Patents

Literature

167 results about "Functionally graded material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

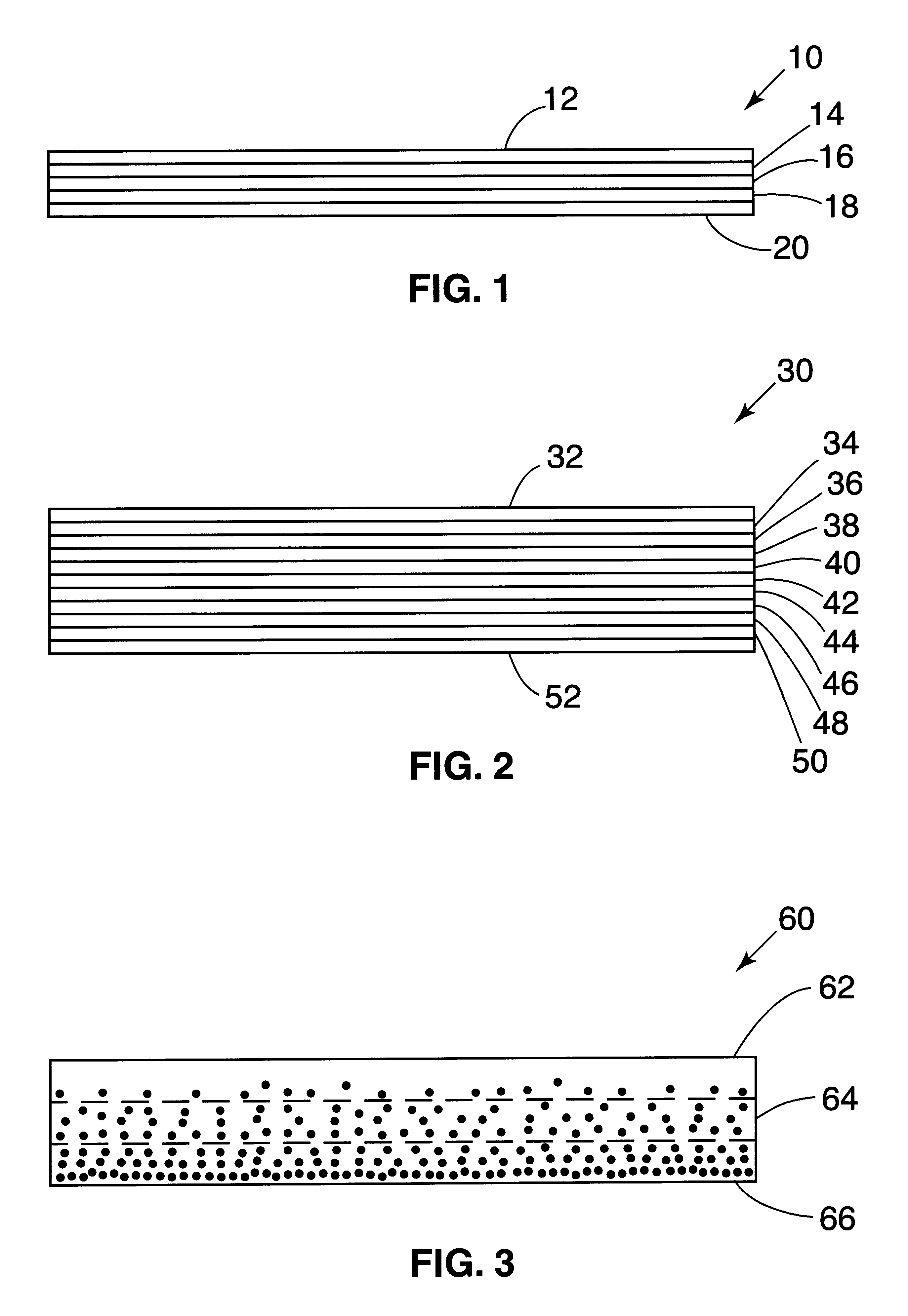

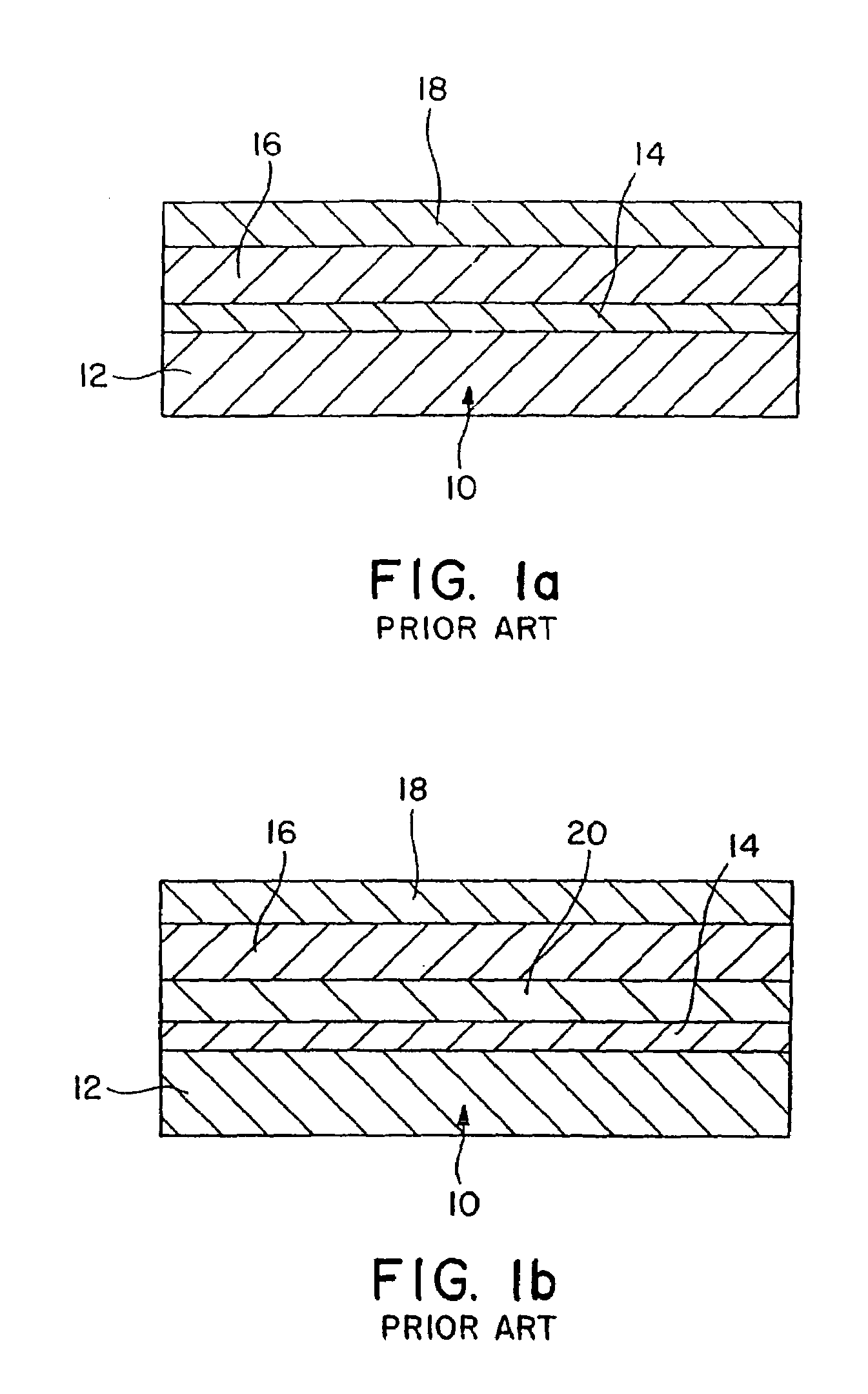

In materials science Functionally Graded Materials (FGMs) may be characterized by the variation in composition and structure gradually over volume, resulting in corresponding changes in the properties of the material. The materials can be designed for specific function and applications. Various approaches based on the bulk (particulate processing), preform processing, layer processing and melt processing are used to fabricate the functionally graded materials.

Methods of forming a metallic or ceramic article having a novel composition of functionally graded material and articles containing the same

ActiveUS20140087210A1Improve fracture toughnessLow costAdditive manufacturing apparatusLayered productsCarbideFunctionally graded material

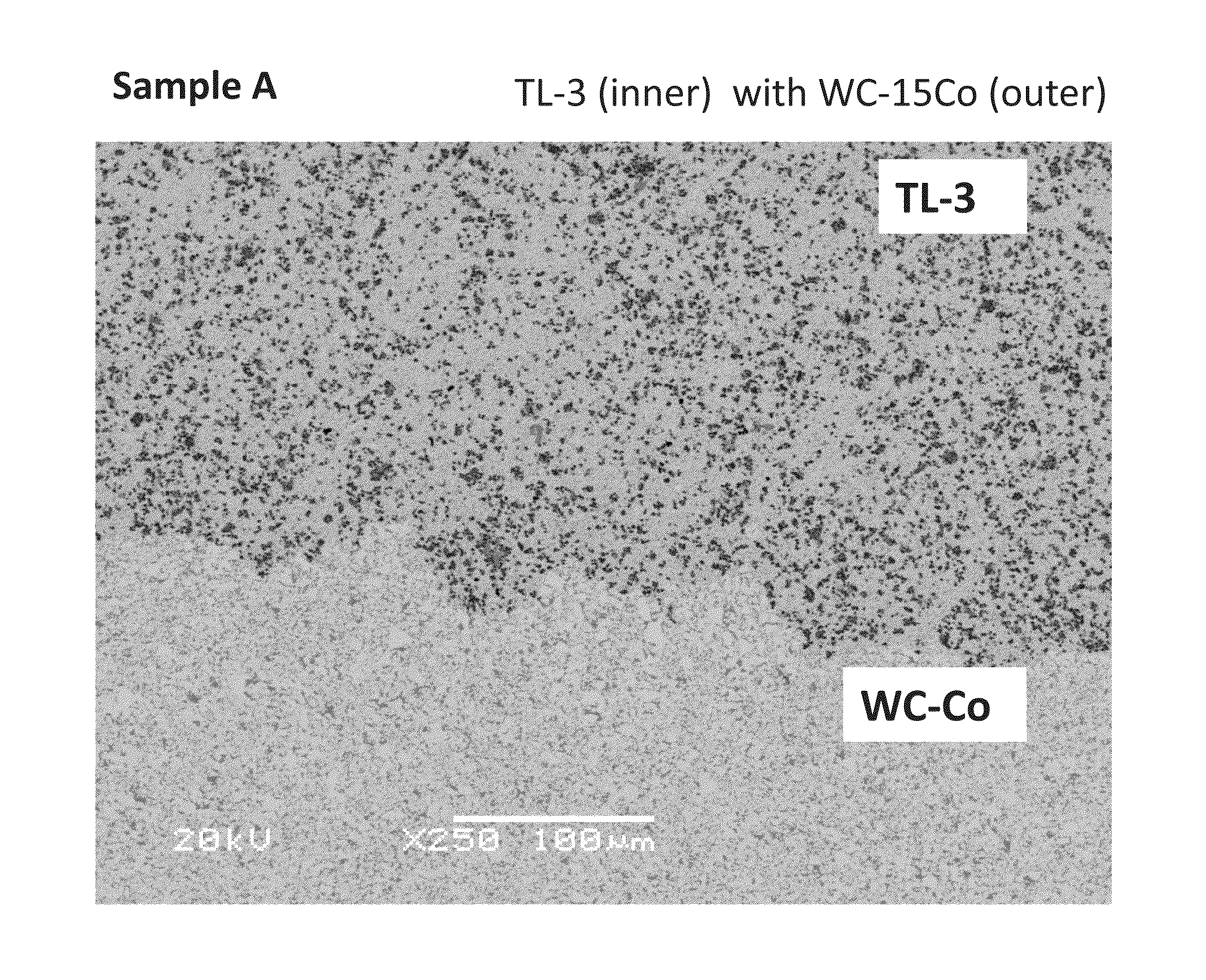

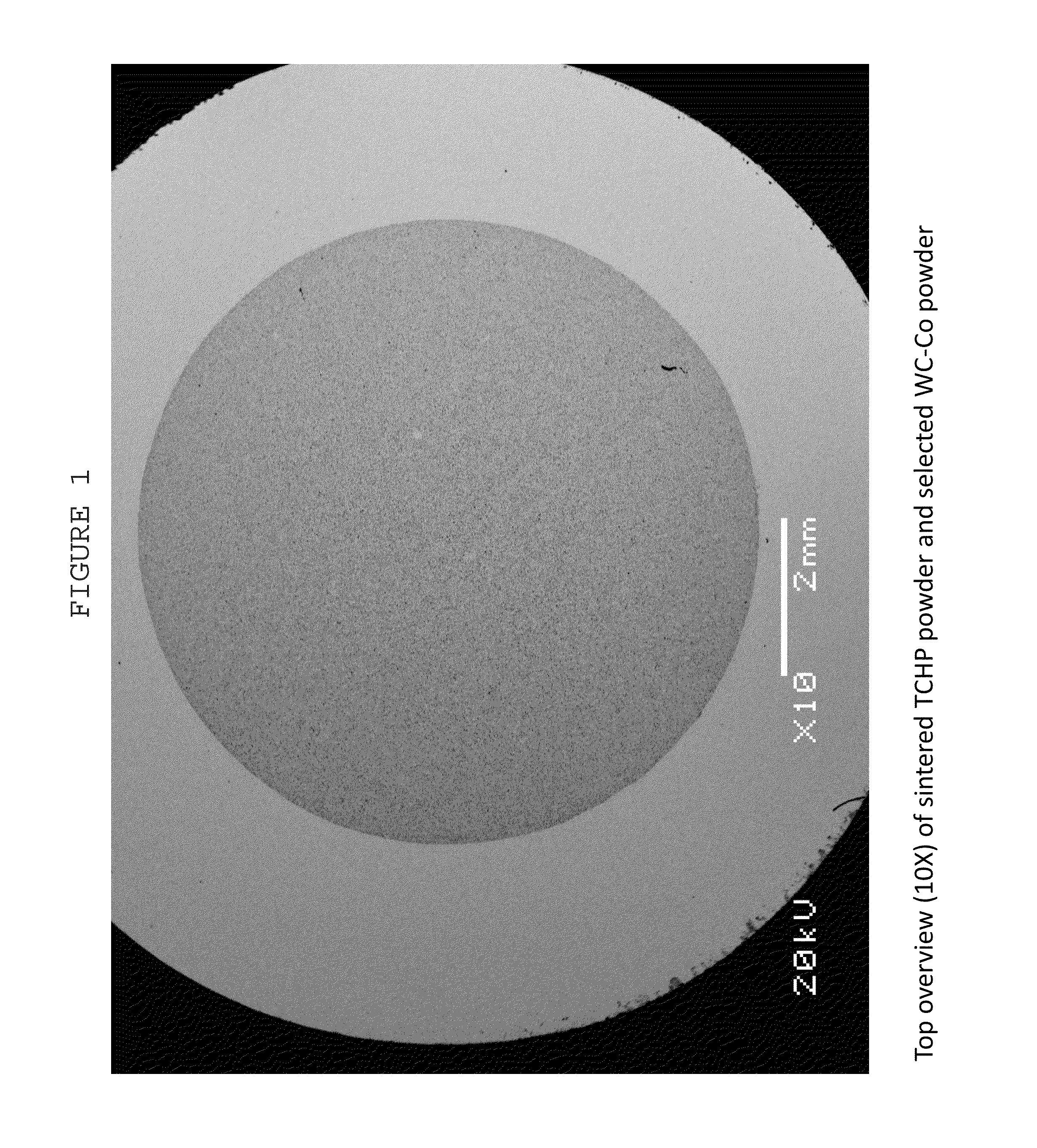

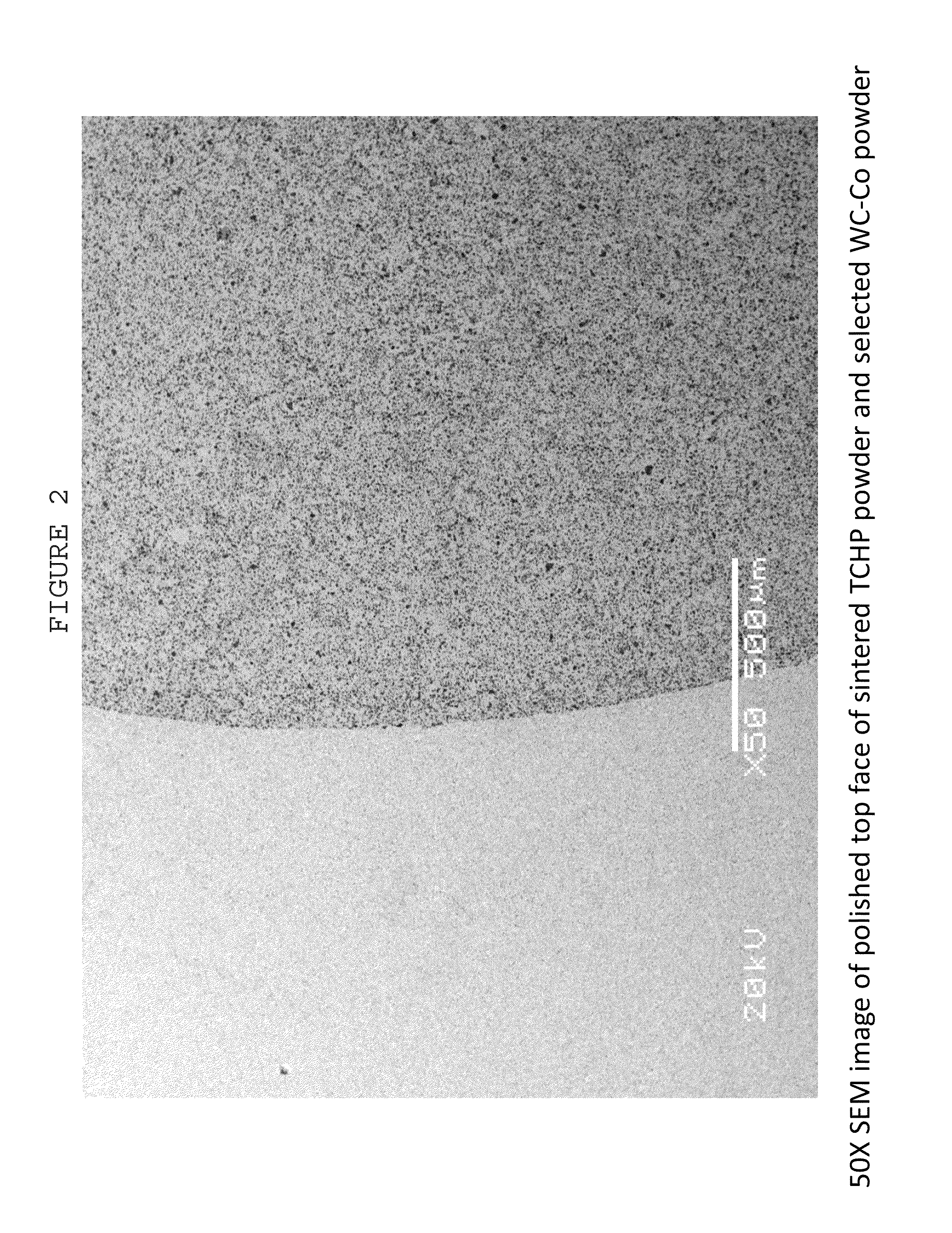

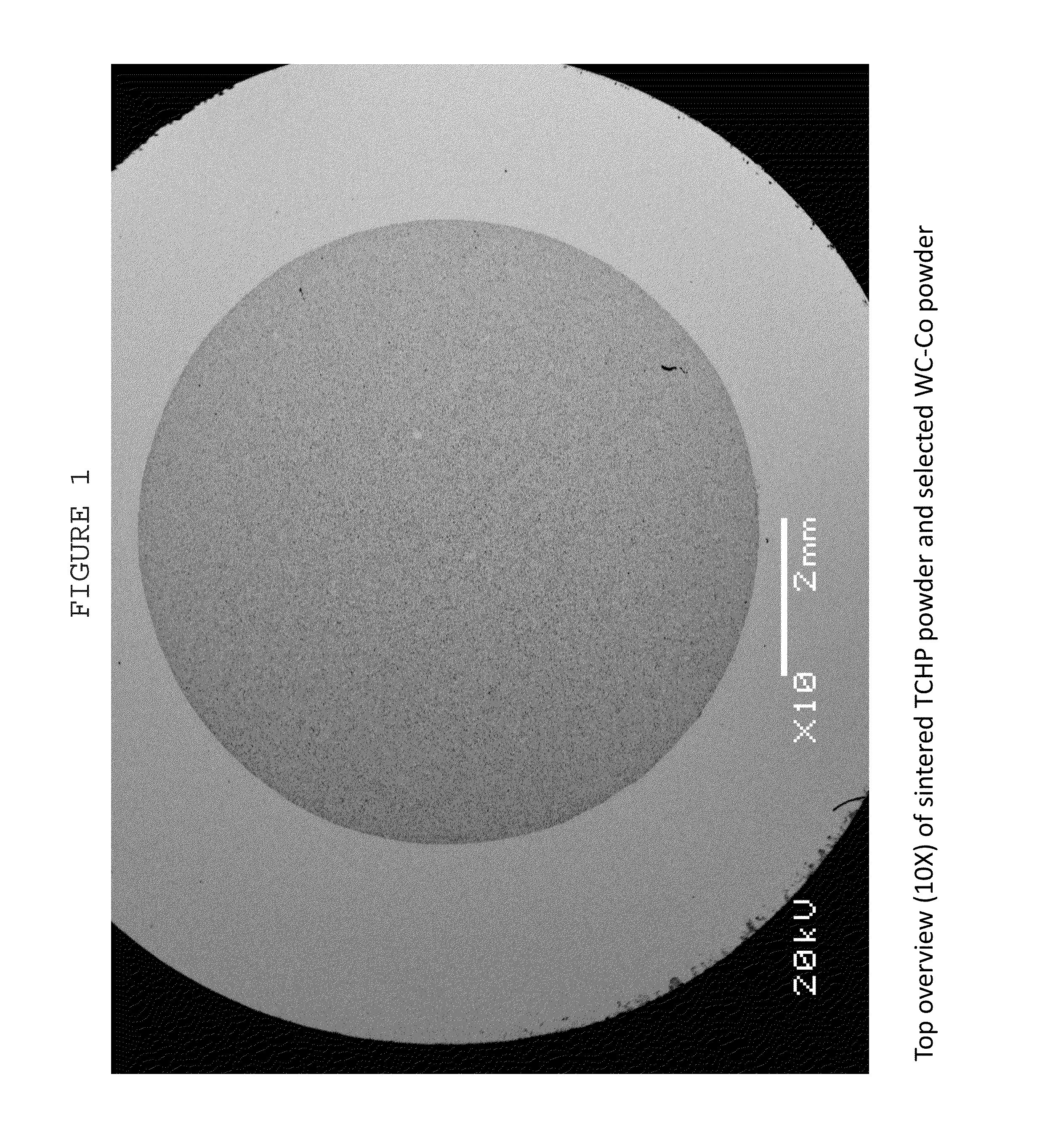

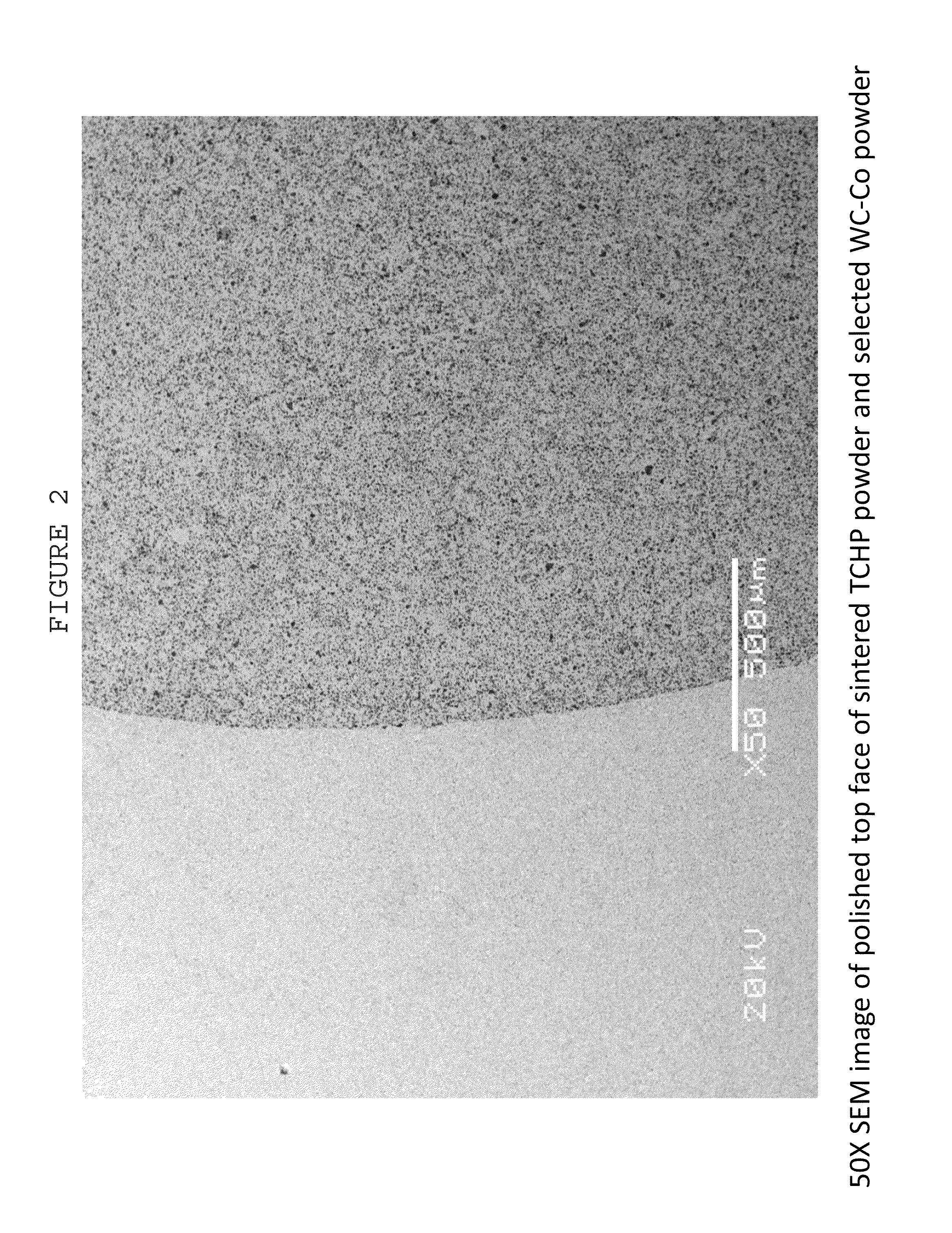

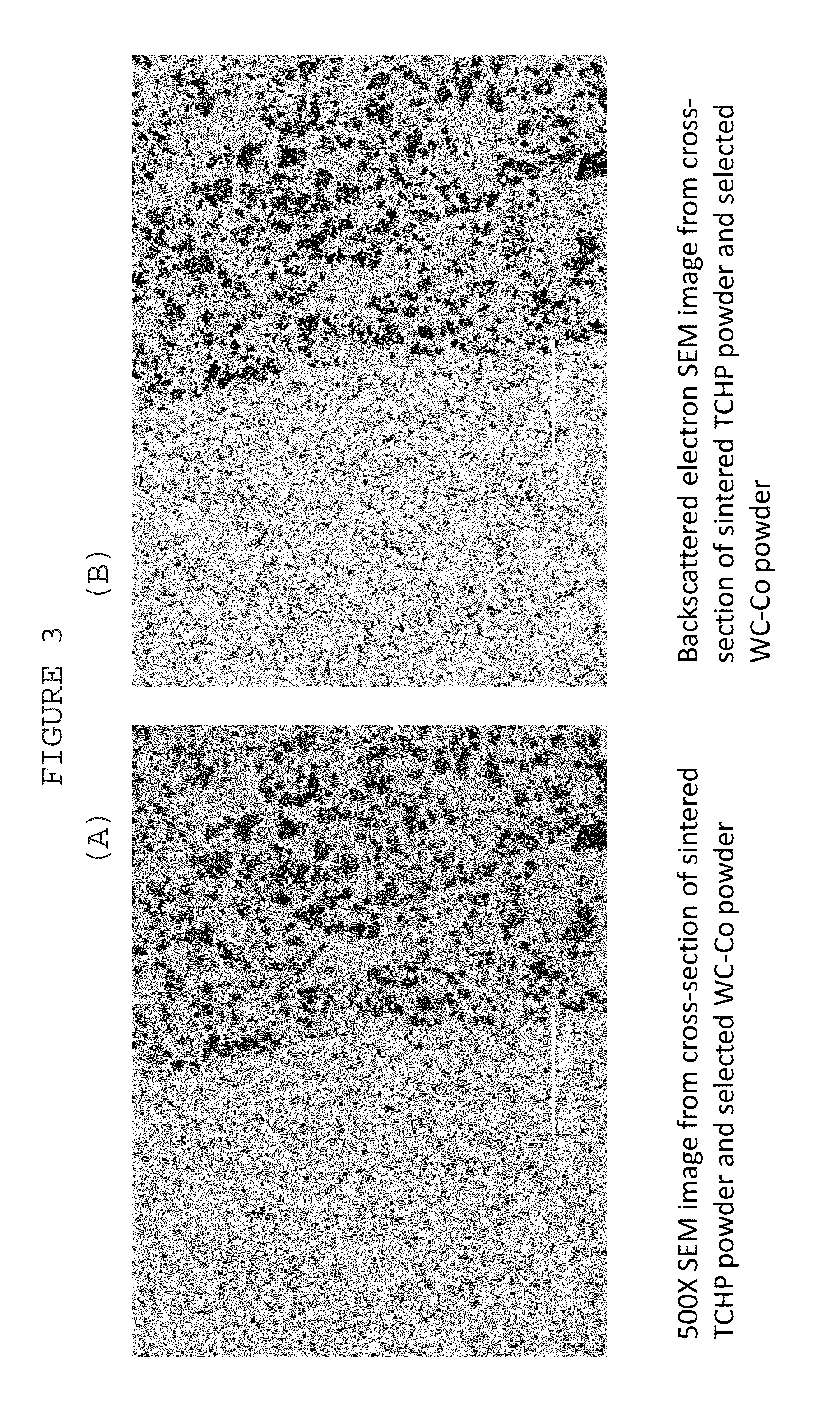

There is disclosed a method of making a metallic or ceramic component, such as a cutting or forming tool, from at least two distinct powder precursors. In one embodiment, the method comprising forming a first mixture comprised of a plurality of coated particles, such as Tough-Coated Hard Powder (TCHP) composite particles created by encapsulating extremely hard core particles with very tough binder and structural materials, and at least one support powder, such as a carbide, typically WC—Co. The mixture is formed into a green body and sintered to form a functionally graded or multicomponent article. Non-limiting examples of the articles made from the disclosed methods are also disclosed and include drills, mills, cutting tools, forming tools, wires dies and mechanical components.

