Patents

Literature

294 results about "Head pressing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Head pressing is a veterinary condition characterized by standing close to a wall or corner face-first without moving. This condition is seen in pets such as dogs and cats, and also other animals such as cows, horses, and goats. Head pressing is usually a sign of a neurological disorder, especially of the forebrain (e.g., prosencephalon disease), or of toxicity due to liver damage, such as portosystemic shunt and hepatic encephalopathy.

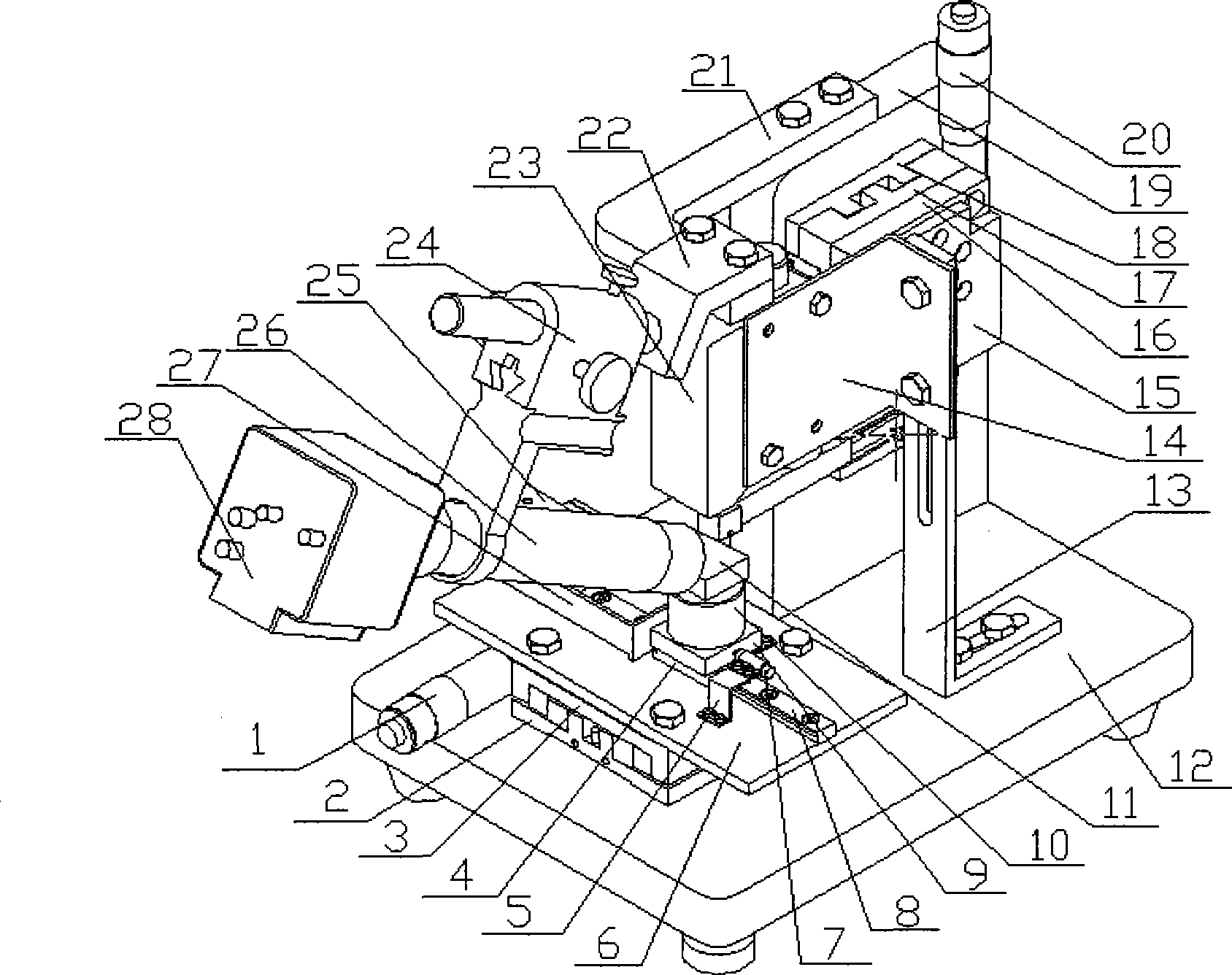

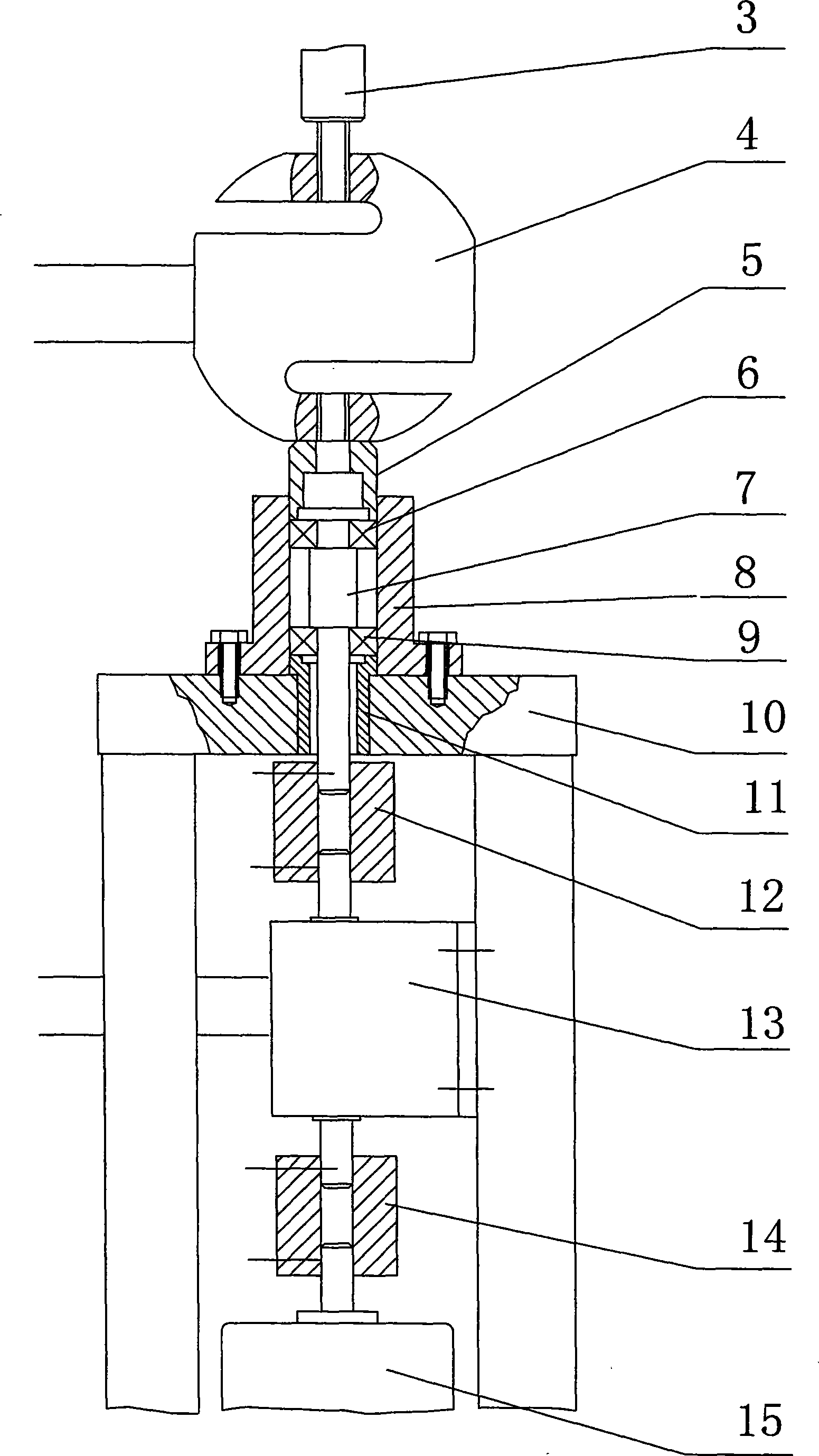

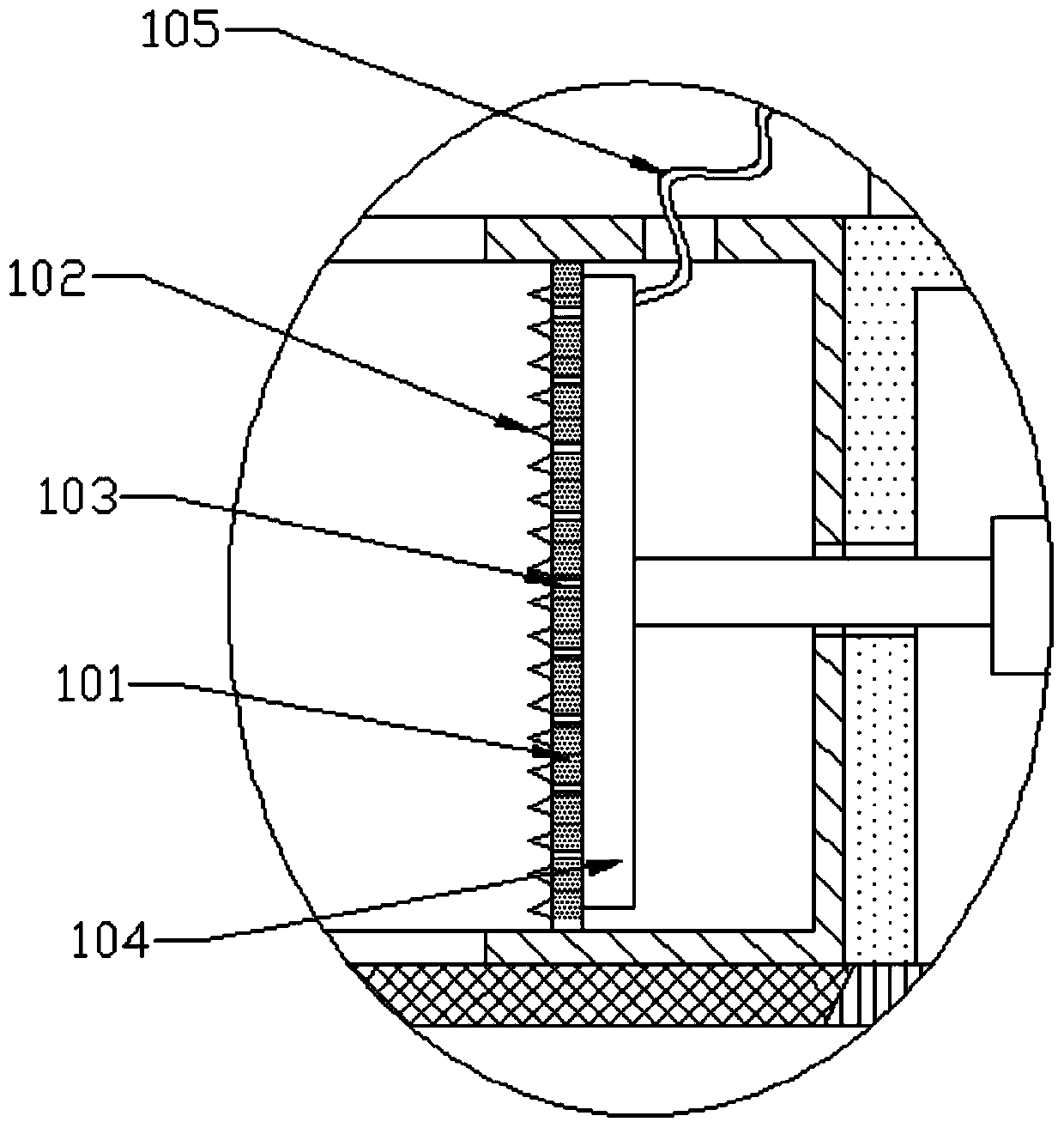

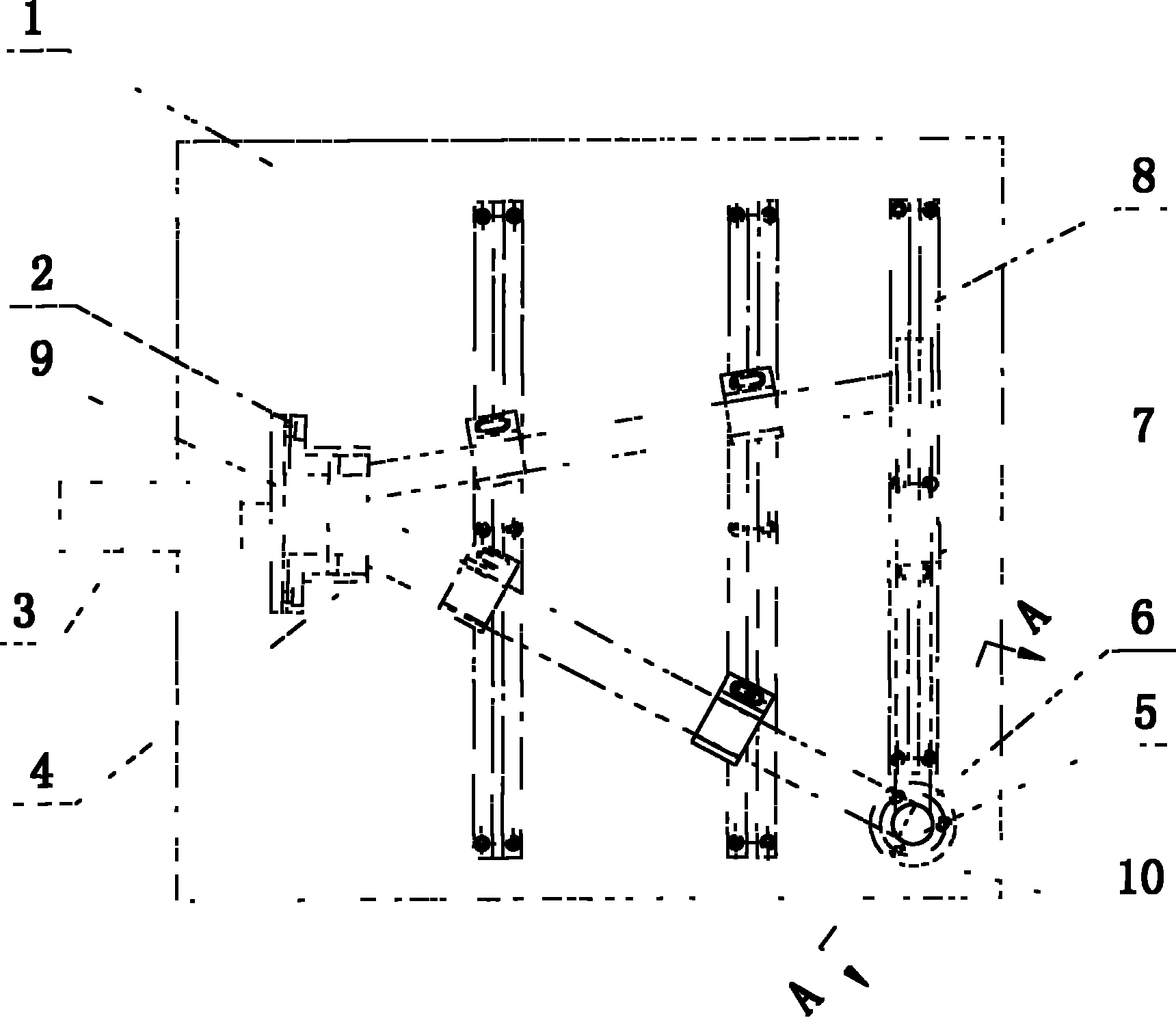

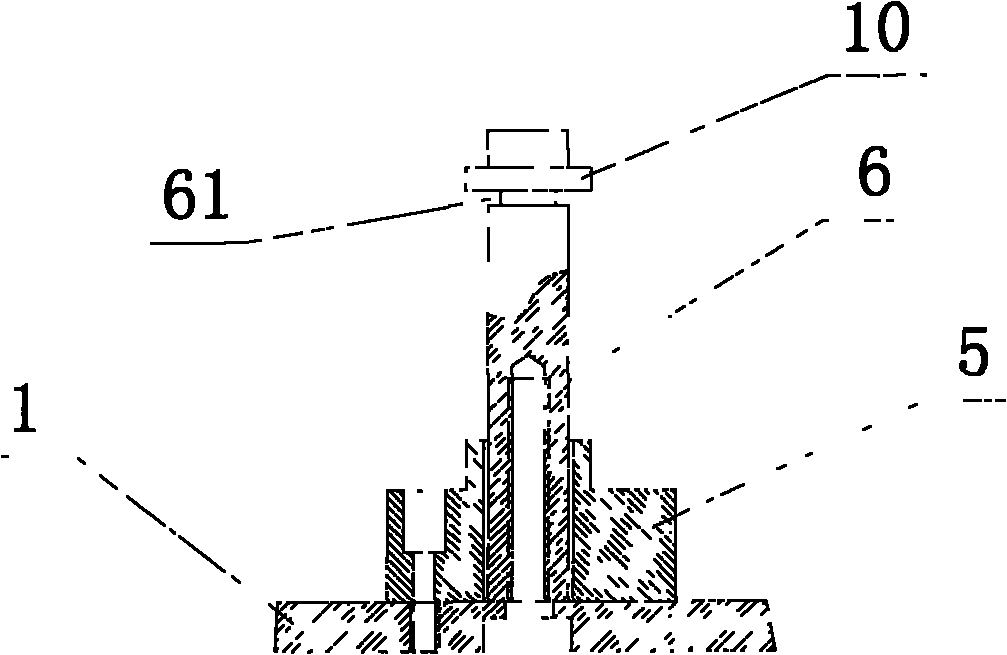

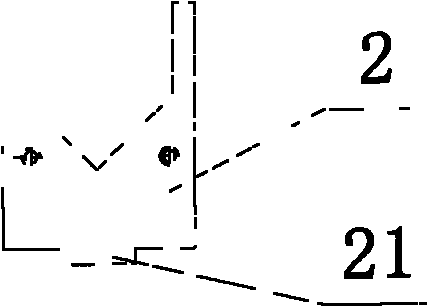

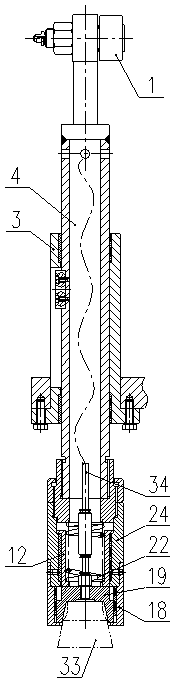

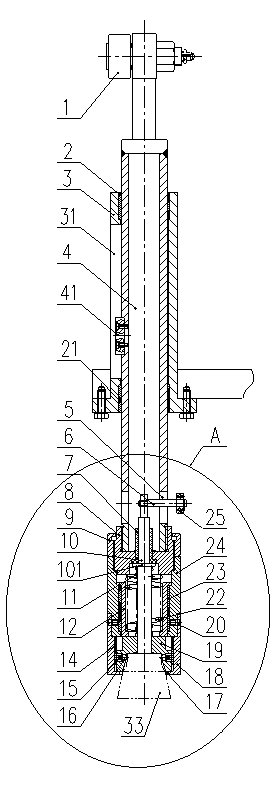

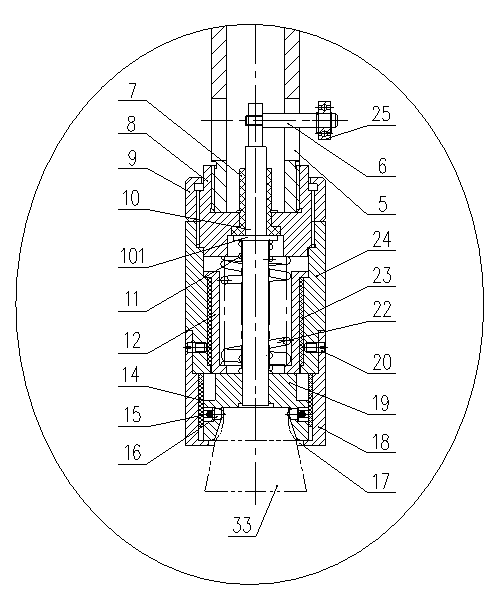

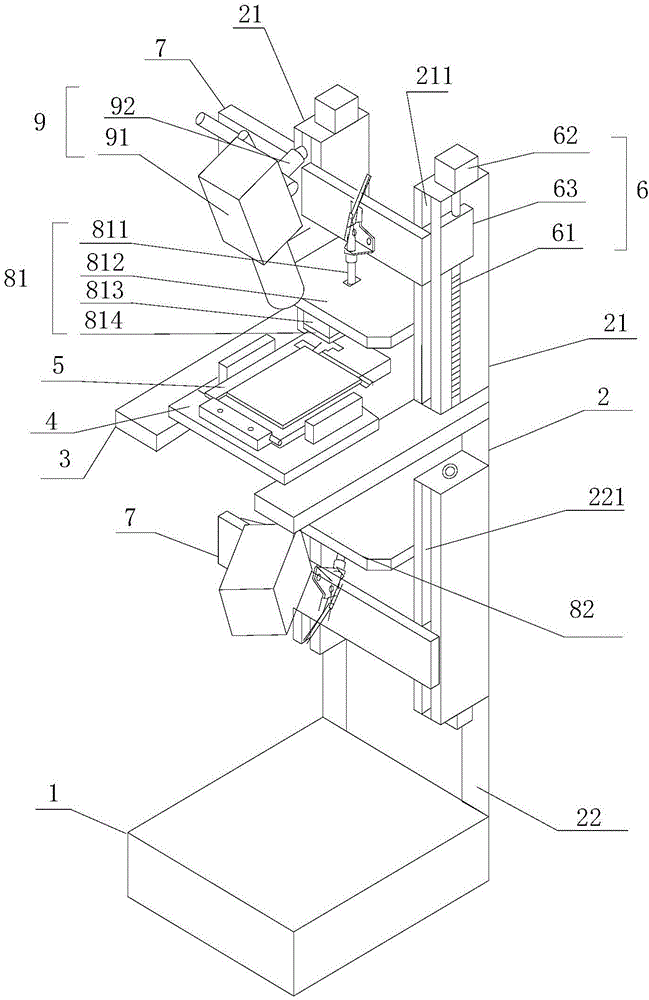

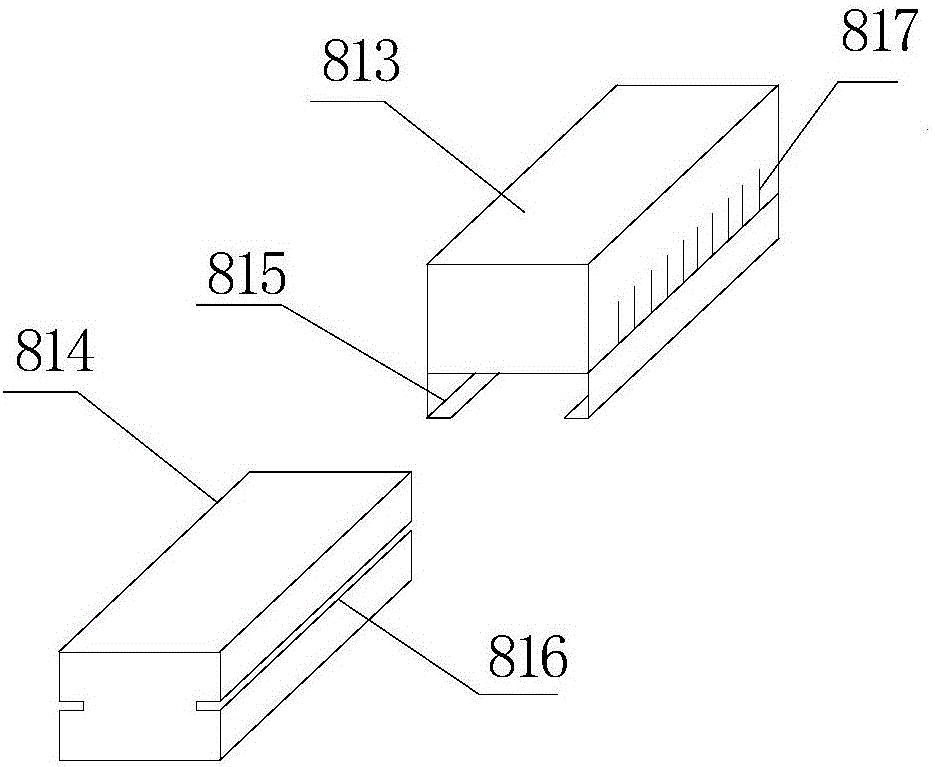

Super-precision trans-scale in-situ nanometer indentation marking test system

ActiveCN101520389AThe test method is accurateAccurate and effective research and testing methodsUsing optical meansInvestigating material hardnessHead pressingImage resolution

The invention relates to a super-precision trans-scale in-situ nanometer indentation marking test system which integrates driving, loading, detecting and micro-nanometer dynamic performance tests, super-precision marking processing and in-situ observation into a whole. The system mainly comprises an objective table, a regulation mechanism, a detection unit, a precise pressed-into driving unit, a detection unit of load signals and displacement signals and a high-resolution digital microscopic imaging system, wherein the objective table is precisely positioned along the directions of the X axis and the Y axis; the regulation mechanism and the precise pressed-into driving unit are in the direction of the Z axis and are assembled on a base; the high-resolution digital microscopic imaging system is used for observing the deforming and damaging conditions of the material in the storing and testing process; the objective table as well as the regulation mechanism and the precise pressed-into driving unit in the direction of the Z axis are assembled on a base; the high-resolution digital microscopic imaging system is arranged on the objective table; a precise dynamic sensor detecting the pressure of a diamond tool head pressed into a material and a sensor I detecting the precise displacement of the objective table in the directions of the X axis and the Y axis are arranged on the objective table; and a sensor II used for detecting the precise displacement of a diamond tool head in the direction of the Z axis of pressed-into depth is arranged on the base by a support I.

