Patents

Literature

2213results about "Electrolytic inorganic material coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

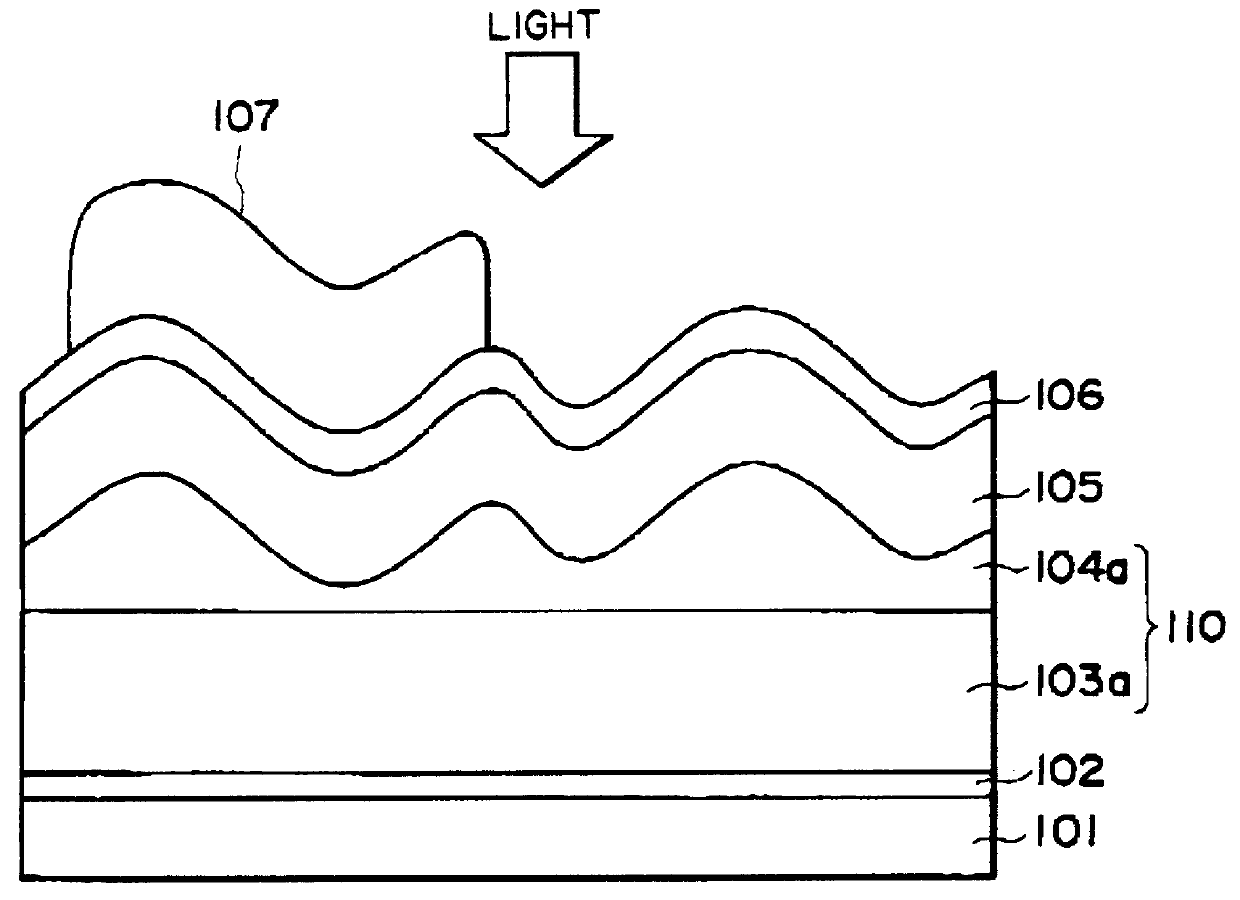

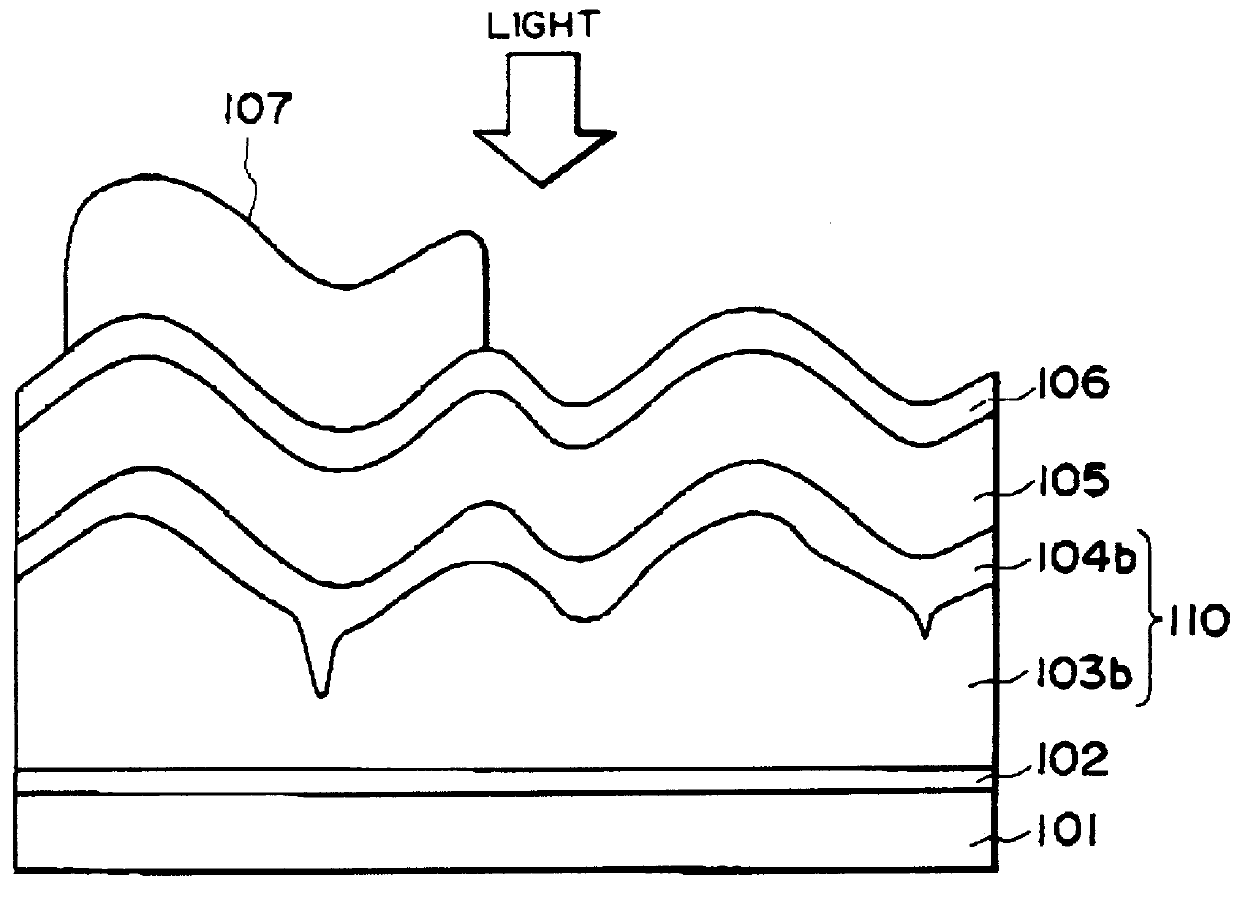

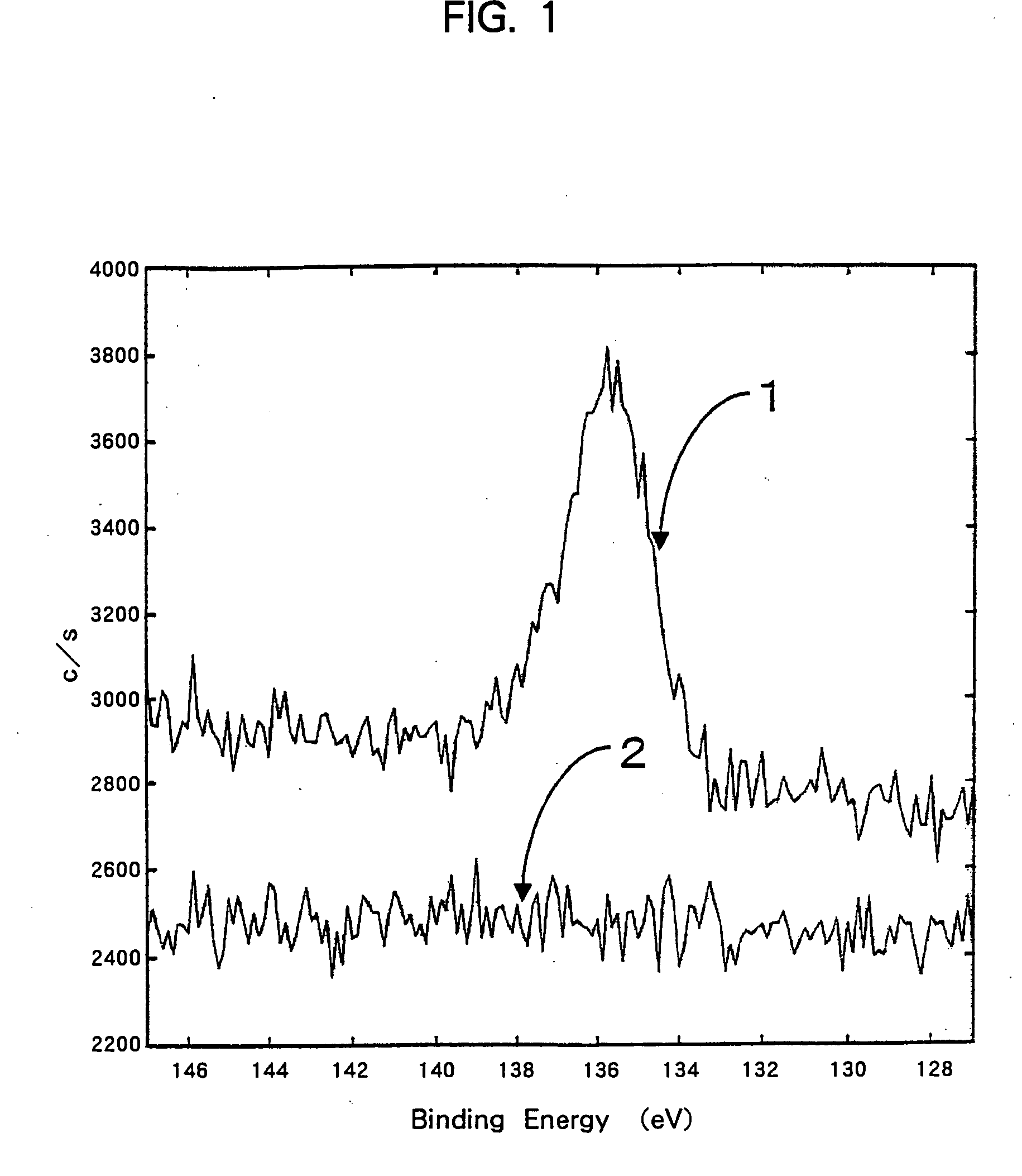

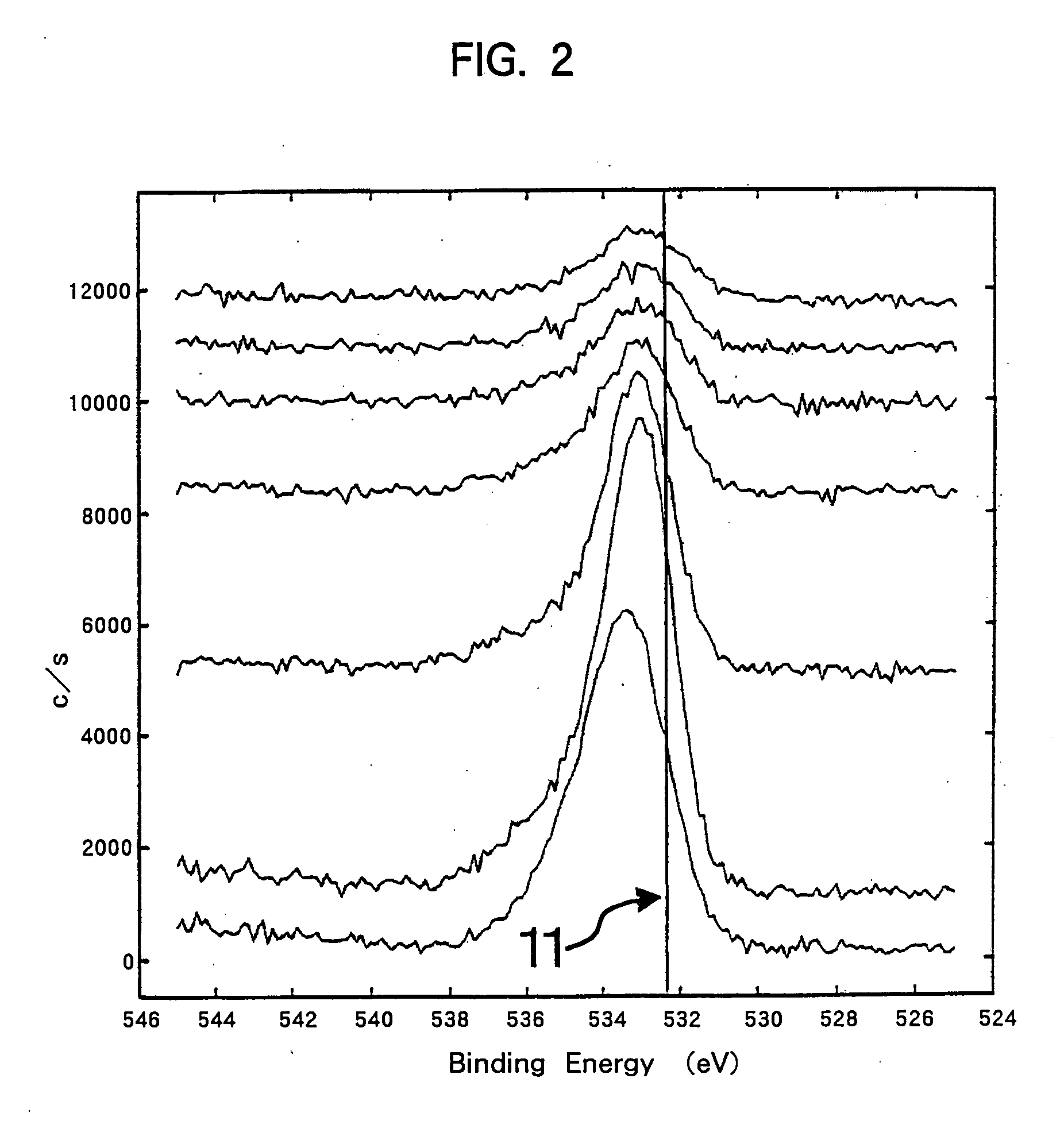

Process for producing photo-electricity generating device

InactiveUS6123824AInhibition of abnormal growthReduce leakage currentElectrolytic inorganic material coatingSurface reaction electrolytic coatingElectricityPower flow

A photo-electricity generating device is produced through the steps of: immersing an electrode and an electroconductive substrate in an aqueous solution comprising nitrate ions and zinc ions, supplying a current passing through a gap between the electrode and the electroconductive substrate to form a first zinc oxide layer on the electroconductive substrate, etching the first zinc oxide layer, and forming a semiconductor layer on the zinc oxide layer. The zinc oxide layer may preferably be formed in two zinc oxide layers under different electrudeposition conditions. In this case, the etching step may preferably be performed between steps for forming these zinc oxide layers. The zinc oxide layer is provided with an unevenness at its surface suitable for constituting a light-confining layer of a resultant photo-electricity generating device.