Owner:ETERNALOY HLDG GMBH

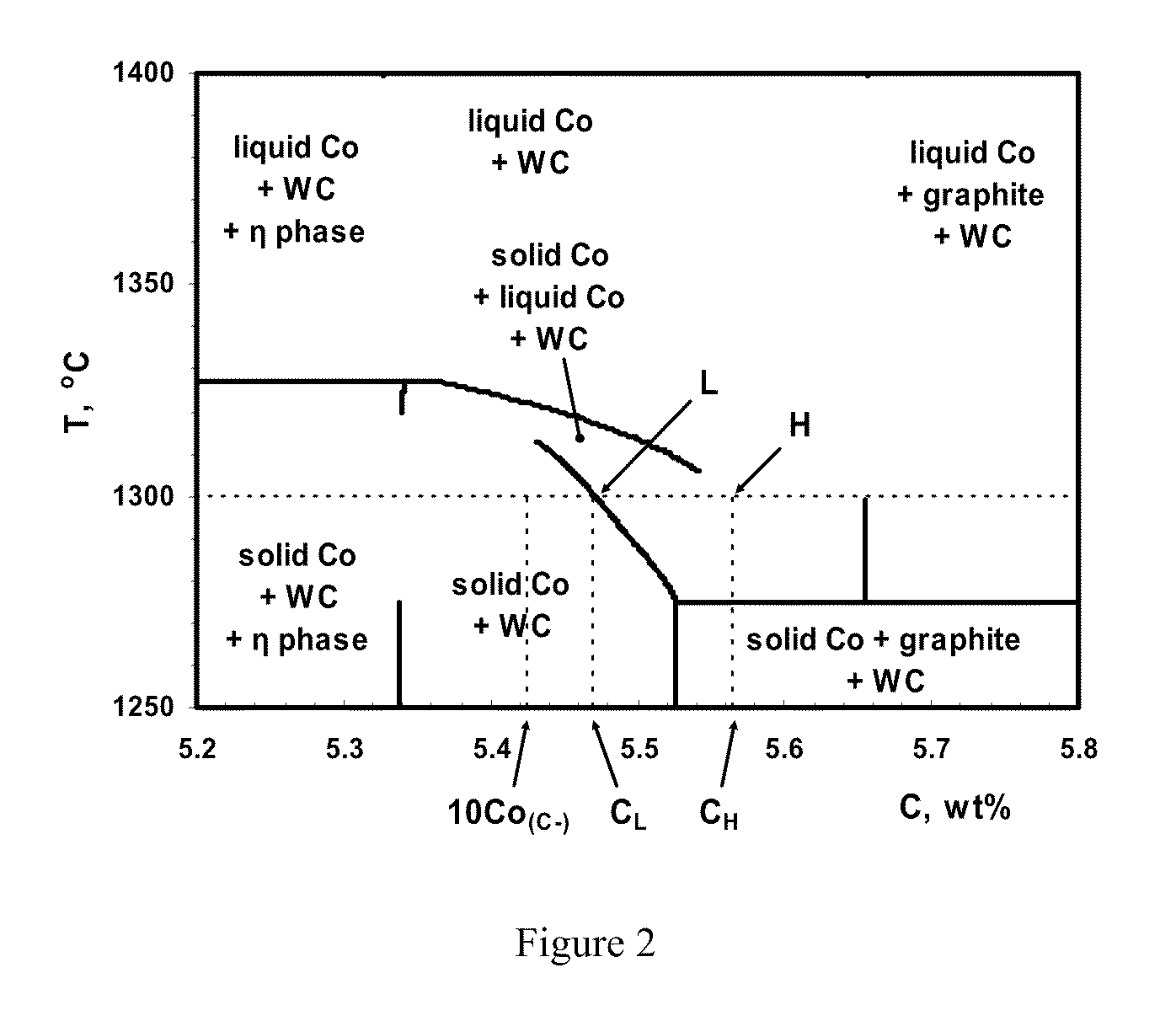

Functionally graded cemented tungsten carbide

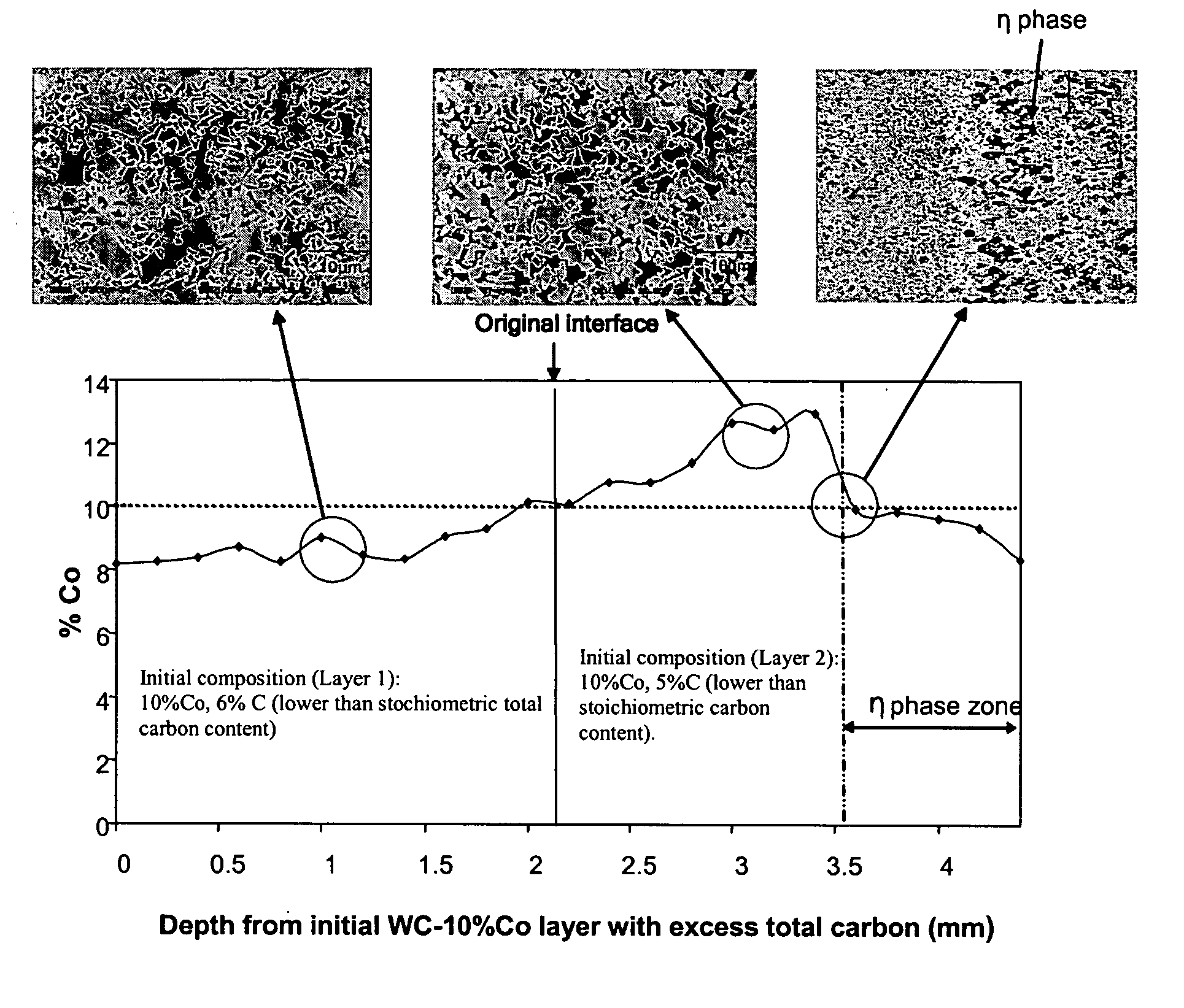

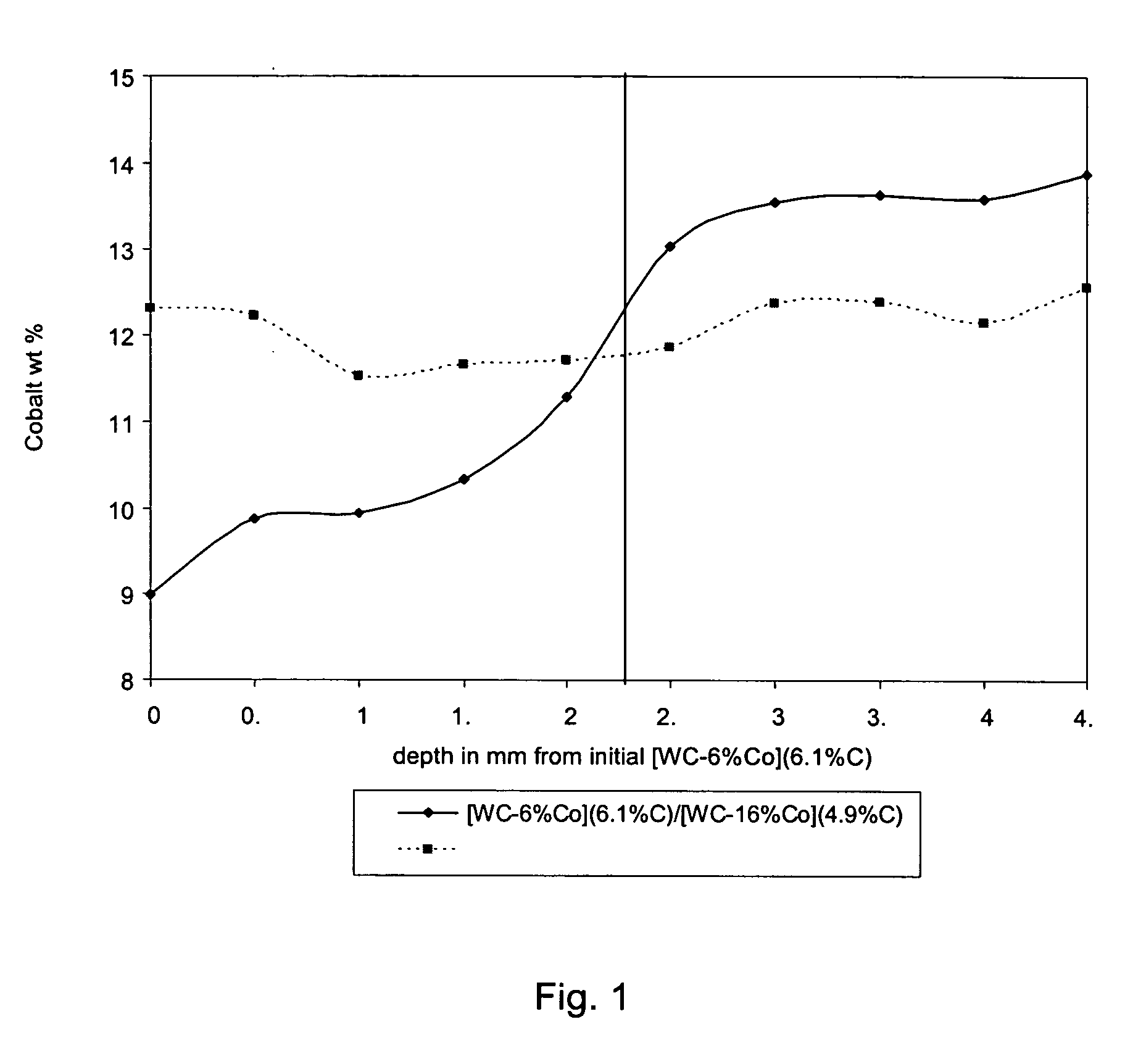

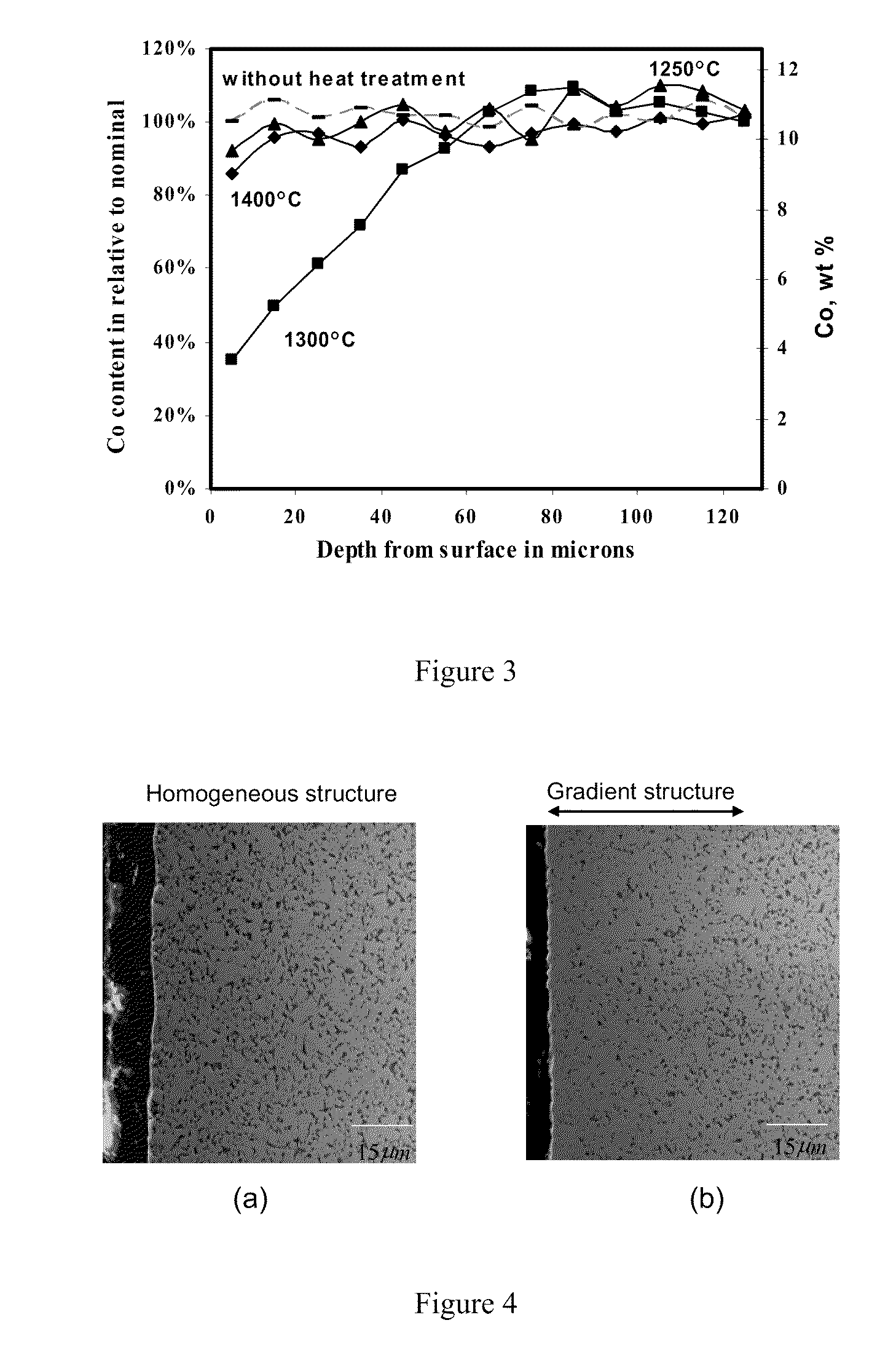

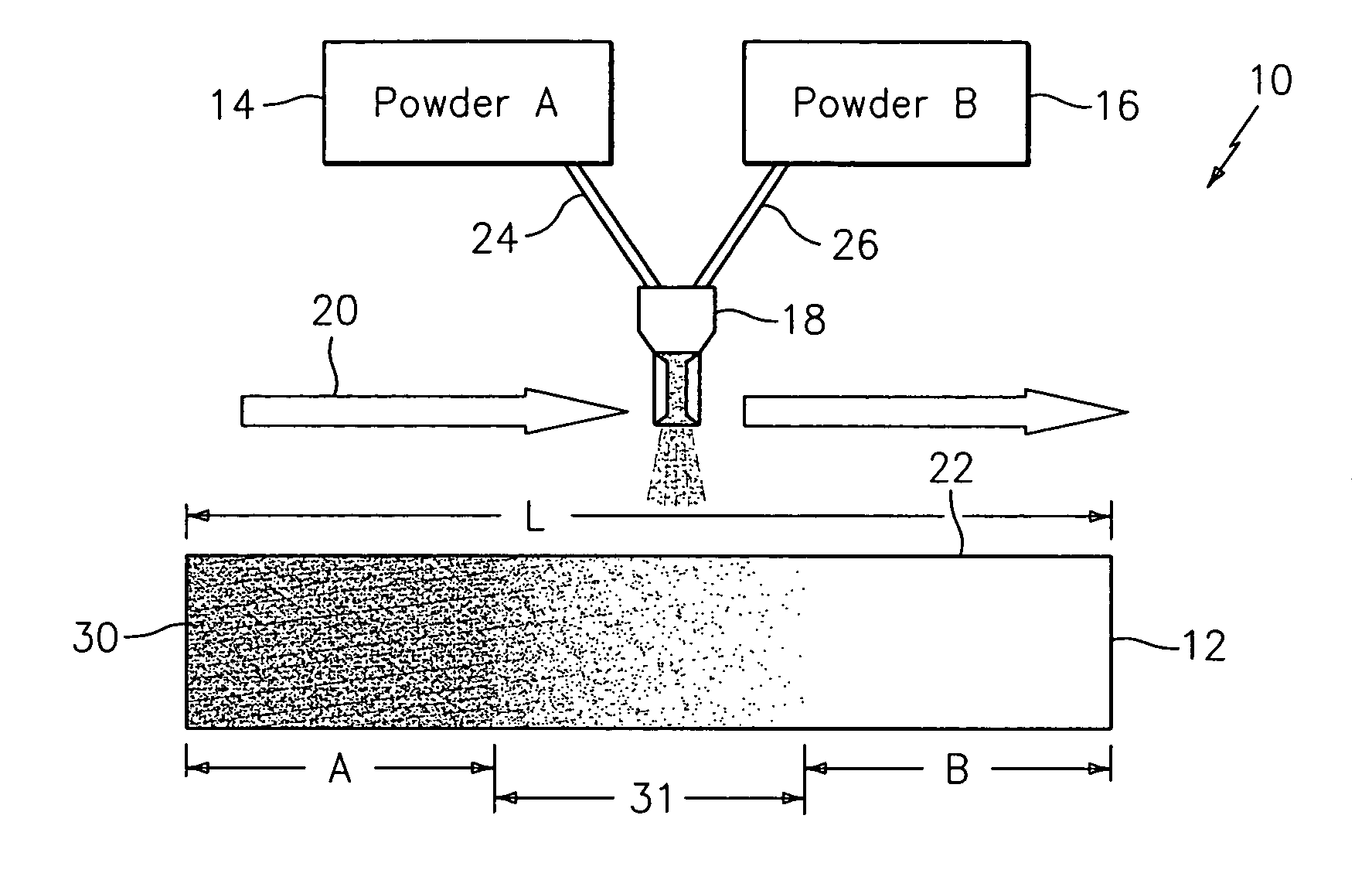

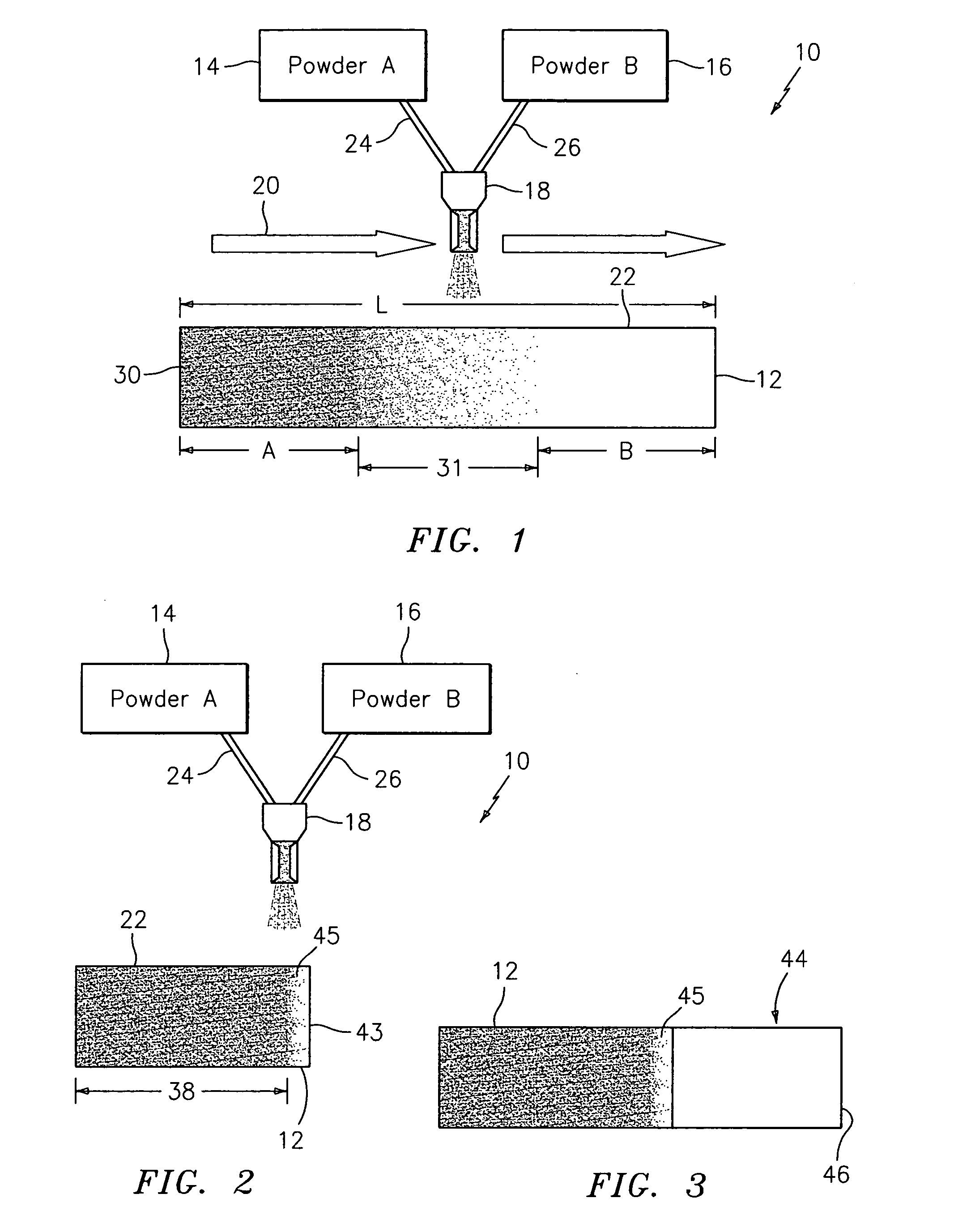

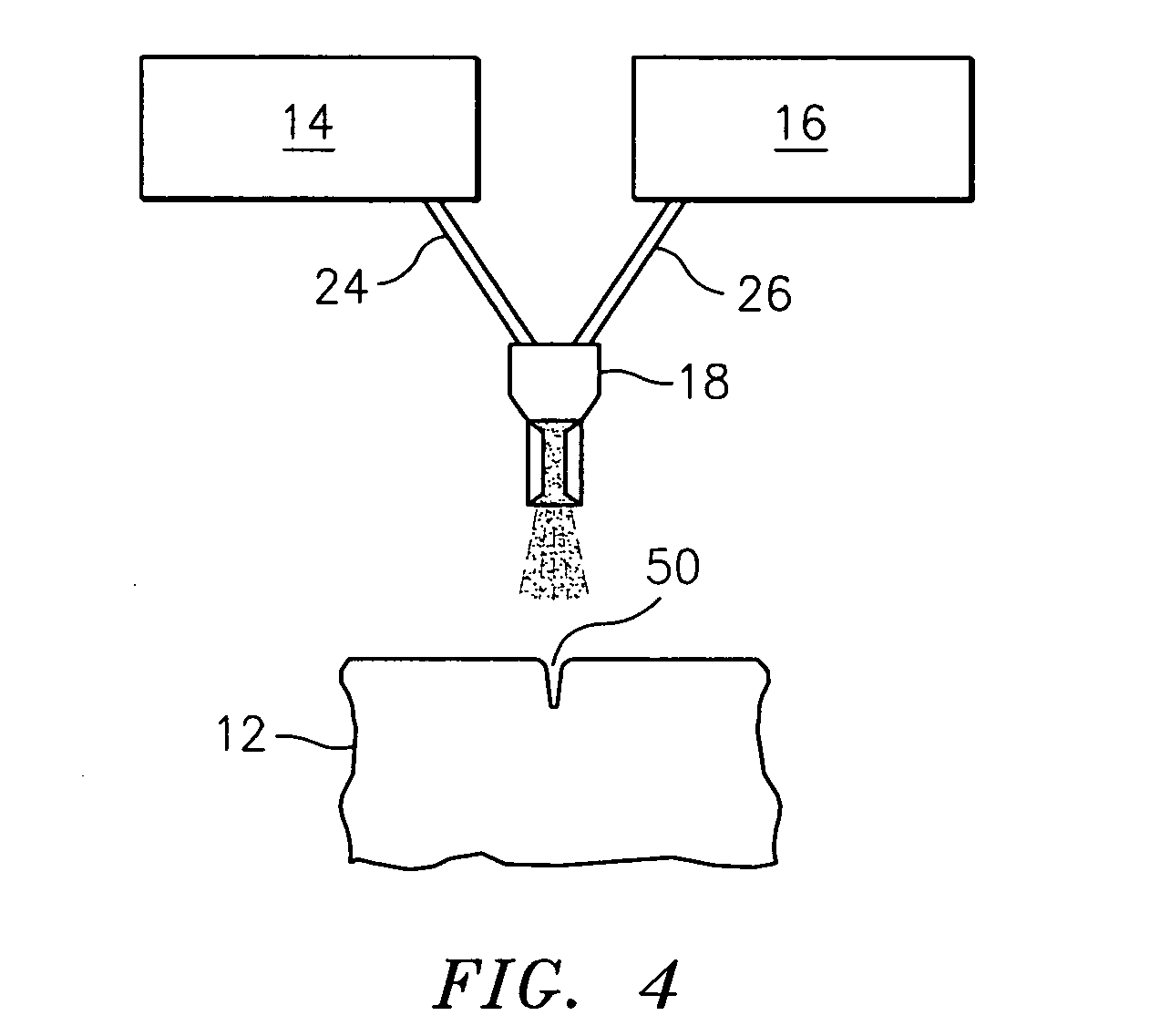

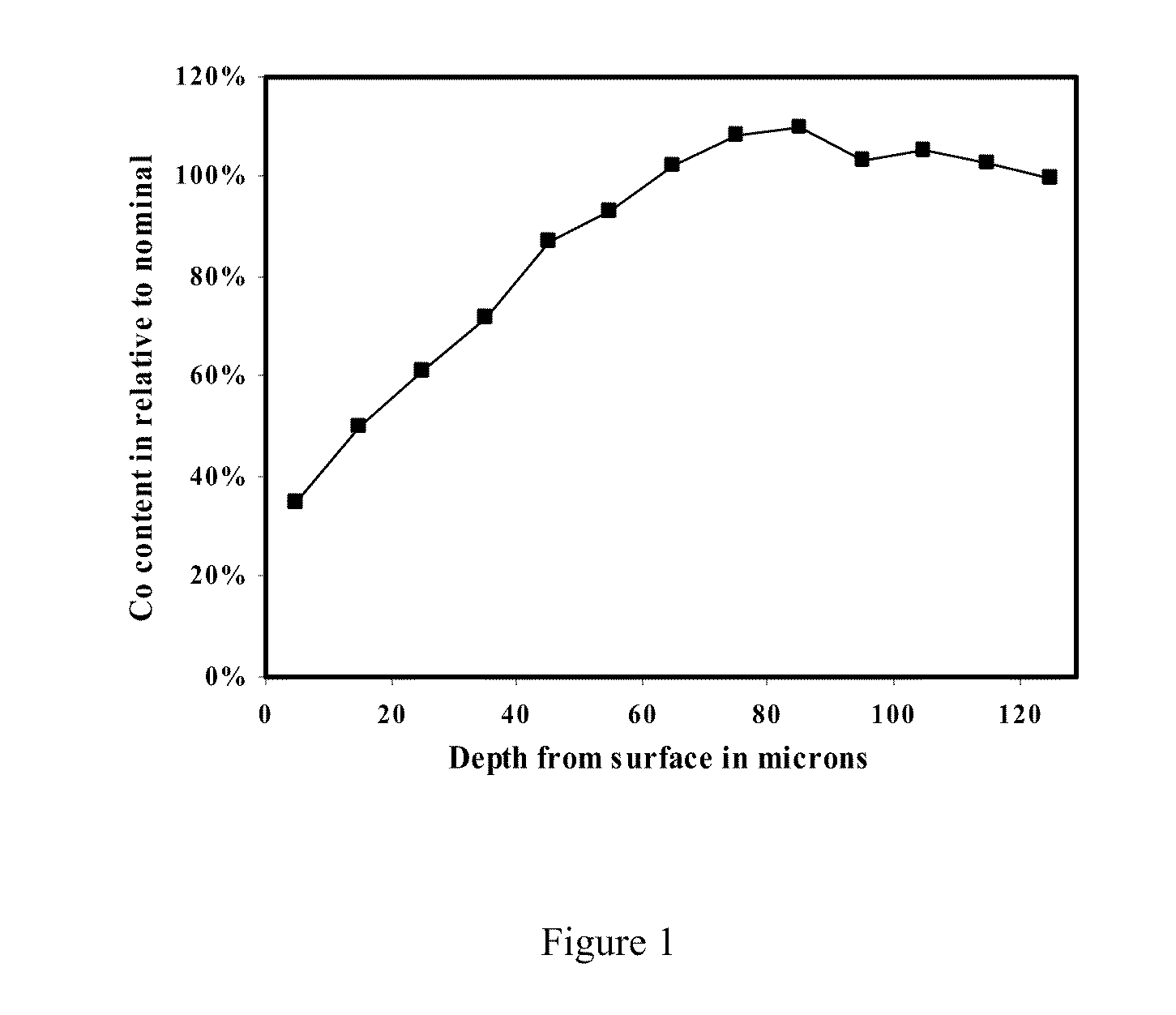

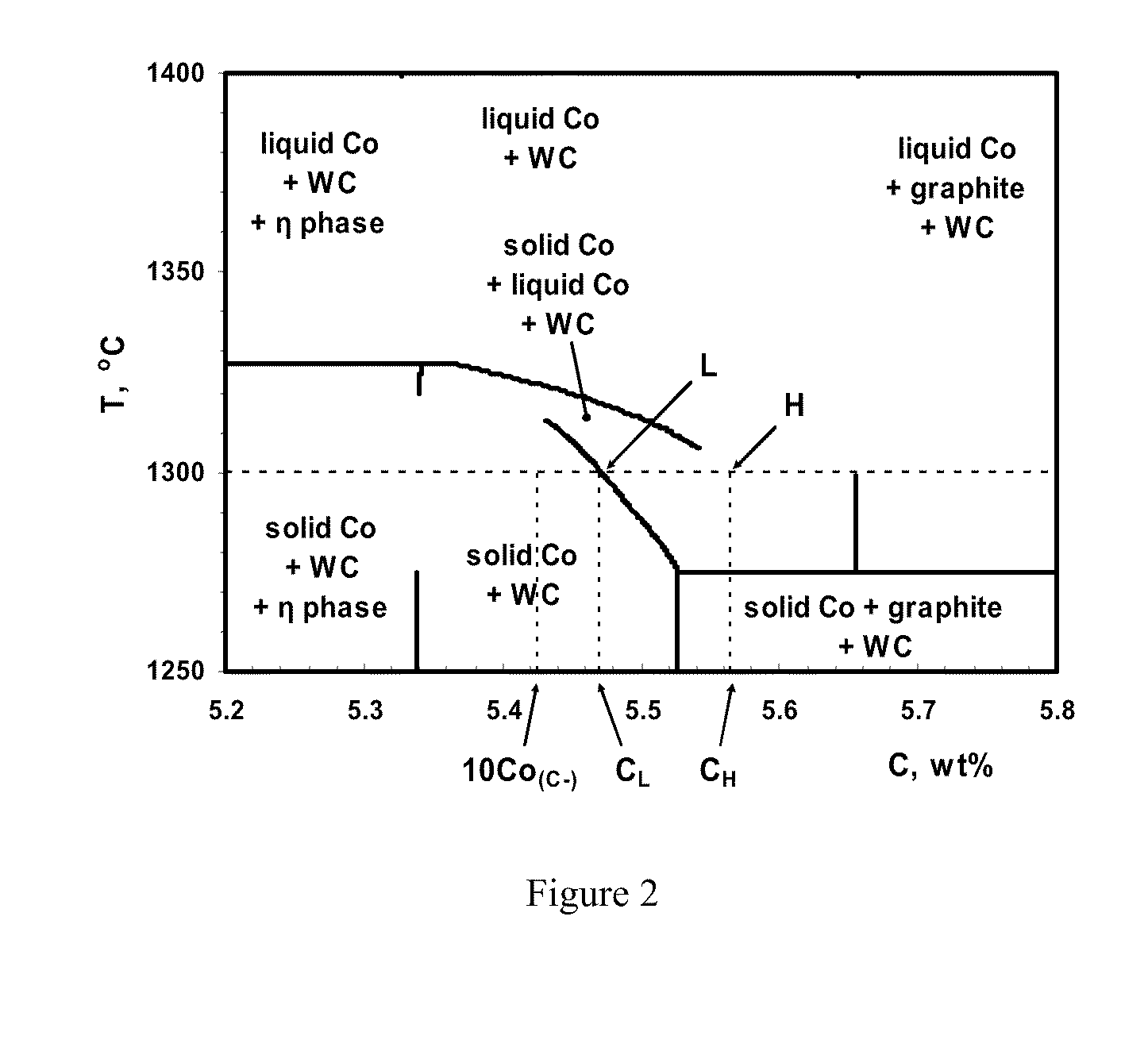

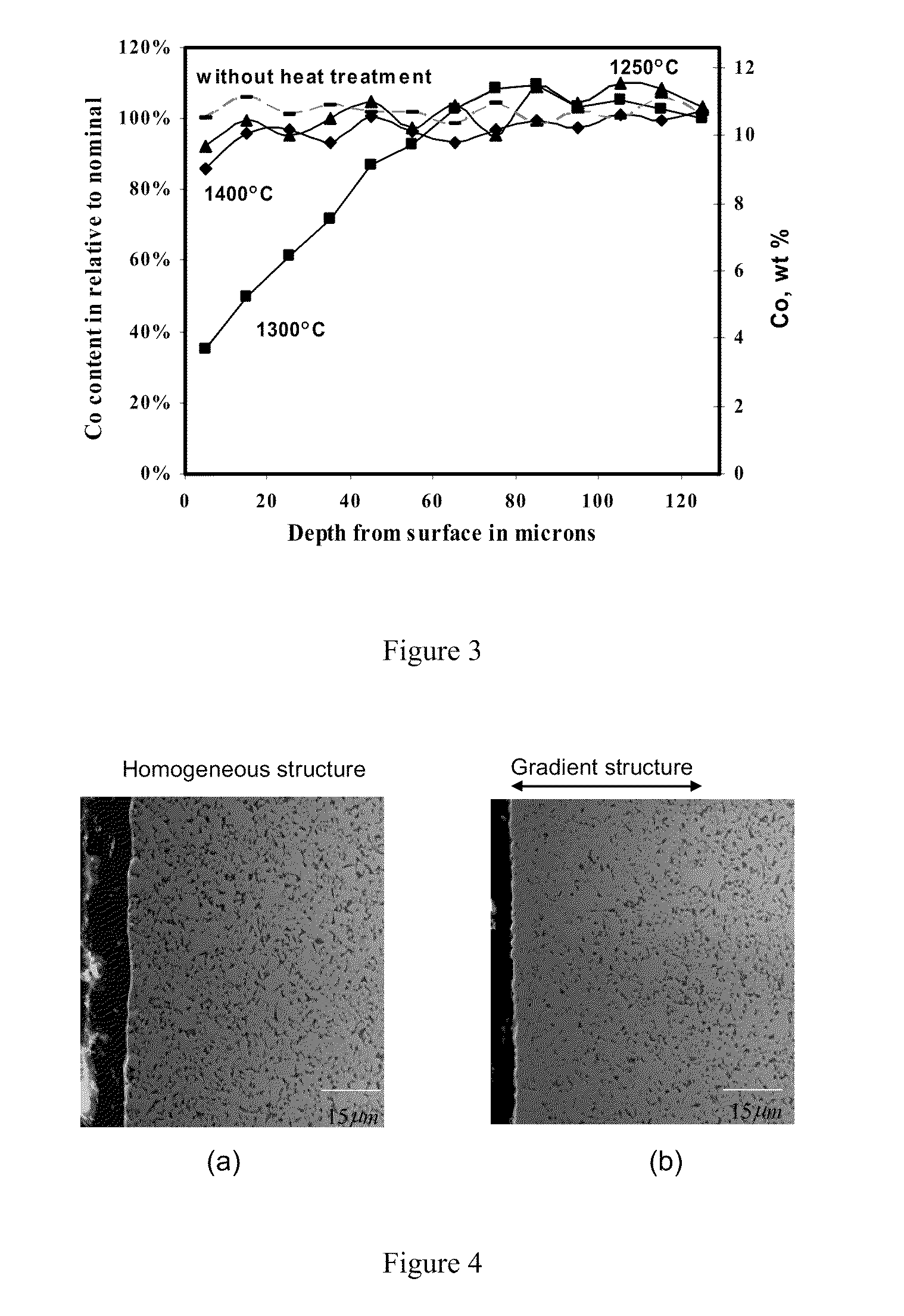

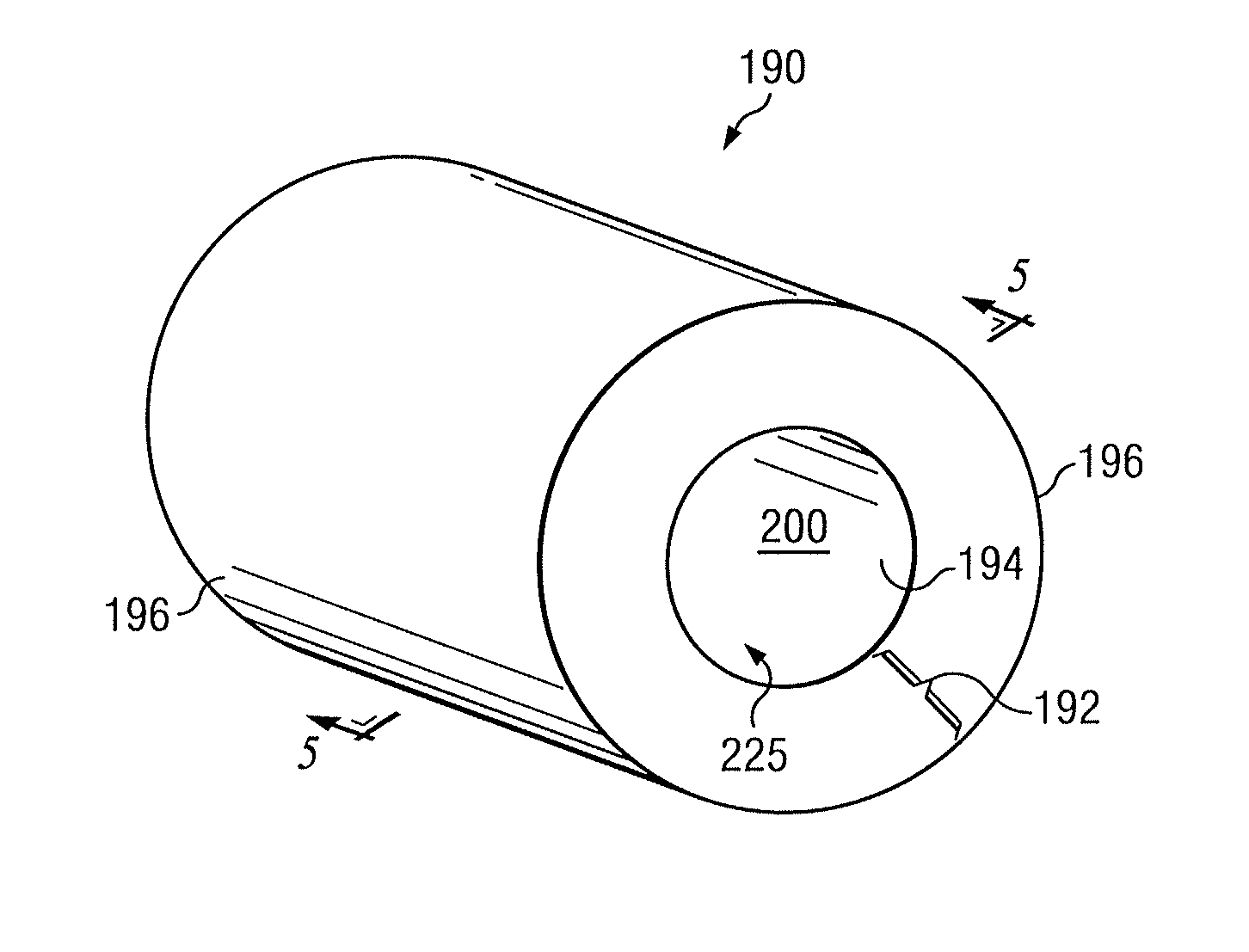

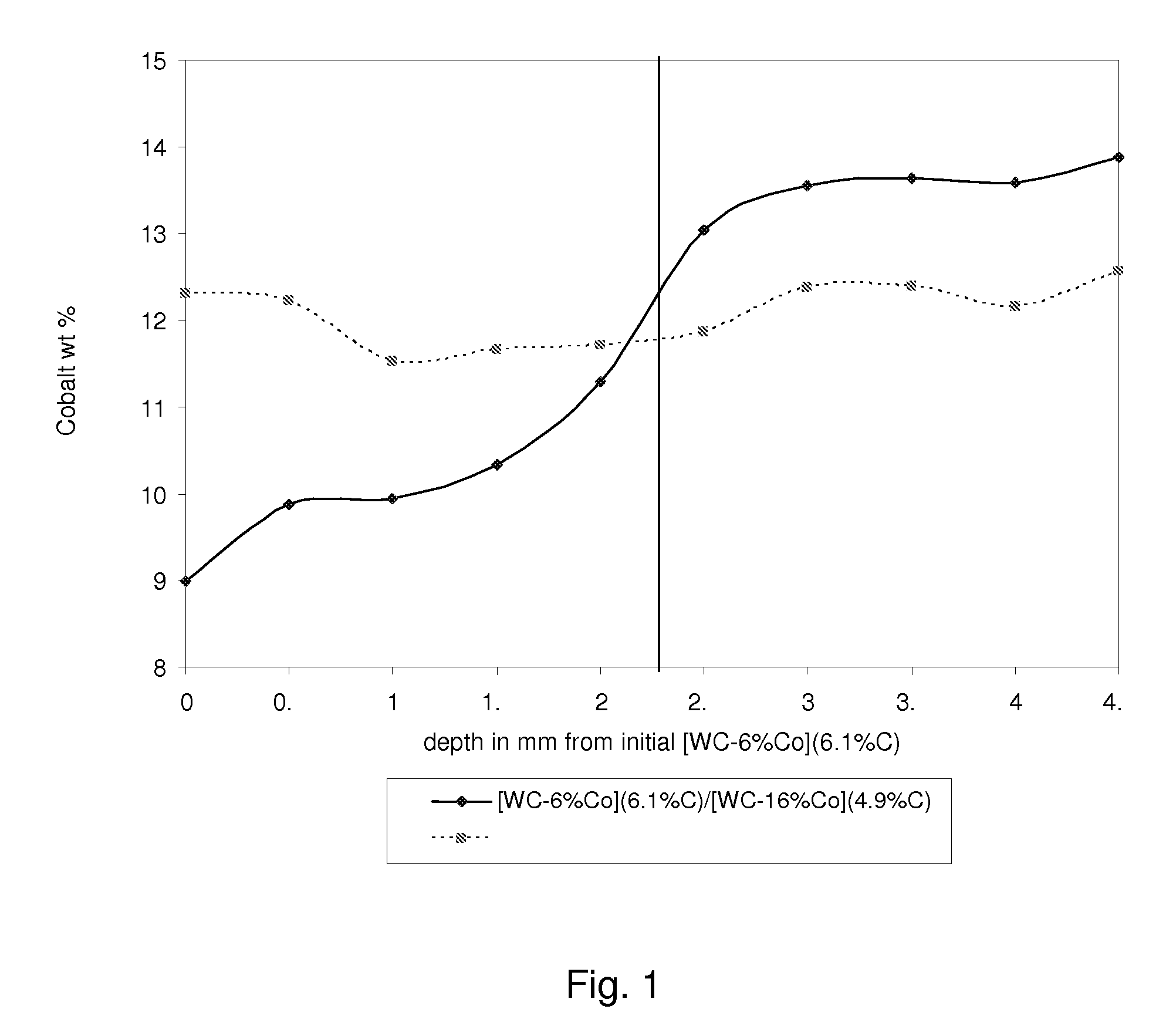

The present invention is a method for producing functionally graded materials that contain a hard phase that is embedded in a metal matrix phase. The material have a continuous gradient of a matrix metal phase. An example of these types of materials include functionally graded cemented tungsten carbide (the hard phase) that has a continuous gradient of cobalt (the matrix metal) from one reference position, for example, one surface of a part, to another reference position, for example, the opposite surface of the part or