Patents

Literature

977 results about "Magnesium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium phosphate is a general term for salts of magnesium and phosphate appearing in several forms and several hydrates...

Lithium titanate composite electrode material with surface coating layer

InactiveCN101764209AChange physical propertiesChange chemical propertiesCell electrodesMagnesium phosphateMagnesium orthophosphate

The invention relates to a battery electrode material, in particular to a lithium titanate composite electrode material with surface coating layer; in the lithium titanate composite electrode material with surface coating layer, the electrode material is composed of lithium titanate particles and a coating layer coated with the surface of the lithium titanate particles; the particle size of the lithium titanate particles is 100nm-95mum, the average thickness of the surface coating layer is 0.2nm-5m, and the particle diameter of the composite electrode material is 0.1-100mum; the material of the surface coating layer is one or mixture of more than one kind of insulation oxide, insulation composite oxide, aluminium phosphate, magnesium phosphate, lithium fluoride, lithium phosphate or LiMPO4, wherein M is magnesium, ferrum, cobalt, nickel, chromium, titanium or vanadium; in the invention, by carrying out surface coating treatment to the surfaces of the existing lithium titanate particles, a layer of protective film is formed on the surface, so as to change the physical and chemical characteristics of the surface of the lithium titanate active material, the surface can not be reacted with electrolyte even if under overpotential condition, so as to avoid ballooning and ensure the capacity and the circularity of the battery not to be reduced.

Owner:SUZHOU PHYLION BATTERY

Ruminant feed additive composition and process for producing the same

InactiveUS6238727B1The implementation process is simpleAnimal feeding stuffAccessory food factorsMagnesium phosphateMagnesium orthophosphate

A ruminant feed additive composition containing (A) lysine magnesium phosphate, (B) magnesium oxide, (C) a binder and (D) water, said water content being between 5 and 15% by weight, and processes for producing the composition.

Owner:AJINOMOTO CO INC

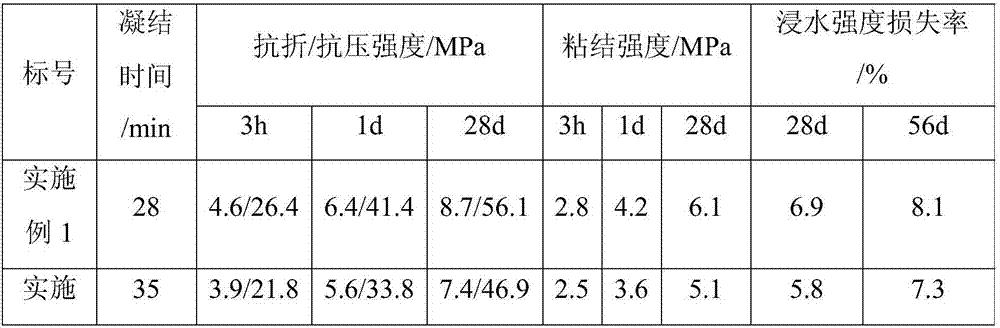

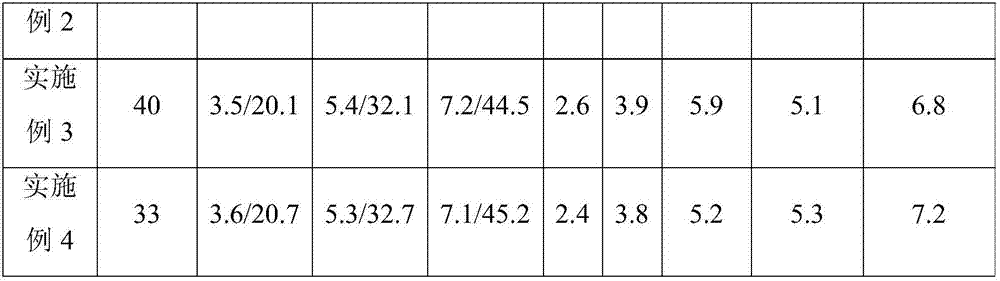

Magnesium phosphate cement based rapid repair mortar and preparation method thereof

ActiveCN105272138AGuaranteed water resistanceImprove performance indicatorsMagnesium phosphateMagnesium orthophosphate

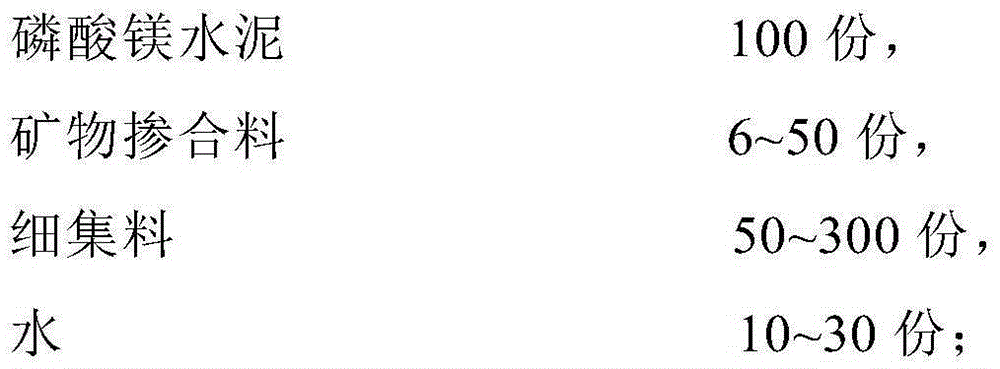

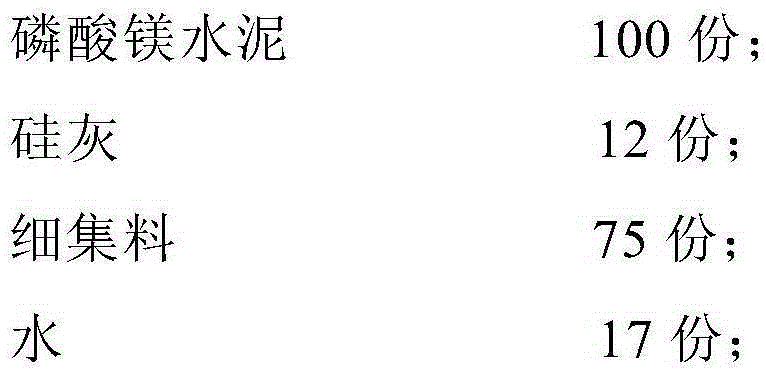

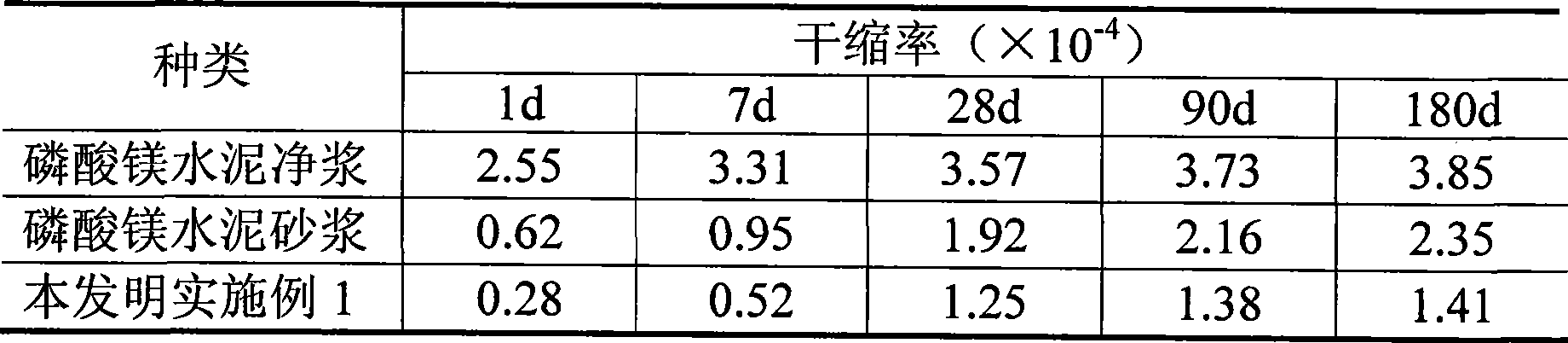

The invention relates to a magnesium phosphate cement based rapid repair mortar and a preparation method thereof. The rapid repair mortar includes the following components by weight: 100 parts of magnesium phosphate cement, 6-50 parts of a mineral admixture, 50-300 parts of fine aggregate, and 10-30 parts of water. The magnesium phosphate cement is obtained by mixing of, by weight, 60-70 parts of metal oxide powder, 20-28 parts of phosphate, 3-6 parts of a retarder and 4-6 parts of a coagulation regulating component. The magnesium phosphate cement based rapid repair mortar is prepared by adopting magnesium phosphate cement as the cementing material, adopting dipotassium phosphate for coagulation regulating modification, and using sand as the fine aggregate, then adding a proper amount of mineral admixture, and performing mixing with water. Compared with the prior art, the magnesium phosphate cement based rapid repair mortar provided by the invention has the advantages of controllable coagulation time, high bonding strength, good stability and high water resistance, etc.

Owner:TONGJI UNIV

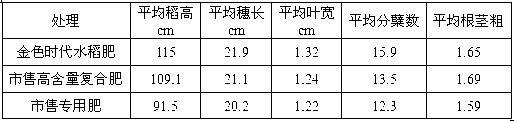

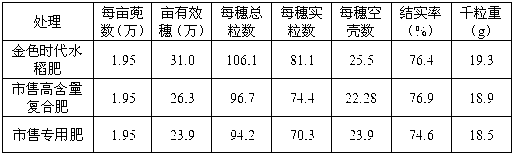

Rice fertilizer capable of improving resistance, quality and yield of rice

InactiveCN102701853AIncrease productionThe effect of increasing production is obviousFertilizer mixturesMagnesium phosphateMagnesium orthophosphate

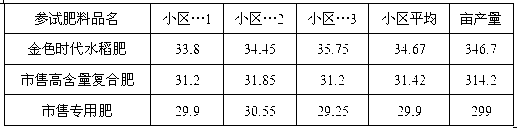

The invention relates to rice fertilizer capable of improving the resistance, quality and yield of rice. The rice fertilizer consists of the following raw materials in percentage by weight: 20.0 to 27.0 percent of urea, 7.0 to 20.0 percent of ammonium sulfate, 5.0 to 13.0 percent of monoammonium phosphate, 9.8 to 17.5 percent of potassium chloride, 10.0 to 18.5 percent of calcium superphosphate, 3.0 to 6.0 percent of calcium-magnesium phosphate, 2.0 to 8.0 percent of soluble silicon, 0.1 to 0.9 percent of amino acid, 5.0 to 30.0 percent of humic acid, 0.5 to 6.0 percent of other trace elements (zinc, manganese, boron, ferrum, copper, molybdenum, selenium and the like), 0.2 to 0.5 percent of activating agent and less than or equal to 2.5 percent of water. The rice fertilizer has the advantages of comprehensively providing the nutrient required by growth of rice, improving the yield and the quality of rice, activating the nutrient of soil, enhancing the capacity of absorbing nutrient by crops, improving a soil structure, enhancing soil fertility, promoting development, and improving the resistance of the crops (disease resistance, pest resistance, drought resistance, flooding resistance, cold resistance, saline-alkaline resistance, lodging resistance and the like).

Owner:王豫希

Phosphate cement based patching material and preparation method thereof

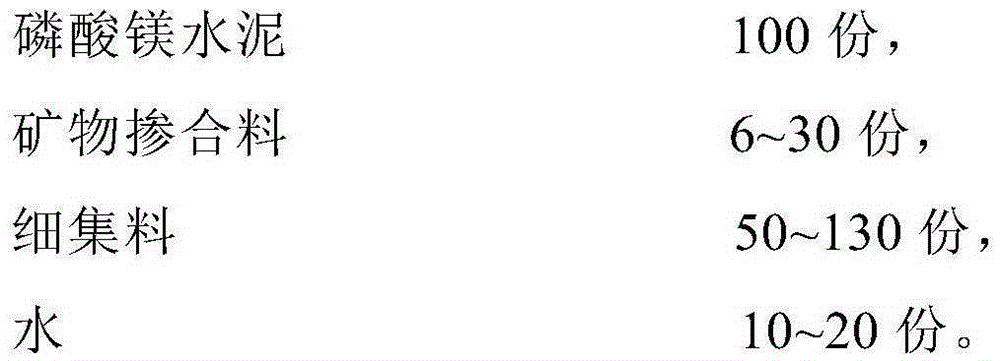

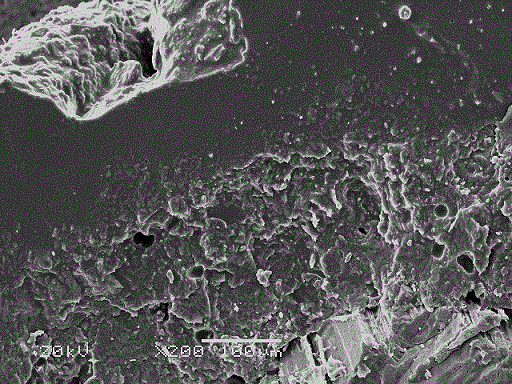

The invention relates to a phosphate cement based patching material and a preparation method thereof. The patching material is prepared from the following ingredients in parts by weight: 100 parts of magnesium phosphate cement, 20 to 40 parts of mineral admixtures, 120 to 140 parts of fine aggregates, 0.5 to 1 part of water glass, 0.5 to 1 part of fiber and 20 to 30 parts of water. The preparation method is characterized in that the raw materials are proportionally weighed; magnesium oxide, monopotassium phosphate and composite retarders are firstly stirred and mixed; then, the magnesium phosphate cement is obtained; then, the mineral admixtures and the fine aggregates are added; after uniform stirring, the water glass, the fiber and the water are added; stirring is performed for 3 to 4 minutes by a stirring machine; the phosphate cement based patching material is obtained. The prepared phosphate cement based patching material by the invention has the advantages that the coagulation time is about 30 minutes; the restoration time is short; the construction is not influenced; the restoration effect is obvious; the application requirement of fast patching the damaged road surface is met; the phosphate cement based patching material is applicable to fast restoration projects of cement concrete pavements.

