Patents

Literature

567 results about "Metal rubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal rubber is a broad, informal name for several conductive plastic polymers with metal ions produced by NanoSonic, Inc, in cooperation with Virginia Tech. This self-assembling nanocomposite is flexible and durable to high and low pressures, temperatures, tensions, most chemical reactions, and retains all of its physical and chemical properties upon being returned to a ground state. NanoSonic’s Metal Rubber™ is an electrically conductive and flexible elastomer. It can be mechanically strained to greater than 1000 percent of its original dimensions while remaining electrically conductive. As Metal Rubber can carry data and electrical power and is environmentally rugged, it has use as a flexible and stretchable electrical conductors in the aerospace/defense, electronics and bioengineering markets.

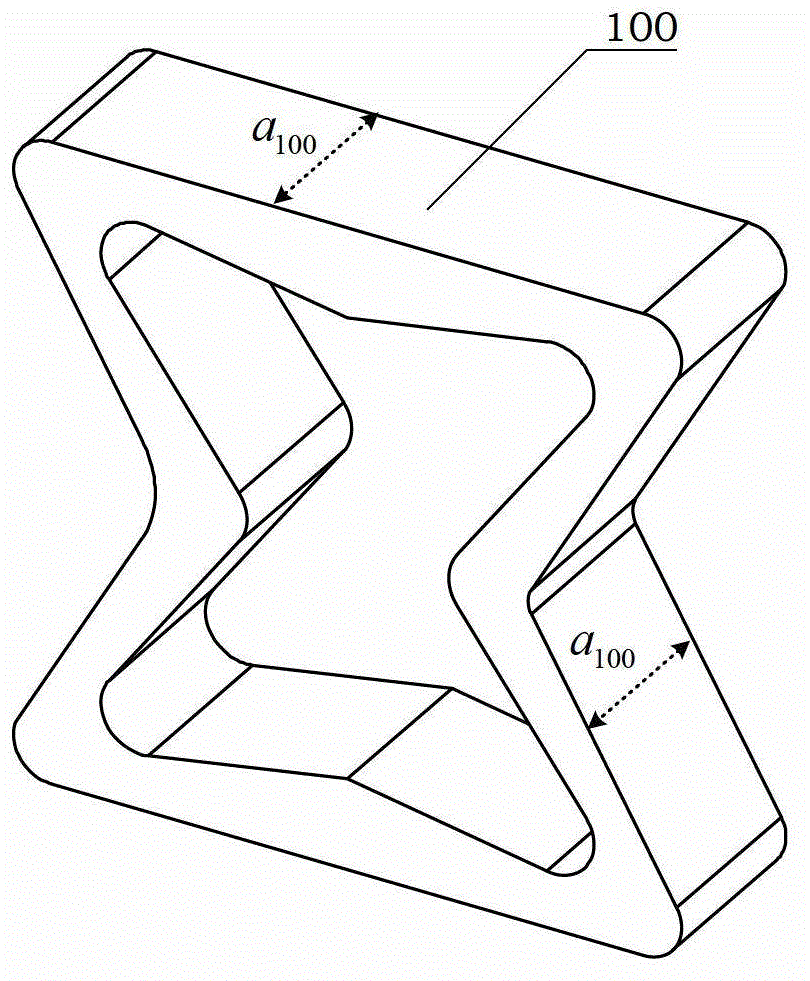

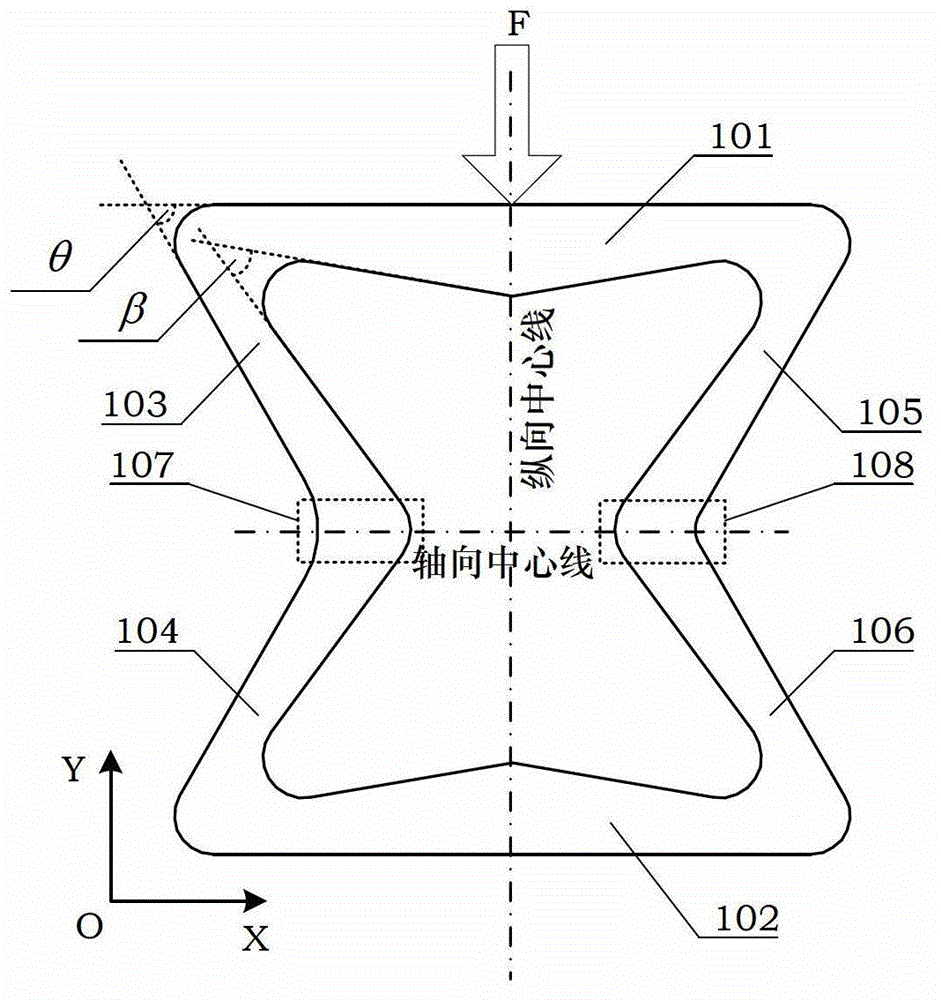

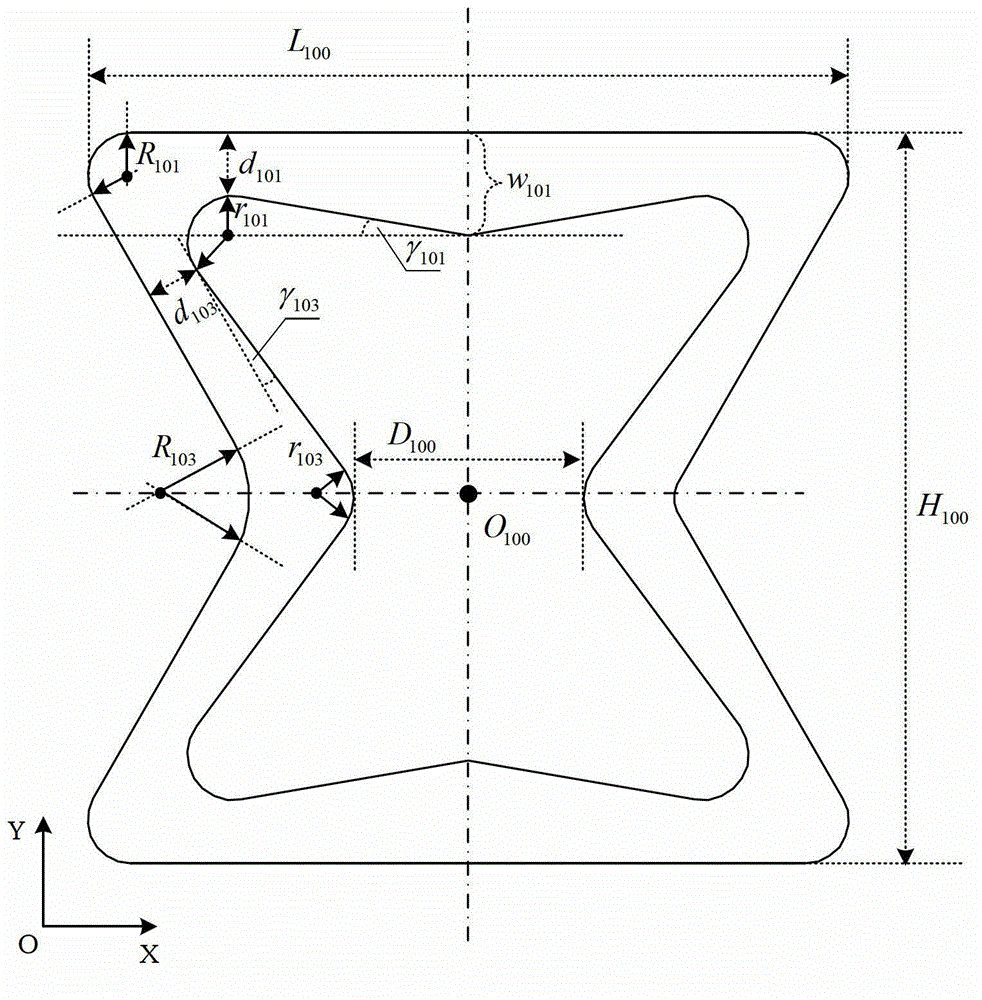

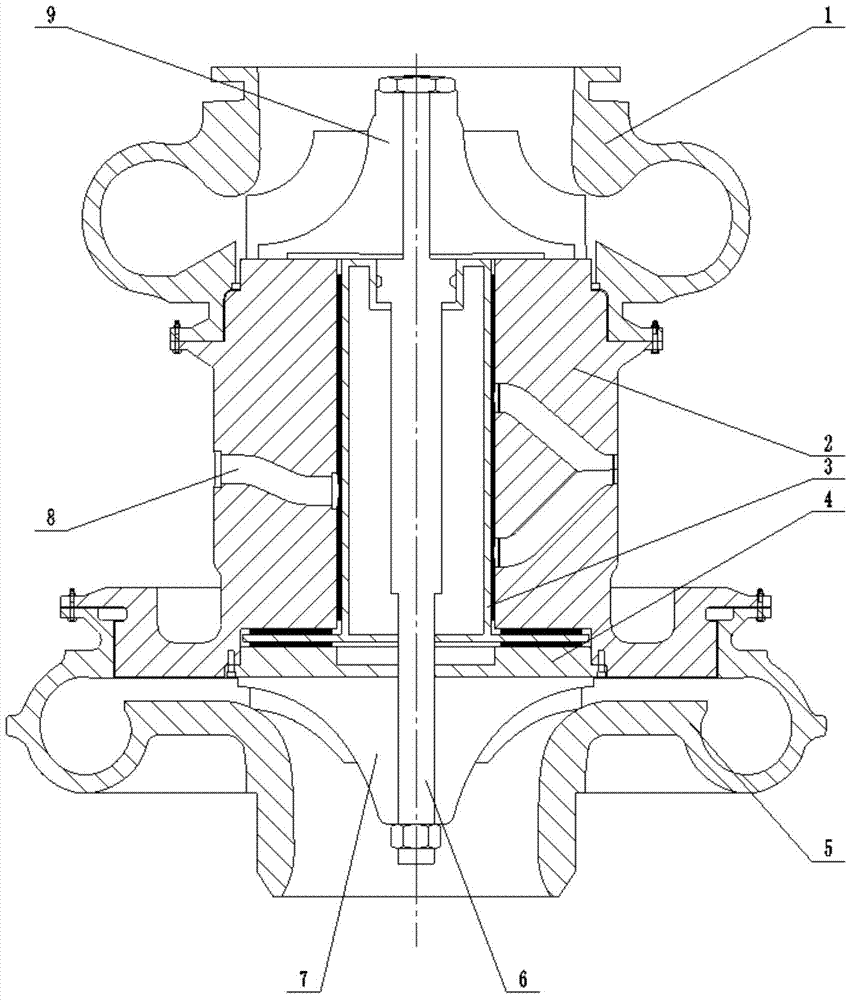

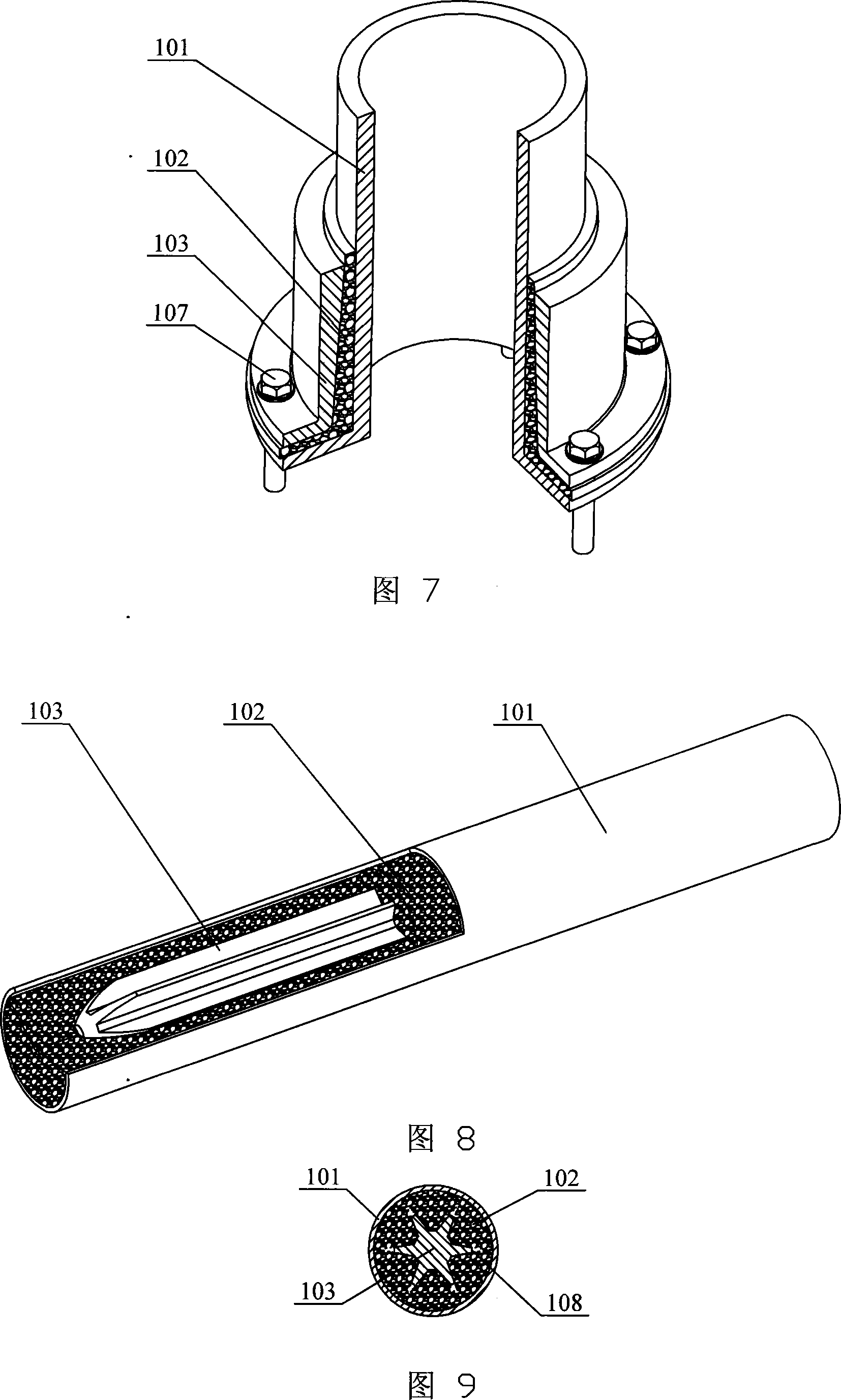

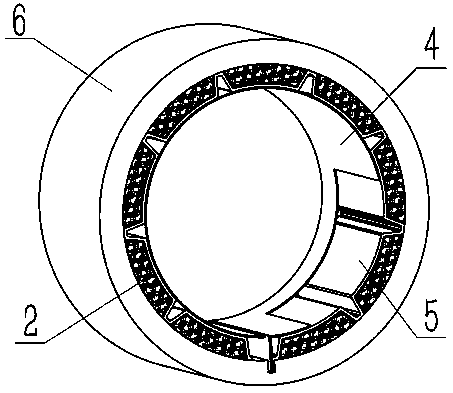

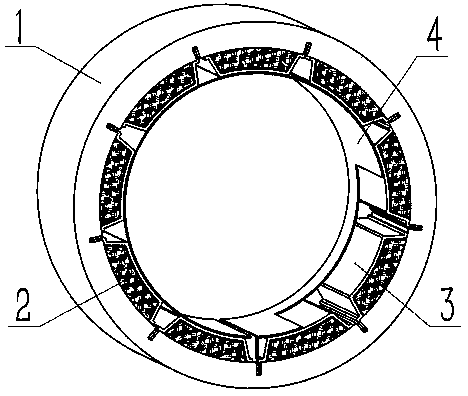

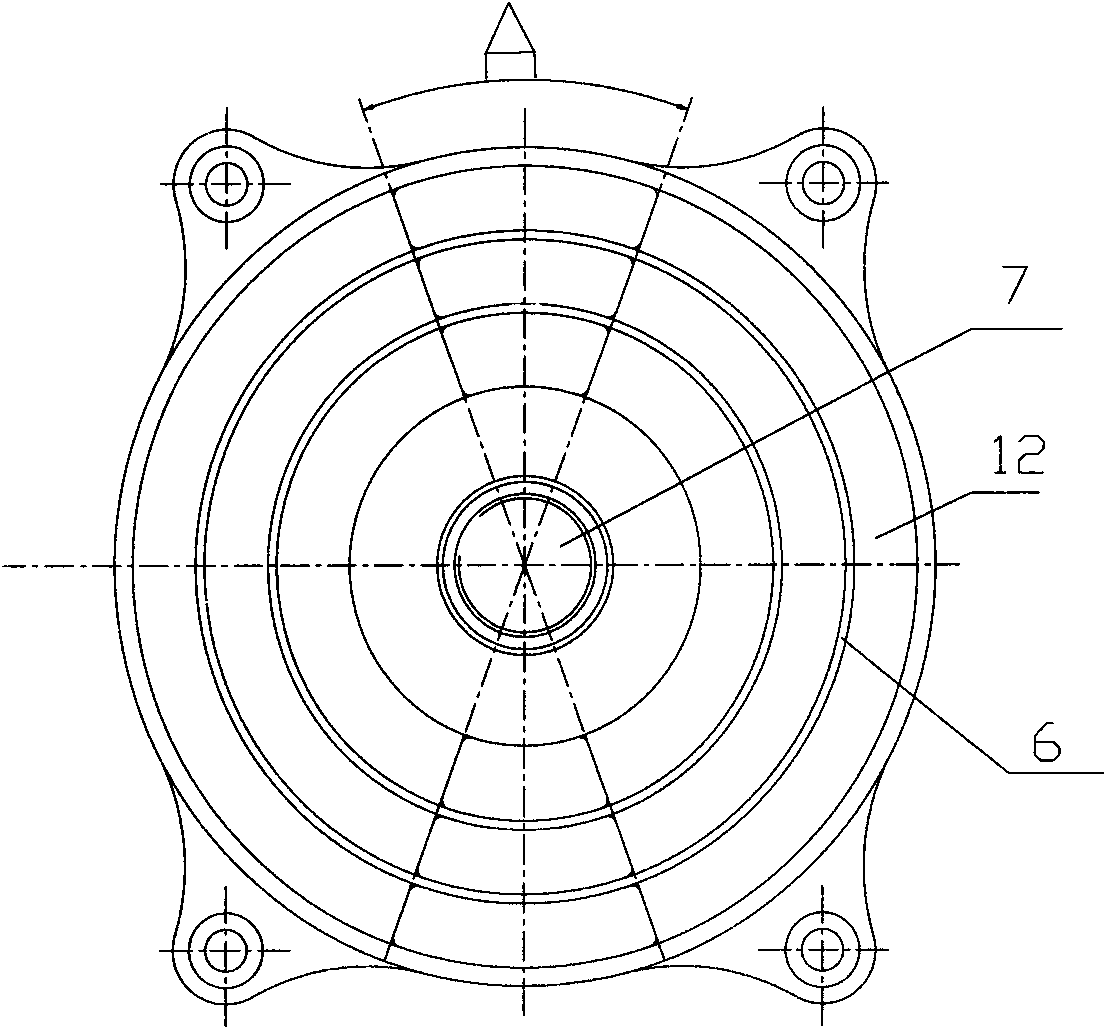

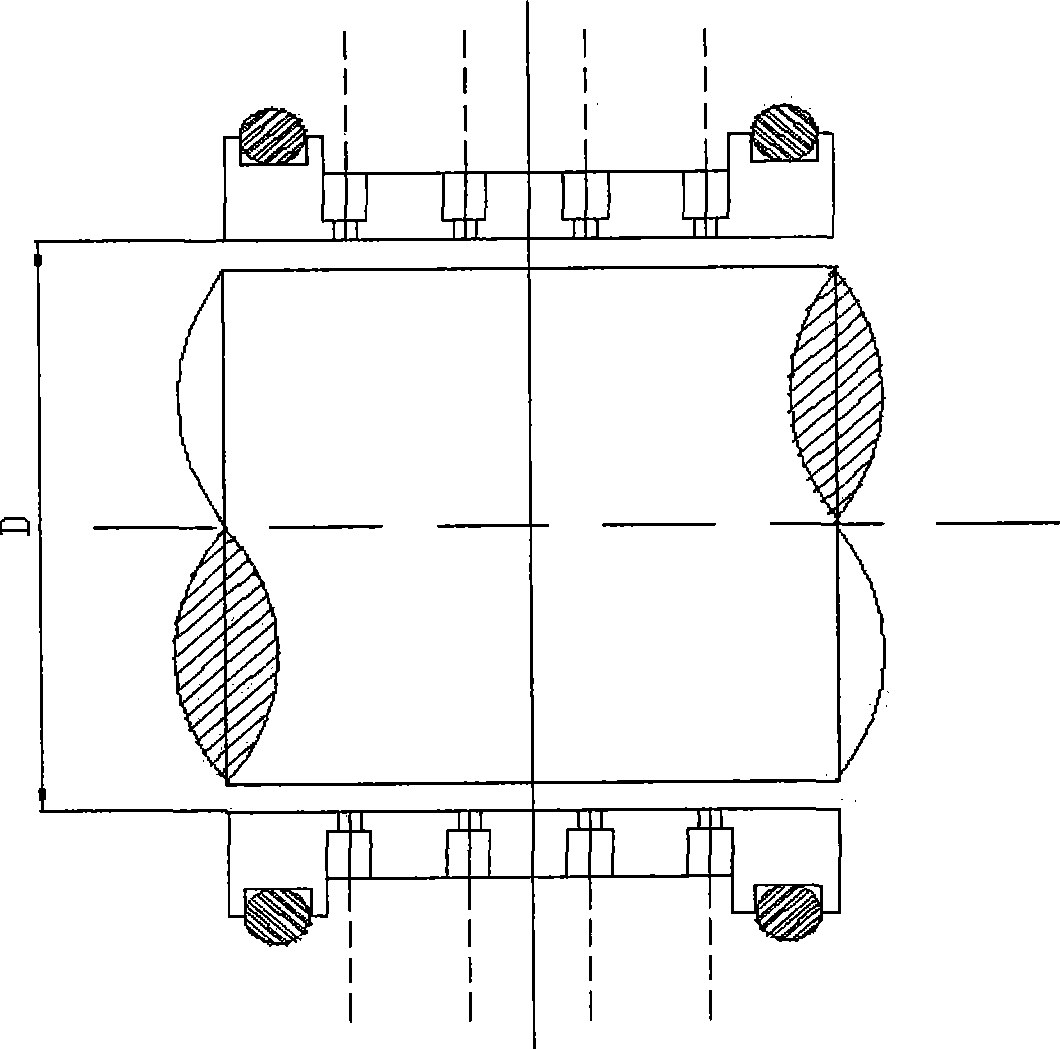

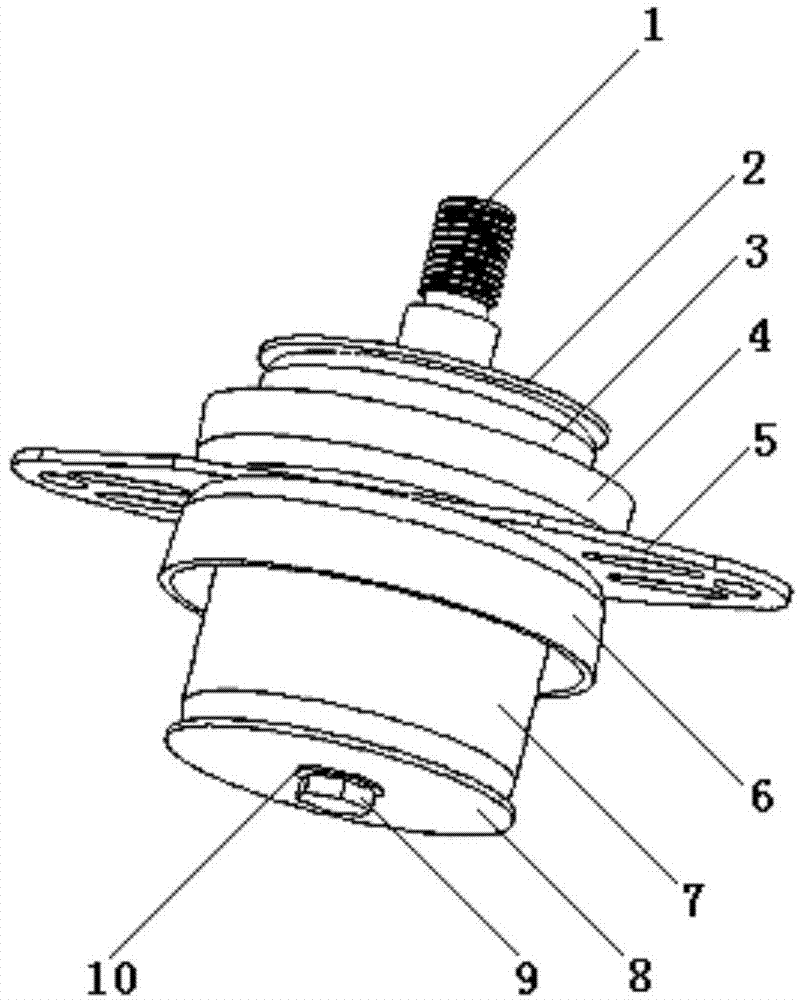

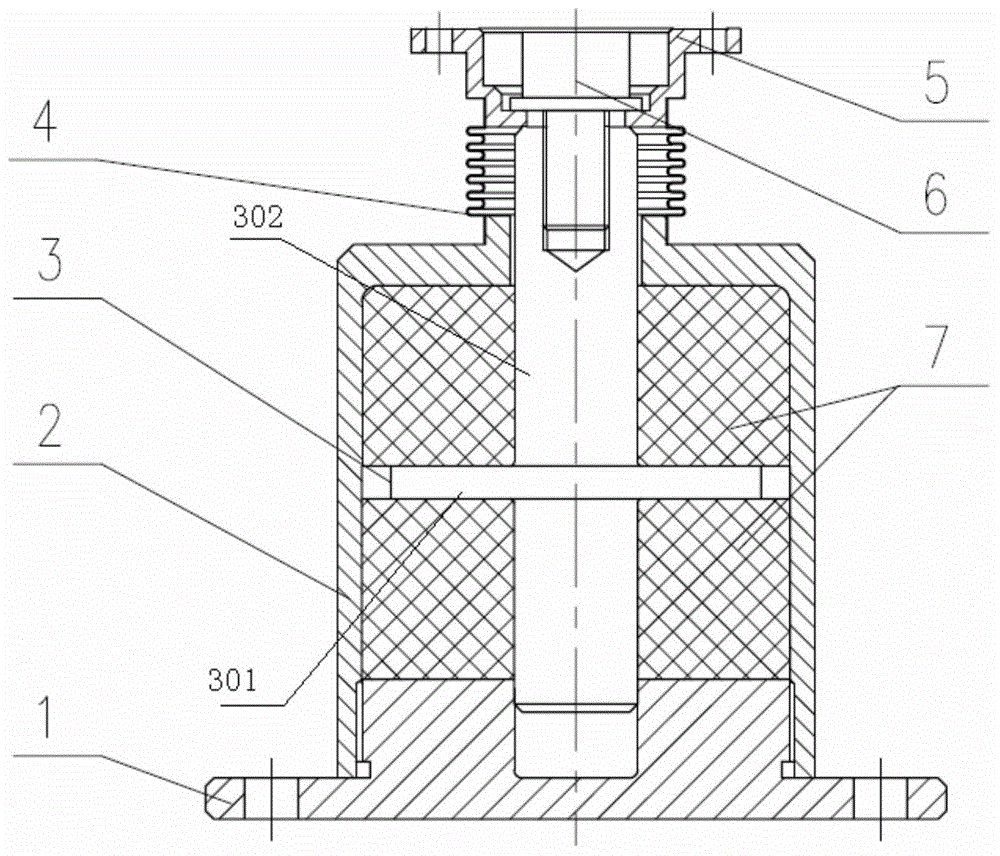

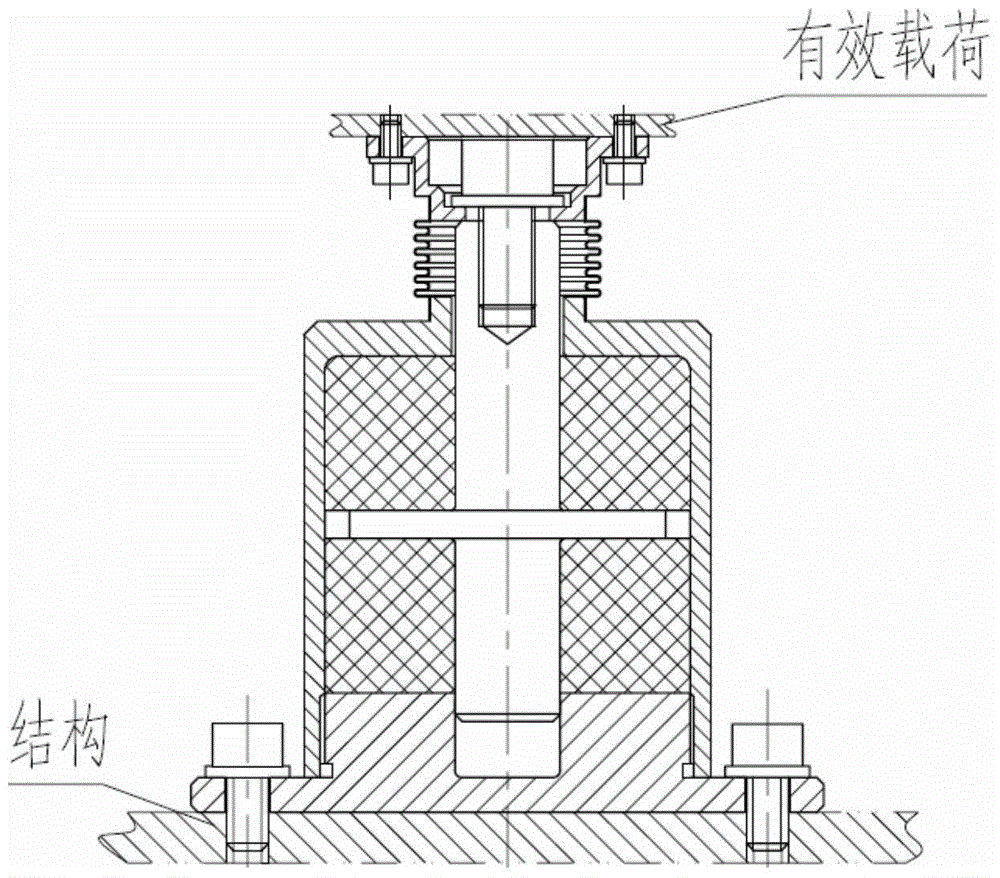

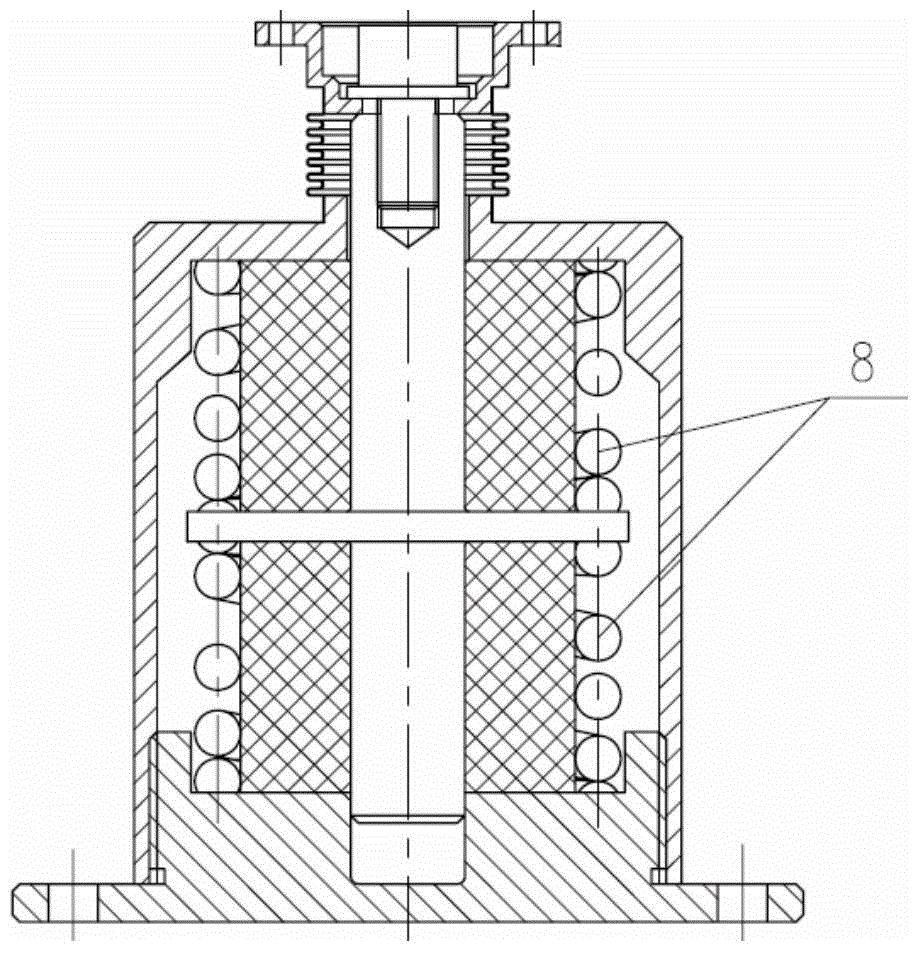

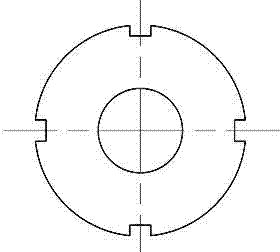

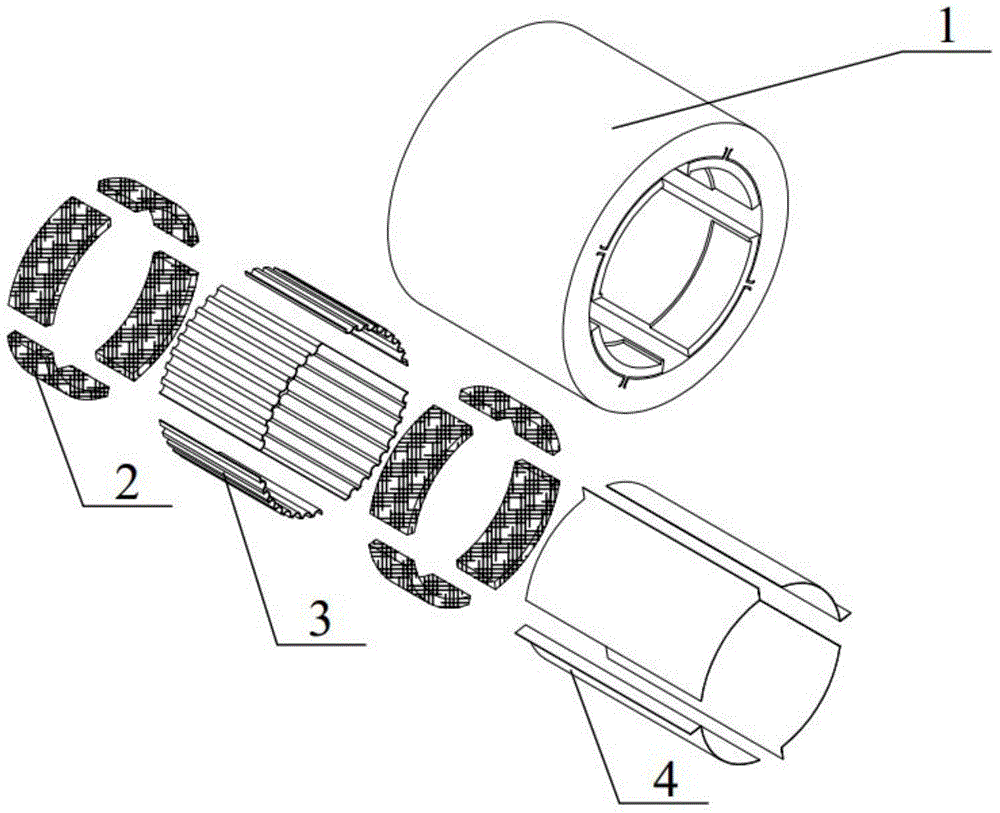

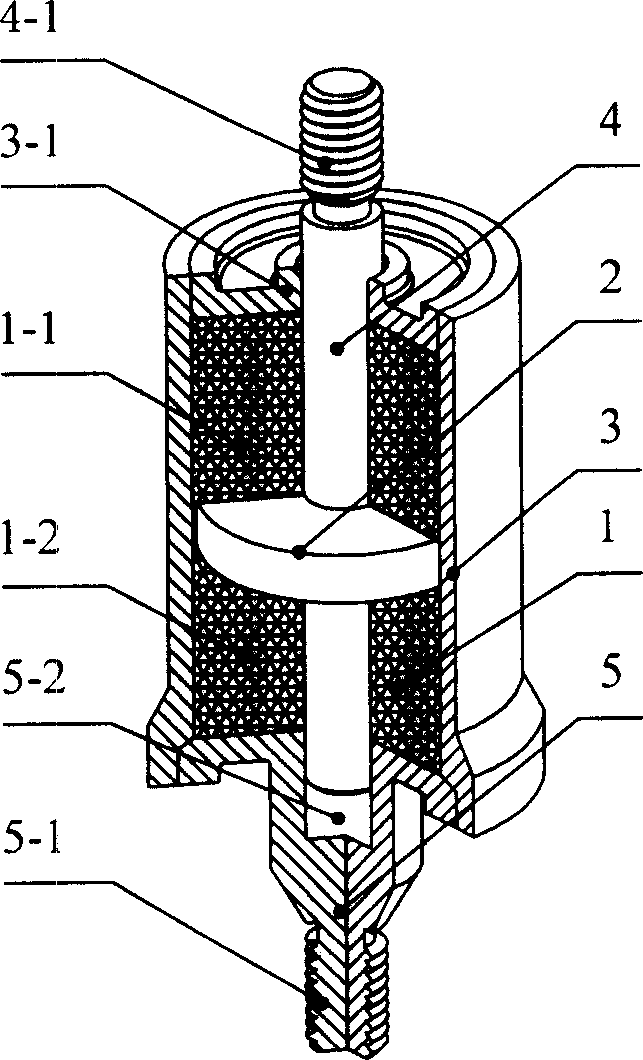

Internally hollow metal rubber vibration isolator with negative Poisson's ratio characteristic

InactiveCN102720785AEnough carrying capacitySufficient structural rigidityLow internal friction springsLoad resistanceMetal rubber

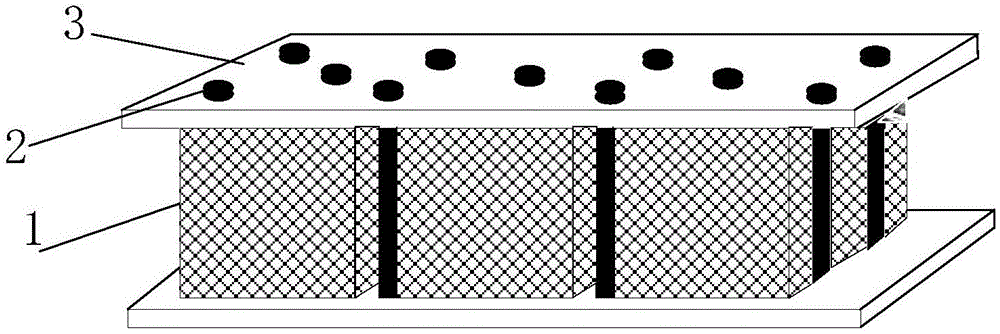

