Patents

Literature

35results about How to "No wet work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combined light steel structure house and mounting method thereof

InactiveCN101418592AHigh degree of factoryReduce the ratio of output value to energy consumptionBuilding constructionsFloor slabSandwich panel

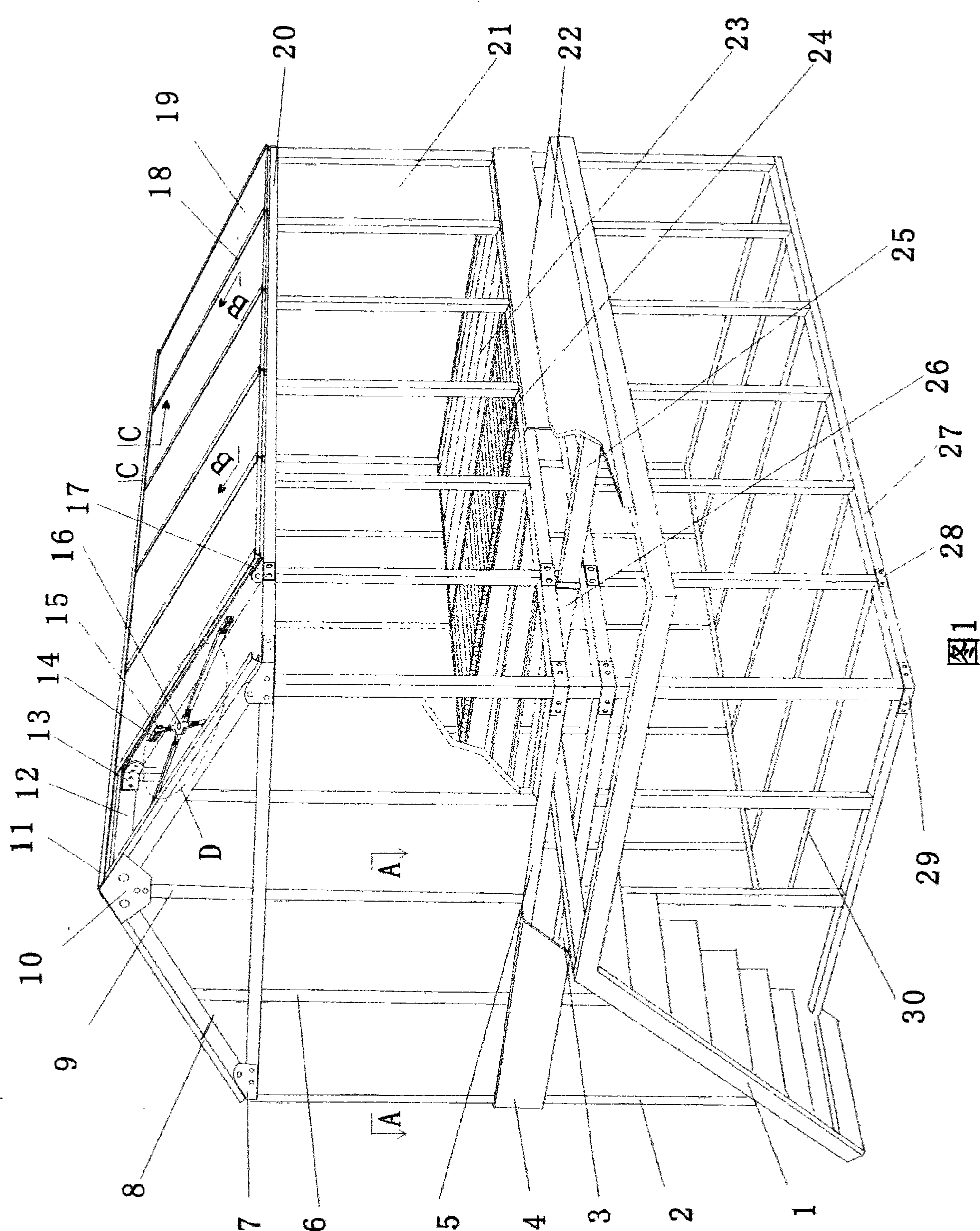

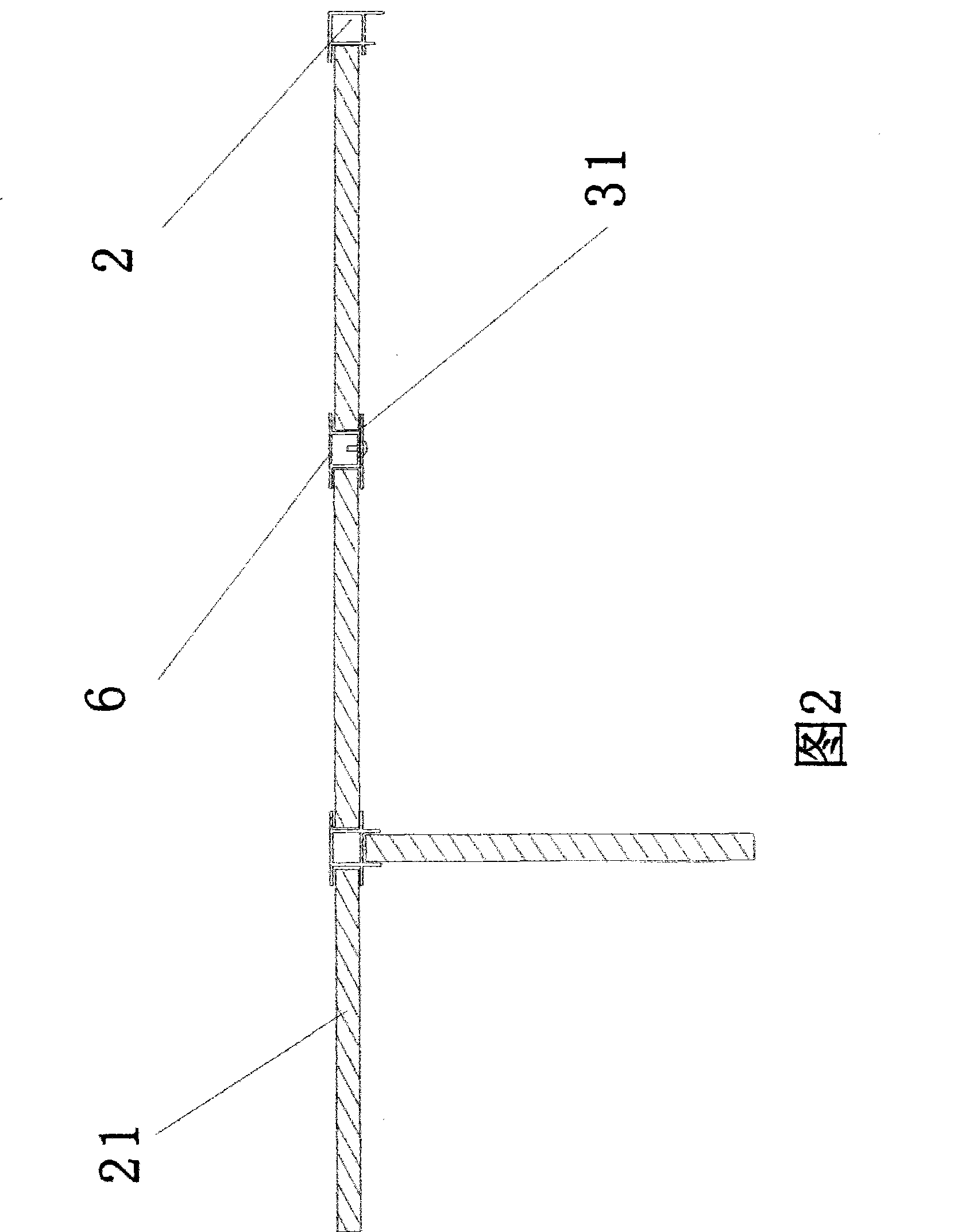

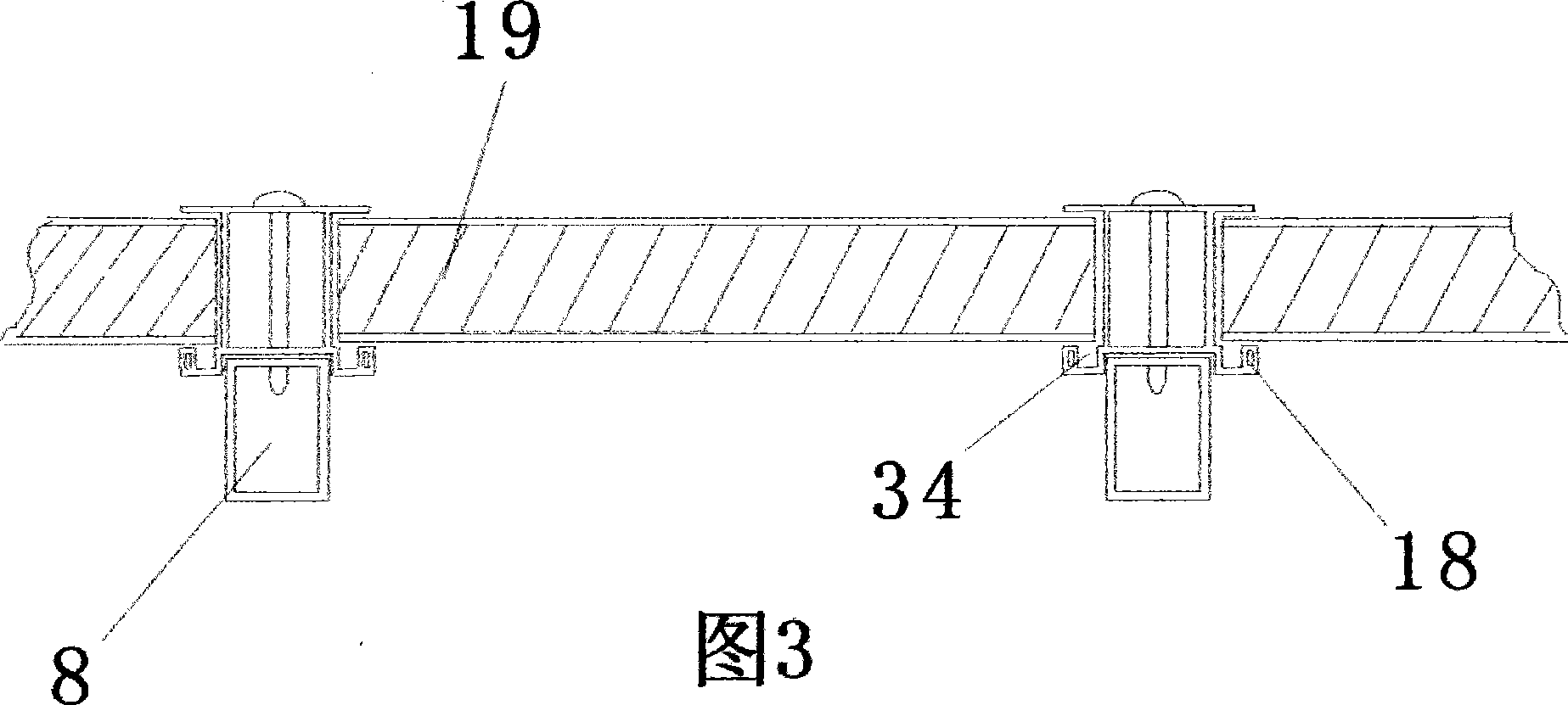

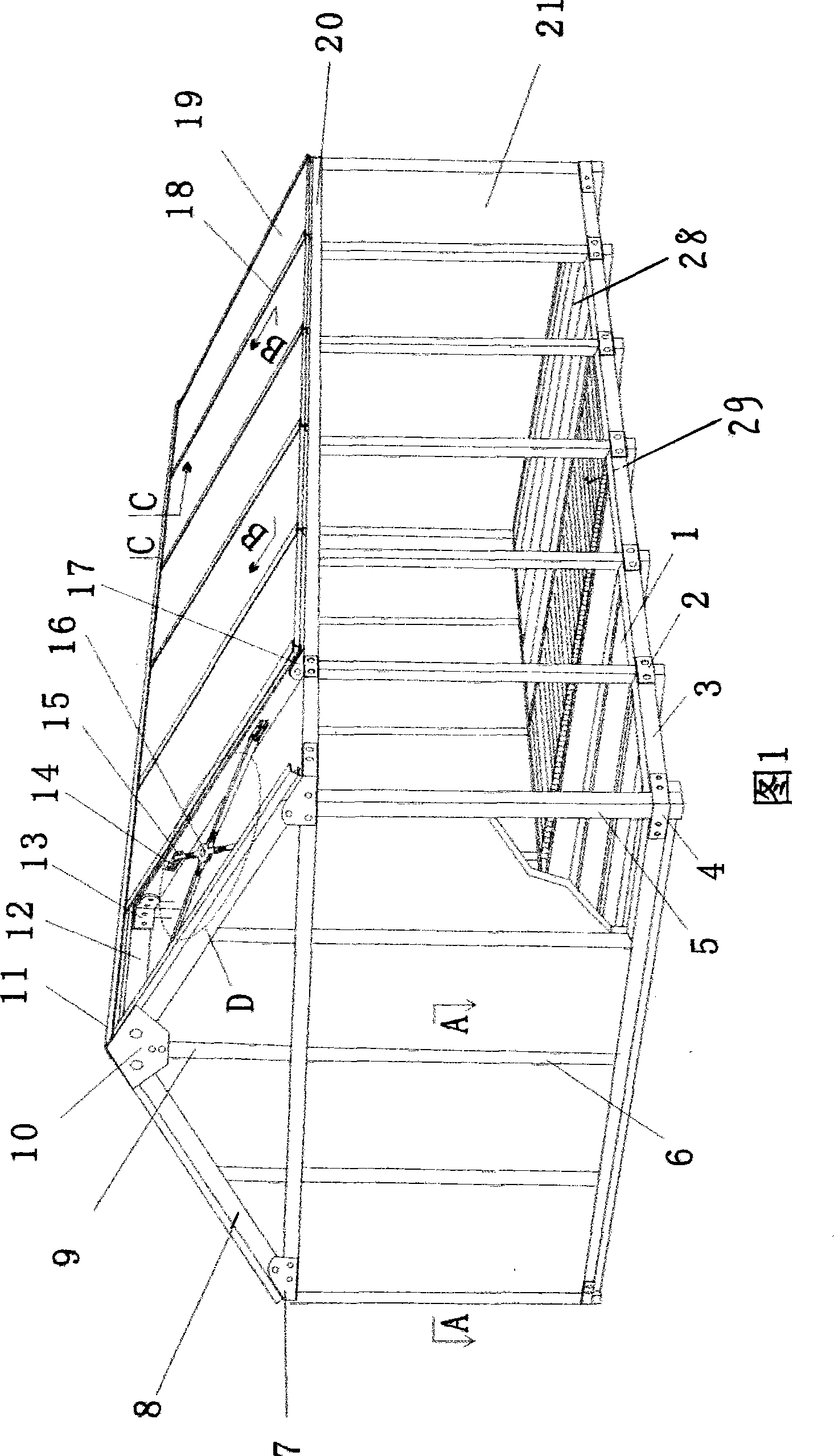

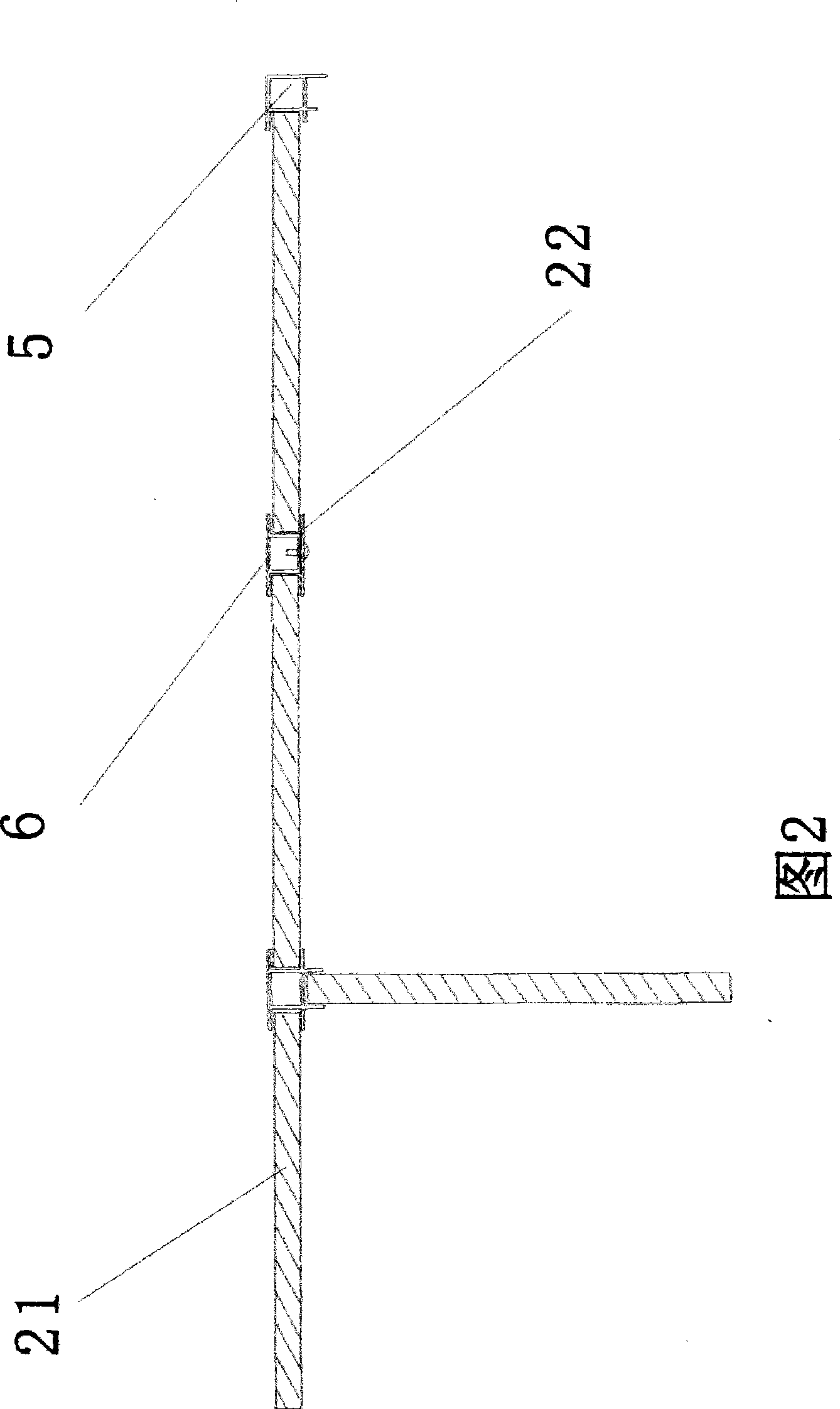

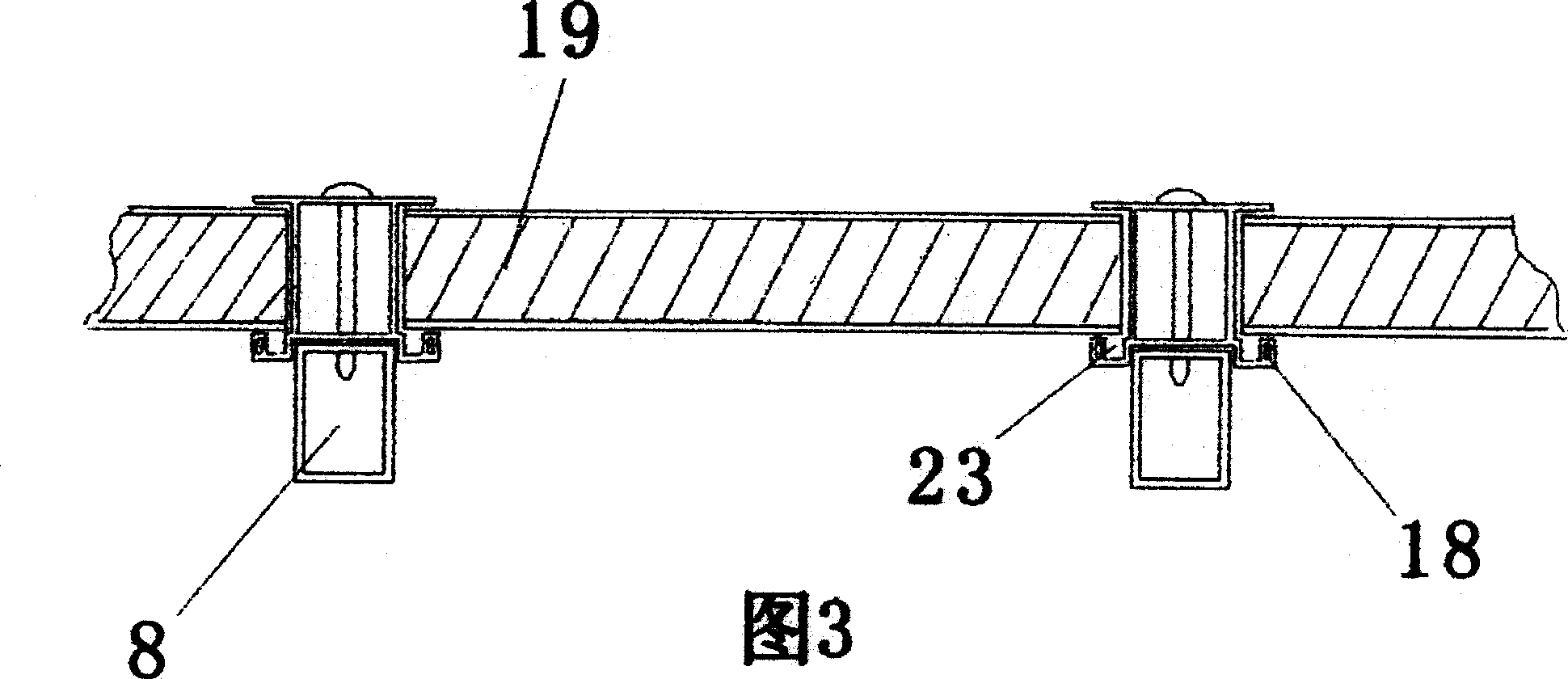

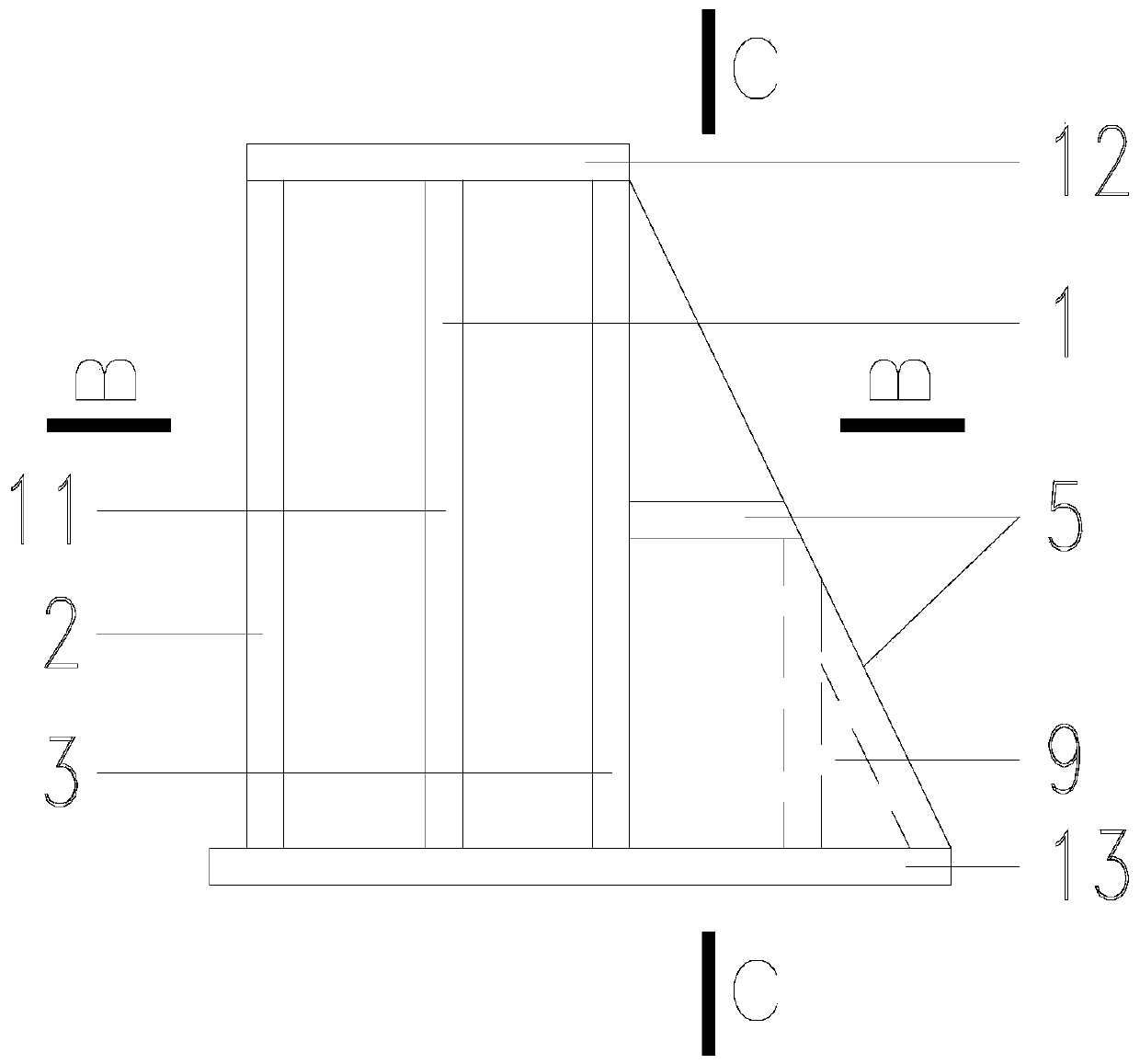

The invention relates to a combined lightweight steel structure building and an assembling method thereof. The combined lightweight steel structure building comprises ground beams, angular upright posts, upright posts, ring beams, sandwich panels, a roof, staircases, doors and windows. The key technical points of the combined lightweight steel structure building are as follows: a plurality of floor bottom girders in parallel are arranged on the ground; four ground beams are arranged on the circumference of each floor bottom girder in turn; bolt fastening sheets which are connected with the ground beams and the ring beams are arranged on joints of upper ends and lower ends of each angular upright post and each upright post respectively; limit baffle plates of wall panels are arranged on angular upright posts and upright posts near the outside of the building; bolt fastening limit treadle bars of the wall panels are arranged on upright posts near the inside of the building; the wall panels comprise wall panels provided with door bodies or wall panels provided with window bodies; metal section supporting layers which are suitable to be connected with balcony bottom girders or / and corridor bottom girders are uniformly distributed between two adjacent floors; metal floor slabs are laid on the metal section supporting layers; and the roof is as follows: a waterproof ridge section is arranged on the upper part of a ridge main girder; the edge of a roof slab is embedded into the ridge section; and a roof slab slot section provided with a drainage channel is arranged on the upper part of a ramp beam of the roof.

Owner:官木喜

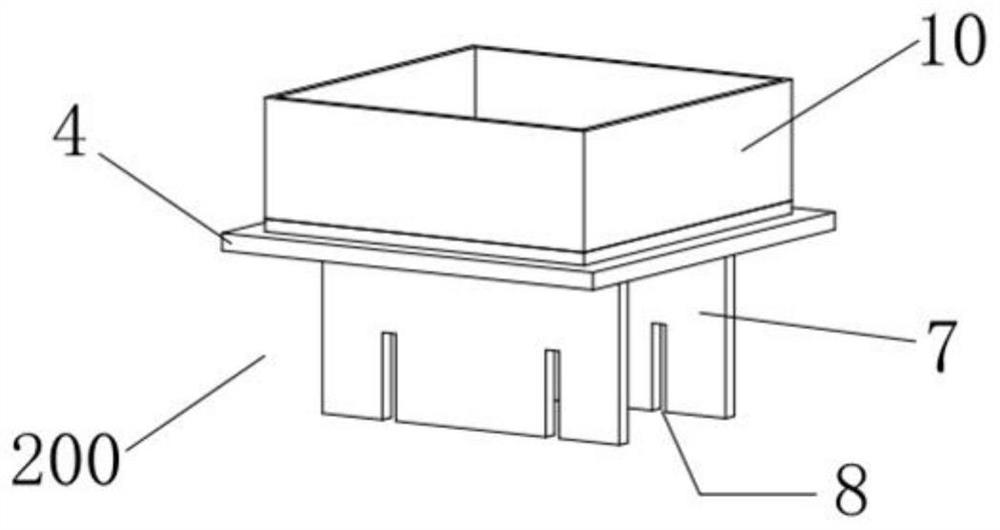

One layer combined type light steel structure house and installation method thereof

InactiveCN101440635ASatisfy the needs of clientsHigh degree of factoryBuilding constructionsSandwich panelBolt connection

The invention relates to a one-story combined type lightweight steel structure house and a mounting method thereof. The house comprises ground beams, corner upright posts, upright posts, ring beams, a sandwich panel, a roof, a door and windows. The house comprises the following technical points: a plurality of parallel floor mudsills are arranged on the ground; the periphery of the floor mudsills are sequentially provided with four ground beams; the connecting parts between the upper ends and the lower ends of each corner upright post and each upright post are provided with a bolt connecting sheet connected with the ground beam and the ring beam respectively; the positions of the corner upright post and the upright post close to the outer side of the house are provided with a limiting baffle plate of a wallboard; the position of the upright post close to the inner side of the house is provided with a bolt connecting and limiting treadle bar of the wallboard; the wallboard comprises the wallboard with a door body or window bodies; and the roof comprises: the upper part of a main girder of a roof ridge is provided with a water retaining roof ridge section; a roof board is embedded into the roof ridge section; and the upper part of an oblique beam of the roof is provided with a roof board slot section with a drainage channel. The method standardizes and generalizes members of the building structure, totally adopts bolt connection without needing welding in mounting and is suitable for the requirement of a routine lightweight structure house.