within the part. The functionally graded materials are sintered via a liquid phase sintering (LPS) technique. In order to achieve the desired continuous gradient of the matrix metal, an initial gradient of one of the chemical elements of the hard phase is designed and built into the part prior to liquid phase sintering. The exact gradient of the composition material elements that will be required depends on factors such as the desired final matrix metal gradient, the dimension of the part to be made, and the sintering time and temperature.

Owner:UNIV OF UTAH RES FOUND

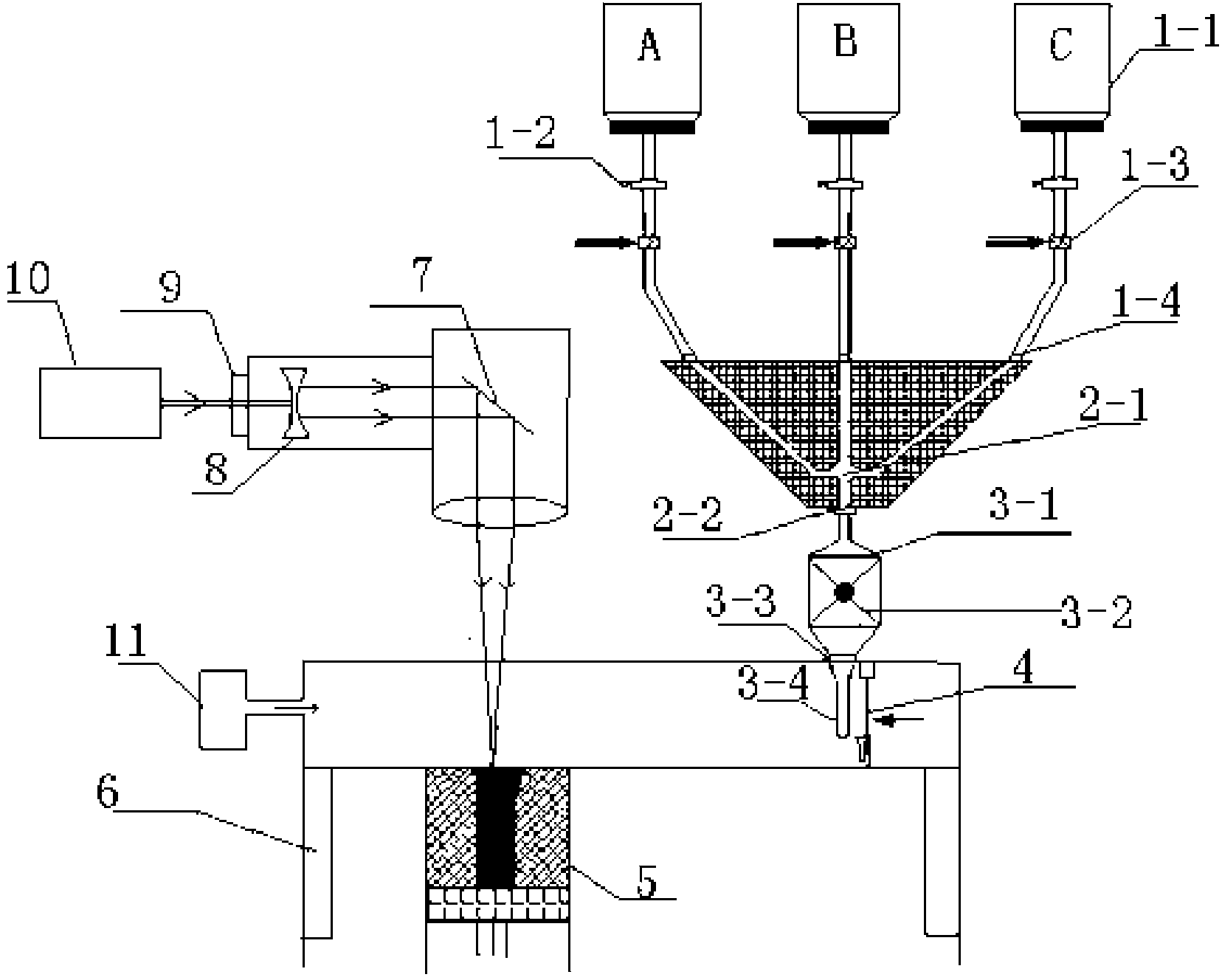

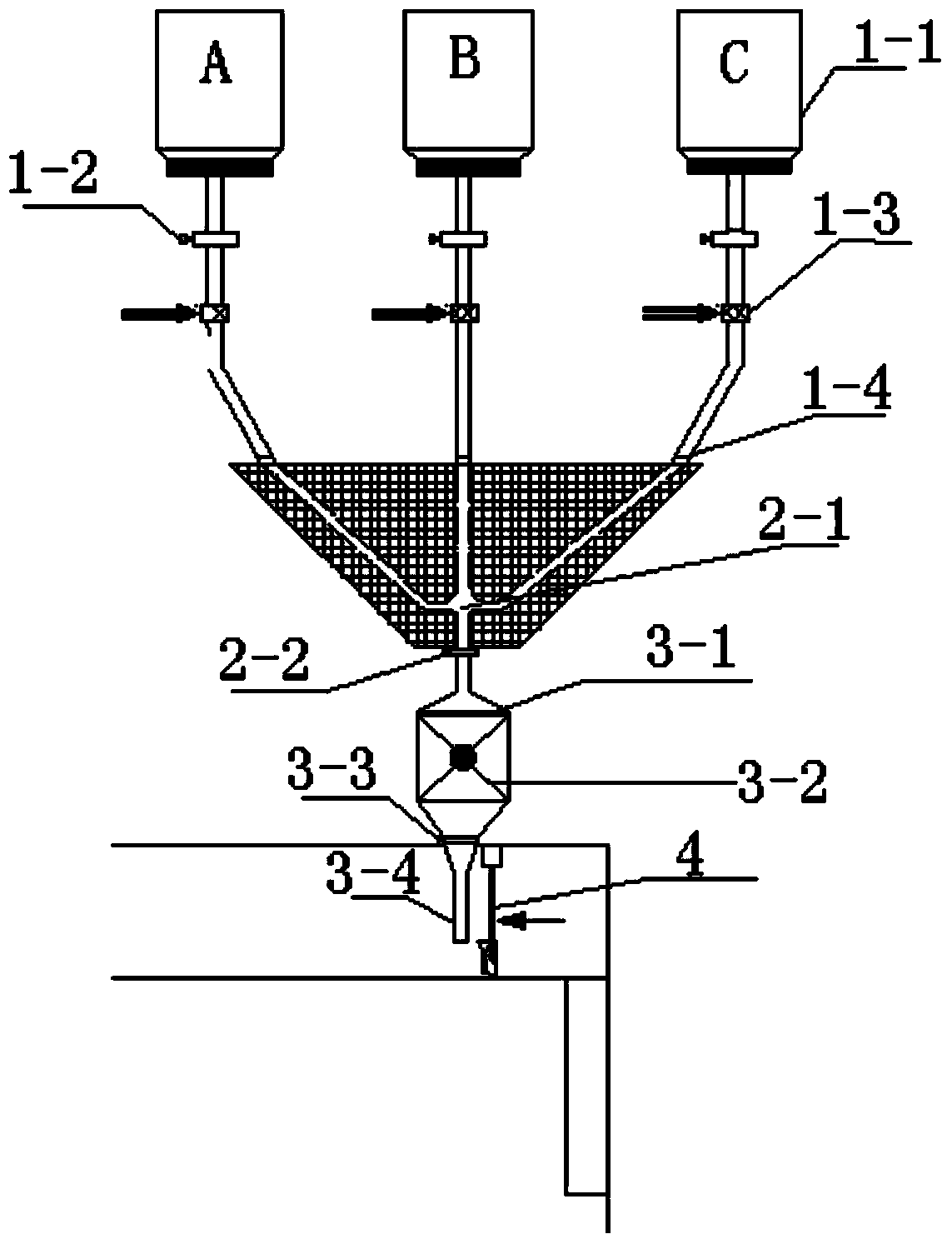

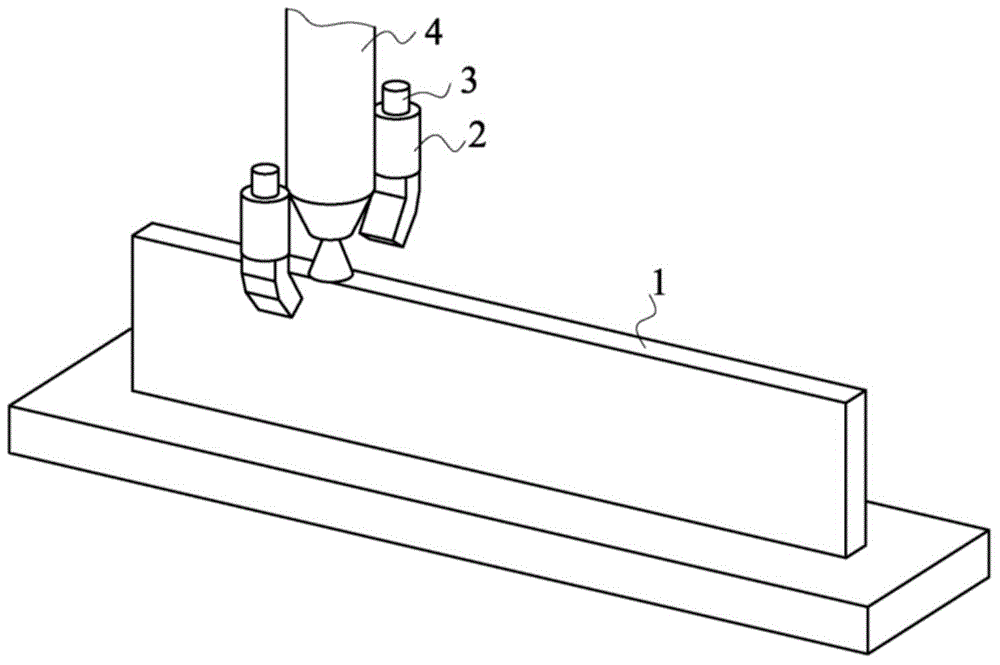

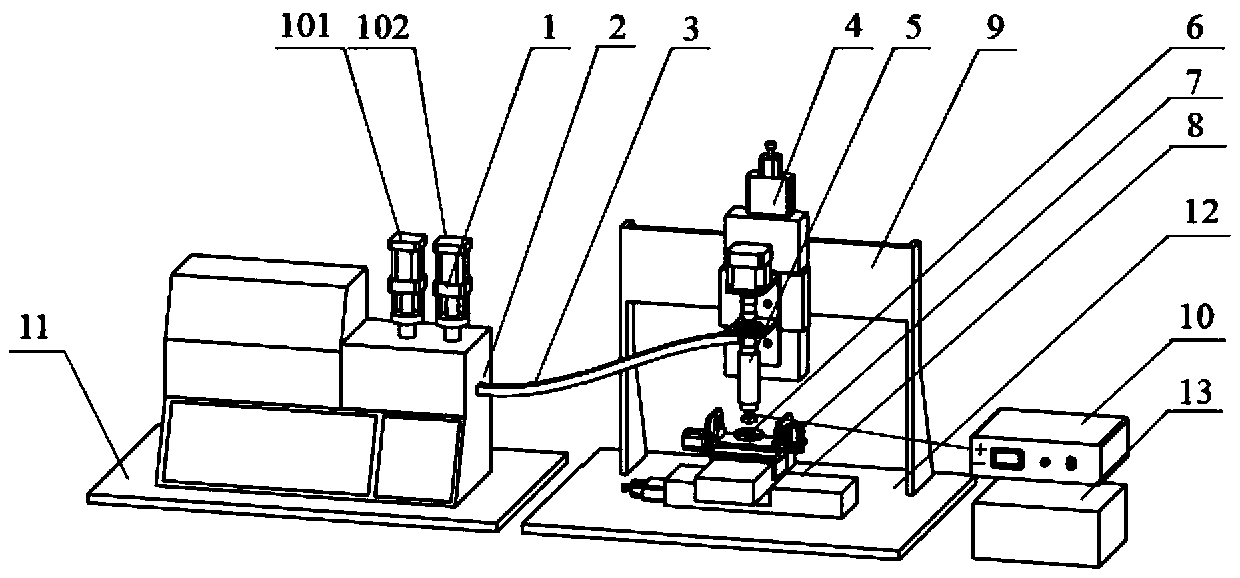

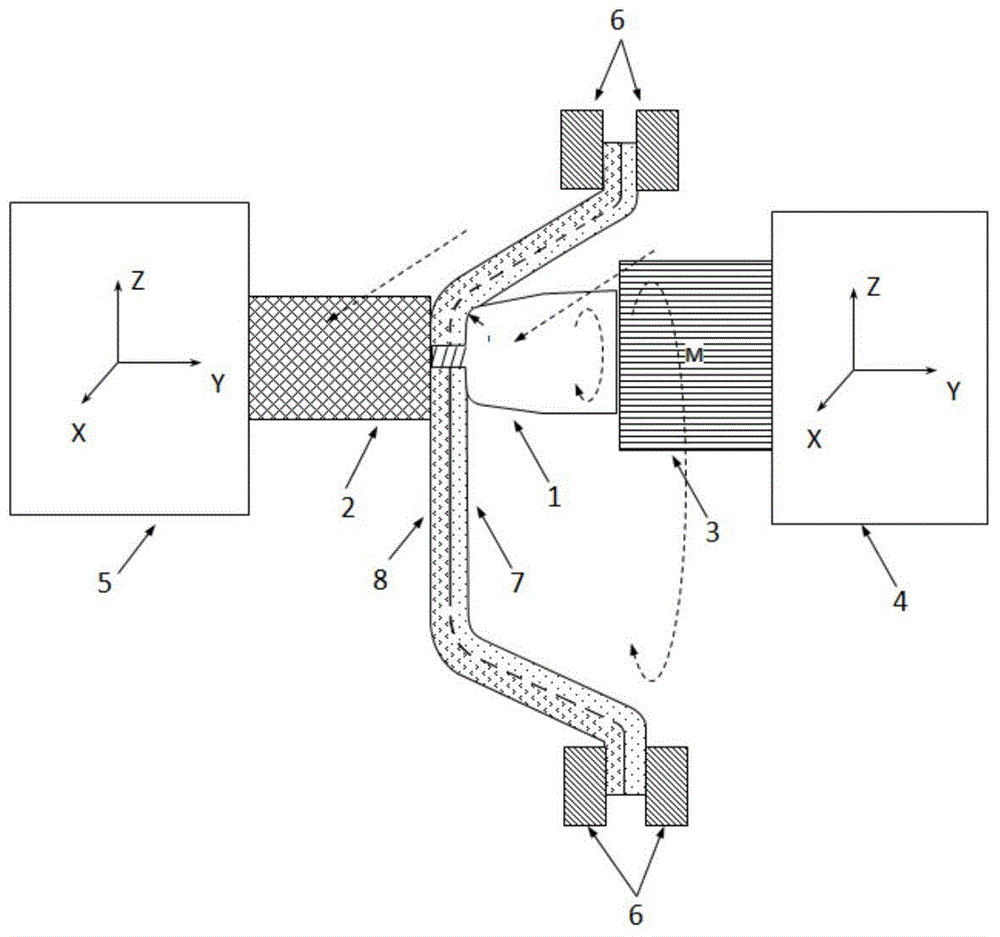

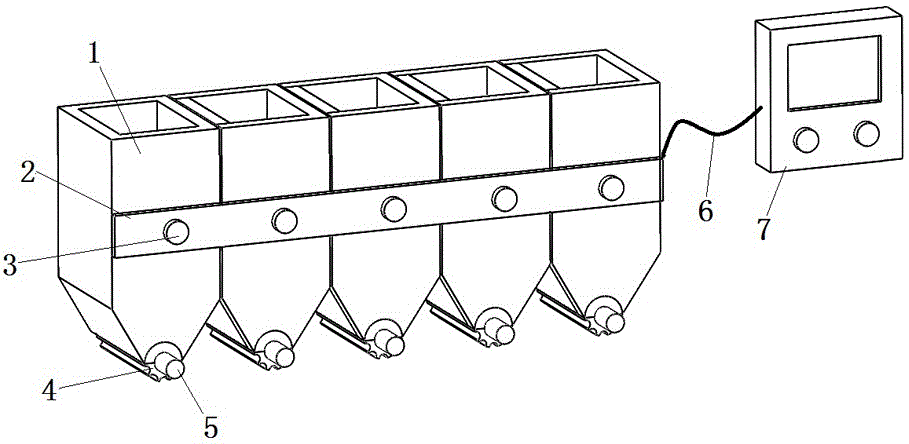

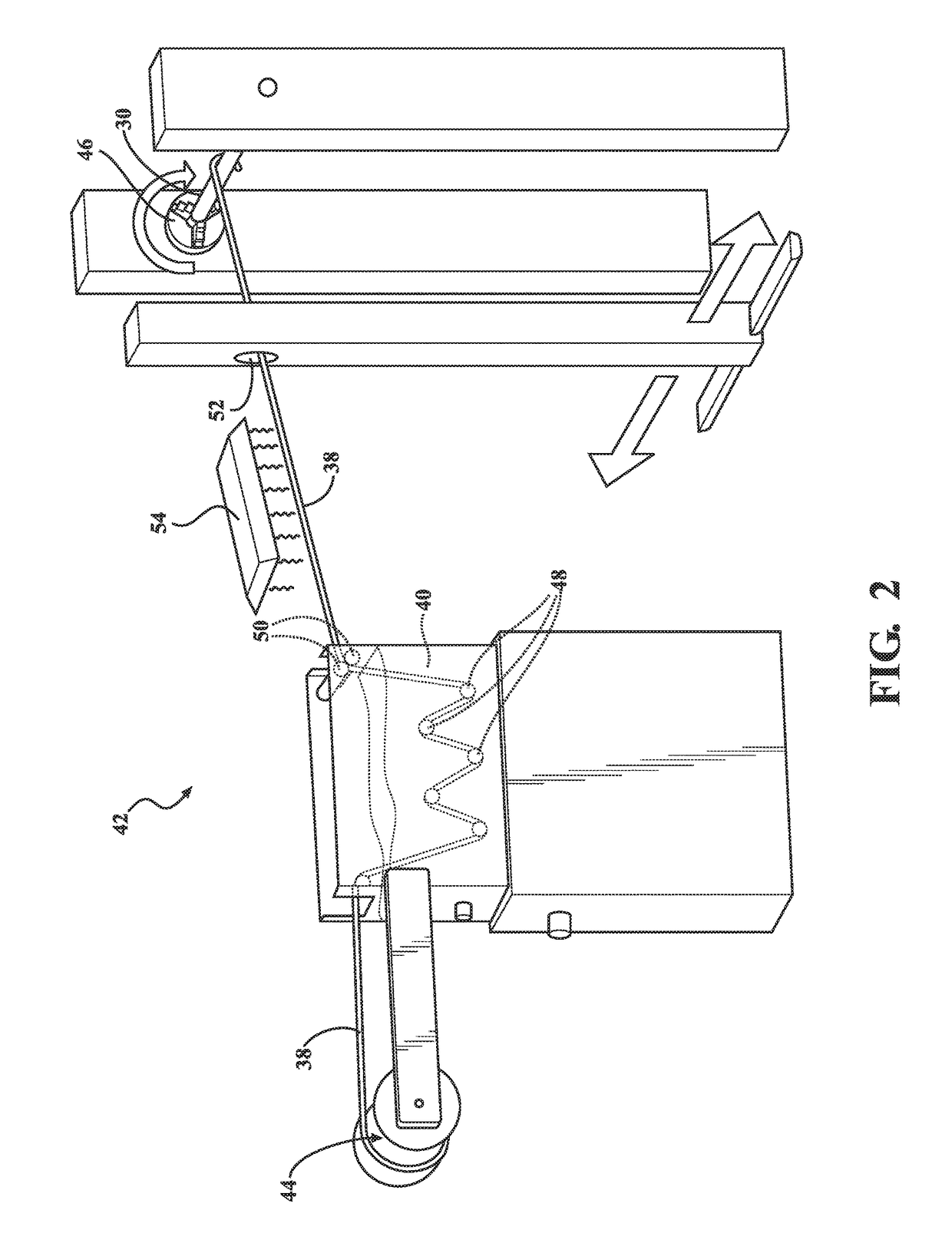

Powder spreading processing based functionally graded material preparation device and method

InactiveCN104001917AImprove performanceReduce development costsMetallic material coating processesVertical planeFunctionally graded material

