Patents

Literature

37results about How to "Longitudinal stiffness is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

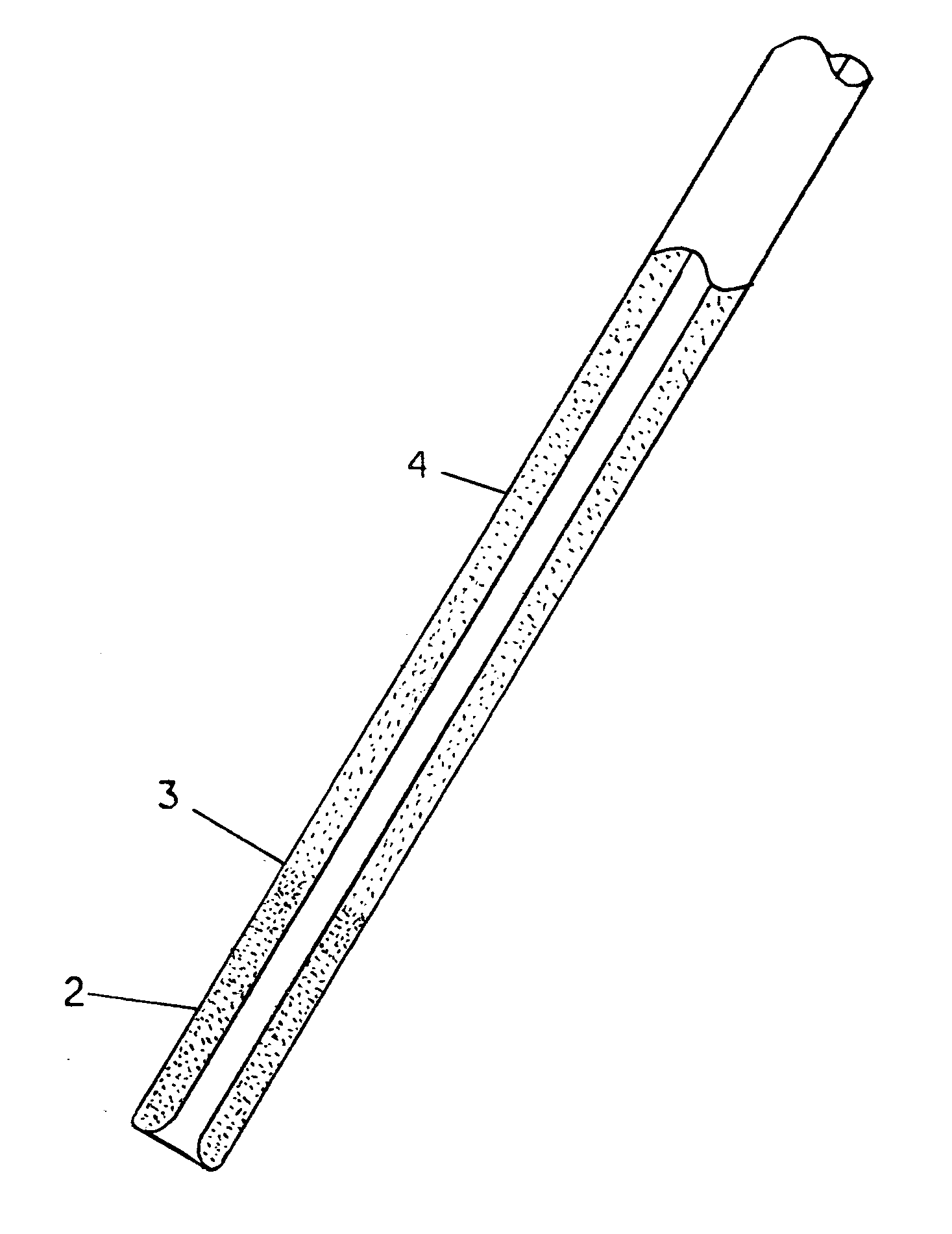

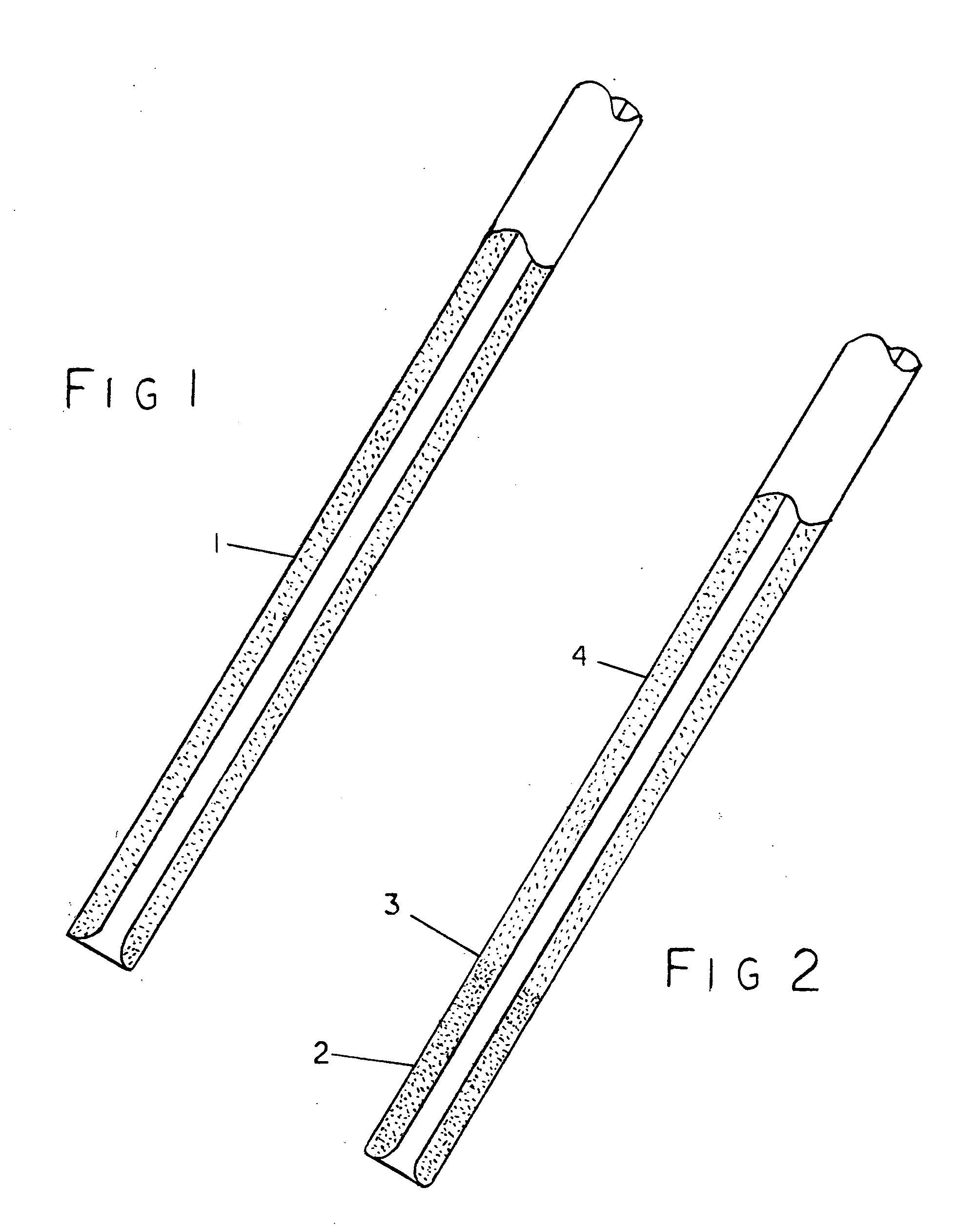

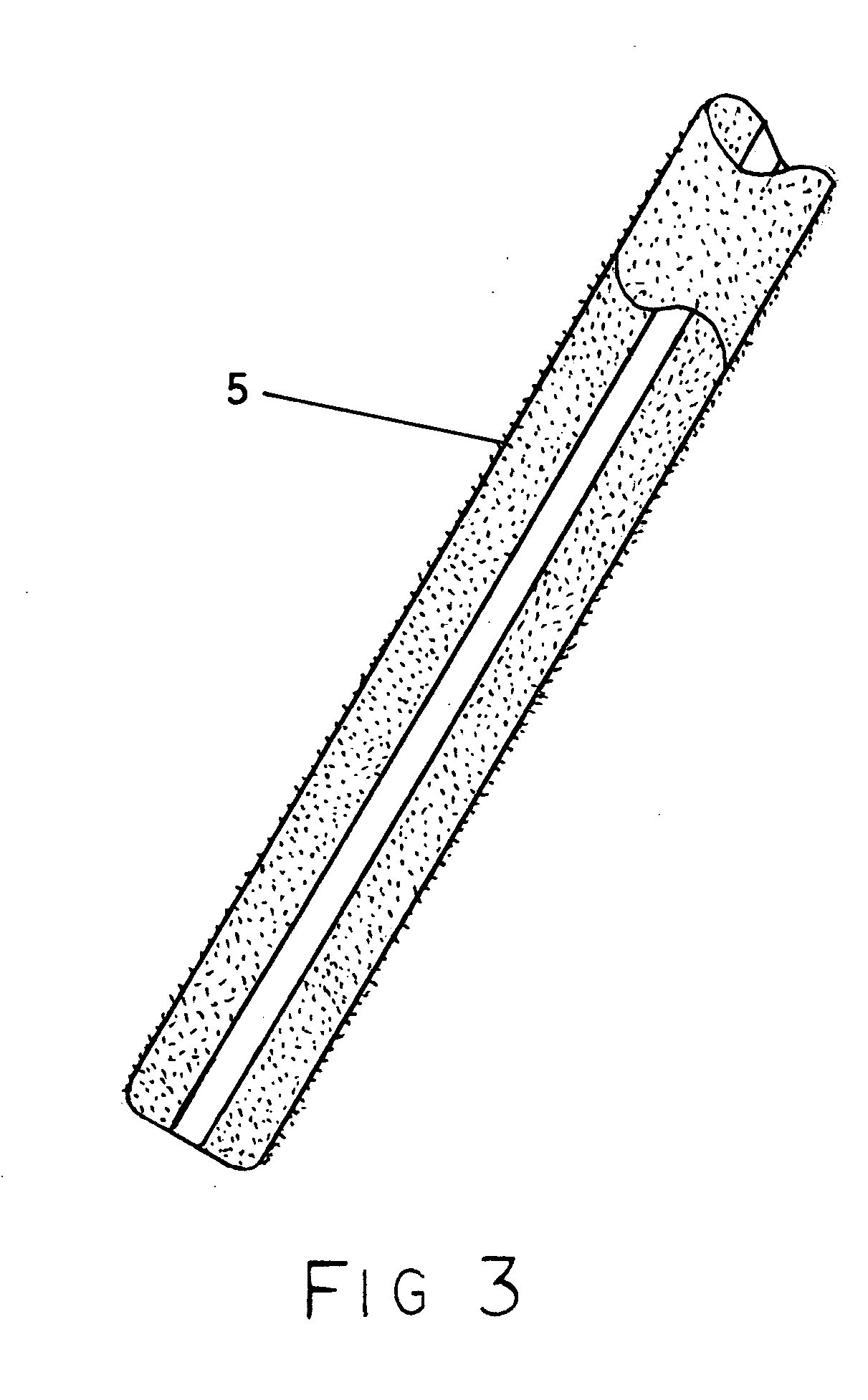

Vibrating, magnetically guidable catheter with magnetic powder commingled with resin, extruded as an integral part the catheter

InactiveUS20050245846A1Preventing accumulative adhesionLongitudinal stiffness is smallCatheterDiagnostic recording/measuringMedicineUltimate tensile strength

A catheter that is produced in which magnetic powder is commingled and becomes an integral part of the catheter, which makes it not only guidable within the body by an external device, but can be made to vibrate at various speeds (cycles per second) and at varying intensities (voltages) to not only prevent its adhesion to vascular walls, but to render plaque into a viscous state, for easy suctioning from the body.

