Patents

Literature

408results about How to ""High capacity density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

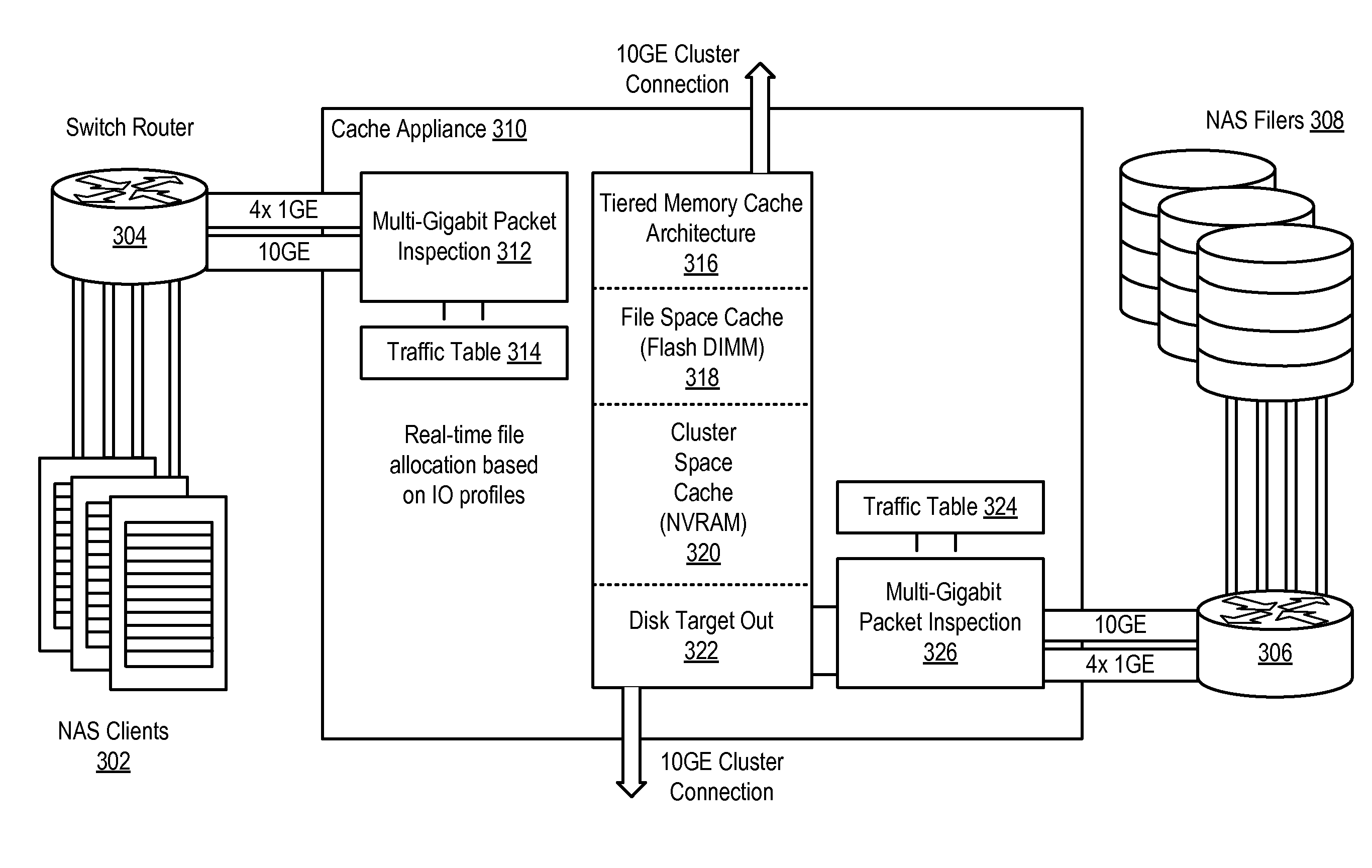

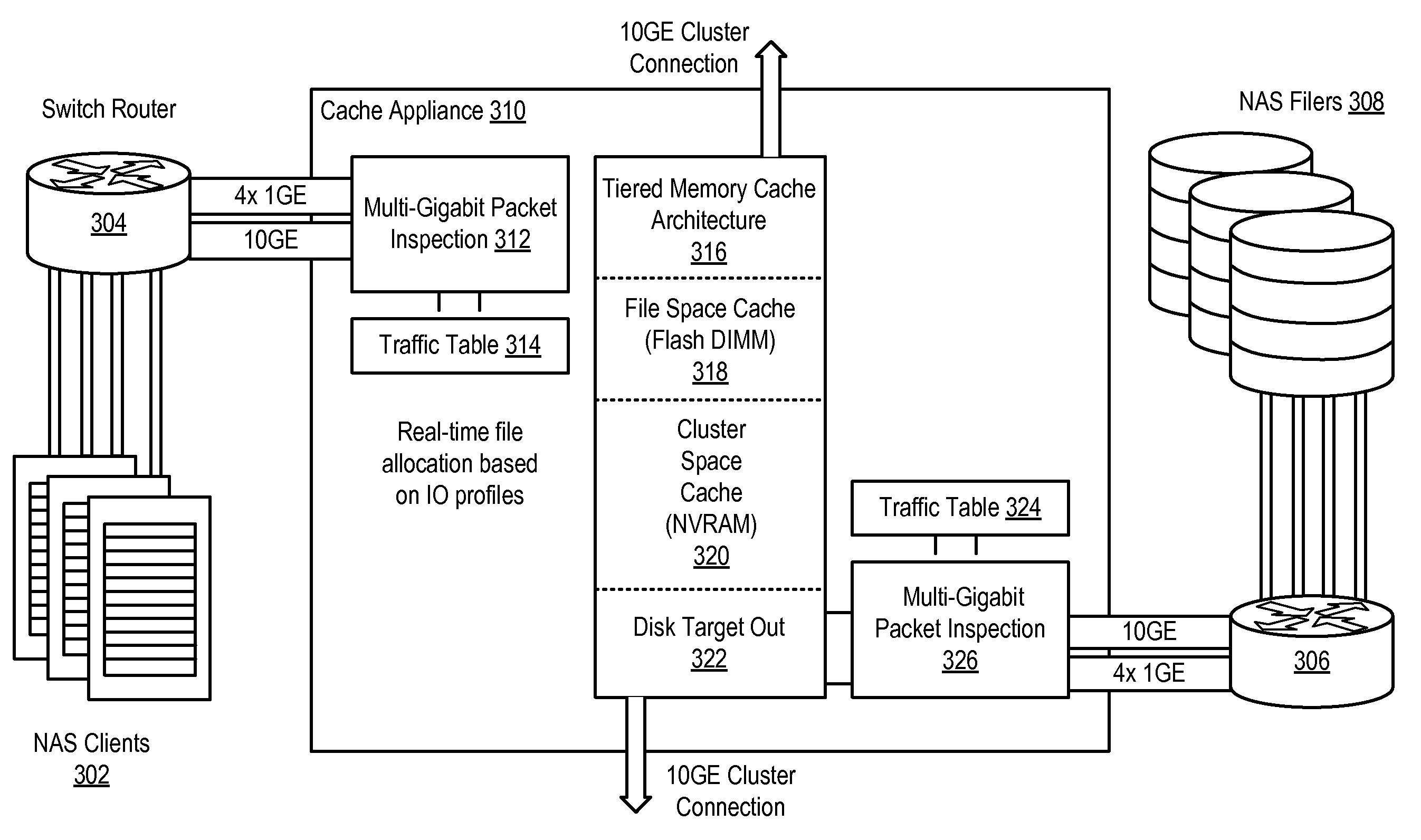

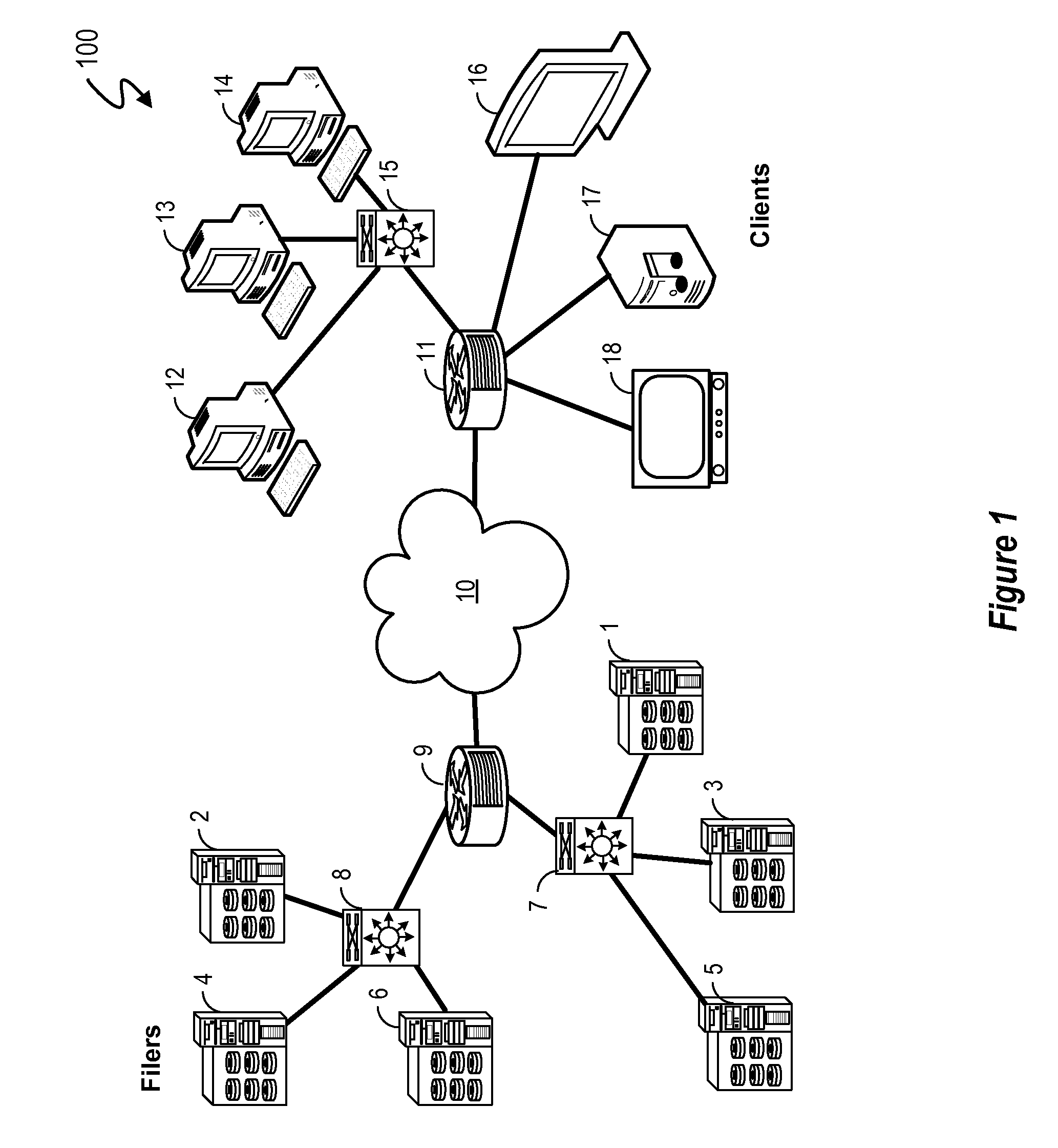

Flash DIMM in a Standalone Cache Appliance System and Methodology

InactiveUS20100023674A1Low costLess power consumptionMemory architecture accessing/allocationMemory adressing/allocation/relocationDIMMClient-side

A method, system and program are disclosed for accelerating data storage in a cache appliance cluster that transparently monitors NFS and CIFS traffic between clients and NAS subsystems and caches files in a multi-rank flash DIMM cache memory by pipelining multiple page write and page program operations to different flash memory ranks, thereby improving write speeds to the flash DIMM cache memory.

Owner:NETWORK APPLIANCE INC

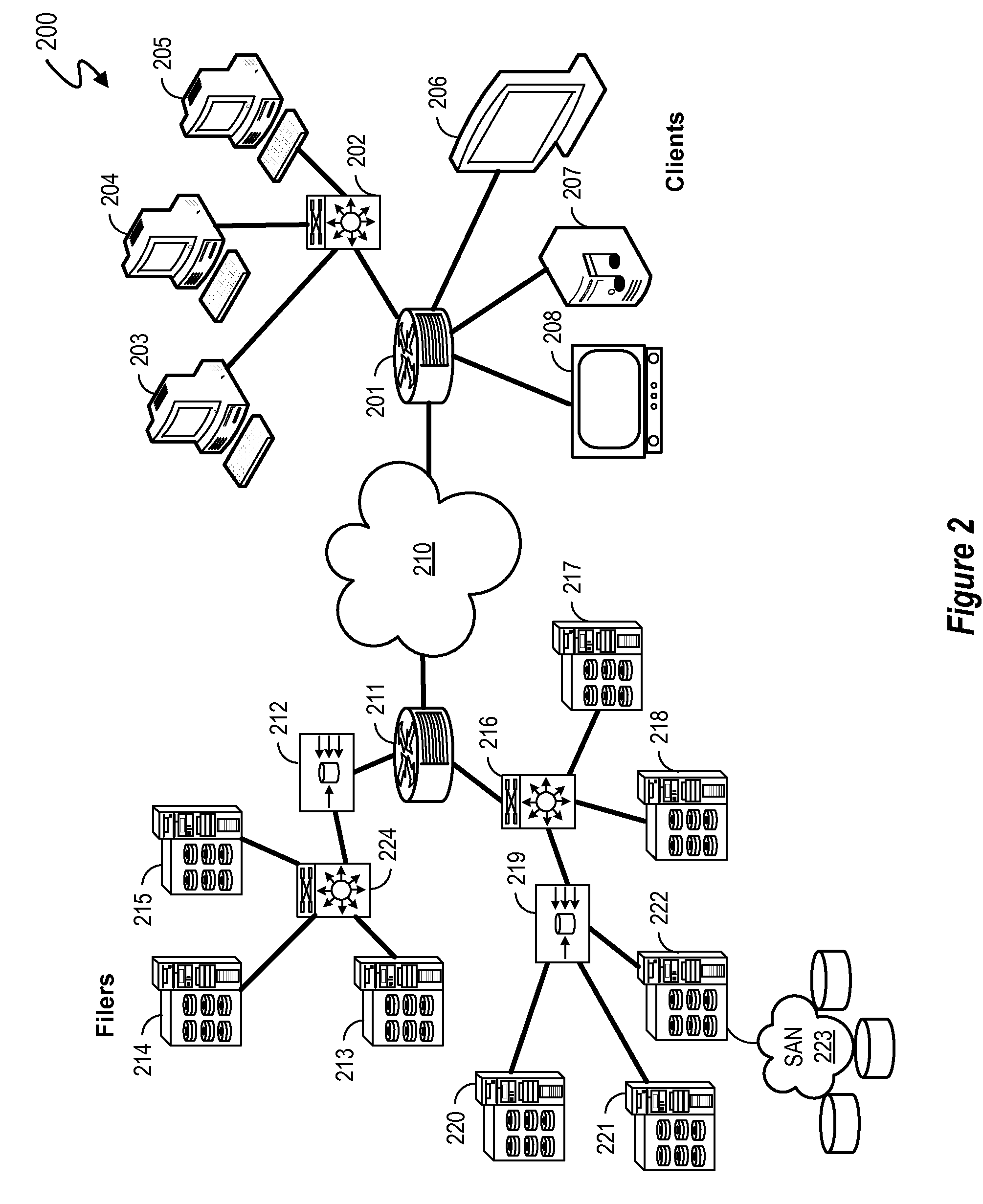

Flash DIMM in a standalone cache appliance system and methodology

InactiveUS7941591B2Low costLess power consumptionMemory architecture accessing/allocationTransmissionDIMMClient-side

