Patents

Literature

29939 results about "Polyvinyl alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This medication is used to relieve dry, irritated eyes.

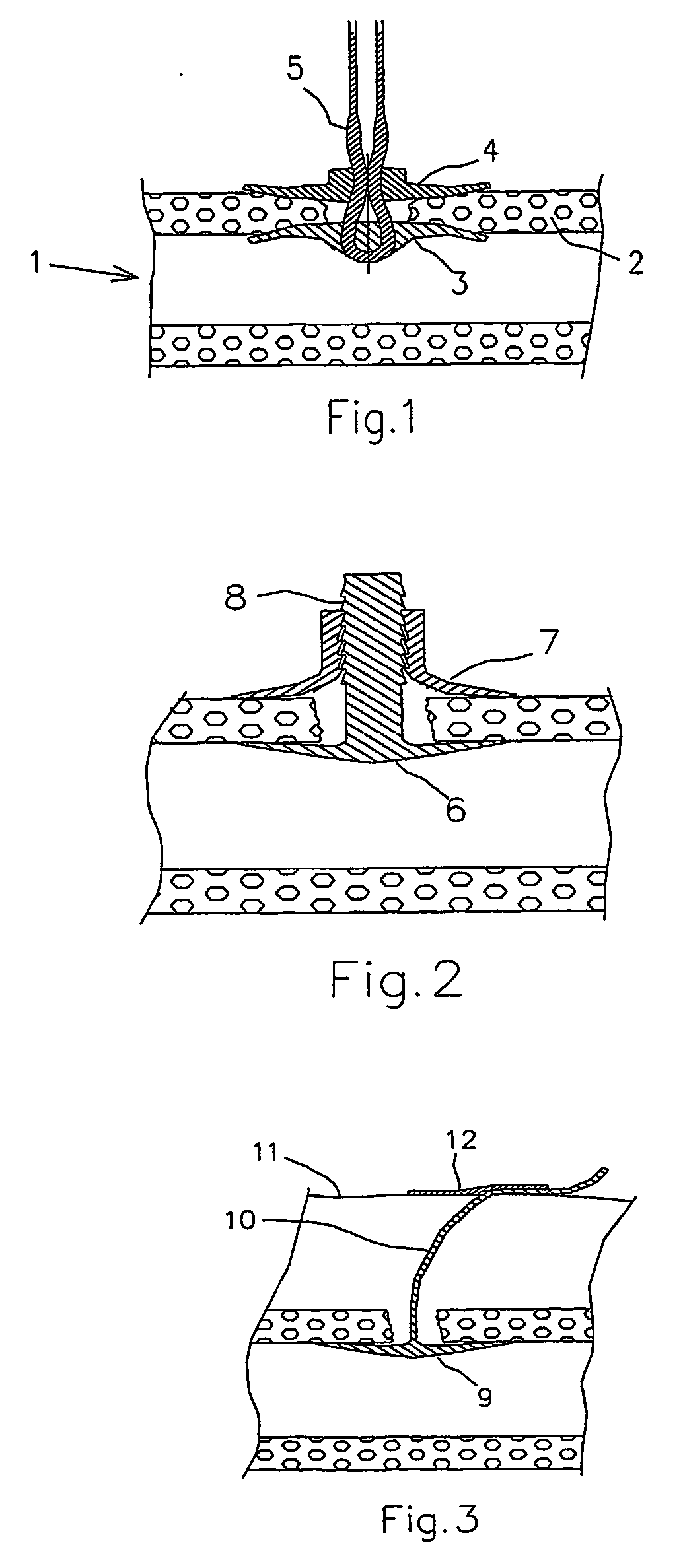

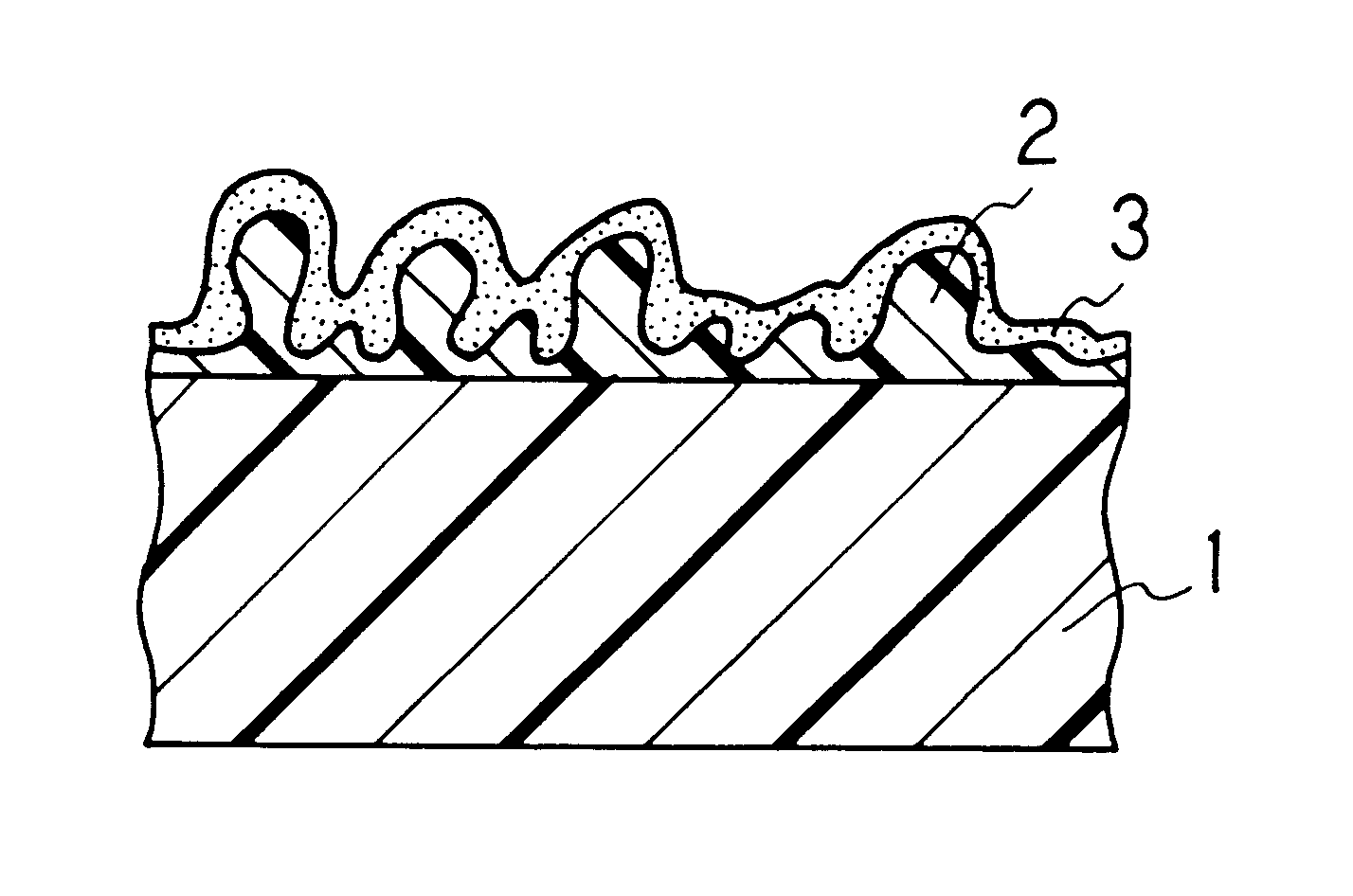

