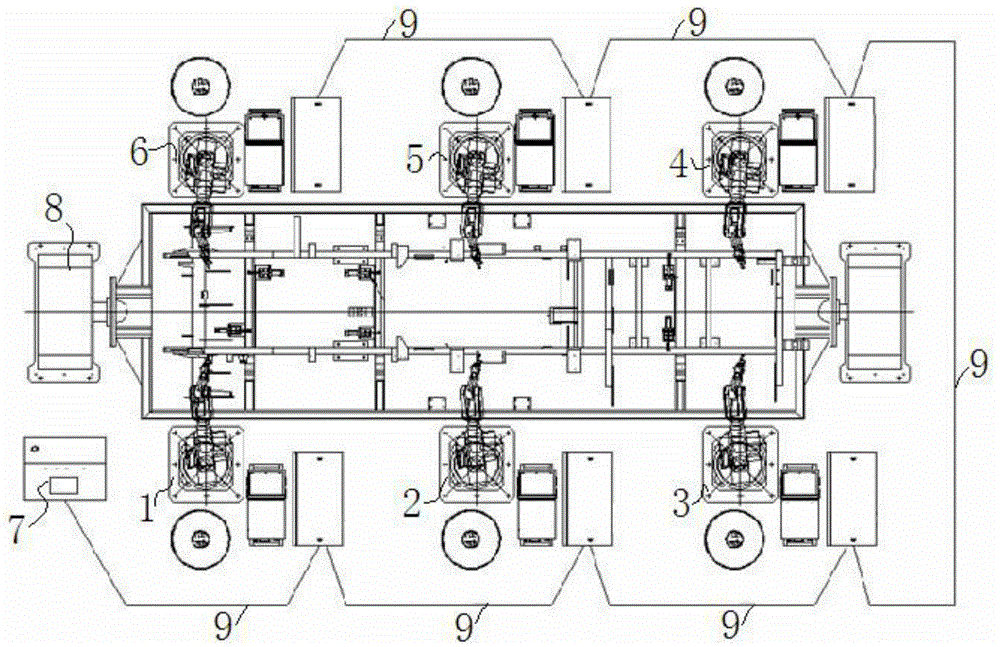

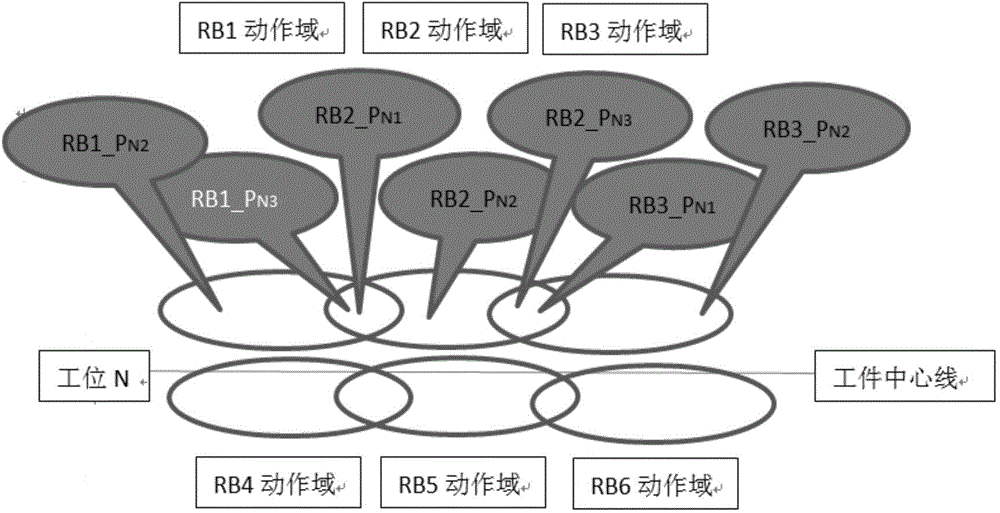

[0025] In a multi-robot welding group control system, such as figure 1 As shown, the PLC electric control cabinet 7 is equipped with a CC-LINK (control and communication link system) master station control module, 6 multifunctional welding robots are distributed on both sides of the workpiece support frame, and the robot control cabinets are equipped with CC-LINK LINK communication card, the master station and each slave station are connected in series according to the figure through the special cable 9 of CC-LINK. The station number of the master station is 0, and the station numbers of each slave station are 1, 5, 9, 13, 17, 21, set the master station and the slave station to have the same communication baud rate, establish a complete CC-LINK link network, and turn on the power to automatically realize the data link. The CC-LINK network is easy to expand. If you nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com