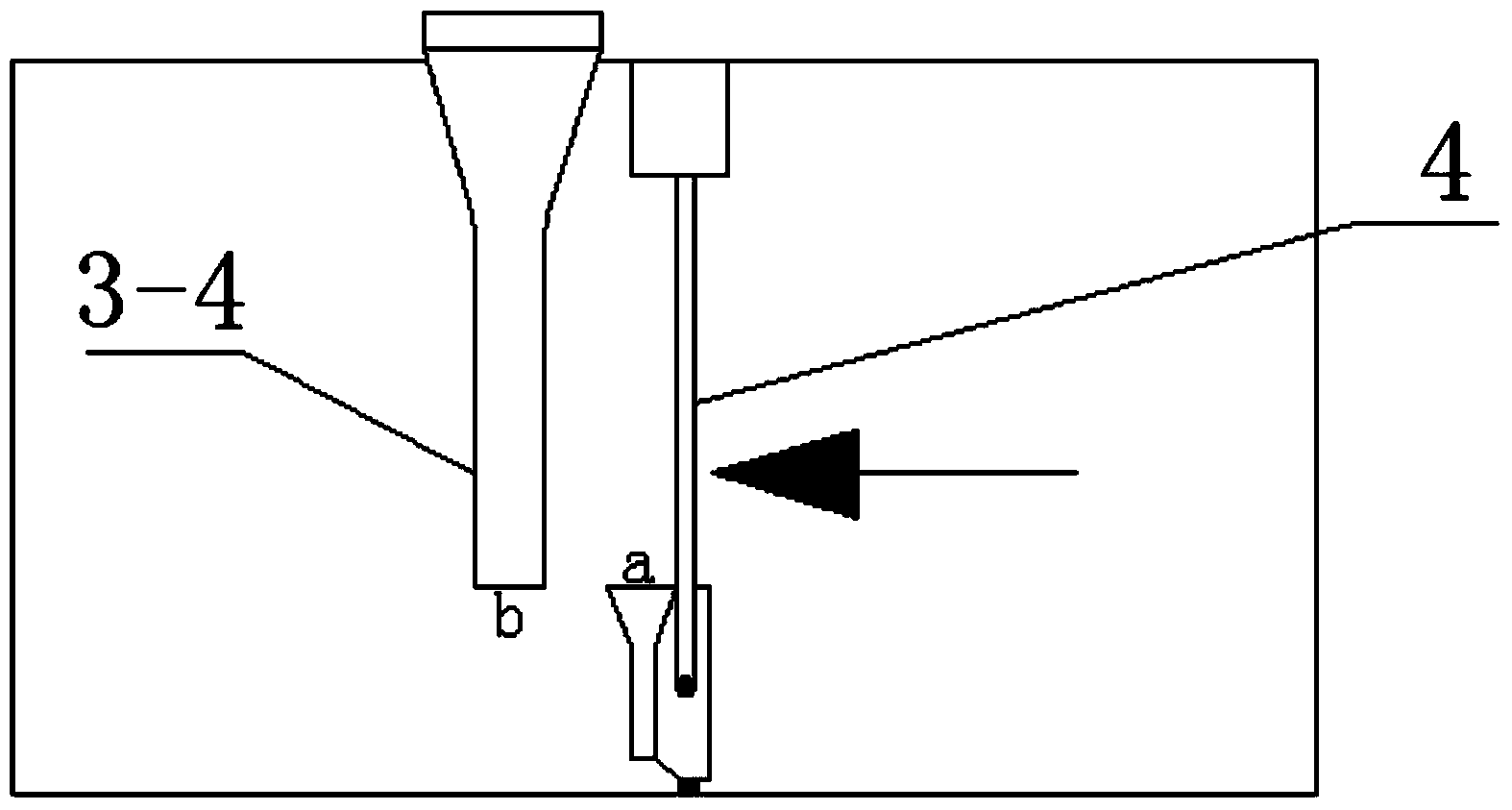

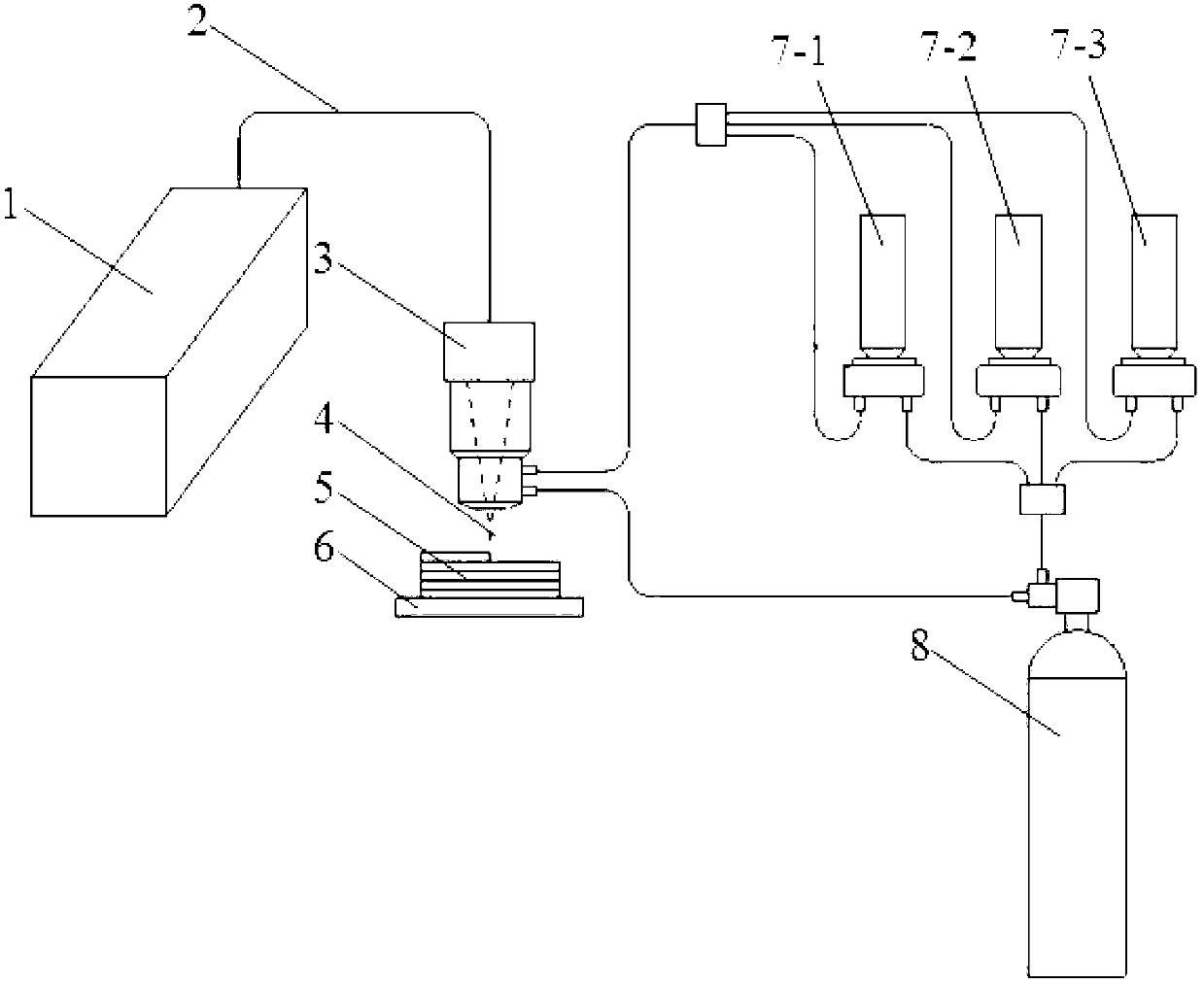

The invention discloses a powder spreading processing based functionally graded material preparation device and method. The powder spreading processing based functionally graded material preparation device comprises a powder spreading device, a feeding device, a powder collecting device and a powder mixing control device; the feeding device, the powder collecting device and the powder mixing control device are connected sequentially from upside to downside through pipelines; the feeding device comprises three powder cylinders, i.e., powder cylinder A, powder cylinder B and powder cylinder C; the powder collecting device comprises a powder collecting chamber; the powder mixing control device is provided; the powder cylinders are connected to the powder collecting chamber through pipelines, and flow controllers and gas power generators are arranged on the pipelines sequentially from upside to downside; a pressure-limiting valve is arranged at the joint of the powder collecting chamber and the powder mixing control device. The functionally graded material which is prepared by adopting the device and method has no obvious interface or separated layer, the gradient change can be realized in a horizontal plane and a vertical plane of substrate during the processing process, good spatial continuity is achieved, direct melting molding of high-melting metal can be realized, and the use range of the functionally graded material is enlarged.

Owner:SOUTH CHINA UNIV OF TECH

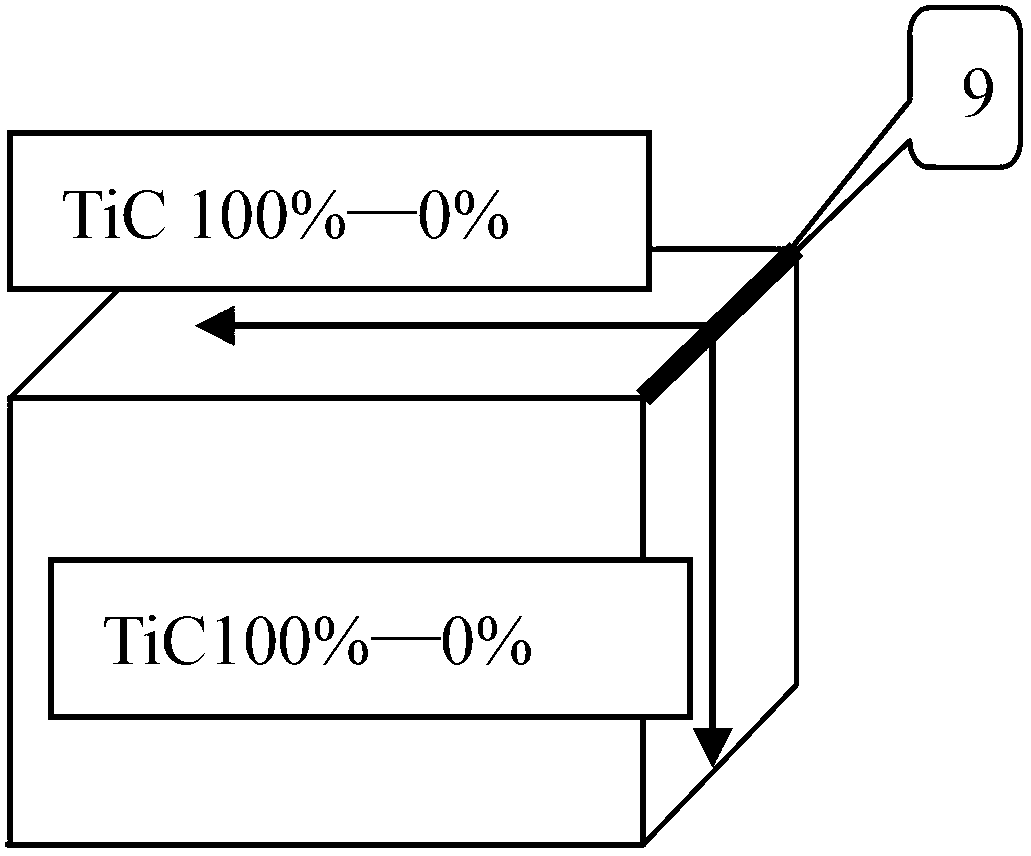

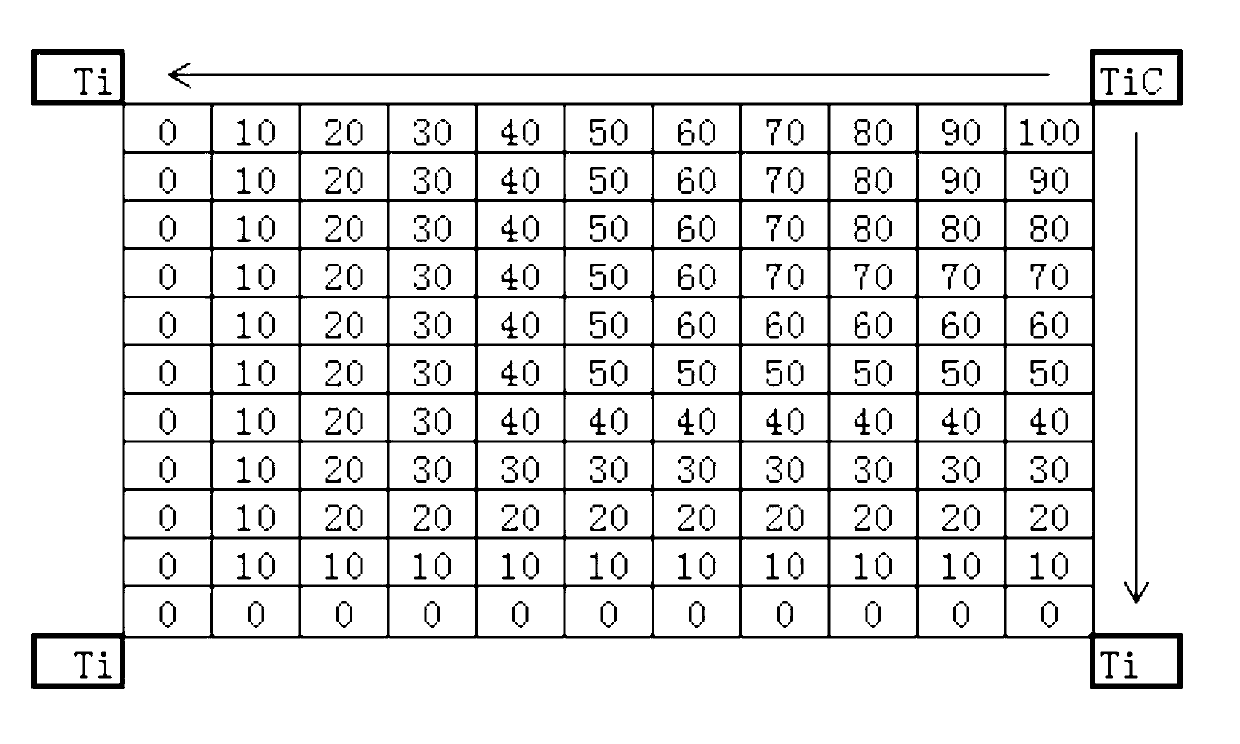

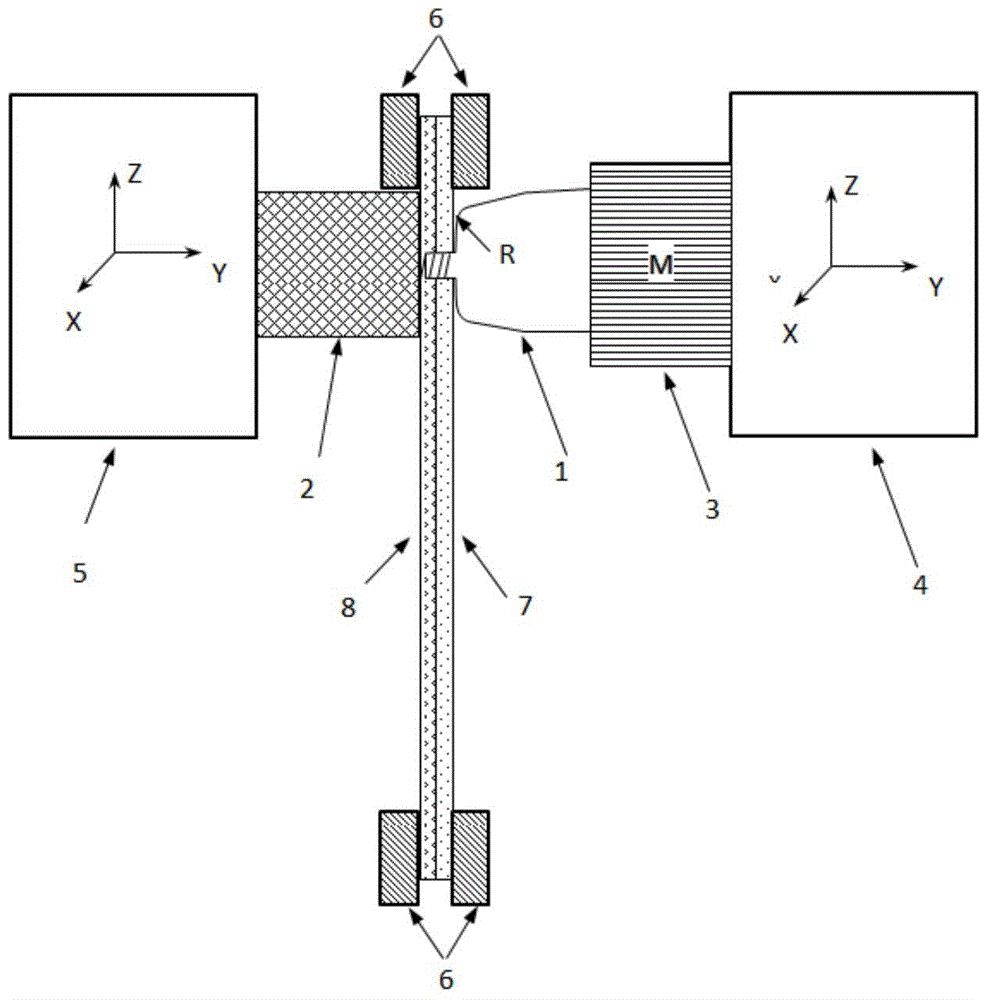

Laser near-net shaping method for metal-ceramic multi-dimensional functionally-graded structural component

The invention discloses a laser near-net shaping method for a metal-ceramic multi-dimensional functionally-graded structural component. According to the laser near-net shaping method for the metal-ceramic multi-dimensional functionally-graded structural component, a laser fast shaping system is used for combining metal powder and ceramic powder, which are used as raw materials and have changeable proportioning rates, to form the multi-dimensional functionally-graded structural component directly. The laser near-net shaping method specifically includes the following steps: firstly, two types or more than two types of metal powder and ceramic powder are dried and respectively placed in different powder barrels of a powder feeding device; secondly, inert gas is used as powder feeding and protecting gas; and lastly, a numerical control program is used for controlling the moving trajectory and the moving speed of a laser machining head and the real-time powder feeding amount of each powder barrel of the powder feeding device, the change of gradients can be realized in a horizontal plane and a vertical plane of a base plate, and therefore the complex multi-dimensional gradient change in the overall space can be realized. On one hand, the laser near-net shaping method for the metal-ceramic multi-dimensional functionally-graded structural component is a direct shaping method, and on the other hand, the laser near-net shaping method is suitable for melting solidification shaping of various high-melting-point materials, and the selection range of the design of functionally-graded materials is expanded.

Owner:DALIAN UNIV OF TECH

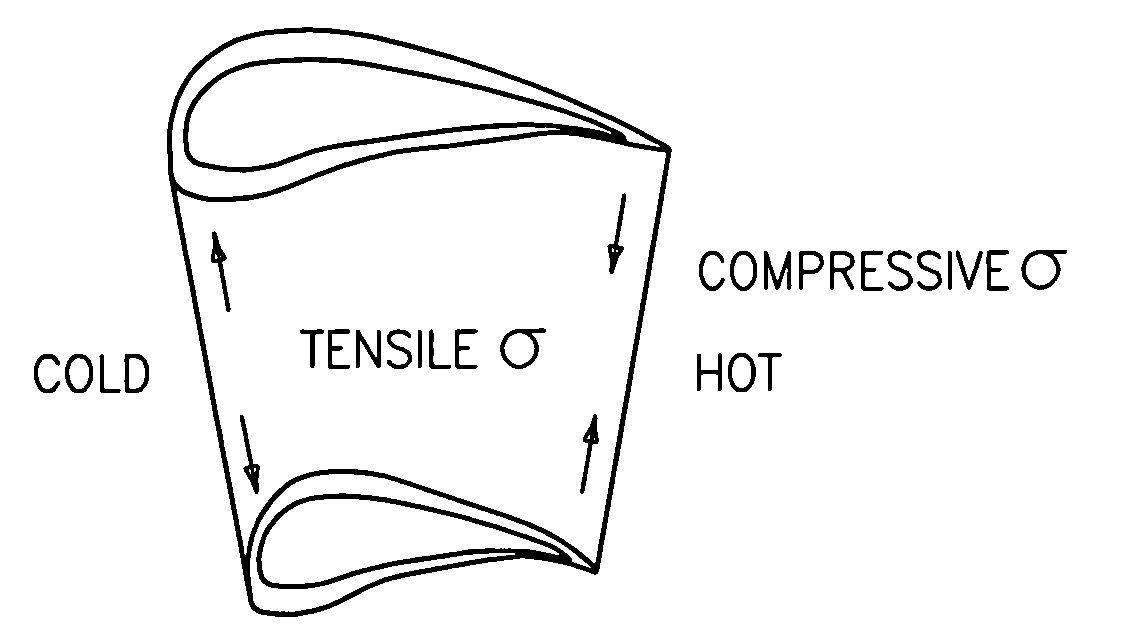

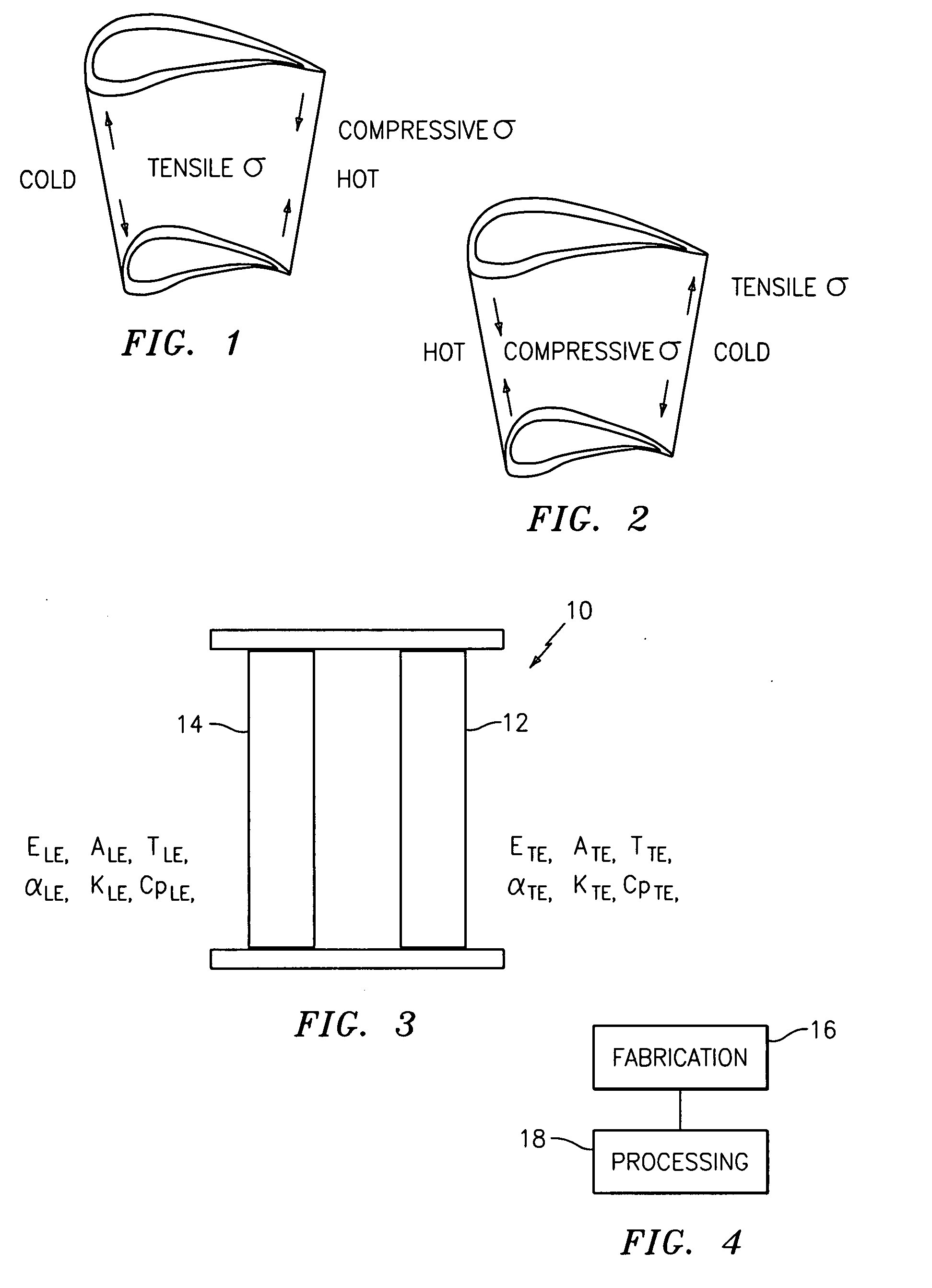

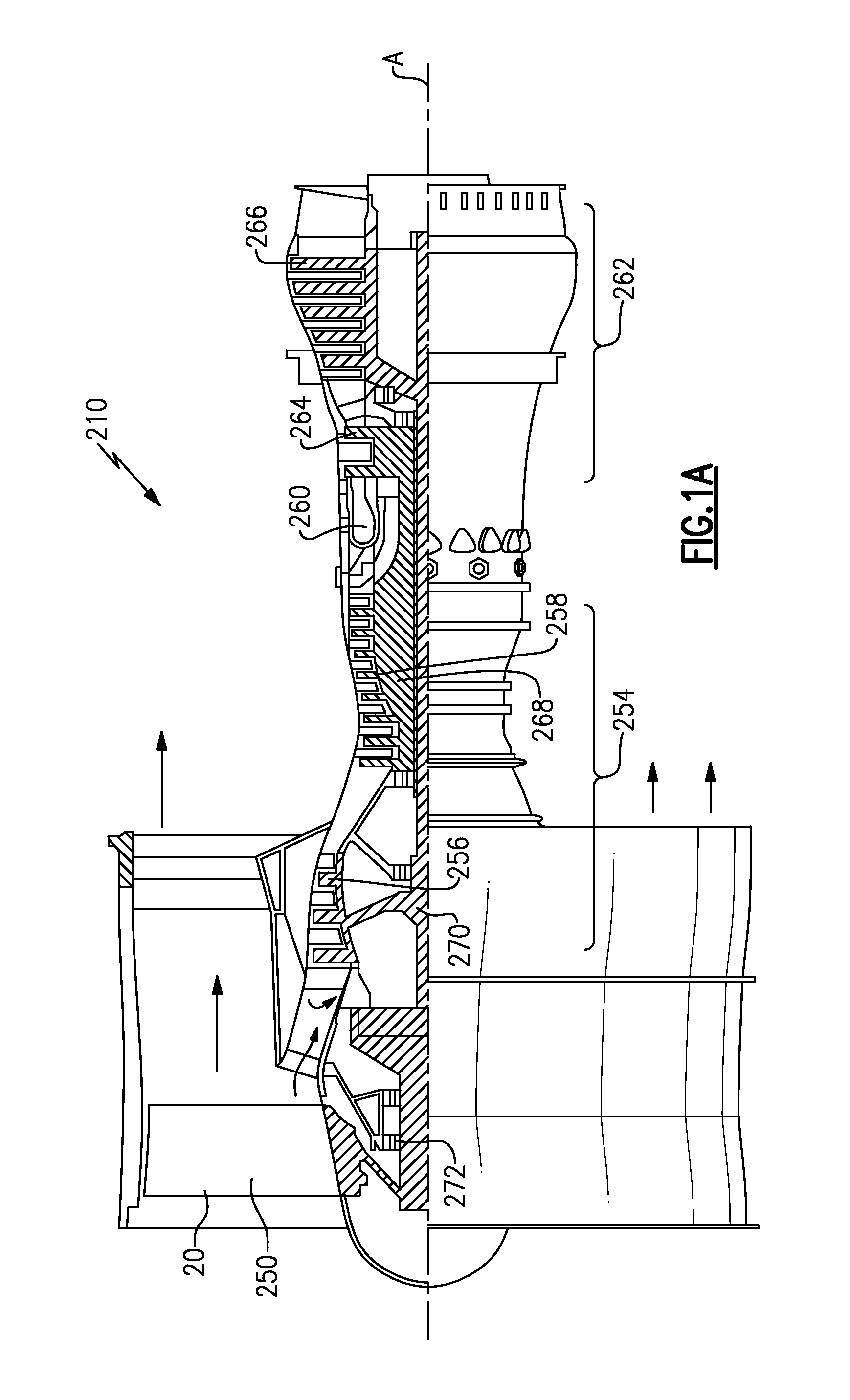

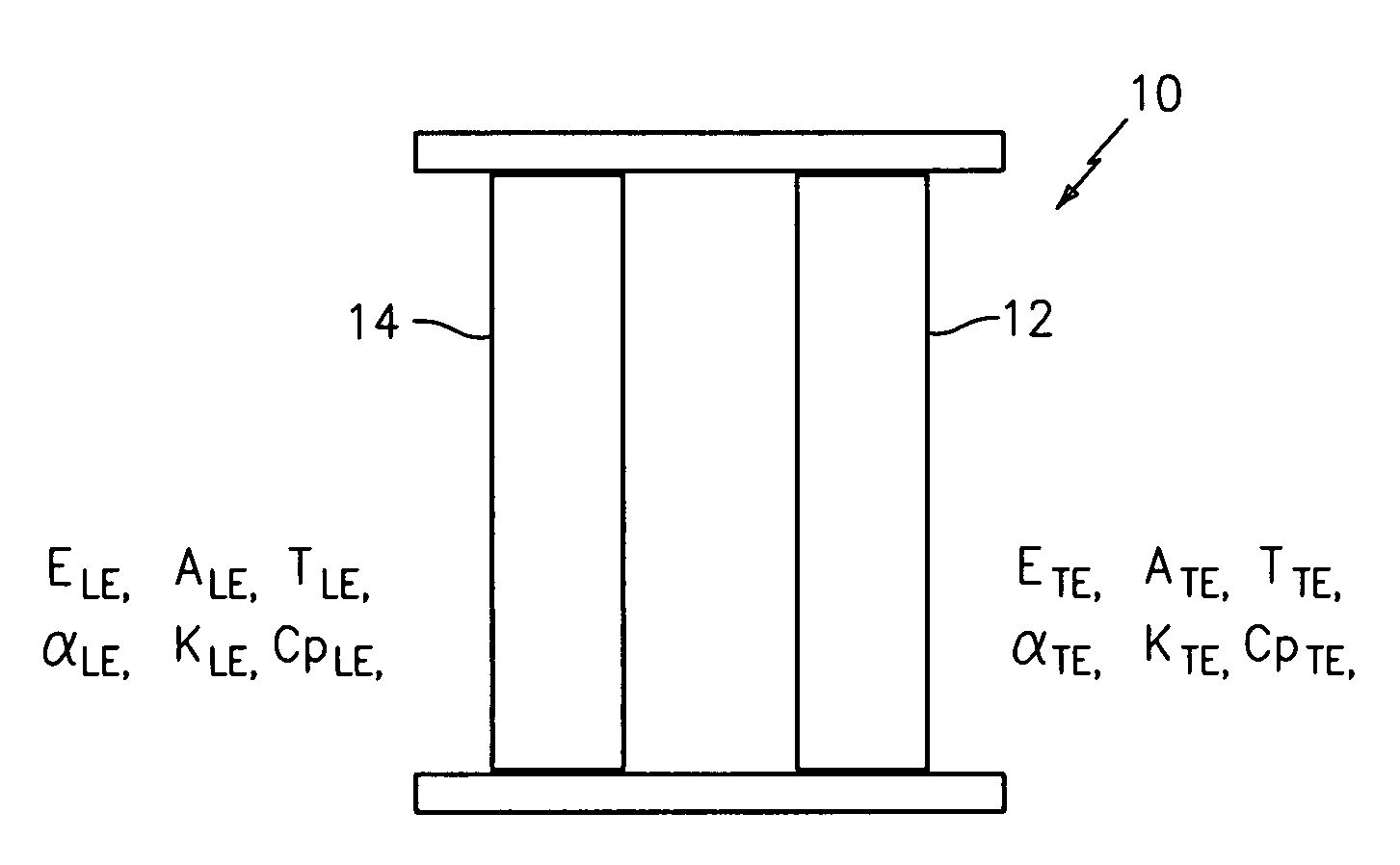

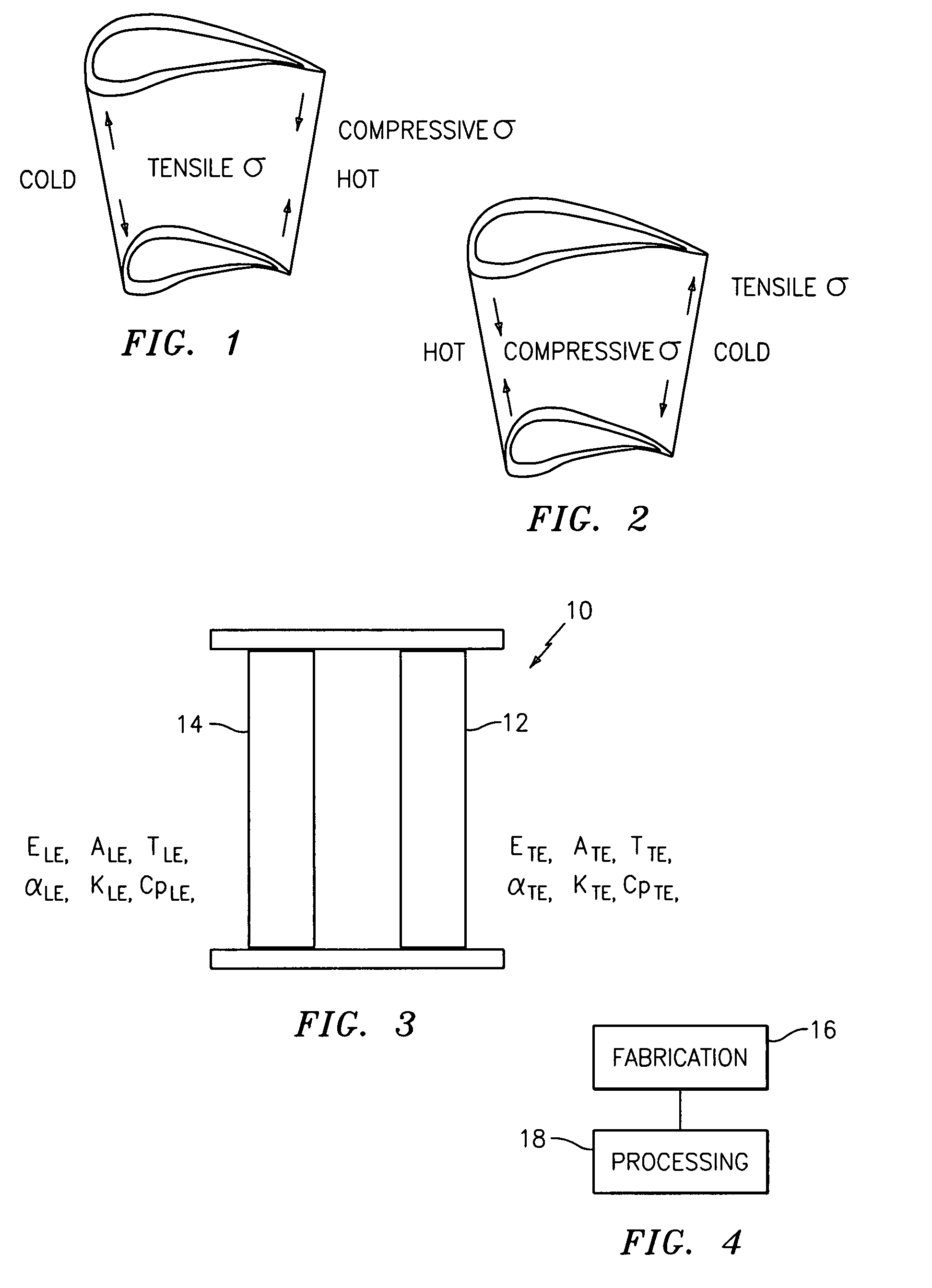

Low transient thermal stress turbine engine components

A turbine vane includes a platform; and at least one airfoil mounted to the platform and having a trailing edge and a leading edge, wherein the vane is composed of a functionally graded material having a first material and a second material, wherein the trailing edge includes a greater amount of the first material than the second material, and the leading edge includes a greater amount of the second material than the first material.