Owner:CANON KK

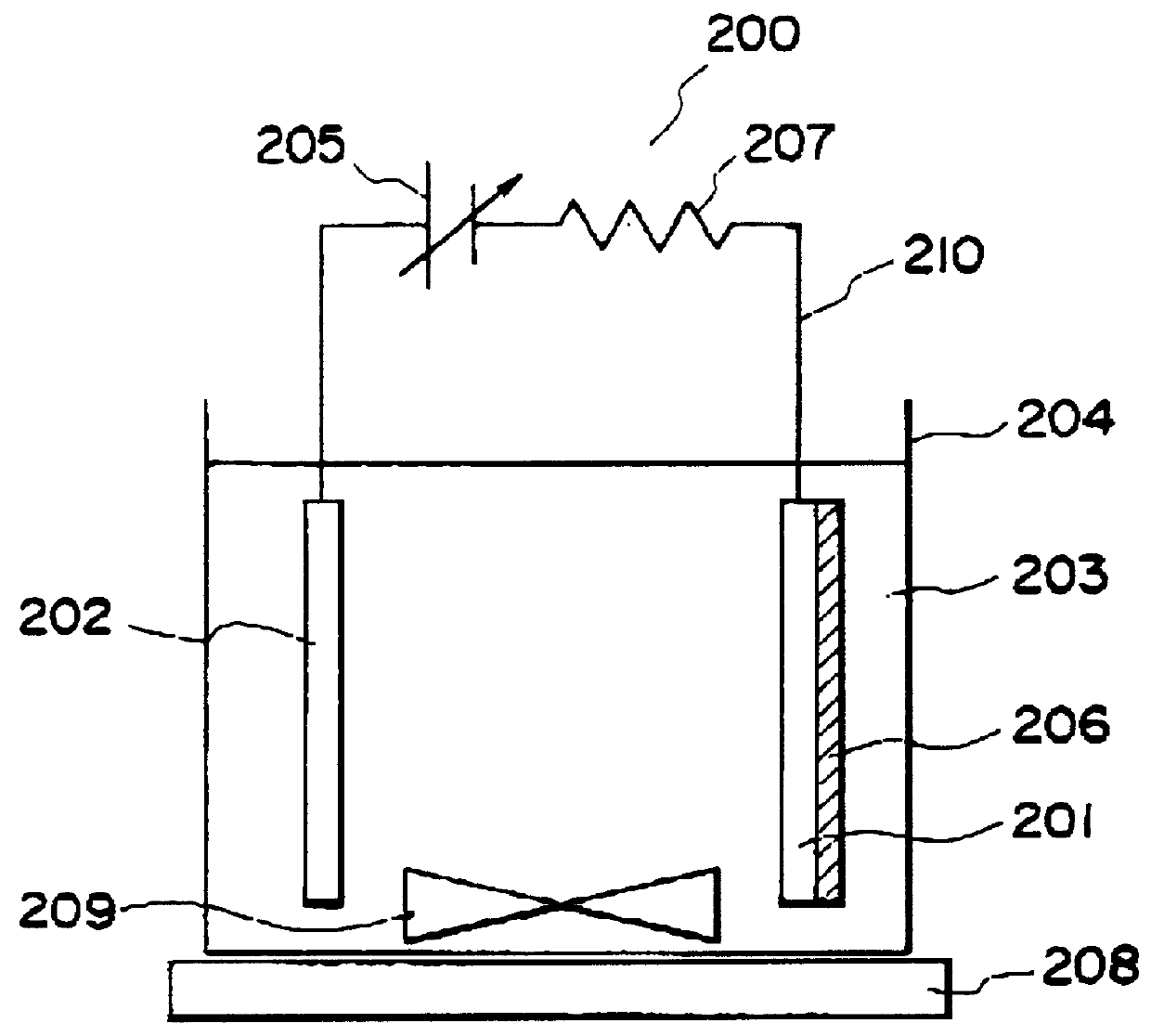

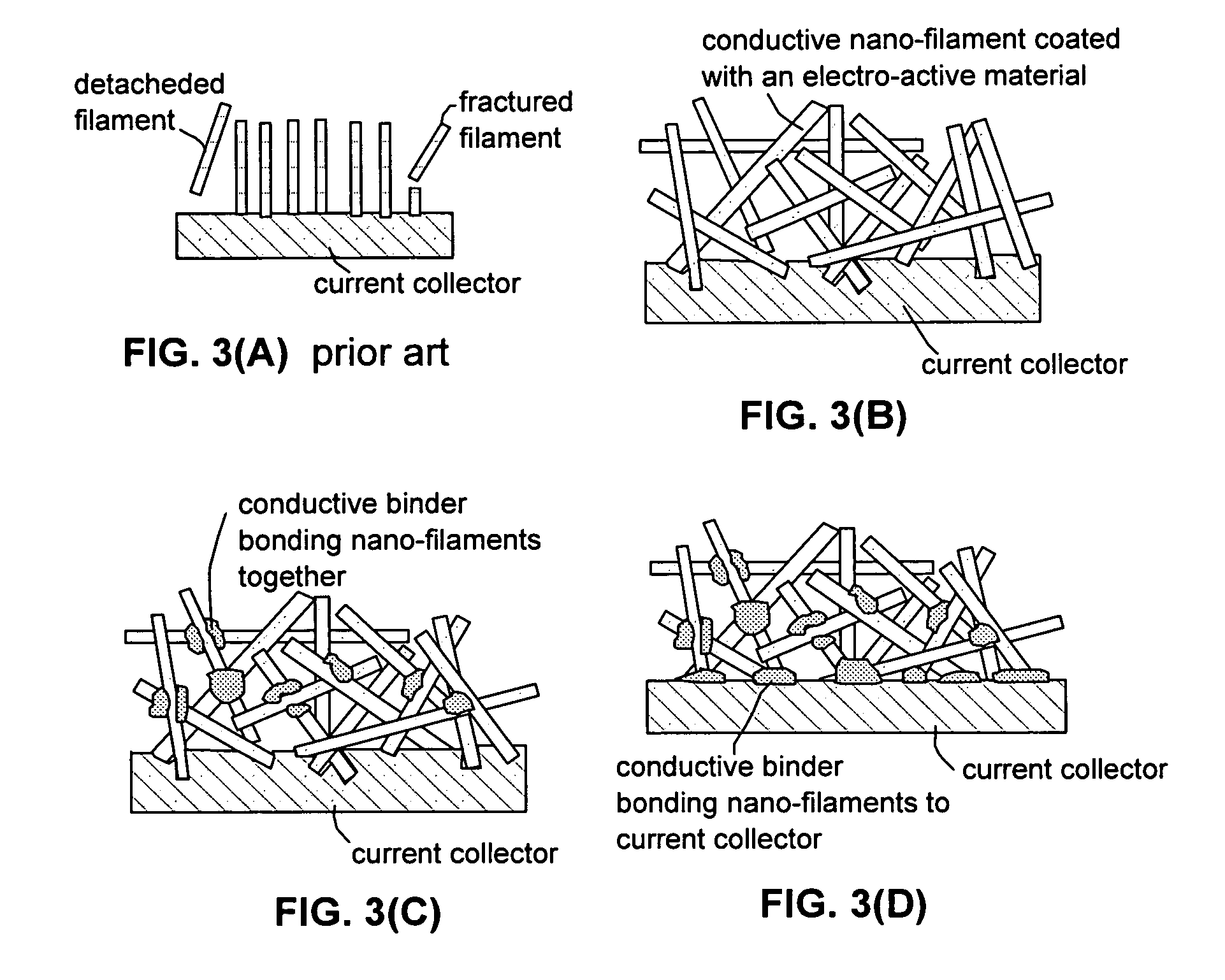

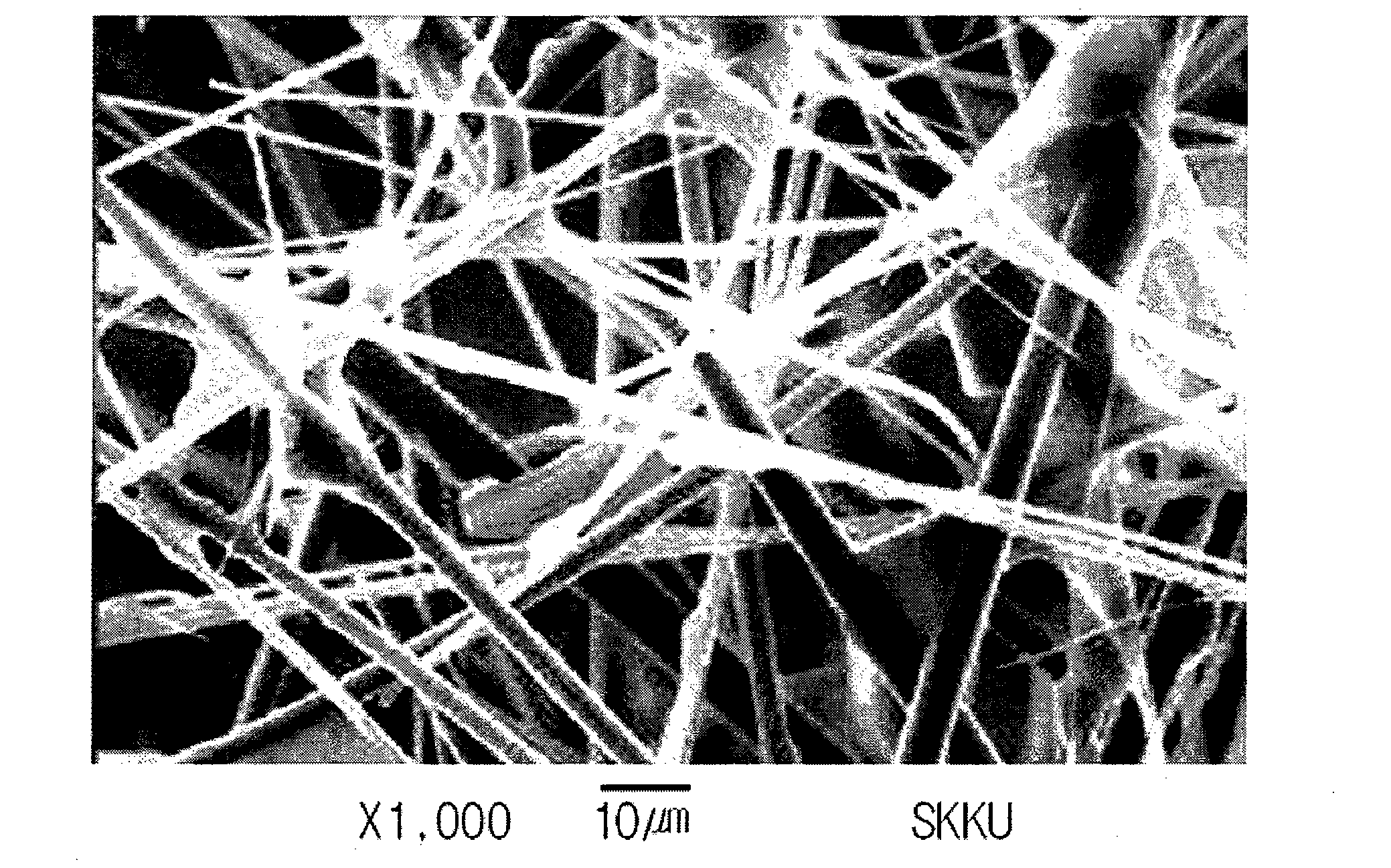

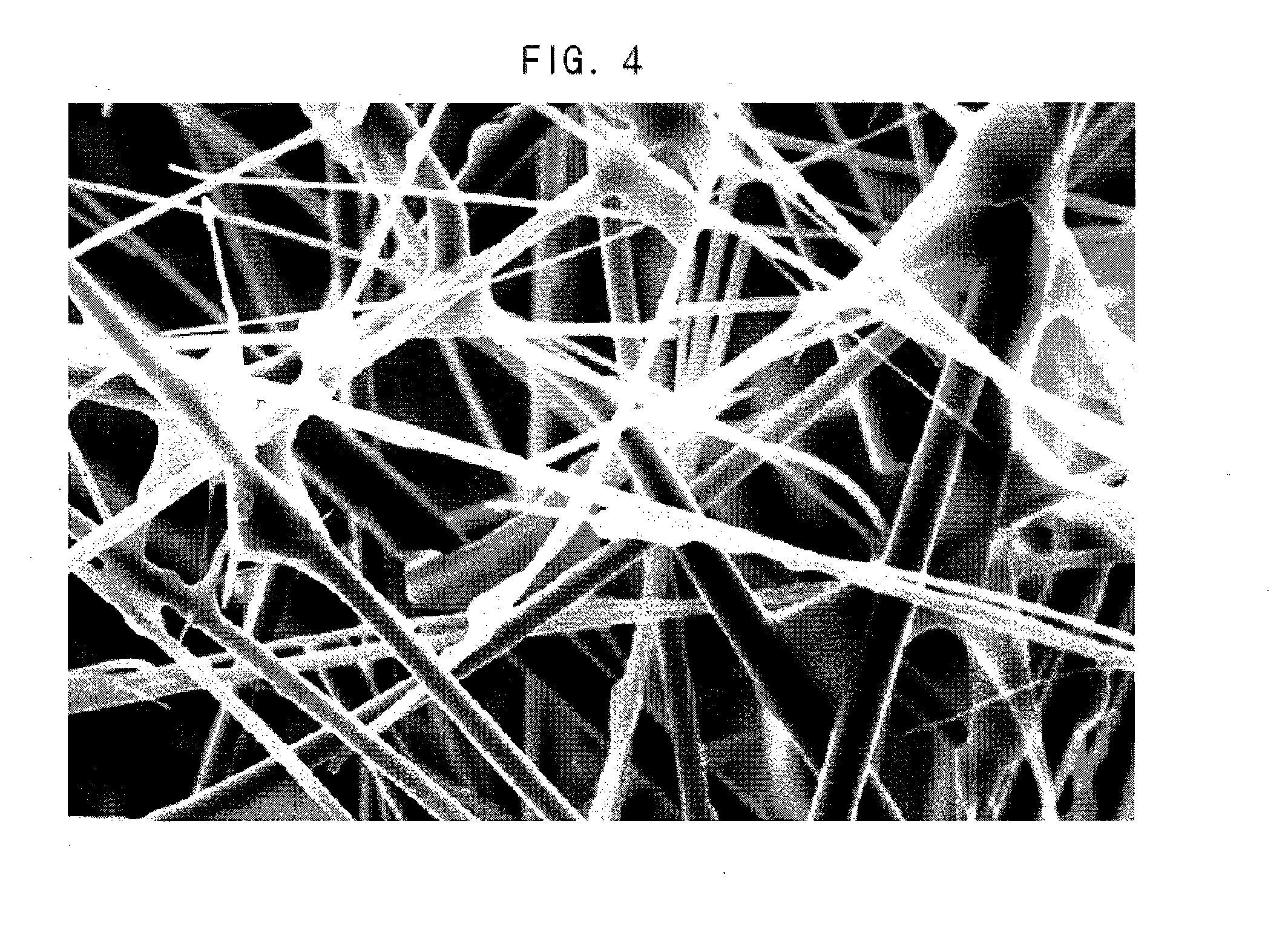

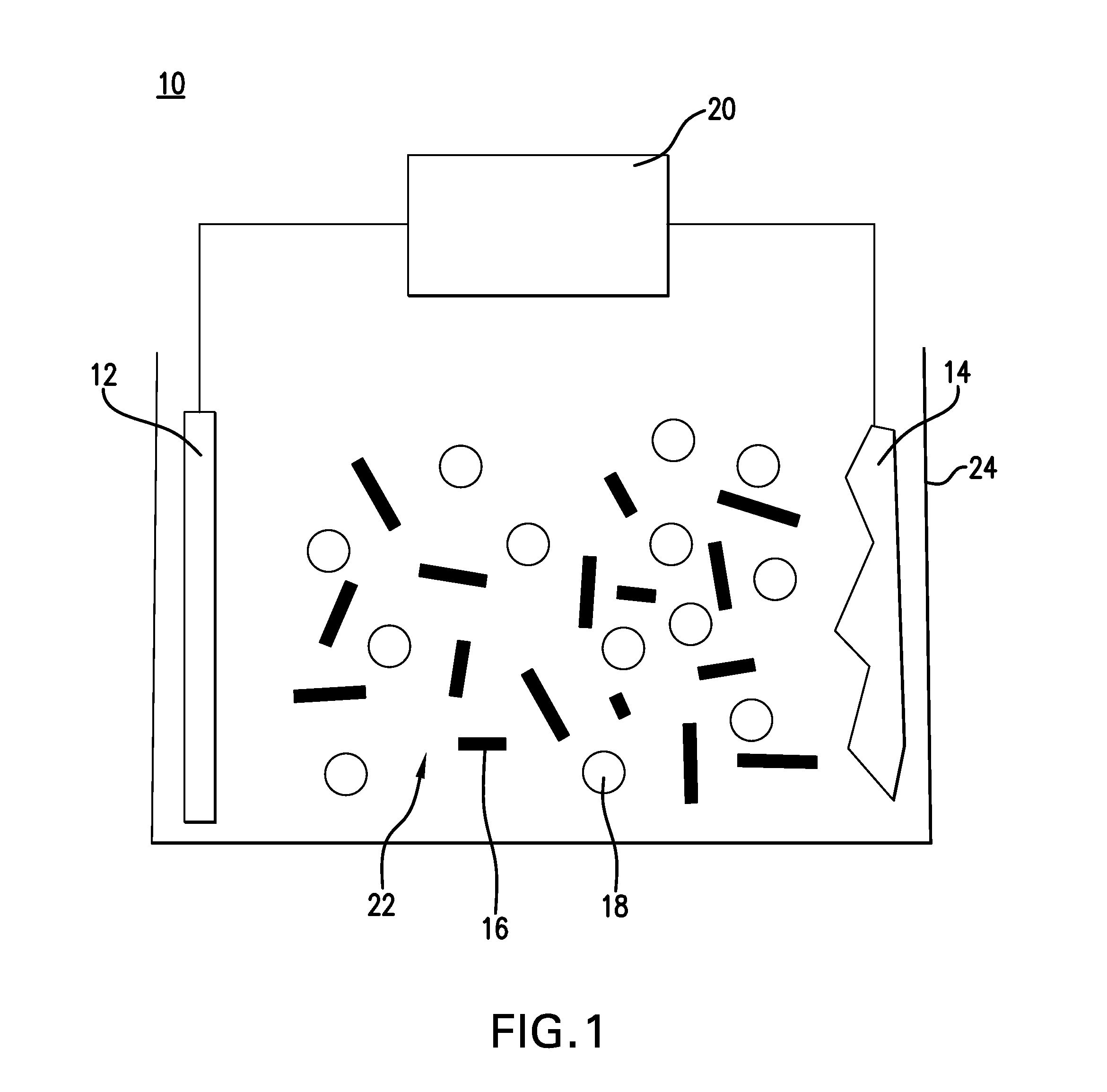

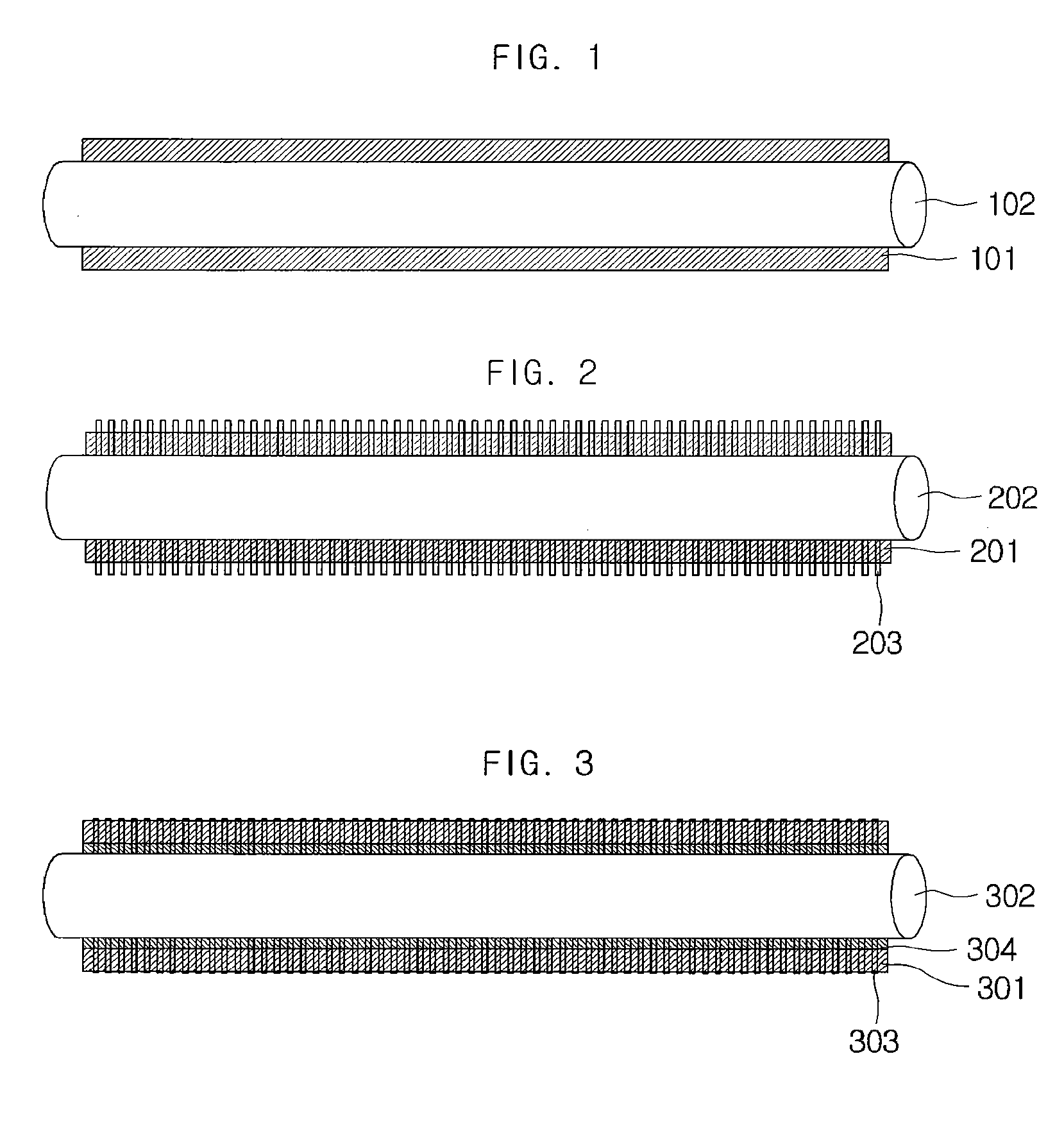

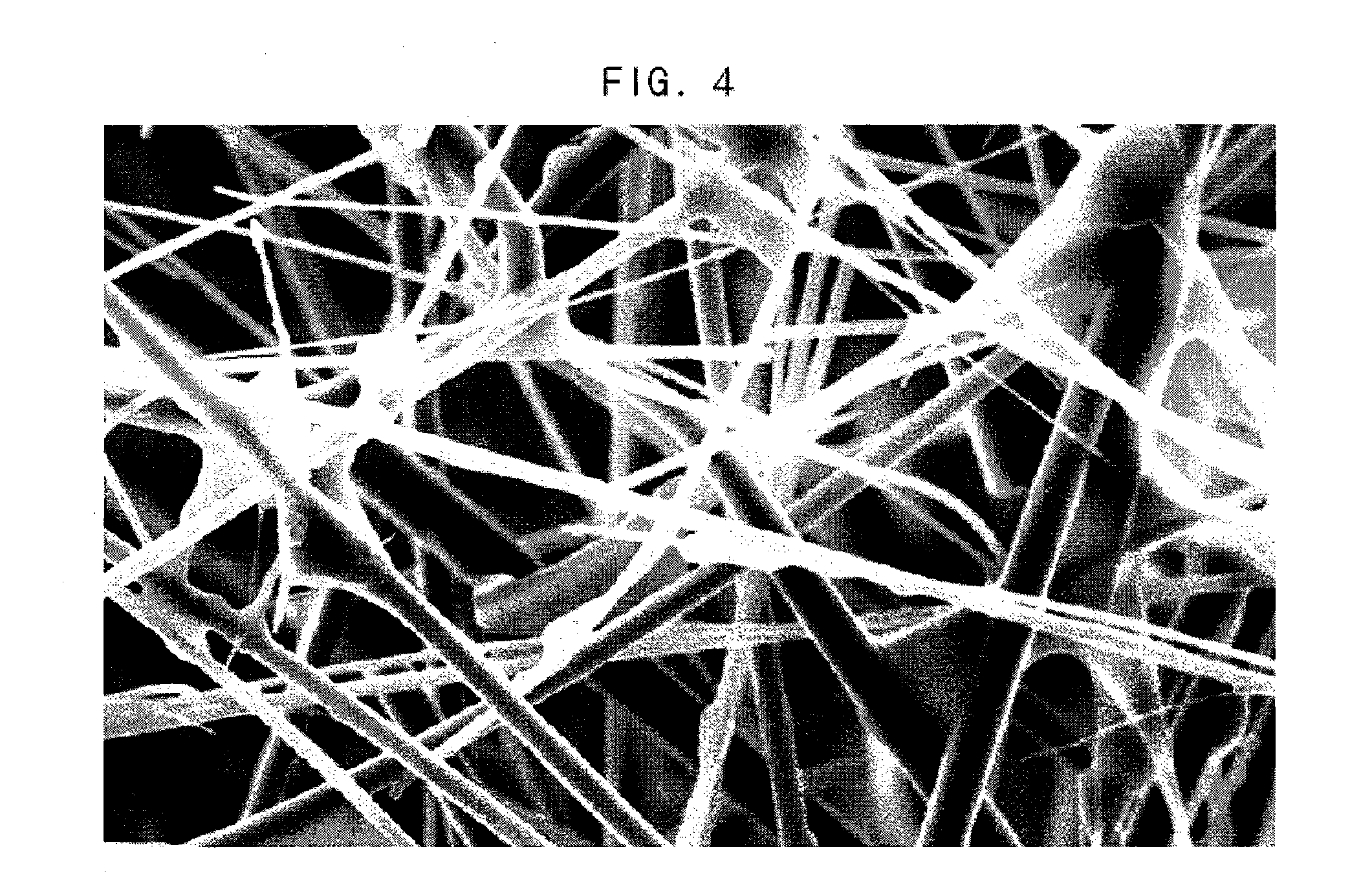

Process for producing hybrid nano-filament electrodes for lithium batteries

ActiveUS20090269511A1High reversible capacityLower internal resistanceCell electrodesFinal product manufactureNanowireElectrical battery

This invention provides a process for producing a hybrid nano-filament composition for use in a lithium battery electrode. The process comprises: (a) providing a porous aggregate of electrically conductive nano-wires that are substantially interconnected, intersected, physically contacted, or chemically bonded to form a porous network of electrically conductive filaments, wherein the nano-wires have a diameter or thickness less than 500 nm; and (b) depositing an electro-active coating onto a surface of the nano-wires, wherein the electro-active coating is capable of absorbing and desorbing lithium ions and the coating has a thickness less than 10 μm, preferably less than 1 μm. This process is applicable to the production of both an anode and a cathode. The battery featuring an anode or cathode made with this process exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

