Simultaneous cooling assisted connection method based on laser additive manufacturing

A connection method and laser additive technology, applied in the field of material processing engineering, can solve the problems of grain size growth, heat loss, joint performance degradation, etc., to achieve the effects of heat loss accumulation, avoiding oxidation, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

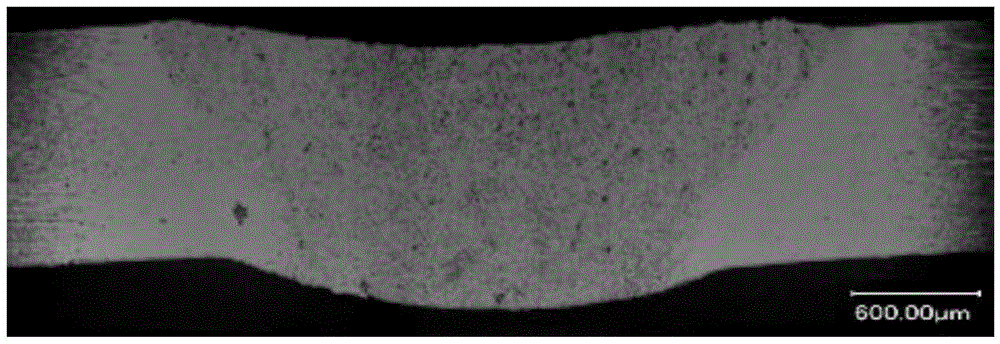

Examples

specific Embodiment approach 1

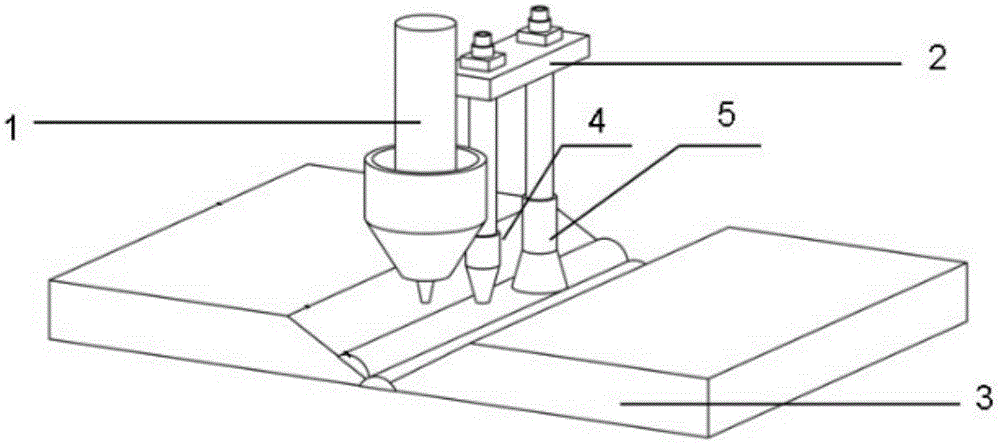

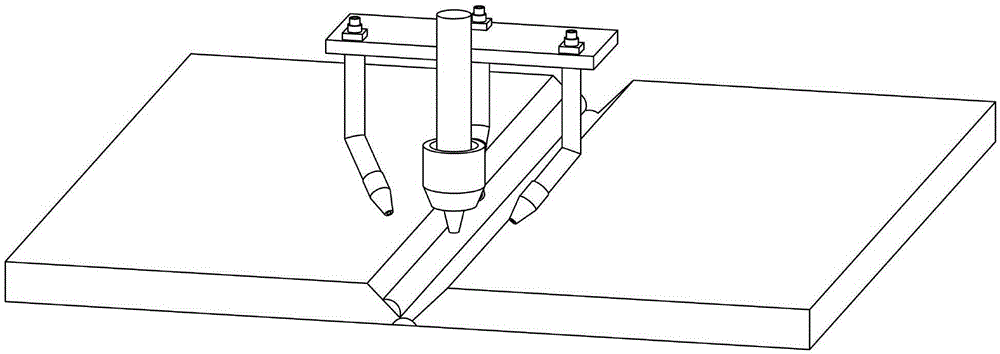

[0029] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment is a synchronous cooling-assisted connection method based on laser additive manufacturing, which is carried out according to the following steps:

[0030] Cooling with a cooling medium (liquid nitrogen or inert gas) to achieve a simultaneous cooling-assisted joining technology based on laser additive manufacturing.

[0031] 1. Connect the cooling device 2 to the laser working head 1 to realize the common movement of the cooling device and the laser head, and the angle between the cooling device 2 and the laser working head 1 is 0°~90°, and the relative position is 10mm~100mm; Fix the cooling device 2 and the laser working head 1 on the robot, and realize the synchronous movement of the cooling device and the laser head by controlling the movement of the robot;

[0032] 2. The workpiece 3 to be connected is grooved, and the groove is processed into a V-shaped groove, and the sur...

specific Embodiment approach 2

[0038] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the laser emitting laser is a semiconductor laser, CO 2 laser, YAG solid-state laser or fiber laser. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0039] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the process parameters of step 4 are: the diameter of the laser spot is 1-5mm, the defocus is -5-+5mm, the laser power is 800-10000W, and the scanning The speed is 10-40mm / s, the powder diameter is 40-100μm, the powder feeding rate is 5-20g / min, the layer thickness is 1-5mm, the scanning distance is 1-4mm, the protective gas is an inert gas, and the protective gas flow rate is 8~30L / min; the cooling medium is liquid nitrogen or inert gas, and the cooling gas flow rate is 0.1~20l / min. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com