Patents

Literature

36results about How to "Improve the level of civilized construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fabricated aluminum alloy formwork system construction method

InactiveCN103206089ABad luckQuality improvementBuilding material handlingSystem constructionAluminium alloy

The invention discloses a fabricated aluminum alloy formwork system construction method. The method includes steps of formwork system designing, formwork mounting, concrete pouring and maintaining, formwork demounting and the like. The fabricated aluminum alloy formwork system construction method is convenient to construct and good in effective.

Owner:成军

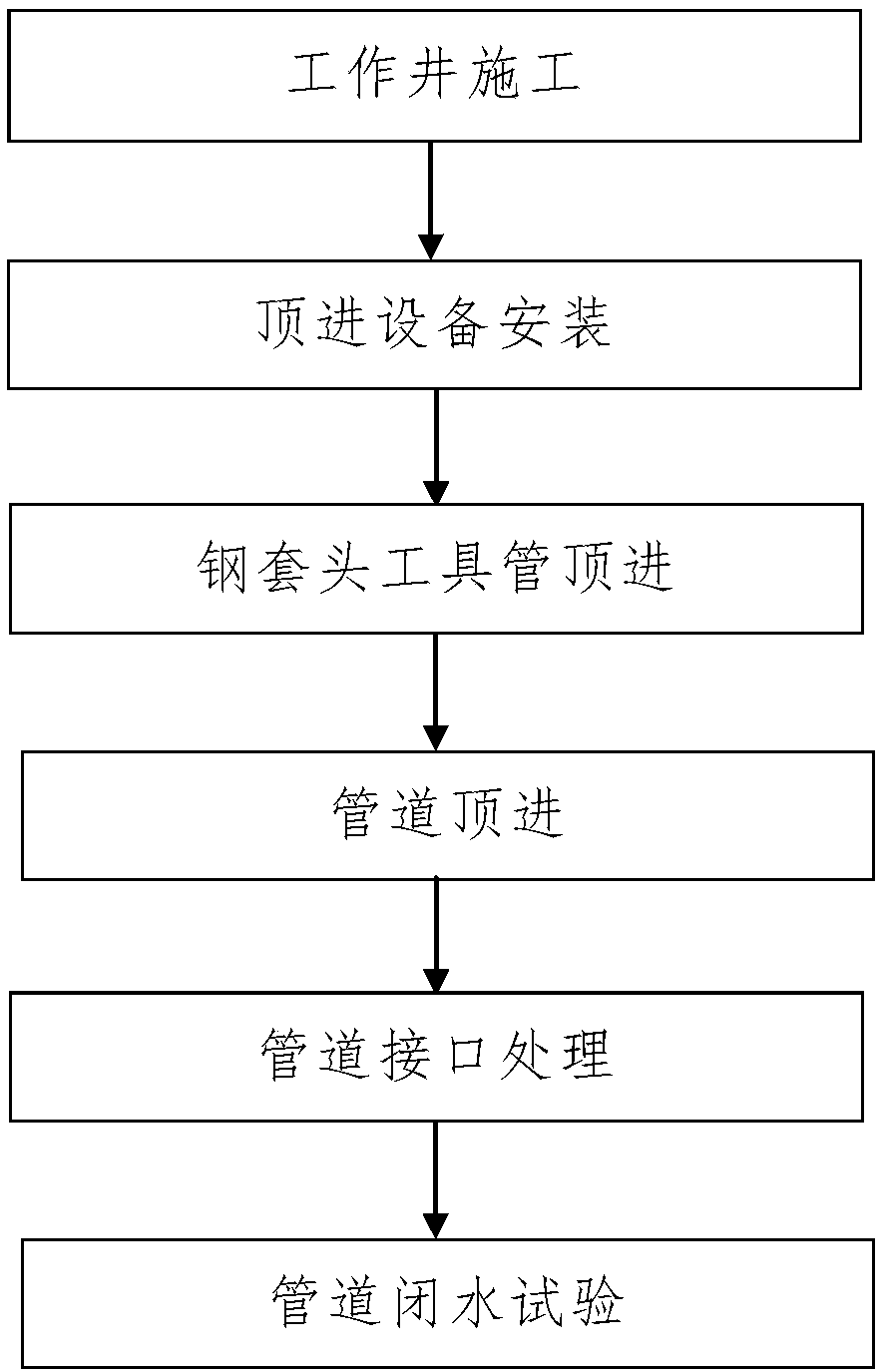

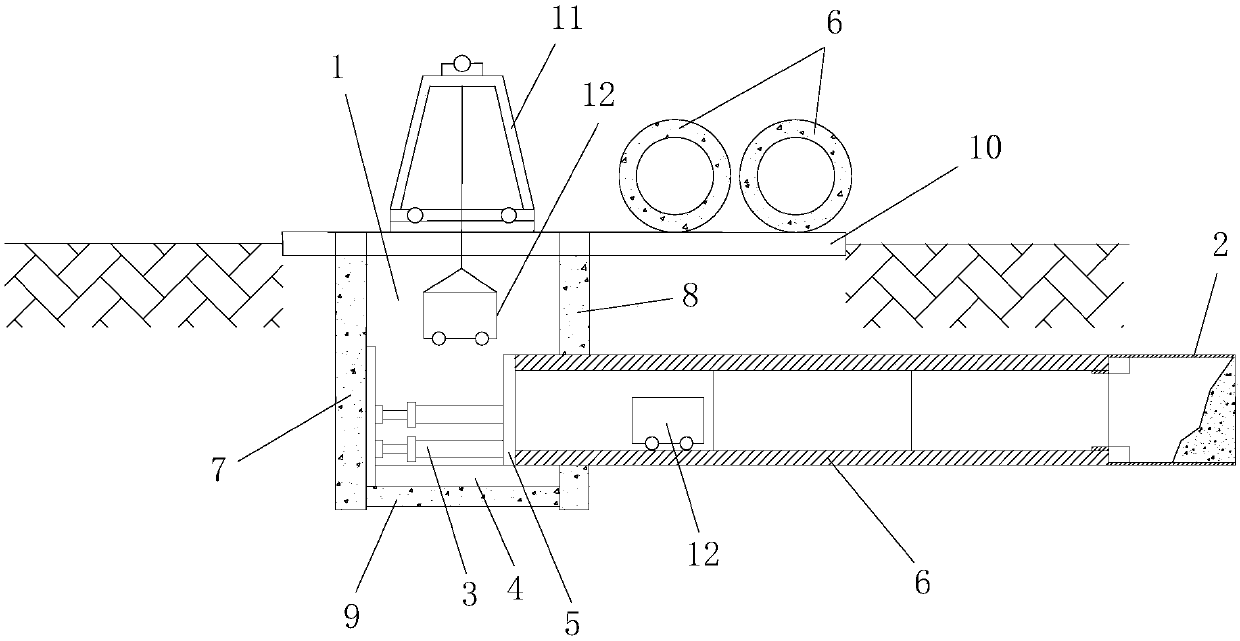

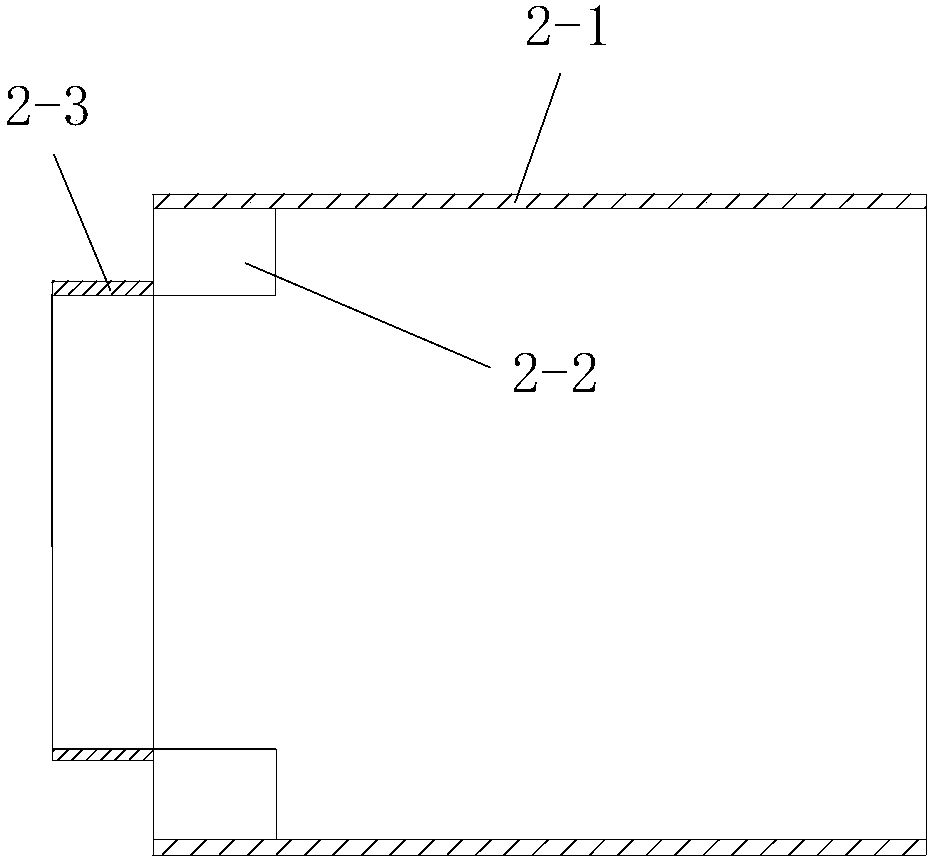

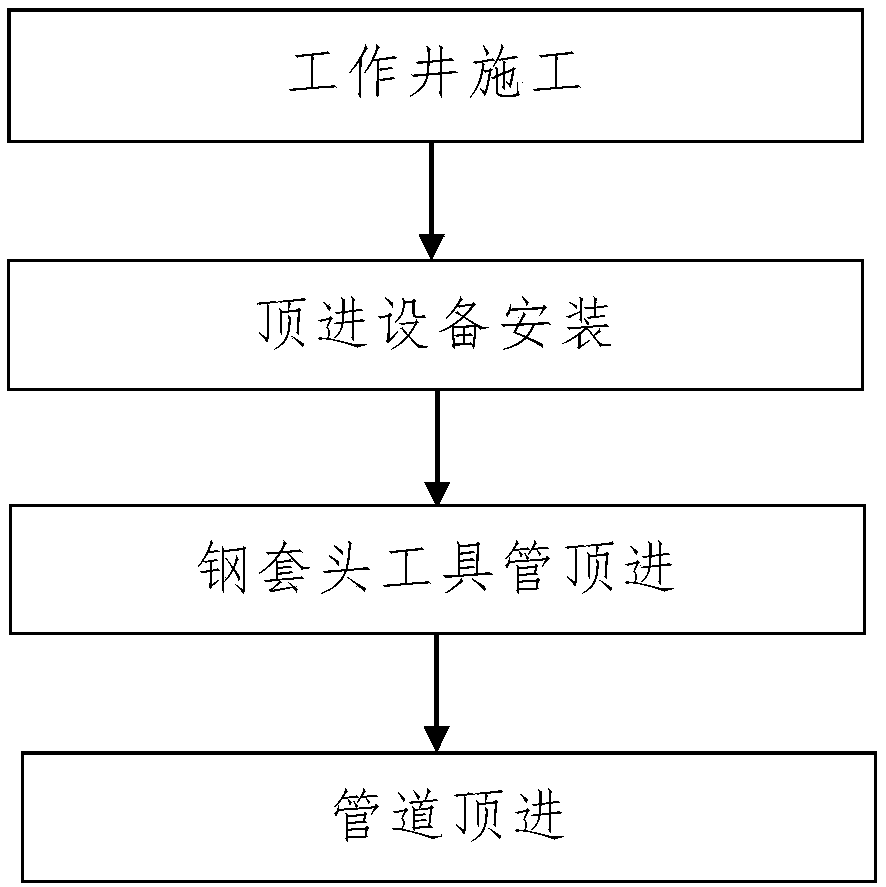

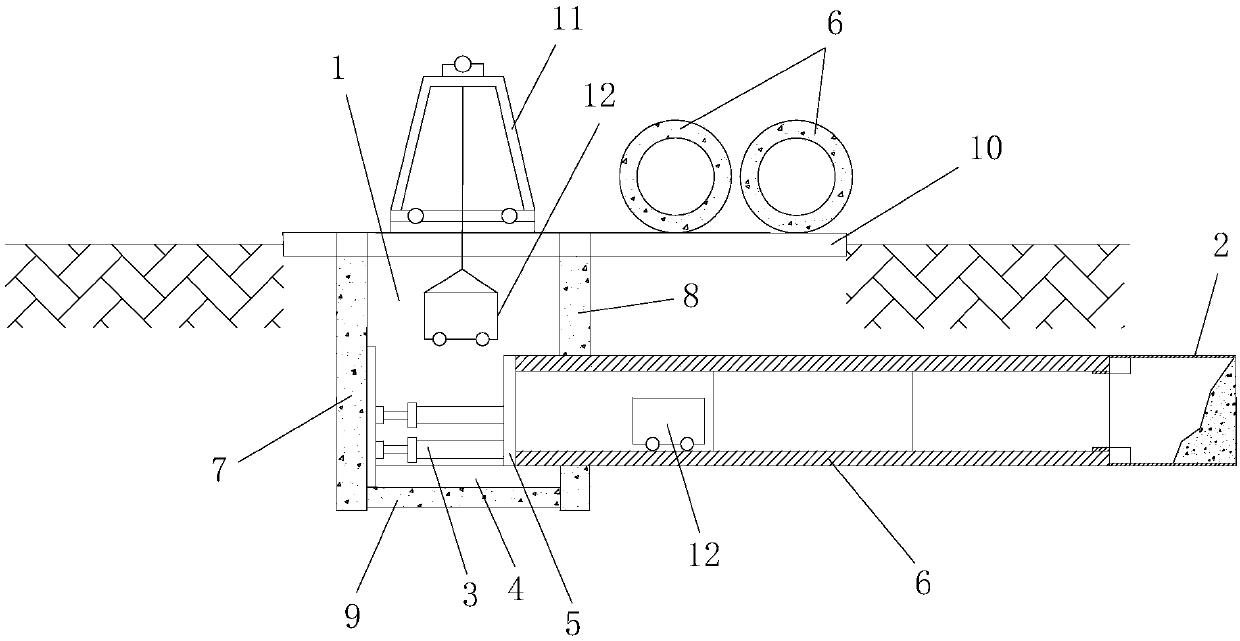

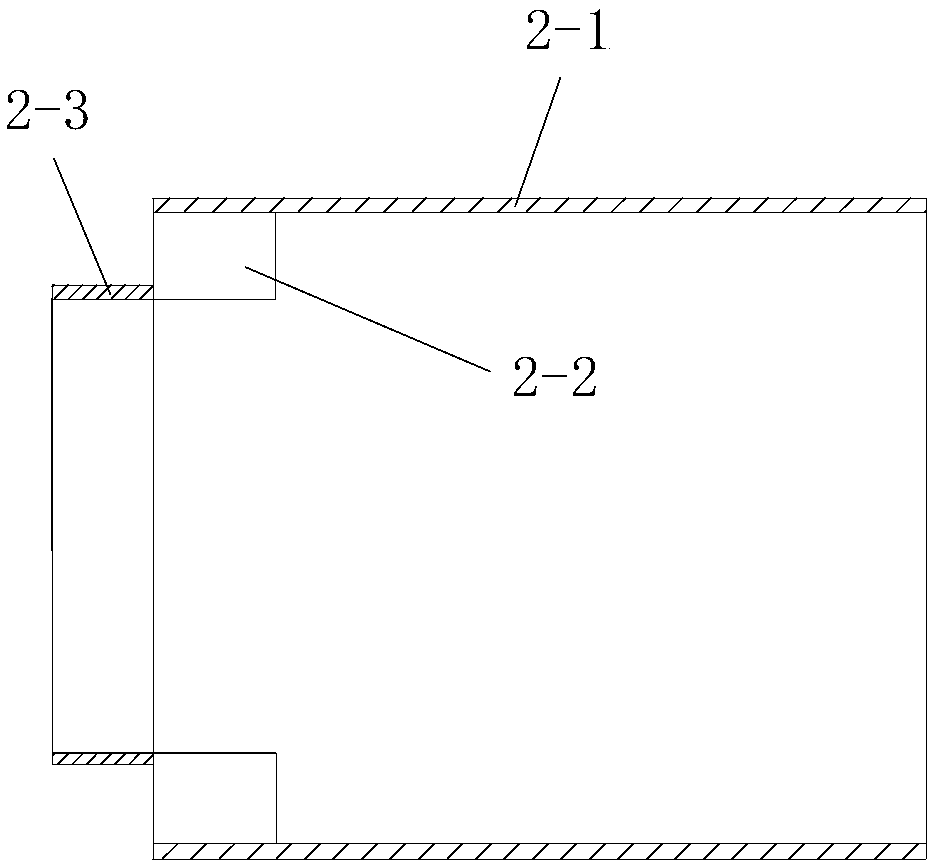

Pipe-jacking construction method for mealy sand stratum

ActiveCN106369223AThe method steps are simpleReasonable designPipe laying and repairEngineeringUnderground pipeline

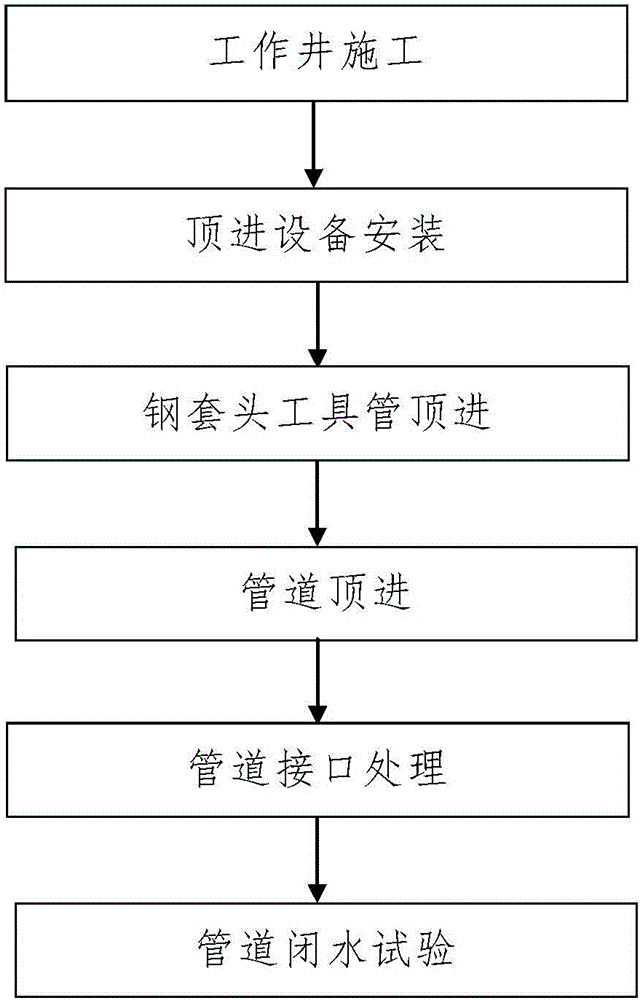

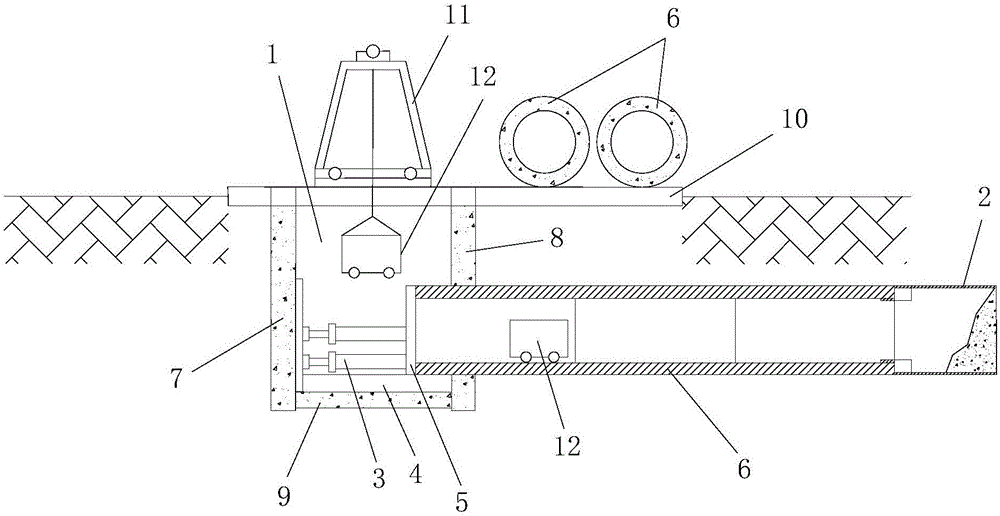

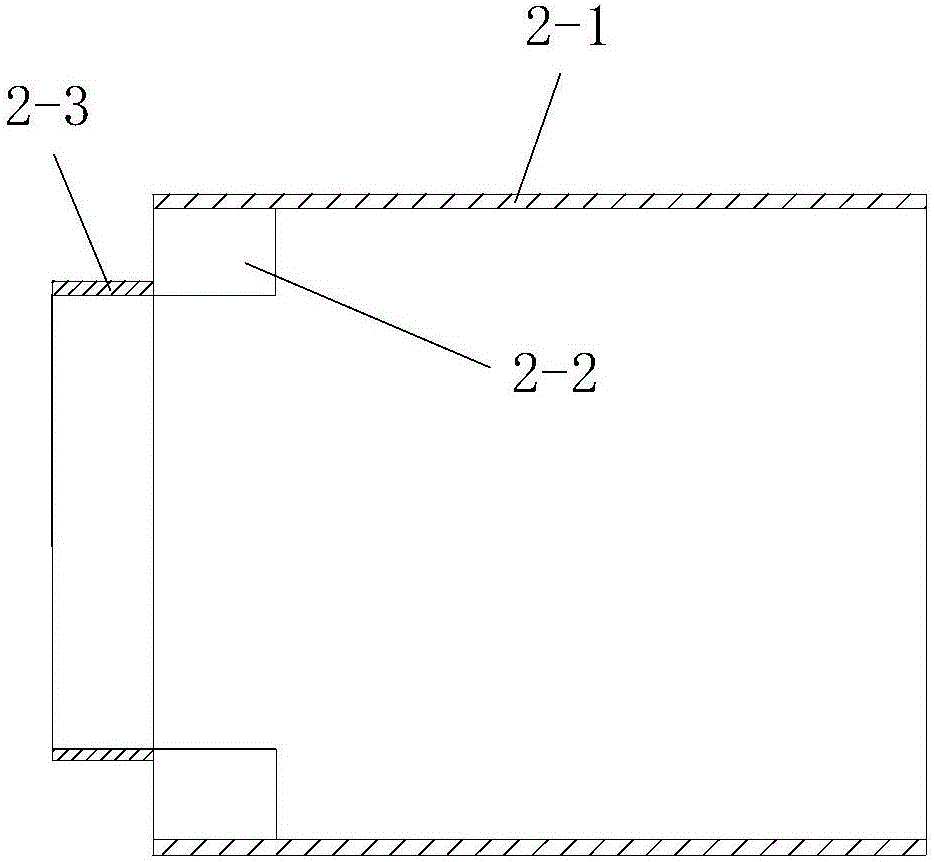

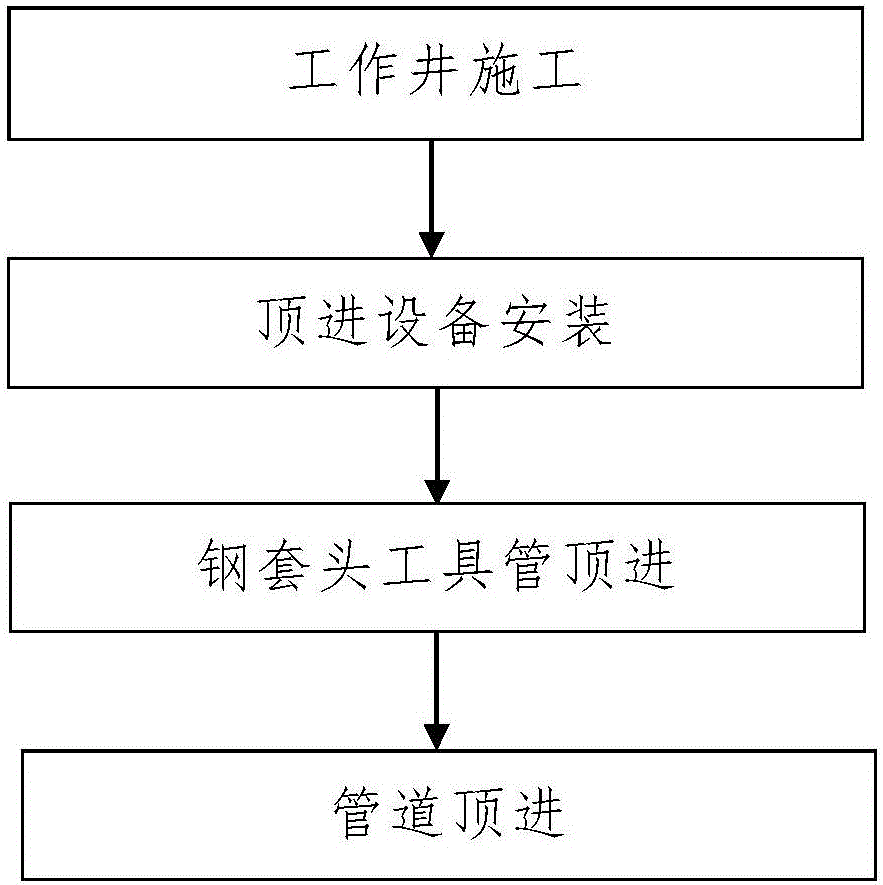

The invention discloses a pipe-jacking construction method for a mealy sand stratum. The pipe-jacking construction method for the mealy sand stratum comprises the steps that firstly, a working well is constructed, specifically, the working well used for jacking a constructed underground pipeline is constructed, the constructed underground pipeline is formed by splicing a plurality of pipeline assembly sections from front to back, and a steel bushing head tool pipe comprises a steel sleeve, a supporting ring mounted on the inner side of the rear end of the steel sleeve, and an insertion opening fixed to the supporting ring; secondly, jacking equipment is mounted, specifically, the jacking equipment is mounted at the bottom of the inner side of the working well; thirdly, the steel bushing head tool pipe is jacked through the process that the steel bushing head tool pipe is hoisted in place, the steel bushing head tool pipe is jacked, and manual intra-pipe earth cutting is conducted; fourthly, the pipeline is jacked, specifically, the multiple pipeline assembly sections of the constructed underground pipeline are jacked from front to back; fifthly, a pipeline port is treated; and sixthly, a closed water test for the pipeline is conducted. According to the pipe-jacking construction method for the mealy sand stratum, the steps are simple, the design is reasonable, construction is easy and convenient, and the using effect is good; and a pipe-jacking construction process of the mealy sand stratum can be completed easily, conveniently and rapidly, and the construction process is safe and reliable.