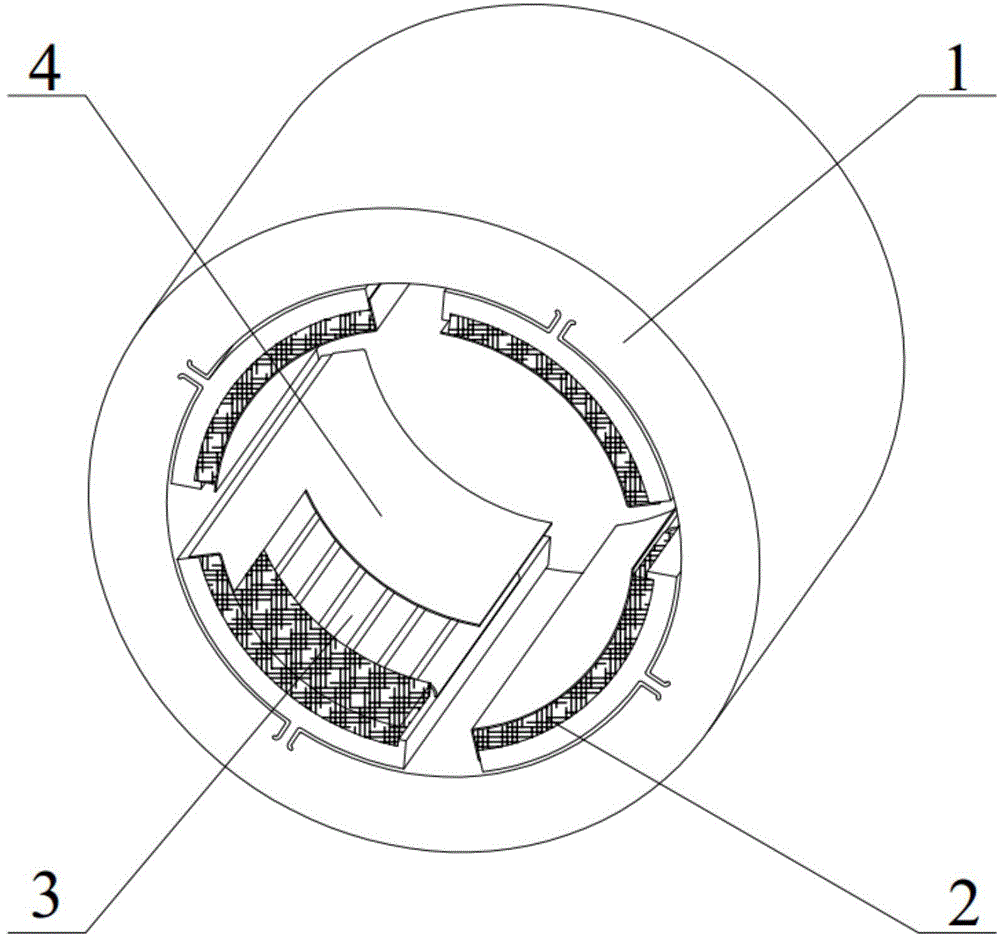

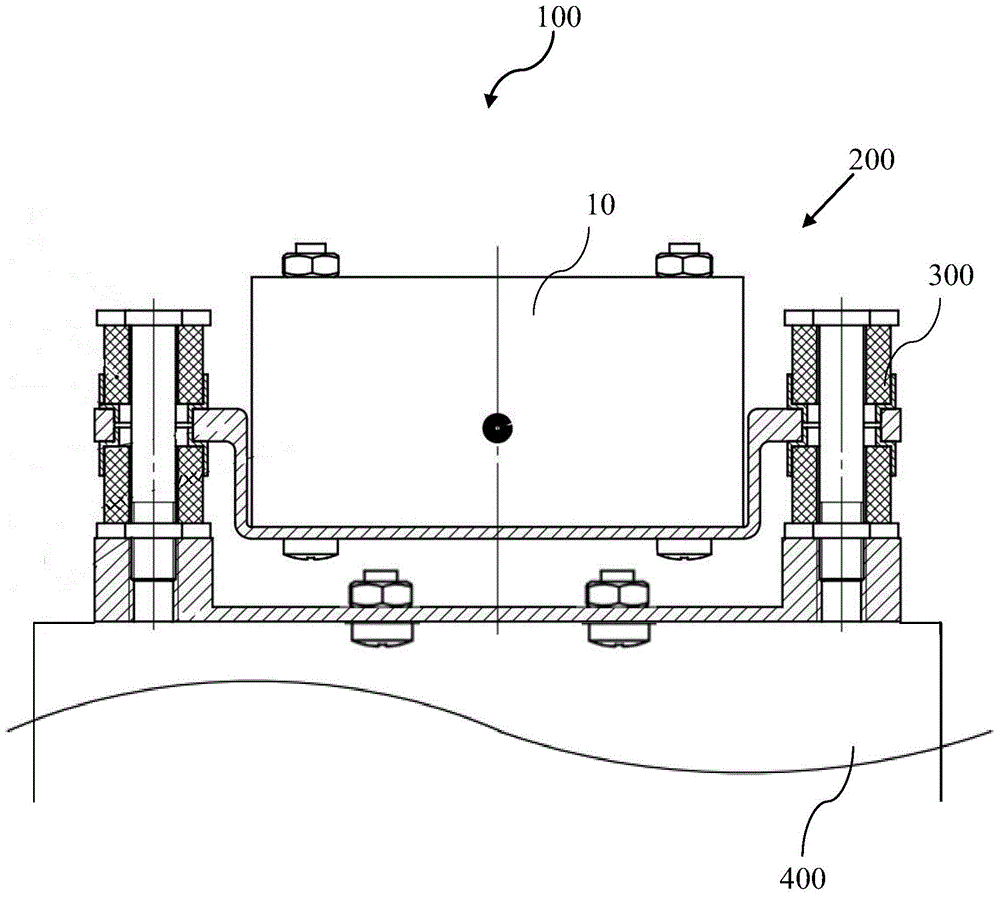

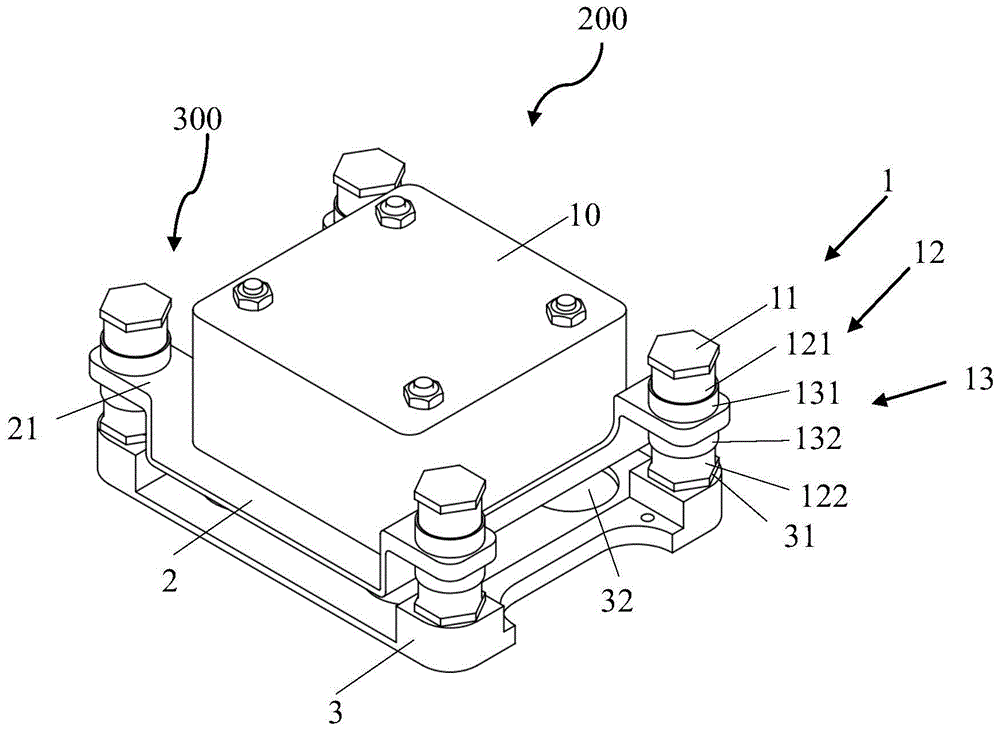

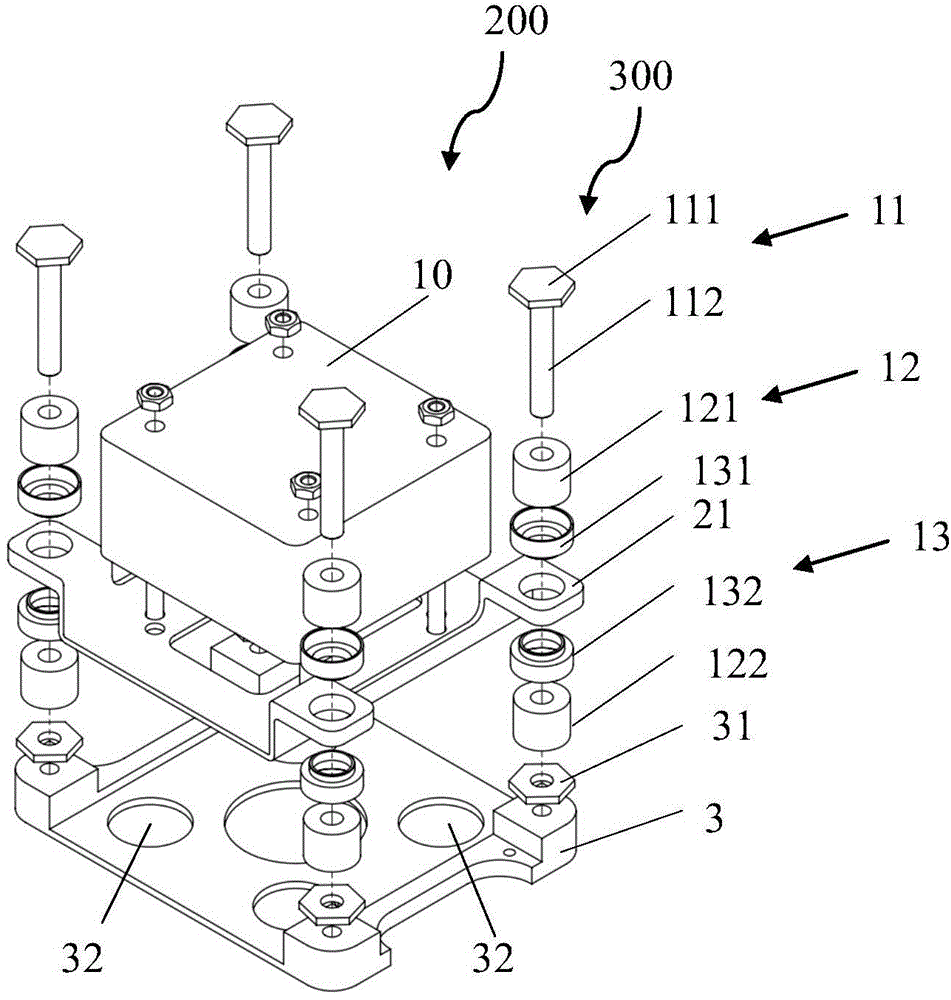

The invention discloses an internally hollow metal rubber vibration isolator with a negative Poisson's ratio characteristic. The internally hollow metal rubber vibration isolator comprises a plurality of complete unit bodies (100) with the same structure and a plurality of complementary unit bodies (200) with the same structure, which are arranged in an overlapped way. Each of the complementary unit bodies is half of each of the complete unit bodies in structure. The overlapped arrangement comprises a middle arrangement part (1), a left-end arrangement part (2), a right-end arrangement part (3), a left complementary arrangement part (4) and a right complementary arrangement part (5), wherein the middle arrangement part (1) is arranged in the middle, the left complementary arrangement part (4) and the right complementary arrangement part (5) are arranged on two sides of the middle arrangement part (1) respectively, the left-end arrangement part (2) is arranged on the left side of the left complementary arrangement part (4), and the right-end arrangement part (3) is arranged on the right side of the right complementary arrangement part (5). According to the internally hollow metal rubber vibration isolator, the problems of vibration fatigue and impact failure of the vibration isolator are solved by utilizing good damping performance of a metal rubber structure damping material on one hand, and the impact load resistance of the vibration isolator is improved through the negative Poisson's ratio characteristic of the stagger arrangement structure of the complete unit bodies and the complementary unit bodies on the other hand.

