Patents

Literature

11149results about How to "Fast construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

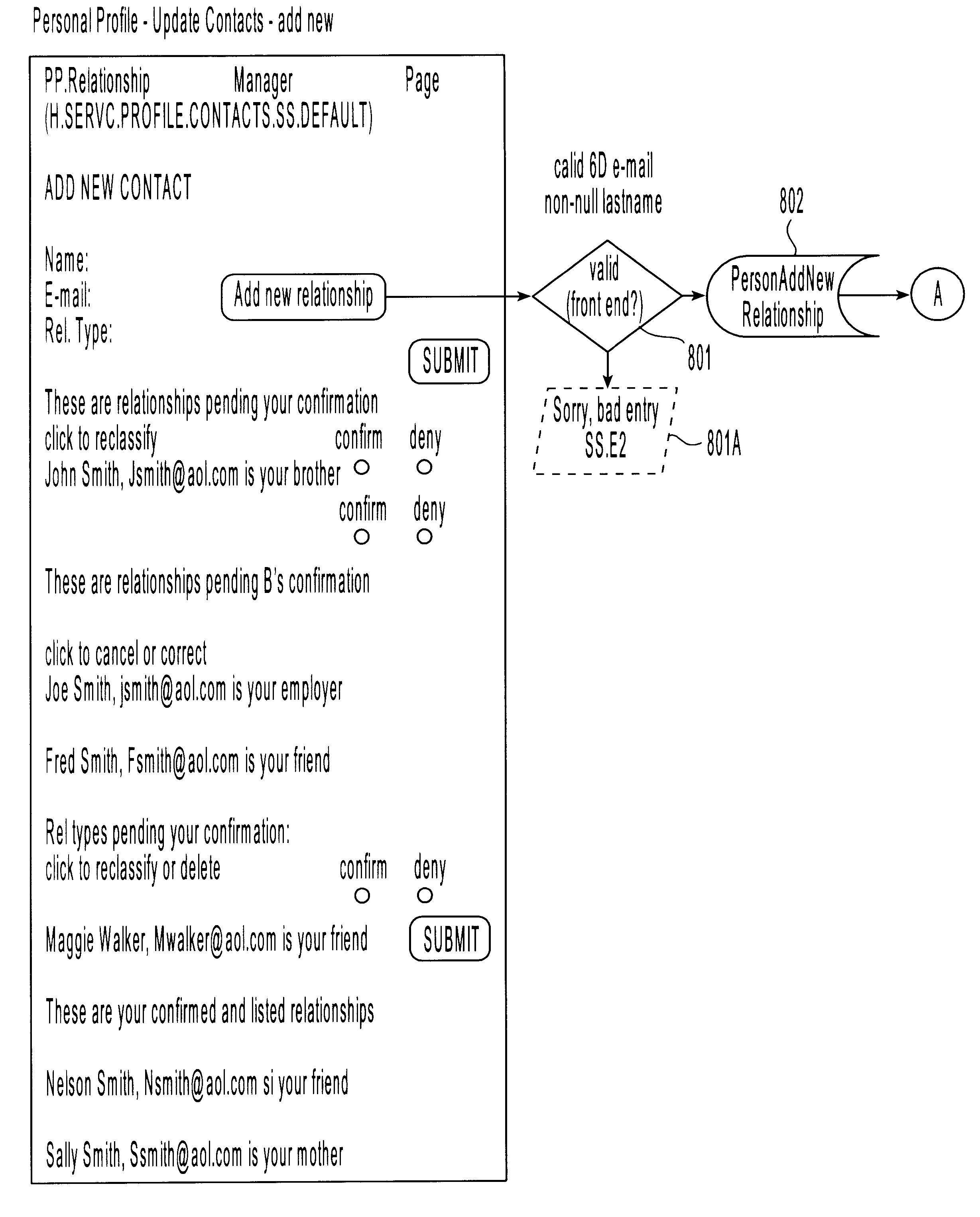

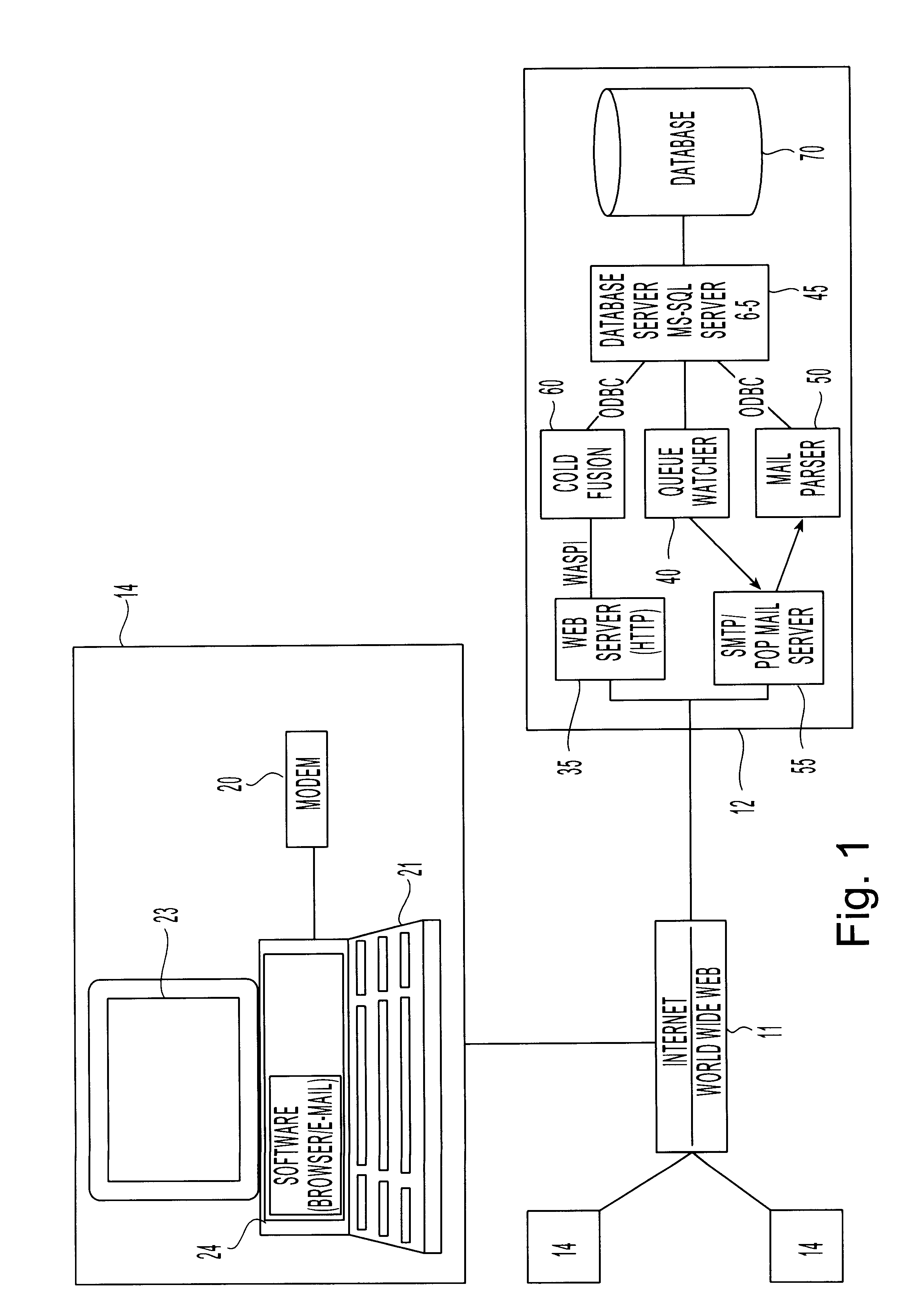

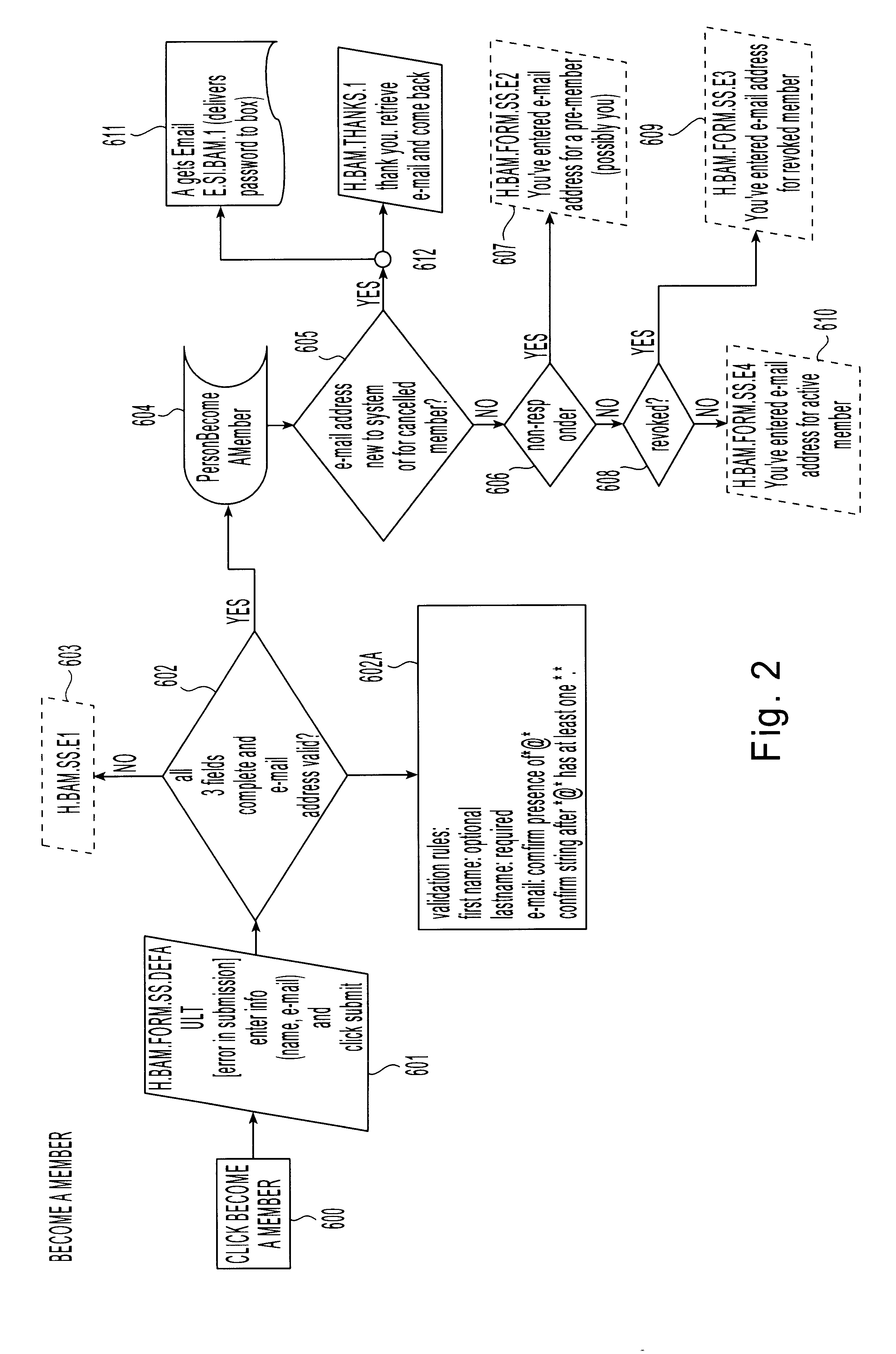

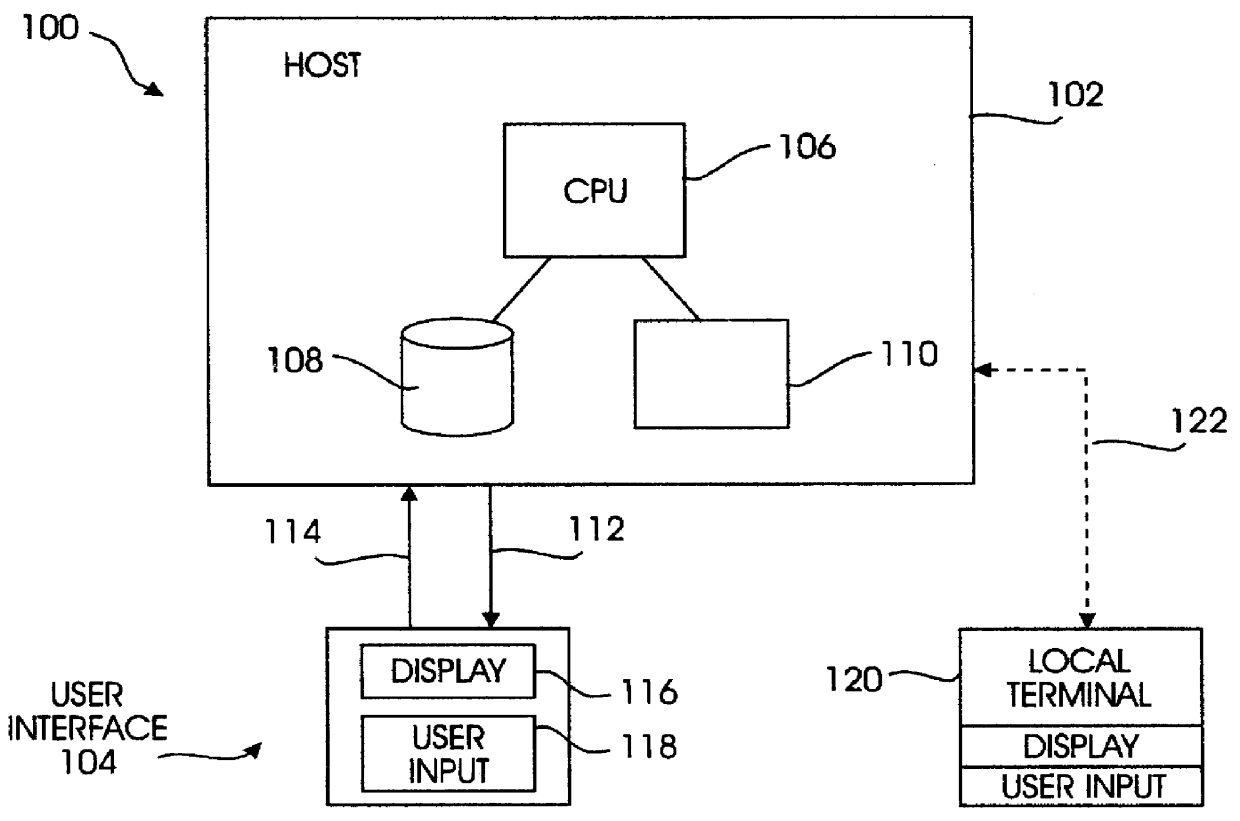

Method and apparatus for constructing a networking database and system

InactiveUS6175831B1Fast constructionGrowthOffice automationSpecial data processing applicationsMutually DefinedDatabase services

A networking database containing a plurality of records for different individuals in which individuals are connected to one another in the database by defined relationships. Each individual has the opportunity to define the relationship which may be confirmed or denied. E-mail messaging and interactive communication between individuals and a database service provider provide a method of constructing the database. The method includes having a registered individual identify further individuals and define therewith a relationship. The further individuals then, in turn, establish their own defined relationships with still other individuals. The defined relationships are mutually defined.

Owner:MACROVIEW COMM CORP +1

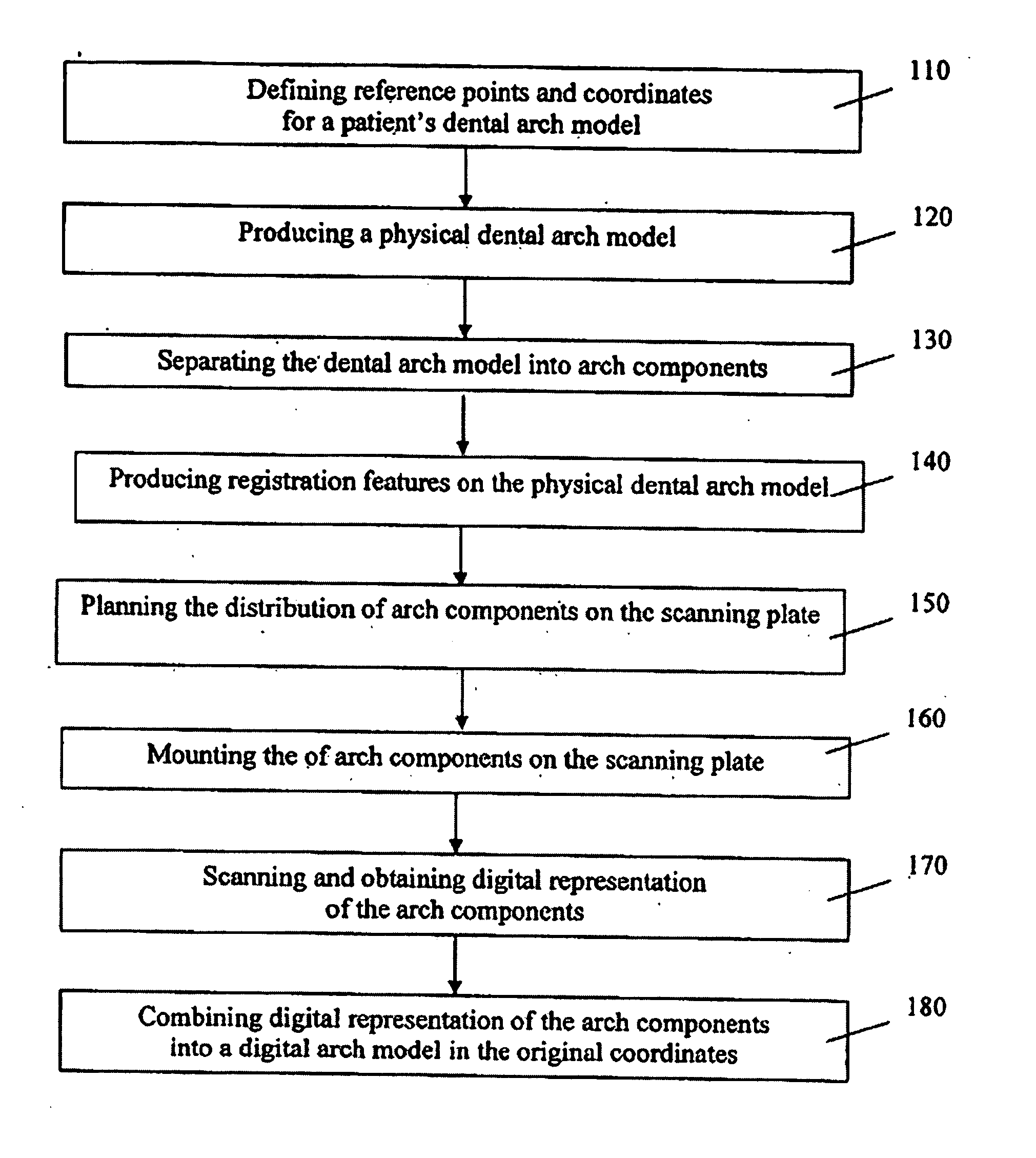

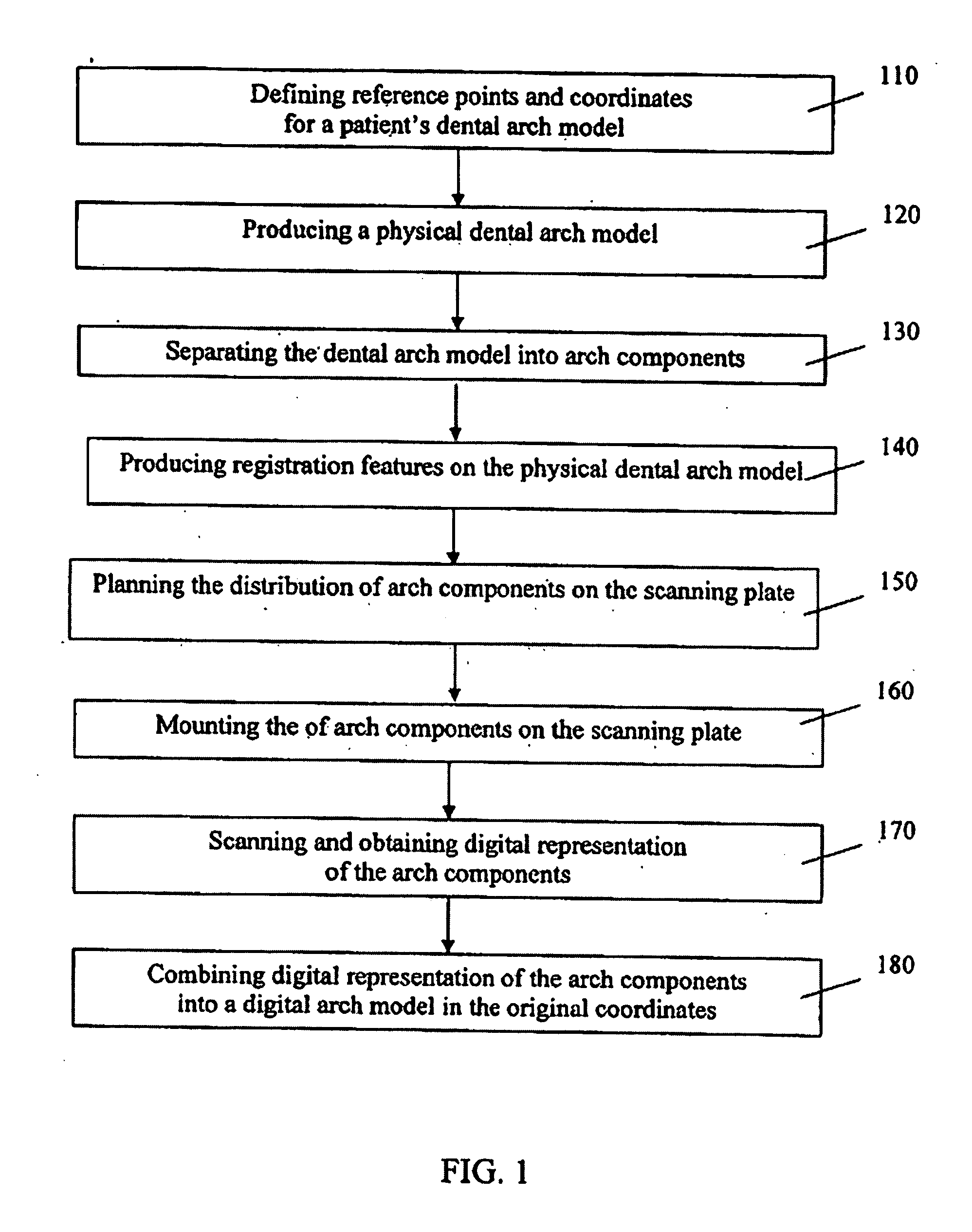

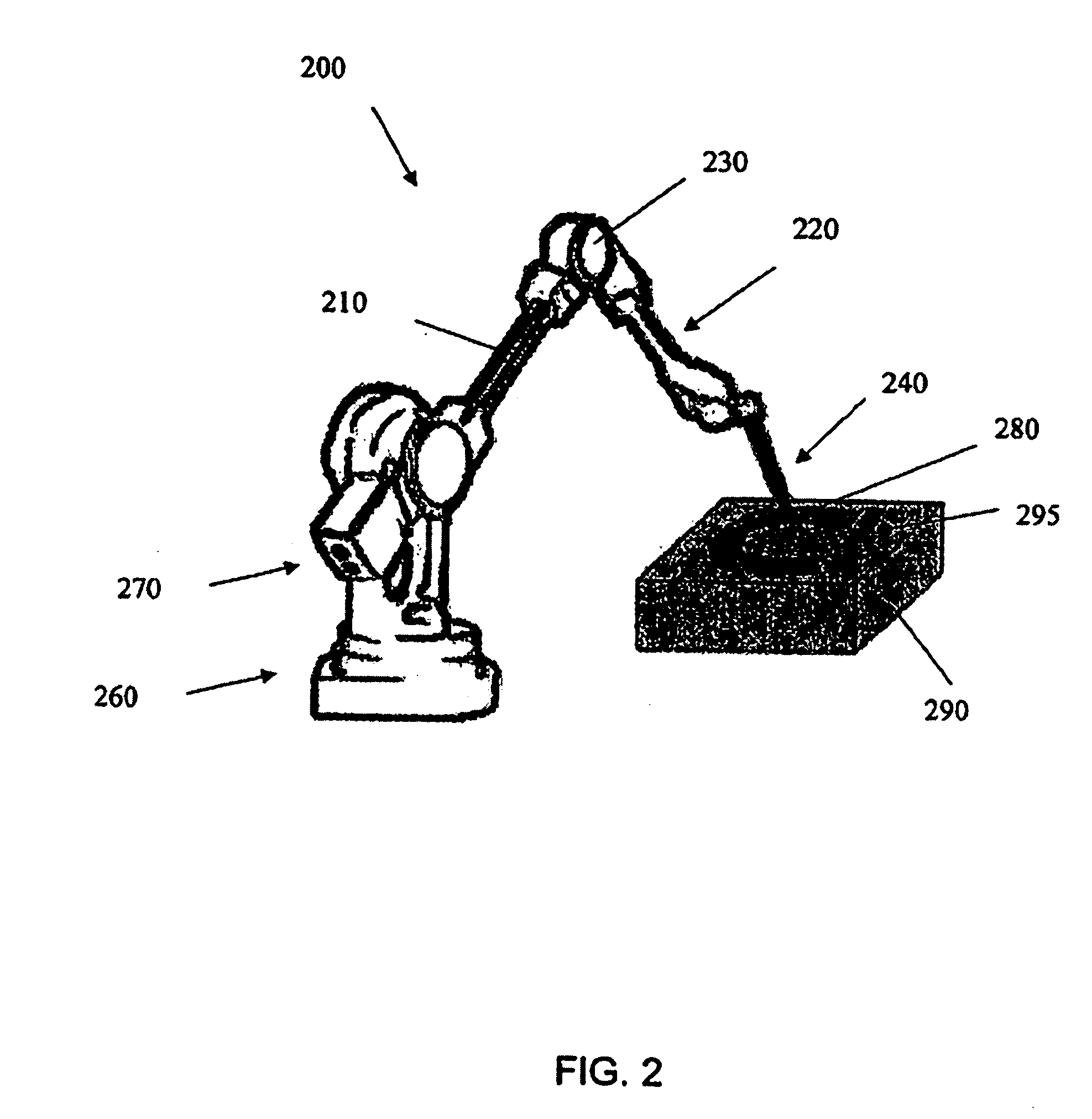

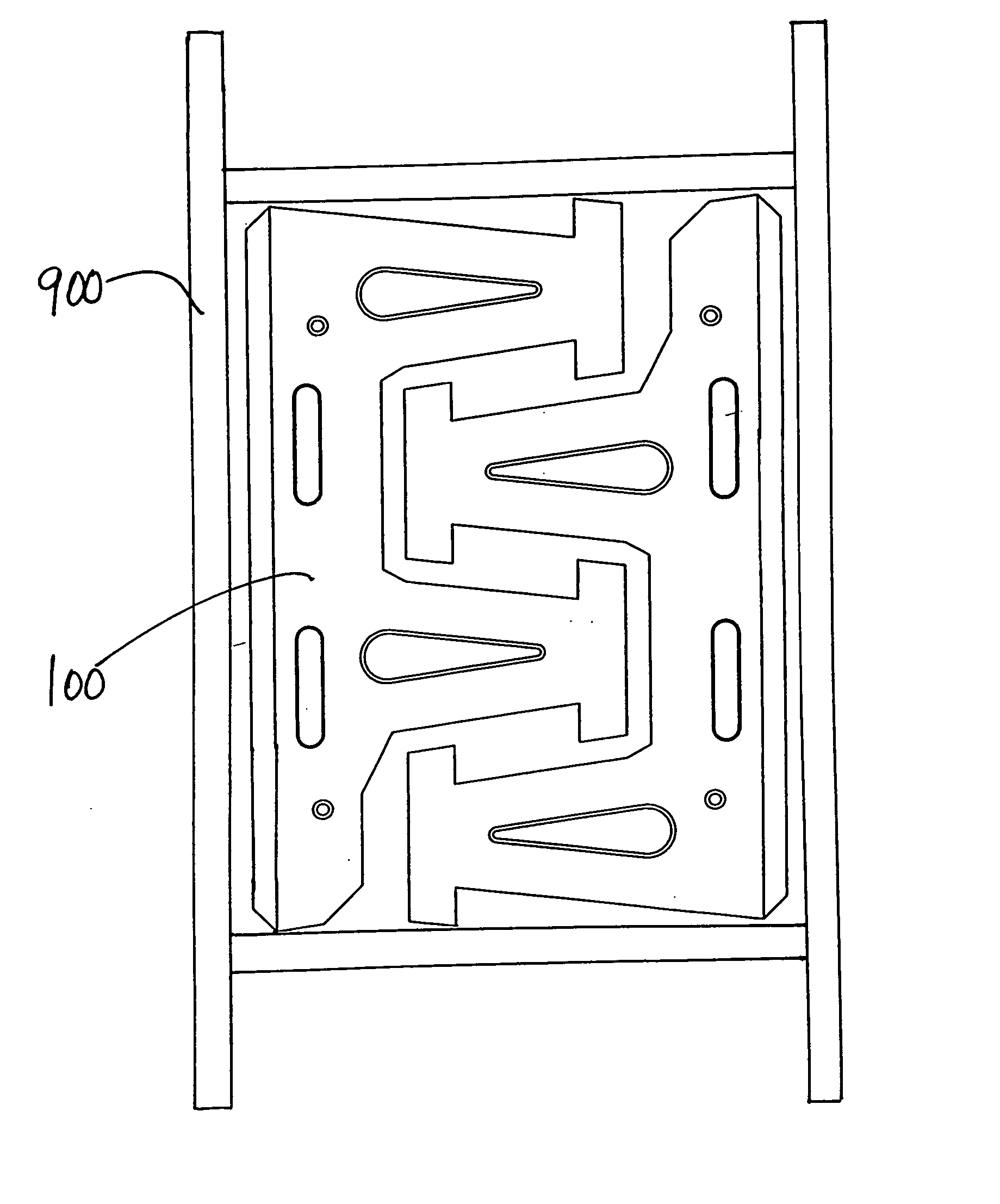

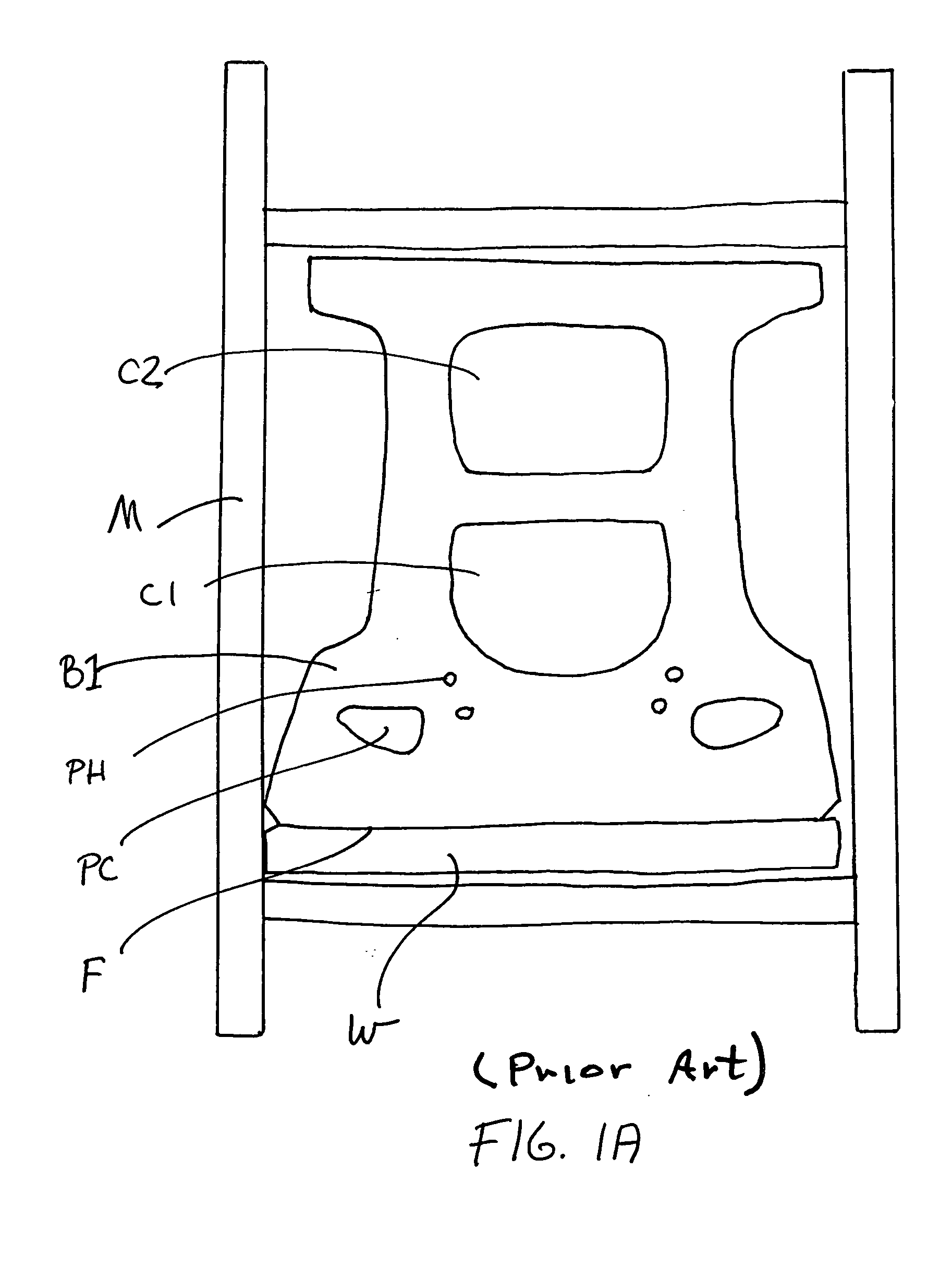

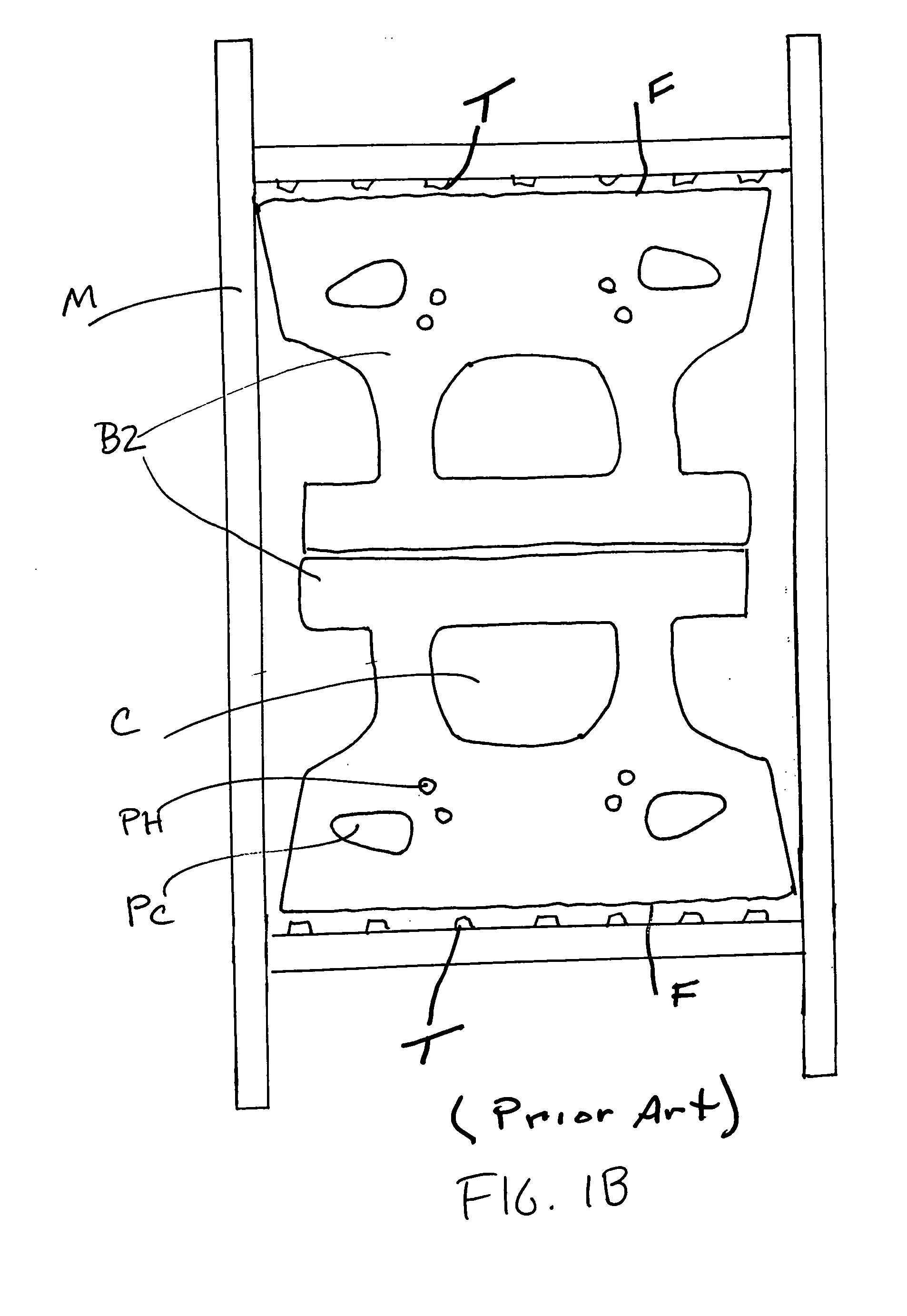

Computer aided orthodontic treatment planning

InactiveUS20060275736A1Easy to captureMore informationImpression capsOthrodonticsComputer aidComputer-aided

