Patents

Literature

1248 results about "Robot welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Robot welding is the use of mechanized programmable tools (robots), which completely automate a welding process by both performing the weld and handling the part. Processes such as gas metal arc welding, while often automated, are not necessarily equivalent to robot welding, since a human operator sometimes prepares the materials to be welded. Robot welding is commonly used for resistance spot welding and arc welding in high production applications, such as the automotive industry.

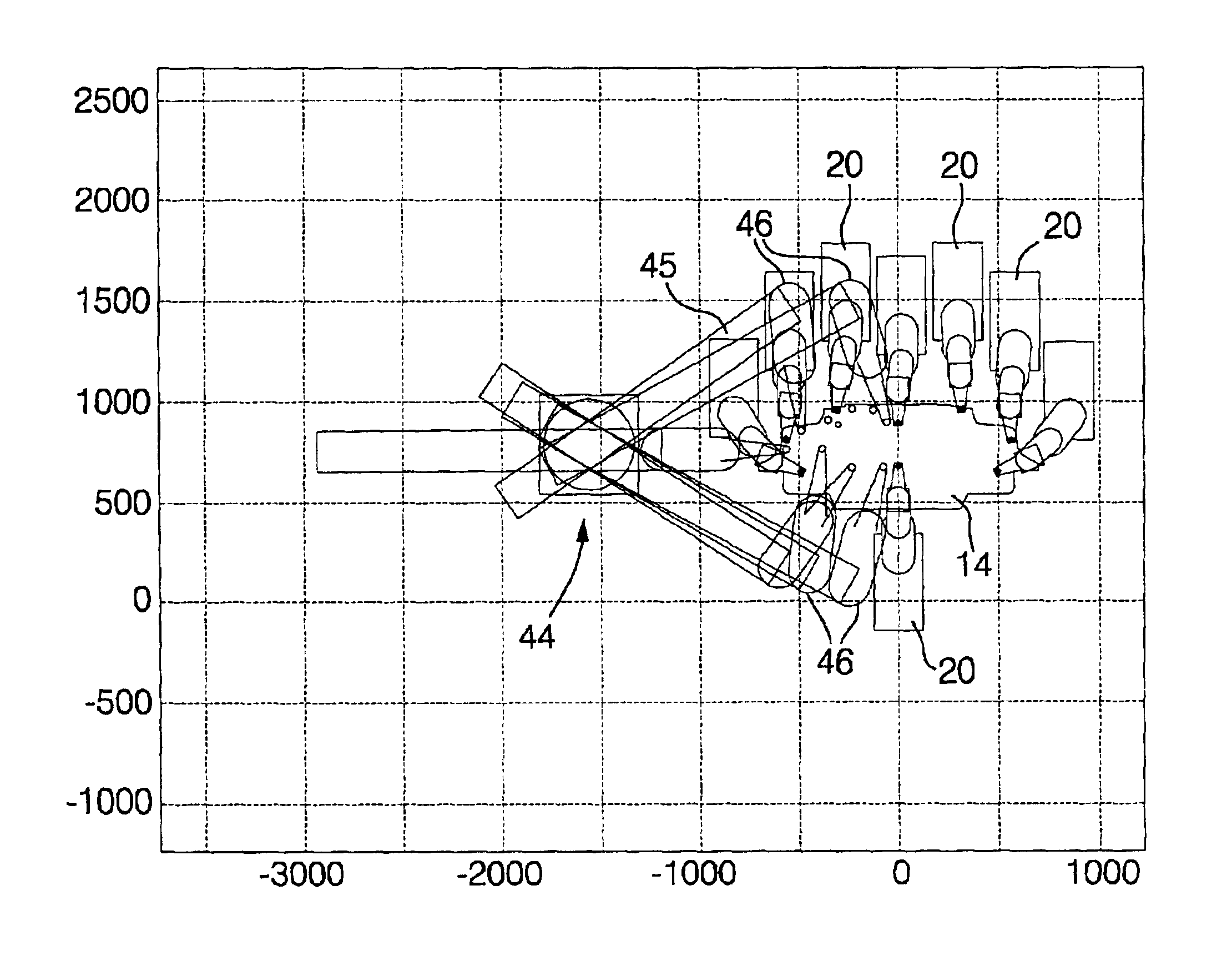

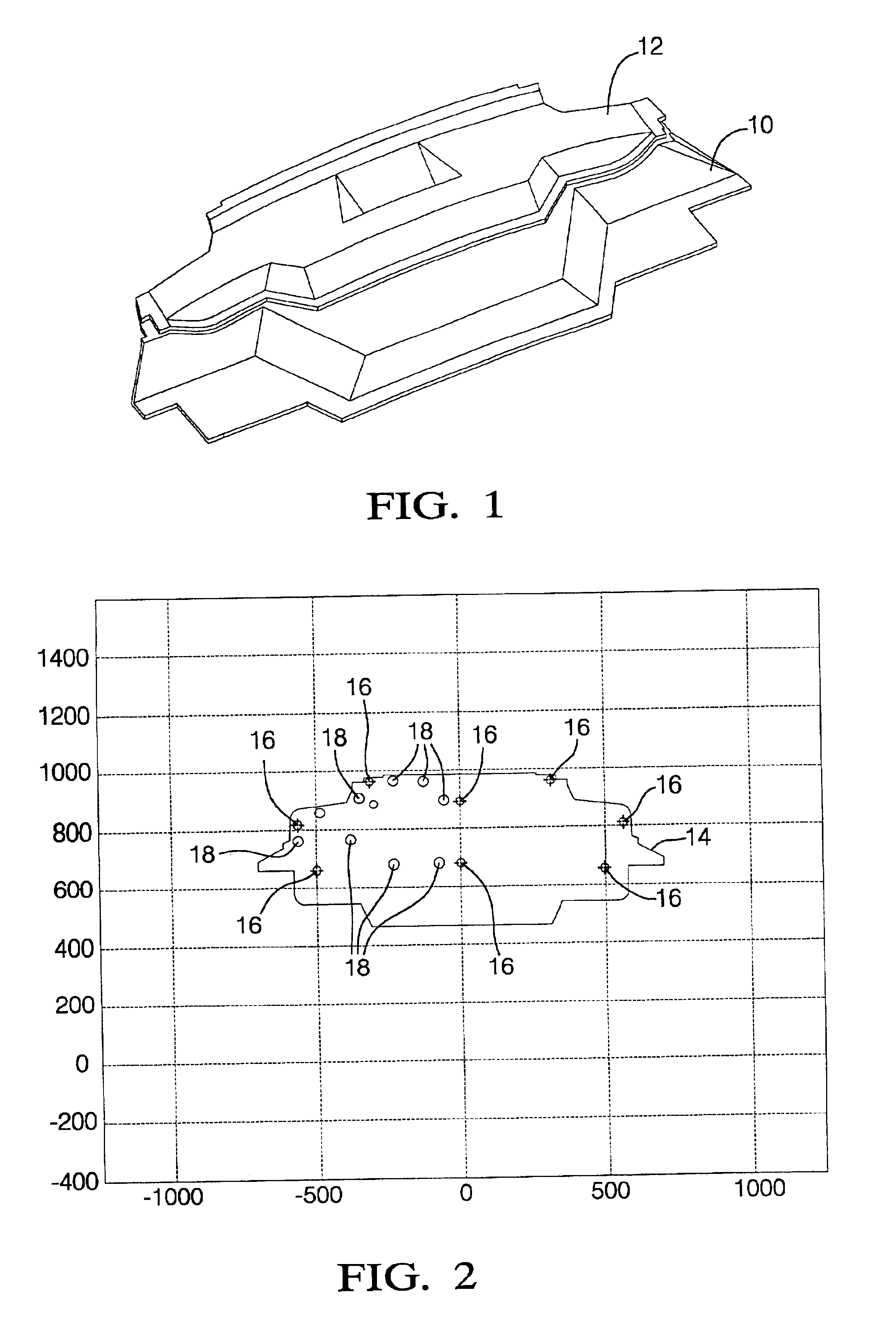

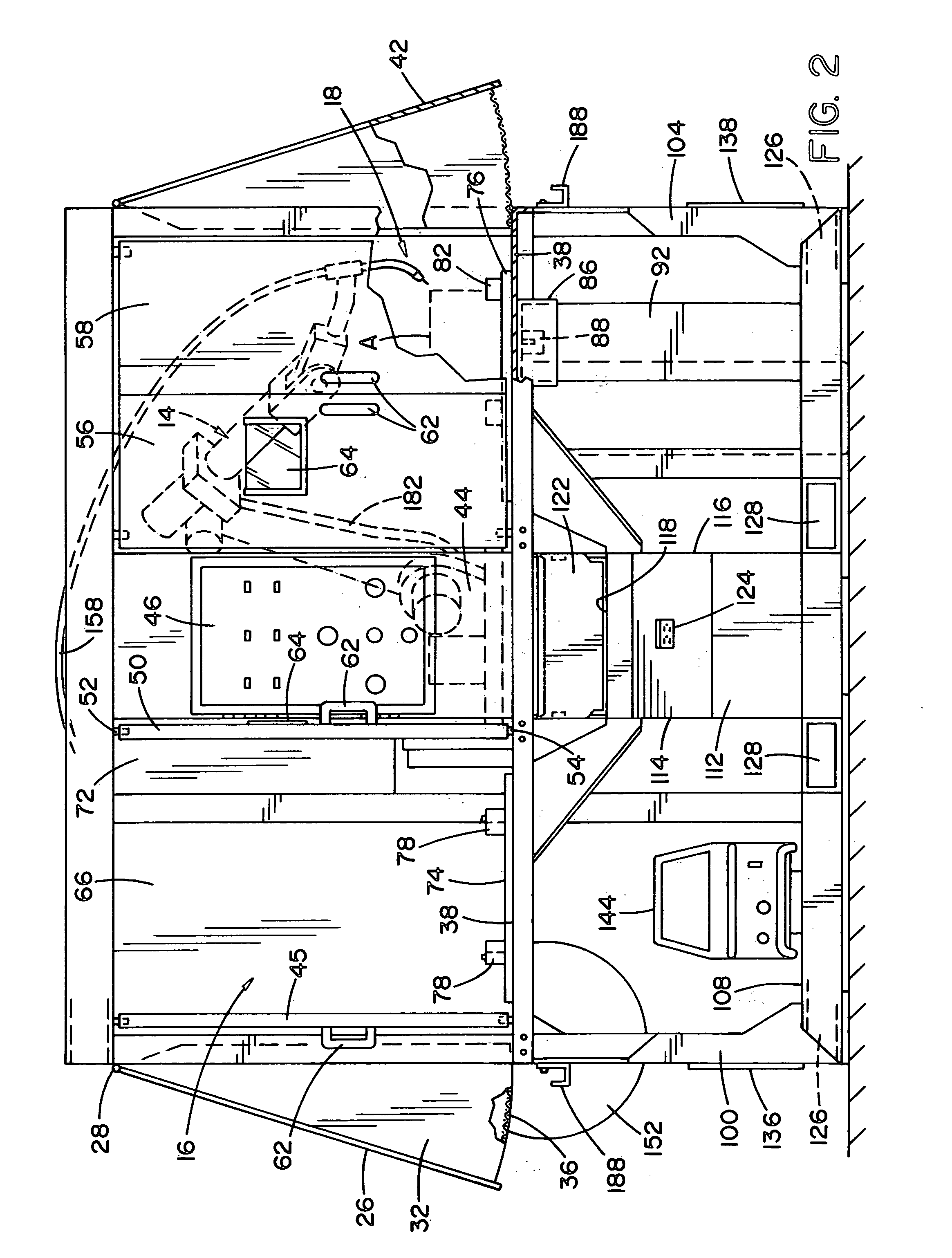

Method for computer-aided layout of manufacturing cells

A computer assisted method is disclosed for making an optimized layout of a manufacturing cell to be used, for example, to locate, hold and process workpieces, such as in robotic welding of an assembly of stamped sheet metal parts. The items to be processed and employed in the cell are identified by physical structure and kinematic characteristics and given an initial location to start the process. Further movements of the parts toward attraction points and away from repelling points are evaluated on the computer by an optimization program to arrive at an optimized cell layout.

Owner:GM GLOBAL TECH OPERATIONS LLC

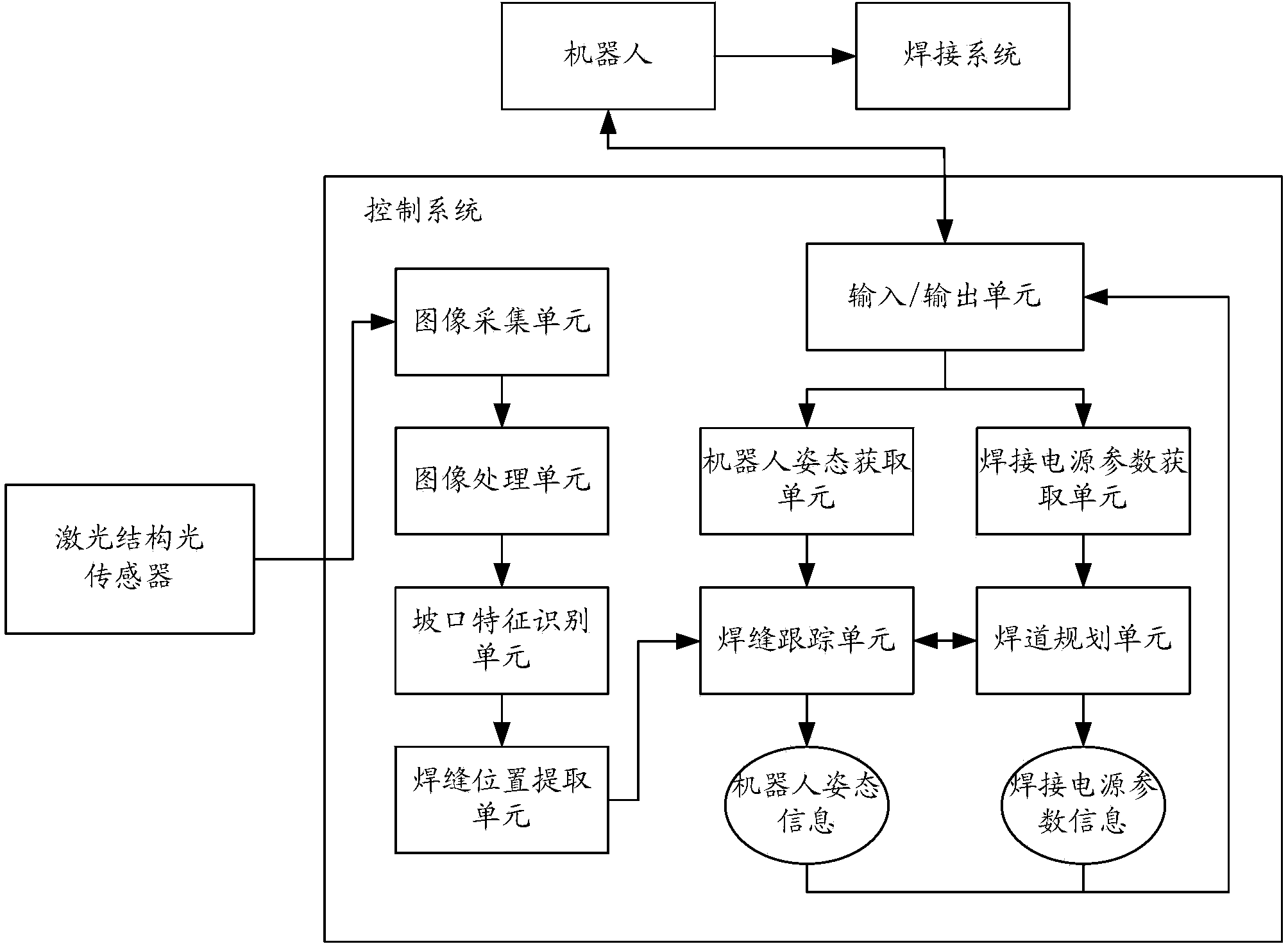

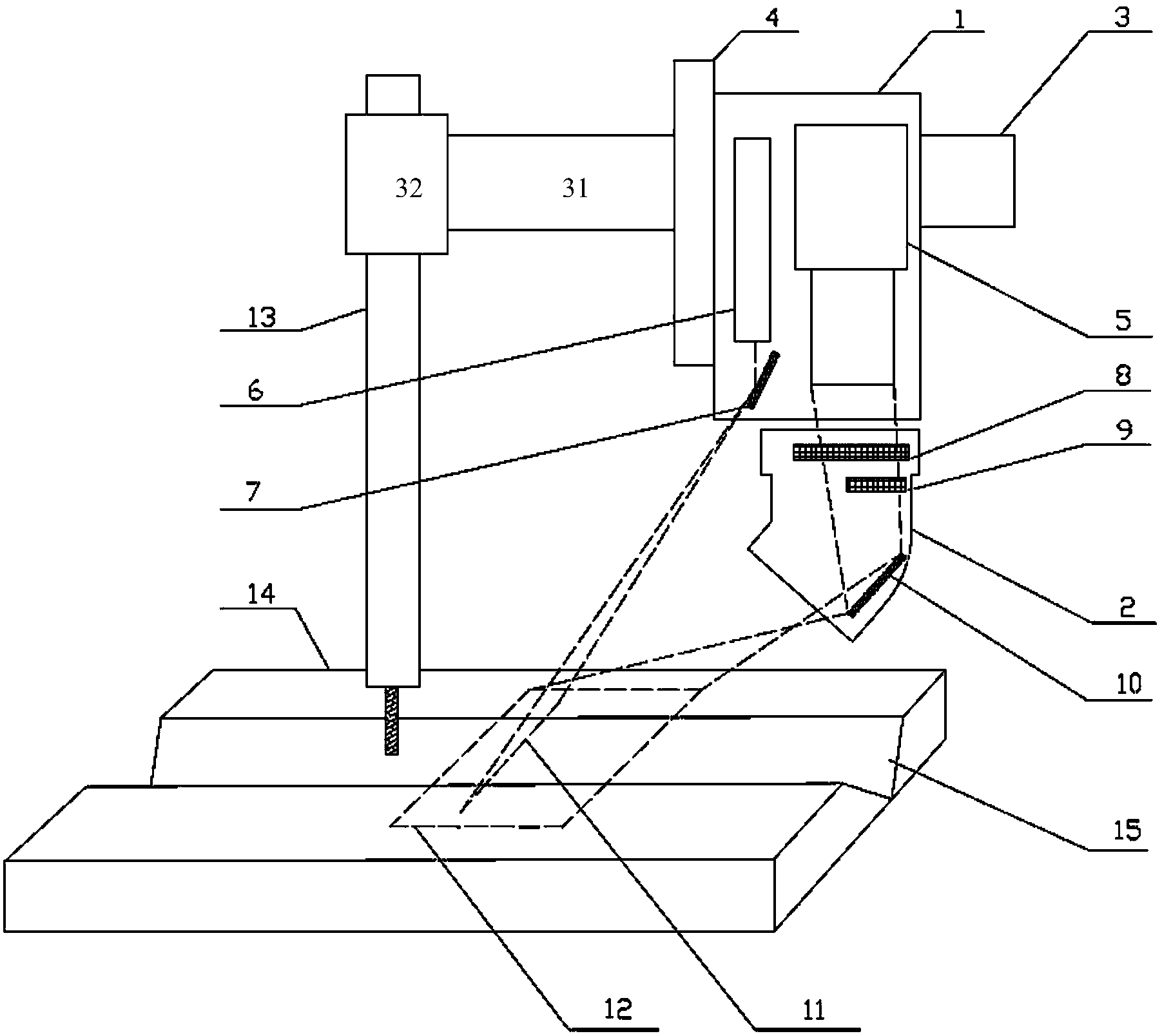

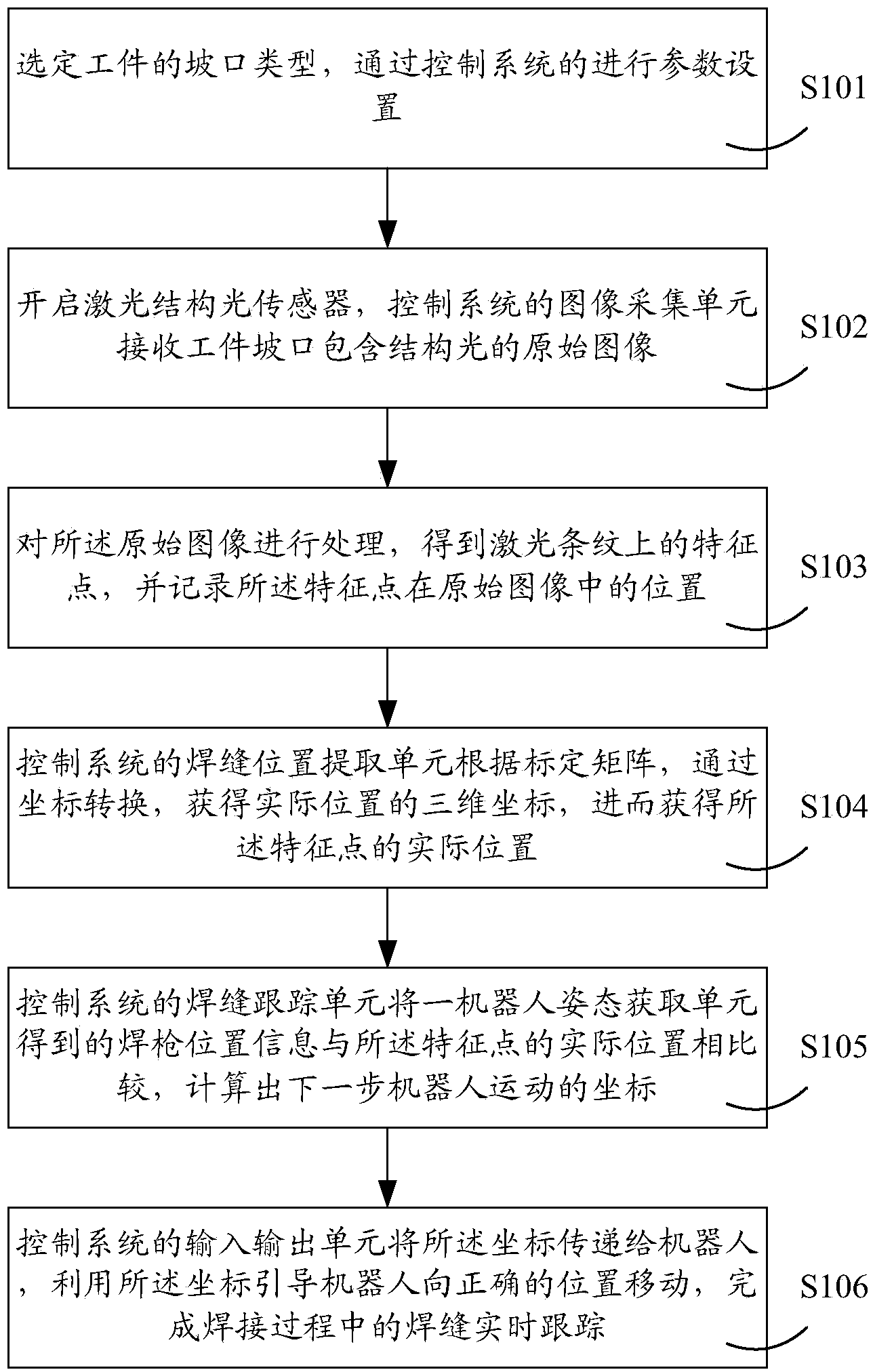

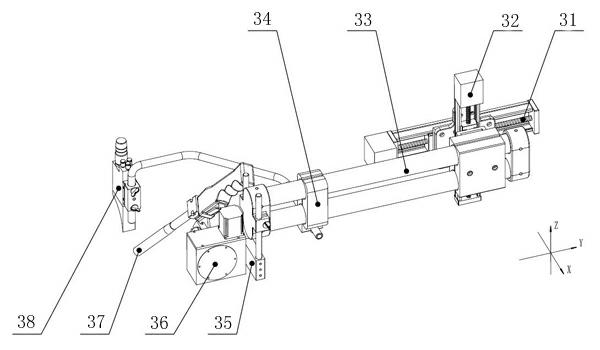

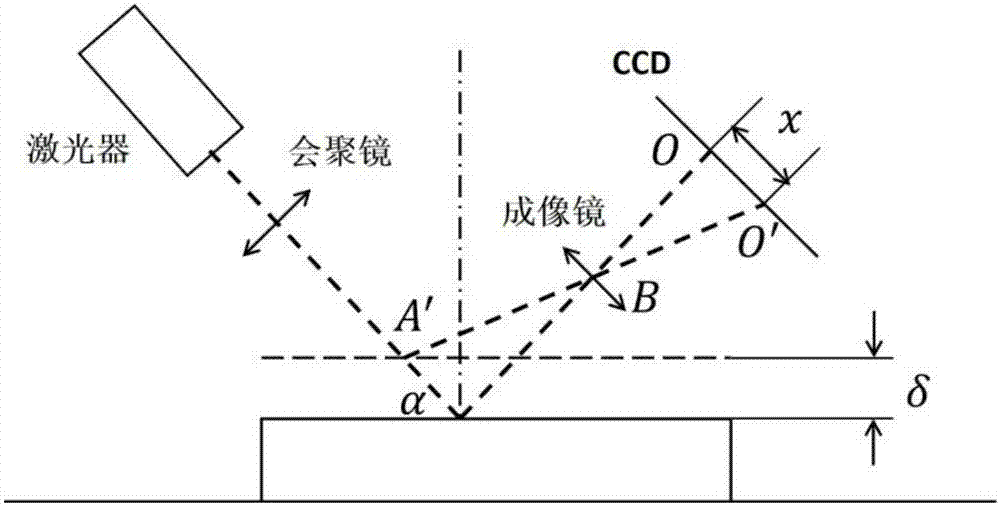

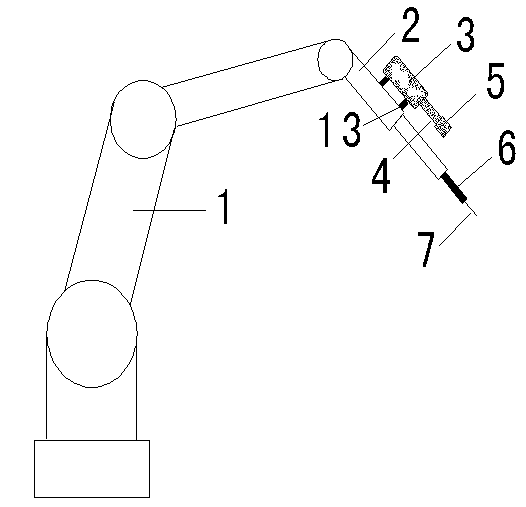

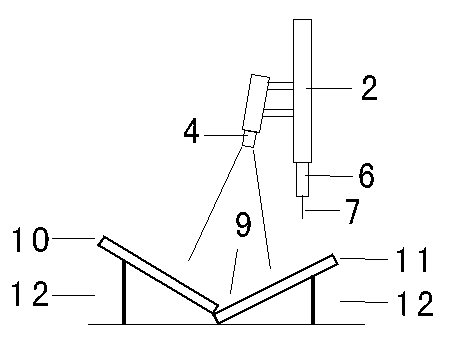

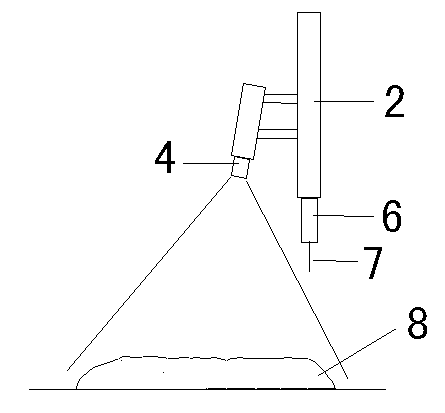

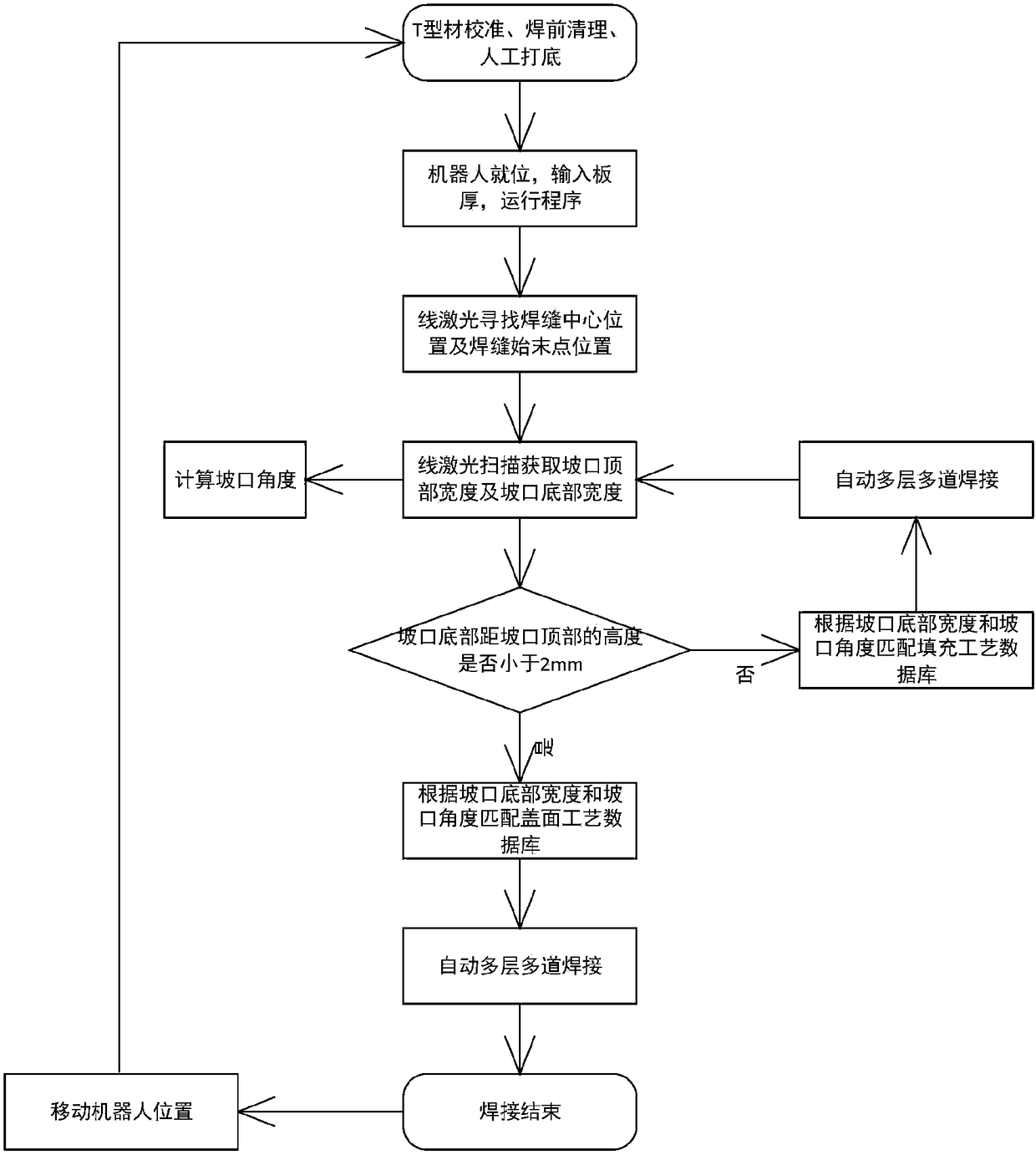

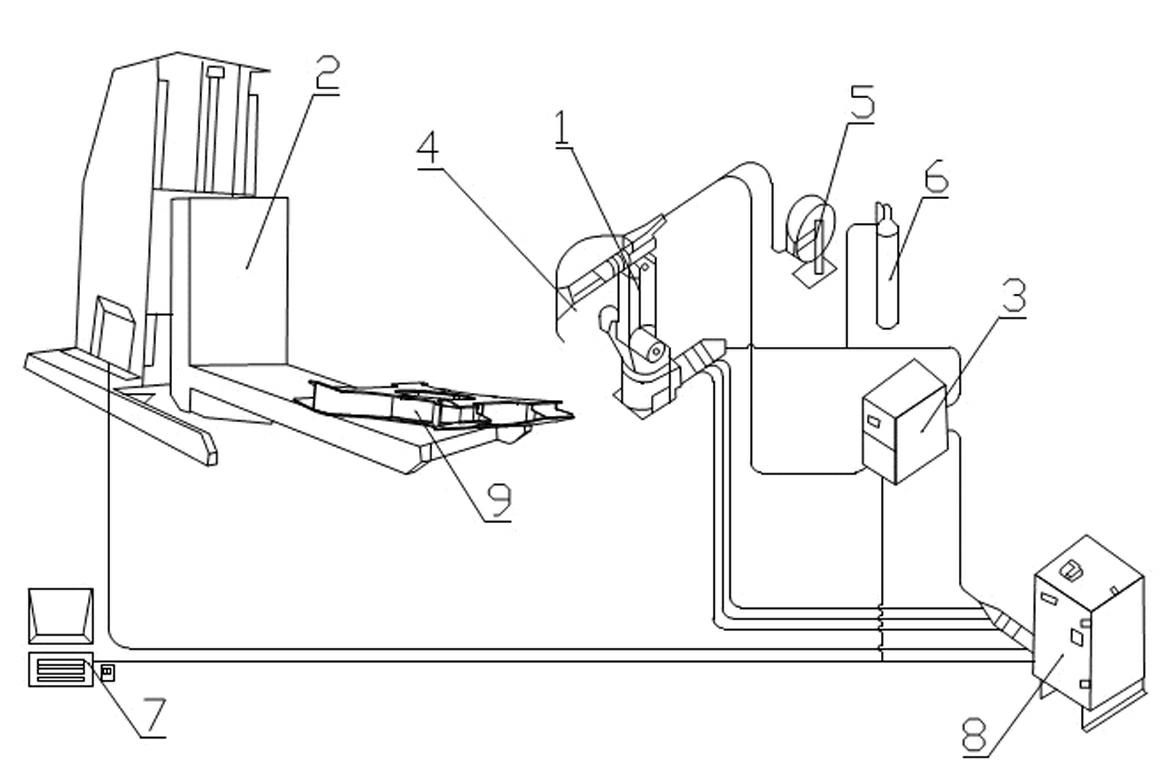

Thick plate robot welding system and multilayer multiple-pass weld real-time tracking and planning method

InactiveCN103934571AEnable real-time planningImprove flexibilityWelding/cutting auxillary devicesArc welding apparatusThick plateControl system

The invention discloses a thick plate robot welding system and a multilayer multiple-pass weld real-time tracking and planning method. The thick plate robot welding system comprises a robot, a laser structure optical sensor, a welding system and a control system. The laser structure optical sensor comprises a main system, an optical system, a clamping system and a cooling system. In the welding process, images containing weld groove feature information can be obtained in real time and transmitted to the control system; the control system obtains the groove information from the images and controls the robot to constantly correct the position of a welding gun in the welding system; meanwhile, the control system adjusts a weld pass track and welding parameters so that multilayer multiple-pass real-time planning can be achieved, and labor efficiency and production quality can be improved.