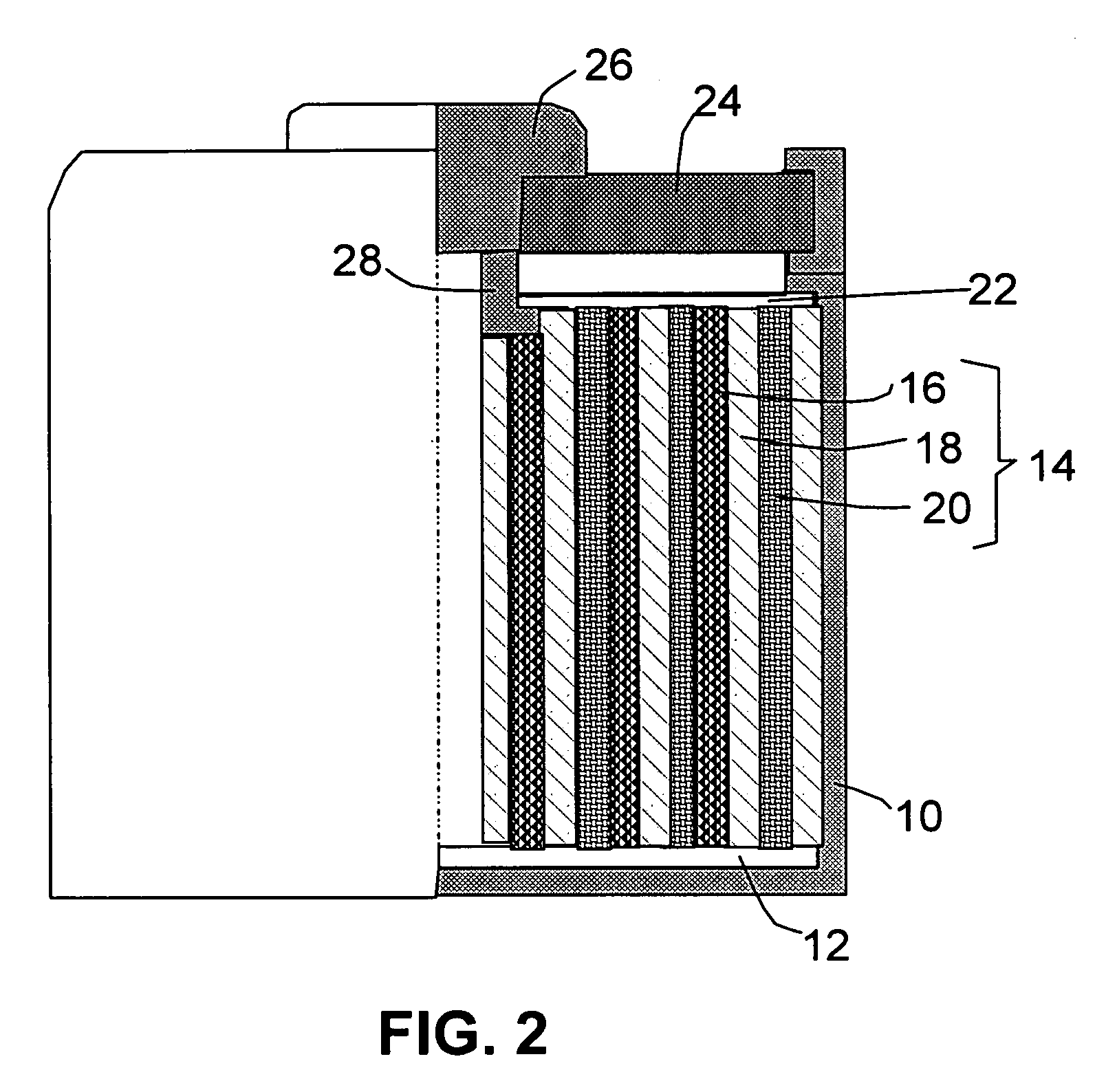

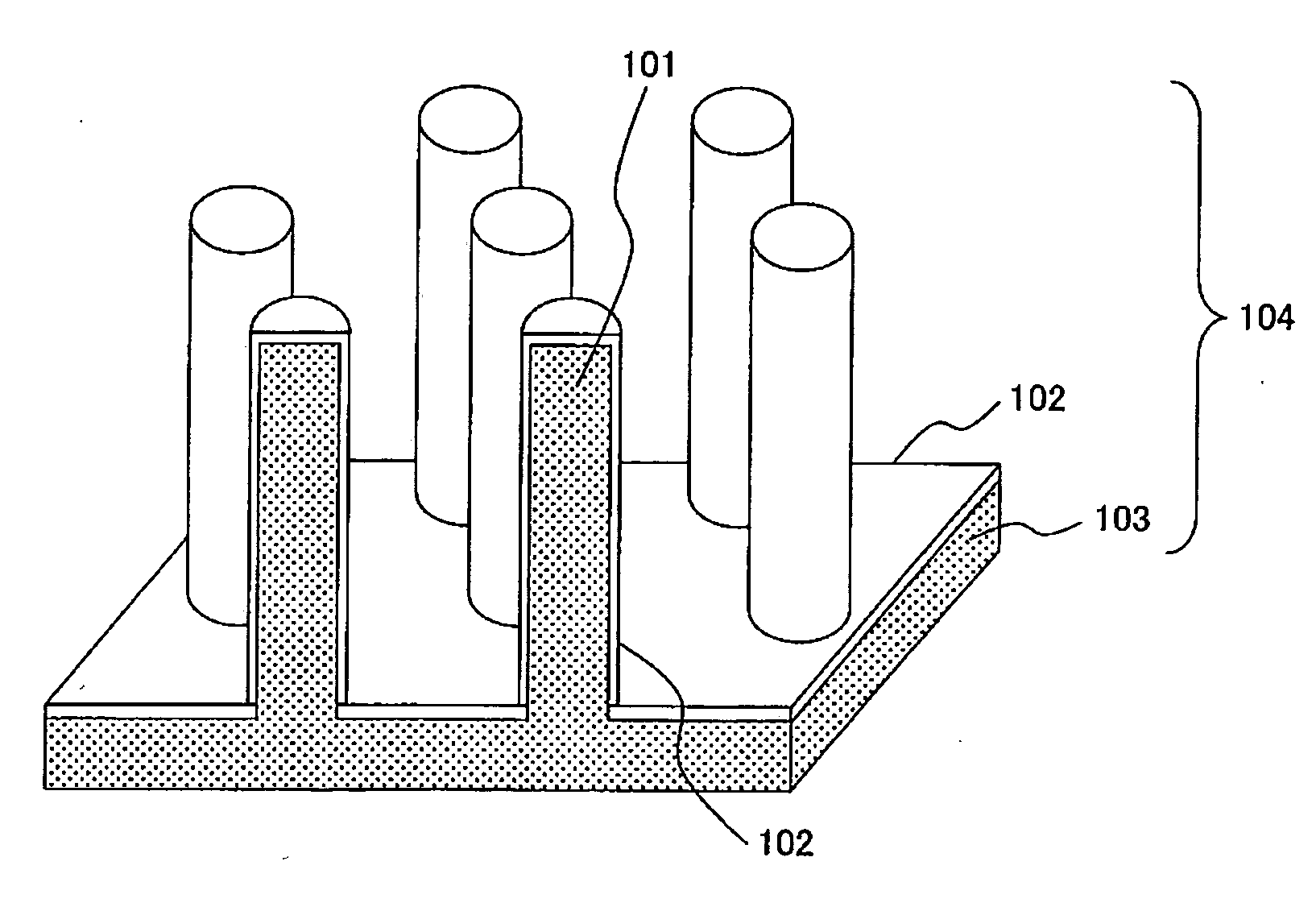

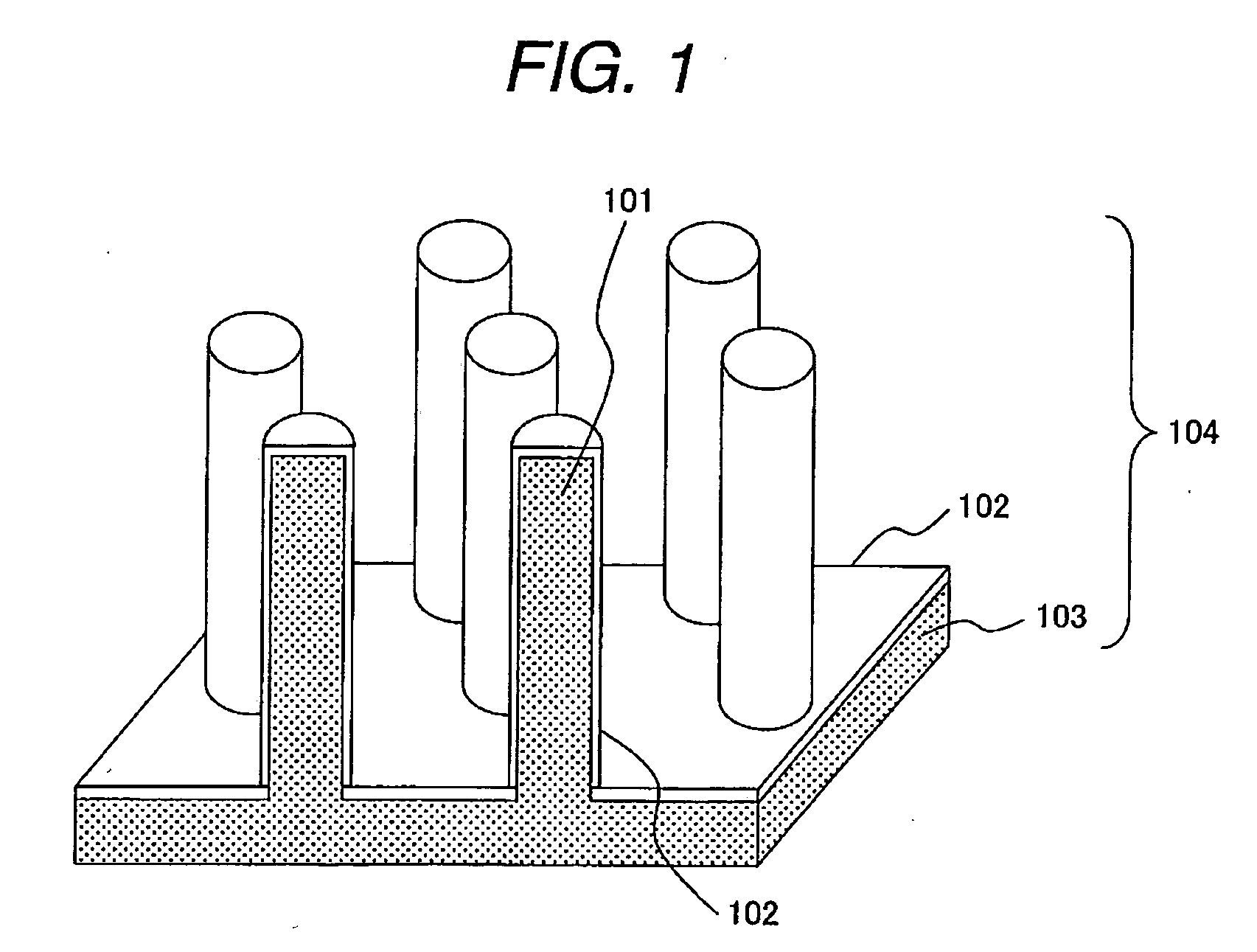

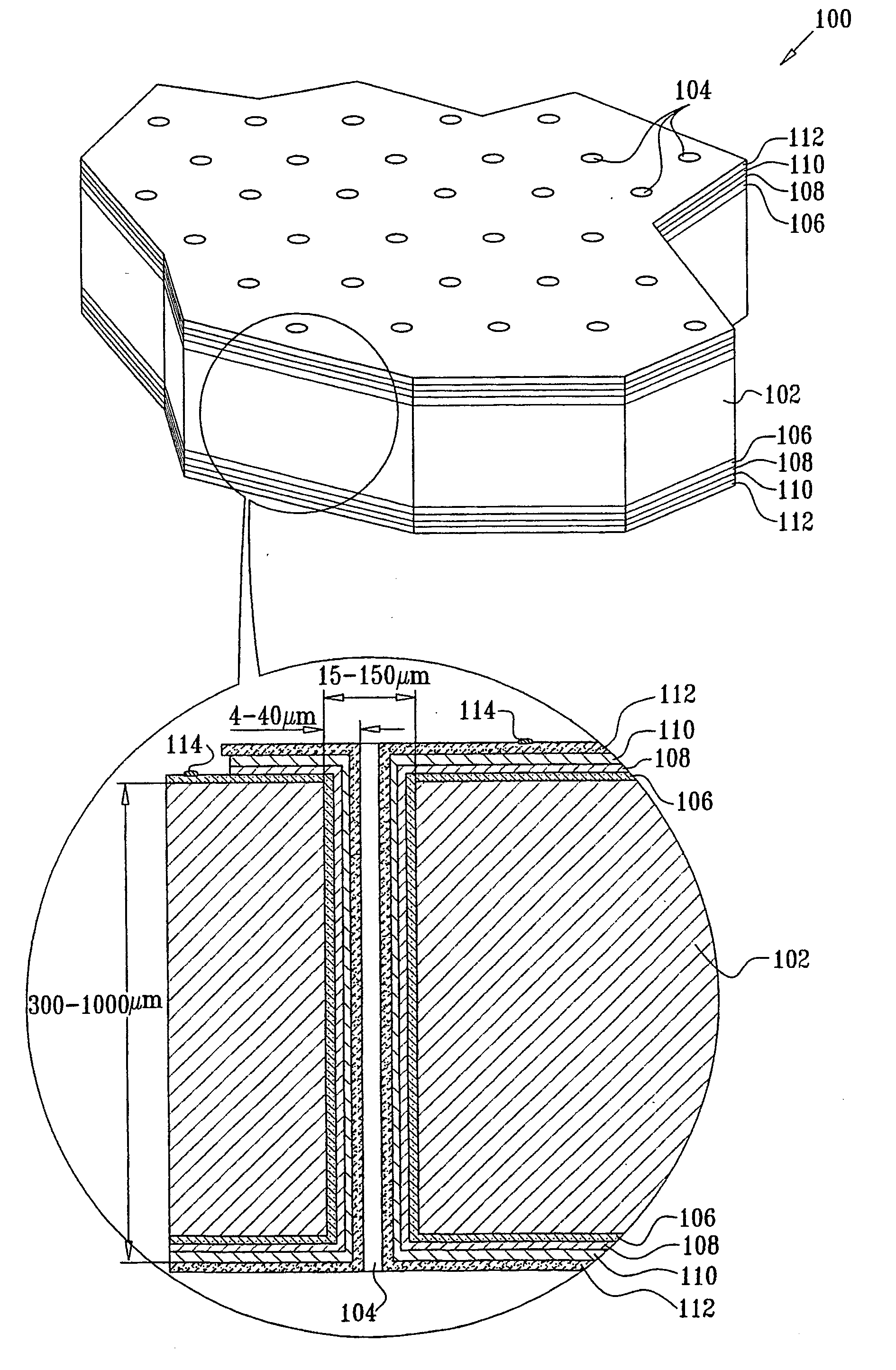

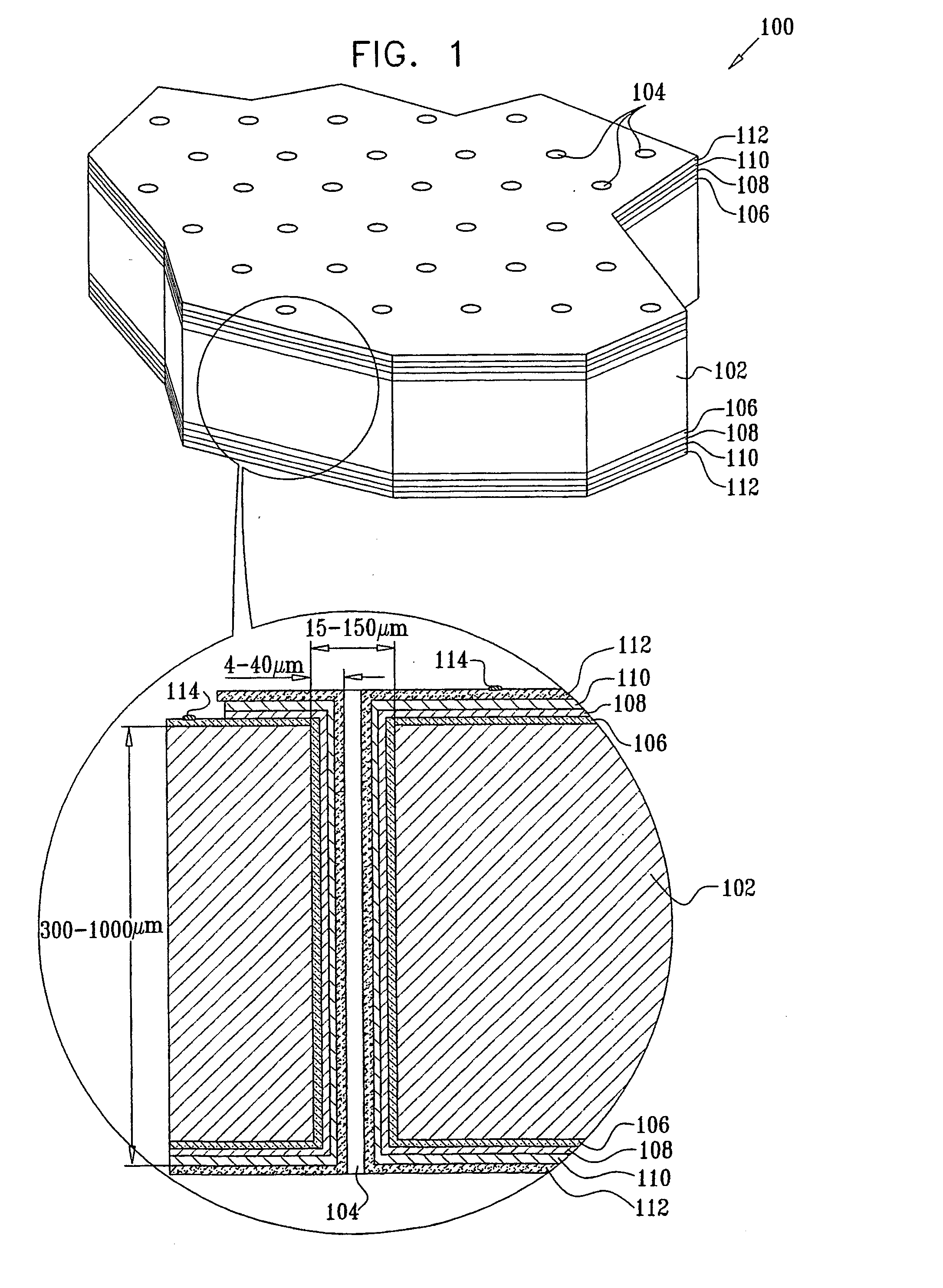

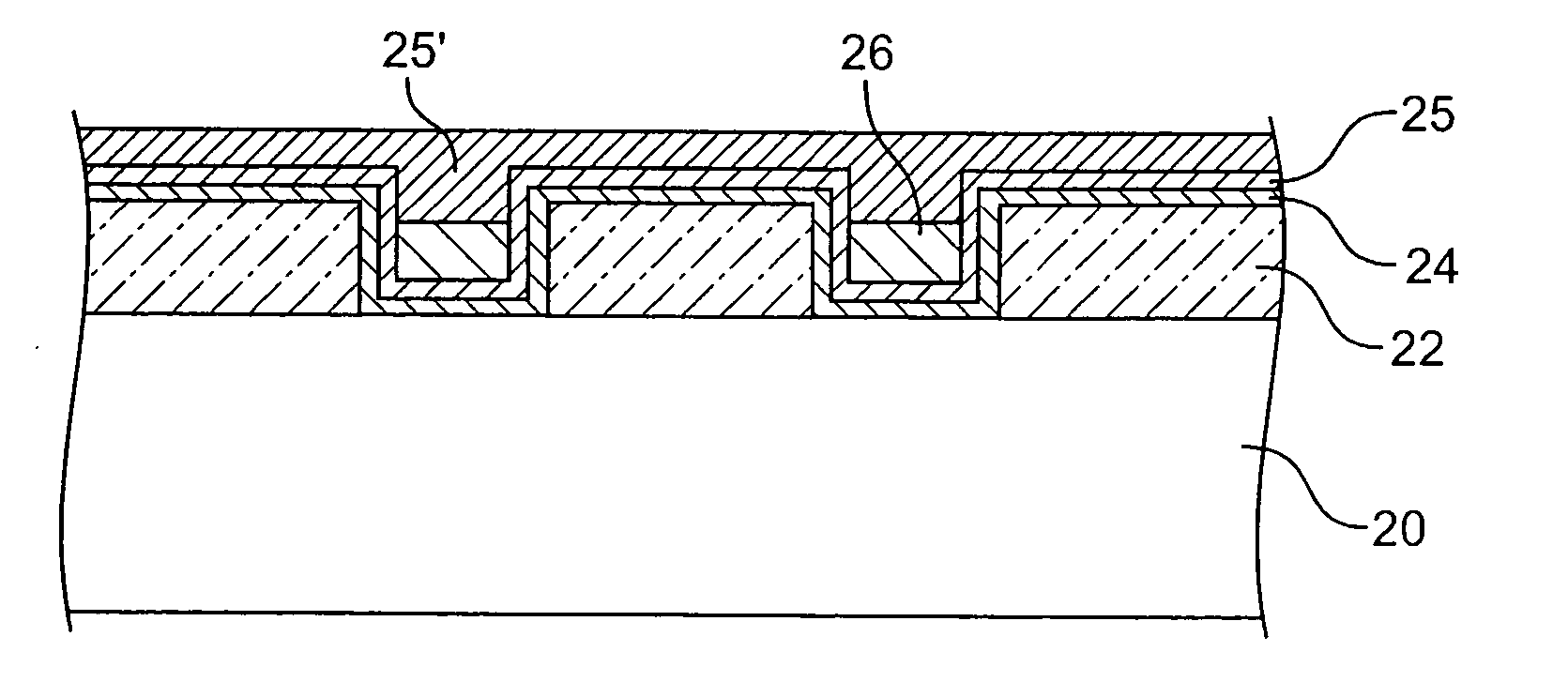

Electrode for use in electrochemical device, solid electrolyte/electrode assembly, and production method thereof

InactiveUS20070059584A1Resistance of electrodeHigh capacity densityMachining electrodesElectrolytic inorganic material coatingNano sizeNanometre

In an electrode in electrochemical device, particularly an anode lithium ion secondary battery, a cathode for use in alkali storage battery, an electrode for use in fuel cell, or a capacitor electrode, a metal structure has nano size micro-pillars is constructed with an electrode active material being formed on the surface of the metal structure. The metal structure having nano size micro-pillars can be formed, for example, by forming a metal layer as an electrode material by plating to the surface of a substrate having pores and then removing the substrate by dissolution, the metal filled in the pores of the substrate to form a group of micro-pillars. And the active material can be formed by depositing metal by plating. Since the active material is in direct contact with the conductive skeleton, the conducting agent for connecting the active materials to each other may not be added at all.

Owner:HITACHI CABLE

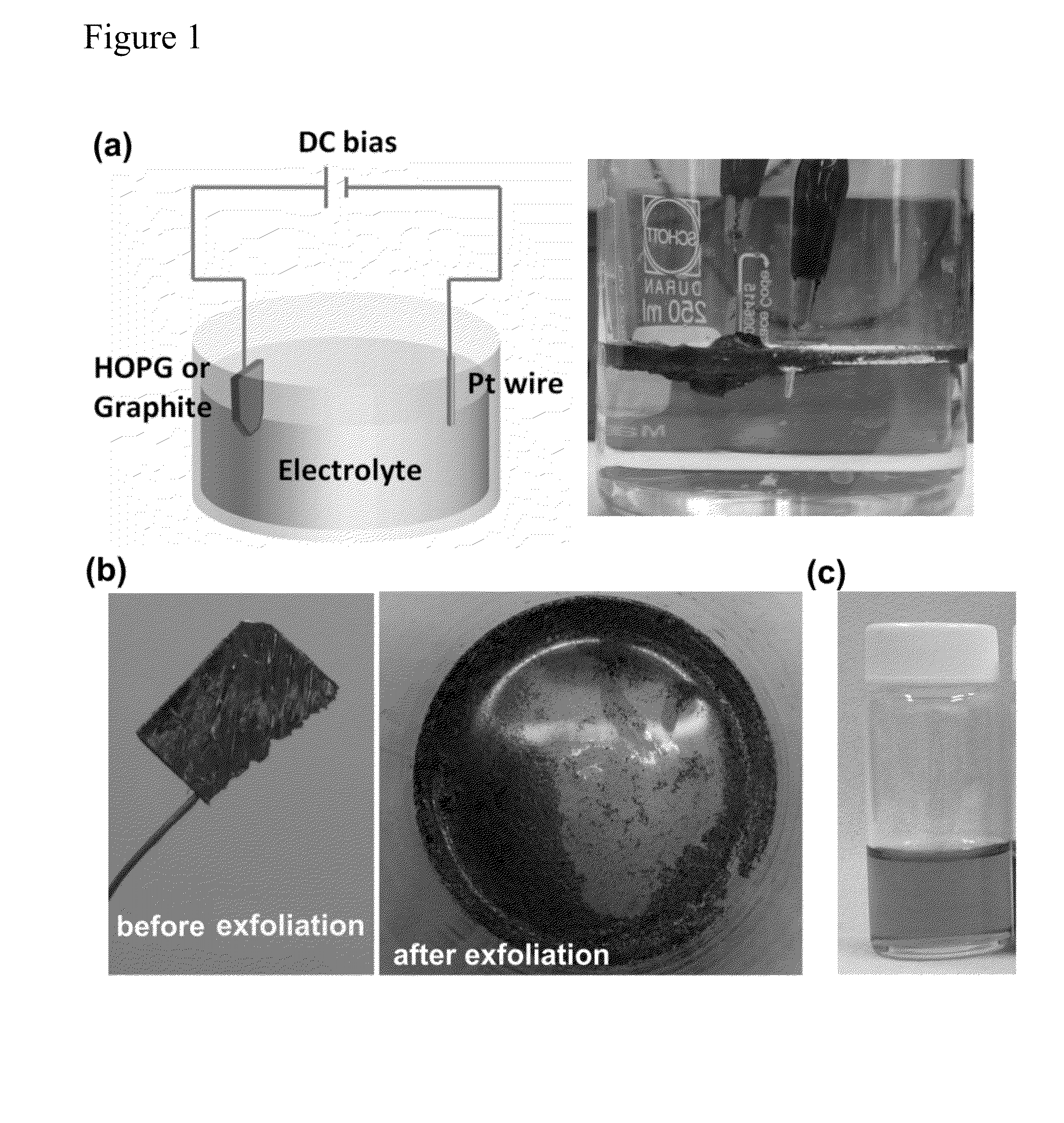

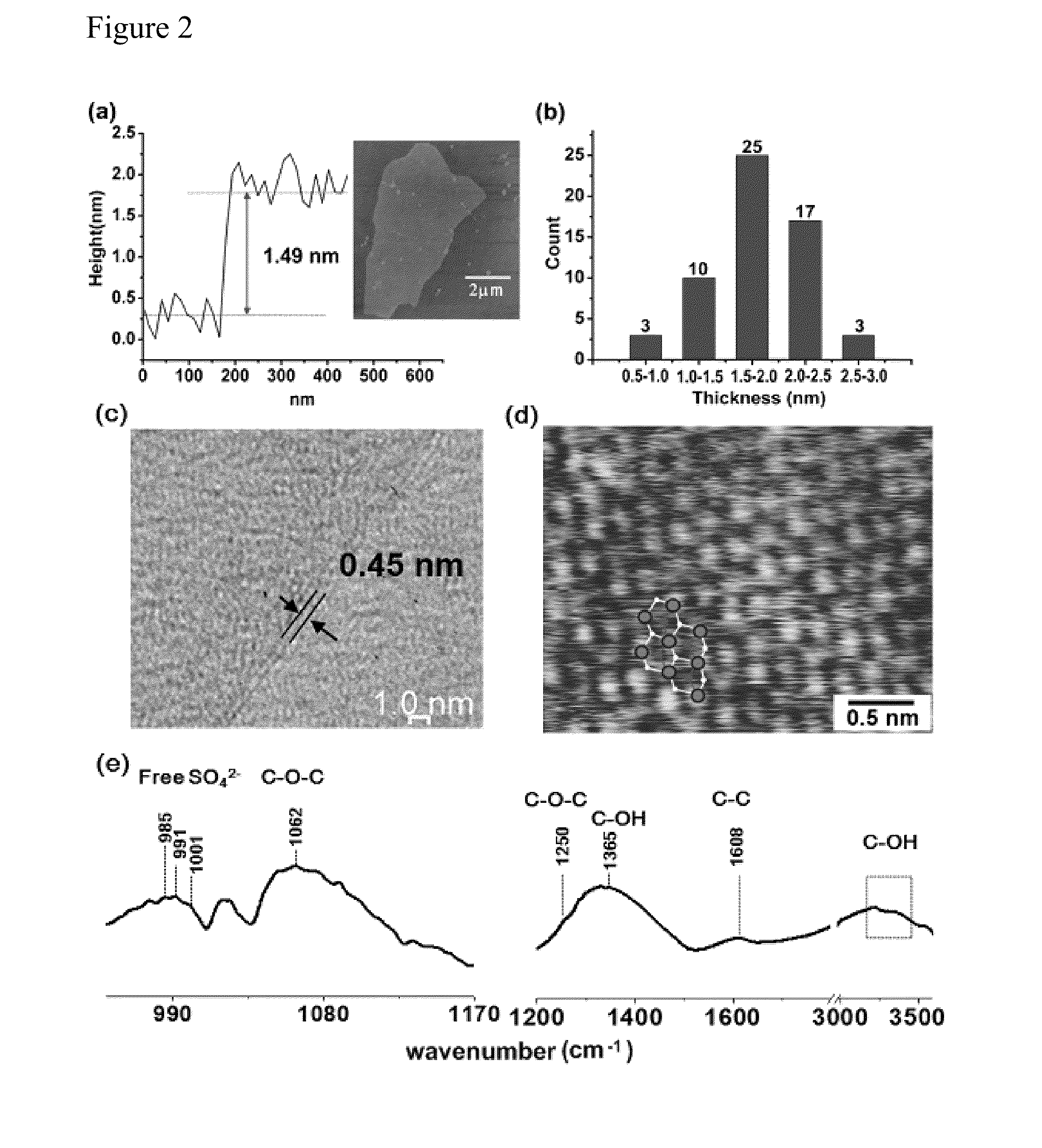

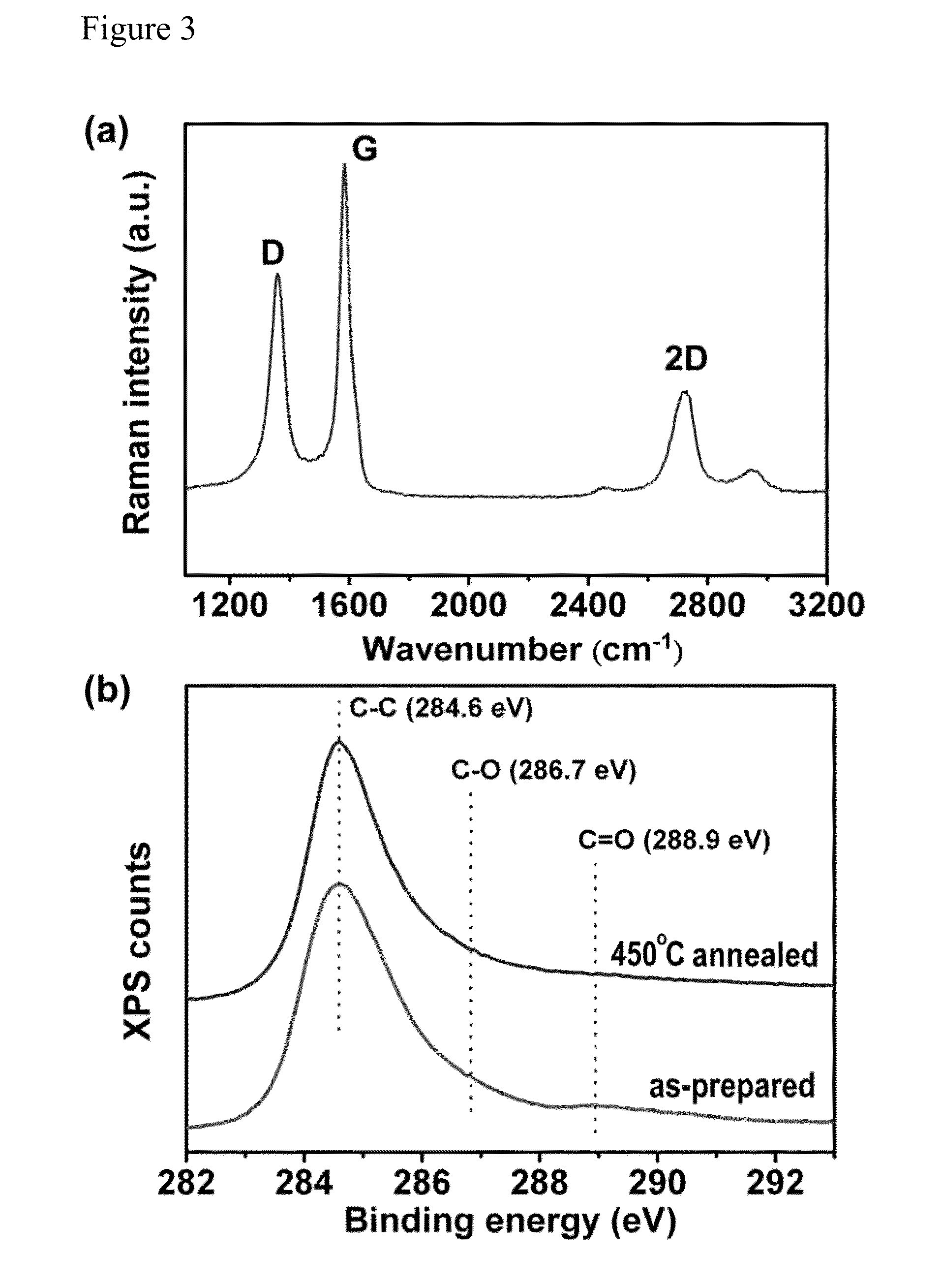

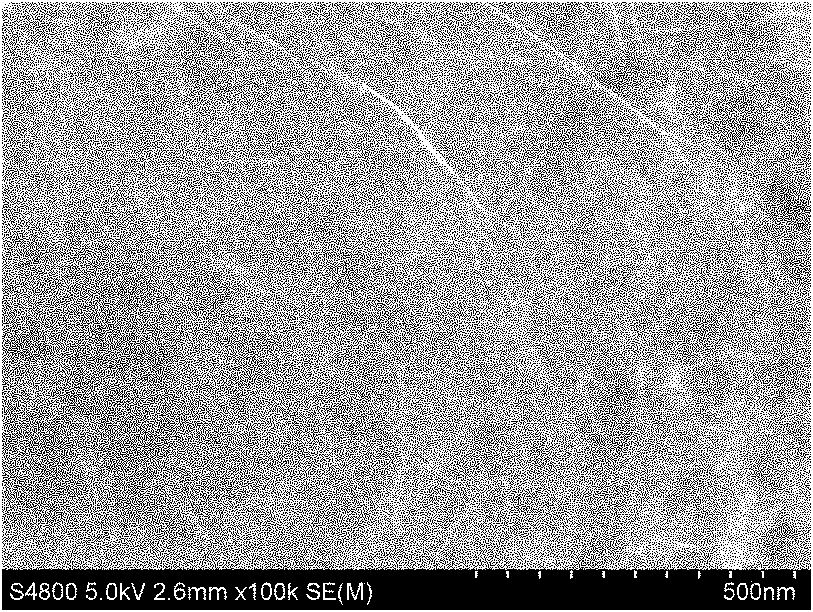

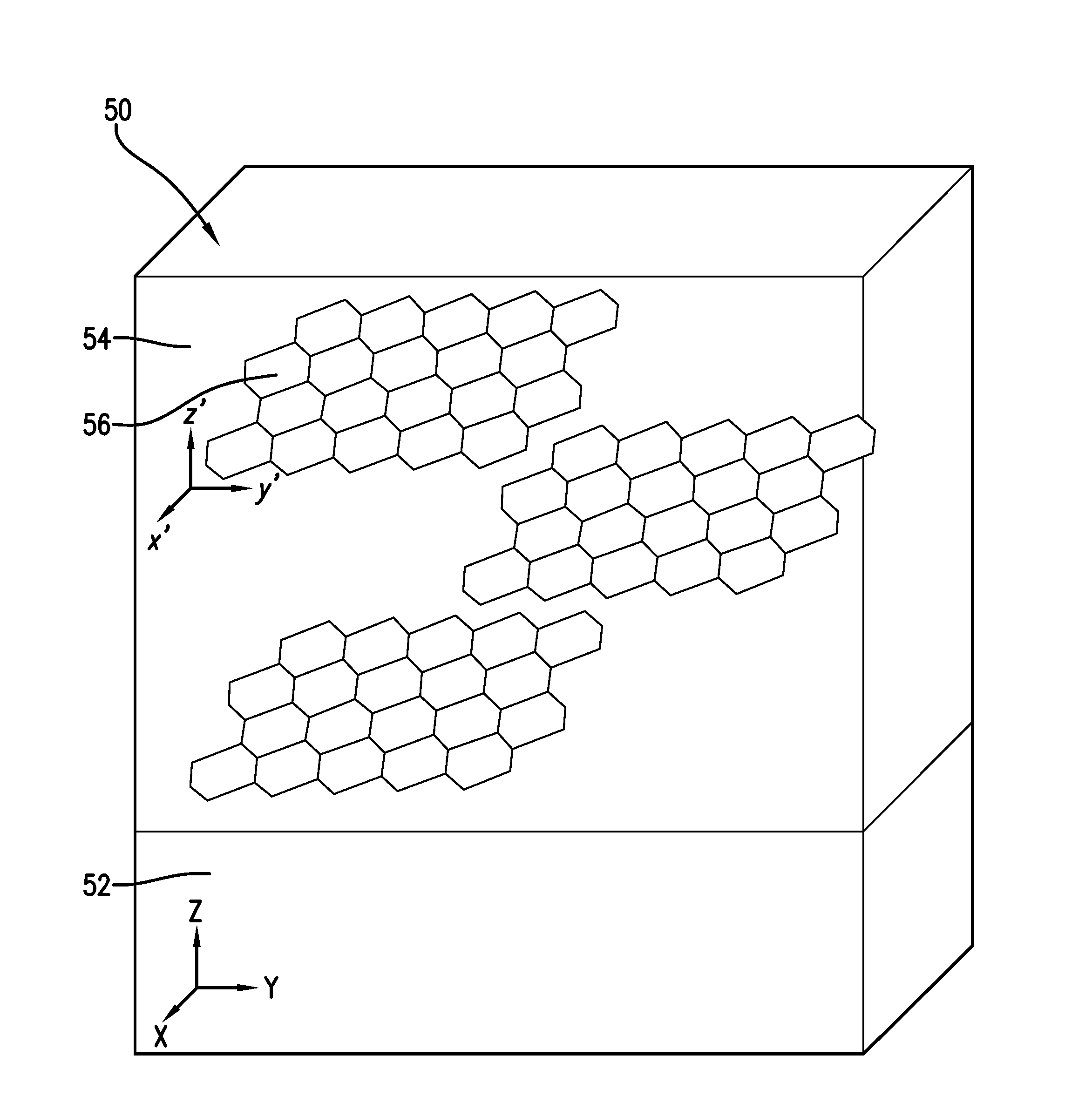

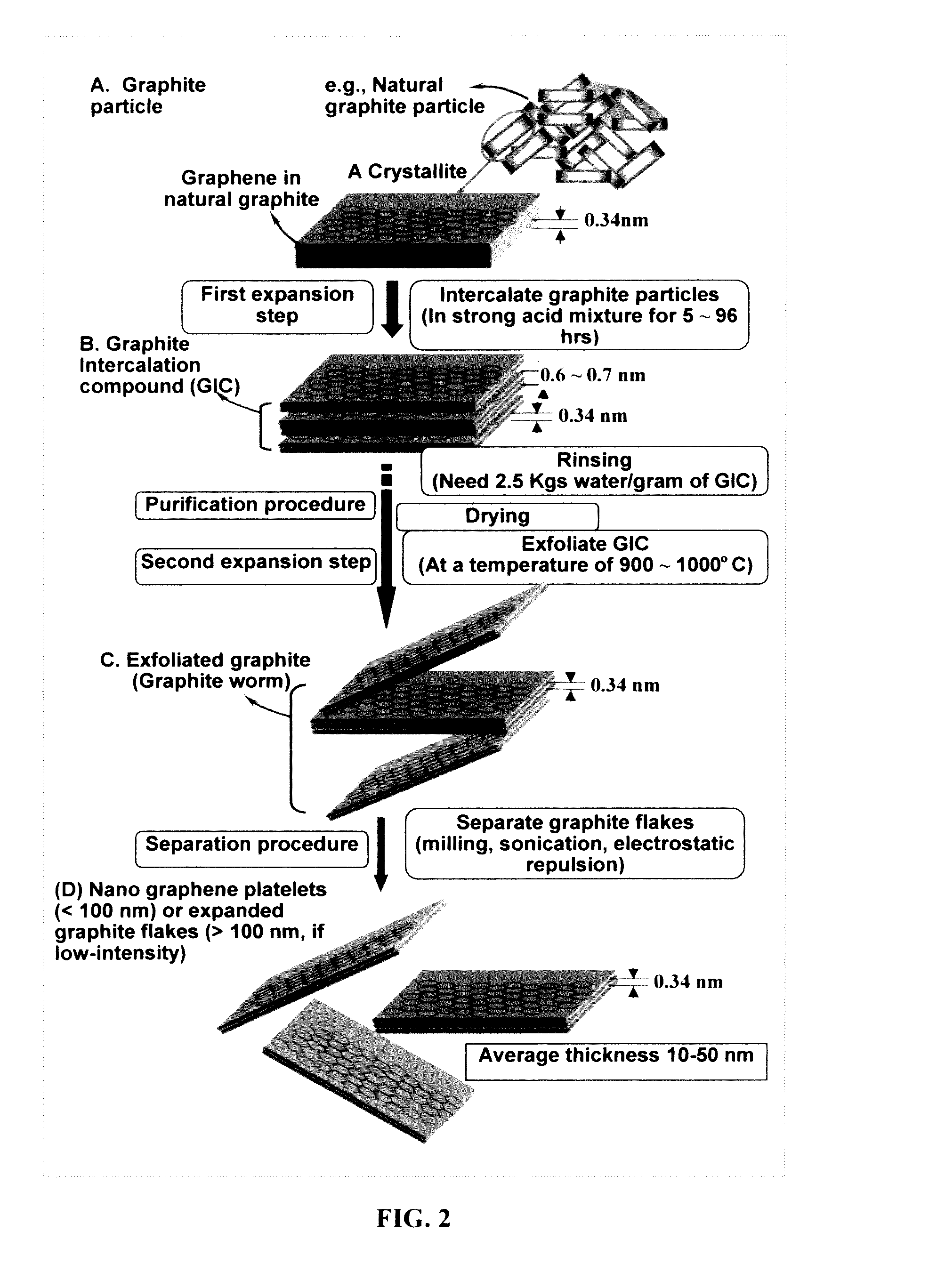

Preparation of graphene sheets

ActiveUS20130001089A1Improve conductivityImprove scalabilityMaterial nanotechnologyElectrolysis componentsOrganic solventGraphene

A method of preparing graphene sheets. The method includes: immersing a portion of a first electrode and a portion of a second electrode in a solution containing an acid, an anionic surfactant, a salt, an oxidizing agent, or any combination thereof as an electrolyte, the immersed portion of the first electrode including a first carbon material and the immersed portion of the second electrode including a second carbon material or a metal; causing a potential to exist between the first and second electrodes; and recovering, from the solution, graphene sheets exfoliated from the carbon material(s). Also disclosed is a method of preparing a graphene film electrode. The method includes: dissolving graphene sheets in an organic solvent to form a solution, applying the solution on a substrate, adding deionized water to the solution on the substrate so that a graphene film is formed, and drying the graphene film.