Owner:中铁二十局集团第五工程有限公司

Silty soil stratum pipe-jacking jacking construction method based on tool pipe with steel sleeve head

ActiveCN106402490AThe method steps are simpleReasonable designPipe laying and repairStructural engineeringEngineering

The invention discloses a silty soil stratum pipe-jacking jacking construction method based on a tool pipe with a steel sleeve head. The method includes the steps that firstly, a work well is constructed, wherein the work well used for jacking a construction underground pipeline is constructed, the construction underground pipeline is formed by splicing a plurality of pipeline splicing joints, the tool pipe with the steel sleeve head comprises the steel sleeve pipe, a supporting ring installed on the inner side of the rear end of the steel sleeve pipe and an inserting port fixed to the supporting ring, the wall thickness of the steel sleeve pipe is 0.8-1.2 cm, and the length of the steel sleeve pipe is 80-120 cm; secondly, a jacking device is installed; thirdly, the tool pipe with the steel sleeve head is jacked, wherein the tool pipe with the steel sleeve head is hoisted in place, the tool pipe with the steel sleeve head is jacked, and a soil is manually excavated in the pipe; and fourthly, pipeline jacking is performed, wherein the pipeline splicing joints in the construction underground pipelines are jacked correspondingly from front to back. The method is simple in step, reasonable in design, easy and convenient to construct, good in using effect, capable of easily, conveniently and fast completing the silty soil stratum pipe-jacking jacking construction process and safe and reliable in construction process.

Owner:中铁二十局集团第五工程有限公司

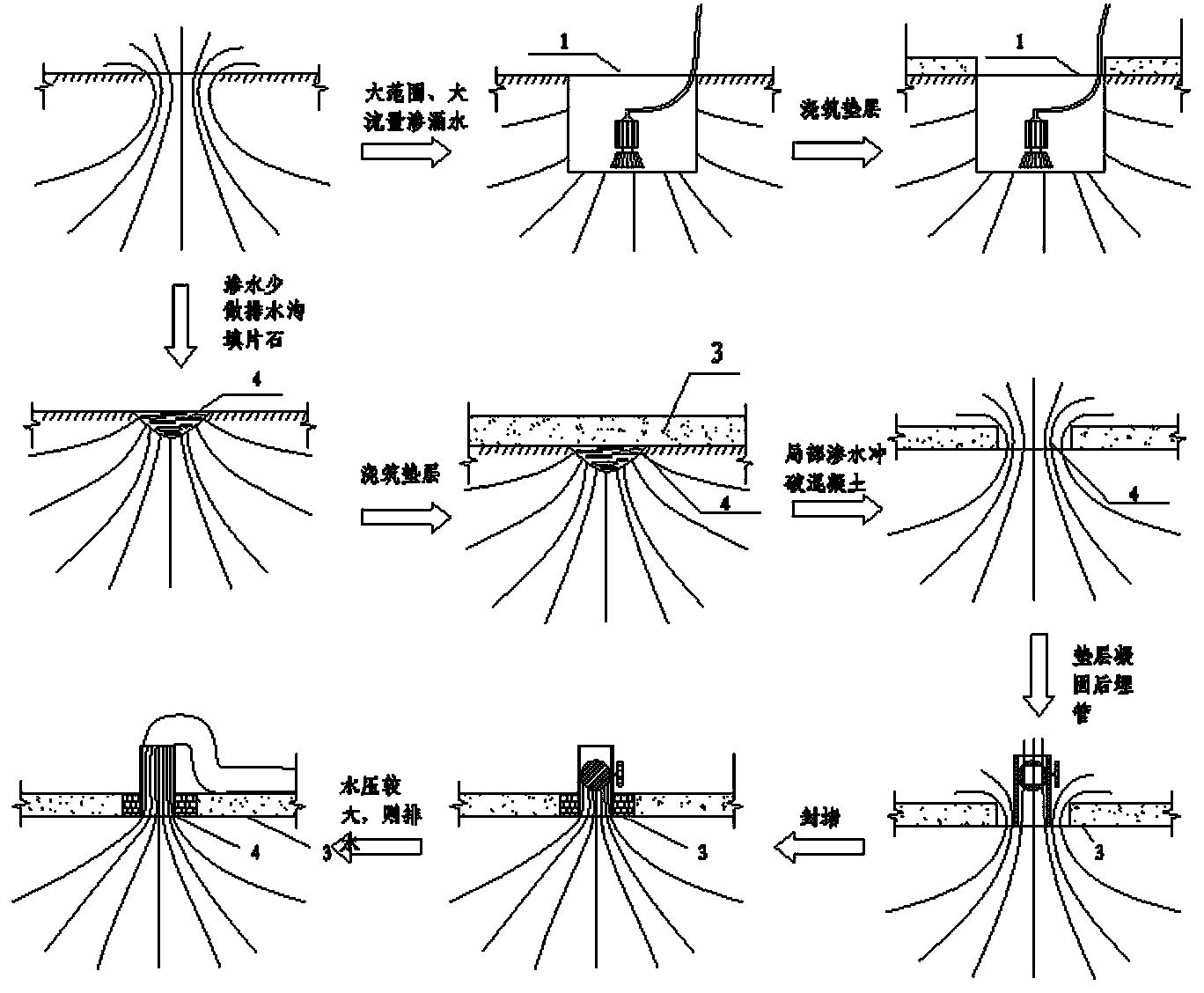

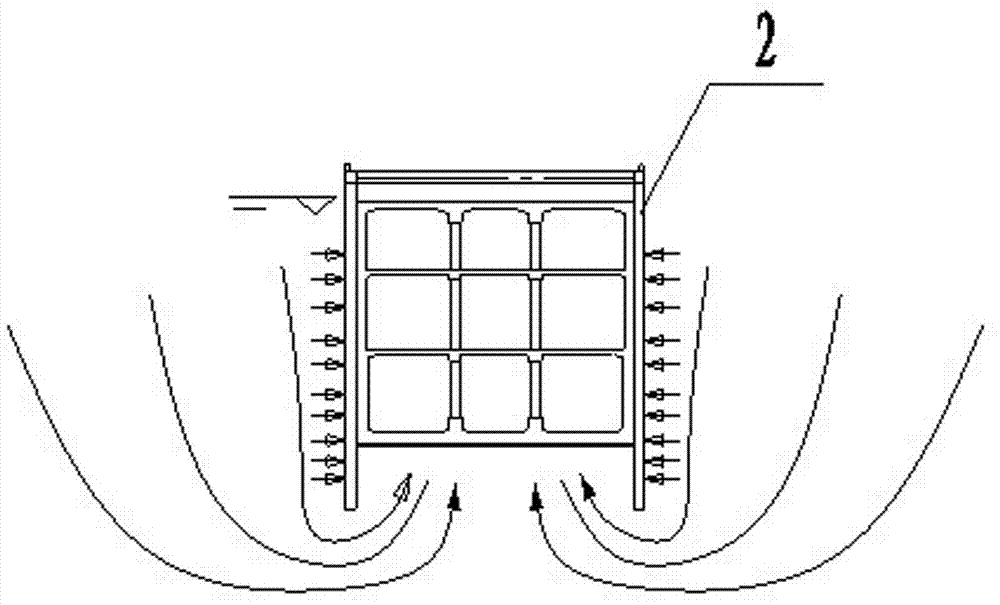

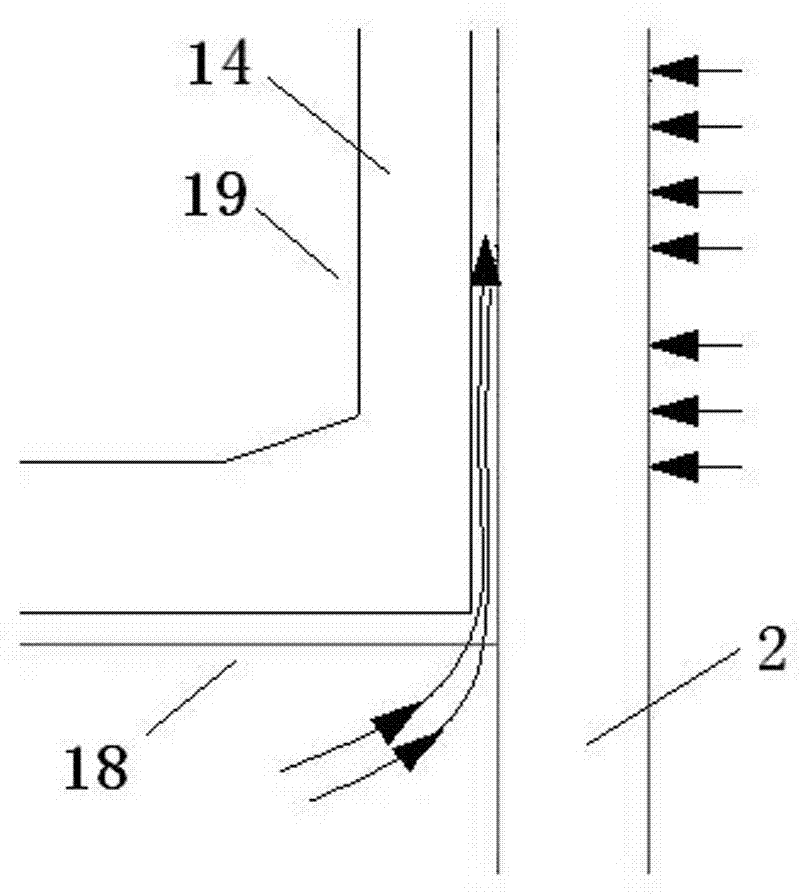

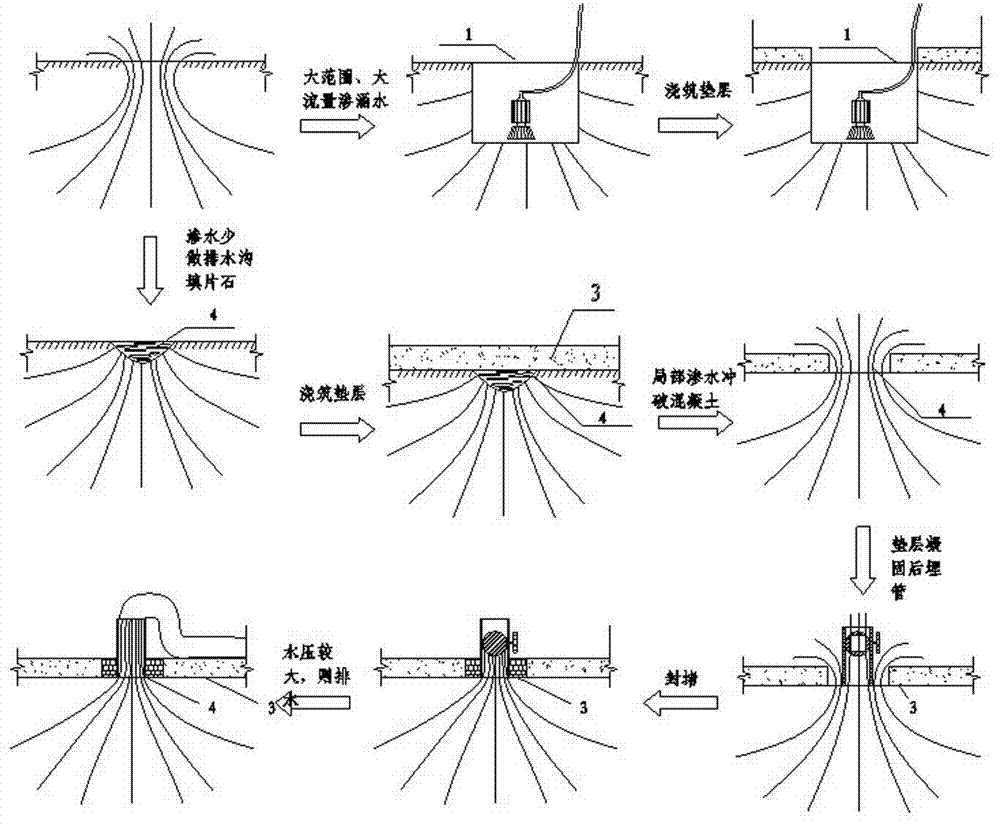

Water seepage control construction method for karst water-rich geological underground structure waterproof construction

The invention relates to the field of basement water-rich geological structure waterproof construction, in particular to a water seepage control construction method for karst water-rich geological underground structure waterproof construction. The problem that waterproof construction is affected due to the fact that existing underground structure waterproof construction only focuses on construction self-waterproofing and is poor in waterproof effect and water pressure and waterways of foundation pit water seepage always exist. The water seepage control construction method includes the steps of water seepage control on baseboard waterproof construction, waterproofing and water draining of baseboards and continuous wall corners, water seepage control on wall waterproof construction, water seepage control on portal waterproof construction, and water seepage control on waterproof construction of expansion joints and post-cast strips. A water seepage control technique at positions such as the baseboards, station structure side walls, the expansion joints and the post-cast strips is realized, structure waterproof performance is improved, waterproof construction is ensured to be performed in a water-free environment, quality of waterproof construction and cement construction under the karst water-rich geological conditions is guaranteed, simplicity and convenience in technological operation are realized, and the water seepage control construction method is wide in application range, reliable in technology, high in superiority and convenient to popularize and apply.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

