Patents

Literature

929 results about "Laser additive manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

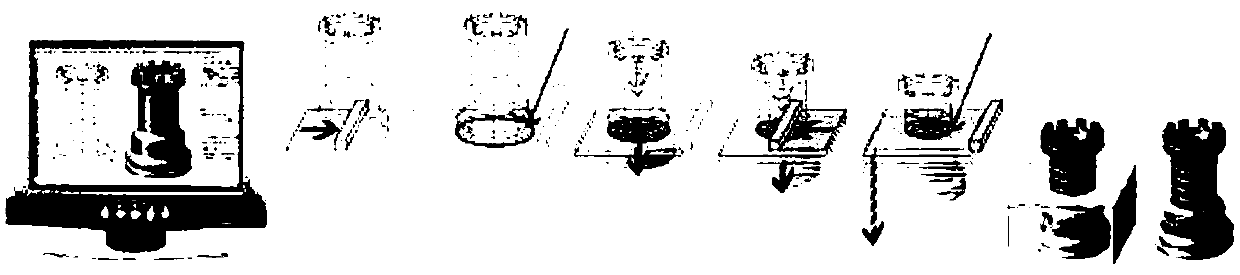

Laser additive manufacturing is a process in which metallic material (in powder or wire form) is deposited in either singular or successive layers to produce a feature on an existing substrate or a new free-form product. Flexibility to match or modify material properties to that of substrate.