Owner:SHANGHAI JIAO TONG UNIV +1

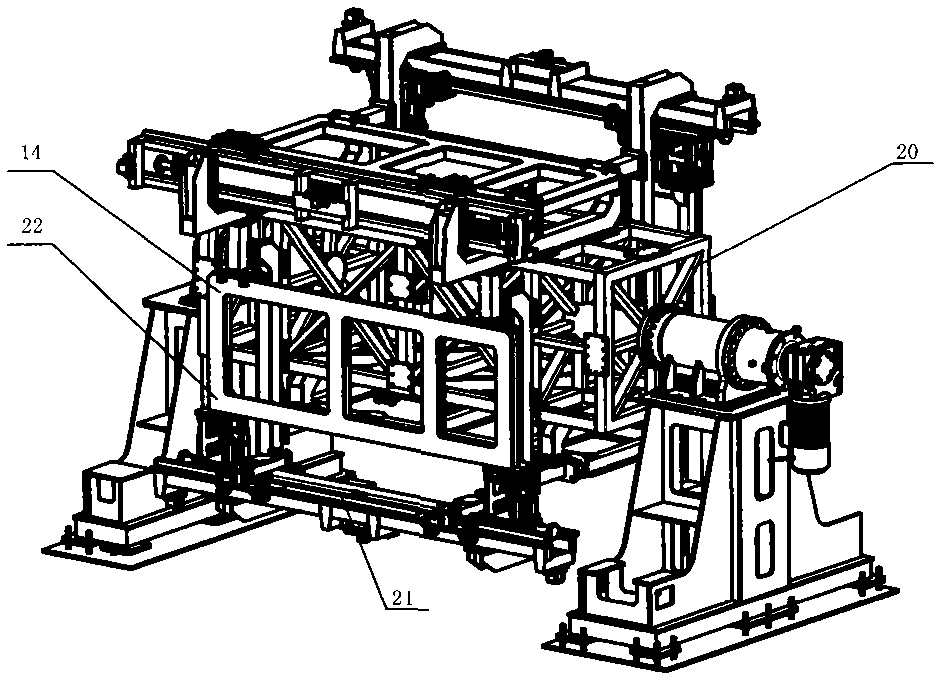

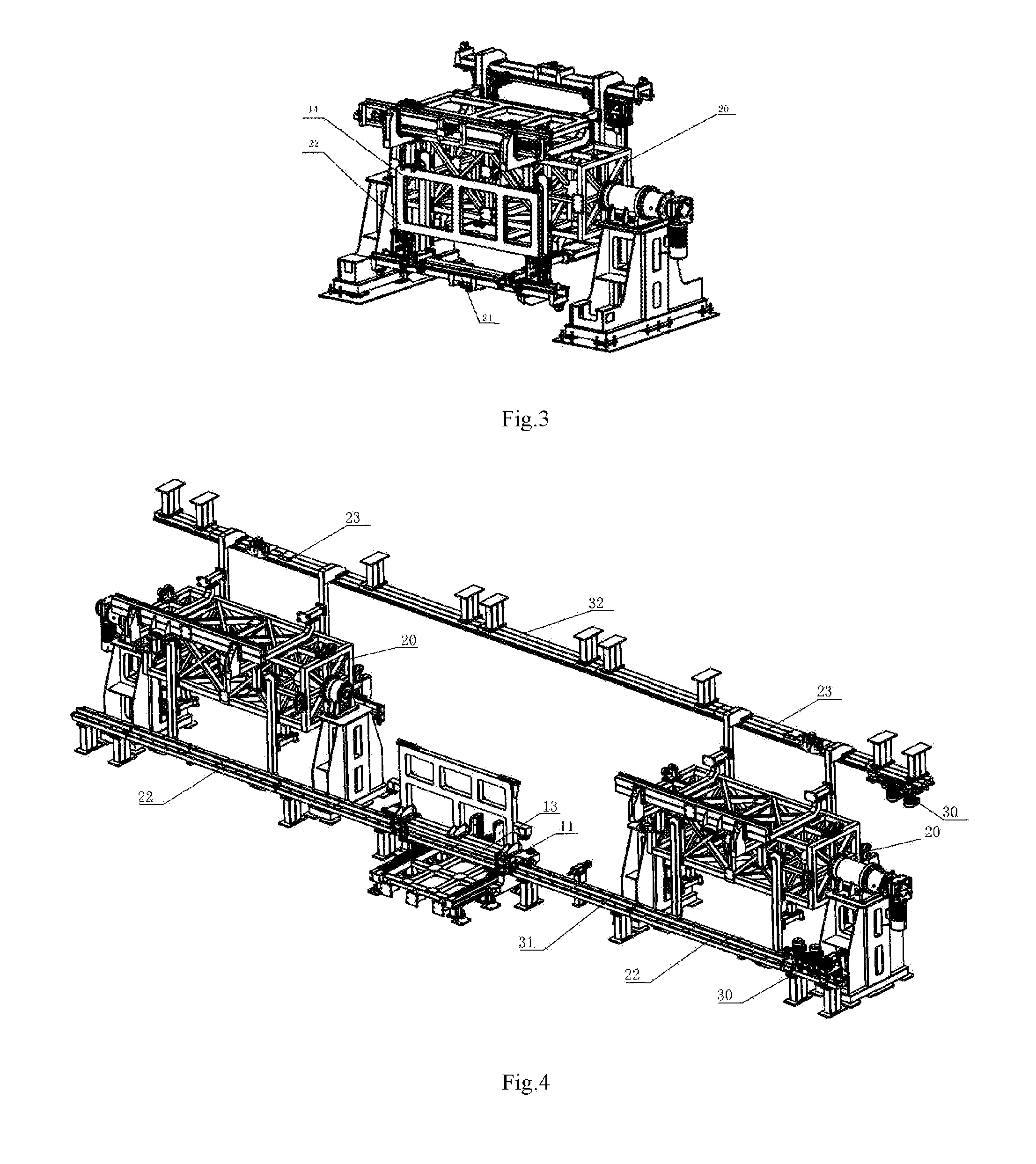

Collinear flexible head splicer suitable for multiple vehicle types

ActiveCN102837138ASmall footprintIncrease the number ofWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSmall footprint

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD

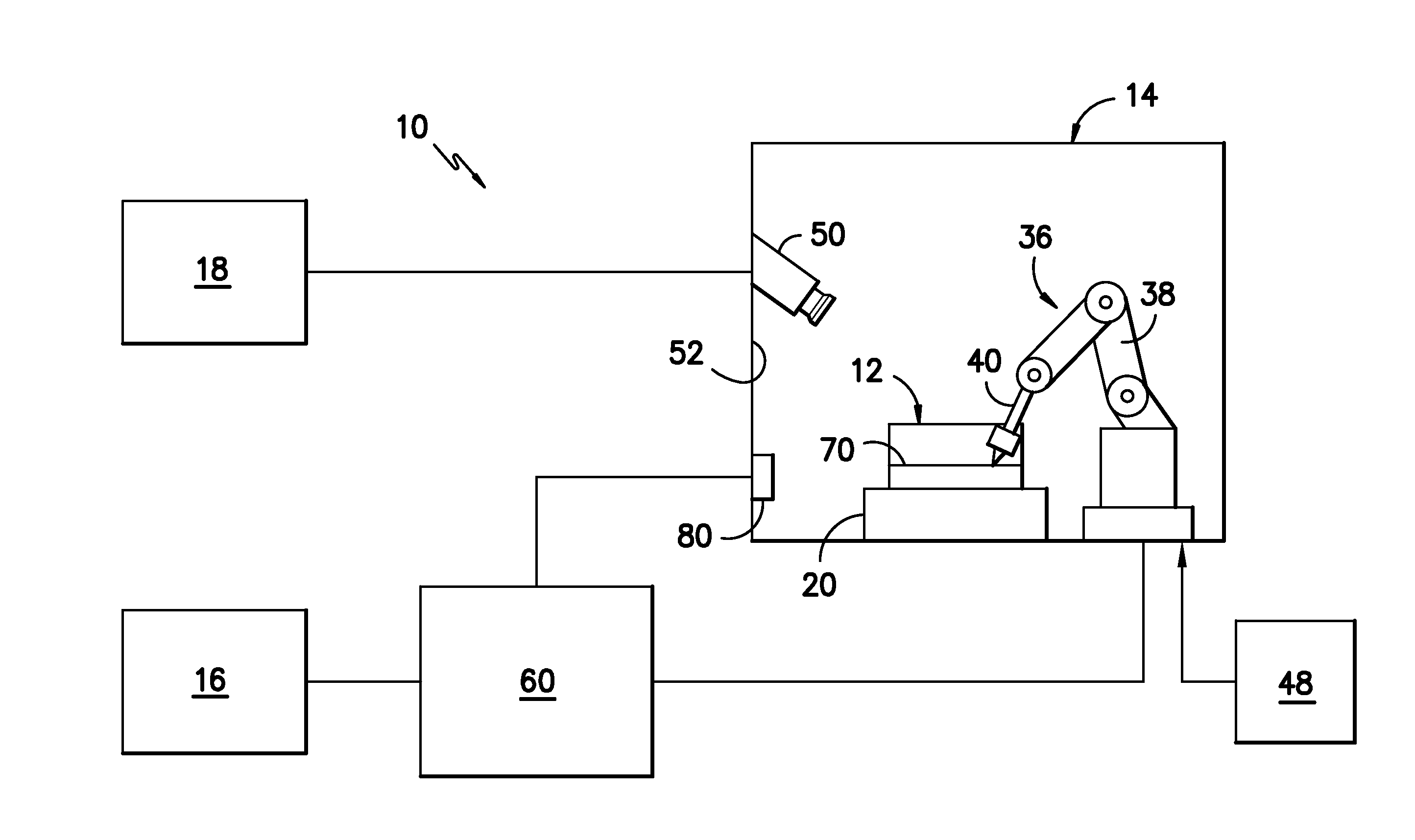

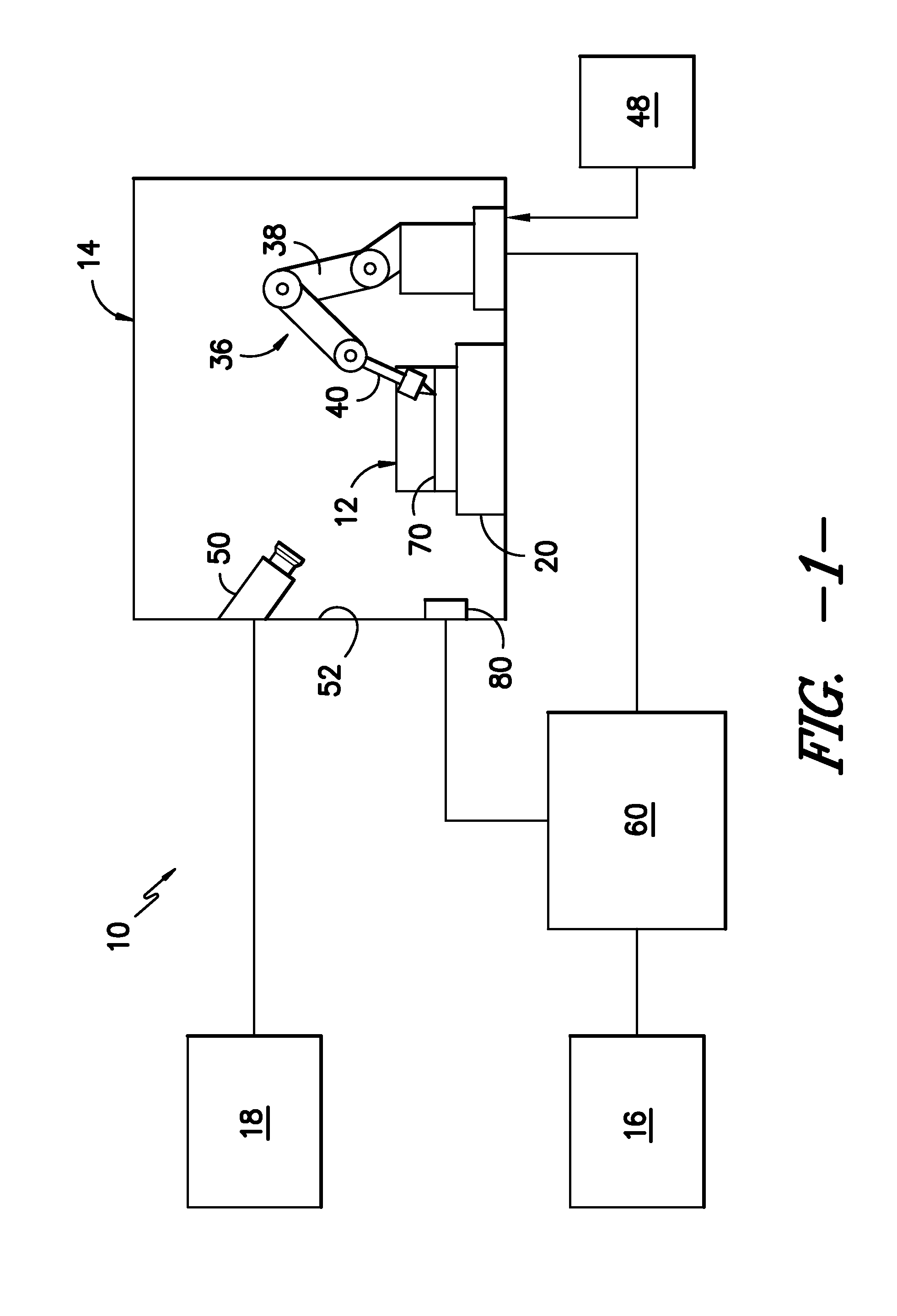

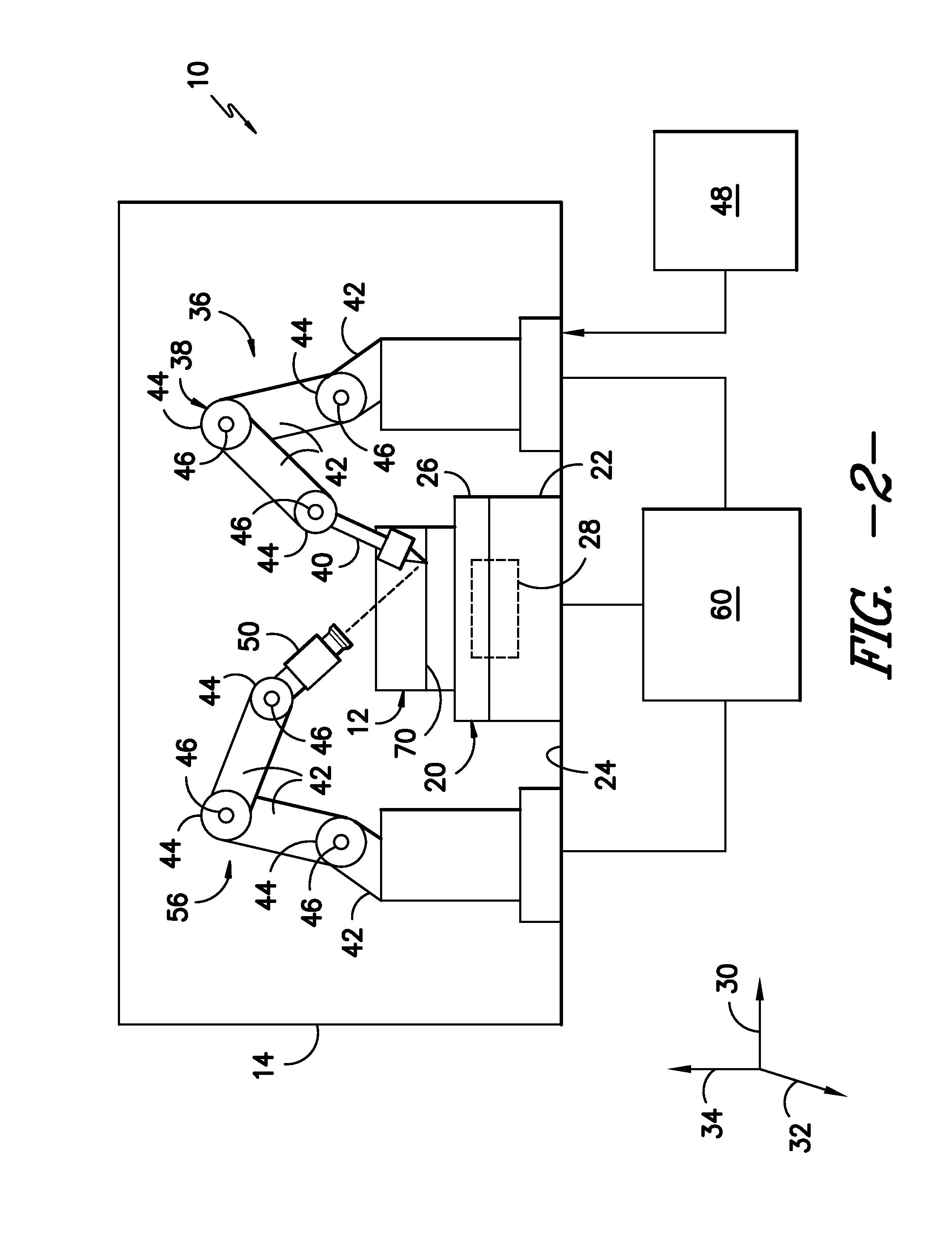

System and method for performing remote welding operations on an apparatus

A system for performing remote welding operations on an apparatus is disclosed. The system may generally include a welding chamber configured to house the apparatus and a robotic welder positioned within the welding chamber. The robotic welder may be configured to perform an actual welding operation on the apparatus. In addition, the system may include a welding simulation device positioned outside the welding chamber and a controller communicatively coupled to the robotic welder and the welding simulation device. The welding simulation device may be configured to perform a simulated welding operation corresponding to the actual welding operation. The controller may be configured to track the movement of the welding simulation device and control the operation of the robotic welder based on the movements of the welding simulation device.

Owner:GENERAL ELECTRIC CO

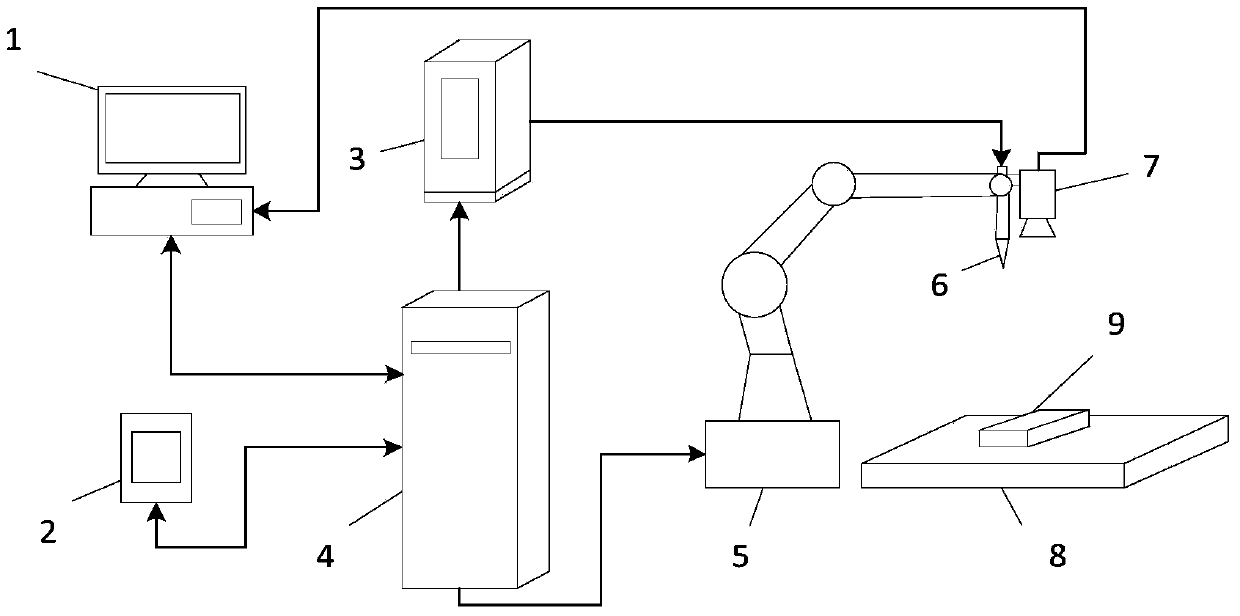

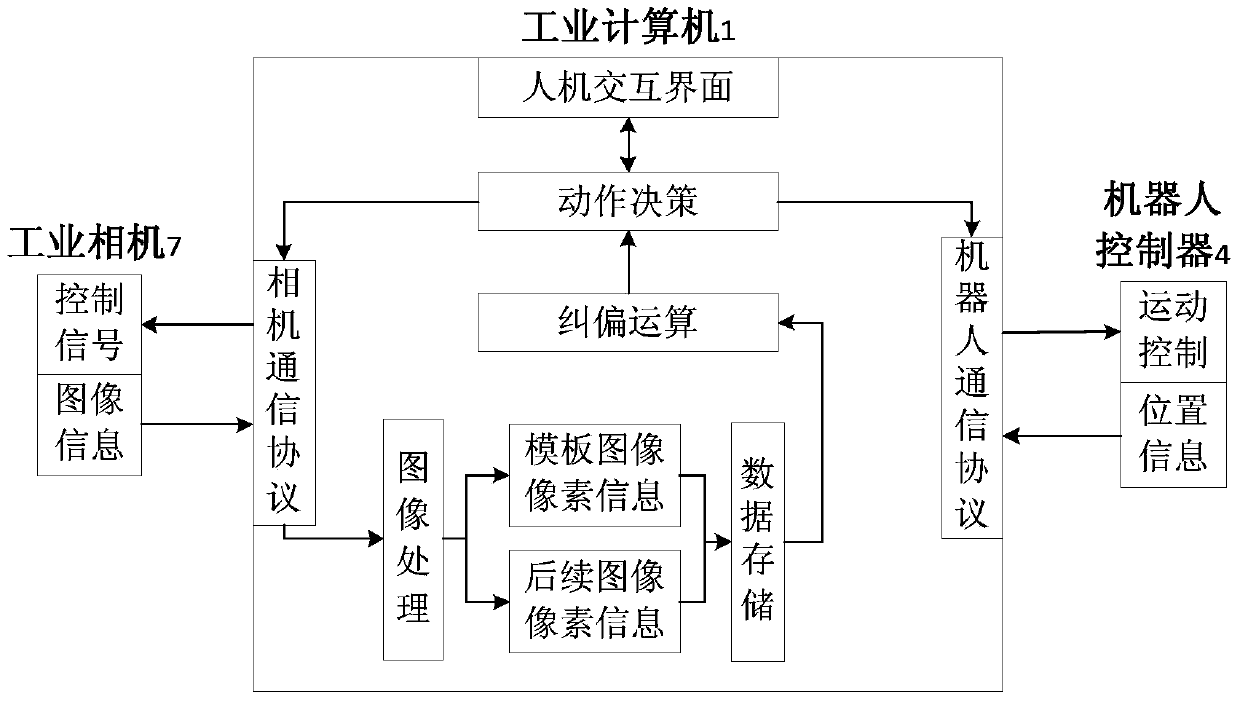

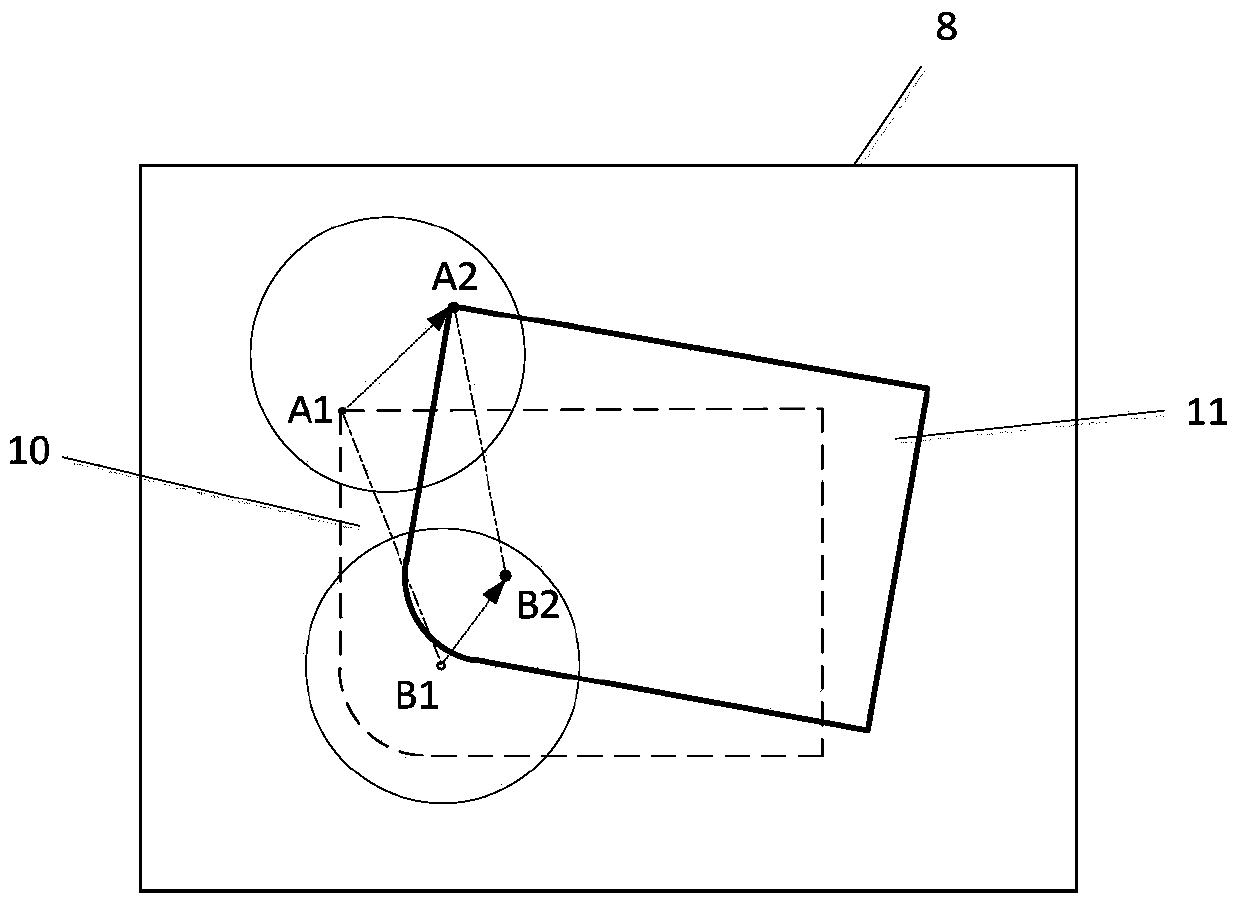

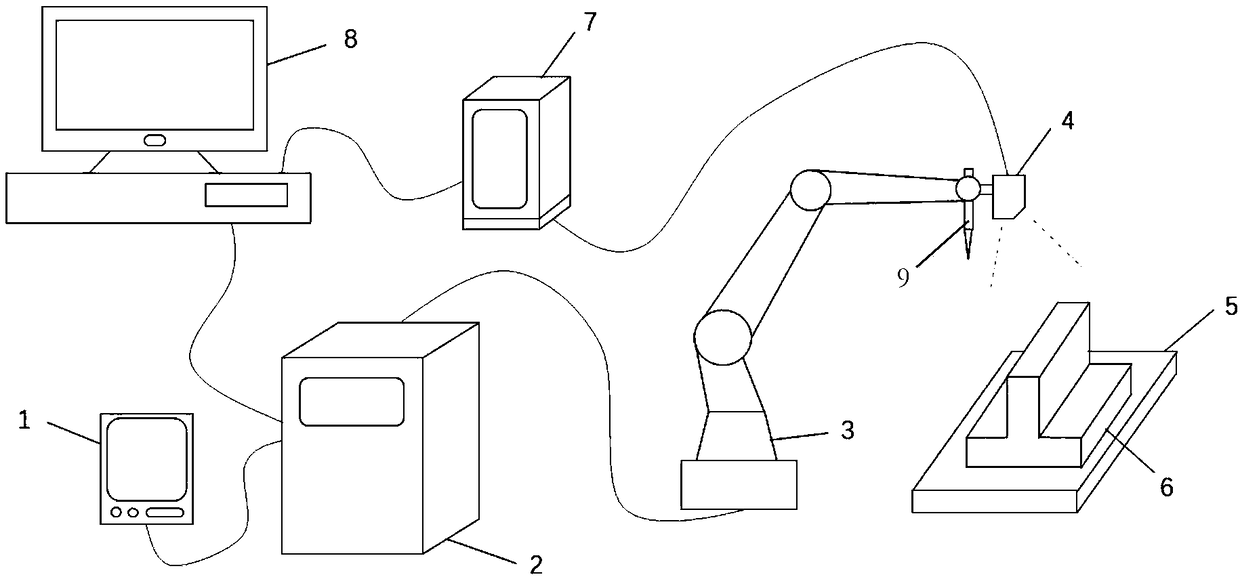

Welding robot with automatic correction function and welding method employing same

InactiveCN104175031AReduce labor intensityMaster quicklyWelding/cutting auxillary devicesAuxillary welding devicesImaging processingWelding power supply

The invention belongs to the field of welding and relates to a welding robot with an automatic correction function and a welding method employing the same. An industrial computer is connected with both a robot controller and an industrial camera; the robot controller is connected with a robot and a welding power supply; the welding power supply is connected with a welding torch; the industrial camera and the welding torch are fixed at the tail end of an arm of the robot; a shooting plane of the industrial camera is perpendicular to the welding torch; a work platform is arranged correspondingly. The method includes the steps: the robot is started to demonstrate a template workpiece, shooting is performed in two characteristic regions to determine a spatial position of the workpiece, the industrial camera transmits images of the characteristic regions to the industrial computer, the robot automatically corrects a deviation of an original demonstration path through an image processing technique and software algorithms. The welding robot is simple to operate and widely applicable; by the application of the welding robot in batch welding operations, repeated demonstrations can be effectively avoided, and work efficiency is improved.

