Micro super capacitor nano-device based on porous graphene-supported polyaniline heterostructure and manufacturing method thereof

A technology of porous graphene and supercapacitors, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of small capacitance and low utilization of the surface area of electrode materials, so as to increase the contact area and increase the capacity and energy density, the effect of increasing conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

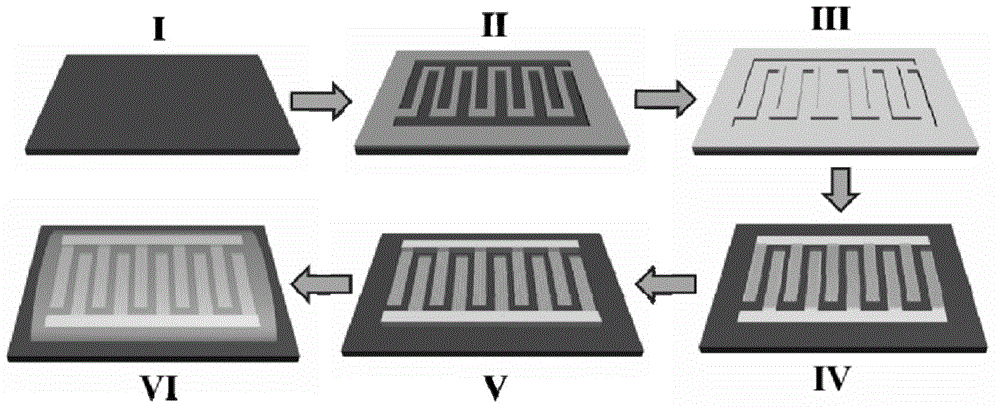

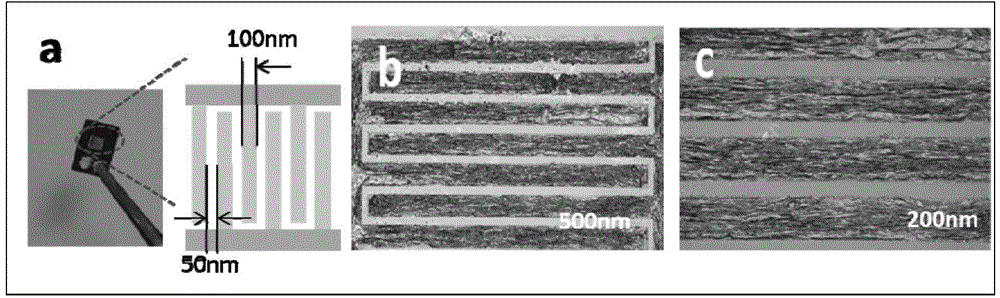

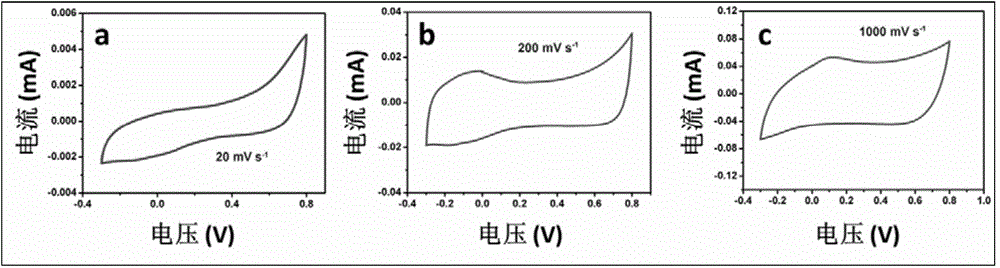

[0028] like figure 1 Shown, the preparation method of porous graphene supported polyaniline heterostructure base micro-supercapacitor nano-device, it comprises the following steps:

[0029] 1) Select the silicon substrate, cut the silicon substrate into an appropriate size, then ultrasonically clean the silicon substrate with isopropanol (IPA) for about 3 minutes, and dry it with nitrogen;

[0030] 2) Use a spin coater to spin coat a layer of 9000A on the substrate. The spin coating speed is 4000r / min, and the spin coating time is 40s.

[0031] 3) Etch the interdigitated electrode pattern on the spin-coated silicon wafer with a photolithography machine, and the exposure time is 28s;

[0032] 4) Development: soak the photoetched substrate in RD6 developer solution for 90s, then soak in deionized water for 30s, then soak in the second portion of deionized water for 30s, and blow dry with nitrogen;

[0033] 5) Metal Thermal Evaporation (PVD): Use a thermal evaporation coater to...

Embodiment 2

[0040] A method for preparing a porous graphene-supported polyaniline heterostructure-based miniature supercapacitor nano-device, comprising the steps of:

[0041] 1) Select the silicon substrate, cut the silicon substrate into an appropriate size, then ultrasonically clean the silicon substrate with isopropanol (IPA) for about 3 minutes, and dry it with nitrogen;

[0042] 2) Use a spin coater to spin coat a layer of 9000A on the substrate. The spin coating speed is 4000r / min, and the spin coating time is 40s.

[0043] 3) Etch the interdigitated electrode pattern on the spin-coated silicon wafer with a photolithography machine, and the exposure time is 28s;

[0044] 4) Development: soak the photoetched substrate in RD6 developer solution for 90s, then soak in deionized water for 30s, then soak in the second portion of deionized water for 30s, and blow dry with nitrogen;

[0045] 5) Metal Thermal Evaporation (PVD): Use a thermal evaporation coater to vapor-deposit metal to pre...

Embodiment 3

[0052] A method for preparing a porous graphene-supported polyaniline heterostructure-based miniature supercapacitor nano-device, comprising the steps of:

[0053] 1) Select polyethylene terephthalate, cut polyethylene terephthalate (PET) into an appropriate size, then ultrasonically clean PET with isopropyl alcohol (IPA) for about 3 minutes, and dry it with nitrogen ;

[0054] 2) Use a spin coater to spin coat a layer of 9000A on the PET substrate. The spin coating speed is 4000r / min, and the spin coating time is 40s.

[0055] 3) Use a photolithography machine to etch the interdigitated electrode pattern on the spin-coated PET substrate, and the exposure time is 28s;

[0056] 4) Development: soak the photoetched PET substrate in RD6 developer solution for 90s, then soak in deionized water for 30s, then soak in the second portion of deionized water for 30s, and blow dry with nitrogen;

[0057] 5) Metal Thermal Evaporation (PVD): Use a thermal evaporation coater to vapor-depo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Interdigital width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com