Owner:RTX CORP

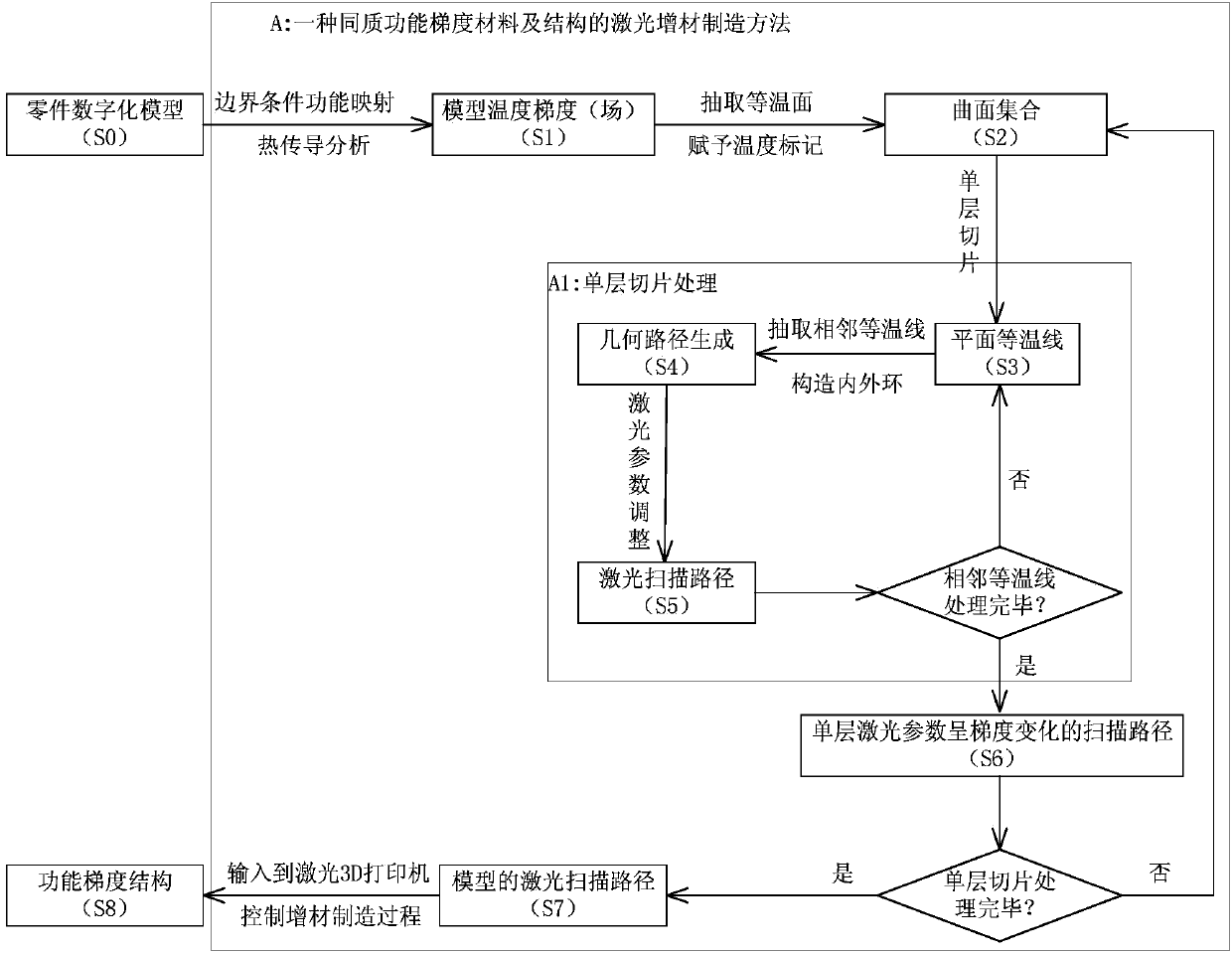

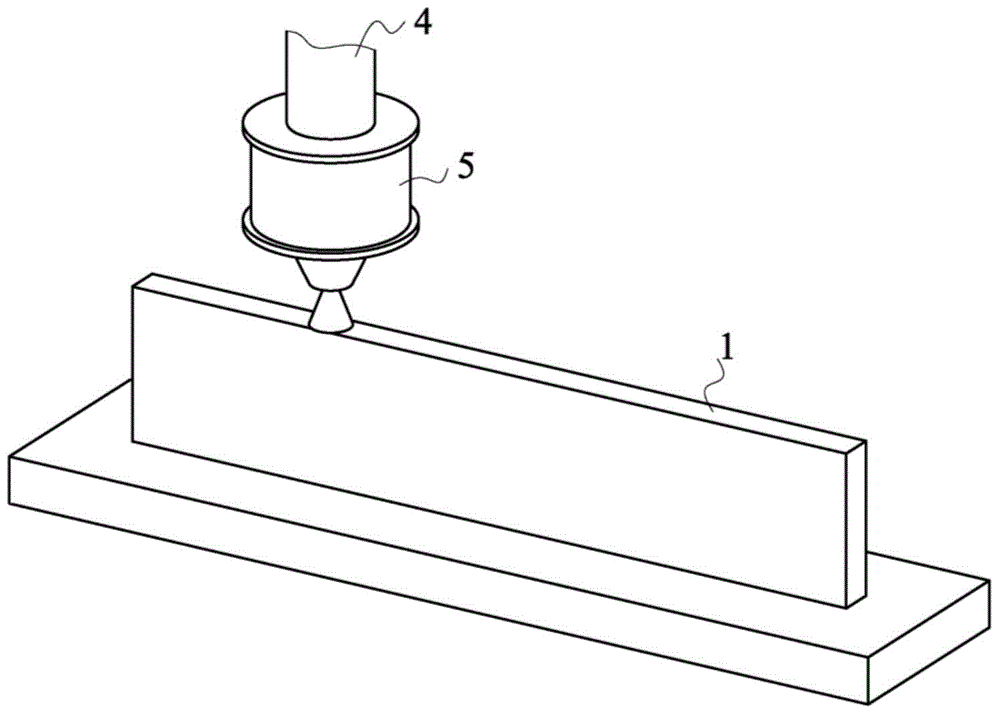

Laser additive manufacturing method for homogeneous functionally graded material and structure

ActiveCN104190930AOvercome functionOvercome structureIncreasing energy efficiencyLaser scanningOptoelectronics

The invention relates to a laser additive manufacturing method for a homogeneous functionally graded material and structure. The method includes the following steps that different functions are mapped into different temperatures which serve as boundary conditions to be exerted on different parts of a three-dimensional model; a three-dimensional finite element method is used for calculating a heat conduction equation of the model, inner temperature graded distribution, namely the temperature field of a model, is obtained, that is a temperature field of the model is obtained; an isothermal surface of the model is extracted, and a curved surface set with different temperature marks is obtained; slicing is conducted on the curved surface set, the intersection outline of each layer and the isothermal surface is obtained, in other words, plane isothermal lines are obtained; slices of each layer are processed, and a scanning route with laser parameters of the single layer in graded variation is obtained; the steps are repeatedly conducted until slicing is completed and a laser scanning route of the model is obtained; the generated laser scanning route is input into a laser 3D printing machine to control the additive manufacturing process, and the homogeneous functionally graded structure is obtained. According to the additive manufacturing method, the fact that the homogeneous functionally graded material and the homogeneous functionally graded structure can be manufactured in an additive mode is achieved, and the fact cannot be achieved through a current laser additive manufacturing method.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

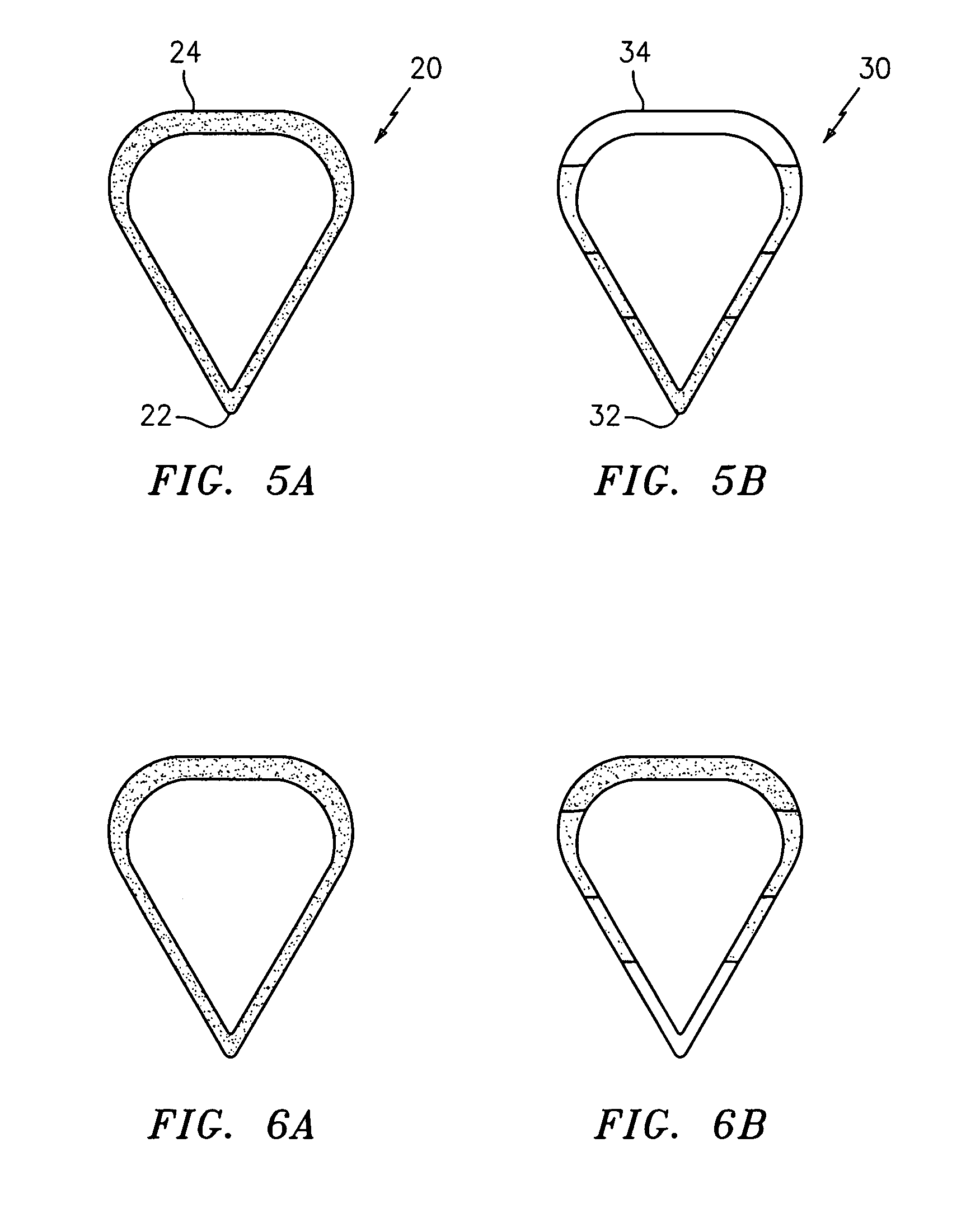

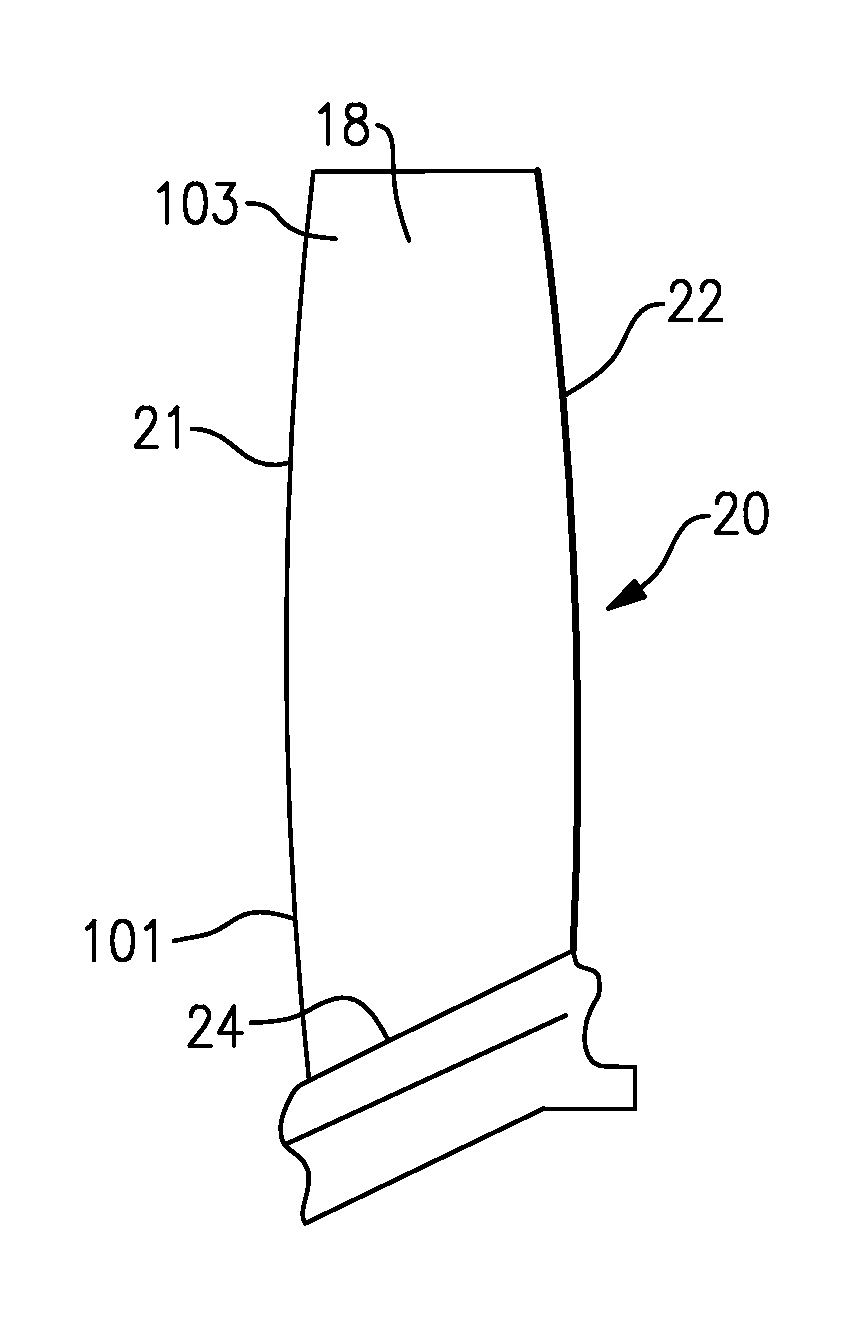

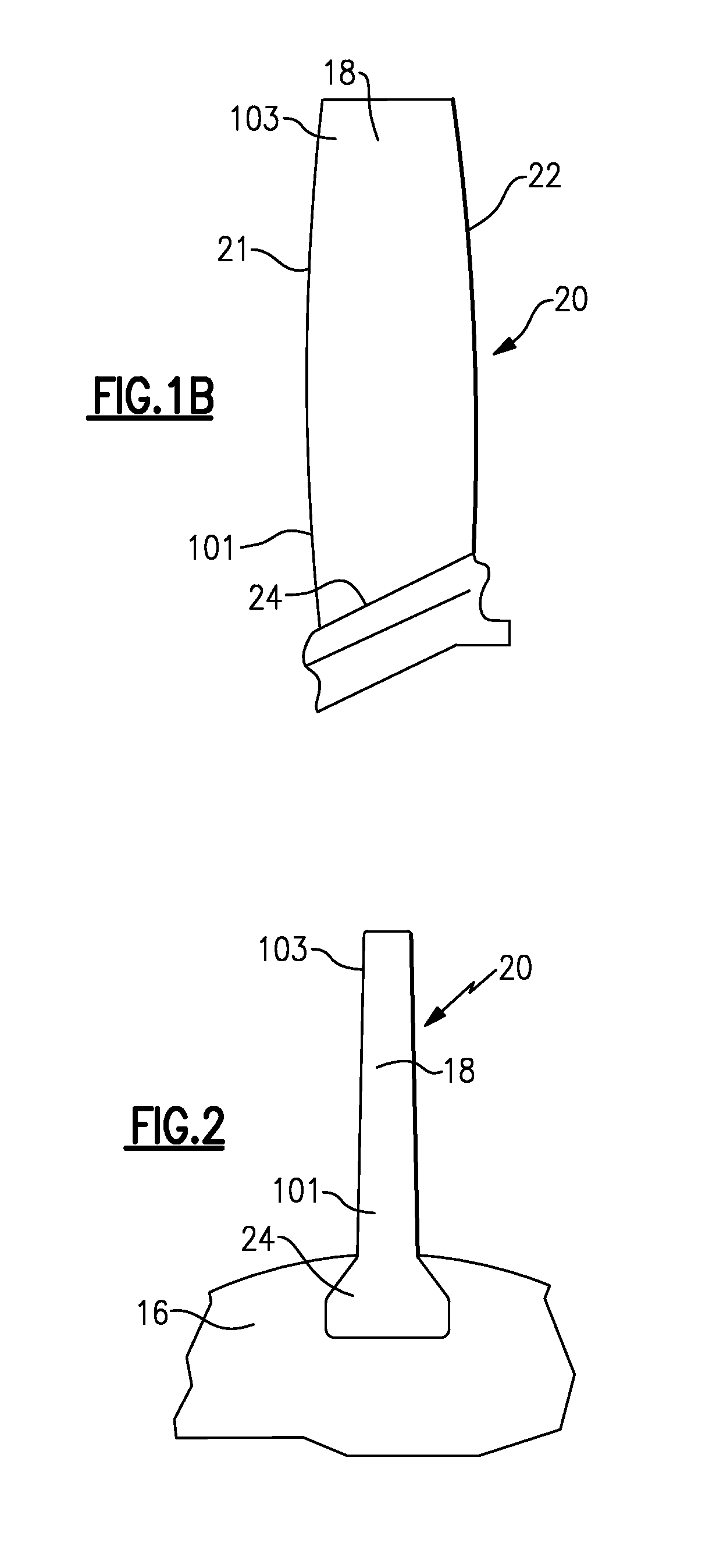

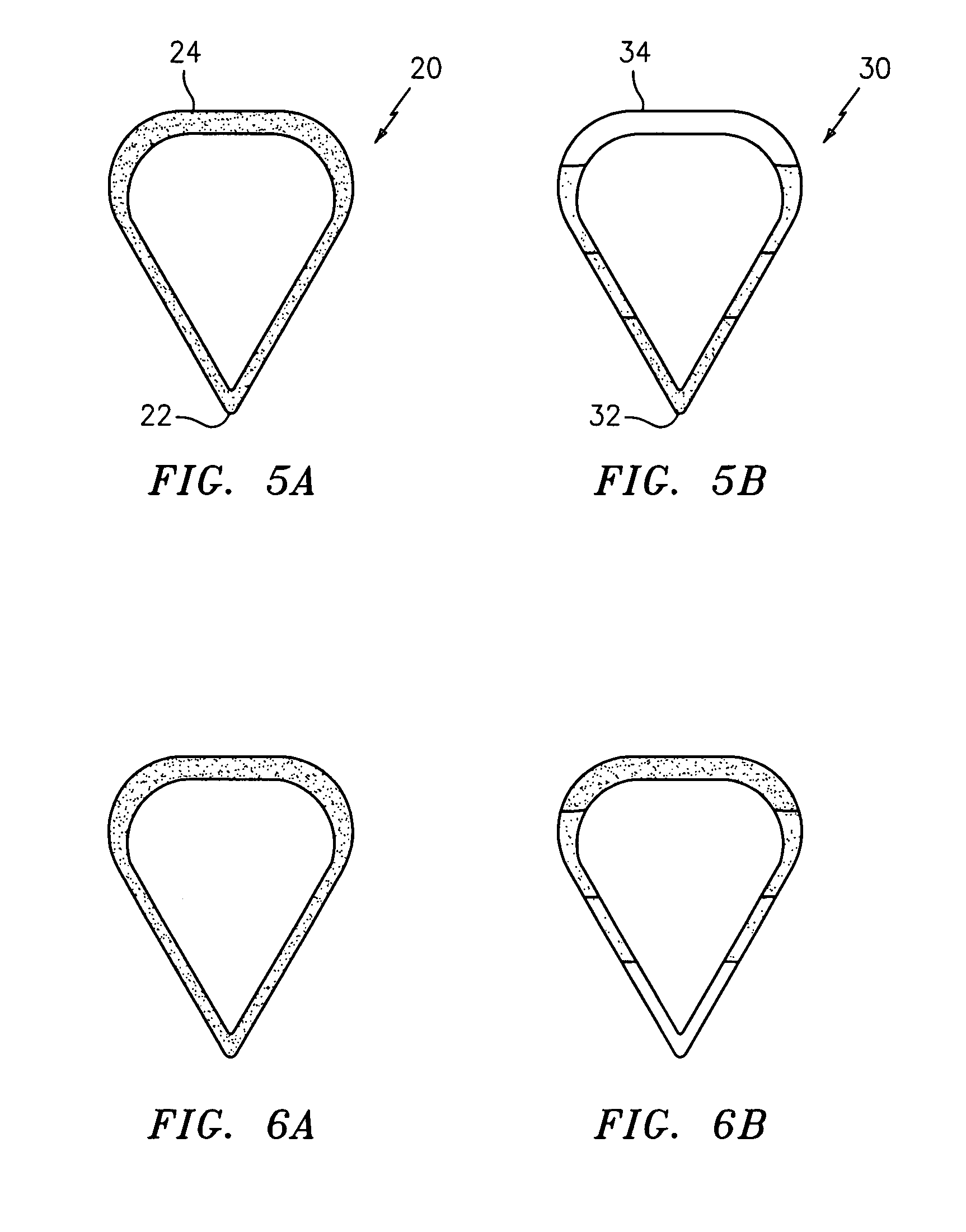

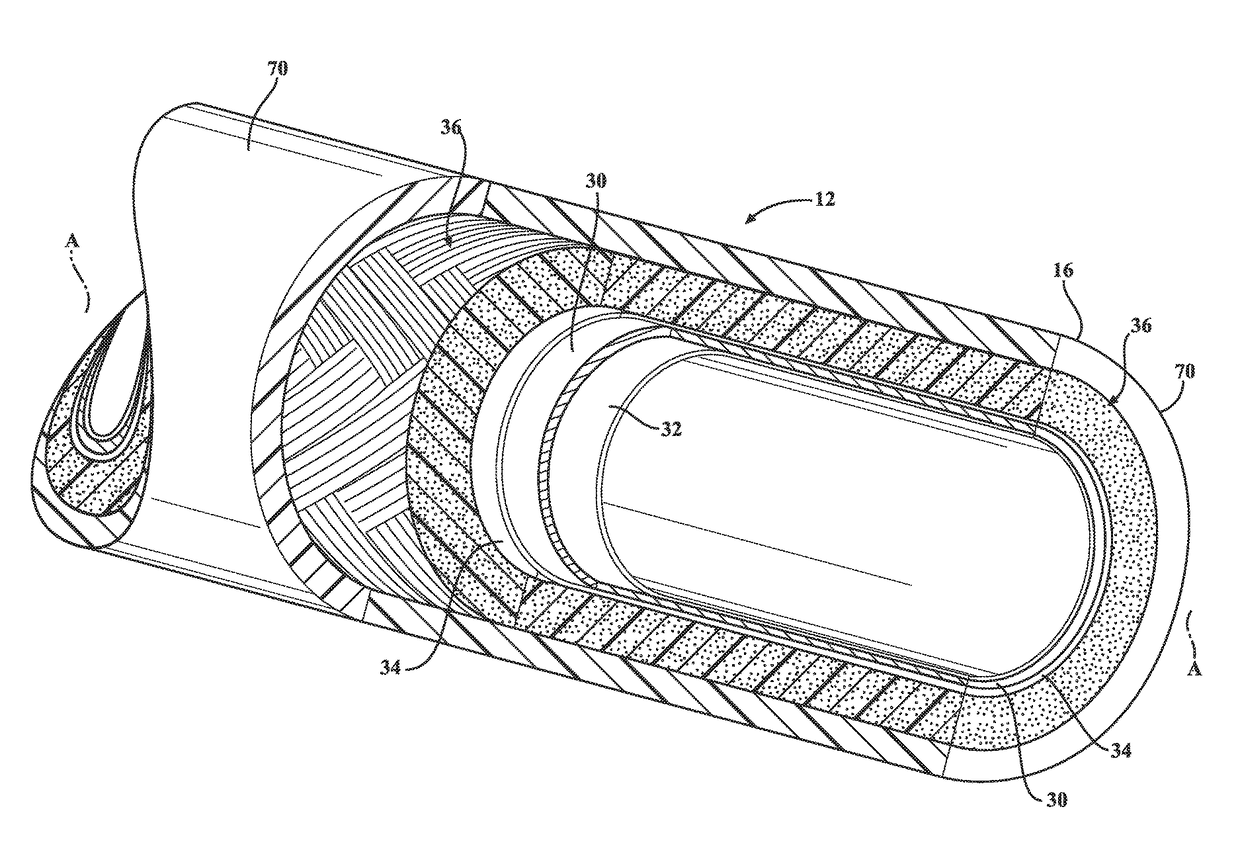

Hollow airfoil construction utilizing functionally graded materials

ActiveUS20130195671A1TurbinesElectric discharge heatingVolumetric Mass DensityFunctionally graded material

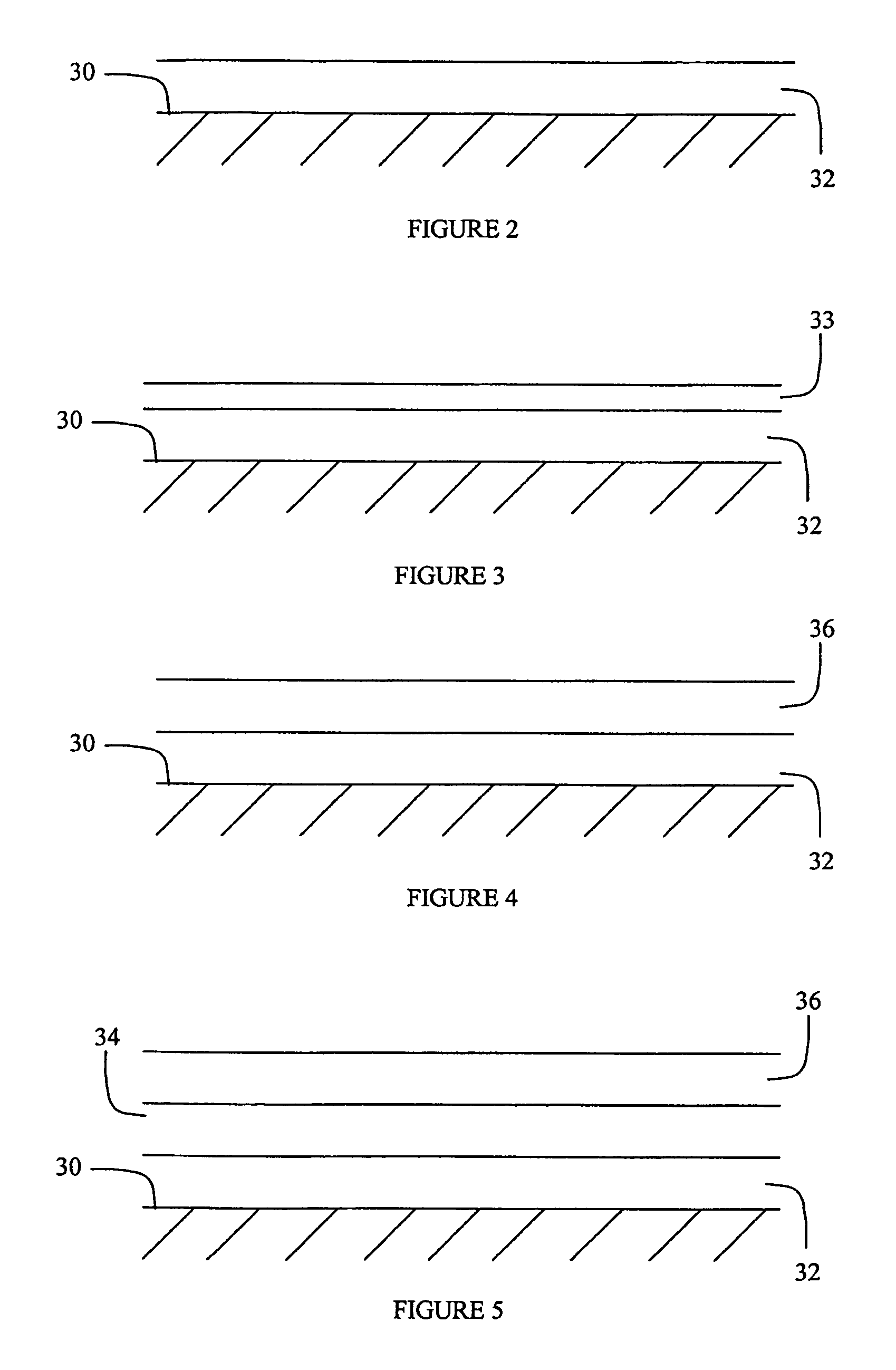

A method of forming an airfoil includes the steps of depositing material to form an airfoil in a first layer, and then depositing material in a second layer on the first layer. The first and second layers have distinct densities. An airfoil is also disclosed. The method provides powerful design advantages.