Owner:BEIHANG UNIV

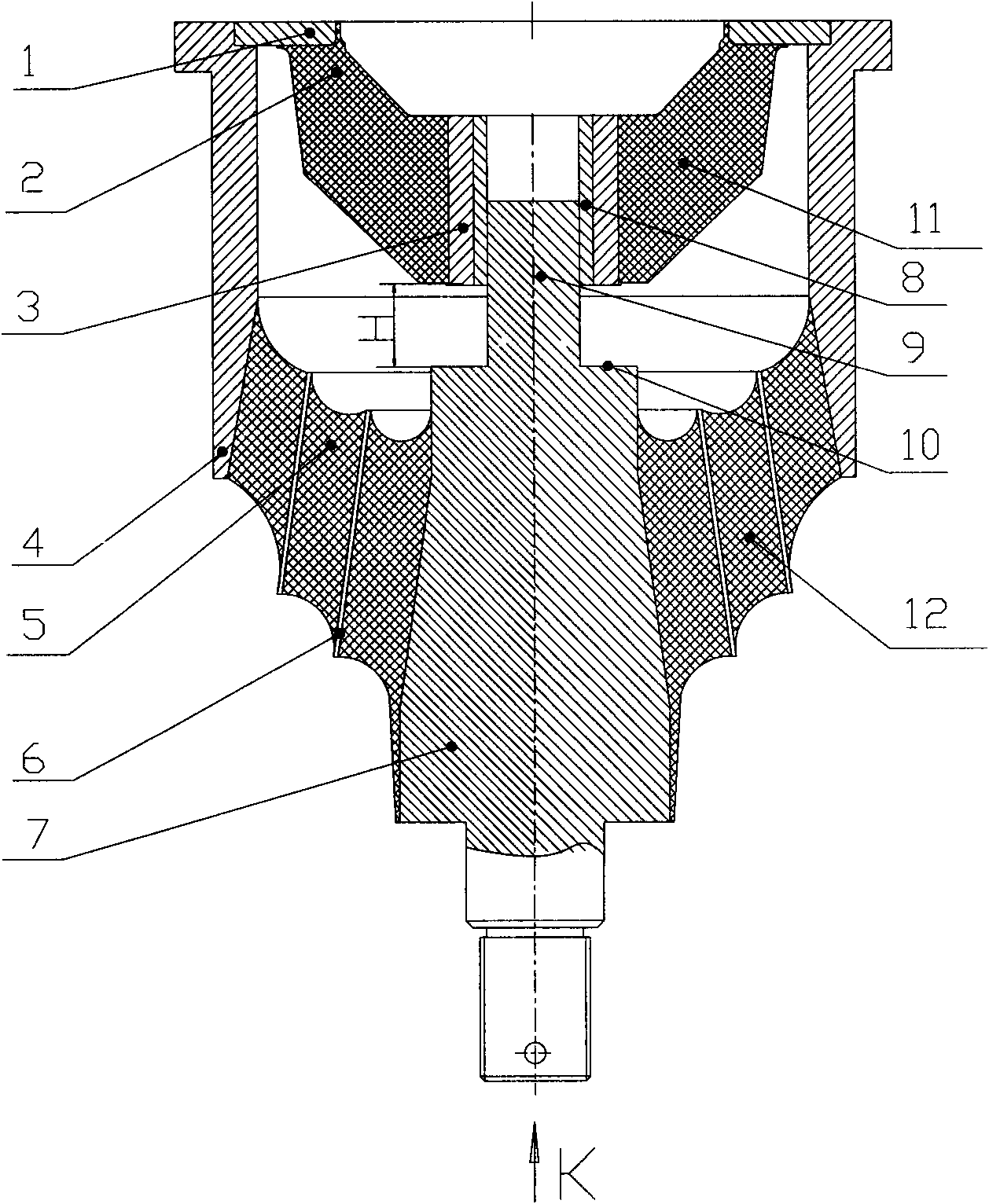

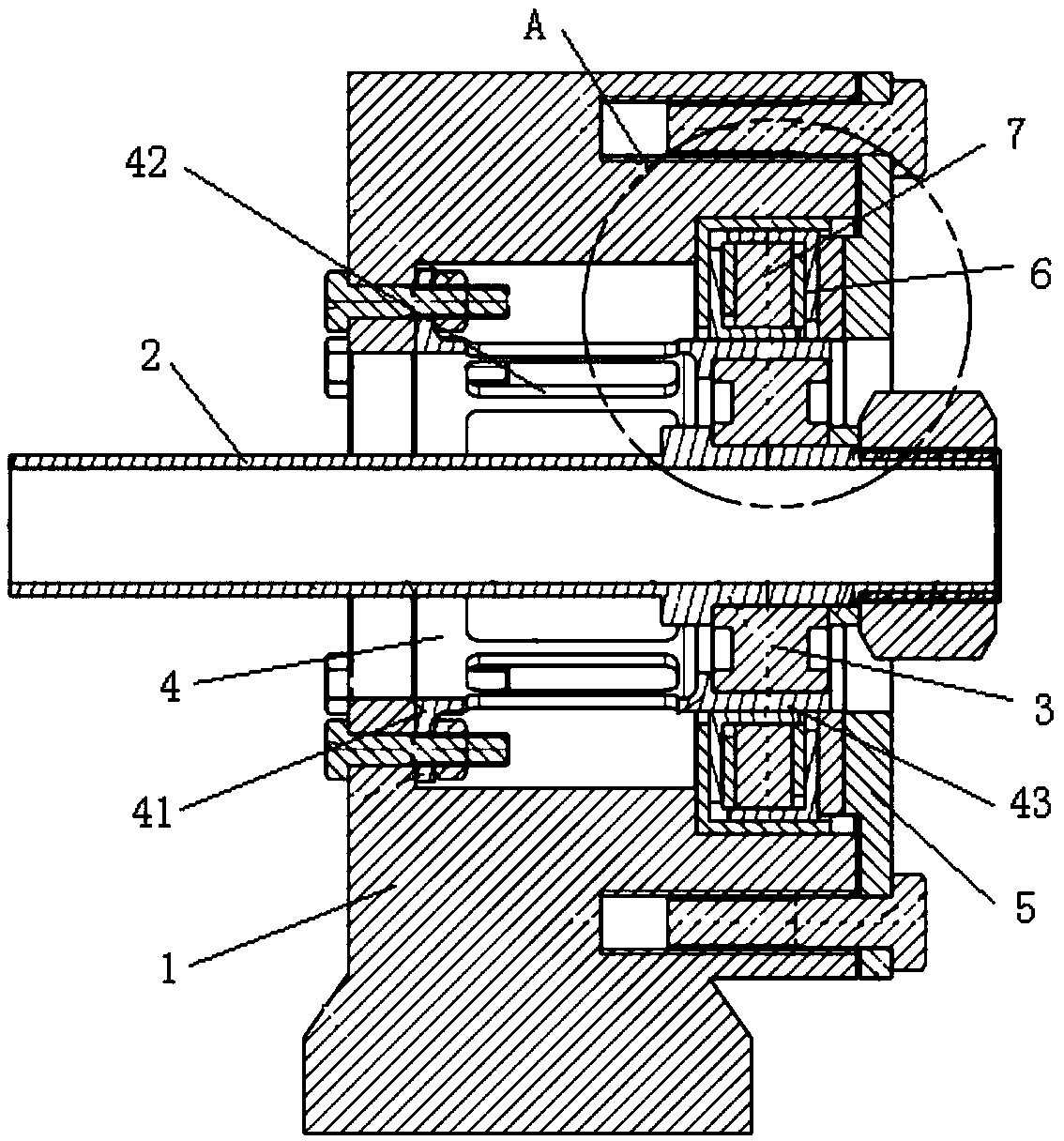

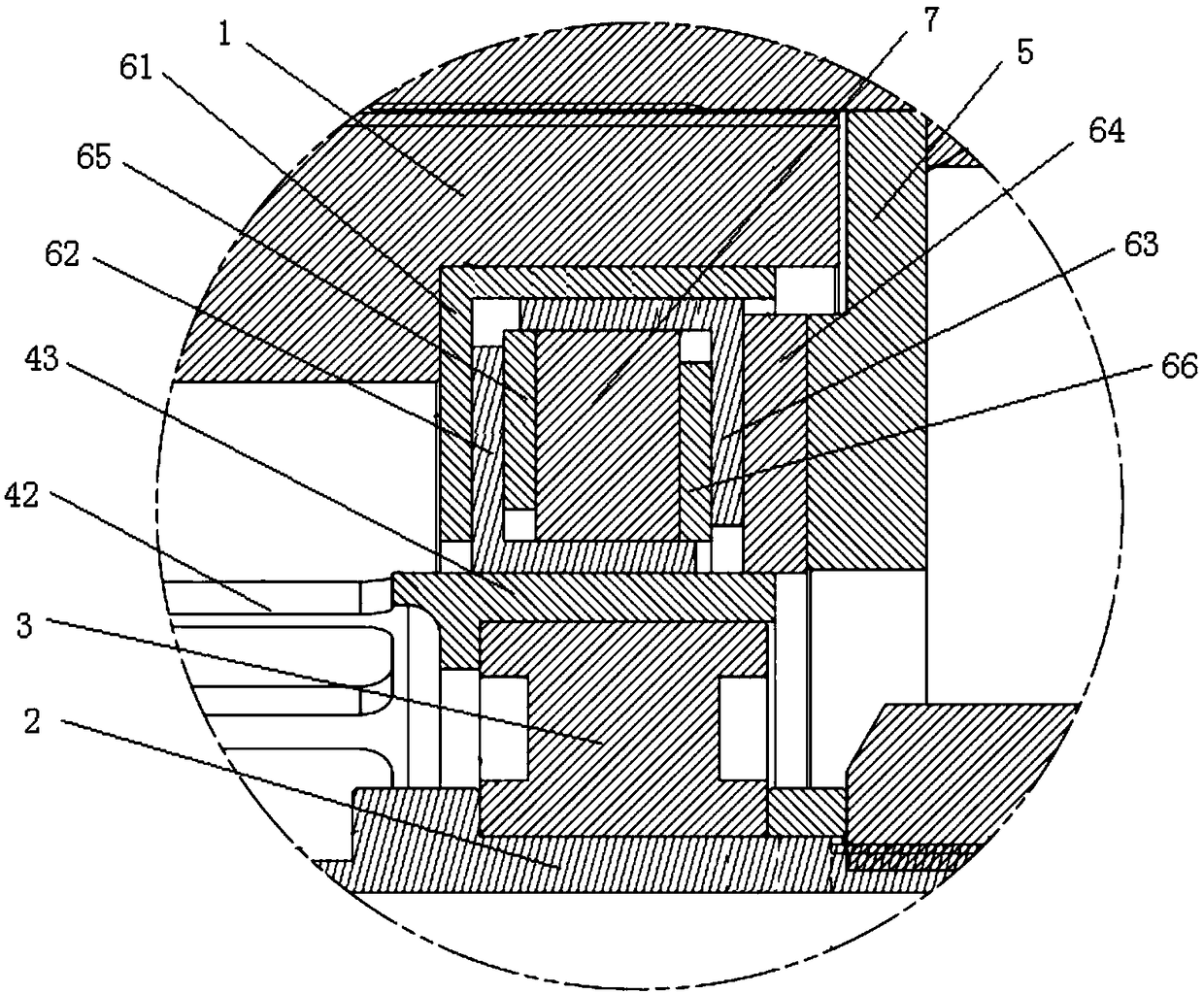

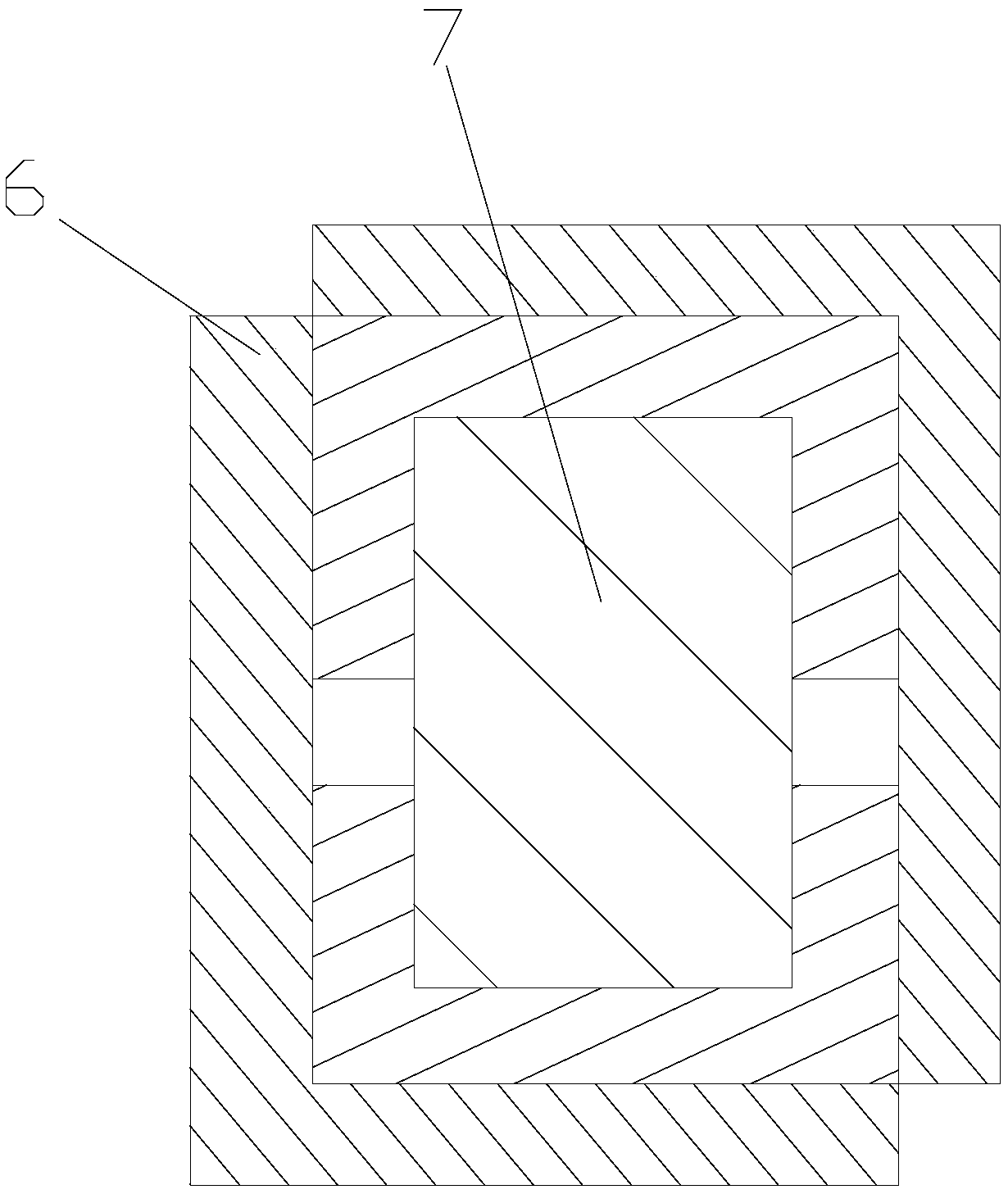

Turbocharger

ActiveCN103670672AEliminate the influence of timingReduce resistanceInternal combustion piston enginesBearingsImpellerAir bearing

The invention relates to a turbocharger which comprises a turbine shell (5), a turbine (7), a rotor shaft (6), a body (2), a thrusting bearing cover (4), a radial thrusting bearing (3), an impeller shell (1) and an impeller (9). The radial thrusting bearing (3) comprises a radial metal rubber block type air bearing, a radial thrusting bearing rotor shaft and a thrusting metal rubber block type air bearing and the radial metal rubber block type air bearing and the thrusting metal rubber block type air bearing respectively comprise a bearing metal rubber block, a bearing elastic foil sheet and a bearing top-layer foil sheet. The turbocharger has the advantages of being suitable for energy recovery of engine tail gas and air inlet supercharge of an engine, capable of avoiding the influence, caused by oil leakage of the turbocharger, on correct timing of the engine through the air bearings, suitable for large-discharge engines due to the small air lubrication resistance and high product rotation speed, long in service life due to the fact that direct physical contact between the surface of the rotor shaft and the inner surface of the bearing is avoided, and remarkable in high-temperature-resistant performance due to the fact that a bearing medium of the bearing is air.

Owner:HUNAN UNIV

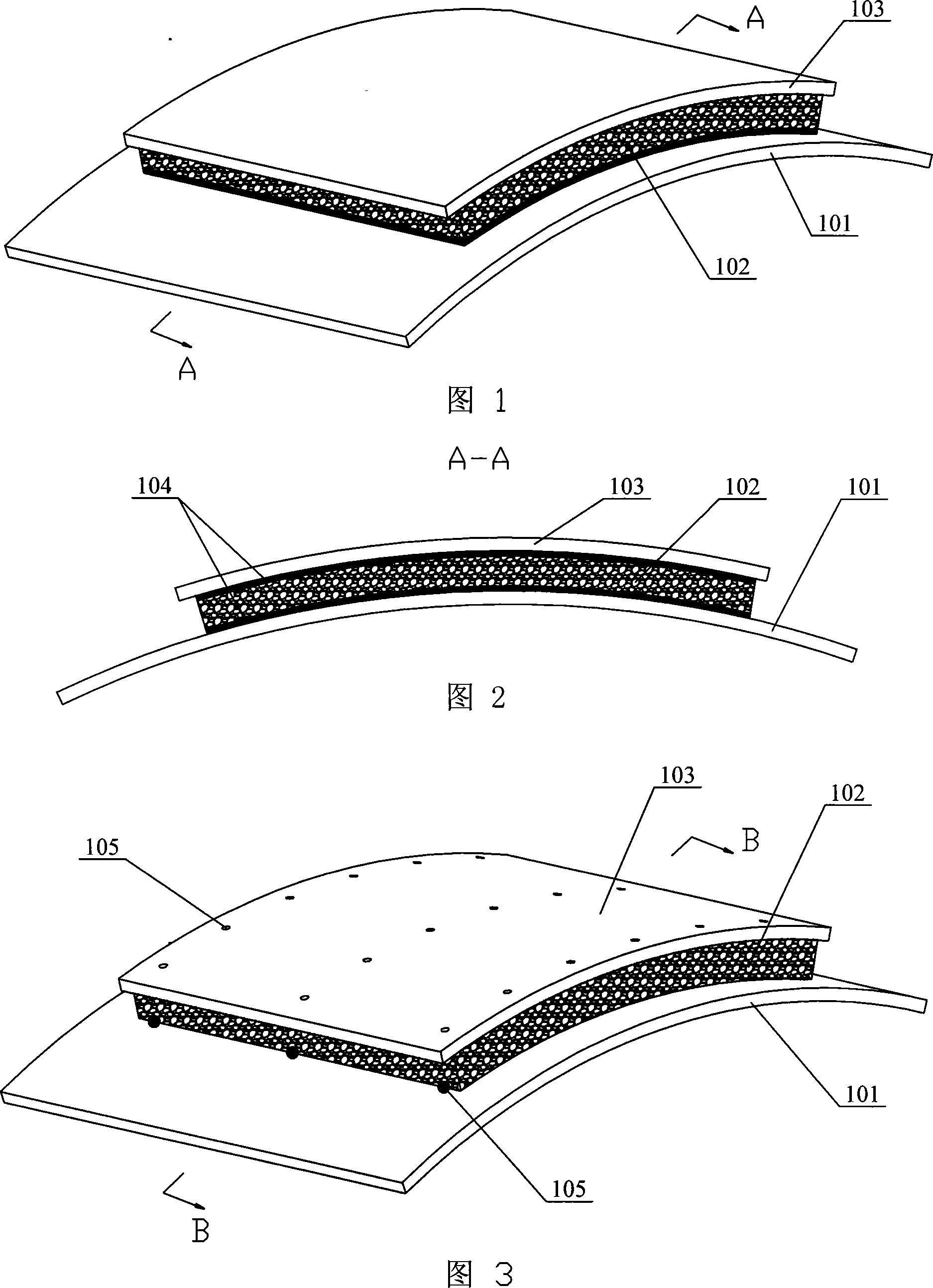

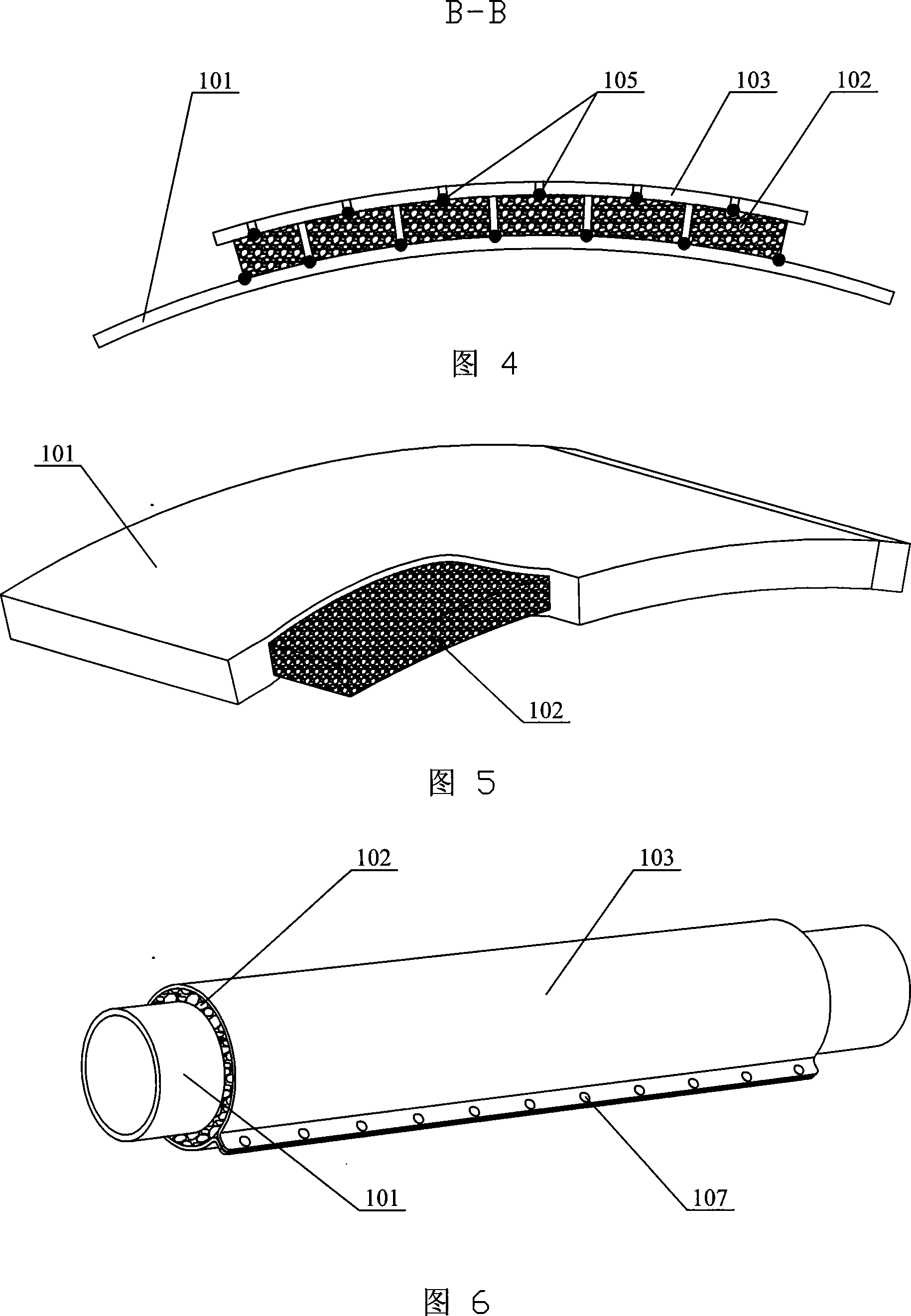

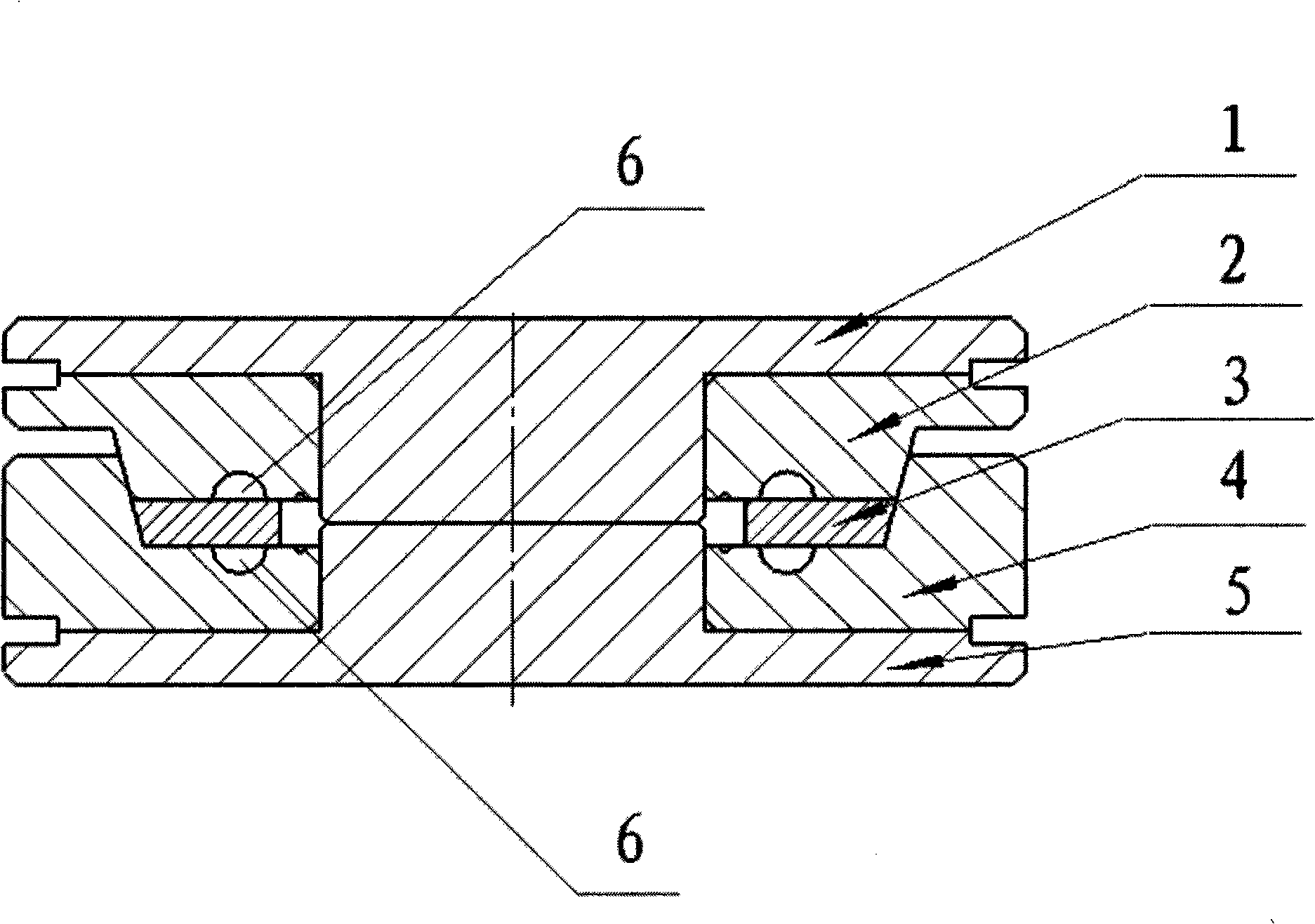

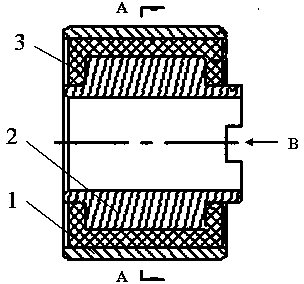

Composite damping material with interlayer being as metal rubber

InactiveCN101093008ACorrosion resistantVarious application methodsHigh internal friction springsRubber materialMetal rubber

This invention relates to a composite damp material with a metal rubber interlayer, in which a metal rubber layer is clamped between a base layer and a restriction layer, the lower surface of the metal rubber layer and the top surface of the base layer, the top surface of the rubber layer and the lower surface of the restriction layer are glued together by adhesives to prepare a composite damp material with a metal rubber interlayer, which replaces traditional rubber materials with metal rubber material having the advantages of anti-corrosion, anti-aging, high and low temperature resistant and not volatile in vacuum.