Owner:WUHAN UNIV OF TECH

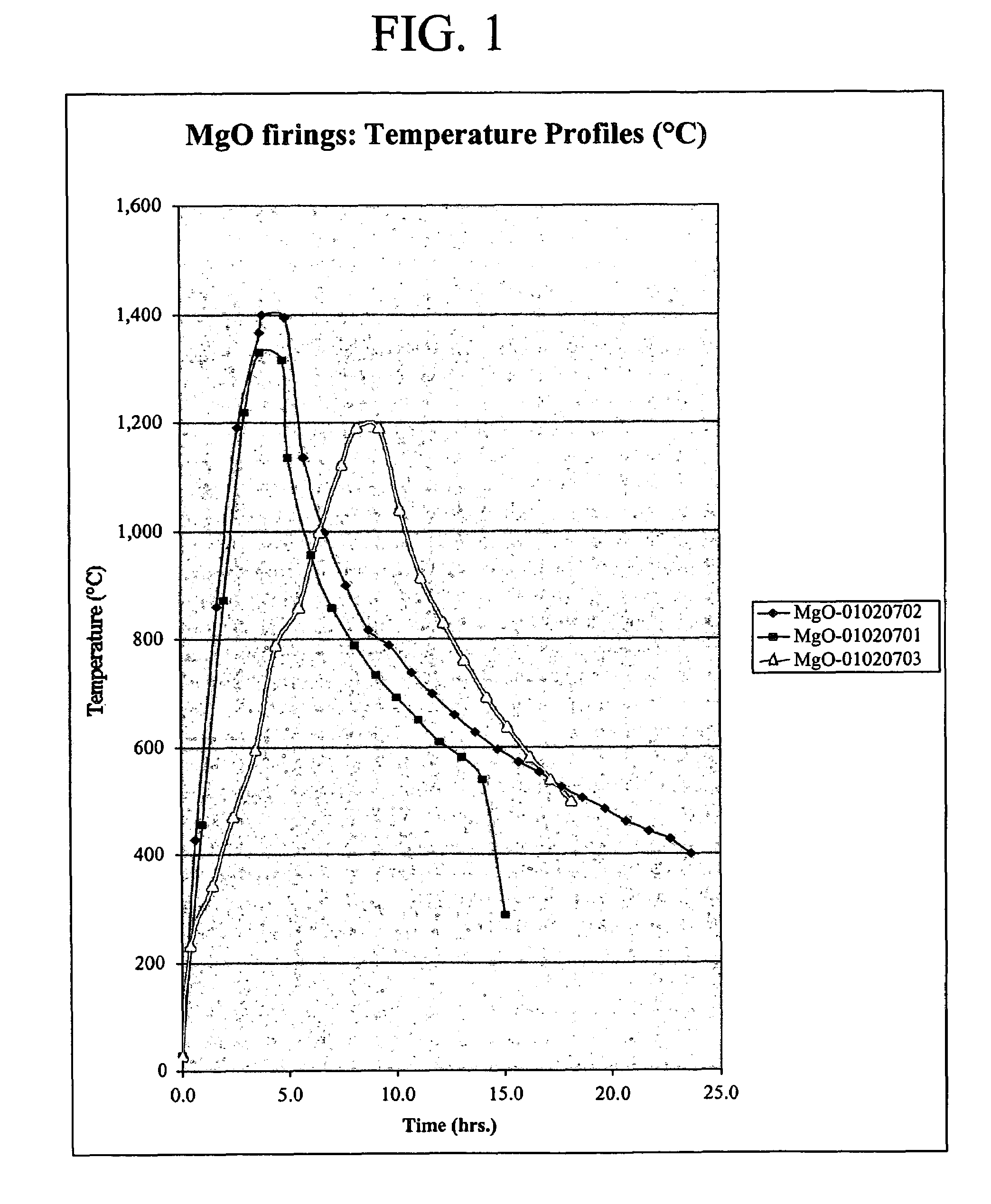

Magnesium phosphate cement prepared by using magnesium oxide byproduct in process of extracting lithium carbonate from salt lake

The invention relates to magnesium phosphate cement prepared by using a magnesium oxide byproduct in the process of extracting lithium carbonate from salt lake. The cement is prepared by uniformly mixing the following raw materials in part by weight: 35 to 50 parts of the magnesium oxide byproduct of the salt lake lithium carbonate, 25 to 55 parts of dihydric phosphate, 2 to 10 parts of adjustable solidification agent and 5 to 35 parts of industrial waste residue powder. The magnesium phosphate cement has the advantages that: the condensing time is randomly adjustable from several minutes to several hours; the magnesium phosphate cement has early strength, high strength, and high bonding strength; later strength is retained; and minimum inflation, low-temperature quick condensing and hardening can be realized and the like. The construction process is simple; the magnesium phosphate cement is extremely suitable for emergent repairing for damages, such as stripping, cracking and the like, of engineering structures in various fields, such as building engineering, traffic engineering and the like, is applied to manufacturing of building material products, such as building mortar, concrete bricks and building blocks, heat preservation wall plates, heat insulation roofs and the like, and is used for curing agents for treating wastes, such as nuclear wastes, urban garbage, sludge andthe like.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Inorganic bone adhesion agent and its use in human hard tissue repair

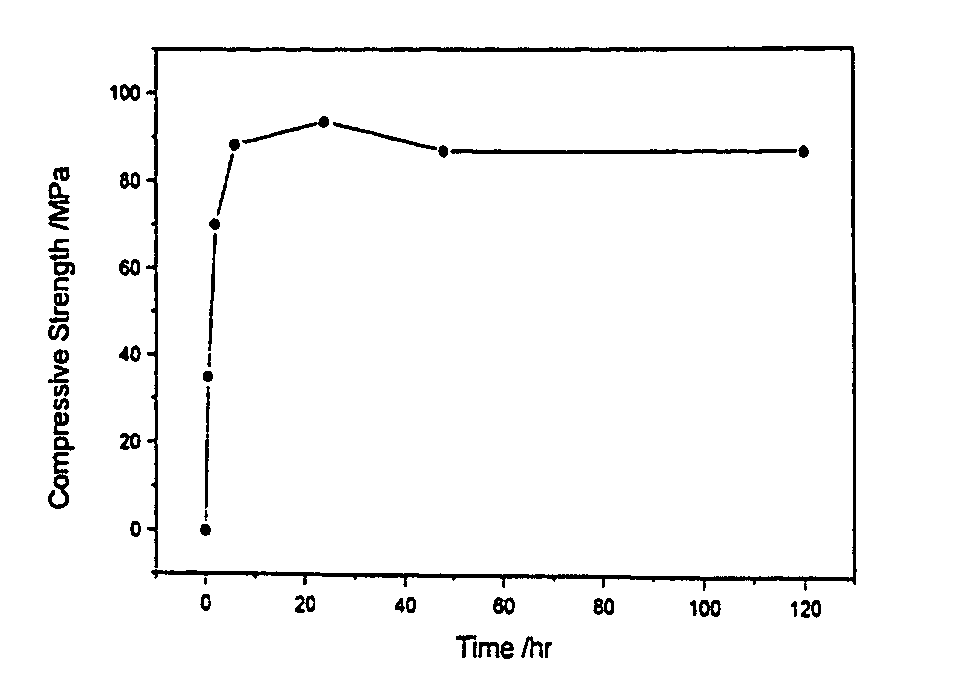

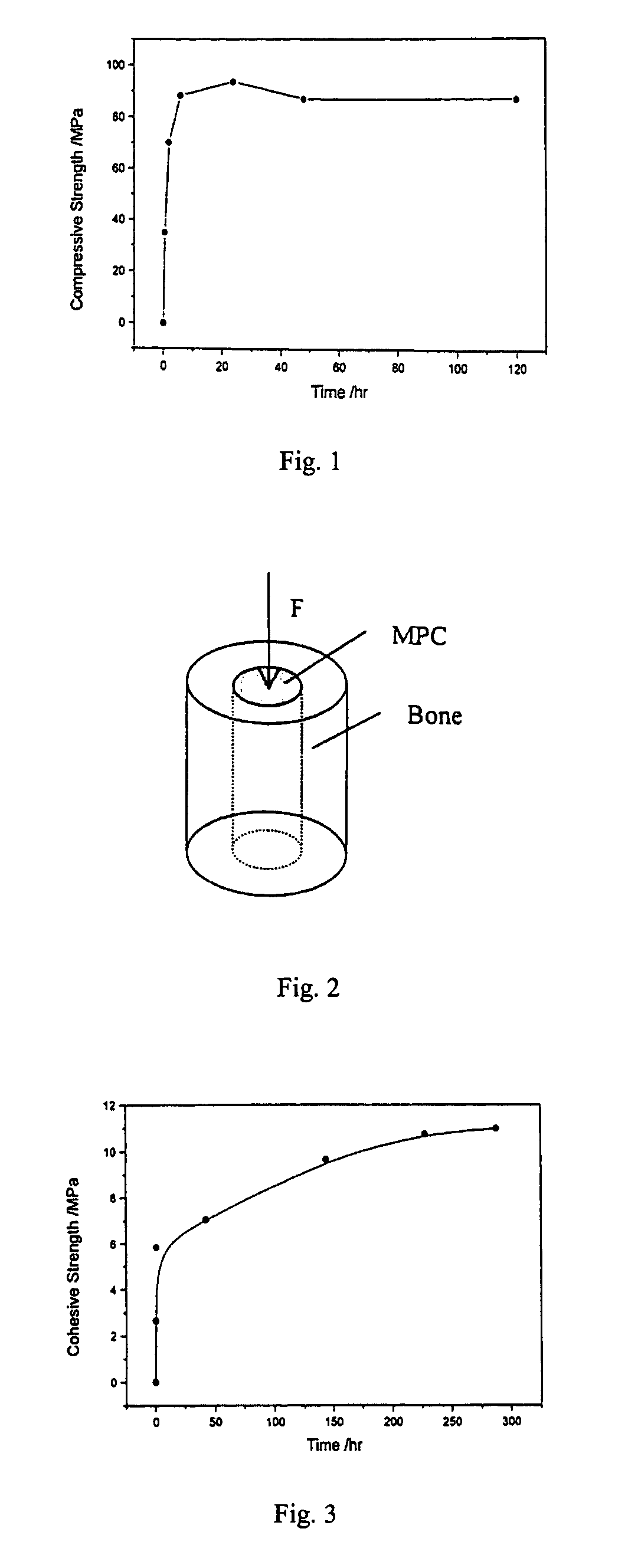

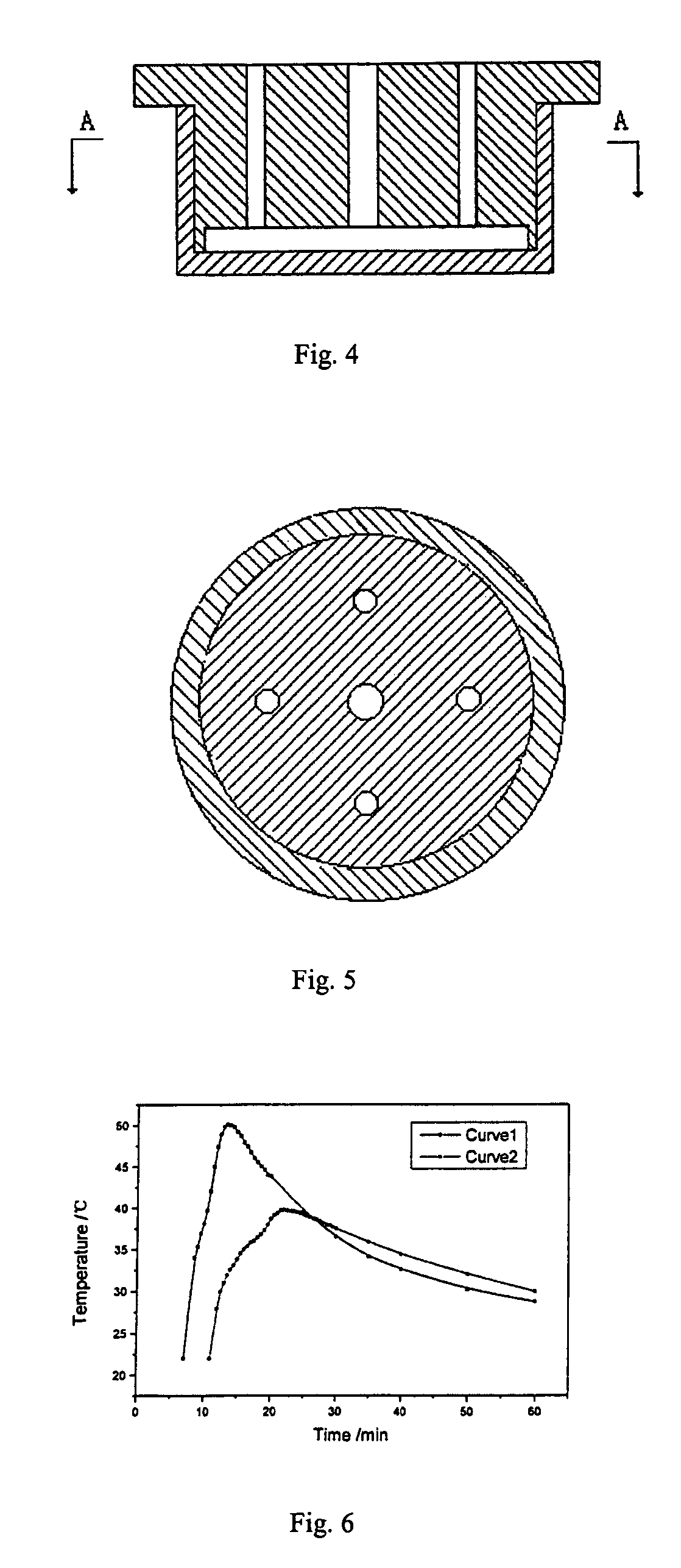

InactiveUS7094286B2High strengthGood biocompatibilityBiocideSurgical adhesivesHydration reactionMagnesium phosphate

The present invention discloses an inorganic bone adhesive and its use in human hard tissue repairs. The inorganic bone adhesive comprises basic compound, phosphate, calcium phosphate bone cement and retarder with the characteristics of rapid hydration rate and high early strength. Inorganic Bone adhesive can be widely used in the artificial joints fixation, screw fixation as well as comminuted fracture fixation. It is a kind of safe and effective adhesive material and beneficial for the fast postoperative recovery. The final hydration reaction products contains the composition of magnesium phosphate, bio-mineral containing ammonium and apatite-like materials, which has excellent biocompatibility and can be gradually absorbed by surrounding tissues after being implanted in vivo, which benefits the in-growth of the new bone.

