Patents

Literature

8238 results about "Floor slab" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

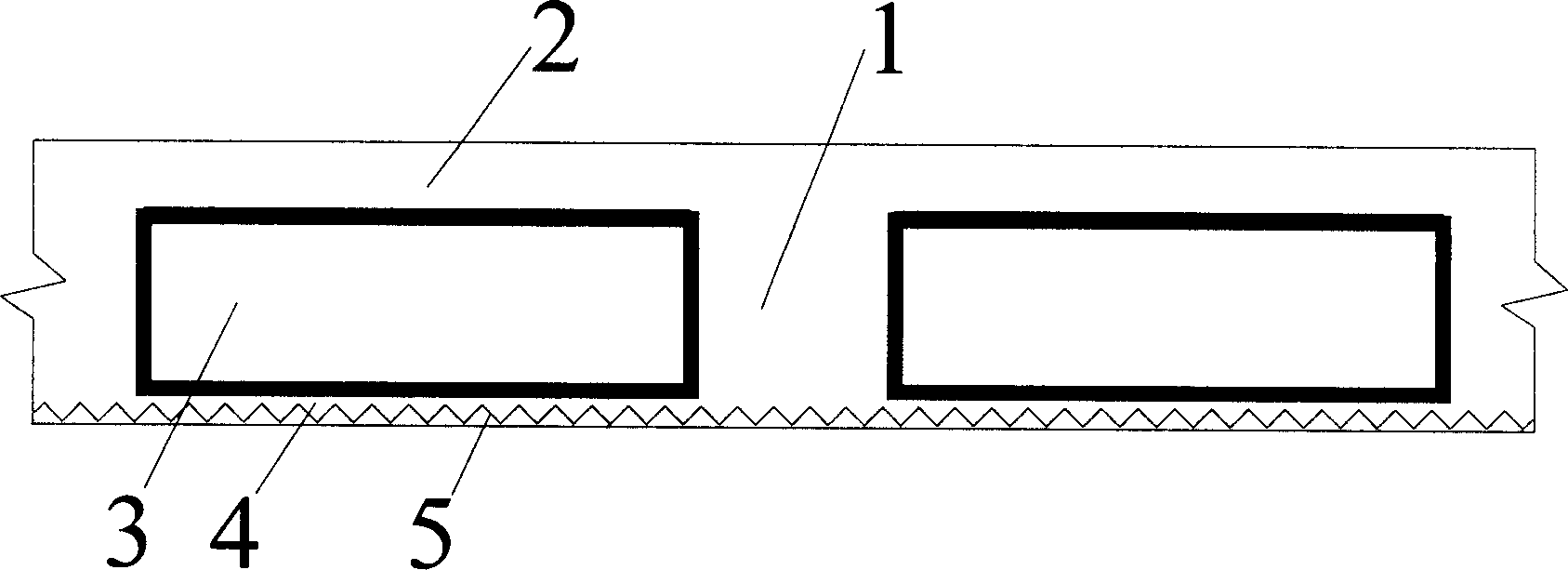

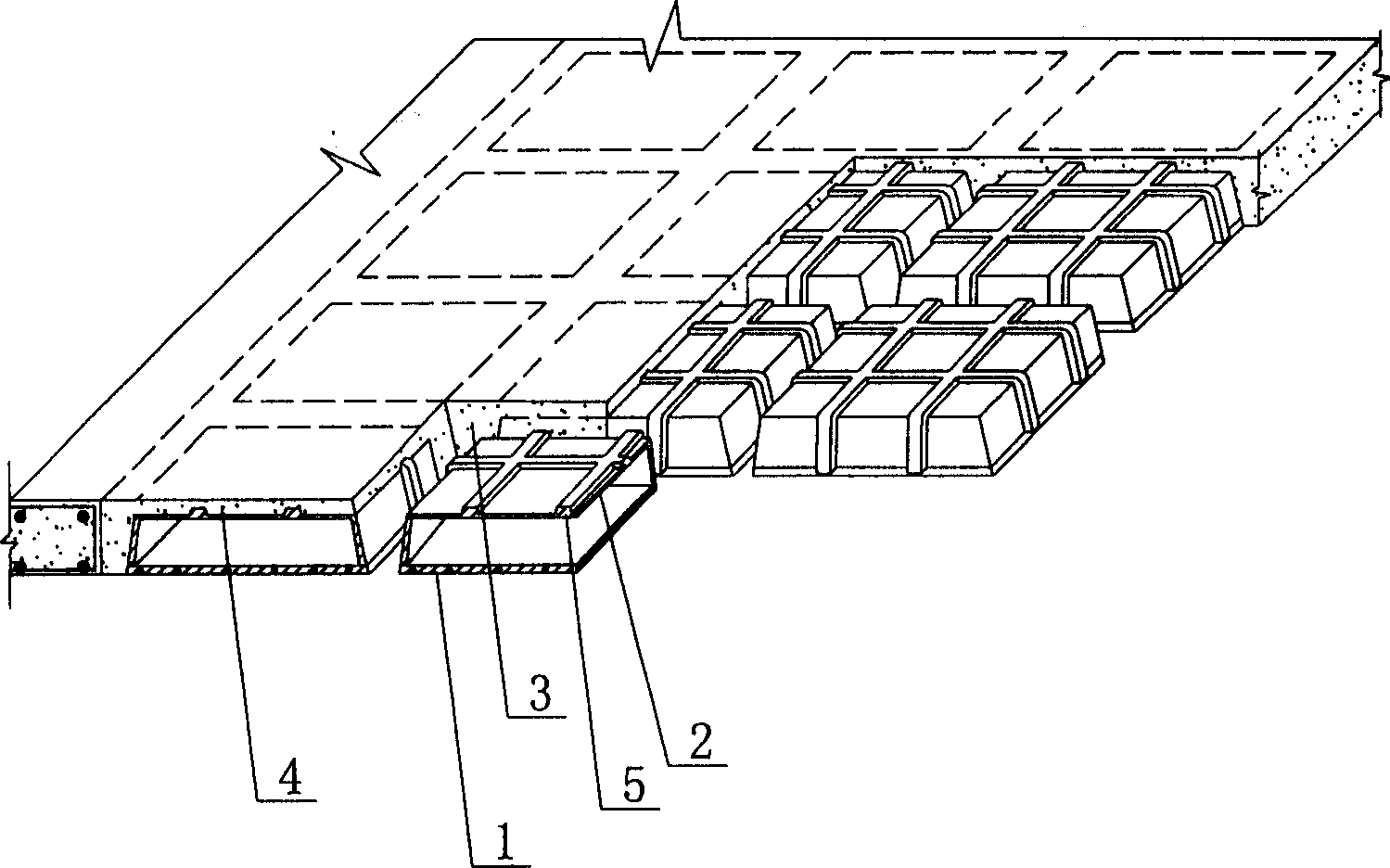

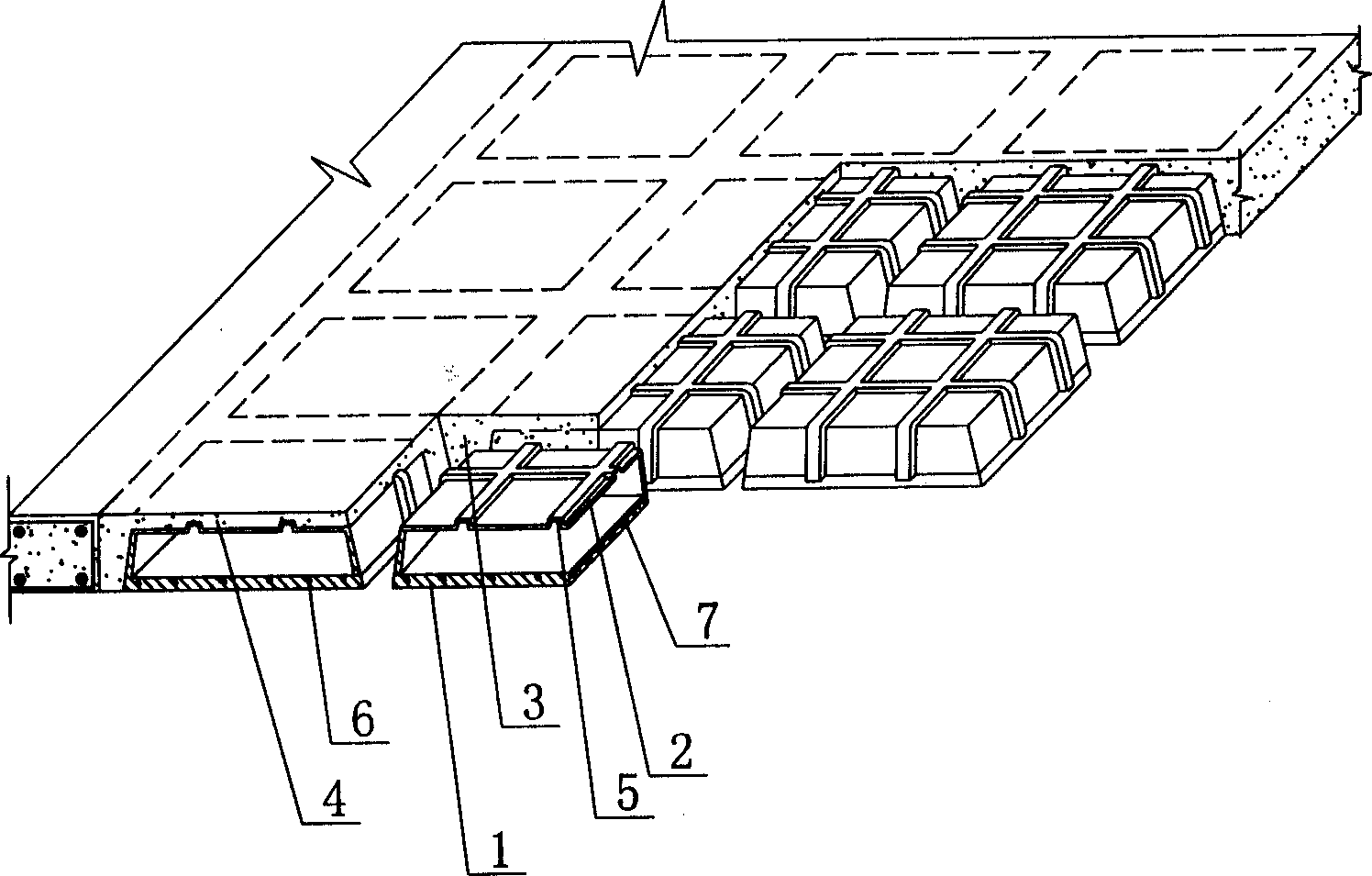

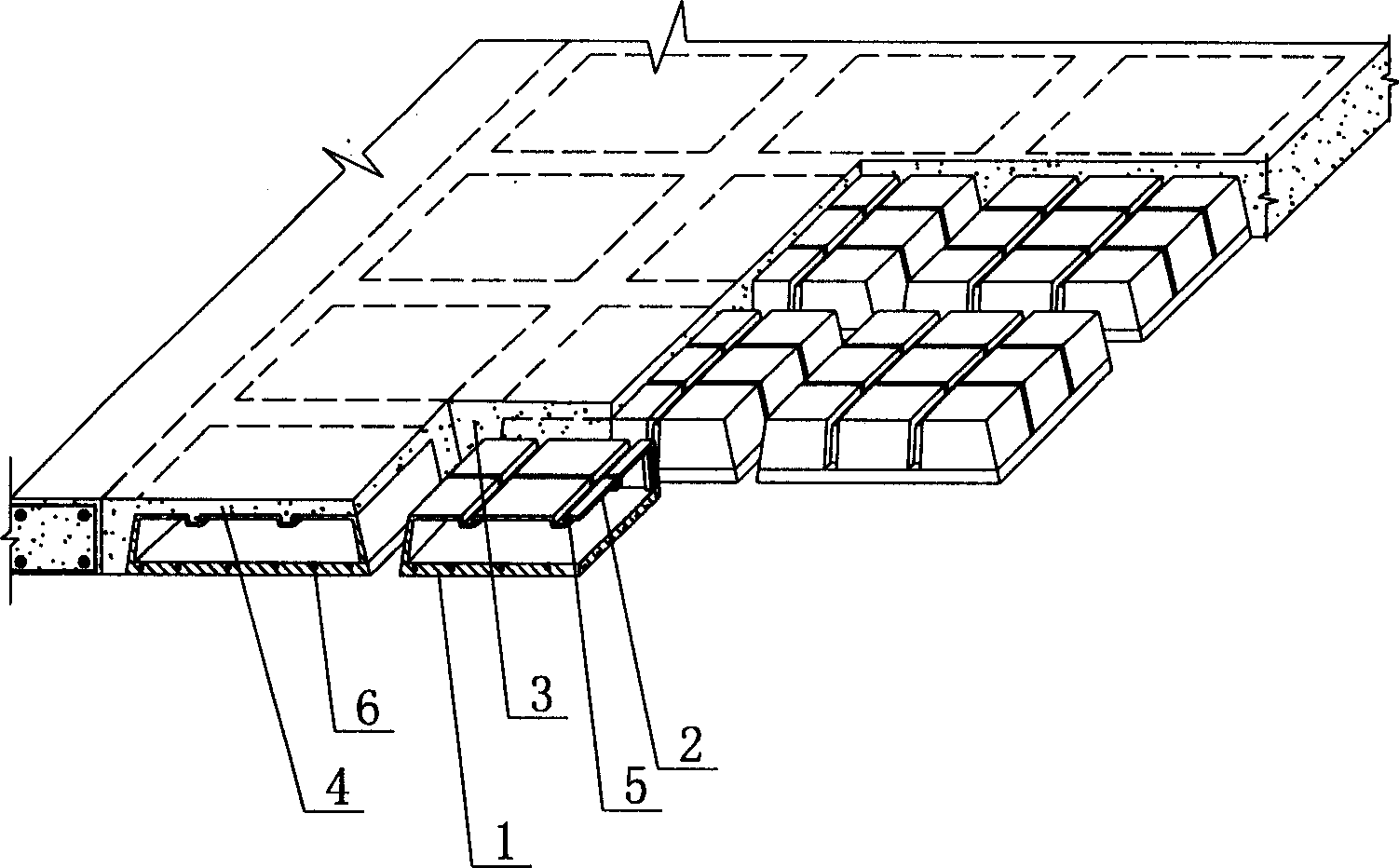

Hollow floor slab with small dense ribs and its production process

InactiveCN1637217ALarge spanSafe and reliable structureFloorsForms/shuttering/falseworksFloor slabLine tubing

The hollow floor slab includes column, solid belt, solid reinforced beam with dense ribs, reinforced facing board, and composite box with lower thin bottom board. The production process includes: a) laying and tying reinforcing steel bar in the floor slab formwork; b) laying the steel wire net and other reinforcing material; c) setting and fixing made composite thin box; d) tying reinforcing steel bar for the facing board; e) fixing reinforcing bars with iron wire; and f) embedding prefabricated pipeline inside the facing board and the dense ribs. The present invention may produce flat sealed floor slab cavity with dense ribs in once deposition.

Owner:HUNAN BDF ENERGY SAVING TECH

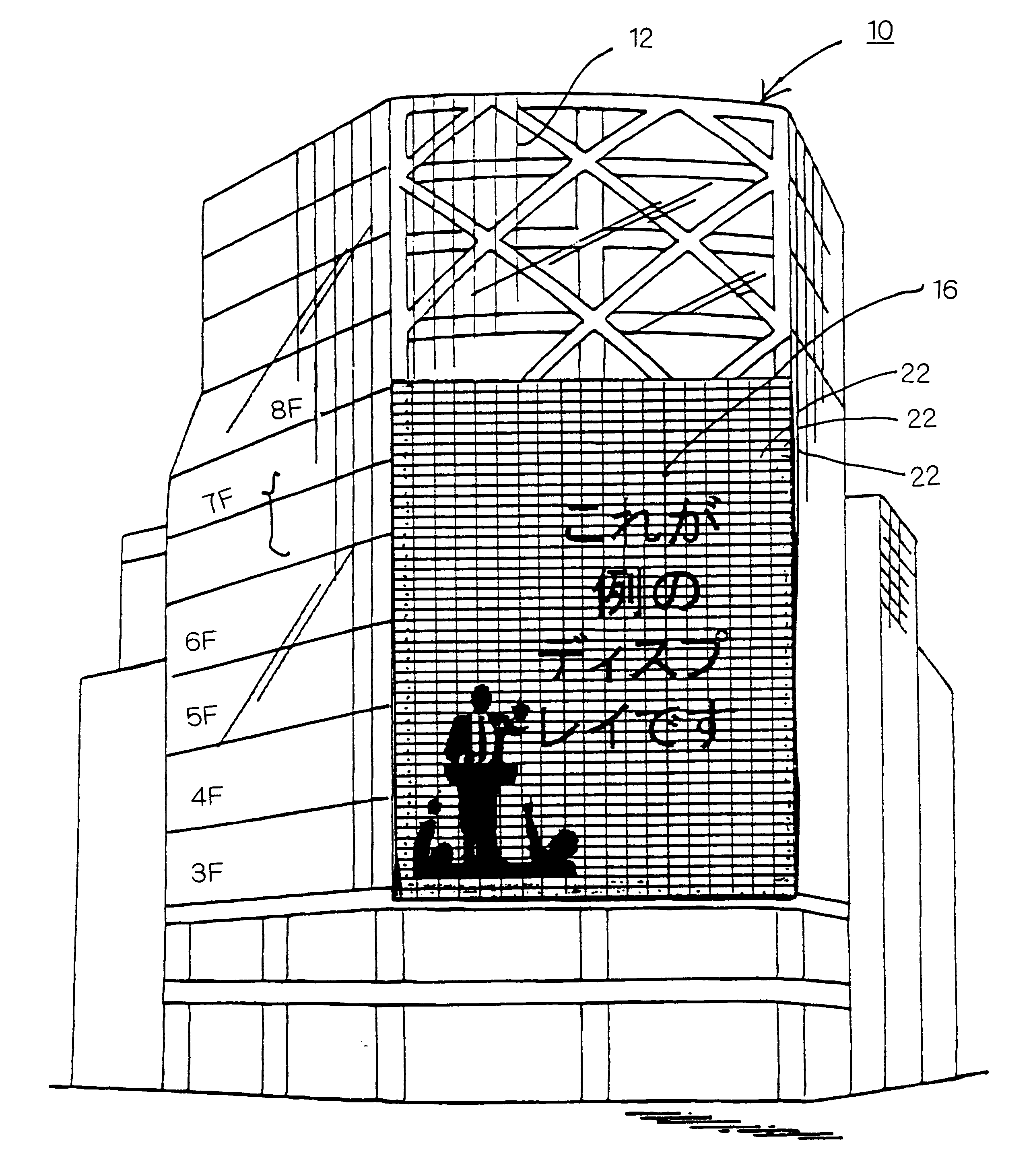

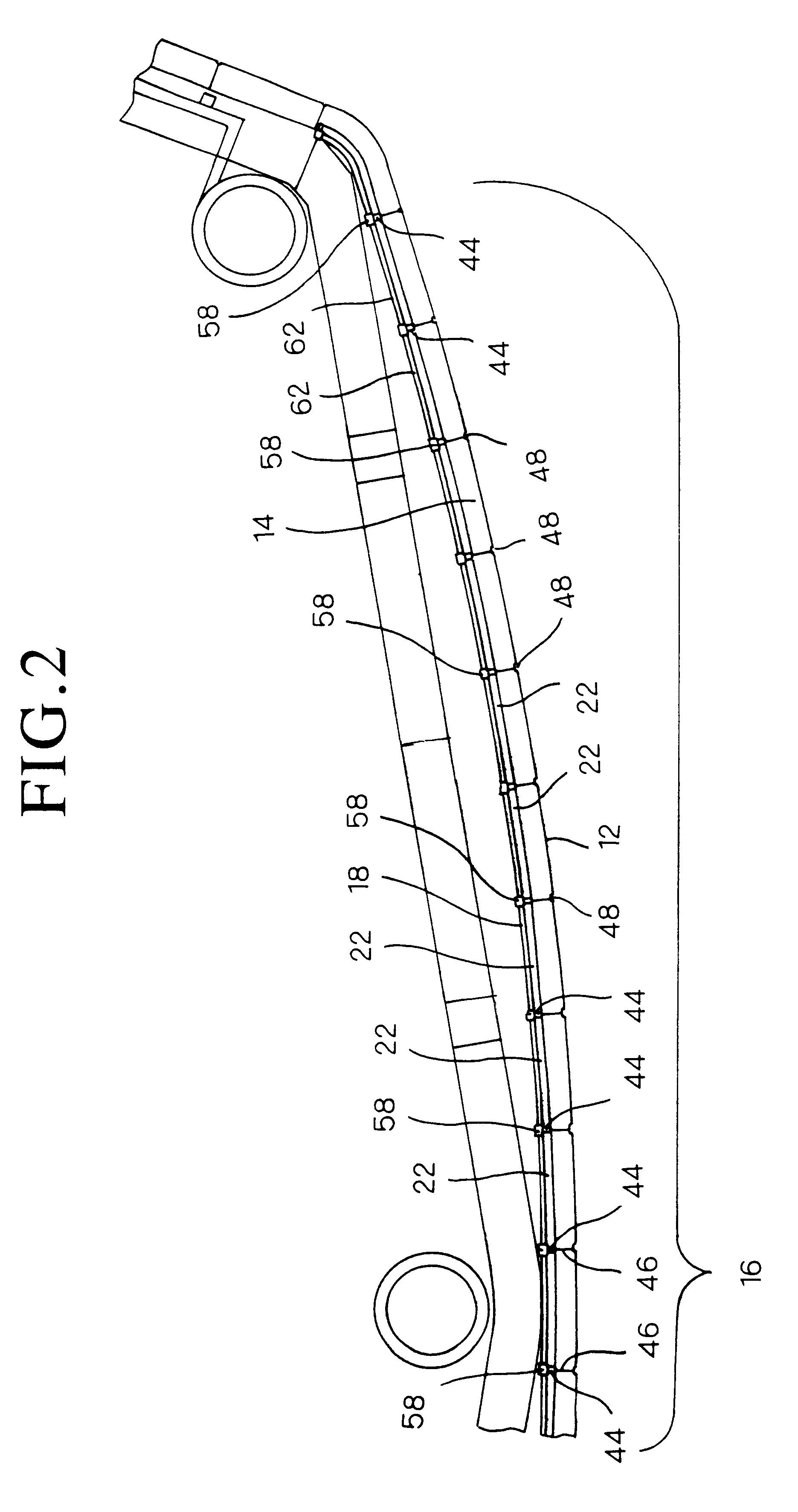

High-rise building with large scale display device inside transparent glass exterior

InactiveUS6237290B1Easy to carryImprove device performanceStampsPublic buildingsFloor slabWindow shutter

A high-rise building with a large scale dot-matrix display device is disclosed. The glass panels arranged in rows and columns form a curtain wall structured transparent outer wall 12 extending over an exterior of a building 10. Each panel is installed apart from end portions of floor slabs to form a void space therebetween. A plurality of louver structured modules 22 are arranged within the void space in rows and columns to form a large scale display area. Each module 22 has a louver-like structure formed of a plurality of posts 24 arranged in substantially parallel relationship and a plurality of parallel, uniformly spaced beams 26 connecting said adjacent posts 24. A plurality of LED combination lamps 28 are mounted on each beam 26 at uniform pitches as those between the adjacent beams 26. The LEDs are driven by drive circuits disposed in each beam 26. The vertical guide members 44 are fixed to the end portions of the floor slabs 20. The guide members 44 are arranged substantially in parallel relationship so that the modules 22 are supported between the adjacent guides 44 at the both lateral sides thereof. A plurality of vertical mullion members 48 fixed to the vertical guide members 44 as spaced apart from each of the vertical guides 44, so that the glass panels 12 are supported therebetween.