Owner:官木喜

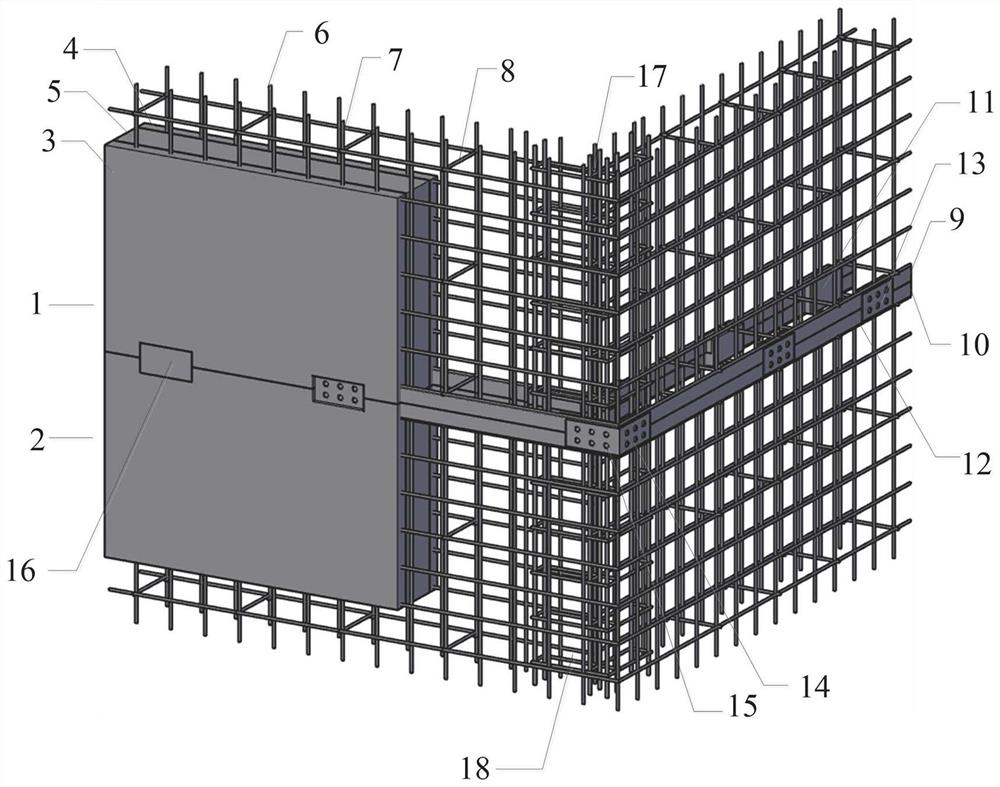

Assembled steel structure building system and construction method thereof

The invention provides an assembled steel structure building system and a construction method thereof. The assembled steel structure building system comprises a steel structure framework system, an assembled and integrated floor system, an assembled outer wall system and an assembled inner wall system; the steel structure framework system comprises double layers of steel plate concrete combined shear wall, steel tube concrete pillars, H-shaped steel beams and connection joints. The steel beams in the steel framework system serves as supports of the assembled and integrated floor system, and the assembled and integrated floor system comprises a precast concrete bottom plate, a cast-in-situ concrete super-position layer and an overhead floor layer located on the cast-in-situ concrete layer. The assembled outer wall system comprises a heat preservation and decoration integrated plate system, a waterproof interface layer and a base wall. According to the assembled steel structure building system, the design concept of separating a supporting body from a filling body is adopted, a large-span space capable of being divided flexibly can be provided, and the assembled steel structure building system and the construction method thereof have the advantages of being high in construction speed, reliable in quality and good in anti-seismic property.

Owner:SHANGHAI IRON & STEEL TECHN INST

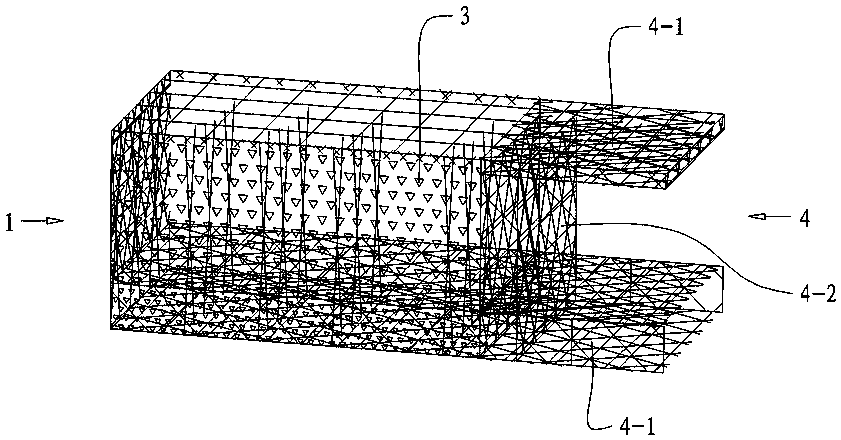

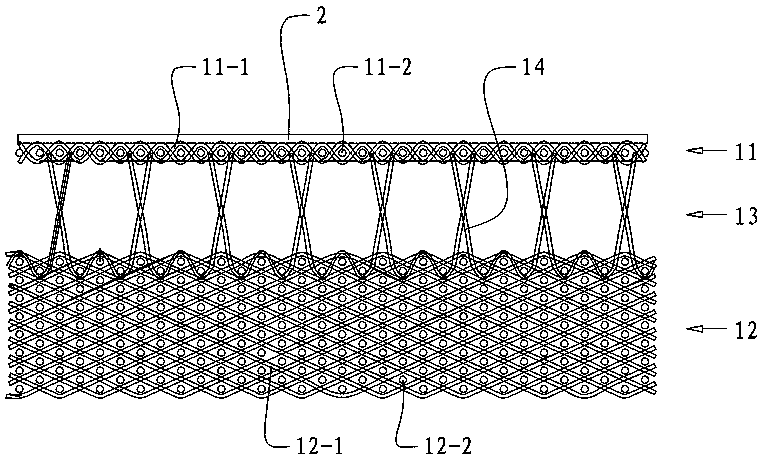

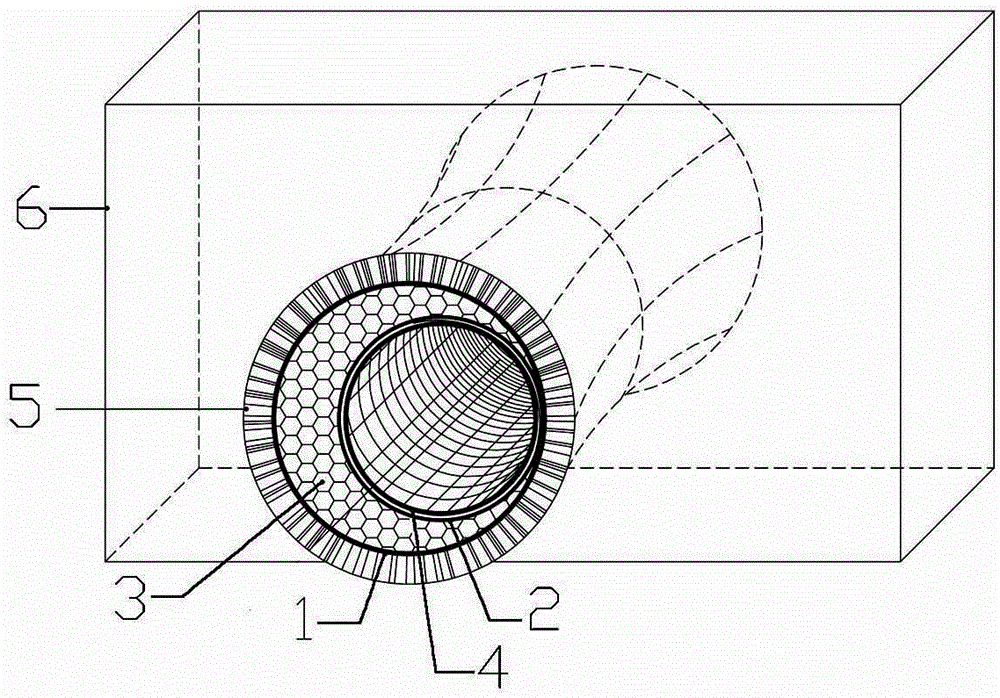

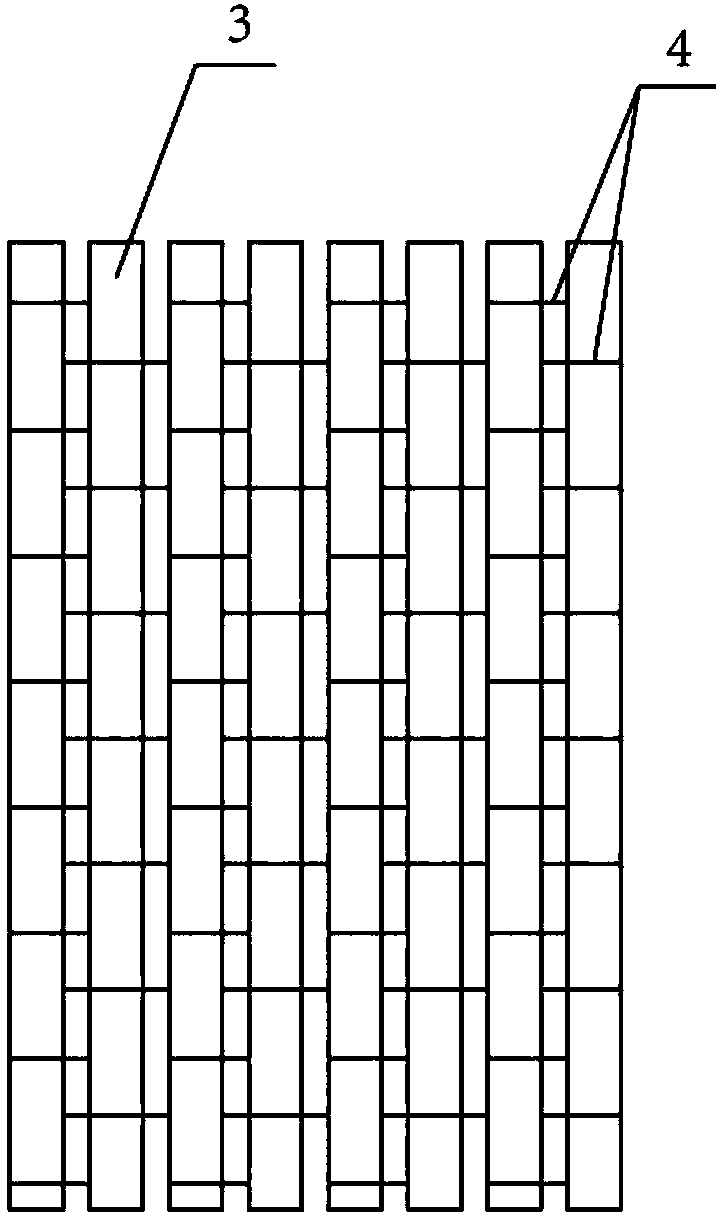

Three-dimensional multilayer-hollow fiber-reinforced concrete blanket capable of achieving lap joint

PendingCN107675831AGood toughening effectHigh strengthConstruction materialBuilding reinforcementsReinforced concreteLap joint

The invention relates to a three-dimensional multilayer-hollow fiber-reinforced concrete blanket capable of achieving lap joint and belongs to the technical field of building materials. The three-dimensional multilayer-hollow fiber-reinforced concrete blanket comprises a three-dimensional hollow-multilayer fabric, a top layer packaging fabric and active dry powder concrete; one side edge or multiside edges of the three-dimensional hollow-multilayer fabric are manufactured into a U-shaped lap-joint part, and the three-dimensional hollow-multilayer fabric comprises a first layer, a second layerand a middle layer; the first layer forms a two-dimensional structure through warp and weft intertwining, and the second layer forms a three-dimensional multilayer structure through warp and weft intertwining; a plurality of grid holes are formed in the first layer, and a three-dimensional hollow structure is formed on the middle layer; vertical warps weave the first layer, the second layer and the middle layer into a three-dimensional integral structure; and the three-dimensional hollow structure is filled with the active dry powder concrete through the grid holes, and the top layer packaging fabric and a first layer package are composited into a whole. The three-dimensional multilayer-hollow fiber-reinforced concrete blanket is a composite concrete blanket which is of a reinforced structure and is high in integrality, reinforced, toughed, resistant to bending and cracking, convenient to use and capable of quickly achieving high-property and low-cost lap joint in the construction process.

Owner:林通泉

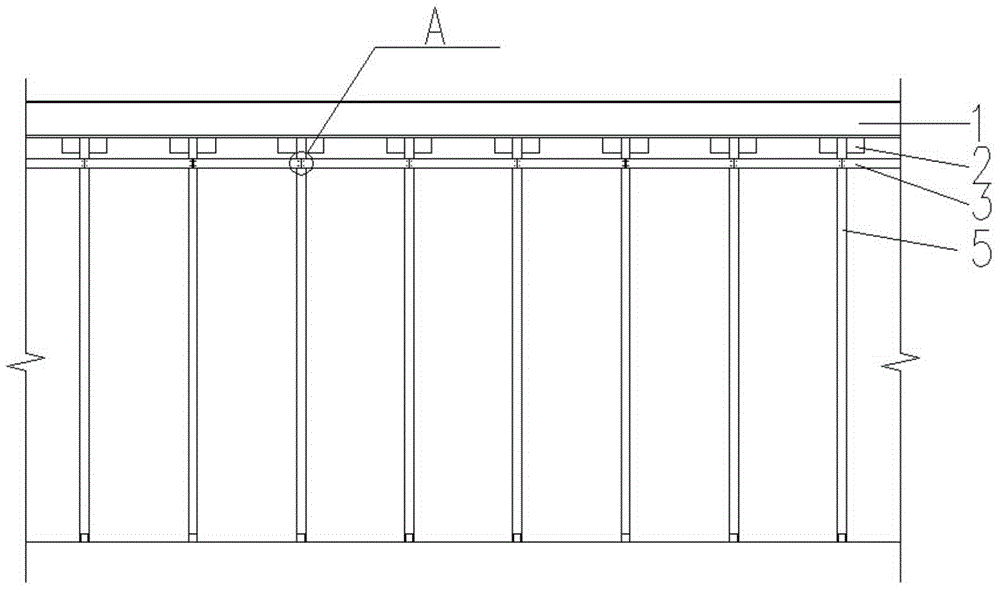

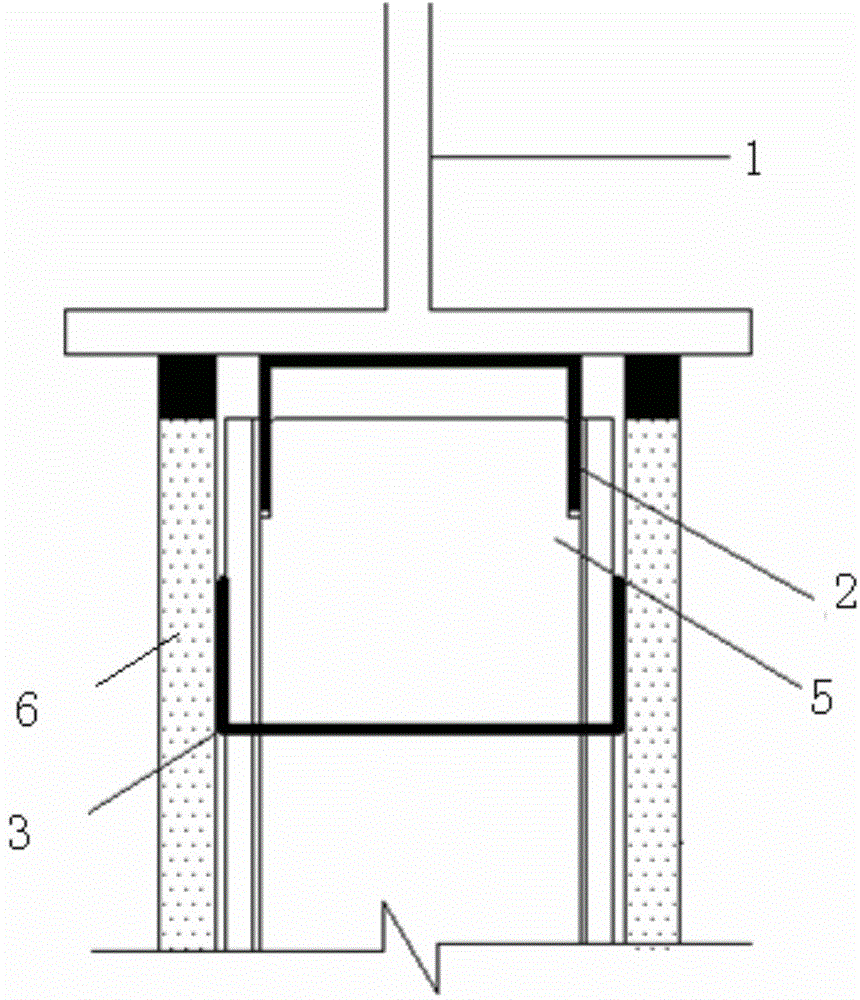

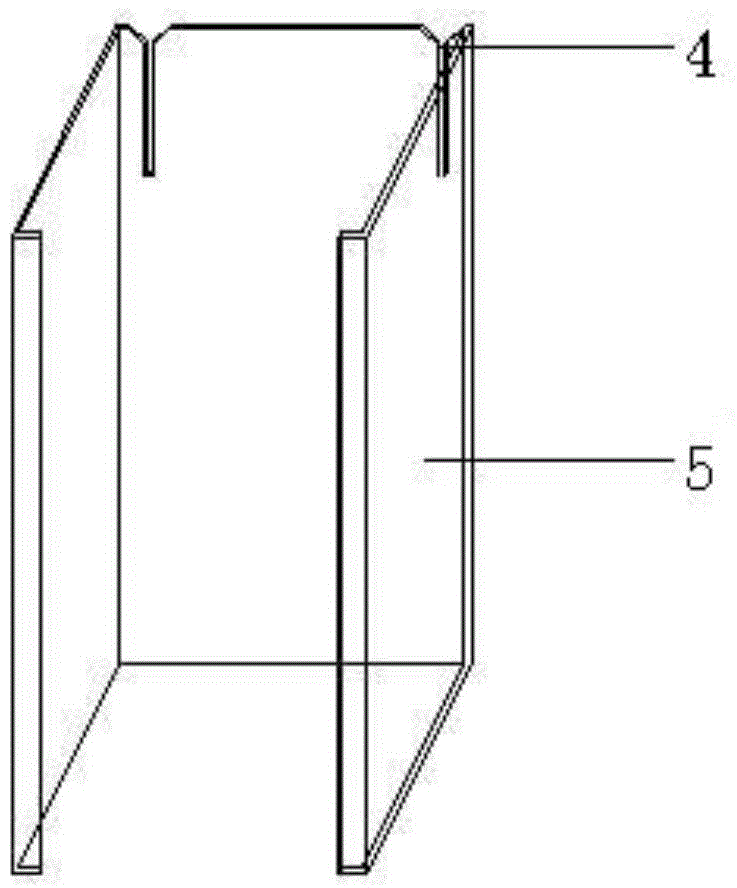

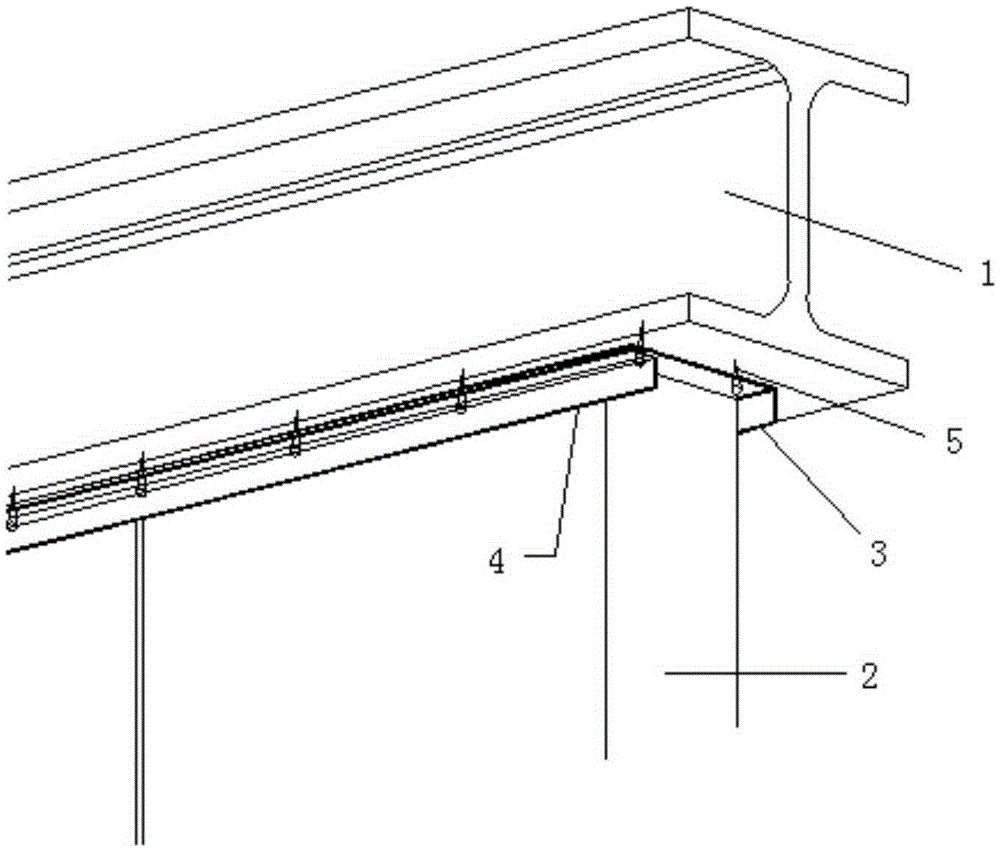

Connecting structure for light steel keel internal parting wall and steel beam

The invention relates to a connecting structure for a light steel keel internal parting wall and a steel beam. The connecting structure comprises a wall plate, a steel beam, horizontal keels and vertical keels, and is characterized in that a U-shaped steel clamp is welded under the steel beam corresponding to each vertical keel; slots matched with the two lateral edges of the U-shaped steel clamp are formed in the back at the upper end of each vertical keel; the two lateral edges of the U-shaped steel clamp are vertically inserted into the slots, so that the U-shaped steel clamp is in sliding connection with the vertical keel; the vertical keels are connected with each other through the horizontal keels located under the U-shaped steel clamp; the wall plate is fixed on the vertical keels. The connecting structure has the advantages that the vertical keels and the wall plate fixed on the vertical keels are in sliding connection with the steel beam, the connecting structure can adapt to the deformation of a structural main body and the construction design and the seismic requirement are met; the component processing and welding can be finished in a factory; on-site operation is reduced; the assembling is convenient and simple; the construction efficiency is high; the industrial production is easily realized; the connecting structure is fit for on-site assembling type light steel keel internal parting wall as well as a prefabricated type light steel keel internal parting wall and is wide in application scope.

Owner:SHENYANG JIANZHU UNIVERSITY

Fabricated wallboard and assembly method and disassembly method of fabricated wallboard

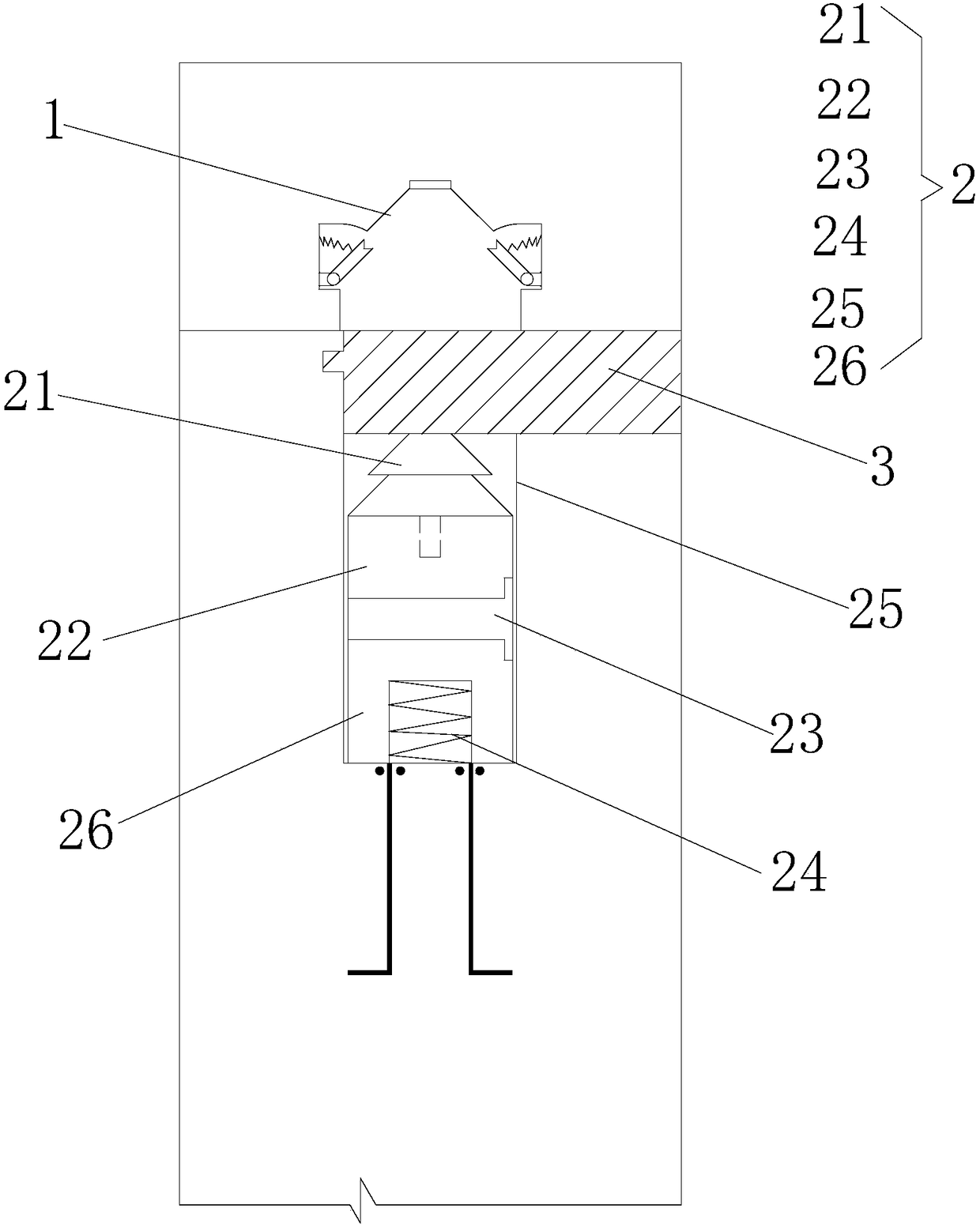

ActiveCN108532793APrevent horizontal movementReduced strength requirementsWallsNon destructiveEngineering

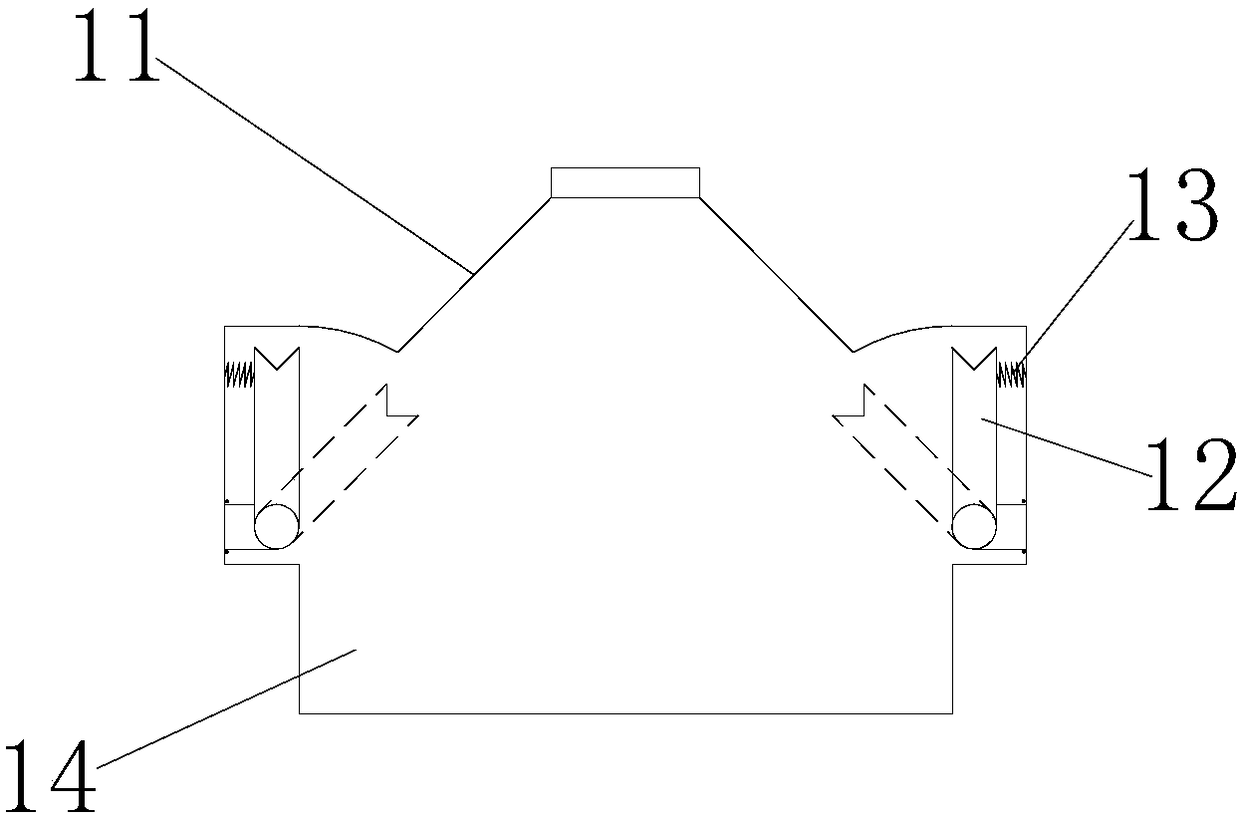

The invention discloses a fabricated wallboard. A tenon and a mortise are separately formed in the two sides of a main body of the wallboard in the height direction of the main body of the wallboard.A pre-buried wall clamping member for connecting a beam is arranged at the top of the main body of the wallboard, wherein the wall clamping member comprises a wall clamping member shell, an ejection member, an intermediate joint, a shearing resistance member and a clamping head which can be connected to a beam clamping member in a clamped mode. The ejection member includes an ejection spring, andthe ejection spring can eject the clamping head into the beam clamping member and connected with the beam clamping member in a clamped mode. A notch is formed in the wall clamping member shell, and acover plate passage communicating with the notch is arranged on the wall facade. The invention also discloses an assembly method for assembling the beam and a wall by using the fabricated wallboard. The invention also discloses a disassembly method of the prefabricated wallboard. The technical problem that the connection between a fabricated wall body and the beam and wall needs to be wet worked in the prior art is solved, the wet installation can be realized, the detachable installation can be realized, and the wall body can be disassembled from the beam by means of non-destructive disassembly.