Methods, devices and systems for digitizing a patient's arch and manipulating the digital dental arch model. In one variation the methods includes producing a physical arch model for the patient's arch, separating the physical arch model into a plurality of arch model components, mounting the arch model components on a scan plate, capturing one or more images of the arch model components, and developing digital representations of the arch model components using the captured one or more images.

Owner:ALIGN TECH

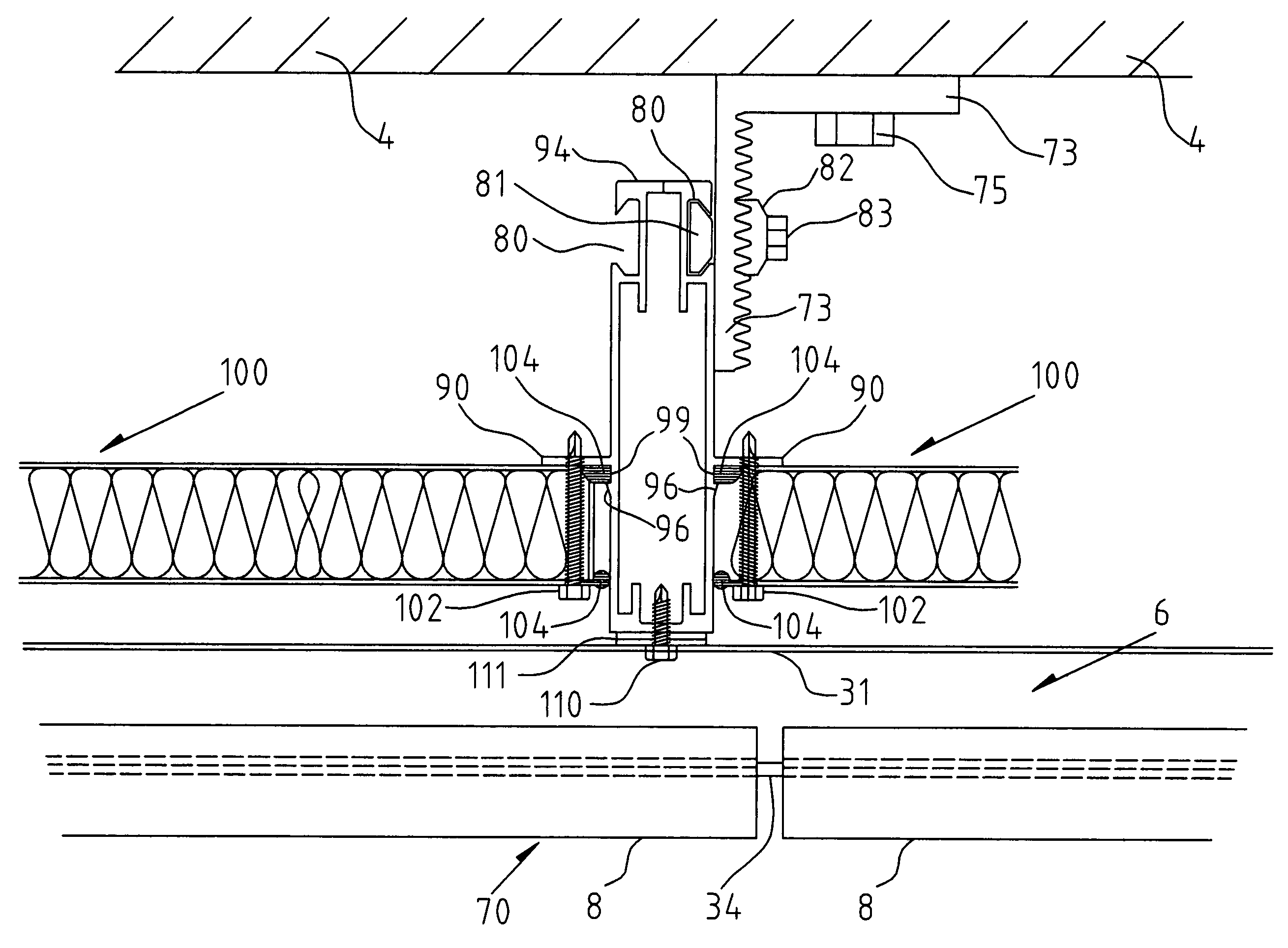

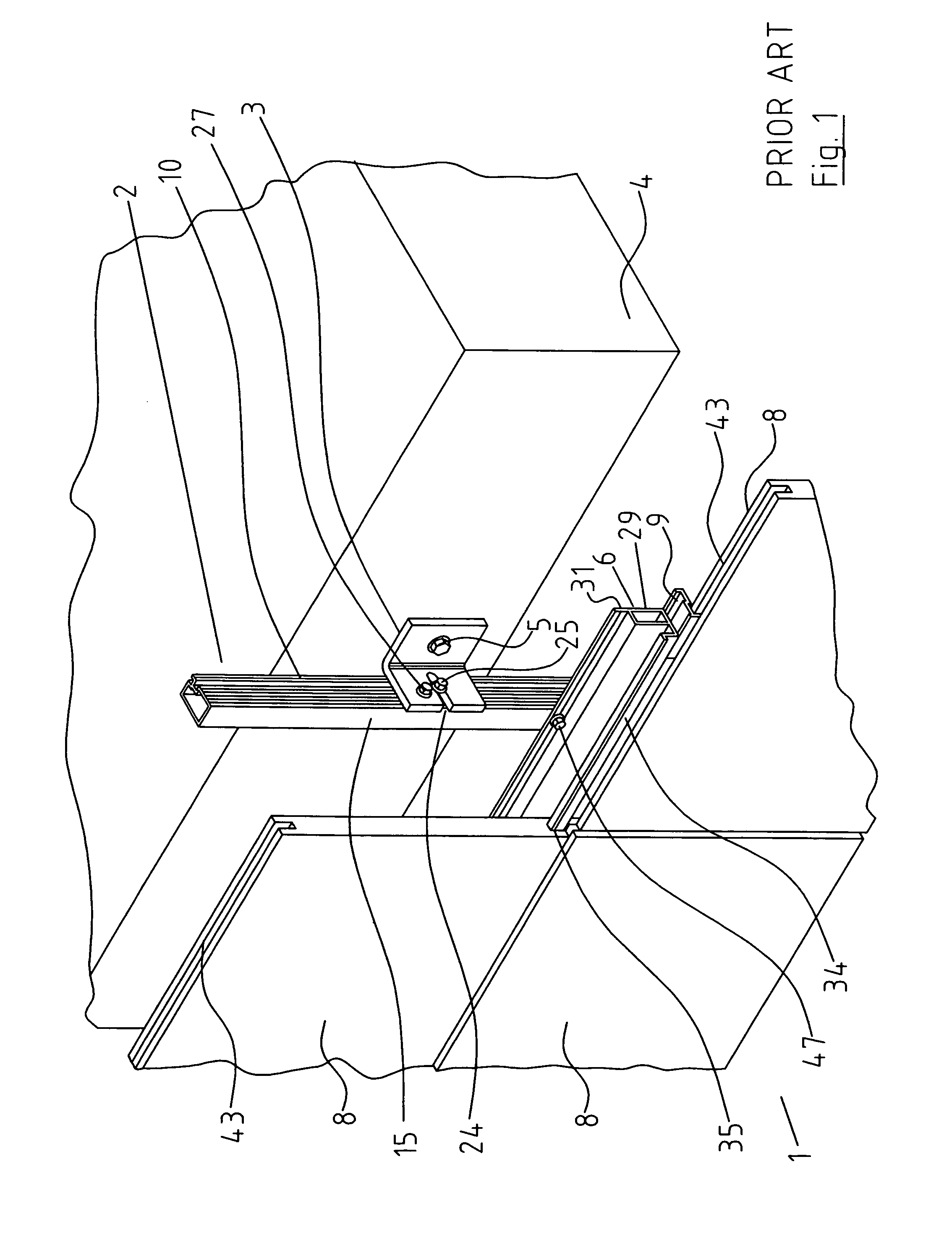

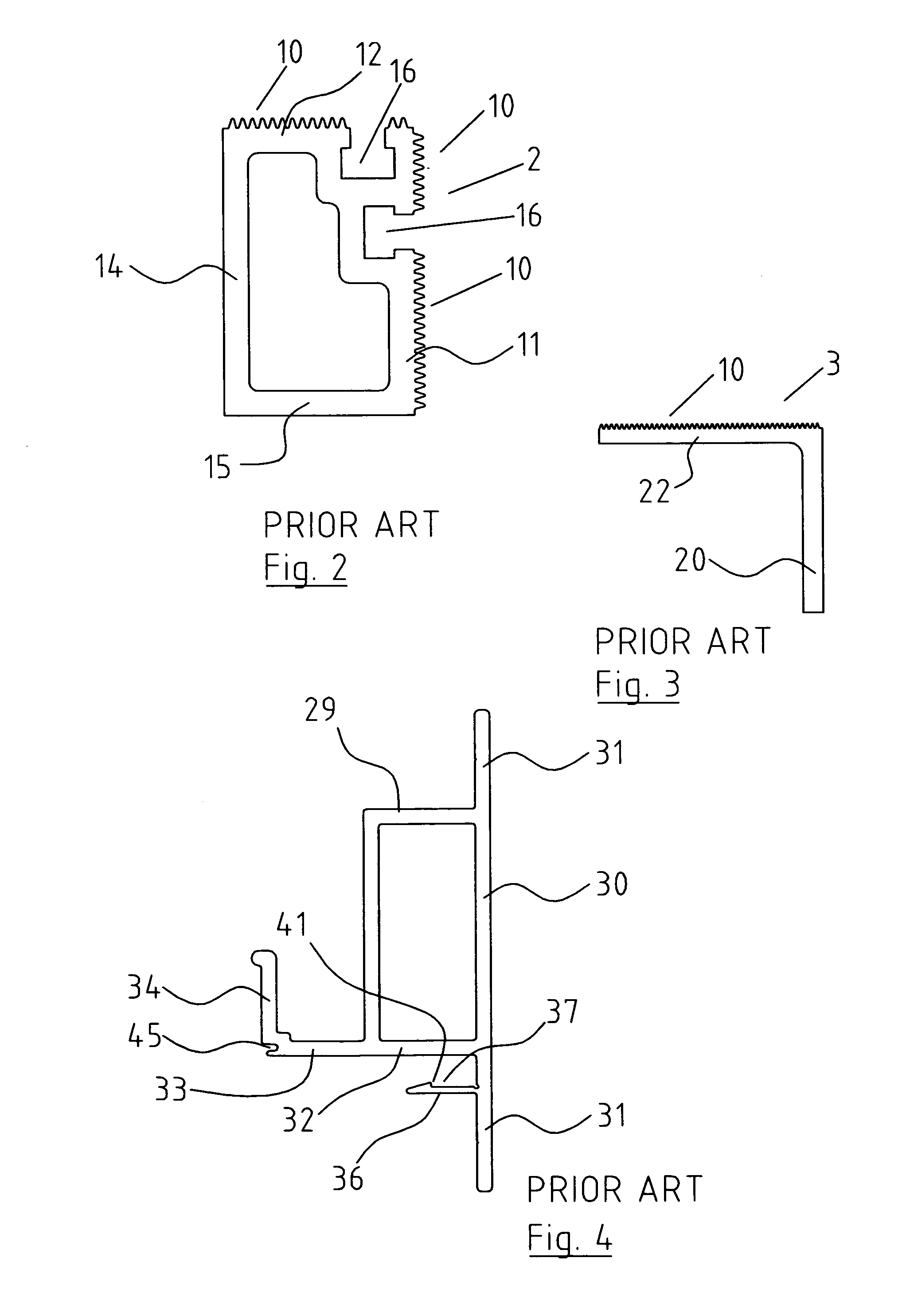

Cladding system

InactiveUS7043884B2Readily and easily and quickly mounted on and removedEasy constructionCeilingsCovering/liningsBraced frameArchitectural engineering

A stone cladding system for building has a support frame formed by a plurality of spaced-apart upright mullions fixed to an exterior of a building by anchor bracket's with a number of horizontal cladding panel support rails mounted in vertically spaced apart rows on the mullions. Each stone cladding panel is mounted between at adjacent pair of vertically spaced-apart rails with a bottom of the cladding panel seated on the lowermost rail and a top of the cladding panel secured to the uppermost rail by a pair of retaining clips. A bottom of each stone cladding panel is fully supported along its length by the lowermost rail.

Owner:CRONOS 2000

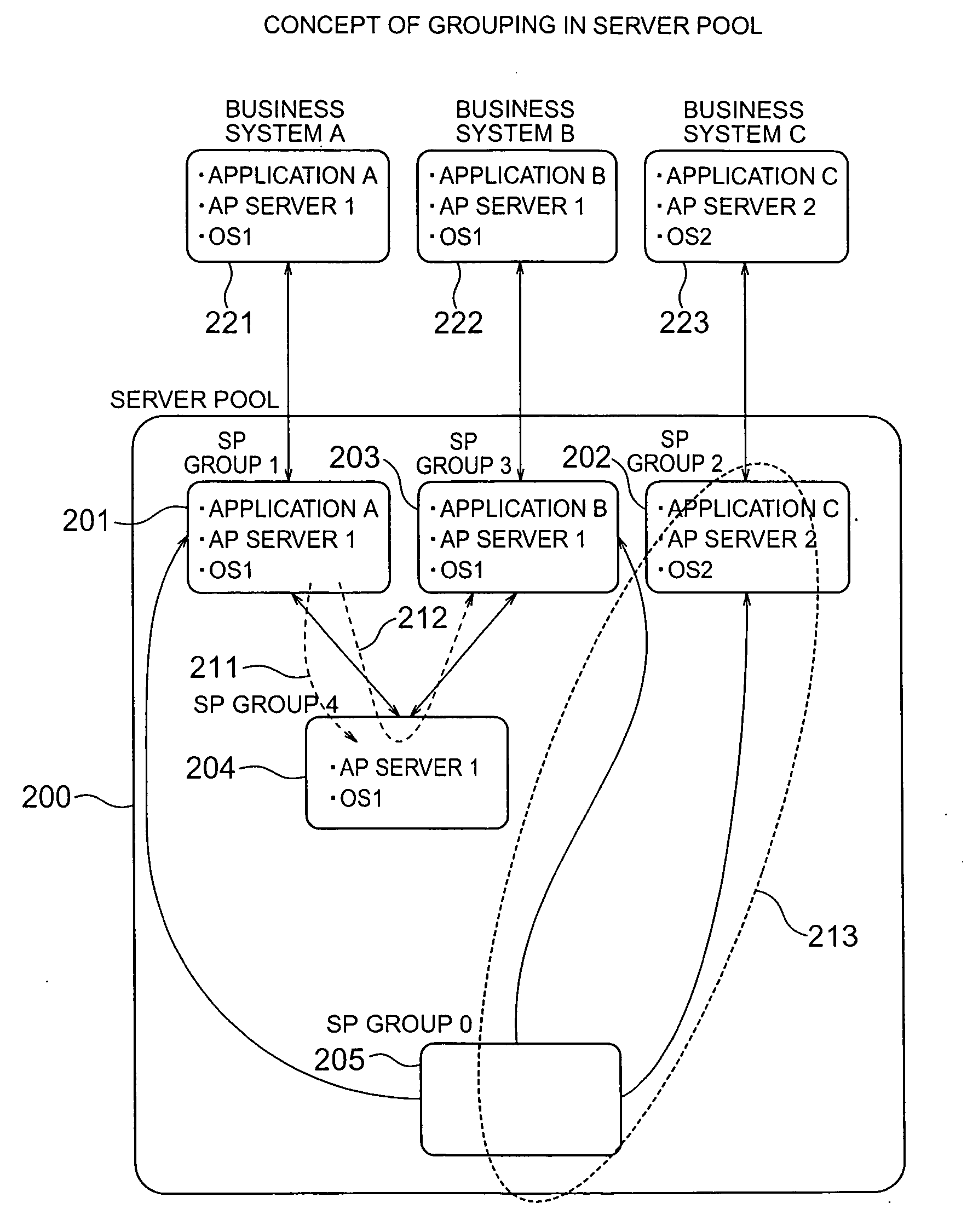

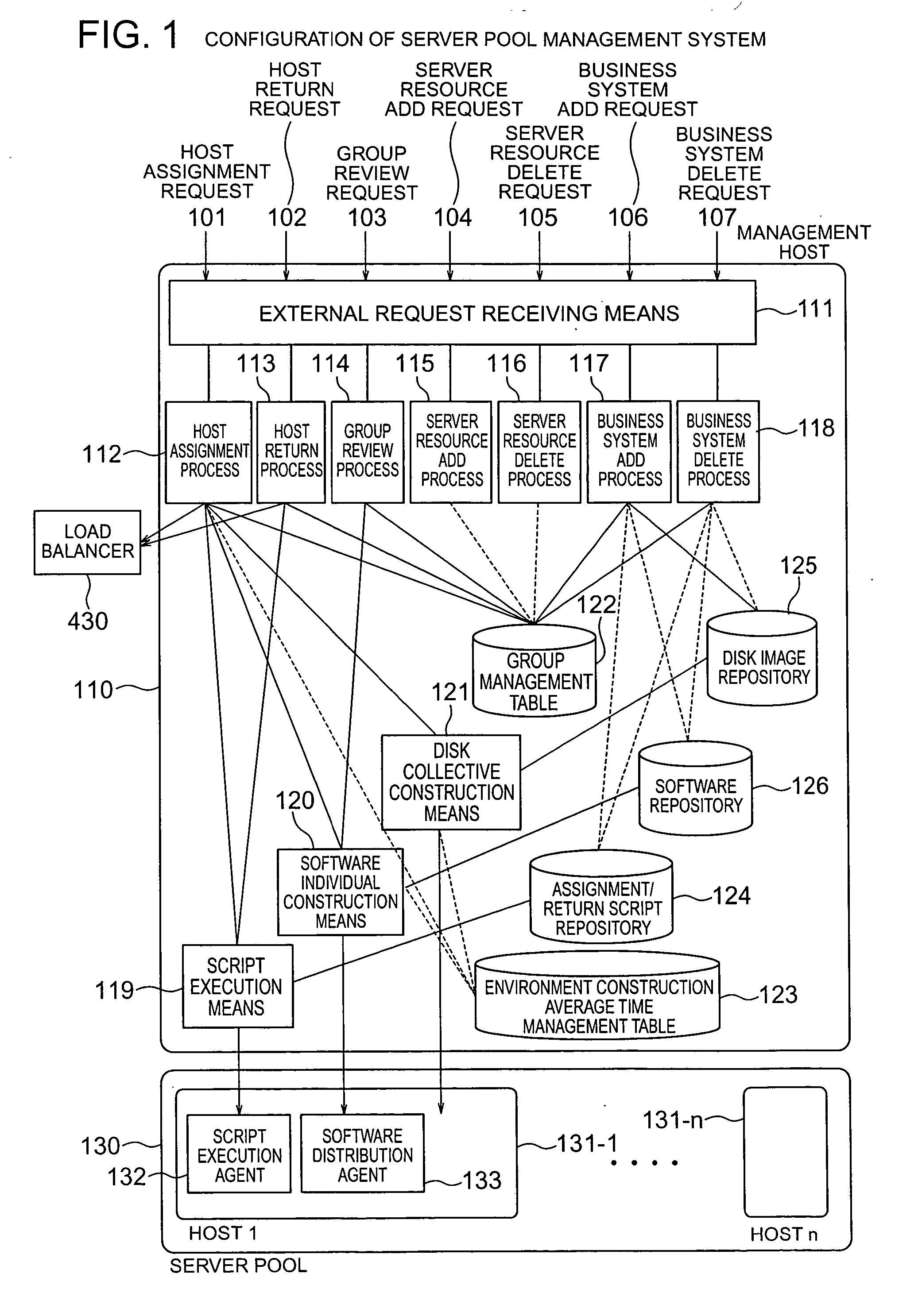

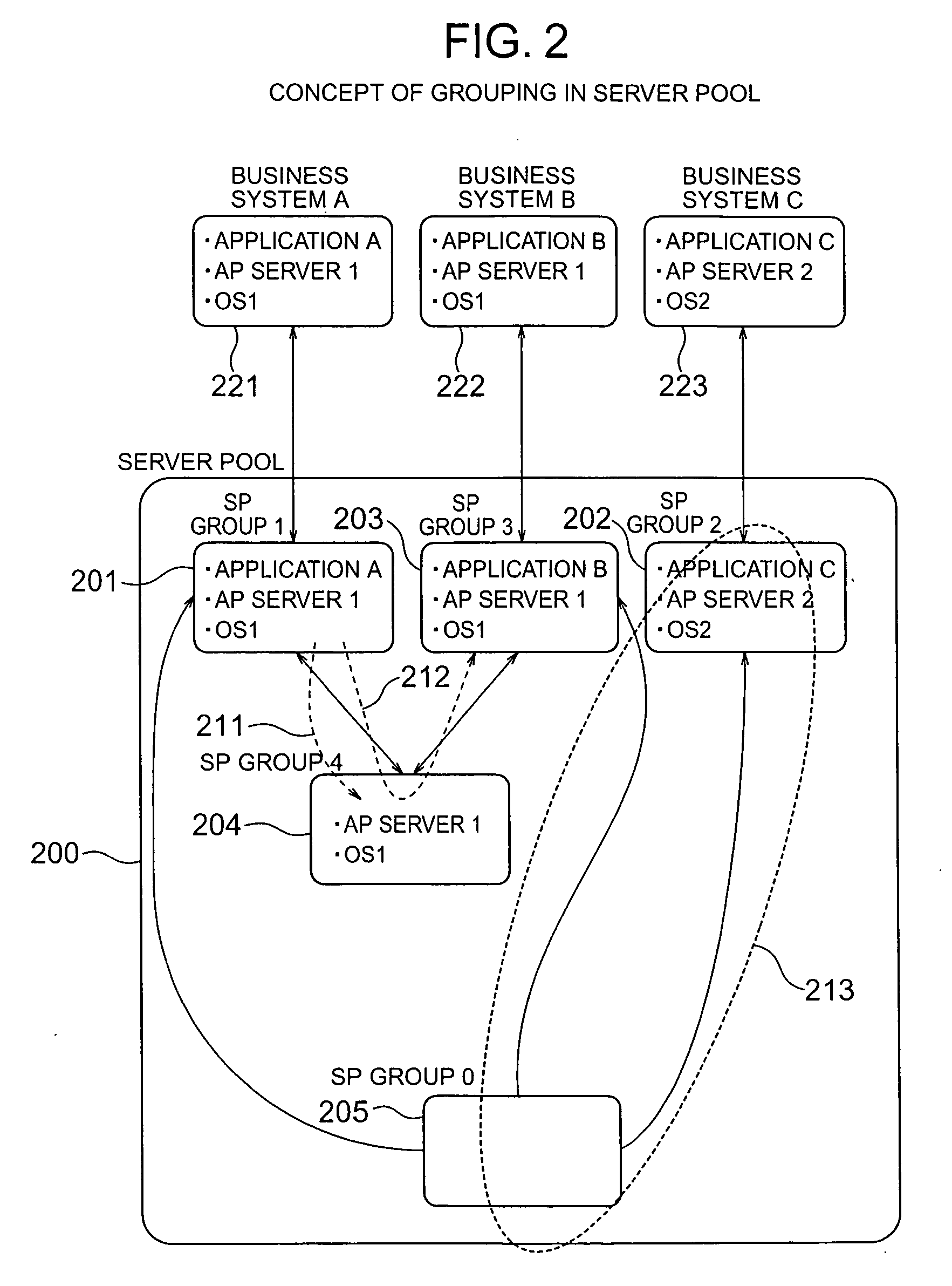

Server pool management method

InactiveUS20070094396A1Reduce buildHeavy loadDigital computer detailsMultiprogramming arrangementsSoftwareSoftware engineering

Standby computers are dynamically divided into groups according to the difference between the software thereof and the software required of a business system. When a computer is made available, the standby computers divided into groups by software structure are searched and an appropriate one is extracted to quickly complete the construction of the software environment. An active computer, if to be transferred to standby mode, is associated with the group having the same software structure as the business system with which the active computer has thus far operated. The active / standby states of the computers are monitored, and the standby computers are changed thereby to widen the possible range of application to other business systems, removing copy operation of disk images from the active computer to the standby computers.