Owner:AVIX

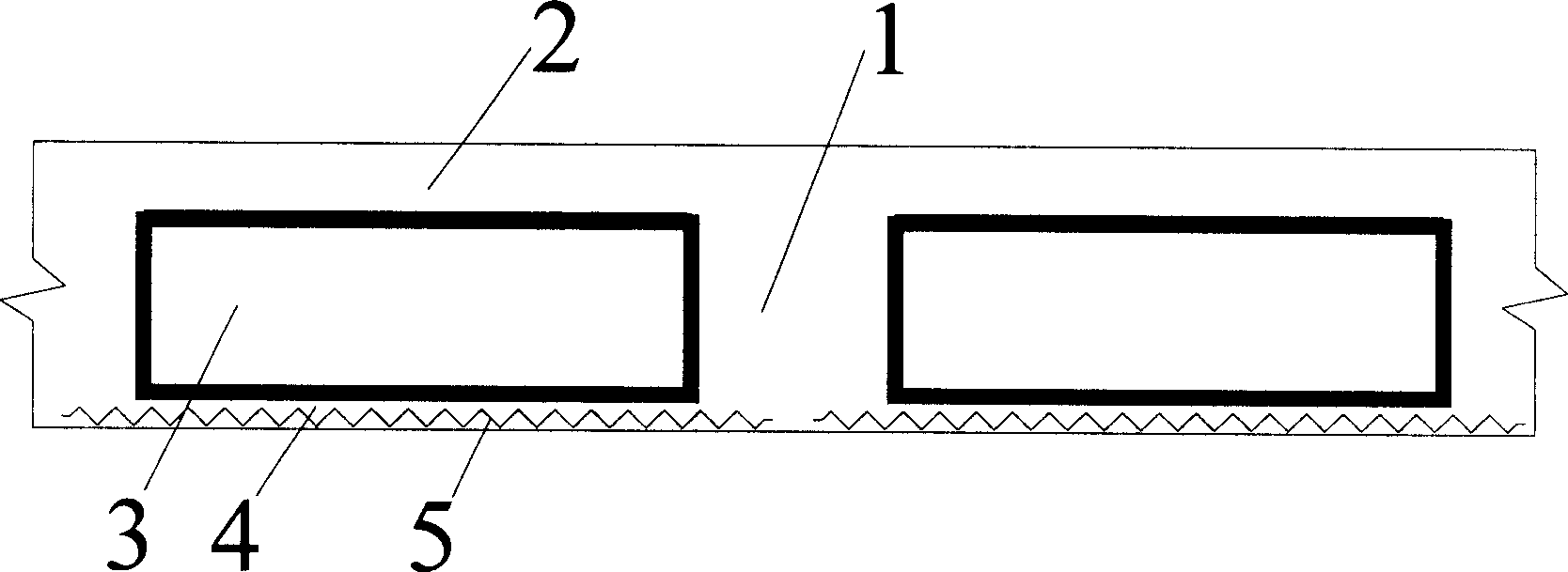

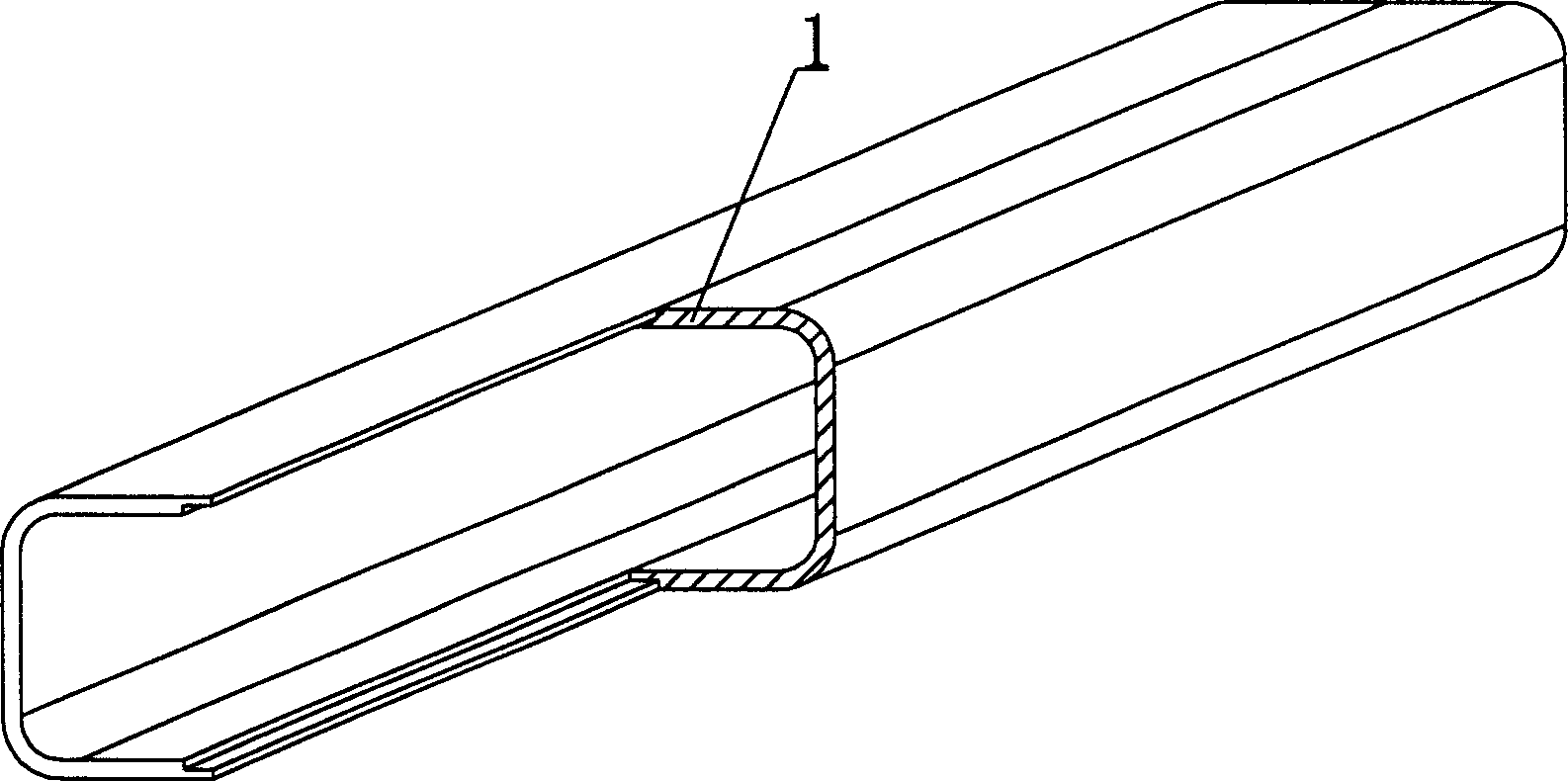

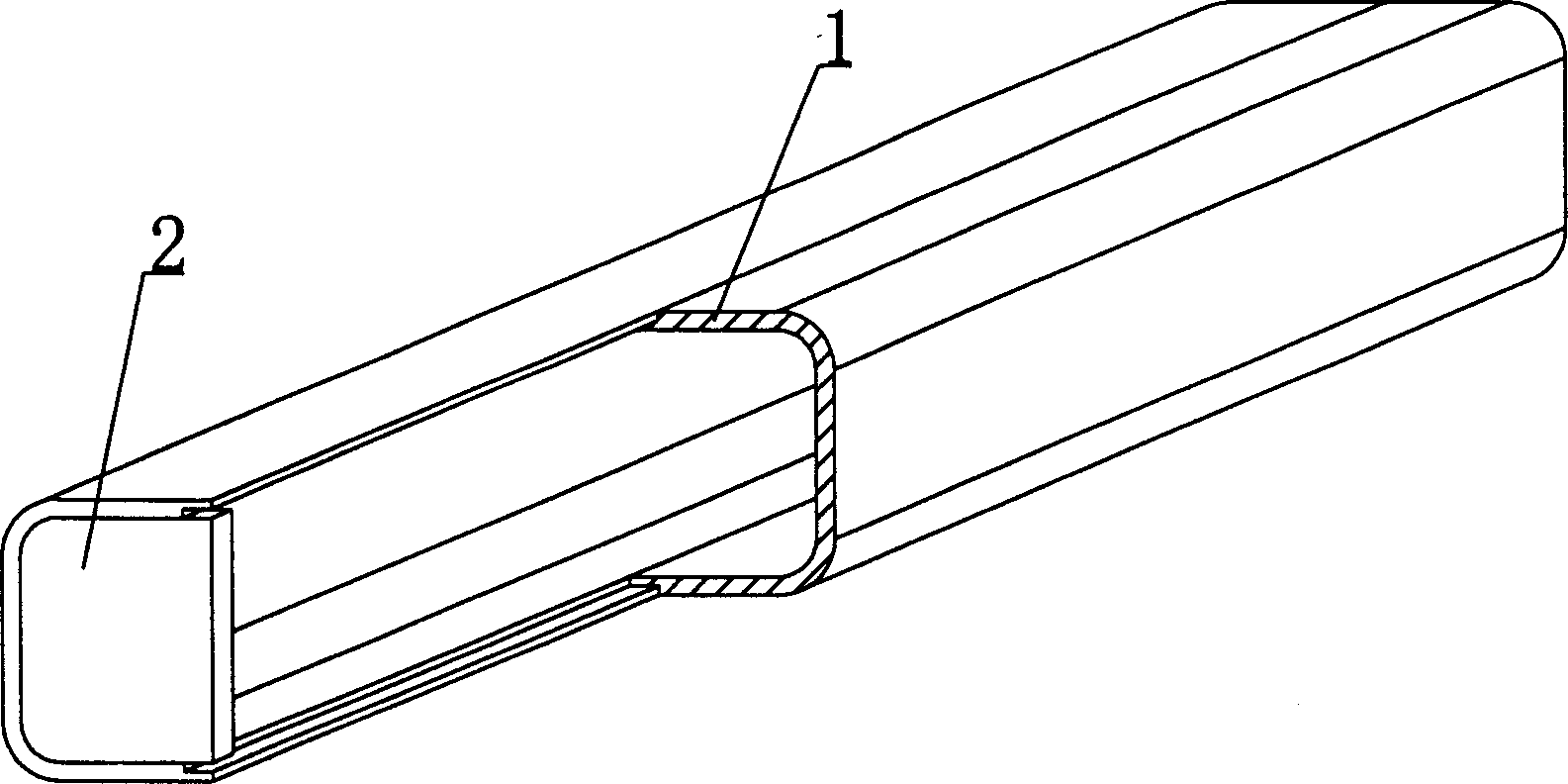

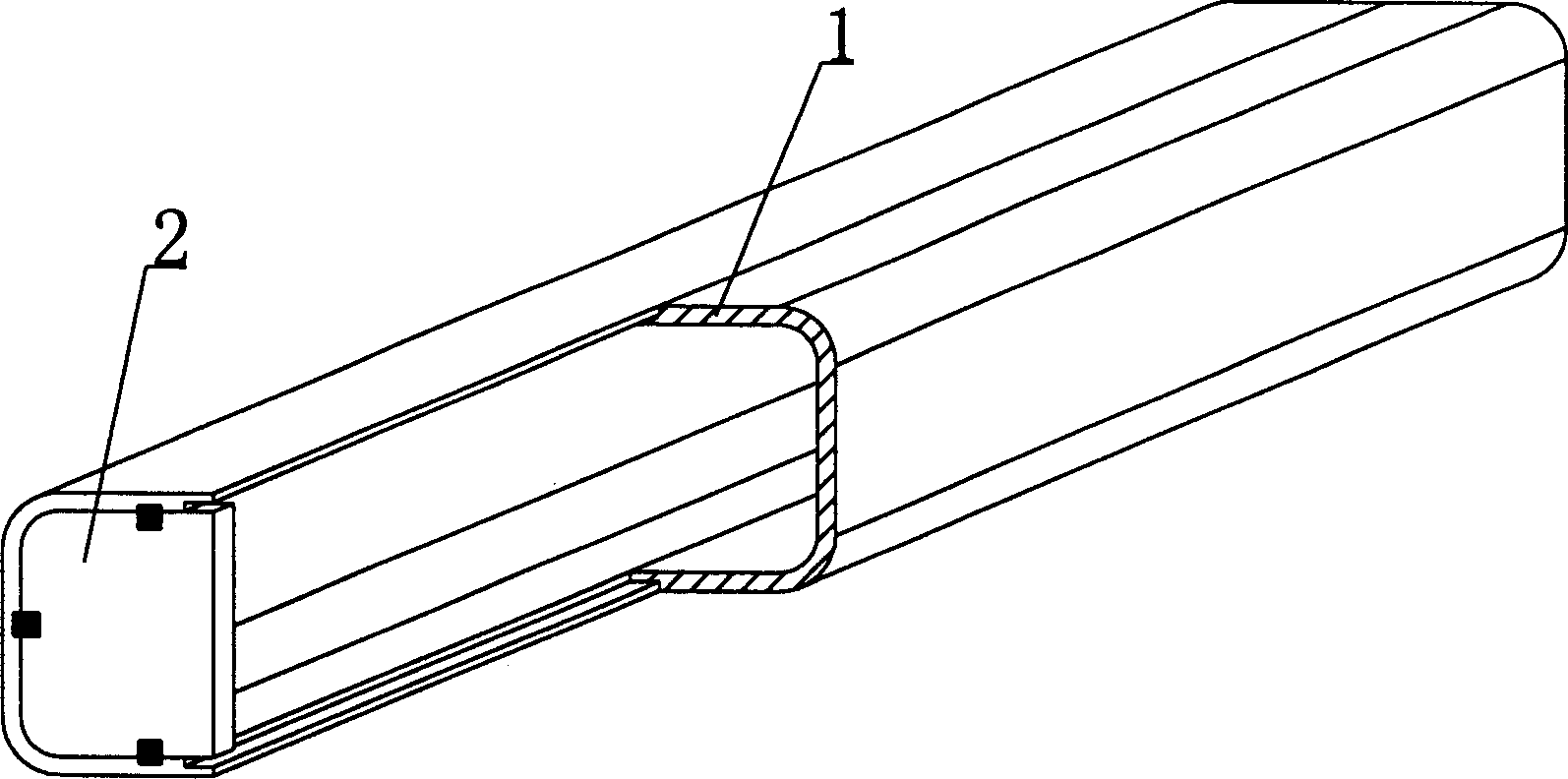

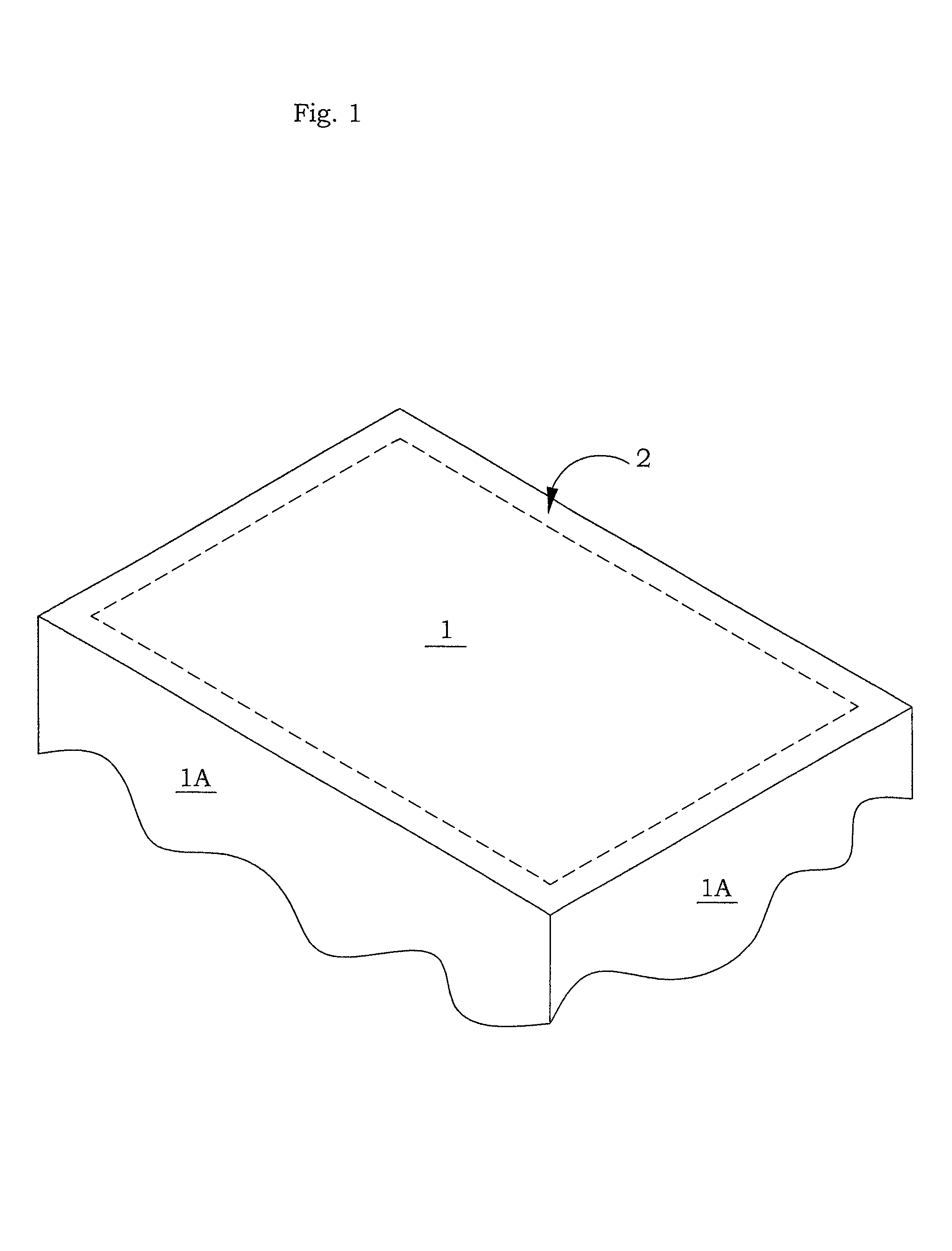

Member for cast-in-situ steel reinforced concrete

A member for in-situ casting the reinforced concrete is composed of two halves, which are fastened together to form a hollow thin-wall member used for in-situ casting hollow floor slab, roof, wall, etc. Said member is made up by die pressing. Its advantages are high strength, low cost, and convenient transportation.

Owner:湖南邱则有专利战略策划有限公司

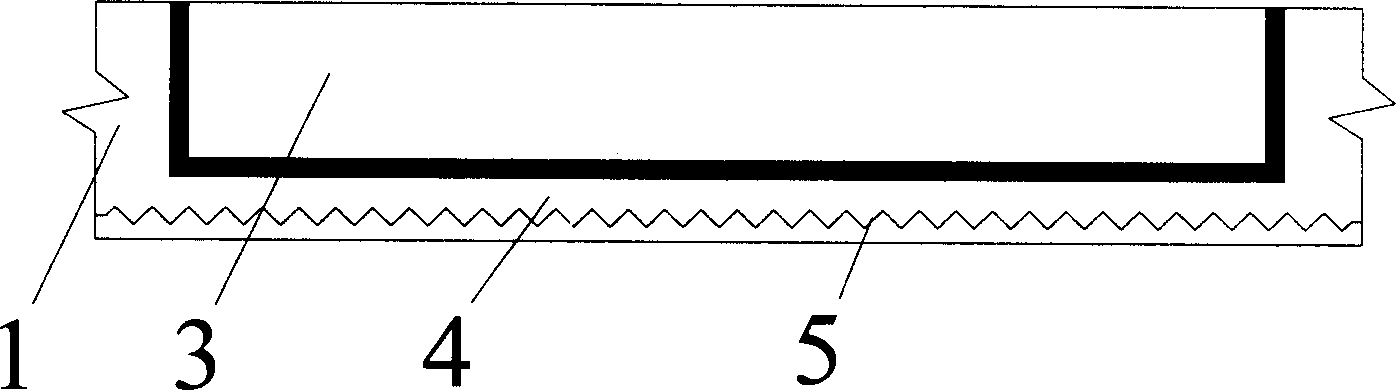

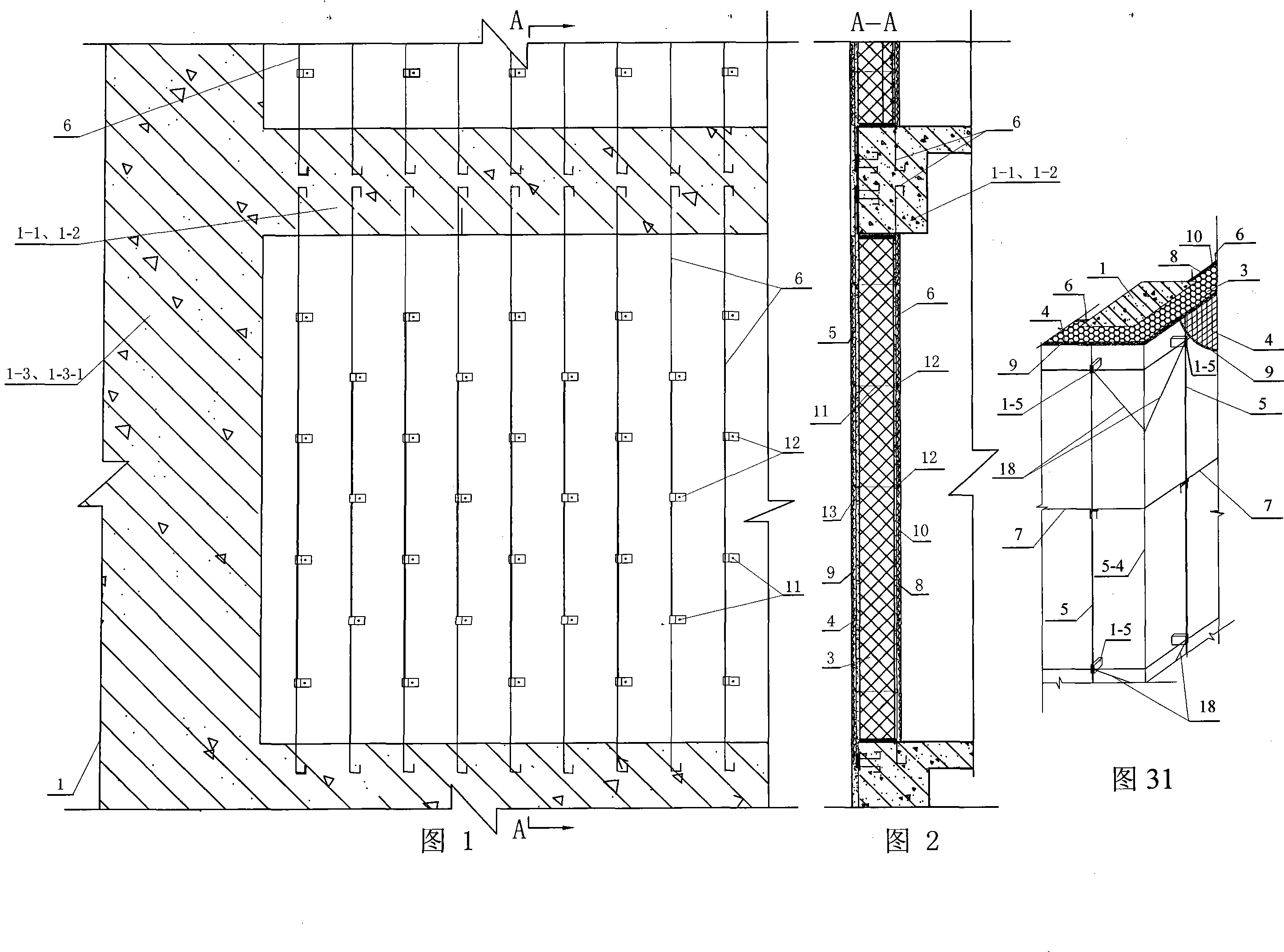

Hollow floor slab with hidden and dense ribs

The floor slab includes bottom plate, hollow form board, in-situ steel bar reinforced concrete hidden ribs and in-situ steel bar reinforced concrete upper plate; and features that the structure bottom plate and hollow form board are connected to form polyhedral structure and that there are reinforcing ribs in the hollow form board. Owing to the structural bottom plate and hollow form board connected into one integral and the hollow form board with reinforcing ribs, the hollow member for the floor slab with hidden and dense ribs has high strength and rigidity and not easy to break, and the floor slab has simple structure, high strength, light weight and easy construction.

Owner:湖南邱则有专利战略策划有限公司

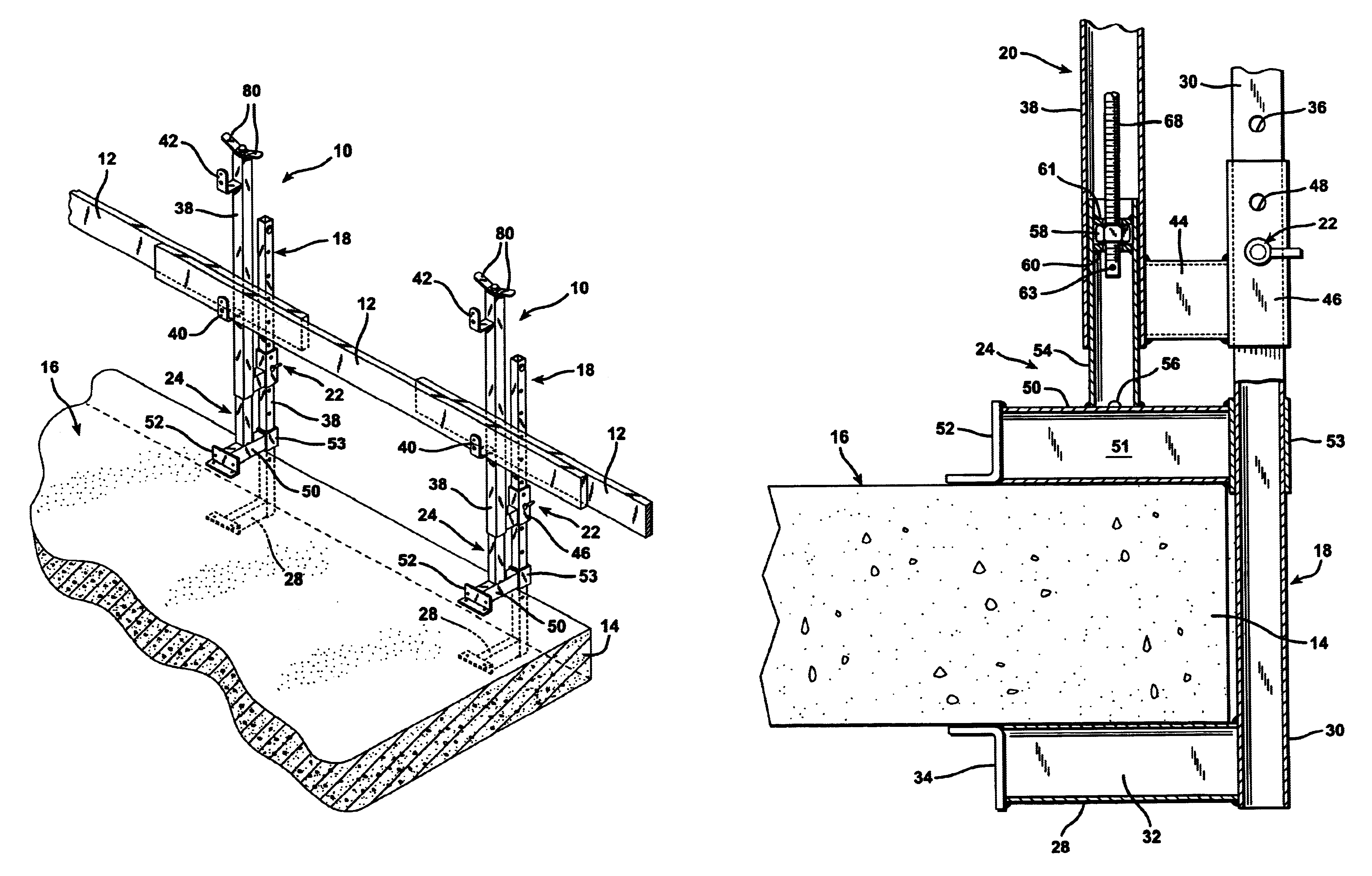

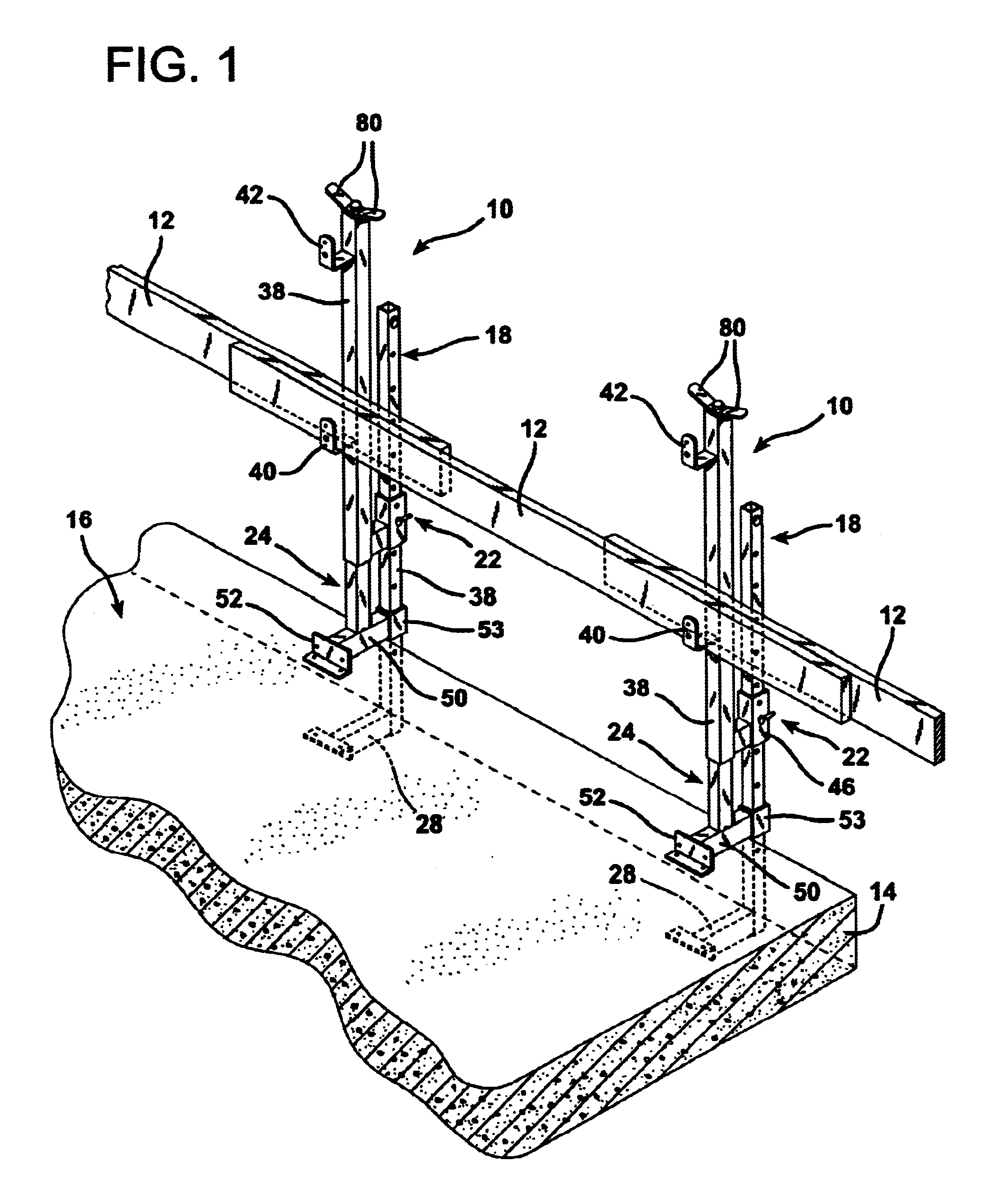

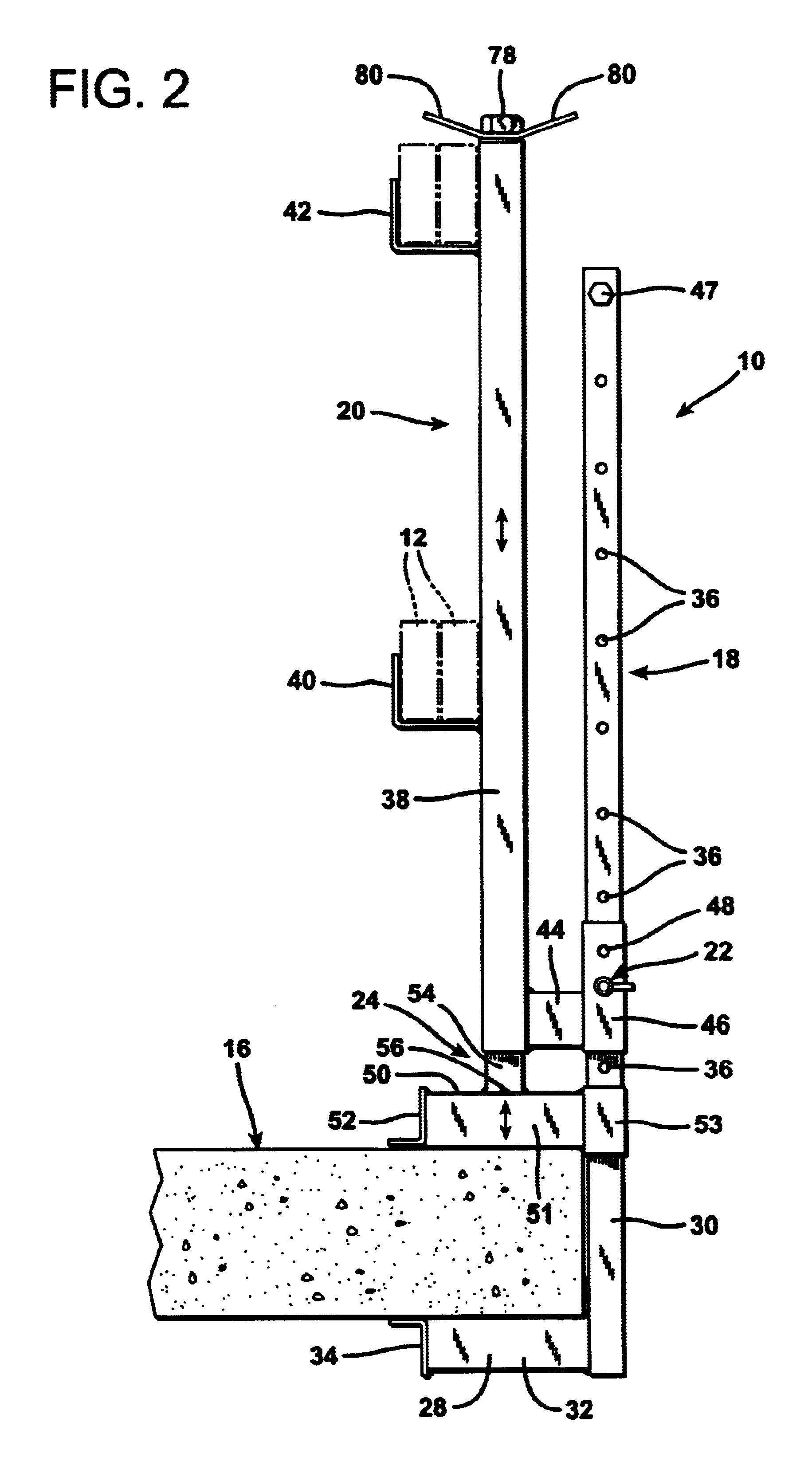

Construction perimeter guard

The present invention is an improved construction perimeter guard stanchion. A dual adjustment system performs both coarse and fine adjustments to tightly clamp a pair of jaws at the lower end of the stanchion upon the edge of a floor slab in an elevated, unfinished building structure. A coarse jaw adjustment sleeve formed of a short section of hollow steel tubing is coaxially disposed about an outboard support member in sliding engagement therewith. The coarse adjustment sleeve has one or more perforations therethrough so that a locking pin can be passed through it and through aligned openings in the outboard support member. A fine adjustment screw member is disposed coaxially within a vertical rail support tube and may be rotated by lever arms to move the upper jaw closer to or further from the lower jaw. Adjustment of the fine positioning mechanism is performed by manipulating handles at the top of the vertical rail support tube. A workman installing the stanchion thereby does not have to stoop over to operate a clamp located down near the concrete slab.

Owner:A 1 PLANK & SCAFFOLD MFG

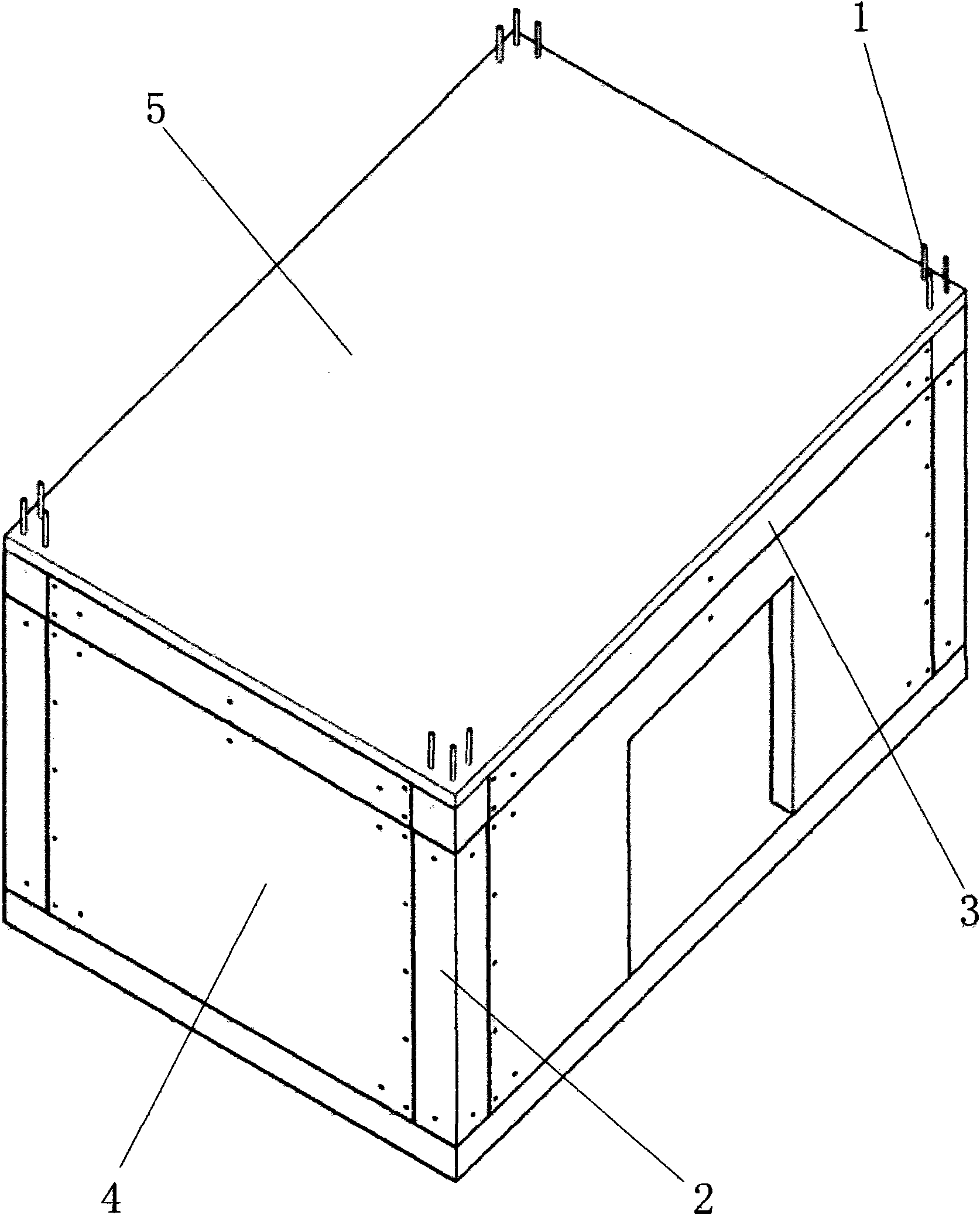

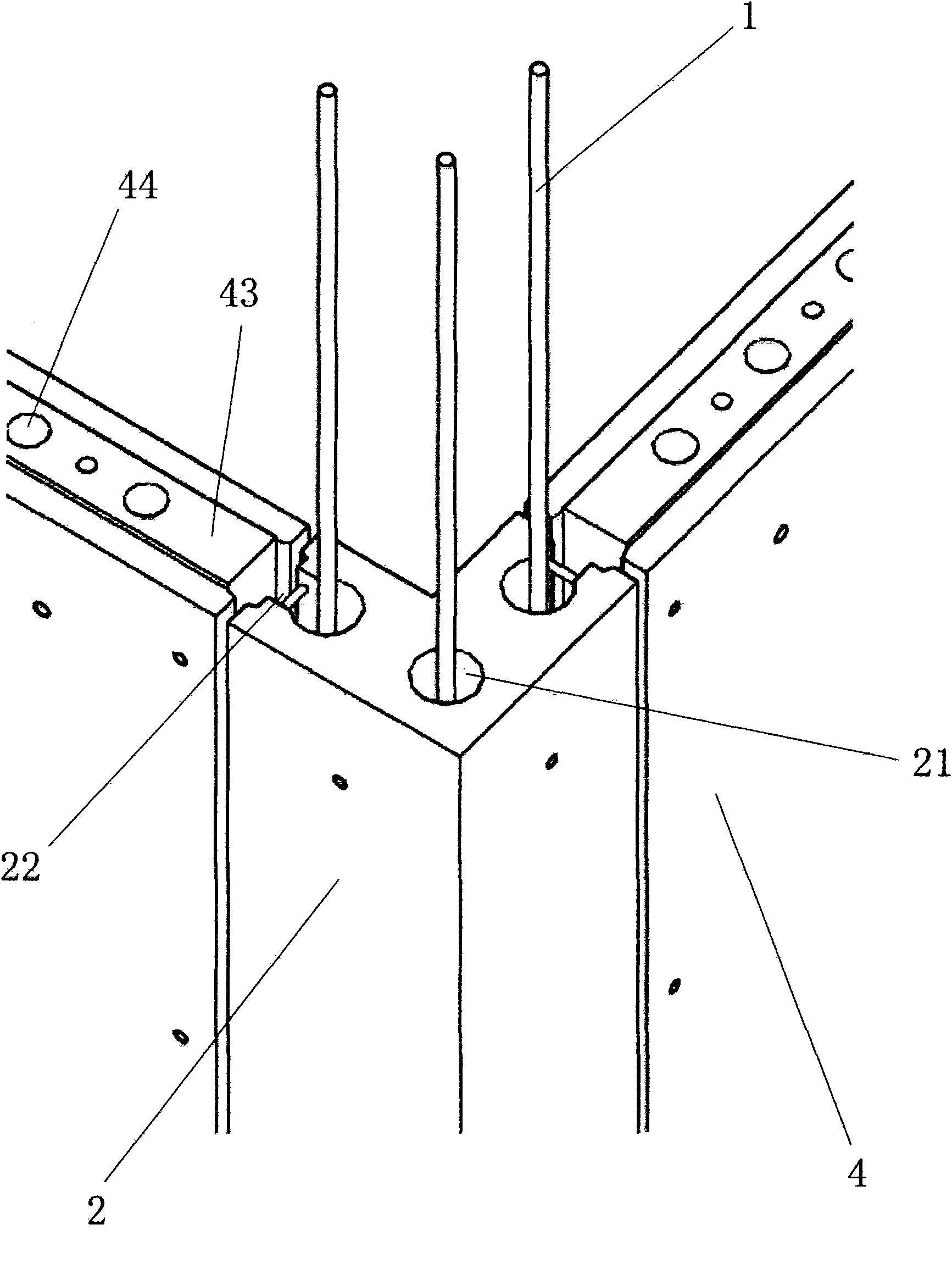

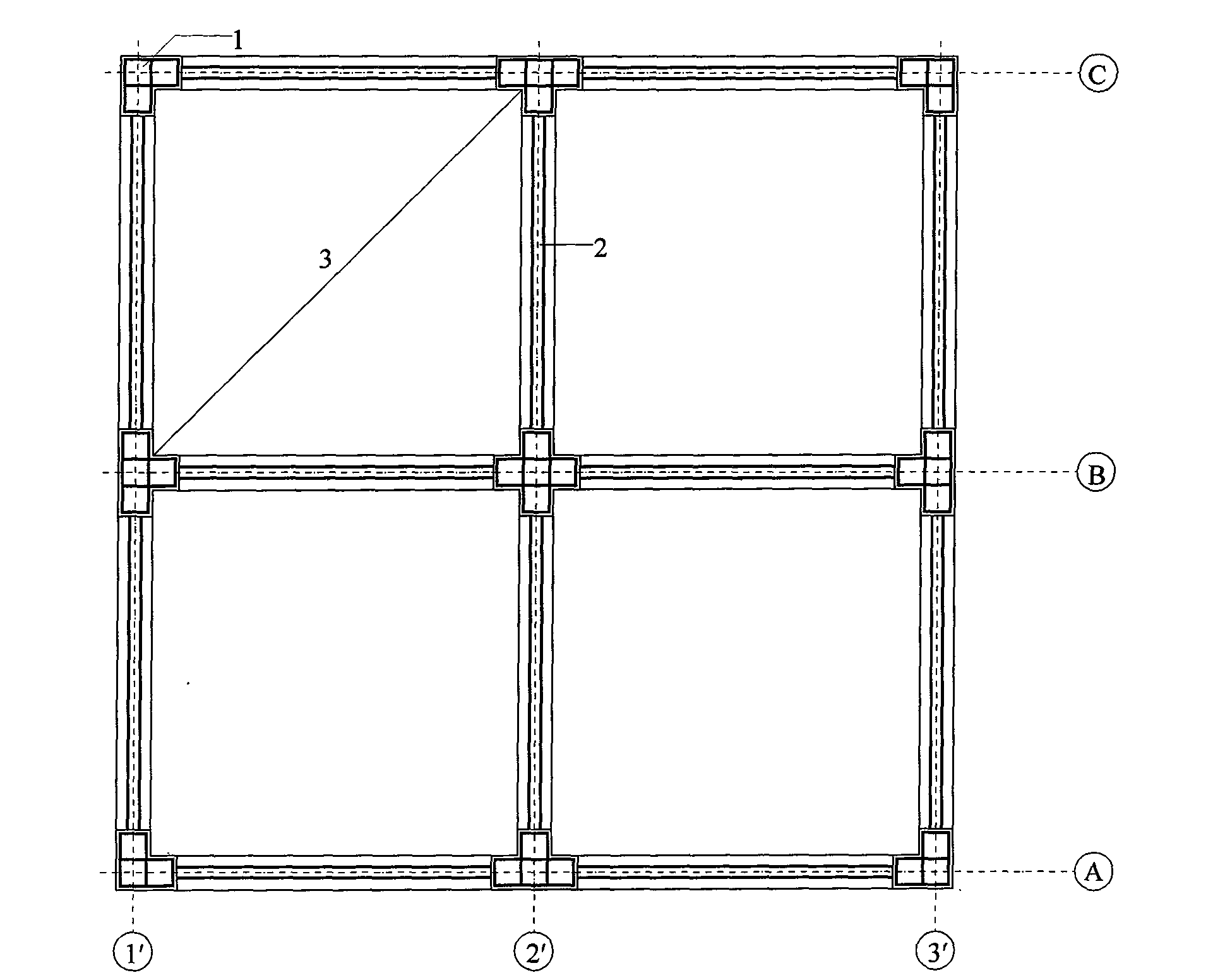

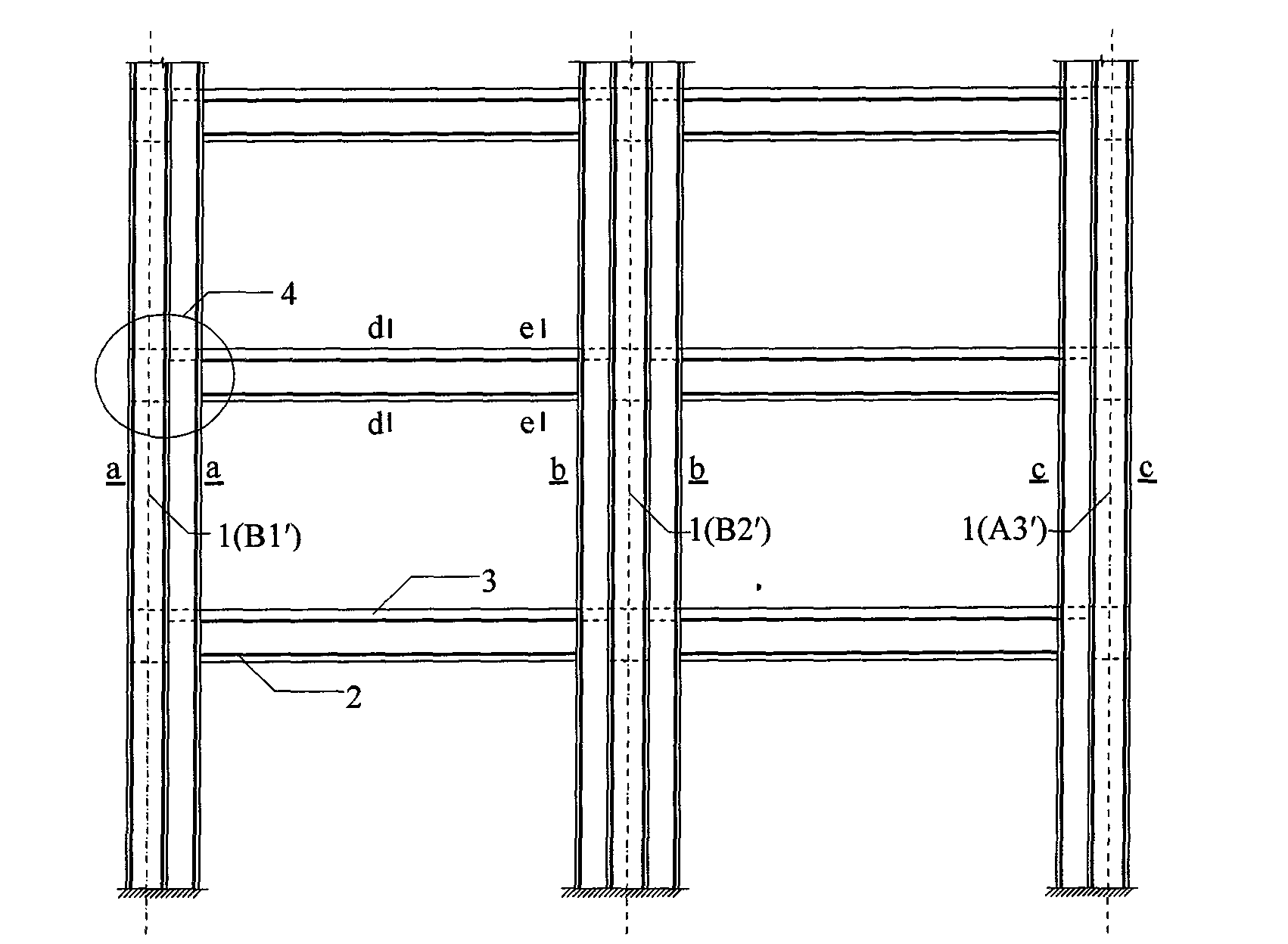

Full-fabricated assembly overall reinforced concrete house and building method thereof

