Patents

Literature

477 results about "Pet substrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

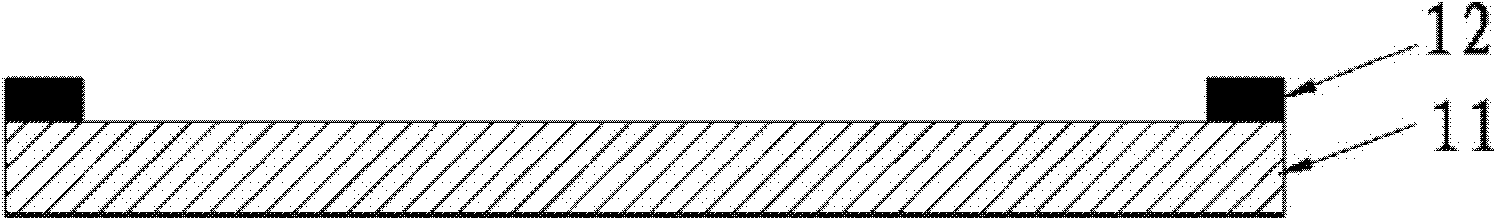

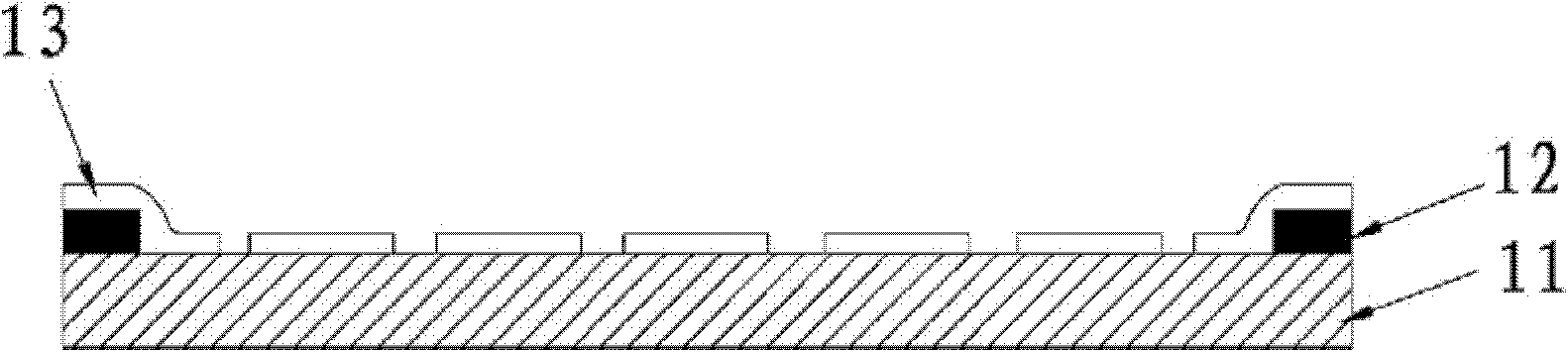

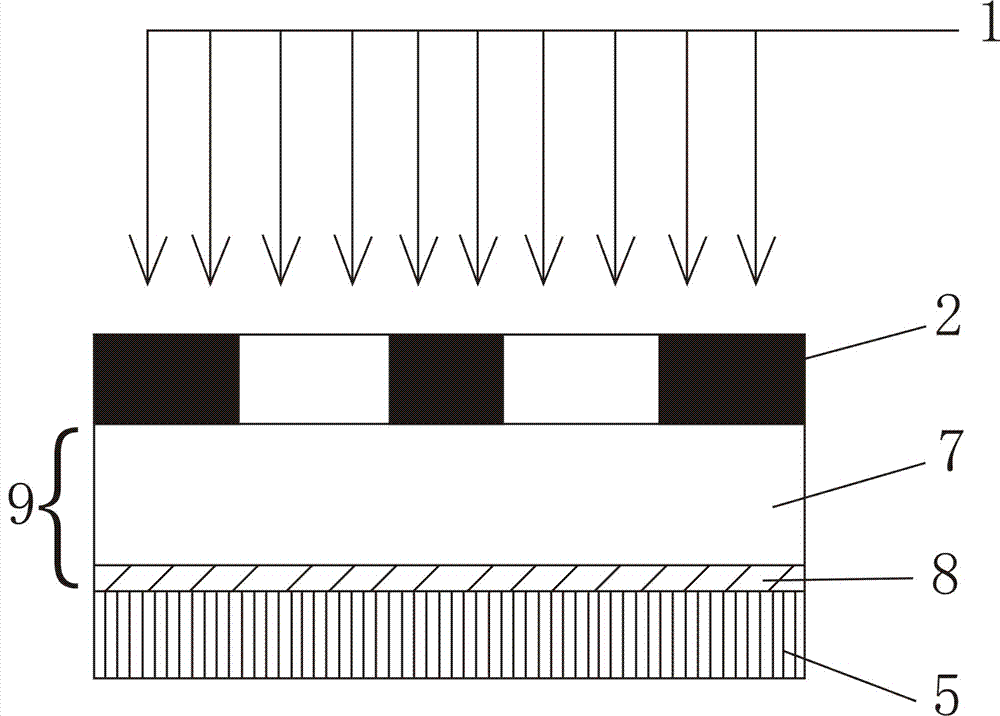

Flexible integrated ultrasonic transducer and preparation method thereof

InactiveCN101894855AIncrease widthHigh gainSolid-state devicesSemiconductor/solid-state device manufacturingAnti jammingGate dielectric

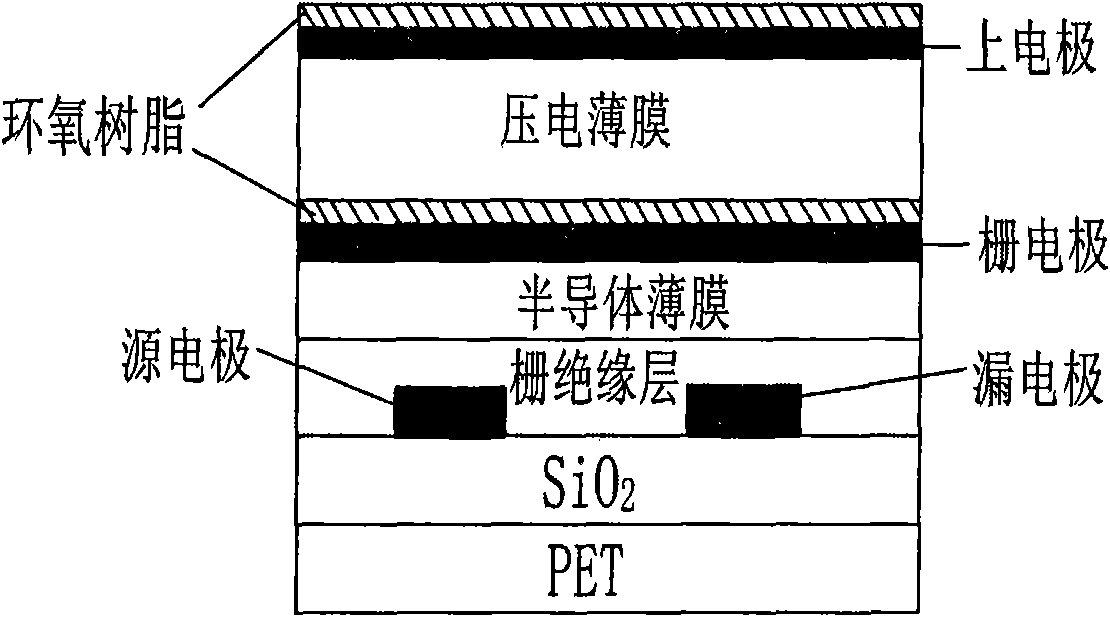

The invention discloses a flexible integrated ultrasonic transducer, which is integrated by an organic thin-film transistor and a piezoelectric sensor. The flexible integrated ultrasonic transducer consists of a substrate, a moisture-proof isolation layer, a source drain electrode, a semiconductor thin-film layer, a gate dielectric layer, a gate electrode layer, an electrical signal coupling layer, a piezoelectric film layer, an electrode layer and an ultrasonic coupling layer in turn. In order to conveniently prepare a two-dimensional flexible ultrasonic transducer array, a layer of silicon dioxide thin film is deposited on a PET substrate and is used for isolating moisture. The piezoelectric material serving a PVDF thin film of an ultrasonic transducer has the advantages of good piezoelectric performance, low acoustic impedance, and good acoustic impedance matching with water and organisms. Therefore, the sensitivity is improved and the frequency band is widened. High flexibility ofthe PVDF thin film provides good technical basis for integrating the piezoelectric sensor. By adopting the organic thin-film transistor as a built-in signal amplifier, the gain and signal-to-noise ratio are increased, and the anti-jamming capability is improved.

Owner:SOUTH CHINA UNIV OF TECH

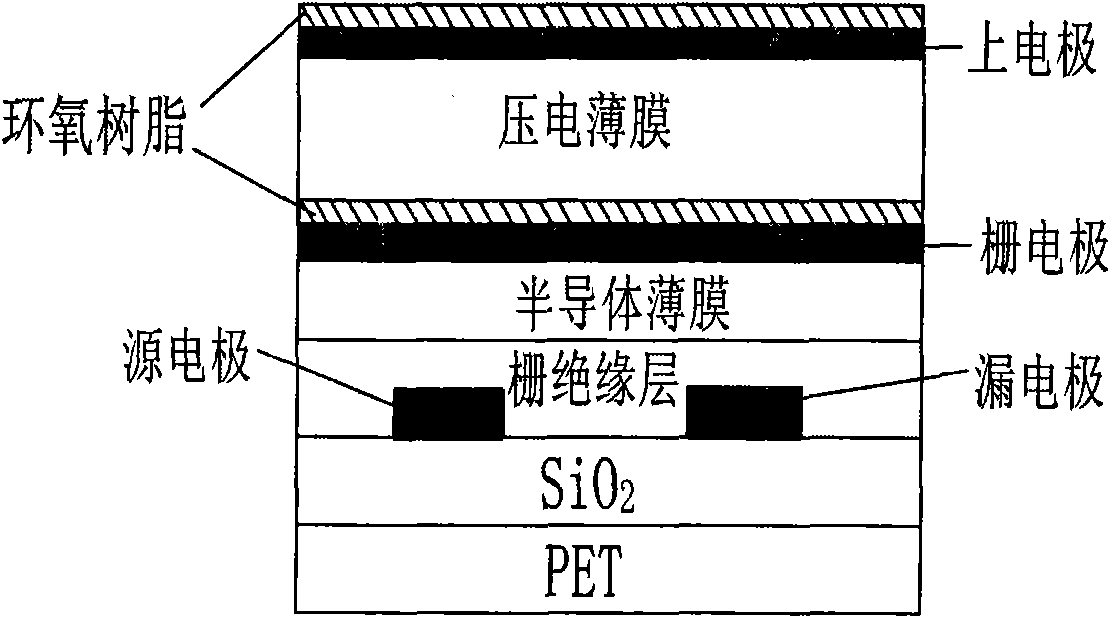

Self-cleaning nano-coating protective film and preparation method thereof

InactiveCN103740292ADifferent curing methodsSimple processFilm/foil adhesivesCoatingsPolyethylene terephthalatePolyethylene terephthalate glycol

The invention relates to the technical field of optical protective films, and in particular relates to a self-cleaning nano-coating protective film and a preparation method thereof. The preparation method comprises the following processing steps: I, preparing a nano-paint having a self-cleaning function; II, coating a PET (Polyethylene Terephthalate) substrate with the nano-paint by using a micro-concave anilox roller; III, forming a layer of nanofilm on the PET substrate by adopting a heat curing way; and IV, coating silica gel and sticking a stripping layer. The PET substrate is coated with the nano-paint having the self-cleaning function by using the micro-concave anilox roller, and the PET substrate is dried and cured in a drying oven, so that the nano-coating having a self-cleaning function is formed on the surface of the PET substrate. The self-cleaning nano-coating protective film can be used by peeling the PET stripping layer off and sticking an adhesive layer to a screen. The self-cleaning nano-coating protective film is convenient to use and easy to operate.

Owner:NALI OPTICAL MATERIAL DONGGUAN

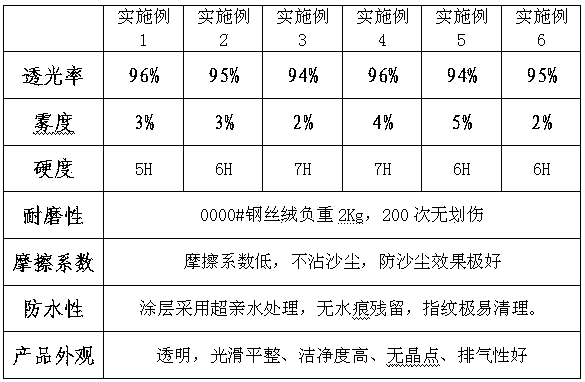

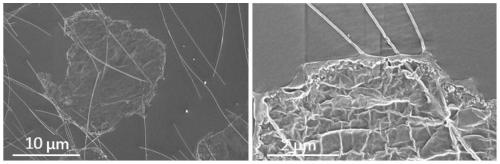

Preparation method of wearable transparent flexible film type strain sensor

PendingCN111141427AHigh light transmittanceHigh sensitivityDecorative surface effectsForce measurement using piezo-resistive materialsPolyethylene terephthalate glycolMetal electrodes

The invention belongs to the field of electronic device application research and relates to a preparation method of a wearable transparent flexible film type strain sensor. The method comprises the following steps that: 1, preparing raw materials; the preparation method comprises the following steps: after a polyethylene terephthalate (PET) substrate is treated with deionized water, ethanol and isopropanol, polydimethylsiloxane (PDMS) is deposited on the PET substrate and is treated, and then, Ti3C2Tx MXene dispersion liquid and silver nanowire (AgNWs) dispersion liquid are deposited on the surface of a formed polydimethylsiloxane (PDMS) film in sequence through spraying or spin-coating, and a sample is stripped from the PET substrate, and an AgNWs / Ti3C2Tx MXene / PDMS transparent flexibleconductive film can be obtained; metal electrodes are led out of the two ends of the AgNWs / Ti3C2Tx MXene / PDMS transparent flexible conductive film; and finally, a polydimethylsiloxane (PDMS) protective layer is uniformly deposited on the surface of the AgNWs / Ti3C2Tx MXene / PDMS transparent flexible conductive film, and packaging is performed, and therefore, the AgNWs / Ti3C2Tx MXene-based wearable transparent flexible film type strain sensor can be obtained. The wearable transparent flexible ultra-sensitive film type strain sensor is novel, simple and convenient, has good concealment, and does not affect appearance.

Owner:LANZHOU UNIVERSITY

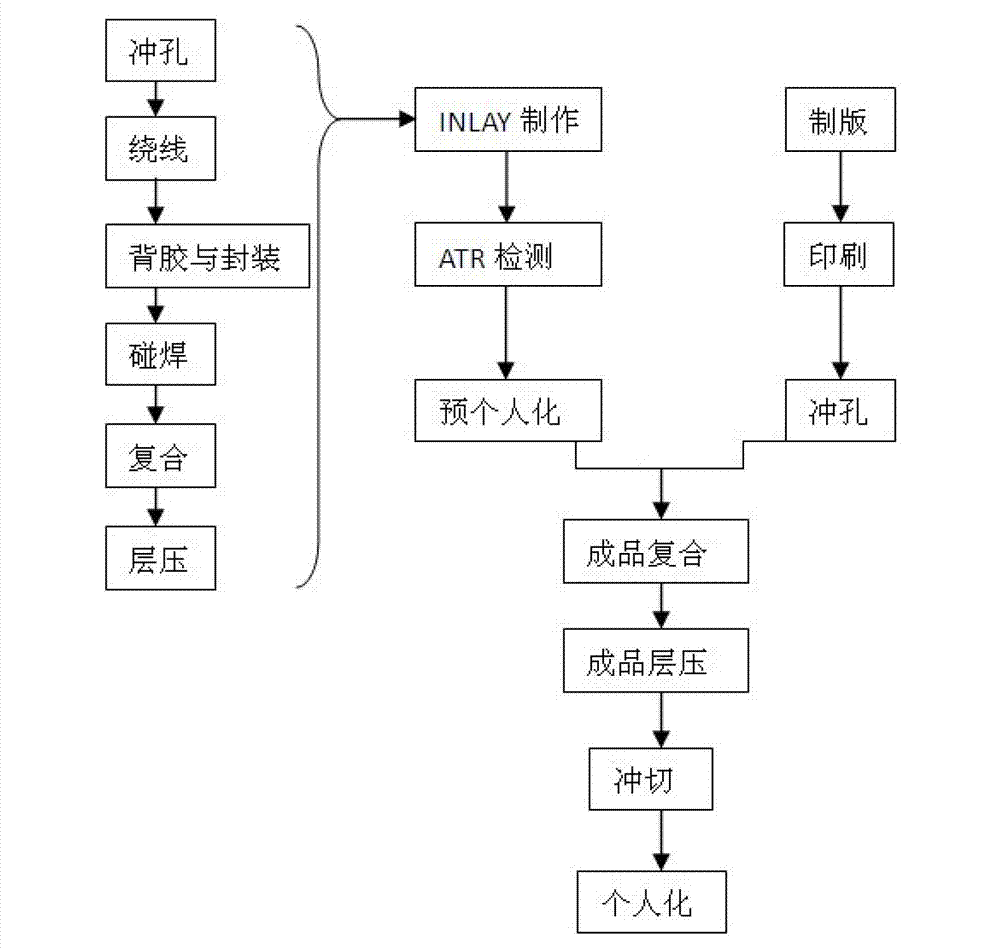

Double-interface intelligent card manufacture process and double-interface intelligent card

InactiveCN103093271AAvoid security issuesRecord carriers used with machinesPersonalizationButt welding

The invention provides double-interface intelligent card manufacture process and a double-interface intelligent card. The manufacture process comprises INLAY manufacture which specifically comprises the following steps of punching, punching through an automatic punching machine and full version chip position holes; winding, adopting an ultrasonic winding technology to achieve a non-contact function of a double-interface intelligent card; adhesive applying and sealing, adopting thermosensitive adhesive with improved flowability to achieve non-excessive-glue during lamination, and hollowing the adhesive at the position where a chip needs butt-welding; butt-welding, connecting the chip and a coil; composition, laminating a layer of soft PVC or PET substrate on a coil face of a chip encapsulating layer to protect an electronic coil circuit, and fixing the substrate through spot welding corresponding to locating holes; and lamination, performing lamination in a laminating device. Under the condition of low cost, the double-interface intelligent card manufacture process completes high-speed encapsulation manufacture and personalization of the card, and can be practically applied to product industrialization.

