Prefabricated detachable foundation pit ladder rest platform and diaphragm wall connection structure

A rest platform and prefabricated assembly technology, which is applied to building construction, on-site preparation of building components, construction, etc., can solve the problems of verticality and flatness that are difficult to meet the precision requirements of prefabricated steel structure ladders, and achieve the application effect Significant, safe and reliable performance, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

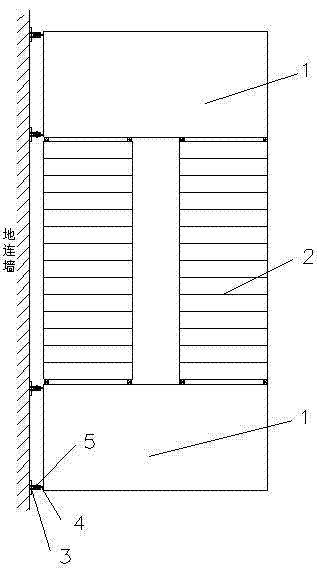

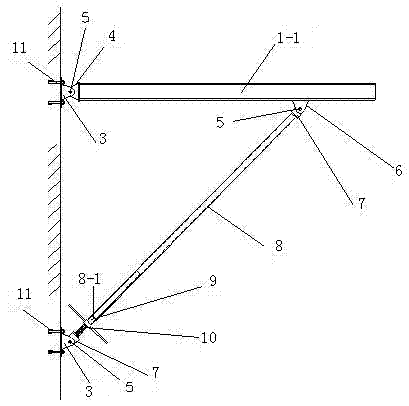

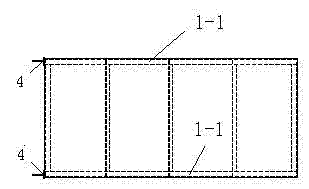

[0042] see Figure 1-Figure 16 , a prefabricated and detachable foundation pit climbing ladder rest platform and ground connection wall connection structure, the connection structure includes the following components: rest platform 1, skew run 2, ground connection wall support 3, long hole hinge 4, bolt 5, Rest platform support 6, brace hinge 7, brace 8, intubation tube 9, spiral support head 10 and expansion tube bolt 11.

[0043] The ground connection wall support 3 is fixed on the ground connection wall with expansion tube bolts 11 as an embedded part; the end of the rest platform 1 is welded with a long hole hinge 4, which is connected with the ground connection wall support 3 through bolts 5, so that the rest The rear end of the platform 1 is connected with the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com