Owner:RTX CORP

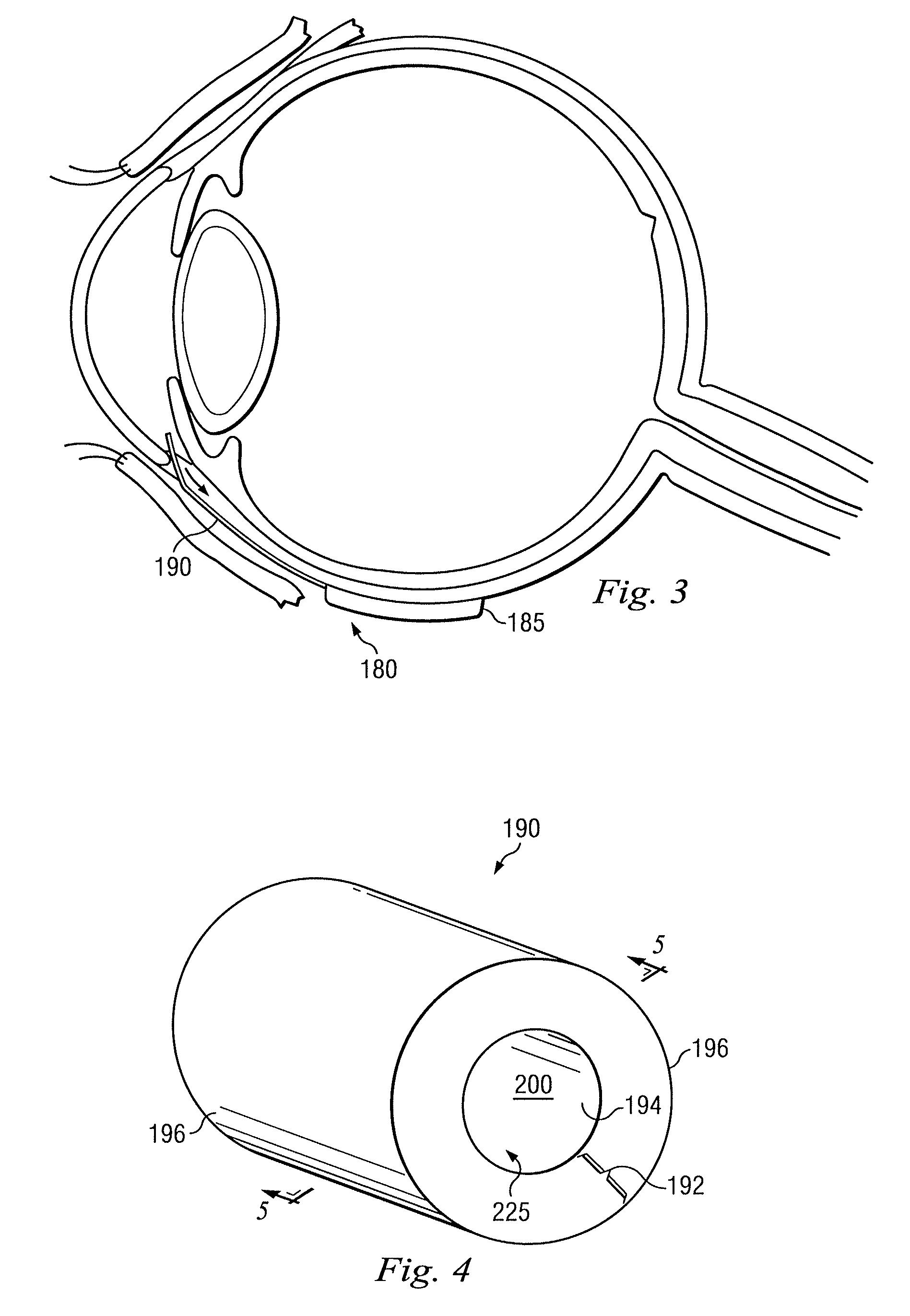

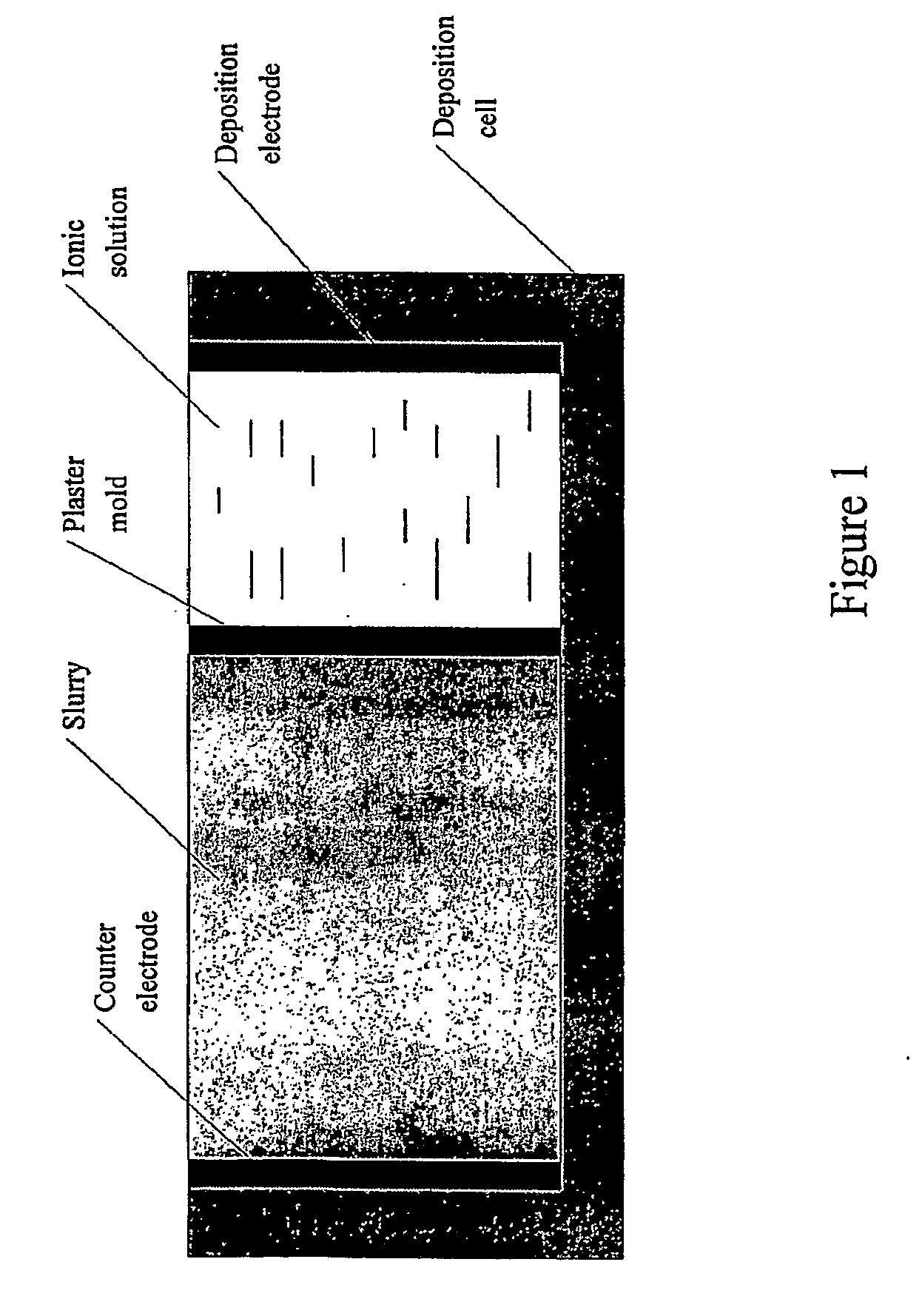

Method of making a functionally graded material

InactiveUS6375877B2Minimize impactMinimize and avoid distortionCeramic shaping apparatusClaywaresSlurryFunctionally graded material

A gelcasting method of making an internally graded article alternatively includes the steps of: preparing a slurry including a least two different phases suspended in a gelcasting solution, the phases characterized by having different settling characteristics; casting the slurry into a mold having a selected shape; allowing the slurry to stand for a sufficient period of time to permit desired gravitational fractionation in order to achieve a vertical compositional gradient in the molded slurry; gelling the slurry to form a solid gel while preserving the vertical compositional gradient in the molded slurry; drying the gel to form a dried green body; and sintering the dry green body to form a solid object, at least one property thereof varying along the vertical direction because of the compositional gradient in the molded slurry.

Owner:UT BATTELLE LLC

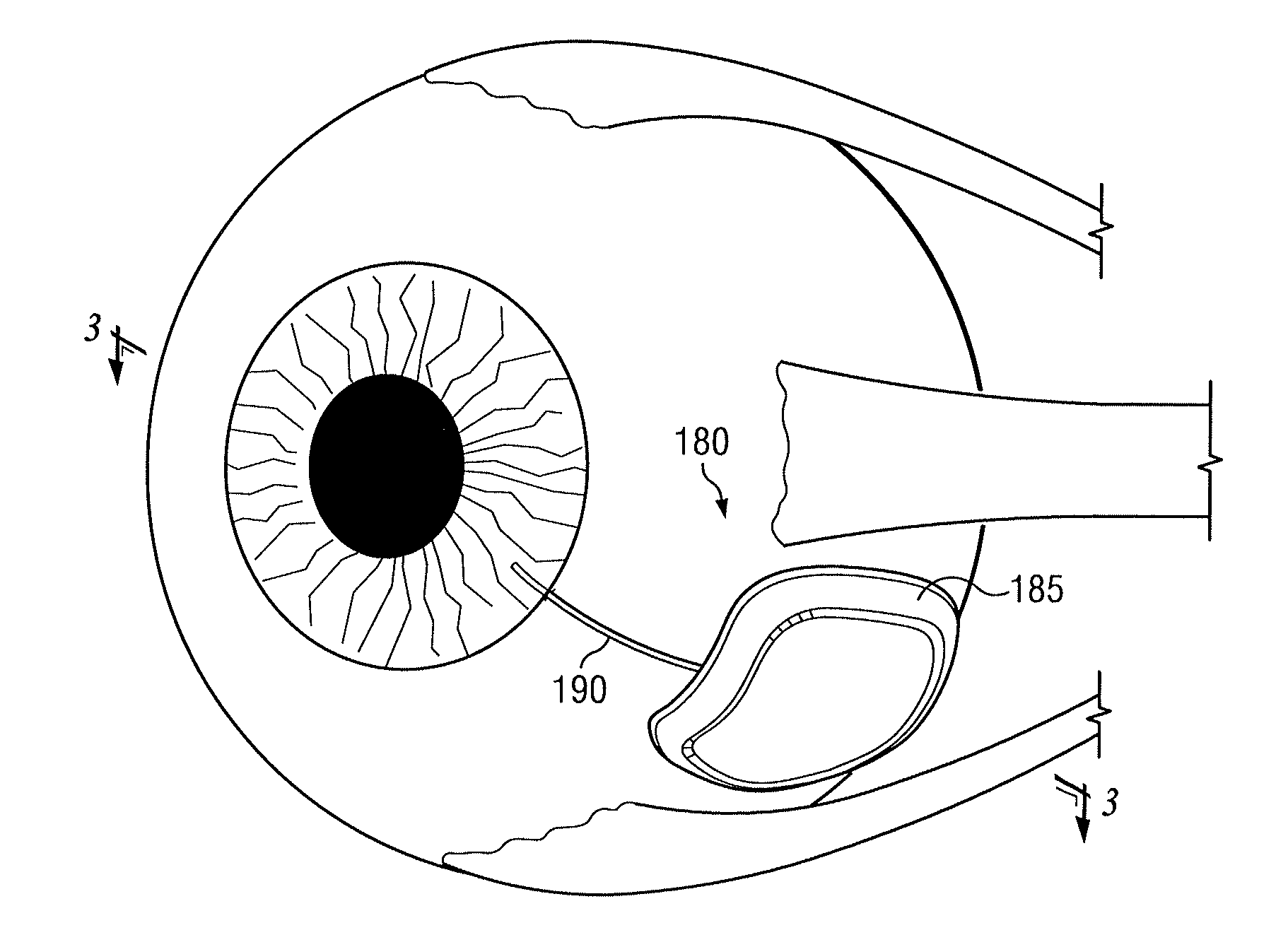

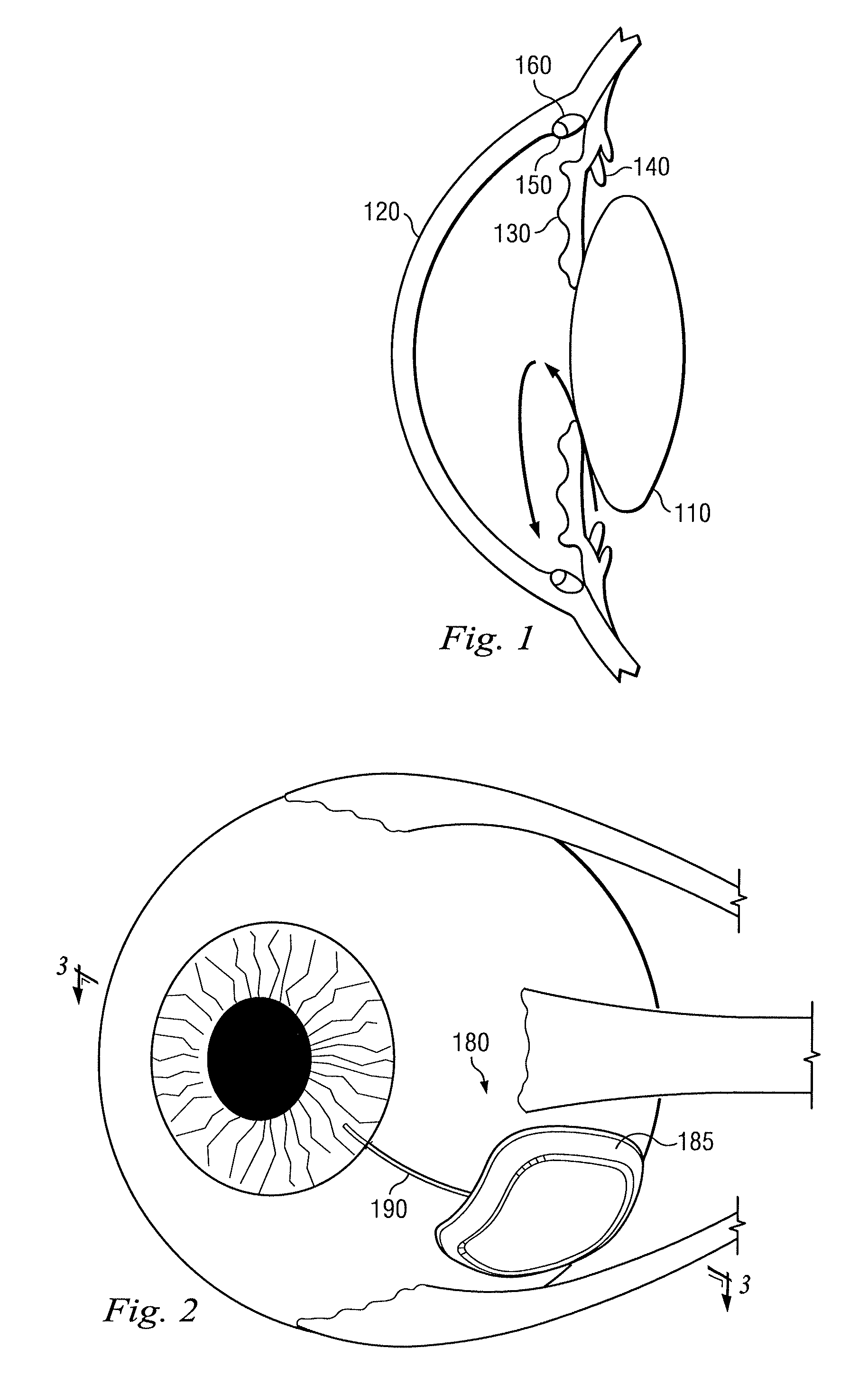

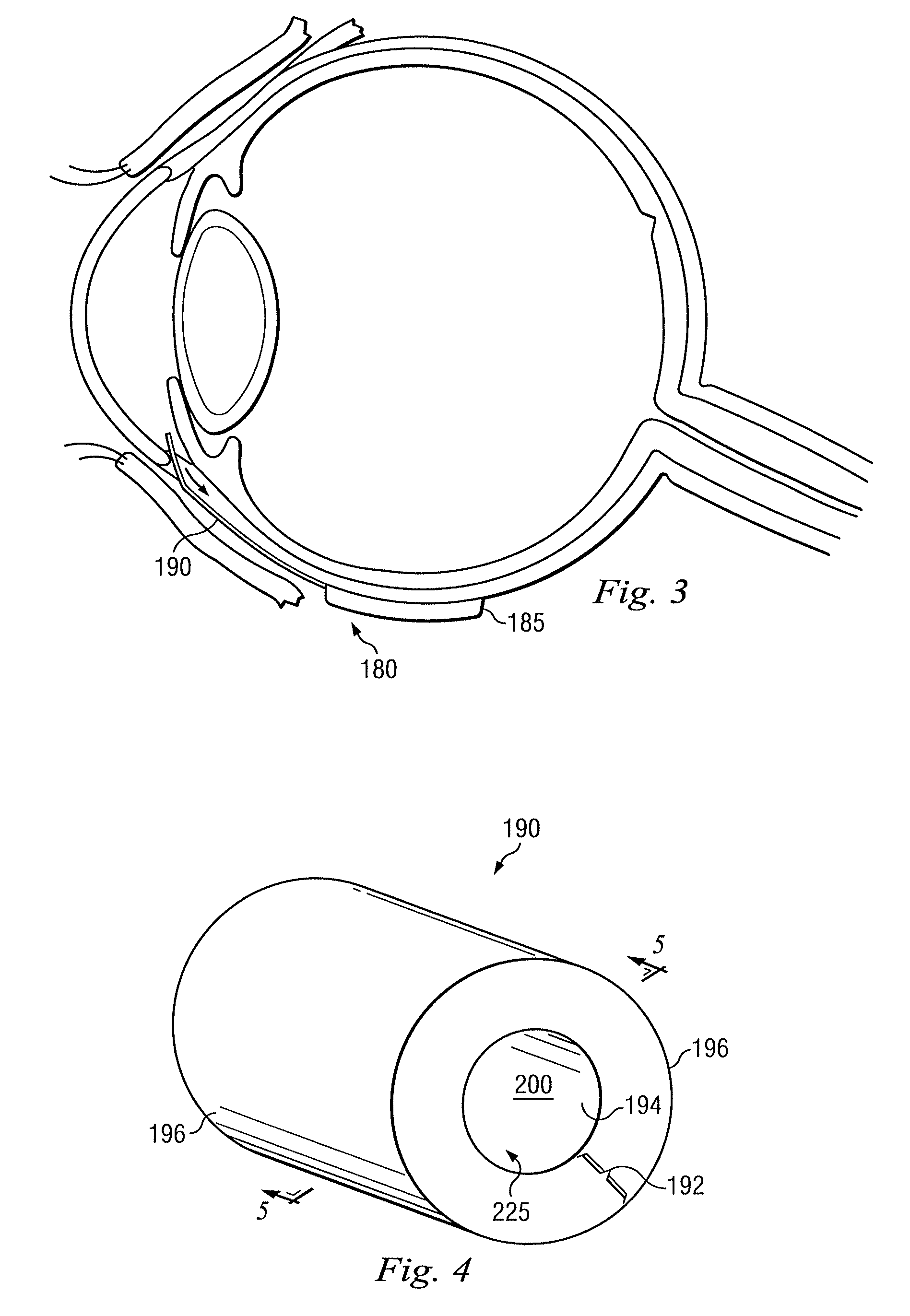

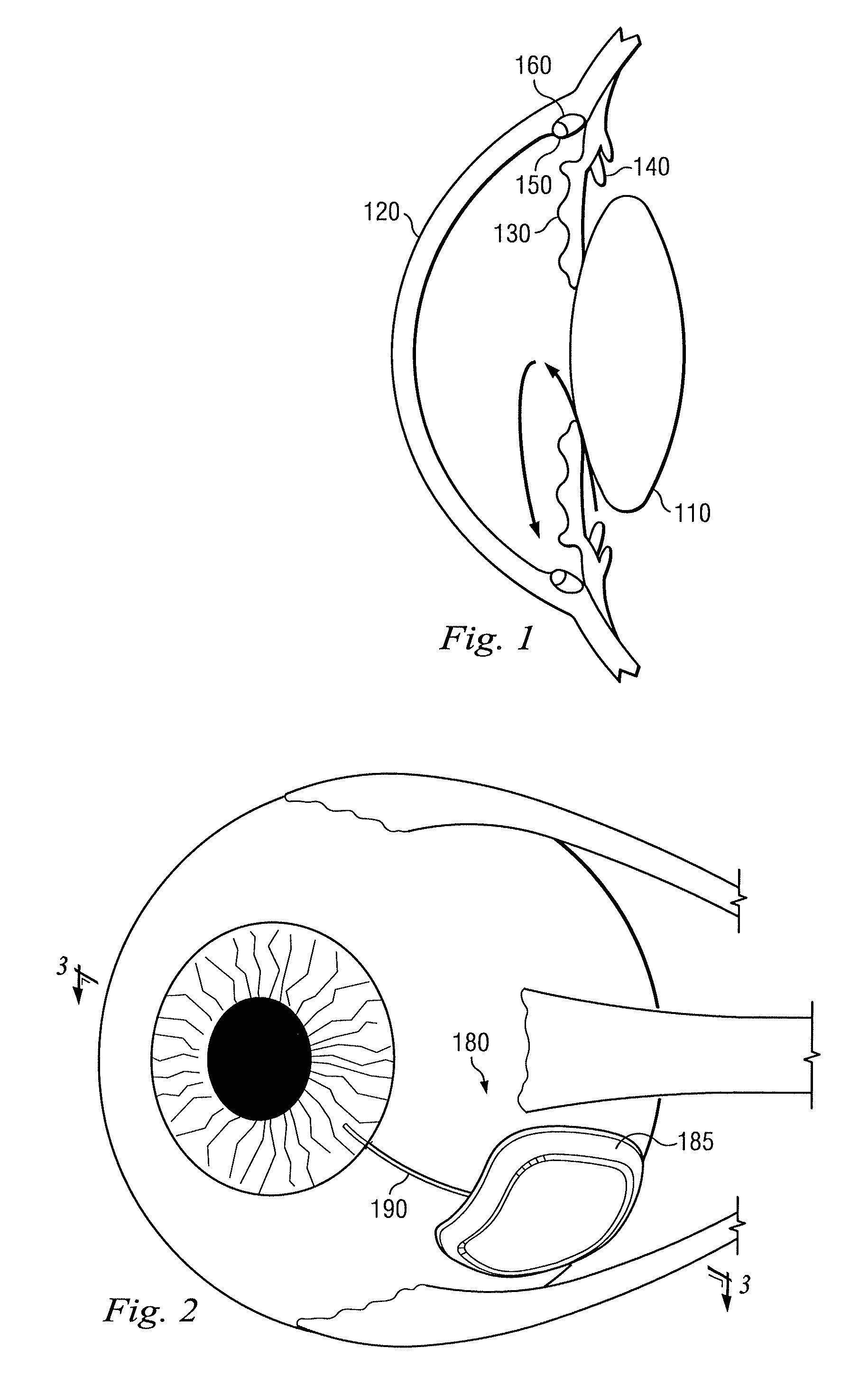

Functionally graded material tube and method for use of the same in implantation

A device for implantation a patient may include a tubular fiber wall that defines at least one opening and at least one lumen continuous with the one opening and adapted to allow the passage of fluid. The tubular fiber wall typically contains a porosity gradient that is adapted to permit passage of different size substances at different locations along the gradient. In one aspect, a second tubular fiber wall substantially encircling the tubular fiber wall.

Owner:ALCON INC

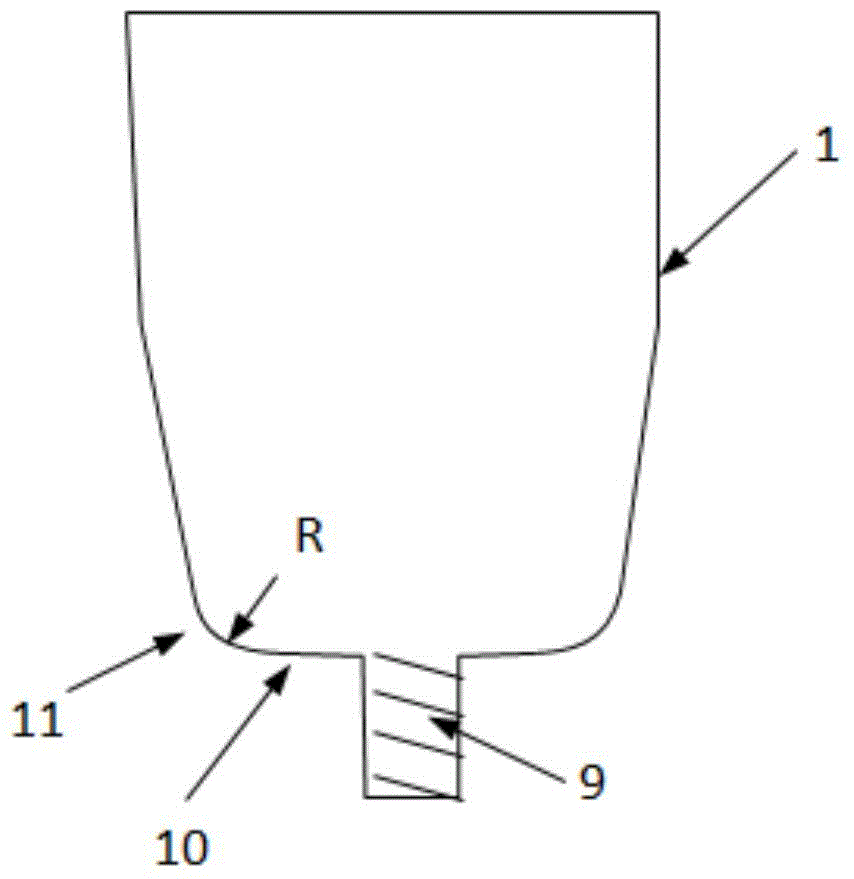

Functionally graded material shape and method for producing such a shape

InactiveCN102199033AThin material handlingMetal layered productsThermal expansionFunctionally graded material

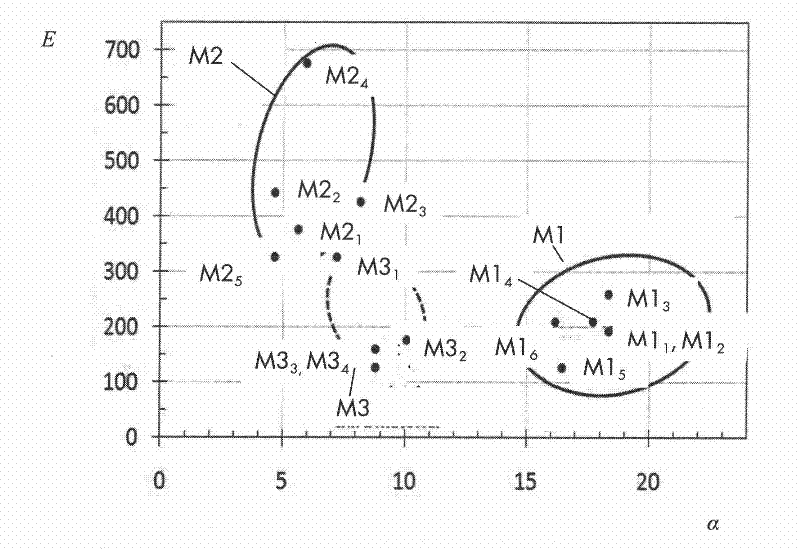

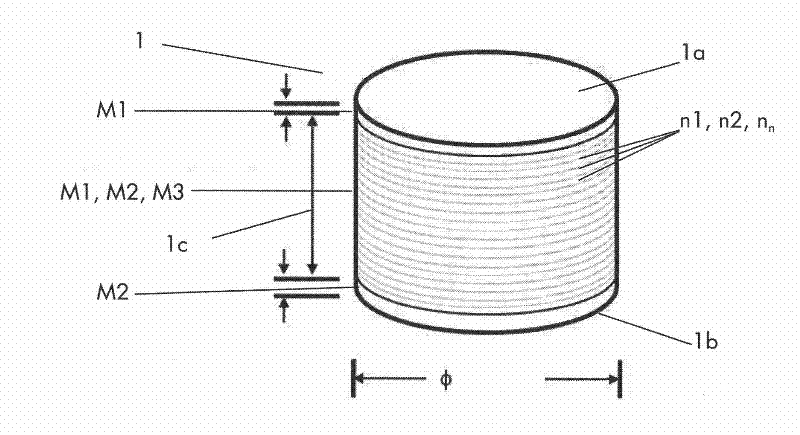

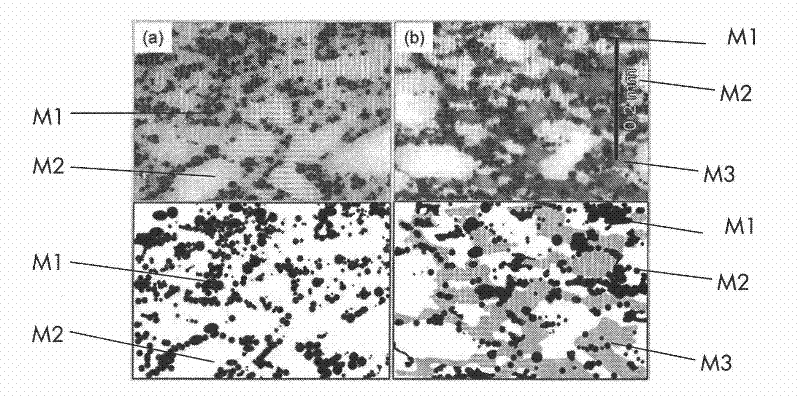

The invention relates to a functionally graded material shape (1) where a first material (M1) is fused with a second material (M2) through sintering and a method of production of said functionally graded material shape (1). Said first material (M1) has a first coefficient of thermal expansion ([alpha]1) and said second material (M2) has a second coefficient of thermal expansion ([alpha]2), differing from the first coefficient of thermal expansion ([alpha]1). The invention is characterized in that the shape (1) further comprises a third material (M3) adapted to, together with M1 and M2, create an intermediate composite material phase intermixed between the first and the second materials (M1, M2). Said third material (M3) has a coefficient of thermal expansion ([alpha]3) intermediate between the first coefficient of thermal expansion ([alpha]1) of the first material (M1) and the second coefficient of thermal expansion ([alpha]2) of the second material (M2).

Owner:DIAMORPH AB

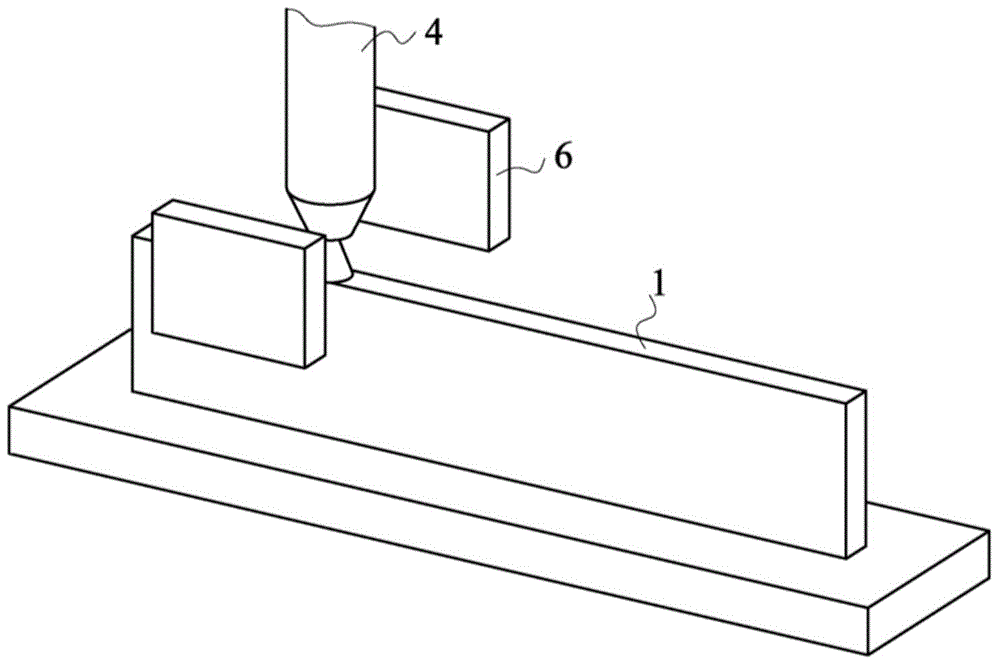

Electromagnetic flexible composite fused deposition direct preparation forming method for gradient part

ActiveCN104959601ARealize integrated manufacturingReduce pollutionAdditive manufacturing apparatusArc welding apparatusNumerical controlPhysical field