Owner:HITACHI LTD

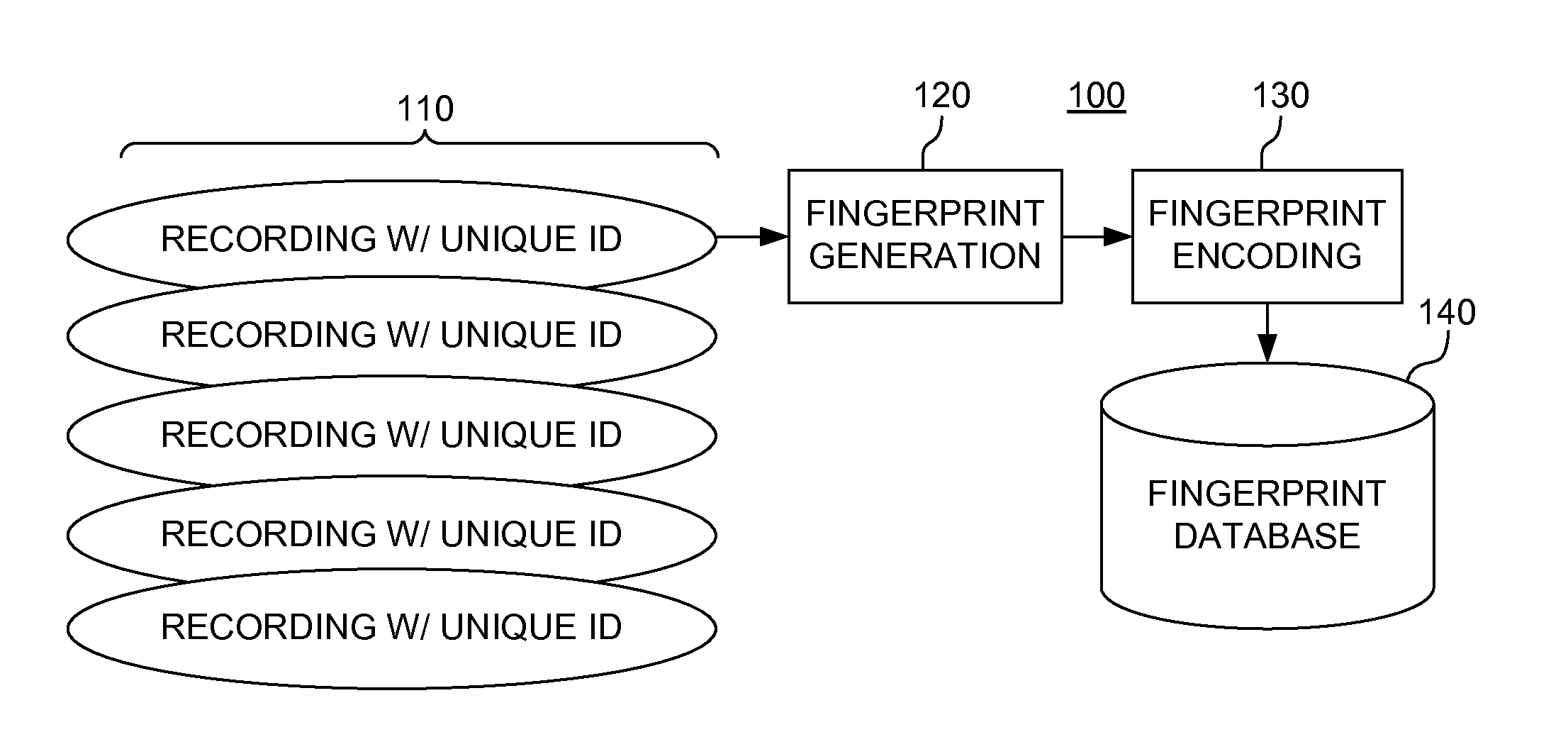

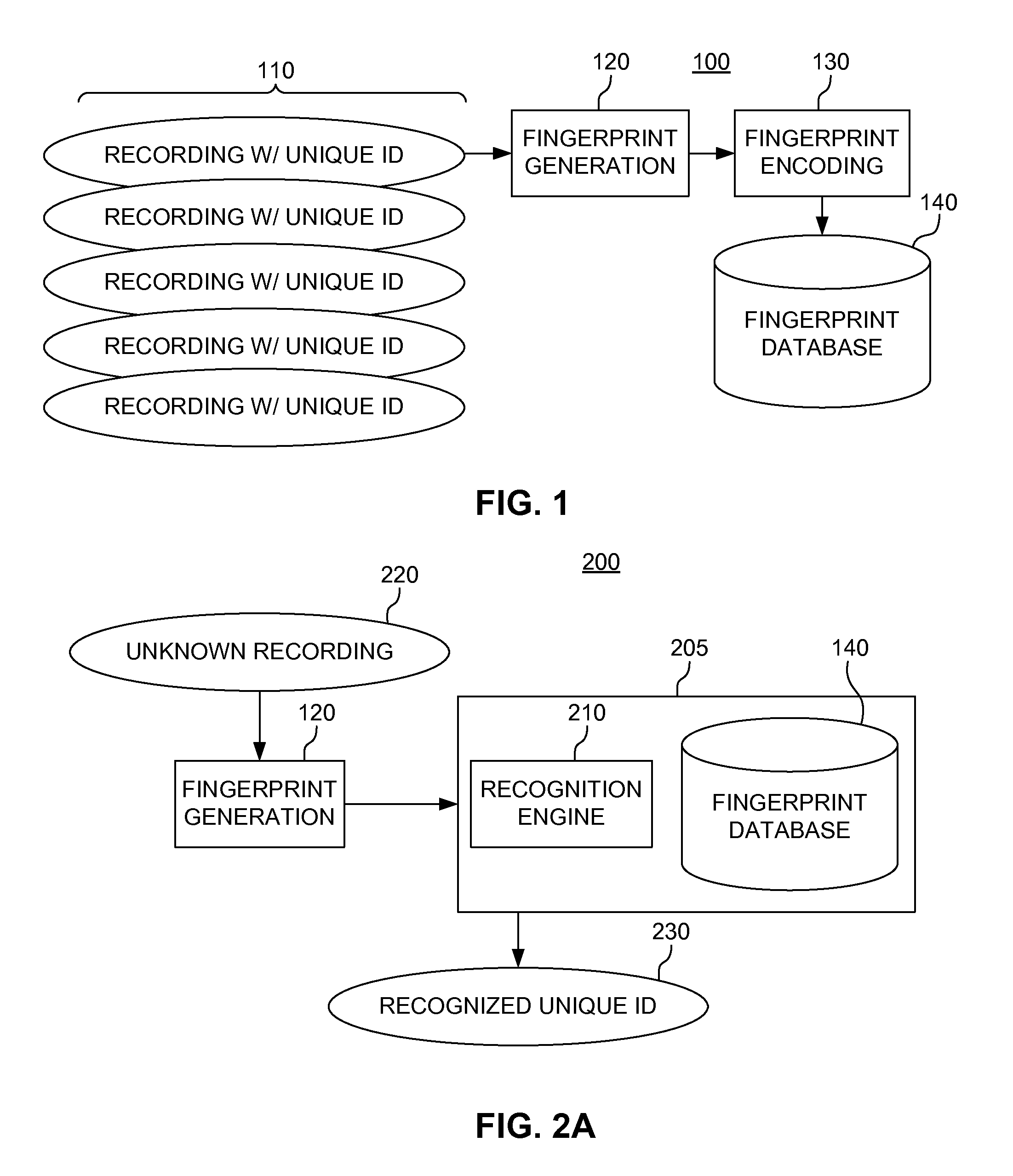

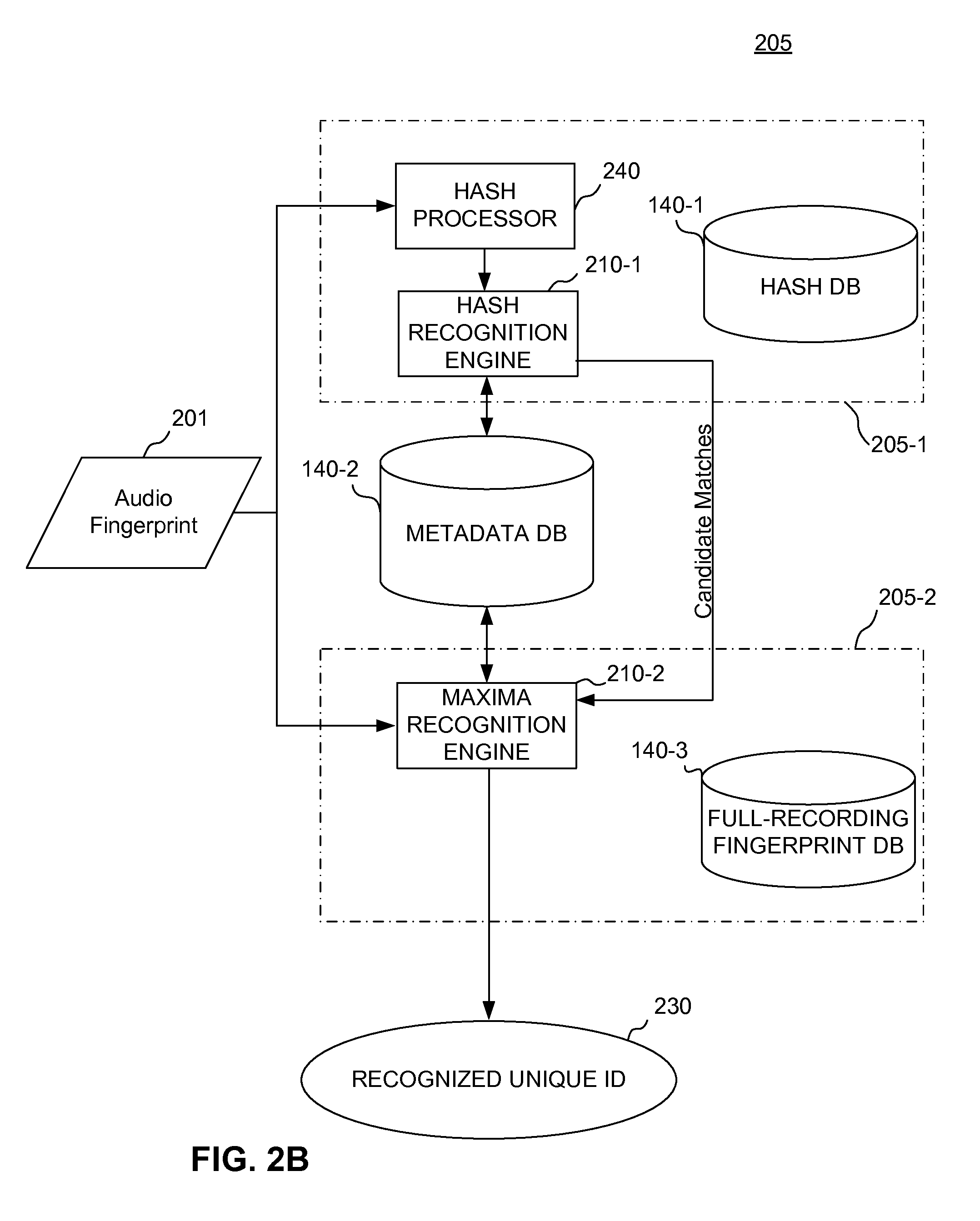

Rolling audio recognition

ActiveUS20110173208A1Fast constructionDigital data information retrievalDigital data processing detailsComputer hardwareAudio recognition

An audio fingerprint is generated by transforming an audio sample of a recording to a time-frequency domain and storing each time-frequency pair in a matrix array, detecting a plurality of local maxima for a predetermined number of time slices, selecting a predetermined number of largest-magnitude maxima from the plurality of local maxima detected by said detecting, and generating one or more hash values corresponding to the predetermined number of largest-magnitude maxima.

Owner:ROVI TECH CORP

System and method of RFID wireless control

InactiveUS20090256708A1Read easily and convenientlyLow costMemory record carrier reading problemsWireless architecture usageWireless controlControl system

A system of RFID wireless control comprises: at least one electronic device having an RFID tag and a receiver, and a controller having a reader for reading and recording the RFID tag of the at least one electronic device to form a list of electronic devices. The electronic device to be controlled is selected from the list, and the controller transmits or receives signals to or from the selected electronic device. The present invention also discloses a method of RFID wireless control for an RFID system.

Owner:HSIAO JUE HSUAN +1

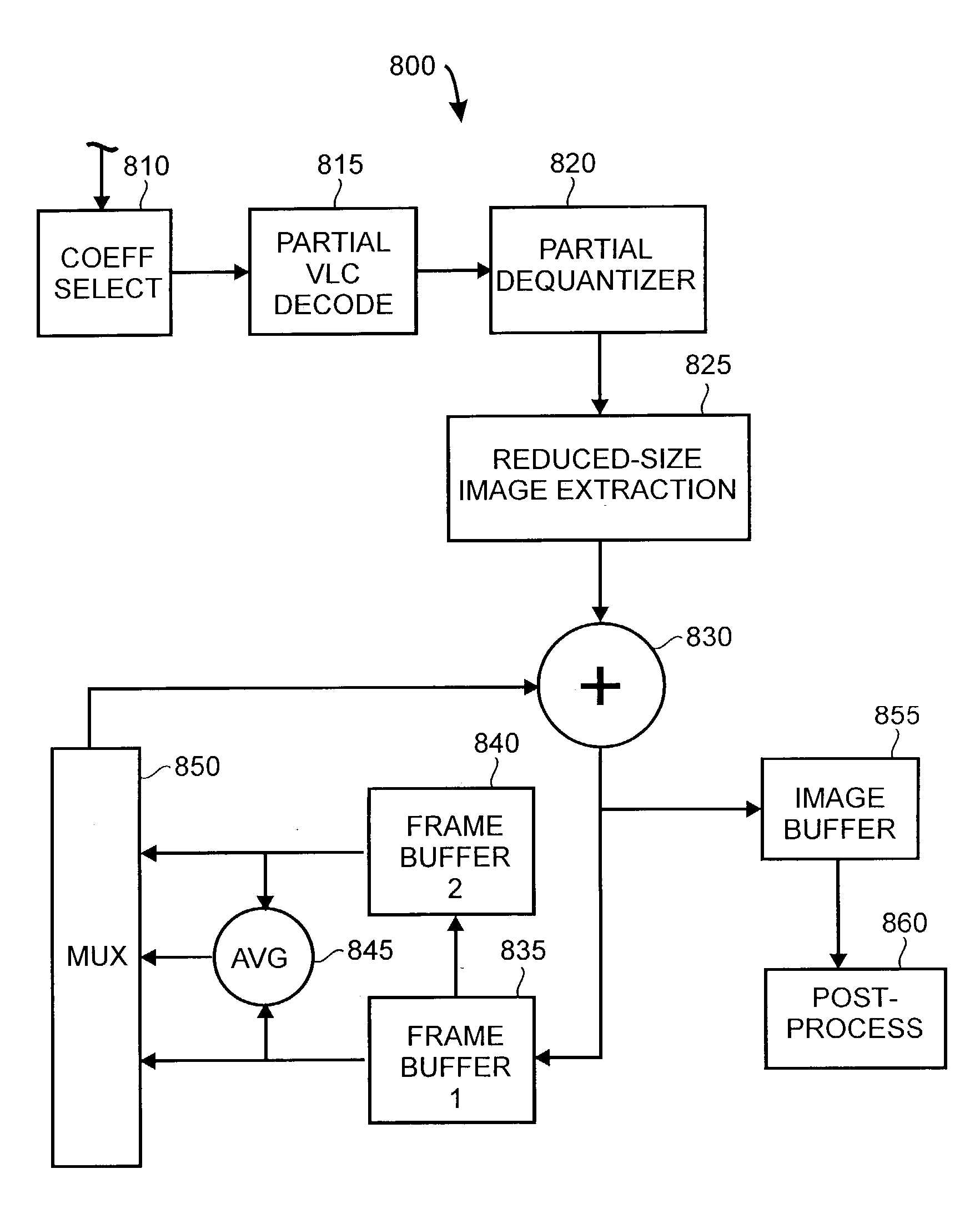

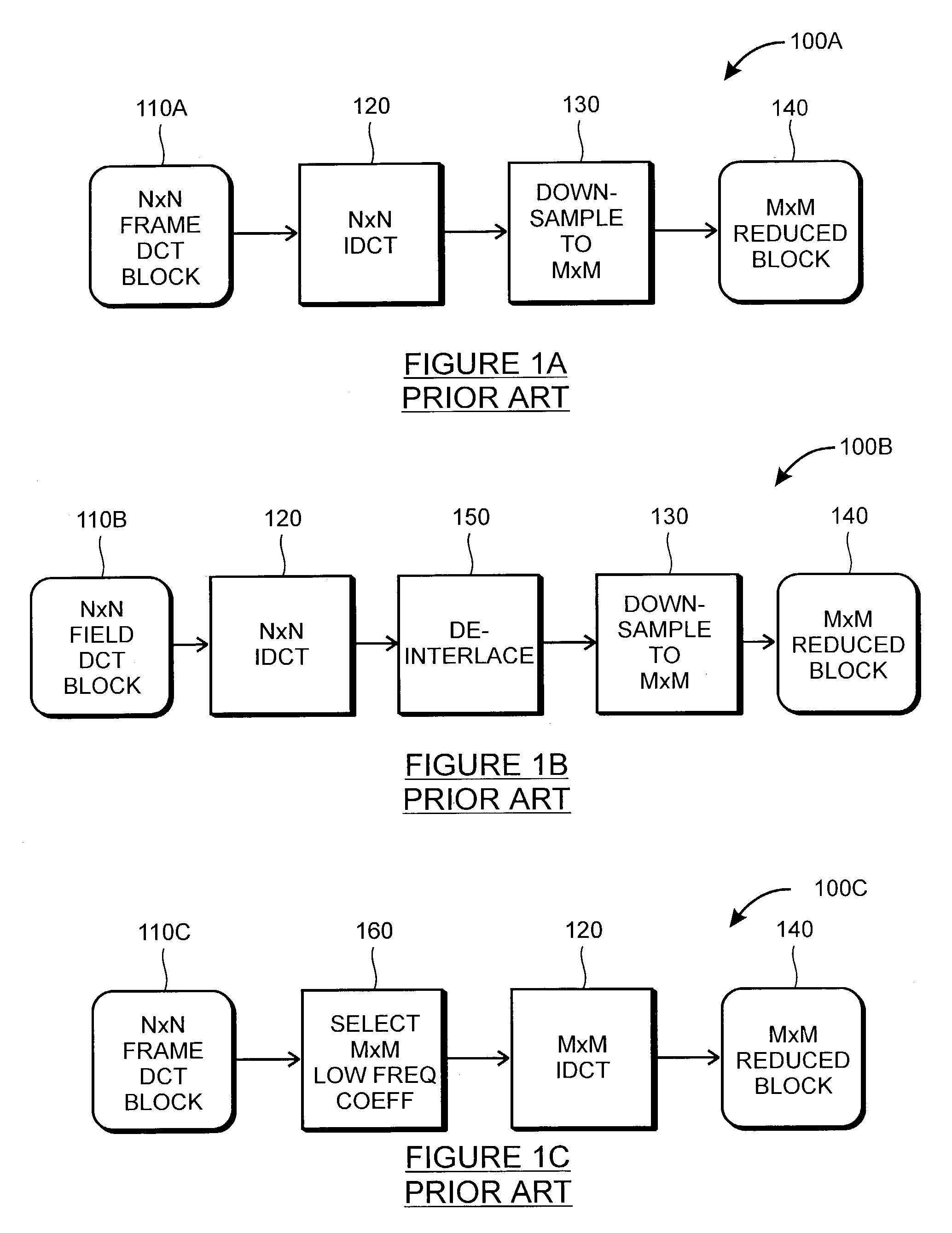

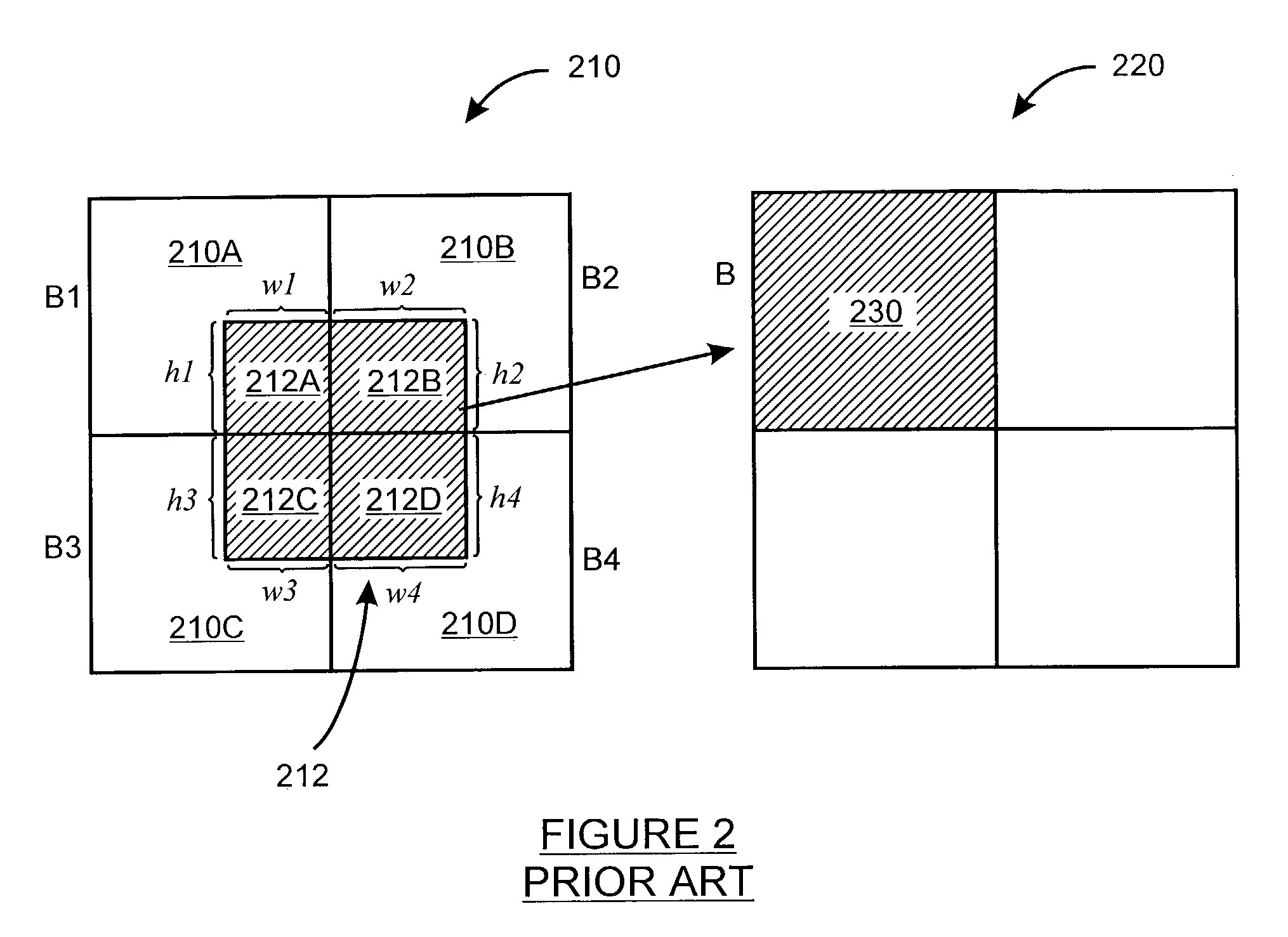

Rapid production of reduced-size images from compressed video streams

ActiveUS7471834B2Simple technologyRapid productionDisc-shaped record carriersFlat record carrier combinationsInterlaced videoReduced size

Methods for fast generating spatially reduced-size images directly from compressed video streams supporting the coding of interlaced frames through transform coding and motion compensation. A sequence of reduced-size images are rapidly generated from compressed video streams by efficiently combining the steps of inverse transform, down-sampling and construction of each field image. The construction of reduced-size field images also allows the efficient motion compensation. The fast generation of reduced-size images is applicable to a variety of low-cost applications such as video browsing, video summary, fast thumbnail playback and video indexing.

Owner:SCENERA INC

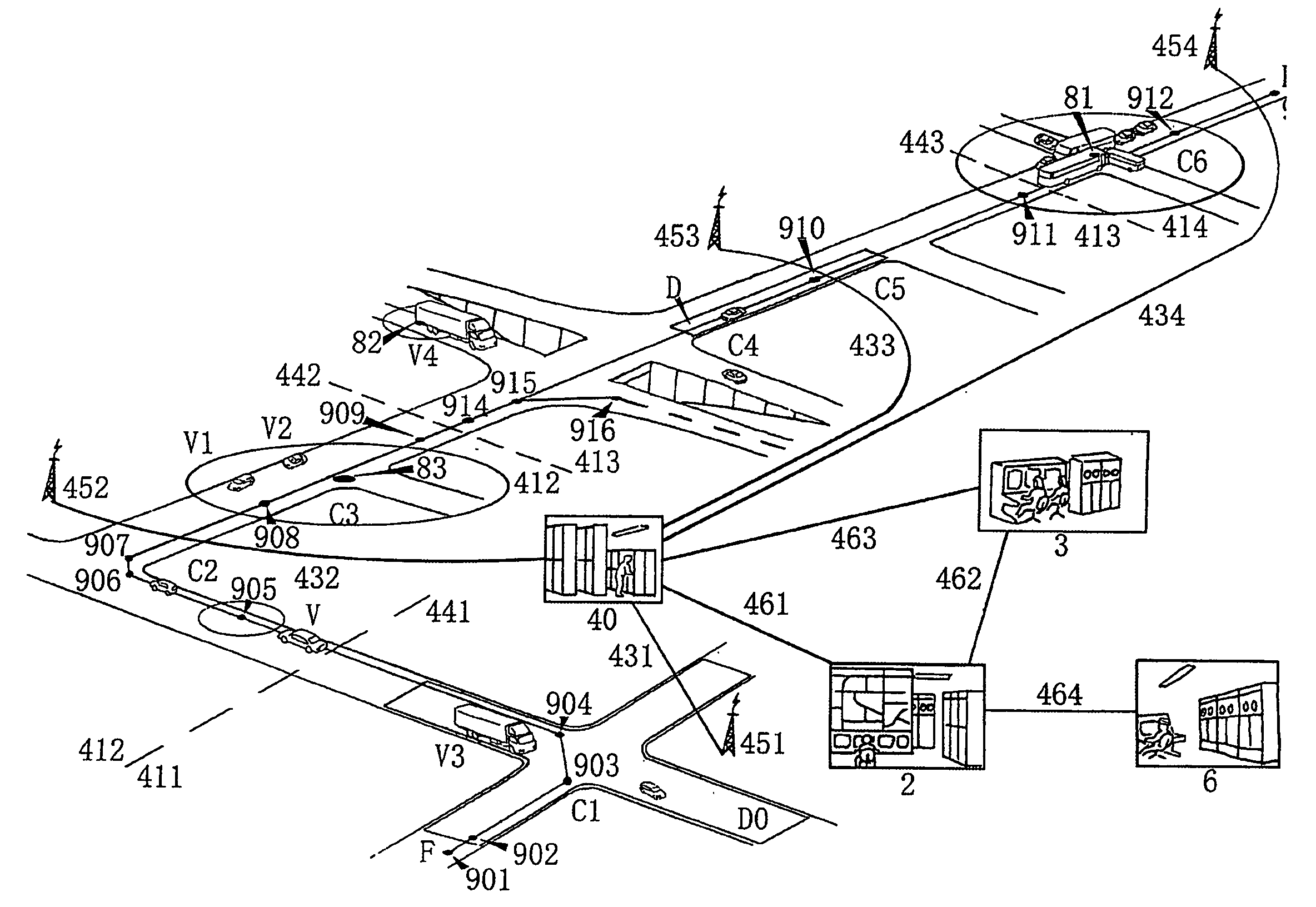

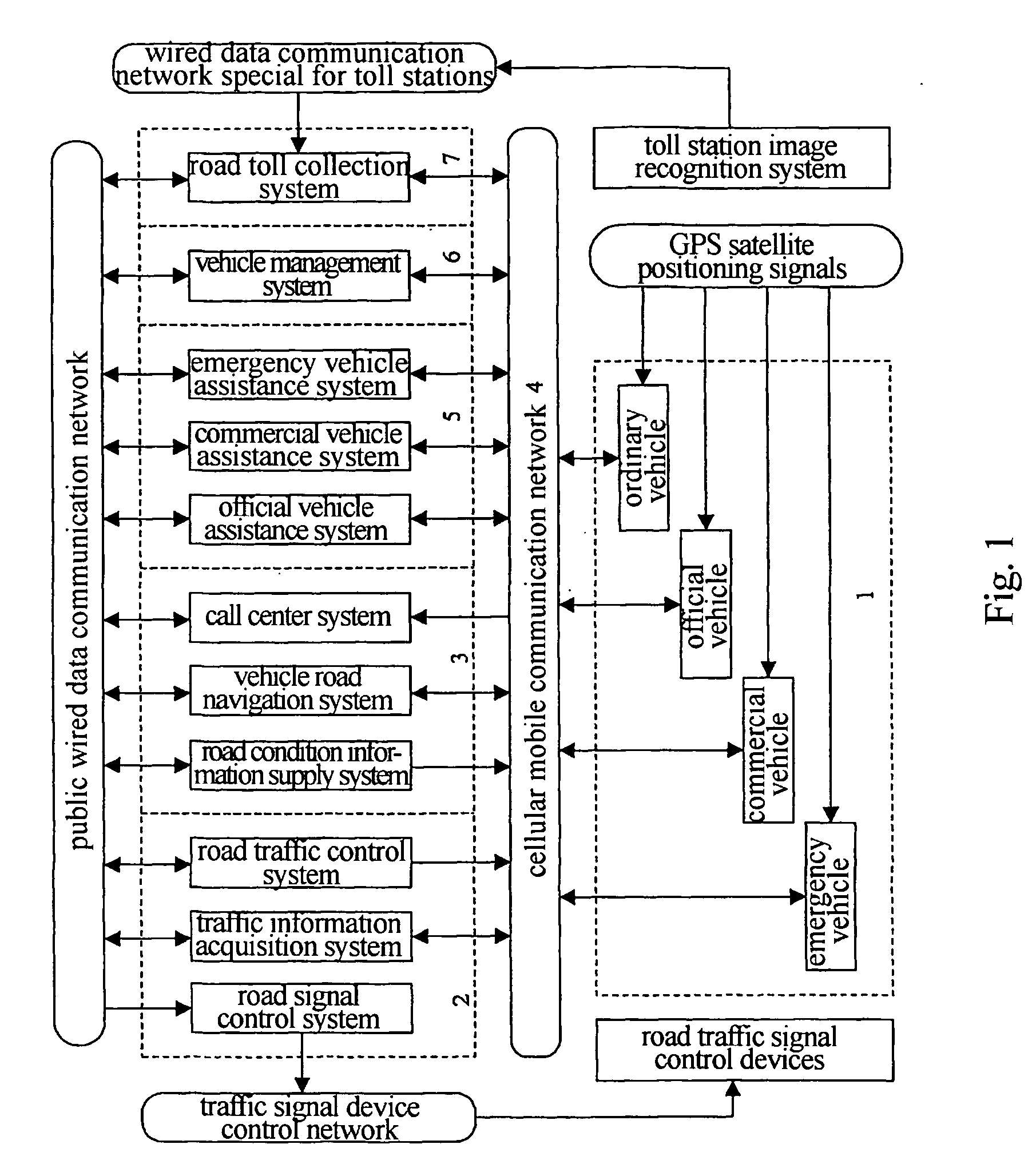

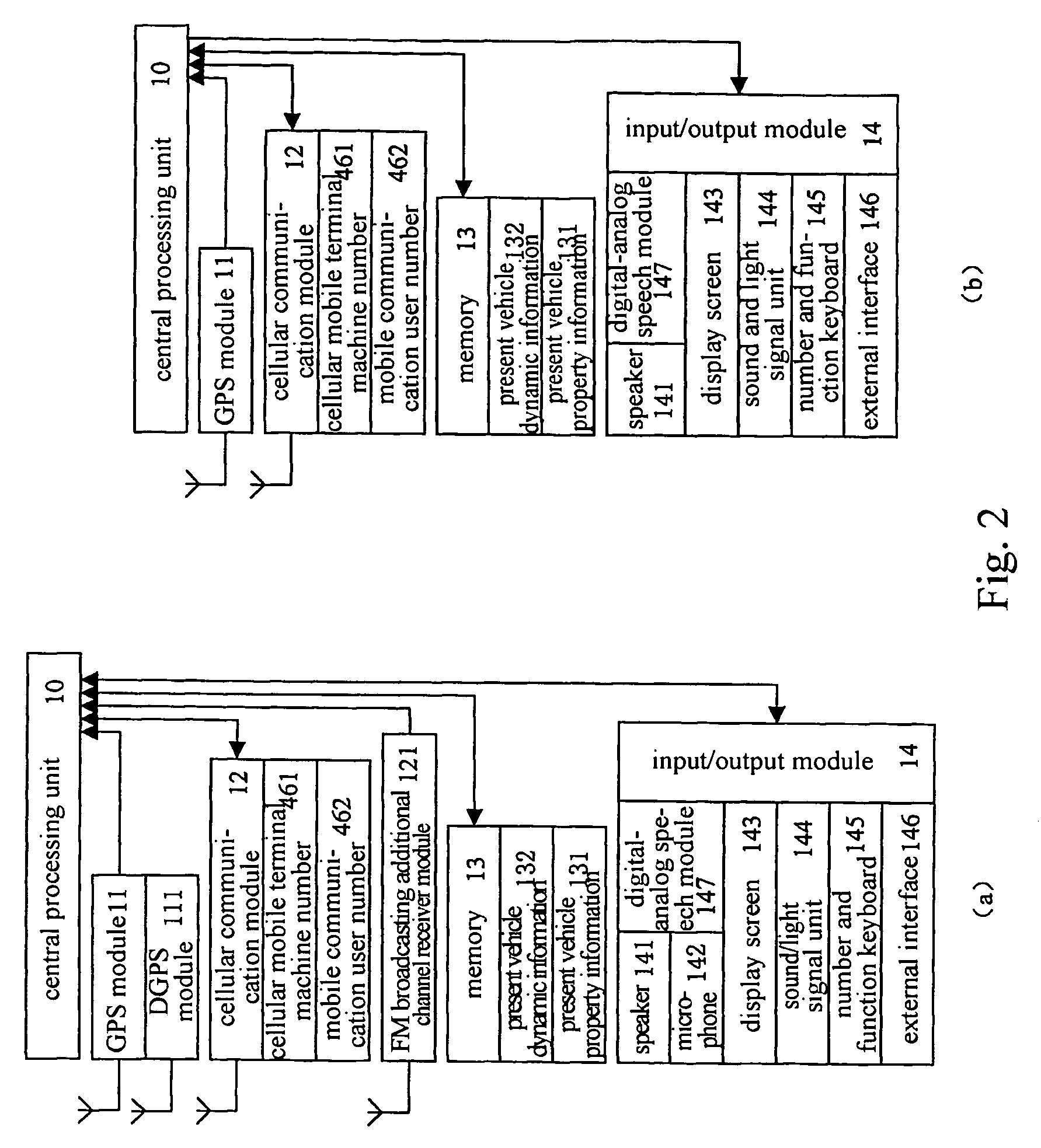

Intelligent traffic system

InactiveUS20060142933A1Rapid system constructionMeet convenient maintenanceAnalogue computers for vehiclesTicket-issuing apparatusWired communicationCollection system

The present invention discloses an intelligent traffic system. The system at least comprises a traffic control center, a traffic information service center, a cellular mobile communication system, a road toll collection system and an in-vehicle terminal, which are connected with each other via a wired communication network. The in-vehicle terminal communicates with the traffic control center, the road toll collection system and the traffic information service center respectively via the cellular mobile communication system. The present invention further claims an in-vehicle terminal used in an intelligent traffic system and a method for realizing an intelligent traffic system with a cellular mobile communication system. By adopting the intelligent traffic system, its construction cost will be reduced greatly.