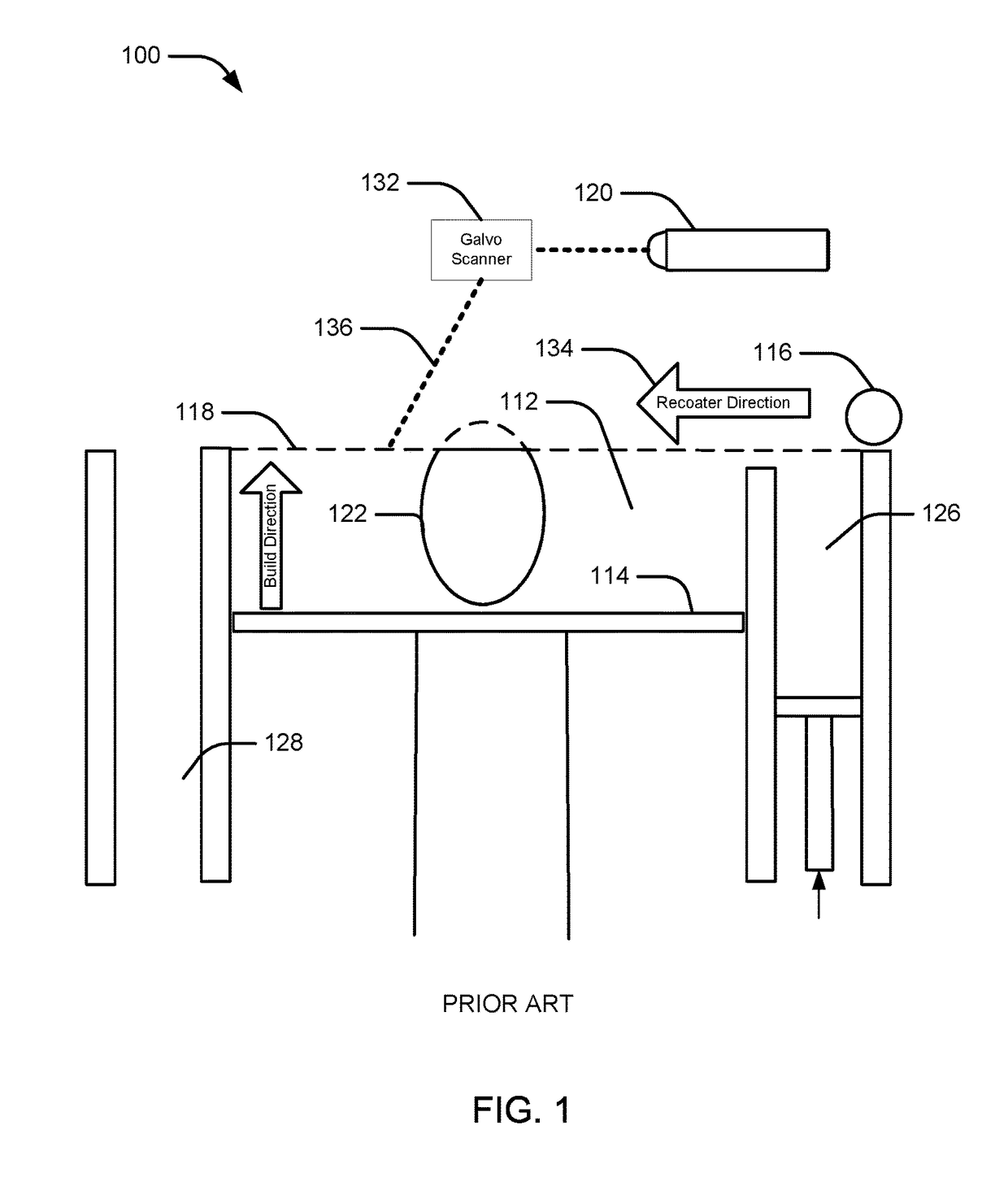

Systems and methods for additive manufacturing and repair of metal components

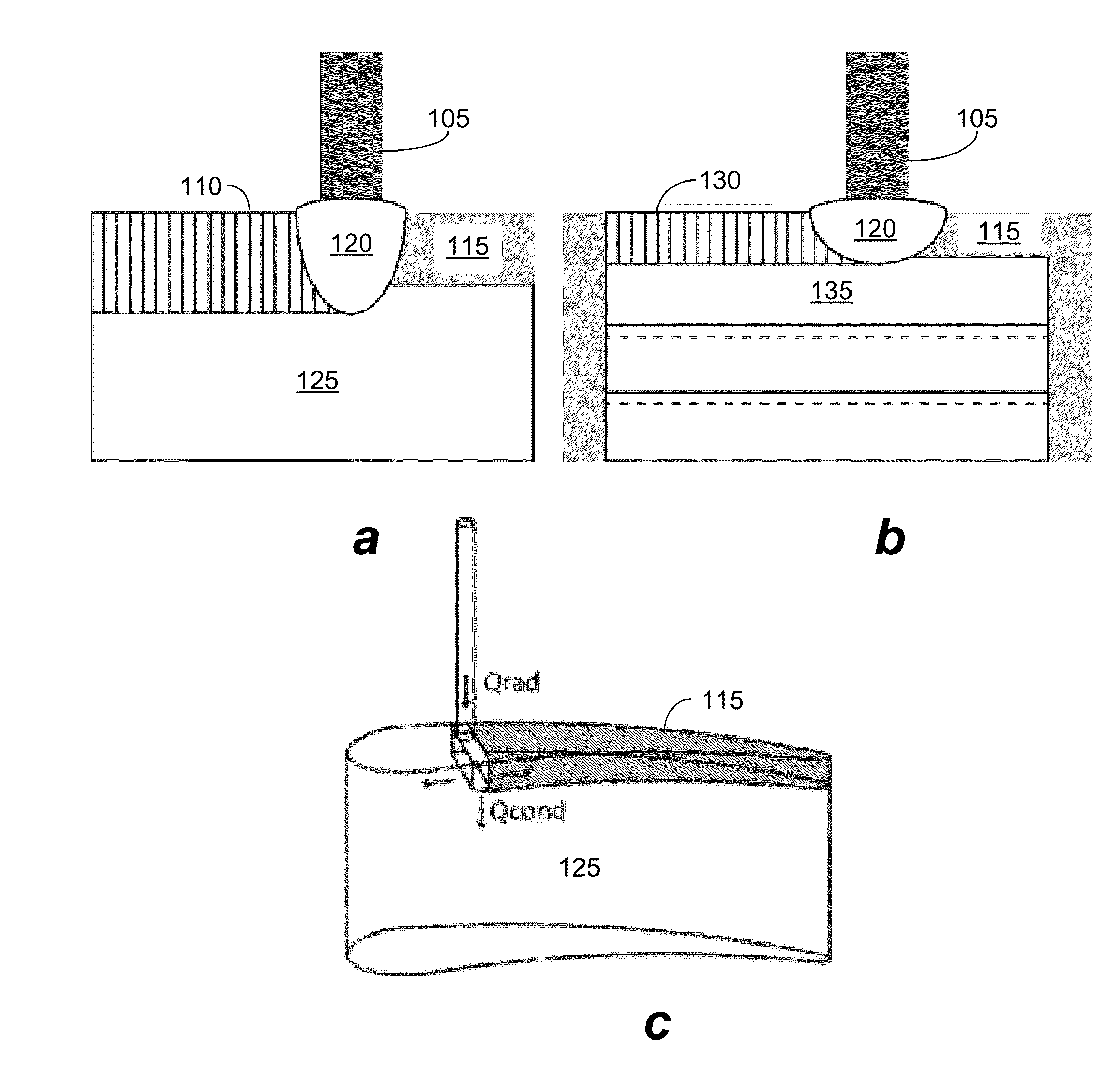

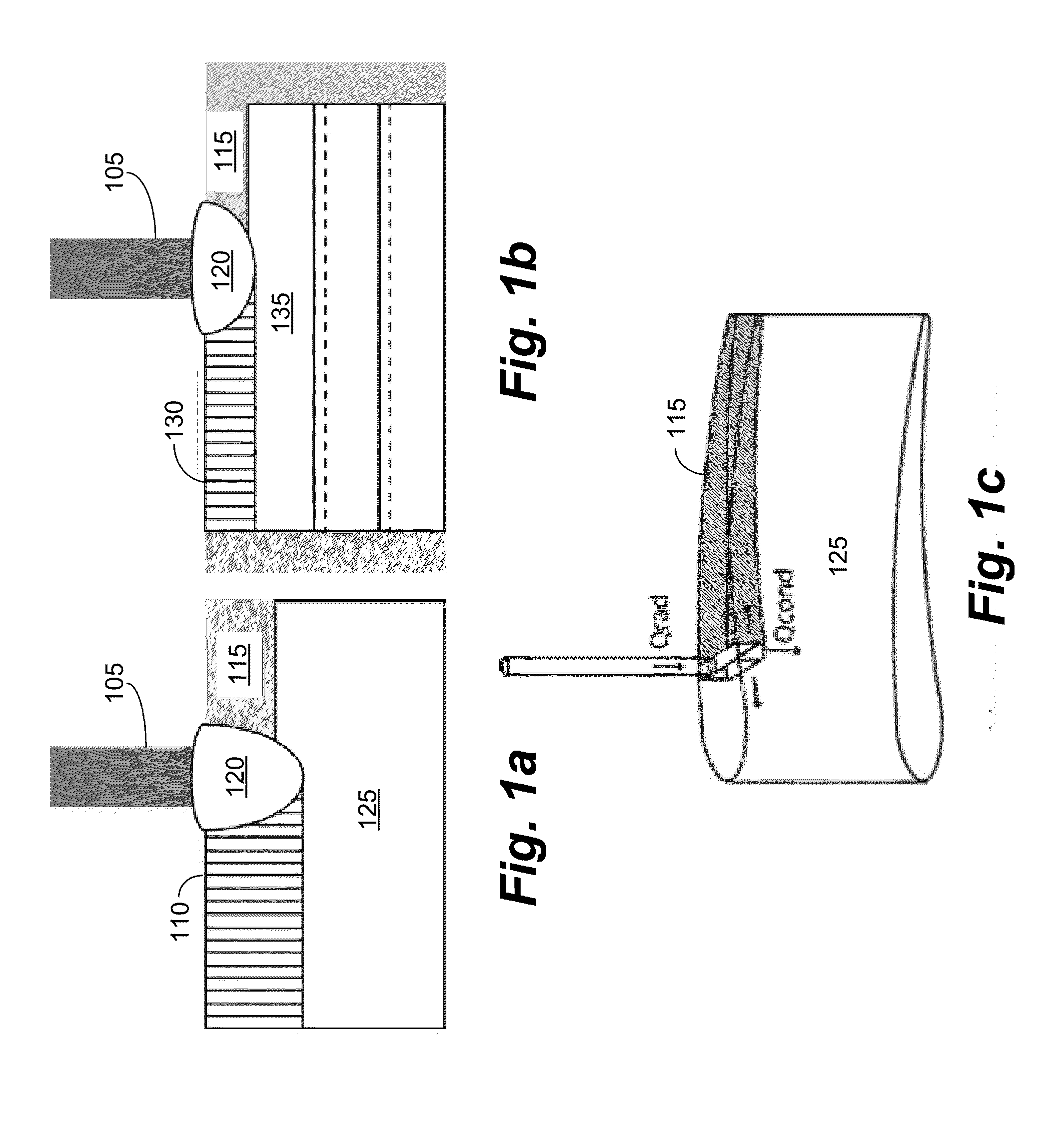

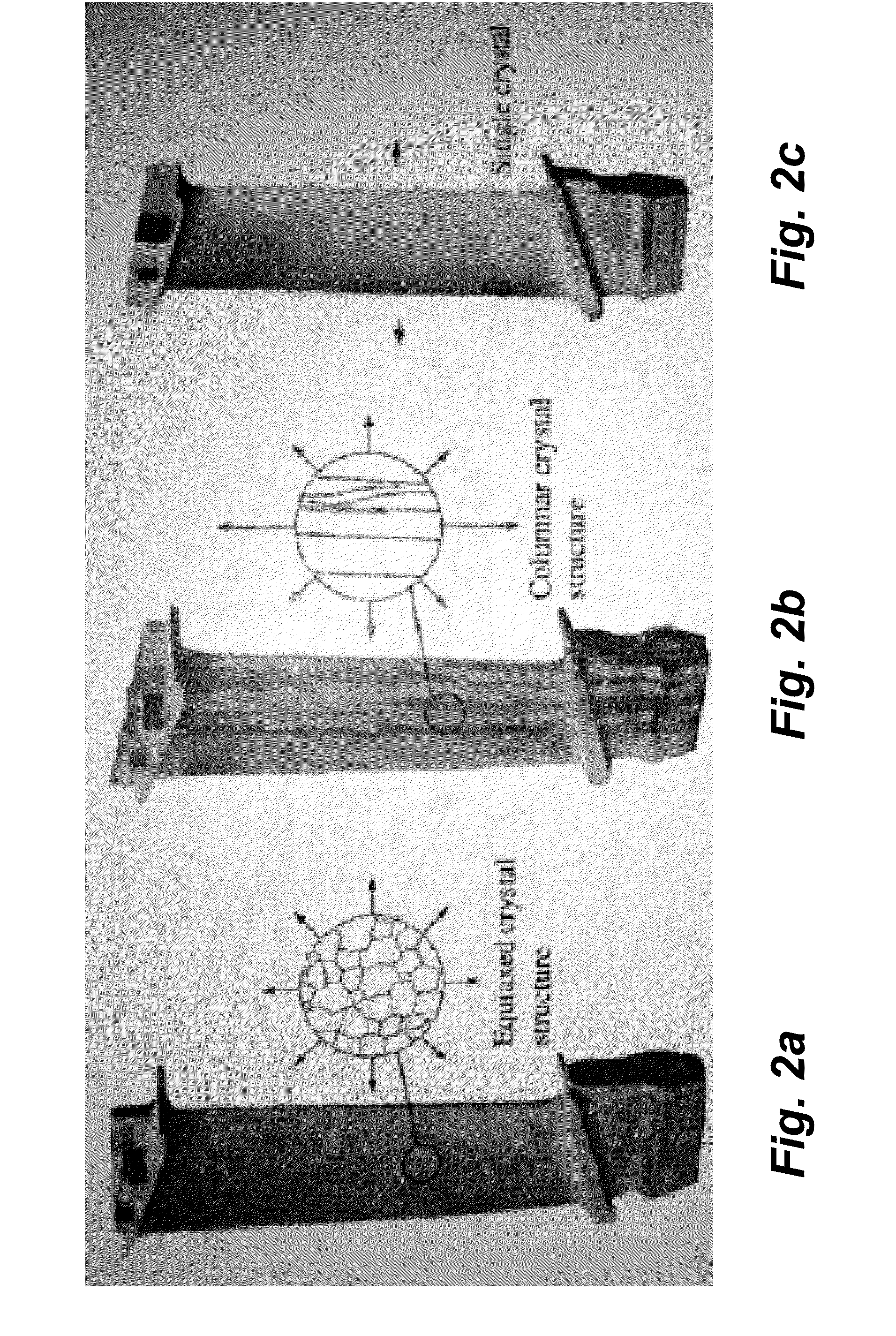

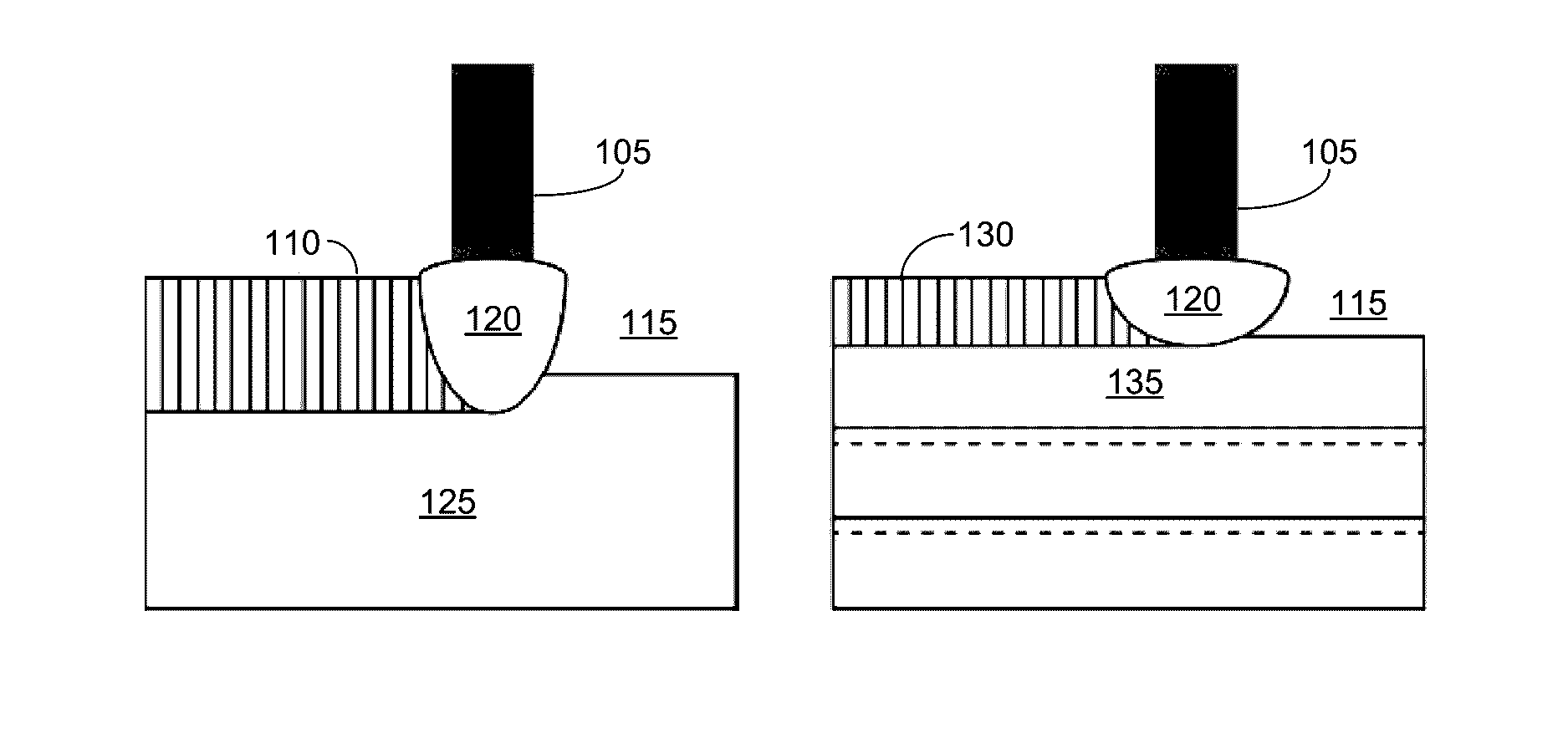

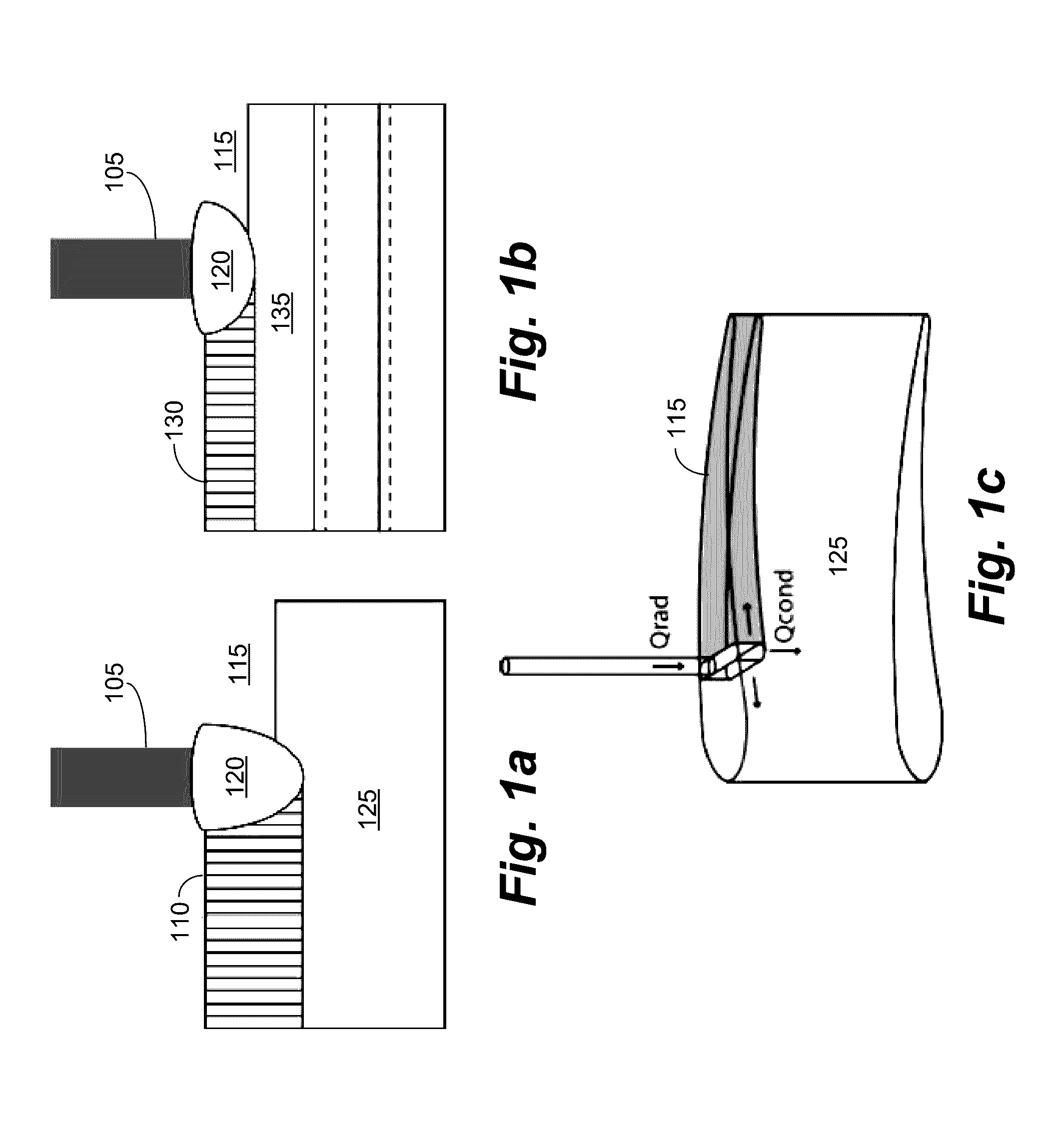

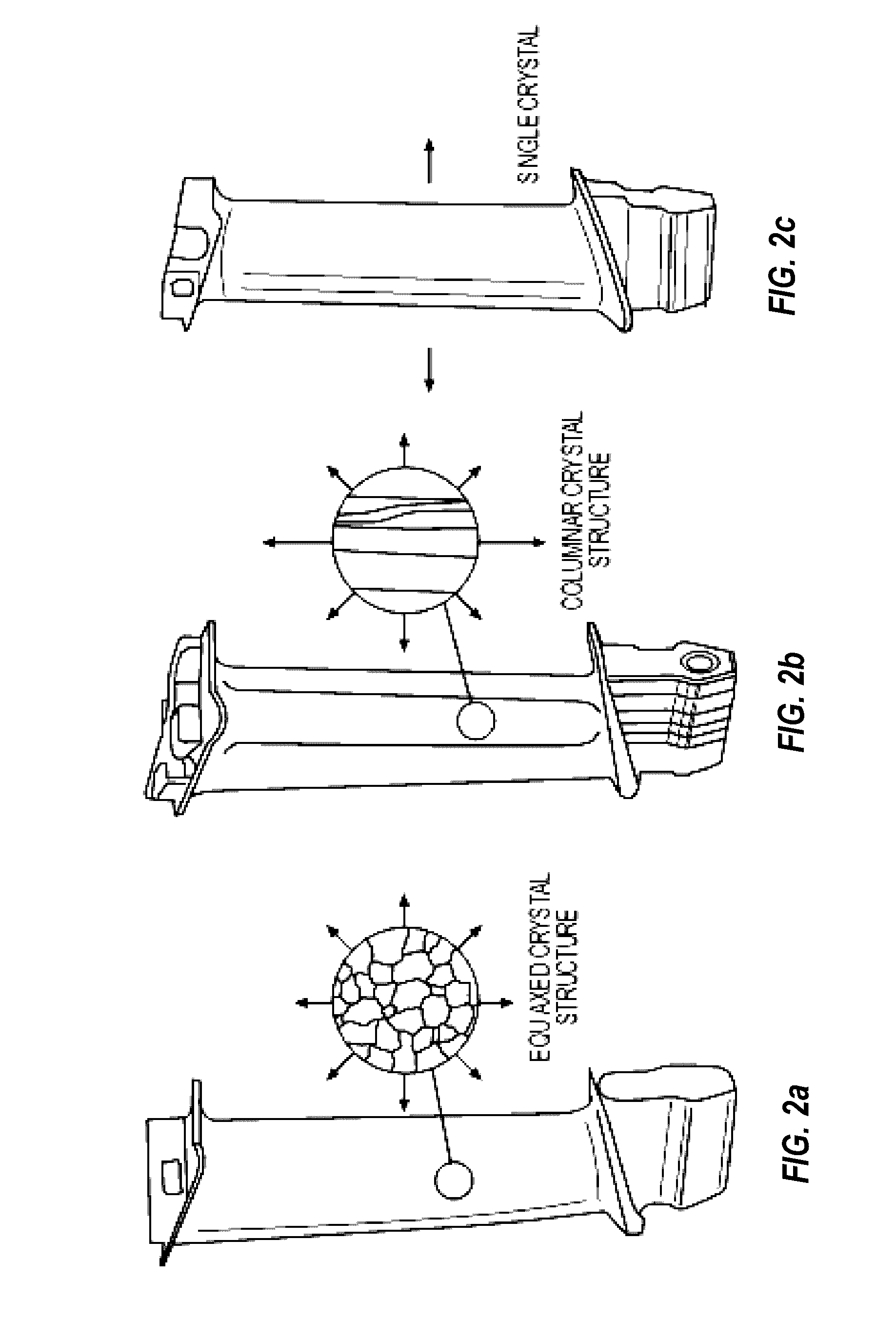

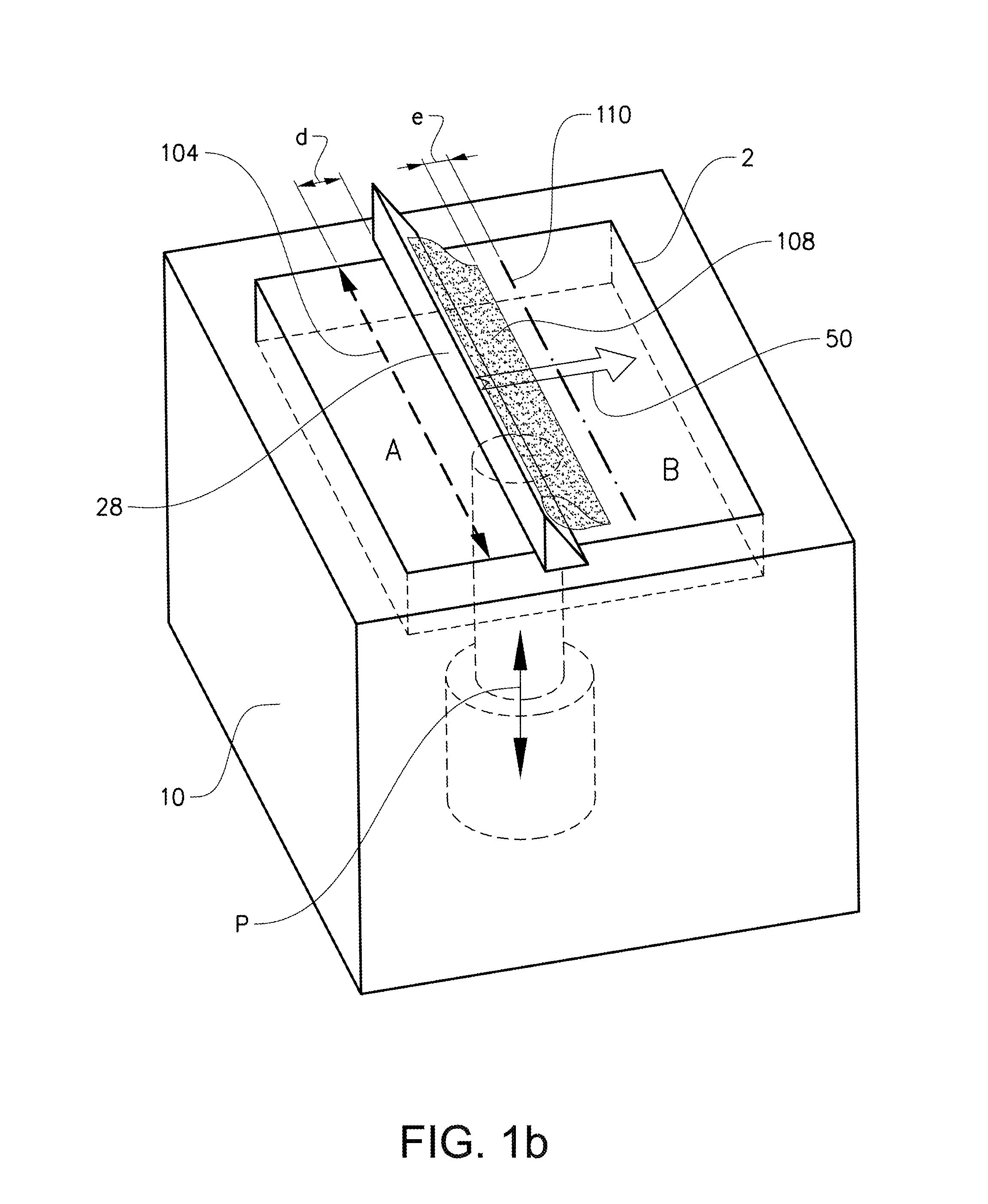

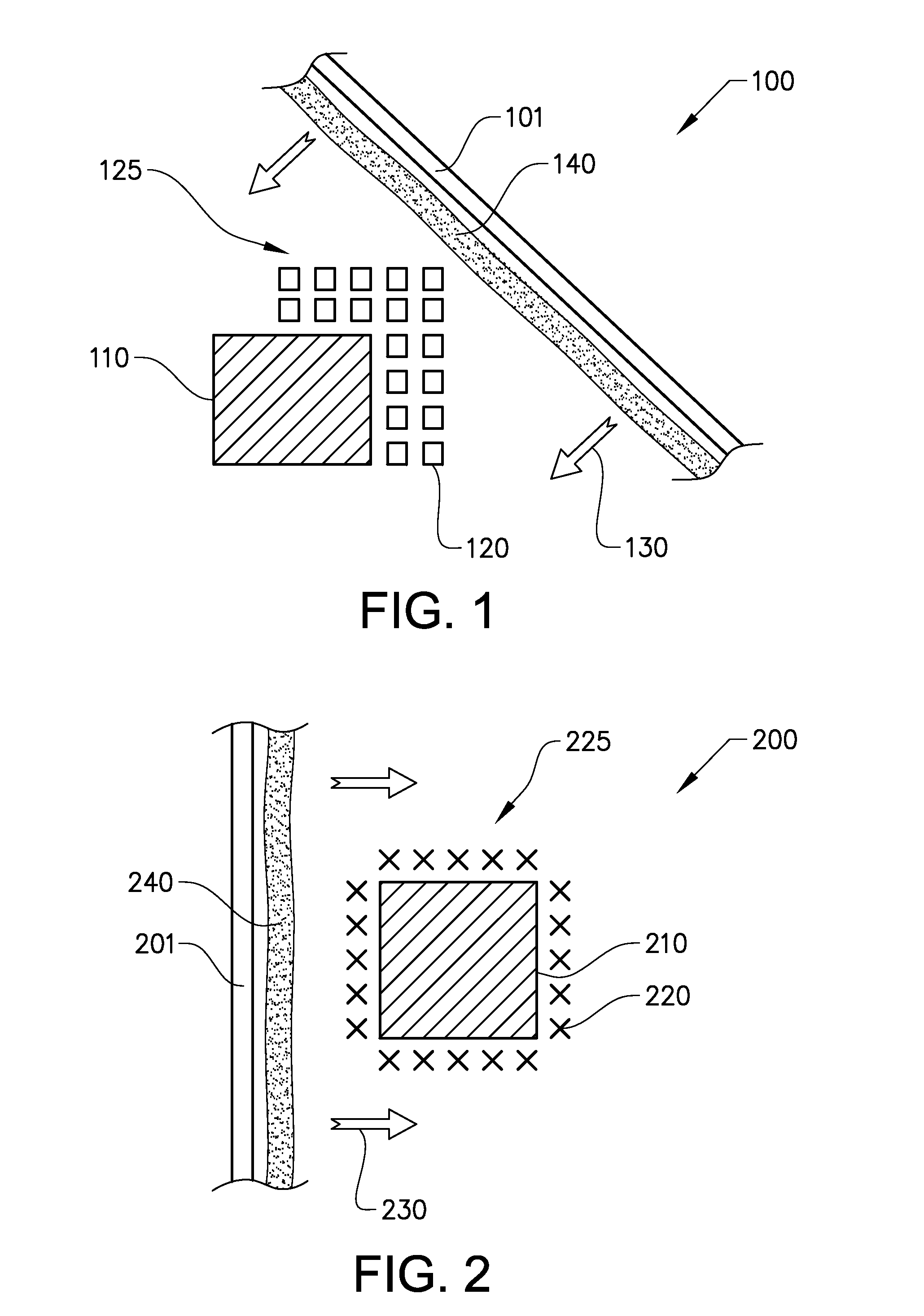

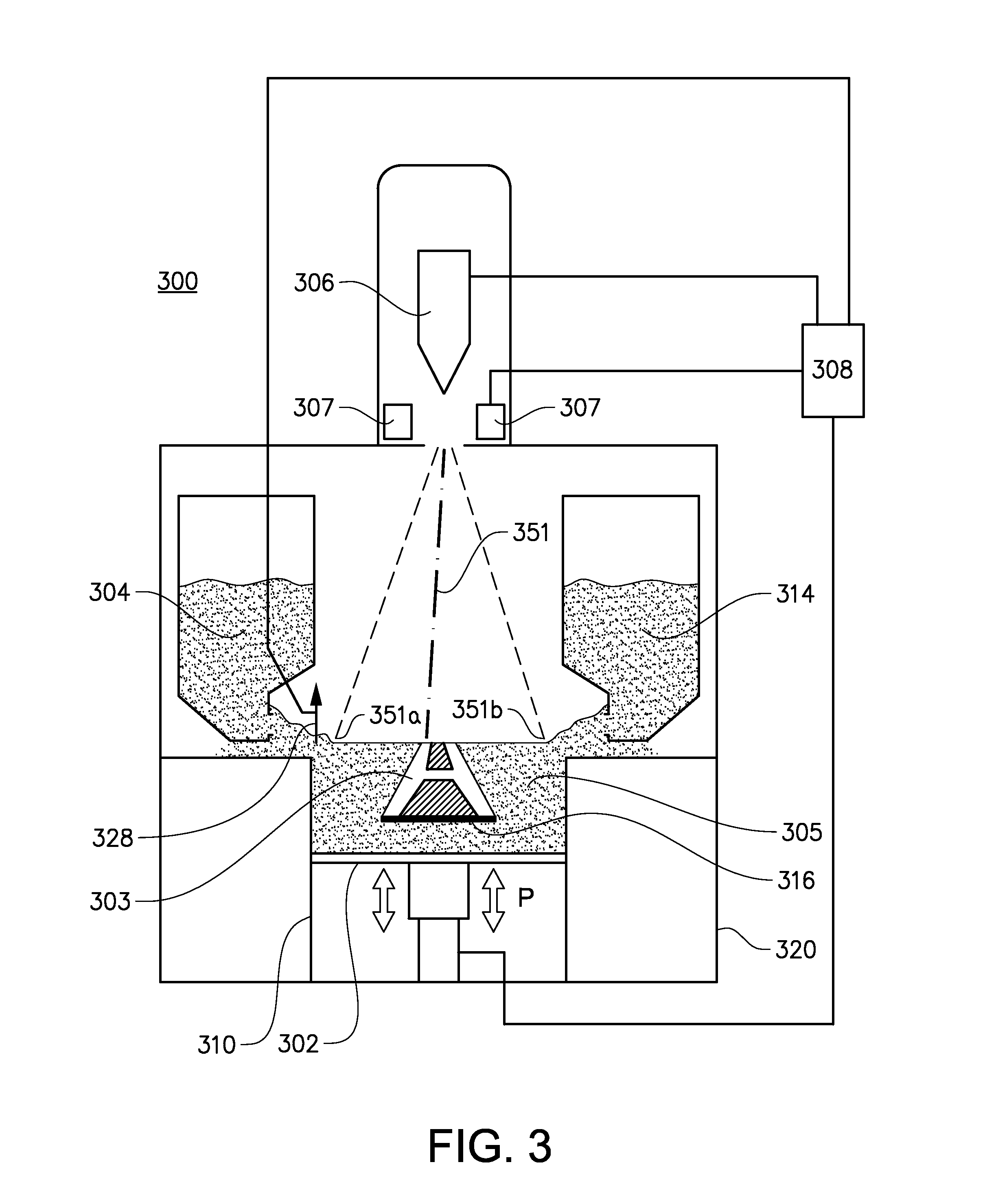

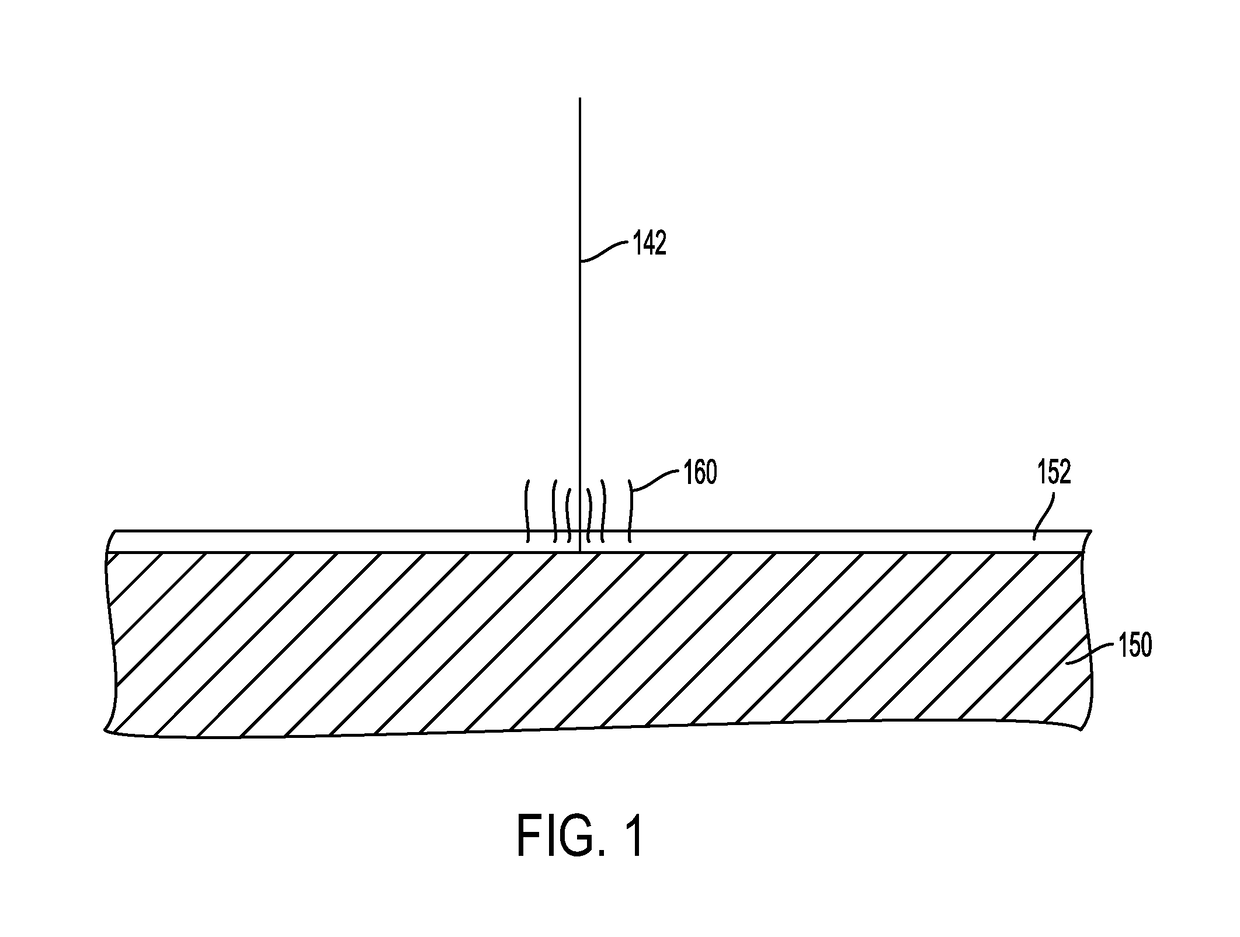

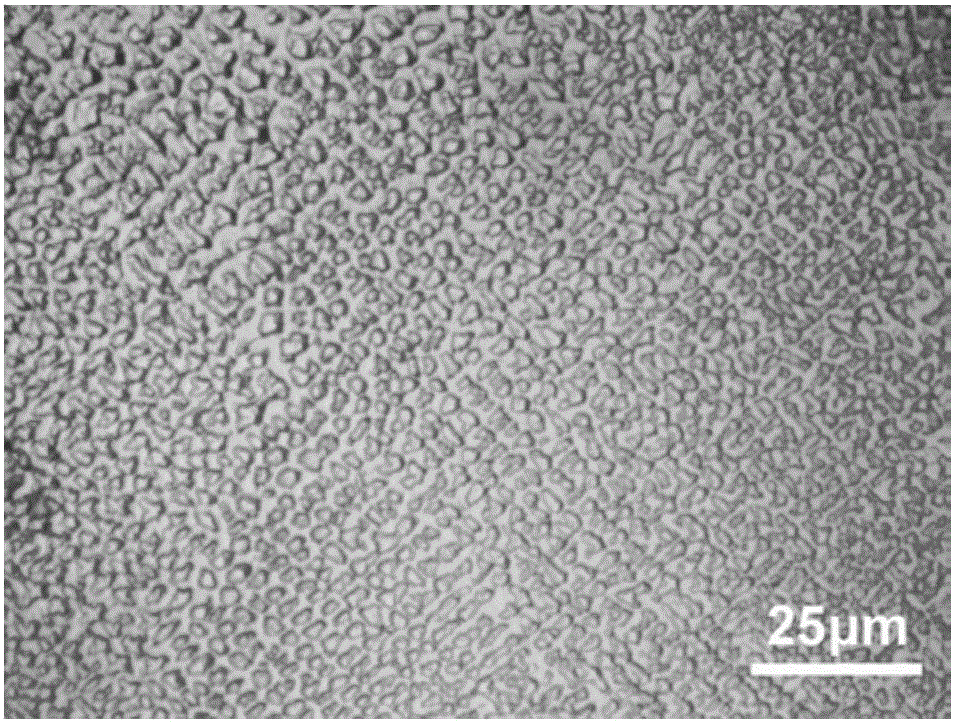

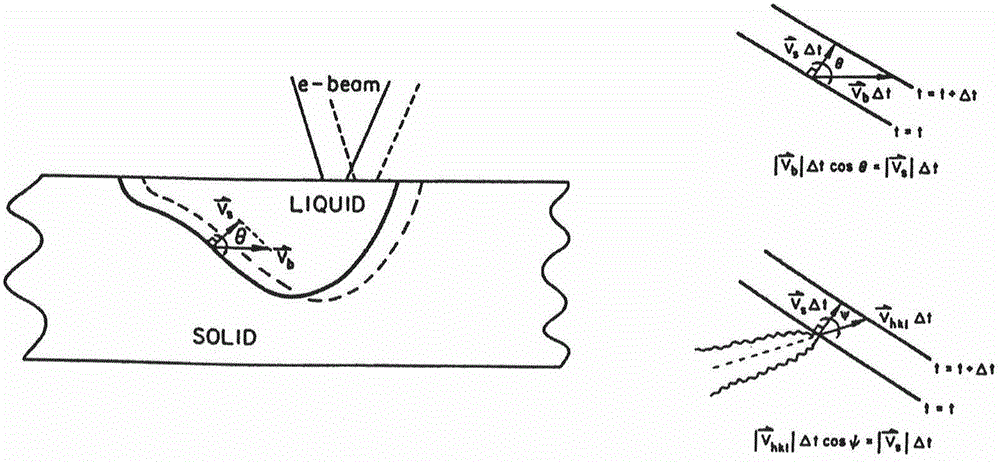

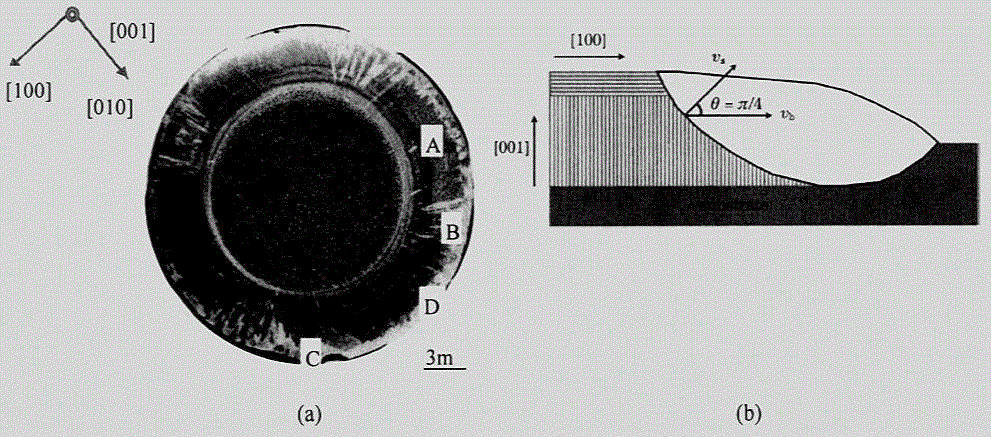

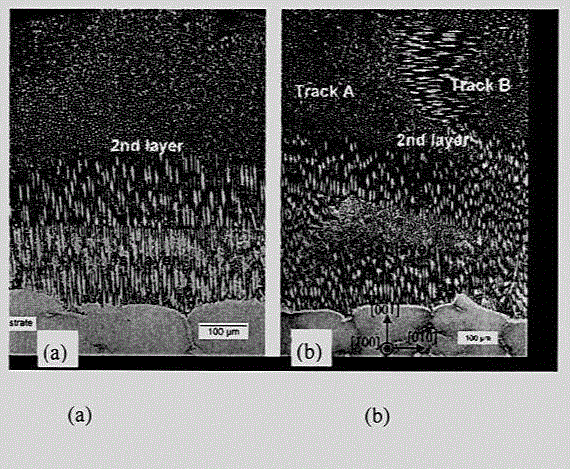

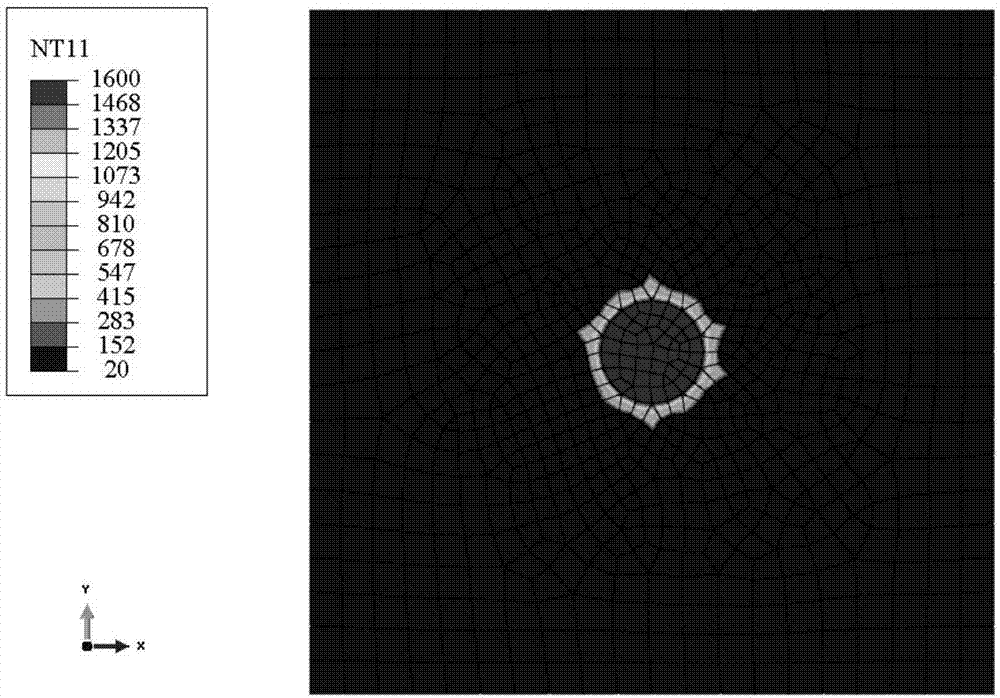

Scanning Laser Epitaxy (SLE) is a layer-by-layer additive manufacturing process that allows for the fabrication of three-dimensional objects with specified microstructure through the controlled melting and re-solidification of a metal powders placed atop a base substrate. SLE can be used to repair single crystal (SX) turbine airfoils, for example, as well as the manufacture functionally graded turbine components. The SLE process is capable of creating equiaxed, directionally solidified, and SX structures. Real-time feedback control schemes based upon an offline model can be used both to create specified defect free microstructures and to improve the repeatability of the process. Control schemes can be used based upon temperature data feedback provided at high frame rate by a thermal imaging camera as well as a melt-pool viewing video microscope. A real-time control scheme can deliver the capability of creating engine ready net shape turbine components from raw powder material.

Owner:GEORGIA TECH RES CORP

Systems and methods for additive manufacturing and repair of metal components

Scanning Laser Epitaxy (SLE) is a layer-by-layer additive manufacturing process that allows for the fabrication of three-dimensional objects with specified microstructure through the controlled melting and re-solidification of a metal powders placed atop a base substrate. SLE can be used to repair single crystal (SX) turbine airfoils, for example, as well as the manufacture functionally graded turbine components. The SLE process is capable of creating equiaxed, directionally solidified, and SX structures. Real-time feedback control schemes based upon an offline model can be used both to create specified defect free microstructures and to improve the repeatability of the process. Control schemes can be used based upon temperature data feedback provided at high frame rate by a thermal imaging camera as well as a melt-pool viewing video microscope. A real-time control scheme can deliver the capability of creating engine ready net shape turbine components from raw powder material.

Owner:GEORGIA TECH RES CORP

Additive manufacturing of three-dimensional articles

ActiveUS20150165524A1Short manufacturing timeQuality improvementHydrogenAdditive manufacturing apparatusLaser additive manufacturingSupport surface

The present invention relates to a method for forming a three-dimensional article through successively depositing individual layers of powder material that are fused together so as to form the article, the method comprising the step of heating a first portion of a support surface while depositing a layer of powder material on a second portion of the support surface.

Owner:ARCAM AB

Laser additive manufacture of three-dimensional components containing multiple materials formed as integrated systems

