Joint structure of NC-UHPC hybrid rigid frame bridge, hybrid rigid frame bridge and construction method of hybrid rigid frame bridge

A rigid frame bridge and structural technology, applied in the field of bridge design, can solve the problems of complex stress on steel-concrete joints and difficult maintenance of steel box girder sections, and achieve reliable shear resistance, small longitudinal compressive stress, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

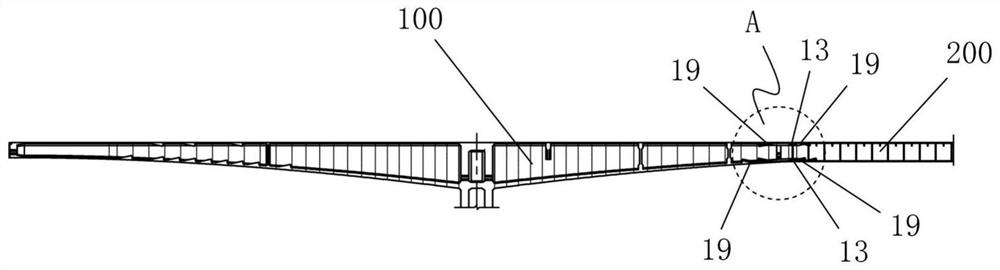

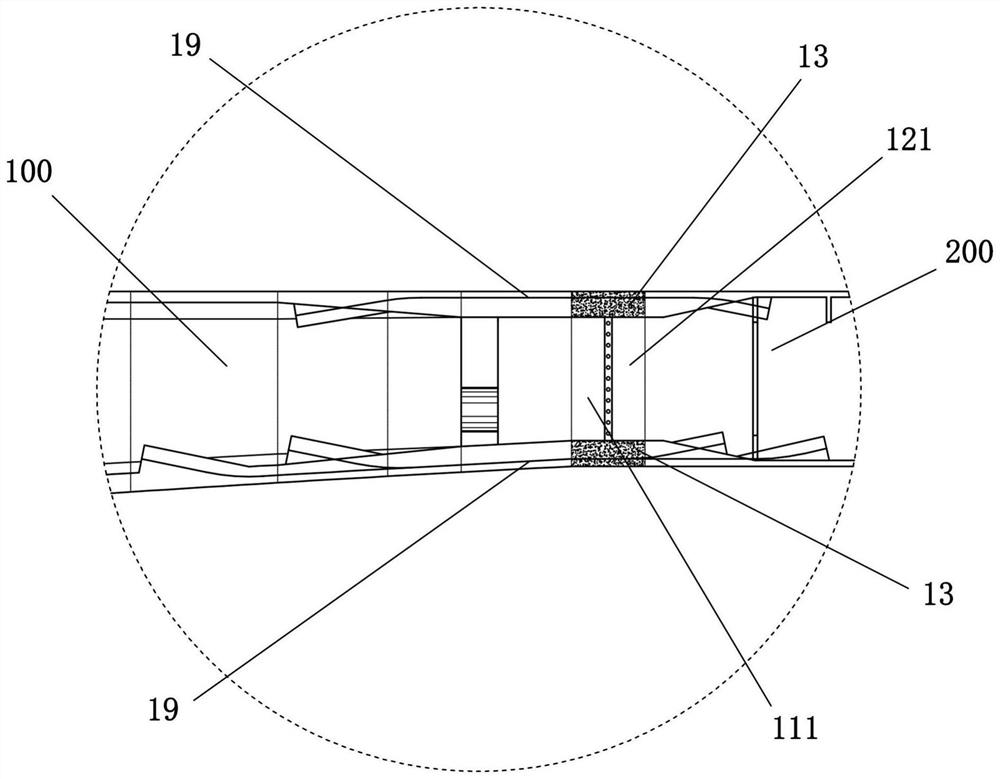

[0048] see Figure 2 to Figure 13 , a joint structure of an NC-UHPC (ordinary concrete-ultra high performance concrete) hybrid rigid frame bridge according to an embodiment of the present invention, the hybrid rigid frame bridge includes an ordinary concrete beam section 100 and an ultra high performance concrete beam section 200; The seam structure includes a first connecting steel plate assembly 11, a second connecting steel plate assembly 12 and a wet joint 13; one end of the first connecting steel plate assembly 11 is pre-embedded at the end of the ordinary concrete beam section 100, and the other end is connected from the ordinary concrete beam The end of the section 100 protrudes; one end of the second connecting steel plate assembly 12 is embedded in the end of the ultra-high performance concrete beam section 200, and the other end protrudes from the end of the ultra-high performance concrete beam section 200, and is connected with the The first connecting steel plate a...

Embodiment 2

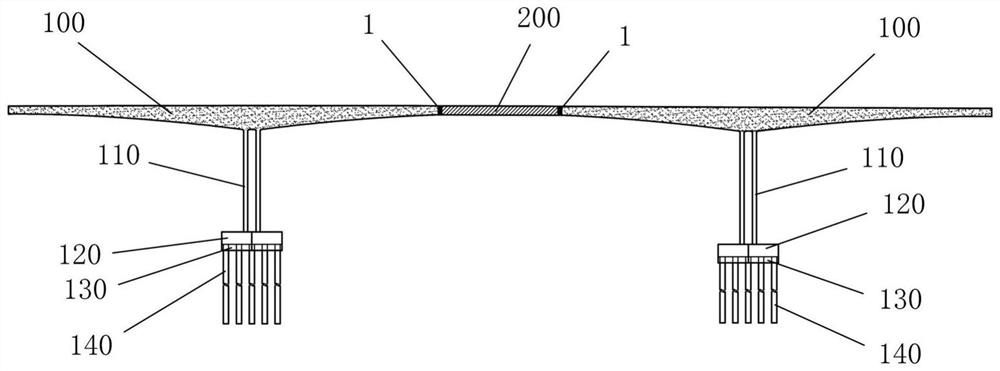

[0058] see Figure 1 to Figure 18 , an NC-UHPC hybrid rigid frame bridge according to an embodiment of the present invention, the hybrid rigid frame bridge mainly includes an ordinary concrete beam section 100 and an ultra-high performance concrete beam section 200 . Among them, a reinforced concrete pier 110, a cap 120, a back cover 130 and a pile foundation 140 are arranged below the ordinary concrete beam section 100; while the ultra-high performance concrete beam section 200 is a mid-span beam section, and its lower part is suspended in the air (see figure 1 ). Both ends of the ultra-high performance concrete beam section 200 are respectively connected to an ordinary concrete beam section 100 through the joint structure of Embodiment 1 of the present invention. The specific structure of the seam structure is as described in Embodiment 1, and will not be repeated here.

[0059] In the above-mentioned NC-UHPC hybrid rigid frame bridge, an ultra-high performance concrete be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com