Owner:JILIN UNIV

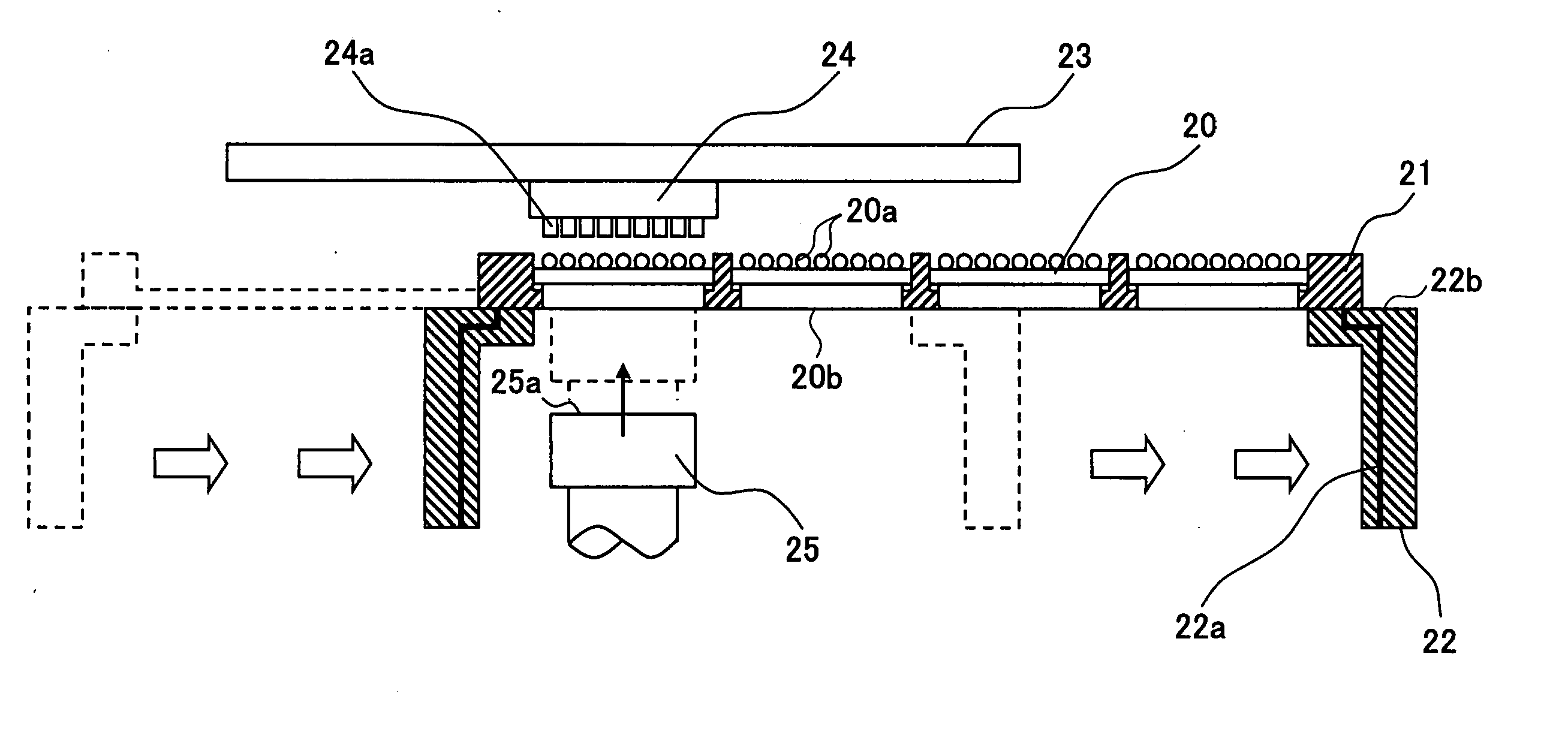

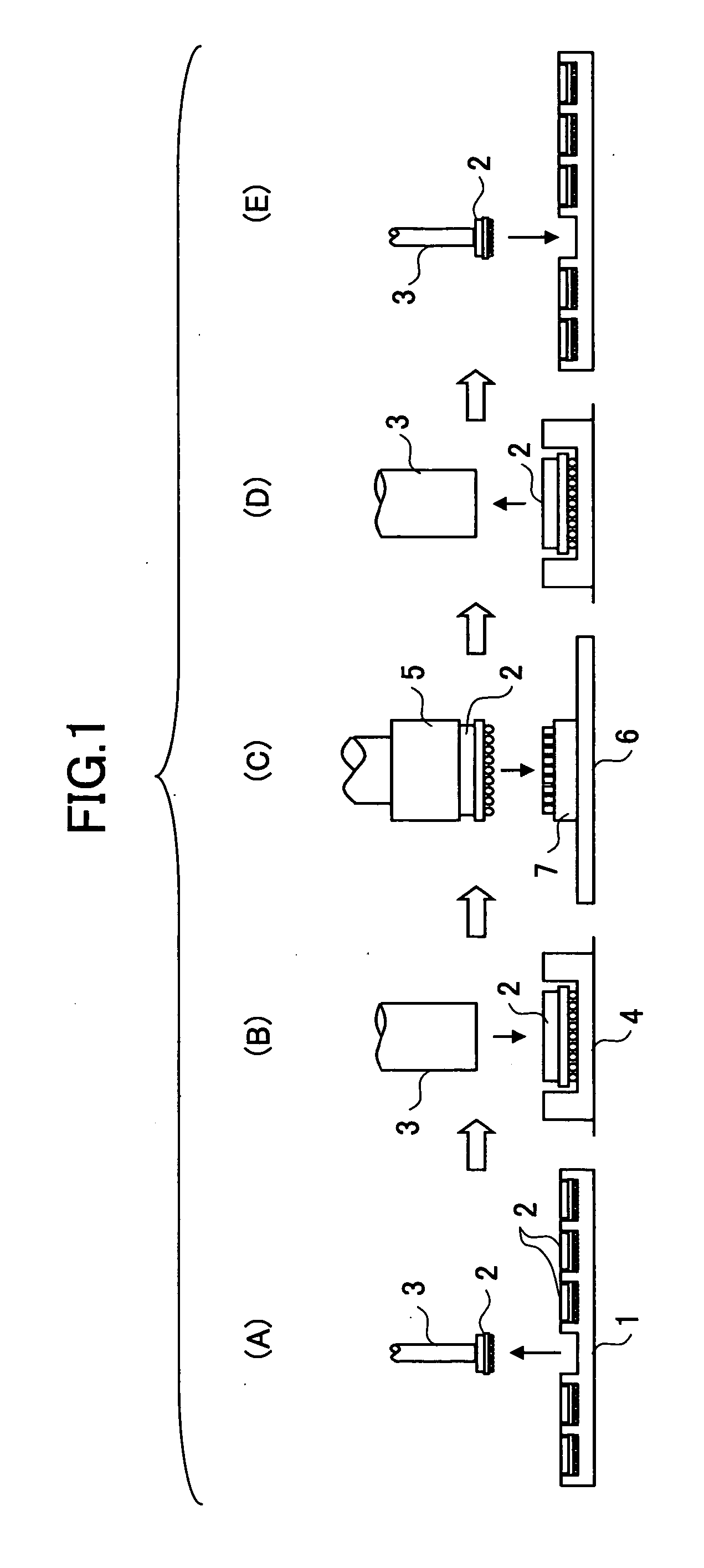

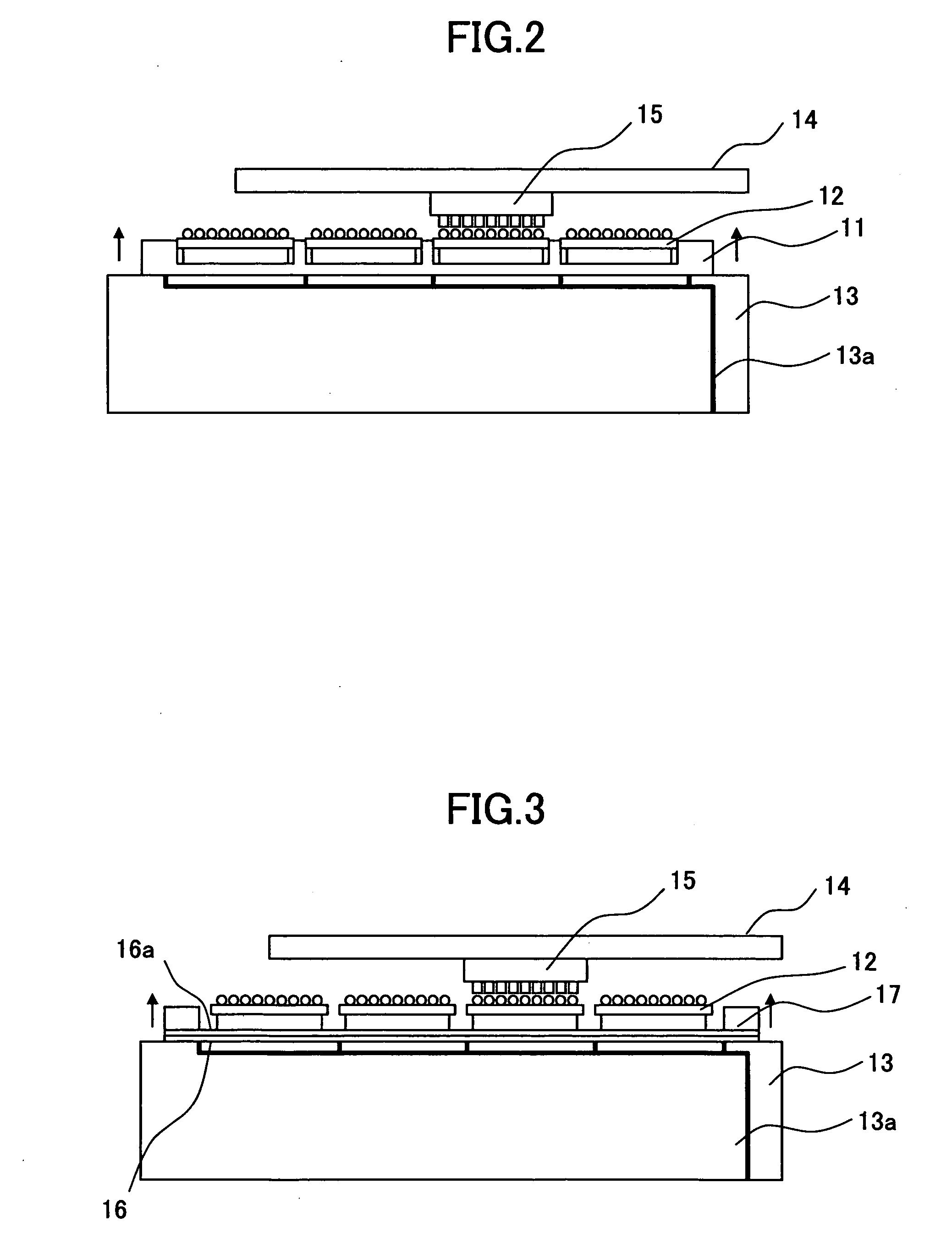

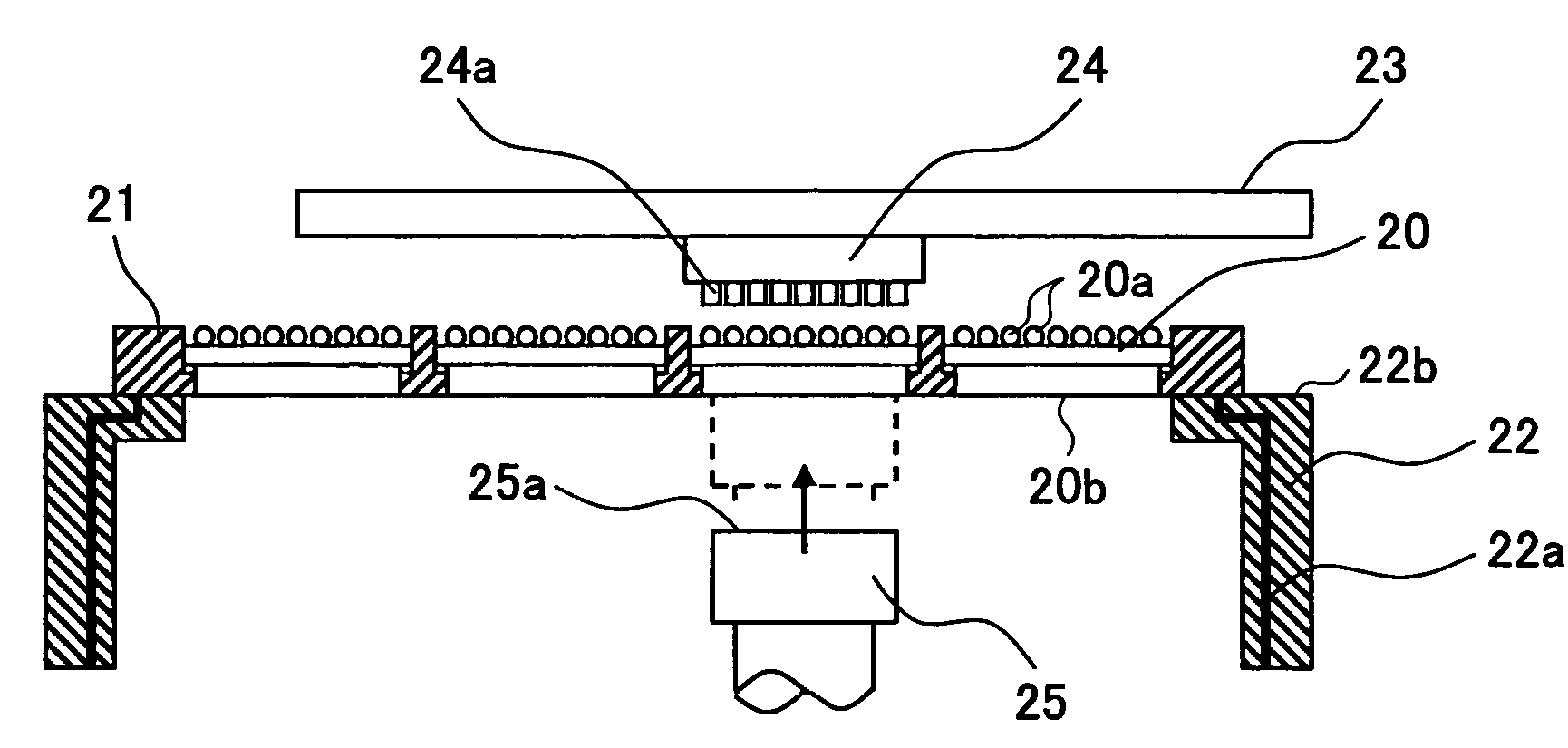

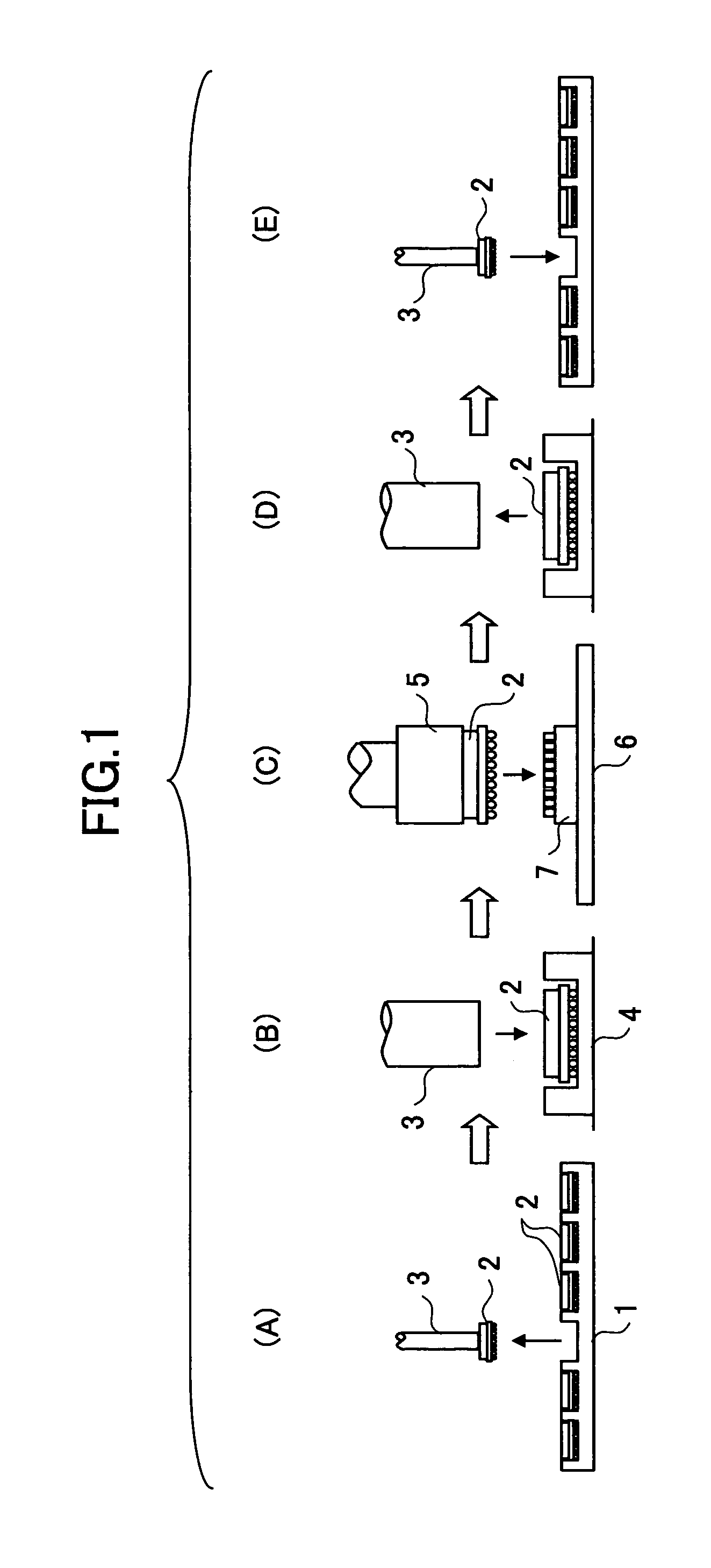

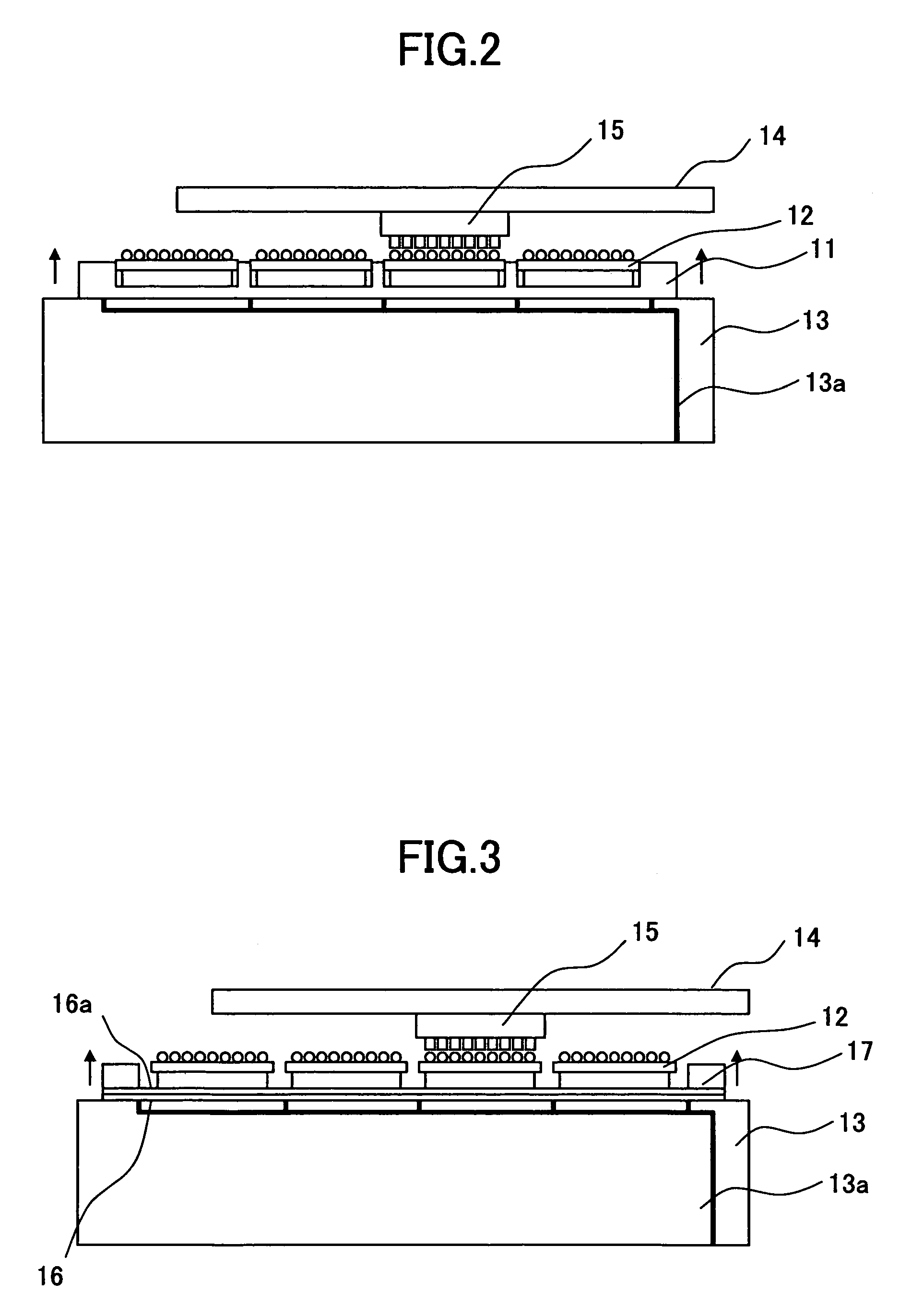

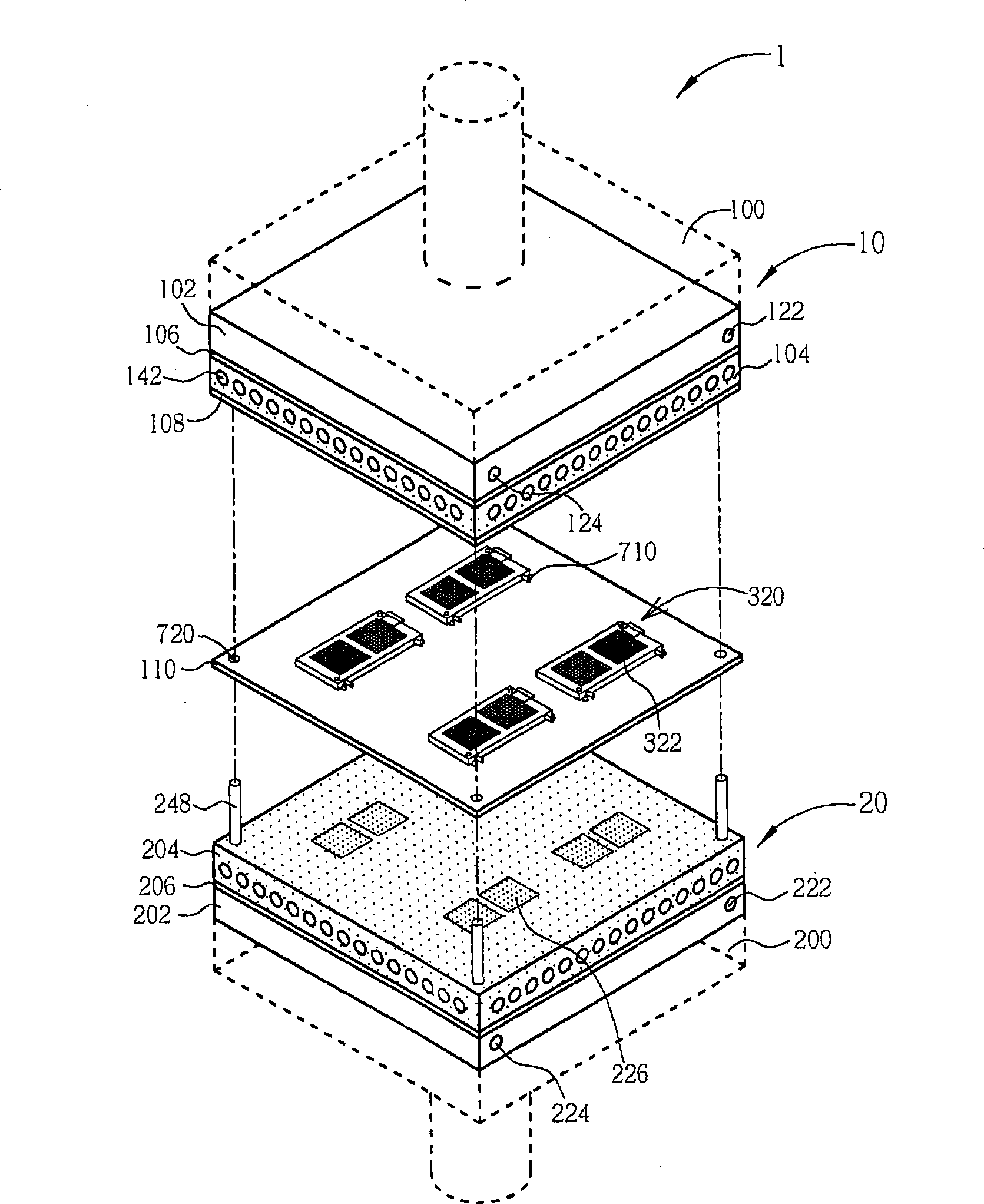

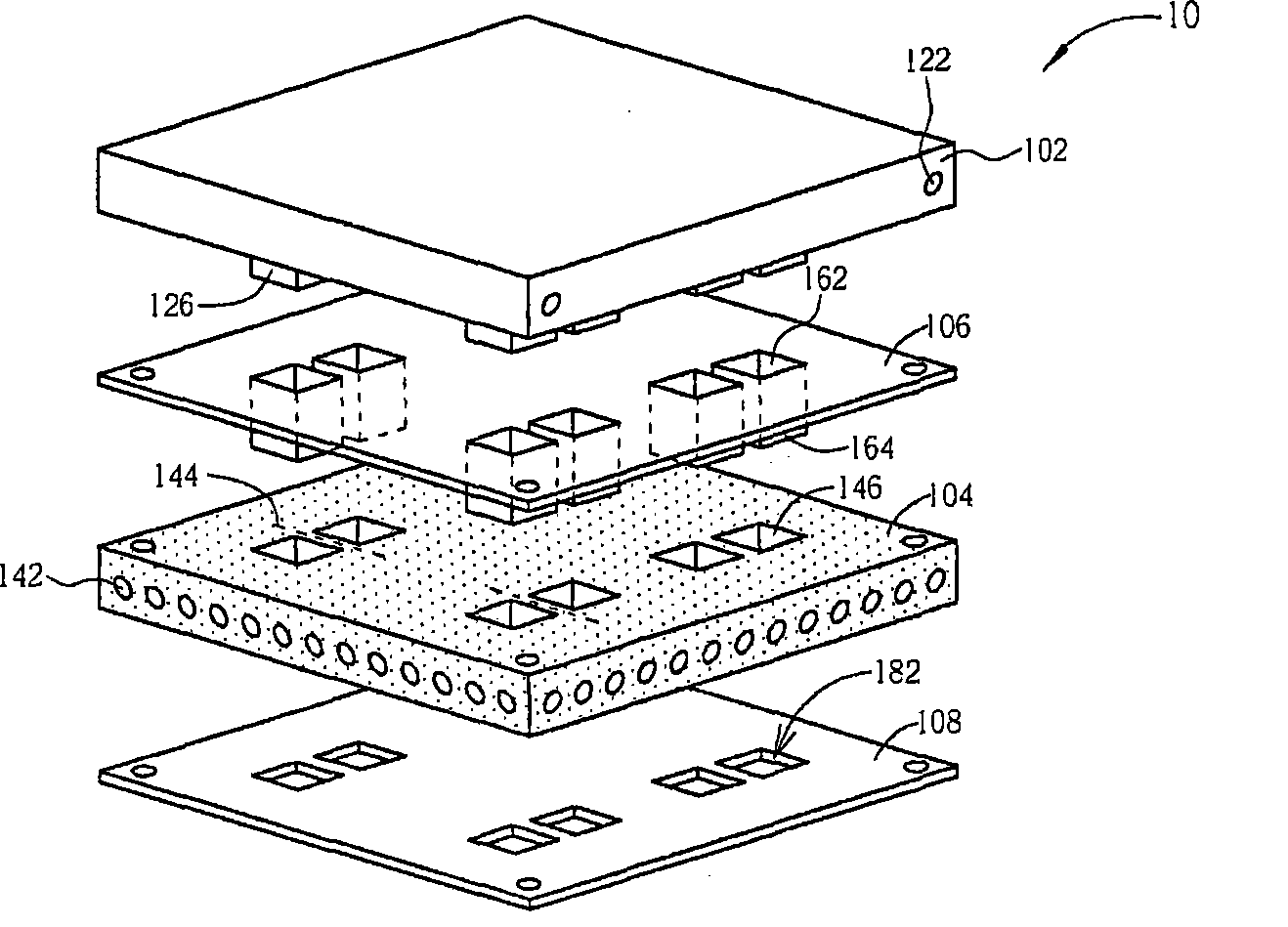

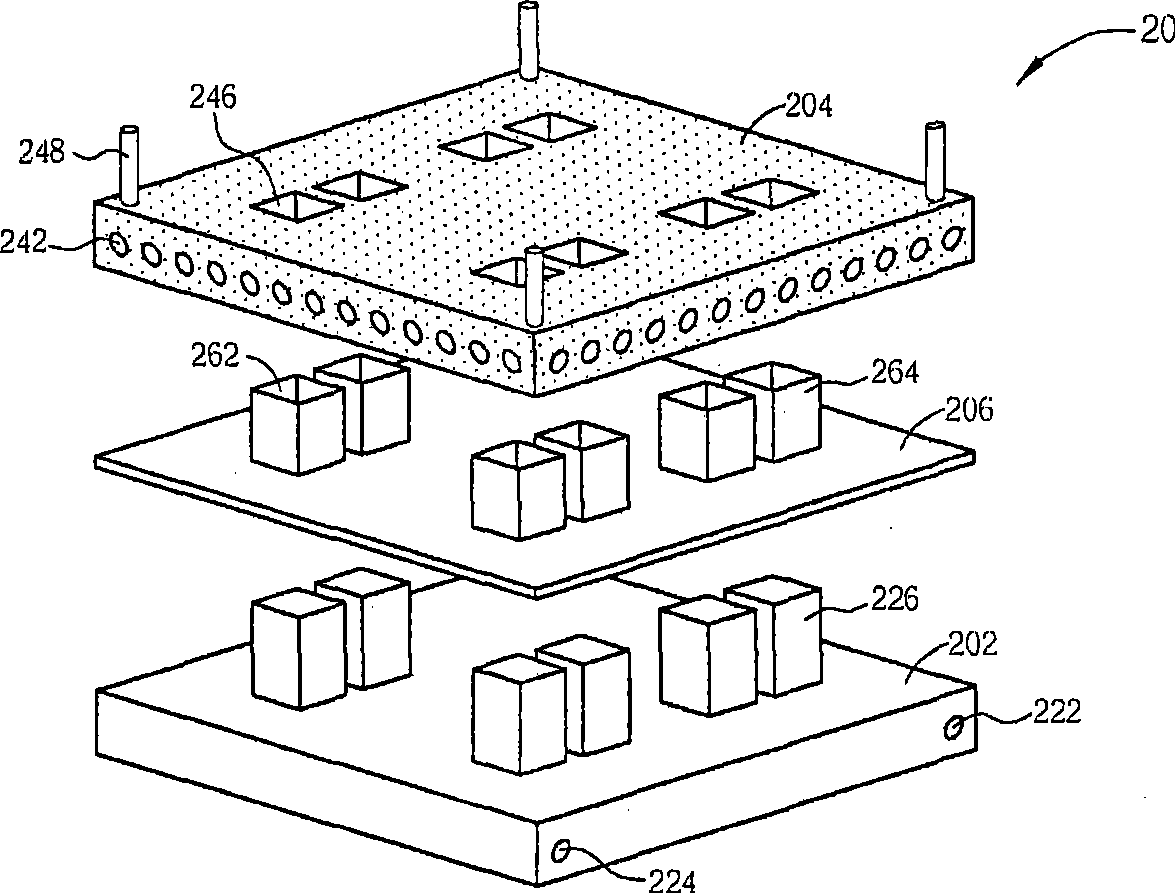

Testing device and testing method of a semiconductor device

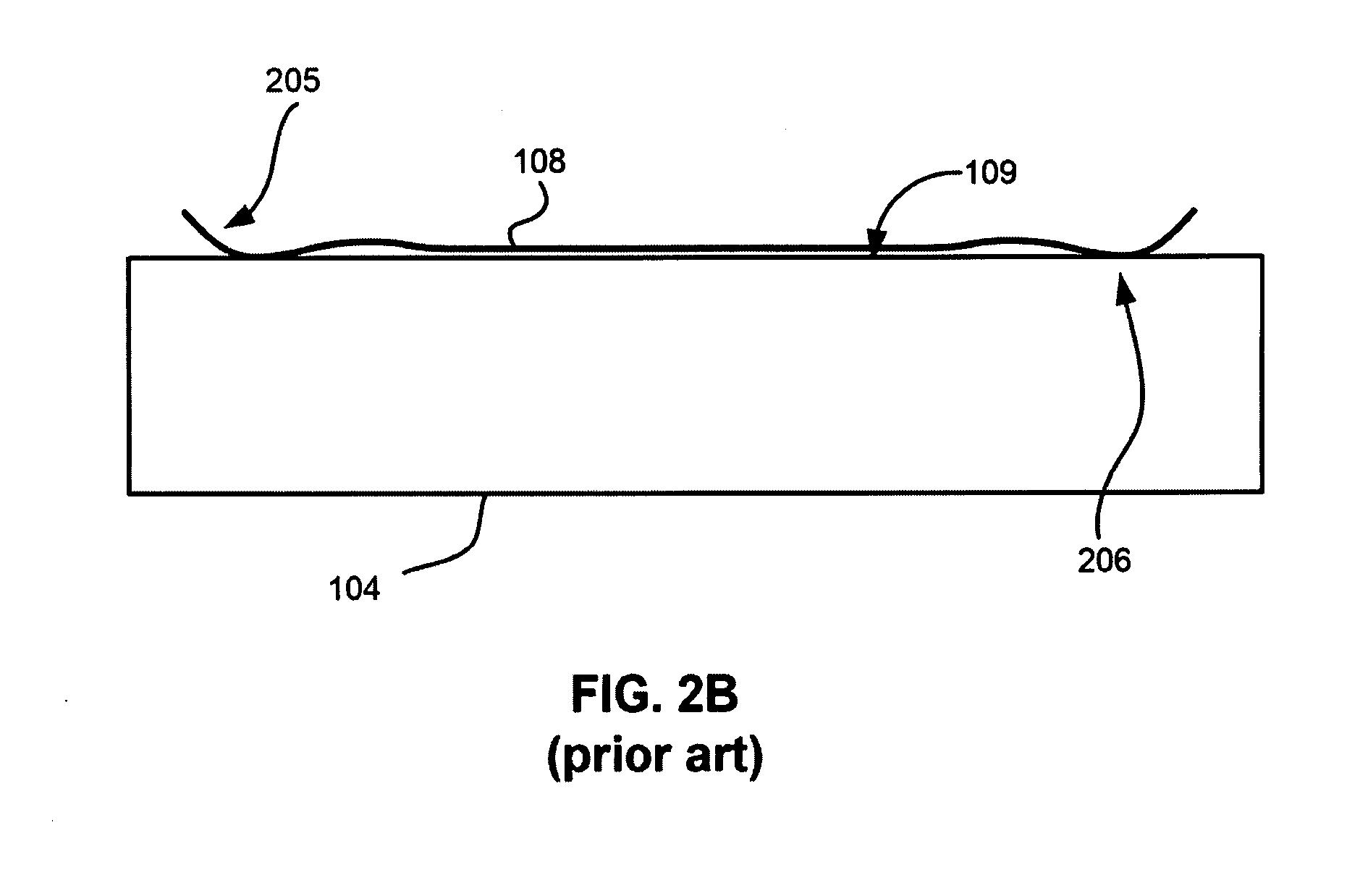

InactiveUS20060220667A1Simple structureEffective temperature controlSemiconductor/solid-state device testing/measurementElectrical testingHead pressingDevice material

A testing device can perform a test on an arbitrary one of a plurality of semiconductor devices by pressing the semiconductor devices onto a contactor from a back side of the semiconductor device. A test circuit board has a contactor provided with contact pieces corresponding to external connection terminals of semiconductor devices to be tested. A support board is capable of mounting the semiconductor devices thereon in an aligned state. A stage supports the support board. A press head presses the semiconductor devices to be tested mounted on the support board so as to cause external connection terminals of the semiconductor devices to be tested to contact with the contact pieces of the contactor. The stage is movable to a position at which at least one of the semiconductor devices to be tested, which are mounted on the support board, faces the contactor.