Owner:郑钢铁 +5

Method for manufacturing damping structural piece of aviation engine supporting system

InactiveCN102644686AWith shape memoryBoth featuresHigh internal friction springsAviationMetal rubber

The invention discloses a method for manufacturing a damping structural piece of an aviation engine supporting system; a shape memorizing alloy wire is manufactured into metal rubber through the combined processes of manufacturing an elastic wire at low temperature, heat setting, winding and full-constraint heat setting; and the damping structural piece which is manufactured through the method has a shape memorizing effect and a variable rigidity characteristic. According to the method for manufacturing the damping structural piece of the aviation engine supporting system, a damping material in the metal rubber structure is integrated with a shape memorizing alloy, and a novel metal structural functional material with the advantages of the metal rubber and the shape memorizing alloy is developed. The material has good damping performance, high deformation capability and high bearing capability, and has the advantages of active and controllable elastic modulus, strong environment adaptability and stable and reliable structure. Because the advantages of the metal rubber and the shape memorizing alloy are integrated, the method can be applied in aviation engine rotor supporting and a non-peak rotor can be realized.

Owner:BEIHANG UNIV

Aero dynamic bearing with metal rubber and elastic chaff composite support structure

ActiveCN103438091AImprove poor reliabilityImprove carrying capacityBearing componentsSliding contact bearingsAir bearingCarrying capacity

Owner:HUNAN UNIV

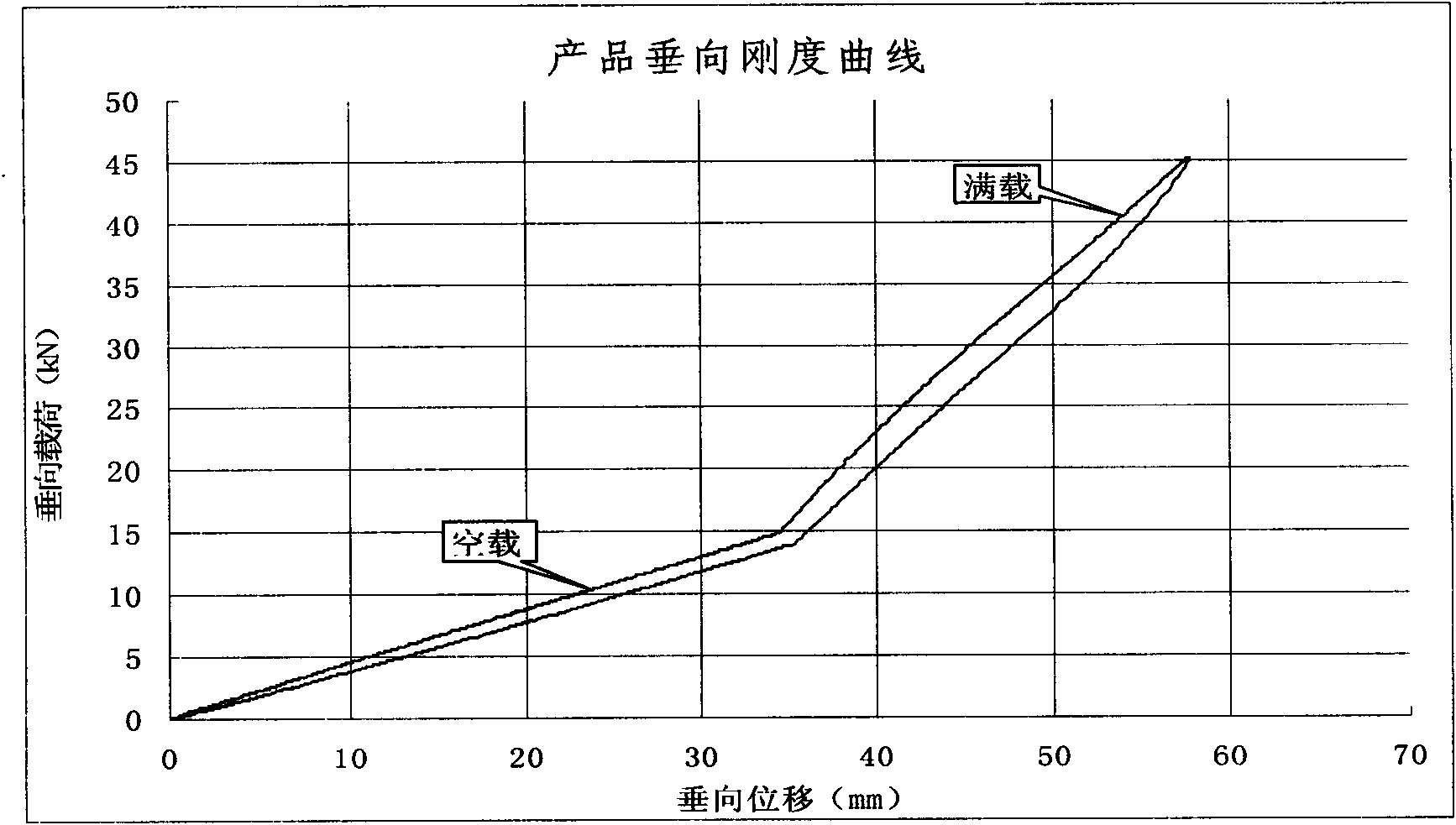

Journal spring buffering method for railbound vehicle bogie and journal spring

ActiveCN101607562ASimple structureReduce weightNon-rotating vibration suppressionAxle-boxes mountingBogieShear stress

The invention relates to a goods van journal spring buffering method used for a railbound vehicle bogie and a journal spring. The method adopts a two-stage buffering way. The journal spring is a composite journal spring formed by combining a main spring and an assistant spring, wherein the main spring still adopts the prior metal-rubber composite conical spring, and a shearing stress frustum rubber pad assistant spring is arranged on the main spring. The shearing stress frustum rubber pad assistant spring is arranged on the main spring, thereby buffering by bearing shearing force when the main spring is compressed and contacted with the assistant spring. The composite journal spring is formed by combining a main spring and a shearing stress frustum rubber pad assistant spring, wherein the main spring is a metal-rubber composite conical spring, and the shearing stress frustum rubber pad assistant spring is connected to the main spring in series. The invention adopts a combination structure of the main spring and the assistant spring, utilizes the rubber to play the elastic buffering role, vertically, longitudinally and transversely provides flexible supporting and positioning for the bogie, transfers traction and brake force during running and improves the running quality of vehicles.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

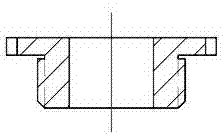

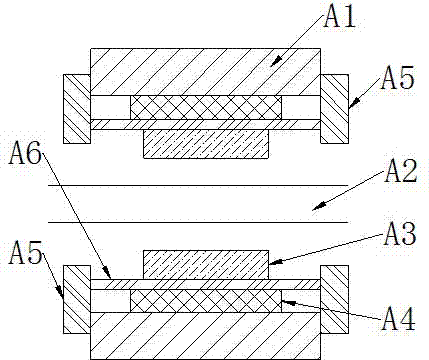

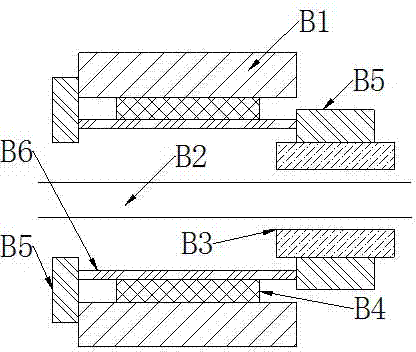

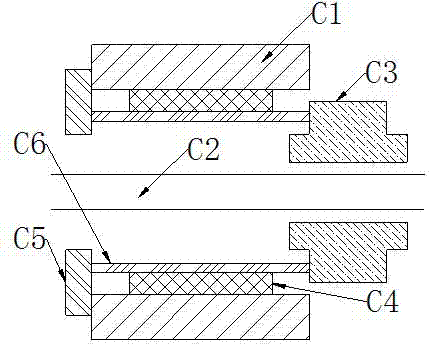

Metal-rubber composite gland bush molding die and molding method thereof

The invention relates to a metal-rubber composite gland bush molding die which comprises an upper core plate, an upper pressure plate, a positioning gasket, a lower pressure plate and a lower core plate. Central columns of the upper core plate and the lower core plates are installed in central holes of the upper pressure plate and the lower pressure plate. The positioning gasket is installed between the upper pressure plate and the lower pressure plate. A metal frame of a metal-rubber composite gland bush is arranged in a die cavity combined by the upper core plate, the lower core plate, the upper pressure plate, the lower pressure plate and the positioning gasket. A matching surface between the positioning gasket, the upper pressure plate and the lower pressure plate has a slope angle of 15 degrees to 20 degrees. The molding die adopts a combination type, so that the molding die is convenient for demounting and the metal-rubber composite gland bush can be taken out very conveniently. The molding die is provided with the split positioning gasket, thereby ensuring that the metal-rubber composite gland bush is convenient for taking out when being positioned and ensuring that the molded metal-rubber composite gland bush can be convenient for taking out. The molding mould has simple structure, convenient manufacturing and low cost. A molding method for molding the metal-rubber composite gland bush has very good effect.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

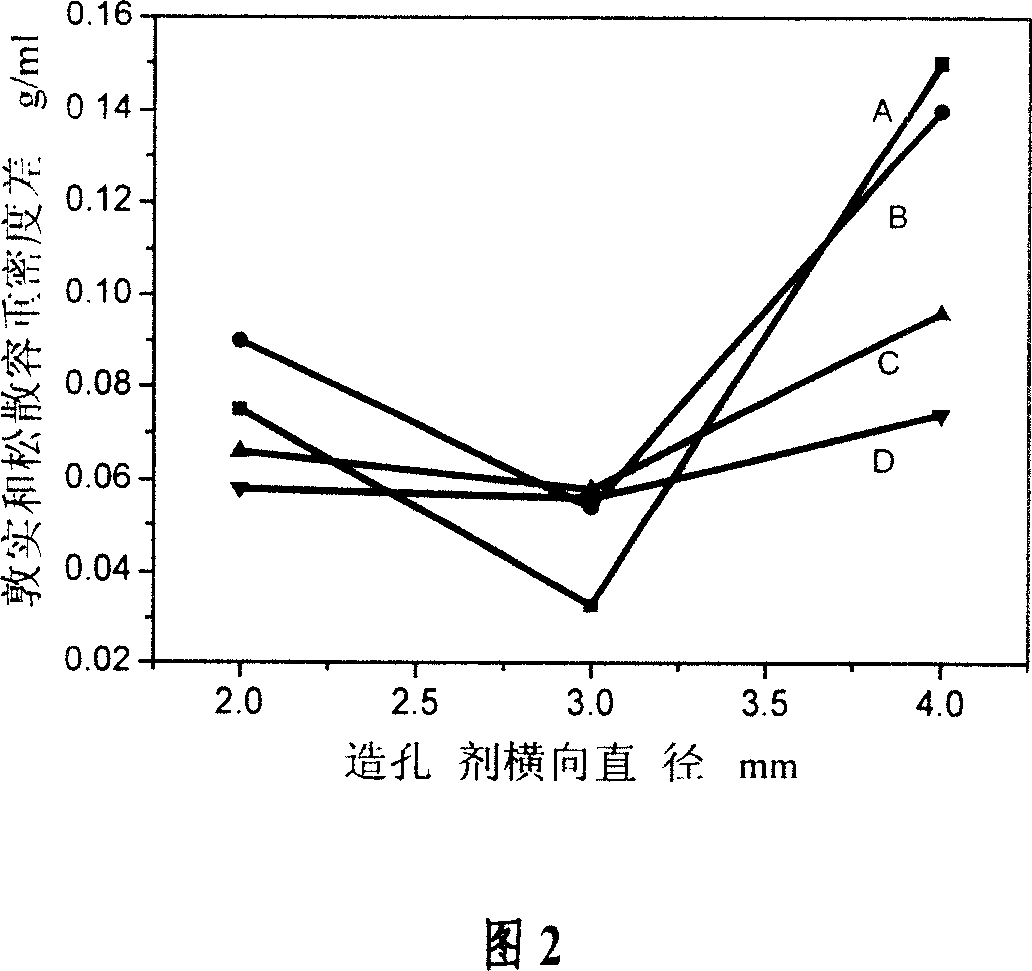

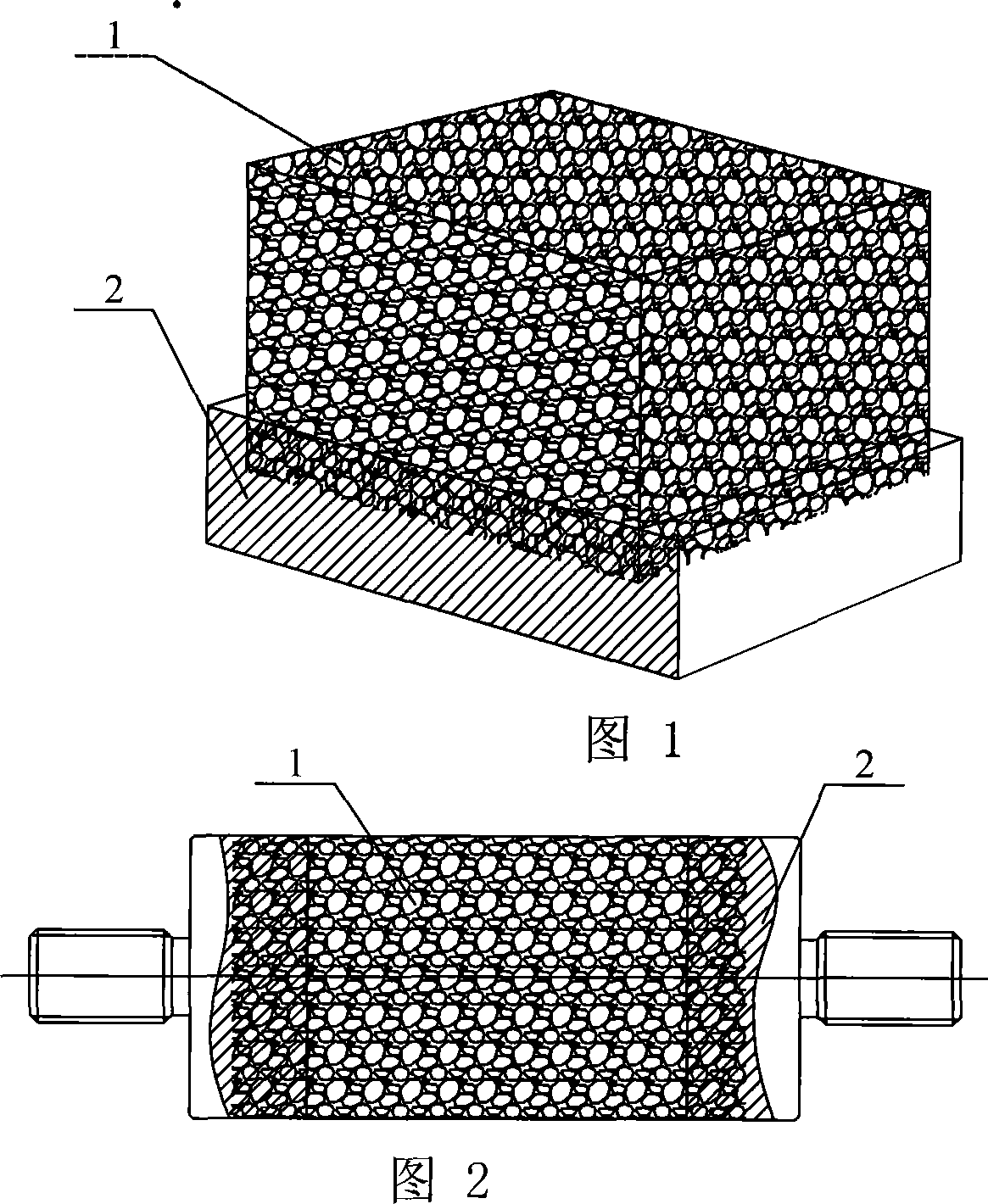

Prepn process of pore forming agent for porous magnesium alloy and porous aluminium and its pore forming method

The present invention relates to pore forming agent, and is especially pore forming agent for porous magnesium alloy and porous aluminum alloy and with controllable pore size, porosity and pore wall thickness and its preparation process and pore forming method. The pore forming agent is prepared with light calcium carbonate, RE carbonate, etc as material and through an extruding and pelletizing process. When it is used, the granular pore forming agent is used as the support and molten magnesium alloy or aluminum alloy is made to seepage flow into the pore forming agent so as to obtain porous magnesium alloy or aluminum alloy after treatment. The porous magnesium alloy and aluminum alloy preparing process can control the pore size, porosity and pore wall thickness effectively, and the alloy is used for sea water cell anode, metal rubber and other porous light metal product.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Internal groove self-lubricating dynamic-static pressure coupling air-float bearing

InactiveCN101413541AImprove wear resistanceImprove stabilityBearing componentsBearingsAir bearingWear resistant

The invention discloses a coupling dynamic-static air bearing with a self-lubricating function of an internal channel, and relates to bearing technologies, and is an air bearing of new structural form. The bearing is structurally characterized in that a bearing body is provided with double-row pressure air supply holes, and a throttle nozzle tangential air supply structure is adopted; inner surface of the bearing is provided with a pressure channel groove structure; the bearing body is made of wear resistant and high temperature resistant materials with self-lubricating property, and technical measures for vibration reduction such as rubber band, metal rubber and elastic composite materials are taken. The coupling dynamic-static air bearing greatly increases the capacity of a floating ring for bearing imposed load and the wear resistant property of static components and dynamic components which contact in a short time, and also reduces the requirements for indexes such as working substances, impurities, temperature and the like. Therefore, the bearing is characterized by simple structure, stable operation and high reliability, and further broadens the technical application range of air bearing products.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