Owner:CASEY DON EWARD

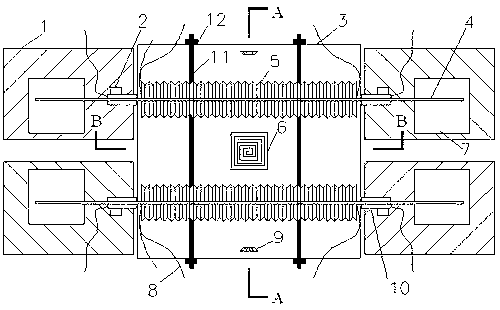

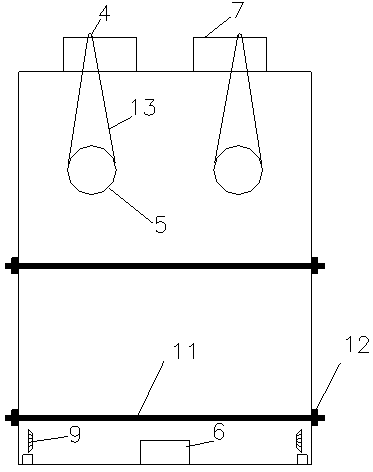

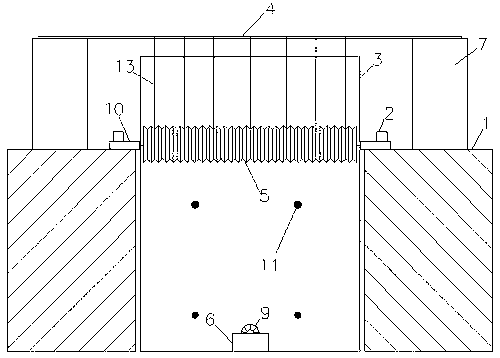

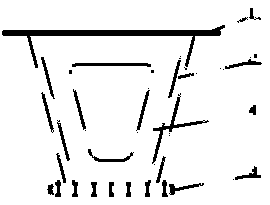

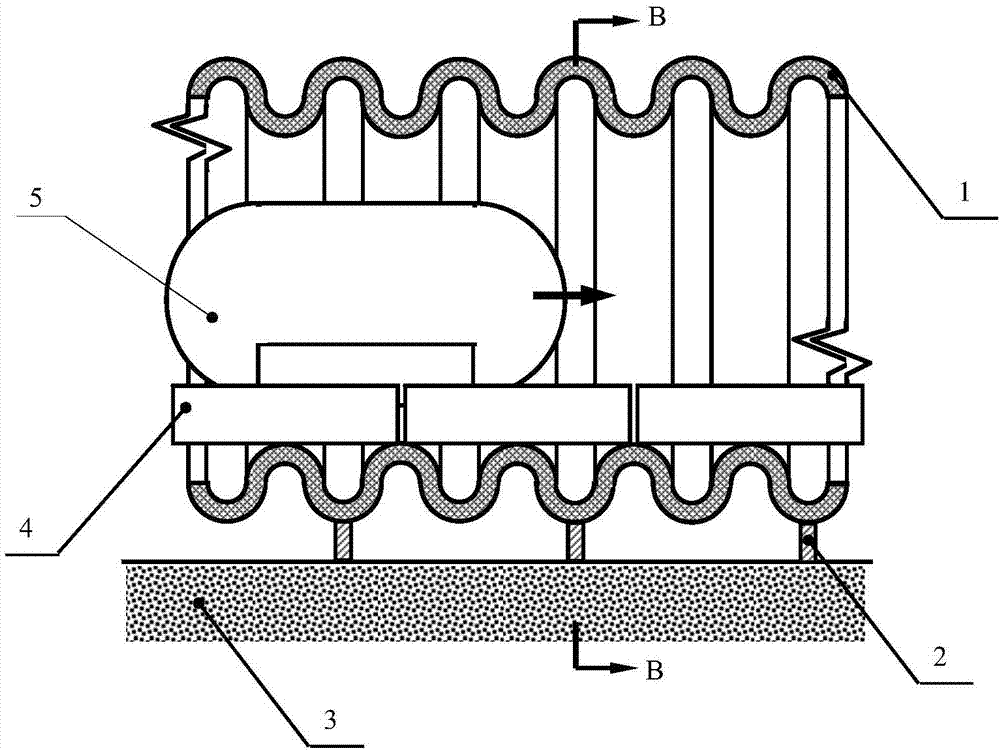

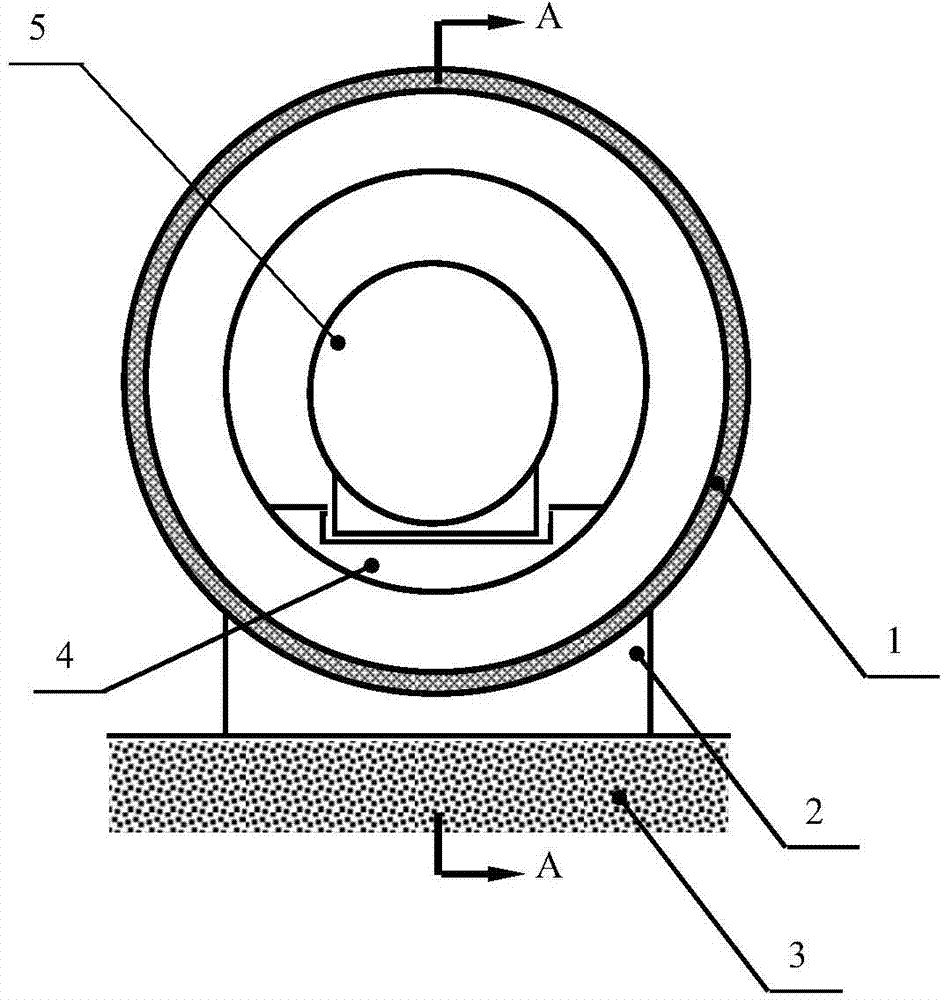

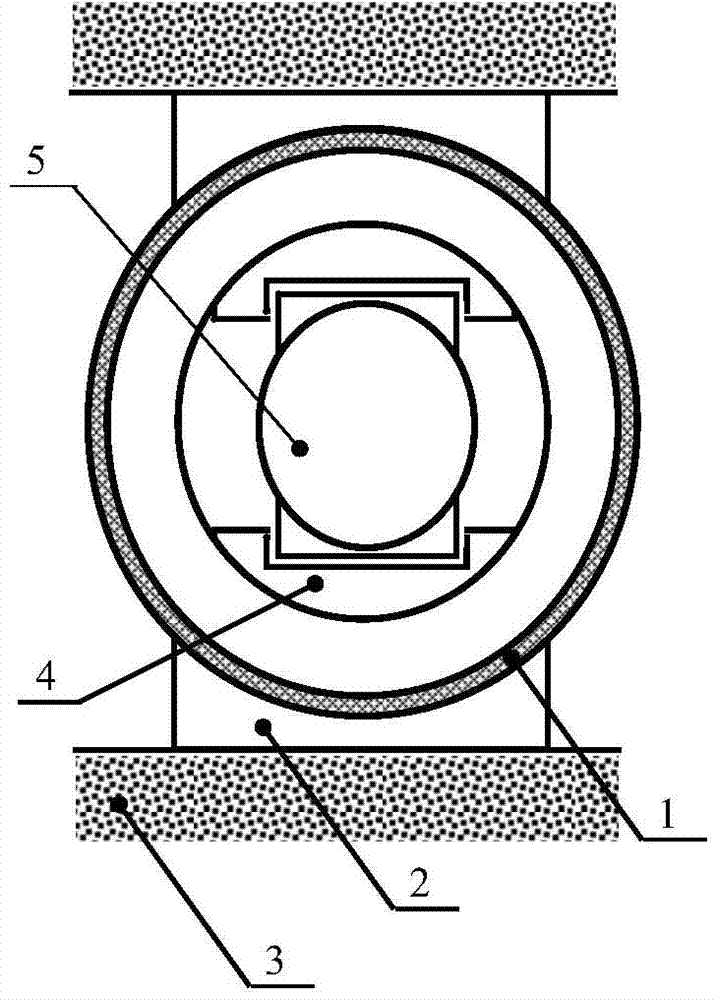

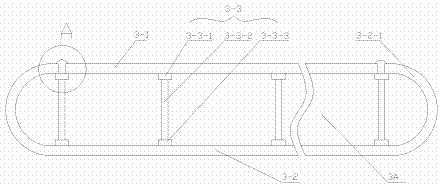

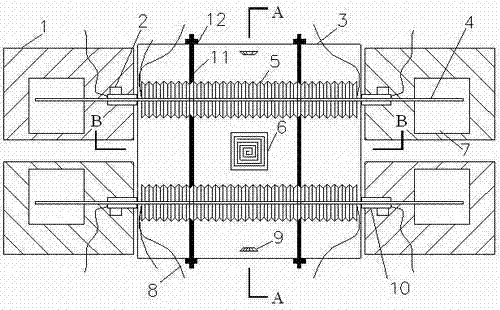

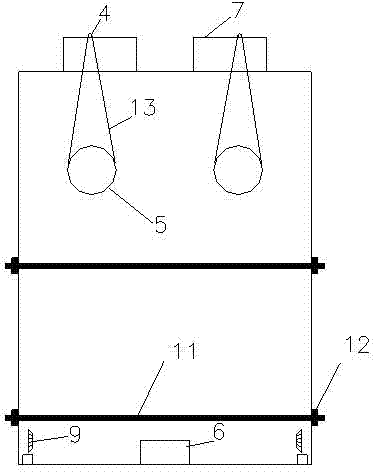

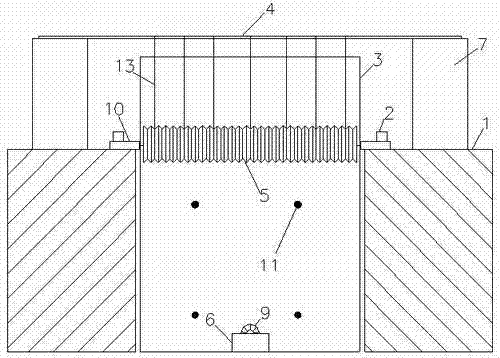

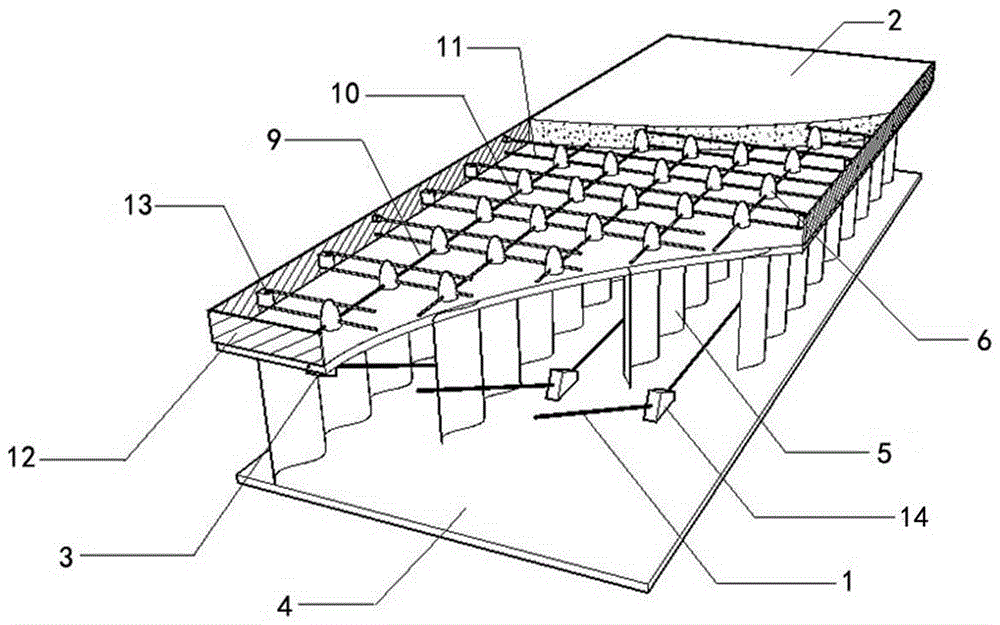

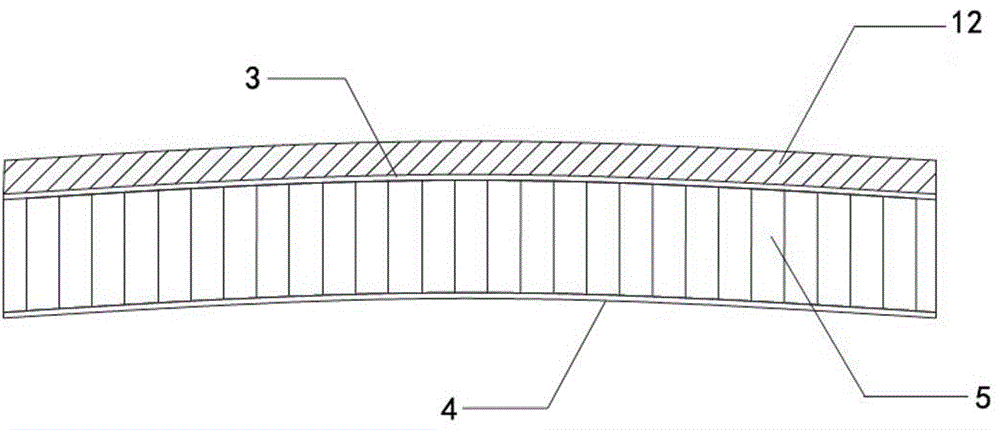

Device and method for testing early thermal expansion coefficient of concrete based on suspension method

ActiveCN103293179ALongitudinal stiffness is smallReduce thicknessMaterial thermal coefficient of expansionTemperature controlMeasurement device

The invention relates to a device and a method for testing an early thermal expansion coefficient of concrete based on a suspension method. The device comprises a corrugated pipe test mould for pouring concrete to be tested to form a concrete corrugated pipe test piece, a plurality of rope rings for suspending the concrete corrugated pipe test piece, a device base for suspending the rope rings, a temperature measurement device used for measuring the temperature change of the concrete in the corrugated pipe test mould and having the measurement end of a first thermocouple wire buried in the corrugated pipe test mould, a deformation measurement device for measuring the deformation amount of the concrete corrugated pipe test piece, and a temperature control box used for adjusting the temperature of a test environment and in which a suspension position of the concrete corrugated pipe test piece is located. According to the method, the concrete corrugated pipe test piece is suspended by adopting the device to measure the early thermal expansion coefficient of the concrete. According to the test device and the test method, the friction between the test piece and the test device is effectively reduced, the test precision is improved, the operation is simple, and the using effect is good.

Owner:FUJIAN TONGLI BUILDING MATERIALS SCI & TECH

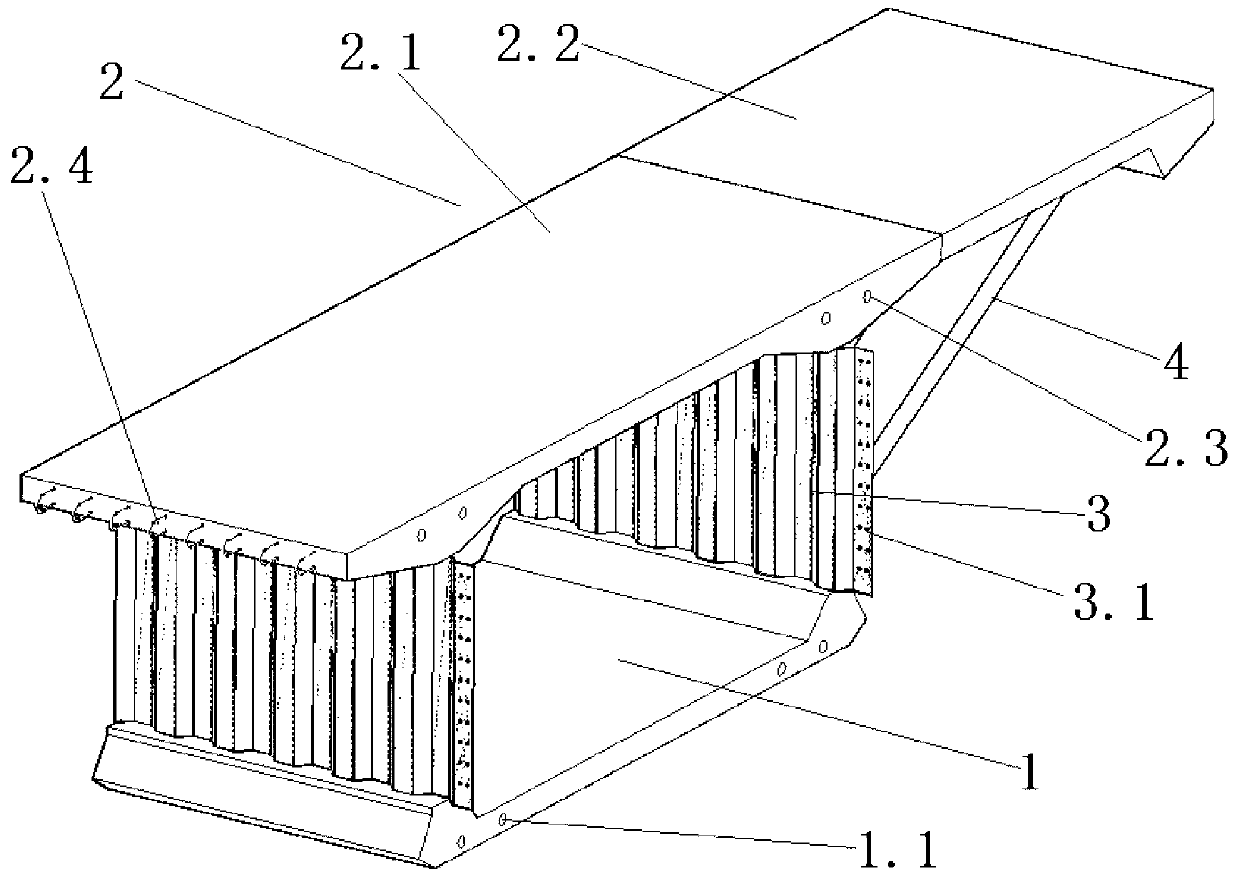

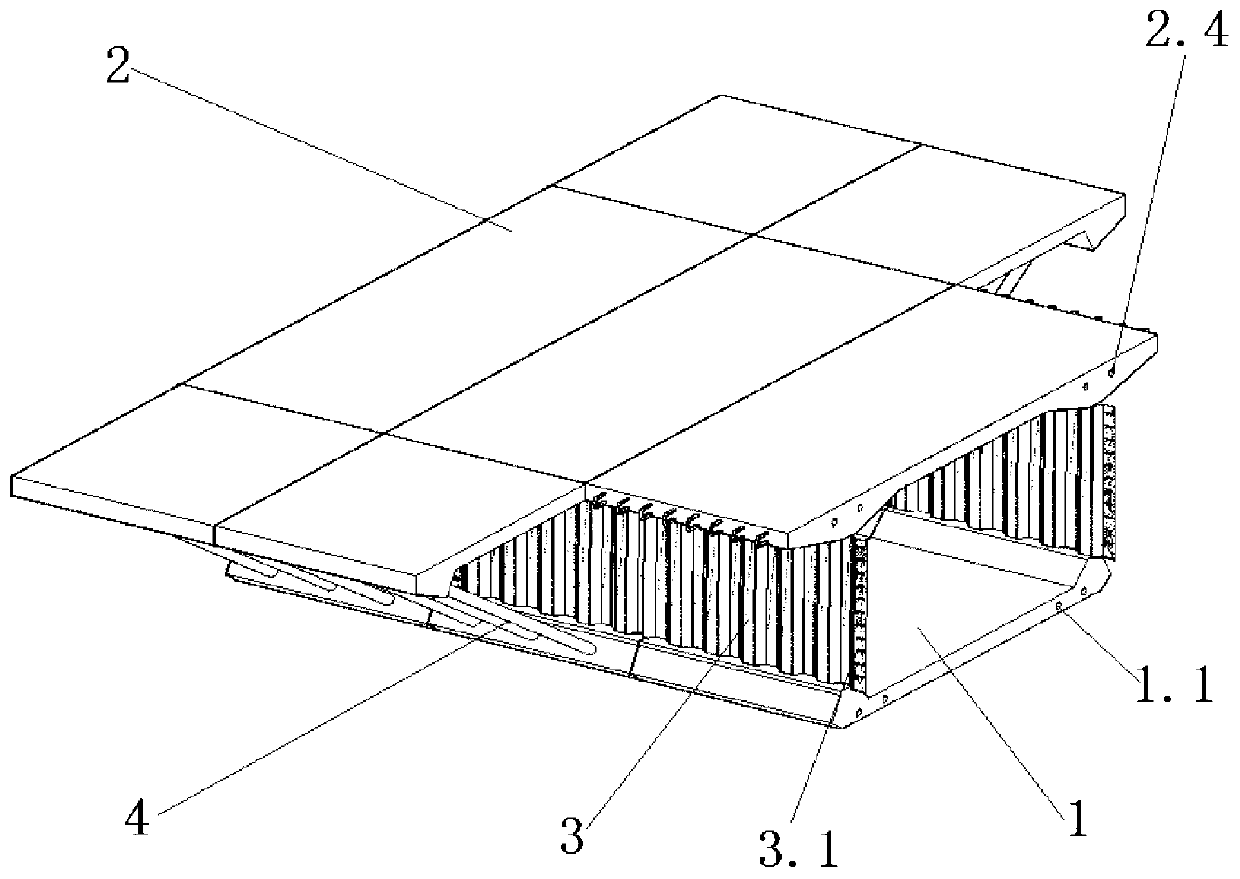

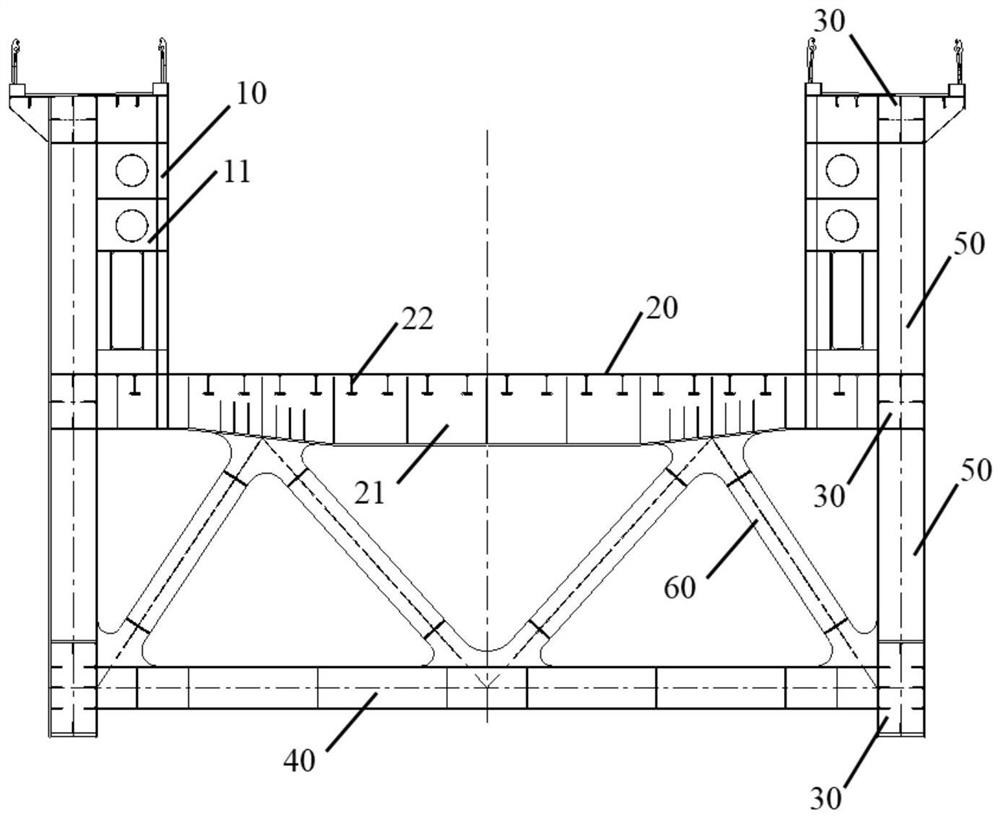

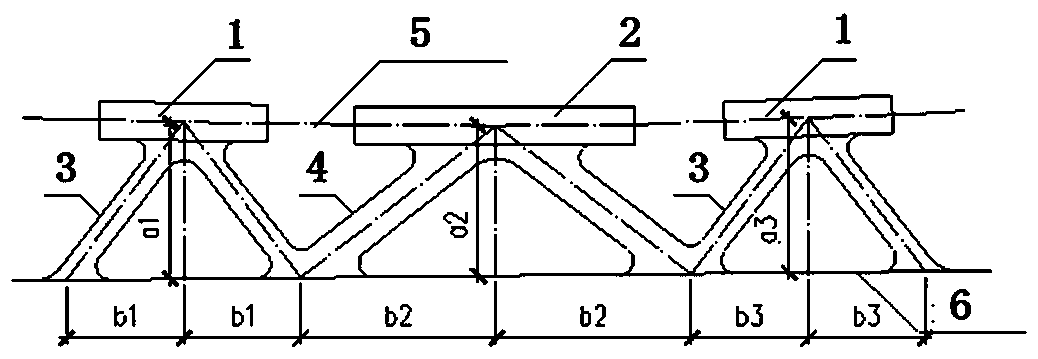

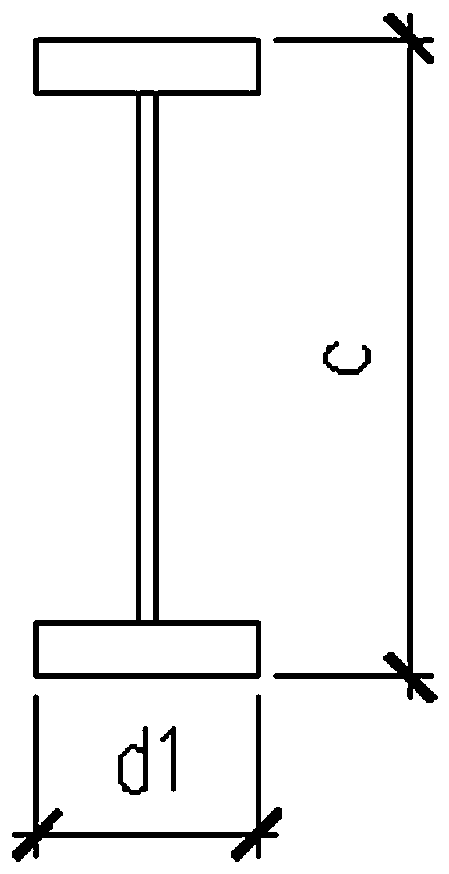

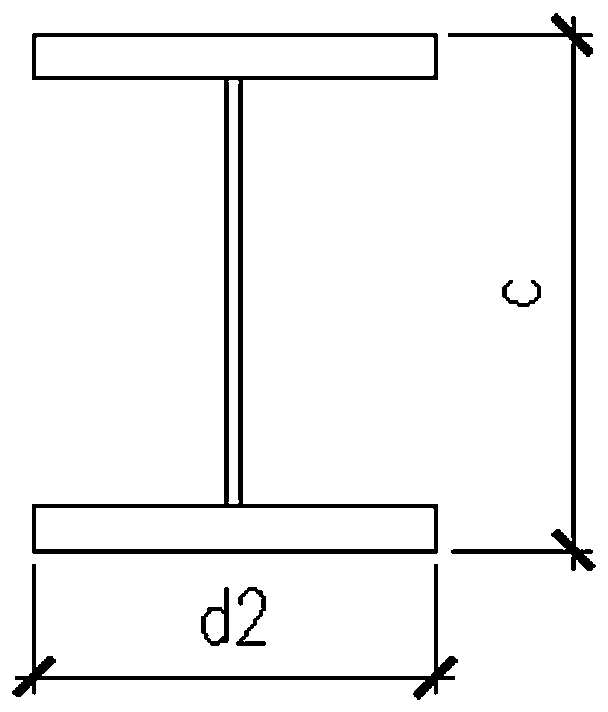

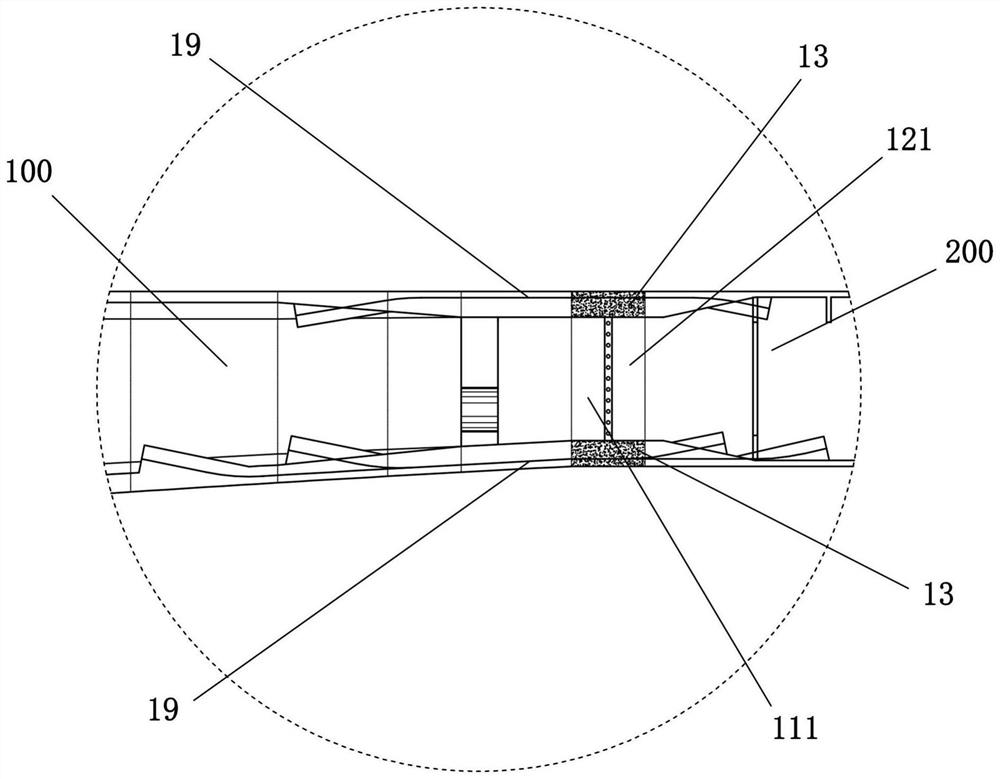

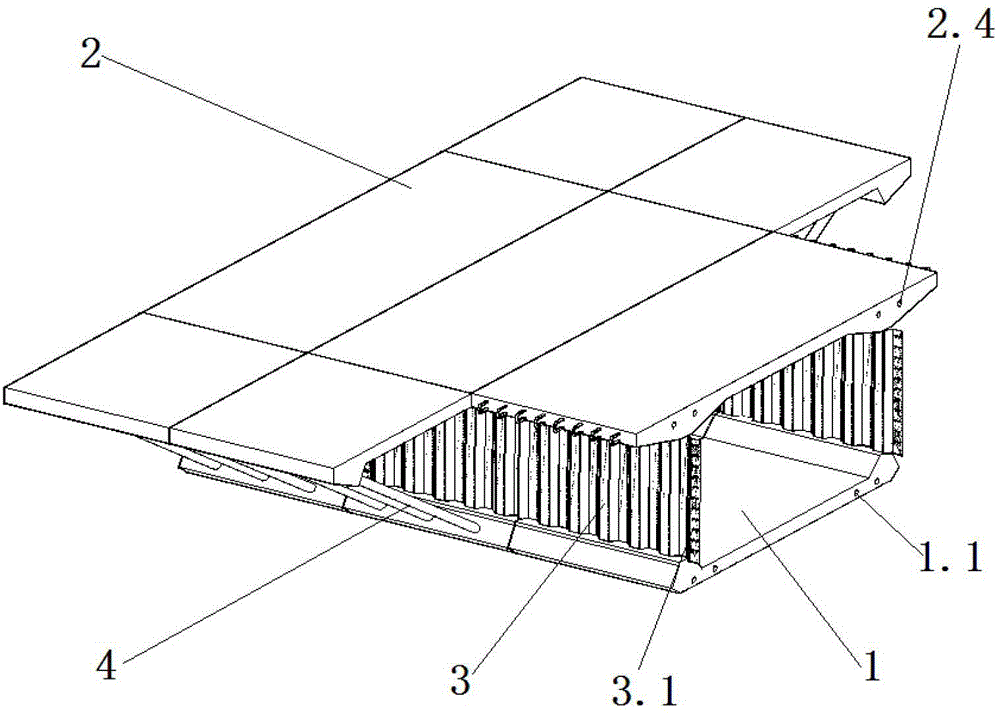

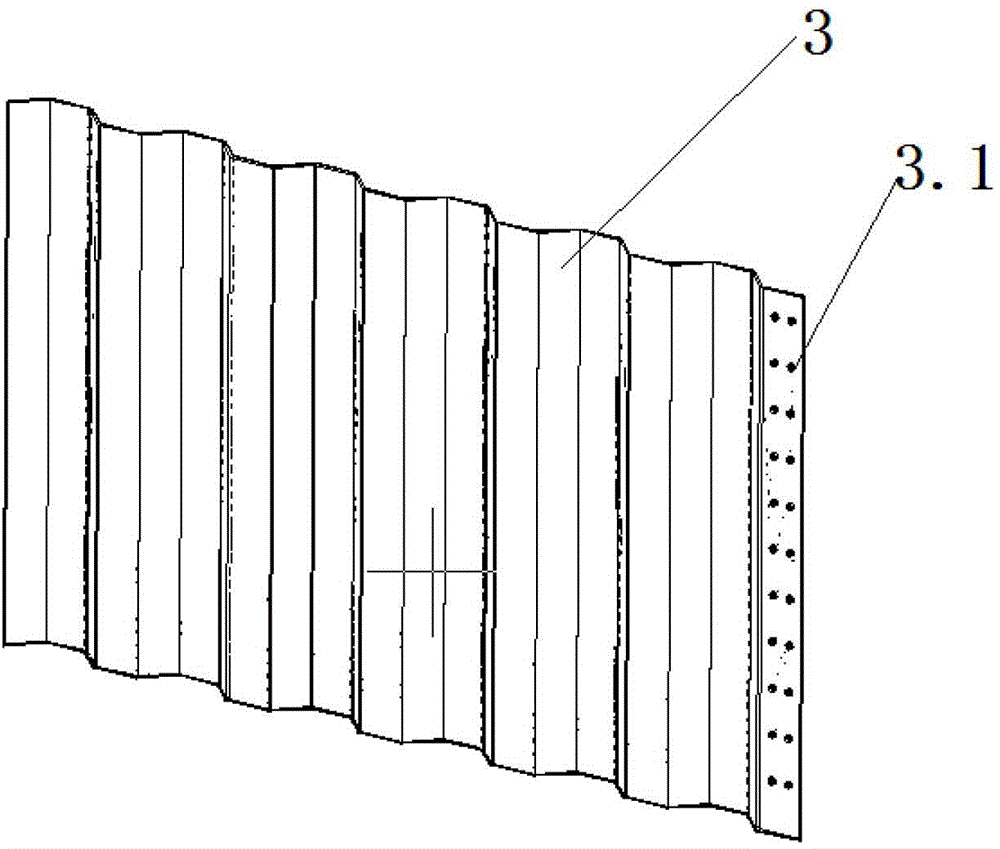

Large-cantilever steel web spinal box beam segment and construction technology

ActiveCN103276662ALow costSmall amount of workBridge structural detailsBridge erection/assemblyPre stressEngineering