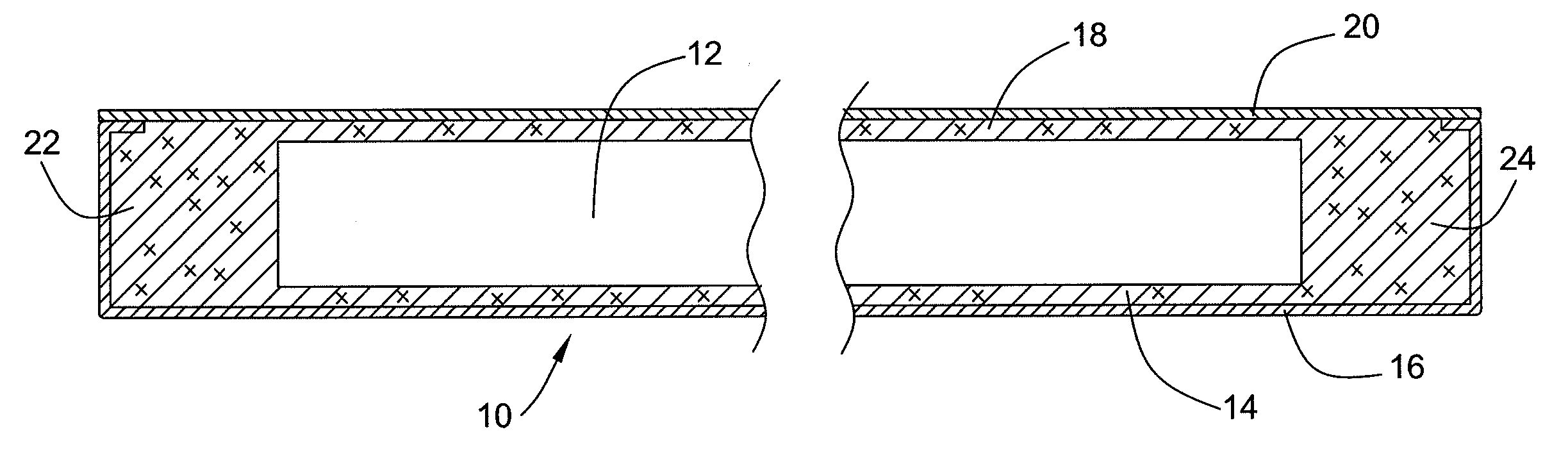

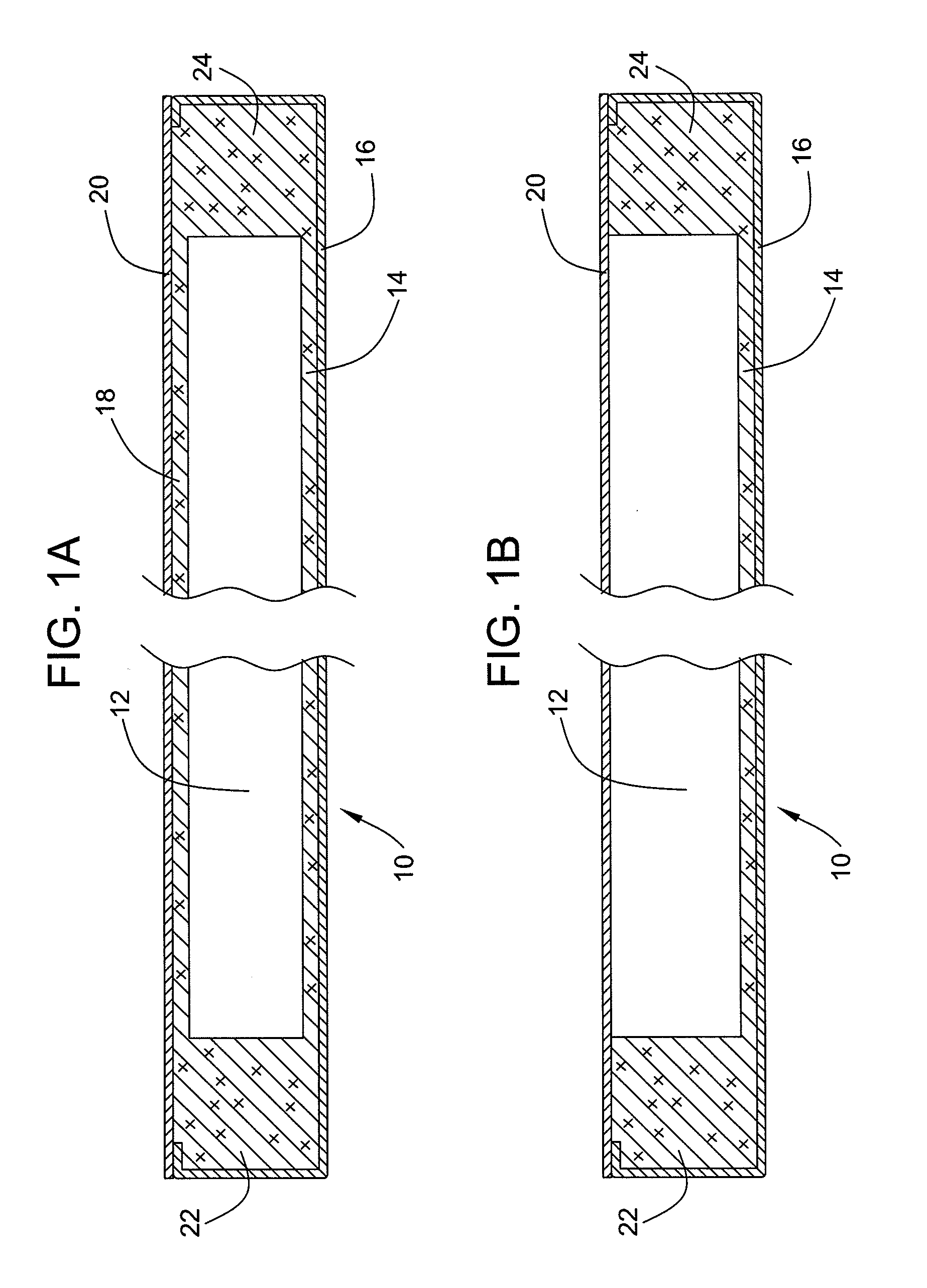

Dissolvable medical sealing device

ActiveUS20050169974A1Shorten the timeSuture equipmentsPharmaceutical delivery mechanismOrganismal ProcessPolyvinyl alcohol

