Powder spreading processing based functionally graded material preparation device and method

A technology of gradient functional material and preparation device, which is applied in the field of laser selective melting and molding to achieve the effect of expanding the scope, improving the comprehensive performance and low development cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

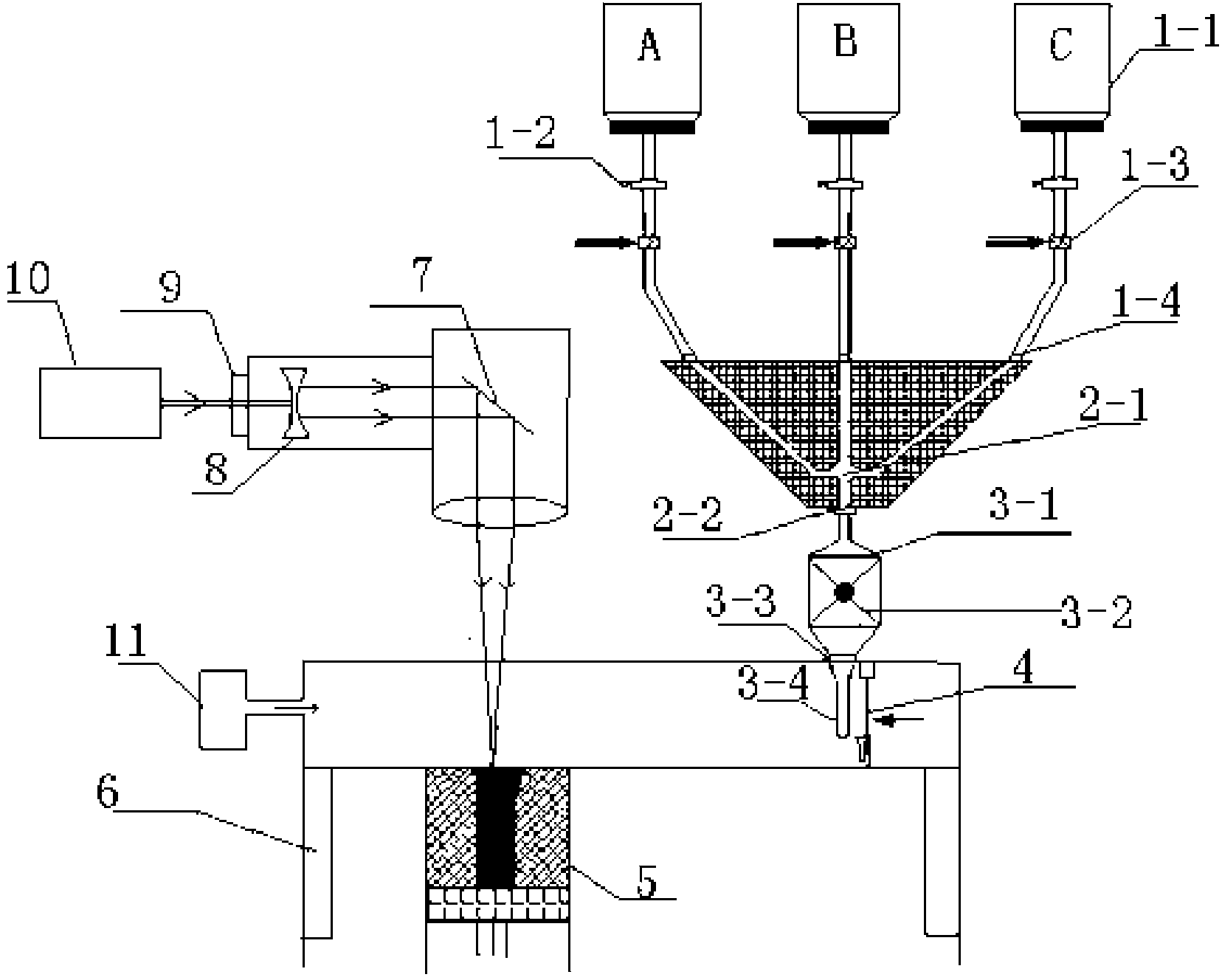

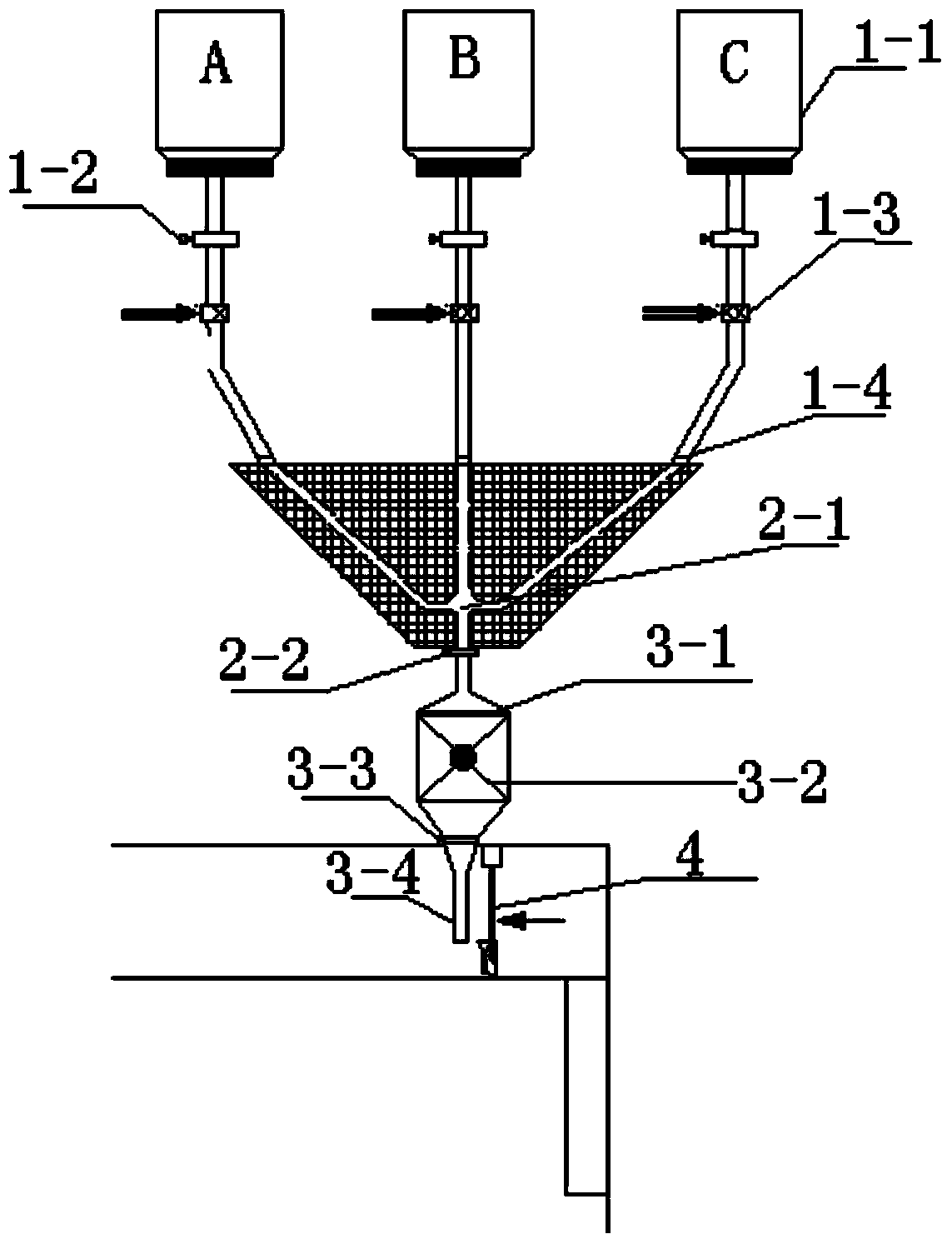

[0038] Such as figure 1 --4 shown. The invention discloses a gradient functional material preparation device based on powder spreading processing, which includes a powder spreading device, a feeding device, a powder collecting device, and a powder mixing control device sequentially connected through pipelines from top to bottom;

[0039] The feeding device includes three powder barrels 1-1, namely A powder barrel, B powder barrel, and C powder barrel;

[0040] The powder collection device includes a powder collection chamber 2-1;