InactiveCN101806095ASmall sizeNo secondary plastering requiredBuilding material handlingFloor slabReinforced concrete

The invention discloses a full-fabricated assembly overall reinforced concrete house which comprises a plurality of column ribs arranged at intervals and respectively and fixedly connected with a foundation, a plurality of column bodies prefabricated in a modularized way, a plurality of wall bodies prefabricated in the modularized way, and a floor slab prefabricated in the modularized way. The invention aims to overcome the defects of the prior art, and improve the full-fabricated assembly overall reinforced concrete house which has simple structure, is convenient to install, saves building materials, is quick to build, and has good overall safety performance. Another purpose of the invention is to provide a method for building the house.

Owner:ZHONGSHAN FAST LIVING PREFABTED HOUSING

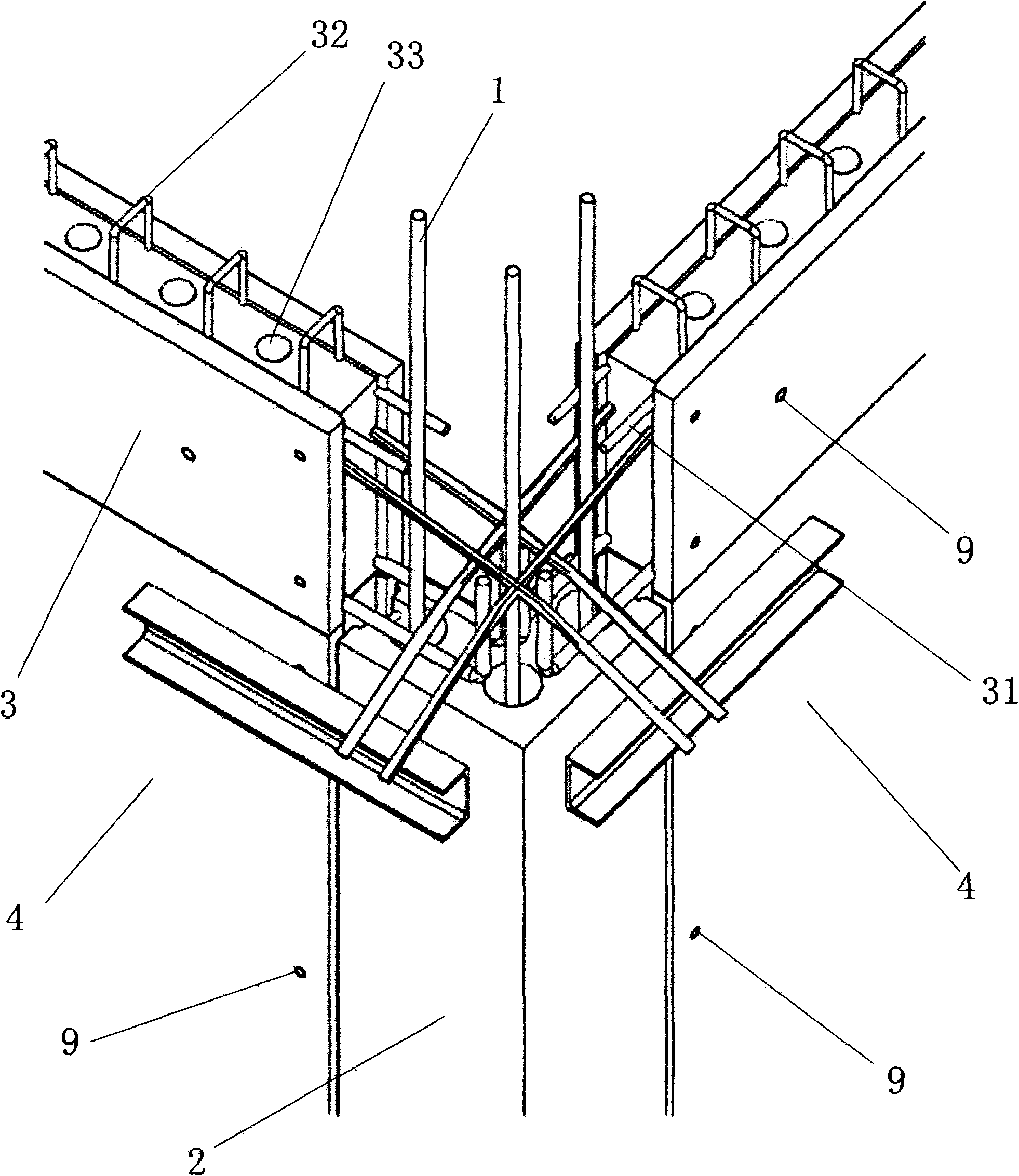

Assembly connecting structure and assembly connecting method of assembled concrete frame and shear wall combination

ActiveCN102808465ASplit location is reasonableEasy to manufactureWallsBuilding material handlingFloor slabRebar

The invention relates to the field of assembled concrete structures, in particular to an assembly connecting structure and an assembly connecting method of an assembled concrete frame and shear wall combination. A cast-in-place strip is disposed between precast columns and precast shear walls to connect column-wall embedded rebars. Vertical through holes are reserved in a precast node-precast beam integrated component to achieve communicated connection of vertical rebars for the upper and lower columns and the upper and lower shear walls. Embedded steel sleeves at the lower ends of the precast columns and the precast shear walls are mutually embedded with projecting rebar segments extending up out of the lower columns and the lower walls, and are integrated with the lower columns and the lower walls through cast mortar. The projecting straight rebars at the upper ends of the precast columns and the precast walls penetrate through the through holes reserved in the precast node-precast beam integrated component and protrude a floor slab, and the precast columns and the precast nodes are firmly integrated with the precast shear walls precast beams by cast mortar. Wet operations such as in-place casting of concrete are reduced to the maximum extent, building quality is improved, construction period is shortened, and energy conservation and emission reduction are achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

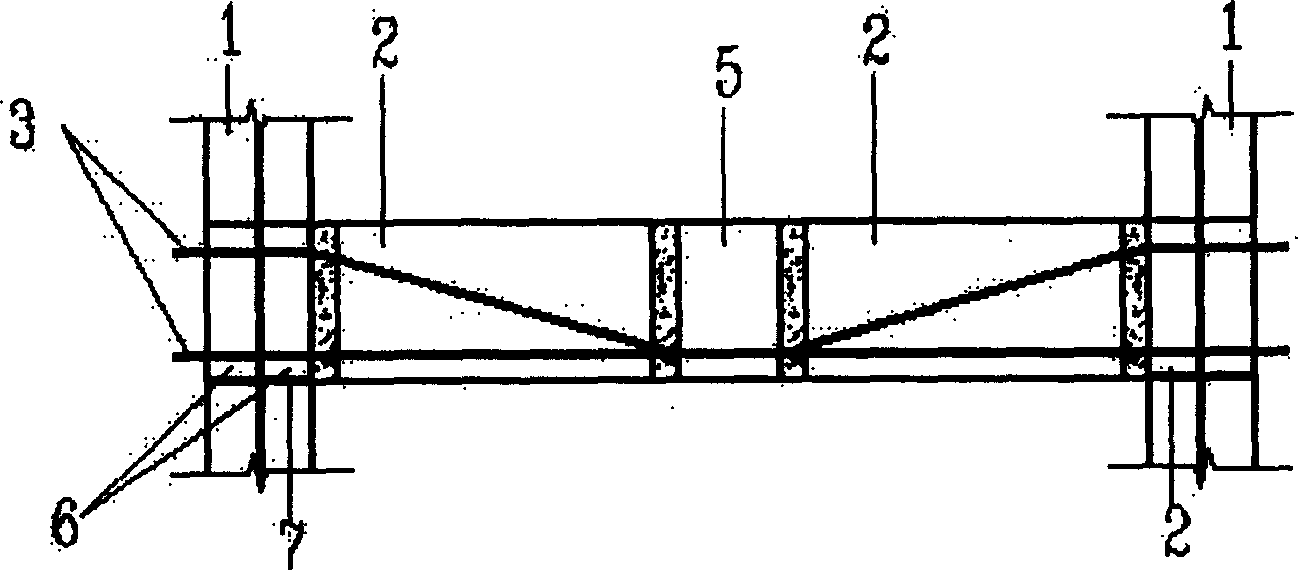

Multi-rib structure system and its connection construction method

InactiveCN1804263AAchieve graded releaseMeet the energy-saving requirements of light buildingsWallsFloor slabPre stressing

The invention relates to a ribbed structure which comprises a ribbed composite wall plate, a hidden frame and a floor. Wherein, the ribbed composite wall plate is a network construction element formed by reinforced steel concrete and light material and divided by the reinforced steel concrete beam as rib beam and rib post in small sections with embedding light material stuffing blocks into the grid; the ribbed composite wall plate also comprises the goatee bar extending from the rib beam and rib post, which is four steel bars with certain anchoring length extending from each rib beam and post and is longitude steel bar whose end is a hook in connection to hook hidden frame; or else the goatee bars are two U-shape closed ring extending from each rob beam an post and is inserted with longitude steel bars in connection; the hidden frame is formed by outer frame post, connection post, and hidden beam which are embedded outside the ribbed composite wall plate while using common concrete, profiled bar concrete or steel structural beam and post; the stuffing material is made from light material with certain strength, volume weight and little elastic modulus; and the floor can select on-situ irrigating concrete, on-sit or prefabricated ribbed composite floor, pre-stress layered floor or special-shaped pre-stress hollow floor.

Owner:姚谦峰

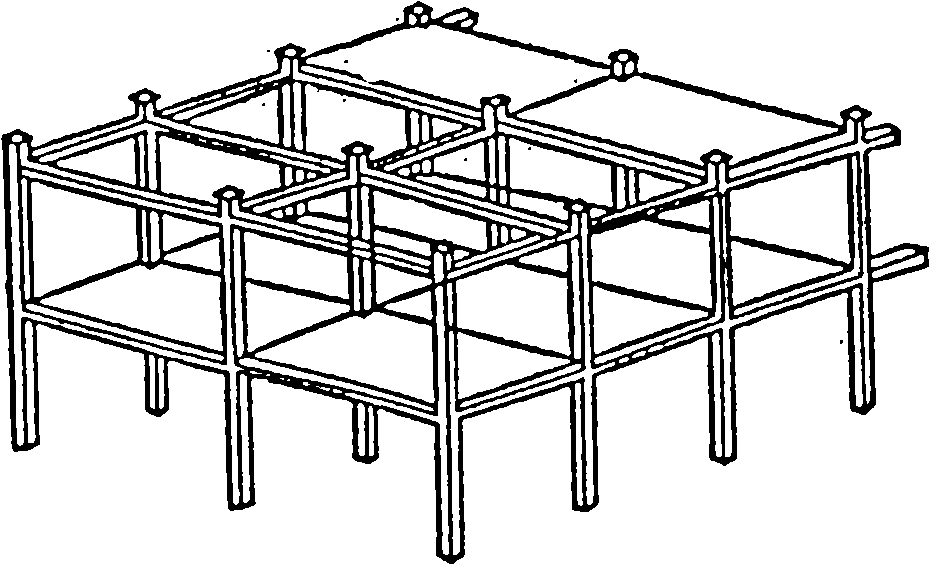

Novel method for quickly assembling low-cost energy-saving house with prefabricated pole, beam, plate

InactiveCN101294419ANo wasteReduce the amount of manual laborBuilding constructionsReinforced concrete columnHigh density

A novel method for rapidly assembling a low-cost energy-saving house with precast columns, beams and slabs comprises the steps of preparing house columns, beam molds and built-in reinforcing steel bars or profiled steel bars, pouring concrete grout into the molds, high-speed rotating in a centrifuge, curing, and demolding to obtain precast reinforced concrete columns and beam components; and inserting the precast columns on a cup foundation element, passing the precast beams through the preformed pores on the precast column, lapping precast floor slabs on the precast beams, and embedding wall slabs inside the embedding grooves of the precast beams, so as to form the major structure of the rapidly assembled low-cost energy-saving house. The inventive method has the advantages of application to industrial production, no air holes in components, high density, high strength, long service life, standardized production, low production cost, low time and raw materials consumption, rapid house construction speed, and high quality; and is a novel energy-saving house construction method in the construction field.

Owner:丁公权 +1

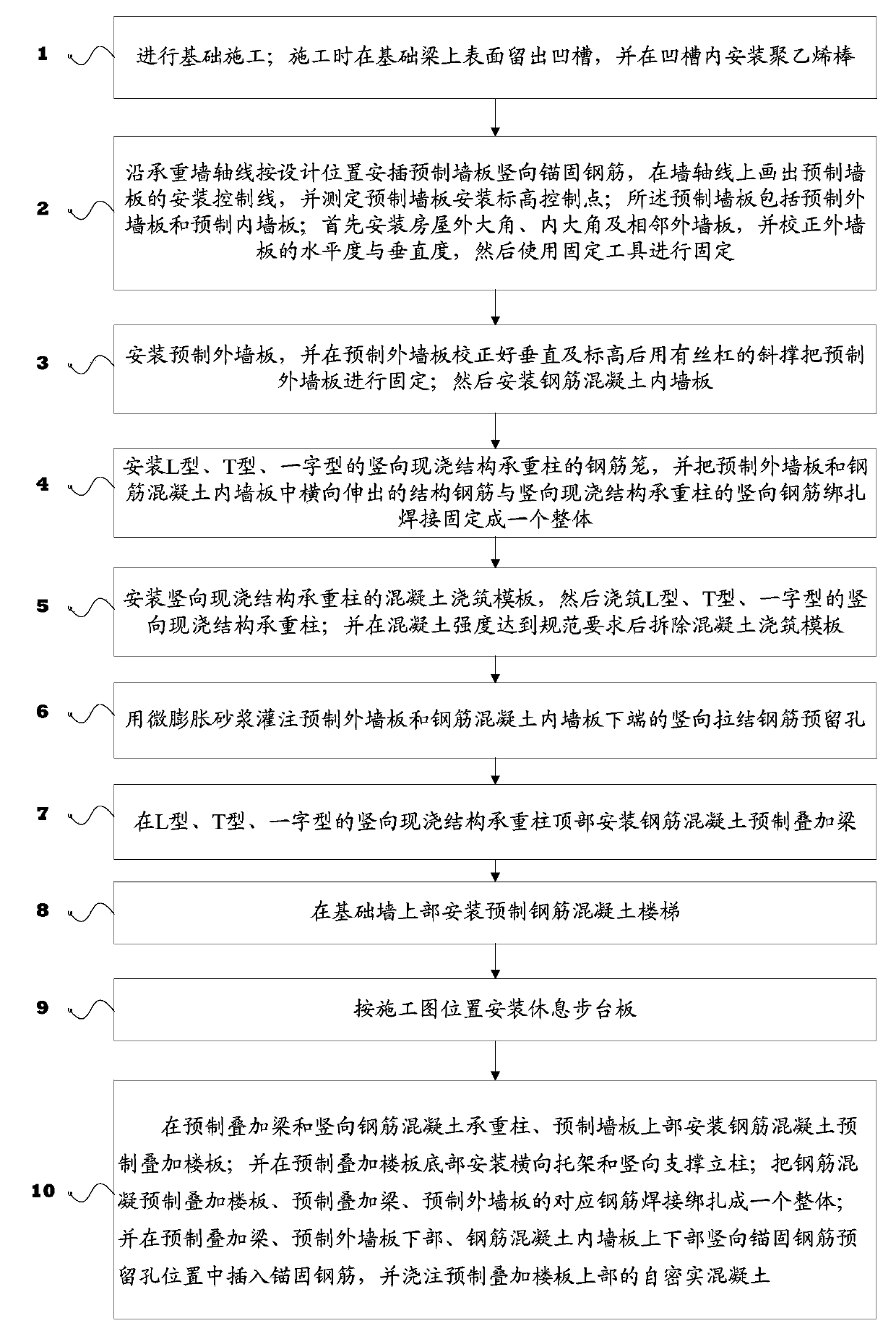

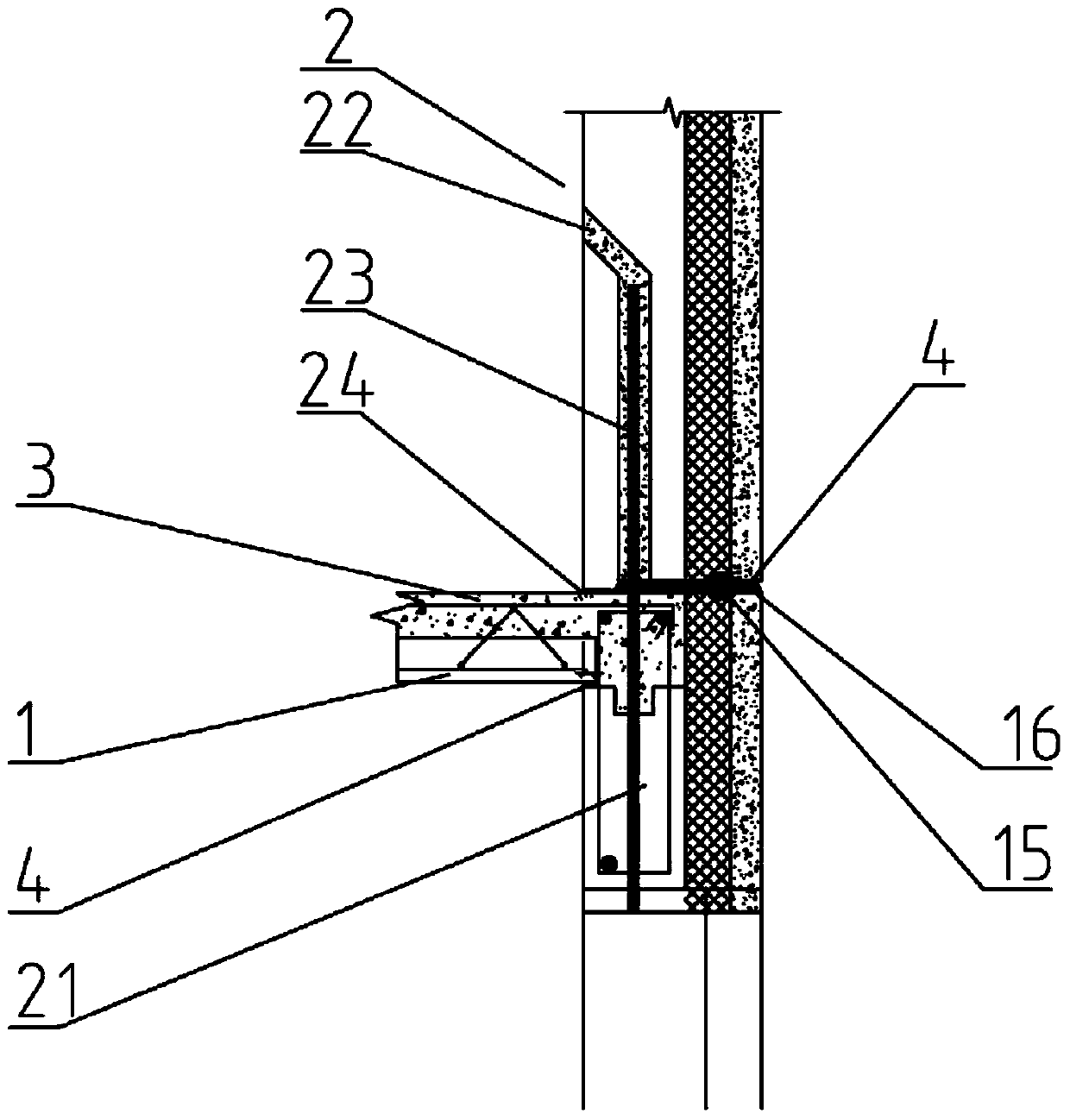

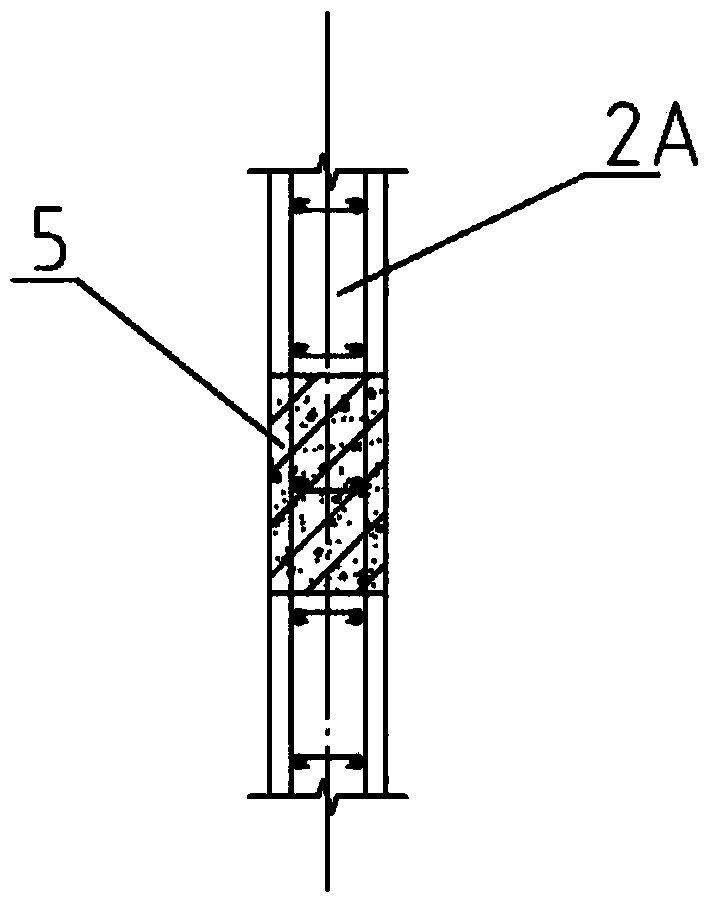

Construction method for reinforced concrete prefabricated house

ActiveCN103422672AImprove construction efficiencyReduce engineering costsBuilding material handlingFloor slabReinforced concrete

The invention provides a construction method for a reinforced concrete prefabricated house. The method comprises the following steps of constructing a foundation; mounting prefabricated wallboards; casting in situ T-shaped, L-shaped and inline vertical heel posts; pouring micro-expansion mortar into vertical steel tie preformed holes in the upper and lower ends of the prefabricated wallboards; mounting reinforced concrete prefabricated superimposed beams; mounting reinforced concrete prefabricated stairs and flat stepping plates; mounting prefabricated superimposed floor slabs on the prefabricated superimposed beams; welding and binding corresponding reinforcements exposed from the prefabricated superimposed floor slabs, the upper ends of the prefabricated superimposed beams and the prefabricated wallboards into a whole, and inserting vertical anchor bars for fixing the upper and lower end parts of the prefabricated superimposed beams and the wallboards, and casting self-compacting concrete on the upper parts of the prefabricated superimposed floor slabs. A 100m-high building can be constructed in an 8 earthquake fortification region such as Beijing by sequential and cyclic construction to a design top layer from bottom to top. According to the method, a technical index of building energy efficiency of 75 percent can be achieved, and the development of a prefabricated house construction technology can be accelerated.