Owner:NETWORK APPLIANCE INC

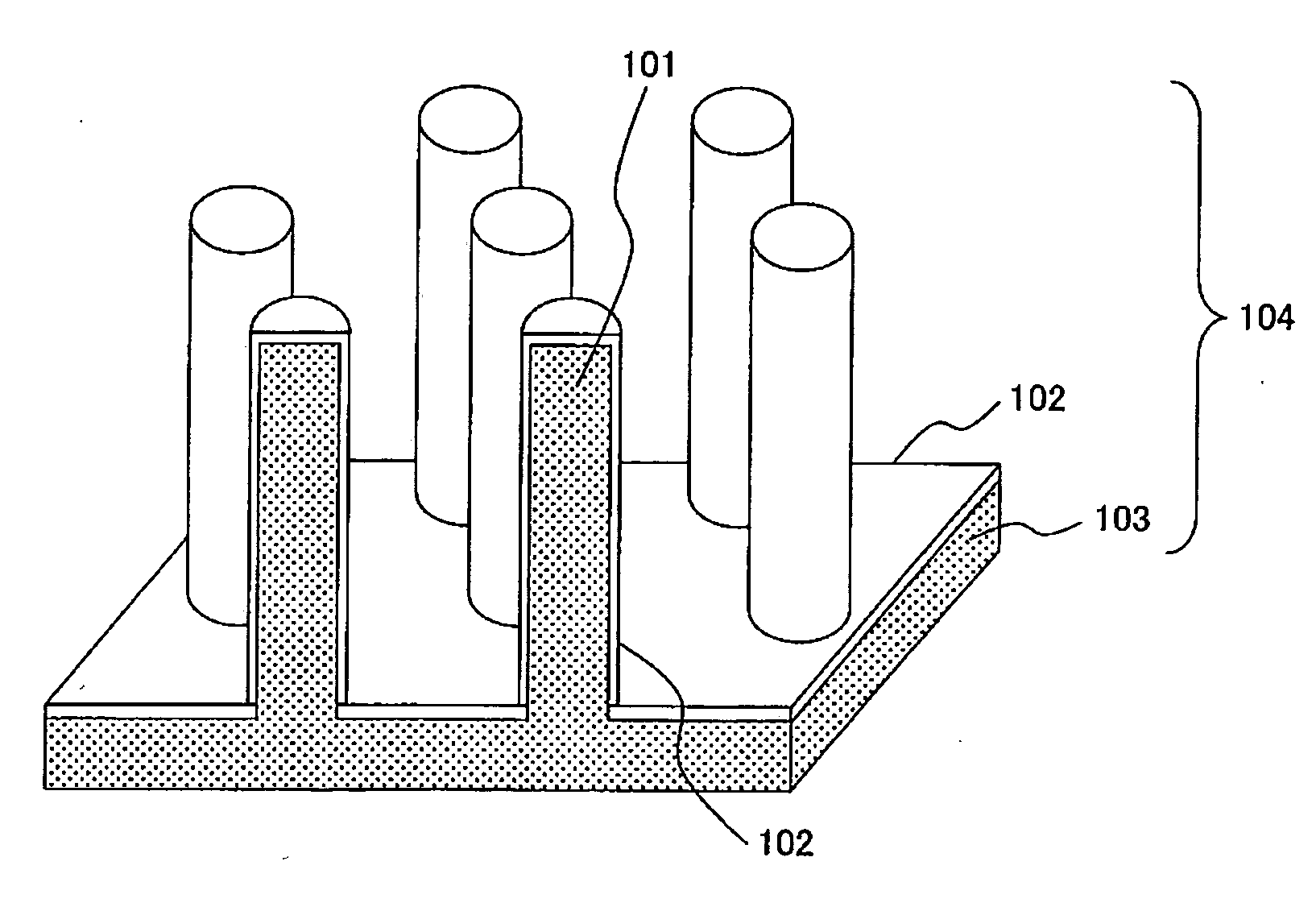

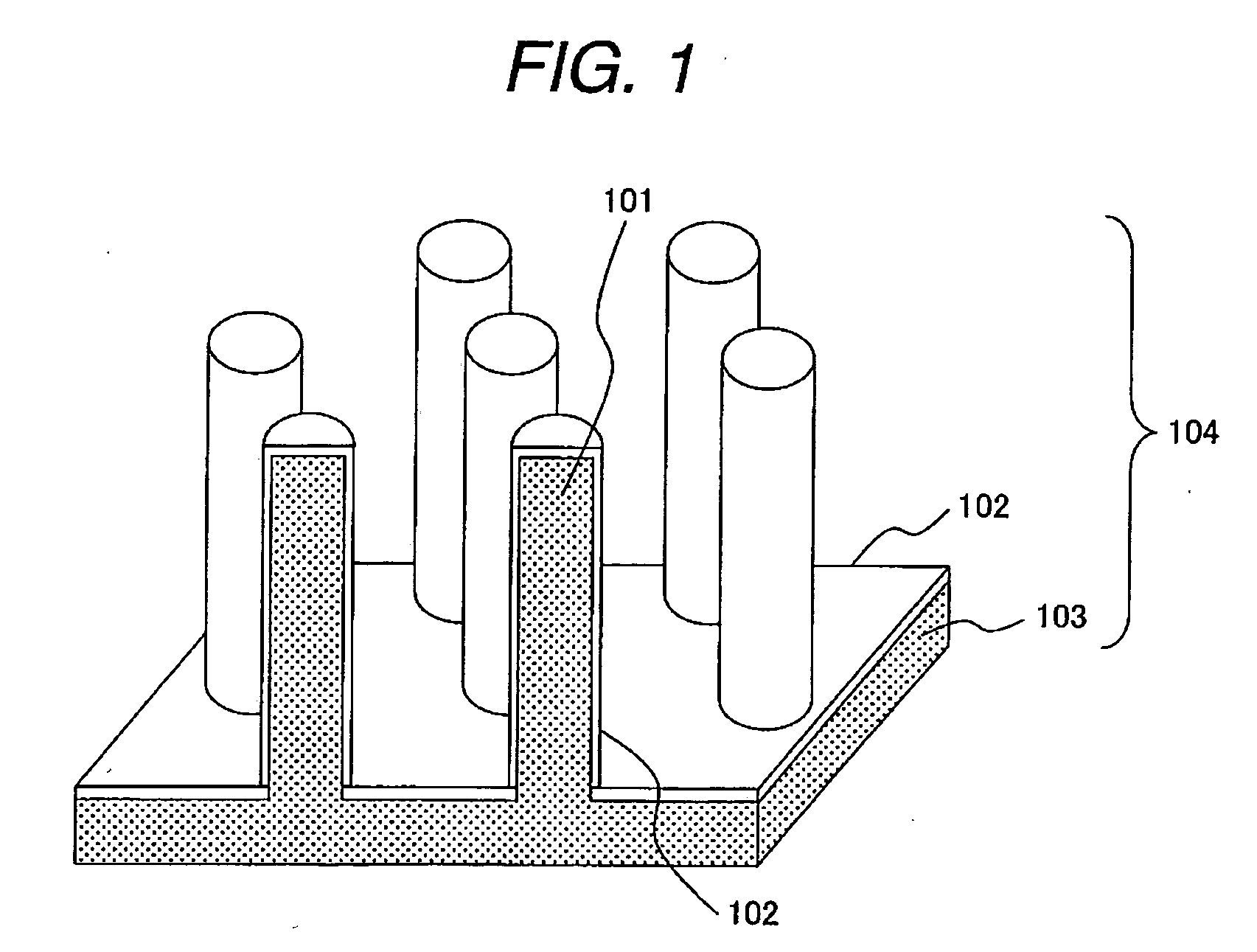

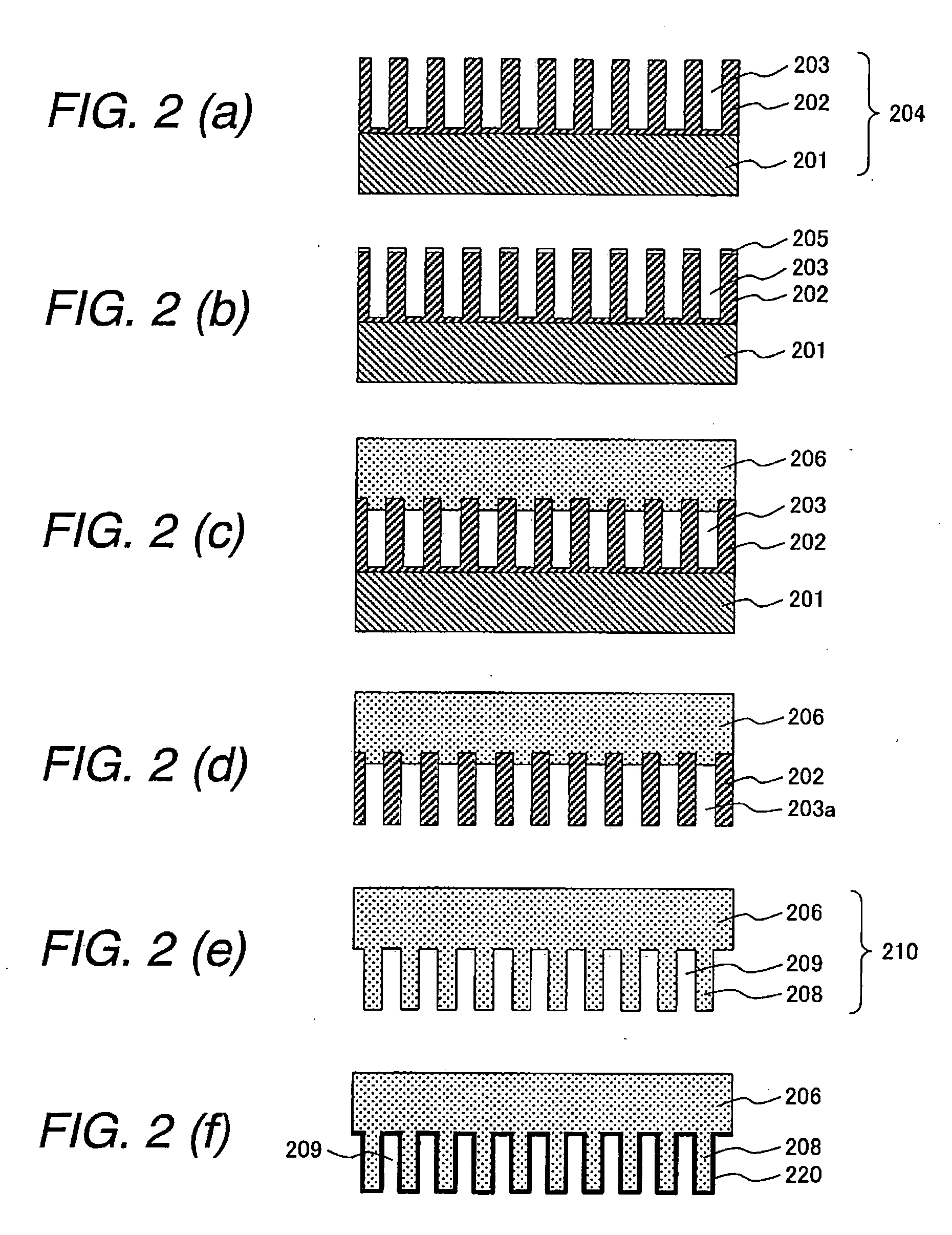

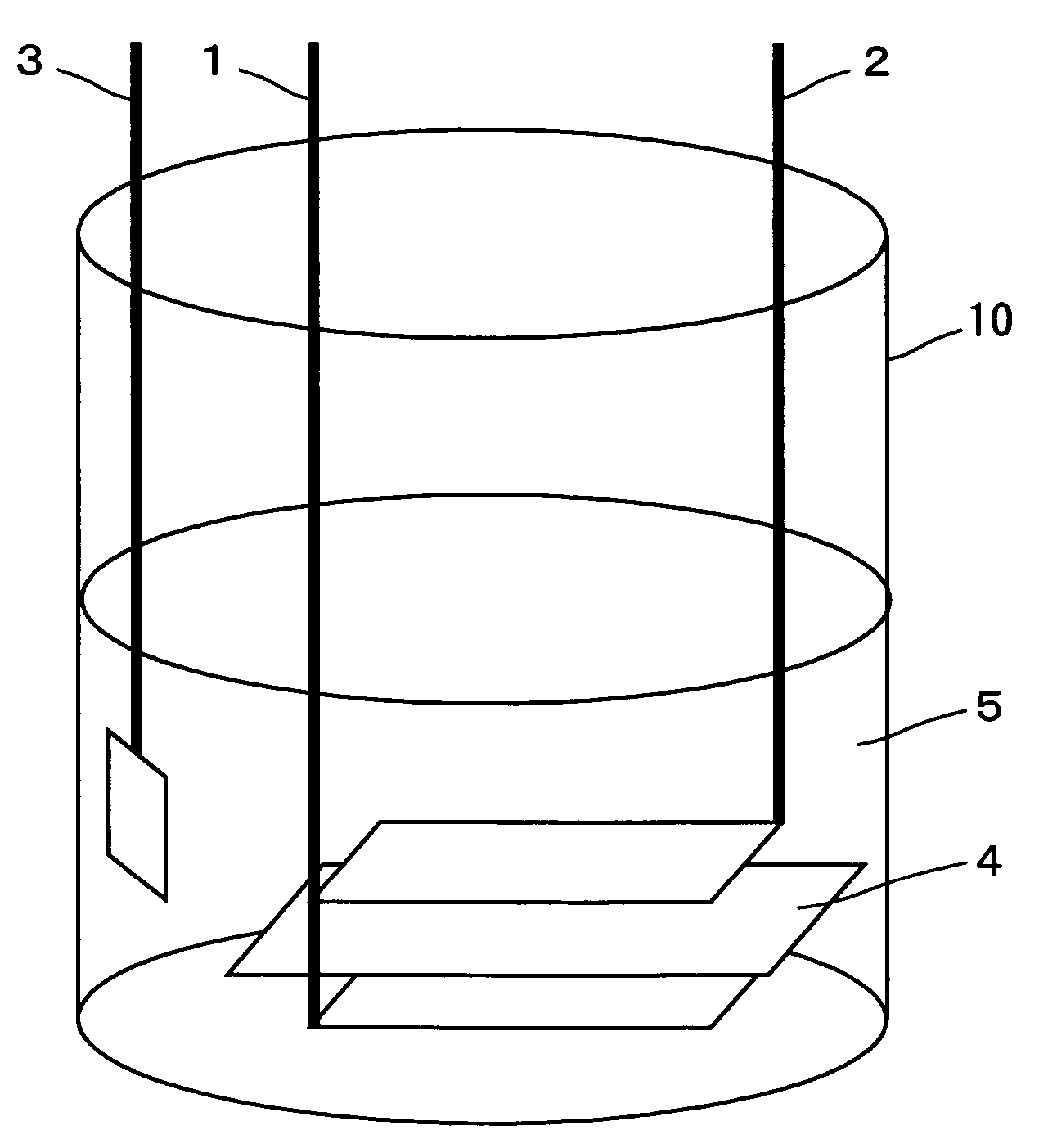

Electrode for use in electrochemical device, solid electrolyte/electrode assembly, and production method thereof

InactiveUS20070059584A1Resistance of electrodeHigh capacity densityMachining electrodesElectrolytic inorganic material coatingNano sizeNanometre

In an electrode in electrochemical device, particularly an anode lithium ion secondary battery, a cathode for use in alkali storage battery, an electrode for use in fuel cell, or a capacitor electrode, a metal structure has nano size micro-pillars is constructed with an electrode active material being formed on the surface of the metal structure. The metal structure having nano size micro-pillars can be formed, for example, by forming a metal layer as an electrode material by plating to the surface of a substrate having pores and then removing the substrate by dissolution, the metal filled in the pores of the substrate to form a group of micro-pillars. And the active material can be formed by depositing metal by plating. Since the active material is in direct contact with the conductive skeleton, the conducting agent for connecting the active materials to each other may not be added at all.

Owner:HITACHI CABLE

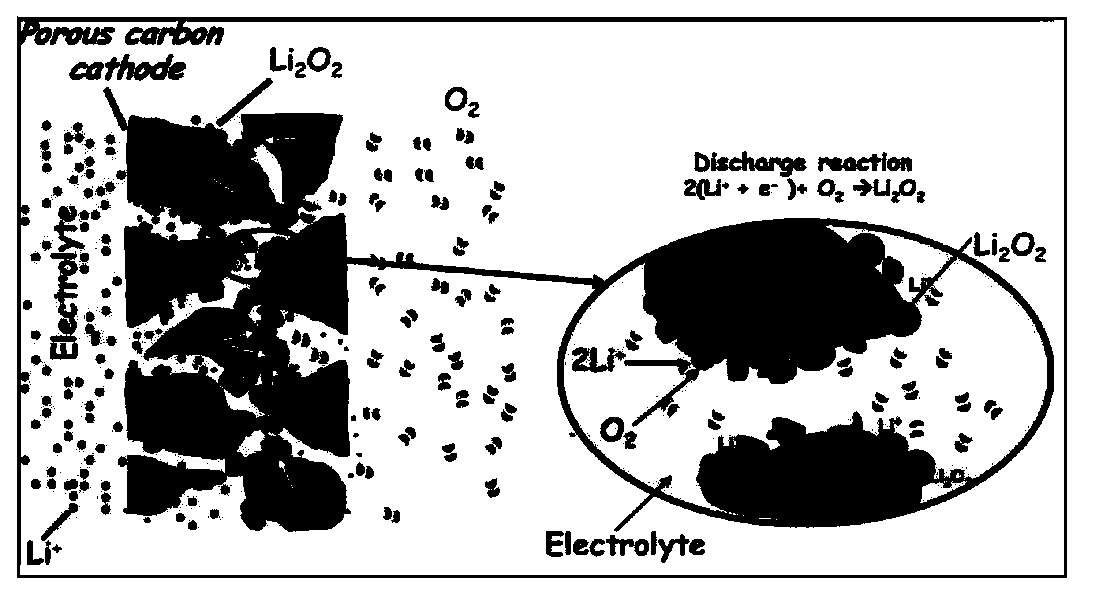

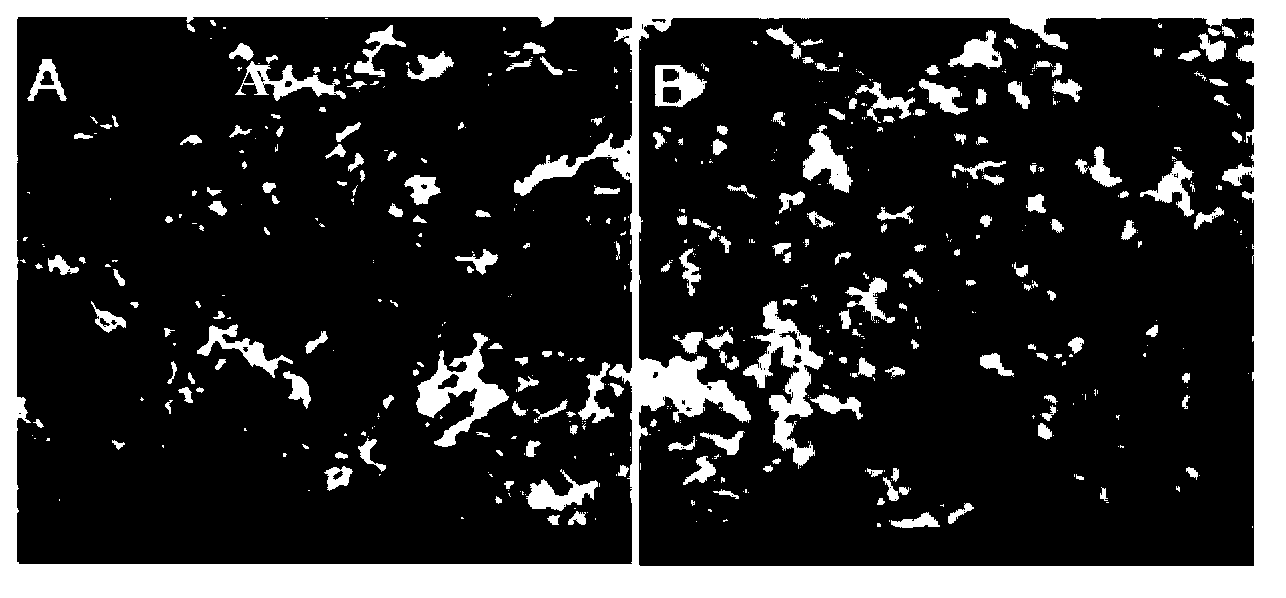

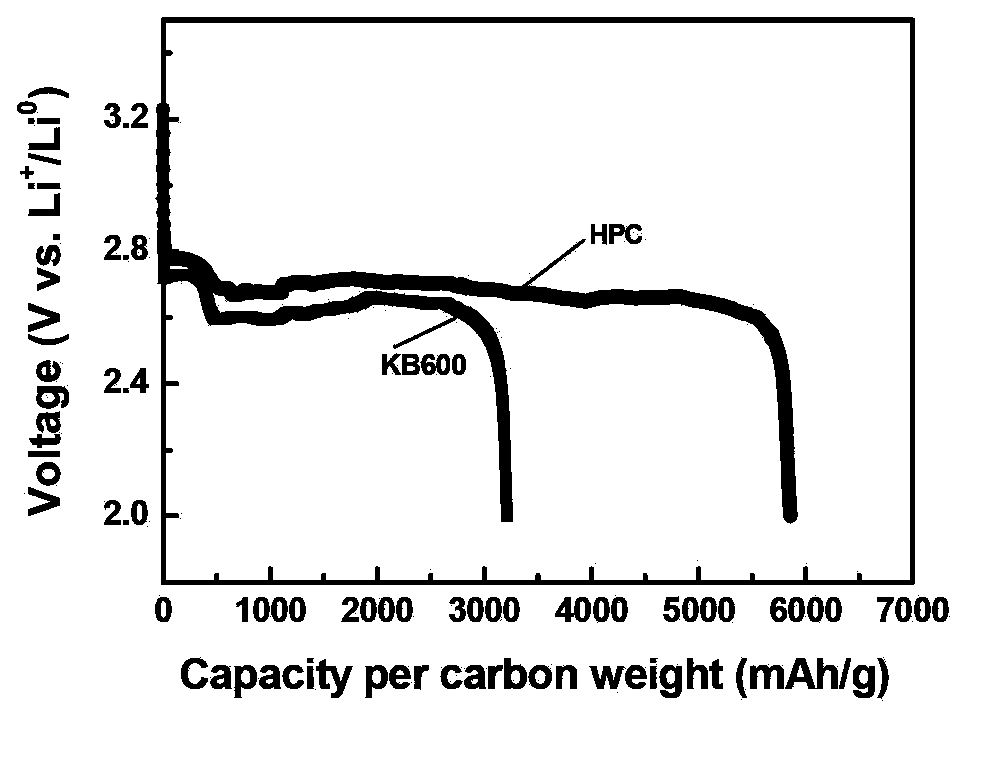

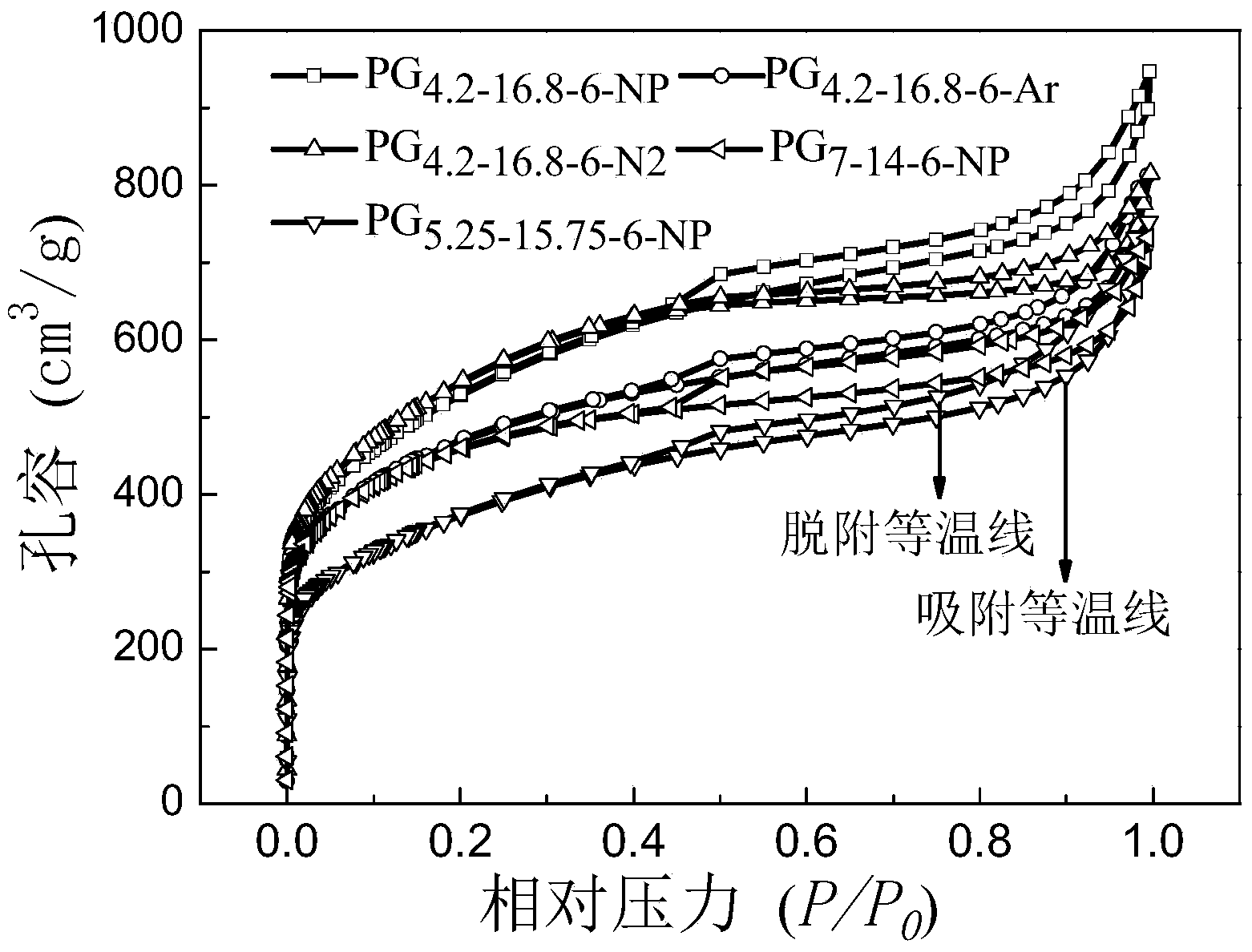

Porous carbon material used for lithium-air cell anode

ActiveCN103855413AShorten the diffusion distanceImprove space utilizationFuel and secondary cellsCell electrodesPorous carbonAir cell

The invention relates to an application of a porous carbon material with a grading pore structure in a lithium-air cell anode, and is characterized in that the carbon material has mutually communicated grading pore structure distribution which has a mesoporous structure for depositing the discharge products and a macroporous structure suitable for transmission of oxygen and an electrolyte. When the carbon material is taken as a material of the lithium-air cell anode, the space utilization rate of carbon material can be increased at maximum limitation during a charge and discharge process, specific discharge capacity, voltage platform and multiplying power discharge capability of the cell can be effectively increased, so that the energy density and power density of the lithium-air cell can be increased. The porous carbon material has the advantages that the preparation technology is simple, the material source is wide, the grading pore carbon material pore structure enables regulation and control, the regulation and control modes are various, and the doping of metal / metal oxide can be easily and simultaneously realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Composite oxide containing lithum, nickel, cobalt, manganese, and fluorine, process for producing the same, and lithium secondary cell employing it

InactiveUS20060057466A1Easy to produceHigh charge-discharge efficiencyLithium compoundsSolid electrolyte cellsCrystallographyManganese

There is obtained an active material for a lithium secondary battery that has a wide usable voltage range, a high charge-discharge cycle durability, a high capacity and high safety and availability. The particles of a lithium-nickel-cobalt-manganese-fluorine-containing composite oxide having an R-3m rhombohedral structure represented by a general formula LipNixMn1-x-yCoyO2-qFq (where 0.98≦p≦1.07, 0.3≦x≦0.5, 0.1≦y≦0.38, and 0≦q≦0.05), and the particles of the lithium-nickel-cobalt-manganese-fluorine-containing composite oxide characterized in that the half-width of the diffraction peak of a (110) plane whose 2θ is 65±0.5° in the X-ray diffraction using a Cu—Kα line is, 0.12 to 0.25° are used as an active substance for a positive electrode.

Owner:AGC SEIMI CHEM CO LTD

Positive active material for non-aqueous electrolyte secondary battery and non-aqueous electrolyte secondary battery comprising same

InactiveUS6893776B2High capacity densityReaction resistance increaseNon-aqueous electrolyte accumulatorsConductive materialComposite oxideNickel

A positive active material for a non-aqueous electrolyte secondary battery includes a lithium-nickel composite oxide represented by the compositional formula LiaNi1−b−cCObMncO2 (a≦1.09, 0.05≦b≦0.35, 0.15≦c≦0.35, and 0.25≦b+c≦0.55). By X-ray diffractometry with a CuKα ray, the lithium-nickel composite oxide exhibits an intensity ratio R ((I012+I006) / I101) of not greater than 0.50, wherein R is the ratio of the sum of the diffraction peak intensity I012 on the 012 plane and the diffraction peak intensity I006 on the 006 plane to the diffraction peak intensity I101 on the 101 plane. The crystallinity of the positive active material of the compositional formula LiaNi1−b−cCobMncO2 can be kept high and it is possible to secure good capacity density and cycle life performance.

Owner:GS YUASA INT LTD

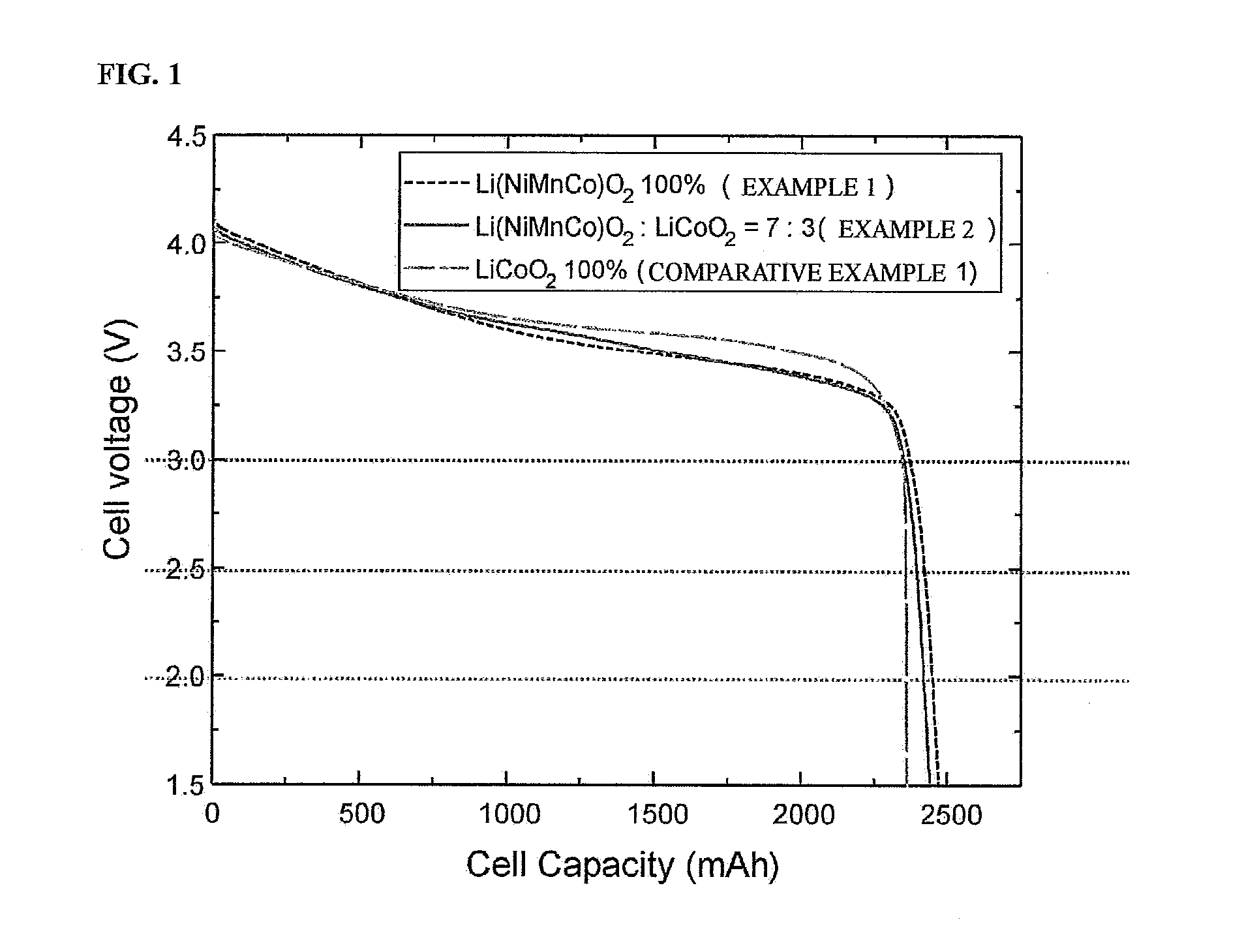

Lithium secondary battery with improved energy density

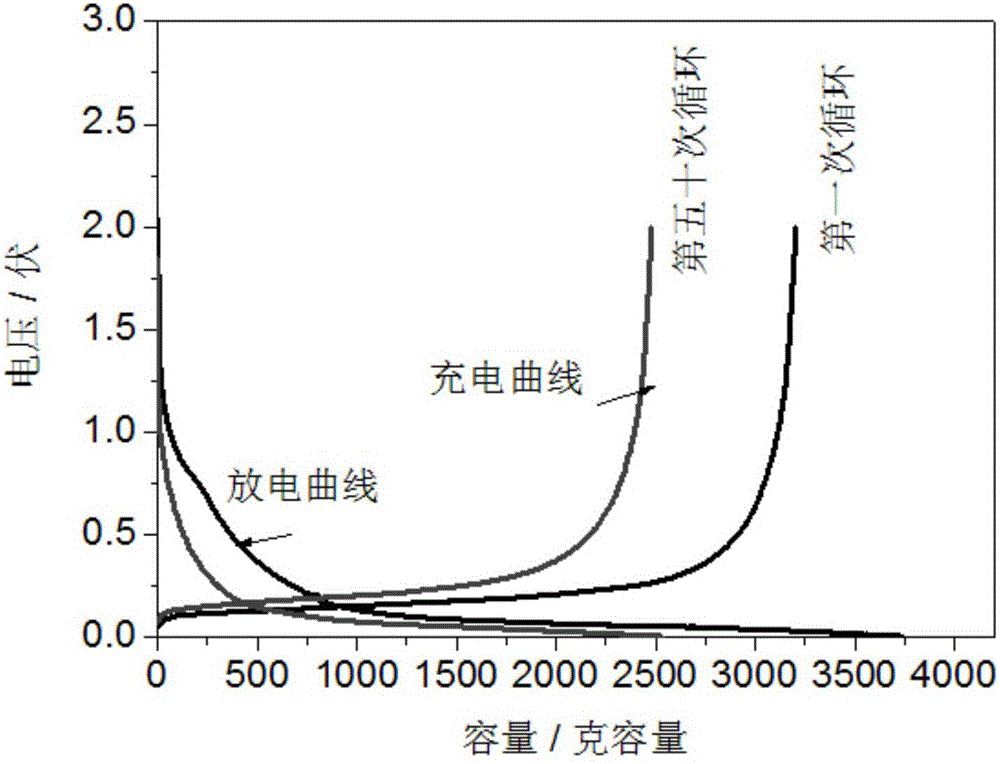

ActiveUS20120028134A1Increase battery capacityHigh capacity densityOrganic electrolyte cellsNon-aqueous electrolyte accumulator electrodesMetalVoltage

Provided is a lithium secondary battery with enhanced energy density including a cathode using a cathode active material containing lithium mixed transition metal oxide absorbing and discharging lithium ions, wherein a final discharge voltage is in the range of about 1.5 V to about 2.75 V. A final discharge voltage can be reduced to 1.5 V to 2.75 V from 3.0 V by using various lithium mixed transition metal oxides as a cathode active material, or by using the various lithium mixed transition metal oxides with the LCO-based cathode material mixed. Compared to typical LCO-based cathode materials of which capacity and energy density do not change even if a final discharge voltage is decreased, a cathode material of the present invention results in further improving capacity by 10-20% as the final discharge voltage is decreased.