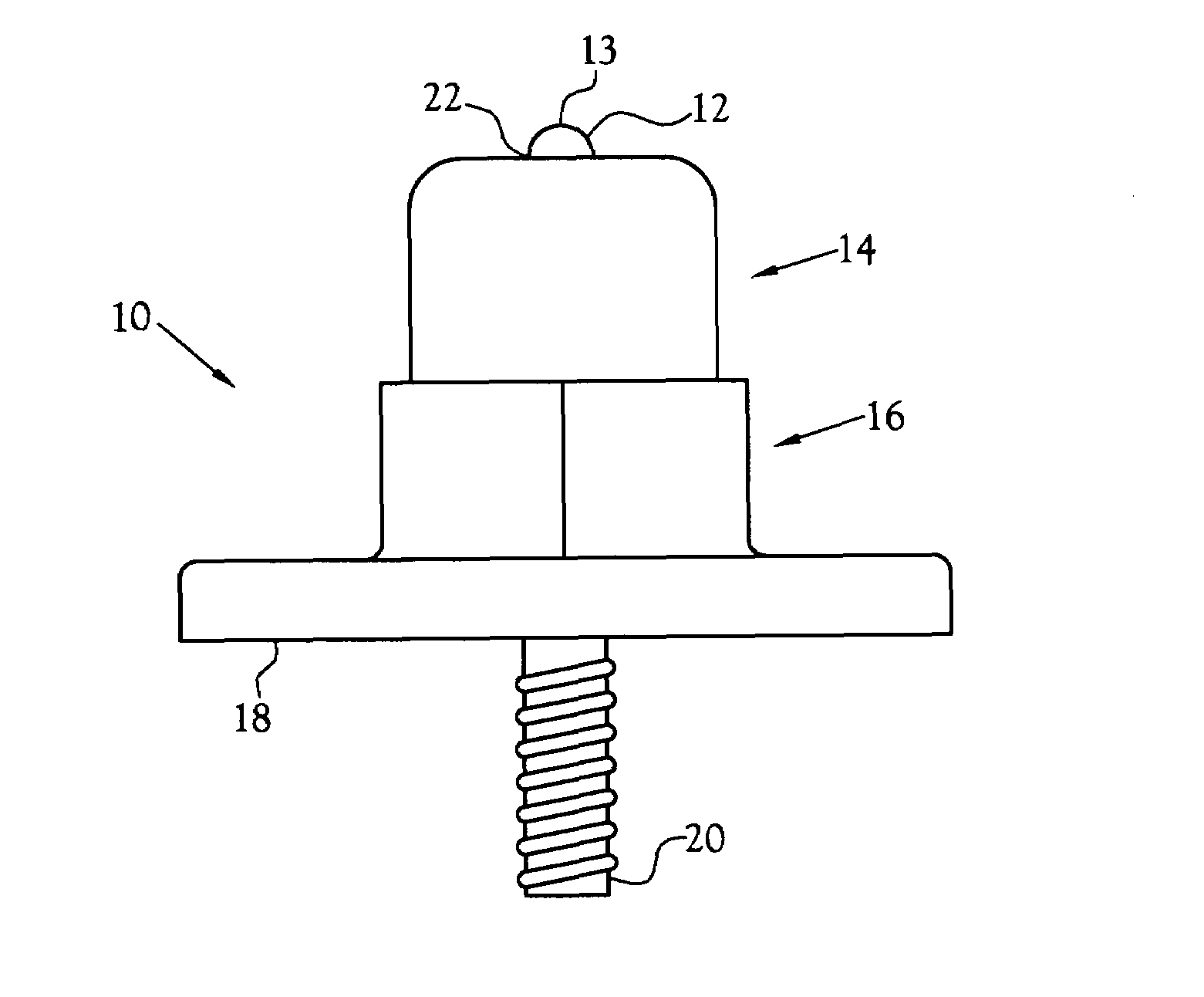

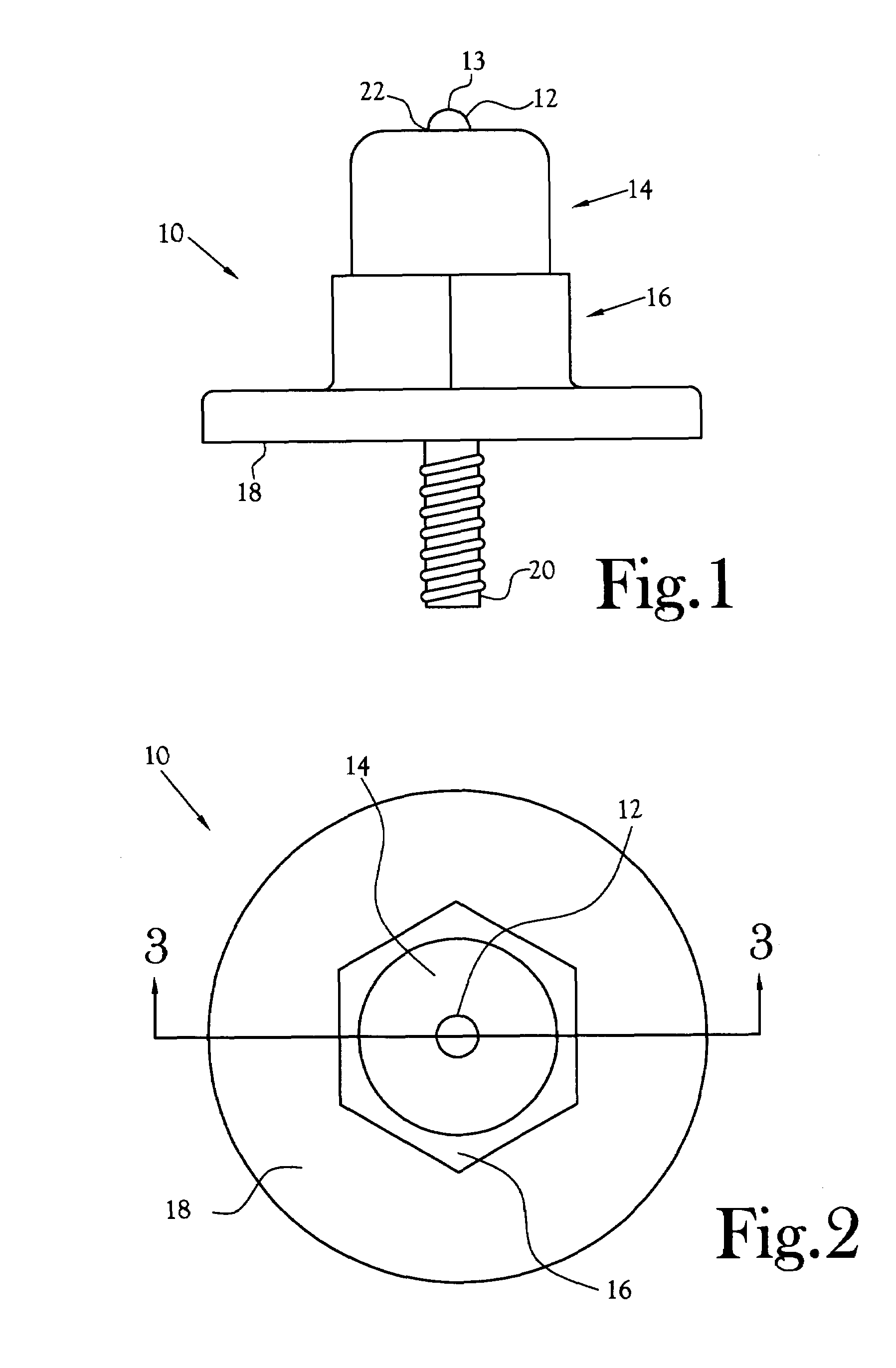

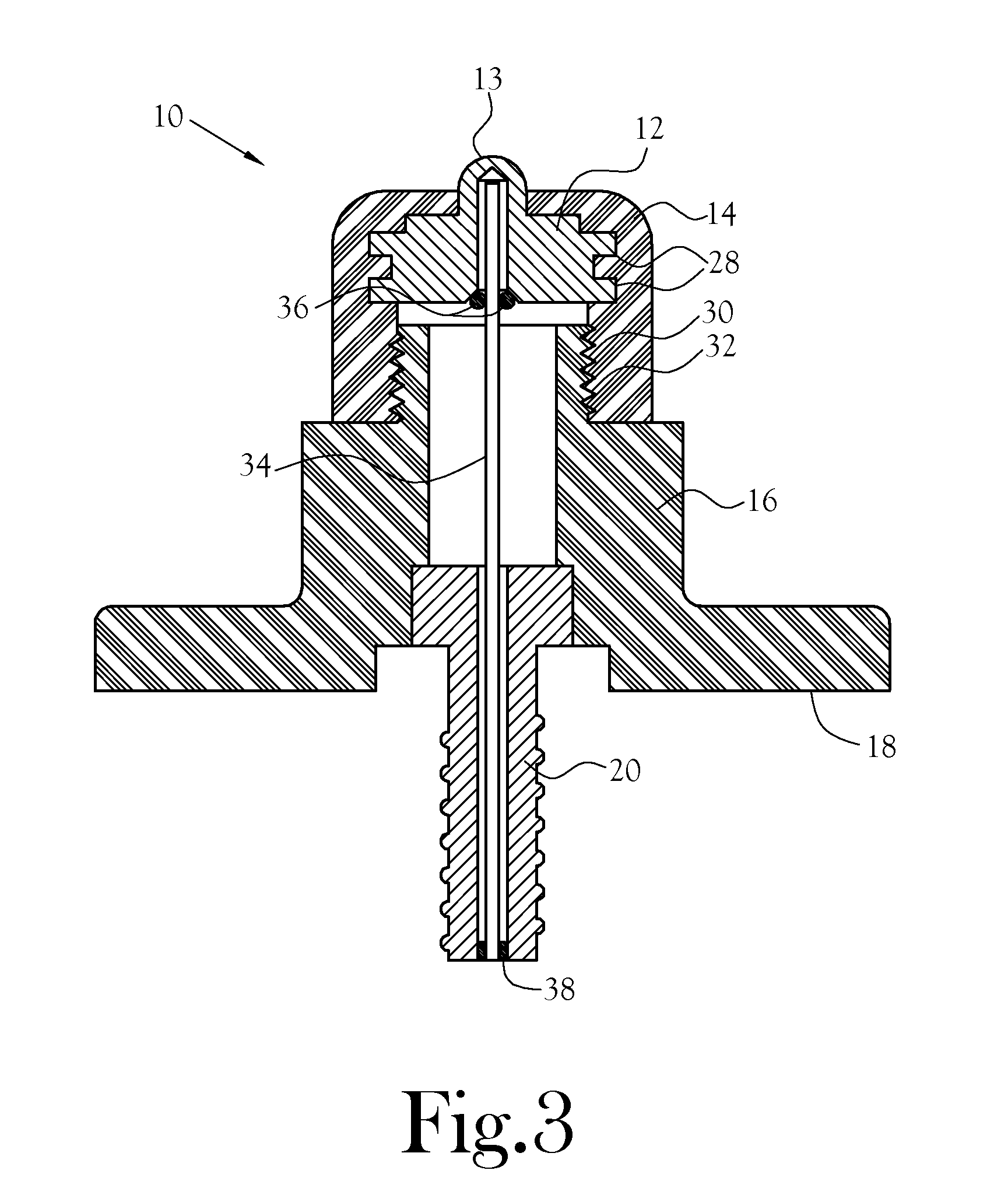

Insulated probe device

Described is an insulated probe device of adjustable axial length for delivering an electroshock stimulus to an animal. The insulated probe device includes an electrode that is positioned in contact with the animal's skin and is disposed within an electrically non-conductive housing. The housing is a two-part housing, where the two parts cooperate such that the ultimate length of the housing is adjustable. The insulated probe devise includes a mounting device that electrically and mechanically secures the insulated probe device to an electronic animal training device. The mounting device is electrically connected to the electrode by way of a conductor, which is disposed within the housing. The conductor is a metal-rubber substance that conducts electricity like a metal and stretches like rubber such that it is capable of various lengths. Consequently, the ultimate length of the insulated probe device is adjustable.

Owner:RADIO SYST CORP

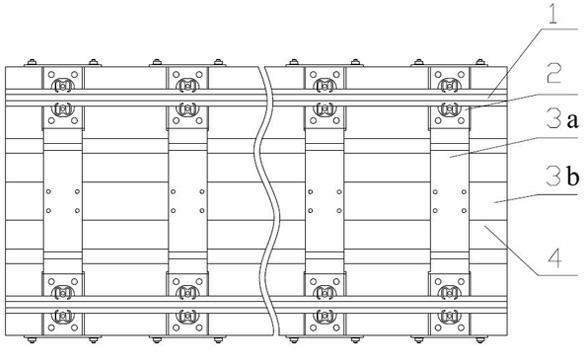

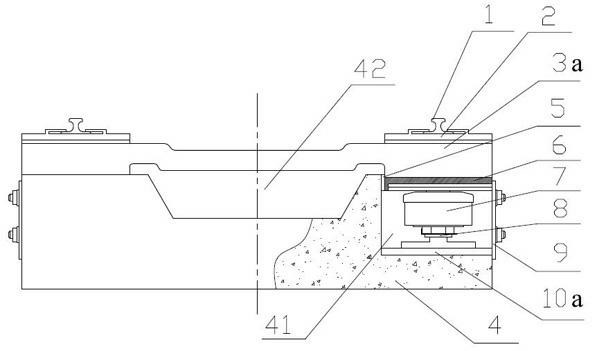

Elastic vibration-reduction ballast bed system

The invention discloses an elastic vibration-reduction ballast bed system, which comprises a concrete ballast bed and a low-frequency vibration isolator installed in the concrete ballast bed. An elastic mechanism in the low-frequency vibration isolator consists of a positive stiffness elastic element made of metal rubber or the positive stiffness elastic element and a negative stiffness elastic element which are connected in parallel. The positive stiffness elastic element is a disc spring, a spiral spring, the metal rubber, a metal rubber-spring armour, a metal rubber-lead core composite spring or any series-parallel combination of the disc spring, the spiral spring, the metal rubber, the metal rubber-spring armour and the metal rubber-lead core composite spring. The negative stiffness elastic element is a disc spring or a diaphragm spring. The elastic vibration-reduction ballast bed system can meet requirements of middle-high-grade vibration reduction and has a simple structure. The site construction process is simple and convenient, and consumed materials of the ballast bed are relatively reduced. Therefore, the elastic vibration-reduction ballast bed system is low in construction cost and suitable for popularization and application in the whole line.

Owner:河北金擘机电科技有限公司 +1

Primer for vulcanization bonding

ActiveUS20060251908A1Molecular weight of the copolymerization oligomerHigh molecular weightMolten spray coatingSemiconductor/solid-state device manufacturingPolymer scienceVulcanization

A primer for vulcanization bonding, which comprises a copolymerization copolymer of amino group-containing alkoxysilane and vinyl group-containing alkoxysilane, and an organometallic compound, can give a metal-rubber composite having a water-resistant adhesiveness equivalent or superior to that of coating type chromate processing agent, without application of harmful coating type chromate processing to a metal, and thus can be effectively used in surface treatment of metals such as stainless steel, etc. for the production of seal products of rubber-bonded metal (e.g. oil seals, packings and gaskets), valves, vibration-controlled or vibration damped products (e.g. vibration-controlled steel sheets and vibration-damped rubber), industrial rubber products, etc.

Owner:NOK CORP

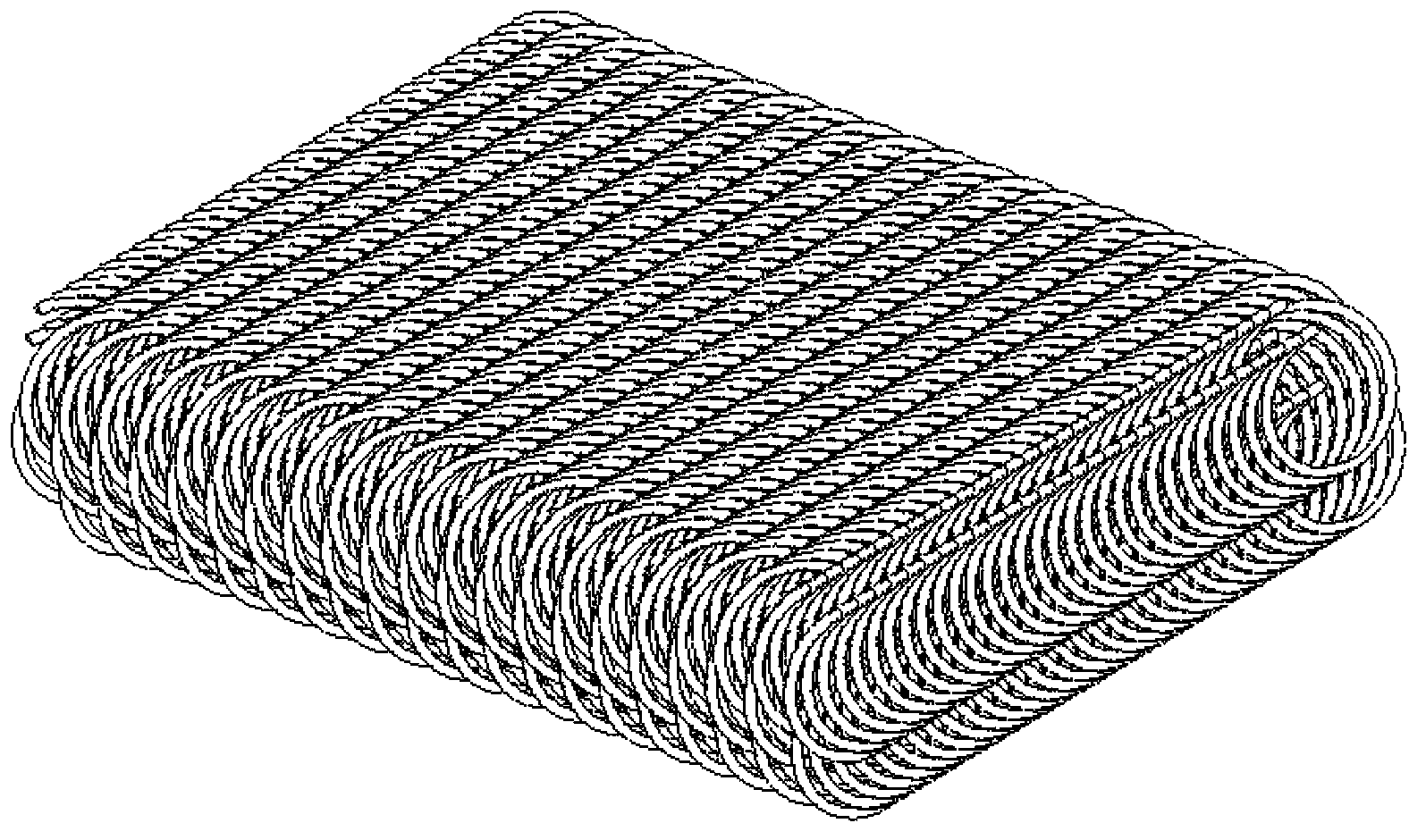

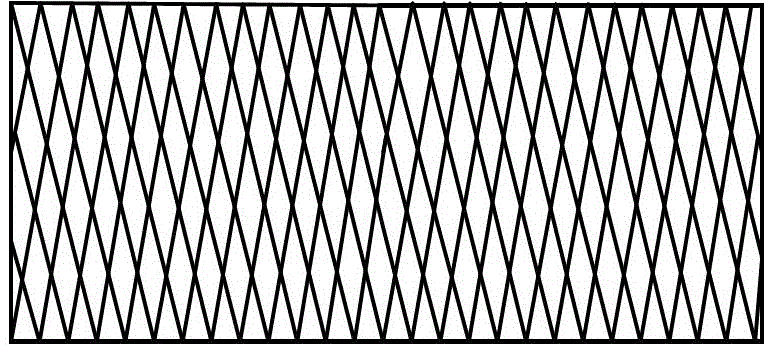

Manufacturing method of metal rubber shock pad

The invention relates to a manufacturing method of a metal rubber shock pad, which comprises following steps: selecting metal wires, and making a net structure through a knitter; rolling metal wire net to ensure that lines are formed on the metal wire net; measuring the length of the metal wire net, and segmenting the metal wire net; making the metal wire net into a blank; and press molding the blank. The manufacturing method simplifies a plurality of procedures such as spiral wind manufacturing, constant pitch drawing and metal wire winding, greatly simplifies the manufacturing process of metal rubber, obviously improves the production efficiency, reduces procedures and time of manual work, improves stability of metal rubber products, reasonably utilizes the metal wires to an extreme, and reduces the heads of the metal wires during the manufacturing process of metal rubber.

Owner:HARBIN ENG UNIV

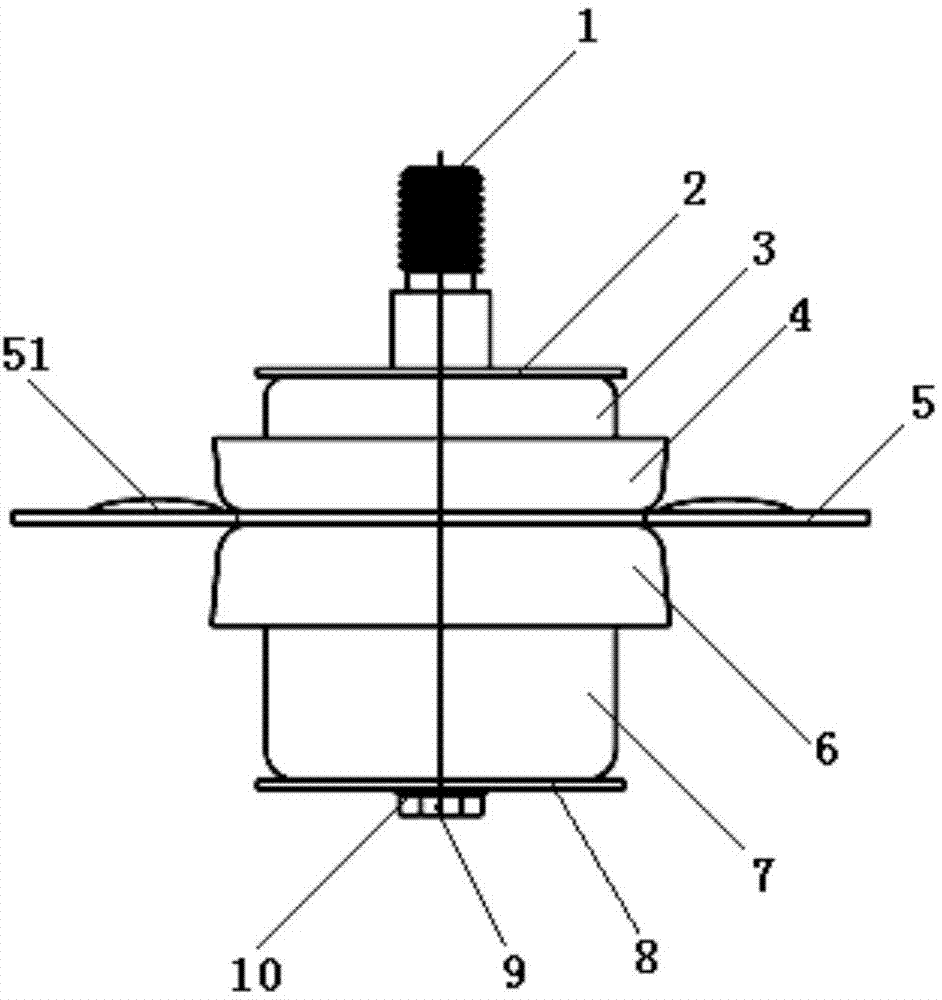

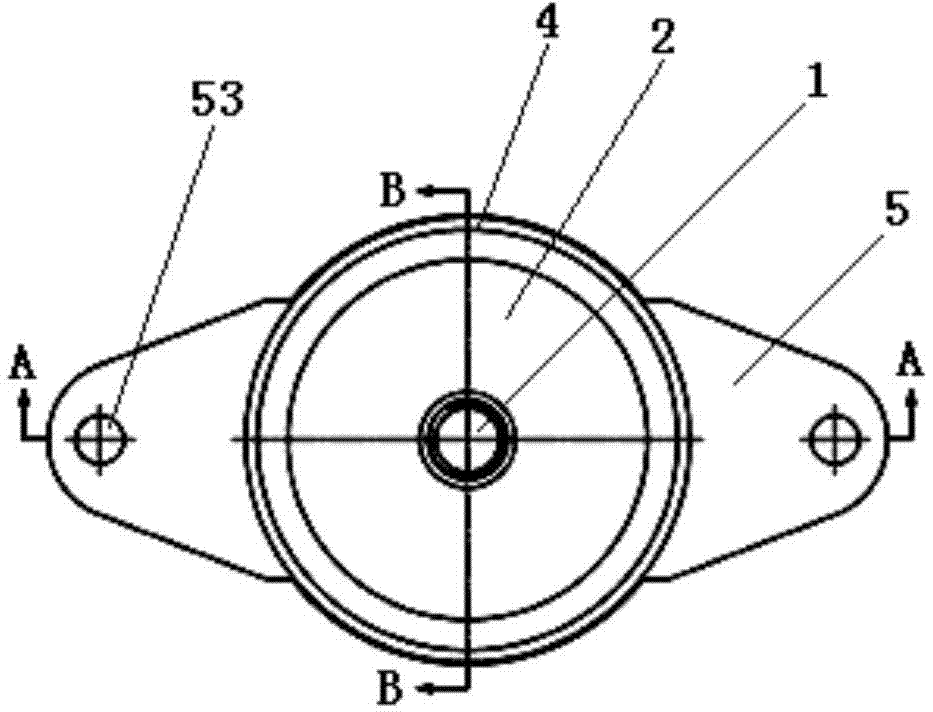

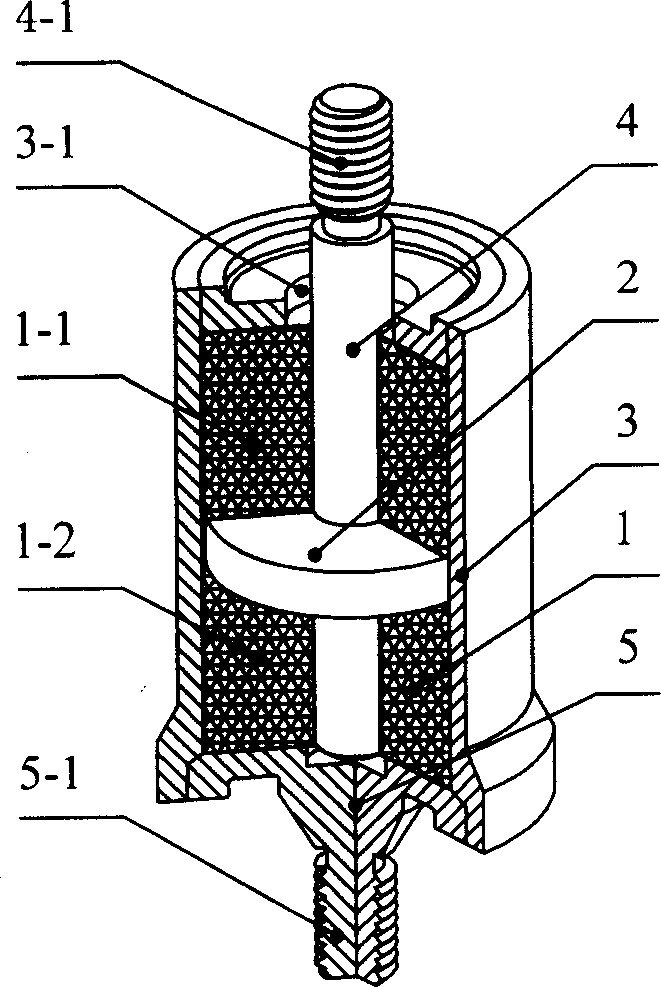

Automobile suspension mechanism

InactiveCN104773058AHigh/low temperature resistantCorrosion resistantJet propulsion mountingInternal combustion mountingEarthquake resistanceMetal rubber

The invention discloses an automobile suspension mechanism. The automobile suspension mechanism comprises a connecting screw rod, an upper cover plate, an upper metal rubber spring, an upper mounting seat, a middle mounting plate, a lower mounting seat, a lower metal rubber spring and a lower cover plate, wherein the upper cover plate, the upper metal rubber spring, the upper mounting seat, the middle mounting plate, the lower mounting seat, the lower metal rubber spring and the lower cover plate sequentially sleeve the connecting screw rod; a rod body of the connecting screw rod is sequentially provided with a mounting part, a convex shoulder and a sleeve part, and the lower cover plate is connected with the tail end of the sleeve part through a fastening piece; the upper and lower mounting seats are respectively connected with the two faces of the middle mounting plate, the upper cover plate and the upper metal rubber spring are sequentially snapped between the convex shoulder and the upper mounting seat, and the lower metal rubber spring is snapped between the lower cover plate and the lower mounting seat; the height of the upper metal rubber spring is 1 / 2-1 / 3 that of the lower metal rubber spring. The automobile suspension mechanism has good elastic and damping properties and has the characteristics of high- / low-temperature resistance, corrosion resistance, aging difficulty, no radiation environment fear and the like; due to the adoption of graded earthquake resistance, vibration absorption, vibration isolation and noise reduction can be better realized, and provided compressive and tensile capability can be accurately matched with actual driving conditions.