Owner:ACAD SINIC

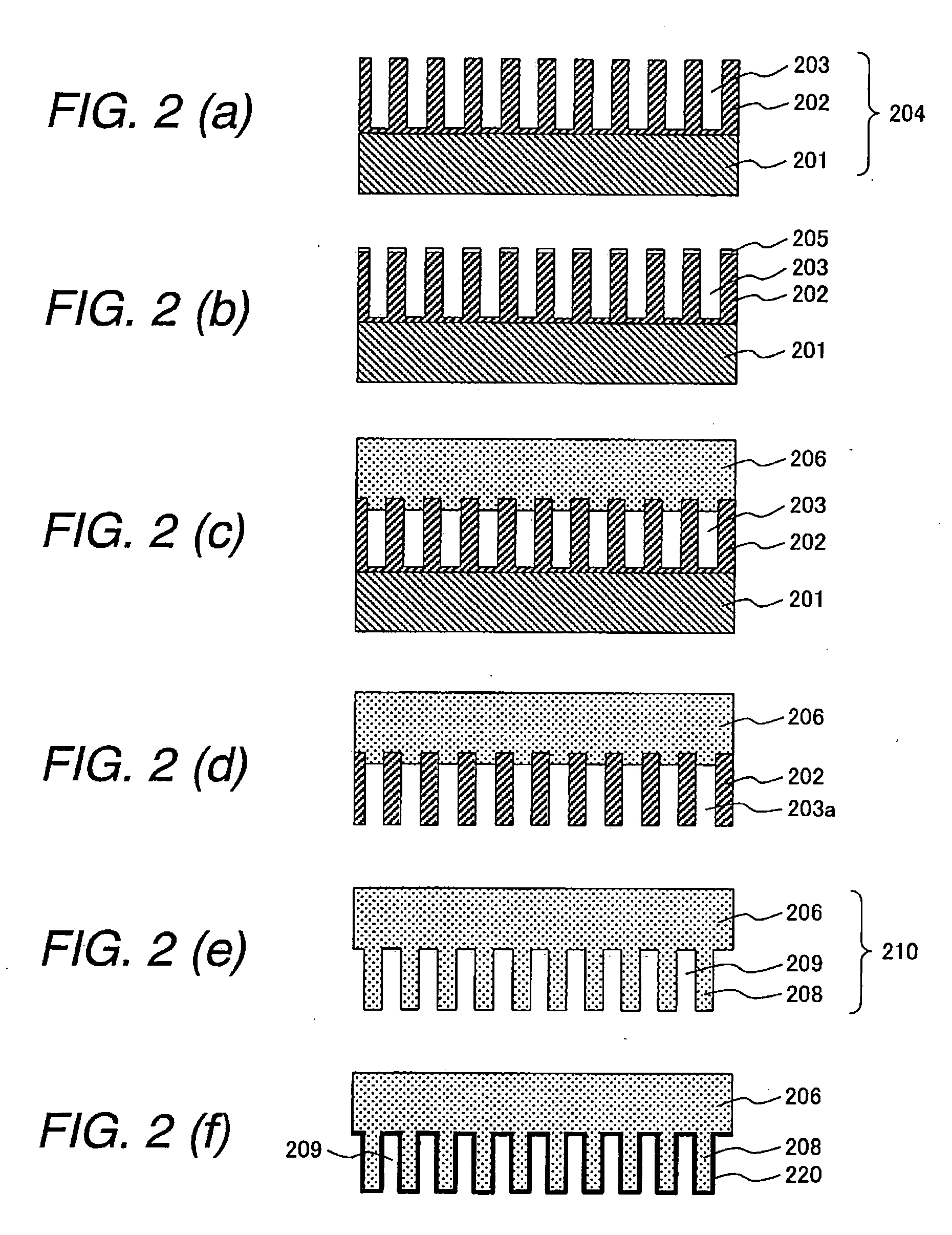

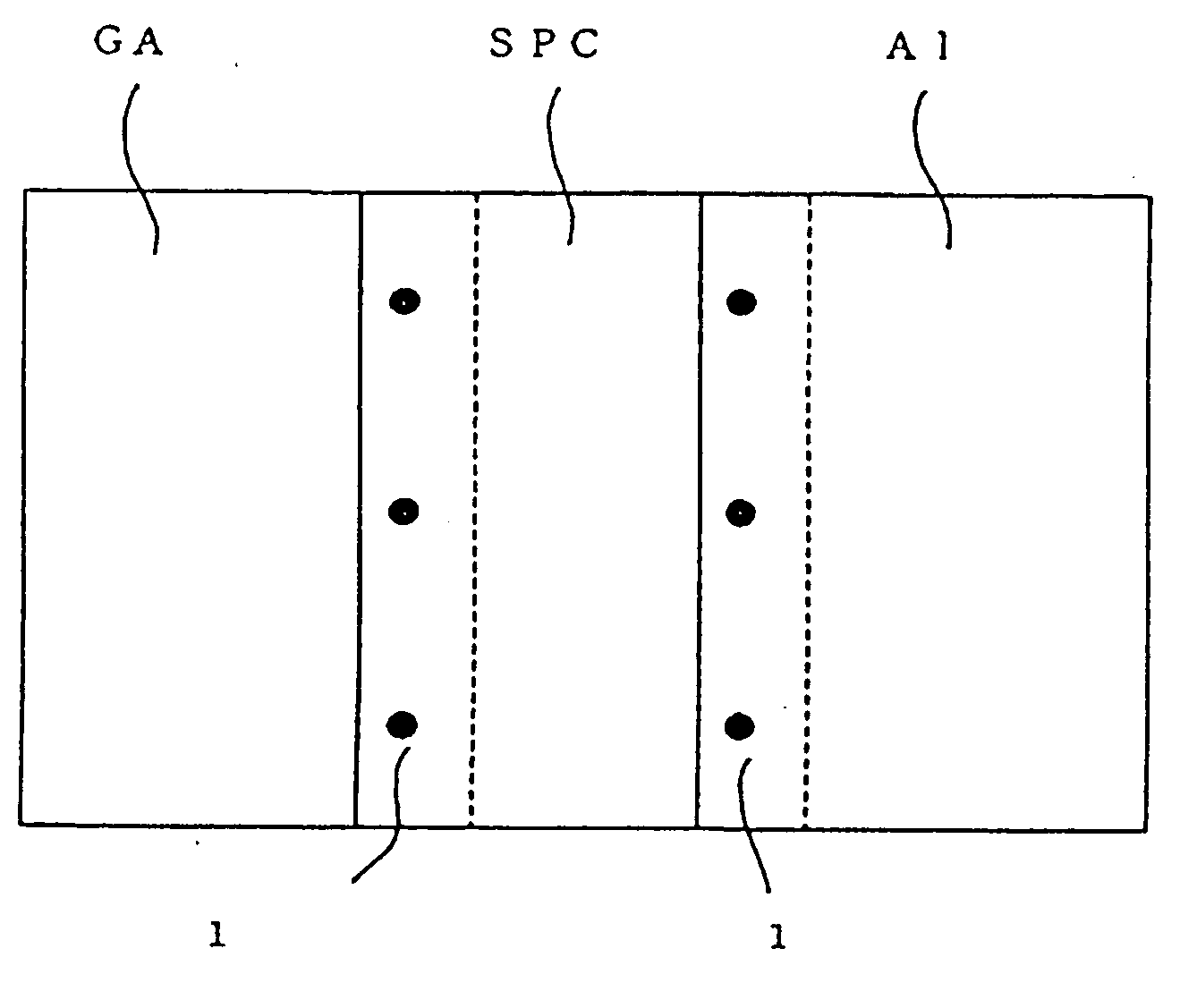

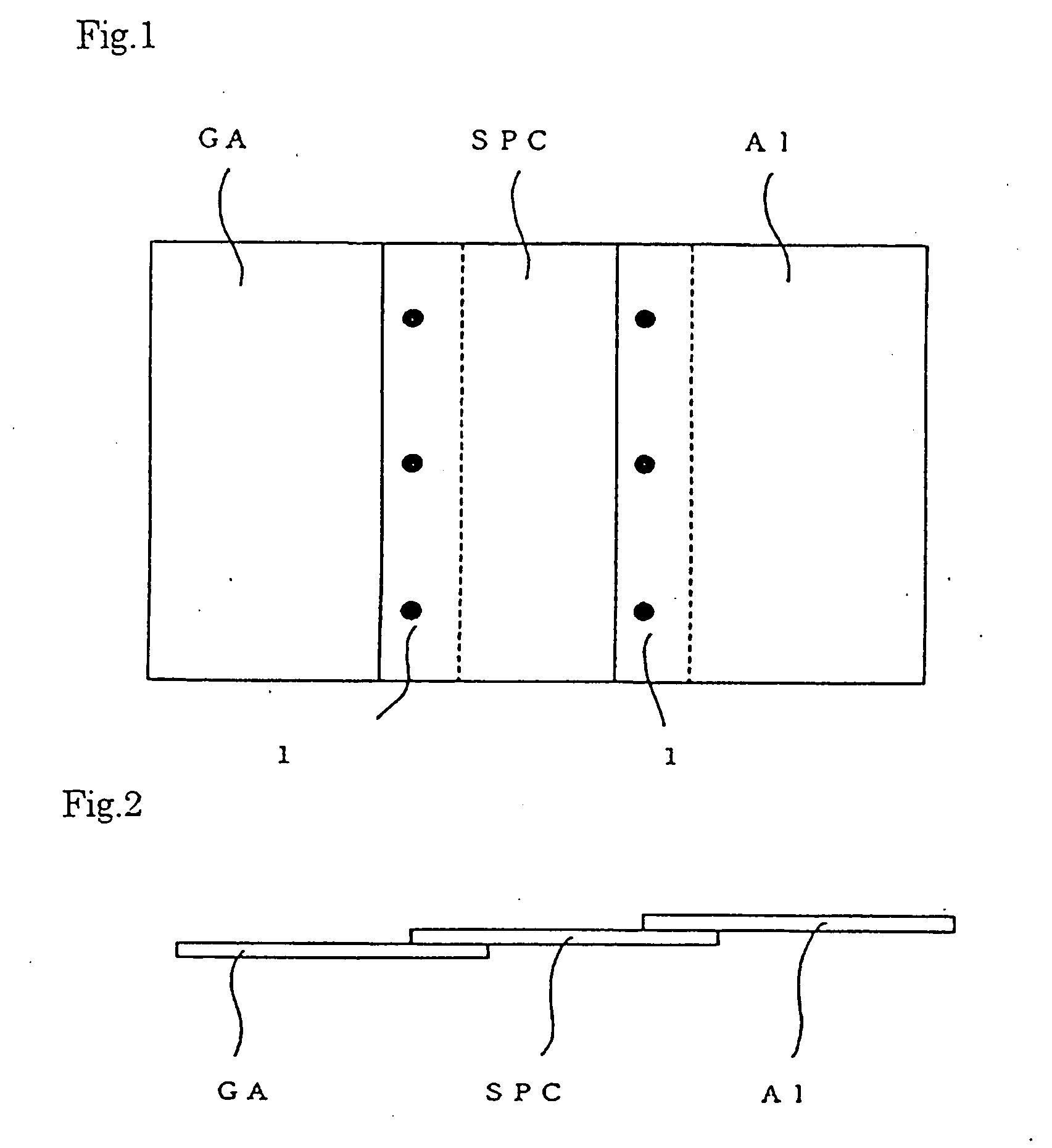

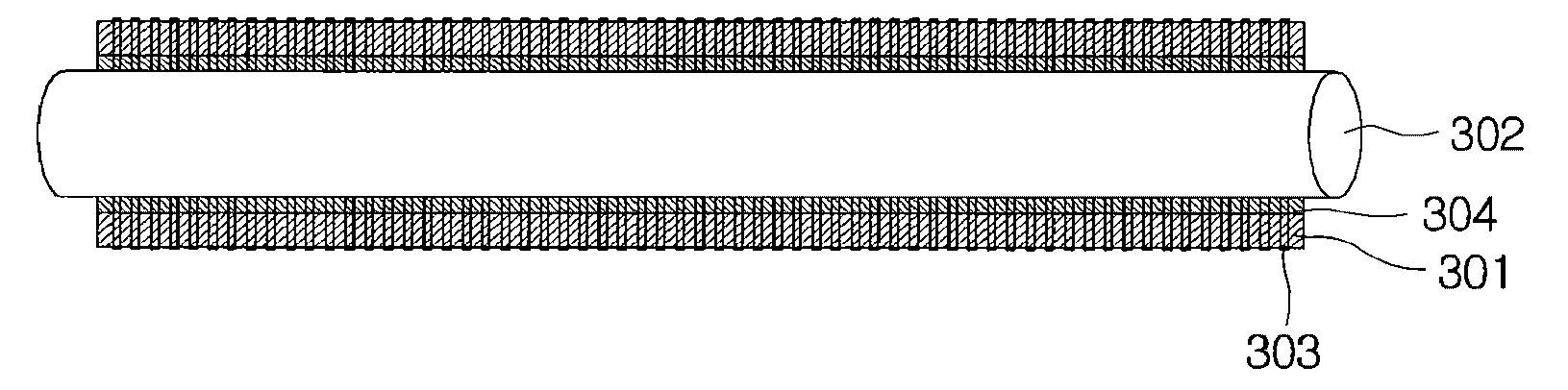

Process for forming zinc oxide film and processes for producing semiconductor device substrate and photo-electricity generating device using the film

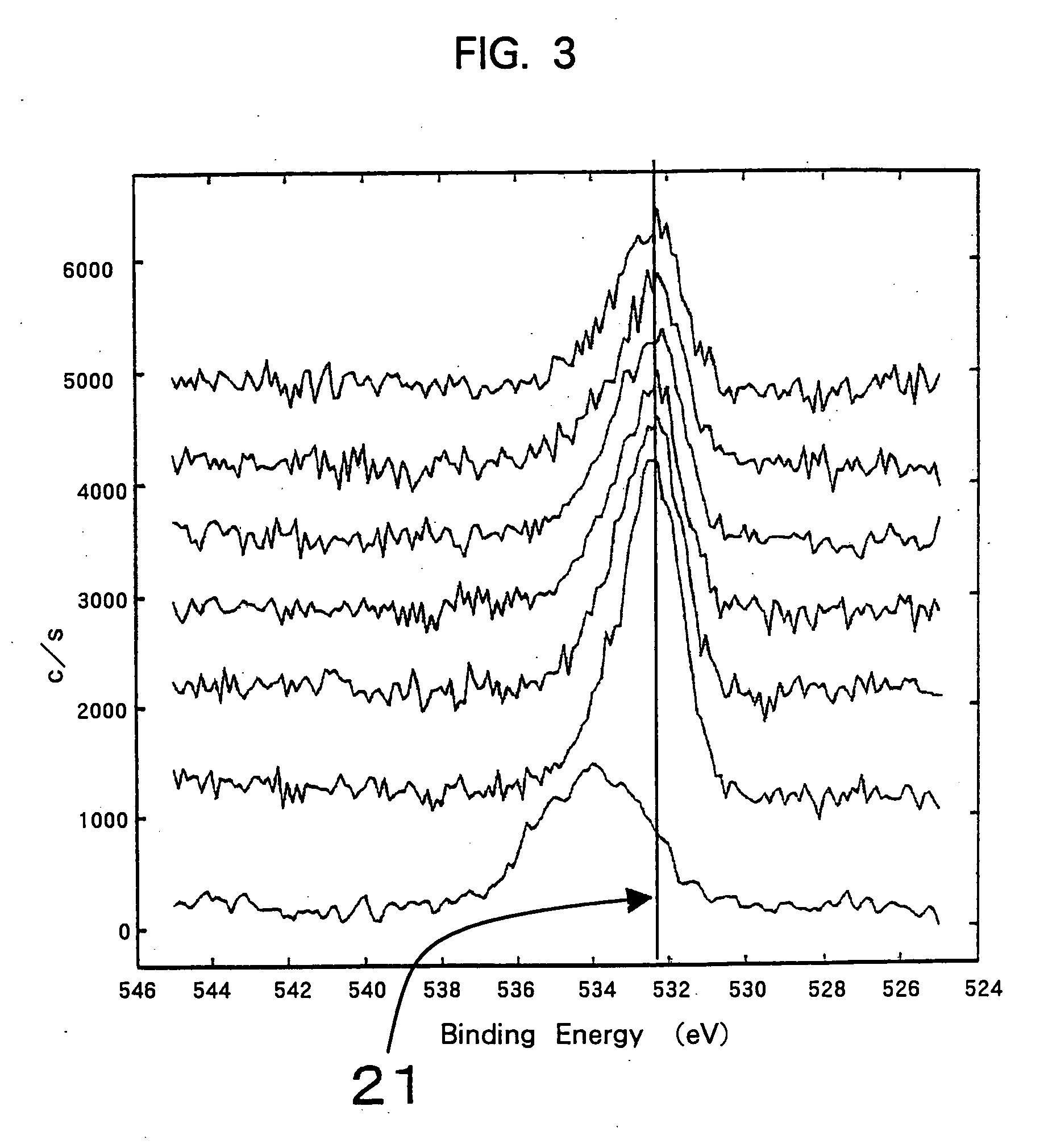

InactiveUS6106689AHigh production yield and reliabilityEnhanced light absorptionElectrolytic inorganic material coatingFinal product manufactureElectricitySurface roughness

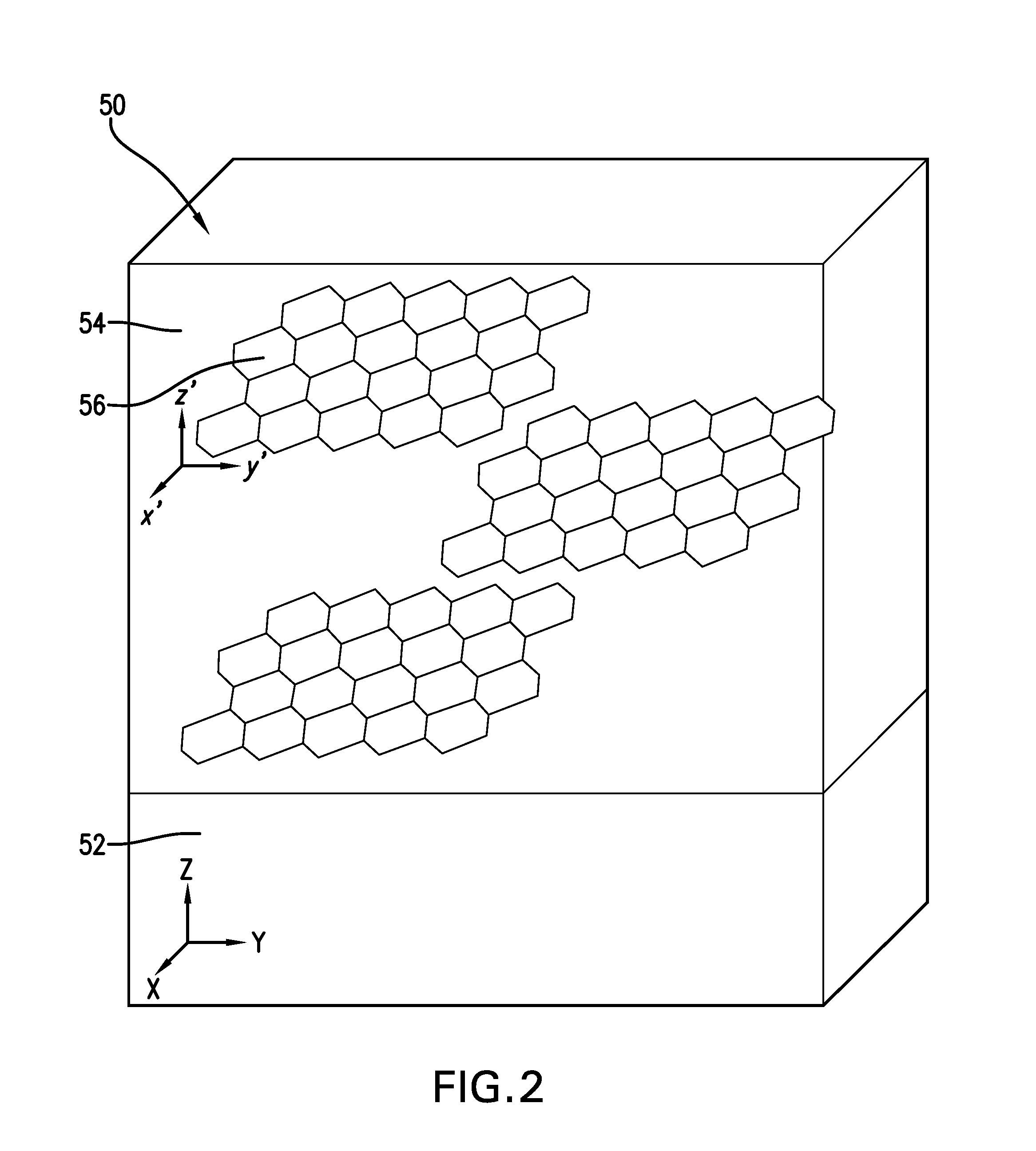

A process for forming a zinc oxide film including immersing an electroconductive substrate having a surface including a plurality of linear projections in an aqueous solution containing at least nitrate ions and zinc ions to form a zinc oxide film on the electroconductive substrate by a liquid-phase deposition. The plurality of linear projections may preferably provide an uneven surface which has a center-line average surface roughness Ra(X) of 15-300 nm when scanned in a direction parallel to the linear projections, a center line average surface roughness Ra(Y) of 20-600 nm when scanned in a direction perpendicular to the linear projections, and an Ra(X) / Ra(Y) ratio of at most 0.8. The thus formed zinc oxide film is provided with an uneven surface suitable for an optical-confinement layer of a photo-electricity generating device excellent in photoelectric performances.

Owner:CANON KK

Preparation method of graphene film

InactiveCN102051651AThickness is easy to controlQuality improvementElectrolytic inorganic material coatingElectrochemistryCrystallinity

The invention relates to a preparation method of a graphene film. In the invention, an electrochemical method is used for preparing a graphene film on the surface of a conductive substrate. The graphene film prepared by the method has the advantages of controllable thickness, controllable size, uniformity, continuity and crystallinity. The graphene film can be widely used in the fields of sensors, transistors, transparent electrodes, capacitors, catalysts, composite materials and the like.

Owner:HUNAN UNIV

Article of manufacture and process for anodically coating an aluminum substrate with ceramic oxides prior to polytetrafluoroethylene or silicone coating

InactiveUS20050115840A1AnodisationElectrolytic inorganic material coatingCeramic coatingSilicone coating

Owner:HENKEL KGAA

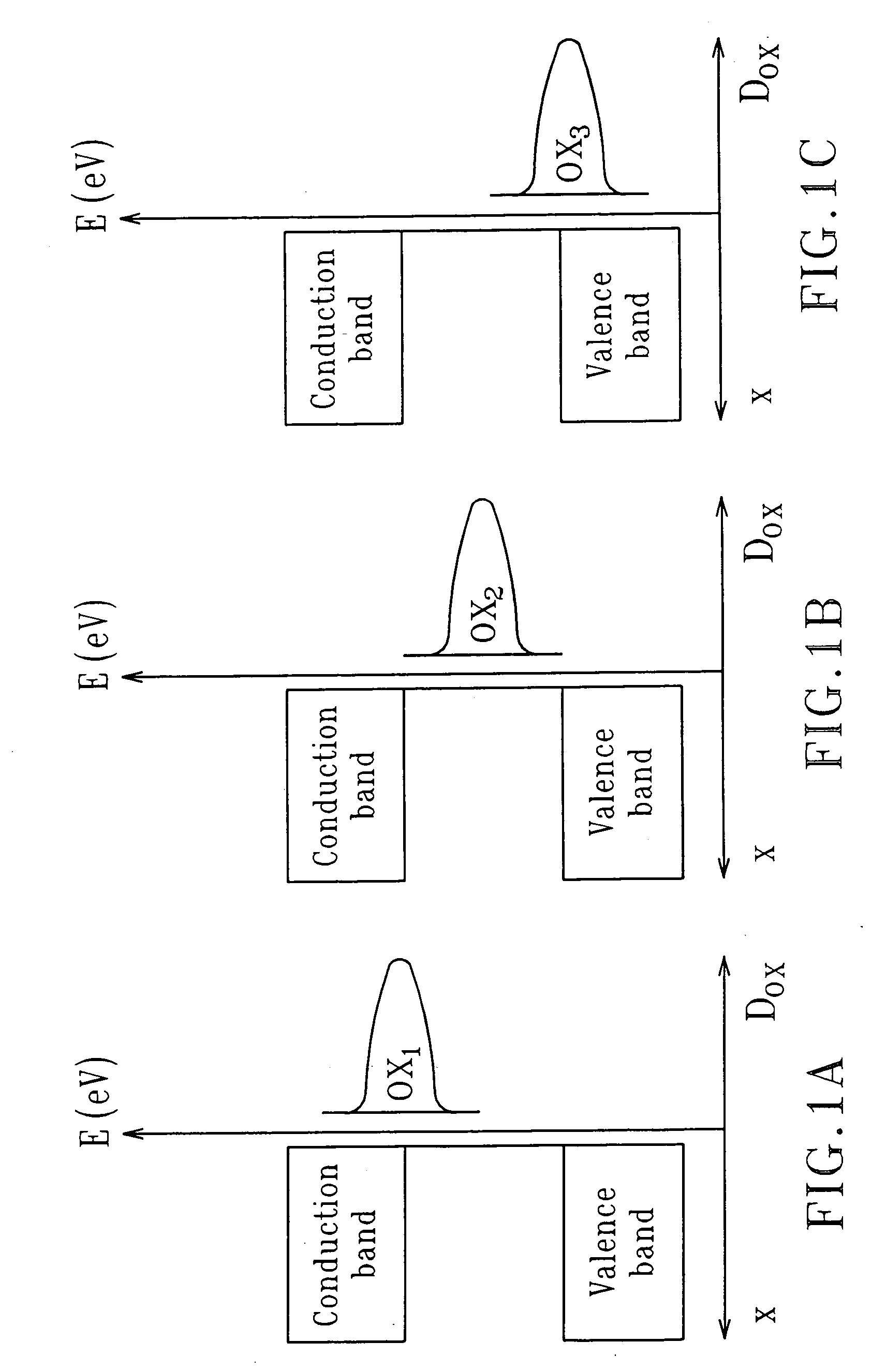

Gate stack engineering by electrochemical processing utilizing through-gate-dielectric current flow

ActiveUS20060166474A1Reduce resistanceAnodisationElectrolytic inorganic material coatingGate dielectricSemiconductor materials

A method is provided for electroplating a gate metal or other conducting or semiconducting material directly on a dielectric such as a gate dielectric. The method involves selecting a substrate, dielectric layer, and electrolyte solution or melt, wherein the combination of the substrate, dielectric layer, and electrolyte solution or melt allow an electrochemical current to be passed from the substrate through the dielectric layer into the electrolyte solution or melt. Methods are also provided for electrochemical modification of dielectrics utilizing through-dielectric current flow.

