Patents

Literature

802 results about "Central cylinder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A scaffolding structure present within the inner region of the ciliary transition zone. The central cylinder lies between the outer doublet and inner singlet microtubules. [GOC:kmv, PMID:2428682, PMID:26124290]

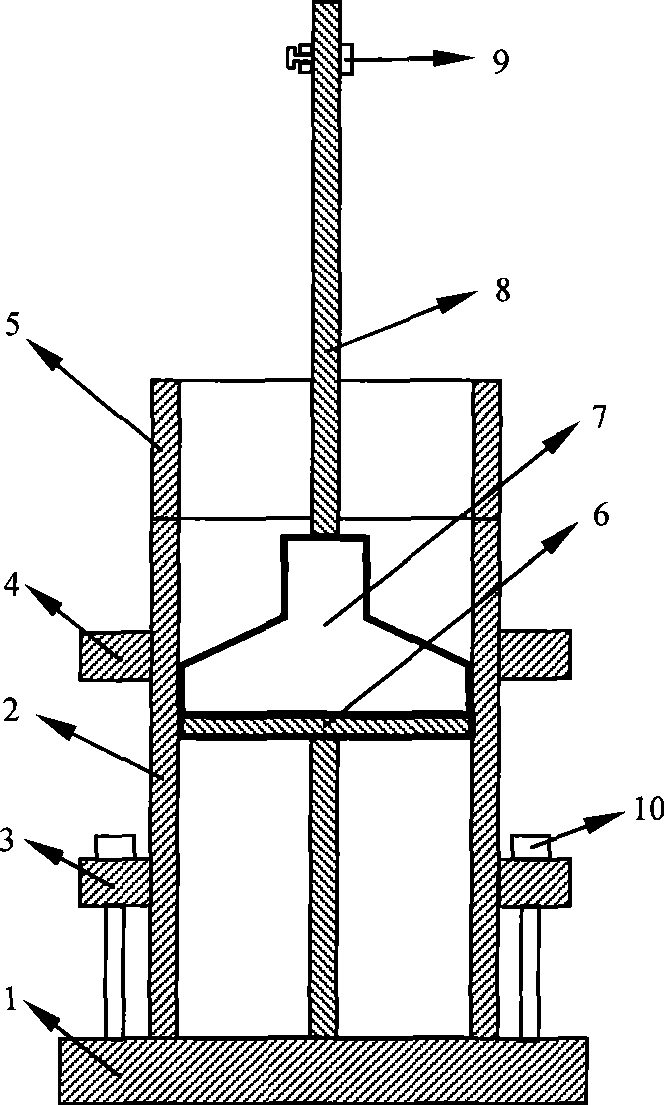

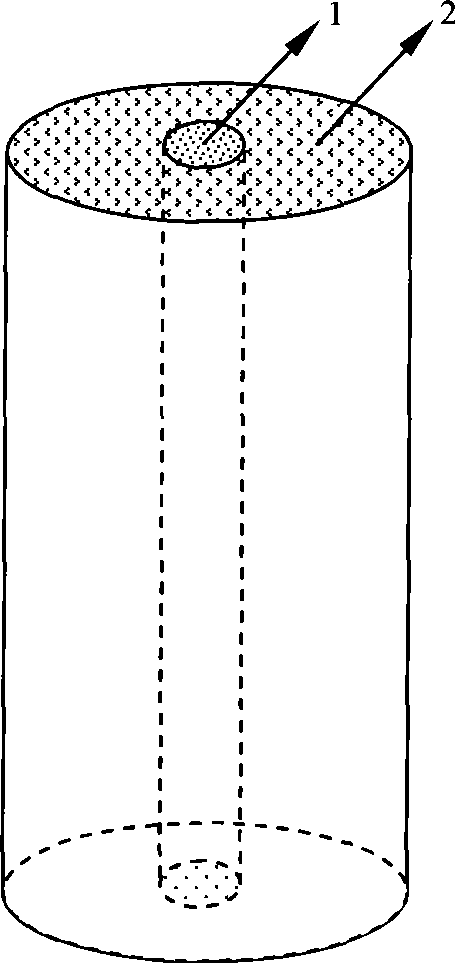

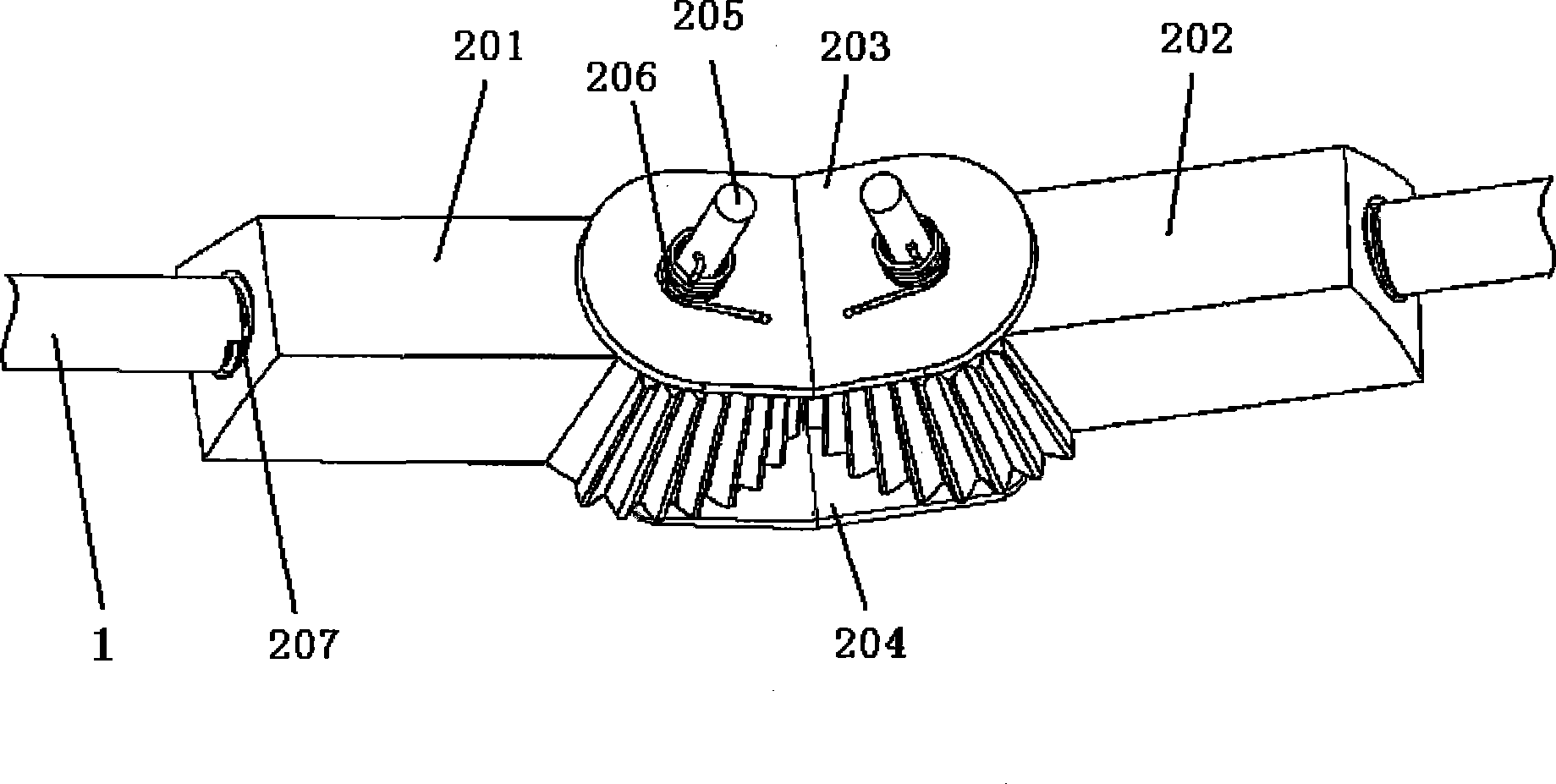

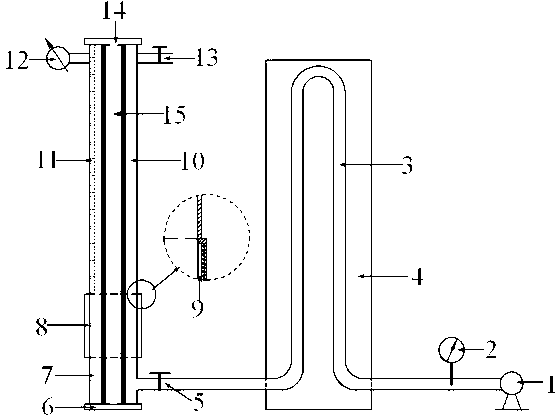

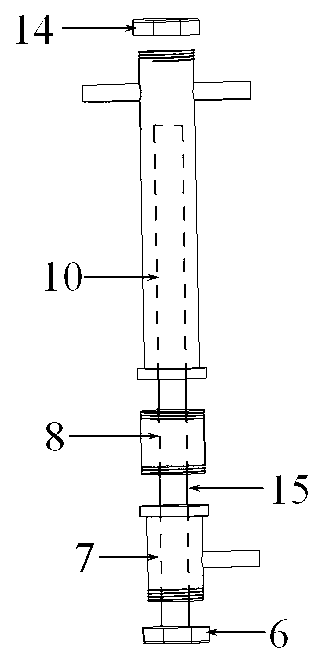

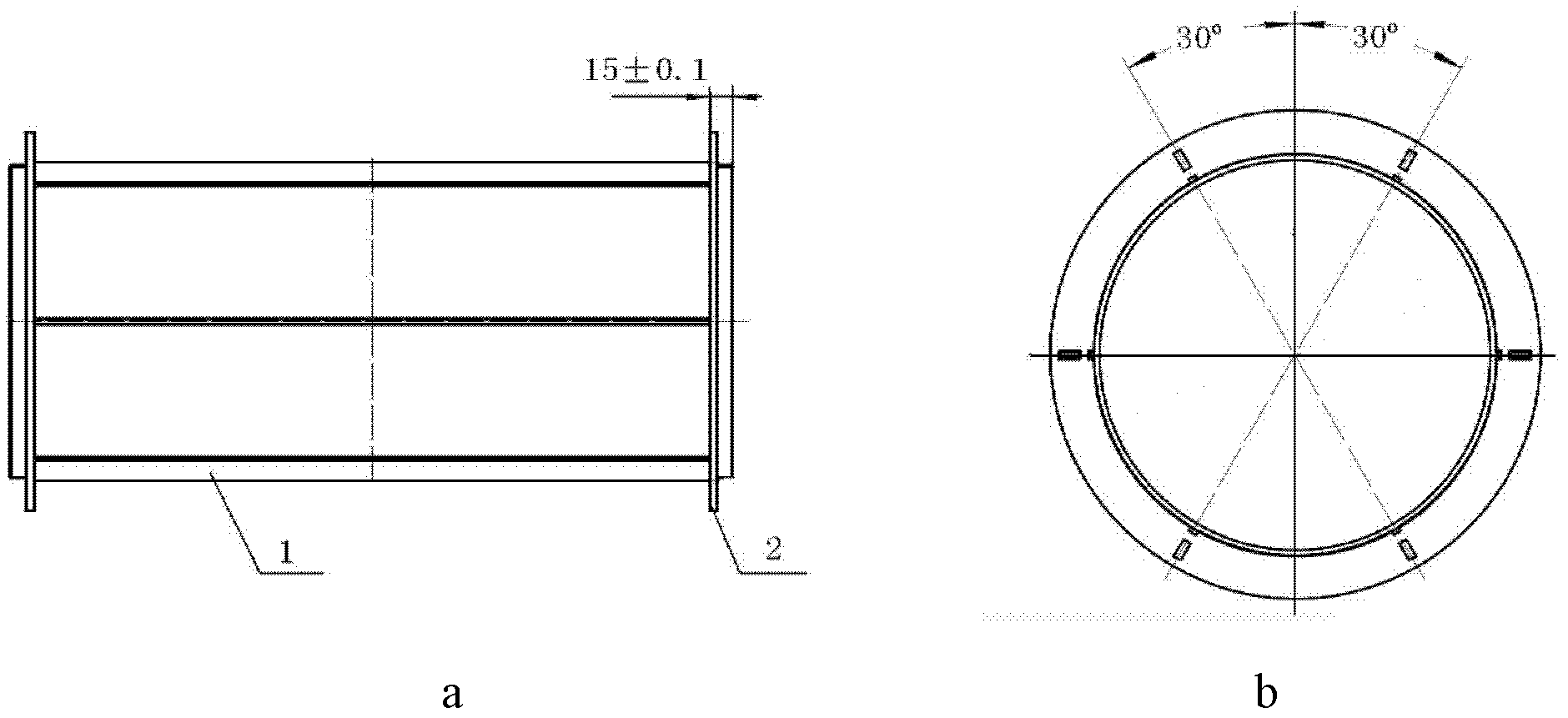

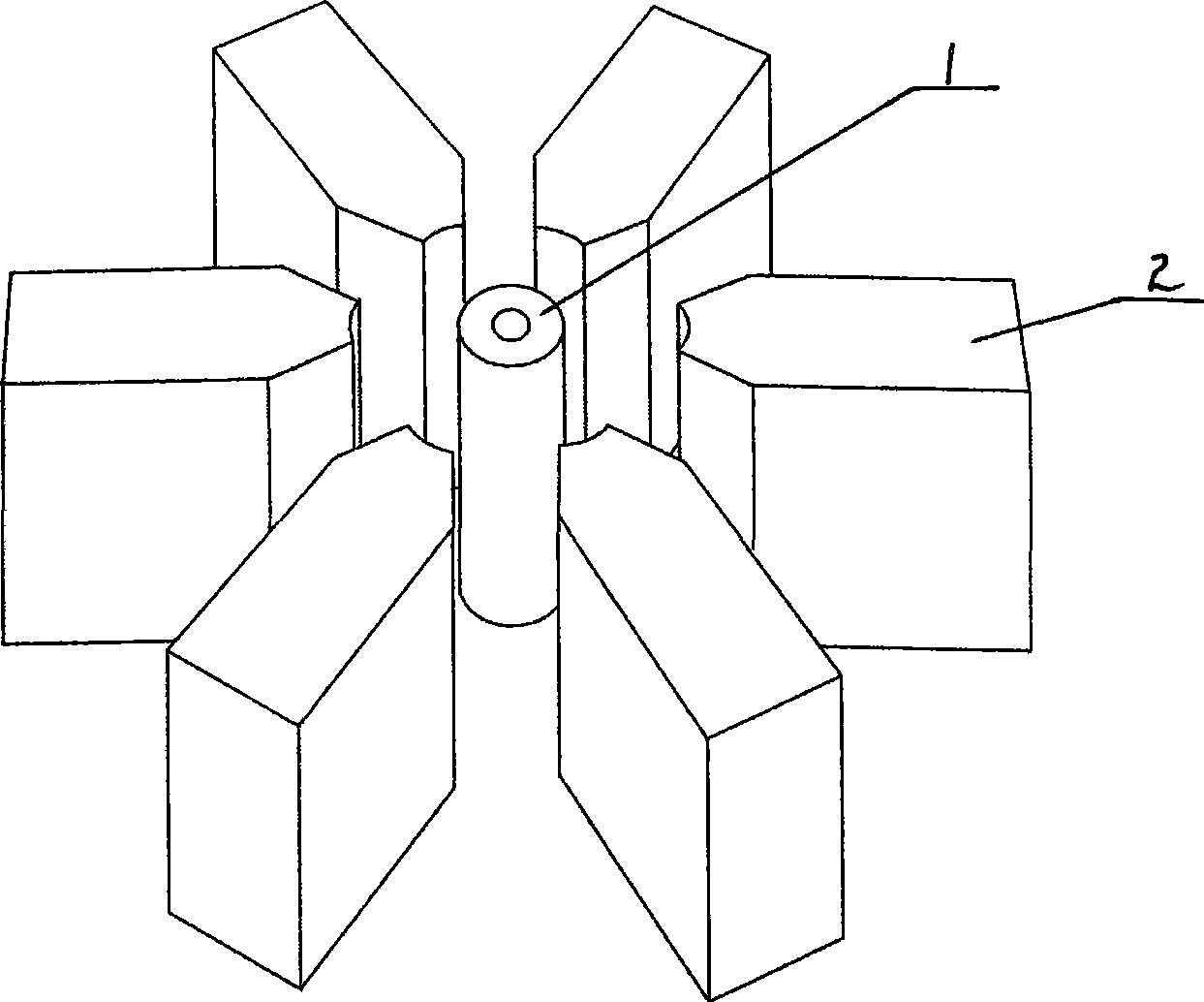

Sample preparing machine and method of soil body rapid triaxial test

InactiveCN101441149ASolve sample preparation technical problemsAvoid duplicate configurationPreparing sample for investigationEarth material testingTriaxial shear testMetal sheet

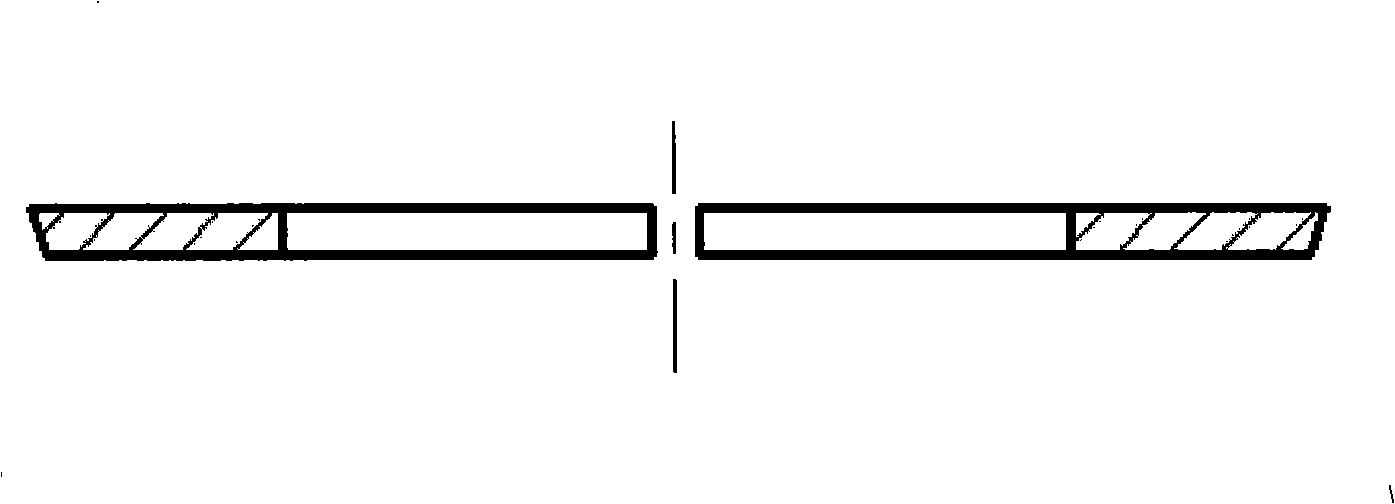

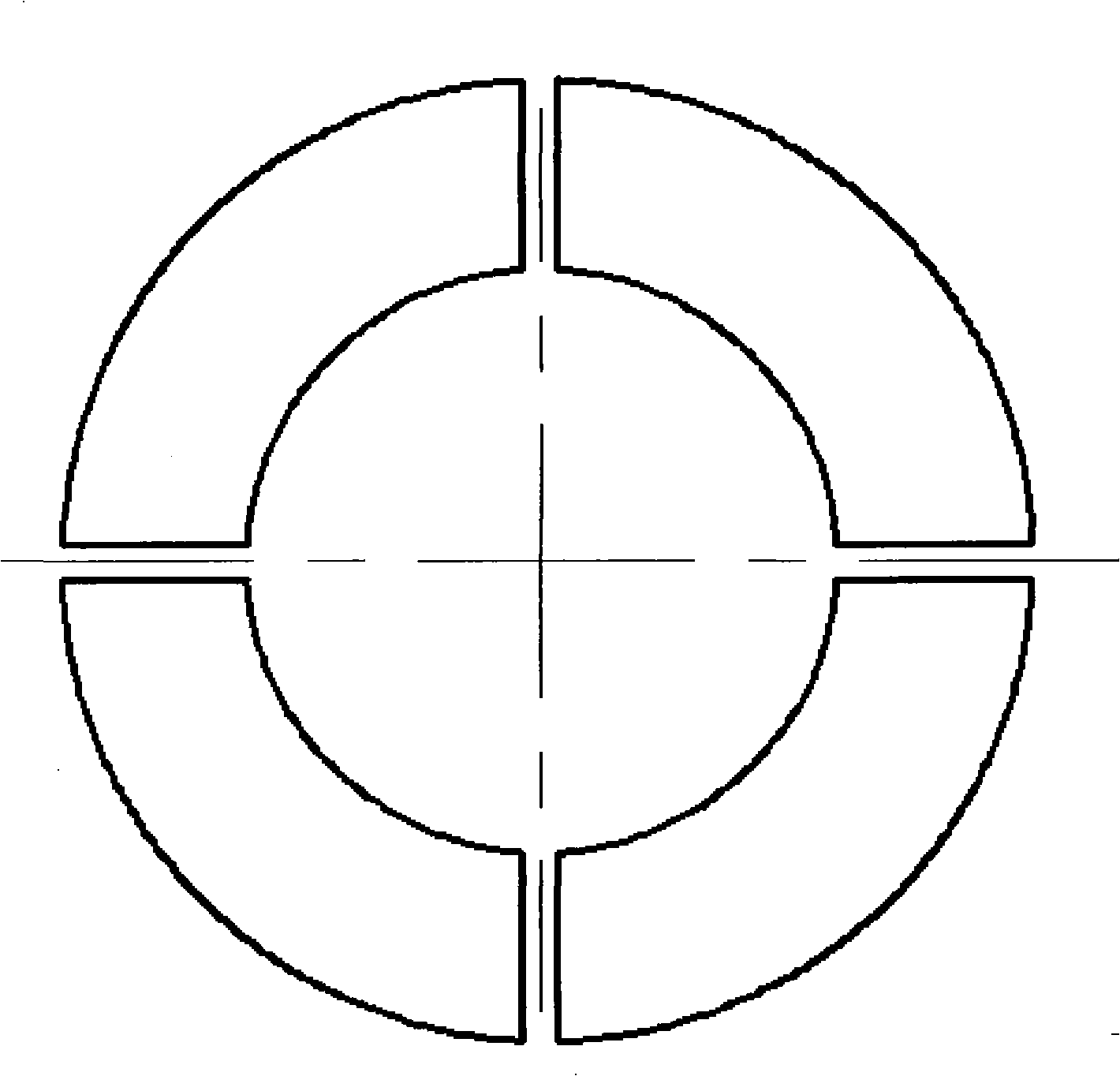

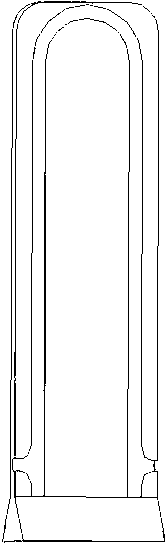

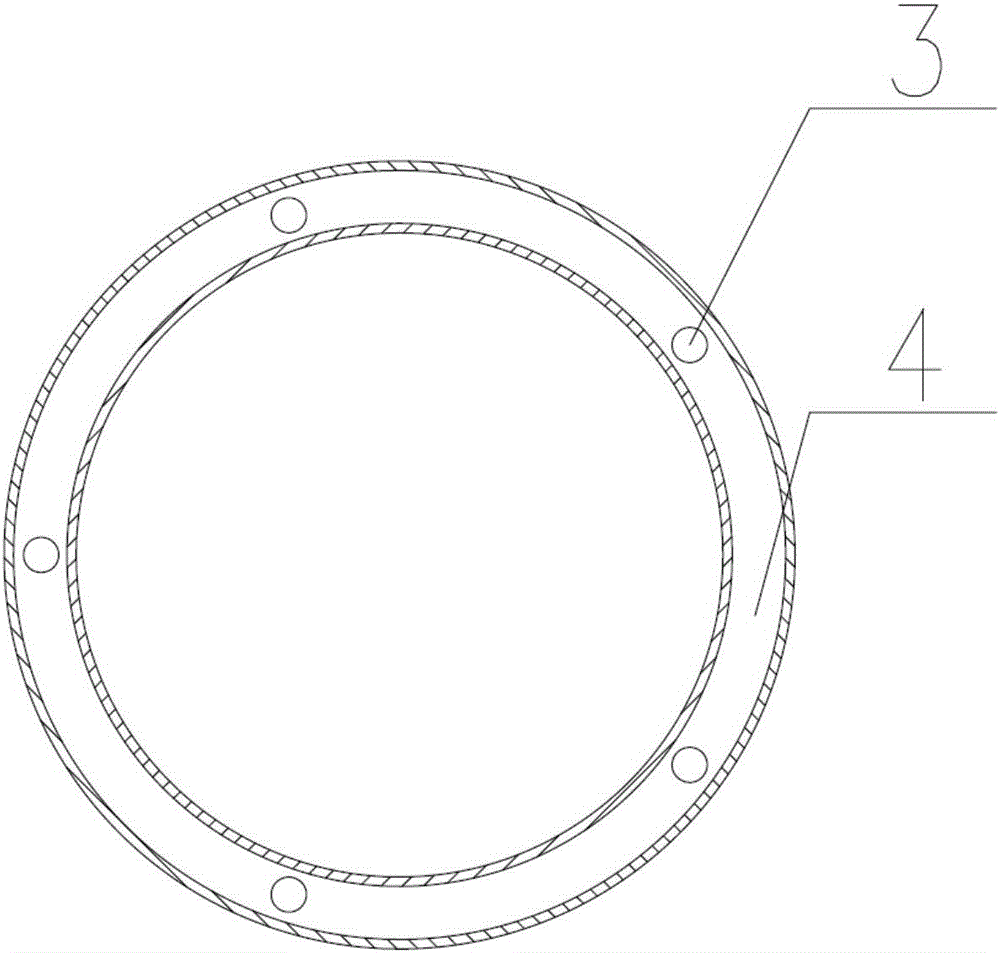

The invention relates to a sample-making device for soil quick triaxial test and a sample-making method thereof. The sample-making device comprises a sample-beating cylinder and a sample-beating device, wherein the sample-beating cylinder comprises a base, a three-section mould, a lower clamp, an upper clamp and a protective cylinder; the sample-beating device comprises a power transmission plate, a compact hammer, a guide bar, a stopper; the base of the sample-beating cylinder is a double-faced base with one face of the central part of the base is a circular fixed groove, the other face of which is a circular fixed groove with a circular hole at the center; the three-section mould is composed of three circular-arc metal sheets with a central angle of 120 DEG. The sample-making method comprises: fixing the guide bar on the base, laminatedly compacting the soil according to the required dry density, sealing the central hole of the base with clay after being compacted, laminatedly pouring sands into the central cylinder hole and compacting the soil according to the required density, finally sealing the upper hole of the cylinder hole with clay. The invention has simple use, convenient operation, testing time saving, good effect for making uniform, standard sand-core cylinder, can be popularized in the field of soil test technique.

Owner:HOHAI UNIV

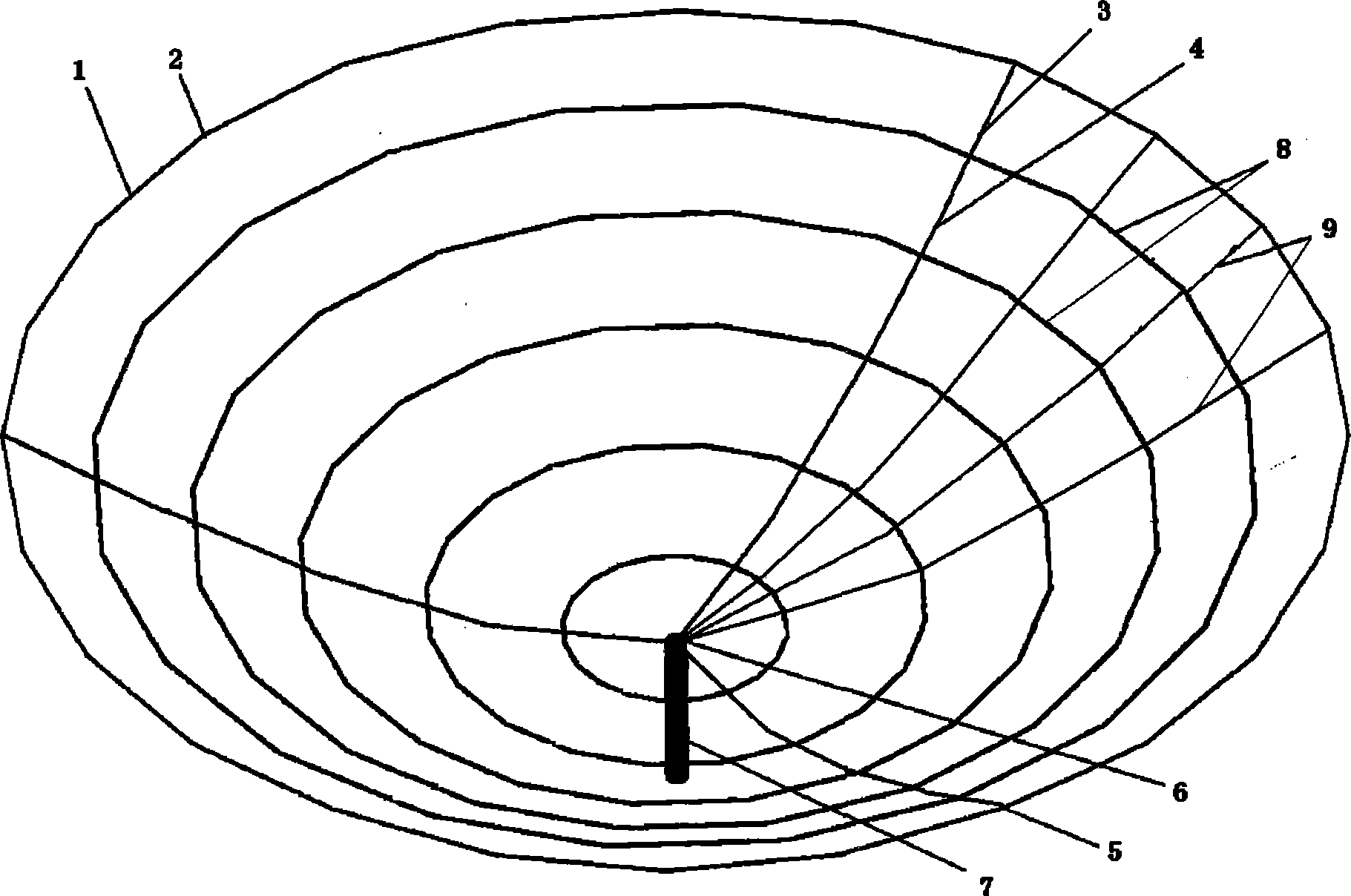

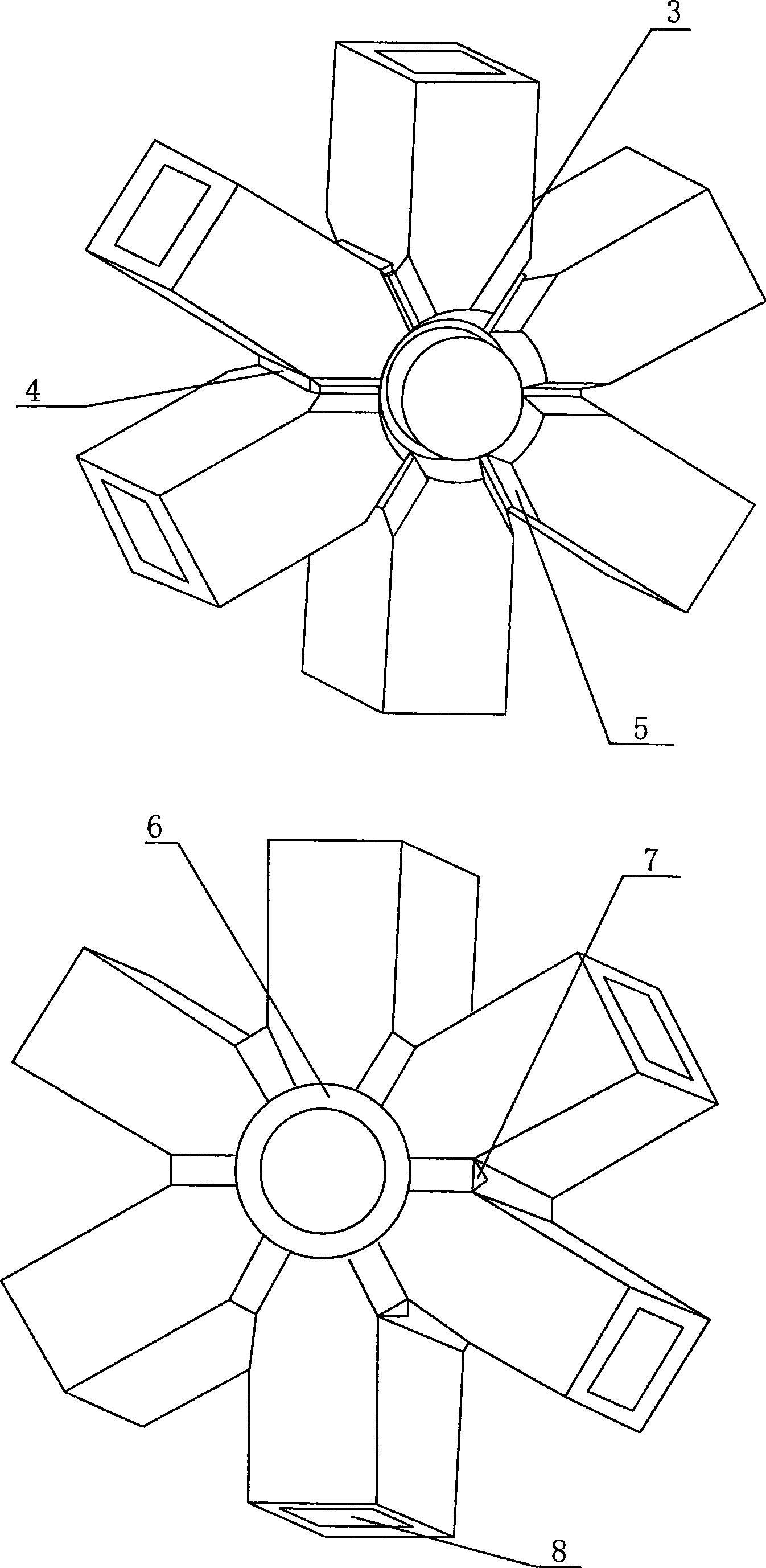

Reflection surface system capable of spacing expansion

InactiveCN101369686ALightweight structureLight in massPivotal connectionsAntennasEngineeringFilm structure

The invention discloses a reflective surface system which can unfold the space, comprising a foldable ring rod, a foldable rib rod, a connecting joint, a central cylinder, and an air aerated circular ring and a driving rope. The foldable ring rod (1) and the foldable rib rod (3) are respectively connected to the ring rod connecting joint (2) and the rib rod connecting joint (4), forming a ring-rib structure; the ring-rib structure is connected to the central cylinder (7) via a ring rib connecting joint (5) and a rib cylinder connecting joint (6); the air aerated circular ring (8) and the driving rope (9) are provided on the grid skeleton in crossing way to form the reflective surface structure. The air aerated circular ring can be solidified after the molding to enhance the structure precision of the reflective surface; the driving rope can enhance the structure precision of the reflective surface; the metal net or the aluminum plating film structure bound to the driving rope eventually form the expected large foldable reflective surface. The invention is used for forming a large foldable device of the foldable antenna, the reflector or gathers.