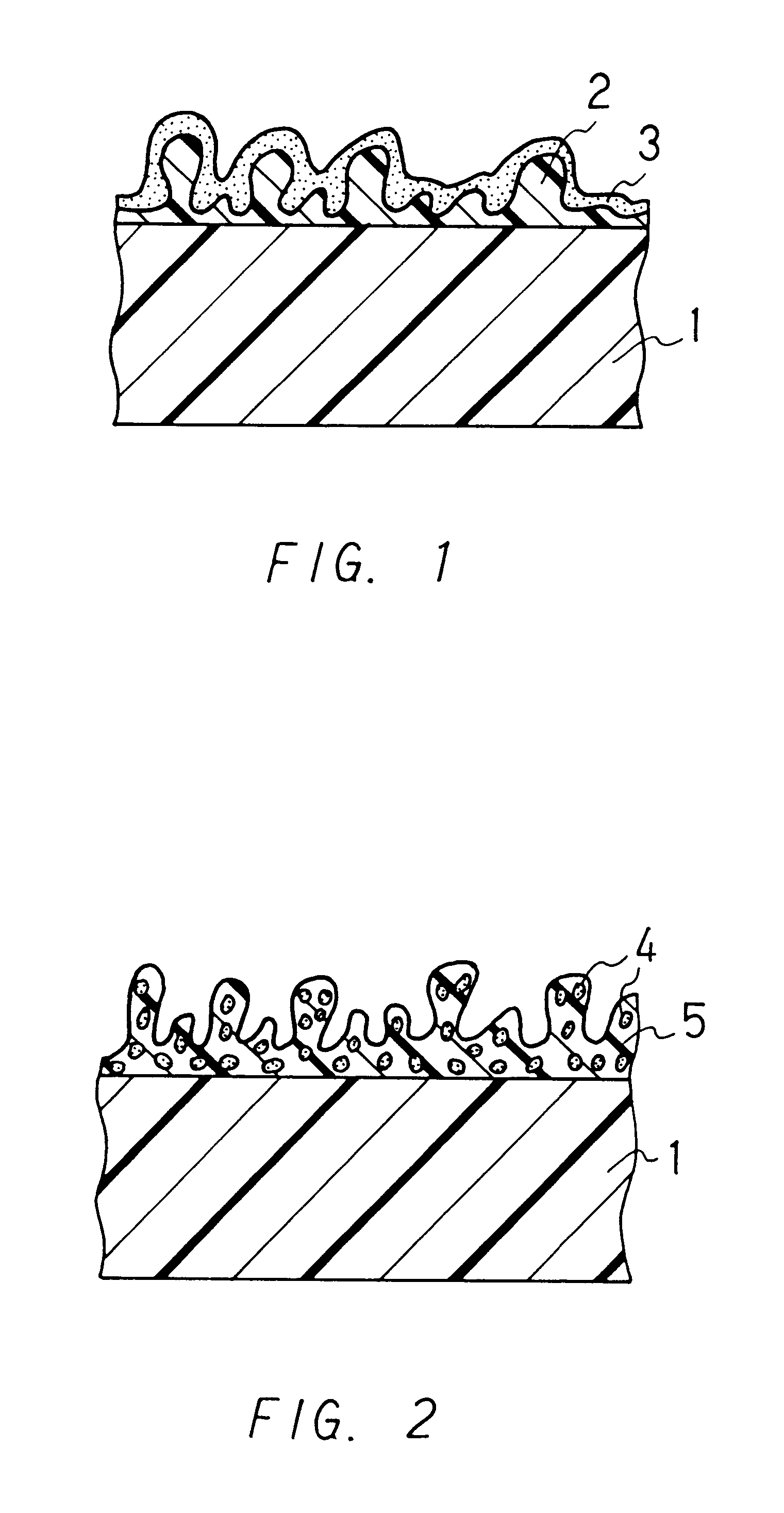

The present invention provides a dissolvable medical sealing device (3, 4; 6, 7; 9) for closing a wound in vessel. A sealing device (3, 4, 6, 7, 9) according to the invention is made of a material that dissolves by means of physical processes, rather than by means of chemical or biological processes. Such a sealing device (3, 4; 6, 7; 9) can be made of polyethylene glycol, polypropylene glycol, copolymers containing ethylene glycol and propylene glycol, polyvinyl alcohol or polyvinyl pyrolidone, or any combinations thereof.