Owner:GLOBALFOUNDRIES US INC

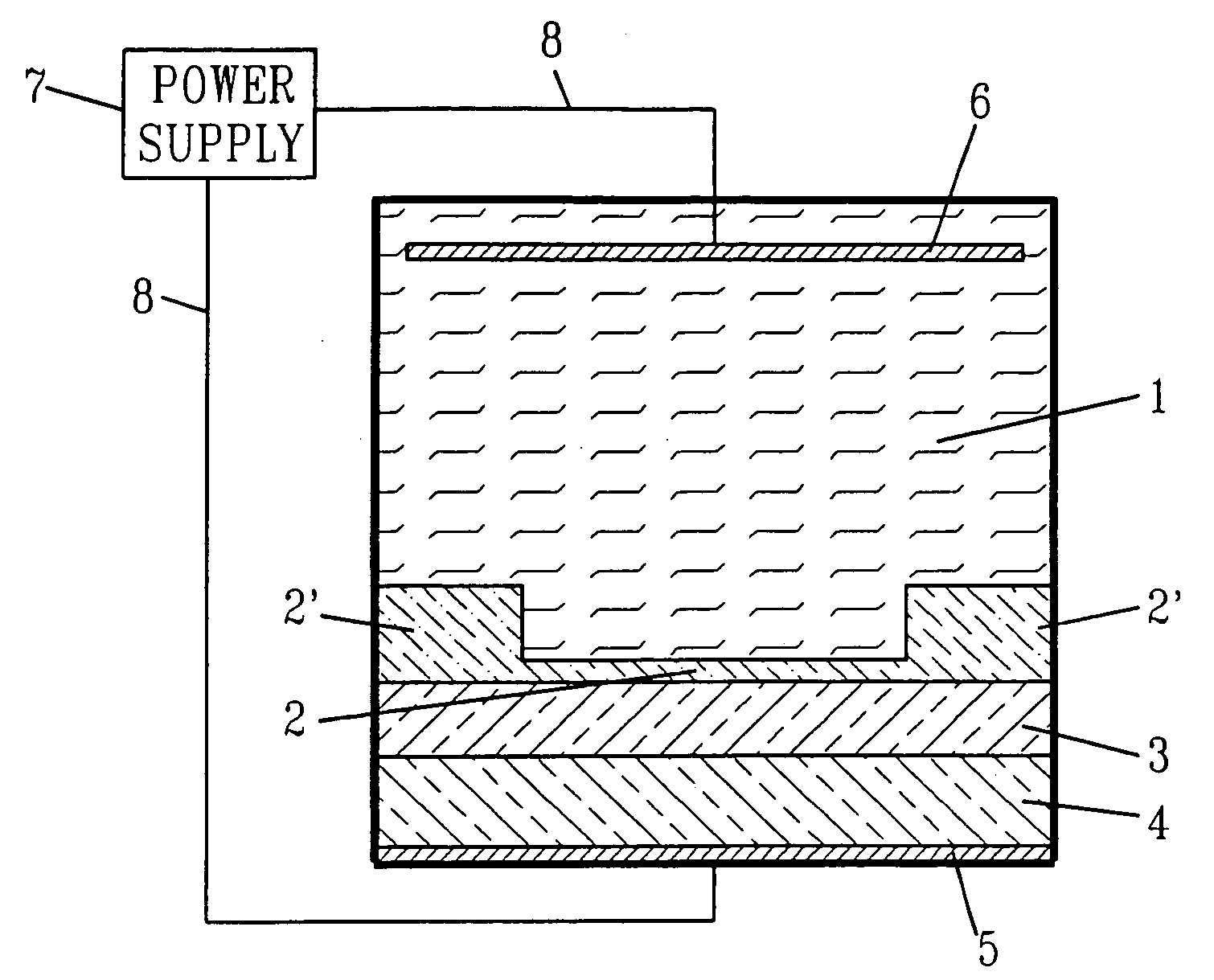

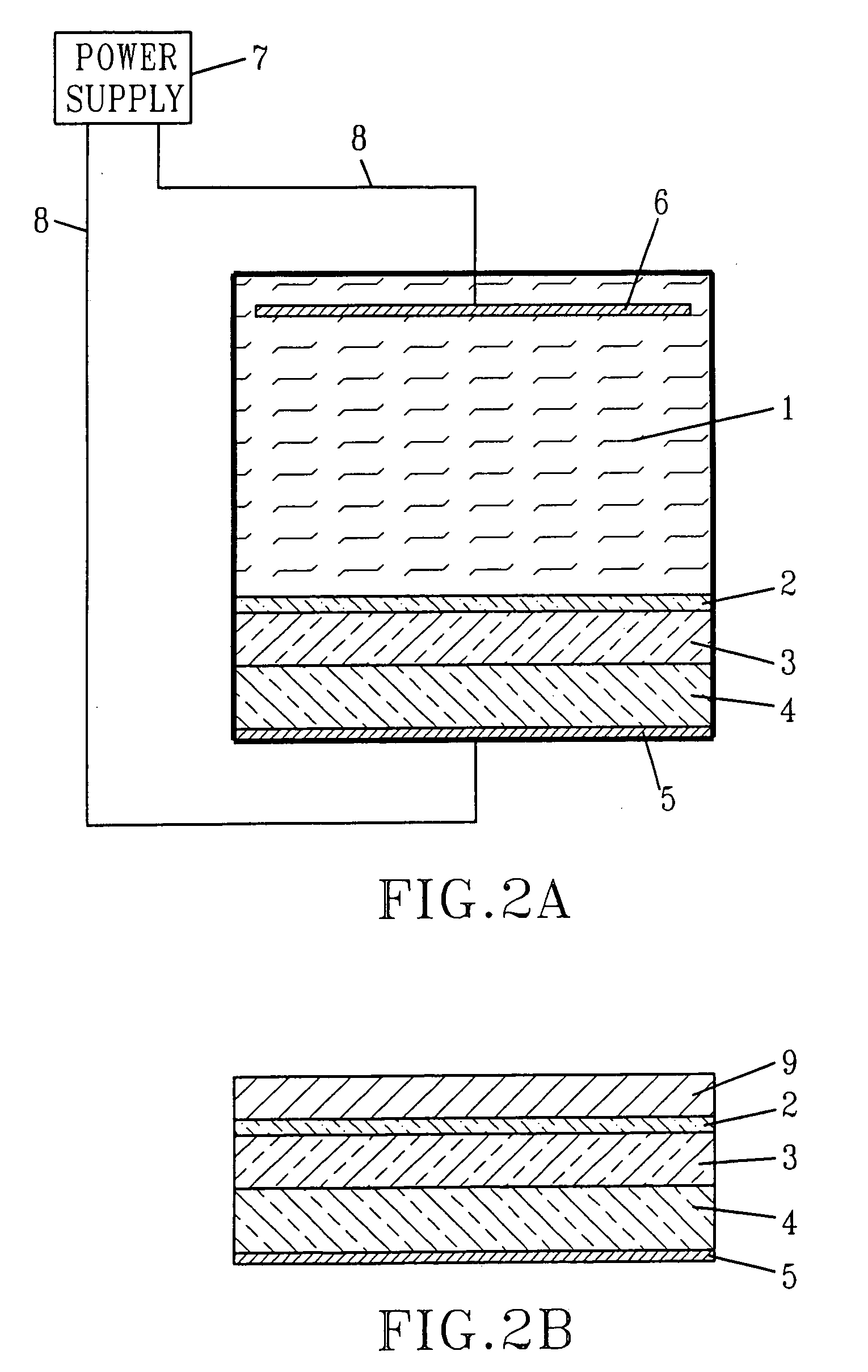

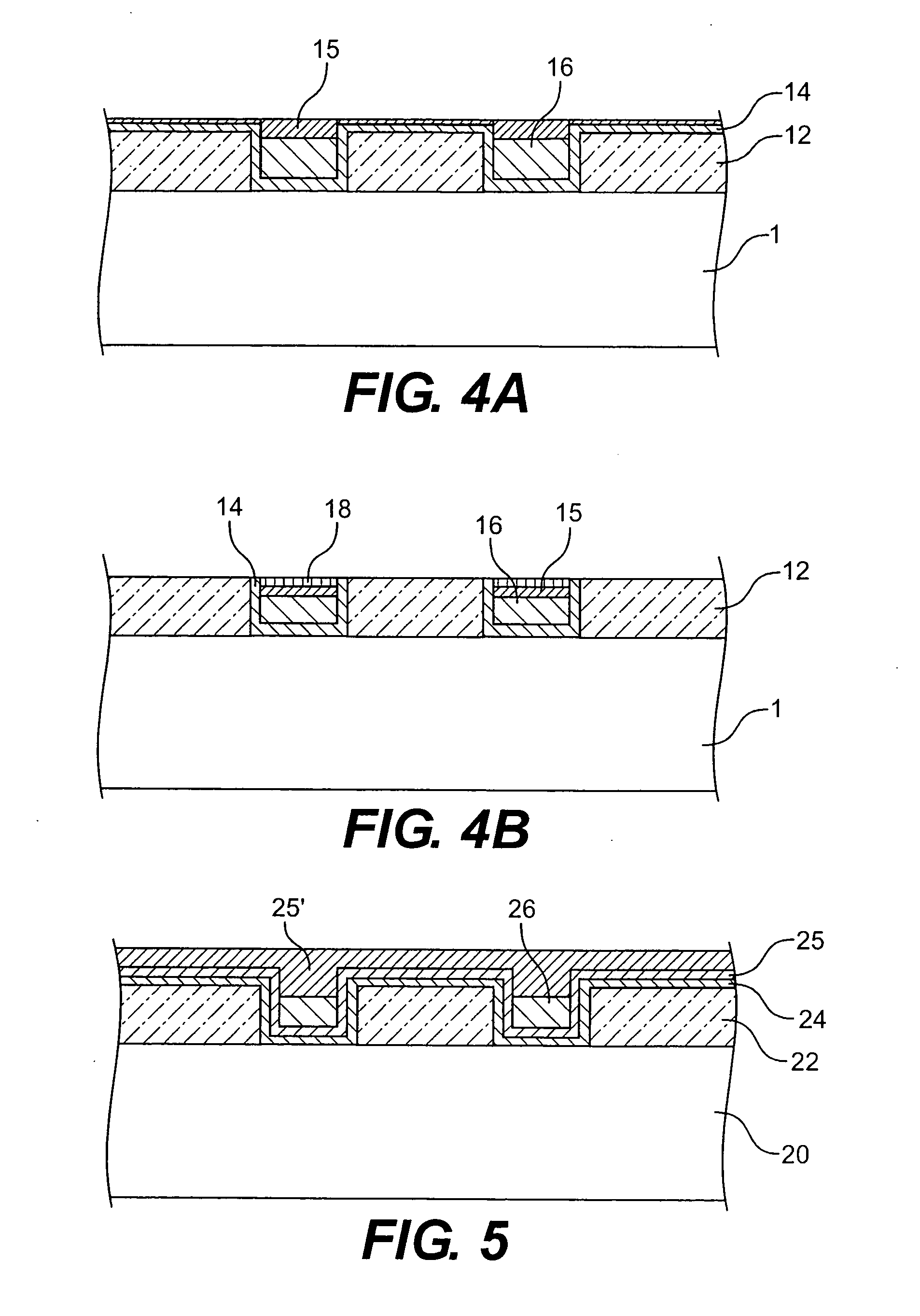

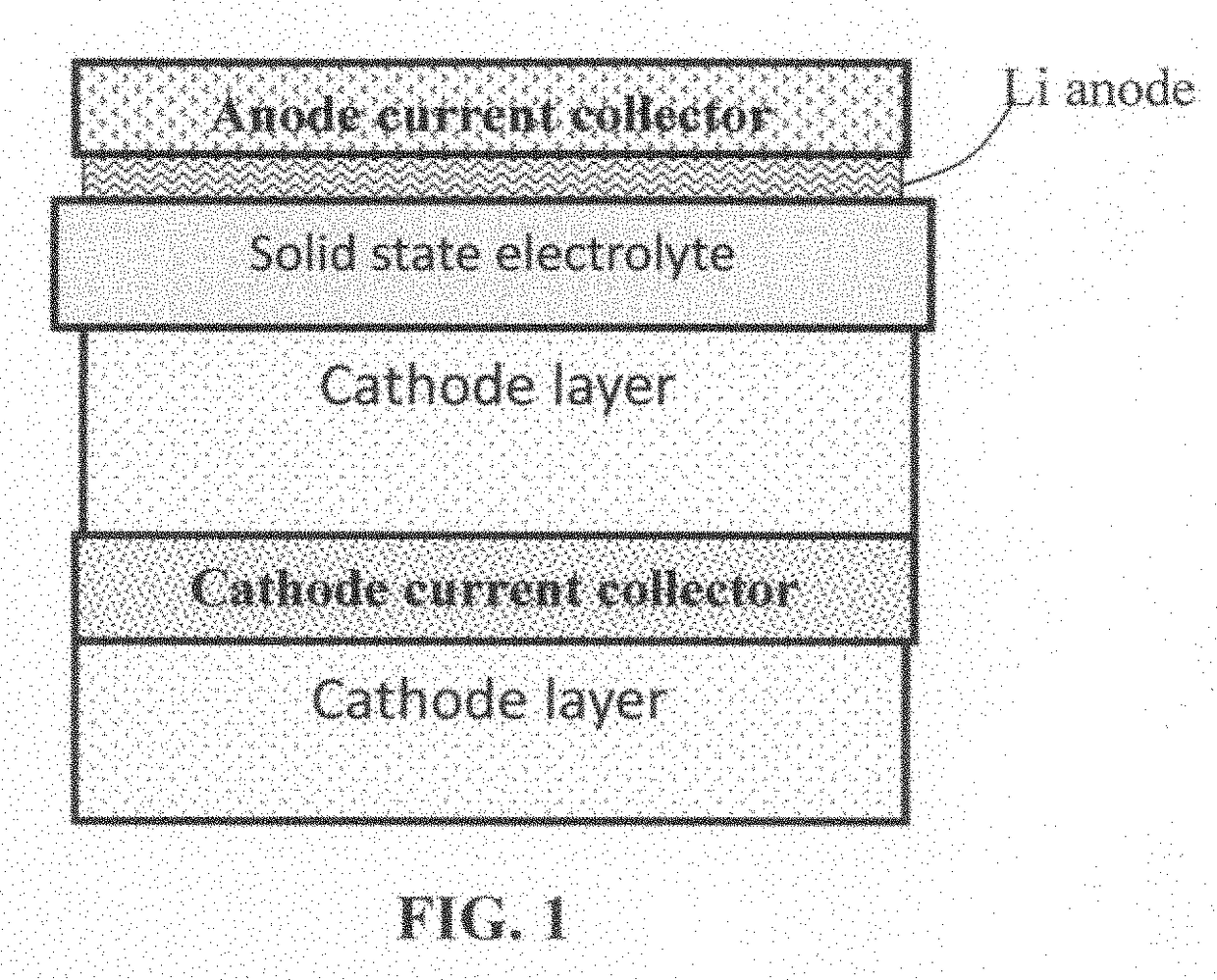

Thin-film cathode for 3-dimensional microbattery and method for preparing such cathode

InactiveUS20060032046A1Electrochemical processing of electrodesElectrolytic inorganic material coatingThin film cathodesThin membrane

A method for producing a microbattery including providing a conductive substrate, forming a thin film cathodic layer on at least one surface of the conductive substrate, subsequently forming a thin film electrolyte layer over the cathodic layer and subsequently forming a thin film anodic layer over the electrolyte layer

Owner:TEL AVIV UNIV FUTURE TECH DEVMENT

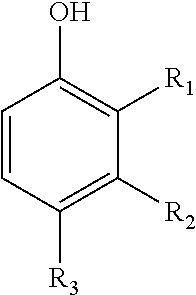

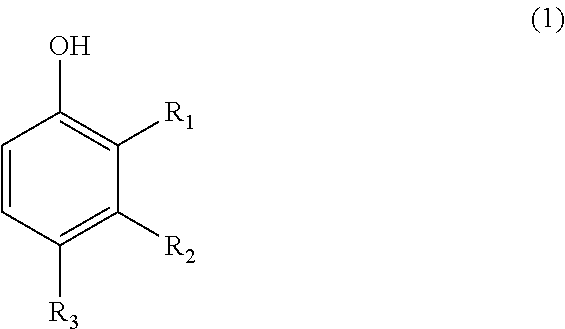

Treating solution for surface treatment of metal and a method for surface treatment

InactiveUS20060185769A1Improve corrosion resistanceAnodisationElectrolytic inorganic material coatingSurface-active agentsOxygen

Treating solution for surface treatment of metal to treat one metal material selected from the group consisting of ferriferous material, zinciferous material, aluminiferous material and magnesiferous material or to treat two or more metal materials selected from the group consisting of ferriferous material, zinciferous material, aluminiferous material and magnesiferous material at the same time, wherein the aqueous surface treating solution contains from 5 to 5000 ppm of at least one compound selected from the group consisting of zirconium compound and titanium compound by the metal element, and from 0.1 to 100 ppm of free fluorine ion, further the pH of the treating solution is from 2 to 6. To the treating solution, calcium compound, magnesium compound, strontium compound, nitric acid group, oxygen acid and / or salt of oxygen acid, polymer compound and surface active agent can be added.

Owner:NIHON PARKERIZING +2

Medical prosthetic devices and implants having improved biocompatibility

Disclosed are medical prosthetic devices or medical implants which exhibit improved biocompatitibly. The devices or implants include a metal material, e.g. titanium, in which the metal surface parts are coated with a corresponding hydride material that contains one or more biomolecule substance. This biomolecule substance may contain one or more biologically active molecules, e.g. bio-adhesives, biopolymers, blood proteins, enzymes, extra cellular matrix proteins, extra cellular matrix biomolecules, growth factors and hormones, peptide hormones, deoxyribonucleic acids, ribonucleic acids, receptors, enzyme inhibitors, drugs, biologically active anions and cations, vitamins, adenosine monophosphate (AMP), adenosine diphosphate (ADP), adenosine triphosphate (ATP), marker biomuolecules, amino acids, fatty acids, nucleotides (RNA and DNA bases), or sugars.

Owner:STRAUMANN HLDG AG

Surface-treated metallic material, method of surface treating therefor and resin coated metallic material, metal can and can lid

InactiveUS20050175798A1Number of step is increasedCorrosion resistance is not sufficientEnvelopes/bags making machineryDead plant preservationElectrolysisO-Phosphoric Acid

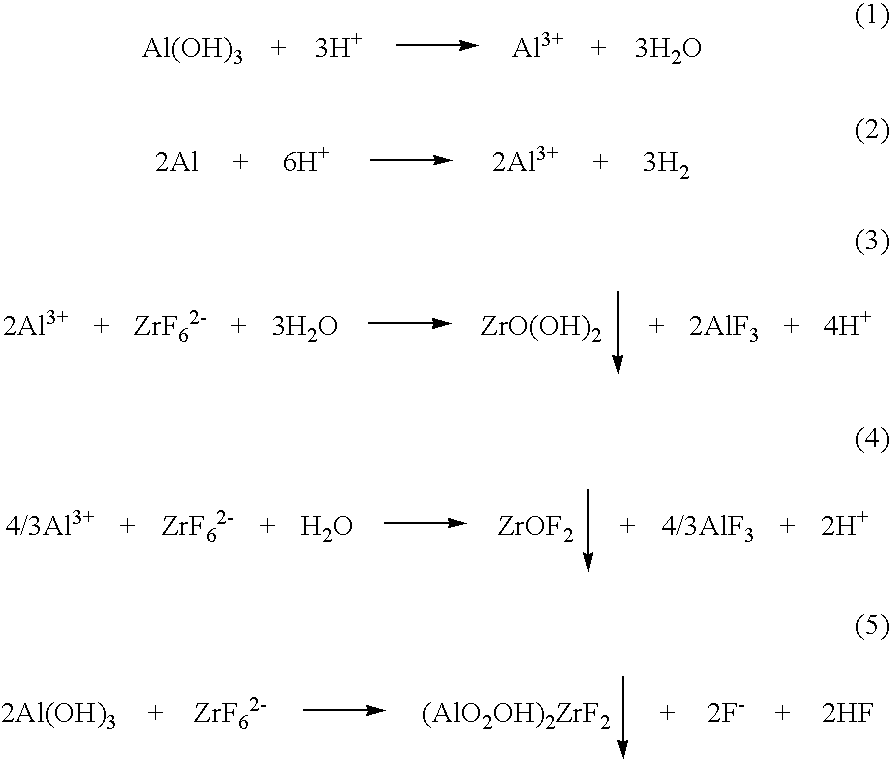

A surface-treated metal material is obtained by forming an inorganic surface-treating layer containing at least Zr, O and F as chief components but without containing phosphoric acid ions on the surfaces of a metal by the cathodic electrolysis or by forming an inorganic surface-treating layer containing at least Zr, O and F as chief components and having an atomic ratio of P and Zr of 0≦P / Zr<0.6 in the uppermost surface on the surfaces of the metal by the cathodic electrolysis at a low cost featuring high productivity, environmental friendliness, scar resistance, adhesion, workability and intimate fitting. By using a metal material obtained by coating the surface-treated metal material with an organic resin and, particularly, with a polyester resin, a metal can or a can lid exhibits excellent adhesion and corrosion resistance even at portions that are worked to a high degree. Further, the can lid exhibits excellent opening performance even after the sterilization by heating.

Owner:TOYO SEIKAN KAISHA LTD

Composite electrode and method for manufacturing the same

InactiveUS20100273051A1Large specific surface areaImprove high temperature stabilityElectrochemical processing of electrodesElectrolytic capacitorsComposite electrodeConductive polymer

A composite electrode and a method for manufacturing the same are disclosed. By using a composite electrode that includes a porous support made of ceramic or metal and a conductive polymer or a metal oxide formed on a surface of the porous support, a capacitor or secondary cell that provides increased charge / discharge capacity and increased energy / output density, as well as high-temperature stability and high reliability, can be manufactured.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Process for preparing a film of an oxide or a hydroxide of an element of groups IIB or IIIA of the periodic table, and the composite structures which include such a film

InactiveUS6030517AGood mechanical integrityImprove adhesionElectrolytic inorganic material coatingDuplicating/marking methodsOxidation stateElectrochemical cell

PCT No. PCT / FR96 / 00495 Sec. 371 Date Oct. 7, 1997 Sec. 102(e) Date Oct. 7, 1997 PCT Filed Apr. 2, 1996 PCT Pub. No. WO96 / 31638 PCT Pub. Date Oct. 16, 1996Process for depositing a film of a metal oxide or of a metal hydroxide on a substrate in an electrochemical cell, wherein (i) the metal hydroxide is of formula M(OH)xAy, M representing at least one metallic species in an oxidation state i chosen from the elements in Groups II and III of the Periodic Table, A being an anion whose number of charges is n, 0<x< / =i and x+ny=i, (ii) the electrochemical cell comprises (a) an electrode comprising the substrate, (b) a counterelectrode, (c) a reference electrode and (d) an electrolyte comprising a conducting solution comprising at least one salt of the metal M, the process comprising the steps of: dissolving oxygen in the electrolyte and imposing a cathode potential of less than the oxygen reduction potential and greater than the potential for deposition of the metal M in the electrolyte in question on the electrochemical cell.

Owner:CENT NAT DE LA RECHERCHE SCI

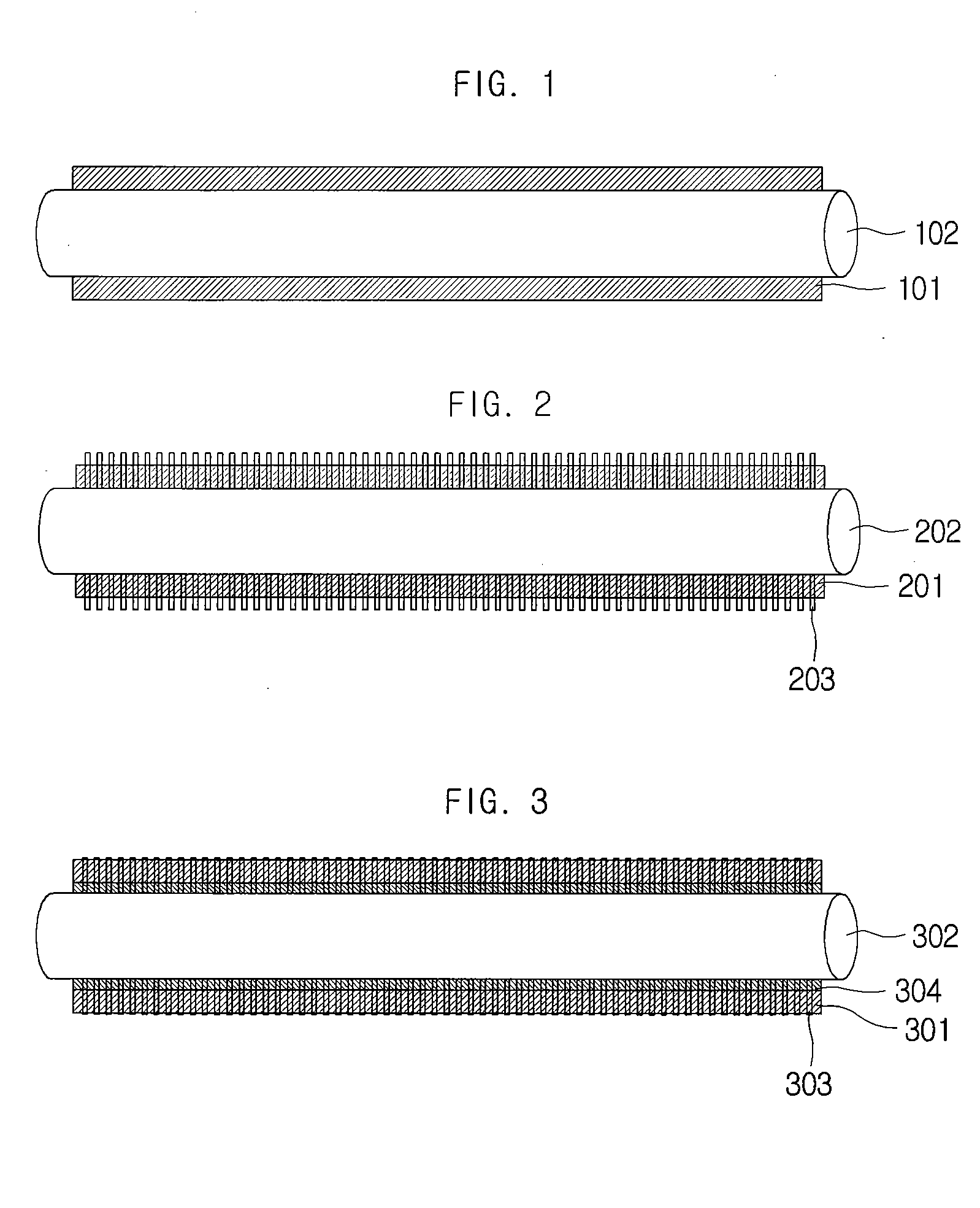

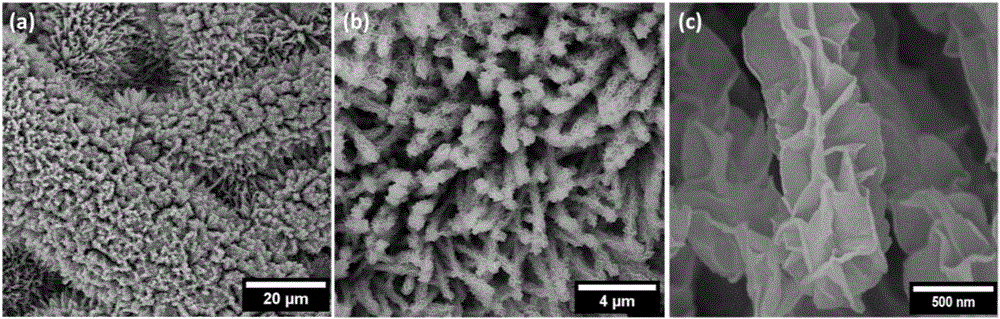

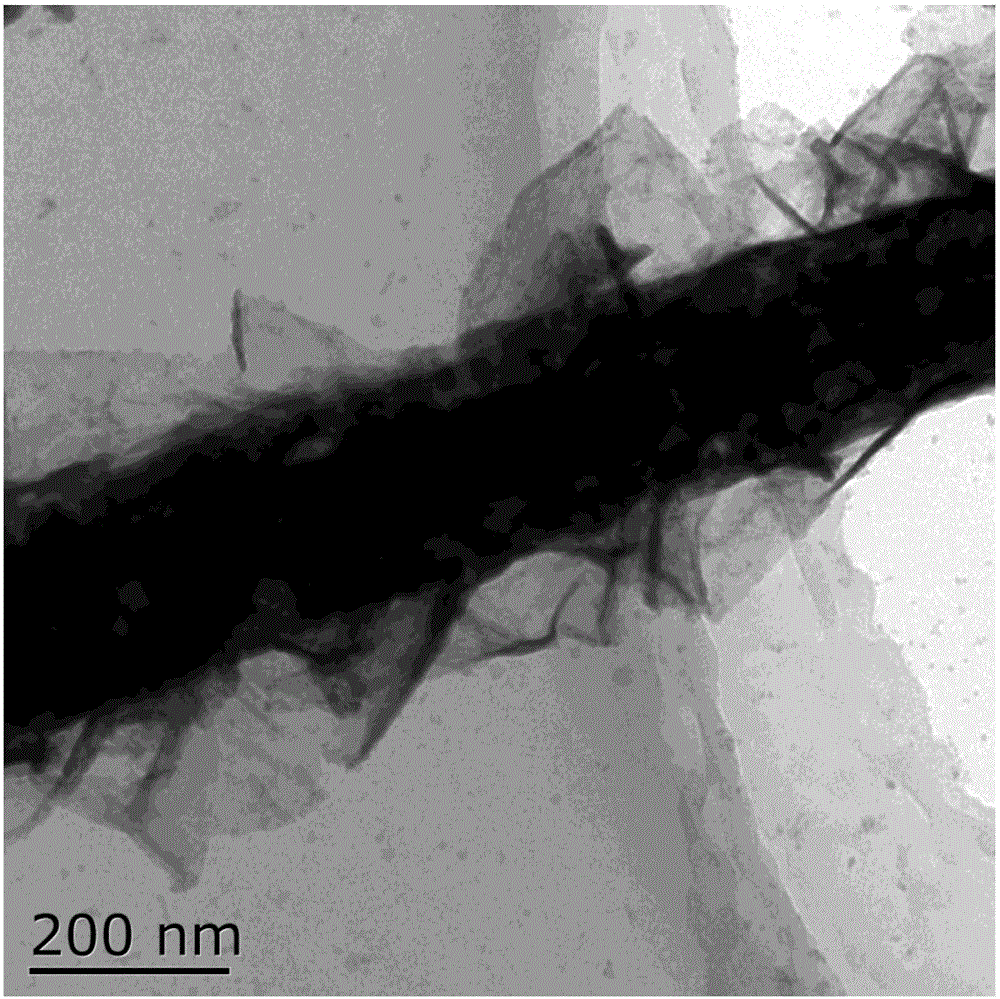

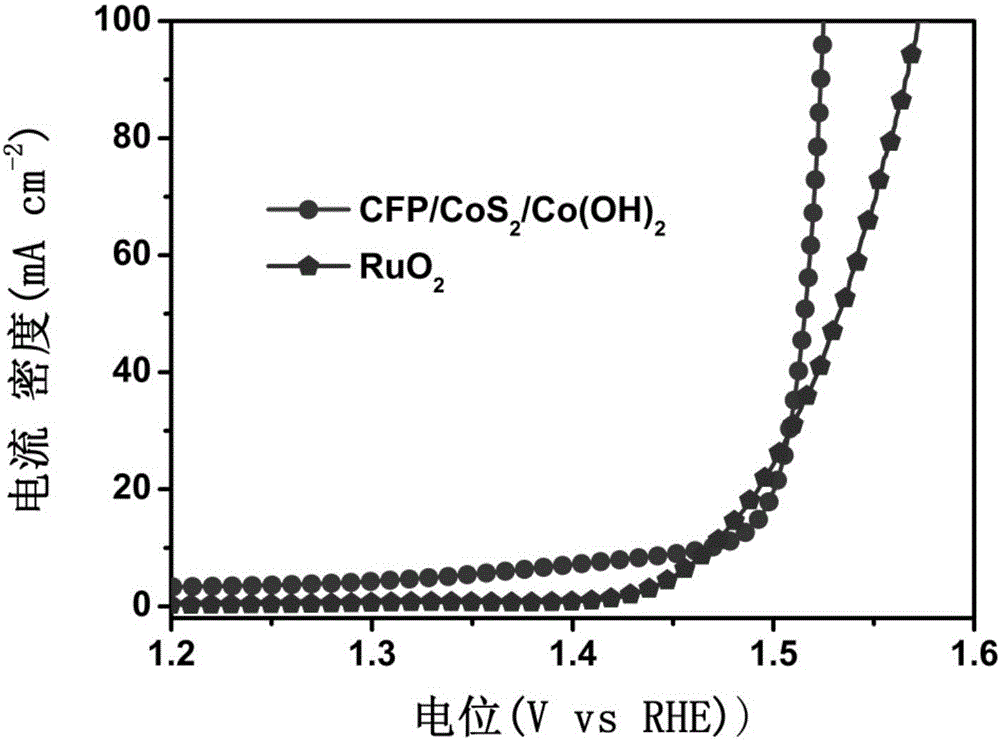

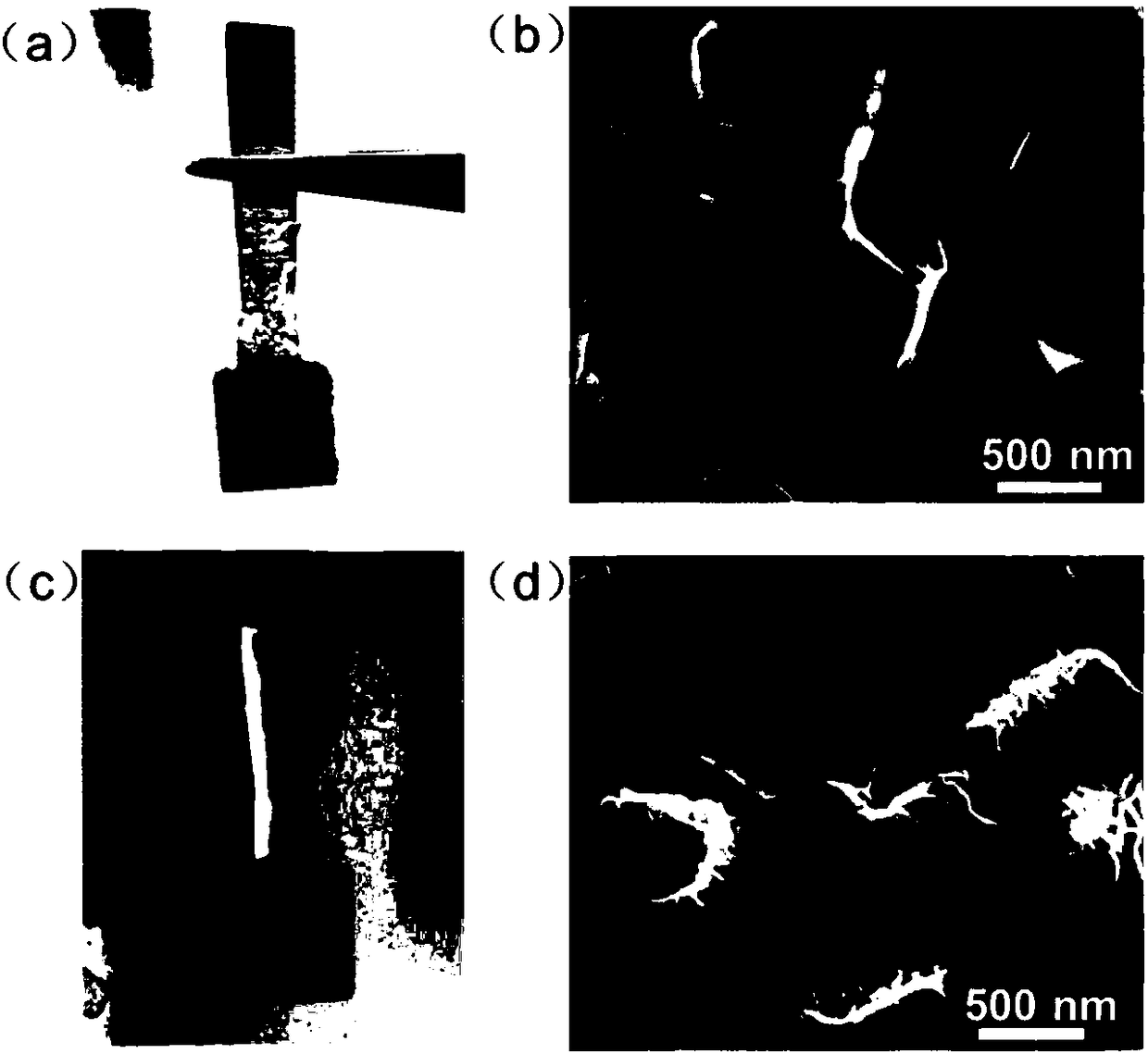

Electrocatalyst with cobalt-based multi-stage nano-composite structure for oxygen production by electrolysis of water and preparation method of electrocatalyst

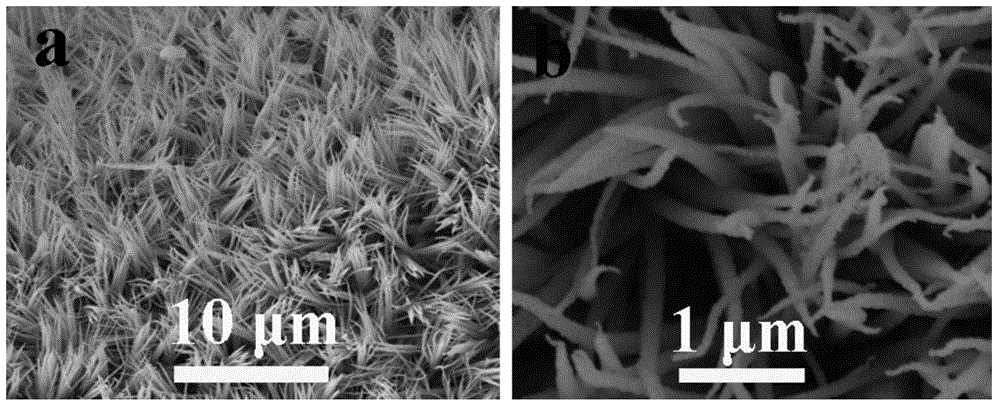

InactiveCN106011926ALow costEasy to operateCobalt sulfidesElectrolytic inorganic material coatingFiberCarbon fibers

The invention provides an electrocatalyst with a cobalt-based multi-stage nano-composite structure for oxygen production by electrolysis of water and a preparation method of the electrocatalyst. The preparation method comprises the following steps: dissolving cobalt nitrate hexahydrate, urea and ammonium fluoride in deionized water to obtain a precursor solution; transferring the precursor solution into a hydrothermal reactor; adding carbon fiber paper; enabling basic cobalt carbonate nanowires to grow on the carbon fiber paper through solvothermal reaction; after finish of reaction, naturally cooling; then taking out a product; washing and drying to obtain a carbon fiver paper loaded basic cobalt carbonate nanowire composite structure; by taking powdered sulfur as the raw material, preparing a carbon fiber paper loaded cobalt sulfide nanowire composite structure through low-temperature sulfuration reaction under the condition of an inert gas; and finally, electroplating the surface of the carbon fiber paper loaded cobalt sulfide nanowire composite structure with a layer of cobalt hydroxide nanosheets by use of the electrochemical deposition method so as to obtain the electrocatalyst with the cobalt-based multi-stage nano-composite structure for oxygen production by electrolysis of water. As the sulfide and the hydroxide of transition metal cobalt are adopted as the catalyst, in comparison with noble metals, the cost of the catalyst is lowered.