Owner:XIDIAN UNIV

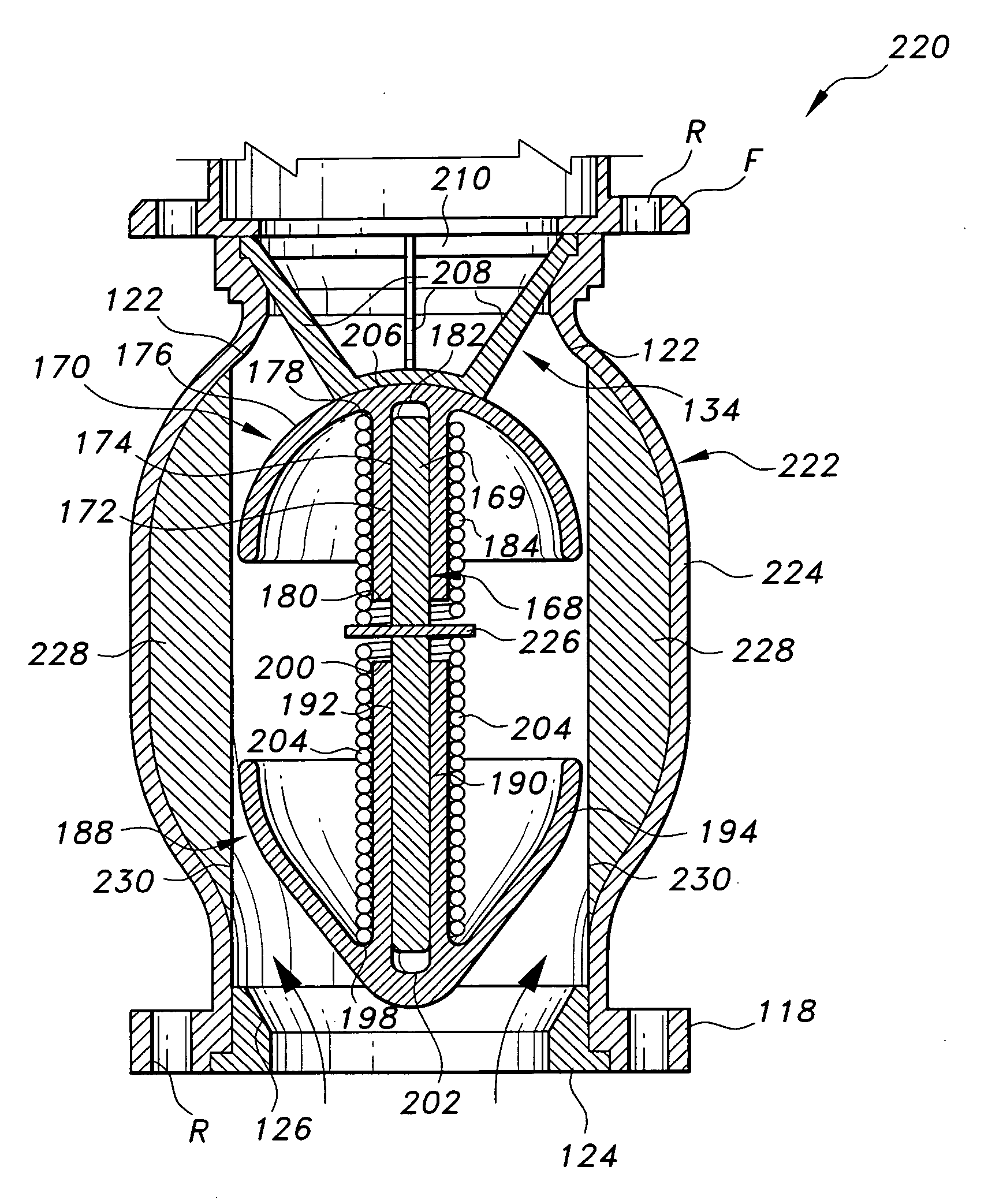

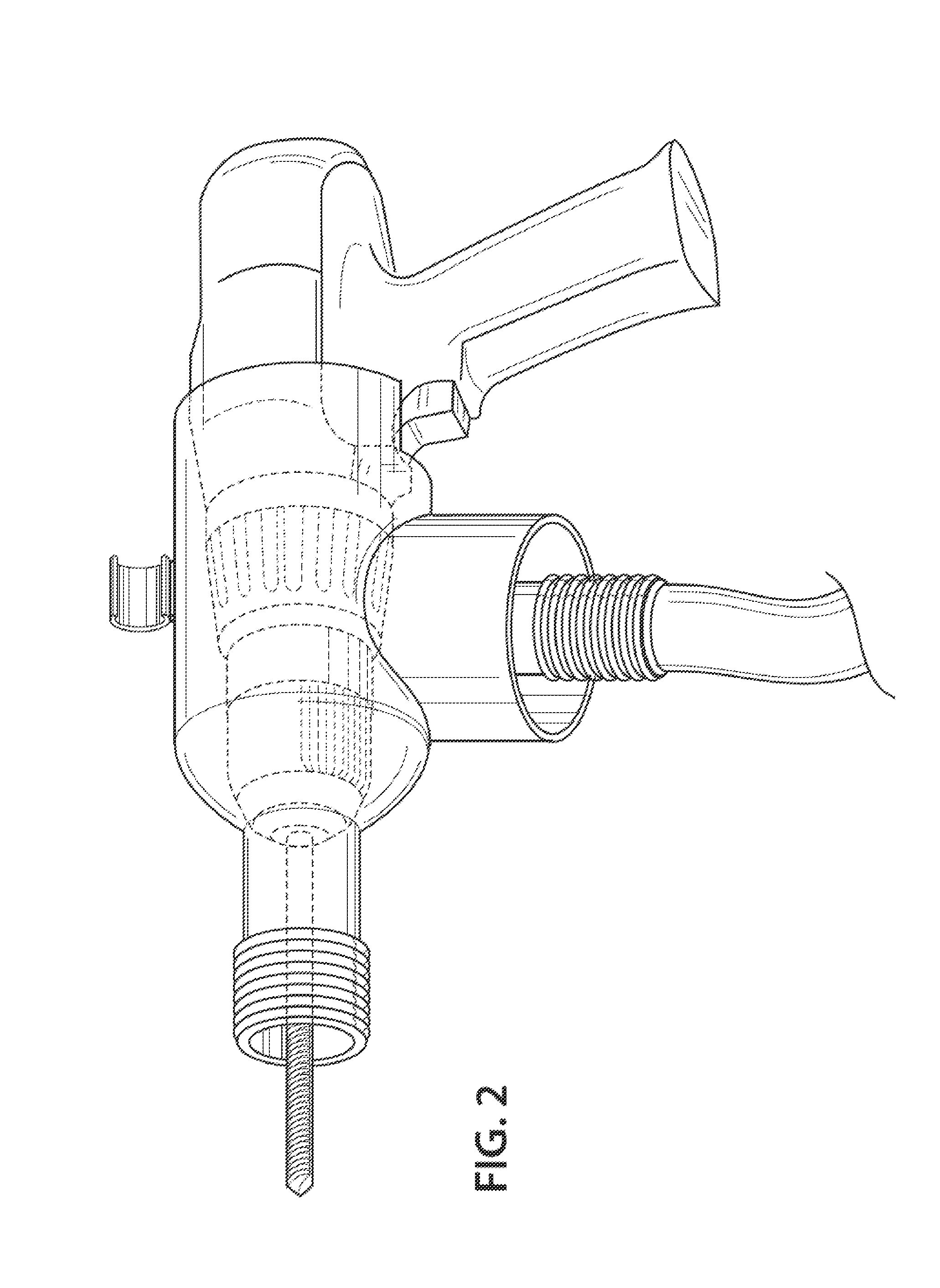

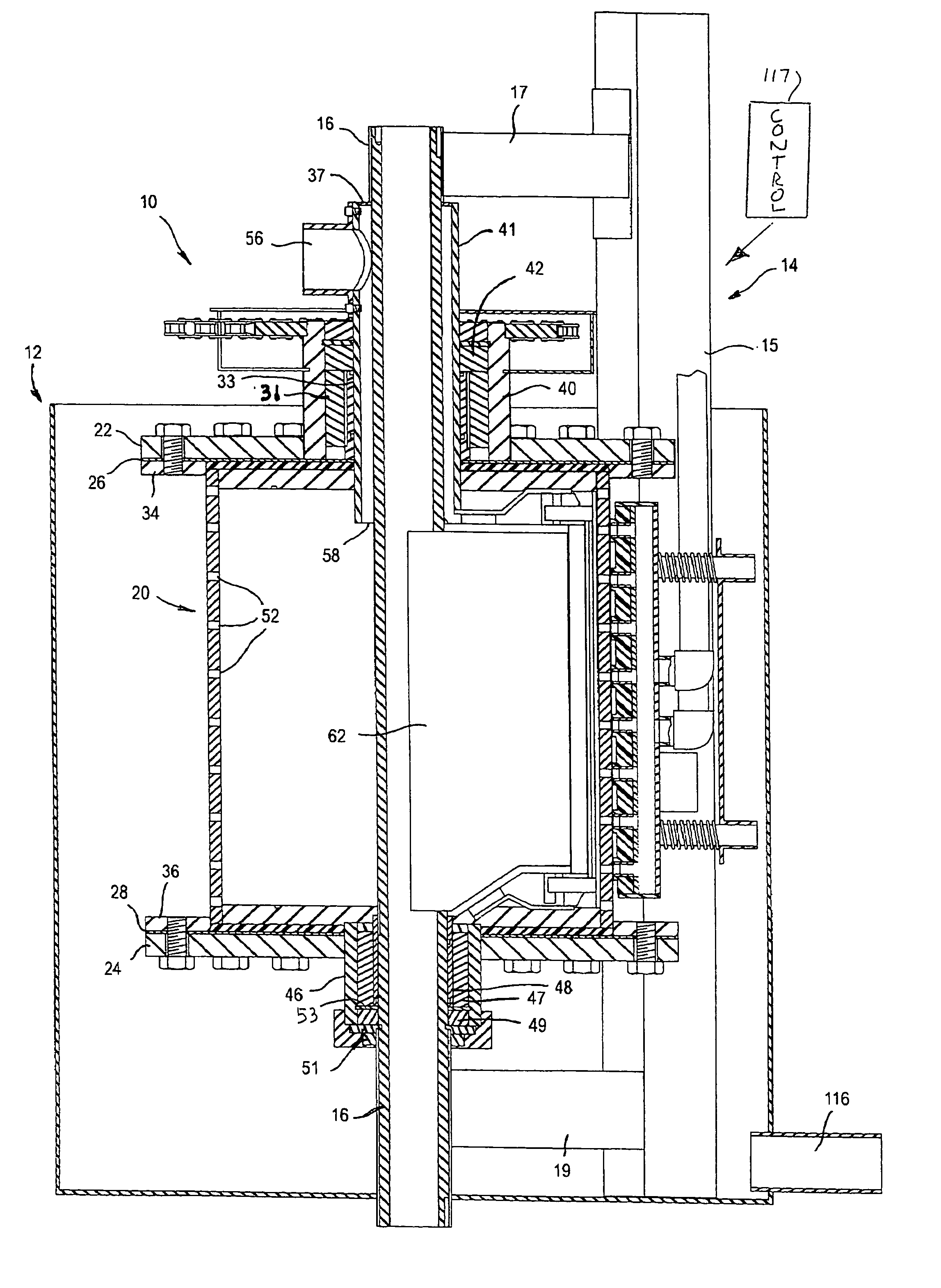

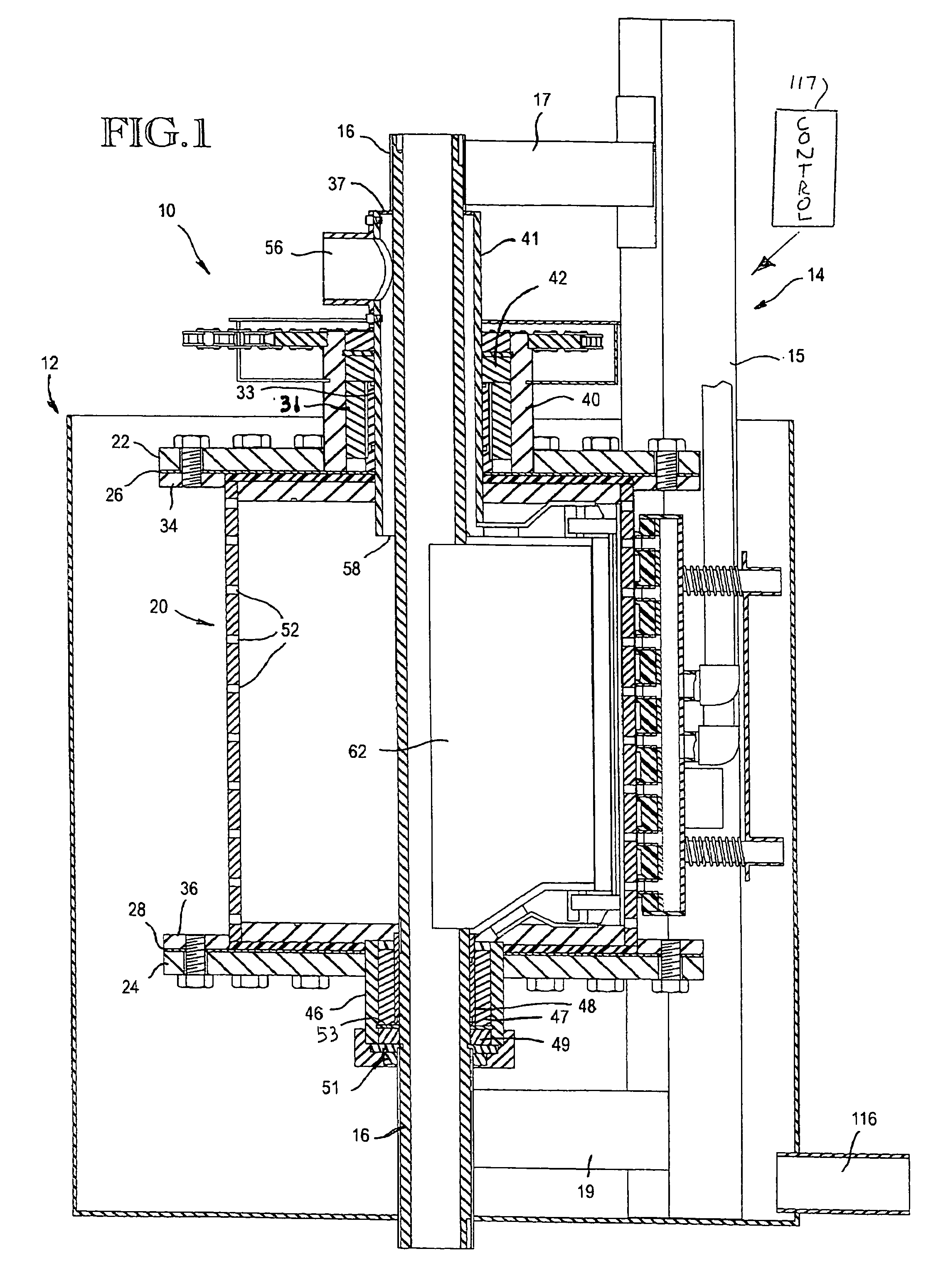

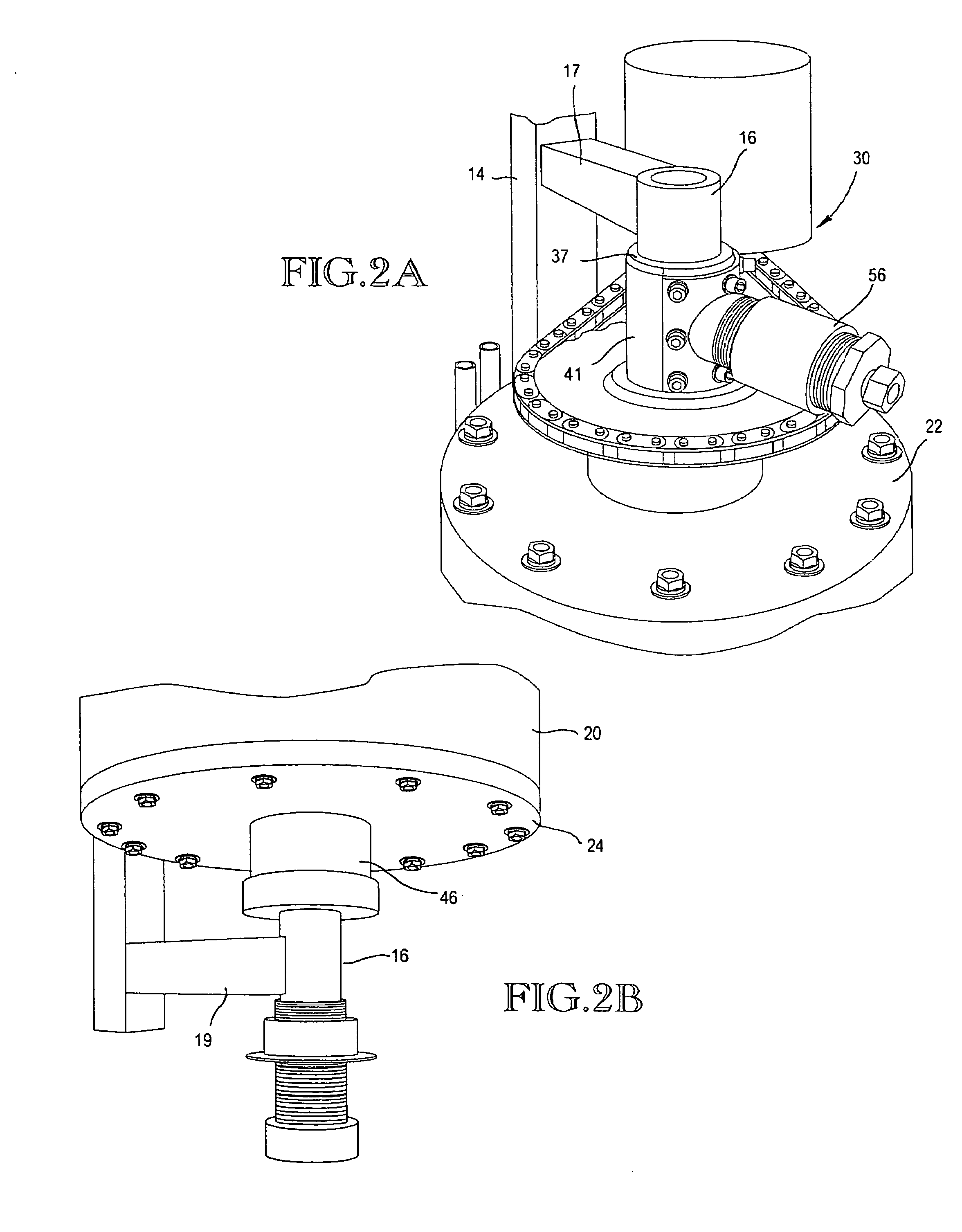

Hydrant knock-off combination flow stop and backflow check valve

ActiveUS20050155645A1Prevent backflowUncontrolled flowCheck valvesEqualizing valvesWater flowEngineering

A hydrant knock-off combination flow stop valve and backflow check valve, mountable between water system riser and a wet-type hydrant having a breakaway flange ring. The vertical valve has a bulbous, cylindrical outer wall having an upper flange connecting to a wet-type hydrant by a break ring and a lower flange connecting to a system riser pipe. One embodiment has radial vertical vanes defining a central cylinder coaxial with the valve and acting as guides for a movable valve element to travel vertically up and down. The lower flange a seat, acting as a check valve with the valve element. The valve has a restraining cage keeping the valve element from engaging an upper seat. Once the break ring is ruptured the valve element seals against the seat, stopping water flow. The preferred valve element is a plastic coated ball. Another embodiment has a double mushroom, spring loaded valve element.

Owner:AVK HLDG AS

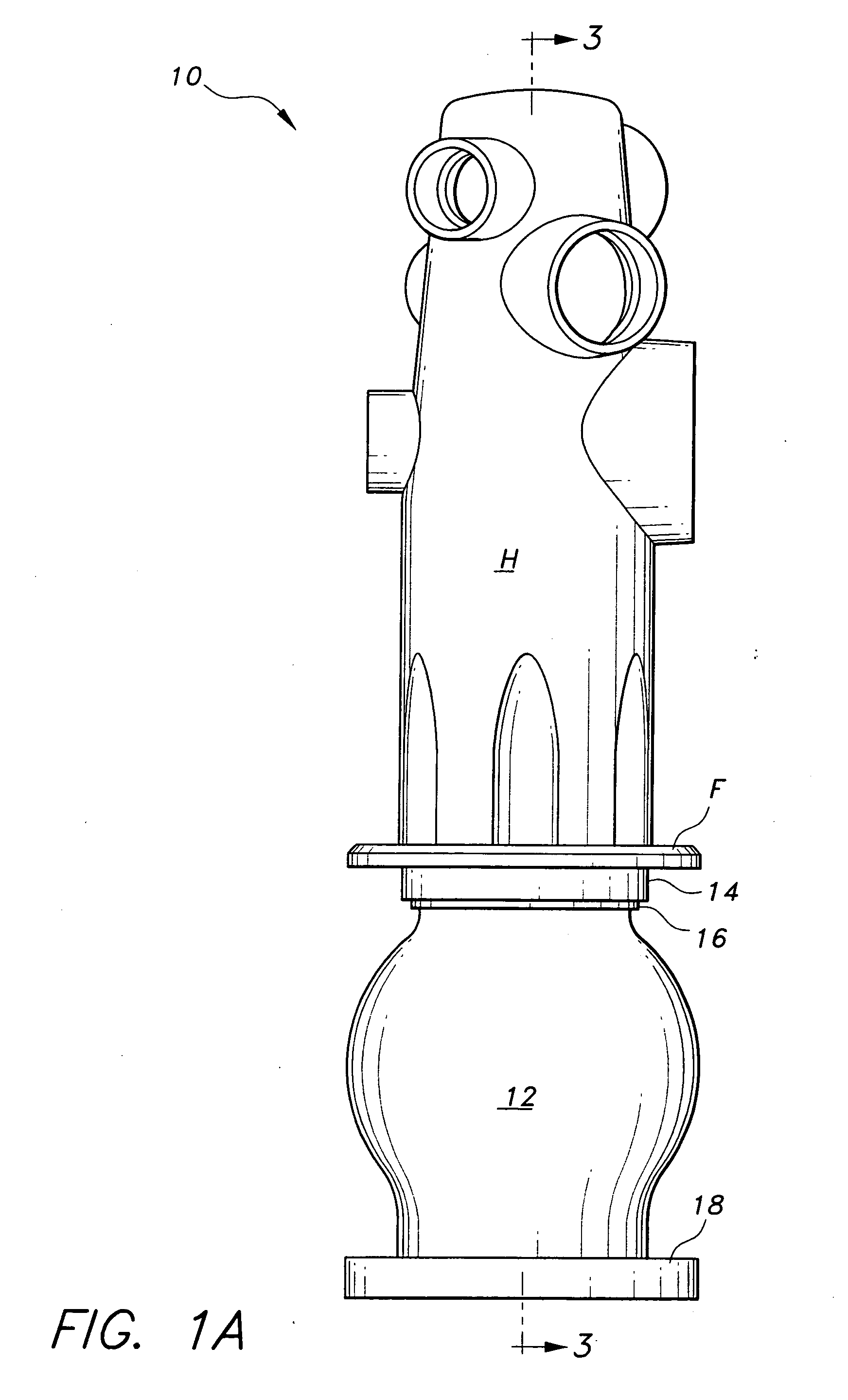

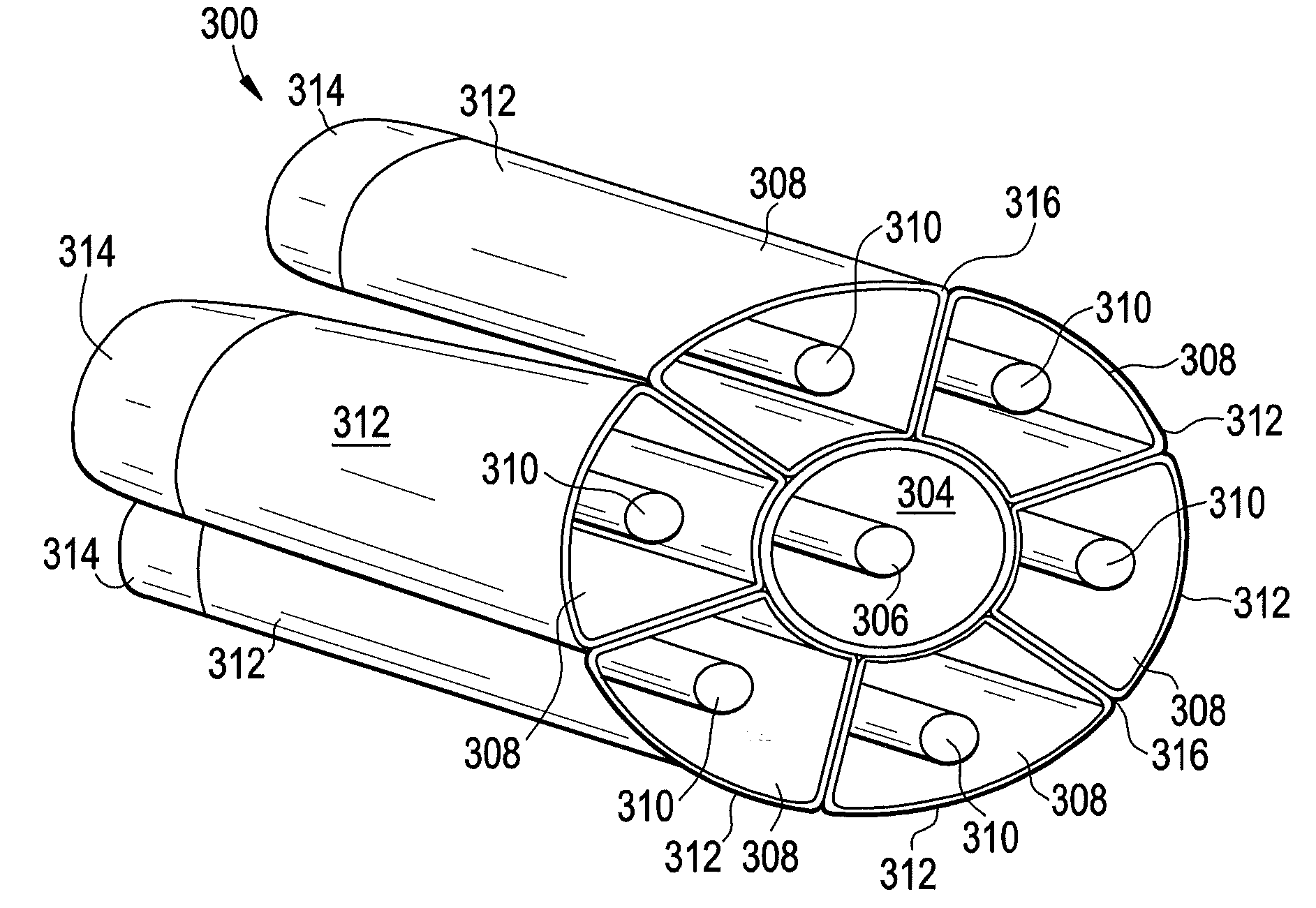

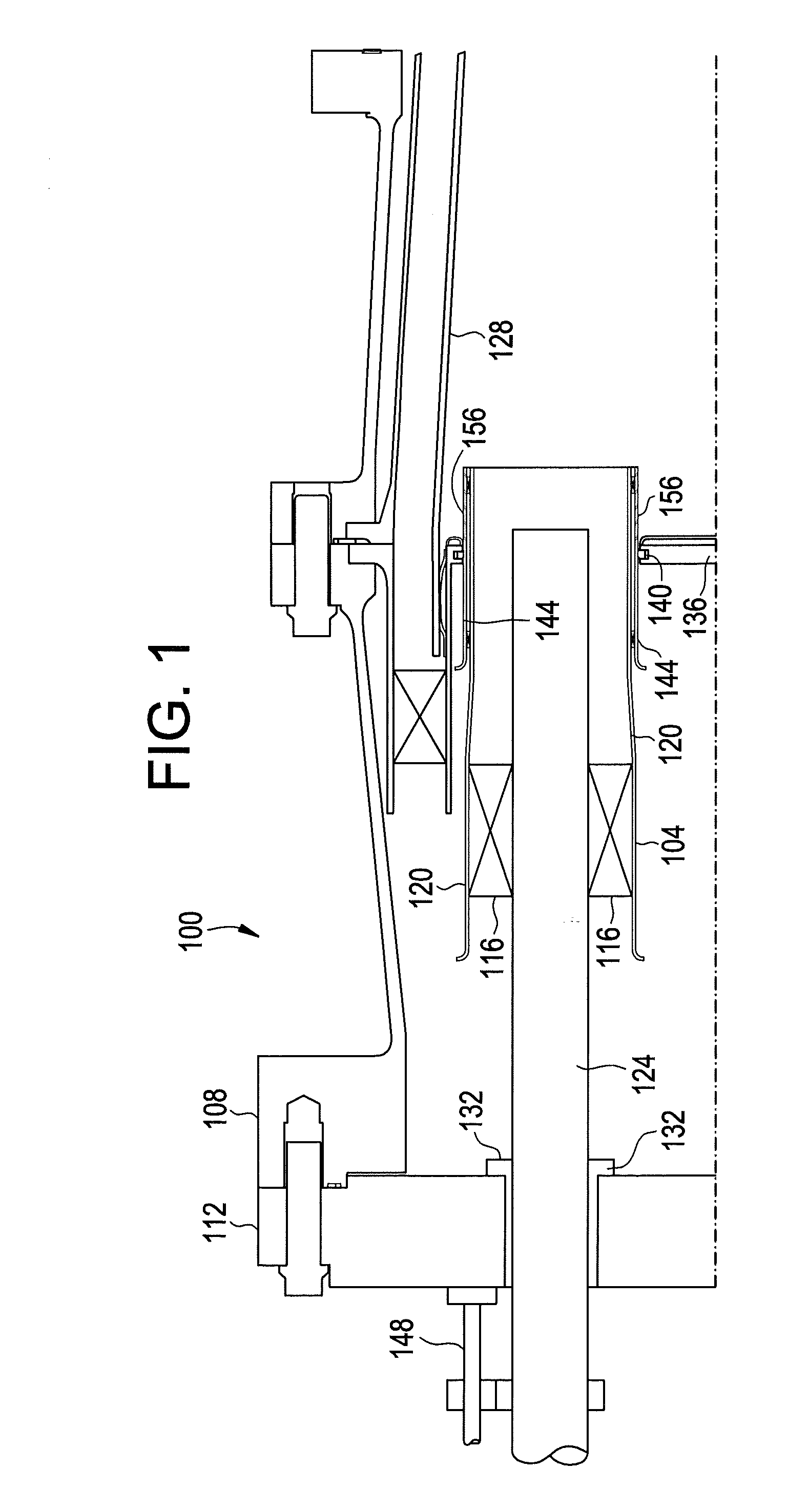

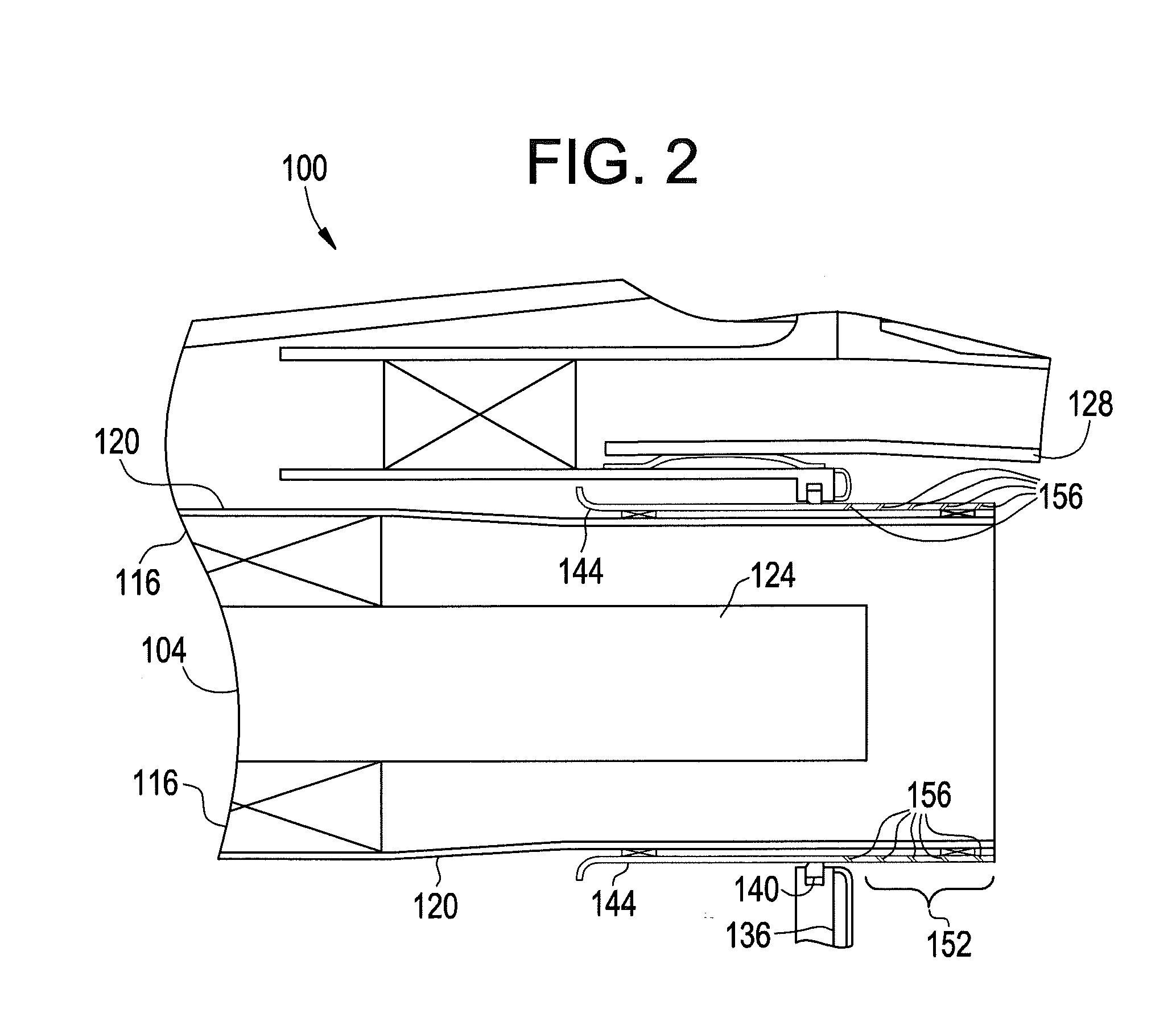

Traversing fuel nozzles in cap-less combustor assembly

A combustor includes a central fuel nozzle assembly and a plurality of outer fuel nozzle assemblies, each of the plurality of outer fuel nozzle assemblies having a center body and an outer shroud, the plurality of outer fuel nozzle assemblies being configured to abut one another in a surrounding relationship to the central cylinder such that no gaps are present between any two abutting ones of the plurality of outer fuel nozzle assemblies. One or more of the plurality of fuel nozzle assemblies may traverse axially back and forth according to embodiments of the invention.