Owner:LG ENERGY SOLUTION LTD

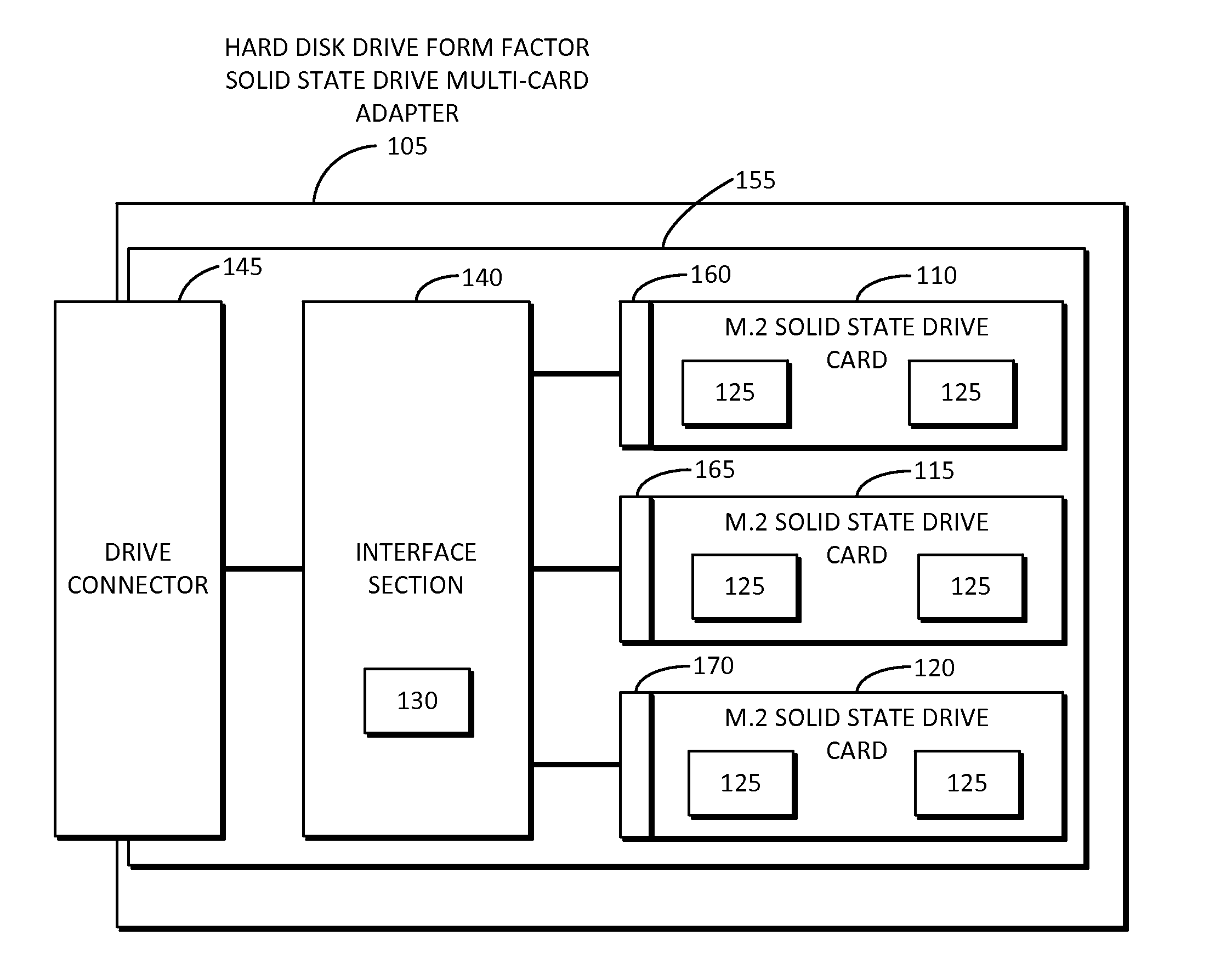

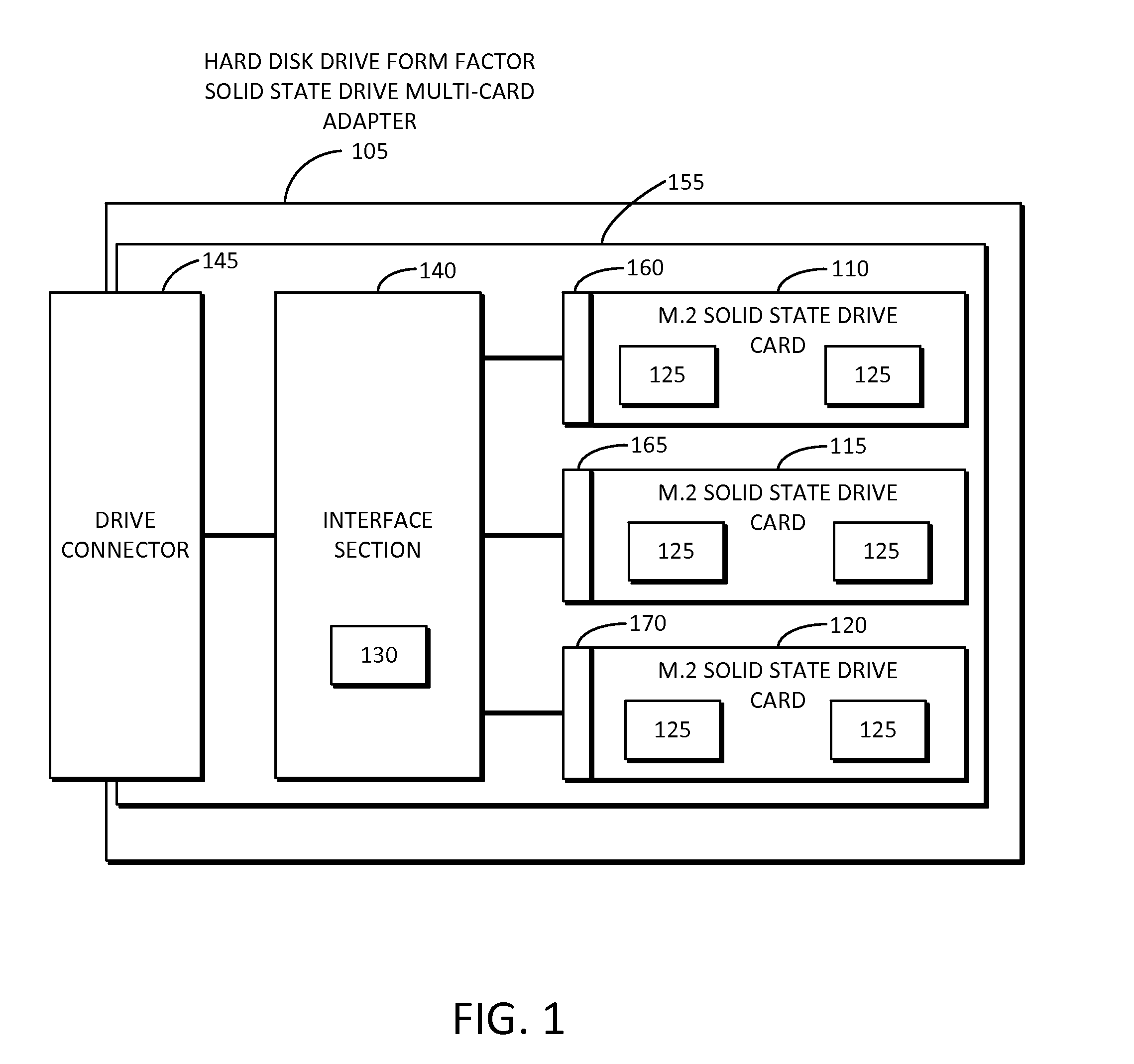

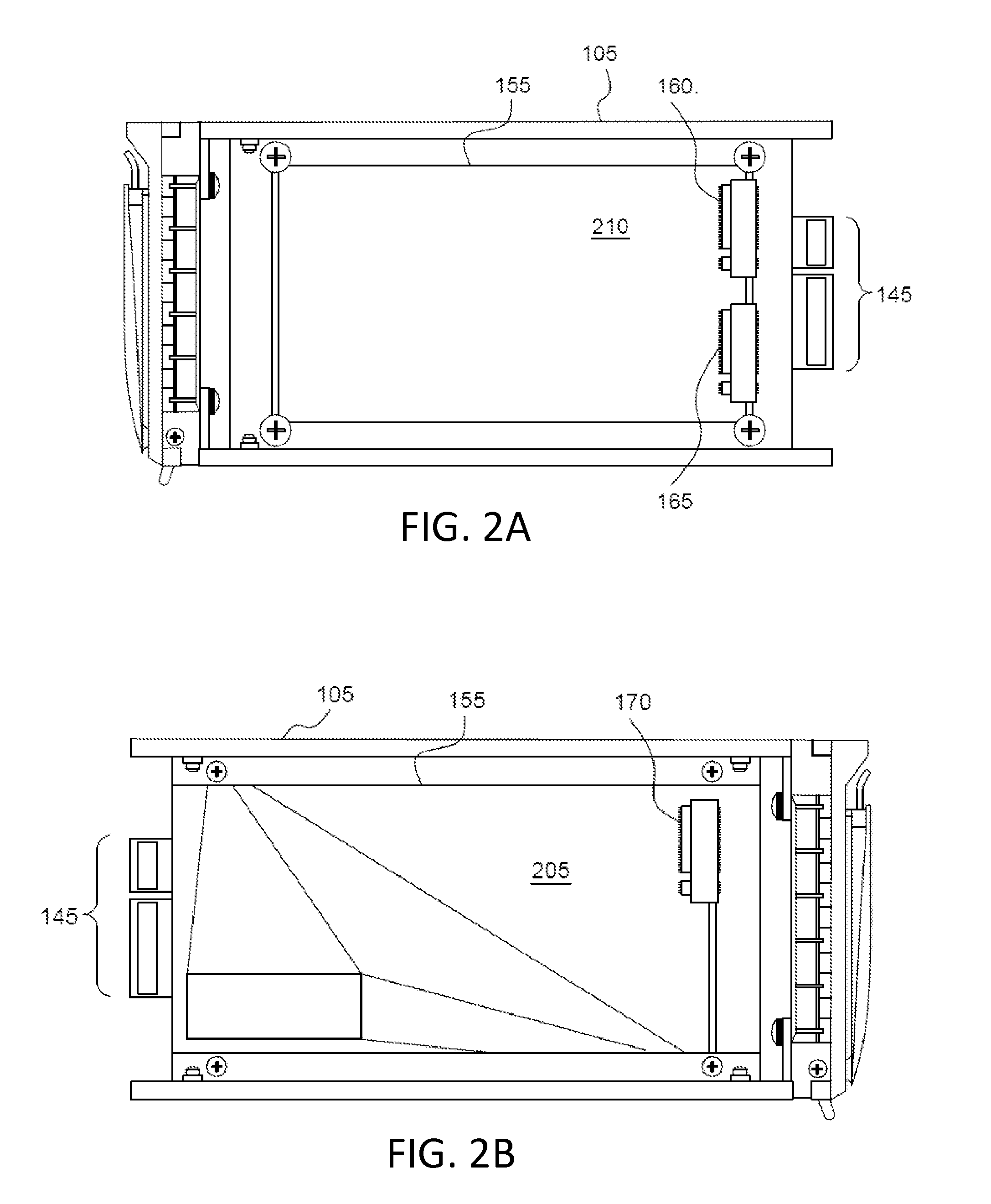

Hard disk drive form factor solid state drive multi-card adapter

Embodiments of the inventive concept include 2.5 inch hard disk drive form factor solid state drive multi-card adapters that can include multiple M.2 solid state drive cards, which can be incorporated into existing enterprise servers without major architectural changes, thereby enabling the server industry ecosystem to easily integrate M.2 solid state drive technology into servers. Multiple M.2 solid state drive cards and a peripheral component interconnect express (PCIe) switch can be included within a 2.5 inch hard disk drive form factor solid state drive multi-card adapter. The solid state drive multi-card adapters can be attached to or seated within drive bays of a computer server that supports non-volatile memory express (NVMe) 2.5 inch drives without any changes to the server architecture, thereby providing a straight-forward upgrade path.

Owner:SAMSUNG ELECTRONICS CO LTD

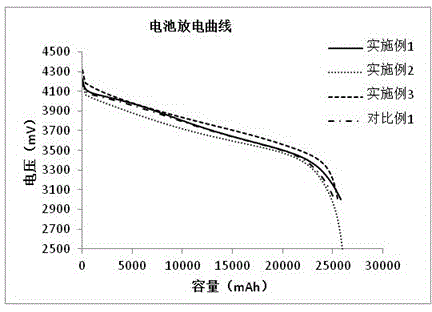

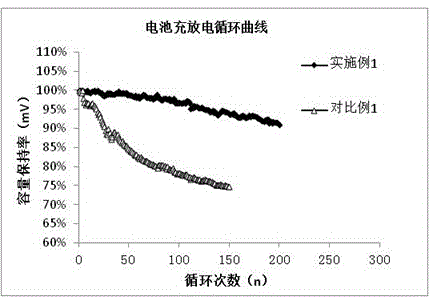

Lithium ion battery adopting lithium-rich manganese-based material as positive electrode and preparation method of lithium ion battery

InactiveCN103560250AIncrease energy densityStable structureMaterial nanotechnologyElectrode carriers/collectorsHigh energyManganese

The invention discloses a lithium ion battery adopting a lithium-rich manganese-based material as a positive electrode and a preparation method of the lithium ion battery. The lithium ion battery adopting the lithium-rich manganese-based material as the positive electrode comprises a positive electrode, a positive electrode surface coating, a negative electrode, a diaphragm and electrolyte. The lithium ion battery adopting the lithium-rich manganese-based material as the positive electrode has the advantages of high energy density, good multiplying power property and long cycling service life.

Owner:TIANJIN ENERGIES

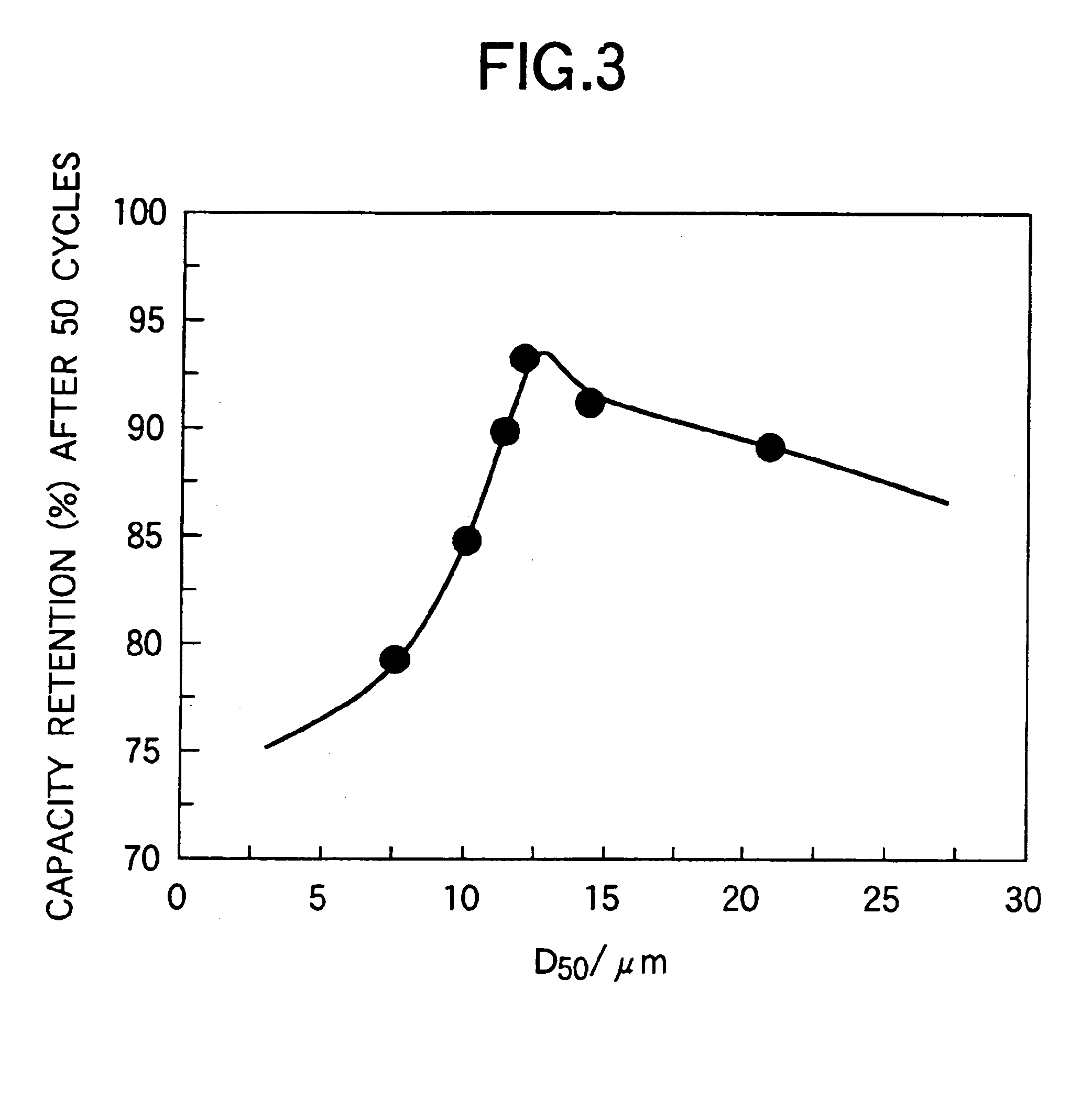

Negative electrode for lithium secondary battery and lithium secondary battery

InactiveUS6946223B2Increase energy densityHigh capacity densityElectrode carriers/collectorsNegative electrodesLithium-ion batteryMaterials science

Owner:SANYO ELECTRIC CO LTD

A composite carbon-based electrode material for super capacitor and method for making same

InactiveCN1567493AImprove conductivityLower internal resistanceHybrid capacitor electrodesElectrolytic capacitorsFiberCarbon fibers

The invention discloses a composite carbon-based electrode material used for super capacitors and its preparing method, and it is composed of nano metals, nano metal composite oxide, activated carbon and nano carbon fiber, effectively using the activated carbon with high specific surface area and the nano carbon fiber to provide a double electric layer capacitor for a super capacitor, combining a Faraday quasi-capacitor provided by the nano metal oxide, and at the same time using the high electric conductivity of the nano carbon fiber and nano metals and the nano cooperation effect, thus increasing its capacitor and power densities and able to obtain the super capacitors with high energy and power densities, and the invention is low-cost and easy for commercial application.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

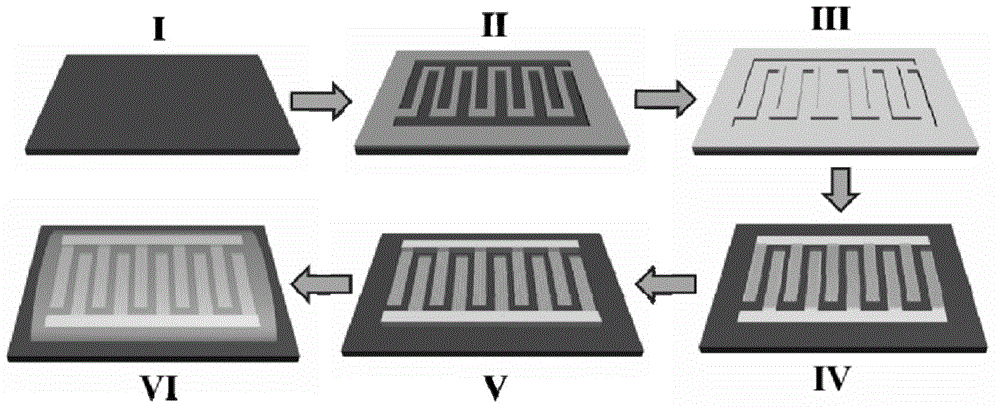

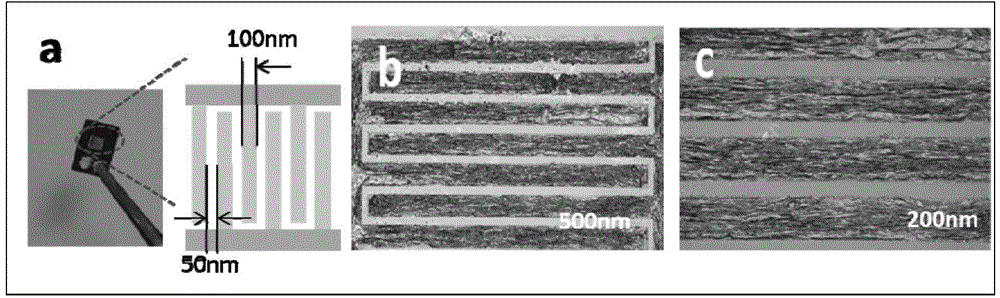

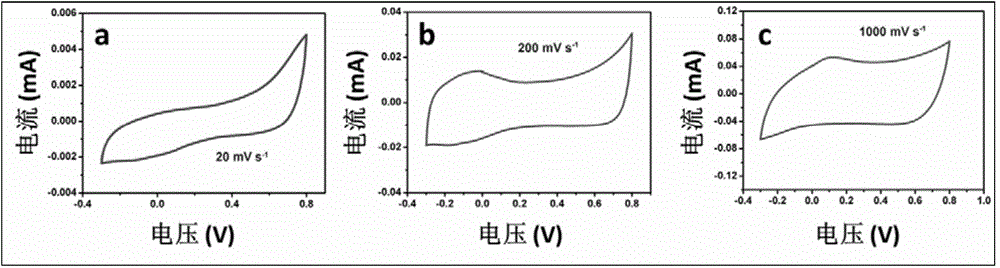

Micro super capacitor nano-device based on porous graphene-supported polyaniline heterostructure and manufacturing method thereof

InactiveCN104637694AIncrease contact areaFacilitate conductionHybrid capacitor electrodesHybrid/EDL manufactureCurrent collectorPorous graphene

The invention relates to a micro super capacitor nano-device based on a porous-graphene-supported polyaniline heterostructure and a manufacturing method thereof. A symmetrical fork electrode structure is formed on a substrate material; forks are 100-200 nanometers in widths; the distances among the forks are 50-100 nanometers; electrolyte is added dropwise; in the fork electrode structure, gold serving as a current collector is taken as the first layer of an electrode material; porous graphene is attached to the gold and is taken as the second layer of the electrode material; polyaniline is coated on the porous graphene and is taken as the surface layer of the electrode material; the gold is 10-20 nanometers in thickness; the porous graphene is 20-40 nanometers in thickness; the polyaniline is 20-40 nanometers in thickness; the electrode material is 50-100 nanometers in total thickness. The micro super capacitor nano-device has the beneficial effects that a micro energy storing device can store more energy on the premise of ensuring high electronic conduction, so that the capacity and energy density of a super capacitor are further increased.

Owner:WUHAN UNIV OF TECH

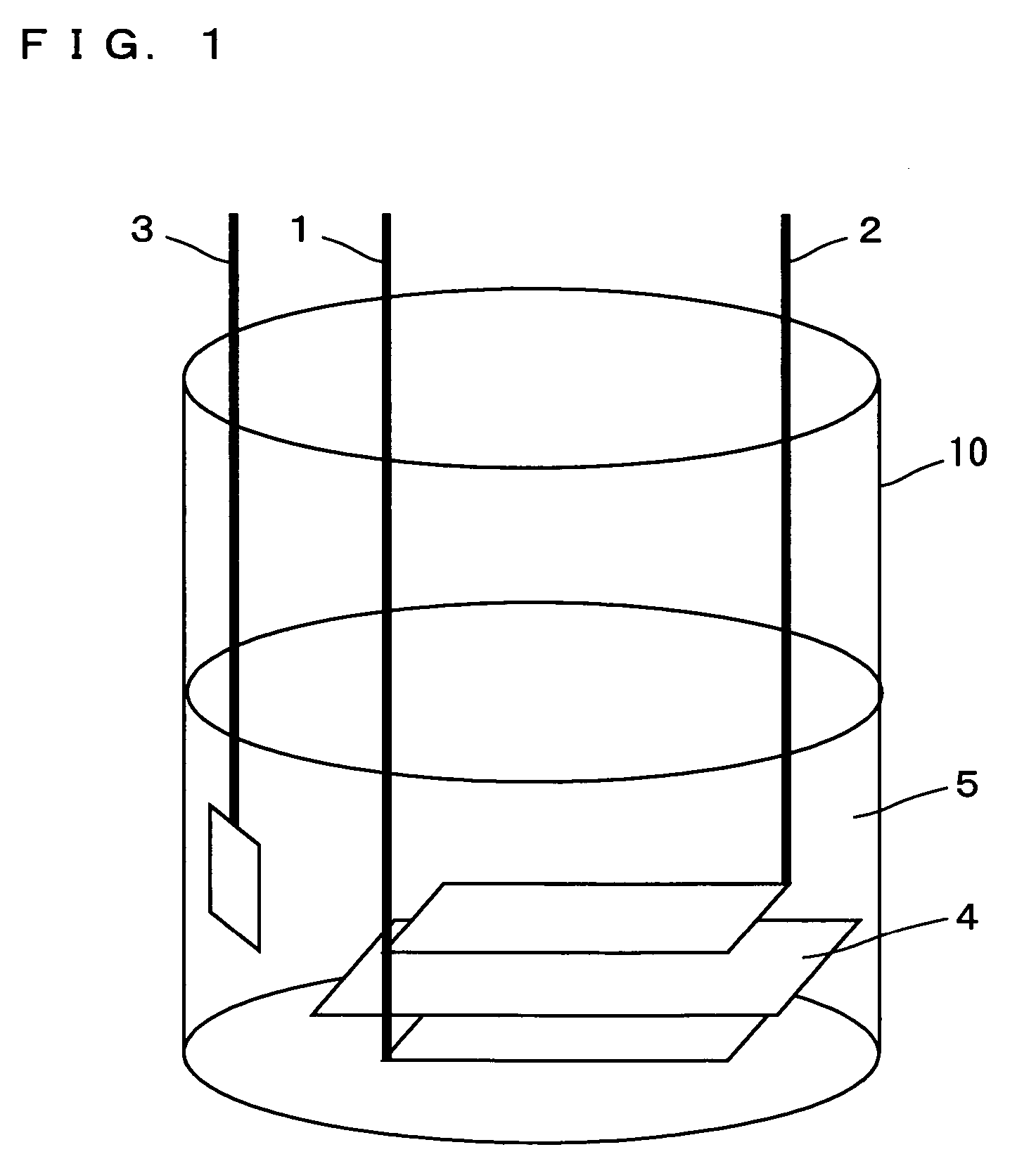

Nonaqueous electrolyte secondary battery

InactiveUS20050136327A1Improve charge/discharge efficiencyImprove cycle performanceOrganic electrolyte cellsLi-accumulatorsLithiumCyclic ether

A positive electrode has a positive-electrode active material obtained from a mixture of elemental sulfur, a conductive agent and a binder. A negative electrode is composed of a carbon material such as graphite, lithium alloy, or the like that can store lithium and release it. A nonaqueous electrolyte contains a first solvent composed of at least one compound selected from the group consisting of cyclic ethers and chain ethers, and a second solvent composed of a room temperature molten salt having a melting point not higher than 60° C. in a volume ratio in the range of 0.1:99.9 to 40:60, and also contains saturated lithium polysulfide.

Owner:SANYO ELECTRIC CO LTD

A mixed super capacitor

InactiveCN1963966AIncrease working voltageHigh capacity densitySecondary cellsCapacitor electrodesElectrolysisEngineering

The related mixed super capacitor comprises: using Ta and RuO2 as the anode and cathode respective; filling H2SO4 electrolyte to form the electrolytic capacitor with anode and the electrochemical capacitor with cathode in series, respectively. This invention increases working voltage and energy storage density, overcomes defects in prior art, and can be used in the impulse power system.