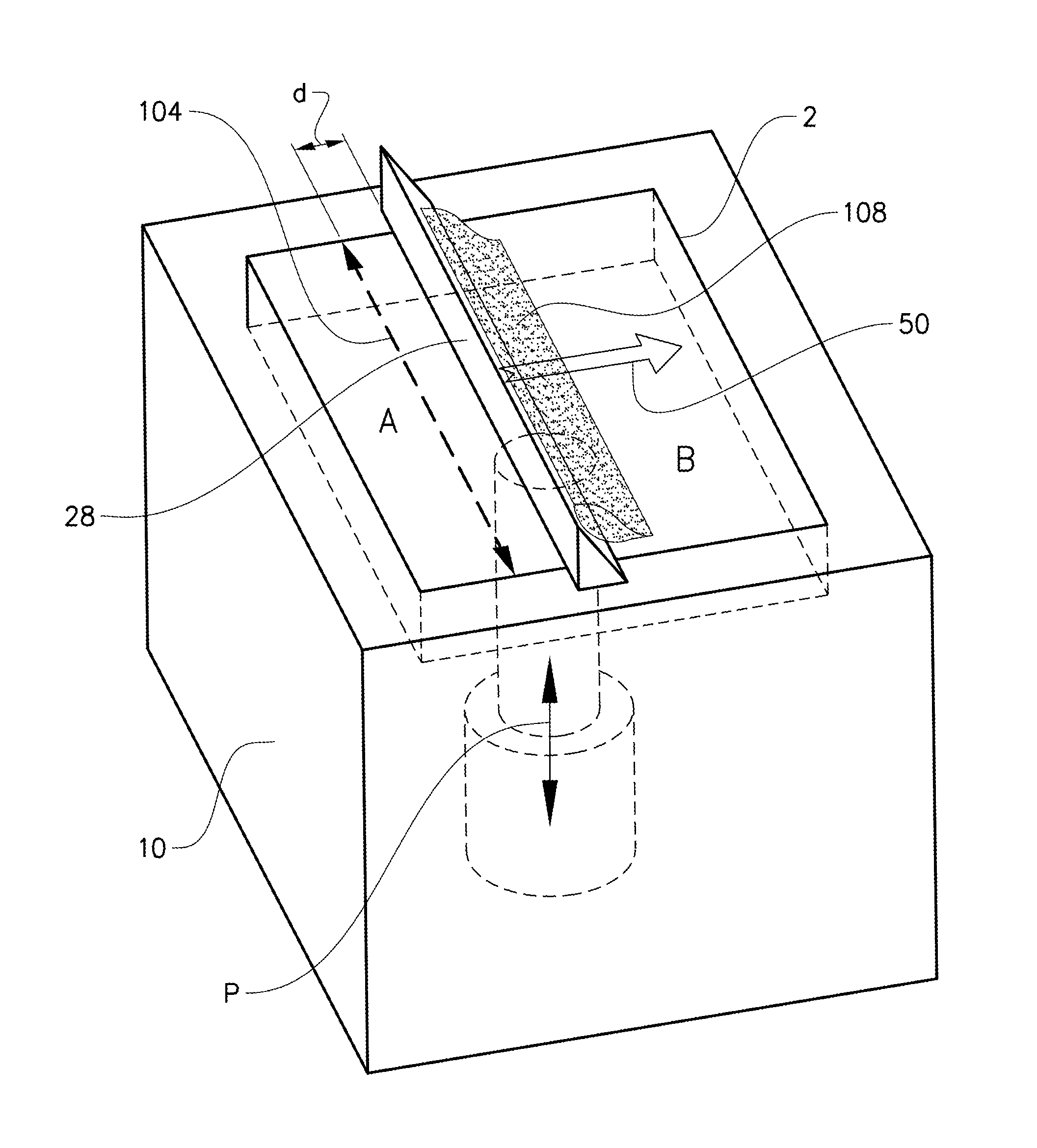

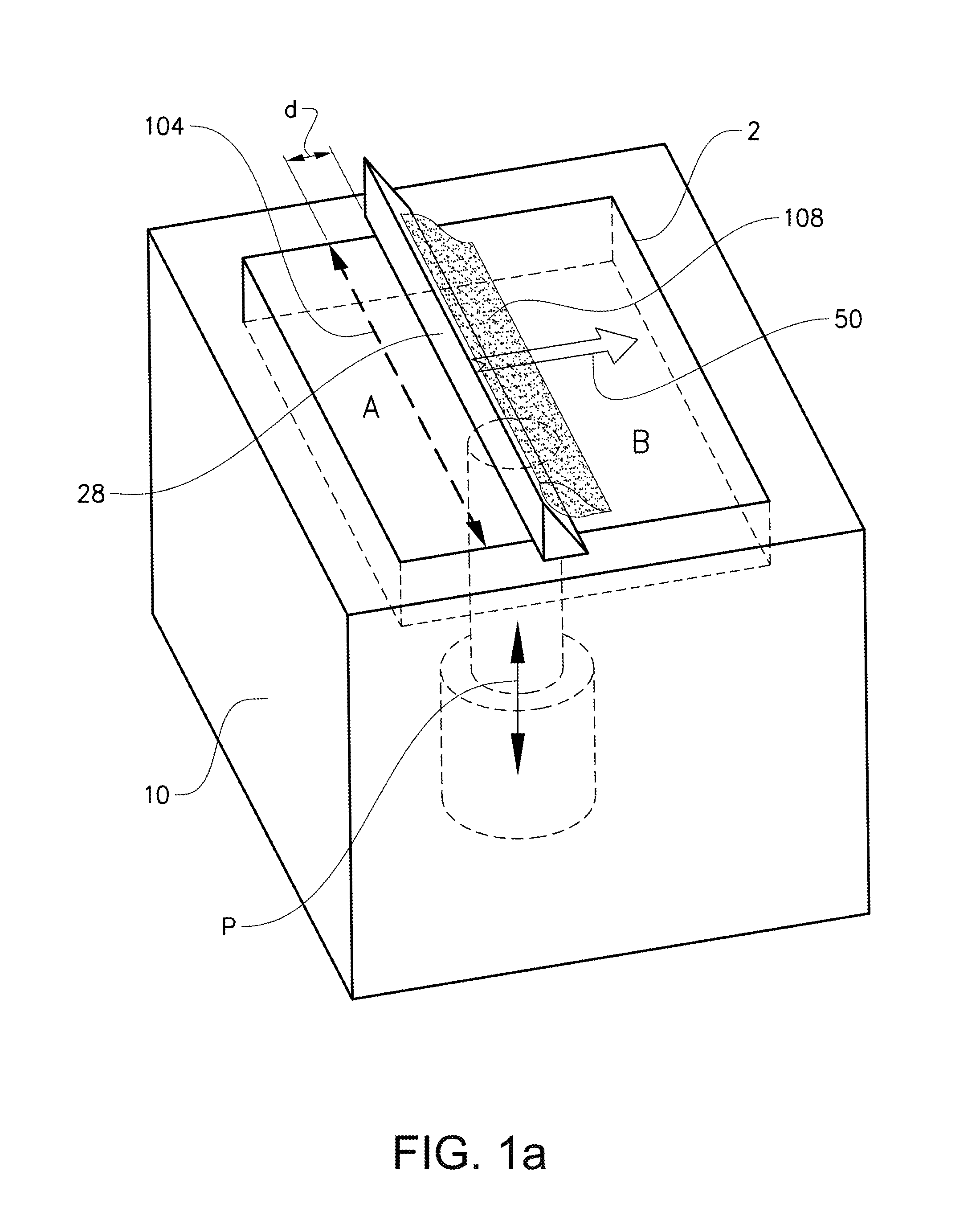

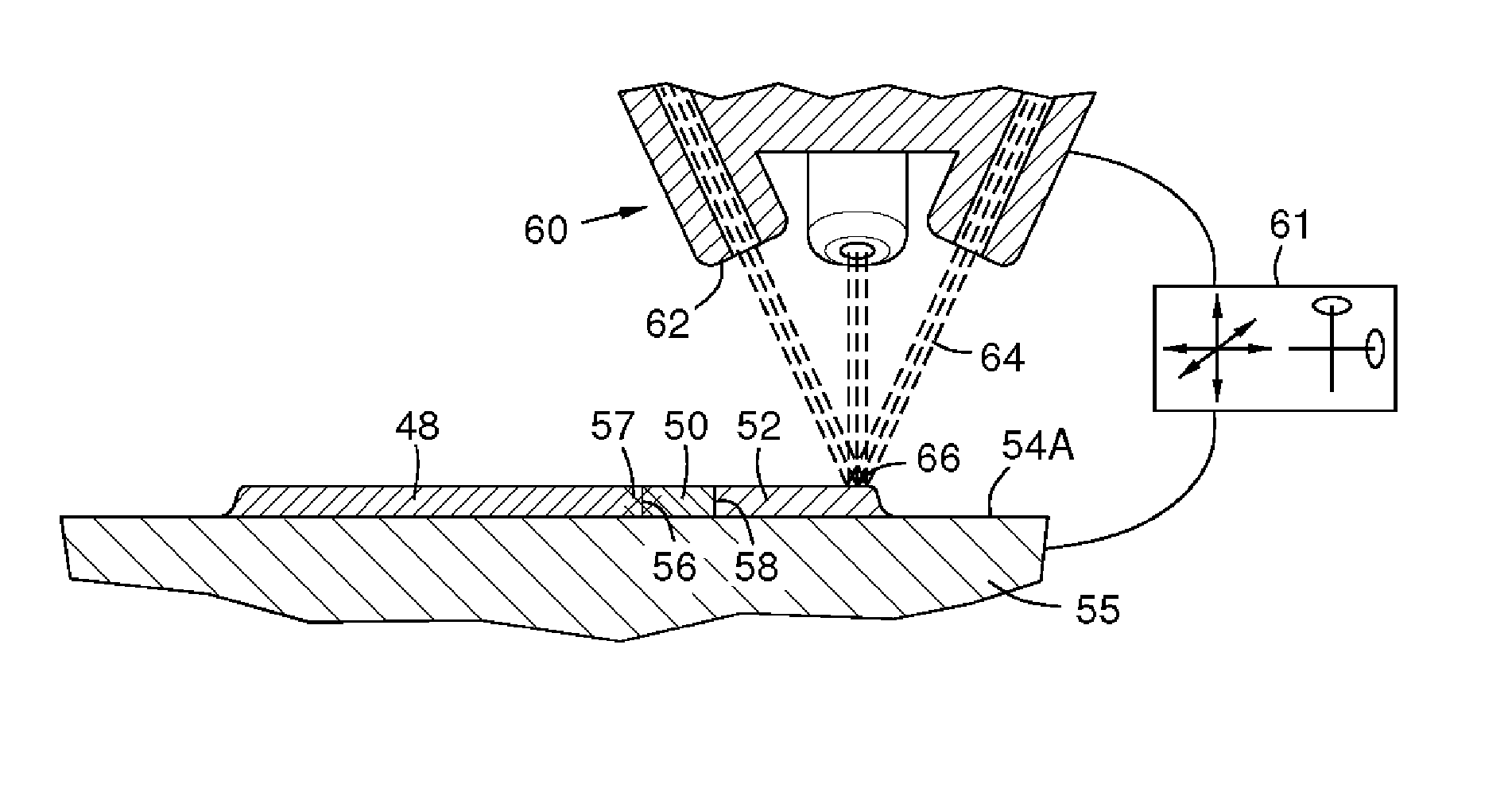

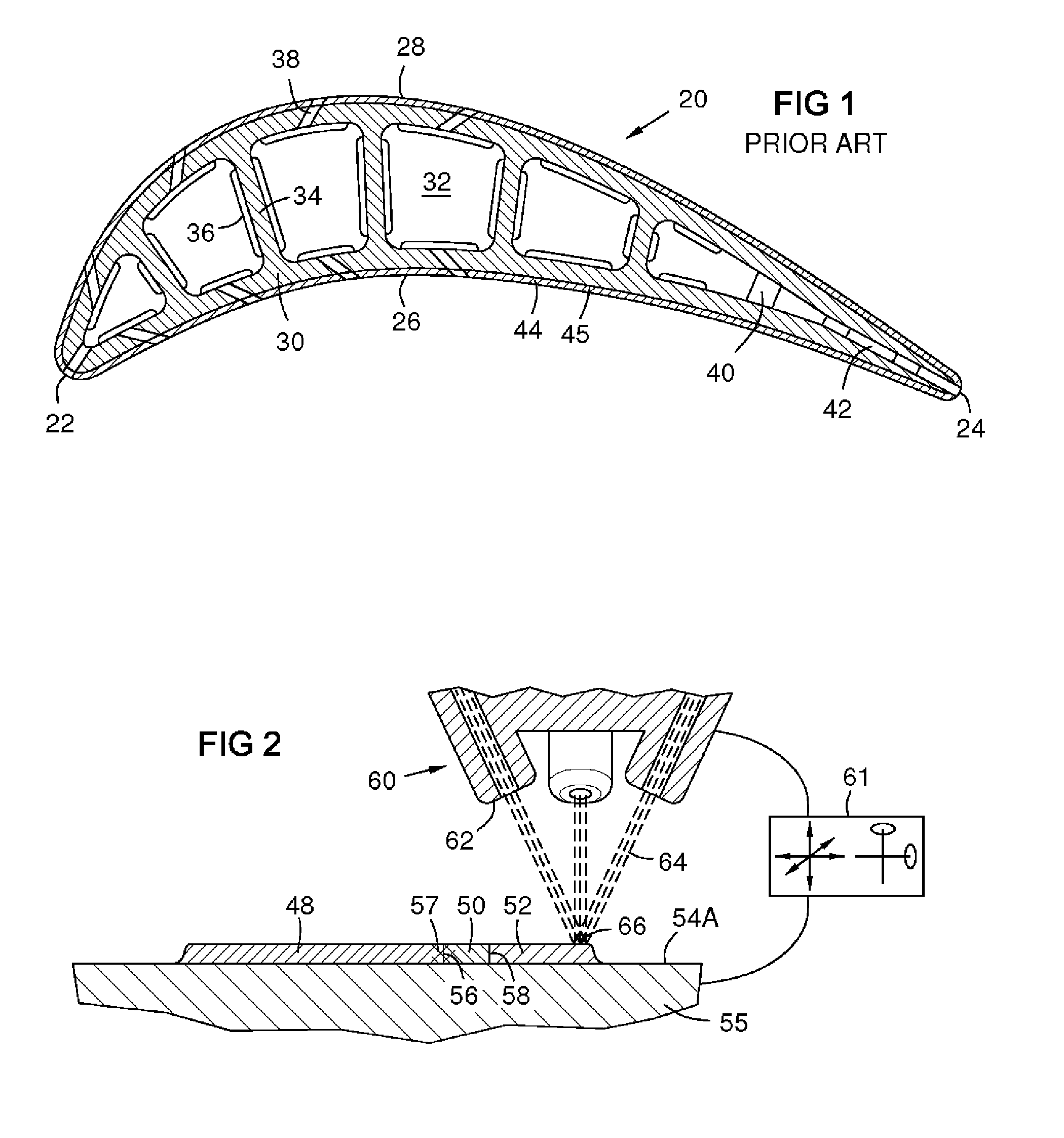

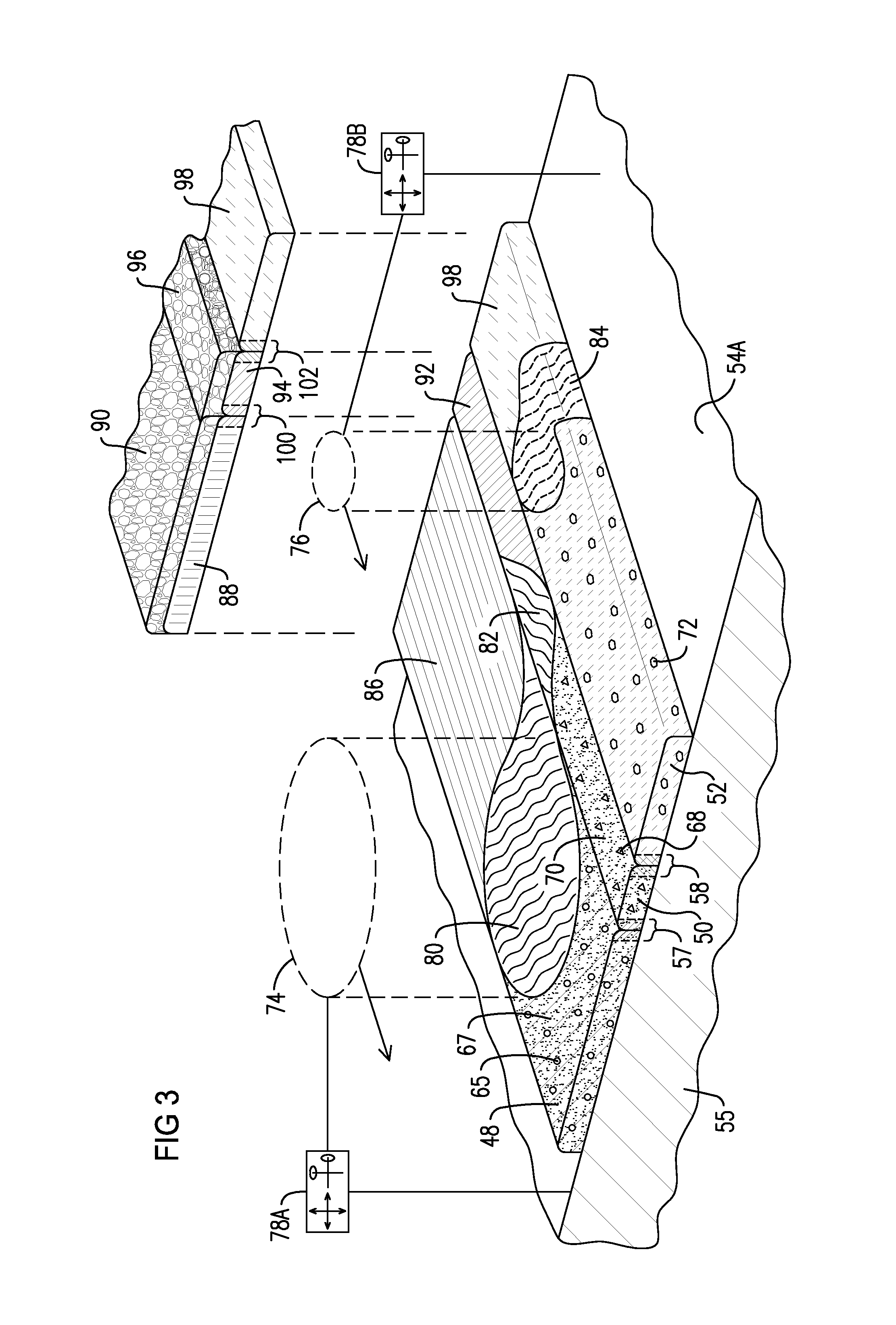

Methods for laser additive manufacture are disclosed in which a plurality of powder layers (48, 50 and 52) are delivered onto a working surface (54A) to form a multi-powder deposit containing at least two adjacent powders layers in contact, and then applying a first laser energy (74) to a first powder layer (48) and a second laser energy (76) to a second powder layer (52) to form a section plane of a multi-material component. The multi-powder deposit may include a flux composition that provides at least one protective feature. The shapes, intensities and trajectories of the first and second laser energies may be independently controlled such that their widths are less than or equal to widths of the first and second powder layers, their intensities are tailored to the compositions of the powder layers, and their scan paths define the final shape of the multi-material component.

Owner:SIEMENS ENERGY INC

Method of additive manufacturing by fabrication through multiple zones

ActiveUS20160303793A1Enhance or speed the refilling of the build regionEnhance or speed the refilling of said build regionManufacturing platforms/substratesAdditive manufacturing with liquidsEngineeringLaser additive manufacturing

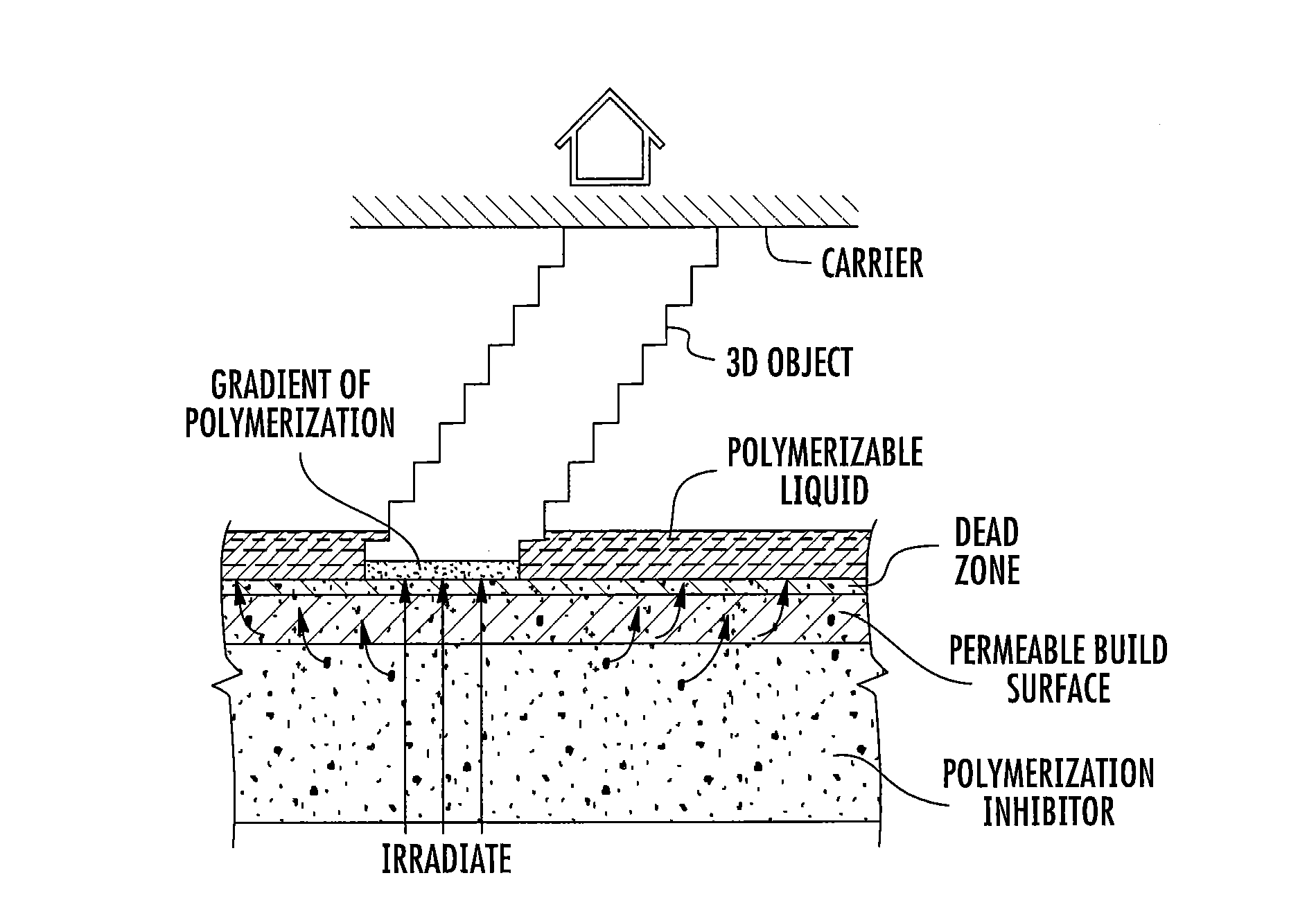

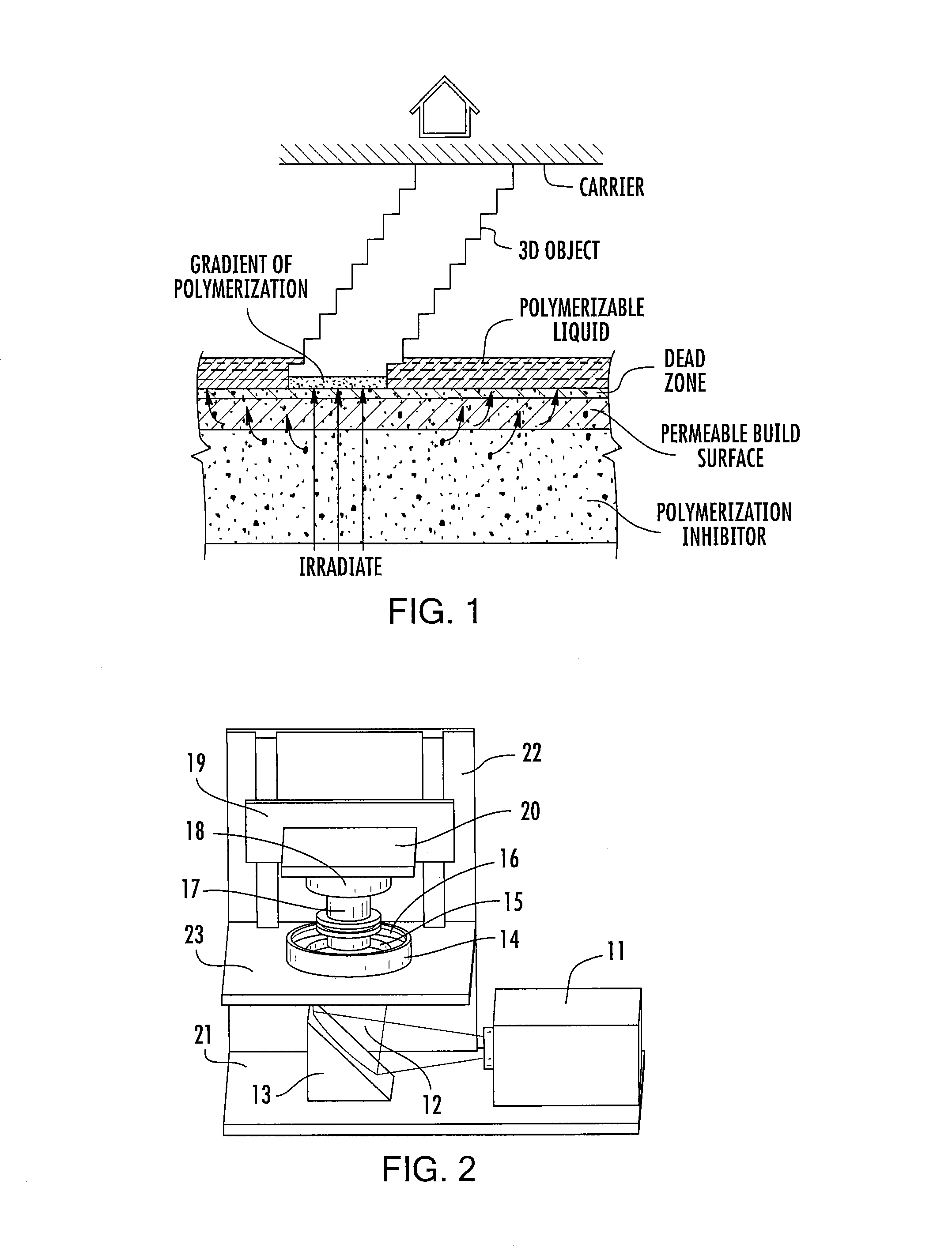

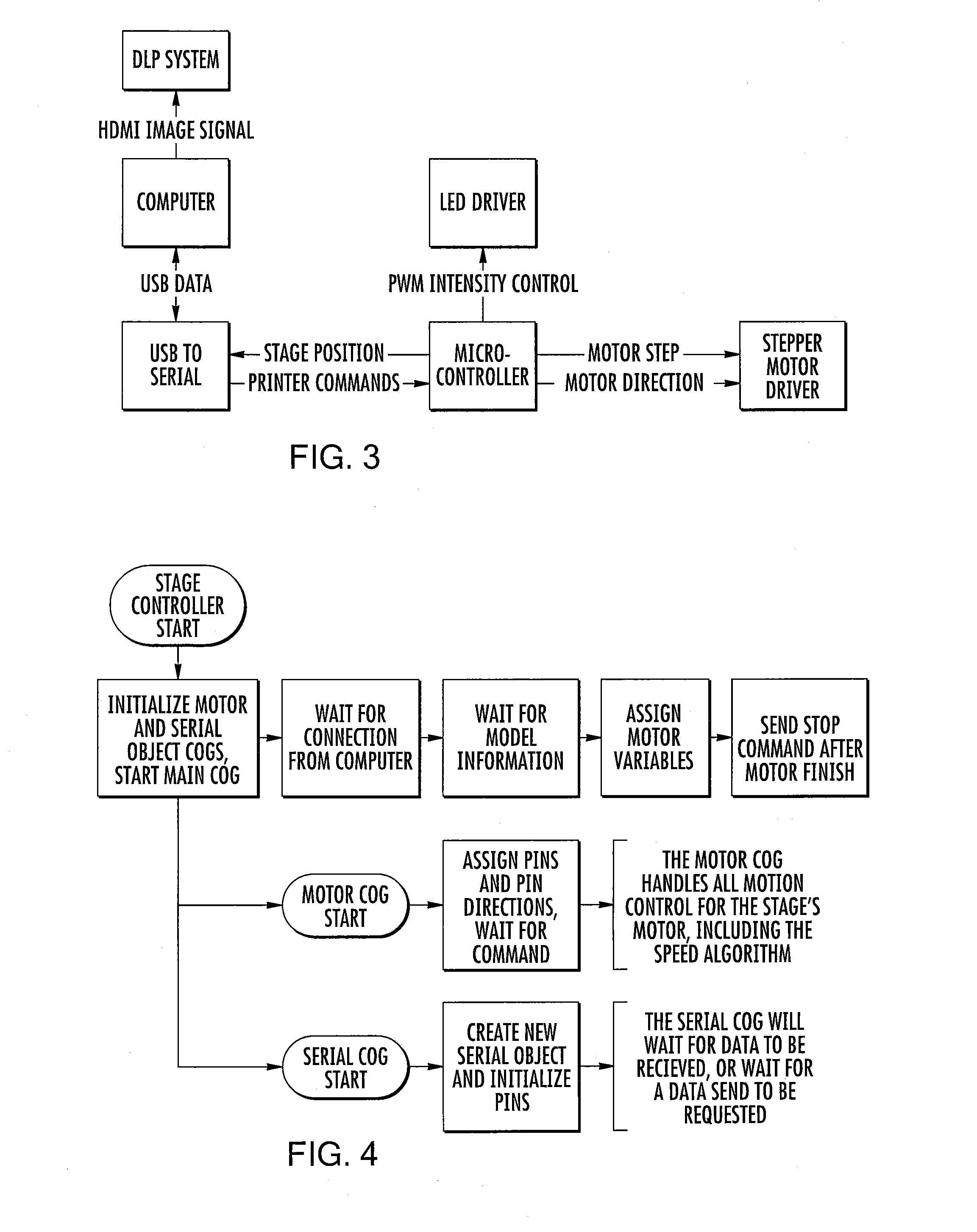

A method of forming a three-dimensional object is carried out by: (a) providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween, with the carrier positioned adjacent and spaced apart from the build surface at a start position; then (b) forming an adhesion segment of the three-dimensional object (c) optionally but preferably forming a transition segment of the three dimensional object; and then (d) forming a body segment of the three dimensional object. In each case, the segment can be formed by: (i) filling the build region with a polymerizable liquid, (ii) continuously or intermittently irradiating the build region with light through the optically transparent, and (iii) continuously or intermittently advancing the carrier away from the build surface, to thereby form that segment from the polymerizable liquid.

Owner:CARBON INC

Method for improved powder layer quality in additive manufacturing

InactiveUS20160129501A1Improve homogeneityMaximize powder layer thickness homogeneityAdditive manufacturing apparatusIncreasing energy efficiencyBeam sourceEngineering

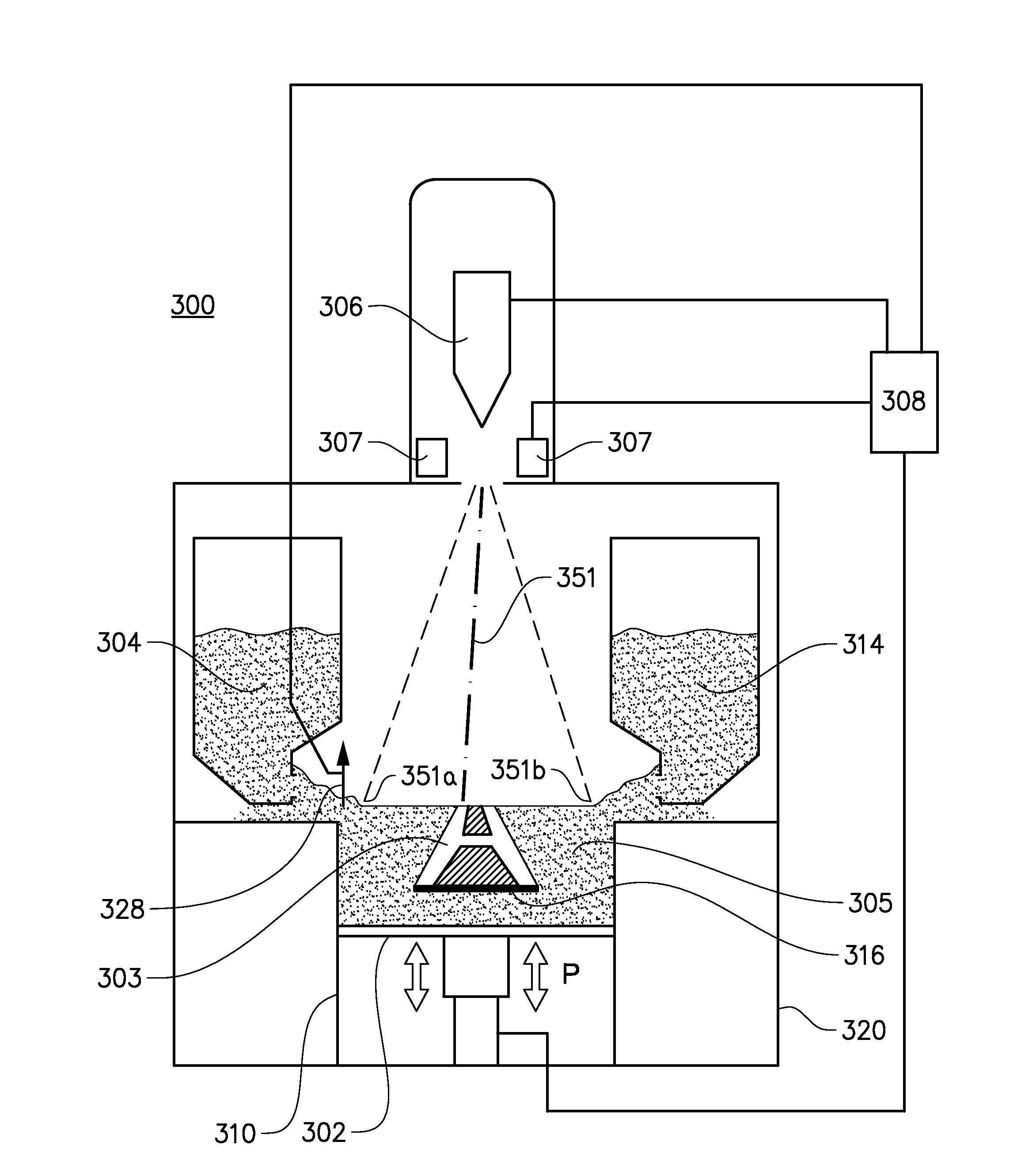

Various embodiments of the present invention relate to a method for forming at a three-dimensional article through successively depositing individual layers of powder material that are fused together with at least one energy beam so as to form the article, said method comprising the steps of generating a model of said three-dimensional article; applying a first powder layer on a work table; directing said at least one energy beam from at least one energy beam source over said work table causing said first powder layer to fuse in first selected locations according to said model to form a first cross section of said three-dimensional article; introducing a predetermined pattern laterally separated from said first cross section for reducing thickness variations in a powder layer provided on top of said first cross section.

Owner:ARCAM AB

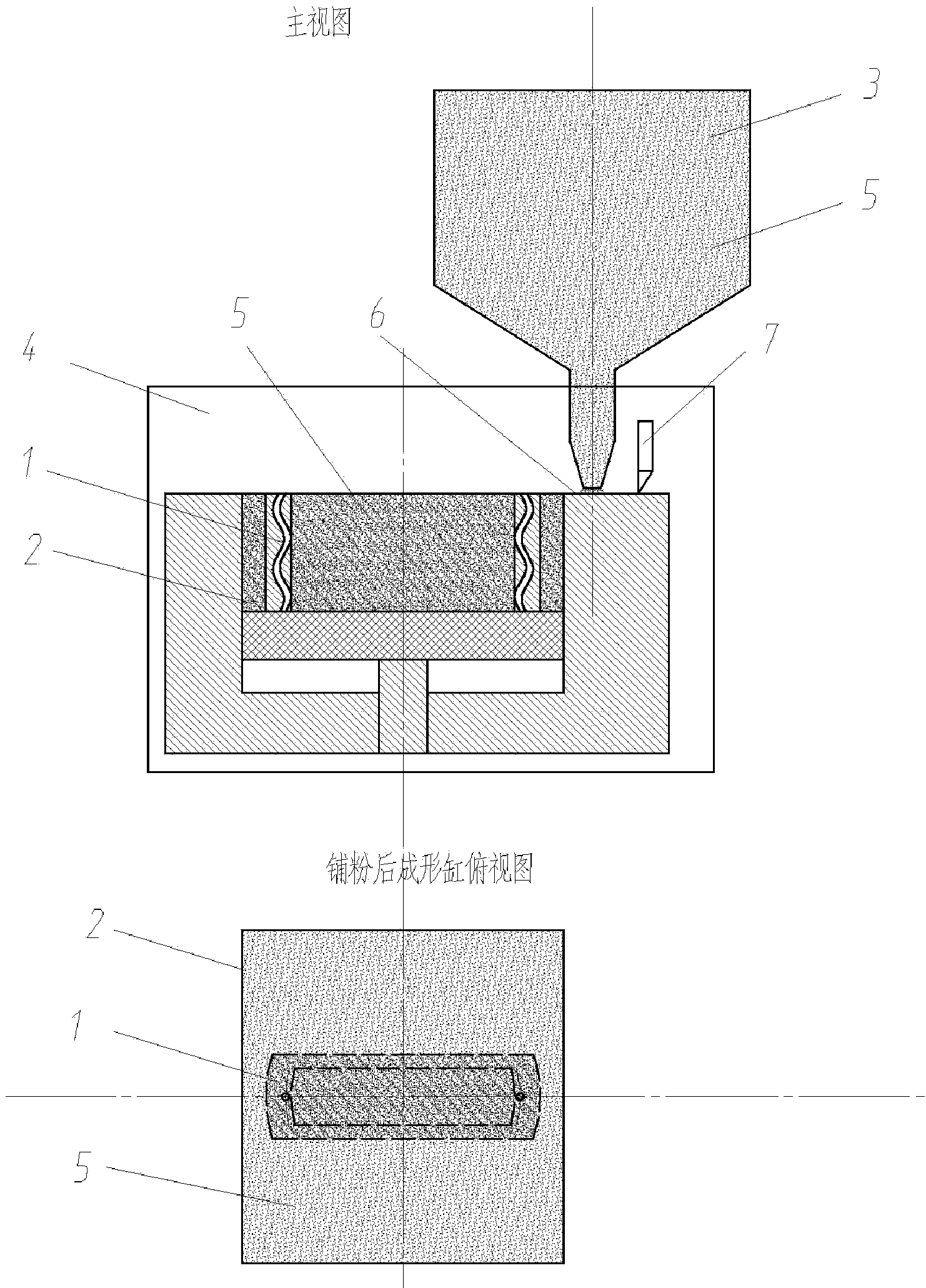

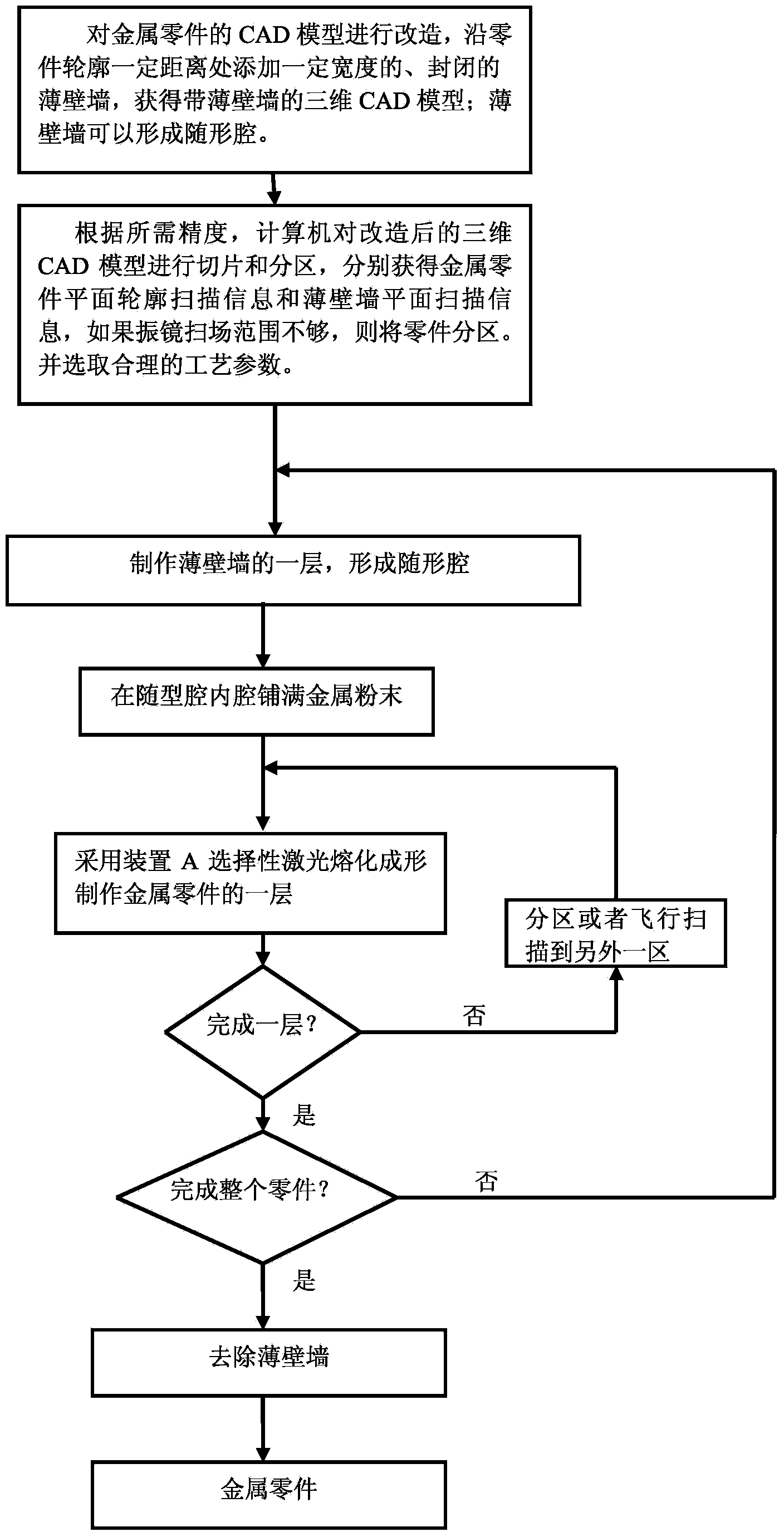

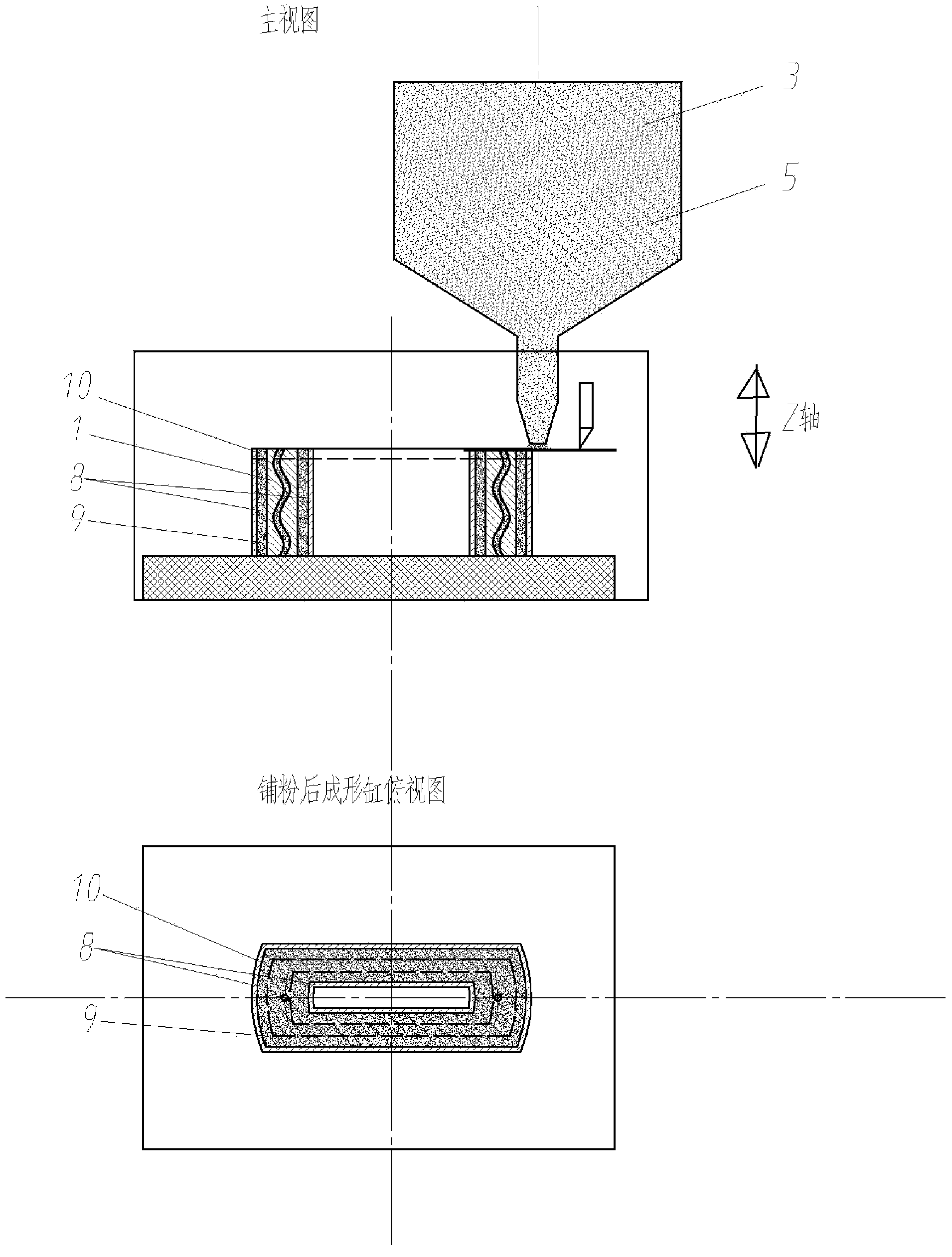

Laser additive manufacturing method and device of metal parts

ActiveCN103726049AMeet the requirements of high precision formingRealization of high-precision forming requirementsMetallic material coating processesSelective laser meltingManufacturing technology