Owner:FENG LUMIN

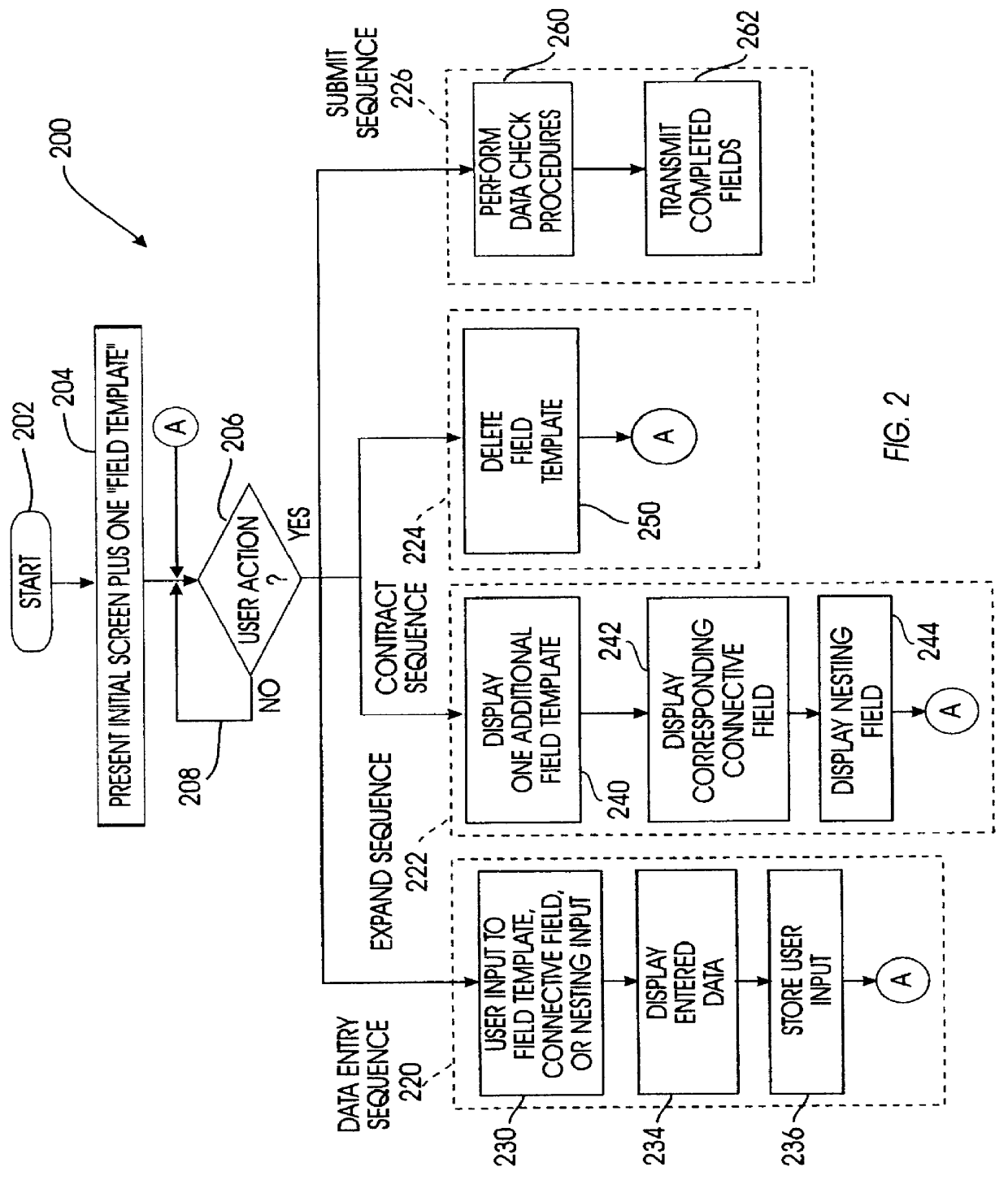

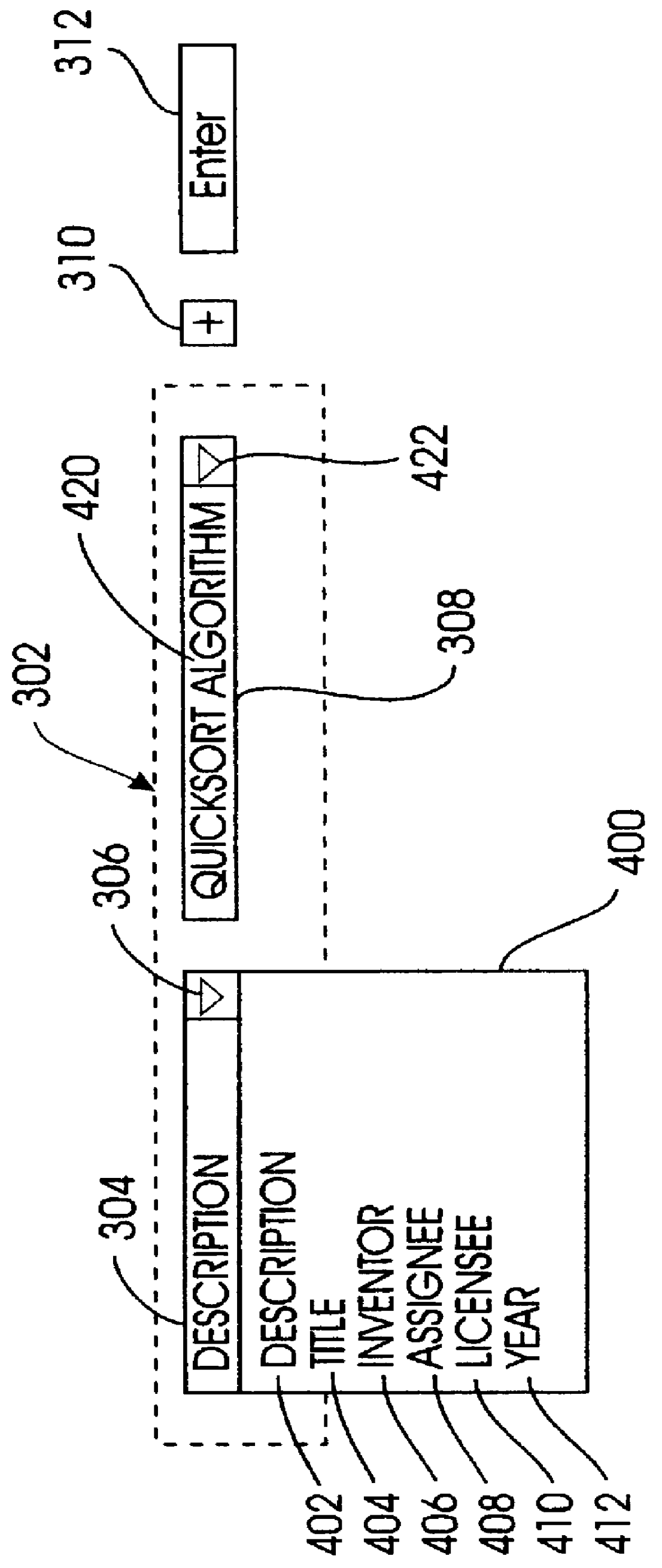

System for creating structured fields on electronic forms

InactiveUS6137488AGreat efficiency and flexibility and powerFacilitates completely custom construction and completionData processing applicationsNatural language data processingGraphical user interfaceLogical relationship

A computer system enables a user to conveniently fill-out, configure, and submit a structure of interrelated data fields, where the order and type of linking between the fields is user selected. A graphical user interface presents a field template having one or more data fields. The user may extend the electronic form by selecting an expand form field; in response to selection of the expand field, the user interface adds a second field template and a connective field to the display. This second template, like the first, includes one or more data fields. Using a connective field, the user identifies a logical relationship between the first field template and the second field template. For instance, the user may select from Boolean or other connective terms to construct a form having a complex format of interrelated fields. As each new field template is added with its corresponding connective field, the user interface also presents a nesting icon, allowing the user to establish a logical hierarchy between the various field templates.

Owner:IBM CORP

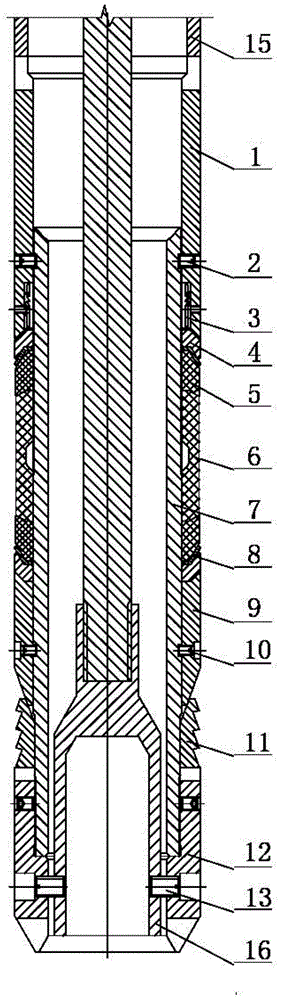

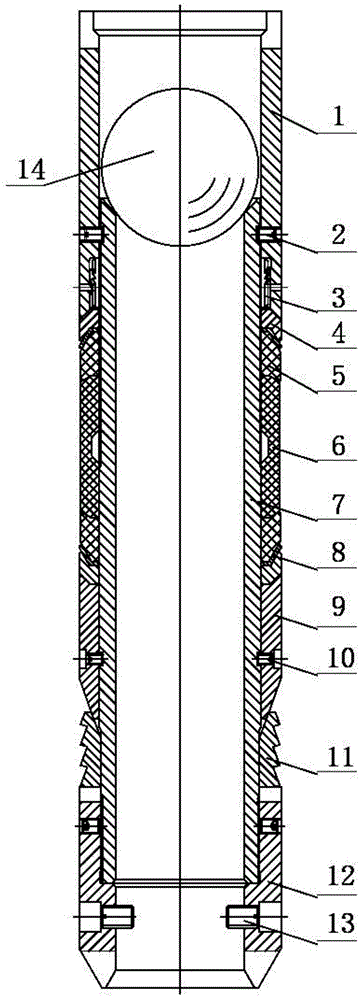

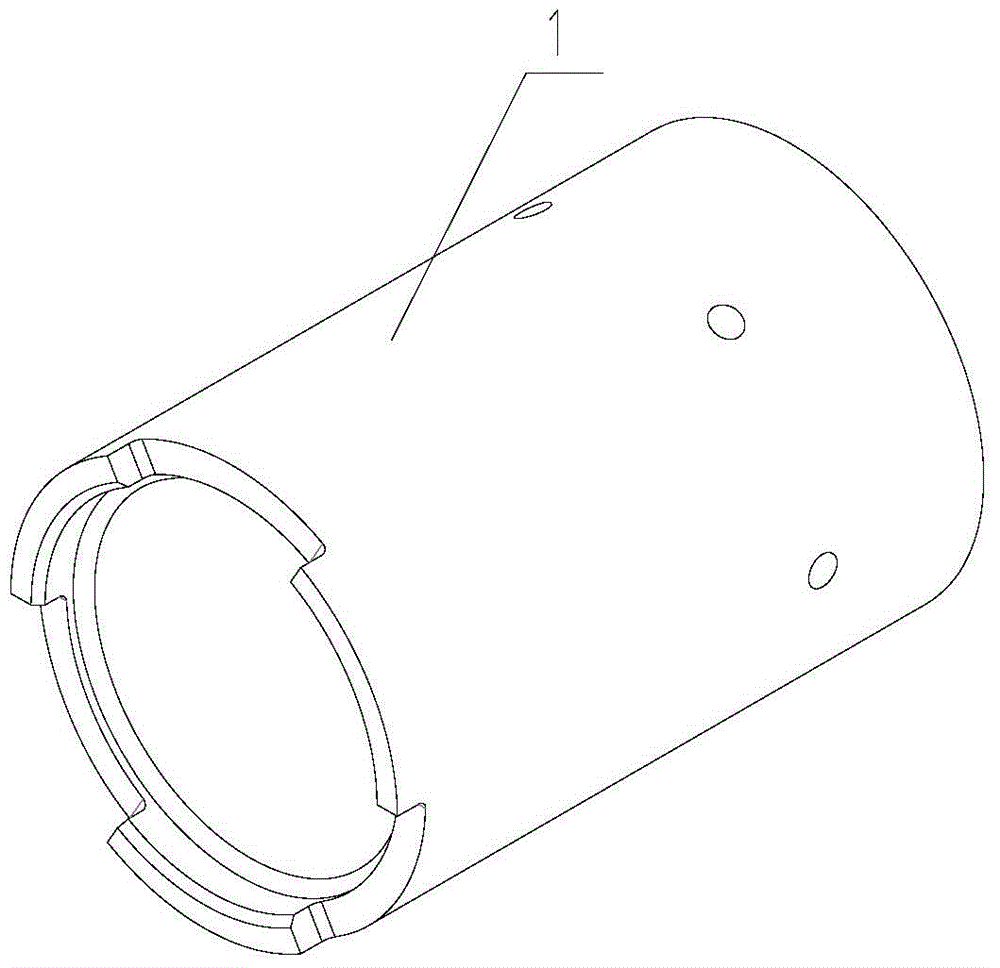

Bridge plug with large drift diameter and setting method of bridge plug

The invention discloses a bridge plug with a large drift diameter. The bridge plug comprises an upper joint, a central tube, a guiding shoe head and a bridge plug assembly; the upper joint is an annular part and is fixedly connected with the outer side of one end of the central tube in a sleeving mode; the central tube is a metal central tube, a soluble ball base is arranged at the end, close to the upper joint, of the central tube, and the central tube is a drillable metal part; the guiding shoe head is an annular part, is fixedly connected with the outer side of the other end of the central tube in a sleeving mode and is provided with a device used for being fixedly connected with a pull rod which is arranged in the bridge plug in a sleeved mode; the middle section of the central tube is sleeved with the bridge plug assembly which is located between the upper joint and the guiding shoe head. The invention further discloses a setting method of the bridge plug with the large drift diameter. The drilling polishing procedure of the bridge plug with the large drift diameter can be omitted, the problems of a long construction period, high operation cost and high construction risk brought by drilling polishing are solved, and the bridge plug is easier and more convenient to use and faster to construct.

Owner:JEREH ENERGY SERVICES

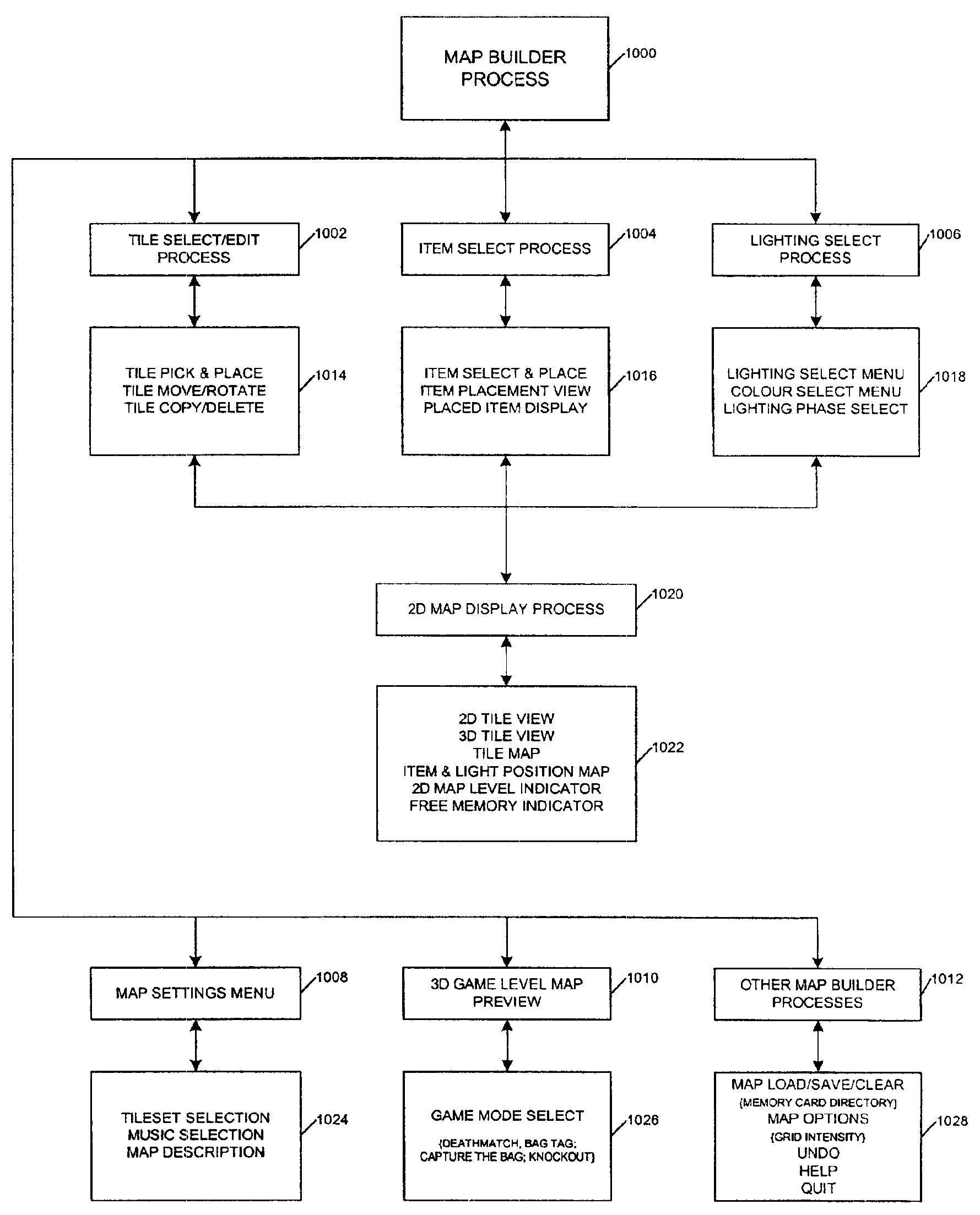

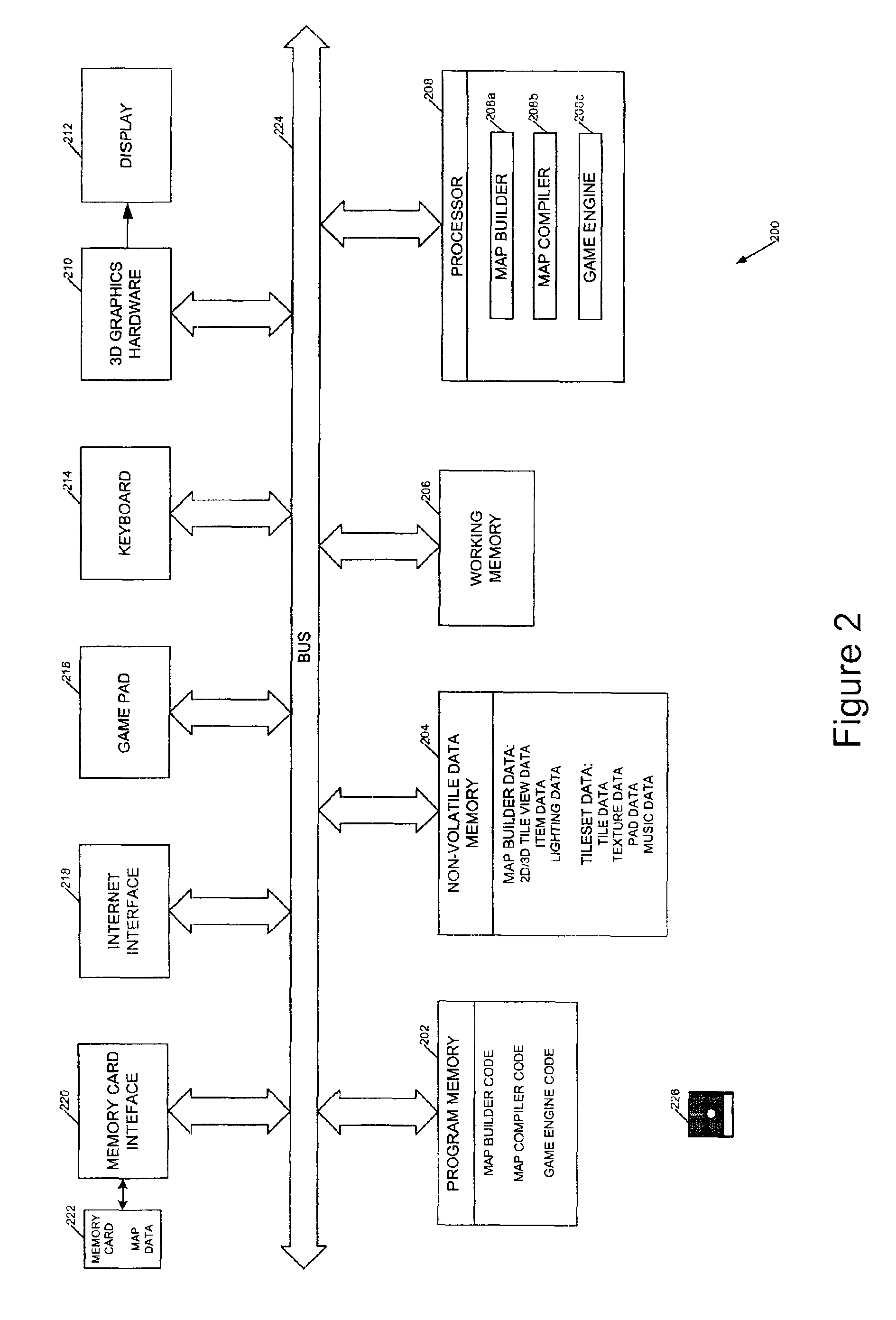

Methods and apparatus for constructing virtual environments

InactiveUS6961055B2Constructed much more quicklyFast constructionCathode-ray tube indicatorsMultiple digital computer combinationsComputer graphics (images)Data combination

The invention relates to methods, apparatus, and software for designing and building virtual environments for playing computer games. A map builder is used to construct one or more two-dimensional maps comprised of tiles selected from a set of tiles, the map or maps representing the virtual environment for the computer game. Data describing the map is then combined with tile data providing 3D geometry to create the virtual environment. The tile data preferably also includes non-visible game-related data such as collision and navigation data, which is also combined to provide game data for the game's virtual environment. The tiles include interfaces for connecting one tile to another and, in a preferred embodiment, two versions of the interface geometry are provided for each tile, one with the interface open, the other with the interface closed.The invention facilitates the rapid construction of 3D virtual environments for playing games.