Owner:GENERAL ELECTRIC CO

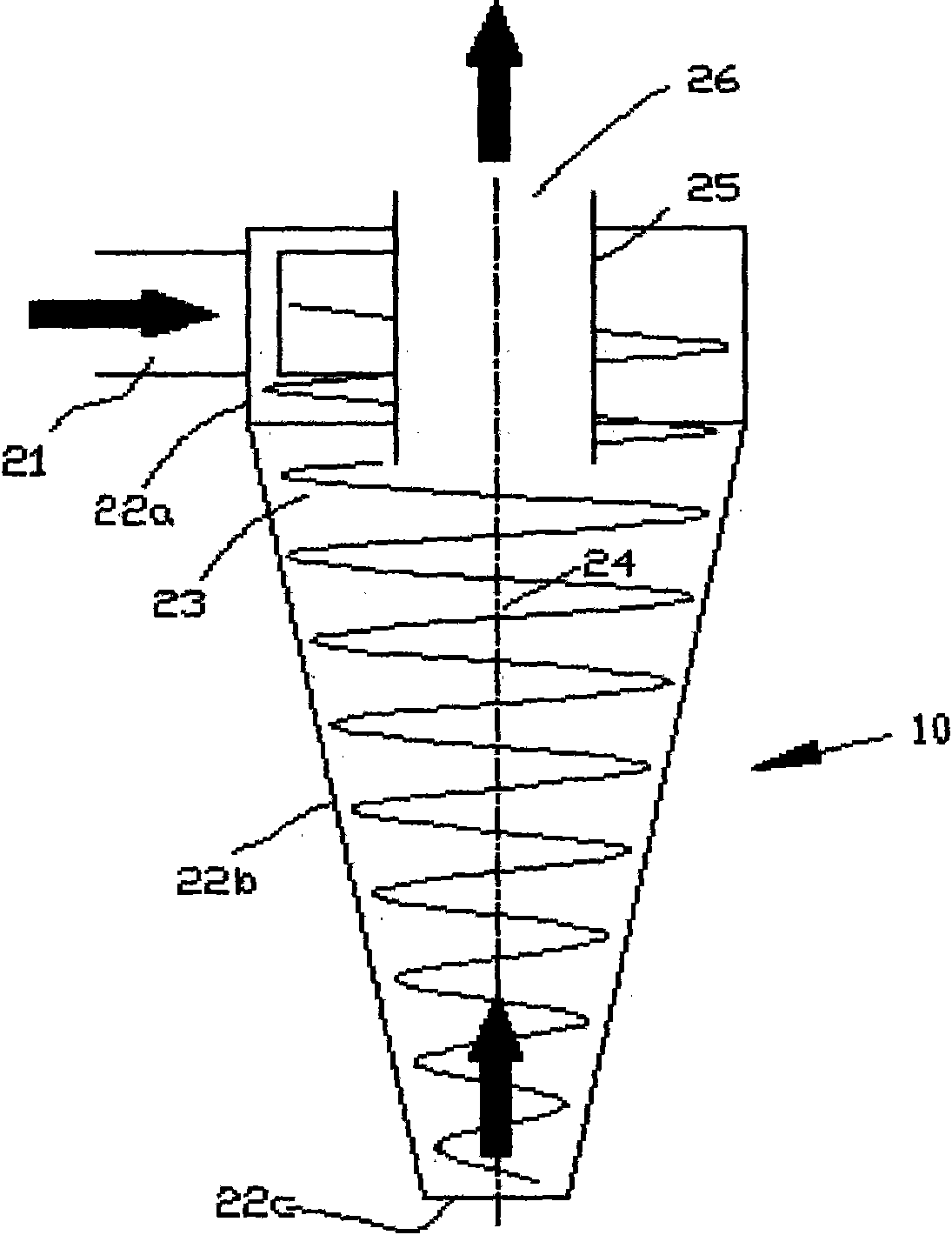

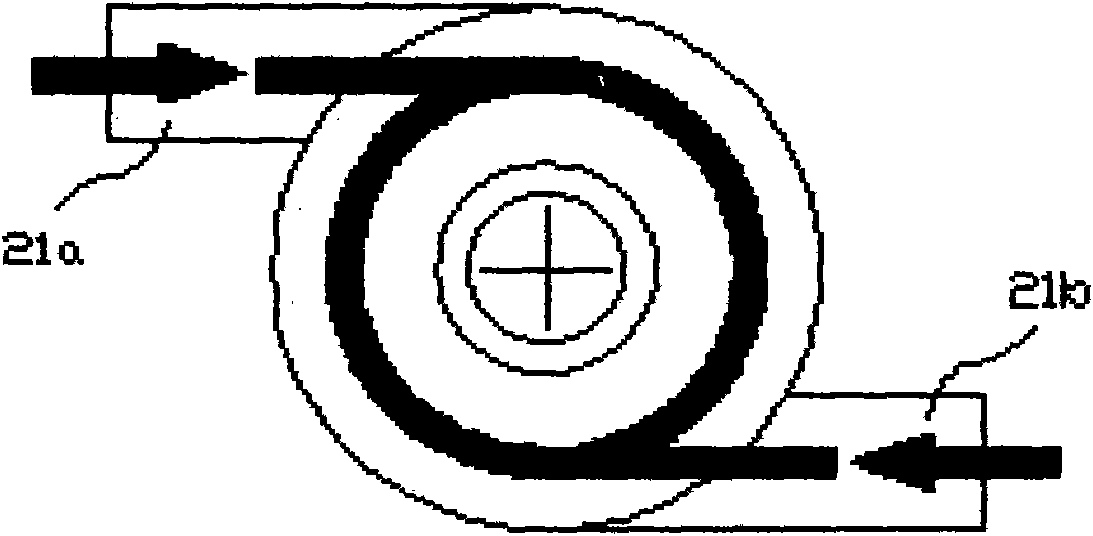

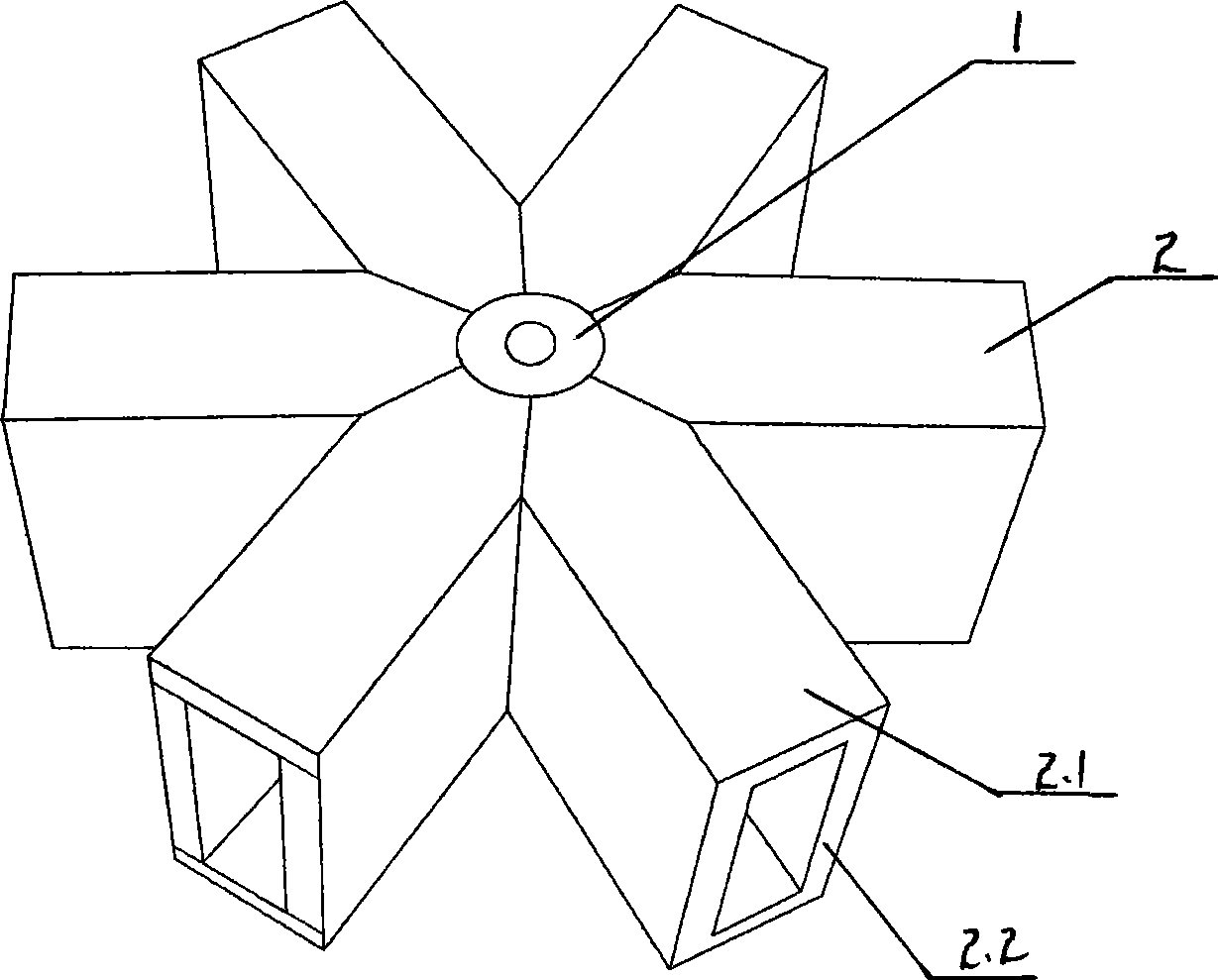

Multistage cyclone separation device of dust collector

InactiveCN101862165AExcellent vortex nuclear deformationReduce resistanceSuction filtersCycloneCyclonic separation

The invention relates to a multistage cyclone separation device of a dust collector, which comprises an upstream first-stage cyclone separation device (1), a downstream second-stage cyclone separation device (2) and a gas flow channel (3), wherein the gas flow channel (3) is used for connecting the upstream first-stage cyclone separation device (1) and the downstream second-stage cyclone separation device (2), the downstream second-stage cyclone separation device (2) comprises a cyclone filter (5), a dust-gas separation cover (6) and a central cylinder (8), at least two tangential air inlets are arranged on the cylindrical later surface of a cyclone cylinder body (20), an exhaust pipe (504) is positioned on the cylindrical top surface of the cyclone cylinder body (20), and the tangential air inlets have equal cross sectional area, are positioned on the same horizontal surface and are arranged relatively to the central shaft of the cyclone cylinder body (20) according to equal phase difference. The invention has the advantages that the short-circuit flow of the exhaust pipe is less than that of a single-gas inlet cyclone separation device, the axial symmetry of a flow field is more excellent, and the proportion that small-granule dust directly enters an exhaust port without cyclone separation after entering a separation chamber is reduced.

Owner:马吉

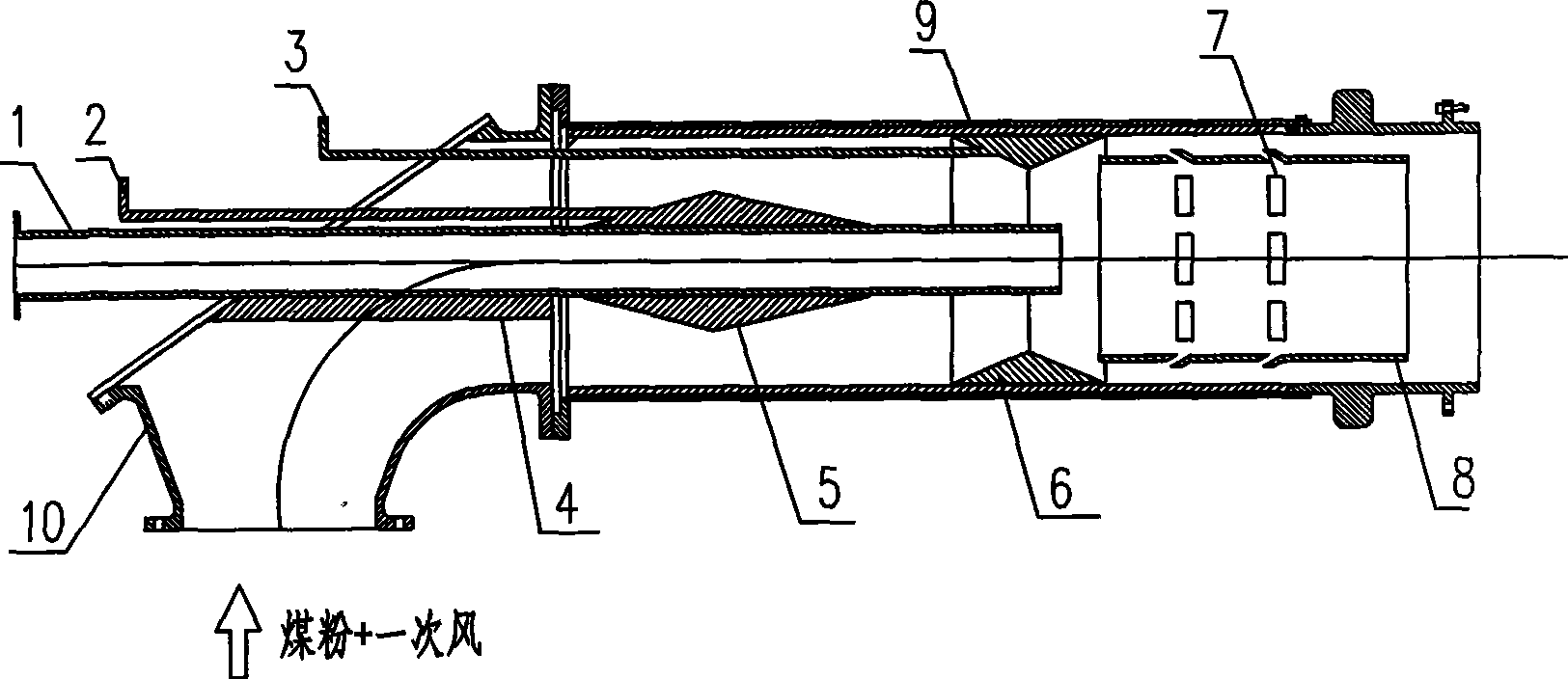

Rotational flow pulverized coal burner

ActiveCN1920382AGood concentration separation effectImprove adaptabilityPulverulent fuel combustion burnersCyclonePower station

The invention relates to a cyclone power coal burner used in the boiler of power station, wherein it comprises: oil gun, or central cylinder, 2-3 step power coal separator, the main nozzles of wedge groove and horn open; 2-3 air nozzles with cyclone generator and horn open, nozzles and gas inlet of central cylinder; at the surface of inner chamber of main nozzle, the inner and outer surfaces of separator, and at the surface of support plate, there are abrasion-resistant layer. The invention has better dense-thin separation effect, while the ratio between dense and thin is 3-7:1; the cyclone strength at 2-3 step nozzle is high with simple adjustment; the resistance of main nozzle is 1 / 3 of background technique to reduce 55-65% of energy consumption, with low nitrogen oxide discharge and stable burning.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

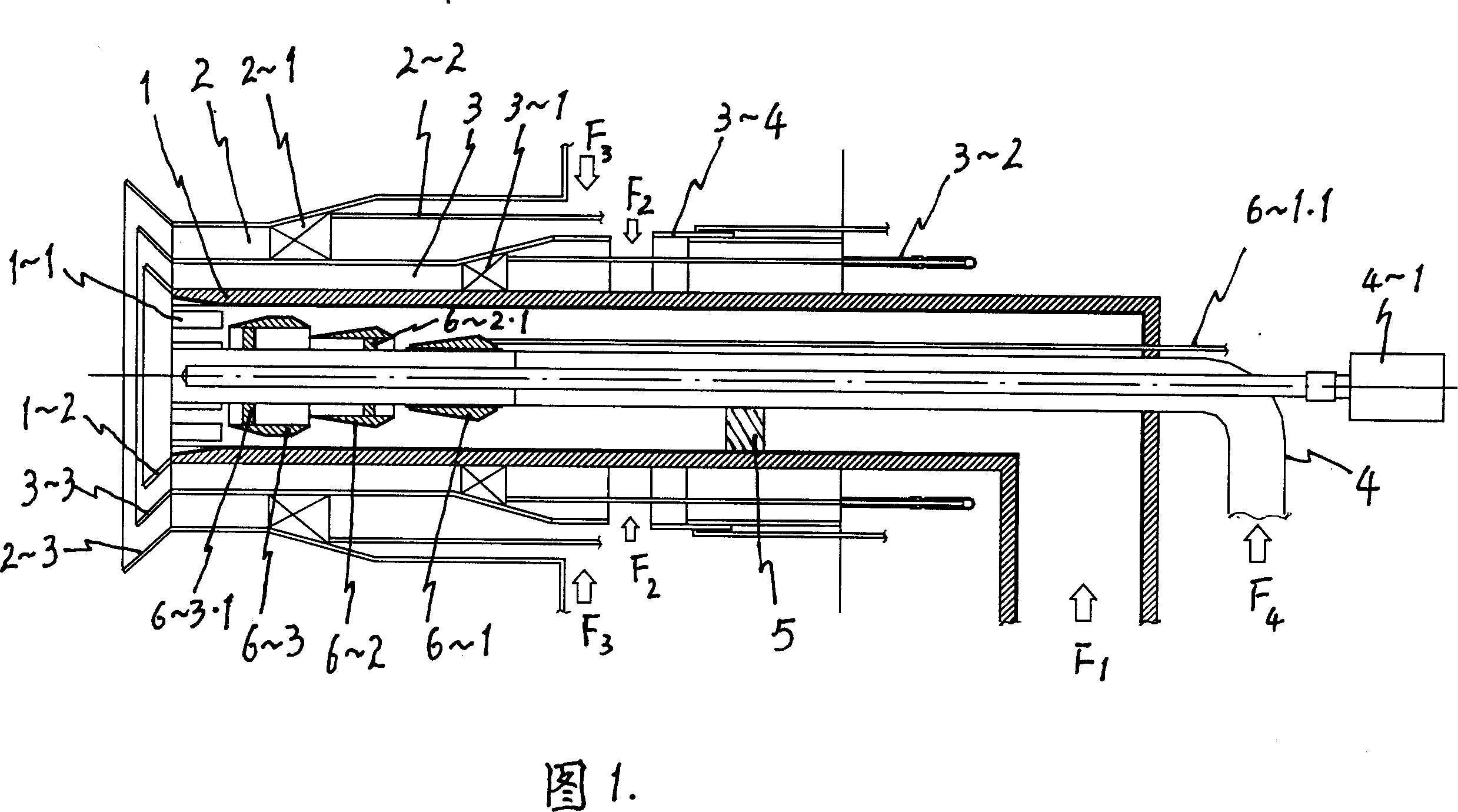

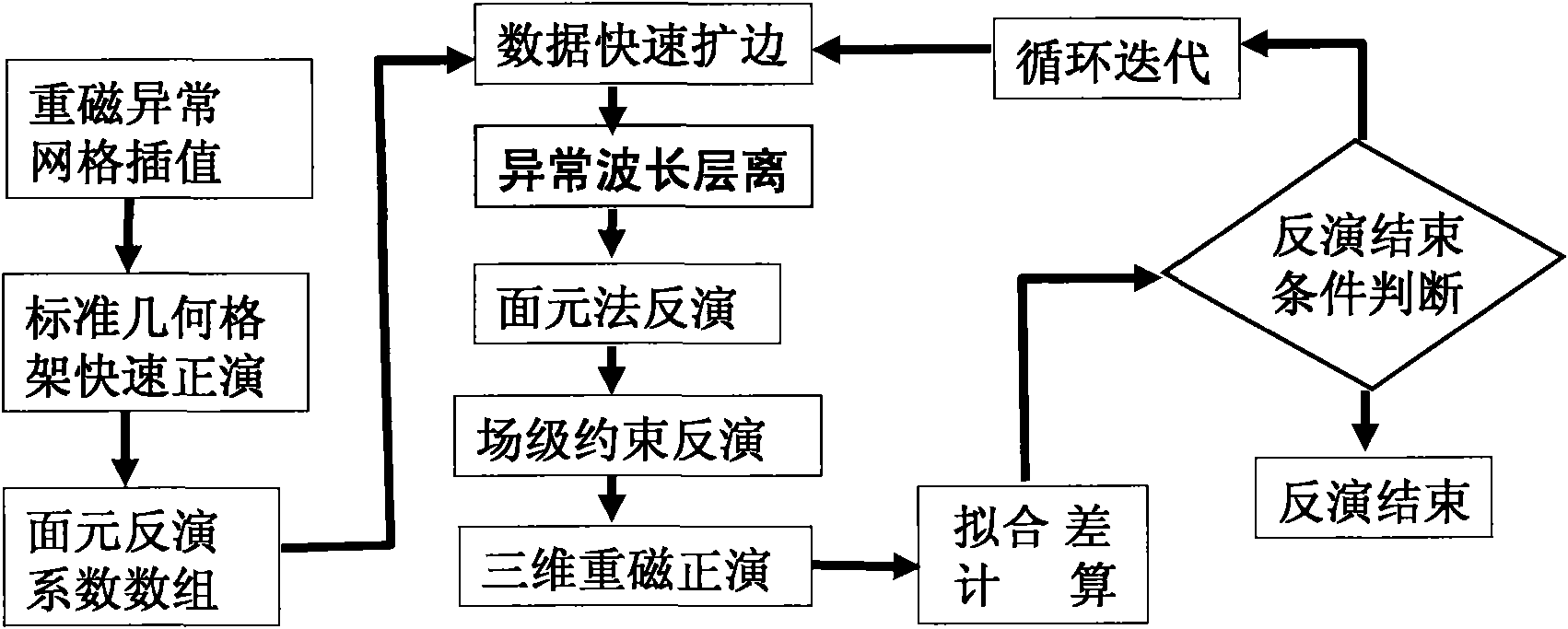

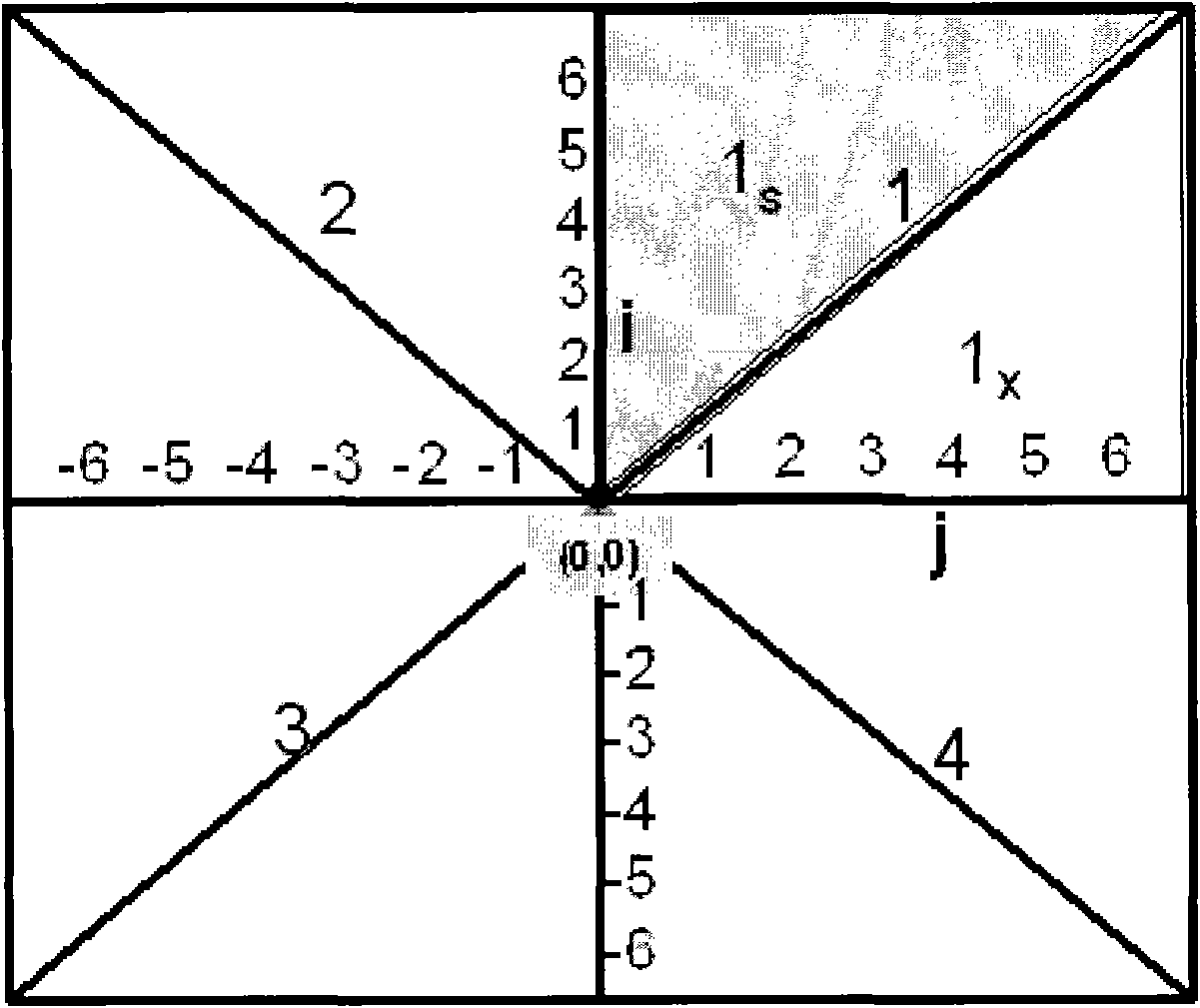

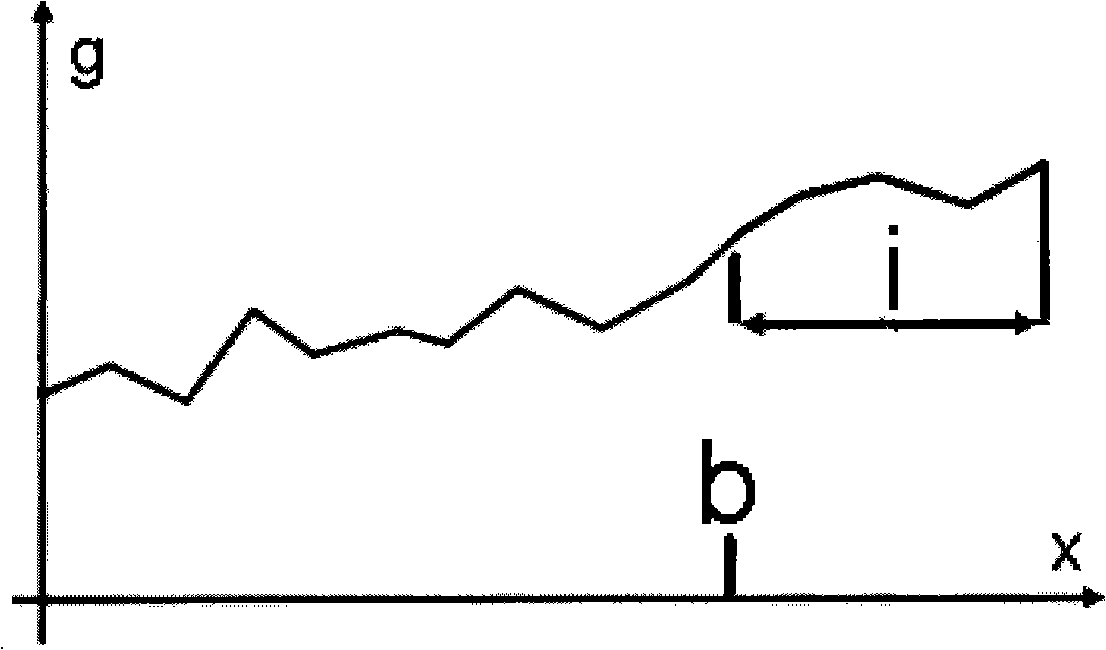

Standard framework-based method for quick three-dimensional gravity and magnetic inversion for physical properties

ActiveCN101661115ASolve practical geological problemsGeological measurementsMagnetic tension forceMagnetic susceptibility

The invention provides a standard framework-based method for quick three-dimensional gravity and magnetic inversion for physical properties in geophysical exploration. The method comprises: gridding gravity and magnetic data first and then converting the data grid into a square node grid; subdividing lower haft space and performing standard framework quick forward calculation and storage; solvingsquare roots of a framework coefficient of a calculation point of a framework central cylinder to obtain a bin inversion coefficient array; performing expansion calculation for quick extrapolation; obtaining a three-dimensional gravity and magnetic anomaly data volume after plane gravity and magnetic anomaly separation; performing inversion physical property numerical range constraint and field level constraint; and obtaining a high-accuracy inversion model by a forward process. The method can reflect the three-dimensional density and magnetic susceptibility distribution of an underground geologic body, solves actual geological problems of a complex region, and has high-efficiency, quick, reliable, effective and practical effects.

Owner:BGP OF CHINA NAT GASOLINEEUM CORP

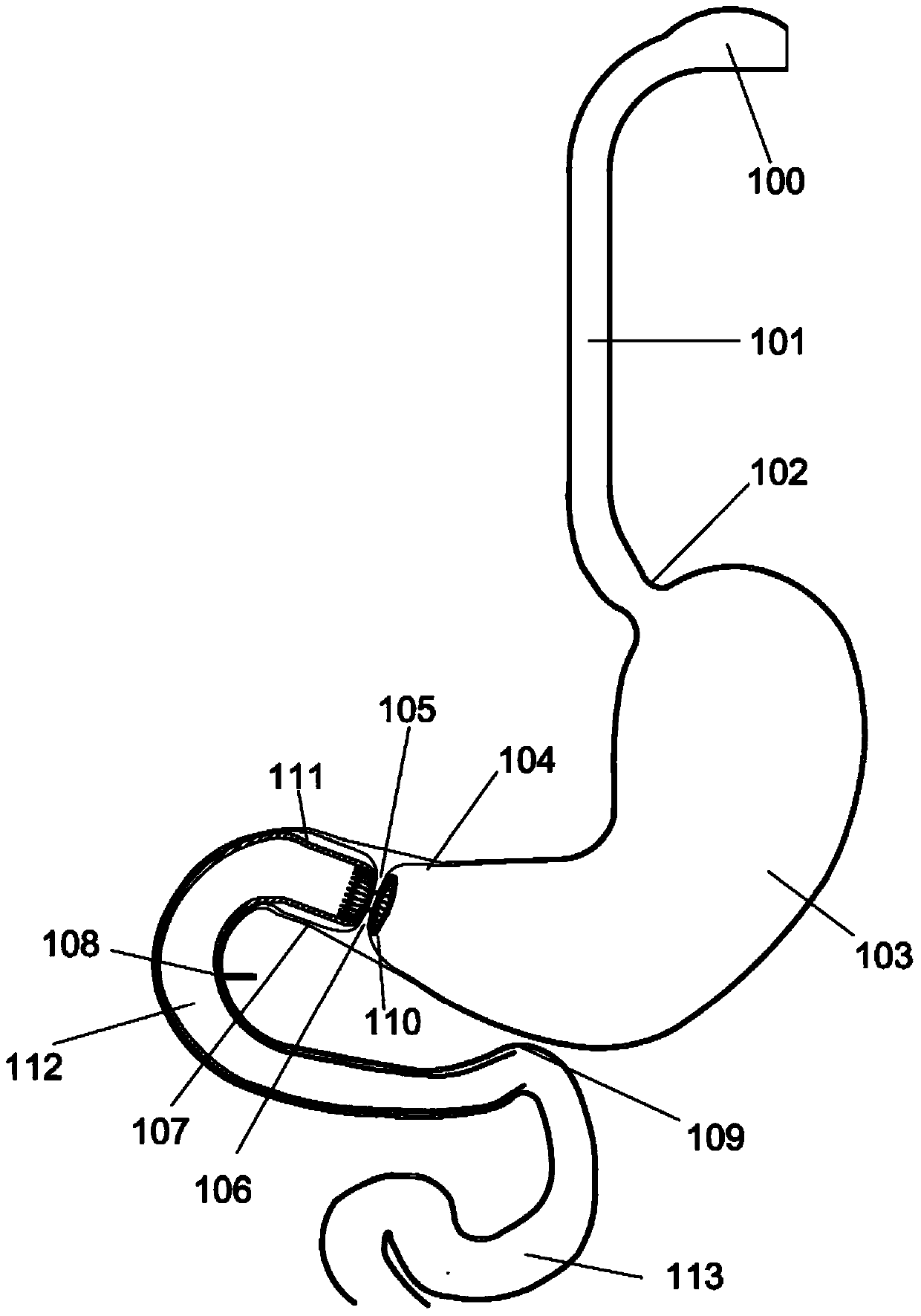

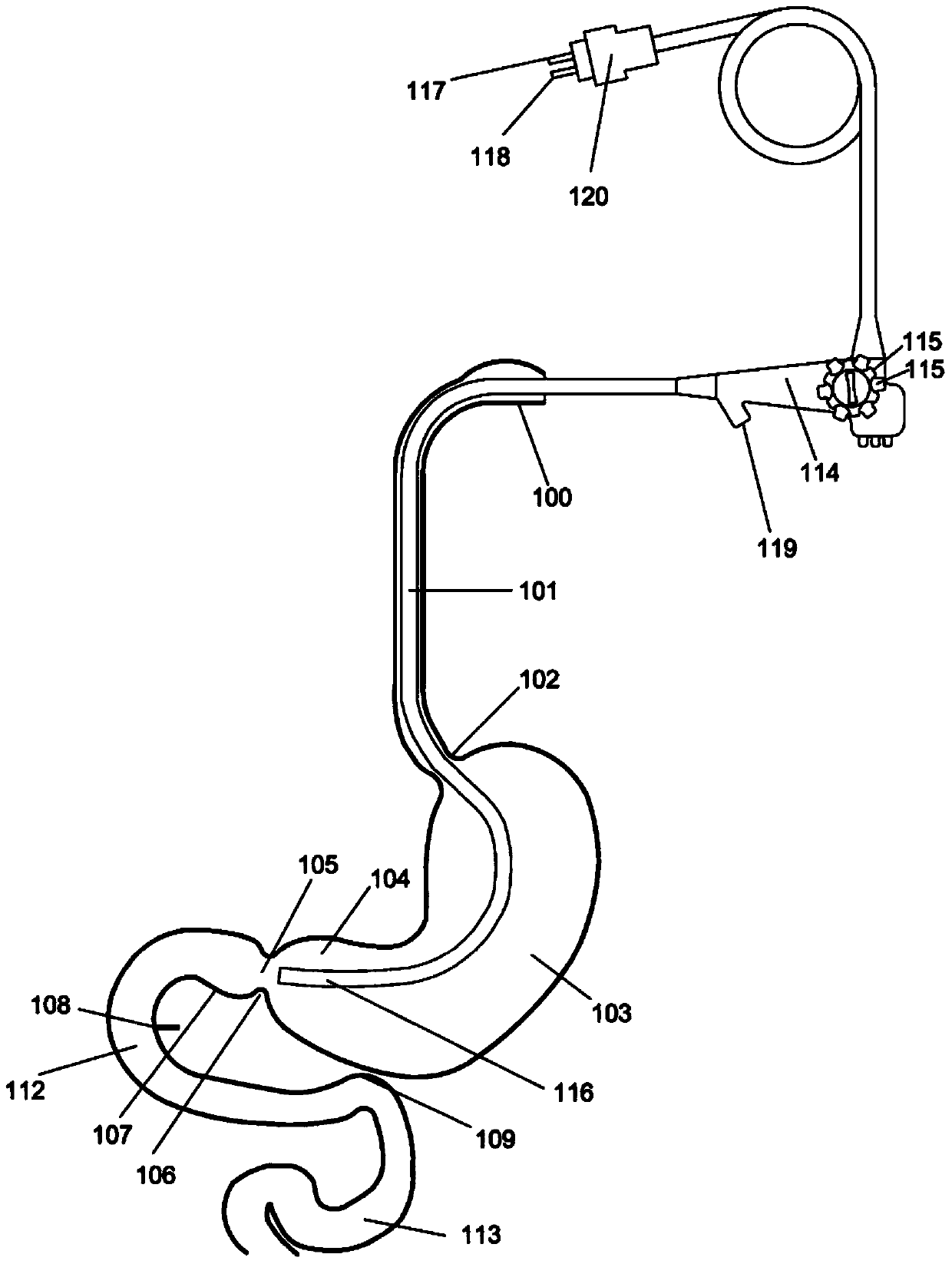

Anchors and methods for intestinal bypass sleeves

A gastrointestinal device for implanting within a pylorus, a duodenal bulb, and a duodenum of a patient's gastrointestinal tract includes an expandable structure includes a proximal portion having a plurality of spring arms and a distal portion having a plurality of spring arms, the proximal and distal portions coupled by a rigid central cylinder having a diameter capable of fitting within the pylorus and having a length greater than a width of the pylorus. A membrane is coupled to and covering at least a portion of one of the proximal portion and the distal portion of the expandable structure. An intestinal bypass sleeve is coupled to at least one of the proximal and distal portions of the expandable structure and having a length sufficient to extend at least partially into the duodenum. In the expanded configuration, the proximal portion has a diameter larger than a maximum opening diameter of the pylorus and further wherein, in the expanded configuration, the distal portion has a diameter larger than a maximum opening diameter of the pylorus.