Owner:DALIAN UNIV OF TECH

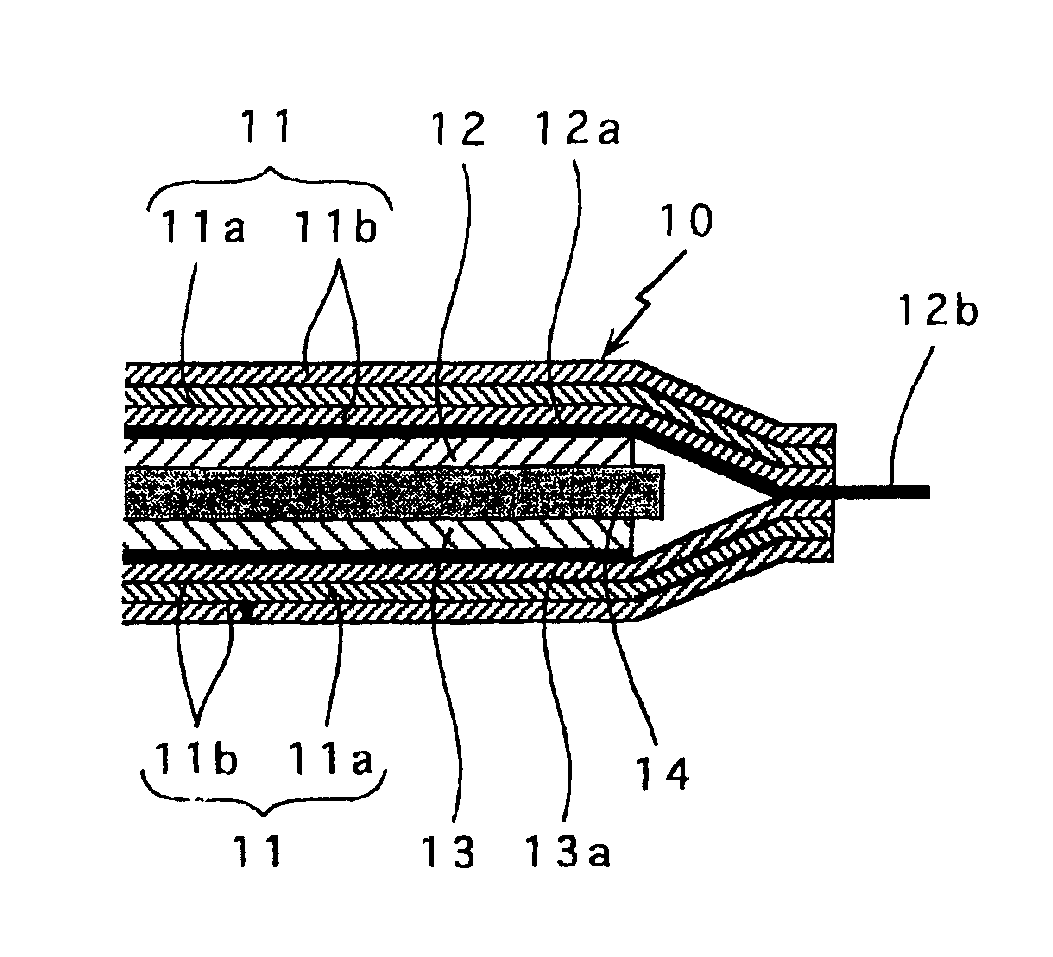

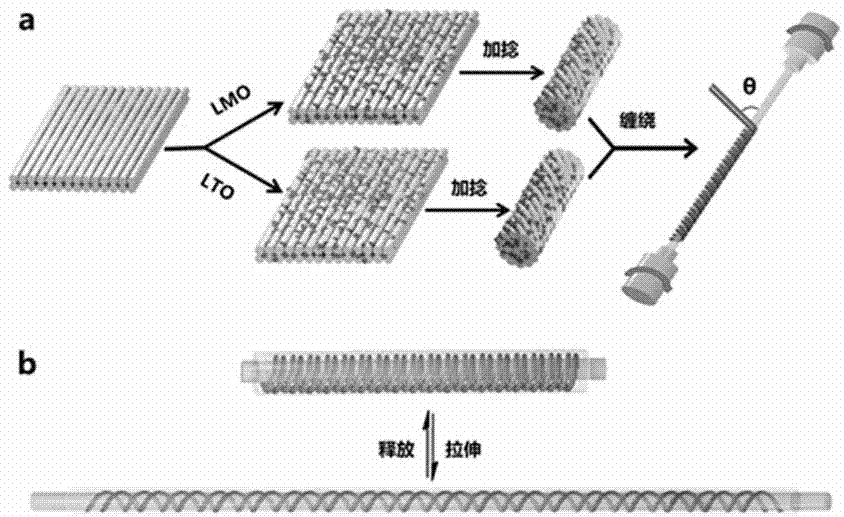

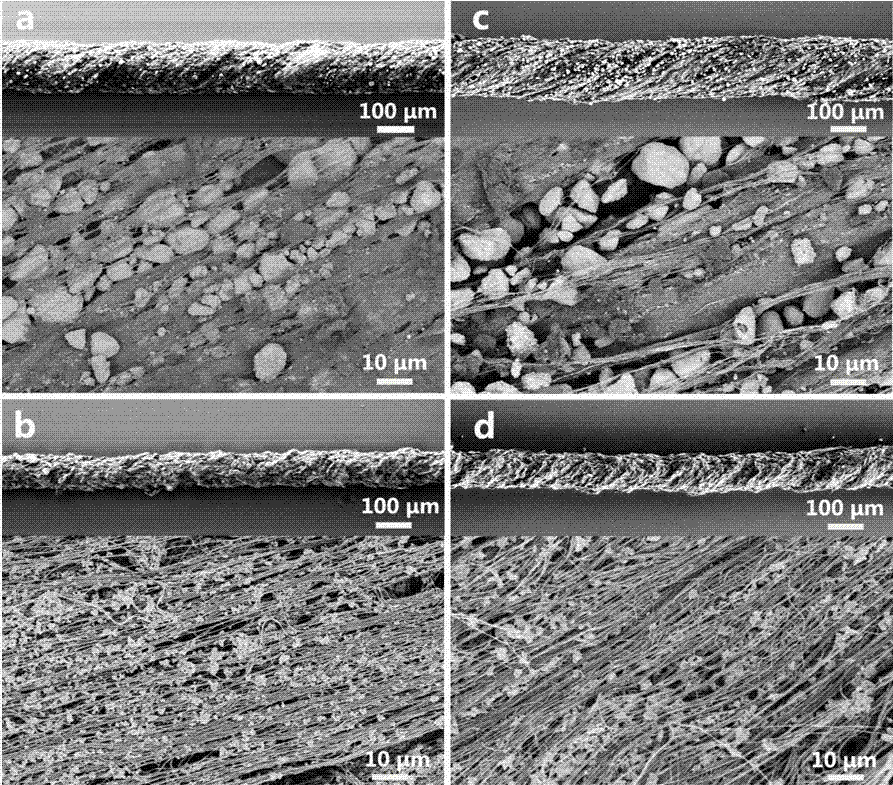

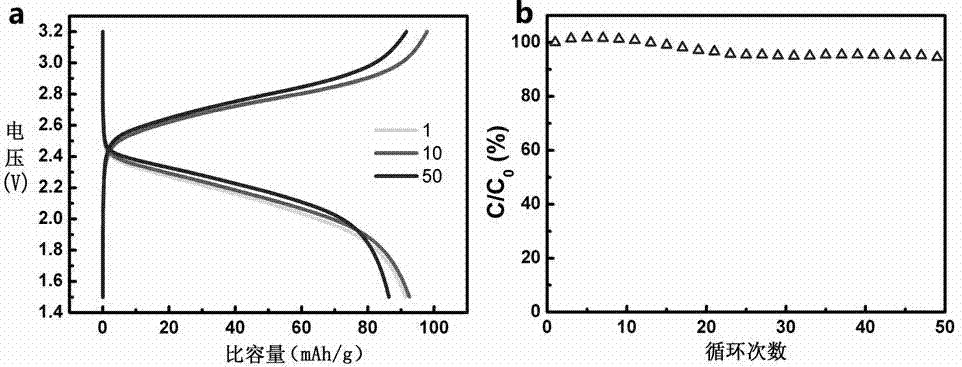

Stretchable linear lithium ion battery and preparation method thereof

ActiveCN103904357AReduce weightReduce volumeCell electrodesFinal product manufactureFiberElectrical battery

The invention belongs to the technical field of energy storage devices and particularly relates to a stretchable linear lithium ion battery and a preparation method thereof. The preparation method comprises the following steps: firstly, preparing a carbon nano tube / lithium manganate composite fiber as an anode and preparing a carbon nano tube / lithium titanate composite fiber as a cathode; respectively winding each of the anode fiber and the cathode fiber on one piece of elastic rubber and coating one layer of ethylene oxide / butanedinitrile / lithium bis(trifluoromethanesulphonyl)imide gel electrolyte; and finally, packaging so as to prepare the linear lithium ion battery. Compared with other mini-type devices, the linear lithium ion battery has a brand-new structure and does not need metal fluid and a binding agent, so that the weight and the volume of the battery are reduced, and furthermore, the specific capacity and the energy density of the battery are improved. Meanwhile, the battery has good flexibility and stretchability and is easy to braid and integrate so that the application prospect is very good.

Owner:宁国市龙晟柔性储能材料科技有限公司

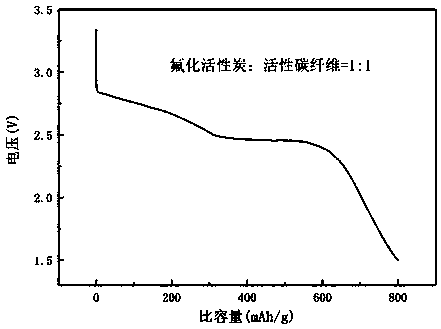

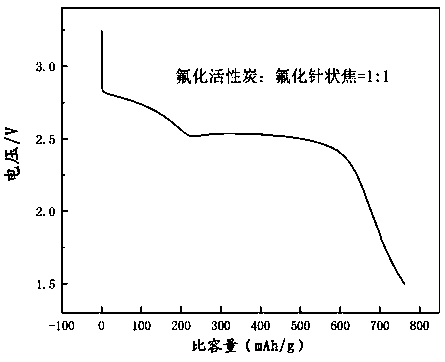

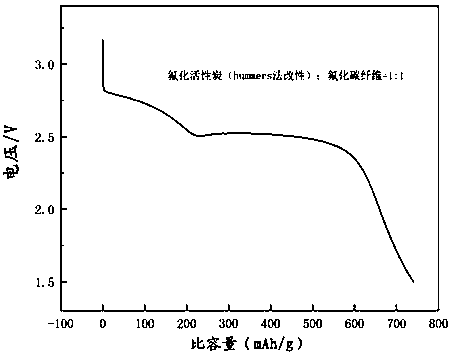

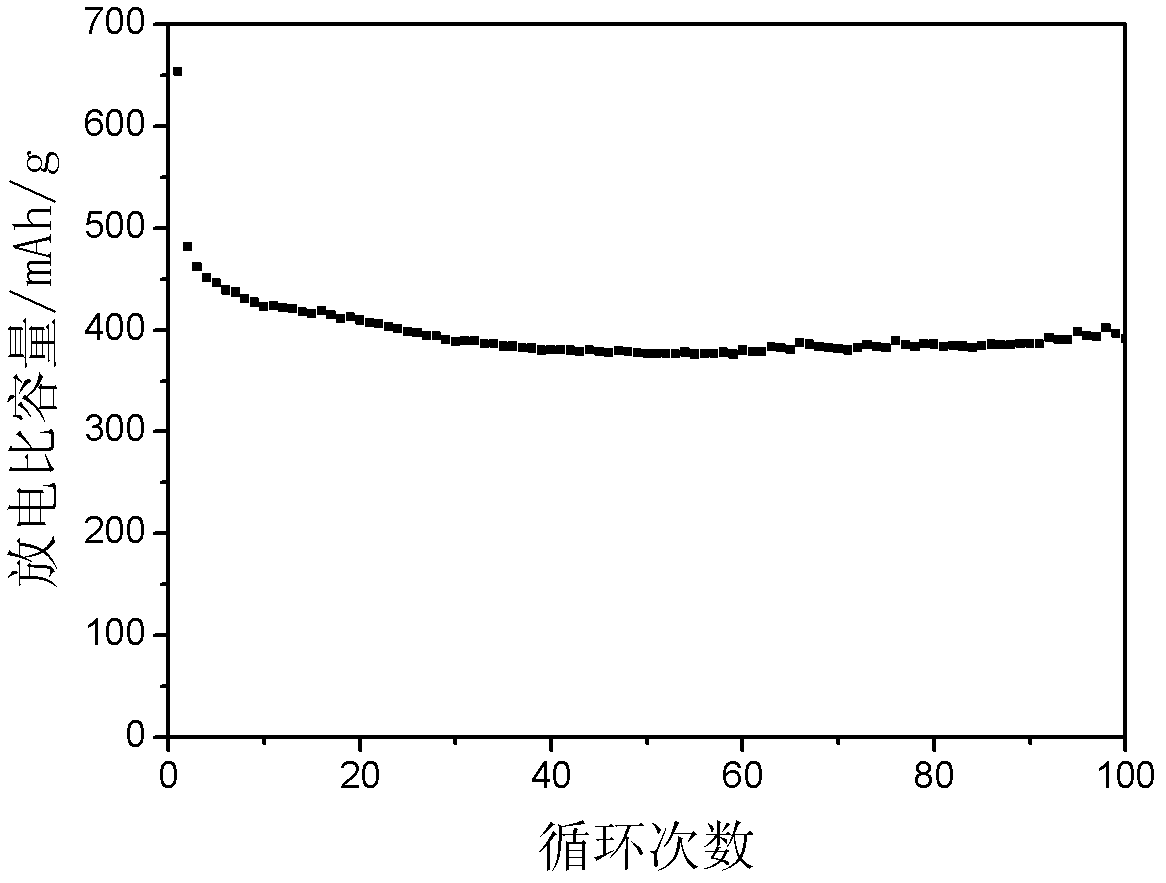

Composite carbon fluoride cathode material for lithium primary battery, preparation method and application thereof

ActiveCN109461923AHigh specific capacityHigh capacity densityCell electrodesNon-aqueous electrolyte cellsMass ratioPorous carbon

The invention belongs to the technical field of a cathode material for a lithium primary battery, particularly relates to the field of preparation of the cathode material for a fluorocarbon battery, and in particular to a composite carbon fluoride cathode material for the lithium primary battery, a preparation method and an application thereof. The material is a composite material prepared by ballmilling and mixing a porous carbon fluoride material having a high tap density and a carbon fluoride material having a high graphitization degree and then fluorinating the mixture. The composite material has a carbon content of 38-60%, a fluorine content of 40-62% and a tap density of greater than 0.8g / ml; the mixing mass ratio is in the range of 1:0.1-1:10; and the composite material has high specific surface area, high tap density and high graphitization degree. Due to the high tap density of the material, the overall high volumetric specific energy of the material is guaranteed; through anion diffusion channel composed of porous carbon fluorides, the voltage hysteresis phenomenon at the initial stage of the battery discharge is effectively improved and the overall discharge performance of the material is improved.

Owner:SHANDONG ZHONGSHAN PHOTOELECTRIC MATERIAL CO LTD

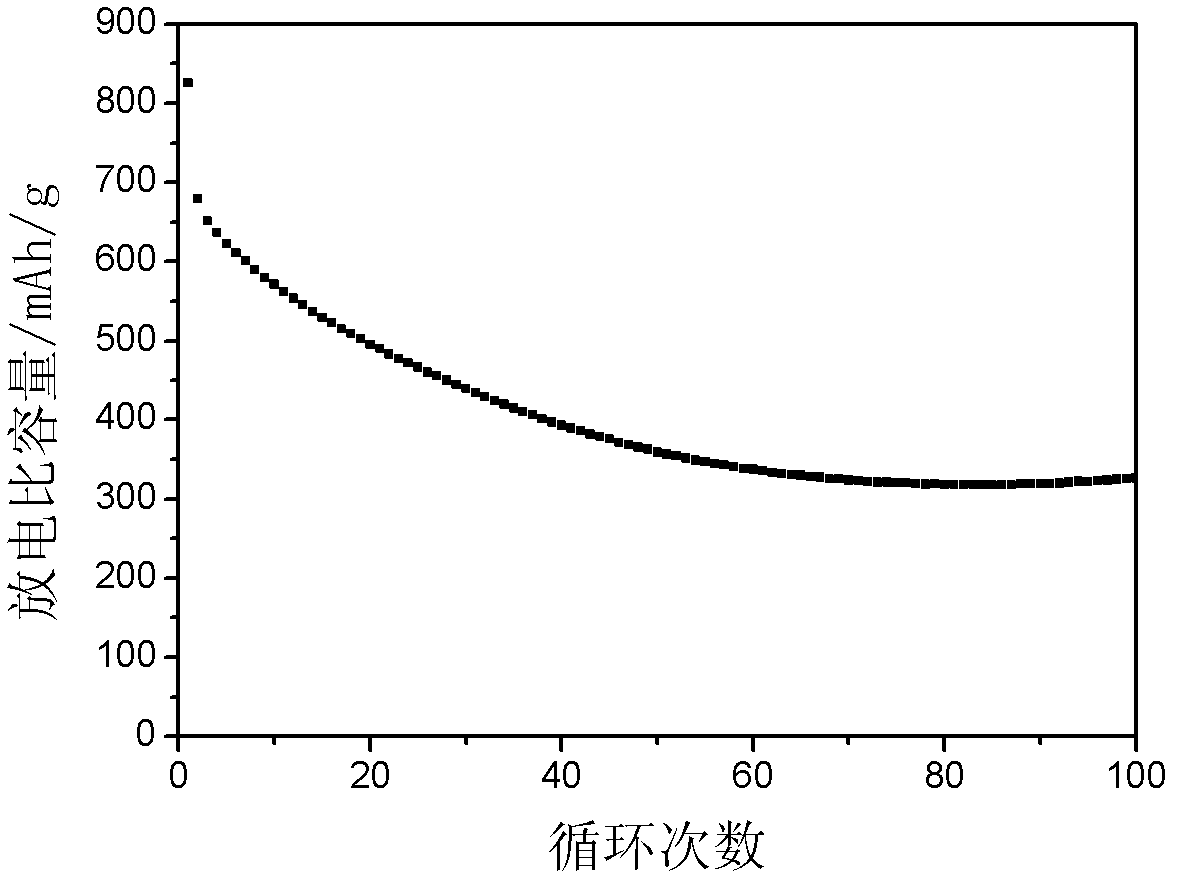

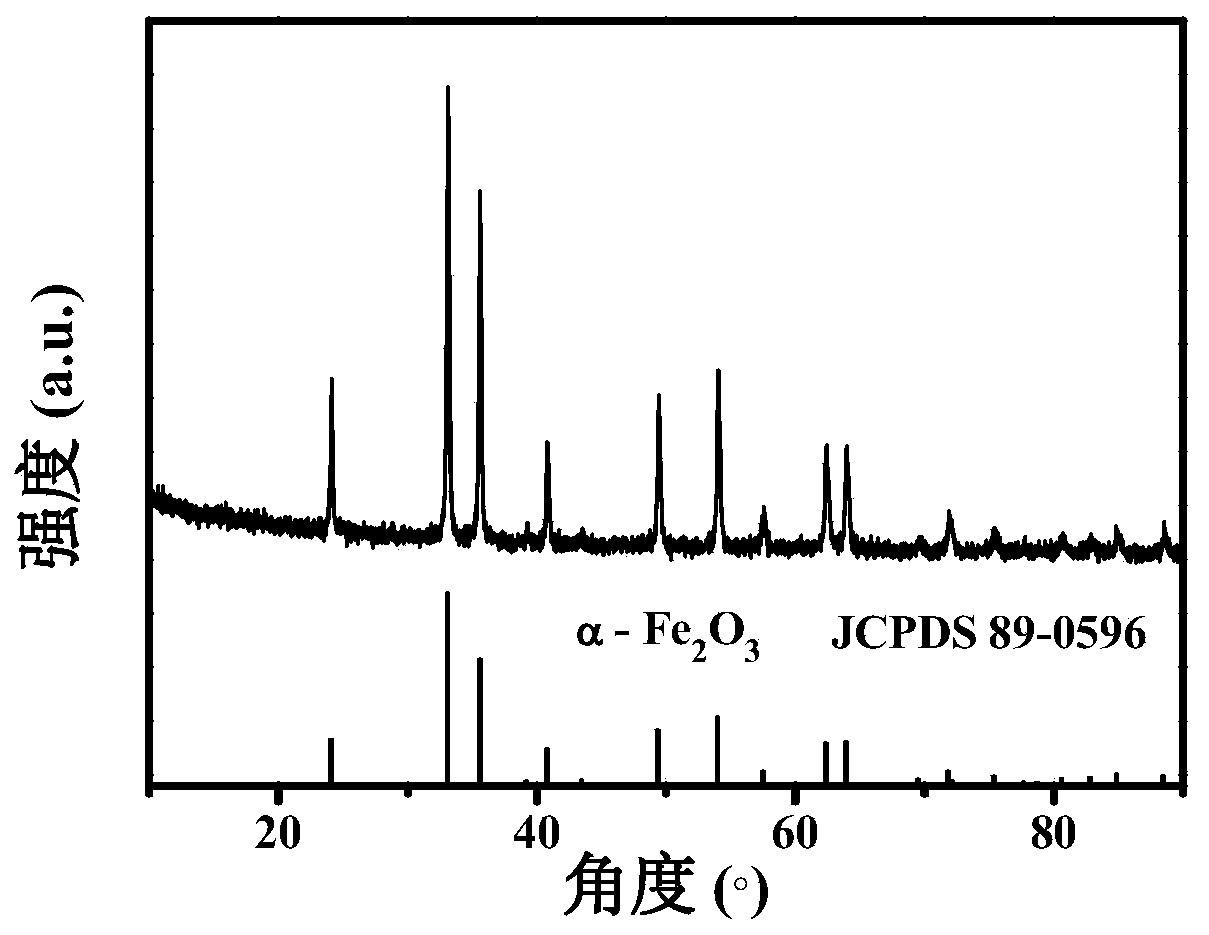

Lithium ion battery composite negative electrode material, its preparation method, negative electrode with application of material thereof and lithium ion battery

InactiveCN102427129ARich sourcesLow costCell electrodesSecondary cellsCarbon compositesLithium electrode

The invention relates to a lithium ion battery composite negative electrode material, its preparation method, a negative electrode with the application of the material thereof and a lithium ion battery. According to the preparation method, Fe2O3 and a carbon material are used as raw materials. The carbon material is one component, random two components or a mixture of three components, wherein the components are selected from the group consisting of acetylene black, graphite and carbon black. A Fe2O3-and-carbon composite powdered material is obtained by ball milling. Or an iron oxide and carbon material containing composite powdered material is obtained by calcining at a certain temperature, wherein the iron oxides contain one, two or three components selected from Fe2O3, Fe3O4 and FeO. The ratio of the iron oxides to the carbon material in the composite powdered material can be adjusted and controlled by changing the initial ratio. The type of the iron oxides can be controlled by controlling the calcining temperature and time. The preparation method of the composite powdered material is simple, has high production efficiency and is suitable for large-scale production. With the application of the composite powdered material, the lithium ion battery negative electrode material is endowed with high discharge capacity and good cycle stability. The electrode prepared by the material has high specific capacity and excellent circularity, and is very suitable for the industrial application of the lithium ion battery.

