Combined light steel structure house and mounting method thereof

A light steel structure, combined technology, applied in the direction of building structure, construction, etc., can solve the problems of poor wind resistance and earthquake resistance, low reuse rate, cumbersome on-site installation, etc., to achieve short construction period and improved effective utilization rate. , the effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

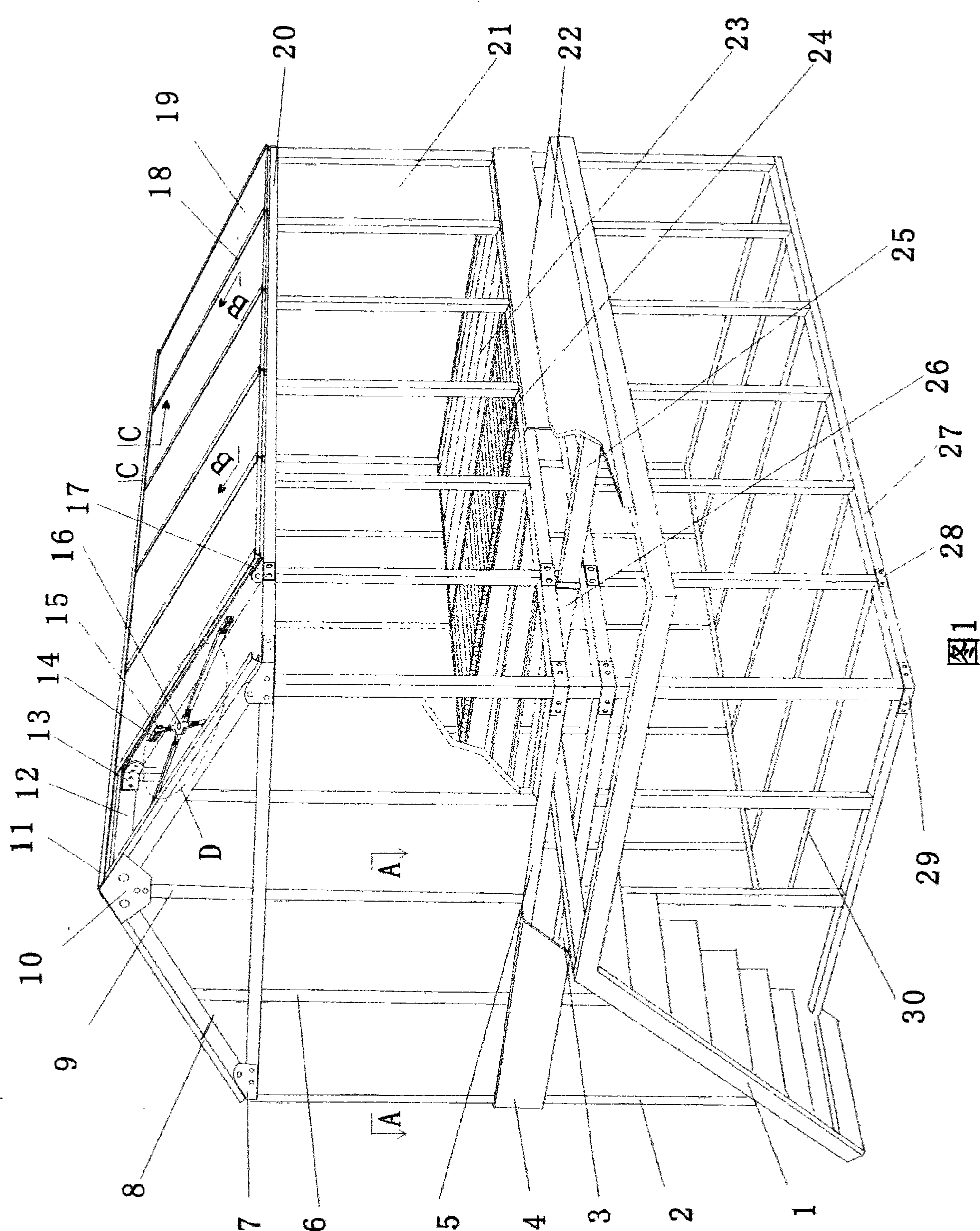

[0042] As shown in Figures 1 to 7, the two-story combined light-steel structure house of the present invention adopts general standard modules for processing, construction and installation, and all steel structure components are assembled with bolts. The two-story combined light steel structure house takes the center axis distance between adjacent corner columns and columns and between columns as a unit.