Owner:SHANGHAI PUJIANG SMART CARD SYST CO LTD

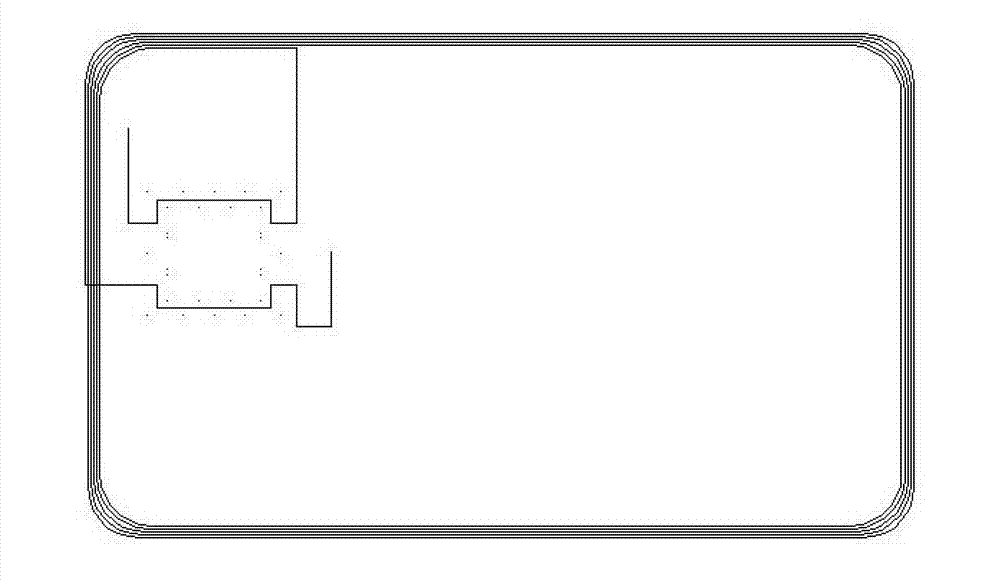

RFID printed antenna hot stamped electronic tag and manufacturing method thereof

ActiveCN105243417AImprove performanceAesthetic performanceRecord carriers used with machinesHot stampingInformation layer

The invention belongs to the field of information technology and anti-counterfeiting printed antennas, and particularly relates to an RFID printed antenna hot stamped electronic tag and a manufacturing method thereof. The electronic tag comprises a PET substrate layer; a release layer, an information layer, a printing layer, a first glue layer, an antenna substrate layer and a printed antenna layer are sequentially from bottom to top arranged on the PET substrate layer; flip chip packaging is carried out on the printed antenna layer, and a second glue layer is arranged on the chip. The PET is selected to serve as the substrate, and the release layer and the information layer are coated on the PET substrate layer; teletext information is then printed, glue is applied, the antenna substrate is printed, conductive oil ink is then printed, flip chip packaging is then carried out on the well-printed antenna, glue is then applied, and after being dried, the tag is transferred to a stuck object in a hot stamping mode. Organic combination between the hot stamping technology and the electronic tag can be realized, the manufactured electronic tag has stable performance, environmental protection is realized, the cost is low, the manufacturing process is relatively simple, the appearance is attractive, damage is not likely to happen, double counterfeiting prevention can be realized, and the anti-counterfeiting force is improved.

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

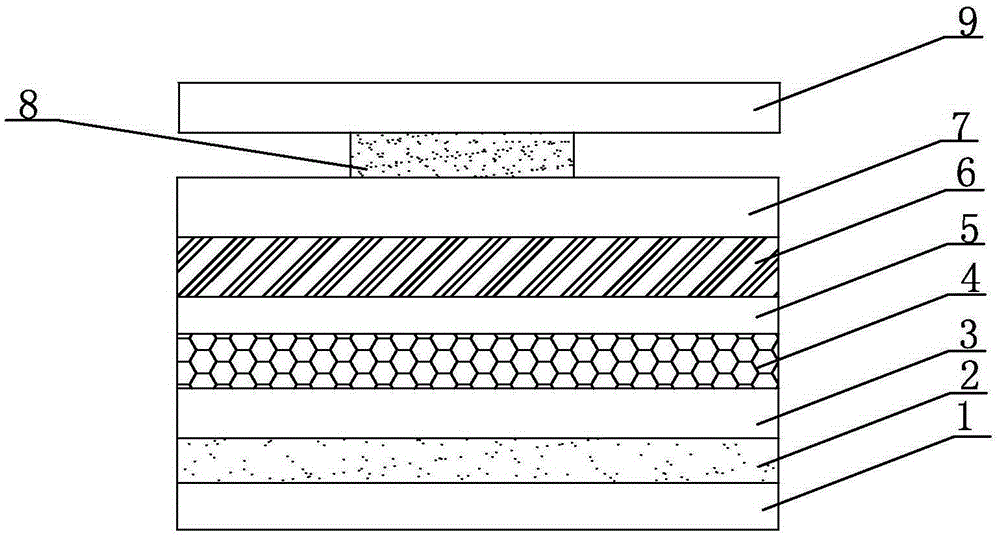

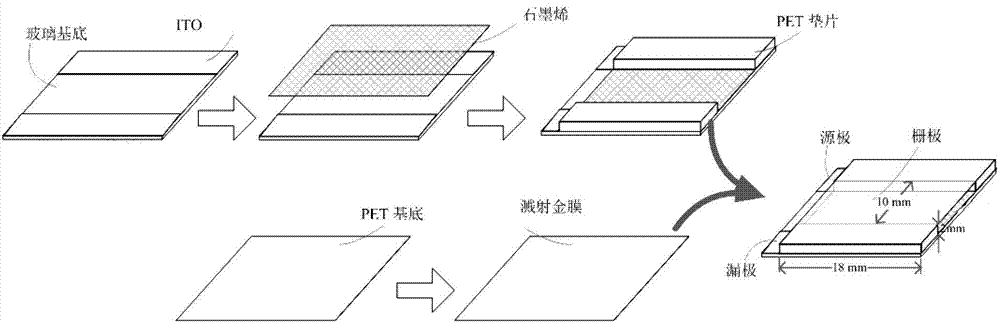

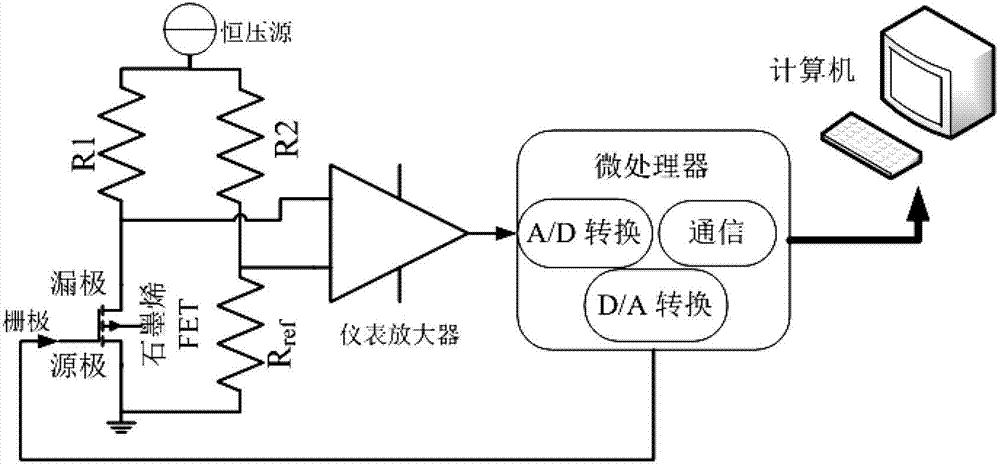

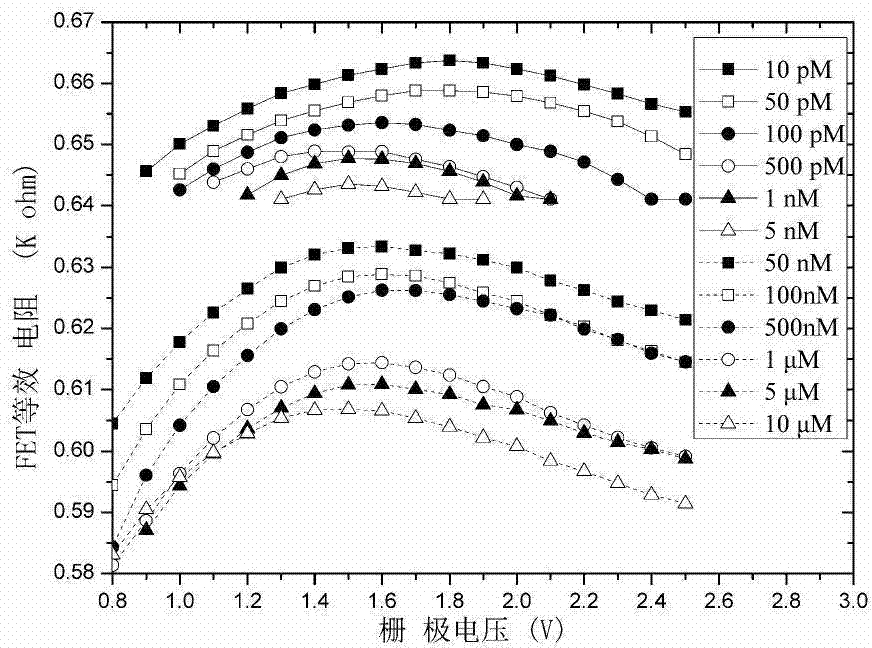

Graphene field-effect transistor biosensor as well as manufacturing method and detecting method thereof

InactiveCN103399071AIncrease the area of actionReduce contact resistanceMaterial analysis by electric/magnetic meansSemiconductor devicesPolyethylene glycolGold film

The invention discloses a graphene field-effect transistor biosensor as well as a manufacturing method and a detecting method thereof. The graphene field-effect transistor biosensor comprises glass substrates, wherein the two sides of each glass substrate are respectively provided with an ITO (indium tin oxide); parts of glass substrates at the same side as well as the ITOs of the parts of glass substrates are covered with graphene; the ITOs at the two sides of each glass substrate without graphene are respectively a source electrode and a drain electrode; a PET (polyethylene glycol terephthalate) gasket is covered on each ITO covered with the graphene and is covered with a PET substrate on which a gold film is sputtered; a sample cell is arranged in the middle of each glass substrate by insulating silica gel; the gold film is taken as a grid electrode. The contact resistance is reduced by means of covering the ITOs with graphene, the plane gold film electrode is taken as the grid electrode to exert a uniform electric field and increase the action area of electrolyte and graphene, and by the two aspects, the detection sensitivity is improved and the detection range is enlarged; by detection, the lower limit of adenosine triphosphate reaches 10pM.

Owner:SHANDONG NORMAL UNIV

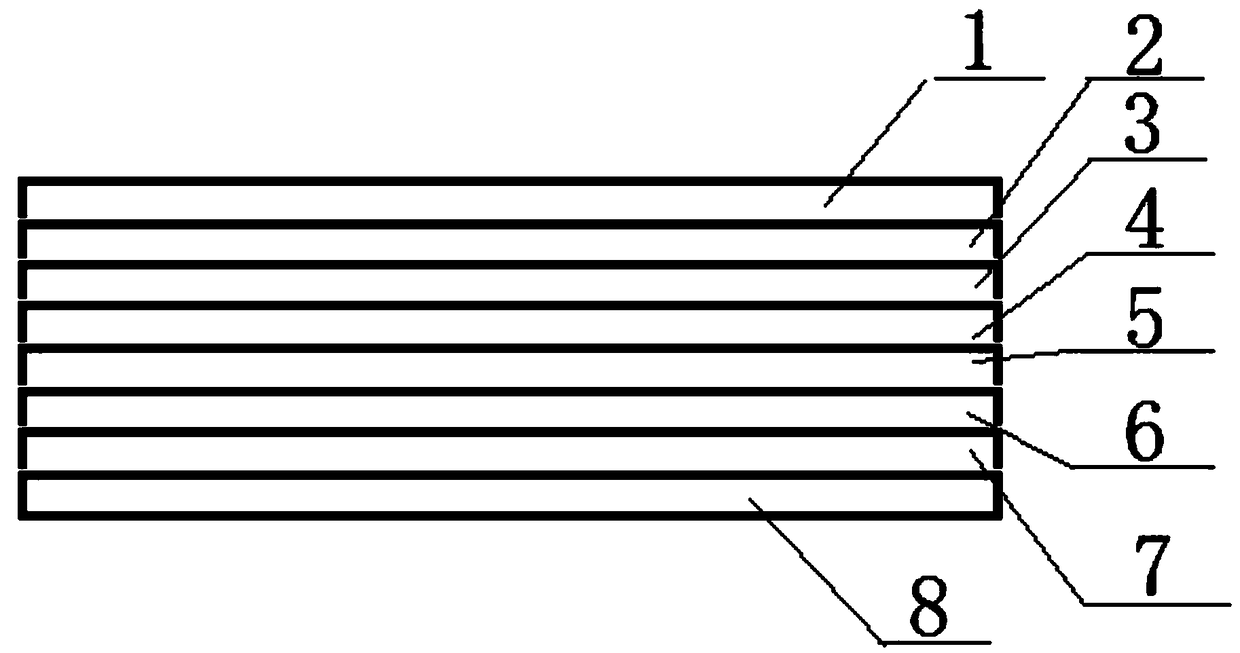

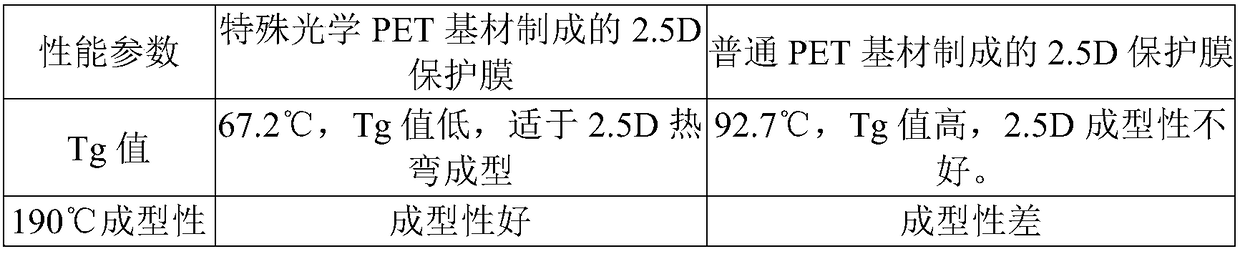

2.5D protective film and preparation method thereof

InactiveCN108192520AHigh light transmittanceLow hazePressure sensitive film/foil adhesivesTectorial membraneGlass cover

The invention provides 2.5D protective film and a preparation method thereof. The 2.5D protective film is of a multi-layer structure, and comprises a PET substrate layer, a first organosilicon pressure-sensitive adhesive protective layer, a polyacrylic resin hardened layer, a first special optical-grade PET substrate layer, an OCA optical polyacrylic adhesive layer, a second special optical-gradePET substrate layer, a second organosilicon pressure-sensitive adhesive protective layer and a PET fluorine release film layer which are adhered sequentially. The 2.5D protective film has high light transmittance, low haze and good hot press formability, and the problems of corner shelling and edge graying which are easily caused by a PC surface which is unresistant to solvents and has poor adhesion after the PC surface is adhered to a mobile phone screen are solved; the hardened layer has high wear resistance, high hardness, AF anti-fingerprint performance and AG smoothness; and organosiliconpressure-sensitive adhesive has the advantages of moderate viscosity, firm adhesion to a glass cover plate of a mobile phone and excellent gas exhausting properties; through the 2.5D protective film,perfect combination of usability and high performance is achieved.