Owner:ZHEJIANG UNIV

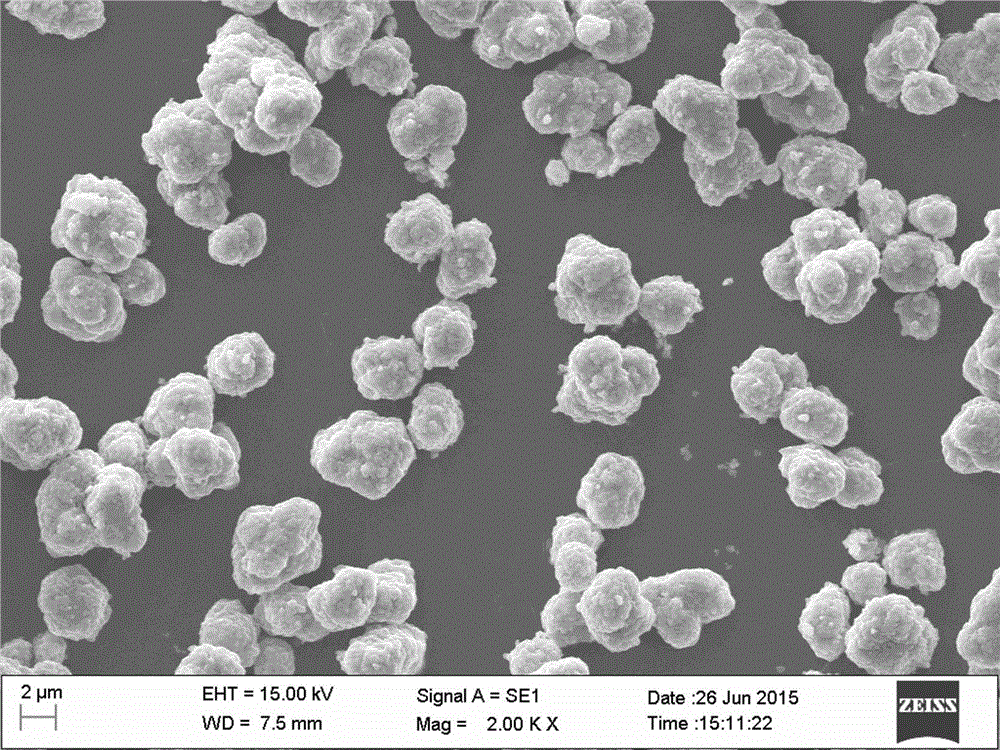

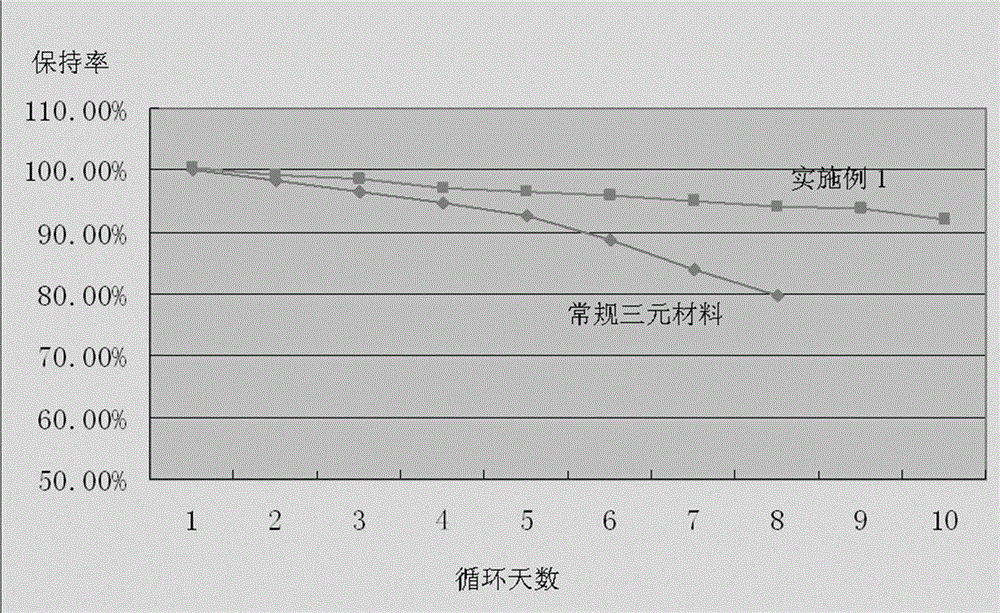

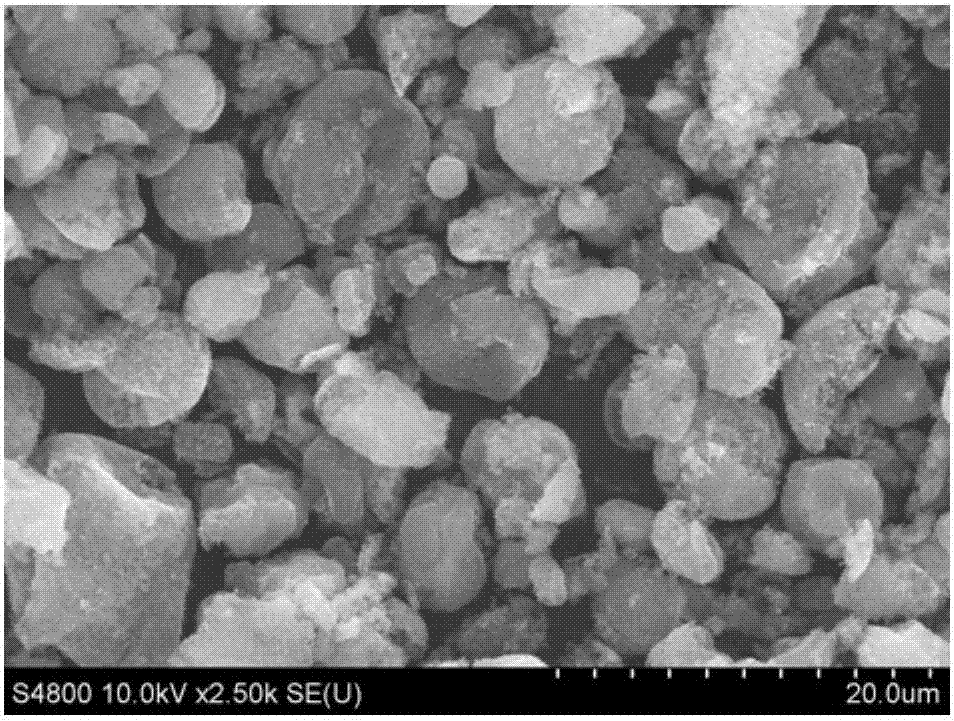

Preparation method of LiFePO4/C modified ternary positive electrode material

ActiveCN105355880AImprove charge and discharge performanceShorten the conduction pathCell electrodesSecondary cellsLithium iron phosphateActive electrode

The invention relates to a preparation method of a LiFePO4 / C modified ternary positive electrode material. Firstly, a ternary positive electrode material is prepared by a coprecipitation method; then a LiFePO4 / C composite material is grown on the surface of the ternary positive electrode material by a solid phase method, and the ternary positive electrode material is subjected to surface coating modification. The lithium iron phosphate active electrode material is adopted for modifying the ternary electrode material, on one hand, the advantages of the two active materials can be integrated to obtain the composite positive electrode material having better cycle performance, higher capacity and larger energy density; on the other hand, a traditional modification method for a ternary material is changed, and the cycle performance of the ternary positive electrode material is improved in the premise of almost no loss of material self capacity.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Method for preparing ultracapacitor-used porous grapheme material

The invention discloses a method for preparing an ultracapacitor-used porous grapheme material, and belongs to the technical field of carbon material preparation. According to the method, coal pitch is used as the carbon source, nanometer calcium carbonate is used as a template, and potassa is used as an activating agent; the three components are ground in a dry method; the mixture is transferred to a corundum ceramic boat, is placed in a pipe furnace, and is subjected to heating activation under a normal pressure condition or a negative pressure condition to directly obtain the ultracapacitor-used porous grapheme material. The method adopts cheap coal pitch and nanometer calcium carbonate as the raw materials, and has the advantages being simple in technology, low in cost, suitable for industrialized production and the like; the material has a specific surface area within the range of 1330-1946 m<2> / g and an average aperture within the range of 2.32-3.08 nm, and can exhibit relatively high volume and energy intensiveness when being used as an electrode material of an ultracapacitor.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

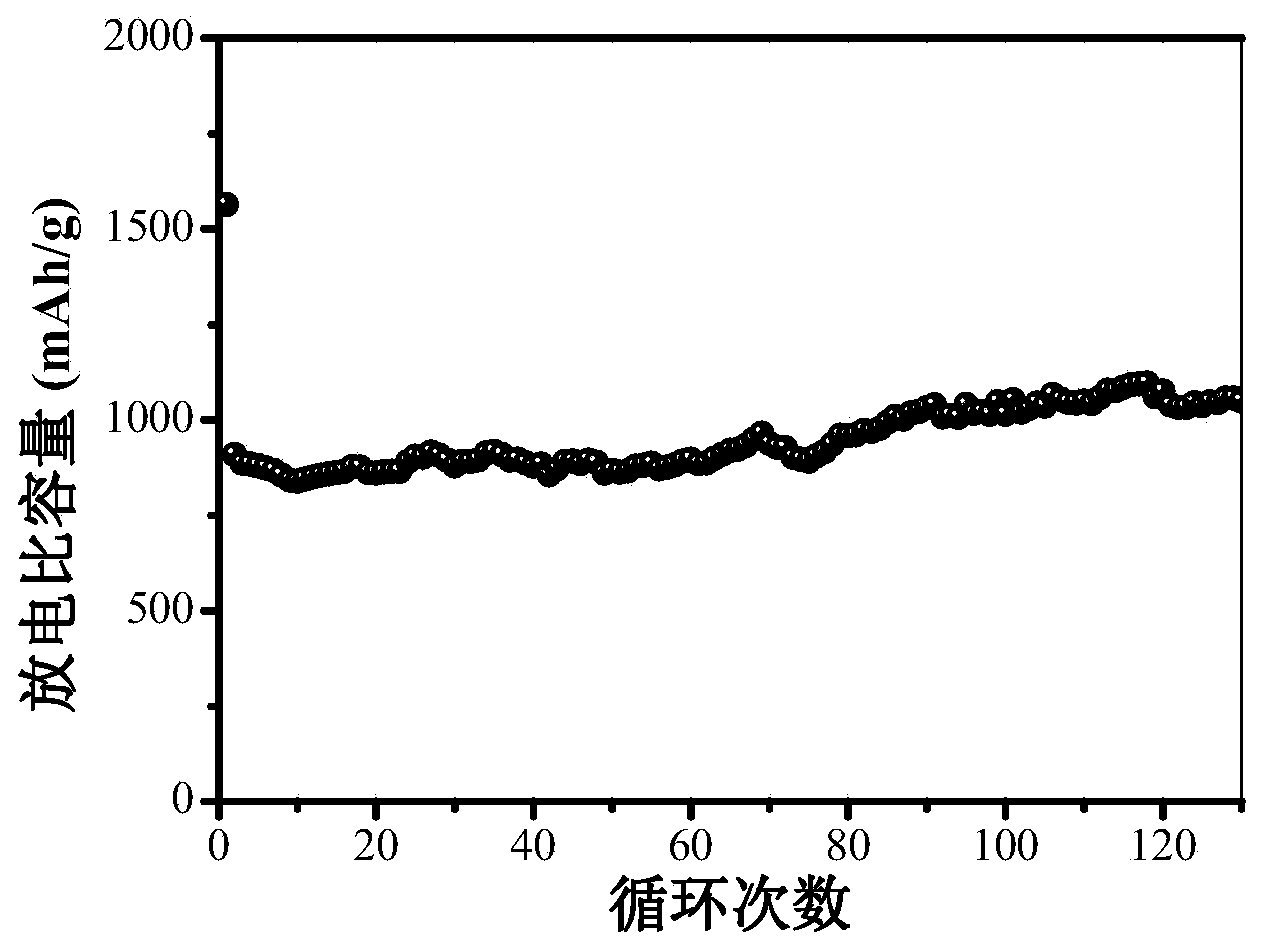

Porous ferric oxide/carbon nanometer plate composite material as well as preparation method thereof and application in preparing lithium ion battery

ActiveCN103682251AThe process is simple and easy to controlHigh product purityMaterial nanotechnologyCell electrodesAmmonium sulfateChemistry

The invention relates to a porous ferric oxide / carbon nanometer plate composite material as well as a preparation method of the porous ferric oxide / carbon nanometer plate composite material and application in preparing a lithium ion battery. The method comprises the following steps of uniformly mixing raw materials including ferrocene and ammonium sulfate in a given mass ratio; calcining the mixture in an inert gas high-pressure reaction kettle, then calcining the mixture in the air at a low temperature to obtain the porous ferric oxide / carbon nanometer plate composite material. The preparation method is simple in process, easy to operate, high in yield and applicable to the mass production. When being used as a lithium ion battery cathode material, the prepared porous ferric oxide / carbon nanometer plate composite material is high in specific capacity and excellent in circulation stability, and the capacity of the material is more than 1000mAh / g after being circulated for 100 times.