Owner:CRYTEK IP HLDG

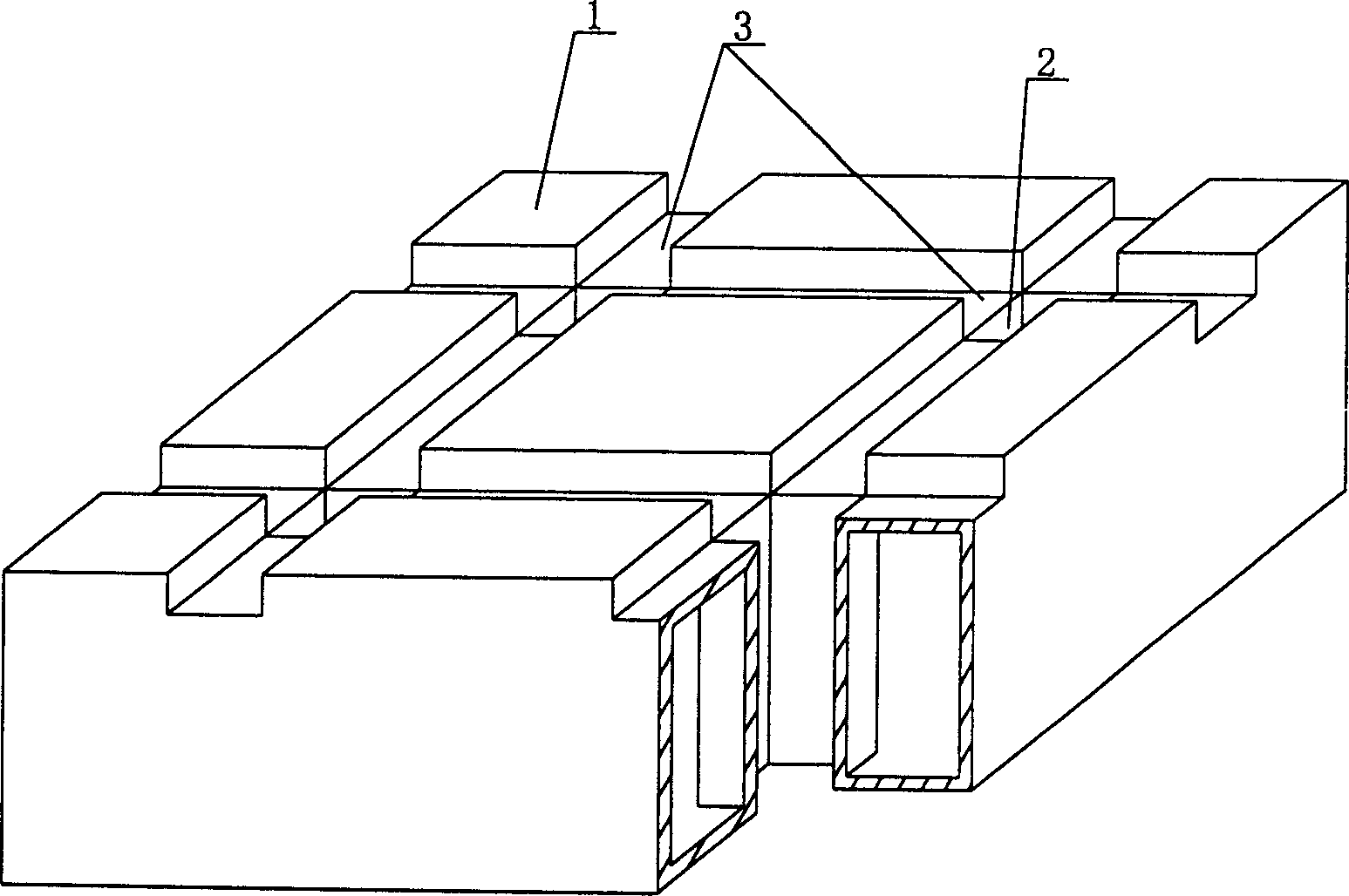

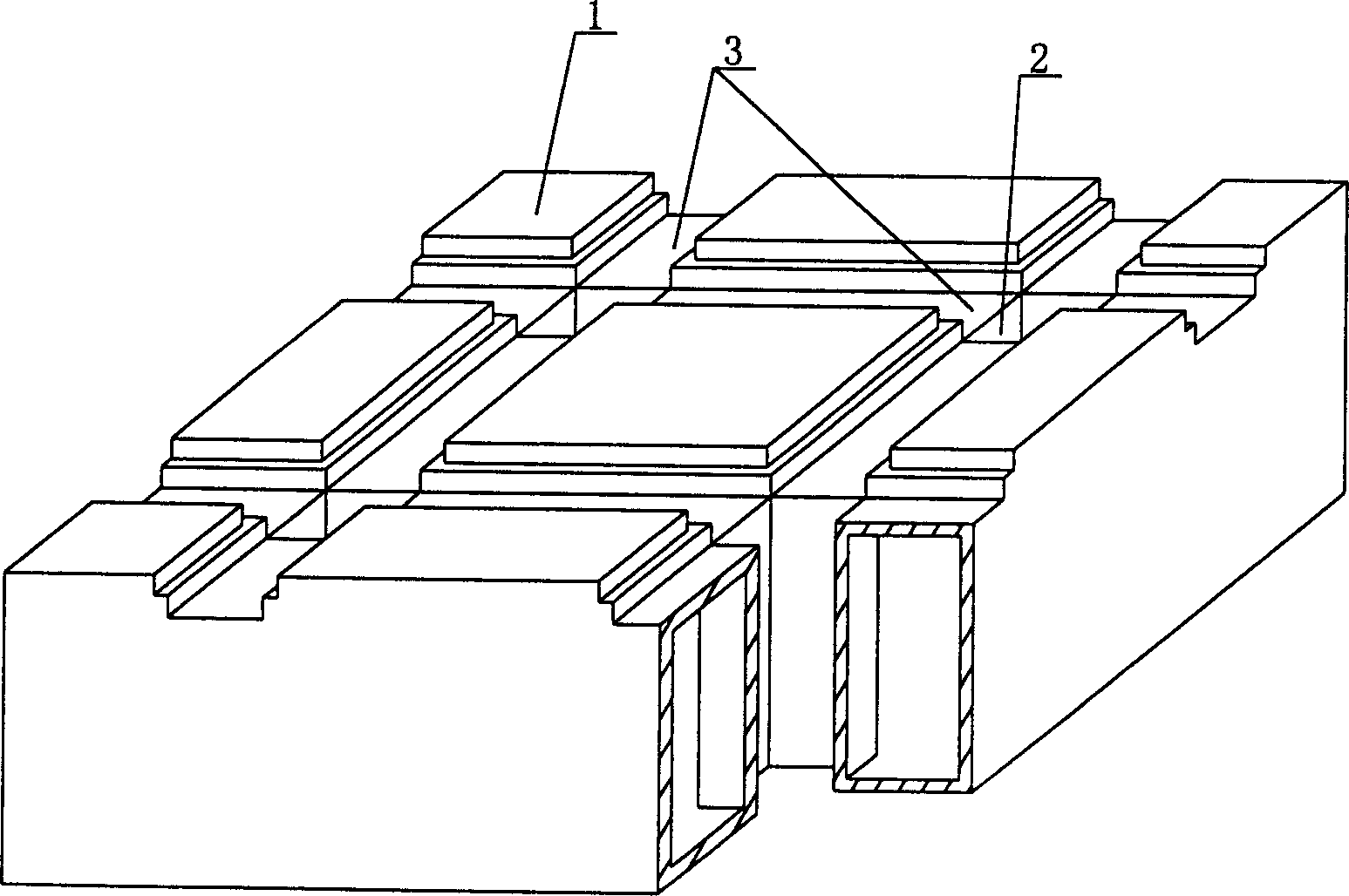

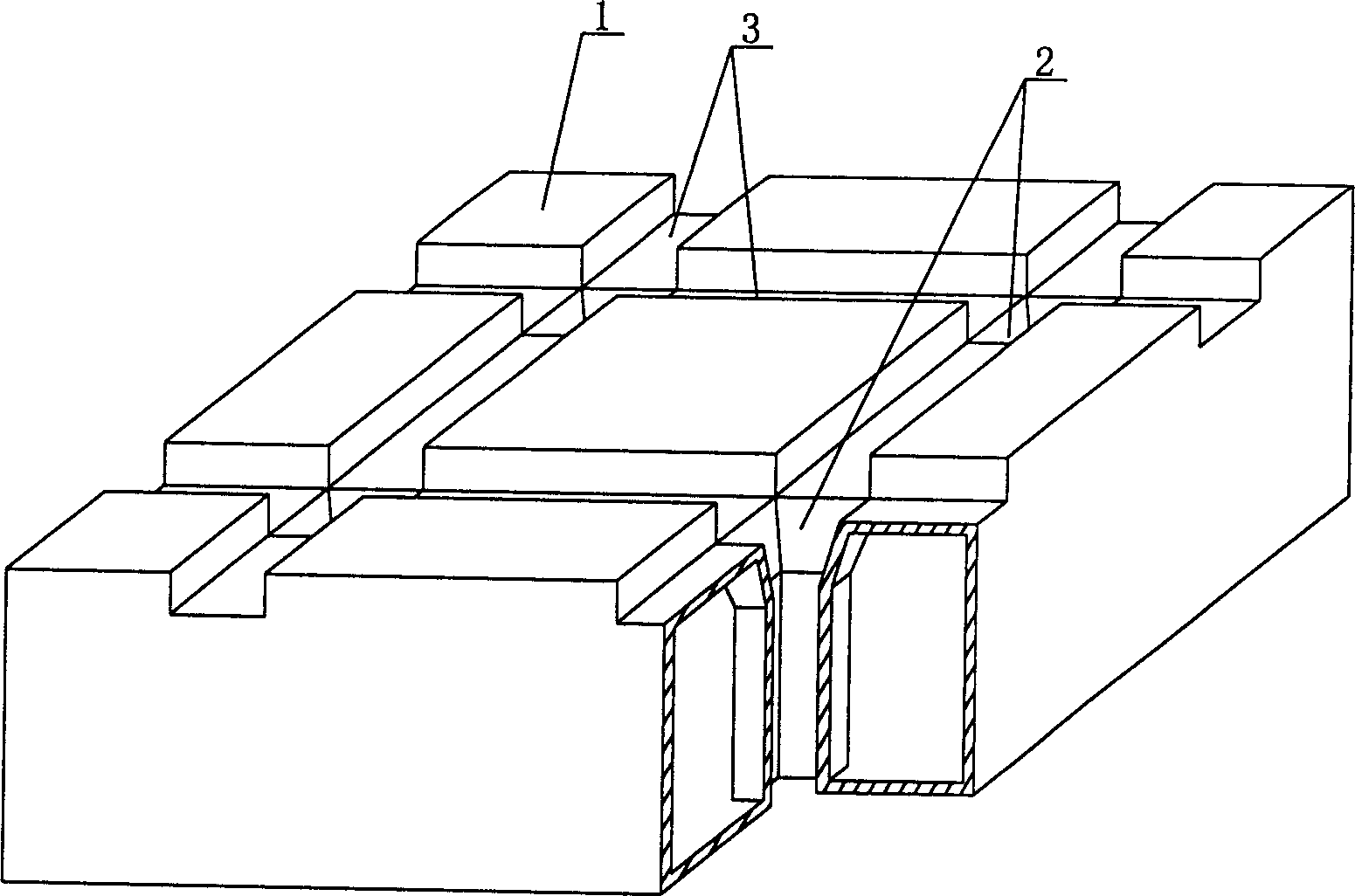

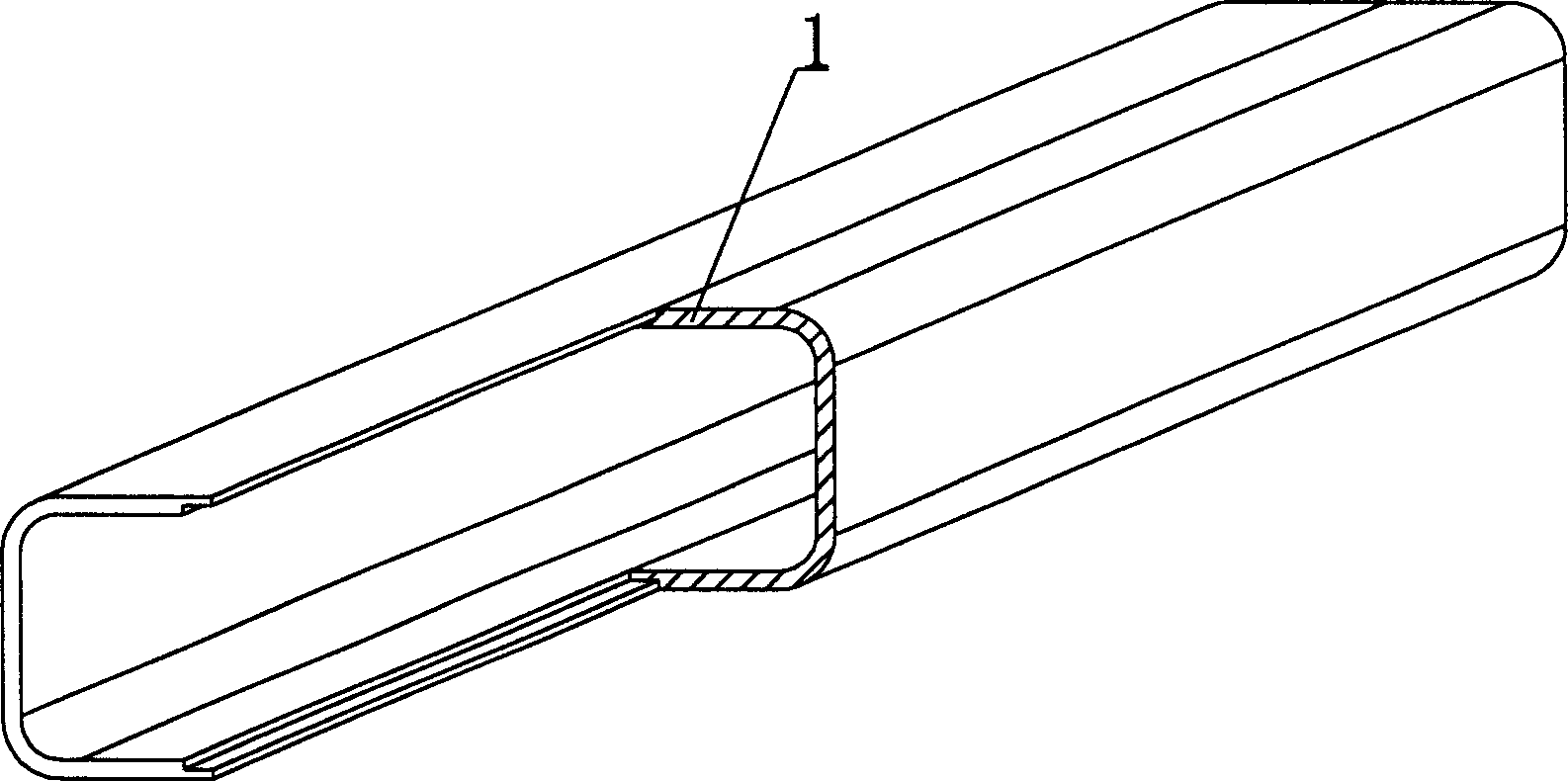

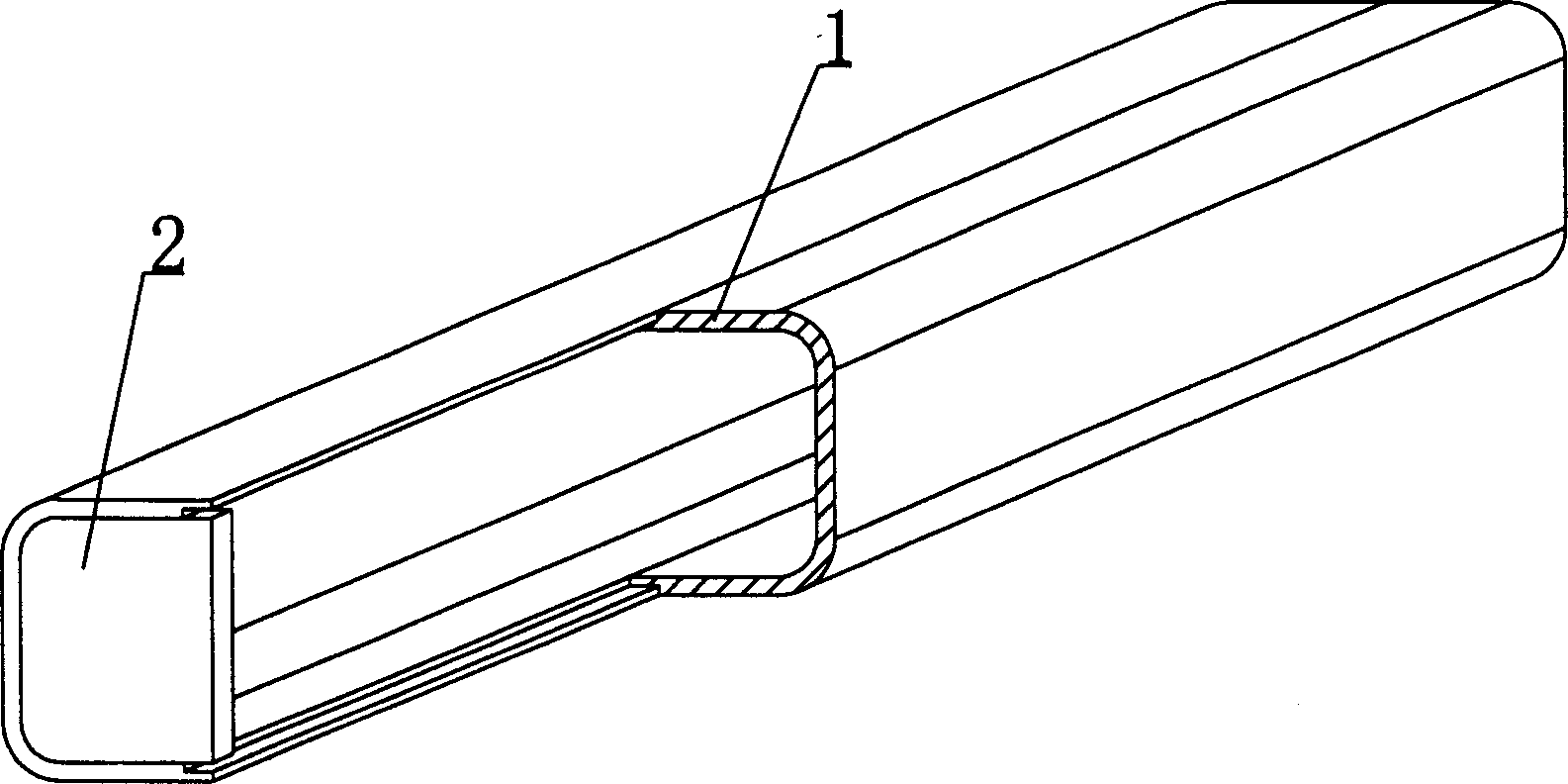

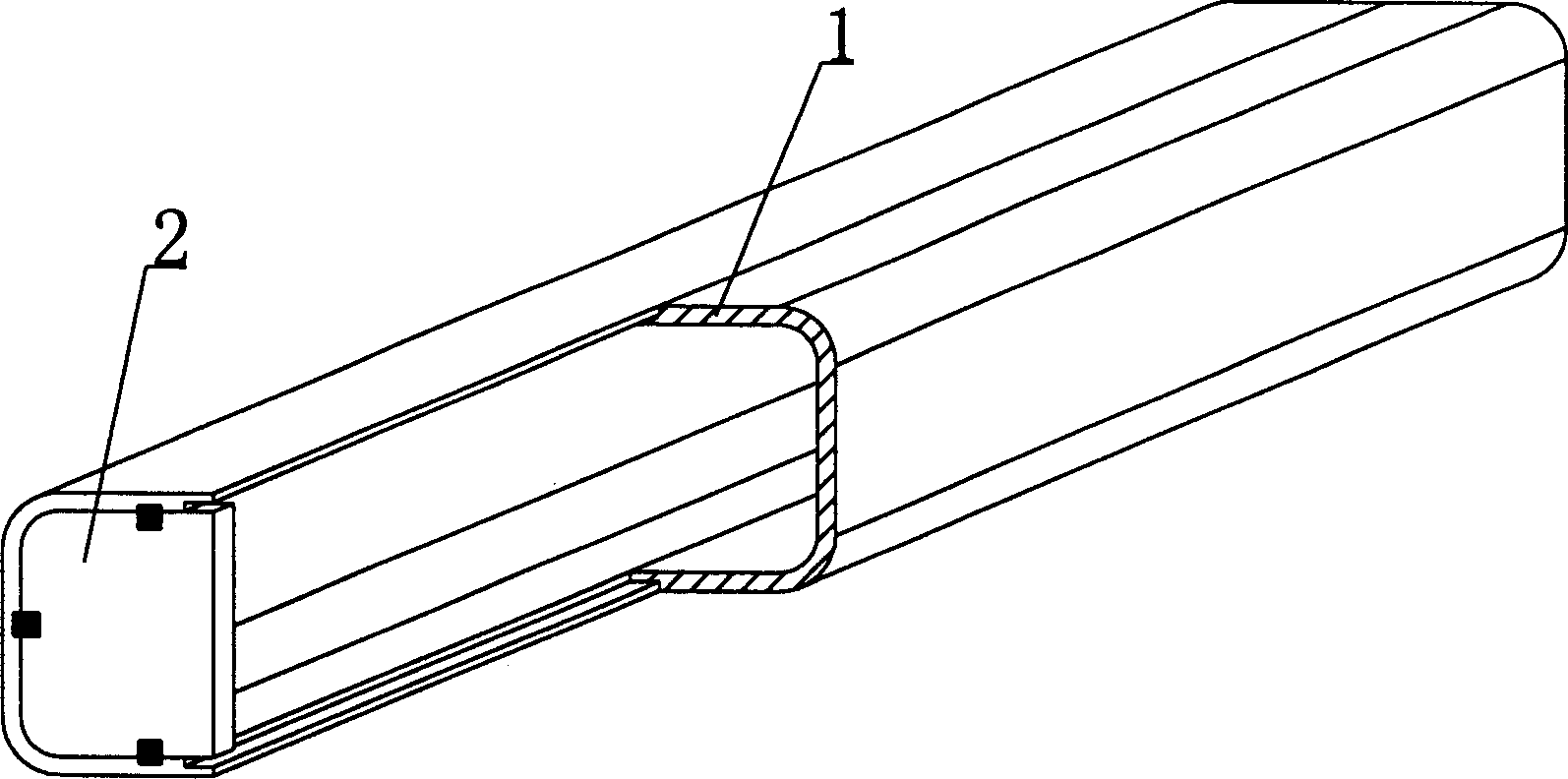

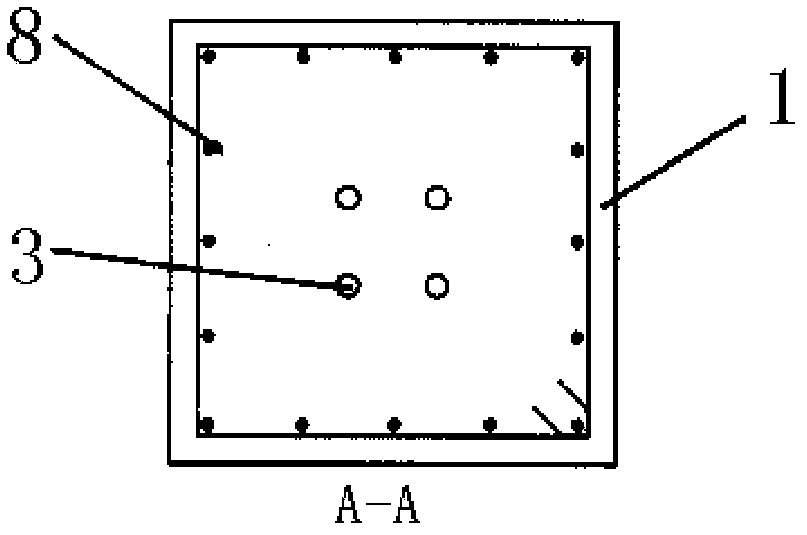

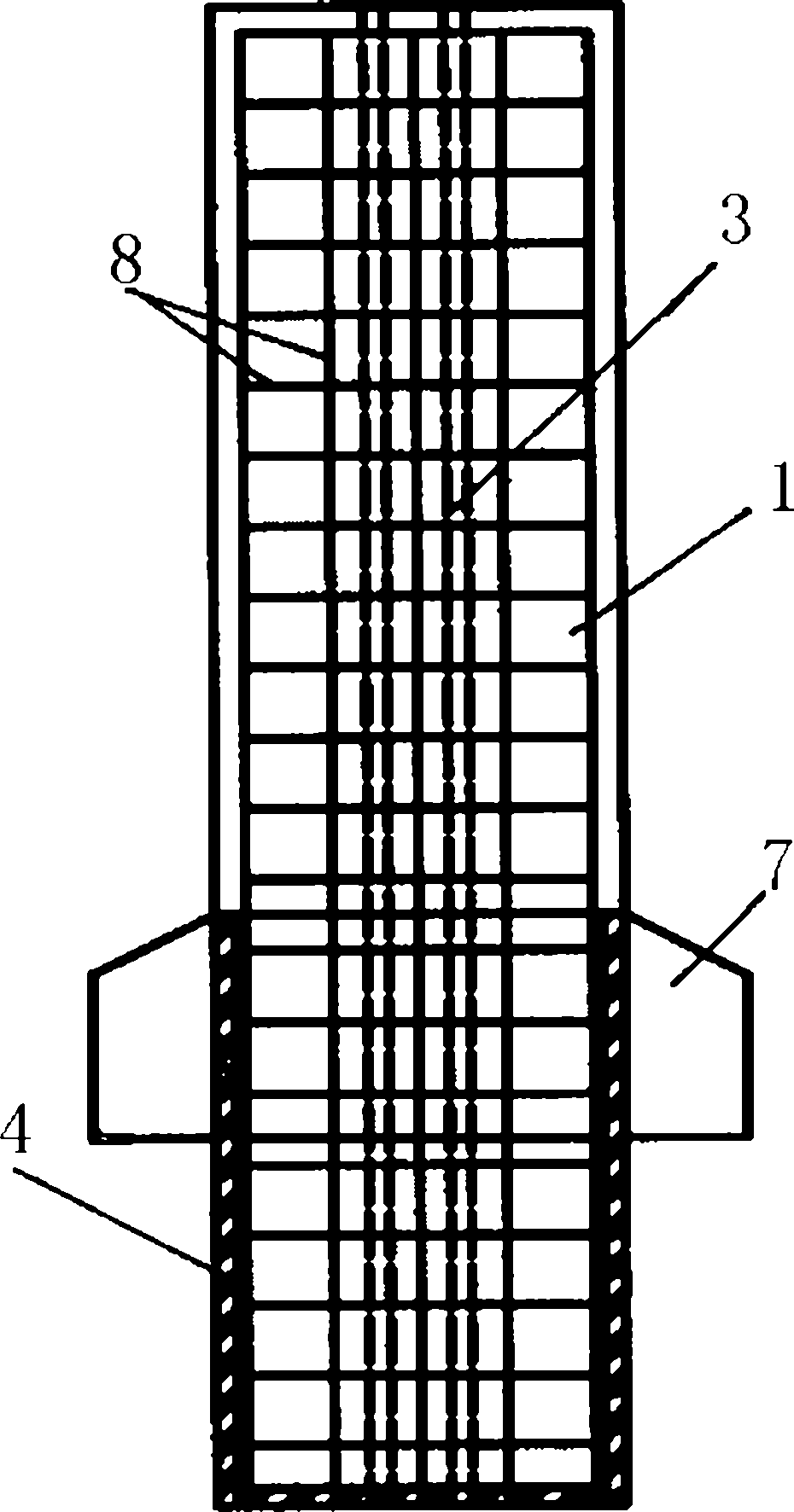

Light weight structural piece for use of filling concrete

InactiveCN1415815ASimple designIncrease production capacityFloorsStructural engineeringUltimate tensile strength

Owner:湖南邱则有专利战略策划有限公司

Member for cast-in-situ steel reinforced concrete

A member for in-situ casting the reinforced concrete is composed of two halves, which are fastened together to form a hollow thin-wall member used for in-situ casting hollow floor slab, roof, wall, etc. Said member is made up by die pressing. Its advantages are high strength, low cost, and convenient transportation.

Owner:湖南邱则有专利战略策划有限公司

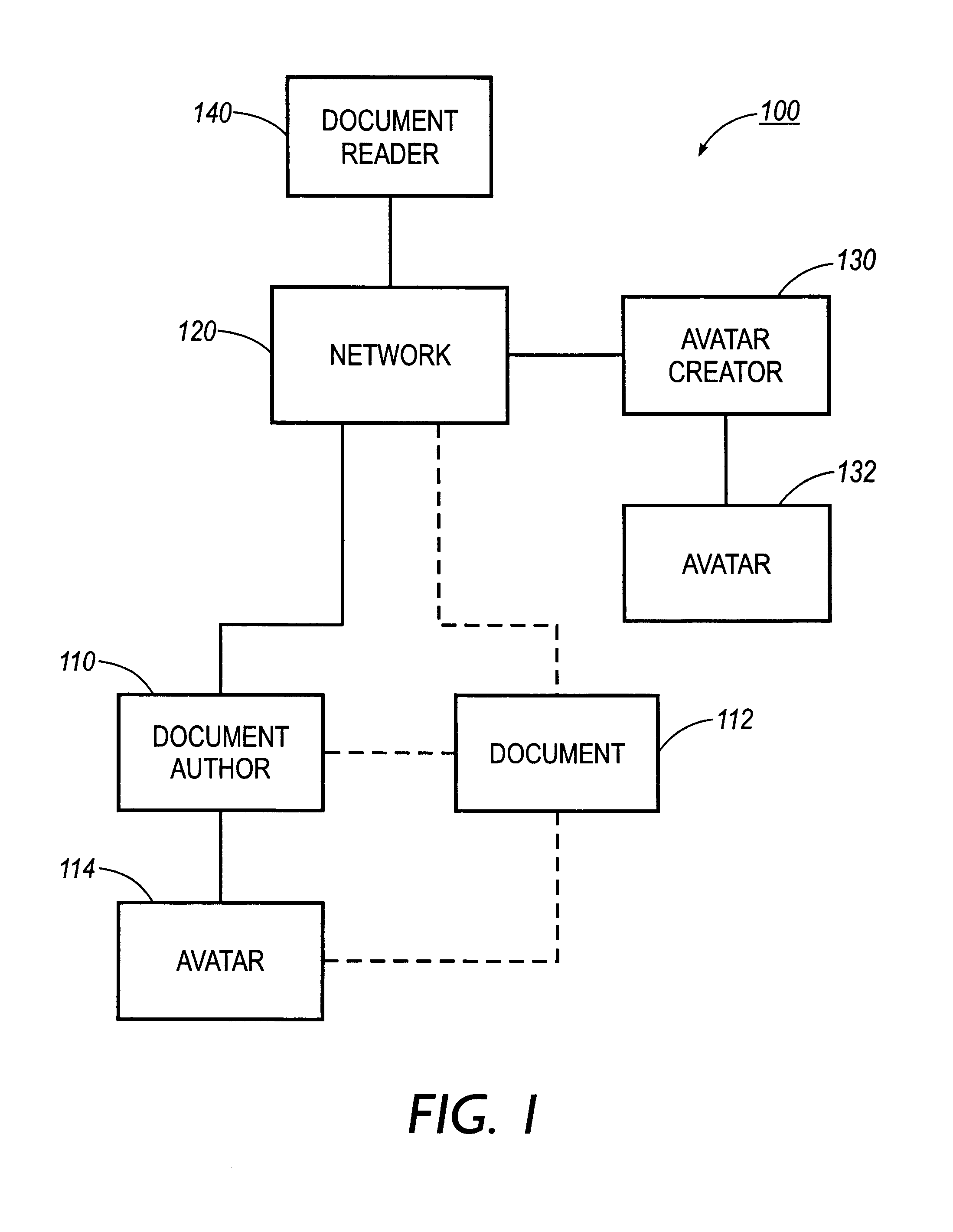

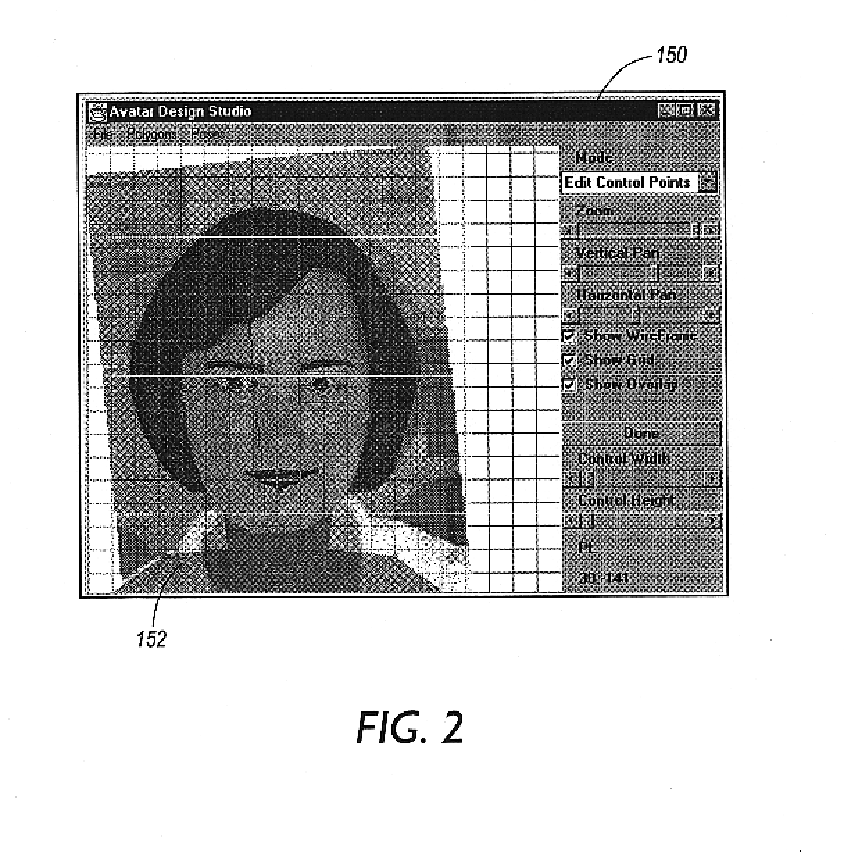

Method and apparatus for creating personal autonomous avatars

InactiveUS7006098B2Quality improvementIncrease volumeAnimationSpeech recognitionScripting languageAnimation

A method and apparatus for facilitating communication about a document between two users creates autonomous, animated computer characters, or avatars, which are then attached to the document under discussion. The avatar is created by one user, who need not be the author of the document, and is attached to the document to represent a point of view. The avatar represents the physical likeness of its creator. The avatar is animated, using an avatar scripting language, to perform specified behaviors including pointing, walking and changing facial expressions. The avatar includes audio files that are synchronized with movement of the avatar's mouth to provide an audio message.

Owner:MAJANDRO LLC

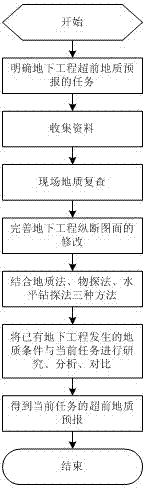

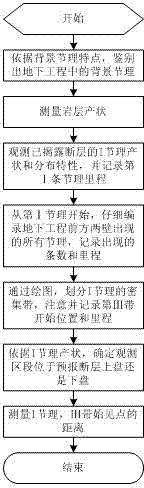

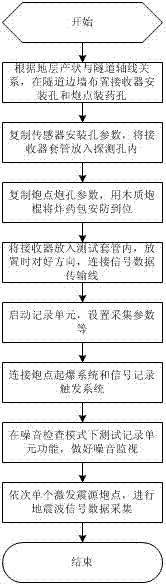

Advanced geological prediction method for underground engineering

InactiveCN102495434AEfficient use ofOptimizing the laws of objective cognitionGeological measurementsGeomorphologyApplicability domain

The invention discloses an advanced geological prediction method for underground engineering. With geology as pivot, the advanced geological prediction method for underground engineering comprises four stages of long-term advanced geological prediction, middle-term advanced geological prediction, short-term advanced geological prediction and impending advanced geological prediction. The advanced geological prediction method comprises the following steps of: (1) making advanced geological prediction tasks for underground engineering for the underground engineering clear; (2) collecting data; (3) carrying out field geological review; (4) perfecting the modification of a longitudinal section drawing of the underground engineering; and (5) adopting combined geological method, geophysical prospecting method and horizontal drilling method to obtain advanced geological prediction. The invention provides the advanced geological prediction method for underground engineering; with geology as pivot, comprehensive geological analysis is carried out in the whole process of advanced geological prediction for underground engineering and the long-term, middle-term, short-term and impending advanced geological predictions are closely combined together to implement combination of geological method, geophysical prospecting method and horizontal drilling method; the comprehensive application of the geophysical prospecting method is optimized; and the advanced geological prediction method for underground engineering, provided by the invention, has the advantages of improving the predication accuracy, reducing predication cost and obtaining wide application range, etc.

Owner:成都畅达通检测技术股份有限公司

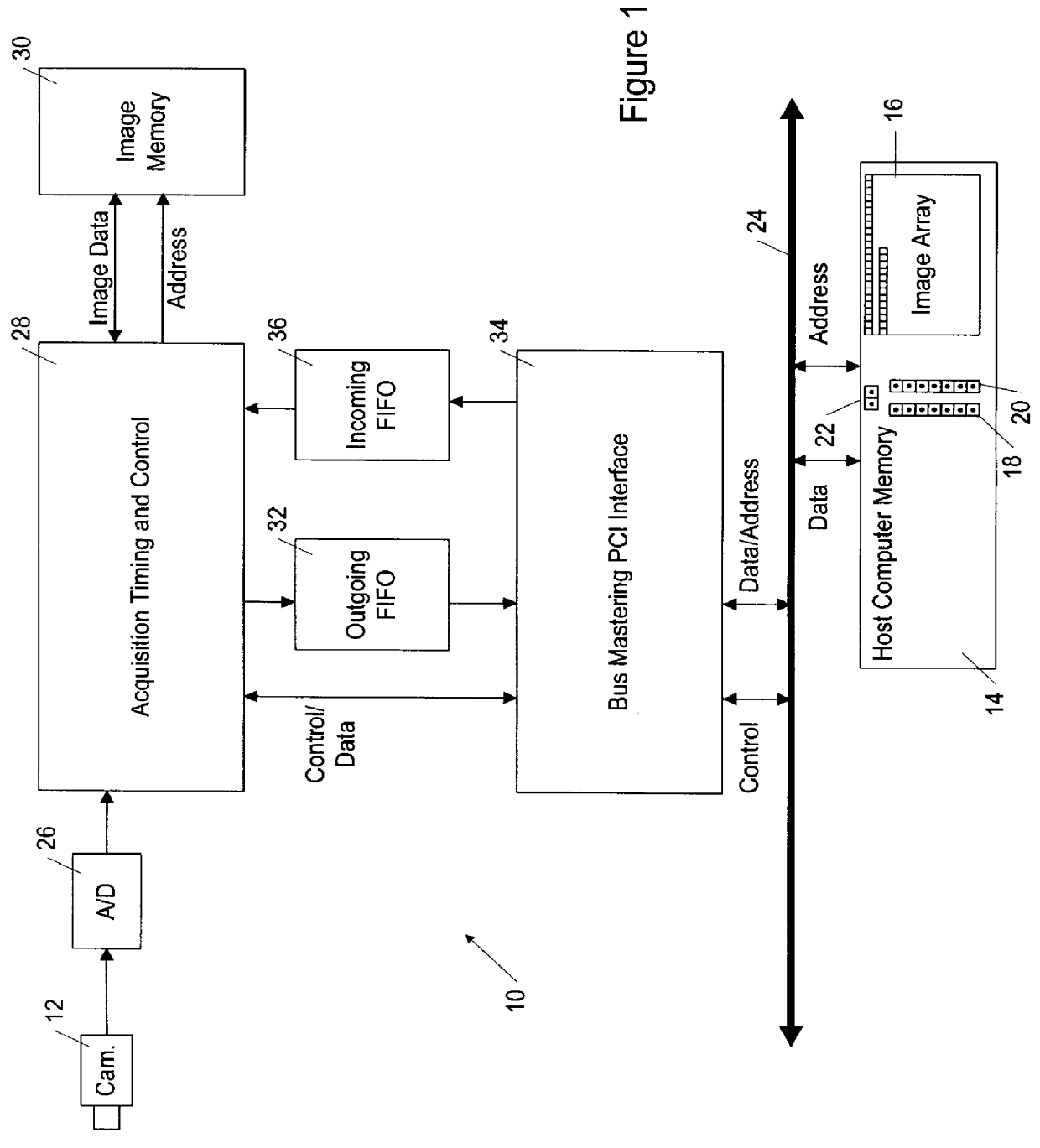

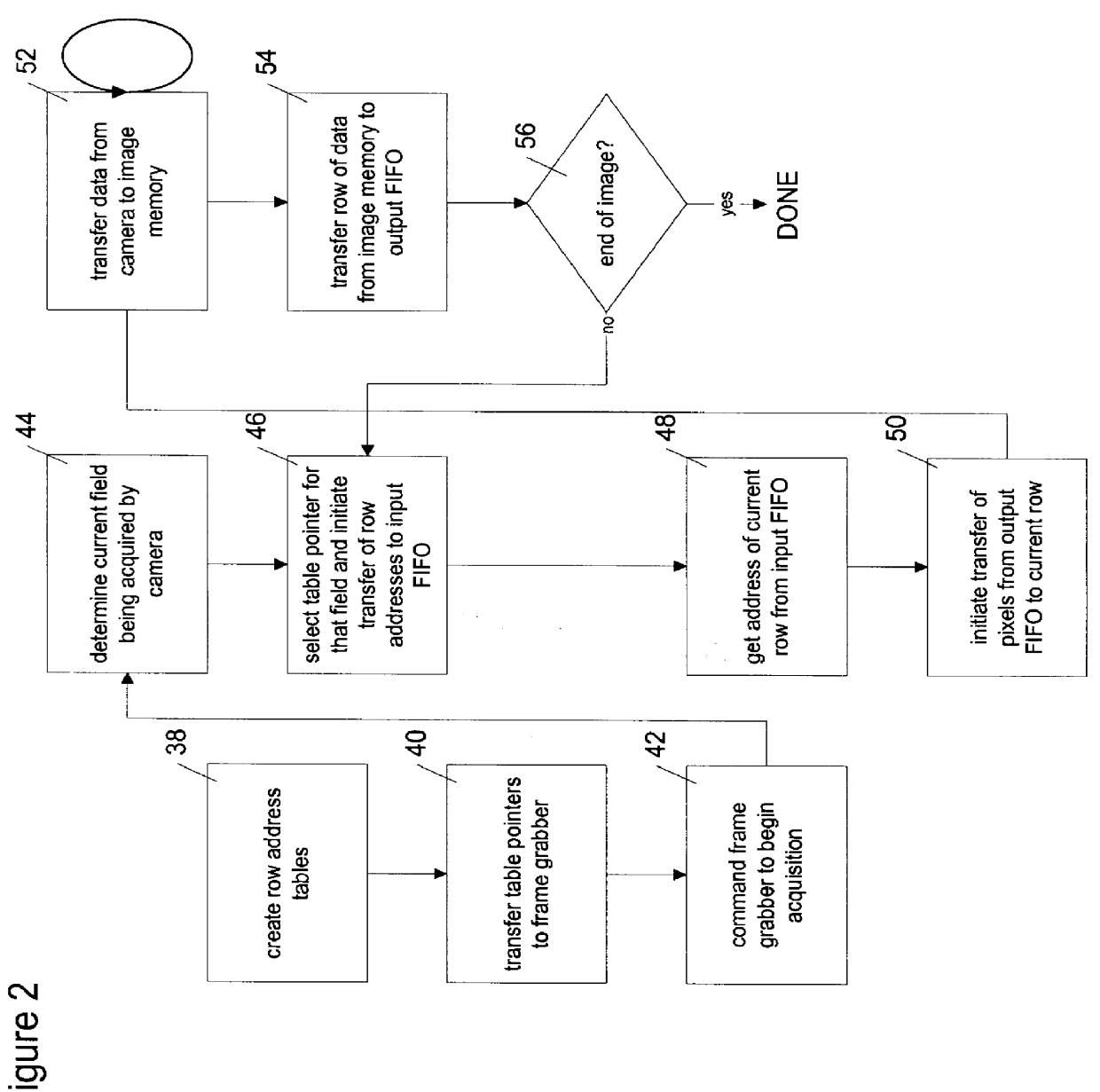

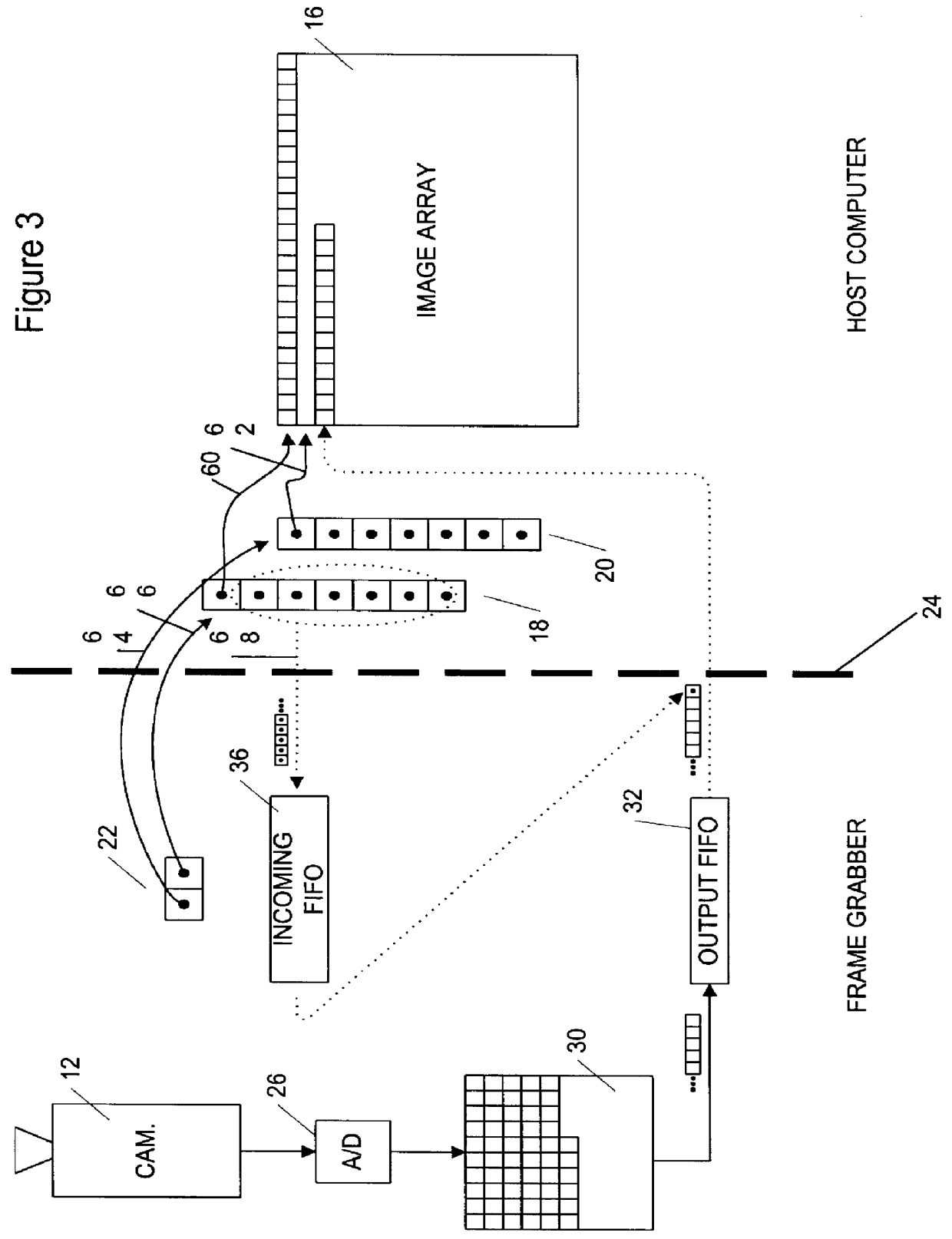

Method and apparatus for high speed image acquisition

InactiveUS6025854AFacilitate formationRapid and efficientTelevision system detailsImage memory managementComputer graphics (images)Image acquisition

The invention provides methods and systems for forming and image from a stream of non-interleaved image date, e.g., a stream of non-contiguous rows of pixels. Such a system includes a memory, in which the image is to be formed (and stored), and a controller, for initiating memory transfers that move rows of pixels from the stream to their (the rows') respective locations in memory. The controller initiates those transfers such that (i) the rows of pixels are transferred to the memory in the order in which they are received from the stream, and (ii) each row of pixels is transferred directly to the location in memory corresponding to that row's respective position in the image.