Owner:BEIJING UNIV OF TECH

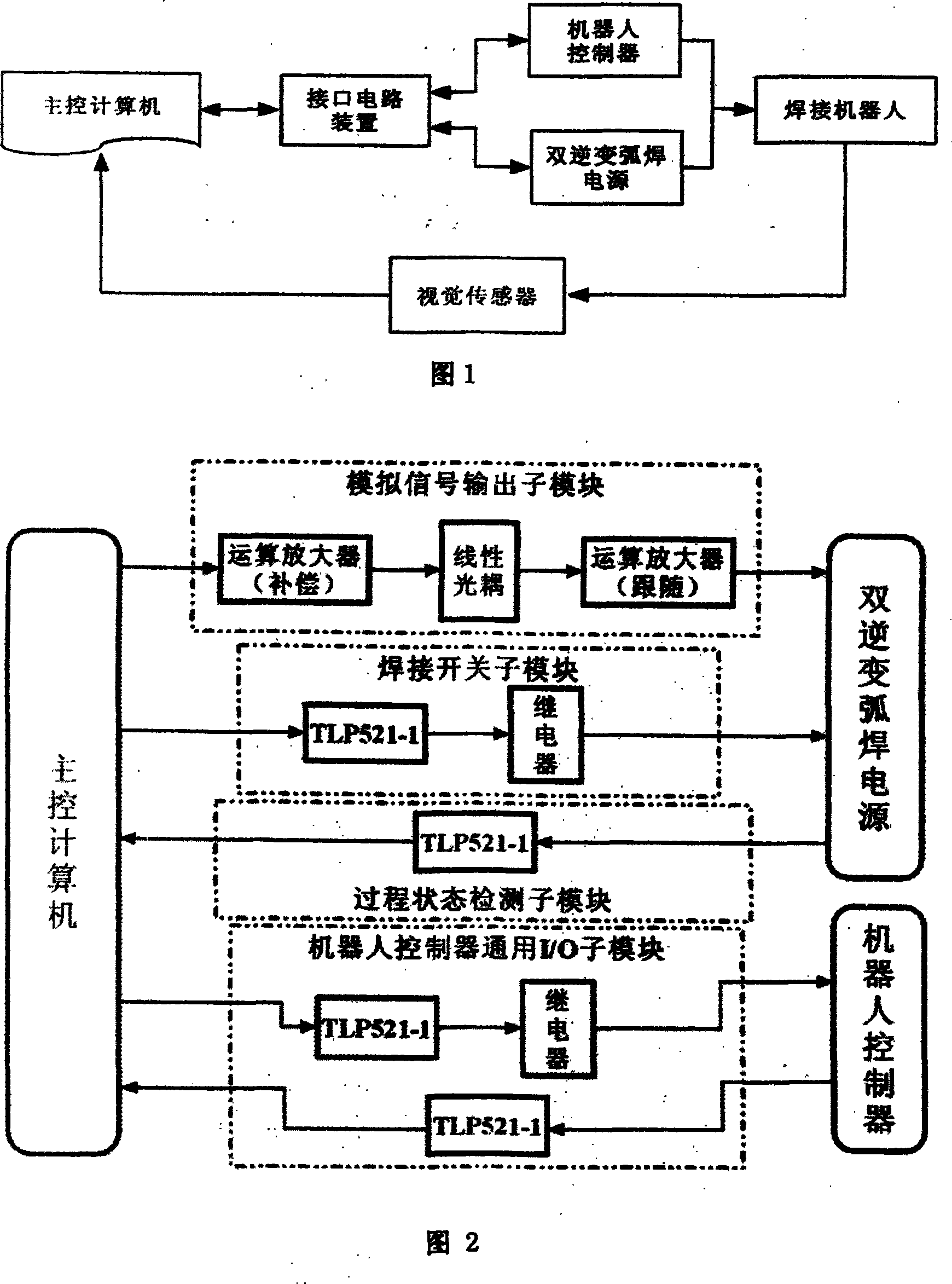

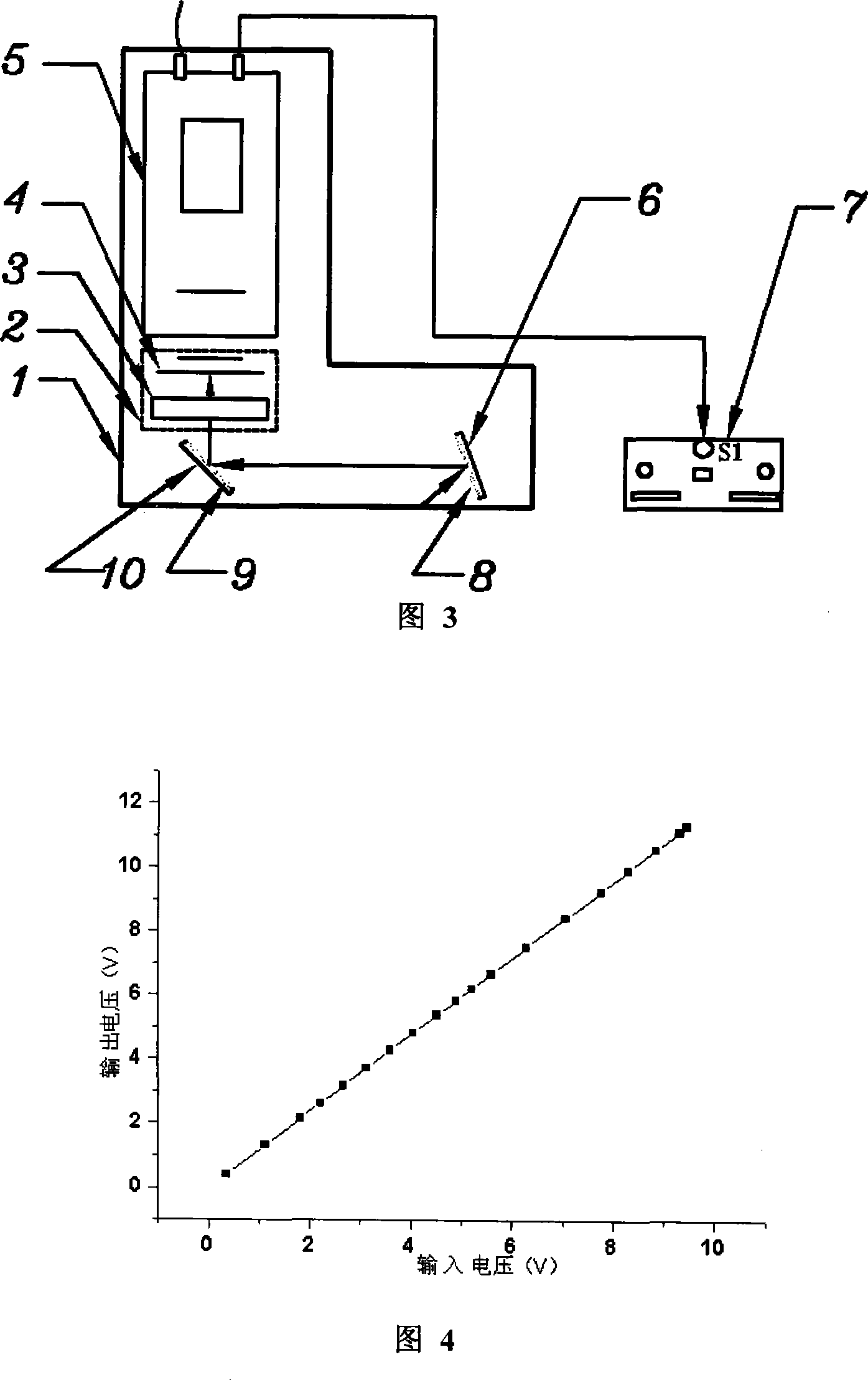

Arc welding robot jointing monitoring system based vision sensing

InactiveCN101224519AMeet local intelligence requirementsFlexible controlArc welding apparatusProgramme total factory controlSimulationVision sensor

The invention provides an arc welding robot welding monitoring system which is based on visual sensing in the arc welding robot technical field. The invention comprises a welding robot, a robot controller, a visual sensing system, an interface circuit device, a main control computer, and a dual inverter arc welding power source; wherein, the visual sensing system dynamically collects the images of a welding pool and transmits the images to the main control computer which receives the image information which is provided by the visual sensor and achieves the image processing; furthermore, the main control computer adjusts the dual inverter arc welding power source and controls the welding robot through the interface circuit device according to the processing results; the interface circuit device consists of a simulation signal output sub-module, a welding switch and process state detection sub-module and a robot controller general I / O sub-module; the welding robot receives a moving instruction signal which is emitted by the main control computer, and the welding is achieved by moving a welding gun. The invention improves the monitoring capability of the user to the welding process of the arc welding robot, and widens the application range of the robots in the welding automation field.

Owner:SHANGHAI JIAO TONG UNIV +1

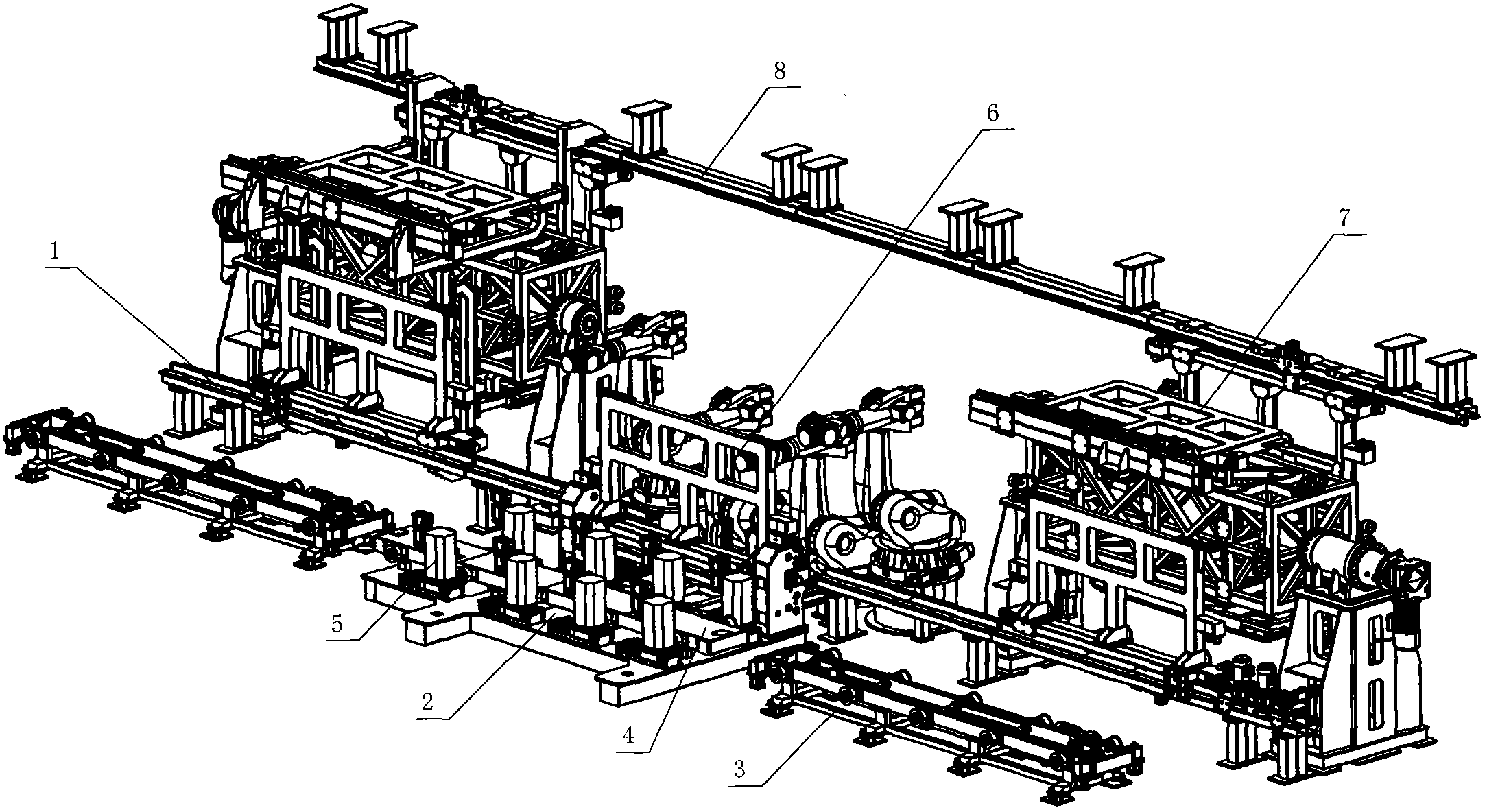

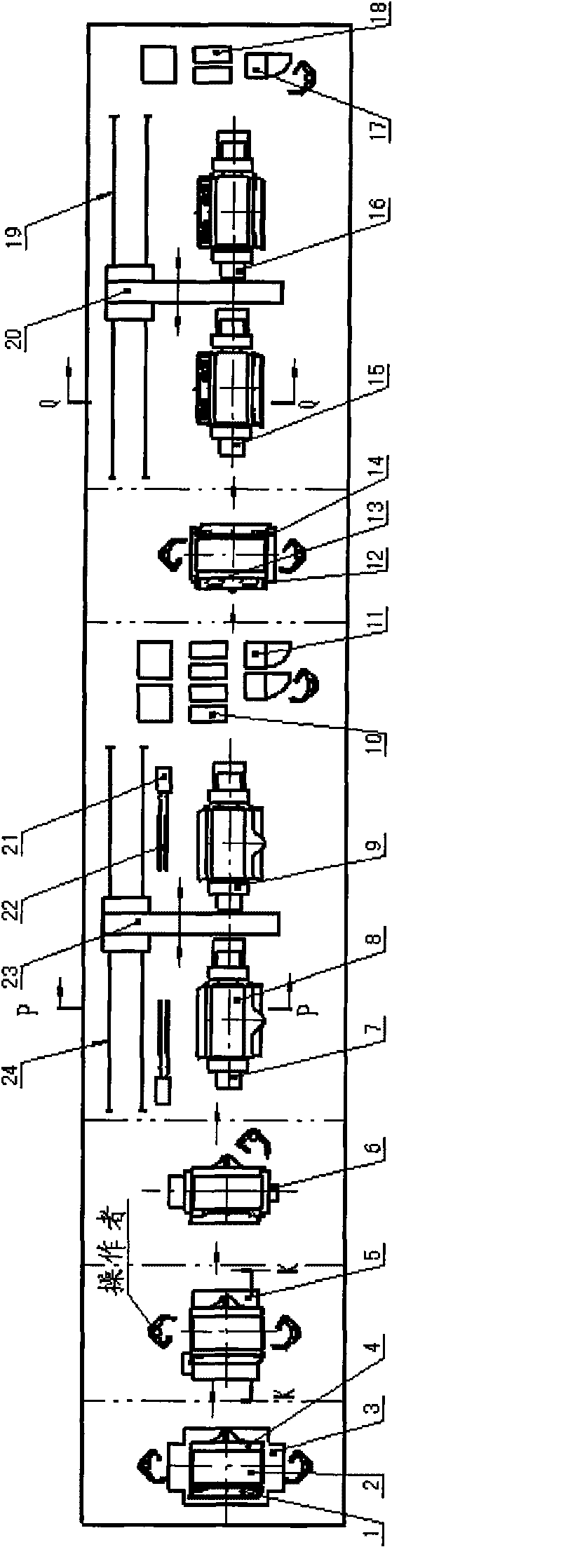

Robot automatic welding production line of middle groove and technological method thereof

ActiveCN101722373AImprove welding qualityEfficient automatic weldingWelding/cutting auxillary devicesArc welding apparatusProduction lineManufacturing technology

The invention relates to the technical field of production manufacturing of a cast middle groove by a heavy-duty scraper conveyor used on coal mines, and provides a robot automatic welding production line of a middle groove and a technological method thereof. The production line designs 8 stations according to the manufacturing process flow of the middle groove, comprises 6 parts of a primary assembly station, a middle plate preheating station, a backing welding station, a middle plate and bottom plate robot welding work station, a secondary assembly station and a bending rail rest robot welding work station, and forms an integrated production line layout of the middle groove. The invention integrates and uses multiple technologies of a welding robot, double-wire welding, digital double-pulse welding power source, computer control, high-efficiency flame preheating and the like, and establishes technical measures of preheating temperature, bevel form, welding sequence, welding parameters and the like; and the welding process is controlled by a computer, thereby realizing high-efficiency automatic robot welding of the middle groove in the overall process. Compared with the traditional manual gas shielded welding, the invention obviously improves the welding quality of the middle groove and increases the welding efficiency by 3-4 times.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