Owner:EAST CHINA UNIV OF SCI & TECH

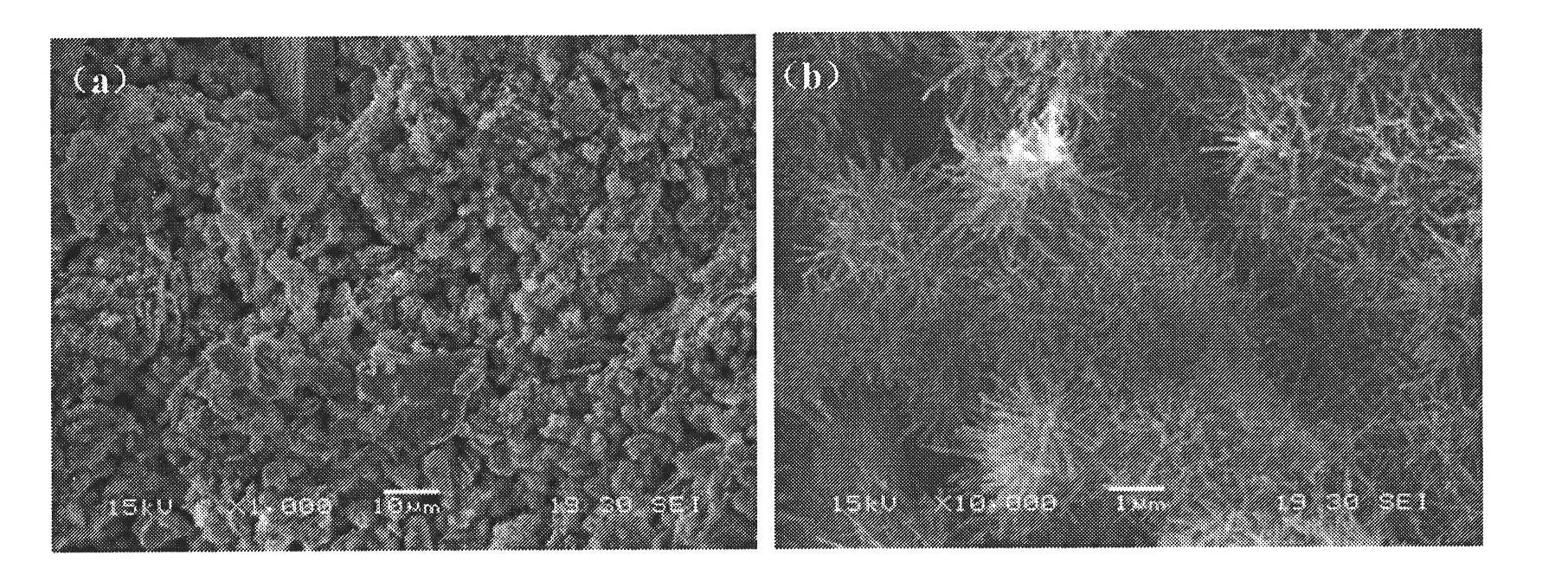

Preparation of nano-HAP coating/magnesium alloy composite biological material

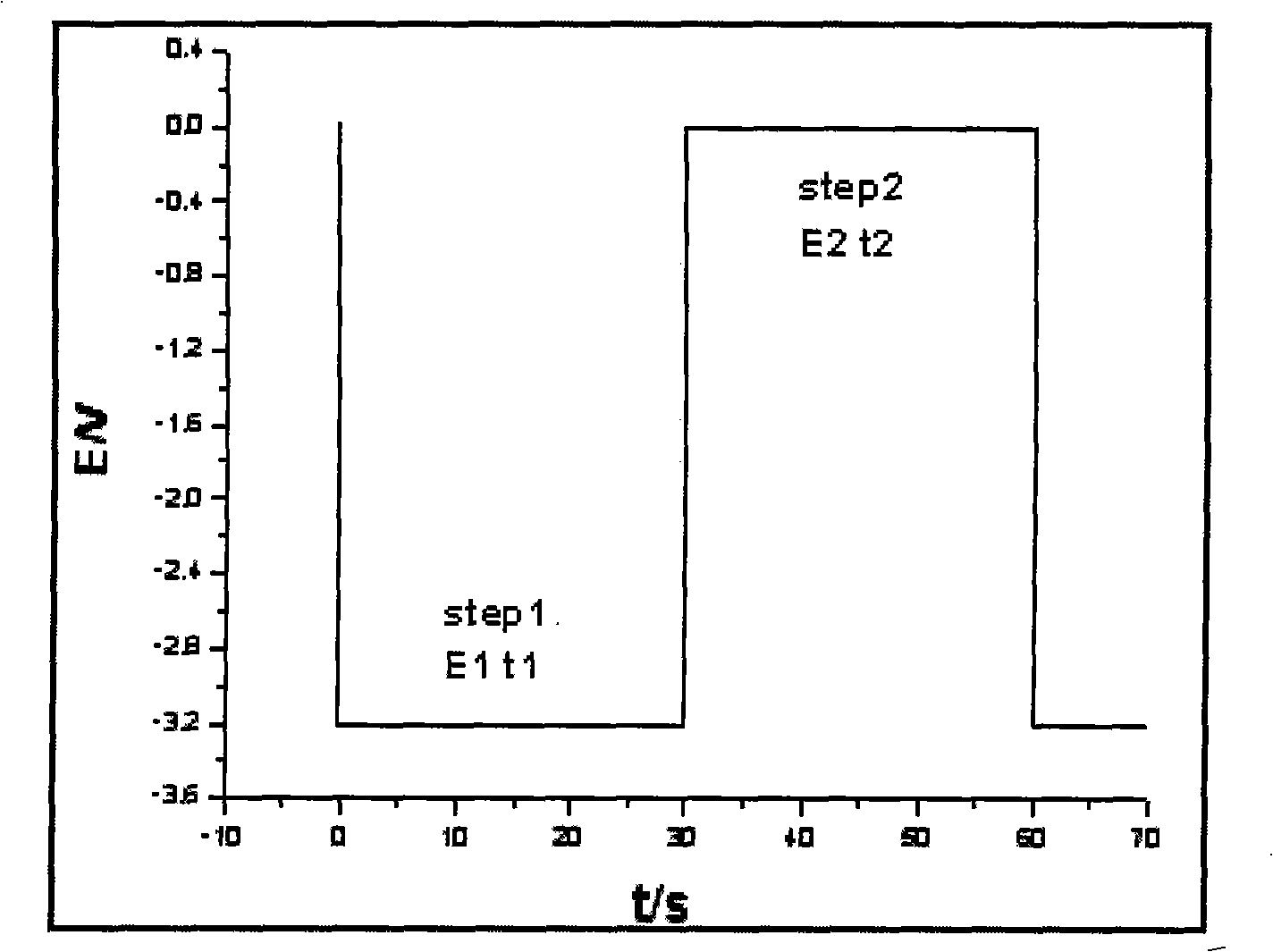

InactiveCN101302638AHigh bonding strengthImprove biological activityElectrolytic inorganic material coatingProsthesisMagnesium phosphateBiocompatibility Testing

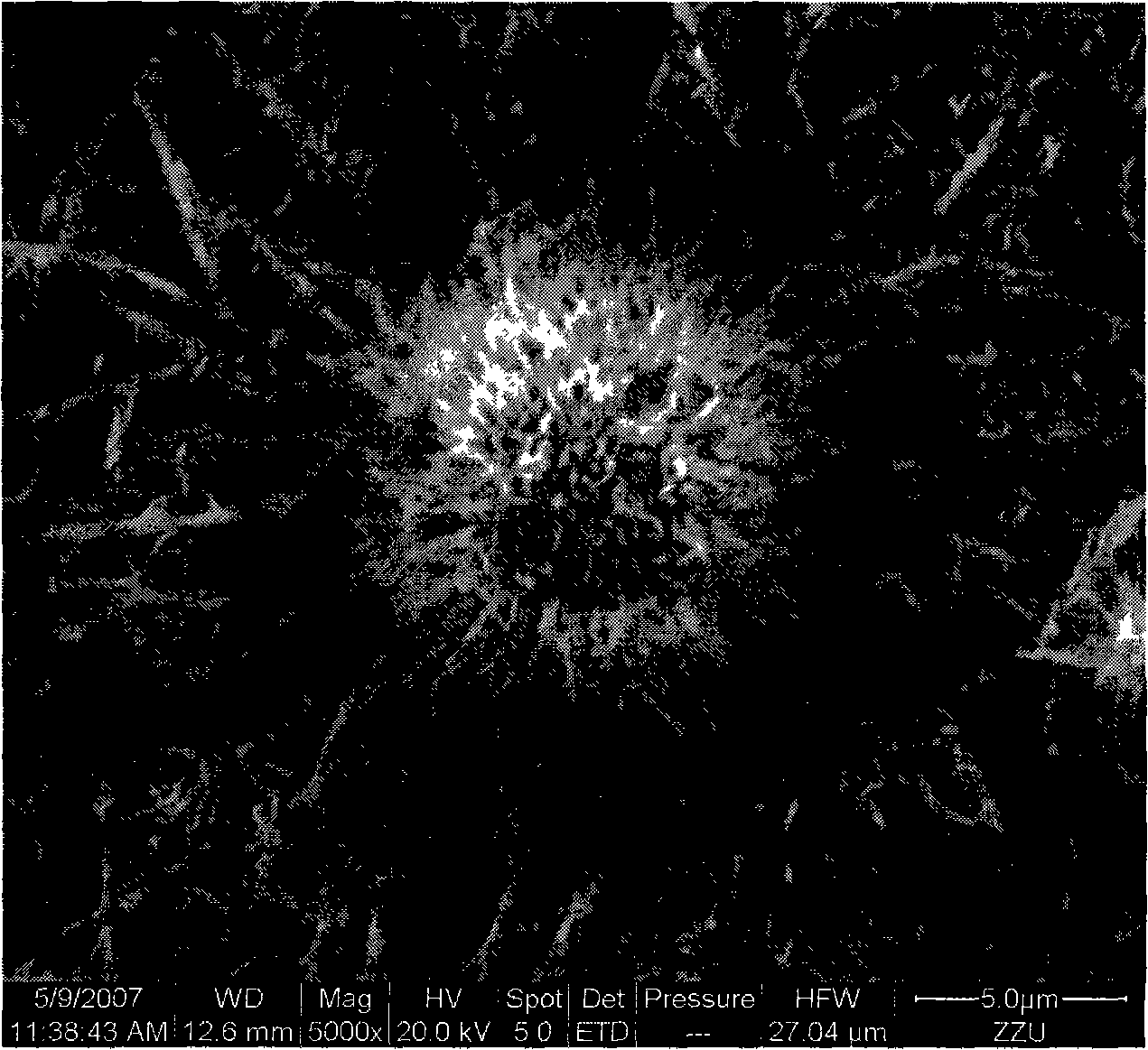

The invention provides a method for making a nano HAP coating / magnesium alloy composite biomaterial. The method is as follows: the method takes a magnesium alloy as a cathode and graphite as an anode; the magnesium alloy and the graphite are placed in electrolyte containing NH4H2PO4, NaHO3 and Ca(OH3)2.4H2O so as to carry out stepped electrodeposition at a temperature of between 60 and 95 DEG C and a voltage of between minus 5 V to minus 1 V and 0 V, thereby effectively improving the interface bonding between a coating and a matrix and reducing hydrogen evolution during electrodeposition; meanwhile, the increase of magnesium ions at an interface can realize in-situ doping of magnesium ions and hydroxyapatite so as to generate a magnesium phosphate transition layer on the surface of the magnesium alloy and to increase bonding strength; thus, a degradable nano acicular hydroxyapatite / magnesium alloy coating composite biomaterial with excellent mechanical property, biocompatibility and corrosion resistance can be obtained. Meanwhile, the method also has the advantages of low cost of raw materials and simple technological operation, etc.

Owner:ZHENGZHOU UNIV

Coated fertilizer for fruit trees and mfg. method

InactiveCN1834069AIncrease profitImprove productivitySuperphosphatesUrea compound fertilisersParaffin waxMagnesium phosphate

Owner:郑升杰

Sterilization soil-improvement slow-release composite fertilizer and preparation method thereof

InactiveCN105347916ASolve the problem of insoluble in waterHas a bactericidal effectFertilizer mixturesSlagCopper carbonate

The invention discloses sterilization soil-improvement slow-release composite fertilizer. The sterilization soil-improvement slow-release composite fertilizer comprises, by weight, 20-25 parts of urea, 10-15 parts of ammonium biphosphate, 10-20 parts of potassium phosphate, 5-10 parts of potassium sulfate, 8-12 parts of sodium silicate, 4-6 parts of magnesium phosphate, 7-9 parts of calcium chloride, 0.2-0.4 parts of zinc ammonium phosphate, 0.1-0.3 parts of copper carbonate, 0.1-0.2 parts of manganese ammonium phosphate, 0.4-0.6 parts of potassium borate, 0.3-0.5 parts of ferric sulfate, 0.2-0.4 parts of sodium molybdate, 20-25 parts of sodium alginate, 35-45 parts of a coating material, 5-10 parts of cassava slag, 5-8 parts of furfural slag, 10-20 parts of chicken manure, 5-10 parts of carbonized rice husk, 10-15 parts of humic acid, 10-15 parts of straws, 5-8 parts of plant ash, 0.2-0.5 parts of biological fungi, 4-6 parts of thermopsine and 3-5 parts of Artemisia argyi powder. The invention also discloses a preparation method of the sterilization soil-improvement slow-release composite fertilizer.

Owner:全椒县琪悦家庭农场

Sheet for whitening cosmetics and method for using the same

InactiveUS6458379B1Easy to storeEfficient use ofCosmetic preparationsBiocideVitamin CMagnesium phosphate

A sheet for whitening cosmetics comprises a sheet-like substrate and an adhesive layer which comprises a wet pressure-sensitive adhesive composition formed on the substrate. The whitening component includes vitamin C or its derivatives such as magnesium L-ascorbyl-2-phosphate, vitamin E nicotinate, kojic acid, hydroquinone, ellagic acid, albumin, galenical extracts, and rice bran extracts. Kojic acid and magnesium L-ascorbyl-2-phosphate are preferred. By contacting the adhesive layer with water and / or a hydrophilic medium such as alcohols, e.g., methanol, ethanol, etc., the wet pressure-sensitive adhesive composition exhibits excellent stickiness and excellent applicability to skin as well as excellent whitening effect with alleviating or eliminating stains, freckles, non-transparency, etc. on the skin.

Owner:NITTO DENKO CORP

Fire resistant water-based self-adhesion coating

The invention discloses a high-temperature resistance water-based self-adhering paint, which comprises the following parts: 10-80% main agent, which contains alkaline metal silicate from one of quaternary amine, tertiary amine and silicate of guanidine (23.5- 46.3% silicate or 67.8-83.9% phosphate); 26.8-45.1% solidifier, which concludes metal oxide, aluminium hydroxide, magnesium fluosilicate, magnesium borate, zinc borate, magnesium phosphate or potassium phosphate; 16.1-32.2% filler, which contains silica, alumina, mullite, boron nitride or mica.