Owner:SOCIONEXT INC

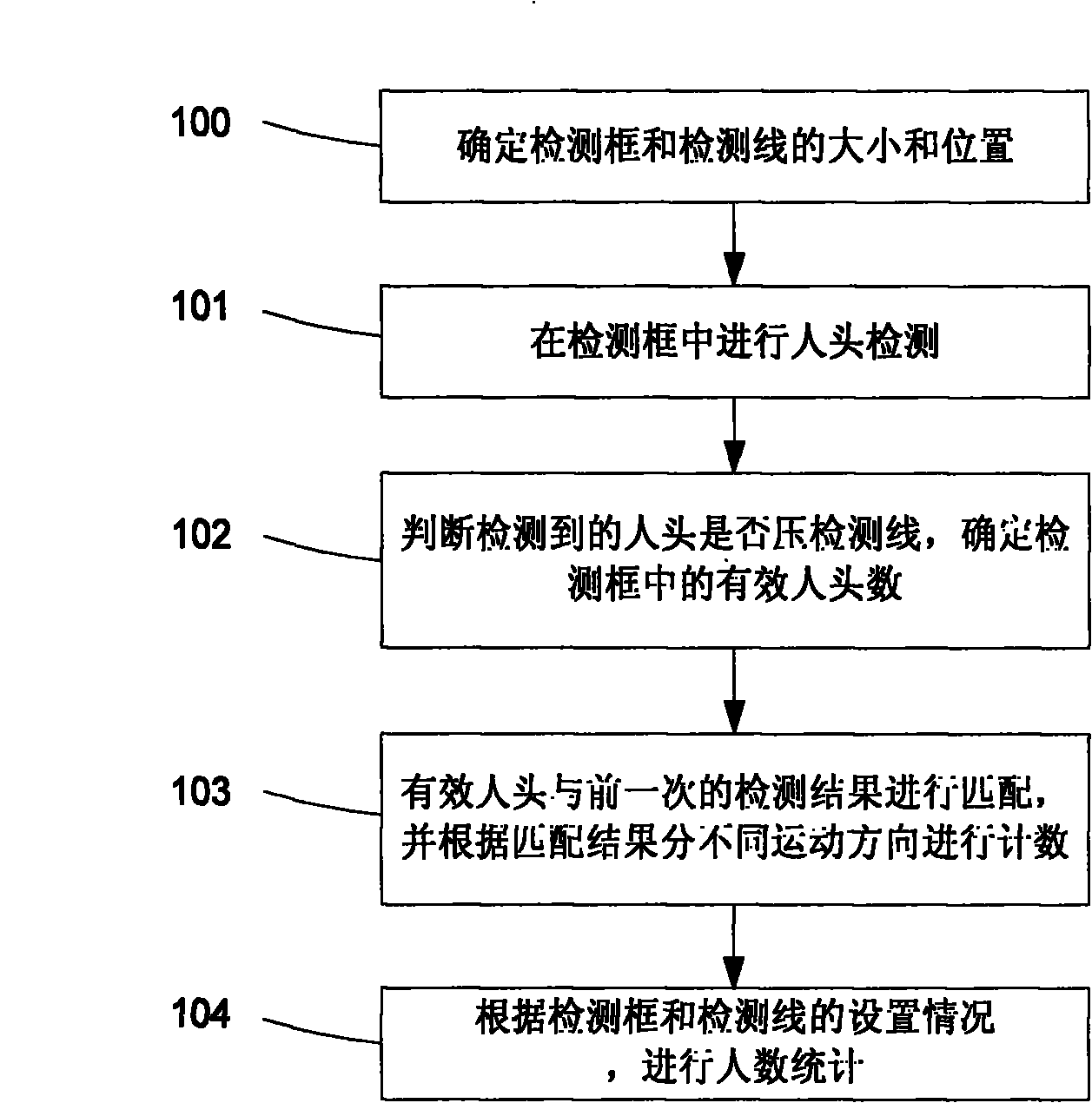

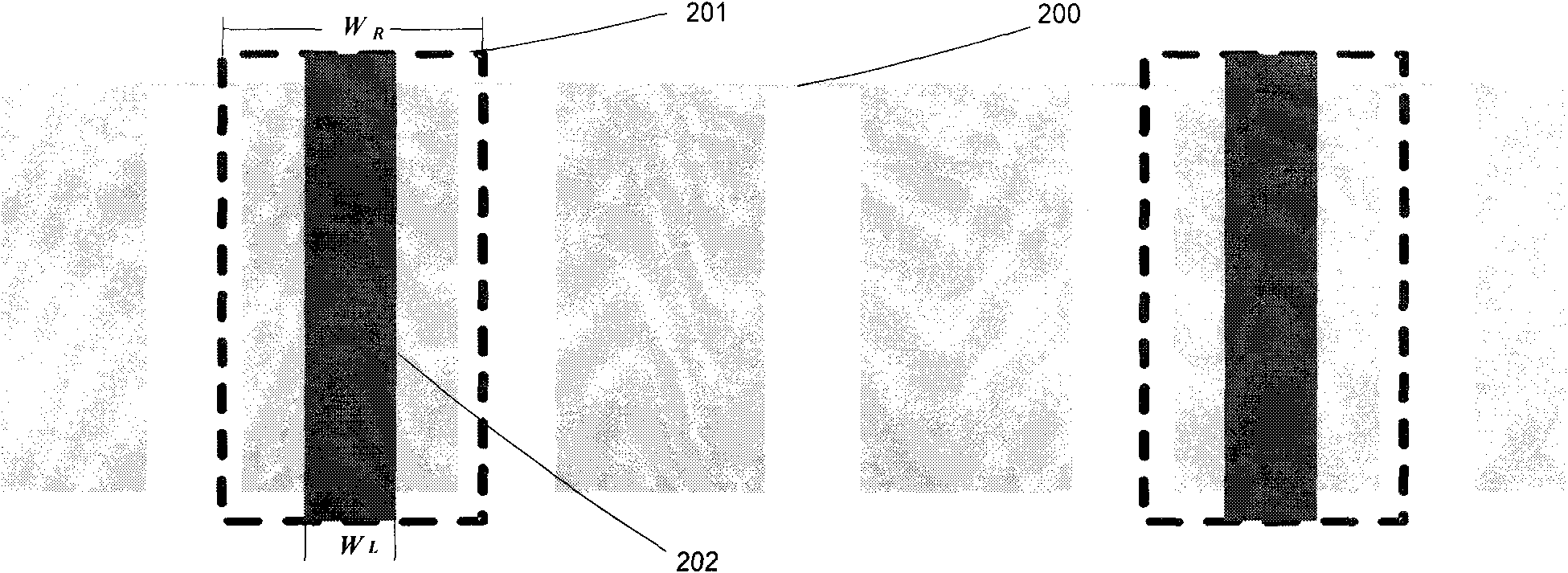

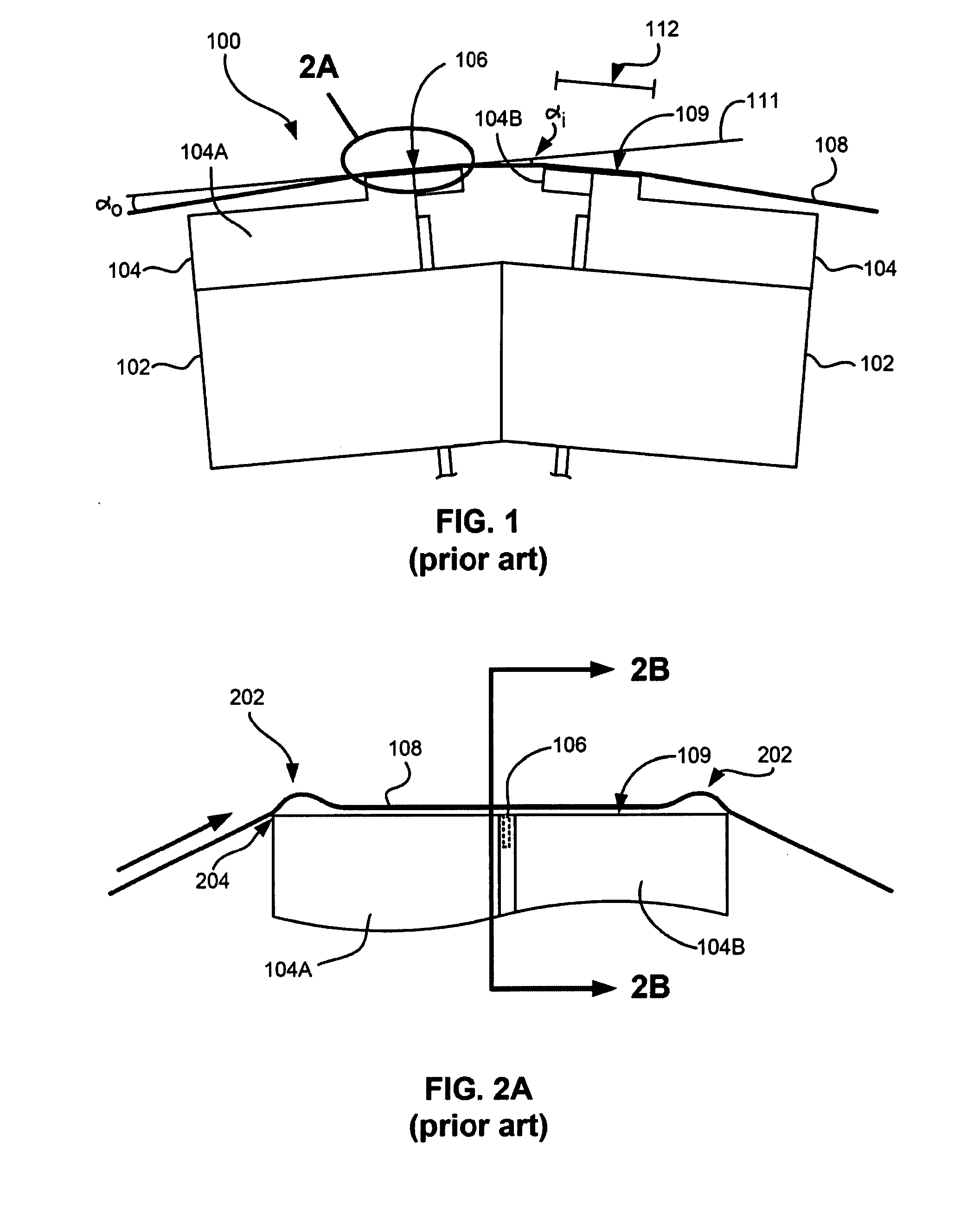

Pedestrian traffic statistical method and system based on traffic monitoring facilities

InactiveCN101847206AImprove efficiencyGuaranteed validityCharacter and pattern recognitionCounting objects with random distributionTraffic capacityHead pressing

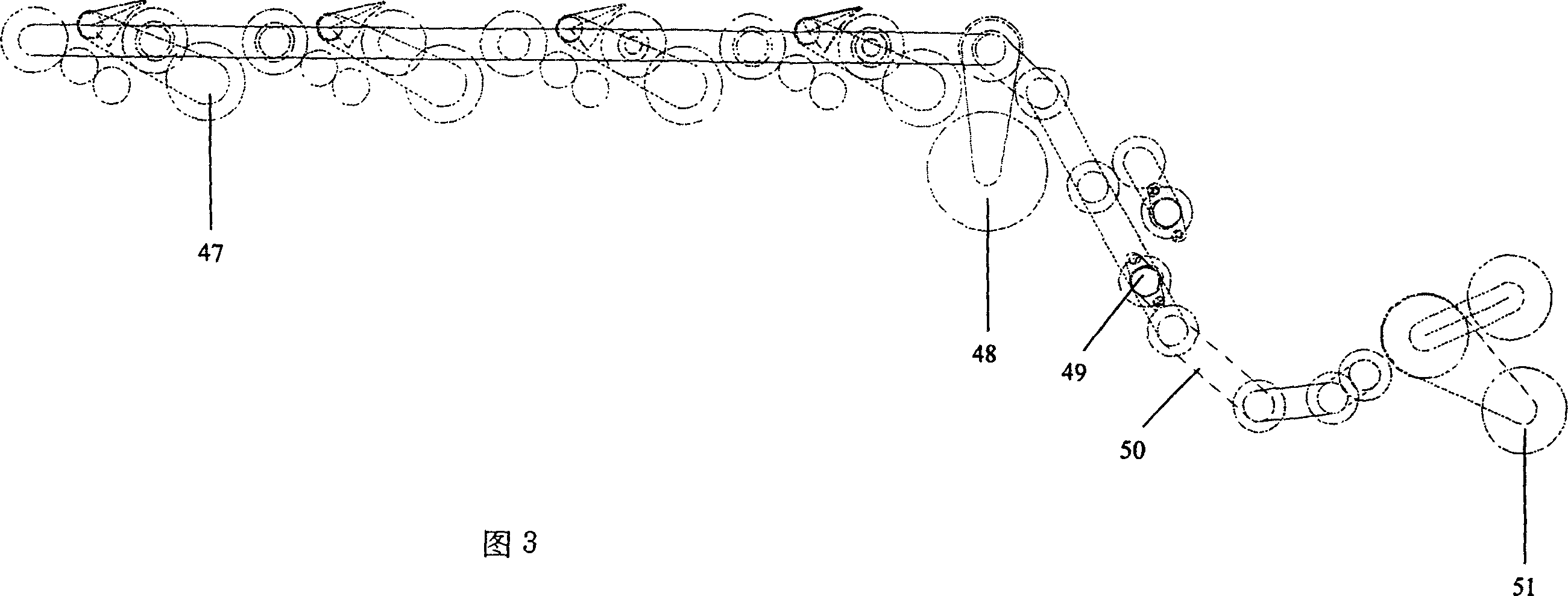

The invention relates to technologies of image processing and computer vision and discloses a pedestrian traffic statistical method which is used for carrying out statistic on pedestrian traffic in different movement directions at crossroads mainly by detecting heads on detection lines. The pedestrian traffic statistical method comprises the following steps of: firstly, detecting heads on a detection frame, and determining whether the detected heads press the detection lines or not so as to determine effective headcount in the detection frame; then matching the result with the previous detection result, and counting with different movement directions according to the matching result; and finally carrying out traffic statistic according to the setting conditions of the detection frame and the detection lines. The pedestrian traffic statistical system comprises a detection setting module, a head detection module, a line-pressing determining module, a result storage module, a head matching module and a traffic statistical module. The invention carries out statistic on pedestrian traffic according to the detection result of each detection line. The invention is simple and easy for implementation, can be used for city roads with complicated backgrounds, and realizes real-time statistic on pedestrian traffic by utilizing the traditional traffic monitoring facilities.

Owner:BEIJING JIAOTONG UNIV

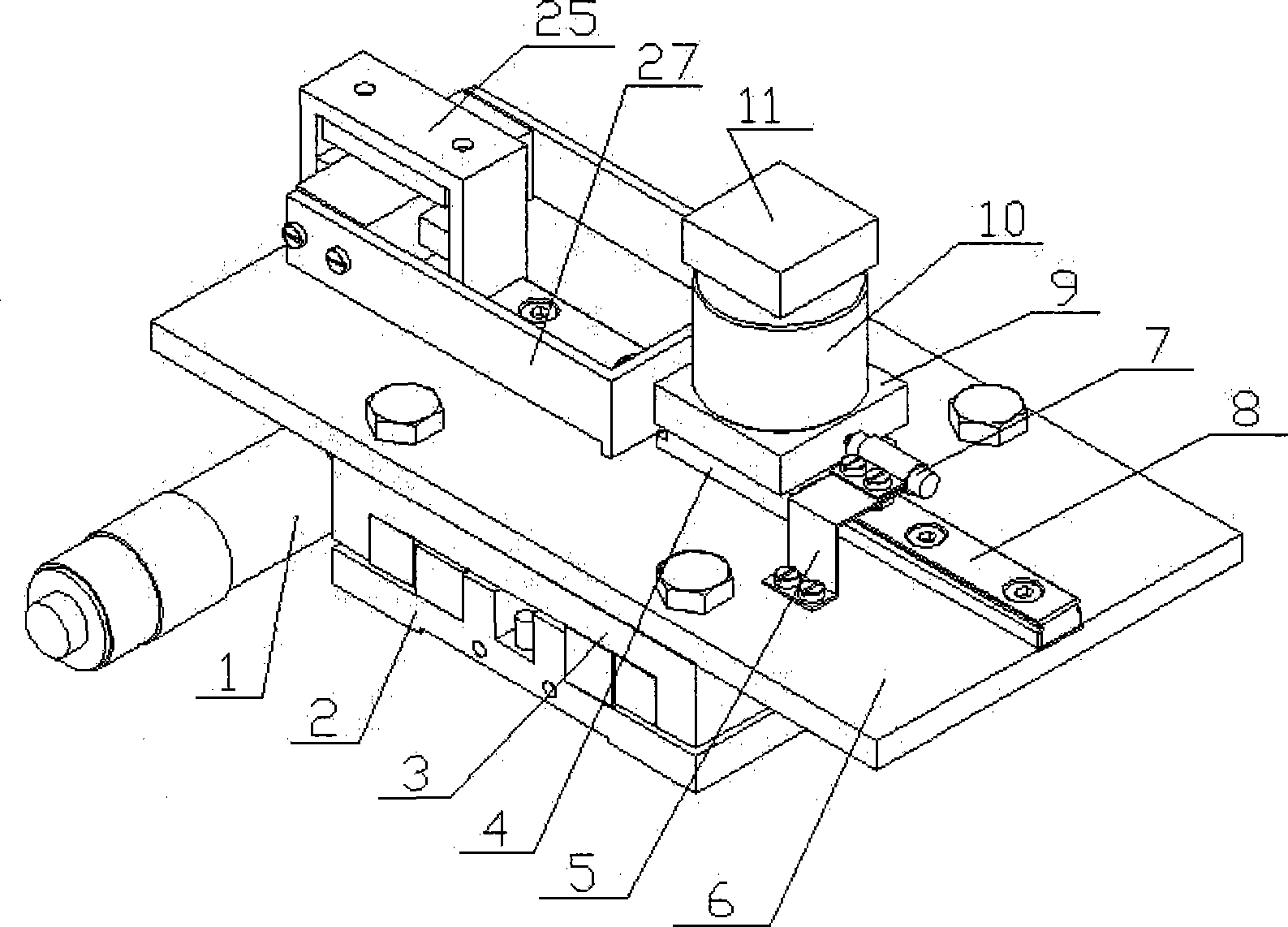

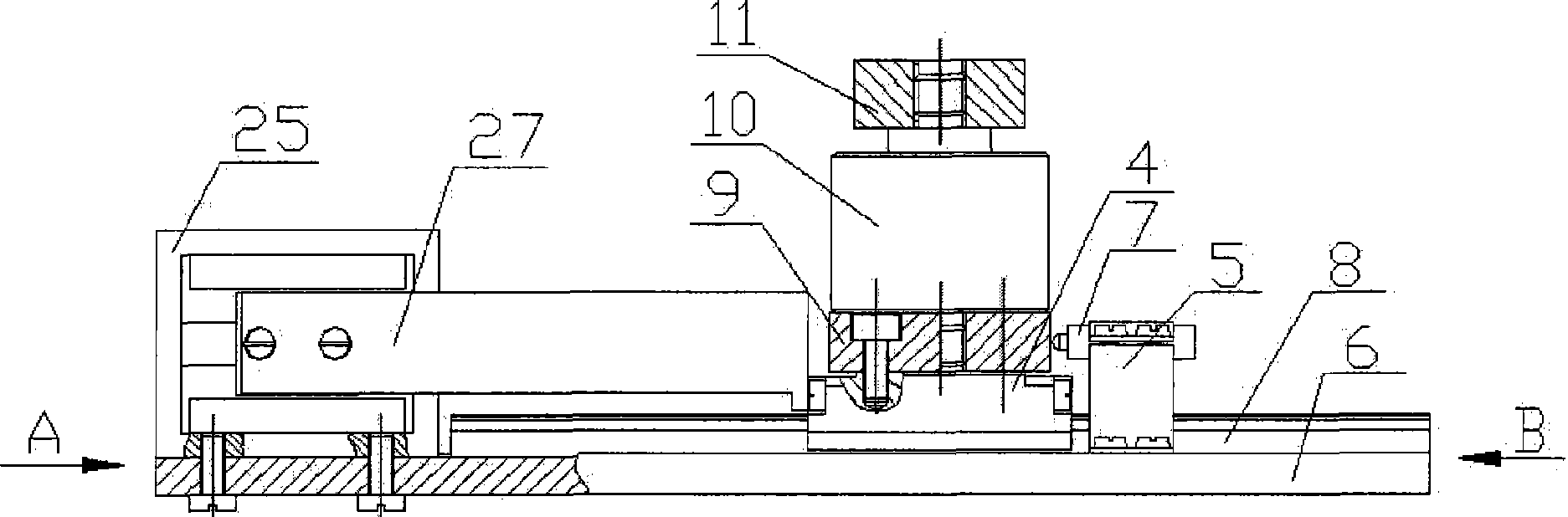

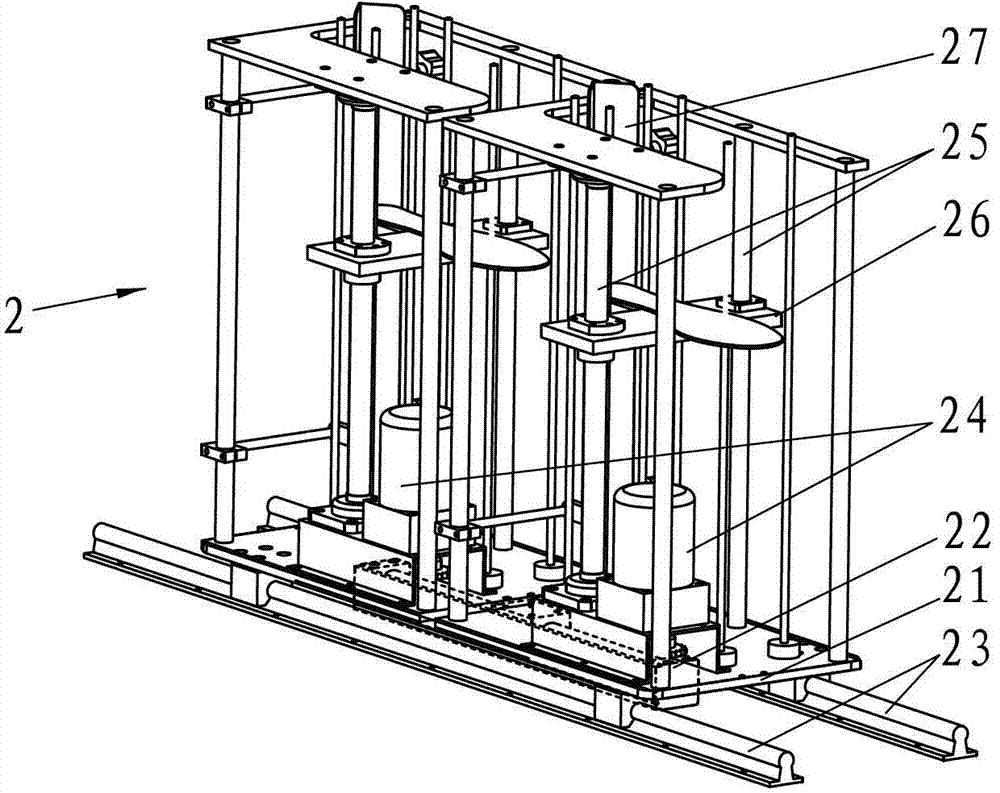

Measuring apparatus for frictional moment of bearing under different axial loads and rotation speeds

ActiveCN101487751AReduce rotation speedUnable to measure frictional torqueWork measurementTorque measurementHead pressingFriction torque

The invention relates to a device for measuring friction torque of a bearing under different axial load and revolution speed, comprising a fixing component, an axial loading component, a display component and a measurement component arranged on a stander base, wherein, the measurement component is arranged in a bearing support by an upper bearing and a lower bearing which are the same and fixed on a stander workbench, a bushing on the workbench supports the end face of the bearing outer ring of the lower bearing, so as not to contact the end face of the inner ring, and a loading head presses the end face of the bearing outer ring of the upper bearing. The two same bearings are used for measurement so that the axial load is not directly applied to a transmission shaft and a driving device to influence and damage the operation of the driving device. The voltage of a direct current motor is adjusted by a voltage regulator, so as to adjust the rotate speed of the motor. The axial load is adjusted by rotating a screw. The device can measure larger and different load and bearings with higher and different rotate speed, has wide measurement range which can be adjusted, can meet different requirements of users, and has the advantages of simple structure, easy fabrication, convenient, accurate and intuitive operation and use, wide universality and strong practicability.

Owner:NINGBO CIXING BEARING

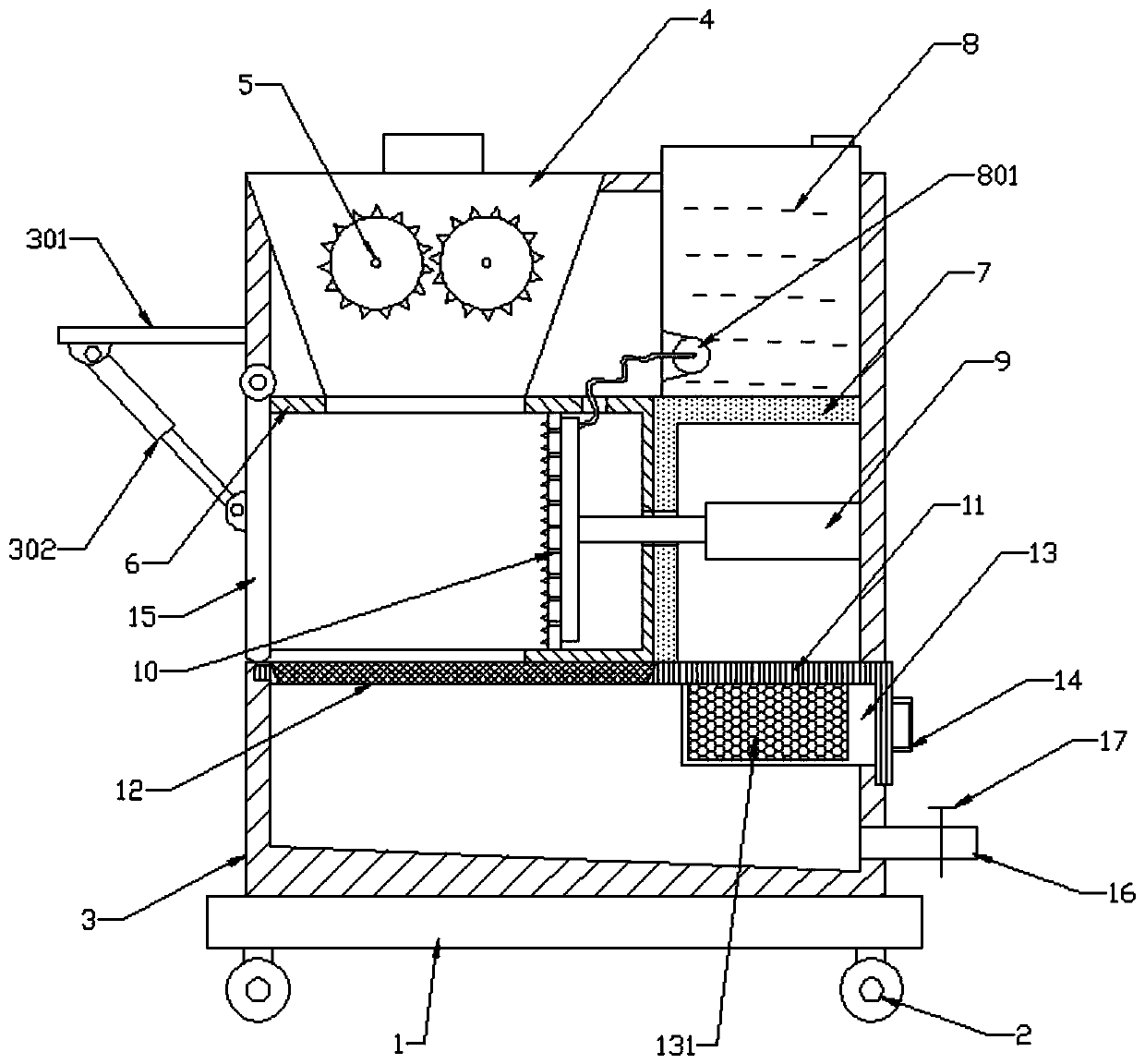

Medical waste solid-liquid separating device with good separation effects

InactiveCN110302864ASmall footprintEasy dischargeSolid waste disposalMedical waste disposalHead pressingMedical waste

The invention discloses a medical waste solid-liquid separating device with good separation effects. The device comprises a bottom seat, wherein the top of the base is connected with a rack, the top of the inner cavity of the rack is connected with a feed hopper, the bottom of the feed hopper is connected with an extruding frame, the right side of the extruding frame is connected to a mounting rack, and the top of the mounting rack is connected to a disinfection box; the mounting rack is internally connected with a first hydraulic telescopic rod, wherein the first hydraulic telescopic rod extends into one end of the extruding frame and is connected with a head pressing assembly; the lower part of the inner cavity of the frame is inserted with a L-shaped plate, wherein the right side of thebottom of the L-shaped plate is connected with a storage frame, and the storage frame is internally provided with an active carbon cloth bag; the left side wall of the rack is hinged with a discharging plate, and the bottom of the right side wall of the rack communicates a discharging pipe. The medical waste solid-liquid separating device has the advantages of being reasonable in structure design, simple in operation and capable of effectively reducing waste occupying space, improving the space utilization rate of the device, and facilitating the discharging of internal residual liquid, thusfurther improving solid-liquid separation effects and achieving high use value.