Owner:NANJING INST OF TECH

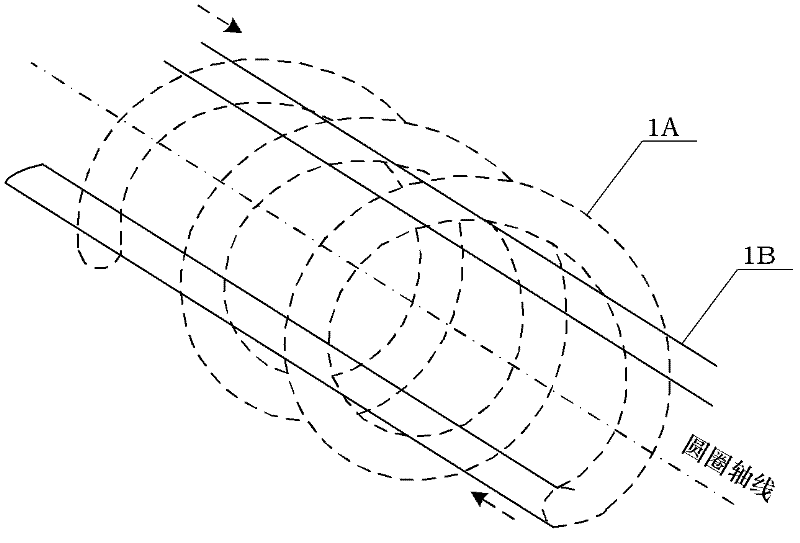

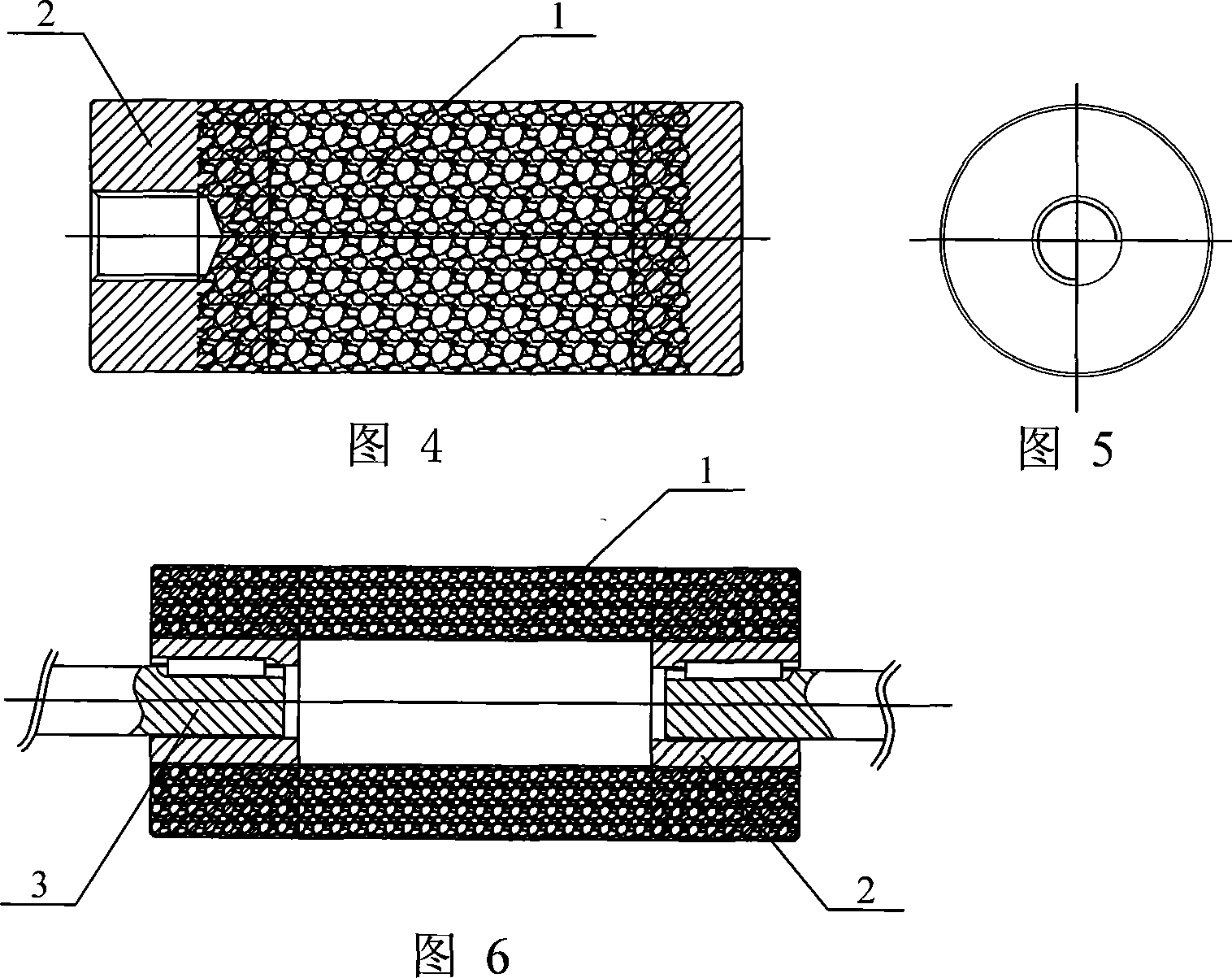

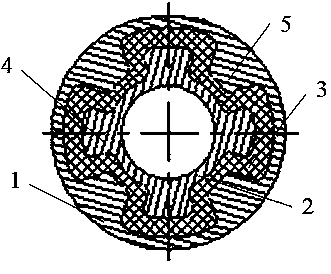

Built-in metal rubber composite vibration reducing material and forming method thereof

InactiveCN101067428AIncrease dampingAvoid dependenceRubber-like material springsLow internal friction springsRubber materialRough surface

The embedded metal rubber compound damping material and the forming method relate to the metal compound damping material. It solves the problem of the no continuous material room, rough surface, no ideal part character, not bear collecting load, not proper for the tension, the shear and the torsion. The connecting part of the metal rubber material is embedded into the continuous material which is fixed with the rubber material. The forming method is: one, preparing the metal rubber material; two, the formed metal rubber material is embedded into the die; three, pouring the liquid metal or the resin into the die. After the liquid metal or the resin solidifying, it is separated from the die and gets the metal rubber compound damping material. The compound material avoids the reliability to the holding structure and decreases the process and cost which has the good damping ability under the out bearing.

Owner:郑钢铁 +4

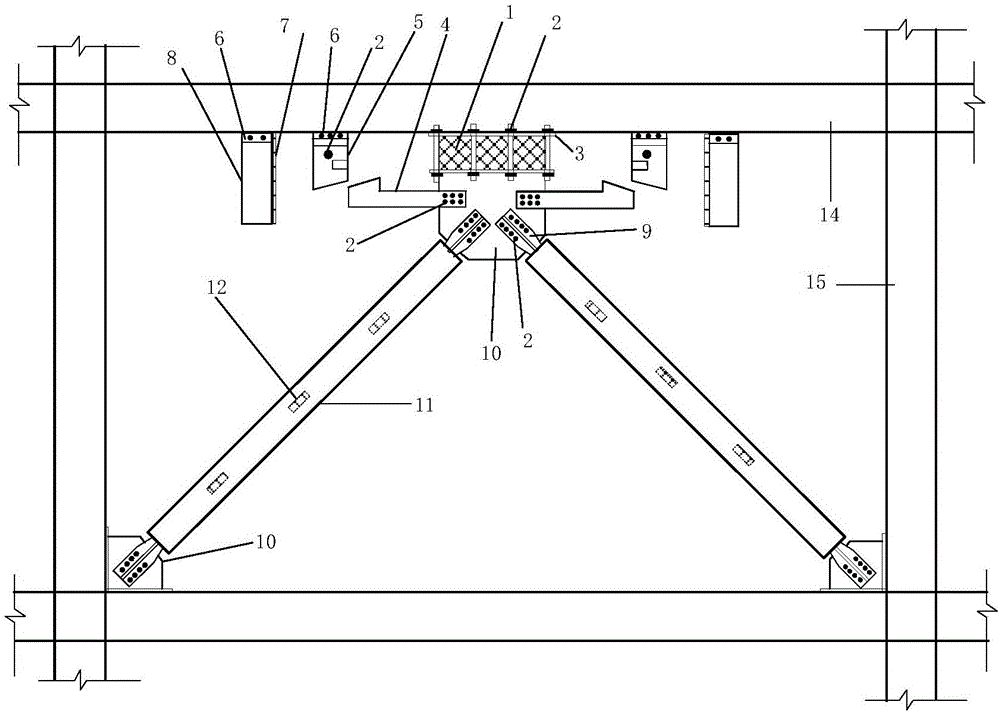

Metal rubber damper and anti-buckling support combined energy dissipating device with limit-locking function

ActiveCN106499077AGive full play to the role of energy dissipation and shock absorptionReduce fatigue loadProtective buildings/sheltersShock proofingMetal rubberEngineering

The invention relates to a metal rubber damper and anti-buckling support combined energy dissipating device with limit-locking function; under small loads like wind load, the metal rubber damper can firstly enter a non-linear state and carry out elastoplasticity energy dissipation because the vibromotive force is low; when the structure bears large earthquake effect, the metal rubber damper will have large deformation; in order to prevent fast damages, when the deformation exceeds a set threshold, the damper will be locked by a locking device and limiting device, and is effectively constrained, thus only having small deformations in an assigned scope; the anti-buckling support starts to perform the energy dissipating ability; metal rubber rings are placed between inner and outer sleeves of the anti-buckling energy dissipating support at intervals so as to allow the anti-buckling energy dissipating support have fixed point yield under the large earthquake effect, thus solving the problems that a normal anti-buckling energy dissipating support cannot determine the yield positions, and a constrain unit needs mortar perfusion, thus enlarging self-weight and wasting materials, the processing process is complex, the support end can be easily damaged, and the yield force is high.

Owner:北京宝和源装备科技发展有限公司

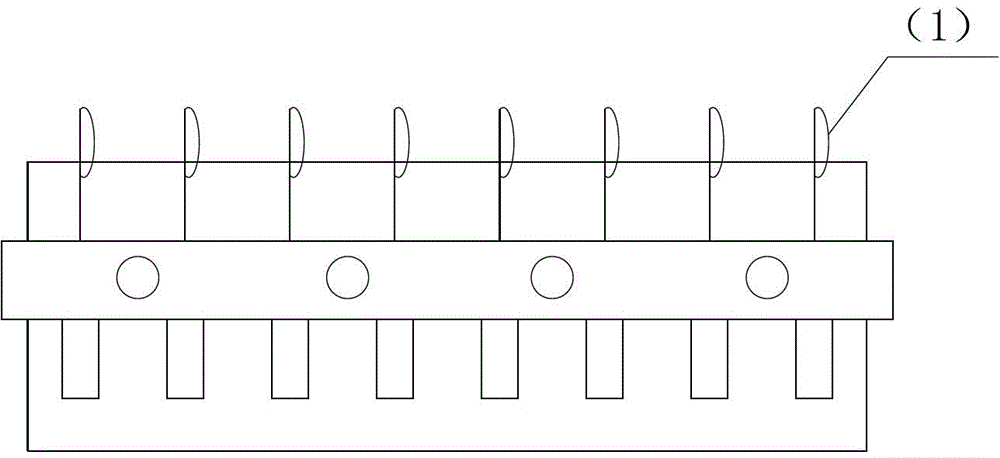

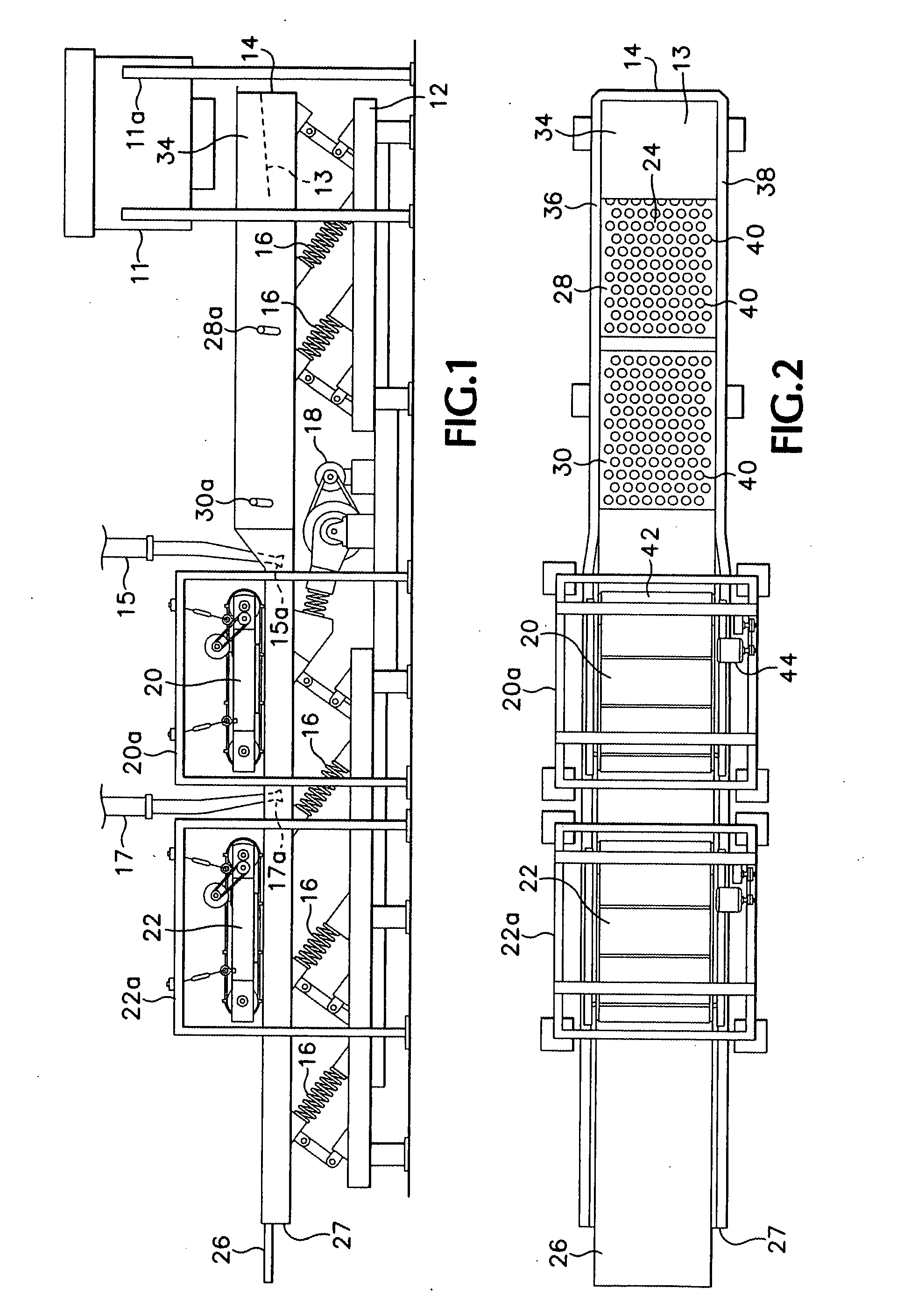

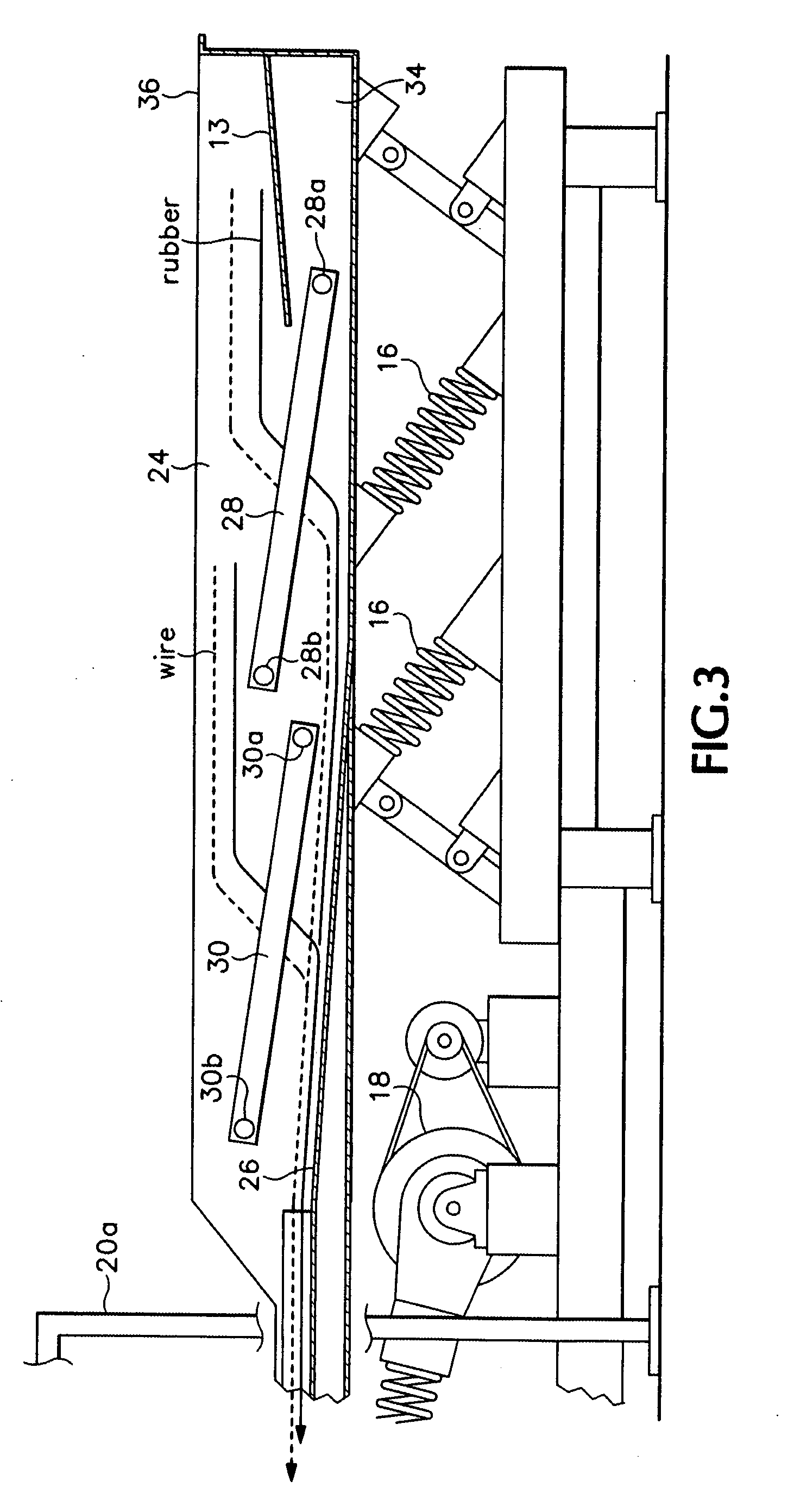

Metal rubber work blank laying device

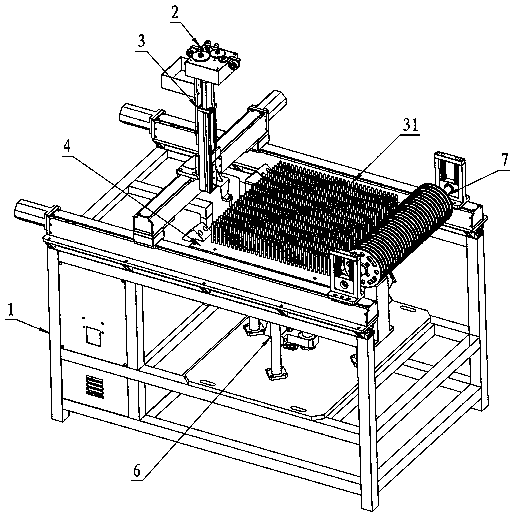

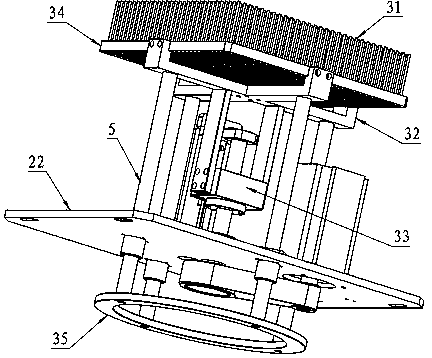

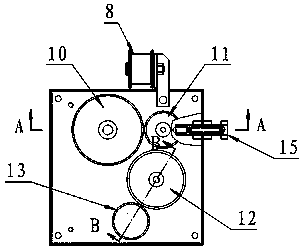

InactiveCN103962479AReduce labor intensitySolve stock forming problemsWire articlesAutomatic controlMetal rubber

A metal rubber work blank laying device comprises a machine frame, a laying mechanism, a laying board and a sizing board, wherein the laying board is horizontally fixed to the machine frame; the sizing board is located at the lower portion of the laying board; a plurality of vertical sizing pins are fixed to the upper surface of the sizing board and penetrate through corresponding through holes in the laying board; the laying mechanism comprises an X-direction linear module, a Y-direction linear module, a Z-direction linear module, a wire guide casing pipe and a connection board; the X-direction linear module is fixed to the machine frame; one end of the Y-direction linear module is fixed to a slide block of the X-direction linear module; the Z-direction linear module is fixed to a slide block of the Y-direction linear module; metal wire spiral coils for manufacturing a metal rubber work blank are wound around the sizing pins through the wire guide casing pipe fixed to a slide block of the Z-direction linear module. Full-automatic control over three-dimensional laying forming of the metal rubber work blank is achieved, the size consistency and performance consistency of products are ensured, the production efficiency is effectively improved, and labor intensity of workers is relieved.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

Scrap-leakage-proof metal-rubber damper suitable for in-orbit application of spacecraft

ActiveCN104061278AAchieve airtightAvoid pollutionNon-rotating vibration suppressionShock absorbersMetal rubberEngineering

The invention discloses a scrap-leakage-proof metal-rubber damper suitable for in-orbit application of a spacecraft. The metal-rubber damper comprises a metal-rubber pressure plate, a shell, a mandrel, a corrugated tube, a corrugated tube flange, a screw and metal-rubber elements. Vibration energy input by a structure is dissipated through friction among metal wires which are engaged and hooked inside a metal-rubber material, so that the aims of damping and reducing vibration are fulfilled. According to the damper, the metal-rubber pressure plate is in threaded connection with the shell, and preloads are applied to the metal-rubber elements on the upper side and the lower side of the horizontal mandrel to keep the metal-rubber elements in compressed states, so that the stability of the damping performance is ensured. The damper has the advantages of simple structure, convenience in installation, suitability for spatial extreme environmental conditions, and the like.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

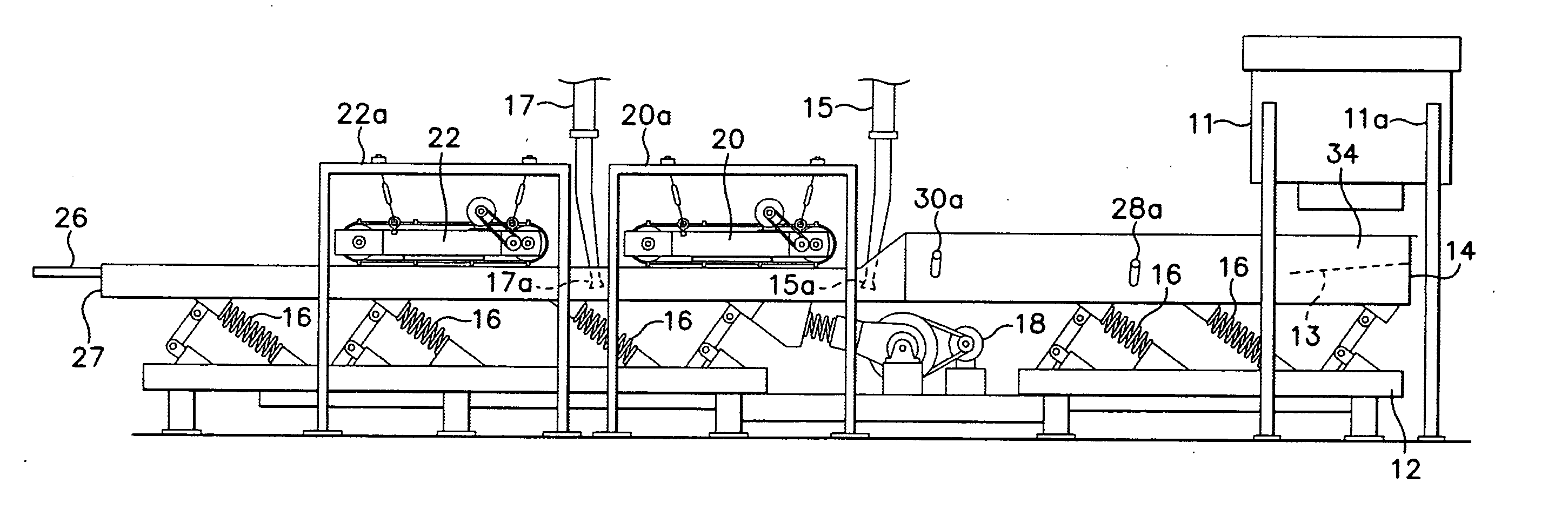

Free wire reclaimer with improved magnetic separation

ActiveUS20060070922A1Reduce cakingEfficient separationGas current separationPlastic recyclingMagnetic separatorReclaimer

A magnetic separation apparatus for separating metallic material from a granulated stream of mixed metallic and nonmetallic material comprises a vibratory conveyor having a trough assembly mounted on a suspension system and coupled to a motor for causing the suspension system to vibrate. The trough assembly includes an upper trough having at least two sections aligned in a predetermined direction of material flow and a lower trough extending in the same direction as and beneath the upper. The upper trough includes one or more gaps of a predetermined width so as to permit material to fall onto the lower trough. Each trough is arranged so as to feed a different output collection point. At least one of the gaps between a downstream section of the upper trough and an upstream section of the upper trough includes the downstream section positioned at a height lower than the upstream section thereby forming a vertical drop between the two sections with the gap positioned therebetween. For each gap, an adjustable gate may be used for adjusting the width of the gap. A magnetic separator may be arranged above the gap in the upper trough so as to pick up free metal. Rubber granules fall through the gap and are deposited in a receptacle, while metal is deposited on the upper trough which feeds a separate receptacle. A declumping zone comprising at least one perforated deck may be situated in-line with the upper and lower troughs.