Owner:COGNEX CORPORATION

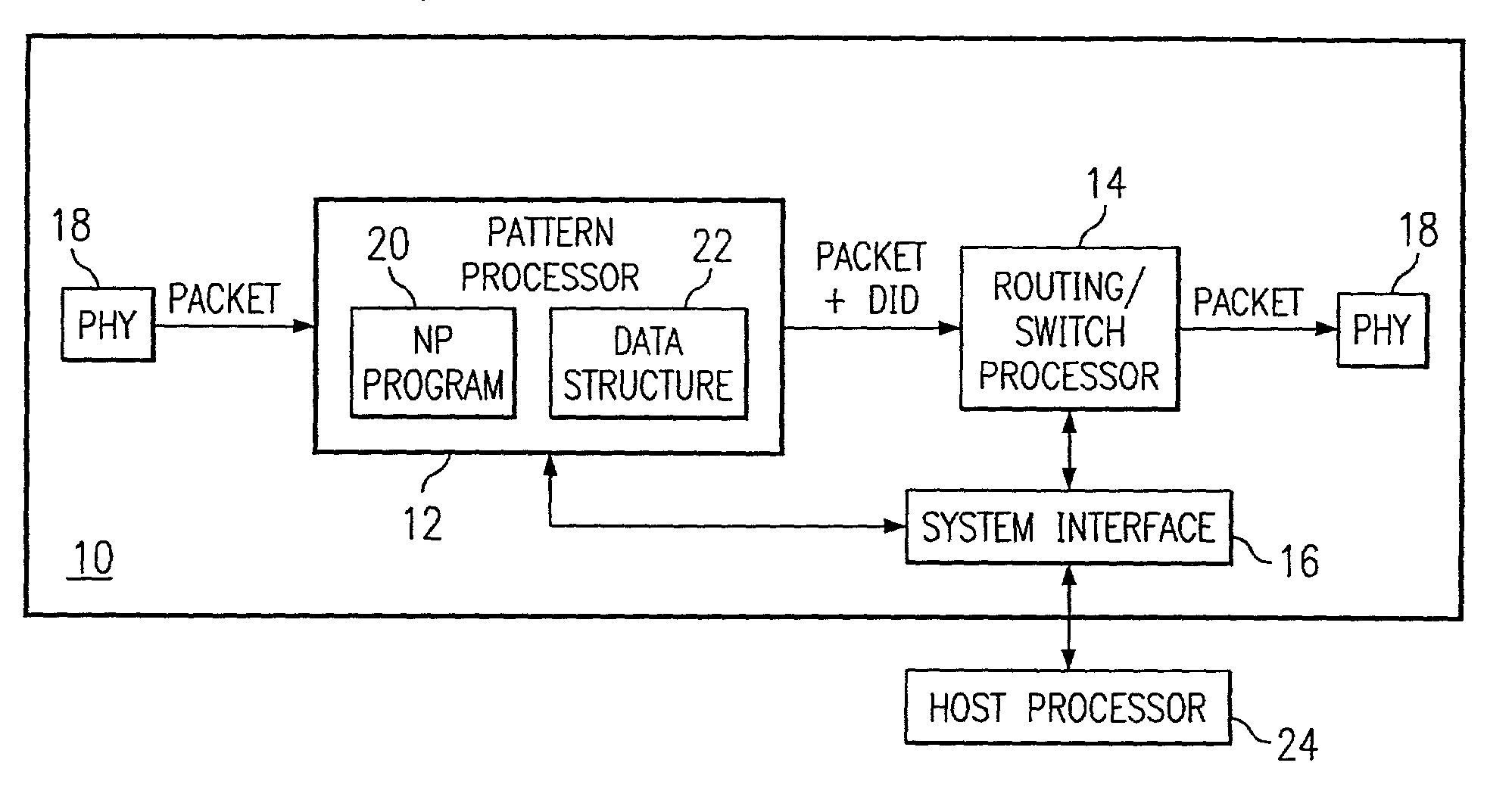

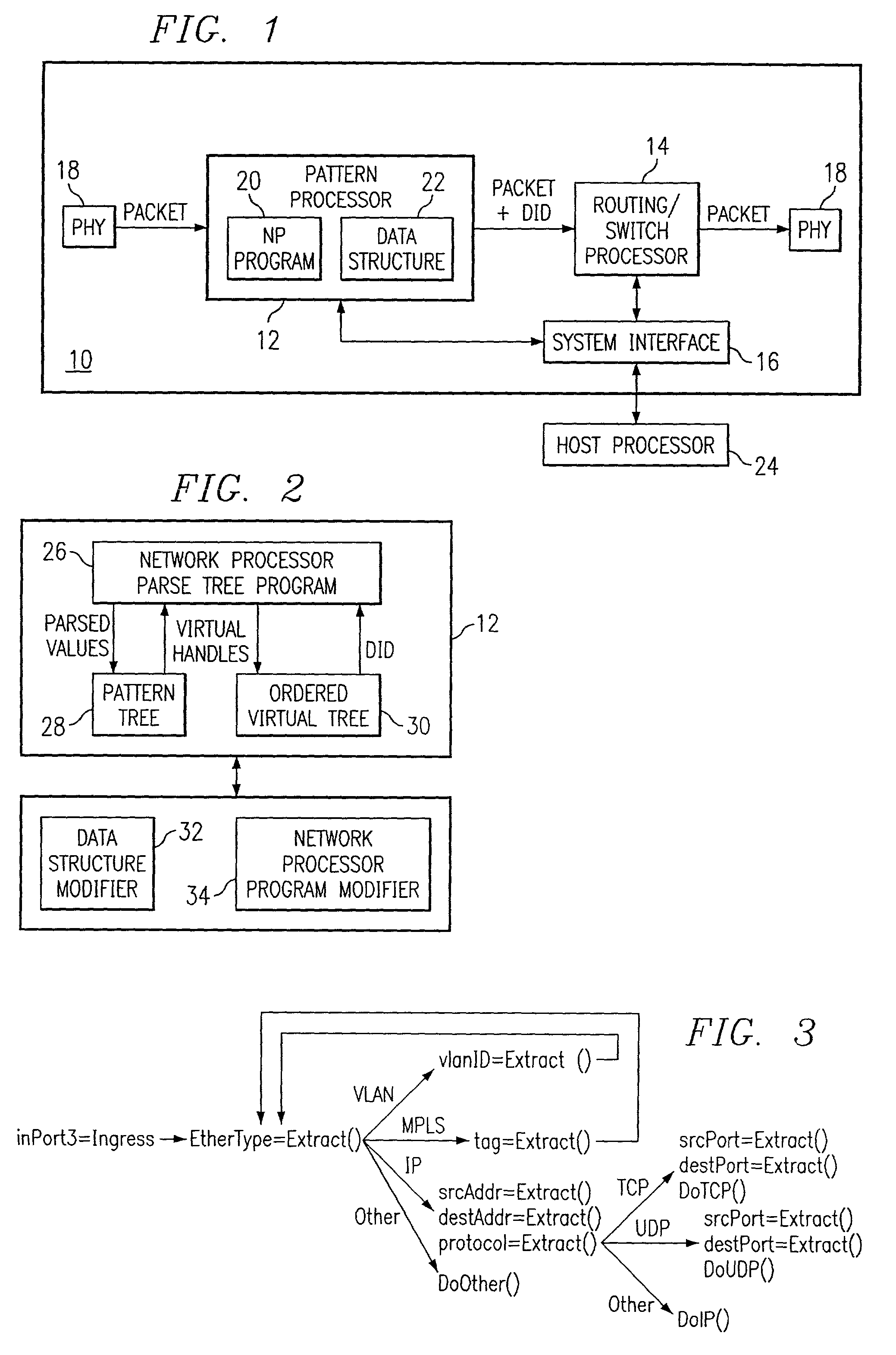

System and method for dynamically constructing packet classification rules

ActiveUS7239639B2Minimal impact on performanceGuaranteed ease of operationData switching by path configurationClassification ruleTree (data structure)

A system and method classifies packets with a programmably fixed network processor program and dynamically updated data structures. The network processor program selects predetermined packet field values of the packets transmitted across the network and classifies the packets by matching one or more packet field values with a data structure. New packet classifications are dynamically created by updating the data structure to associate one or more predetermined packet field values with the new packet classification. For instance, a parse tree program extracts packet header information and matches the packet header information to the data structure. A pattern tree data structure provides longest prefix matches and an ordered tree data structure provides combination matches so that classification of arbitrary Boolean combinations of extracted header fields can be formed.

Owner:TREND MICRO INC

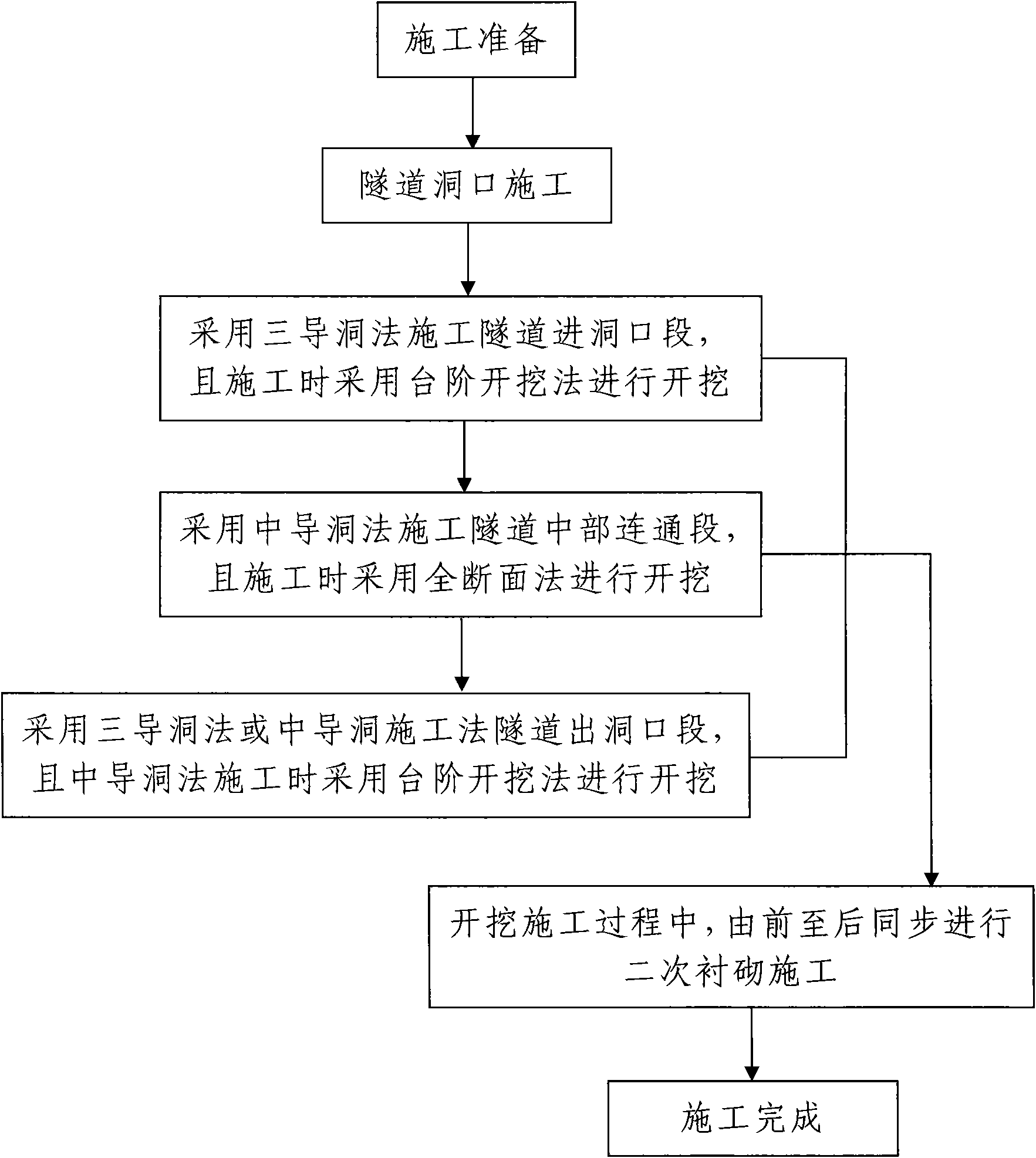

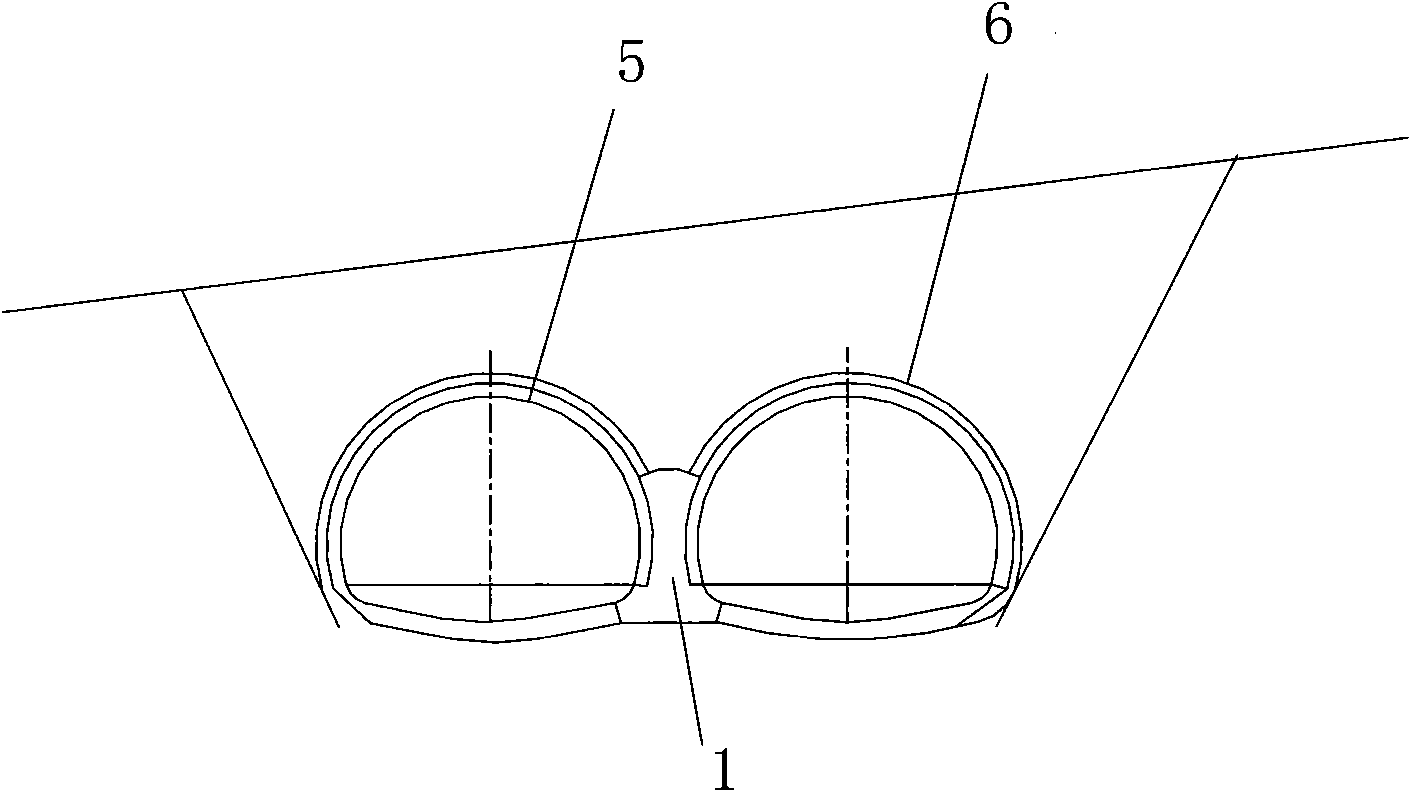

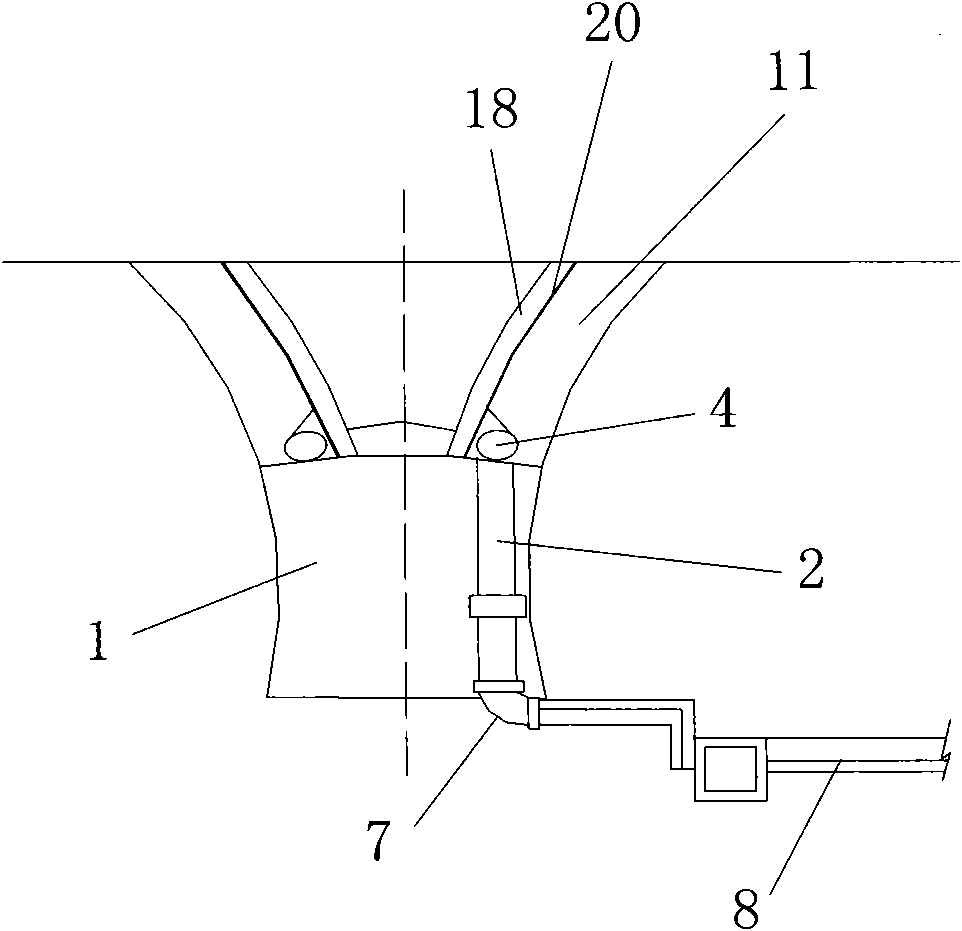

Carst region double-arch road tunnel construction method

ActiveCN101864960AReasonable designSimplify construction stepsUnderground chambersTunnel liningTunnel constructionChannel inlet

The invention discloses a carst region double-arch road tunnel construction method, which comprises the following steps; 1. carrying out construction preparation; 2. carrying out construction at channel openings; 3. adopting a three-pilot-tunnel method for constructing the channel inlet opening section, and adopting a step digging method for digging during the three-pilot-tunnel method construction; 4. adopting a middle-pilot-tunnel method for constructing the middle communication section of the channel, and adopting a full cross section method for digging during the middle-pilot-tunnel method construction; 5. adopting the three-pilot-tunnel method or the middle-pilot-tunnel method for constructing the channel outlet opening section, adopting the step digging method for digging when the middle-pilot-tunnel method is adopted for digging construction of the channel outlet opening section, and synchronously carrying out secondary lining construction from the front part to the back part in the digging construction process of the channel inlet opening section, the middle communication section of the channel and the channel outlet opening section. The invention has the advantages of reasonable design, simple and convenient construction, safe and reliable construction process, flexible construction mode, short construction period and greatly simplified construction steps, and effectively overcomes various defects during the traditional carst region double-arch road tunnel construction.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

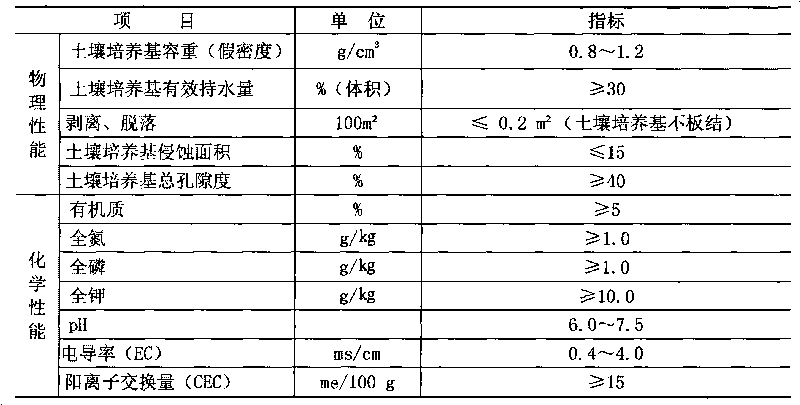

Ecological protection method for high steep side slope

The invention relates to an ecological protection method for a high steep side slope. The method mainly comprises the steps of slope surface treatment, concrete shotcrete and rock bolt support, vegetating hole arrangement, net spreading, spray material preparation, granule spray sowing, maintenance, management, and the like. In the method, guest soil materials such as humus loam rich in organic matters and clay are utilized to undergo a granule reaction after mixed with a granule agent at the moment of spray sowing so as to form a greening template which has the same high order granule structure as natural soil and strong erosion resistance and can suppress water and soil loss. After a diversified mature plant community which is in harmony with surrounding vegetation environment is formed, the slope surface can be protected, which can effectively resist diseases and insect pests and maintain the ecological balance. Post maintenance management and expenses can be saved. All used materials can be naturally degraded, have no pollution to the environment and can purify air and beautify the environment. Equipment of the method does not need to be hung on the slope surface for construction, and spray sowing operations are carried out only below the slope surface, thus the method has high construction speed and safety. The method is suitable for slope surfaces which are difficult to green, and the like, such as various high steep and unstable slope surfaces, bare slope surfaces having high greening expected values, and the like.

Owner:河南国网宝泉抽水蓄能有限公司

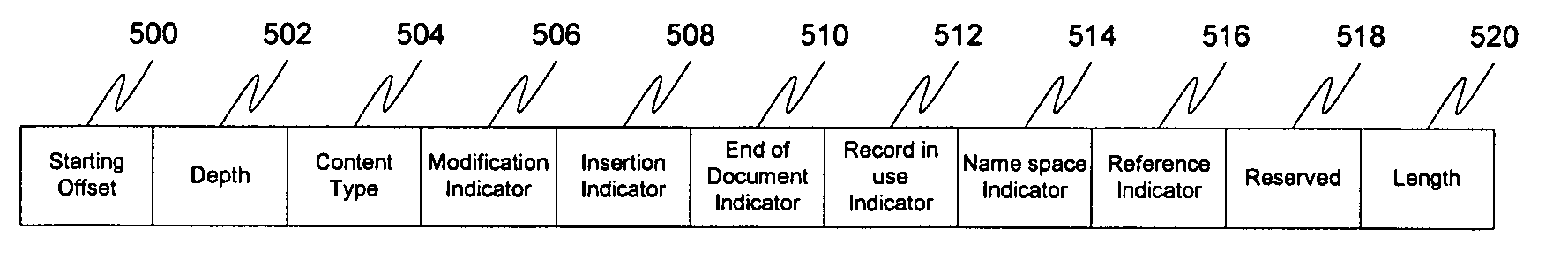

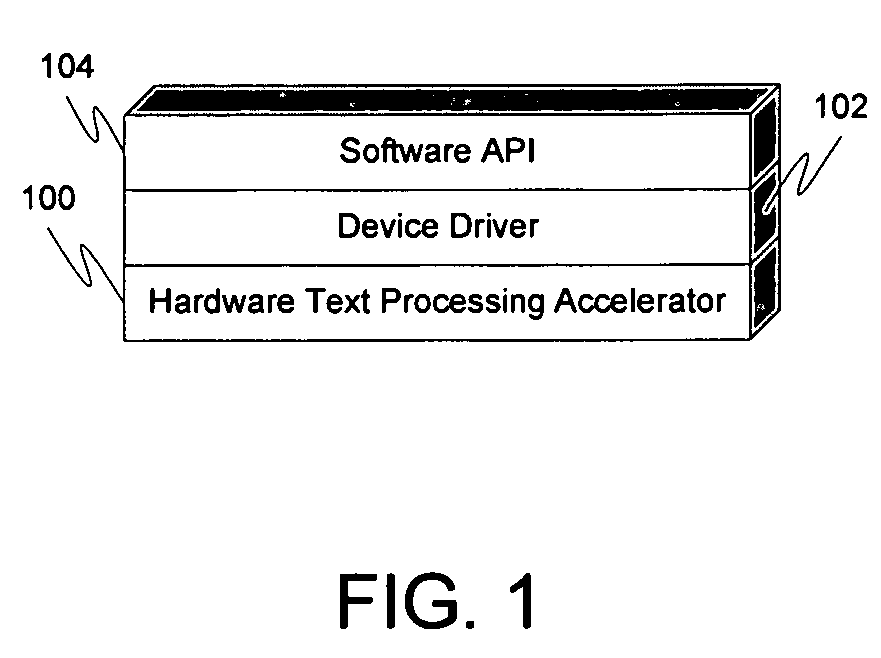

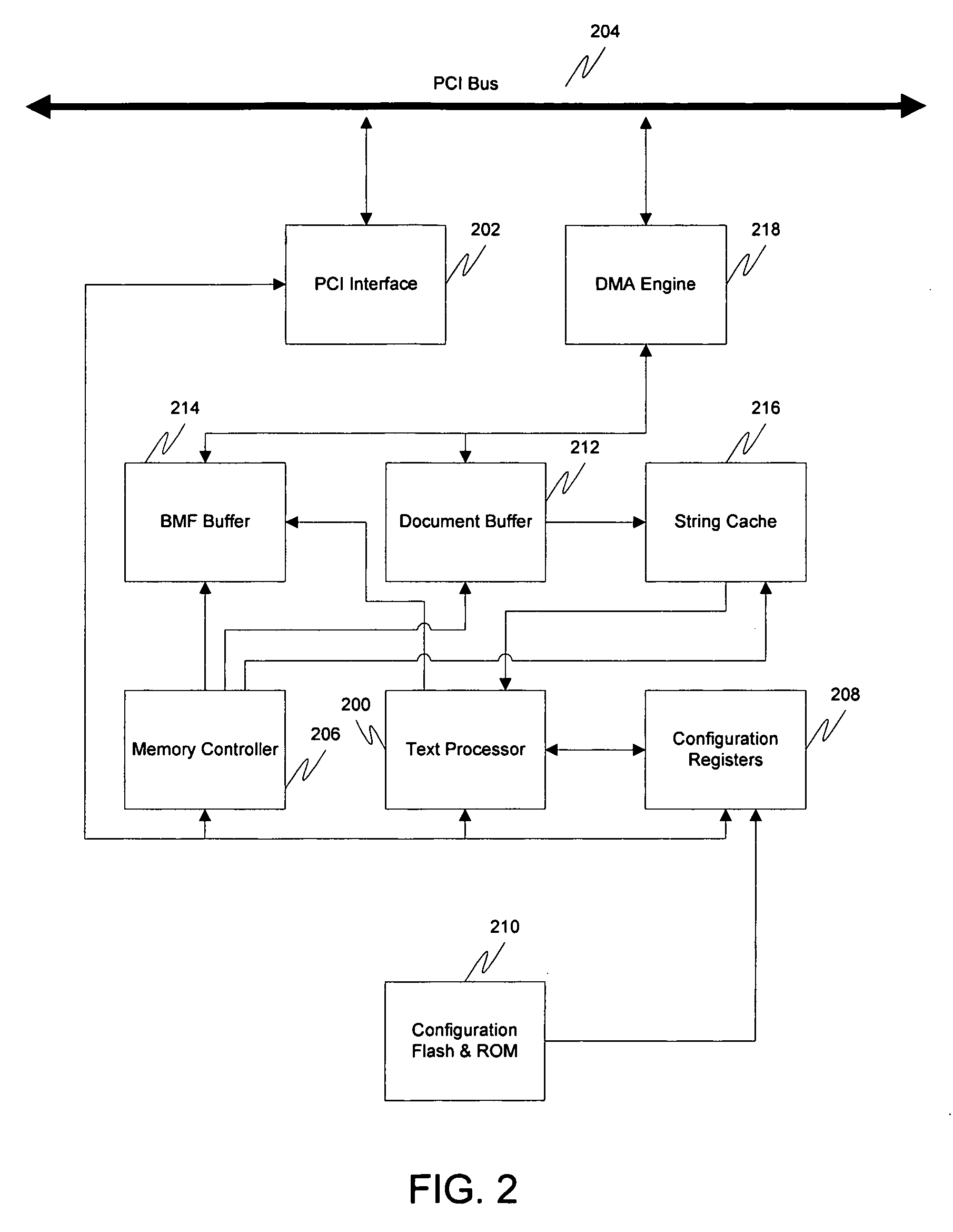

Processing structured data

InactiveUS7761459B1Way fastFast constructionNatural language data processingSemi-structured data mapping/conversionSequential dataComputer science

The present invention provides a fast and efficient way of processing structured data by utilizing an intermediate file to store the structural information. The structured data may be processed into a Binary mask Format (BMF) file which may serve as a starting point for post-processing. A tree structure built on top of the BMF file may be constructed very quickly, and also takes up less space than a DOM tree. Additionally, BMF records may reside entirely in the memory and contain structural information, allowing SAX-like sequential data access.