Owner:新纶电子材料(常州)有限公司

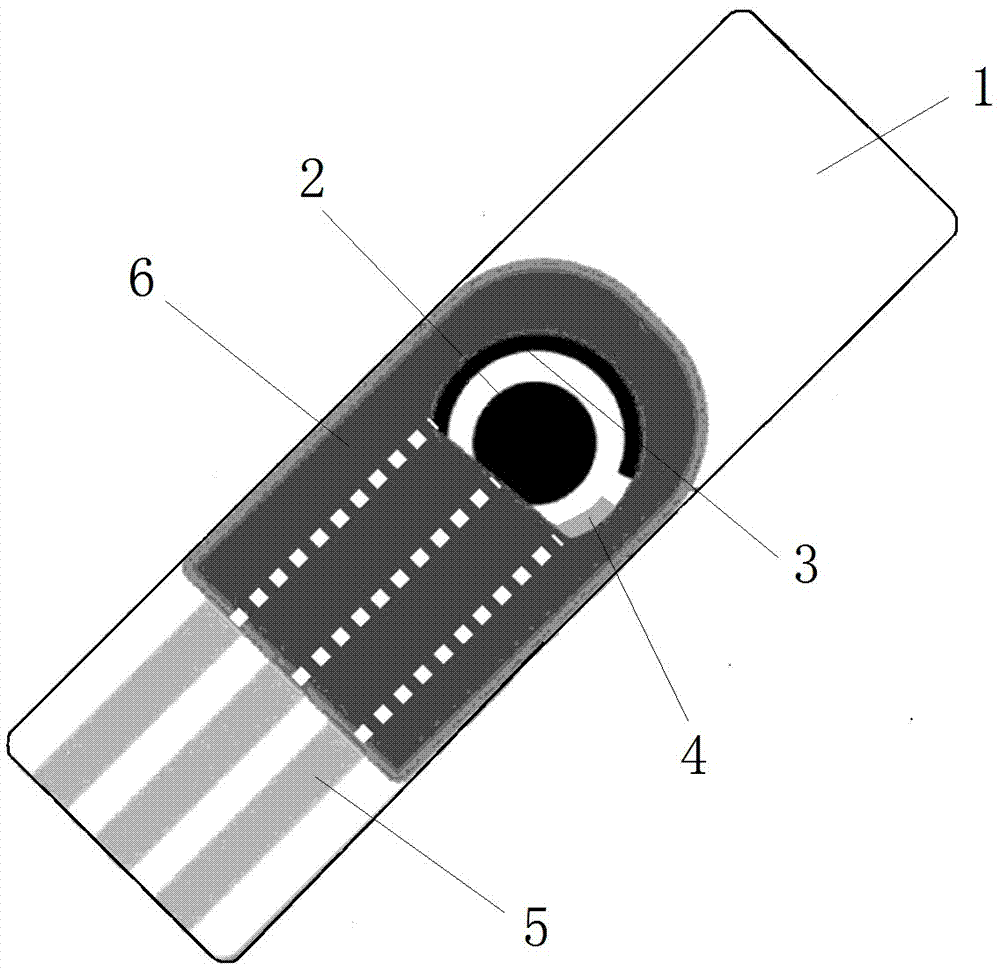

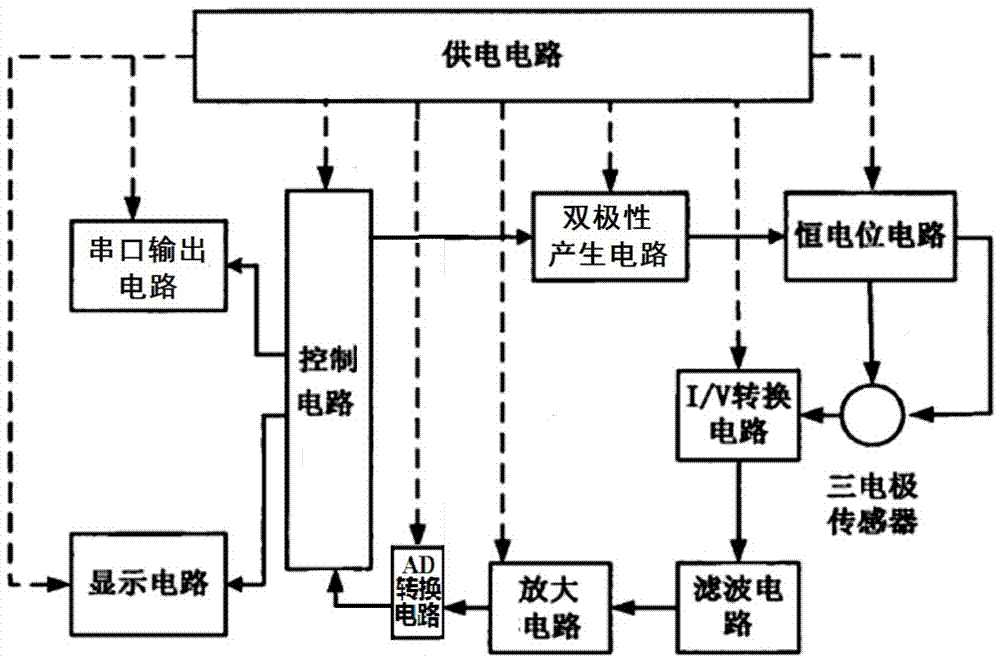

Electrochemical heavy metal detector constructed based on graphene test paper electrode and detection method thereof

PendingCN107966485AImprove accuracyImprove practicalityConductive pattern formationMetallic pattern materialsIon contentInsulation layer

The invention discloses an electrochemical heavy metal detector constructed based on a graphene test paper electrode and a detection method thereof; the electrochemical heavy metal detector includes an electrochemical detection system and a graphene printing paper electrode connected to an input end of the electrochemical detection system; the graphene test paper electrode includes a PET substrate, and a work electrode, a counter electrode, a reference electrode, a silver conductive baseline and an insulating layer printed on the PET substrate by a printing process; the working electrode is printed graphene, the counter electrode is printed carbon, the reference electrode is printed silver / silver chloride, and a layer of bismuth film is deposited on the surface of the working electrode. The electrochemical heavy metal detector is used for detecting the content of heavy metal ions in a lake water sample, the recovery rate of 10 times of repeated testing is 92.5%, the RSD is less than 5%, the testing time is less than 15 minutes, and the detection limit is less than 1 [mu]mol / L; the relative deviation is less than 5% compared with that of an atomic absorption method, so the electrochemical heavy metal detector has high accuracy and practicality.

Owner:CHINA PETROLEUM & CHEM CORP +1

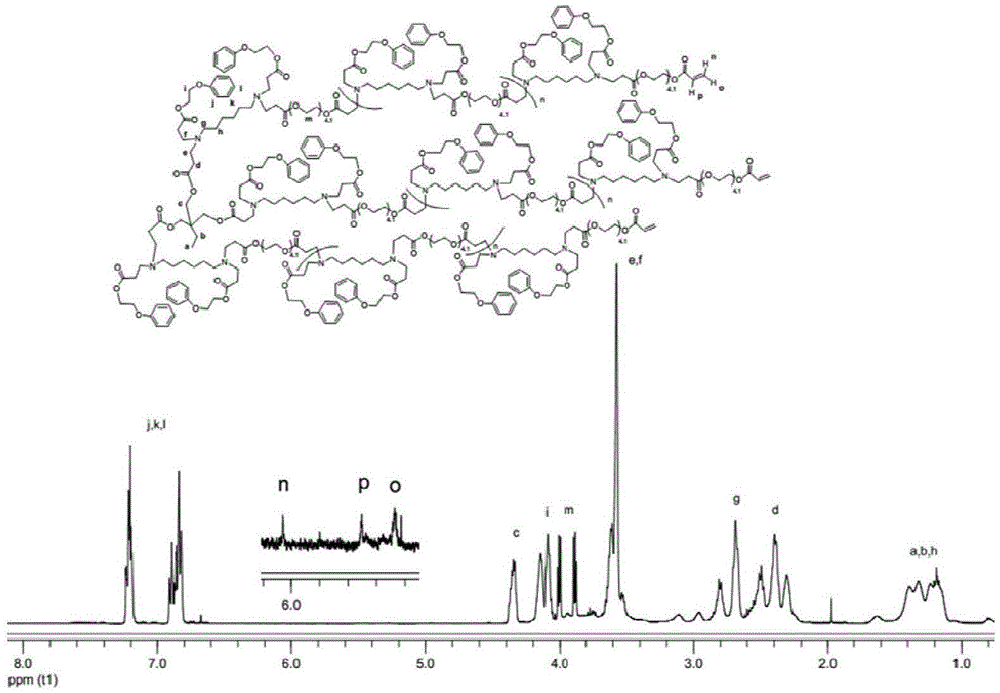

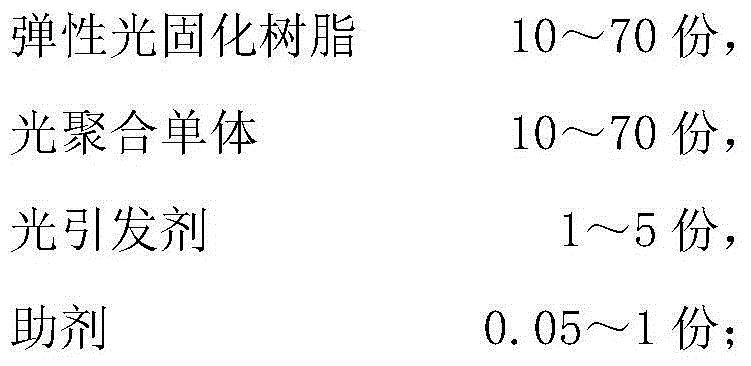

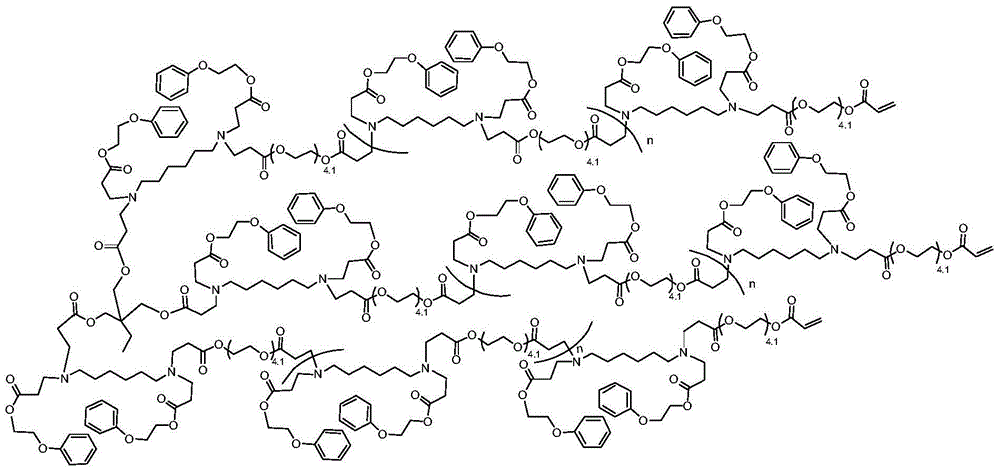

Ultraviolet light curing elastic self-healing coating composition

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

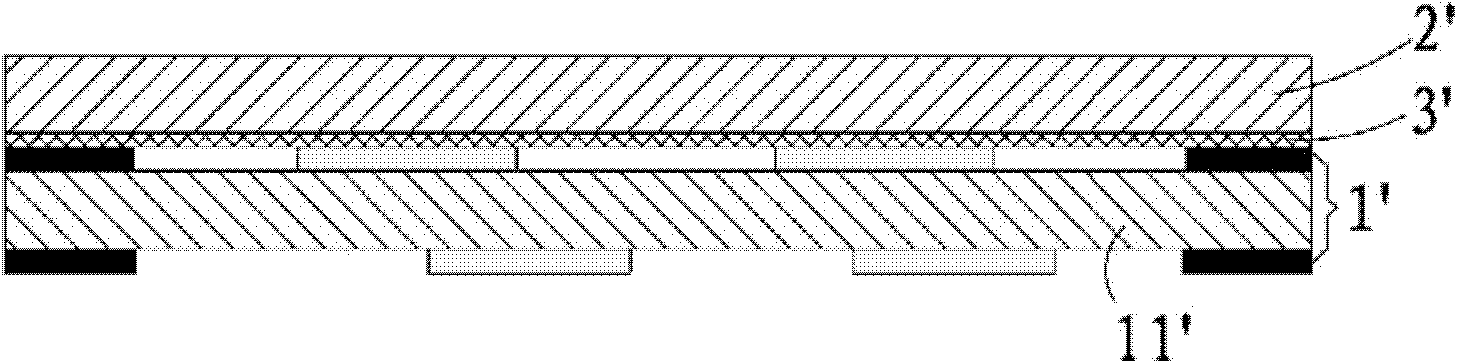

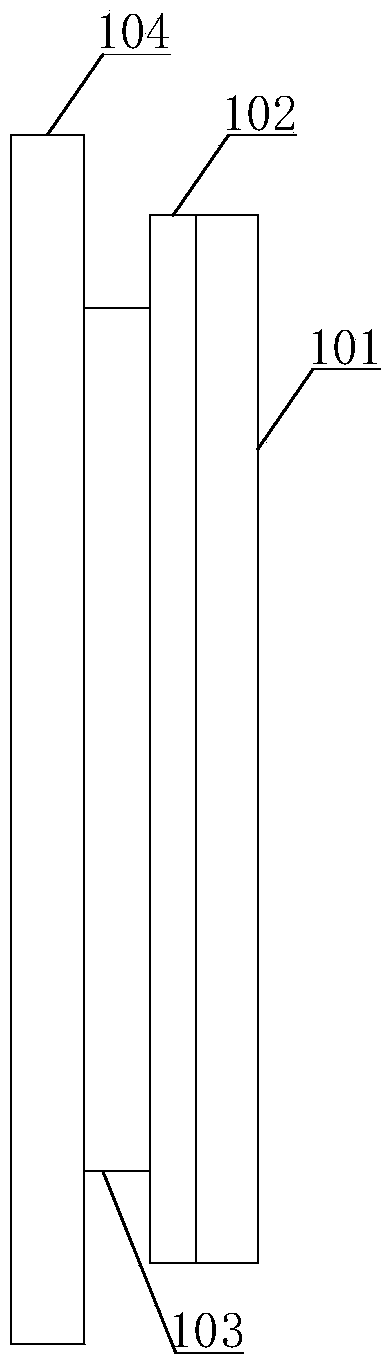

Integrated capacitive touch screen, manufacturing method and touch screen terminal

InactiveCN102279683AOvercome the shortcomings of the structureReduce light lossInput/output processes for data processingPet substrateTouchscreen

The invention is applicable to the technical field of touch screen production, and provides an integrated capacitive touch screen, a manufacturing method thereof, and a touch screen terminal. The integrated capacitive touch screen includes a panel glass, and also includes a PET base film with the same size as the panel glass, the panel glass is provided with a window frame, a first ITO pattern and metal electrode leads, and the PET base film is provided with There is a second ITO pattern, and the side of the panel glass with the first ITO pattern is opposite to the side of the PET base film with the second ITO pattern and bonded by optical glue. The integrated capacitive touch screen provided by the invention has small thickness, reduces light loss, and can reduce the production cost of the touch screen and the terminal applying the touch screen.