Owner:长沙曙光医疗科技有限公司

Testing device and testing method of a semiconductor device

InactiveUS7129726B2Simple structureEffective temperature controlSemiconductor/solid-state device testing/measurementContactless circuit testingHead pressingSemiconductor

Owner:SOCIONEXT INC

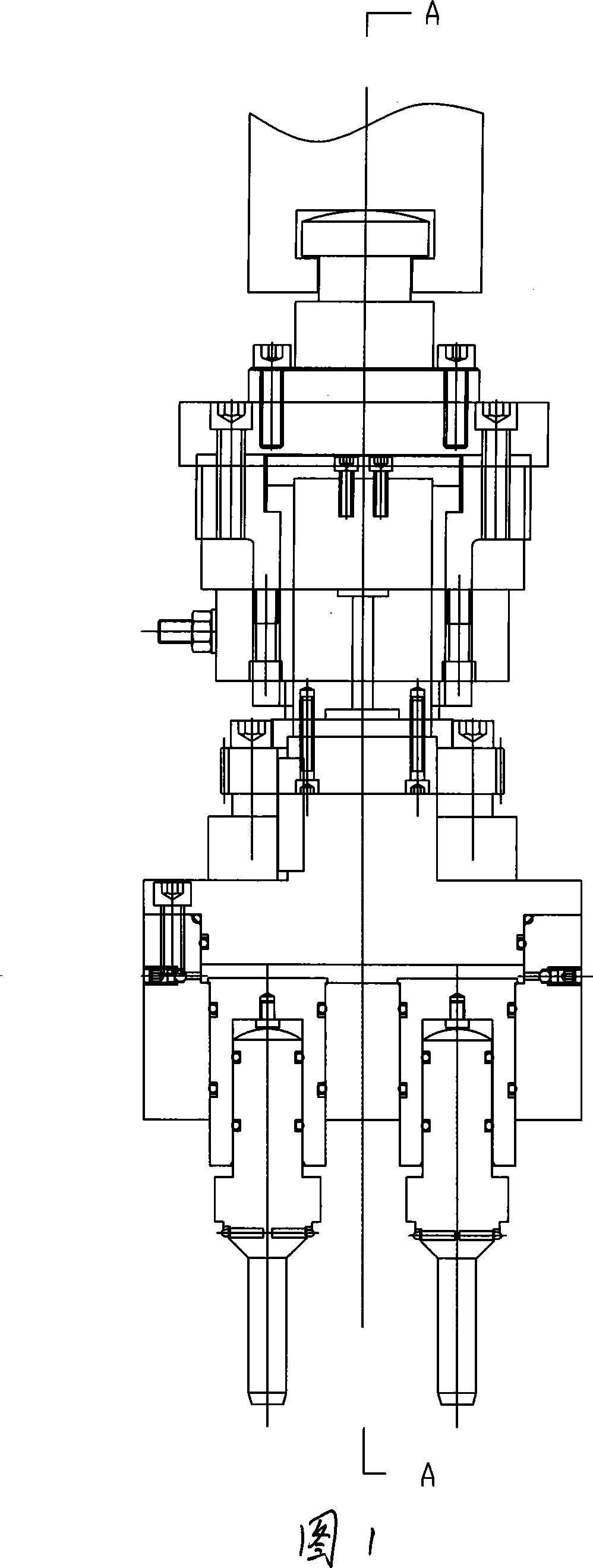

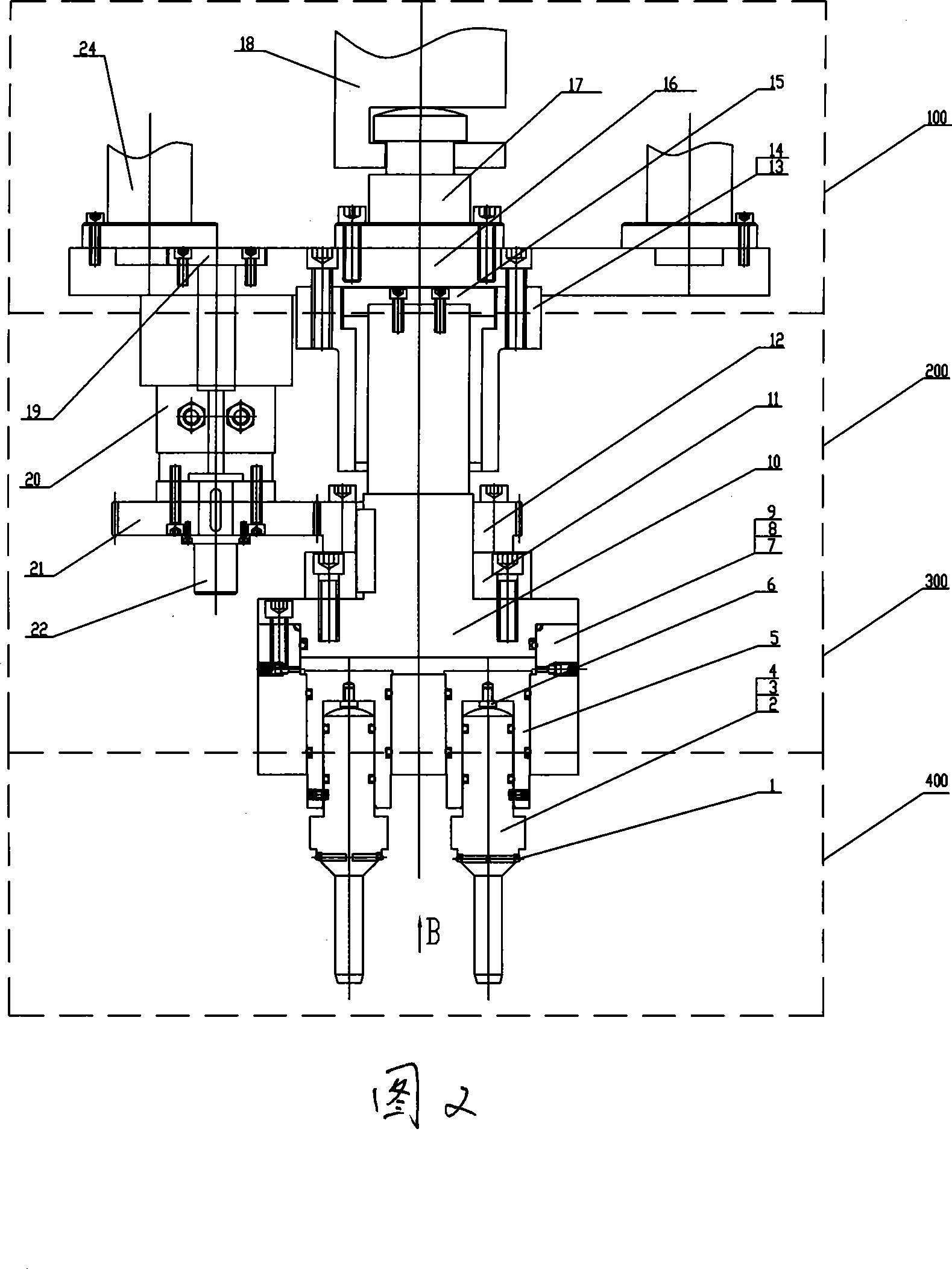

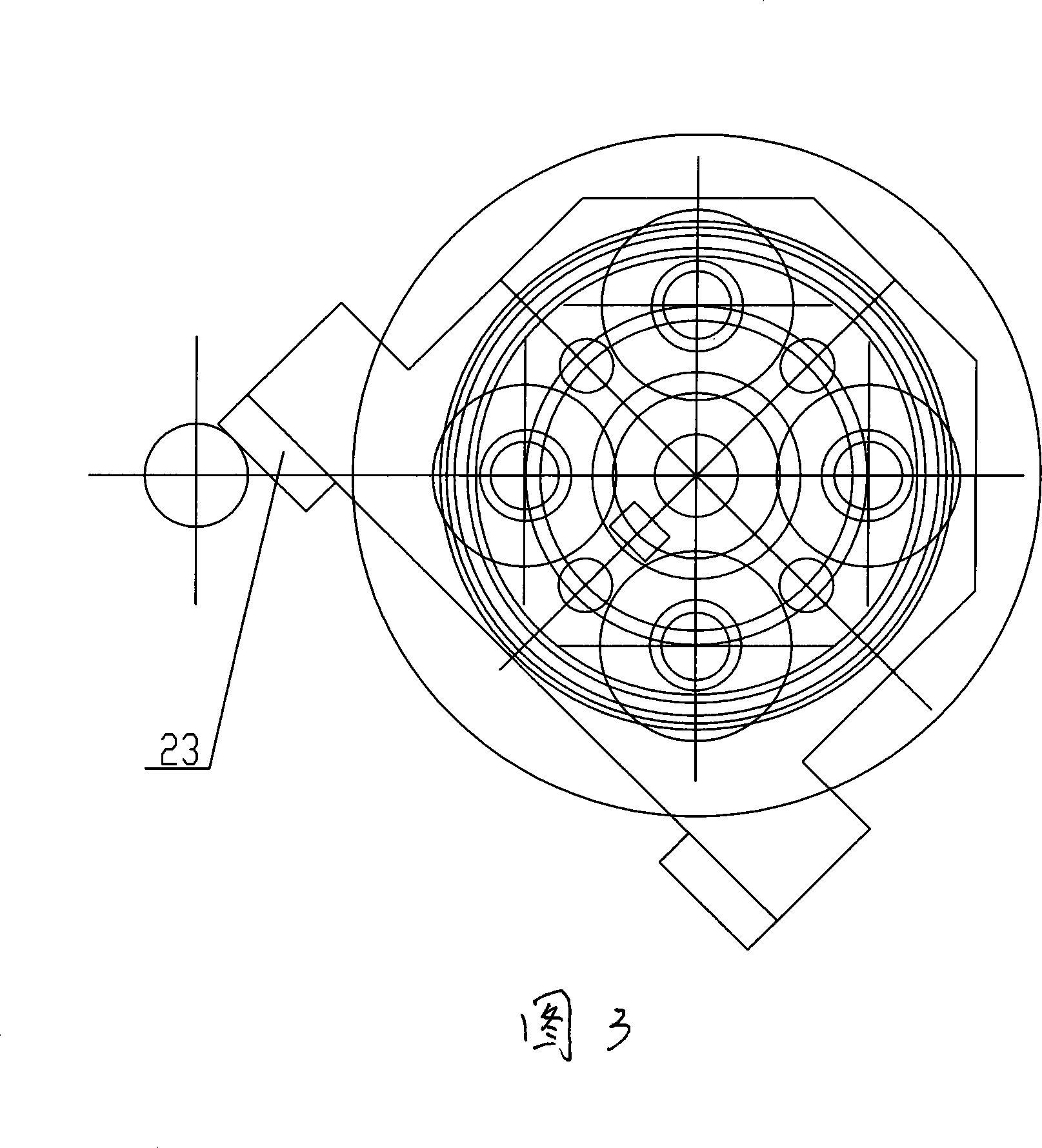

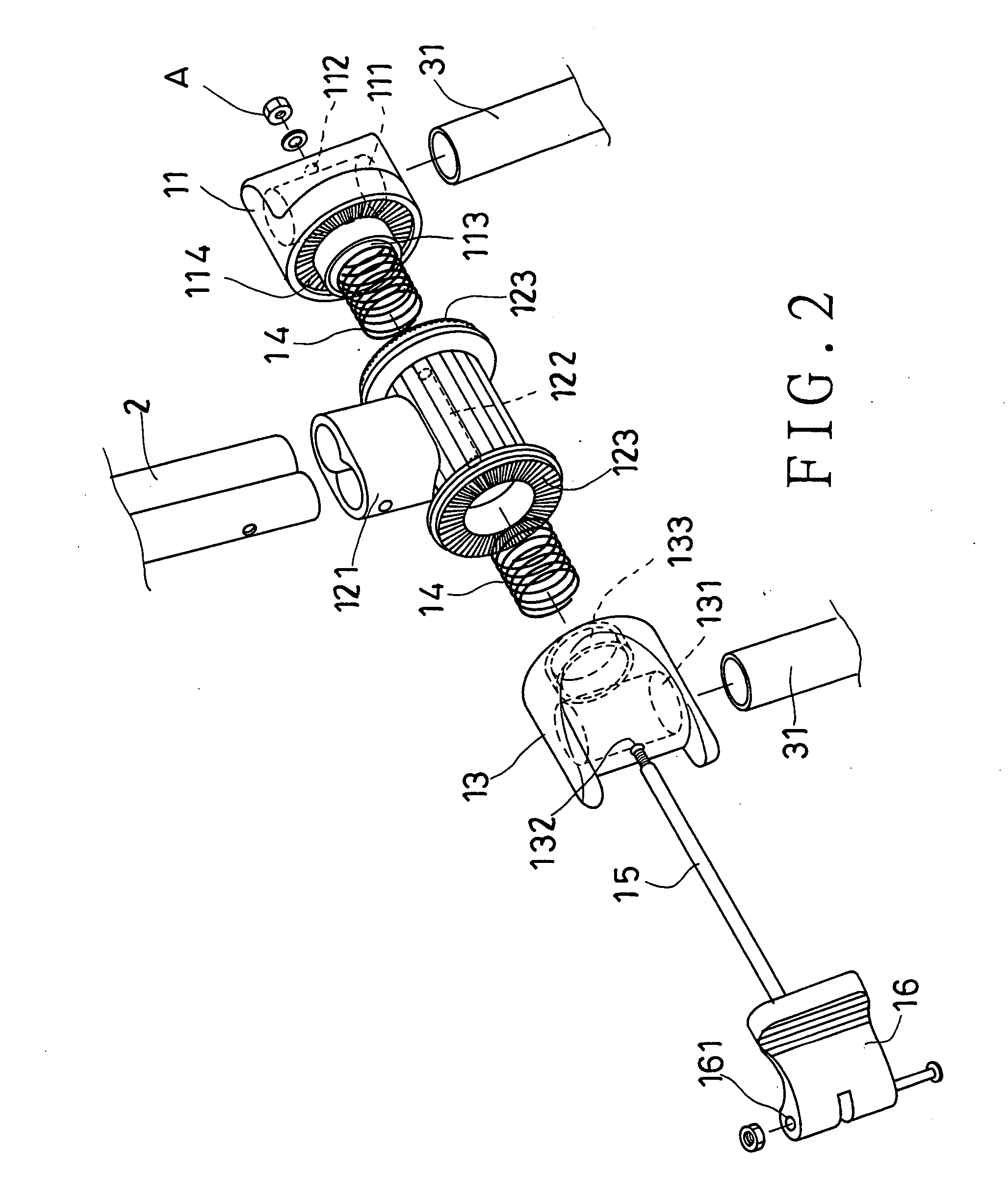

Self-adapting multi-headed press mounting machine

InactiveCN101224545ASimple structureHigh degree of automationMetal working apparatusFree rotationHead pressing

The invention discloses a self-adaptive multi-head press fit mechanism. The invention is characterized in that the press fit system comprises 4 pressing heads which are respectively arranged in 4 pistons, are supported by an O-shaped sealing ring and are positioned by a positioning pin so as to form a floating connection. The 4 pistons are arranged in an oil cylinder body; the oil cylinder body and a pressing head body are fixedly connected through a bolt. Viscous pressure oil is fully injected in a cavity formed between the oil cylinder body and the pressing head body; the cavity is sealed by steel balls and screws. The pressing head body is fixed on a bracket through an oil-free bearing and a flange and can be freely rotated. The pressing head body is fixed with pressing plates and gears; the pressing plates are arranged according to required phase positions; the initial phase position is determined by a gear pair; a mating gear is arranged on a pneumatic swing platform; the positioning pin is arranged on the mating gear; the gear pair is driven by the pneumatic swing platform to rotate; the shape of the pressing plate can control the required angles and can automatically lock the phase position. The pneumatic swing platform is arranged on the bracket which is pushed by the oil cylinder to advance and achieves the press fit by the guidance of a guide rod.

Owner:DALIAN ZHIYUN AUTOMATION

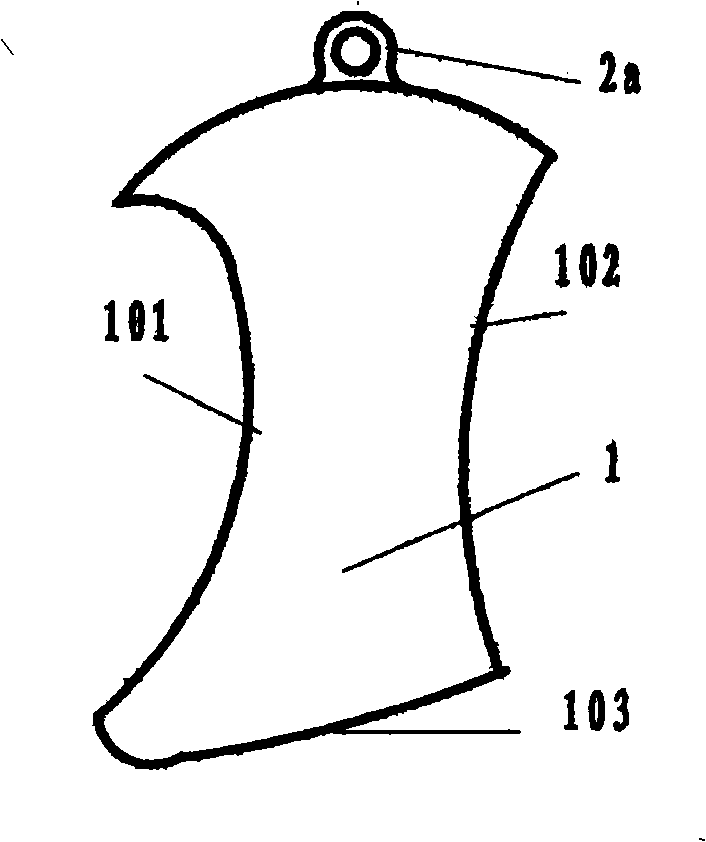

The method of the orientation profiling of the lanthanide permanent magnet and preparation device for the same

InactiveCN1996514AReduce volumeReduce consumptionPermanent magnetsInorganic material magnetismHead pressingRare earth

This invention relates to one rare each permanent part pressing and shaping method and its magnetic adding device and taking device, wherein, the shaping method comprises the following steps: top head presses the material case into magnetic powder into mode; top and down heads unmoved and negative mode elevates to fill powder into magnetic field; top head and negative mode unmoved, the top head presses into magnetic part; the negative mode drops till whole magnetic part outside negative mode; the top head elevates to push pull bar into finally product area; the materials add devices comprises materials case and barrel with changeable height.

Owner:姚燕 +1

Sorting and counting machine

InactiveCN1558376AChange the method of removing banknotesChange the way of operationPaper-money testing devicesHead pressingElectric machinery

The present invention, clearing and classifying machine, is one bank note clearing, classifying and identifying equipment used in bank and other financial organism. It has structure including frame, bank note feeding mechanism, detecting channel, several bank note separating mechanisms, several bank note accepting mechanisms, conveying channel and auxiliary bank note exit. The frame consists of seat, front frame and back frame; the bank note feeding mechanism consists of separator, friction wheel, feeding wheel and feeding motor; the detecting channel consists of upper and lower sensor installing boards, magnetic head pressing wheel, conveying wheel and pressing wheel; the bank note separating mechanism consists of guide wheel, shift fork and several wheels; the bank note accepting mechanism consists of accepting wheel, accepting stage and motor; the conveying channel consists of motor and other parts; and the auxiliary bank note exit consists of exit stage, conveying wheel, etc.

Owner:李庆宁

Automatic fiber placing device for placing fibrous composite material

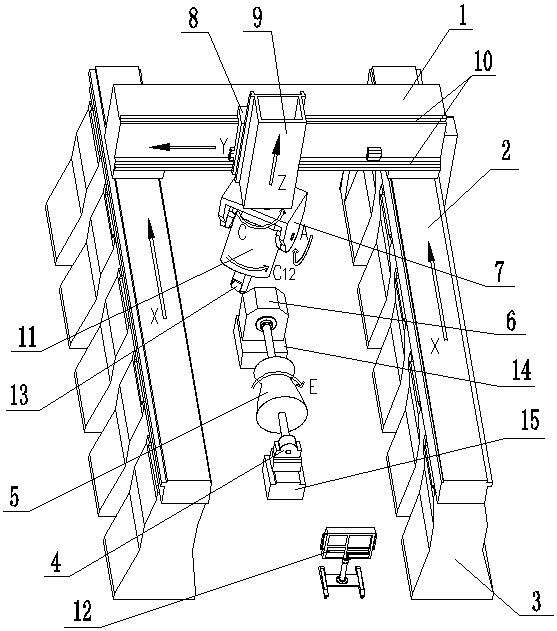

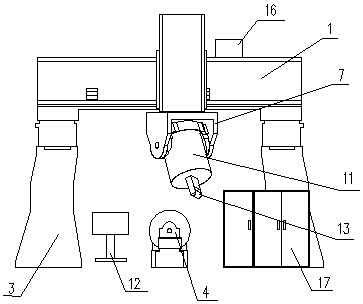

PendingCN108422685ATurn freely and convenientlyGuaranteed rotation attitude at any angleHead pressingControl system

The invention discloses an automatic fiber placing device for placing a fibrous composite material. Two servo motors A drive two output gears to be rotated along an X-directional long rack, so a crossbeam is driven to be slid along a longitudinal beam; a servo motor B drives a sliding base to be slid along the cross beam; a servo motor C drives a Z-directional screw rod to be rotated, so a ram isdriven to be upwards and downwards slid along the sliding base; a C-axis rotation mechanism fixed on a fixing body drives a C-axis rotation body to be rotated along a C-axis of a center shaft of theC-axis rotation body; an A-axis rotation mechanism drives a swinging body to be rotated along an A-axis of an axial lead of two coaxial shafts; a C1-axis rotation mechanism fixed on the swinging bodydrives a creel to be rotated along a C1-axis of a center shaft of the creel; a fiber placing head and a fiber placing head press roller are fixed at the lower end of the creel; a control system controls the C-axis, C1-axis and A-axis rotation mechanisms and a brake device to be operated; and a servo motor D drives a workpiece to be rotated along a rotation principal axis of the workpiece. The automatic fiber placing device is high in placement precision, rapid in speed, high in placement working efficiency, and stable in placement quality.