Owner:CHONGQING UNIV

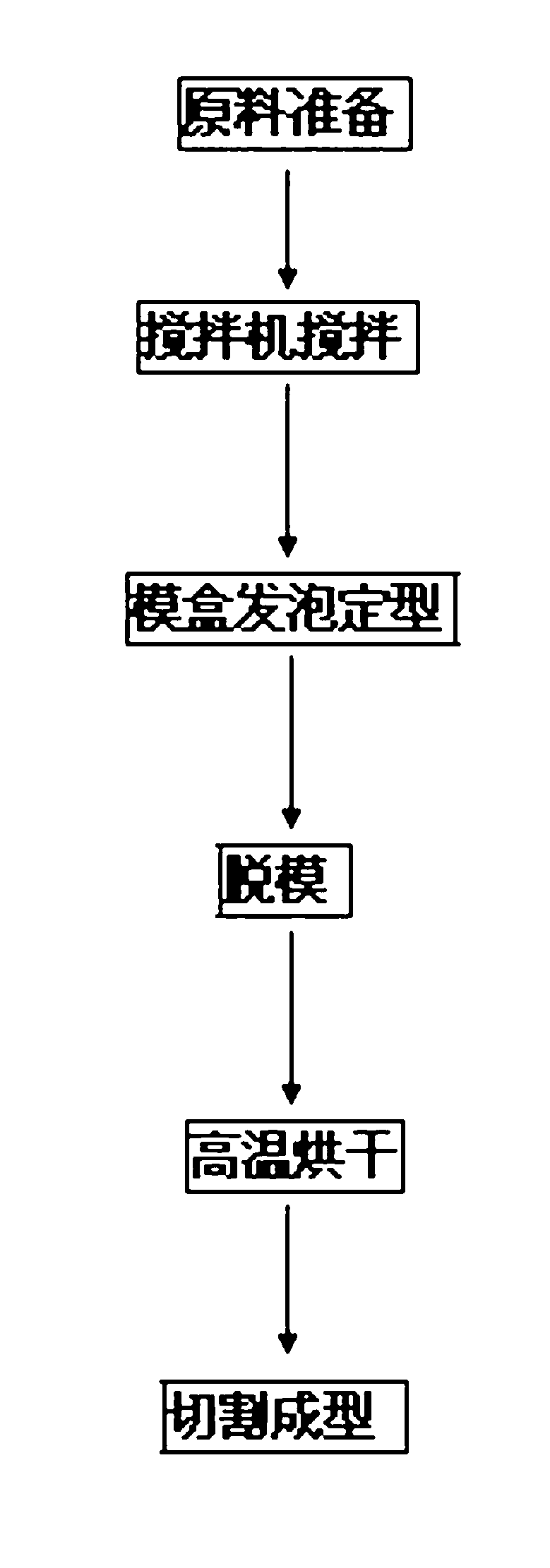

Exterior wall thermal insulation board with high performance and preparation process thereof

The invention discloses an exterior wall thermal insulation board with high performance and a preparation process thereof. The thermal insulation board is composed of 100-200 parts of pearlite, 50-100 parts of an adhesive, 50-100 parts of hydrogen peroxide, 10-20 parts of calcium stearate, 5-10 parts of calcium formate, 10-20 parts of sodium fluorosilicate, 0.5-1 part of tensile fiber, 10-20 parts of blast furnace slag and 5-10 parts of a waterproofing agent. The preparation process comprises steps of raw material preparation, and mold box foaming molding. The thermal insulation board has advantages of low density, high strength and high plasticity; the preparation process realizes factorization production, prefabricated construction, and is efficient, energy-saving, safe and reliable; and combustion performance of the product accords with the grade A requirements.

Owner:哈密市祥昊工贸有限公司

Light inner wall and steel beam connection structure with self-tapping screws

The invention discloses a light inner wall and steel beam connection structure with self-tapping screws. The connection structure comprises a steel beam, an L-shaped clamping set and the self-tapping screws. The L-shaped clamping set comprises a first L-shaped clamp and a second L-shaped clamp. One end of the long edge of the first L-shaped clamp is connected with the steel beam through one self-tapping screw, the other end of the long edge of the first L-shaped clamp and the long edge of the second L-shaped clamp are connected with the steel beam through the remaining self-tapping screws, and a space is formed between the short edge of the first L-shaped clamp and the short edge of the second L-shaped clamp and used for containing a light inner wall board. Construction is convenient and fast, on-site assembly is easy and convenient, wet construction and pollution are avoided, and constructing site positioning is accurate; the connection structure can be directly completed in a factory, on-site workloads are reduced, construction efficiency is greatly improved, and industrial production can be easily achieved; connection is firmer, a lower flange of the steel beam looks more attractive, and the light inner wall and steel beam connection structure is suitable installing light inner walls and body structures of a multi-rise and high-rise steel structure building and is wide in adaptability.

Owner:SHENYANG JIANZHU UNIVERSITY

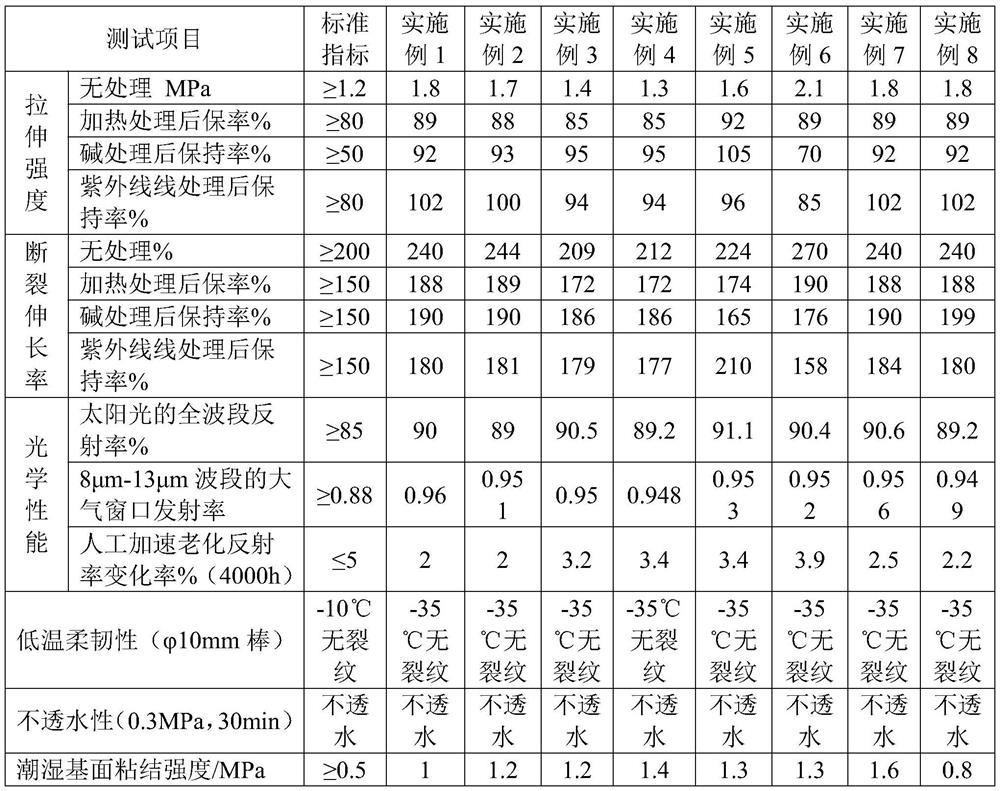

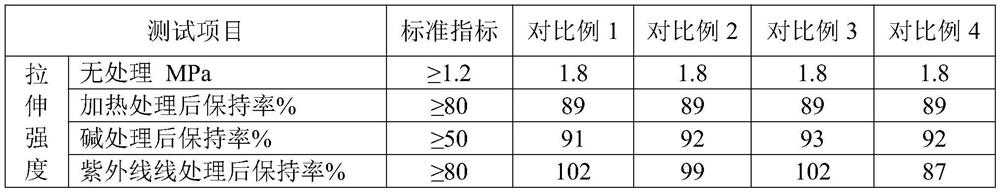

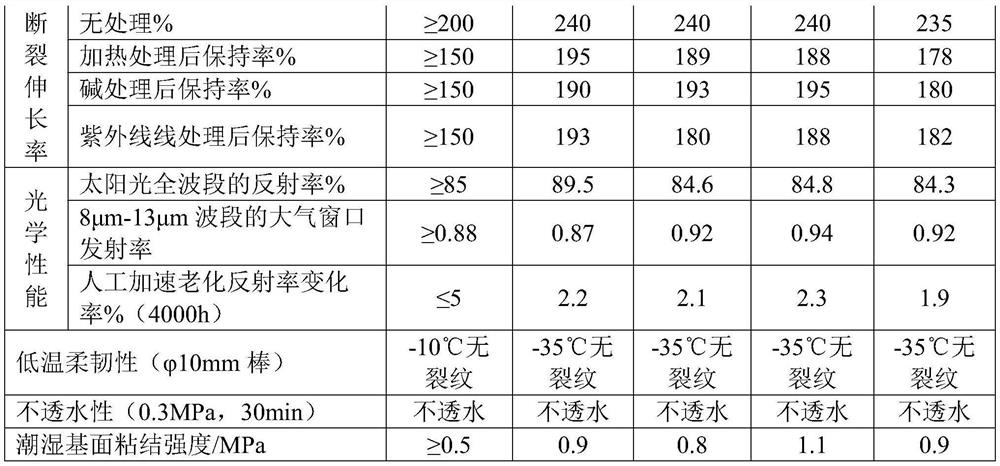

Polymer cement radiation refrigeration paint and coating

ActiveCN113563779AHigh-strength waterproof performanceEase of construction and constructionPolyurea/polyurethane coatingsReflecting/signal paintsWave bandPolymer chemistry

The present invention relates to a polymer cement radiation refrigeration paint. The polymer cement radiation refrigeration paint comprises a liquid material and a powder material, the powder material comprises a base material, the powder material further comprises functional fillers, the functional fillers comprise a main filler and an auxiliary filler, the oil absorption amount of the main filler is less than or equal to 20, the oil absorption amount of the auxiliary filler is smaller than or equal to 30, the reflectivity of the main filler to the full wave band of sunlight is larger than or equal to 90%, and the atmospheric window emissivity of the auxiliary filler at the wave band of 8-13 microns is larger than or equal to 0.94. The invention also relates to a coating which comprises a polymer cement radiation refrigeration coating formed by the polymer cement radiation refrigeration paint. The polymer cement radiation refrigeration coating formed by the polymer cement radiation refrigeration paint has excellent waterproof performance, and meanwhile, an energy-consumption-free cooling effect can be provided for an existing matrix.