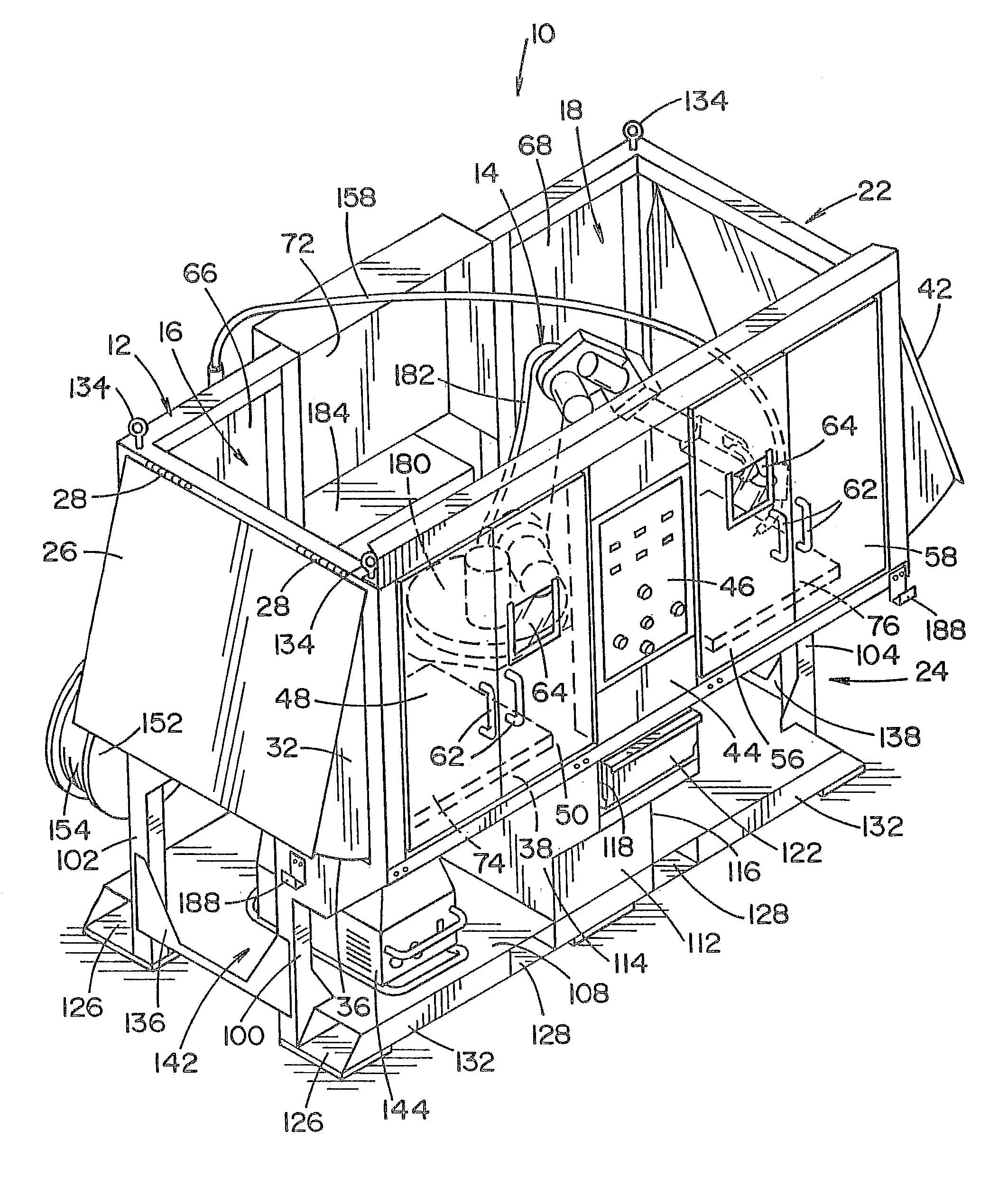

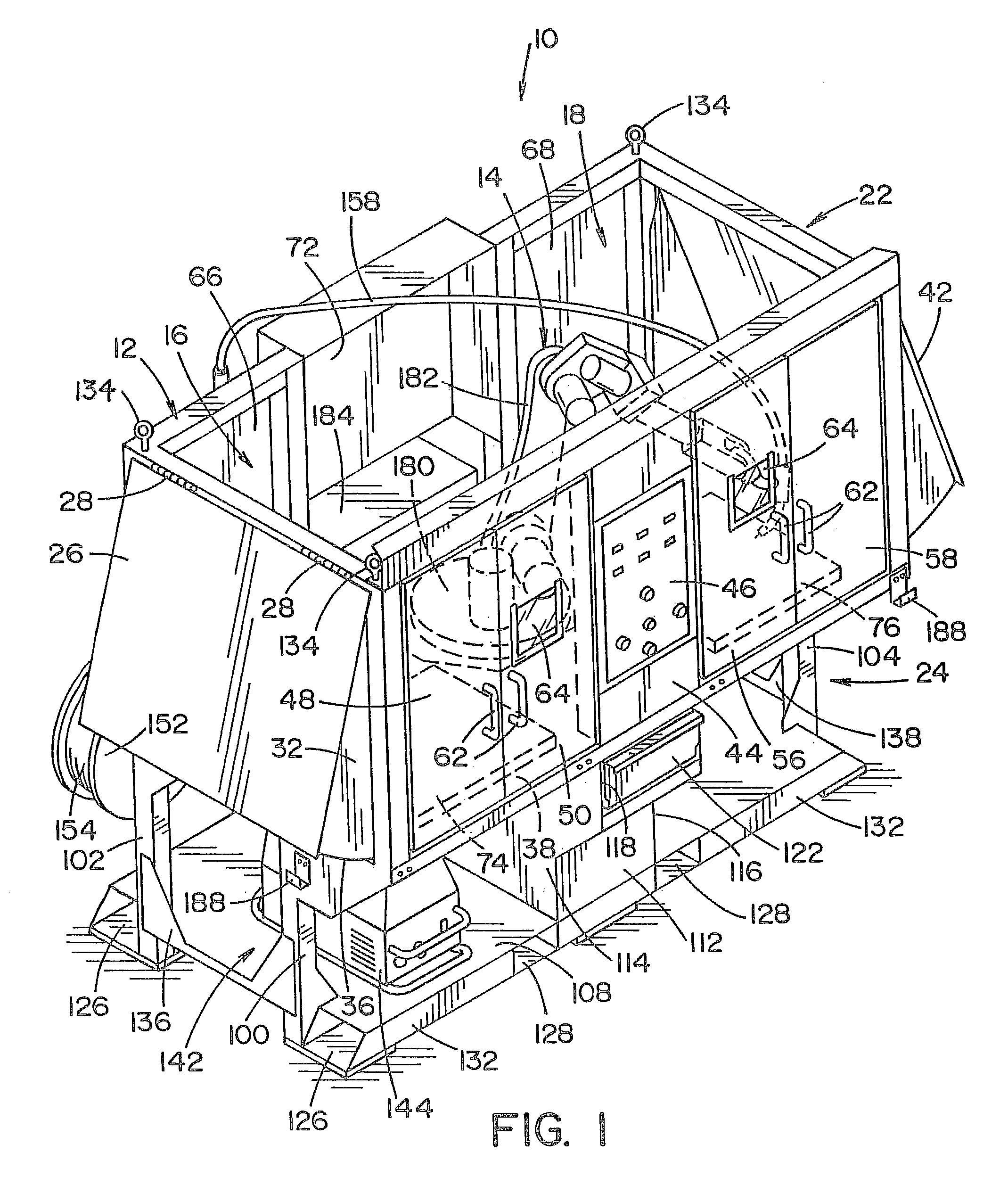

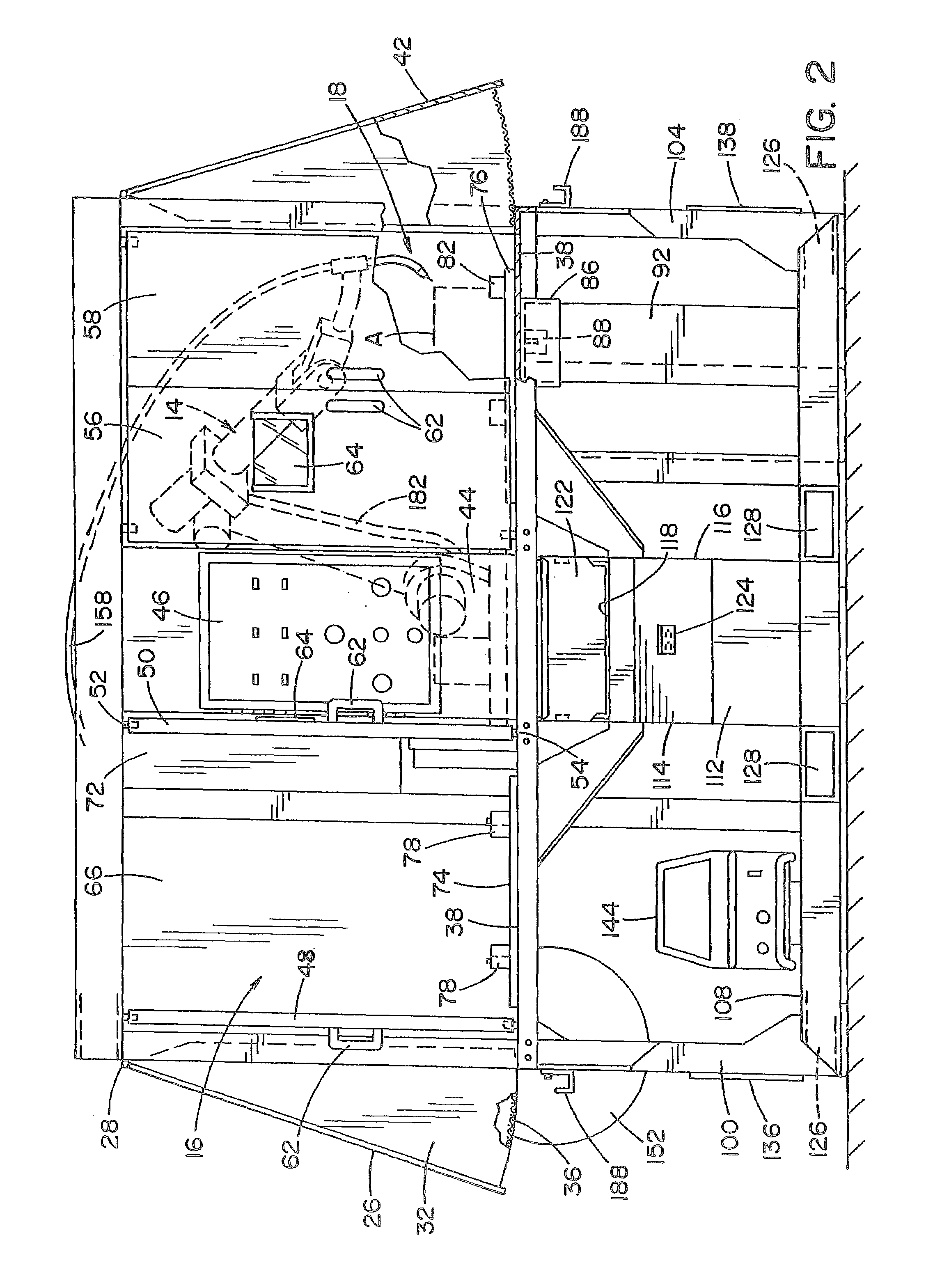

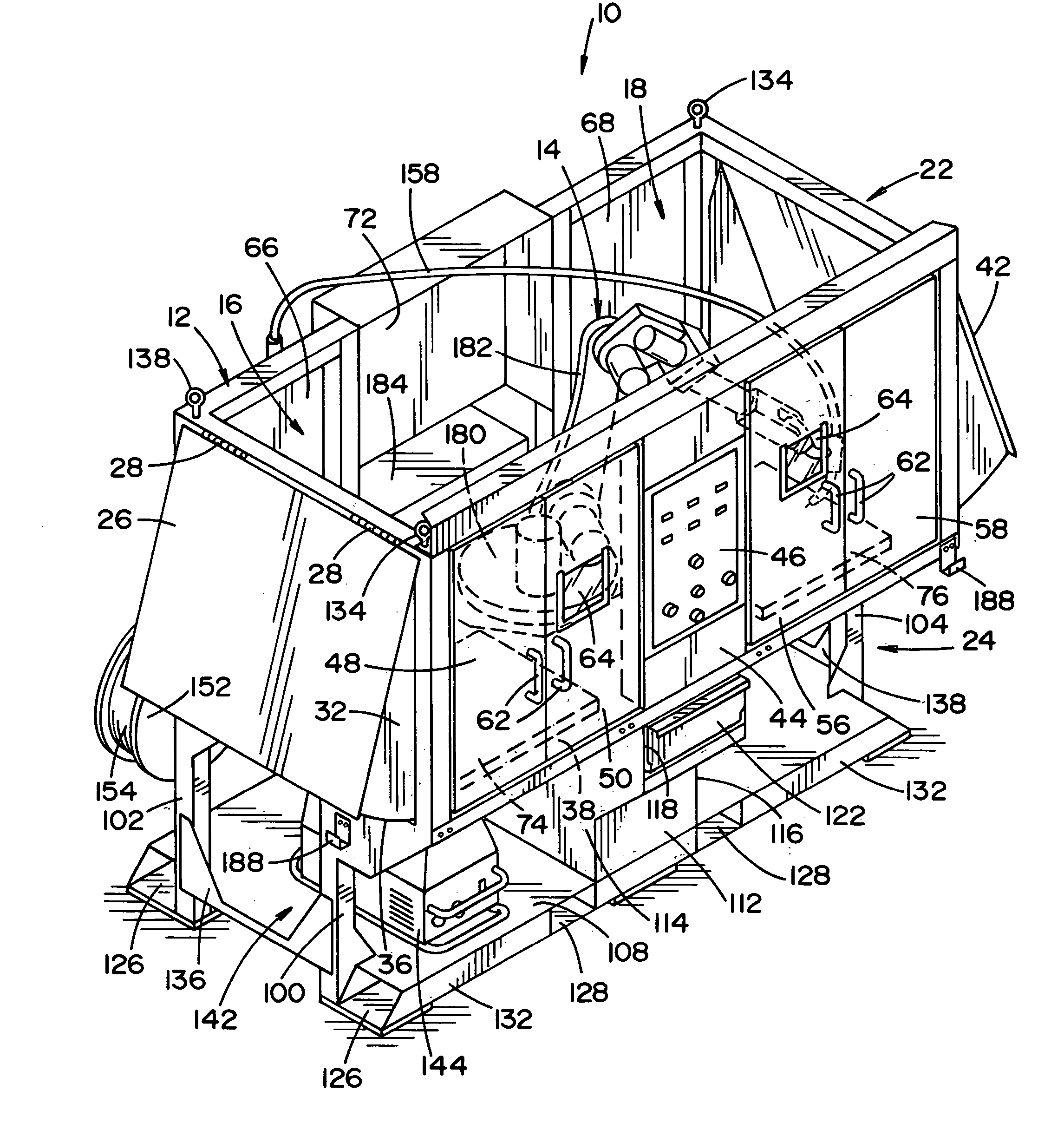

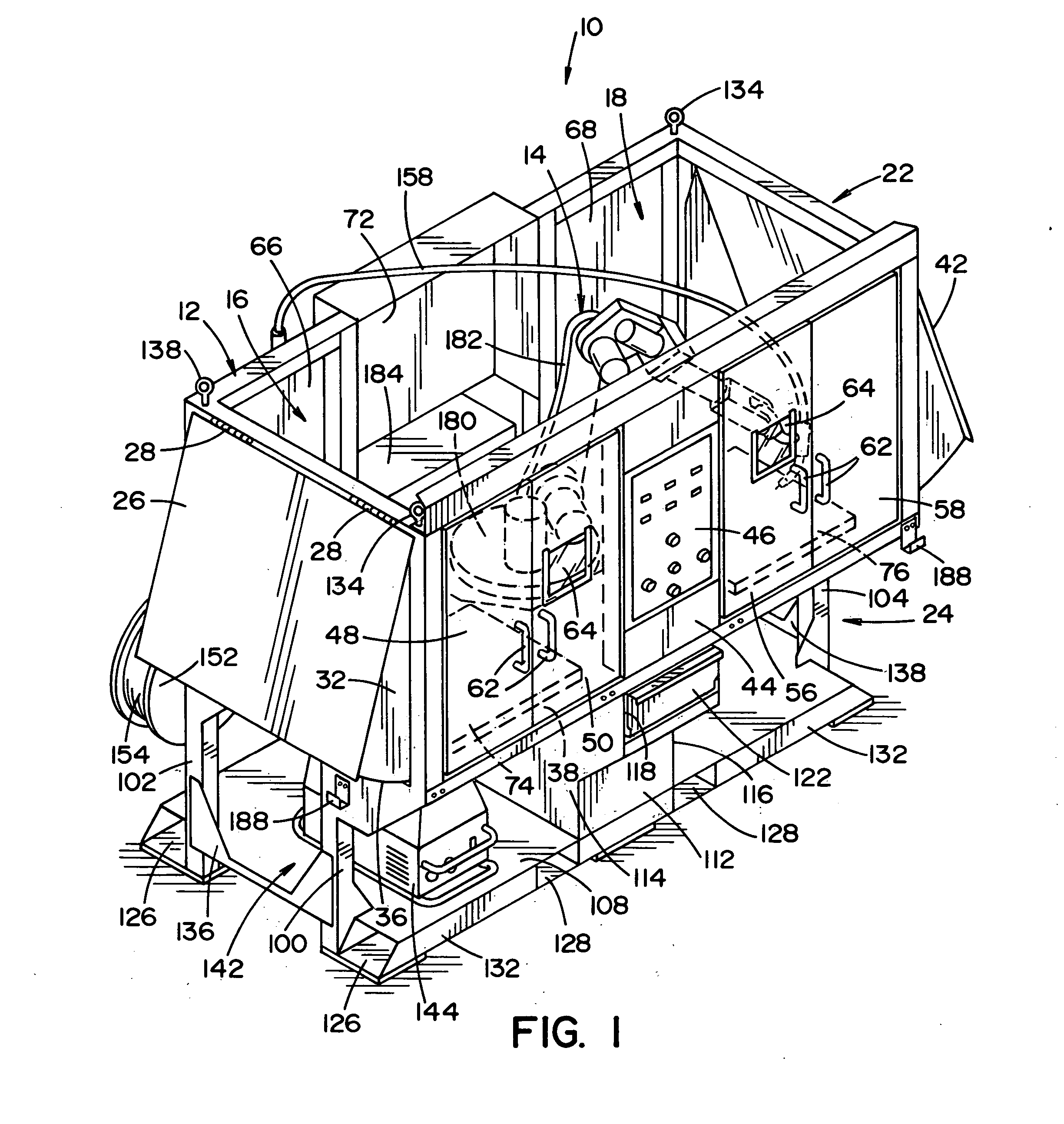

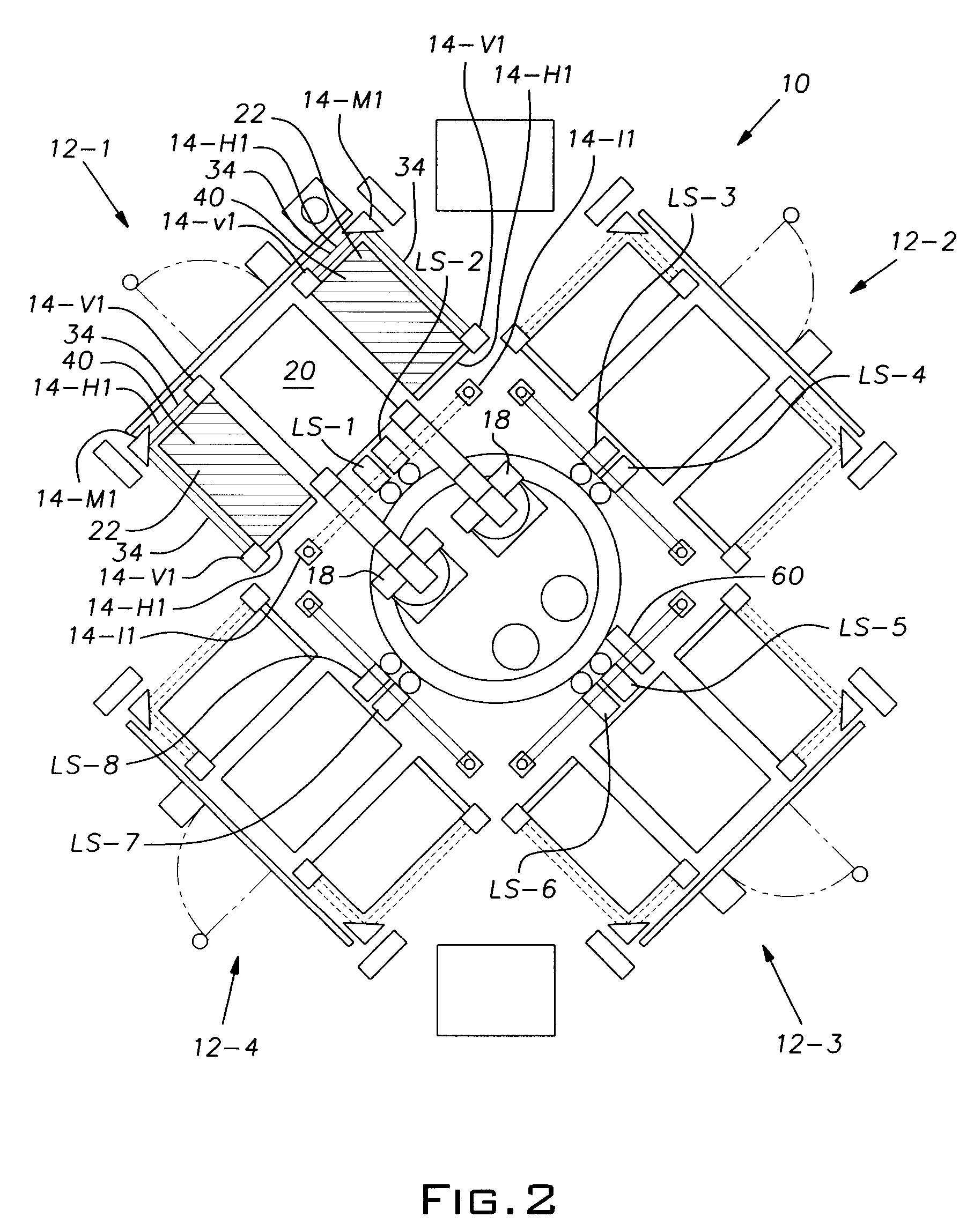

Robotic welding cell unit

InactiveUS7238916B2Easily fitted into bedMore freedom of movementElectric heatingForging/hammering/pressing machinesRobot weldingEngineering

Owner:LINCOLN GLOBAL INC

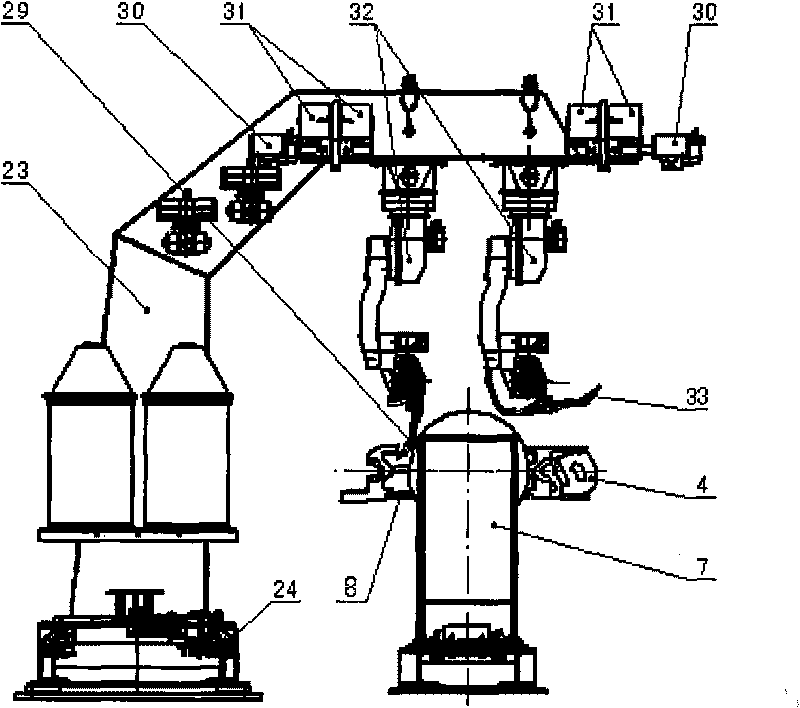

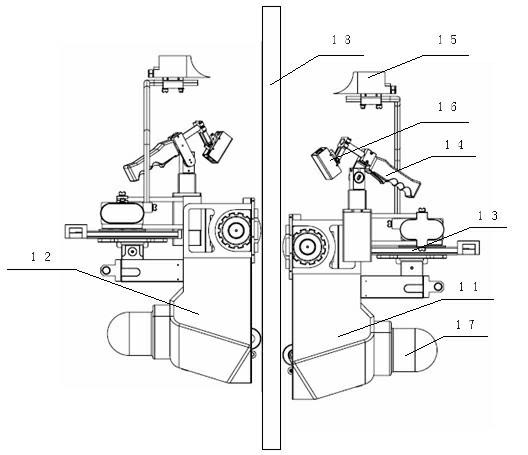

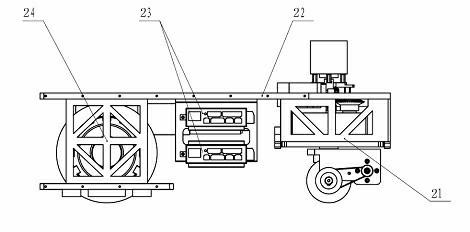

Autonomous mobile double-sided double-arc welding robot system

ActiveCN102672315AHigh steering precisionImprove adsorption capacityWelding accessoriesSteering angleDrive wheel

The invention belongs to the technical field of robot welding, particularly an autonomous mobile double-sided double-arc welding robot system. The autonomous mobile double-sided double-arc welding robot system comprises robot bodies, a control system and a welding system; the robot bodies, the control system and the welding system are connected by cables; two robot bodies, two sets of robot body control boxes, two sets of sensing systems and two welding guns are provided; each two sets of corresponding equipment are symmetrically arranged; and the two robot bodies are respectively adsorbed at both sides of a workpiece to be welded. The autonomous mobile double-sided double-arc welding robot system has the advantages that a creeping device adopts a contact magnetic wheel adsorption and non-contact clearance adsorption composite mode and is of a three-wheel structure; all wheels are driving wheels; a redundancy control steering mode is adopted; the steering on a magnetic conducting wall surface is implemented by the differential velocity of two rear wheels and the controlled steering of the front wheel; the steering accuracy of a wall climbing robot is improved by accurately controlling the steering angle of the front wheel; the autonomous mobile double-sided double-arc welding robot system has good movement flexibility, can steer around the center of a vehicle body and has the minimum steering radius of 0; and a robot can be reliably adsorbed on the magnetic conducting wall surface and the free and flexible movement of the robot can be implemented.

Owner:DONGFANG ELECTRIC CORP LTD

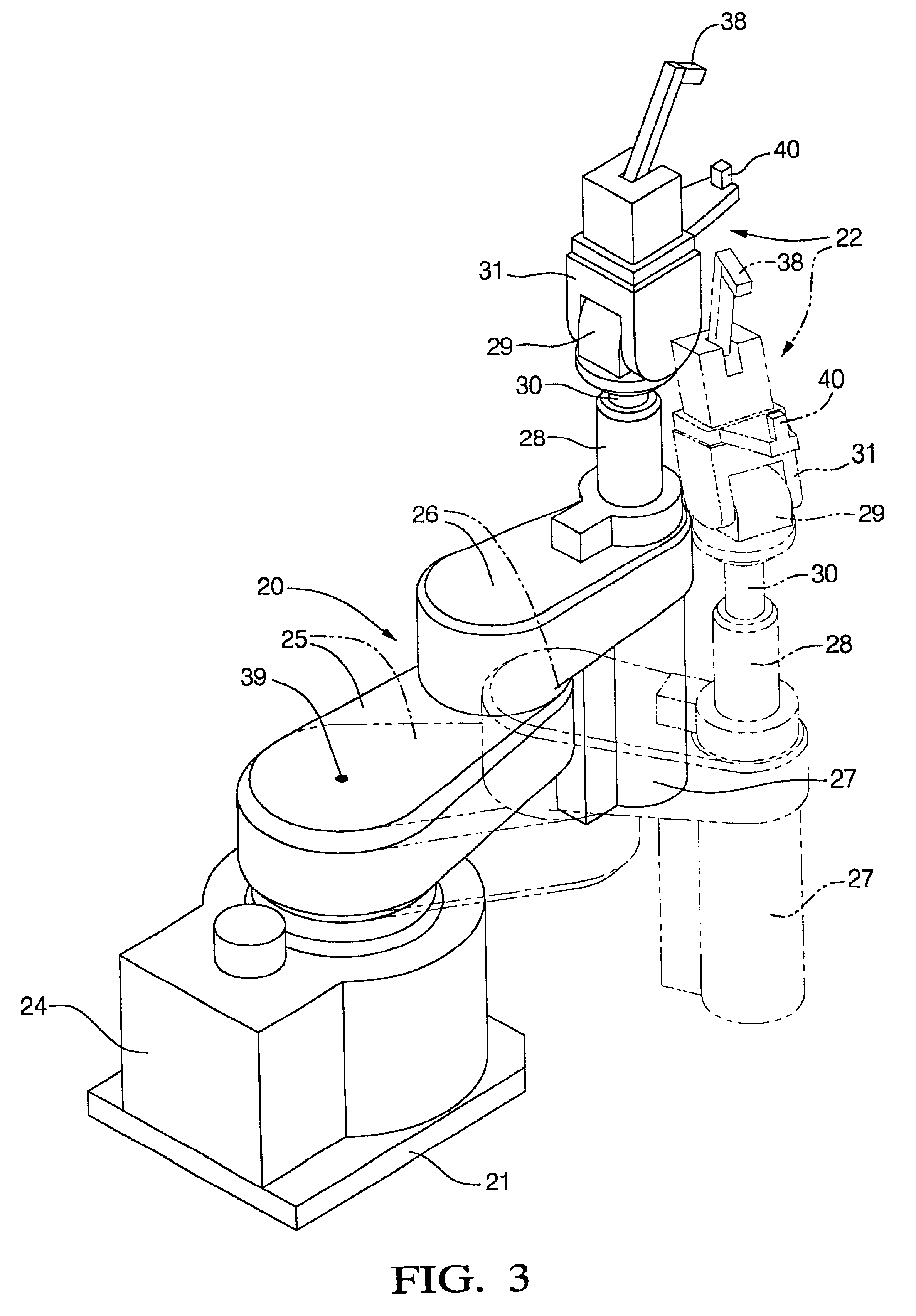

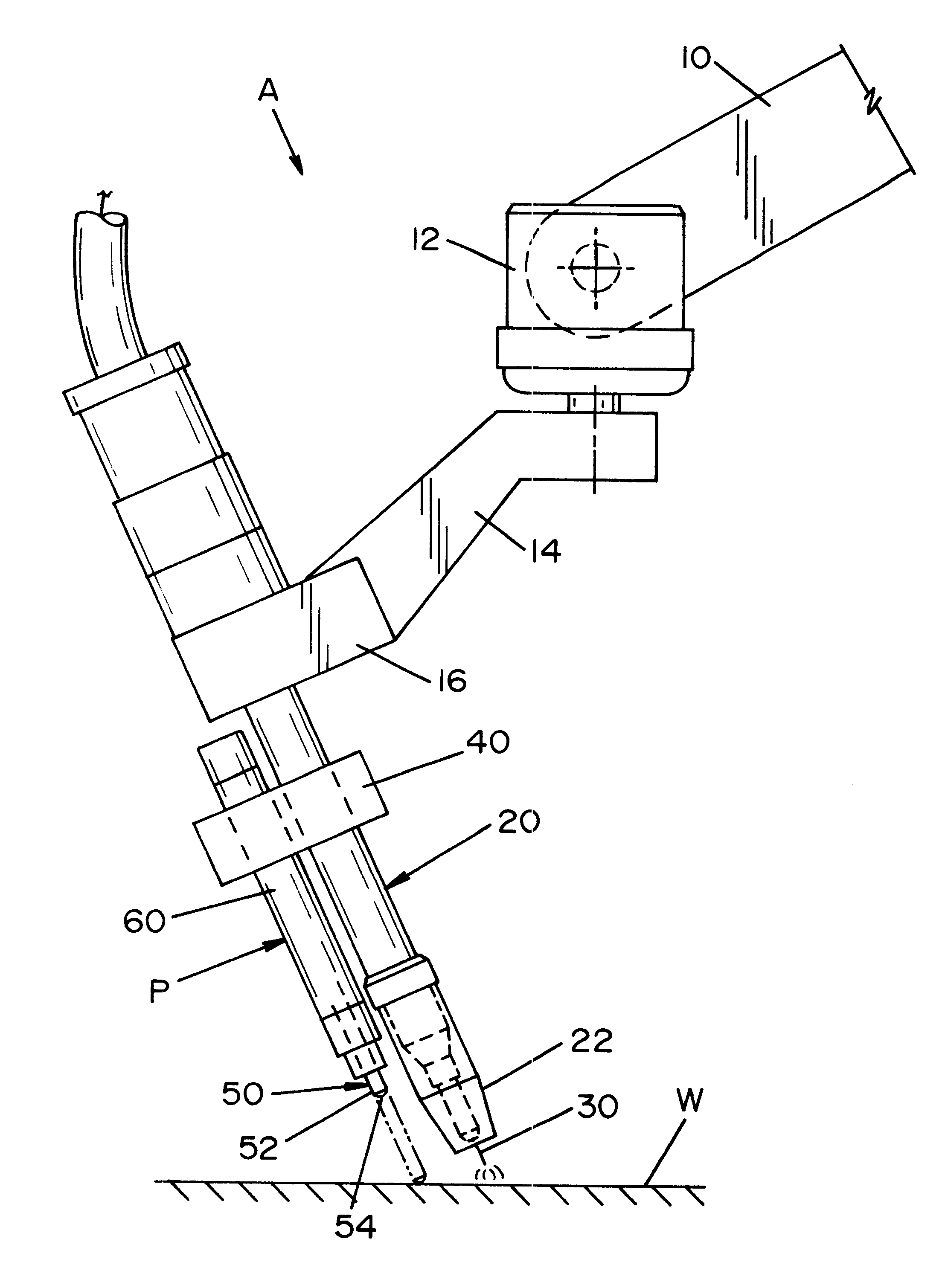

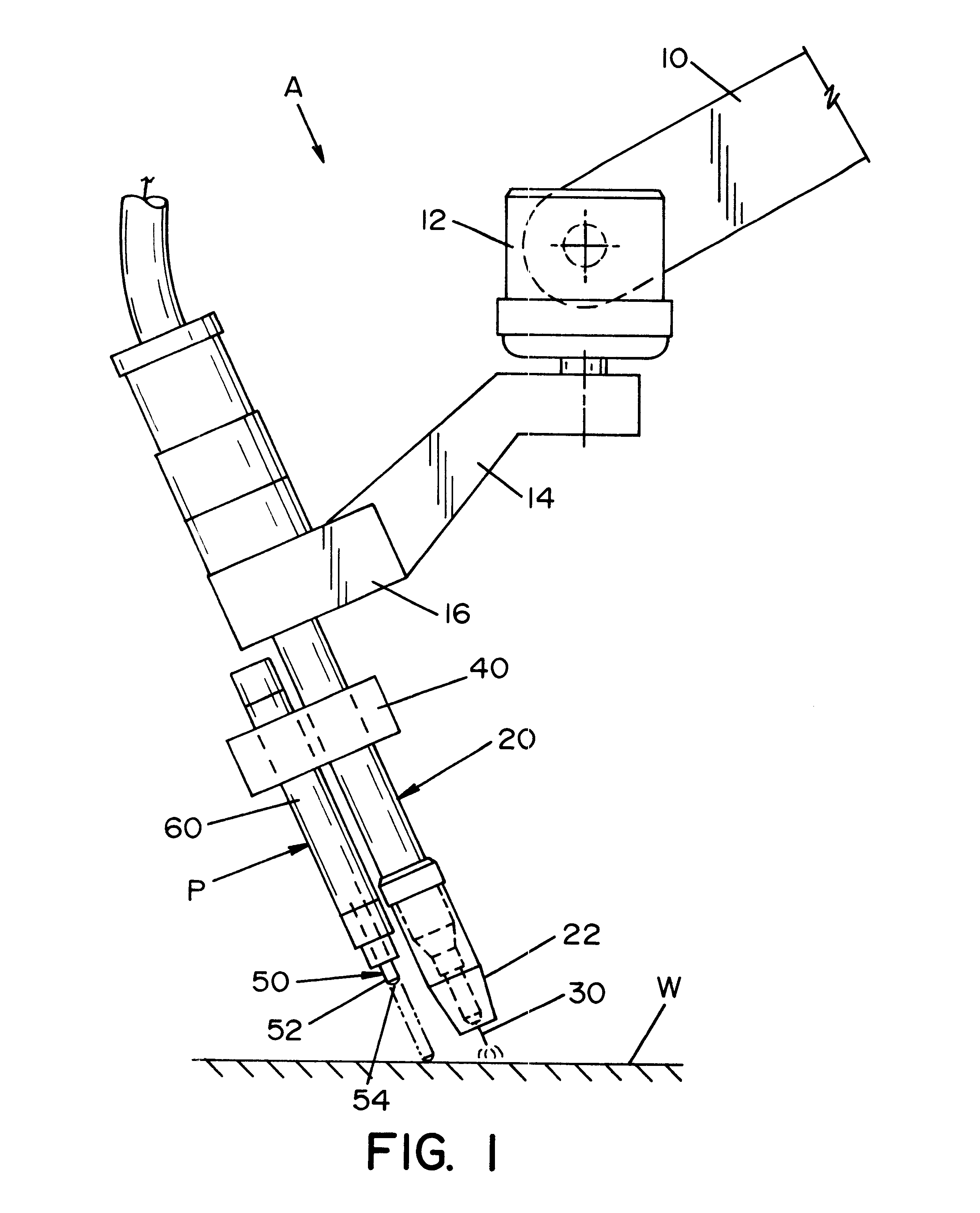

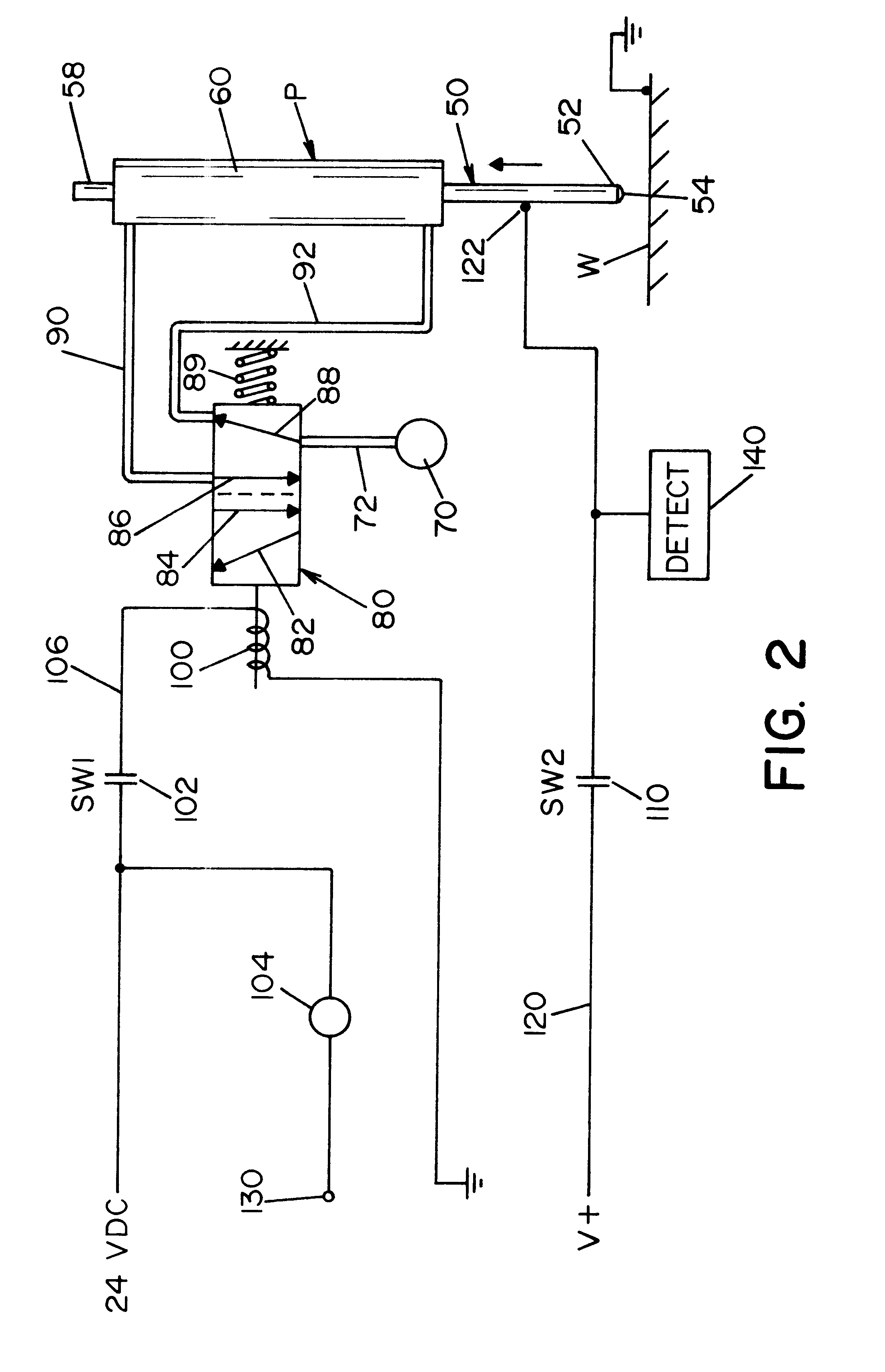

Probe for touch sensing

A probe for touch sensing to determine the position of a workpiece in a robot welding system using a robot driven welding gun for advancing a welding wire in a given direction toward a workpiece. The gun is movable by a robot controlled arm in a selected weld path and the probe comprises a rigid, elongated feeler with a touch tip which feeler is carried by a mechanism fixed with respect to the gun and movable by the mechanism between a retracted position and a known extended position wherein the feeler extends from the mechanism a fixed distance having an outermost contact point for the touch tip where the point has a known spatial relation to the gun. A detector detects when the contact point touches the workpiece to locate the workpiece. Several touches are used to determine the orientation of the workpiece for automatic welding.