Owner:METAMODIX

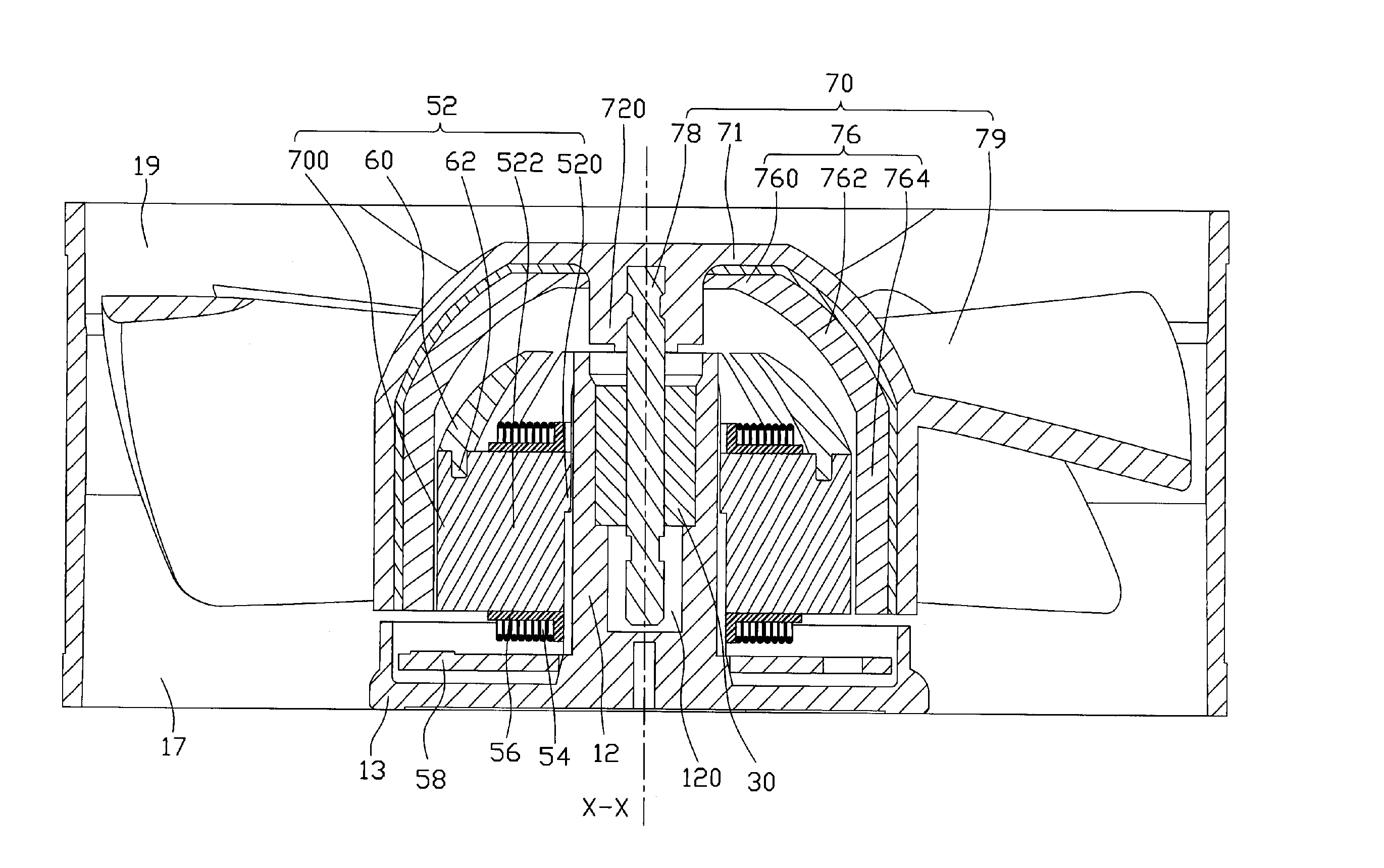

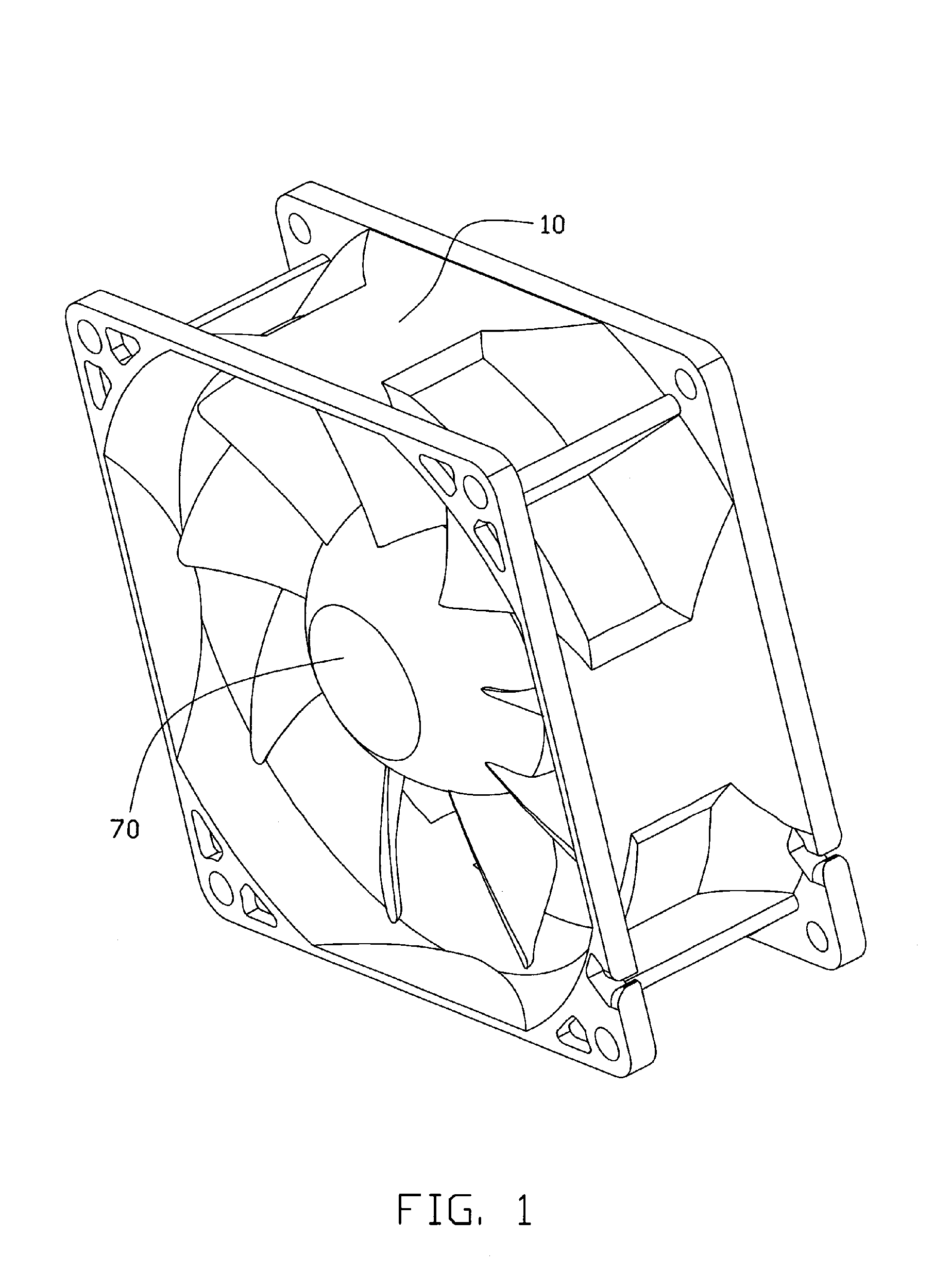

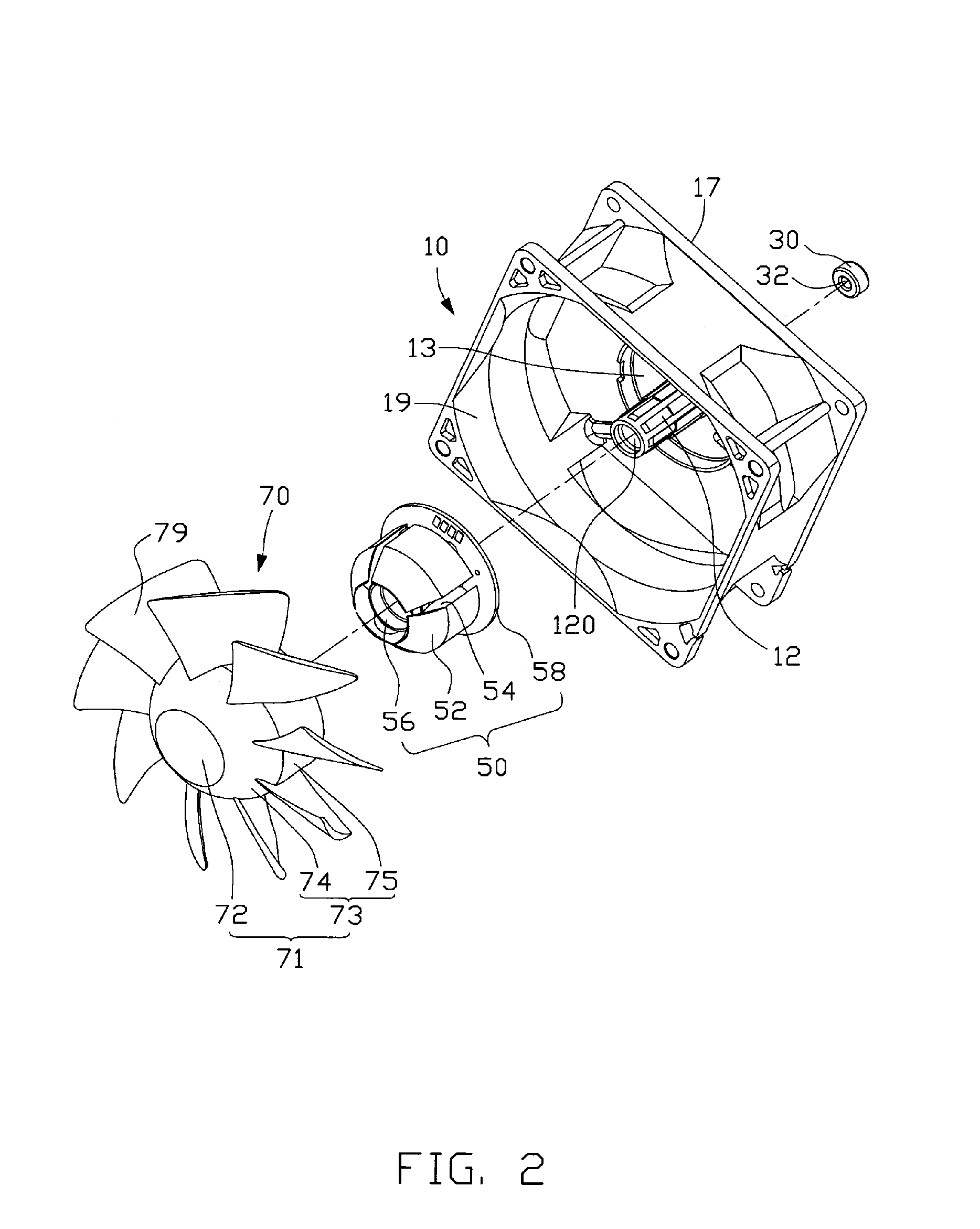

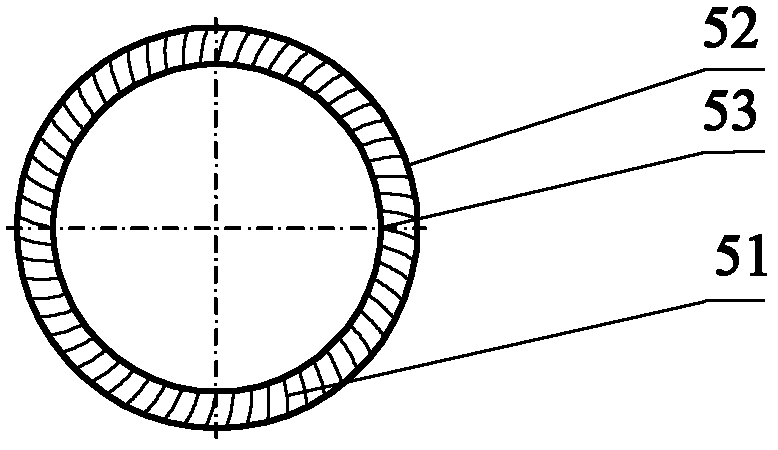

Electric fan

InactiveUS20070075598A1Small sizeIncrease speedMagnetic circuit stationary partsPiston pumpsStator coilMagnetic poles

An electric fan includes a frame (10) having a central tube (12) extending therefrom, a bearing (30) received in the central tube, a stator (50) mounted around the central tube, and a rotor (70) being rotatably supported by the bearing. The frame defines an air inlet (19) and an air outlet (17) at two different sides thereof. The stator includes a stator core (52) having a central cylinder (520). A plurality of radial posts (522) extends from the central cylinder. A plurality of magnetic poles (524) is formed at free ends of the posts. A plurality of stator coils (54) is wound around the posts. Each magnetic pole includes a lower portion (700) adjacent to the air outlet and an upper portion (60) adjacent to the air inlet. The upper portions expand radially along a direction from the air inlet to the air outlet.

Owner:HON HAI PRECISION IND CO LTD

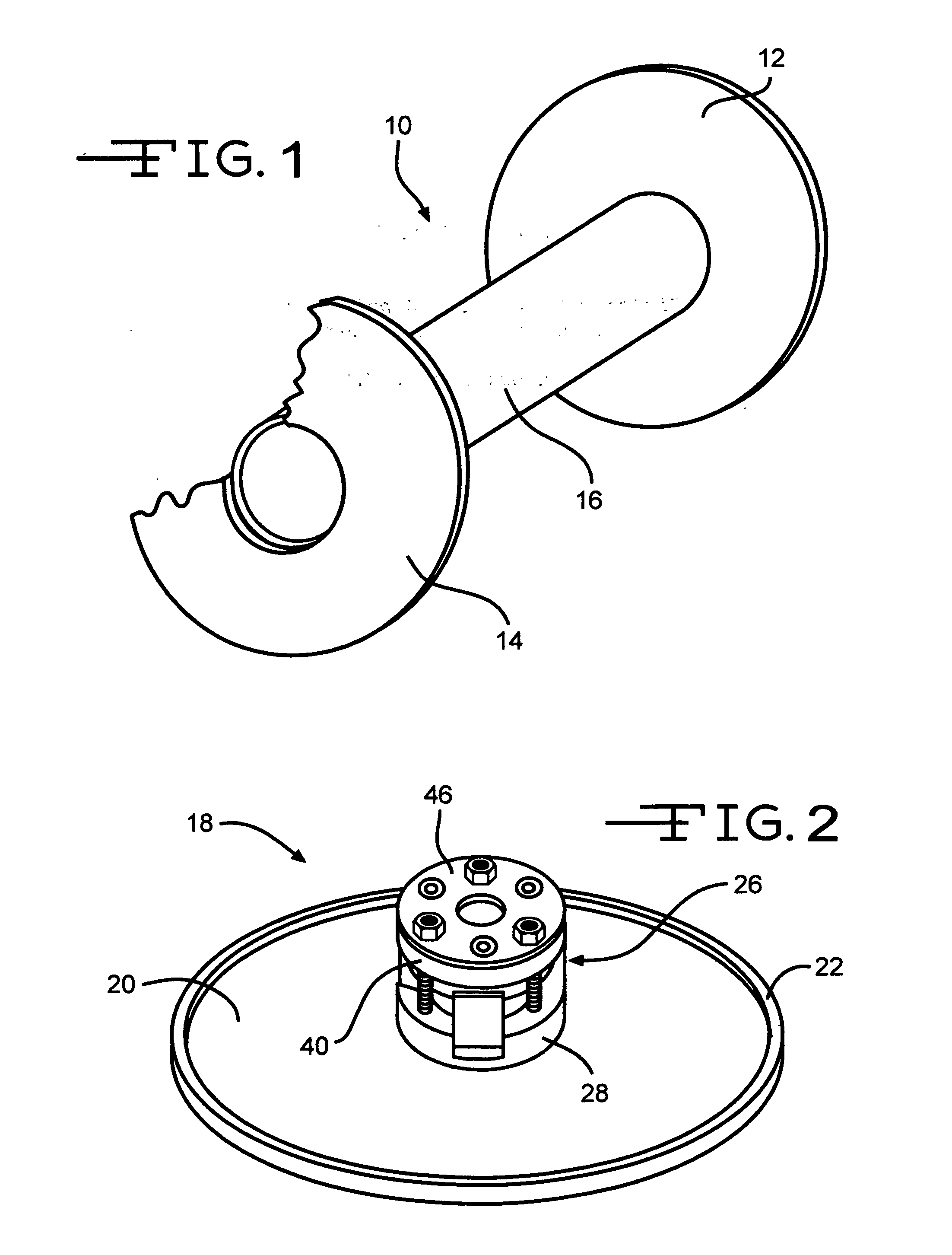

Wire spool repair device and method of using same

The present invention advantageously provides a wire spool repair device for a damaged wire spool having a central cylindrical portion with an axial bore and inner cylinder surface and a pair of opposing end plates attached thereto, the repair device including: an end plate, an attachment mechanism disposed on said end plate, a plurality of gripping fingers pivotally attached to said attachment mechanism and operative between retracted and attachment positions, and wherein insertion of said attachment mechanism into the axial bore of a wire spool and pivoting of said plurality of gripping fingers to the attachment position causes said plurality of gripping fingers to move into contacting relationship with the inner cylinder surface of the wire spool thereby attaching the repair device to the wire spool.

Owner:PERRY MICHAEL STEVEN

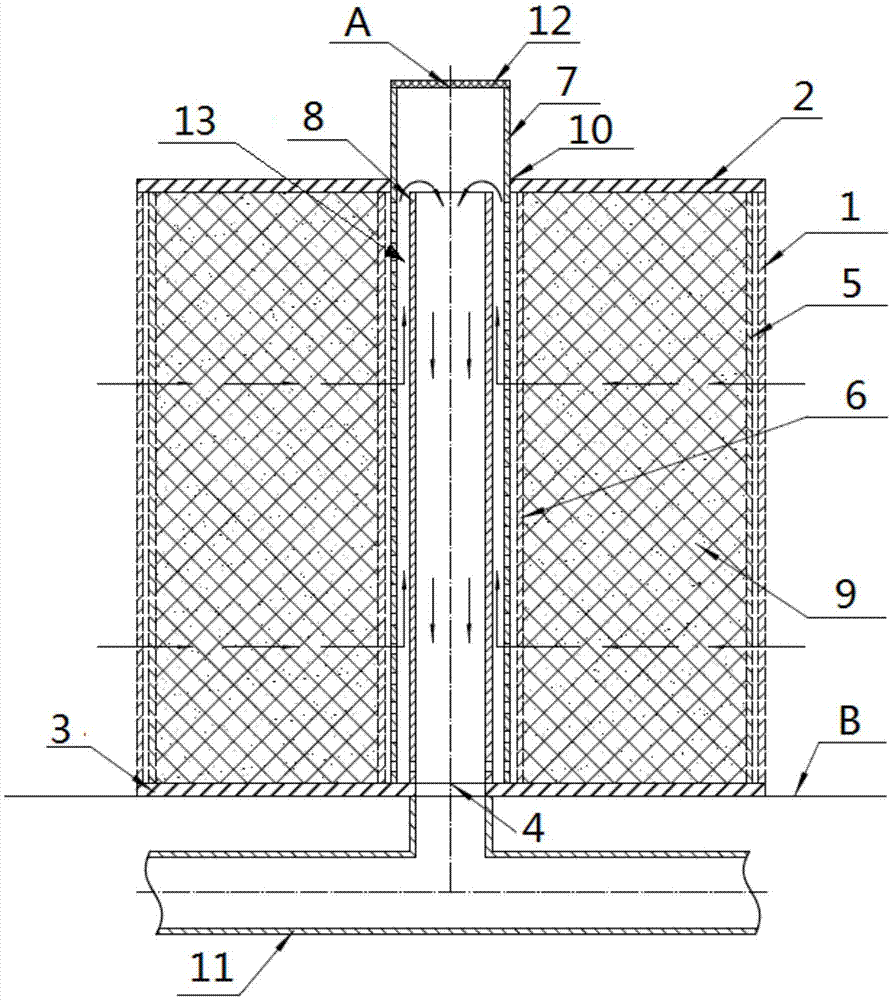

Efficient rainwater filter

ActiveCN105435495AGuaranteed utilizationGuaranteed processing efficiencyMembrane filtersLoose filtering material filtersFilter mediaEngineering

The invention discloses an efficient rainwater filter and belongs to the technical field of rainwater treatment devices. The efficient rainwater filter comprises a filter communicated with a drain pipe, a collecting pipe with a water hole is coaxially arranged in the filter, and a central cylinder is coaxially arranged in the collecting pipe. The central cylinder is provided with an overflow hole, the bottom end of the central cylinder is communicated with the drain pipe, and a rainwater retention channel is formed between the collecting pipe and the central cylinder. Rainwater accumulated in the rainwater retention channel is discharged through the overflow hole in the central cylinder. The efficient rainwater filter is simple in structure and convenient to manufacture and use; in the whole filtering process, not only is full contact between the rainwater and a filtering medium guaranteed, but also pollutants in the rainwater can be effectively removed, and the filtering medium utilization rate and the treatment efficiency of the filter are also guaranteed.

Owner:WUHAN MEIHUA YUSHUI ENVIRONMENT CO LTD

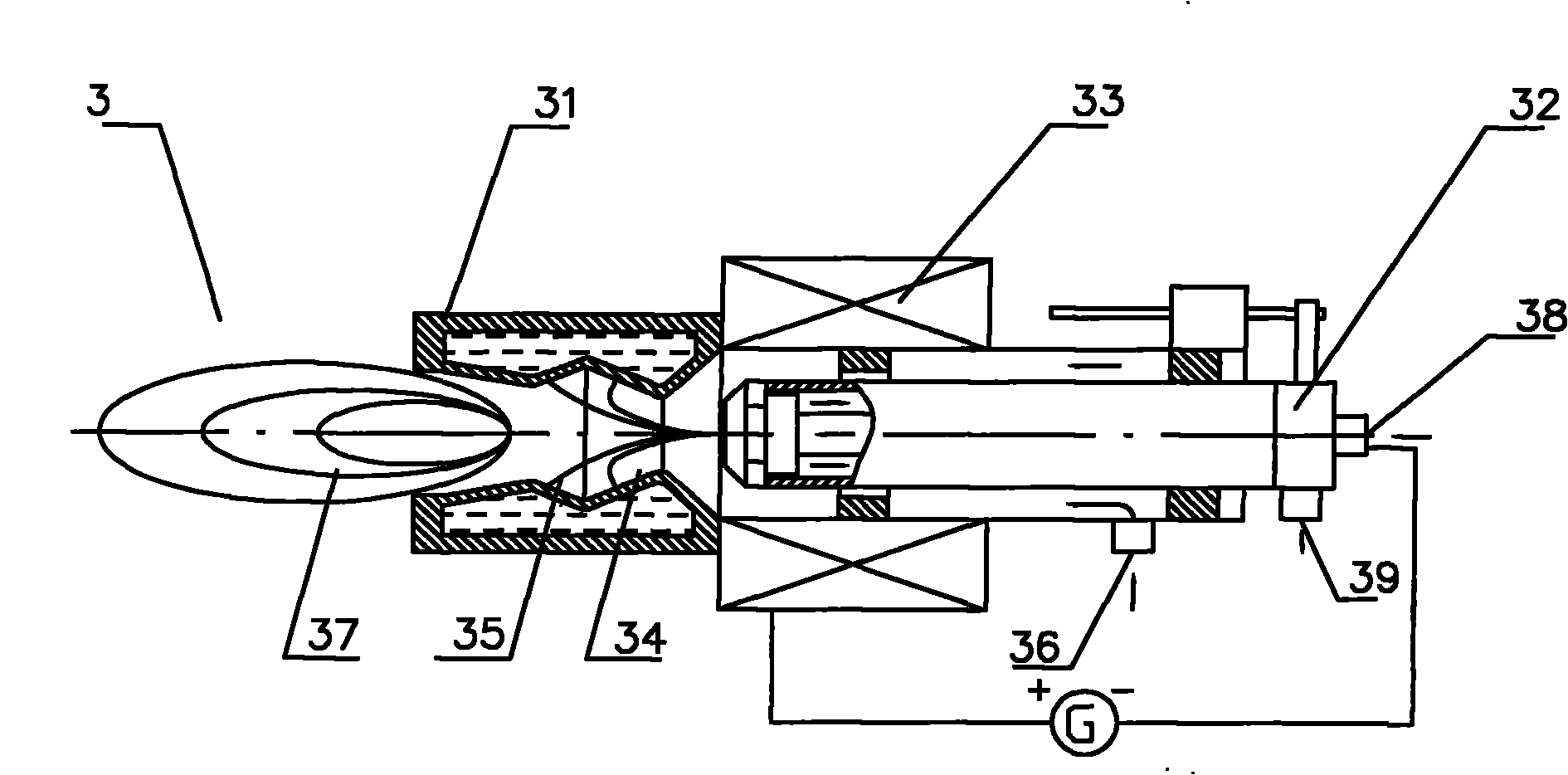

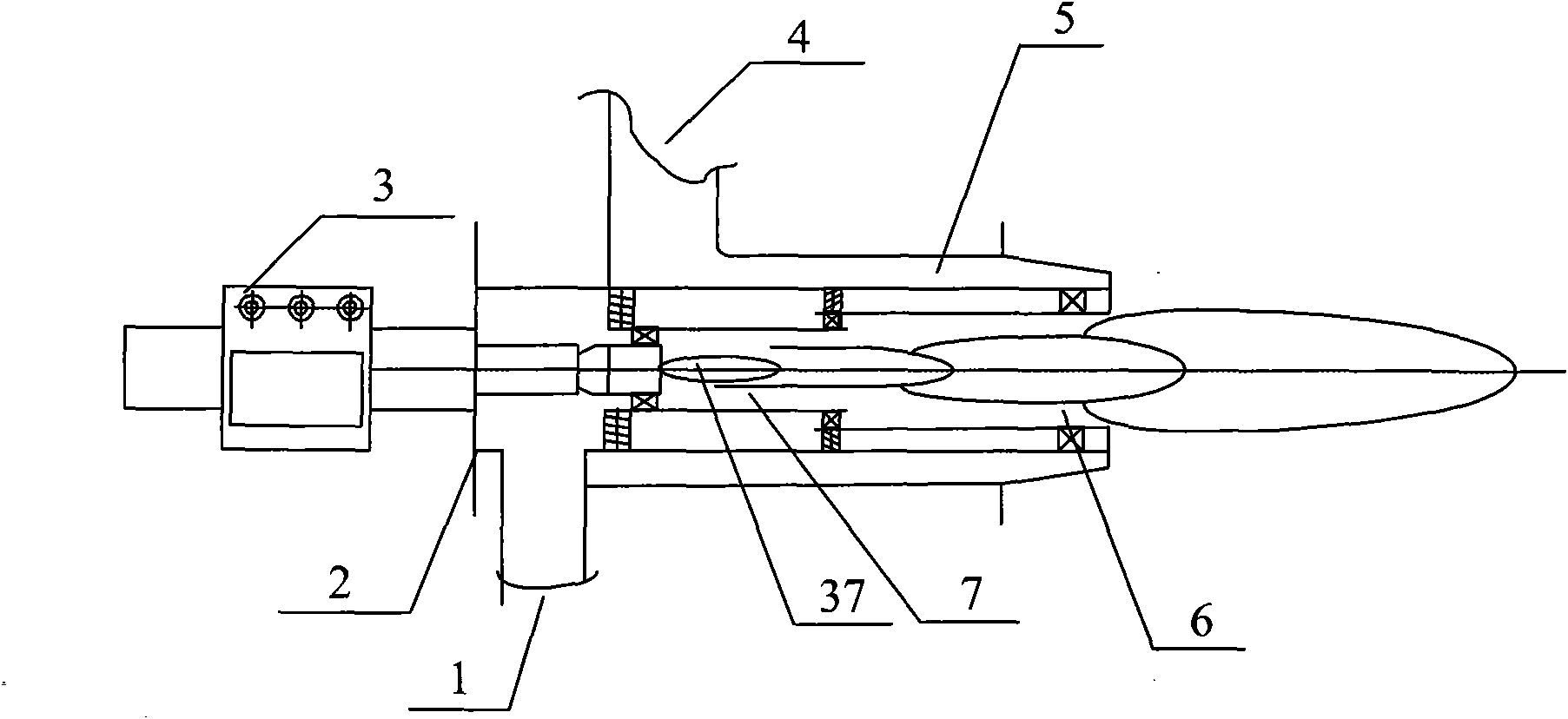

Improved plasma ignition nozzle of coal dust gasifier and mode

InactiveCN101886816AEasy to installGood effectIncandescent ignitionElectrochemical responseCombustion chamber

The invention relates to an improved plasma ignition nozzle of a coal dust gasifier. The improved plasma ignition nozzle is connected with a plasma generator and comprises an external sleeve, and a primary combustion chamber of a central cylinder and a secondary combustion chamber of an internal sleeve which are arranged sequentially from the center of the external sleeve to outside, wherein concentrated coal dust and air are introduced into the primary combustion chamber of the central cylinder, plasma arc and the coal dust undergo a strong electrochemical reaction in the primary combustion chamber of the central cylinder, the coal dust is subjected to splitting decomposition to generate a large number of volatile components, and the volatile components are ignited to generate primary flame; the volatile components and the coal dust are continuously combusted in the secondary combustion chamber of the internal sleeve, and the subsequently introduced coal dust is ignited to realize fractional combustion to generate secondary flame; and the secondary combustion chamber is cooled by using high-speed oxygen in the external sleeve, supporting combustion is performed at the same time, and oxygen, which is required by the combustion of unburned fixed carbon ejected from the secondary combustion chamber in a hearth, is supplemented to generate tertiary flame. The improved plasma ignition nozzle and an ignition mode have the advantages of convenient installation, stable and reliable effect, wide application in various coal dust feeding gasifiers, simple structure, low cost and safe operation.