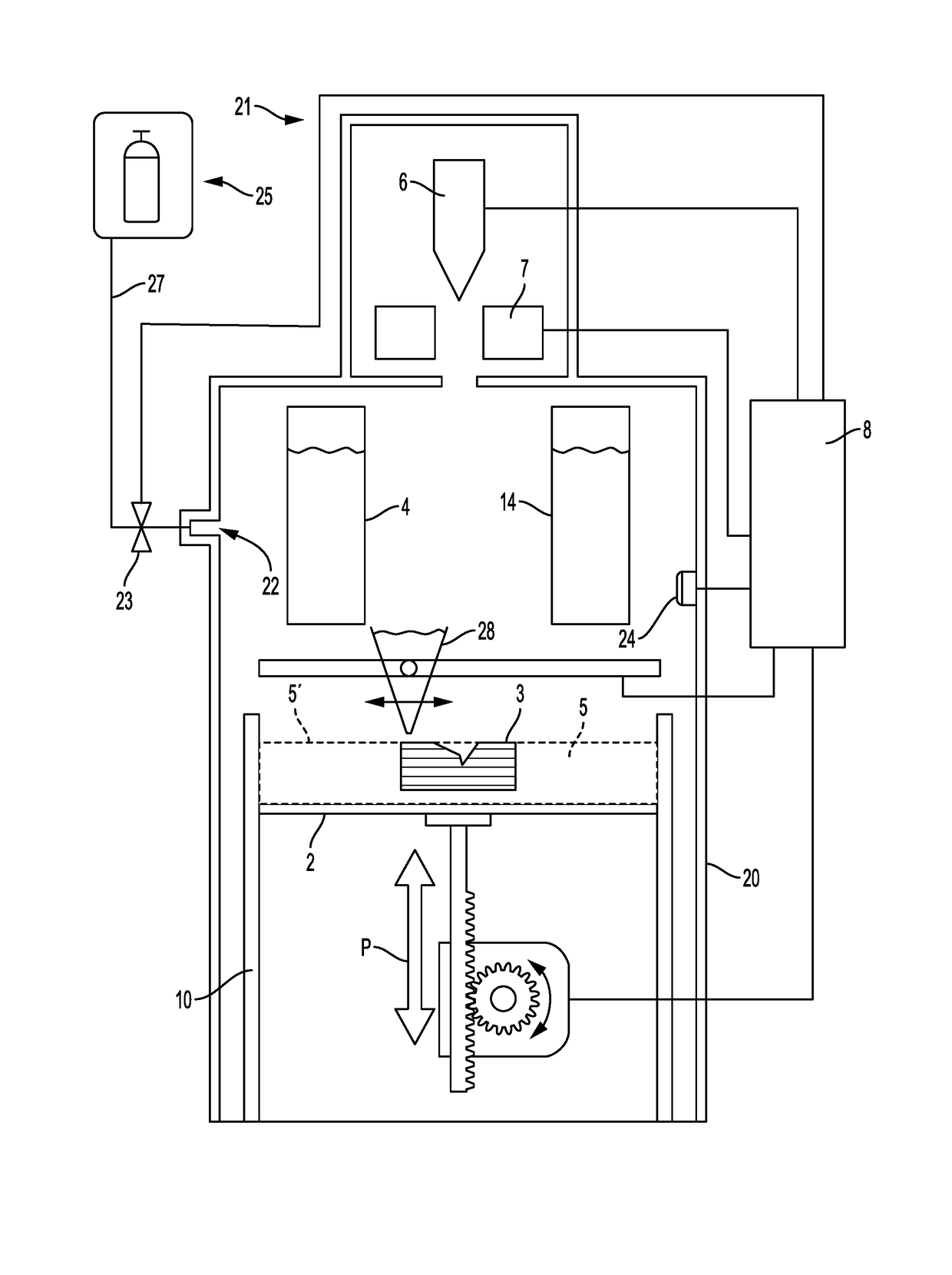

The invention discloses a laser additive manufacturing method and a laser additive manufacturing device of metal parts. In the laser additive manufacturing method, a layered-manufactured profile-followed cylinder is used as a forming cylinder, namely before each metal part layer is manufactured, a layer of closed thin wall is manufactured, the formed cavity is used as the profile-followed cavity, the height of the profile-followed cavity is the same as that of the metal part layer to be manufactured, and the shape of the profile-followed cavity is adapted to that of the metal part layer to be manufactured, so as to provide a plane reference and a cavity for laying powder; the layered-manufactured profile-followed cylinder is used, a scanning galvanometer is used for performing selective laser melting and forming, the metal part layers are manufactured layer by layer, layers of the profile-followed cavities are finally stacked to form the profile-followed cylinder, and the layers of metal parts are stacked to form metal parts. The laser additive manufacturing device comprises a laser galvanometer melting and forming device and a thin wall preparation device which alternatively work, so as to accomplish the selective laser melting and forming process. The method and the device keep the advantages of the selective laser melting (SLM) metal additive manufacturing technology, uses the profile-followed cylinder to break the limit of the conventional SLM device fixed-size forming cylinder, and thus achieving the high-precision manufacture of the large-size even over-sized parts.

Owner:TECH LASER TECH SHANGHAI CO LTD

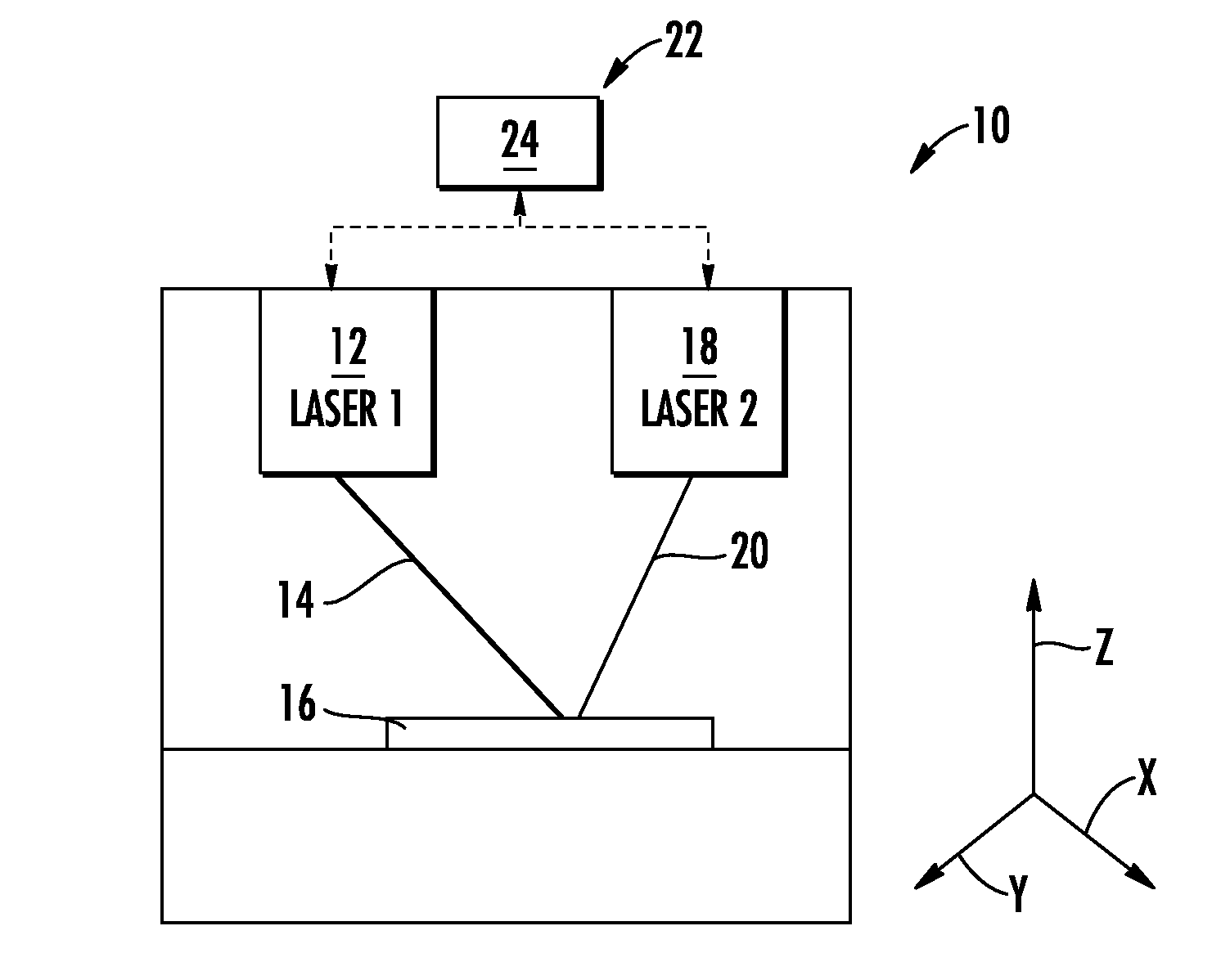

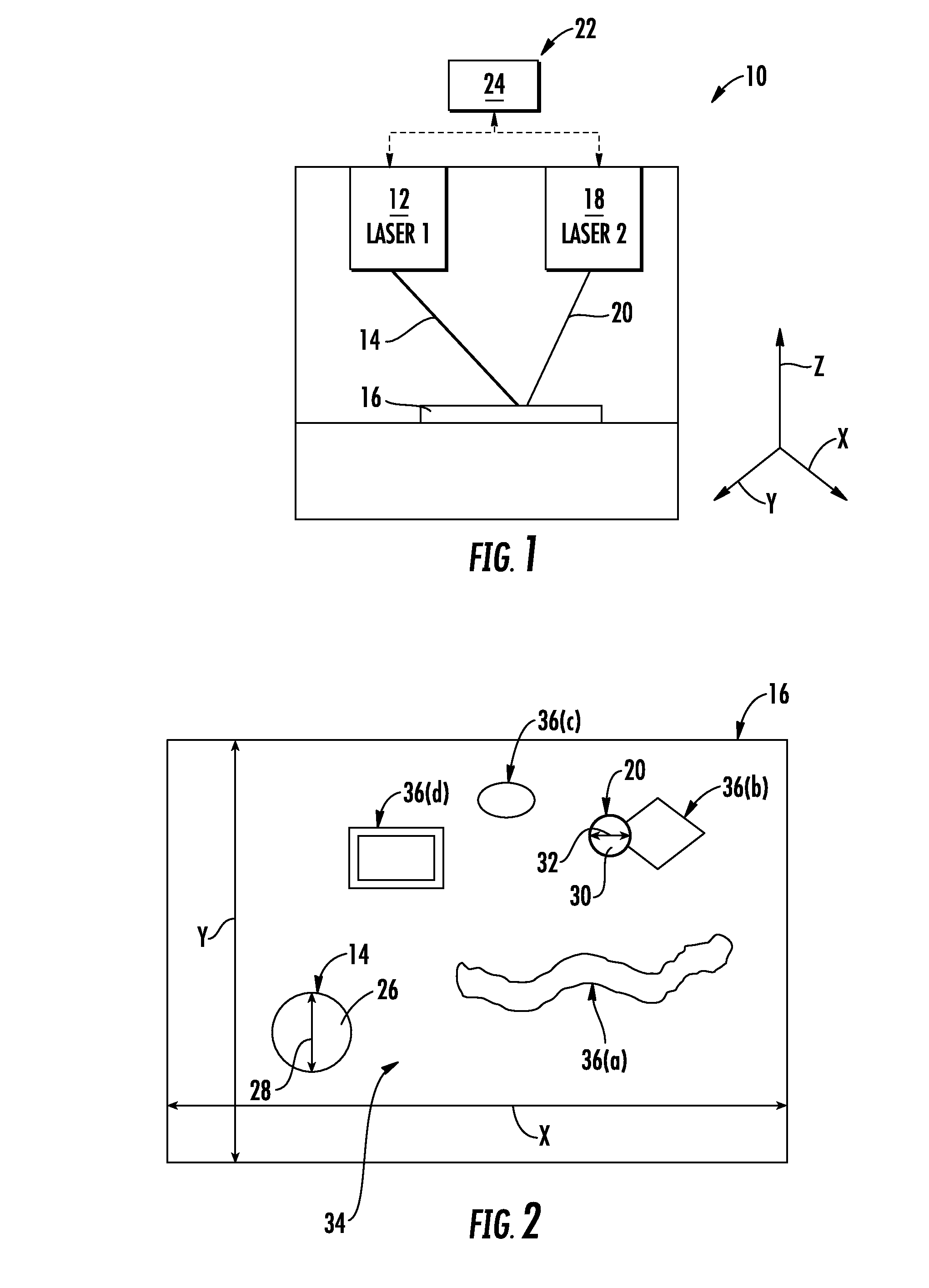

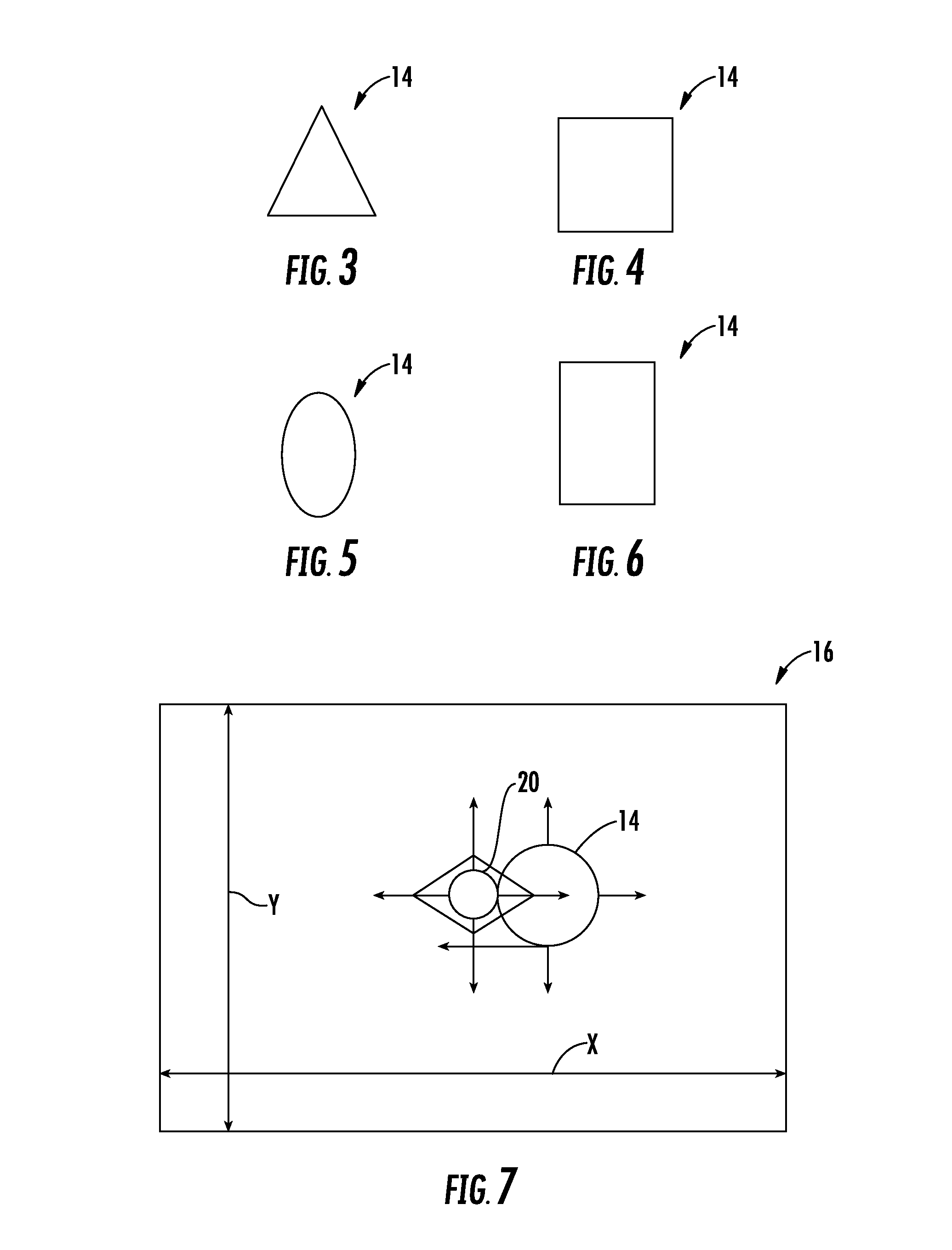

System and method for multi-laser additive manufacturing

InactiveUS20160318129A1Additive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsLaser additive manufacturing

A system and method for additive manufacturing an object using multiple lasers is disclosed herein. The system includes a first laser generating a first focused laser beam having a first surface area where the first focused laser beam is directed onto a first quantity of a powder material on a substrate so as to fuse particles of the powder material in a first layer of the substrate. A second laser generating a second focused laser beam having a second surface area where the second laser beam is directed onto a second quantity of the powder material on the substrate so as to fuse particles of the powder material in the first layer of the substrate. The first surface area of the first focused laser beam is greater than the second surface area of the second focused laser beam.

Owner:GENERAL ELECTRIC CO

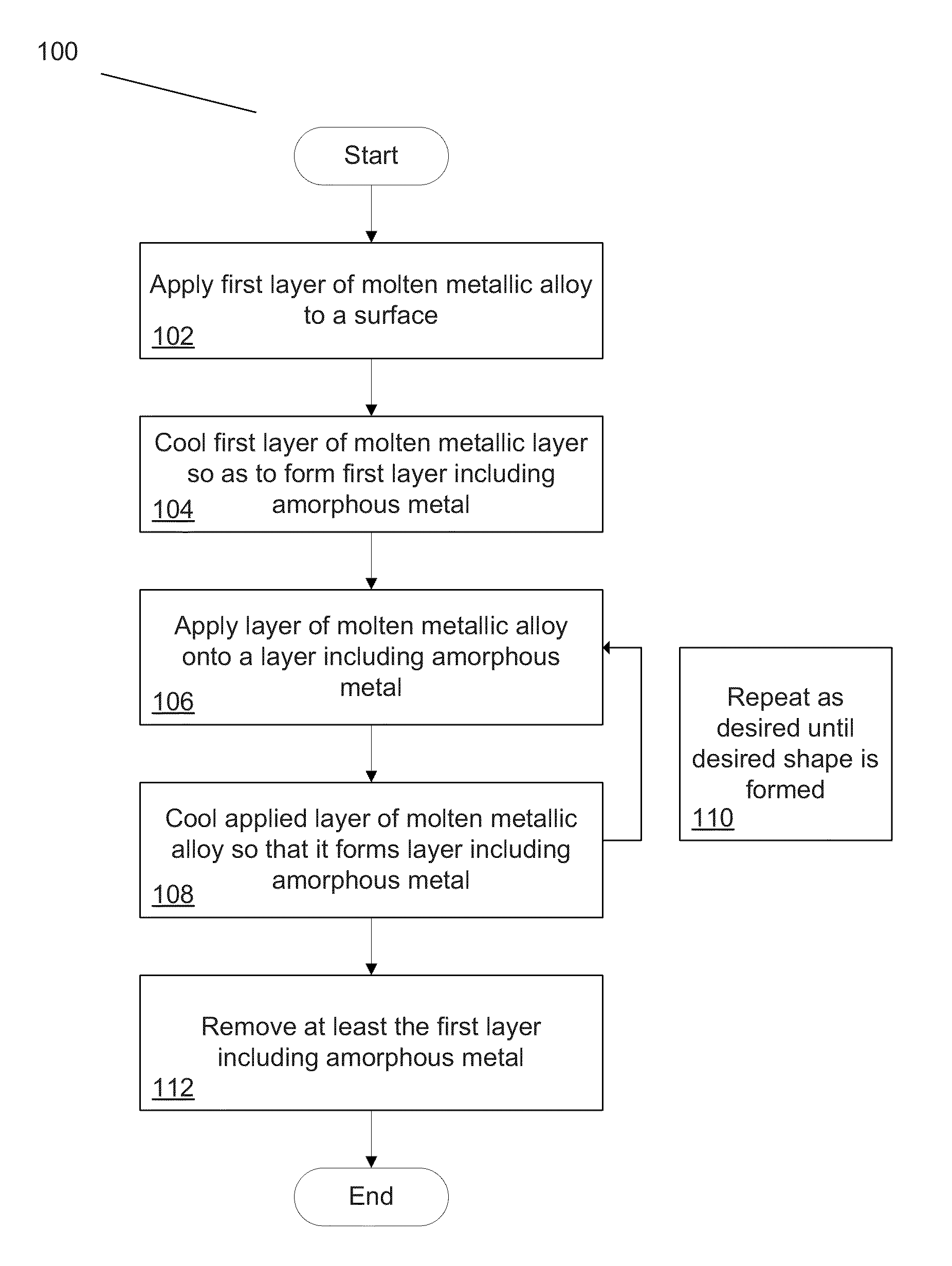

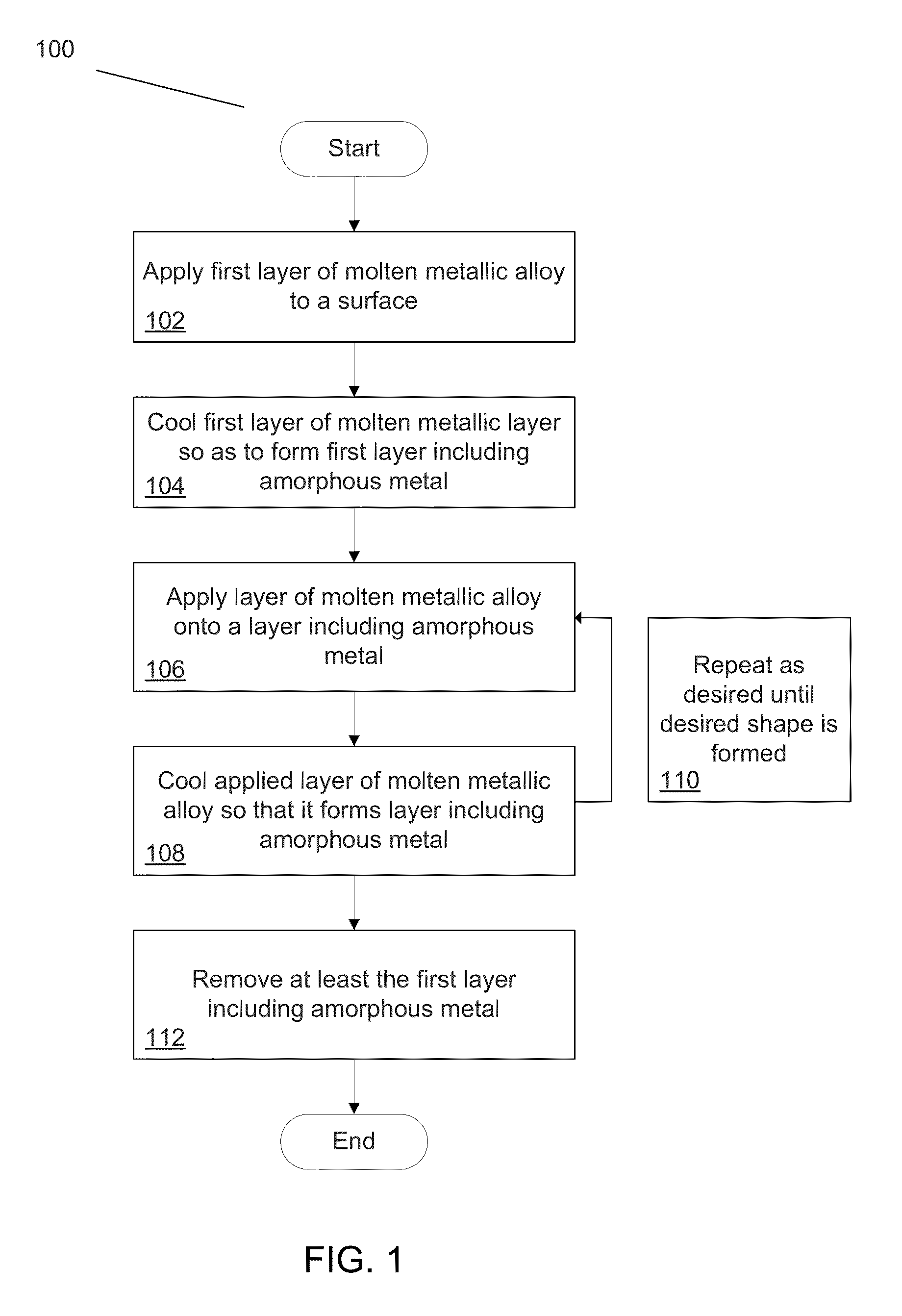

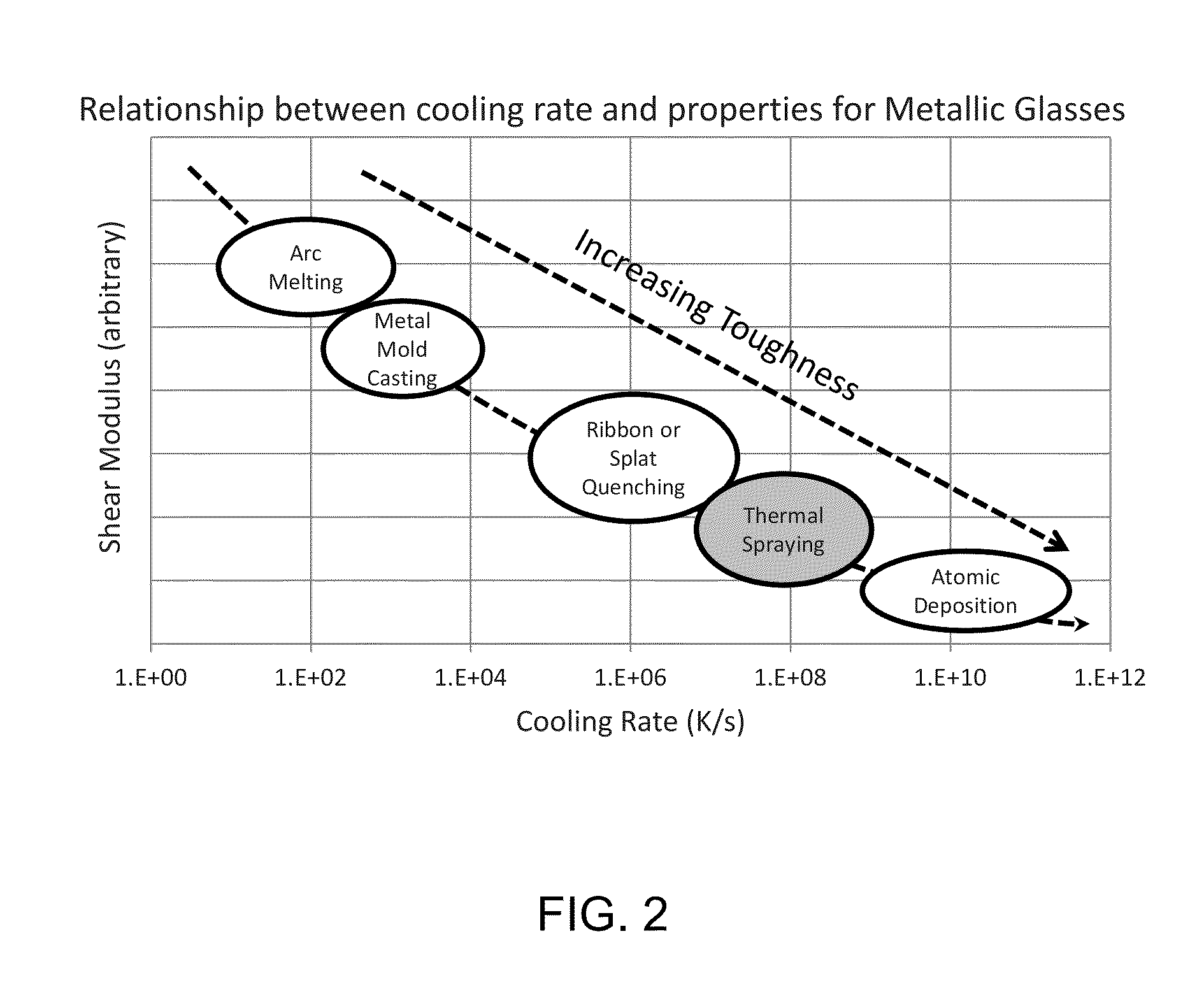

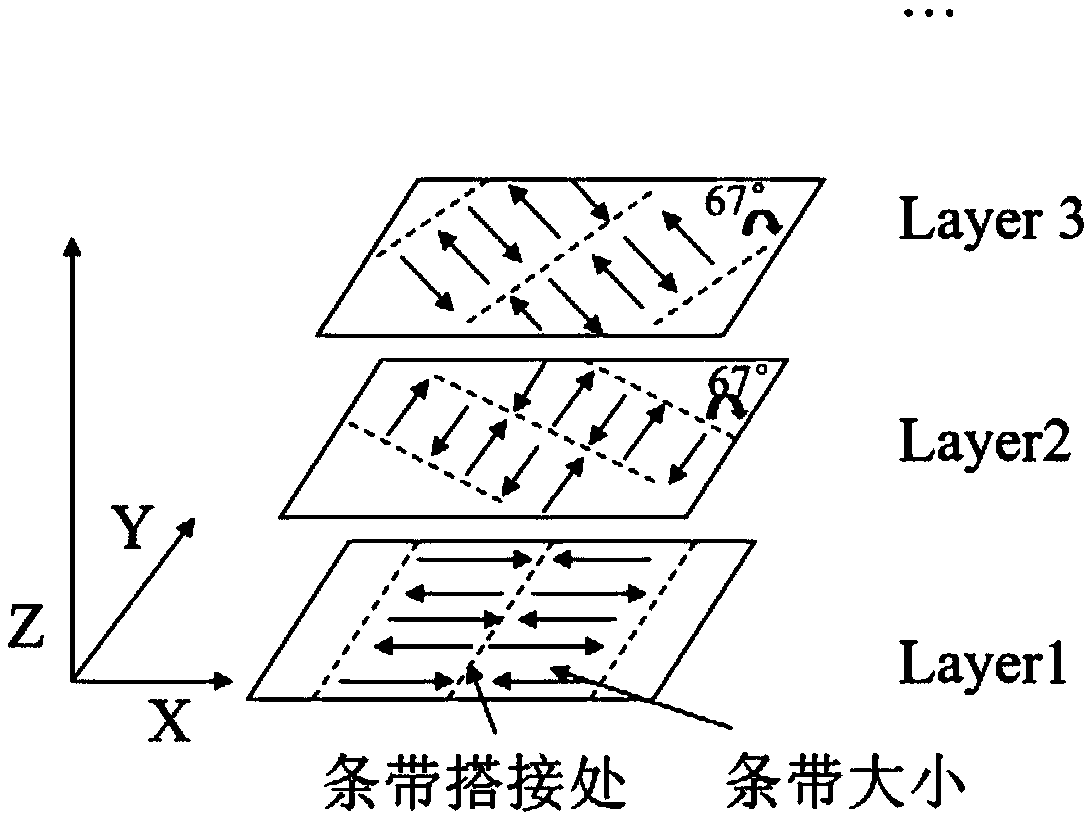

Systems and methods for fabricating objects including amorphous metal using techniques akin to additive manufacturing

ActiveUS20140202595A1Additive manufacturing apparatusMolten spray coatingLaser additive manufacturingAmorphous metal

Systems and methods in accordance with embodiments of the invention fabricate objects including amorphous metals using techniques akin to additive manufacturing. In one embodiment, a method of fabricating an object that includes an amorphous metal includes: applying a first layer of molten metallic alloy to a surface; cooling the first layer of molten metallic alloy such that it solidifies and thereby forms a first layer including amorphous metal; subsequently applying at least one layer of molten metallic alloy onto a layer including amorphous metal; cooling each subsequently applied layer of molten metallic alloy such that it solidifies and thereby forms a layer including amorphous metal prior to the application of any adjacent layer of molten metallic alloy; where the aggregate of the solidified layers including amorphous metal forms a desired shape in the object to be fabricated; and removing at least the first layer including amorphous metal from the surface.