The invention discloses a large-cantilever steel web spinal box beam segment and a construction technology. The large-cantilever steel web spinal box beam segment comprises a unit box beam bottom plate and a unit box beam top plate, wherein two steel webs are arranged between the unit box beam bottom plate and the unit box beam top plate, the unit box beam top plate comprises a top plate cross beam arranged in the middle of the unit box beam top plate and wing plates fixedly connected to the two transverse sides of the top plate cross beam, a reinforcing system is arranged between the transverse outer side of each wing plate and the unit box beam bottom plate, a top plate prestressed pore channel is formed in the unit box beam top plate in the longitudinal direction, bolting preformed holes are formed in the two longitudinal ends of each steel web, and a bottom plate prestressed pore channel is formed the unit box beam bottom plate in the longitudinal direction. According to the large-cantilever steel web spinal box beam segment and the construction technology, each component is of a sectional type structure, fractional hoisting can be adopted, the weight of hoisting is light, the requirements for transportation and hoisting equipment are greatly reduced, and construction can be directly finished by means of matching of a conventional truck-mounted crane or a crawler crane and a small-tonnage beam transporting vehicle.

Owner:CCCC SECOND HARBOR ENG

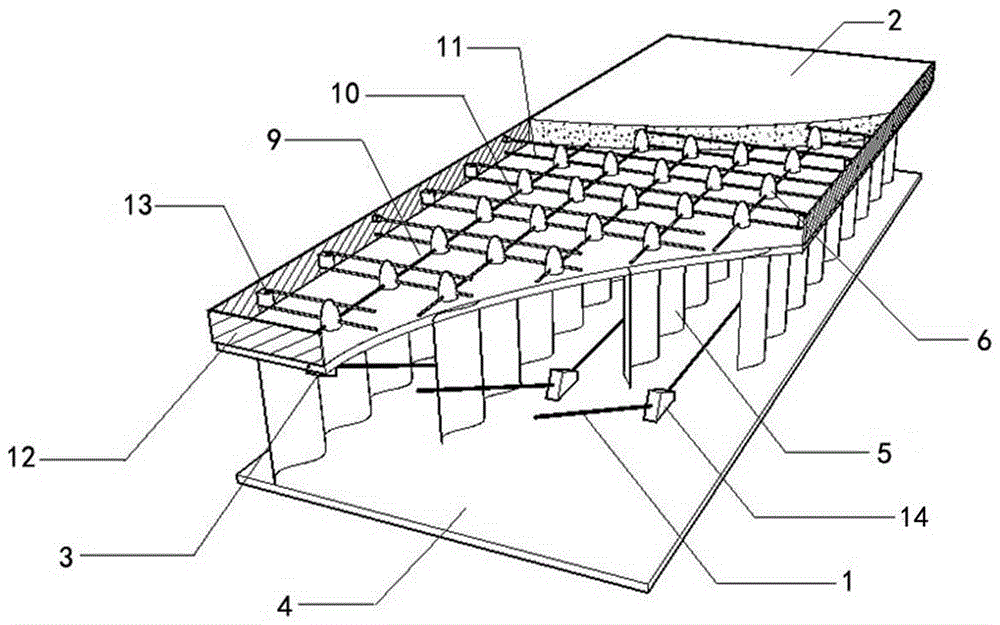

Steel box type composite beam forming method

Disclosed is a steel box type composite beam forming method. A split type processing method is utilized in a bottom box and a plug welding technology and an anti-deformation technology are utilized to effectively solve the problems of positioning of force transmission ribs, deformation of the bottom box and the like, and the prefabrication efficiency of steel-concrete composite bridges is improved by reasonably adjusting production processes. The adopted technical scheme of the steel box type composite beam forming method comprises utilizing steel plates as raw materials, leading the raw materials to be subjected to top plate forming, bottom box forming and wave plate forming, and performing assembling and welding to form a prefabricated steel box type composite beam. According to the steel box type composite beam forming method, assembly line production is utilized and large-scale processing and assembling of bottom boxes can be achieved in factories.