Owner:武汉昱峰科技产业发展有限公司

Low transient thermal stress turbine engine components

Owner:RTX CORP

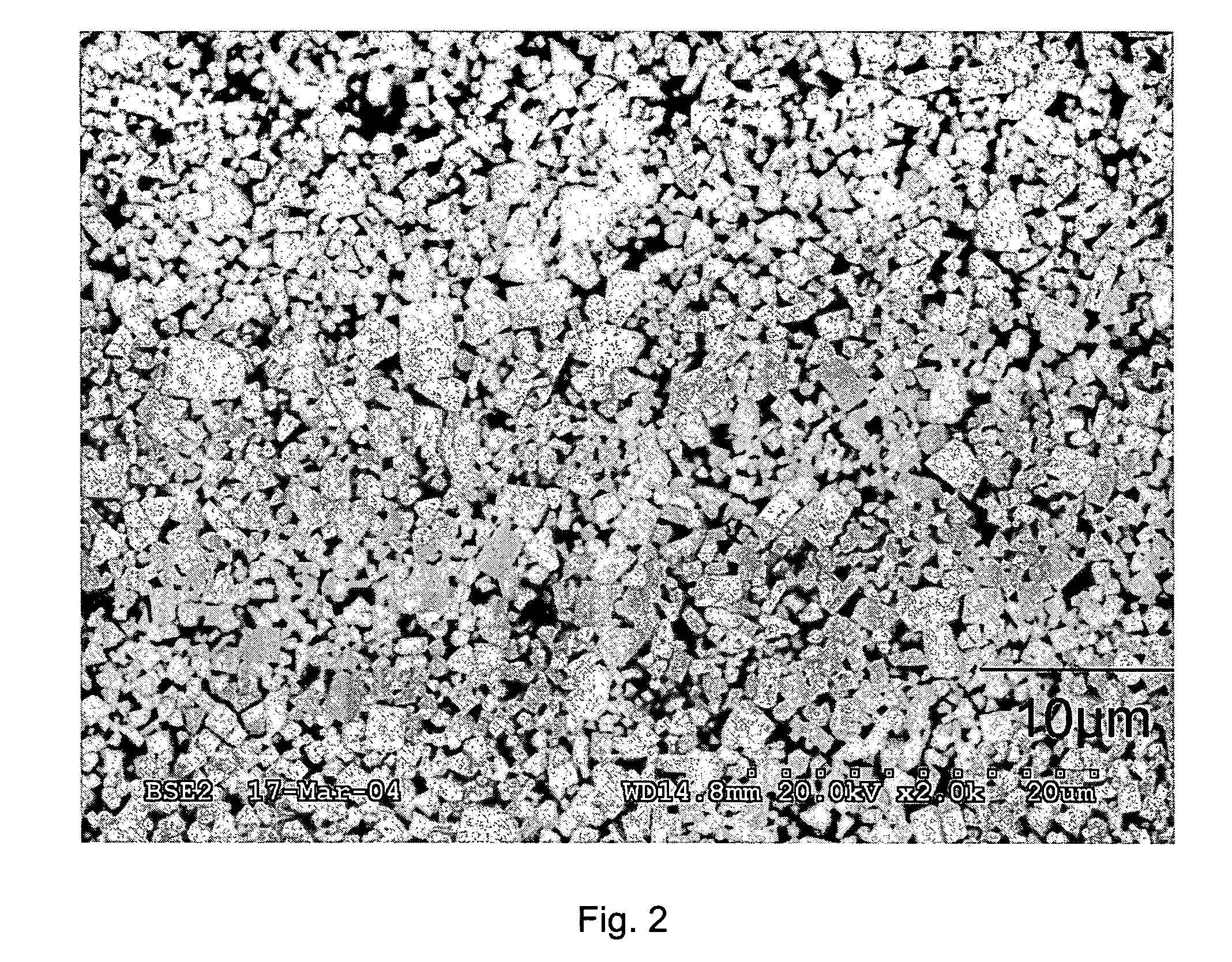

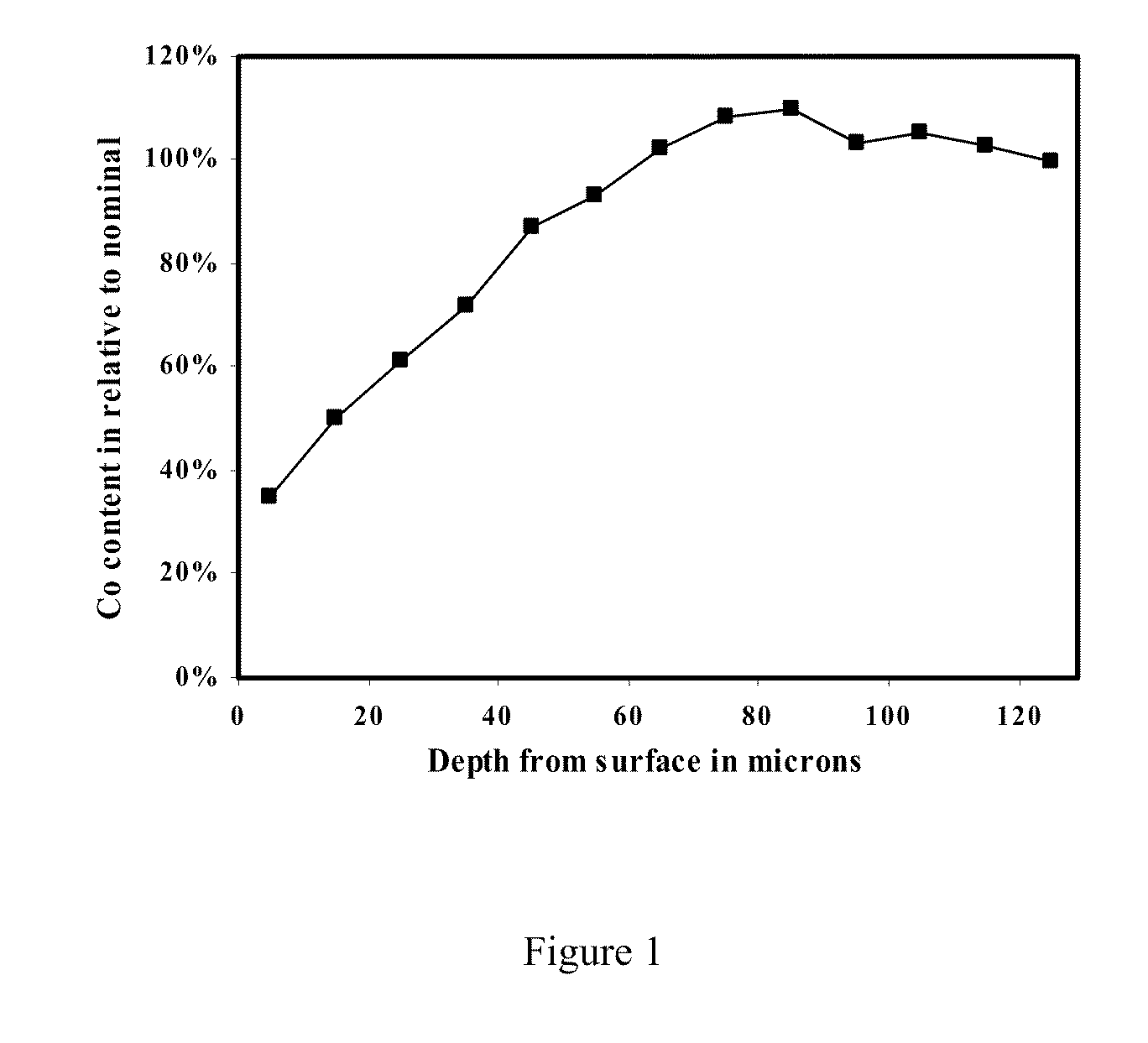

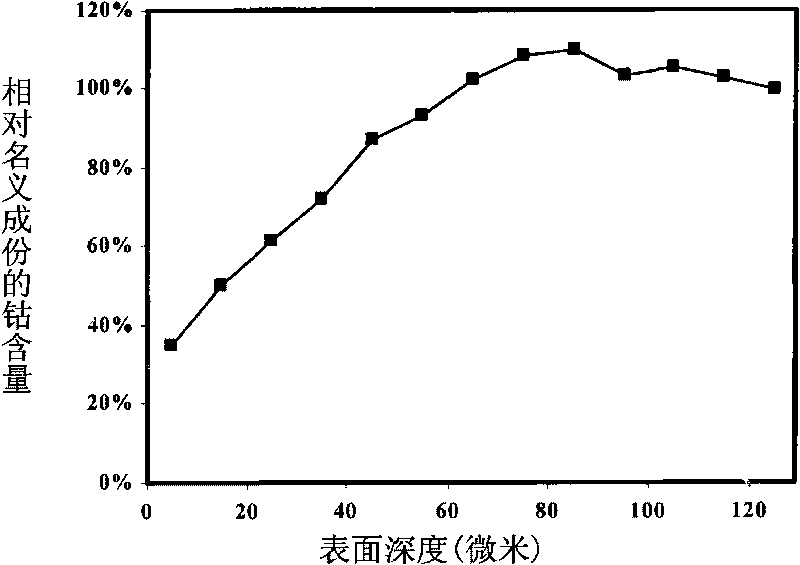

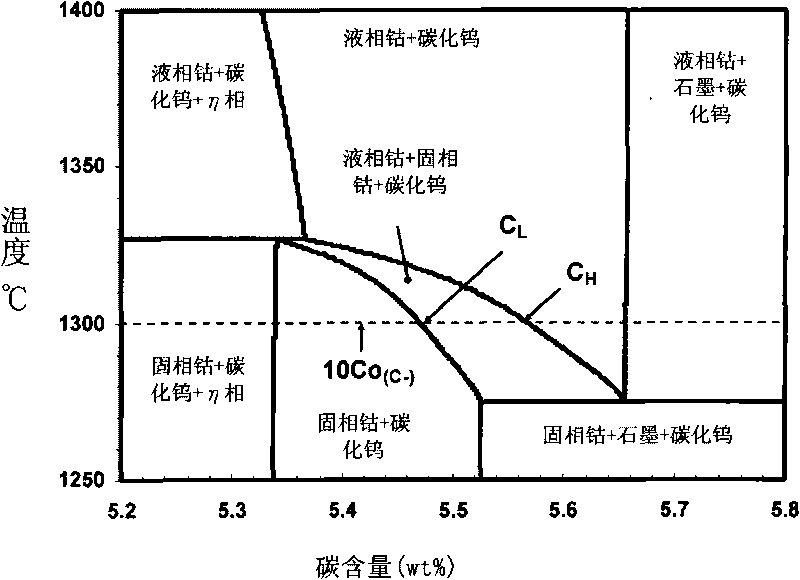

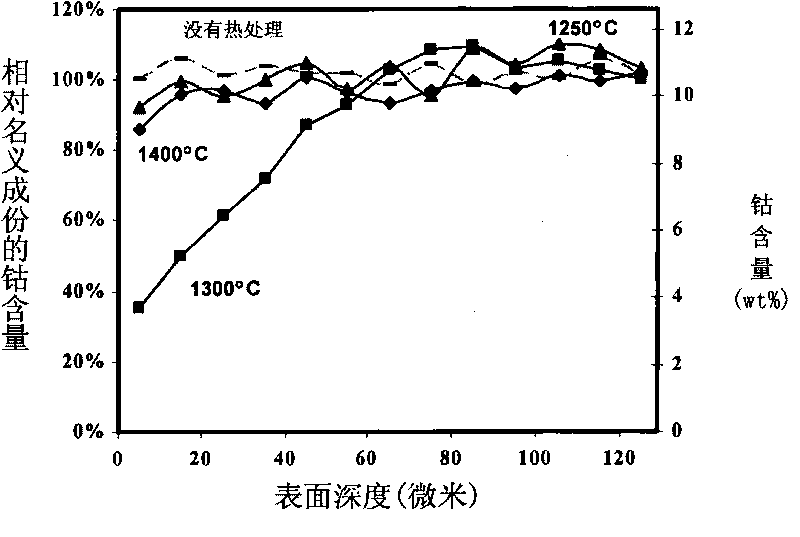

Method for making functionally graded cemented tungsten carbide with engineered hard surface

A method for manufacturing functionally graded cemented tungsten carbide with hard and wear-resistant surface and tough core is described. The said functionally graded cemented tungsten carbide (WC—Co) has a surface layer having a reduced amount of cobalt. Such a hard surface and tough core structure is an example of functionally graded materials in which mechanical properties are optimized by the unique combination of wear-resistance and toughness. WC—Co with reduced-cobalt surface layer may be fabricated through a carburization heat treatment process following conventional liquid phase sintering. The graded WC—Co thus obtained contains no brittle η phase.

Owner:UNIV OF UTAH RES FOUND

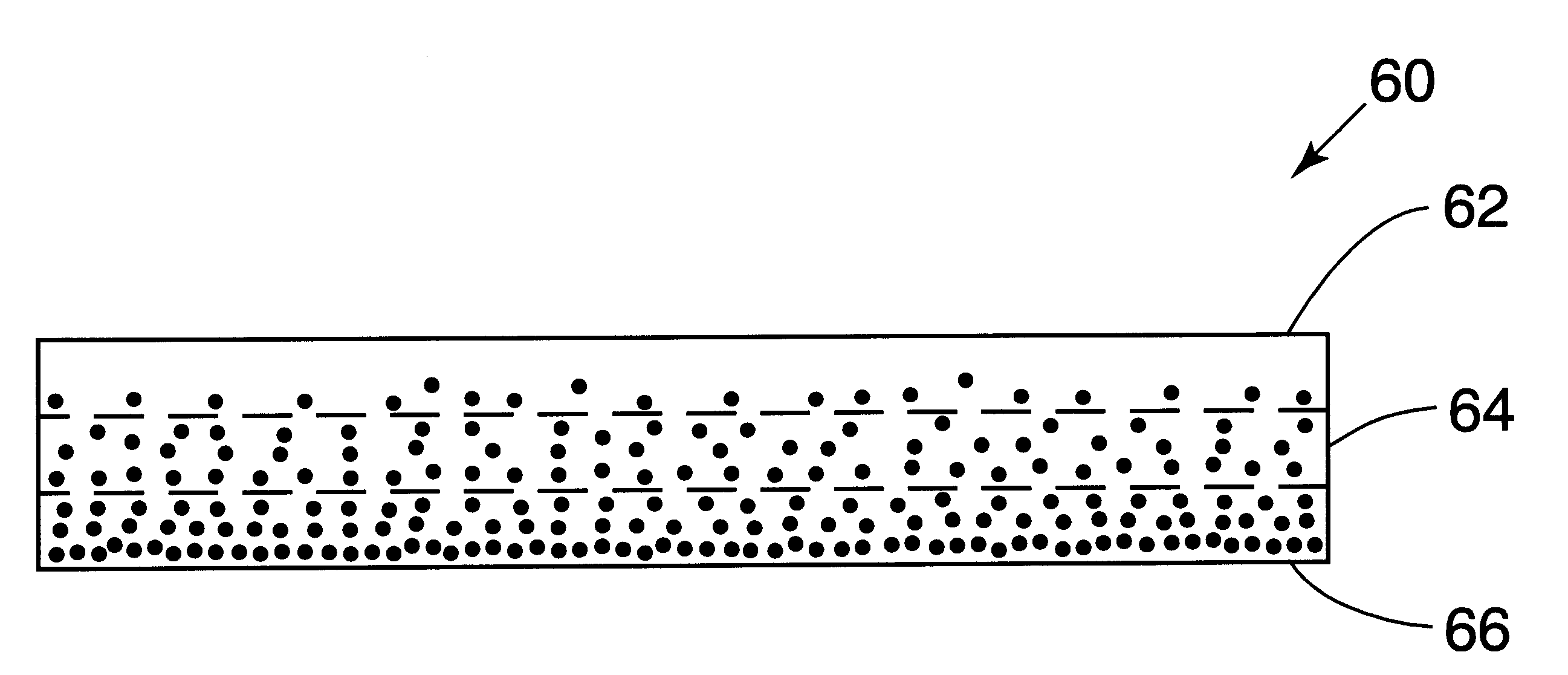

Method and system for creating functionally graded materials using cold spray

A method and system for depositing multiple materials onto a substrate is described. The method broadly comprises the steps of providing a source of a first powder material to be deposited, providing a source of a second powder material to be deposited, and sequentially depositing the first powder material and the second powder material onto the substrate at a velocity sufficient to deposit the materials by plastically deforming the materials without metallurgically transforming the particles of powder forming the materials.

Owner:RAYTHEON TECH CORP

Functionally graded cemented tungsten carbide with engineered hard surface and the method for making the same

ActiveUS20100101368A1High hardnessSolid state diffusion coatingWear resistantFunctionally graded material

A method for manufacturing functionally graded cemented tungsten carbide with hard and wear-resistant surface and tough core is described. The said functionally graded cemented tungsten carbide (WC—Co) has a surface layer having a reduced amount of cobalt. Such a hard surface and tough core structure is an example of functionally graded materials in which mechanical properties are optimized by the unique combination of wear-resistance and toughness. WC—Co with reduced-cobalt surface layer may be fabricated through a carburization heat treatment process following conventional liquid phase sintering. The graded WC—Co thus obtained contains no brittle η phase.

Owner:UNIV OF UTAH RES FOUND

Functionally graded material tube and method for use of the same in implantation

A device for implantation a patient may include a tubular fiber wall that defines at least one opening and at least one lumen continuous with the one opening and adapted to allow the passage of fluid. The tubular fiber wall typically contains a porosity gradient that is adapted to permit passage of different size substances at different locations along the gradient. In one aspect, a second tubular fiber wall substantially encircling the tubular fiber wall.

Owner:ALCON INC

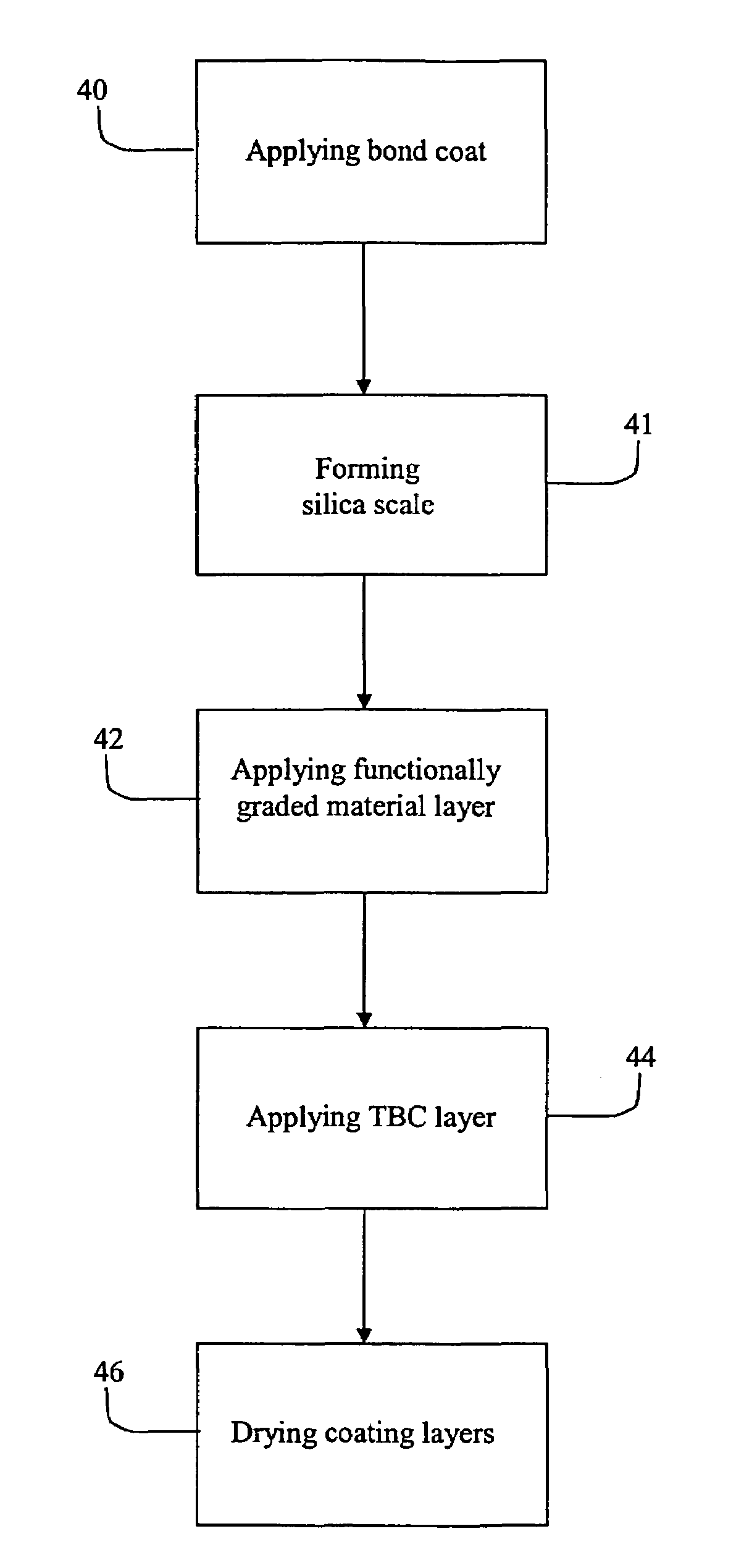

Bond coating and thermal barrier compositions, processes for applying both, and their coated articles

A coated article includes an article having at least one surface and composed of a molybdenum based refractory metal alloy base substrate, a niobium based refractory metal alloy base substrate or a silicon base substrate. A bond coat layer is disposed upon the surface. The bond coat layer includes a molybdenum disilicide base compound and at least one of the following: silicon nitride, silicon carbide or tantalum oxide. A process for coating the article includes the steps of applying upon the article's surface the aforementioned bond coat layer. A functionally graded material layer is applied upon the bond coat layer. The functionally graded material layer comprising molybdenum disilicide, mullite and at least one of the following: silicon nitride, silicon carbide or tantalum oxide. A thermal barrier coating layer is then applied upon the functionally graded material layer.

Owner:RTX CORP

Method of making a functionally graded material

A gelcasting method of making an internally graded article alternatively includes the steps of: preparing a slurry including a least two different phases suspended in a gelcasting solution, the phases characterized by having different settling characteristics; casting the slurry into a mold having a selected shape; allowing the slurry to stand for a sufficient period of time to permit desired gravitational fractionation in order to achieve a vertical compositional gradient in the molded slurry; gelling the slurry to form a solid gel while preserving the vertical compositional gradient in the molded slurry; drying the gel to form a dried green body; and sintering the dry green body to form a solid object, at least one property thereof varying along the vertical direction because of the compositional gradient in the molded slurry.

Owner:UT BATTELLE LLC

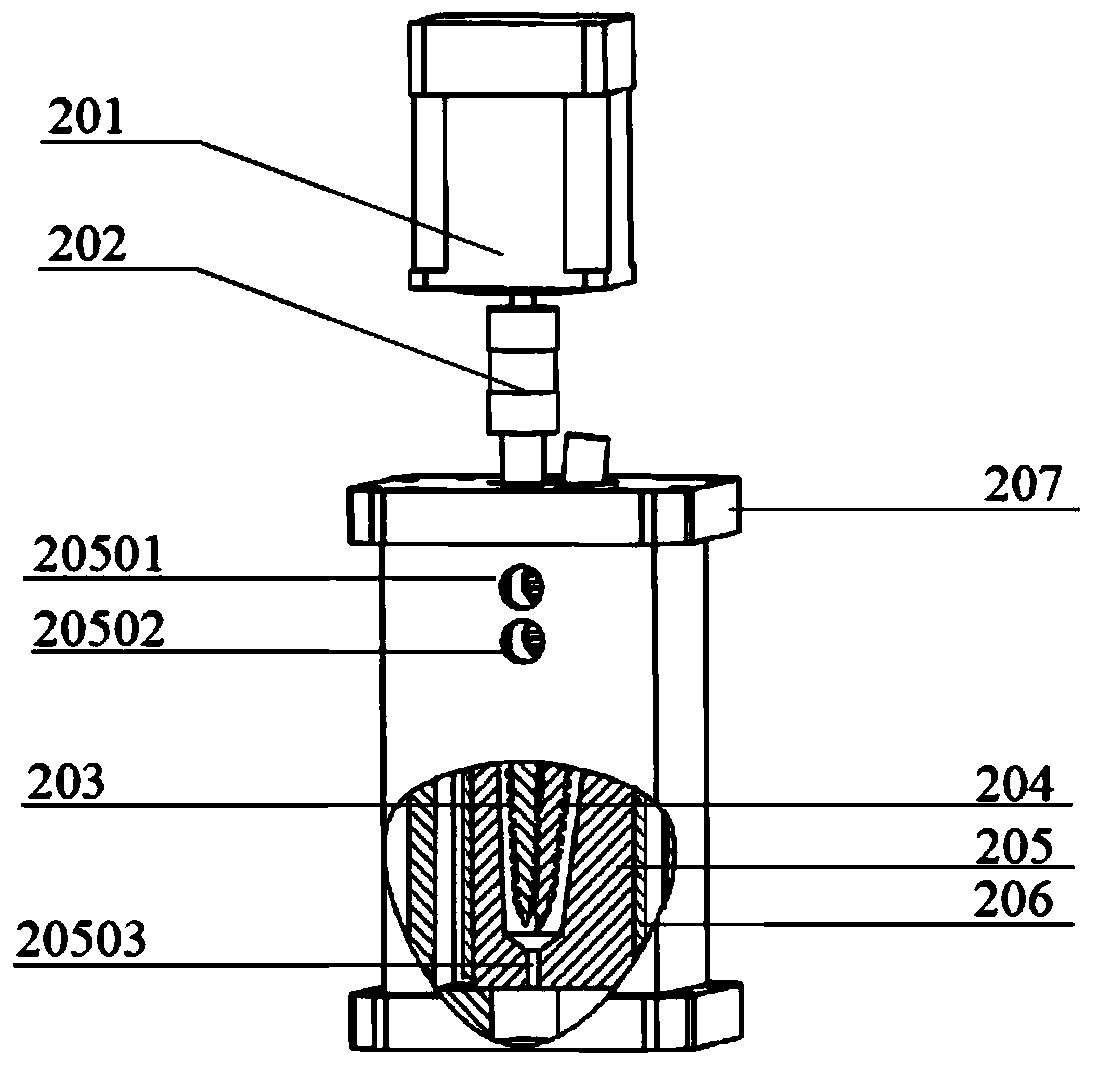

3D printer for integral manufacturing of functionally graded material and forming structure, and working method thereof

PendingCN109732905APrecise Controlled ExtrusionContinuous and stable printingAdditive manufacturing apparatus3D object support structuresImage resolutionEngineering

The invention provides a 3D printer for integral manufacturing of a functionally graded material and a forming structure, and a working method thereof. A feeding module, a mixing module and a printingsprayer are split; and through ingenious arrangement of the components, integral manufacturing of the continuous functionally graded material and the complex three-dimension structure can be achieved. The 3D printer has the characteristics and outstanding advantages of active, efficient and uniform mixing of various materials, high print resolution (due to micro-nano microscale characteristic structure printing), diverse applicable materials, high production efficiency, low cost and simple structure; and particularly, the 3D printer can achieve integral manufacturing of the continuous functionally graded material and the complex three-dimension structure based on material composition and microstructures.

Owner:QINGDAO 5D INTELLIGENT ADDITIVE MFG TECH CO LTD

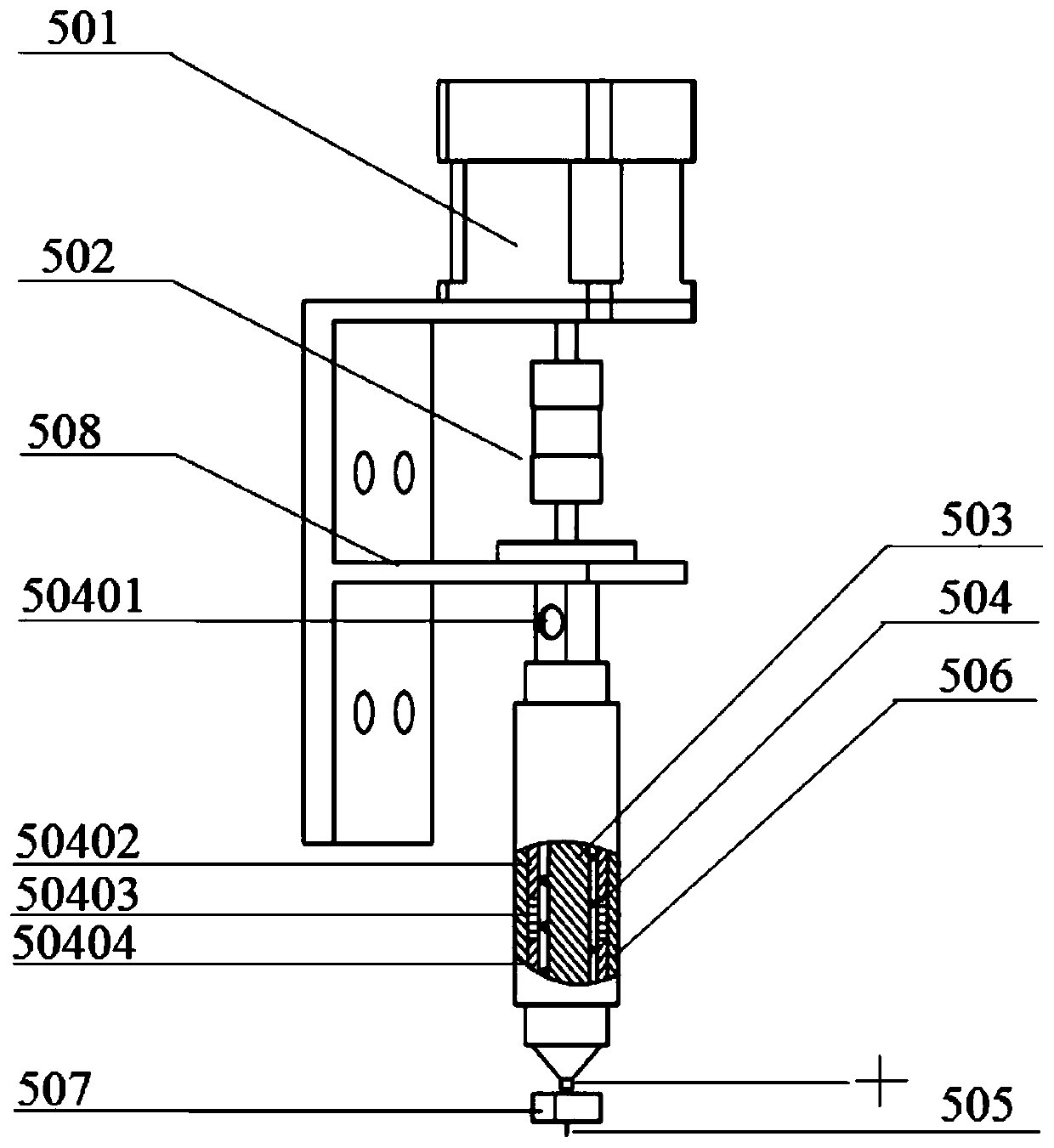

Incremental sheet metal stirring composite forming device and method

The invention relates to an incremental sheet metal stirring composite forming device and method. The forming device comprises an incremental stirring forming tool head, a reverse roof pressure head, a spindle motor, a main drive unit, an auxiliary drive unit and a sheet metal fixture. The forming method includes: generating an incremental forming track according to a three-dimensional model of a machining part to be machined to serve as a synchronous movement track of the main drive unit and the auxiliary drive unit; controlling the spindle motor to rotate, allowing the incremental stirring forming tool head to be driven to rotate by the spindle motor to be inserted in the interior of a sheet metal to be machined, and the reverse roof pressure head and the incremental stirring forming tool head pressing the sheet metal; respectively controlling the incremental stirring forming tool head and the reverse roof pressure head to move synchronously according to the synchronous movement track to complete incremental sheet metal stirring composite forming. Compared with the prior art, the incremental sheet metal stirring composite forming device and method has the advantages that functionally graded materials can be integrated in welding and forming, the manufacturing process is shortened, the number of tools is reduced, and the problem that traditional functionally graded materials are poor in extension and cannot be formed can be avoided as well.