Owner:TERUMO MEDICAL CORP

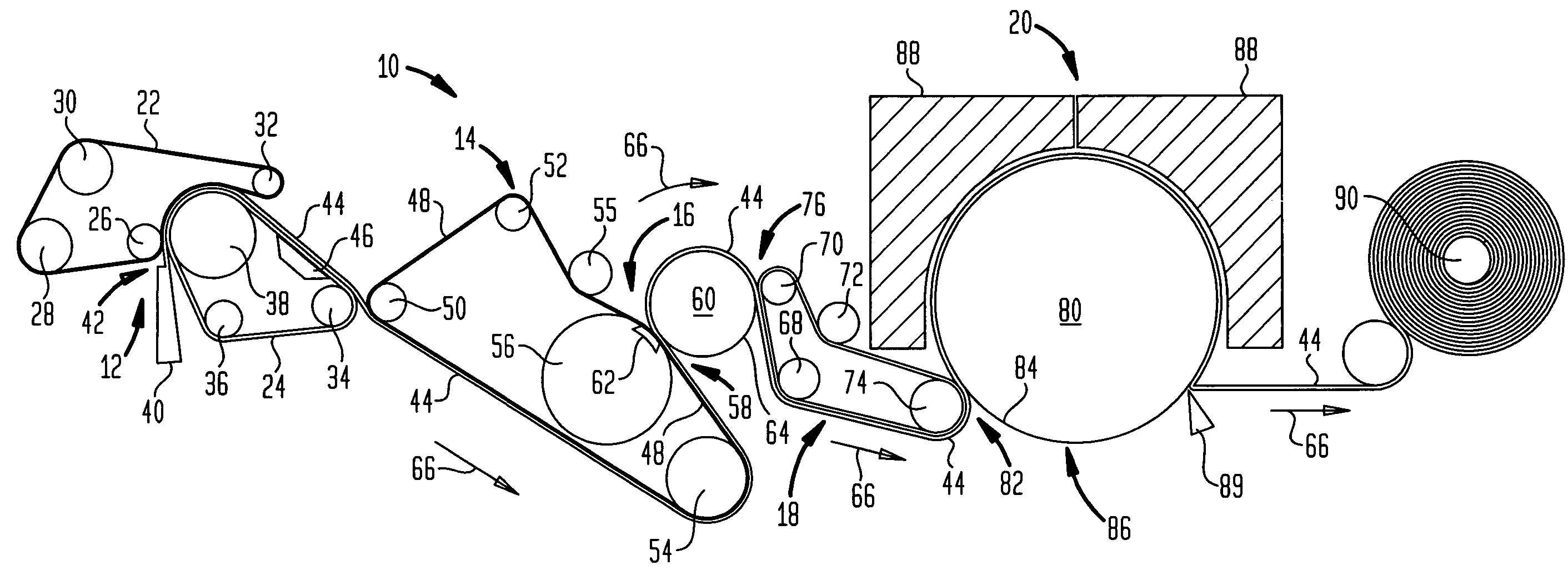

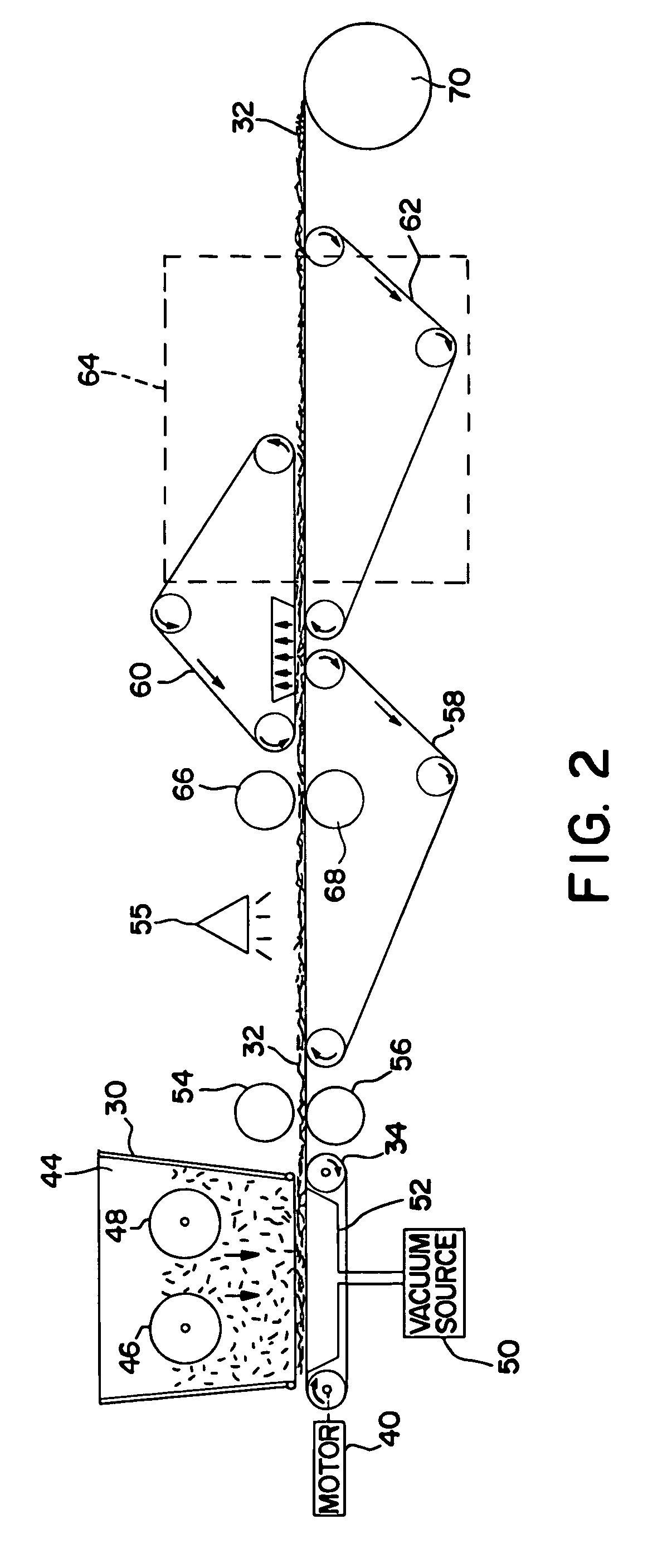

Fabric crepe process for making absorbent sheet

ActiveUS7399378B2High speed transmissionGuaranteed high speed operationNatural cellulose pulp/paperMechanical working/deformationFiberAdhesive

A process for making absorbent cellulosic paper products such as sheet for towel, tissue and the like, includes compactively dewatering a nascent web followed by wet belt creping the web at an intermediate consistency of anywhere from about 30 to about 60 percent under conditions operative to redistribute the fiber on the belt, which is preferably a fabric. In preferred embodiments, the web is thereafter adhesively applied to a Yankee dryer using a creping adhesive operative to enable high speed transfer of the web of intermediate consistency such as a poly(vinyl alcohol) / polyamide adhesive. An absorbent sheet so prepared from a papermaking furnish exhibits an absorbency of at least about 5 g / g, a CD stretch of at least about 4 percent, and an MD / CD tensile ratio of less than about 1.1, and also exhibits a maximum CD modulus at a CD strain of less than 1 percent and sustains a CD modulus of at least 50 percent of its maximum CD modulus to a CD strain of at least about 4 percent. Products of the invention may also exhibit an MD modulus at break 1.5 to 2 times their initial MD modulus.