Owner:BAOSHAN IRON & STEEL CO LTD

Double-layer enveloped slow/controlled release fertilizer and preparation method thereof

InactiveCN104860751AGuaranteed sustained release effectSustained release can be adjustedFertilizer mixturesMagnesium phosphatePhosphoric acid

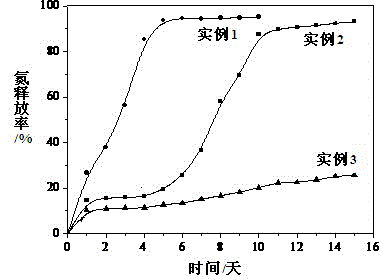

The invention discloses a double-layer enveloped slow / controlled release fertilizer and a preparation method thereof, belonging to the technical field of slow / controlled release fertilizer for agriculture. The key points of the technical scheme are that the double-layer enveloped slow / controlled release fertilizer is mainly made from the raw materials in parts by weight: 50-60 parts of urea, 20-40 parts of magnesium phosphate, 15-25 parts of starch-modified polyacrylic acid water-absorbent resin and 1-2 parts of rosin ethanol solution with the binder mass concentration of 10%, wherein the inner core of the double-layer enveloped slow / controlled release fertilizer is urea particles, the inner-layer envelope is magnesium phosphate, the outer-layer envelope is starch-modified polyacrylic acid water-absorbent resin. The invention also discloses a preparation method of the double-layer enveloped slow / controlled release fertilizer. As the double-layer envelope is adopted, the inner-layer envelope guarantees the slow-release property of the urea inner core, the outer-layer envelope after absorbing water can be swelled, the soil moisture can be kept while the slow-release property of the fertilizer is further adjusted, the irrigation period is prolonged, and dual-significance is obtained for increasing utilization rate of fertilizers and water in China.

Owner:HENAN NORMAL UNIV

High-early-strength magnesium phosphate concrete and preparation method thereof

InactiveCN101386518AQuickly restore functionalityFast setting and hardeningSolid waste managementMagnesium phosphateHazardous substance

The invention discloses a quick-hardening early strength magnesium phosphate concrete, which is mainly prepared from the following components in weight percentage: 12.7 to 30 percent of magnesia, 8.7 to 20 percent of phosphate, 1.2 to 15 percent of retarder, 10 to 25 percent of fine aggregate, 10 to 50 percent of water and the balance being water. The concrete material has the characteristics of quick coagulation and hardening, high early strength, good erosion resistance and the like, and can be widely applied to the quick repairing in projects or structures such as railways, airfields, bridges, harbors and docks and the quick solidification and closing of toxic and harmful substances, and can also be applied to the civil engineering and building construction under the sever conditions of sulfate erosion, marine corrosion, low temperature and the like. The invention has the advantages of simple preparation method, process and necessary equipment, low cost, no pungent ammonia gas generation in the construction and convenient popularization and application.

Owner:汪宏涛

Water-resistant magnesium phosphate cement and application thereof

InactiveCN104591570AReduce penetrationIncreased durabilityBuilding constructionsOrganic fertilisersIronstoneMagnesium phosphate

The invention provides water-resistant magnesium phosphate cement. The water-resistant magnesium phosphate cement comprises the following components: dead burned magnesia, phosphate and mineral waste residues, wherein the molar ratio of magnesium element in the dead burned magnesia to phosphorus element in the phosphate is (4-5):1; the content of the mineral waste residues by mass is 10-30% of the total mass of the magnesium phosphate cement; the mineral waste residues are residues of iron ores obtained after mineral separation and smelting; the water-resistant magnesium phosphate cement provided by the invention not only can improve the early strength but also can maintain the strength for a long time, the permeability is reduced and the water resistance is improved, thereby providing favorable conditions for the improvement of the endurance of the magnesium phosphate cement.

Owner:ZHEJIANG UNIV OF TECH

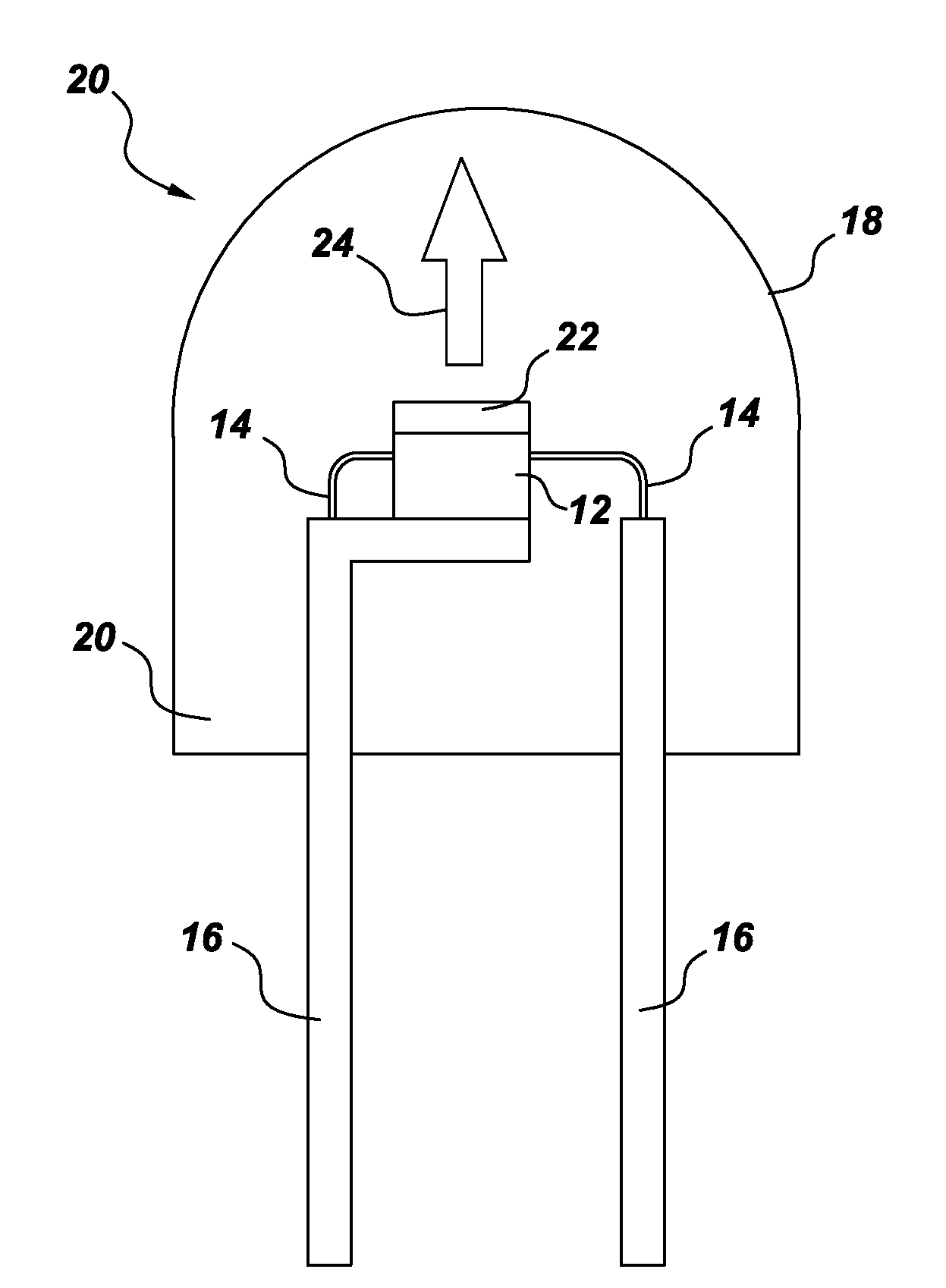

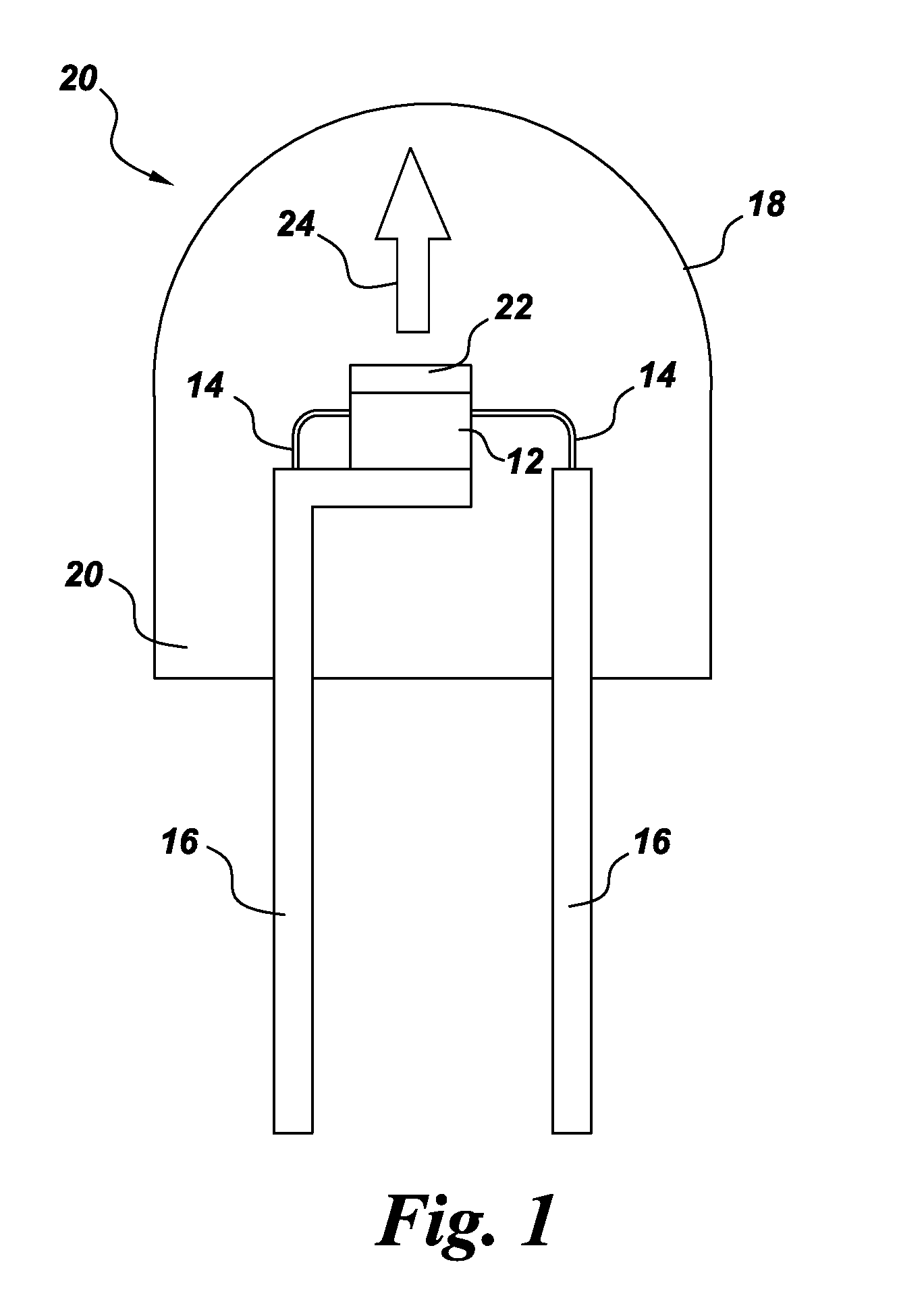

Color stable phosphors

ActiveUS20110279011A1Discharge tube luminescnet screensLamp detailsZinc hydroxideMagnesium phosphate

An LED lamp includes a light source configured to emit radiation with a peak intensity at a wavelength between about 250 nm and about 550 nm; and a phosphor composition configured to be radiationally coupled to the light source. The phosphor composition includes particles of a phosphor of formula I, said particles having a coating composition disposed on surfaces thereof;((Sr1−zMz)1−(x+w)AwCex)3(Al1−ySiy)O4+y+3(x−w)F1−y−3(x−w) Iwherein the coating composition comprises a material selected from aluminum oxide, magnesium oxide, calcium oxide, barium oxide, strontium oxide, zinc oxide, aluminum hydroxide, magnesium hydroxide, calcium hydroxide, barium hydroxide, strontium hydroxide, zinc hydroxide, aluminum phosphate, magnesium phosphate, calcium phosphate, barium phosphate, strontium phosphate, and combinations thereof; andA is Li, Na, K, or Rb, or a combination thereof;M is Ca, Ba, Mg, Zn, or a combination thereof; and0<x≦0.10, 0≦y≦0.5, 0≦z≦0.5, 0≦x≦x.