Owner:洪都建设集团有限公司

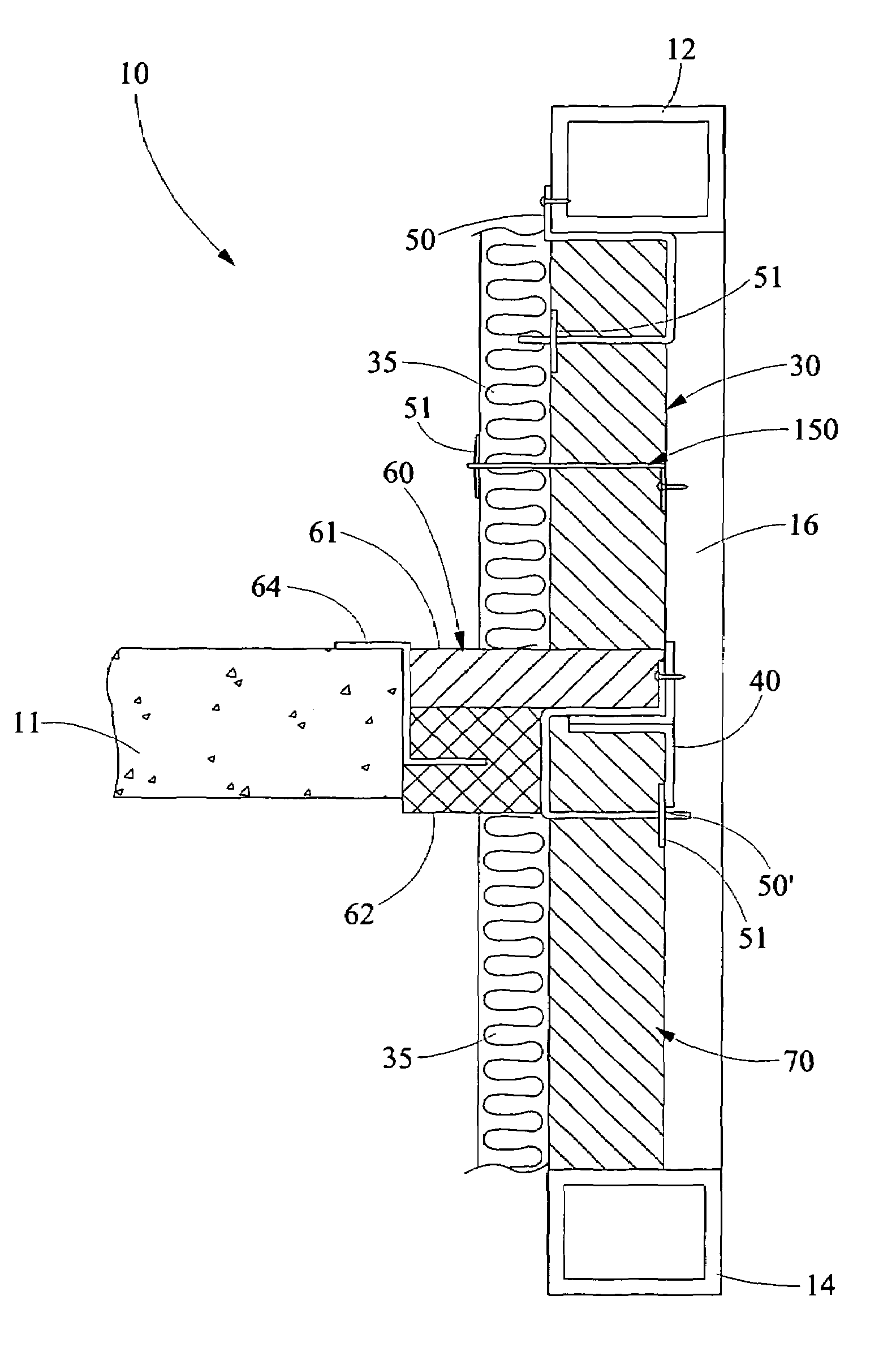

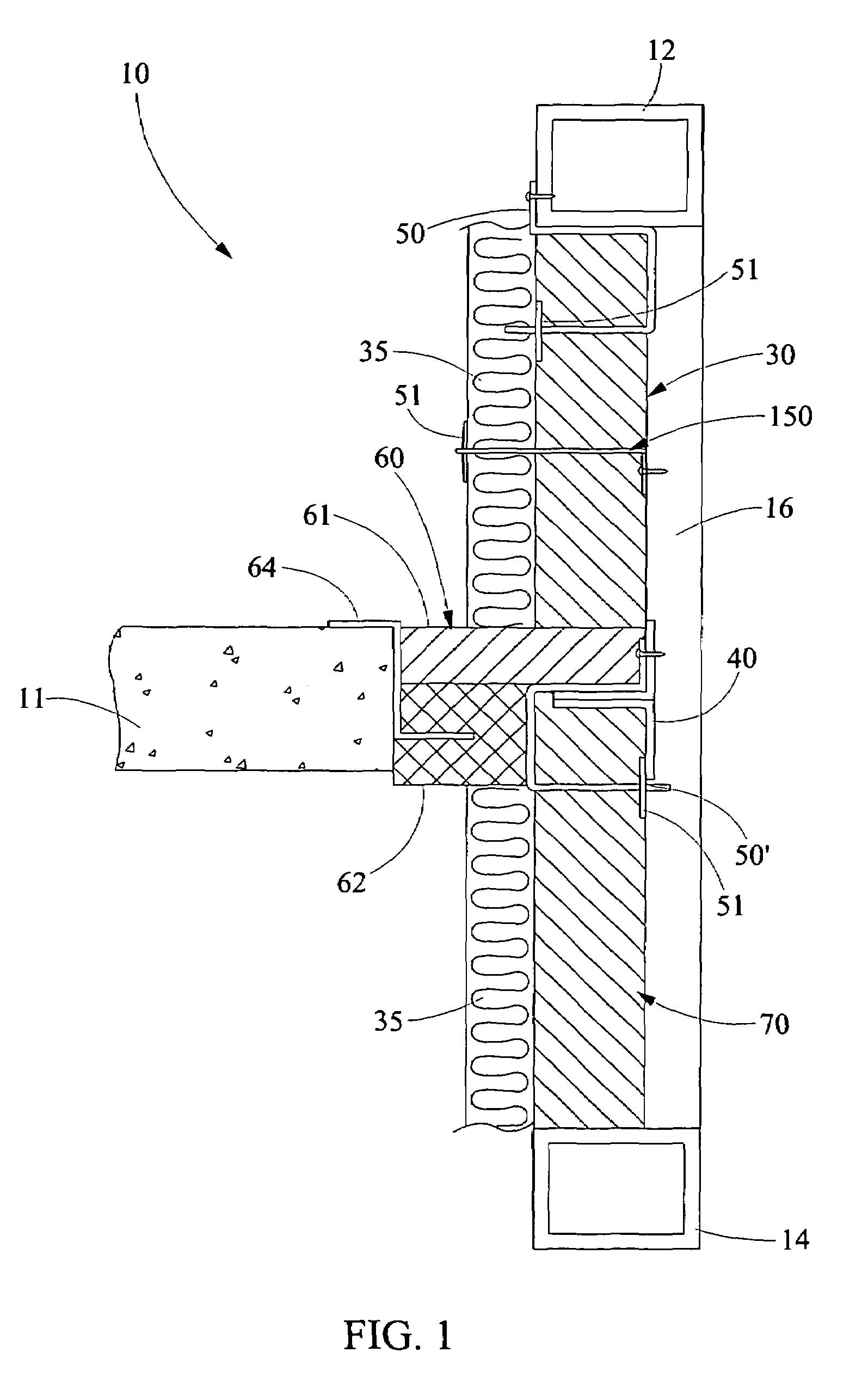

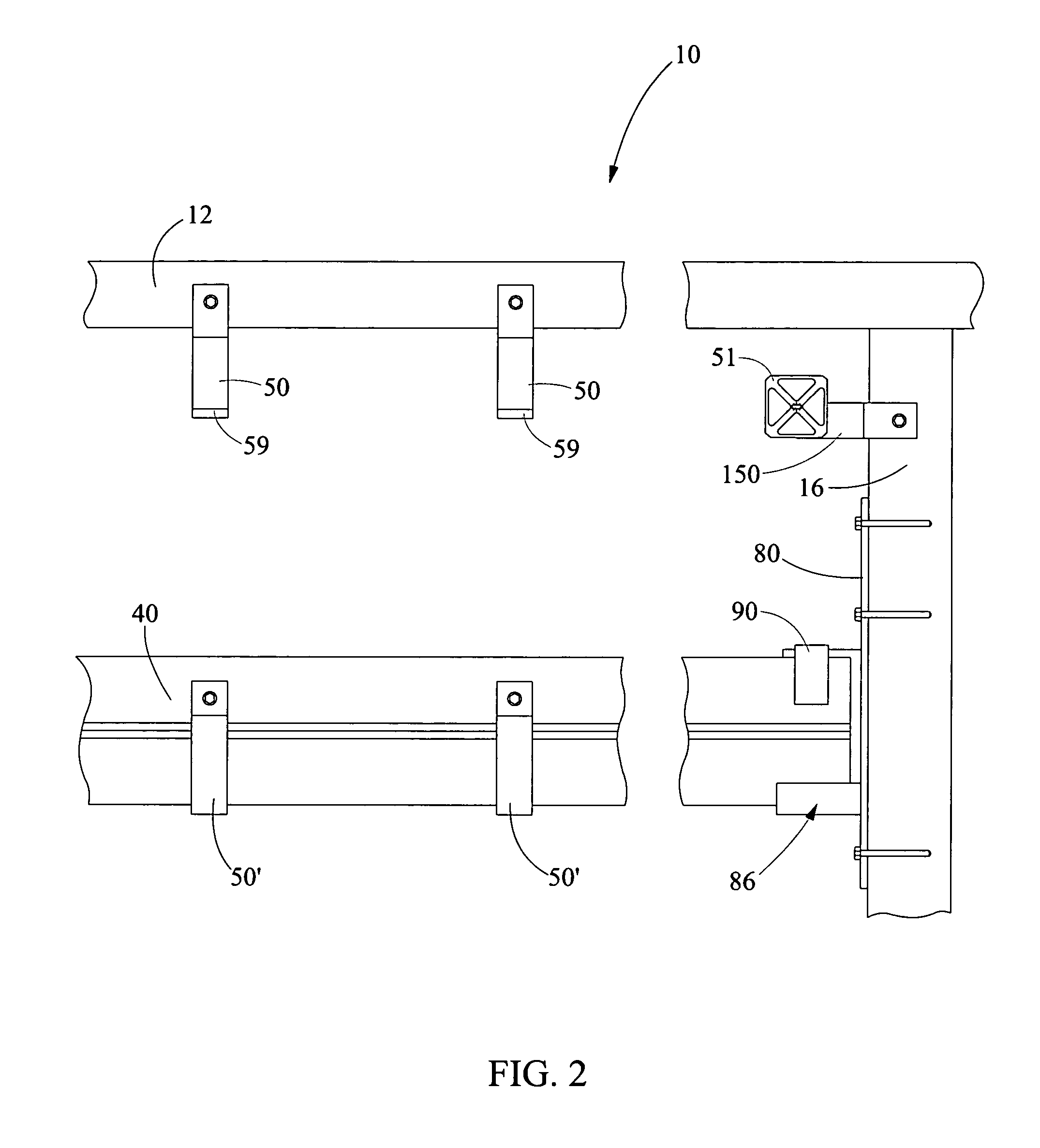

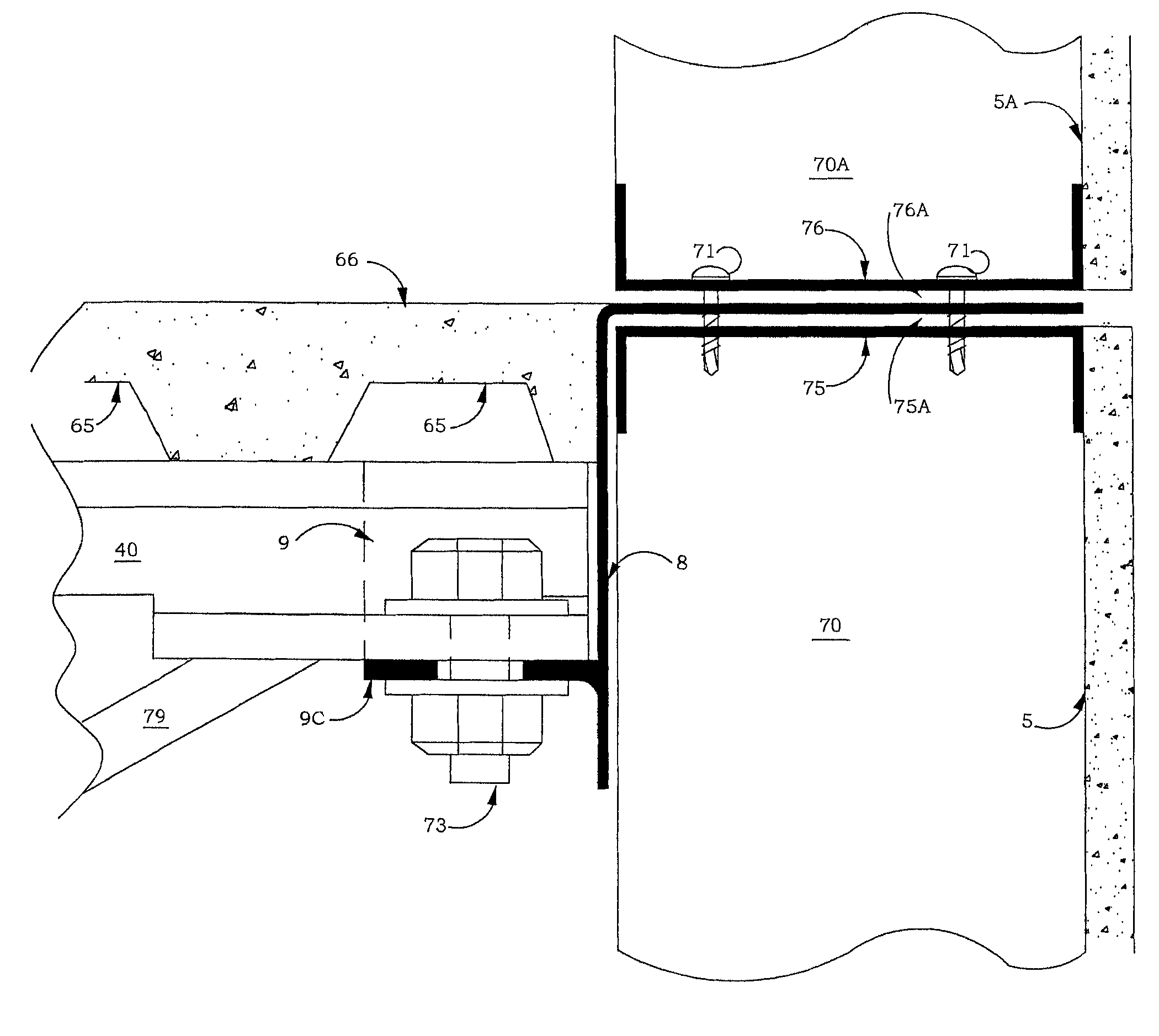

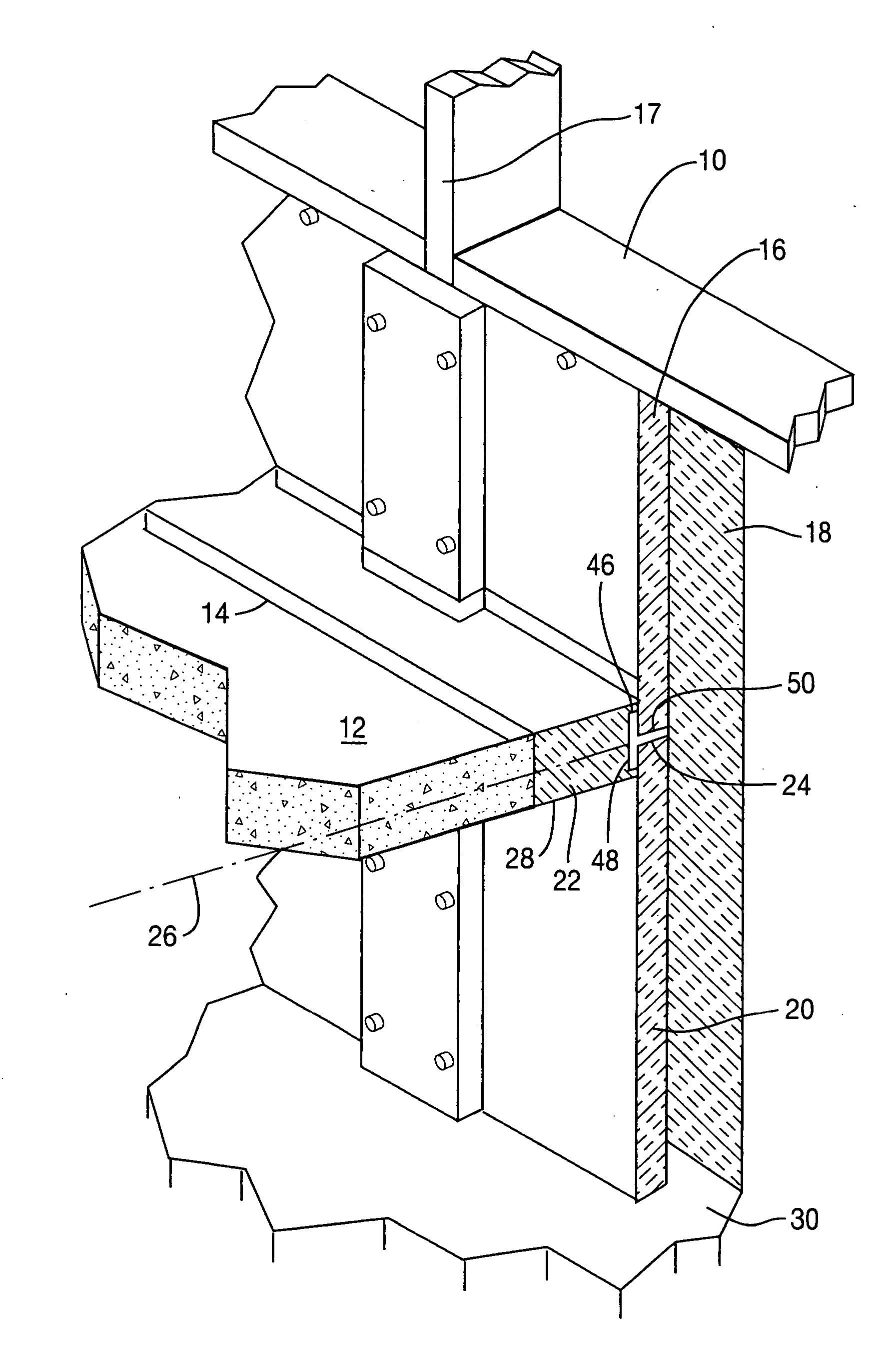

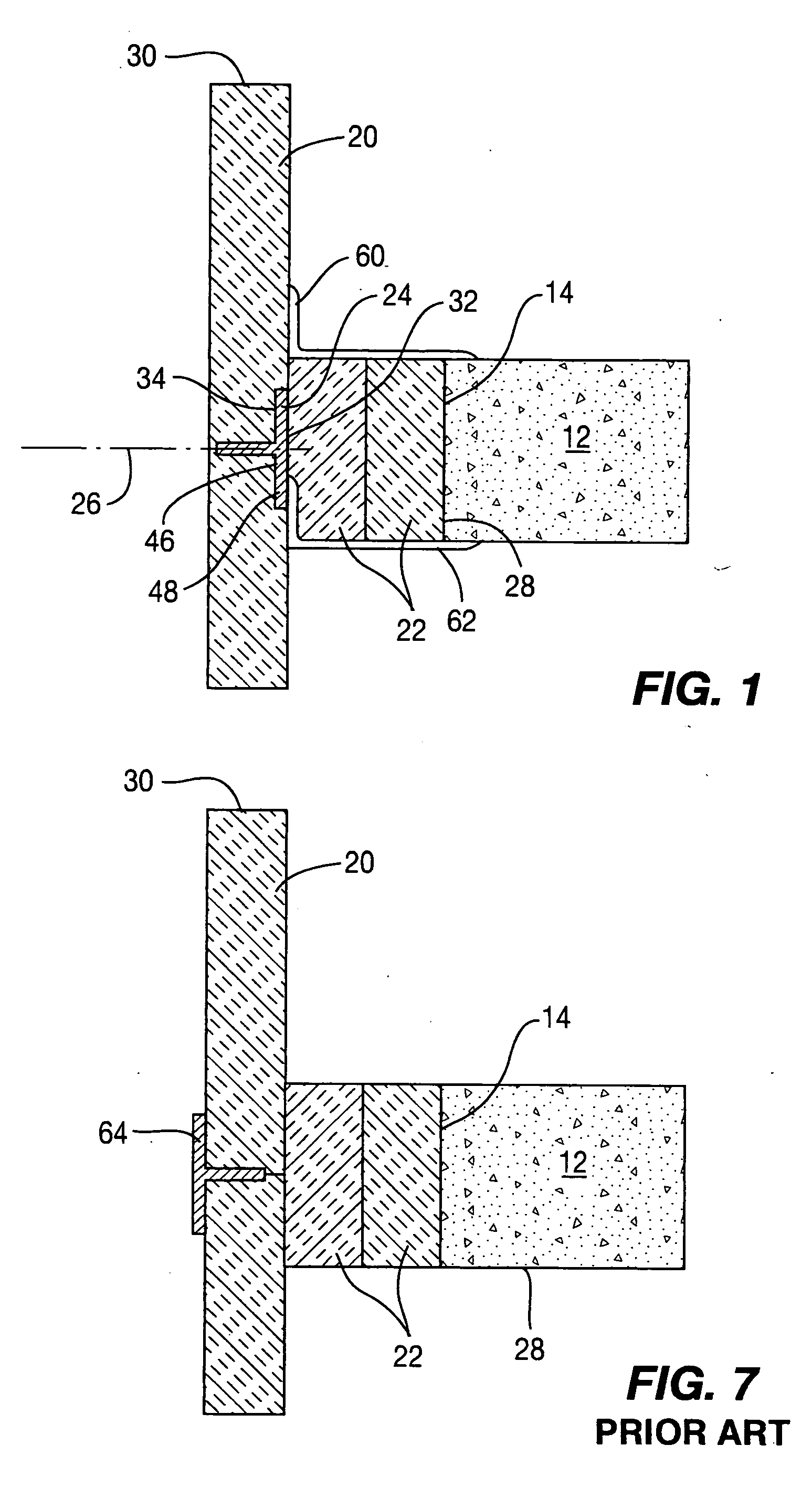

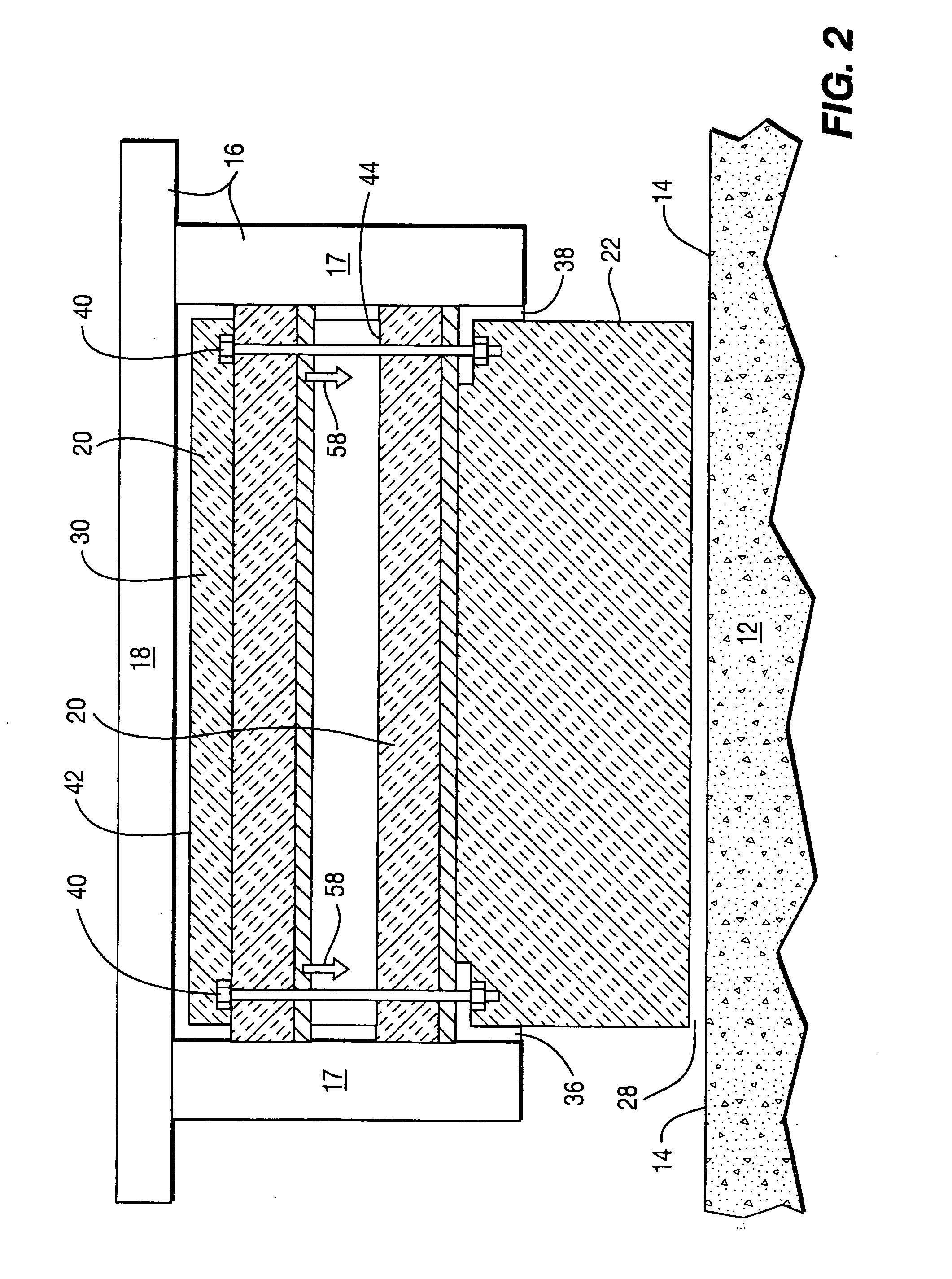

Interlocking curtain wall insulation system

ActiveUS7424793B1Maintain structural integrityEliminates oversight and difficulty and disadvantageWallsPublic buildingsFloor slabEngineering

The interlocking curtain wall insulation system comprises a frame connected to a building structure having at least first and second parallel transoms, at least first and second parallel mullions, the at least first and second parallel transoms operably engaging the at least first and second parallel mullions. The device further comprises an insulation including a safing insulation extending between a floor slab and the backer bar and compressively fit therein, an upper curtain wall insulation depending from an upper insulation hanger and compressing the safing insulation, and a lower curtain wall insulation depending from a lower insulation hanger.

