Welding method and equipment for multifunctional threaded fastener

A technology of threaded fasteners and welding methods, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high cost, inability to take out, increase production cost, etc., and achieve low welding pressure, good welding quality, and welding. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

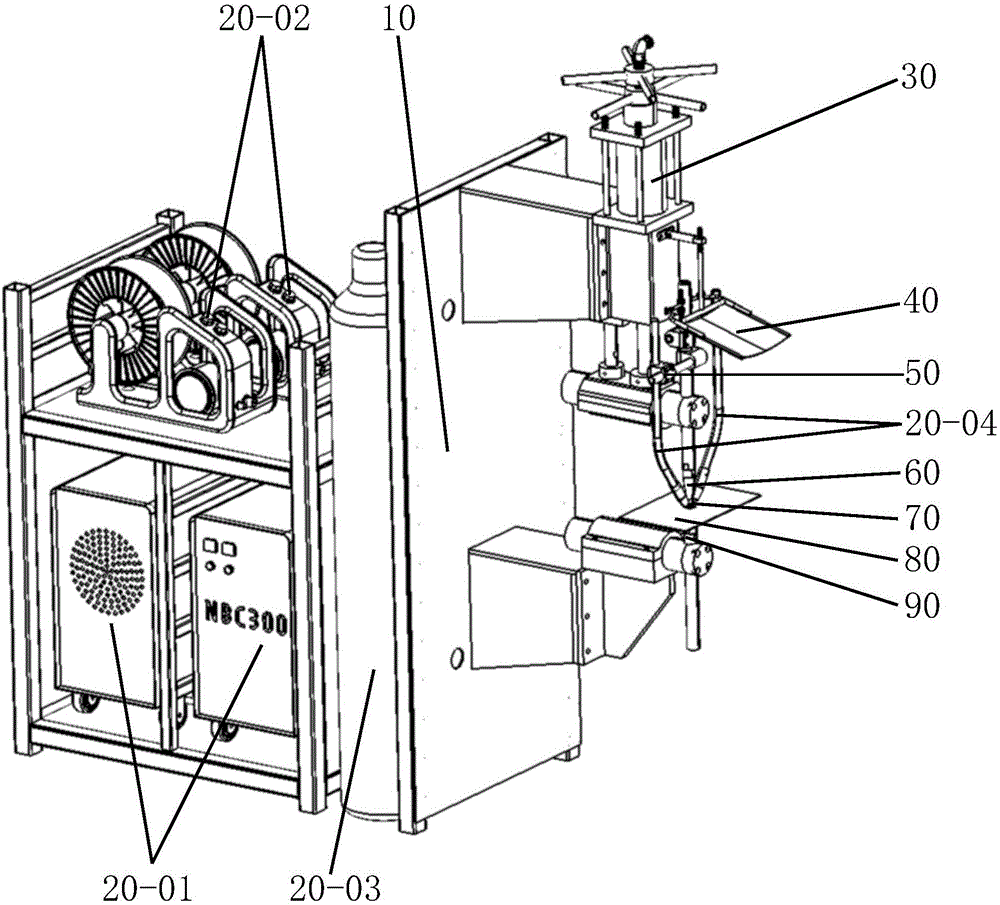

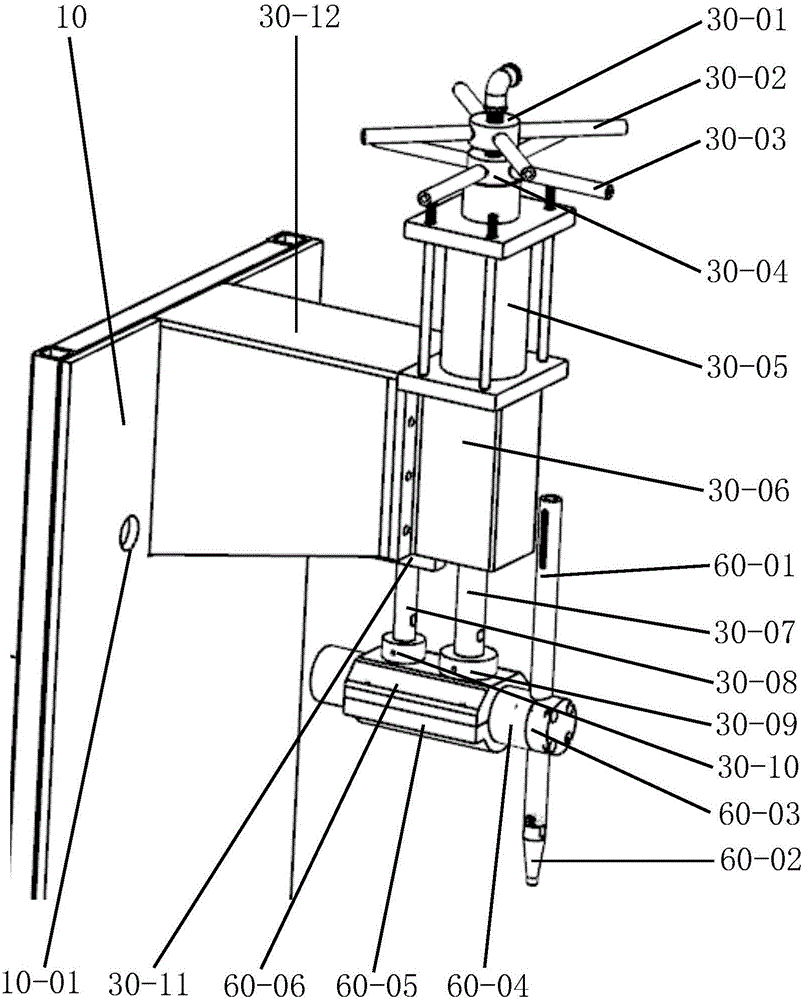

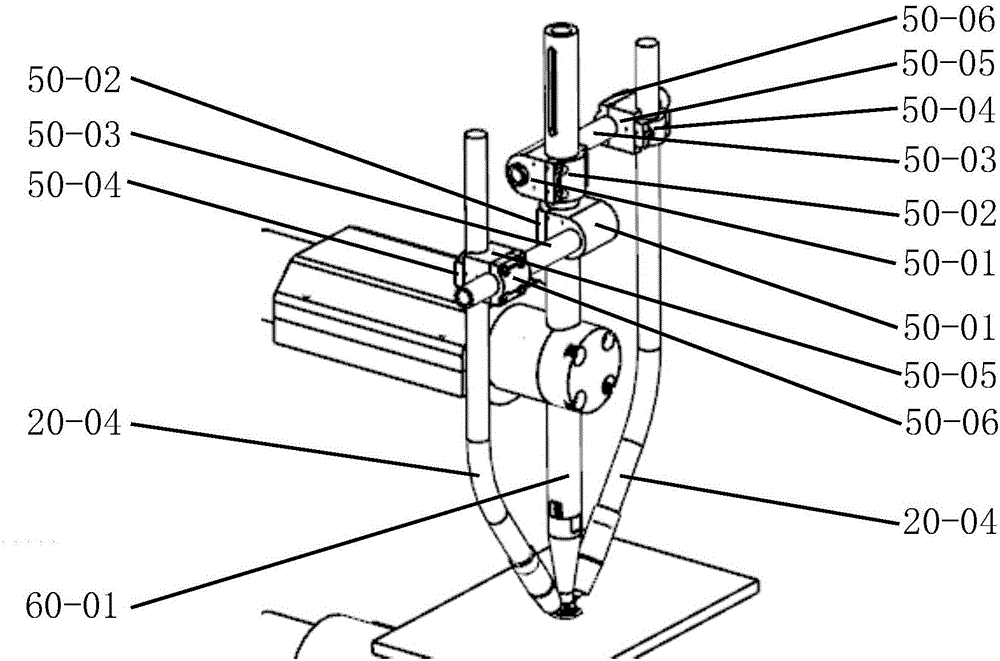

[0063] Embodiment 1: Welding power supply (20-01) and wire feeding mechanism (20-02) are placed at the rear of the body (10). What is used here is a welding machine with the wire feeding mechanism outside the power supply. Of course, the wire feeding mechanism can also be used Welder inside the power supply. One welding power supply (20-01) can be placed at the rear of the body (10), or two, three, four or even more can be placed squarely. Correspondingly, the clamping welding torch (20-04) can also be equipped with Hands, two, three, four or even more. The welding power supply (20-01) placement area is provided with heat dissipation holes or heat dissipation windows to facilitate the heat dissipation of the welding power supply. And when the welding power source needs to weld other products, it should be easy to take out from the body (10). There is a welding terminal at the rear of the body (10), and the output terminal of the welding power supply (20-01)—the positive or n...

Embodiment 2

[0076] Embodiment 2: This embodiment is the technical scheme of welding bolts, such as Figure 6 shown. Except for the positioning mechanism (90), other structures of the device are consistent with Embodiment 1. The lower adjusting rod (90-05) of the positioning mechanism (90) is connected with the bolt positioning rod (90-11), and the bolt insulating sleeve (90-10) of high-strength insulating material is arranged in the bolt positioning rod (90-11). Positioning holes for positioning bolts (70-01) are arranged in the insulating sleeve (90-10). The upper workpiece (80-01) of the bolt positioning rod (90-11) is the positioning surface in the up and down direction, and the pressing surface at the lower end of the pressing rod (60-02) is larger than the bearing surface (70-01) of the bolt (70-01). -1) Small. Since the bolt (70-01) does not need bumps, the bearing surface (70-01-1) of the bolt (70-01) can also be made smaller than the projection welding bolt.

[0077] In additi...

Embodiment 3

[0079] Embodiment 3: This embodiment is a technical scheme for welding pipe fittings with holes at the welding place and nuts, such as Figure 7 shown. This embodiment adopts a TIG welding machine, and the welding torch of the welding machine is installed on the lower adjustment column, and a positioning frame of a round pipe (80-02) is added in addition. The positioning frame (90-12) is connected with the lower adjustment column concave block (90-06) above the lower adjustment column clamp block (90-07). There is an adjusting gasket between the positioning frame (90-12) and the lower adjusting column clamping block (90-07), which is used to adjust the position of the vertical direction of the positioning frame (90-12). Adjustment hole is arranged on the spacer connecting block (90-12-3), is used for adjusting the position of spacer (90-12) front and rear direction. The plane above the positioning longitudinal bar (90-12-1) is the positioning surface of the round pipe (80-02...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com