Owner:邢台路桥千山桥梁构件有限责任公司

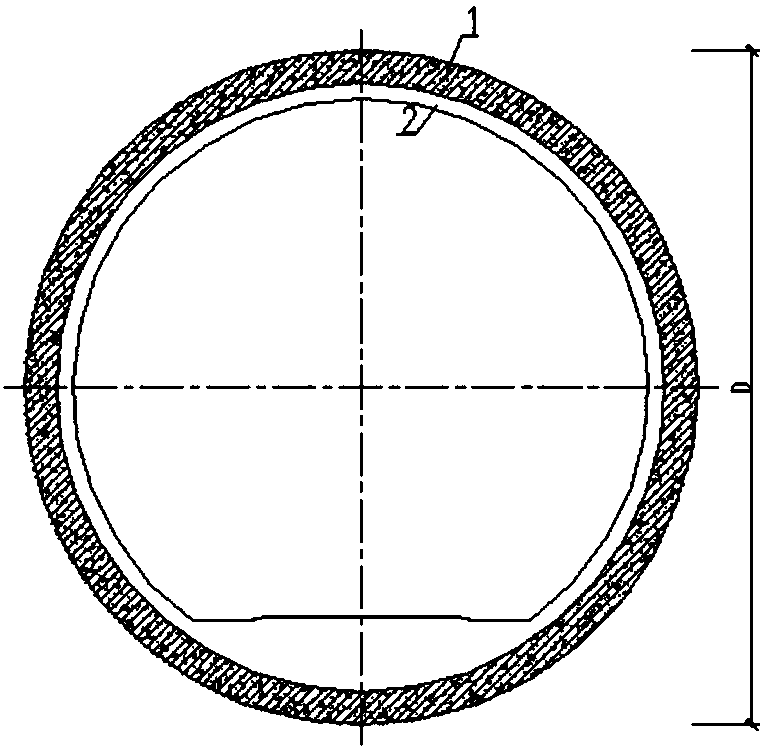

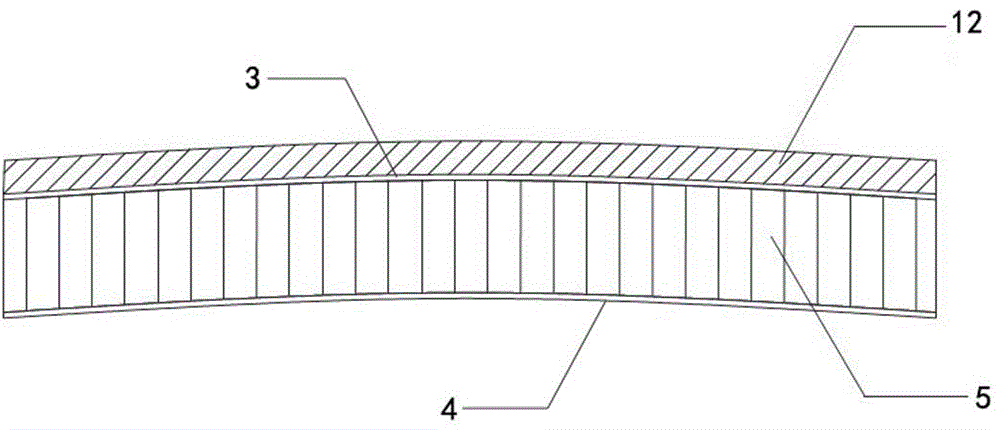

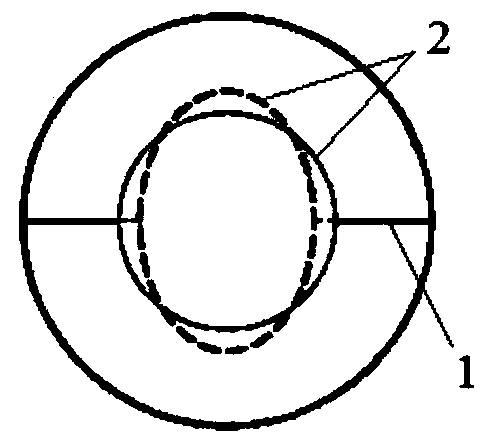

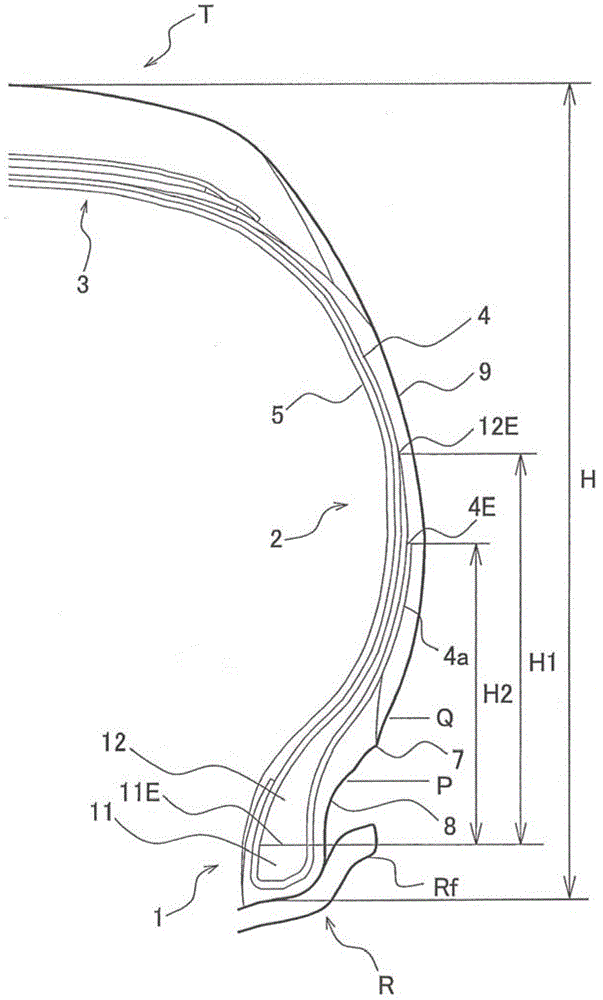

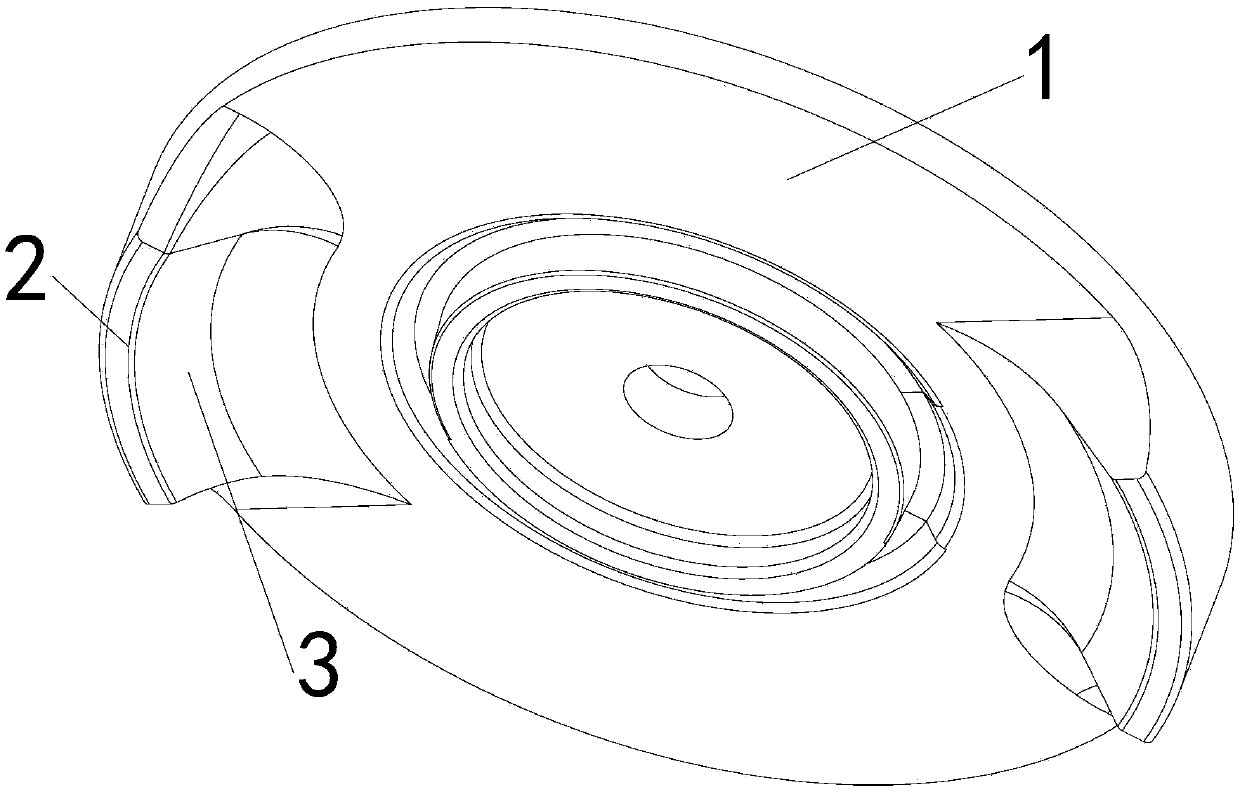

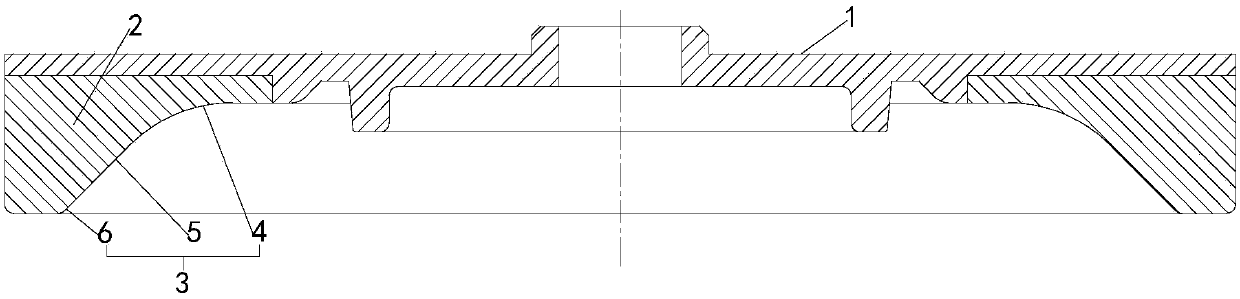

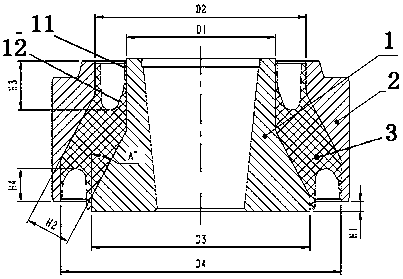

Pneumatic tire

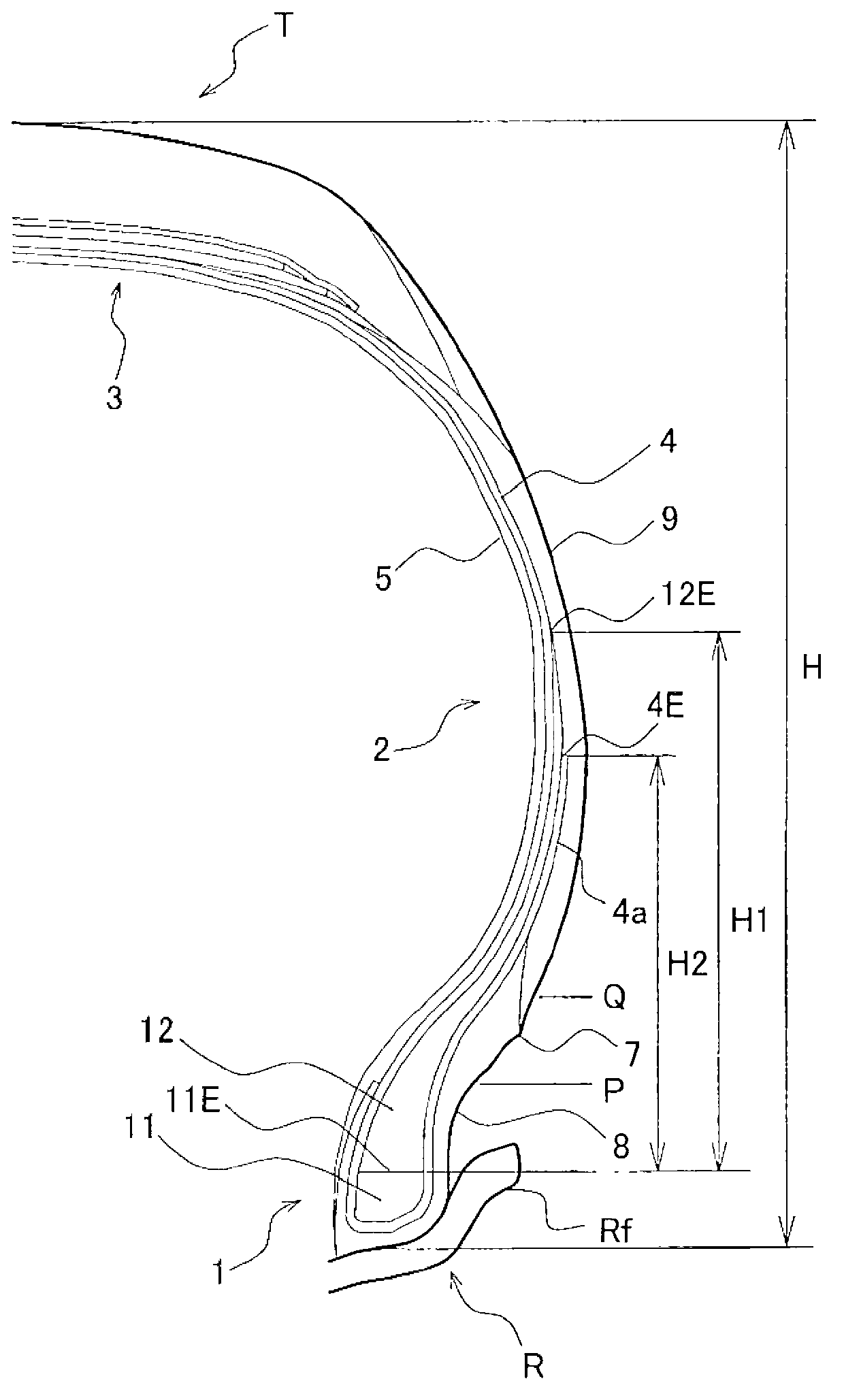

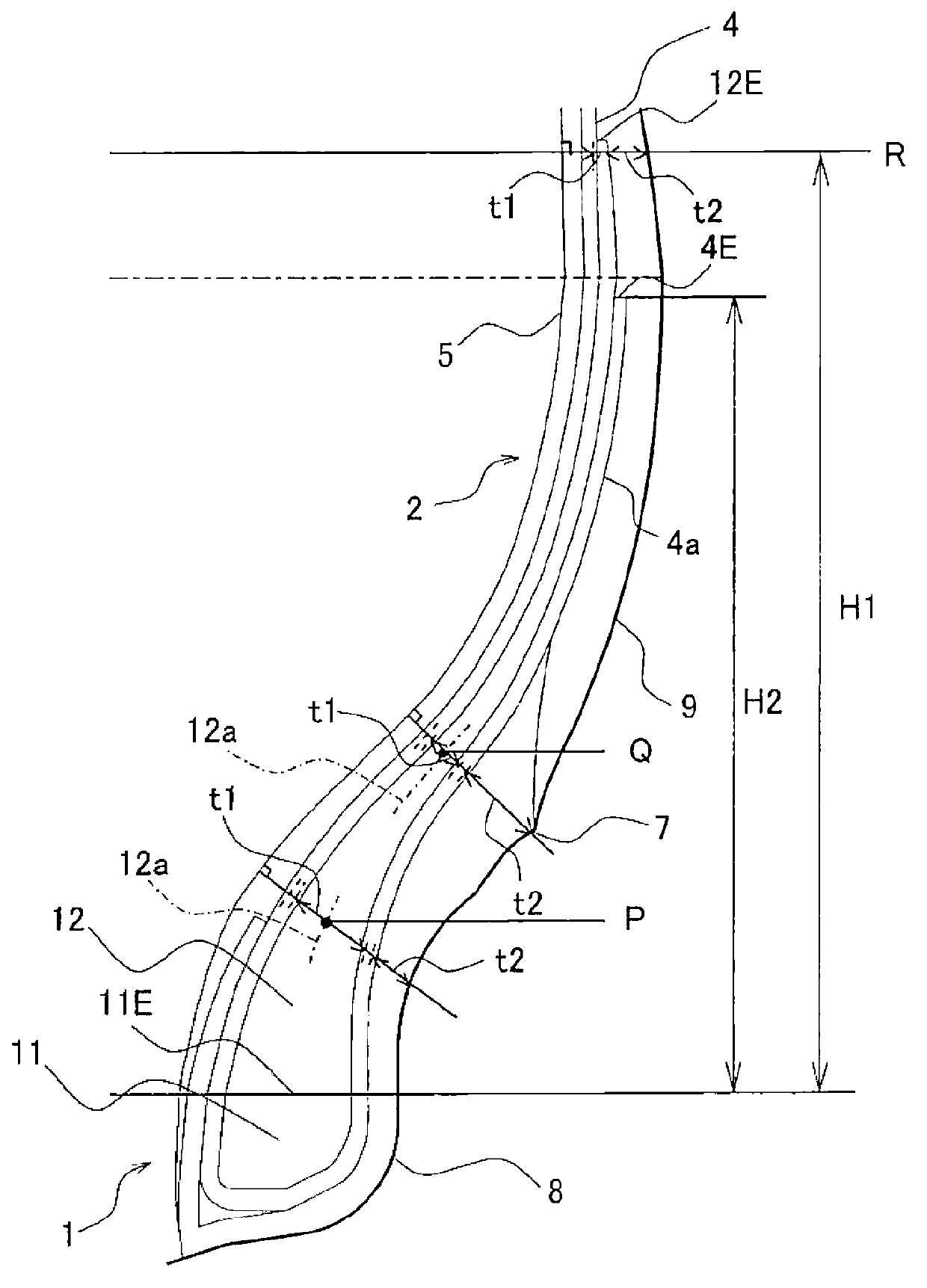

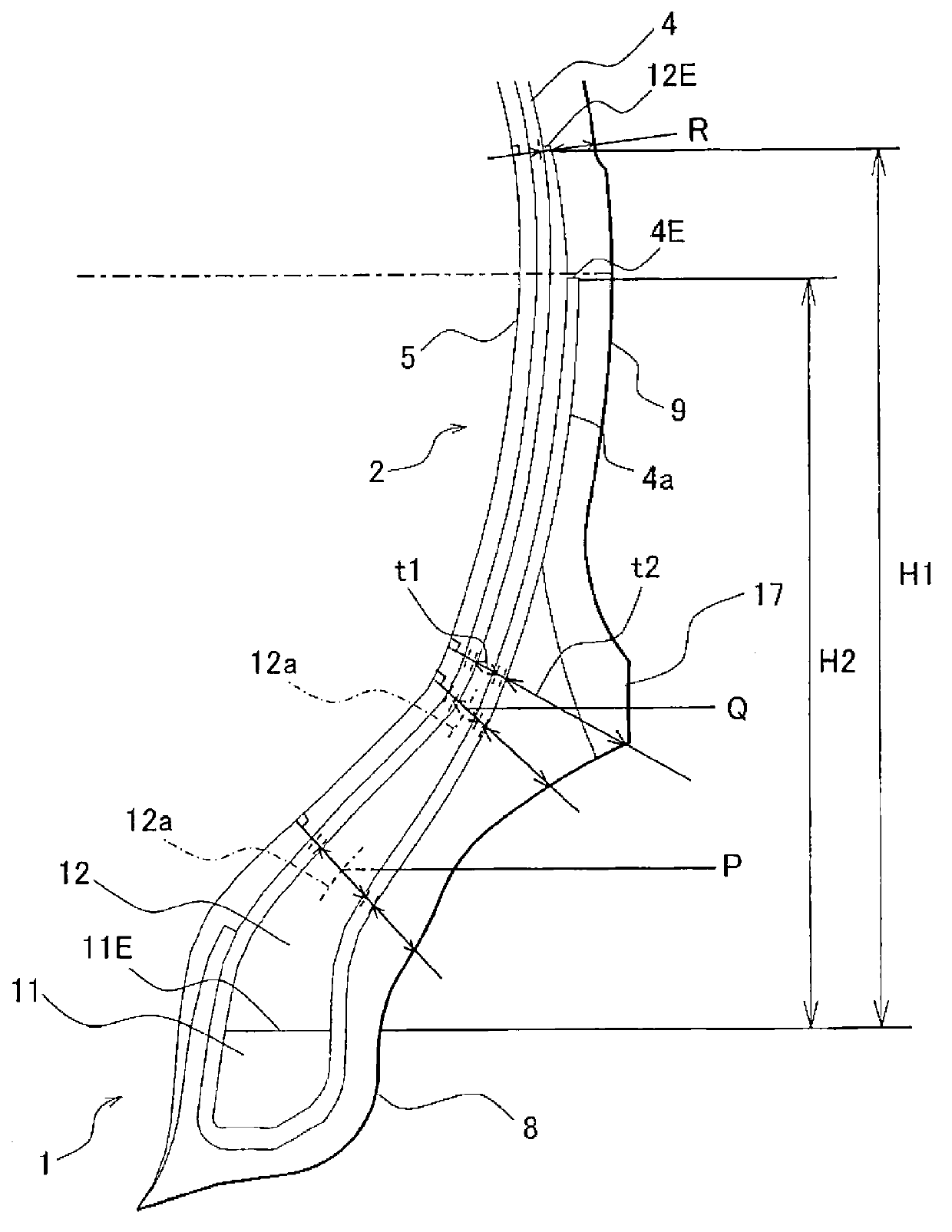

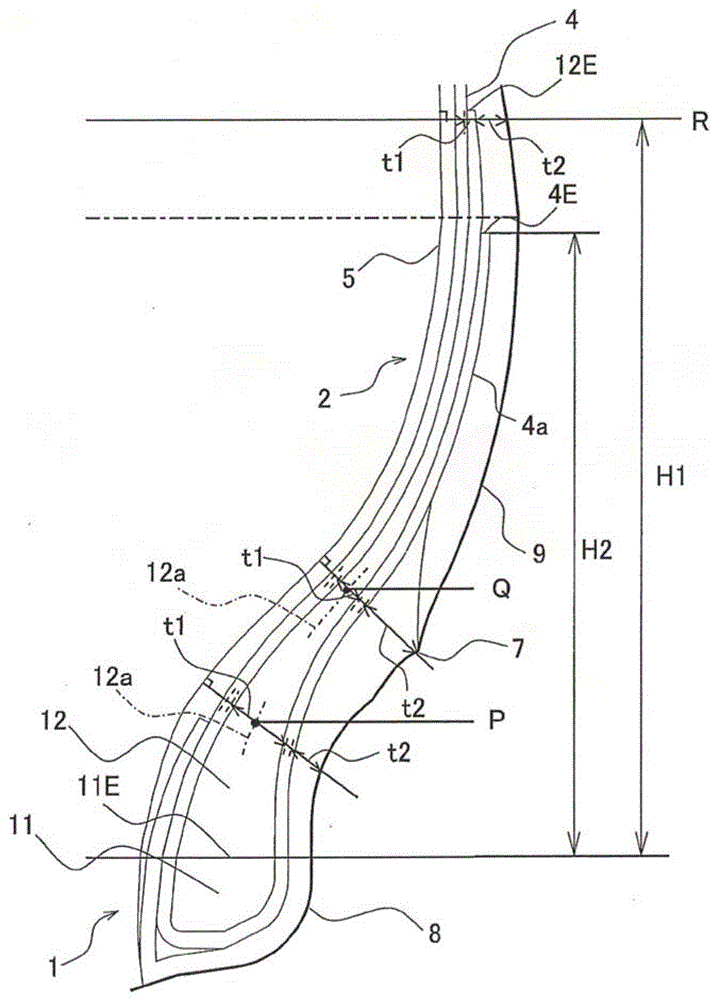

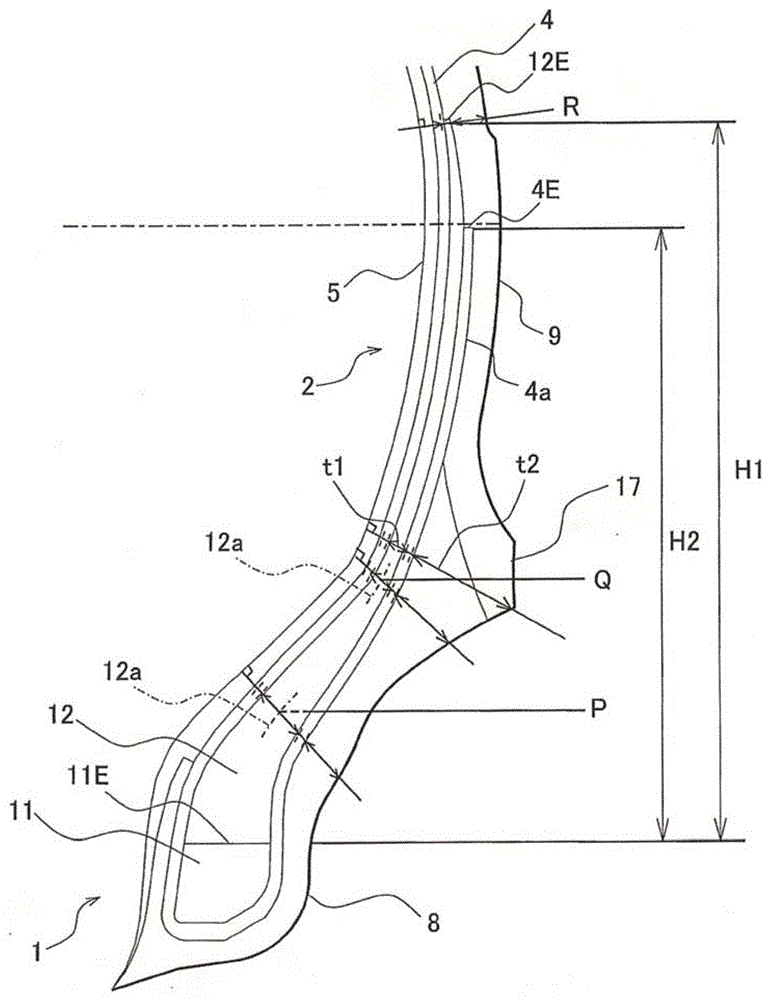

ActiveCN103129327AIncrease lateral stiffnessLongitudinal stiffness is smallTyre beadsTire beadEngineering

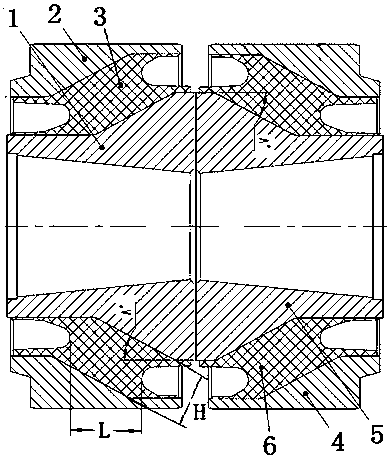

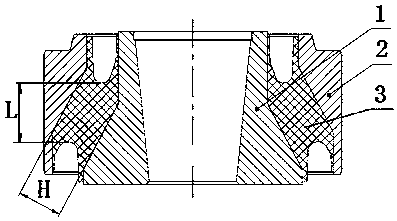

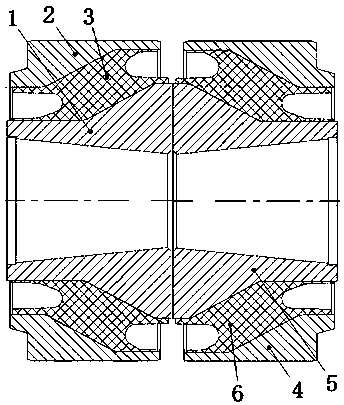

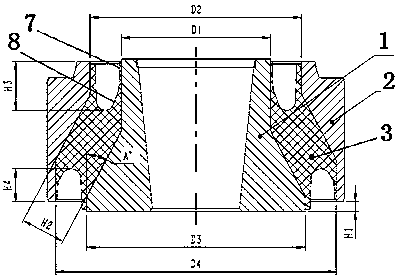

The invention provides a pneumatic tire which limits the mass of the tire while improving the driving stability and comfort. The pneumatic tire comprises a bead core (11) embedded in a bead part (1), a bead filler (12) arranged at the tire radial outside of the bead core (11), a carcass ply (4) which can be wound up around the bead core (11) from internal towards external, and side wall rubber (9) which constitutes an external wall of a tire. The section height (H1) of the bead filler (12) with a tire radical outer end (11E) of the bead core (11) as a reference constitutes 50 to 70% of tire section height (H). The thickness (t1) of the bead filler (12) at the position Q, which is 20mm from the tire radical outer end of the bead filler (11) to the tire radial outside, is smaller than 1.7mm, and the thickness (t1) decreases gradually towards the tire radical outside. A winding-up end (4E) of the carcass ply (4) is terminated at a position closer to the tire radical inside than a peripheral end (12E) of the bead filler.

Owner:TOYO TIRE & RUBBER CO LTD

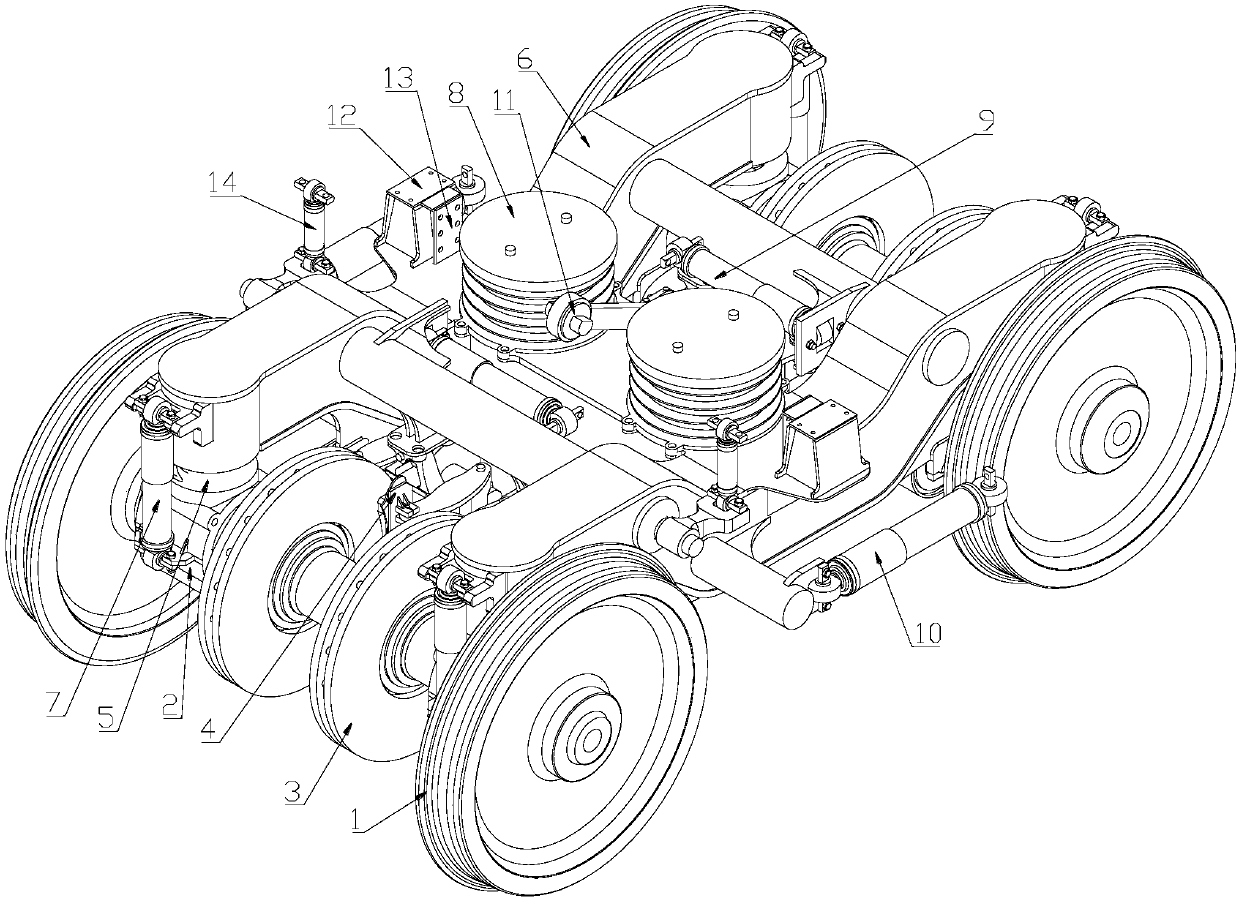

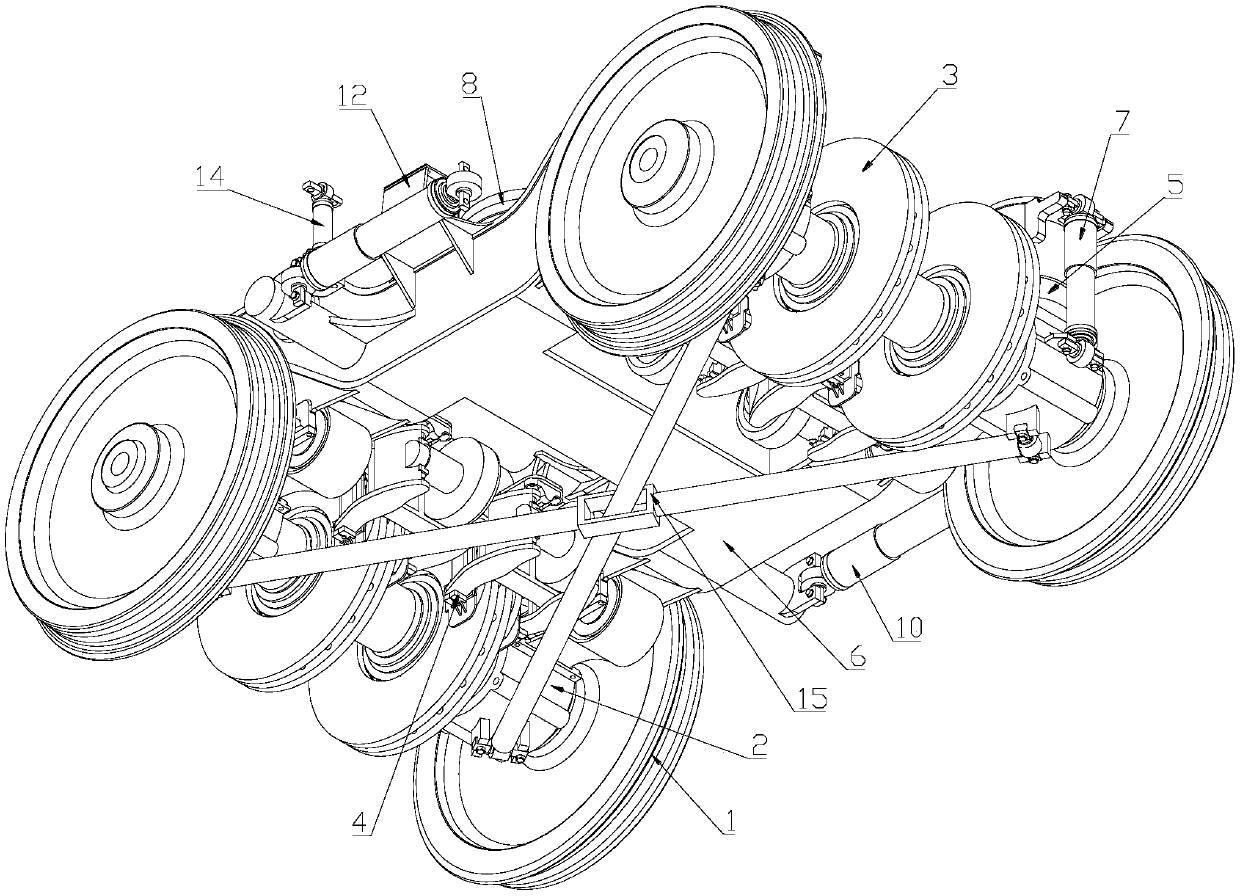

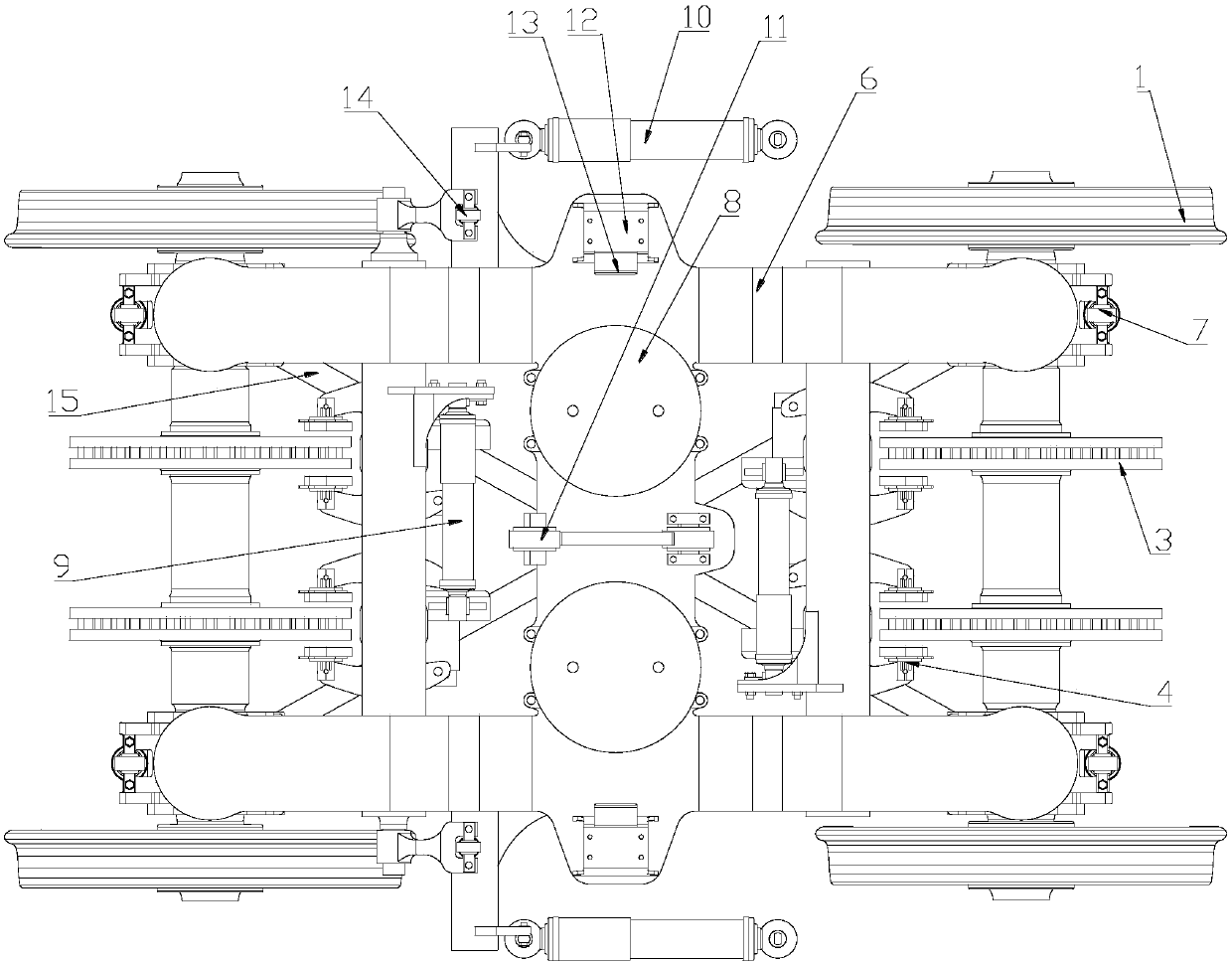

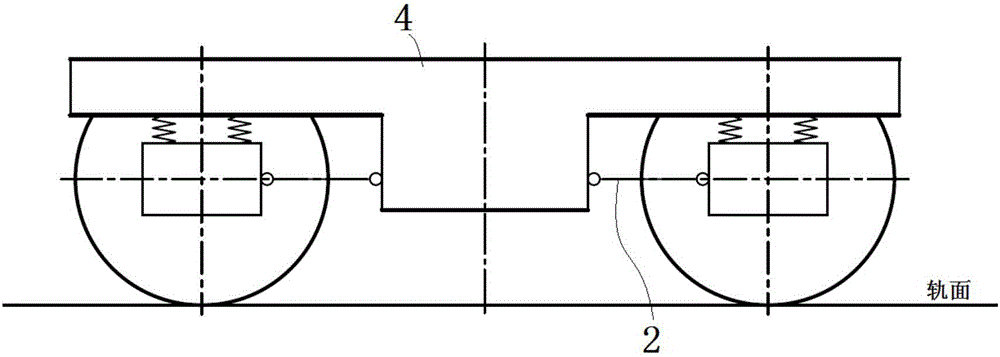

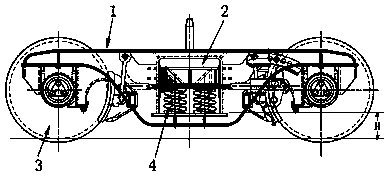

Axle box embedded bogie for high speed railway wagon

The invention discloses an axle box embedded bogie for a high speed railway wagon. An H-shaped integral truss and an embedded axle box are adopted; an anti-snake vibration absorber and a secondary transverse vibration absorber are arranged on the truss; the anti-snake vibration absorber is longitudinally connected to the two sides of a truss side frame; and the secondary transverse vibration absorber is transversely connected to the end part of a truss small cross beam. A primary suspension of the axle box embedded bogie for the high speed railway wagon is located by using an axle box rotatingarm; and under coordination of a wheel pair crossed supporting device, the vehicle stability is enhanced. Compared with a traditional truck, the axle box embedded bogie for the high speed railway wagon has the advantage that a problem of insufficient anti-roll ability provided by a secondary suspension is solved because an anti-roll torsion bar device is additionally mounted. According to the axle box embedded bogie for the high speed railway wagon, a high speed railway wagon bogie overall scheme satisfying a cargo transporting realistic demand is designed for a problem that an operation speed of an existing truck bogie cannot satisfy a demand. According to the axle box embedded bogie for the high speed railway wagon, on the basis of an axle box embedded type integral truss structure bogie, the critical value of velocity is increased by improving the anti-snake motion performance and the motion stability during operation.