Owner:THERMAFIBER

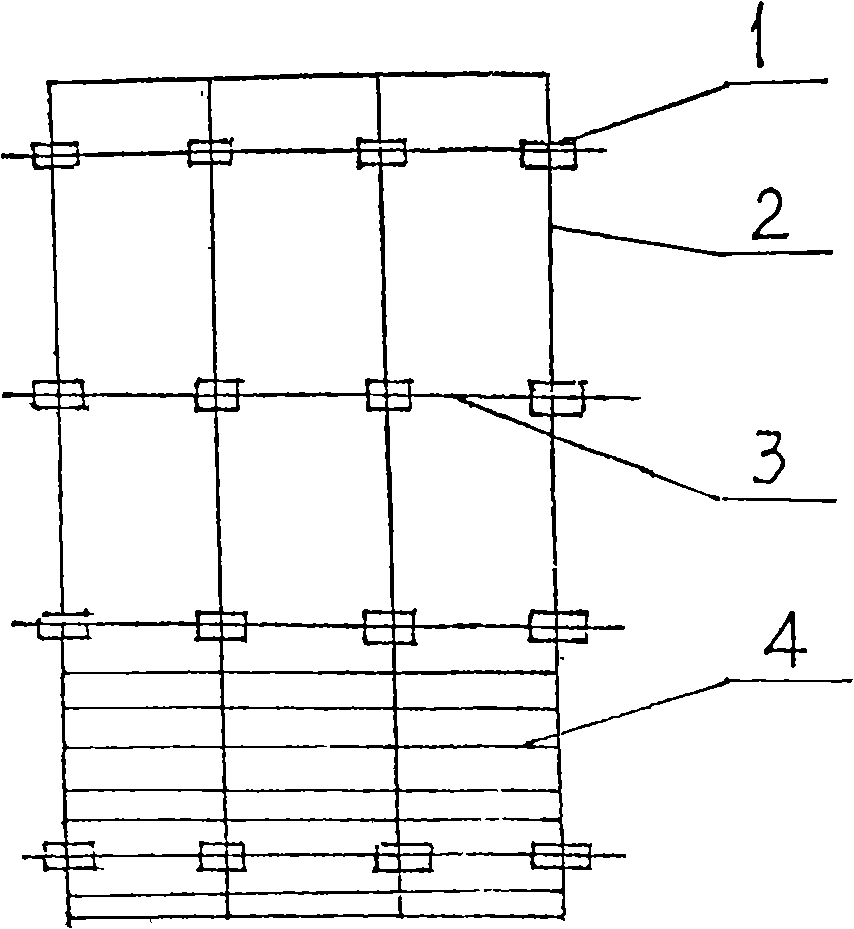

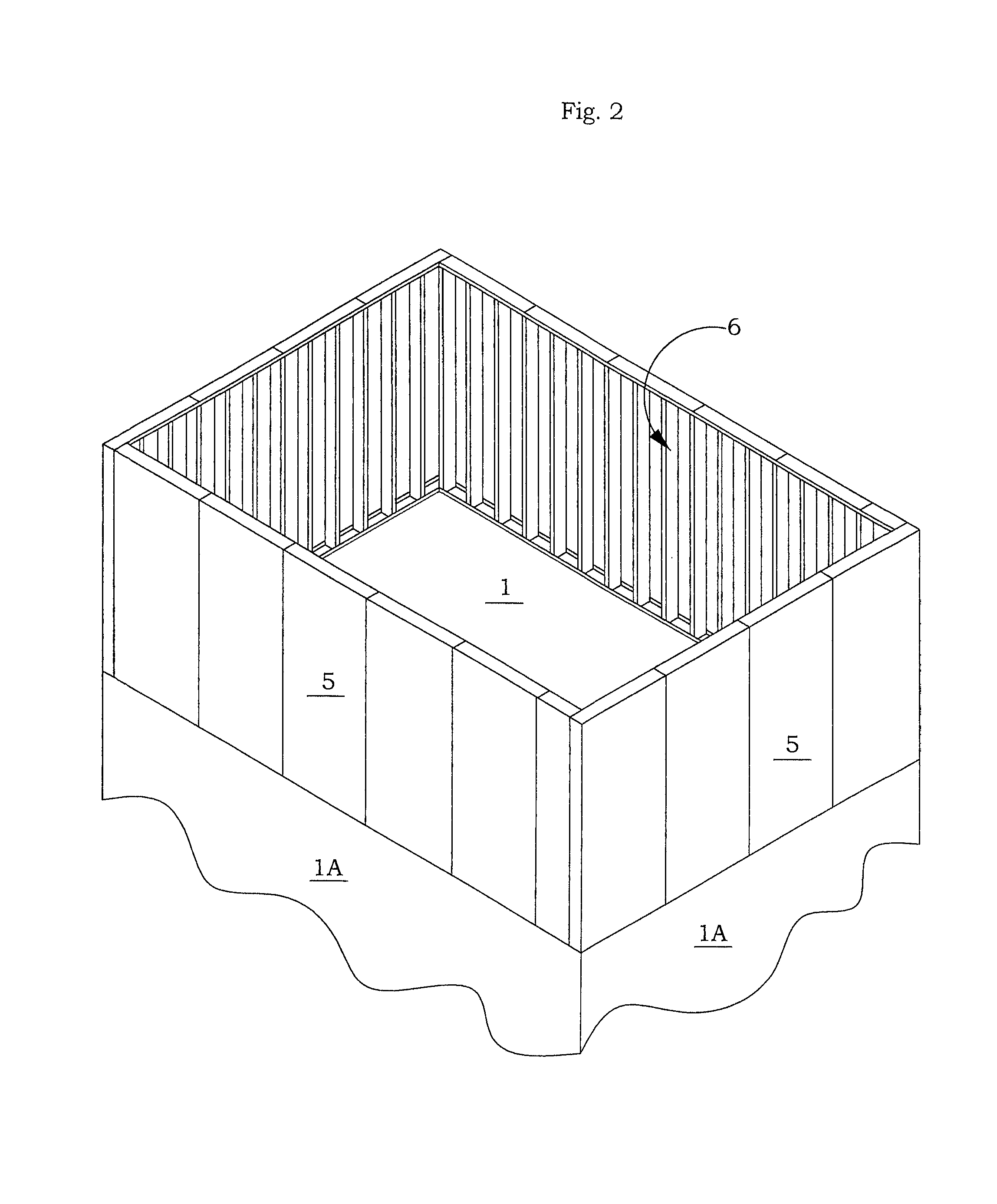

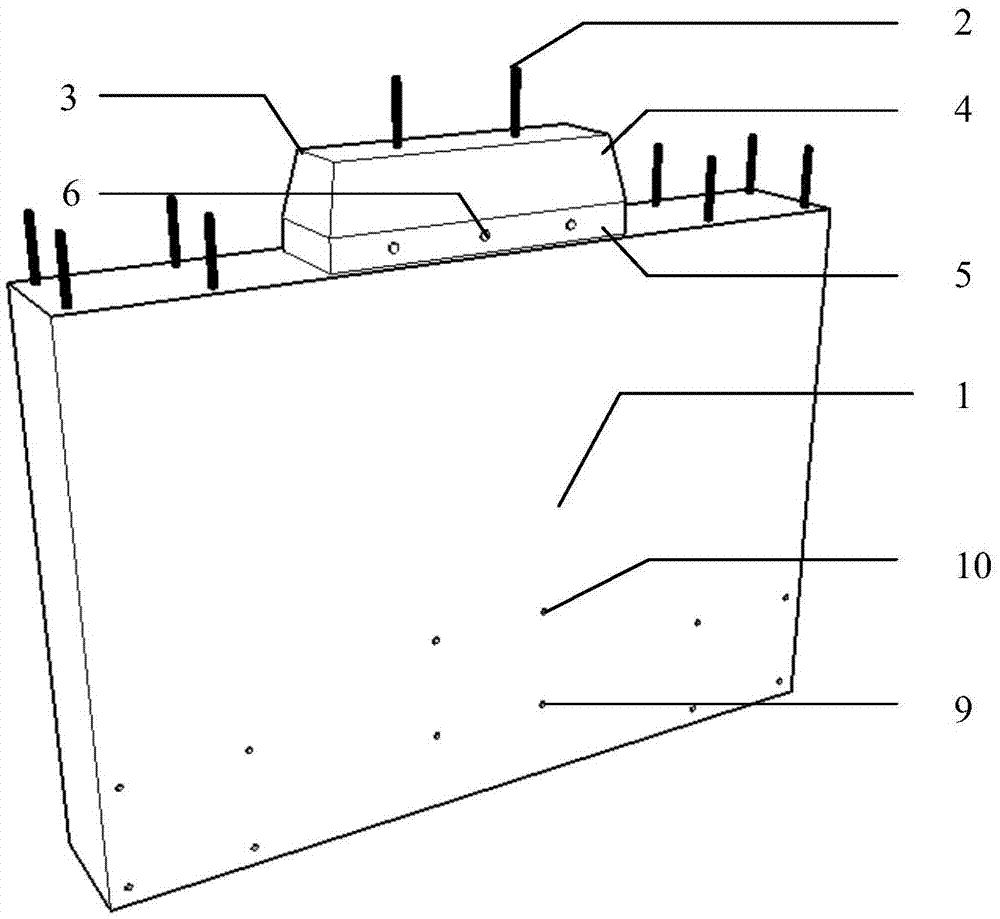

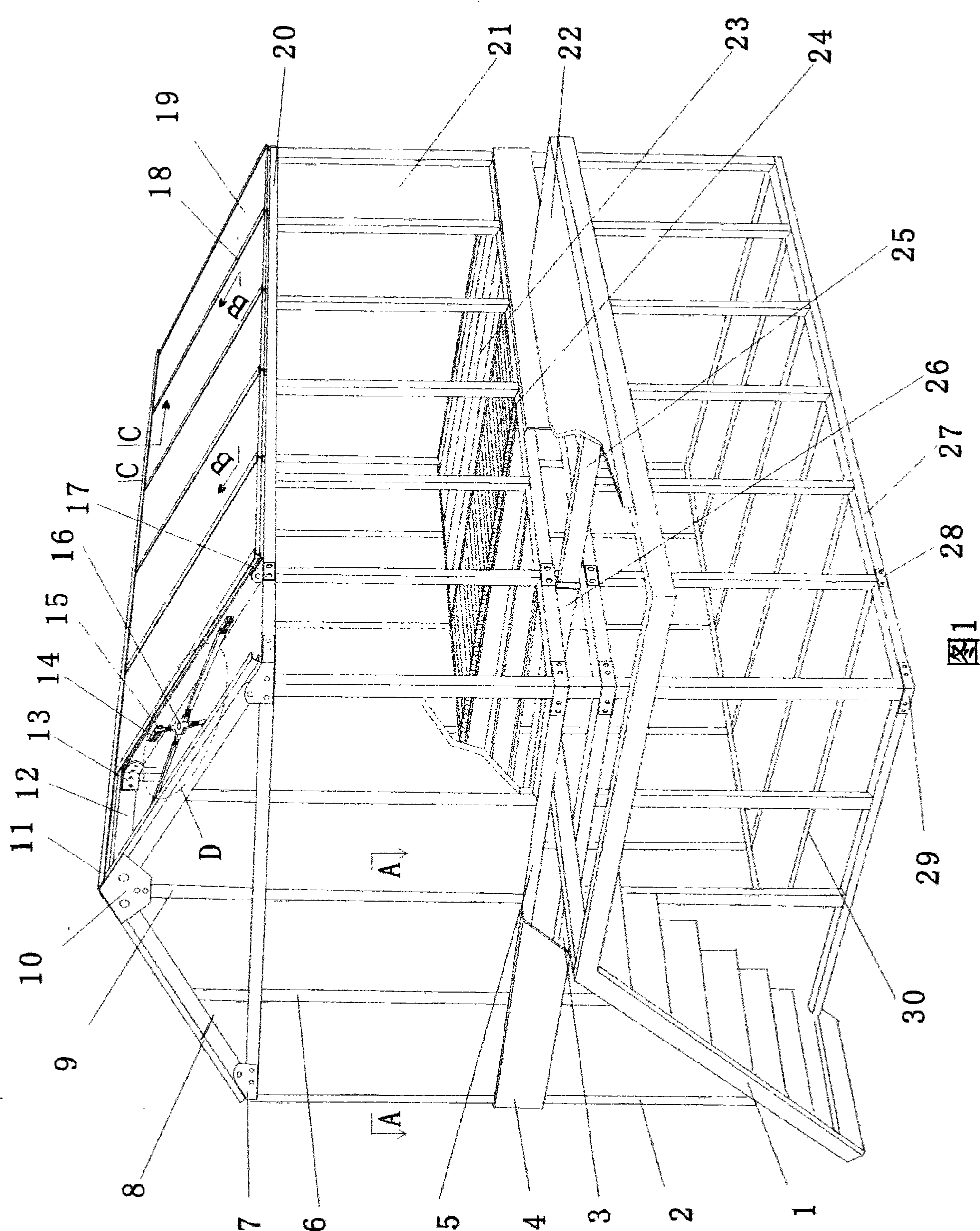

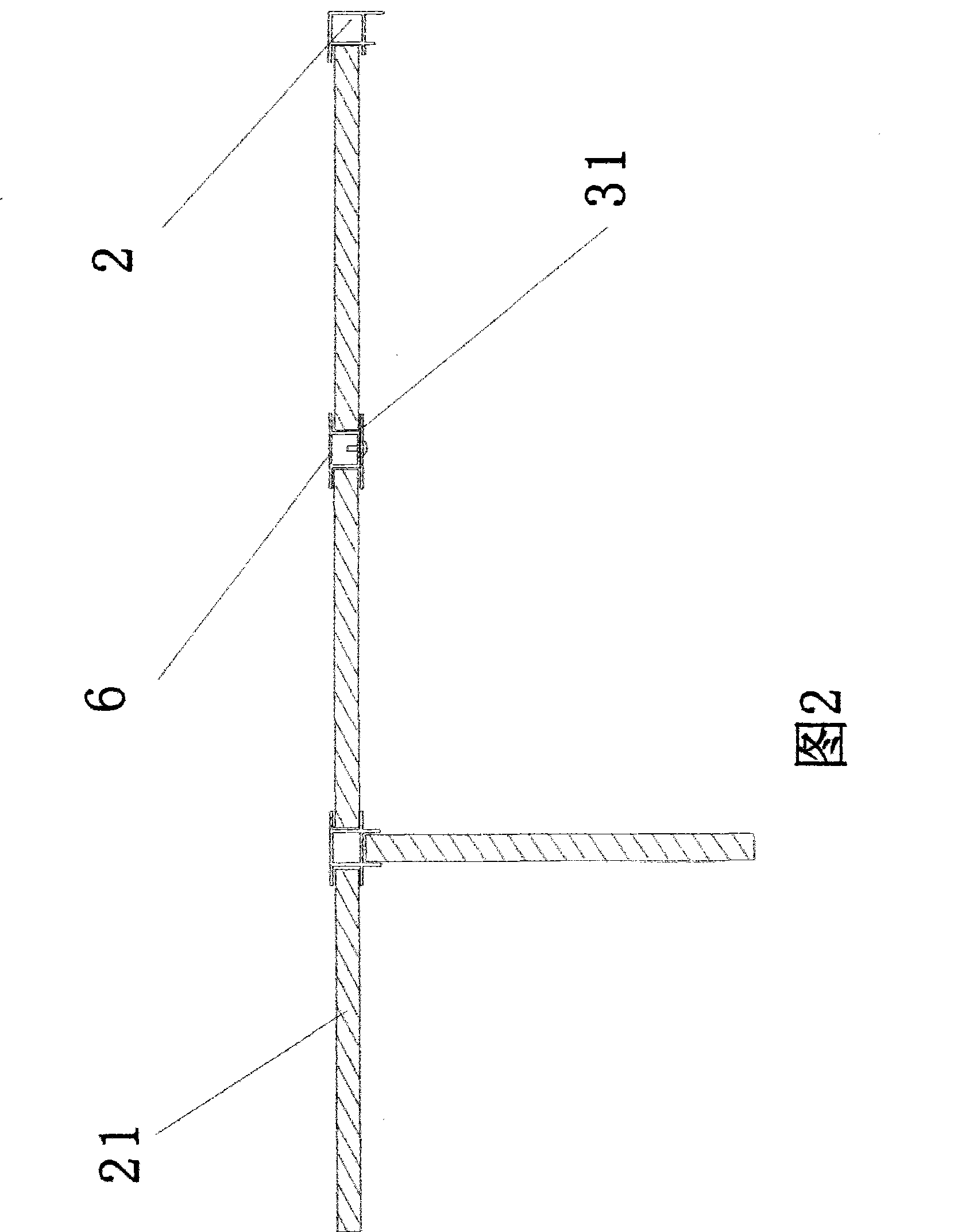

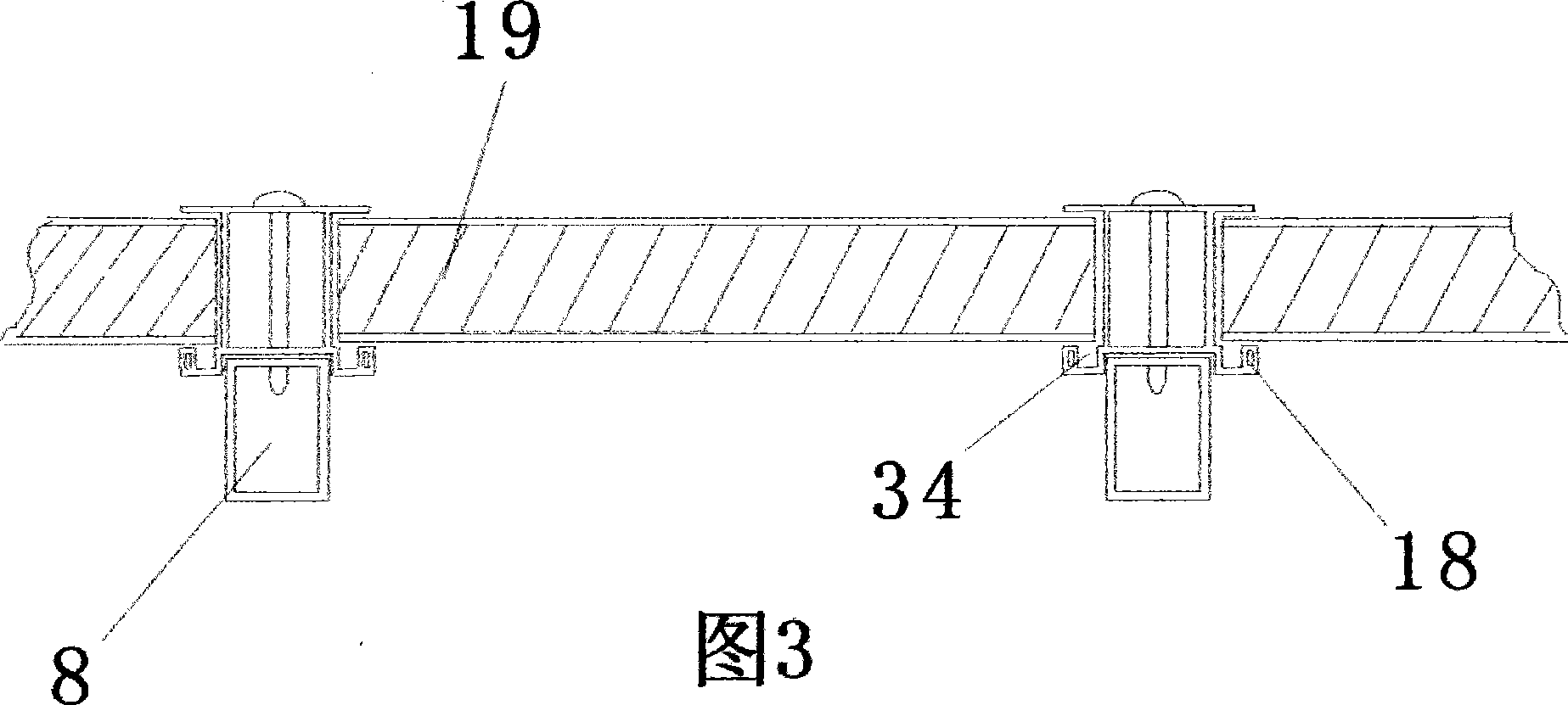

Assembled integral building and construction method thereof

ActiveCN101818539AGuarantee the construction qualityLow costBuilding componentsBuilding material handlingFloor slabReinforced concrete

The invention discloses an assembled integral building and a construction method thereof. The assembled integral building comprises a reinforced concrete wall and floor slabs, wherein the reinforced concrete wall is formed by hoisting and assembling prefabricated composite insulating wallboards integrally at a construction site; a board body of each prefabricated composite insulating wallboard comprises a structure layer, an insulating layer and a protective layer from the inside to the outside in turn; a reinforcement cage is arranged in the structural layer; steel meshes are arranged in the concrete of the protective layer; the structural layer, the insulating layer and the protective layer are anchored together by inserting connecting members in a dotted distribution; the left and right edges of the protective layer and the insulating layer protrude out of the structural layer; a lower edge of the protective layer extends downward to form a bulged opening; the top parts of the protective layer and the insulating layer upward protrude out of the structural layer; and an upper edge of the protective layer is provided with a notch which corresponds to the bulged opening of the prefabricated composite insulating wallboard adjacent to an upper layer. The building overcomes the defects of erecting shuttering on site, binding steel bars and concreting in a traditional construction method, speeds up the construction, and lowers the construction cost; and the construction quality of the building structure can be sufficiently guaranteed.

Owner:雄安万科绿色研发有限公司

Express framing building construction system

A light steel framing construction technique for light gauge load bearing wall type buildings uses specialized brackets to suspend poured slab floors. Multiple stories of the building can be erected without waiting for individual concrete slab floors to be poured and set at each story. During construction, a building is protected from torsional warping, such as may be occur under wind loads, by a series of lateral and diagonal bracing structures at each level affixed in a plane perpendicular to the load bearing elements. Multiple concrete floor slabs can be poured sequentially or simultaneously, as desired, during the construction process.

Owner:SUN REALTY SERVICES

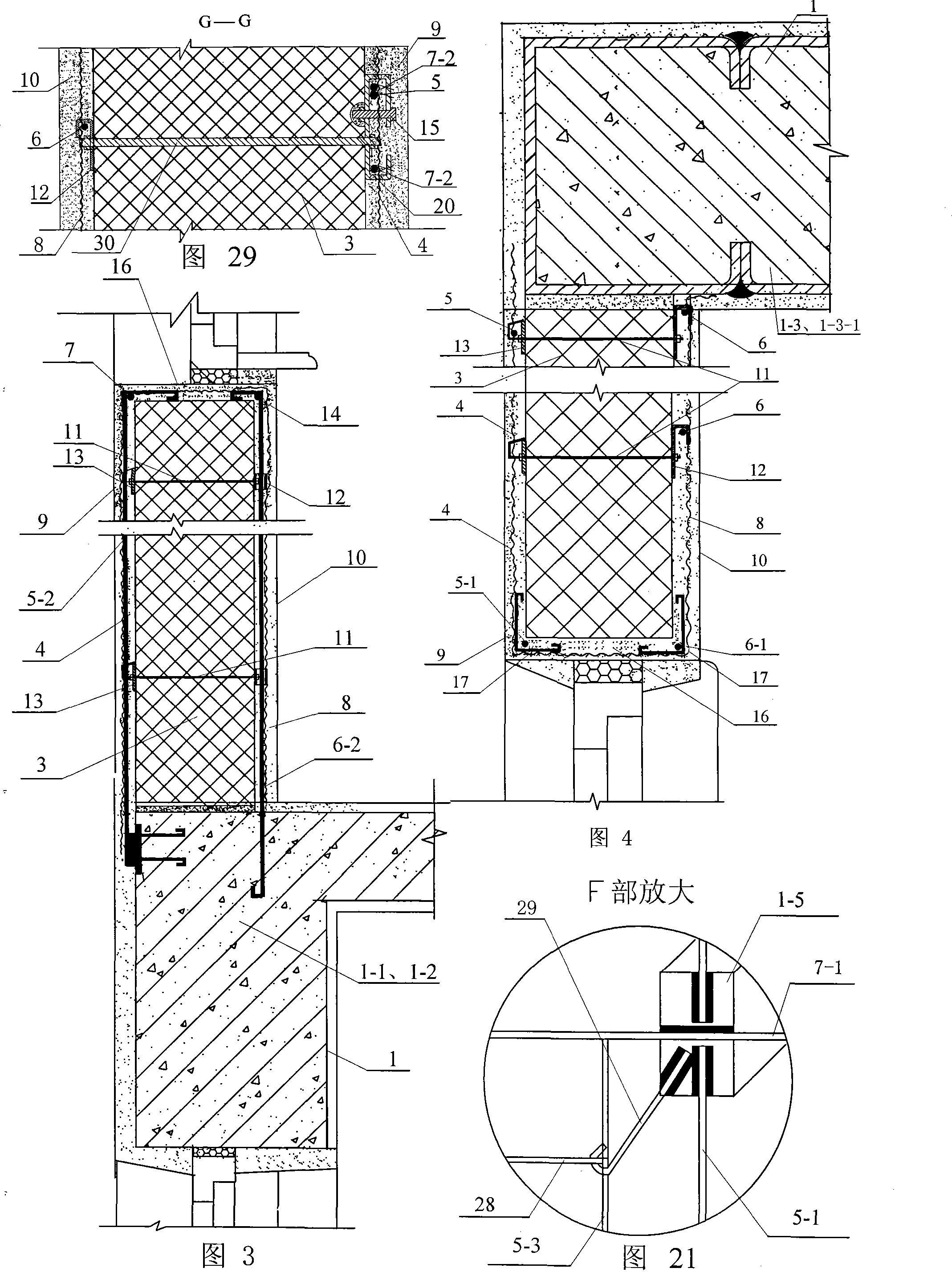

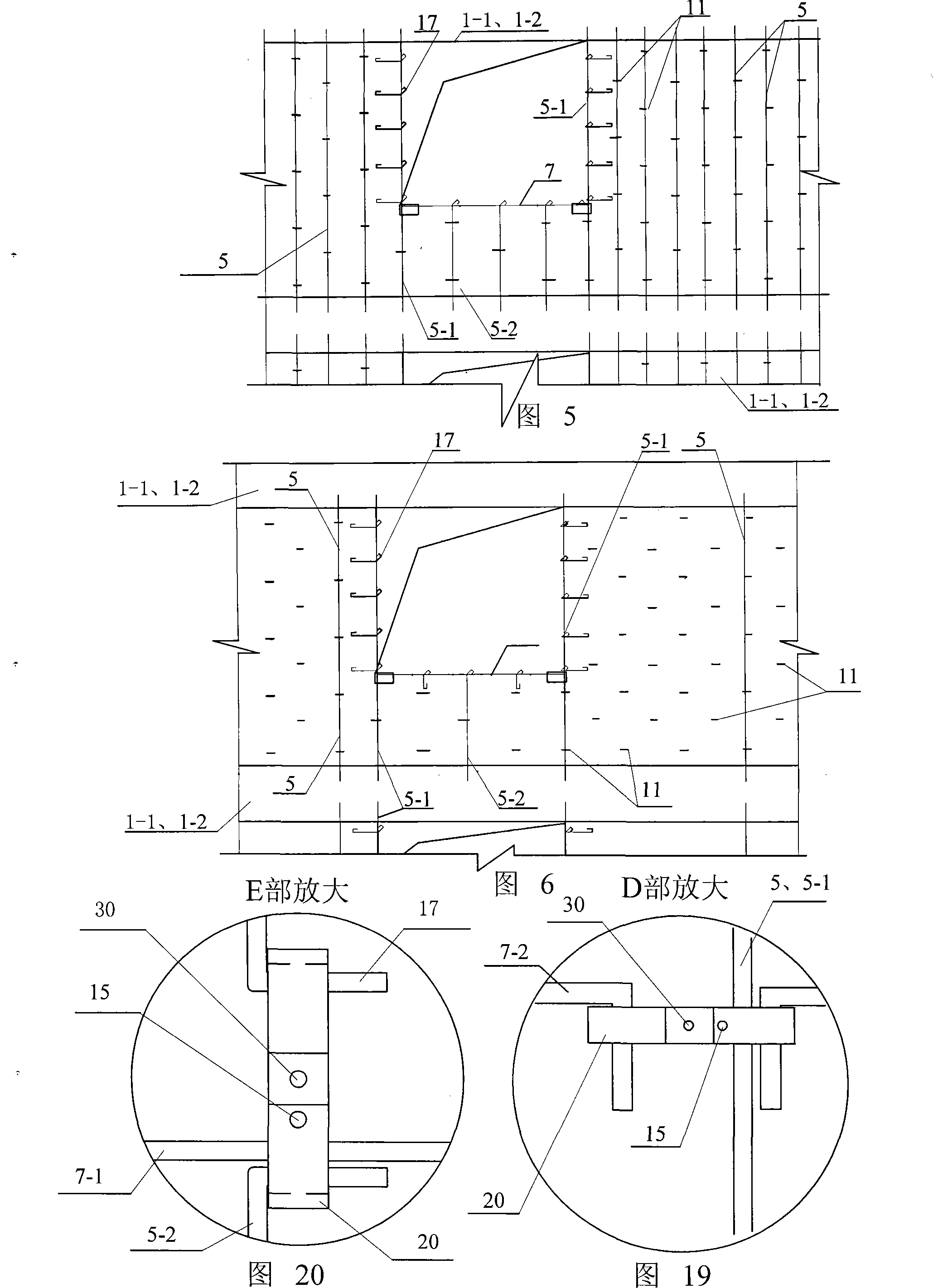

Plastering composite wall with reinforcing steel bar and/or metal net equipped at inter and outer or two-side

InactiveCN101168977AImprove securityImprove mechanical performanceCovering/liningsWallsFloor slabRebar

The utility model relates to a compound wall with reinforcing bars and / or metal mesh plastering on the inside and outside or on both sides, which relates to a building compound wall. Aiming at the incomplete structure of the bundled composite thermal insulation wall with support. Option 1: Outdoor vertical steel bars (5) and indoor vertical steel bars (6) are fixed to the outside and inside of the load-bearing member (1) of the main building structure, and the inner and outer sides of the core layer (3) are provided with inner and outer protection plan 2: the vertical steel bar (5-2) under the outdoor window sill and the vertical steel bar (6-2) under the indoor window sill are fixed to the cantilever plate (1-2); plan 3: indoor The vertical reinforcement (6) is fixed to the indoor floor of the load-bearing member (1) of the main structure of the building; scheme 4: the indoor vertical reinforcement (6) on both sides of the air layer, and the inner and outer sides of the indoor metal mesh are provided with protective layers (10 -1), the air layer (3-1) is located between the protective layers (10-1) on both sides. The invention has the advantages of good earthquake resistance, good wind load resistance, low cost, convenient construction, good safety of the outer decorative surface layer, increased indoor usable area, and meets the requirements of low energy consumption buildings.

Owner:吴淑环

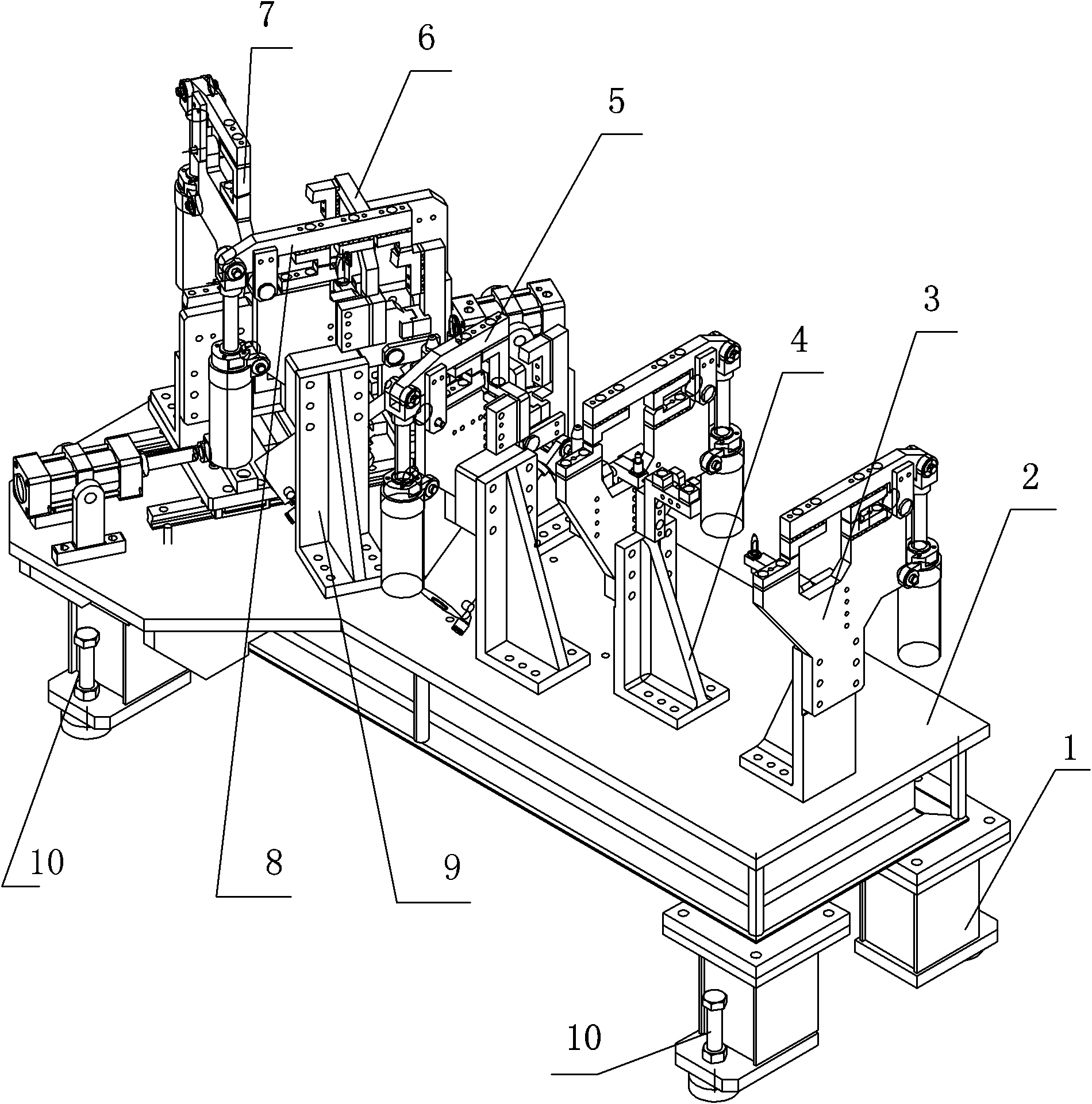

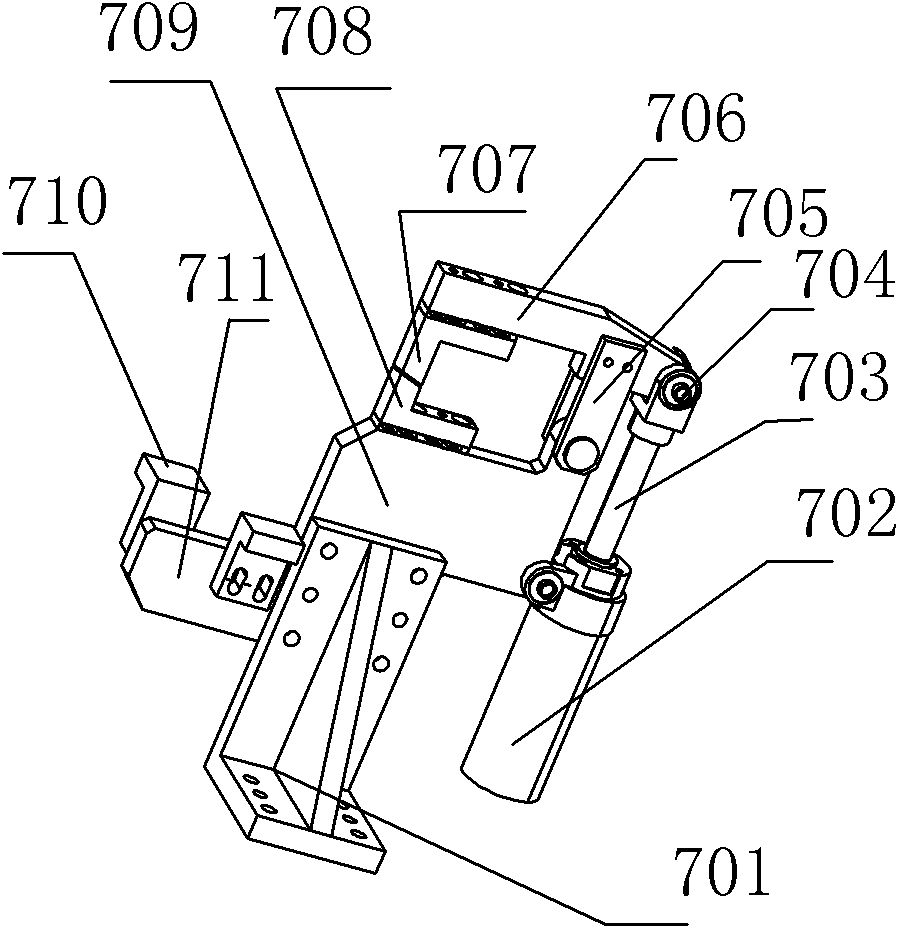

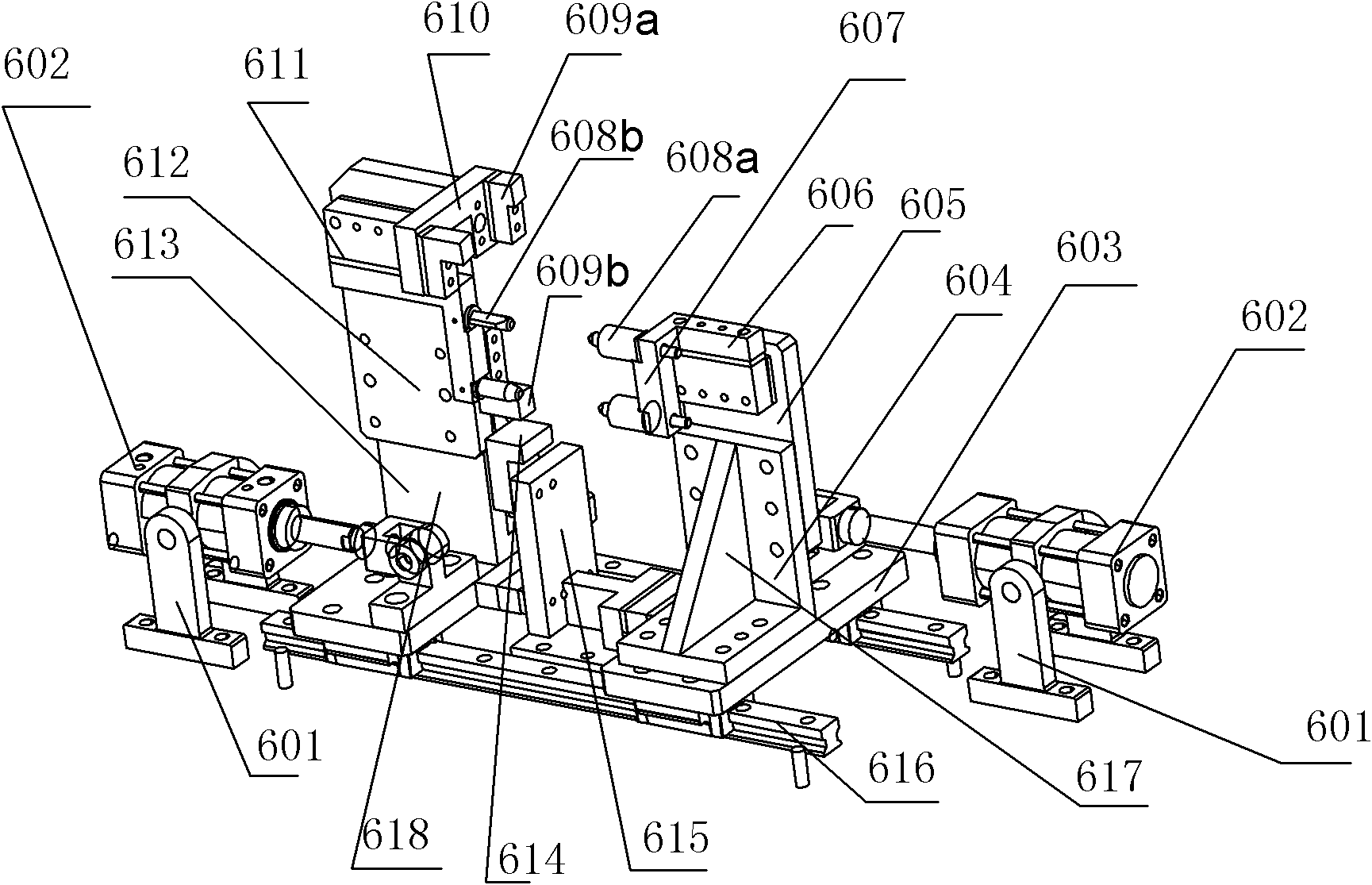

Clamp for longitudinal beam of rear floor slab of automobile

InactiveCN102248346ASolve tack weldingEnsure consistencyWelding/cutting auxillary devicesAuxillary welding devicesFloor slabStructural engineering

The invention discloses a clamp for of a longitudinal beam of a rear floor slab of an automobile, comprising support legs and a support table fixed on the support legs, wherein a sliding and clamping device and a plurality of positioning and clamping devices are arranged on the support table, wherein the sliding and clamping device is used for fixing parts to be welded on the longitudinal beam of the rear floor slab; the positioning and clamping devices are used for fixing the longitudinal beam of the rear floor slab and the parts to be welded on the longitudinal beam of the rear floor slab; each positioning and clamping device comprises a first angle seat, a fist template fixedly connected with the first angle seat and a clamping arm which is rotationally matched with the first template; first positioning pins which are matched with mounting hole sites on the longitudinal beam of the rear floor slab are arranged on the at least one first angle seat in the positioning and clamping device; the sliding and clamping device comprises a second angle seat and a second template which is fixedly connected with the second angle seat; and second positioning pins matched with the mounting hole sites of the parts to be welded on the longitudinal beam of the rear floor slab are arranged on the second template. According to the clamp, clamping and welding the longitudinal beam of the rear floor slab of the automobile can be realized, the positioning and welding the longitudinal beam of the rear floor slab of the automobile are effectively solved and the welded consistency is ensured.