Owner:LINCOLN GLOBAL INC

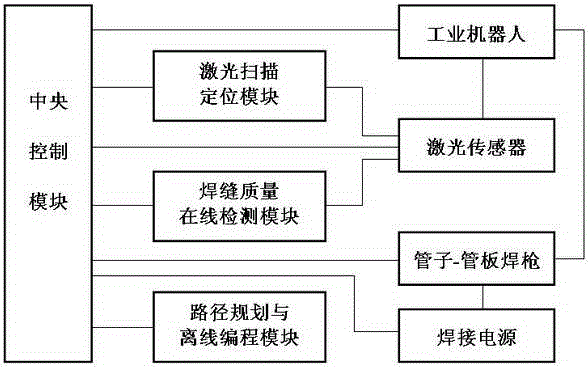

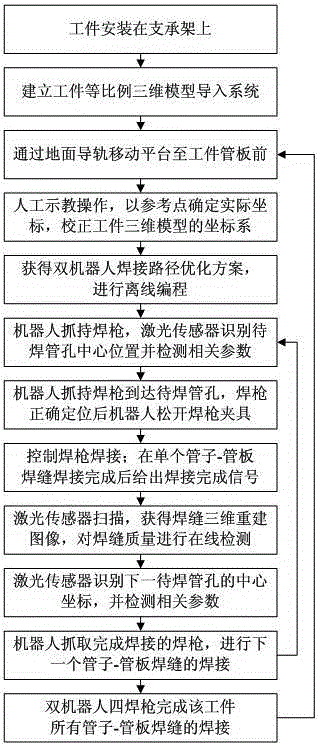

Robot welding system and welding method thereof

ActiveCN105195868AImprove work efficiencyHigh repeatabilityProgramme-controlled manipulatorHeat exchange apparatusLaser scanningVapor generator

The invention provides a robot welding system and a welding method thereof and suitable for pipe-pipe plate welding for a vapor generator of a main device in a nuclear island. According to the invention, a path planning and off-line programming module is used for planning an anti-collision welding path for an industrial robot and performing off-line programming on a planned scheme; a laser scanning positioning module obtains the circle centre coordinate of a pipe hole according to scanning results and performing initial welding position identification and autonomous guiding; the two industrial robots controlled by a central control module are matched with four pipe-pipe plate welding guns to perform welding on all pipe-pipe plate welding lines on a pipe plate; and an on-line welding line quality detection module obtains a three-dimensional reconstruction image according to welding line laser scanning results and performing on-line detection on welding line quality according to morphologies of the welding lines. Due to adoption of the system and the method disclosed by the invention, the pipe-pipe plate welding efficiency is improved, and the stability of the welding line quality is ensured.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

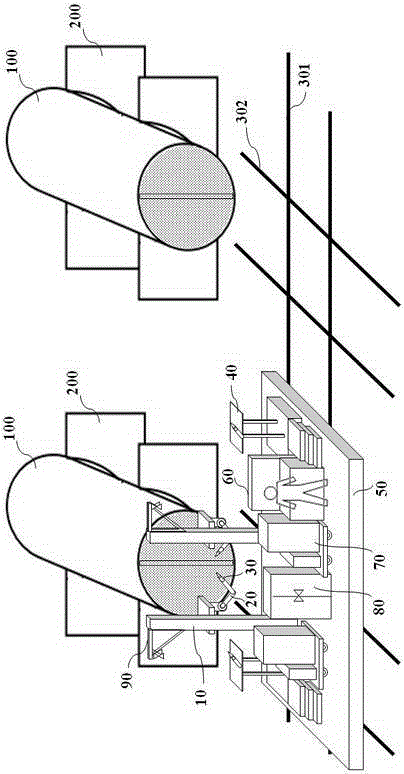

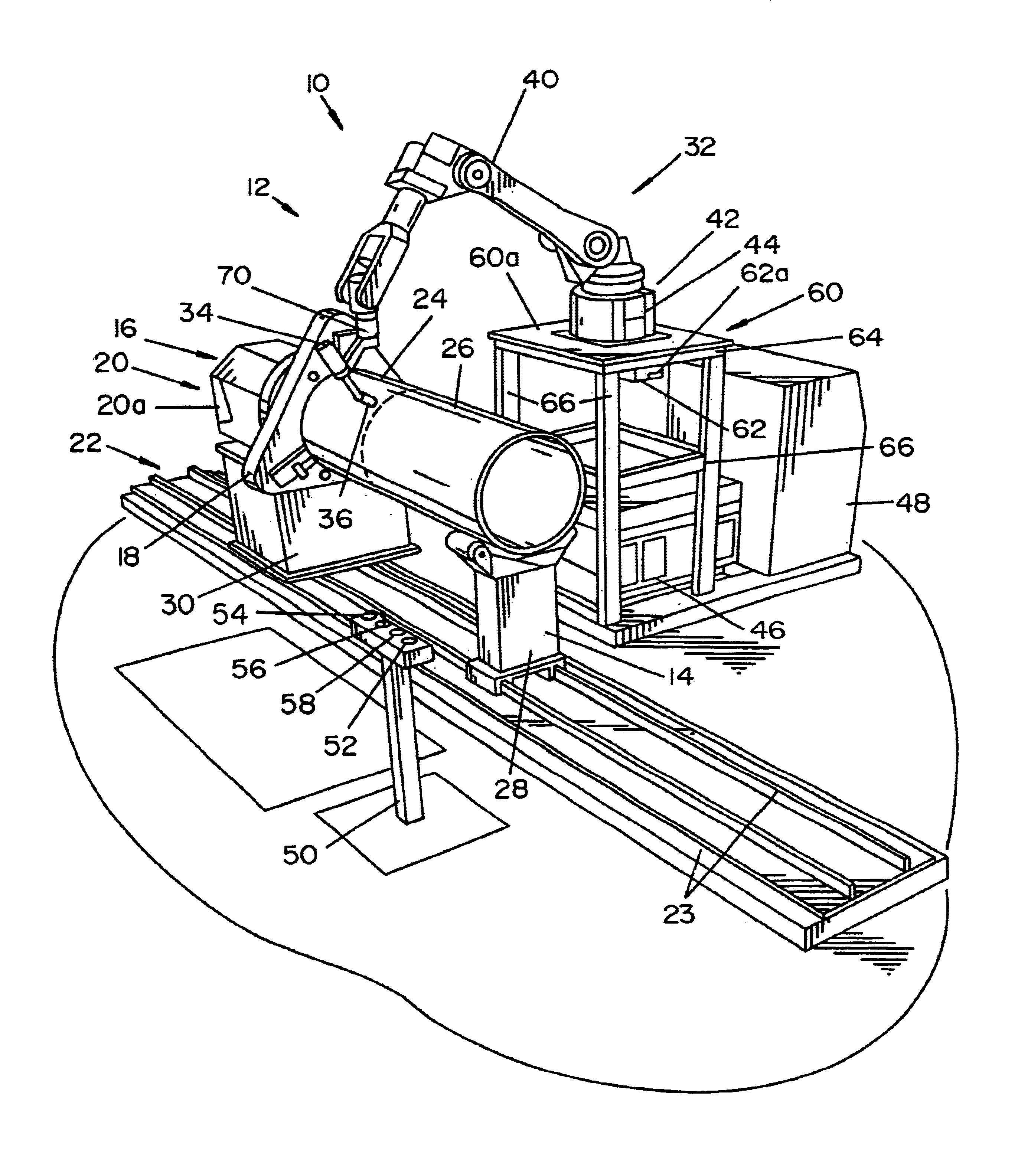

Robotic cylinder welding

A first embodiment of the present application is directed to a method and system used to weld a cylindrical workpiece. A substantially cylindrical workpiece is loaded into a workpiece support, and a robotic welding arm is positioned located at a start position. A value representing a size of the cylindrical workpiece is input into a robot controller via a system interface. Inputting of the size value to the robotic interface obtains a control program. Operation of the obtained control program is initiated by an operator, causing the robot arm to move a preprogrammed distance toward a work surface of the workpiece. Then a welding process is performed by the welder carried on the robot arm in accordance with the control program. The process includes initiating operation of the welder, and moving the welder in a pattern appropriate for the welding operation. The workpiece and welder are moved relative to each other so as to perform the welding process as determined by the control program.

Owner:LINCOLN GLOBAL INC

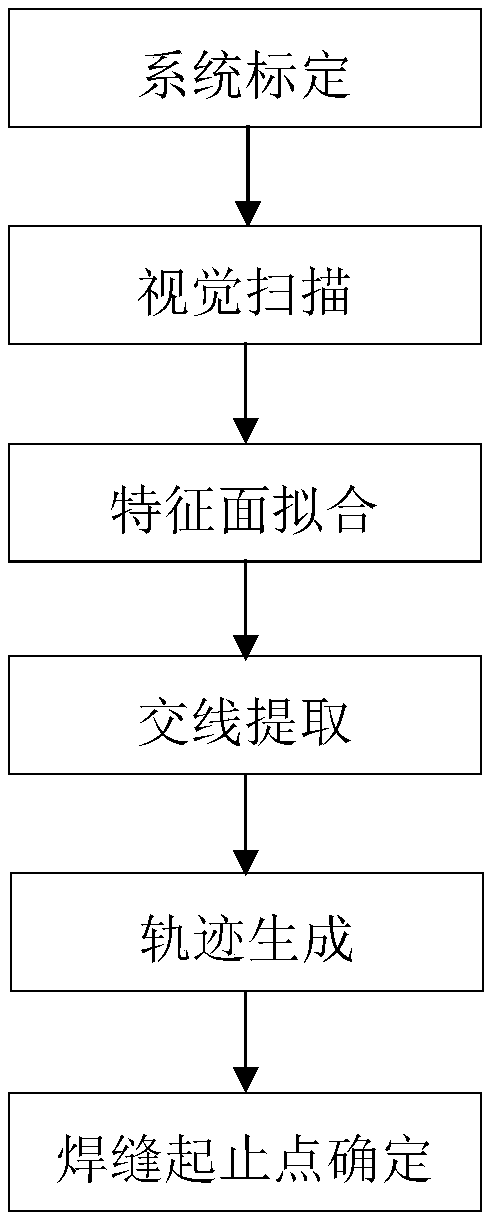

Robot welding track autonomous programming system and method based on vision sensing

InactiveCN108453439AImprove manufacturing flexibilityImprove programming efficiencyWelding/cutting auxillary devicesAuxillary welding devicesMan machineSimulation

The invention relates to a robot welding track autonomous programming system and method based on vision sensing. The system and the method can be widely applied to the field of automatic welding. According to the system and the method, at first, a vision scanning method is utilized for obtaining a three-dimensional model of the appearance of a workpiece to be welded; then by means of preprocessingand point could fitting of scanned data, the characteristic face is obtained; the equation of a path to be welded is obtained by means of the intersecting line of the characteristic face, the weldingtrack is generated automatically. According to the system and the method, welding teaching-free programming is achieved, the method has an obvious advantage compared with an existing online teachingmethod, the system and the method have high adaptability to workpieces of different shape characteristics, the flexible requirement of production practicality is met, man-machine combined operation isavoided, and the production efficiency and the safety are improved.

Owner:TSINGHUA UNIV TIANJIN HIGH END EQUIP RES INST LUOYANG ADVANCED MFG IND RES & DEV BASE

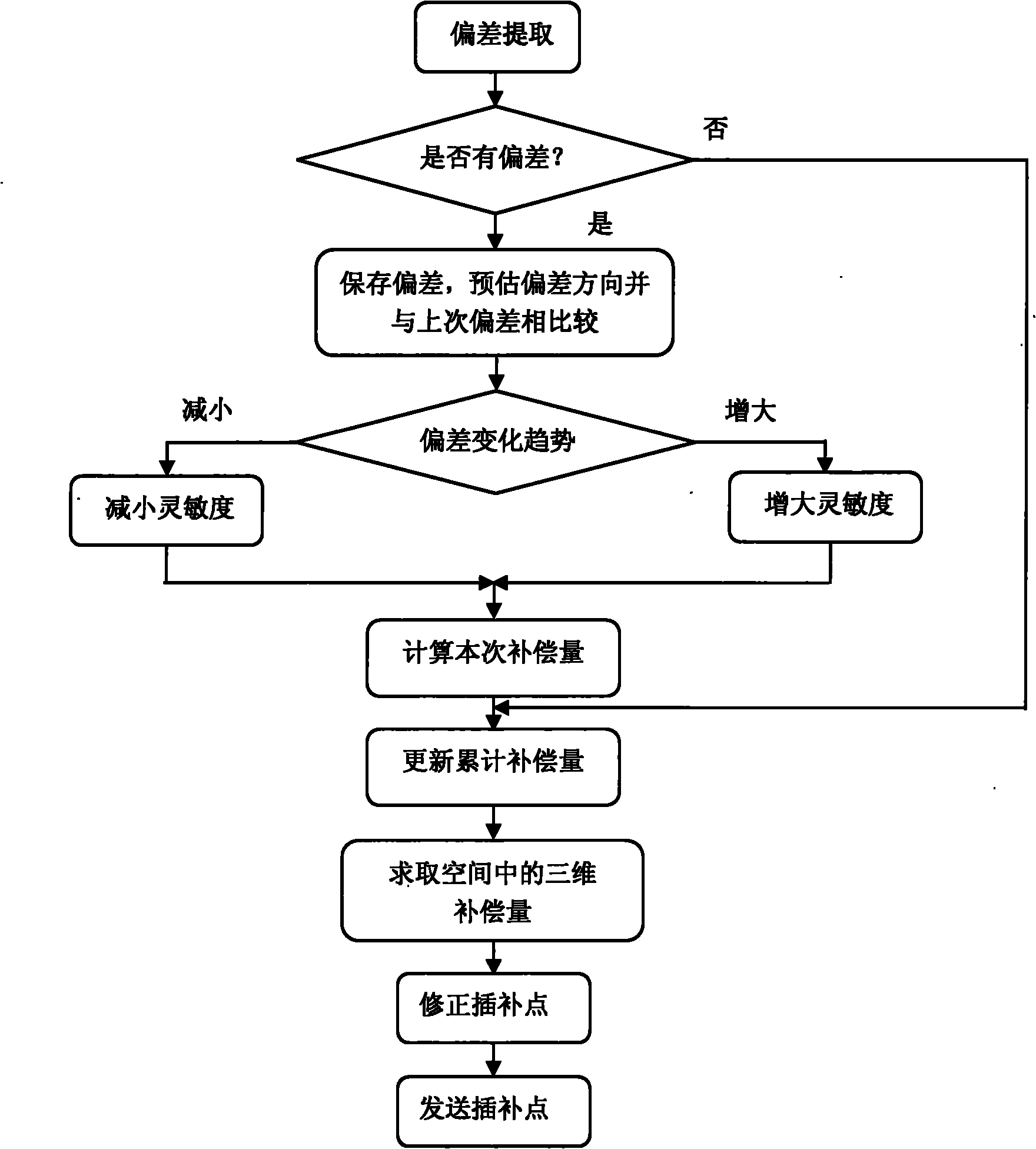

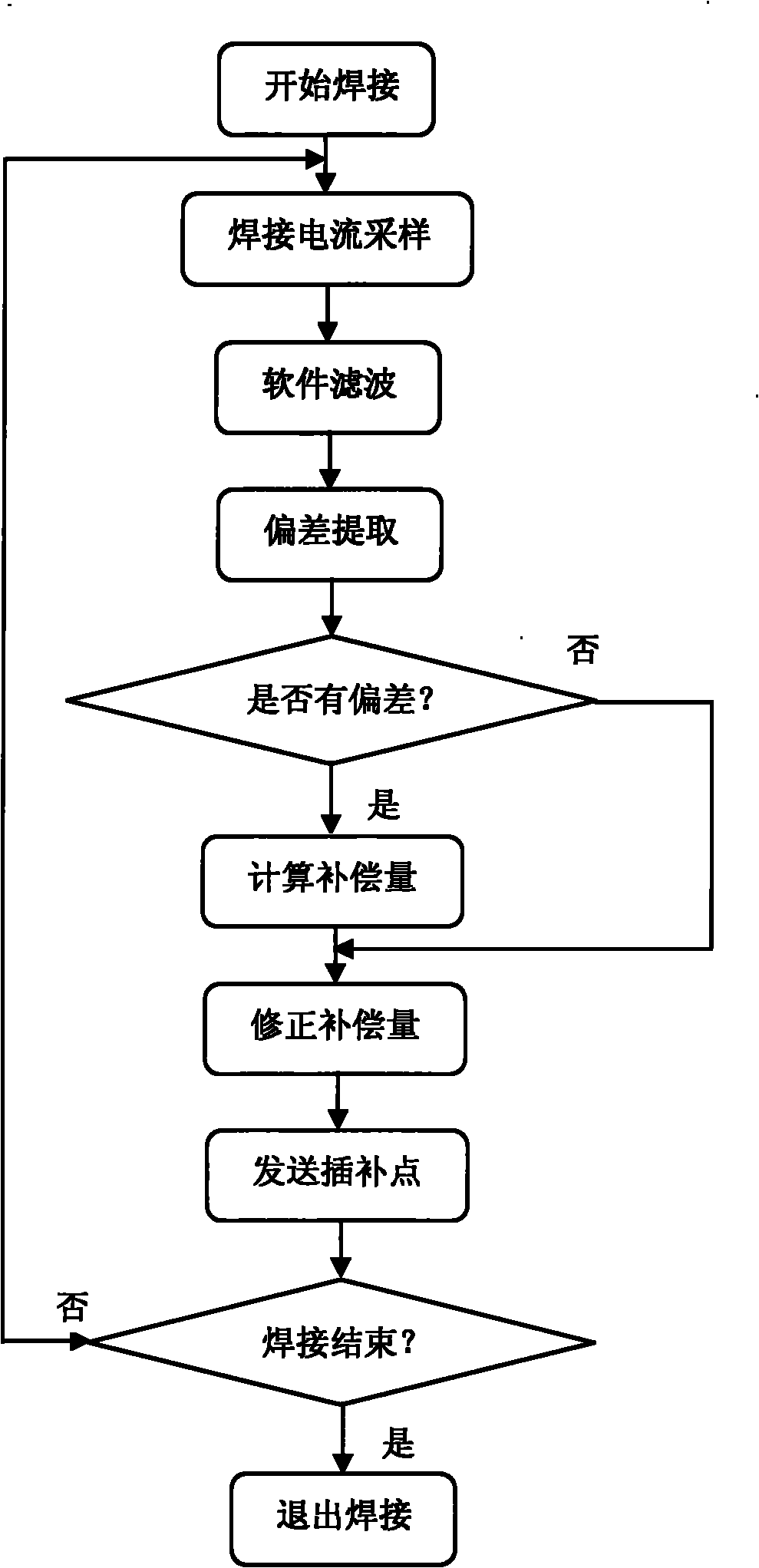

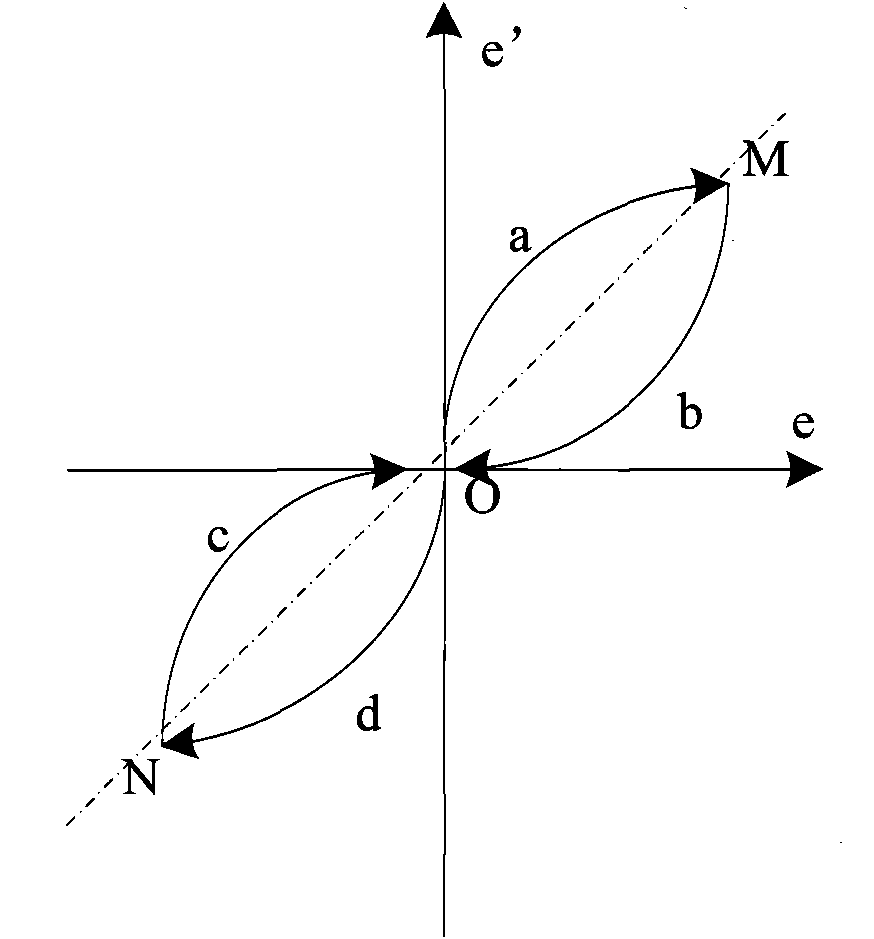

Robot welding line tracking deviation compensation method

The invention relates to a robot welding line deviation compensation method based on arc oscillation welding line tracking, comprising the steps of: 1, detecting a welding current, sampling, filtering collected welding current data; 2, extracting deviation of the filtered current data, fitting a deviation direction, extracting according to an integral differential method, obtaining a compensation dosage and a transverse deviation value of a height deviation direction; 3, storing the transverse deviation value, adjusting the sensitivity; 4, computing a compensation dosage of the deviation by combining with the transverse deviation value and the sensitivity; 5, updating and accumulating deviation compensation dosages along the height direction and the transverse direction; 6, converting a three-dimensional compensation dosage into interpolation points of x axis, y axis and z axis; and 7, sending the compensated interpolation points to a control part of the robot. The invention can not generate jump change aiming at the compensation dosages, can ensure the stability of the system at a certain degree, and has better molding of a welding line subjected to the deviation compensation and tracking error of generally within + / -mm.

Owner:昆山华恒机器人有限公司

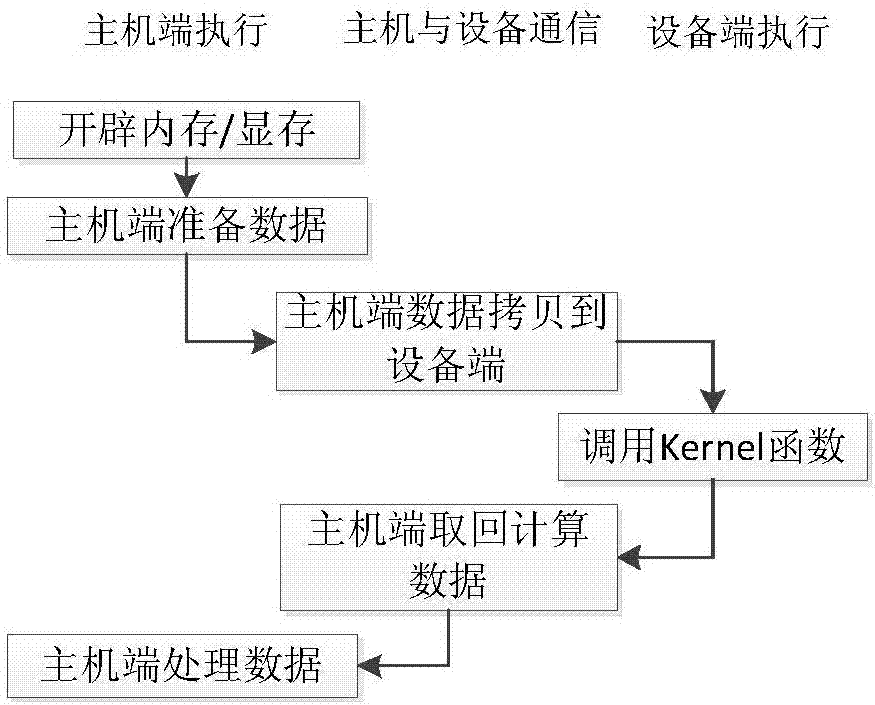

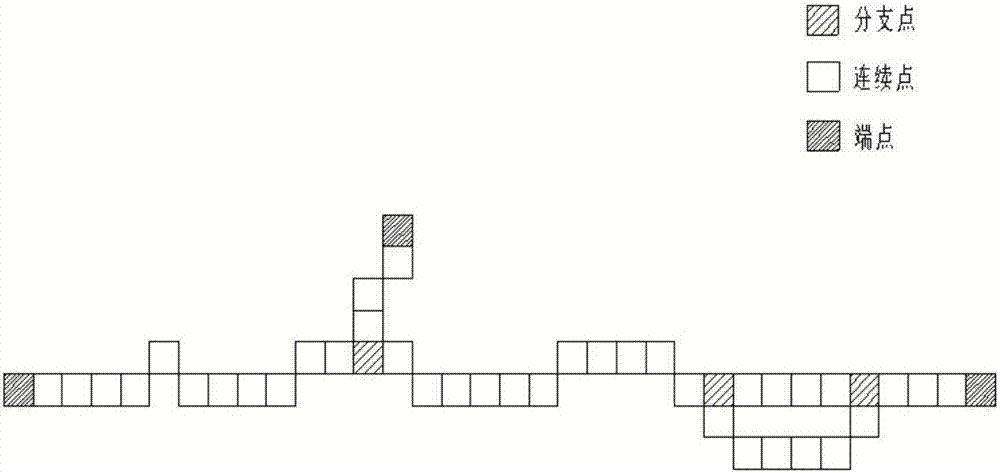

Three-dimensional detection and welding seam inflection point identifying method for multilayer multiple welding seams of robot

ActiveCN107876970AGuaranteed accuracy requirementsEnsure real-time requirementsProgramme-controlled manipulatorLaser beam welding apparatusFeature vectorThree dimensional morphology

The invention discloses a three-dimensional morphology detection and welding seam inflection point identifying method for multilayer multiple welding seams of a robot. The three-dimensional detectionand welding seam inflection point identifying method comprises the following steps that 1, a camera, line structural light and the robot are calibrated; 2, a welding seam structure light image is obtained and processed; and 3, the three-dimensional spatial morphology of the multilayer multiple welding seams is obtained, and inflection point characteristics are identified, specifically, the processcomprises the following steps that 3.1, the eigenvector of a calculated hessian matrix during extraction of a center line is recorded; 3.2, according to the direction of the eigenvector, the threshold value of the eigenvector difference is set to identify inflection points of the multilayer multiple welding seams; and 3.3, according to model data calculated in the step 1, the sub-pixel coordinatevalue of the center line under a camera coordinate system is converted to be under a robot coordinate system and serves as the three-dimensional data of the welding seam surface for being used for robot welding. According to the three-dimensional detection and welding seam inflection point identifying method for the multilayer multiple welding seams of the robot, the precision is high, the reliability is high, and real-time performance is good.