Owner:深圳豪威显示科技有限公司

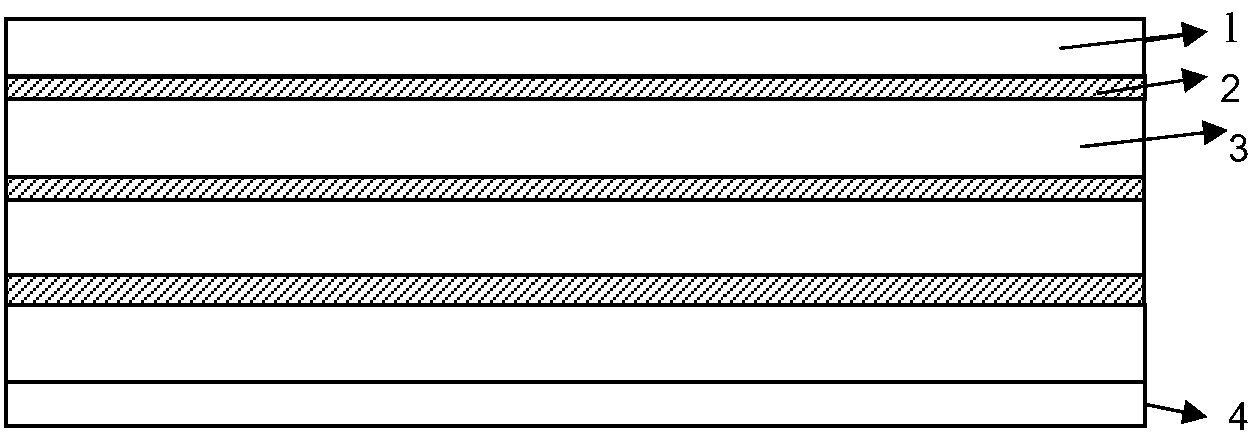

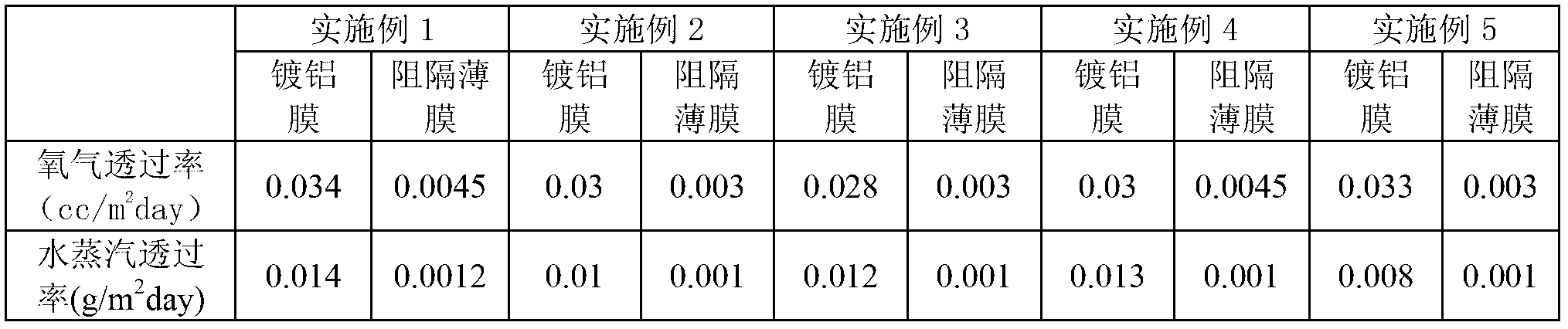

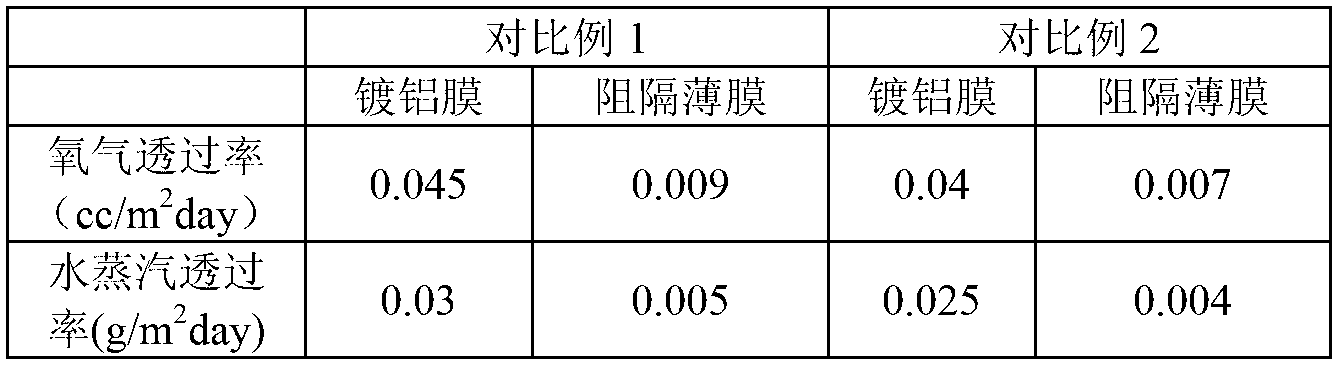

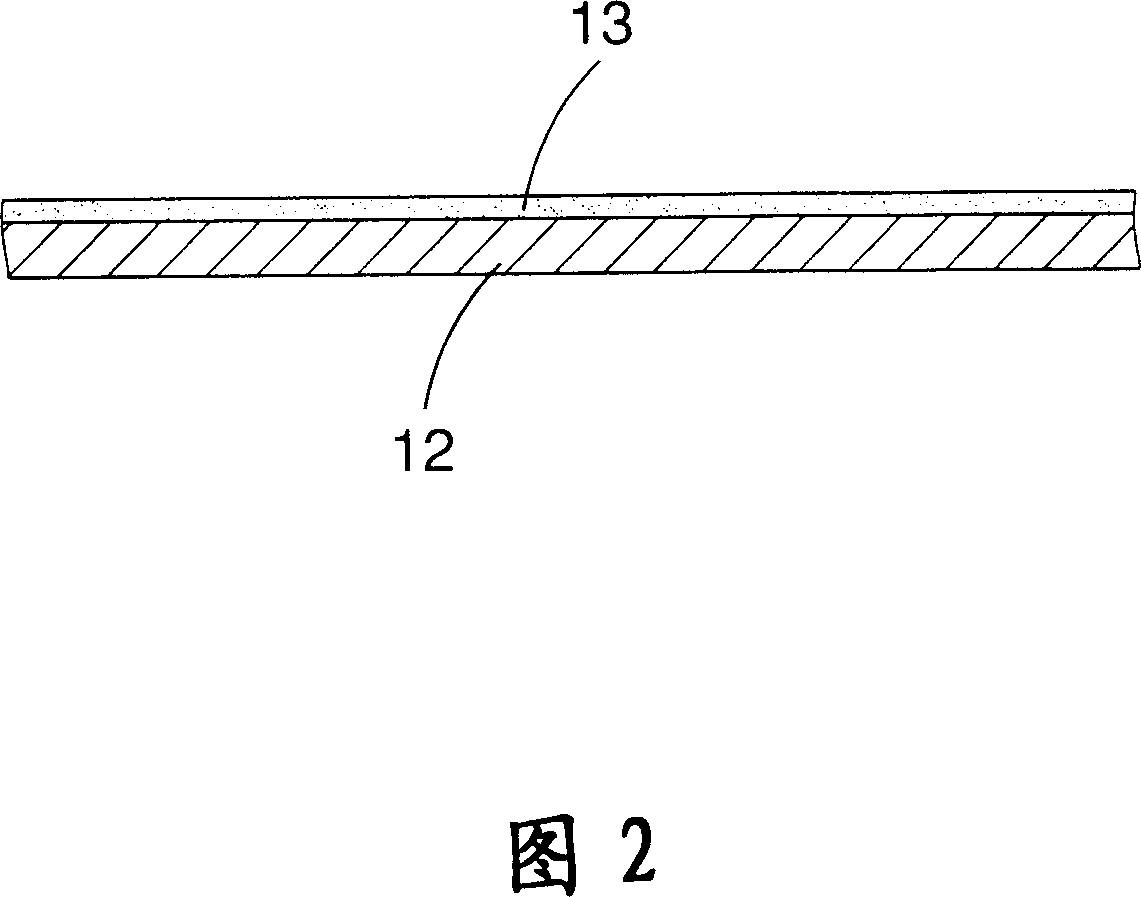

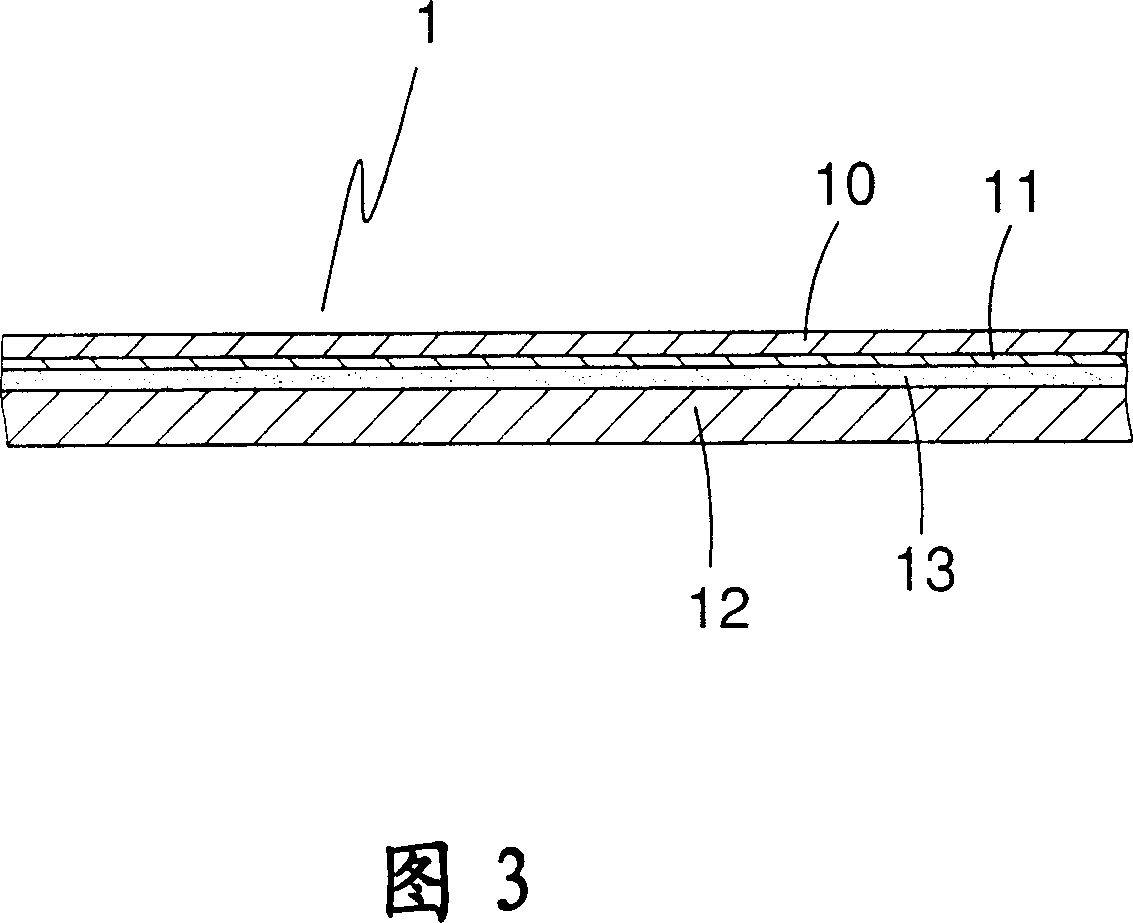

Barrier film and vacuum insulating board adopting same

ActiveCN103057212AHigh gas barrierHigh barrierVacuum evaporation coatingSputtering coatingPolyethylene terephthalateSurface layer

The invention provides a barrier film and a vacuum insulating board compounded by utilizing the barrier film. The barrier film is formed by adhering a surface layer, a gas barrier layer and a heat seal layer, wherein the gas barrier layer consists of at least one aluminum-plated polyethylene terephthalate (PET) film layer. The preparation process of the aluminum-plated PET film comprises the following of: (1) arranging a PET substrate film in an aluminum-plating chamber for performing vacuum aluminum plating, and forming an aluminum-plating layer on the surface of the PET substrate film; and (2) introducing nitrogen into the aluminum-plating chamber in stages after aluminum plating is ended, introducing the nitrogen until the nitrogen pressure is 800-1200pa at the first time, maintaining for 8-12 hours, introducing the nitrogen until the nitrogen pressure is 1300-1500pa, maintaining for at least 12 hours, and obtaining the aluminum-plated PET film. Compared with the conventional aluminum-plated film prepared by the prior art, the aluminum-plated film has the advantages that the overall barrier performance of the barrier film can be effectively improved, so that the requirements can be met in occasions with strict barrier performance requirement.