Owner:江苏海四达电源有限公司

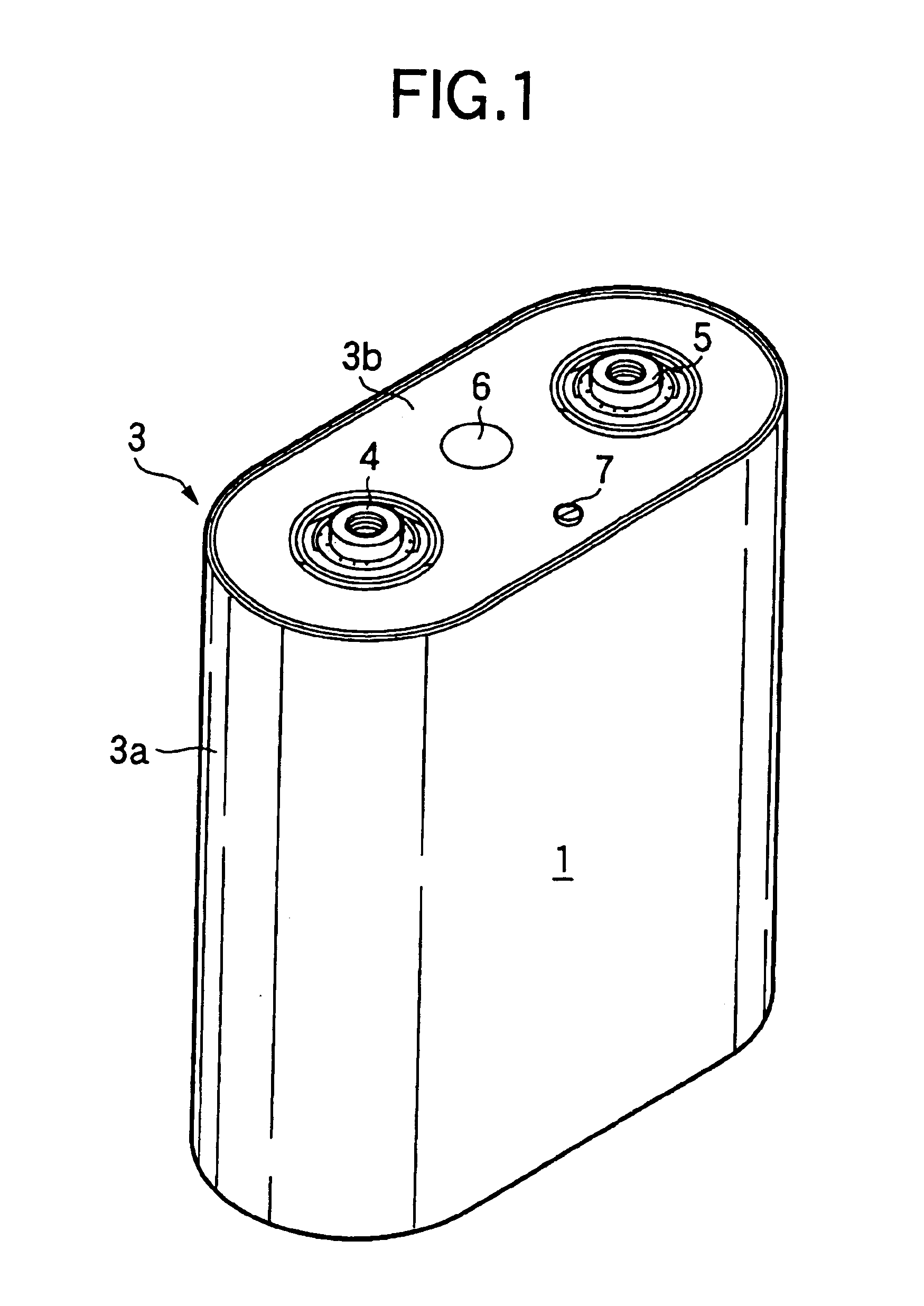

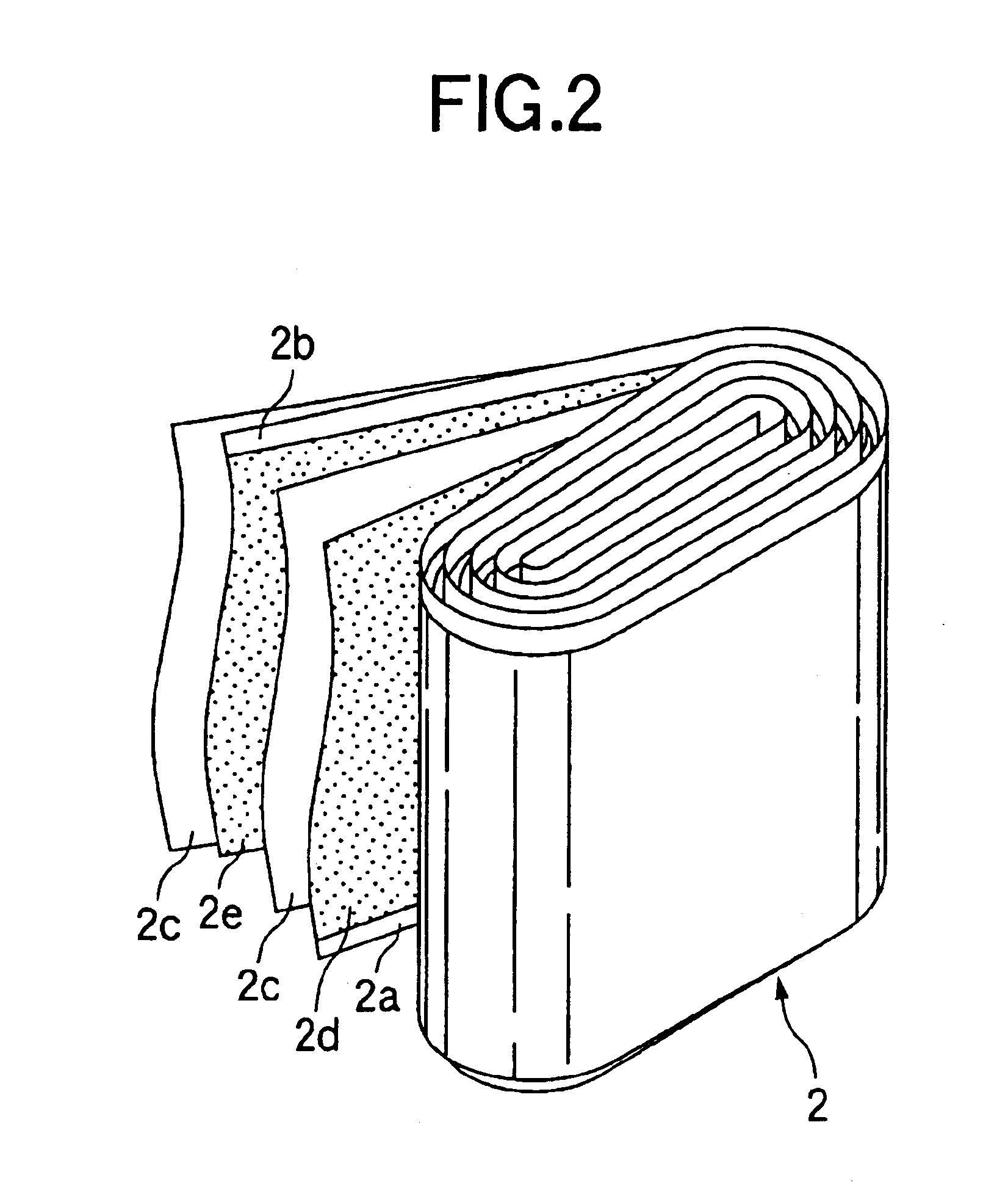

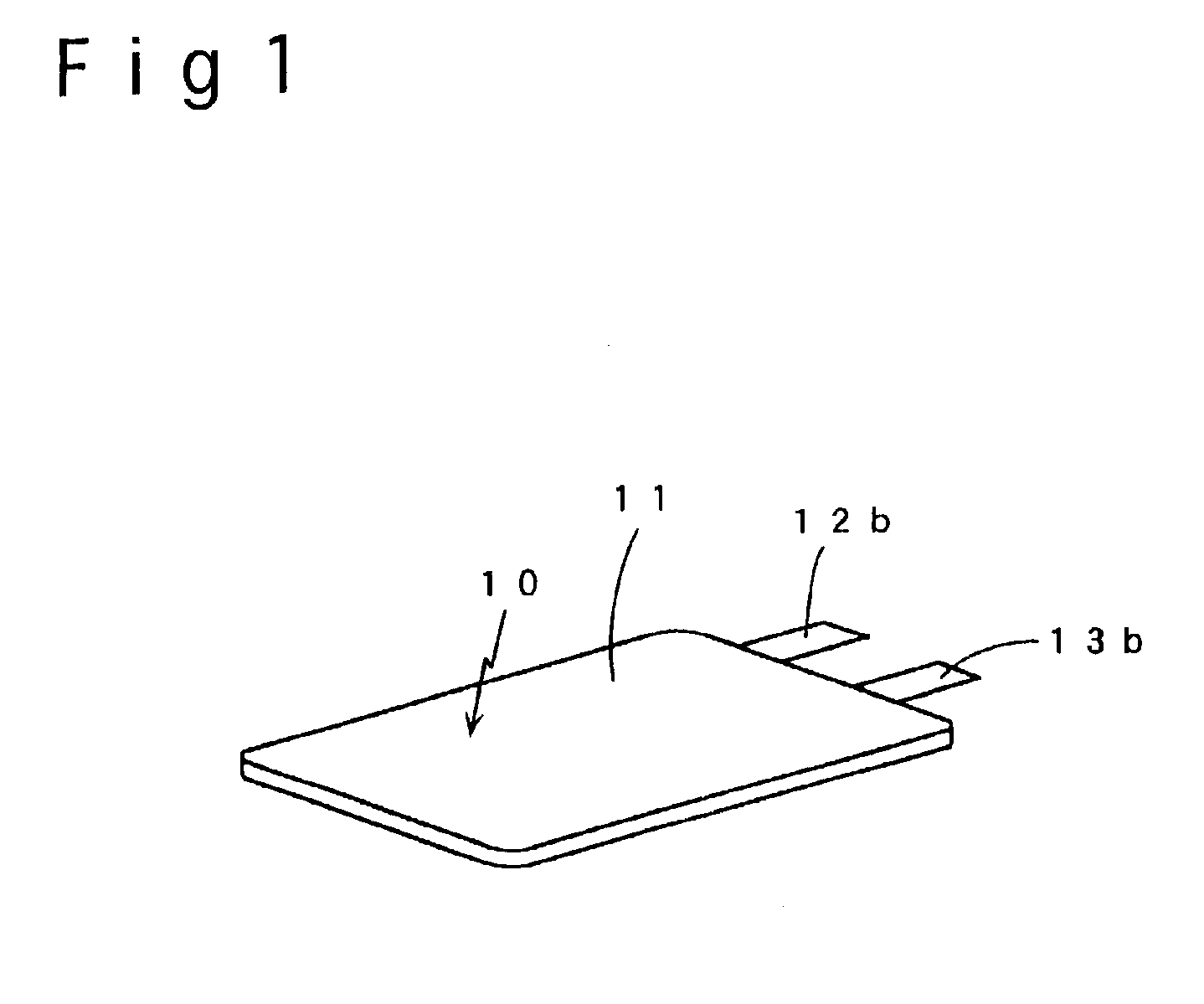

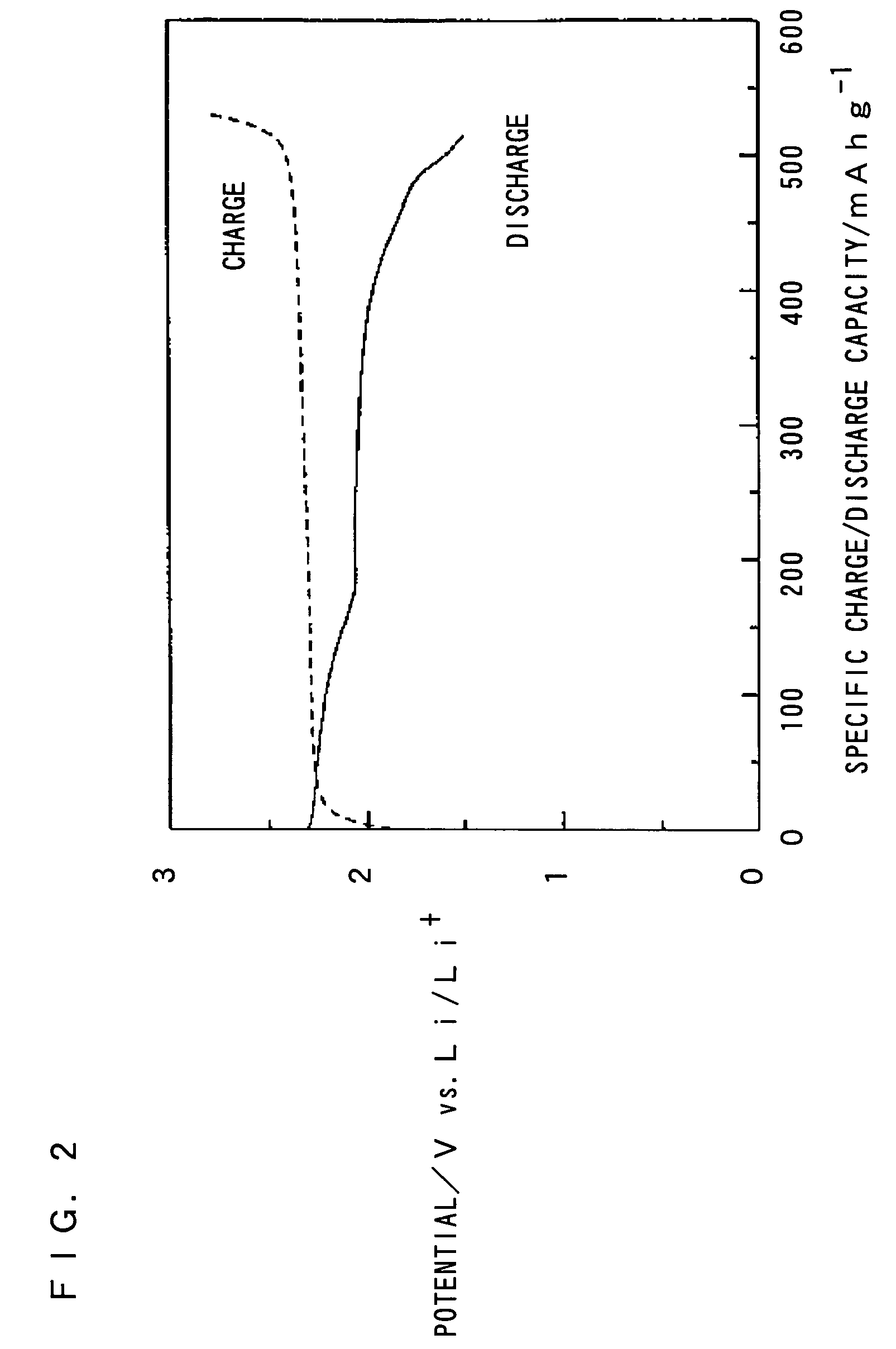

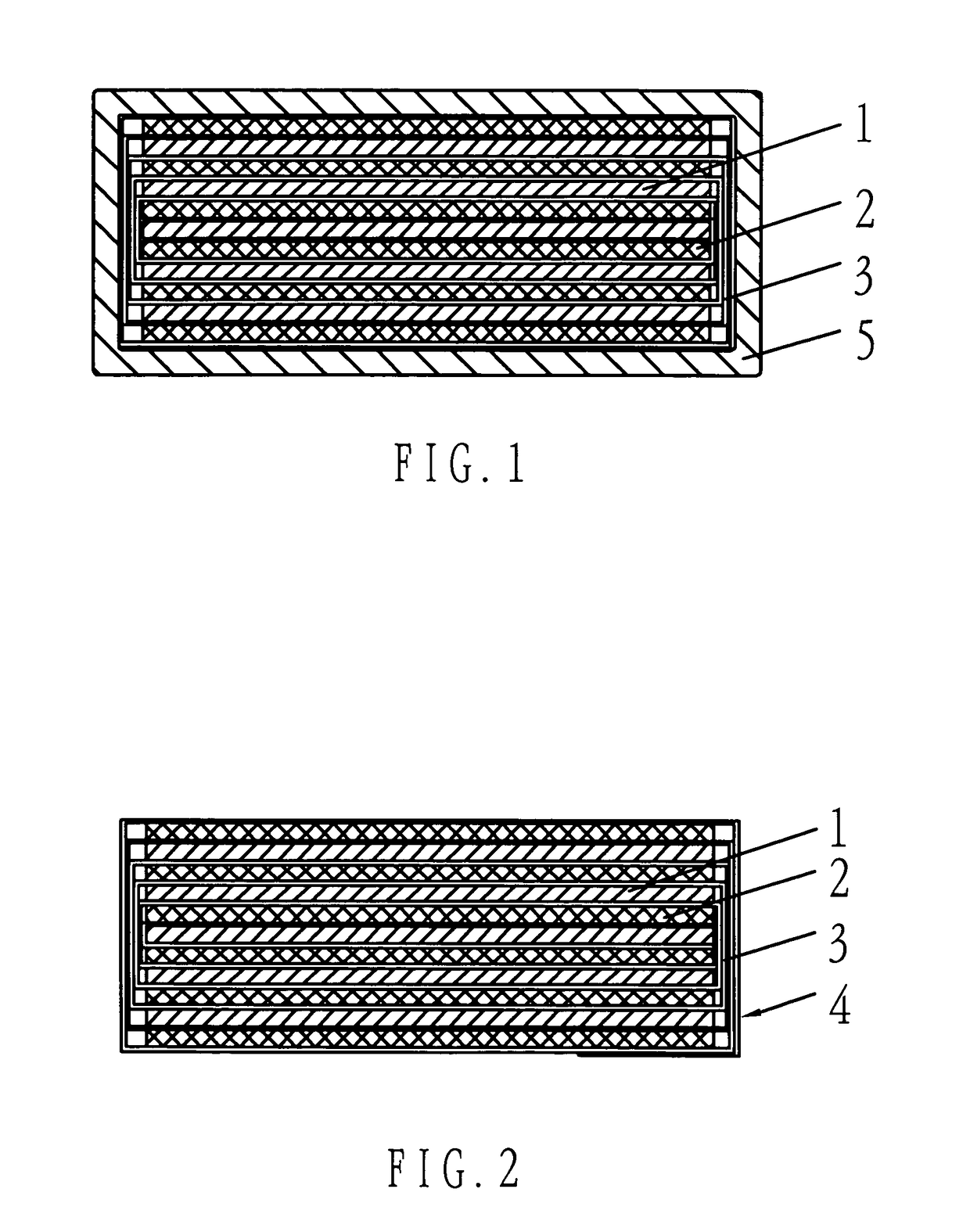

Lithium ion secondary battery

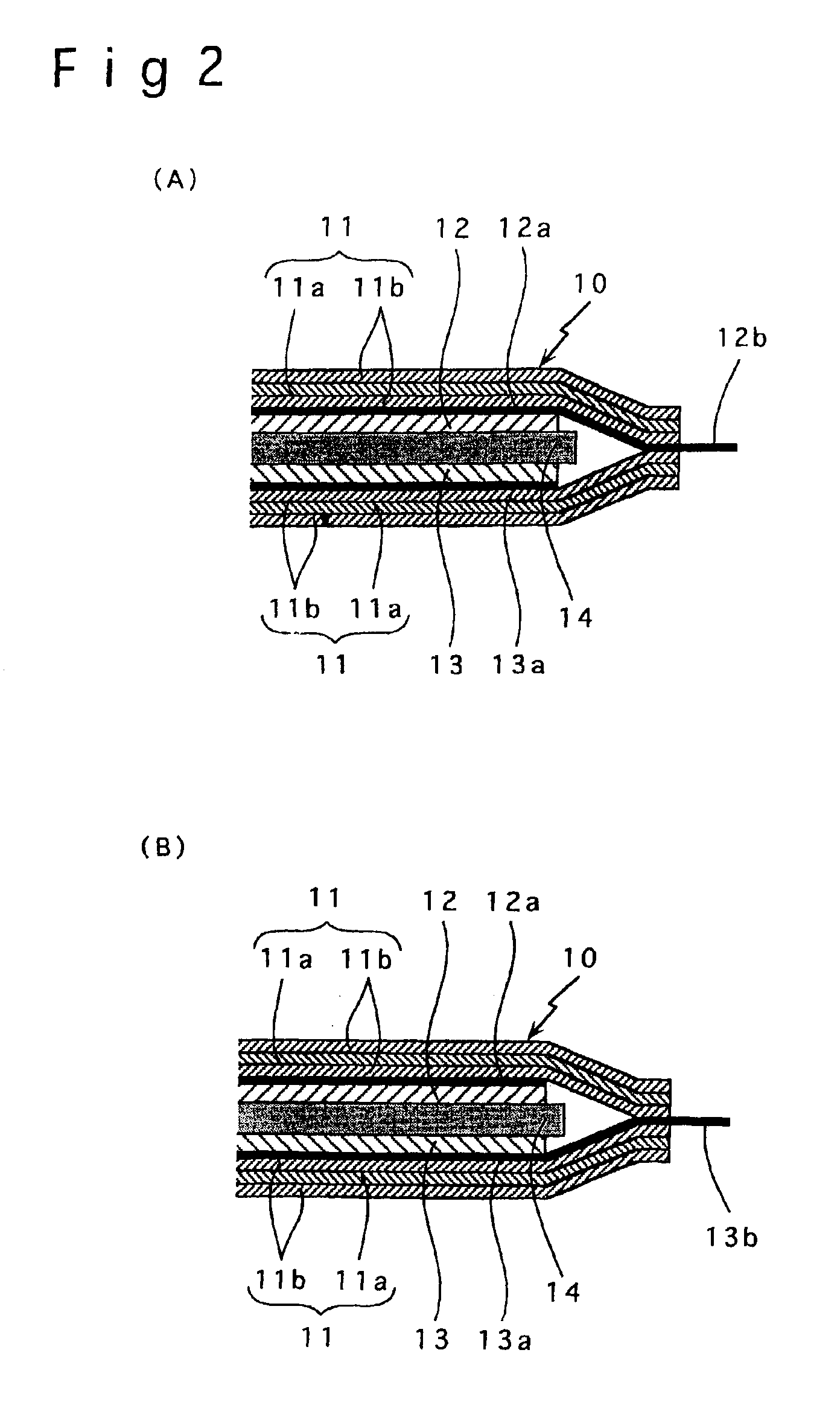

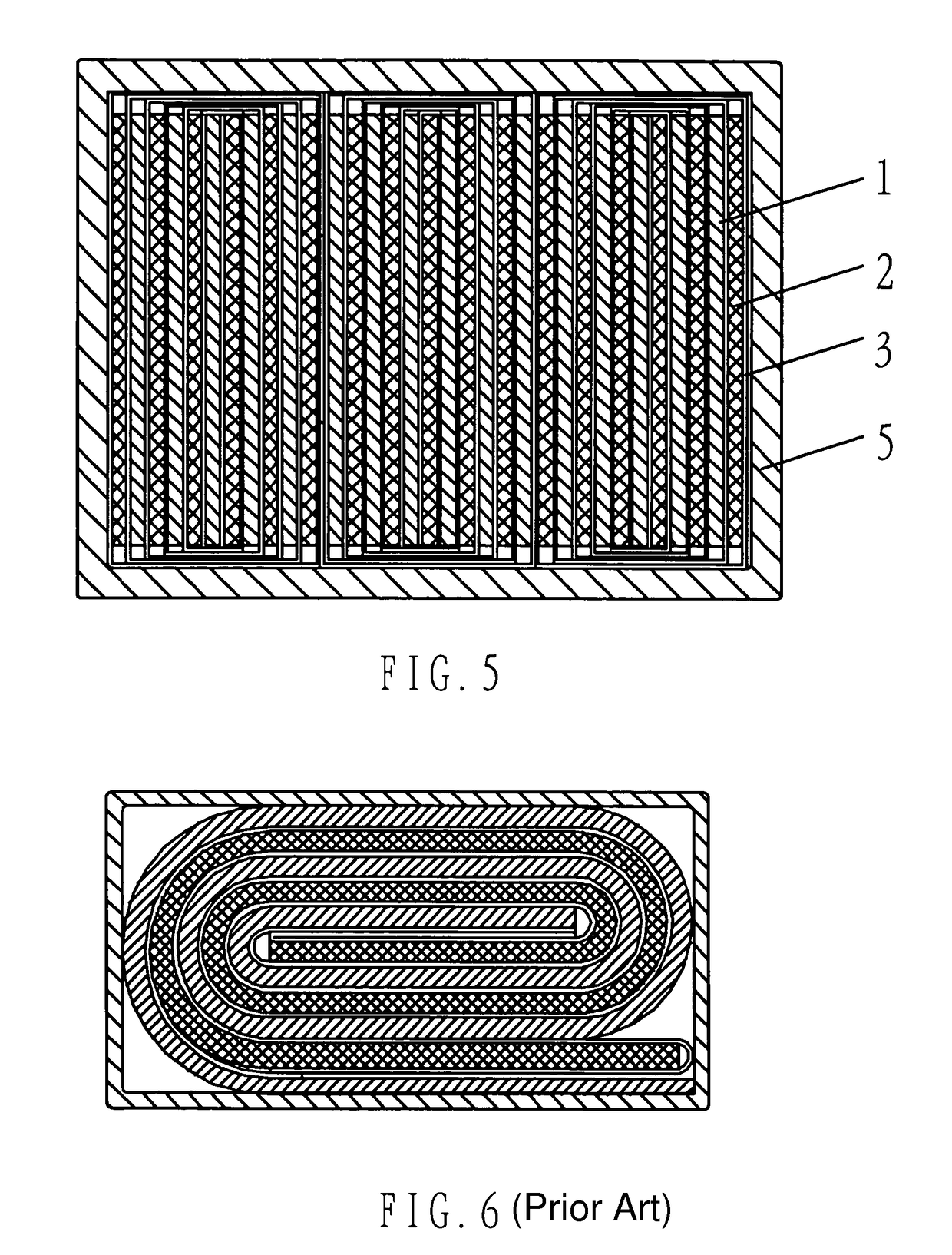

ActiveUS7906233B2Effective internal spaceHigh capacity densityElectrode manufacturing processesCell seperators/membranes/diaphragms/spacersLithiumElectrical conductor

Owner:BYD AMERICA CORP

Preparation method of porous silicon/graphene composite material

InactiveCN104009235AWide variety of sourcesLow costCell electrodesSecondary cellsCarbonizationOxygen

The invention relates to a preparation method of a porous silicon / graphene composite material, and belongs to the technical field of lithium ion batteries. The method comprises: firstly, performing acid pickling of rice husks, then performing low-temperature aerobic or anaerobic pyrolysis to obtain pyrolyzed rice husks; dipping the pyrolyzed rice husks in a transition metal salt solution, performing high-temperature catalytic carbonization to obtain catalytically-carbonized rice husks; performing low-temperature oxidation of the catalytically-carbonized rice husks, mixing with reductive metal, performing high-temperature metal thermal reduction under an anaerobic condition, and then performing acid pickling of the reduction product to obtain the porous silicon / graphene composite material. The porous silicon / graphene composite material prepared by the method has the characteristics of large capacity density, good rate capability, high first coulombic efficiency, stable cycle performance, and the like.

Owner:KUNMING UNIV OF SCI & TECH

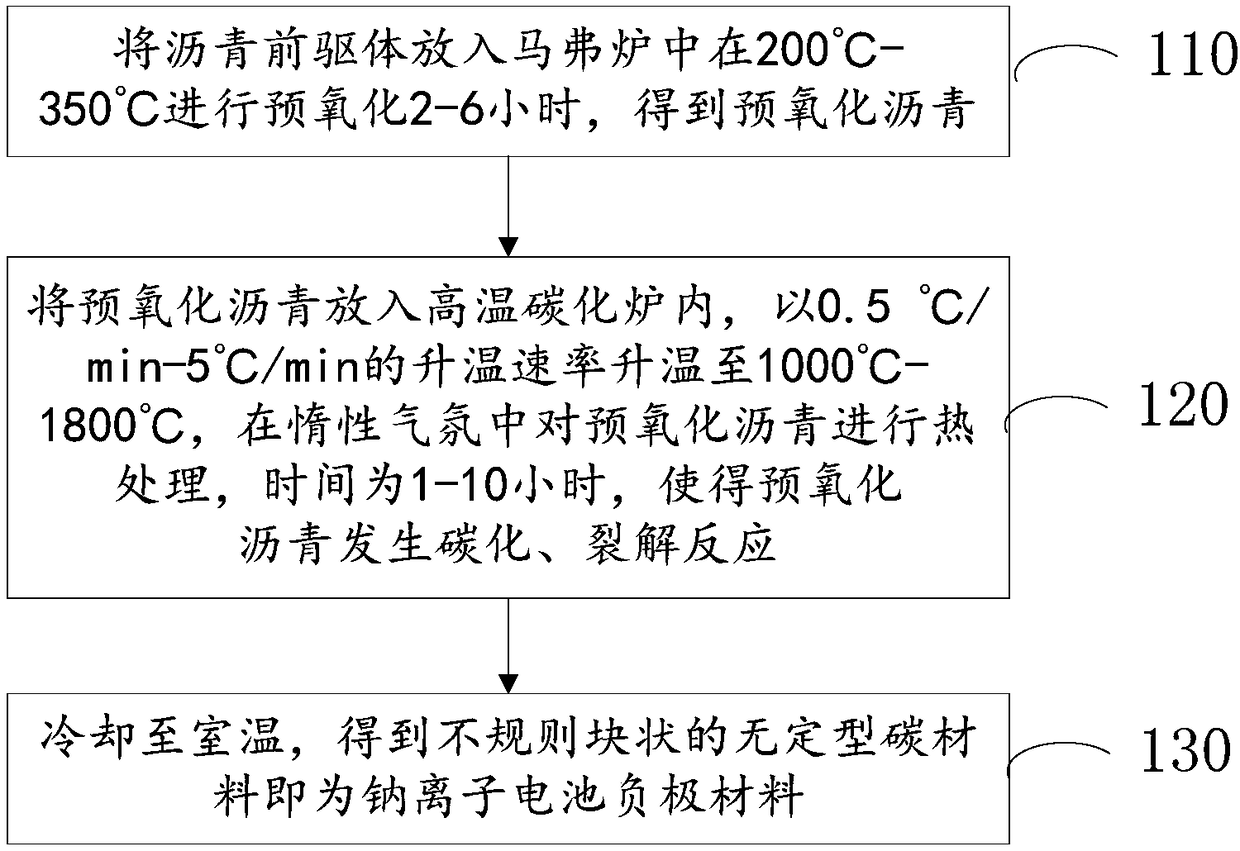

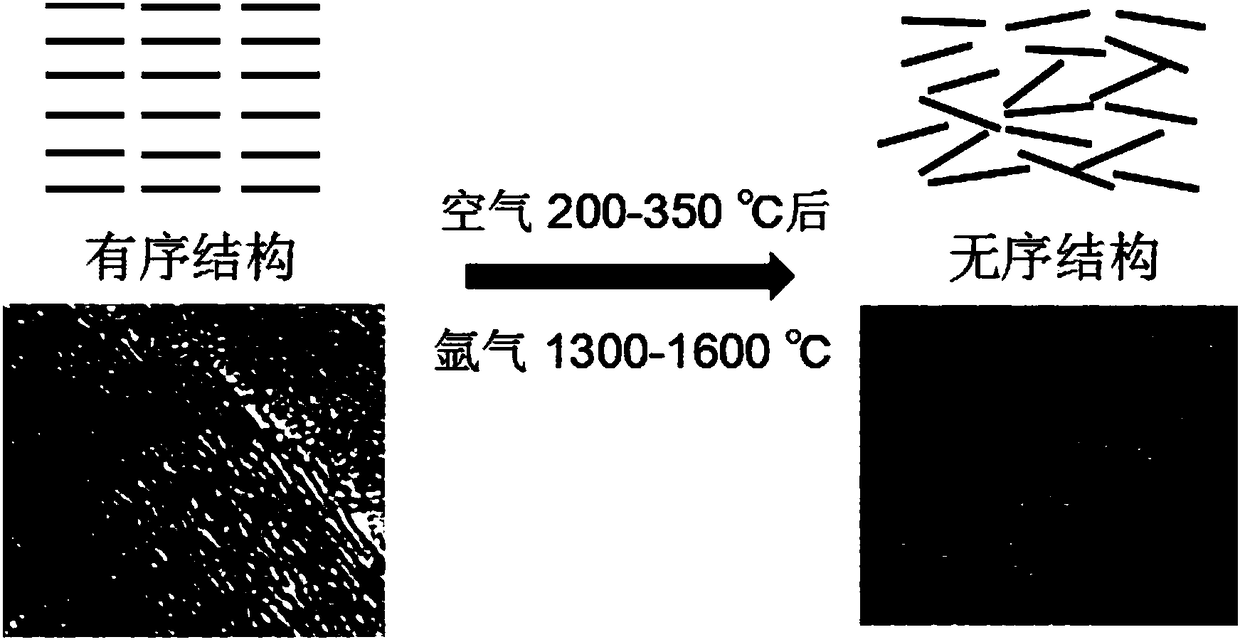

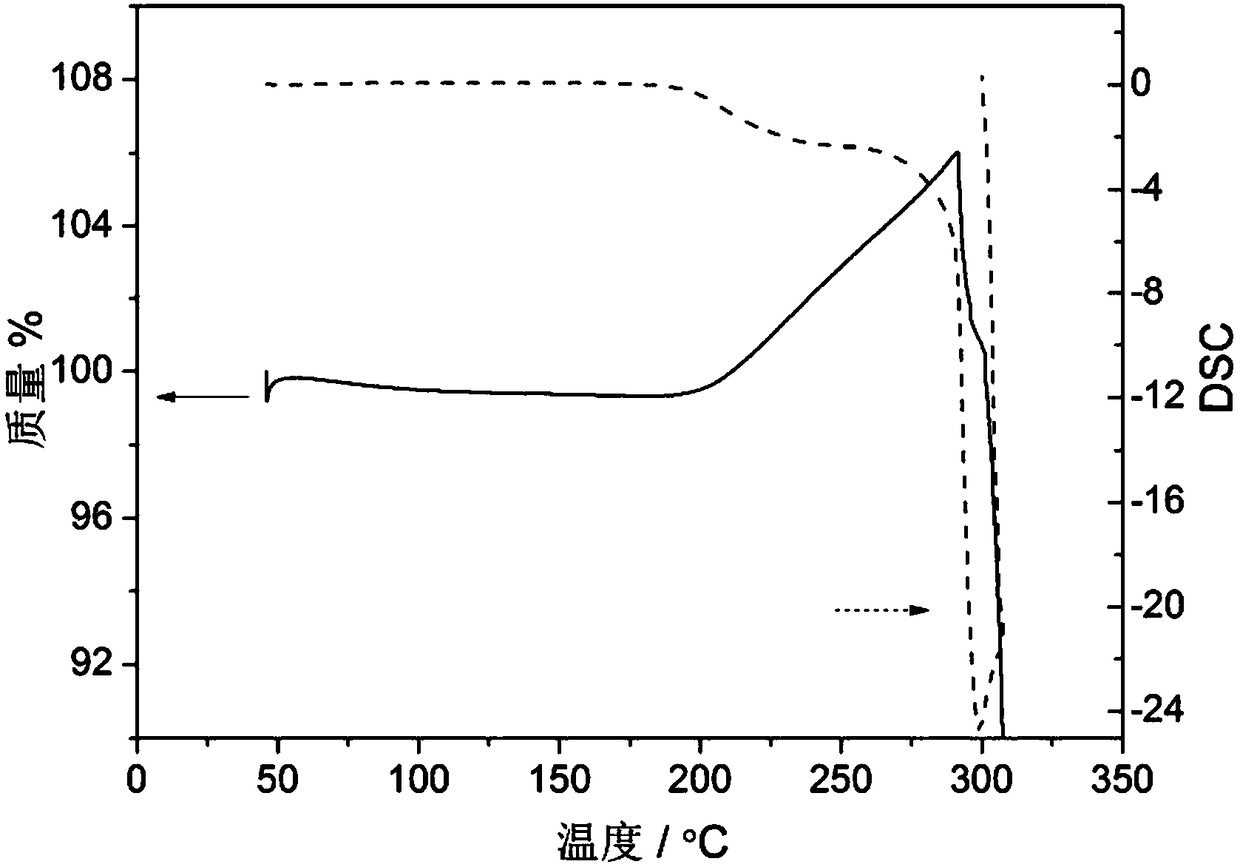

Asphalt-based negative electrode material for sodium ion battery and preparation method and application thereof

InactiveCN109148883AImproved magnification performanceLow costElectrode thermal treatmentSecondary cellsElectrical batteryPhysical chemistry

The embodiment of the invention relates to an asphalt-based negative electrode material for a sodium ion battery and a preparation method and application thereof. The method comprises the following steps: putting an asphalt precursor into a muffle furnace at 200 DEG C to 350 DEG C for preoxidation for 2 to 6 hours to obtain preoxidized asphalt; putting the preoxidized asphalt into a high-temperature carbonization furnace, and the temperature of the preoxidized asphalt rising to 1300 DEG C to 1600 DEG C at a heating rate of 0.5 DEG C / min to 5 DEG C / min, performing heat treatment on the preoxidized asphalt in an inert atmosphere for 1 to 10 hours to cause carbonization and cracking reaction of that preoxidized asphalt; wherein oxygen in the preoxidized asphalt is used for breaking the ordered structure of the asphalt in the carbonization process of the preoxidized asphalt to form a disordered structure with wedge-shaped cracks, and the carbon yield is improved and the cost is further reduced; and cooling is performed to reach room temperature to obtain an irregular lumpy amorphous carbon material, that is the negative electrode material for the sodium ion battery.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI +1