Owner:ZHEJIANG UNIV OF TECH

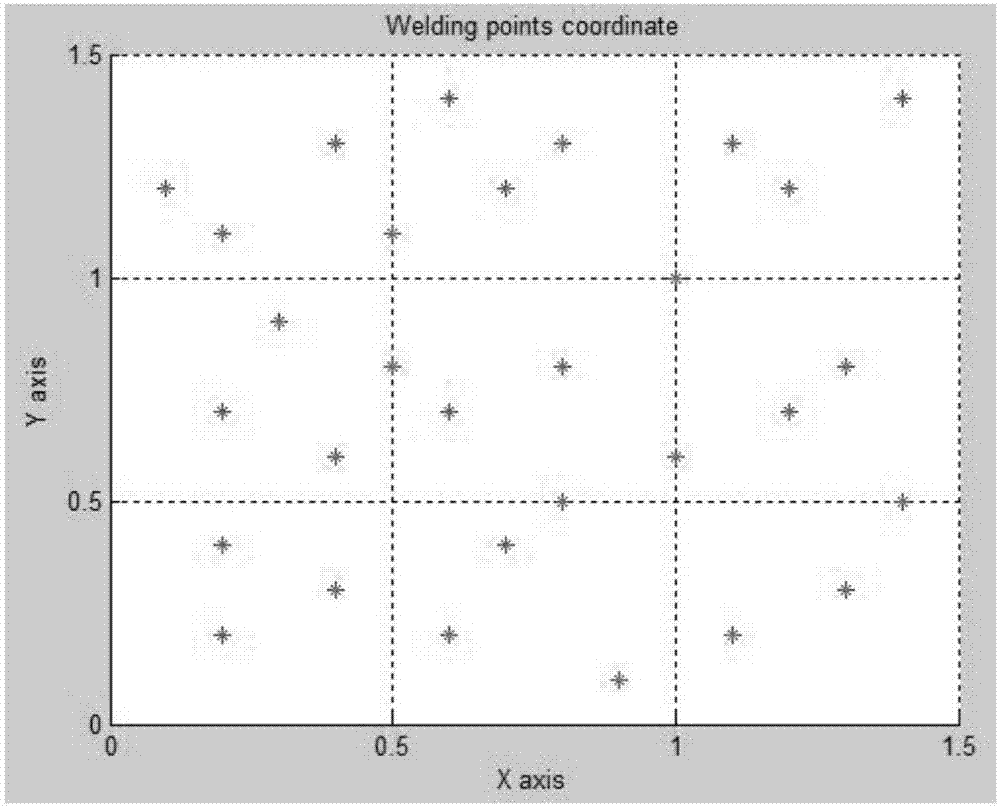

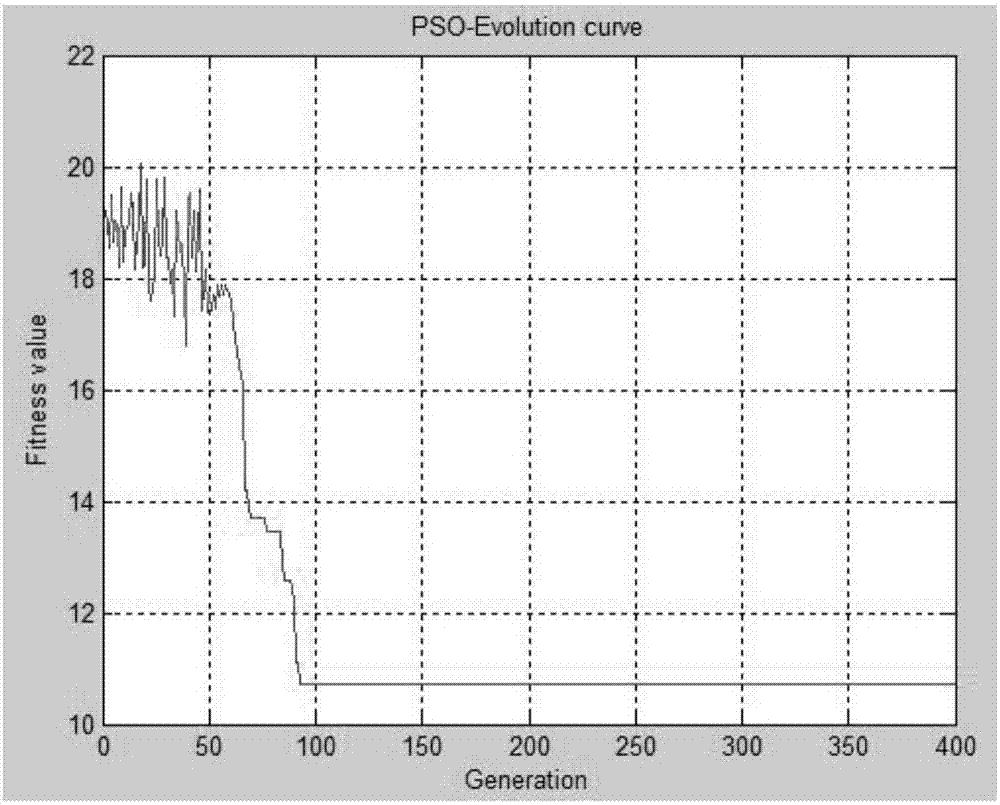

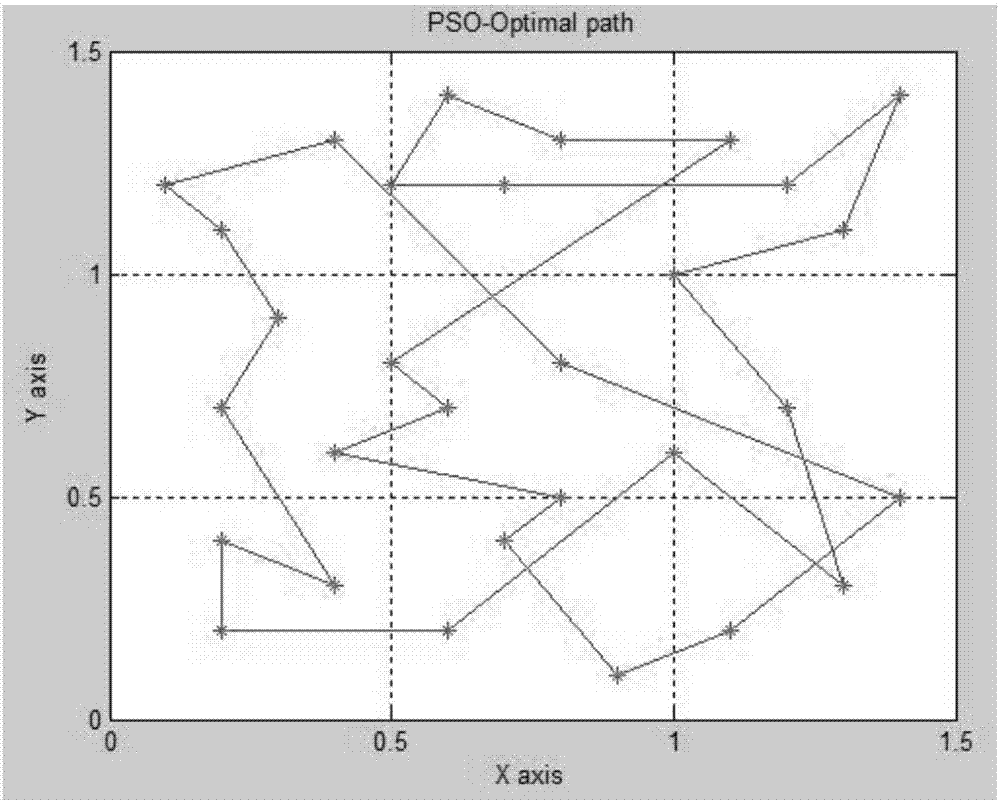

Welding robot welding path planning method based on discrete particle swarm optimization

InactiveCN107150341AImprove adaptive adjustment abilityQuick searchProgramme controlProgramme-controlled manipulatorMathematical modelEngineering

The invention discloses a welding robot welding path planning method based on discrete particle swarm optimization. The method comprises the steps of: (1) building a mathematical model of a path of a welding robot; (2) building a model of particle swarm optimization; (3) analyzing behavior parameters solved by the particle swarm optimization; (4) planning the path of the welding robot by the particle swarm optimization; and (5) outputting optimal path. The method adopts the particle swarm optimization; and through setting of different inertia weight formulas, the self-adaption adjusting capacity of the particle swarm optimization is improved, so that the purpose of balancing local search capacity and global search capacity of the particle swarm optimization is achieved, and the optimal solution is searched quickly by the particle swarm optimization.

Owner:NANJING UNIV OF SCI & TECH

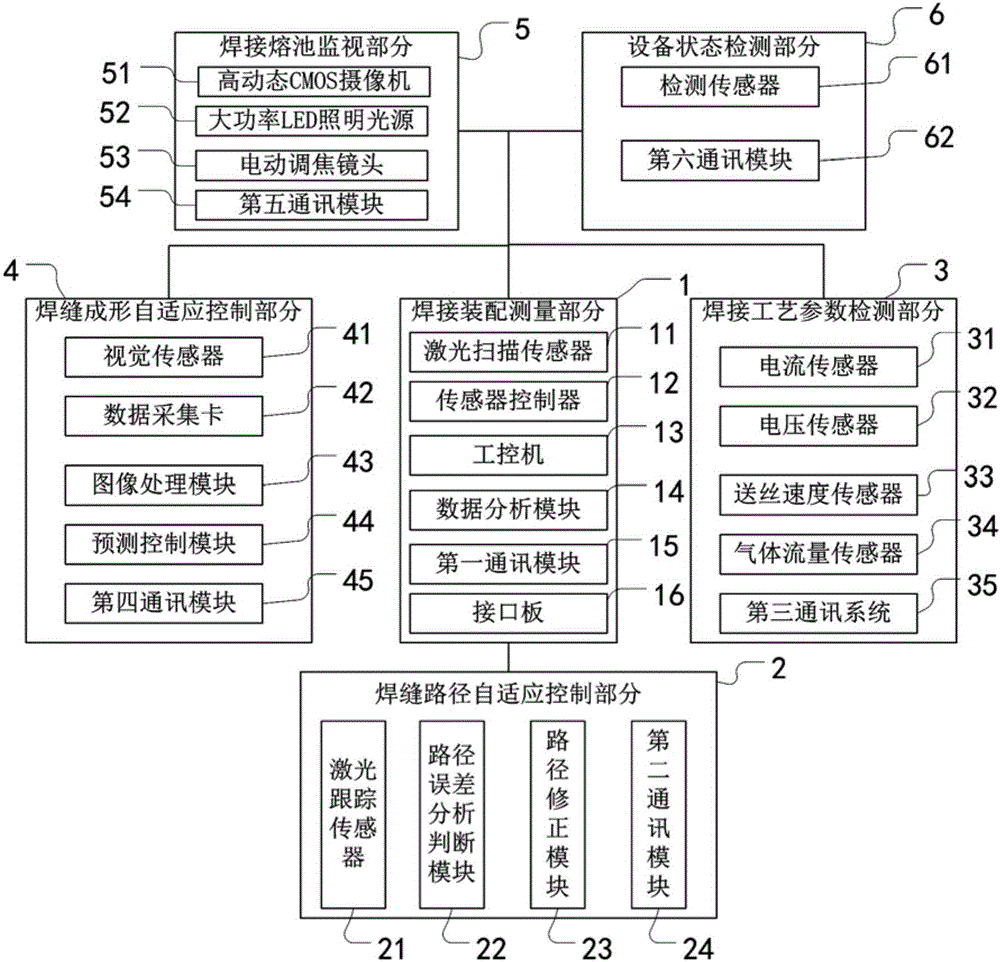

Intelligent robot welding system

ActiveCN106041258ARealize automatic real-time trackingImprove the level of intelligenceArc welding apparatusControl engineeringSelf adaptive

The invention provides an intelligent robot welding system. The intelligent robot welding system comprises a welding, assembling and measuring part, a welding line path self-adaptation control part, a welding technology parameter detecting part, a welding line forming self-adaptation control part, a welding molten pool monitoring part and an equipment state detecting part. The welding, assembling and measuring part is used for online detecting and analyzing welding and assembling parameters or information in the welding environment with high precision. The welding line path self-adaptation control part is used for adjusting the welding path in real time and correcting the deviation of the welding path. The welding technology parameter detecting part is used for detecting and recording welding parameters in the welding process. The welding line forming self-adaptation control part is used for adjusting various assembling parameters during welding in real time. The welding molten pool monitoring part is used for collecting and processing images in the welding area during welding and displaying, recording and storing the images in real time. The equipment state detecting part is used for detecting the running parameters of the whole robot welding system in real time.

Owner:JIANGSU BEIREN ROBOT SYST CO LTD

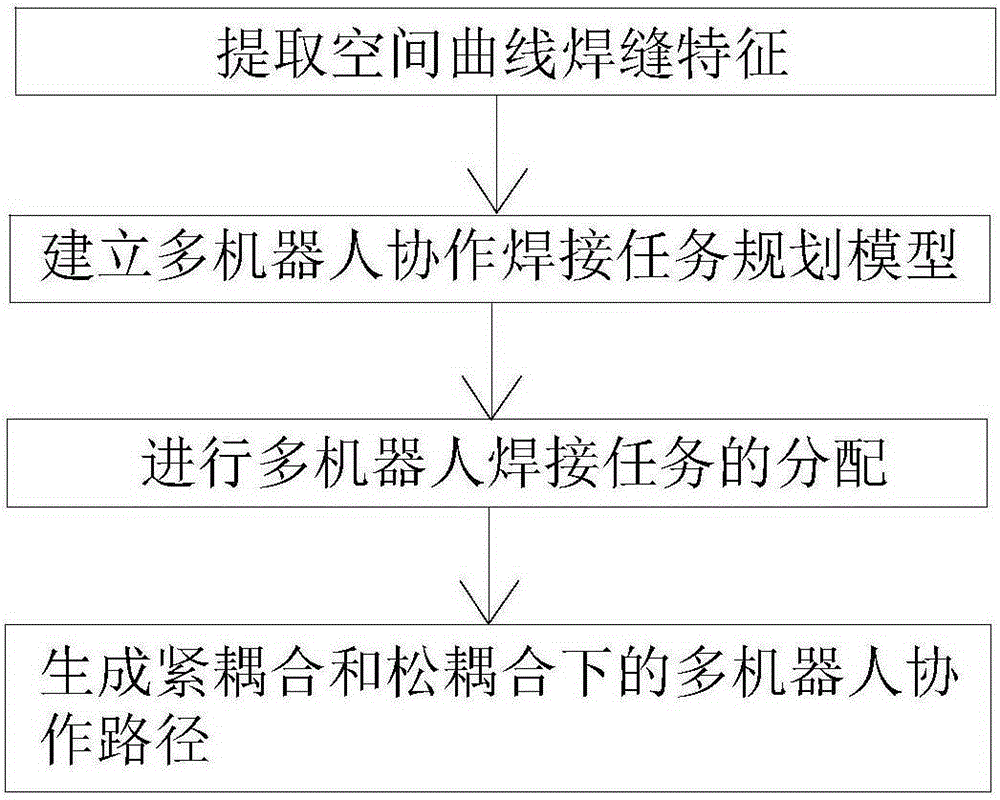

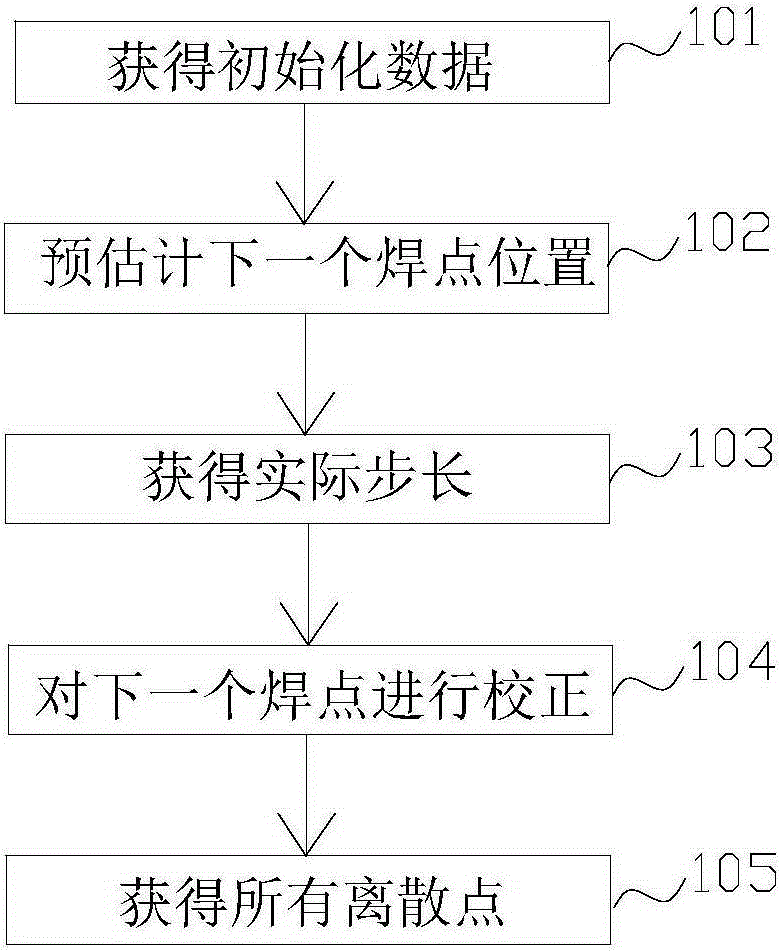

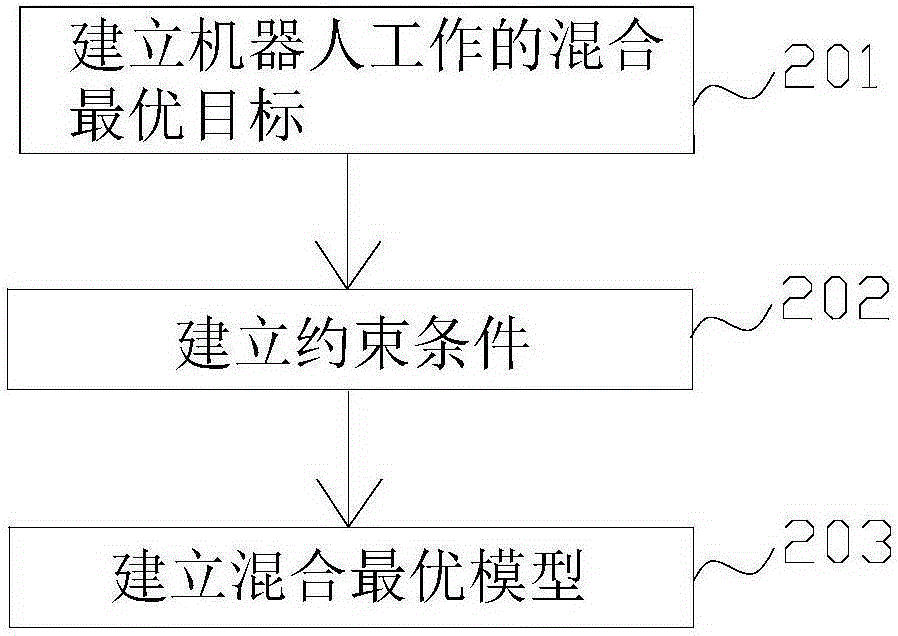

Task decoupling-based multi-robot collaboration welding path generation method

The invention discloses a task decoupling-based multi-robot collaboration welding path generation method. The method includes the following steps that: first step, based on a to-be-welded workpiece model, a chord tolerance and minimum step-combined method is adopted to perform discretization processing on welding seams through non-equidistant point sampling, so that space curve welding seam features can be extracted; second step, a multi-robot cooperative welding task planning model is established; third step, a multi-operator multi-chromosome structured improved genetic algorithm is adopted to distribute multi-robot welding tasks; and fourth step, a motion closed chain-based multi-robot master-slave type collaboration motion model is established, so that multi-robot cooperation paths under tight coupling and loose coupling are generated. According to the method of the invention, the unified multi-robot cooperation welding model is established according to the coupling relations of multiple master-slave robots, and therefore, task planning efficiency of multi-robot cooperation welding can be effectively improved.

Owner:SOUTHEAST UNIV

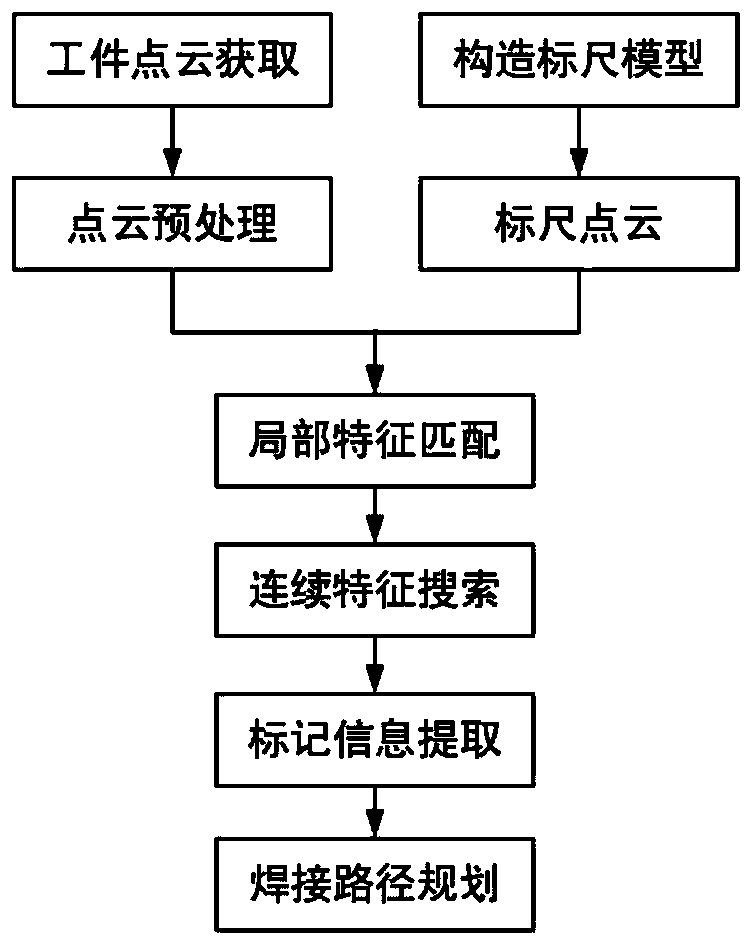

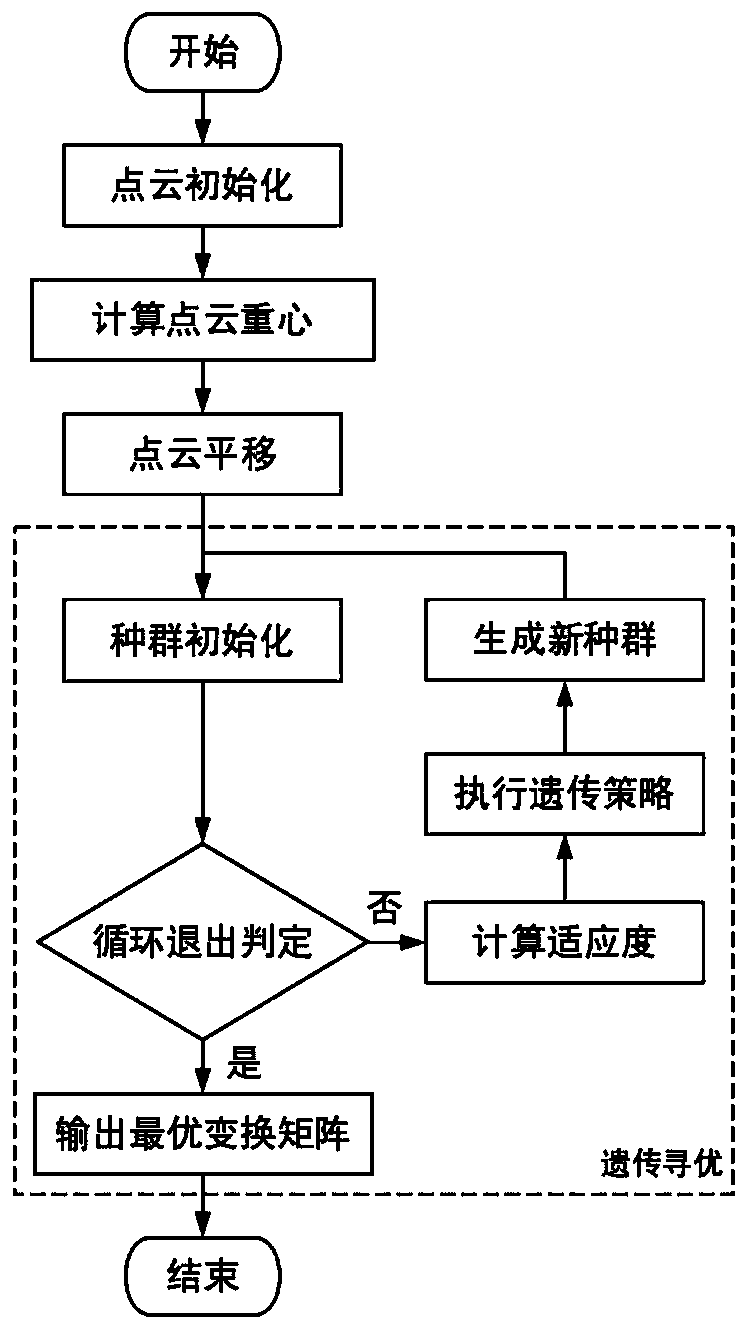

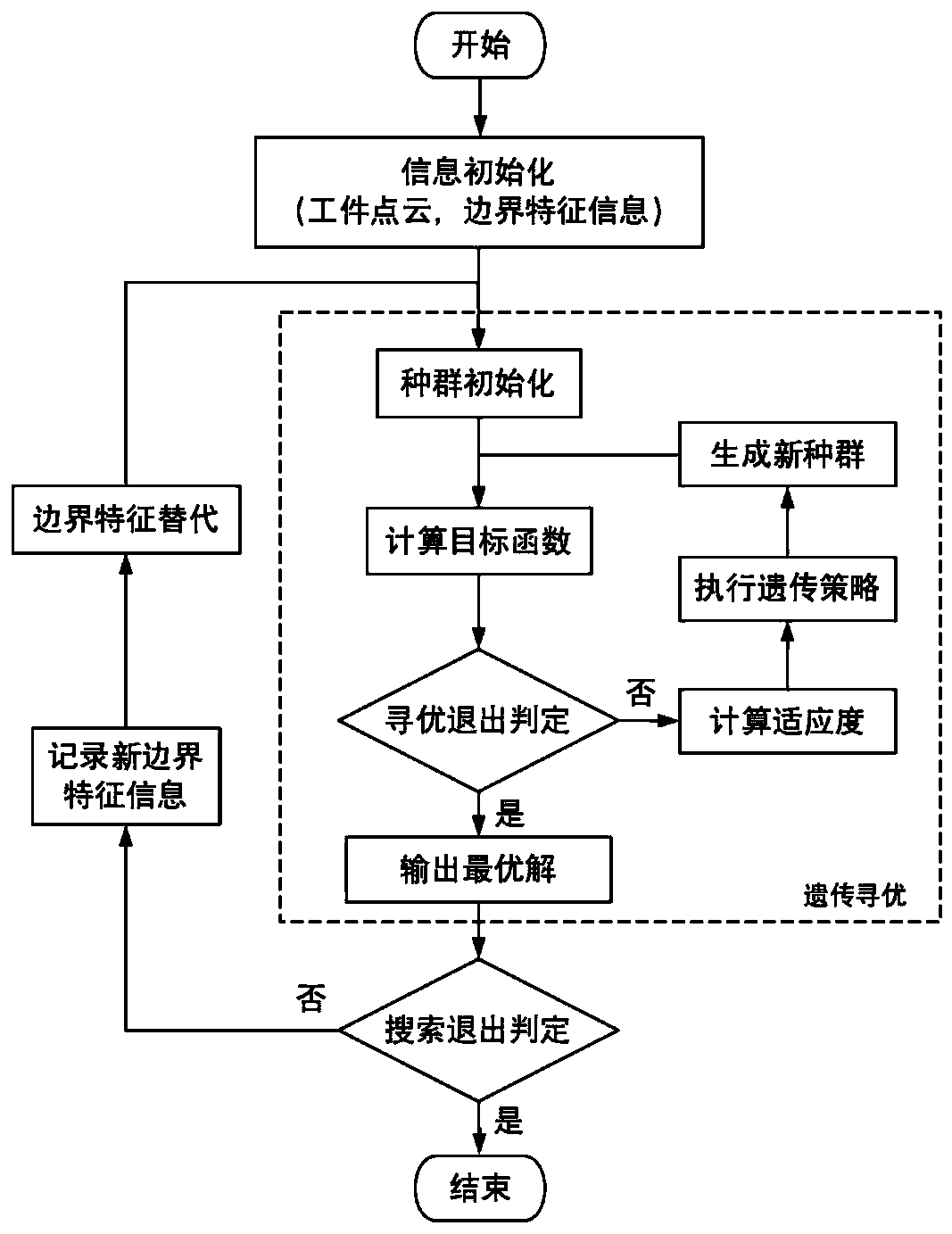

Robot welding path autonomous planning method based on 3D point cloud data

ActiveCN110227876AReduce in quantityRealize automatic extractionProgramme-controlled manipulatorArc welding apparatusPoint cloudPlanning approach

The invention discloses a robot welding path autonomous planning method based on 3D point cloud data. The robot welding path autonomous planning method comprises the following steps of acquiring the original three-dimensional cloud data of a workpiece weld profile, and preprocessing the original three-dimensional cloud data; according to the workpiece weld characteristics, constructing ruler CAD models with the same characteristics, and converting characteristic surface information of ruler CAD models as three-dimensional point cloud data; performing local registration operation on the three-dimensional point cloud data of the ruler CAD models and the three-dimensional point cloud data generated after the workpiece weld profile is preprocessed; according to the local registration operation, performing continuous characteristic searching, thereby obtaining complete workpiece weld information; extracting weld position and posture information marked in the complete workpiece weld information; and processing the extracted weld position and posture information, and planning the robot welding path. The self-adaptability of robot welding can be improved, and the workload of scene teachingand off-line programming of operating staff can be remarkably reduced.