Owner:ZHEJIANG JINGANG AUTOMOBILE +1

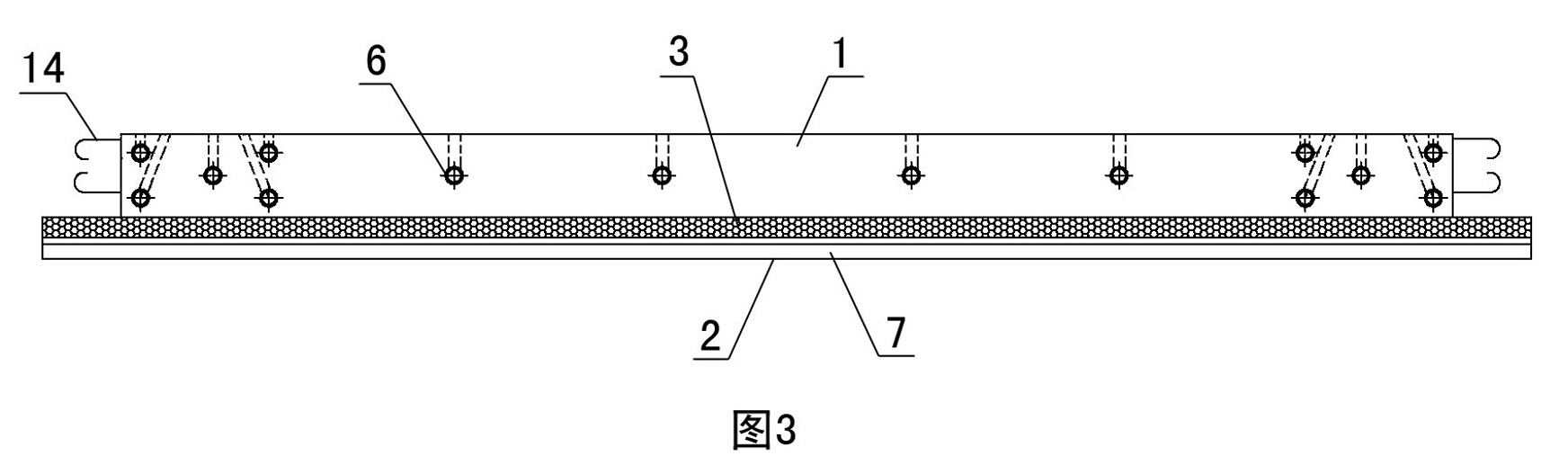

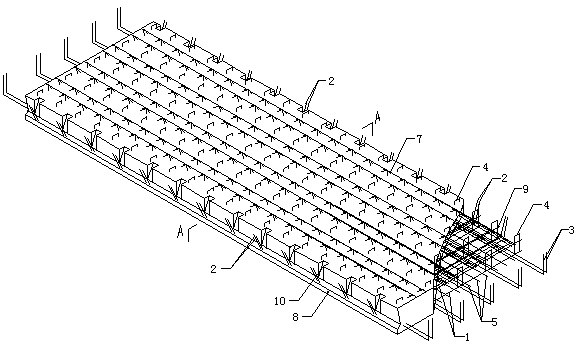

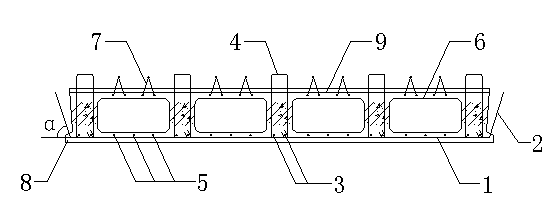

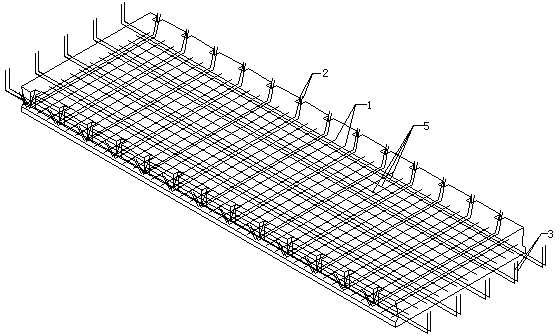

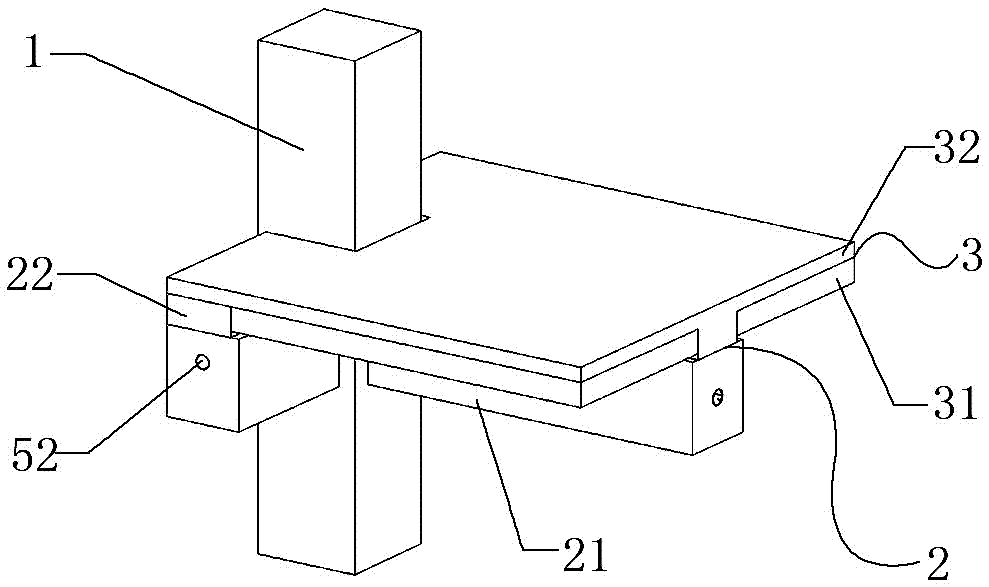

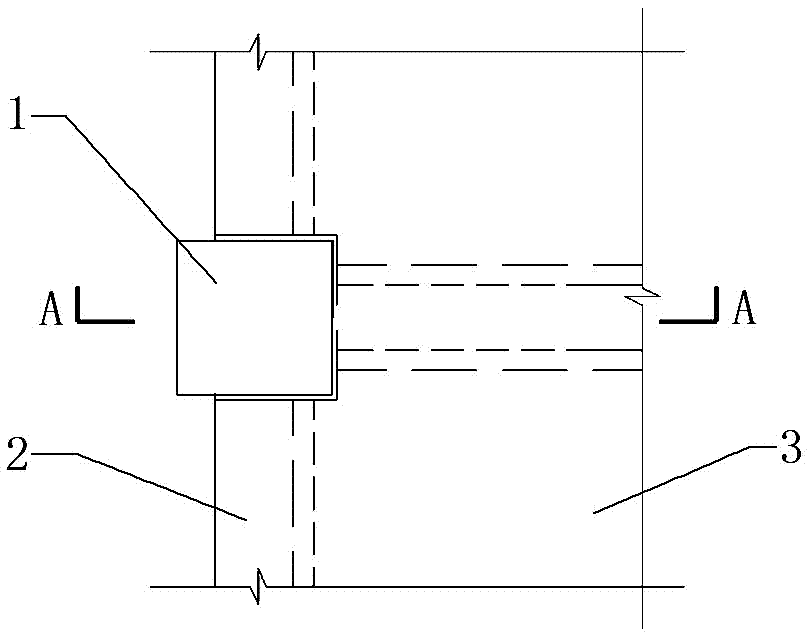

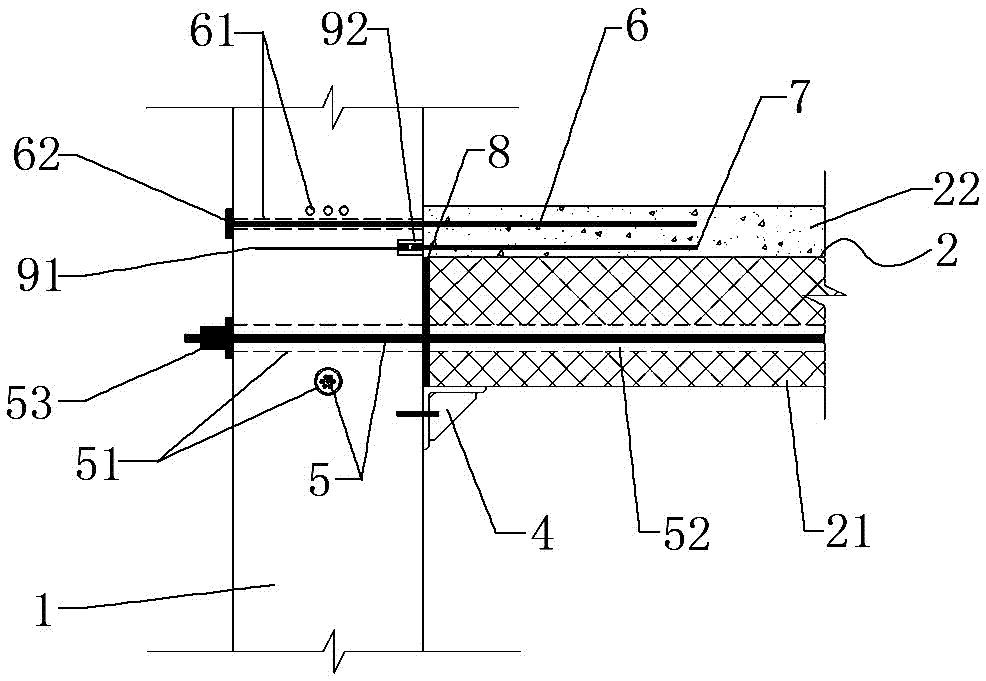

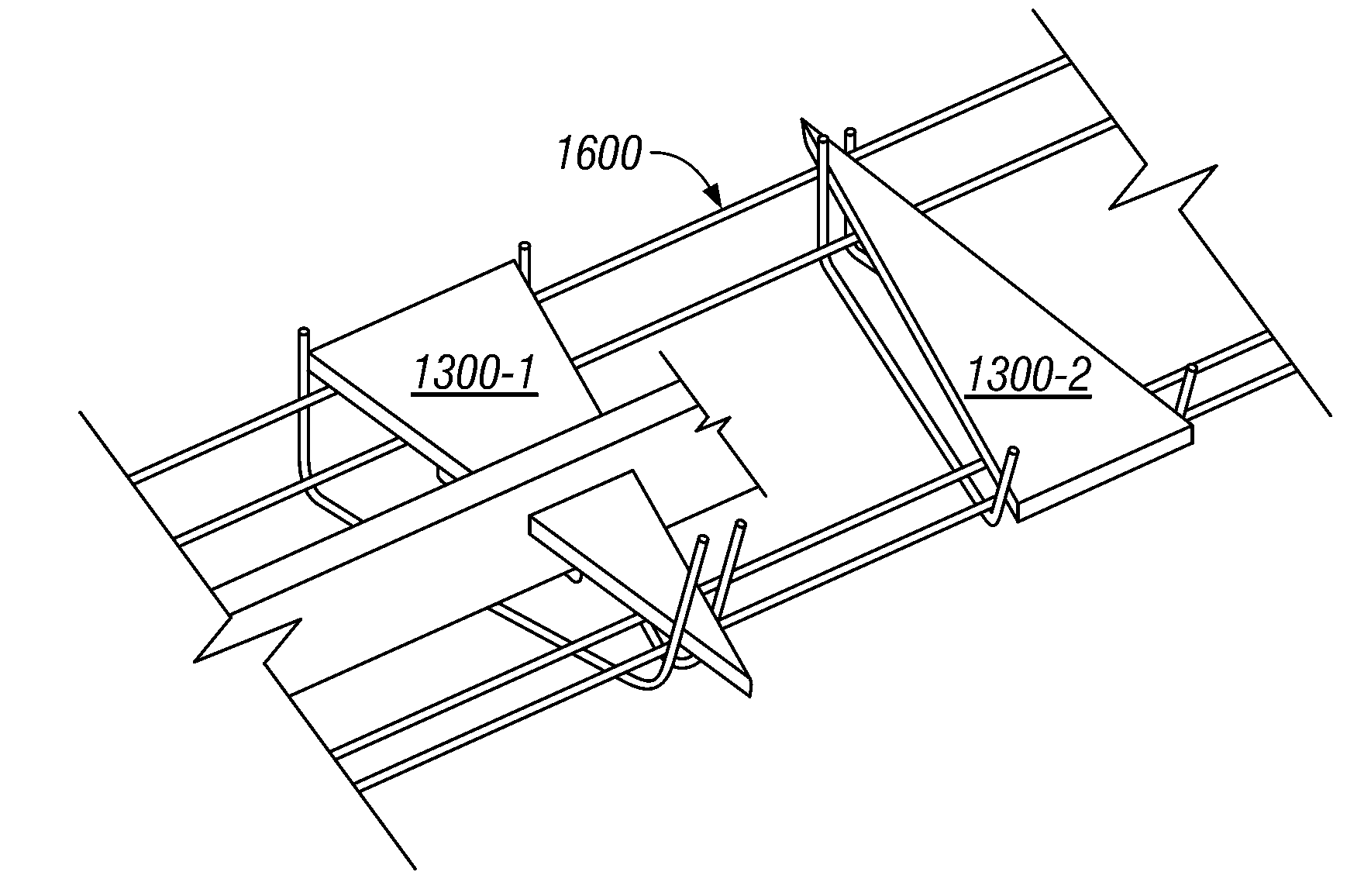

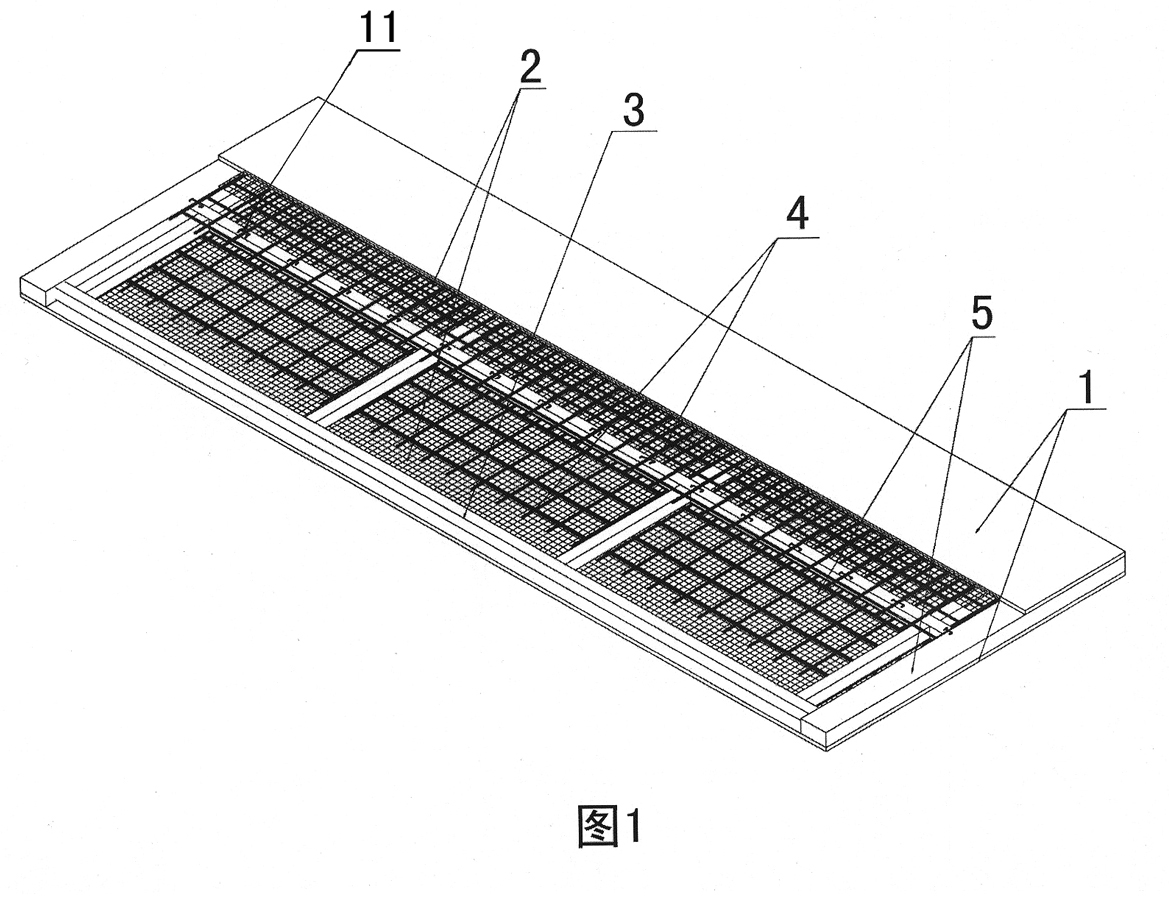

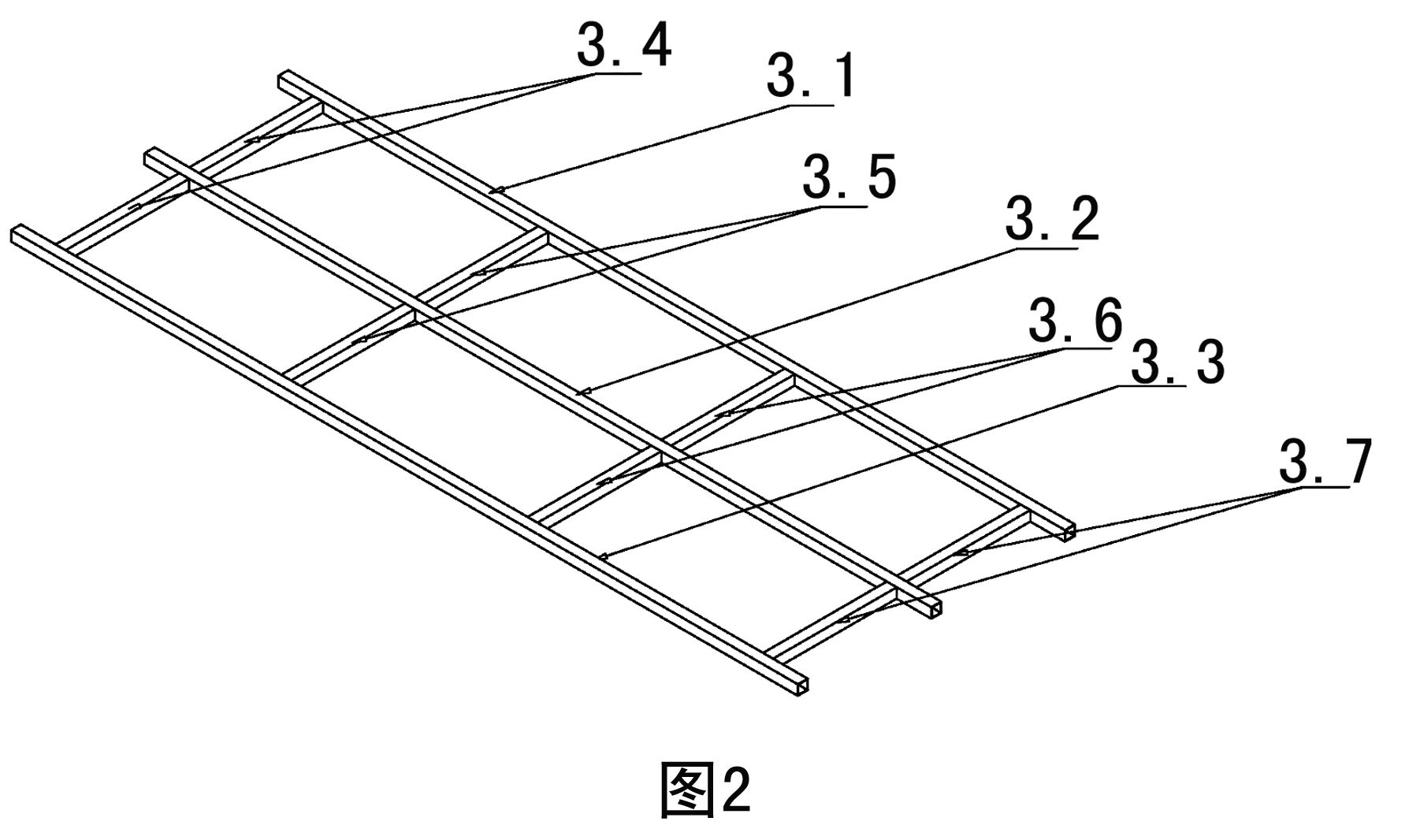

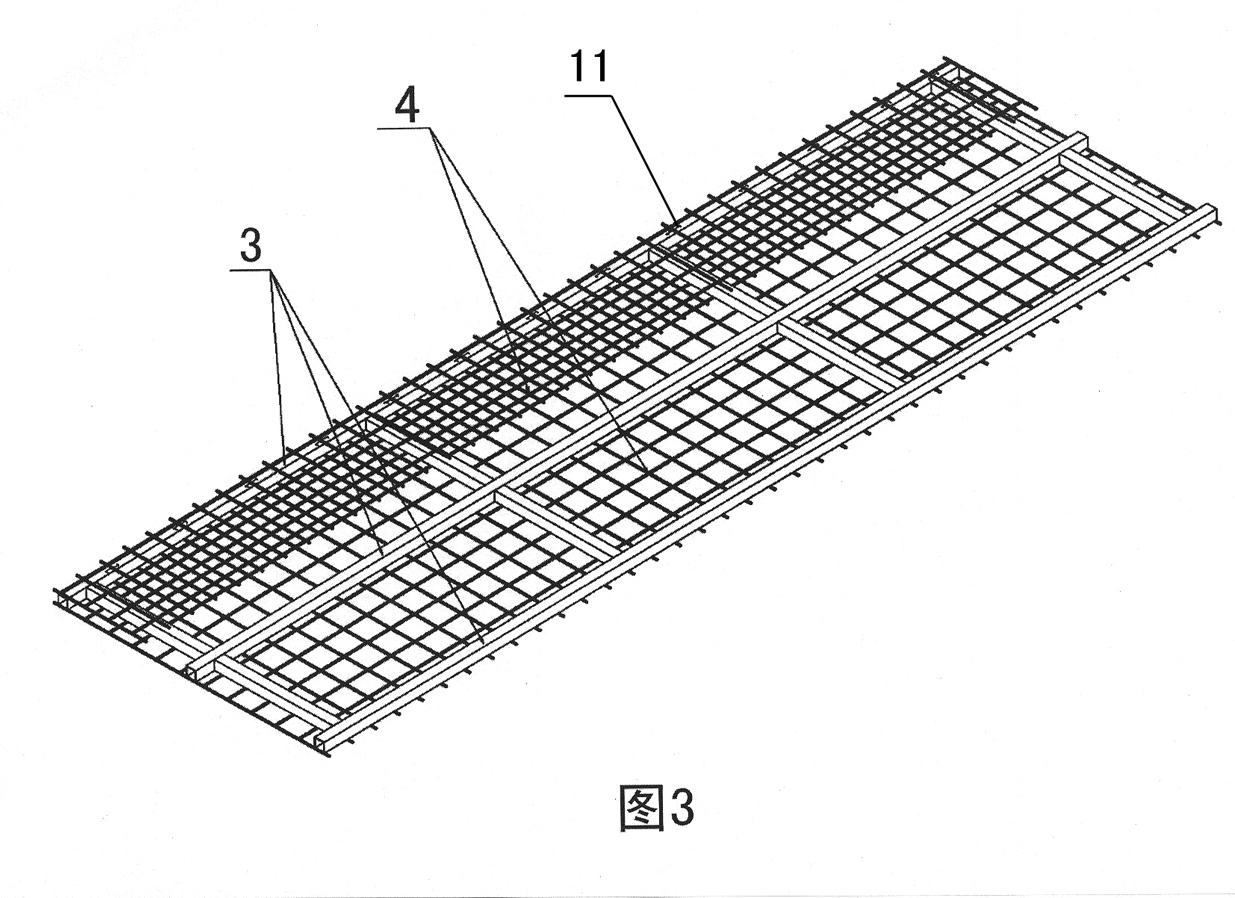

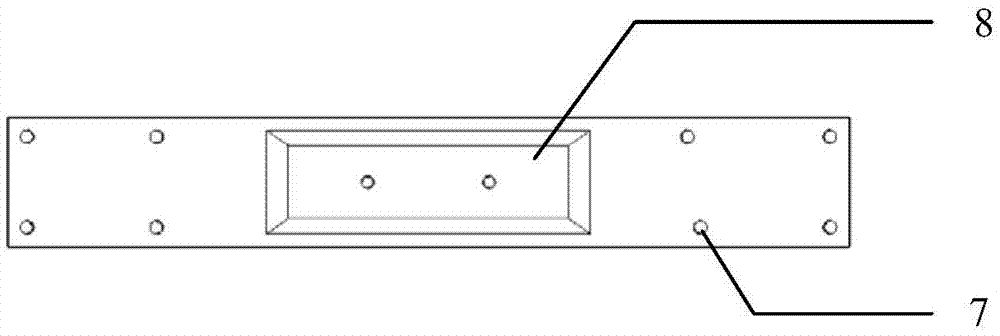

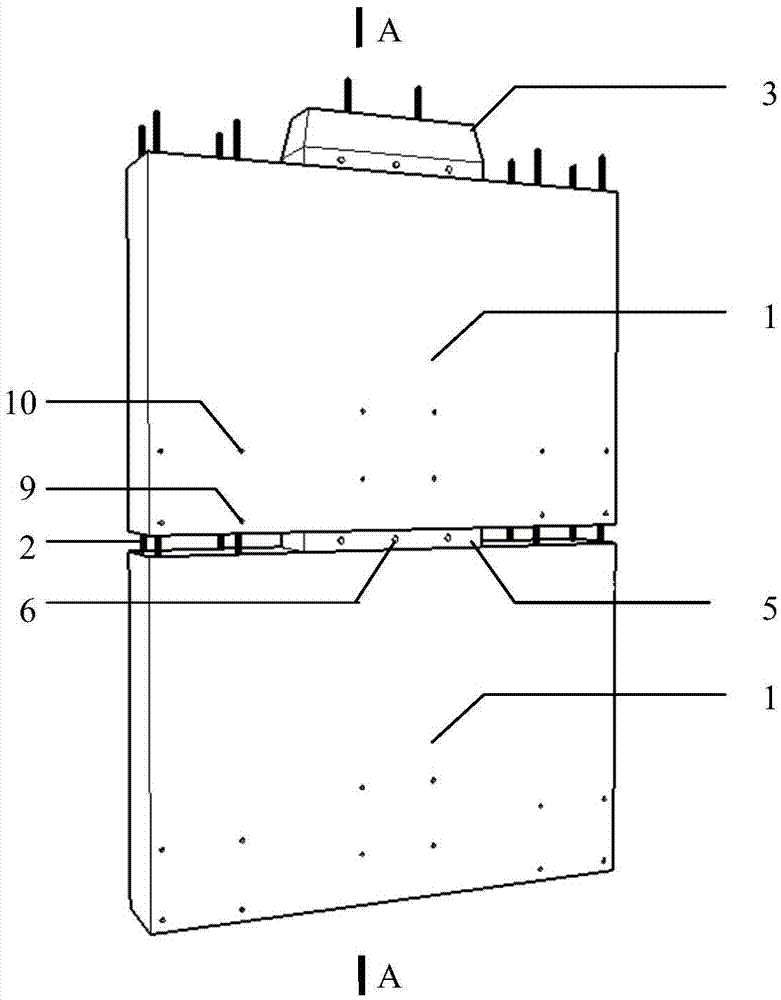

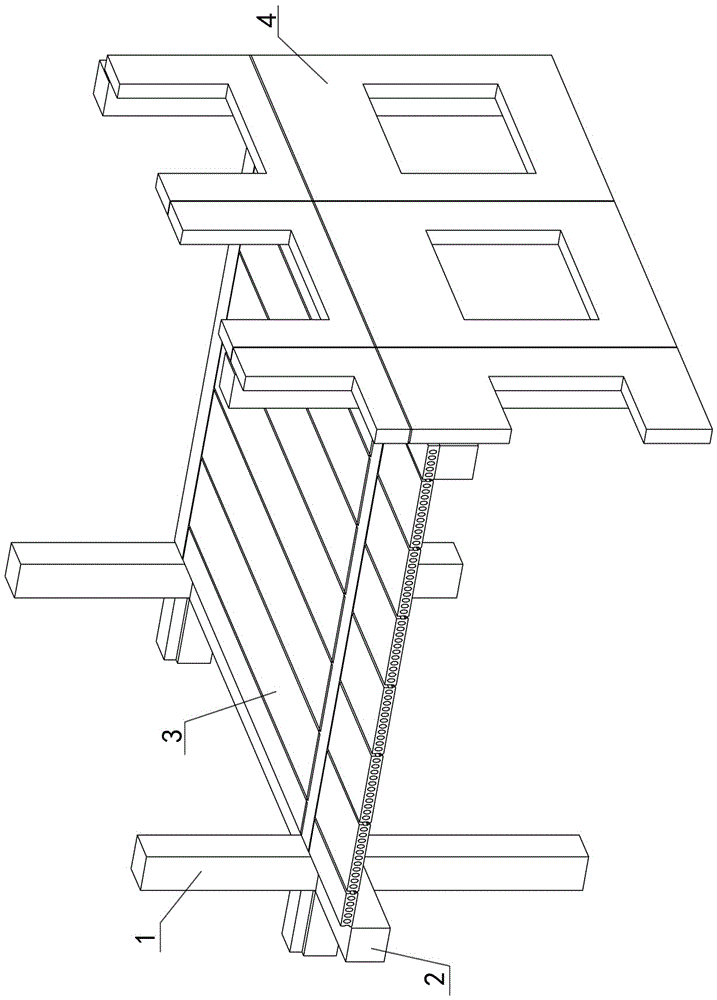

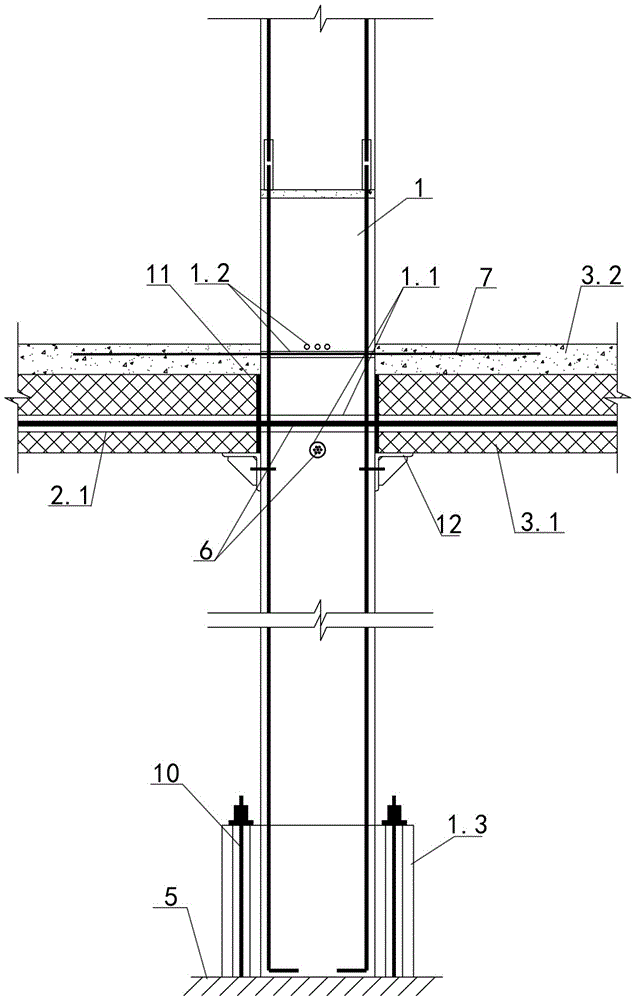

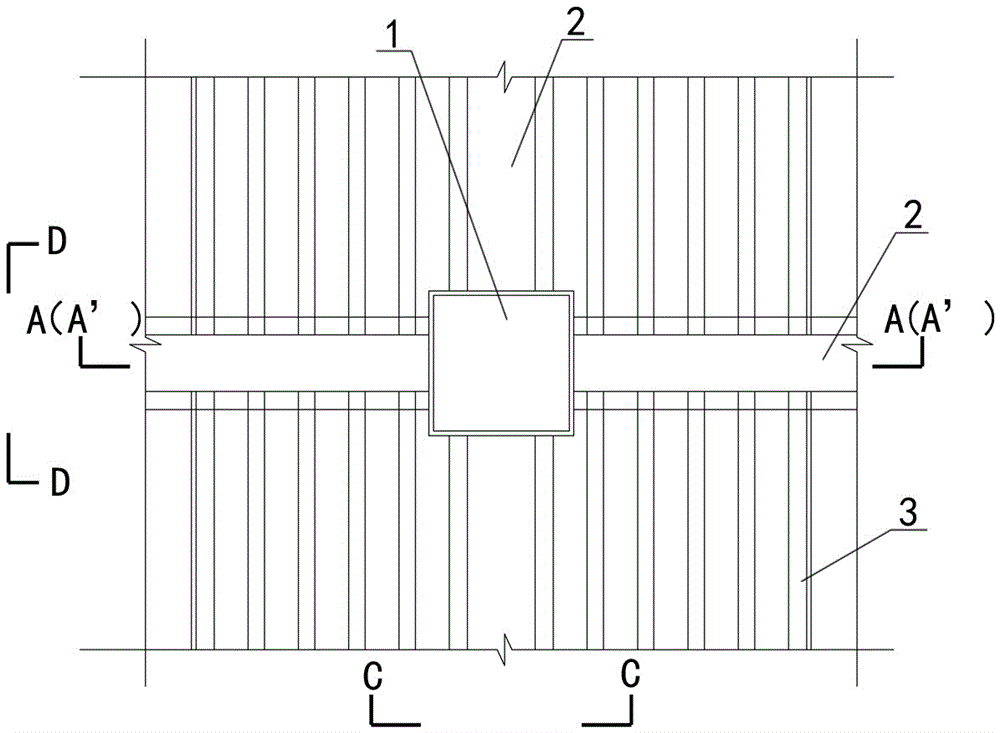

Integrally fabricated box-shaped multi-ribbed composite floor

The invention relates to an integrally fabricated box-shaped multi-ribbed composite floor, and belongs to a prefabricated concrete structural component. The integrally fabricated box-shaped multi-ribbed composite floor is characterized in that the composite floor mainly comprises bottom transverse reinforcement bars, bottom linkage reinforcement bars, lower ribbed beam longitudinal ribs, ribbed beam stirrups, bottom longitudinal reinforcement bars, shutterings, truss ribs, flanges, top transverse reinforcement bars, wedge-shaped grooves and a concrete layer, wherein the bottom linkage reinforcement bars, the bottom transverse reinforcement bars, the lower ribbed beam longitudinal ribs, the bottom longitudinal reinforcement bars, the ribbed beam stirrups, the top transverse reinforcement bars and the truss ribs form a steel reinforcement framework of the composite floor; the concrete layer is poured with a conventional concrete pouring method, the flanges are arranged at the bottoms of the front side and the rear side of a concrete slab body, the connecting position of two composite floors forms a U-shaped groove by the flanges, and crack pouring of post-poured concrete is facilitated; and the wedge-shaped grooves are formed in the front side part and the rear side part of the concrete slab body at intervals respectively, the wedge-shaped grooves between every two adjacent composite floors form shear keys, and the shearing resistance between the composite floors is increased.

Owner:CHINA MCC17 GRP

Pre-stressing-force fabricated concrete-frame-joint connecting structure and construction method thereof

PendingCN107165272AImprove integrityImprove energy consumptionGirdersProtective buildings/sheltersFloor slabPre stress

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Load transfer plate for in situ concrete slabs

A tapered load plate transfers loads across a joint between adjacent concrete floor slabs. The top and bottom surfaces may taper from approximately 4 inches wide to a narrow substantially pointed end over a length of approximately 12 inches. The tapered load plate accommodates differential shrinkage of cast-in-place concrete slabs. When adjacent slabs move away from each other, the narrow end of the tapered load plate moves out of the void that it created in the slab thus allowing the slabs to move relative to one another in a direction parallel to the joint. Tapered load plates may be assembled into a load-plate basket with the direction of the taper alternating from one tapered load plate to the next to account for off-center saw cuts. A tapered load plate and an end cap may be used to provide load transfer across an expansion joint.