Owner:中亨新型材料科技有限公司

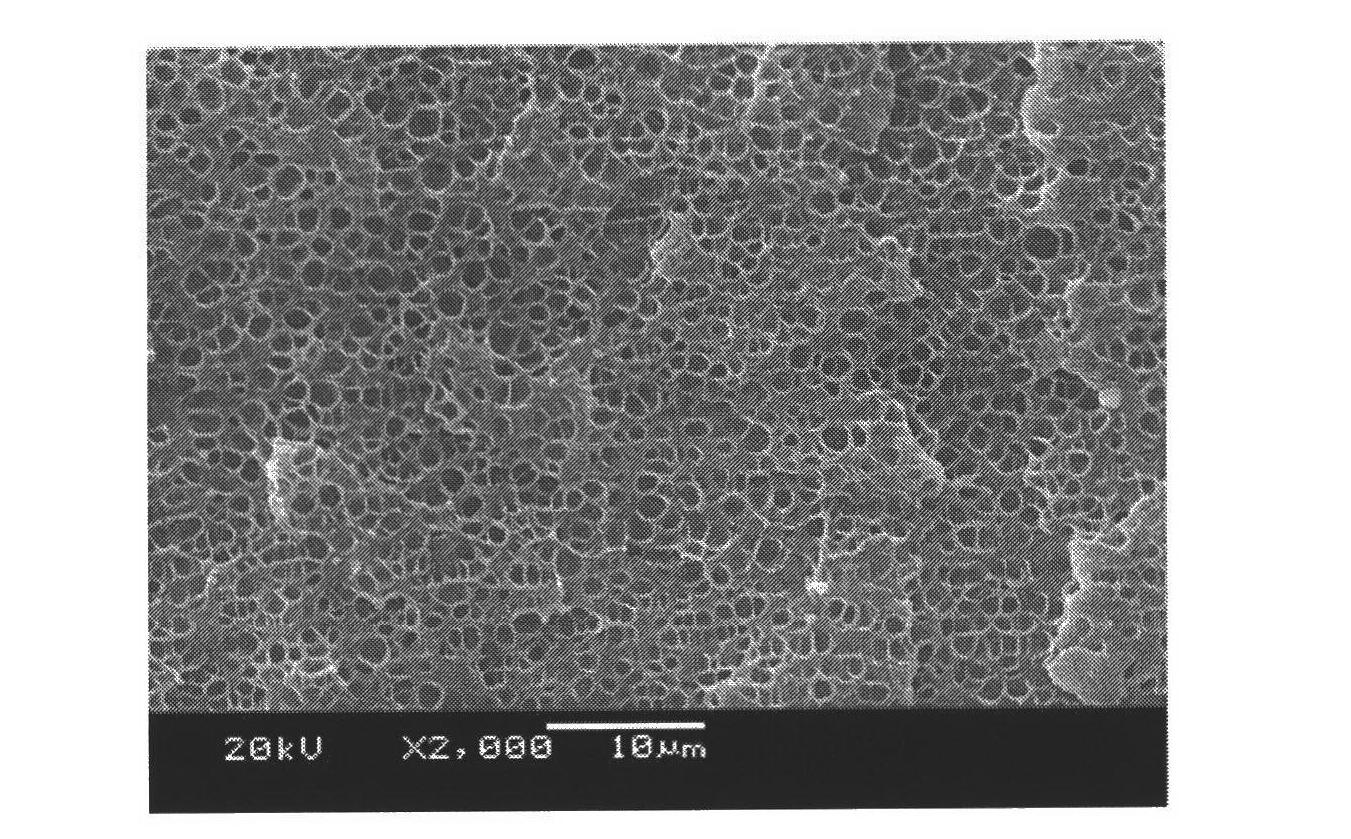

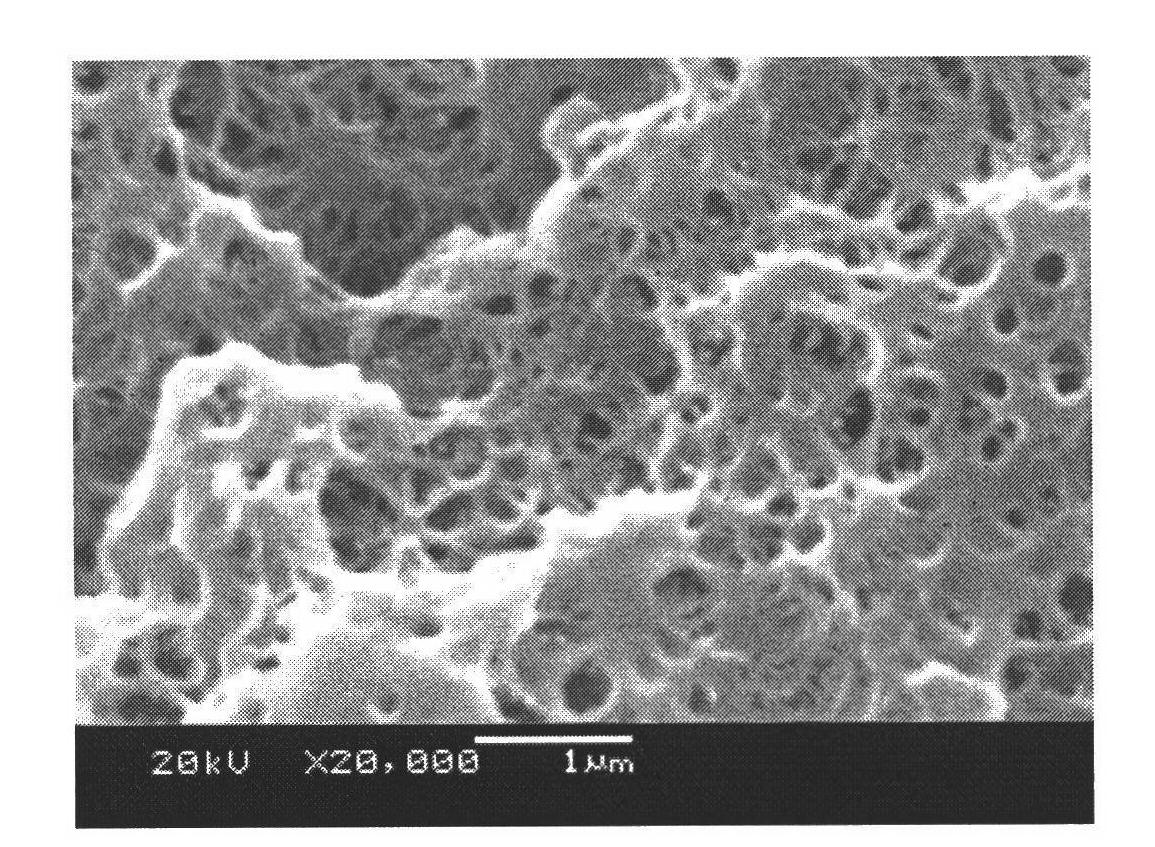

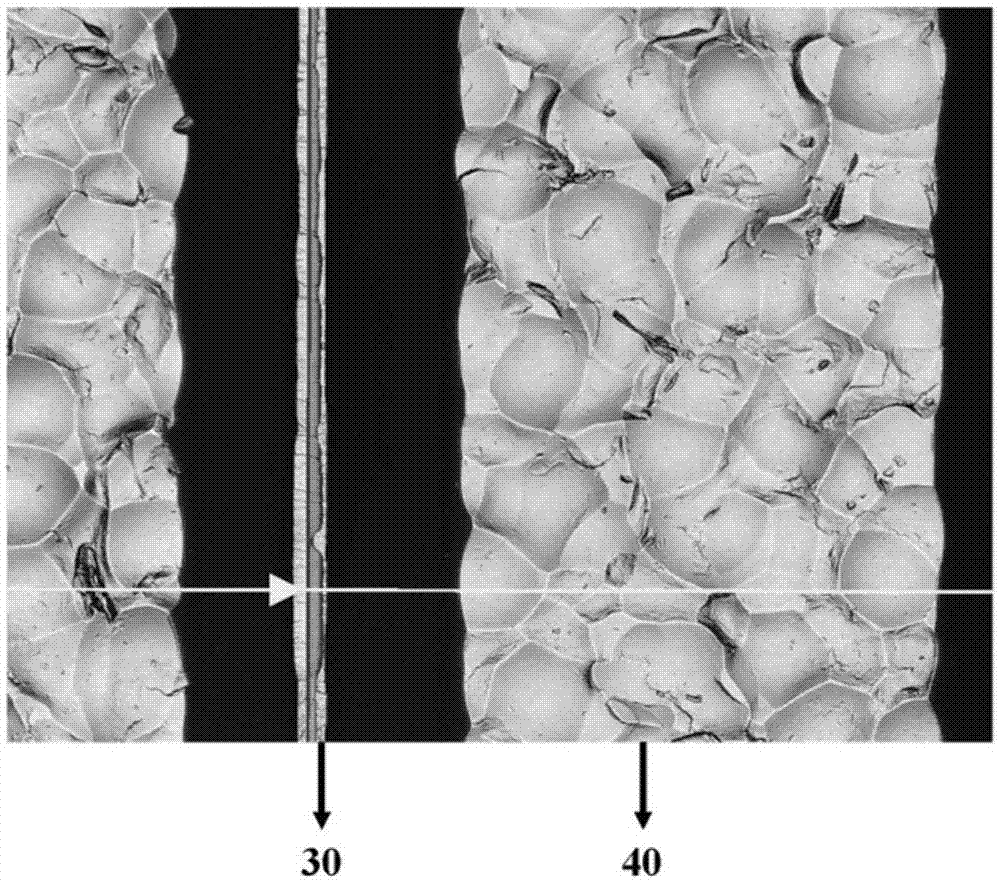

Method for preparing nano-pore structured polyethylene terephthalate (PET) foams by foaming through supercritical CO2

InactiveCN102585271AMeet the needs of developmentPolyethylene terephthalate glycolPolyethylene terephthalate

The invention aims to provide a method for preparing a polyethylene terephthalate (PET) nano-pore foaming material by inducing crystallization of PET through supercritical CO2, and aims to overcome the defect in the prior art and meet the development requirements of related fields. The PET is swelled and permeated by the supercritical CO2 at appropriate temperature, so that a large amount of CO2 can be dissolved in a PET substrate, and the crystallization of the PET can be induced when the concentration of the CO2 reaches a certain specific value; and therefore, a special crystal form and crystallinity distribution of the PET substrate are induced after the PET is swelled for appropriate time, temperature is quickly raised under the condition to make the CO2 in the PET substrate be supersaturated, and the foaming PET material with nano-aperture is obtained by nucleating and foaming.

Owner:EAST CHINA UNIV OF SCI & TECH

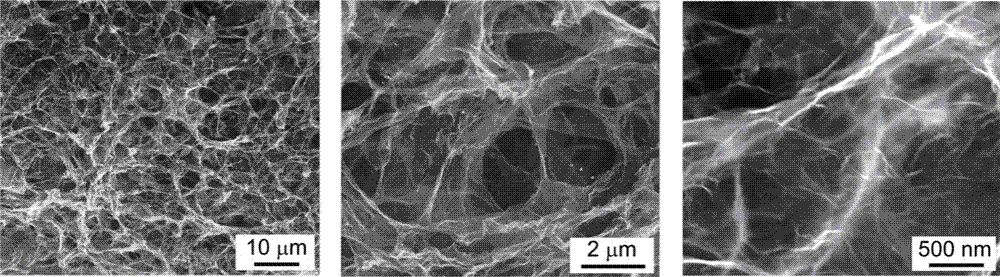

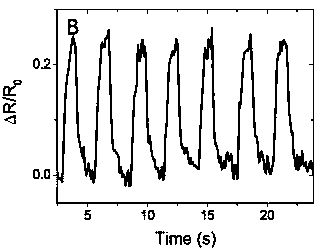

Preparation method of high-sensitivity electronic skin

InactiveCN108078543AImprove conductivityImprove mechanical propertiesDiagnostic recording/measuringSensorsPolyvinyl alcoholPet substrate

Provided is high-sensitivity electronic skin. The skin is of a sandwich structure made of polyvinyl alcohol-silver nanowires / graphene-PDMS. By means of a spraying mode, a layer of overlapped accumulational silver-nanowire conductive networks are formed on the surface of a PET substrate, and then a layer of graphene mixed by large graphene and small graphene is evenly sprayed and dispersed on thesilver-nanowire conductive networks; the graphene precipitates among the silver-nanowire networks or on the adjacent communicated silver nanowires, correspondingly the conductivity of the conductive networks is further improved, and after that, by means of a rotary coating mode, the surfaces of the conductive networks are rotatably coated with a layer of polyvinyl alcohol solution to serve as thebase body of the electronic skin; at last, after polyvinyl alcohol is dried, a composite membrane is separated from a PET membrane and transferred into a drying oven, the surface of the composite membrane is turned over, a layer of PDMS membrane is evaporated on the surface, in contact with PET, of the composite membrane, and therefore the electronic skin of the sandwich structure can be obtained.

Owner:韩金玲

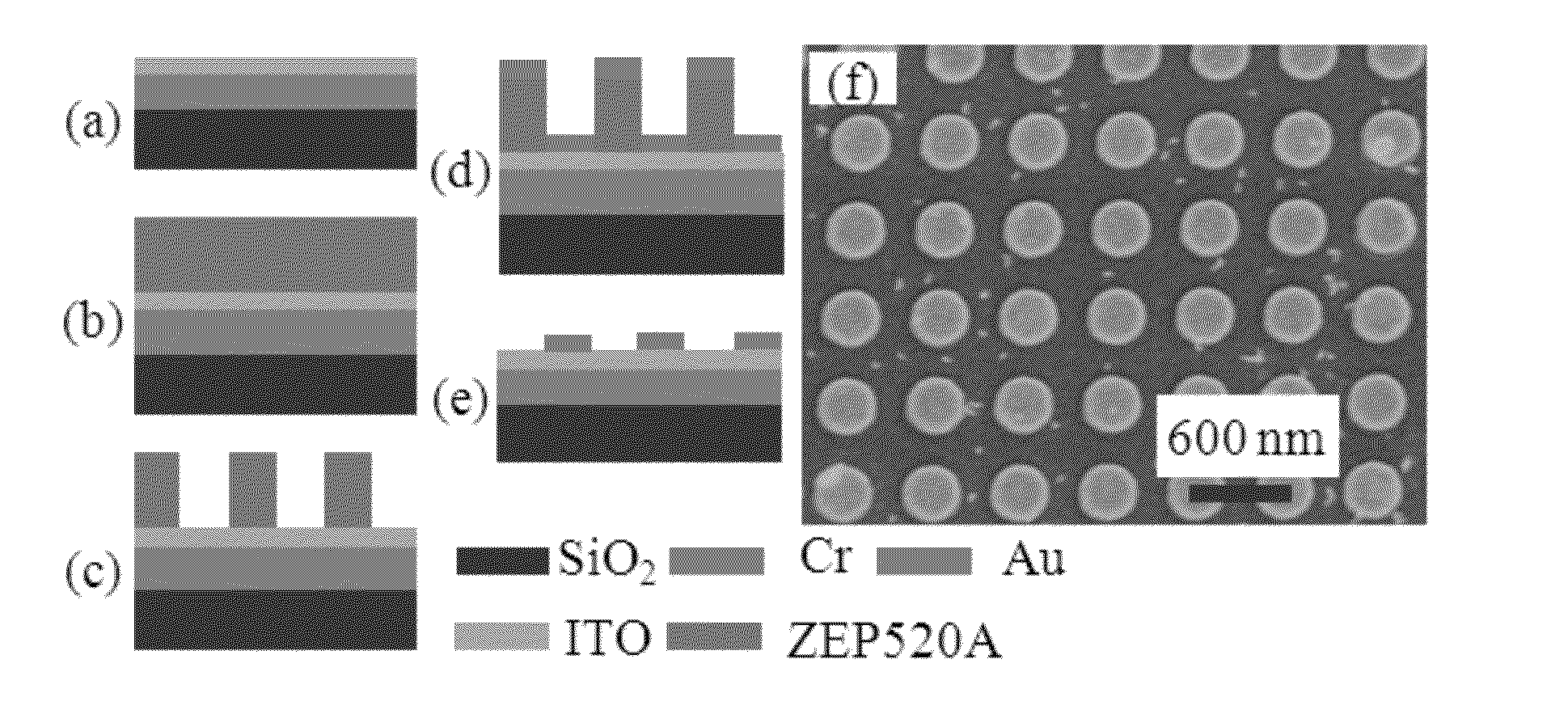

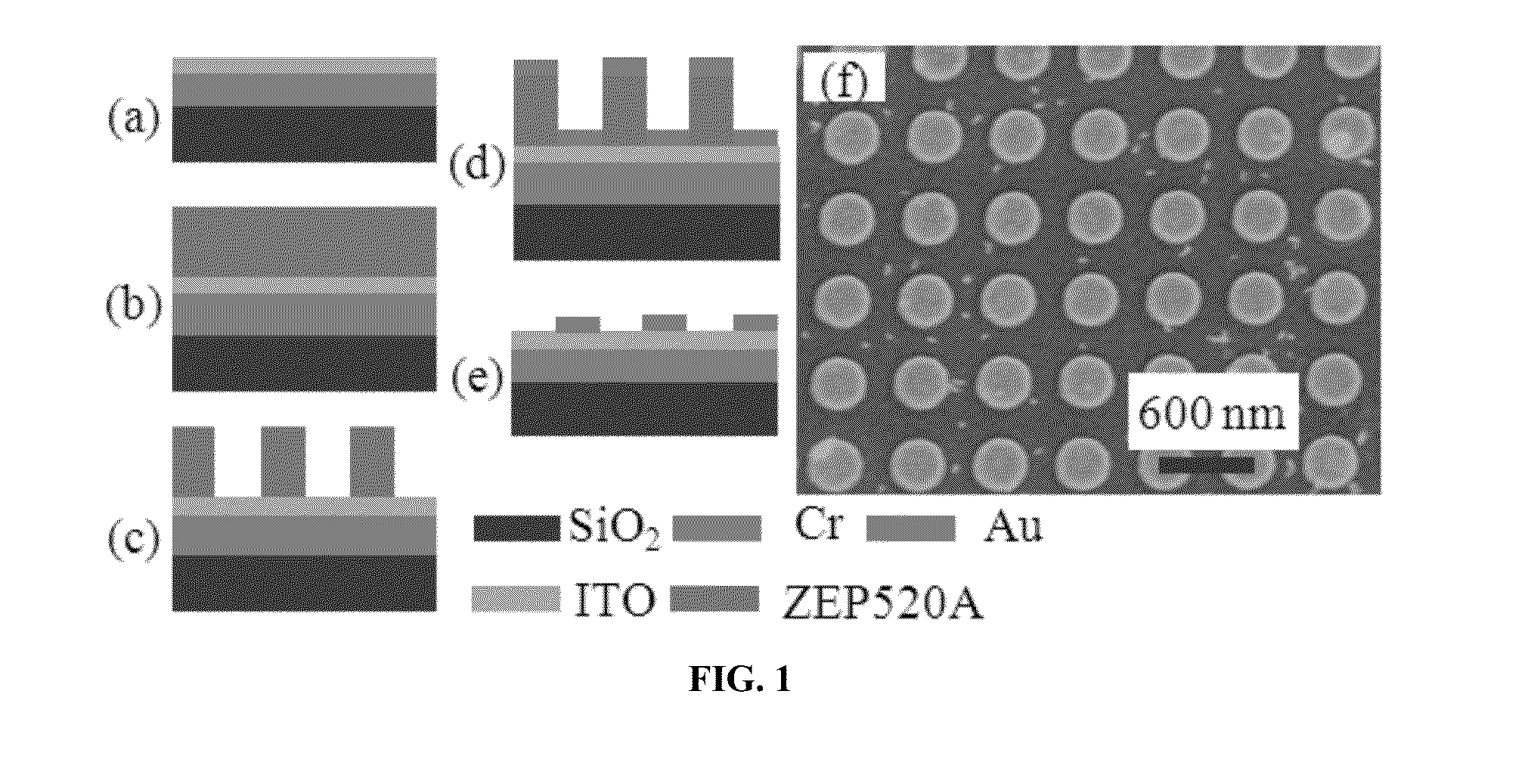

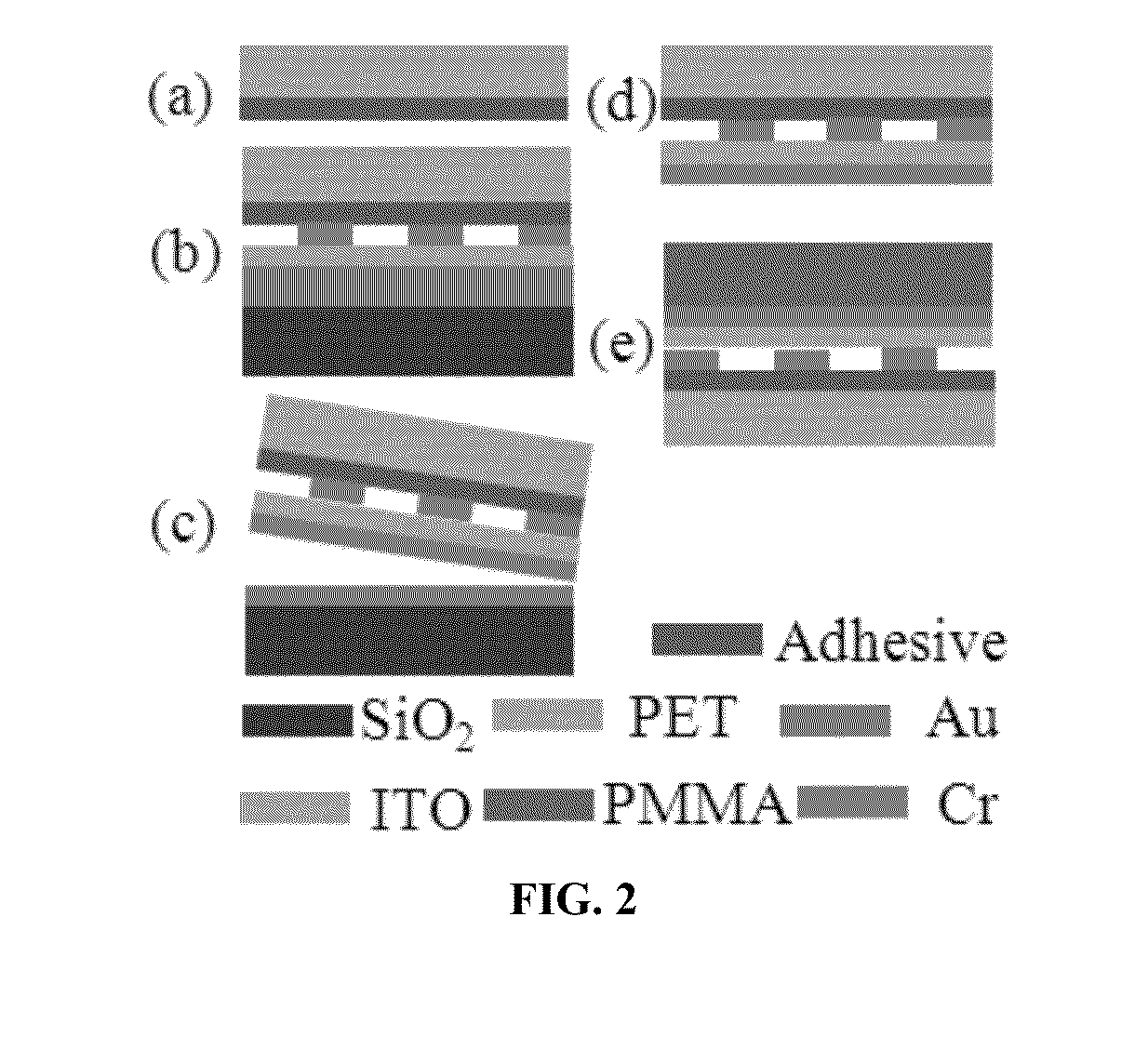

Highly Flexible Near-infrared Metamaterials

ActiveUS20130177775A1Structural alterationLamination ancillary operationsSynthetic resin layered productsPHYSICAL MANIPULATIONSEngineering

A novel multilayer flexible metamaterial that can work at near infrared (NIR) regime that can be fabricated on transparent PET substrate using flip chip transfer (FCT) technique. An embodiment of the present invention also provides novel NIR metamaterial device that can be transformed into various shapes by bending the PET substrate, wherein said metamaterial device is tunable via physical manipulation of its flexible substrate with no requirement to change the material composition of the substrate. The flexibility allows the novel NIR metamaterial device to bend and stretch, which can alter the device structure. Since the resonant frequency of each device is a function of the device structure, the resonant frequency can be tuned by the bend and stretch of the substrate. Another embodiment of the present invention further provides novel tunable sensors and emitters using such flexible metamaterials and devices.