Owner:CALIFORNIA INST OF TECH

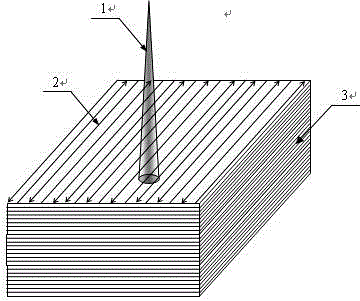

Method for removing cracks of Rene104 nickel-based superalloy during laser additive manufacturing

ActiveCN108941560AEliminate cracksInhibition of large size cracksAdditive manufacturing apparatusTransportation and packagingRoom temperatureStress relief

Owner:CENT SOUTH UNIV

Method for additive manufacturing

ActiveUS20170341141A1Affect propertyEasily ionizedAdditive manufacturing apparatusSolid state diffusion coatingHydrogenChemical reaction

A method for forming a three-dimensional article through successive fusion of parts of a metal powder bed is provided, comprising the steps of: distributing a first metal powder layer on a work table inside a build chamber, directing at least one high energy beam from at least one high energy beam source over the work table causing the first metal powder layer to fuse in selected locations, distributing a second metal powder layer on the work table, directing at least one high energy beam over the work table causing the second metal powder layer to fuse in selected locations, introducing a first supplementary gas into the build chamber, which first supplementary gas comprising hydrogen, is capable of reacting chemically with or being absorbed by a finished three-dimensional article, and releasing a predefined concentration of the gas which had reacted chemically with or being absorbed by the finished three dimensional article.

Owner:ARCAM AB

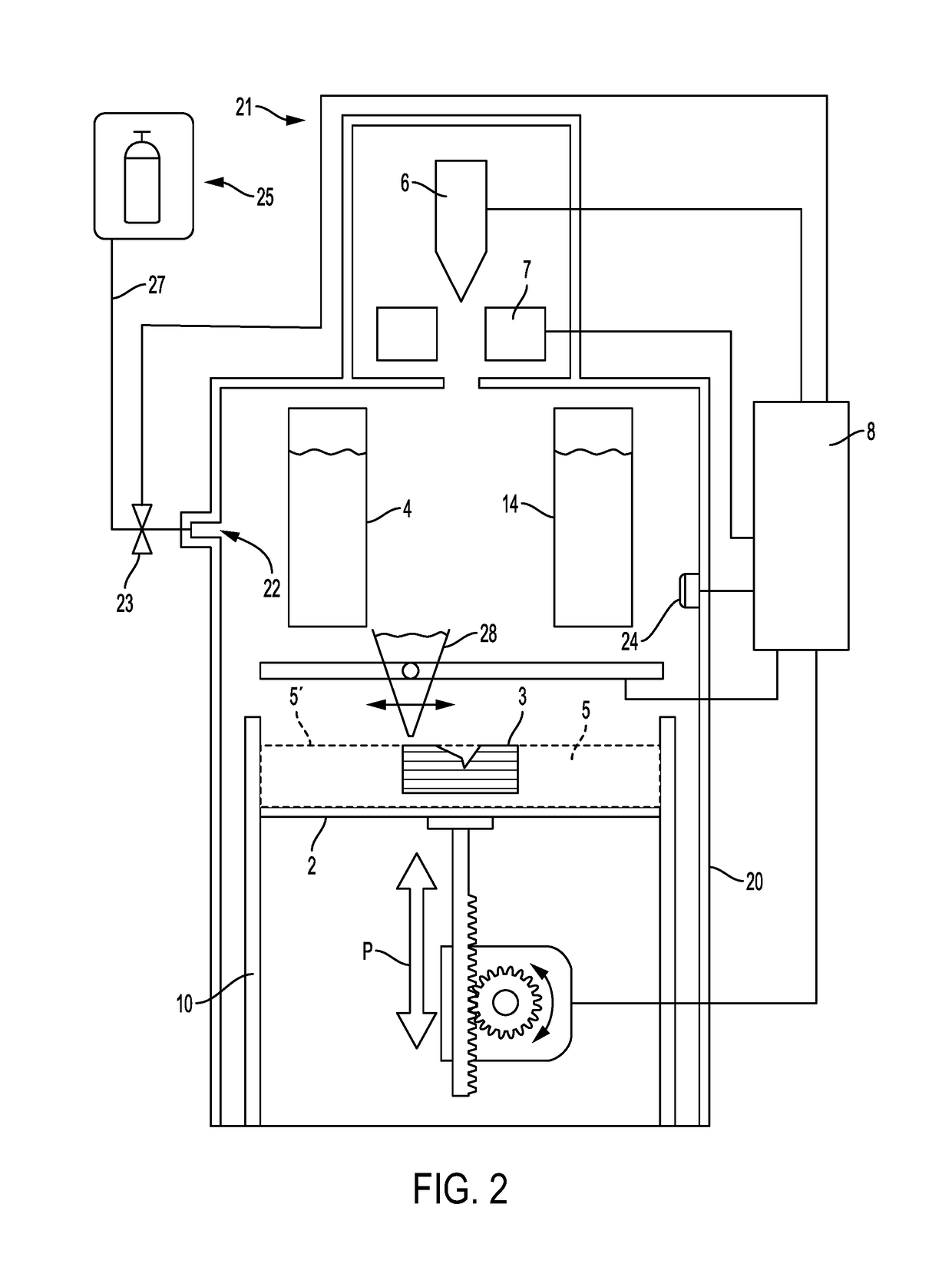

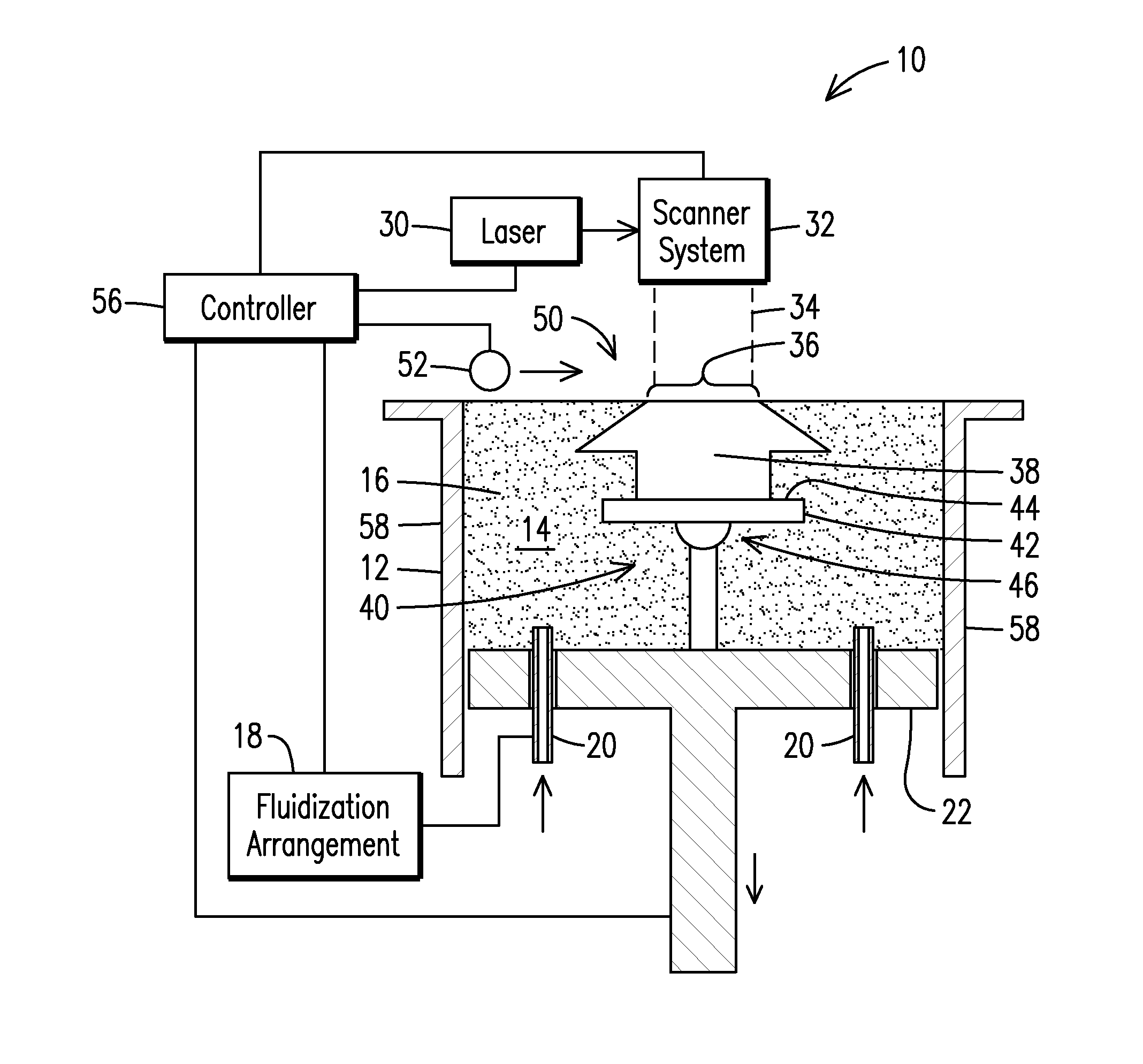

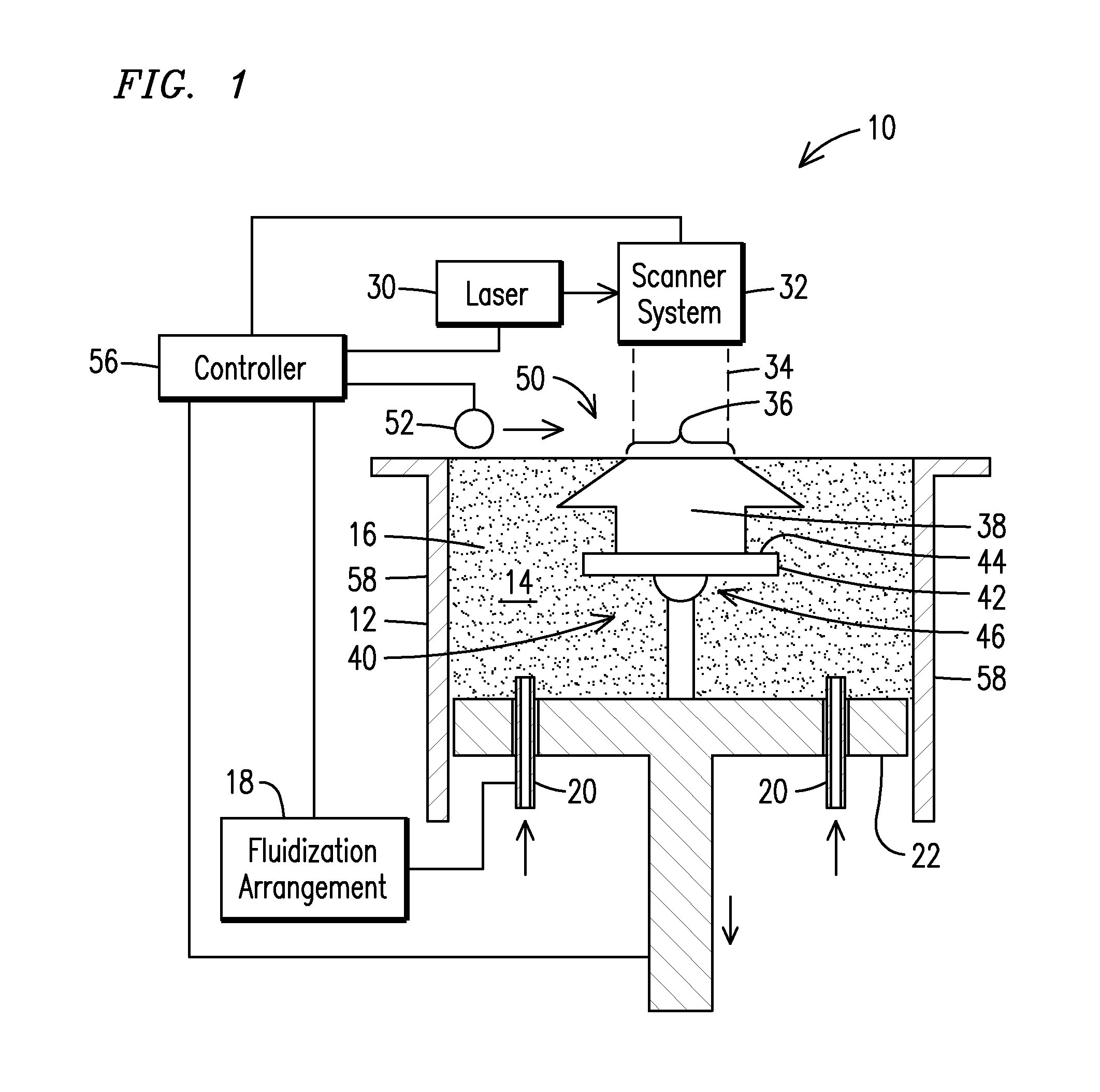

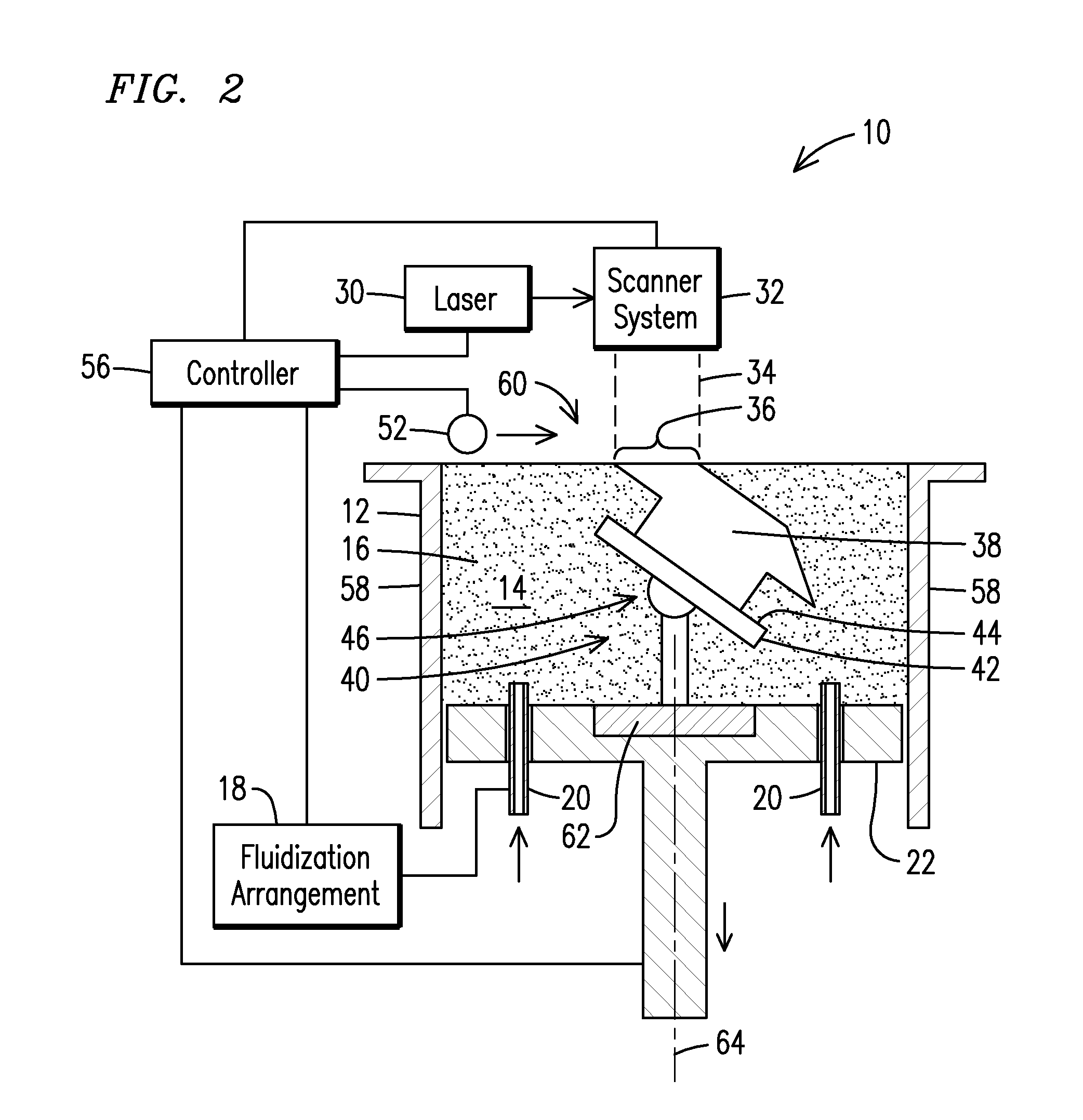

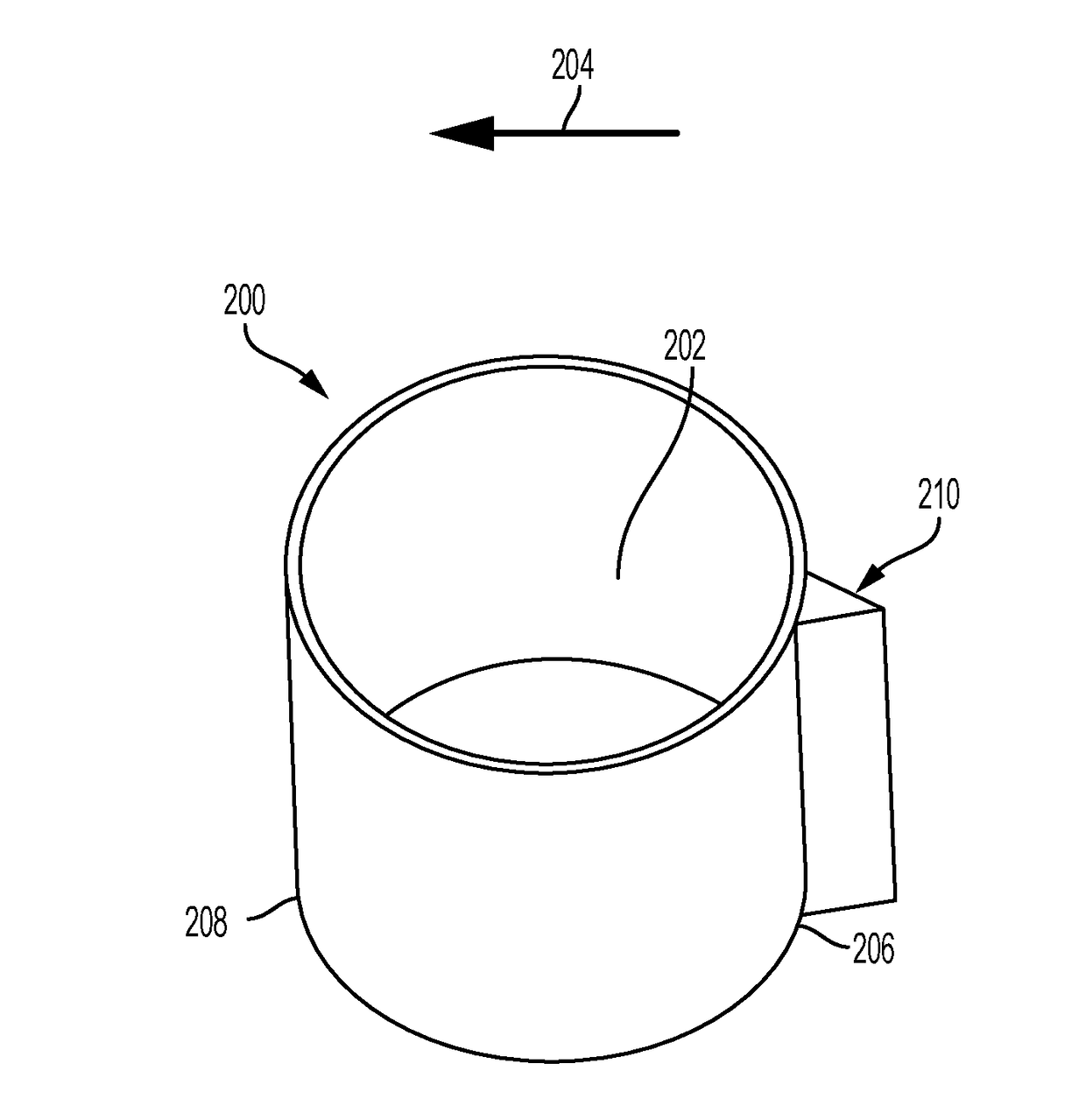

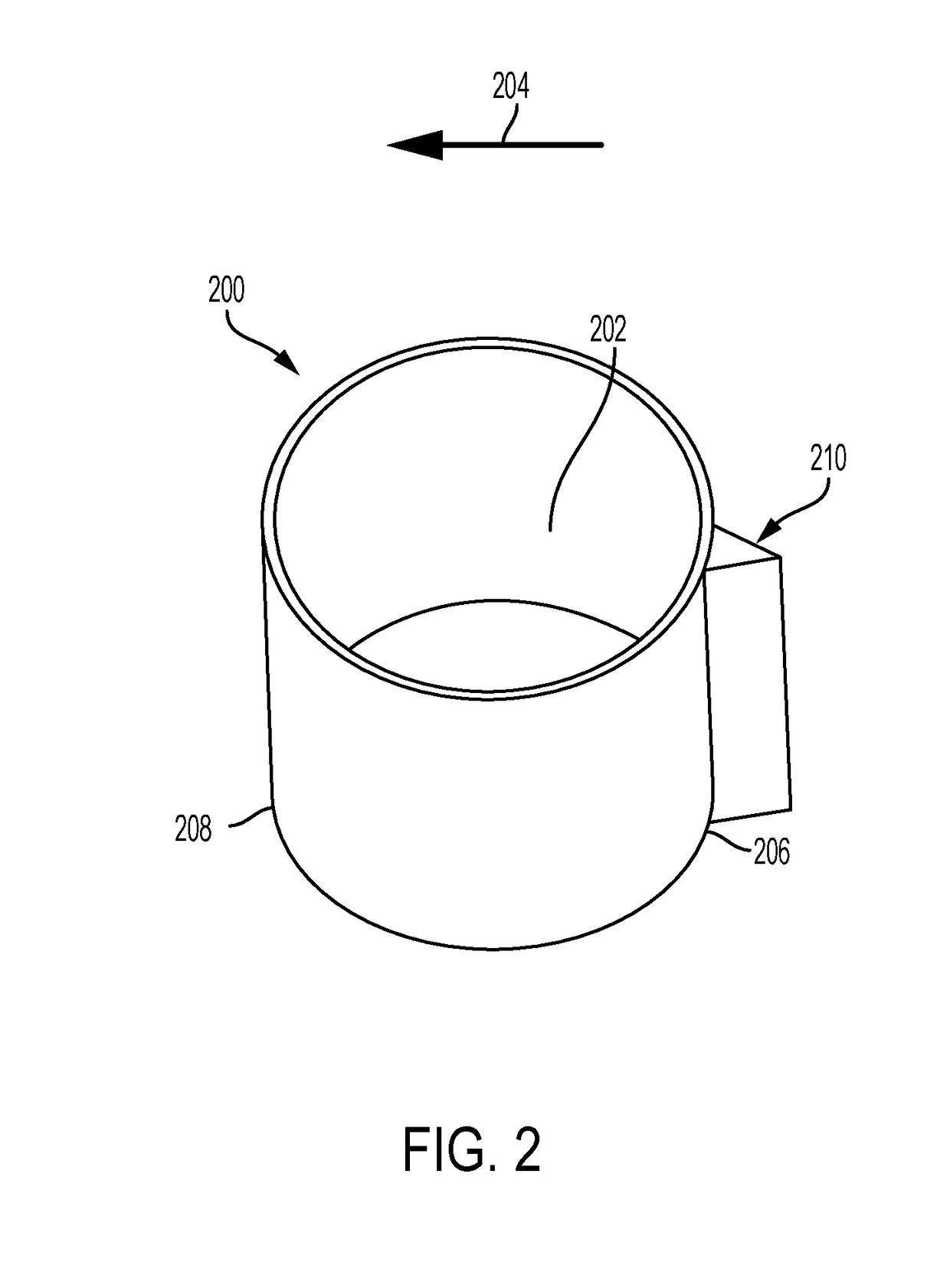

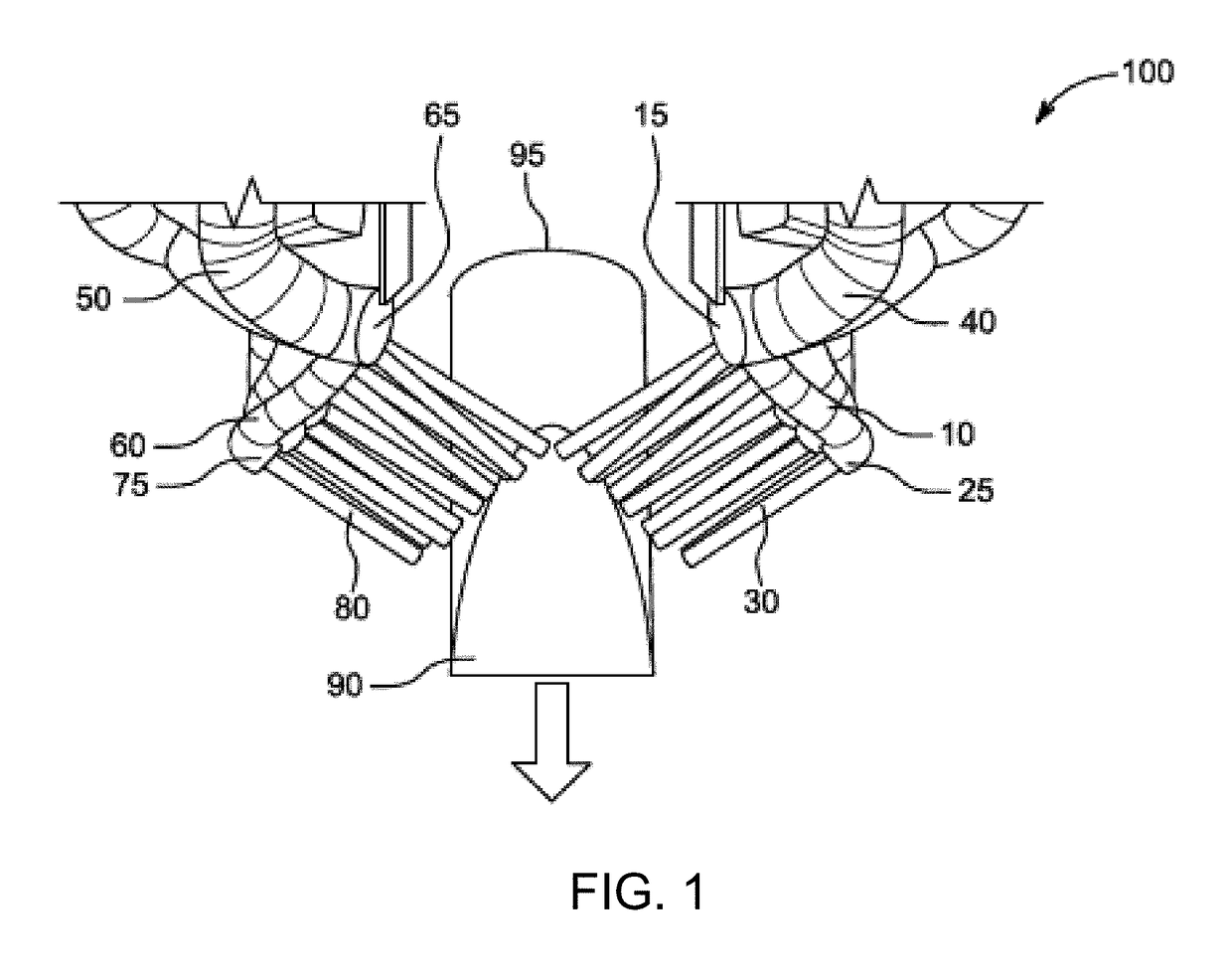

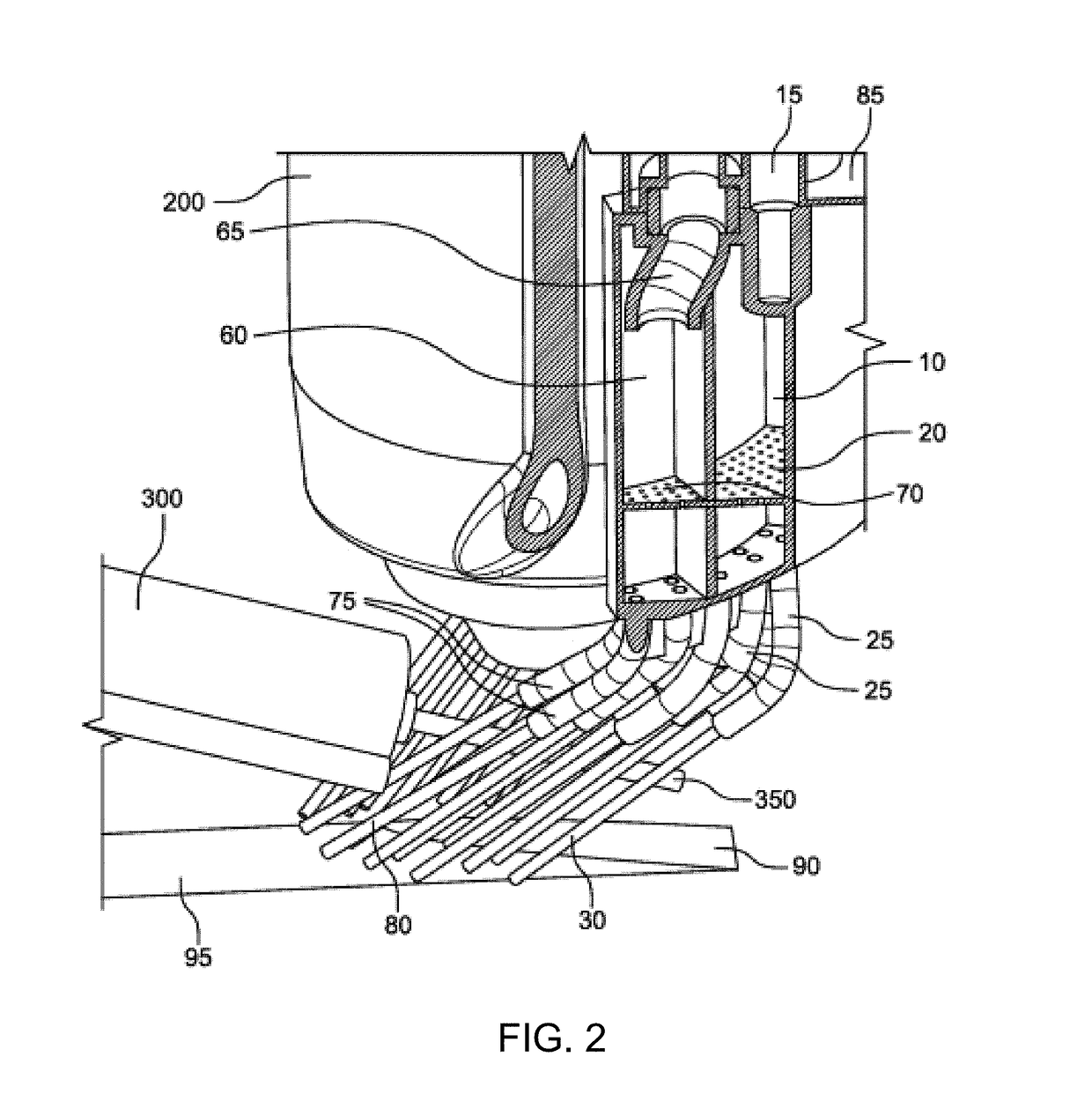

Articulating build platform for laser additive manufacturing

ActiveUS20160067923A1Additive manufacturing apparatusAuxillary shaping apparatusMarine engineeringMetallic materials

An additive manufacturing apparatus (10) including: a container (12) configured to bound a bed of powdered metal material; a fluidization arrangement (18) configured to fluidize the bed of powered material; an articulation mechanism (40) disposed within the container and configured to support and to rotate a component (38) about at least one horizontal axis; and an energy beam (34) configured to selectively scan portions (36) of a surface of the bed of powdered metal material to melt or sinter the selectively scanned portions onto the component.