Owner:JIANGSU UNIV

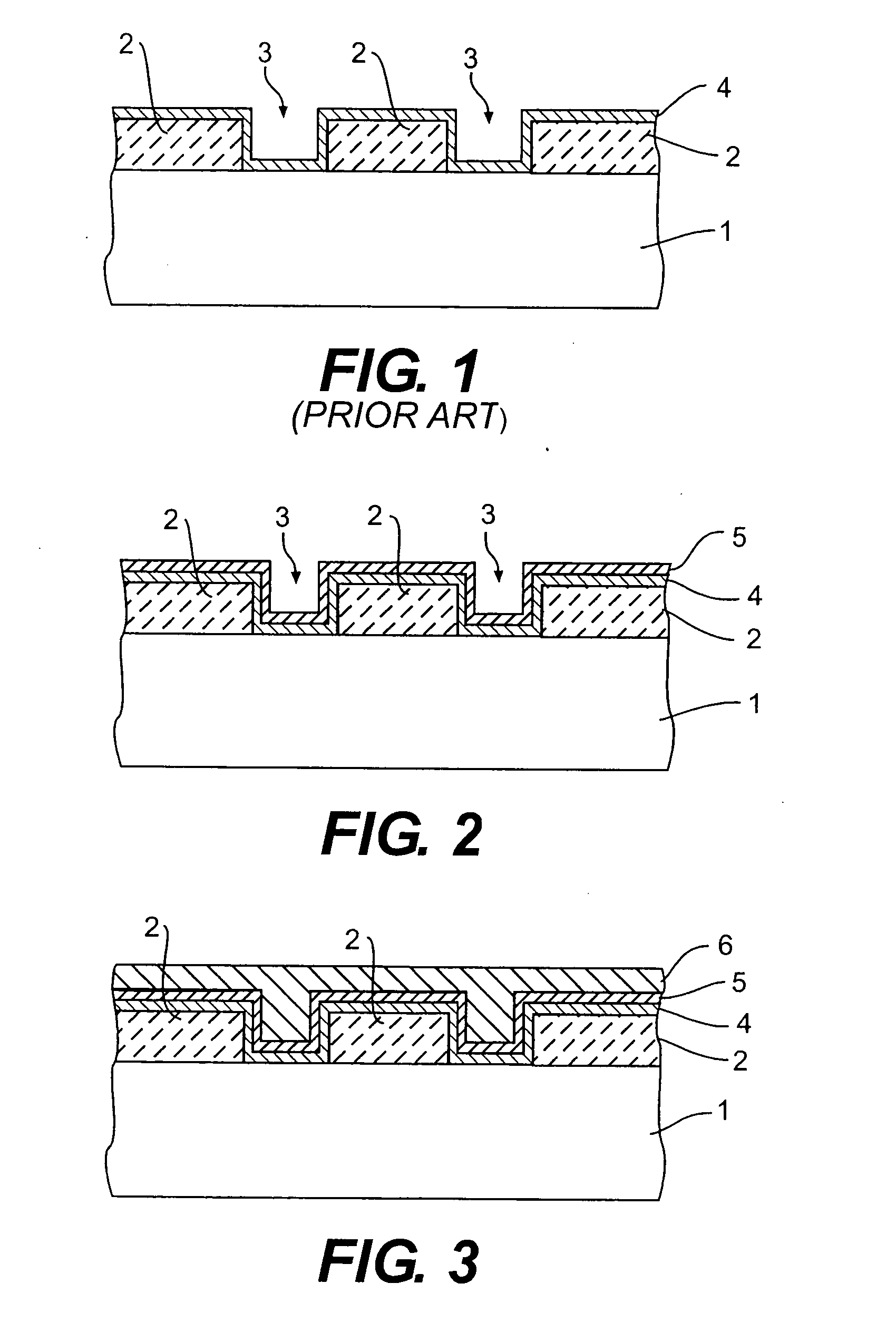

Electroplated CoWP composite structures as copper barrier layers

ActiveUS20050104216A1Electrolytic inorganic material coatingSemiconductor/solid-state device detailsOptoelectronicsCopper

A composite material comprising a layer containing copper, and an electrodeposited CoWP film on the copper layer. The CoWP film contains from 11 atom percent to 25 atom percent phosphorus and has a thickness from 5 nm to 200 nm. The invention is also directed to a method of making an interconnect structure comprising: providing a trench or via within a dielectric material, and a conducting metal containing copper within the trench or the via; and forming a CoWP film by electrodeposition on the copper layer. The CoWP film contains from 10 atom percent to 25 atom percent phosphorus and has a thickness from 5 nm to 200 nm. The invention is also directed to a interconnect structure comprising a dielectric layer in contact with a metal layer; an electrodeposited CoWP film on the metal layer, and a copper layer on the CoWP film.

Owner:TAIWAN SEMICON MFG CO LTD

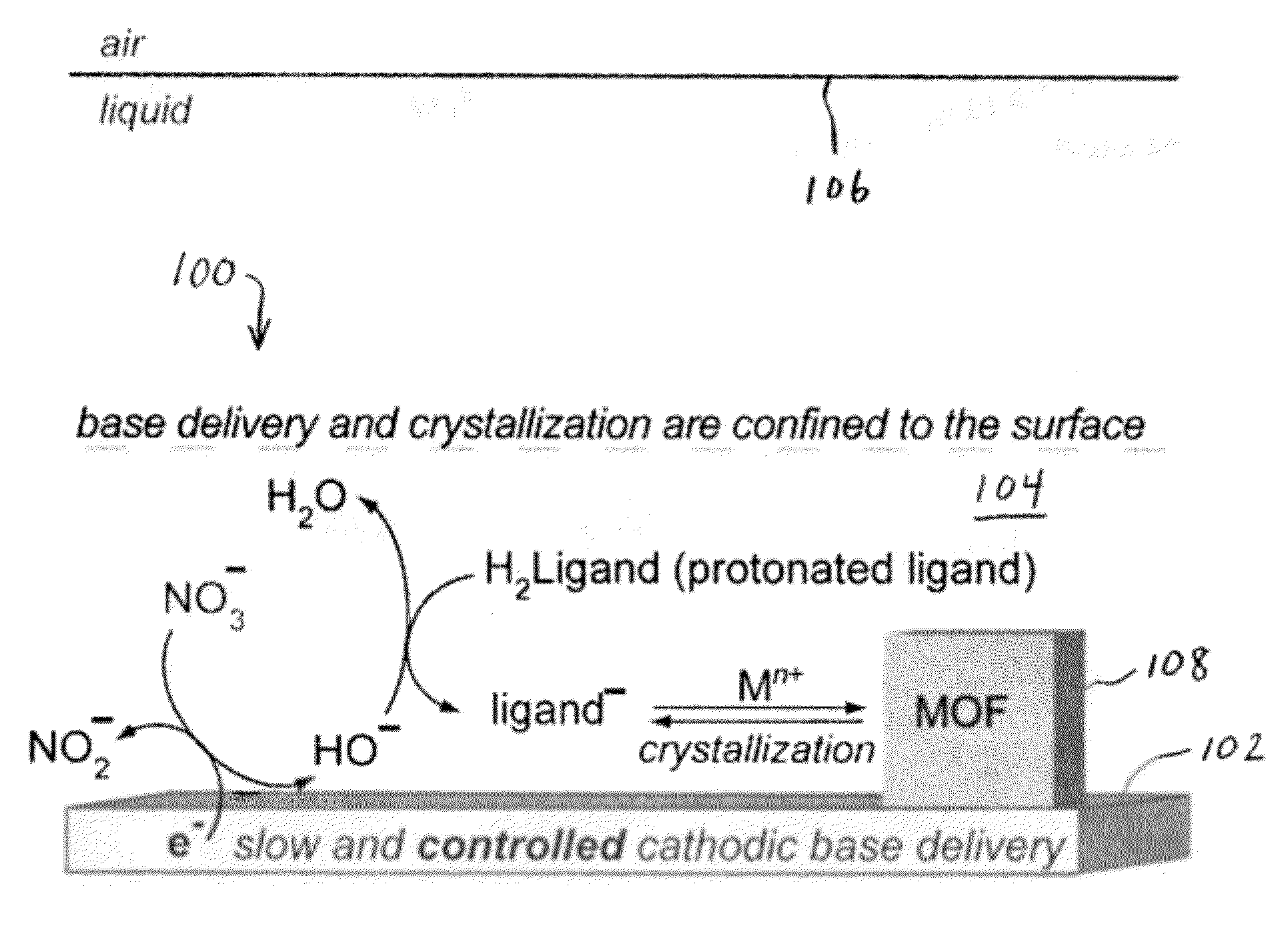

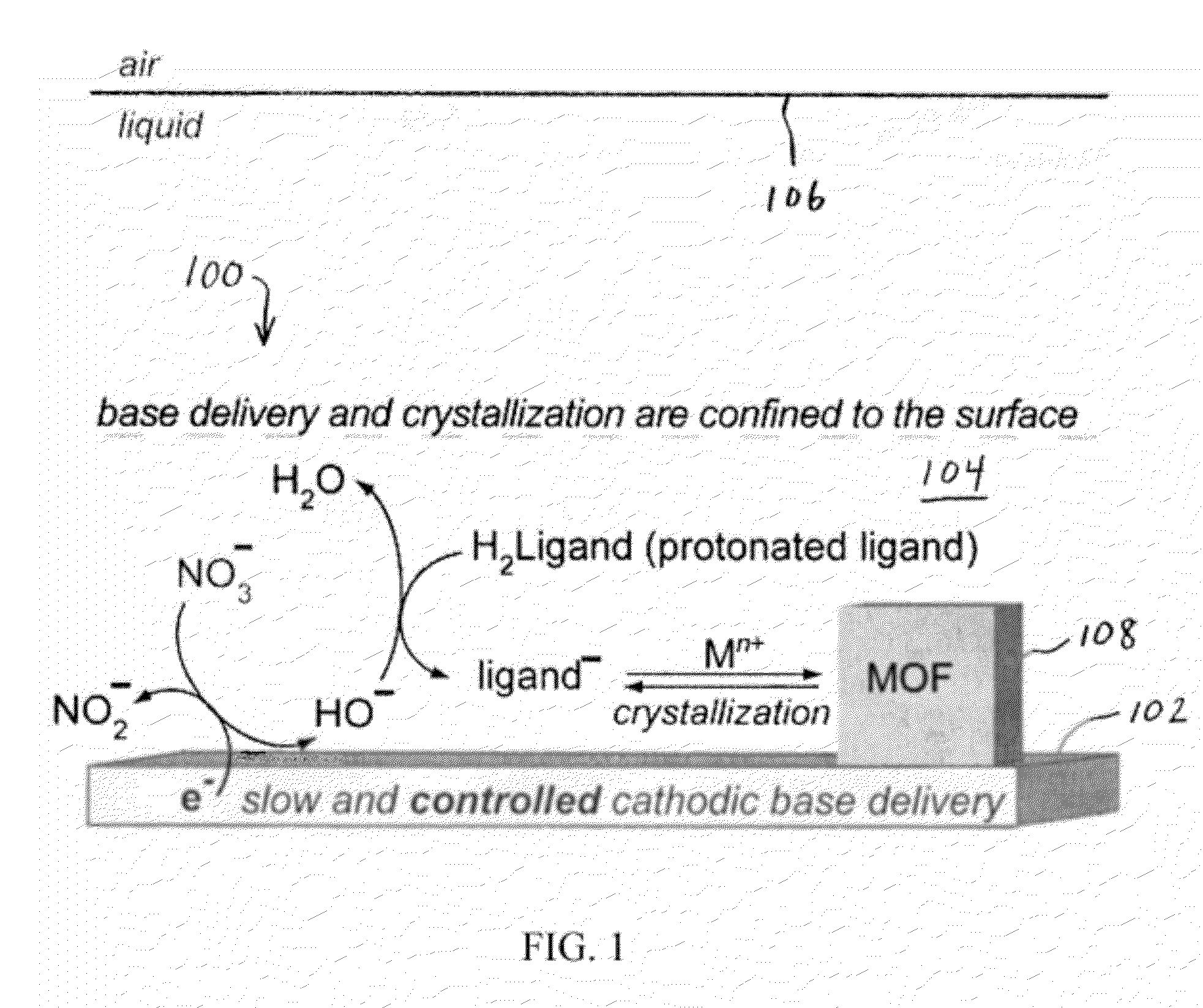

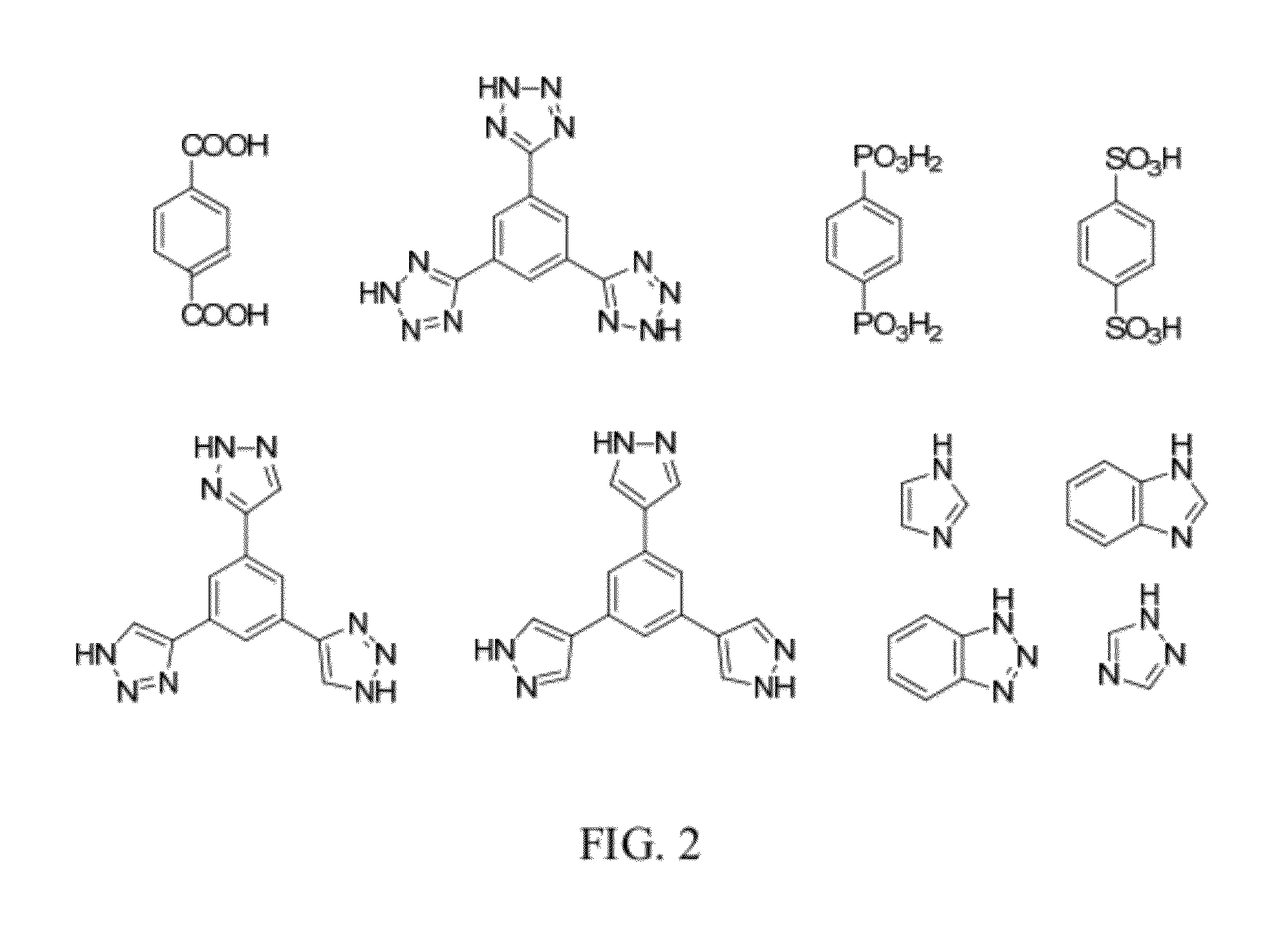

Methods for Electrochemically Induced Cathodic Deposition of Crystalline Metal-Organic Frameworks

InactiveUS20120297982A1Fast reaction timeActive material electrodesIsotope separationPower flowMetal-organic framework

Embodiments of the invention relate to a method for preparing crystalline metal-organic frameworks (MOFs). The method includes the steps of providing an electrolyte solution in contact with a conductive surface, and applying a current or potential to the conductive surface in contact with the electrolyte solution. The electrolyte solution includes a protonated organic ligand, a metal ion, and a probase. Application of the reductive current or potential to the conductive surface produces the crystalline metal-organic framework (MOF) deposited on the conductive surface. The MOFs produced by the method may be incorporated into a gas separation membrane, a purification filter, and / or a sensor.

Owner:MASSACHUSETTS INST OF TECH

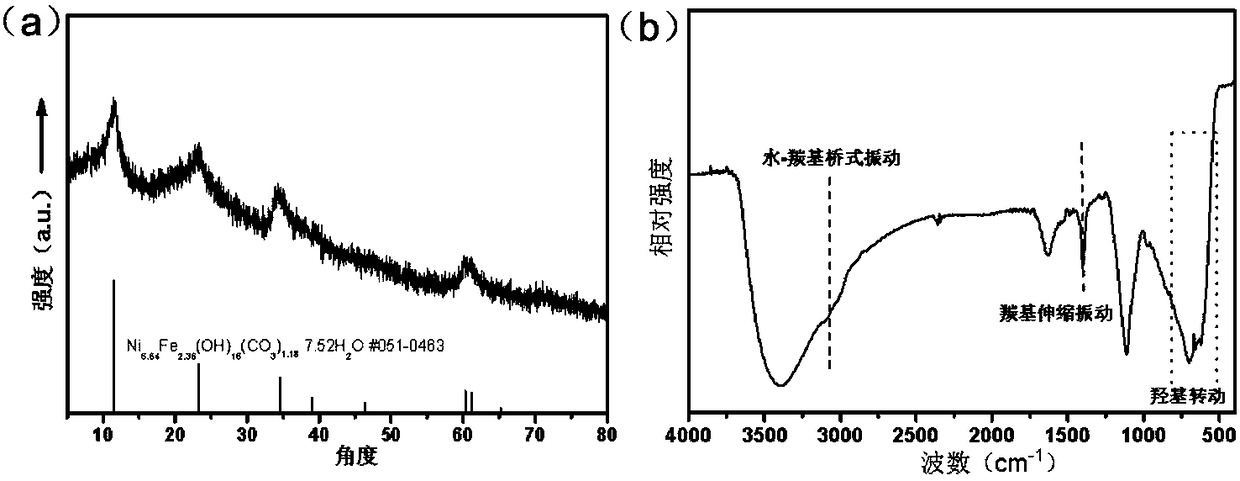

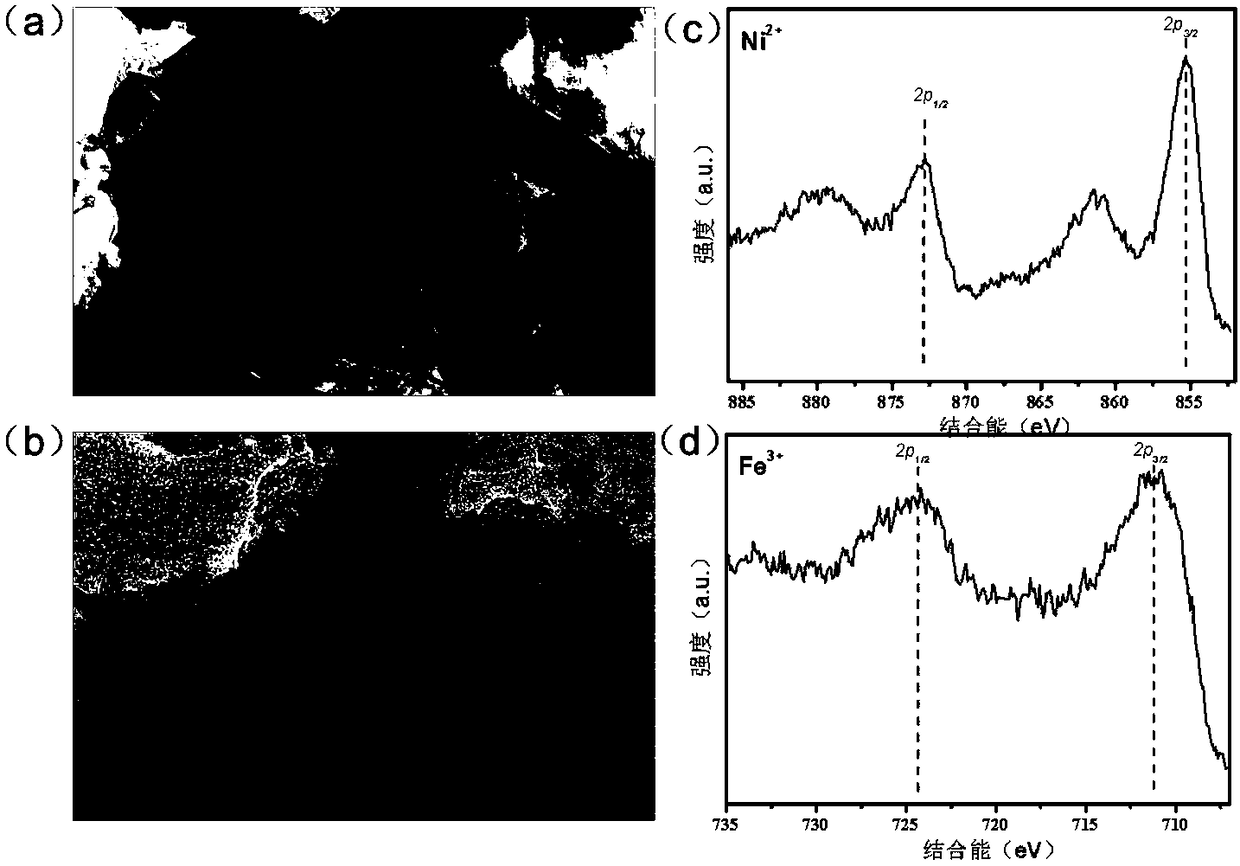

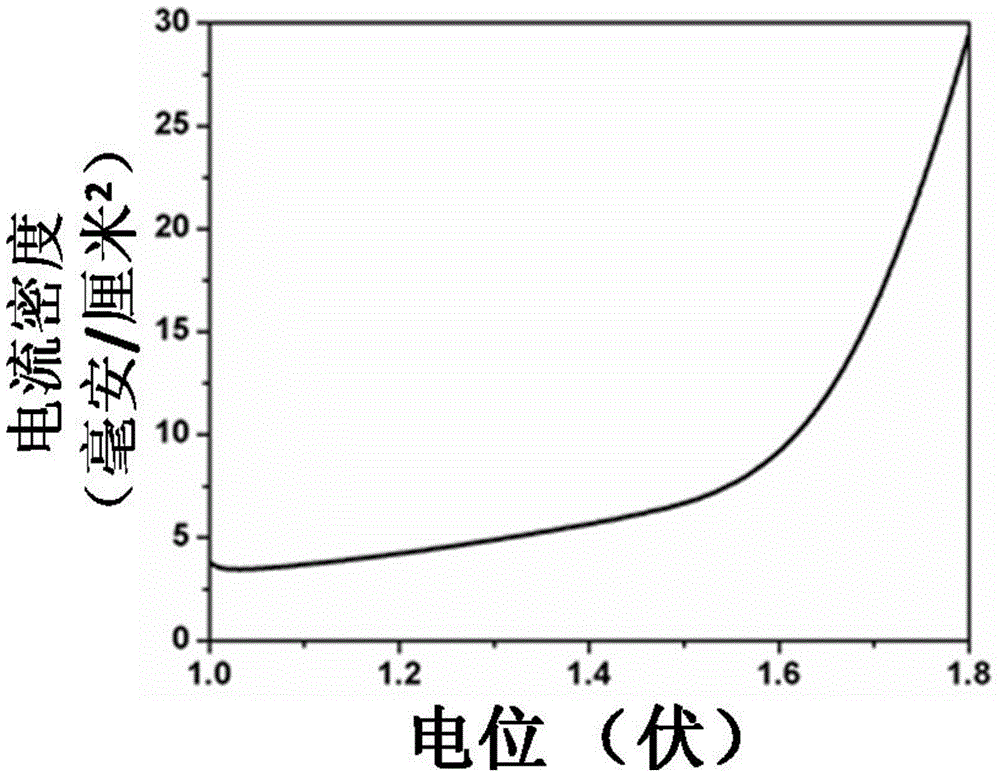

Nickel-iron hydrotalcite based electro-catalytic oxygen evolution electrode and preparation and application thereof

InactiveCN108193227AWide variety of sourcesLow priceElectrolytic inorganic material coatingElectrode shape/formsElectrolysisOxygen

The invention belongs to the technical fields of material sciences and electro-catalytic hydrogen production, and particularly relates to a nickel-iron hydrotalcite based electro-catalytic oxygen evolution electrode and preparation thereof, wherein the nickel-iron hydrotalcite based electro-catalytic oxygen evolution electrode can be used in an electrolytic water oxygen evolution reaction in an alkaline medium. An electrode system takes a nickel-iron hydrotalcite structure as a catalytic activity center and takes nickel foam as an electrode material; in the alkaline medium, the nickel-iron hydrotalcite based electro-catalytic oxygen evolution electrode can efficiently electrolyze water to prepare oxygen, the overall overcurrent polishing of electrolytic water is reduced greatly, and good stability is showed; according to the preparation technology of the nickel-iron hydrotalcite based electro-catalytic oxygen evolution electrode, a nickel-iron hydrotalcite composite structure is grownon the nickel foam base through an in-situ electrodeposition method; and the resources of required raw materials are wide, the price is low, the technology is mature and stable, operation is easy, convenient and fast, controllability is high, the process does not produce poison, and the nickel-iron hydrotalcite based electro-catalytic oxygen evolution electrode is suitable for mass production andthe industrial electrolytic water reaction.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method of making a composite article comprising a ceramic coating

InactiveUS6919012B1Improve propertiesSuperior physical/mechanical and protective propertyAnodisationCellsSurface layerCeramic coating

A ceramic coating is formed on a conductive article by immersing a first anodic electrode, including the conductive article, in an electrolyte comprising an aqueous solution of alkali metal hydroxide and an alkali metal silicate, providing a second cathodic electrode in contact with the electrolyte, and passing an alternating current from a resonant power source through the first electrode and to the second electrode while maintaining the angle φ between the current and the voltage at zero degree, while maintaining the voltage within a predetermined range. The resulting ceramic coated article comprises a coating which includes a metal, silicon, and oxygen, wherein the silicon concentration increases in the direction from the article surface toward an outer surface of the ceramic coating surface layer.