Owner:SOUTHWEST JIAOTONG UNIV

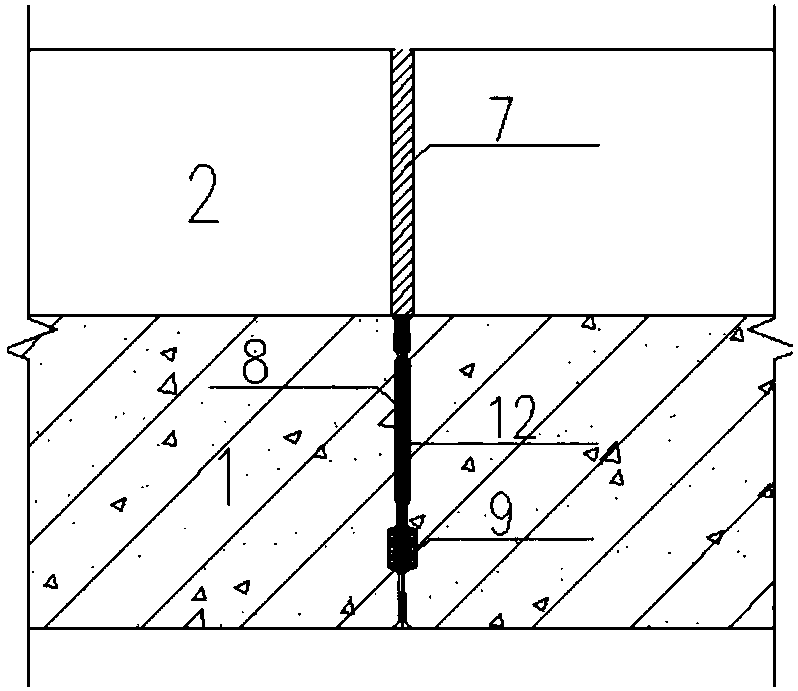

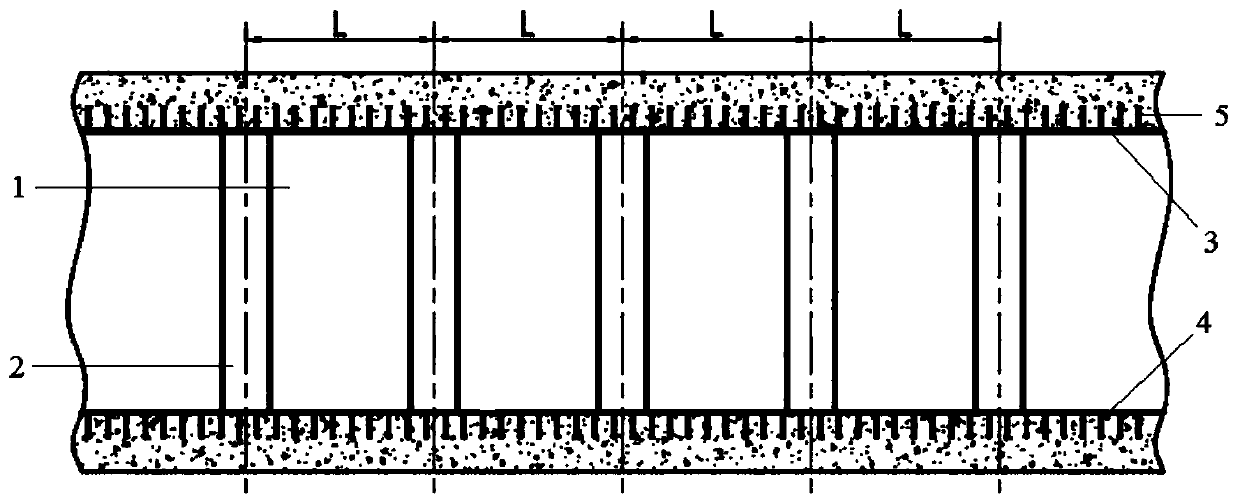

Double-layer lining shield tunnel deformation joint structure and shield tunnel

PendingCN108150192AReduce the amount of openingImprove waterproof effectUnderground chambersTunnel liningTransverse shearEngineering

The invention discloses a semi-flexible and semi-rigid double-layer liner shield tunnel deformation joint structure. The structure comprises segments and linings, and laminated structural connection is formed between the segments and the linings in a non-deformation joint section; in a deformation joint section, the segments is continuously provided with N segment deformation joints at a predetermined length L at each interval, and N is an integer greater than or equal to 1; in positions corresponding to deformation joints of the segments, the linings are provided with lining small sections, lining deformation joints are arranged at the junction of the lining small sections and adjacent non-deformation joint sections, and the lining deformation joints and the segment deformation joints arearranged longitudinally in a staggered mode; and the invention further discloses a shield tunnel. According to the semi-flexible and semi-rigid double-layer liner shield tunnel deformation joint structure and the shield tunnel, the longitudinal rigidity of the deformation joints is higher than that of conventional flexible deformation joints, the opening amount of the segment joints can be reduced effectively, and the waterproof effect of a double-layer lining structure is improved; N segment deformation joints are arranged at the deformation joint sections to jointly share the opening amountof the segment joints; and the segments and the lining deformation joints are staggered in space, and the transverse shear can be resisted effectively to prevent slab staggering.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

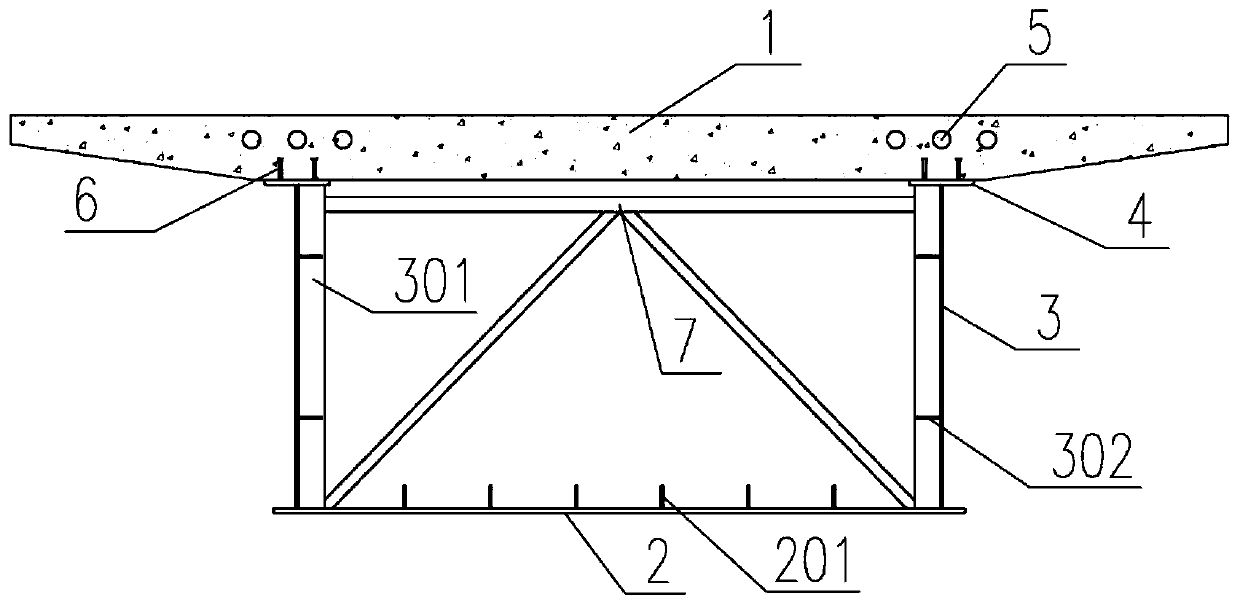

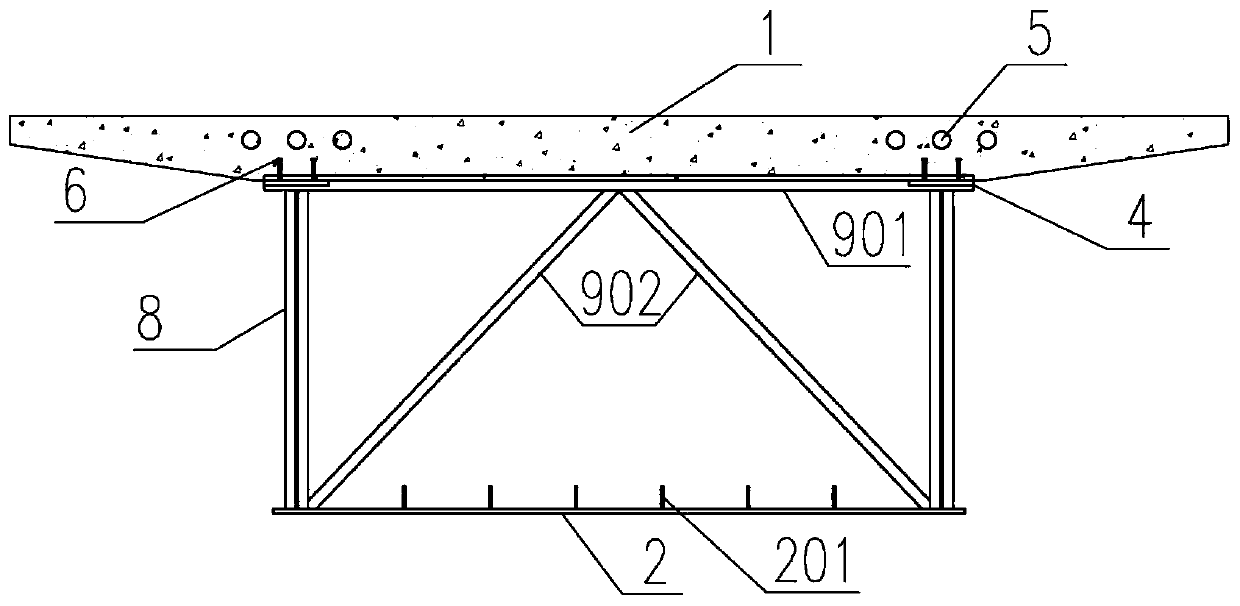

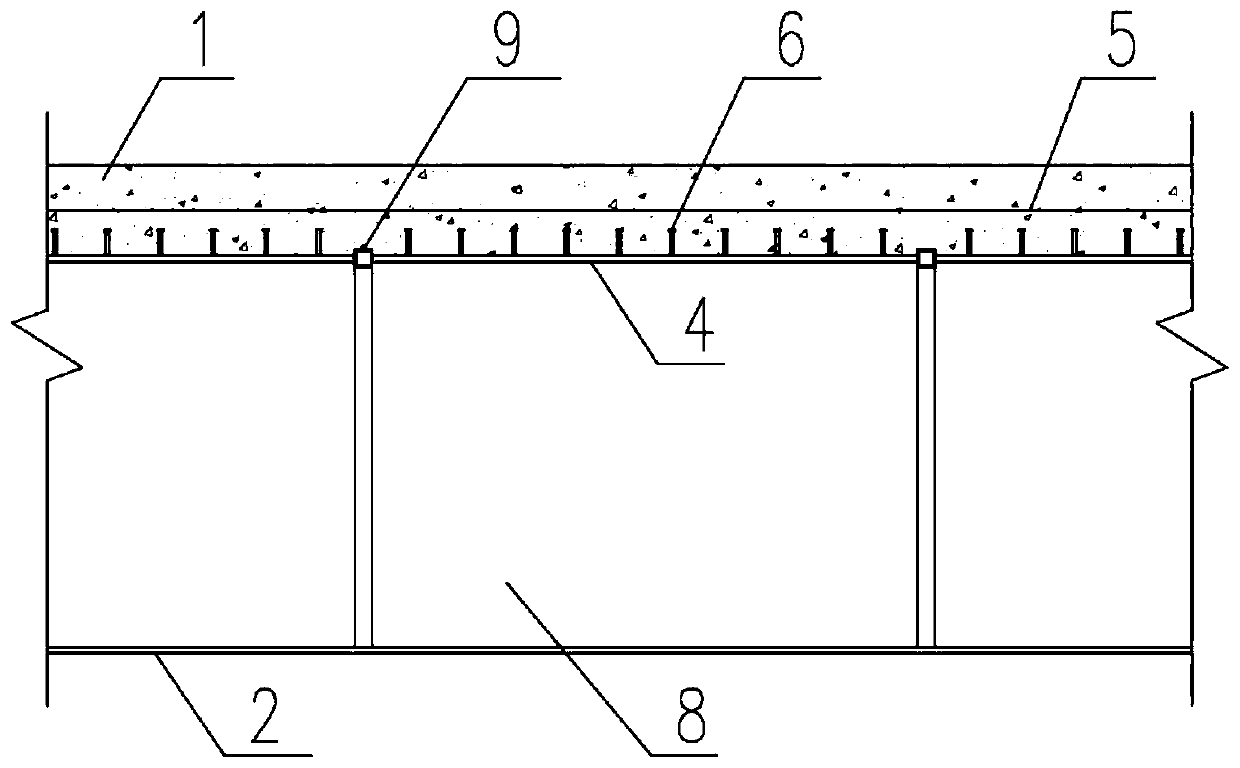

Steel pipe stiffened web steel-concrete composite box girder

PendingCN110067186AImprove integrityIncrease stiffnessBridge structural detailsBridge materialsMetallurgyCross bracing

The invention discloses a steel pipe stiffening web steel-concrete composite box girder. The steel pipe stiffened web steel-concrete composite box girder comprises a concrete top plate, steel pipe stiffening webs, a steel bottom plate, cross-bracing structures and an upper flange plate, the steel bottom plate is welded to the lower edge of the steel pipe stiffening webs on both sides, the upper edge of the steel pipe stiffening webs is welded to the upper flange plate, and the steel pipe stiffening webs, the steel bottom plate and the upper flange plate are welded into a groove-type steel structure; the concrete top plate is connected to the top part of the upper flange plate through a connecting part, the steel pipe stiffening webs, the steel bottom plate, the upper flange plate and the concrete top plate form a box girder structure, and a plurality of cross-bracing structures are arranged in a support point of the box girder and the middle of the box girder. According to the steel pipe stiffening web steel-concrete composite box girder, the longitudinal stiffness of steel webs and the upper flange plate can be reduced, the prestressing efficiency is improved, meanwhile the deformation coordination ability of the concrete top plate and the steel structure is coordinated, secondary internal force generated by shringkage and creep of concrete and temperature are reduced.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

Process for producing pre-tensioned and pre-stressed concrete pile mold

The invention relates to a process for producing a pre-tensioned and pre-stressed concrete pile mold and is applicable to production of pre-stressed and pre-tensioned concrete tubular piles. The process comprises the following steps of: firstly, preparing components, namely a matchboard, a tubular wall, longitudinal bars, annular bars, links, bolts, an end plate, an end connecting plate and running wheels; secondly, sequentially connecting all components, performing spot welding on all components into a whole, and thus obtaining half steel molds; and finally, combining the molds and performing finish machining. The process has the advantages that: the produced whole steel mold is small in cavity size error and good in straightness; the produced tubular pile or square pile is good in straightness; the smoothness of appearance is good, the whole longitudinal rigidity is good, and annular strength is improved; the whole coaxiality is ensured; and steel, processes and materials are saved, and the quality of produced products is higher.