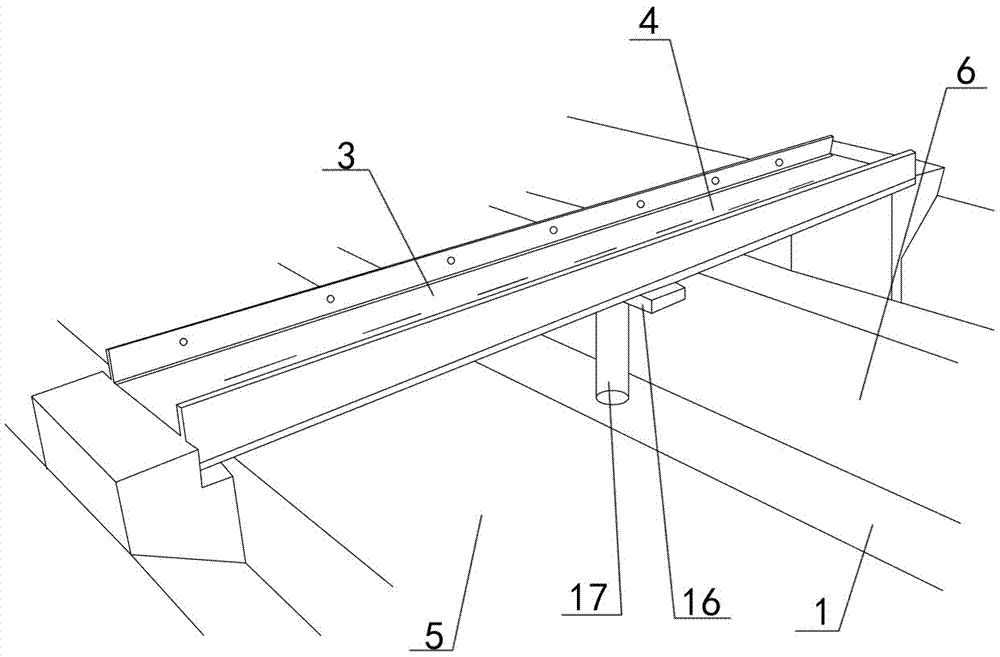

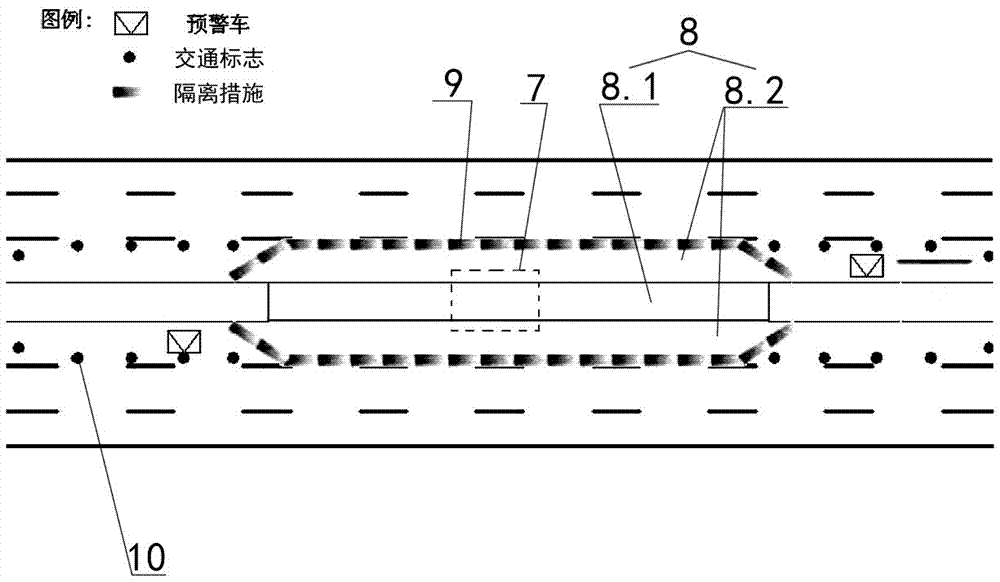

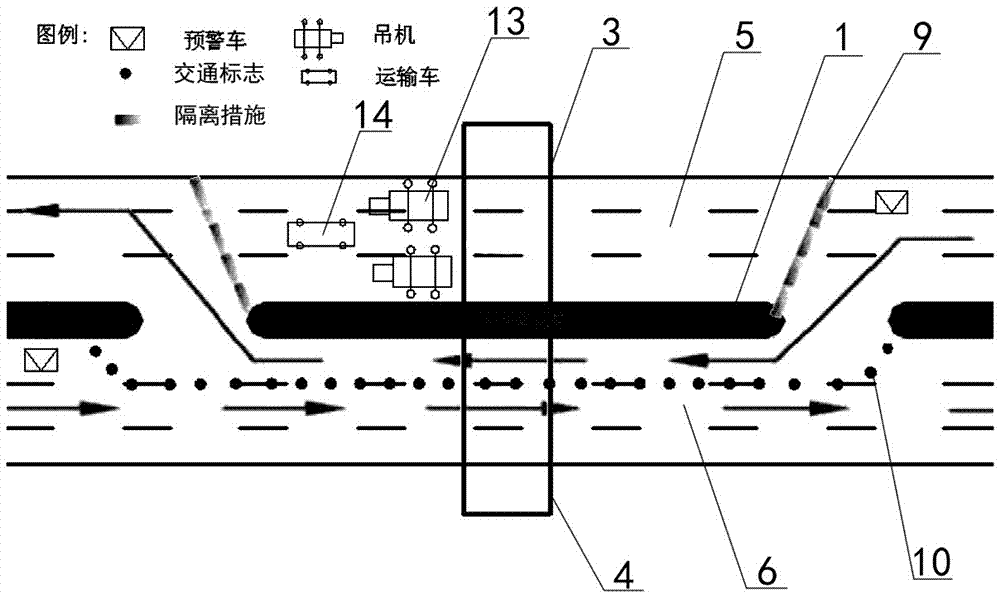

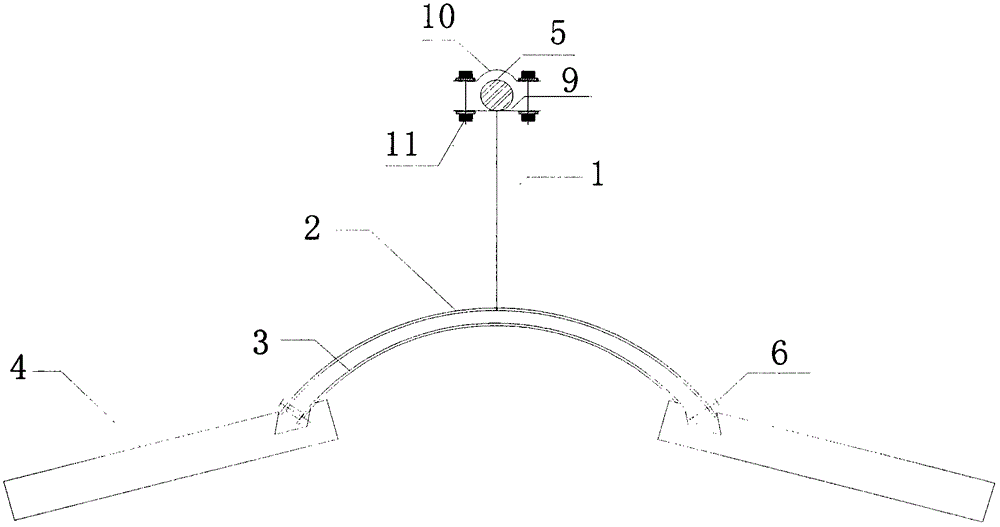

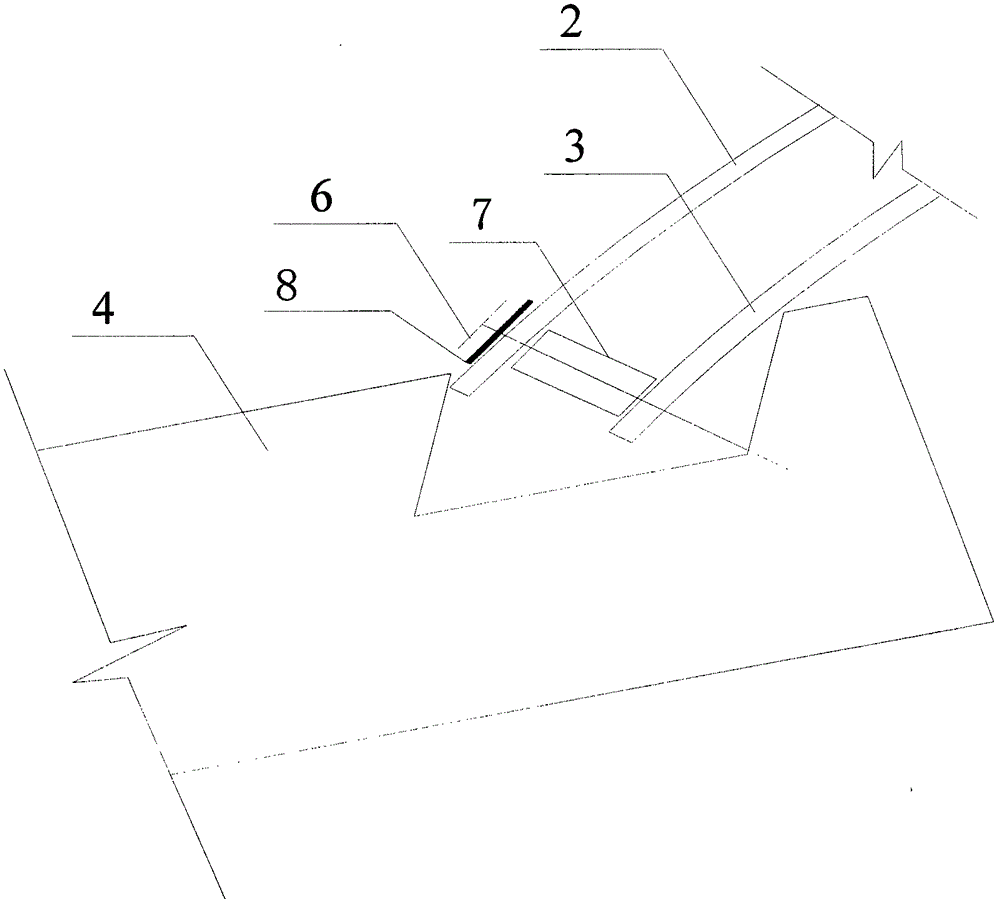

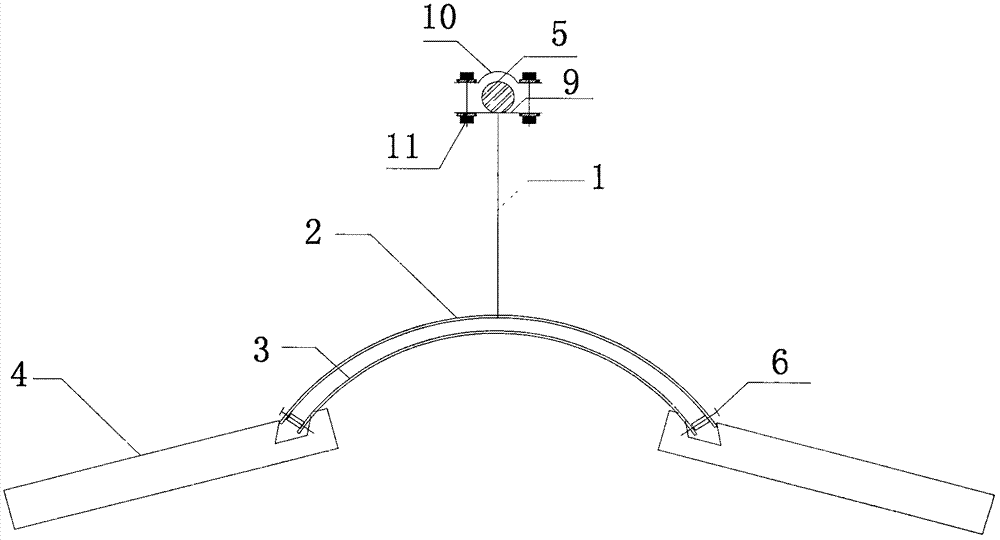

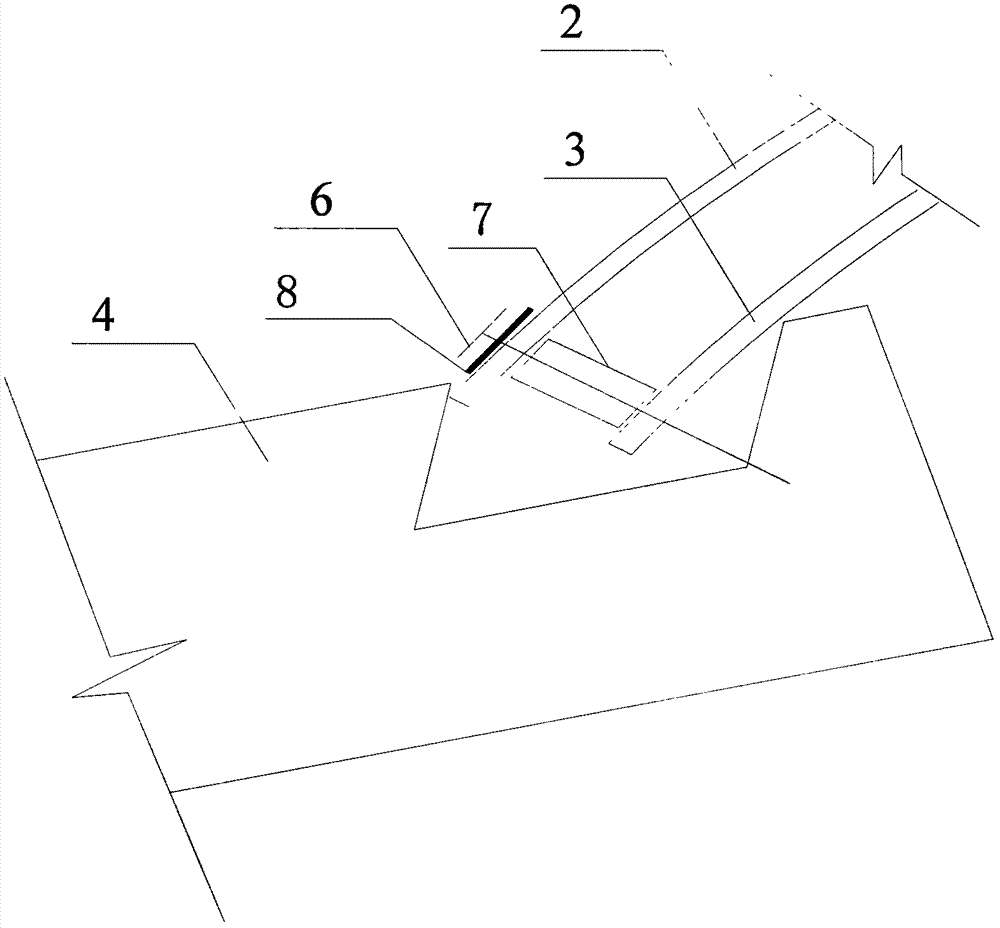

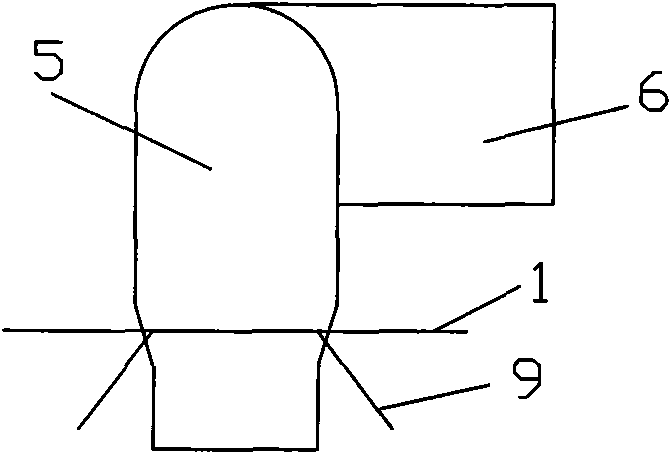

Construction method and special guard screen for static demolition and home position reconstruction of overpass bridge

PendingCN107268462AImprove the level of civilized constructionEnsure safetyRoadwaysBuilding repairsSocial benefitsEconomic benefits

The invention relates to a construction method and a special guard screen for static demolition and home position reconstruction of an overpass bridge. A static demolition method comprises the following steps of performing mid-span bridge surface separation; performing hoisting hole arrangement, blocking, symmetric cutting and hoisting away on anti-collision walls on two sides; performing hoisting hole arrangement and hinging crack cutting and separation on same-span simply supported beams; and performing sequential hanging away one by one from left to right or from right to left and the like. A home position reconstruction method comprises the following steps of constructing stand columns and bent caps, constructing beam plates, constructing auxiliary engineering, and the like. According to the construction method disclosed by the invention, the structure of the overpass bridge is demolished according to the requirement that the traffic is not interrupted, a method comprising the following steps of determining the sequence of demolishing the bridge and separating spans, blocking and cutting anti-collision guardrails, and cutting and lifting a main beam is adopted, so that beam members are cut into blocks, are hoisted by a crane, and can be directly transported away by a transporting vehicle; the method is high in civil construction degree, simple and easy to operate, wide in application range, and easy to popularize; the situation that passing under the overpass bridge and the construction are safe is guaranteed; during construction, the situation that passing of the highway is smooth and safe is guaranteed; the civil construction degree is high; and the construction method has good social benefits and economic benefits.