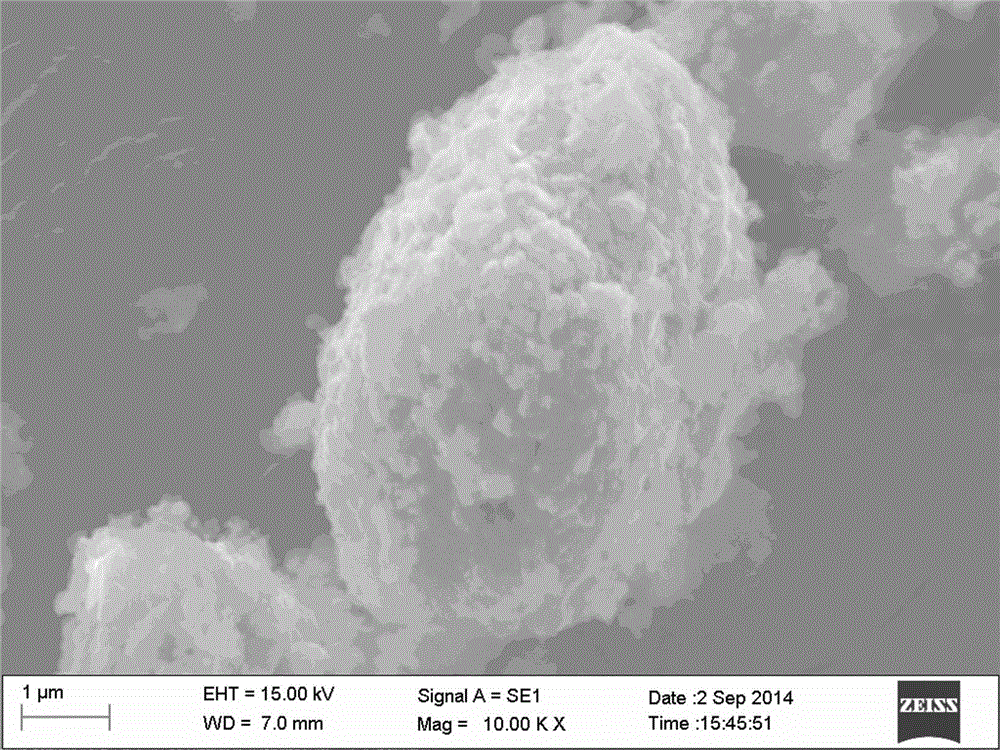

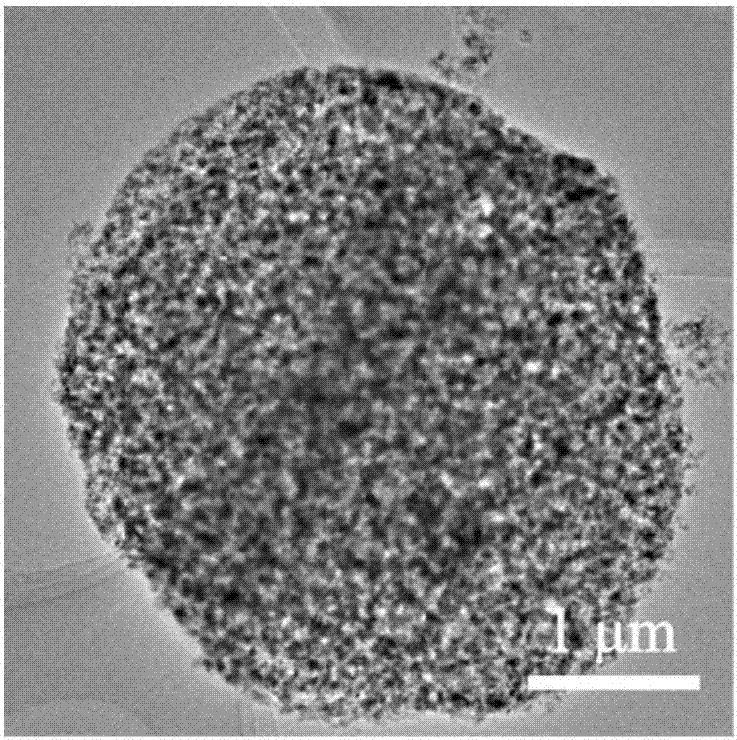

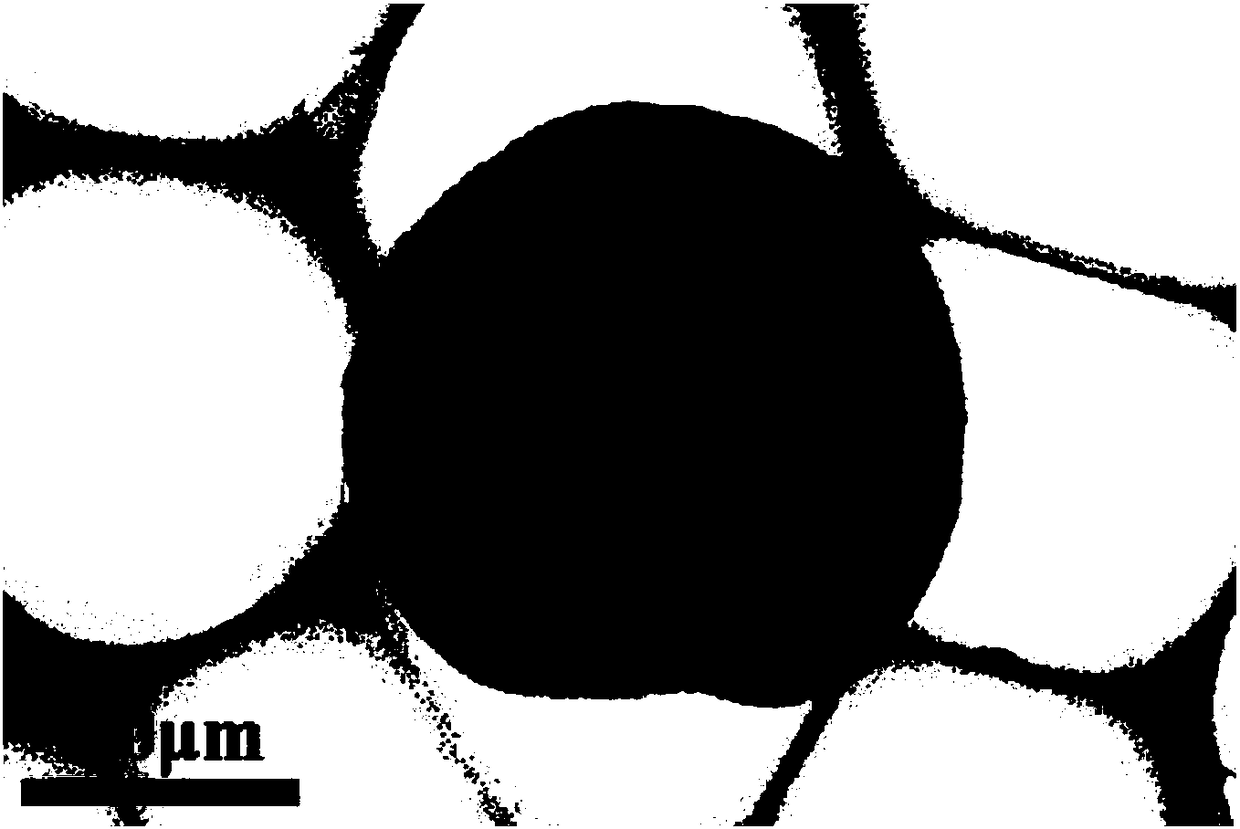

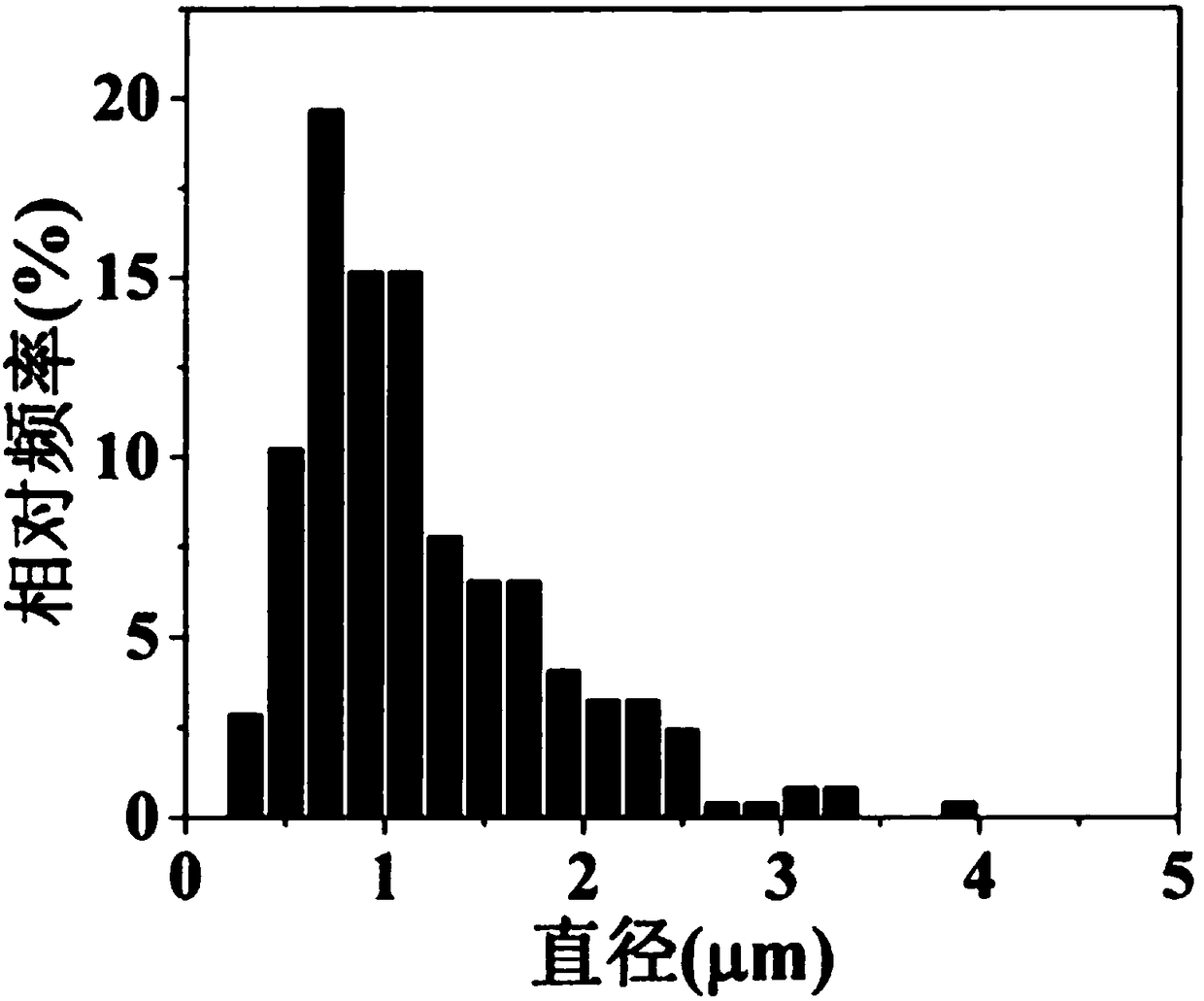

Micronano-structure carbon silicon composite microsphere and preparation method and application thereof

InactiveCN107240677ALow costSimple process routeMaterial nanotechnologyCell electrodesMicrosphereCharge discharge

The invention relates to a micronano-structure carbon silicon composite microsphere and a preparation method and application thereof. According to the preparation method, a silicon dioxide nanoparticle, a protection agent and a carbon nanometer material are combined and micronano-structurized by a spray drying method, a carbon / silicon dioxide composite microsphere is obtained by thermal processing under non-oxidization atmosphere, and the micronano-structure carbon silicon composite microsphere is further obtained by a metallothermic reduction method. The preparation method is low in cost, simple in process and low in energy consumption and can be promoted on a large scale; moreover, the carbon silicon nanoparticle in the obtained micronano-structure carbon silicon composite microsphere is provided with a core-hollow shell structure, and the micronano-structure carbon silicon composite microsphere is high in charge-discharge volume specific capacity and has cycle stability when used as a lithium ion battery negative electrode material.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Positive Electrode Active Material For Lithium Ion Battery