Owner:BAODING BIAOZHENG MACHINE TOOL

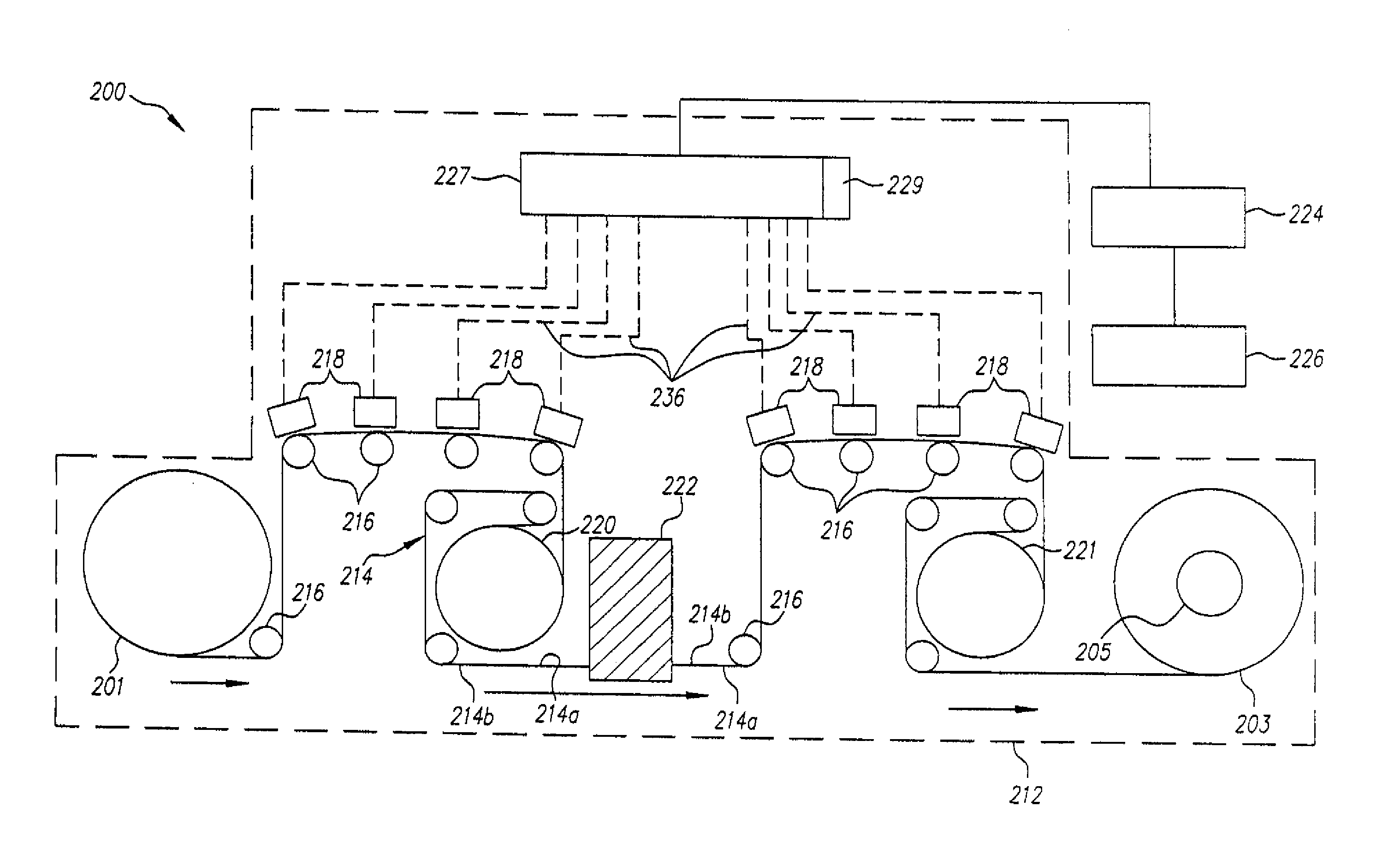

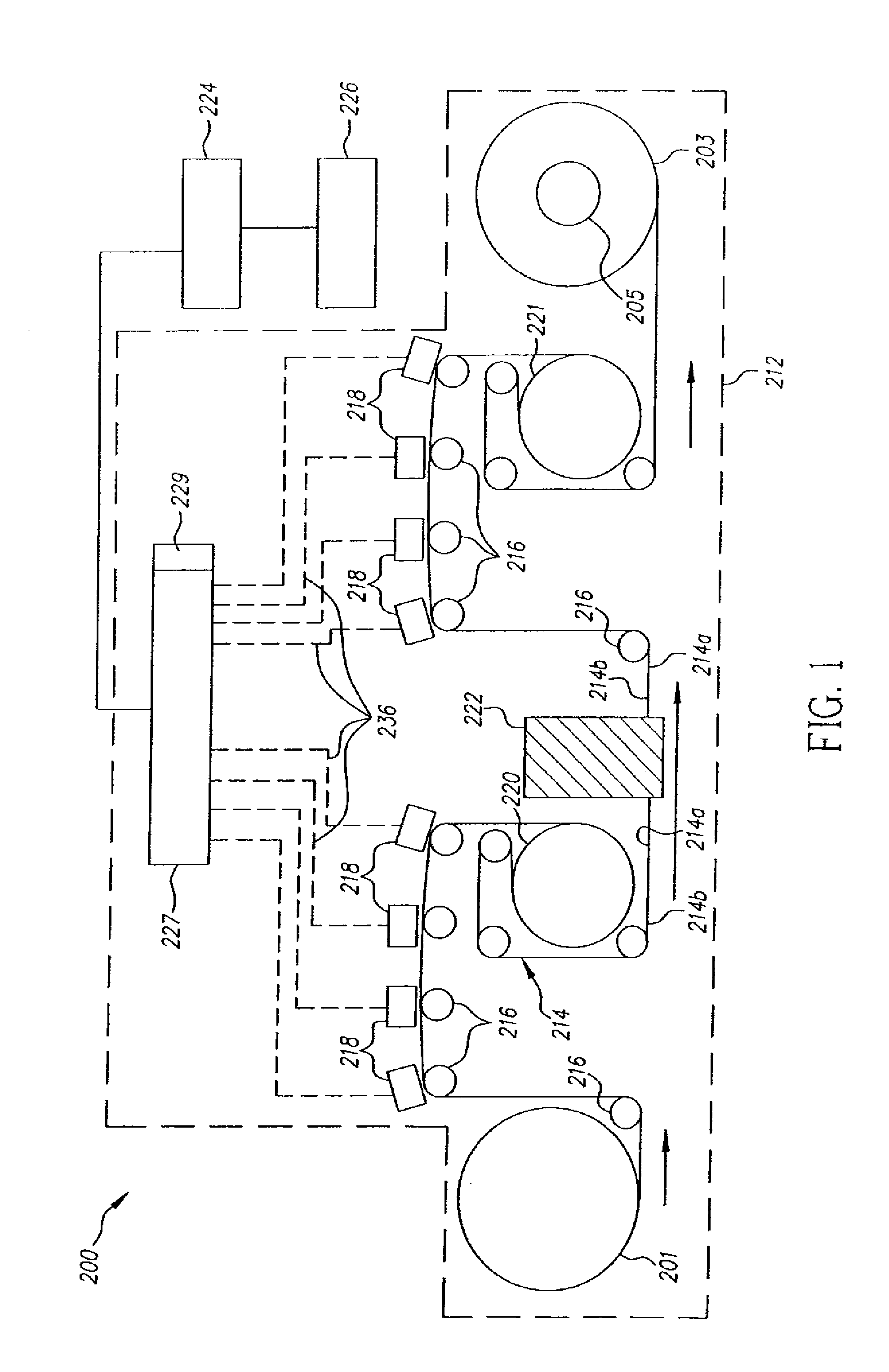

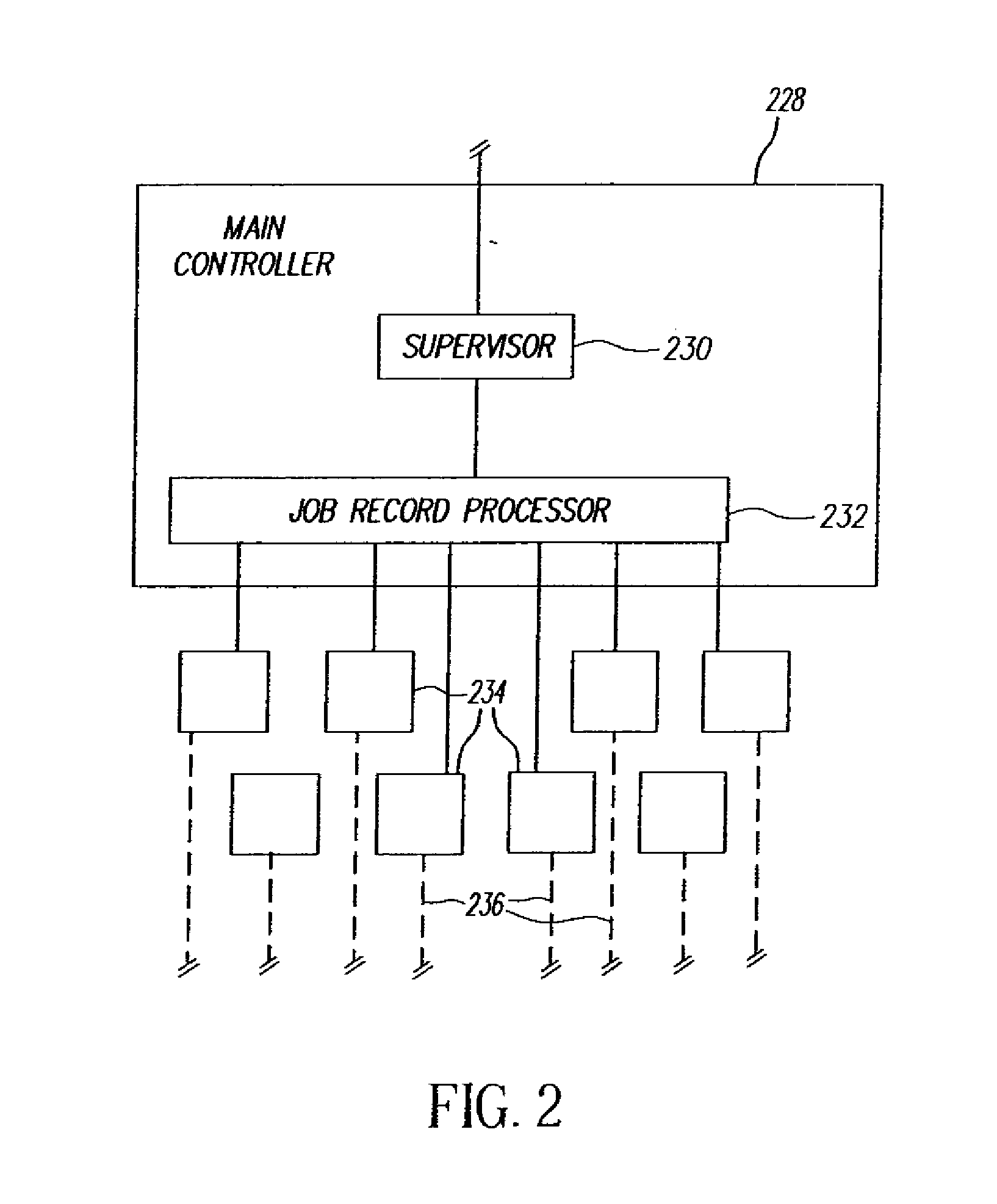

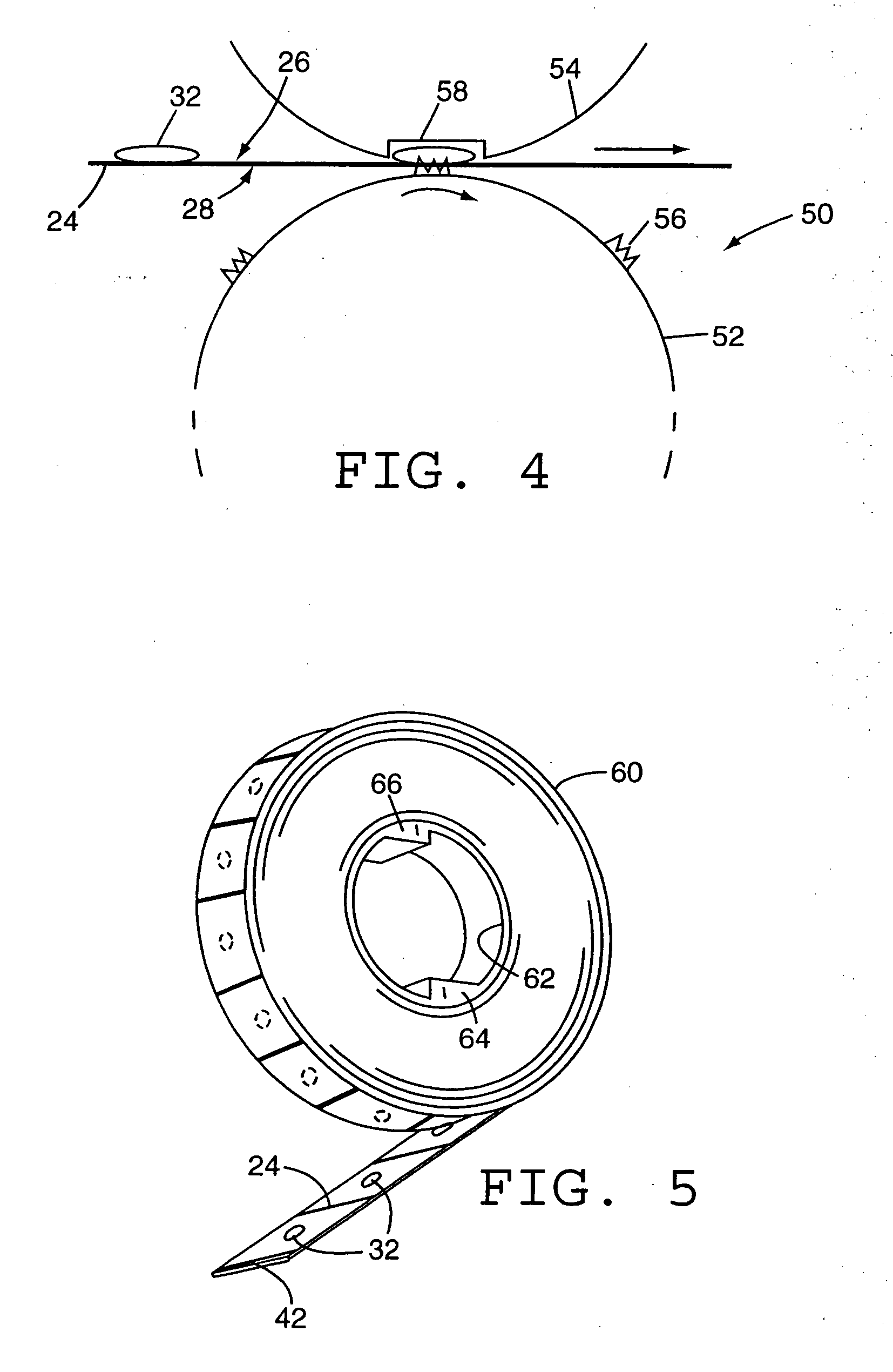

Multi-head press data delivery rate control

ActiveUS20090027716A1Visual presentation using printersOther printing apparatusHead pressingData transmission

In a printing method and systems, segments of a first print job are distributed to respective downstream processors and are processed to provide printable frames, which are stored in respective print queues. Each print queue supplies a respective one or more printheads. The printable frames are sequentially printed on a continuously transported receiver. A maximum printing duration of each of the print queues is computed periodically during the printing. The transport speed is regulated to trend the maximum printing durations toward a predetermined baseline. The sending of a second print job to the downstream processors is delayed, while processing of the first print job is completed. The delaying is counter to the regulating and reduces the print queues of the first print job non-uniformly relative to the baseline.

Owner:EASTMAN KODAK CO

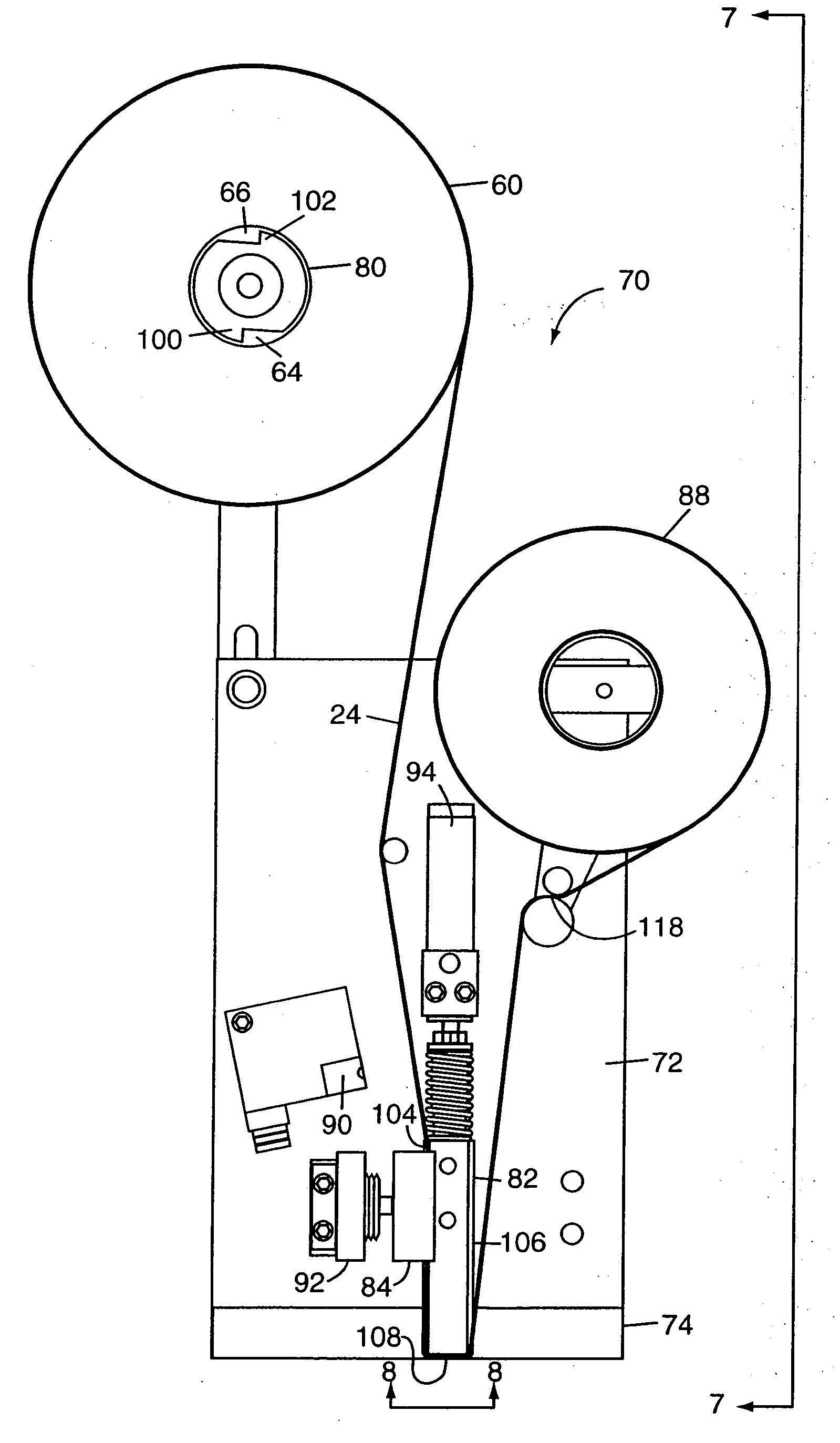

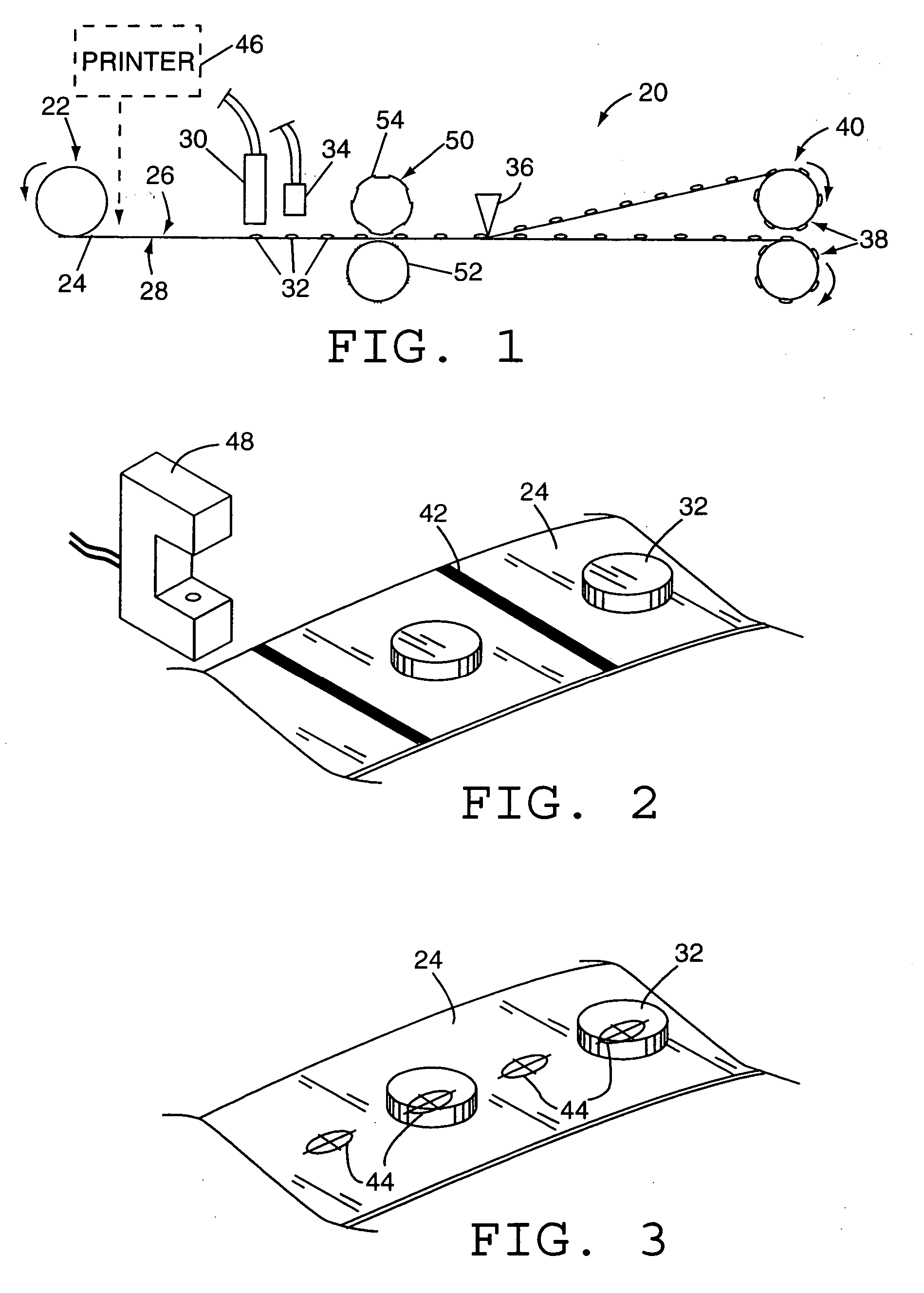

Adhesive segment applicator method and apparatus and roll of adhesive segments for use therewith

InactiveUS20060040085A1Facilitates assured releaseLamination ancillary operationsLaminationAdhesive beltHead pressing

An automated system and method for applying thermoplastic adhesives to work pieces from a roll of adhesive segments applied to an adhesive segment-laden carrier release tape. The adhesive segment is applied from the adhesive segment-laden carrier release tape onto a work piece by the use of an automatically actuated applicator head that contacts the surface of the adhesive segment-laden carrier release tape opposite the adhesive segment thereon to push the adhesive segment against the work piece to apply the adhesive segment to the work piece. The applicator head may include one or more sharp projections thereon that pierce through the carrier release tape, but not through the adhesive segment thereon, as the head presses the carrier release tape and adhesive segment against the work piece to facilitate assured release of the adhesive segment from the carrier release tape and application of the adhesive segment to a work piece by the applicator head. Alternatively the adhesive segment carrier release tape may be pre-perforated underneath each adhesive segment thereon.

Owner:GLUE DOTS INT

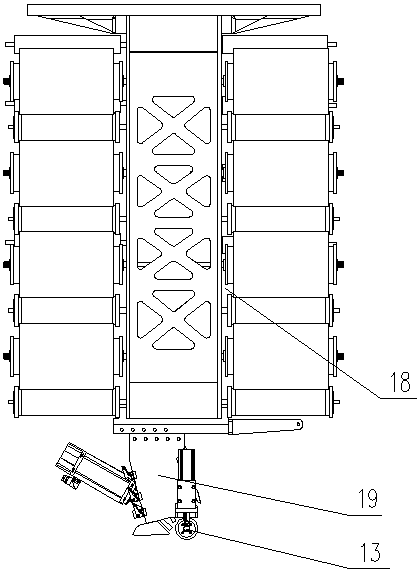

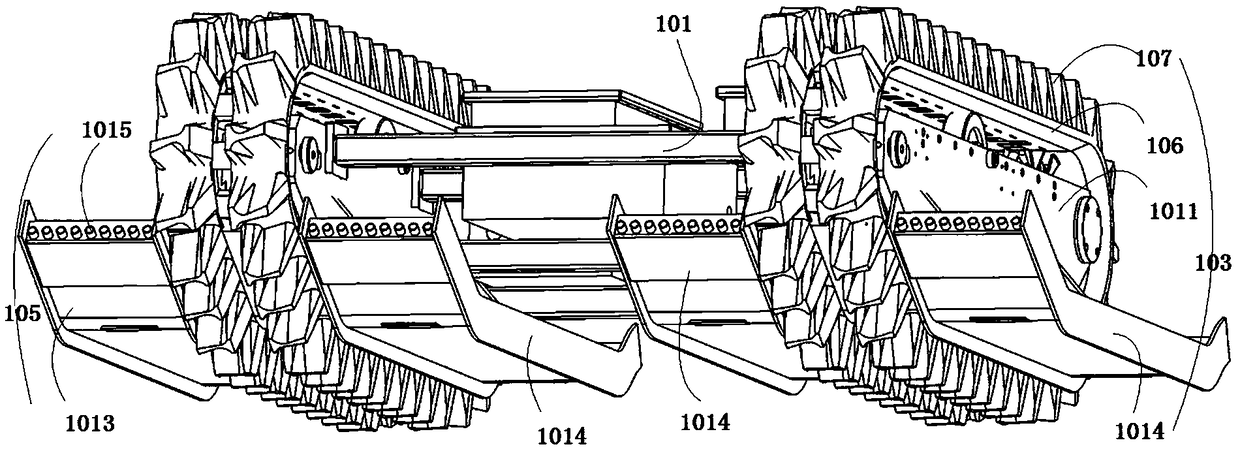

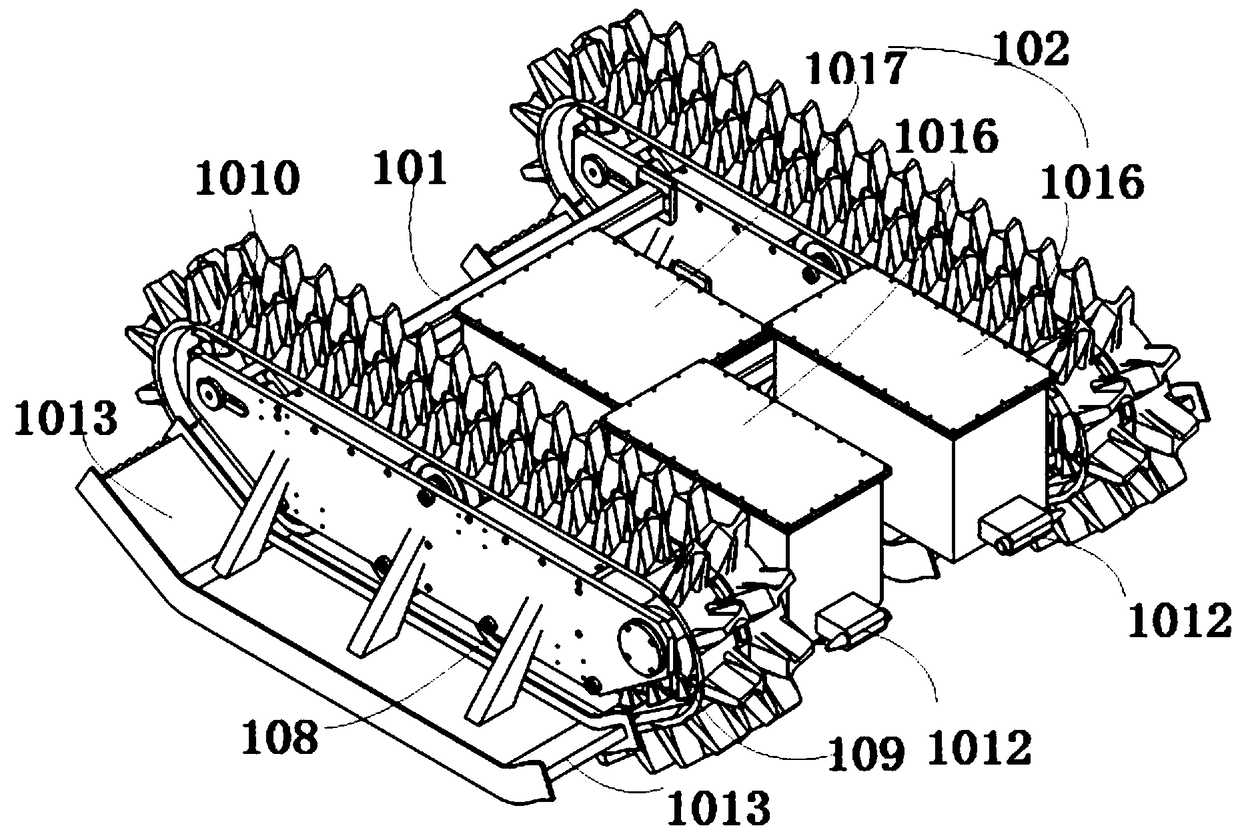

Floatable track type special underwater operation robot suitable for extremely soft geology

ActiveCN109291743AKeep goingGuaranteed smooth progressAmphibious vehiclesEndless track vehiclesOcean bottomHead pressing

Owner:SHANGHAI JIAO TONG UNIV

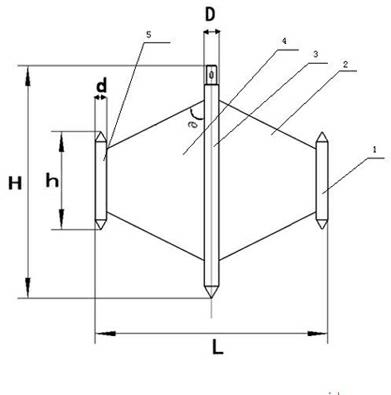

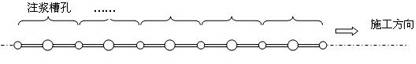

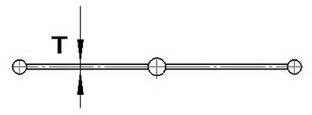

Tri-cone-head pressing grooving plate and grouting slot construction method

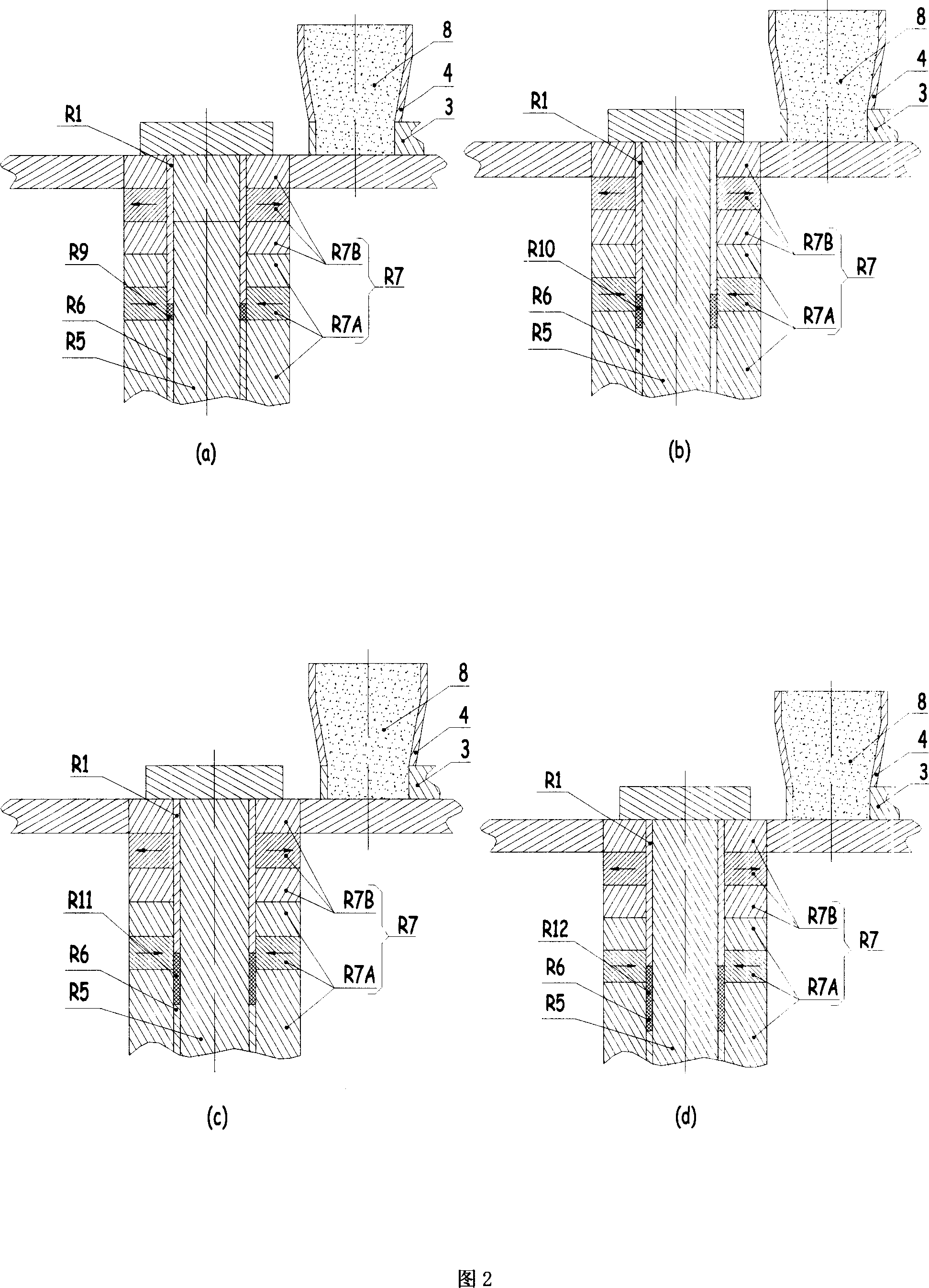

ActiveCN102425199AImprove continuityFast constructionProtective foundationSoil-shifting machines/dredgersHead pressingPetroleum engineering

The invention discloses a tri-cone-head pressing grooving plate, which comprises a middle drill rod, a left drill rod and a right drill rod, wherein the left drill rod and the right drill rod are same in shape and size; the left drill rod is connected to the middle drill rod through a left wing plate; the right drill rod is connected to the middle drill rod through a right wing plate; the left wing plate and the right wing plate are same in shape and size; central lines of the middle drill rod, the left wing plate, the right wing plate, the left drill rod and the right drill rod are all in a same horizontal plane; the lower end of the middle drill rod is a cone head while the upper end is provided with a connecting head; and the two ends of the left drill rod and the right drill rod are both conical. The invention also discloses a grouting slot construction method by using the tri-cone-head pressing grooving plate. According to the construction method, continuous grouting slots can beconstructed in a soil body; a continuous, uniform, regular and ultrathin high polymer impervious wall is formed after the slots are grouted; and the construction method is characterized by convenience and quickness in construction, small disturbance to a dam, capability of forming continuous ultrathin grouting slots, and the like.