Owner:ZHEJIANG COMM CONSTR GRP CO LTD

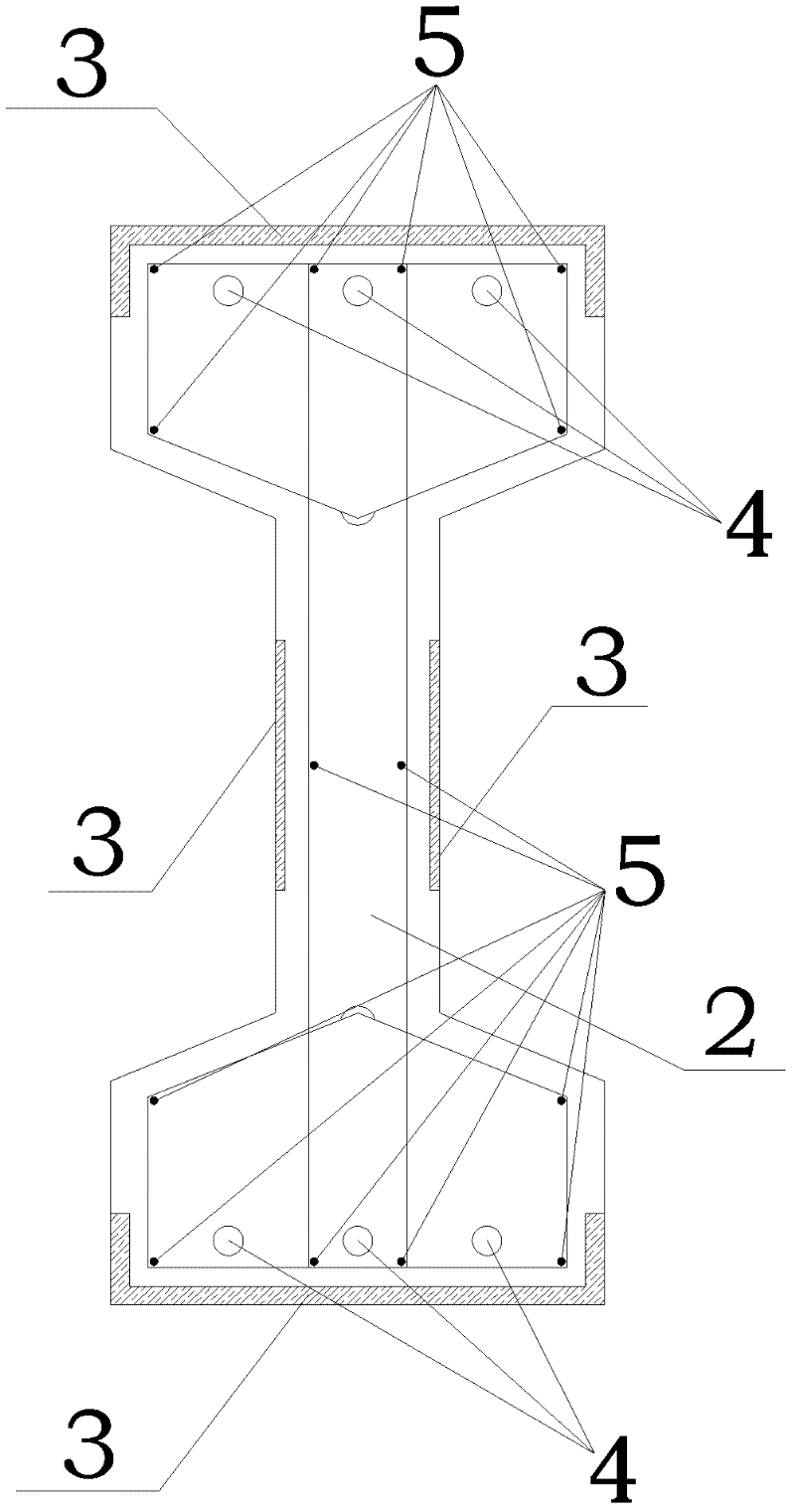

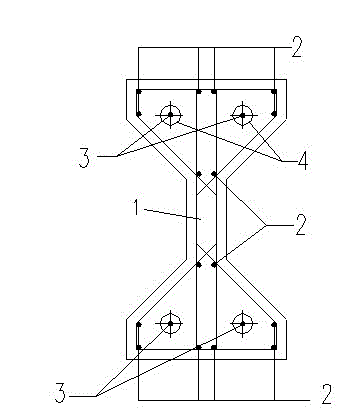

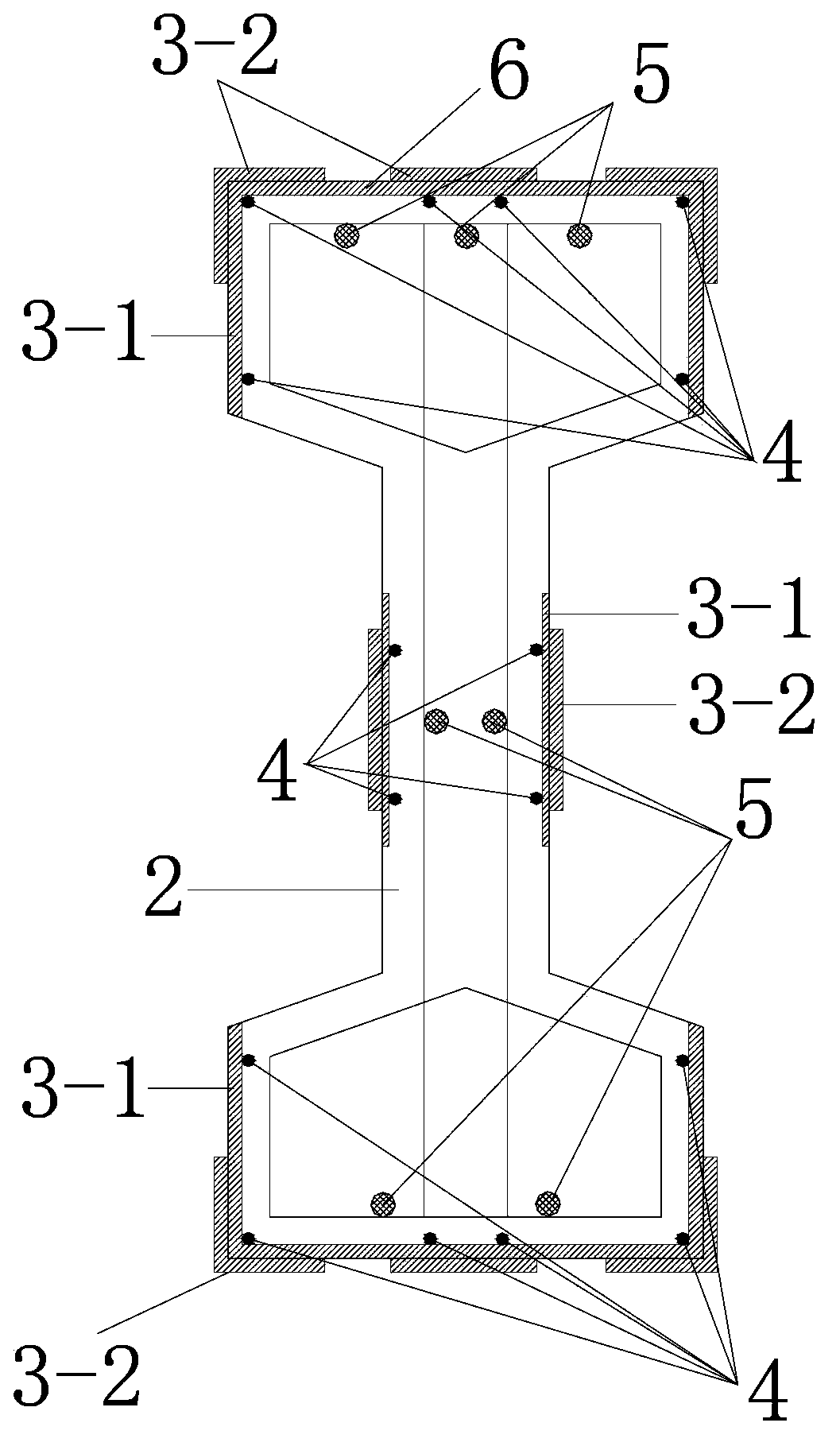

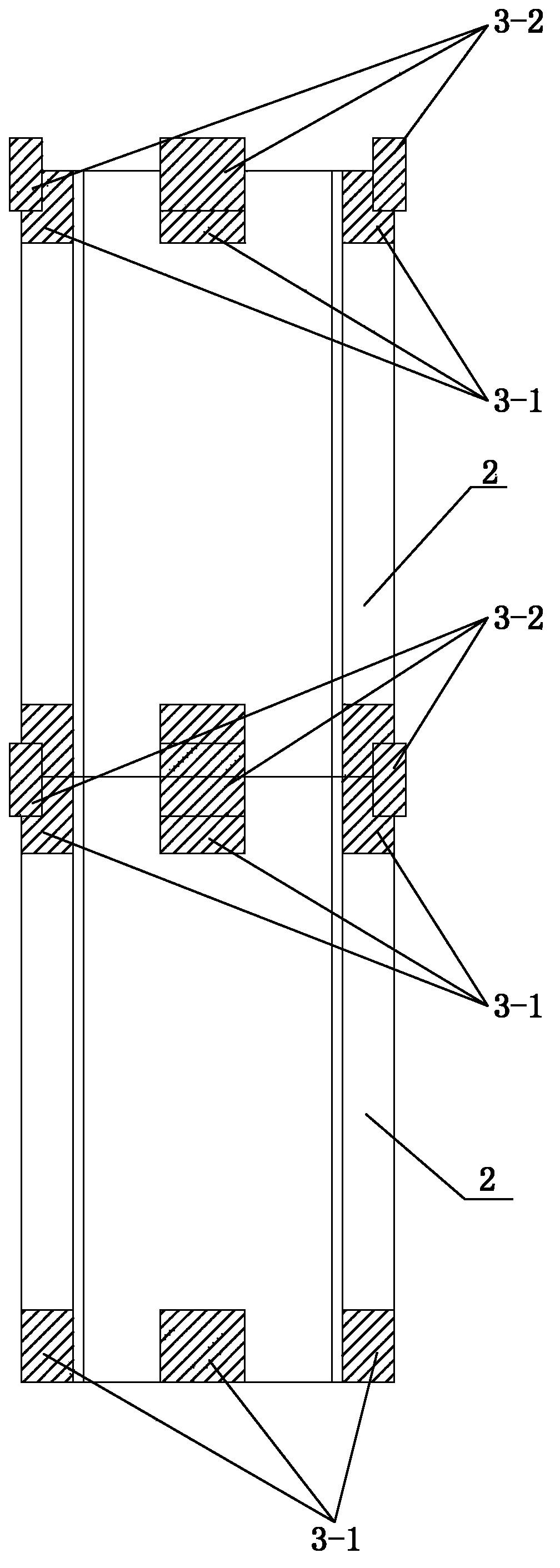

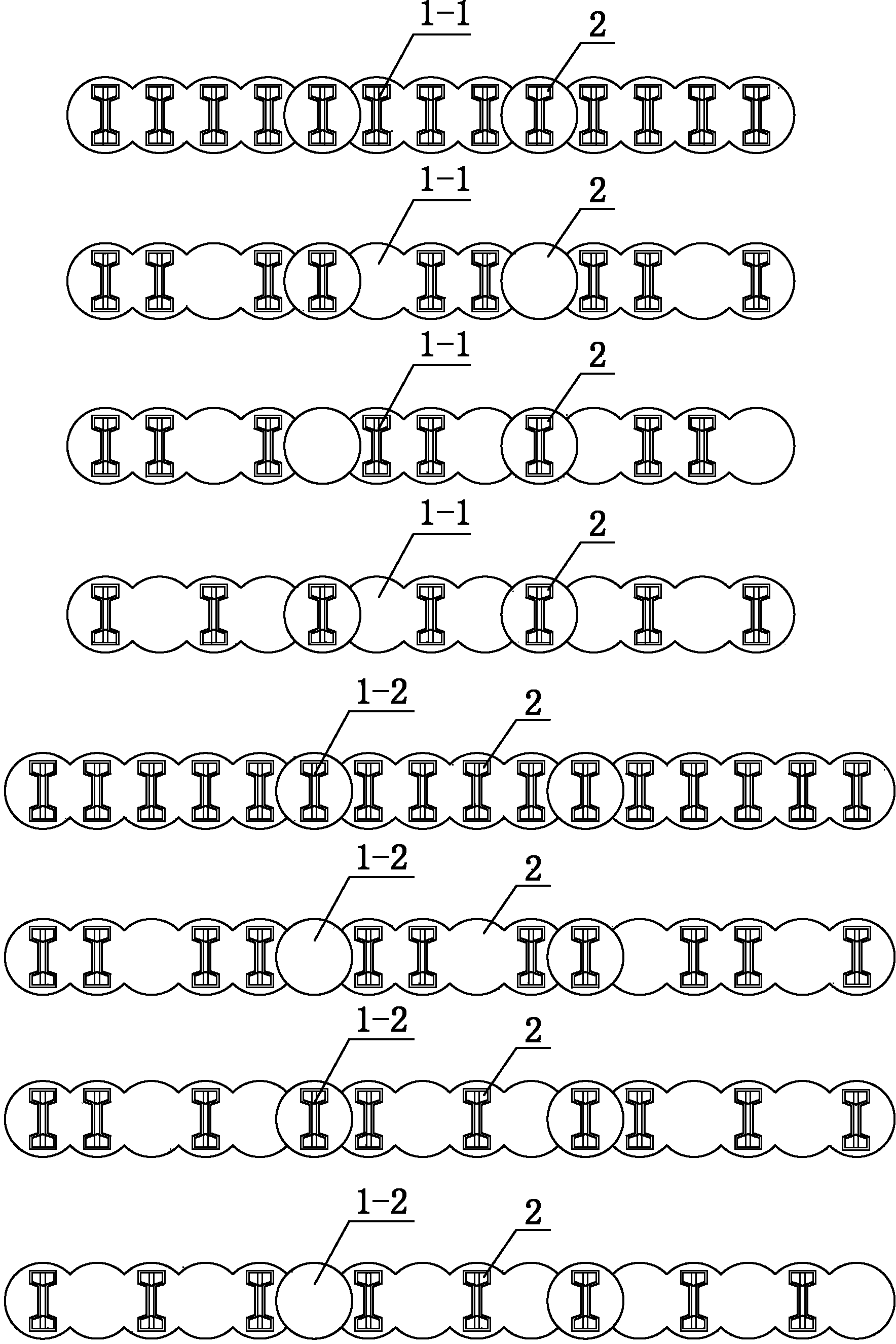

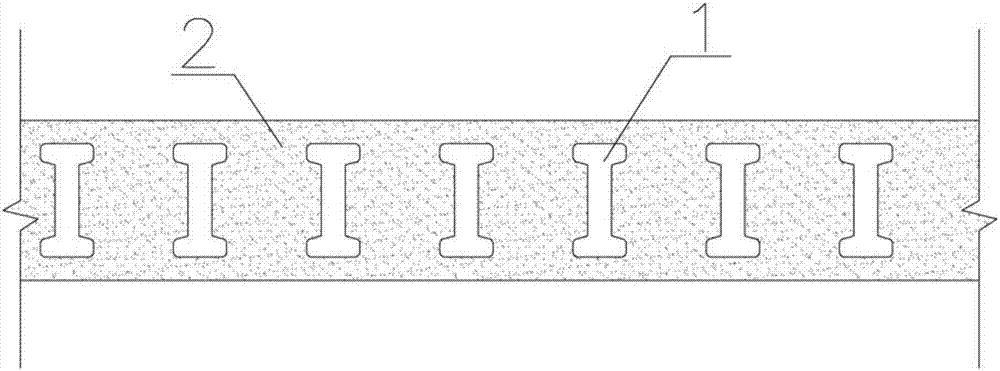

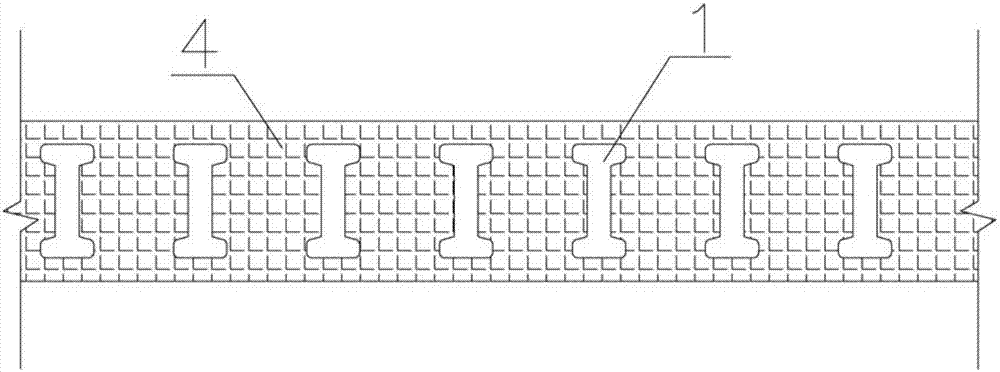

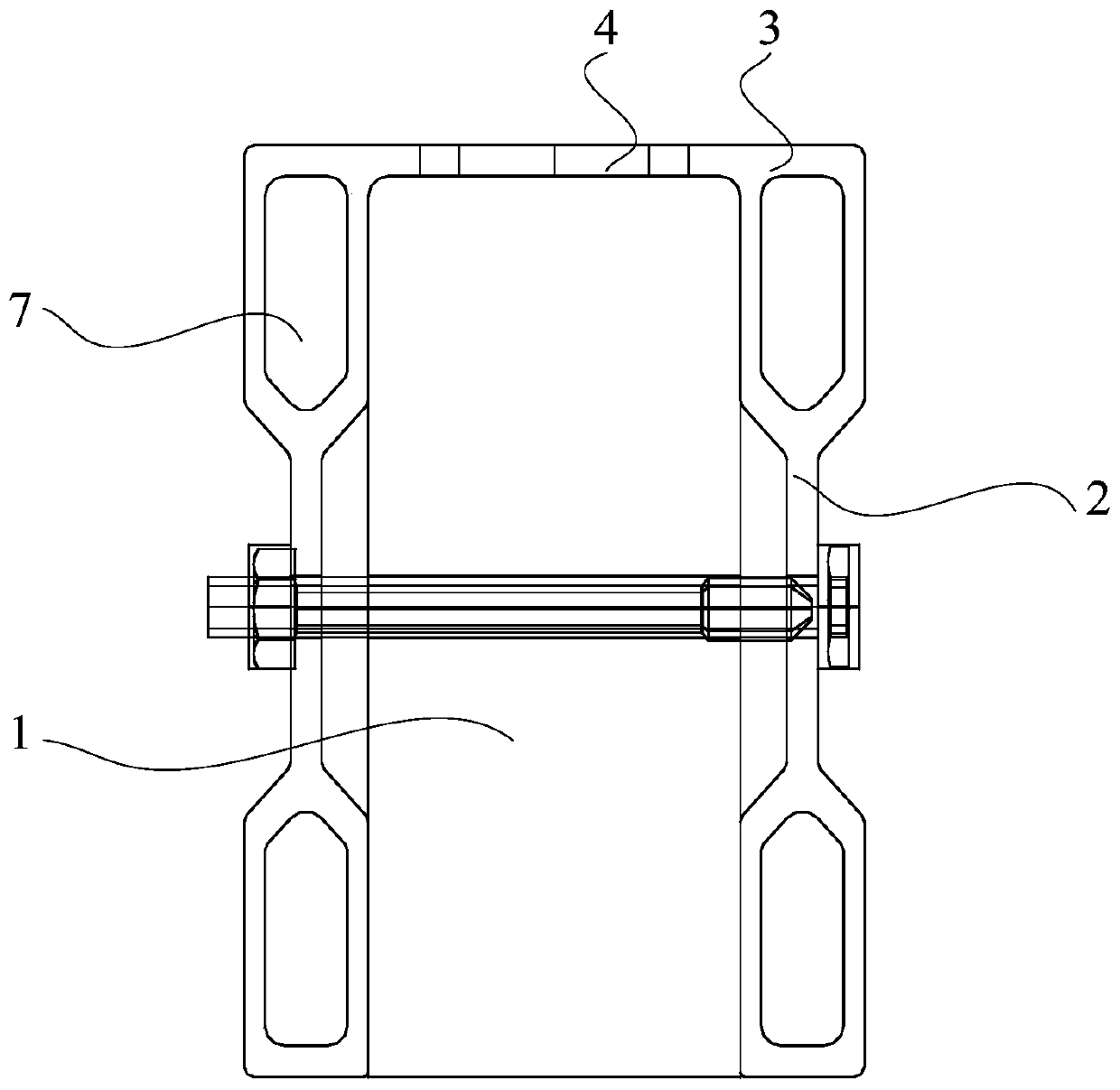

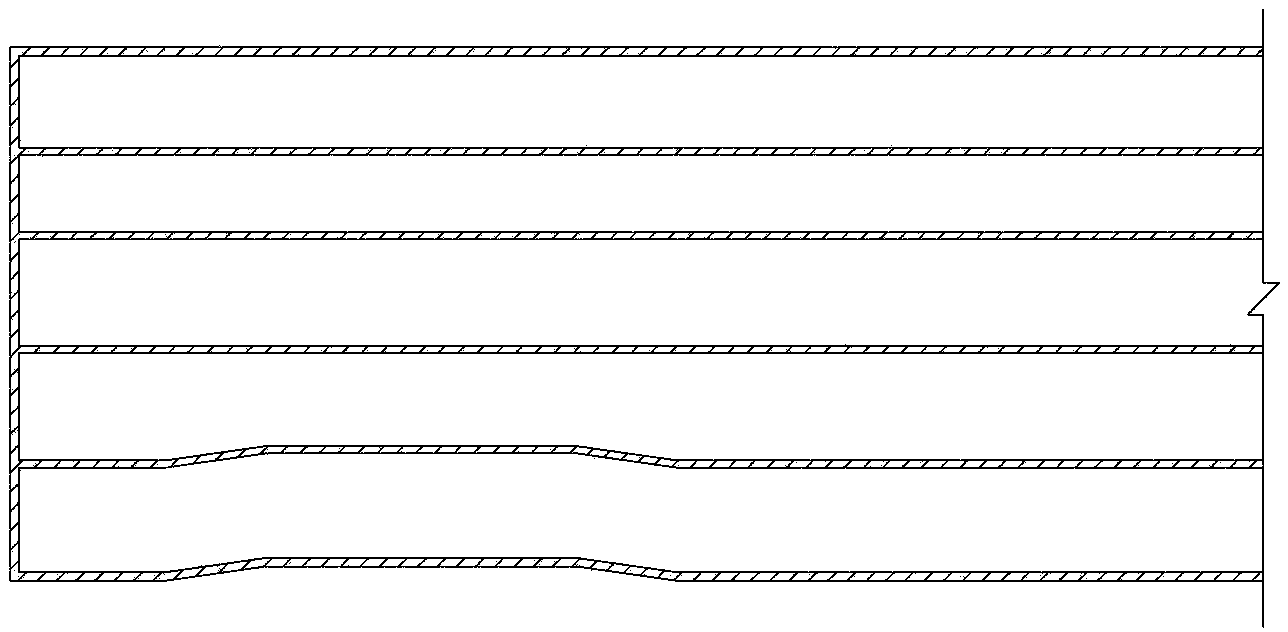

Prestressed reinforcement and non-prestressed reinforcement combined H-shaped reinforced concrete sheet pile and manufacture method thereof

InactiveCN102518120AIncrease stiffnessIncreased durabilityCeramic shaping apparatusBulkheads/pilesEnvironmental resistanceReinforced concrete

The invention relates to a prestressed reinforcement and non-prestressed reinforcement combined H-shaped reinforced concrete sheet pile and a manufacture method thereof. The H-shaped reinforced concrete sheet pile adopts an I-shaped structure; and prestressed reinforcement and non-prestressed reinforcement are arranged in the H-shaped reinforced concrete sheet pile at the same time. Compared with the prior art, the H-shaped reinforced concrete sheet pile has the advantages of good bending resistance and shearing resistance, low cost, high efficiency, zero contamination, environmental protection and the like.

Owner:SHANGHAI CHENGDI CONSTR

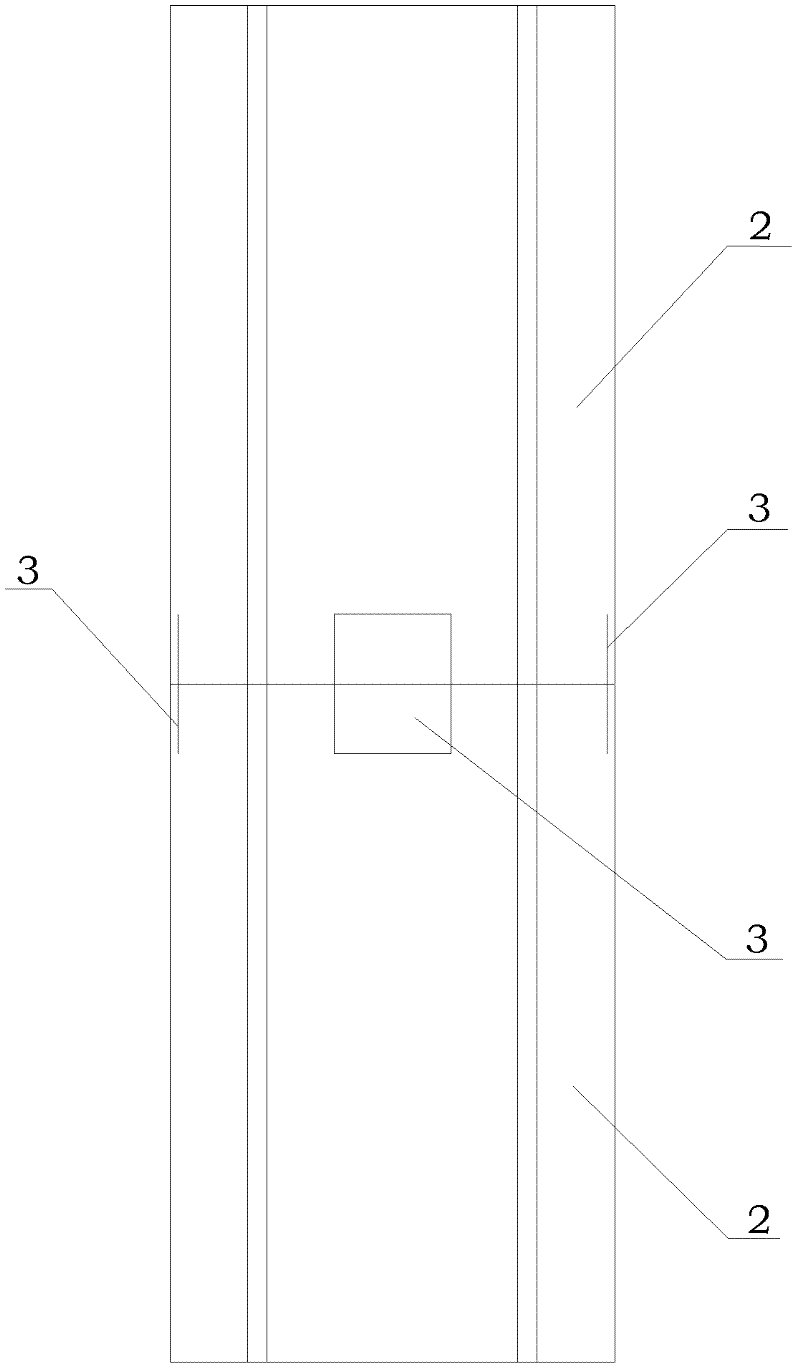

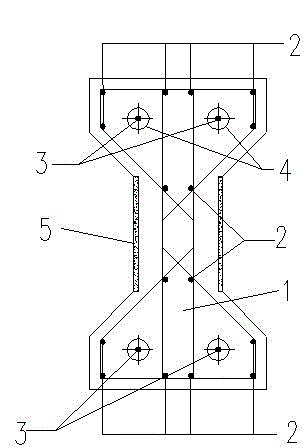

Cast-in-place post-tensioning method-based I-shaped support pile and manufacturing method of support pile

The invention discloses a cast-in-place post-tensioning method-based I-shaped support pile and a manufacturing method of the support pile. According to the support pile, an I-shaped pile body is arranged on a prefabricated template; a plurality of prestressed ribs and non-prestressed ribs are symmetrically distributed on the I-shaped pile body; embedded pipes are coaxially sleeved outside all the prestressed ribs; and a reinforcing part of the I-shaped pile body is provided with embedded irons. The manufacturing method comprises the main steps of manufacturing components such as the prefabricated template and a steel reinforcement framework; erecting the steel reinforcement framework on the prefabricated template; fixing the embedded pipes and the embedded irons on the steel reinforcement framework; pouring concrete on the prefabricated template; plastering and maintaining in sequence after the concrete is poured; performing prestressed tensioning after the concrete strength is reached; and storing for later use after the tensioning is finished. With the mode, the rigidity of the pile body is improved, the durability of the pile body is increased, the vibration and the elastic deformation are reduced, the bending and shear resistance is enhanced, the deformation of a foundation pit can be greatly reduced, and the cost can be reduced by 30-40 percent.

Owner:JIANGSU DINGDA BUILDING NEW TECH +1

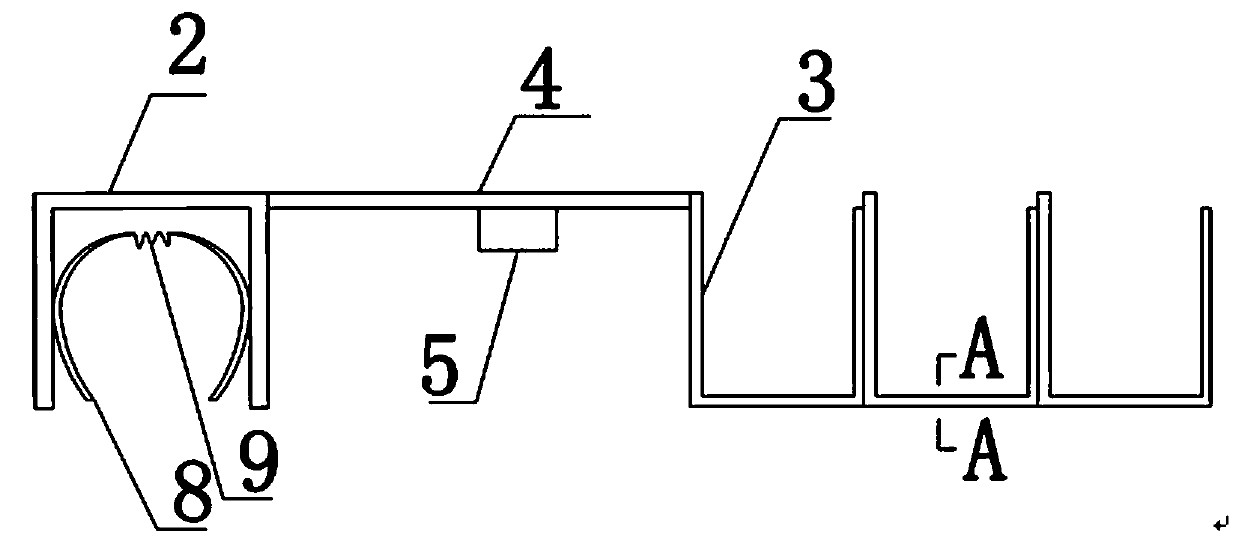

Cable protection device

InactiveCN105591331AWon't hurtAvoid the risk of crushingElectrical apparatusElectricityGeotechnical engineering

A cable protection device comprises a hanging hook and an insulating sheath which sleeves the hanging hook. The hanging hook comprises a fixed U-shaped groove with a downward opening and multiple cable U-shaped grooves each with an upward opening. The U-shaped groove of the fixed U-shaped groove is internally provided with an elastic fixing clamp. The adjacent cable U-shaped grooves are directly fixed. The fixed U-shaped groove and the cable U-shaped grooves are connected through a connecting rod, and the connecting rod is stretchable. The cable protection device is advantaged in that the cable protection device has a simple structure and improves the electricity safety in the construction field.

Owner:CHINA NUCLEAR IND 22ND CONSTR

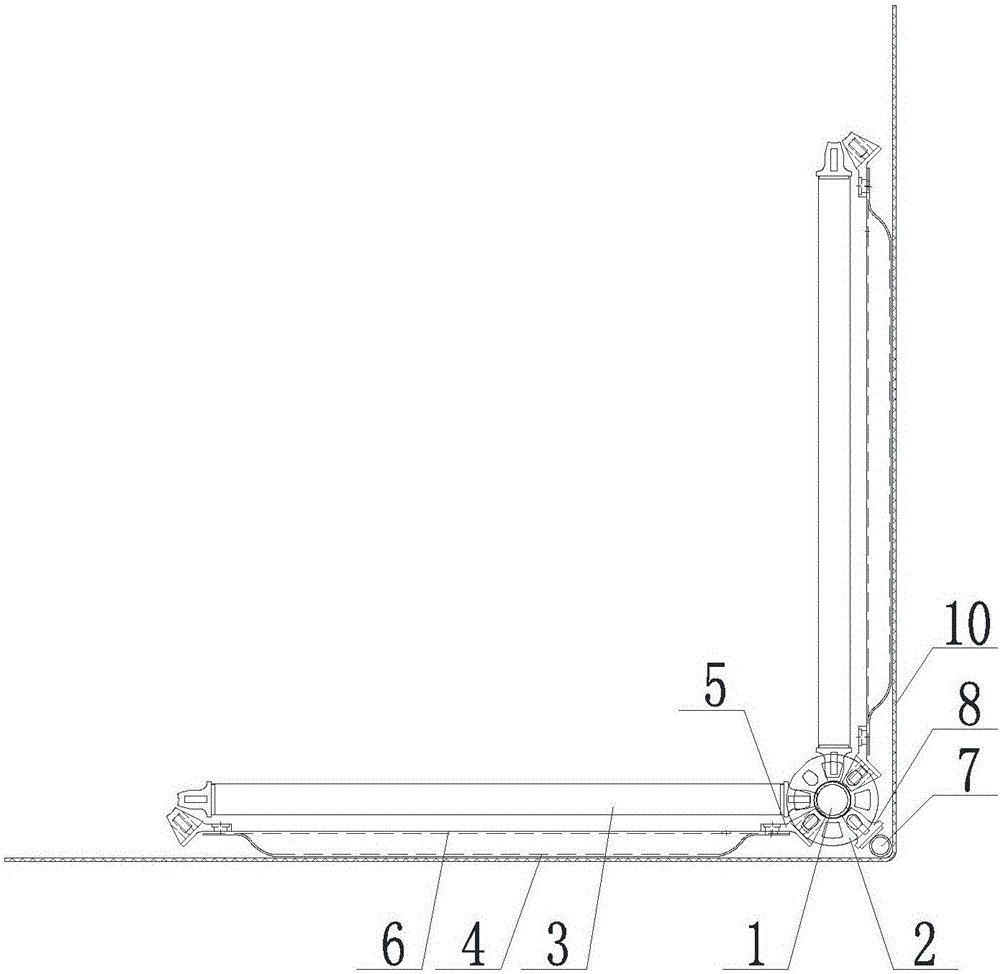

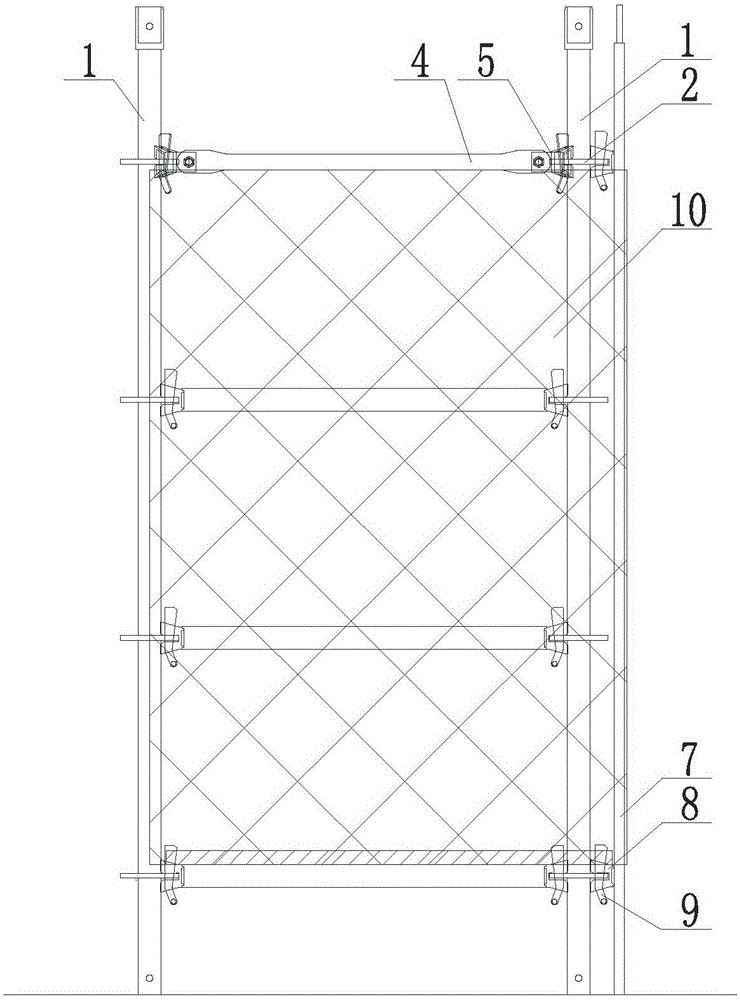

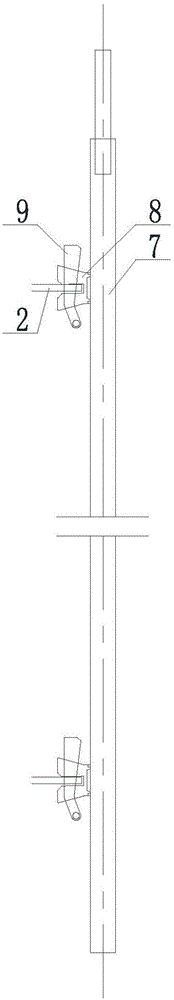

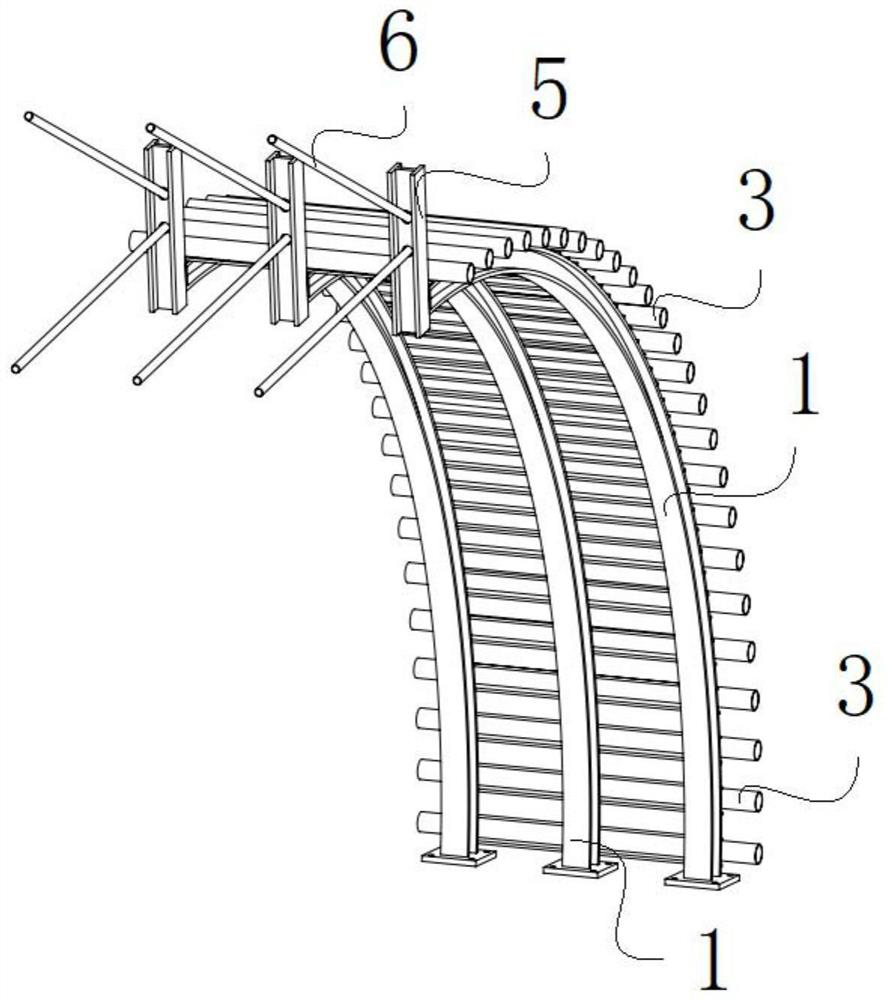

External corner externally-hanging safety net connecting assembly for ring lock scaffold and externally-hanging safety net device

The invention discloses an external corner externally-hanging safety net connecting assembly for a ring lock scaffold and an externally-hanging safety net device, and relates to the technical field of building construction equipment. The external corner externally-hanging safety net connecting assembly for the ring lock scaffold and the externally-hanging safety net device aim at solving the problem that stable connection between the external corner of an existing ring lock scaffold and an externally-hanging safety net can not be ensured, and consequently potential safety hazards exist. The external corner externally-hanging safety net connecting assembly comprises a vertical rod arranged at the external corner of the ring lock scaffold, and a connector, wherein one end of the connector is movably connected with a connecting disc of the ring lock scaffold, and the other end of the connector is fixedly connected with the vertical rod. The externally-hanging safety net device comprises a plurality of horizontal connecting assemblies, a plurality of external corner externally-hanging safety net connecting assemblies and a plurality of dense-mesh safety nets. Each horizontal connecting assembly comprises a connecting rod and ring lock connecting pieces, wherein the connecting rod is arranged on the outer sides of outer vertical rods of the ring lock scaffold, the ring lock connecting pieces are arranged at the two ends of the connecting rod, and the connecting rod is connected to the outer vertical rods on the two sides in a bolted mode through the ring lock connecting pieces at the two ends. The external corner externally-hanging safety net connecting assemblies are movably connected with the connecting discs. The dense-mesh safety nets are bound to the connecting rods of the horizontal connecting assemblies and the vertical rods of the external corner externally-hanging safety net connecting assemblies.