Owner:OLIMEX GROUP

PZT amorphous alloy plating solution and method for plating a PZT amorphous alloy using the same

ActiveUS9909225B2Reduce variationImprove precisionCellsElectrolytic inorganic material coatingLead zirconate titanateAlloy

The present invention relates to the lead-zirconate-titanate (PZT) amorphous alloy plating solution which may be used to form a PZT amorphous alloy film having excellent mechanical and physical properties and a method for plating a PZT amorphous alloy using the same. The PZT amorphous alloy plating solution may include a Pb precursor, a Zr precursor, and a Ti precursor. 10˜50 parts by weight of the Zr precursor and 5˜30 parts by weight of the Ti precursor may be included based on 100 parts by weight of the Pb precursor. Accordingly, electrical conductivity can be improved because the PZT amorphous alloy plating solution has a structure which has low crystallinity or which is amorphous. Furthermore, excellent electrical characteristics can be achieved because the PZT amorphous alloy plating solution has excellent conductivity or chemical stability.

Owner:CAMMSYS CORP

Method to produce metal matrix nanocomposite

InactiveUS20140374267A1Electrolytic inorganic material coatingElectrophoretic coatingsNanocompositeMaterials science

A method for coating a substrate includes disposing a deposition composition in a container. The deposition composition includes a plurality of nanosheets and a metal material. The method also includes disposing a substrate in the container, contacting the substrate with the deposition composition, applying a voltage to the substrate, electrodepositing, on the substrate, a coating that includes a metal from metal ions and the nanosheets in response to biasing the substrate at the first potential.

Owner:BAKER HUGHES INC

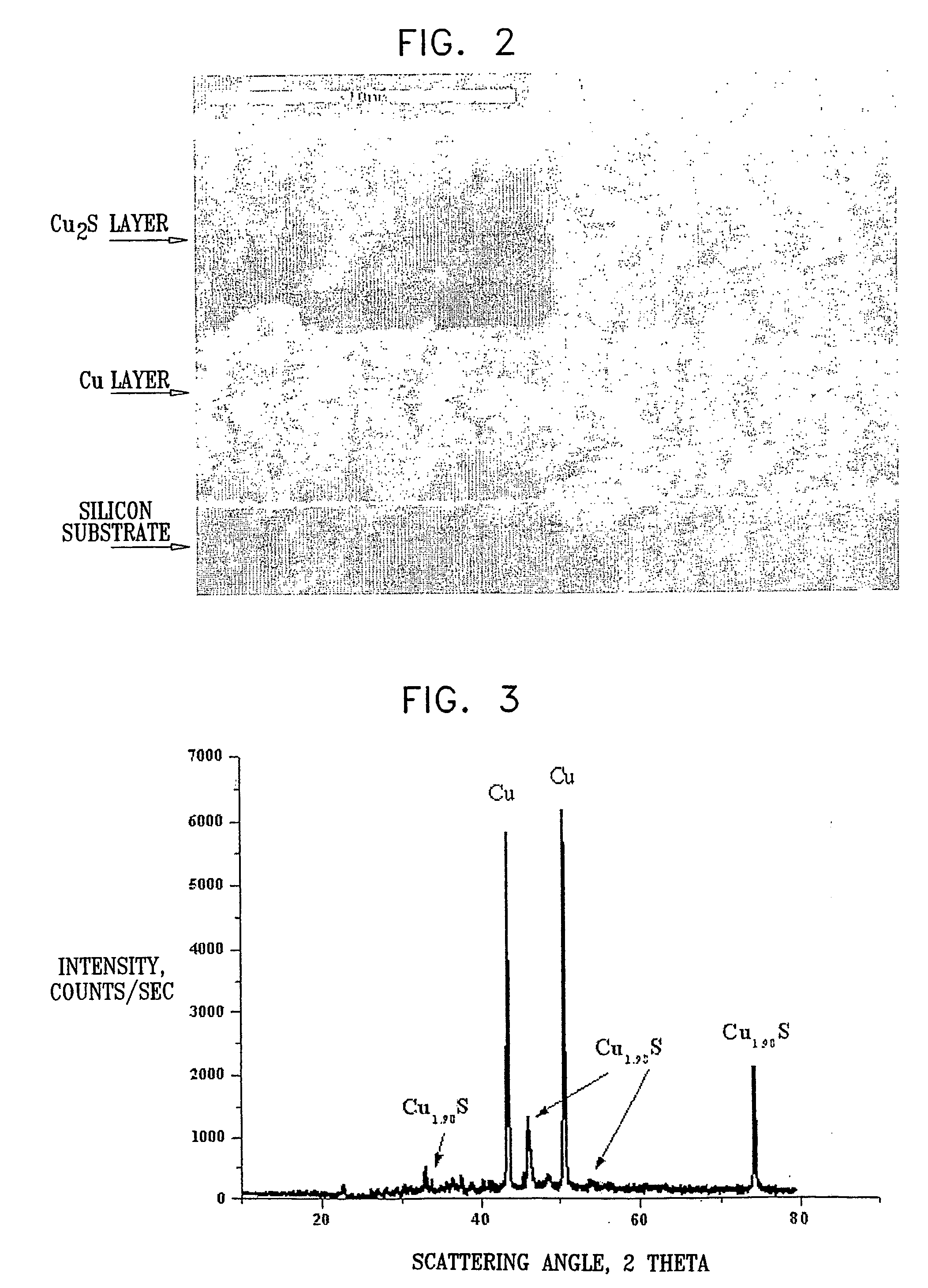

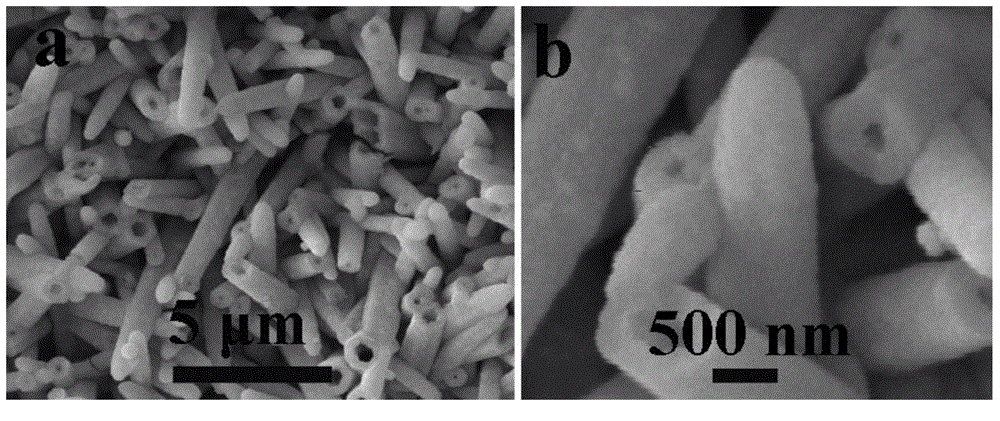

Self-supporting transitional metal sulfide catalyst and preparation methods and applications thereof

InactiveCN105013512AEasy to prepareReduce manufacturing costPhysical/chemical process catalystsElectrolytic inorganic material coatingDecompositionMetallic sulfide

The present invention provides a self-supporting transitional metal sulfide catalyst and preparation methods and applications thereof, pertaining to the field of alkaline full electrolytic cell water decomposition. A preparation method of the catalyst comprises: mixing a metal salt of a transitional metal element with a sulfur source, and adding a surfactant, a catalyst carrier, and an alkaline solution to obtain a mixed solution; and then adding a transitional metal conductive substrate to the mixed solution to react to obtain a self-supporting transitional metal sulfide catalyst. Alternatively, a preparation method of the catalyst comprises: mixing a metal salt of a transitional metal element with a sulfur source, and a surfactant, a catalyst carrier, and an alkaline solution to obtain a mixed solution; and then with a transitional metal conductive substrate being used as a working electrode, performing electrodeposition in the obtained transitional metal sulfide electrolyte, to obtain a self-supporting transitional metal sulfide catalyst. The present invention also provides the self-supporting transitional metal sulfide catalyst prepared with the above two methods. The prepared sulfide catalyst, when applied in a battery, has excellent performance in electric hydrogen evolution and oxygen evolution.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

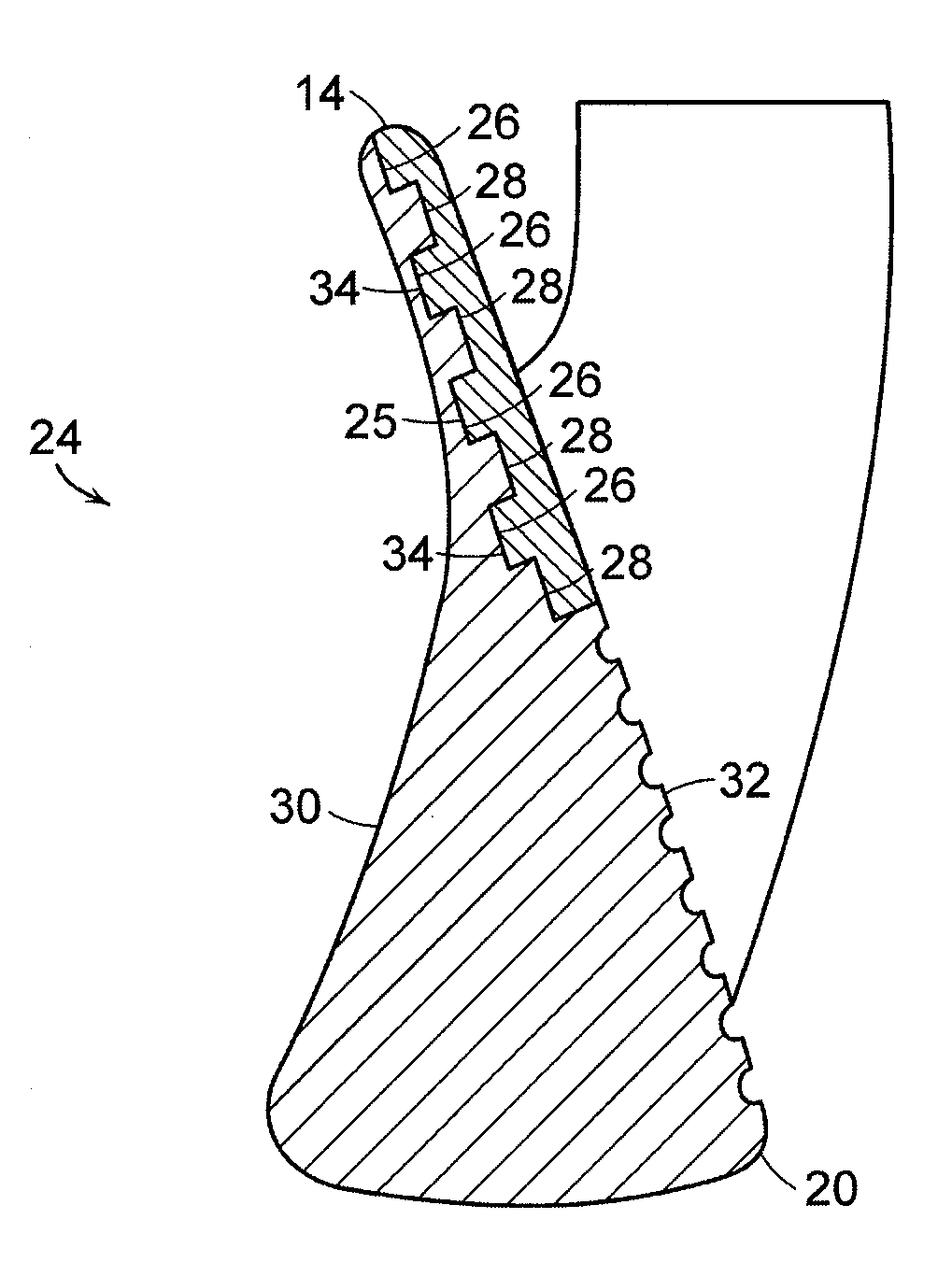

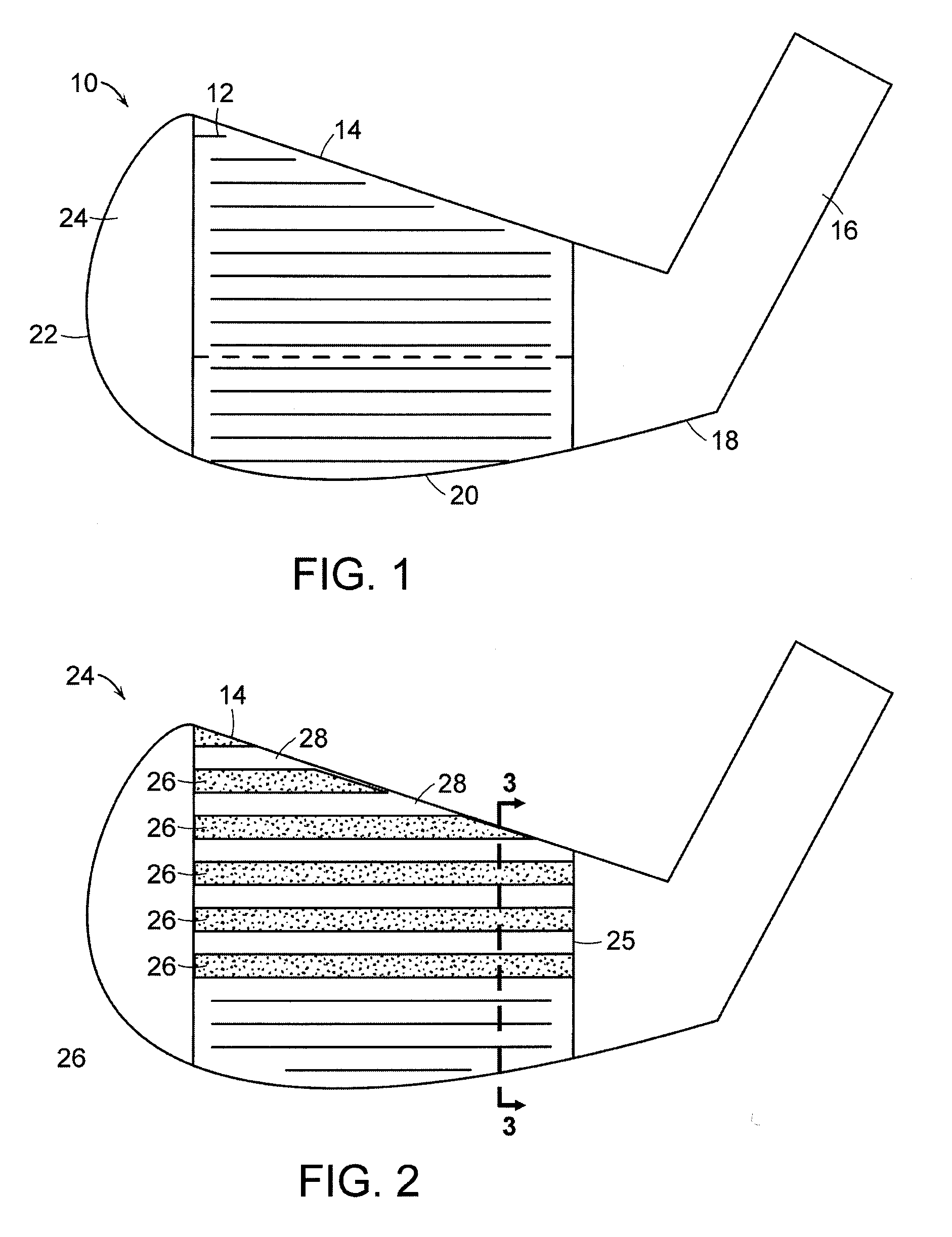

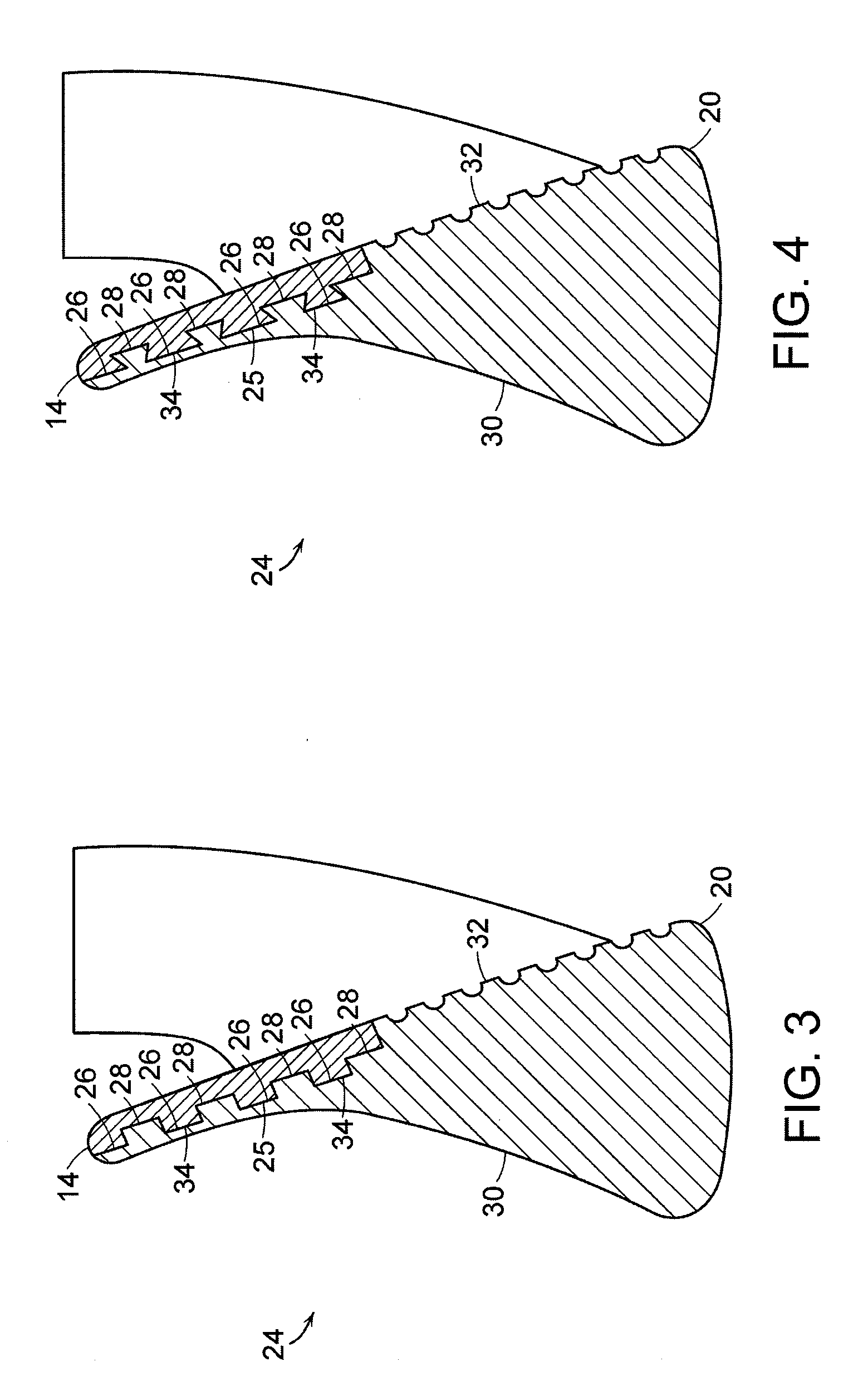

Multi-metal golf clubs

InactiveUS20080076597A1Improve performanceAnodisationElectrolytic inorganic material coatingFriction reductionGolf Ball

A composite material golf club head is provided having a body made from a first metal and a face insert press fitted to a portion of the body and made from a second metal. The metals are chosen so that the first metal is heavier than the second metal. The second metal is disposed towards the front and top of the body, and is preferably hard-anodized. In addition, an interlocking structure, for example rectangular or dove tail shaped channels, is provided in the body so that the face insert becomes embedded in the interlocking structure to anchor the face insert to the body. Portions of the golf club head, such as the face insert or sole plate, are anodized to protect against corrosion. The anodized coating is colored to improve aesthetic characteristics or infused with a polymer to increase or reduce friction.

Owner:COBRA GOLF

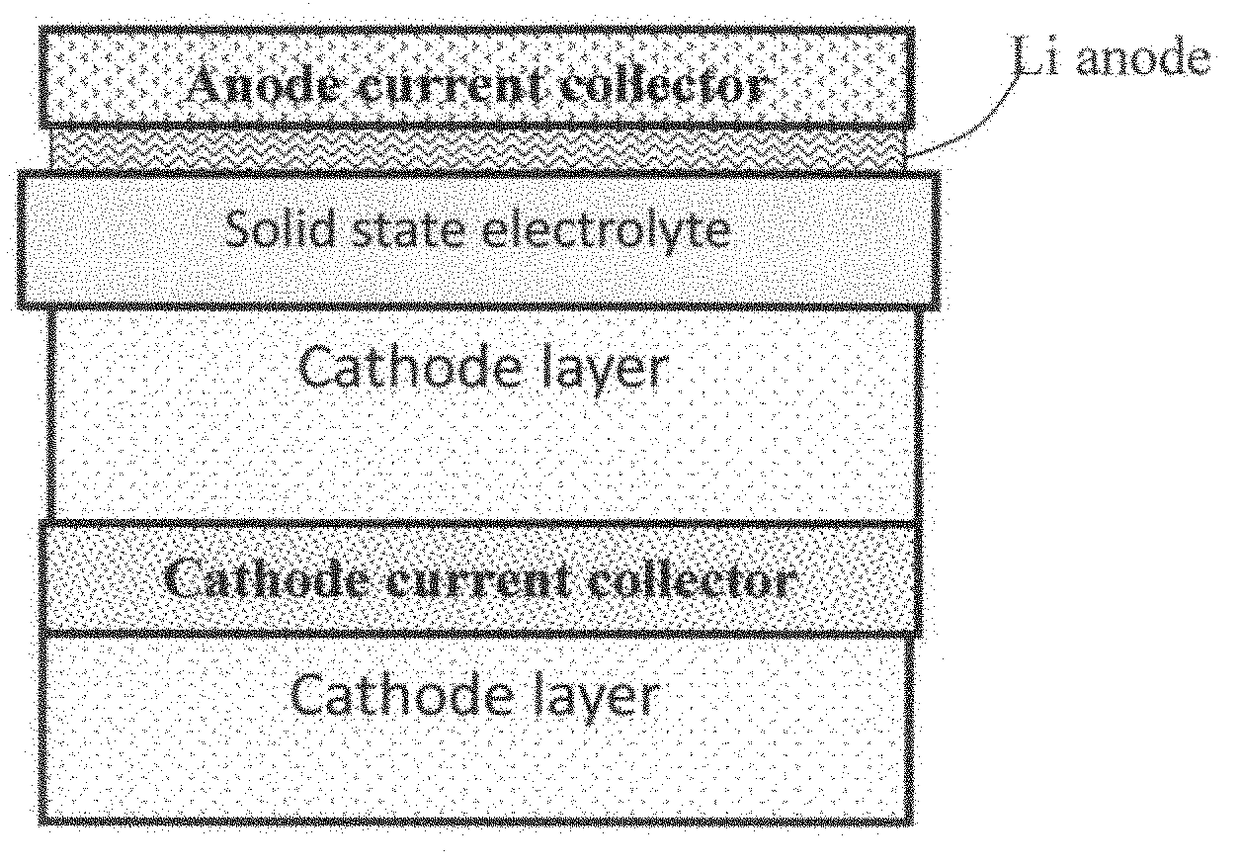

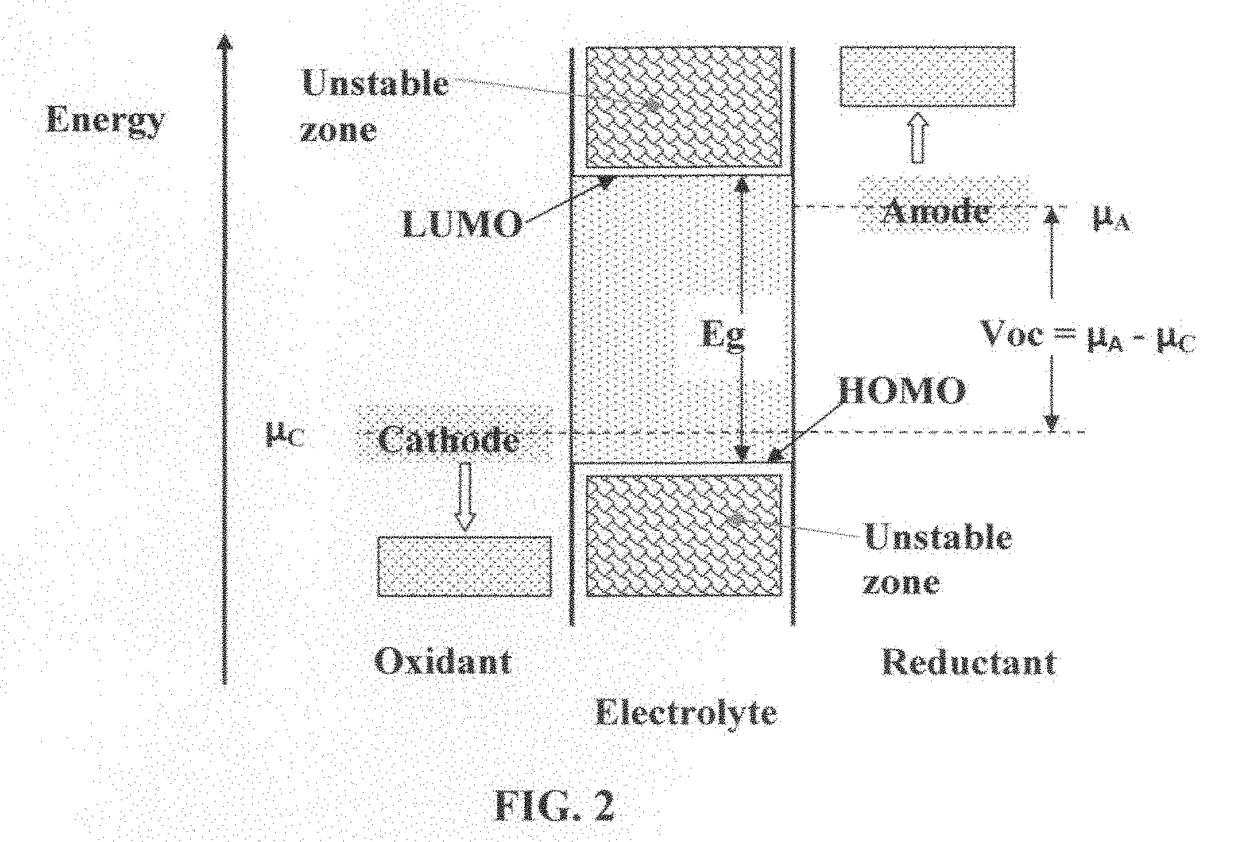

Solid state electrolyte for lithium secondary battery

ActiveUS20170194663A1Reduce electrical conductivityLow ionic conductivitySolid electrolytesFuel and secondary cellsSolid state electrolytePhysical chemistry

Provided is a solid state electrolyte composition for a rechargeable lithium battery. The electrolyte composition comprises a lithium ion-conducting polymer matrix or binder and lithium ion-conducting inorganic species that is dispersed in or chemically bonded by the polymer matrix or binder, wherein the lithium ion-conducting inorganic species is selected from Li2CO3, Li2O, Li2C2O4, LiOH, LiX, ROCO2Li, HCOLi, ROLi, (ROCO2Li)2, (CH2OCO2Li)2, Li2S, LixSOy, or a combination thereof, wherein X=F, Cl, I, or Br, R=a hydrocarbon group, x=0-1, y=1-4; and wherein the polymer matrix or binder is in an amount from 1% to 99% by volume of the electrolyte composition. Also provided are a process for producing this solid state electrolyte and a lithium secondary battery containing such a solid state electrolyte.

Owner:GLOBAL GRAPHENE GRP INC

Method of electrolytically depositing a pharmaceutical coating onto a conductive osteal implant

InactiveUS20080011613A1Electrolytic inorganic material coatingPretreated surfacesCalcium biphosphateConductive materials

A method of electrolytically depositing a pharmaceutical coating onto a conductive osteal implant. The implant is submerged into an electrolytic cell containing an electrolysis solution of the pharmaceutical and acts as a cathode. When current is applied to the electrolytic cell, the pharmaceutical coating forms on the implant. The pharmaceutical can comprise bisphosphonates, including calcium salts. The implants can comprise any conductive material suitable for use as an osteal implant. The implants can also be electrolytically coated with calcium phosphate before coating with a pharmaceutical.

