Installation method of metro depot assembly type concrete track bridge

A technology for subway depots and installation methods, which is applied in the erection/assembly of bridges, tracks, and track laying, etc., can solve the problems of unstable construction quality on site, affecting the safety of maintenance trains, corrosion of rail bridge pillars, etc., so as to reduce the input of turnover materials. , The effect of good appearance and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

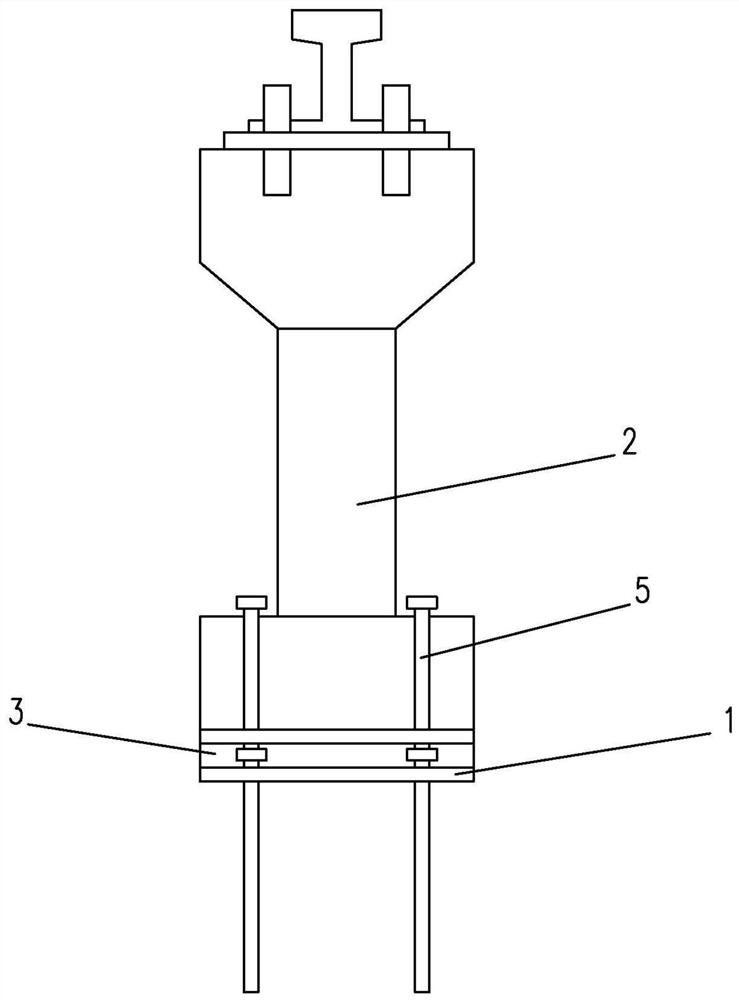

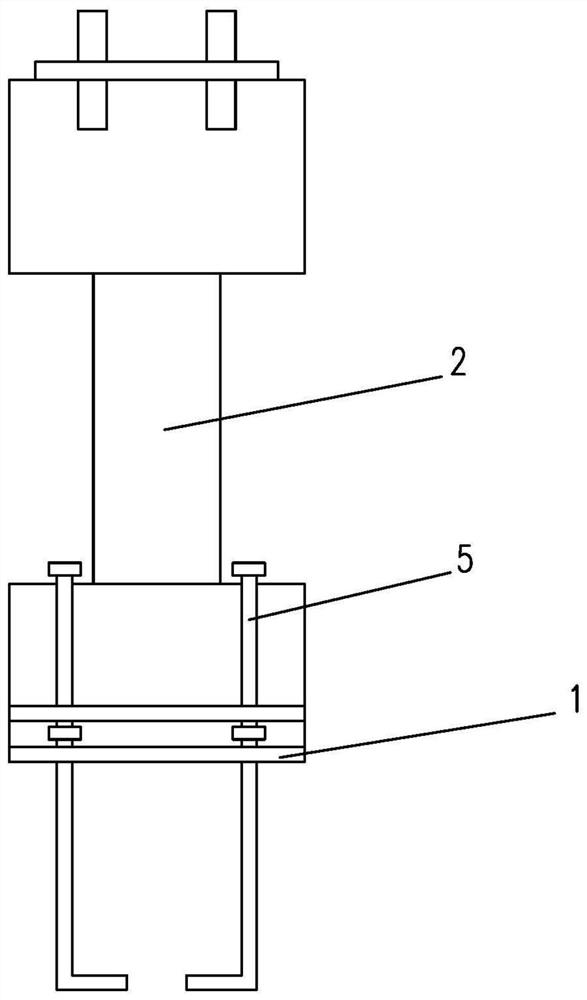

[0030] like figure 1 , figure 2 As shown, the installation method of the prefabricated concrete track bridge of the subway depot of the present invention comprises:

[0031] The embedded part 1 is installed and fixed;

[0032] Production of prefabricated concrete track bridges;

[0033] The prefabricated concrete track bridge 2 is connected with the embedded parts 1 in the ground structure;

[0034] track;

[0035] Fill track mastic 3.

[0036] The installation method of the prefabricated concrete track bridge in the subway depot of the present invention, wherein, before the embedded parts are installed and fixed, the steel bars of the ground structure and the formwork of the maintenance trench are installed; after the embedded parts are installed and fixed, the embedded parts are accepted; Structural concrete is poured, cured, filled with track mortar and then ground decoration.

[0037] In the installation method of the prefabricated concrete track bridge in the subwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com