Owner:SHANGHAI NO 4 CONSTR

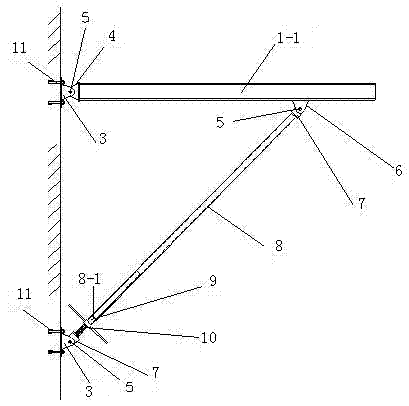

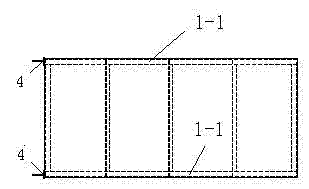

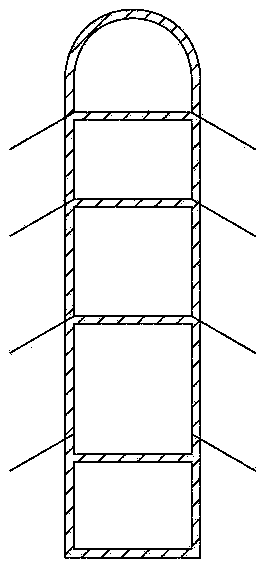

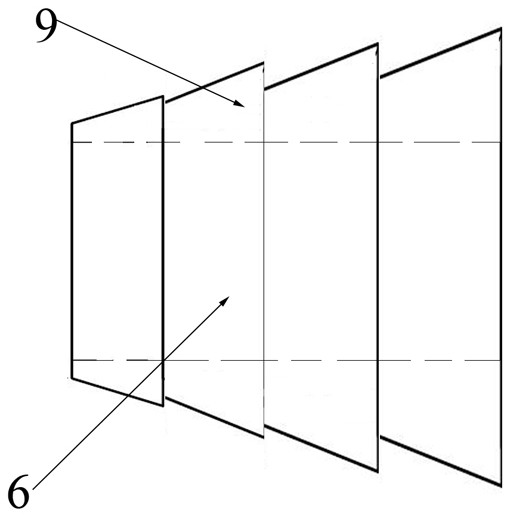

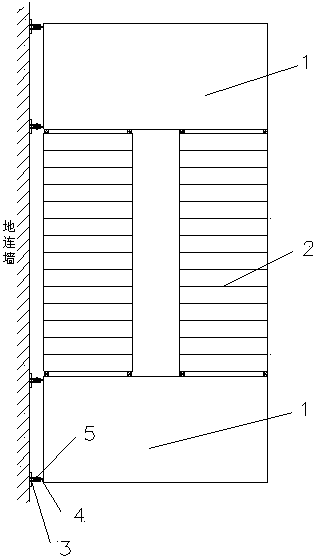

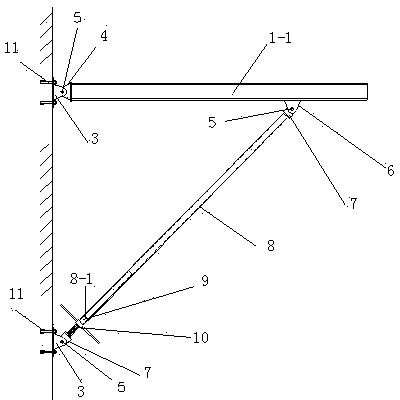

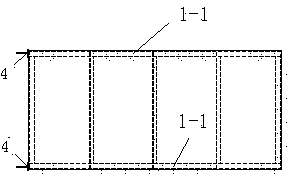

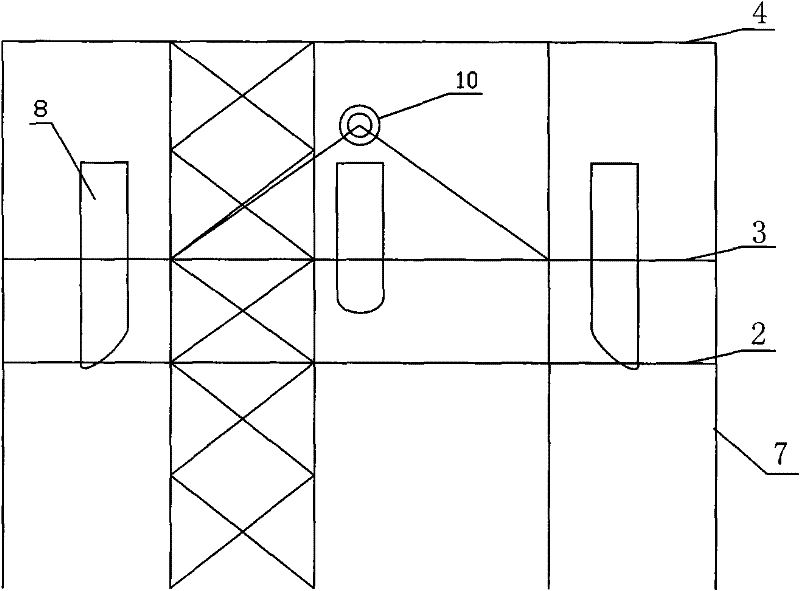

Prefabricated detachable foundation pit ladder rest platform and diaphragm wall connection structure

ActiveCN102926555AThe effect of angle adjustment is remarkableQuick SetupShaping building partsBuilding construction

The invention relates to a prefabricated detachable foundation pit ladder rest platform and diaphragm wall connection structure. The connection structure comprises a rest platform, an inclined running platform, a diaphragm wall bearing, a long hole hinge, a bolt, a rest platform bearing, a diagonal bracing hinge, a diagonal bracing, an insertion pipe, a spiral support head and a tube expansion bolt, wherein the diaphragm wall bearing is fixed on the diaphragm wall through the tube expansion bolt as an embedded part; and the long hole hinge is welded on the rear end part of the rest platform, and is connected with the diaphragm wall bearing through the bolt, so that the rear end part of the rest platform is connected with the diaphragm wall. The rest platform bearing is welded on the lower edge of a side rib of the rest platform; the diagonal bracing hinge is welded on the upper end of the diagonal bracing, and is connected with the rest platform bearing through the bolt; the insertion pipe is inserted into the lower end of the diagonal bracing; the spiral support head is inserted into the insertion pipe; and the diagonal bracing hinge is welded on the lower end of the spiral support head, and is connected with the diaphragm wall bearing anchored on the lower part of the diaphragm wall through bolt. The invention provides a safe and reliable prefabricated steel ladder for rapidly, conveniently and economically erecting a passage for construction in a deep foundation pit.