Owner:JIANGSU HAI HENG BUILDING MATERIAL MACHINERY CO LTD

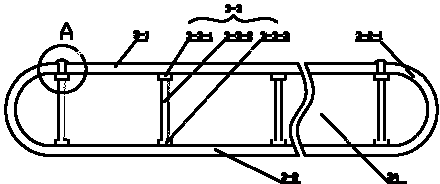

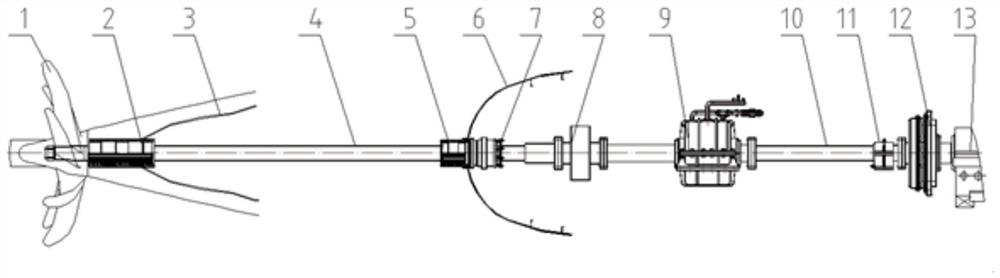

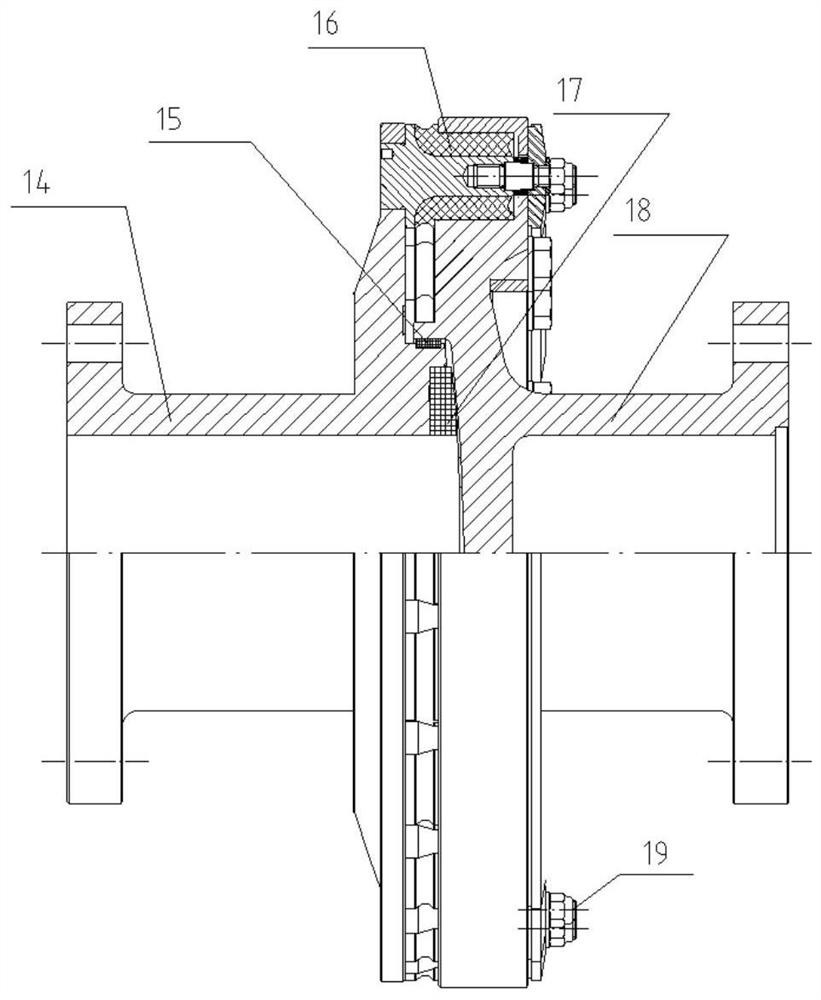

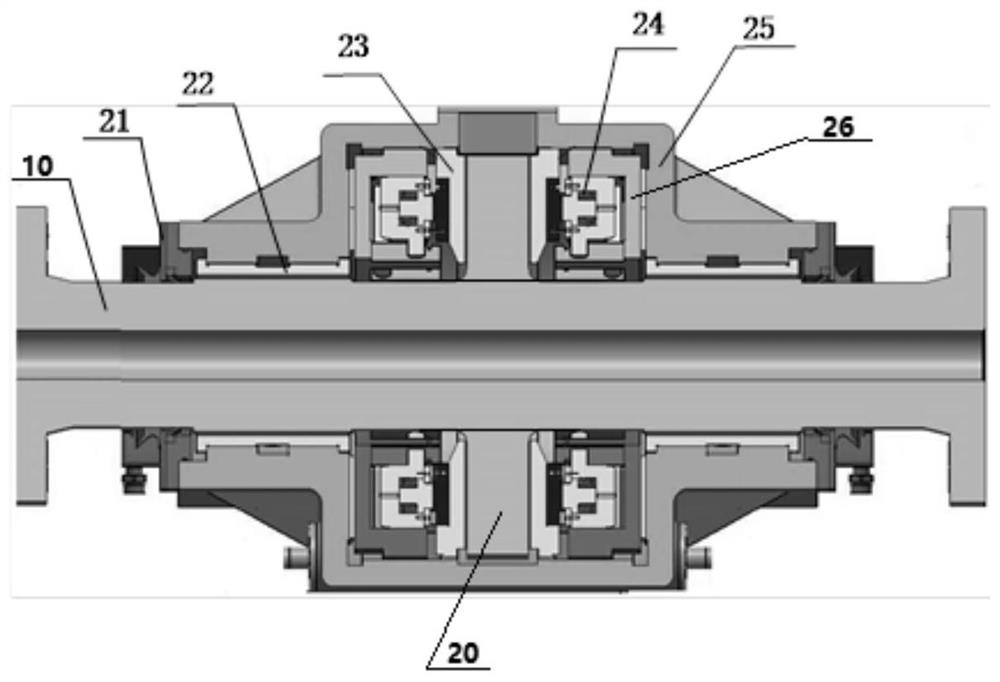

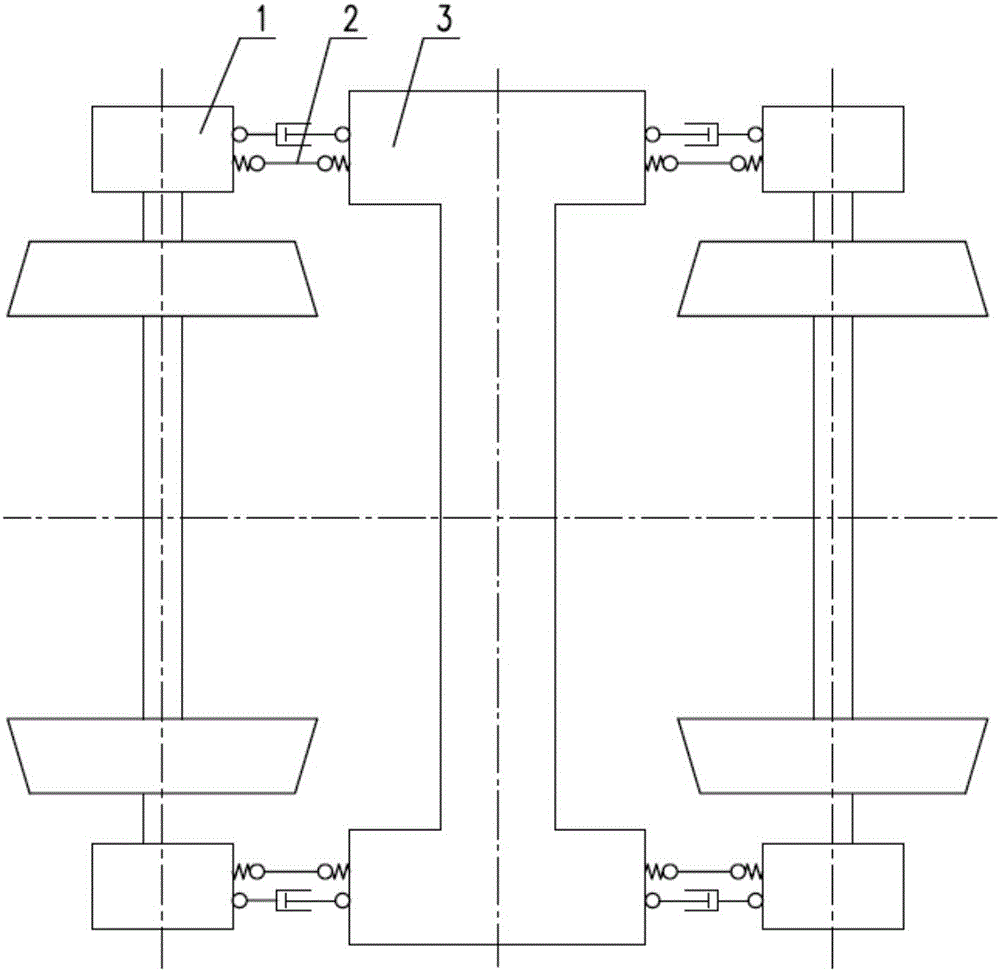

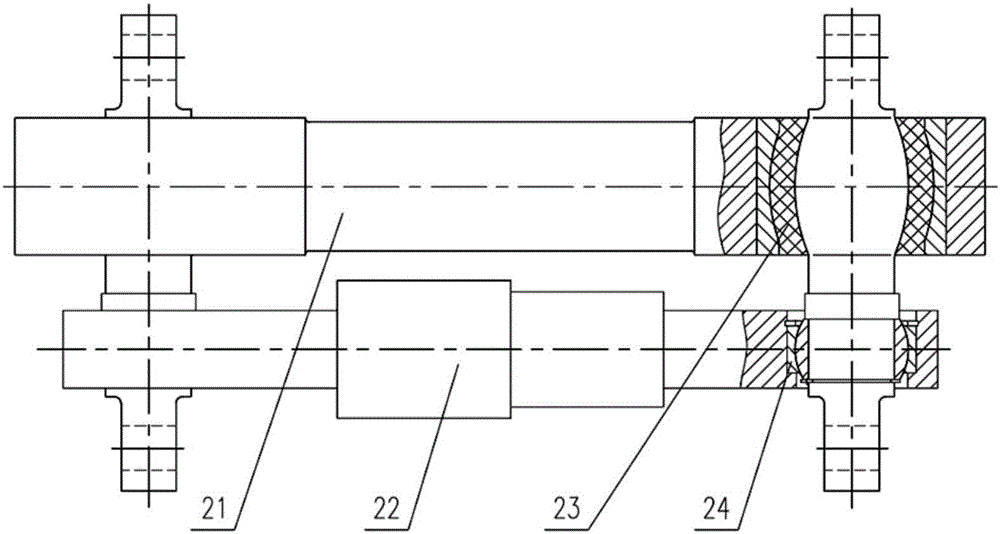

Two-stage longitudinal vibration isolation shafting

ActiveCN113335488AGood vibration isolationLongitudinal stiffness is smallWater acting propulsive elementsPropulsive transmissionIsolatorMarine propulsion

The invention relates to the field of ship propulsion system design, and particularly discloses a two-stage longitudinal vibration isolation shafting which is provided with a propeller, a stern rear bearing, a stern light shell structure, a stern shaft, a stern front bearing, a pressure-resistant body structure, a stern shaft sealing device, a longitudinal vibration isolator, a vibration isolation thrust bearing, a middle shaft, a middle bearing, an elastic coupler, a propulsion motor and the like from the stern to the bow. By arranging the longitudinal vibration isolators and the vibration isolation thrust bearings, the whole shafting forms a two-stage longitudinal vibration isolation system, the mass ratio u of the two-stage vibration isolation system is designed to be 0.5-1, the mass ratio is increased as much as possible during design, the rigidity ratio is designed to be u + 1, and the shafting can have the better vibration isolation effect than a single-stage vibration isolation system at the middle-high frequency band except the second-order inherent frequency, and vibration noise generated by the ship tail propeller-shaft system is reduced.

Owner:CHINA SHIP DEV & DESIGN CENT

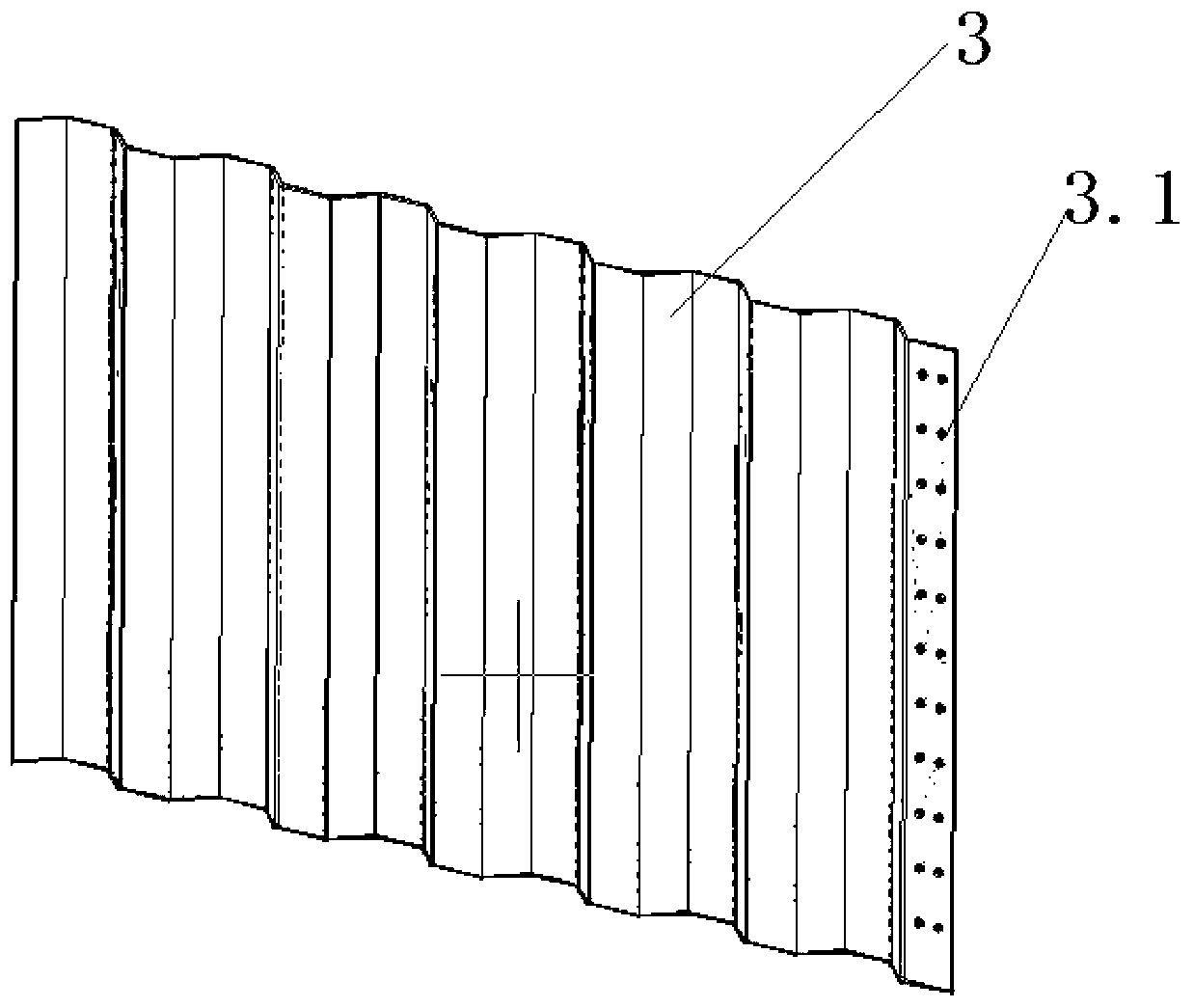

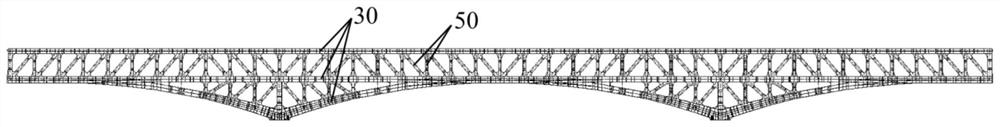

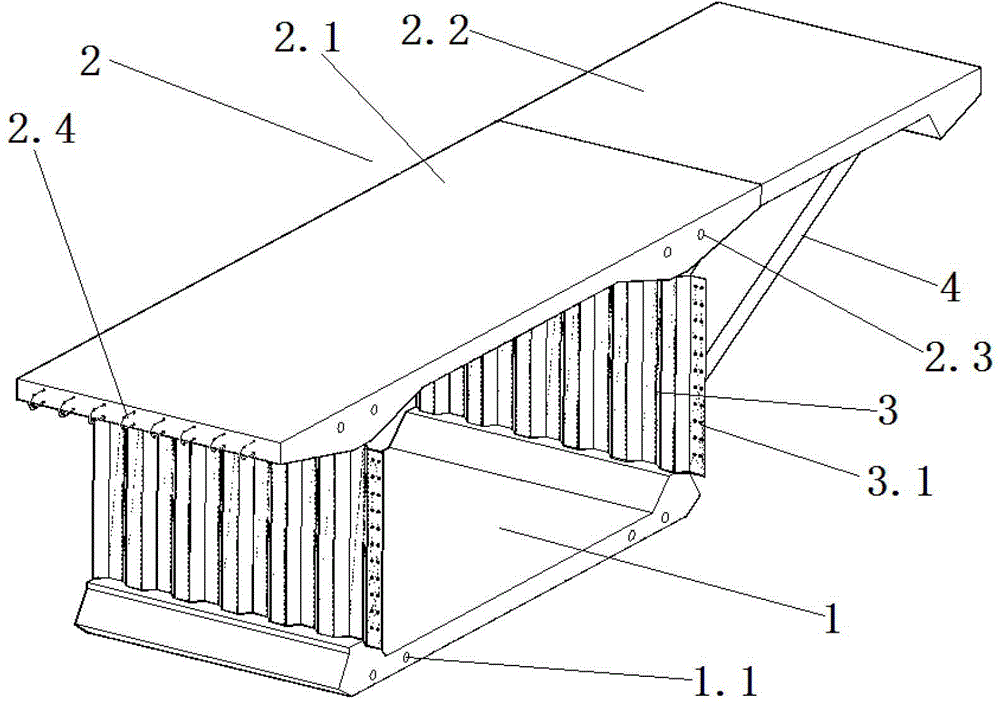

Truss type steel aqueduct with corrugated web plates

PendingCN112049078ALongitudinal stiffness is smallImprove water tightnessBridge applicationsArtificial water canalsLong spanStructure support

The invention discloses a truss type steel aqueduct with corrugated web plates. The truss type steel aqueduct with corrugated web plates comprises a steel box girder body using the corrugated web plates, and at least two truss supporting structures, wherein the steel box girder body is symmetrically arranged along the central axis, uses a groove-shaped or U-shaped cross section, and consists of the corrugated web plates and a bottom plate; the at least two truss supporting structures are symmetrically arranged along the central axis; each truss supporting structure consists of chord members, lateral bracings arranged between two truss lower chord members, web members, and cross bracings arranged between two truss web members; each corrugated web plate is positioned between the lateral bracings of the truss supporting structures; the bottom plate is supported on the cross bracings; and partition plates are arranged at the inner sides of the lateral bracings for providing lateral supportfor the corrugated web plates. An all-steel structure is used; the watertight performance is good; the structure can be assembled and constructed on site after being prefabricated in sections in a factory; the construction speed is high; and the construction quality can be easily guaranteed. Compared with a concrete structure, the steel structure has the advantages of small dead weight and higherspanning capacity, so that the steel structure is more suitable for construction of large flow cross section and large-span aqueducts.

Owner:ANHUI TRANSPORT CONSULTING & DESIGN INST +1

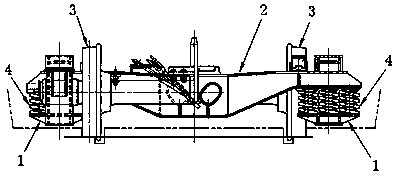

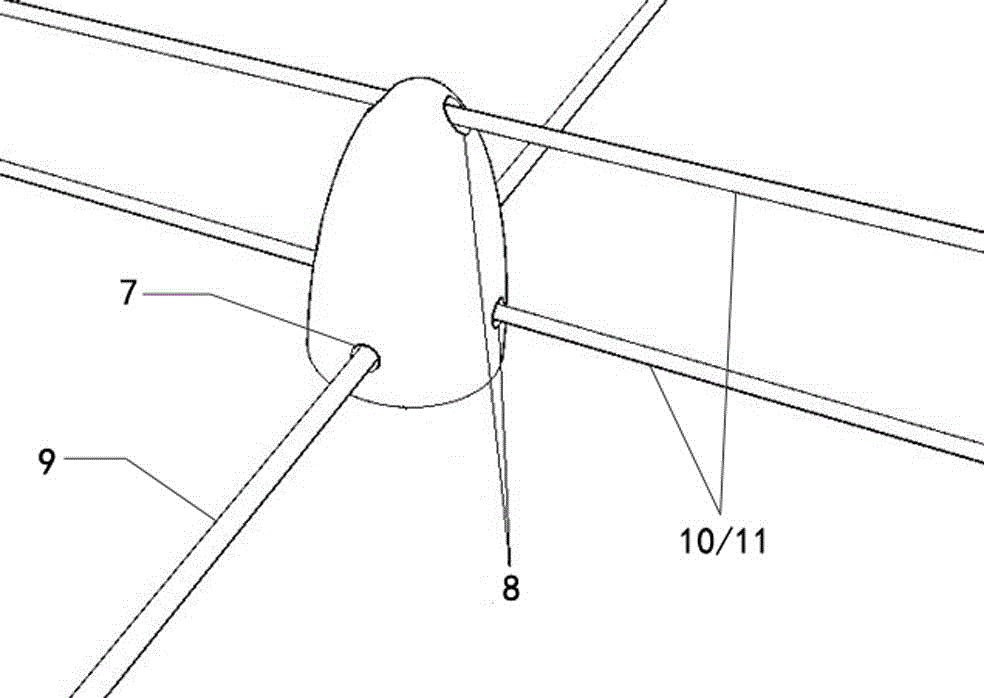

Middle or low speed magnetic suspension train running mechanism with the air spring positioned in the middle

InactiveCN101112872AReduce in quantitySimple structureBogie-underframe connectionsElectric propulsionLow speedAir spring

A middle and low speed maglev train walking mechanism with an air spring arranged in the middle consists of a movable-type walking module and a fixing-point type walking module. Both the walking modules have a bolster transversely arranged in the middle position of a suspension frame; the end part of the bolster is fixedly supported on the suspension frame by the air spring. The center of the movable-type walking module bolster is pinned with a traction block by a connecting pin; the front part and the rear part of the traction block are respectively articulated with a traction arm; the other end of the traction arm is articulated with a vehicle body; both ends of the bolster are articulated with two traction rods on the suspension frame; the external sides at two ends of the bolster are suspended with a hoist rod; the other end of the hoist rod is articulated with the vehicle body. The central position of the fixing-point walking module bolster is provided with a pin hole connected with the central pin of the vehicle body; both ends of the bolster are articulated with the traction rod on the suspension frame; the traction rod is respectively arranged on the front part and the rear part of the suspension frame. The walking mechanism has the advantages of simple structure, low production cost, easy installation and manufacture, large beeline motor power, high efficiency and fast operation speed of the maglev train.

Owner:SOUTHWEST JIAOTONG UNIV

Central buckle structure of self-anchored suspension bridge

PendingCN109183604AUnbalanced force realizationIncrease stiffnessSuspension bridgeBridge structural detailsEngineeringSteel bar

The invention provides a central buckle structure of a self-anchored suspension bridge, being characterized in that a plurality of pairs of rigid central buckles are arranged in the middle span, and each of which comprises a central buckle cable clip and a central buckle bar shaft; the central buckle cable clip is installed on the main cable; the central buckle bar shaft is welded or bolted by twoI-shaped steel bars; the two I-shaped steel bars are herringbone distributed; the upper end of the central buckle bar is connected with the central buckle cable clip; and the lower end of the centralbuckle bar shaft is connected with the main beam. By adjusting the slope and section size of each central buckle, the stiffness coordination of many pairs of rigid central buckles can be realized, and the combined central buckles with different slope and section can be formed, so that many pairs of central buckles can work together and share the unbalanced force between the main cable and the main beam equally. A self-anchored suspension bridge central buckle structure can effectively solve the bending unfavorable problem of the bottom of the main tower of a long-span self-anchored suspensionbridge and the slip problem of the main cable at the tower top.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

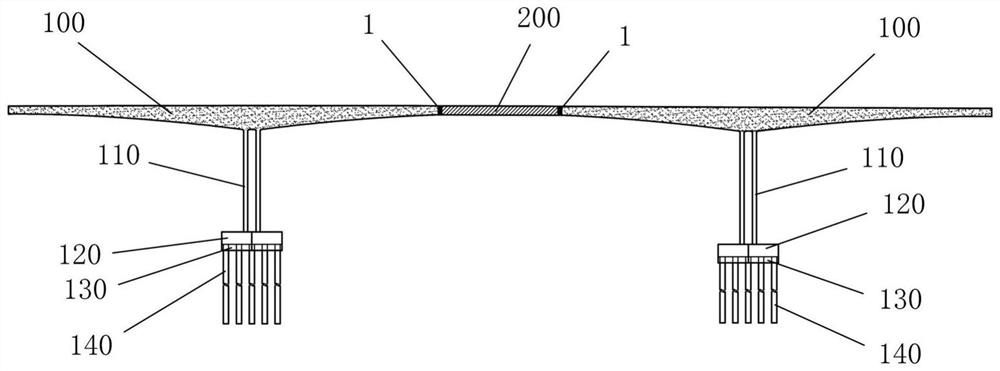

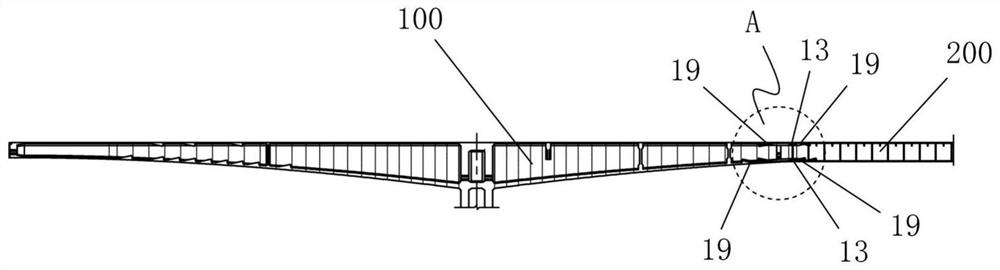

Corrugated web prestress FRP-concrete combined box beam and construction method thereof

InactiveCN105780637ALightweight and high strengthReduce down deflectionBridge materialsPre stressPrestressed concrete

The invention belongs to the field of new material new structures and combination structures in civil engineering and particularly relates to a corrugated web prestress FRP-concrete combined box beam and a construction method thereof. The combined box beam comprises an FRP box beam body, and every two adjacent corrugated webs between a top plate and a bottom plate form a box beam box chamber; and each box beam box chamber is internally provided with an external prestress bar, the two ends of each external prestress bar are connected to the two longitudinal ends of the top plate correspondingly, tension can enable the FRP box beam body to generate a pre-camber in the height direction, and concrete is poured at the top of the box beam body. Each external prestress bar is tensioned in the corresponding box beam box chamber, so that a beam body generates a certain pre-camber in the height direction; thus, the lower flexibility of the FRP-concrete combined box beam under the vehicle load is decreased, the method that the use quantity of FRP or concrete materials is increased to meet structural rigidity in the past is changed, the self weight of the structure is decreased, and the manufacturing cost is reduced; and the problems of shrinkage creep of a traditional prestressed concrete structure and prestress bar loosening and the like are solved.

Owner:SHANXI UNIV

Joint structure of NC-UHPC hybrid rigid frame bridge, hybrid rigid frame bridge and construction method of hybrid rigid frame bridge

PendingCN113047161AQuick dockingEasy constructionBridge structural detailsBridge erection/assemblyConcrete beamsArchitectural engineering

The invention discloses a joint structure of an NC-UHPC hybrid rigid frame bridge, the hybrid rigid frame bridge and a construction method of the hybrid rigid frame bridge. The hybrid rigid frame bridge comprises common concrete beam sections and ultra-high performance concrete beam sections, the ultra-high performance concrete beam sections are midspan beam sections, and the two ends of each ultra-high performance concrete beam section are connected with the corresponding common concrete beam section through the joint structure; the joint structure comprises a first connecting steel plate assembly, a second connecting steel plate assembly and a wet joint, and one end of the first connecting steel plate assembly is embedded in the end of a common concrete beam section and extends out of the end of the common concrete beam section; and one end of the second connecting steel plate assembly is embedded in the end of the ultra-high-performance concrete beam section and extends out of the end of the ultra-high-performance concrete beam section to be connected with the first connecting steel plate assembly. The hybrid rigid frame bridge solves the problems of midspan downwarping and web cracking of a common concrete large-span continuous rigid frame bridge, complex stress of a steel-concrete combined section of a common concrete-steel hybrid rigid frame bridge, and difficult maintenance of a steel box girder section.