Owner:GE LIGHTING SOLUTIONS LLC

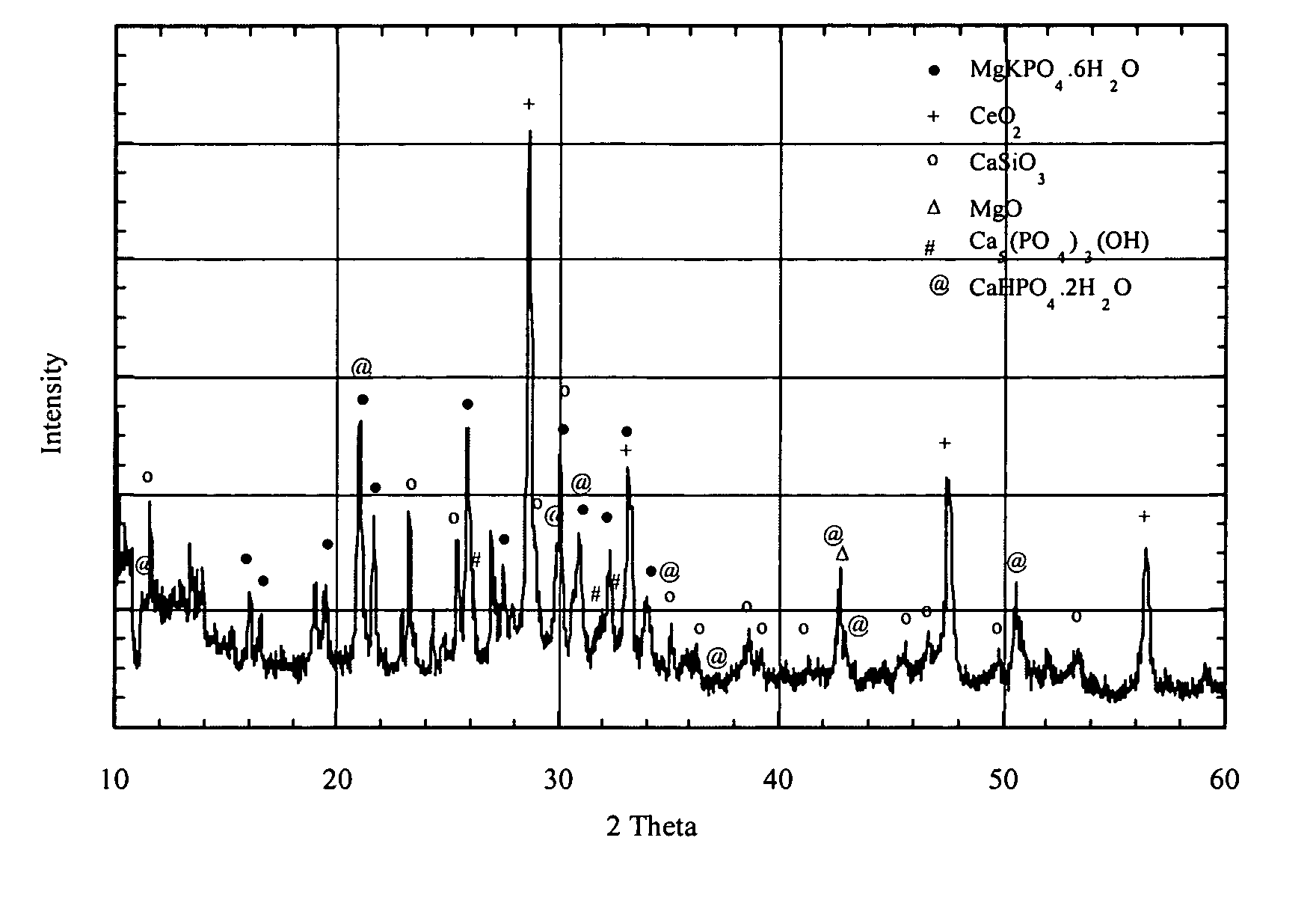

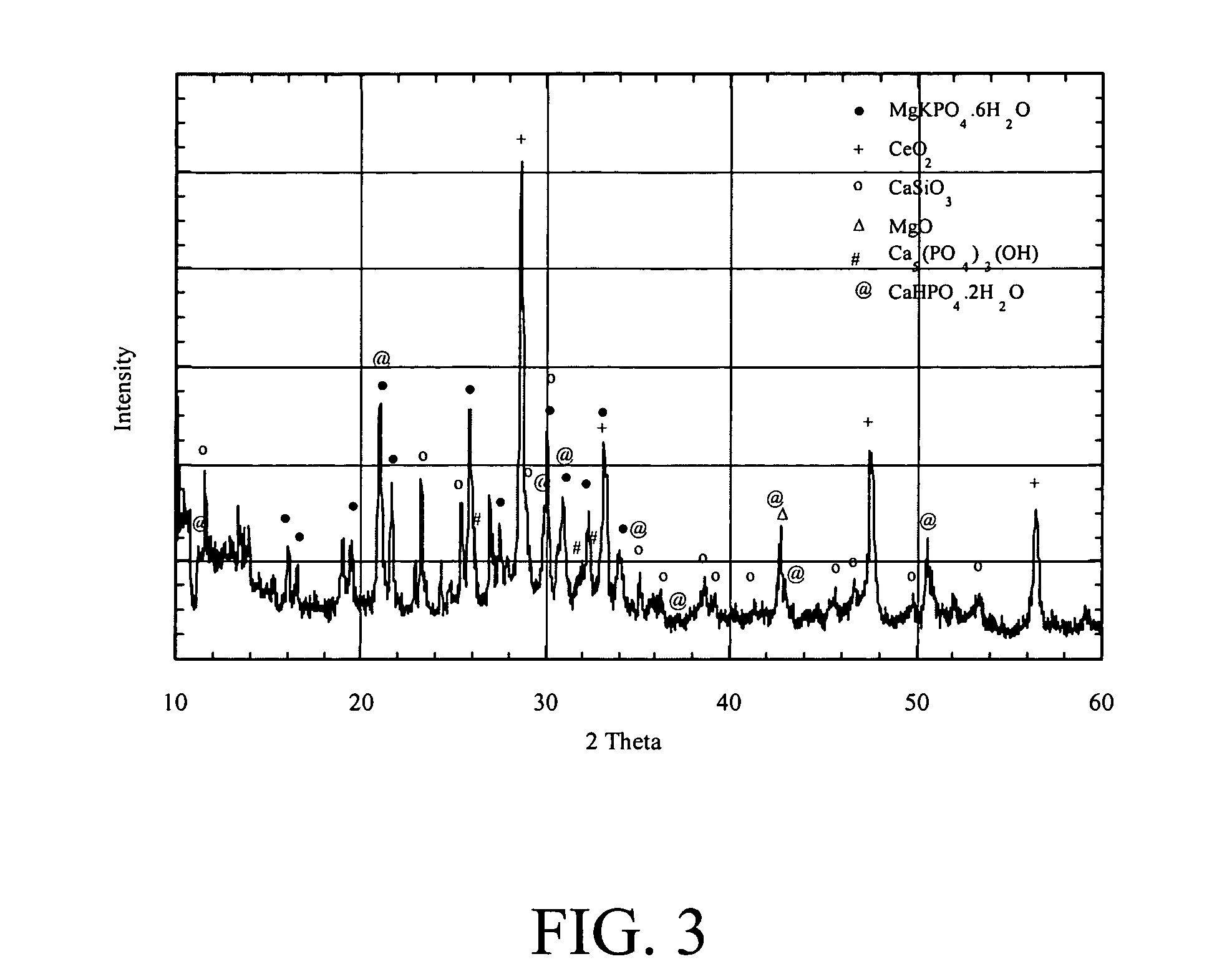

Method and product for phosphosilicate slurry for use in dentistry and related bone cements