Owner:HONG KONG BAPTIST UNIV

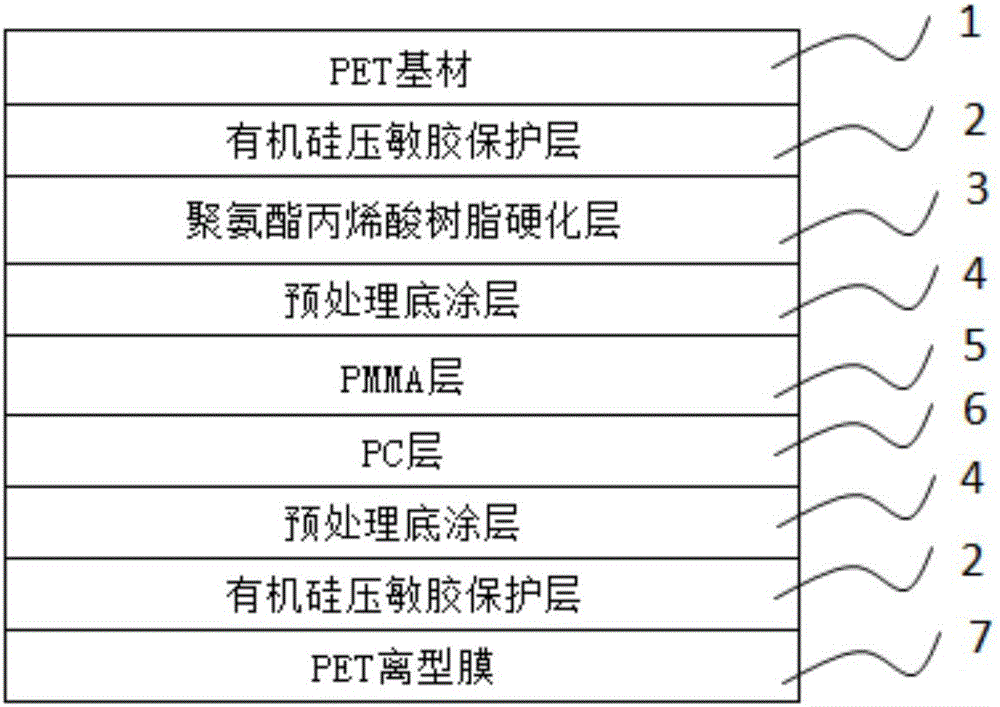

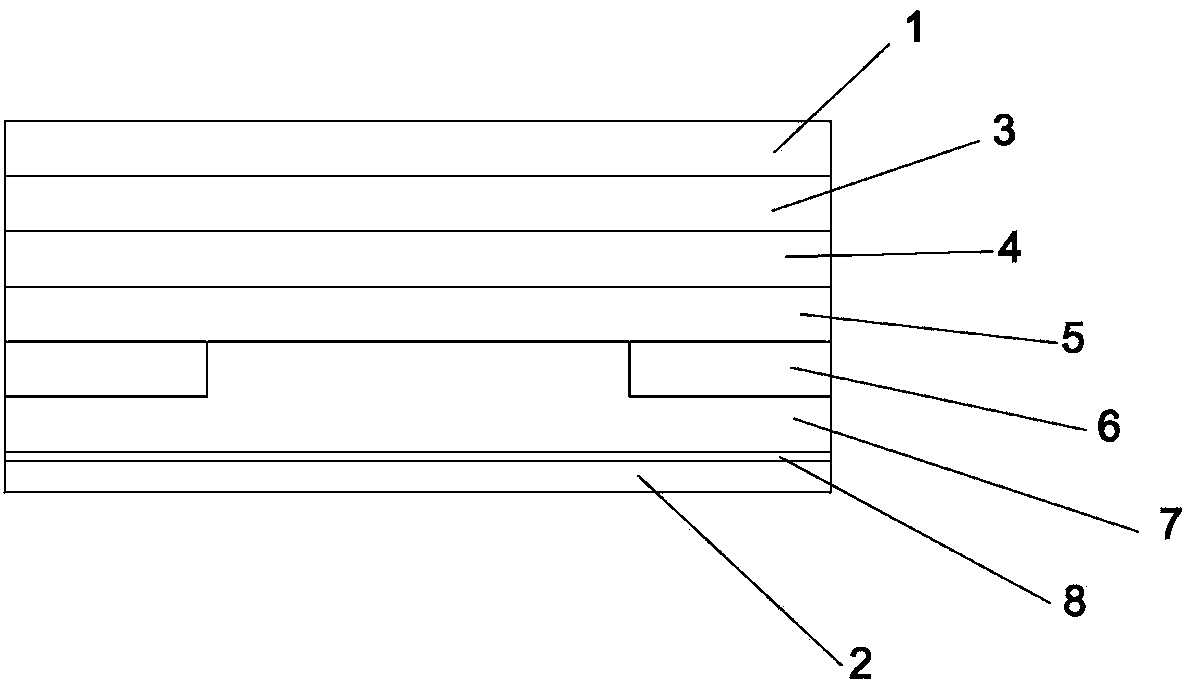

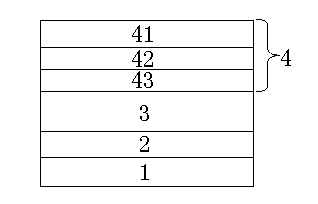

Protective film and preparation method thereof

InactiveCN106393903AHigh light transmittanceLow hazeSynthetic resin layered productsLaminationTectorial membraneAcrylic resin

The invention discloses a 2.5D protective film, which consists of a PET substrate 1, an organosilicon pressure-sensitive adhesive protective layer 2, a polyurethane acrylic resin hardened layer 3, a PMMA layer 5, a PC layer 6, an organosilicon pressure-sensitive adhesive protective layer 2 and a PET release film 7 from top to bottom in order. The contact surface of the PMMA layer 5 and the polyurethane acrylic resin hardened layer 3 is coated with a pretreatment priming coat 4, and the contact surface of the PC layer 6 and the organosilicon pressure-sensitive adhesive protective layer 2 is coated with a pretreatment priming coat 4. The invention also discloses a preparation method of the protective film. According to the invention, the good hot bending performance of PC / PMMA solves the solvent intolerance and poor adhesion problems of the PC surface, and by means of the low peel strength and high exhaust organosilicon pressure-sensitive adhesive, perfect combination of usability and high performance can be realized.

Owner:惠州市摩码菱丽光电材料有限公司

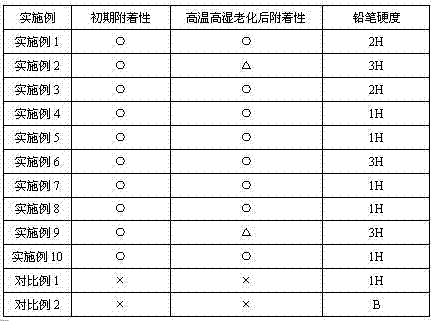

A hard coating composition and hardened film containing the hard coating composition

ActiveCN102268201AReduce internal stressImprove adhesionSynthetic resin layered productsCoatingsIndium tin oxidePet substrate

Provided are a hard coating composition and a hardened membrane containing the same. The hard coating composition comprises, by weight, 30 to 80 parts of hydroxyl-containing acrylate monomers, 1 to 10 parts of an photoinitiator, 20 to 70 parts of a solvent and 0.1 part to 5 parts of a reactive organosilicon surface wetting auxiliary agent, wherein, the hydroxyl-containing acrylate monomers are a mixture of hydroxyl-containing multi-functional acrylate monomers and hydroxyl-containing low functional acrylate monomers mixed according to a weight ratio of 2:8 to 8:2. The composition provided in the invention has excellent adhesion to a PET substrate surface which is never treated and a PET substrate surface which has corona or a failure coating bottom; hardness of the hardened layer of the obtained hardened membrane is greater than 1H, and therefore, the hardened membrane can be used as a hardened membrane of an indium tin oxide (ITO) touch screen, an in-mold label (IML), or the like.

Owner:CHINA LUCKY FILM CORP

Nano-silver flexible conductive membrane and preparation method thereof

ActiveCN103992495AStable electrical conductivity on the surface of the filmLow resistivityConductive layers on insulating-supportsPretreated surfacesCellulosePolyethylene glycol

The invention relates to the technical field of conductive membranes, particularly to a nano-silver flexible conductive membrane and a preparation method thereof. The nano-silver flexible conductive membrane comprises a PET substrate layer, wherein corona treatment is performed on the surface of the PET substrate layer; a conductive coating layer which is arranged on the surface of the PET substrate layer comprises the following raw materials in percentage by weight: 50-75% of absolute ethyl alcohol, 2-5% of terpilenol, 1-3% of acetyl tributyl citrate, 2-8% of joint cement, 1-5% of polyethylene glycol 400, 2-3% of span 85, 1.5-3% of ethyl cellulose, 3-8% of silver powder of 20-40 nanometers, and 10-18% of silver powder of 150-450 nanometers. The nano-silver flexible conductive membrane, provided by the invention, has the characteristics of stable surface conductivity of the formed film, low resistivity, high light transmittance and strong adhesive force. The preparation process of the nano-silver flexible conductive membrane is simple and mature, coating equipment is simple, the operation is convenient, the cost is low, and the nano-silver flexible conductive membrane facilitates popularization and application.

Owner:杨佳雯

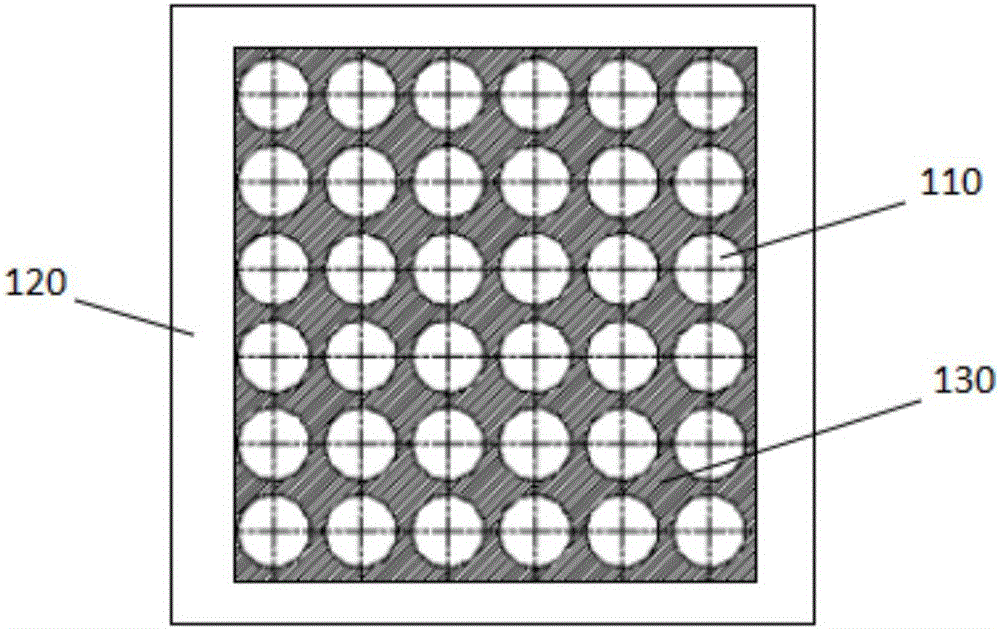

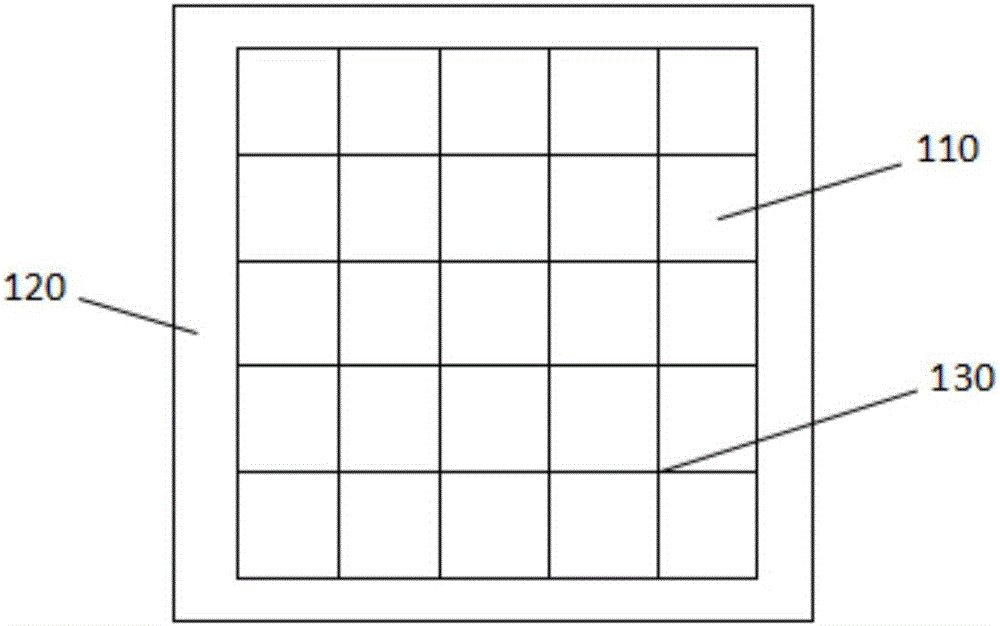

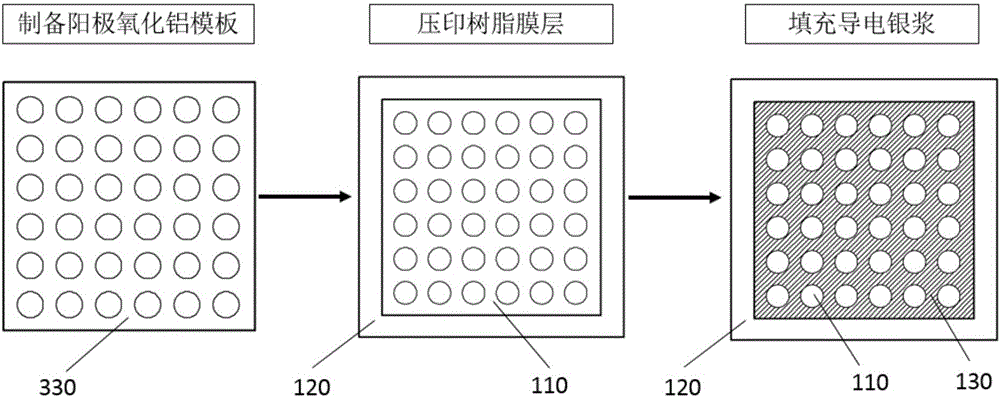

Nanometer scale flexible transparent circuit and preparation process thereof

ActiveCN105898987AImprove production efficiencyLow costConductive pattern formationMetallic pattern materialsState of artSilver paste

The invention relates to a nanometer scale flexible transparent circuit and a preparation method thereof. The nanometer scale flexible transparent circuit is composed of a PET substrate, a UV light-cured resin and nanoscale silver paste; the UV light-cured resin is laid on the PET substrate; and the nanoscale silver paste is filled in a structure gap of the UV light-cured resin. Compared with the prior art, the nanometer scale flexible transparent circuit provided by the invention is simple in structure and reasonable in design, a nano rolled template is manufactured by adopting a processing technology of anodized aluminum, so that the preparation efficiency of a resin structure is high, the cost is low, and the limit that traditional machining cannot produce a nanostructure can be broken through; besides, the nanostructure in an array arrangement can be quickly prepared, and the commercial demands of being low in cost, fast, large in area, high in resolution and high in throughput can be satisfied.

