SPAR platform hard tank

A platform and hard tank technology, applied in the field of SPAR platform hard tank design, can solve the problems of increased oil production and maintenance costs, the inability to use TTR risers, and the inability to open central wells, etc., to improve construction efficiency, excellent hydrodynamic performance, The effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

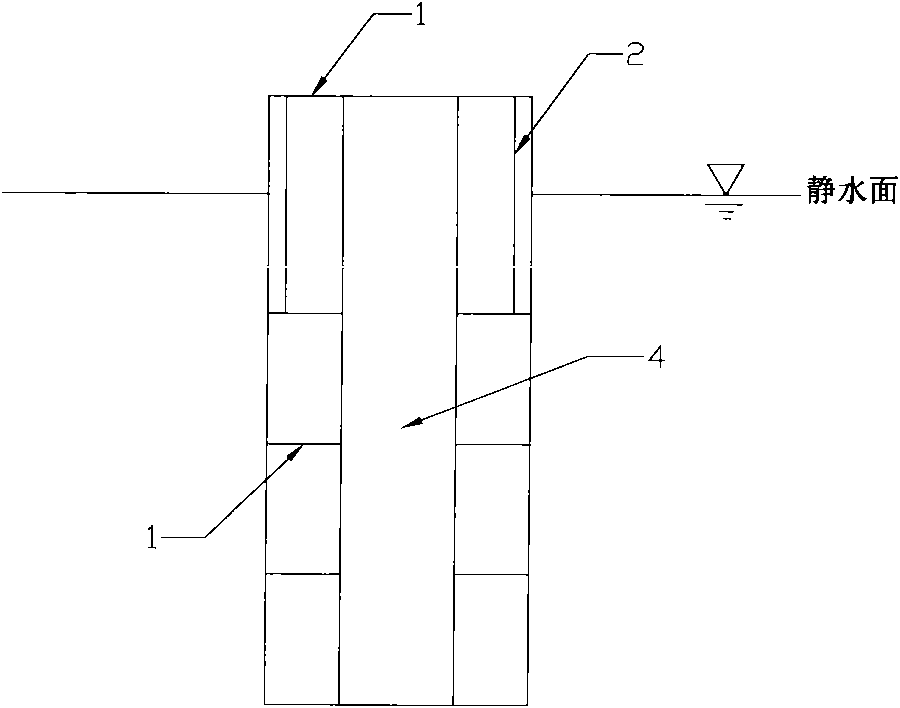

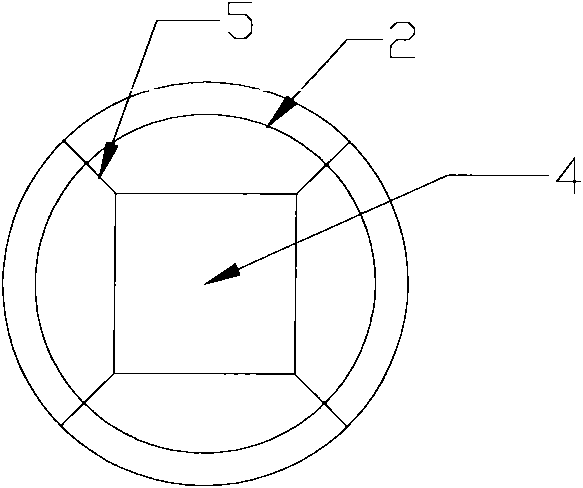

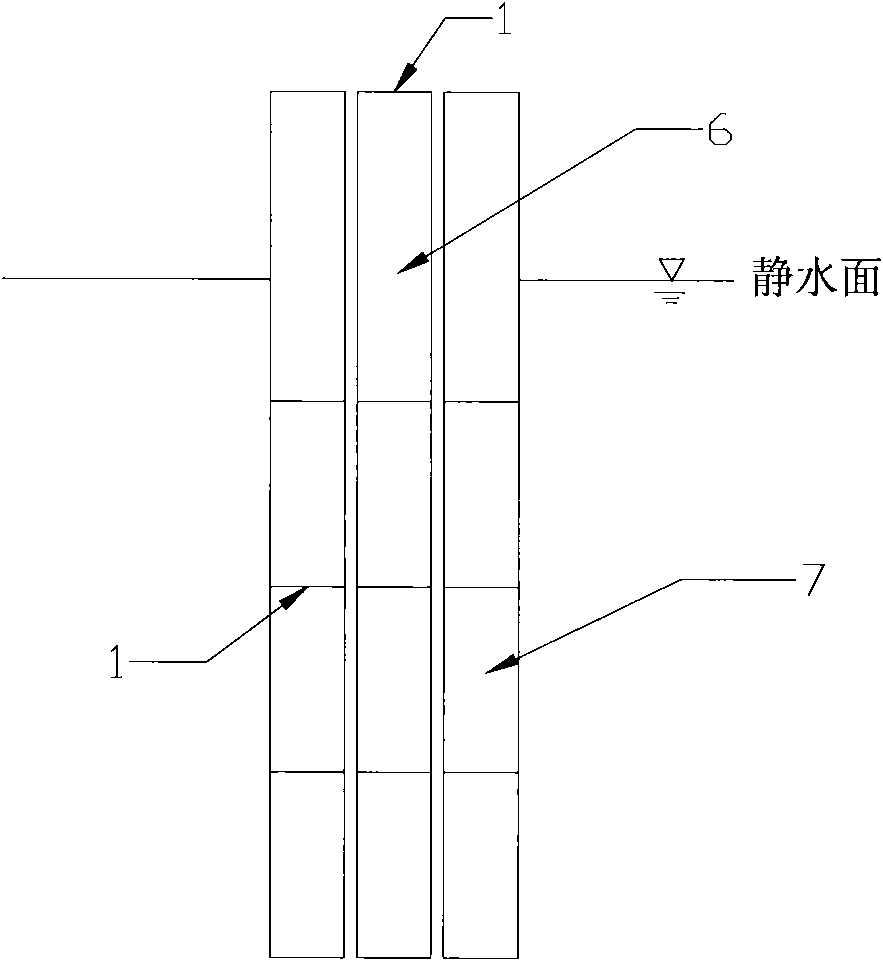

[0020] The type of SPAR platform hard cabin of the present invention is as Figure 5 As shown, a peripheral cylinder (7) is provided on the outside of the central cylinder (6), and the peripheral cylinder (7) provides the required buoyancy for the SPAR platform; the diameter of the central cylinder (6) is to be able to provide The degree of sufficient area; in the central column (6), there is a central well (4), and the TTR riser can pass through the central well (4) deck (1), divide the cylinder into several compartments, and the functions of the compartments can be determined according to needs ; Peripheral cylinders (7) are all located below the still water surface to reduce the force of wave currents on the horizontal direction of the SPAR platform; the top deck (1) of the peripheral cylinders (7) can be either horizontal or sloped; in the central cylinder ( 6) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com