Owner:NINGBO RADI COOL ADVANCED ENERGY TECH CO LTD

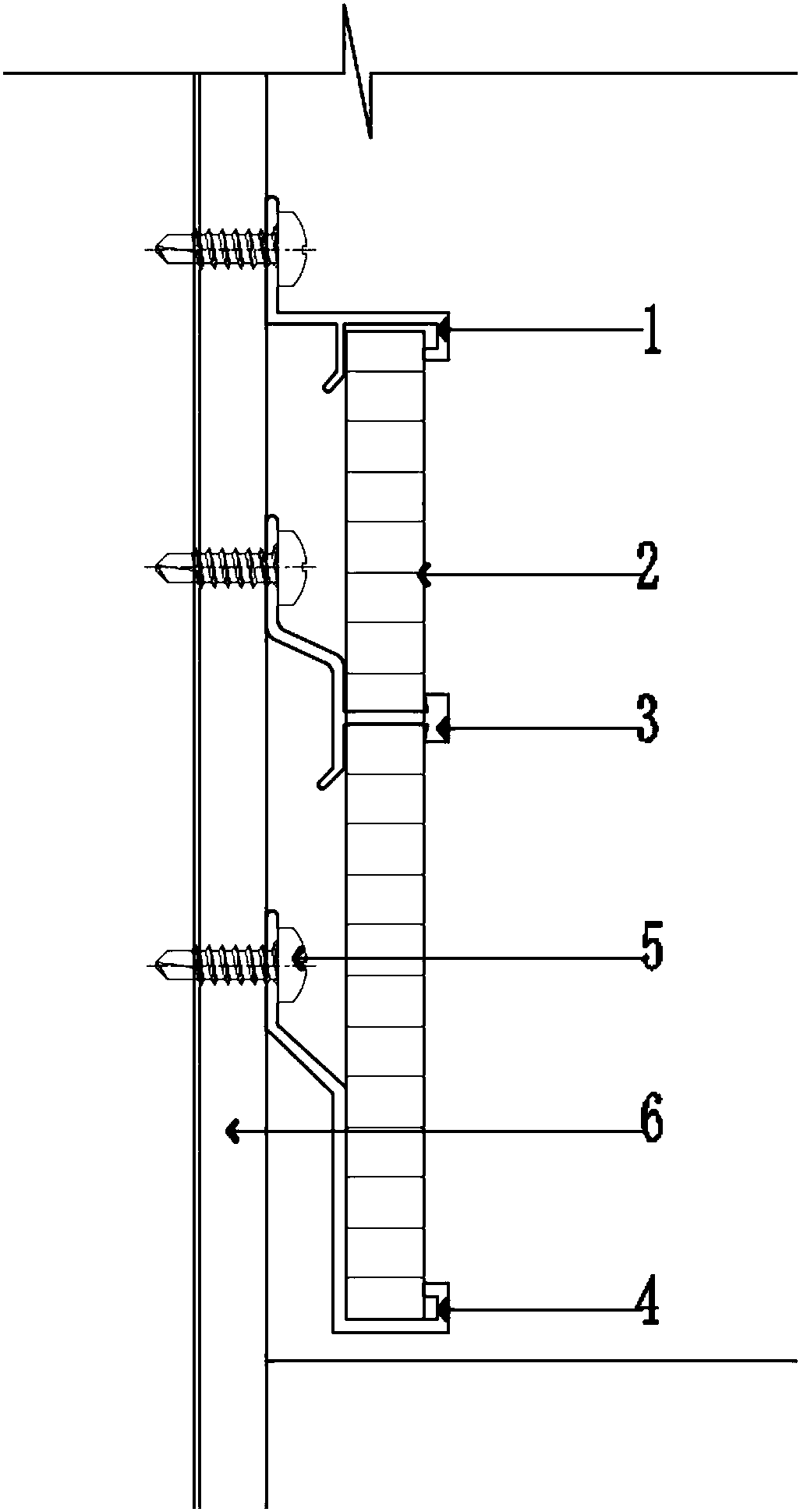

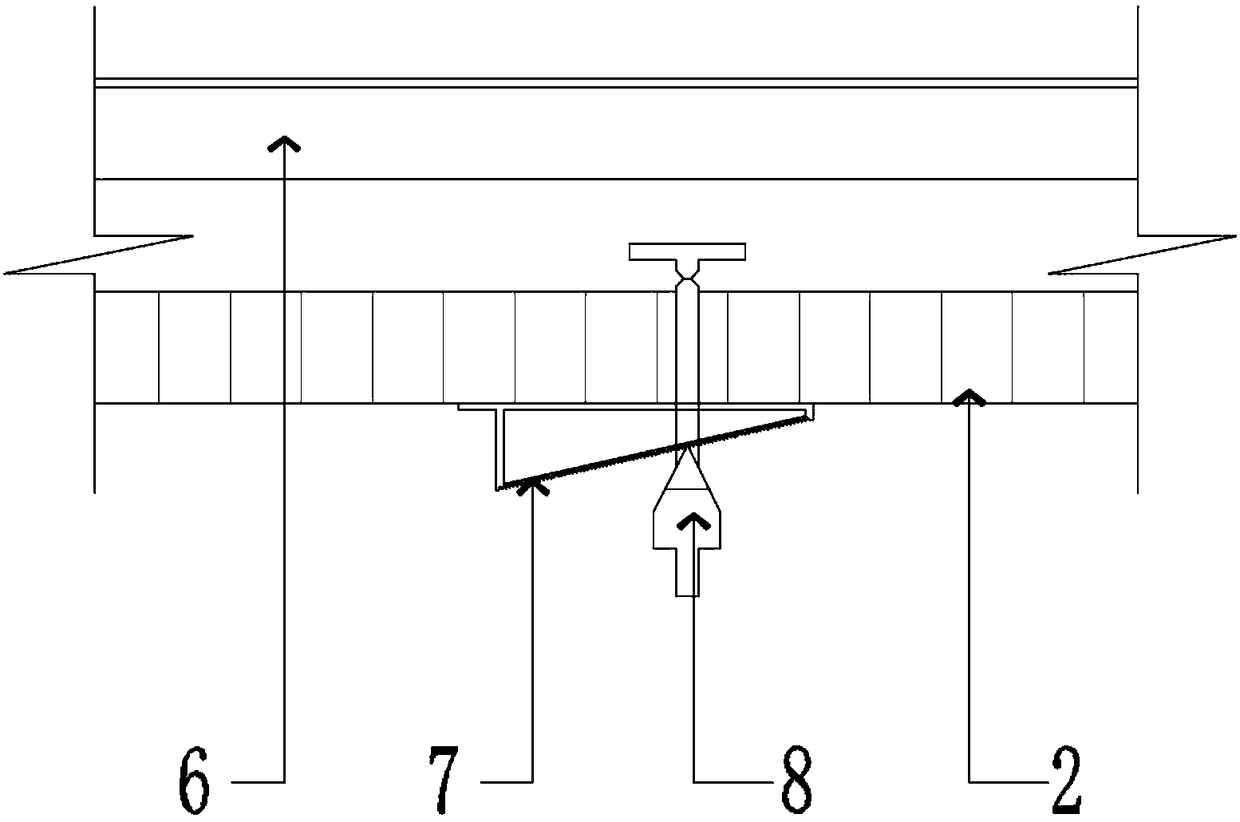

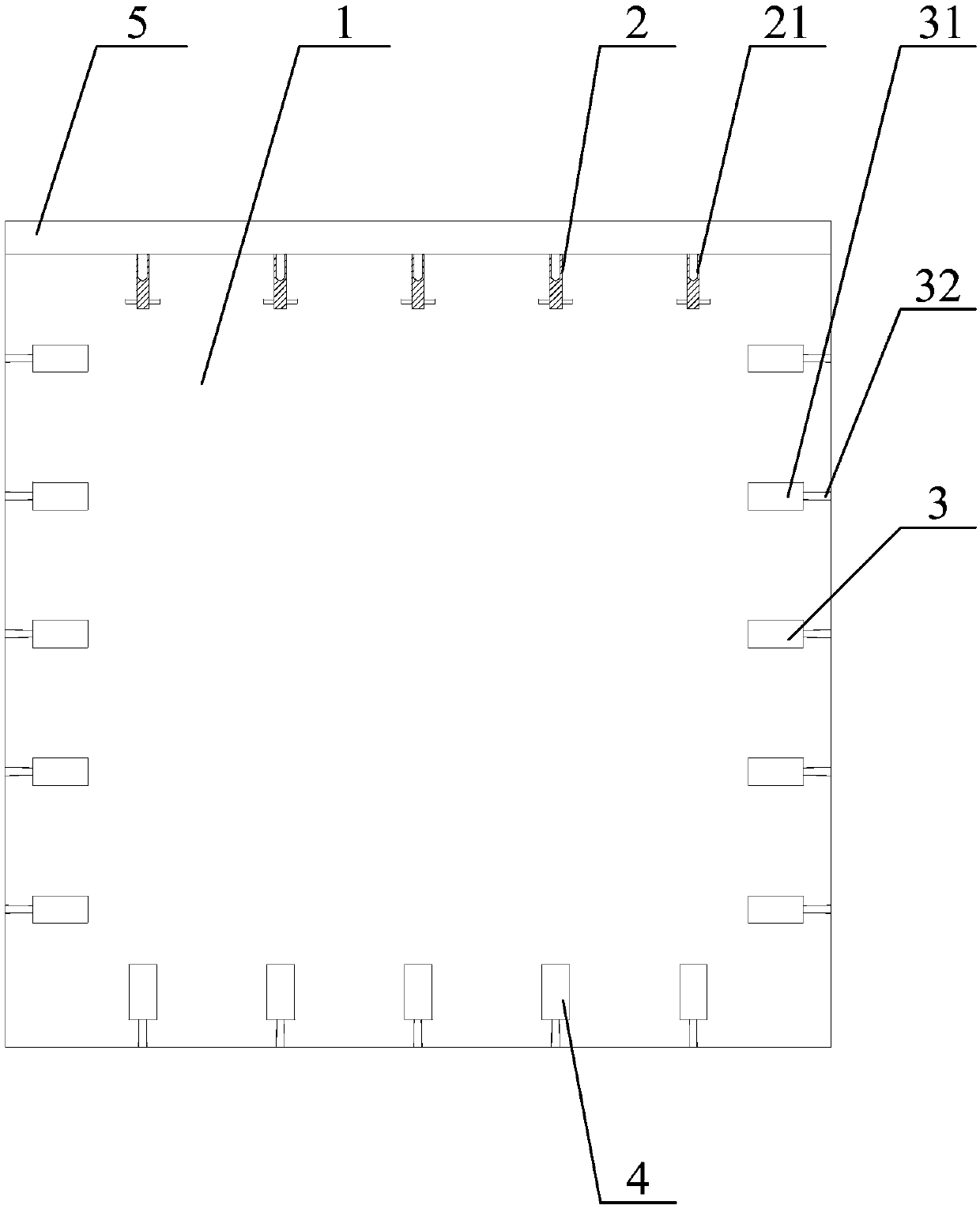

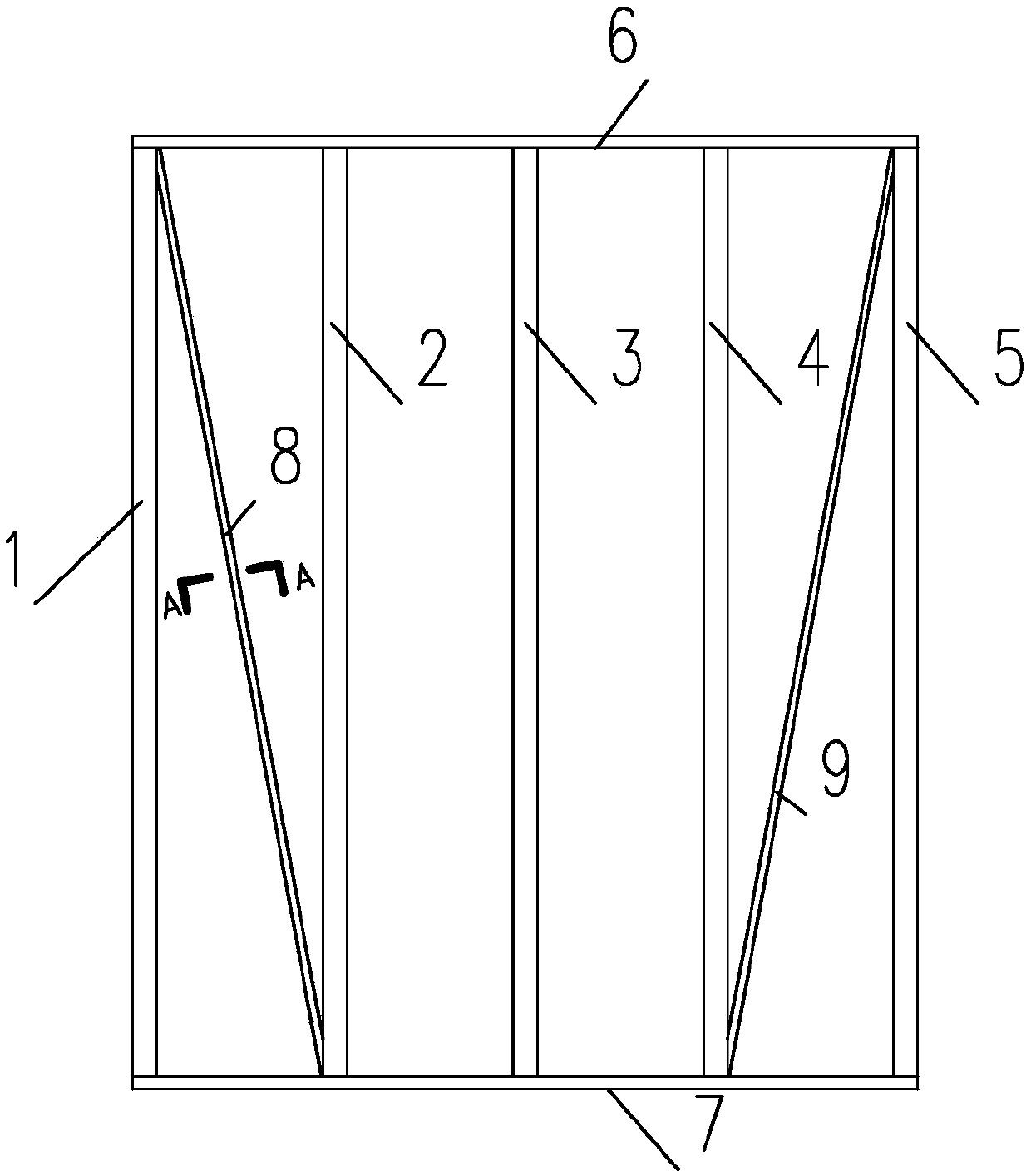

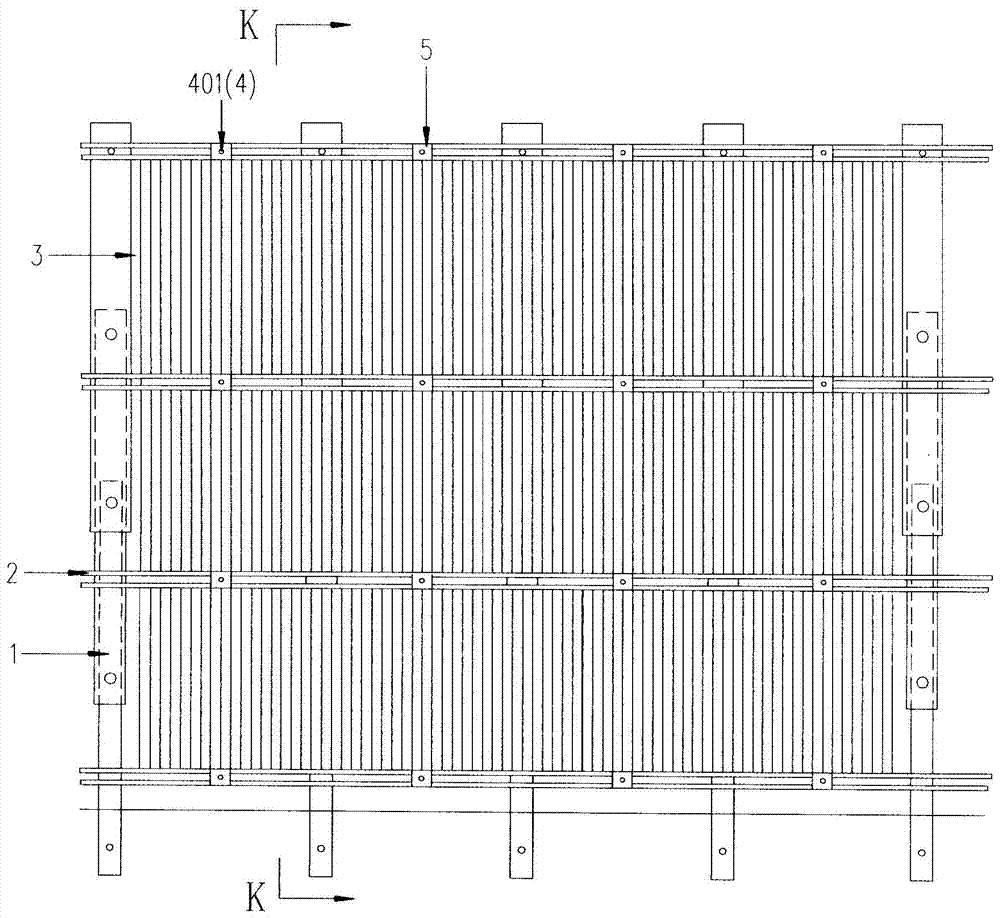

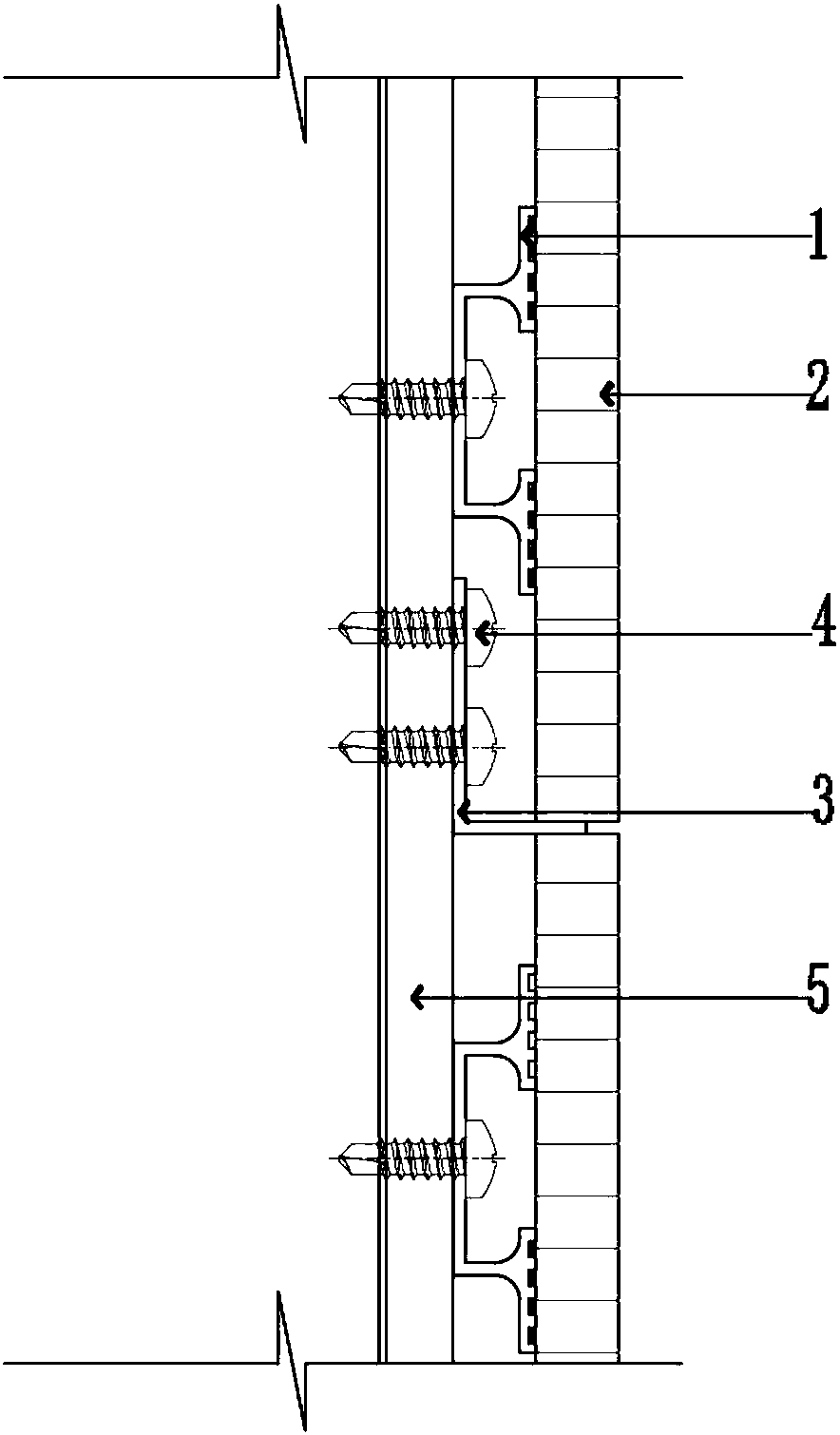

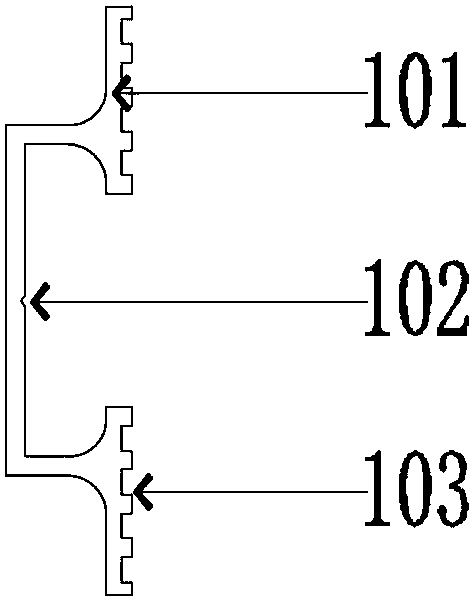

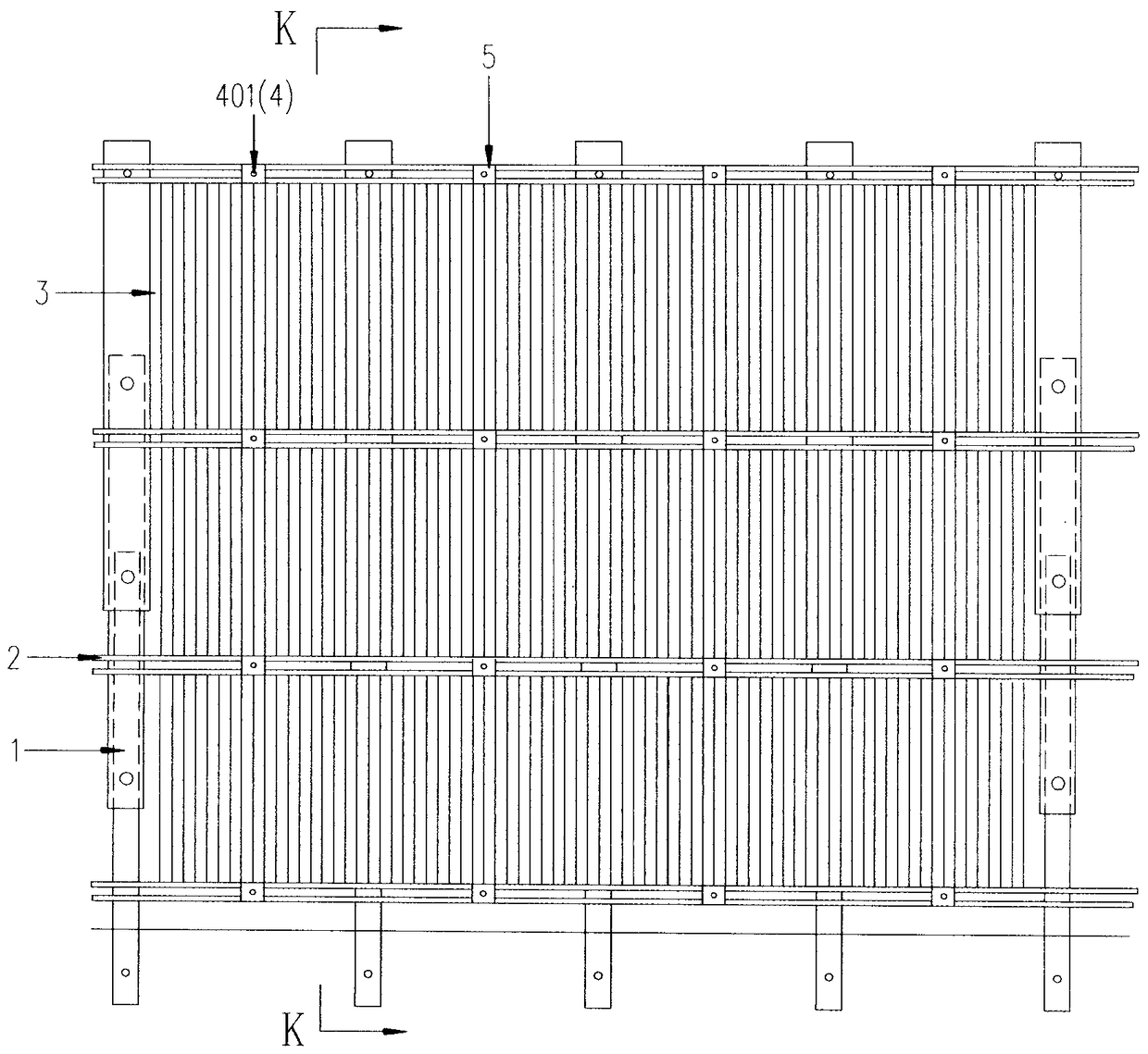

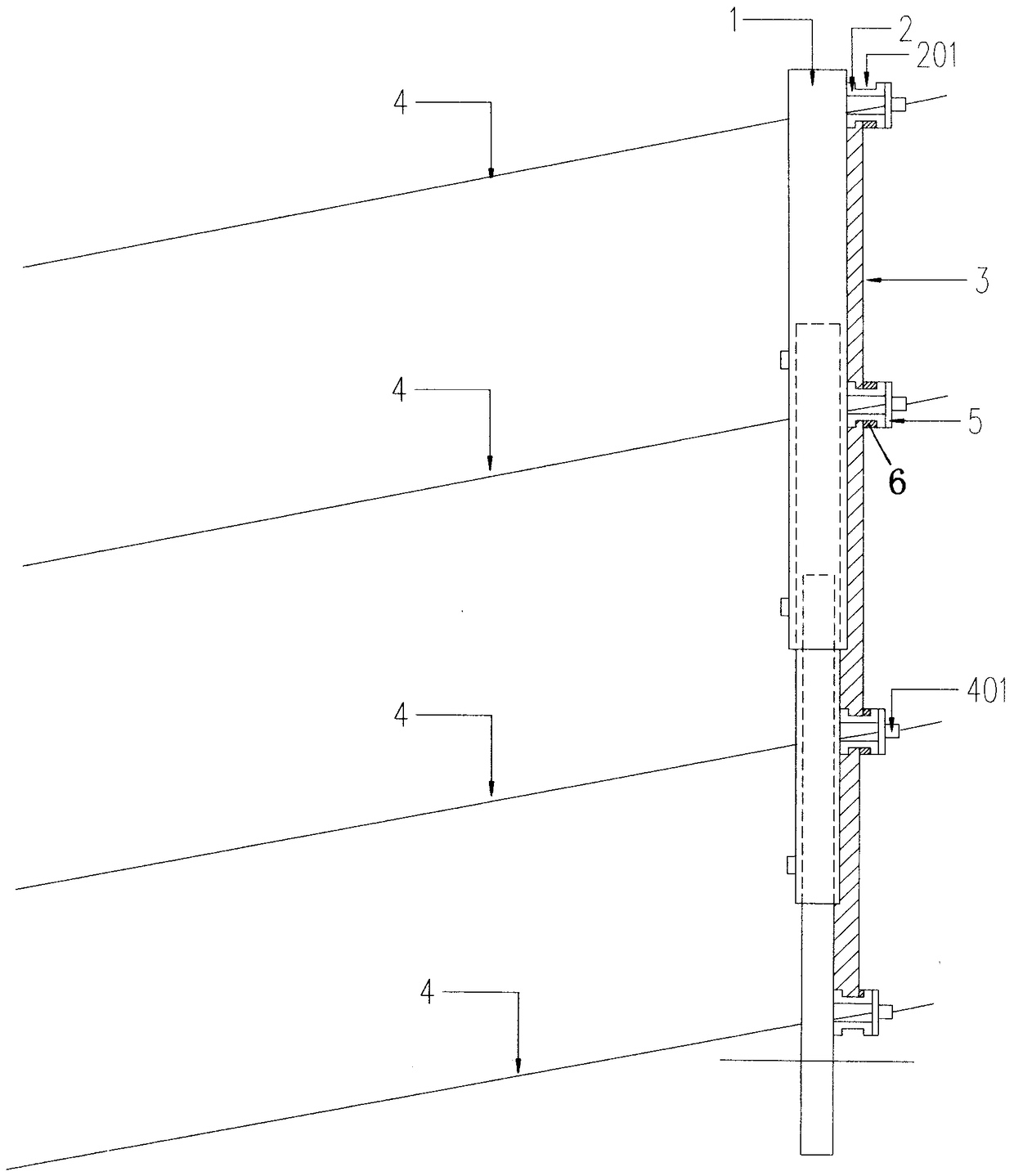

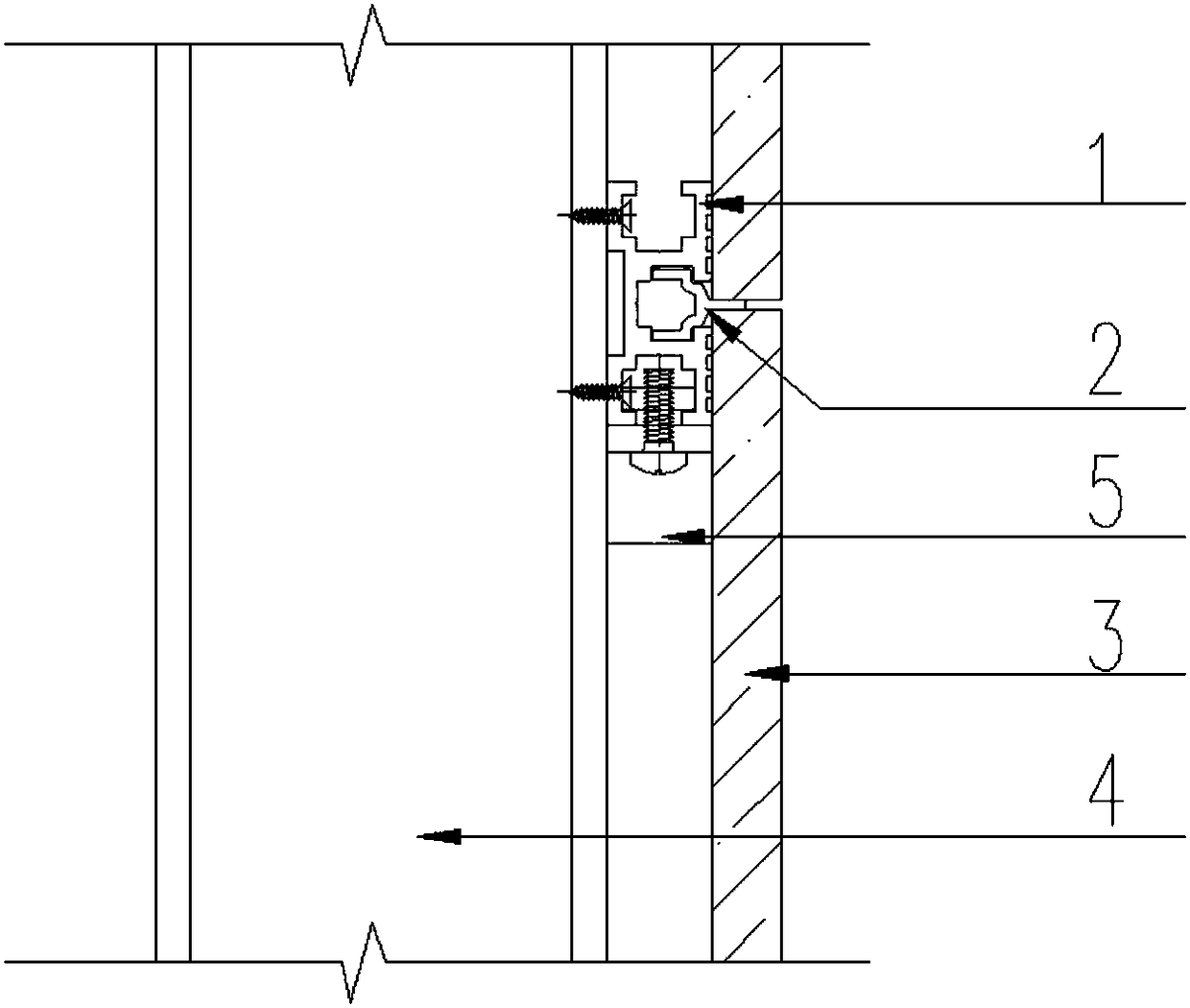

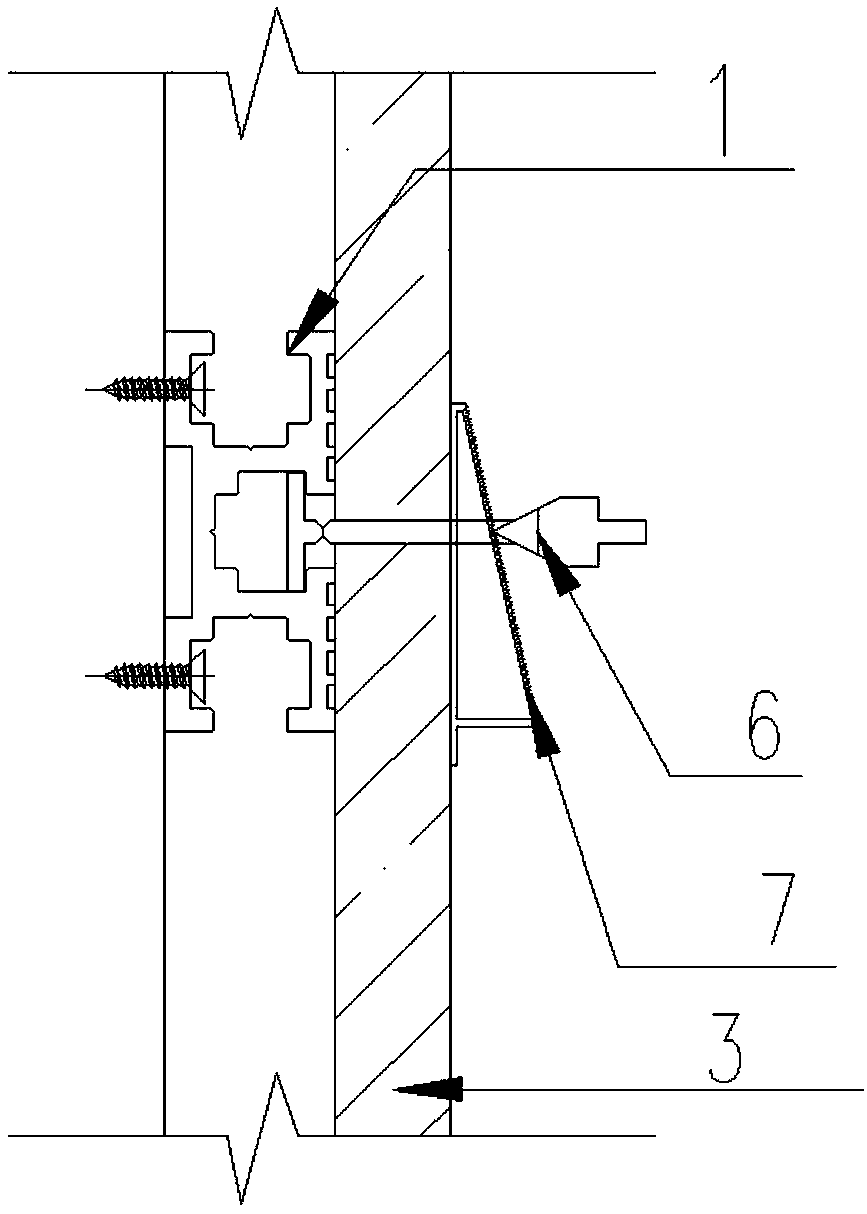

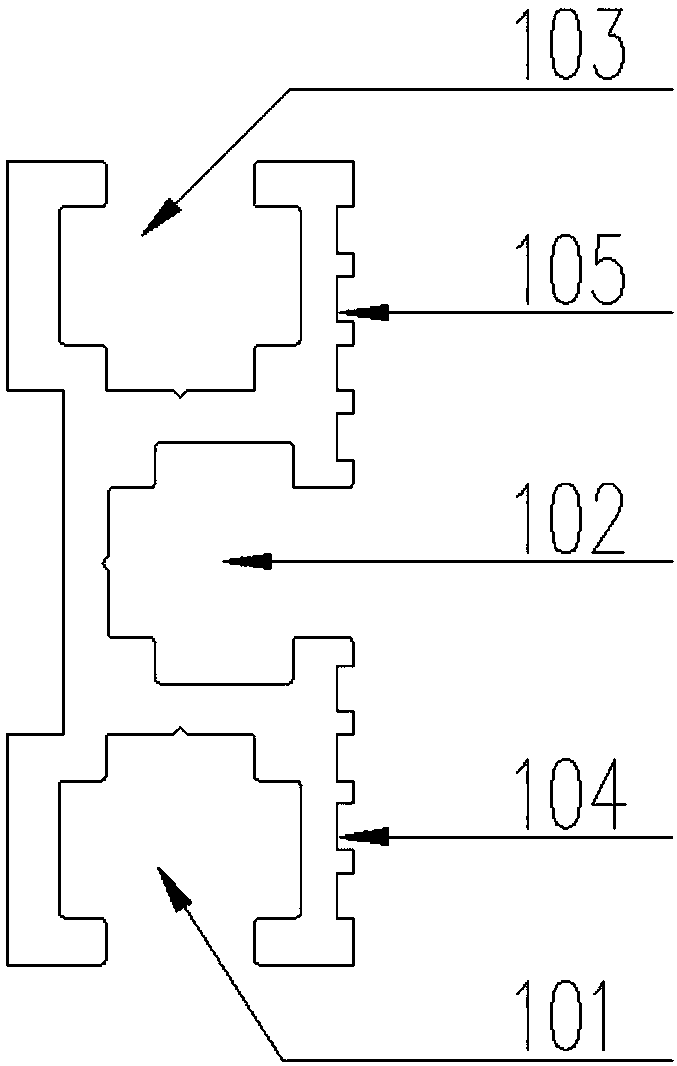

Assembled indoor exposed frame wall brick system and construction method thereof

The invention discloses an assembled indoor exposed frame wall brick system and a construction method thereof. The system comprises a top support (1), wall bricks (2), a middle support (3), a bottom support (4), self-tapping screws (5), a leveling keel (6), a flattening device cap (7) and drawing strips (8), the leveling keel (6) is fixed on a solid wall by a bolt and leveled, the bottom support (4) is fixed on the leveling keel (6) by the first self-tapping screw (5), wall bricks (2) are placed into the bottom support (4) and coated with a structural adhesive, the middle support (3) is mounted on the leveling keel (6) by the second self-tapping screw (5), the wall brick (2)are clamped into the middle support (3) and coated with a structural adhesive, each drawing strip (8) is mounted in avertical seam of two wall bricks, the top support (1) is mounted on the leveling keel (6) by the third self-tapping screw (5), the top of one wall brick is clamped into the top support and coated with a structural adhesive, the bottom of the wall brick falls on a supporting strip, the wall bricks are supported, the dead weight of each wall brick is transferred onto the leveling keel (6), and thedrawing strips are tightened by the flattening device cap. The wall bricks are constructed by a drying method.

Owner:上海品宅装饰科技有限公司

Wall system

PendingCN107724542AReasonable forceEasy to splitBuilding constructionsFloor slabArchitectural engineering

The invention relates to the technical field of wall structure assembly, in particular to a wall system. The wall system comprises a prefabricated foundation, prefabricated floor slabs and wall boardassemblies, wherein each wall board assembly comprises multiple prefabricated wall boards, a top bolt installing portion, a bottom bolt installing portion and side bolt installing portions are arranged at the top, the bottom and two sides of each prefabricated floor slab, multiple prefabricated wall boards form a square shape and are fixedly connected through matching of the side bolt installing portions and bolts. A basic bolt installing portion is arranged on the prefabricated foundation. Floor slab bolt installing portions are arranged on the prefabricated floor slabs. By adopting a full-dry bolt mechanical-fastened connection mode, the structural system is reasonable in stress, slab members are used as main members, the members are convenient to dismount, and the wall system is simplein design and suitable for the structural systems of fabricated buildings. All the members have no extending-out bars, production, storage and transportation of prefabricated members are facilitated,the wall system is suitable for production based on production lines, the production and transportation costs are reduced, almost no wet operation is adopted, a constriction process is simple, and theconstruction efficiency is high.