Owner:SHANGHAI JIAO TONG UNIV

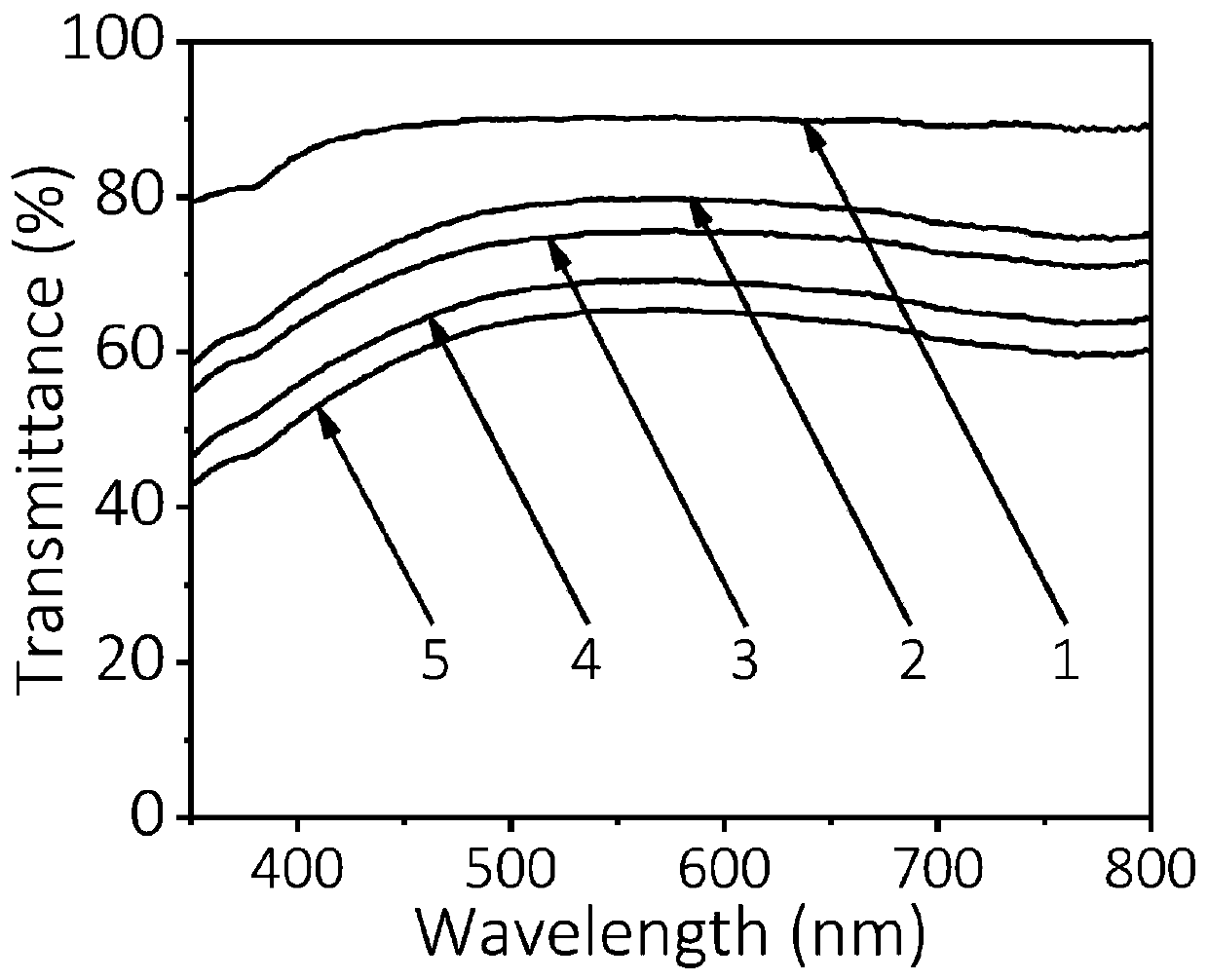

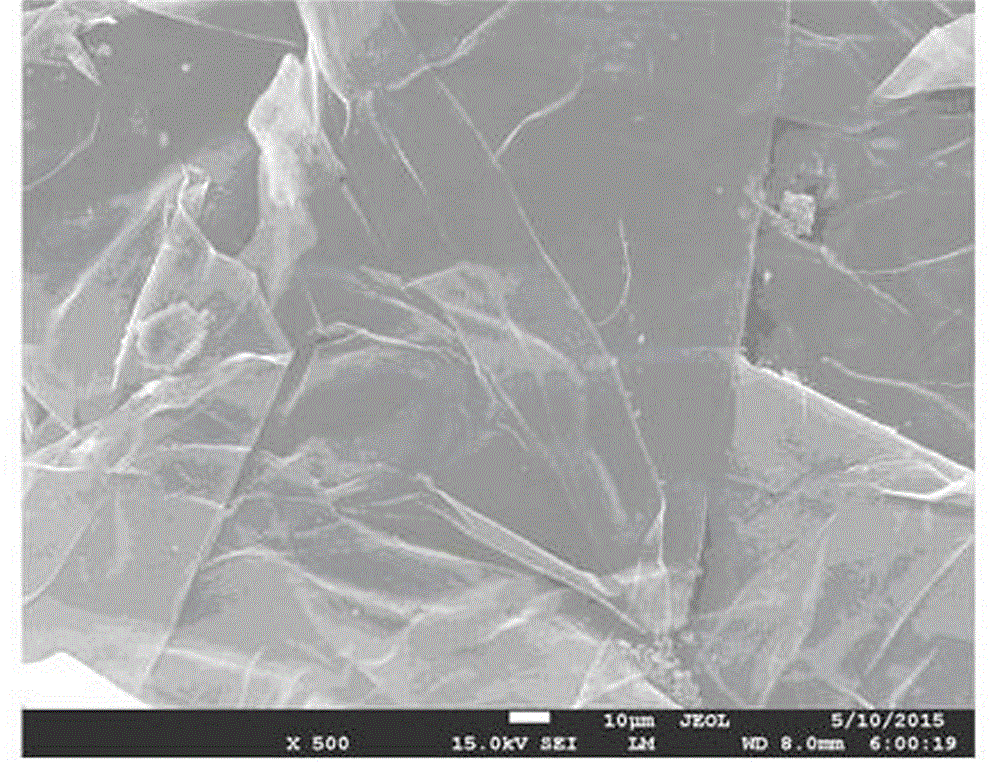

Preparation method of self-supporting PEDOT/PSS transparent conductive film

InactiveCN104934140AImprove stabilityImprove conductivityCable/conductor manufacturePolymer scienceThin membrane

The invention discloses a preparation method of a self-supporting PEDOT / PSS transparent conductive film, and belongs to the field of conducting polymer function materials. The method comprises the following steps that a PEDOT / PSS dispersion liquid is configured, and stirred uniformly in a sample bottle by magnetic force; a PET substrate which is cleaned by washing is coated with the PEDOT / PSS dispersion liquid under certain condition, and heated and dried to form a film; and the film is washed by deionized water (or formic acid) so that the film is disengaged from the PET substrate, the film is dried by heating or vacuum freezing, and the self-supporting PEDOT / PSS transparent conductive film is obtained. The method is simple in operation, and the prepared film is smooth in surface, high in light transmission and conductivity performance, and soft, and can be bent at will.

Owner:ZHENGZHOU UNIV

Multi-layered material having stereo-texture

InactiveCN1947998AAdd dimensionAvoid deformationDecorative surface effectsSynthetic resin layered productsPet substrateAluminium

A multi-layer material with concave-convex veins on its surface is composed of a surficial PET membrane with concave-convey veins formed by ironing, an aluminum layer with same concave-convex veins, an EVA resin layer for supporting the convex part of said veins, and a PET substrate.

Owner:陈福生 +2

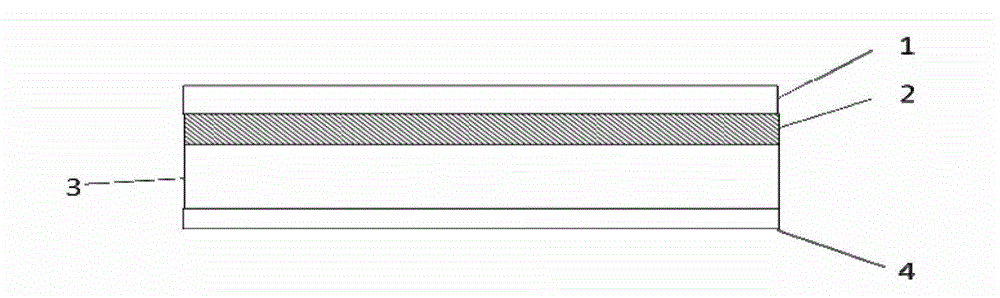

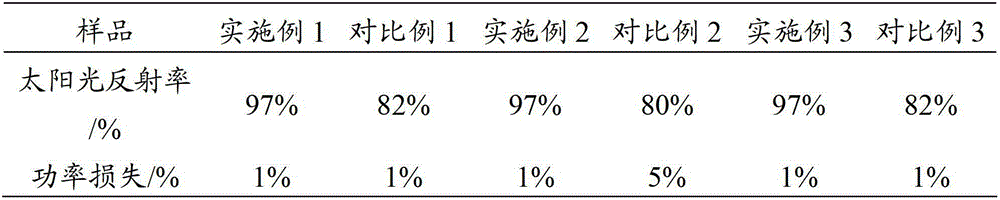

Solar battery package material and solar battery

ActiveCN102975448AAvoid degradationGood weather resistanceSynthetic resin layered productsCoatingsUltravioletEngineering

The invention provides a solar battery package material and a solar battery, wherein the solar battery package material comprises a transparent EVA (Ethylene-Vinyl Acetate) film, a white EVA film compounded on the transparent EVA film, and a back board compounded on the white EVA film; the back board comprises a PET (Poly Ethylene Terephthalate) substrate and a fluororesin-contained film composited on the PET substrate; the PET substrate is composited on the white EVA film; and the white EVA film is prepared by raw materials by weight part of: 100-200 parts of EVA resin, 0.1-3 parts of cross-linking agent, 0.1-0.5 part of antioxygen, 0.1-0.5 part of ultraviolet stabilizer and 5-30 parts of additive, wherein the additive is prepared by the components of: titanic oxides, silicon oxides, aluminous oxides or stannic oxides. The solar battery is packaged by the solar battery package material provided by the invention.

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD +1

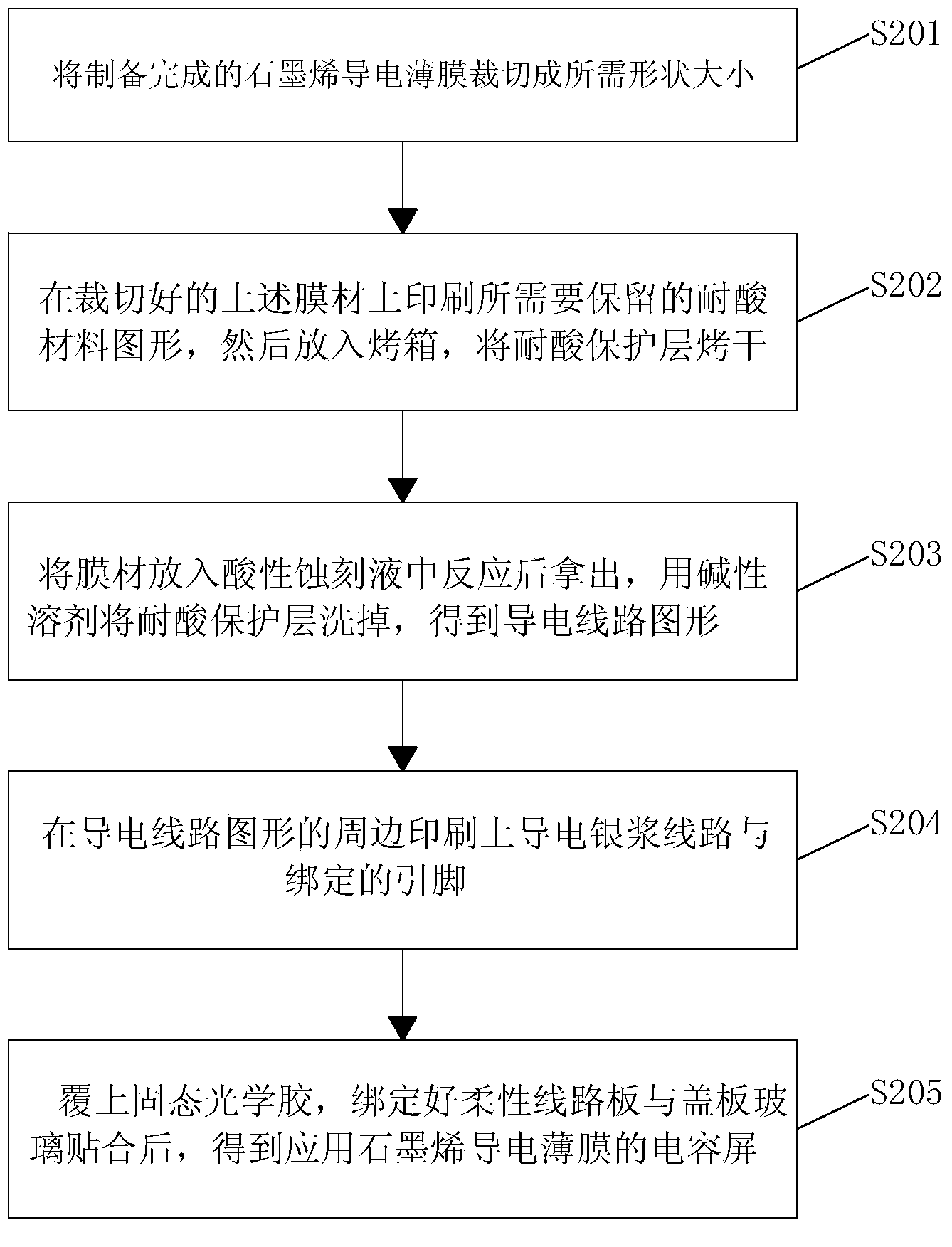

Grapheme conductive film applied capacitive screen and manufacturing method thereof

InactiveCN103455230AImprove conductivityEasy conductivityInput/output processes for data processingGlass coverGas phase

The invention discloses a grapheme conductive film applied capacitive screen and a manufacturing method thereof. The capacitive screen comprises a PET (polyethylene glycol terephthalate) substrate, a grapheme conductive film, solid-state optical cement and a glass cover. The PET substrate is bonded with the lower surface of the grapheme conductive film, and the upper surface of the grapheme conductive film is bonded with the glass cover through the solid-state optical cement. The grapheme conductive film applied capacitive screen has the advantages that the capacitive screen applied with the grapheme conductive film has excellent conductivity, permeability and the like as the grapheme conductive film with excellent conductivity, high optical permeability and durability is used for substituting for an indium tin oxide (ITO) conductive film on a capacitive screen sensor; the manner of producing the grapheme conductive film by means of chemical vapor deposition is superior to the manner of producing the ITO conductive film by means of magnetron sputtering in terms of complexity in preparation of raw materials, price, equipment input and adaptability to the market requirement.

Owner:无锡宇宁智能科技有限公司

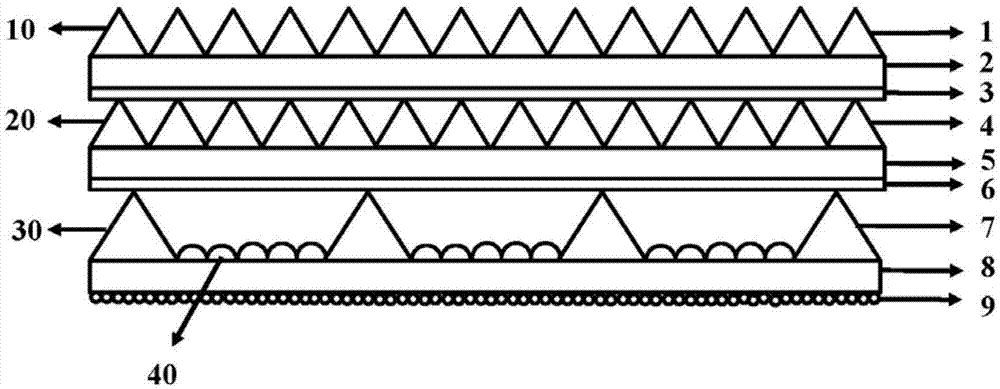

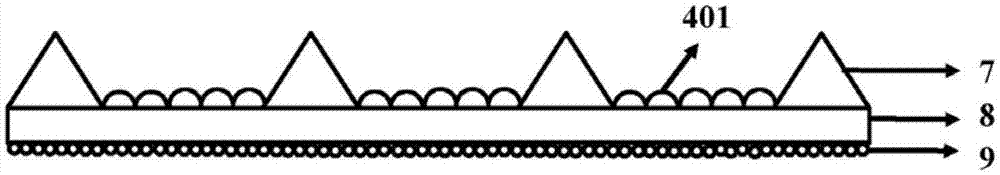

Composite brightness enhancement film and backlight module

The invention relates to the technical field of optical films, and especially relates to a composite brightness enhancement film and a backlight module to solve problems that a conventional backlight module is high in thickness and assembling procedures are complicated. The composite film sequentially comprises a first prism film, a first bonding layer, a second prism film, a second bonding layer and a third prism film. The third prism film comprises a third prism layer, a third PET substrate layer and a back coating layer. The third prism layer is formed by a plurality of third prism strips and a plurality of diffusion regions, the third prism strips and the diffusion regions being arranged alternately. The composite brightness enhancement film has brightness enhancement and diffusion effects. If the composite brightness enhancement film is assembled into the backlight module without mounting of a diffusion film, the thickness of the backlight module is reduced. The composite brightness enhancement film exhibits good luminance, uniformity and covering properties.