Owner:NORTH CHINA POWER ENG

Metal-rubber composite gland bush molding die and molding method thereof

The invention relates to a metal-rubber composite gland bush molding die which comprises an upper core plate, an upper pressure plate, a positioning gasket, a lower pressure plate and a lower core plate. Central columns of the upper core plate and the lower core plates are installed in central holes of the upper pressure plate and the lower pressure plate. The positioning gasket is installed between the upper pressure plate and the lower pressure plate. A metal frame of a metal-rubber composite gland bush is arranged in a die cavity combined by the upper core plate, the lower core plate, the upper pressure plate, the lower pressure plate and the positioning gasket. A matching surface between the positioning gasket, the upper pressure plate and the lower pressure plate has a slope angle of 15 degrees to 20 degrees. The molding die adopts a combination type, so that the molding die is convenient for demounting and the metal-rubber composite gland bush can be taken out very conveniently. The molding die is provided with the split positioning gasket, thereby ensuring that the metal-rubber composite gland bush is convenient for taking out when being positioned and ensuring that the molded metal-rubber composite gland bush can be convenient for taking out. The molding mould has simple structure, convenient manufacturing and low cost. A molding method for molding the metal-rubber composite gland bush has very good effect.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

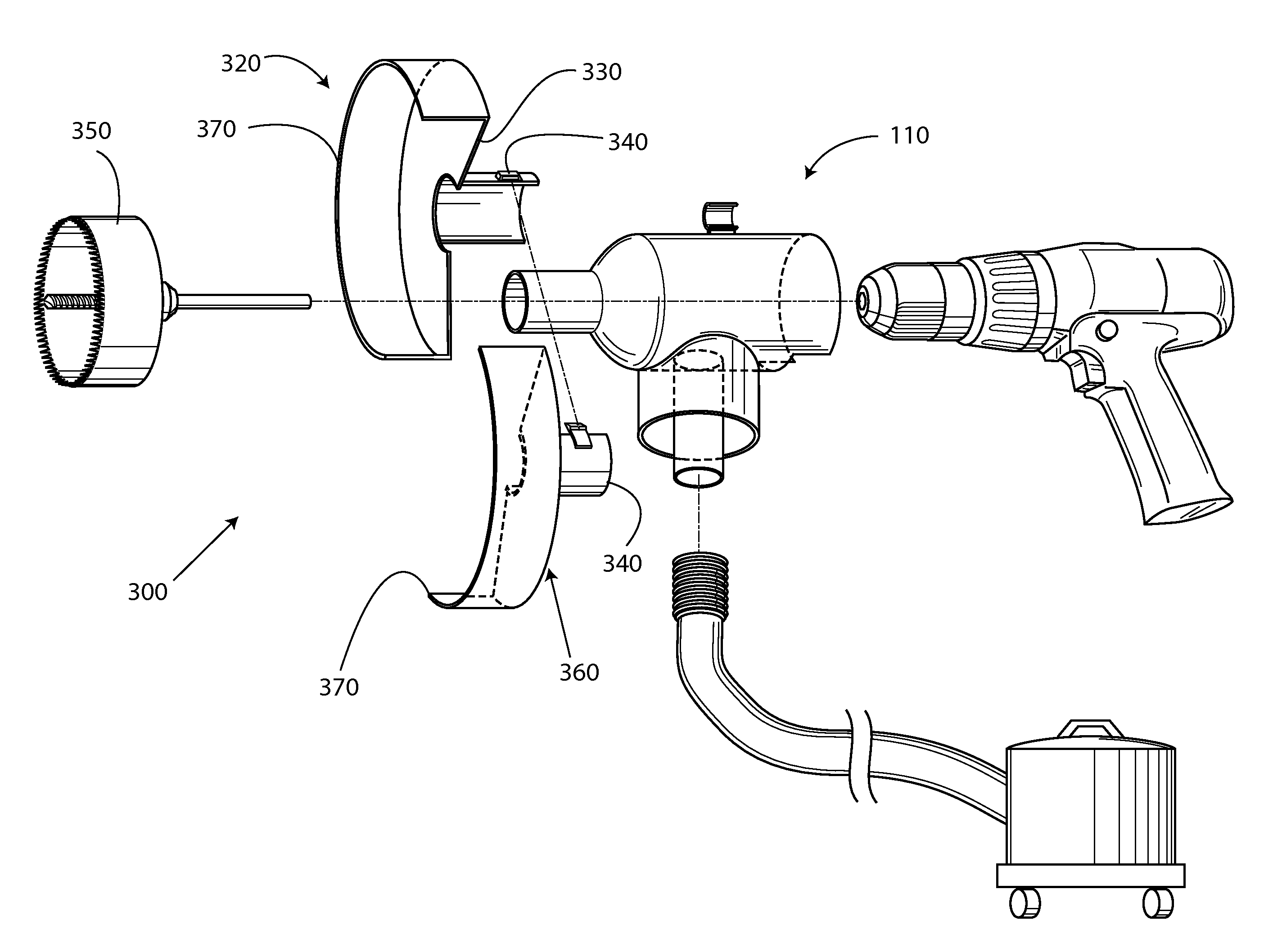

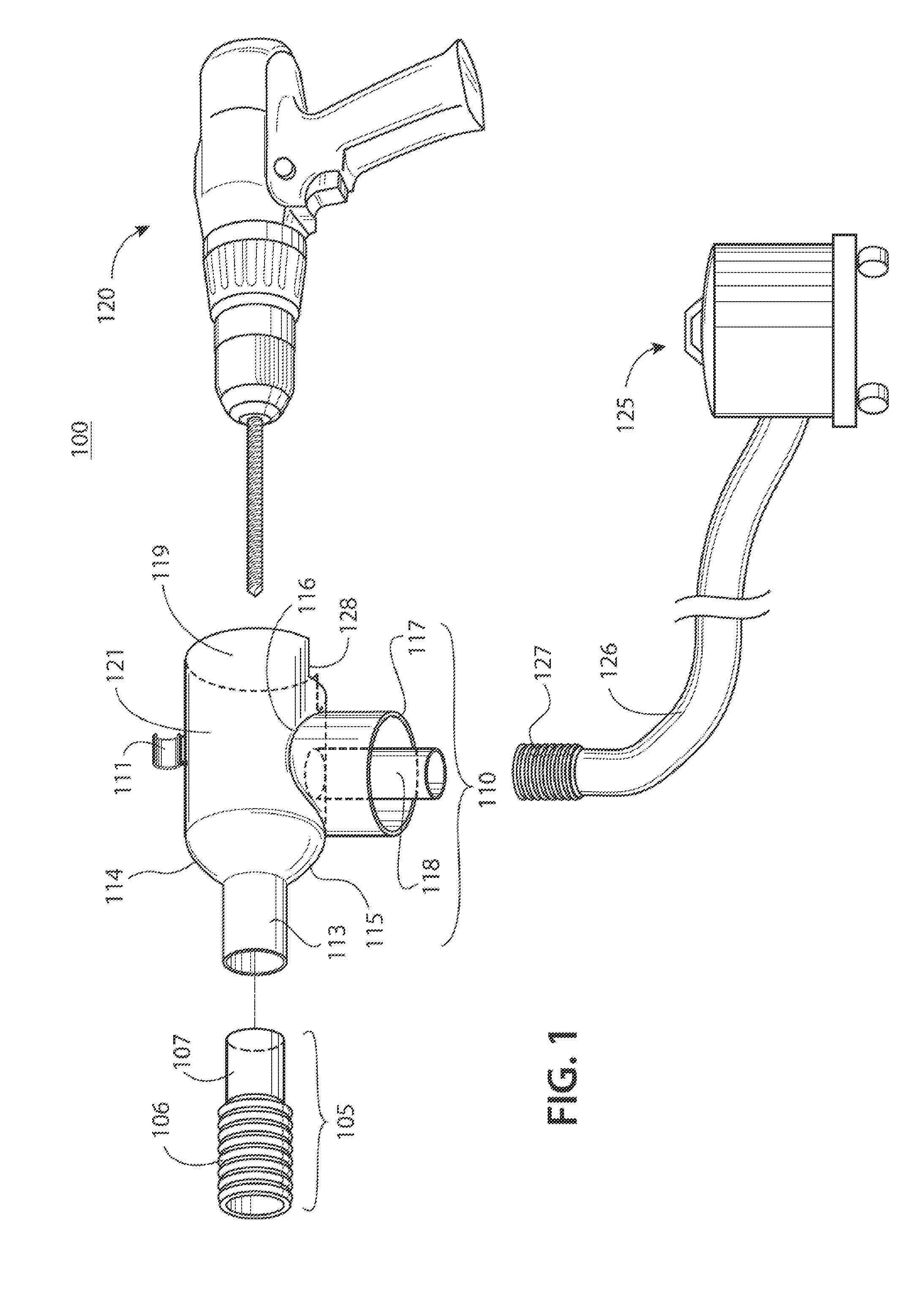

Dust Free Drill System

InactiveUS20140093320A1Thread cutting feeding devicesPortable power-driven toolsCircular sawEngineering

Hammer drills and similar devices have an ongoing dust and debris problem that is solved by a protector device covering the drill in a main body protector shielding a user from the materials. The protector device has an evacuation region on its underside with multi dimensional adapters for attaching hoses of varying sizes. Additionally, an insertable collapsible accordion cylinder assists in covering the debris falling from different size drills being used. A second embodiment has a circular saw dust protector attachment arranged as two half moons or 1 / 4 moon and 3 / 4 moon having a central cylinder at their respective tops that are to be held together with a mechanical latch.

Owner:SULLIVAN MARK D

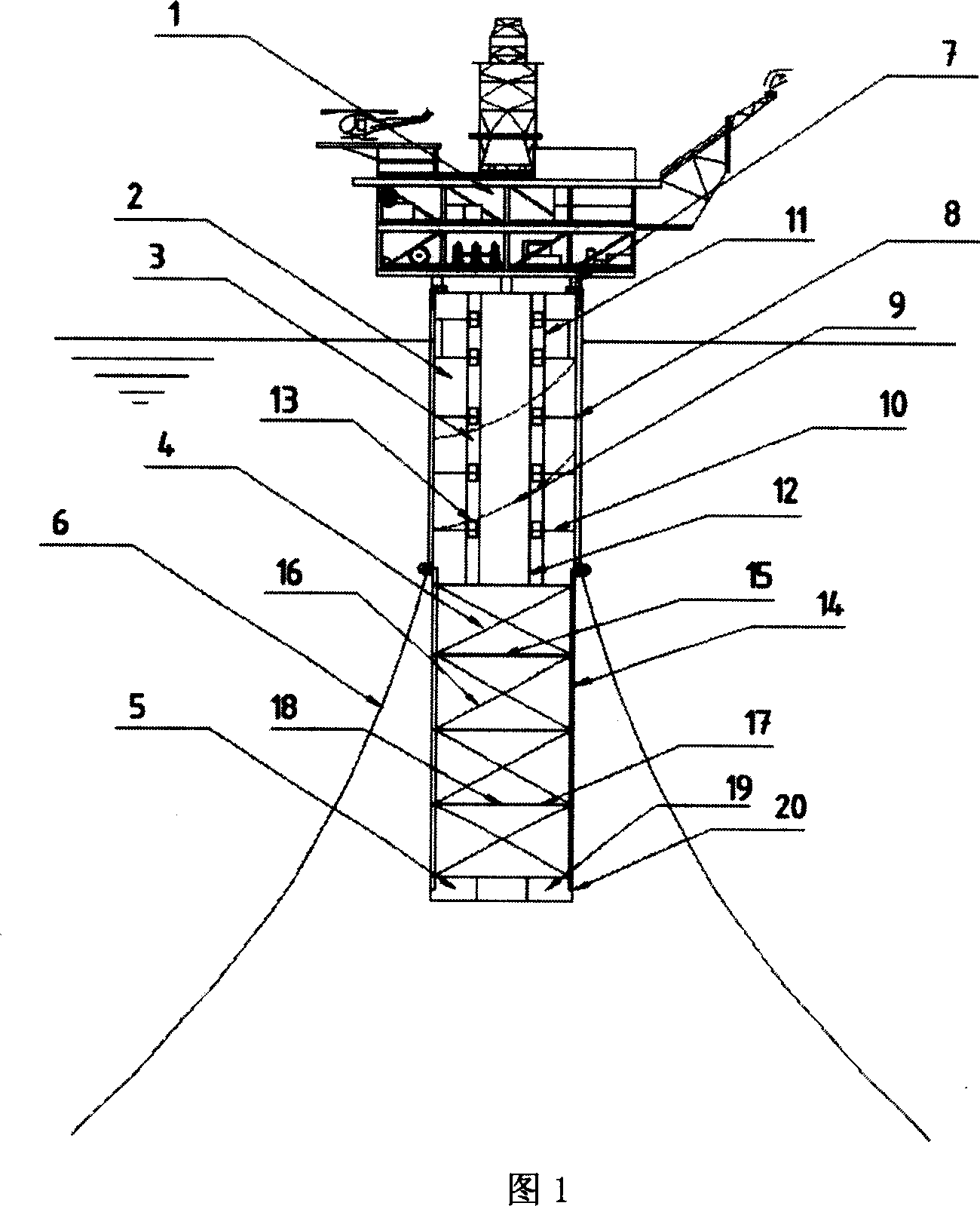

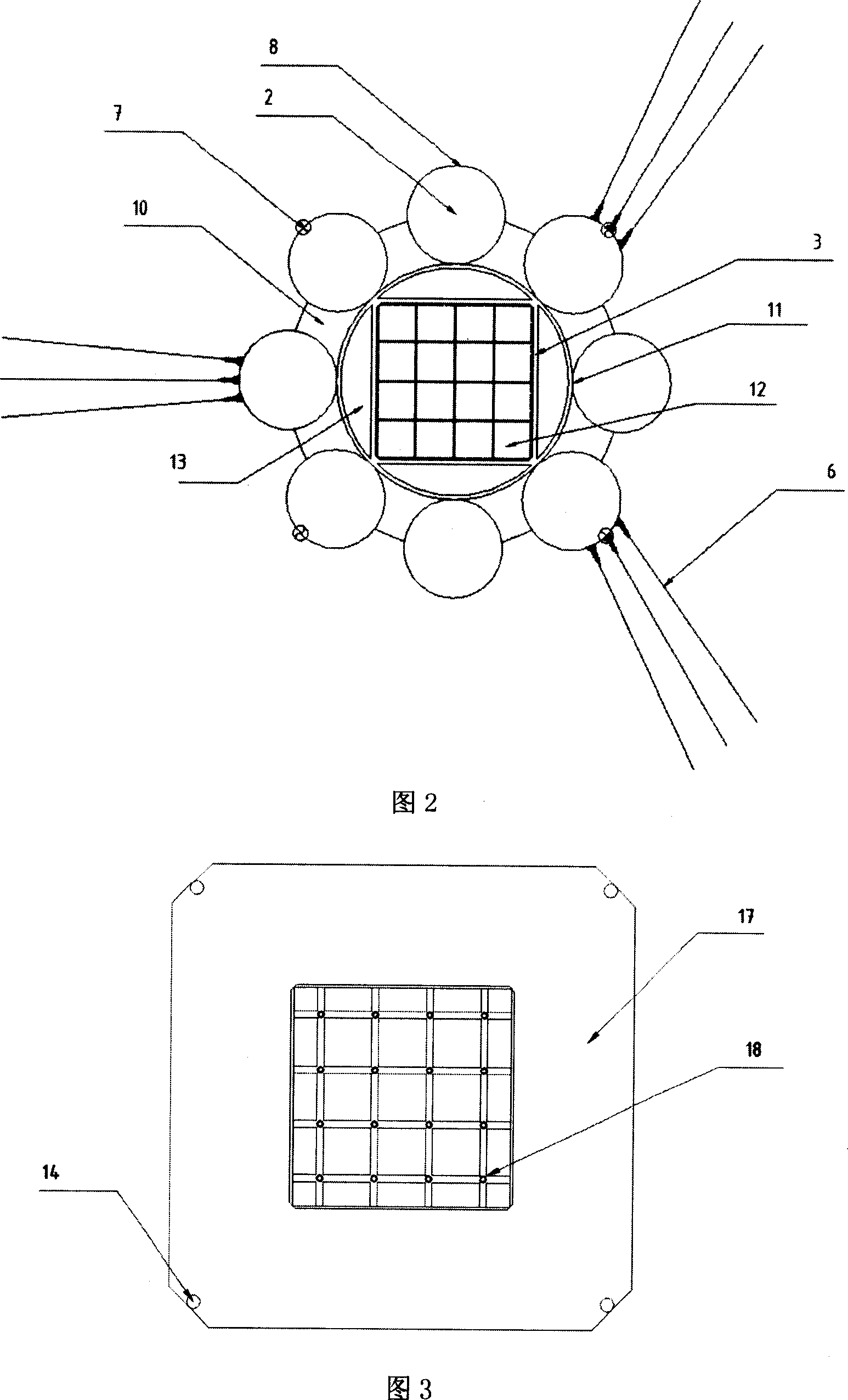

Multiple column truss type spar platform with central well

InactiveCN101007562AEasy to installEasy to passWaterborne vesselsFloating buildingsMooring systemEngineering

A multi-column trussed-beam upright column platform with central well belongs to marine engineering technology field. The invention include: top module, hard cabinet, central cylinder, trussed structure, soft cabinet and mooring system. The top module is connected with the upper part of hard cabinet through the deck legs, the hard cabinet encircles surround the central cylinder, the lower part of hard cabinet is connected with trussed structure, the lower part of trussed structure is connected with soft cabinet. The mooring system is connected with the outer part of hard cabinet. Said central cylinder includes: central cylinder shell, central well and reinforced beam structure. The central well is installed in the central cylinder shell through the reinforced beam structure. The central cylinder of the invention is equipped with central well in itself, so it enables the installment of buoyancy tank and top tensioning stand pipe, due to the stand pipe system is decoupled with the movement of platform, while is protected by platform main body, so it can maintain smaller movement and bears smaller environmental loads, thereby the dry collected oleoresin can be used on the platform, it is facilitating for installment and maintenance of the equipment.

Owner:SHANGHAI JIAO TONG UNIV

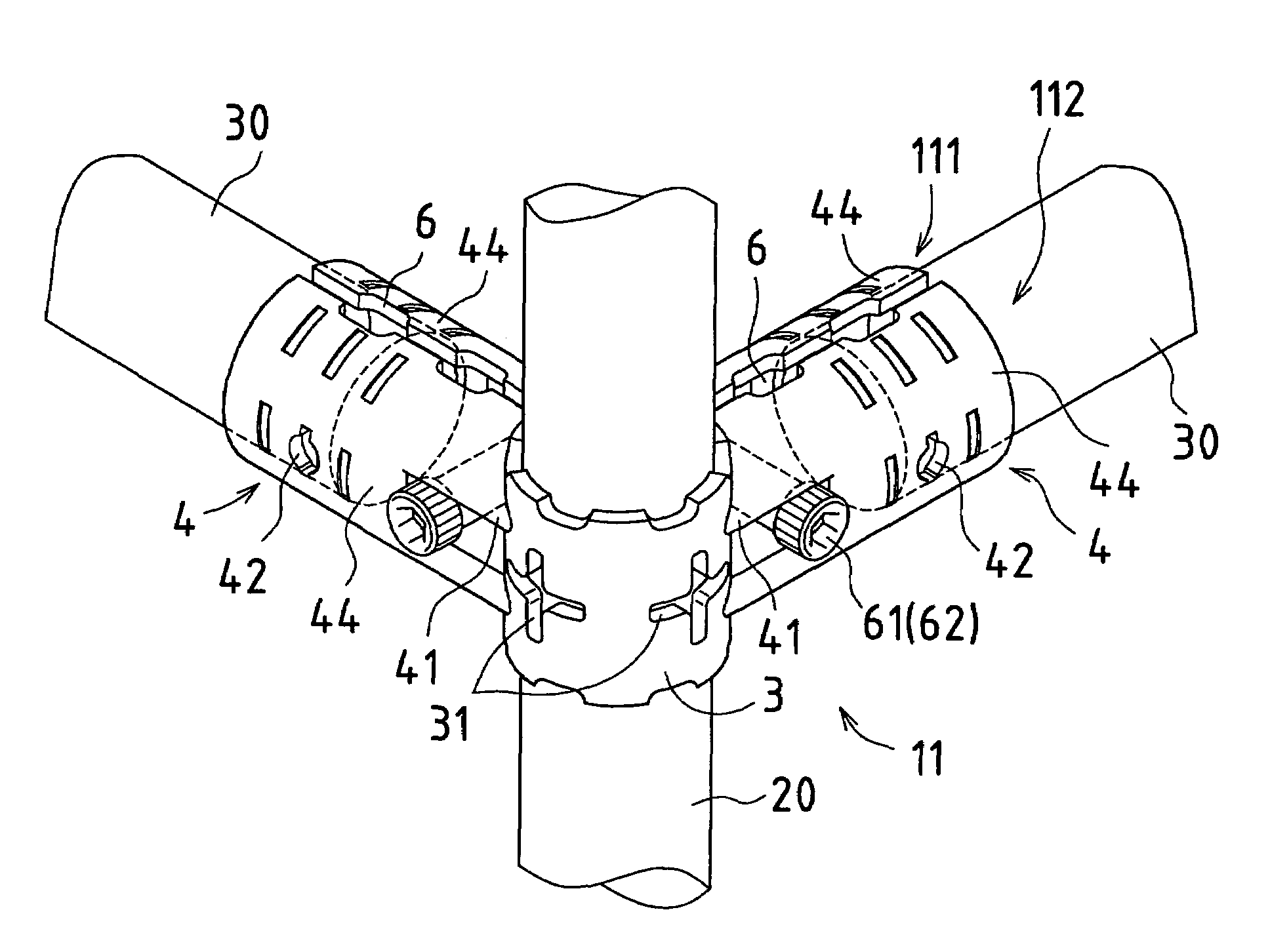

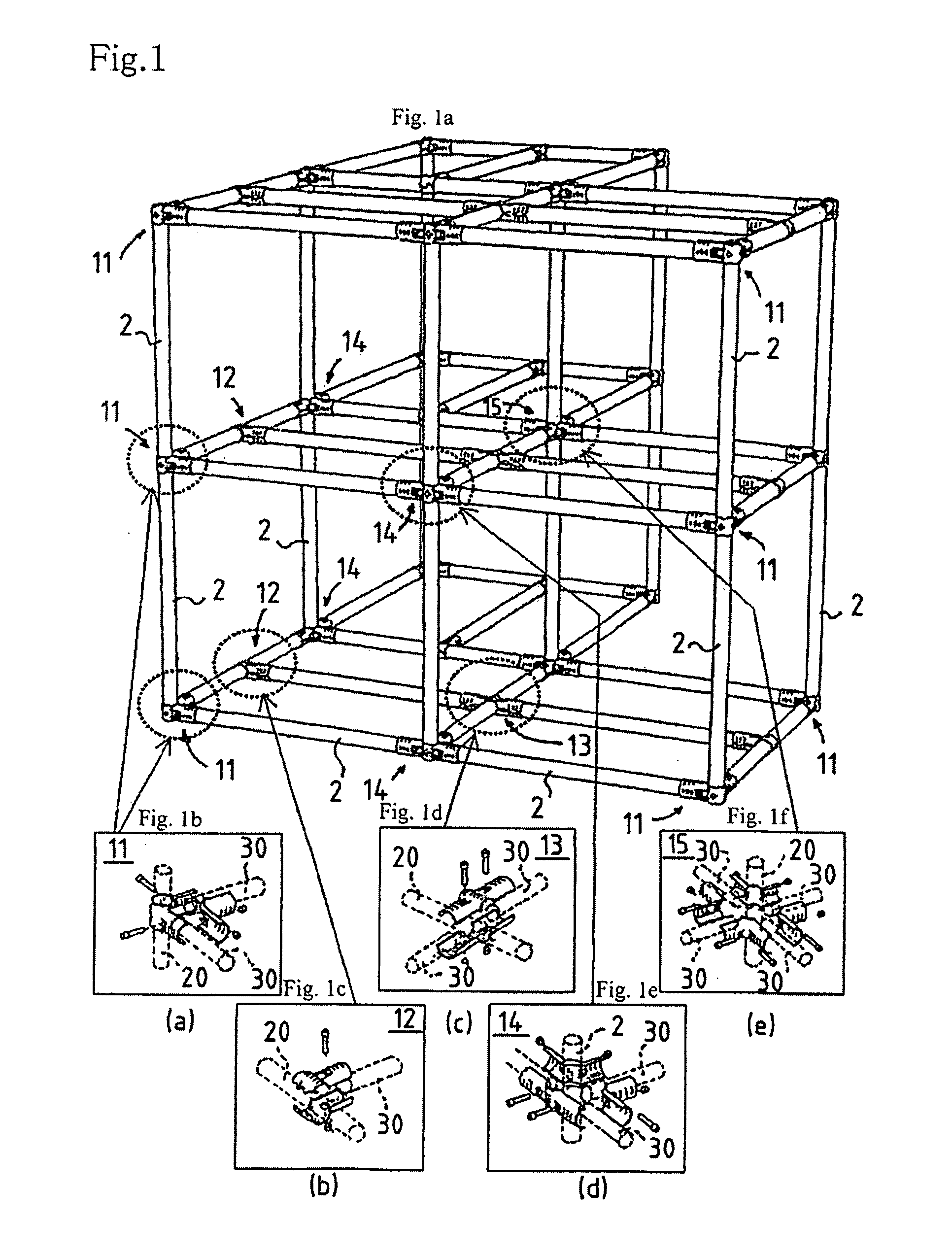

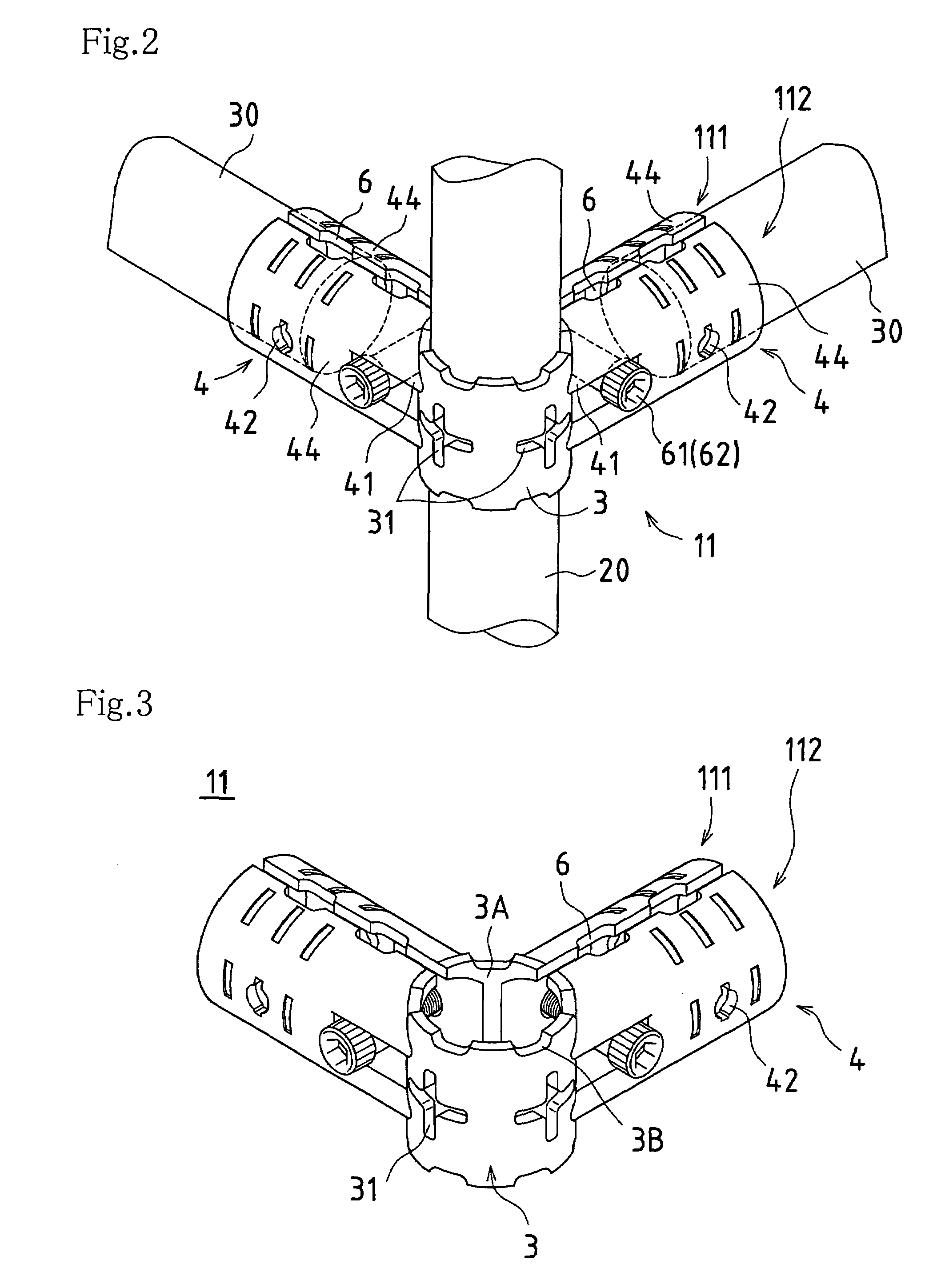

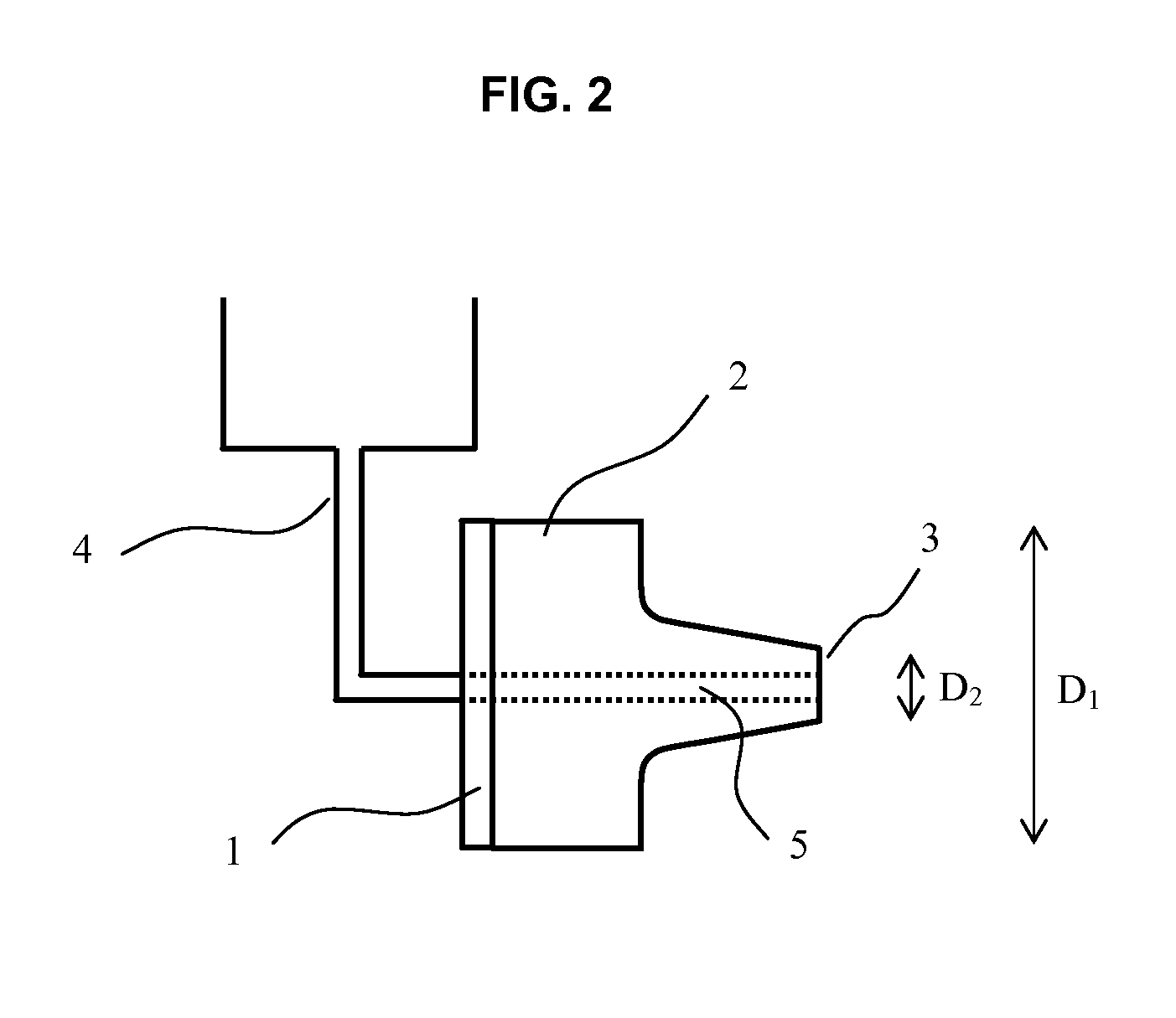

Pipe fitting and assembly using such pipe fittings

A pipe fitting of the present invention comprises a combination of a plurality of split fittings and has a central cylinder and an extended cylinder which outwardly projects from the central cylinder, the central cylinder and the extended cylinder being capable of receiving pipes from orthogonal directions with respect to each other. The extended cylinder includes a bolt hole which locates near the central cylinder and which penetrates the extended cylinder. The central cylinder has an aperture provided in a side surface thereof. Each split fitting is fixed on the pipes by a bolt and nut via the respective bolt hole.

Owner:SEKISUI JUSHI KK +1

Liquid dispensing apparatus based on piezoelectrically driven hollow horn

InactiveUS20080128527A1Simple geometryEasy to manufactureMovable spraying apparatusSpray nozzlesMechanical engineeringCentral cylinder

Owner:THE HONG KONG POLYTECHNIC UNIV

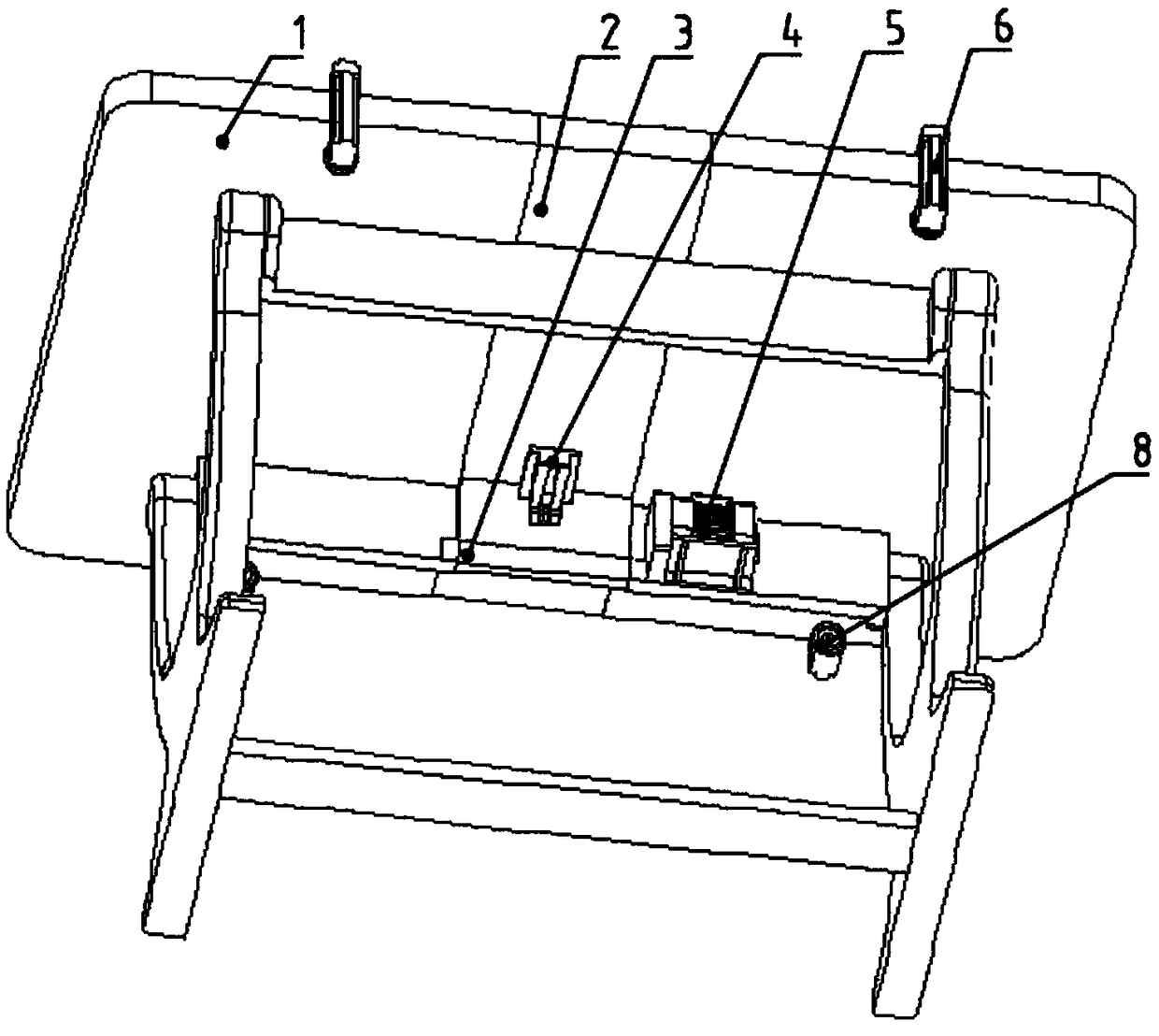

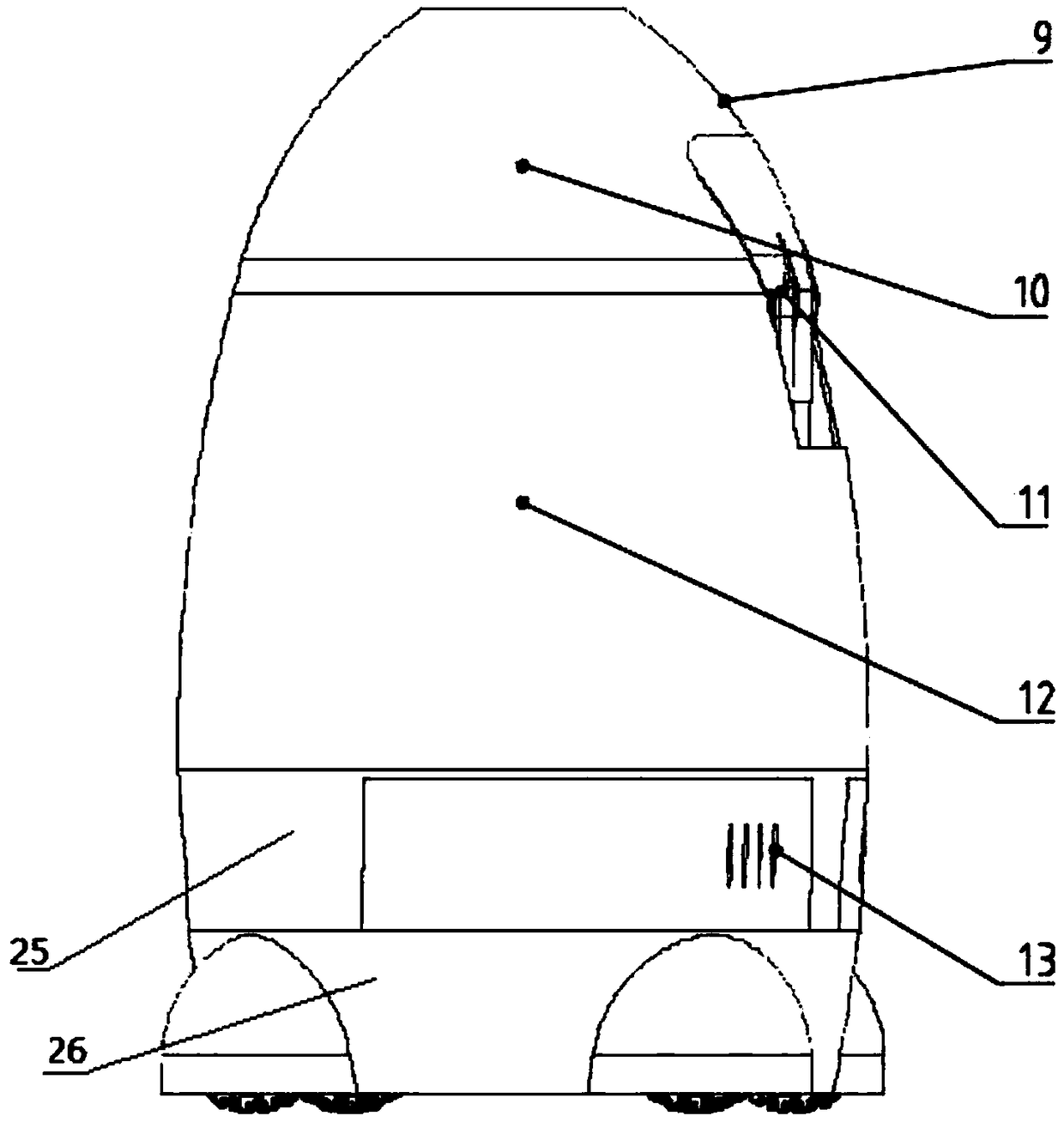

A tableware collection, cleaning and sorting robot system

ActiveCN109199292ARealize self-cleaningImprove battery lifeTableware washing/rinsing machine detailsCarpet cleanersRobotic systemsEngineering

The invention discloses a tableware collection, cleaning and sorting robot system, which relates to the technical field of intelligent food and beverage, comprising a fixed table and a mobile robot. The fixed table comprises a table body and a cleaning device installed on both sides of the table body. The middle of the table body is a central panel that can incline downward. The bottom of the central panel is provided with a signal emitter. The bottom of the mobile robot is provided with a moving chassis. The inside of the mobile robot is a cavity structure, and a central cylinder which playsa supporting role is arranged at the middle of the cavity structure, and a washing layer, a separation layer and a collection layer are arranged sequentially from top to bottom along the central cylinder. The robot system has reasonable structure design, which can collect tableware, clean tableware, separate tableware and tidy table and is easy to use and flexible to move.

