Preparation of nano-HAP coating/magnesium alloy composite biological material

A technology of composite biomaterials and magnesium alloys, which is applied in the field of preparation of nano-HAP coatings/magnesium alloy composite biomaterials, can solve the problems of affecting phosphate nucleation, low bonding strength, and not very dense coatings, etc., to avoid matrix Effects of overheating, increasing bonding strength, and avoiding phase transition of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

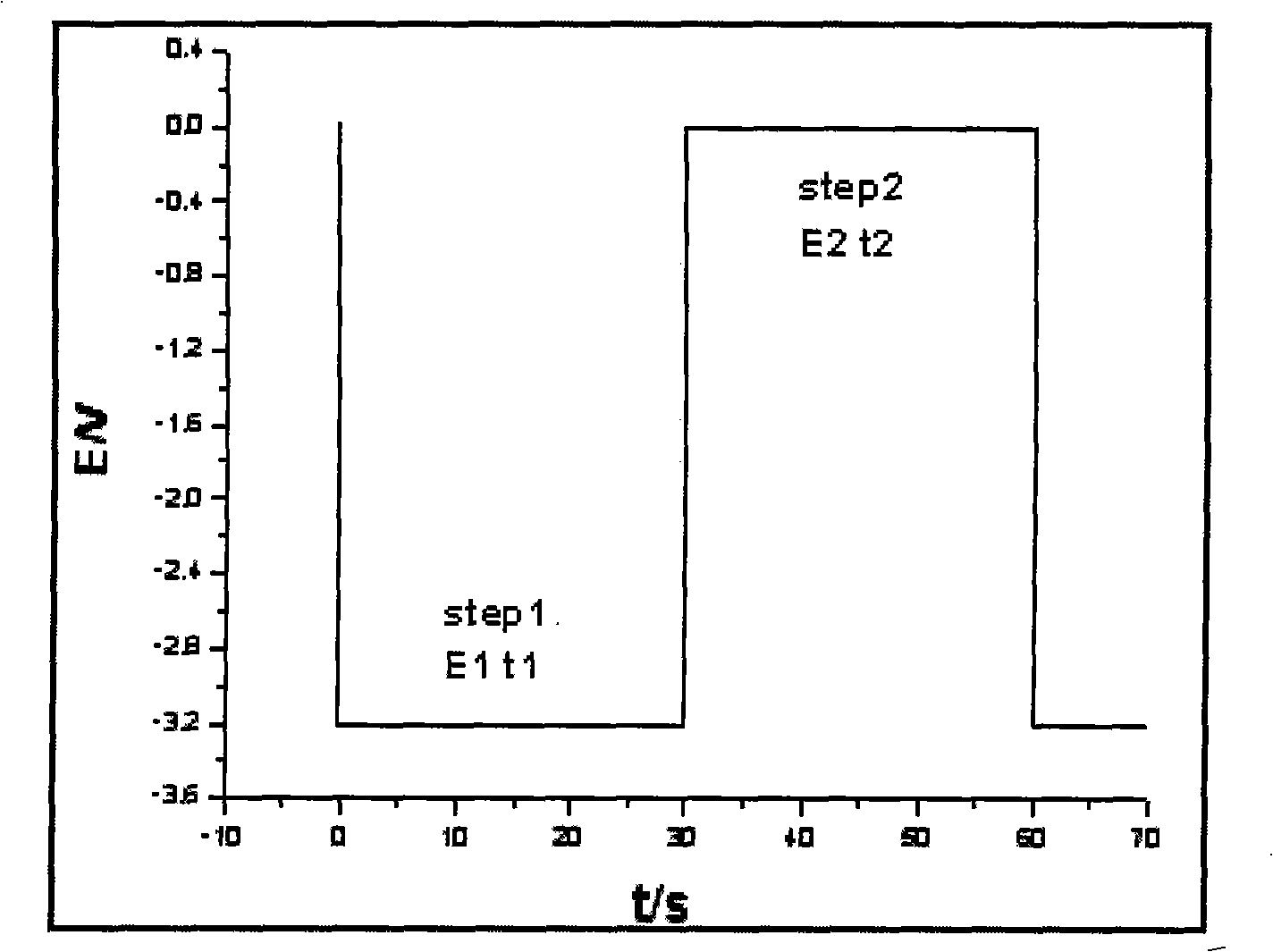

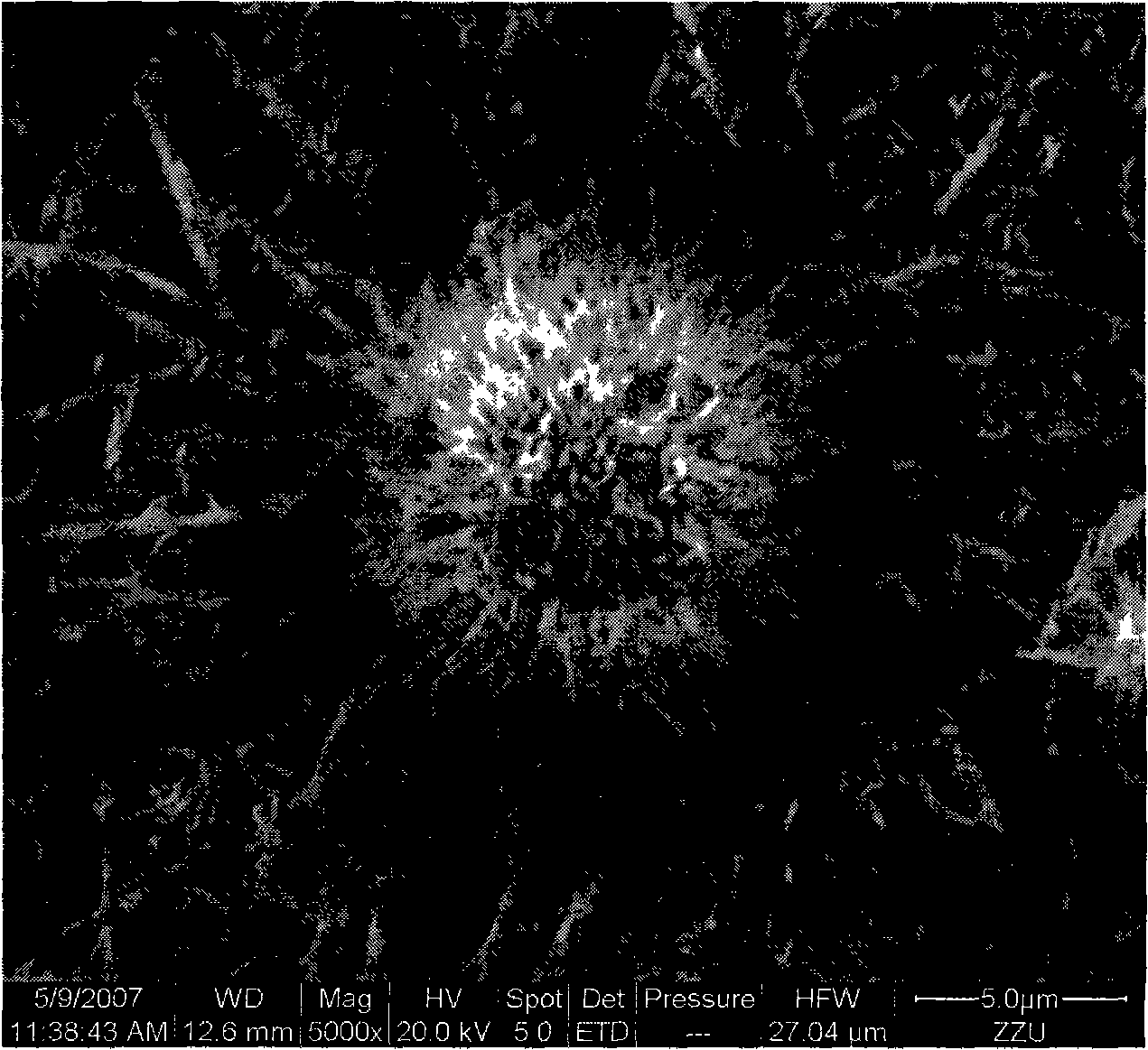

Method used

Image

Examples

Embodiment 1

[0033] AZ31 magnesium alloy is used as the base material, and its alloy composition (wt%) is: Al 3.13%, Zn 1.21%, Mn 0.47%, Si 0.04%, Mg balance.

[0034] (1) Preparation of coating electrolyte: weigh NH 4 h 2 PO 4 (99.5%) 0.54g, NaNO 3 (99%) 6.38g, Ca(NO 3 ) 2 .4H 2 O (99%) 1.89g is configured into 750ml of dilute solution, that is, the atomic ratio of calcium and phosphorus is adjusted to 1.67, stirred evenly with a glass rod; 3 or (CH 2 Oh) 3 CNH 2 Adjust the pH value of the solution to 5.0, stir well and evenly, and obtain the electrolyte solution for use.

