Metal rubber combined elastic vibration reducing primary spring for axle box

A technology of metal rubber and metal spring, which is applied in the direction of shock absorber, axle box installation, spring/shock absorber, etc. It can solve the problem that a series of springs cannot provide horizontal and vertical limit functions, adjust a wide range of stiffness, and increase parts Installation and other issues, to achieve the effect of small longitudinal stiffness, reduce longitudinal displacement, and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

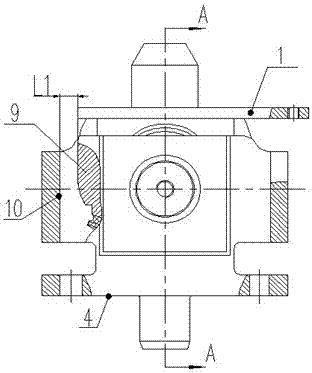

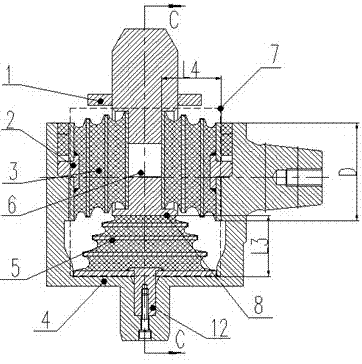

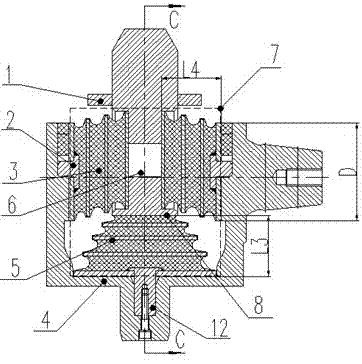

[0009] The accompanying drawings show an embodiment of the present invention, and the present invention will be further described below in conjunction with the accompanying drawings.

[0010] As can be seen from the accompanying drawings, the present invention is a series of springs with horizontal and vertical stop performances, including a top plate 1 and a base 4, and between the top plate 1 and the base 4 is a spring composed of three metal rubber joints. The composite rubber-metal spring 7 formed by the combination of the vibrating parts; the three metal-rubber elastic damping parts of the composite rubber-metal spring 7, wherein two metal-rubber elastic vibration-damping parts are rubber-metal circular stacks 3, two The rubber-metal round stack 3 is installed vertically on both sides of the iron part 6 at the lower part of the mandrel connected with the top plate 1, and the other metal rubber combined with the elastic damping part is a square rubber stack 5, and the squar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com