Owner:GPCP IP HLDG LLC

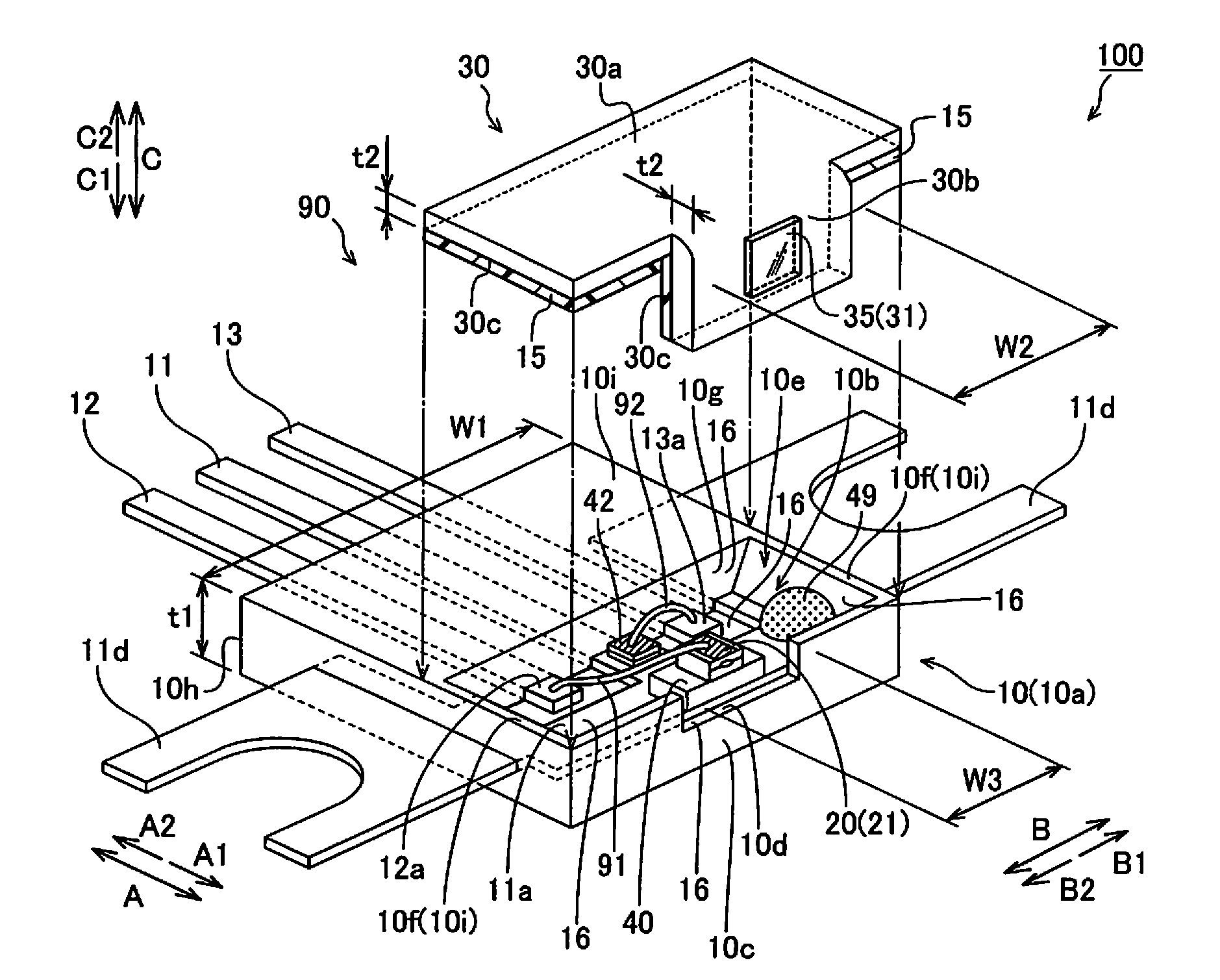

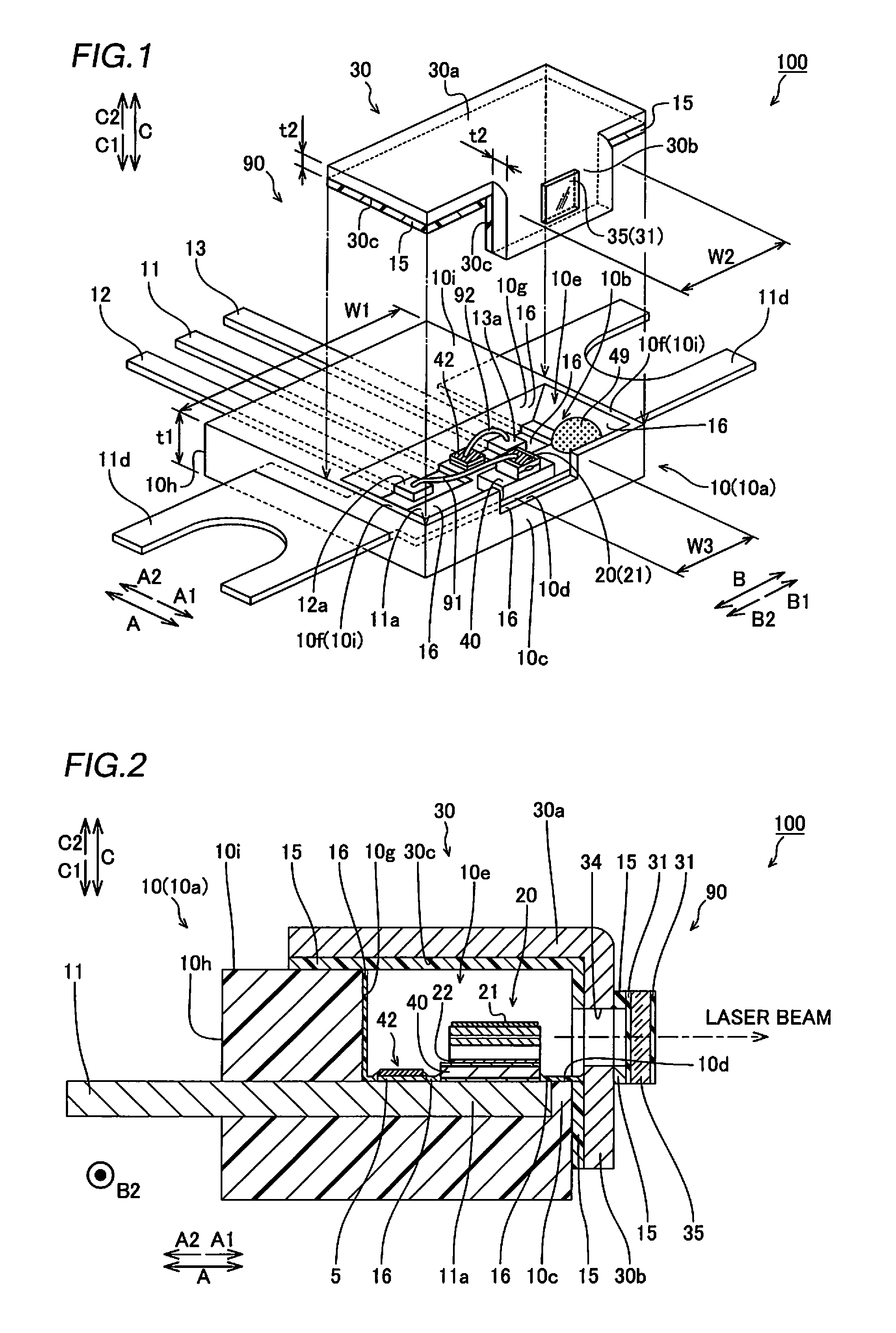

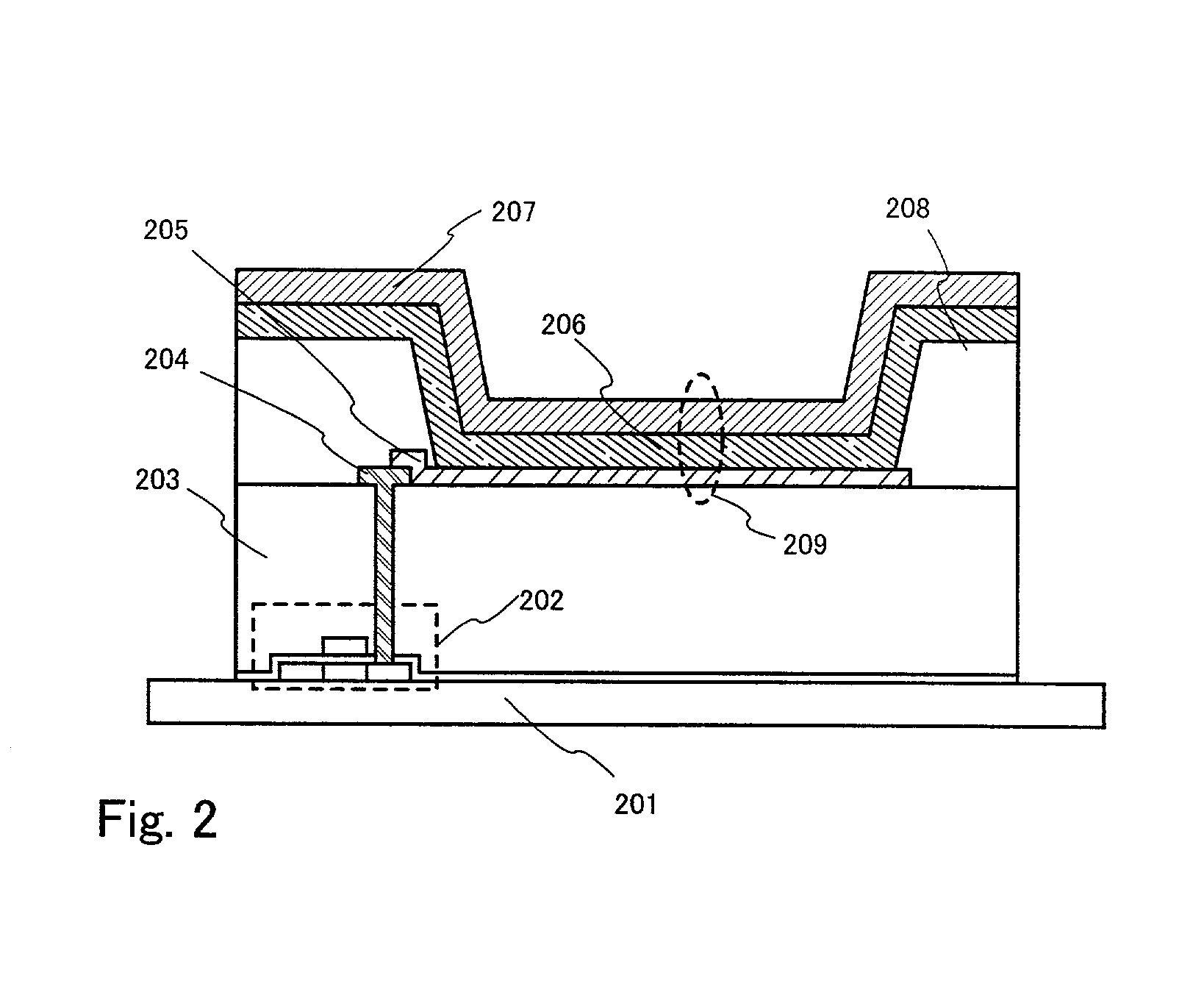

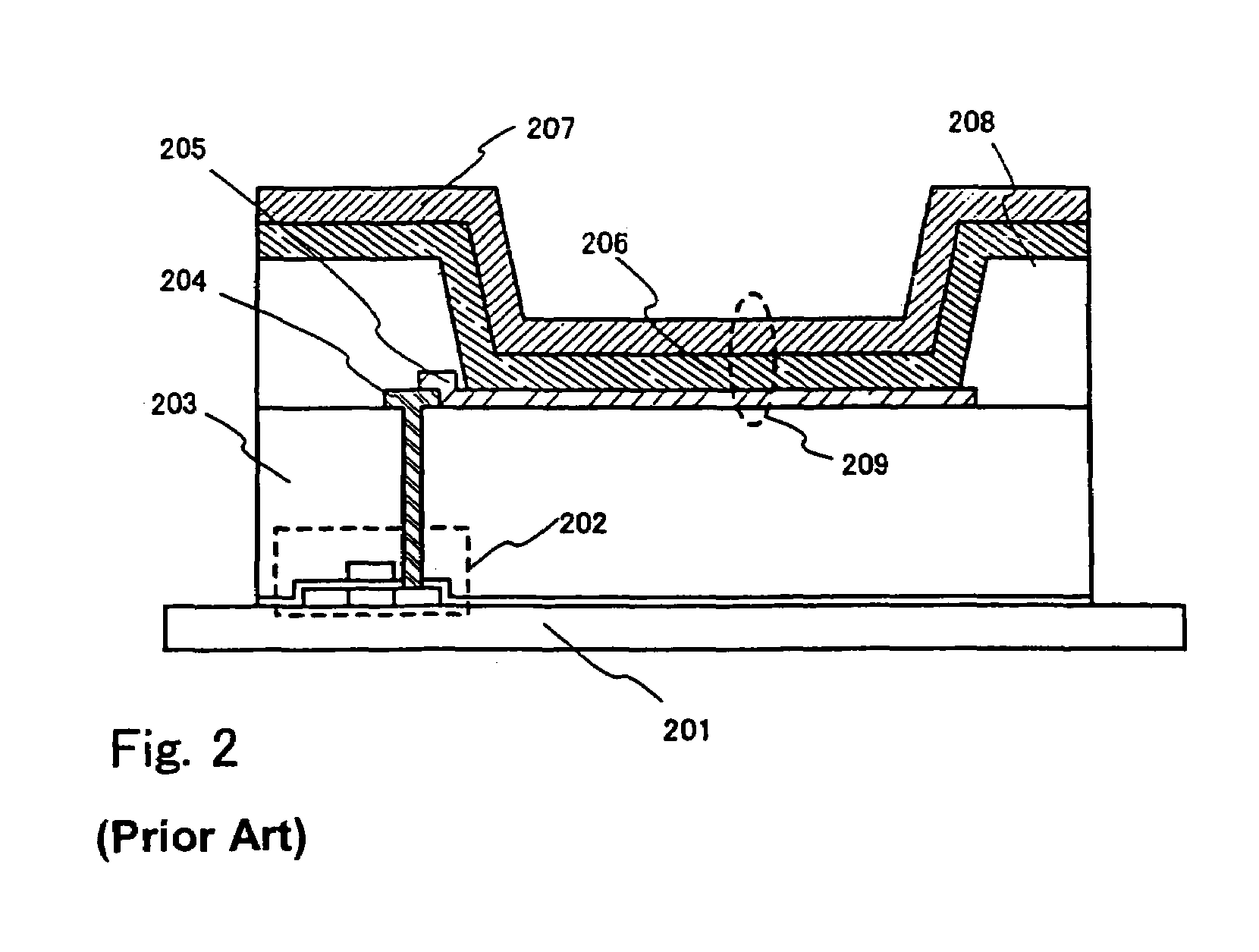

Semiconductor laser apparatus and optical apparatus

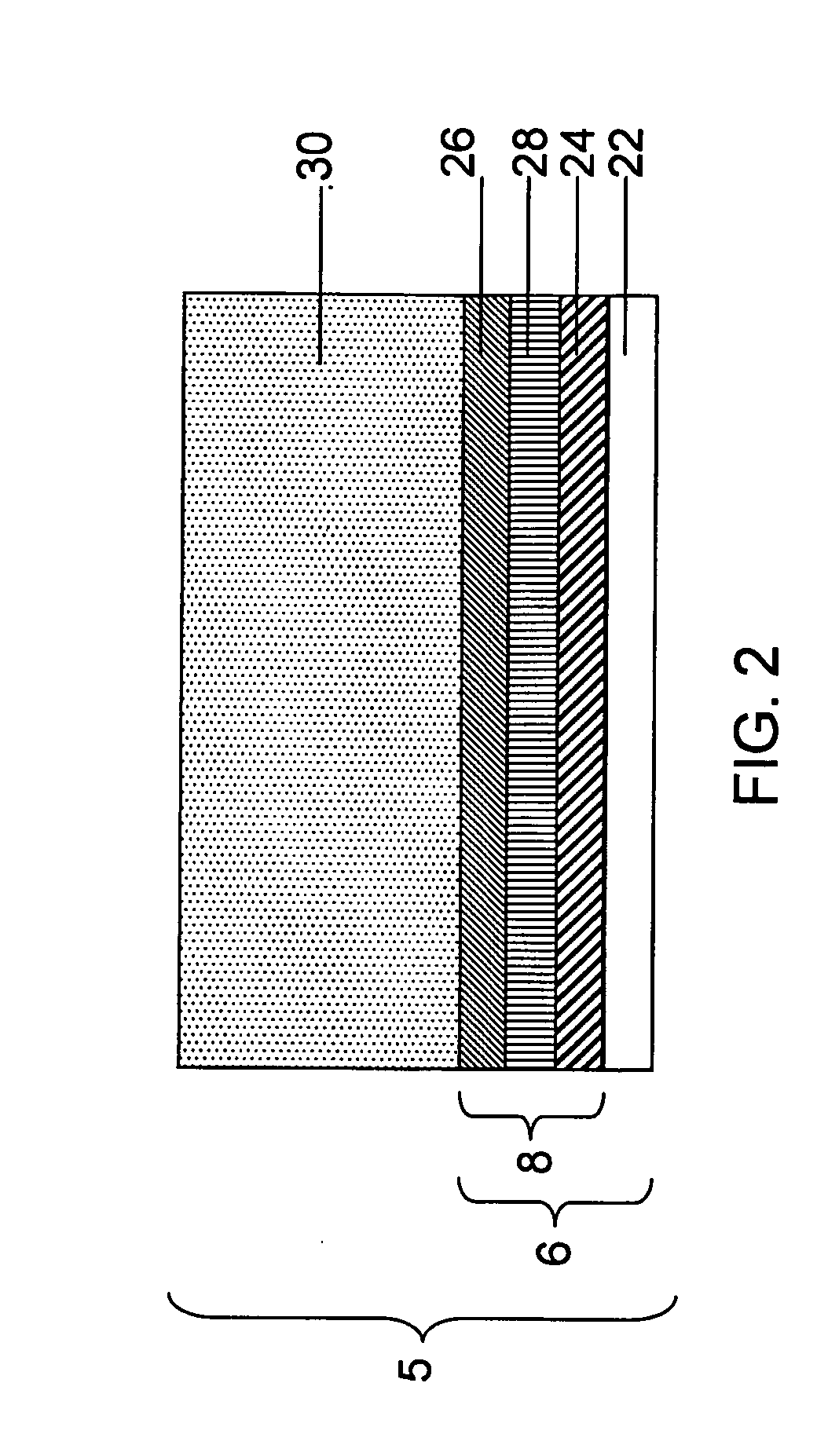

InactiveUS20120033695A1Improve sealingPromote absorptionSolid-state devicesSemiconductor lasersPolyvinyl alcoholSemiconductor chip

This semiconductor laser apparatus includes a package constituted by a plurality of members, having sealed space inside and a semiconductor laser chip arranged in the sealed space, while surfaces of the members located in the sealed space are covered with a covering agent made of an ethylene-polyvinyl alcohol copolymer.