Owner:XI AN JIAOTONG UNIV

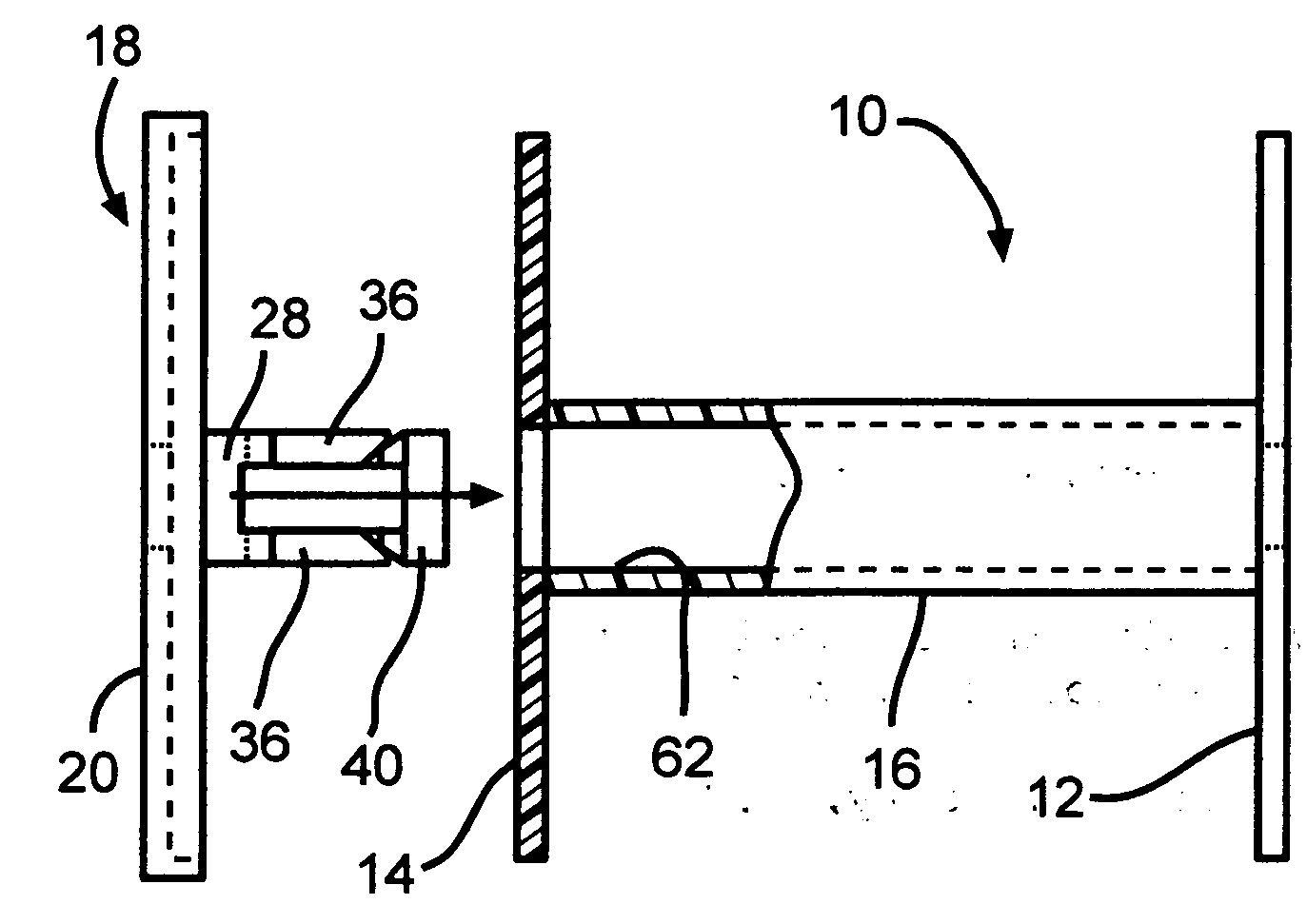

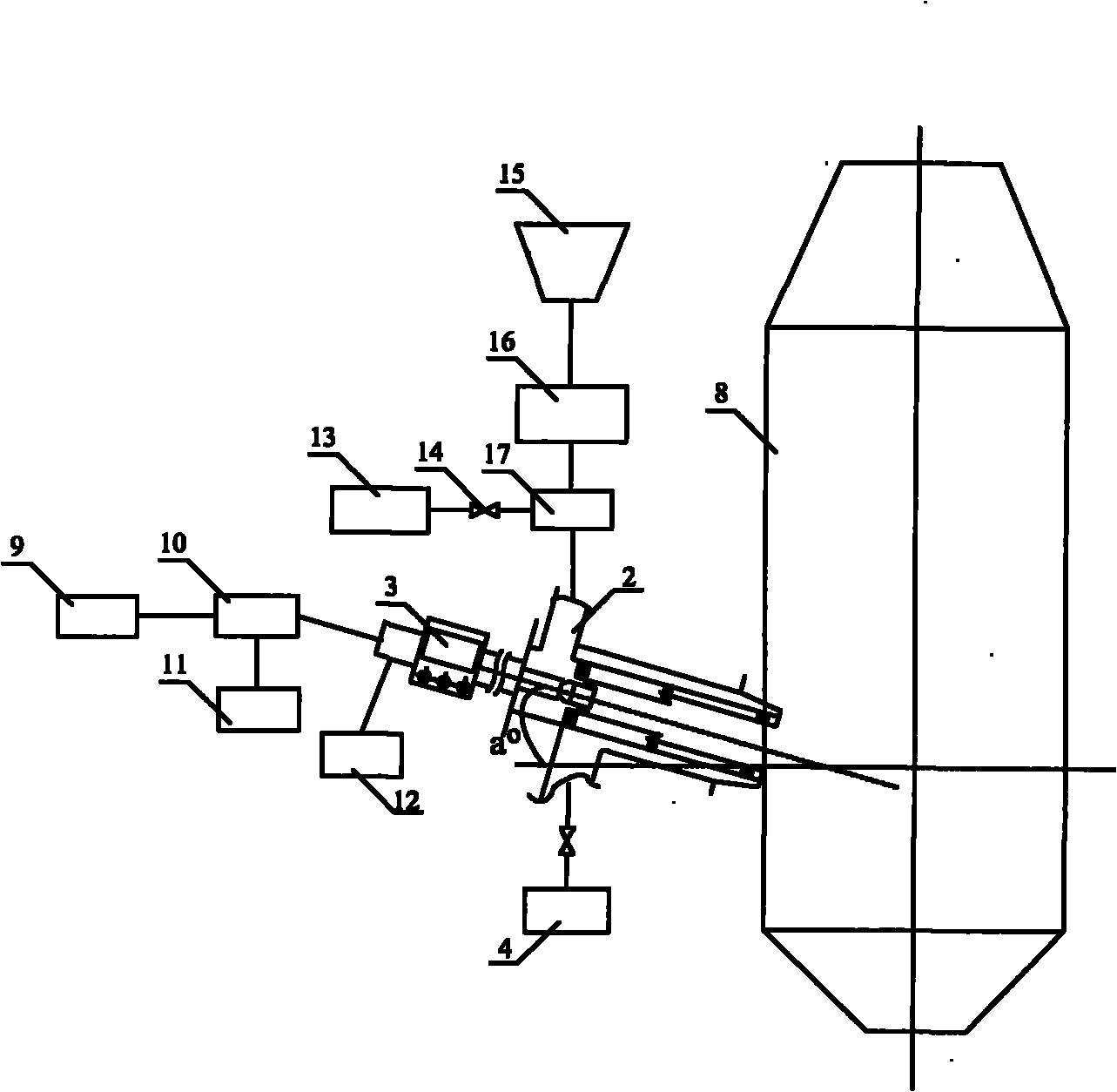

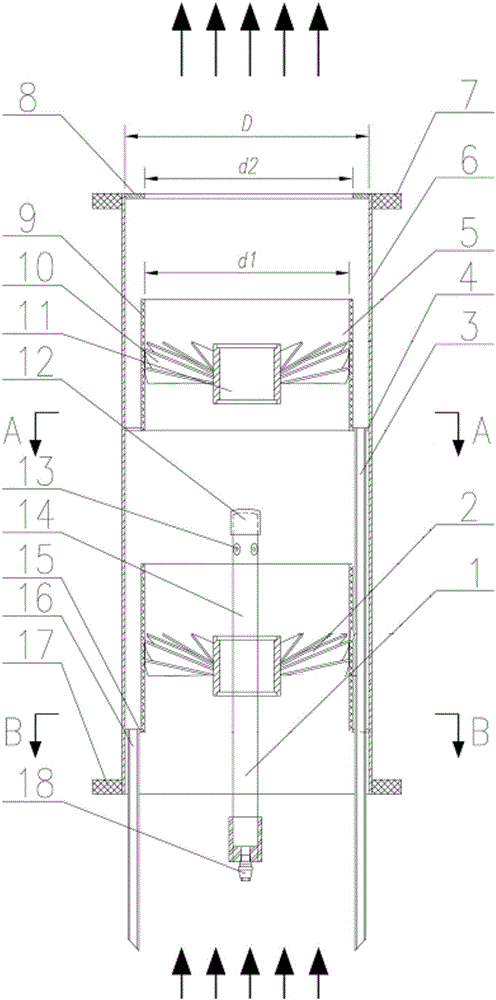

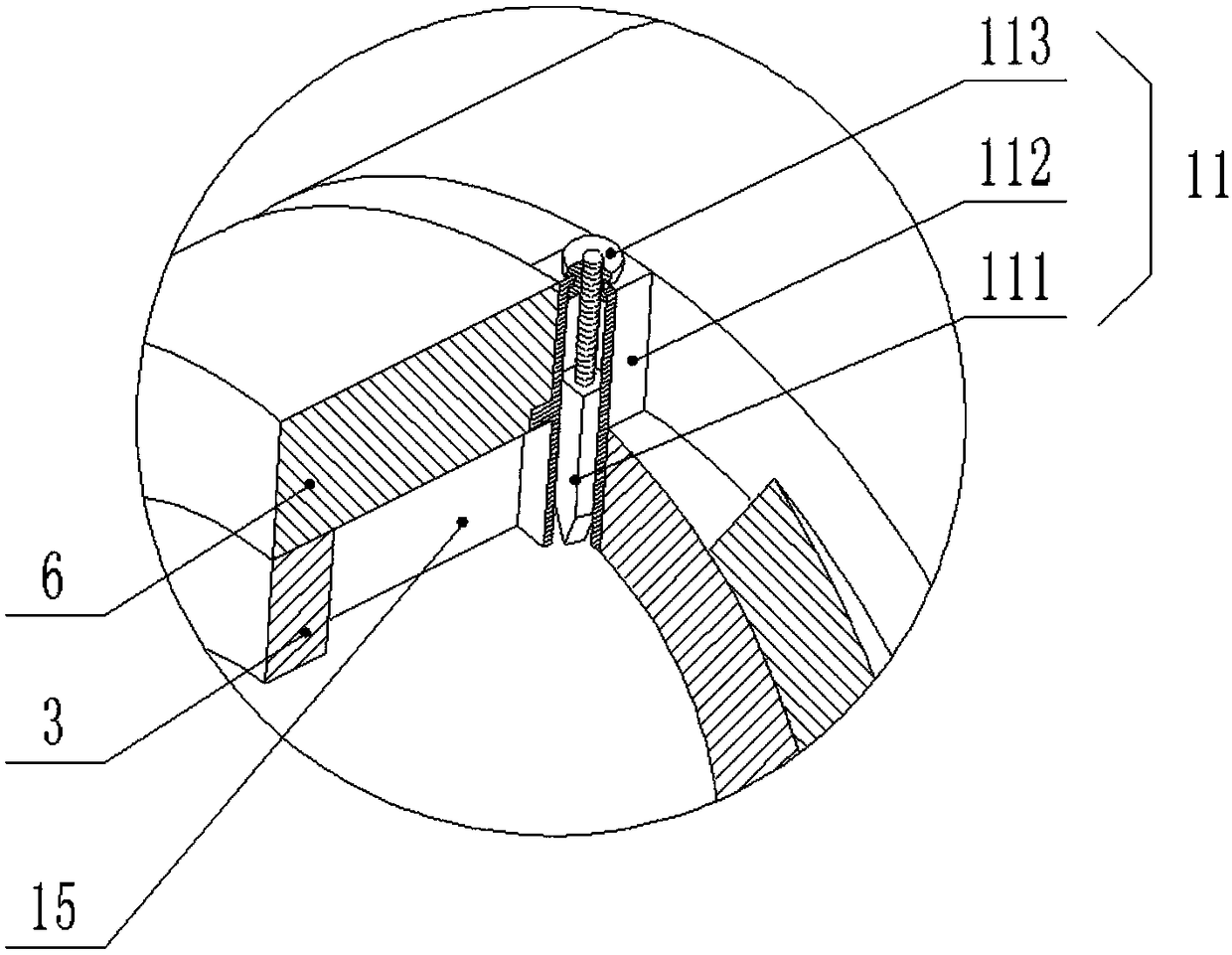

Experimental apparatus and experimental method for simulating gas-well annulus pressure carrying and air cutting processes

The invention relates to an experimental apparatus and an experimental method for simulating gas-well annulus pressure carrying and air cutting processes. A central cylinder is the key structure of the experimental apparatus, and comprises a rock-core clamping cylinder, a rubber sleeve, an upper sealing cover, a lower sealing cover, a central column, an upper-end pressure-detecting cylinder and a lower-end air inlet cylinder. A rock core is disposed in the rock-core clamping cylinder. Annulus protective liquid with certain height is injected into the central cylinder from a valve II, and the whole device is guaranteed to be in a sealing state. Air is injected into the central cylinder through an air compressor to realize simulation of a gas-well annulus pressure carrying process. In addition, on the condition that the rock core is not mounted, experimental to-be-tested liquid with certain height is injected into the central cylinder, and an air cutting process can be simulated. The experimental apparatus is simple in structure, convenient to assemble and reliable in performance, two different experimental processes can be simulated by one experimental device, and high popularization and application value is provided.

Owner:SOUTHWEST PETROLEUM UNIV

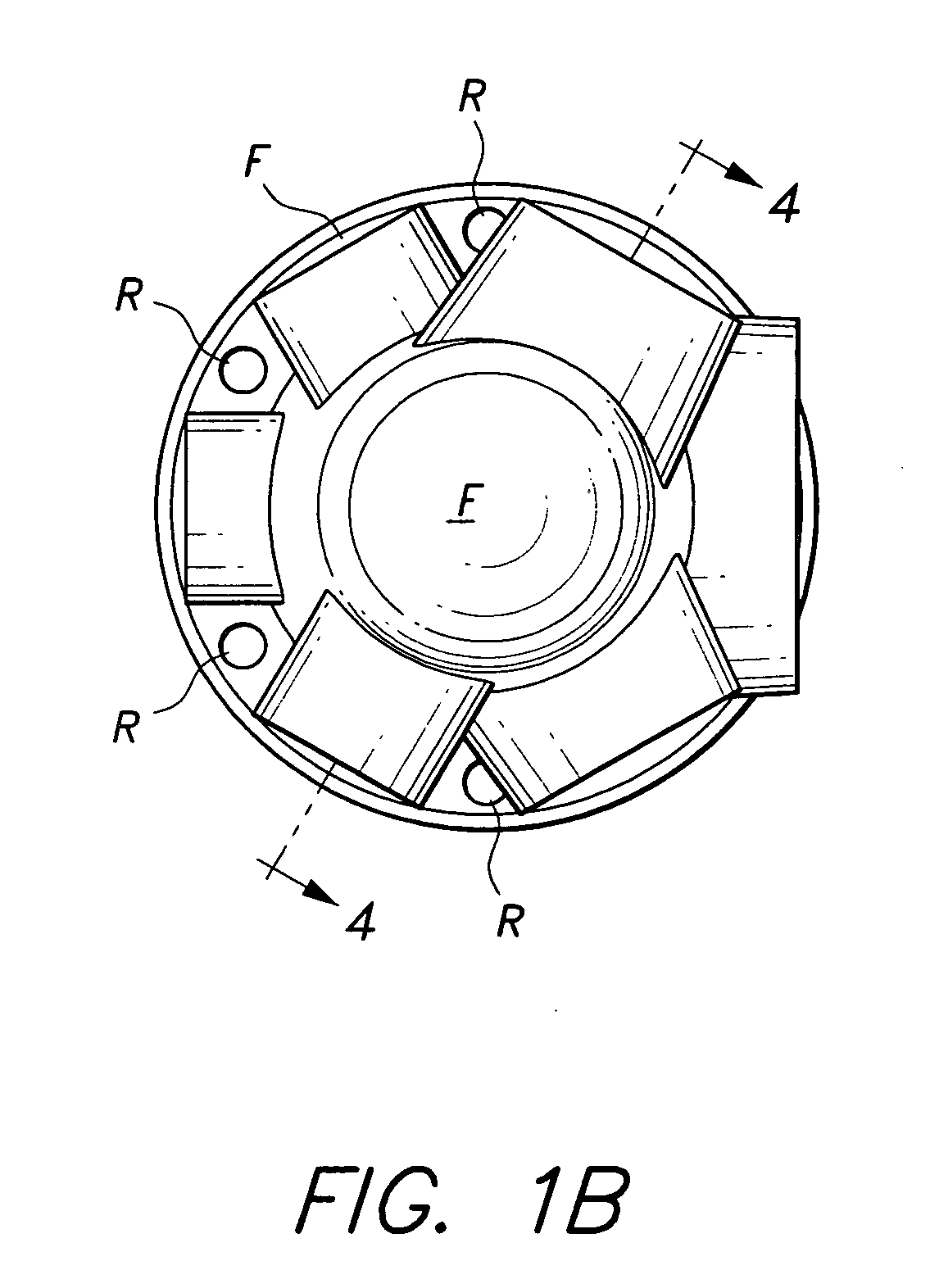

Self-cleaning, continuously operating filter apparatus for fluids

InactiveUS20080053889A1Treatment involving filtrationMoving filtering element filtersEngineeringCentral cylinder

The filter apparatus for an incoming liquid which includes a retentate and a permeate includes a housing with a frame and a hollow drum assembly mounted for rotation within the housing about a fixed central cylinder. The drum assembly has openings in the drum wall. An inlet assembly delivers the incoming liquid under pressure to the drum assembly. A filter assembly is mounted to the inside of the drum. A trough assembly is mounted so as to be in communication with the central cylinder and is in a fluid-tight relationship to the interior surface of the filter assembly as the drum rotates past the trough assembly. A manifold is fixedly mounted but has a substantially fluid-tight relationship with the exterior of the drum, and is configured to cover successive columns of drum openings as the drum rotates. Pressurized gas is directed to the manifold at selected times, such that as the drum turns, and retentate is collected on the interior surface of the filter as the incoming liquid is forced through the filter assembly, pressurized fluid from the manifold dislodges the retentate off into the trough and out the outlet assembly.