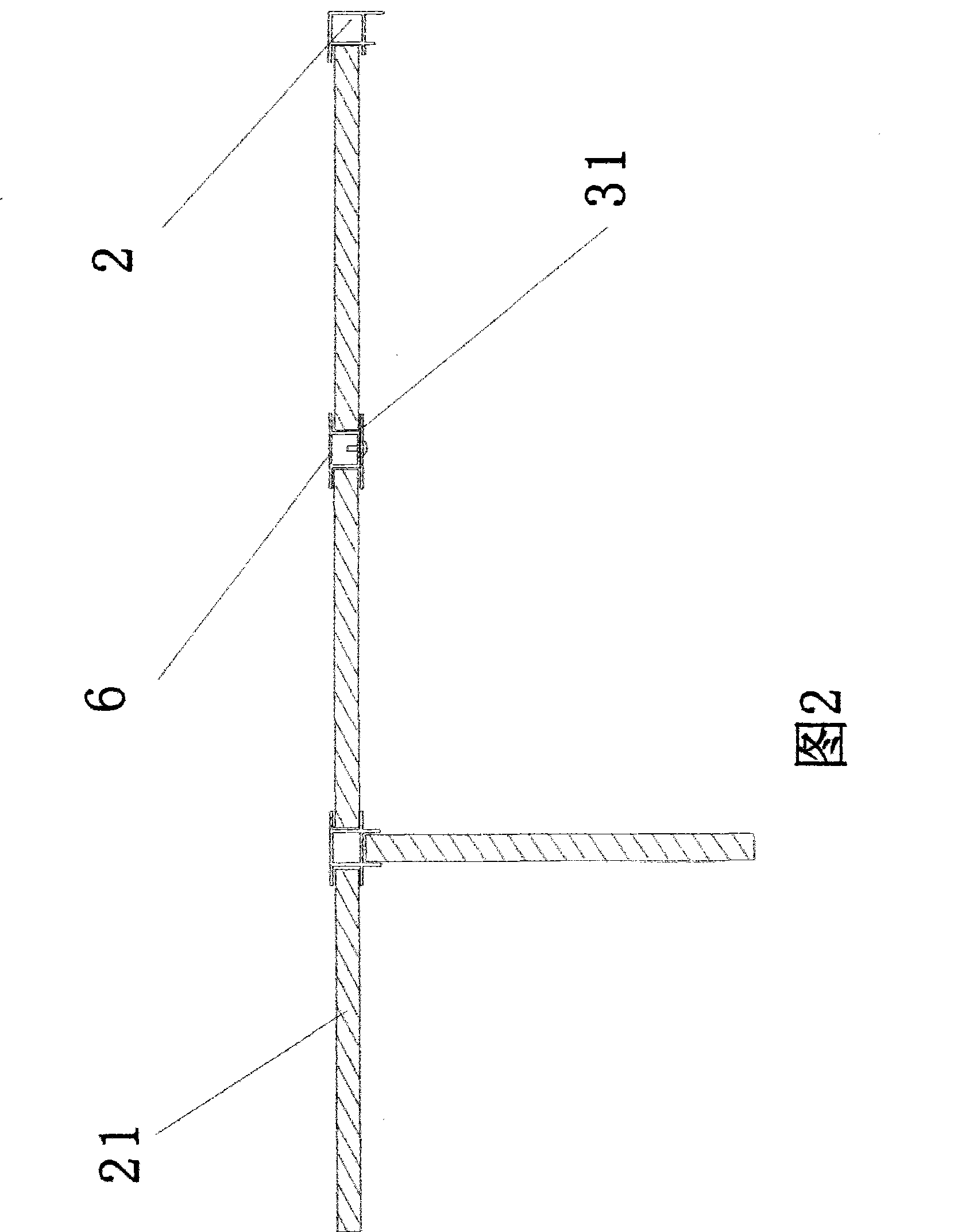

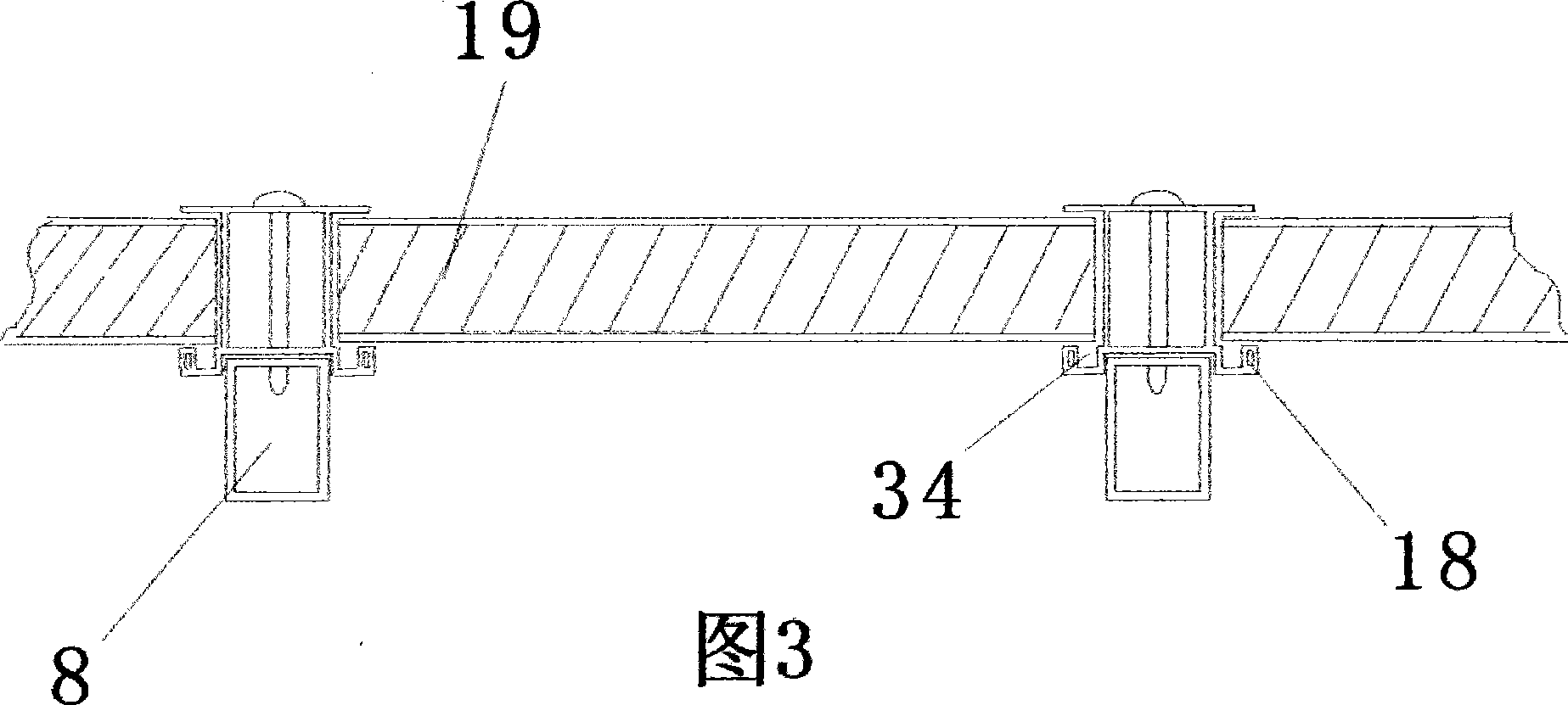

[0043] It includes: stairs 1, four ground beams 27, several floor bottom beams 30, a number of floor bottom beams 30 parallel to each other are arranged on the ground where the light steel structure house is installed, and the peripheral positions of the floor bottom beams are sequentially Four ground beams 27 are provided, and at the joints of the lower end and the upper end of each corner column 2 and column 6, a beam connection piece 28 with bolts and a corner joint connecting the ground beam 27 and the upper ring beam 3 of the first floor are respectively provided. Sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com