[0035] (2) Substrate material pretreatment: AZ31 magnesium alloy substrate is wire-cut into rectangular blocks, polished and polished sequentially with 100-1000 metallographic sandpaper, washed with deionized water, and prepared with acetone and alcohol mixed solution, the volume ratio of which is 1:1 , place the matrix material in the mixed solution for ultrasonic cleaning for 10 minutes to remove oil, and d...

Embodiment 2

[0039] Using ZK60 magnesium alloy as the base material, its alloy composition (wt%) is: Zn 5.83%, Zr 0.45%, Mn 0.04%, Ca 0.02%, Mg balance.

[0040] (1) Electrolyte configuration: weigh NH 4 h 2 PO 4 (99.5%) 2.7g, NaNO 3 (99%) 3.2g, Ca(NO 3 ) 2 .4H 2 O (99%) 9.45g, configured into 750ml of dilute solution, that is, adjusting the calcium-phosphorus atomic ratio to 1.67, stirring evenly with a glass rod, and using HNO 3 or (CH 2 Oh) 3 CNH 2 Adjust the pH value of the solution to 6.0, stir well and evenly, and obtain the electrolyte solution for use.

[0041] (2) Pretreatment of substrate materials: AZ31 magnesium alloy substrates are cut into rectangular pieces by wire, polished and polished sequentially with 100-1000 metallographic sandpaper, washed with deionized water, and mixed with acetone:alcohol with a volume ratio of 0.8:1. , place the matrix material in the mixed solution for ultrasonic cleaning for 5 minutes to remove oil, and dry at room temperature; put 30%...

Embodiment 3

[0045] AZ80 magnesium alloy is used as the base material, and its alloy composition (wt%) is 7.98% of Al, 0.32% of Zn, 0.23% of Mn, and the balance of Mg.

[0046] (1) Electrolyte configuration: weigh NH 4 h 2 PO 4 (99.5%) 0.54g, NaNO 3 (99%) 9.6g, Ca(NO 3 ) 2 .4H 2 O (99%) 2.26g, configured into 750ml of dilute solution, that is, adjusting the calcium-phosphorus atomic ratio to 2.0, stirring evenly with a glass rod, and using HNO 3 or (CH 2 Oh) 3 CNH 2 Adjust the pH value of the solution to 4.2, stir well and evenly, and obtain the electrolyte solution for use.

[0047] (2) Pretreatment of substrate materials: AZ31 magnesium alloy substrate wire-cut rectangular blocks, polished and polished sequentially with 100-1000 metallographic sandpaper, washed with deionized water, and prepared with a mixed solution of acetone:alcohol with a volume ratio of 0.5:1 , place the matrix material in the mixed solution for ultrasonic cleaning for 15 minutes to remove oil, and dry at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com