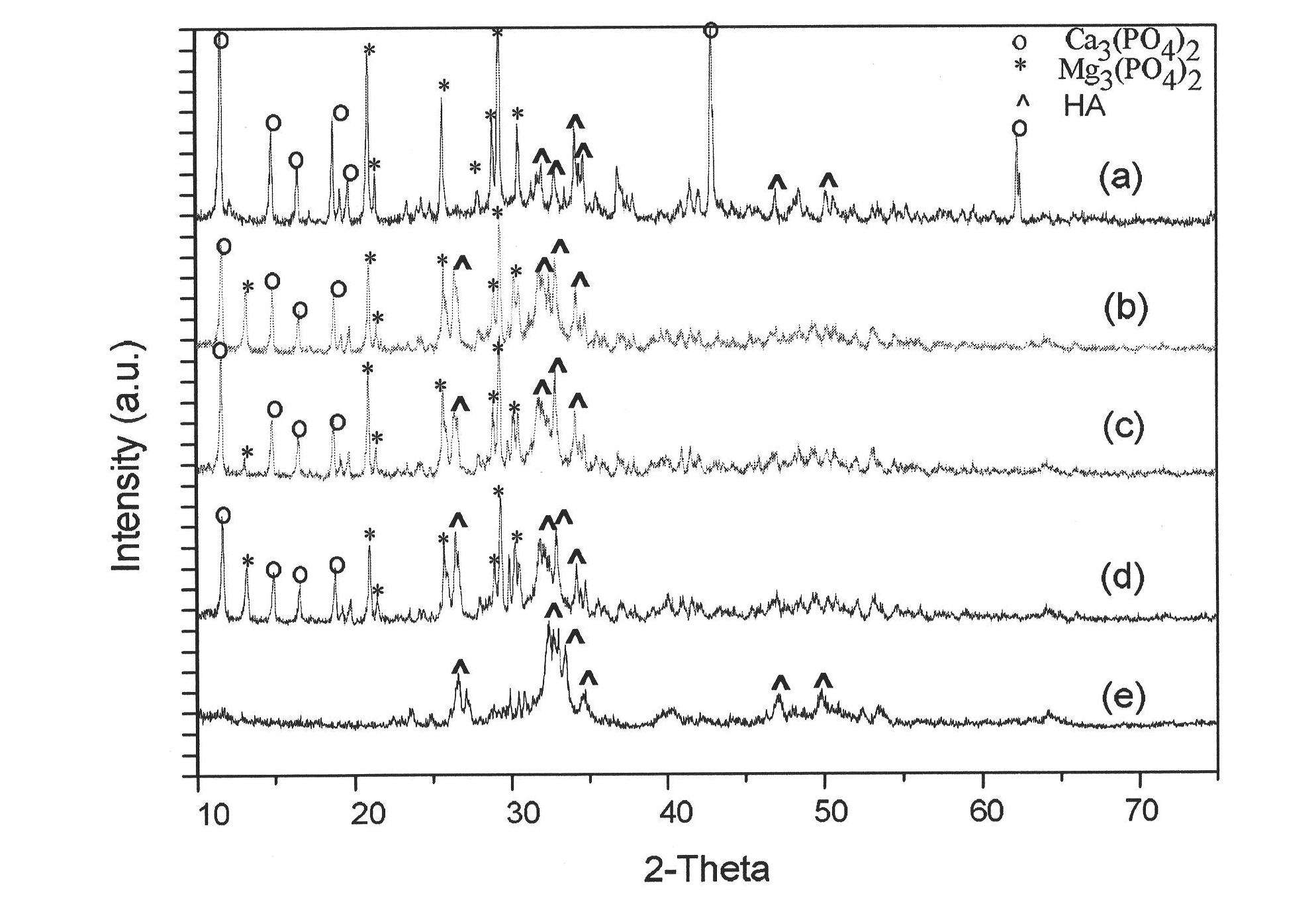

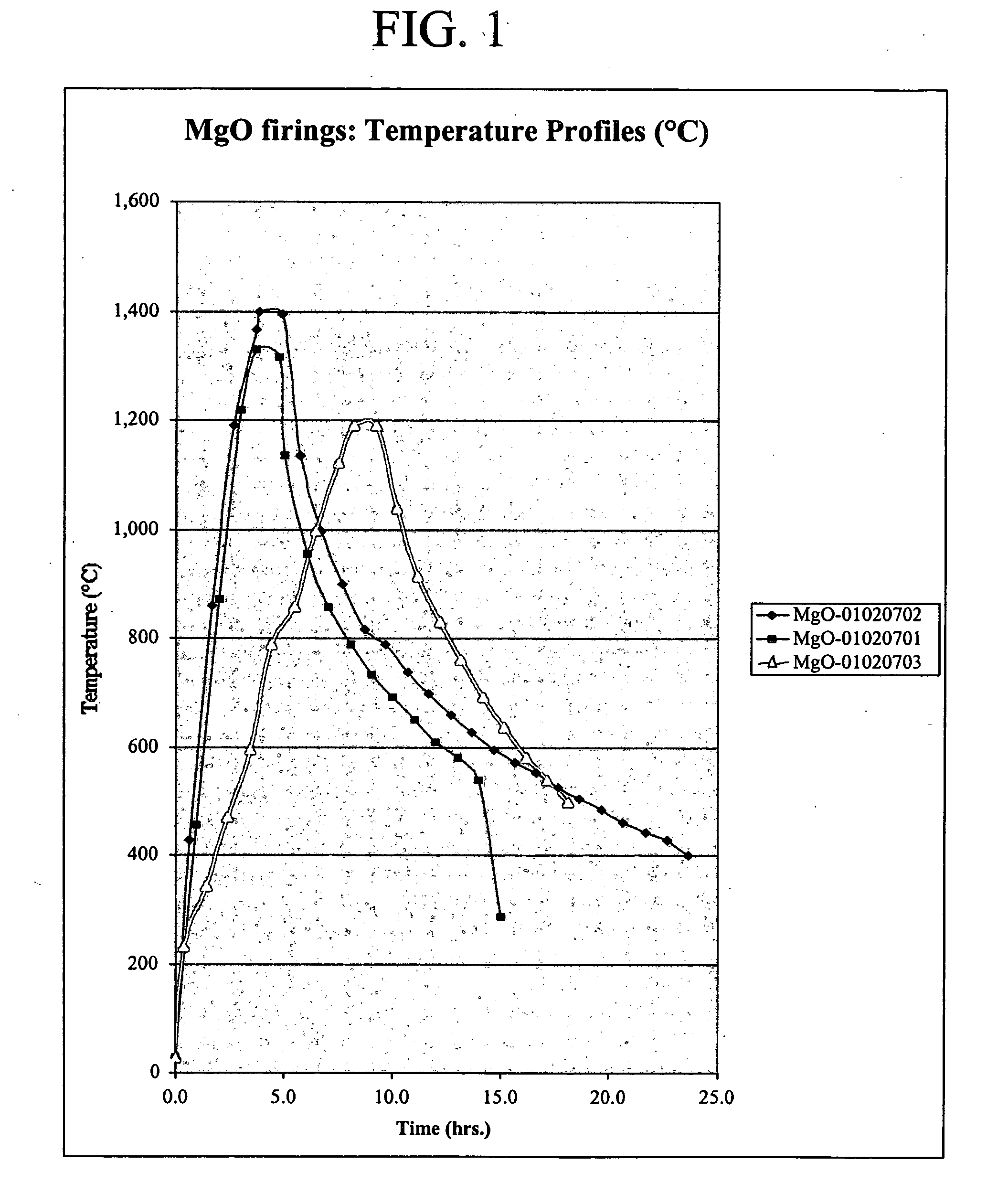

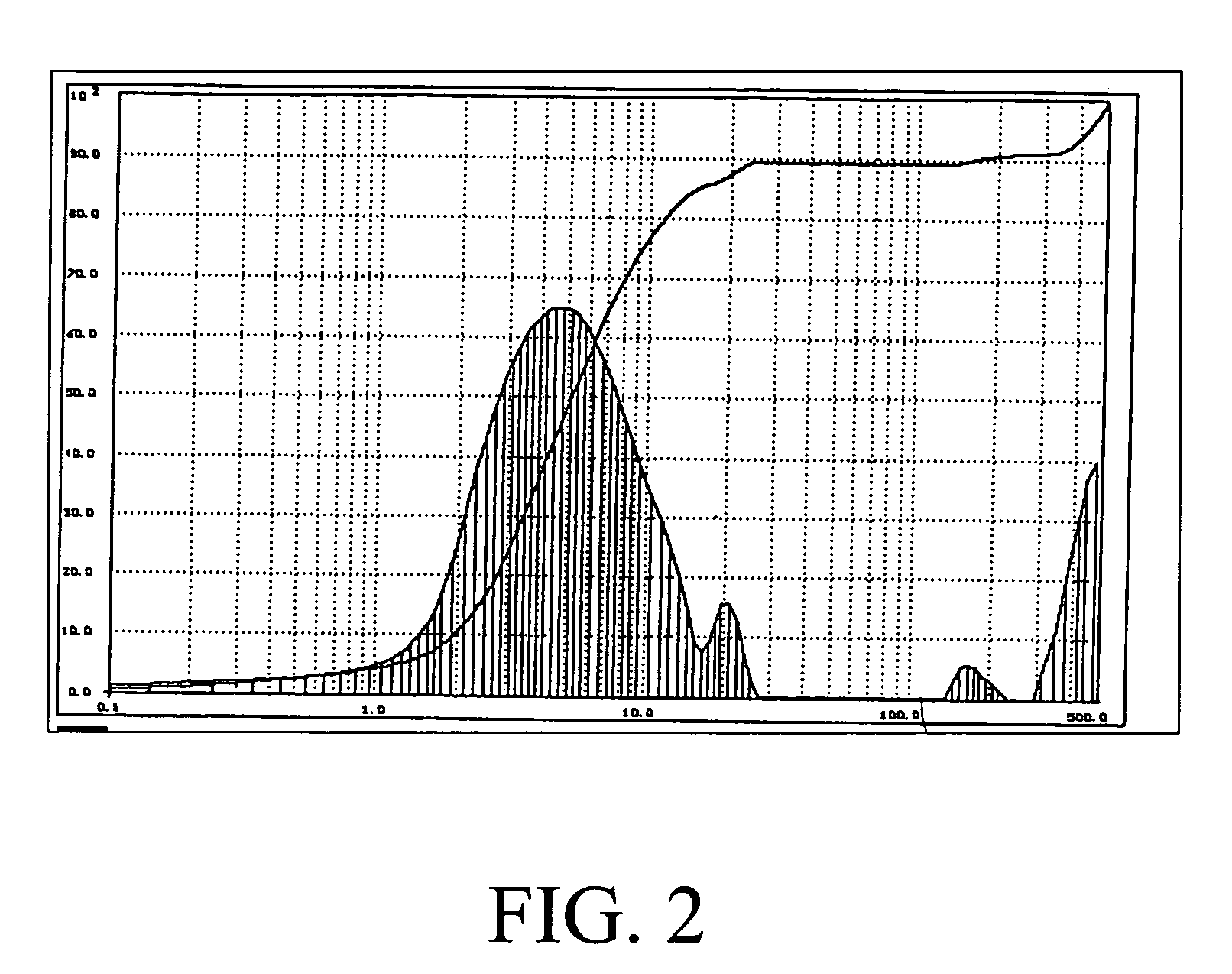

The present invention is directed to magnesium phosphate ceramics and their methods of manufacture. The composition of the invention is produced by combining a mixture of a substantially dry powder component with a liquid component. The substantially dry powder component comprises a sparsely soluble oxide powder, an alkali metal phosphate powder, a sparsely soluble silicate powder, with the balance of the substantially dry powder component comprising at least one powder selected from the group consisting of bioactive powders, biocompatible powders, fluorescent powders, fluoride releasing powders, and radiopaque powders. The liquid component comprises a pH modifying agent, a monovalent alkali metal phosphate in aqueous solution, the balance of the liquid component being water. The use of calcined magnesium oxide as the oxide powder and hydroxylapatite as the bioactive powder produces a self-setting ceramic that is particularly suited for use in dental and orthopedic applications.

Owner:UCHICAGO ARGONNE LLC +1

Method for recycling magnesium from middle-low grade high-magnesium phosphate rock

The invention discloses a method for recycling magnesium from middle-low grade high-magnesium phosphate rock, which is used for pretreating phosphate rock serving as a raw material and recycling magnesium during wet phosphoric acid production. The method comprises the following steps of: removing magnesium from the middle-low grade high-magnesium phosphate rock with a magnesium removing agent by using a chemical method and dissolving most magnesium in the phosphate rock out of phosphate rock pulp; after a magnesium removing reaction is finished, performing solid-liquid separation on the formed pulp, wherein an obtained solid filter cake is magnesium-removed phosphate concentrate which can be put into the wet production of phosphoric acid; putting filtrate serving as magnesium-removed pulp into a next precipitation reaction procedure, adding an appropriate amount of neutralizing precipitant to adjust the pH value to 7.5-9.0 and undergoing a precipitation reaction; and performing solid-liquid separation after the reaction, and drying the solid precipitate which is ammonium magnesium phosphate with air stream to obtain a finished ammonium magnesium phosphate slow-release fertilizer. The obtained filtrate (containing ammonium sulfate) can be returned to wet phosphoric acid production.

Owner:中化重庆涪陵化工有限公司

Method of treating magnesium oxysulfate or magnesium oxychloride article with water soluble phosphate solution

This application relates to a treating method for magnesium oxysulfate cement (MOS) or magnesium oxychloride cement (MOC) articles. The MOS or MOC article is molded, cured and dried, then the article is treated in water soluble phosphate solution for periods of 0.5 to 90 minutes. When the MOS or MOC article is treated in water soluble phosphate solution, phosphate can penetrate into MOS or MOC article, react with the non-active magnesia remaining in MOS or MOC article to form magnesium phosphate cement (MPC). After such treatment, MOS or MOC phase is bonded by magnesium phosphate cement (MPC), many defects for MOS or MOC article, such as cracks, distortion, chalking, effloresce, poor durability, and so on, can be reduced or eliminated.

Owner:KONG XIANGHUA

Magnesium phosphate cement foamed lightweight wall building block

InactiveCN102344277AImprove stabilityReduce weightBuilding componentsCeramicwareMagnesium orthophosphateMagnesium phosphate

The invention provides a magnesium phosphate cement foamed lightweight wall building block. The building block comprises components of, by weight: 1 part of magnesium oxide, 0.4 to 0.6 parts of magnesium sulfate, 0.3 to 1 part of fly ash or other industrial slag, and 0.2 to 2 parts of ammonium dihydrogen phosphate. According to the invention, magnesium oxide and ammonium dihydrogen phosphate are added into a container; water is added into the container, and the materials are stirred; magnesium sulfate is added into the container, and the solution is regulated to 15-30 Baume degree; fly ash or other slag is added into the container, and the mixture is well mixed; the slurry is poured into a building block mold, foamed, demolded, and cured, such that the building block is produced. With long-term tests, the building block provided by the invention is stable in a long term, and does not scumming. During the production process, air gaps are formed by the foaming agent, such that the weight of the building block is reduced, and better acoustic insulation and thermal insulation effects are provided.

Owner:卞智铨

Alkali metal magnesium phosphate hydrate buffering feed mineral

InactiveUS6451361B1Improve buffering effectAnimal feeding stuffAccessory food factorsMagnesium phosphateMagnesium orthophosphate

A bioavailable water soluble animal feed mineral composition which provides buffering of animal digestive fluids to near-neutral pH comprising an alkali metal magnesium phosphate hydrate providing a total of between 1.5 and 4.7 equivalent weights of alkali metal and magnesium per molecule of phosphorus. Water of hydration amounting to between 6 and 12 percent is required for effectiveness. An effective composition, Na2Mg(PO4) 0.8 H2O, is prepared by stepwise reaction of sodium carbonate and magnesium oxide with orthophosphoric acid in a rotating pan equipped for high intensity mixing.

Owner:AGRINUTRIENTS TECH GRP INC

Calcium magnesium injectable bone cement and preparation method and application thereof

The invention discloses a product used for forming calcium magnesium injectable bone cement, comprising solid phase powder obtained by uniformly mixing composite phosphoric acid calcium salt and magnesium phosphate powder as well as curing solution obtained by dissolving dextrin and hydrophosphate in water. The invention also discloses a calcium magnesium injectable bone cement and preparation method and application thereof. The curing solution and solid phase powder in the product are uniformly mixed and blended into paste, thus obtaining water phase high efficiency scattering-resistant rapid curing bone cement capable of being injected with calcium magnesium and injectable product used for preparing bone tissue wound repairing. The invention is low in cost of raw materials, preparation method is simple, the obtained calcium magnesium injectable bone cement has strong scattering-resistance and rapid curing speed.

Owner:EAST CHINA UNIV OF SCI & TECH

Rapid repair material based on building broken stones and preparation method thereof

The invention relates to building stone repairing. A rapid repair material based on building broken stones comprises a gelation mixture which quickly solidifies with water, wherein the gelation mixture comprises the following components in parts by weight: 40-55 parts of magnesium phosphate cement, 40-50 parts of sand and 10-15 parts of silica sol. A preparation method of the materials comprises the following steps of: 1, preparing the magnesium phosphate cement; 2, mixing the magnesium phosphate cement, the sand and the silica sol so as to form the gelation mixture which comprises the following components in parts by weight: 40-55 parts of magnesium phosphate cement, 40-50 parts of sand and 10-15 parts of silica sol. The gelation mixture can be quickly solidified with the water to repair the stones. In addition, the gelation mixture is gelatineous before being solidified and facilitates construction; after the solidification, the small solidification shrinkage rate and a durable effect are obtained; and the repair material has high hardness and good water resistance after the solidification.

Owner:SHANGHAI JIANWEI CULTURAL HERITAGE CONSERVATION TECH CO LTD

Method and product for phosphosilicate slurry for use in dentistry and related bone cements

ActiveUS20050028705A1Strong and long-lasting bondHigh strengthBiocideImpression capsMagnesium phosphateApatite

The present invention is directed to magnesium phosphate ceramics and their methods of manufacture. The composition of the invention is produced by combining a mixture of a substantially dry powder component with a liquid component. The substantially dry powder component comprises a sparsely soluble oxide powder, an alkali metal phosphate powder, a sparsely soluble silicate powder, with the balance of the substantially dry powder component comprising at least one powder selected from the group consisting of bioactive powders, biocompatible powders, fluorescent powders, fluoride releasing powders, and radiopaque powders. The liquid component comprises a pH modifying agent, a monovalent alkali metal phosphate in aqueous solution, the balance of the liquid component being water. The use of calcined magnesium oxide as the oxide powder and hydroxylapatite as the bioactive powder produces a self-setting ceramic that is particularly suited for use in dental and orthopedic applications.

Owner:UCHICAGO ARGONNE LLC +1

Magnesium phosphate cement grout material

InactiveCN102643073AImprove volume stabilityEarly hardening fastSolid waste managementMagnesium phosphateNegative temperature

The invention discloses a magnesium phosphate cement grout material, which belongs to the technical field of building materials. The magnesium phosphate cement grout material is prepared through the following components, parts by weight, 100 parts of phosphate, 100-400 parts of metal oxide, 5-150 parts of coal ash, 5-150 parts of grounded slag, 10-100 parts of thickening time control agent and 26-300 parts of water. According to the proportion, the metal oxide, the phosphate, the thickening time control agent, the coal ash and the grounded slag are mixed evenly and placed in a blender, water is added and the mixture is stirred evenly, and the magnesium phosphate cement grout material is obtained. The grout material has the advantages of being good in volume stability, large in flowing degree, indehiscent, high in early-stage strength, capable of constructing under the negative temperature and the like.