Owner:HUNAN PROVINCIAL COMM PLANNING SURVEY & DESIGN INST CO LTD

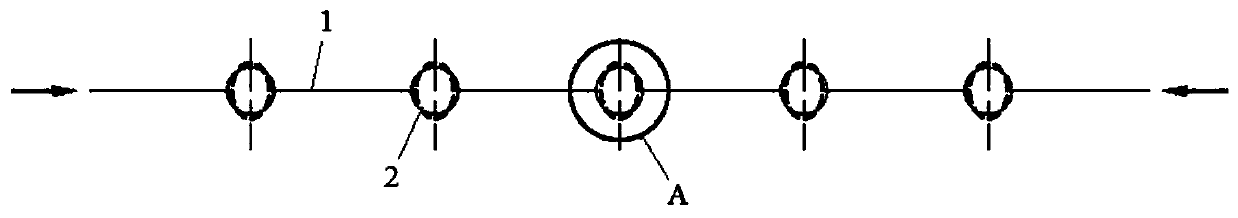

Vacuum magnetic levitation tunnel

ActiveCN103661421AReduce uniformity impactLongitudinal stiffness is smallRailway tunnelsWave crestLevitation

The invention relates to a vacuum magnetic levitation tunnel which comprises a tunnel shell, supports, a roadbed and magnetic levitation blocks for being fixed on the tunnel shell to be suspended and driving a levitation vehicle. The vacuum magnetic levitation tunnel is characterized in that the longitudinal profile of the tunnel shell is a corrugated pipe hook face, and a transverse profile is in a circle or oval shape; one ends of the magnetic levitation blocks are fixed at the positions of the inner side of the bottom of the tunnel shell at equal longitudinally-striding wave pitch number interval, and the other ends of the magnetic levitation blocks are used for sliding supporting; the supports are installed at the positions, at the wave crests equal distance away from the longitudinally-fixing positions of the magnetic levitation blocks, on the outer side of the bottom of the tunnel shell, and the supports are fixed on the roadbed. The buttock line of the corrugated pipe hook face of the tunnel shell is a sine curve and the like. Obviously, fewer materials can be used in the vacuum magnetic levitation tunnel, the longitudinal rigidity of the vacuum magnetic levitation tunnel is reduced to convert the longitudinal internal stress generated by temperature changes into longitudinal elastic deformation, meanwhile, the radial rigidity of the vacuum magnetic levitation tunnel is increased to enable deformation to be not prone to being caused when vacuum and track loads are borne, the temperature change stress is averagely divided by the supports, the uniformity influences of the temperature change stress on magnetic buoyancy and magnetic driving force are reduced, and the components are widely applied to the vacuum magnetic levitation tunnel.

Owner:王昕鑫

Steel box type composite beam forming method

ActiveCN103410081BAvoid diversionLongitudinal stiffness is smallBridge erection/assemblyEngineeringAssembly line

Disclosed is a steel box type composite beam forming method. A split type processing method is utilized in a bottom box and a plug welding technology and an anti-deformation technology are utilized to effectively solve the problems of positioning of force transmission ribs, deformation of the bottom box and the like, and the prefabrication efficiency of steel-concrete composite bridges is improved by reasonably adjusting production processes. The adopted technical scheme of the steel box type composite beam forming method comprises utilizing steel plates as raw materials, leading the raw materials to be subjected to top plate forming, bottom box forming and wave plate forming, and performing assembling and welding to form a prefabricated steel box type composite beam. According to the steel box type composite beam forming method, assembly line production is utilized and large-scale processing and assembling of bottom boxes can be achieved in factories.

Owner:邢台路桥千山桥梁构件有限责任公司

Large cantilever steel web spine box girder segment

ActiveCN103276662BLow costSmall amount of workBridge structural detailsBridge erection/assemblyCantileverTruck

The invention discloses a large-cantilever steel web spinal box beam segment and a construction technology. The large-cantilever steel web spinal box beam segment comprises a unit box beam bottom plate and a unit box beam top plate, wherein two steel webs are arranged between the unit box beam bottom plate and the unit box beam top plate, the unit box beam top plate comprises a top plate cross beam arranged in the middle of the unit box beam top plate and wing plates fixedly connected to the two transverse sides of the top plate cross beam, a reinforcing system is arranged between the transverse outer side of each wing plate and the unit box beam bottom plate, a top plate prestressed pore channel is formed in the unit box beam top plate in the longitudinal direction, bolting preformed holes are formed in the two longitudinal ends of each steel web, and a bottom plate prestressed pore channel is formed the unit box beam bottom plate in the longitudinal direction. According to the large-cantilever steel web spinal box beam segment and the construction technology, each component is of a sectional type structure, fractional hoisting can be adopted, the weight of hoisting is light, the requirements for transportation and hoisting equipment are greatly reduced, and construction can be directly finished by means of matching of a conventional truck-mounted crane or a crawler crane and a small-tonnage beam transporting vehicle.

Owner:CCCC SECOND HARBOR ENG

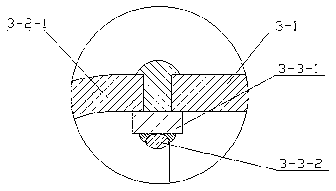

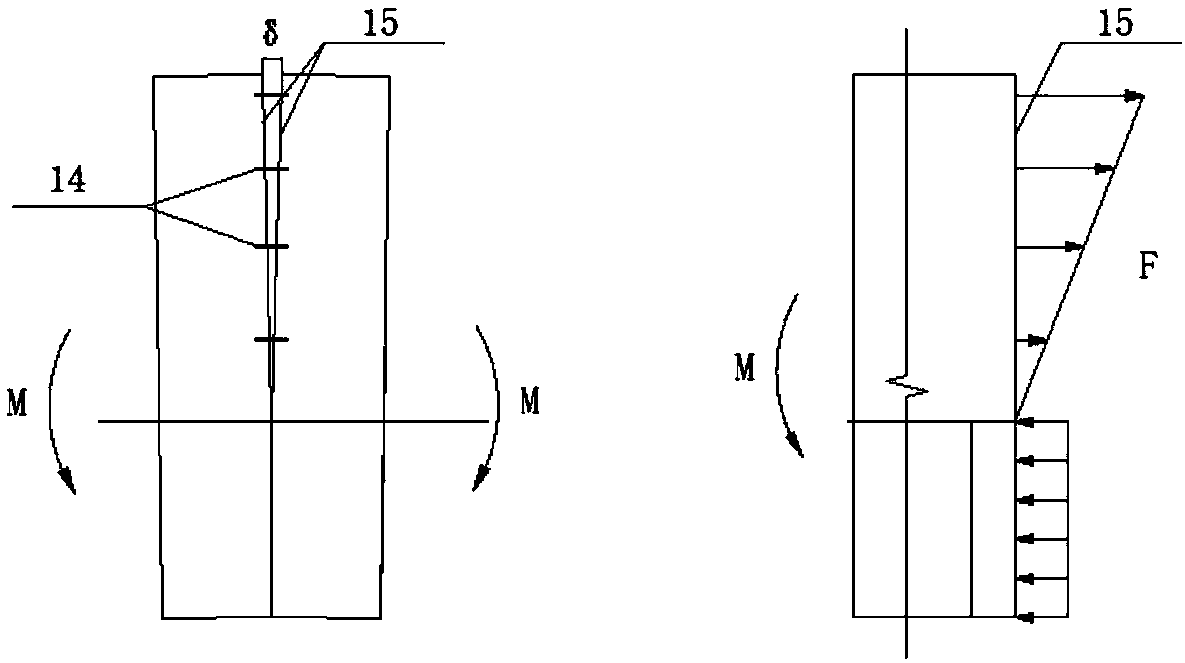

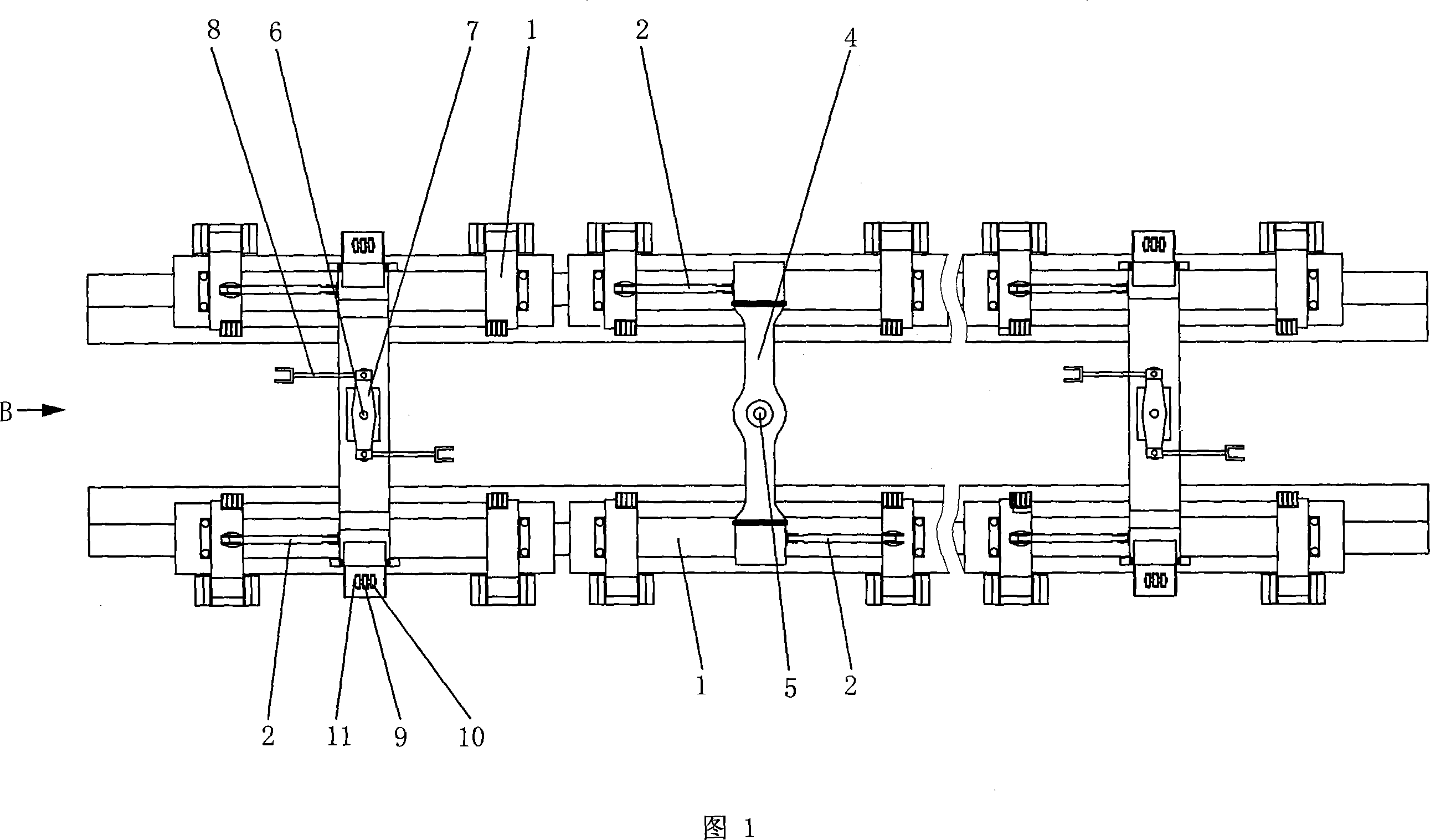

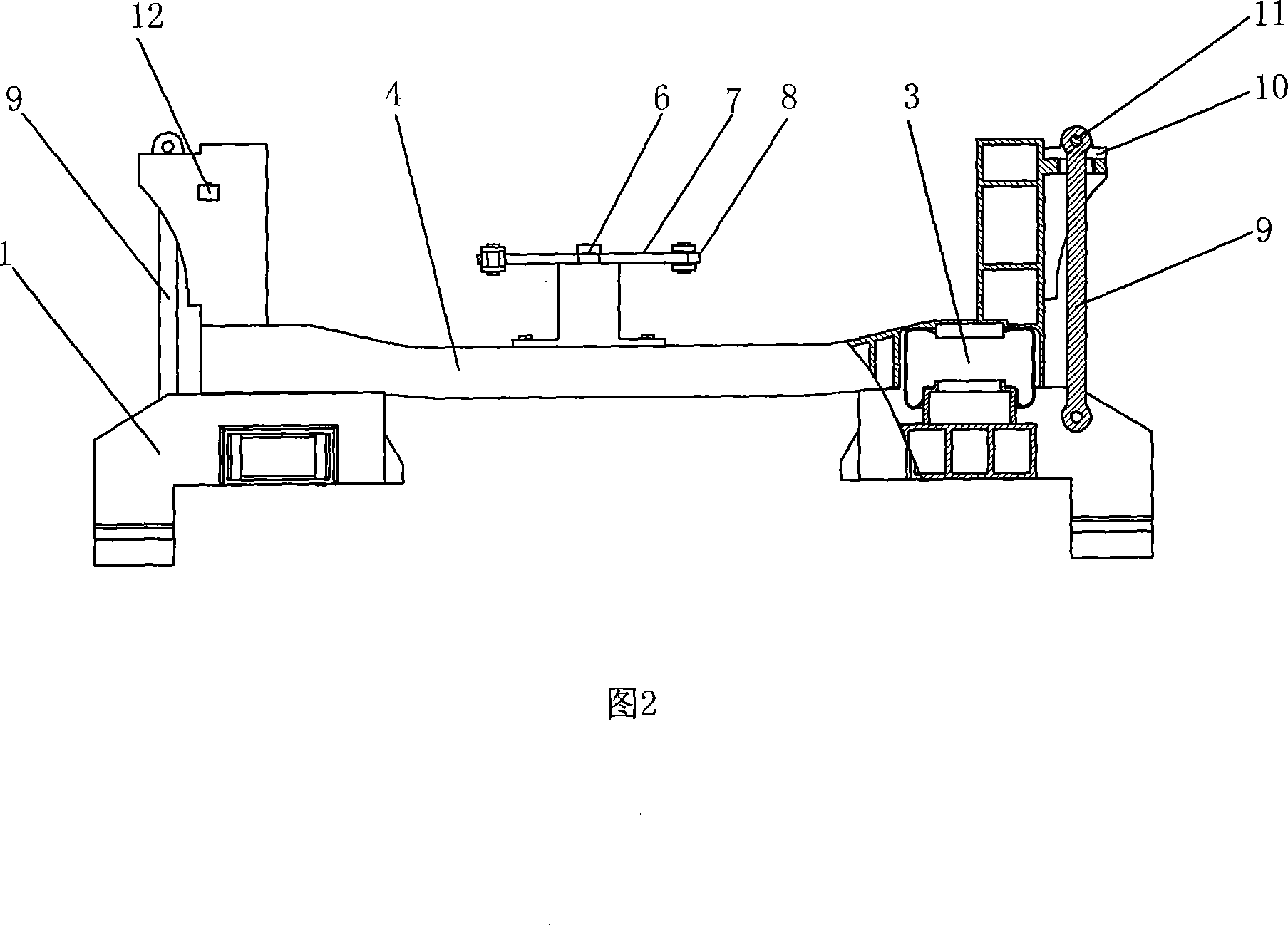

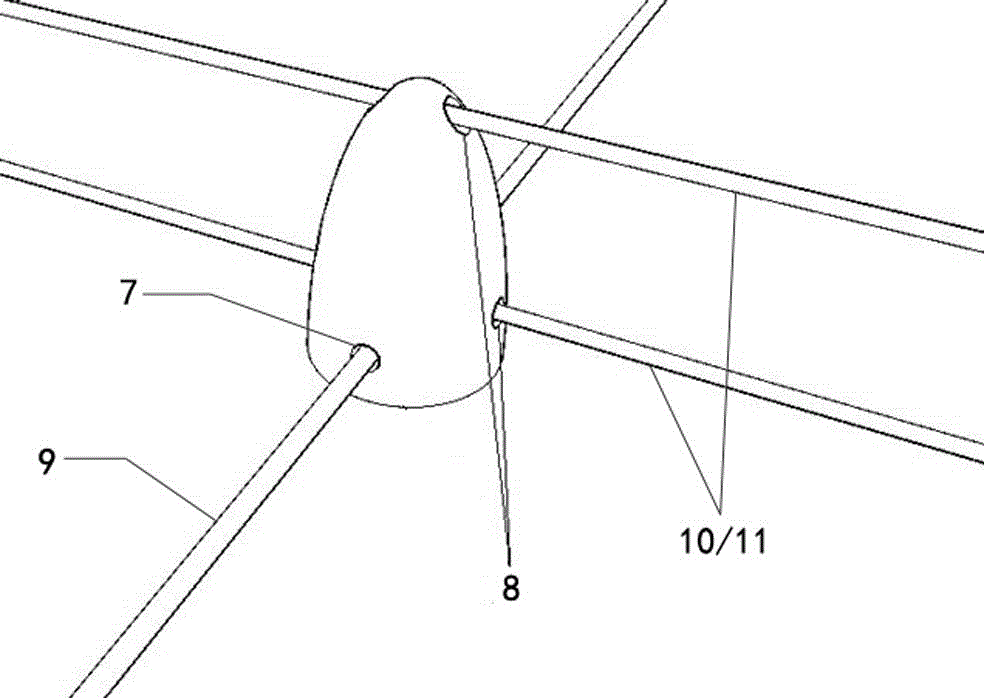

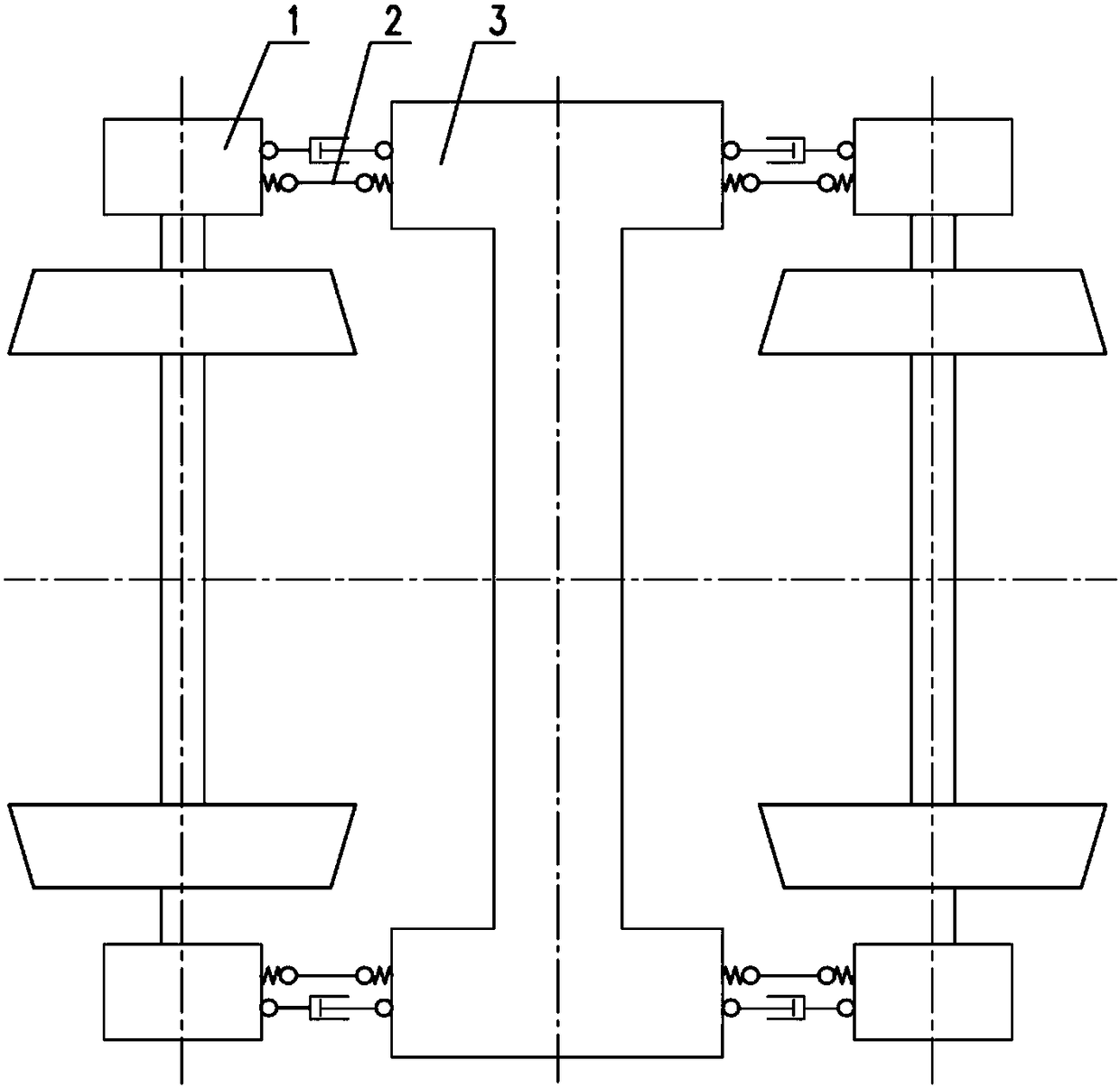

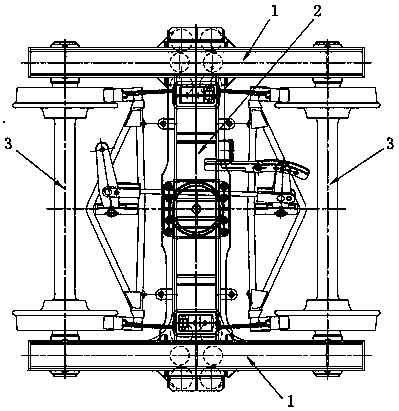

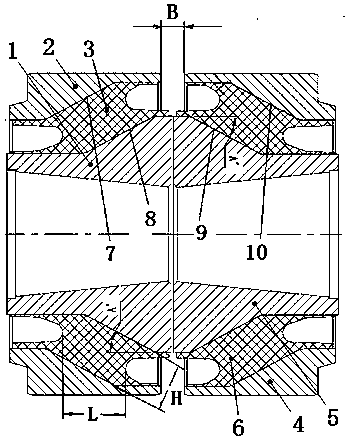

Railway vehicle and bogie thereof

ActiveCN106428082AReduce wearLongitudinal stiffness is smallWheel axle self-adjustmentsAxle-boxes mountingBogieEngineering

The invention discloses a railway vehicle and a bogie thereof. The bogie comprises a frame, and wheel-set axle boxes arranged on two sides of the frame, wherein the frame and the wheel-set axle box on the corresponding side are flexibly connected through a combined flexible connecting element with variable longitudinal rigidity. According to the railway vehicle and the bogie thereof, provided by the invention, the frame and the wheel-set axle box on the corresponding side are flexibly connected through a pull rod assembly with variable longitudinal rigidity, so that the longitudinal rigidity between the frame and the wheel-set axle box can be automatically and adaptively changed, and the curved radial through capacity of an ordinary bogie is obviously improved. Therefore, the bogie has a relatively good radial function, and that the linear operating performance of the bogie is not reduced is ensured.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

Steel pipe-steel plate combined type corrugated steel web

InactiveCN110644346AIncreased shear capacityLongitudinal stiffness is smallBridge structural detailsPre stressPipe

The invention discloses a steel pipe-steel plate combined type corrugated steel web. The steel pipe-steel plate combined type corrugated steel web comprises at least two steel plates and at least onesteel pipe, wherein at least one side of the opposite sides of each steel plate is connected with one steel pipe, the two opposite sides of each steel pipe are correspondingly connected with at leastone steel plate, all the steel plates are arranged in parallel, the axes of all the steel pipes are arranged in parallel, and are located in the same plane; and the steel plates are connected to the side wall of the steel pipe; different types of thin-walled steel pipes can generate different types of buckling deformation under the action of external force perpendicular to the pipe wall, the steelplate-steel plate combined type corrugated steel web just uses the buckling deformation of the thin-wall steel pipes under the action of the longitudinal force for reducing the constraint effect of the whole web plate on a top bottom plate of a combined box girder bridge, reducing the influence of the shrinkage and creep of the top bottom plate concrete part, and improving the longitudinal prestress efficiency; and meanwhile, the thin-wall steel pipes in such combined type web plate further plays a stiffening role on a flat steel plate, and improvs the shearing buckling performance of the steel plate.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Concrete Early Thermal Expansion Coefficient Test Device and Test Method Based on Suspension Method

ActiveCN103293179BLongitudinal stiffness is smallReduce thicknessMaterial thermal coefficient of expansionTemperature controlMeasurement device

The invention relates to a device and a method for testing an early thermal expansion coefficient of concrete based on a suspension method. The device comprises a corrugated pipe test mould for pouring concrete to be tested to form a concrete corrugated pipe test piece, a plurality of rope rings for suspending the concrete corrugated pipe test piece, a device base for suspending the rope rings, a temperature measurement device used for measuring the temperature change of the concrete in the corrugated pipe test mould and having the measurement end of a first thermocouple wire buried in the corrugated pipe test mould, a deformation measurement device for measuring the deformation amount of the concrete corrugated pipe test piece, and a temperature control box used for adjusting the temperature of a test environment and in which a suspension position of the concrete corrugated pipe test piece is located. According to the method, the concrete corrugated pipe test piece is suspended by adopting the device to measure the early thermal expansion coefficient of the concrete. According to the test device and the test method, the friction between the test piece and the test device is effectively reduced, the test precision is improved, the operation is simple, and the using effect is good.