Owner:王复明

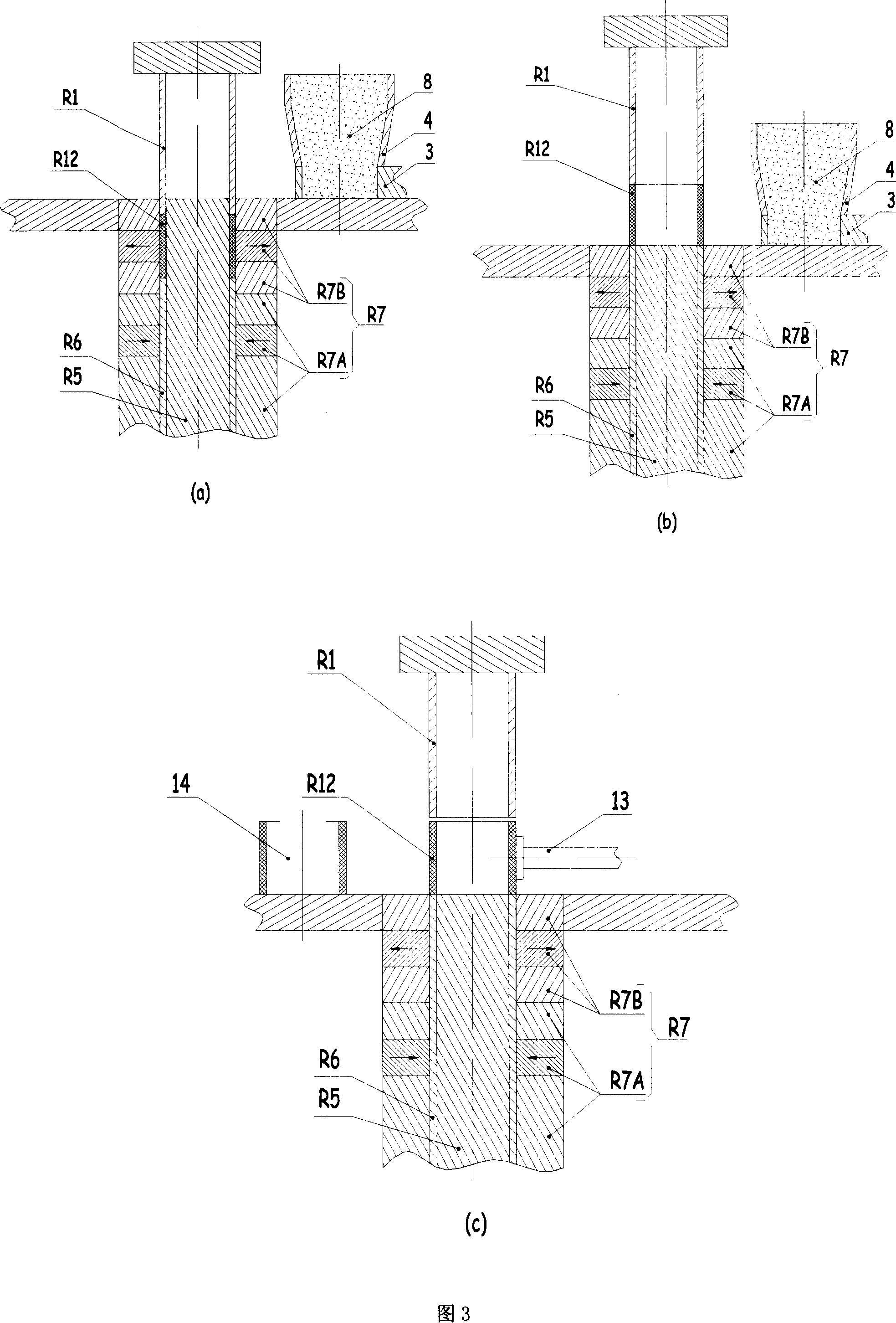

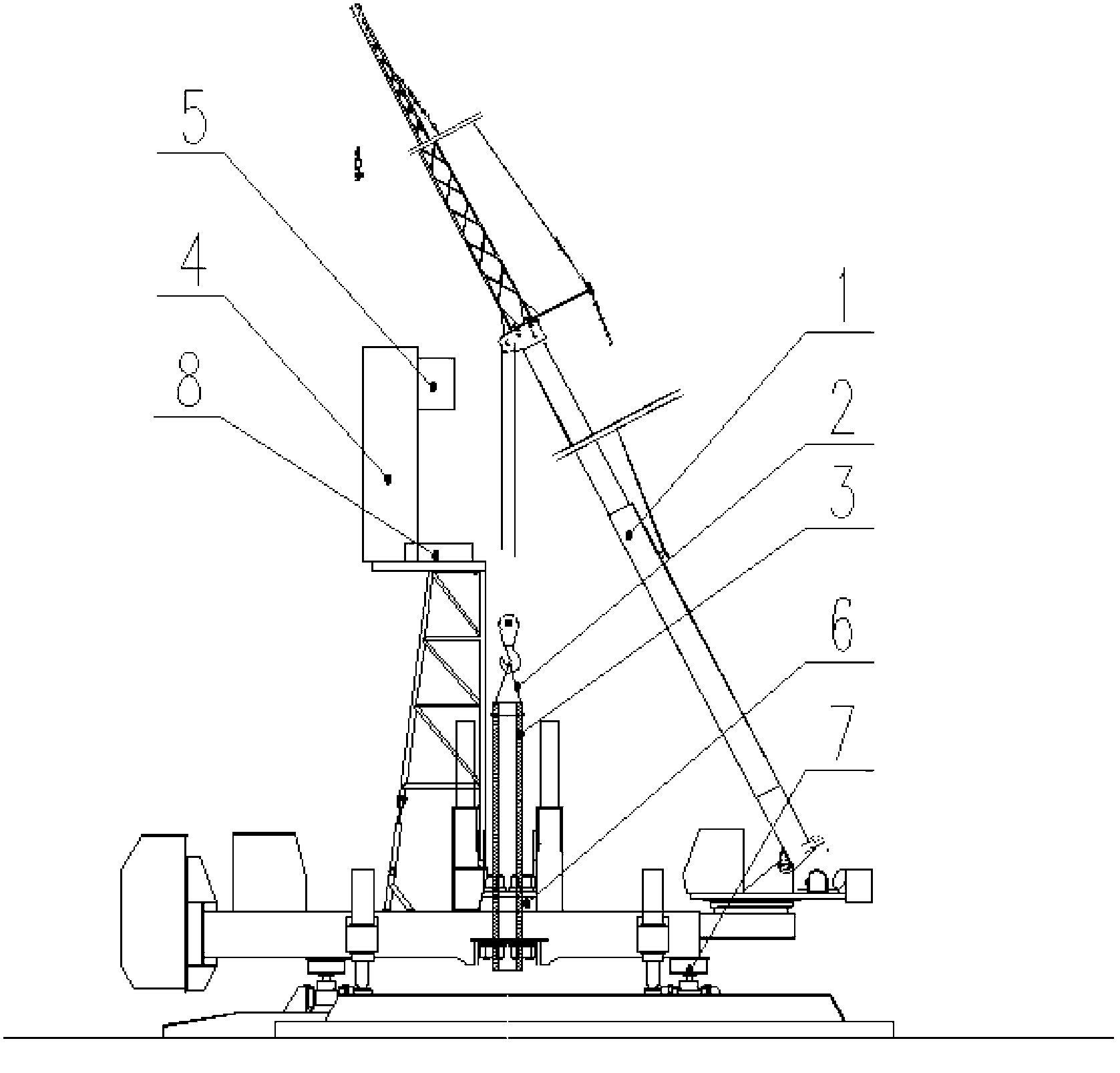

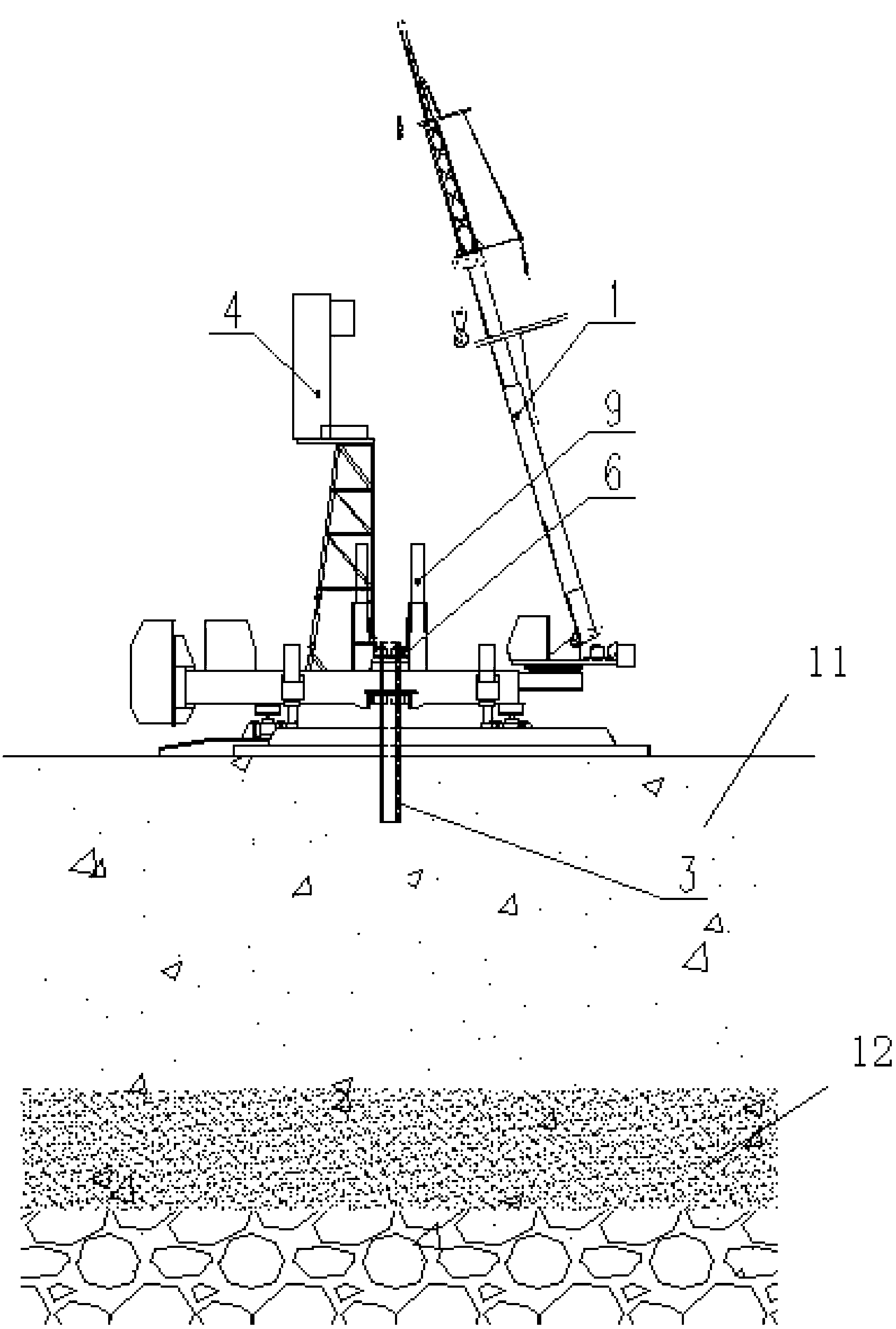

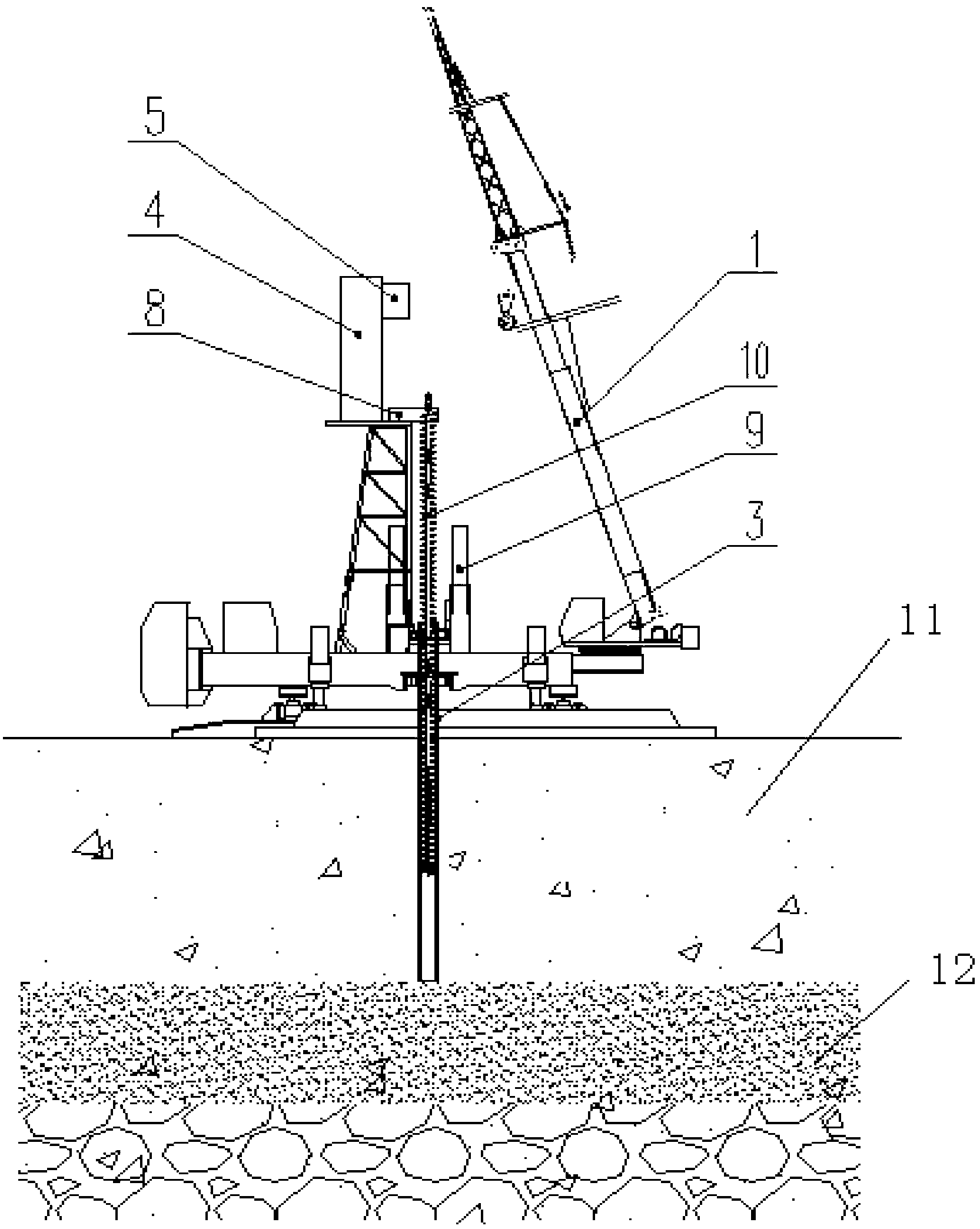

Construction method combining static pressure pile sinking with middle-digging hole guiding for buildings or bridges

InactiveCN102704481AImprove construction efficiencyReduce construction costsBulkheads/pilesHead pressingEngineering

The invention discloses a construction method combining static pressure pile sinking with middle-digging hole guiding for buildings or bridges. Equipment comprises a static force pile driver, a truss additionally arranged on the static force pile driver and capable of shifting, a power head assembled on the truss, a power head pressing device, a stem changing device for a long auger stem, and a drill stem driving tool. The construction method comprises the following steps: (1) measuring the piles position, and putting a machine in position; (2) hanging piles and preparing; (3) sinking the piles under static pressure; (4) receiving the piles; (5) mounting the long auger stem; (6) hanging the long auger stem in guided hole and sinking the piles; and (7) terminating the pile pressing. The invention provides the construction method with the advantages of capability of penetrating thicker sand beds, high construction efficiency and low construction cost.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

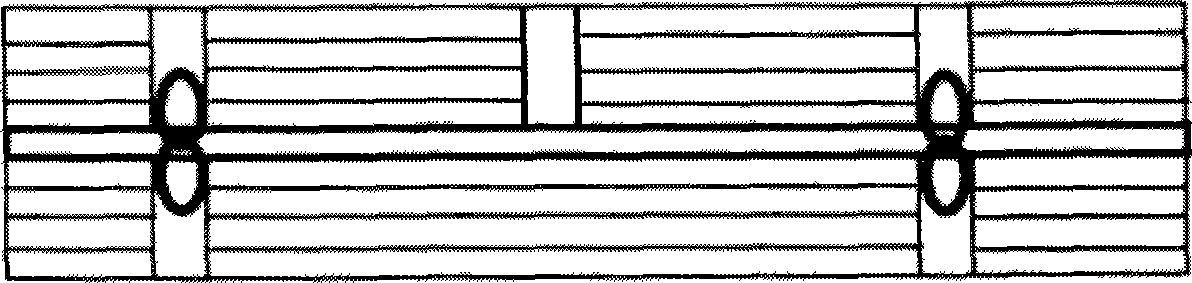

Method for producing high multilayered blind hole multilayer board by double head pressing insertion pin

ActiveCN101500376AEasy alignmentEasy to drillMultilayer circuit manufacturePrinted element electric connection formationHead pressingElectroplating

The invention discloses a method for adopting a double head pressure contact pin to produce a multi-layer plate for a multi-layer dead hole. A backboard is divided into a plurality of sub-plates. When the sub-plates is produced by hole drilling, galvanization, surface treatment and other procedures, the double head pressure contact pin is used for pressing and being connected with an upper sub-plate and a lower sub-plate for purpose of lamination and press so as to finally form a motherboard. The holes at corresponding positions of the upper sub-plate and the lower sub-plate can together form an integral through hole though the double head pressure contact pin. The other holes in which no contact pins are inserted are dead holes. The pressed plates can be used directly without wet treatment. The invention can improve the contraposition, drilling and galvanization of the high multi-layer backboard, solves the problem on the protection of mechanical dead holes, optimizes the backboard production procedures, improves the productivity and reduces the product scrap rate.

Owner:SHENNAN CIRCUITS

Tape drive system

InactiveUS20090067097A1Disposition/mounting of recording headsRecord information storageHead pressingMagnetic tape

A tape drive system according to one embodiment includes a support for engaging a tape; and a head directly opposing the support such that a tape engaging the support is positioned between the head and the support, the head being for performing at least one of reading from a tape and writing to a tape, wherein, during an operation period when the head is reading from or writing to a tape, the head is positioned such that at least one of the following occurs: the head does not contact the tape for a majority of the operation period; the head does not contact the tape for at least a portion of the operation period; and the head engages the tape for at least a portion of the operation period, the head pressing the tape towards the support when engaging the tape.

Owner:IBM CORP

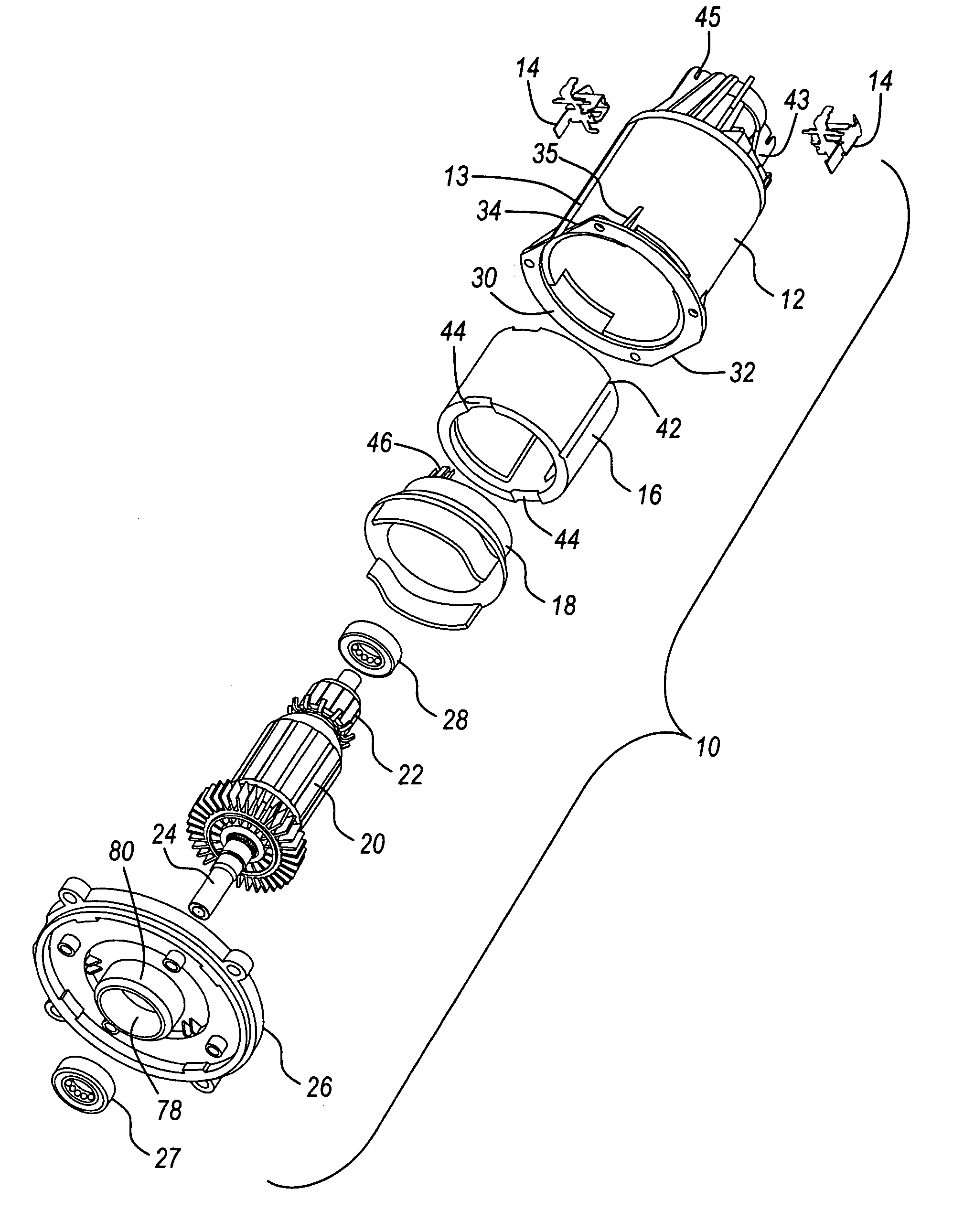

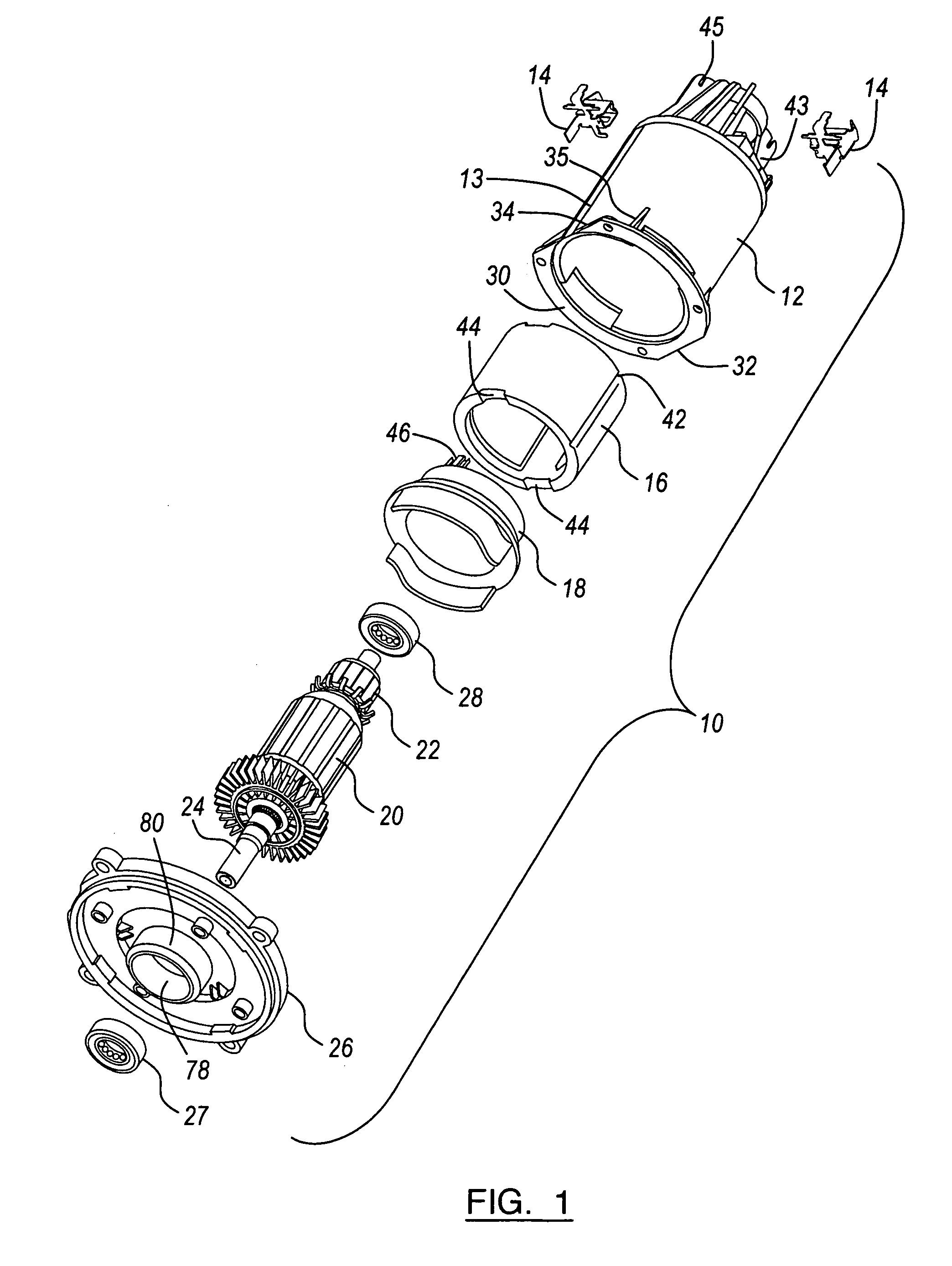

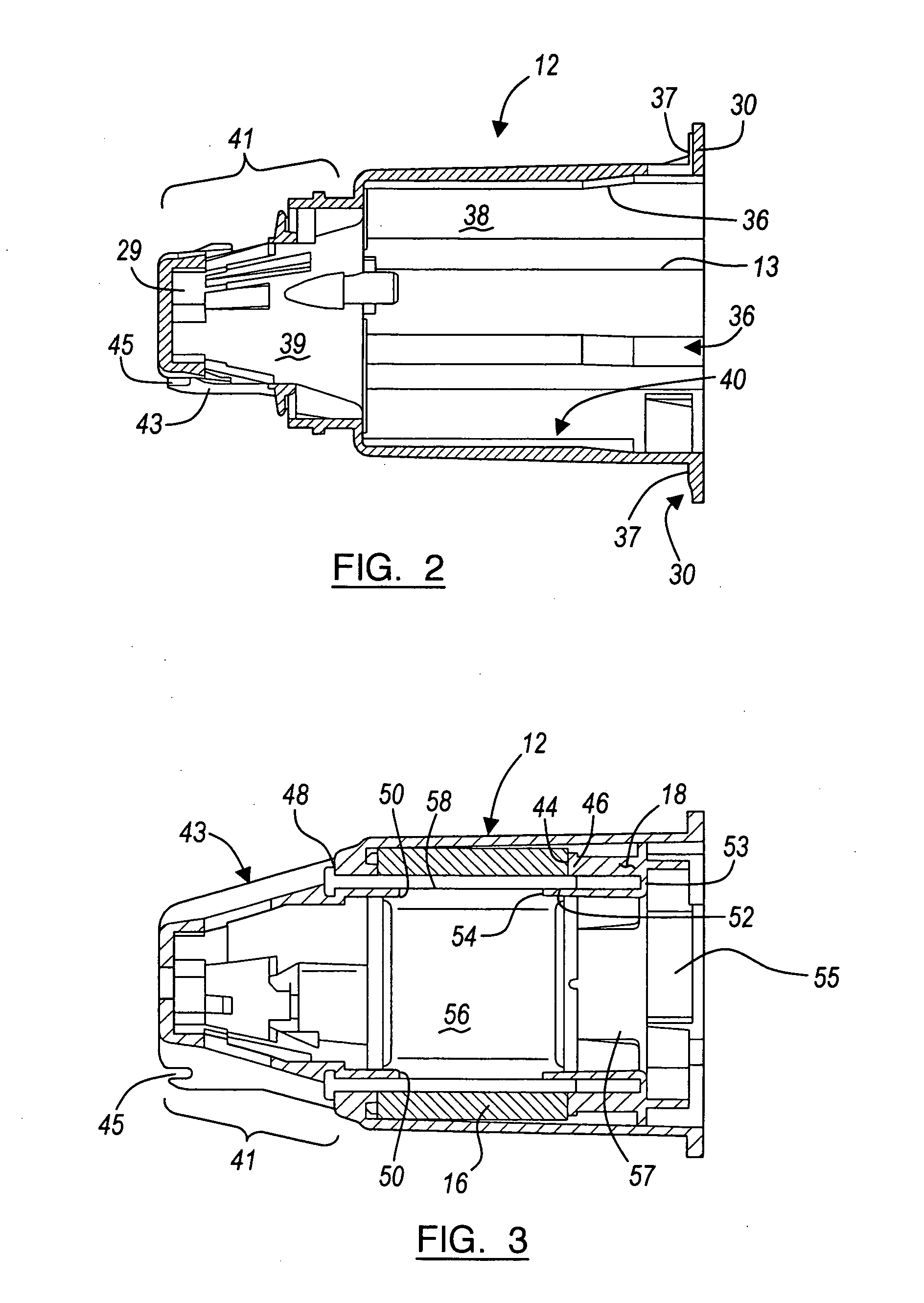

Electric motor brush assembly

An electrically conductive brush box is located against the upper surface of a base and has crimping tabs located against an oppositely disposed crimping surface. The base is formed of high temperature resistant plastic. A field case housing has a seat with a retention member adapted to retain the base against the seat. A screw is threaded into the field case housing such that the head presses against a surface of the base member to retain the base member in the seat. The screw member is located in non-contacting relationship with the electrically conductive brush box. A spacer member is adapted to space the portion of the crimping tab against the crimping surface away from the field case housing. The brush box includes a biasing member holder and the crimping tabs are located adjacent the holder.

Owner:BLACK & DECKER INC

Welding clamping device for front tripod of bicycle

InactiveCN101934456AEasy to adjustImprove efficiencyWelding/cutting auxillary devicesAuxillary welding devicesHead pressingEngineering

The invention discloses a welding clamping device for a front tripod of a bicycle. The device comprises a bottom plate, a bicycle head press block, a propelling device, a five-way pipe positioning device, at least two fixing sliding chute plates and at least three pipe cushion blocks, wherein the propelling device is arranged at the left end of the bottom plate; the front end of the propelling device is provided with the bicycle head press block; the five-way pipe positioning device is arranged at the lower right corner of the bottom plate; each fixing sliding chute plate is provided with thepipe cushion block; a vertical fixing sliding chute plate is arranged above the five-way pipe positioning device; and the bottom plate between the five-way pipe positioning device and the bicycle head press block is also provided with at least one fixing sliding chute plate. The device has the advantages of convenient adjustment, one-step clamping, one-step welding of the front tripod, manpower and labor saving, high efficiency, reduction in errors of repeated clamping and higher quality.

Owner:ZHEJIANG NORMAL UNIVERSITY

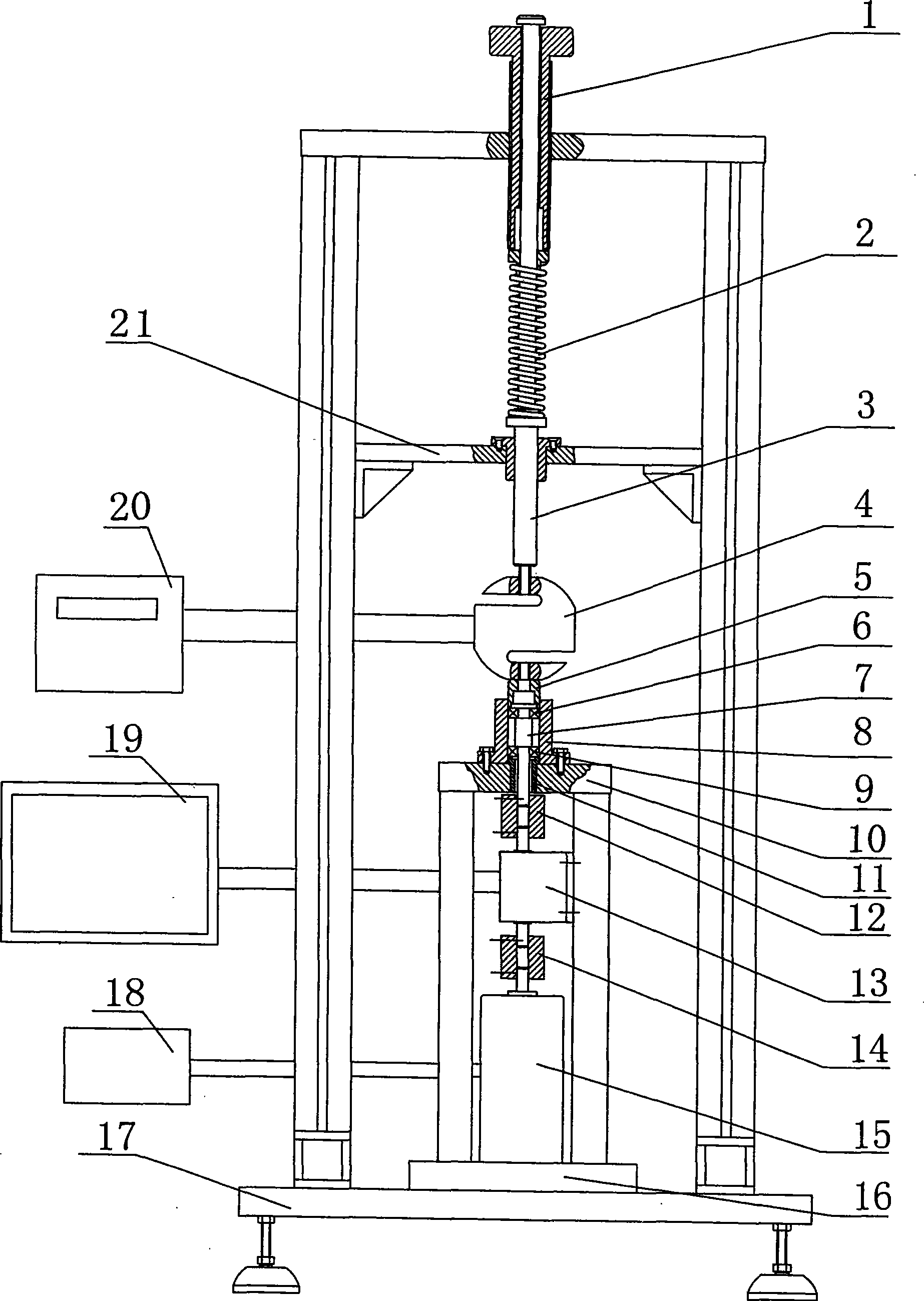

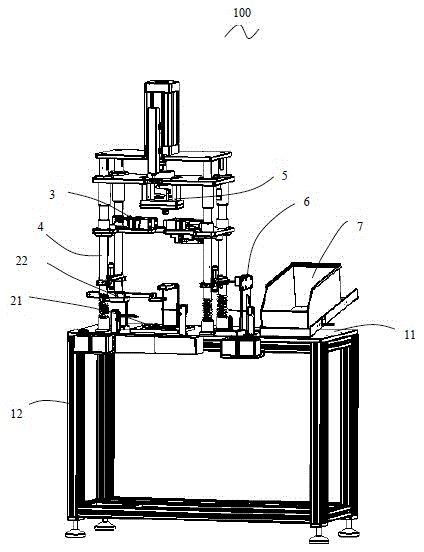

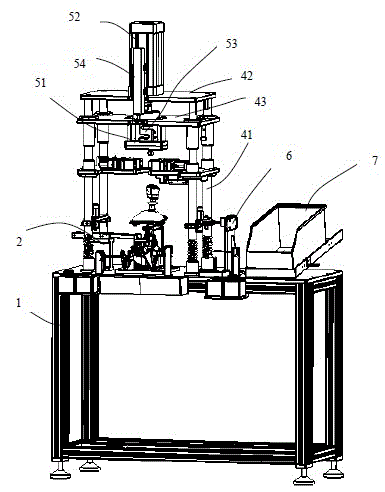

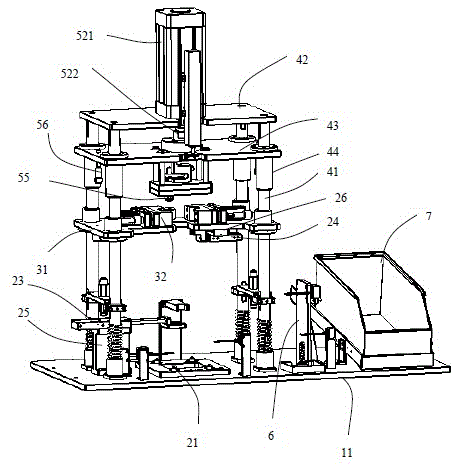

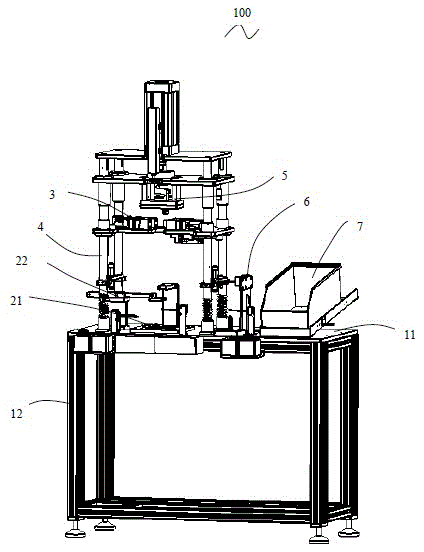

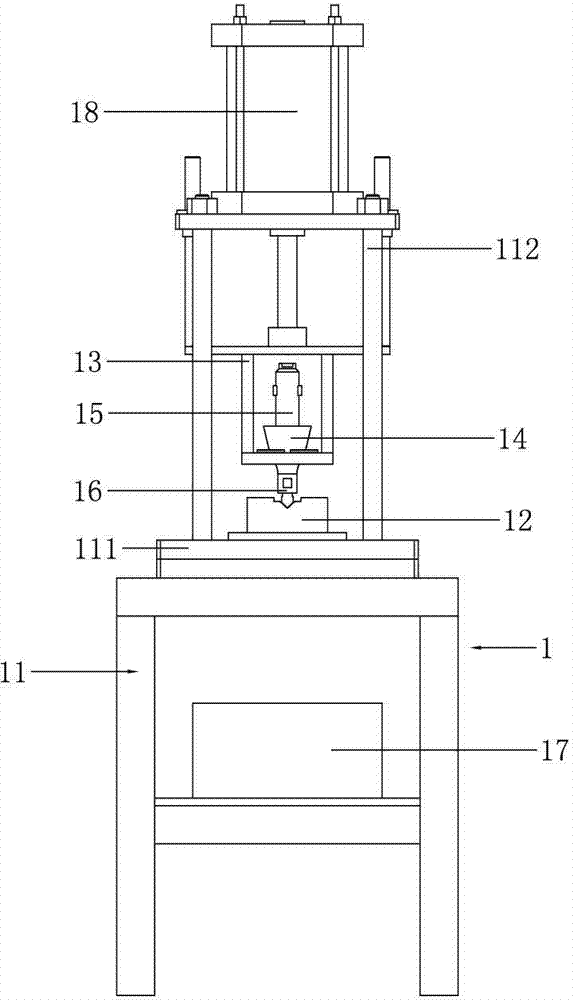

Ball head pressing equipment

InactiveCN104015031AFully automatedMake sure it fits in placeMetal working apparatusHead pressingForce sensor

The invention relates to ball head pressing equipment used for mounting a ball head on an operating rod of a workpiece. The ball head pressing equipment comprises a working table, a workpiece holder fixed on the working table and used for fixing the workpiece, a travel frame arranged on the working table, and a pressing device arranged on the travel frame and capable of vertically moving along the travel frame, wherein the pressing device comprises a pressing plate used for pressing the ball head on the operating rod, a cylinder used for driving the pressing plate to move, a force sensor fixed on the pressing plate and used for detecting the thrust of the cylinder to the pressing plate, and a displacement detecting piece arranged at one side of the cylinder and used for detecting the displacement of the pressing plate. The ball head pressing equipment realizes the ball head pressing automation, guarantees the pressing in place and reduces the erroneous judgment through being provided with the pressing device which comprises the pressing plate, the cylinder, the force sensor and the displacement detecting piece.