Owner:LEATH WILLIAM M

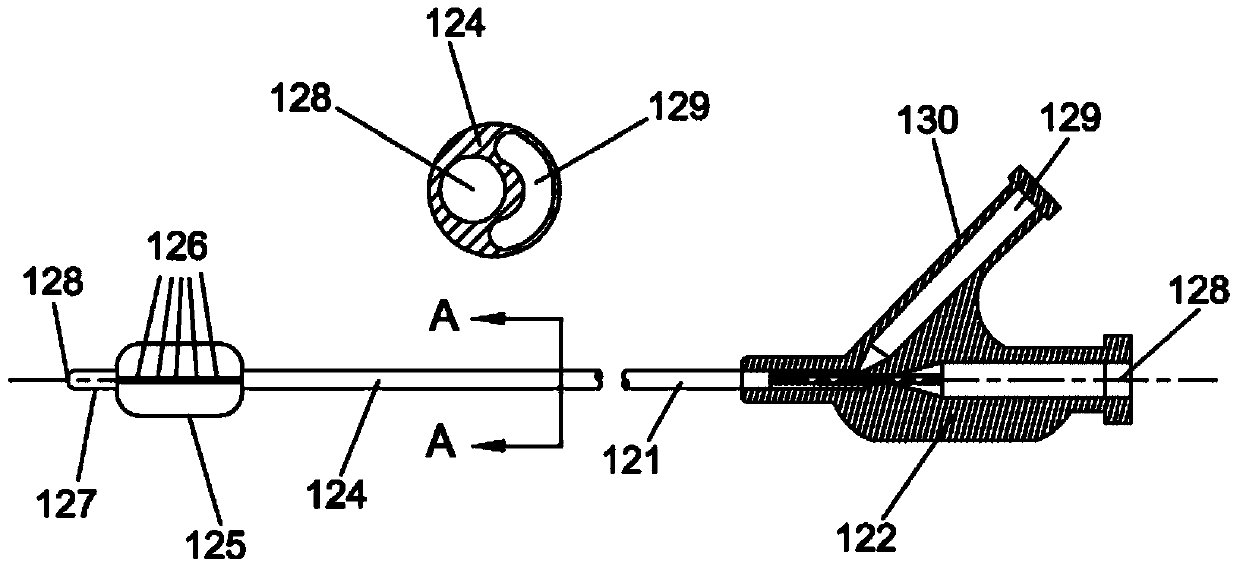

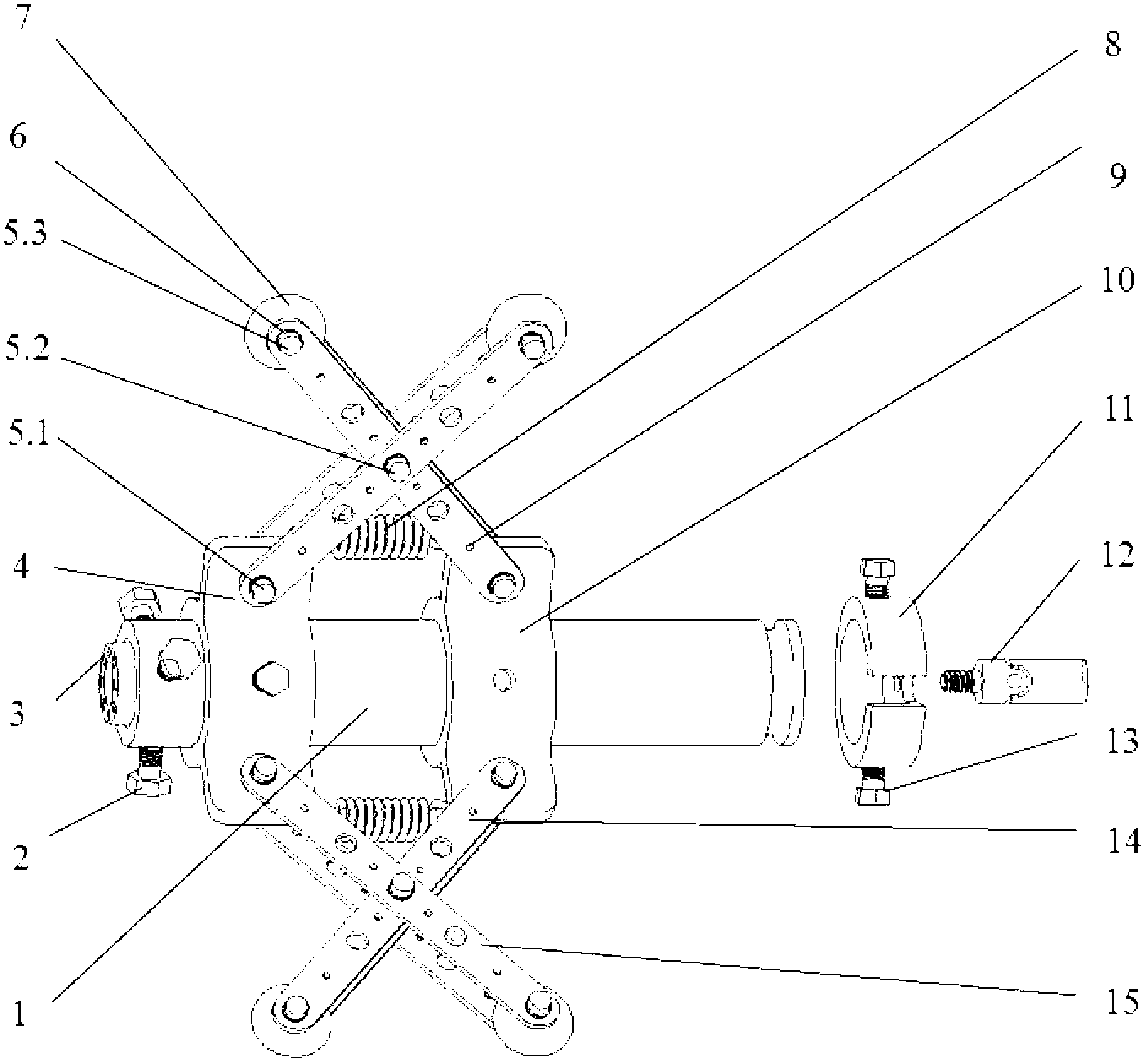

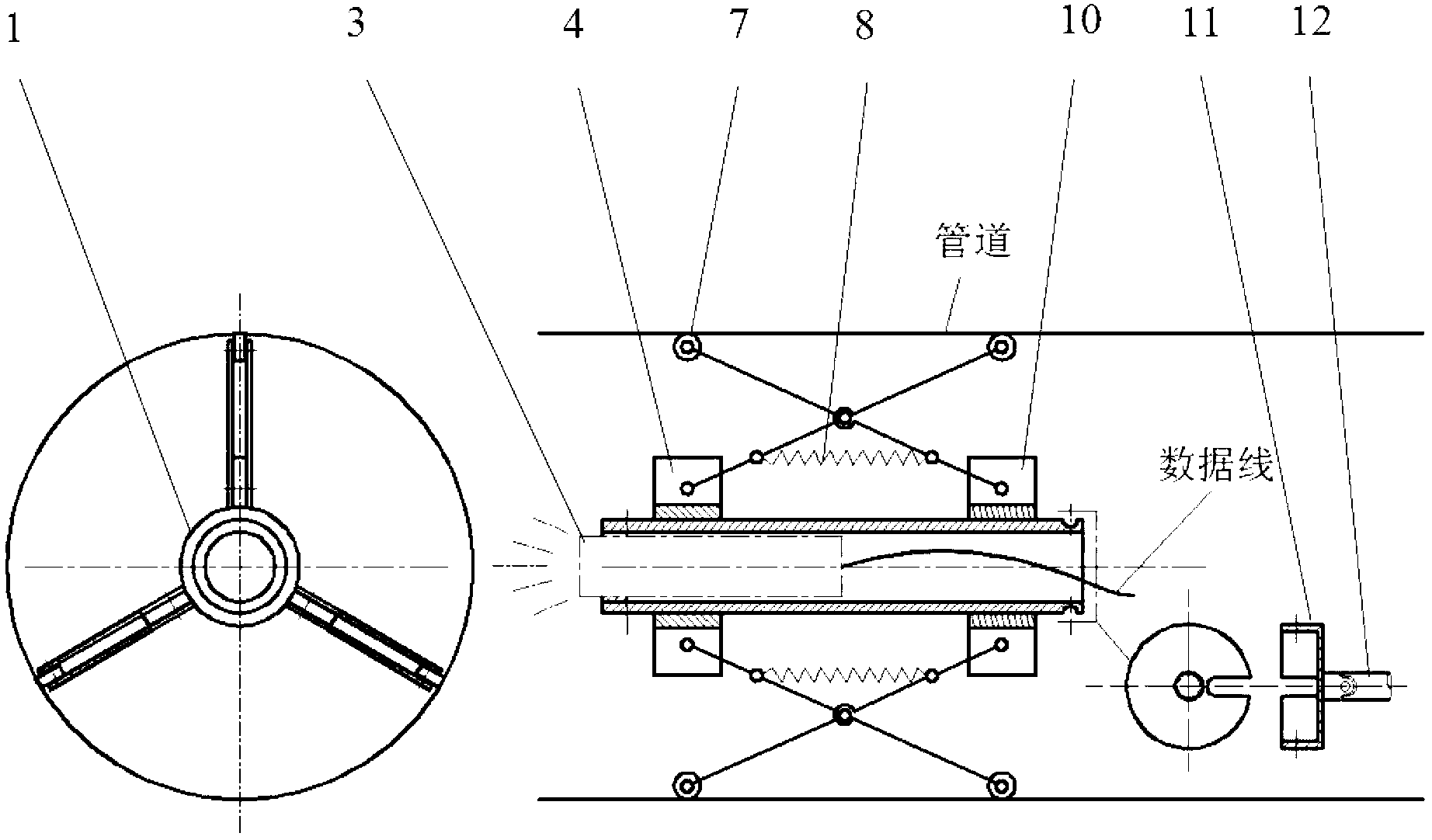

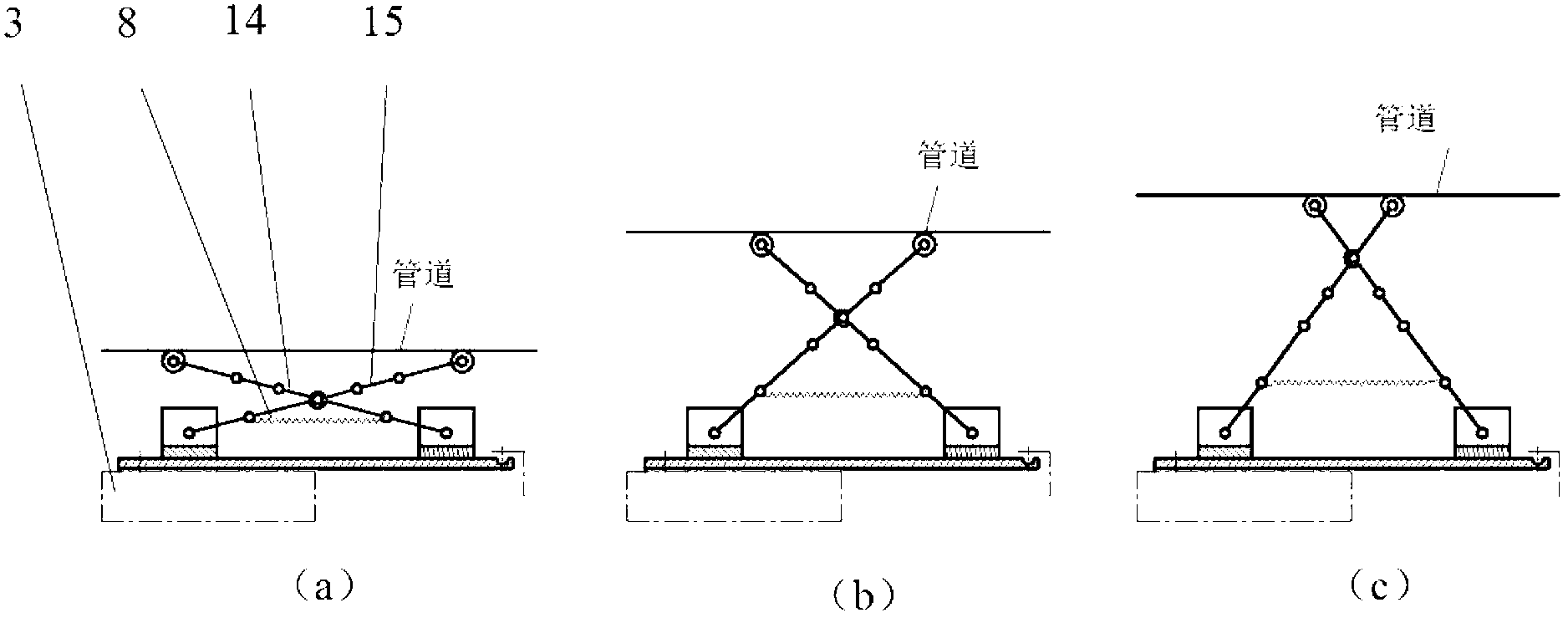

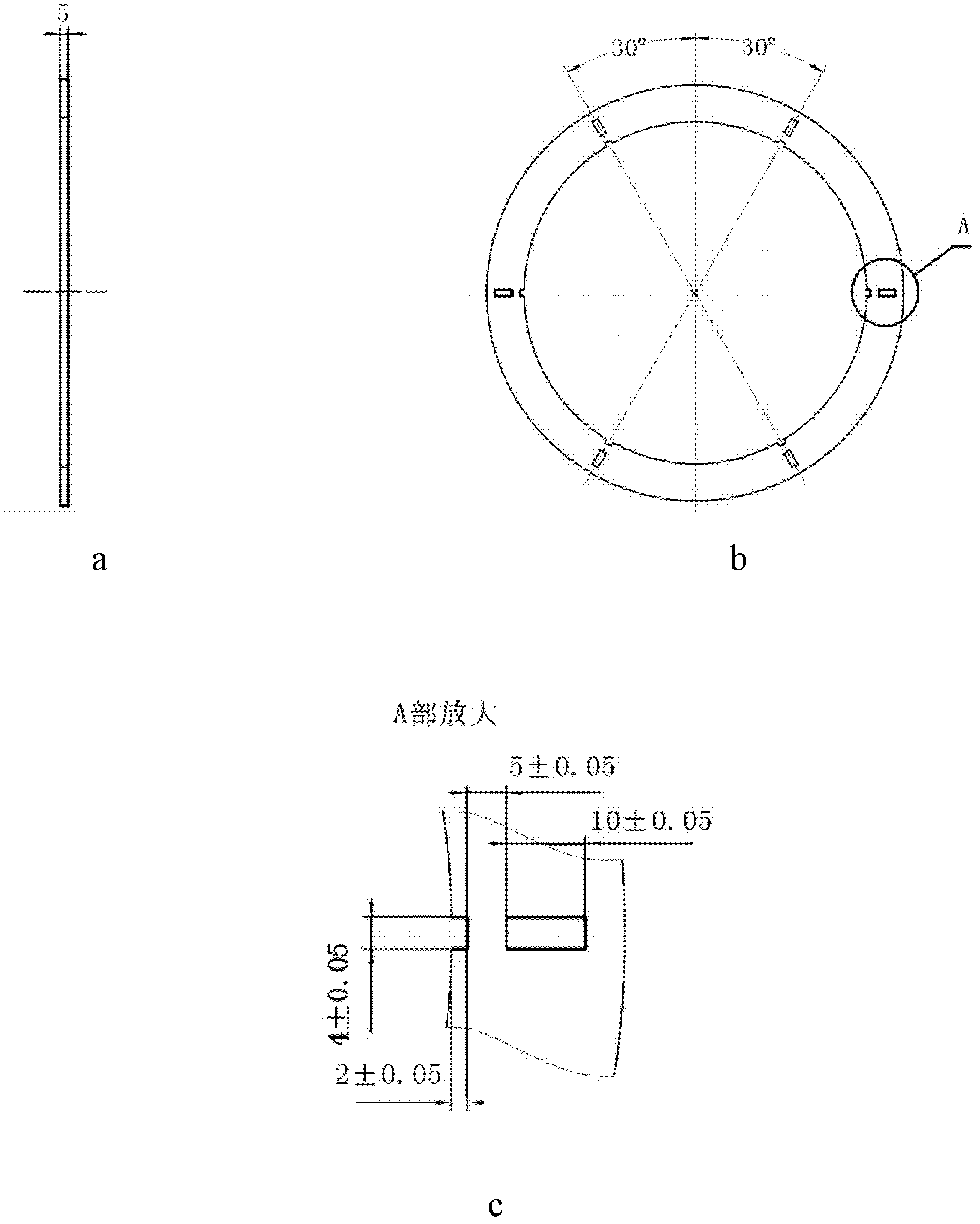

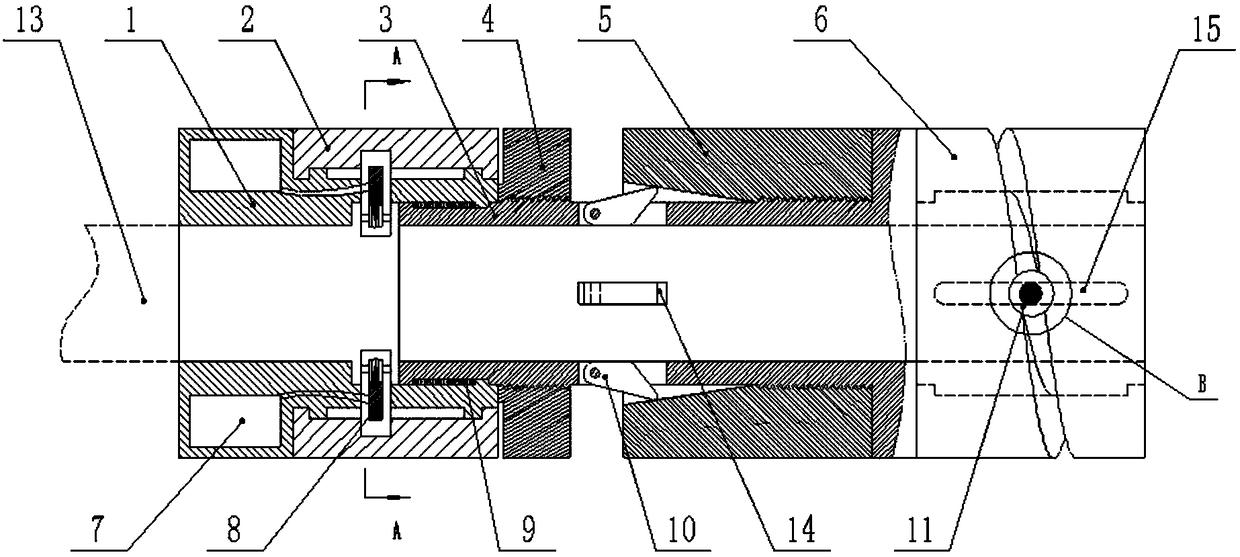

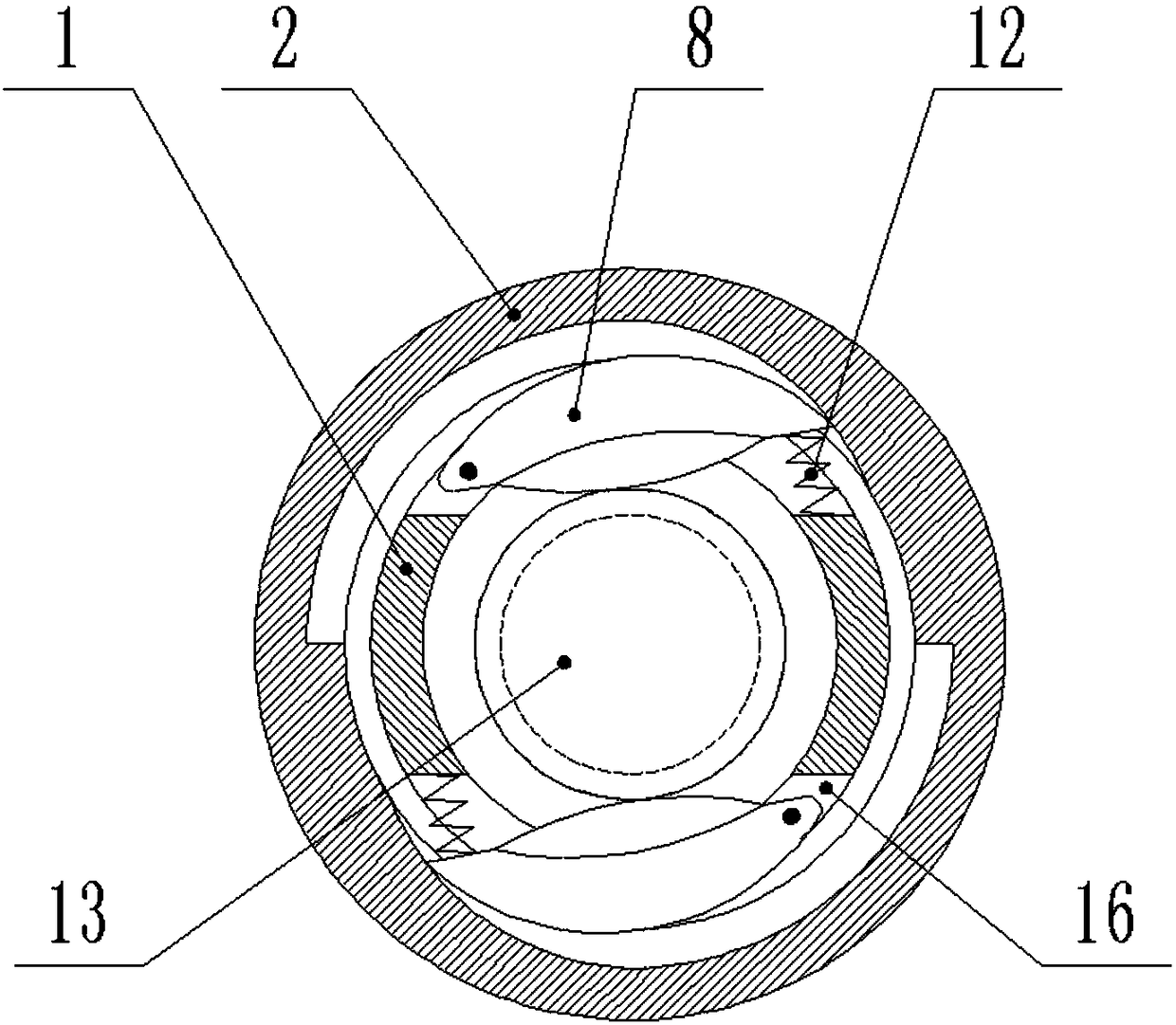

Video detection camera automatic centering device in pipe

The invention discloses an automatic centering device mainly used for a camera to detect videos in a pipe. The video detection camera automatic centering device in the pipe keeps the camera in the central position of a pipeline all the time. The centering device is mainly composed of a central cylinder, sleeves, springs, supporting rods and the like, wherein the camera is arranged inside the central cylinder, the two sleeves are arranged on the central cylinder, one sleeve is axially fixed, the other sleeve can slide freely on a central cylinder body, a supporting part is composed of three sets of supporting rods, the supporting robs are distributed in a 120-degree circumference mode, each supporting rod is composed of a supporting rod body, a wheel, a pin, a clamp ring and corresponding parts, the two supporting rods respectively arranged on the two sleeves are crossed and are connected through the pins, each supporting rod is provided with a small hole to fix a spring, the springs play a role in guaranteeing that the three sets of supporting rods are contacted with the pipe wall all the time, and through the assembly of different positions of three motion secondary connecting holes in the middles of the supporting rods, three connecting schemes of the supporting rods are obtained, and therefore the centering device is applicable to work in a large pipe diameter range.

Owner:CHANGZHOU UNIV

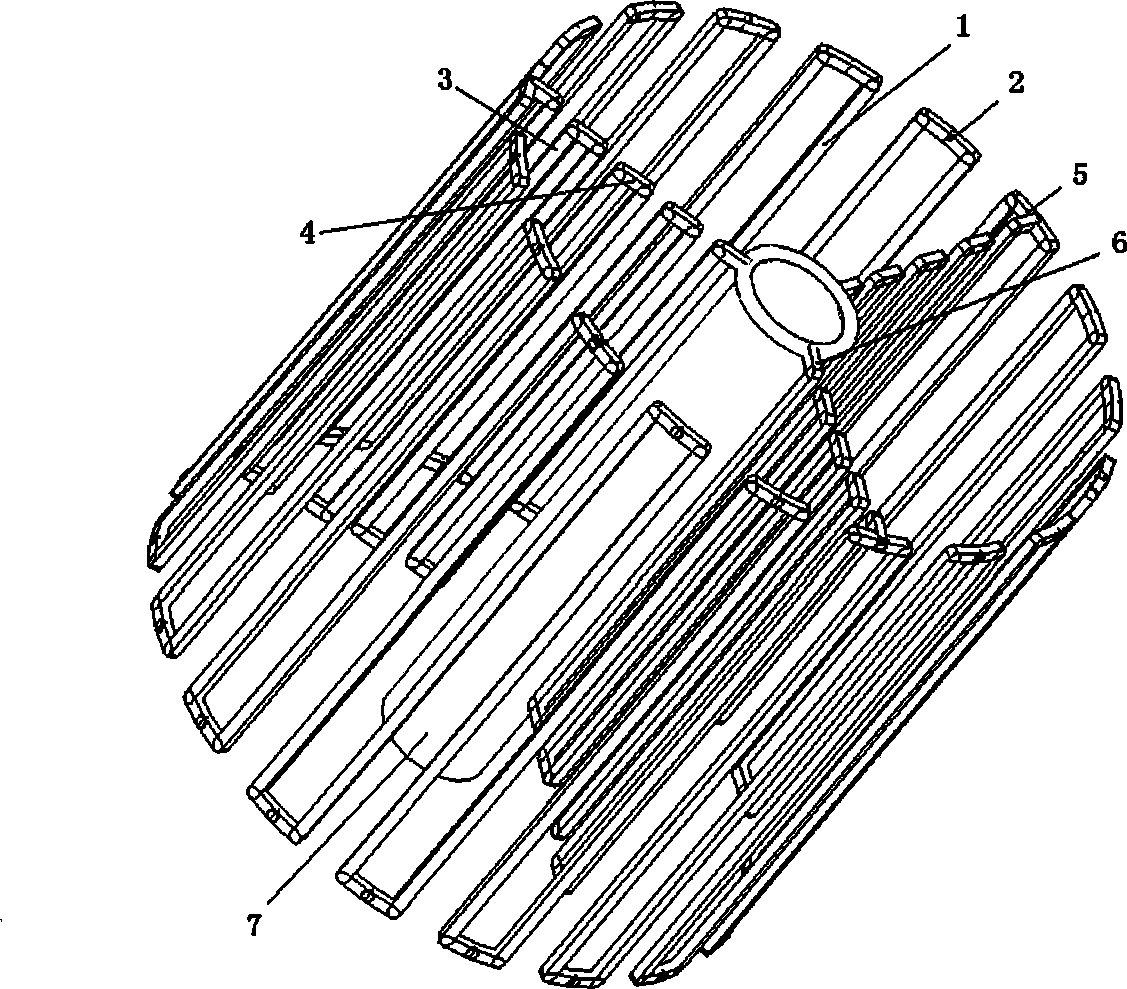

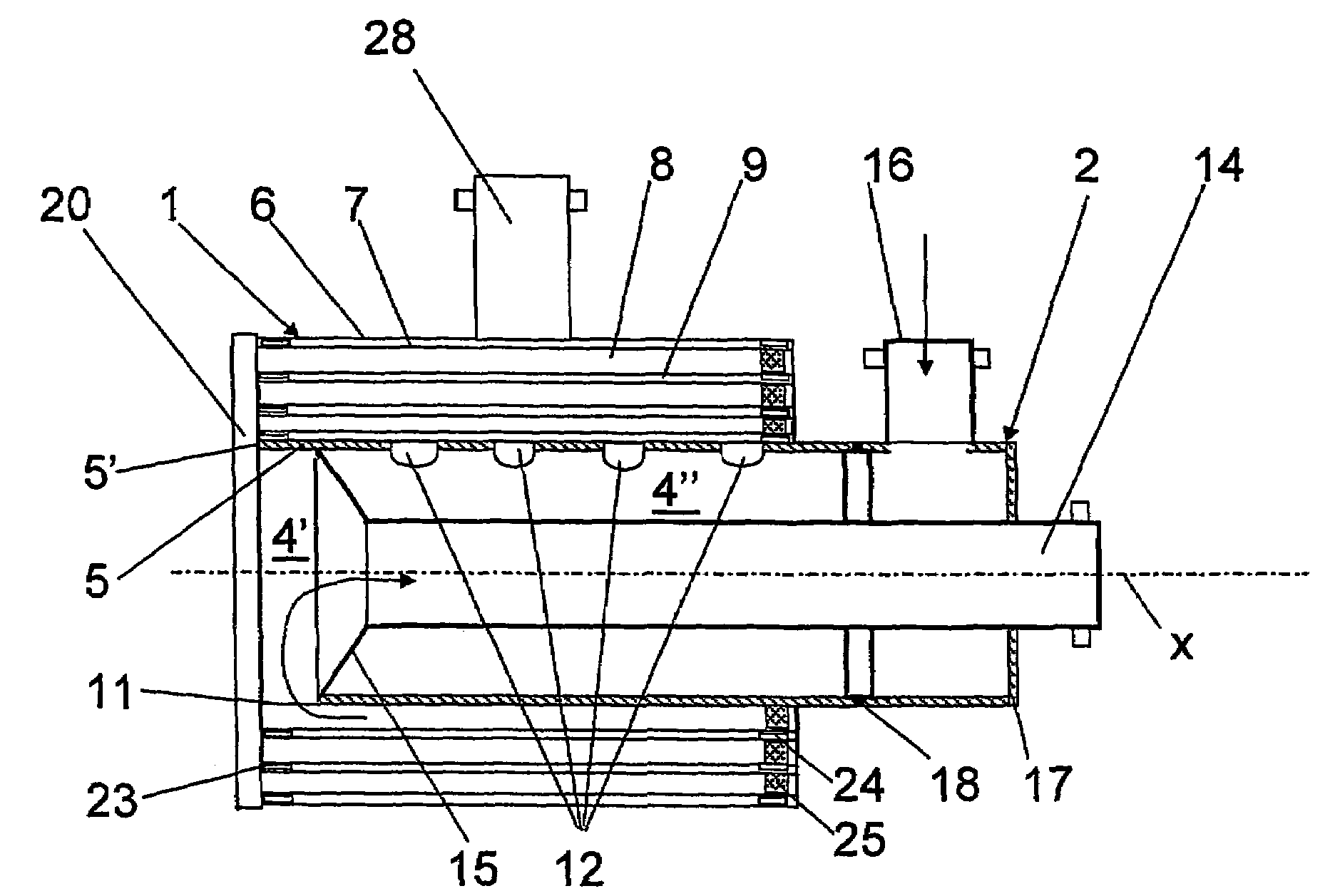

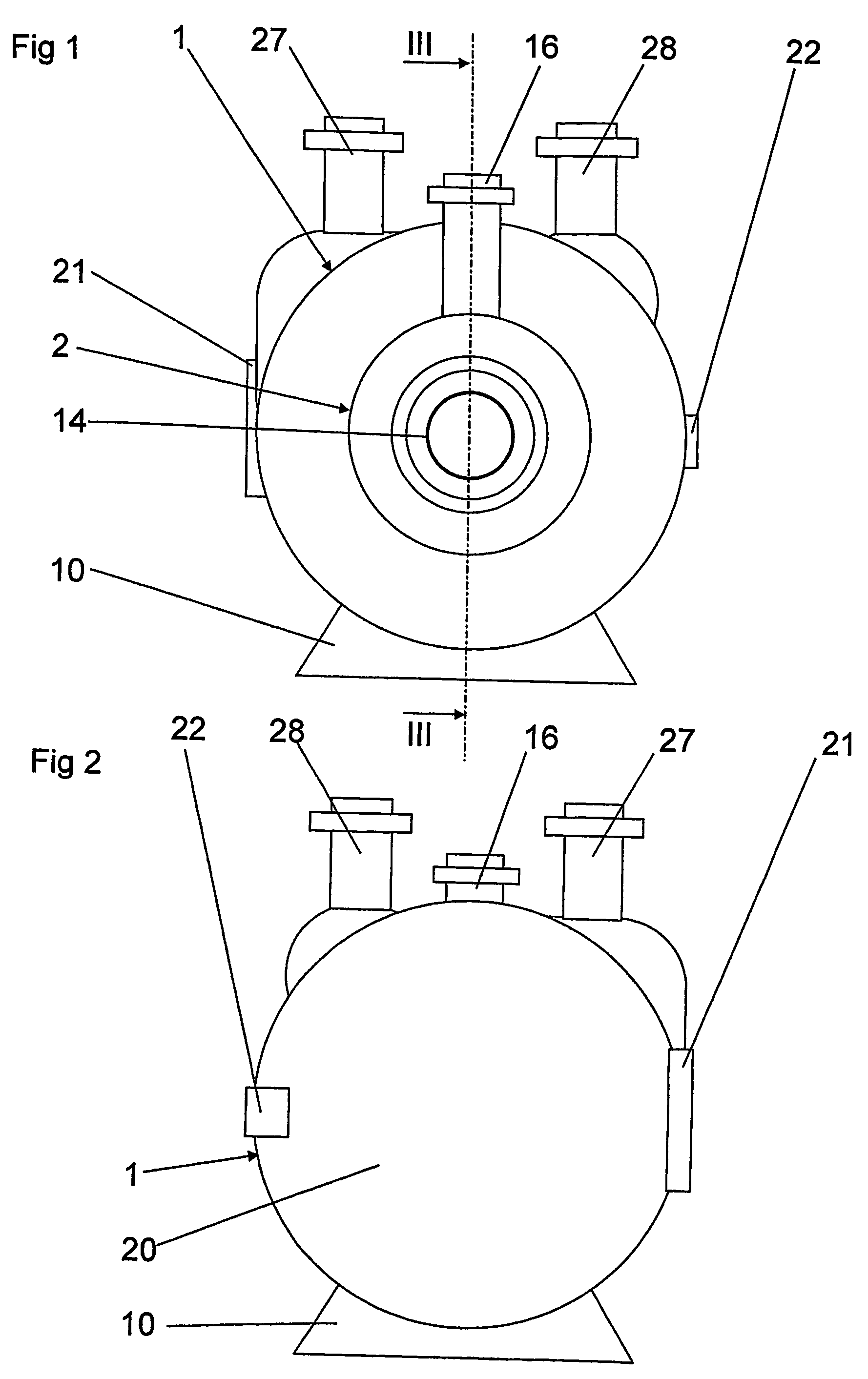

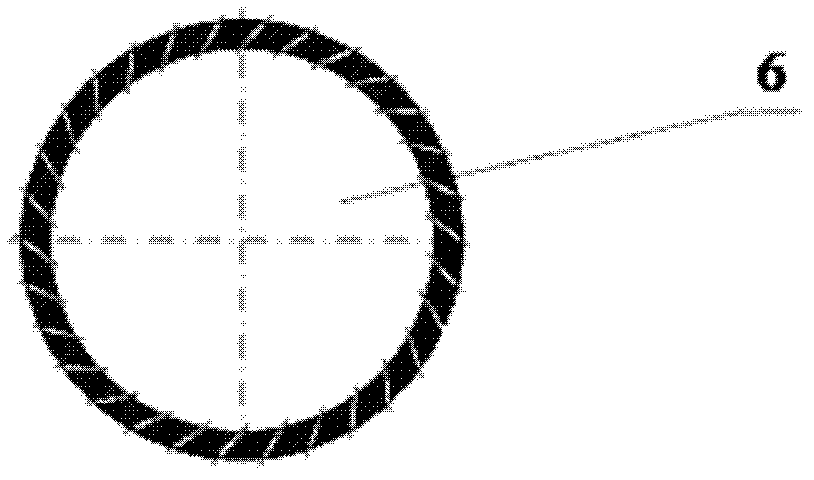

Spiral heat exchanger

InactiveUS7640972B2Simple waySimple designHeat exchanger casingsStationary tubular conduit assembliesInterior spaceEngineering

The invention relates to a spiral heat exchanger including a central cylinder (5) and at least two spiral sheets (6, 7). The sheets extend from the cylinder to form a first spiral-shaped flow channel (8) for a first medium and a second spiral-shaped flow channel (9) for a second medium. The cylinder forms an inner space within the cylinder. The cylinder includes a first opening (11) communicating with the first flow channel and a second opening (12) communicating with the second flow channel. A pipe (14) extends into the inner space of the cylinder. A first communication channel, communicating with the first flow channel via the first opening, is formed within the pipe. A second communication channel, communicating with the second flow channel via the second opening, is formed in the inner space outside the pipe.