Owner:SANY CONSTR TECH CO LTD

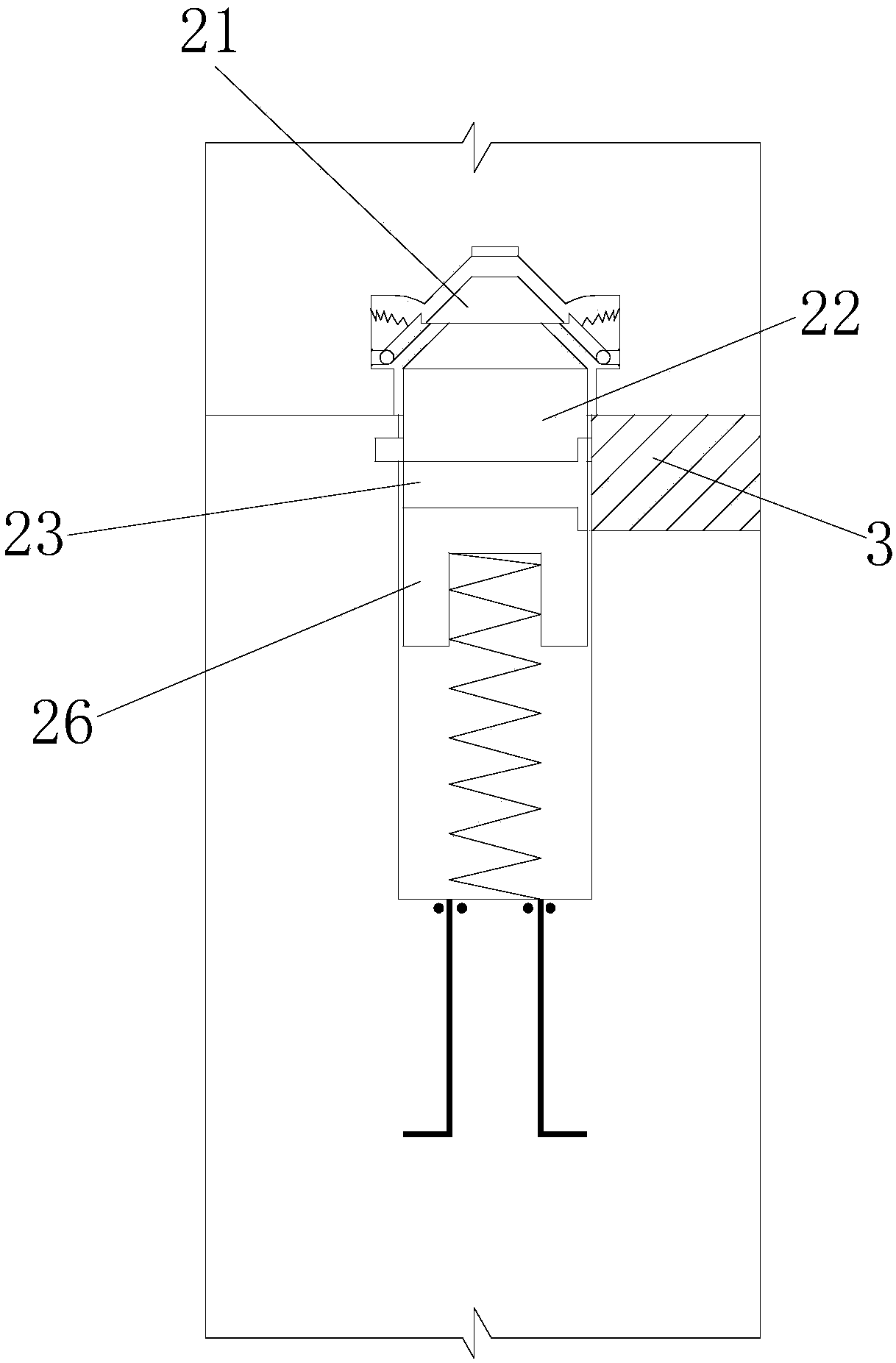

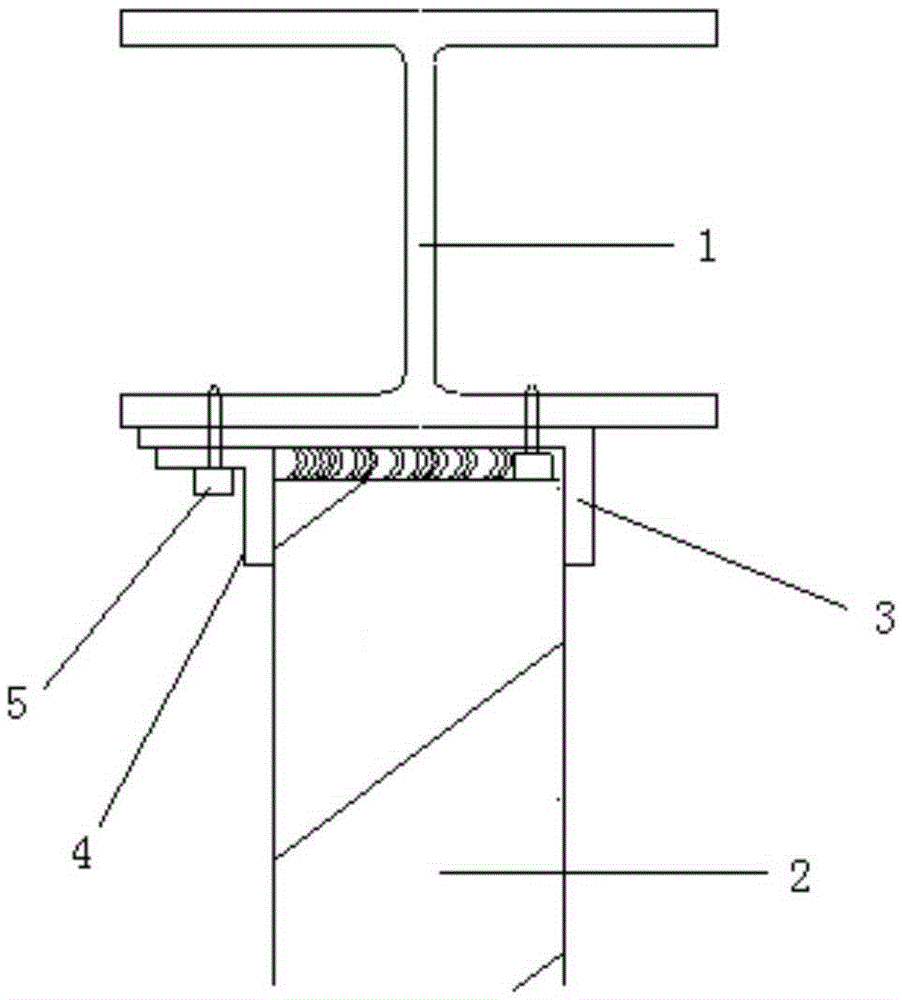

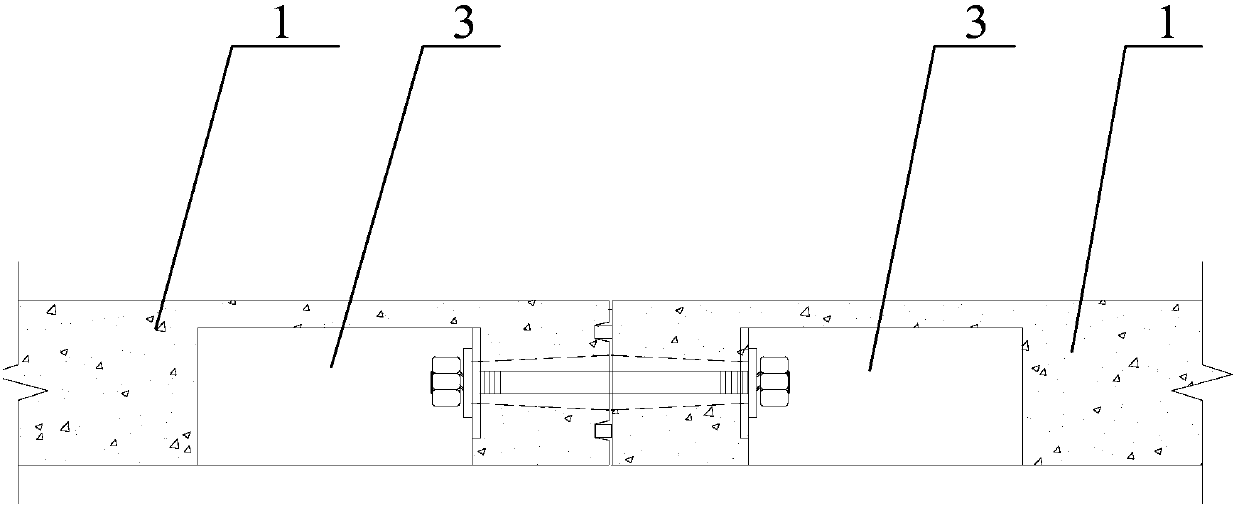

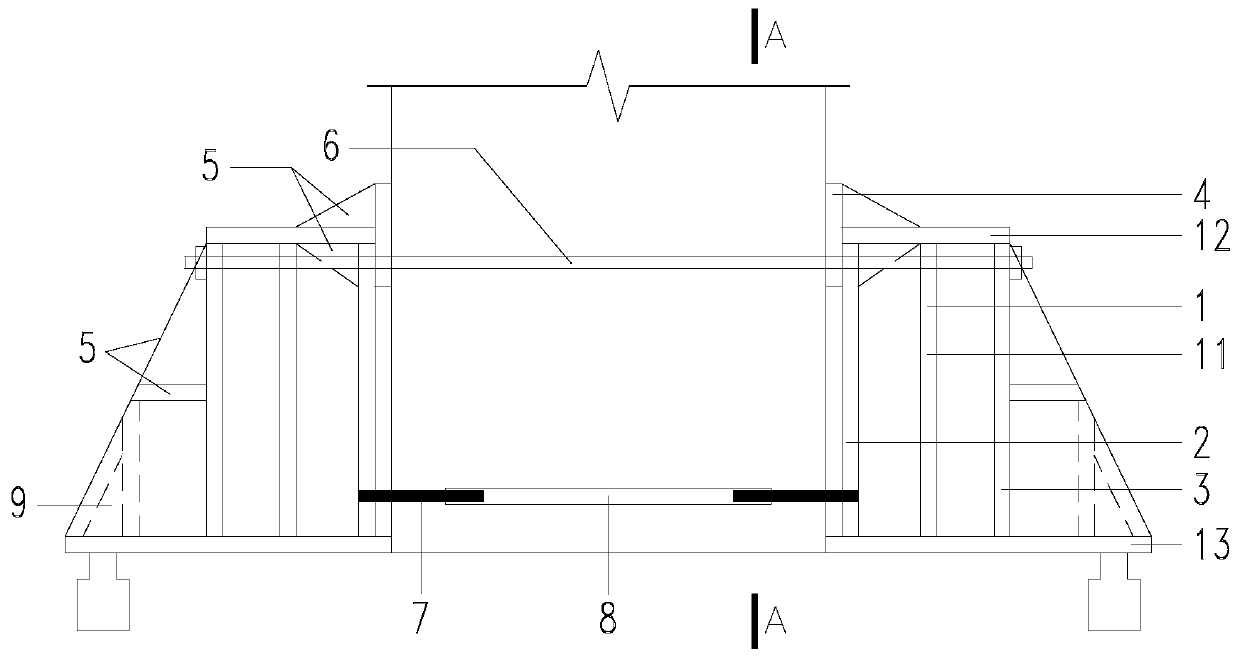

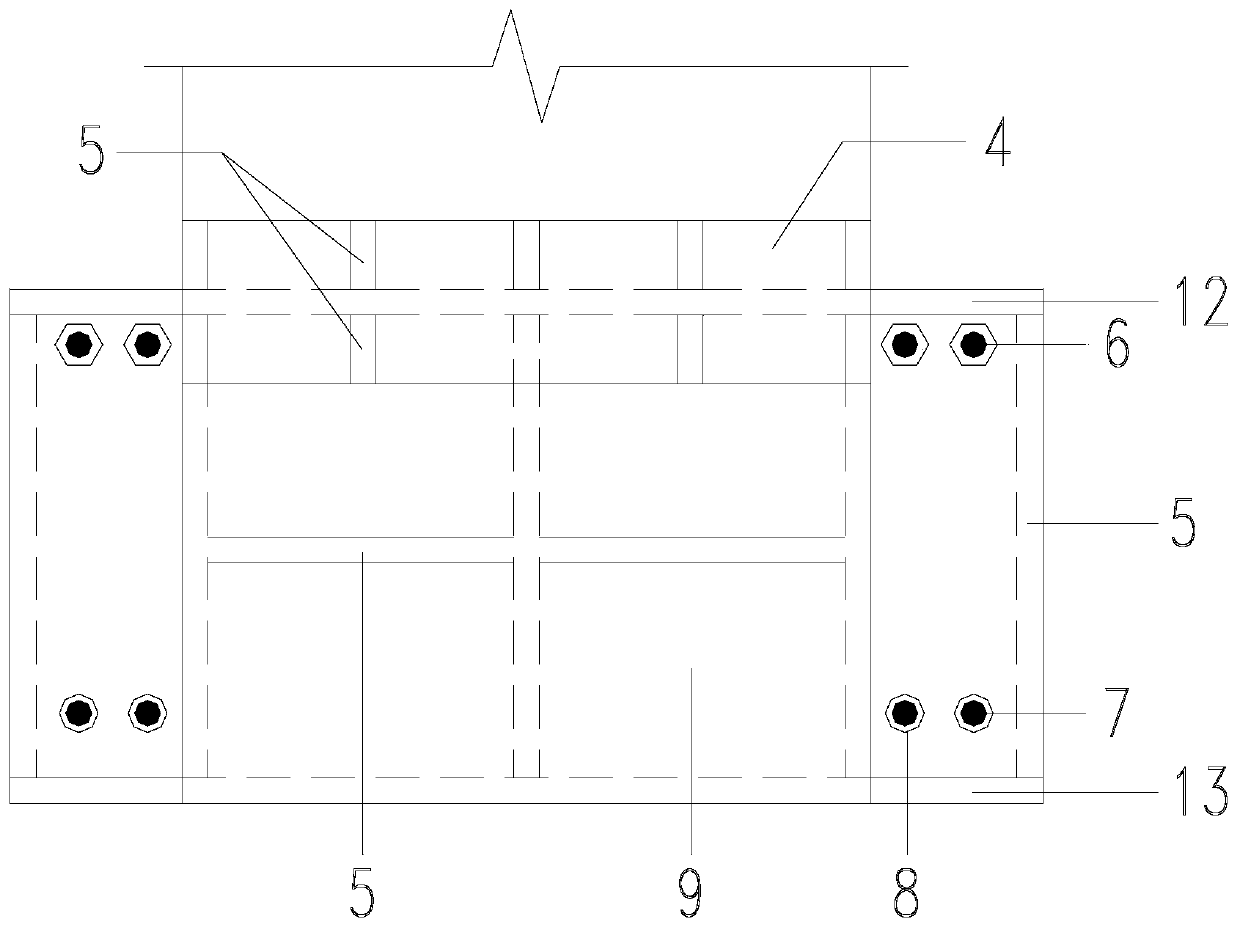

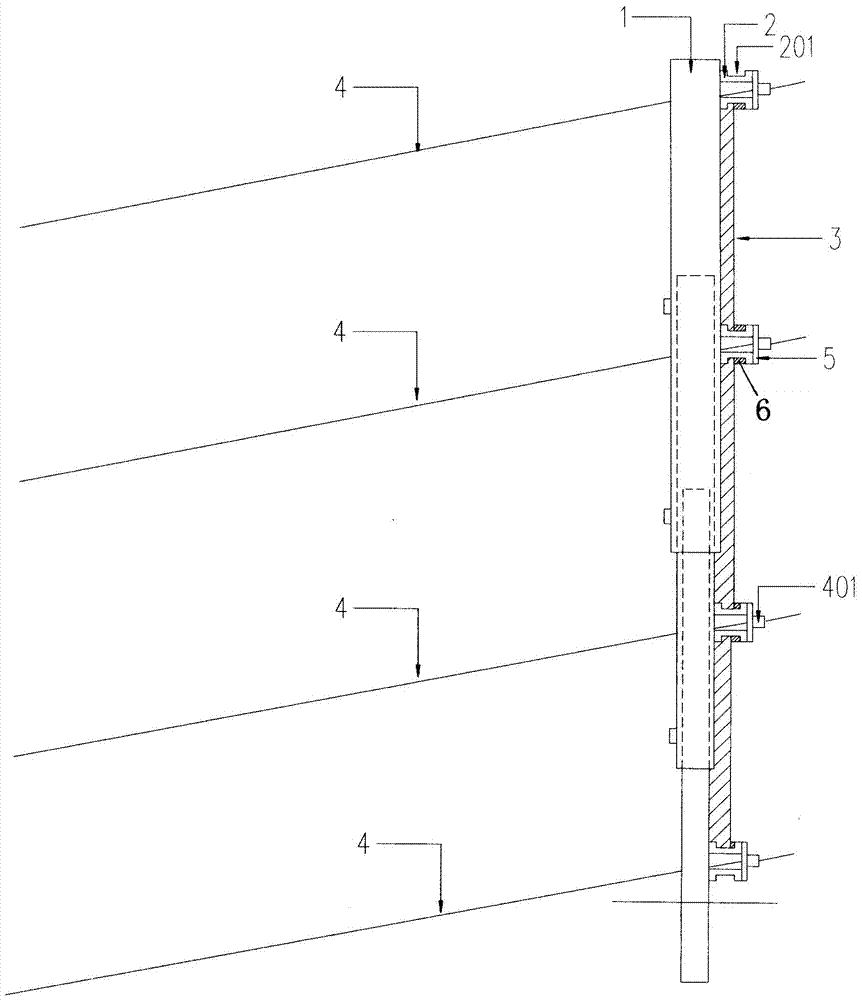

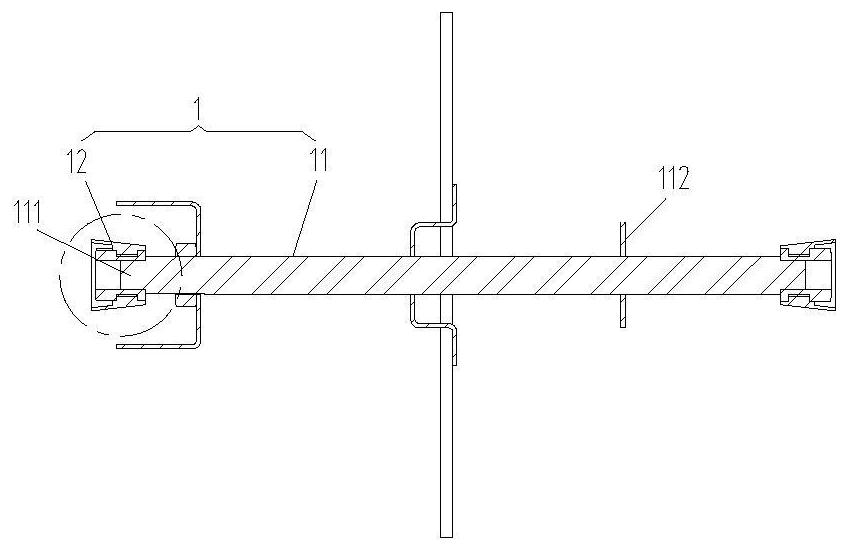

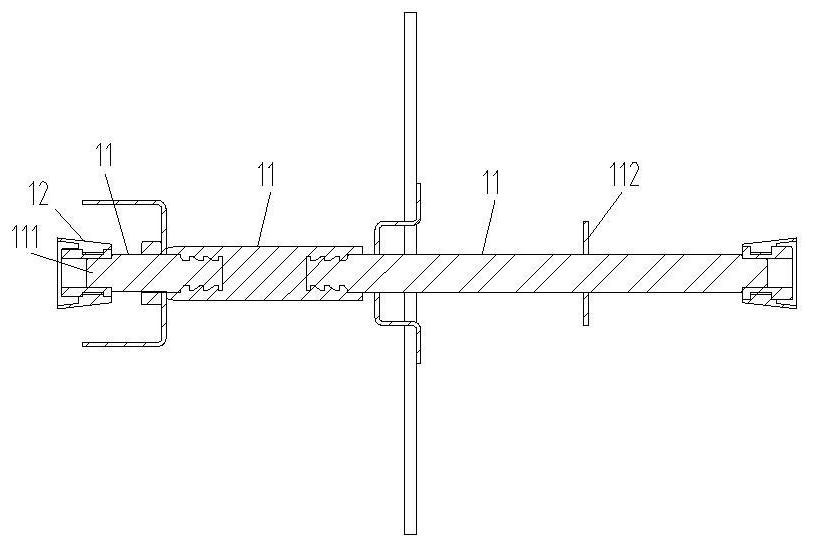

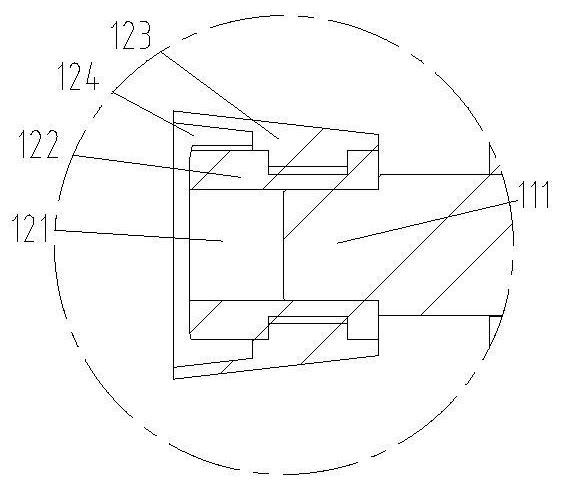

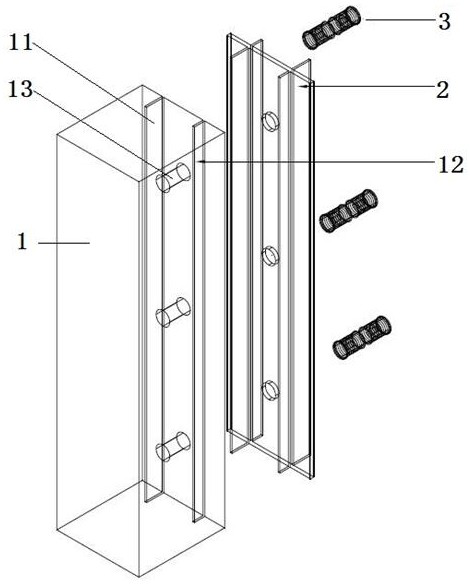

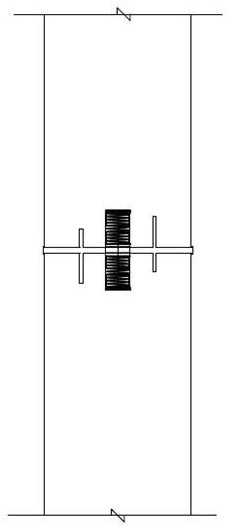

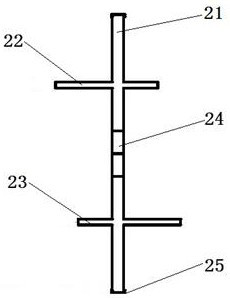

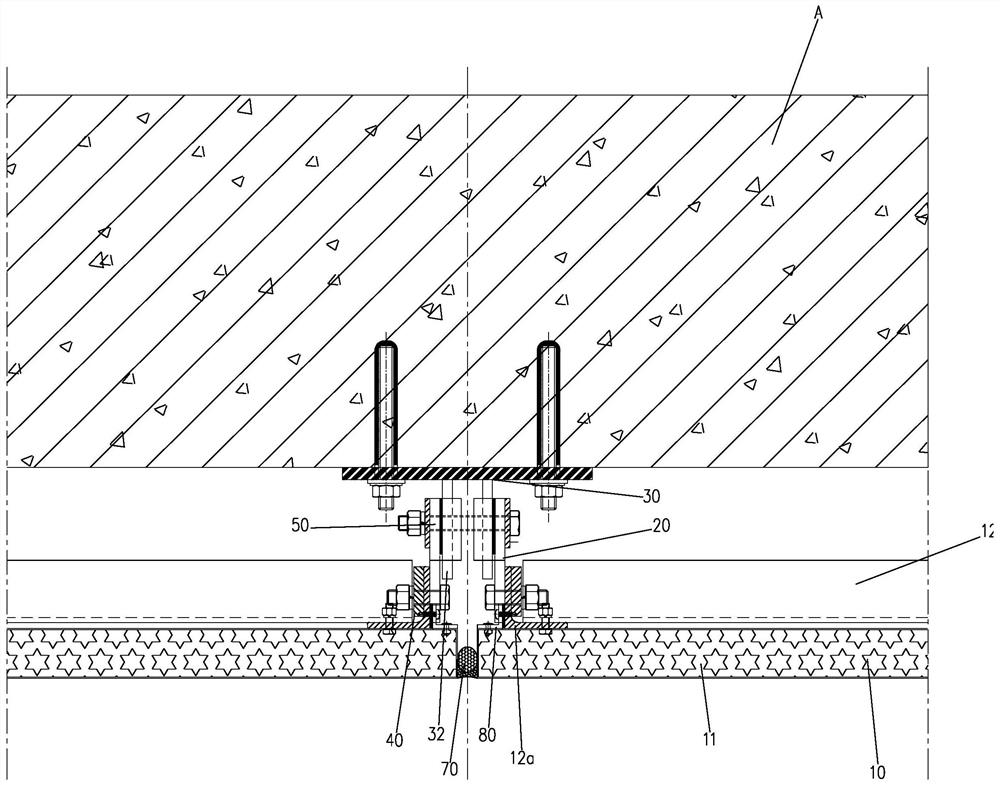

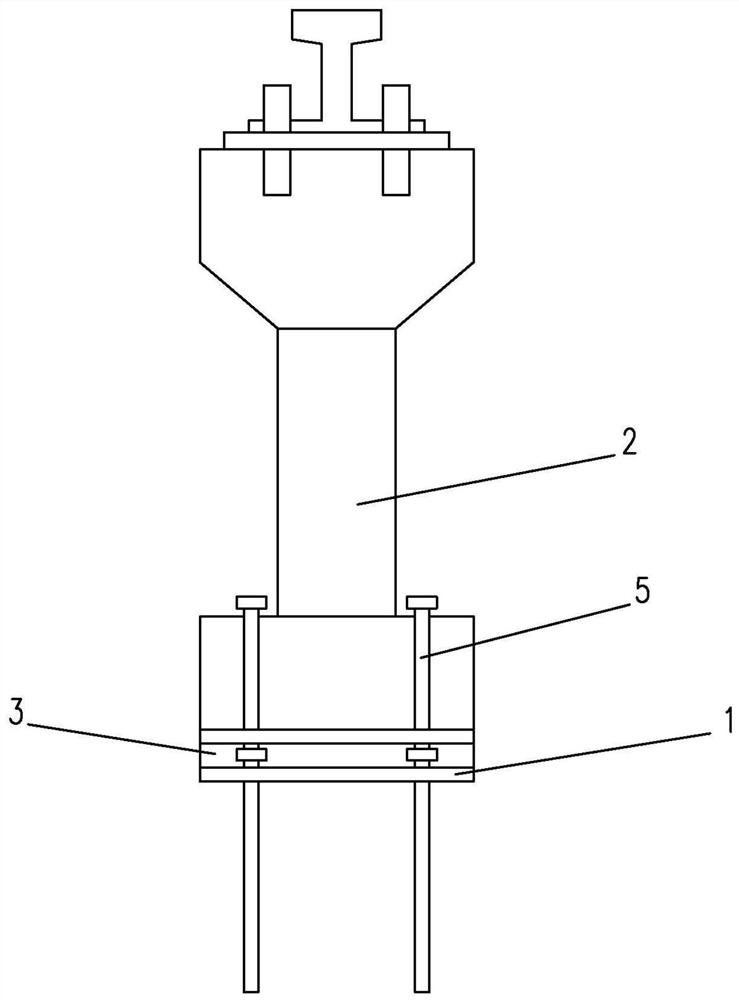

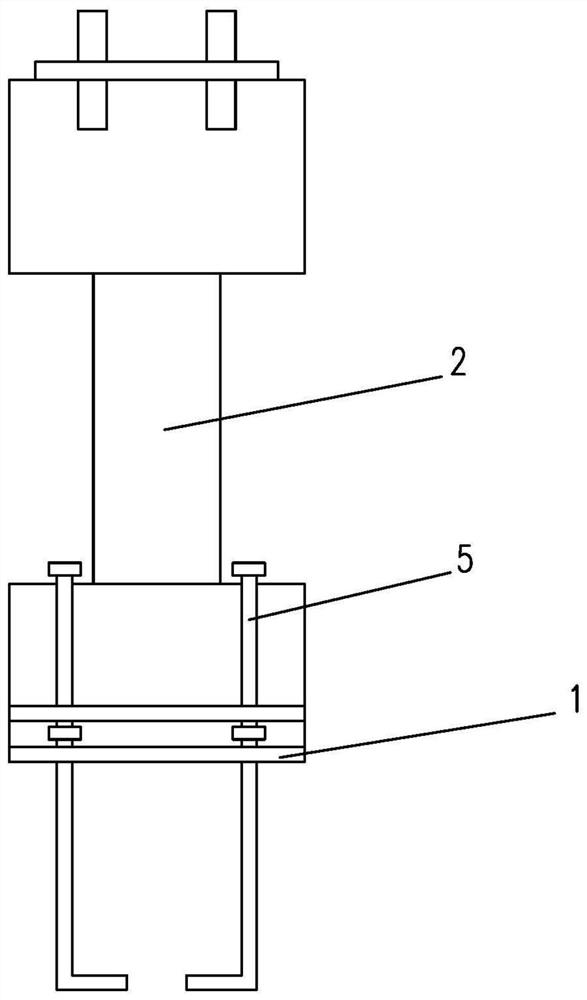

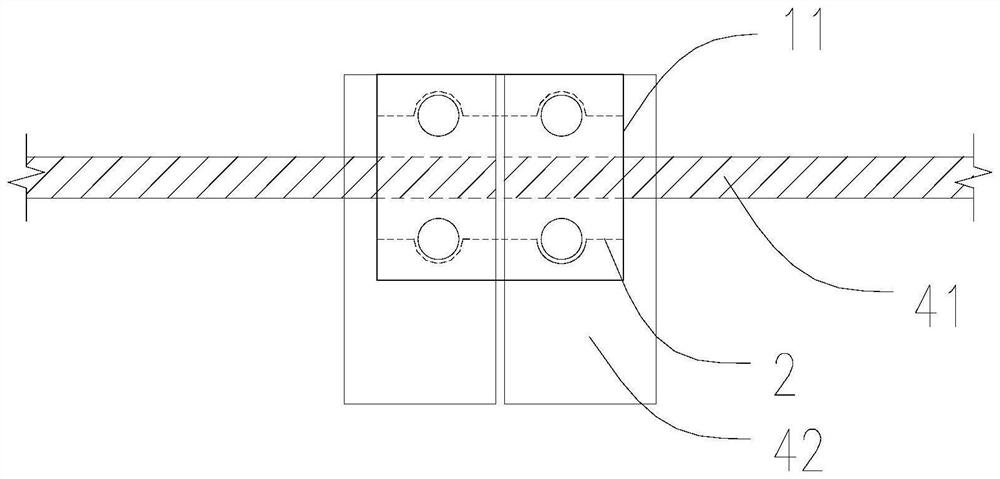

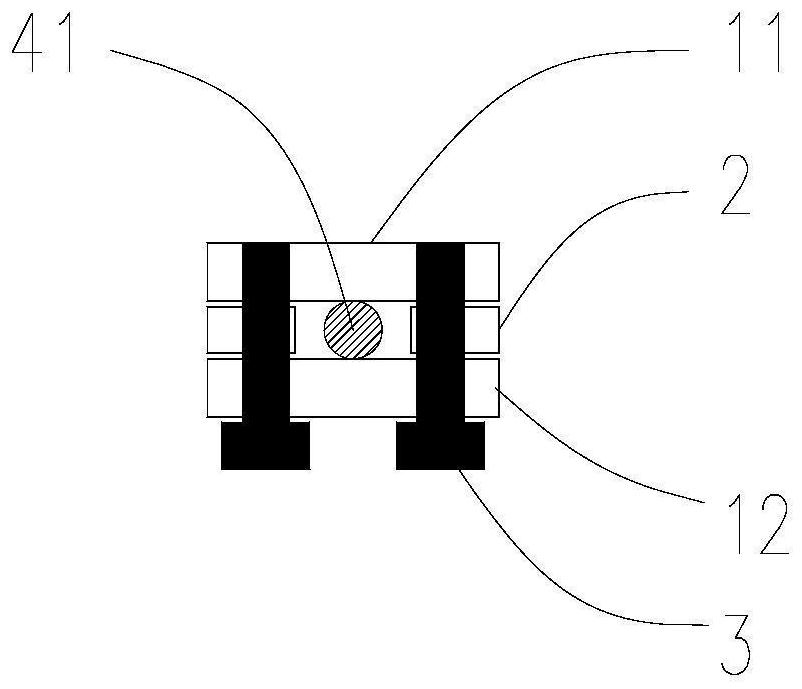

Self-balancing steel underpinning device

The invention relates to a self-balancing steel underpinning device. The self-balancing steel underpinning device comprises inequilateral flange I-shaped steel (1), first connecting steel plates (2) which are arranged on the inner side of the inequilateral flange I-shaped steel (1), second connecting steel plates (3) which are arranged on the outer side of the inequilateral flange I-shaped steel (1), compression steel plates (4) which are welded on upper flanges (12) of the inequilateral flange I-shaped steel, and stiffening ribs (5) which are welded among the components described above; connecting screws (7) are arranged on one sides of the first connecting steel plate (2); and a split screw (6) is arranged between the second connecting steel plates (3). Compared with the prior art, the self-balancing steel underpinning device is suitable for column underpinning with different loads, is convenient to construct, and is detachable and reusable.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

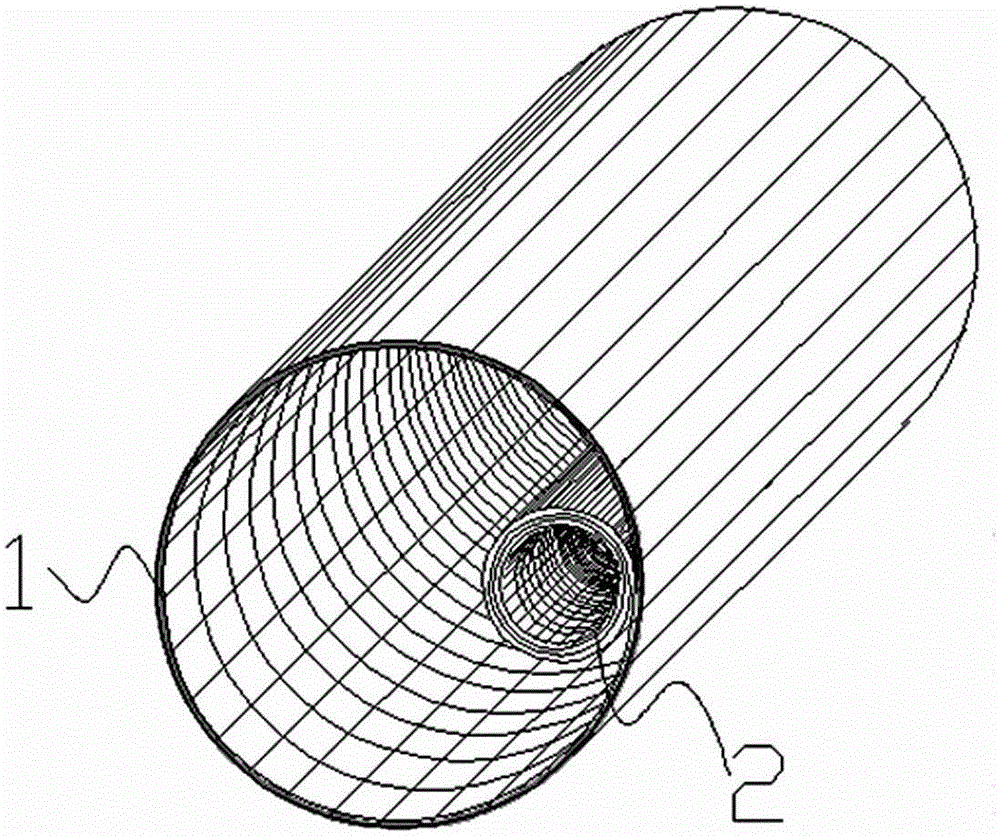

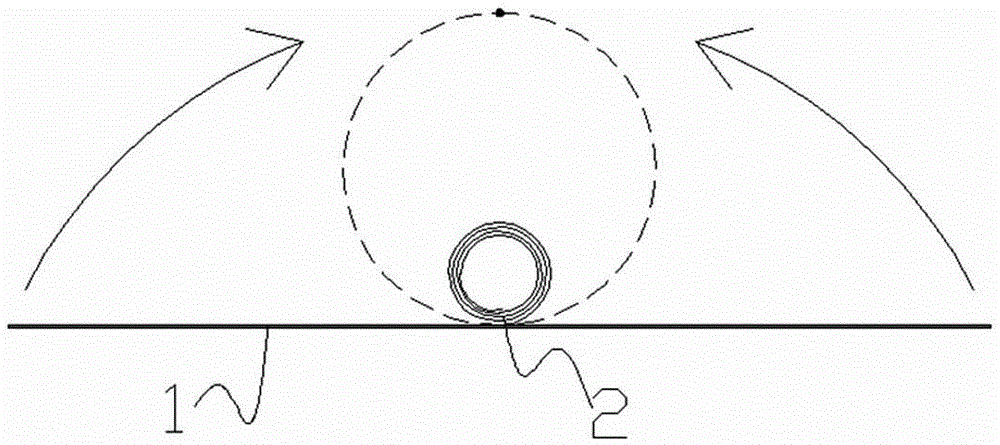

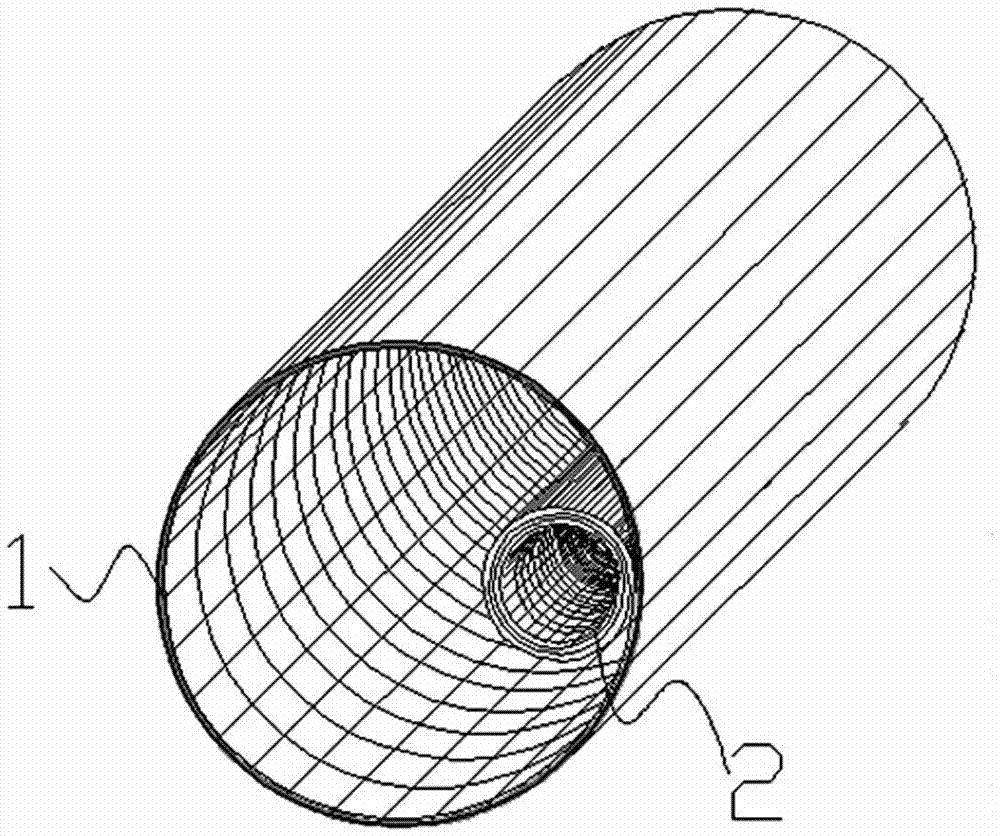

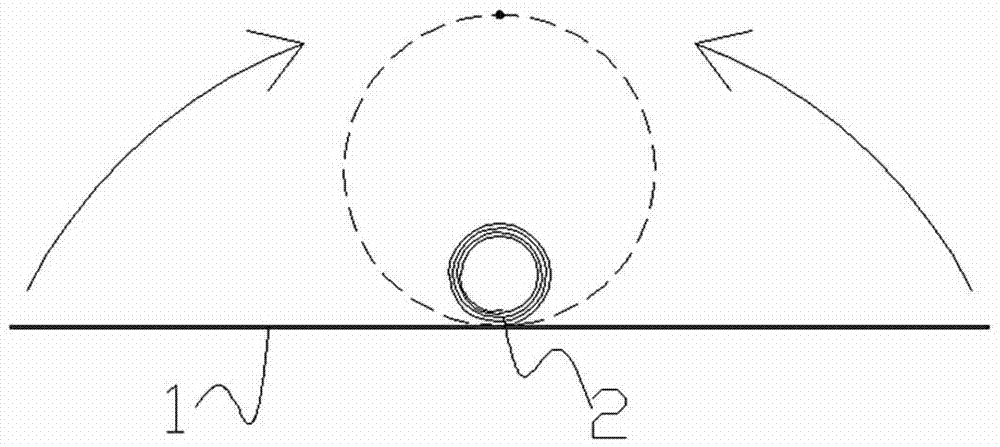

Novel wall bushing and through-wall hole blocking method adopting same

ActiveCN105040959AReasonable designSimple structureBuilding insulationsVertical ductsPetroleum engineering

The invention discloses a novel wall bushing and a through-wall hole blocking method adopting the same. A stress metal reel is sleeved with a sleeve of the novel wall bushing, the axis of the stress metal reel is parallel to the central axis of the sleeve, the stress metal reel is adaptive to different diameters of equipment pipes, and the outmost end edge of the stress metal reel is welded to the inner wall of the sleeve to be fixed. During through-wall hole blocking, the sleeve is inserted into an elastic rubber sealed tube matched with the sleeve firstly, the two ends of a gasket can be lengthened and integral transverse movement is maintained when the elastic rubber sealed tube penetrates through a wall transversely, the lengthened gasket is retracted naturally when the sleeve is located in the middle of the wall, and then the sleeve and the wall are closely fastened; an equipment pipe is made to pass through the center of the stress metal reel to be tightly wrapped with the stress metal reel, and finally the space between the sleeve and the stress metal reel is filled with filling foam glue. On a construction site, the wall bushing can be precisely measured and cut according to wall thickness. Through the cooperation of the wall bushing and the elastic rubber sealed tube, operation is easy, and the novel wall bushing is adaptable to various pre-formed holes and after-formed holes.