Owner:HOHAI UNIV

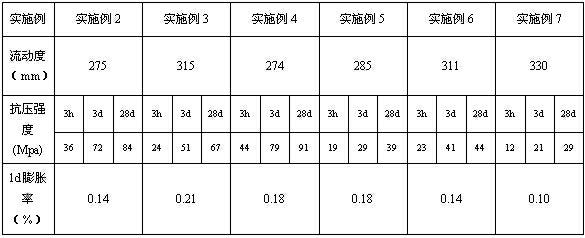

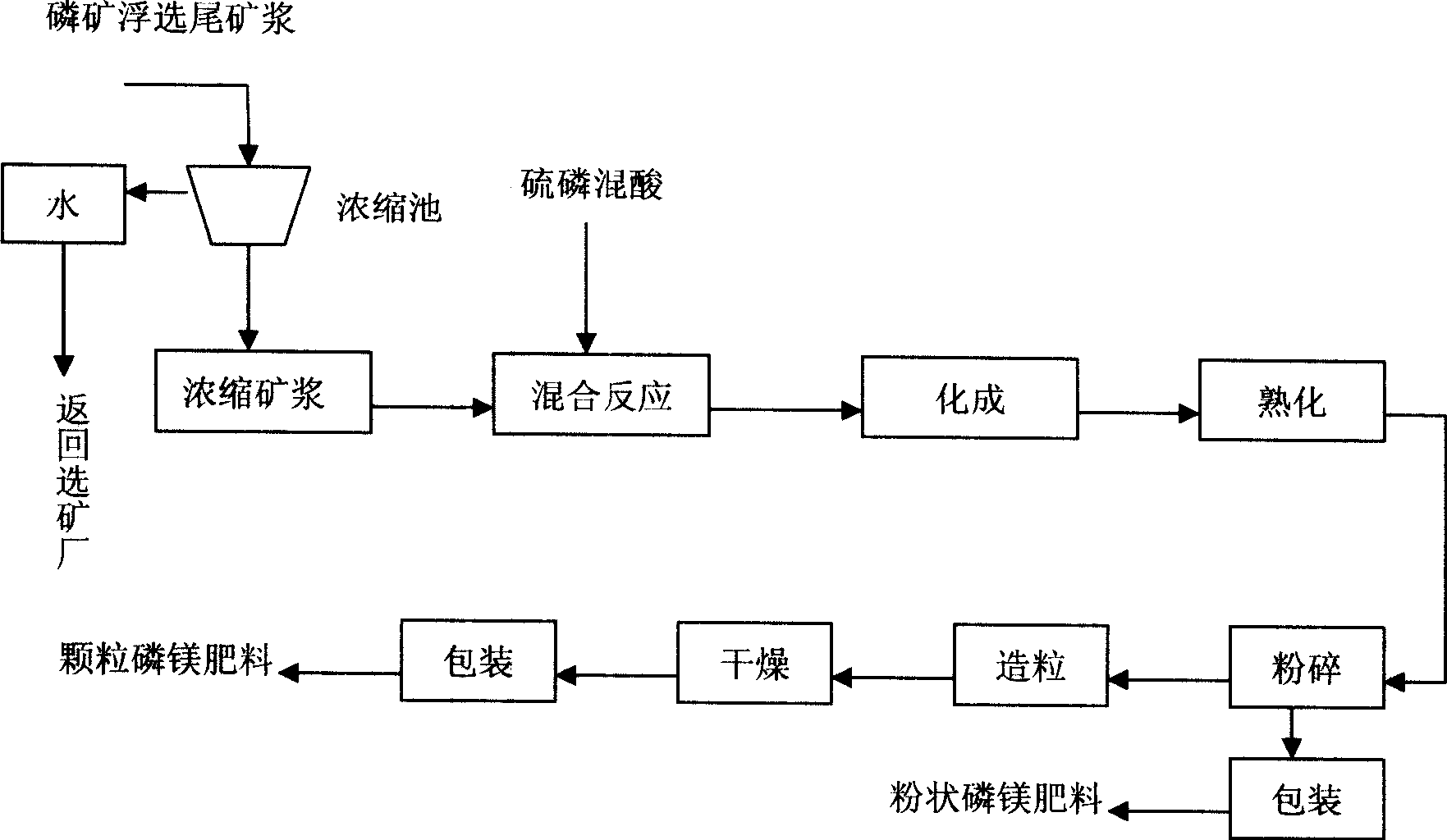

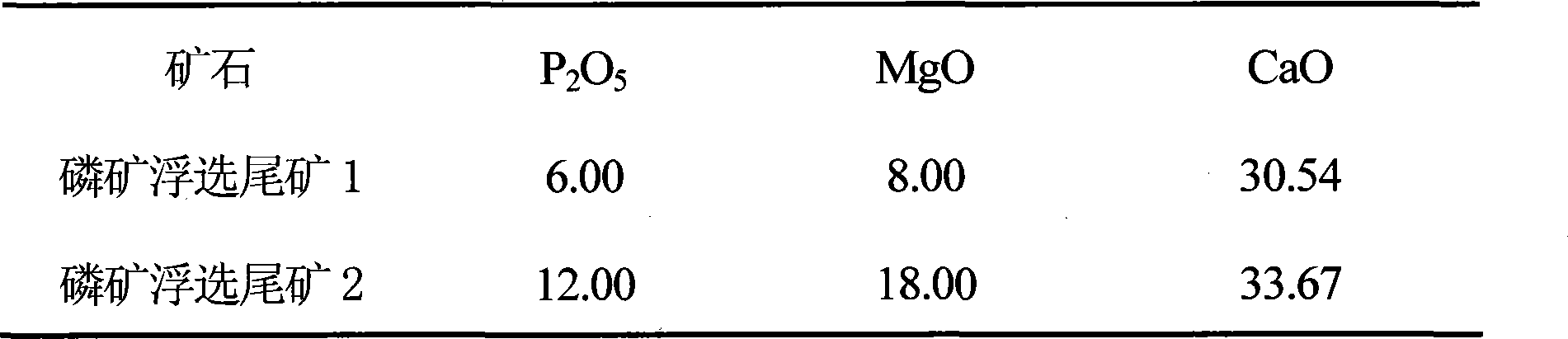

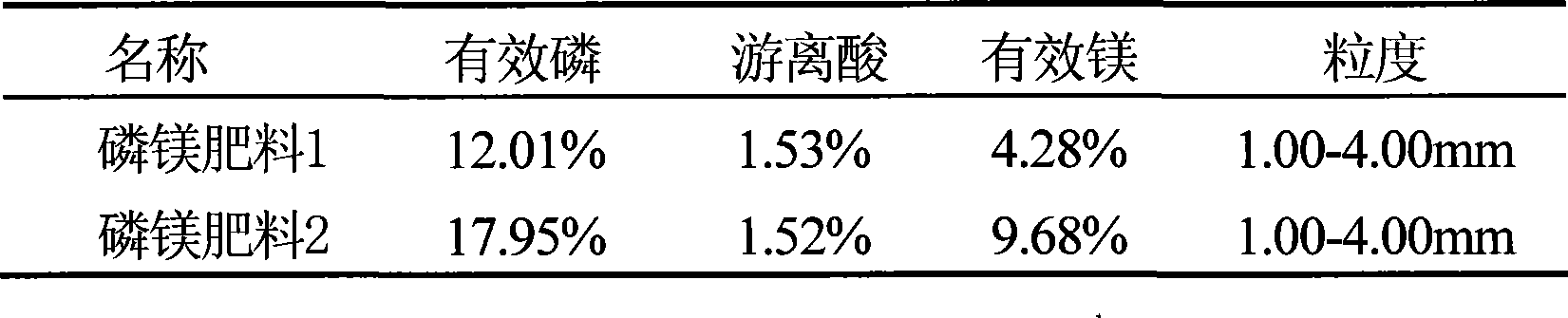

Method for directly preparing phosphor magnesium fertilizer with by-product mine tailing of phosphorus ore floatation

The invention relates to a preparation method of magnesium phosphate fertilizer, in particular to a method which takes phosphate flotation byproduct tailings in medium low-grade as raw materials to prepare industrial-grade magnesium phosphate fertilizer, and belongs to the field of chemical technology. The preparation method is characterized in that the preparation method comprises the following steps: first: taking flotation phosphate tailing slurry as the raw material, controlling the liquid water content to be between 40 percent and 45 percent; second: leading the tailing slurry in step (1) to a mixed reactor, starting a mixer, and controlling the rotate speed to be 400 r / min to 500 r / min; third: adding parathion mixed acid with a certain molar ratio into the reaction in the mixed reactor in step (2), carrying out chemical reaction when the mixed reactor warms up to a certain temperature, reaches a certain mixed reaction time and goes into a chemical chamber; fourth: delivering fresh magnesium phosphate fertilizer obtained from step (3) into a ripening warehouse for ripening; fifth: smashing the magnesium phosphate fertilizer obtained from step (4) to be directly packed to obtain power-shaped magnesium phosphate fertilizer products; sixth: smashing and delivering the magnesium phosphate fertilizer obtained from step (4) to a back pelletizer for pelleting to make grain-shaped magnesium phosphate fertilizer products.

Owner:YUNNAN CHEM RES INST

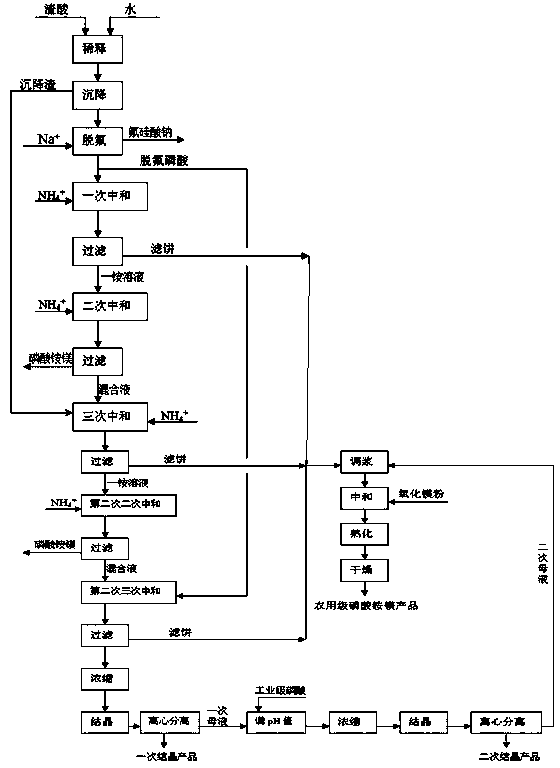

Method for producing monoammonium phosphate and magnesium ammonium phosphate by using wet concentrated phosphoric acid residues

ActiveCN104058378AReduce solid particlesEffective liquid-solid separationPhosphatesMagnesium phosphatePhosphoric acid

The invention provides a method for producing monoammonium phosphate and magnesium ammonium phosphate by using wet concentrated phosphoric acid residues. According to the method, concentrated phosphoric acid residues are adopted as raw materials and sodium fluorosilicate, industrial monoammonium phosphate and magnesium ammonium phosphate are respectively obtained through the processes of dilution and sedimentation, defluorination, fractional multistep neutralization, concentration and crystallization, primary mother liquor pH value adjustment, size mixing of filter cake and secondary mother liquor, magnesia powder neutralization and the like. The method is little in equipment investment, low in production cost and good in product quality and has the advantages that the problem that acid residues of ammonium phosphate plants can be only used for producing low value-added products is solved and the low-cost industrial monoammonium phosphate slow release fertilizer magnesium ammonium phosphate with high quality and inexpensive can be obtained.

Owner:昆明隆祥化工有限公司

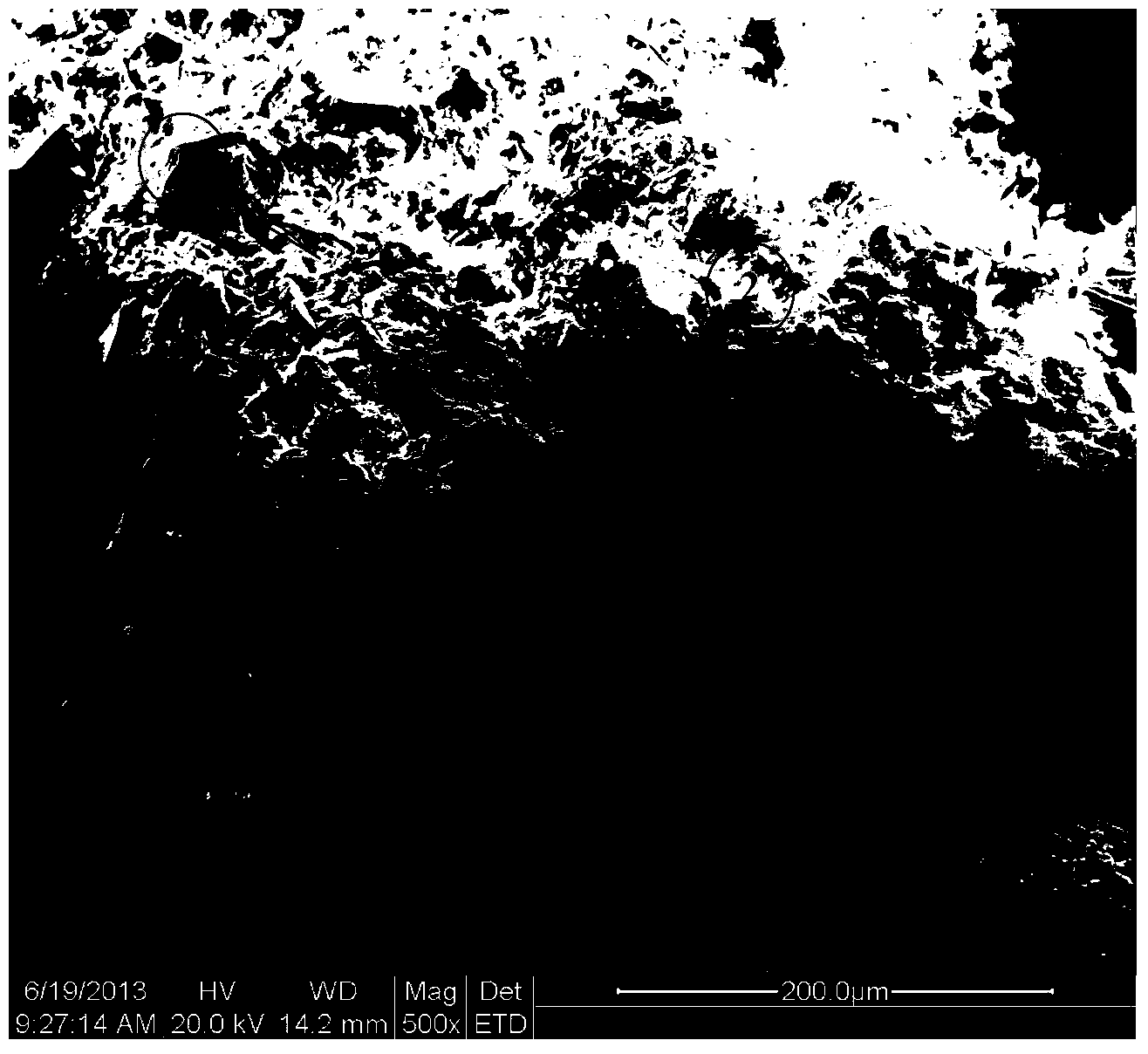

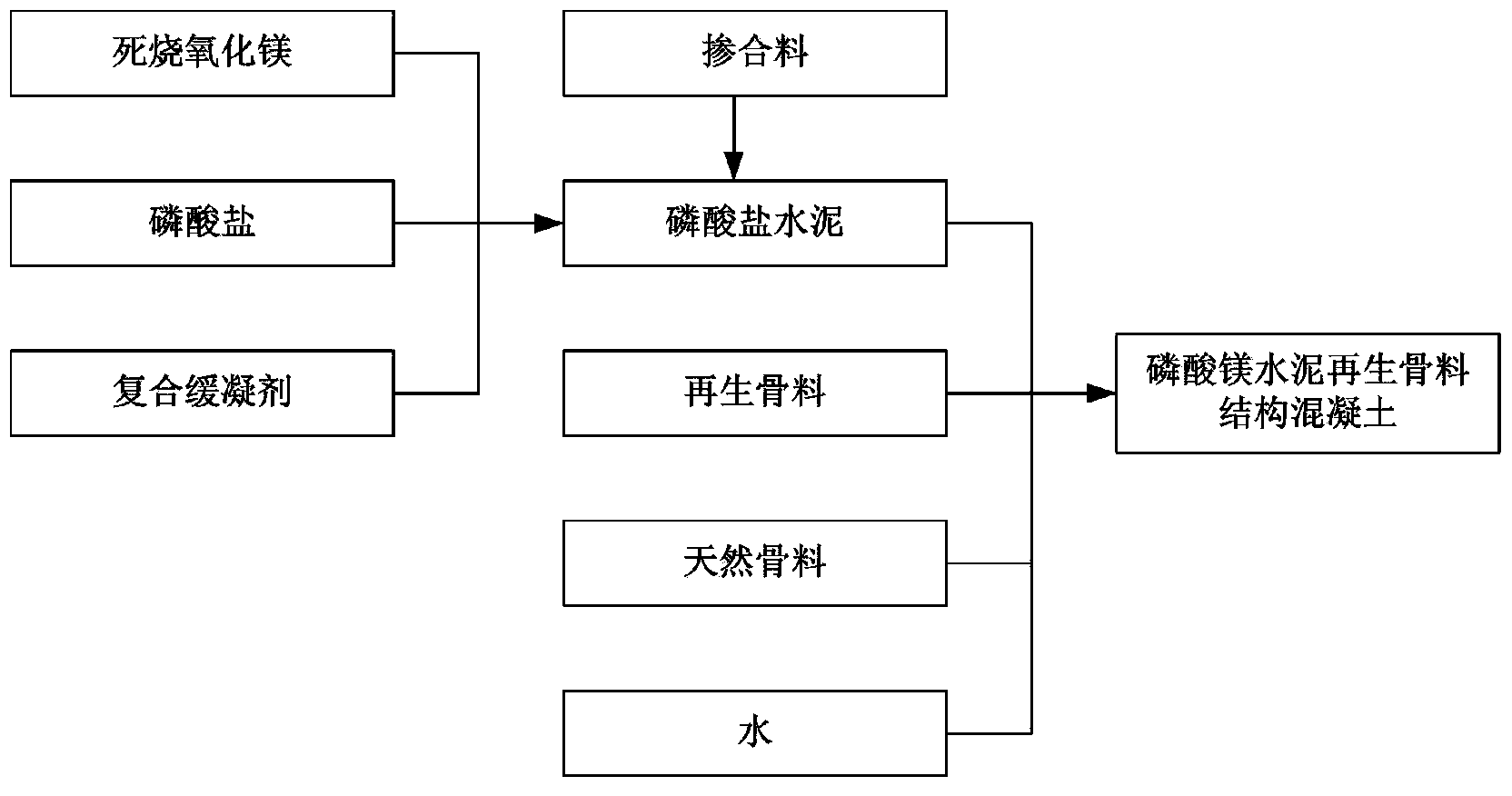

Magnesium phosphate cement recycled aggregate structure concrete and preparation method thereof

InactiveCN104072091AEarly hardening fastHigh strengthSolid waste managementAggregate (composite)Magnesium phosphate

The invention discloses magnesium phosphate cement recycled aggregate structure concrete and a preparation method thereof. The magnesium phosphate cement recycled aggregate structure concrete comprises the following components by weight percent: 12-30% of magnesium oxide, 8-20% of phosphate, 2-10% of composite retarder, 5-15% of admixture, 5-20% of recycled fine aggregate, 5-30% of recycled coarse aggregate, 0-10% of natural fine aggregate, 0-15% of natural coarse aggregate, and the balance being water. High early strength, small shrinkage rate, strong adhesive property and good corrosion resistance of the concrete are ensured by the magnesium phosphate cement; stable growth of the strength of the concrete is ensured by the admixture, and the durability and the volume stability are improved. The magnesium phosphate cement recycled aggregate structure concrete has the beneficial effects that the concrete material is applicable to the structure concrete and high-performance recycled aggregate concrete, can be applied to civil engineering in bad environments such as sulphate attack, marine corrosion, high-temperature environment and low-temperature environment, efficient utilization of the waste concrete is achieved, mining of natural gravel is reduced, the construction cost is reduced, and the targets of recycling wastes and protecting environment are achieved.