Owner:TIANJIN NO 2 CONSTR ENG

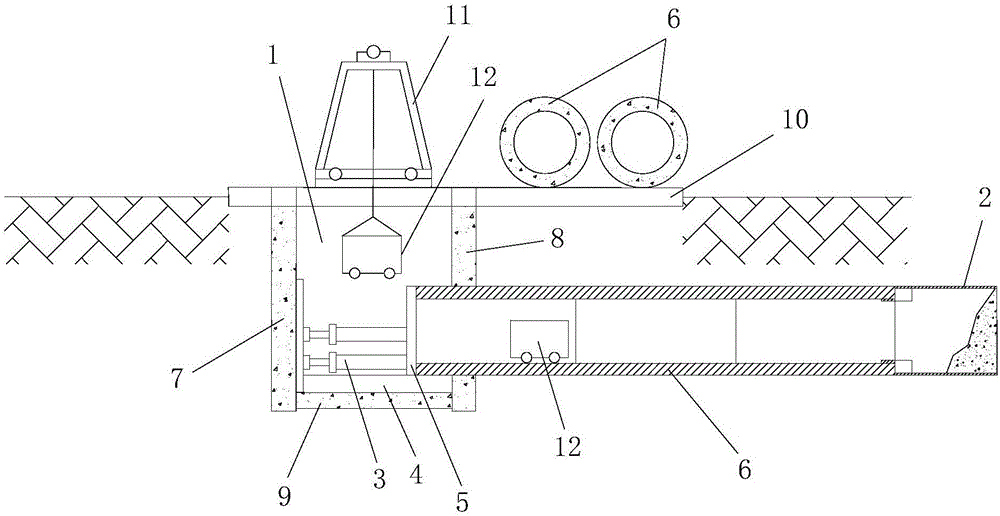

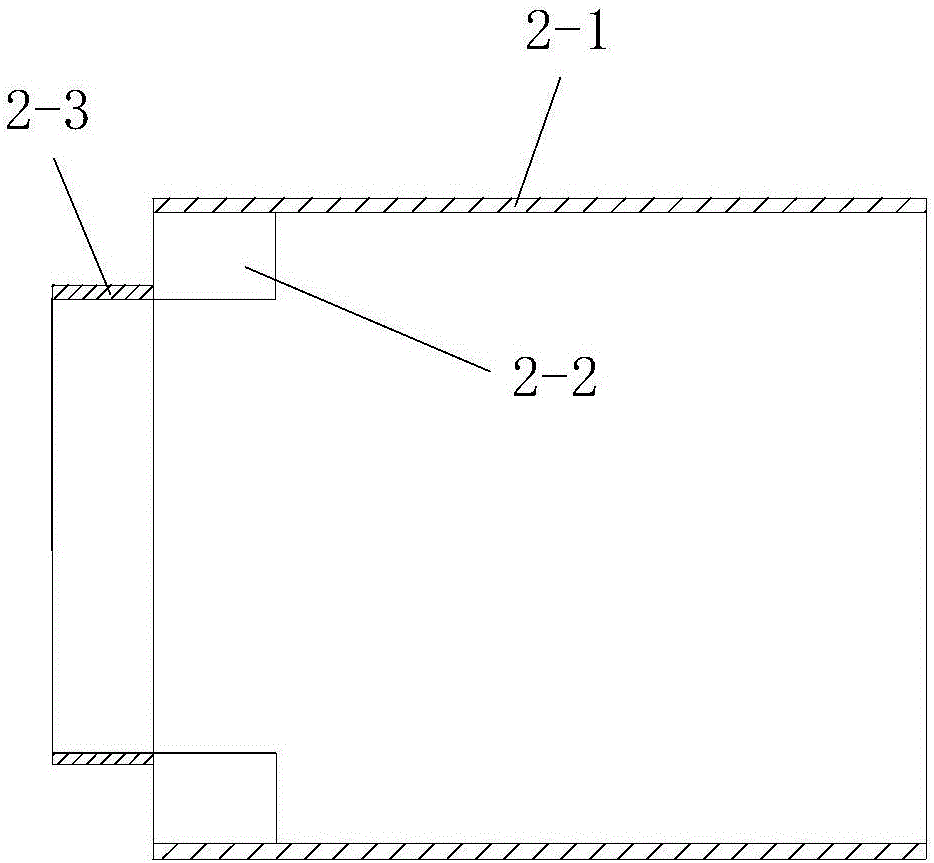

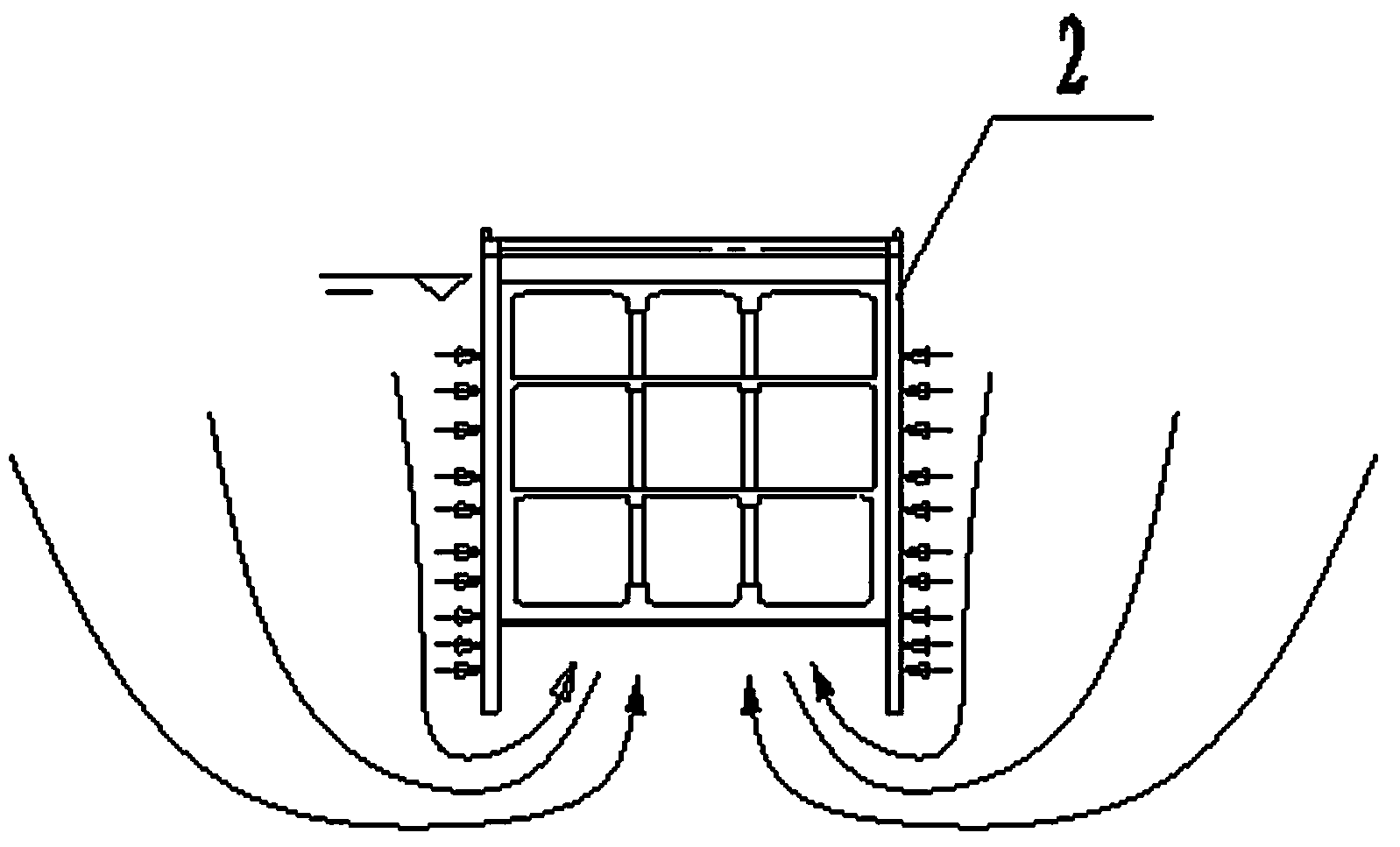

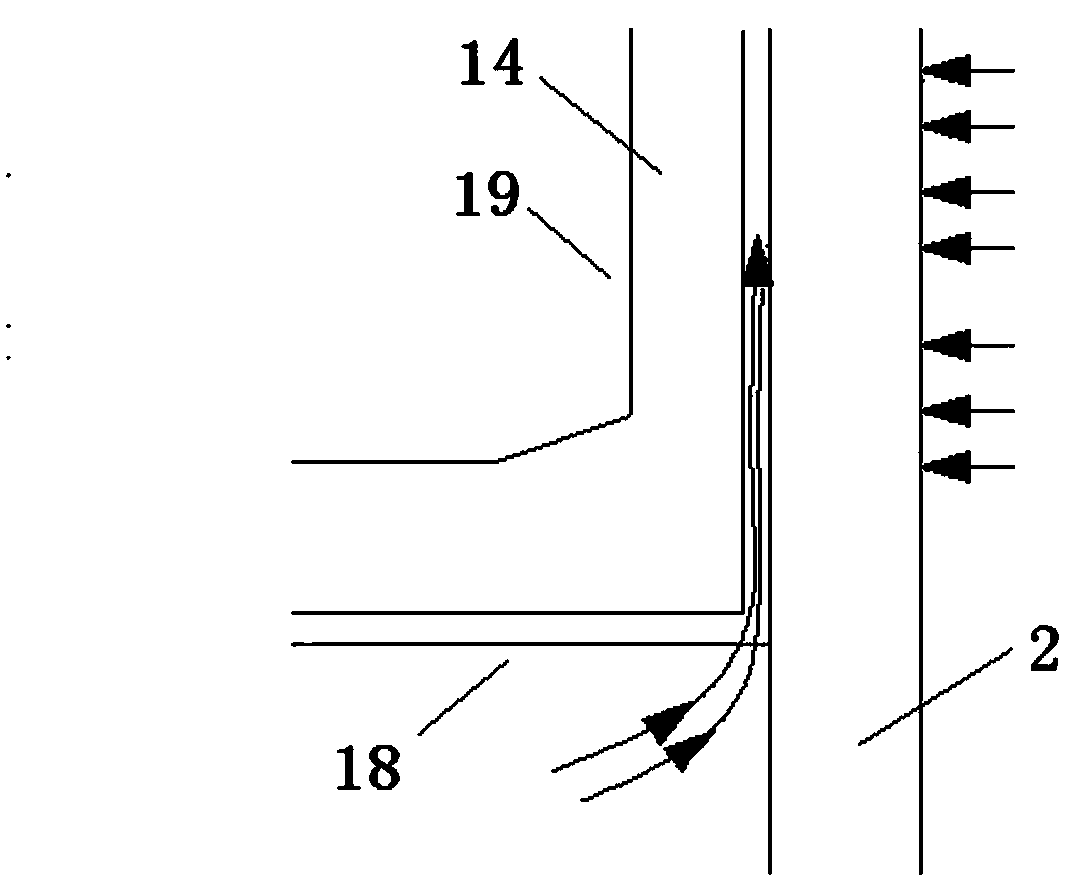

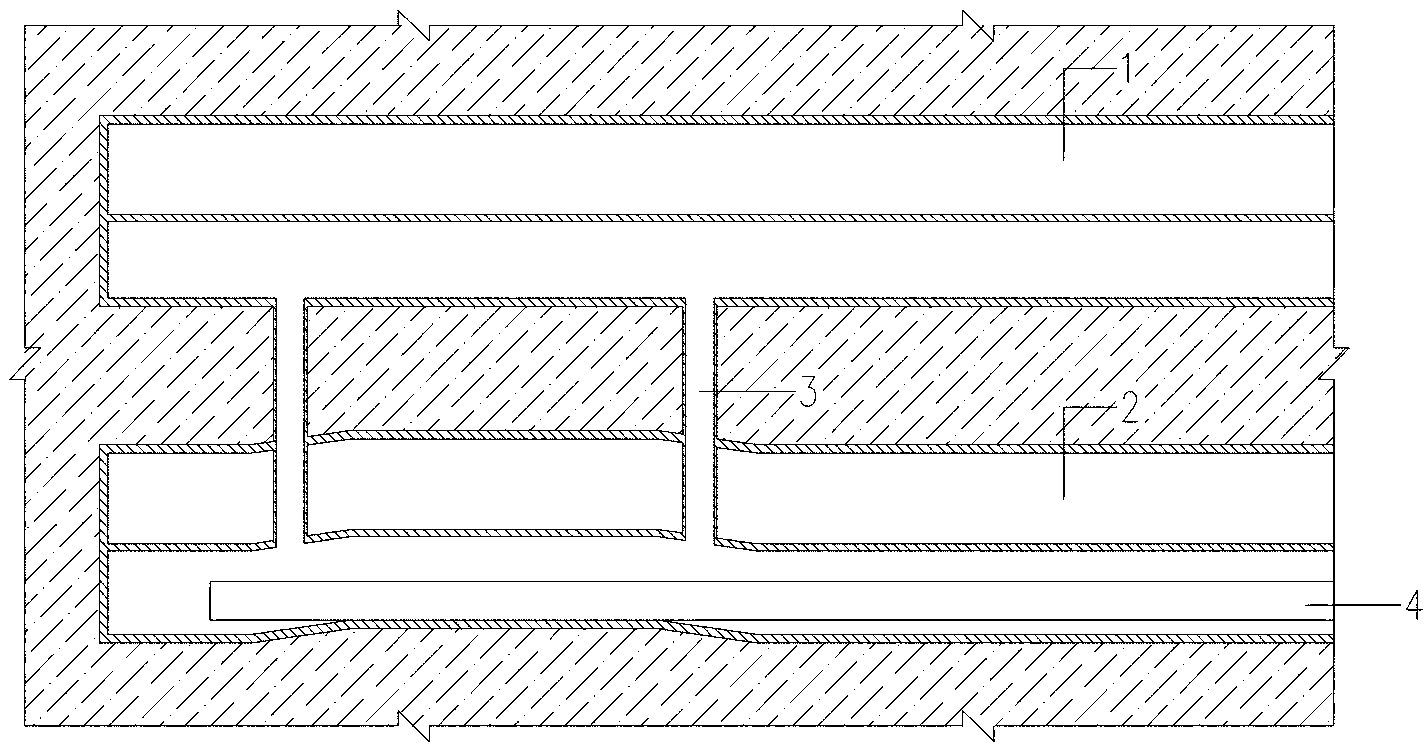

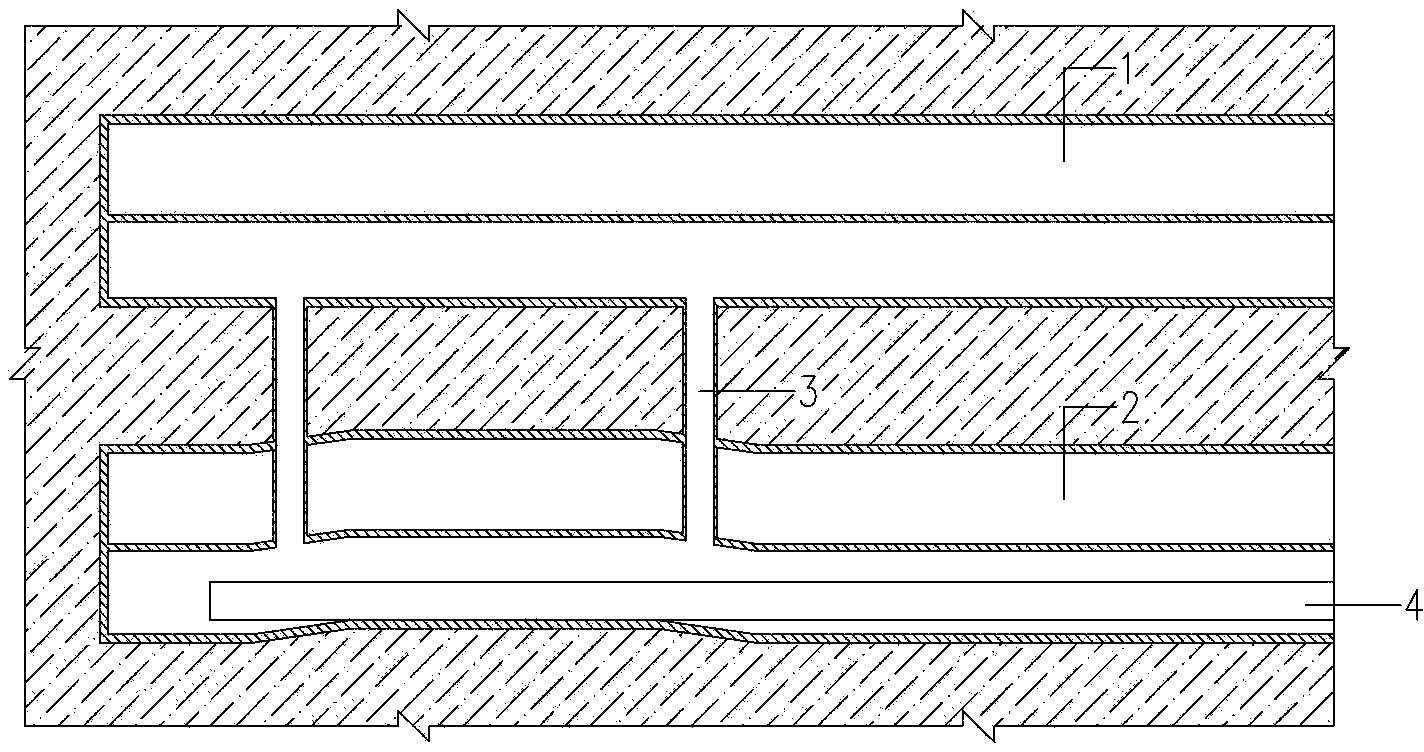

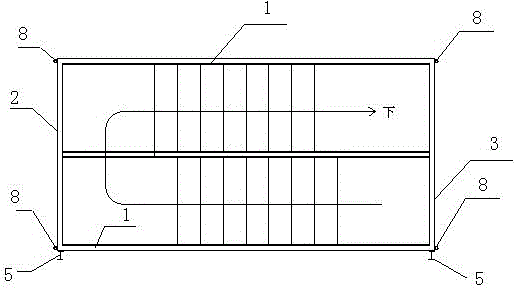

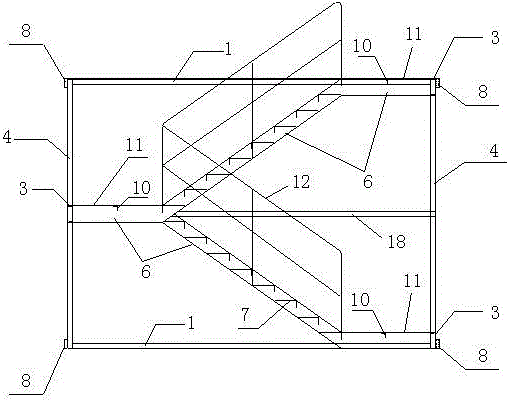

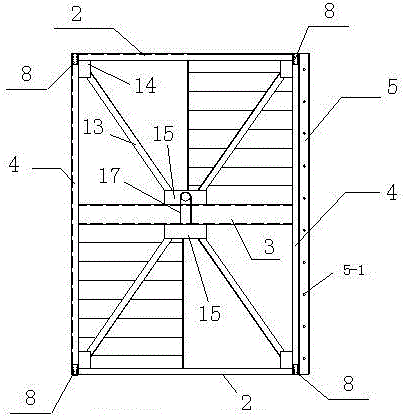

Up-down separating type underground excavation station construction passageway structure provided with mucking transport equipment and construction method

ActiveCN103061773AImprove completenessImprove work efficiencyTunnelsArchitectural engineeringOperating environment

The invention discloses an up-down separating type underground excavation station construction passageway structure provided with mucking transport equipment and a construction method. The structure comprises an upper construction passageway, a lower construction passageway, a plurality of muck passageways and the mucking transport equipment, up-down separating type construction passageways are adopted, the upper construction passageway is located above the lower construction passageway, the upper construction passageway and the lower construction passageway are horizontal passageways, reserved with a certain distance in the vertical direction and separated by undisturbed soil masses, and bodies of the two passageways are mutually unconnected and respectively connected to a construction shaft. The upper construction passageway and the lower construction passageway are communicated by the aid of the muck passageways arranged between the same, the muck passageways are arranged at intervals along the horizontal direction, and the bottom of the lower construction passage way is provided with the mucking transport equipment. By the structure and the method, influences of underground excavation station construction on surroundings can be reduced, risk of underground excavation station construction is lowered, underground excavation station in-cave operating environment is improved, mechanical construction degree and working efficiency are improved, unnecessary excavation, fill, primary support structure erecting and detaching are avoided, and engineering investment is saved.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

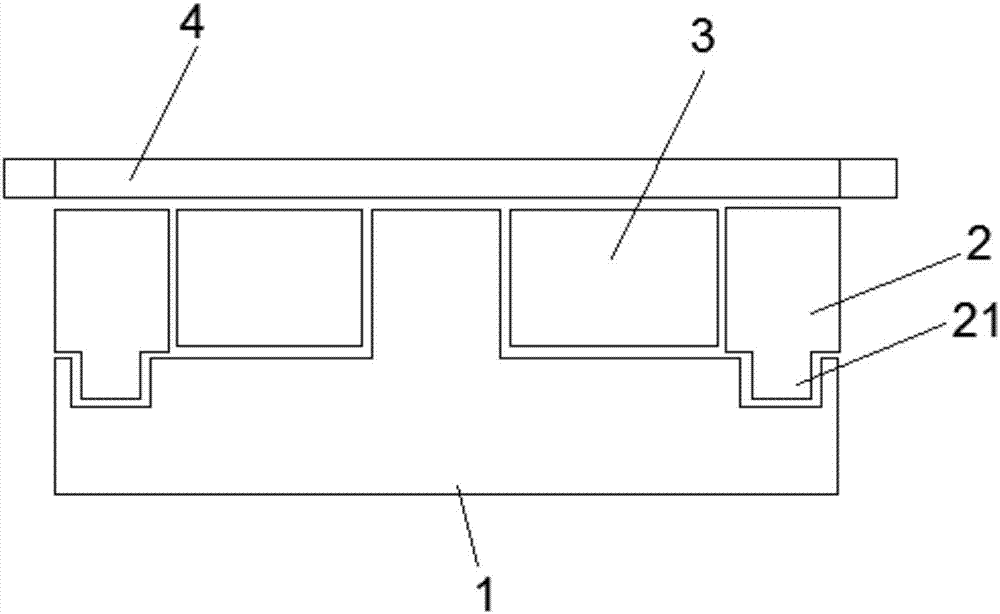

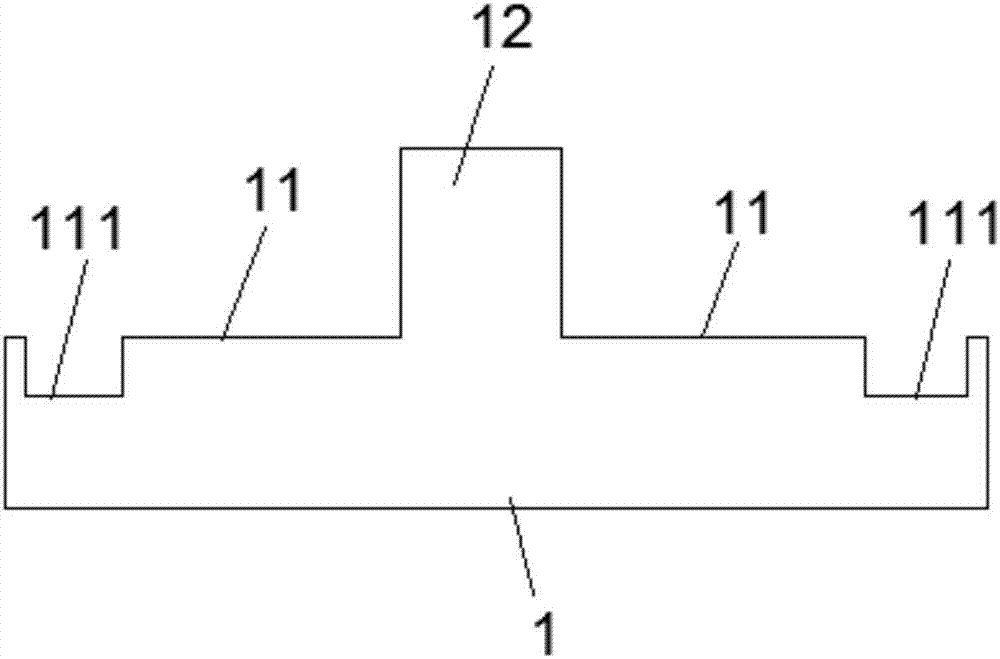

Precast concrete road system and construction method

ActiveCN108004866AEasy to replaceImprove the level of civilized constructionSingle unit pavingsPaving gutters/kerbsRoad surfaceBasic block

The invention discloses a precast concrete road system and a construction method and relates to the technical field of road construction. The road system comprises a basic layer, a curb layer, a filling layer and a pavement layer; the basic layer is paved with concrete precast basic blocks with reversed-T-shaped longitudinal sections; the curb layer is paved with rectangular solid concrete precastcurb blocks; the filling layer is paved with precast filling blocks of a box-shaped structure; and the pavement layer is laid at the top of a structure composed of a vertical layer of the basic layer, the curb layer and the filling layer, and the pavement layer is paved with concrete precast pavement board blocks. By the adoption of the system, the basic layer is paved with the multiple basic blocks in an attached and crossed mode, the curb layer is paved with the multiple curb blocks in an attached and crossed mode, the filling layer is paved with the multiple filling blocks in an attached and crossed mode, the pavement layer is paved with the multiple pavement board blocks in an attached and crossed mode, the system is convenient to transport, easy to lay, short in site construction time, high in construction efficiency, capable of being reused, easy to replace after being damaged and small in construction waste.

Owner:马晓鹤

Clamping seat enclasping tile type lightning protection net and construction method thereof

InactiveCN104652719AAvoid rain leakageAdvanced connection technologyRoof coveringRubber ringEngineering

The invention relates to a building component, in particular to a clamping seat enclasping tile type lightning protection net for building construction. The clamping seat enclasping tile type lightning protection net comprises galvanized round steels, galvanized flat steels, galvanized screws, sealing rubber rings, galvanized gaskets, a lightning wire, buckling tiles and roof tiles; the middle positions on the galvanized flat steels are connected with the galvanized round steels; the upper ends of the galvanized round steels are connected with the lightning wire; saw kerfs are formed at the positions where the roof tiles are joined with the buckling tiles; screw holes are formed at both ends of the galvanized flat steels; holes are reserved at both tail ends of the buckling tiles; the sealing rubber rings are arranged between the galvanized flat steels and the buckling tiles; the galvanized gaskets are arranged between the galvanized screws and the galvanized flat steels; the galvanized flat steels are connected with the buckling tiles by the galvanized screws; the tail ends of the galvanized screws are embedded into the saw kerfs of the roof tiles; the galvanized screws are tightly connected with each contact point. The connecting mode of the clamping seat enclasping tile type lightning protection net adopts the advanced technology; the clamping seat enclasping tile type lightning protection net is simple and convenient to operate and is convenient to install, move and repair; the clamping seat enclasping tile type lightning protection net avoids the problem that when holes are formed in the tops of the buckling tiles for installation, not only is labor wasted, but also quality defects of roof rain leakage and the like are easy to cause.

Owner:ZHONGTAI CONSTR GROUP

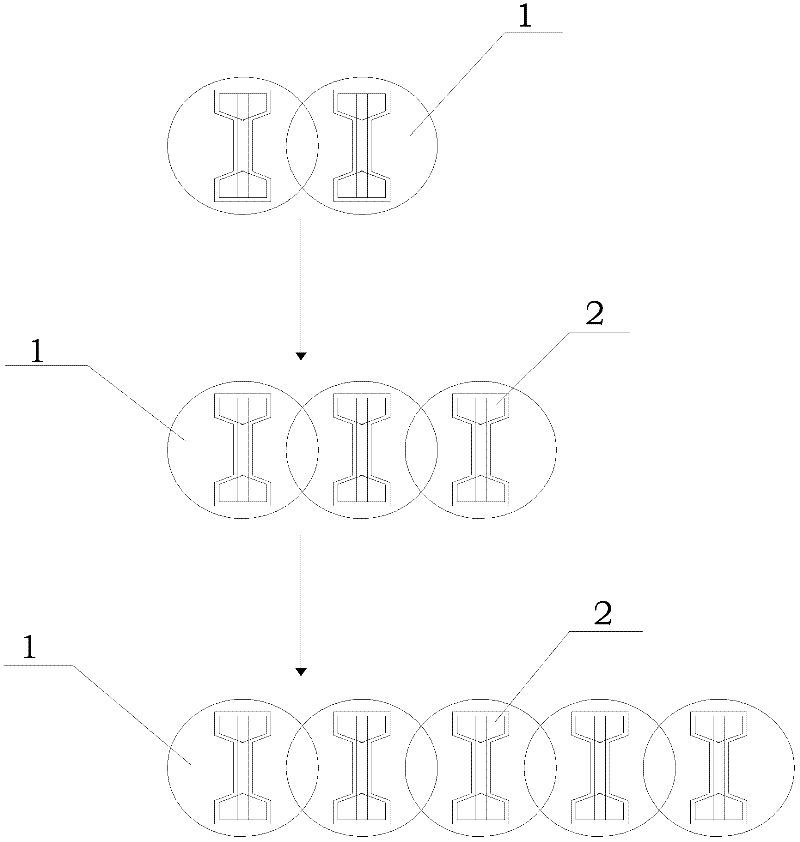

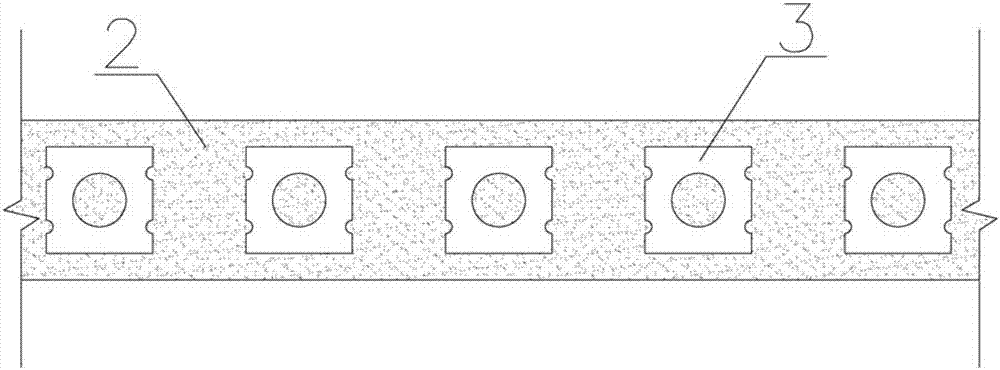

Novel mixed reinforcement H-shaped sheet pile and five (six)-shaft cement soil mixing wall combined building envelope and construction method thereof

The invention relates to a novel mixed reinforcement H-shaped sheet pile and five (six)-shaft cement soil mixing wall combined building envelope and a construction method thereof. The building envelope is suitable for soil retaining and water stop of foundation pit and riverway envelopes; and high-strength reinforcements and conventional (grade II, grade III and grade IV) reinforcements are synchronously arranged in novel mixed reinforcement H-shaped sheet piles. The high-strength reinforcements are tensioned with low prestress; the conventional reinforcements are tensioned without the prestress; the high-strength reinforcements and the conventional reinforcements are respectively connected with pile caps; and the pile caps are connected with each other to form a multi-section H-shaped sheet pile building envelope. Compared with the prior art, the novel mixed reinforcement H-shaped sheet pile and five (six)-shaft cement soil mixing wall combined building envelope has such advantages as good bending and shearing resistance, low brittleness, good ductility, low cost, high effect and no pollution; and multiple sections can be connected to achieve the long and deep effects.

Owner:SHANGHAI CHENGDI CONSTR +1

A construction method for pipe jacking in silt soil stratum

ActiveCN106369223BThe method steps are simpleReasonable designPipe laying and repairUnderground pipelineBuilding construction

The invention discloses a pipe-jacking construction method for a mealy sand stratum. The pipe-jacking construction method for the mealy sand stratum comprises the steps that firstly, a working well is constructed, specifically, the working well used for jacking a constructed underground pipeline is constructed, the constructed underground pipeline is formed by splicing a plurality of pipeline assembly sections from front to back, and a steel bushing head tool pipe comprises a steel sleeve, a supporting ring mounted on the inner side of the rear end of the steel sleeve, and an insertion opening fixed to the supporting ring; secondly, jacking equipment is mounted, specifically, the jacking equipment is mounted at the bottom of the inner side of the working well; thirdly, the steel bushing head tool pipe is jacked through the process that the steel bushing head tool pipe is hoisted in place, the steel bushing head tool pipe is jacked, and manual intra-pipe earth cutting is conducted; fourthly, the pipeline is jacked, specifically, the multiple pipeline assembly sections of the constructed underground pipeline are jacked from front to back; fifthly, a pipeline port is treated; and sixthly, a closed water test for the pipeline is conducted. According to the pipe-jacking construction method for the mealy sand stratum, the steps are simple, the design is reasonable, construction is easy and convenient, and the using effect is good; and a pipe-jacking construction process of the mealy sand stratum can be completed easily, conveniently and rapidly, and the construction process is safe and reliable.

Owner:中铁二十局集团第五工程有限公司

Method for hoisting terrace for furnace top raw gas pipeline

InactiveCN101709344AReduce consumptionReduce the amount of work at heightBlast furnace componentsBlast furnace detailsSteel frameTube socket

The invention relates to a method for hoisting a terrace for a furnace top raw gas pipeline. The terrace is provided with multiple layers which have steel frame structures and are connected into a whole. The method comprises that: the first layer of terrace is hoisted in a carrying mode, before the first layer of terrace is hoisted, all structural members on the first layer of terrace are welded completely, and then a temporary pull rod is arranged through a supporting point of a horizontal tube socket of an ascending tube so as to fix the first layer of terrace; a tripod diagonal rod is hinged to a horizontal brace by bolts; when the terrace is hoisted, a hook of a crane hooks a lifting lug on a horizontal tube of the ascending tube for hoisting, so that the first layer of terrace is put to the right position; the terraces from a second layer to a top layer are hoisted in an integral insertion mode; and before the terraces are hoisted, all frames of the top layer of terrace and other terraces are assembled integrally on the basis of the first layer of terrace, then a monorail and a hoist are arranged in place and fixed, and the integrally-assembled terrace is put to the right position by the crane. Through the method, construction cost can be saved, construction period is shortened, construction environment is improved, the consumption of on-site auxiliary materials is reduced and the safety degree of hoisting and construction is improved.

Owner:CHINA FIRST METALLURGICAL GROUP

Seat-clamped tile-buckled type architectural anti-thunder net

PendingCN107503475AAvoid rain leakageAdvanced connection technologyRoof coveringRubber ringRoof tile

The invention relates to an architectural component, in particular to a seat-clamped tile-buckled type anti-thunder net for architecture construction. The structure includes galvanized round steel, galvanized flat steel, galvanized screw rods, sealed rubber rings, galvanized gaskets, an overhead grounding wire, buckling tiles and roofing tiles, wherein the middle position of the galvanized flat steel is connected with the galvanized round steel, and the upper end of the galvanized round steel is connected with the overhead grounding wire; saw bites are formed in the positions where the roofing tiles are jointed with the buckling tiles; the two ends of the galvanized flat steel are provided with screw holes, the two tail ends of each buckling tile are reserved with holes, the sealed rubber rings are installed between the galvanized flat steel and the buckling tiles, the galvanized gaskets are installed between the galvanized screw rods and the galvanized flat steel, and the galvanized screw rods are connected with the buckling tiles through the galvanized screw rods; the tail ends of the galvanized screw rods are embedded into the saw bites of the roofing tiles, and the galvanized screw rods are tightly connected with each contact point. The seat-clamped tile-buckled type architectural anti-thunder net is advanced in connection mode technique, simple to operate, convenient to install, move and maintain and capable of avoiding the quality defect problems that slotting and installation on the top portions of the buckling tiles waste manpower and are likely to cause rain leakage on a roof.

Owner:ZHONGTAI CONSTR GROUP

Enclosure structure combined with prefabricated members and mixing wall and construction method

InactiveCN107882017AIncrease stiffnessIncreased durabilityExcavationsBulkheads/pilesSoil mixingEngineering

The invention relates to an enclosure structure combined with prefabricated members and a mixing wall and a construction method. The enclosure structure is suitable for enclosure soil blocking and water stopping of foundation pits and riverways. The prefabricated members have two modes, namely, the city land assembling type H-shaped enclosure pile members and the water-stopping prefabricated centrifugal rectangular pile enclosure structures. The mixing wall is a continuous square cement-soil mixing wall and can be constructed through two construction methods, namely the TRD construction methodand the CSM construction method. The prefabricated members are pressed into the mixing wall according to the requirement to form enclosure. Compared with the prior art, the enclosure structure has the advantages that the bending and shear resistance is good, the brittleness is small, the ductility is good, the cost is low, the efficiency is high, pollution is avoided, multiple sections can be connected, and the enclosure structure can be constructed to be longer and deeper.

