Preparation method of high-sensitivity electronic skin

An electronic skin and high-sensitivity technology, which is applied in the field of preparation of high-sensitivity electronic skin, can solve the problems of high cost and complicated electronic skin process, and achieve the effect of good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

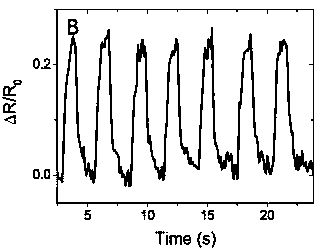

Image

Examples

Embodiment 1

[0015] First prepare a high-quality silver nanowire ethanol solution with a concentration of 0.01mg / ml, fix a piece of high-temperature-resistant PET film on a heating table, use a spray gun to spray a layer of silver nanowire conductive network on the PET surface, and then prepare a concentration of 0.01mg / ml of a mixed solution of large and small pieces of graphene, the graphene is also deposited on the surface of the above-mentioned silver nanowire conductive network by spraying, to obtain a silver nanowire conductive layer evenly covered by graphene, and then, using the method of spin coating, A layer of polyvinyl alcohol polymer is spin-coated on the surface of the above-mentioned conductive layer. After the polymer is dried, use tweezers to separate the conductive structure from the PET film from the PET surface. After coating a layer of PDMS and cooling to room temperature, a sandwich-structured electronic skin can be obtained.

Embodiment 2

[0017] First prepare a high-quality silver nanowire ethanol solution with a concentration of 0.2mg / ml, fix a piece of high-temperature-resistant PET film on a heating table, use a spray gun to spray a layer of silver nanowire conductive network on the PET surface, and then prepare a concentration of 0.05mg / ml of a mixed solution of large and small pieces of graphene, the graphene is also deposited on the surface of the above-mentioned silver nanowire conductive network by spraying, to obtain a silver nanowire conductive layer evenly covered by graphene, and then, using the method of spin coating, A layer of polyvinyl alcohol polymer is spin-coated on the surface of the above-mentioned conductive layer. After the polymer is dried, use tweezers to separate the conductive structure from the PET film from the PET surface. After coating a layer of PDMS and cooling to room temperature, a sandwich-structured electronic skin can be obtained.

Embodiment 3

[0019] First prepare a high-quality silver nanowire ethanol solution with a concentration of 0.5mg / ml, fix a piece of high-temperature-resistant PET film on a heating table, use a spray gun to spray a layer of silver nanowire conductive network on the PET surface, and then prepare a concentration of 0.1mg / ml of a mixed solution of large and small pieces of graphene, the graphene is also deposited on the surface of the above-mentioned silver nanowire conductive network by spraying, to obtain a silver nanowire conductive layer evenly covered by graphene, and then, using the method of spin coating, A layer of polyvinyl alcohol polymer is spin-coated on the surface of the above-mentioned conductive layer. After the polymer is dried, use tweezers to separate the conductive structure from the PET film from the PET surface. After coating a layer of PDMS and cooling to room temperature, a sandwich-structured electronic skin can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com