Owner:SIEMENS ENERGY INC

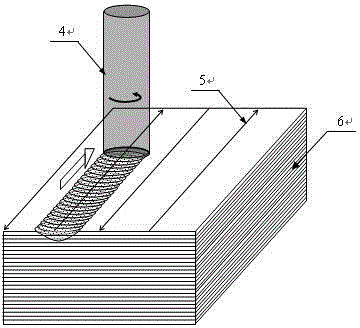

Metal laser melting additive manufacturing method

ActiveCN104404509AEliminate cracksSpheroidization EliminationAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMetallic materials

The invention discloses a metal laser melting additive manufacturing method. After each layer is machined by utilizing the laser additive manufacturing method, a single-layer laser photocoagulation area is modified by utilizing a selective friction stir welding, photocoagulation cracks are eliminated and nanocrystalline is formed. Each additive-manufactured layer is subjected to laser melting and friction stir welding and multiple layers are machined by the method repeatedly, so that nanocrystalline complex metal components with high strength and ductility and no cracks are manufactured. The laser melting additive manufacturing method provided by the invention comprises a selective laser melting technique based on powder bed formation and a laser engineering near-net forming technique based on laser coaxial powder feeding, wherein the involved metal materials comprise an aluminum base, a copper base, a titanium base, an iron base, a nickel base and a cobalt base; the selective friction stir welding can eliminate cracks, balling and holes generated during laser additive manufacturing and improves the formation quality; the selective friction stir welding can crush network carbides in a laser photocoagulation structure, so that the crushed network carbides are distributed in a dispersion manner, and the structure is regulated to be the nanocrystalline.

Owner:CENT SOUTH UNIV

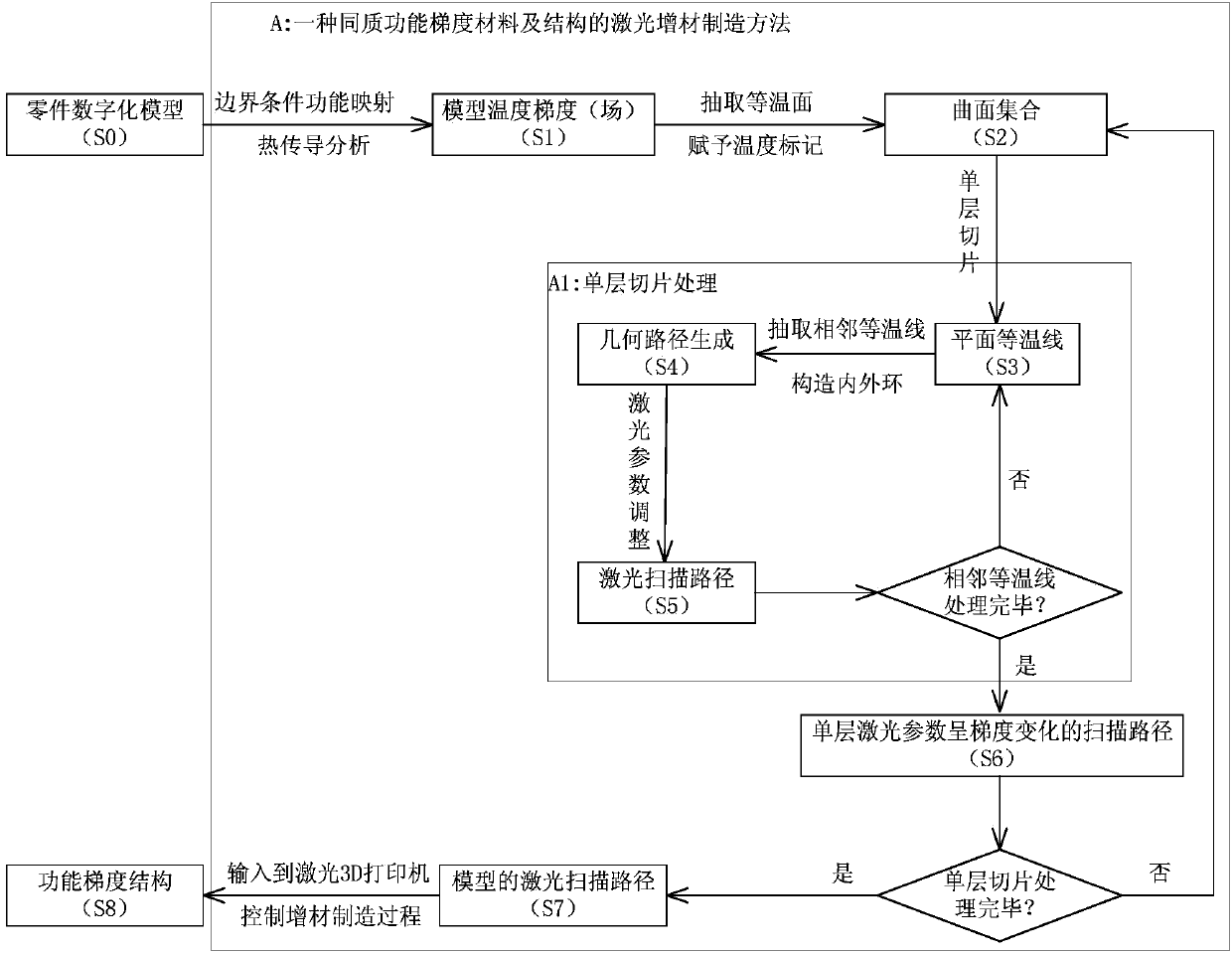

Laser additive manufacturing method for homogeneous functionally graded material and structure

ActiveCN104190930AOvercome functionOvercome structureIncreasing energy efficiencyLaser scanningOptoelectronics

The invention relates to a laser additive manufacturing method for a homogeneous functionally graded material and structure. The method includes the following steps that different functions are mapped into different temperatures which serve as boundary conditions to be exerted on different parts of a three-dimensional model; a three-dimensional finite element method is used for calculating a heat conduction equation of the model, inner temperature graded distribution, namely the temperature field of a model, is obtained, that is a temperature field of the model is obtained; an isothermal surface of the model is extracted, and a curved surface set with different temperature marks is obtained; slicing is conducted on the curved surface set, the intersection outline of each layer and the isothermal surface is obtained, in other words, plane isothermal lines are obtained; slices of each layer are processed, and a scanning route with laser parameters of the single layer in graded variation is obtained; the steps are repeatedly conducted until slicing is completed and a laser scanning route of the model is obtained; the generated laser scanning route is input into a laser 3D printing machine to control the additive manufacturing process, and the homogeneous functionally graded structure is obtained. According to the additive manufacturing method, the fact that the homogeneous functionally graded material and the homogeneous functionally graded structure can be manufactured in an additive mode is achieved, and the fact cannot be achieved through a current laser additive manufacturing method.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

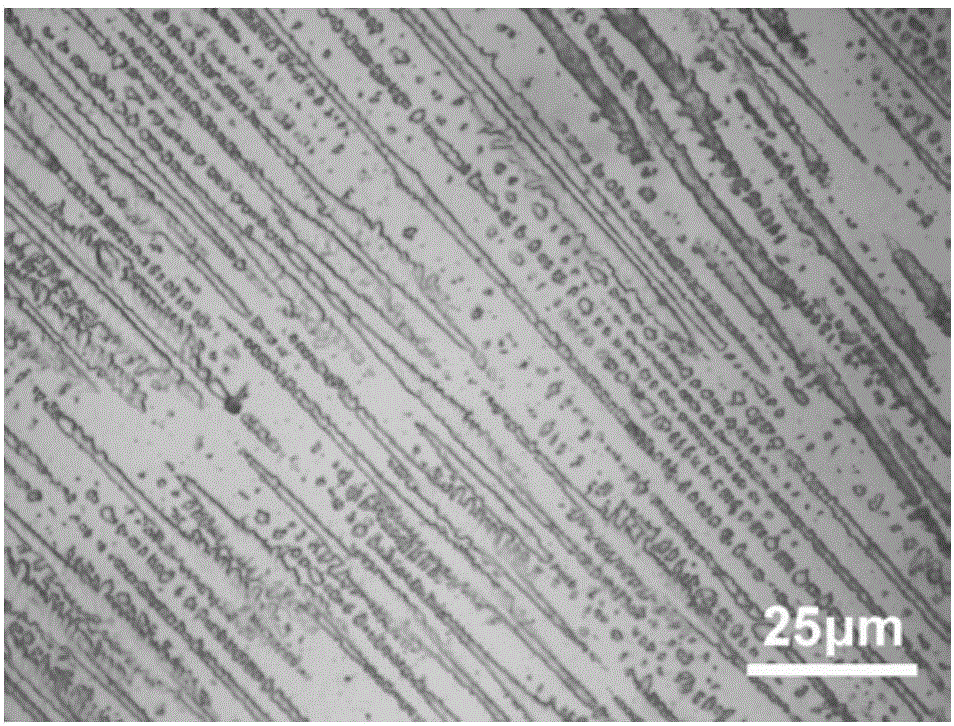

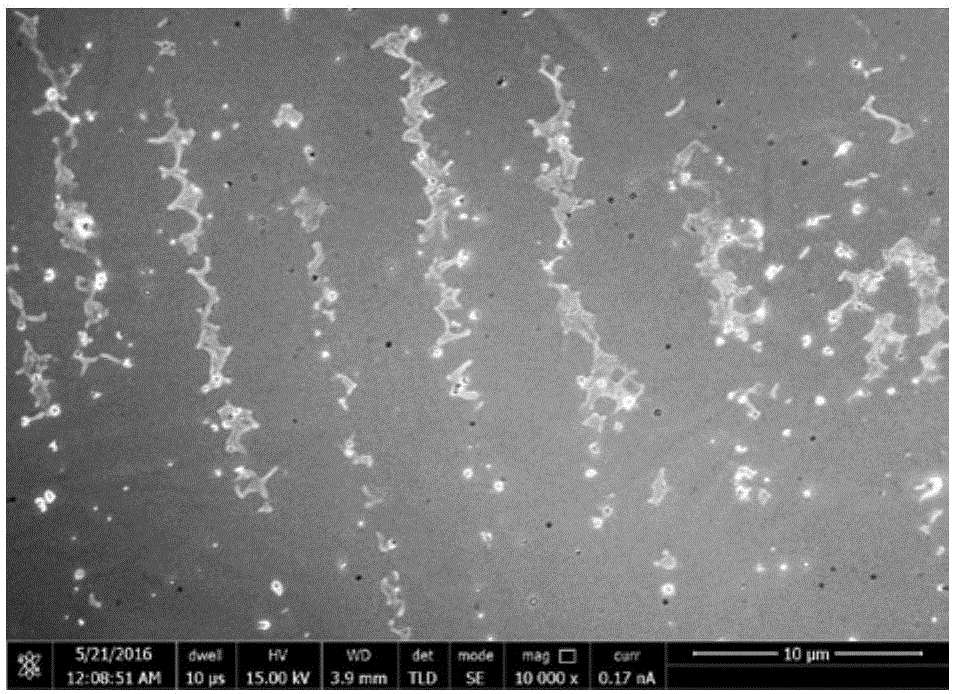

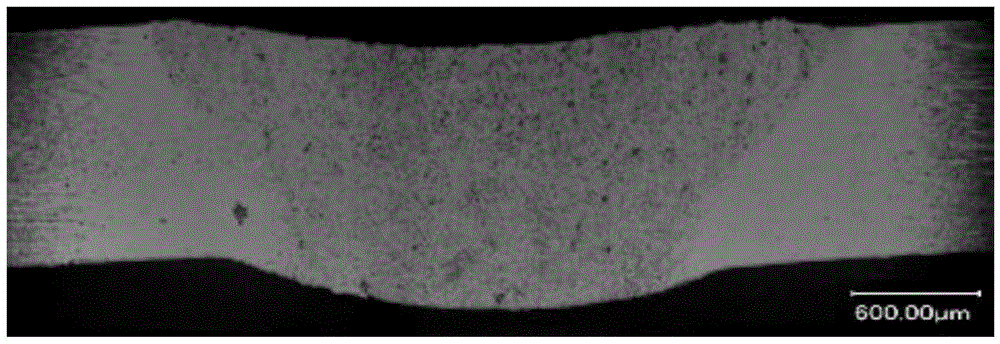

Method for controlling brittleness Laves phases in laser additive manufacturing process of nickel-based high-temperature alloy

InactiveCN106077647AReduce heat buildupIncrease cooling rateAdditive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsLaser source

The invention discloses a method for controlling brittleness Laves phases in the laser additive manufacturing process of a nickel-based high-temperature alloy. Firstly, laser additive manufacturing technological parameters are initially optimized, and a cooling medium is adopted for cooling the bottom of a base material; then a laser modulation technology is used for modulating a laser source, and superior laser modulation parameters are obtained, wherein the peak power of square waves ranges from 600 W to 1000 W, the pulse frequency of the square waves ranges from 10 HZ to 100 HZ, and the duty ratio of the square waves ranges from 0.3 to 0.6; the wave peak power of sawtooth waves ranges from 600 W to 1200 W, the wave trough power of the sawtooth waves is 0 W, and the pulse frequency of the sawtooth waves ranges from 10 HZ to 100 HZ; and according to the parameters of sine waves, the wave peak power ranges from 600 W to 1000 W, the wave trough is 0 W, and the pulse frequency ranges from 10 HZ to 100 HZ; and finally, laser additive manufacturing and forming of the nickel-based high-temperature alloy are conducted according to the above parameters, and a formed part with all small equiaxial dendritic structures and small discrete Laves phases is obtained. By means of the laser modulation method, the precipitation behavior of the Laves phases in the laser additive manufacturing process of the nickel-based high-temperature alloy can be effectively controlled, the cracking sensibility of parts obtained through laser additive manufacturing is reduced, and the microstructure is improved.

Owner:HUNAN UNIV

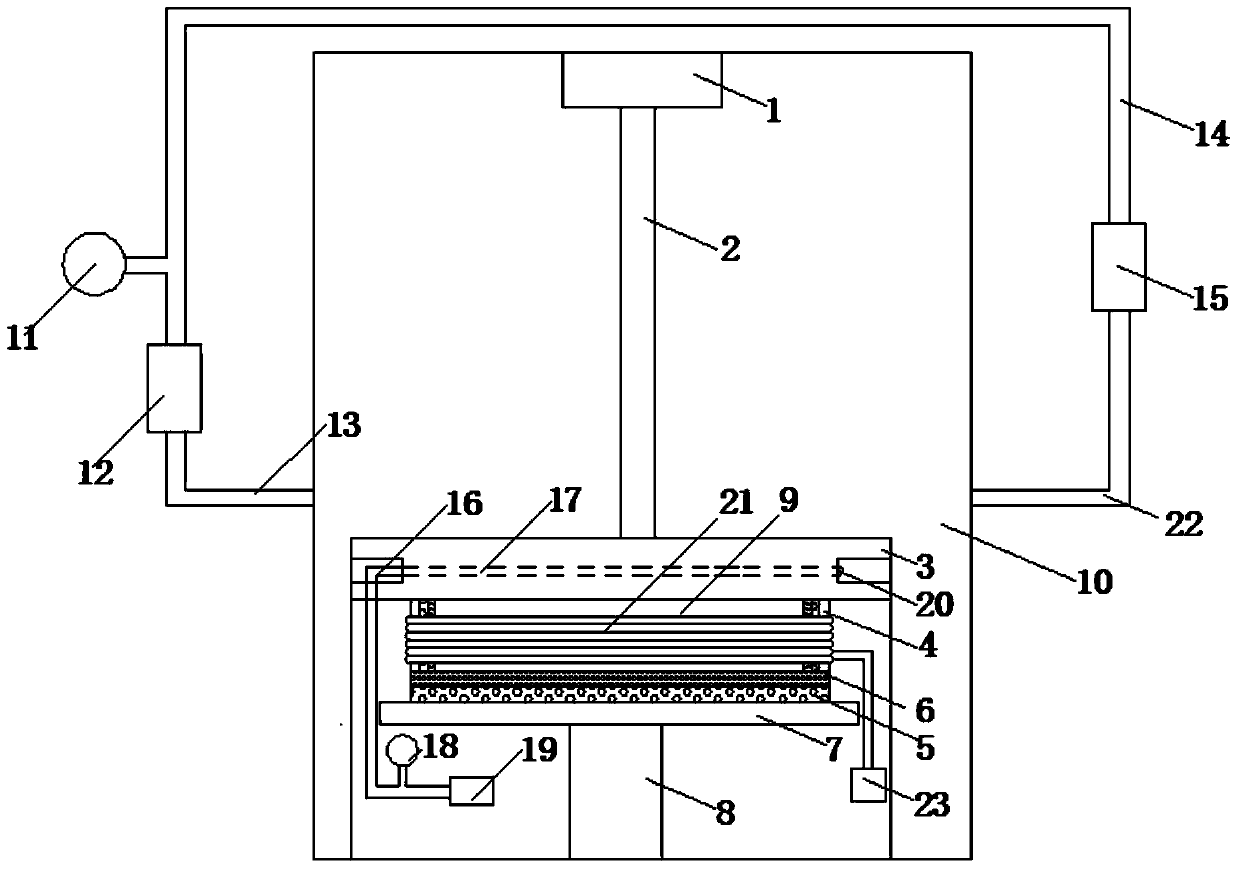

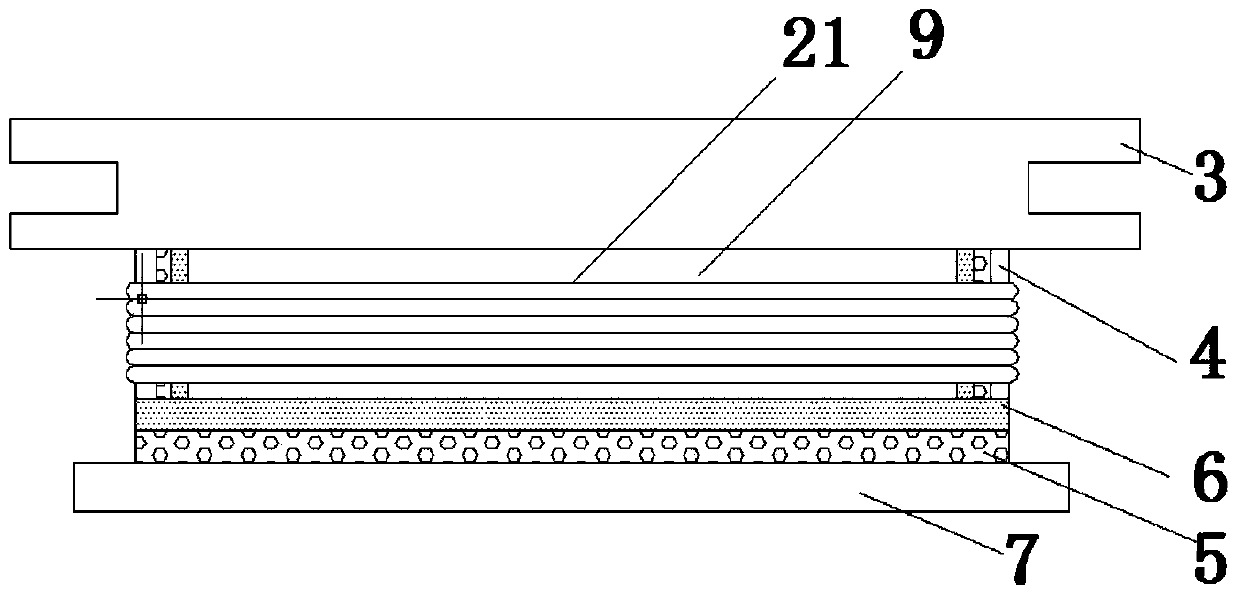

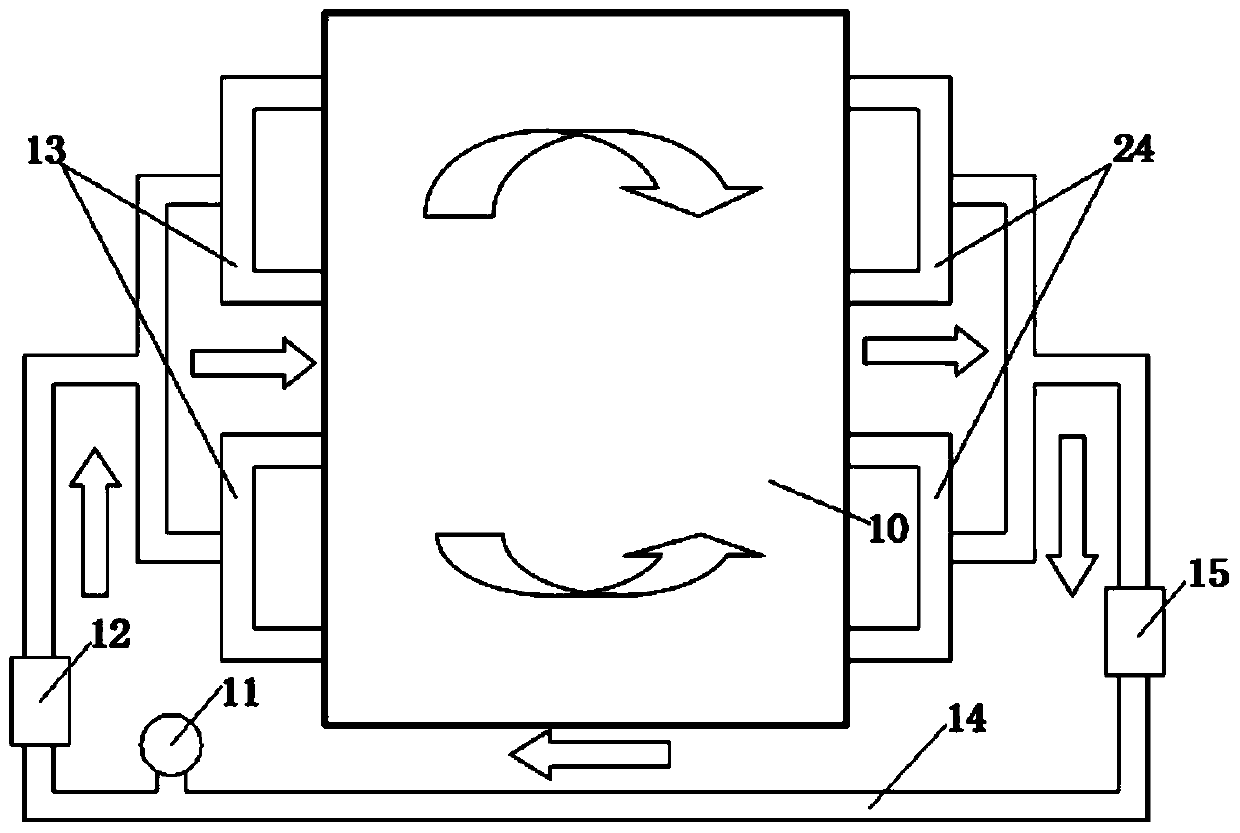

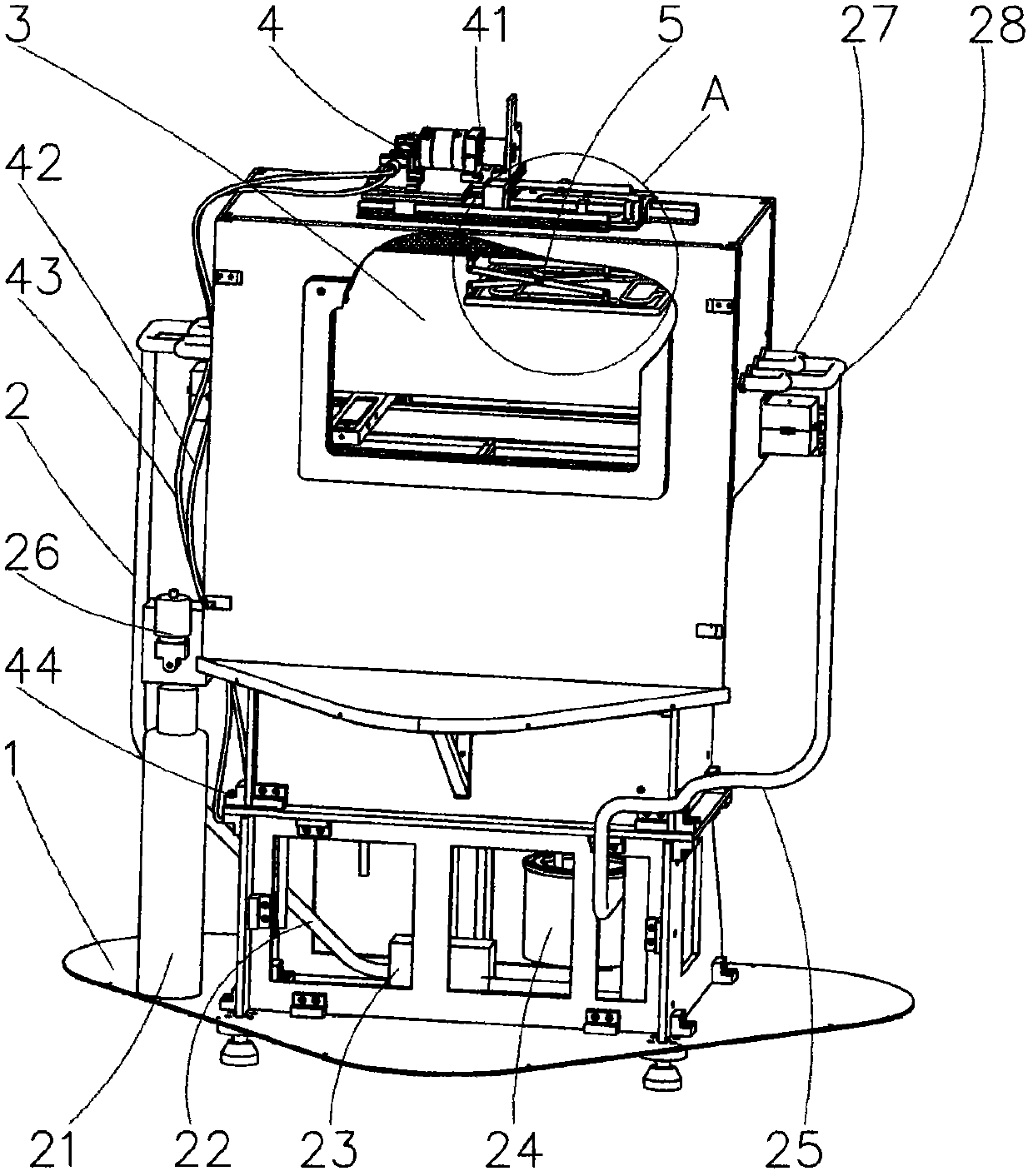

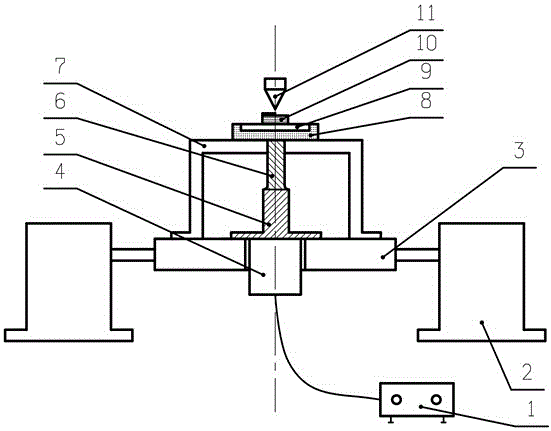

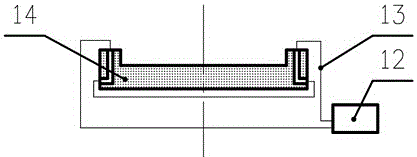

High-temperature powder bed system for laser additive manufacture

ActiveCN103990798AImprove energy utilizationShorten warm-up timeIncreasing energy efficiencyThermodynamicsInsulation layer

The invention discloses a high-temperature powder bed system for laser additive manufacture. The system comprises a working cavity, a laser device, a workbench, an electromagnetic heating layer, a heat insulation component and a laminar flow temperature uniforming component, the workbench is arranged in the working cavity, the electromagnetic heating layer is mainly composed of an electromagnetic induction plate and a coil, the electromagnetic heating layer is placed on the lower surface of the workbench and is attached to the workbench, and heat can be directly conducted to the workbench. A cooling flow way is arranged in the workbench, the bottom face and the side face of the electromagnetic heating layer are surrounded by the heat insulation component, and heat insulation and heat preservation of the electromagnetic heating layer can be achieved. The laminar flow temperature uniforming component is arranged outside the working cavity and used for achieving air flow circulation in the working cavity, and even temperature distribution of the workbench can be achieved. According to the part size, the work table board can be heated to be at the high temperature, heat preservation is performed, and temperature uniformization and the cooling functions after machining can be achieved. The aims of protecting the systems, and improving energy utilization rate and heating efficiency can be achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Methods and leading edge supports for additive manufacturing

ActiveUS20170232511A1Additive manufacturing apparatusIncreasing energy efficiencyLeading edgeEngineering

The present disclosure generally relates to methods for additive manufacturing (AM) that utilize support leading edge structures in the process of building objects, as well as novel leading edge support structures to be used within these AM processes. The support structure is positioned adjacent the object between the object and a first side of the powder bed. The support structure has a shape that tapers outward in the direction from the first side to the object