Owner:BEIJING HONG KONG YUAN CONSTR DECORATION ENG

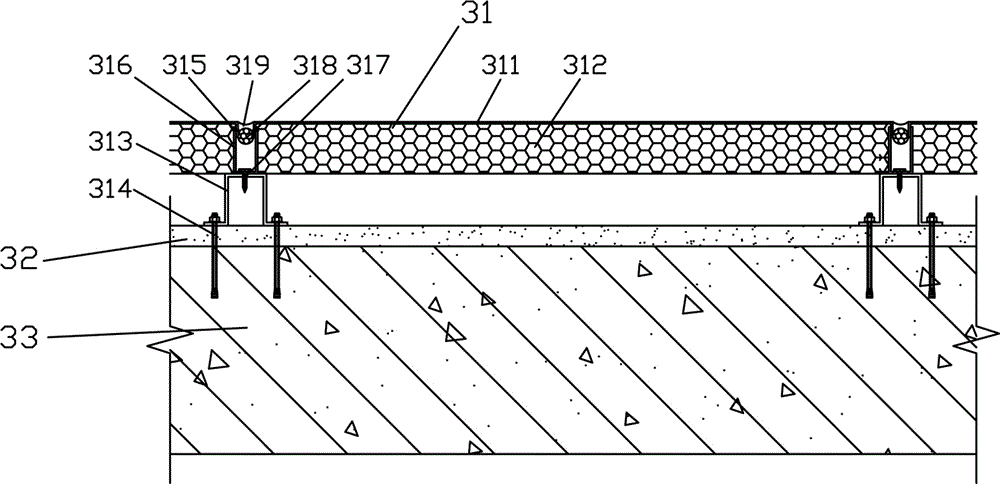

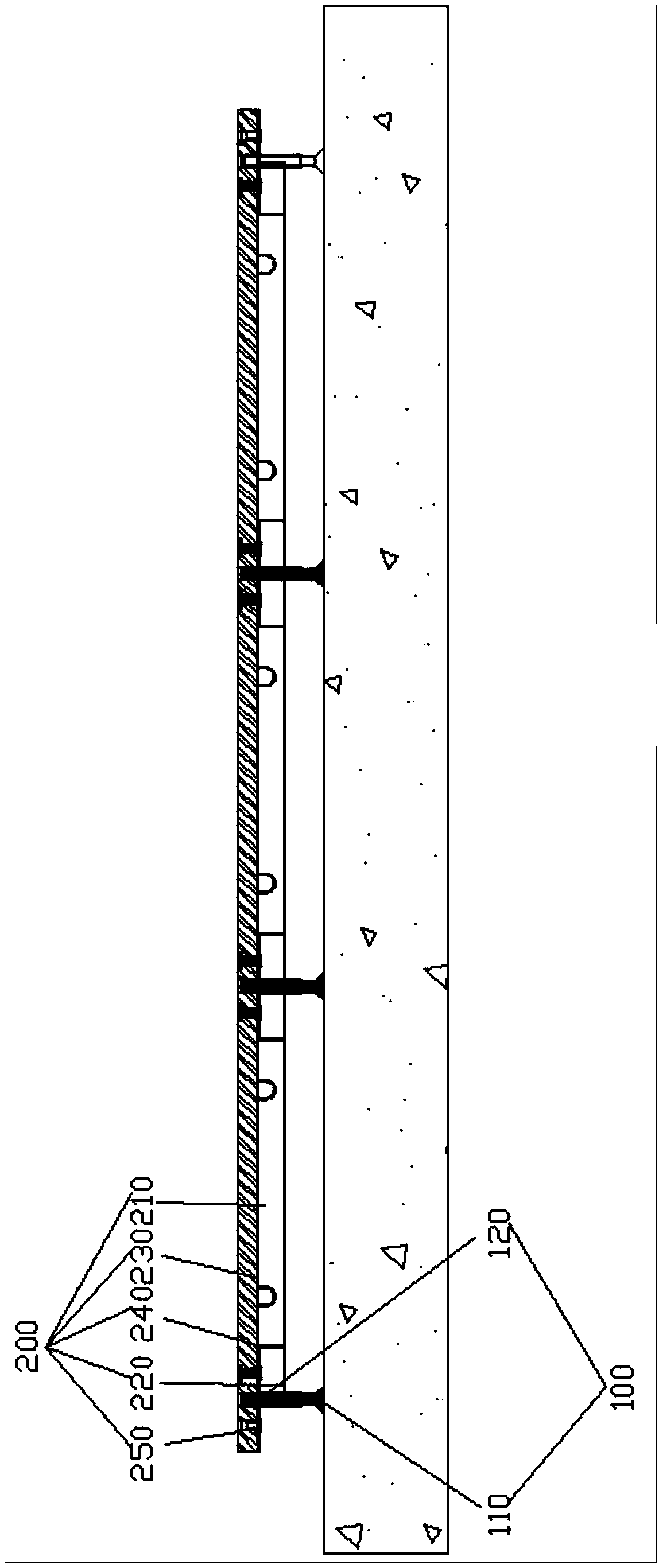

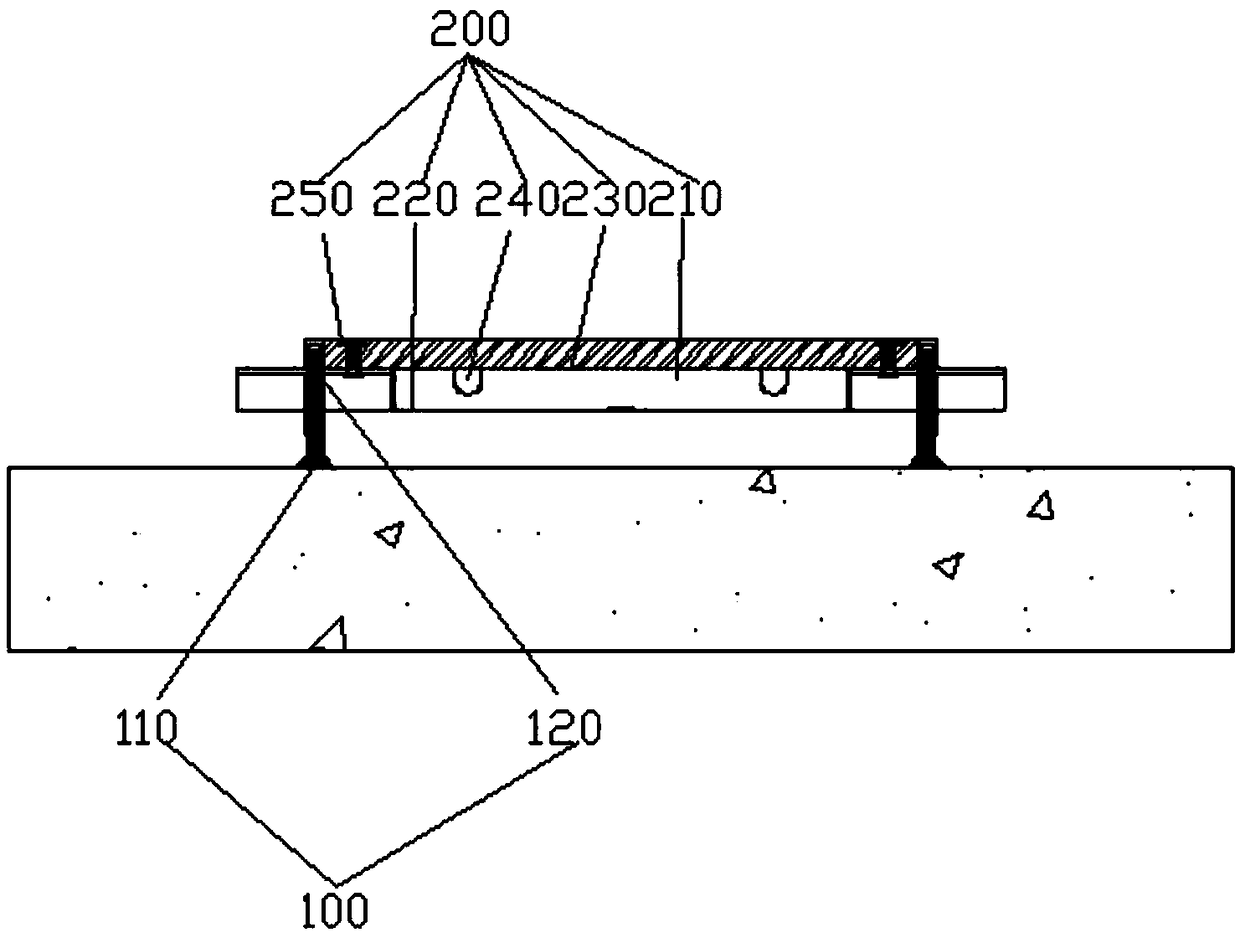

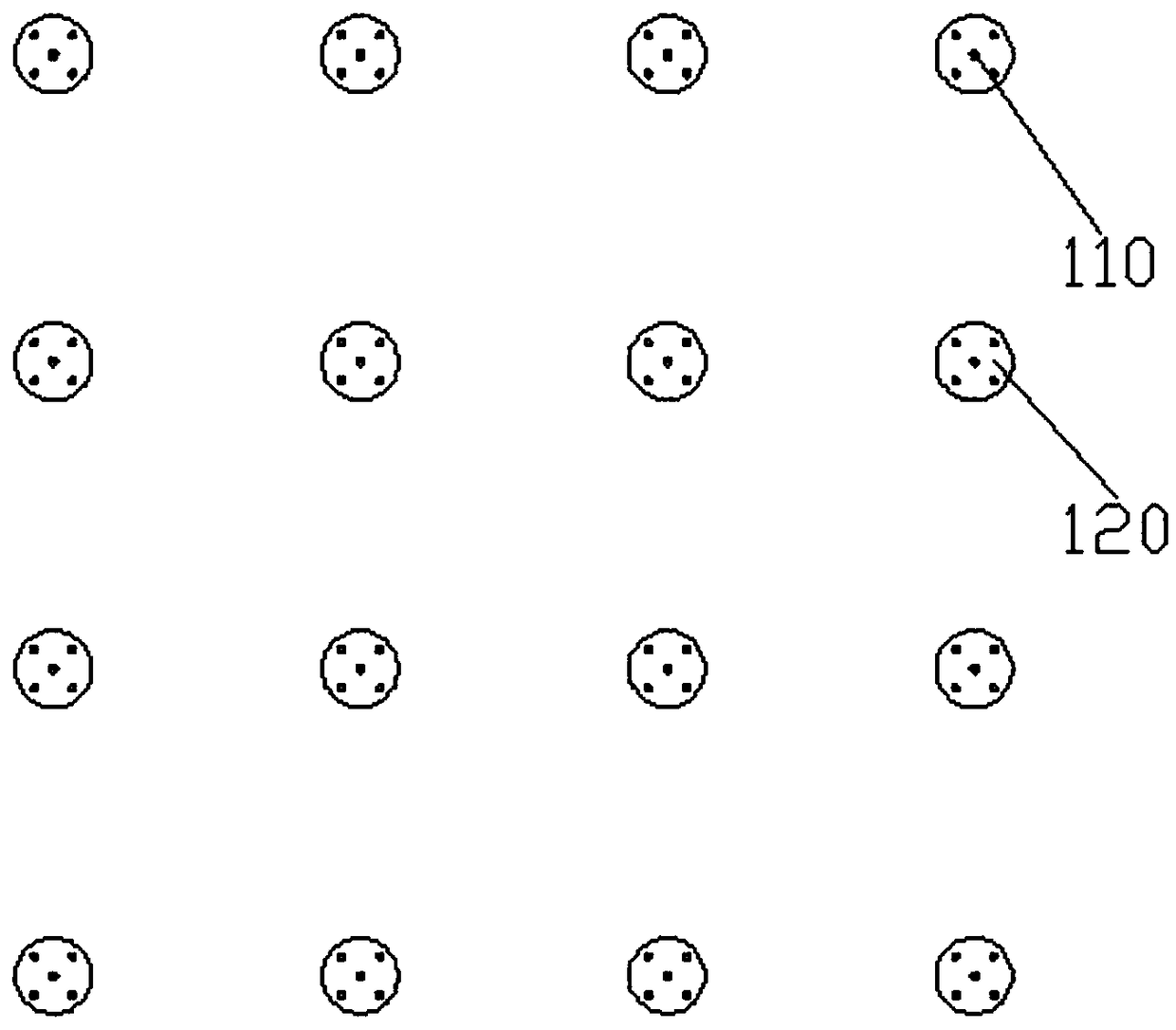

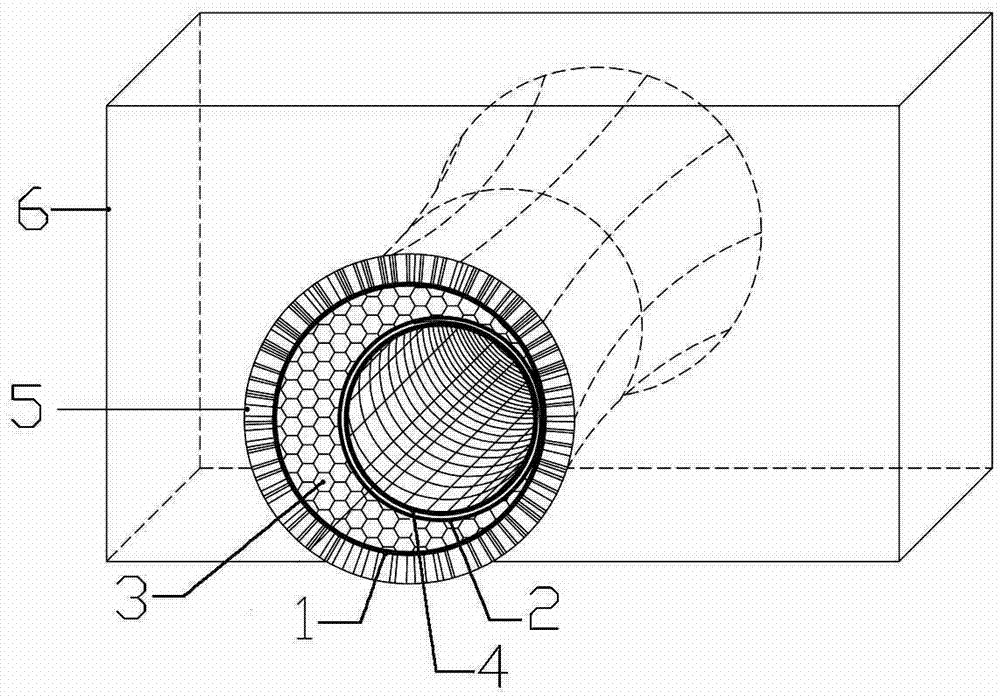

Assembled dry floor heating system

PendingCN108571763AGood product consistencyQuality guaranteedLighting and heating apparatusHot-water central heatingSteel platesHeating system

Provided is an assembled dry floor heating system. The system comprises a support member and a floor heating module. The support member comprises an adjustable screw and a circular limit bracket. Thefloor heating module includes an EPS insulation board, a heat conduction steel plate, a floor heating water pipe, a panel and a large flat head screw. The circular limit bracket of the support memberis centered on the center of the circle, four vertical-up small nut columns are arranged symmetrically at a fixed width, and a large nut column vertically welded downward is arranged at the center ofthe circle. The EPS insulation board of the floor heating module is combined with the heat conduction steel plate and placed on the circular limit bracket, and the floor heating water pipe is lain. The circle center position of the panel in which an opening is formed is the same as the circle center position of the circular limit bracket in which an opening is formed of the support member. The system has a wide application range, a small number of constituting components and a very short construction period, due to a fully assembled structure of the system, the whole process has no wet operation, prefabrication is conducted in a factory, no waste is generated at a construction site, the system can be reused, and be high in efficiency and environmental-protection, product consistency is good, installation is conveniently conducted, quality is guaranteed, and excellent mechanical performance is achieved.

Owner:上海品宅装饰科技有限公司

Cold-formed steel composite wall sandwiched with light-weight fabricated anti-buckling supports

PendingCN109555243APrevent slippingHave the effect of re-constrainingWallsProtective buildings/sheltersKeelSeismic resistance

The invention belongs to the field of building engineering, and particularly relates to a cold-formed steel composite wall sandwiched with anti-buckling supports, and wall surface plate material layers and cold-formed steel are used as constraining parts for the anti-buckling supports. The cold-formed steel composite wall includes upper and lower guide rails transversely arranged and vertically-and-oppositely-arranged keel columns, and the anti-buckling supports and outer cover wall panels are sandwiched between the vertically-and-oppositely-arranged keel columns. Steel strips are used as corematerials in the sandwiched supports, a wrap-around cross-section body composed of wall surface plate materials such as OSB plates and the cold-formed steel is used as a constraining member, and thewrap-around cross-section body in the constraining member are connected with the outer cover wall panels correspondingly by self-tapping screws. According to the cold-formed steel composite wall sandwiched with the anti-buckling supports, the side resistant ability of the cold-formed steel composite wall can be improved, the steel strips can be brought into full play under compression and tension,and the seismic resistance of the wall can be improved. The cold-formed steel composite wall includes the anti-buckling supports, wherein the anti-buckling supports are fabricated, no wet work exists, construction is simple, less labor is applied, and the requirements of green buildings and fabricated buildings are met.

Owner:SHENYANG JIANZHU UNIVERSITY

Assembly type recyclable deep foundation pit supporting system and construction method thereof

The invention relates to an assembly type recyclable deep foundation pit supporting system and a construction method thereof. The construction method comprises the following steps: enabling a row of vertical holes to be formed in the ground, and placing a vertical supporting body in each of the vertical holes to form a plurality of vertical supporting bodies; performing the first step earth excavation, enabling first anchor bolt holes or anchor cable holes to be formed in the inner sides of the foundation pit, placing anchor bolts or anchor cables, and performing cement grouting; enabling second anchor bolt holes or anchor cable holes to be formed, placing anchor bolts or anchor cables, and performing cement grouting; mounting first transverse support beams, applying a prestressing force, mounting second transverse support beams, and applying a prestressing force; mounting a first layer of vertical baffles between the first and second transverse support beams, and applying a prestressing force; repeating the steps to form the plurality of transverse support beams; and performing backfilling on the foundation pit and dismantling. The invention further provides the assembly type recyclable deep foundation pit supporting system which has the benefits as follows: the construction is simple, convenient, quick, safe and reliable, the materials can be used repeatedly and can completely replace conventionally used disposable piles, a large amount of steel bars and concrete are saved, and the problem that the materials in the conventional deep foundation pit supporting system cannot be recycled is solved.

Owner:河北建科唐秦建筑科技有限公司

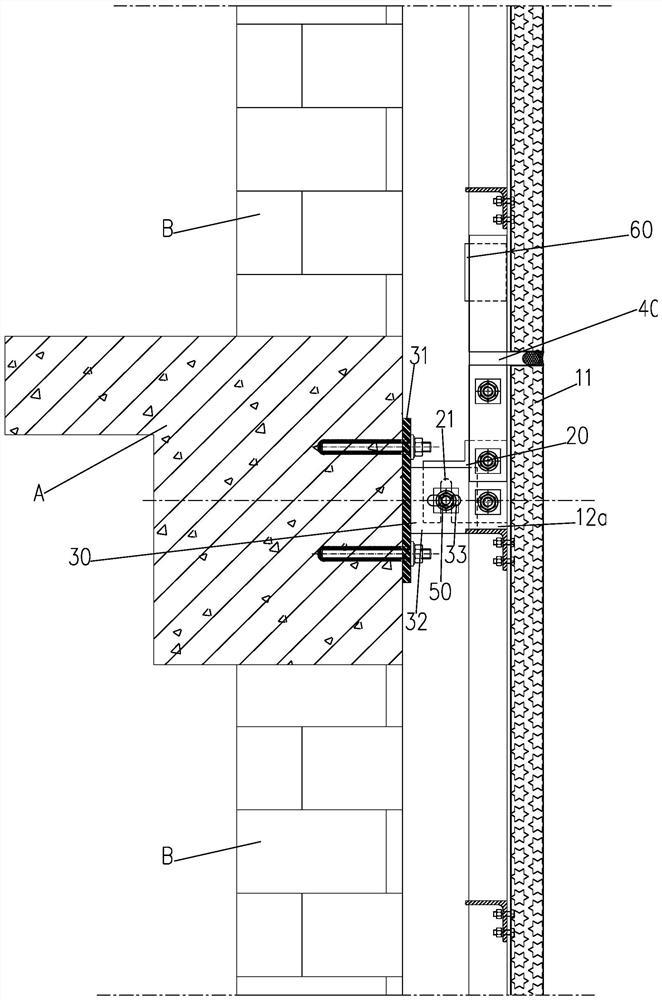

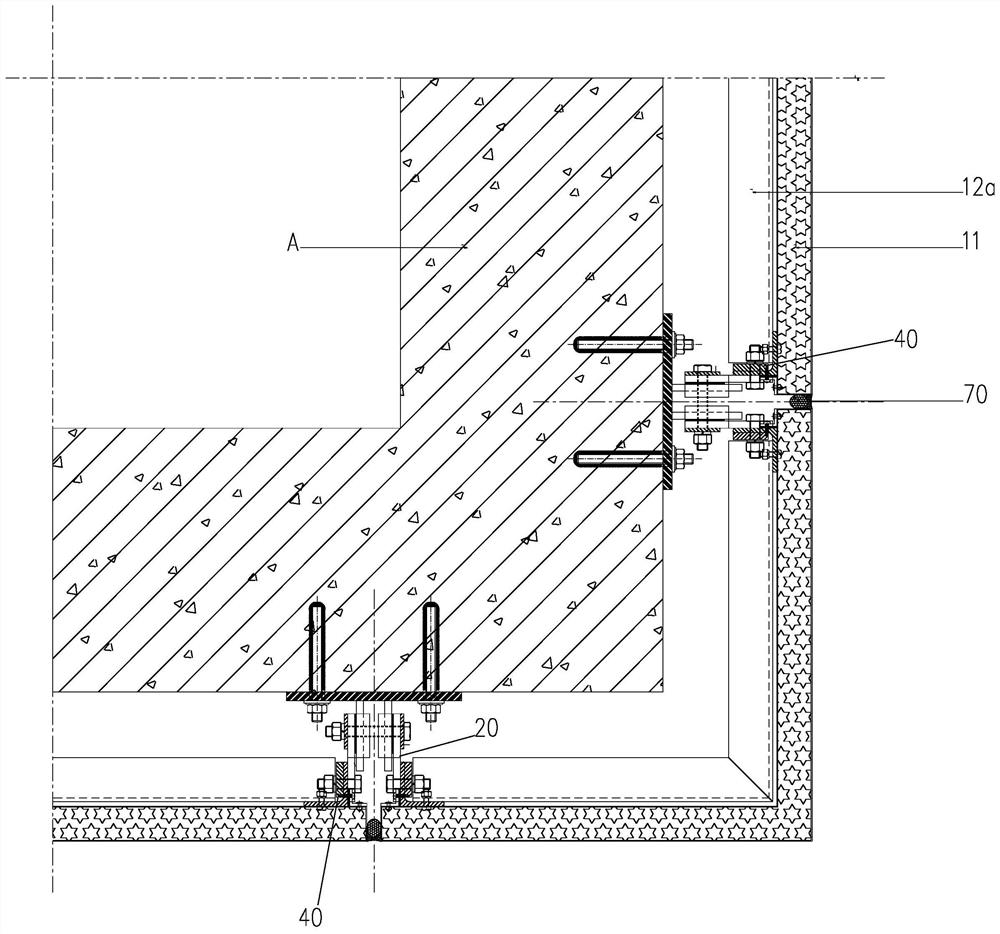

Wall body, hanging plate bolting assembly and construction method thereof

PendingCN112663834AImprove stabilityReduce construction proceduresCovering/liningsWallsPunchingStructural engineering

The invention provides a wall body, a hanging plate bolting assembly and a construction method thereof. The wall body comprises a supporting positioning piece, a fixed connecting piece and a hanging assembly used for hanging a hanging plate. According to the wall body, the hanging plate bolting assembly and the construction method thereof, the firmness of connecting the hanging plate is improved, the construction procedures are reduced, and the construction efficiency is improved; wet-free operation and pollution are avoided, and the requirement of a green building is met; cutting and punching are avoided on a construction site, so that dust pollution is avoided; and the outer wall modeling is diversified, the exterior of a cast-in-place wall body structure can be directly hung on the hanging plate in a dry mode without secondary treatment, and complex modeling assembly type installation can be designed. The wall body is suitable for wall bodies with different heat preservation standards and different types, namely, flexible application of various combination modes can be achieved by adopting different types of supporting positioning pieces and hanging plates, and the wall body is suitable for different energy-saving standards, namely, buildings with energy conservation level from 65 to near zero.