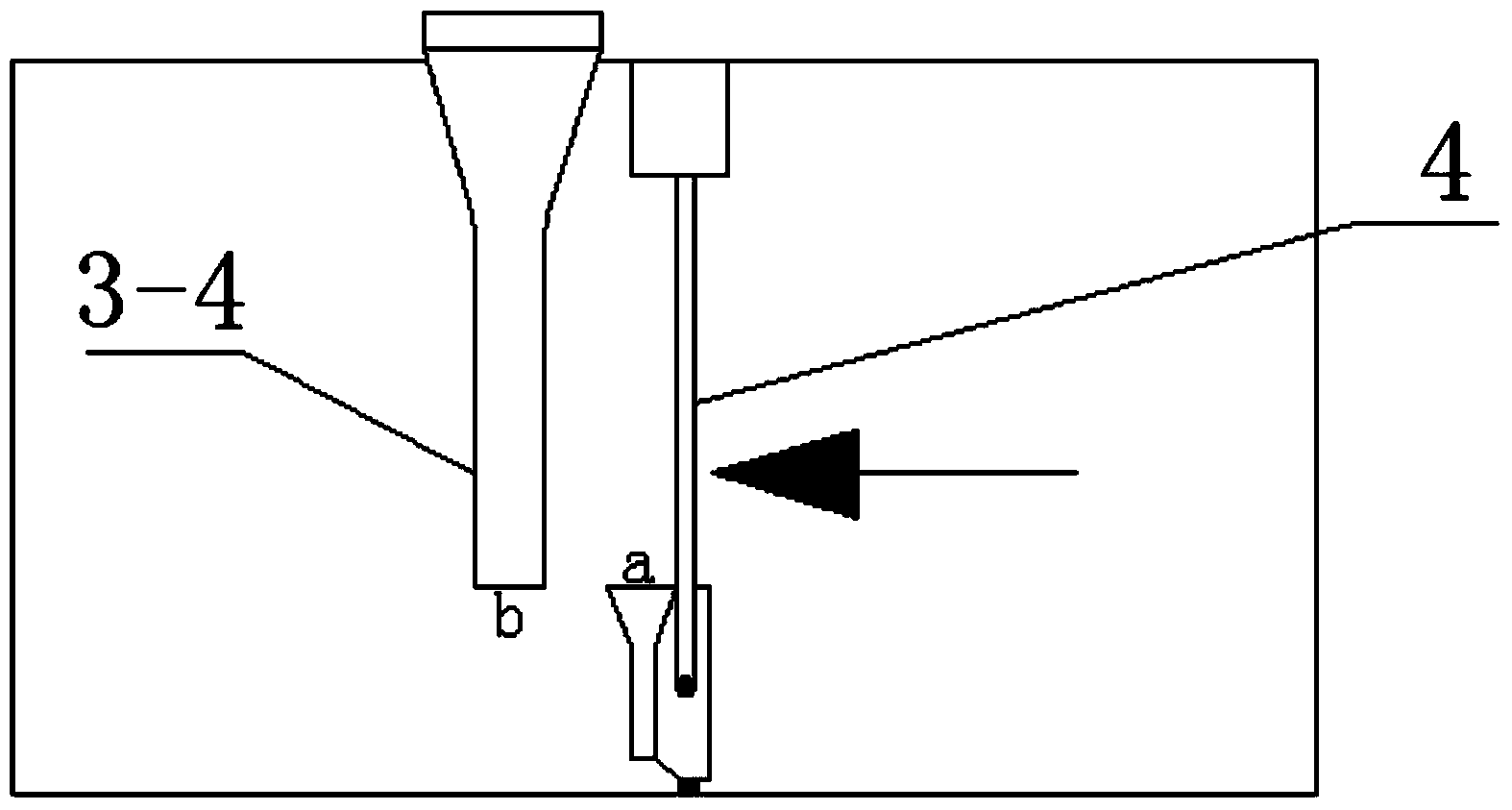

[0041] The powder mixing control device includes a buffer screen 3-1, a stirring blade 3-2, a control switch 3-3, and a powder supply port 3-4 arranged sequentially from top to bottom;

[0042] The powder barrel 1-1 is connected to the powder collection chamber 2-1 through a pipeline, and a flow controller 1-2 and a gas power generator 1-3 are arranged in sequence on this pipeline from top to bottom;

[0043] A pressure limiting valve 2-2 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com