Owner:FUJIAN TONGLI BUILDING MATERIALS SCI & TECH

Pneumatic tire

ActiveCN103129327BIncrease lateral stiffnessLongitudinal stiffness is smallTyre beadsTire beadEngineering

Owner:TOYO TIRE & RUBBER CO LTD

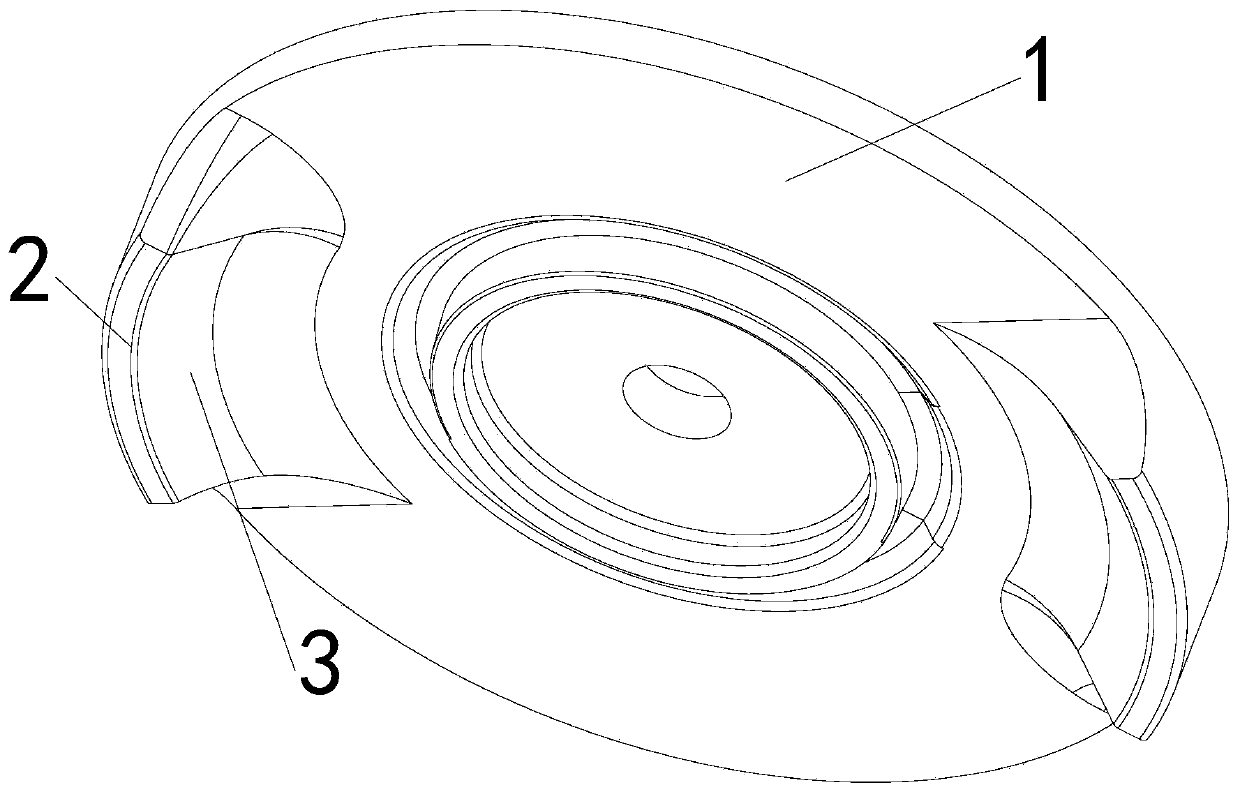

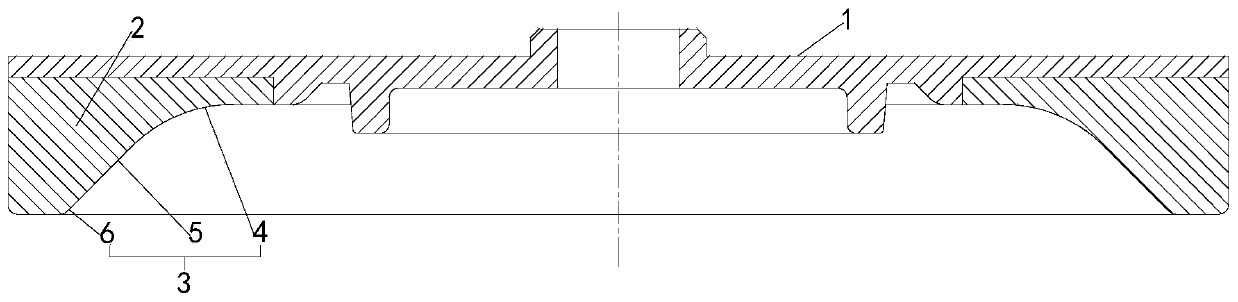

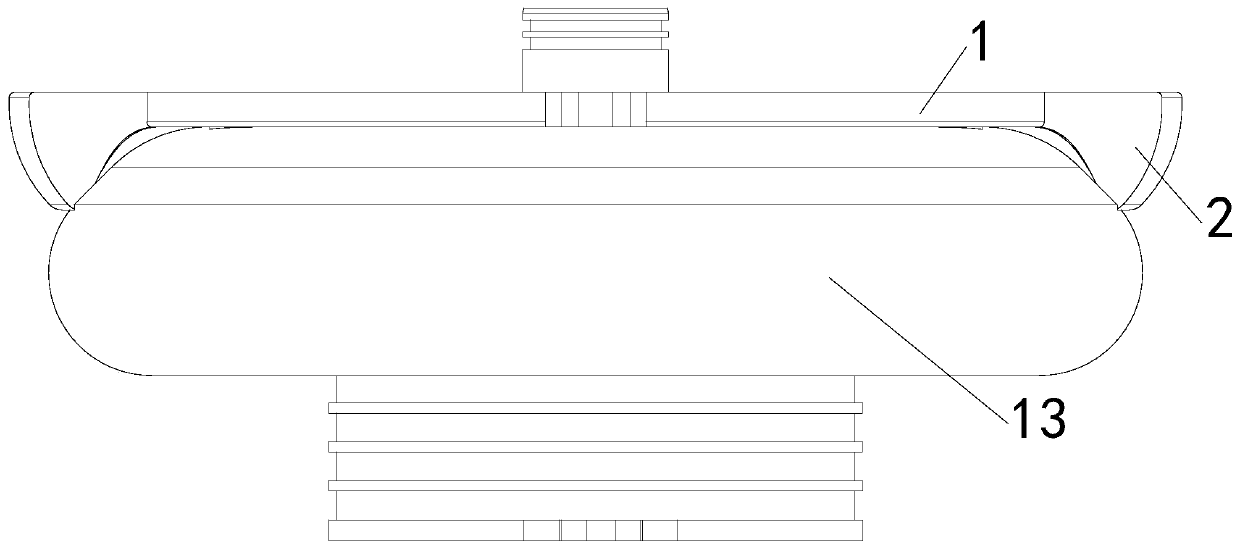

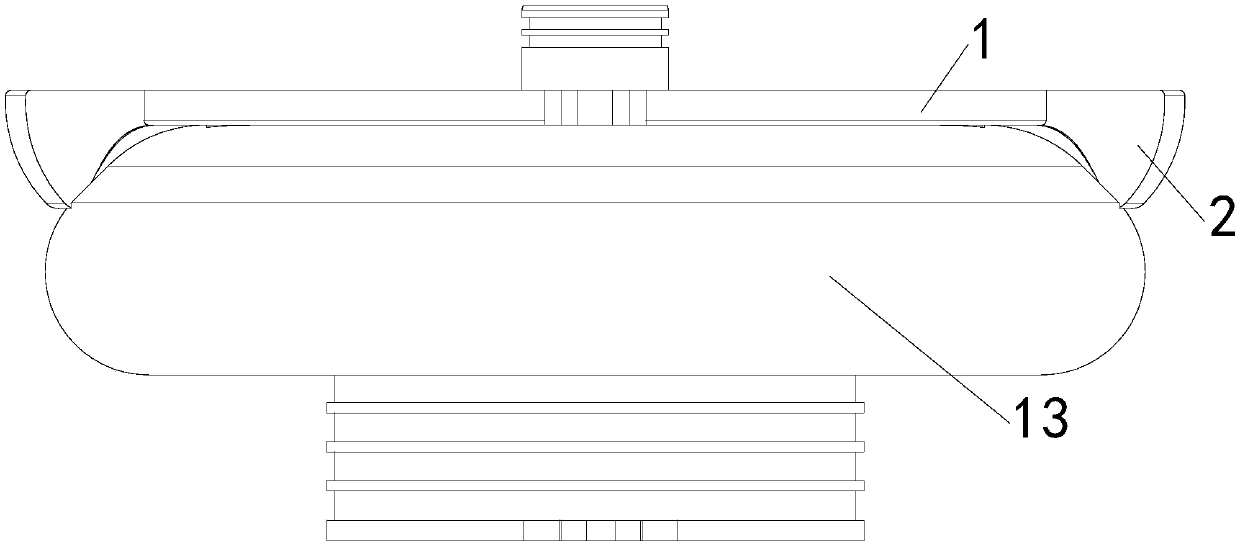

Empty spring cover and empty spring

ActiveCN107859708BLongitudinal stiffness is smallReduce interactionMachine part testingSpringsAir springEngineering

The invention provides an air spring upper cover, an air spring, an air spring upper cover test tool and an air spring upper cover manufacturing method. The air spring upper cover comprises a cover plate and two stopping parts, wherein the two stopping parts are fixedly connected onto the same board surface of the cover plate; the two stopping parts are distributed at an interval so as to enable the air spring upper cover to be U-shaped, and the two stopping parts can limit the transversal displacement of an air spring air bag along a vehicle from the two sides of the air spring air bag. According to the air spring upper cover, the air spring, the air spring upper cover test tool and the air spring upper cover manufacturing method, a vehicle can meet the requirement of a smaller gyroscopicmoment during the curve driving process and the requirement of little transversal shaking.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

A rail vehicle and its bogie

ActiveCN106428082BReduce wearLongitudinal stiffness is smallWheel axle self-adjustmentsAxle-boxes mountingBogieAgricultural engineering

The invention discloses a railway vehicle and a bogie thereof. The bogie comprises a frame, and wheel-set axle boxes arranged on two sides of the frame, wherein the frame and the wheel-set axle box on the corresponding side are flexibly connected through a combined flexible connecting element with variable longitudinal rigidity. According to the railway vehicle and the bogie thereof, provided by the invention, the frame and the wheel-set axle box on the corresponding side are flexibly connected through a pull rod assembly with variable longitudinal rigidity, so that the longitudinal rigidity between the frame and the wheel-set axle box can be automatically and adaptively changed, and the curved radial through capacity of an ordinary bogie is obviously improved. Therefore, the bogie has a relatively good radial function, and that the linear operating performance of the bogie is not reduced is ensured.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

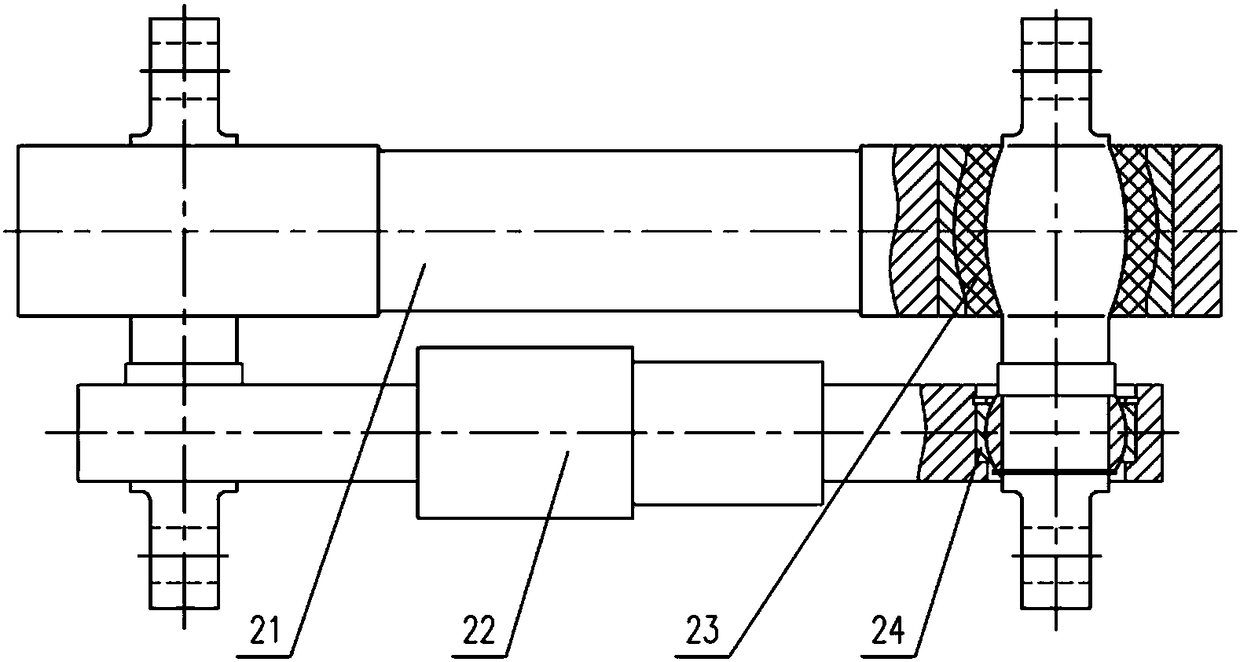

Method for Preventing Axlebox Bearing from Abrasion by Adjusting Rubber Layer Thickness and Rotary Arm Node

ActiveCN106627638BAvoid wear and tearWear prevention or reductionAxle-boxes mountingTorsional rigidityBearing wear

The invention discloses a method for adjusting the thickness of rubber layers to prevent an axle box bearing from being abraded and tumbler joints. The method for adjusting the thickness of the rubber layers to prevent the axle box bearing from being abraded comprises the steps that a combination structure of two conical inner hole tumbler joints is adopted, and the longitudinal rigidity, axial rigidity, torsional rigidity and deflection rigidity of the tumbler joints are changed by increasing the thickness of the tumbler joint rubber layers, so that the longitudinal rigidity and the deflection rigidity of the tumbler joints are lowered; meanwhile, the torsional rigidity is prevented from being lowered by increasing the axial rigidity, and axle bearing abrasion is effectively lowered; the thickness of the left and right rubber layers is 22-30 mm, and the length of the left and right rubber layers is 35-60 mm. The longitudinal rigidity, axial rigidity, torsional rigidity and deflection rigidity of the tumbler joints are changed by increasing the thickness of the tumbler joint rubber layers, and the longitudinal rigidity and the deflection rigidity of the tumbler joints are lowered; meanwhile, by increasing the axial rigidity, the torsional rigidity is prevented from being lowered, and the axle bearing abrasion is effectively lowered.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

The method of adjusting the stiffness by changing the structural size of the pivoting arm joints and the pivoting arm joints

A method for adjusting the rigidity by changing the structural size of a rotation arm node can improve the rigidity matching performance of the rotation arm node by changing the structural size of the rotation arm node. A two tapered inner hole rotation arm node combined structure is adopted, the rigidity performance of the rotation arm node is changed by changing the size of a rubber profile of the rotation arm node and the diameter size of an inner sleeve and an outer sleeve of the rotation arm node, and then the longitudinal rigidity and the deflection rigidity of the rotation arm node are lowered. The rigidity of the rotation arm node is adjusted by matching the size of the rubber profile and the diameter size of the inner sleeve and the outer sleeve of the rotation arm node, the longitudinal rigidity and the deflection rigidity of the rotation arm node are lowered, and the longitudinal rigidity of the rotation arm node is controlled in 11-13 KN.mm<-1>; the deflection rigidity is lowered by controlling the longitudinal rigidity, the axial rigidity is improved, the axial rigidity of the rotation arm node is controlled in 6-8 KN.mm<-1>, and the torsional rigidity will not decrease. The experiment proves that the method can effectively prevent or relieve abrasion of bearings in a axle box.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

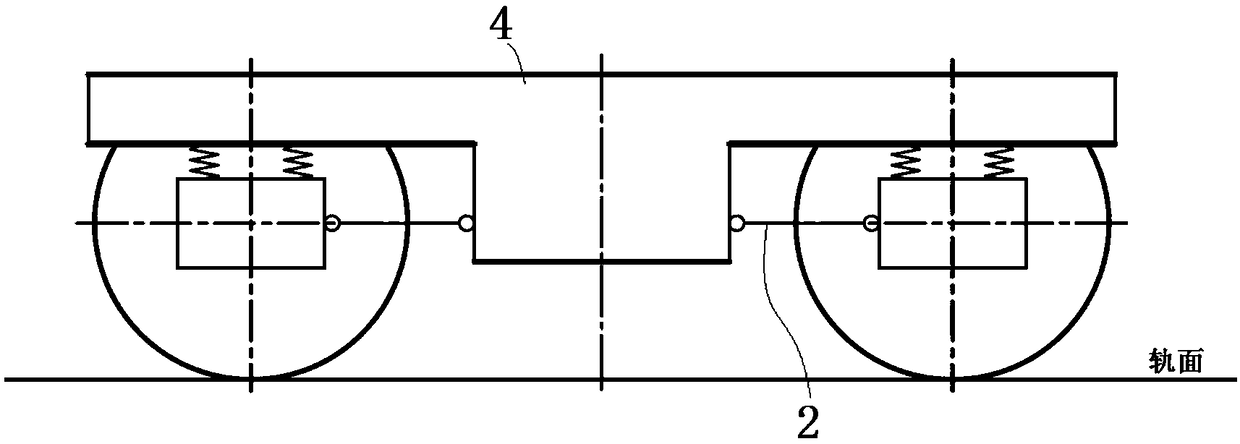

Low floor rail flat car, bogie and welding method

The invention also relates to a low floor rail flat car bogie comprising two sets of wheel pairs, springs and three main parts formed by two side frames and a swing bolster. The side faces of the sideframes are provided with saddle-shaped large circuitous arc shapes, the height of a bottom plate of a shaft box is reduced, the height of the portion, where a lower core disc is fixed, of the middleportion of the swing bolster is lower than the height of the two ends, and the height of the bearing surface of the bogie is further reduced. After the technical measures are taken, the height difference between the surface of the lower core disc and the rail surface is not larger than 495 mm, and the requirement for the low bearing surface of a subway flat car is met. The invention also relates to the low floor rail flat car comprising the bogie and a car body mounted on the bogie; and when the low floor rail flat car is no-load, the height of a floor from the rail surface is not higher than800 mm, loading, unloading and transportation of engineering equipment and apparatuses are facilitated, and meanwhile, the net height and the effective volume on the floor are increased.

Owner:ZHUZHOU XUYANG ELECTRICAL & MECHANICAL TECH DEV CO LTD

Air spring upper cover, air spring, air spring upper cover test tool and air spring upper cover manufacturing method

ActiveCN107859708ASmall turning momentReduce lateral shakeMachine part testingSpringsAir springAirbag deployment

The invention provides an air spring upper cover, an air spring, an air spring upper cover test tool and an air spring upper cover manufacturing method. The air spring upper cover comprises a cover plate and two stopping parts, wherein the two stopping parts are fixedly connected onto the same board surface of the cover plate; the two stopping parts are distributed at an interval so as to enable the air spring upper cover to be U-shaped, and the two stopping parts can limit the transversal displacement of an air spring air bag along a vehicle from the two sides of the air spring air bag. According to the air spring upper cover, the air spring, the air spring upper cover test tool and the air spring upper cover manufacturing method, a vehicle can meet the requirement of a smaller gyroscopicmoment during the curve driving process and the requirement of little transversal shaking.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

Corrugated web prestressed frp-concrete composite box girder and its construction method

InactiveCN105780637BLightweight and high strengthReduce down deflectionBridge materialsPre stressPrestressed concrete

Owner:SHANXI UNIV

The Method of Preventing Axlebox Bearing from Abrasion by Adjusting the Joint Parameters of the Rotary Arm and the Joint of the Rotary Arm

ActiveCN106627641BAvoid wear and tearReduce wearAxle-boxes mountingTorsional rigidityComposite structure

Provided is a method for preventing axle box bearing abrasion by adjusting pivoted arm node parameters. The method is characterized in that a two-section tapered inner hole pivoted arm note composite structure is adopted, the longitudinal rigidity, axial rigidity, torsional rigidity and deflection rigidity of a pivoted arm node are changed by adjusting parameters of all aspects of the pivoted arm node, the longitudinal rigidity and the deflection rigidity of the pivoted arm node are reduced, a transverse load of a vehicle passing through a curve at a high speed is reduced, by increasing the axial rigidity, the phenomenon that the torsional rigidity of the pivoted arm node is reduced is avoided, and therefore bearing abrasion inside an axle box is reduced. Accordingly, pivoted arm type axle box positioning is adjusted by improving the longitudinal rigidity and the axial rigidity of the pivoted arm node, the transverse load of the vehicle passing through the curve at a high speed is reduced, and the bearing abrasion inside the axle box is prevented or reduced.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com