Owner:XIMPLEWARE A CALIFORNIA CORP

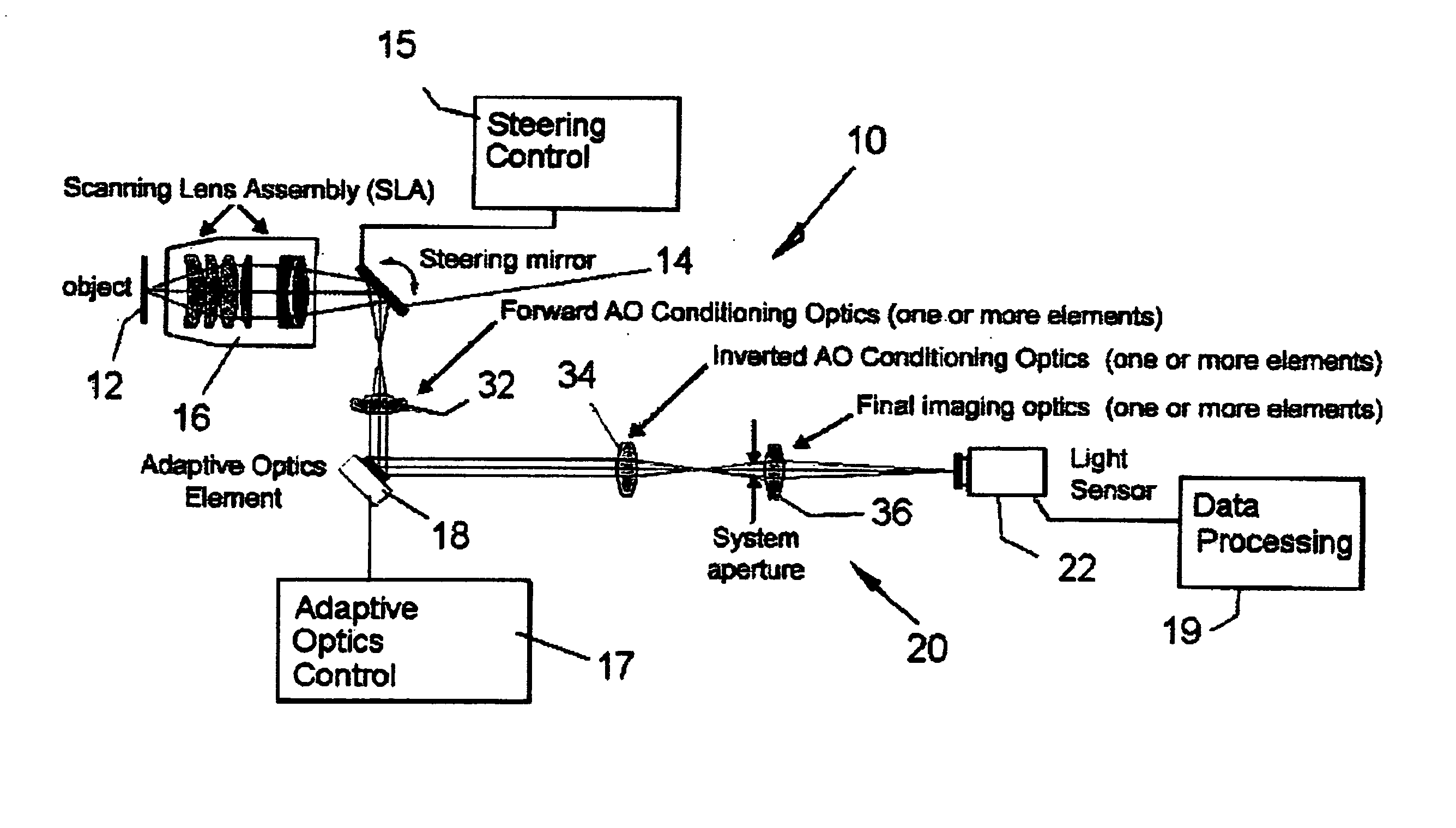

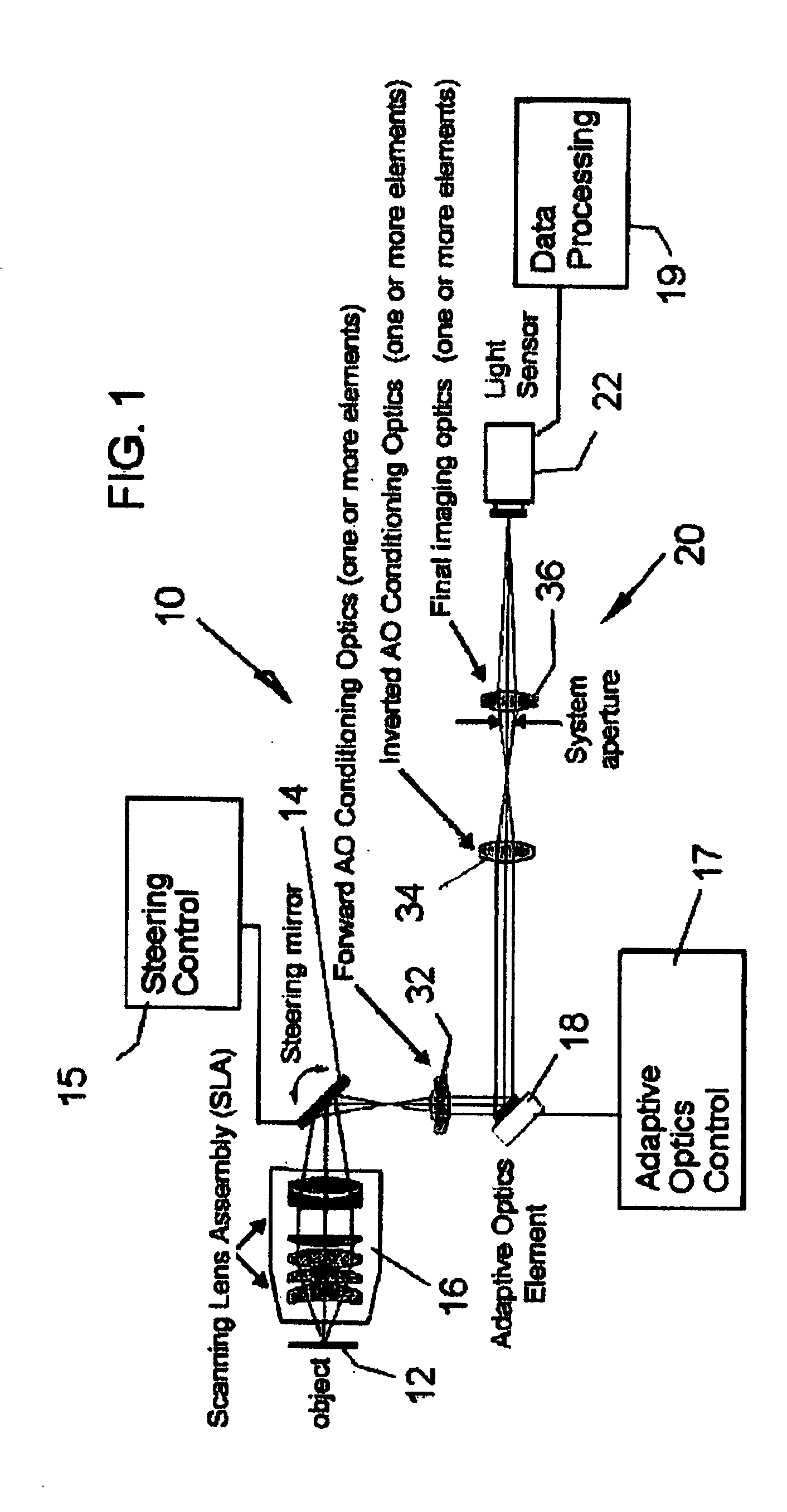

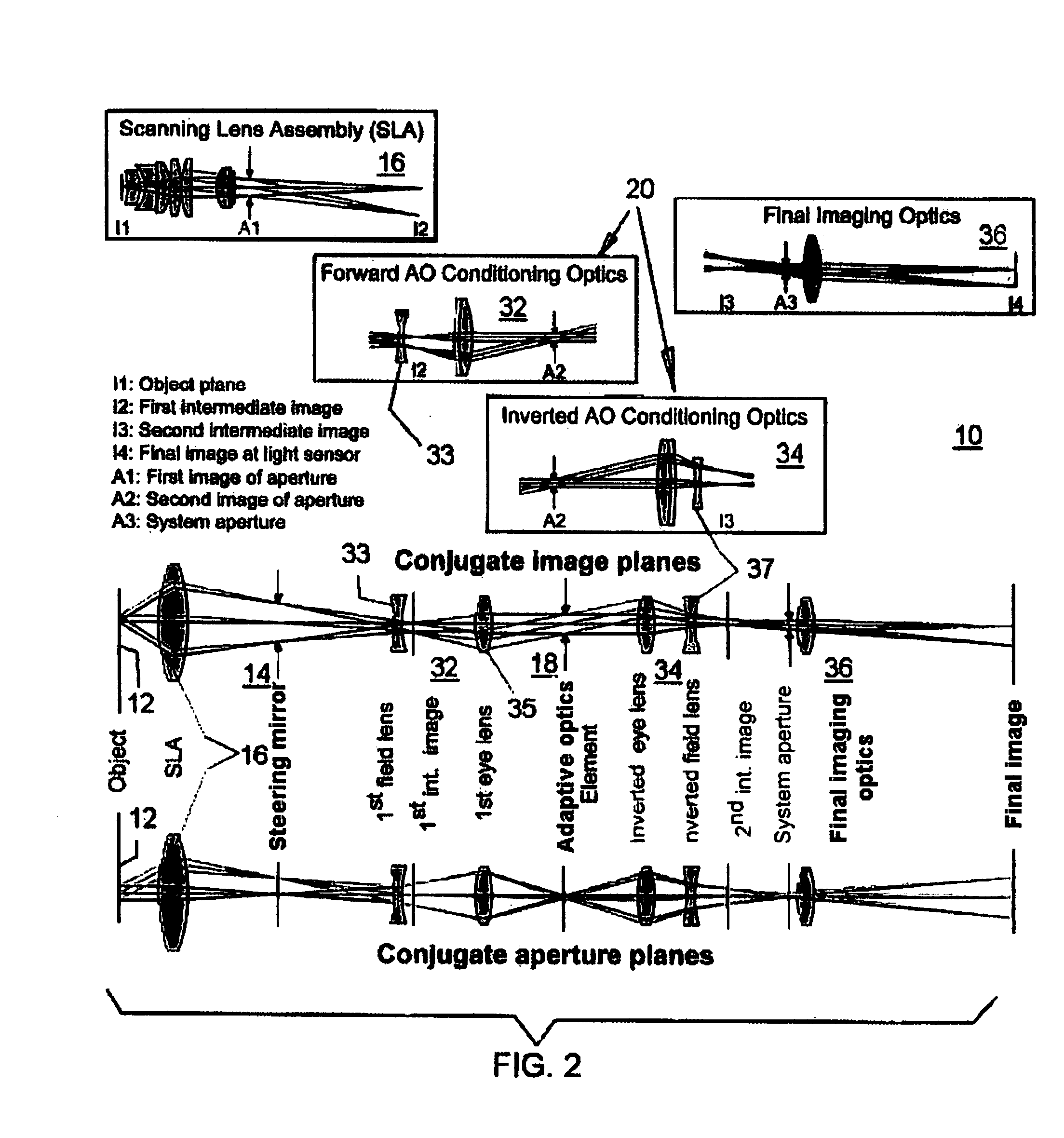

Adaptive-scanning optical microscope

ActiveUS20070253057A1Improve performanceScanner lens is simplifiedMicroscopesPosition dependentOptical aberration

An adaptive scanning optical microscope has a scanner lens assembly for acquiring images from different parts of an object plane and for forming a preferably curved image field having at least some aberration which varies as a function of the part of the object plane from which the image is acquired. A steering mirror selects the field of view and steers light from the object and along a light path from the object plane to a final image plane. An adaptive optics element receives the steered light from the object and compensates for the field position dependent optical aberrations and additional optics are along at least part of the light path for conditioning and focusing the light as it moves from the steering mirror, past the adaptive optics element and to the final image plane.

Owner:RENESSELAER POLYTECHNIC INST

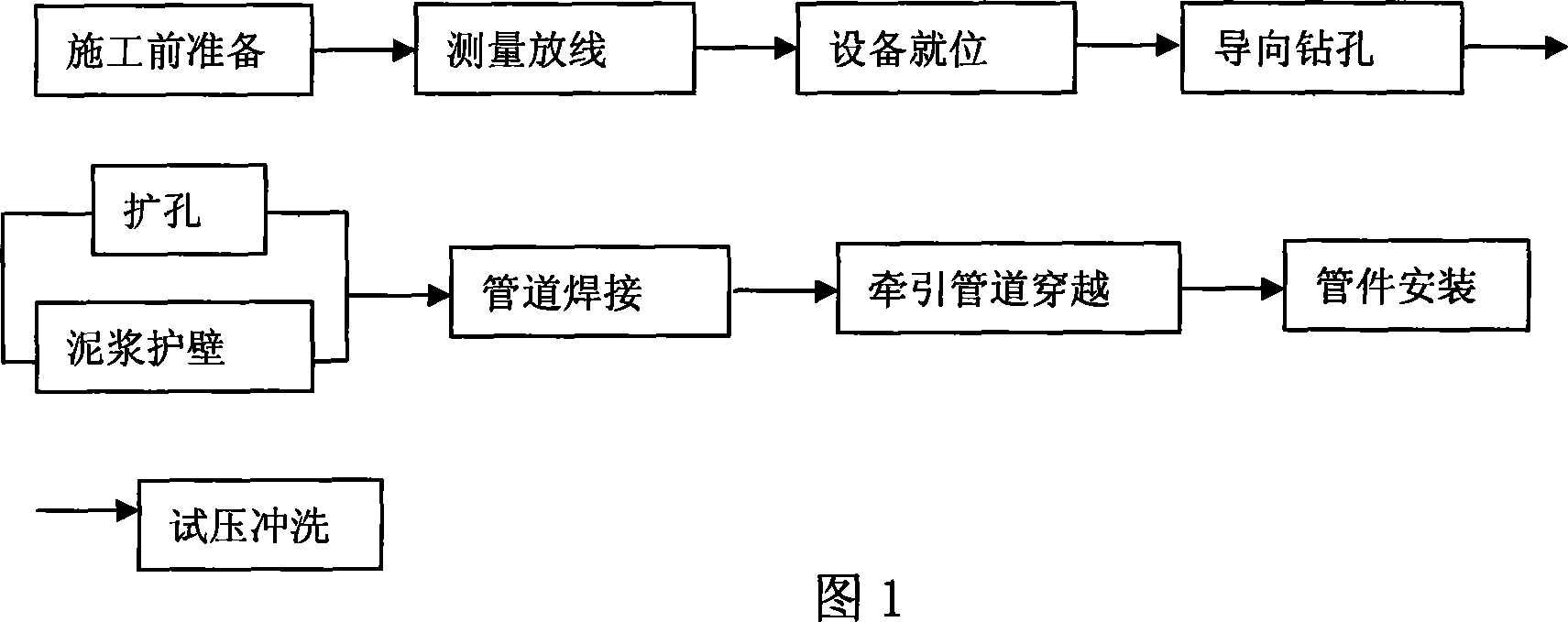

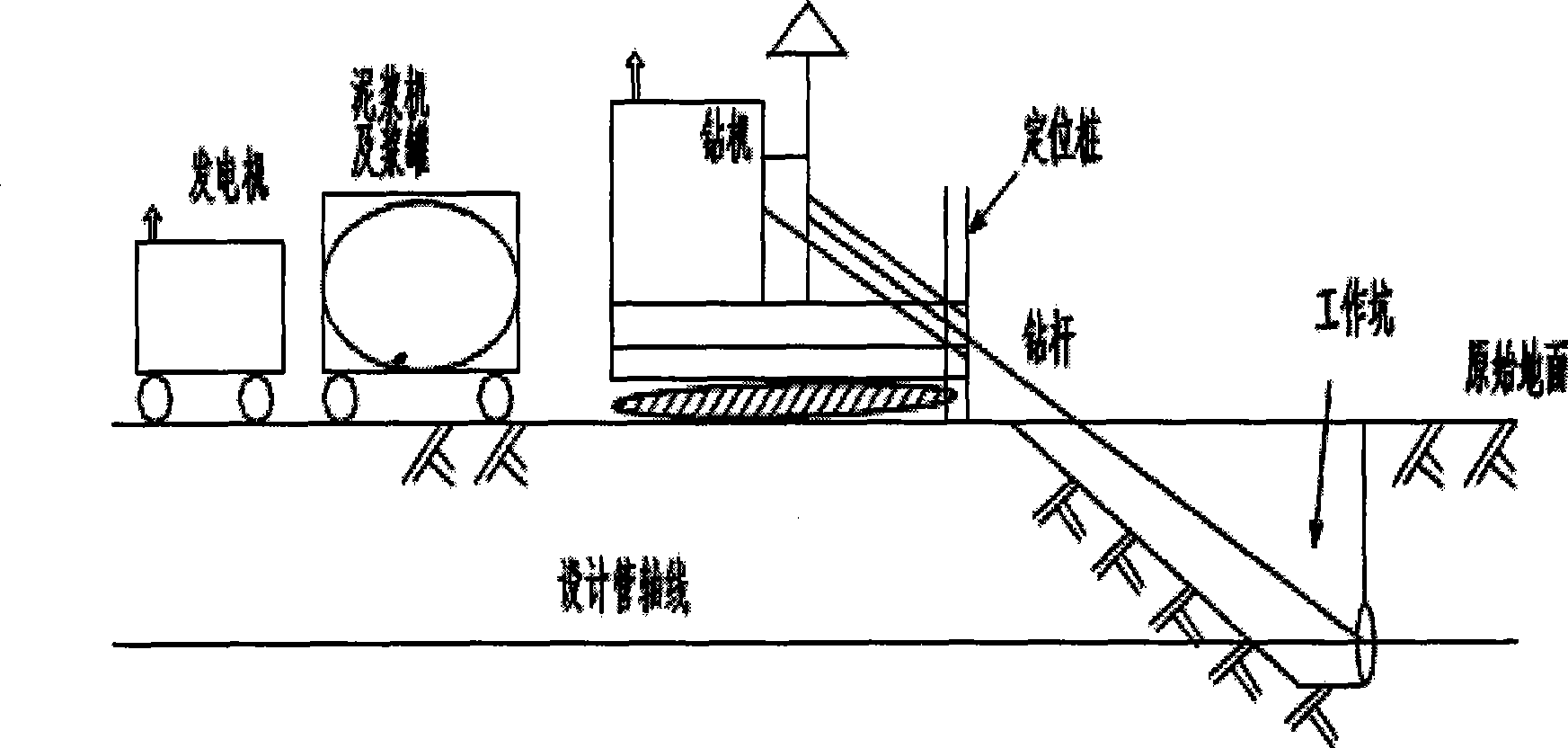

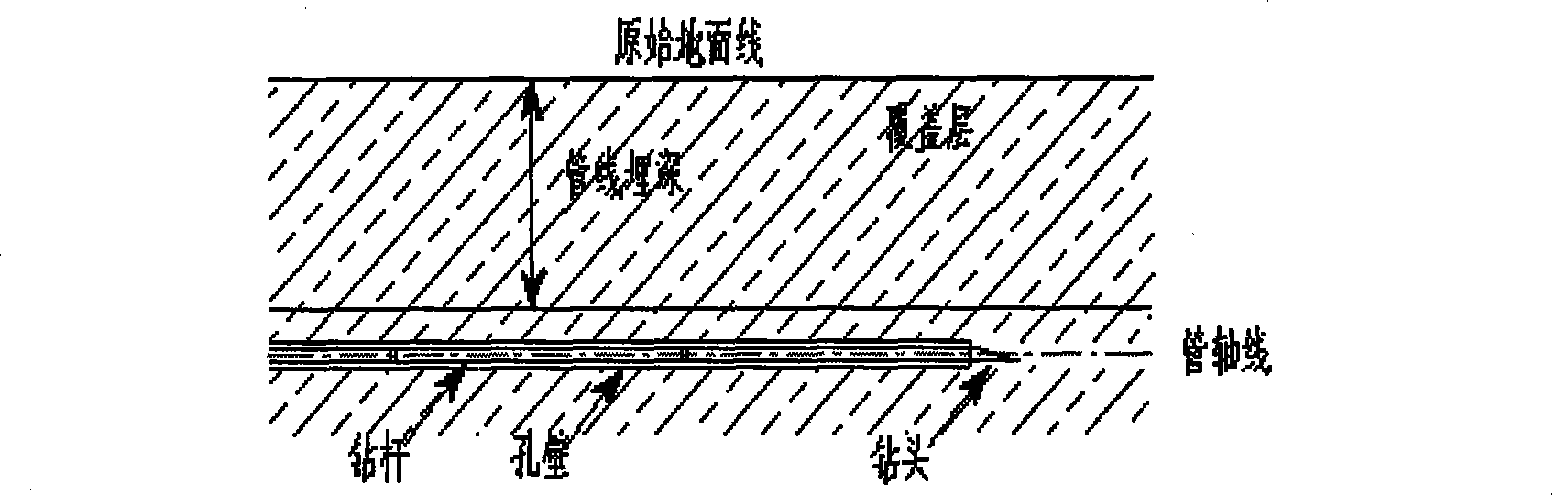

Non-digging tube-pulling construction method

InactiveCN101457853AReduce excavationReduce backfill workloadPipe laying and repairSocial benefitsGeomorphology

The invention relates to a non-excavation tube pulling construction method which comprises the following steps: (1) preparation work: understanding stratum and underground condition, calculating the number of chambering and the size of a return compandor, and formulating the control data of a pipeline midline and elevation and correction measures; (2) measuring plane surface, controlling payingoff, and measuring the elevation of each pile; (3) setting an active well, and receiving and setting a drilling machine; (4) preparing drilling fluid; (5) drilling pilot holes,; (6) adopting the compandor to chambering, cleaning the hole at the same time, and protecting walls with slurry; (7) welding the pipeline; (8) pulling the tube, and simultaneously pulling a steel tube with the same length as that of the tube; (9) casting slip and fixing; (10) mounting tubes; (11) testing pressure and flushing. The invention can effectively increases economical benefit and social benefit, and has the advantages of environmental protection and energy saving.

Owner:江苏广宇建设集团有限公司

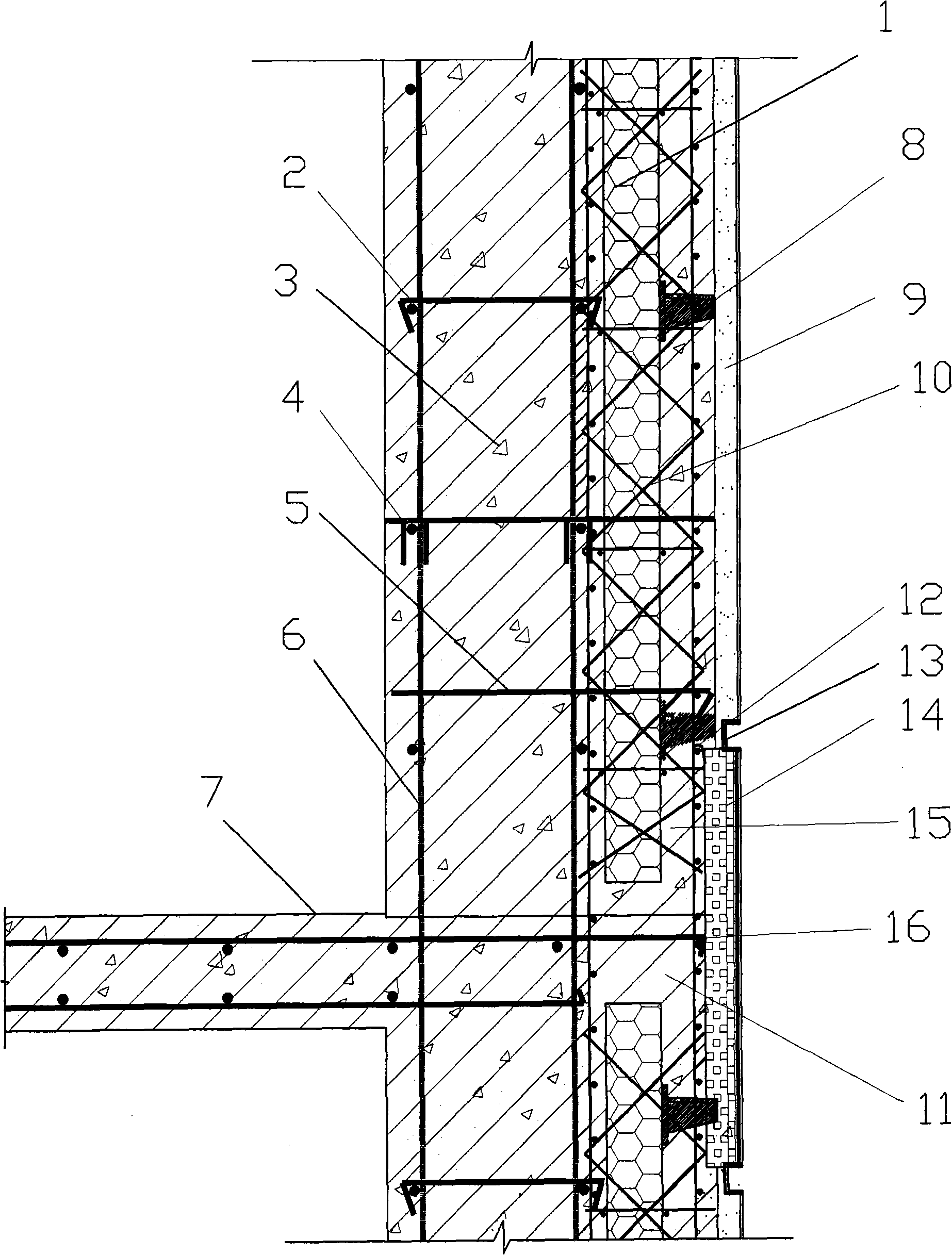

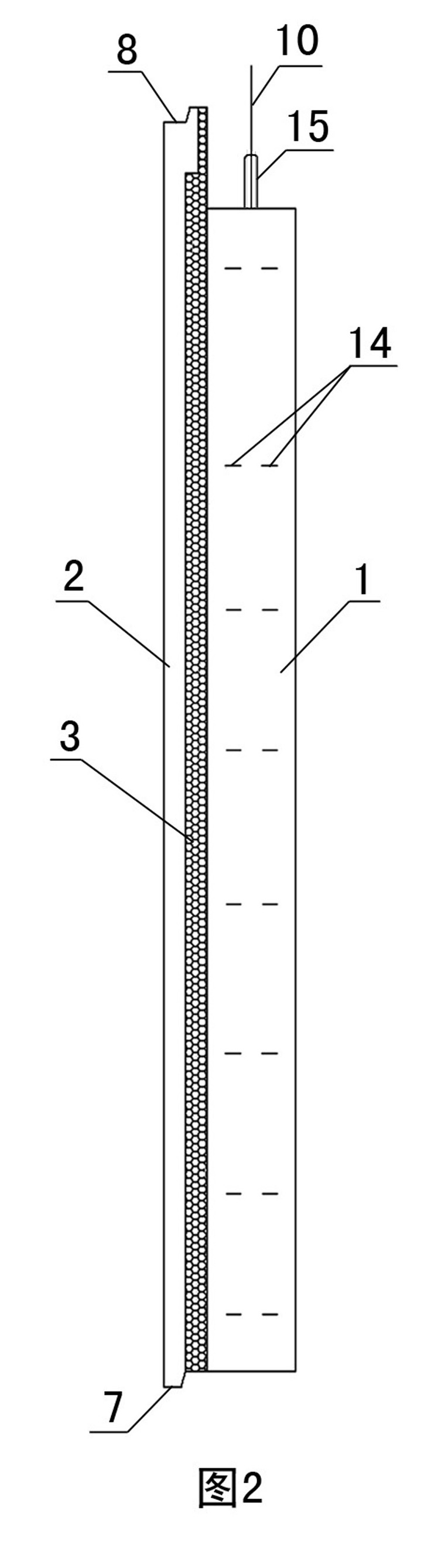

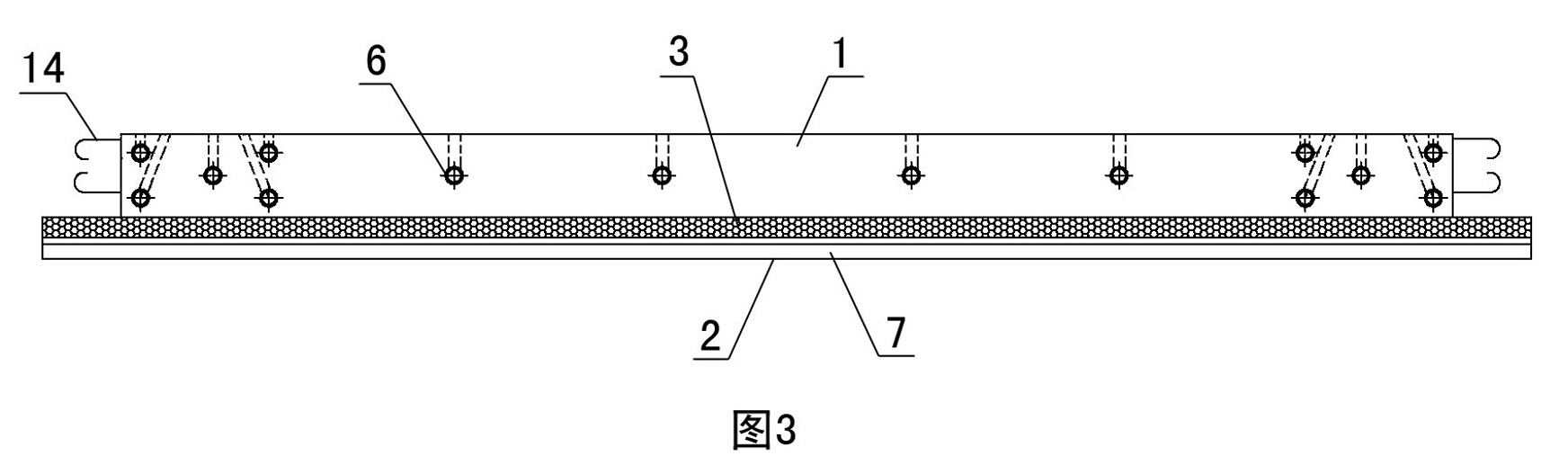

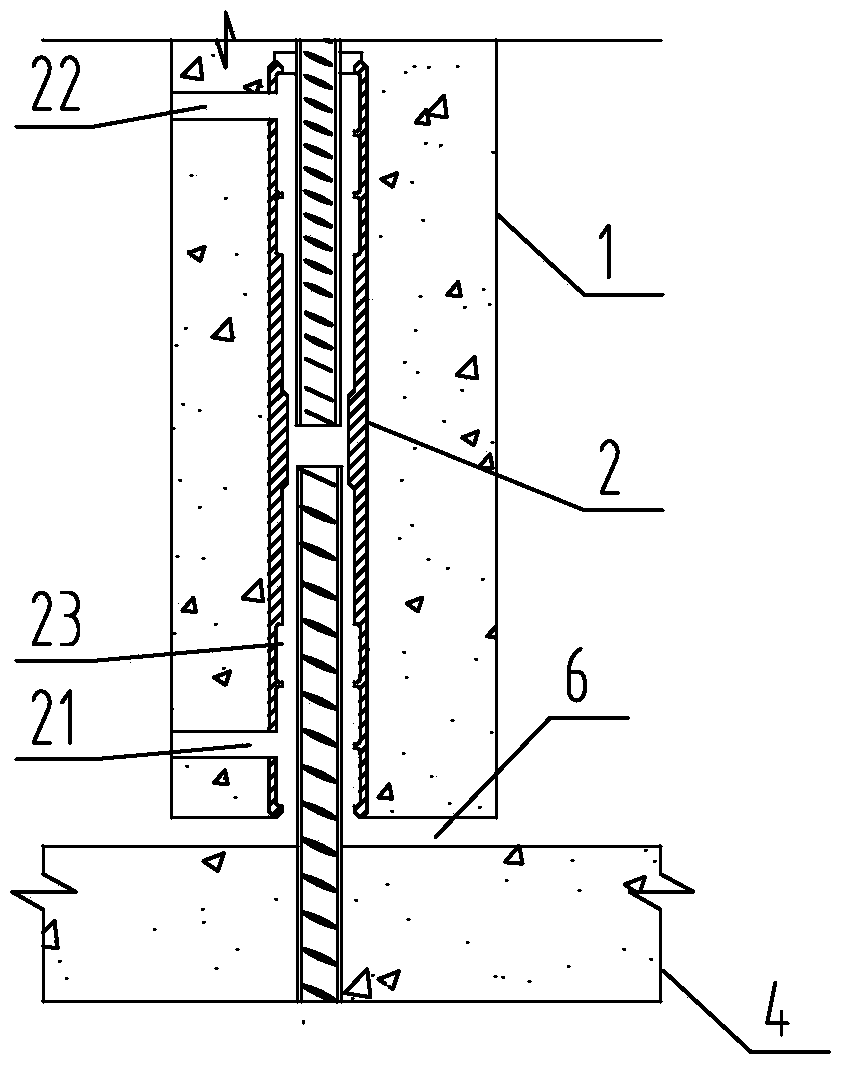

Externally reinforced concrete irrigated and heat preservation wall structure embedded energy-saving system and its construction method

ActiveCN101319525ANovel structureImprove thermal insulation performanceWallsClimate change adaptationInsulation layerSteel bar

The invention relates to an energy-saving system for a reinforced concrete outer-casting built-in heat insulation wall body structure and a construction method thereof, which can effectively solve the problems of external wall heat insulation of a high-rise building with high heat insulation requirement and cracking and falling of a heat insulation layer. The system is produced by a wall body and reinforcing steel bars in the wall body which are cast by concrete. The method comprises the following steps that: a reinforcing steel bar frame of the wall body is produced and arranged, namely parallel vertical reinforcing steel bars and indoor floor-connecting board tie bars perpendicular to the parallel vertical reinforcing steel bars are bound together, a grid board is hoisted and externally suspended outside the vertical reinforcing steel bars of the wall body, and is bound with the vertical reinforcing steel bars of the wall body by hooked bars and binding steel bars as well as framework positioning bearing bars, then a framework is arranged on the framework positioning bearing bars and is firmly bound with reinforcing steel bars of beams and boards of a floor, lapping bars are reserved, a heat insulation grid board is firstly arranged, then reinforcing steel bars of corbel brackets of a balcony and an air conditioning board external wall are bound, finally the concrete is cast, the curing is performed, and the framework is removed to repair the structure. The system has good heat insulation effect, energy conservation, environmental protection, simple method, and huge economic benefit and social benefit.