Owner:GENERAL ELECTRIC CO

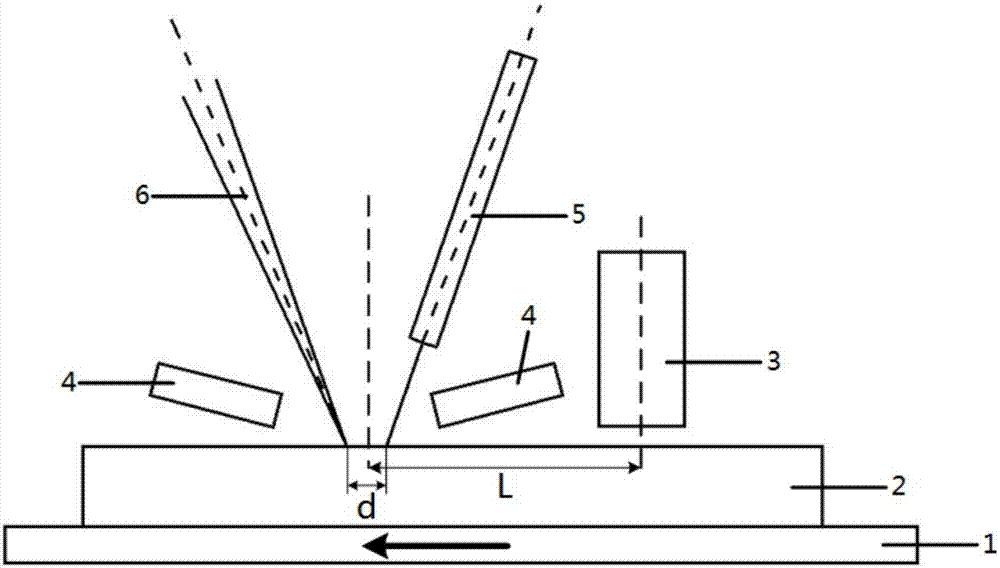

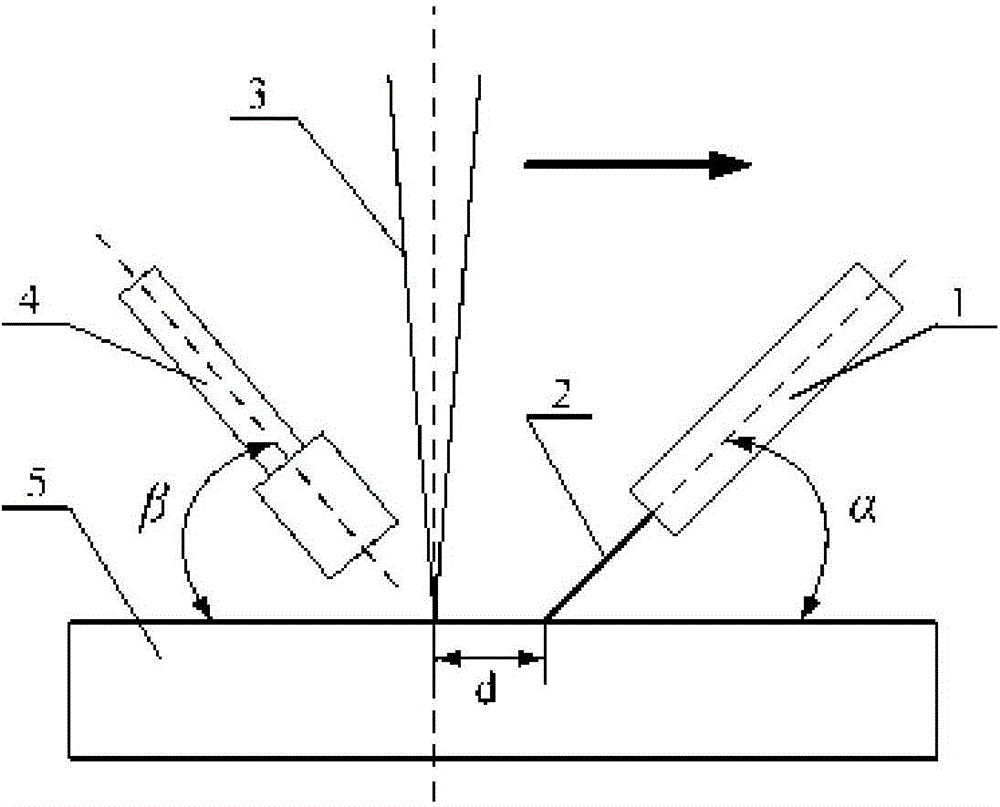

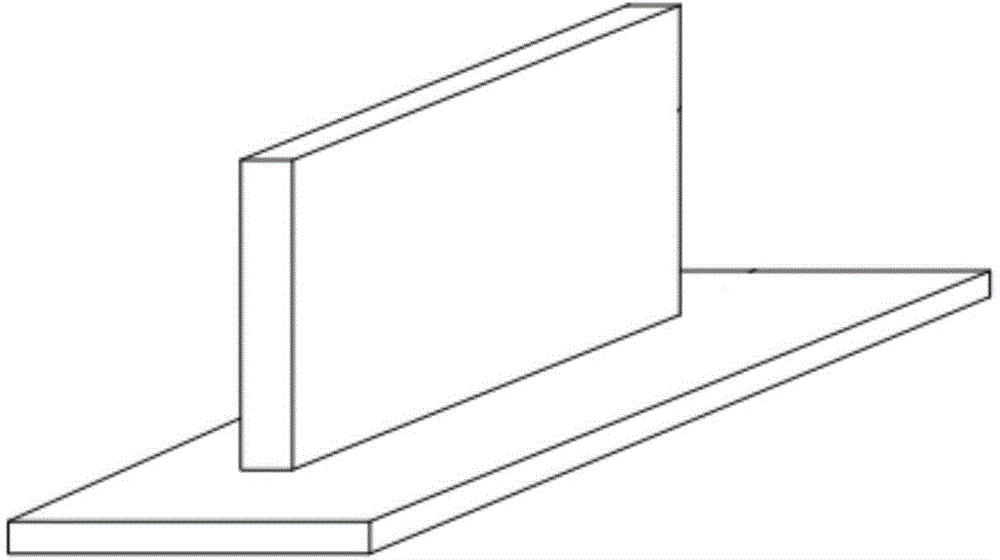

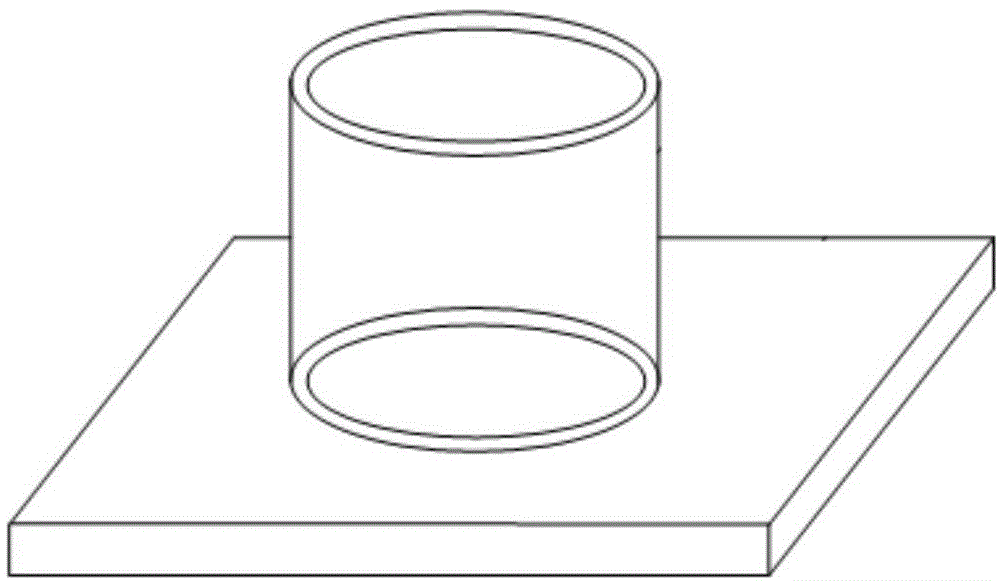

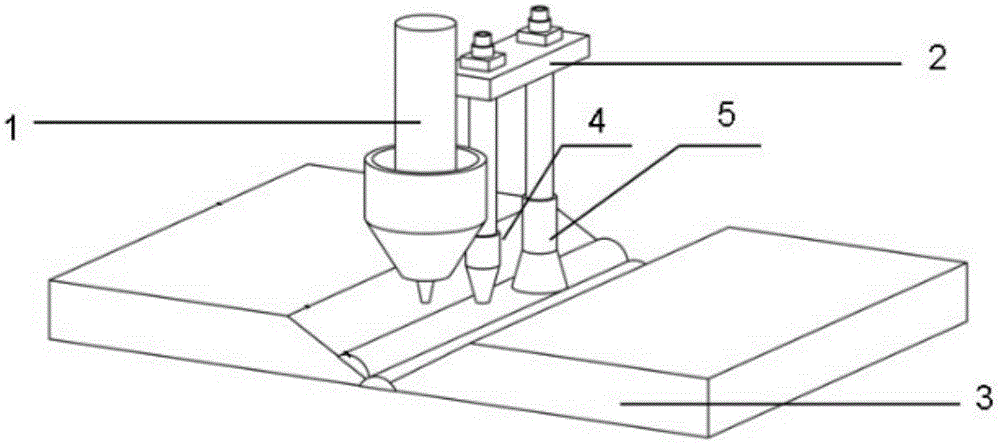

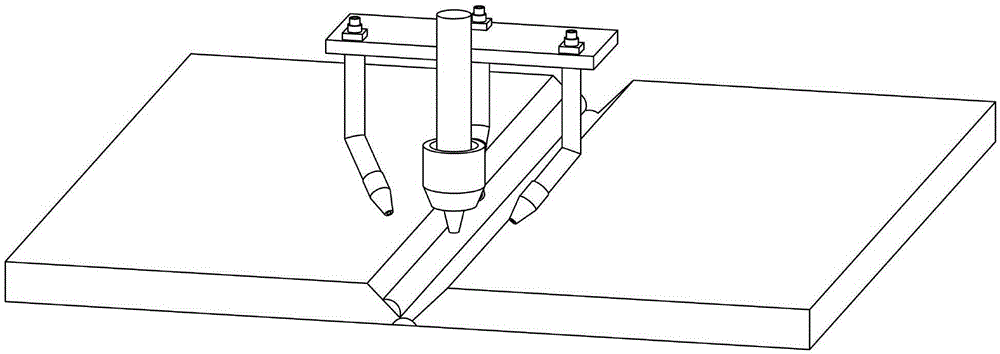

Laser-CMT welding aluminum alloy additive manufacturing method and forming system

PendingCN107283061AImprove stabilityImprove interlayer bonding performanceWelding/soldering/cutting articlesLaser beam welding apparatusSlag (welding)Molten bath

The invention discloses a laser-CMT welding aluminum alloy additive manufacturing method and a forming system. A laser and an electric arc are adopted as a composite heat source, the cold metal short circuiting transfer manner is adopted, and additive manufacturing forming for an aluminum alloy component is achieved. According to the provided laser-CMT welding additive manufacturing method, the problems that in the process of aluminum alloy component manufacturing through laser additive, the required laser power is high, and forming is difficult are solved, the problems that in the traditional process of aluminum alloy manufacturing through electric arc additive, the heat input amount is large, deformation is serious, and a molten bath is prone to overflowing or webbing are solved, and the problem that in the process of aluminum alloy manufacturing through CMT welding additive, incomplete fusion or slag inclusion or the like is likely to happen is solved; and the additive manufacturing method based on the laser-electric arc composite heat source principle is provided for additive manufacturing forming for the aluminum alloy component.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN +1

Copper alloy laser-cold metal transition compound heat source material increase manufacturing method

InactiveCN104625412AImprove absorption rateQuality improvementWelding/soldering/cutting articlesLaser beam welding apparatusHeat-affected zoneSource material

Owner:JIANGSU UNIV OF SCI & TECH

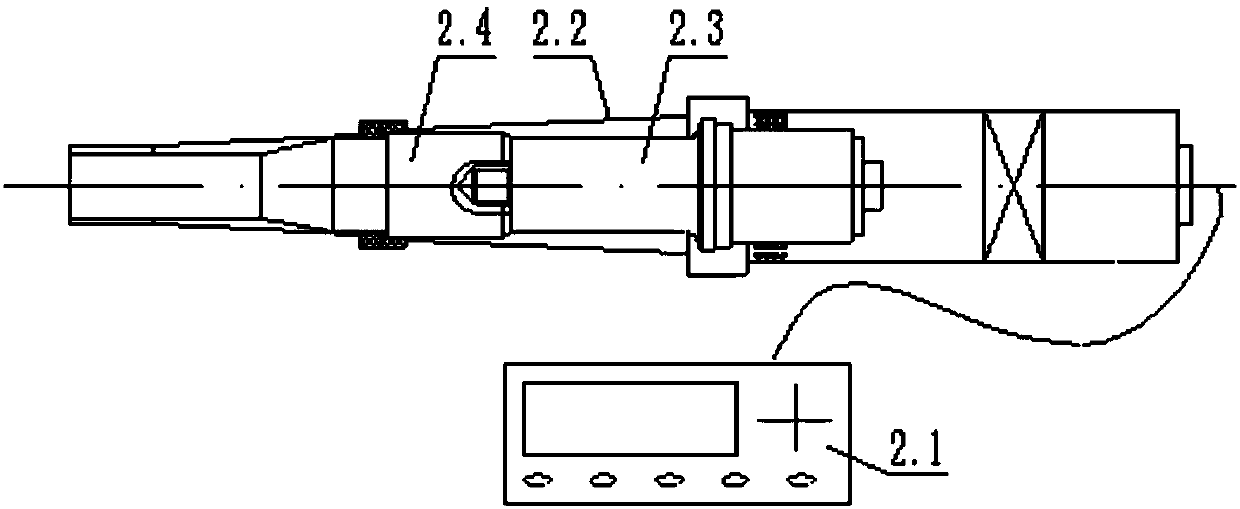

Simultaneous cooling assisted connection method based on laser additive manufacturing

InactiveCN105414746AGrain refinementImprove welding efficiencyLaser beam welding apparatusMetallurgyMartensitic stainless steel

The invention relates to a simultaneous cooling assisted connection method based on laser additive manufacturing, and aims to solve the problems of an increase in the crystal grain size, a decrease in the connector performance, and the like caused by the fact that heat cannot be effectively dissipated when titanium alloy, carbon stainless steel, martensitic stainless steel and other materials being relatively low in heat conductivity are involved in connection processes based on a laser additive manufacturing method. According to the method, a cooling device is arranged for being combined with a laser welding machine and a welding powder feeder, so as to achieving a cooling process; heat accumulated in the welding process can be effectively dissipated, so as to refine crystal grains; the welding efficiency and the connector performance are improved; in order to solve the problem that an oxidation phenomenon is likely to occur in the welding process, the cooling process is performed according to a cooling method adopting liquid nitrogen, inert gas or the like, so that connector oxidation can be effectively avoided when a cooling effect is exerted.

Owner:HARBIN INST OF TECH

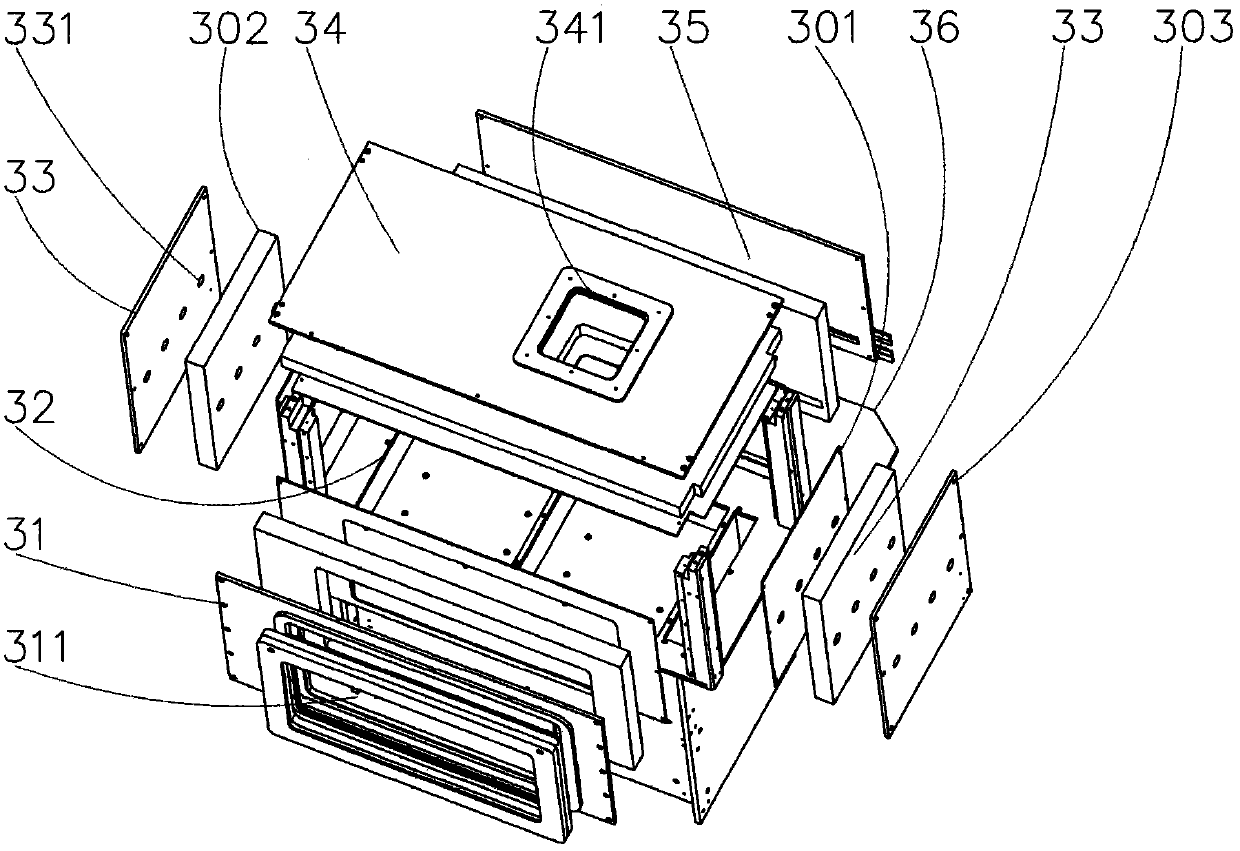

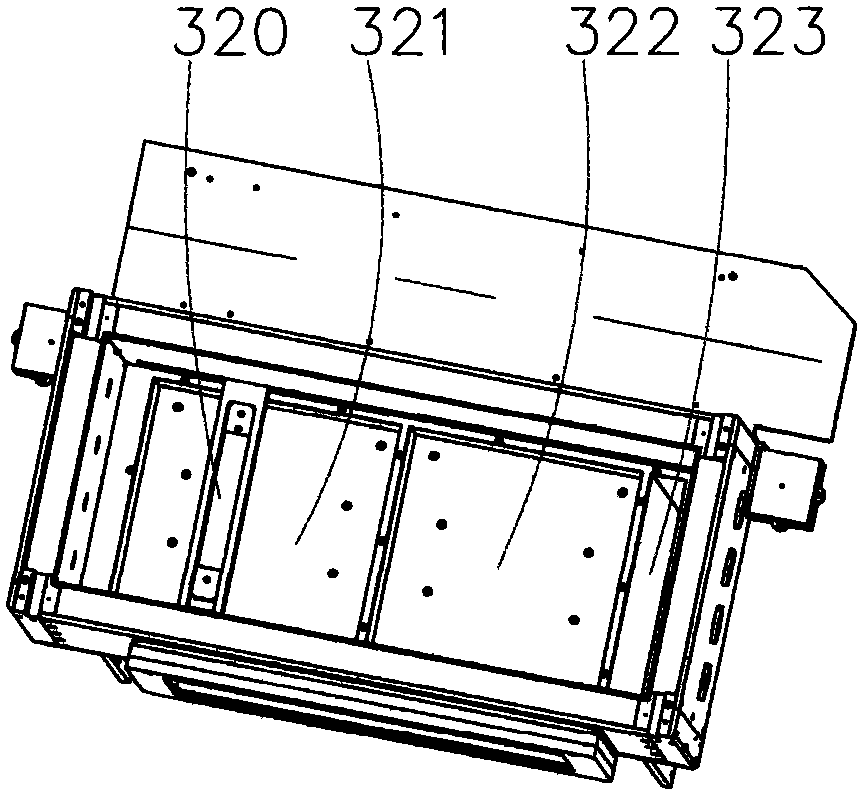

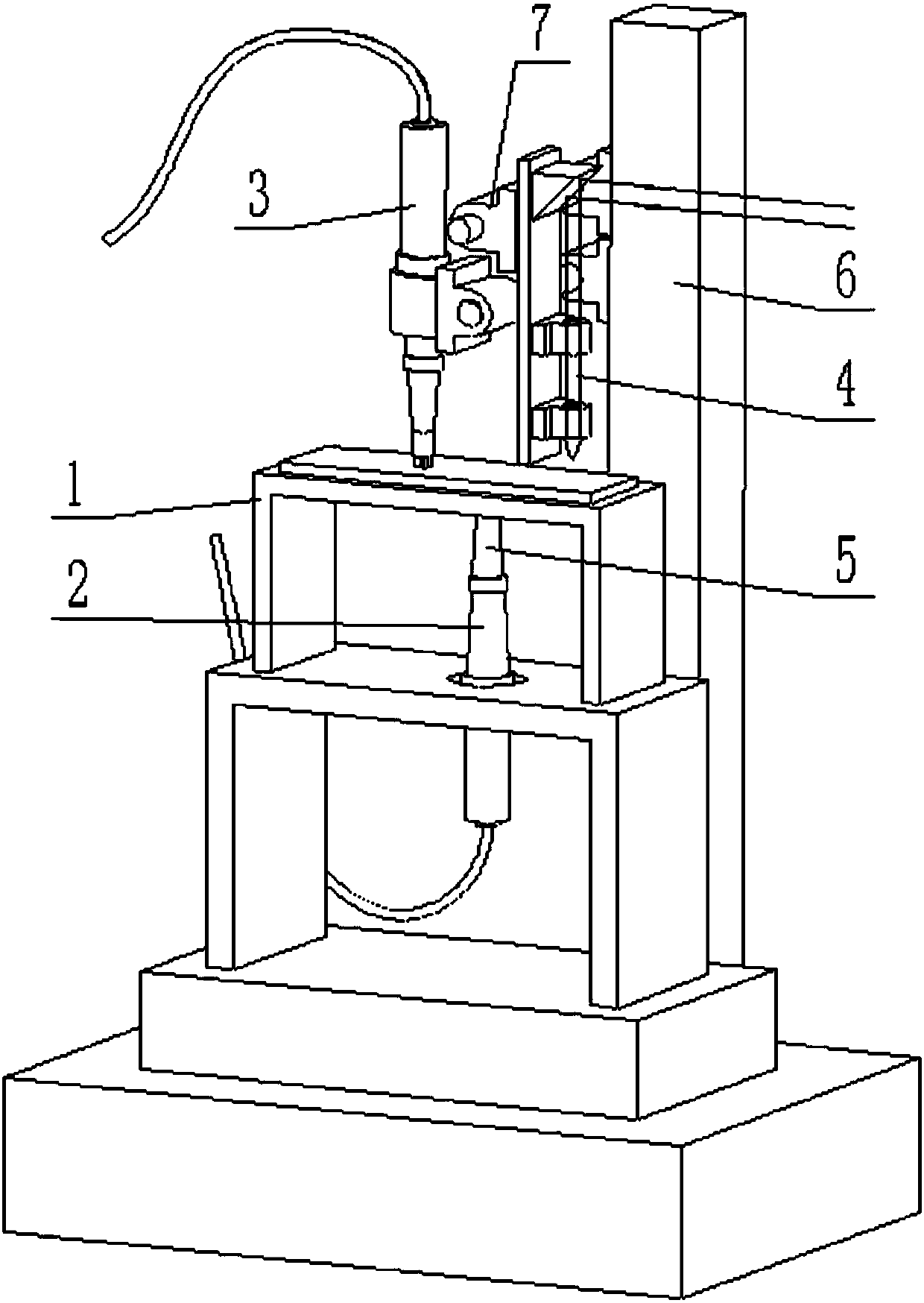

Manufacturing equipment of laser additive

ActiveCN103737933AReduce in quantityReduce lossesIncreasing energy efficiencyEngineeringProtection system

The invention provides manufacturing equipment of a laser additive. The manufacturing equipment comprises a frame, a work cavity, a laser system, an atmosphere protection system and a preheating system, wherein the work cavity is a sealed cavity defined by a heat insulation sandwich panel; a scanning galvanometer of a laser system is arranged at the top of the external part of the work cavity; the preheating system is a three-dimensional flexible heating system, and has a plurality of radiation heating layers with adjustable interlayer spaces arranged at the top inside the work cavity; an air feed pipe and an air return pipe of the atmosphere protection system are divided into a plurality of passages to be respectively connected with two sides of the work cavity through U-shaped tee joints, so that the circulation of inactive gas inside the work cavity is achieved. By adopting the manufacturing equipment of the laser additive, the space can be effectively saved, the heat loss is reduced, the heating efficiency is improved, the energy consumption is reduced, the temperature inside the work cavity is relatively even in distribution, the protective effect on the processing process caused by an internal atmosphere is obvious, different types of materials (metal, macromolecule and the like) can be molded, the processing deformation is reduced, and the excellent quality of molded spare parts is ensured.

Owner:GUANGZHOU OGGI3D ELECTROMECHANICAL

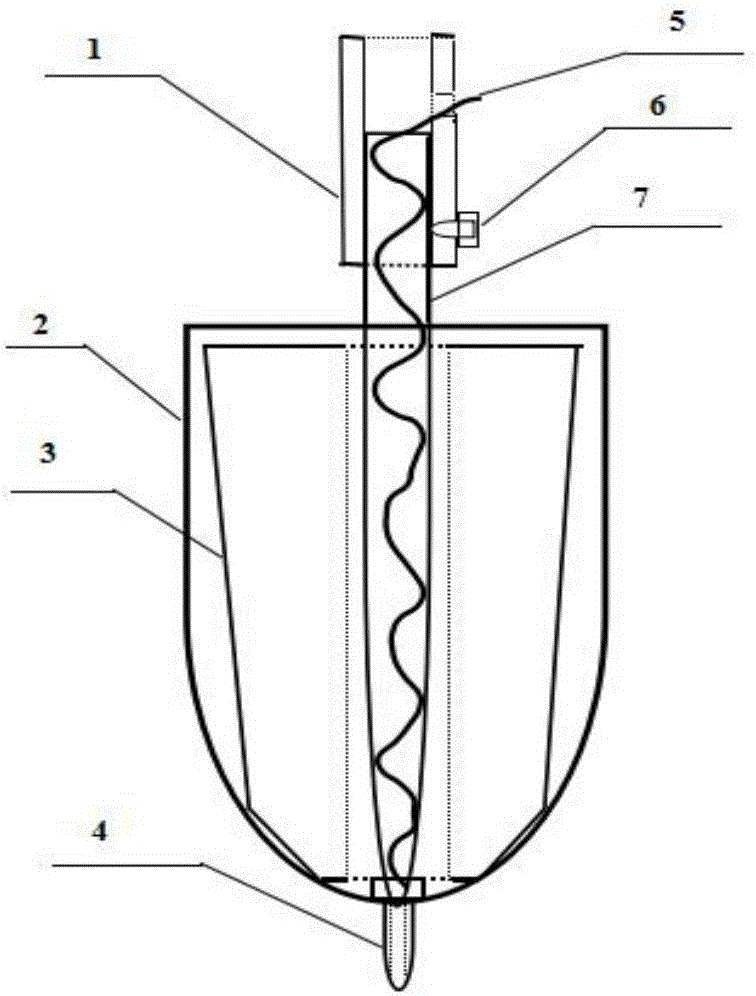

Ultrasonic-assisted laser material additive manufacturing device and realization method thereof

ActiveCN106363173AImprove bonded stateGood mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyNumerical controlCavitation

The invention discloses an ultrasonic-assisted laser material additive manufacturing device, which comprises a precise double-shaft numerical control rotating table, a support fastening base, a mold, an ultrasonic device, a base plate and a powder supply spray nozzle, wherein the precise double-shaft numerical control rotating table mainly consists of a double-support rotating table and a processing table; the support fastening base is arranged on the processing table; the mold is arranged on the support fastening base and is provided with a groove; the ultrasonic device is arranged in a way of passing through the processing table and the support fastening base and is connected with the bottom of the mold; the base plate is arranged in the groove formed in the mold; the powder supply spray nozzle is positioned above the base plate. The invention also provides a realization method of the ultrasonic-assisted laser material additive manufacturing device. The ultrasonic vibration is transmitted to the base plate, so that the base plate generates resonance; ultrasonic vibration stirring is performed in a molten pool formed under the laser effect in the laser material additive manufacturing process; a cavitation effect and a mechanical effect are generated; the combination state between layers can be improved; the formation probability of microsegregation and air holes inside forming elements can be reduced; meanwhile, crystal grains are refined; the residue stress is reduced; the forming elements with the good mechanical property are obtained.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

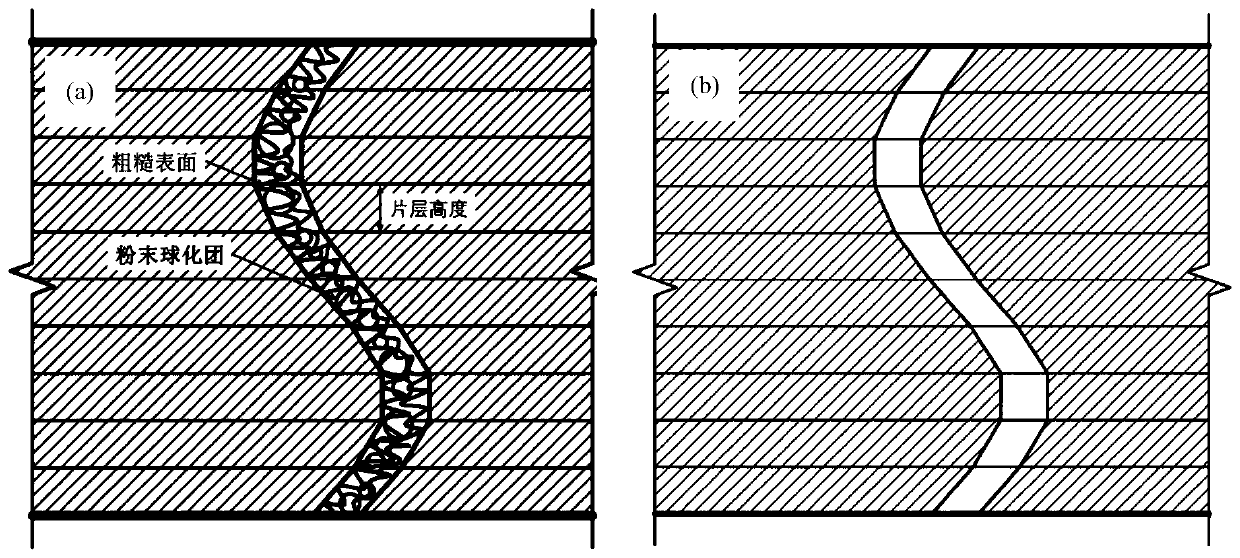

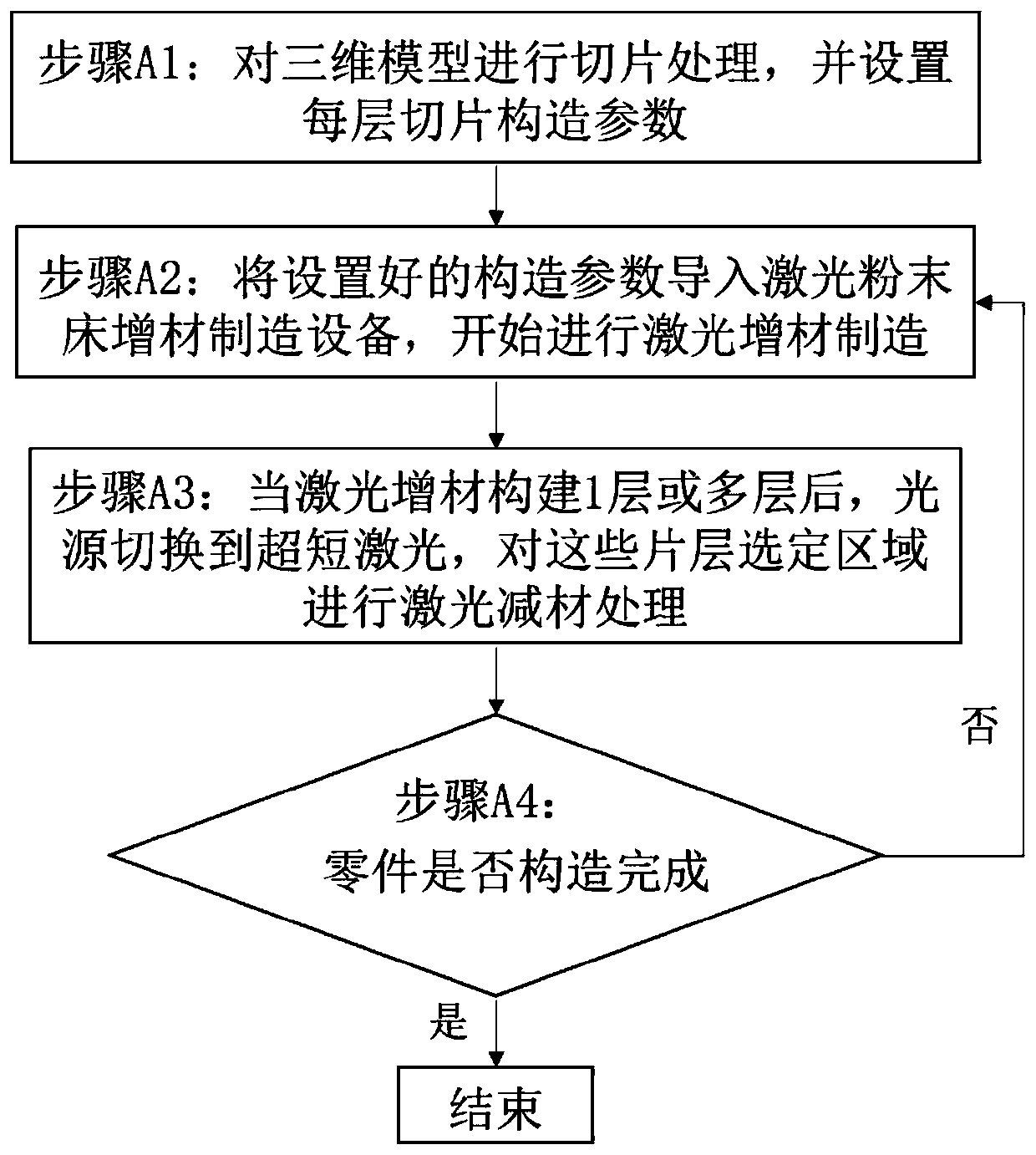

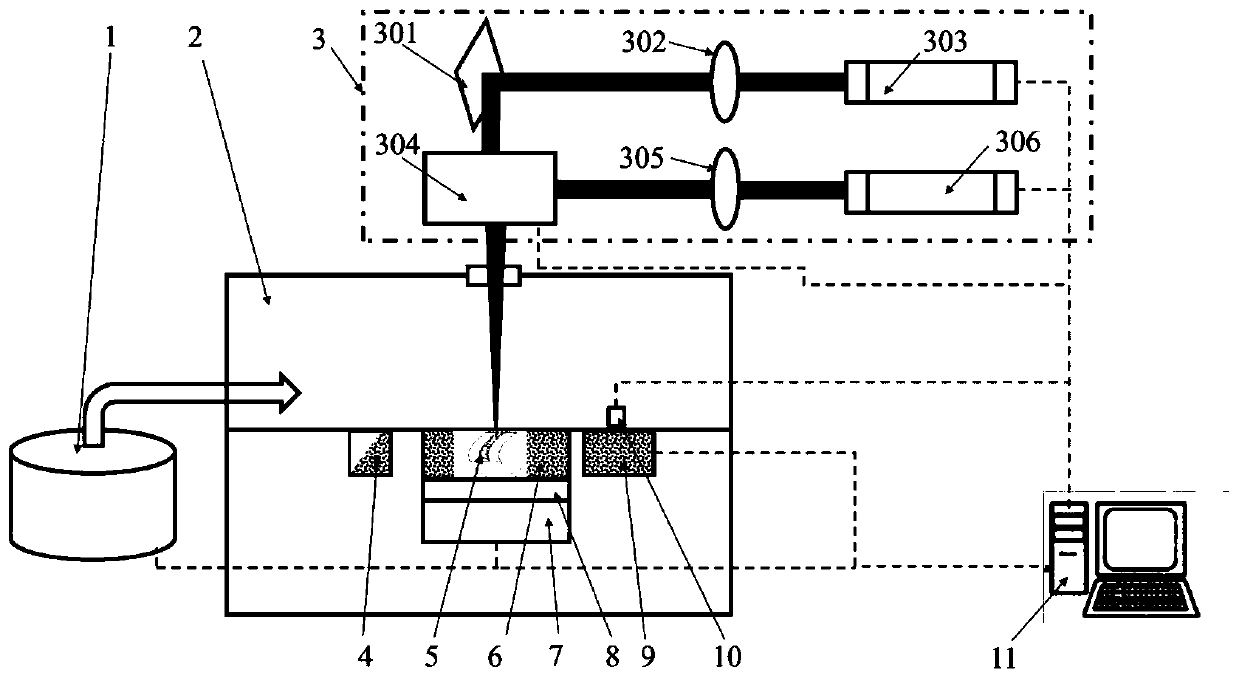

Near-net forming method and device for composite manufacturing fine workpiece based on laser additive manufacturing and subtractive manufacturing

PendingCN110369725AShort duration of actionChange the surface morphologyAdditive manufacturing apparatusIncreasing energy efficiencyFine structureLaser processing

The invention belongs to the field of laser processing, and relates to a near-net forming method and device for composite manufacturing a fine workpiece based on laser additive manufacturing and subtractive manufacturing. According to the method, the construction parameters of a three-dimensional digital-to-layer slicing layer are generated by utilizing software, laser additive manufacturing processing is carried out, and ultrafast pulse laser subtractive manufacturing processing is carried out alternately in the laser additive manufacturing processing process to form a three-dimensional entity. The device comprises a computer control device, a sealing molding chamber, a light path selecting system and an inert protection gas source; during additive manufacturing processing, the computer control device controls the light path selecting system to select the laser emitted by an additive manufacturing laser device and perform laser additive manufacturing processing; and during subtractivemanufacturing processing, the computer control device controls the light path selecting system to select ultrafast pulse lasers emitted by a subtractive manufacturing laser device and perform the ultrafast pulse laser subtractive manufacturing processing. According to the near-net forming method and device, the preparation of complex and fine-structure parts can be completed in a high-precision and integrated manner, the defects that traditional laser additive manufacturing is low in the forming precision, high in roughness and cannot be used for preparing a fine and complex inner cavity areovercome.