Owner:ILLINOIS TOOL WORKS INC

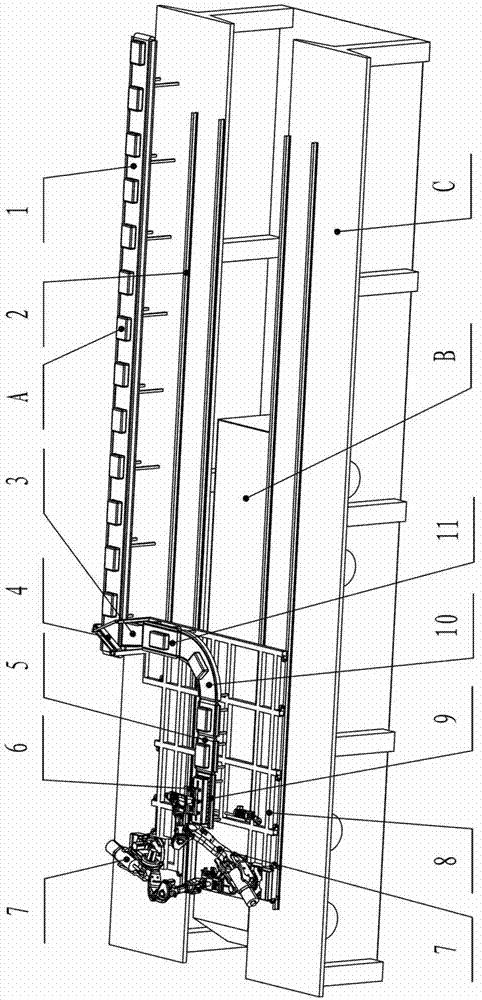

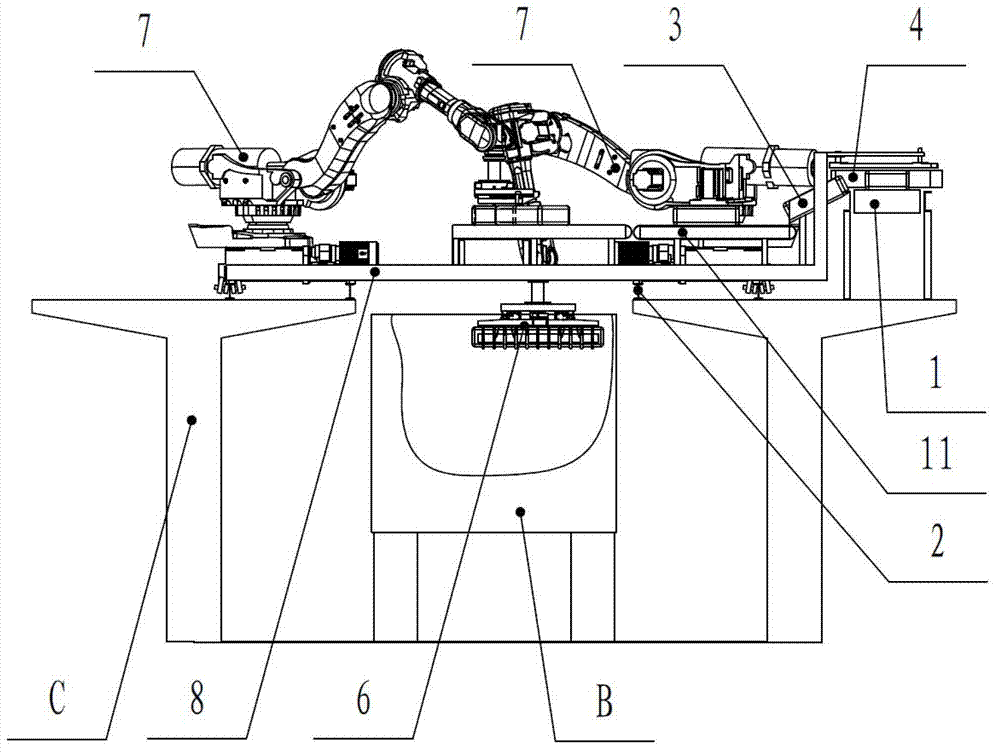

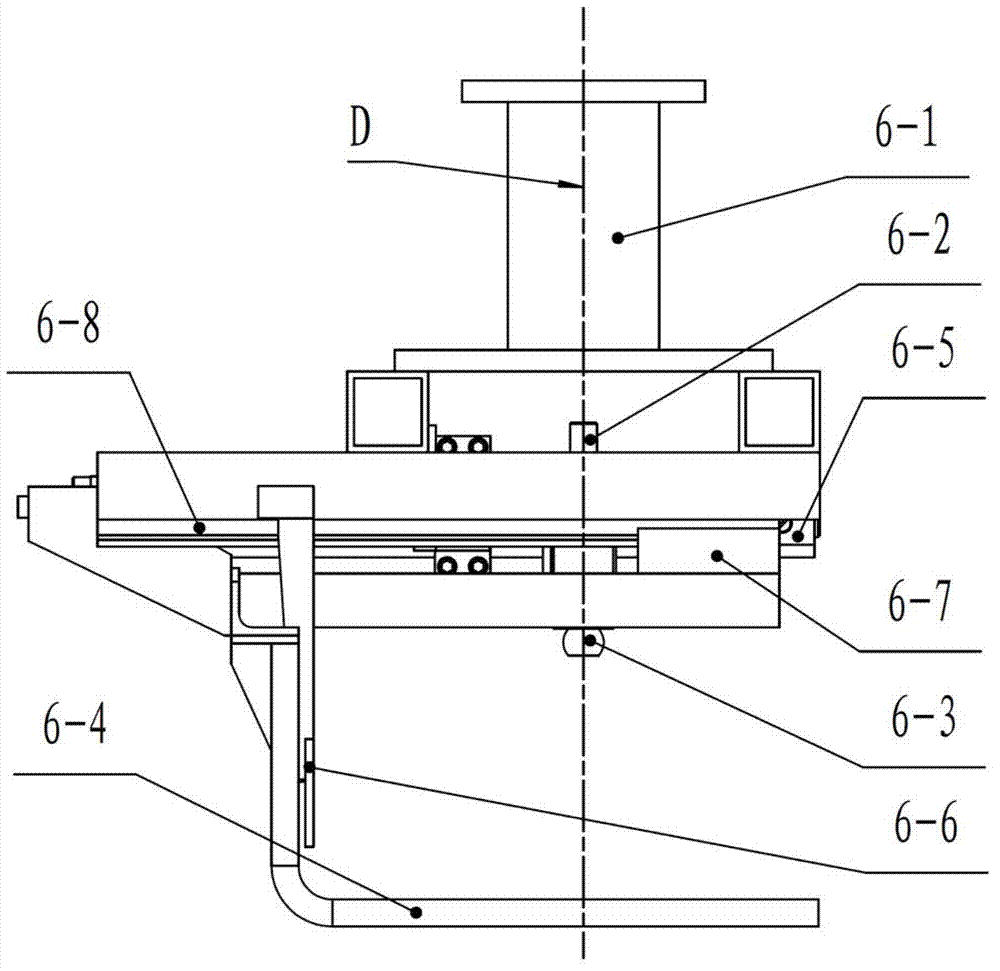

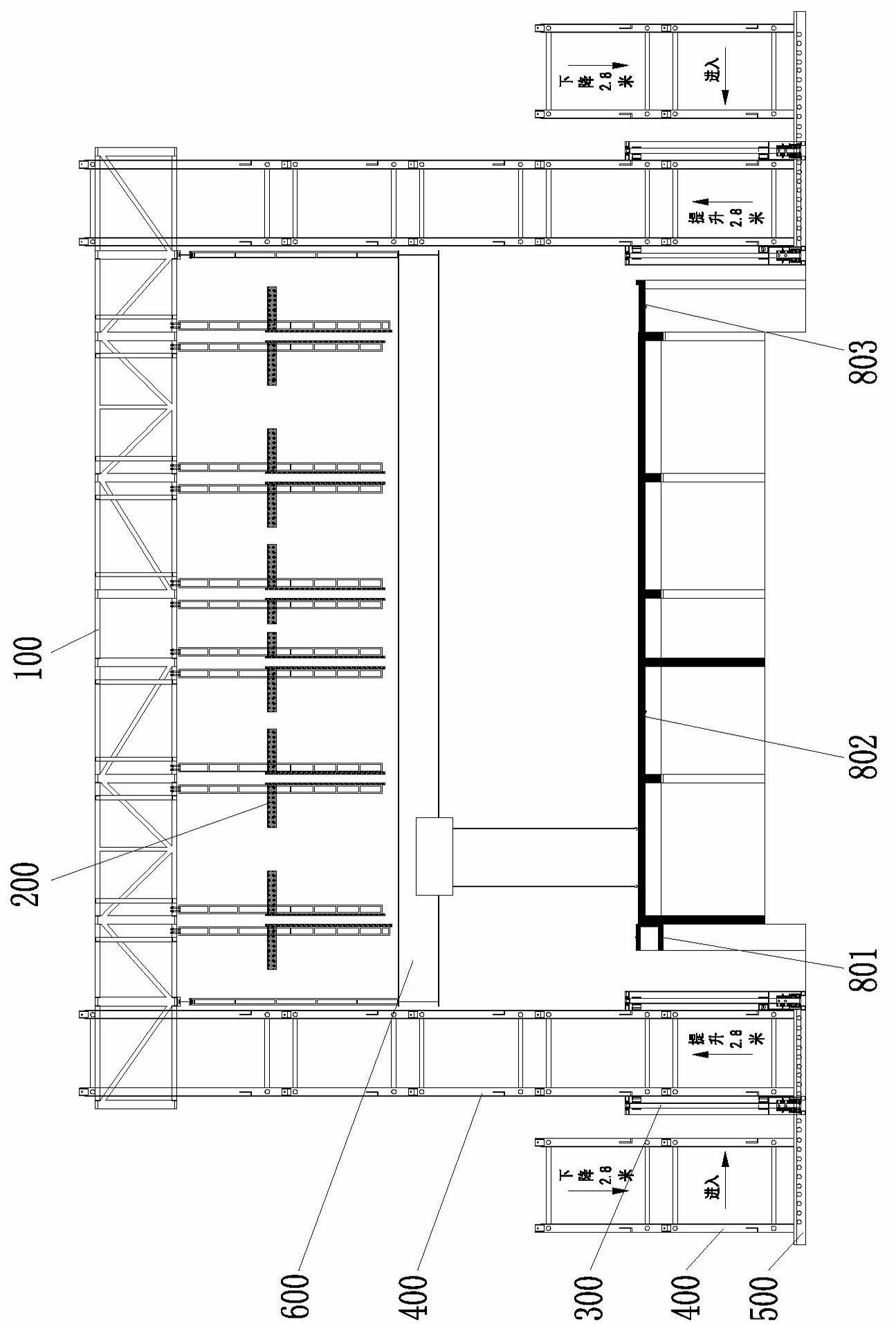

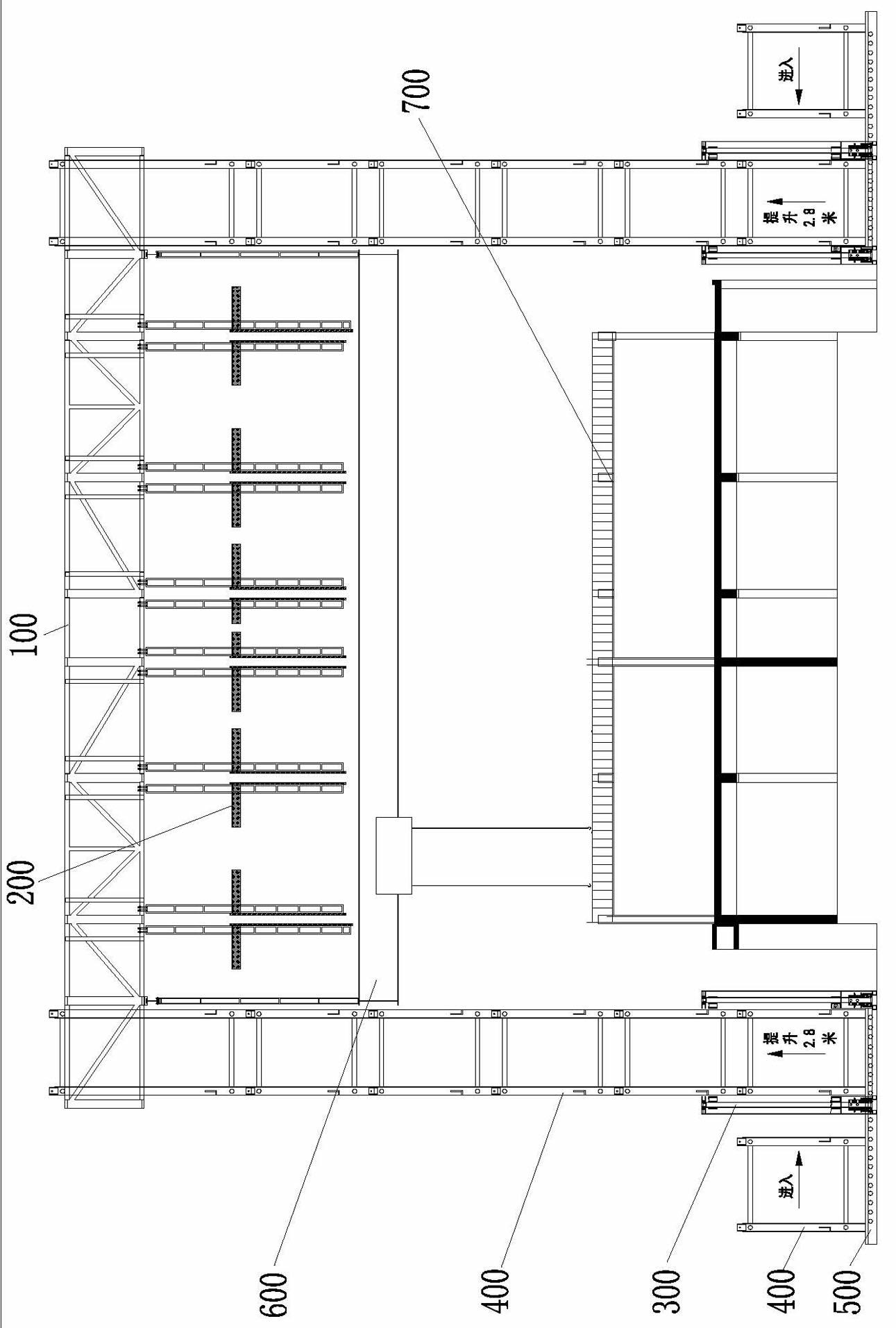

Method and device for automatic cargo loading

The invention provides a method for automatic cargo loading, comprising the following process steps: 1. carriage positioning; 2. vertical conveying; 3. horizontal offline; 4. conveying steering; 5. grouping; 6. grabbing; 7. layer-by-layer arranging; 8. stacking up; 9. backward movement of mechanism; and 10. complementation of loading. The device for implementing the method comprises a long conveyor (1), an offline mechanism (4), a lower chute (3), a transitional conveyor (11), a bend conveyor (10), a suspension conveyor (5), a grouping machine (9), a mechanical arm (6), a robot (7), a movable platform (8) and a guide rail (2), wherein the guide rail (2) is fixed on floor slabs of a plant (C), and a carriage (B) is arranged below the movable platform (8). Based on the characteristics of wide working range and flexible action of the robot, the method and device provided by the invention can stack up cargos regularly, can meet with the loading requirements of a goods van with a carriage plate and an overlength carriage and realizes the automatic loading of cargos.

Owner:HARBIN BOSHI AUTOMATION

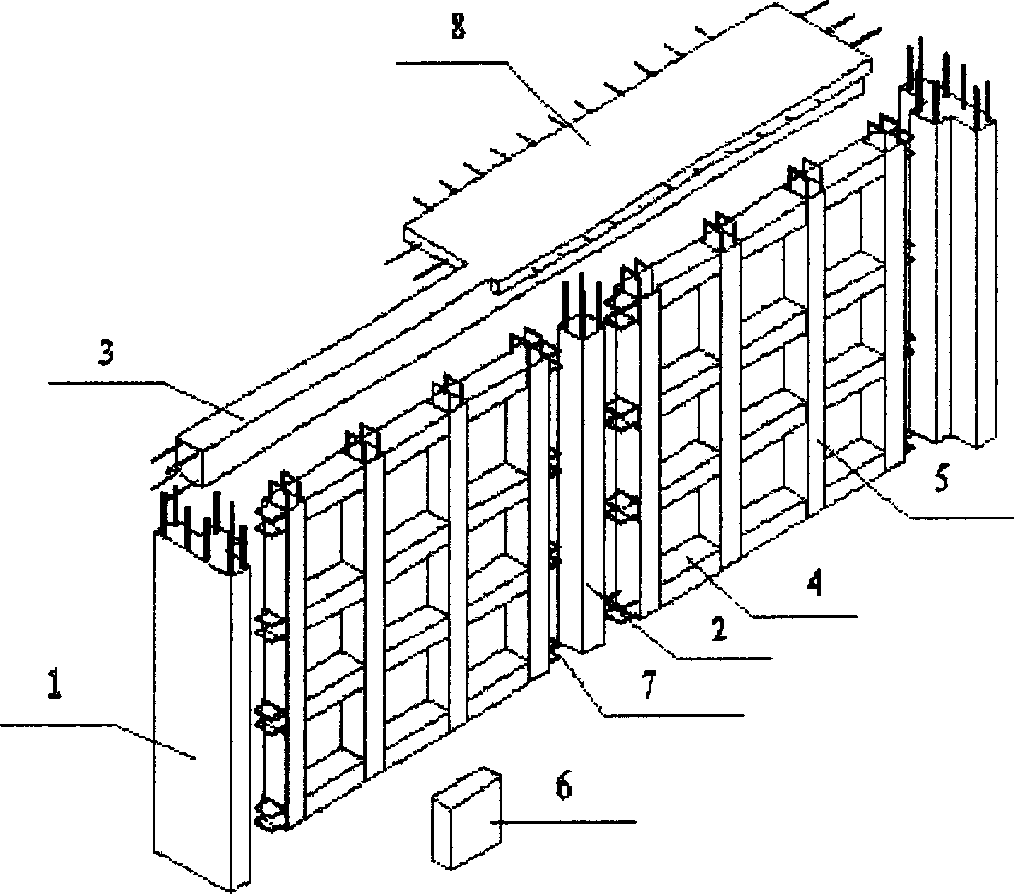

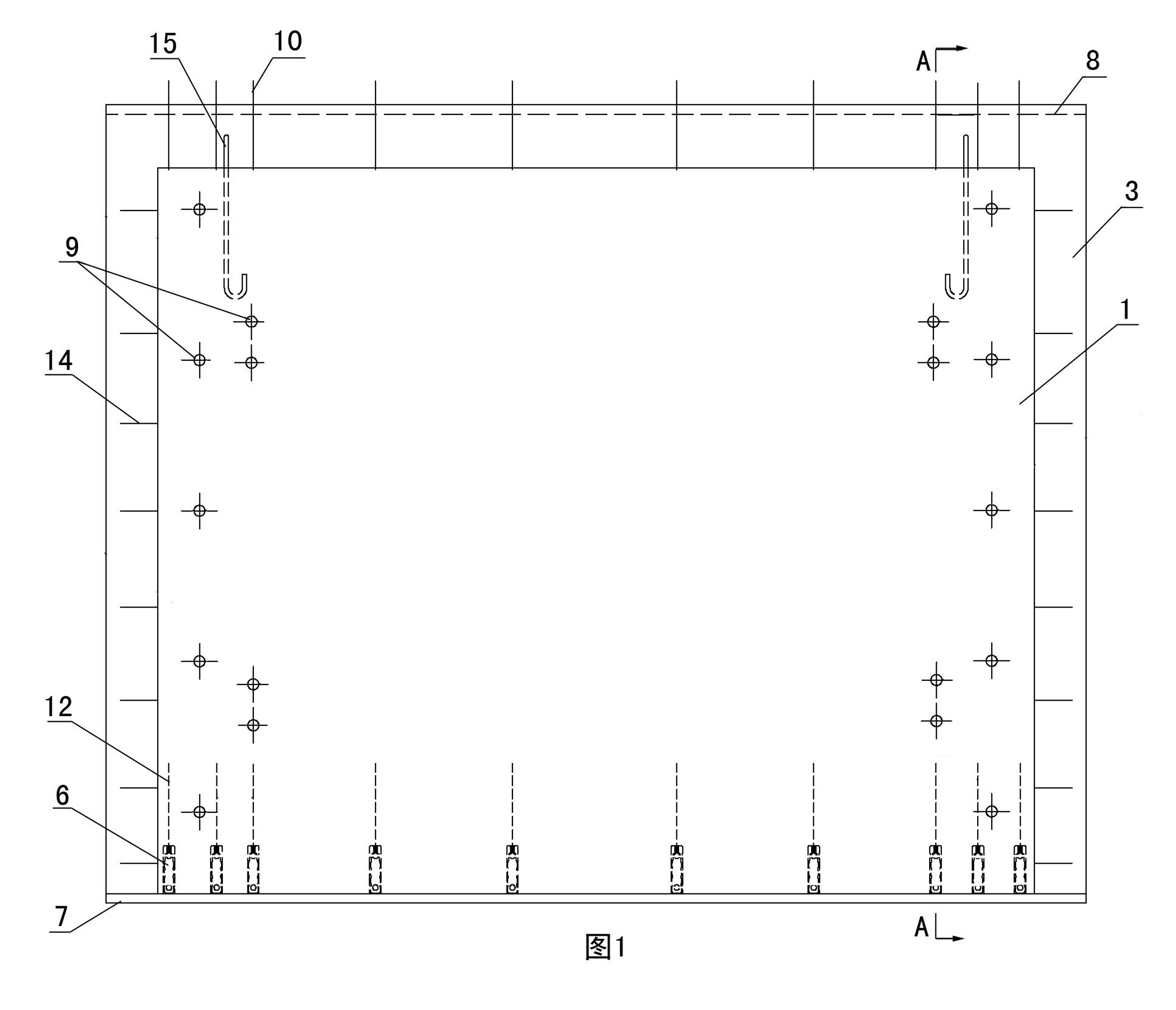

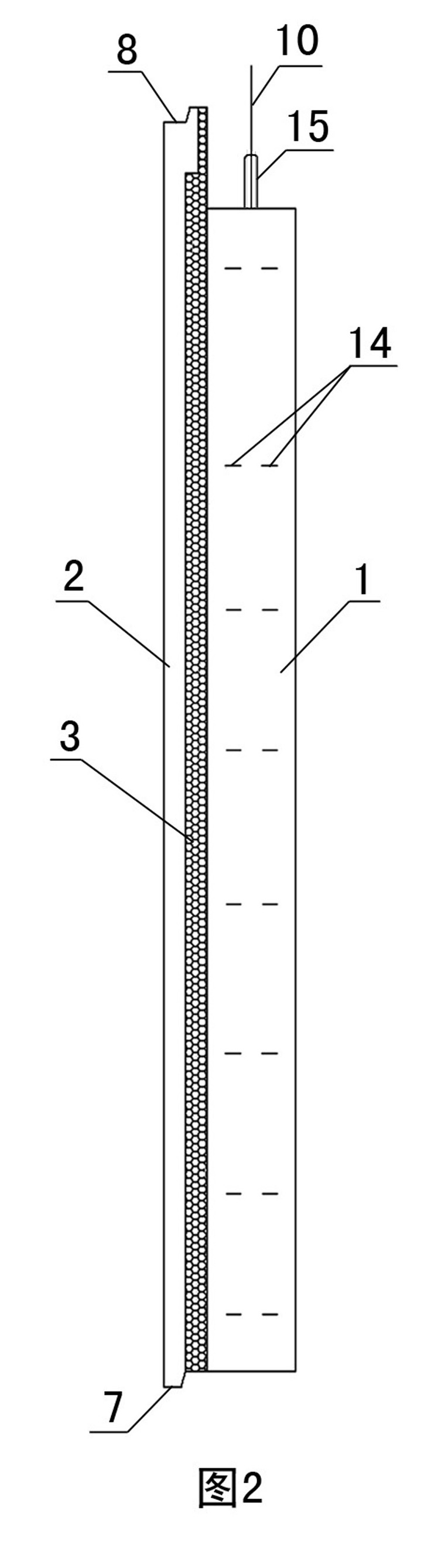

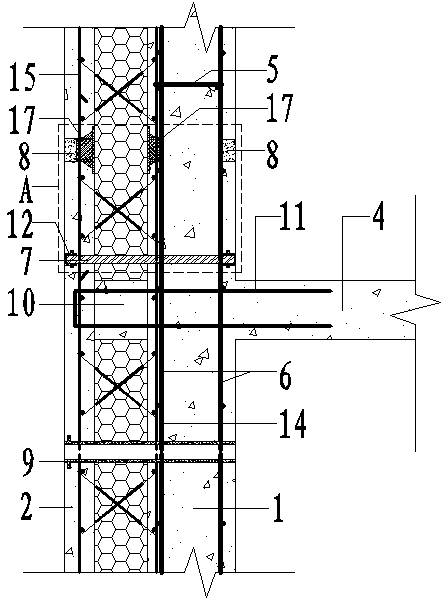

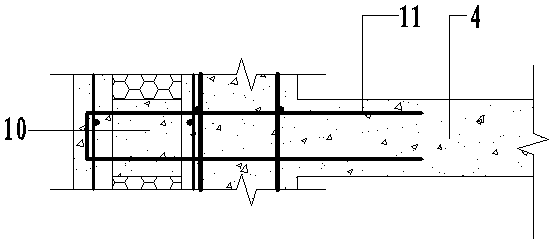

Built-in latticed steel frame exterior protected structural slab as well as building and production and construction method thereof

The invention discloses a built-in latticed steel frame exterior protected structural slab as well as a building and a production and construction method thereof. The built-in latticed steel frame exterior protected structural slab is of a solid core sandwich structure; the intermediate layer of the structural slab is a foamed cement filled layer; the two sides of the intermediate layer are combined with surface layers; the inner part of the foamed cement filled layer is provided with a built-in latticed steel frame; one side or two sides of the built-in latticed steel frame is or are covered with a steel wire mesh sheet or steel wire mesh sheets; the surface layer is a high-strength and anti-crack mortar strengthening surface layer internally doped with fiber silks and laid with fiber meshes; and a latticed steel frame net is formed by welding square steel tubes which are arranged vertically and horizontally at crossing intervals. The structural slab of the invention solves the problems that the existing building cover panel has low strength, is not convenient to be connected with a keel, is easy to fragment and has poor heat insulation property and the like, has the performances of energy conservation, environment protection, earthquake resistance, heat protection, heat preservation, heat insulation and sound insulation and the like, and can be widely applied in house buildings with lightweight-steel-construction wall bodies, floors and roofs.

Owner:筑巢(北京)科技有限公司

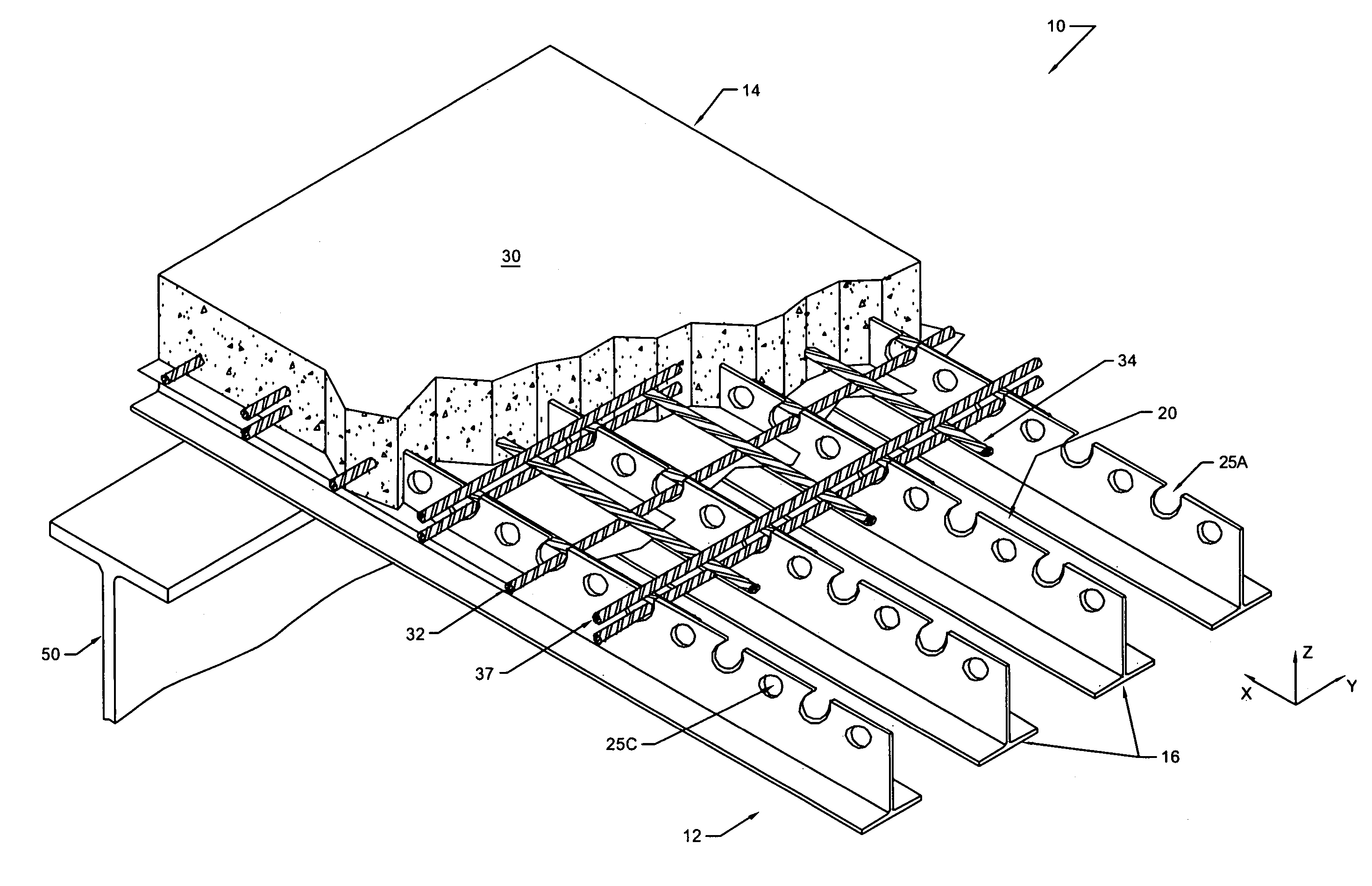

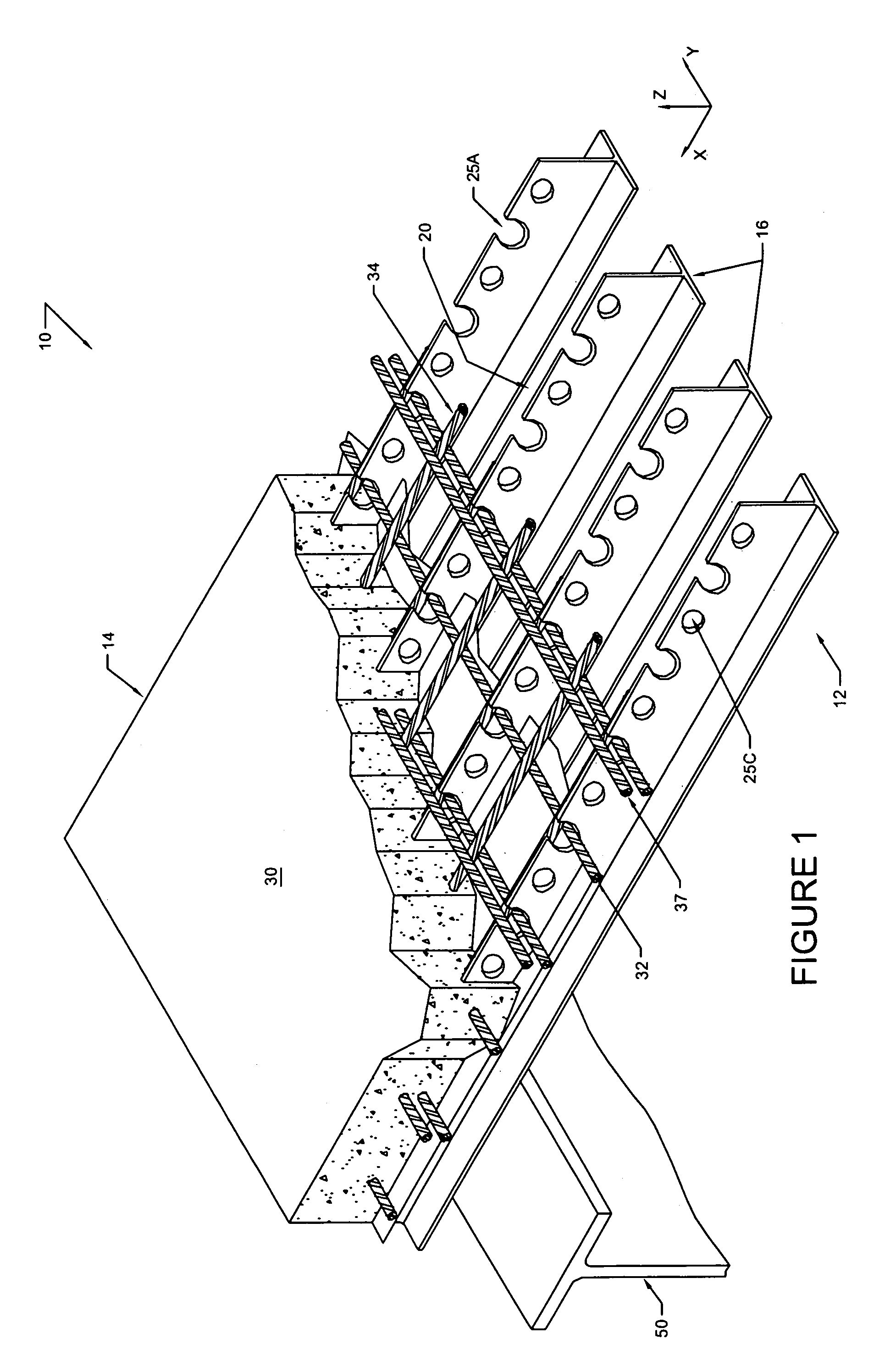

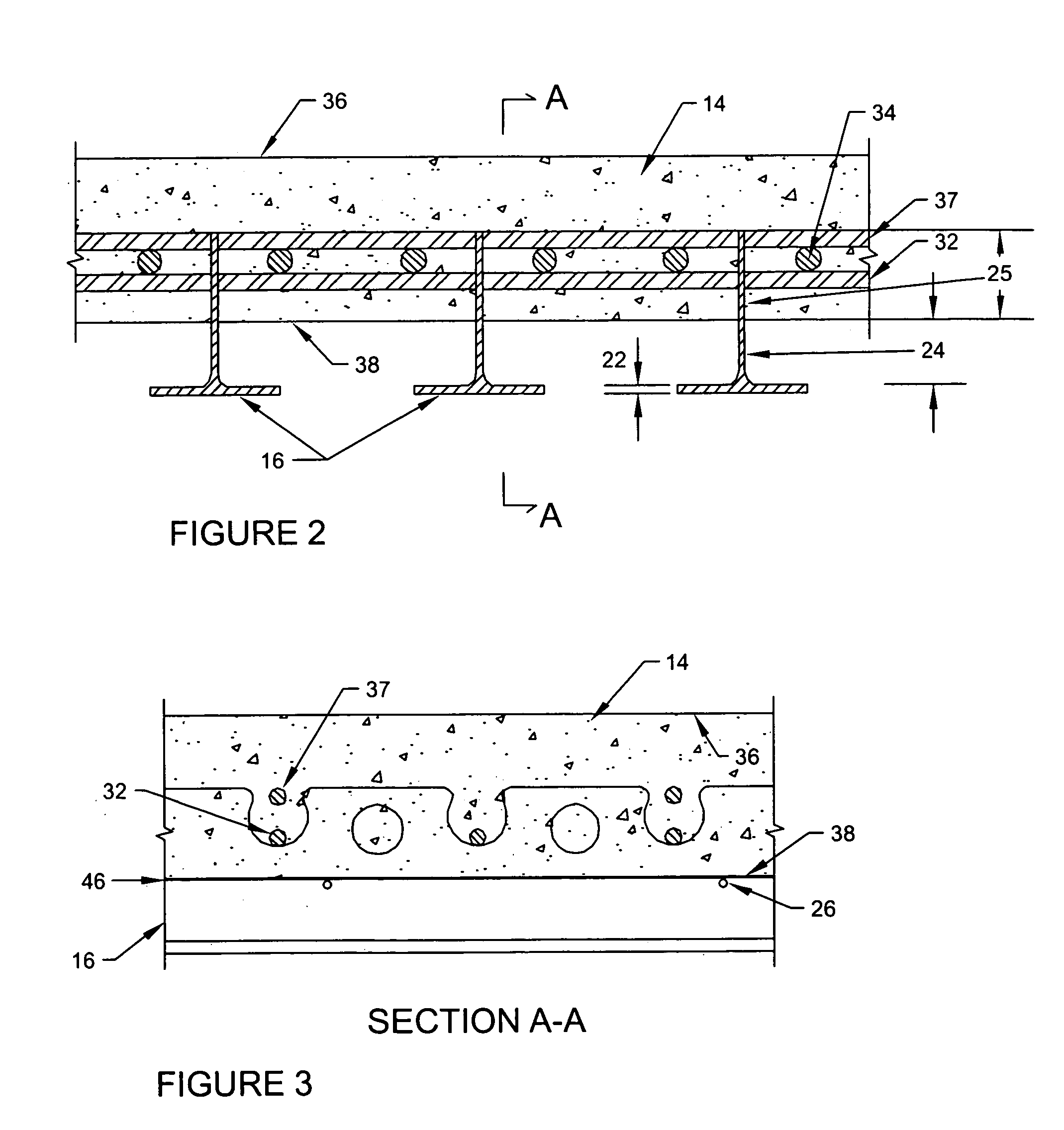

Prestressed or post-tension composite structural system

InactiveUS7197854B2Improved shear connectionEliminates some of the punching and all of the weldingFloorsBridge structural detailsGratingFloor slab

A prestressed or post-tensioned composite structural system for bridge floors, road beds, pedestrian walkways, building floors, building walls, or similar structural elements. The structural system comprises a composite structure comprising an unfilled grating as a base component, and a prestressed, post-tensioned reinforced concrete slab as a top component. The base grating component is preferably a plurality of main bearing bars without any distribution bars or tertiary bars. The upper portions of the main bearing bars are embedded in the concrete component permitting horizontal shear transfer and creating a composite deck structure which maximizes the use of tensile strength of steel and the compressive strength of concrete.

Owner:D S BROWN

Means and method for fireproof sealing between the peripheral edge of individual floors of a building and the exterior wall structure thereof

InactiveUS20070204540A1Avoid overall overheatingIncrease ratingsBuilding roofsWallsFloor slabEngineering

A construction and a method for fireproof sealing between the outer edges of a floor and the exterior wall structure of a building which includes the placement of an insulation support member between the safing insulation positioned immediately around the floor edge, and the spandrel insulation extending between the vertical studs inside of the outer cladding. Safing insulation is normally compressed prior to placement, and this compression is maintained by positioning the insulation support member in abutment therewith. Also, by positioning the insulation support member between the safing insulation and the spandrel insulation, the support member itself is protected which enhances maintenance of the effective seal of the slot between the floor and the outer cladding. Also during installation, the insulation support member can be used to achieve a desired compression of the safing insulation by positioning it after initial positioning of the insulation member such that it is compressed during final installation of the insulation member.