Owner:山东南矿智能装备有限公司

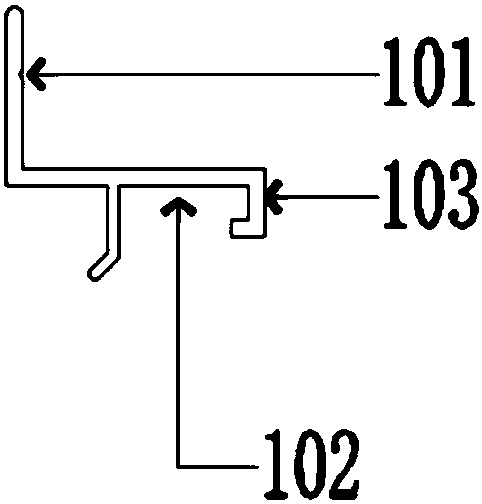

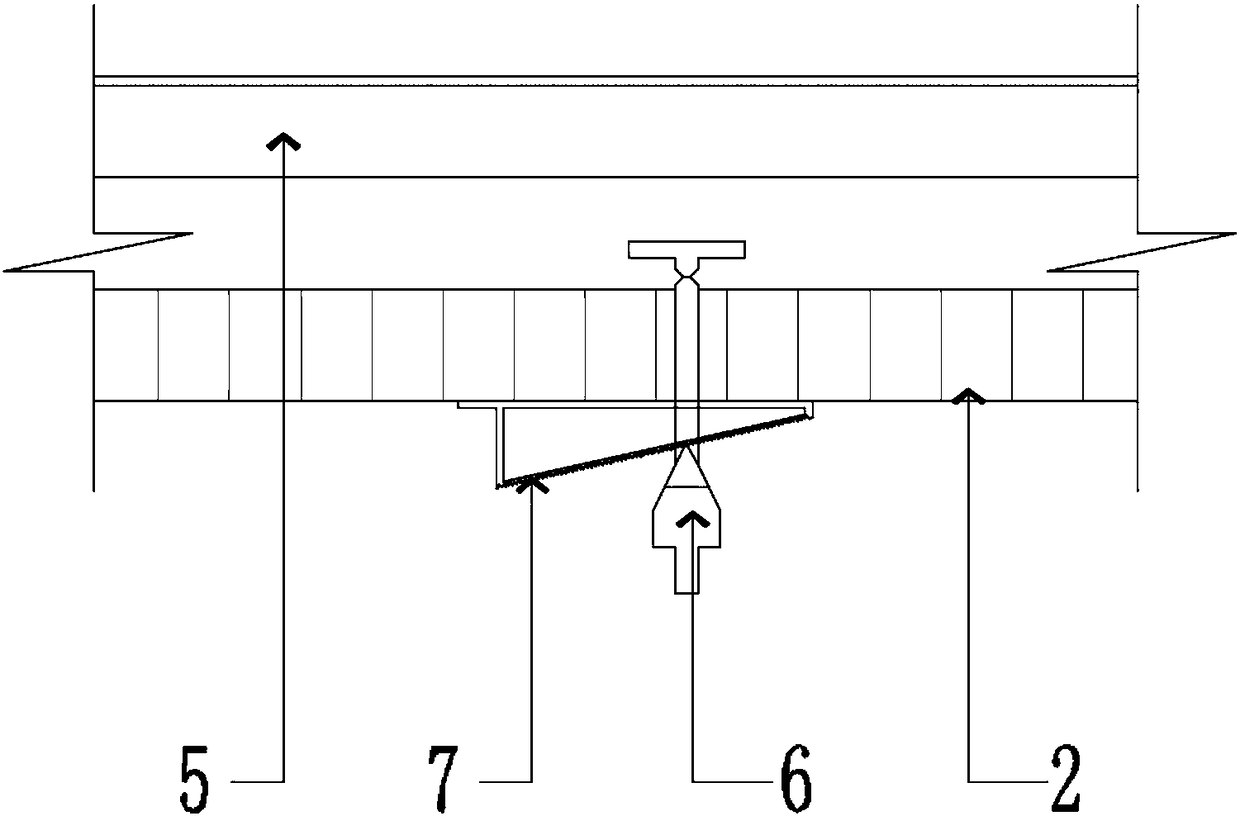

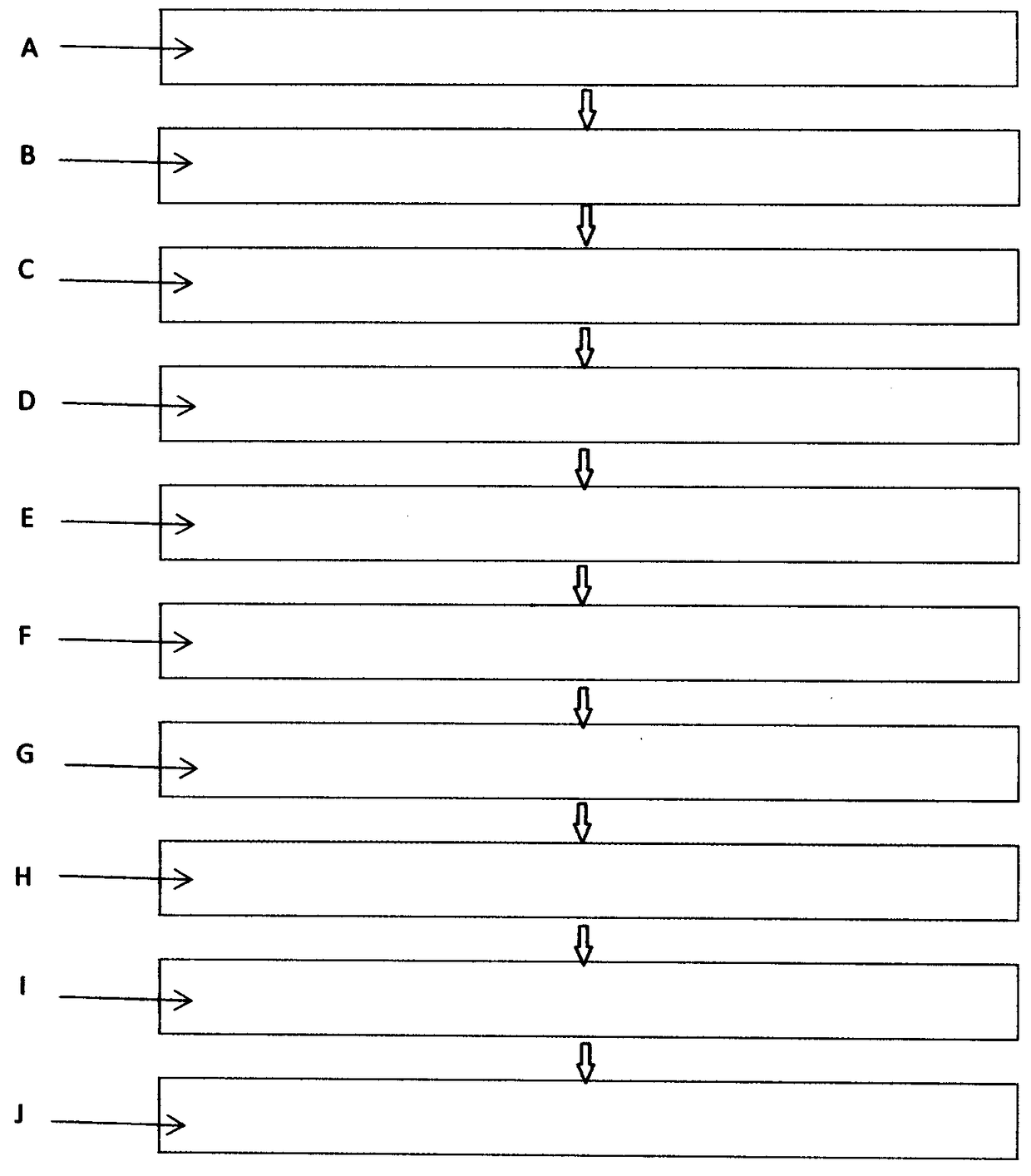

Prefabricated indoor hidden frame type wall brick system and construction method thereof

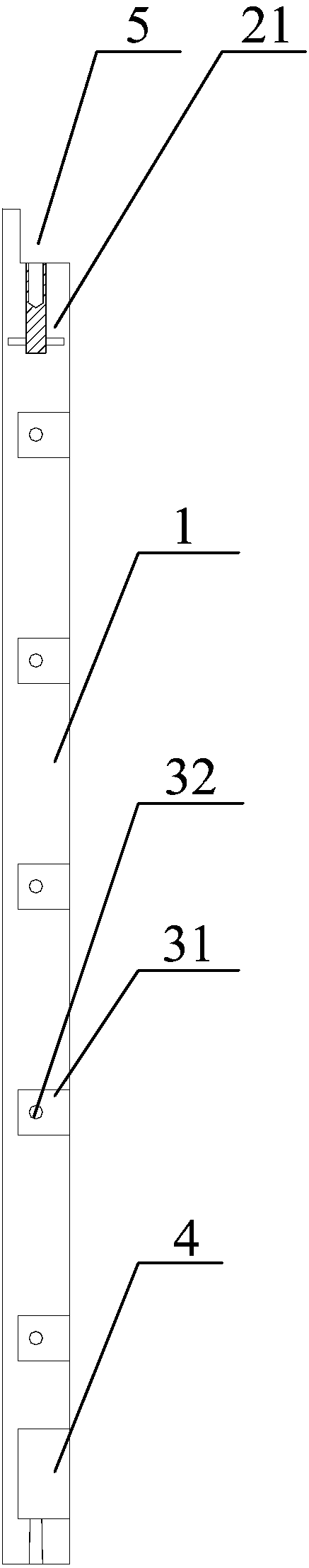

The invention discloses a prefabricated indoor hidden frame type wall brick system and a construction method thereof. The prefabricated indoor hidden frame type wall brick system comprises rubber reinforced keels (1), wall bricks (2), L-shaped corner connectors (3), self-tapping screws (4), a leveling keel (5), pulling strips (6) and flattening machine caps (7). The leveling keel (5) is fixed to asolid wall with bolts and leveled; the L-shaped corner connectors (3) are fixed to the leveling keel with the self-tapping screws (4) and structural glue is applied; the wall bricks (2) are supportedby the L-shaped corner connectors (3) and then glued to the rubber reinforced keels (1); and then the pulling strips (6) are installed into two of the wall bricks of a vertical gap, the bottom portions of the wall bricks fall on the L-shaped corner connectors, and the wall bricks are supported and the self weight of the wall bricks is transferred to the leveling keel; and finally, the flatteningmachine caps tighten the pulling strips. The dry construction of the wall bricks is realized.

Owner:上海品宅装饰科技有限公司

Assembly type L-shaped composite wallboard full-length force transmission steel plate self-tapping screw block connecting structure and manufacturing method

PendingCN114592746AOvercoming the Drawbacks of Thermal Bridge ProblemsSolve the problem of blind areas for connection constructionClimate change adaptationProtective buildings/sheltersMechanical engineeringWall plate

The invention discloses an assembly type L-shaped composite wallboard full-length force transmission steel plate self-tapping screw block connecting structure and a construction method. The structure is used for assembly of an L-shaped upper composite wallboard and an L-shaped lower composite wallboard which are used for bearing a small earthquake effect in a multi-story building. The invention discloses a full-length force transmission steel plate self-tapping screw block which is a steel-concrete combined plate block with a built-in steel structure, wherein the steel-concrete combined plate block is formed by connecting upper and lower full-length force transmission steel plates through self-tapping screws and linear and L-shaped connecting steel plates, and the thickness of the plate section external contour concrete thin plates is larger than that of the plate section external contour concrete thin plates; a full-length force transmission steel plate self-tapping screw block connecting structure is composed of a self-tapping screw block and a force transmission steel plate section without the self-tapping screw block. The self-tapping screw set block resists bidirectional shearing force, bending moment and torque of an earthquake and can transmit a vertical load; the butt-joint steel plate section is mainly used for transmitting a vertical load; the L-shaped constructional columns are concrete embedded columns located at the inner corners of the wallboards. The composite wallboard has the remarkable technical advantages that the upper and lower L-shaped composite wallboards are assembled and constructed quickly, the connecting performance, the durability and the thermal performance are good, and wet operation is avoided.

Owner:BEIJING UNIV OF TECH

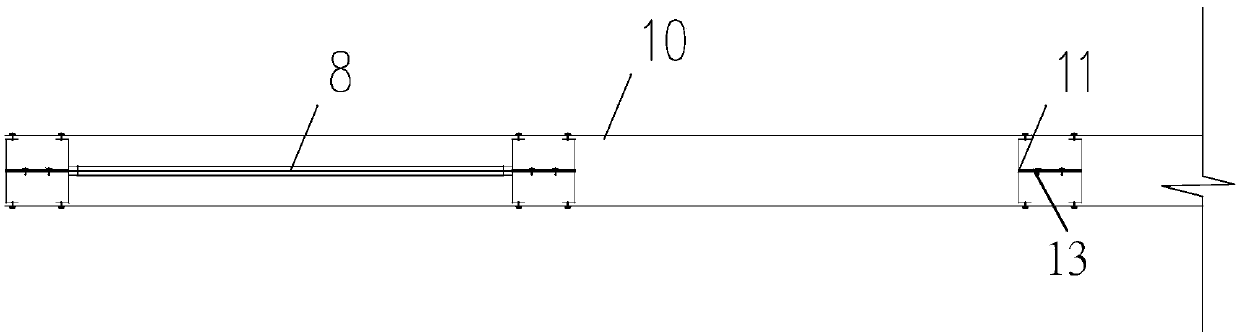

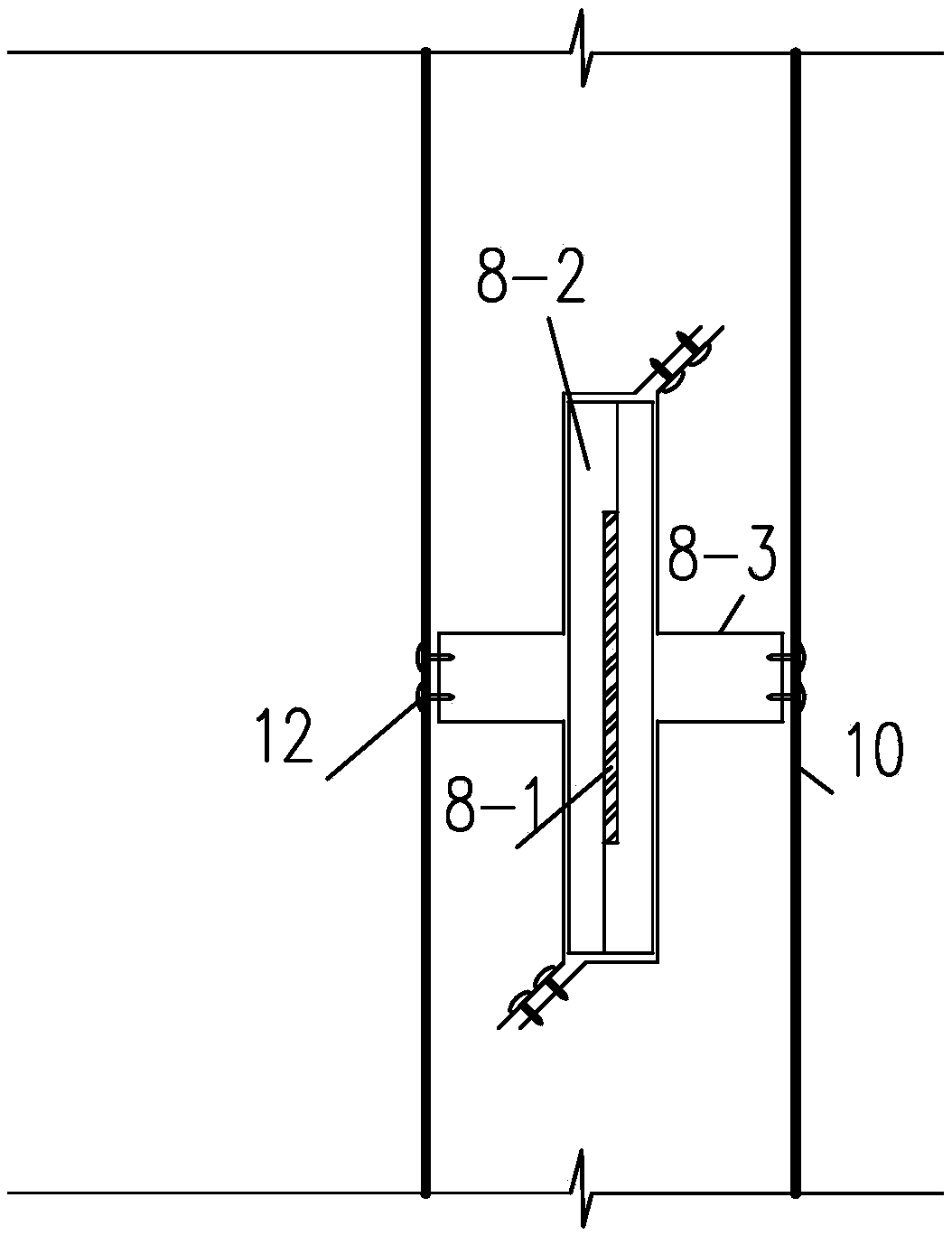

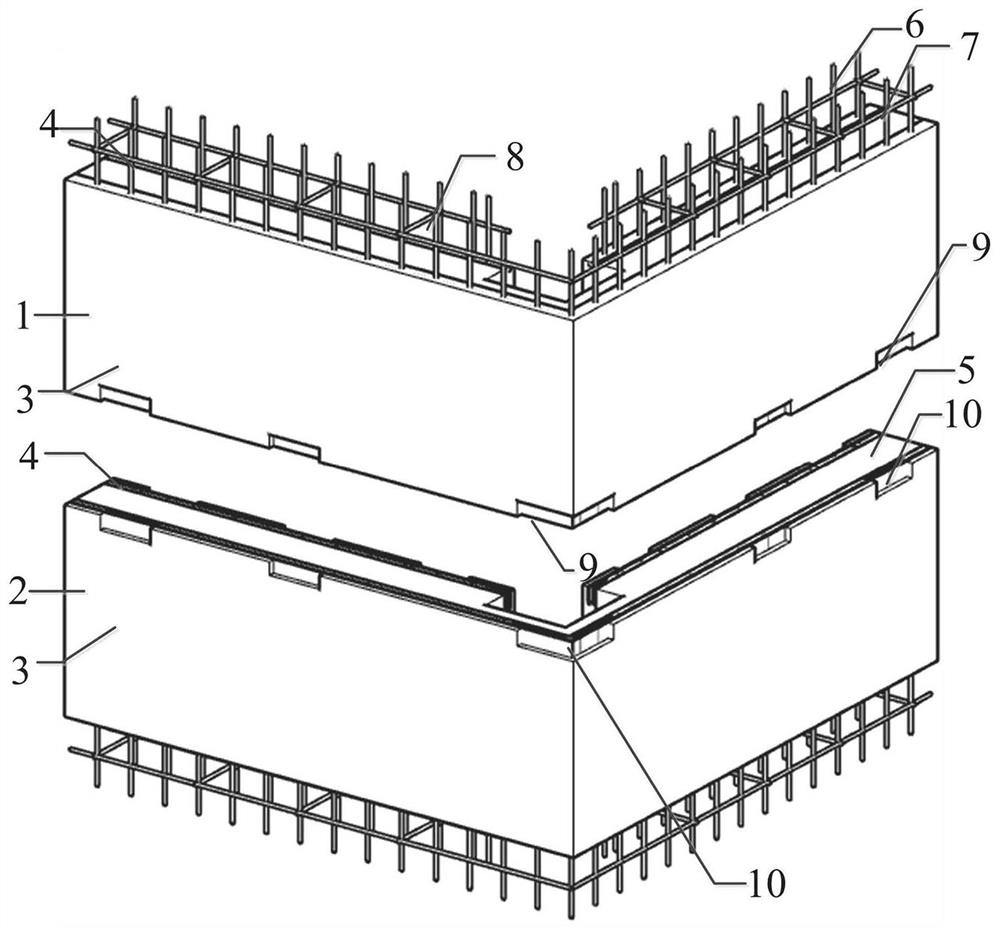

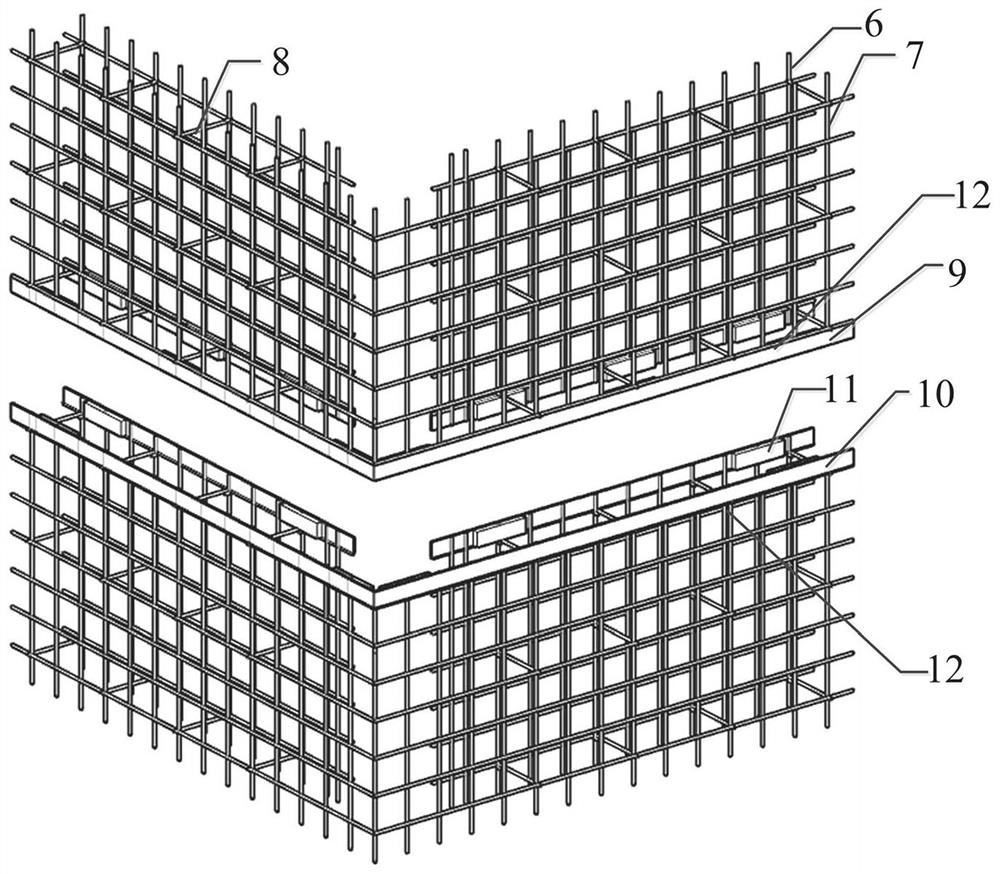

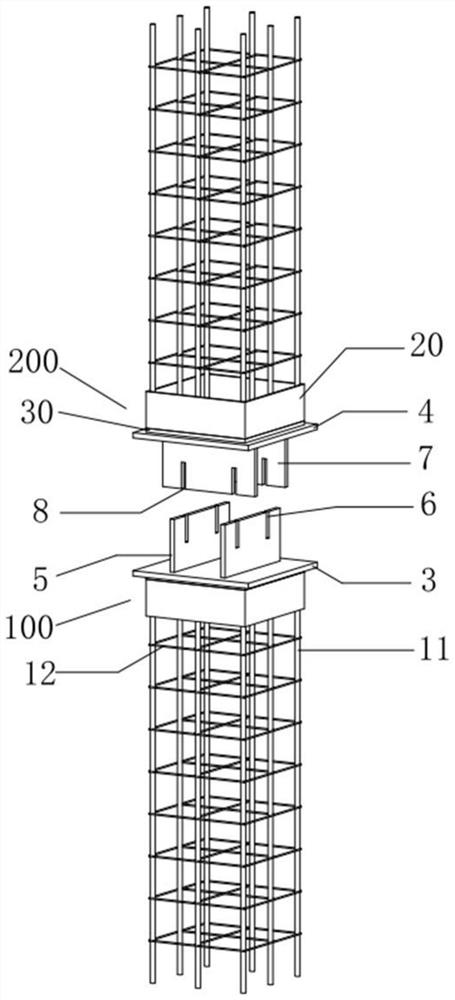

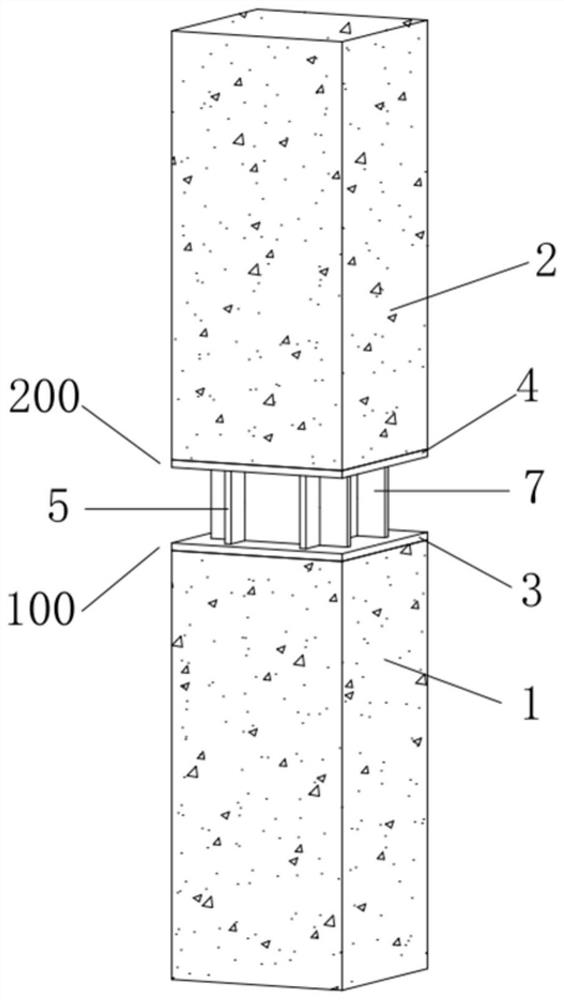

A prefabricated prefabricated column splicing rigid connection node and construction method

ActiveCN111877831BFirmly connectedAct as a constraintStrutsProtective buildings/sheltersStructural engineeringMechanical engineering

Owner:SHANGHAI INST OF TECH

Construction method and support system of assembleable and recoverable deep foundation pit support system

Owner:河北建科唐秦建筑科技有限公司

Reinforcing and vibration reducing fabricated wall connecting structure and mounting method thereof

PendingCN113775231AImprove stabilityImprove vibration resistanceWallsProtective buildings/sheltersArchitectural engineeringRubber mat

The invention discloses a reinforcing and vibration reducing fabricated wall connecting structure. The reinforcing and vibration reducing fabricated wall connecting structure comprises a fabricated wall, a reinforcing connecting piece and a vibration reducing combined piece. Deep caulking seams, shallow caulking seams and mounting holes are formed in the fabricated wall; the reinforcing connecting piece comprises a base plate, long reinforcing ribs and short reinforcing ribs, wherein the long reinforcing ribs and the short reinforcing ribs are arranged on the base plate, an assembly through hole is further formed in the middle of the base plate; and the vibration reducing combined piece is formed by assembling a vibration reduction rubber pad, a vibration reduction spring section, a center connecting section and an end connecting section. The invention further discloses an installation method of the structure. The long reinforcing ribs and the short reinforcing ribs are arranged on the reinforcing connecting piece, so that the overall stability of wall connection is improved; the vibration reducing combined piece is arranged between the wall connections, so that the vibration resistance of the wall connections is improved; and the decoration effect of a veneer is ensured by reinforcing the through decoration lines on the connecting pieces. Parts of the structure are all produced in factories, assembly type assembly is adopted in a construction site, wet operation is avoided, construction is convenient and fast, and labor intensity is reduced.

Owner:ZHEJIANG YASHA DECORATION

Unit type insulative and decorative integrated outer wall system of metal panel

PendingCN111719794ASimple structureImprove quality controlCovering/liningsStructural engineeringExternal cladding

The invention relates to a unit type insulative and decorative integrated outer wall system of a metal panel. The system comprises a unit type plate which is fixedly connected to a wall through a joint part. The unit type plate comprises an insulative and decorative integrated board. A unit type steel framework plate block is arranged on the inner side surface of the insulative and decorative integrated board. The unit type steel framework plate block comprises angle iron plates which are arranged on the inner side surface of the insulative and decorative integrated board vertically and horizontally. Aluminum angle parts are arranged on two sides of the unit type steel framework plate block. The panel of one side of each aluminum angle part is fixedly connected to each angle iron plate while the panel of the other side is fixedly connected to the unit type steel framework plate block. The joint part is a hook part fixedly connected to each angle iron plate. A suspended connecting partis fixedly connected to the wall, strip holes, the hole length direction of which directs to the unit type plate, are formed in the suspended connecting part, hanging holes formed staggered with the strip holes in a same plane are formed in the hook part, the hook part can be adjusted up and down and front and back relative to the suspended connecting part, and fastening bolts are arranged betweenthe strip holes and the hanging holes of the hook part.

Owner:安徽人禾建筑节能科技有限公司

Installation method of metro depot assembly type concrete track bridge

PendingCN114032769AGuaranteed durabilityReduce investmentBridge erection/assemblyRailway track constructionTrackwayArchitectural engineering

An installation method of a metro depot assembly type concrete track bridge comprises the steps of installing and fixing embedded parts; producing the assembly type concrete track bridge; connecting the assembly type concrete track bridge with an embedded part in a ground structure; laying rails; and filling track cement. The installation method of the metro depot assembly type concrete track bridge has the main advantages that the installation speed is high, and the construction period is shortened; labor force and turnover material investment can be reduced, and the construction cost is low; the mounting precision is high, and the track laying requirement is met; factorization processing and maintenance are adopted, the durability of the concrete is guaranteed, the concrete is firm and durable, and the service life can be prolonged; the appearance effect is good; noise, dust and wet operation are avoided, and the civilized construction degree is high.