Owner:SHANGHAI UNIV OF ENG SCI

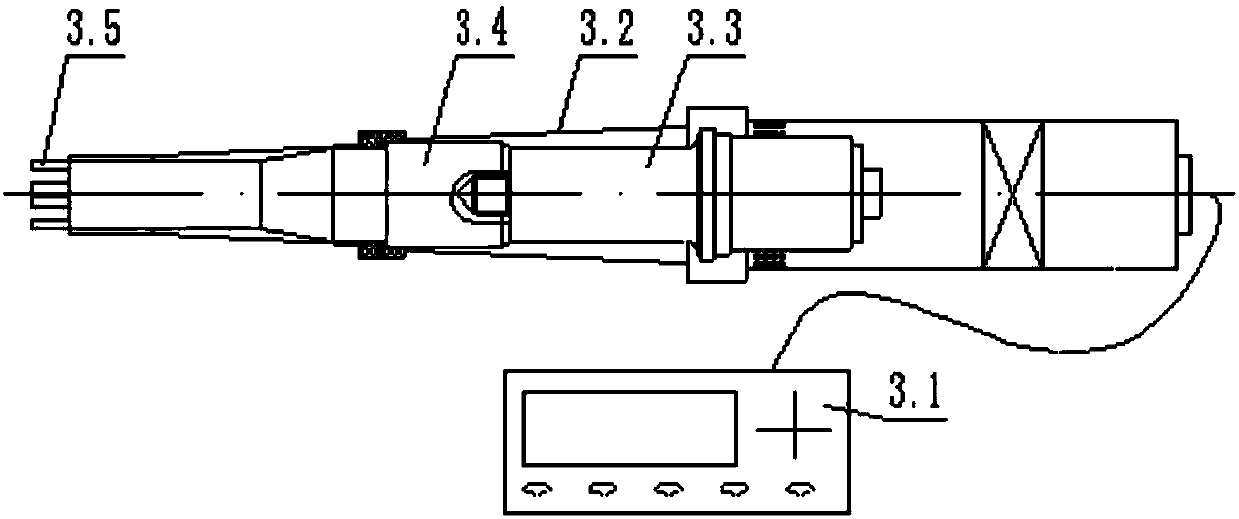

Double-ultrasonic-assisted laser additive manufacturing device and method

InactiveCN107812942AGrain refinementReduce forming residual stressAdditive manufacturing apparatusIncreasing energy efficiencyUltrasonic assistedDual action

The invention discloses a double-ultrasonic-assisted laser additive manufacturing device. The double-ultrasonic-assisted laser additive manufacturing device comprises a sample installation rack, an ultrasonic stirring system, an ultrasonic peening system and a laser additive manufacturing system. The laser additive manufacturing system and the ultrasonic peening system are arranged on the upper side of the sample installation rack, the ultrasonic stirring system is arranged on the lower side of the sample installation rack, the laser additive manufacturing system and the ultrasonic peening system are oppositely arranged, and a sample passes through the ultrasonic peening system after passing through the laser additive manufacturing system. According to the double-ultrasonic-assisted laseradditive manufacturing device, the double effects of ultrasonic stirring and ultrasonic peening are conducted on an anti-flaming titanium alloy in the laser additive manufacturing process, structure refinement and homogenization of the anti-flaming titanium alloy are achieved, and the alloy structure and the mechanical property can be effectively regulated and controlled.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

Laser power regulating method based on model features

InactiveCN107599382ASmall amount of calculationEasy to operateAdditive manufacturing apparatus3D object support structuresClassical mechanicsLaser additive manufacturing

The invention belongs to the technical field of laser material additive manufacturing, and particularly relates to a laser power regulating method based on model features. The laser power regulating method comprises the following steps that a special region with a complex structure in a model is obtained, slicing processing is conducted on the workpiece model, and preprocessing is conducted on thesplice contour of a special region in the contour data of each layer, the laser power of the point needed to be adjusted is calculated point-by-point; and the slice contour of a non-special region ineach layer contour data is filled in a conventional filling mode; and the process is repeated until layer processing of all slices of the workpiece model is finished, and finally the laser printing path data of the workpiece model is generated. According to the laser power regulating method based on the model features, the heat accumulation effect generated by excessively intensive scanning and printing of in the local region of the laser is utilized, and the laser power of the progressive contour ring filling path in the region is adjusted dynamically, so that adverse effects caused by the heat accumulation effect is avoided, and the fact that the temperature of a material molten pool is stable in the melting temperature range of powder materials all the time is guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for manufacturing monocrystalline and directional solidified part through laser 3D printer

InactiveCN105108142ASave materialEasy to organizeTurbinesPolycrystalline material growthCrystal orientationPhysical chemistry

The invention discloses a method for manufacturing a monocrystalline and directional solidified part through a laser 3D printer. The powder laying laser additive manufacturing technology is adopted in the method, the relative growth speed along the front crystal orientation of a solidification interface of a laser molten pool is calculated, and a complete directional solidified or monocrystalline part with local signal orientation can be obtained through finely controlling a process. The laser is an optical fiber laser (wavelength: 1.07 [mu]m). The size and the structure of the part accord with the design requirement. The method can be used for manufacturing a metal printed part having a qualified shape, material is saved, and the shaping efficiency of metalwork can be greatly raised.

Owner:HANGXING LIHUA BEIJING TECH CO LTD

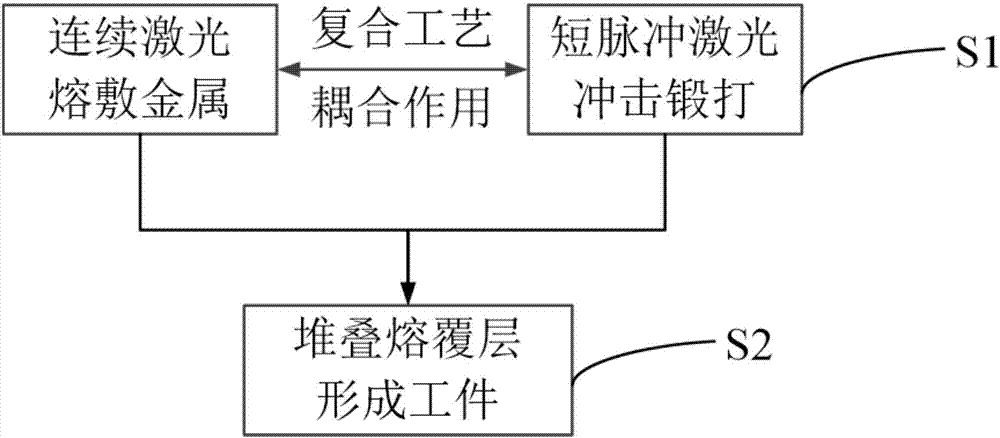

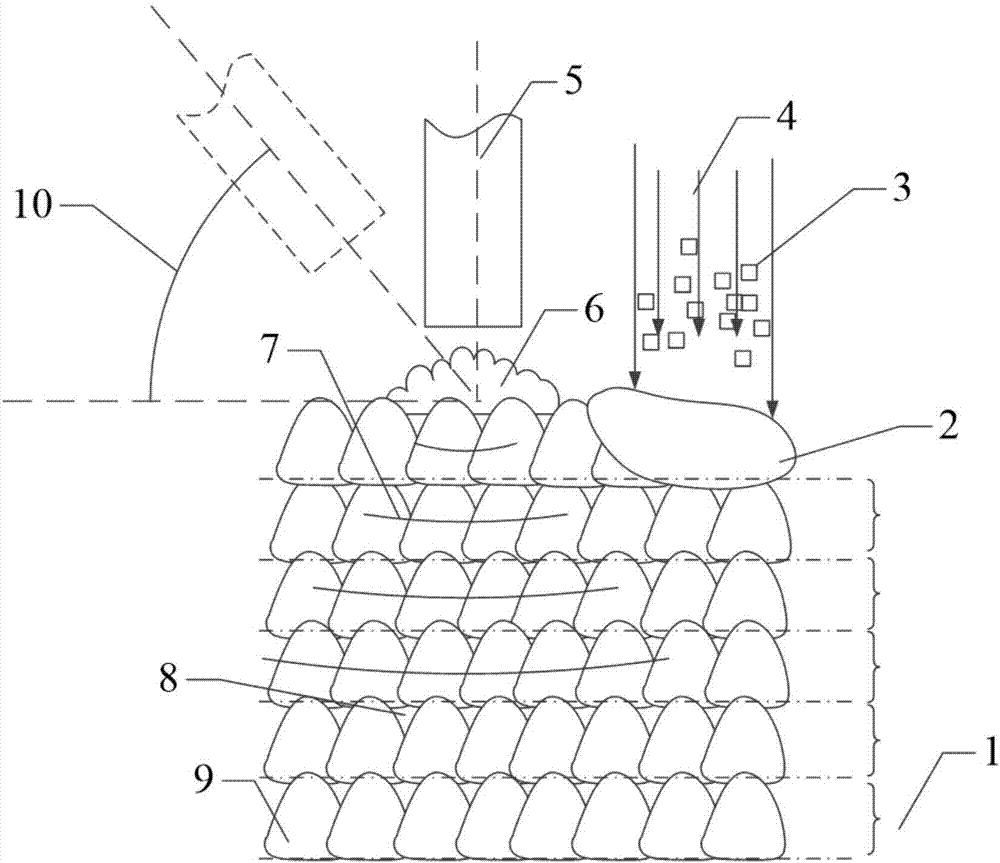

Method for additive manufacturing through depositing, forming, impacting, forging and compositing through double laser beams

InactiveCN107475709AWith laser pulse energyWith laser pulse widthAdditive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsLaser beams

Owner:GUANGDONG UNIV OF TECH

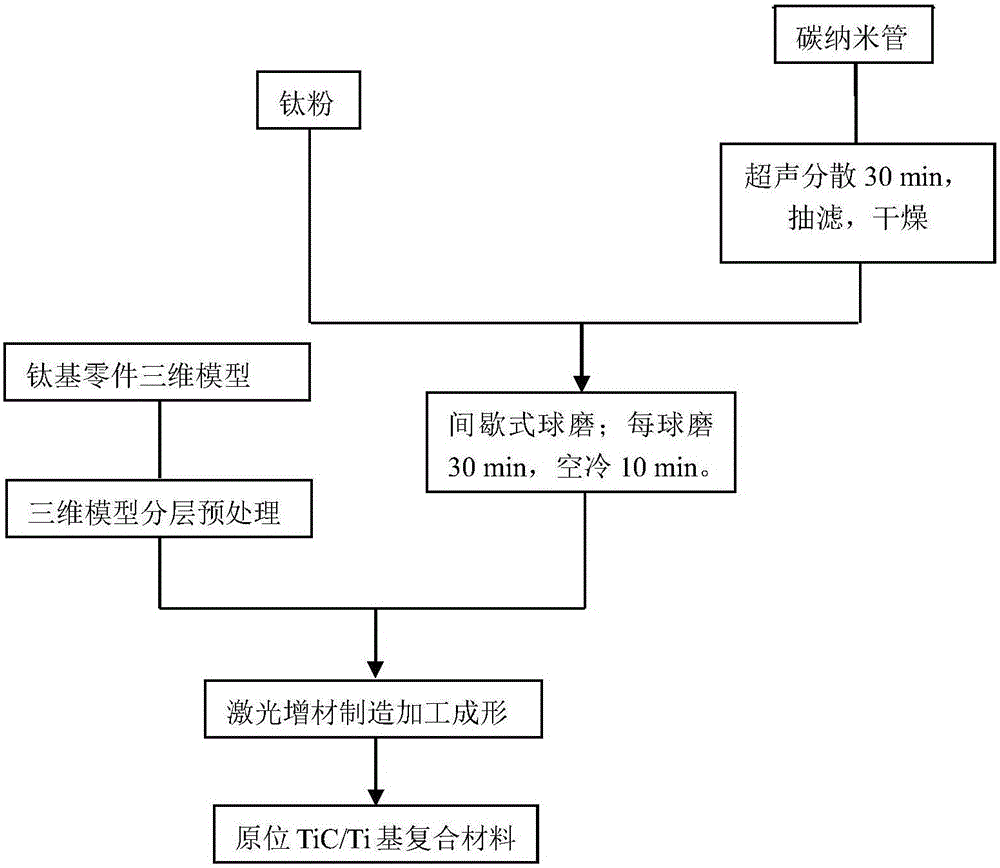

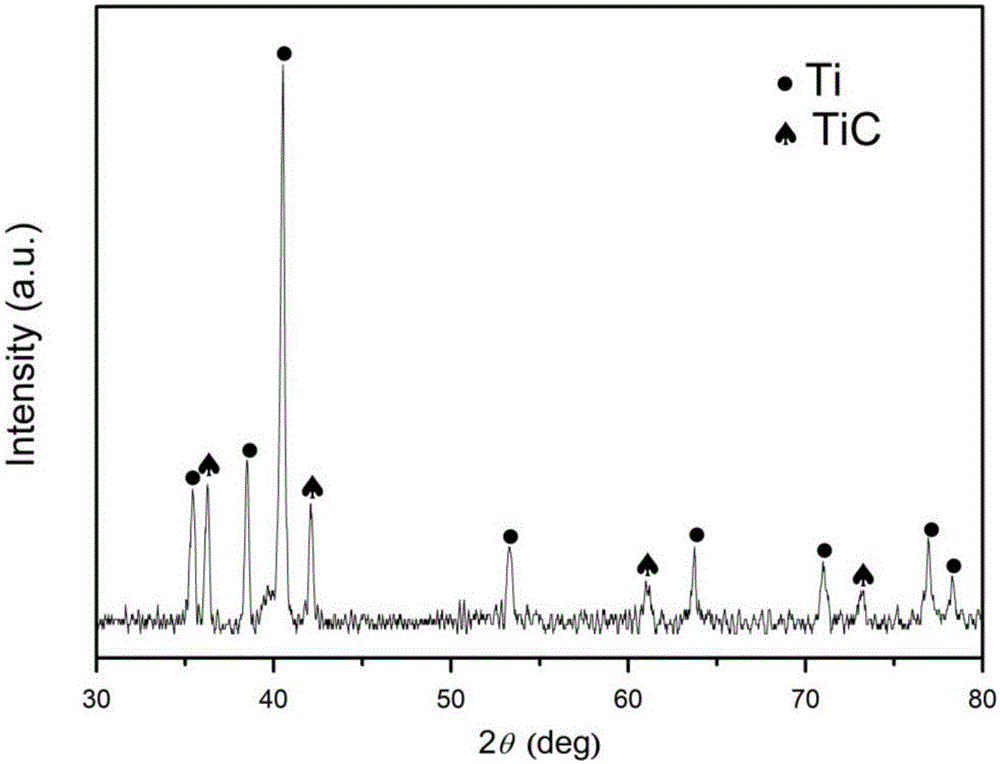

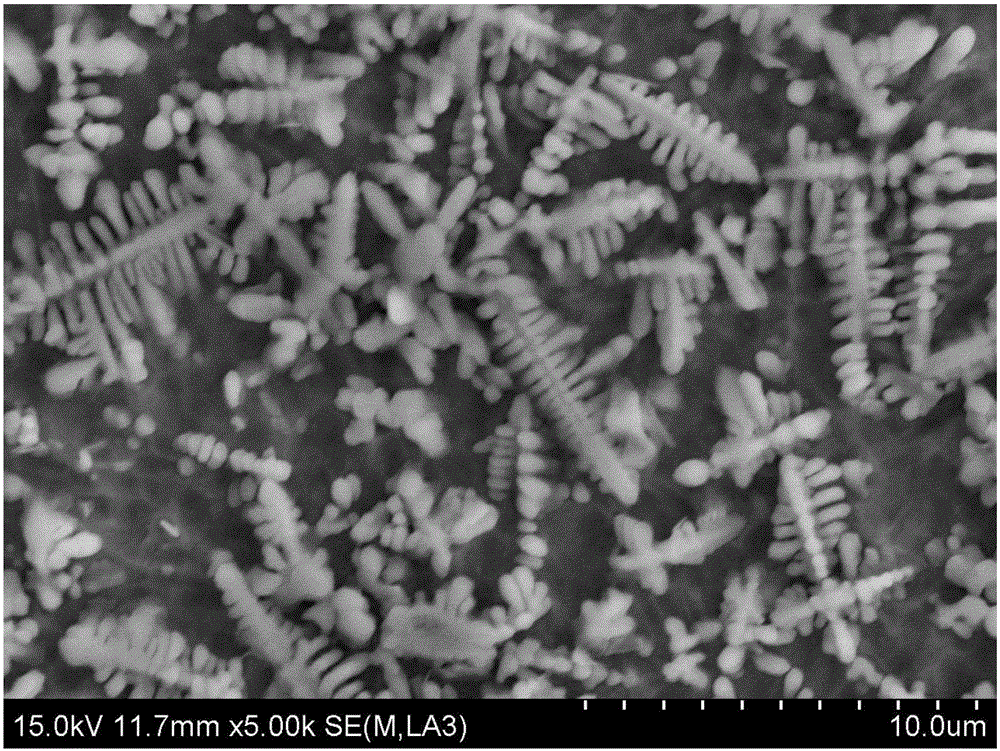

Method for manufacturing high-performance in-situ TiC reinforced titanium-based composite workpiece on basis of CNTs and laser additive manufacturing and processing technology

ActiveCN105033254AGood interface wettabilityTightly boundAdditive manufacturing apparatusIncreasing energy efficiencyTitanium matrix compositesCarbon nanotube

The invention discloses a method for manufacturing a high-performance in-situ TiC reinforced titanium-based composite workpiece on the basis of CNTs and a laser additive manufacturing and processing technology. The method includes the following steps that (1) the carbon nano tubes are subjected to preliminary ultrasonic dispersion treatment; (2) pure titanium powder with the average particle size of 45-75 microns is mixed with the carbon nano tubes to obtain a mixture, and CNTs / Ti mixed powder is obtained by ball-milling the mixture through a ball mill under the protection of argon; and (3) the ball-milled CNTs / Ti mixed powder is shaped through a laser additive manufacturing and processing method so as to obtain a high-performance in-situ TiC reinforced titanium-based composite body. The method has the advantages that in-situ TiC reinforcement phases are formed on the basis of a CNTs in-situ reaction and evenly distributed in a titanium substrate, and the interface bonding strength is high; grains of a composite are refined remarkably; net forming or near-net forming of a test piece can be achieved; any complex heterogeneous part can be formed.

Owner:南京瑞德增域三维技术发展有限公司

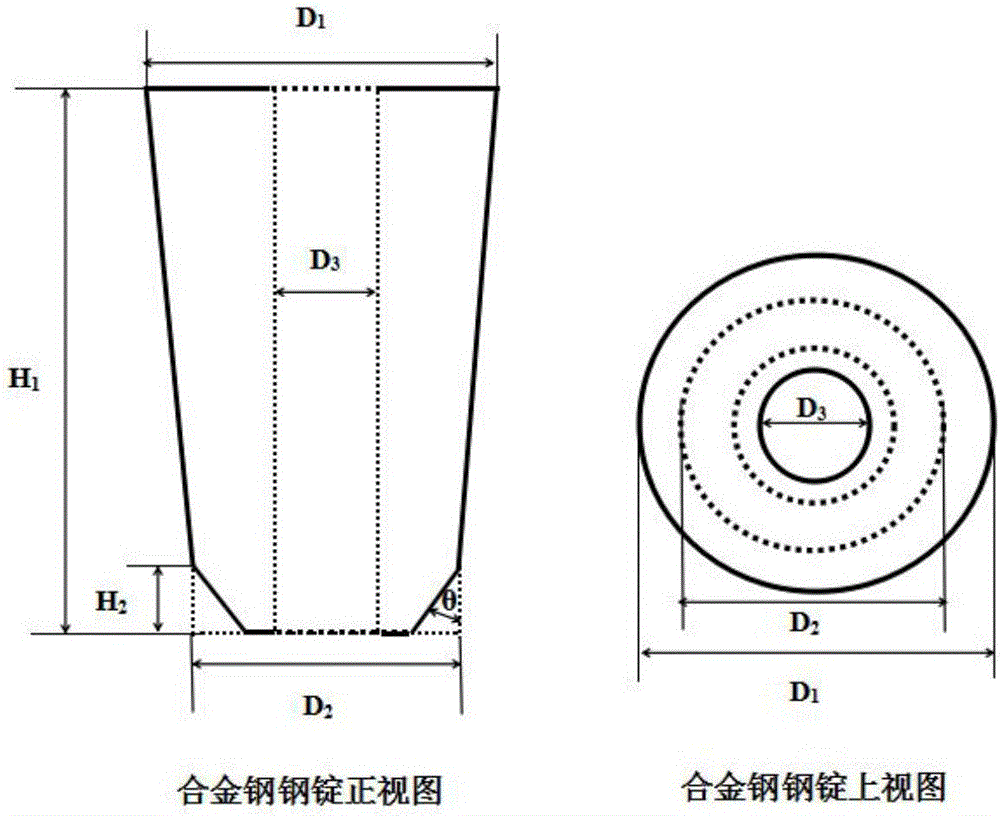

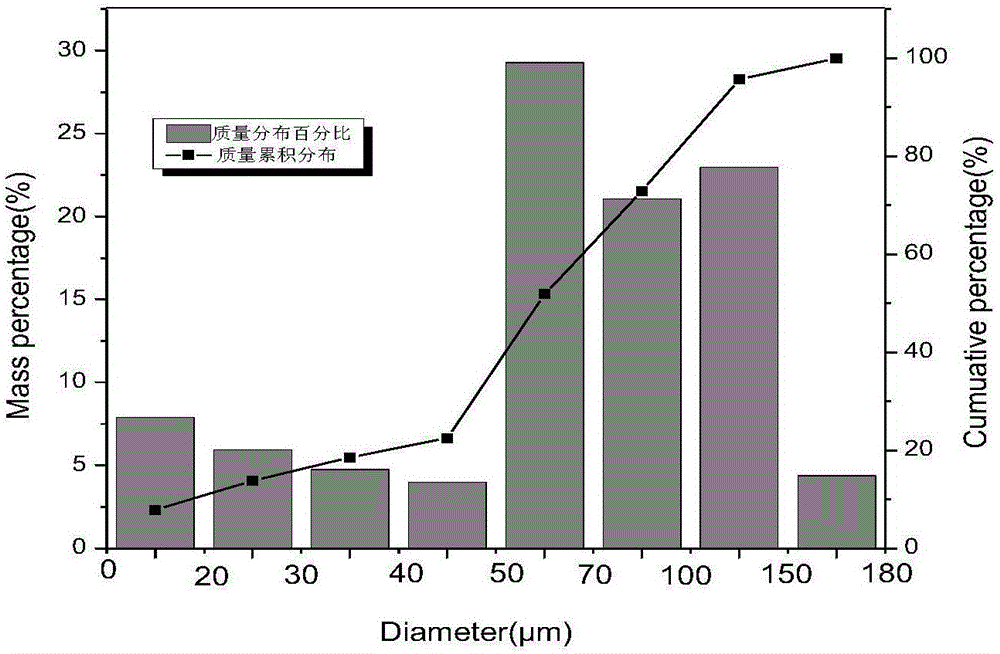

24CrNiMoRe alloy steel powder of laser additives and production method thereof

ActiveCN106399863AActive control of sphericityActive regulation of particle size distributionAdditive manufacturing apparatusTransportation and packagingApparent densityChemical composition

The invention discloses 24CrNiMoRe alloy steel powder of laser additives and a production method thereof. The alloy steel powder is composed of, by weight, 0.23-0.27% of C, 0.90-1.15% of Cr, 0.90-1.15% of Ni, 0.45-0.60% of Mo, 0.90-1.15% of Mn, 0.30-0.45% of Si, 1-2% of Re(Y) and the balance Fe. The alloy steel powder is spherical, the particle size is 1-180 micrometers, the apparent density is 4.74-4.97 g / cm<3>, and the hollow sphere rate is smaller than 2%. The mobility of the 24CrNiMoRe alloy steel powder with the particle size being 1-50 micrometers is 15.6-18.7s / 50g, and the mobility of the 24CrNiMoRe alloy steel powder with the particle size being 50-180 micrometers is 14.3-15.1s / 50g. According to the production method, the spherical powder with the mobility being good, the particle size being controllable, the hollow sphere rate being low and the structure toughness being high can be produced through vacuum crucible induction smelting and gas atomizing methods and by adjusting the technological parameters of gas atomizing and can be applied to laser additive manufacturing of friction parts of brake discs of high-speed rails.

Owner:NORTHEASTERN UNIV

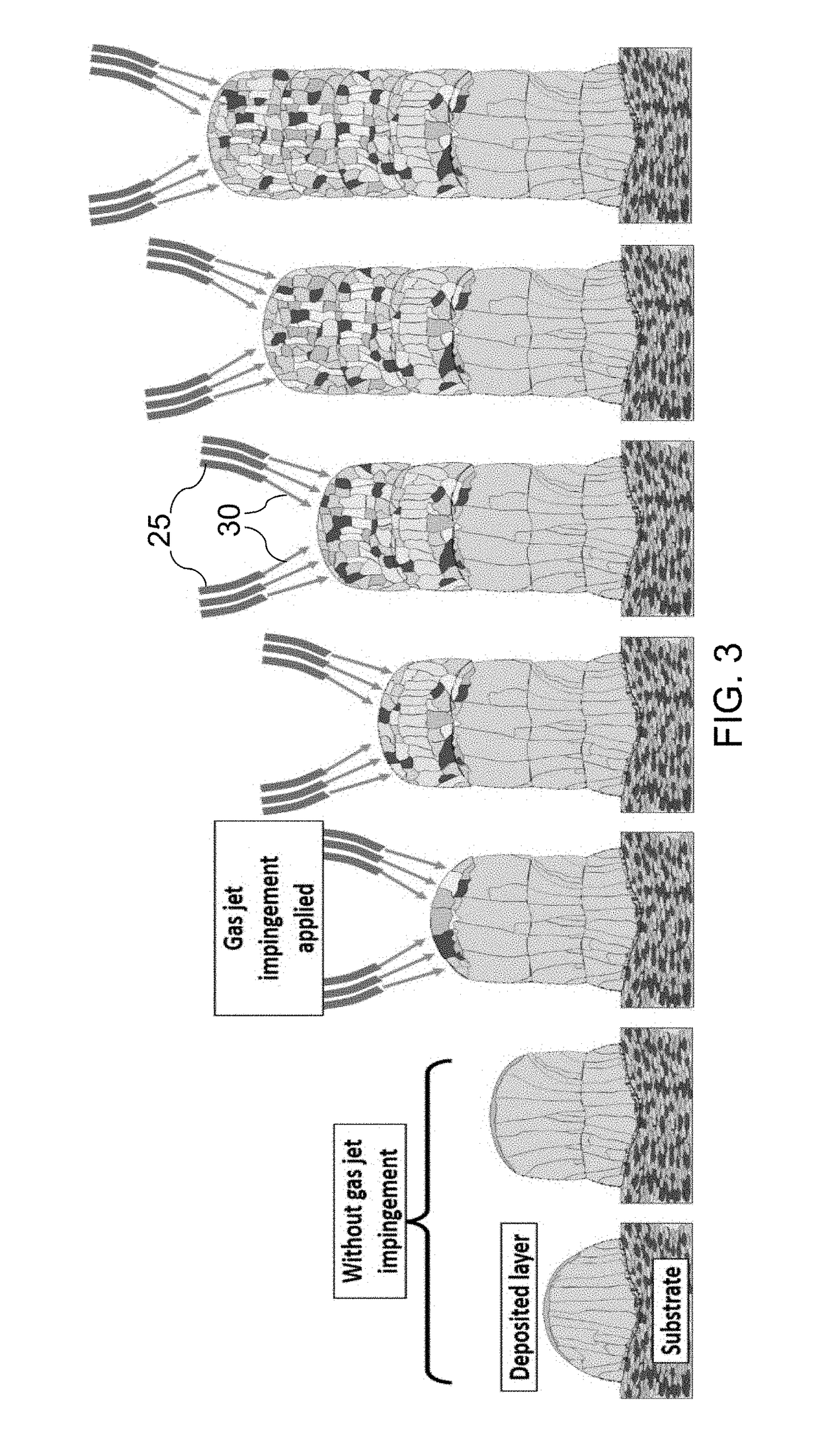

Solidification refinement and general phase transformation control through application of in situ gas jet impingement in metal additive manufacturing

PendingUS20190001437A1Reduce grain sizeIncrease deposition productivityAdditive manufacturing apparatusWelding/cutting auxillary devicesTitaniumTitanium alloy

Owner:NORSK TITANIUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com