Owner:ALFA LAVAL CORP AB

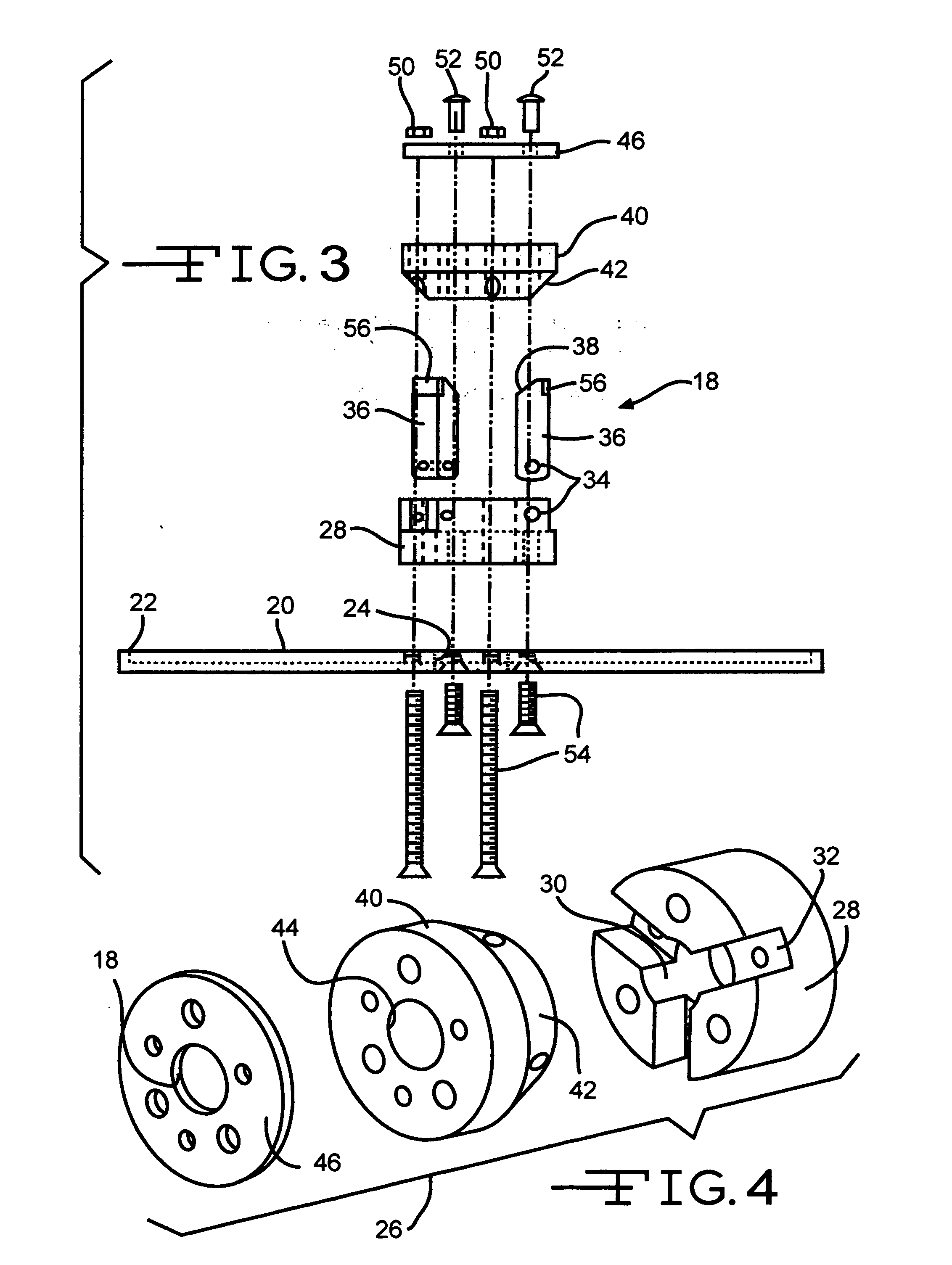

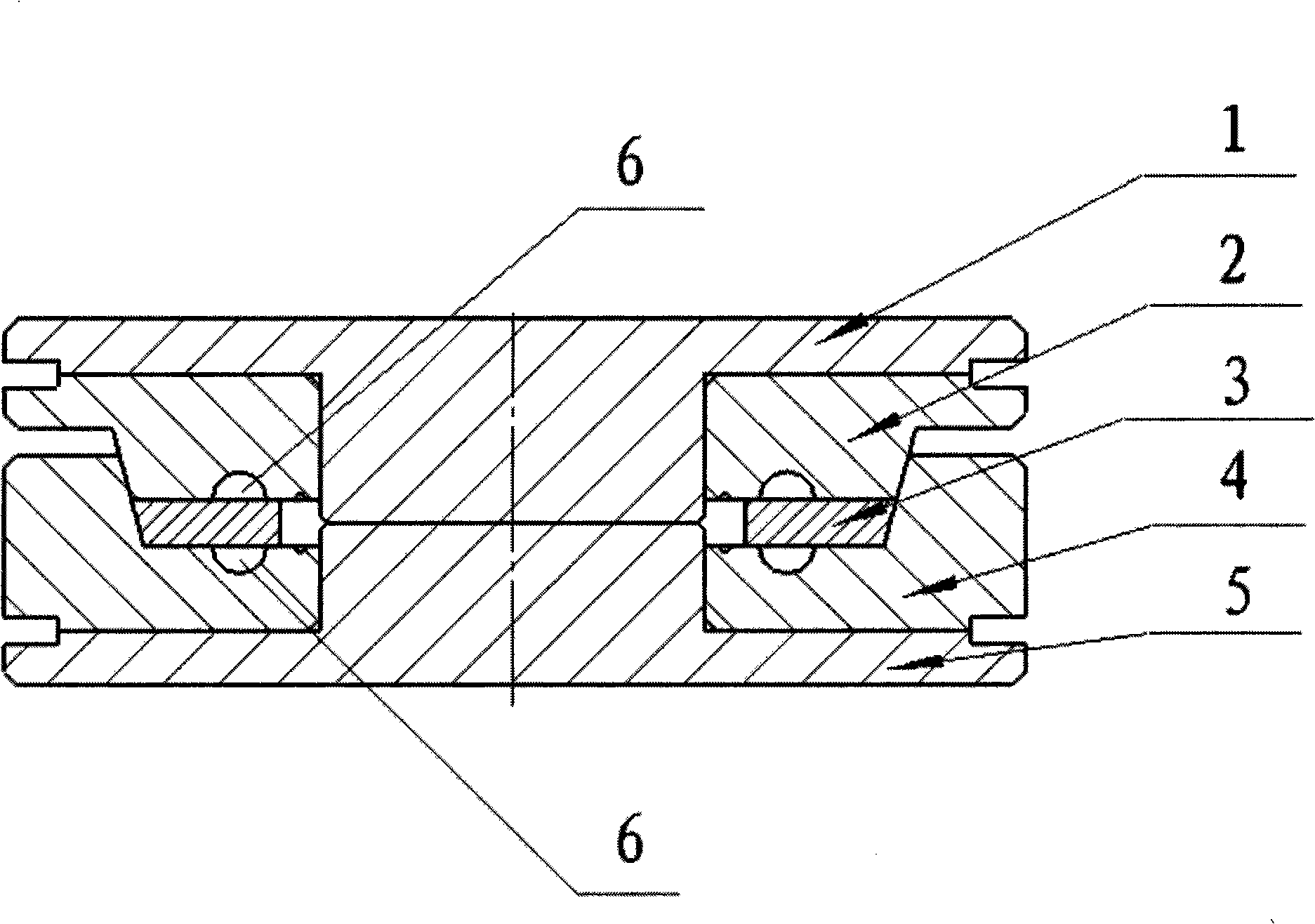

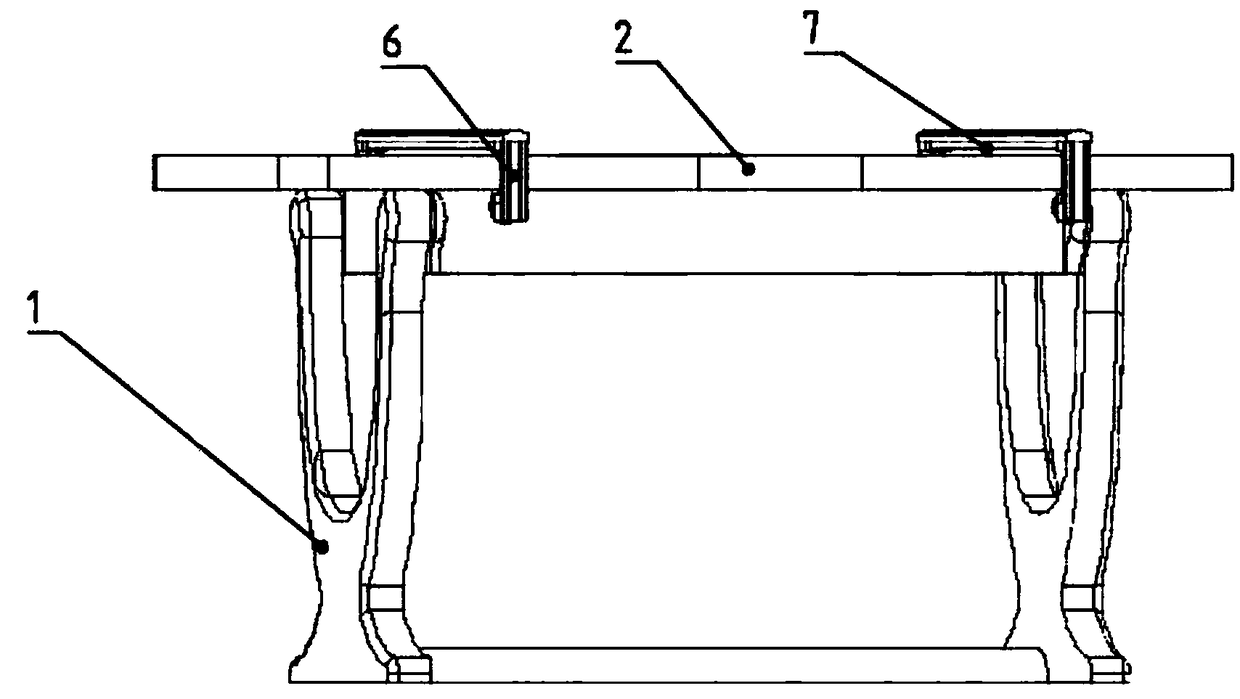

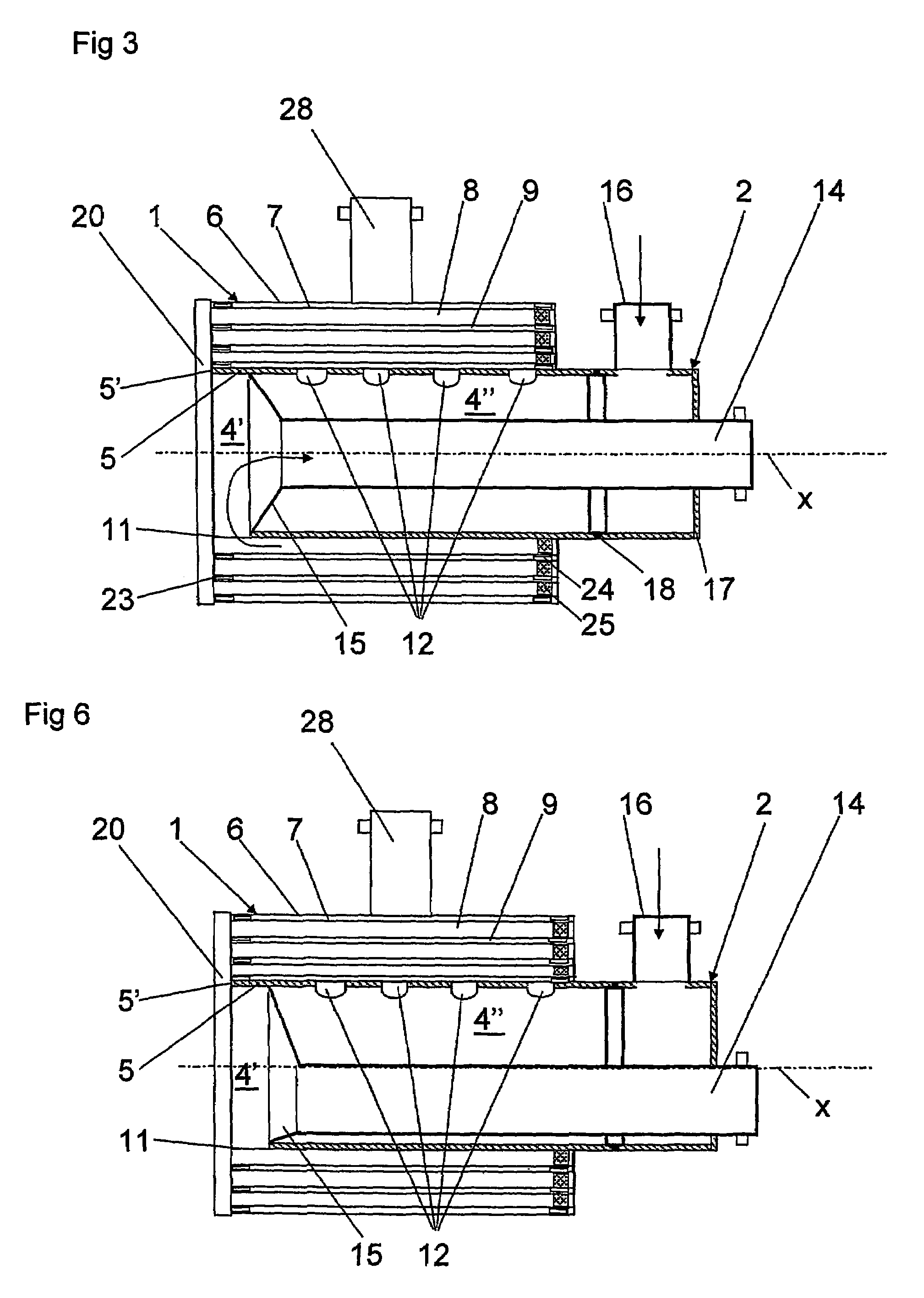

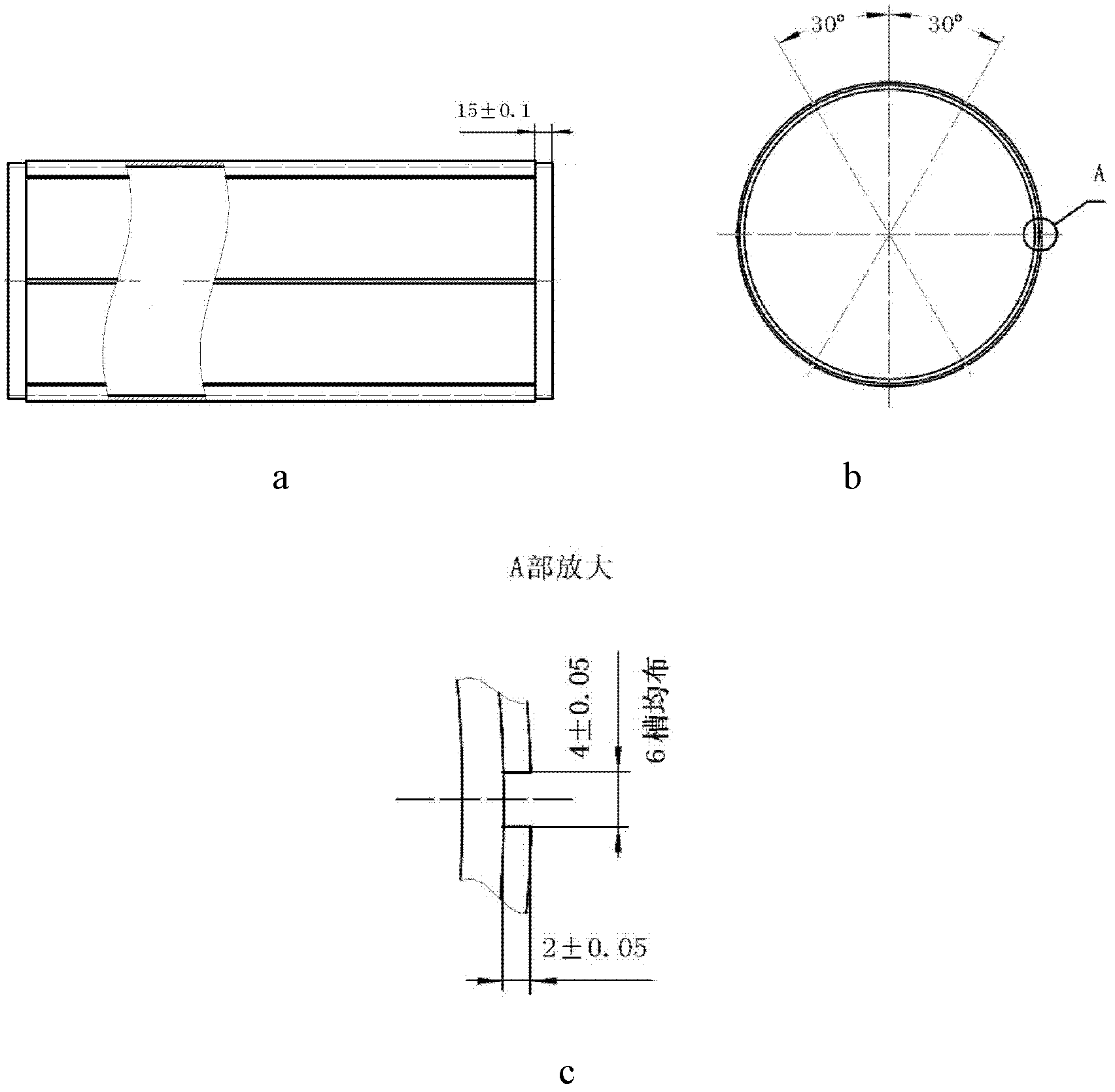

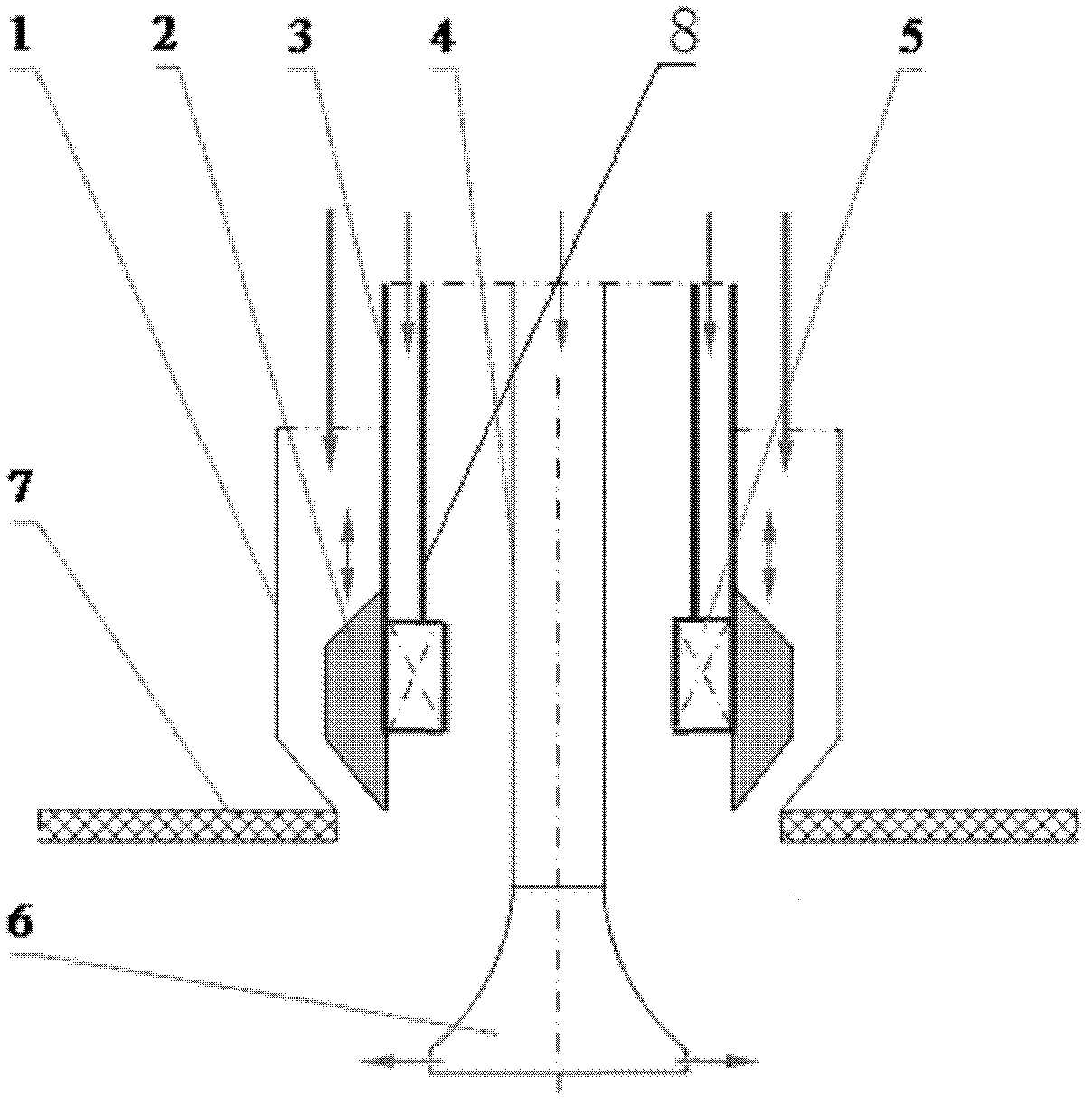

Framework applied to superconductive solenoid magnet

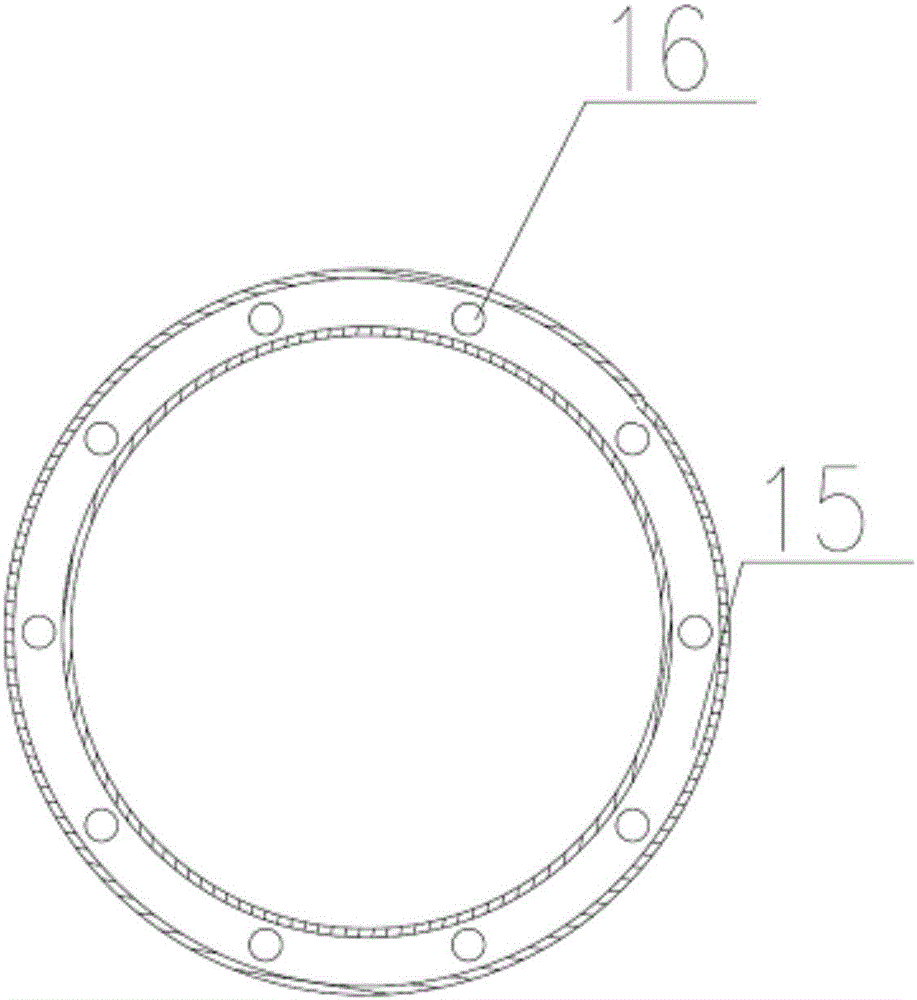

ActiveCN102496439AHigh thermal conductivityGuaranteed uptimeTransformers/inductances coils/windings/connectionsSuperconducting magnets/coilsSuperconducting solenoidCooling down

The invention relates to a framework applied to a superconductive solenoid magnet. The framework is characterized in that two end plates are sleeved on and closely clung to boss structures at two ends of a central cylinder; six rectangular gaps of each end plate are arranged corresponding to six rectangular slots of the central cylinder to form six rectangular holes; the diameters of the two endsof the central cylinder are small diameters and are equal to the diameters of inner through holes of the end plates, and the diameter of each boss is a large diameter and is equal to the inner diameter of a solenoid magnet to be wound. The framework applied to the superconductive solenoid magnet, disclosed by the invention, has a simple structure, is convenient to manufacture; and through adoption of the stainless steel framework device, excellent support is provided for a superconductive solenoid coil and an excellent cooling channel is provided for cooling down the superconductive solenoid coil by using a coolant by utilizing a.

Owner:西部超导材料科技股份有限公司

Tube bundle type dedusting and demisting device with liquid collection function

InactiveCN106582121AOvercoming serious secondary entrainmentOvercome efficiencyDispersed particle separationEngineeringRotational flow

The invention discloses a tube bundle type dedusting and demisting device with a liquid collection function and belongs to the field of waste gas treatment. The device comprises n tube bundle type dedusting and demisting units, and n is greater than or equal to 1. Each tube bundle type dedusting and demisting unit comprises a demisting unit barrel, m rotational flow assemblies and m cylindrical outer barrels are arranged in the demisting unit barrel; each rotational flow assembly comprises a plurality of rotational flow blades and a central cylinder; liquid holding rings are arranged in annular zones between the demisting unit barrels and the cylindrical outer barrels; and a plurality of liquid discharge pipes are arranged on the liquid holding rings. According to the device, the problems that secondary entrainment is severe and the efficiency is low during multi-stage design in the prior art are solved, and the device has the advantages of high efficiency, low resistance, high practicability and reliability and the like.

Owner:南京宇行环保科技有限公司

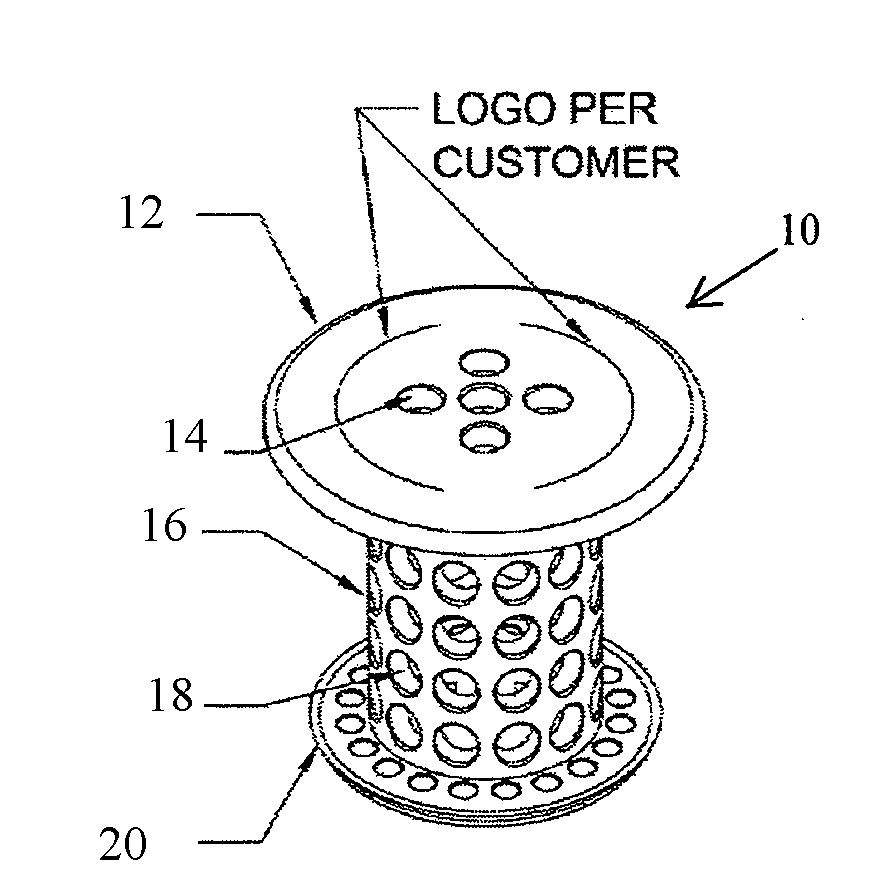

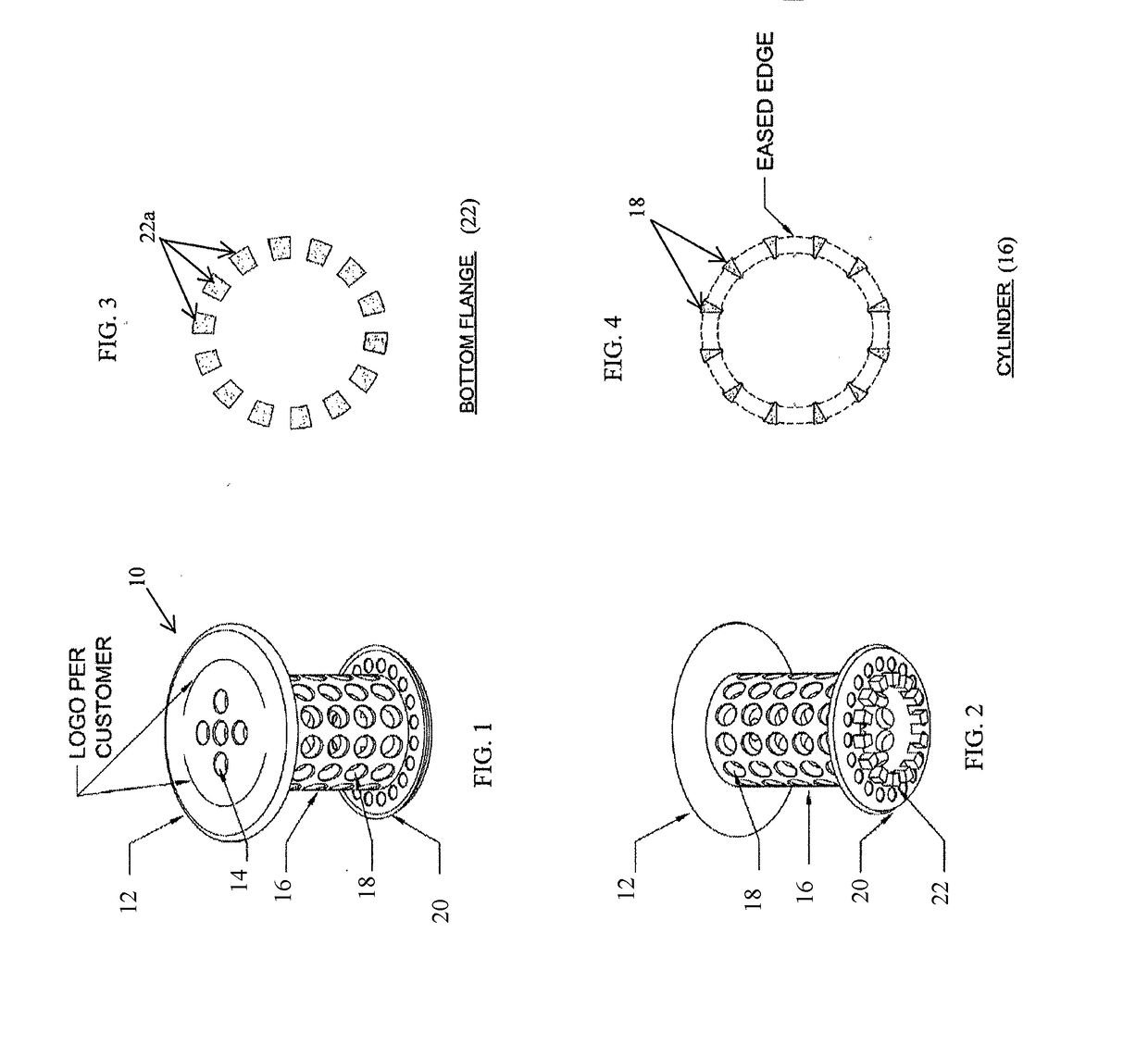

Hair straining device

ActiveUS20170073949A1Prevent hairImprove viewing effectDomestic plumbingMechanical engineeringShower

A straining device includes a top seal element, a central cylinder element and a bottom seal element and is positioned in a drain pipe of a shower, sink or bathtub to prevent hair from clogging the drain pipe while providing an aesthetically appealing appearance and allowing for easy cleaning.

Owner:JUKA INNOVATIONS CORP

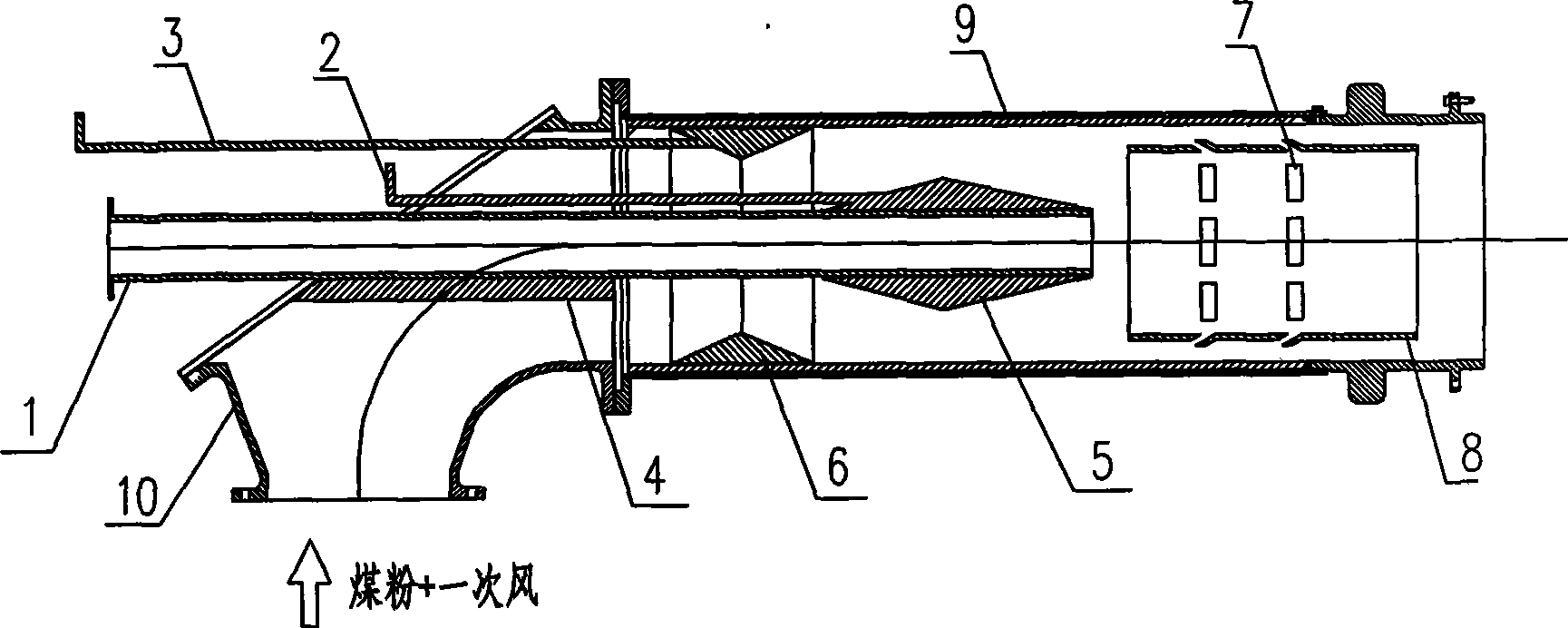

Micro oil pulverized coal burner

ActiveCN101545632AEasy to igniteMeet performance characteristicsPulverulent fuel combustion burnersPower stationCombustor

The invention provides a micro oil pulverized coal burner, which comprises an elbow joint provided with a pulverized coal inlet and a primary air pipe connected with the elbow joint, wherein the center of the primary air pipe is provided with a micro oil doper and a central cylinder in turn; the outer wall of the micro oil doper is provided with at least one condensation body which can telescopically move; the inner wall of the primary air pipe is provided with at least one guide ring which can telescopically move; the central cylinder is also provided with an air film wind opening; and the structures of the condensation body and the guide ring which can telescopically move are that: the condensation body is connected with an inner pull rod, the guide ring is connected with an outer pull rod, and the inner and the outer rods can be pushed in or pulled out manually or automatically pushed in or pulled out by an actuator. Because the outer wall of the micro oil doper is provided with at least one condensation body which can telescopically move, and the inner wall of the primary air pipe is provided with at least one guide ring which can telescopically move, the internal structure of the burner can be changed according to operating conditions; under the states of micro oil ignition and normal combustion, different concentration distribution requirements of the pulverized coal are met; and the micro oil pulverized coal burner is used for the oil saving ignition start and the low-load stable combustion in pulverized coal fired boilers in large-sized power stations.

Owner:EASTERN BOILER CONTROL CO LTD +1

Double rotational flow premix type metallurgical nozzle

The invention discloses a double rotational flow premix type metallurgical nozzle which solves the problem that a material in the metallurgical nozzle is not mixed fully with a gas. The double rotational flow premix type metallurgical nozzle comprises a central cylinder of a feed pipe, wherein the feed pipe is externally and sequentially provided with a separating pipe having an increasing diameter and an air cavity pipe in a sleeved manner; a rotational flow mixer is arranged at the front end of the feed pipe; the rotational flow mixer is provided with a plurality of flow guide sheets which are arranged circumferentially between two concentric rings; and the inner wall of the end of the air cavity pipe which enters into a furnace cavity is tapered, so that the gas flowing out rushes to the material which comes from the feed pipe. According to the nozzle disclosed by the invention, the material and the gas are mixed for the second time, so that the mixing is ensured to be sufficient, generation of raw material stack and furnace accretion is avoided, stability of furnace conditions is enhanced, overhaul loss of the furnace conditions is reduced, heat efficiency of the reaction is improved, temperature at the upper part of a reaction tower is improved, and a chassis of a rotational flow type sprayer has low abrasion and no water leakage fault.

Owner:JINLONG COPPER

Insulated wire stripper

InactiveCN108270140AConvenient clamping and positioning operationRealize reversing cuttingLine/current collector detailsCable installation apparatusAnnular cutterMechanical engineering

The invention relates to an insulated wire stripper, comprising an inner cylinder body. The inner cylinder body is sleeved with a middle sleeve, an ejection sleeve, a clamping sleeve and a longitudinal cutting sleeve on the outer ring sequentially from left to right. The middle sleeve is also sleeved with an annular cutting sleeve on the outer ring. Four circumferentially distributed rectangular clamping block mounting grooves are formed in the central cylinder wall of the inner cylinder body. Four clamping blocks are respectively hinged in the four clamping block mounting grooves. The outer end of each clamping block abuts against a conical opening wall of the clamping sleeve. A spiral guiding groove is formed in the wall of the longitudinal cutting sleeve. An axial guiding groove is formed in the cylinder wall of the inner cylinder body. A longitudinal slider is mounted at the intersection position of the two guiding grooves. Two annular cutter mounting grooves are symmetrically arranged at the circumferential center of the central cylinder wall of the middle sleeve. Two annular cutters in central symmetry and in the shape of an arc sheet are respectively mounted in the two annular cutter mounting grooves. The outer side of each annular cutter abuts against the inner wall of an involute groove of the inner ring of the annular cutting sleeve.

Owner:YANTAI MUPING POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

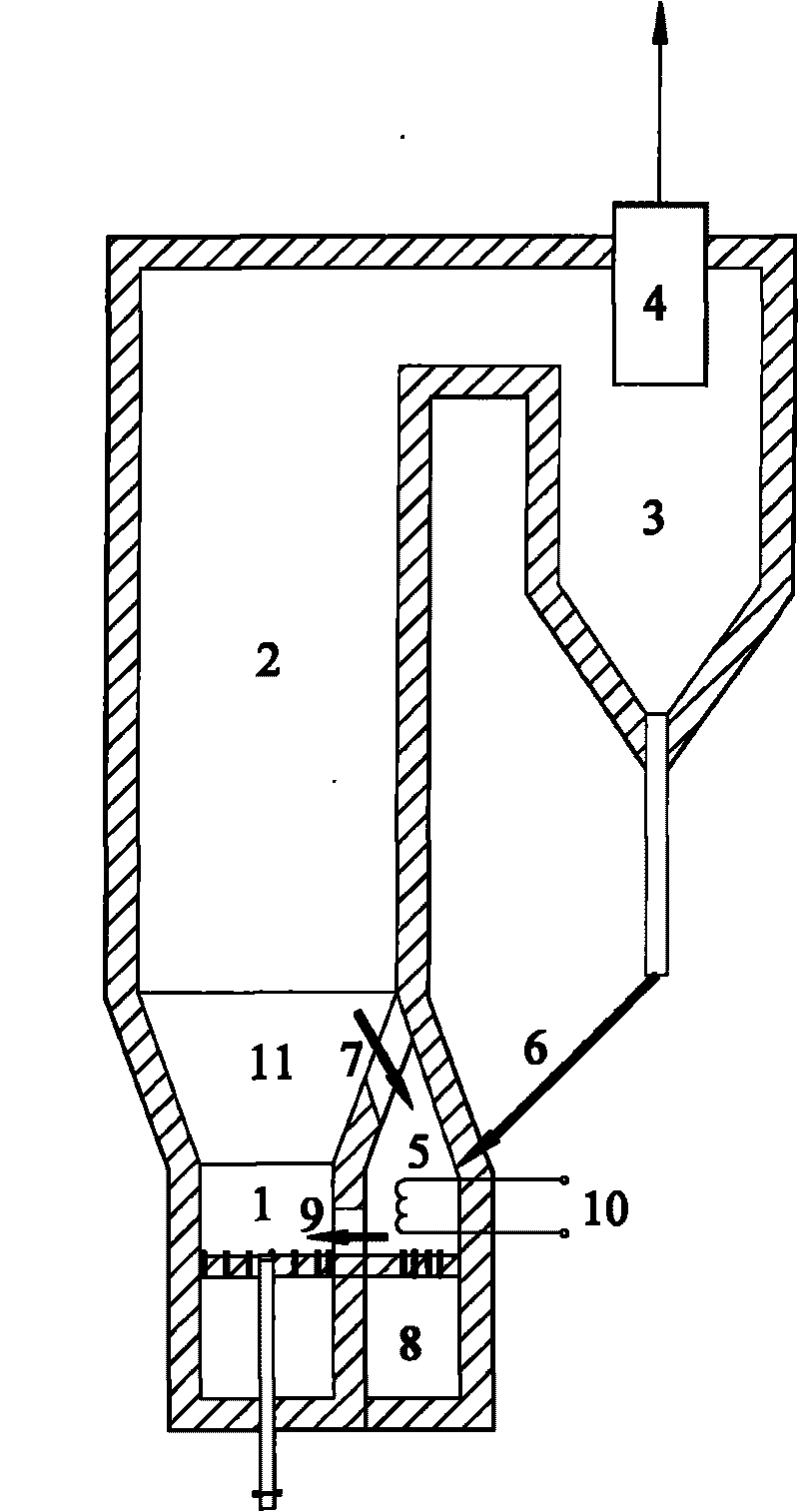

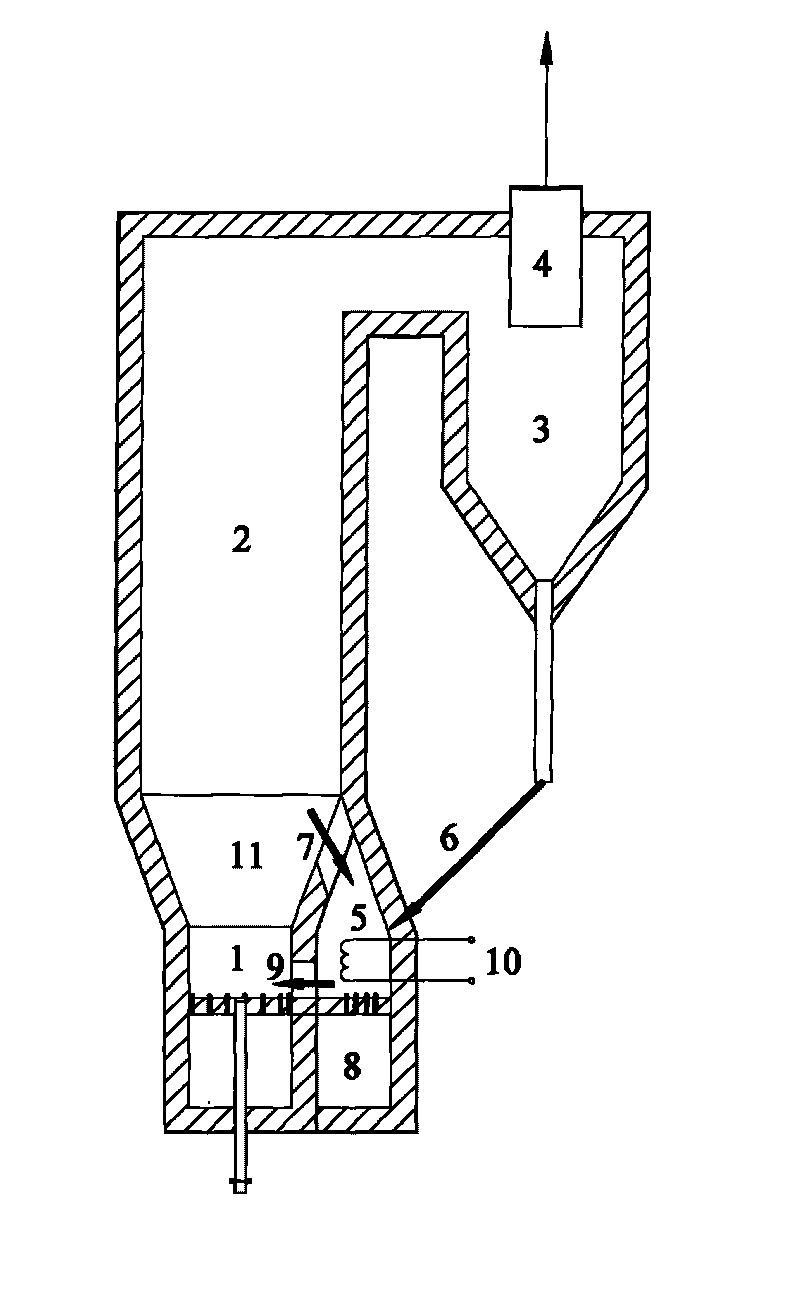

Oxygen-enriched combustion external bed heat exchanger of circulating fluidized bed

InactiveCN101694296AImprove heat transfer efficiencyImprove desulfurization efficiencyFluidized bed combustionIndirect carbon-dioxide mitigationCombustionHearth

The invention relates to an oxygen-enriched combustion external bed heat exchanger of a circulating fluidized bed, which introduces coke and a desulfurating agent in a hearth into the heat exchanger for combustion while absorbing separated ash and reducing temperature, simultaneously carries out desulfuration and can improve the heat exchanging effect of the external bed heat exchanger so as to solve the problem of difficult distribution of a heating surface of the circulating fluidized bed oxygen-enriched combustion. The lower part of the external bed heat exchanger (5) is communicated with a dense-phase area (1) of the lower part of the hearth of the circulating fluidized bed by an opening (9), and the upper part thereof is communicated with a transition section (11) of the hearth of the circulating fluidized bed by an opening (7); a dilute-phase area (2) of the circulating fluidized bed is communicated with a gas-solid separator (3); the upper part of the gas-solid separator (3) is connected with the heating surface of the tail part thereof by a central cylinder (4), the lower end thereof is communicated with the external bed heat exchanger (5) by a vertical pipe and a feeding pipe (6) of the external bed heat exchanger, and the lower end of the external bed heat exchanger (5) is connected with an external bed air chamber (8); and the solid particles separated by the gas-solid separator (3) and the solid particles with good fluidization in the hearth enter the external bed heat exchanger (5) for mixed combustion.

Owner:SOUTHEAST UNIV

Method for manufacturing multi-rod converging valve type space net shell node

InactiveCN101519893AThe amount of processing is smallThe preparation process is shortBuilding constructionsComputer moduleEngineering

The invention relates to a method for manufacturing a multi-rod converging valve type space net shell node. The method comprises the following steps that: each converging valve type space net shell node is decomposed into several independent structure units, wherein the structure unit comprises a plurality of node valves and a central cylinder; a steel structure blank of the structure unit is manufactured according to geometric data of the structure unit; the node valve blank is processed according to geometric intersecting information of each structure unit so as to form a node valve module with a welding groove, a datum hole and a datum plane are processed for the central cylinder so as to form a central cylinder module; the structure unit modules formed in the same group are positioned and spliced on a tooling workbench, and adjacent node valves, the node valve module and the central cylinder module are subjected to spot welding in sequence so as to form nodes; the nodes are welded; the nodes are subjected to thermal treatment; and the nodes are subjected to treatment and surface treatment. The method has the advantages of short manufacture process flow, high automatic degree, high production efficiency and low manufacturing cost.

Owner:江阴纳尔捷机器人有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com