Owner:中铁电气化局集团北京建筑工程有限公司

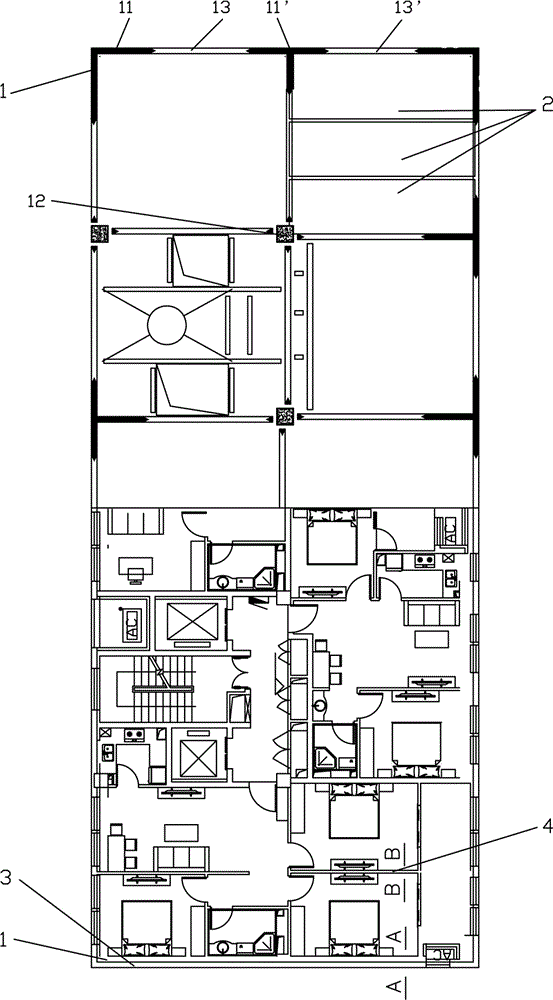

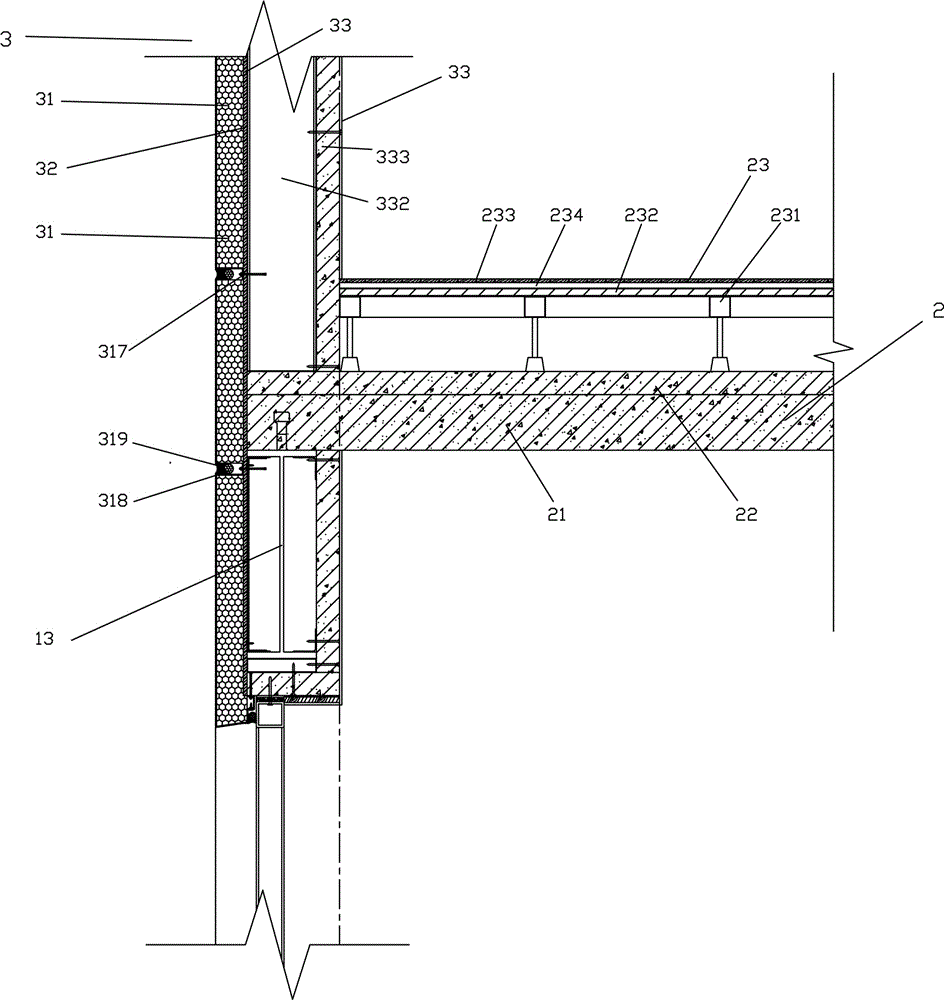

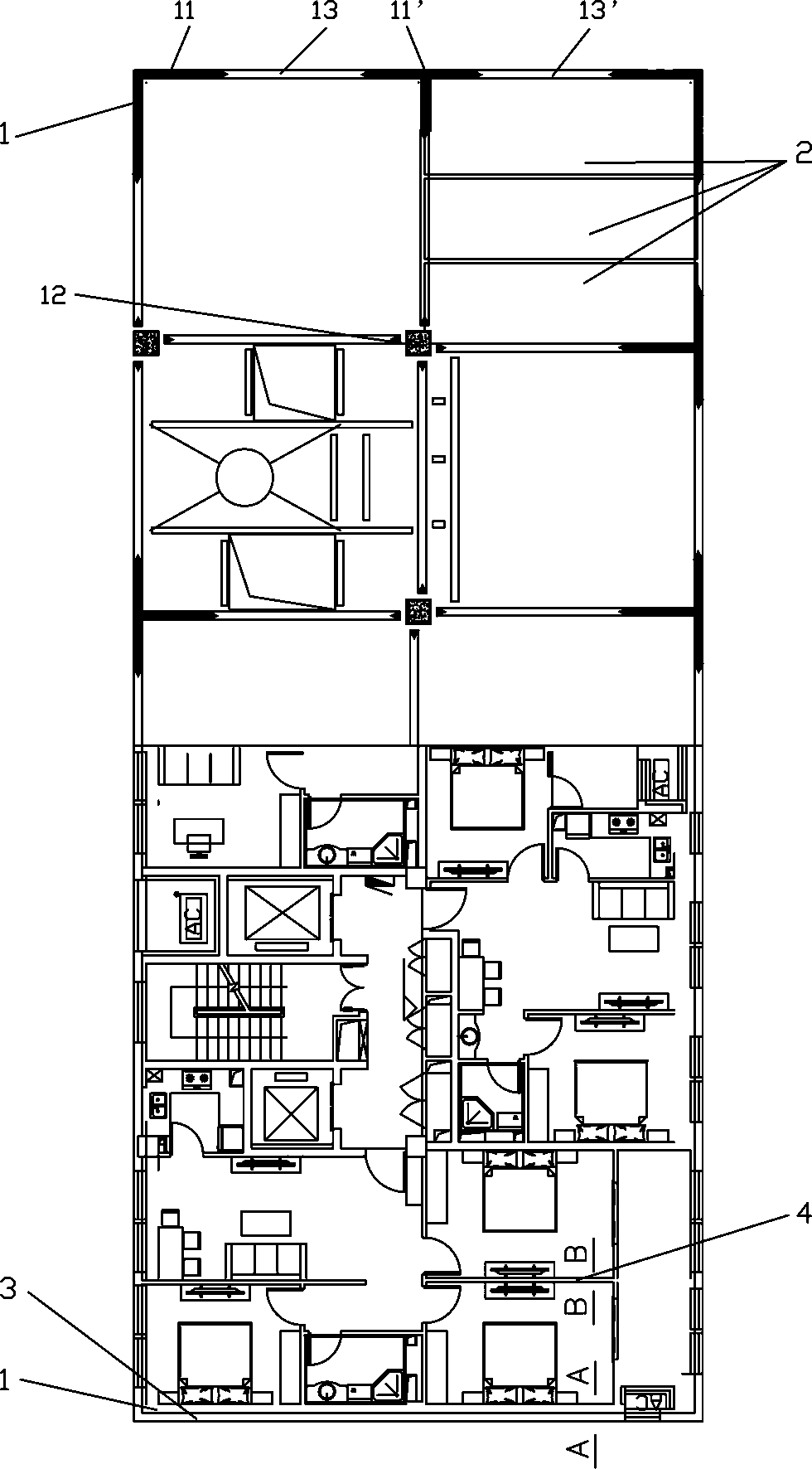

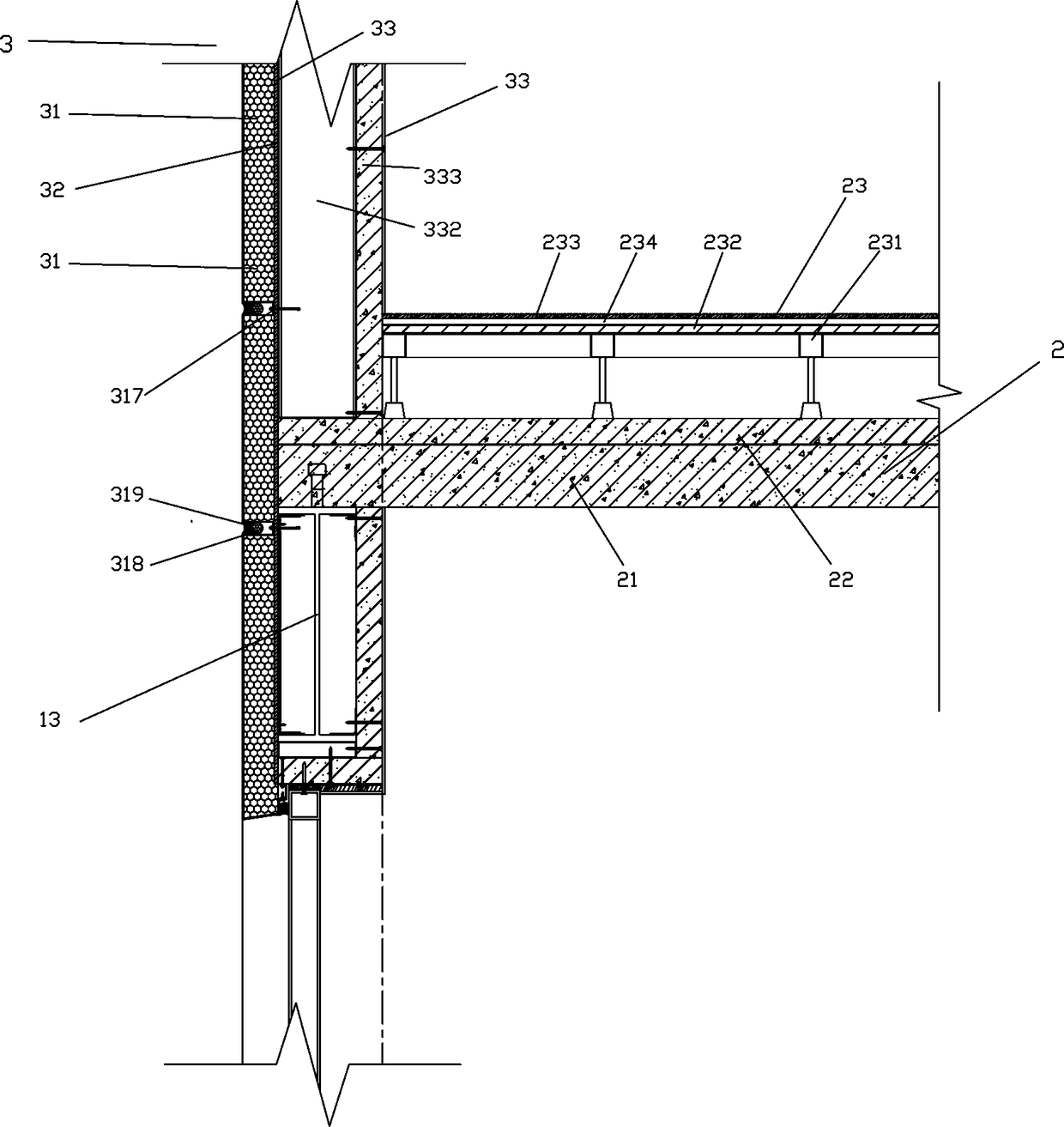

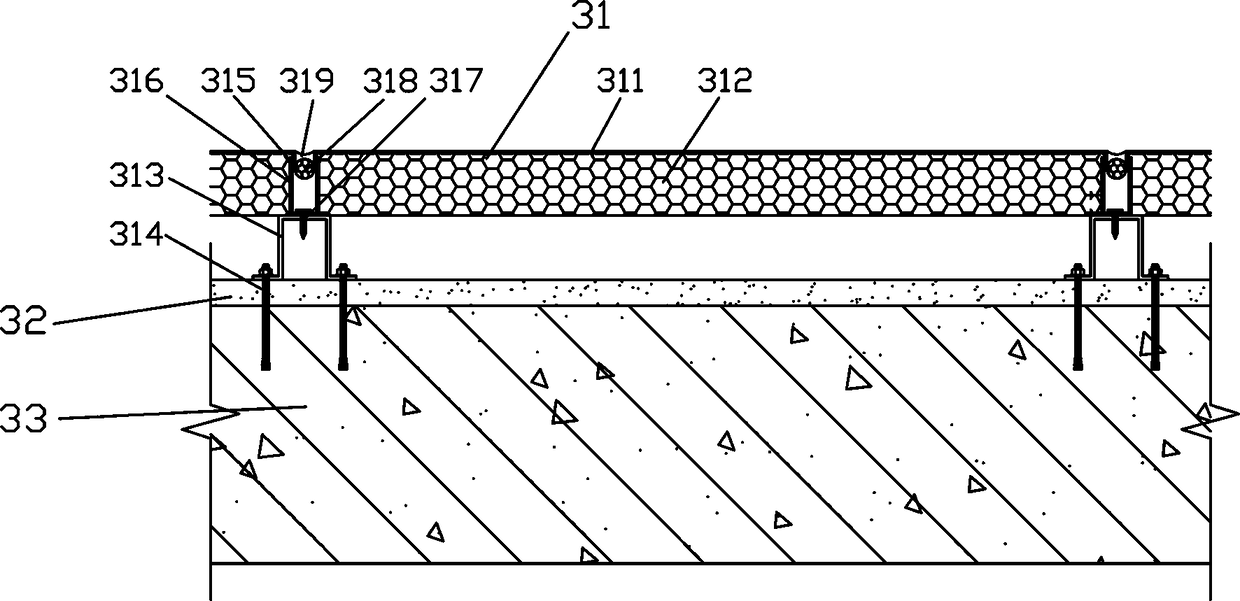

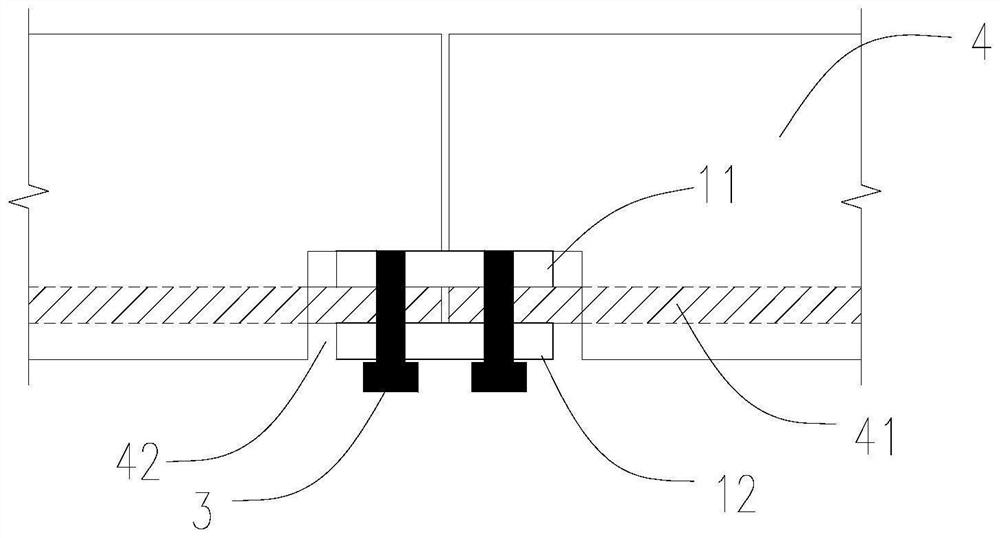

A prefabricated steel structure building system and its construction method

The invention provides an assembled steel structure building system and a construction method thereof. The assembled steel structure building system comprises a steel structure framework system, an assembled and integrated floor system, an assembled outer wall system and an assembled inner wall system; the steel structure framework system comprises double layers of steel plate concrete combined shear wall, steel tube concrete pillars, H-shaped steel beams and connection joints. The steel beams in the steel framework system serves as supports of the assembled and integrated floor system, and the assembled and integrated floor system comprises a precast concrete bottom plate, a cast-in-situ concrete super-position layer and an overhead floor layer located on the cast-in-situ concrete layer. The assembled outer wall system comprises a heat preservation and decoration integrated plate system, a waterproof interface layer and a base wall. According to the assembled steel structure building system, the design concept of separating a supporting body from a filling body is adopted, a large-span space capable of being divided flexibly can be provided, and the assembled steel structure building system and the construction method thereof have the advantages of being high in construction speed, reliable in quality and good in anti-seismic property.

Owner:SHANGHAI IRON & STEEL TECHN INST

Fabricated deviation adjustment high-strength steel bar mechanical connecting device and construction method

PendingCN114412074AReduce additional eccentricityAdditional eccentricity facilitatesBuilding reinforcementsRebarBolt connection

The invention discloses an assembly type deviation adjustment high-strength steel bar mechanical connecting device and a construction method. The assembly type deviation adjustment high-strength steel bar mechanical connecting device comprises an upper connecting plate, a lower connecting plate, a filling plate and two prefabricated plates. Mounting grooves are formed in the bottoms of the opposite surfaces of the two prefabricated slabs, and reinforcing steel bars are arranged in the two prefabricated slabs; the ends of the steel bars in the two prefabricated slabs stretch out of the mounting grooves and stretch into the upper connecting plate and the lower connecting plate, the ends of the two steel bars are oppositely arranged, and the upper connecting plate and the lower connecting plate are connected through bolts. Two filling plates are arranged between the upper connecting plate and the lower connecting plate and located on the two axial sides of the steel bars respectively, the distance between the two filling plates is larger than the diameter of the steel bars, and the thickness of the filling plates is smaller than the diameter of the steel bars. And under the condition of axis deviation of different steel bars, rapid equal-strength connection is realized.

Owner:CHANGAN UNIV

Carbon fiber prepreg fabric for repairing and reinforcing structure

InactiveCN110479566ASo as not to damageHigh strengthBuilding repairsGeotextilesCarbon fibersFiber bundle

The invention belongs to the field of construction repair and reinforcement, and particularly relates to a carbon fiber prepreg fabric for repairing and reinforcing a structure. The carbon fiber prepreg fabric comprises an insulation protection layer and a carbon fiber prepreg weaving layer, wherein the carbon fiber prepreg weaving layer comprises a longitude line and a latitude line, the longitude line is formed by unidirectional pre-impregnated carbon fiber bundle lines, the latitude line is formed by hot melting lines, and the hot melt lines are fixed together with the pre-impregnated carbon fiber bundle lines through heating. The carbon fiber prepreg fabric is convenient to construct, free of large equipment, free of wet operation, free of dynamic fire, free of on-site fixing facilities, small in construction occupied site and high in construction work efficiency. Meanwhile, the abrasion-resistant insulation protection layer protects the carbon fiber prepreg braided layer from being damaged and plays an insulating protection role, the durability is higher, the maintenance period is longer, the hot melting lines are arranged in a single-shape arrangement, the hot melting lines which are arranged in parallel are firmer, and the strength of the fabric is improved.

Owner:四川佐杭科技有限公司

A Construction Method for Closing Holes Through Walls by Using Wall-Through Sleeves

ActiveCN105040959BReasonable designSimple structureBuilding insulationsVertical ductsEngineeringCartridge device

A novel wall-piercing sleeve and a construction method for wall-penetrating hole sealing using the same, wherein the sleeve of the novel wall-piercing sleeve is provided with a stress metal reel, the central axis of which is parallel to the central axis of the sleeve, and the stress metal reel The barrel can be self-adaptive according to the diameter of the equipment pipe, and its outermost end is welded on the inner wall of the sleeve for fixing; in the construction of sealing the hole through the wall, first insert the sleeve into the matching elastic rubber sealing tube , when crossing the wall horizontally, both ends of the spacer can be elongated and kept moving horizontally as a whole, when the sleeve is in the middle of the wall, the elongated spacer can be retracted naturally, and the sleeve is tightly bound to the wall; put the device The pipe passes through the center of the stress metal reel, so that the stress metal reel tightly wraps the equipment pipe, and finally, foam glue is filled between the sleeve and the stress metal reel. On the construction site, the wall bushing can be accurately measured and cut according to the wall thickness, and the elastic rubber sealing tube is used in conjunction with it. The operation is simple and easy, and it can be adapted to various reserved holes and rear openings.

Owner:BEIJING HONG KONG YUAN CONSTR DECORATION ENG

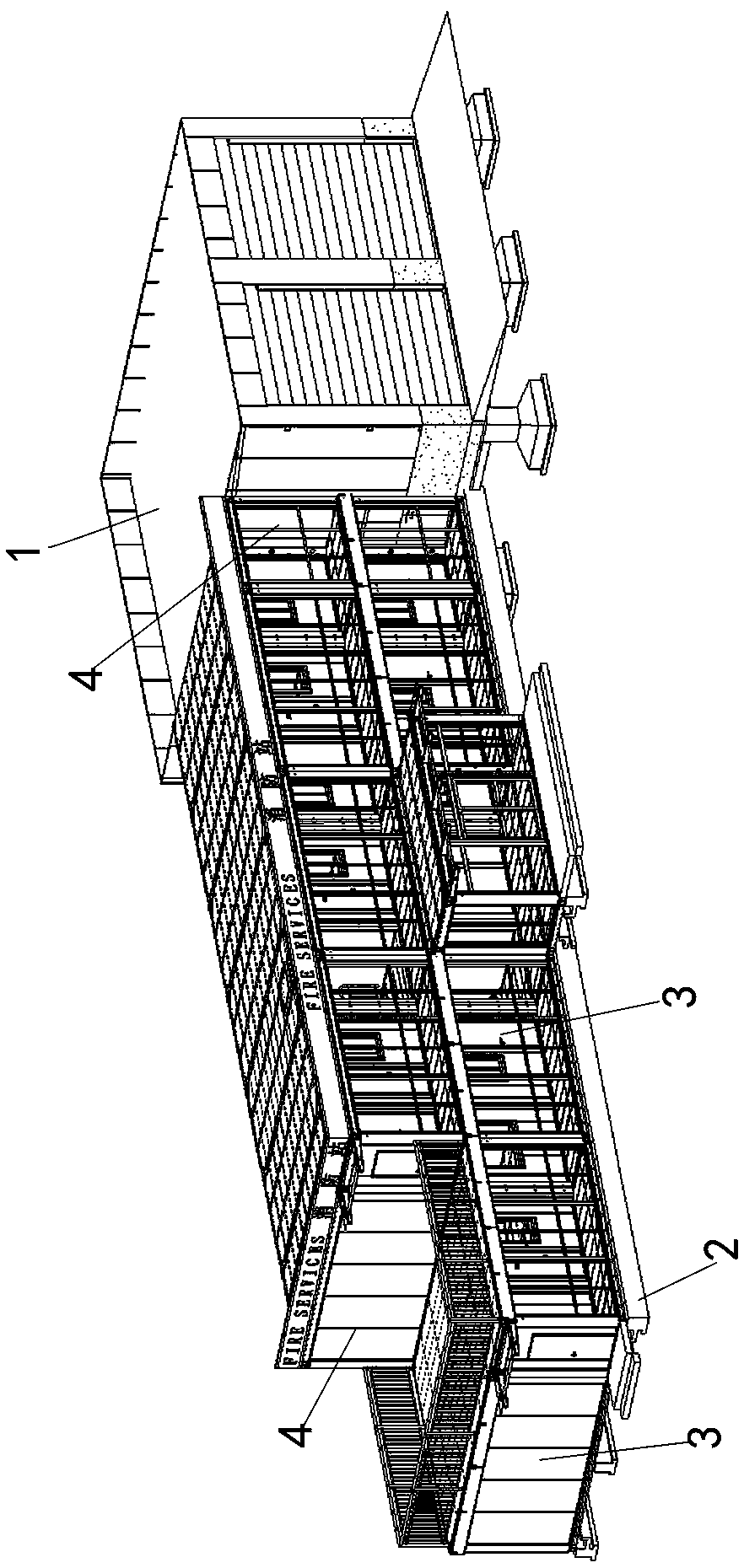

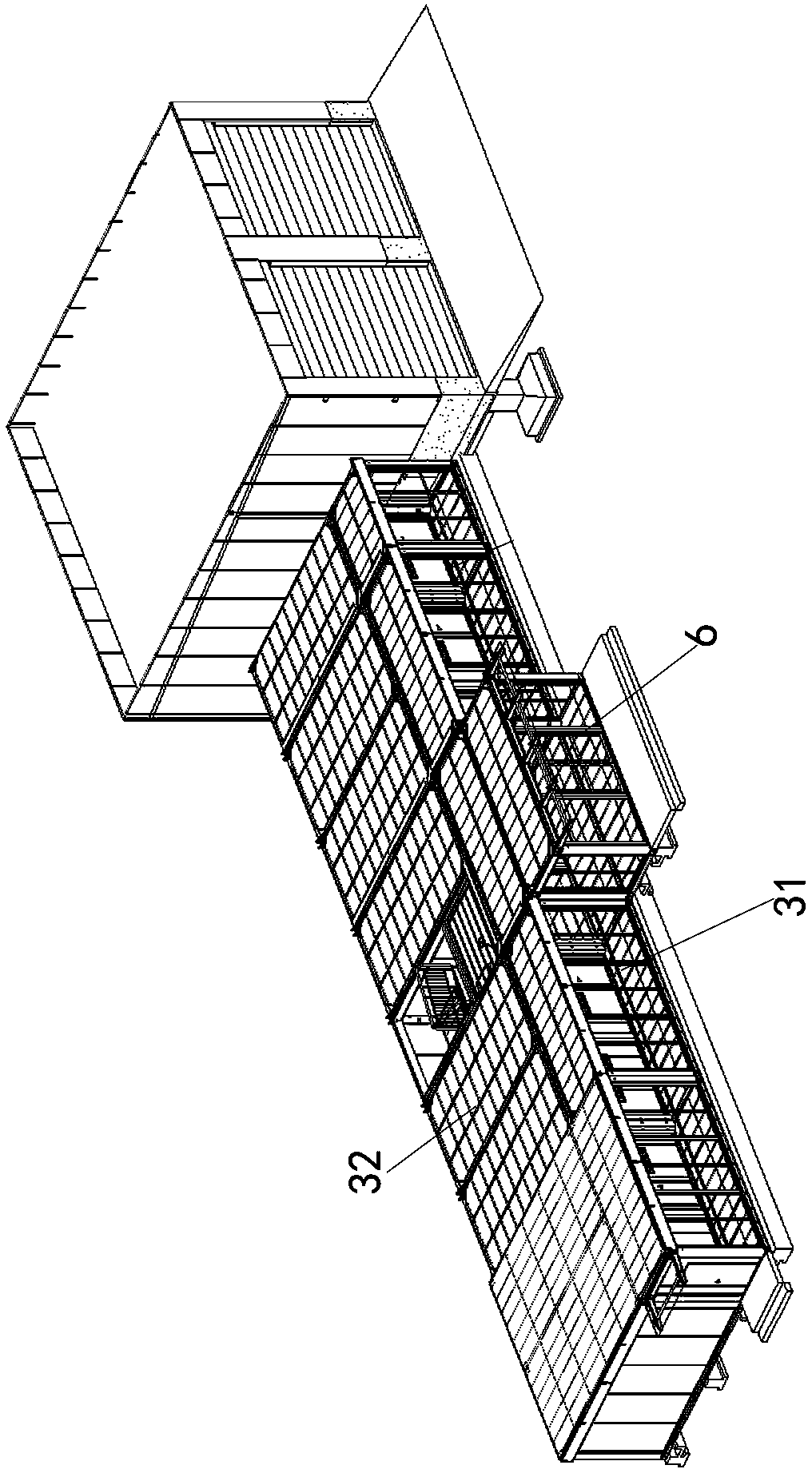

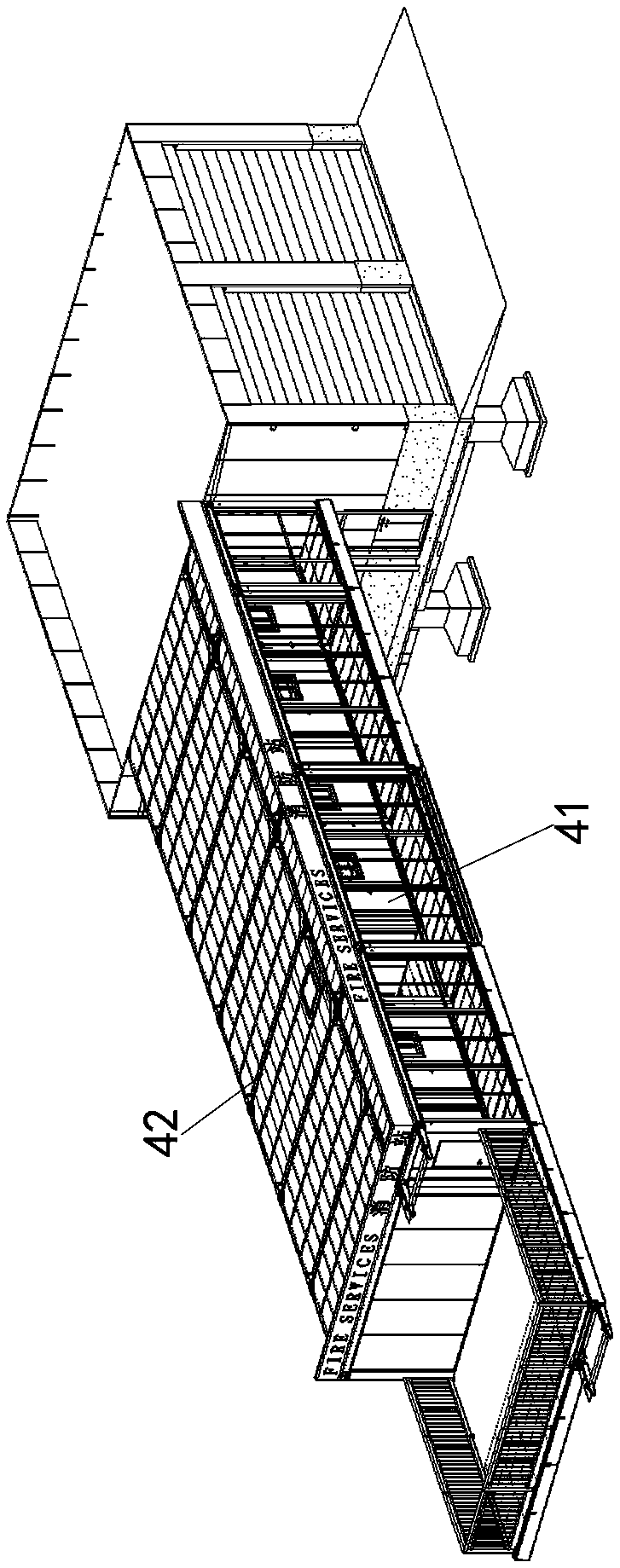

Two-layer modular fire station and construction method thereof

InactiveCN111075252AGuaranteed normal functionEasy to transportBuilding constructionsArchitectural engineeringFire house

The invention discloses a two-layer modular fire station and a construction method thereof. The station comprises a steel structure fire house and a modular integrated house communicating with one side of the steel structure fire house, wherein the modular integrated house comprises a foundation and a two-layer modular box fixedly connected to the upper side of the foundation, the two-layer modular box comprises a first-layer integrated box and a second-layer integrated box, and modules of the first-layer integrated box and the second-layer integrated box are fixedly connected through upper and lower connection assemblies. According to the fire station, function use of the fire station is considered, a corridor area and an activity area are distinguished, so that it is guaranteed that fire-fighting personnel can take fire-fighting action within the shortest time, the modules are all factory prefabricated, a main body structure is composed of four main parts such as a top frame, a bottom frame, top and bottom corner pieces and corner columns, the corner columns are connected with the top frame and the bottom frame through bolts, and are bolted to the top frame and the bottom frame,and the modules are assembled and inserted on site, and are fixed through the bolts.

Owner:中建集成科技有限公司

Prefabricated indoor dry hanging type wall brick and construction method thereof

The invention discloses a prefabricated indoor dry hanging type wall brick system and a construction method thereof. The prefabricated indoor dry hanging type wall brick system comprises frame keels (1), supporting strips (2), wall bricks (3), a light steel keel partition wall (4), connecting corner pieces (5), pulling strips (6) and flattening machine caps (7). The frame keels (1) are fixed to the partition wall or a civil wall body by a light steel keel, and the supporting strips (2) are fixed into the frame keels in sections; the vertical frame keels and horizontal transverse frames are connected by the connecting corner pieces (5) to form a mouth-type frame; the pulling strips (6) are installed into the frame keels (1), and the mouth-type frame keels (1) accommodate structural glue; the structural glue is tightly attached the wall bricks (3) to the front end surfaces of the frame keels, and the bottom portions of the wall bricks (3) fall on the supporting strips (2); and finally, the flattening machine caps tighten the pulling strips. The dry construction of the wall bricks is realized.

Owner:上海品宅装饰科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com