Reinforcement cage lifting device

A steel cage and spreader technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve problems such as butt joints and difficulties of easily deflected steel cages, and achieve the effect of ensuring progress and quality, easy docking, and ensuring verticality

Inactive Publication Date: 2011-06-15

HENAN MINE CRANE

View PDF5 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a steel cage hanger to solve the problem that the existing steel cage is easy to deflect when hoisting, which makes it difficult to connect the steel cage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

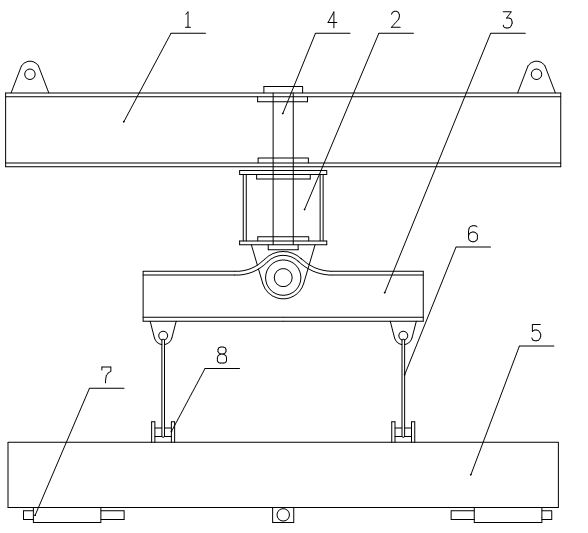

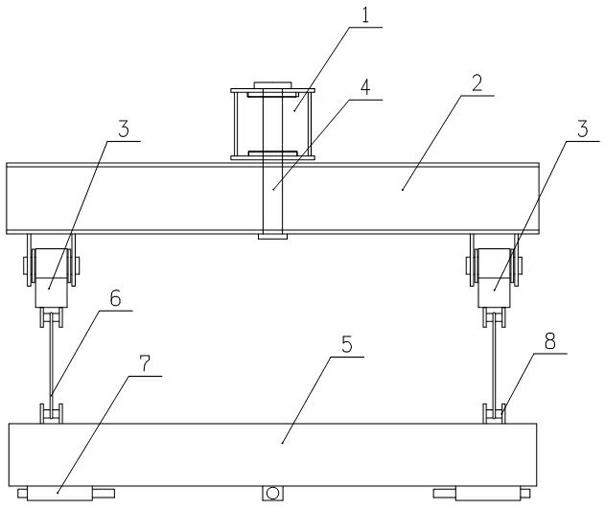

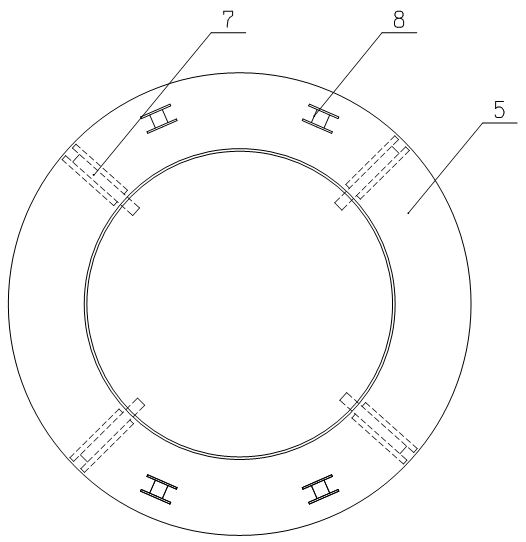

The invention discloses a reinforcement cage lifting device, which comprises an upper beam, a middle beam, lower beams and an annular beam for connecting a reinforcement cage, wherein the two ends of the upper beam are fixed with a lifting lug for connecting a crane respectively; the middle beam is hinged to the center of the upper beam through a connecting shaft vertically inserted into the middle beam; the lower beams are hinged to the two ends of the middle beam through pin shafts horizontally inserted into the centers of the lower beams respectively; and the annular beam is horizontally suspended on the lower beams by corresponding suspenders. When in use, the reinforcement cage lifting device connects the reinforcement cage to the annular beam in a suspension way, and when the reinforcement cage is jointed, can conveniently drive the reinforcement cage to horizontally rotate, flexibly regulate the vertical angel of the reinforcement cage and ensure the verticality of the reinforcement cage in a jointing process to easily and rapidly finish the jointing of the reinforcement cage, increase the jointing speed of the reinforcement cage and improve the jointing quality of the reinforcement cage by hinging fit among the upper, middle and lower beams, thereby ensuring the progress and quality of pile foundation construction.

Description

Steel cage spreader technical field The invention relates to a sling used for hoisting a reinforcement cage in pile foundation construction. Background technique At present, in the pile foundation construction of bridges, high-rise buildings or high-speed railways, it is necessary to dig deep pile holes first, and then put a reinforcement cage in the pile holes and then pour cement to form a reinforced concrete structure. Because the pile holes are very deep, the reinforcement cages need to be fabricated in sections, and then lowered into the pile holes by a crane, and the main bars on the two reinforcement cages are manually screwed through the connecting sleeves to form a reinforcement skeleton. The existing reinforcement cages are hoisted by ropes or hooks, which are easy to stretch and deform the reinforcement cages. In addition, the reinforcement cages are prone to deflection during the transportation process, making adjustment difficult, and the upper and lower reinf...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B66C1/10B66C1/12B66C1/62B66C13/08

Inventor 高明利任海涛

Owner HENAN MINE CRANE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com