Owner:XIHUA UNIV

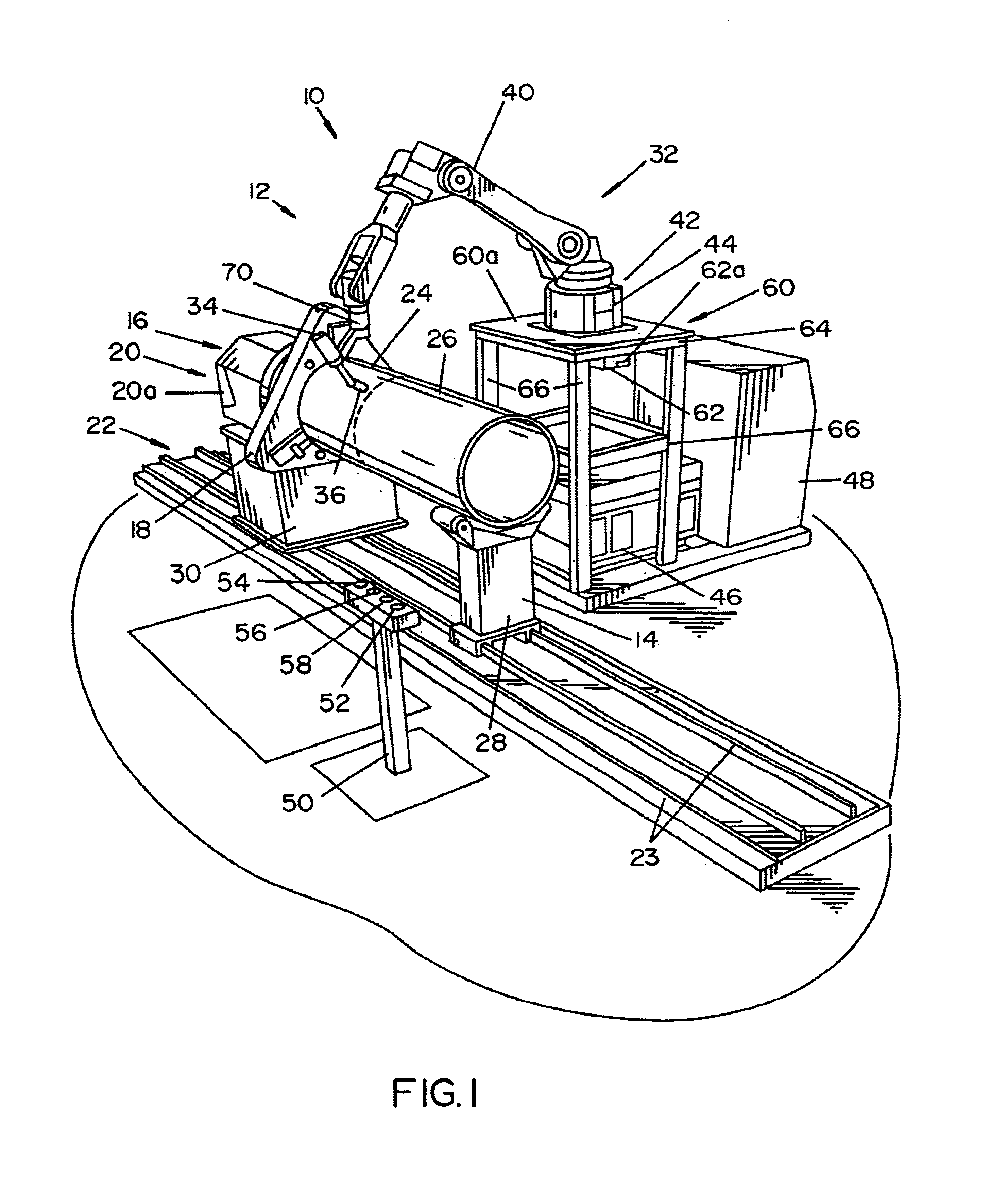

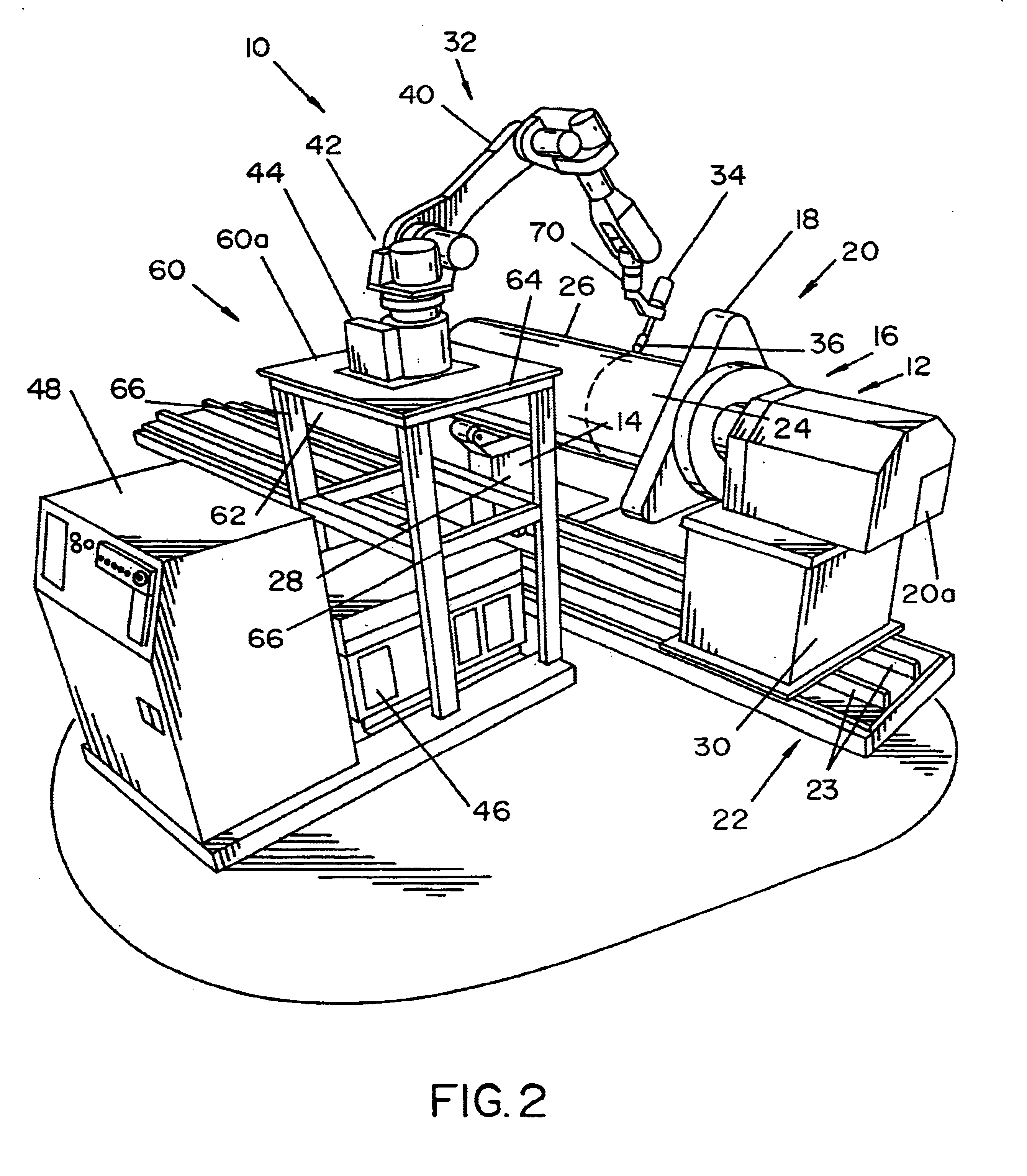

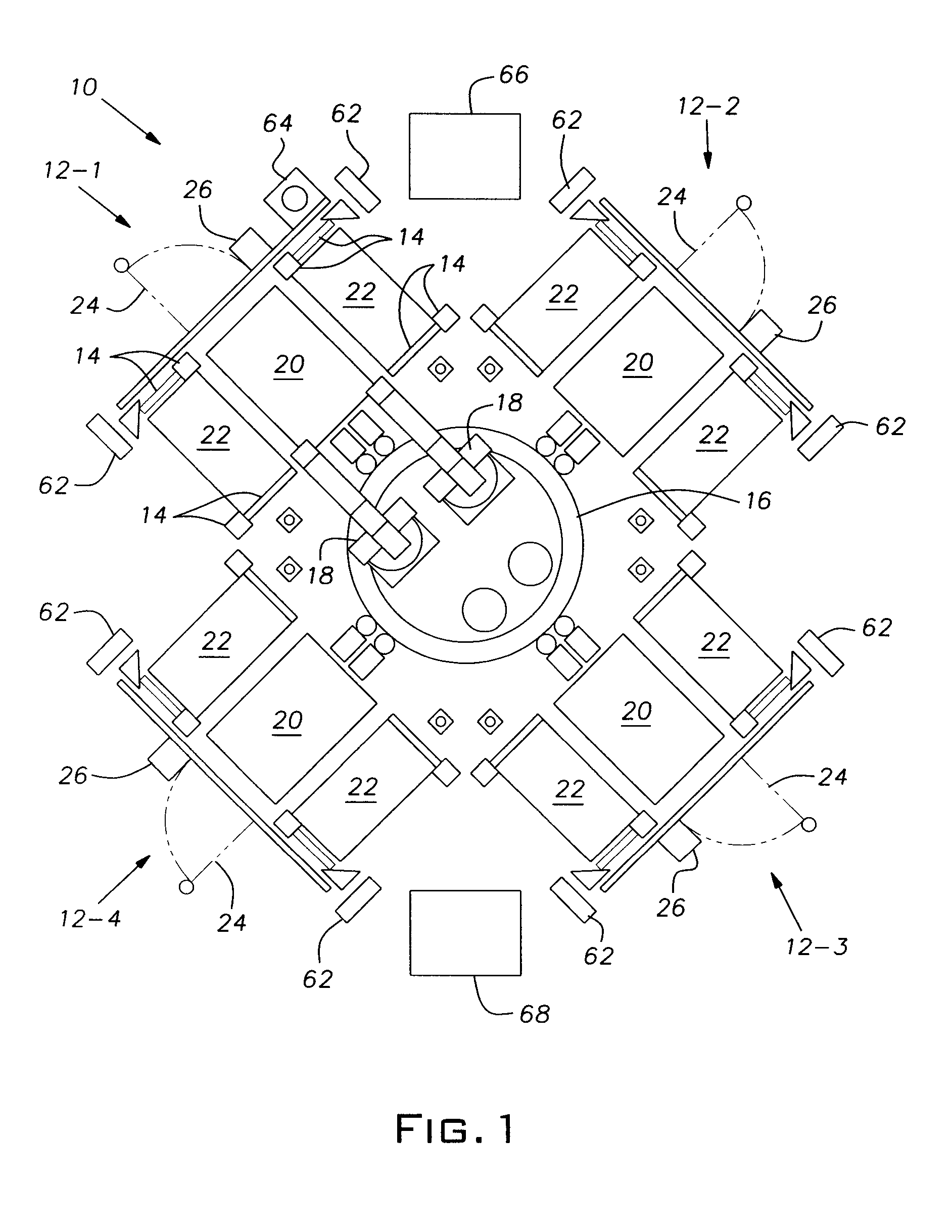

Robotic welding cell unit

InactiveUS20060108342A1Easily fitted into bedMore freedom of movementElectric heatingForging/hammering/pressing machinesRobot weldingEngineering

A portable welding cell unit includes a frame structure in which first and second welding stations are disposed. A robot arm is also provided within the frame. The robot arm can pivot between the first and second welding stations such that a work piece can be welded in the first welding station while a work piece is being loaded into or unloaded from the second welding station.

Owner:LINCOLN GLOBAL INC

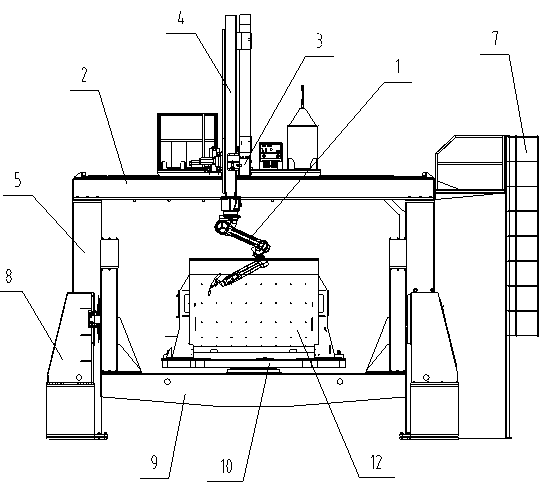

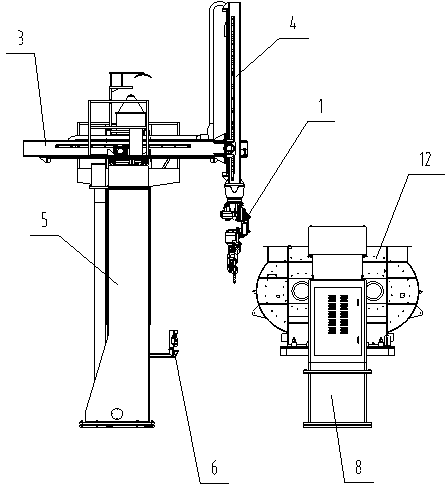

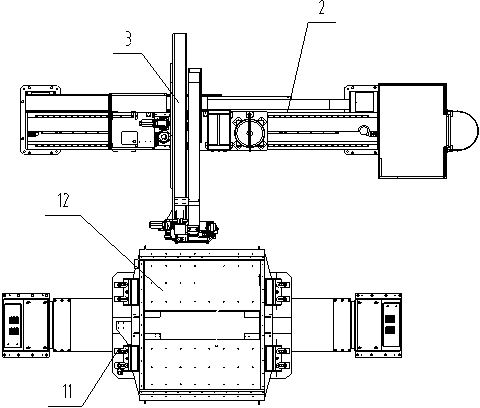

Robot welding workstation for cylinder body

InactiveCN103170707AImprove accessibilityReduce volumeWelding/cutting auxillary devicesElectrode supporting devicesOperation modeWorkstation

The invention discloses a robot welding workstation for a cylinder body. The robot welding workstation for the cylinder body comprises an arc welding robot, a welding positioner and a movable sliding table. The movable sliding table mainly comprises a shaft X, a shaft Y and a shaft Z, wherein the shaft X, the shaft Y and the shaft Z are perpendicular to one another, the shaft X and the shaft Y are horizontally arranged, the shaft Z is vertically arranged, two ends of the bottom portion of the shaft X are connected with upright columns, the top portion of the shaft X is connected with the shaft Y in a sliding mode, and one end portion of the shaft Y is connected with the shaft Z in a sliding mode. The arc welding robot is mounted at the bottom end of the shaft Z, and the welding positioner is arranged beside the movable sliding table and corresponds to the arc welding robot. The robot welding workstation for the cylinder body has the advantages that a traditional manual welding operation mode is replaced, automatic welding of the cylinder body of a stirring machine is realized, and welding efficiency and welding quality are improved.

Owner:成都佳士科技有限公司

Device and method for visual detection of welding quality of robot

InactiveCN103231162AEasy to detectRealize closed-loop feedback controlManipulatorWelding accessoriesClosed loop feedbackAssistive equipment

The invention provides a device and a method for visual detection of welding quality of a robot. The device and the method are characterized in that a visual gun is connected with a welding arm, moves along with a welding gun head, observes welding points and sends scanned picture information to a visual system. The visual system compares the received picture information with standard recipe data and detects and judges weldment splicing errors before welding, welding point quality after welding and a welding process in real time. The method includes: building splicing error detecting standard recipe data, building a welding point standard recipe after welding, building detecting standard recipe data during the welding process, obtaining tracks of the welding points before welding and weldment splicing error picture information, welding point picture information after welding and picture information during the welding process, and comparing the information with the standard recipe data. The device and the method have the advantage of achieving real-time detecting of the welding quality and closed loop feedback control, the detection device is matched with the robot directly to be installed, extra servo follow-up devices are not required to be designed and installed, and investment of a large amount of auxiliary devices is saved.

Owner:柳州市自动化科学研究所

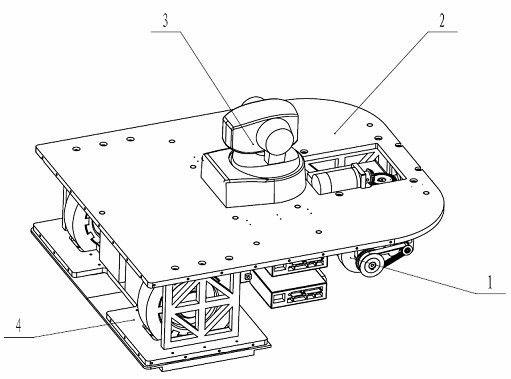

Composite magnetic adsorption visual detection climbing robot

The invention belongs to the technical field of robot welding and particularly relates to a composite magnetic adsorption visual detection climbing robot which comprises a frame, a front wheel module and a back wheel module, wherein the front wheel module and the back wheel module are installed at two ends of the frame. A visual detection pan tilt is installed on the frame, the composite magnetic adsorption visual detection climbing robot is of a three-wheel structure, and three wheels are all driving wheels. The composite magnetic adsorption visual detection climbing robot has the advantages that the composite magnetic adsorption visual detection climbing robot adopts a wheel-type movement mechanism, all wheels are driving wheels, movement flexibility is good, the robot can swerve around the center of the robot body, and the minimum turning radius is 0. An adsorption device simultaneously adopts a magnet wheel and a permanent magnet interval adsorption device, a front wheel adopts the magnet wheel, compactness of the structure is improved while guaranteeing adsorption force, and simultaneously the permanent magnet interval adsorption device is installed on a chassis and around back wheels to guarantee that the robot has strong loading capability.

Owner:DONGFANG ELECTRIC CORP LTD

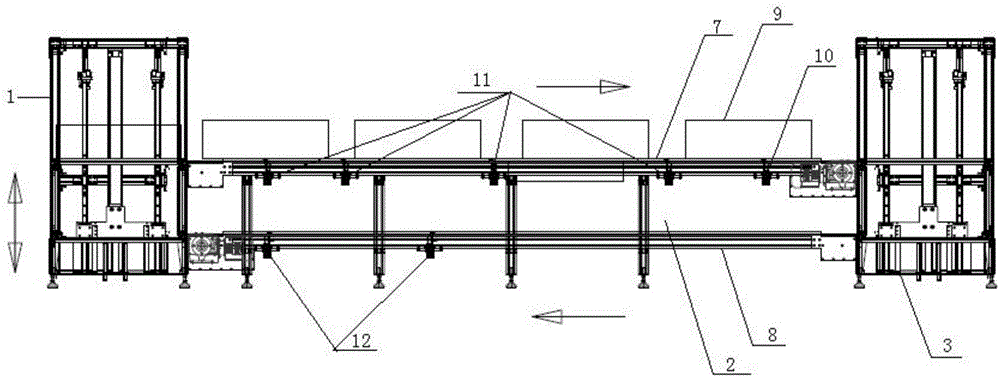

Circular material conveying system of robot welding device

InactiveCN106219187AFacilitate automated productionReduce labor costsConveyor partsMechanical conveyorsEngineeringMechanical engineering

The invention discloses a circular material conveying system of a robot welding device. The system sequentially comprises a lifting machine I, a double-layer conveying line and a lifting machine II; the lifting machine I comprises a lifting table body I and a motor for controlling the lifting table body I to ascend and descend; the double-layer conveying line comprises a horizontal upward layer conveying belt, a horizontal downward layer conveying belt and a motor for controlling the horizontal upward layer conveying belt and the horizontal downward layer conveying belt to transmit; the vertical distance between the upper layer conveying belt and the lower layer conveying belt is consistent with the distance of vertical movement of the lifting table body I and / or the lifting table body II; the lifting machine II comprises a lifting table body II and a motor for controlling the lifting table body II to ascend and descend; the lifting machine I corresponds to the feeding station, the lifting machine II corresponds to the discharging station, the double-layer conveying line corresponds to multiple stations, the robot welding device is located at the welding station corresponding to the double-layer conveying line, and a positioning gear stop is arranged at the welding station corresponding to the double-layer conveying line.

Owner:NANJING ENIGMA IND AUTOMATION TECH CO LTD

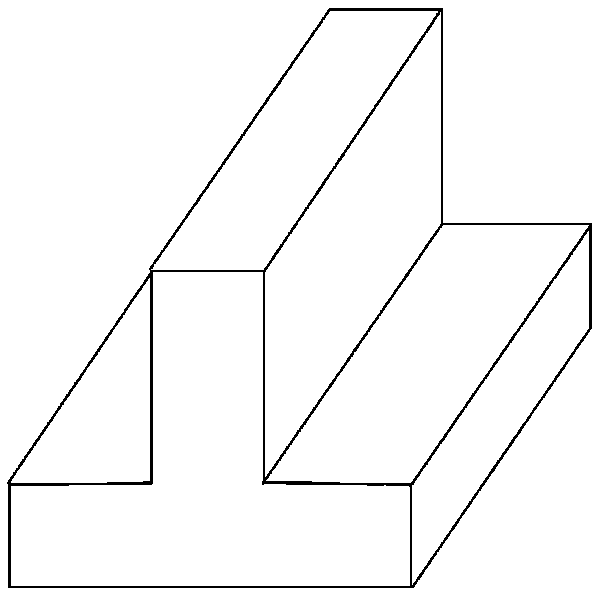

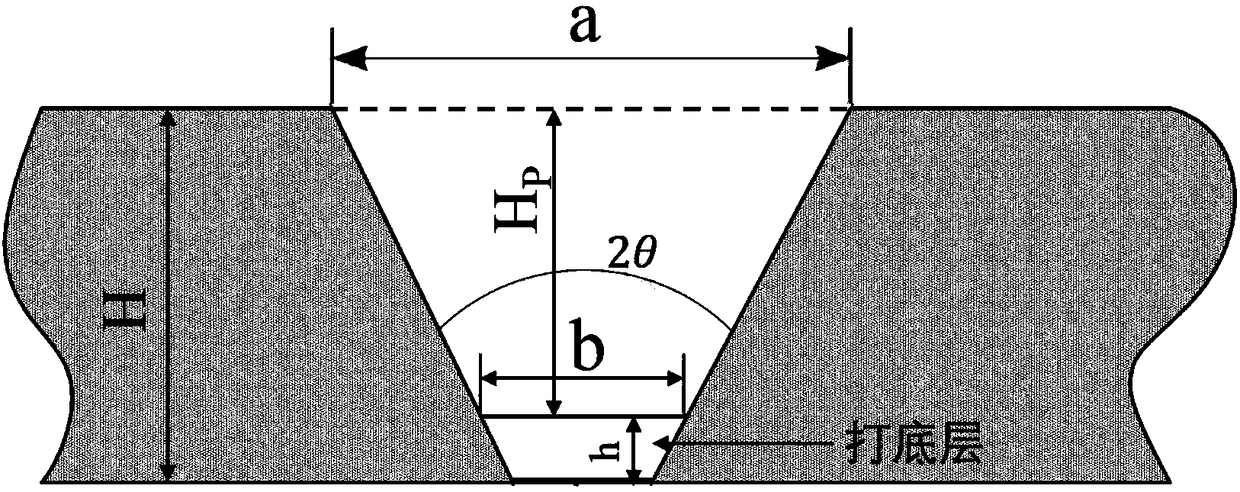

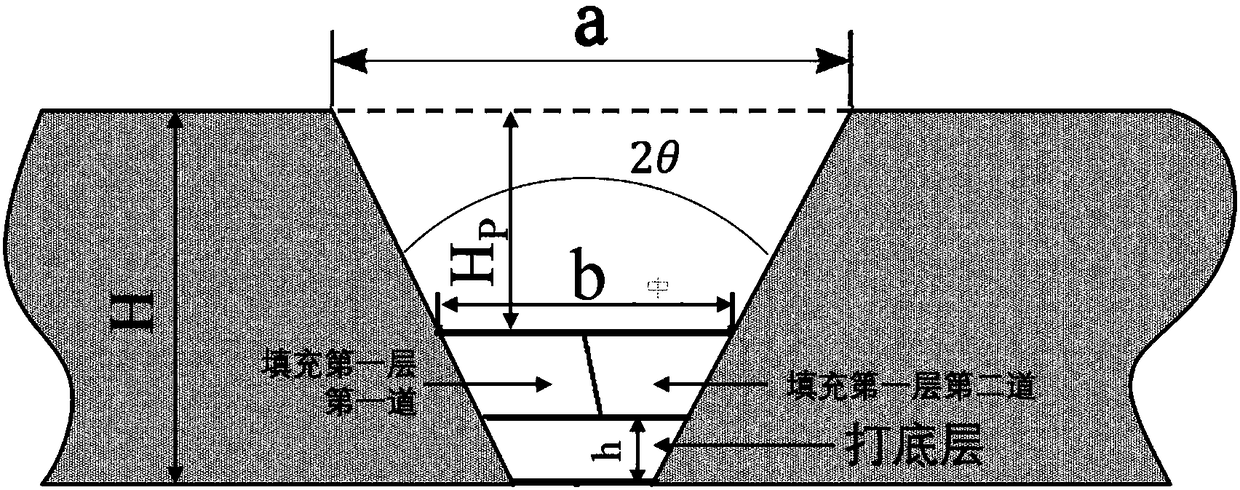

Multilayer and multipass welding method of robot

ActiveCN108188548AReduce the difficulty of buildingWide applicabilityWelding accessoriesRobotic systemsThick plate

The invention relates to a multilayer and multipass welding method of a robot, which is used for groove welding seams of thick plates. Multilayer and multipass automatic MAG welding is performed on athick plate taking a T-shaped panel as an example by adopting a robot, the robot system is integrated with an arc welding robot, an arc welding power supply system, a robot welding gun system, a linelaser scanning system and a robot control system, groove information such as the groove top width, the groove bottom width, the groove central position and the like of a V-shaped groove welding seam can be obtained by the line laser scanning system, a groove bottom width matching process database is obtained through line laser scanning so as to complete one to two layers of multilayer and multipass welding, and the line laser scanning is performed for many times so as to complete the multilayer and multipass welding of the whole welding seam. According to the method, the problem of inaccuratepaths caused by excessive layers and passes in traditional multilayer and multipass automatic welding is effectively solved.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP +1