Owner:SHANGHAI JIAO TONG UNIV

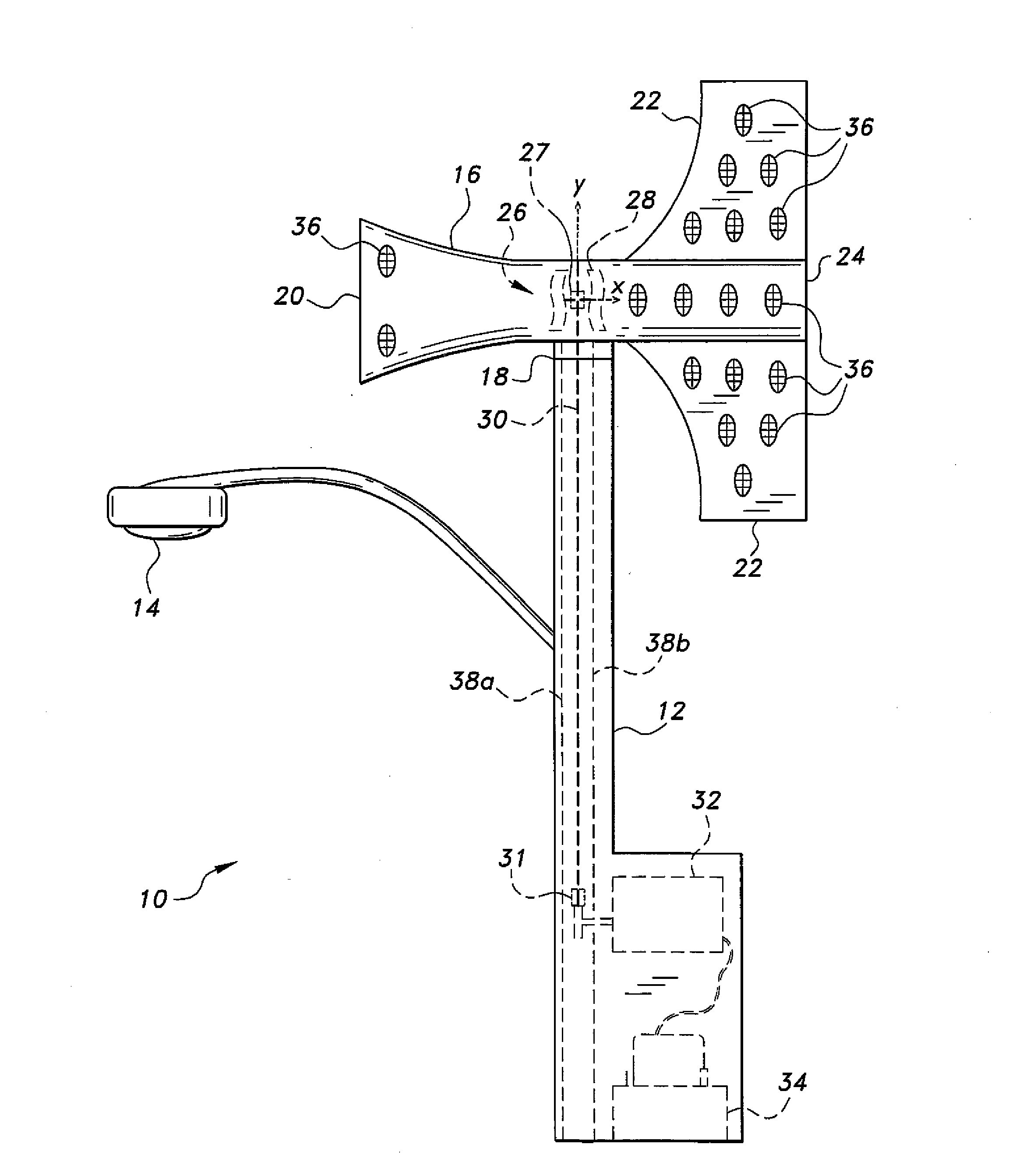

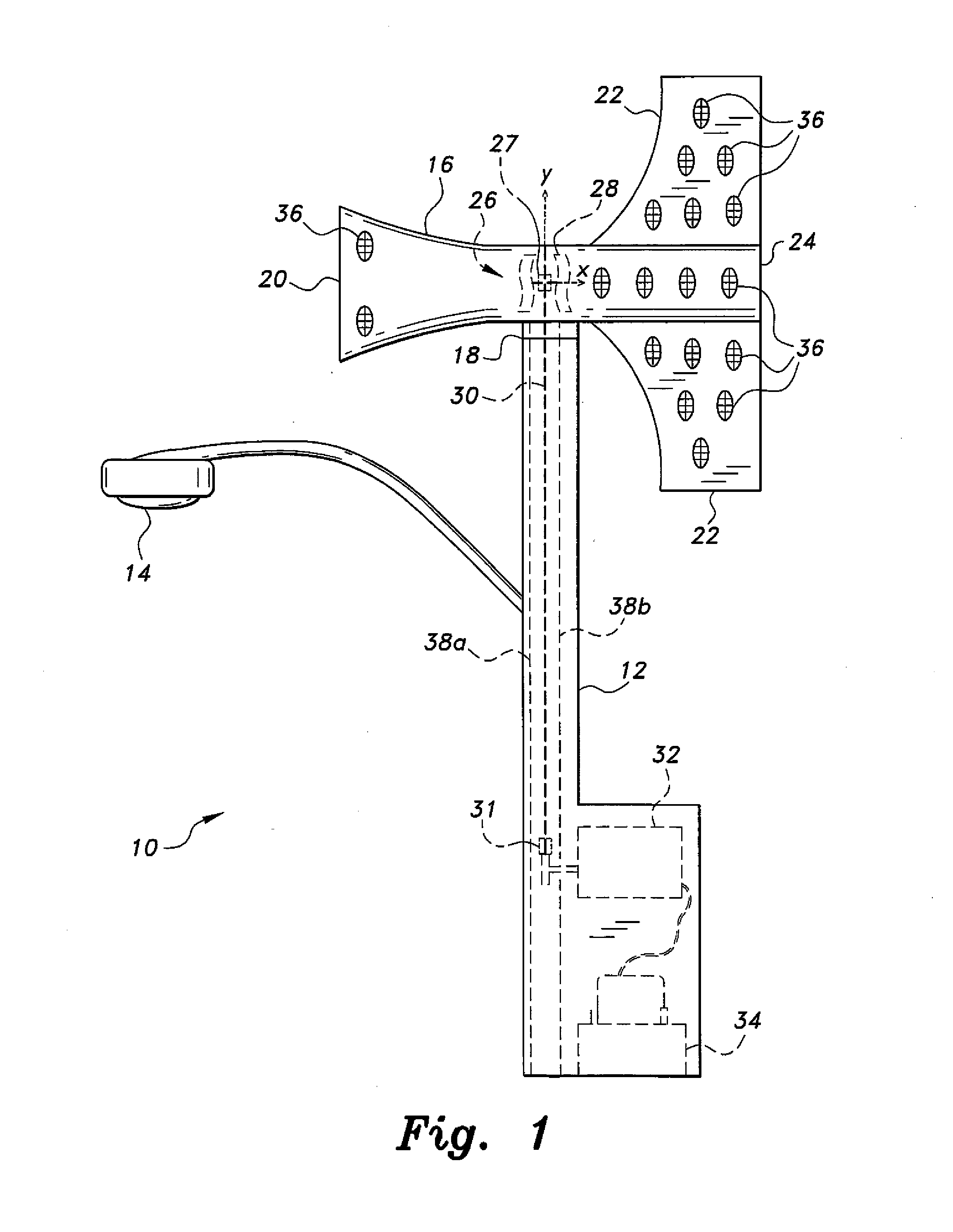

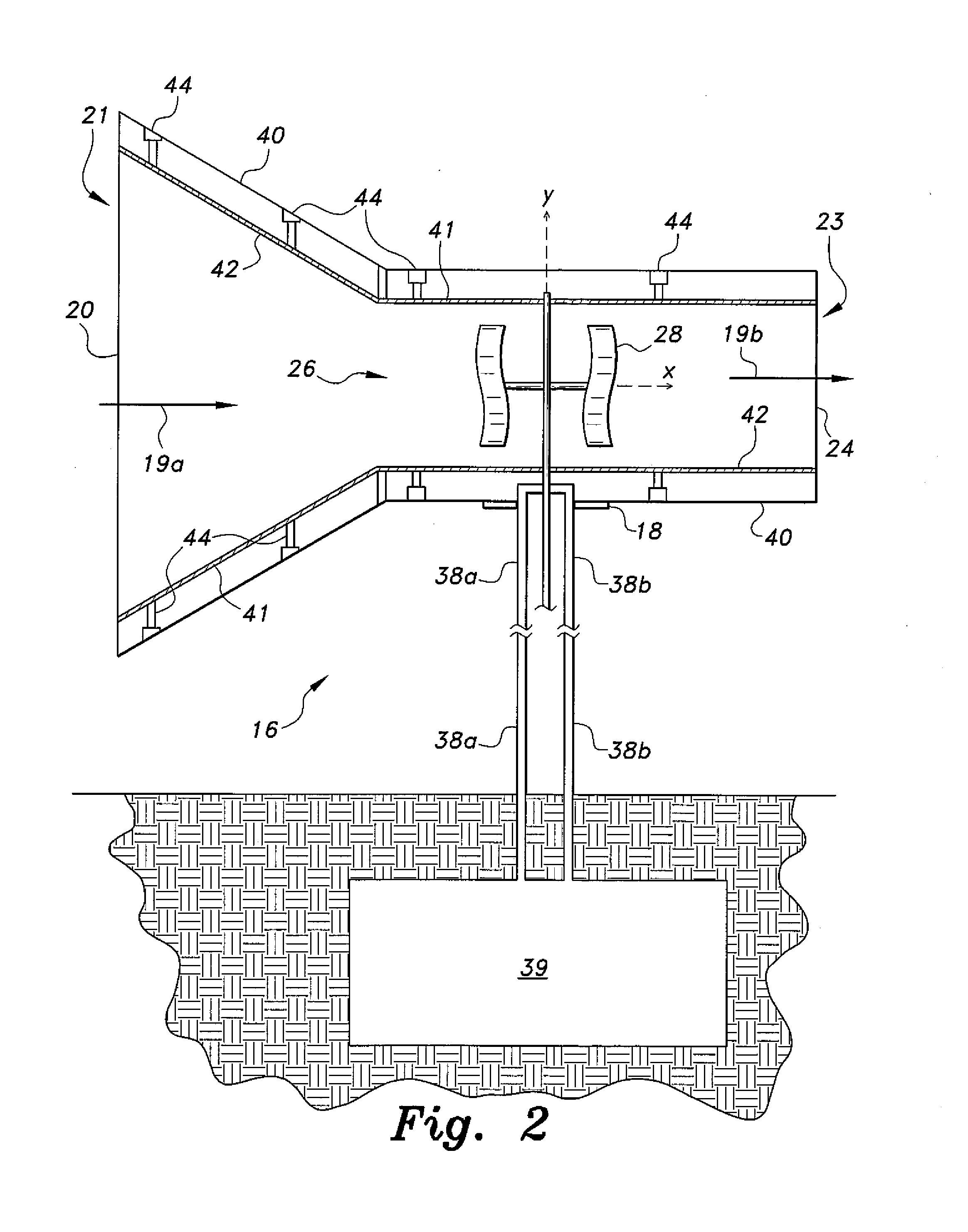

Electrical power generation system using renewable energy

InactiveUS20150167636A1Increase in air velocityReduce and substantially preclude chanceWind motor with solar radiationDc network circuit arrangementsVertical axis wind turbinePrevailing winds

The electrical power generation system using renewable energy is particularly adapted to provide electrical power to an independent or remotely situated electrical device such as a street light, emergency call box, or illuminated road sign. The system includes a pivotally mounted venturi with vanes assuring that the venturi is oriented into the prevailing wind. A vertical axis wind turbine is installed in the venturi throat, and drives a shaft extending through the column upon which the venturi is installed to a generator at the base of the column. The venturi and vanes may include photovoltaic cells thereon for further electrical power. The venturi may be heated from a geothermal source, and may include a variable diameter internal wall to adjust the cross-sectional area of the throat of the venturi. The use of functionally graded materials and other phase change materials may also improve the performance of the device.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Method for forming functionally graded material on basis of selection laser melted powder metallurgy

ActiveCN106623924AQuick and precise preparationPrecise thickness controlAdditive manufacturing apparatusIncreasing energy efficiencyFunctionally graded materialLaser

The invention provides a method for forming a functionally graded material on basis of selection laser melted powder metallurgy. The forming method comprises the steps that an SLM technology and a powder sintering technology are combined, SLM forming is conducted firstly, a material with different components are laid on different cross sections of parts, the contour of the material and the partial structure inside the part are formed through laser melting, after the contour of the whole part is formed, the part is subjected to high-temperature sintering, and unmelted powder inside the contour of the part is sintered. According to the method, the thickness of the functionally graded material can be accurately controlled, and an FGM material with the excellent quality is prepared; meanwhile, parts with any complex shapes can be manufactured rapidly and accurately, the manufacturing procedures are greatly simplified, the processing cycle is shortened, and the production cost is lowered.

Owner:山西阳宸中北科技有限公司

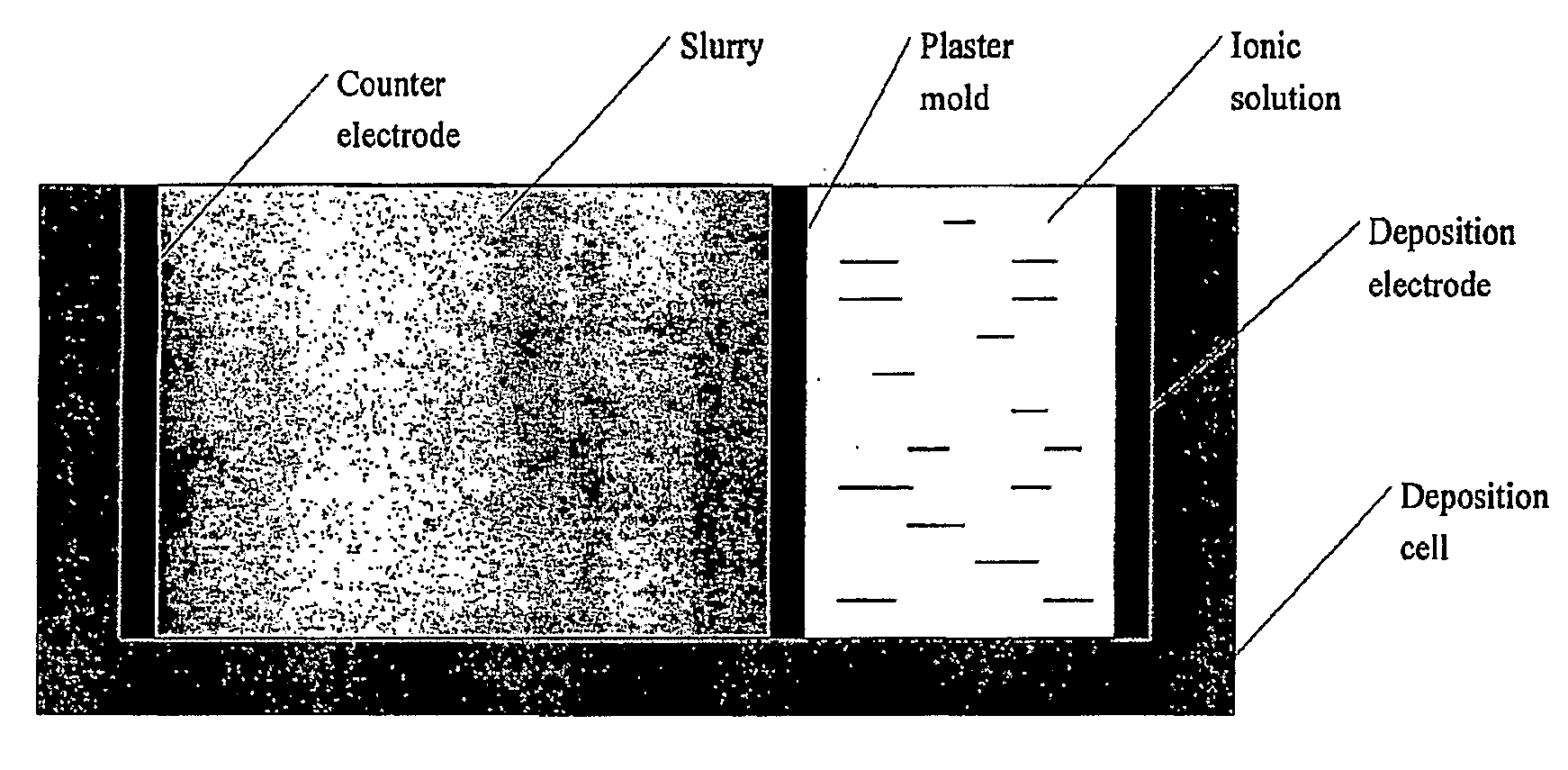

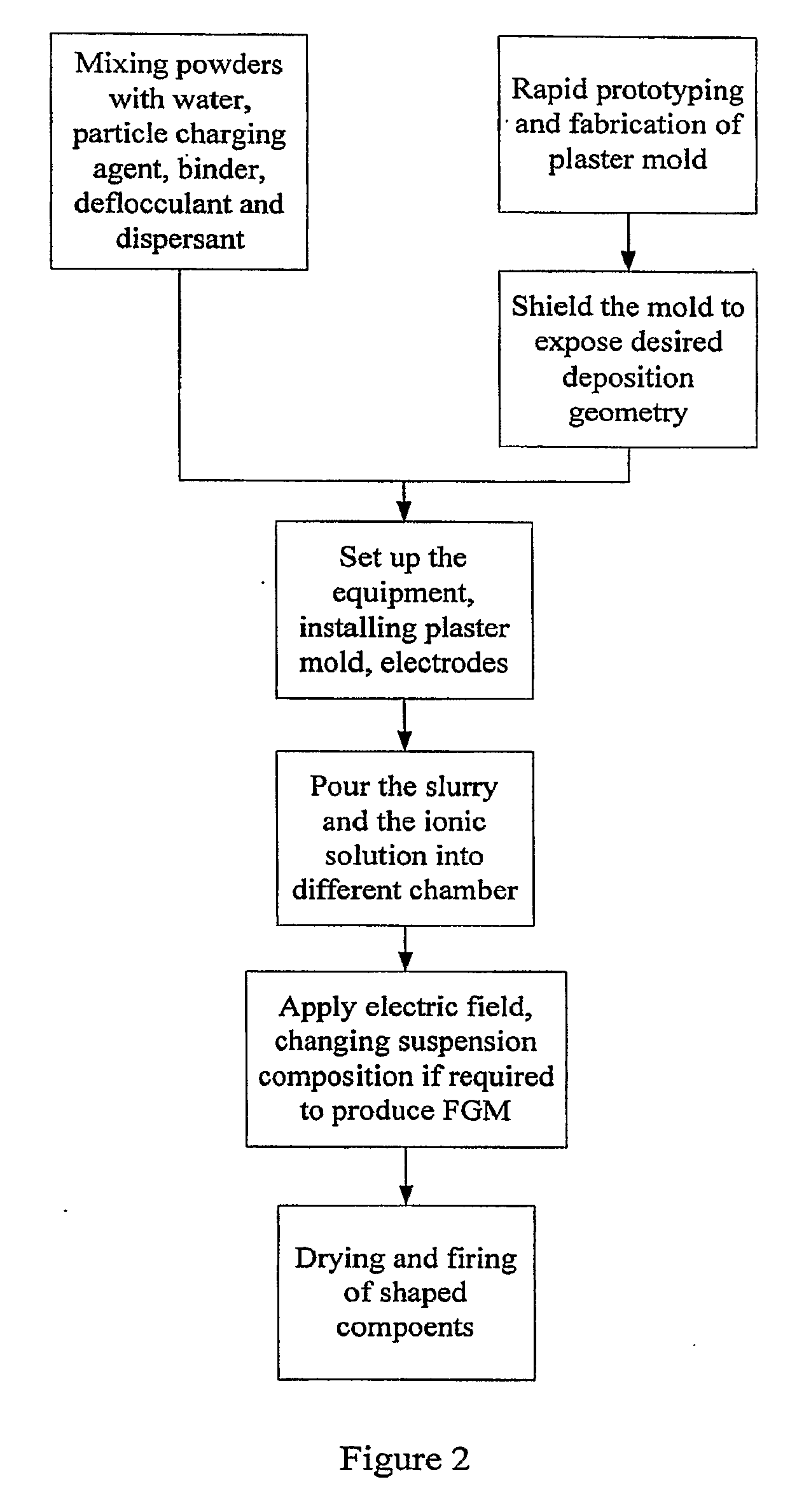

Hybrid slip casting-electrophoretic deposition (EPD) process

ActiveUS20090288952A1Well formedEliminate depositsElectrolysis componentsVolume/mass flow measurementEngineeringFunctionally graded material

The invention provides novel a hybrid slip casting-Electrophoretic Deposition (EPD) process which can be used to produce arbitrary shape geometries with controlled materials properties. The invention provides processes for the fabrication of Functionally Graded Materials (FGM) by a controlled Electrophoretic Deposition (EPD).

Owner:SAN DIEGO STATE UNIV RES FOUND

Functionally graded cemented tungsten carbide

Owner:UNIV OF UTAH RES FOUND

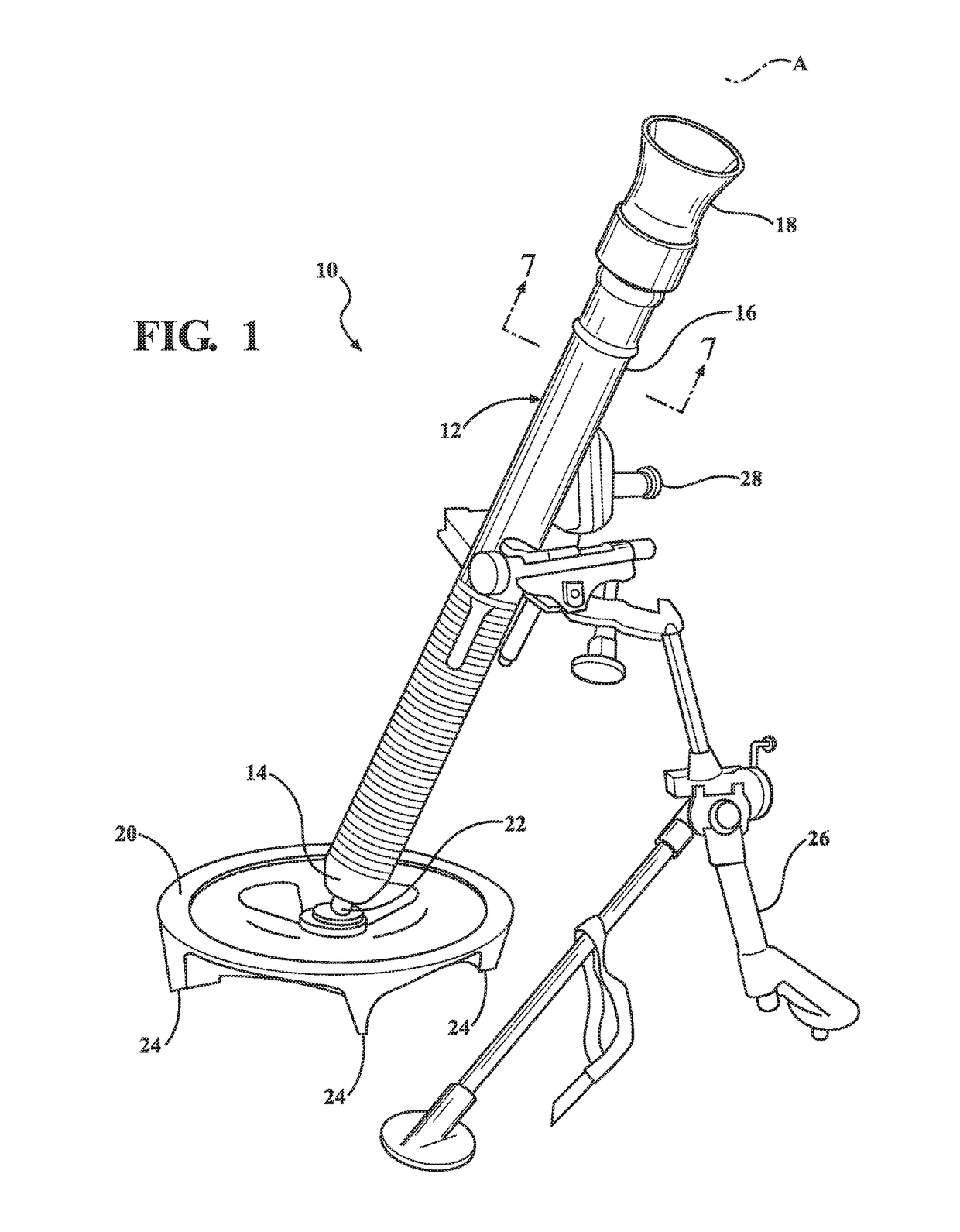

Lightweight composite mortar tube

A composite barrel assembly for a gun, such as a muzzle-loading mortar for fin-stabilized projectiles. The composite construction of the barrel has a plurality of generally concentric layers built-up around a rigid supporting liner which may be fabricated from any of several metal or ceramic compositions. An inner thermal barrier coating of inorganic glass, metal refractory alloy, chromium alloy, functionally graded material or ceramic is disposed within the liner. An overwrap layer of continuous fibers embedded in a matrix surrounds the liner. The matrix is either a resin, polymer, ceramic, glass or metal. An outer shell of continuous fibers embedded in a high temperature polymer matrix surrounds the overwrap. When the liner is made from a metal-based composition, an outer thermal barrier coating may be applied in between the liner and the overwrap.

Owner:PROOF RES

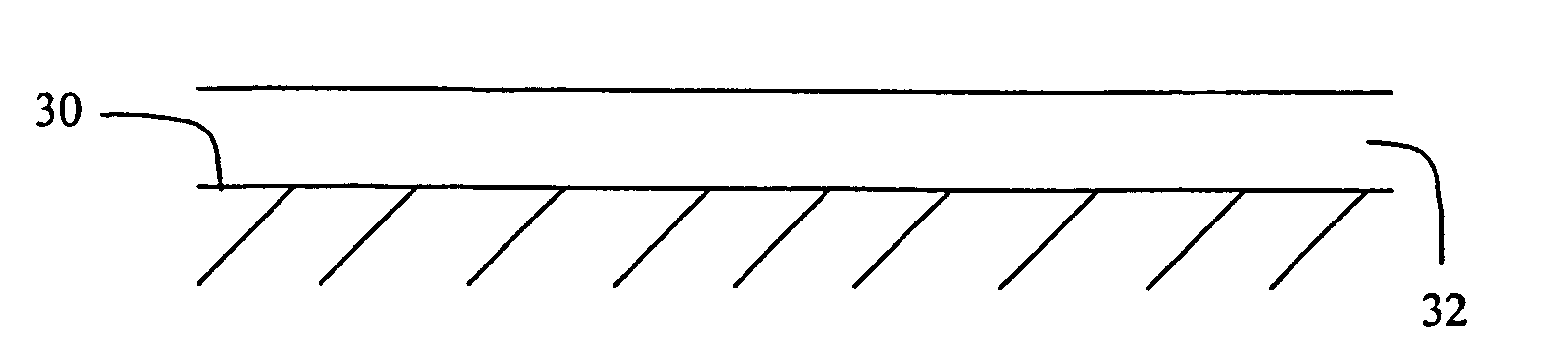

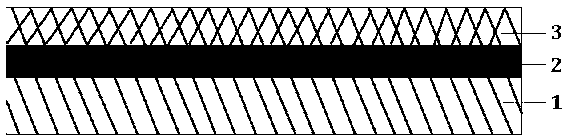

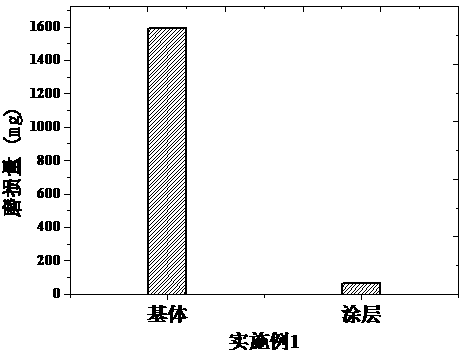

Composite wear-resistant liner of sandwich structure

InactiveCN103057207AAvoid consumptionImprove toughnessCeramic layered productsMetal layered productsConventional castingMetallic materials

The invention discloses a multi-layer composite super-wear-resistant liner of sandwich structure and a preparation process of the liner, belonging to the field of preparation of wear-resistant liners. The wear-resistant liner is composed of a substrate support layer, a bonding transition layer and a hard surface wear-resistant layer by compositing functionally graded materials, wherein the substrate support layer is formed by compression instead of conventional casting; the bonding transition layer is formed by flame remelting with self-fluxing alloy material, having good substrate invasion and high bonding strength; and the hard surface wear-resistant layer is formed by flame remelting with ceramic alloy material, having excellent bonding performance and high abrasive resistance. Compared to the prior art, by gathering the advantages of high toughness of the metal material and high abrasive resistance of the ceramic alloy material, the multi-layer composite super wear-resistant liner of sandwich structure and the preparation process thereof disclosed by the invention have the advantages of simple substrate forming process, low cost, and strong controllability of coating material and process, so that complicated technology for heating processing during an alloy casting process is avoided and the service life is prolonged by more than 10 times compared with that of ordinary steel liners.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

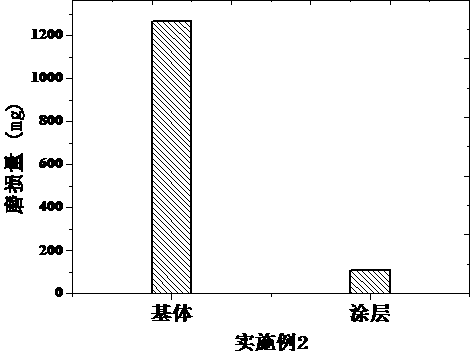

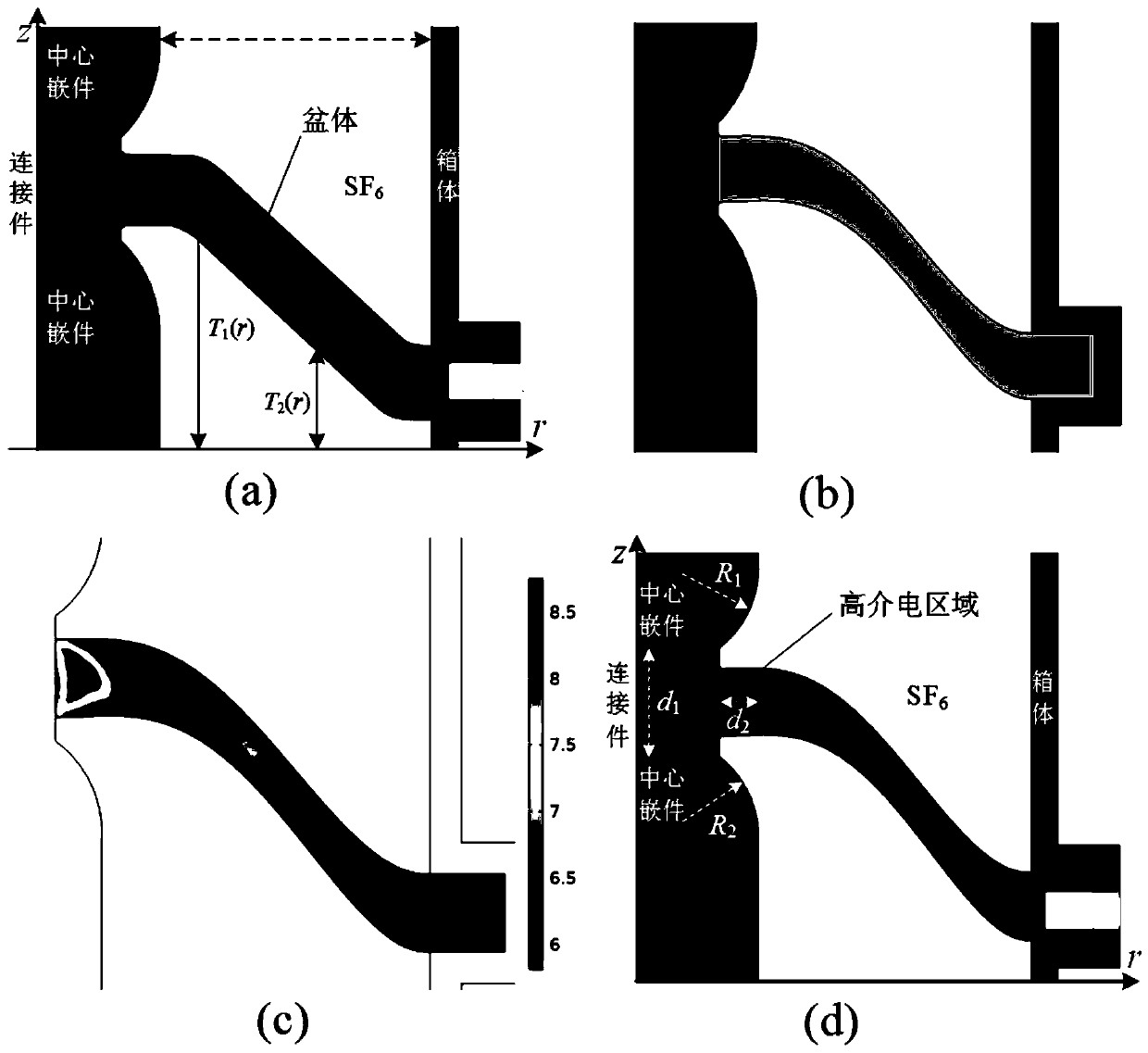

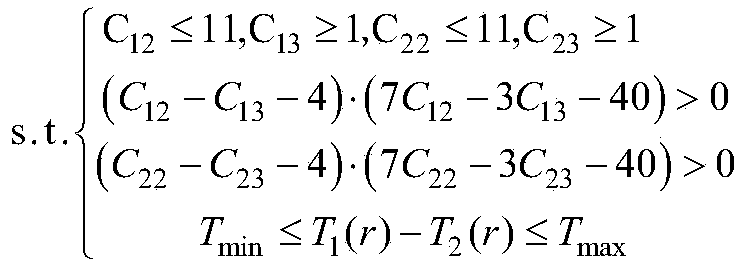

Multi-level optimization design method of GIS/GIL basin-type insulator with high electrical resistance

ActiveCN111553089AImprove breakdown voltageReduce volumeArtificial lifeDesign optimisation/simulationEngineeringFunctionally graded material

The invention discloses a multi-level optimization design method of a GIS / GIL basin-type insulator with high electrical resistance. The method comprises a preliminary design stage and a detailed design stage. In the preliminary design stage, the basic shape of the GIS / GIL basin-type insulator is constructed by adopting contour shape optimization, the shapes of a convex surface and a concave surface of a basin body are described by utilizing a two-dimensional contour function, dielectric functionally graded material distribution is considered to be introduced, dielectric property space distribution is adjusted by utilizing topological optimization to actively regulate and control electric field distribution, and a creeping electric field is further deeply homogenized; in the detailed designstage, according to a dielectric distribution topological optimization result, the optimized gradient insulation area is converted into a high dielectric area with a constant dielectric constant, thesizes of the high-voltage side metal accessory and the high dielectric area are finely adjusted, an optimal size parameter is found out by adopting a genetic algorithm or an ant colony algorithm so as to finish the design of the basin-type insulator for GIS / GIL. The design space can be fully expanded, depth suppression of a creeping electric field is achieved, and the purpose of increasing the breakdown voltage of the basin-type insulator is achieved.

Owner:XI AN JIAOTONG UNIV

Functionally graded cemented carbide with engineered hard surface and the method for making the same

Owner:UNIV OF UTAH RES FOUND

Methods of forming a metallic or ceramic article having a novel composition of functionally graded material and articles containing the same

ActiveUS9186726B2Improve fracture toughnessLow costAdditive manufacturing apparatusLayered productsMechanical componentsCarbide

There is disclosed a method of making a metallic or ceramic component, such as a cutting or forming tool, from at least two distinct powder precursors. In one embodiment, the method comprising forming a first mixture comprised of a plurality of coated particles, such as Tough-Coated Hard Powder (TCHP) composite particles created by encapsulating extremely hard core particles with very tough binder and structural materials, and at least one support powder, such as a carbide, typically WC—Co. The mixture is formed into a green body and sintered to form a functionally graded or multicomponent article. Non-limiting examples of the articles made from the disclosed methods are also disclosed and include drills, mills, cutting tools, forming tools, wires dies and mechanical components.

Owner:ETERNALOY HLDG GMBH

Bond coating and thermal barrier compositions, processes for applying both, and their coated articles

A coated article includes an article having at least one surface and composed of a molybdenum based refractory metal alloy base substrate, a niobium based refractory metal alloy base substrate or a silicon base substrate. A bond coat layer is disposed upon the surface. The bond coat layer includes a molybdenum disilicide base compound and at least one of the following: silicon nitride, silicon carbide or tantalum oxide. A process for coating the article includes the steps of applying upon the article's surface the aforementioned bond coat layer. A functionally graded material layer is applied upon the bond coat layer. The functionally graded material layer comprising molybdenum disilicide, mullite and at least one of the following: silicon nitride, silicon carbide or tantalum oxide. A thermal barrier coating layer is then applied upon the functionally graded material layer.

Owner:RTX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com