Owner:ACTION EQUIP CO INC

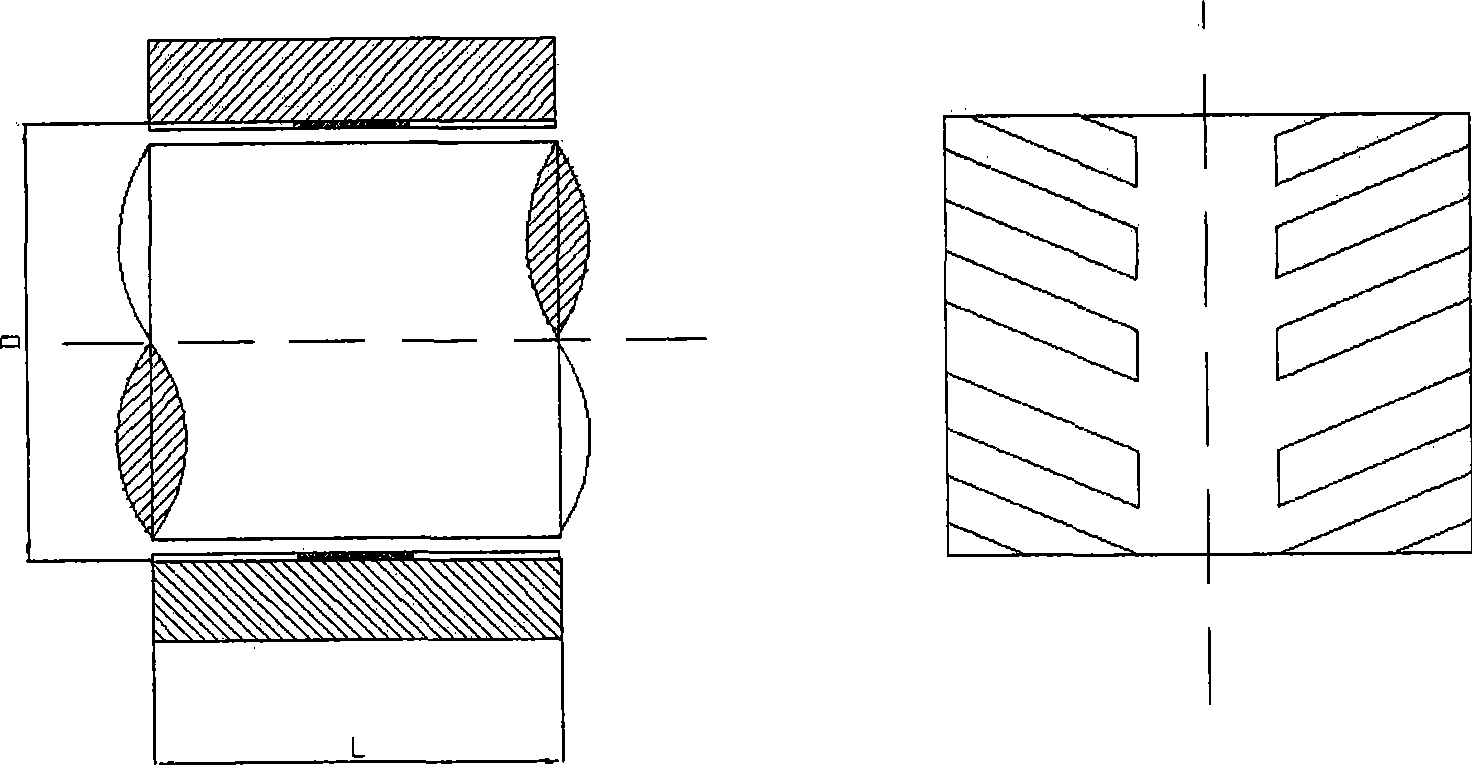

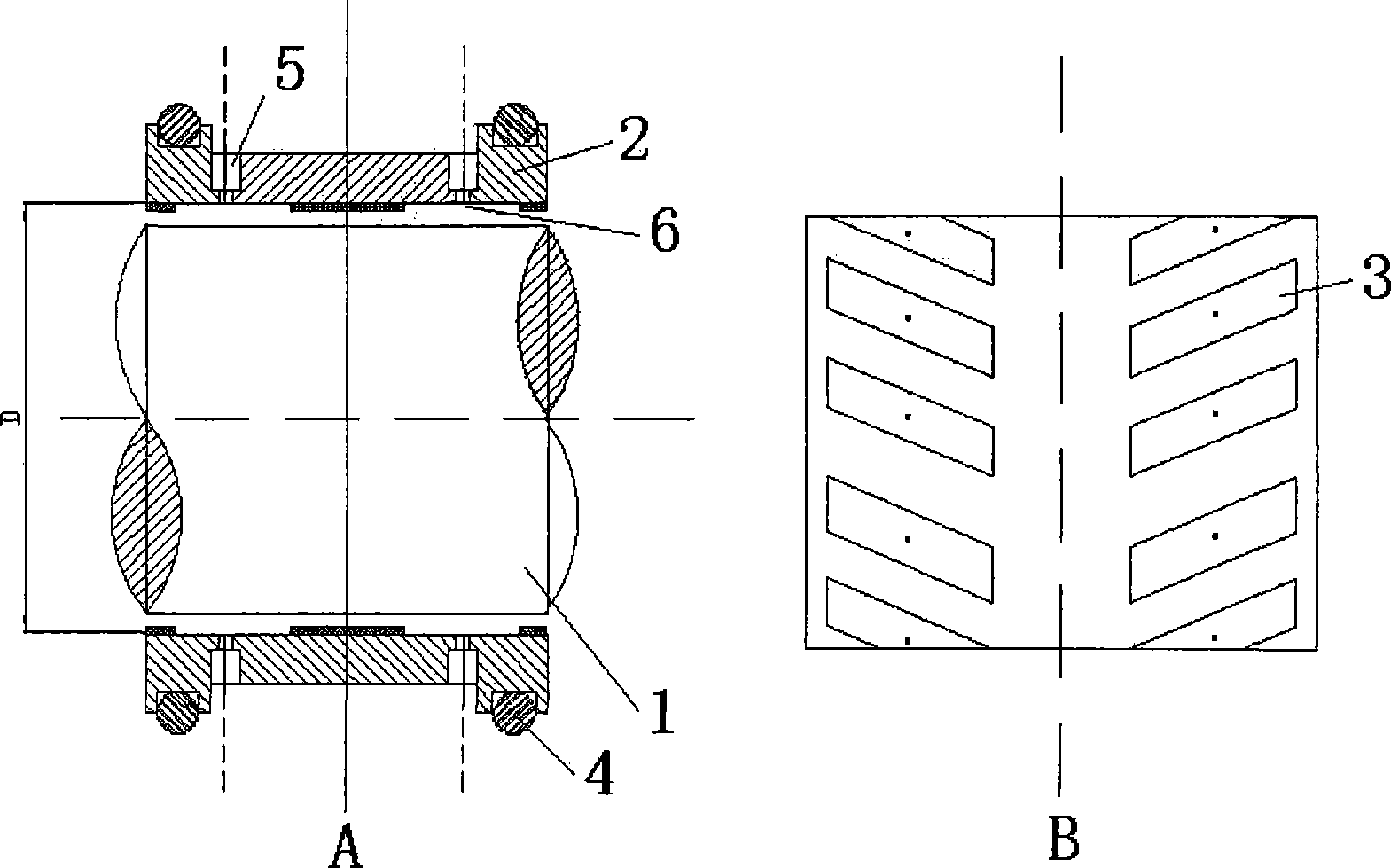

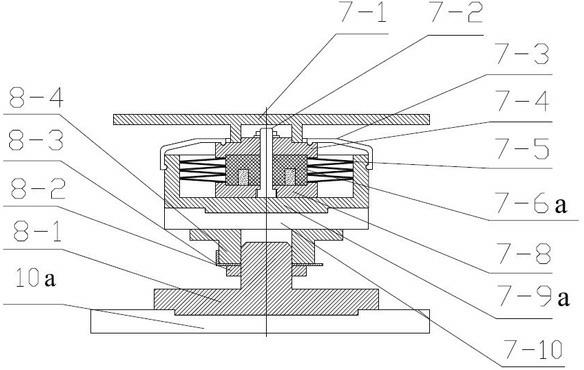

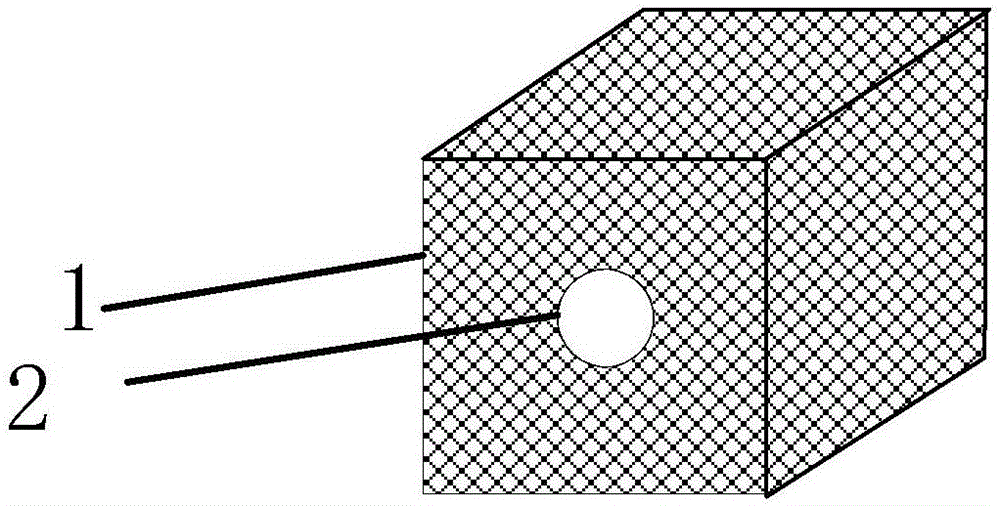

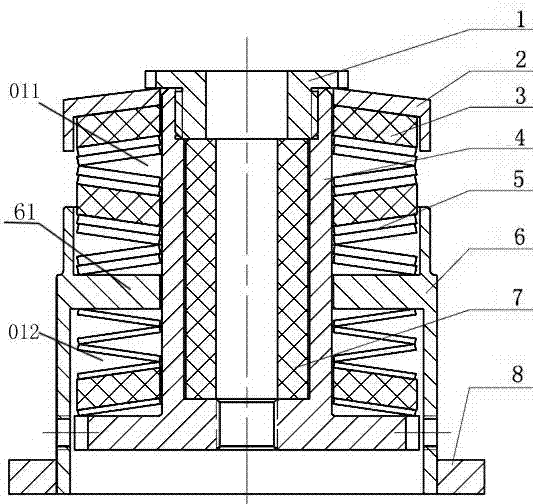

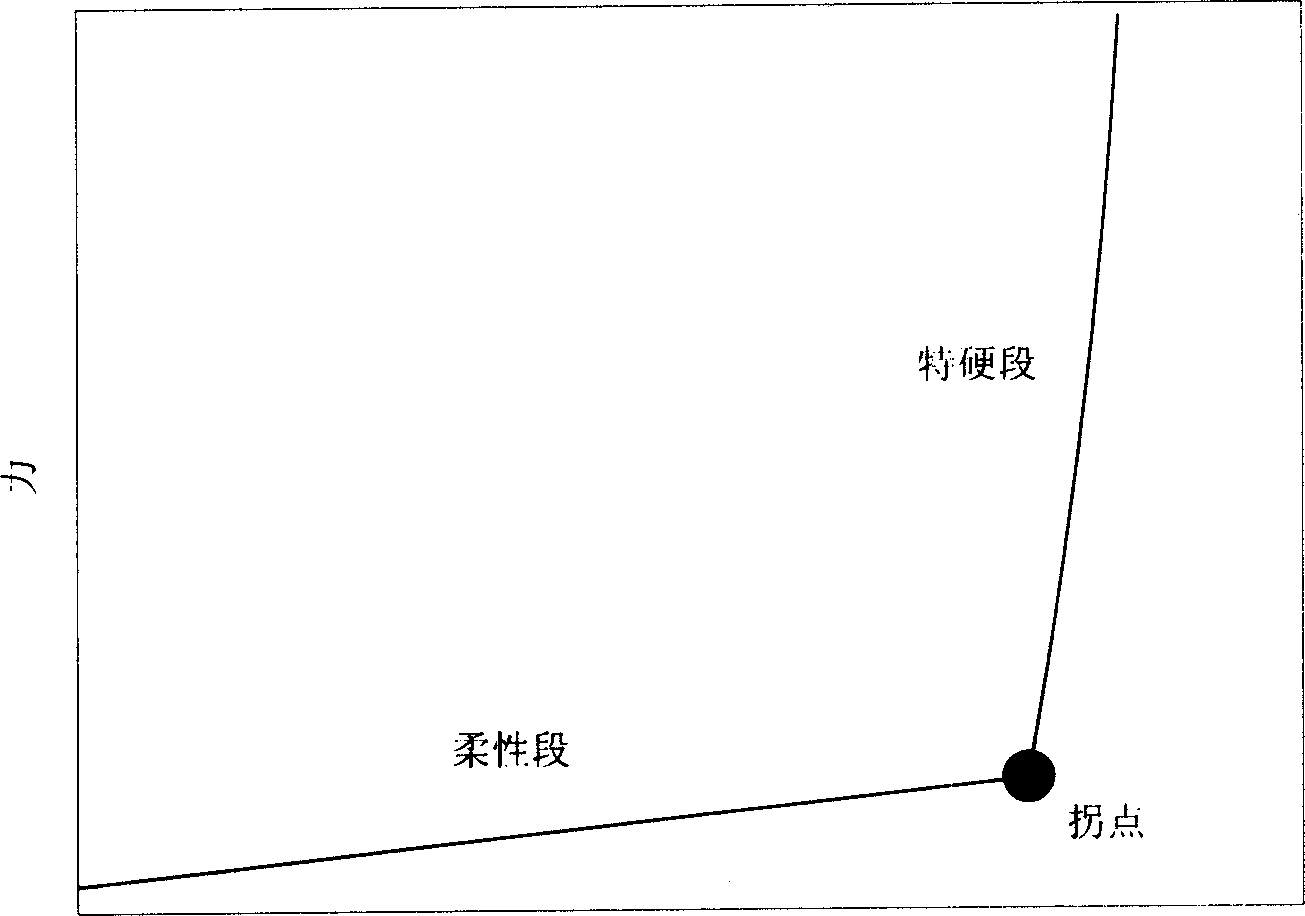

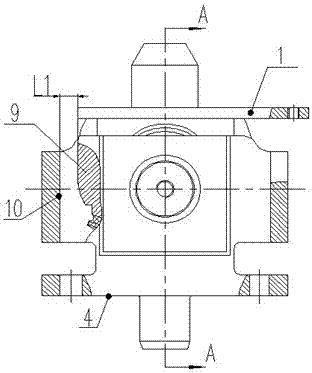

Metal rubber-disc spring all-metal three-way composite support for piping vibration isolation and impact resistance

ActiveCN103711990AIncrease dampingDifferent dampingPipe supportsNon-rotating vibration suppressionVertical vibrationMetal rubber

The invention provides a metal rubber-disc spring all-metal three-way composite support for piping vibration isolation and impact resistance. The metal rubber-disc spring all-metal three-way composite support comprises metal rubber mats and disc springs, a center net, a locking nut, a pressure cover, a guide holder, a mounting base and a base plate, wherein the metal rubber mats and the disc springs are used for bearing vertical vibration and impact load, the center net is used for bearing horizontal vibration and impact load, the locking nut, the pressure cover, the guide holder, the mounting base and the base plate are used for supporting and fixing an elastic component. By the aid of large bearing capacity and flexible rigidity characteristic, Coulomb damping among the disc springs, and the Coulomb damping between hard rigidity characteristic of the metal rubber mats and the disc springs, the flexible and hard rigidity complex characteristics and larger damping on the vertical bearing direction can be realized. The metal rubber-disc spring all-metal three-way composite support is compact in structure, light in weight, high in high-temperature environment adaptability, good in damping capacity, and lower in vibration isolation frequency, and vertical rigidity has higher static rigidity and lower dynamic rigidity; besides, considerations are also given to shock isolation and a limiting function, so that three-way impact acceleration responses and impact displacement responses can be kept within a reasonable range.

Owner:SHANGHAI JIAO TONG UNIV

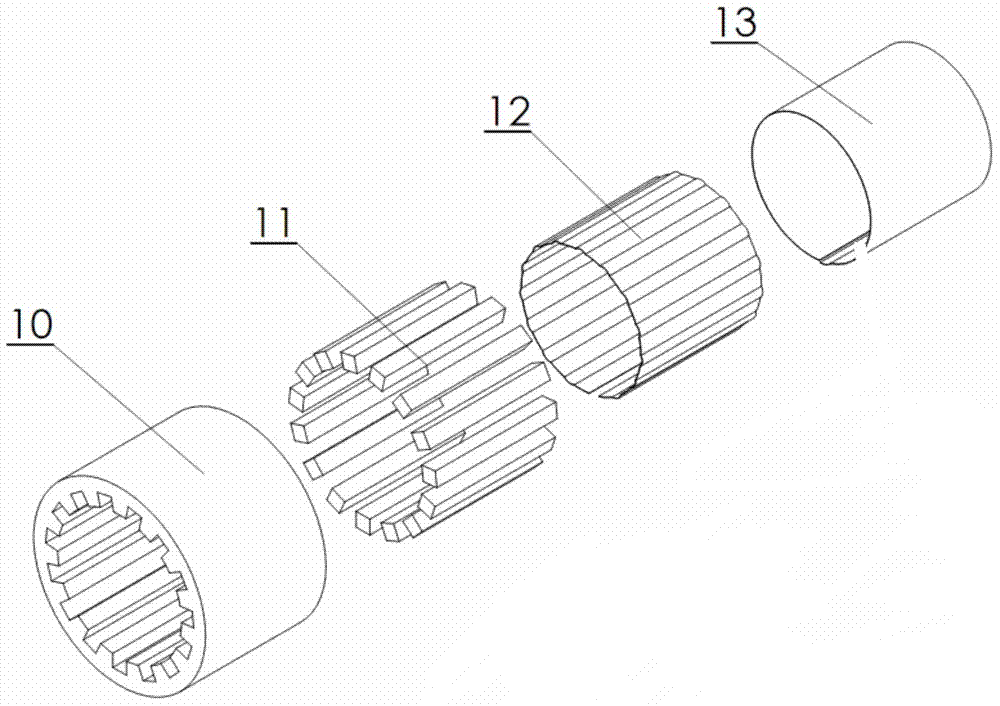

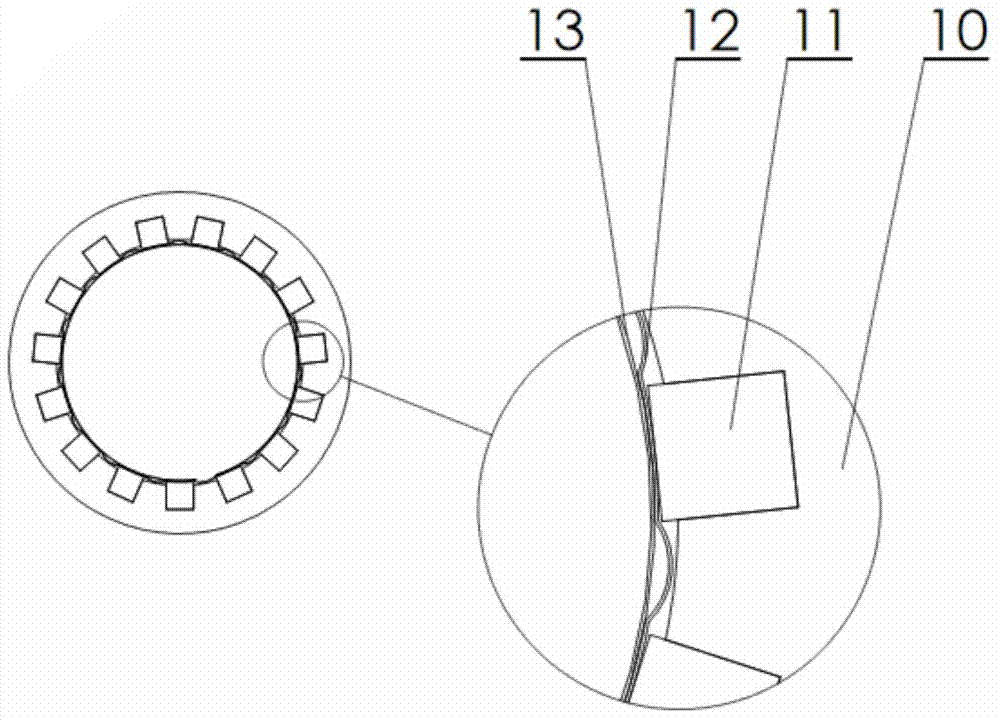

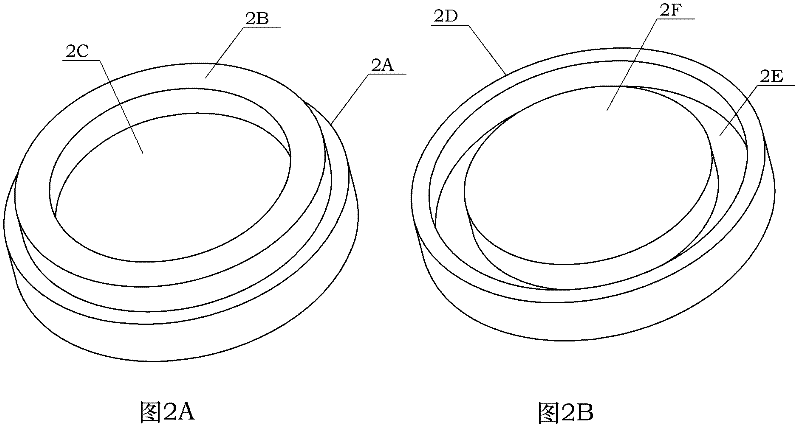

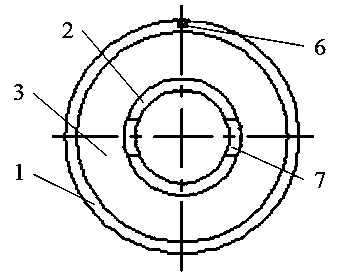

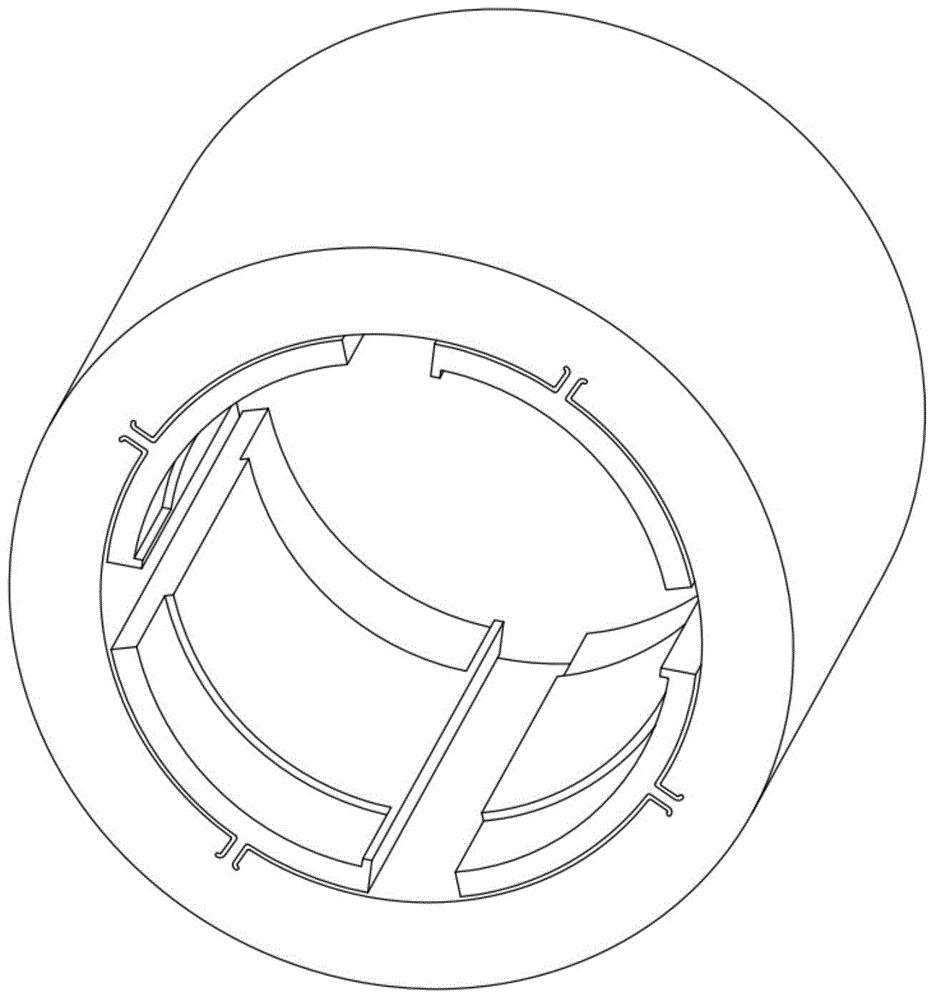

Splined metal-rubber composite spherical hinge and manufacturing and assembling method thereof

ActiveCN103438135AMeet different requirementsTuning to change torsional stiffnessRubber-like material springsMetal rubberTorsional load

The invention discloses a splined metal-rubber composite spherical hinge which comprises three layers, including a metal outer casing, a metal inner casing and an elastic rubber, wherein the internal surface of the metal outer casing and the external surface of the metal inner casing are respectively provided with splined sawteeth in the axial direction according to performance demands; the sawteeth on the metal outer casing and the metal inner casing mesh with each other and are vulcanized with the elastic rubber to form an integral body; and the shape, size and quantity of the sawteeth can be regulated according to the demands of the product performance. The shape, size, quantity and interval of the sawteeth between the metal outer casing and the metal inner casing can be regulated according to the demands of product performance to satisfy different performance requirements of different application occasions; and the interval of the sawteeth between the outer casing and the metal inner casing can be regulated to change the clockwise and counterclockwise torsional rigidity of the product so as to satisfy different rigidity requirements. The invention has the capacity for buffering instantaneous shock load and torsional load of mechanical vibrations.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Combined support device of magnetic bearing rotor system

The invention discloses a combined support device of a magnetic bearing rotor system. The combined support device comprises a base, a rotor assembly and a magnetic bearing assembly, wherein the rotor assembly is supported by the magnetic bearing assembly, the magnetic bearing assembly is supported by a squirrel-cage type elastic support device, the squirrel-cage type elastic support device is supported by the base, and a metal rubber ring is arranged between the squirrel-cage type elastic support device and the base. The combined support device of the magnetic bearing rotor system, provided by the invention, is capable of effectively inhibiting the vibration of a high-speed magnetic bearing rotor system. According to the combined support device, good damping property of a metal rubber material can be effectively utilized, the rotating speed of the rotor system can be controlled so as to meet the requirement of a design criteria of critical speed of rotation of the rotor system, and a magnetic bearing is favorably popularized and applied.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Novel tilting pad radial gas bearing

The invention discloses a novel tilting pad radial gas bearing which comprises a bearing body, an elastic tilting surface supporting structure and a top foil, wherein the elastic tilting surface supporting structure consists of metal rubber blocks and an elastic foil and is arranged on the tilting surface of the bearing body; the top foil covers the metal rubber blocks and the elastic foil; the pad of the bearing body and a bearing housing are of an integral structure; the pad of the bearing body is connected with the bearing housing by virtue of a flexible beam; and grooves are formed in two ends of the pad. A wave-shaped bulge is formed on the elastic foil, and a rectangular strip-shaped foil is reserved in one end of the bulge; the elastic foil is arranged in the middle of the pad of the bearing body; one end of the reserved rectangular strip-shaped foil is fixed on the tilting surface, and the other end of the reserved rectangular strip-shaped foil is freely arranged; and the metal rubber blocks are arranged in the grooves in two ends of the pad. The tilting pad radial gas bearing provided by the invention has the characteristics of high bearing capacity, high rigidity, high damping property and high stability.

