Multilayer and multipass welding method of robot

A multi-layer, multi-pass, robot technology, applied in the field of robot multi-layer multi-pass welding, can solve the problems of difficulty, many layers, and many groove information, and achieves the effect of great flexibility and overcoming too many layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical solutions and advantages of the present invention clearer, the implementation method of the present invention will be further described in detail below in conjunction with the accompanying drawings.

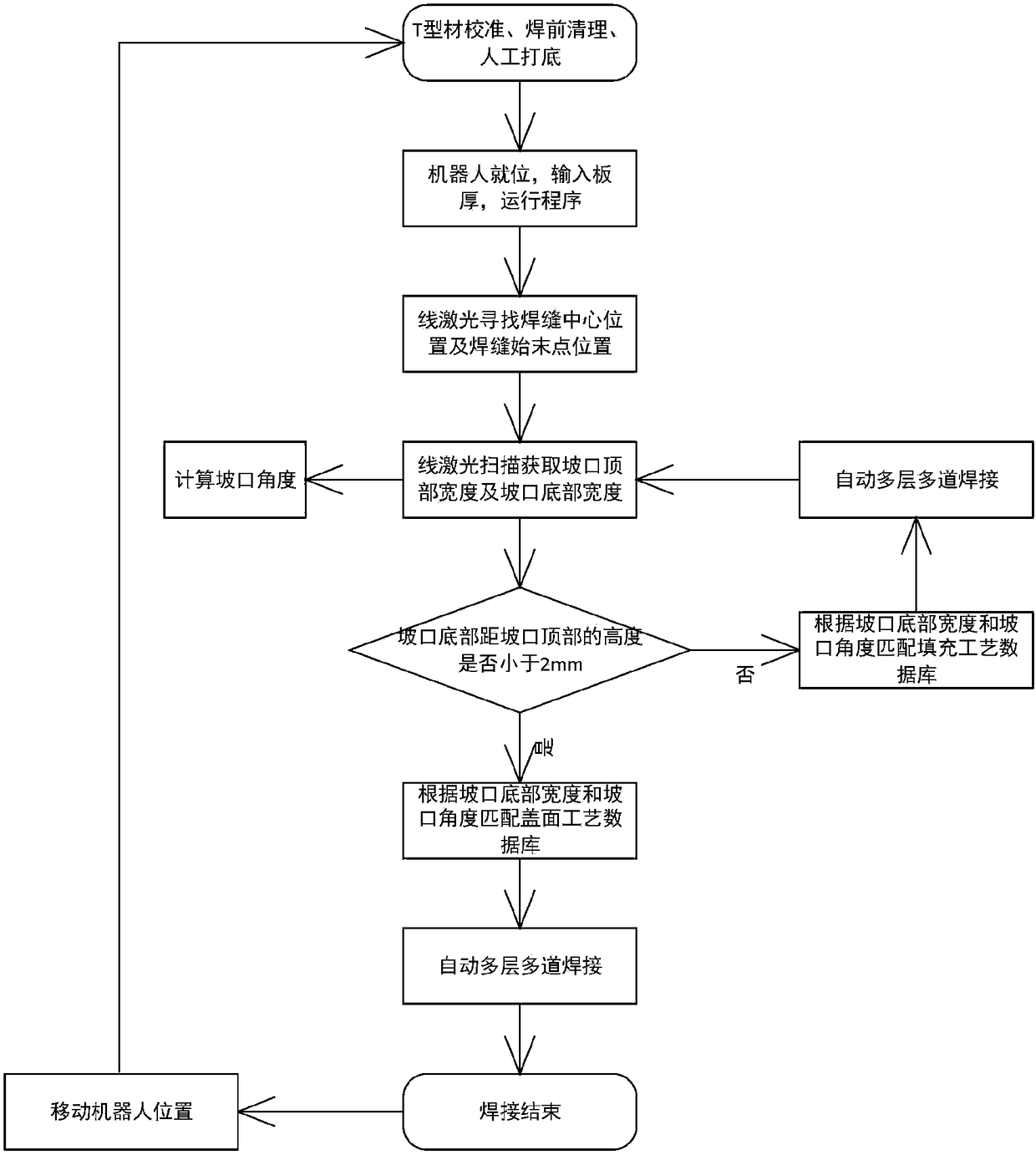

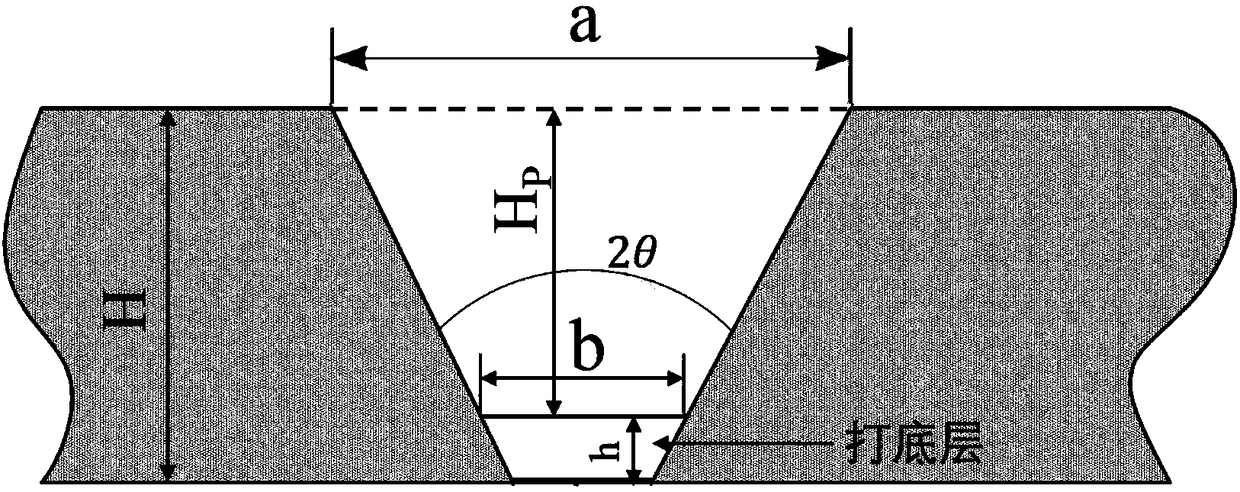

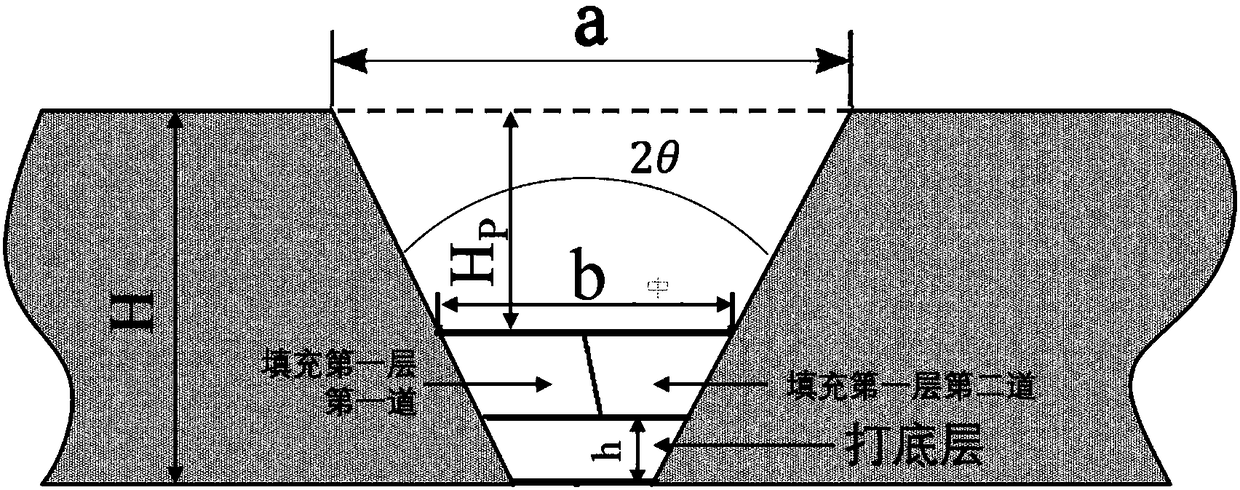

[0031] The invention provides a robot multi-layer and multi-pass welding method for thick plate groove welds, especially designed for multi-layer and multi-pass welding of T-profile panels. figure 1 It is a schematic flow chart of the robot multi-layer and multi-pass welding method for thick plate groove welds according to the embodiment of the present invention. The present invention uses a robot system to perform multi-layer and multi-pass automatic MAG welding on thick plates. The robot system includes an arc welding robot, an arc welding Power supply system, robot welding torch system, line laser scanning system and robot control system. The robot control system has an arc welding software package: it can control welding process parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com