Owner:SHANGHAI CHENGDI CONSTR +1

Construction method of pipe jacking in silt soil layer based on steel sleeve tool pipe

ActiveCN106402490BThe method steps are simpleReasonable designPipe laying and repairEngineeringUnderground pipeline

Owner:中铁二十局集团第五工程有限公司

Water seepage control construction method for waterproof construction of karst water-rich geological underground structure

The invention relates to the field of basement water-rich geological structure waterproof construction, in particular to a water seepage control construction method for karst water-rich geological underground structure waterproof construction. The problem that waterproof construction is affected due to the fact that existing underground structure waterproof construction only focuses on construction self-waterproofing and is poor in waterproof effect and water pressure and waterways of foundation pit water seepage always exist. The water seepage control construction method includes the steps of water seepage control on baseboard waterproof construction, waterproofing and water draining of baseboards and continuous wall corners, water seepage control on wall waterproof construction, water seepage control on portal waterproof construction, and water seepage control on waterproof construction of expansion joints and post-cast strips. A water seepage control technique at positions such as the baseboards, station structure side walls, the expansion joints and the post-cast strips is realized, structure waterproof performance is improved, waterproof construction is ensured to be performed in a water-free environment, quality of waterproof construction and cement construction under the karst water-rich geological conditions is guaranteed, simplicity and convenience in technological operation are realized, and the water seepage control construction method is wide in application range, reliable in technology, high in superiority and convenient to popularize and apply.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

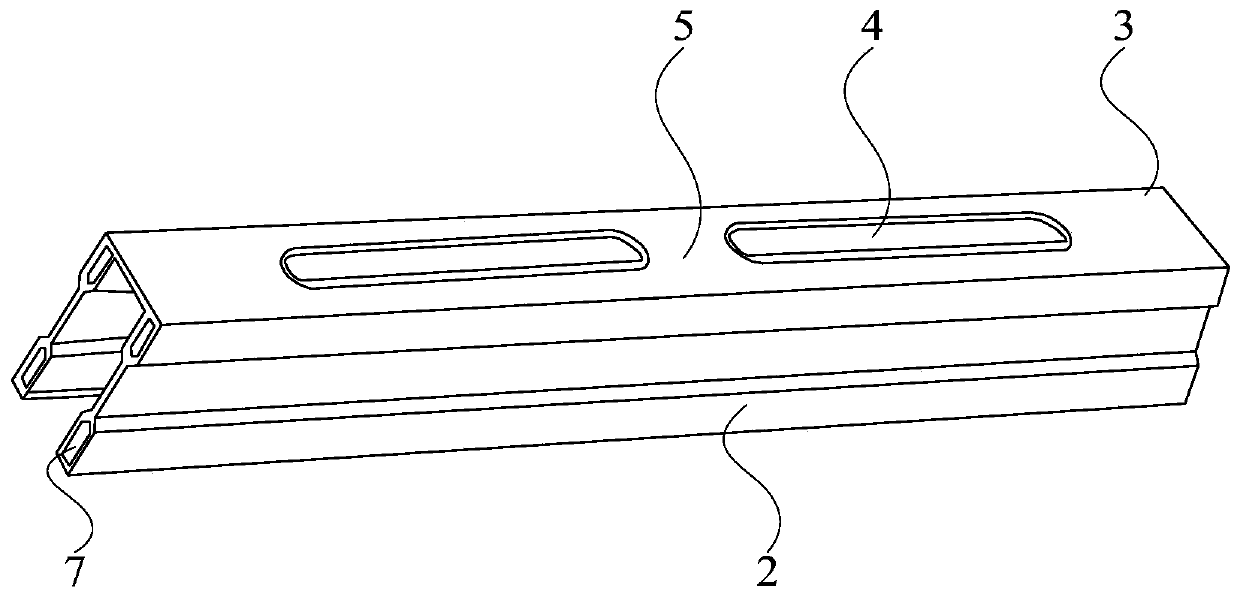

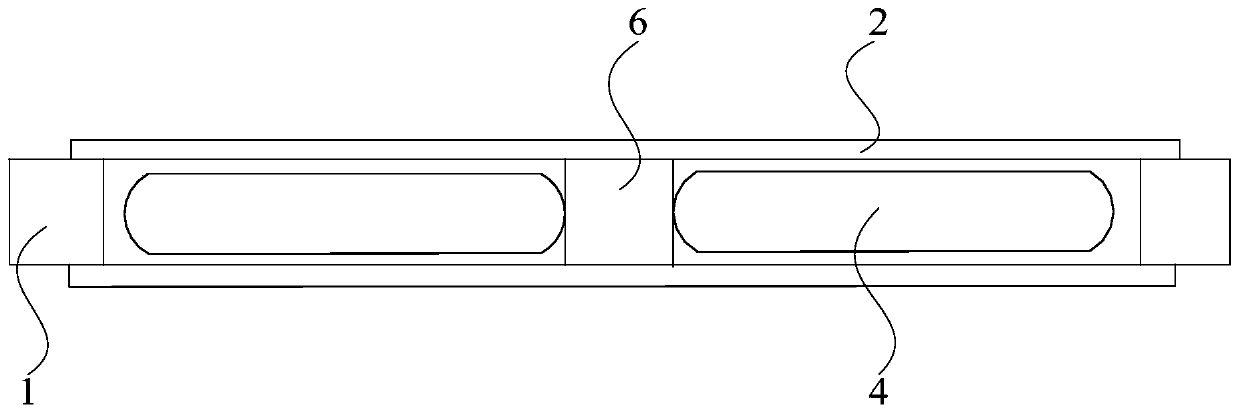

Alloy keel structure and manufacturing method thereof

The invention discloses an alloy joist structure and a manufacture method thereof; the alloy joist structure comprises a main joist body; each end of the main joist body is provided with an end wood block that is greater than the end of the main joist body, the main joist body comprises two side supports and a beam bottom, the two side supports and the beam bottom are of U-shaped structure, the beam bottom is provided with a plurality of beam bottom holes, a connection strip is connected between the beam bottom holes, and a support wood block is disposed in the connection strip. By using the alloy joist structure and the manufacture method thereof, work time is saved, labor intensity of workers is lowered, labor efficiency is improved, the cost is lowered, construction civilization level is increase, and the flatness of a concrete wall is guaranteed.

Owner:曹立英

Protection structure for rapidly entering semi-cutting single-pressure open cut tunnel and construction method

PendingCN111794774AAvoid protectionReduce riskUnderground chambersDrainageEcological environmentArchitectural engineering

The invention discloses a protection structure for rapidly entering a semi-cutting single-pressure open cut tunnel and a construction method. The construction method comprises the following steps of S1, construction preparation; S2, construction of a slope top intercepting ditch; S3, side and back slope excavation and support; S4, construction of a bias wall foundation and a lower wall body; S5, construction of a cover arch and a pipe shed; S6, construction of a back haunch fillet of arch of the open cut tunnel; S7, construction of an upper wall body of a bias wall; and S8, hidden tunnel excavation and primary support, wherein after construction of the back haunch fillet of arch is completed, according to the advanced geological forecast and monitoring measurement result, a reserved core soil three-step partial excavation method is adopted for construction, hidden tunnel soil body is excavated, after construction of an inverted arch primary support is completed, the inverted arch primary support and the back haunch fillet of arch are closed into a ring, tunnel construction is completed, and smooth tunnel entering is achieved. According to the method, damage of vegetation at the opening of the tunnel is avoided, the construction period is saved, the construction cost and the safety risk are reduced, good social benefits are generated, and on the premise that the construction safety of the ecological environment is guaranteed, the problem of difficulty in entering of the semi-cutting single-pressure tunnel is effectively solved.

Owner:YUNNAN CONSTR INVESTMENT HLDG GRP CO LTD

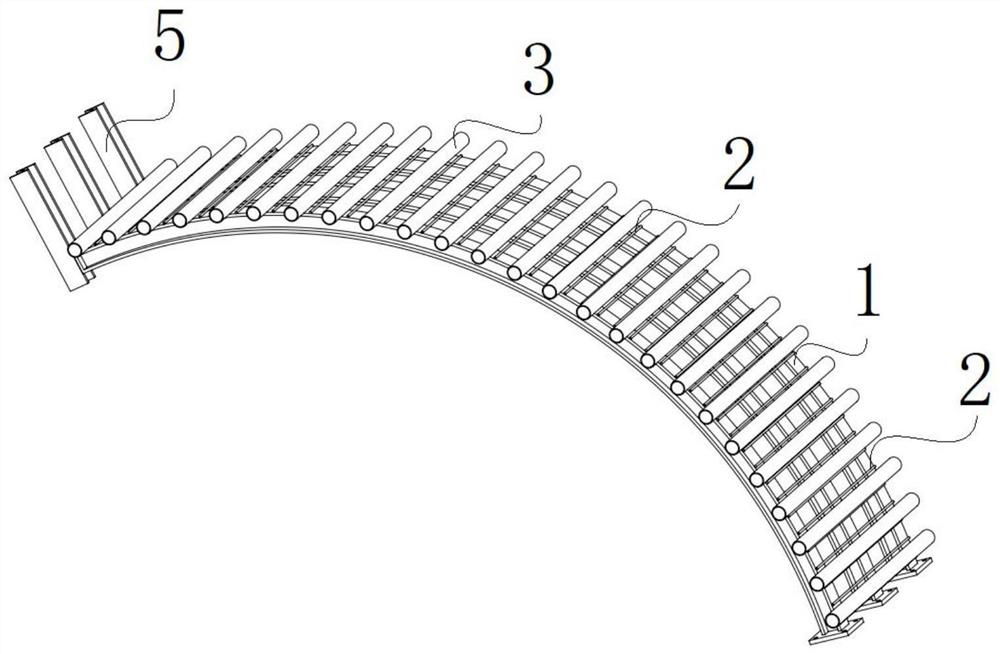

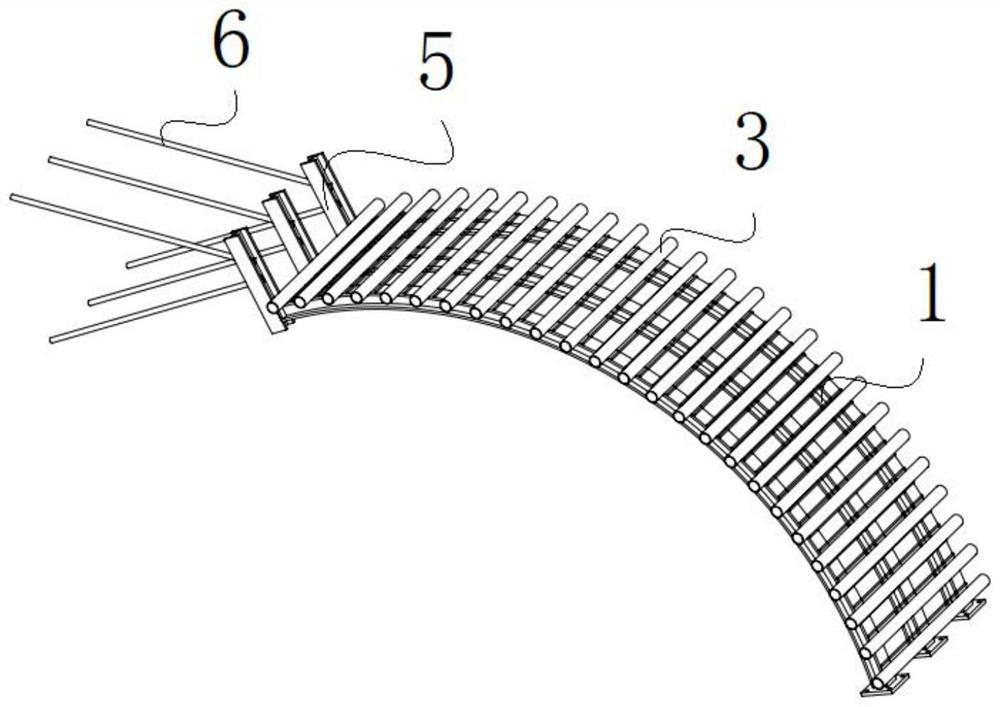

Installation method of metro depot assembly type concrete track bridge

PendingCN114032769AGuaranteed durabilityReduce investmentBridge erection/assemblyRailway track constructionTrackwayArchitectural engineering

An installation method of a metro depot assembly type concrete track bridge comprises the steps of installing and fixing embedded parts; producing the assembly type concrete track bridge; connecting the assembly type concrete track bridge with an embedded part in a ground structure; laying rails; and filling track cement. The installation method of the metro depot assembly type concrete track bridge has the main advantages that the installation speed is high, and the construction period is shortened; labor force and turnover material investment can be reduced, and the construction cost is low; the mounting precision is high, and the track laying requirement is met; factorization processing and maintenance are adopted, the durability of the concrete is guaranteed, the concrete is firm and durable, and the service life can be prolonged; the appearance effect is good; noise, dust and wet operation are avoided, and the civilized construction degree is high.

Owner:中铁电气化局集团北京建筑工程有限公司

Construction channel structure and construction method of upper and lower separated underground excavation station equipped with slag removal transportation equipment

ActiveCN103061773BImprove completenessImprove work efficiencyTunnelsArchitectural engineeringOperating environment

The invention discloses an up-down separating type underground excavation station construction passageway structure provided with mucking transport equipment and a construction method. The structure comprises an upper construction passageway, a lower construction passageway, a plurality of muck passageways and the mucking transport equipment, up-down separating type construction passageways are adopted, the upper construction passageway is located above the lower construction passageway, the upper construction passageway and the lower construction passageway are horizontal passageways, reserved with a certain distance in the vertical direction and separated by undisturbed soil masses, and bodies of the two passageways are mutually unconnected and respectively connected to a construction shaft. The upper construction passageway and the lower construction passageway are communicated by the aid of the muck passageways arranged between the same, the muck passageways are arranged at intervals along the horizontal direction, and the bottom of the lower construction passage way is provided with the mucking transport equipment. By the structure and the method, influences of underground excavation station construction on surroundings can be reduced, risk of underground excavation station construction is lowered, underground excavation station in-cave operating environment is improved, mechanical construction degree and working efficiency are improved, unnecessary excavation, fill, primary support structure erecting and detaching are avoided, and engineering investment is saved.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

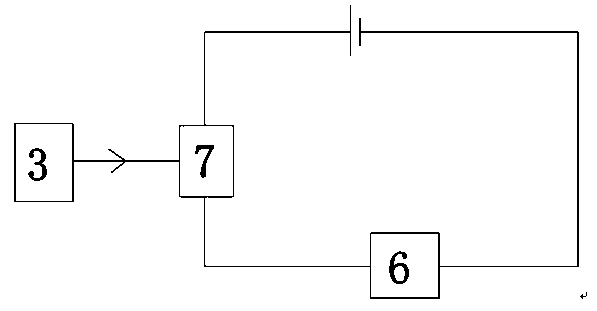

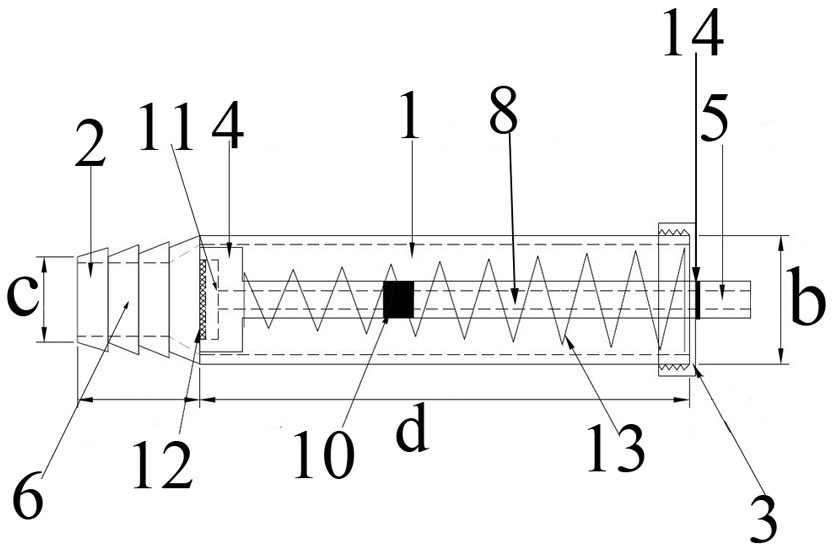

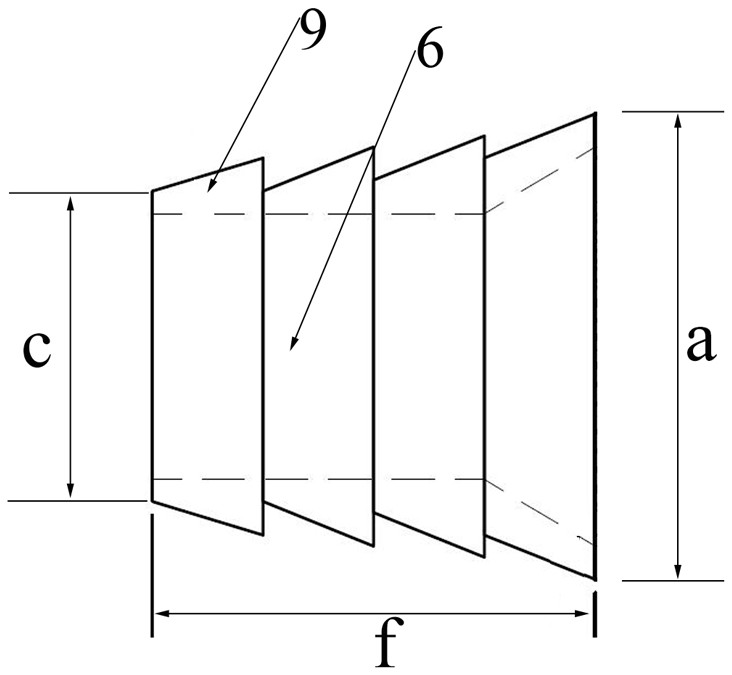

A sleeve grouting plumpness detection device and its application method

ActiveCN110907630BReduce workloadEase of workMaterial testing goodsBuilding material handlingClassical mechanicsStructural engineering

A sleeve grouting plumpness detection device and its use method, comprising a grout filling device pipe body, variable-diameter taper openings and sealing caps respectively arranged on both sides of the grout replenishing device pipe body, and movable plugs arranged in the grout replenishing device pipe body The head and the sliding connecting rod fixedly connected with the movable plug head, there is a slurry inlet channel in the tapered mouth, and the two ends of the inlet channel are respectively connected with the grouting sleeve and the pipe body of the grouting device; the outer diameter of the tapered mouth is from The entrance of the grouting material becomes larger gradually, and the movable plug and the sliding connecting rod are provided with an exhaust channel that runs through. One end of the exhaust channel is connected with the slurry inlet channel, and the other end is connected with the atmosphere. 1. An elastic piece is sleeved on the outer side of the sliding connecting rod, and the sliding connecting rod is provided with a zero point mark for observing the fullness of grouting and a grouting mark for observing whether the grouting is complete. The invention reduces the workload of the grouting workers and reduces the work difficulty of the quality inspectors, the grouting quality supervision is intuitive and convenient, and full inspection can be achieved.

Owner:CHINA CONSTR SCI & TECH CO LTD

Prefabricated detachable foundation pit ladder rest platform and diaphragm wall connection structure

ActiveCN102926555BThe effect of angle adjustment is remarkableTo adjust the levelShaping building partsBuilding construction

Owner:TIANJIN NO 2 CONSTR ENG

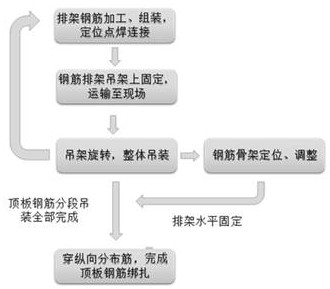

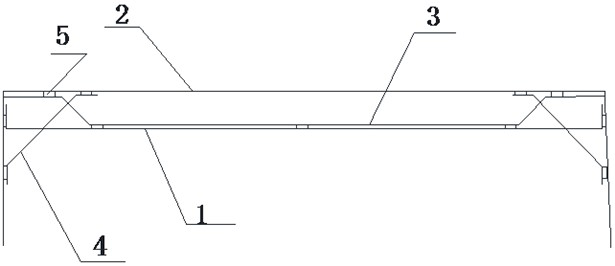

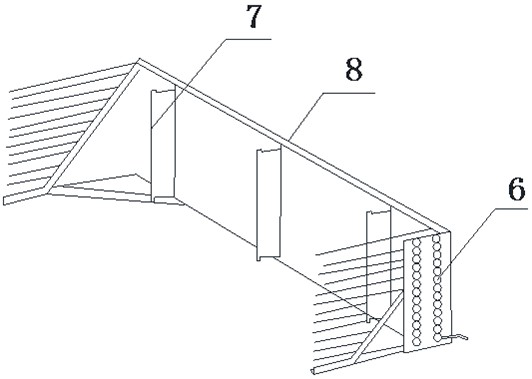

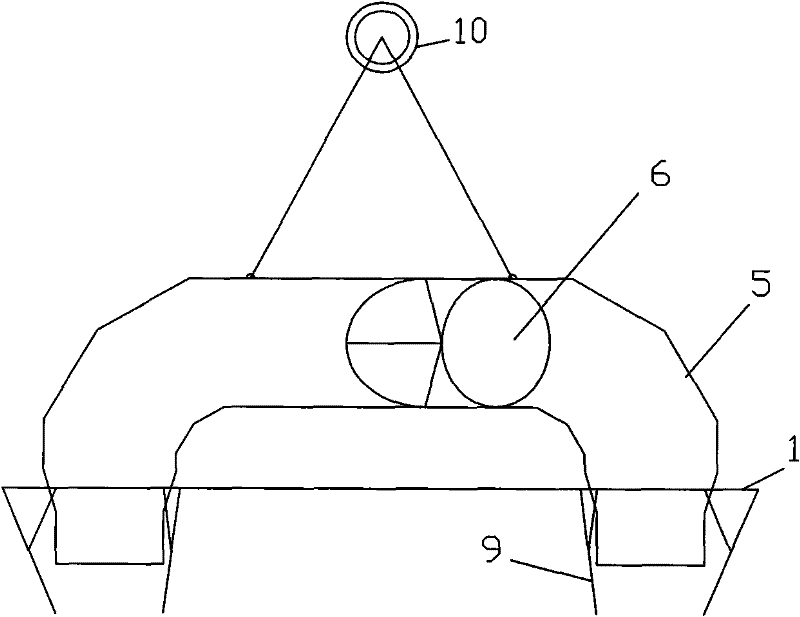

A construction method for overall hoisting after pre-bundling of steel bars for the roof of cast-in-place pipe gallery

ActiveCN109695255BRealize factory installationReduce tying timeArtificial islandsUnderwater structuresNumerical controlArchitectural engineering

The invention discloses an overall hoisting construction method for pre-bundled steel bars for a cast-in-place pipe rack roof panel. The method comprises the following steps: processing, assembling and tack welding and connecting framed bent steel bars; fixing framed bent steel bars with a hanging bracket and transporting to a construction site; performing positioning adjustment on a framework ofthe steel bars, and performing overall hoisting; positioning, adjusting and decoupling the framework of the steel bars to complete the pre-binding. The steel bars are processed by numerical control equipment to ensure the processing precision of the steel bard, and the steel bars are pre-bundled through a steel bar positioner, so that the overall size of the framework of the steel bars is ensuredto be accurate; the overall hoisting of the steel bars is implemented by means of fine adjustment and other measures, so that the deviation of the site installation position of the steel bars is reduced, and the purpose of improving the installation quality of the main steel bars of a pipe rack is achieved; in the process of steel bars binding of a pipe rack roof panel, most of the main construction content is completed from a non-main line construction line, thereby saving the process time; the steel bar transportation, on-site storage and steel bar binding standardization are realized by theapplication of the steel bar hanging bracket of the pipe rack roof panel.

Owner:CTCE GRP ROAD & BRIDGE ENG CO LTD +1

Method for hoisting terrace for furnace top raw gas pipeline

InactiveCN101709344BReduce consumptionReduce the amount of work at heightBlast furnace componentsBlast furnace detailsSteel frameTube socket

The invention relates to a method for hoisting a terrace for a furnace top raw gas pipeline. The terrace is provided with multiple layers which have steel frame structures and are connected into a whole. The method comprises that: the first layer of terrace is hoisted in a carrying mode, before the first layer of terrace is hoisted, all structural members on the first layer of terrace are welded completely, and then a temporary pull rod is arranged through a supporting point of a horizontal tube socket of an ascending tube so as to fix the first layer of terrace; a tripod diagonal rod is hinged to a horizontal brace by bolts; when the terrace is hoisted, a hook of a crane hooks a lifting lug on a horizontal tube of the ascending tube for hoisting, so that the first layer of terrace is putto the right position; the terraces from a second layer to a top layer are hoisted in an integral insertion mode; and before the terraces are hoisted, all frames of the top layer of terrace and otherterraces are assembled integrally on the basis of the first layer of terrace, then a monorail and a hoist are arranged in place and fixed, and the integrally-assembled terrace is put to the right position by the crane. Through the method, construction cost can be saved, construction period is shortened, construction environment is improved, the consumption of on-site auxiliary materials is reduced and the safety degree of hoisting and construction is improved.