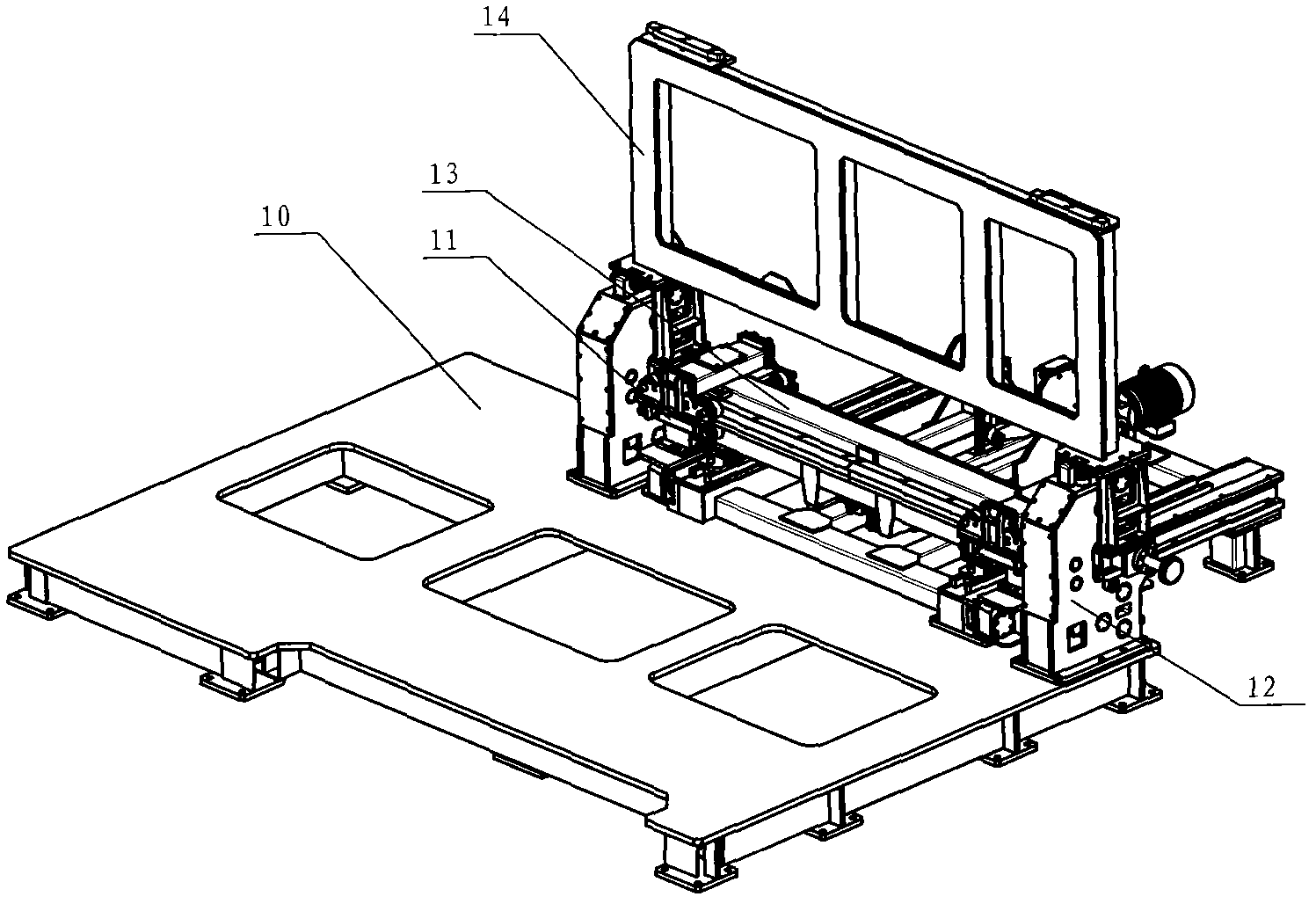

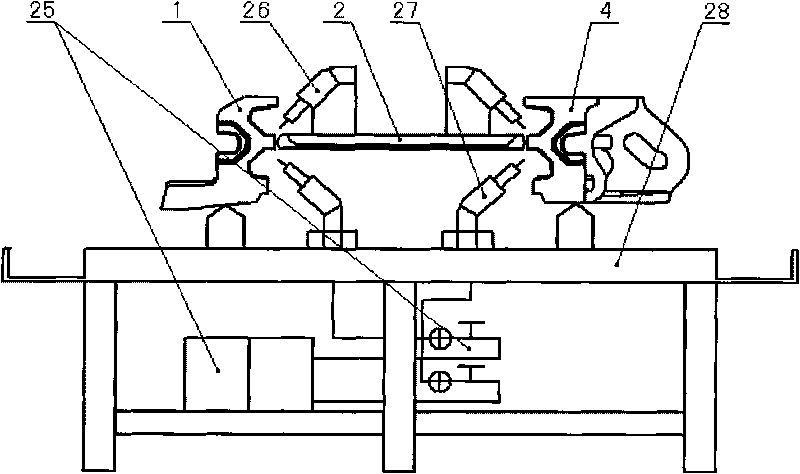

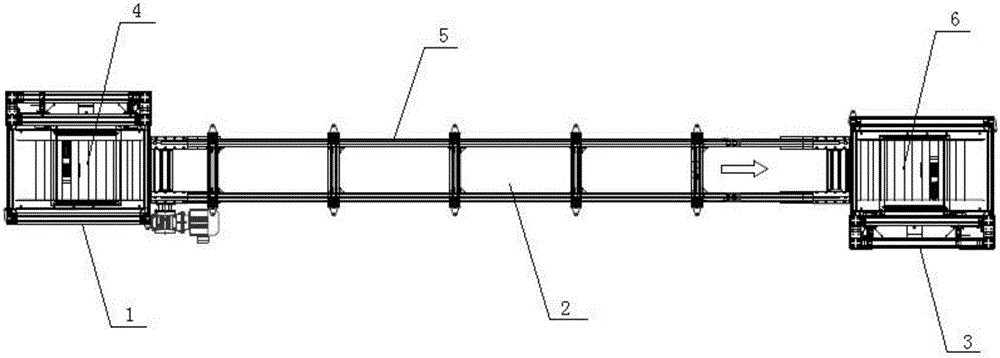

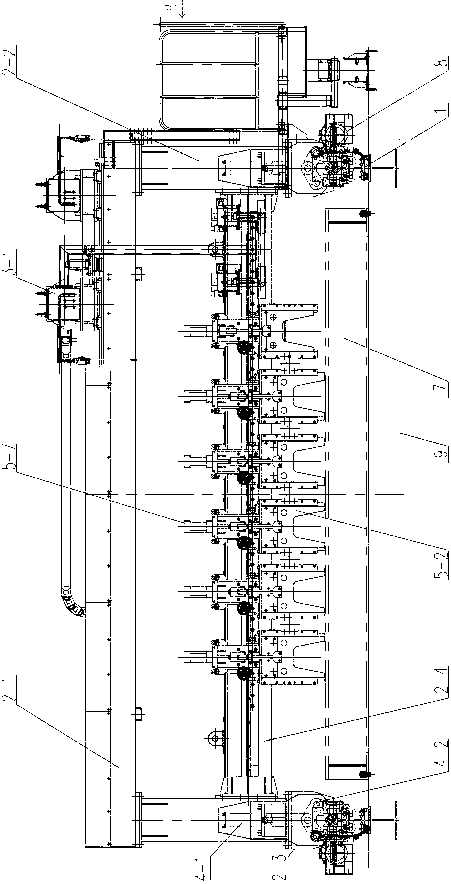

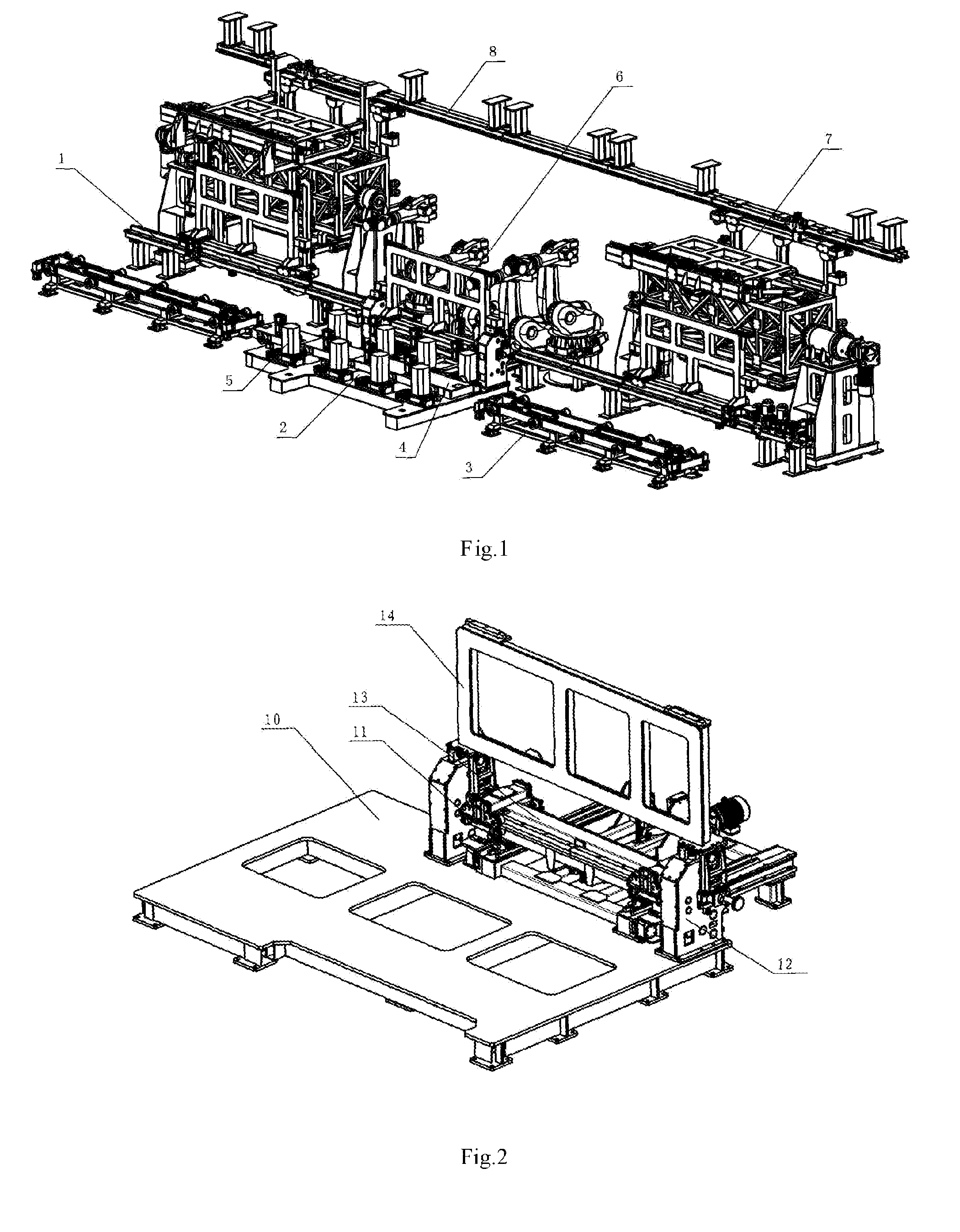

Automatic assembling and tack welding system for U-shaped rib plate units

ActiveCN103008933AImprove assembly accuracyHigh automatic assembly production efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRobot welding

The invention discloses an automatic assembling and tack welding system for U-shaped rib plate units, which comprises a pair of parallel rails and a gantry, the gantry can move on the rails, and an assembling platform is laid between the two rails; the gantry comprises an upper crossbeam, a lower crossbeam, four uprights and two traveling beams, the upper crossbeam and the lower crossbeam are respectively fixed between the two front uprights, and one gantry-traveling mechanism is respectively arranged on the bottom of each of the two traveling beams; a movable welding system is arranged on the upper crossbeam; and a movable two-dimensional adjustable positioning and pressing system is arranged on the lower crossbeam. Because the two-dimensional adjustable positioning and pressing system is combined with a polishing and dedusting system and the robotic welding system, the polishing and dedusting of the area to be welded of the U-shaped rib plate units, the positioning and pressing of U-shaped ribs and robotic tack welding can be full-automatically controlled together, and the automatic assembling and tack welding system has the advantages that the assembly precision of the U-shaped ribs of orthotropic bridge plate units is high, the automatic assembly and production efficiency is high, and the quality of welding lines is stable.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

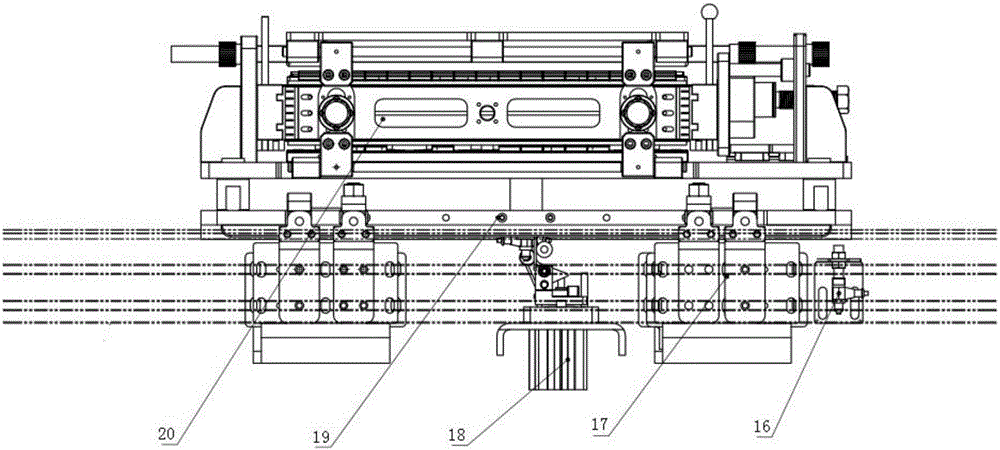

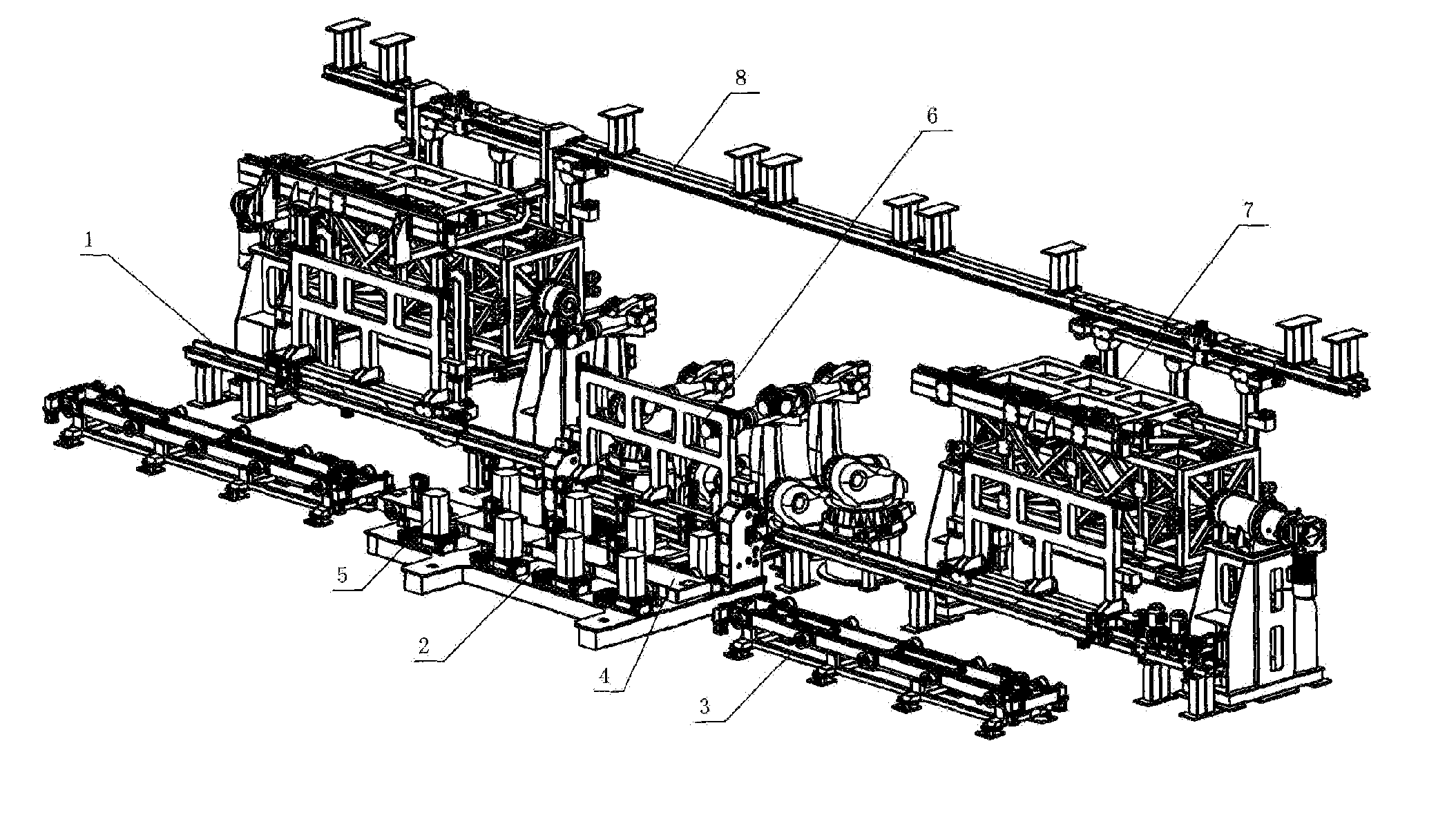

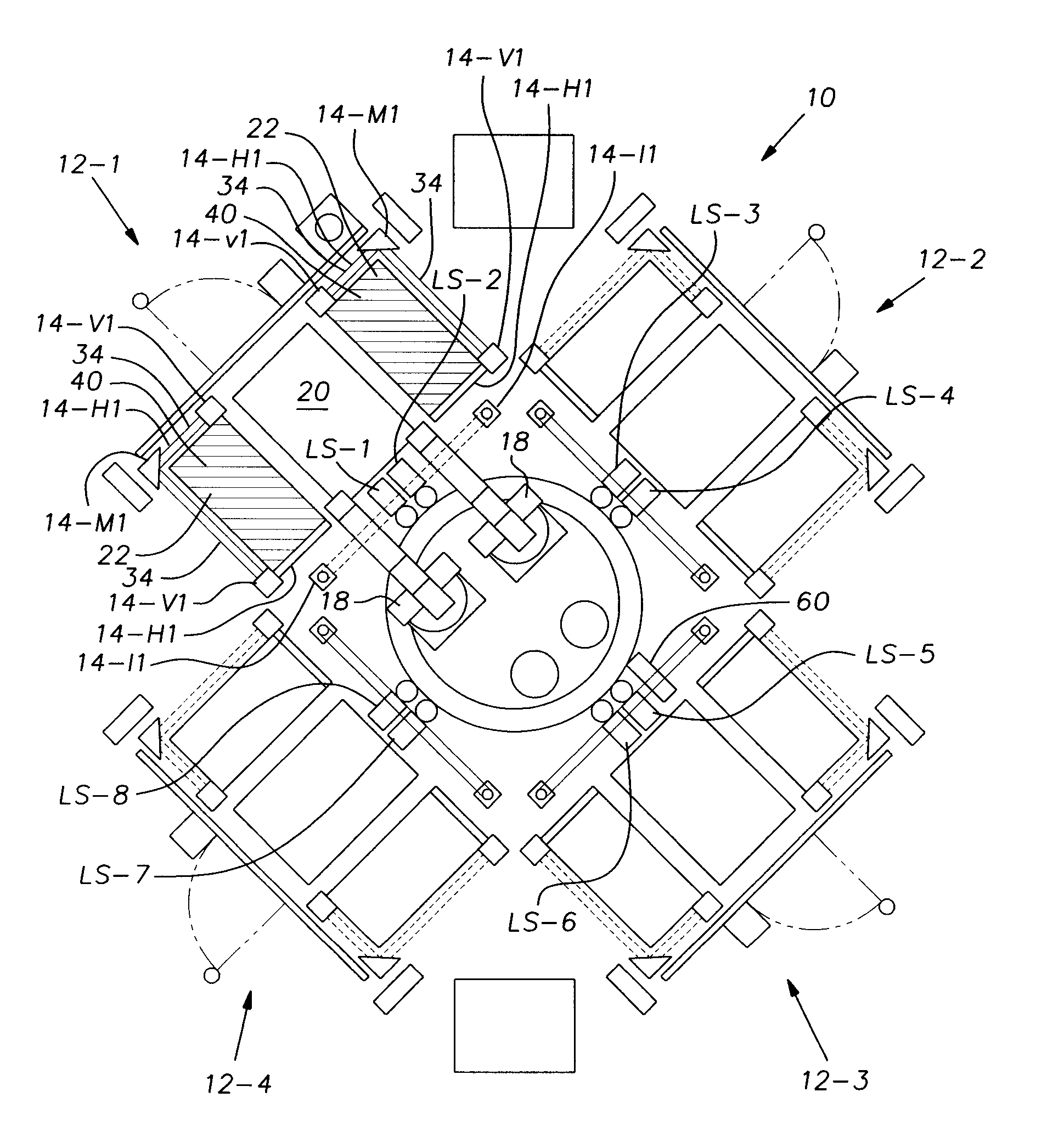

Multi-vehicle model collinear flexible framing system

ActiveUS20150001279A1Improve production efficiencyRapid paceWelding/cutting auxillary devicesAuxillary welding devicesProduction lineTransport system

A multi-vehicle type co-production line flexible framing is disclosed, comprising a robot welding system, a high speed transport system, a floor panel intelligent flexible positioning system, and a side panel flexible positioning and switching system. The floor panel intelligent flexible positioning system is correspondingly connected to a transfer rail of the high speed transport system. The side panel flexible positioning and switching system comprises a side panel fixture consolidation system, a fixture storage system, and a fixture switching and rail system. The side panel fixture consolidation system corresponds to the side of the floor panel intelligent flexible positioning system. The fixture storage system is arranged on two sides of the side panel fixture consolidation system in the transfer direction of the high speed transport system. The fixture switching and rail system is connected between the side panel fixture consolidation system and the fixture storage system. The improved structure is relatively compact and practical, has a short switching time, a high production efficiency, and a small floor area, and may use a large number of welding robots, fully satisfying the capacity requirement of 60JPH of the automobile factory.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD

Turntable welding system with light curtain protection

InactiveUS20100044414A1Avoid injuryProgramme-controlled manipulatorWelding/cutting auxillary devicesRobot weldingWelding process

A robotic welding system is provided that includes multiple welding cells equidistantly spaced in a circular arrangement, multiple perimeter light curtains to provide safety protection around the welding cells, a turntable centrally located in the circular arrangement, and multiple welding robots attached to the turntable. The welding system further includes a first welding process and a second welding process whereby both the first welding process and the second welding process each include a primary welding operation and a secondary welding operation whereby the turntable rotates between the welding cells to perform the primary and secondary welding operations.

Owner:HONDA MOTOR CO LTD

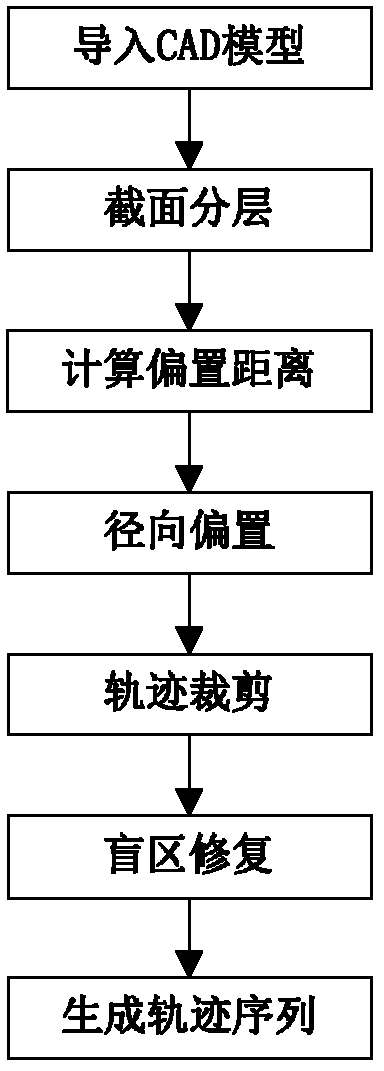

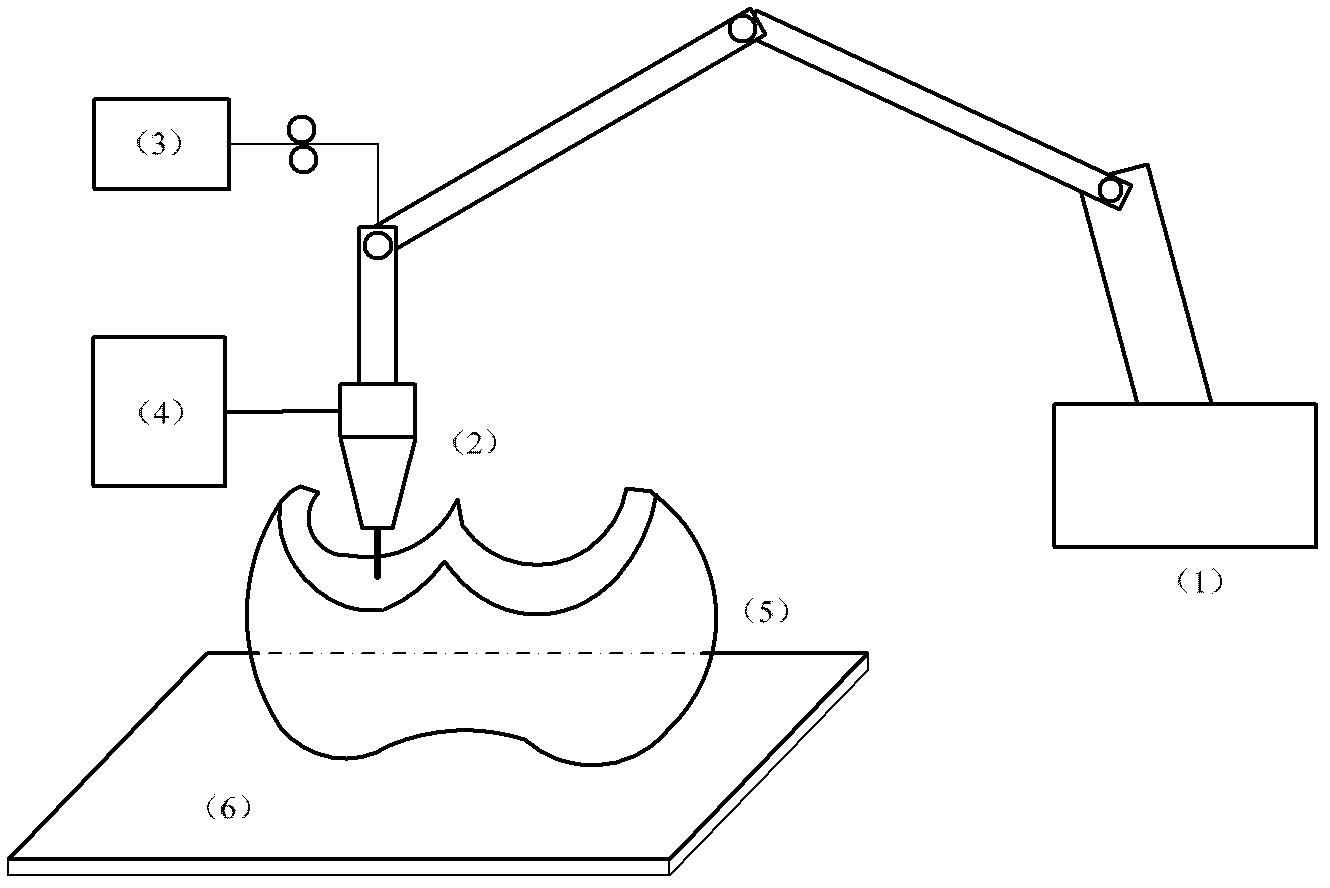

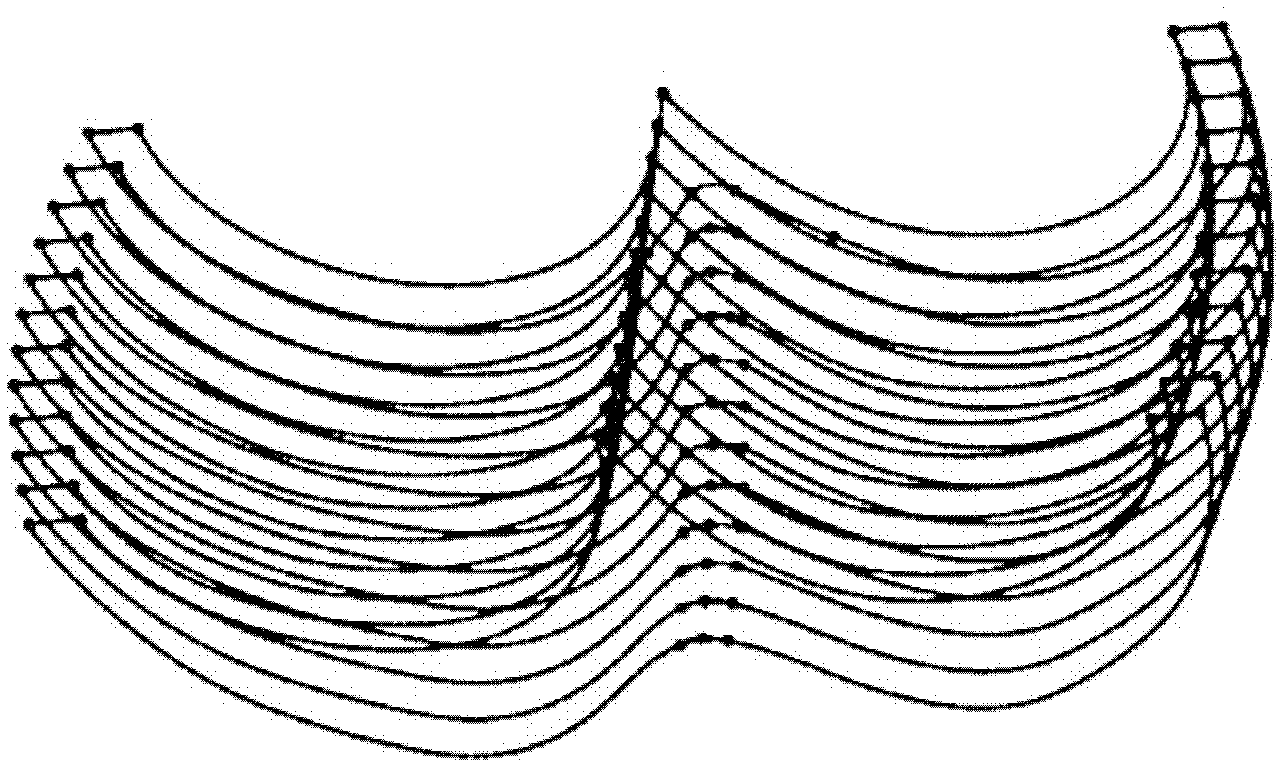

Path planning method for complicated-shape workpiece of robot bead weld based on radial bias

InactiveCN102218578AImprove efficiencyPromote generationArc welding apparatusService efficiencyWorkload

The invention relates to a path planning method for a complicated-shape workpiece of robot bead weld based on radial bias. In the method, a robot welding path is automatically planned based on a workpiece computer assisted drafting (CAD) model, contour lines on one side of the cross section of the workpiece are adopted as bias lines, contour lines on another side of the cross section are subjected to radial deflection successively, welding path lines of the cross section are automatically generated to ensure the appearance precision of the workpiece and distance between the path lines and solve the problems of self-cross of rings, straight line segment disappearance and the like. For the bias lines with excessively-changed curvature, subsection bias is performed according to curvature characteristics to adapt to complicated profile, a repair arithmetic is designed according to the requirement of a welding process and appearance characteristics of a workpiece model, the deflected path lines are adjusted to repair a dead area, and the workloads required by repairing welding and polishing are reduced. Due to the adoption of different appearances such as the complicated-shape workpiece of an arc welding robot in the method, the programming time of robot welding operation can be greatly shortened, and the service efficiency of the robot is obviously improved.

Owner:SOUTHEAST UNIV

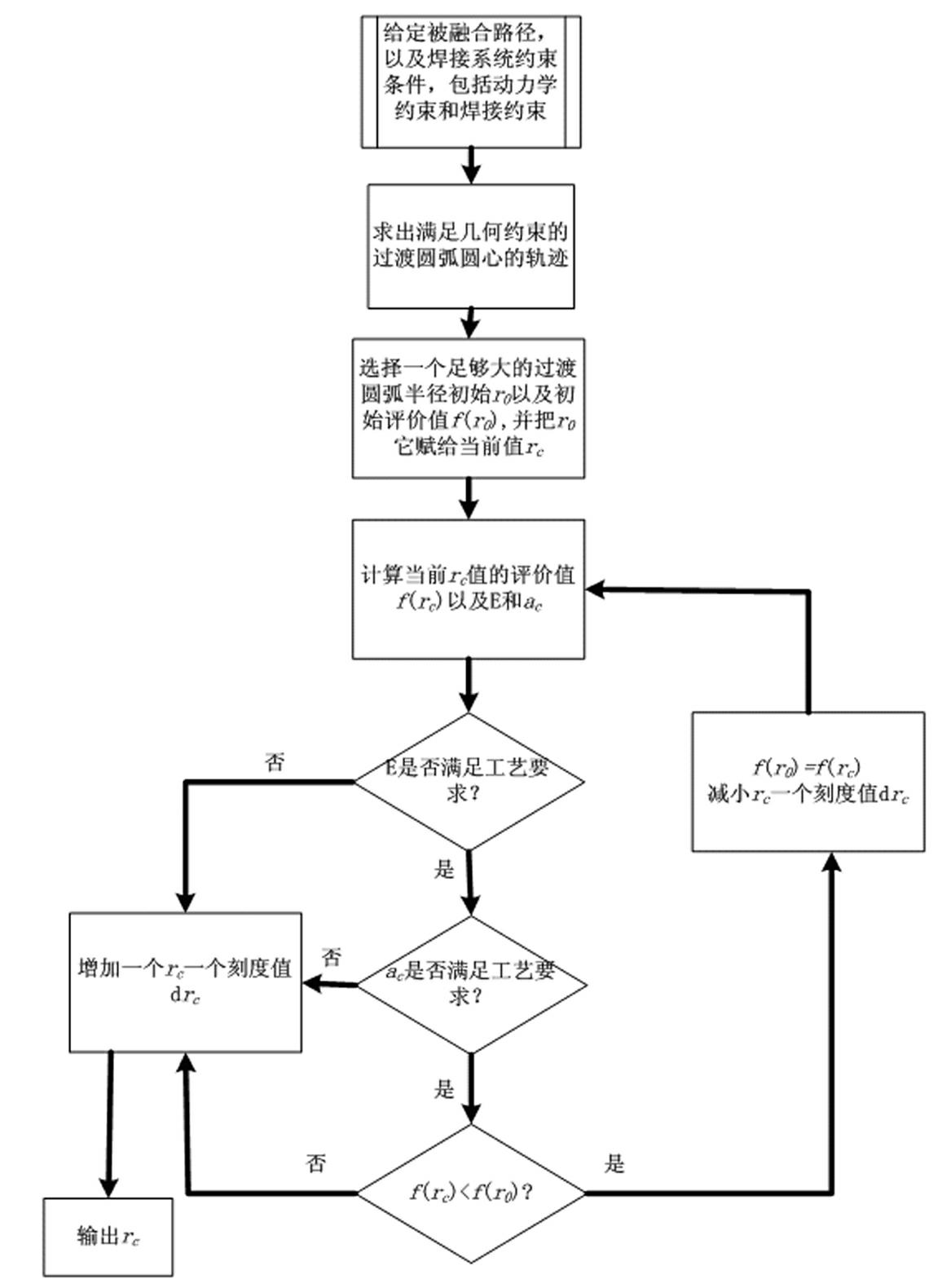

Transitional track planning method for welding robot

InactiveCN102091879AExecution time minimizationFacet joint torque fluctuationsWelding apparatusSimulationStraight segment

The invention discloses a transitional track planning method for a welding robot. The transitional track is used for fusing a straight segment welding line and an arc segment welding line, geometric constraint conditions of adjacent fused straight segment welding line and fused arc segment welding line of a workpiece to be welded are imported into a robot path planning module to generate a transitional segment arc welding line track, and by controlling the arc radius of the transitional segment track, welding constraint conditions and robot welding system dynamic constraint conditions are metwhen the robot welds the transitional segment. The track planning method is suitable for switching different segments of tracks and planning transitional tracks, and solves the problem of smoothness of transiting from the straight segment welding line to the arc segment welding line when the robot performs arc welding.

Owner:CHANGSHA HONGDIAN AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com