Owner:HUNAN UNIV

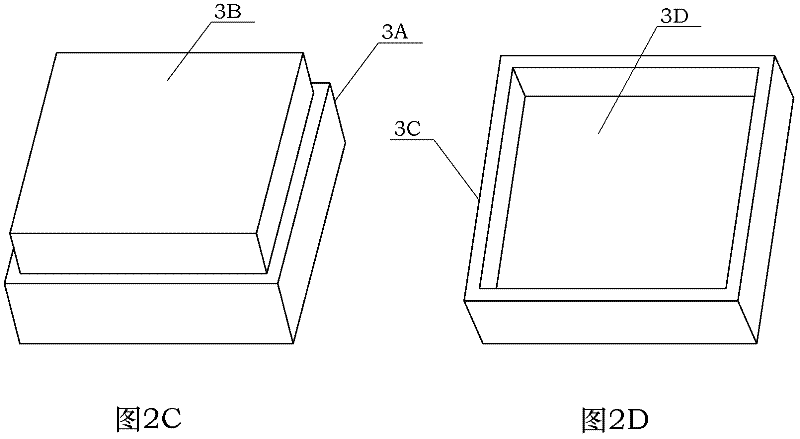

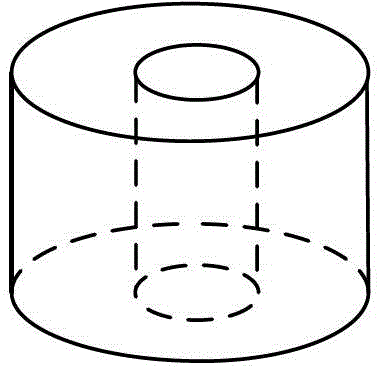

Multifunction metal rubber flexible connecting piece

InactiveCN1888464AImprove flexibilityExcellent nonlinear stiffness characteristicsSpringsMetal rubberArchitectural engineering

There is disclosed a multi-functional metal-rubber flexible connecting piece, which has a cylindrical restrained casing with a flexible pad and a hold-down ring inside. A connecting-rod passes longitudinally through the centre of the hold-down ring and is jointed firmly with the hold-down ring. One end of the connecting-rod extends from one end of the restrained casing and the other end of the restrained casing is fixed on the base.

Owner:郑钢铁 +4

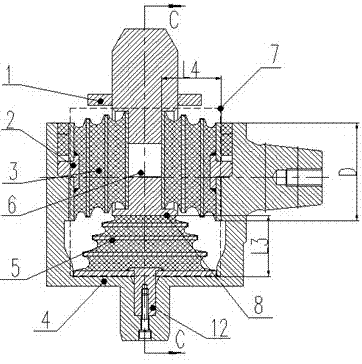

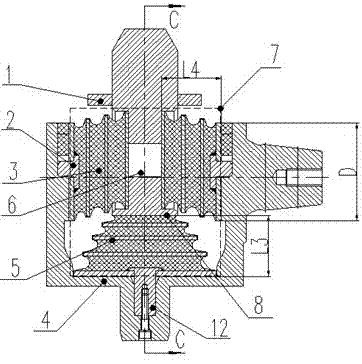

Mouse cage elastic support metal rubber damper

ActiveCN109058380AGuaranteed stabilityAffect safe operationVibration suppression adjustmentsMetal rubberStructural engineering

The invention discloses a mouse cage elastic support metal rubber damper. The mouse cage elastic support metal rubber damper comprises an elastic support module; the elastic support module comprises abracket, a rotating shaft inserted in the bracket, a bearing sleeving the rotating shaft, and a mouse cage elastic support for supporting the rotating shaft and the bearing; the mouse cage elastic support comprises an elastic support mounting edge fixedly connected with the bracket, an elastic strip arranged on the side of the elastic support mounting edge, and an elastic support bearing base arranged at the end of the elastic strip for mounting the bearing; an end cover is arranged at the end of the bracket; a cavity structure module and metal rubber for providing support damping to a rotorsystem are arranged around the elastic support bearing base; the cavity structure module, the inner end surface of the end cover, the inner wall surface of the bracket and the outer wall surface of the elastic support bearing base form a closed cavity; and the metal rubber is arranged in the closed cavity. In the mouse cage elastic support metal rubber damper, the main support damping is providedto the rotor system through the metal rubber, so that the stable linear support rigidity in the wider extrusion deformation range is guaranteed.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Damping component, crystal oscillation device, frequency synthesizer and electronic device

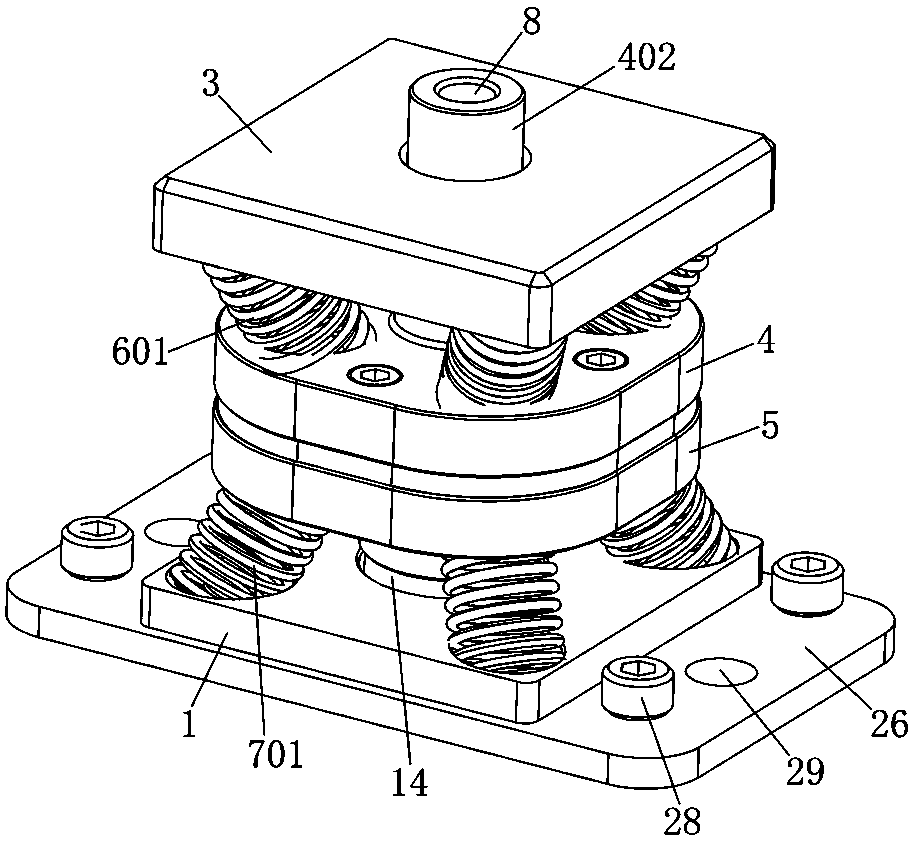

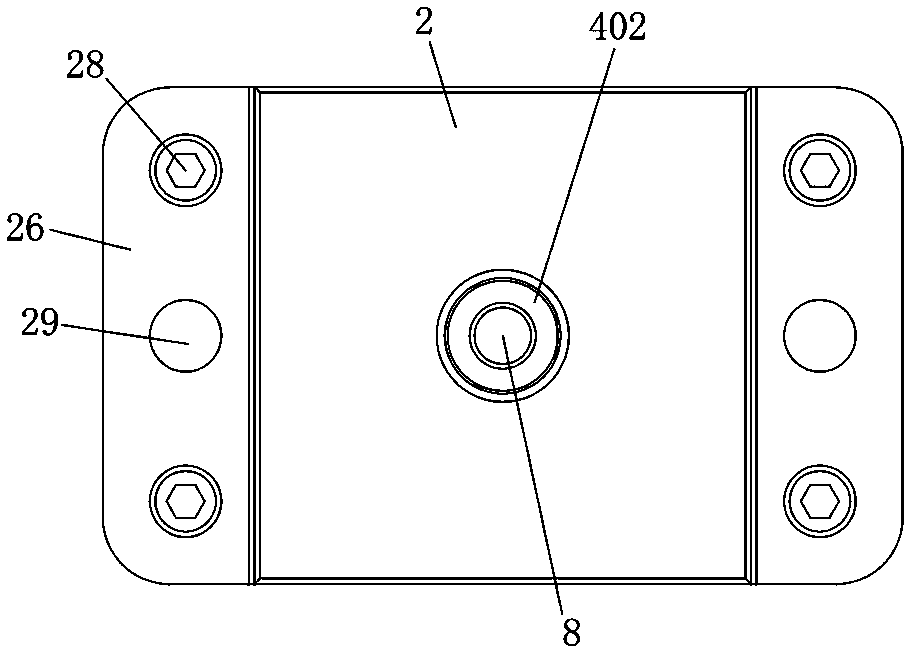

ActiveCN104632992AAdjustable stiffnessAdjustable dampingNon-rotating vibration suppressionMetal rubberFrequency synthesizer

The invention relates to a metal rubber crystal oscillator damping device. A crystal oscillator is mounted on a bracket; four connecting screw rods with adjustable rigidity and damping are connected with a bottom plate at four corners of the bracket; each connecting screw rod with the adjustable rigidity and damping consists of an adjusting guide pillar, cylindrical metal rubber, a rigid sleeve and a locking sheet, wherein the adjusting guide pillar penetrates through the cylindrical metal rubber, the rigid sleeve and the bracket and is in threaded connection with the locking sheet; a groove is formed in the middle of the bracket; the crystal oscillator is placed in the groove; bosses are arranged on the four corners and are fixedly connected with the rigid sleeves; the cylindrical metal rubber parts are embedded into the rigid sleeves. The device has the advantages that the structure is simple and portable, the installation is convenient, the rigidity and the damping are adjustable, three-dimensional vibration damping performance is excellent, the endurance performance is good, the high temperature resistance, the low temperature resistance and the corrosion resistance are realized, the aging cannot be easily caused, and the like; the practicability is stronger, and the application prospects are wide.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

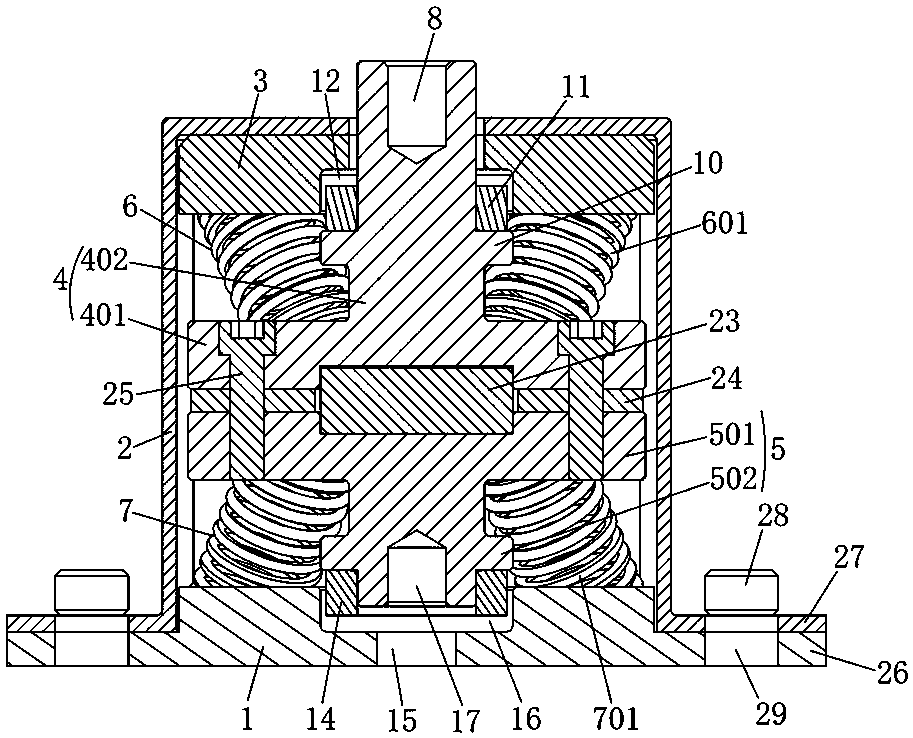

Adjustable double-layer metal rubber damping vibration absorber and working method thereof

ActiveCN109372943AGood high and low temperature resistanceAccelerated corrosionNon-rotating vibration suppressionMetal rubberEngineering

The invention relates to an adjustable double-layer metal rubber damping vibration absorber and working method thereof. The vibration absorber comprises a base seat and an outer shell fixedly connected to the base seat, wherein an end cover, an upper fixing support and a lower fixing support are sequentially arranged between the inner top surface of the outer shell and the base seat from top to bottom. An upper spring assembly is connected between the end cover and the upper fixing support, metal rubber damping elements are arranged between the upper fixing support and the lower fixing support, and a lower spring assembly is connected between the lower fixing support and the base seat. According to the adjustable double-layer metal rubber damping vibration absorber and working method thereof, the vibration absorber is reasonable in structure, the composite structure of the metal rubber and the springs is adopted, the rigidity of the vibration absorber is adjusted mainly through the springs, and the metal rubber damping element not only increases the damping of the vibration absorber, but also can be applied to various working conditions. Through the combination of the metal rubberand the springs, the overall rigidity and the damping of the vibration absorber can be adjusted to the most appropriate performance parameter interval in practical application, the comprehensive performance of the vibration absorber is improved, and a good vibration reduction effect is achieved.

Owner:FUZHOU UNIV

Method of preparing compound sealing component used for internal combustion engine

InactiveCN101190558AImprove performance qualityHigh strengthDomestic articlesMetal rubberExternal combustion engine

The invention provides a production method of a composite sealing element used for an internal combustion engine. A frame is firstly produced by metal and / or engineering plastic through the molding technology and then is arranged in a mould and a rubber sealing line is synthesized on the frame by using the molding technology, in this way, the composite sealing element with the frame being made of metal and / or engineering plastics and the composite rubber being taken as the sealing line is produced. The sealing element produced by the production method of the composite sealing element used for the internal combustion engine has good stability and endurance and has the advantages of former metal rubber composite sealing element. In addition, because of adopting the molding technology and producing the frame before compositing the sealing line, the utilization ratio of raw materials is 100 percent in theory; the resource consumption is reduced; the problems that the costs of former sealing element without asbestos and stamping and producing the metal rubber composite sealing element after a whole plate making is too high in costs, etc. are solved; and the problems of resource consumption and environmental pollution caused by using solvent in the process of producing the two sealing elements are eliminated.

Owner:舟山海山机械密封材料股份有限公司

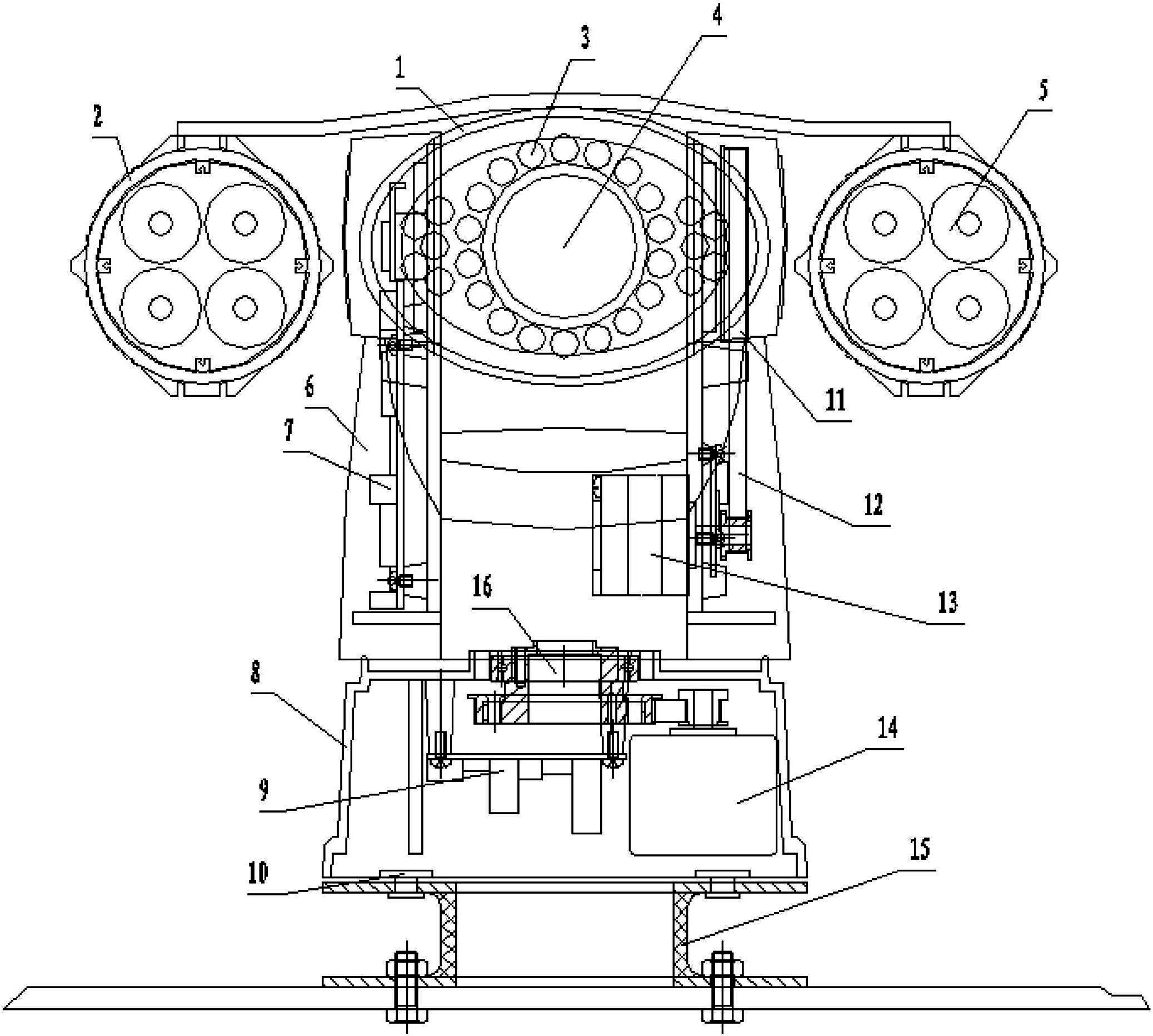

Small-size multifunctional vehicle-mounted digital high-definition camera

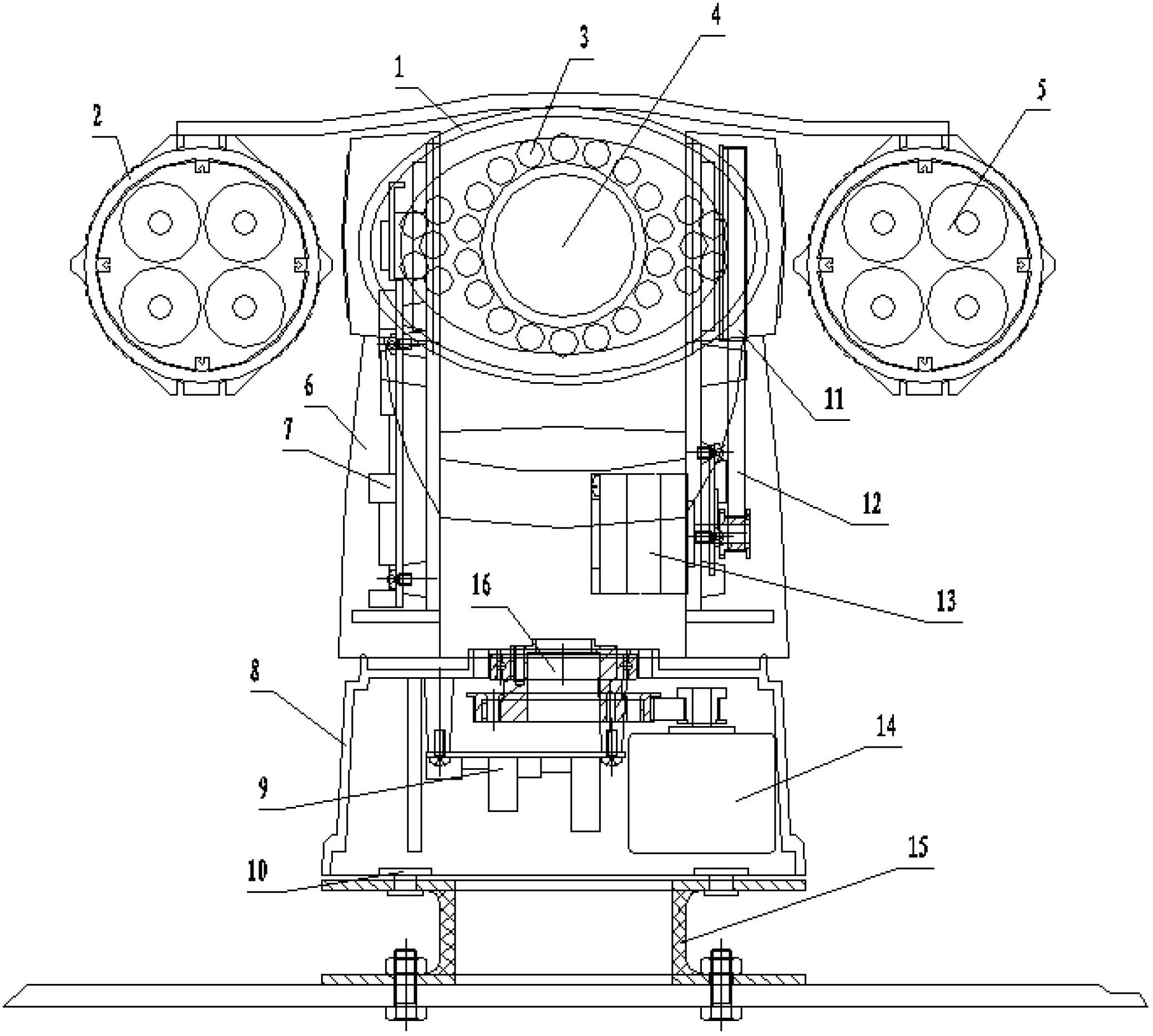

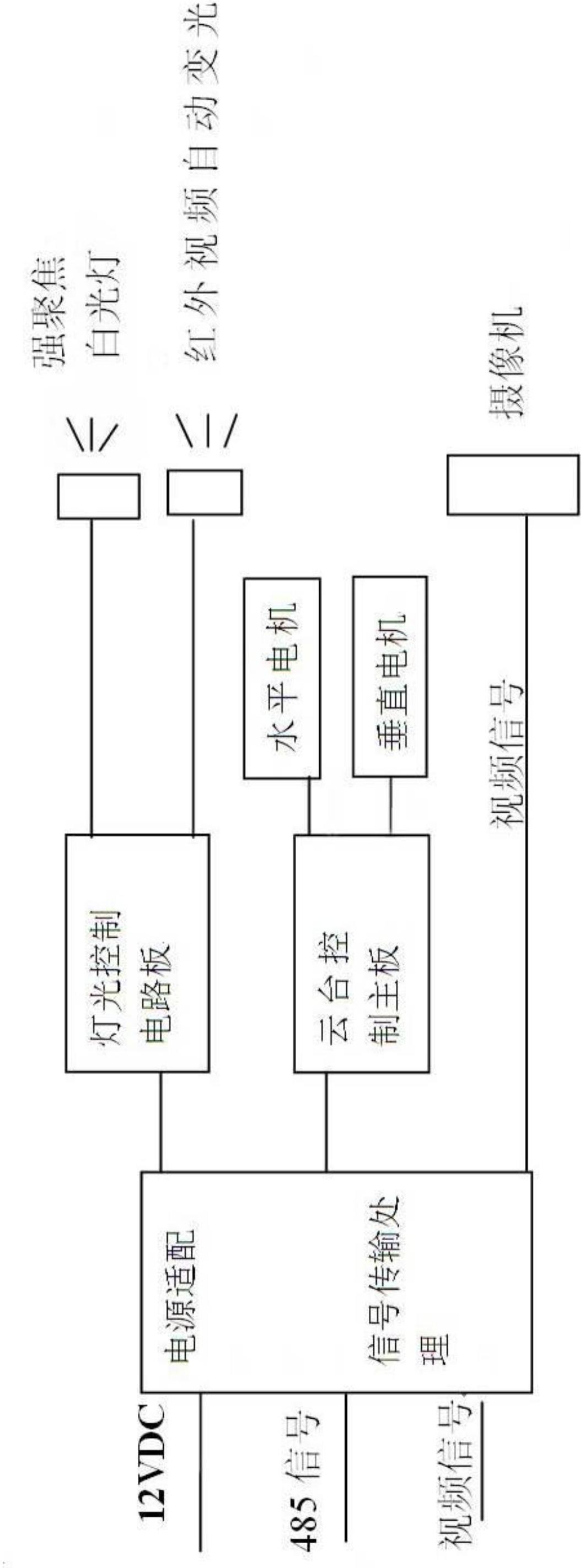

ActiveCN102692787AReduce volumeVersatileTelevision system detailsColor television detailsMetal rubberInfrared lamp

The invention provides a small-size multifunctional vehicle-mounted digital high-definition camera, which is characterized by comprising a combined infrared lamp (3), a camera (4), an accent light (5), a base (8), a vertical synchronizing wheel (11), a vertical belt (12), a vertical motor (13), a horizontal motor (14) and a conductive sliding ring (16). The lower part of the base (8) is connected with a metal rubber combined damping bracket (15) through a quick mounting structure (10). The camera (4) is a 2,000,000-pixel digital high-definition camera. According to the small-size multifunctional vehicle-mounted digital high-definition camera, a scheme of overall changing and combining on the aspects of a structure and a circuit is provided by comprehensively analyzing and researching the conventional vehicle-mounted cloud deck on the market aiming at the defects of the conventional infrared vehicle-mounted cloud deck on the market of old type, fewer functions and poor definition. The invention provides the small-size multifunctional vehicle-mounted digital high-definition camera with a novel structure and functions for the market; and the requirements of good quality, light weight, high stability, resource saving and convenience can be met.

Owner:宜兴市普天视电子有限公司

Metal rubber combined elastic vibration reducing primary spring for axle box

ActiveCN102198835AExtended service lifeGuaranteed uptimeNon-rotating vibration suppressionShock absorbersMetal rubberElastic vibration

The invention relates to a metal rubber combined elastic vibration reducing primary spring for an axle box. The spring comprises a top plate and a base, wherein a composite rubber metal spring formed by combining three metal rubber combined elastic vibration reducing pieces is sandwiched between the top plate and the base; in the three metal rubber combined elastic vibration reducing pieces of the composite rubber metal spring, two metal rubber combined elastic vibration reducing pieces are round rubber piles, and the other metal rubber combined elastic vibration reducing piece is a square rubber pile; the two round rubber piles are vertically arranged on the two sides of an iron piece on the lower part of a mandrel connected with the top plate; the square rubber pile is arranged between the bottom surface of the lower part of the mandrel and the base; and the composite structure rubber metal spring which can bear loads in Fz, Fx and Fy directions simultaneously is formed by combiningthe two round rubber piles and the square rubber pile. The three metal rubber combined elastic vibration reducing pieces are arranged at different positions, and rubber has a good function of slowingdown the disappearance of vibration, so that the spring has high vibration reducing property.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com