Owner:SPECIFIED TECH

Mixed steel-concrete composite frame structure

ActiveCN101581115AEfficient use ofImprove structural fire resistanceBuilding constructionsFloor slabReinforced concrete

Owner:TSINGHUA UNIV

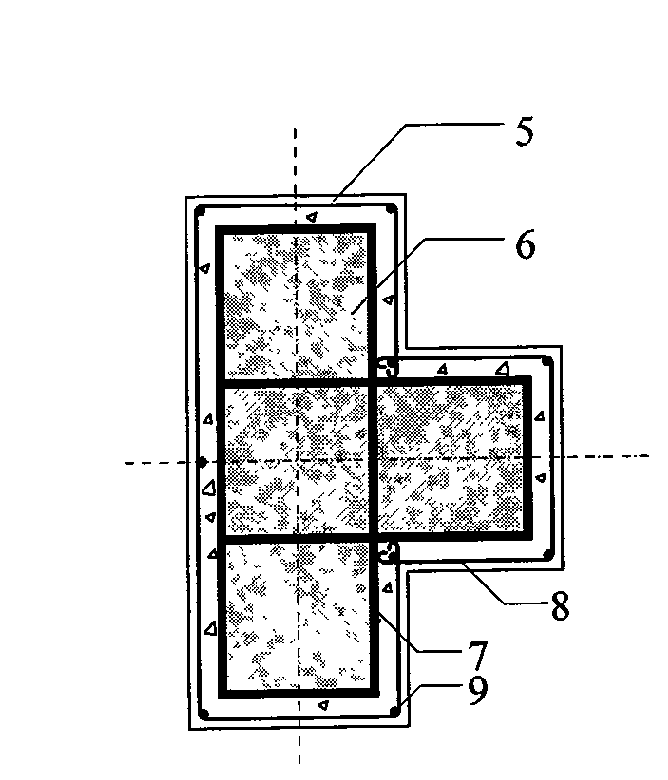

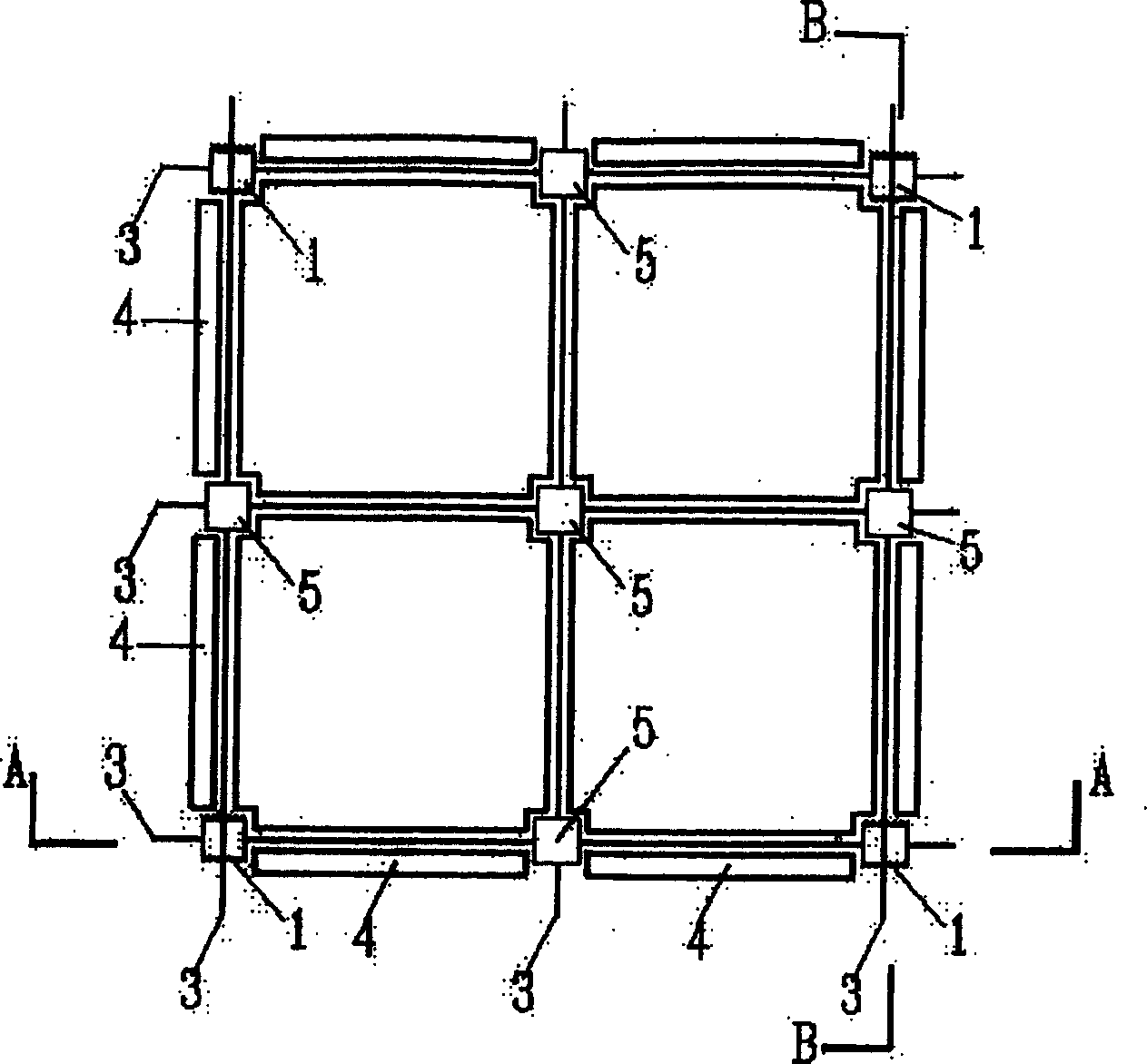

Compound type connection shear wall structure and assembling method thereof

ActiveCN105442727AEasy assembly and constructionPrecise construction and assemblyWallsFloor slabUltimate tensile strength

The invention discloses a compound type connection shear wall structure and an assembling method thereof. The compound type connection shear wall structure comprises N shear wall components of the same structure, wherein every two adjacent shear wall components are connected through a compound shear key and a key groove so that a compound type connection shear wall can be formed. Due to the mutual guide-in effect of the compound shear keys and the key grooves, the construction precision is improved, and eccentric compression generated by inaccurate assembling is avoided. Because the shear key on each shear wall component below can bear the weight of the corresponding shear wall component above when the next layer is assembled, assembling of a wall body of a previous layer can be instantly conducted after floor pouring is completed without waiting till floor concrete reaches the strength, and the assembling cycle of floors can be greatly shortened. The shear keys of the shear wall components below are embedded in the key grooves of the shear wall components above, the shear keys can bear transverse shearing force, the shear resistance of the structure is enhanced, and reliability of the structure is enhanced.

Owner:ZHEJIANG UNIV +2

Steel-steel concrete fully prefabricated assembling structure

InactiveCN1554839AEnsure safetyImprove bearing capacityBuilding constructionsHigh strength concreteFloor slab

The fully prefabricated assembled steel-steel concrete structure includes two kinds of assembling forms. The first one is fully prefabricated assembled steel column-steel concrete structure, and its prefabricated steel column consists of H-shaped steel column, reinforcing concrete ribs, supporting steel plate and prestress-shearing force friction nodes with shear resisting strips. The second one is fully prefabricated assembled prefabricated steel pipe-concrete column-steel concrete structure, and the prefabricated steel pipe-concrete column consists of steel pipe with square cross section, micro expanding high strength concrete cast inside the steel pipe and shear resisting strips attached to the outer wall of the steel pipe to form preshearing force-friction type nodes. The present invention has raised antiseismic performance, area utilization, construction efficiency, fireproof performance, low cost and small member size, and is suitable for various buildings.

Owner:KUNMING UNIV OF SCI & TECH

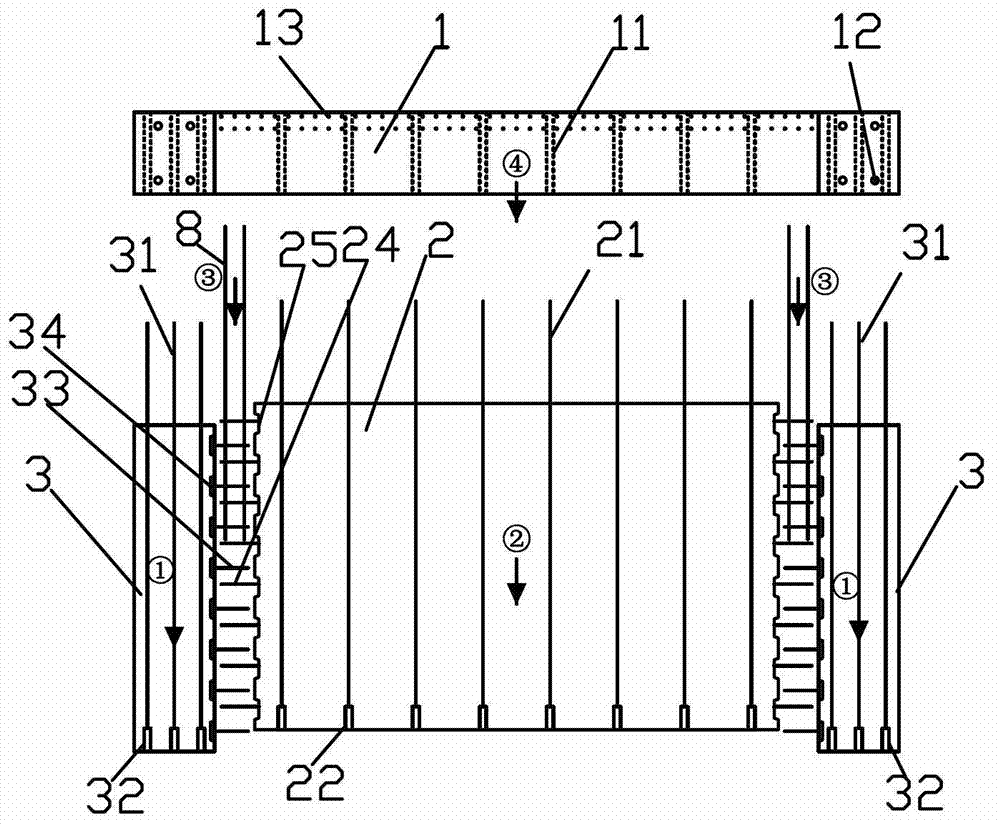

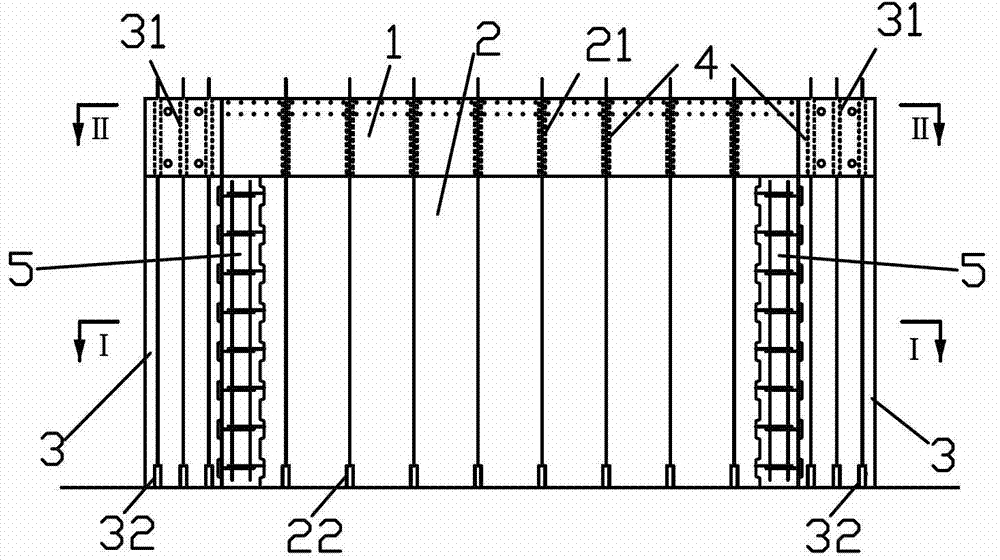

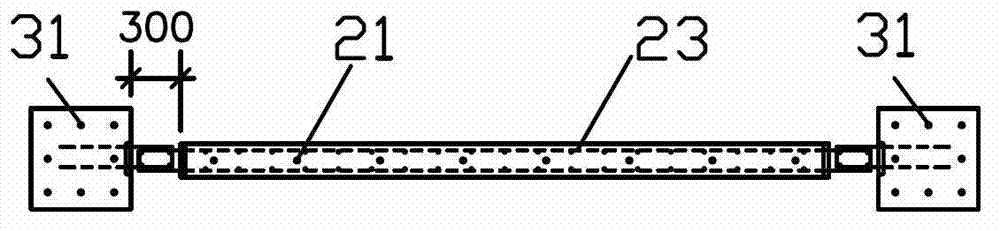

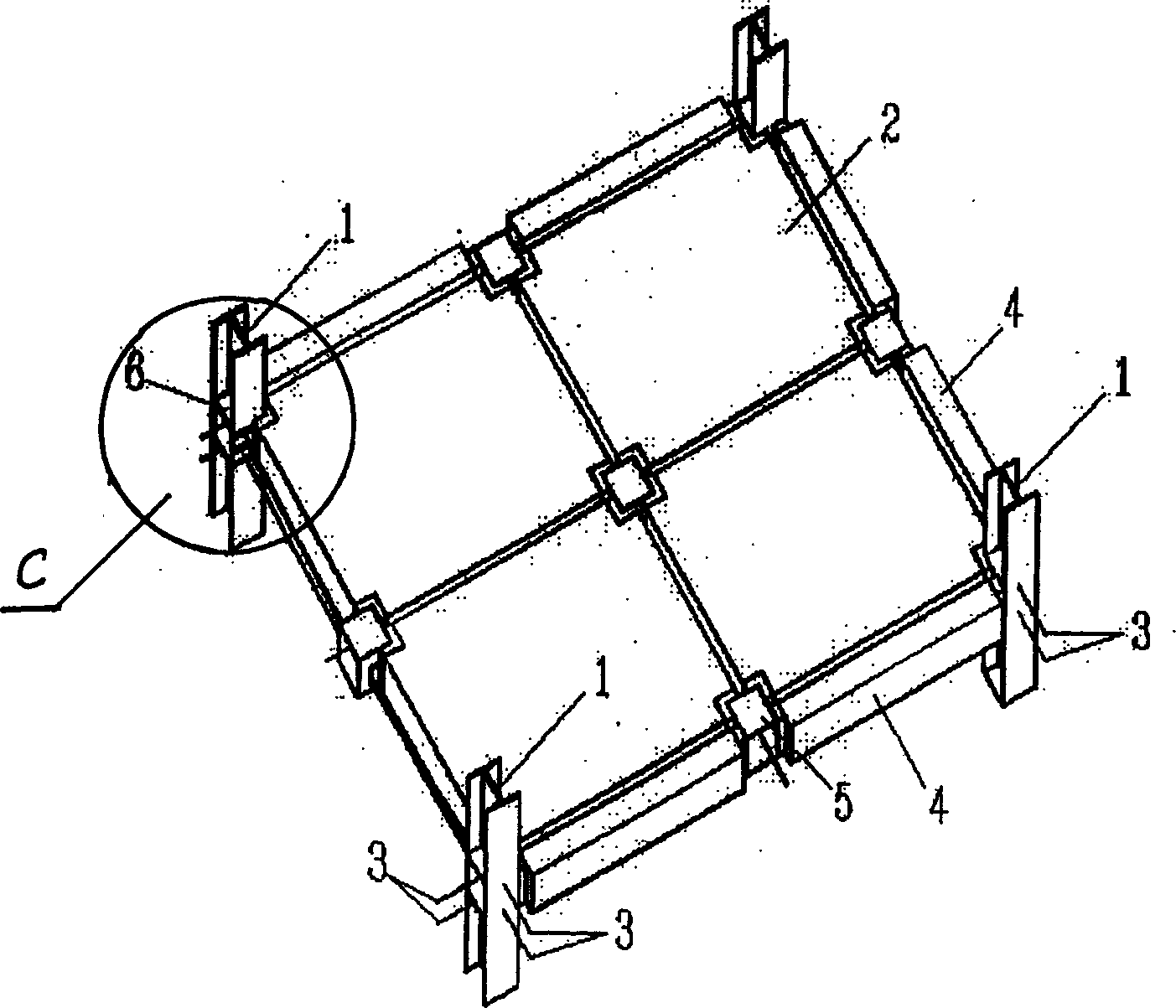

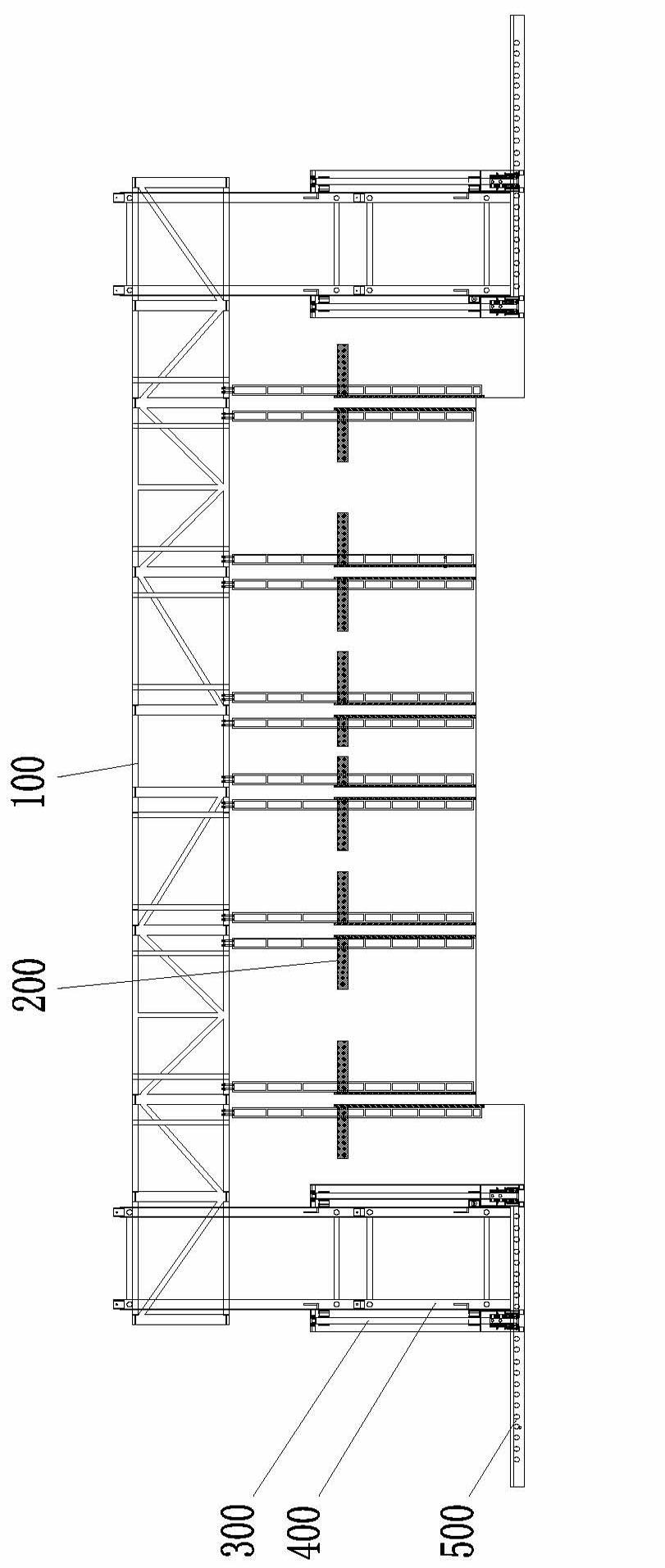

Column-through assembled prestressed concrete frame system and construction method thereof

ActiveCN106499051AEfficient constructionImprove seismic performanceBuilding constructionsReinforced concrete columnFloor slab

The invention discloses a column-through assembled prestressed concrete frame system and a construction method thereof. The system comprises a foundation, a prefabricated reinforced concrete column, a prefabricated reinforced concrete beam, a superimposed floor slab and an external hung prefabricated wallboard, wherein a column prestressed duct is formed in the prefabricated reinforced concrete column; a beam prestressed duct is formed in the prefabricated reinforced concrete beam; post-tensioned unbonded prestressed tendons are penetrated into the beam prestressed duct and the column prestressed duct; energy-dissipation steel bars are anchored between the prefabricated reinforced concrete column and the superimposed floor slab. The structure provided by the invention has a good seismic performance; the lower part of a beam-column joint is subjected to unreinforced connection so that the structure is simple; the post-tensioned unbonded prestressed tendons and a replaceable column base energy dissipater are used so that the structure is less damaged and easy to be repaired in the earthquake; a construction manner of using the prefabricated superimposed floor slab and prestressed assembly makes site construction convenient and rapid and saves a lot of supports compared with a traditional prefabricated assembly structure; the column-through assembled prestressed concrete frame system provided by the invention is used in combination with lateral supports, shear walls and other lateral force resisting members, and is applicable to most high-rise public buildings.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

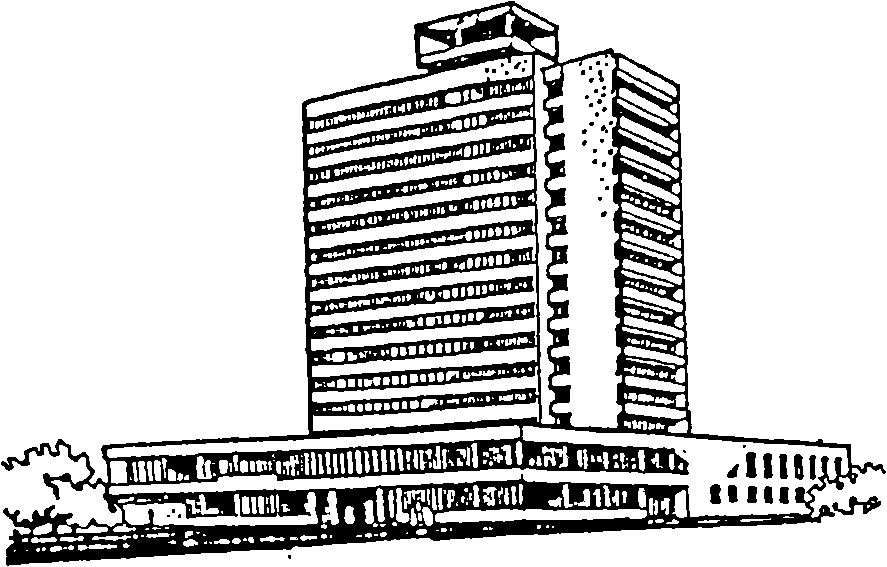

Quick construction method for high-rise buildings

InactiveCN102505845AFast constructionImprove construction qualityForms/shuttering/falseworksBuilding material handlingFloor slabRebar

The invention discloses a quick construction method for high-rise buildings, which includes: hoisting an integral lifting device; positioning all pneumatic pouring mould opening and closing devices; assembling single cradle units integrally to form an integrated mould cradle assembly while fixedly mounting the pneumatic pouring mould opening and closing devices below the integrated mould cradle assembly; starting all four-screw lifters to jack the integrated mould cradle assembly; hoisting reinforcement cages of walls and beams of a floor; falling the integrated mould cradle assembly, driving the pneumatic pouring mould opening and closing devices to close the moulds horizontally; pouring concrete and then opening the moulds after concrete is solidified; lifting the integrated mould cradle assembly upwards; hoisting floor slabs, prefabricated boards for superposed parts of balconies, prefabricated stairs and prefabricated bay windows; laying cast-in-situ reinforcing meshes of the superposed floor slabs and casting concrete on the superposed floor slabs; repeating the above steps until completing building of all floors; and finally removing the integrated mould cradle assembly and a lifting support. The quick construction method for the high-rise buildings has the advantages of quick construction, high construction quality, safety and reliability in construction and low construction cost.

Owner:DONGGUAN HUANAN JUNYE MACHINERY MFG CO LTD

Structure and construction method of cast-in-site style welded steel frame composite concrete shear wall

ActiveCN103195193AGuaranteed section sizeSolving Linear Thermal Bridge ProblemsWallsBuilding material handlingFloor slabSandwich board

The invention relates to a structure and a construction method of a cast-in-style welded steel frame composite concrete shear wall. The structure comprises an indoor concrete layer, an outdoor concrete layer and a wire frame insulation sandwich board. The wire frane insulation sandwich board is coated between the indoor concrete layer and the outdoor concrete layer. At least two rectangular and groove-typed cantilever holes are arranged at the top of the sandwich board, and each cantilever hole is provided with a U-shaped cantilever anchor bar which penetrates through the sandwich board and a floor slab to be fixedly connected with the floor slab. The construction method includes site preparation work, binding of load-bearing steel bars of a wall body and edge member steel bars, custom processing of the sandwich boards, installation of the sandwich boards, pavement of template positioning pieces and wall bushings, fixation of water and electric pipes inside the wall body, binding of ordinary blocks on both sides of the wall body steel bars, erecting of the templates, pouring of the concrete, removing of the templates and concrete curing. Since a series of composite wall construction methods are adopted, problems existing in the prior art are solved, and a composite heat preservation technology is improved.

Owner:石家庄晶达建筑体系有限公司

Combined light steel structure house and mounting method thereof

InactiveCN101418592AHigh degree of factoryReduce the ratio of output value to energy consumptionBuilding constructionsFloor slabSandwich panel

The invention relates to a combined lightweight steel structure building and an assembling method thereof. The combined lightweight steel structure building comprises ground beams, angular upright posts, upright posts, ring beams, sandwich panels, a roof, staircases, doors and windows. The key technical points of the combined lightweight steel structure building are as follows: a plurality of floor bottom girders in parallel are arranged on the ground; four ground beams are arranged on the circumference of each floor bottom girder in turn; bolt fastening sheets which are connected with the ground beams and the ring beams are arranged on joints of upper ends and lower ends of each angular upright post and each upright post respectively; limit baffle plates of wall panels are arranged on angular upright posts and upright posts near the outside of the building; bolt fastening limit treadle bars of the wall panels are arranged on upright posts near the inside of the building; the wall panels comprise wall panels provided with door bodies or wall panels provided with window bodies; metal section supporting layers which are suitable to be connected with balcony bottom girders or / and corridor bottom girders are uniformly distributed between two adjacent floors; metal floor slabs are laid on the metal section supporting layers; and the roof is as follows: a waterproof ridge section is arranged on the upper part of a ridge main girder; the edge of a roof slab is embedded into the ridge section; and a roof slab slot section provided with a drainage channel is arranged on the upper part of a ramp beam of the roof.

Owner:官木喜

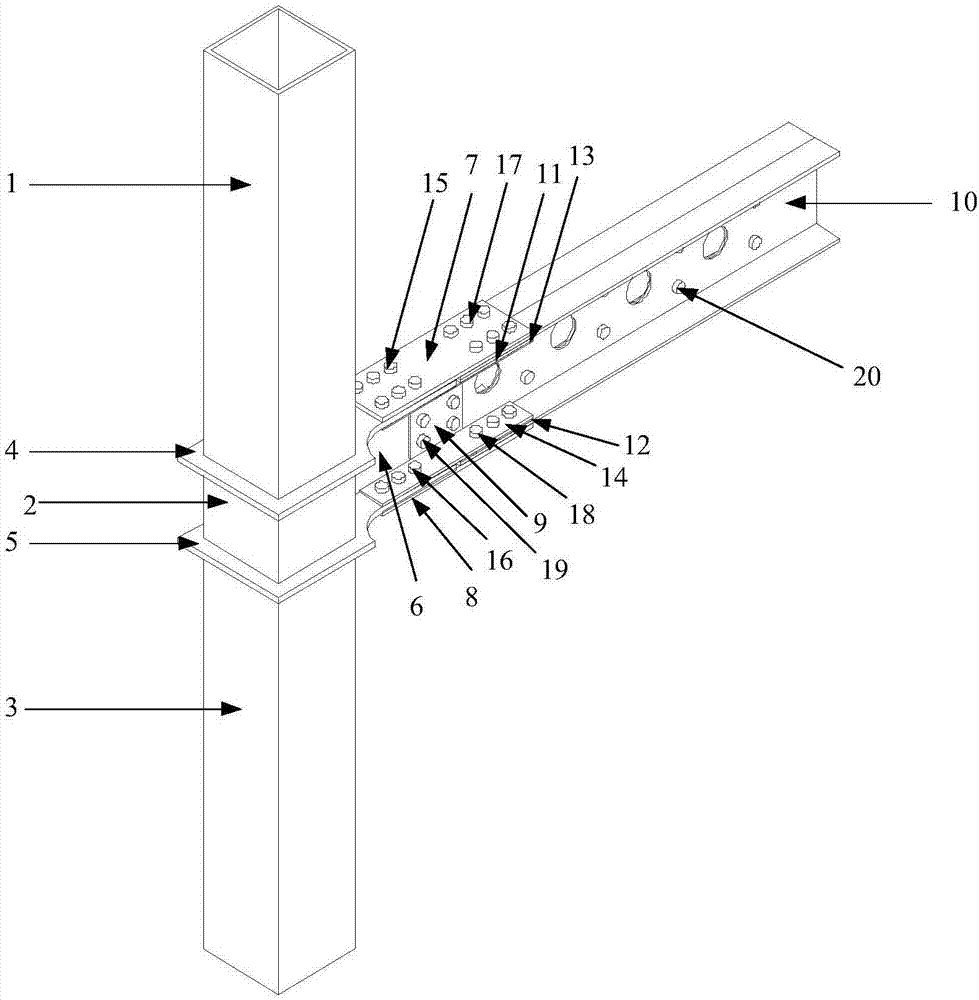

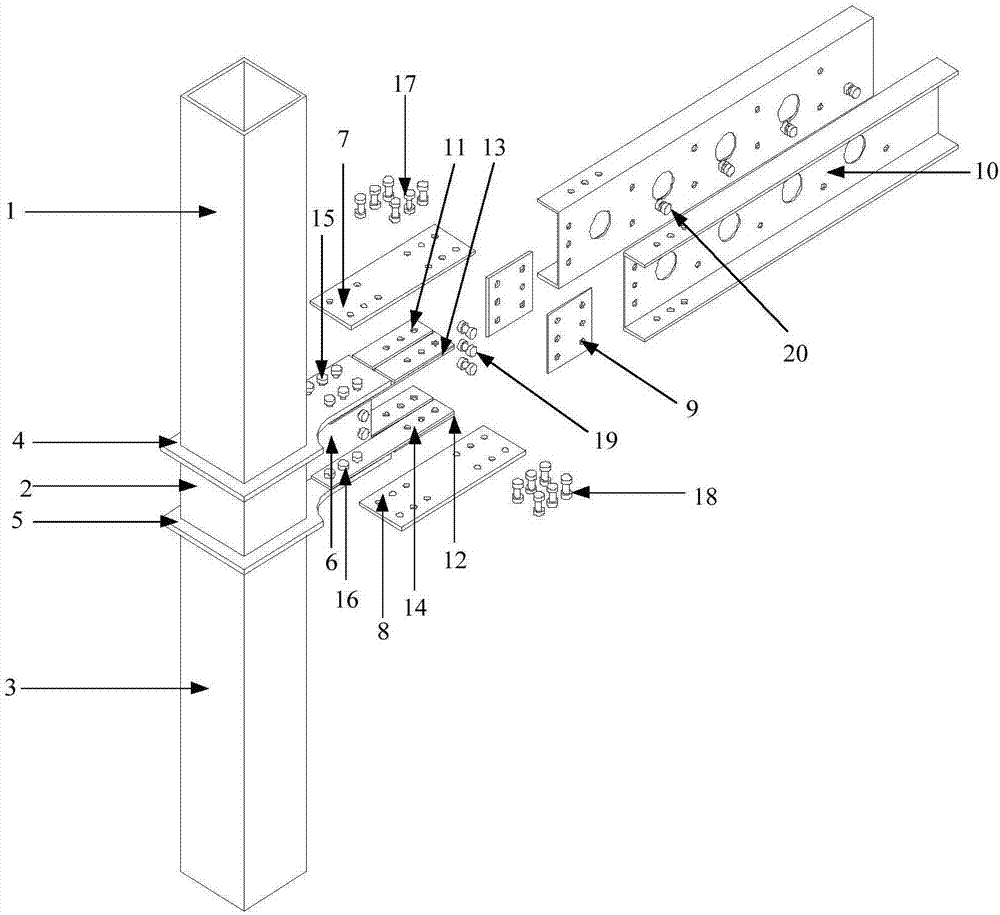

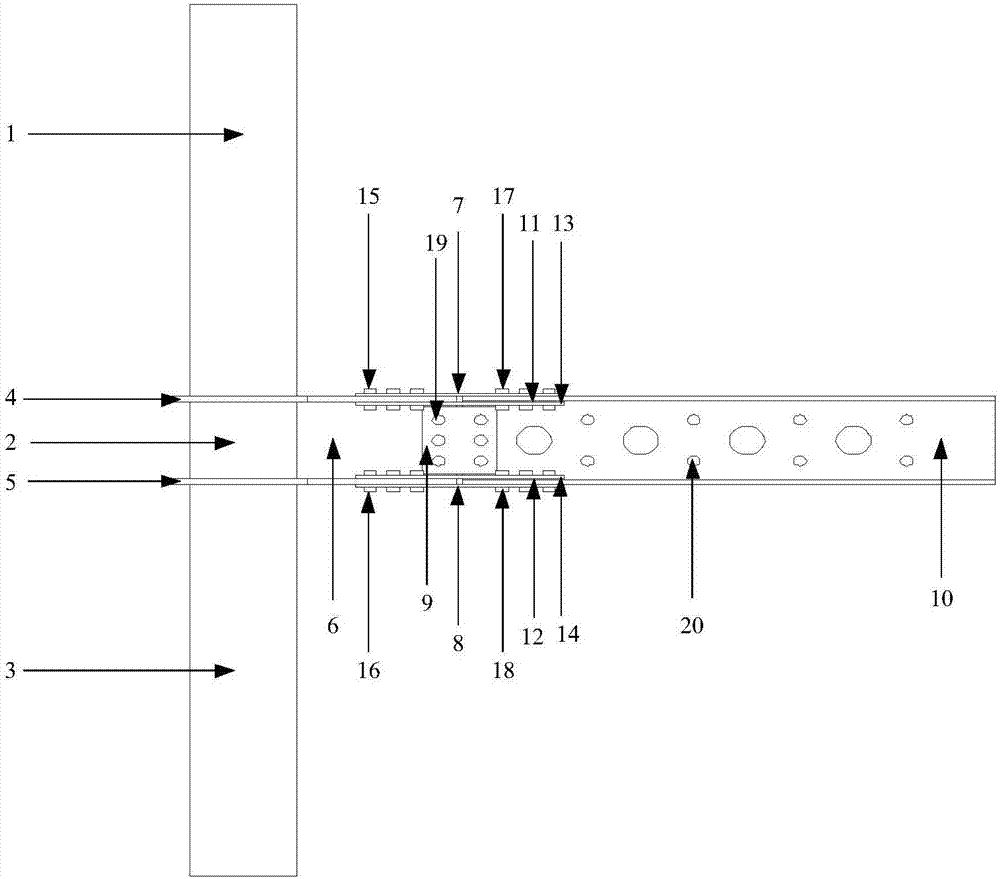

Assembly channel steel punching beam column joint connecting device capable of achieving function recovery

InactiveCN106869325AAvoid complex stress fieldsReduce construction difficultyFloorsFloor slabPunching

The invention relates to an assembly channel steel punching beam column joint connecting device capable of achieving function recovery and belongs to the field of structural engineering. The assembly channel steel punching beam column joint connecting device capable of achieving function recovery is composed of a square steel pipe column with a cantilever beam section, a channel steel punching beam section and a connecting device of the cantilever beam section and the channel punch beam section. All welding parts of the joint connection device are all finished in a factory, so that precision and quality of welds are easier to control. Construction speed is greatly increased and construction quality is greatly improved, and a spatial structure of the channel punch beam section of the channel is conducive to pipeline penetration; the channel steel punching beam and a floor can be assembled and molded in the factory to form modular assembly units. Then all the modular assembly unit and the square steel pipe column with the cantilever beam section achieve assembly connection through the channel steel punching beam. Joints of the connection device can be used for both of beam end reinforcing and cover plate connection weakening. A multi-energy dissipation mechanism can be realized, a plastic hinge is transferred to a cover plate and a connecting plate. The function of structures can be recovered only by replacing the connecting plate after an earthquake.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com