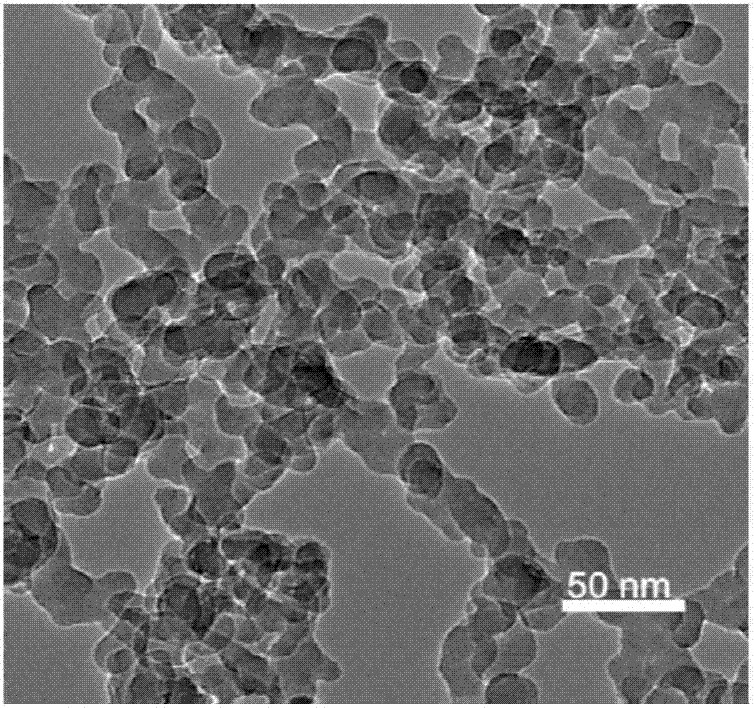

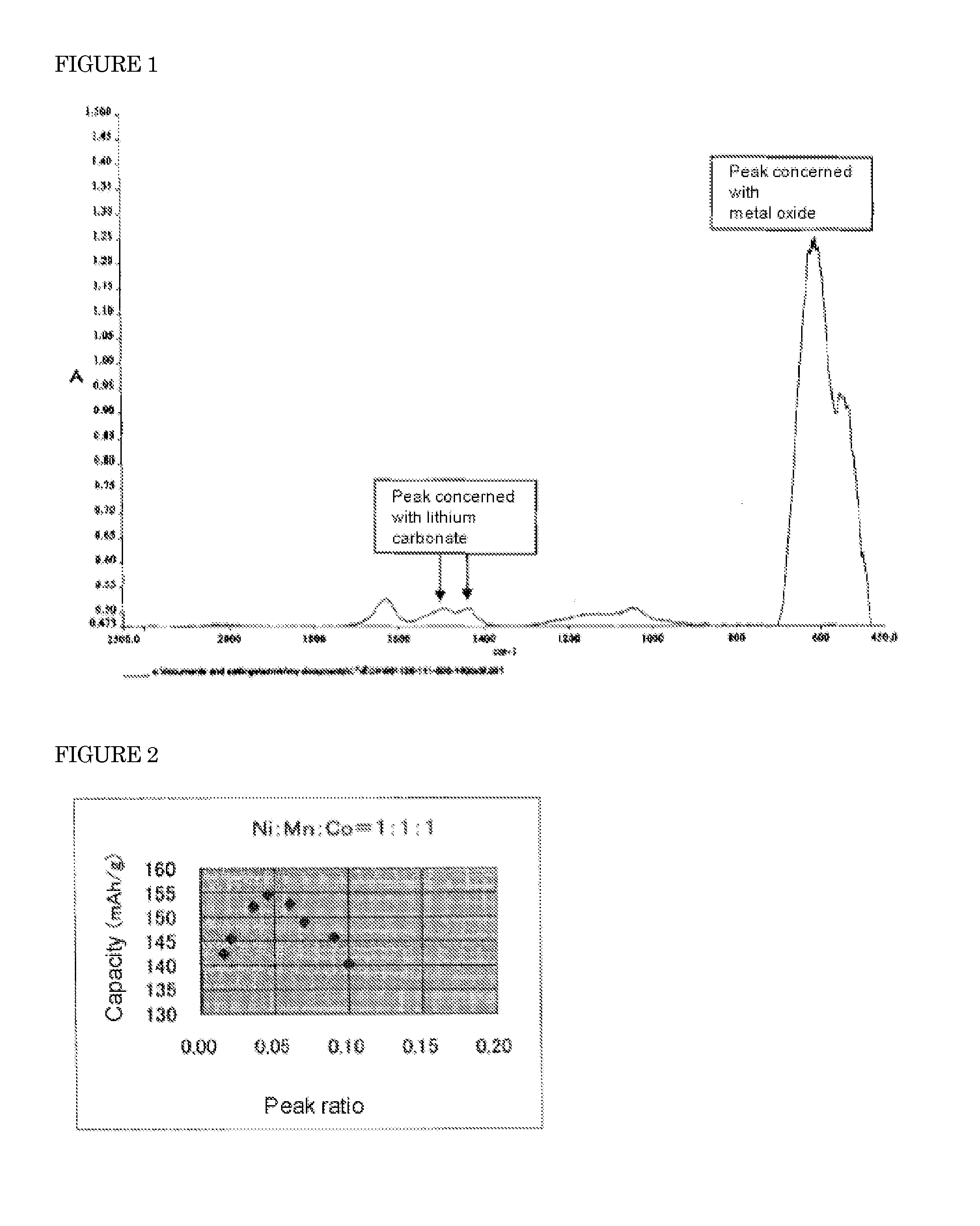

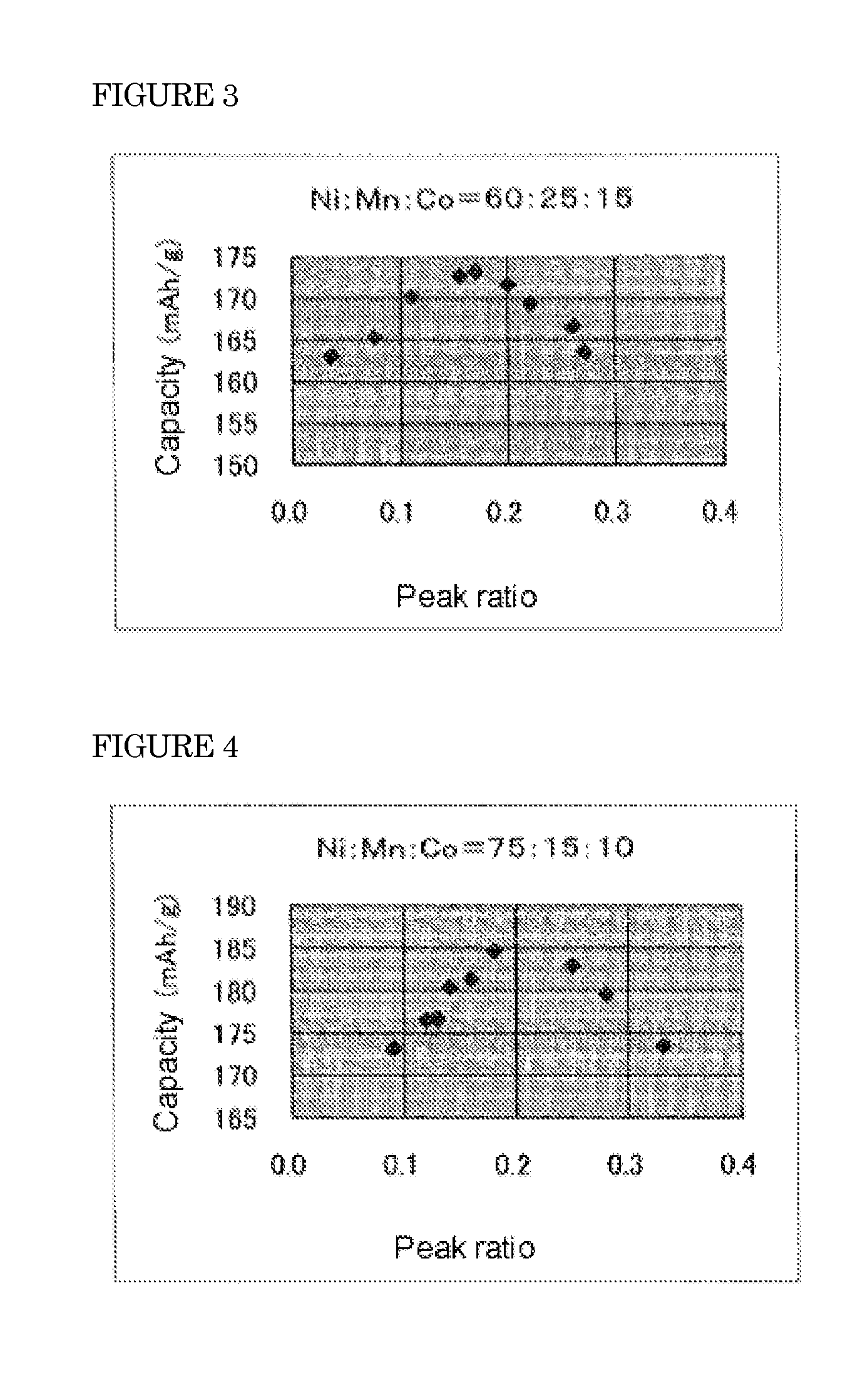

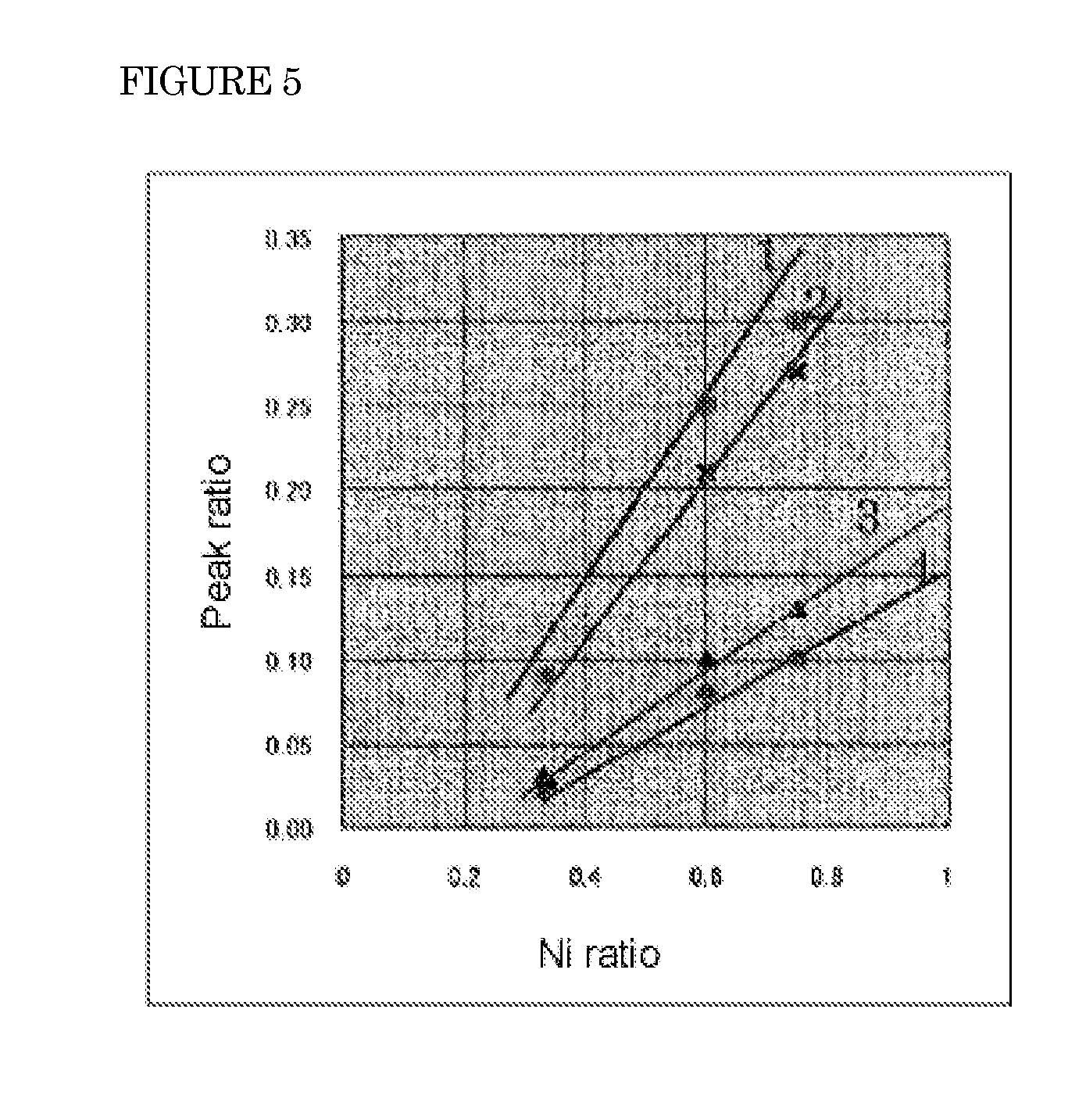

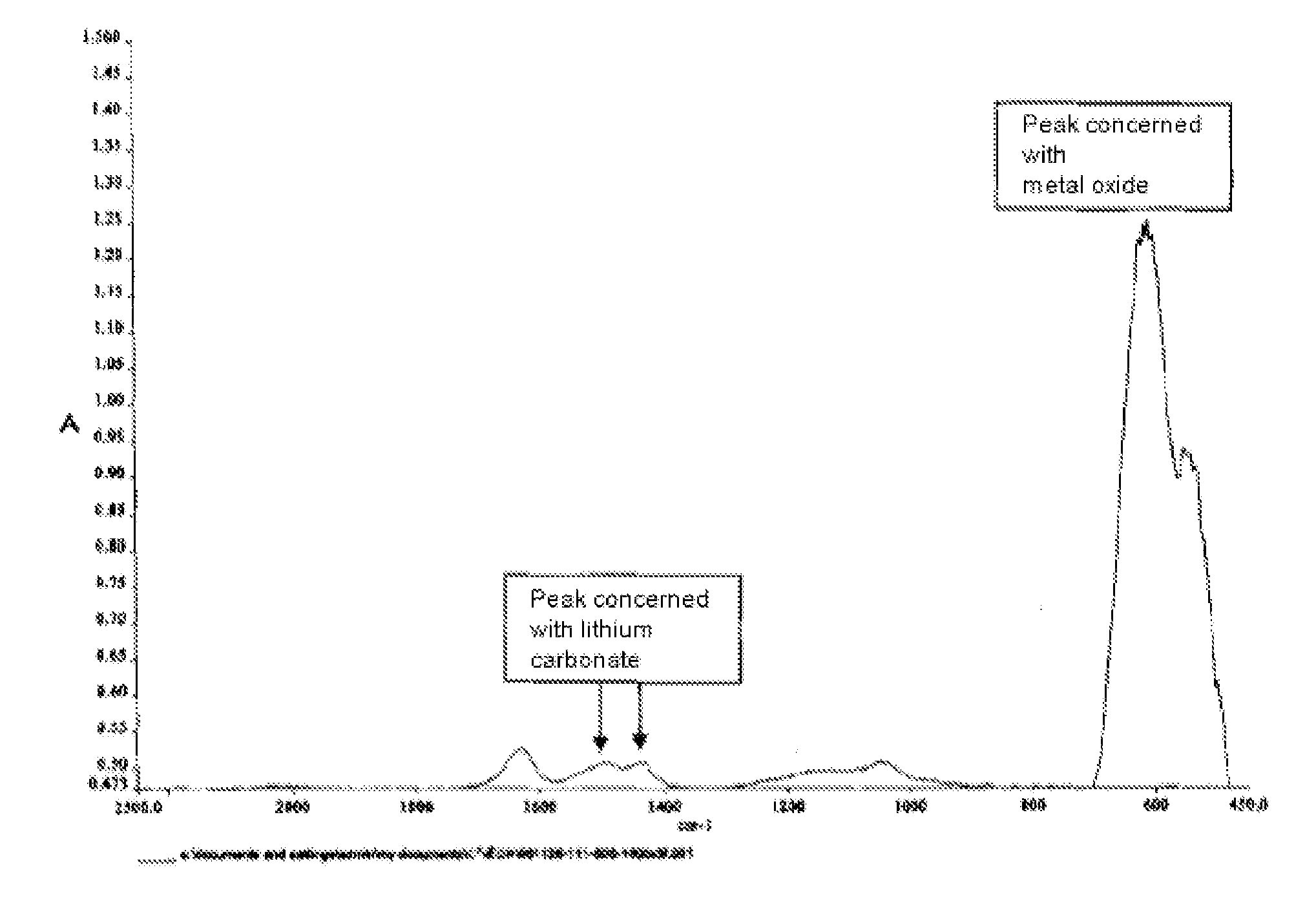

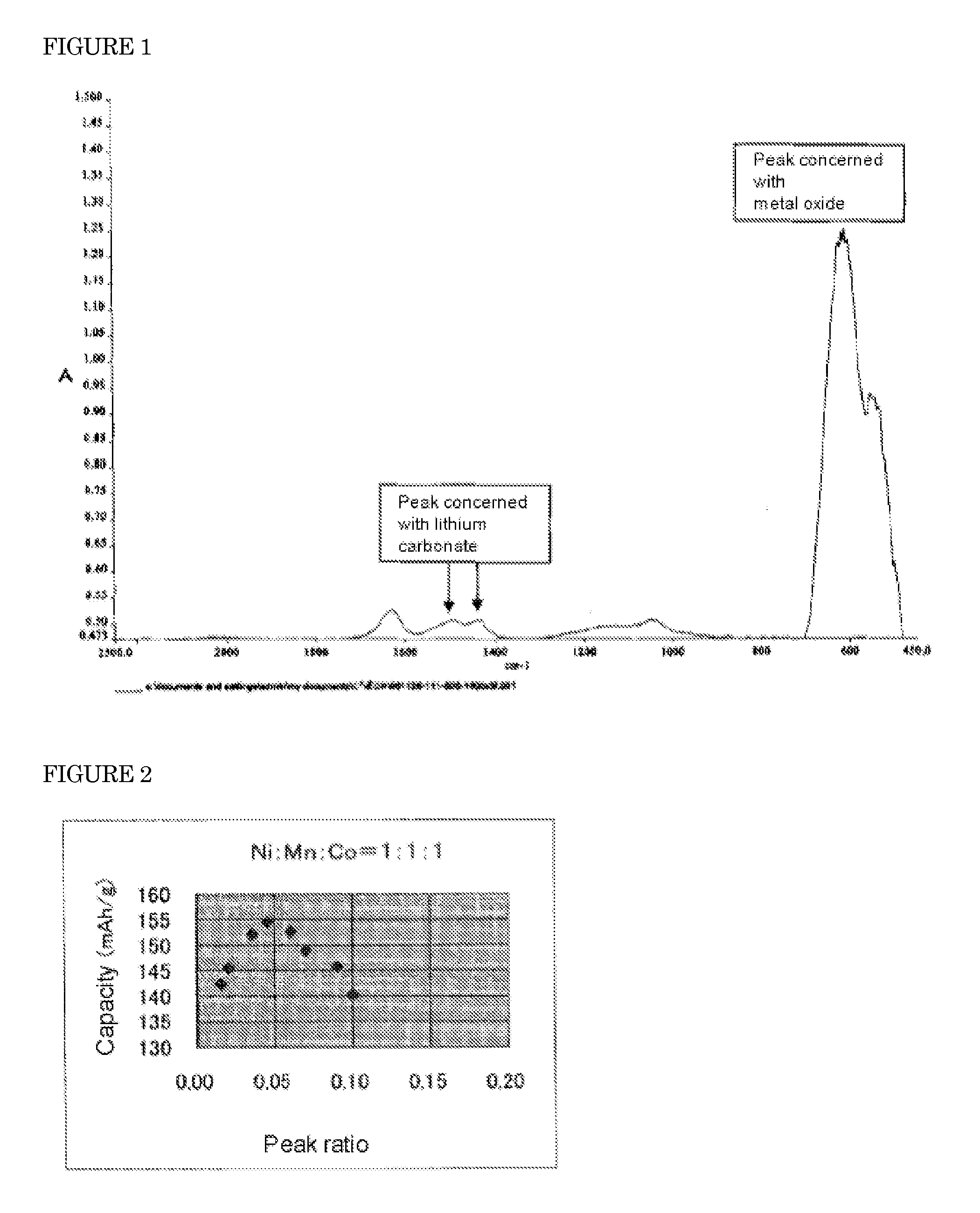

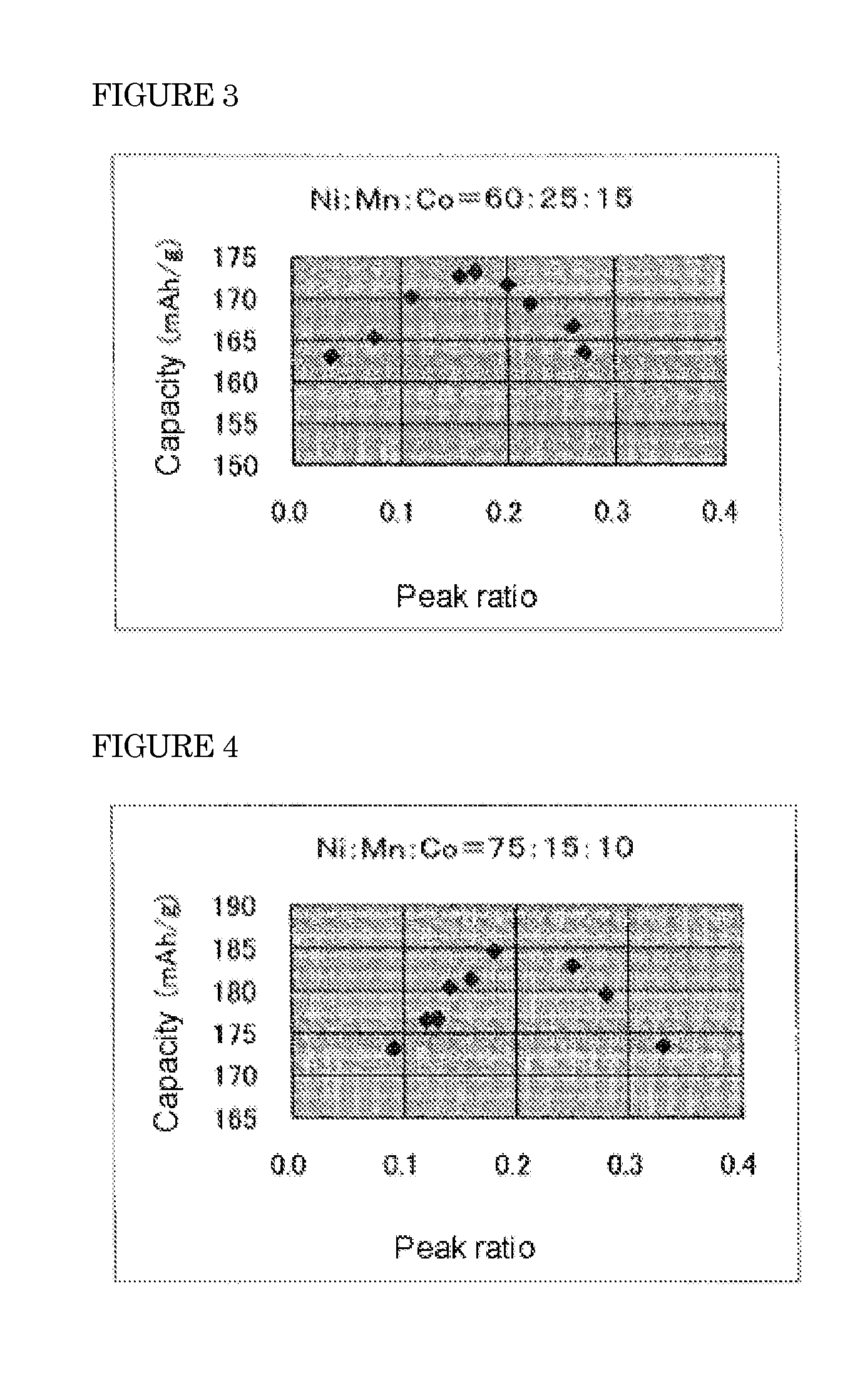

ActiveUS20120034525A1Speedup of researchSpeedup of developmentRadiation pyrometrySecondary cellsPhysical chemistryLithium-ion battery

Disclosed is a positive electrode active material that provides an improved capacity density. Specifically disclosed is a positive electrode active material for a lithium ion battery with a layered structure represented by Lix(NiyM1-y)Oz (wherein M represents at least one element selected from a group consisting of Mn, Co, Mg, Al, Ti, Cr, Fe, Cu, and Zr; x is in the range from 0.9 to 1.2; y is in the range from 0.3 to 0.95; and z is in the range from 1.8 to 2.4), wherein, when a value obtained by dividing an average of peak intensities observed between 1420 and 1450 cm−1 and between 1470 and 1500 cm−1 by the maximum intensity of a peak appearing between 520 and 620 cm−1 in an infrared absorption spectrum obtained by FT-IR is represented by A, A satisfies the following relational formula: 0.20y−0.05≦A≦0.53y−0.06.

Owner:JX NIPPON MINING& METALS CORP

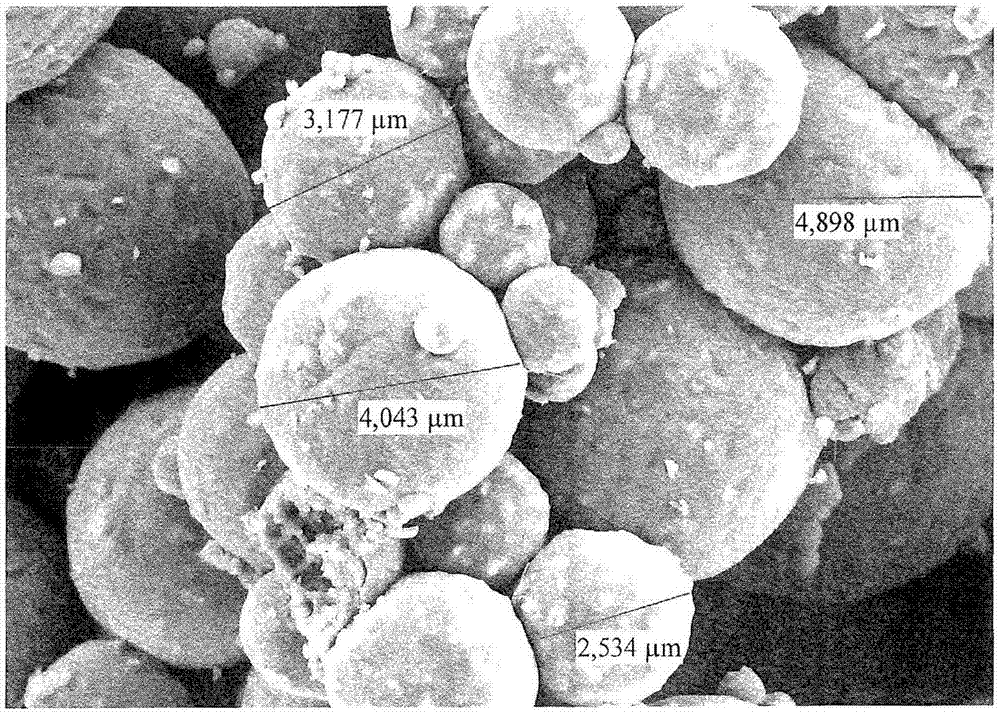

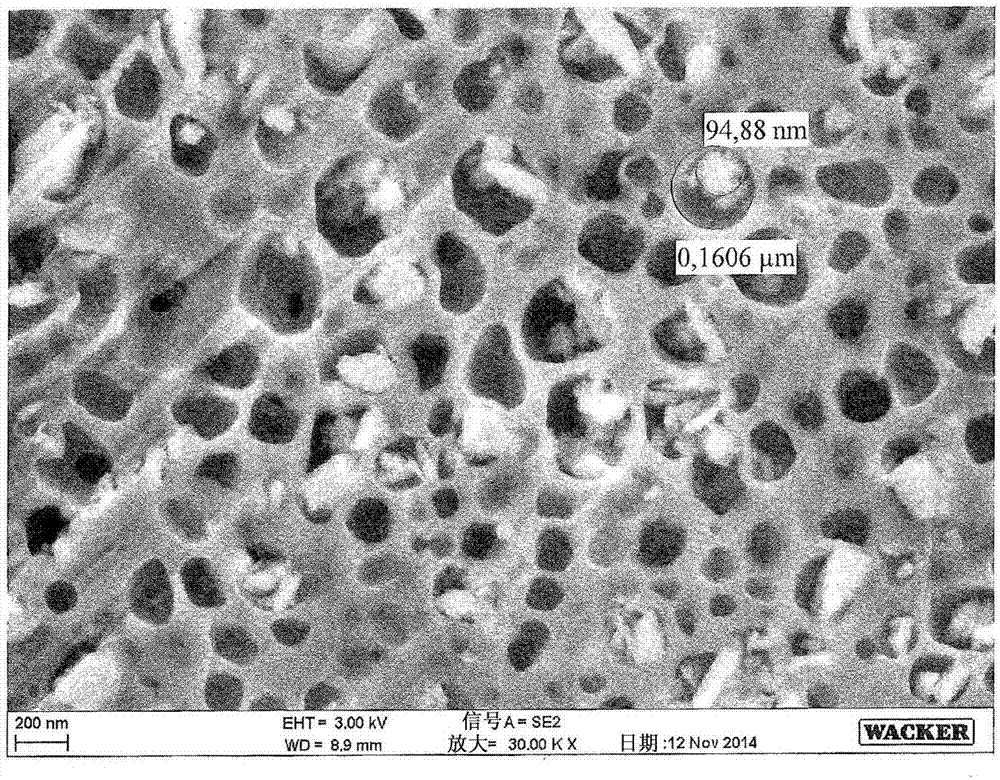

Composite core-shell particles

ActiveCN107431189AIncrease volume capacityImprove cycle stabilitySiliconSecondary cellsPorous carbonCarbonization

The invention relates to composite core-shell particles wherein the core is a porous, carbon-based matrix which contains silicon particles enclosed in pores of the matrix; the pores containing the silicon particles have a diameter of not less than 60 nm as determined by scanning electron microscopy (SEM); the shell can be obtained by carbonizing one or more carbon precursors selected from among the group comprising tars, pitches, hard carbon, soft carbon and hydrocarbons having 1 to 20 carbon atoms, resulting in a non-porous shell.

Owner:WACKER CHEM GMBH

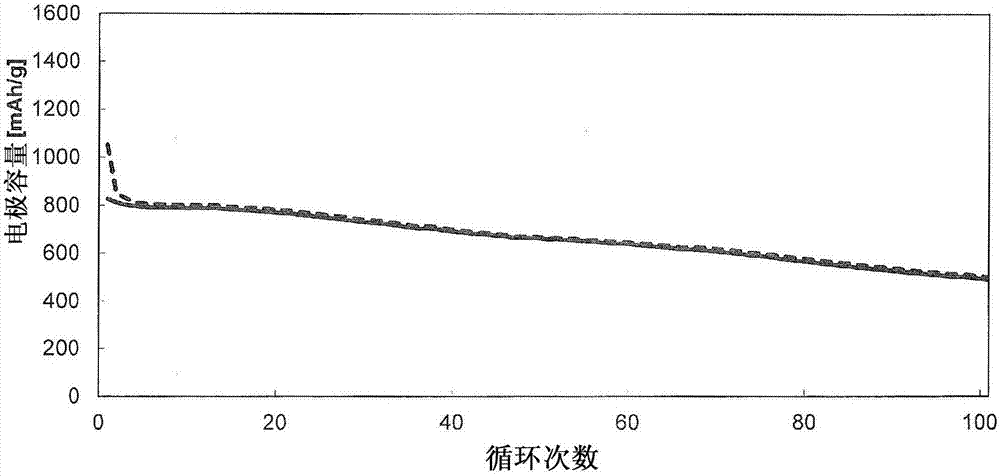

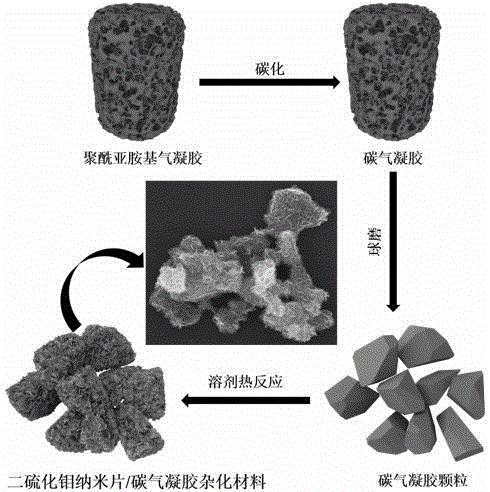

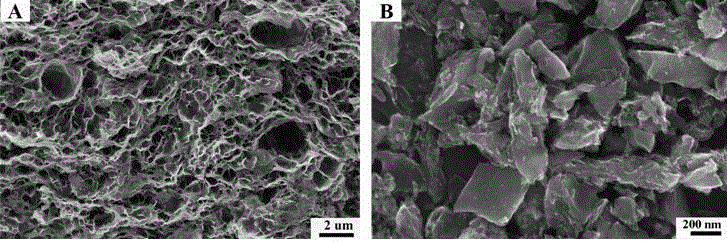

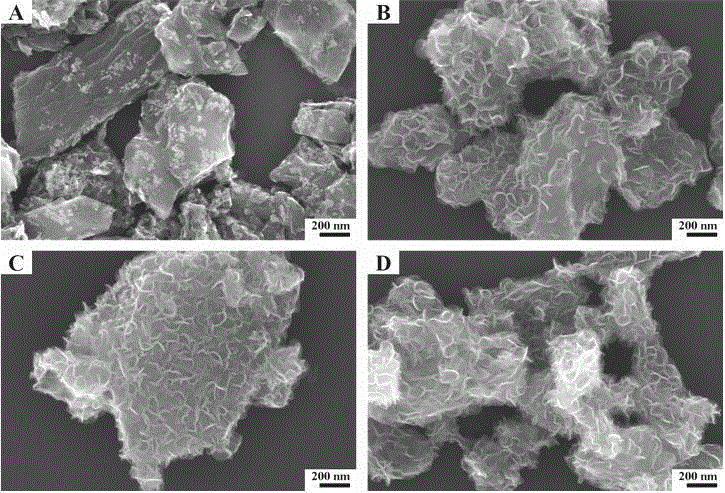

Molybdenum disulfide nanosheet/carbon aerogel hybrid material and preparation method therefor

The present invention belongs to the technical field of carbon aerogel, and particularly relate to a molybdenum disulfide nanosheet / carbon aerogel hybrid material and a preparation method therefor. The hybrid material is prepared by growing a molybdenum disulfide nanosheet in situ on a carbon aerogel particle with an irregular angular structure by using molybdenum salt and sulfosalt. The raw materials comprises the carbon aerogel, the molybdenum salt, and the sulfosalt. The preparation process comprises: carrying out a sol-gel method, carrying out freeze drying, and carrying out a high-temperature carbonized technology, thereby obtaining the carbon aerogel; obtaining the carbon airgel particle with the irregular angular structure by using a grinding or milling method; and and growing the molybdenum disulfide nanosheet in situ on the carbon aerogel particle by using a solvothermal method. The molybdenum disulfide nanosheet / carbon aerogel hybrid material prepared by the method disclosed by the invention has the characteristics that the molybdenum disulfide nanosheet has few layers ( only 3-6 layers), and is uniformly distributed on the carbon aerogel, so that the hybrid material can be used as an ideal catalyst material with high performance, an electrode material for new energy devices such as a lithium-ion battery or solar cells, and the like.

Owner:FUDAN UNIV

Positive electrode active material for lithium ion battery

ActiveUS8748041B2Speedup of research and developmentHigh capacity densityRadiation pyrometrySecondary cellsPeak intensityLithium-ion battery

Disclosed is a positive electrode active material that provides an improved capacity density. Specifically disclosed is a positive electrode active material for a lithium ion battery with a layered structure represented by Lix(NiyM1-y)Oz (wherein M represents at least one element selected from a group consisting of Mn, Co, Mg, Al, Ti, Cr, Fe, Cu, and Zr; x is in the range from 0.9 to 1.2; y is in the range from 0.3 to 0.95; and z is in the range from 1.8 to 2.4), wherein, when a value obtained by dividing an average of peak intensities observed between 1420 and 1450 cm−1 and between 1470 and 1500 cm−1 by the maximum intensity of a peak appearing between 520 and 620 cm−1 in an infrared absorption spectrum obtained by FT-IR is represented by A, A satisfies the following relational formula: 0.20y−0.05≦A≦0.53y−0.06.

Owner:JX NIPPON MINING & METALS CORP

Preparation method of porous hollow carbon microsphere co-doped with oxygen and nitrogen

ActiveCN108511204ASimple processEnvironmentally friendlyHybrid capacitor electrodesIndustrial wasteControllability

The invention discloses a preparation method of a porous hollow carbon microsphere co-doped with oxygen and nitrogen. A spherical precursor (namely composite microsphere) is obtained by spray drying on a mixed solution of lignin and a metal compound, the crosslinking degree of the spherical precursor is improved by oxidizing the spherical precursor in air in advance, so that the spherical morphology during the subsequent carbonization process protected by inert atmosphere is maintained, and the porous hollow carbon microsphere co-doped with oxygen and nitrogen is finally obtained by oxidization of concentrated nitric acid. The preparation method is simple in process, production on a large scale is easily achieved, moreover, the main raw material lignin is industrial waste such as papermaking and is low in cost, and high utilization of the microsphere can be achieved; and the porous hollow carbon microsphere prepared by the method is uniform in grain size, high in size controllability and has relatively large specific area and developed hierarchical hole structure, and the electrochemical performance is excellent when the porous hollow carbon microsphere is used as a supercapacitorelectrode material.

Owner:张家港博威新能源材料研究所有限公司

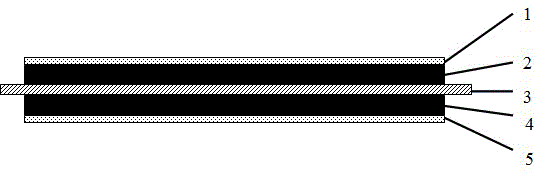

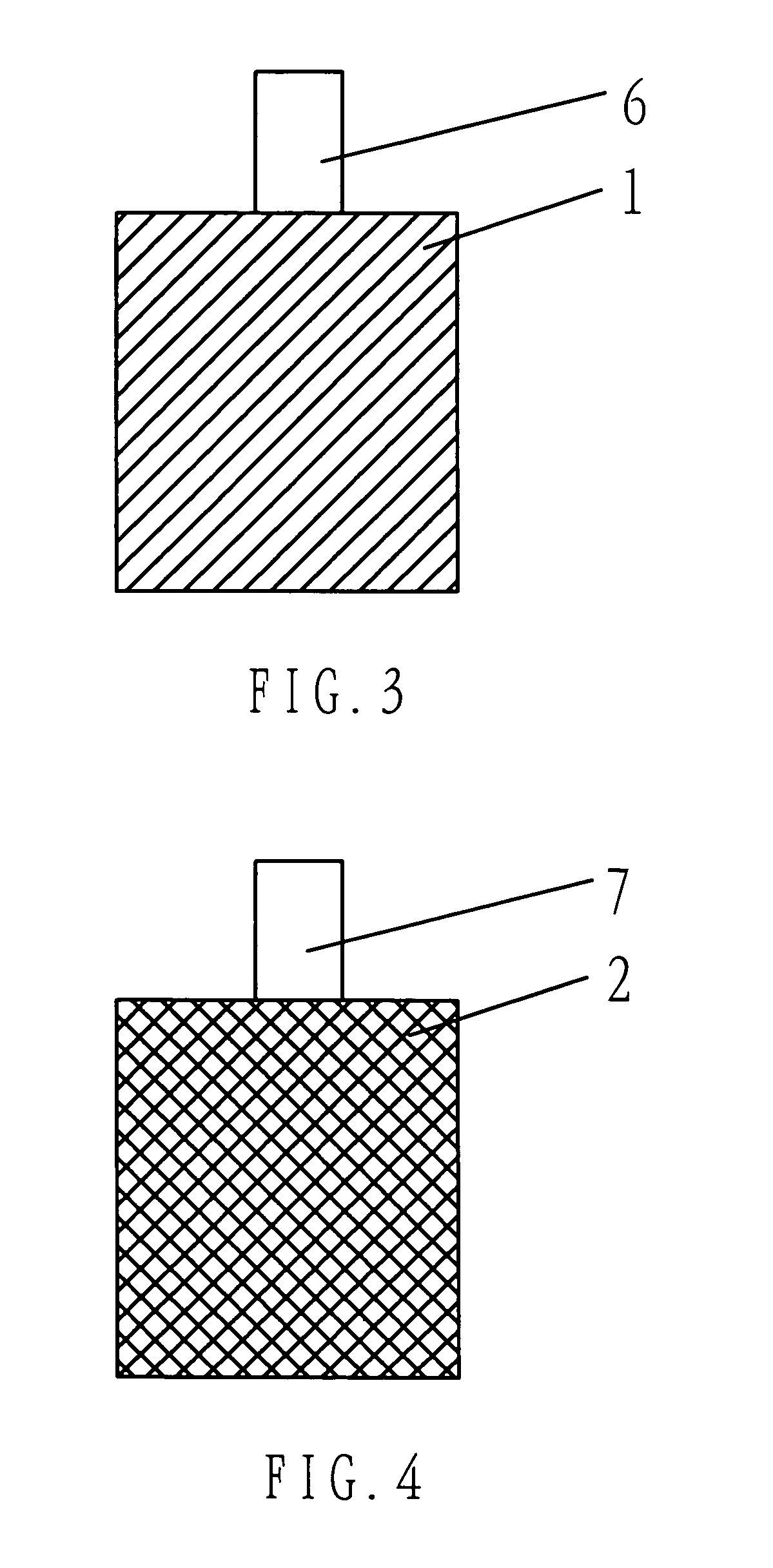

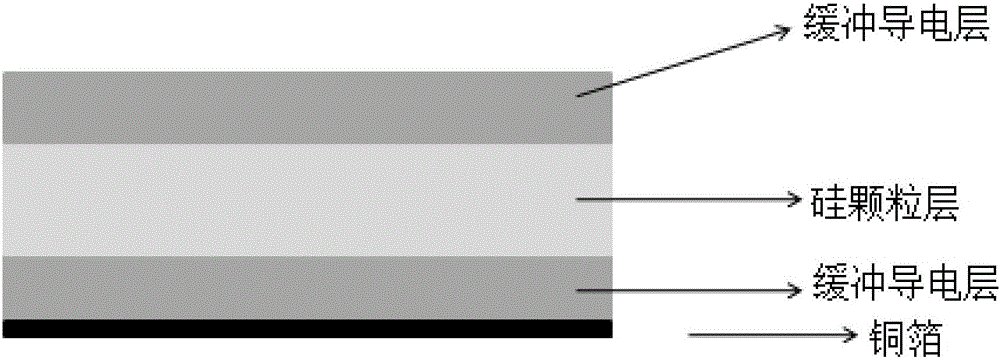

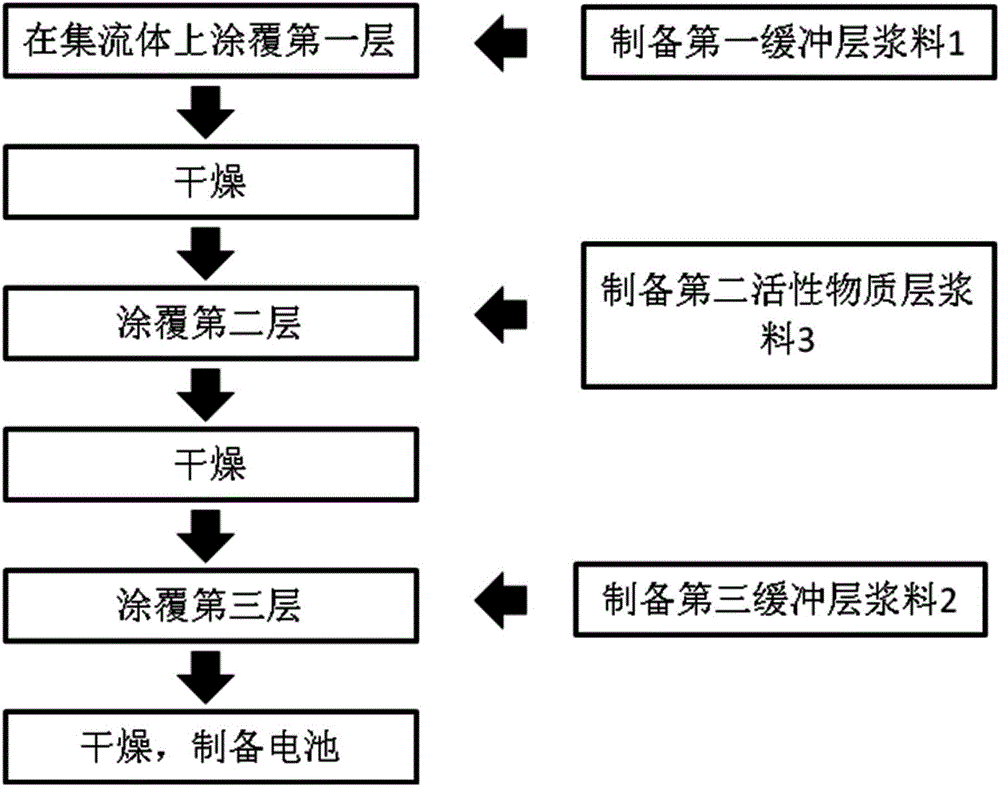

Electrode plate and lithium ion battery

InactiveCN105789556AImprove buffering effectReduce adverse effectsSecondary cellsNon-aqueous electrolyte accumulator electrodesSize changeOptoelectronics

The invention provides an electrode plate which comprises a current collector layer, a first conductive layer, an outer conductive layer and a first silicon material layer, wherein the first conductive layer is arranged on the surface of the current collector layer; the first silicon material layer is arranged on the surface of the outer conductive layer; n groups of silicon material layers and conductive layers are sequentially and alternatively arranged between the first conductive layer and the first silicon material layer. The invention further provides a lithium ion battery which comprises the electrode plate provided by the technical scheme of the invention. According to the electrode plate, the conductive layers have a relatively good buffer function on the silicon material layer, after lithium is embedded, the size of the silicon material layer is increased, then conductive layers on two sides can be compressed, in a lithium removed state, the size of the silicon material layer is reduced and the thickness is recovered, and the conductive layers on two sides are elastic and can be recovered to original thickness, so that due to the multi-layer electrode plate structure, a sufficient buffer space can be provided for the silicon material layer, and along with shrinkage of the silicon material layer, relatively good stability and interface contact property of the multi-layer structure can be maintained, and adverse influence caused by silicon material size change in the battery circulation process can be avoided.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com