Owner:SIP GOLDWAY TECH

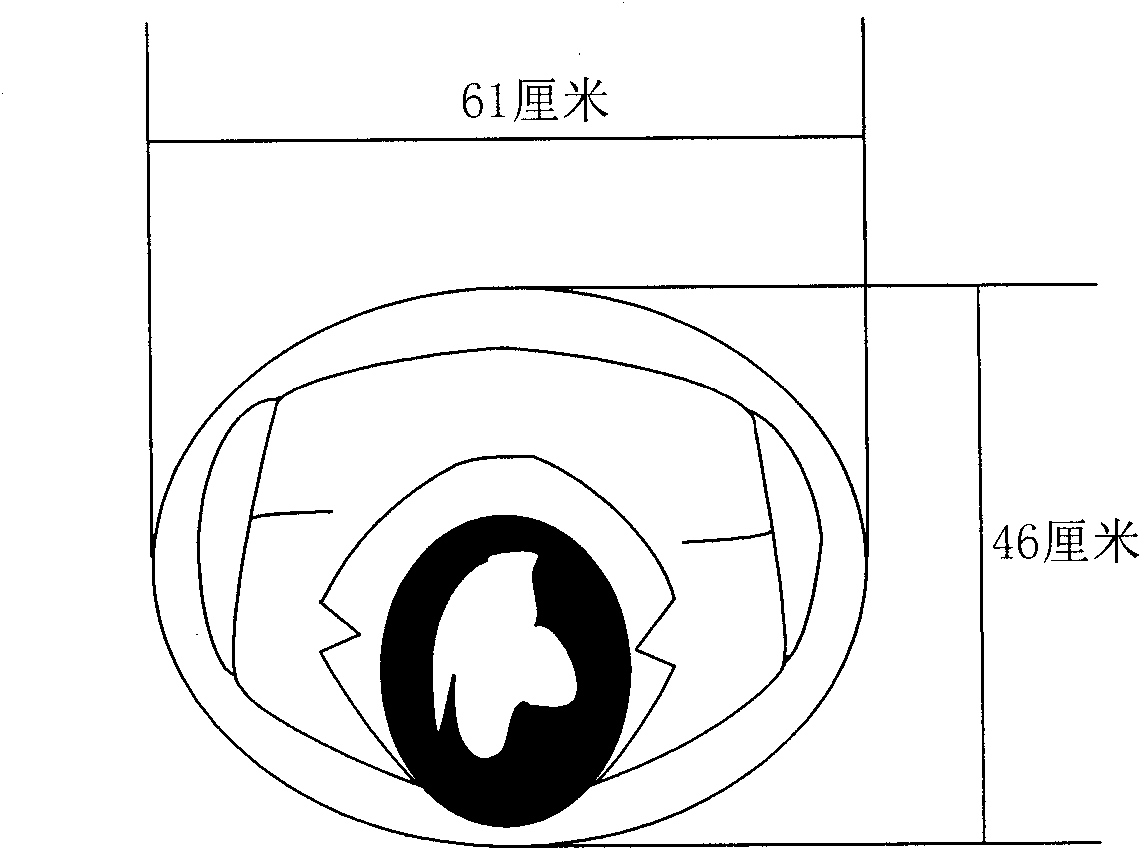

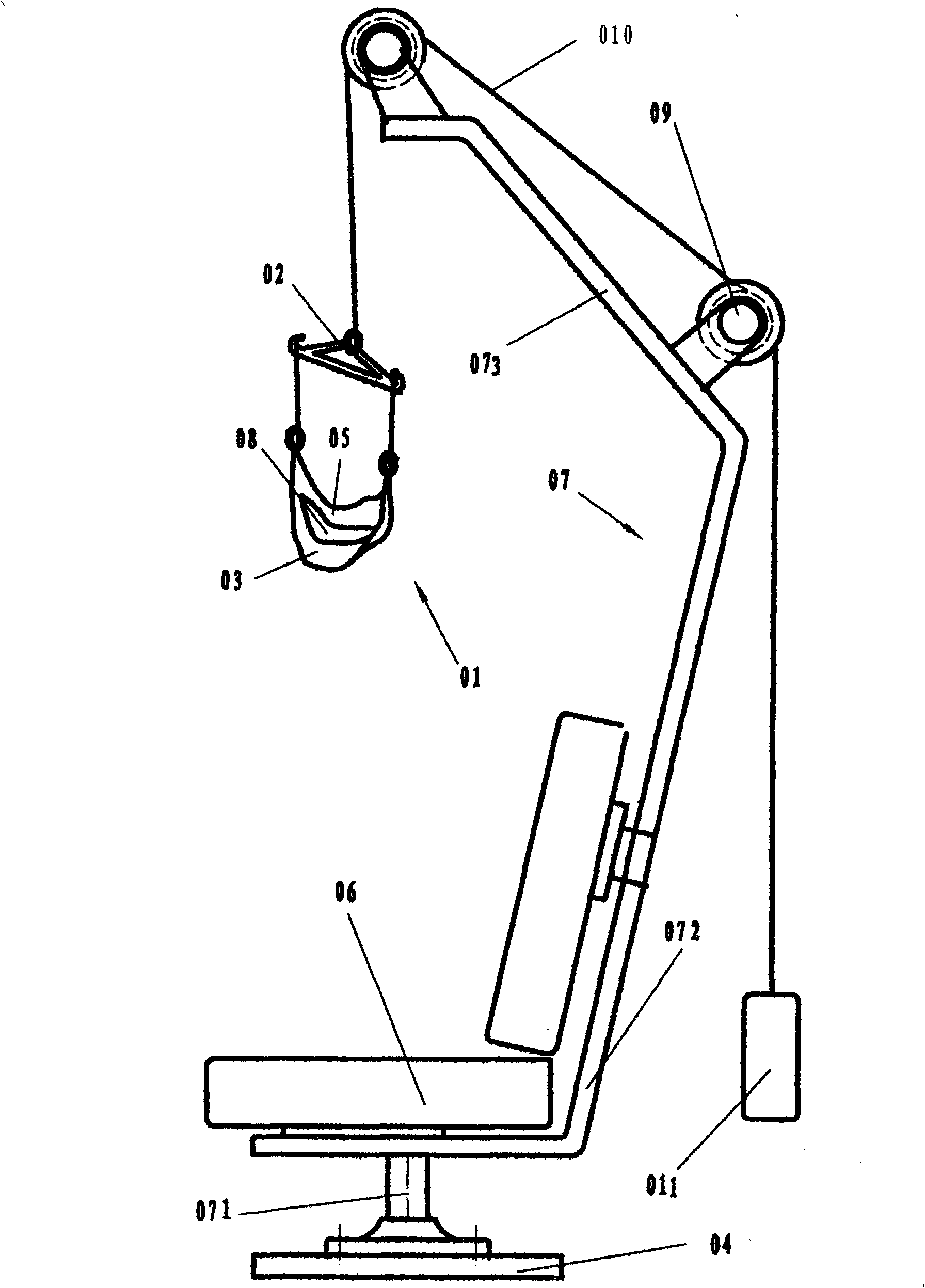

Head-support and cervical vertebra rehabilitation computer chair mounted with the same

InactiveCN101313810AHave rehabilitationPreventiveChiropractic devicesStoolsHead pressingCervical spondylosis

The invention discloses a head support and a cervical vertebrae healing computer chair provided with the head support. The head support comprises a head support body which supports a head, and a connecting piece, wherein, the head support body is provided with an entrance for the head to enter and exit and a front port which has a shape equivalent to the front shape of the head, the head support body is a shaped shell which is made of a hard material and can support the head, when the lower part of the head presses on an inner cavity of the lower part of the shell, other parts of the head and the shell are in a non-contact state. The method also provides the cervical vertebrae healing computer chair provided with the head support, comprising a computer chair, a support and a chassis, wherein, the computer chair and the support are arranged on the same chassis, and the head support of the invention is arranged on the support of the front upper part of the computer chair. The cervical vertebrae healing computer chair provided with the head support is a combination of the computer chair and the head support of the invention through the support. The cervical vertebrae healing computer chair provided with the head support is suitable for people who have cervical spondylosis but can not work without a computer and healthy people who often use computers for preventing the cervical spondylosis.

Owner:闫淑敏 +1

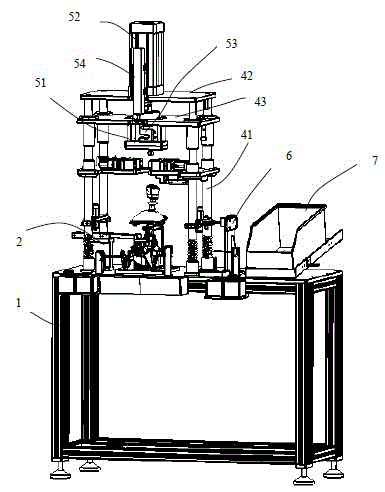

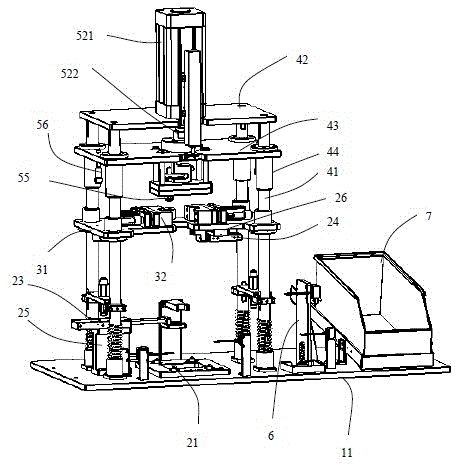

Ball head pressing and mounting equipment

InactiveCN104015033AEasy to fixNot easy to shakeWork holdersMetal working apparatusHead pressingEngineering

The invention relates to ball head pressing and mounting equipment which is used for mounting a ball head on an operating rod of a workpiece. The equipment comprises a work table, a stroke frame which is arranged on the work table, a workpiece clamp which is fixed on the work table and is used for fixing the workpiece, and a pressing and mounting device which is arranged on the stroke frame and can move up and down along the stroke frame, wherein the workpiece clamp comprises a first clamping element and a second clamping element which are relatively arranged to be used for crisscross clamping the operating rod of the workpiece; the first clamping element comprises a first piston cylinder, a first piston which is formed by outwards extension from the inside of the first piston cylinder, and a first clamping part which is arranged at the end part of the first piston to be used for clamping the operating rod; the second clamping element comprises a second piston cylinder, a second piston which is formed by outwards extension from the inside of the second piston cylinder, and a second clamping part which is arranged at the end part of the second piston to be used for clamping the operating rod; the first clamping part and the second clamping part are relative and are used for crisscross clamping the operating rod.

Owner:SIP GOLDWAY TECH

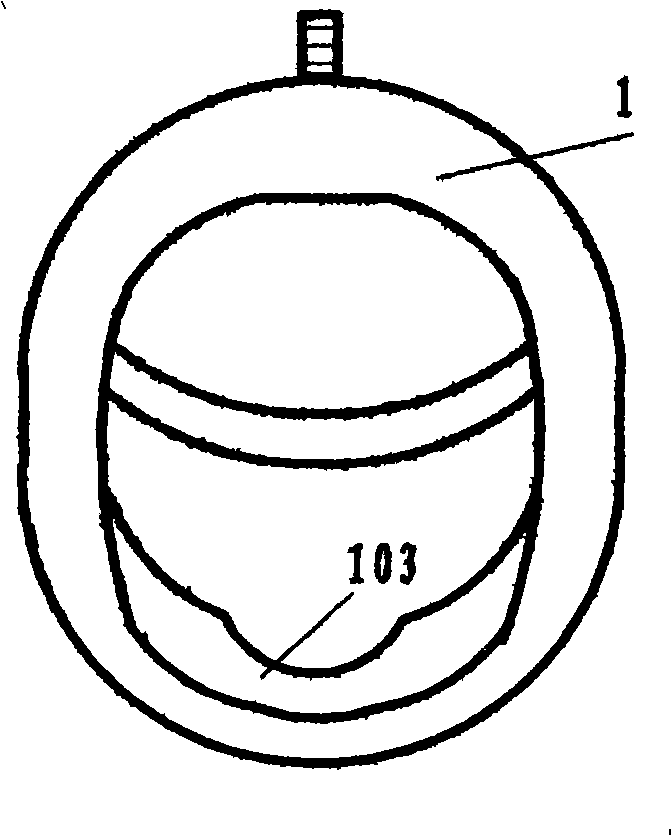

Cap head pressing device

InactiveCN102838064AImprove stabilityReduce manufacturing costCapsClosure using capsHead pressingBottle cap

The invention discloses a cap head pressing device for sealing and pressing a bottle cap in beverage machinery. The cap head pressing device comprises a lifting shaft which is movably arranged in a guide seat, wherein a roller is arranged at the upper end of the lifting shaft; a connection block and a cap pressing seat are fixedly connected with the lower end of the lifting shaft; a spring sleeve and a balance spring are arranged inside the cap pressing seat; a protecting bush is fixedly connected to the lower end of the cap pressing seat; a cap pressing body is arranged inside the protecting bush; a plurality of small holes are arranged in the cap pressing body; a claw head capable of clamping the bottle cap is arranged in each small hole; an elastic O-shaped ring is hooped at the outer end of the claw head; a cap opening rod movably penetrates through the connection block and the cap pressing body; the inner end of a cap opening pin shaft is connected with the upper end of the cap opening rod; the outer end of the cap opening pin shaft stretches out a cap opening elongated slot on the side wall of the lifting shaft and then a cap opening roller is arranged, and a clamping spring is sheathed on the cap opening rod. The cap head pressing device disclosed by the invention can be applicable to bottle caps in multiple specifications and the stability of cap pressing is greatly improved.

Owner:JIANGSU ASG PACKAGING MACHINERY GRP

Ultrasonic-assisted punching process

The invention discloses an ultrasonic-assisted punching process. The ultrasonic-assisted punching process comprises the following steps that a, a stainless steel sheet is placed on the upper surface of a lower punching die of a punching machine; b, a driving air cylinder is started, a piston rod of the driving air cylinder drives an ultrasonic amplitude transformer, an ultrasonic transducer and a punching tool head to move downwards through a movable mounting frame, and the punching tool head presses the stainless steel sheet tightly, wherein the pressure value of the driving air cylinder ranges from 0.13 MPa to 0.15 MPa; c, after the pressure of the driving air cylinder is maintained for 4.5-5.5 seconds, an ultrasonic generator is started, wherein the power value of the ultrasonic generator is 4200 W, and the vibration frequency of the ultrasonic amplitude transformer is 2000 Hz; d, after the ultrasonic generator is started continuously for 1.5 seconds and then is shut down, the driving air cylinder continues to maintain pressure; e, after pressure maintenance is completed, the driving air cylinder is reset; f, the stainless steel sheet is taken down from the lower punching die. Through the design of the process steps, the ultrasonic-assisted punching process can effectively improve the punching bent-forming accuracy, the punching load is small, and the energy consumption is low.

Owner:DONGGUAN UNIV OF TECH

Electric heating press-fit device capable of local temperature control and pressure control

InactiveCN101369664AEasy to operateFuel cells groupingSolid electrolyte fuel cellsTemperature controlHead pressing

An electric heating compressing device comprises an upper fixture, comprising a first heating press plate, a first cooling plate and a first heat faulting fixture, wherein the first cooling plate comprises a first cooling heat capable of adjusting elastic coefficient, penetrating through the first heat faulting fixture and the first heating press plate; a lower fixture, comprising a second heating press plate, a second cooling plate and a second heat faulting fixture, wherein the second cooling plate comprises a first cooling heat capable of adjusting elastic coefficient, penetrating through the second heat faulting fixture and the second heating press plate relative to the first cooling head. During the pressing process, the second cooling head and the first cooling head press plates press towards opposite directions and cool a same low temperature area on a module to be pressed.

Owner:NAN YA PRINTED CIRCUIT BOARD CORPORATION

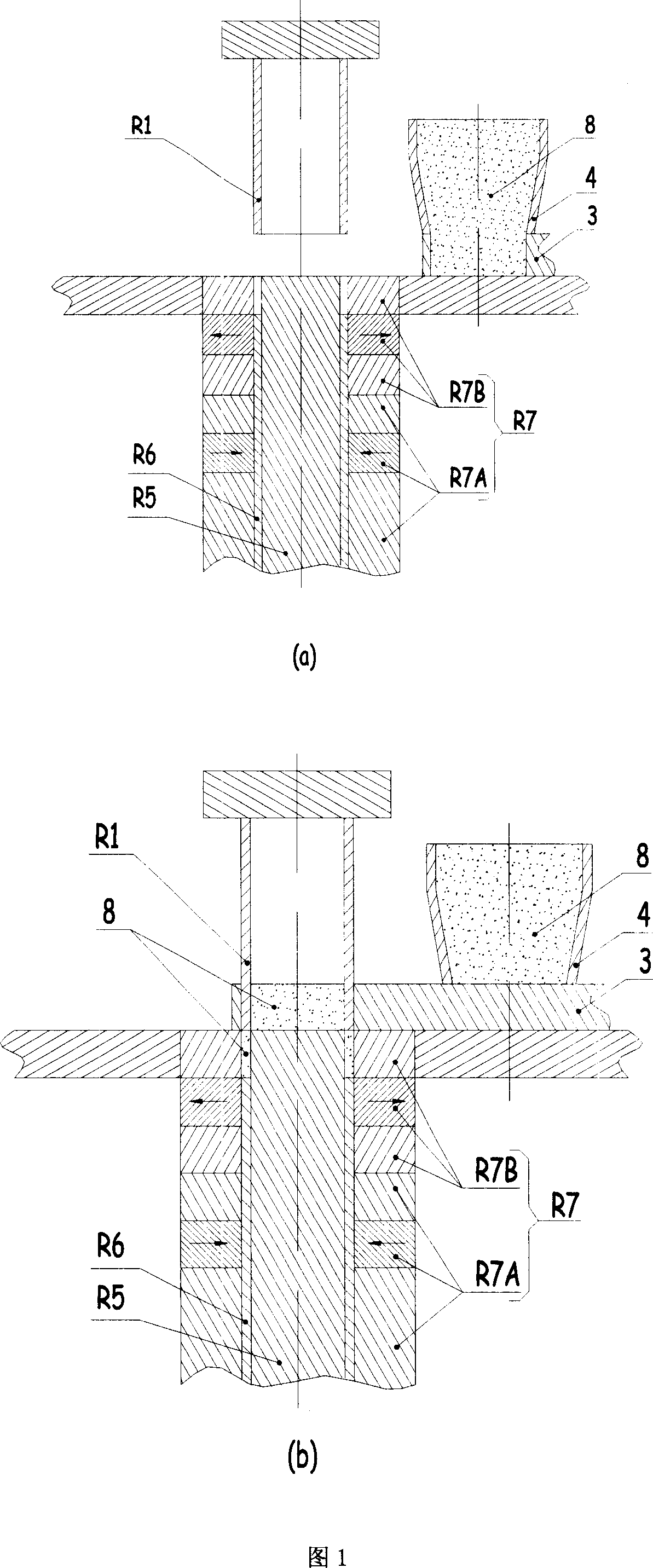

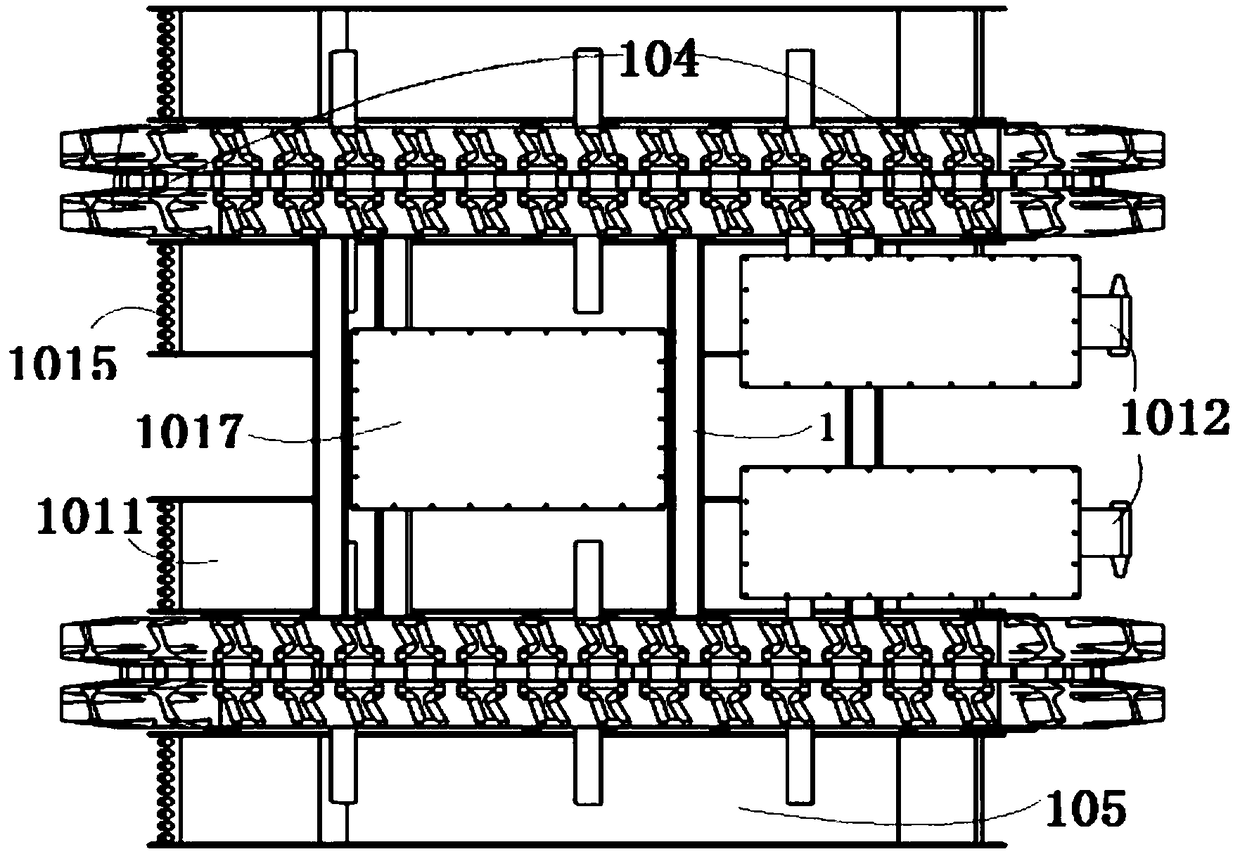

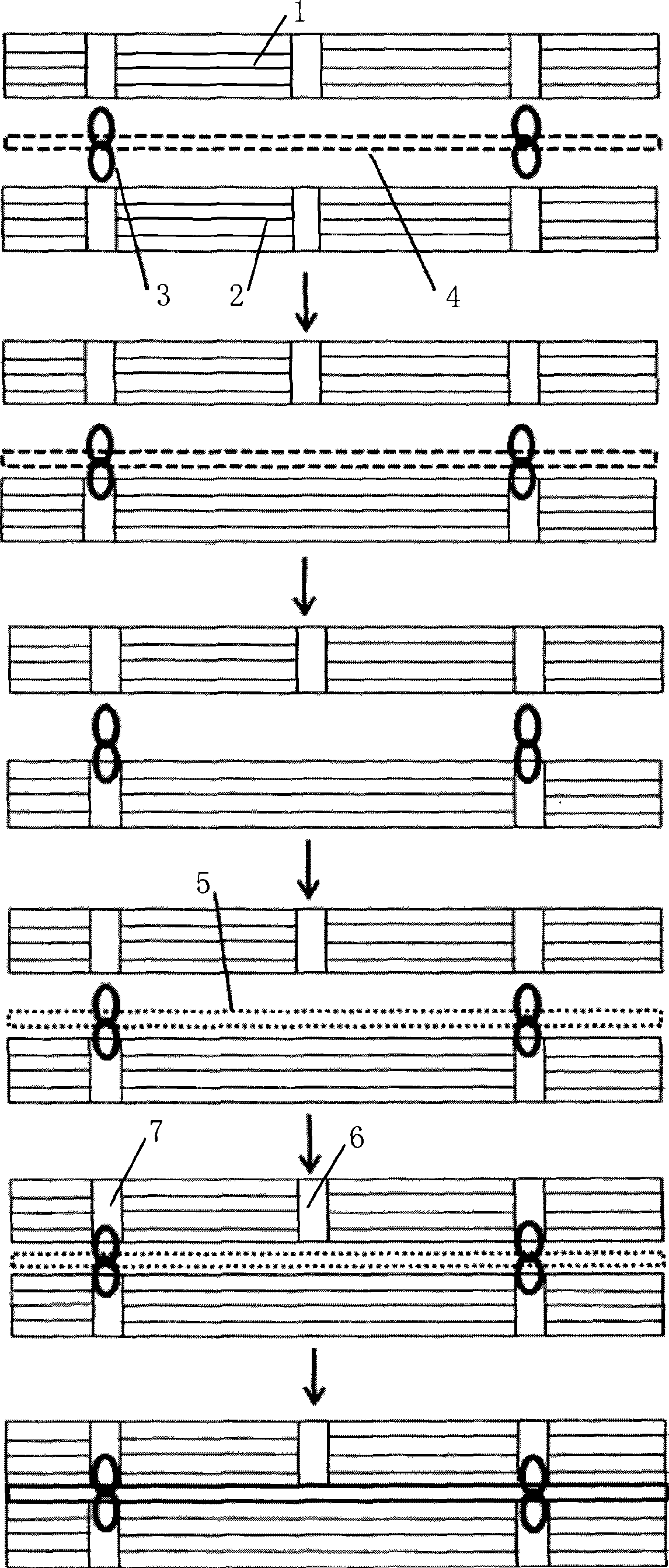

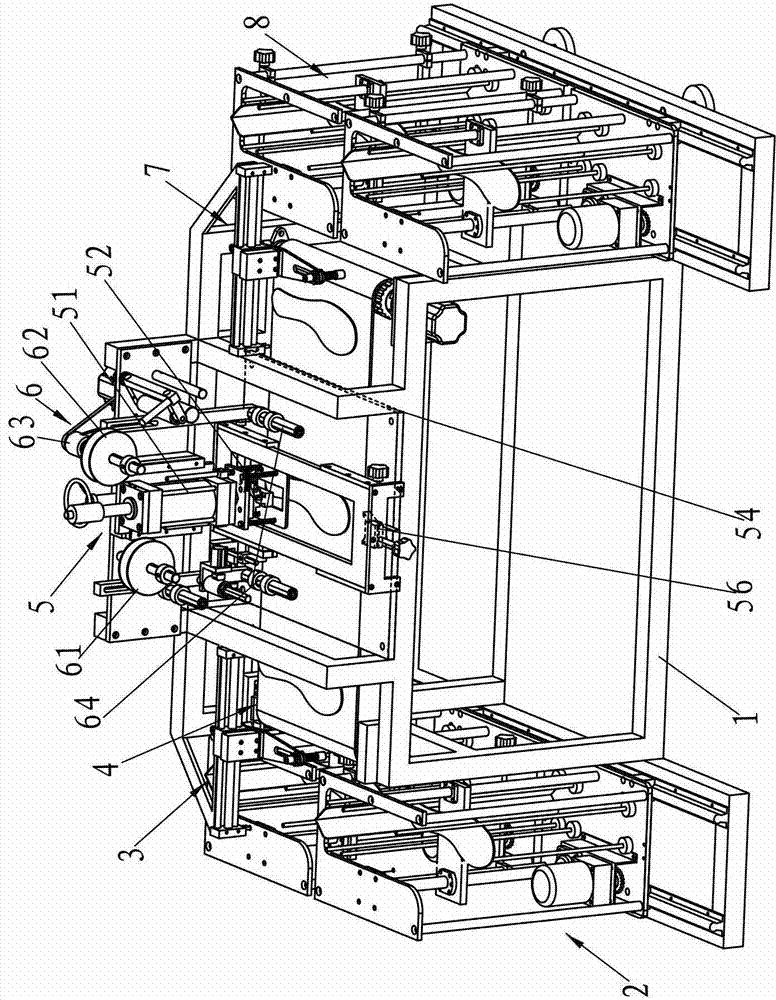

Dual-pressing-head pressing equipment and pressing process for flexible circuit board

InactiveCN106455355ANovel structural designImprove processing efficiencyPrinted circuit assemblingNon-linear opticsHead pressingLiquid-crystal display

The invention provides dual-pressing-head pressing equipment and pressing process for a flexible circuit board. The dual-pressing-head pressing equipment comprises a base, a bracket, a workbench, moving mechanisms, connecting plates, pressing apparatuses and a control system, wherein a cross beam is mounted in the middle part of the bracket for dividing the bracket into an upper sub-bracket and a lower sub-bracket; the workbench is mounted on the cross beam; the moving mechanisms are mounted on the upper and lower sub-brackets; the connecting plates are fixedly connected with the moving mechanisms on the upper and lower sub-brackets respectively; the pressing apparatuses are mounted on the corresponding connecting plates respectively; and the control system is used for controlling the operation of the moving mechanisms. The product is creative in structural design, and can perform one-time pressing on the front and back surfaces of a liquid crystal display screen; and compared with the processing time, including two times of positioning and two times of manual chip mounting, in the prior art, the processing efficiency of the pressing equipment is greatly improved.