Owner:HENAN JINYUAN CONSTR

Construction method of hydroelectric power station surge chamber vertical shaft under soft rock geological condition

ActiveCN101349064ASimple designEnsure safetyArtificial islandsUnderwater structuresSteam-electric power stationGeomorphology

The invention relates to a method for constructing a drilled shaft of a surge chamber in a hydropower station under the condition of weak rock geology; the excavation diameter of the drilled shaft is more than or equal to 20 meters; and the depth of the drilled shaft is more than or equal to 50 meters. The method comprises the following steps: firstly, a safe prestress reinforcing measure is adopted; a prestress anchor rope is arranged in a side slope of the drilled shaft; the deep rock holes in the periphery of the drilled shaft are subjected to consolidation and grouting; the periphery of the drilled shaft is cast with reinforced concrete for locking a mouth, etc; the construction sequence of excavating the drilled shaft comprises that: a raise-boring machine drills a guide hole of phi 216 millimeters from top to bottom; the raise-boring machine enlarges and excavates a small guide well of phi 1, 400 millimeters; a slag slipping guide well of phi 2, 500 millimeters is enlarged and excavated manually from bottom to top; and the slag slipping guide well is enlarged and excavated from top to bottom. The slag slipping guide well is excavated by manual drilling and blasting; slag is naturally slipped and mechanically loaded in the bottom of the well; a large well is enlarged and excavated through drilling and blasting by a manual air drill; and the skimmed slag in a hydraulic backhoe well slips to the bottom of a passage through the slag slipping guide well and is mechanically loaded in the bottom of the well. The construction method has the characteristics of having reasonable construction arrangement, alternately and simultaneously carrying out a plurality of construction types and saving the construction period.

Owner:SINOHYDRO BUREAU 5 +1

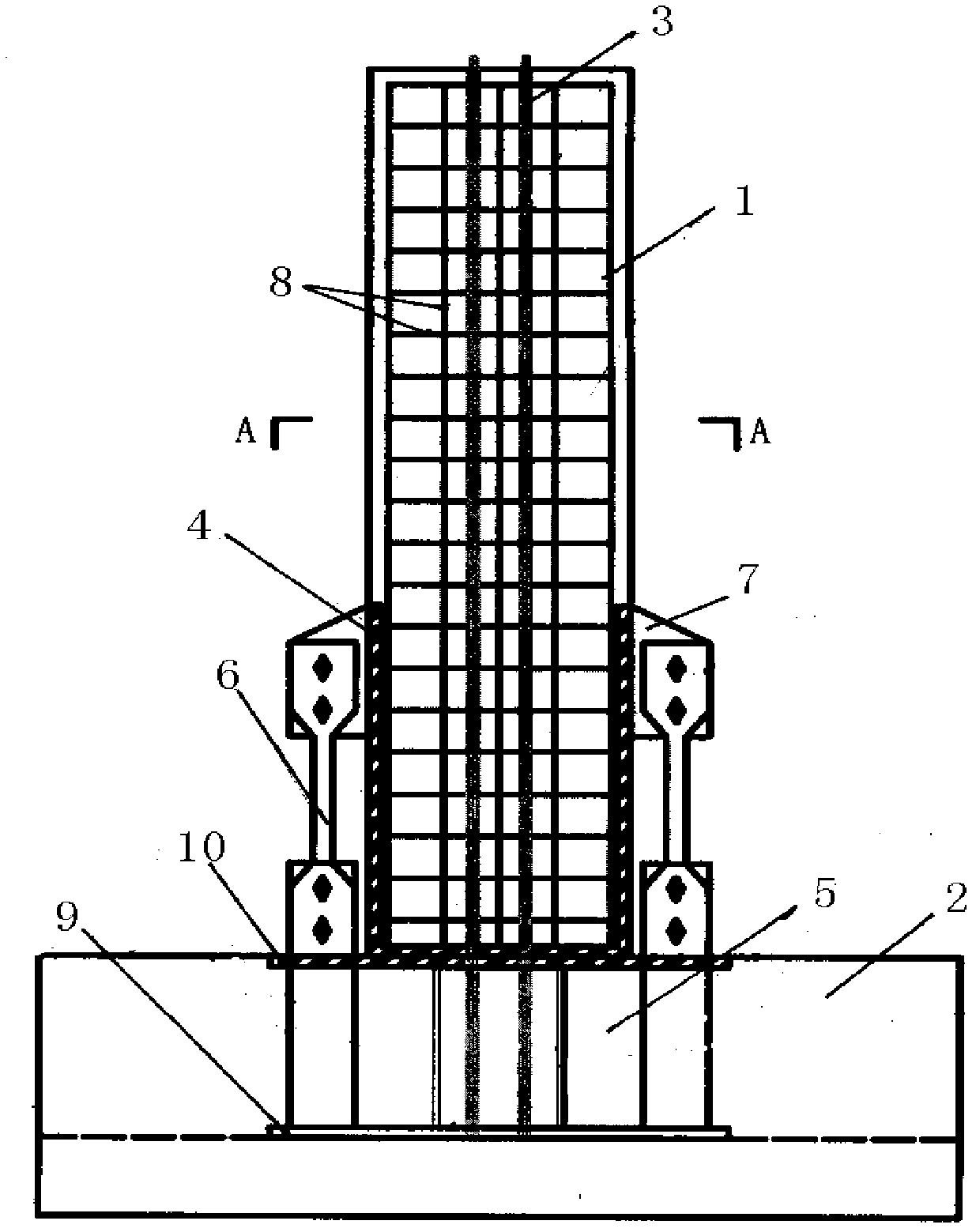

Assembled integral building and construction method thereof

ActiveCN101818539AGuarantee the construction qualityLow costBuilding componentsBuilding material handlingFloor slabReinforced concrete

The invention discloses an assembled integral building and a construction method thereof. The assembled integral building comprises a reinforced concrete wall and floor slabs, wherein the reinforced concrete wall is formed by hoisting and assembling prefabricated composite insulating wallboards integrally at a construction site; a board body of each prefabricated composite insulating wallboard comprises a structure layer, an insulating layer and a protective layer from the inside to the outside in turn; a reinforcement cage is arranged in the structural layer; steel meshes are arranged in the concrete of the protective layer; the structural layer, the insulating layer and the protective layer are anchored together by inserting connecting members in a dotted distribution; the left and right edges of the protective layer and the insulating layer protrude out of the structural layer; a lower edge of the protective layer extends downward to form a bulged opening; the top parts of the protective layer and the insulating layer upward protrude out of the structural layer; and an upper edge of the protective layer is provided with a notch which corresponds to the bulged opening of the prefabricated composite insulating wallboard adjacent to an upper layer. The building overcomes the defects of erecting shuttering on site, binding steel bars and concreting in a traditional construction method, speeds up the construction, and lowers the construction cost; and the construction quality of the building structure can be sufficiently guaranteed.

Owner:雄安万科绿色研发有限公司

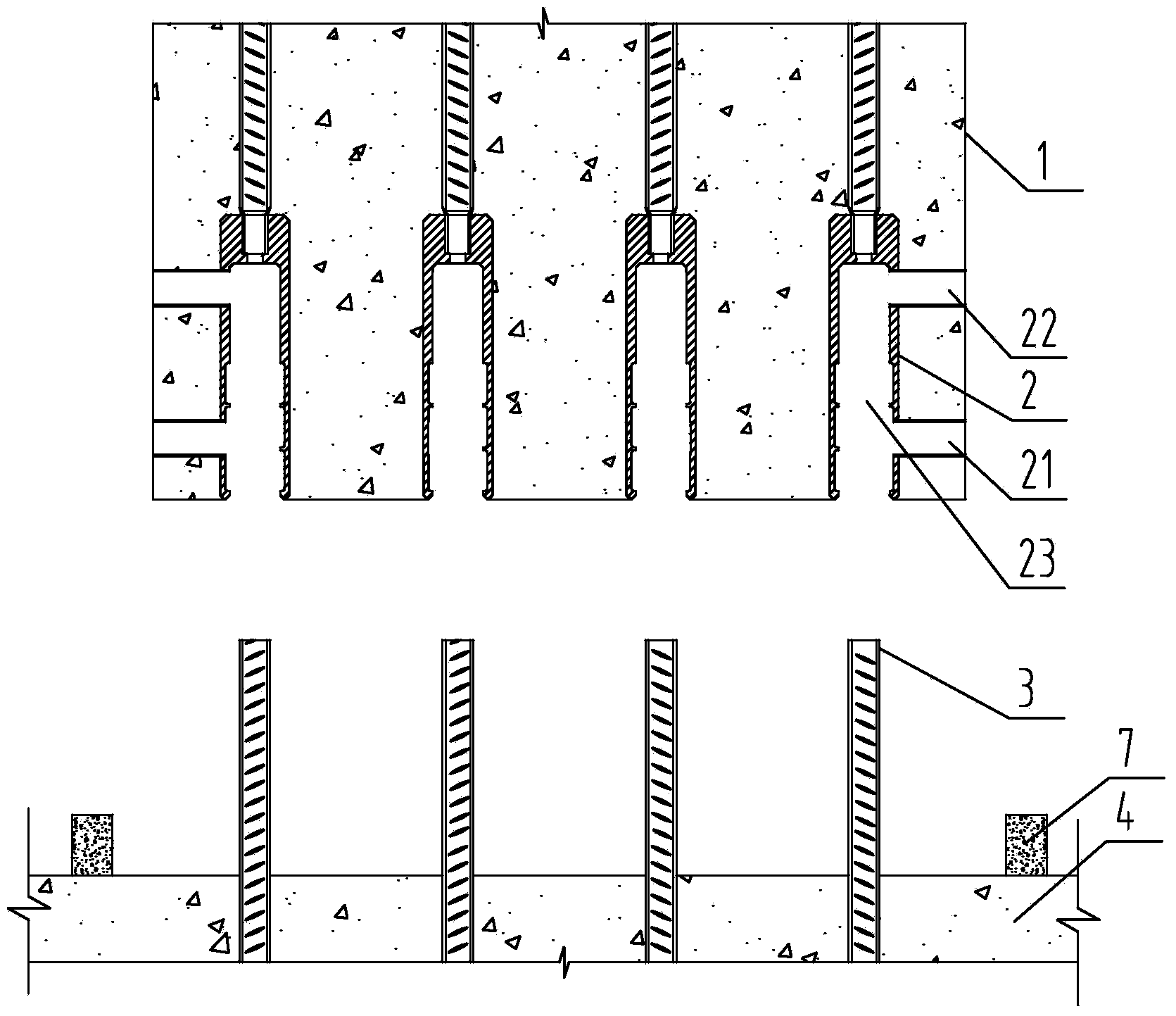

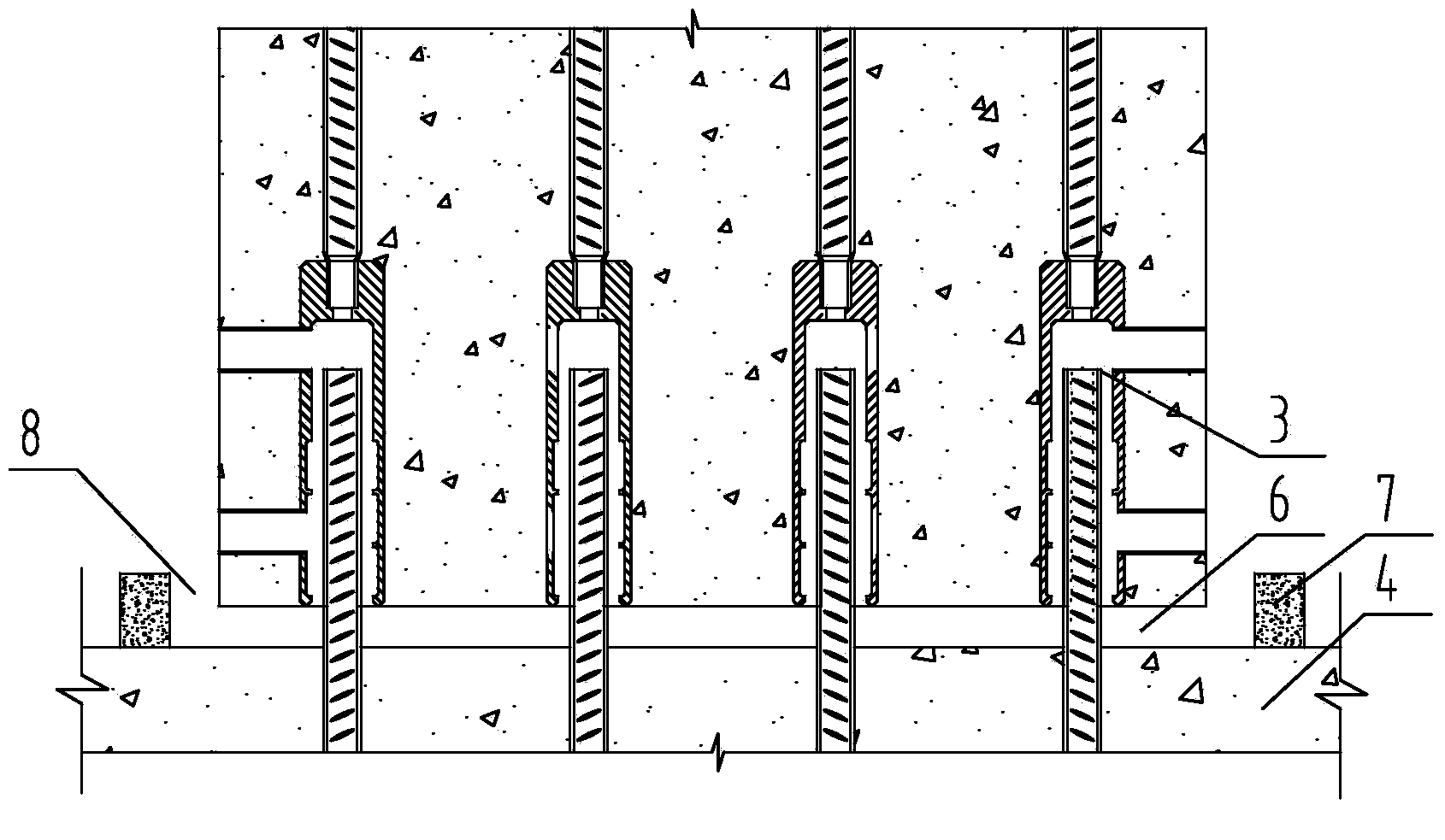

Grouting connection construction method

ActiveCN104314314AFast constructionImprove efficiencyBuilding reinforcementsBuilding material handlingRebarPrecast concrete

The invention discloses a grouting connection construction method which is used for connecting vertical reinforcements of an assembled concrete structure. The grouting connection construction method includes the steps: firstly, embedding a plurality of grouting connection devices at one end of a precast concrete unit to be connected in advance; secondly, lifting the precast concrete unit and then manufacturing a grouting box dam; thirdly, grouting horizontal gaps and then grouting the grouting connection devices. The grouting connection devices are connected with connection reinforcements extending out of a lower unit. Plugging grouting of the horizontal gaps and grouting of the grouting connection devices can be performed within the same day, so that the mounting efficiency of the precast concrete unit is greatly improved, the grouting connection construction method can be implemented in a subzero temperature environment even in winter, construction difficulty is reduced, and working efficiency is improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Semi-rigid base layer disease detection and high polymer grouting rapid servicing technology

ActiveCN101261264AAchieve losslessQuick checkMaterial testing goodsRoads maintainenceEngineeringRoad surface

The invention discloses a semi-rigid base pavement damage detection and polymer grouting fast maintenance technology, which utilizes a falling weight deflectometer (FWD) and a ground penetrating radar (GPR) to detect and evaluate the performance of the pavement, identify the pavement damage and realize the lossless and fast detection of the semi-rigid base pavement damage. A grouting hole is perforated on the section that needs damage treatment and polymeric materials are injected into the hole to repair the pavement. The maintenance technology has the advantages of speedy construction, good durability, strong pertinence and excellent waterproof performance of the injected polymeric materials, which not only saves a large amount of funds and construction periods and avoids the adverse social effects caused by long affected traffic, but also is beneficial to environmental protection and resources-saving . The semi-rigid base pavement damage detection and polymer grouting fast maintenance technology of the invention integrates damage lossless detection technology such as the FWD and the GPR, etc. with the polymer grouting fast maintenance technology, thus providing a whole set of advanced, efficient, economical and practical technology for detecting and maintaining the semi-rigid base pavement damage.

Owner:SAFEKEY ENG TECHZHENGZHOU

Method of making wall block

InactiveUS20050016106A1Fast constructionMaximize useMould separation apparatusLighting and heating apparatusEngineeringBuilding construction

A method of making a wall block and a mold box therefore. The wall block design maximizes the use of the mold box. The method produces wall blocks having a large surface area front face compared to the front face size of prior art blocks. The blocks have about one third more front surface area. This results in faster construction of walls and a faster construction sequence. The method of making the blocks makes efficient use of mold space and material, resulting in higher production yields and / or higher total daily production square footage.

Owner:KEYSTONE RETAINING WALL SYST

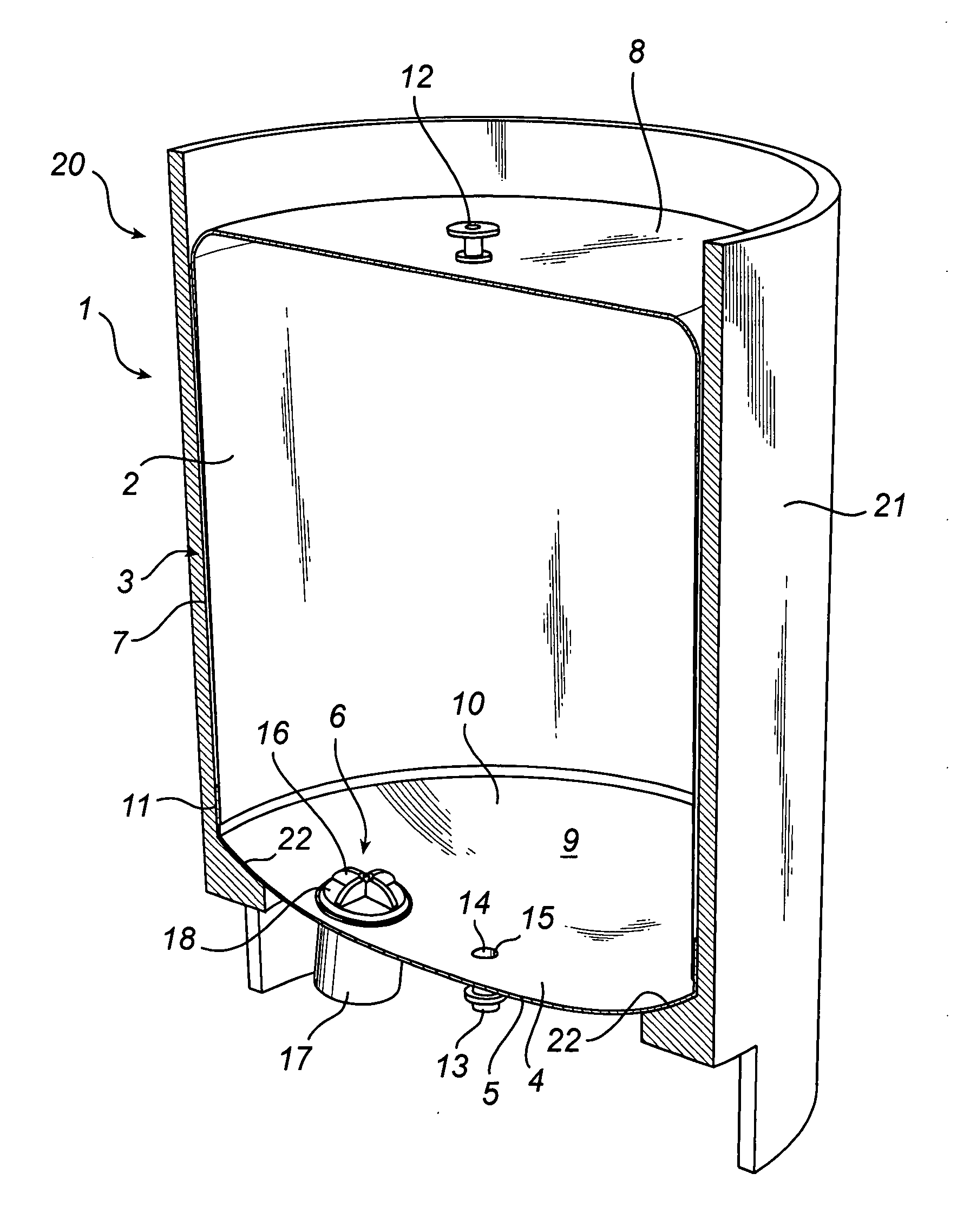

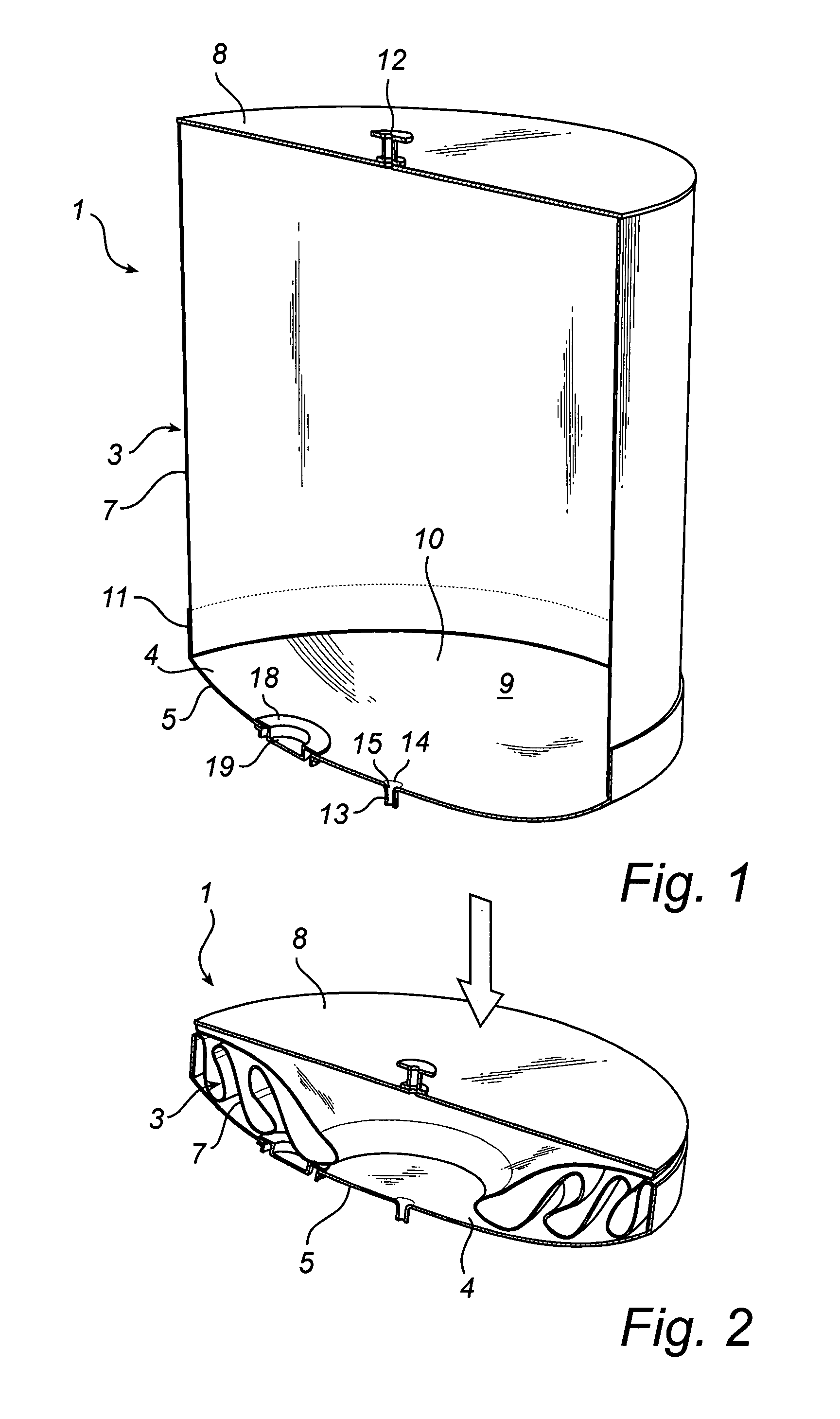

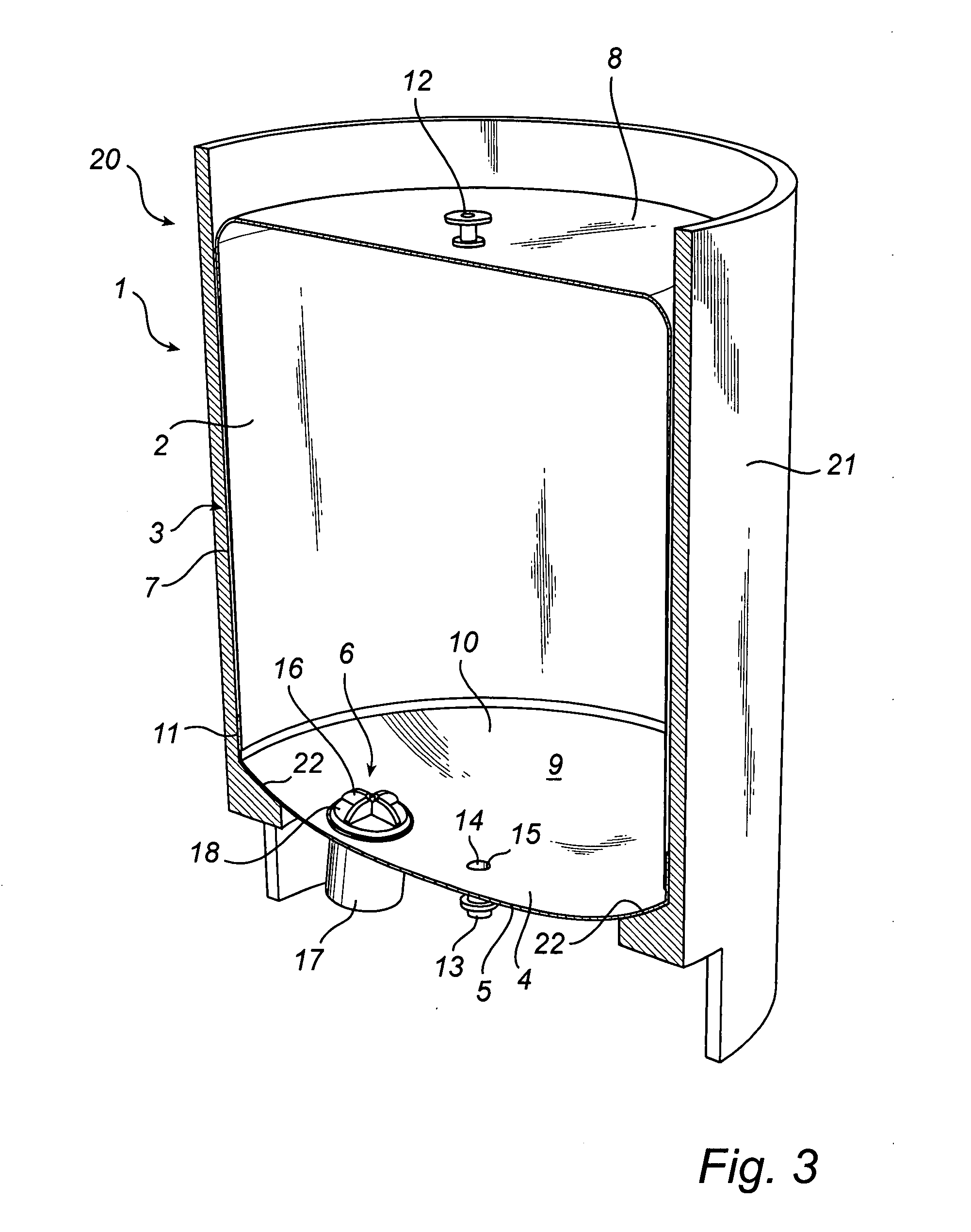

Disposable unit

InactiveUS20070253287A1Simple and effective problemsSimple and effective and risksRotary stirring mixersLarge containersEngineeringProcessing element

A disposable unit (1) for processing products (2) has a thin-walled container (3) of a soft material for holding the products and a processing unit (6) inside the container to make the products move. The container is in its lower portion (4) reinforced with a support (5) of a dimensionally stable material, which support has a smooth surface (9) and supports the container over its lower portion so as to counteract the occurrence of folds and other irregularities in the lower portion and the impairment of an even process effect. The inside (10) of the support is substantially cup-shaped without corners to give the lower portion of the container an optimal geometry and, consequently, an optimal process effect.

Owner:MERCK CHEM & LIFE SCI AB

External energy-consumption self-resetting bridge pier stud structure system and realization method thereof

InactiveCN102304892AStable energy consumptionEnsure safetyBridge structural detailsBridge erection/assemblyBridge engineeringExternal energy

The invention discloses an external energy-consumption self-resetting bridge pier stud structure system and a realization method thereof, belonging to the field of bridgework. The structure system mainly comprises a bridge pier stud, a bridge abutment, an unbonded prestressed reinforcement, an external energy consumption device, a pier embedded part and a bridge abutment embedded part, wherein the bridge pier stud and the bridge abutment are connected by the unbonded prestressed reinforcement and the external energy consumption device, so that residual deformation can be effectively reduced, and energy consumption can be guaranteed. The external energy-consumption self-resetting bridge pier stud structure system is flexible in design and has specific structure stress. The unbonded prestressed reinforcement on the axis position of the pier stud can be used for generating self-resetting restoring force. The problem that the traditional bridge pier has larger residual deformation and cannot continuously serve after the earthquake loading action is solved. The bridge pier has enough strength and rigidity. The external energy-consumption self-resetting bridge pier stud structure system is realized in a cast-in-situ or prefabricating mode and is easy to construct and is a novel pier stud structure system which is advanced and practical and can realize quick replacement and repair after the earthquake..

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com