Owner:THE UNIV OF BRITISH COLUMBIA

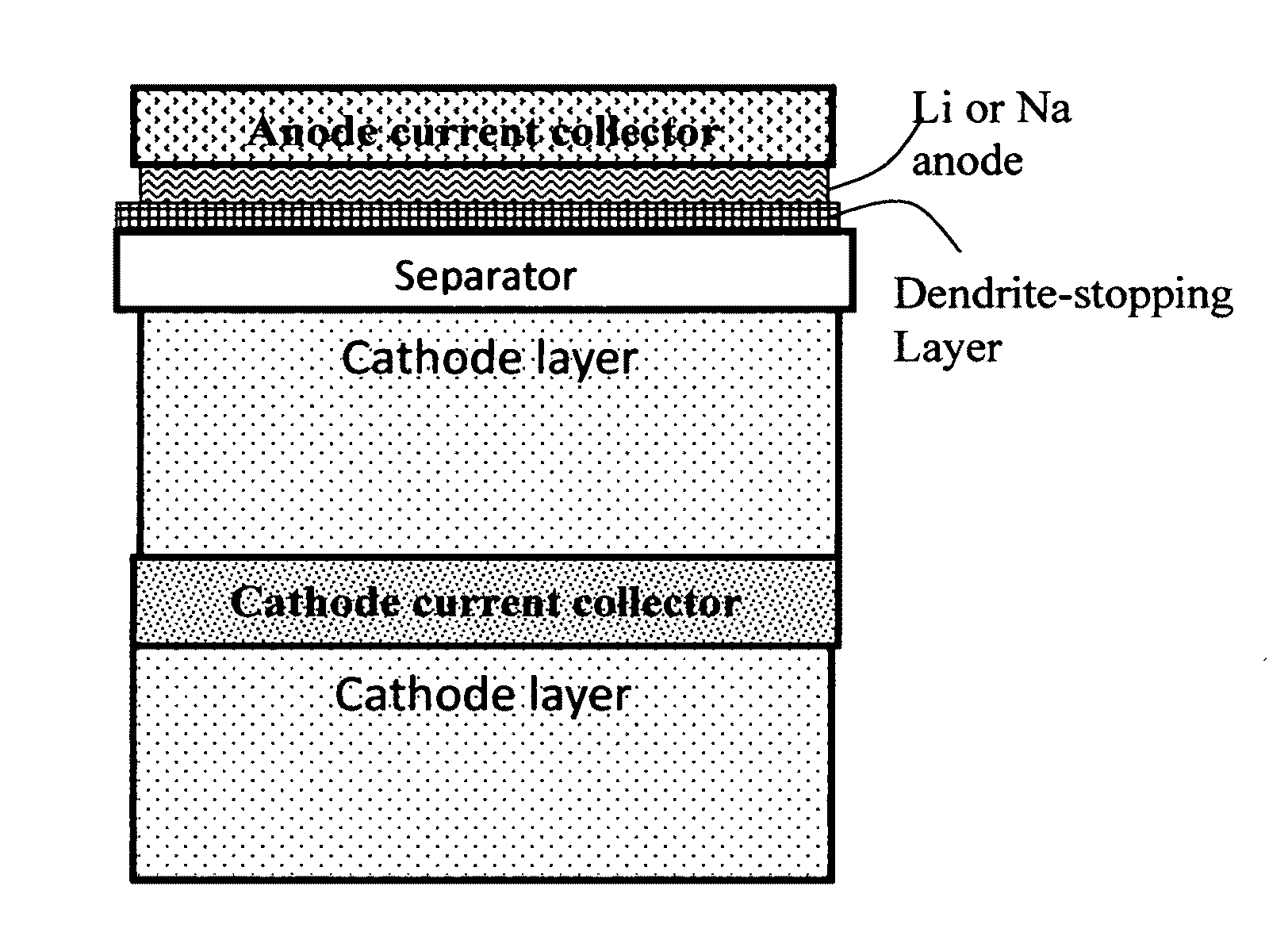

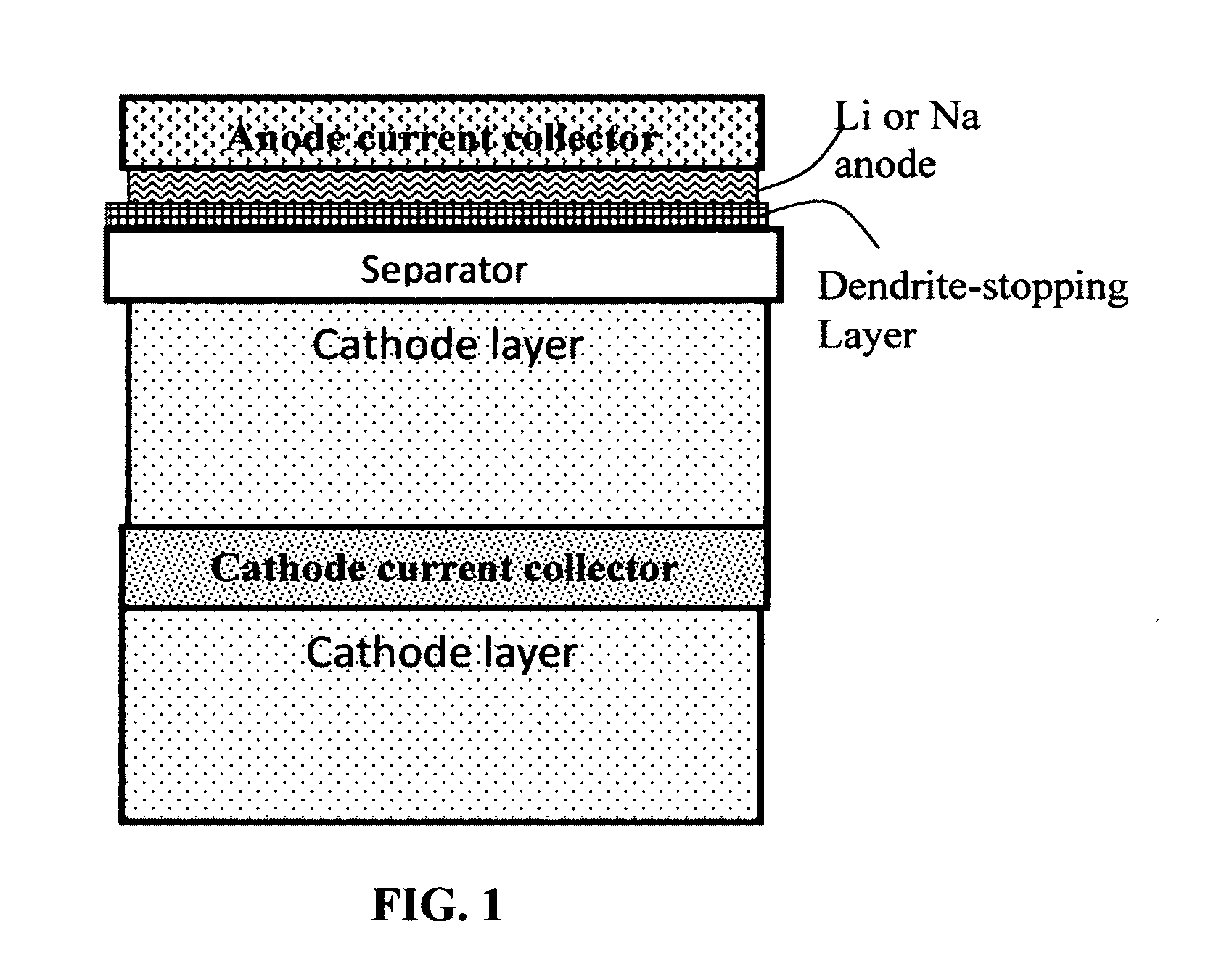

Carbon matrix-and carbon matrix composite-based dendrite-Intercepting layer for alkali metal secondary battery

ActiveUS20160344010A1Increase energy densityReduce material costsNon-aqueous electrolyte accumulatorsElectrolytic inorganic material coatingPhysical chemistryGraphite

A dendrite penetration-resistant layer for a rechargeable alkali metal battery, comprising an amorphous carbon or polymeric carbon matrix, an optional carbon or graphite reinforcement phase dispersed in this matrix, and a lithium- or sodium-containing species that are chemically bonded to the matrix and / or the optional carbon or graphite reinforcement phase to form an integral layer that prevents dendrite penetration through this integral layer in the alkali metal battery, wherein the lithium- or sodium-containing species is selected from Li2CO3, Li2O, Li2C2O4, LiOH, LiX, ROCO2Li, HCOLi, ROLi, (ROCO2Li)2, (CH2OCO2Li)2, Li2S, LixSOy, Na2CO3, Na2O, Na2C2O4, NaOH, NaiX, ROCO2Na, HCONa, RONa, (ROCO2Na)2, (CH2OCO2Na)2, Na2S, NaxSOy, or a combination thereof, wherein X=F, Cl, I, or Br, R=a hydrocarbon group, x=0-1, y=1-4; and wherein the lithium- or sodium-containing species is derived from an electrochemical decomposition reaction.

Owner:GLOBAL GRAPHENE GRP INC

Method of surface treating metal and metal surface treated thereby

InactiveUS20040244875A1Improve corrosion resistanceImprove uniformityElectrolytic inorganic material coatingSurface reaction electrolytic coatingElectrolysisMetallic substrate

It is an object of the present invention to provide a method of metal surface treatment and a surface treated metal thereby, which has excellent corrosion resistance and can form a coat having high corrosion resistance on metal substrates such as iron, zinc, aluminum and magnesium. A method of metal surface treatment comprising the step of forming a chemical conversion coat on the surface of a metal article to be treated by a chemical conversion treatment reaction by a chemical conversion treatment agent containing a zirconium-containing compound and a fluorine-containing compound, wherein said chemical conversion treatment reaction is conducted through cathodic electrolysis treatment.

Owner:NIPPON PAINT CO LTD

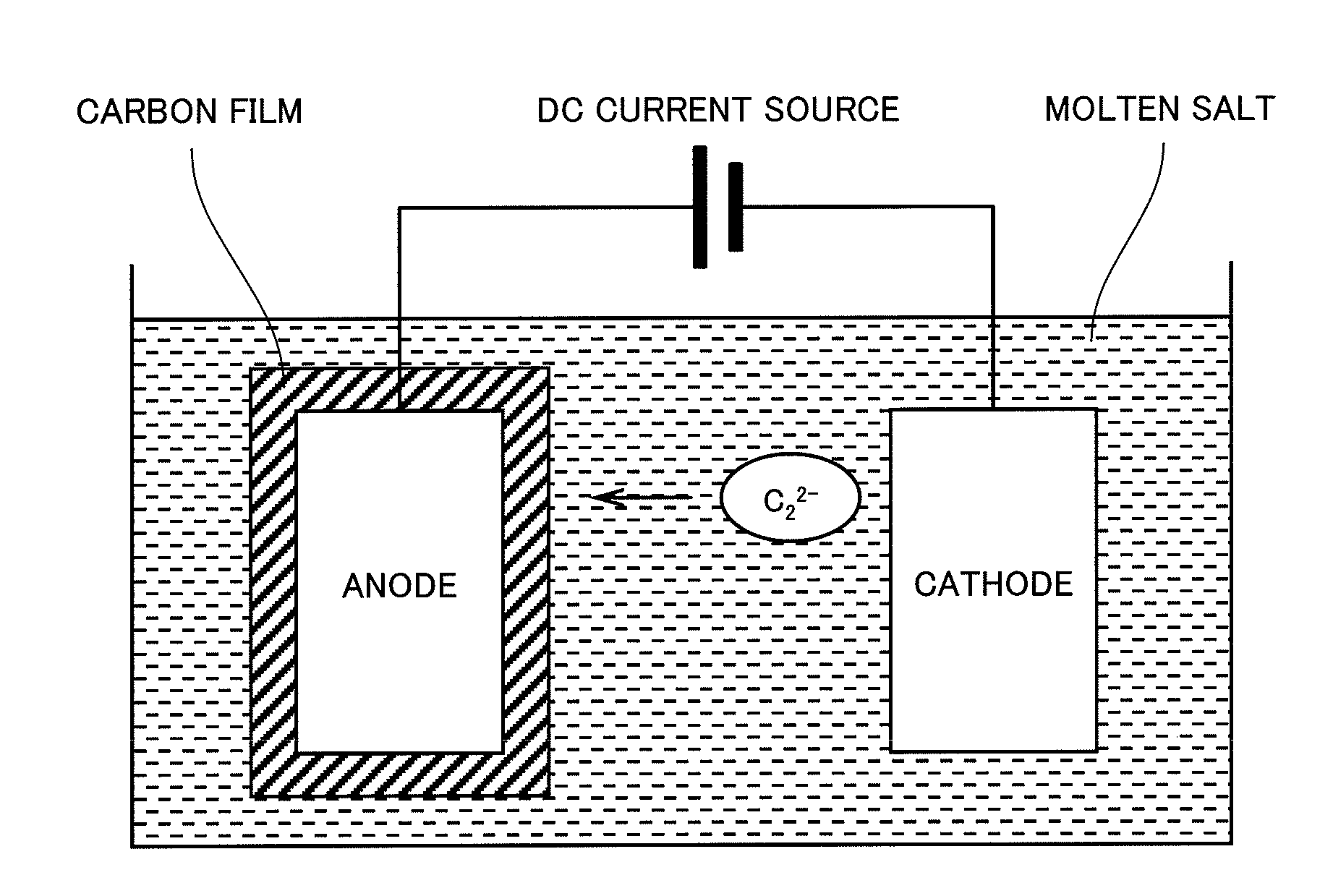

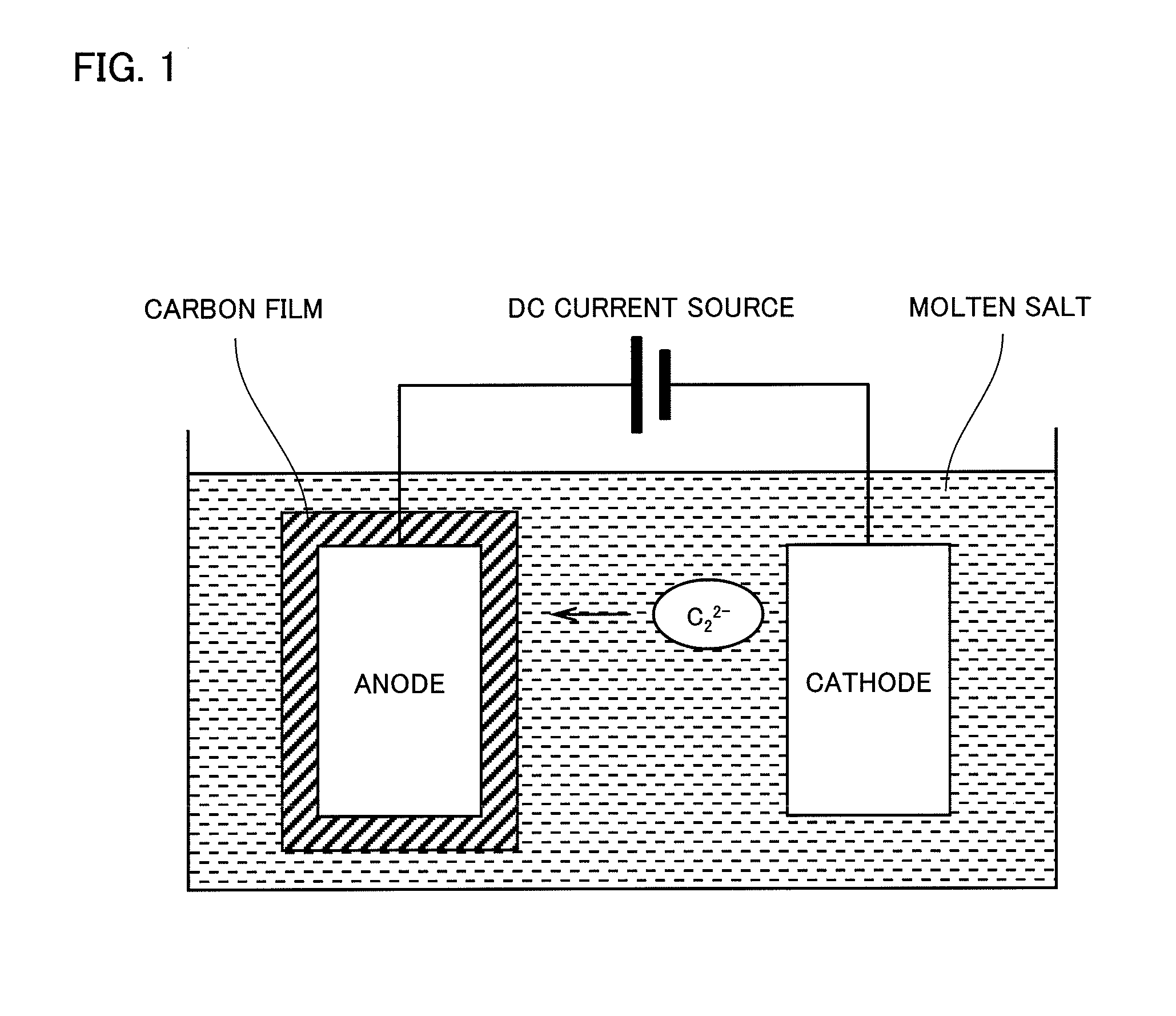

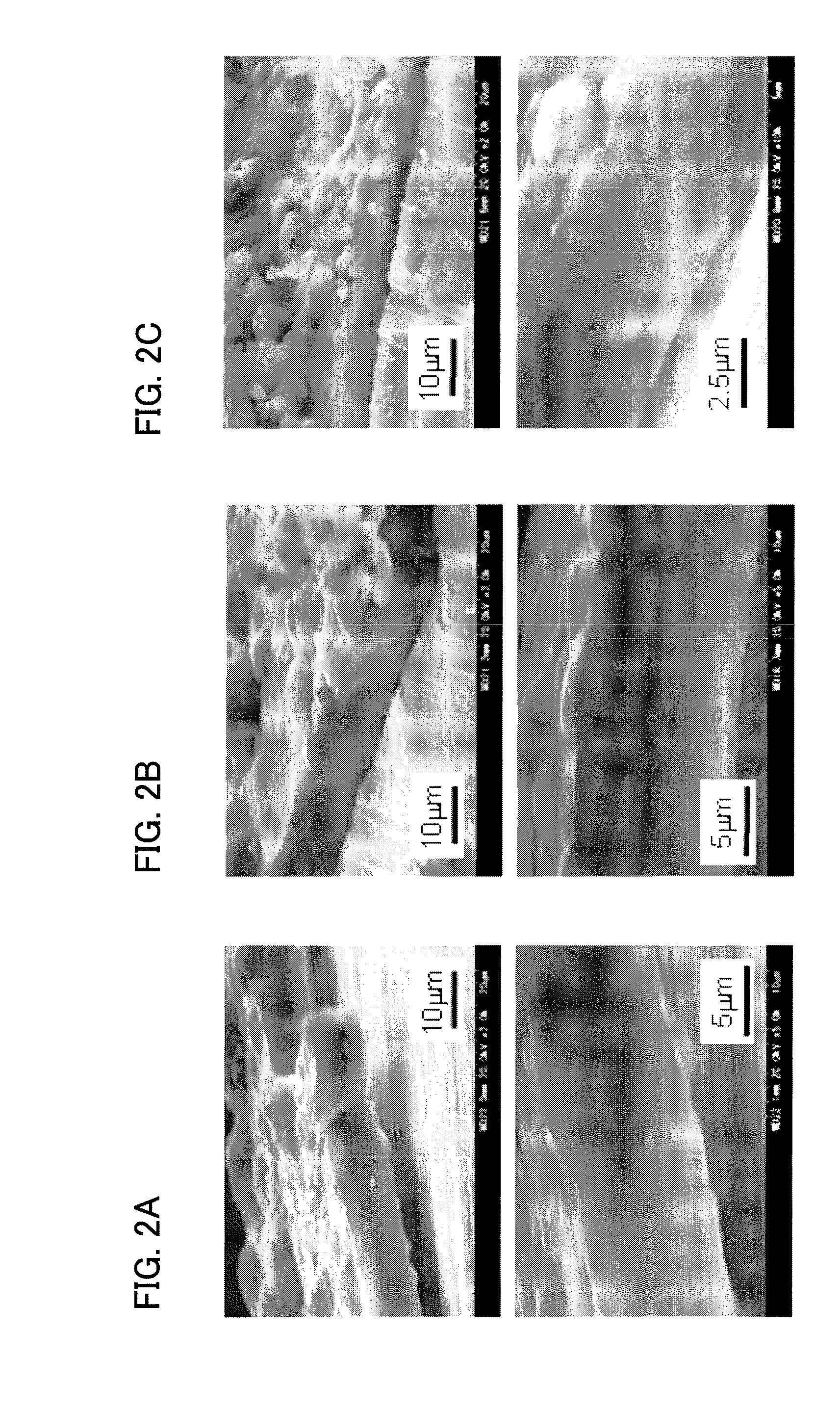

Method for electrochemically depositing carbon film on a substrate

ActiveUS20110290655A1Simple waySimple equipmentElectrolytic inorganic material coatingCarbon filmCarbide

Dense carbon films are deposited on a conductive substrate by placing the substrate acting as anode in a molten salt electrolyte bath containing a source of carbide ion and applying DC current across the substrate and a counter electrode acting as cathode also placed in the molten salt electrolyte bath. The carbide ions are electrochemically oxidized to deposit a carbon film on the surface of the substrate.

Owner:TOYOTA BOSHOKU KK +3

Composite electrode and method for manufacturing the same

InactiveUS20120111730A1Large specific surface areaImprove high temperature stabilityMaterial nanotechnologyElectrochemical processing of electrodesComposite electrodeConductive polymer

A composite electrode and a method for manufacturing the same are disclosed. By using a composite electrode that includes a porous support made of ceramic or metal and a conductive polymer or a metal oxide formed on a surface of the porous support, a capacitor or secondary cell that provides increased charge / discharge capacity and increased energy / output density, as well as high-temperature stability and high reliability, can be manufactured.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

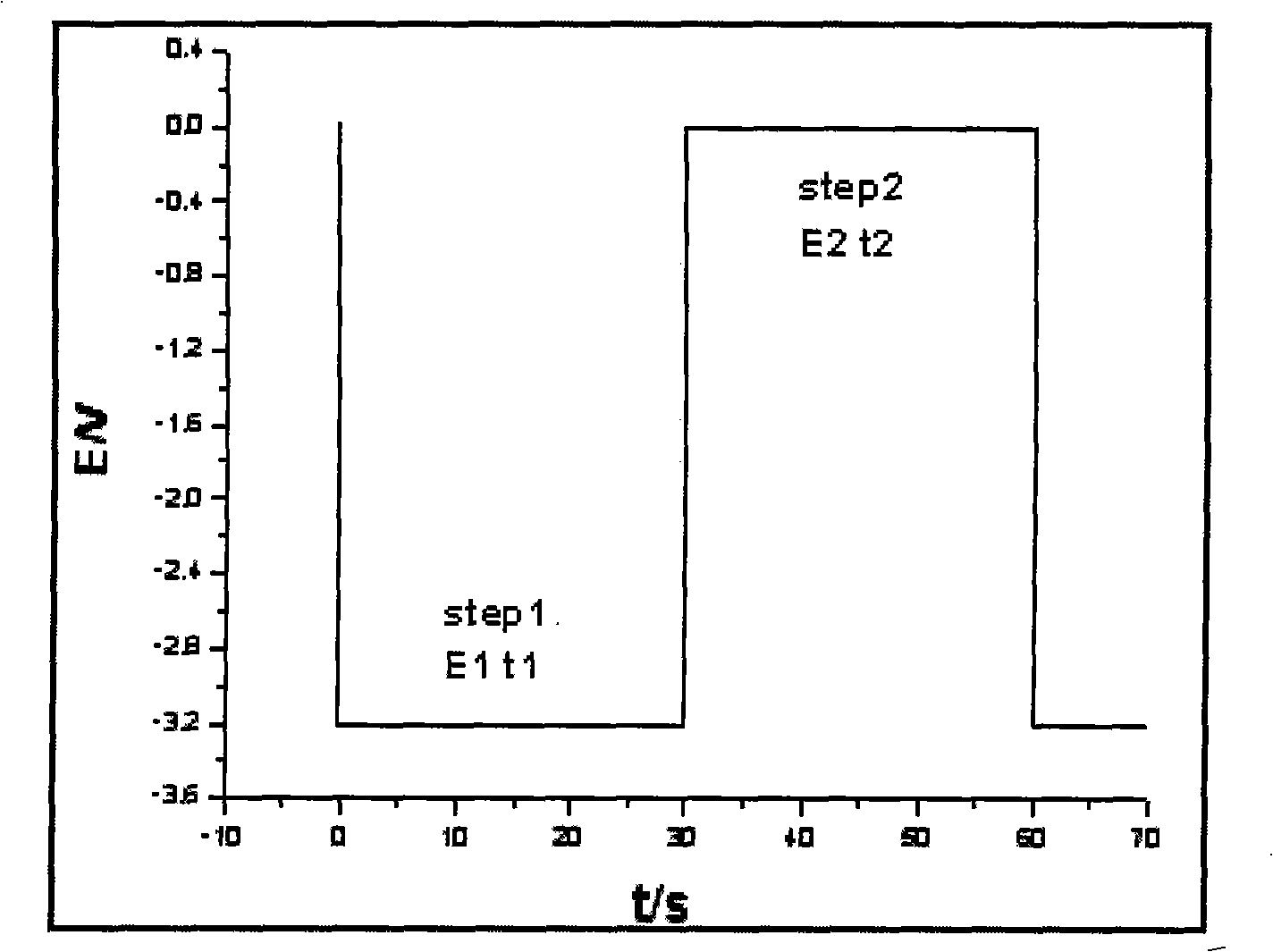

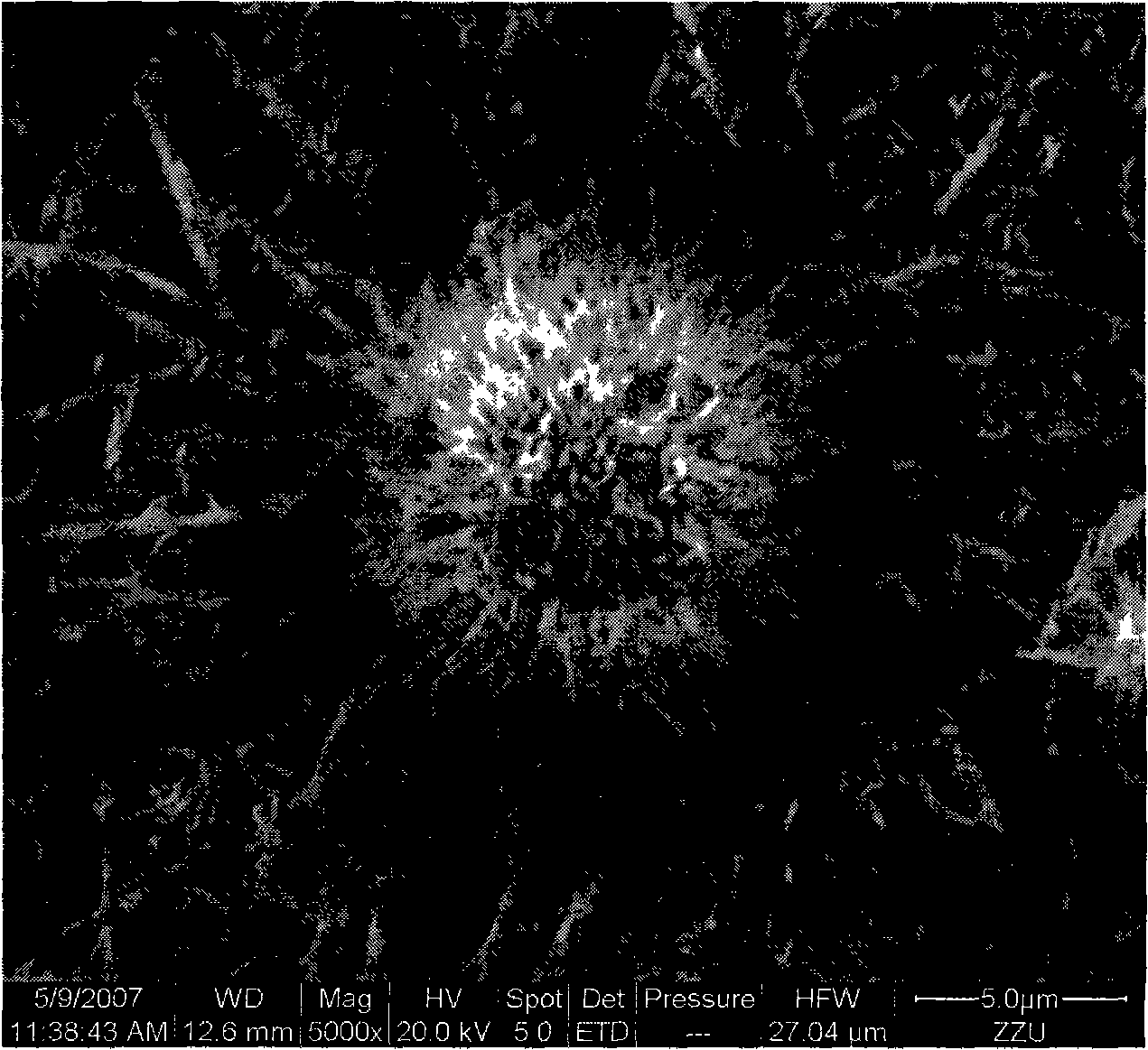

Preparation of nano-HAP coating/magnesium alloy composite biological material

InactiveCN101302638AHigh bonding strengthImprove biological activityElectrolytic inorganic material coatingProsthesisMagnesium phosphateBiocompatibility Testing

The invention provides a method for making a nano HAP coating / magnesium alloy composite biomaterial. The method is as follows: the method takes a magnesium alloy as a cathode and graphite as an anode; the magnesium alloy and the graphite are placed in electrolyte containing NH4H2PO4, NaHO3 and Ca(OH3)2.4H2O so as to carry out stepped electrodeposition at a temperature of between 60 and 95 DEG C and a voltage of between minus 5 V to minus 1 V and 0 V, thereby effectively improving the interface bonding between a coating and a matrix and reducing hydrogen evolution during electrodeposition; meanwhile, the increase of magnesium ions at an interface can realize in-situ doping of magnesium ions and hydroxyapatite so as to generate a magnesium phosphate transition layer on the surface of the magnesium alloy and to increase bonding strength; thus, a degradable nano acicular hydroxyapatite / magnesium alloy coating composite biomaterial with excellent mechanical property, biocompatibility and corrosion resistance can be obtained. Meanwhile, the method also has the advantages of low cost of raw materials and simple technological operation, etc.

Owner:ZHENGZHOU UNIV

Popular searches

Semiconductor/solid-state device manufacturing Volume/mass flow measurement Fluid pressure measurement by electric/magnetic elements Vacuum evaporation coating Sputtering coating Peptide preparation methods Liquid/solution decomposition chemical coating Electroforming by electrophoresis Ion implantation coating Silicon compounds

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com