Owner:YANCHENG INST OF TECH

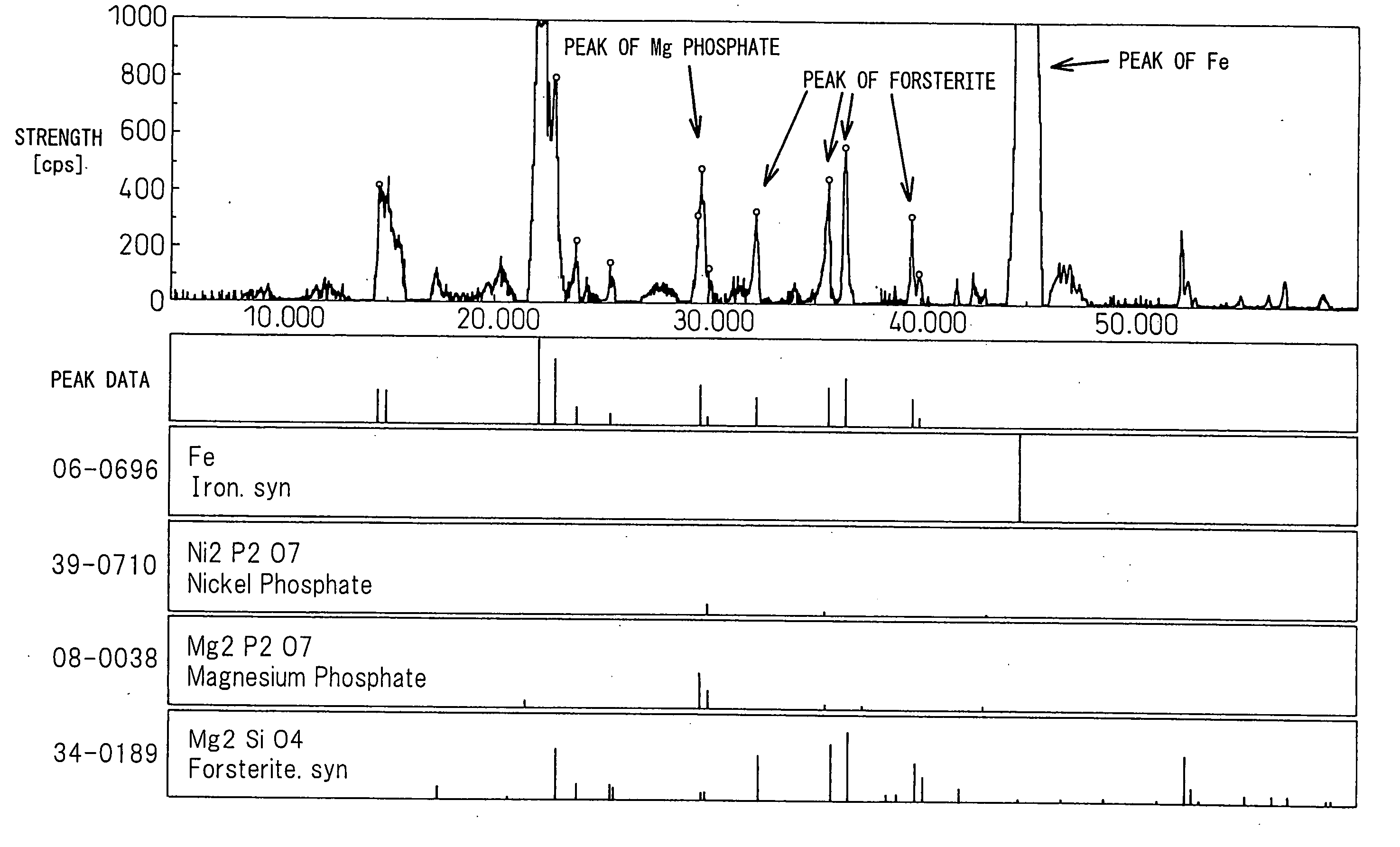

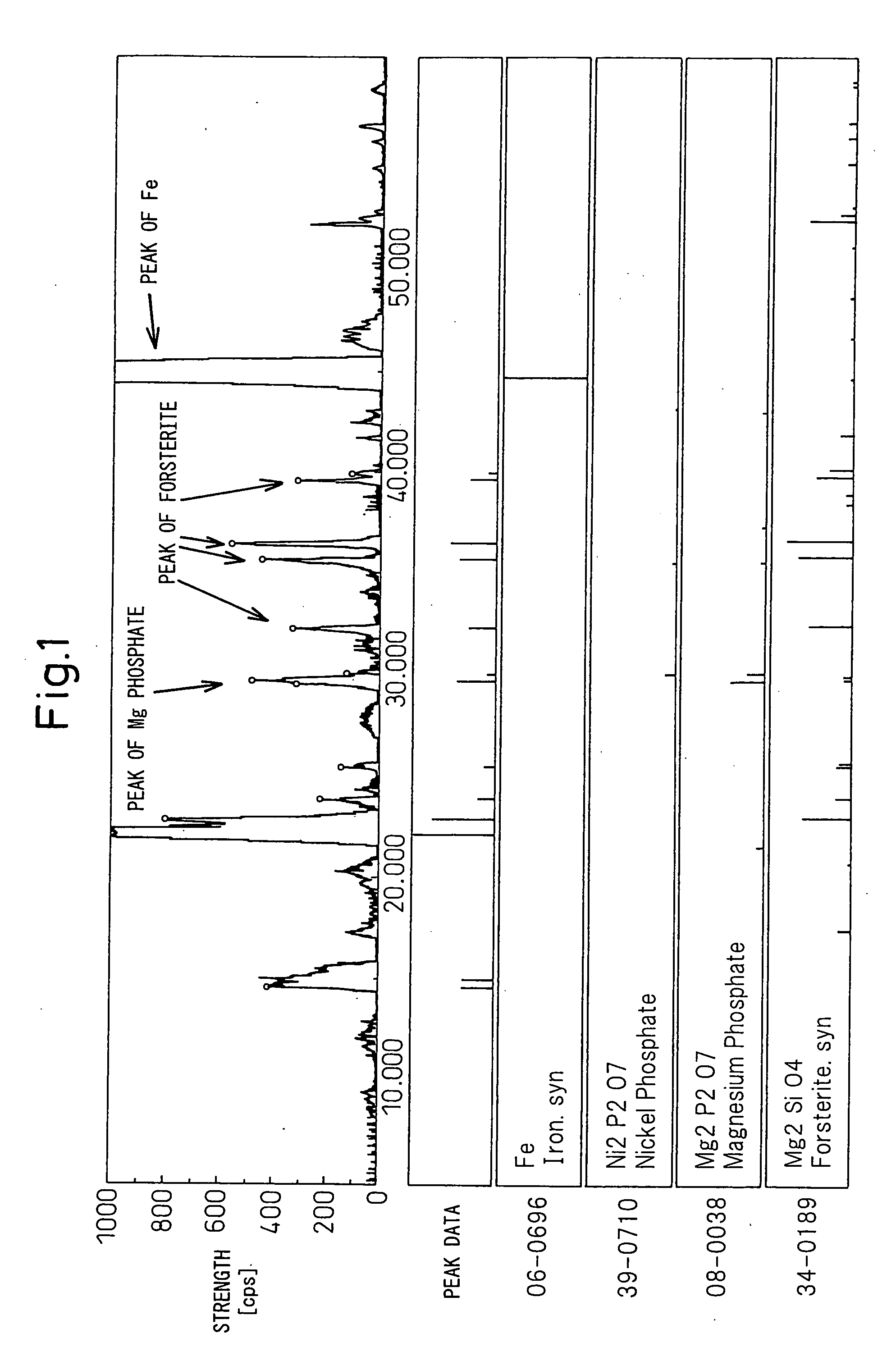

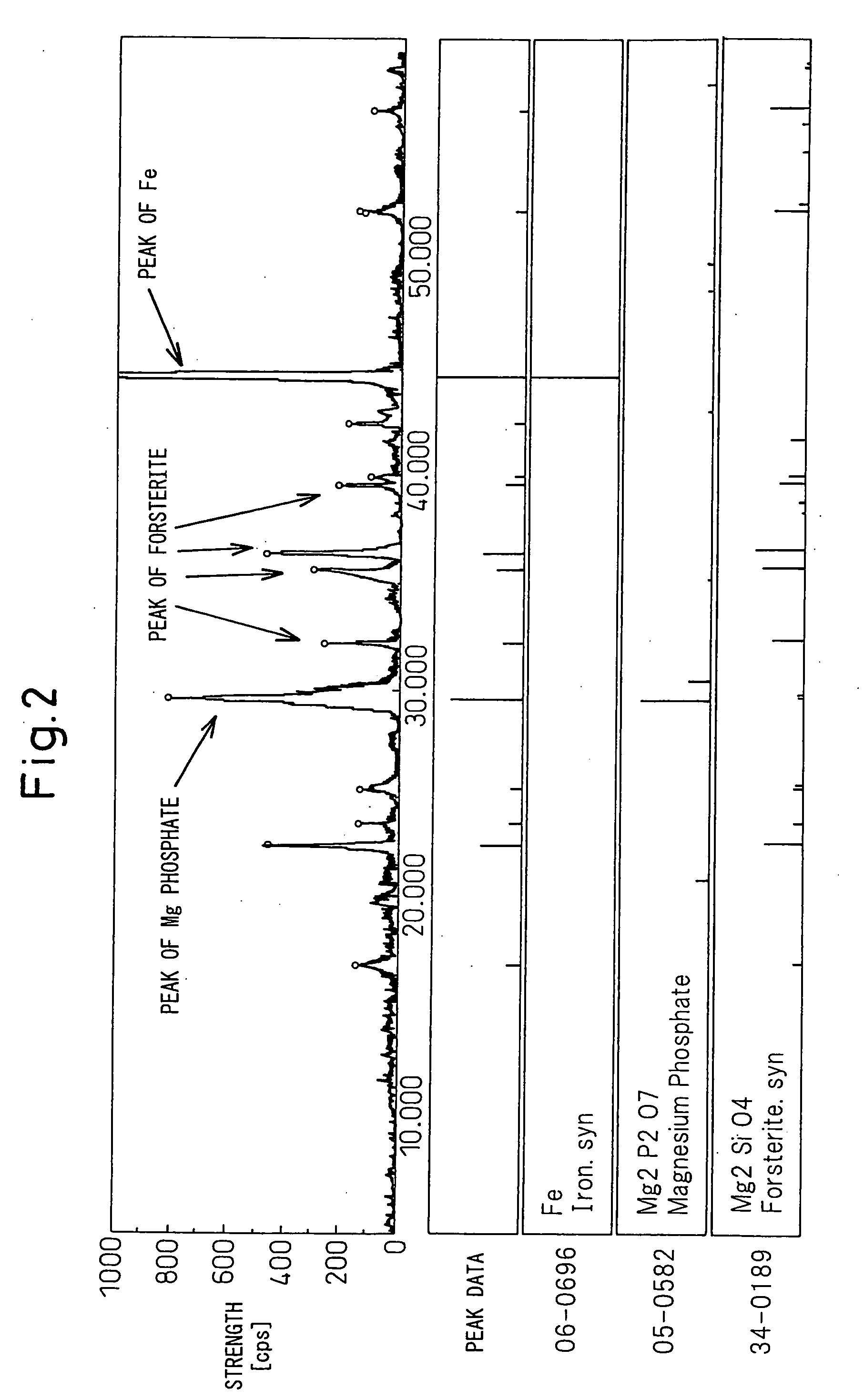

Grain-Oriented Electrical Steel Sheet Having High Tensile Strength Insulating Film and Method of Treatment of Such Insulating Film

ActiveUS20090233114A1Reduced stabilityPretreated surfacesInorganic material magnetismColloidal silicaMagnesium phosphate

Grain-oriented electrical steel sheet having a chrome-free high tensile strength insulating film characterized by comprising steel sheet on the surface of which is formed an insulating film containing a phosphate and colloidal silica as main ingredients and containing crystalline magnesium phosphate uniformly dispersed over the entire surface.

Owner:NIPPON STEEL CORP

Industrial high-concentration phosphorus-containing wastewater treatment method

InactiveCN104086019ASimple processGood effectWater contaminantsMultistage water/sewage treatmentHigh concentrationMagnesium phosphate

The invention discloses an industrial high-concentration phosphorus-containing wastewater treatment method. The method comprises the following steps: adding a fluorine removal agent to high-concentration acidic phosphorus-containing wastewater with the P by P2O5 content of 0.15-2.2%, the F content of 0.01-0.35% and the Ca content of 0.1-0.45% to adjust the pH value of the wastewater to 4.5-6.5, allowing obtained wastewater to stand, and discharging formed fluorine-containing sludge; continuously adding a precipitating agent to the obtained upper layer clear liquid to adjust the pH value of the wastewater to 8.0-9.0, converting P to a magnesium phosphate precipitate, flocculating the obtained clear liquid to realize standard reaching emission or factory reuse; and dissolving the magnesium phosphate precipitate in fertilizer-grade phosphoric acid to obtain a P and Mg-containing mixed liquid, and carrying out metric N source addition to make struvite. The fluorine removal agent is magnesium oxide, magnesium carbonate, magnesian marble or dolomite; and the precipitating agent is magnesium hydroxide or sodium hydroxide. The wastewater treatment method has the advantages of simple process flow, good fluorine and calcium effects, and maximal recovery of the P resource on the premise that standard reaching of emitted water is guaranteed.

Owner:HUBEI FORBON TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com