Owner:NINGBO CHANGYANG TECH

Method for producing high-transmittance transparent and conductive nano-silver wire film

ActiveCN108395558AGood dispersionEvenly distributedEpoxy resin coatingsElectrically-conductive paintsEpoxyOrganic solvent

The invention discloses a method for producing a high-transmittance transparent and conductive nano-silver wire film. The method comprises the following steps: S1, performing hydrophilic modificationtreatment on the surface of a high-transmittance PET substrate; and S2, uniformly coating the modified surface of the high-transmittance PET with a conductive nano-silver wire coating solution by using a scraper rod, and drying the coated high-transmittance PET to obtain the high-transmittance film with a conductive coating, wherein the conductive nano-silver wire coating solution mainly comprisesepoxy resin, a curing agent, sulfhydryl silica gel, nano-silver wires and an organic solvent, the solid content of the conductive nano-silver wire coating solution is 10-5%, the weight percentage ofthe nano-silver wires in the conductive nano-wire coating solution is 0.05-0.4%, and the weight percentage of the sulfhydryl silica gel in the conductive nano-silver wire coating solution is 0.5-4%. Asmall amount of the sulfhydryl silica gel is added to an epoxy resin solution, the coordination effect of the sulfhydryl silica gel and the silver wires is utilized to improve the dispersibility of the nano-silver wires in the solution, and the obtained conductive film product has high light transmittance, low haze and good adhesion.

Owner:JIANGYIN TONGLI OPTOELECTRONICS TECH

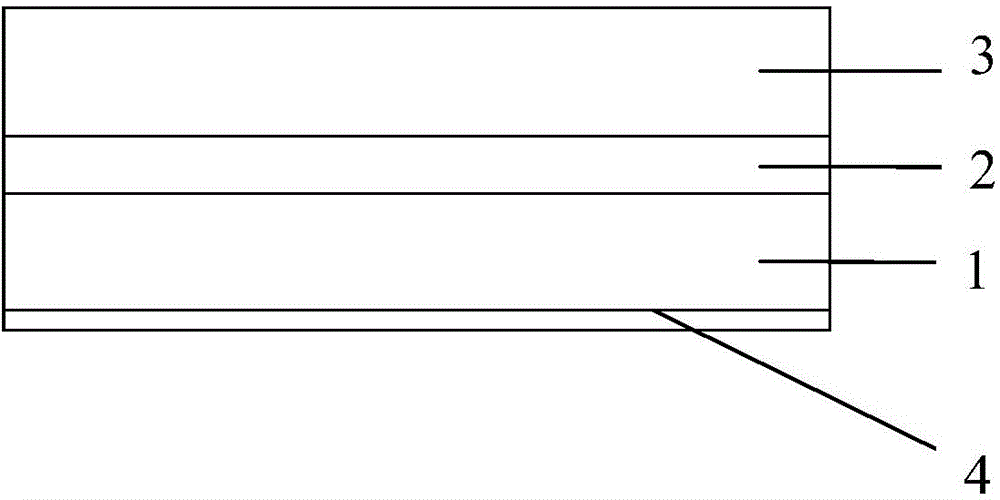

Hardened protective film and production method thereof

InactiveCN106147636AIncrease exhaustFix issues that affect normal useFilm/foil adhesivesPolyureas/polyurethane adhesivesOptical transmittanceHardness

The invention discloses a hardened protective film and a production method thereof. The hardened protective film is composed of a PET substrate, a pressure-sensitive rubber layer, a release film and a hardened layer, wherein one side of the PET substrate is a hardened treatment layer, and the other side of the PET substrate is bonded with the pressure-sensitive rubber layer through the release film. The protective film is high in surface hardness and has the advantages of being scratch-proof, excellent in abrasion resistance and the like. In addition, the protective film is high in light transmittance and excellent in exhausting property and weatherability and does not cause pollution to an adhered object.

Owner:上海精珅新材料有限公司

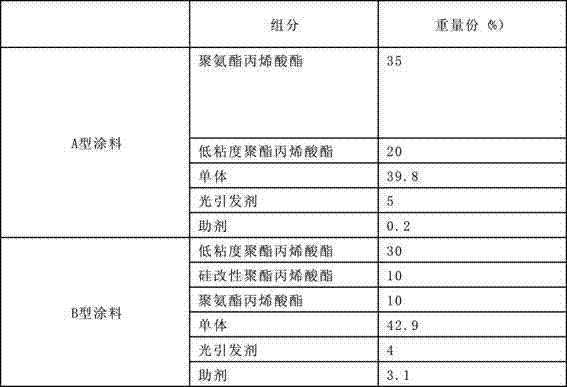

UV curing coating for make-up copying of holographic patterns and use method of UV curing coating

ActiveCN103319994AClear holographic textureSeamlessPolyurea/polyurethane coatingsForme preparationPolyesterUV curing

The invention relates to a UV coating for UV make-up copying of holographic patterns and a use method of the UV coating. The UV coating comprises a B-type coating and an A-type coating. The B-type coating comprises low-viscosity polyester acrylate, silicone-modified polyester acrylate, a polyurethane acrylate, monomers, auxiliaries and photoinitiators. The A-type coating comprises a polyurethane acrylate, the low-viscosity polyester acrylate, the monomers, auxiliaries and the photoinitiators. The B-type coating is added drop by drop between a holographic nickel plate and a transparent PET substrate, then a transparent holographic film plate is obtained by processing; then the A-type coating is added drop by drop between the transparent holographic film plate and the transparent PET substrate, a transparent holographic plate is copied out by processing; a transparent holographic large plate is obtained through repeated operation; a broad-width holographic dedicated mother plate is obtained through metallization processing on a coating curing layer of the transparent holographic large plate. The UV coating has a good adhesion on the plastic substrate, a bad adhesion on the holographic nickel plate, scratch resistance, and a good solvent resistance, and is benefit for completely copying and transferring of holographic patterns on the nickel plates.

Owner:湖北华工图像技术开发有限公司

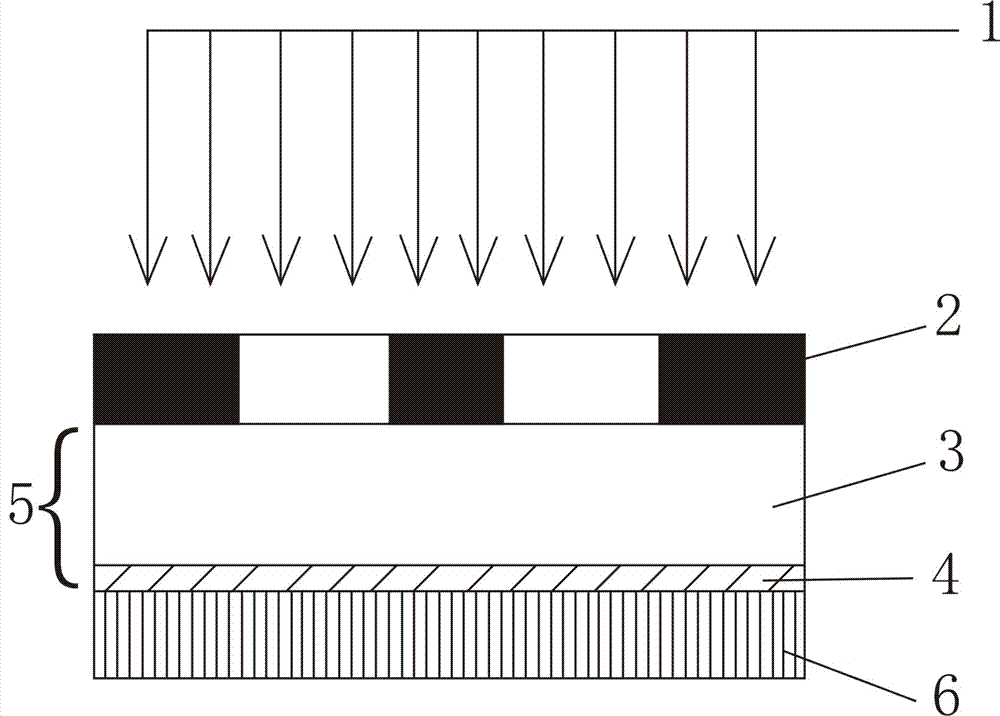

OGS touch screen and manufacturing method thereof

InactiveCN103645817AAvoid breakingHigh hardnessInput/output processes for data processingUltravioletEngineering

The invention discloses an OGS touch screen and a manufacturing method of the OGS touch screen. The OGS touch screen comprises an upper protective layer and a lower protective layer. A glass layer, an optical glue layer, an optical-level PET layer, multiple ink layers and a printing face whole-face-plated transparent conductive layer are sequentially arranged between the upper protective layer and the lower protective layer from top to bottom. The printing face of the whole-face-plated transparent conductive layer is coated with a photoresistance layer. According to the OGS touch screen, the tempered glass layer and an optical-level PET substrate are adopted, the glass layer and the optical-level PET layer adhere to each other through the optical glue layer, the ink layers are printed on the printing face of the optical-level PET layer, and the outer surface of the glass layer and the outer surface of the printing face whole-face-plated transparent conductive layer are respectively provided with a protective film so that the whole product can be protected; the surface of the printing face whole-face-plated transparent conductive layer is coated with the photoresistance layer so that the photoresist surfaces are irradiated by ultraviolet rays through the films and a conductive layer circuit can be formed on the printing face whole-face-plated transparent conductive layer.

Owner:金振平 +2

Three-layer scratch-resistant PET (polyethylene terephthalate) protective film

InactiveCN103171183AEffective protectionNot easy to bruiseSynthetic resin layered productsPolyethylene terephthalateTransmittance

The invention discloses a three-layer scratch-resistant PET (polyethylene terephthalate) protective film. The protective film comprises a PET release film, a PET substrate and a PET protective film, wherein the hardening treatment surface of the PET substrate is fit with the PET protective film; the non-hardening treatment surface of the PET substrate is fit with the PET release film via a glue layer; the PET protective film comprises a PET protective film substrate, a PET protective film glue layer and a scratch-resistant coating, which are fit in sequence; and the scratch-resistant coating is fit with the hardening treatment surface of the PET substrate. The protective film has the beneficial effects that the protective film has the functions of automatic adsorption and automatic exhaust, can eliminate bubbles, has low viscosity, is easy to strip, can be repeatedly pasted without affecting the use effect, has durable and stable performances, has ultrahigh light transmittance and surface hardness and a good touch effect, can effectively protect screens and is not easy to bump, scratch and pollute.

Owner:KUNSHAN HANBAO TAPE TECH

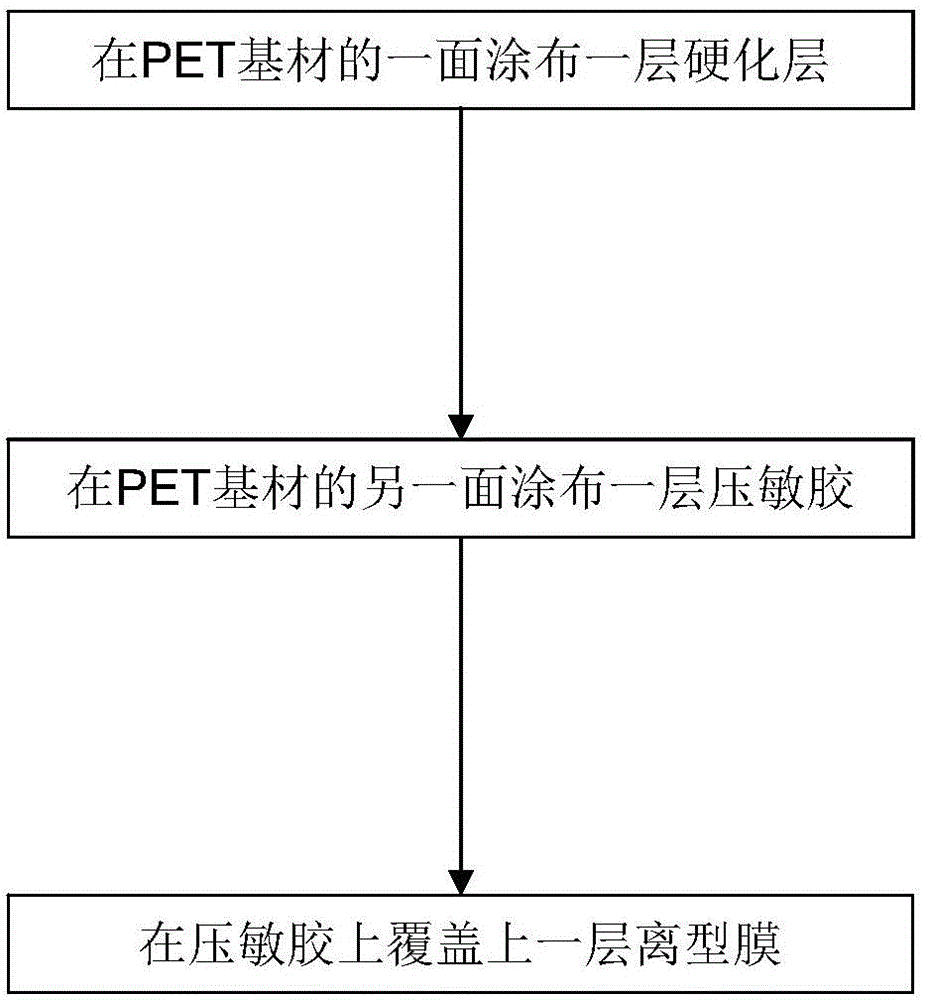

PET (Polyethylene Terephthalate) protection film for cover plate glass manufacturing procedure or delivery process and preparation method thereof

ActiveCN108864977ASolve the problem of energy consumptionSmall peeling forceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesTectorial membranePolyethylene terephthalate

The invention discloses a PET (Polyethylene Terephthalate) protection film for a cover plate glass manufacturing procedure or a delivery process and a preparation method thereof. The PET protection film comprises an optical-grade PET substrate layer, a solvent-free UV-curing low-stripping-force antistatic pressure sensitive adhesive layer and a non-silicon release film layer; the preparation method of the PET protection film comprises the following steps: 1) preparing a solvent-free UV-curing low-stripping-force antistatic pressure sensitive adhesive; 2) coating the optical-grade PET substratelayer with the solvent-free UV-curing low-stripping-force antistatic pressure sensitive adhesive; 3) carrying out UV illumination curing and laminating a non-silicon release film. According to the PET protection film disclosed by the invention, the utilized UV-curing low-stripping-force antistatic pressure sensitive adhesive has extremely excellent cohesive strength and has relatively good instant adhering performance on cover plate glass. When the protection film is used for the cover plate glass manufacturing procedure or the delivery process, the stripping force is stable, no residual adhesive is formed and no pollution is caused; meanwhile, the protection film has relatively small influences on surface tension on a glass surface, and the secondary printing performance and OCA (OpticalClear Adhesive) adhesive adhering performance are not influenced.

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

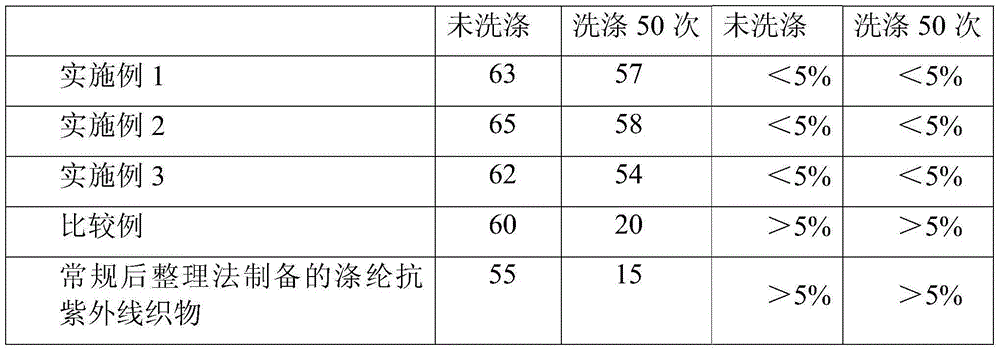

Anti-ultraviolet polyester fibers and preparation method thereof

InactiveCN105088389ASolve the problem of uniform distribution of small particle sizeSimple methodMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterUltraviolet

The invention belongs to the field of textiles, and in particular relates to anti-ultraviolet polyester fibers. The anti-ultraviolet polyester fibers are prepared by melt-spinning the following materials in parts by weight: 100 parts of PET chips and 1-5 parts of anti-ultraviolet polyester master batches, wherein the anti-ultraviolet polyester master batches are prepared by melt-blending and extruding the PET chips, and 2-5% of pre-treated nano-ceramic powder, 1-3% of an anti-oxidant, 0.5-2% of a lubricating agent and 0.4-3% of a dispersant based on the weight of the PET chips; and the pre-treated nano-ceramic powder is obtained by coating the nano-ceramic powder with a hydroxypropyl-beta-cyclodextrin solution. According to the anti-ultraviolet polyester fibers and the preparation method thereof, the problem about uniform distribution of small-particle nano-ceramic powder in a PET substrate is solved; high-efficiency and long-lasting anti-ultraviolet polyester fibers are prepared by melt-spinning; and the method disclosed by the invention is simple and feasible, and is applicable to industrial popularization and use.

Owner:俞尧芳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com