Owner:贵州乾萃科技有限公司

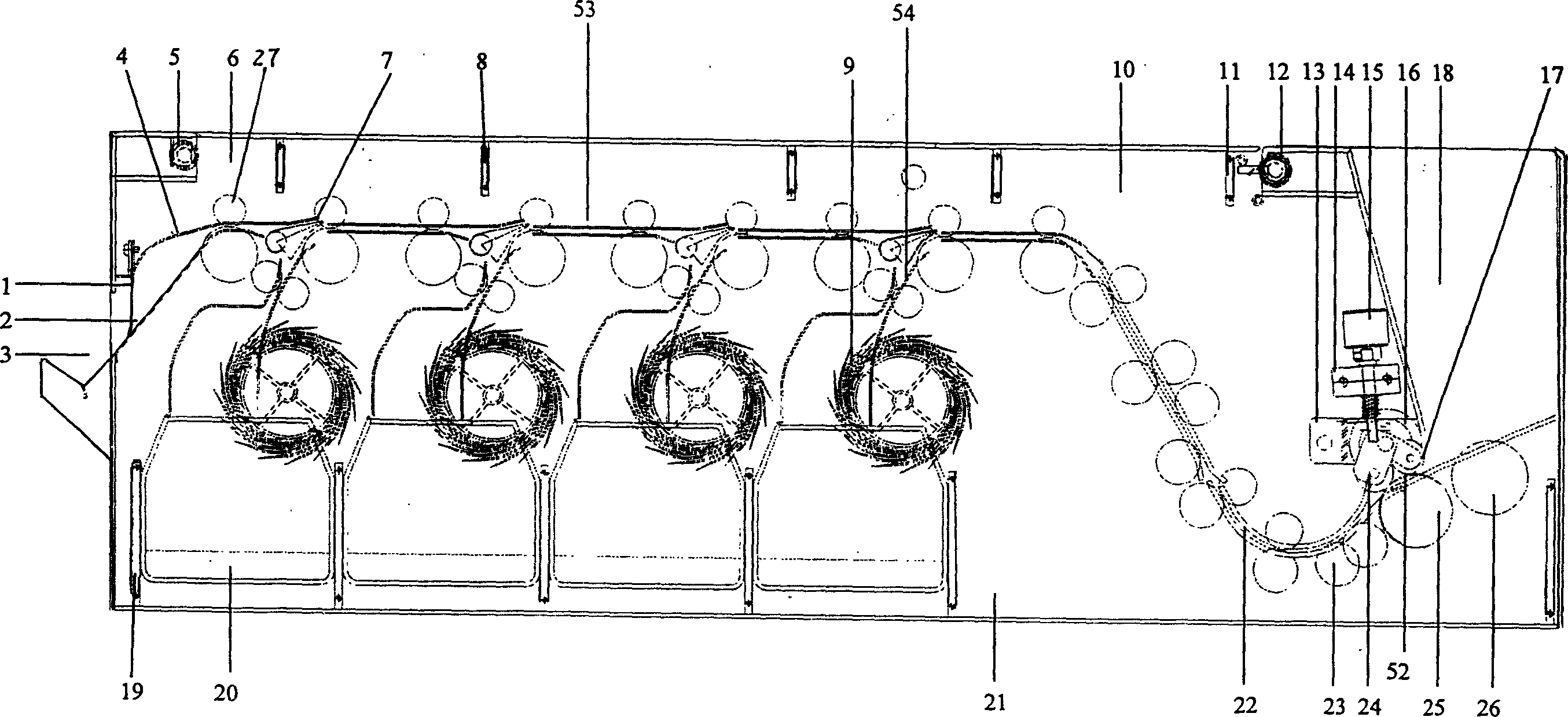

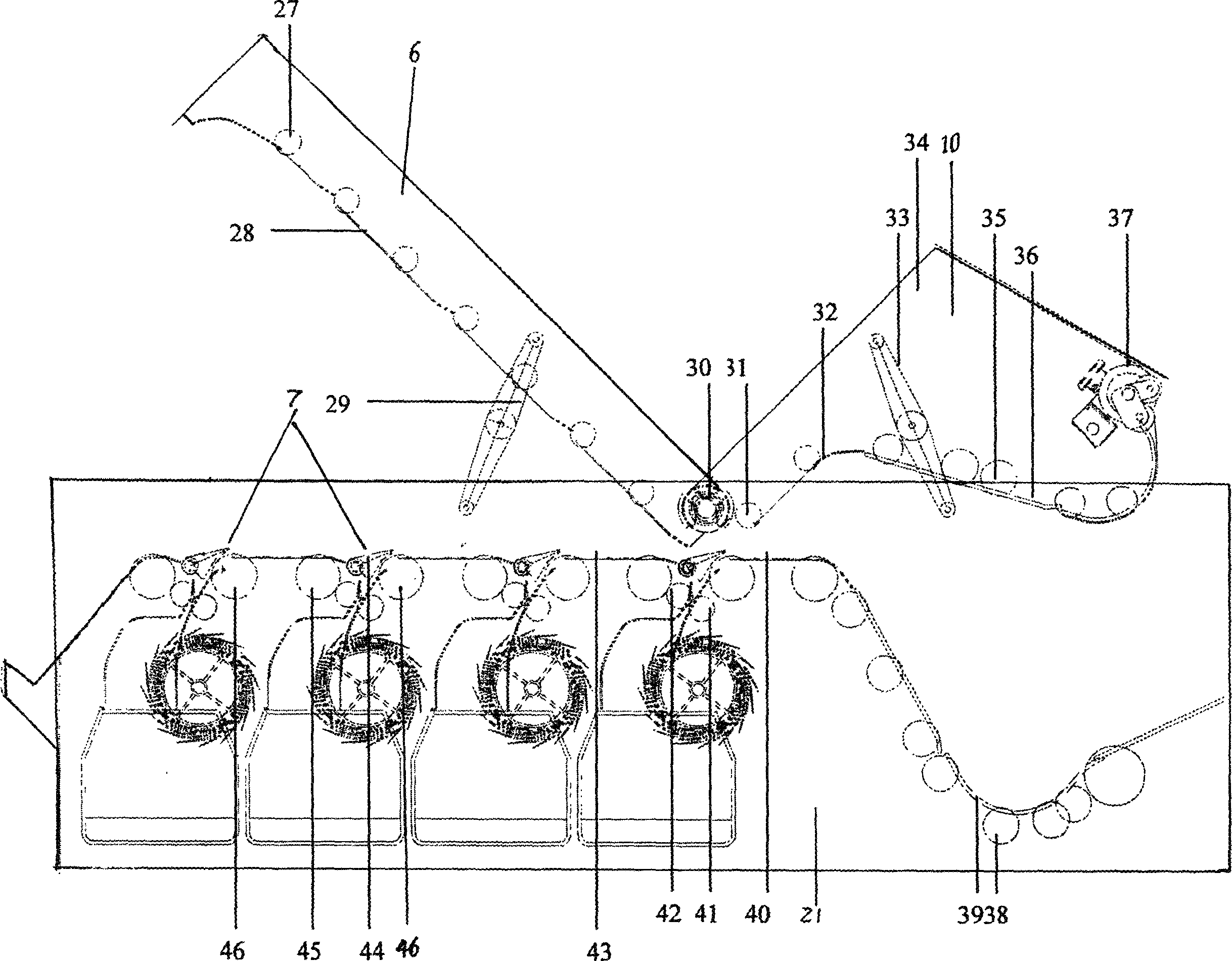

Automatic insole thermoprinting machine

InactiveCN102948966AAutomatic hot stampingImprove work efficiencyShoemaking devicesHead pressingEngineering

The invention relates to the technical field of shoemaking machines, in particular to an automatic insole thermoprinting machine comprising a frame, and an insole feeding bench device, an automatic feeding device, an insole conveying device, a thermoprinting machine head, a thermoprinting label coiling mechanism, an automatic receiving device and an insole receiving bench device which are arranged on the frame; when the machine works, stacked insoles are put onto the insole feeding bench device; the automatic feeding device picks up an insole, puts the insole onto the insole conveying device and conveys the same to be below the thermoprinting machine head; the thermoprinting machine head presses the thermoprinting label of the thermoprinting label coiling mechanism to the insole and carries out thermoprinting; after thermoprinting, the insole conveying device conveys the insole to the other end, and the automatic receiving device picks up the insole and puts the same onto the insole receiving bench device; and when stacked insoles subjected to thermoprinting reach a certain height, the stacked insoles only need to be taken out. According to the automatic insole thermoprinting machine, the thermoprinting of insoles is realized automatically, the labor intensity of a worker is low, the working efficiency is high, and the production cost is reduced.

Owner:东莞市腾宇龙机械能源科技股份有限公司

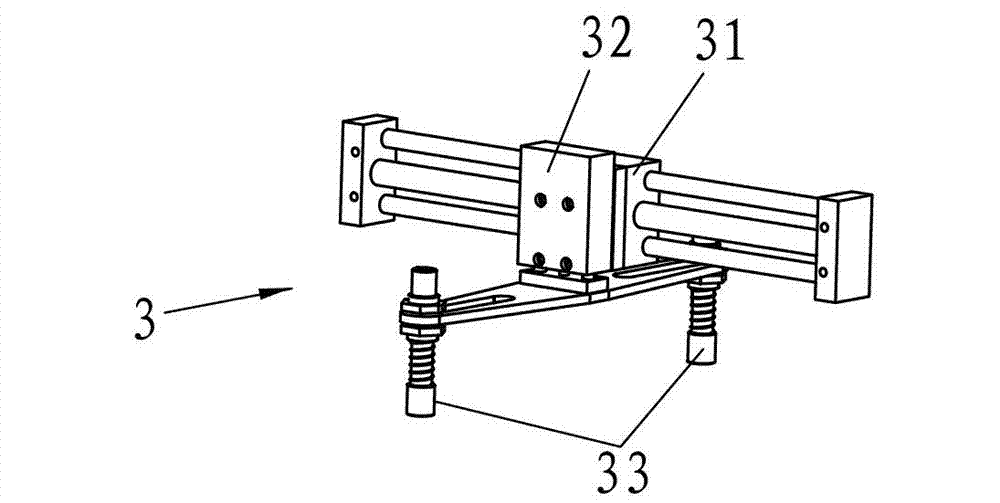

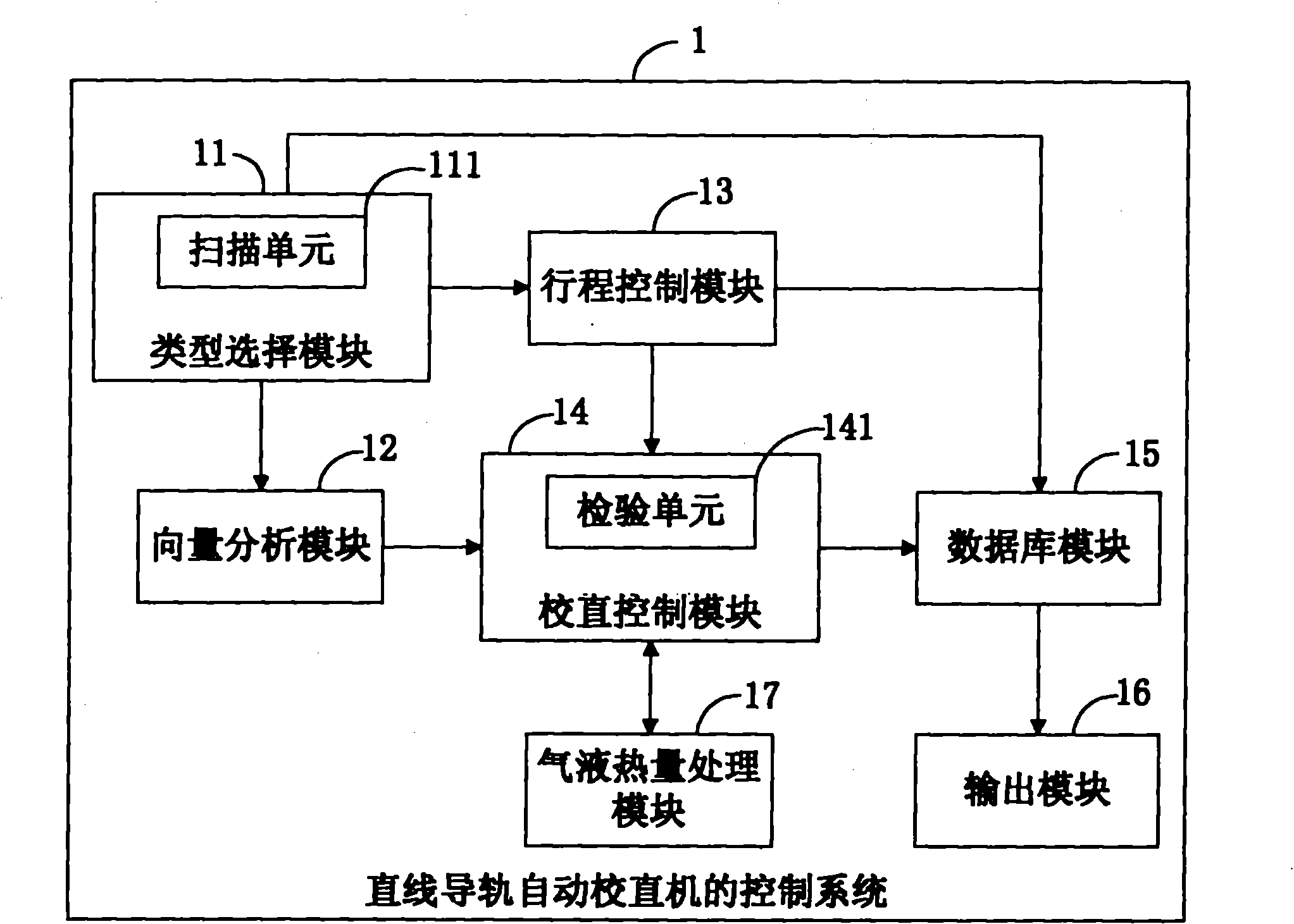

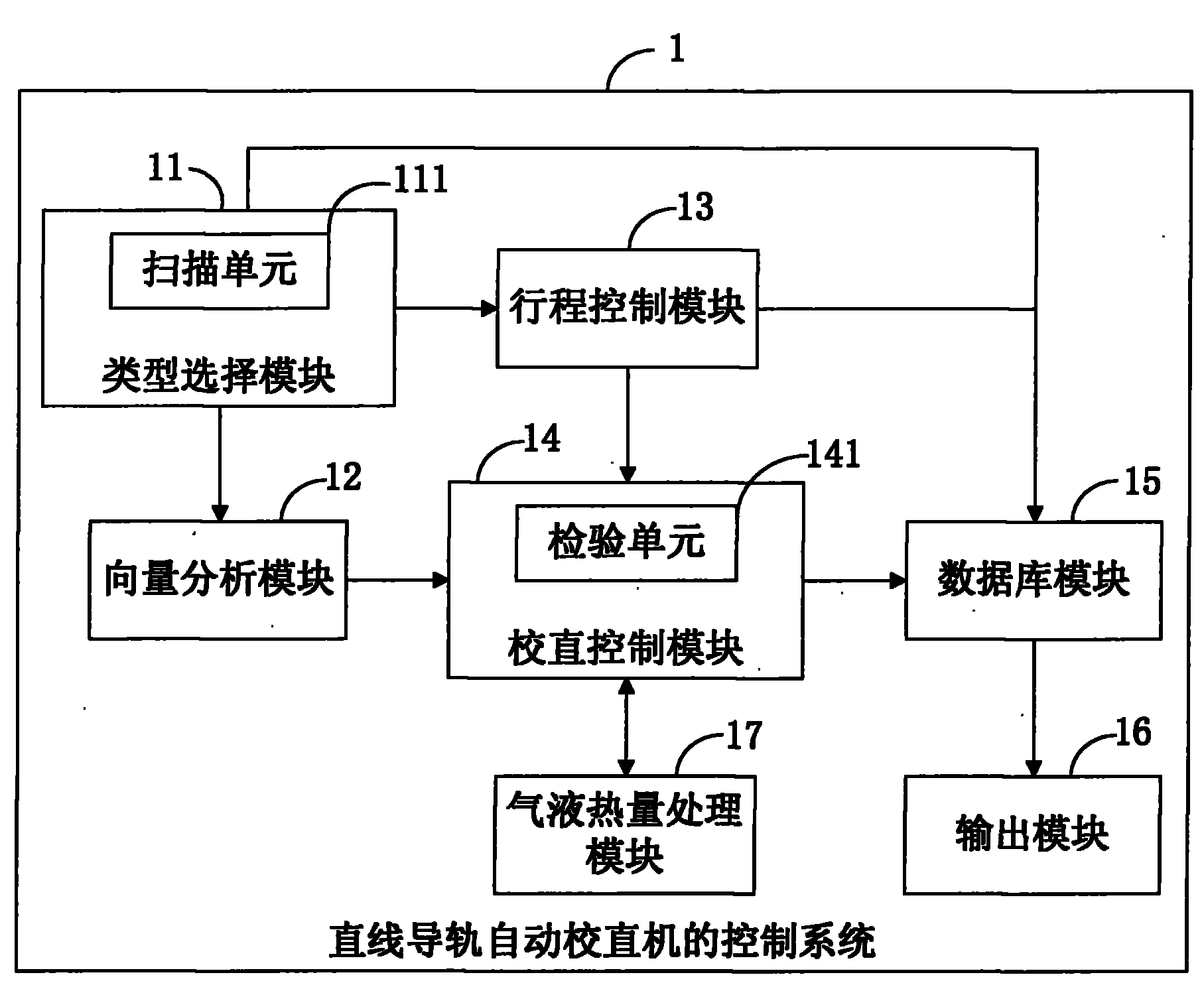

Control system of automatic straightener for linear guide rails

ActiveCN102151720AWith priority alignment point selection functionFewer work cyclesHead pressingControl system

The invention provides a control system of an automatic straightener for linear guide rails. The automatic straightener for the linear guide rails is at least provided with a straightening pressure head and two supporting parts. The control system firstly builds correction models of the linear guide rails in two vertical directions, connects measuring points positioned on a surface into a continuous curve, counts all curves on the linear guide rails, determines the position coordinates of pressure points of a positive curved surface and two supporting points of a negative curved surface and successive pressing sequences of curve segments according to the curvature of the curve segments, sets the maximal correction quantity of the straightening pressure head and the two supporting parts, then drives the two supporting parts to respectively support against the two supporting points of the negative curved surface of a selected curve segment so that the straightening pressure head presses the pressure points of the positive curved surface of the selected curve segment to carry out straightening operation and saves the correction models, the maximal correction quantities and straightening logs of the linear guide rails to carry out journey compensation variation and data correction when straightening the curve segment of a more secondary priority level so as to carry out high-accuracy and high-efficiency straightening on the linear guide rails.

Owner:上海莱必泰数控机床股份有限公司

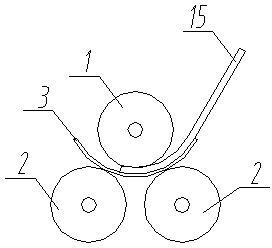

Rolling method for circular tube

A rolling method for a circular tube comprises the following steps that a steel plate needing to be rolled is cut into a rectangular shape; the rectangular steel plate is placed in a roller machine for rolling; the rolled steel plate is detached from the roller machine; a connector of the rolled steel plate is welded to form a semi-finished circular tube; a defect detecting test is performed on welding seams of the connector of the semi-finished circular tube; the semi-finished circular tube is placed back to the roller machine for repeated rolling; the semi-finished circular tube rotates circularly on the roller machine, and pressure on the semi-finished circular tube is gradually increased; the fished circular tube is detached. According to the rolling method for the circular tube, head pressing is not required, curving is directly performed, and the circular tube is placed back to the roller machine for repeated rolling after a longitudinal joint of the circular tube is welded; pressure head materials do not need to be welded any longer; after head pressing, the pressure head materials are cut off and then the curving is performed. In this way, the rolling process is simpler, working procedures are more reasonable, the rolling accuracy of the circular tube is enhanced, the working efficiency for manufacturing is improved, materials and labor force are saved, and production efficiency for the circular tube is guaranteed.

Owner:CHINA 22MCC GROUP CORP

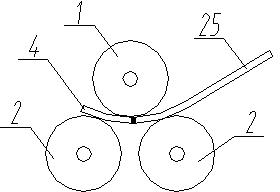

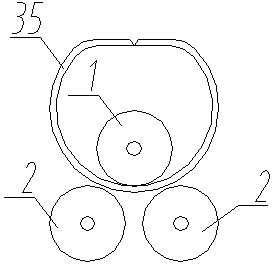

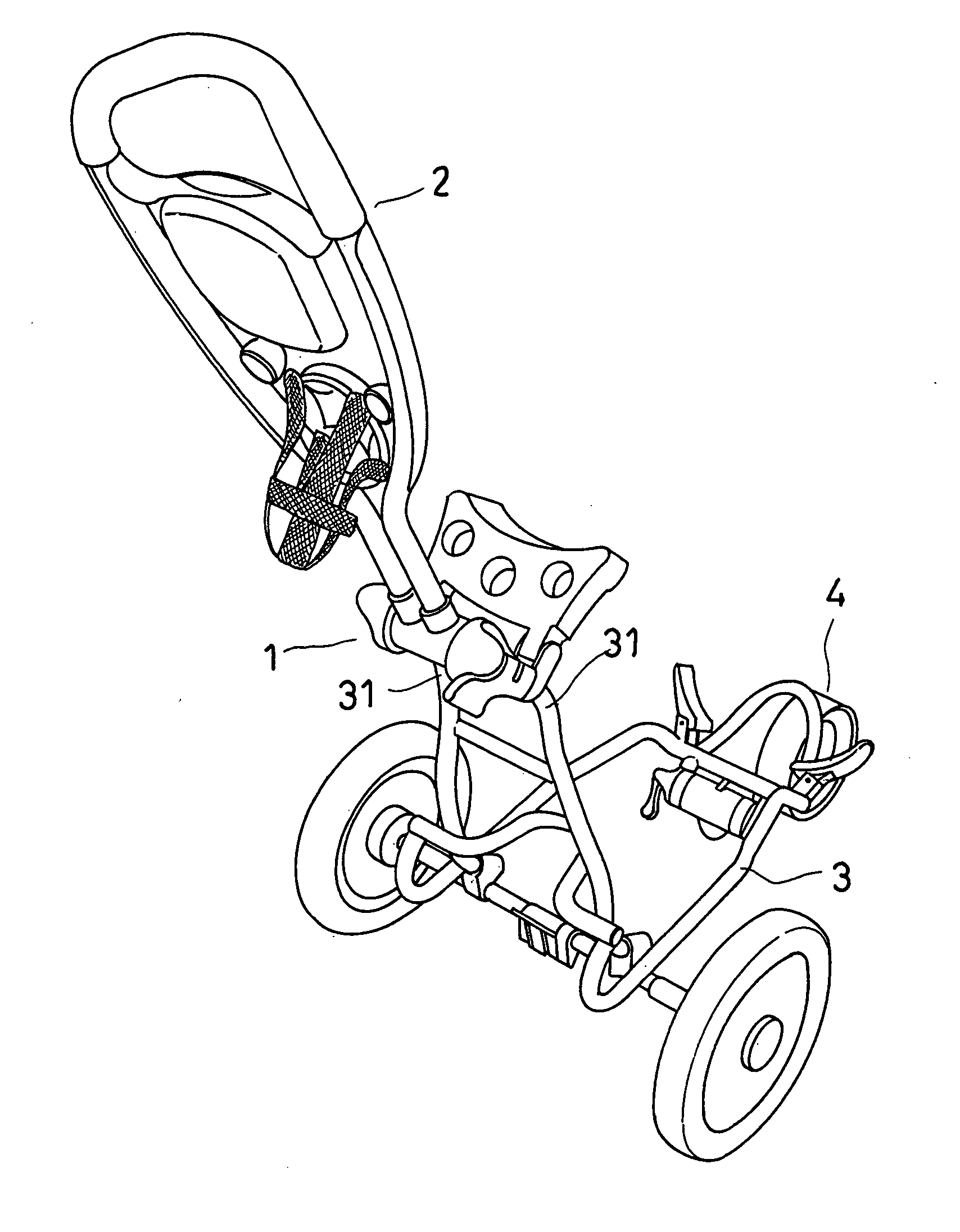

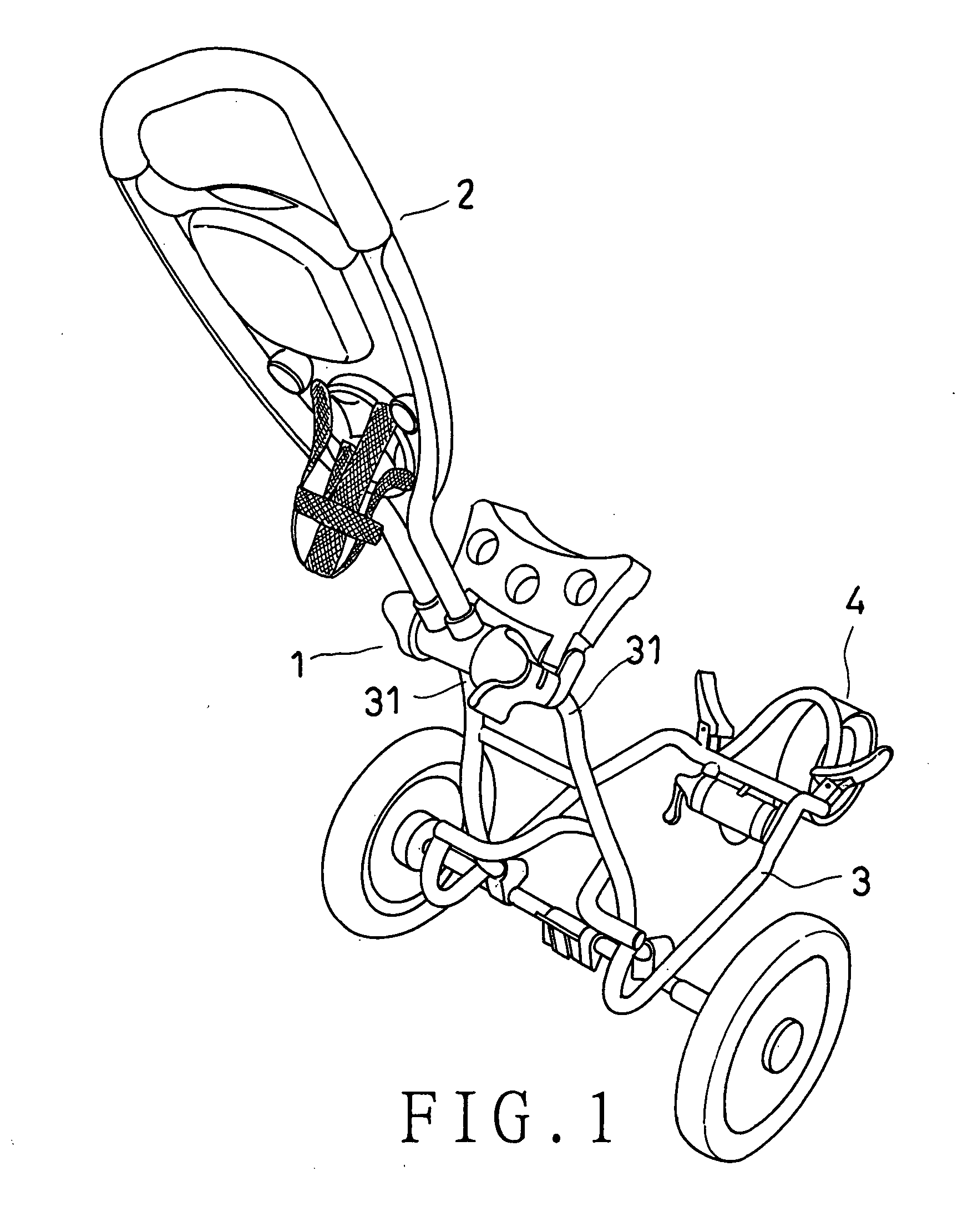

Folding structure of a golf cart

InactiveUS20080246238A1Carriage/perambulator with single axisHand carts with one axisHead pressingEngineering

A foldable golf cart has a folding mechanism interposed between a handle part and a frame; the frame has first and second rod parts; the folding mechanism includes a fixed piece secured to the first rod part, an acting piece positioned around the second rod part in a movable manner, a cylinder interposed between the fixed piece and the acting piece, a connecting rod, and a cam-headed pressing bar, which is pivoted to one end of the connecting rod at its cam-shaped head for moving the folding mechanism between a loosening configuration and a fixing one; the fixed piece, the acting piece and the cylinder have opposing toothed sides; the connecting rod is passed through the fixed piece, the acting piece, and the cylinder, and securely joined at other end to a threaded element positioned on an outer side of the fixed piece.

Owner:SPORTS WORLD ENTERPRISE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com