Owner:CHINA FIRST METALLURGICAL GROUP

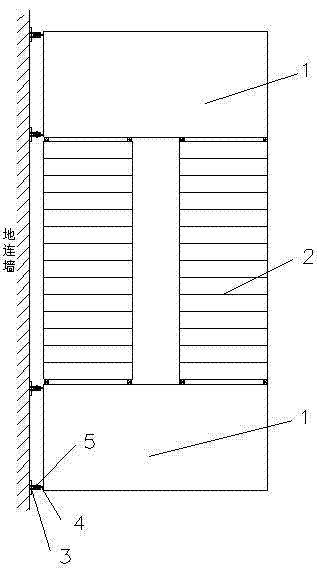

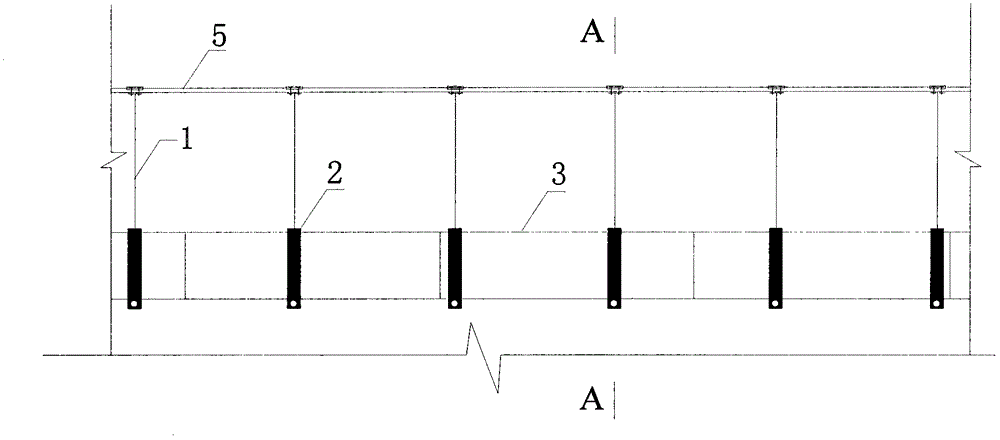

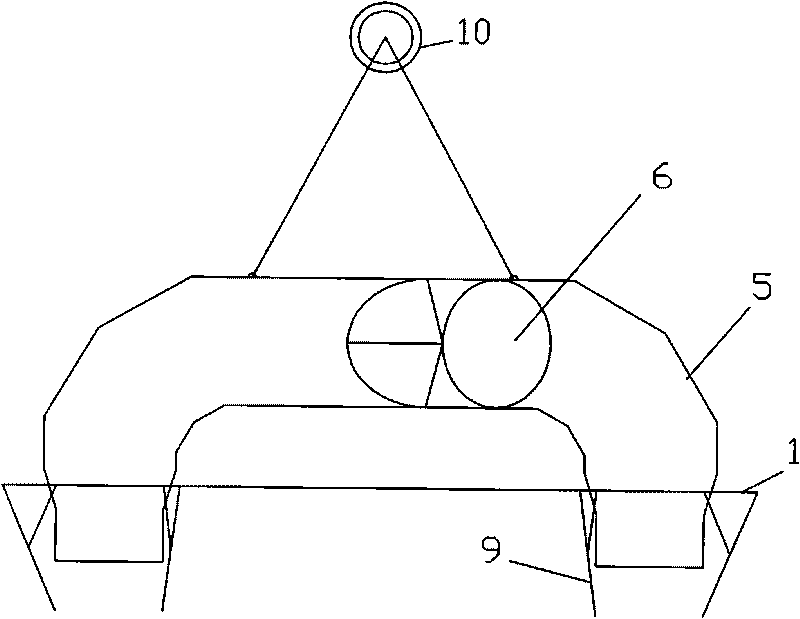

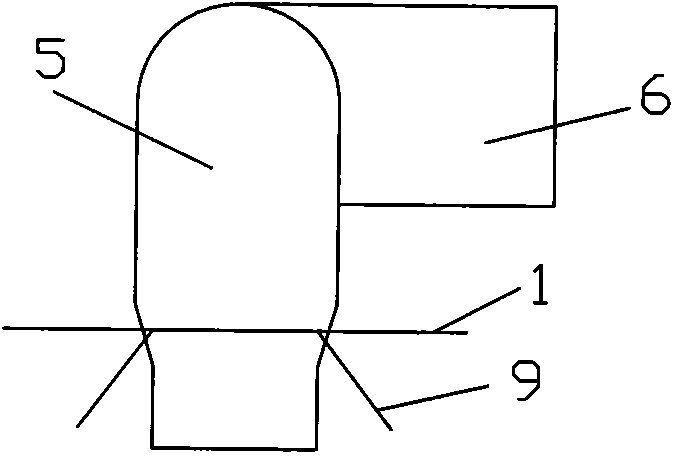

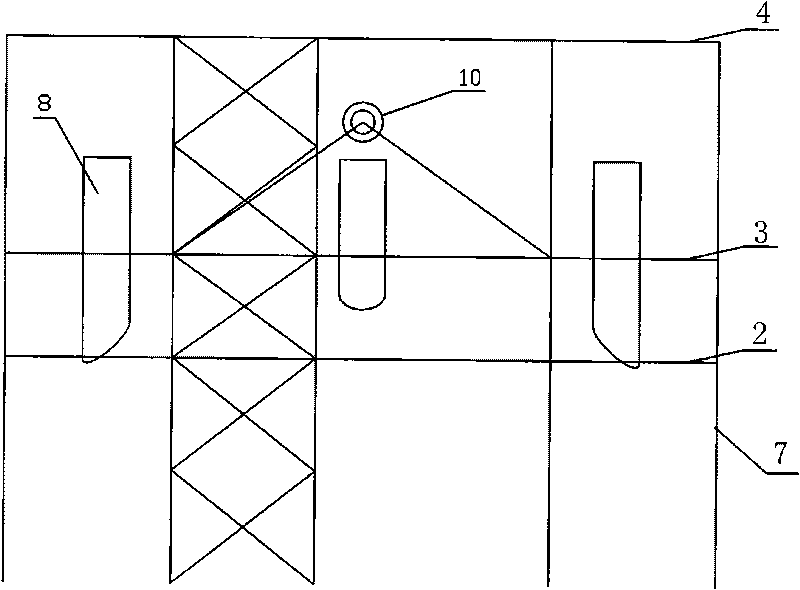

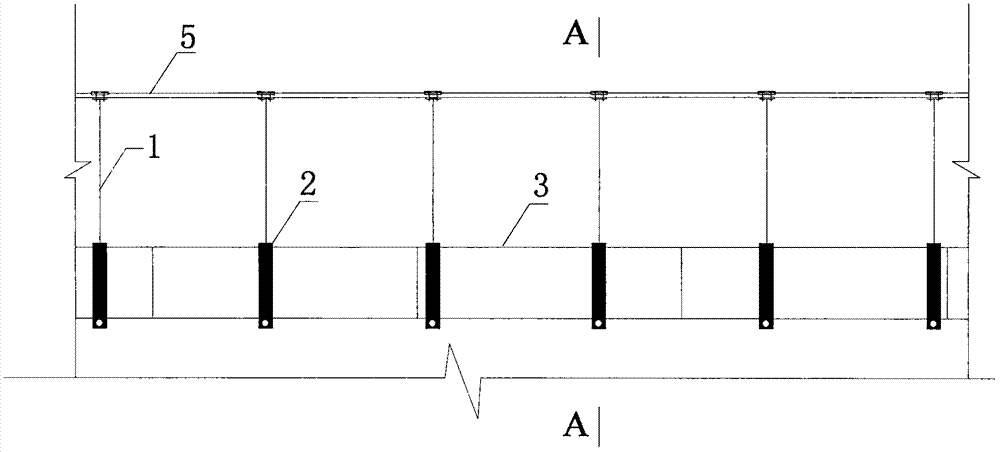

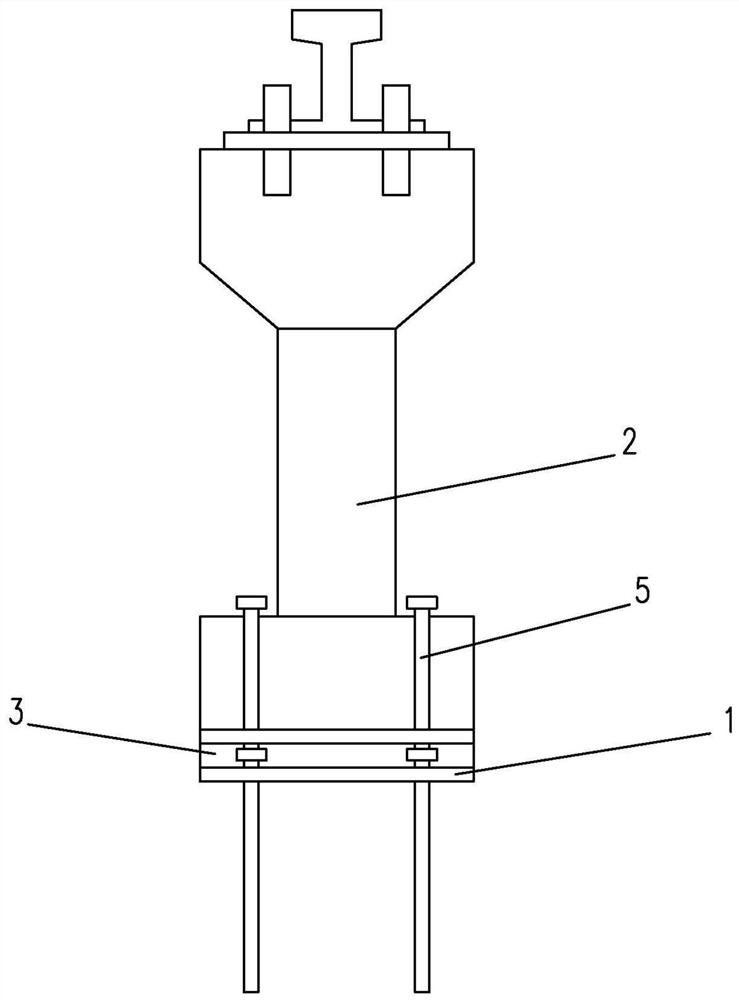

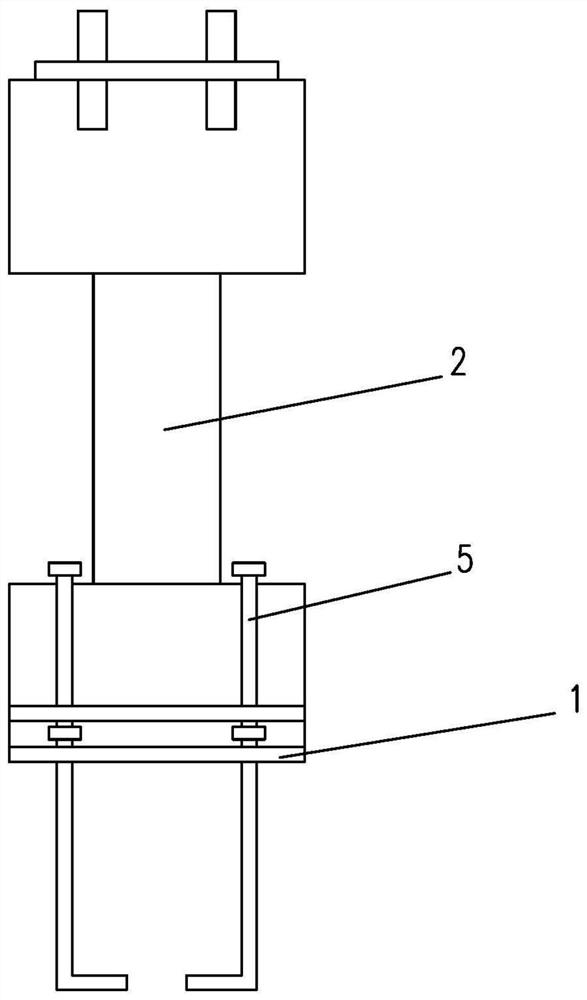

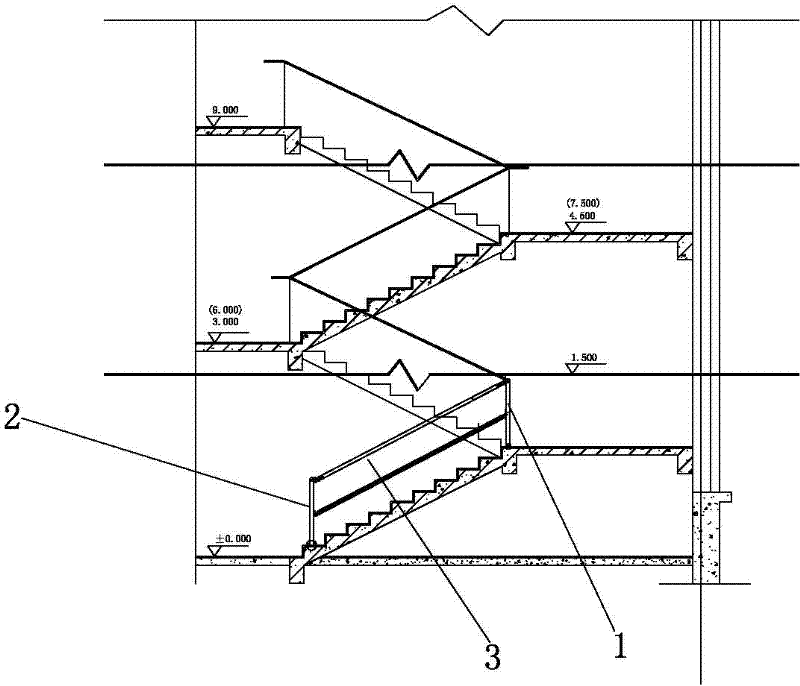

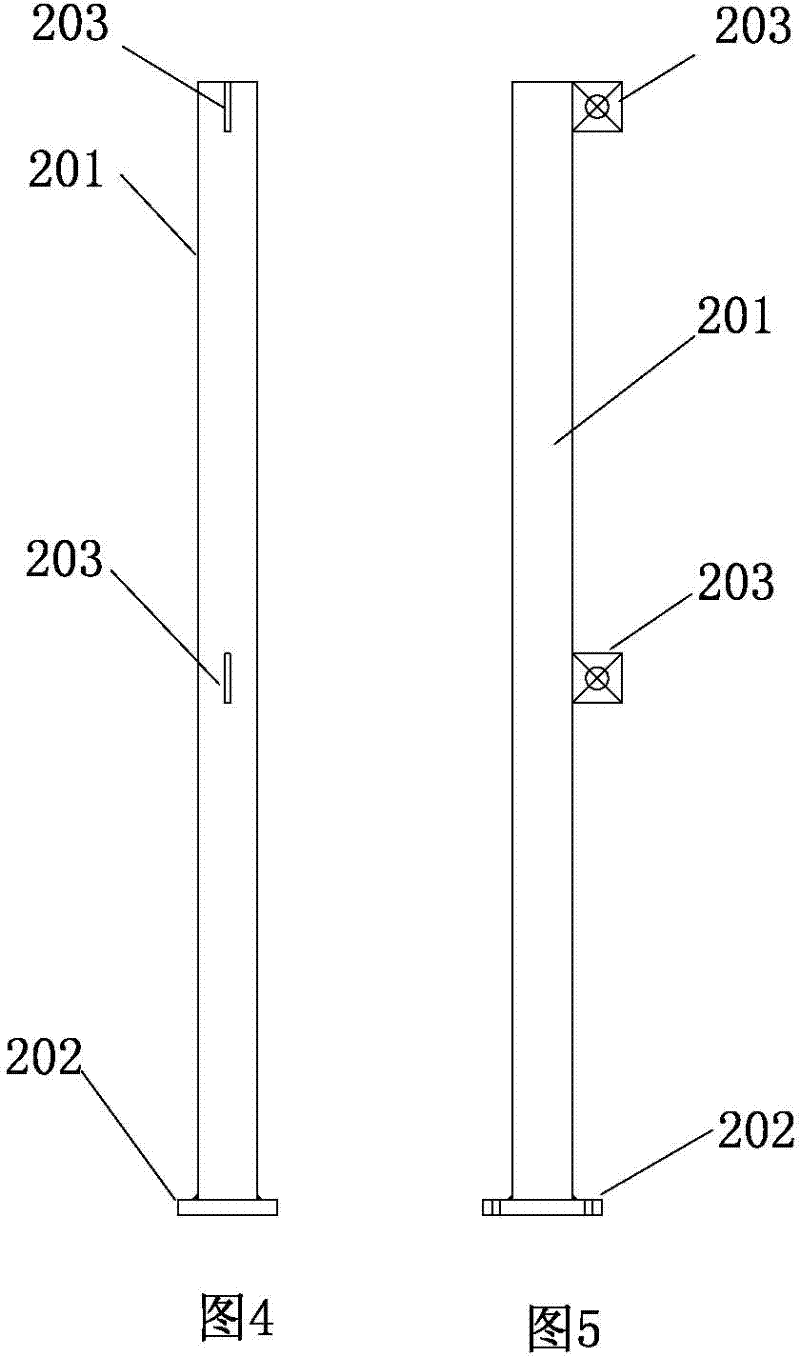

Assembled temporary protective railing for stairs

InactiveCN102296766ASimple structureGood stabilityBuilding material handlingStairway-like structuresEngineeringBaluster

An assembled temporary protective railing for stairs, which is characterized in that it is mainly composed of a corner column (1), a column (2) and an adjustable handrail (3), and the column (2) is fixed on the ground of the bottom and top stairs by expansion bolts Above, the corner column (1) is fixed on the ground of the stairs except the bottom and top floors by expansion bolts, one end of the adjustable handrail (3) on the bottom and top floors is connected to the corner column (1) through connecting bolts, and the other end is also connected to the corner column (1) by connecting The bolts are connected to the columns (2), and the two ends of the adjustable handrails (3) except the top and bottom floors are respectively connected to the corresponding corner columns (1) through connecting bolts. The invention has good stability, safety and reliability, convenient assembly and disassembly, and is beneficial to improving the level of civilized construction on construction sites.

Owner:JIANGSU PROVINCIAL CONSTR GRP CO LTD

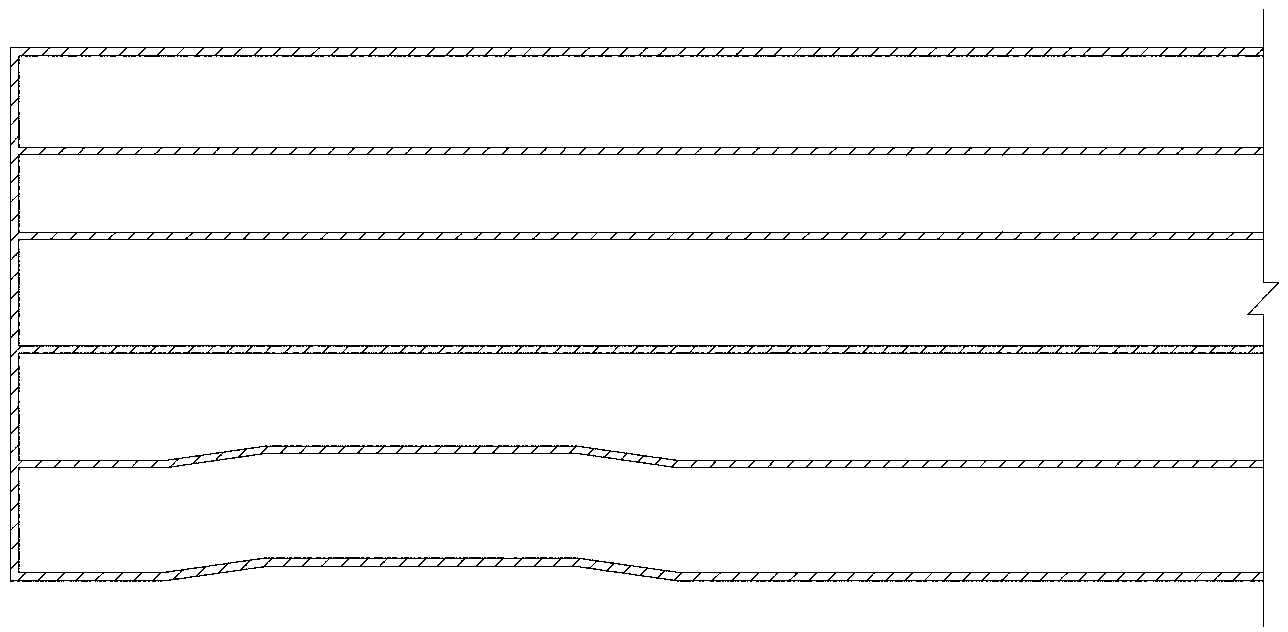

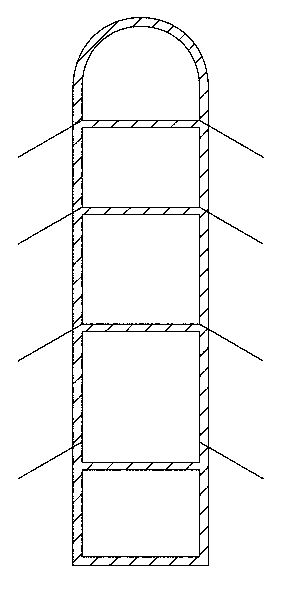

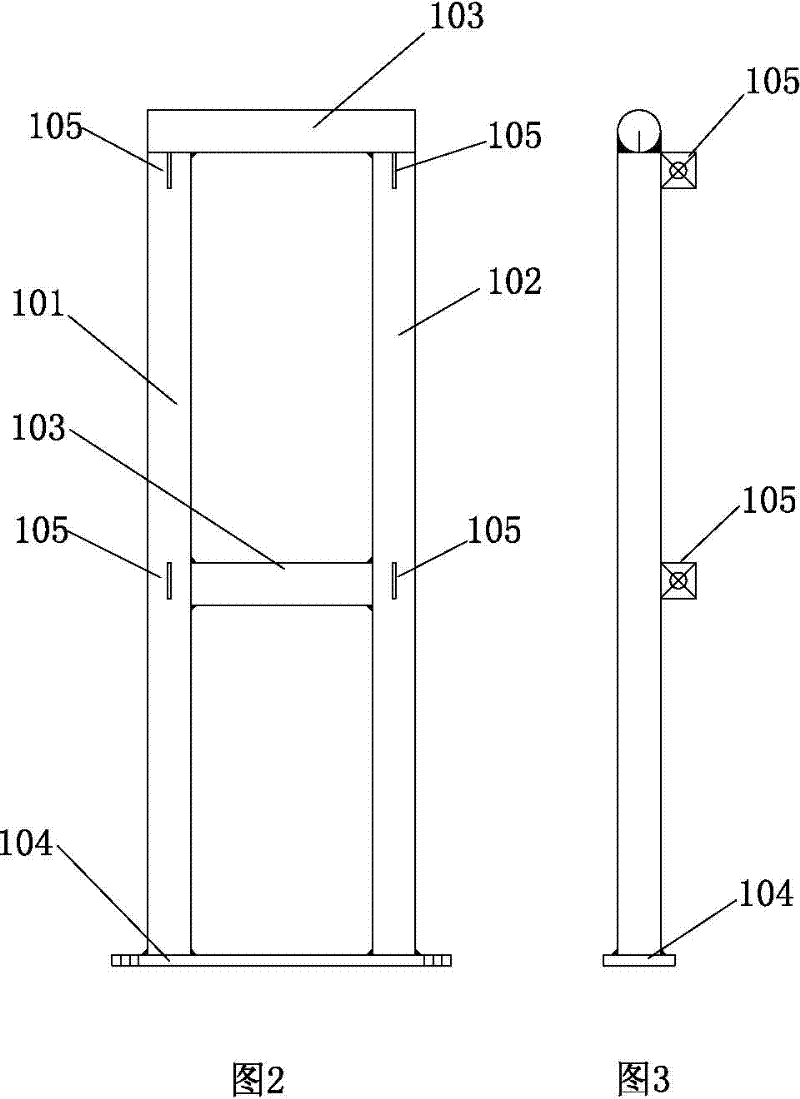

Single-layer three-dimensional prefabrication with excavation of foundation pit and assembly of sunken construction ladder and construction method

ActiveCN104533106BSolve problemsPrevent accidental fallsShaping building partsVertical stabilizationPlinth

The invention relates to a single-layer three-dimensional prefabricated sunken construction ladder stand assembled along with excavation of a foundation pit and a construction method. The ladder stand is formed by assembling ladder stand main structures, namely a plurality of single-layer ladder stand bodies, a vertical stabilization mechanism and a smooth sinking mechanism. The ladder stand main structures are the multi-layer integral ladder stand through connecting and assembling of single-layer three-dimensional steel ladder stand prefabricated components, connecting pipes located on the four corners of the side elevation of the steel ladder stand and inner penetration bolts. The vertical stabilization mechanism is formed by meshing guide rails fixed to the upper end of the side elevation of an even wall and sliding rails fixed to the side elevation of the ladder stand. The stable sinking mechanism is composed of lifting beams welded to guide rail bases, manual blocks hung on the lifting beams, and a lifting nose arranged on the ladder stand. According to the single-layer three-dimensional prefabricated sunken construction ladder stand assembled along with the excavation of the foundation pit and the construction method, in the groove excavating process, the prefabricated steel ladder stand is installed in a whole layer successively in a time section dividing mode, as the foundation pit is constantly deepened, the ladder stand stably sinks by itself through a sinking lifting beam device assembled on the ladder stand, an upper channel and a lower channel can be constructed in the deep foundation pit fast, conveniently and economically, and safety and reliability are achieved.

Owner:TIANJIN NO 2 CONSTR ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com