Owner:SANYO ELECTRIC CO LTD

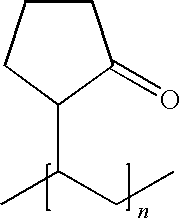

Method of embolization using polyvinyl alcohol microspheres

The present invention relates to microspheres useful for embolization which comprises polyvinylalcohol. The present invention also relates to an injectable suspension suitable for embolization which comprises the polyvinylalcohol microspheres and a suitable liquid carrier. The present invention further relates to a method for prophylactic or therapeutic embolization which comprises administering to a mammal an injectable suspension containing the polyvinylalcohol microspheres and a suitable liquid carrier. Finally, the present, invention relates to a process for producing the polyvinylalcbhol microspheres.

Owner:BIOSPHERE MEDICAL SA (FR)

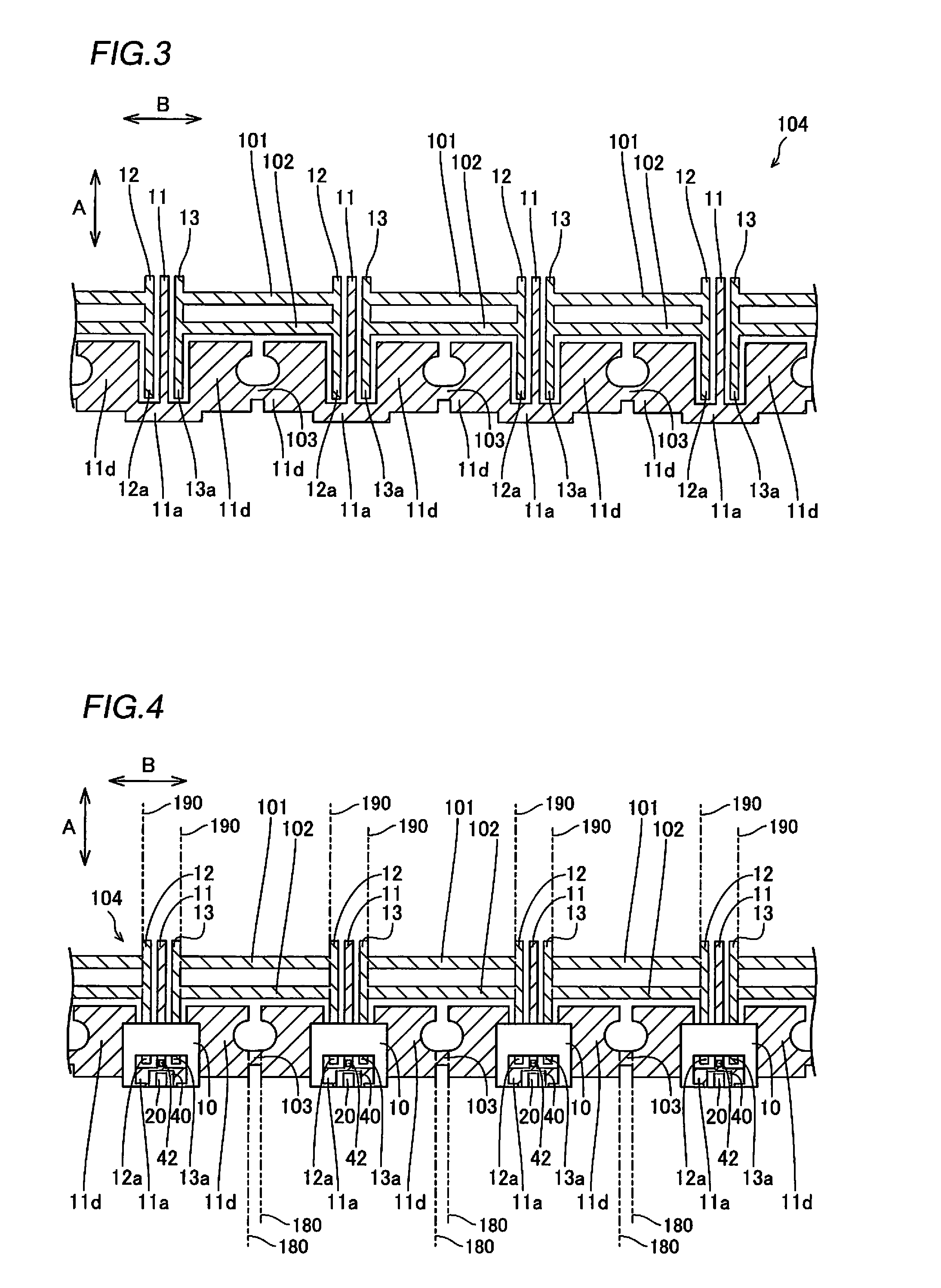

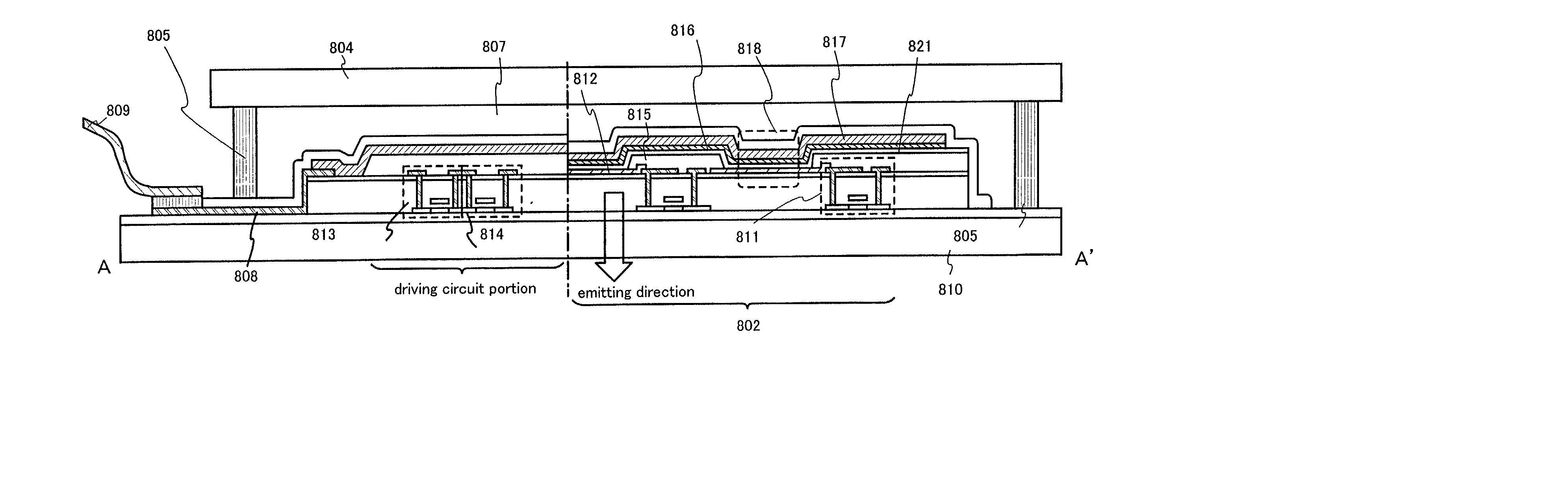

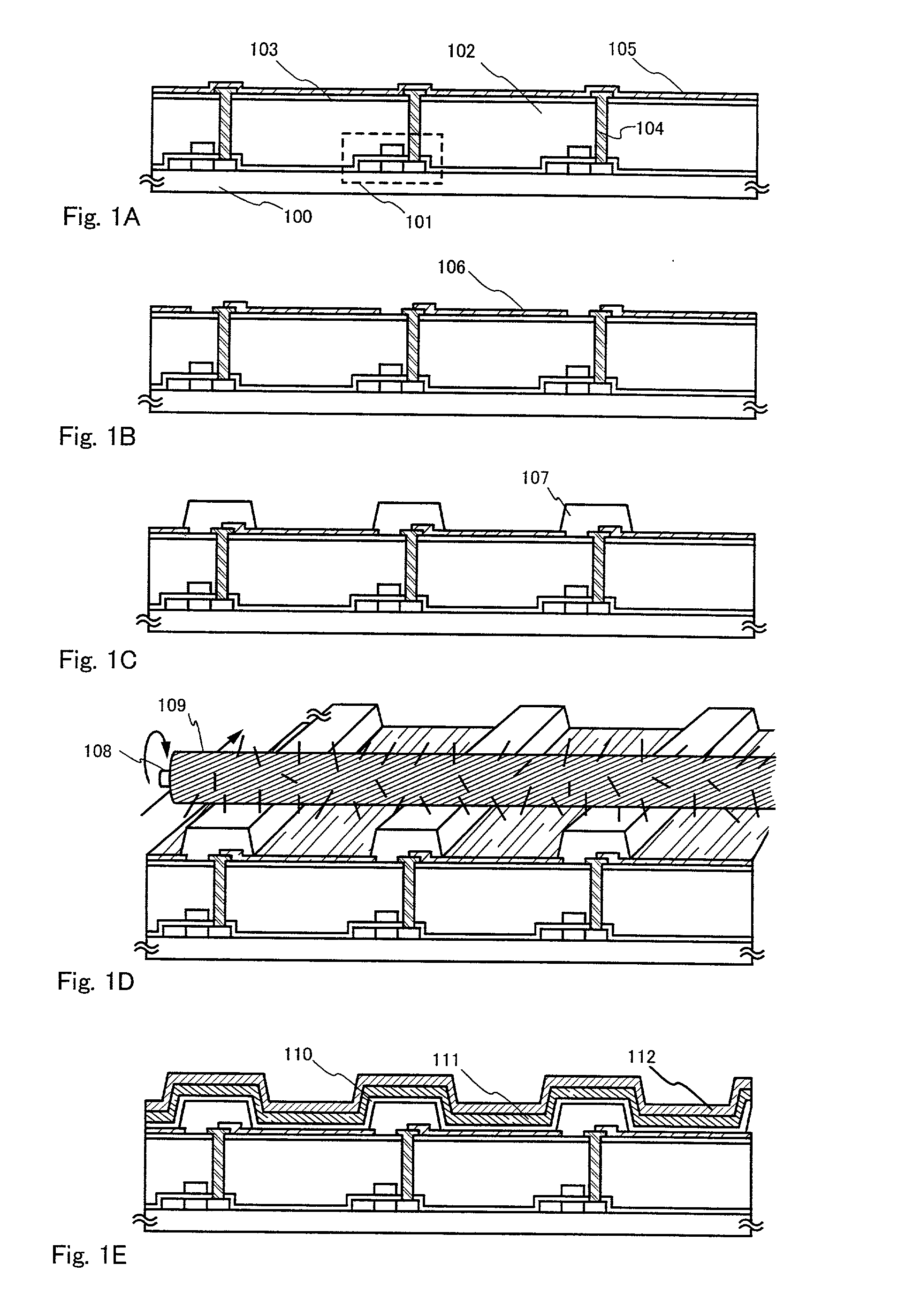

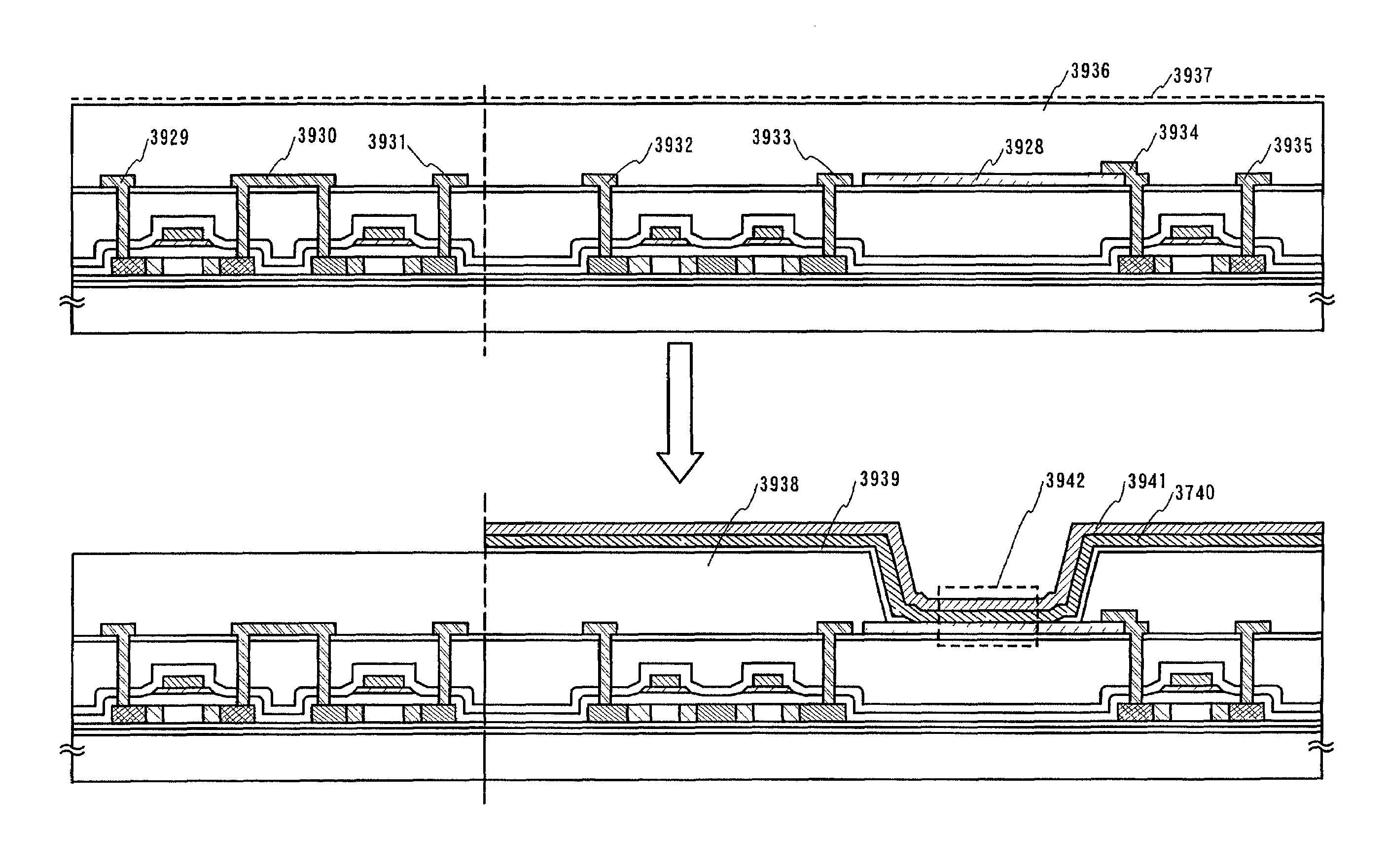

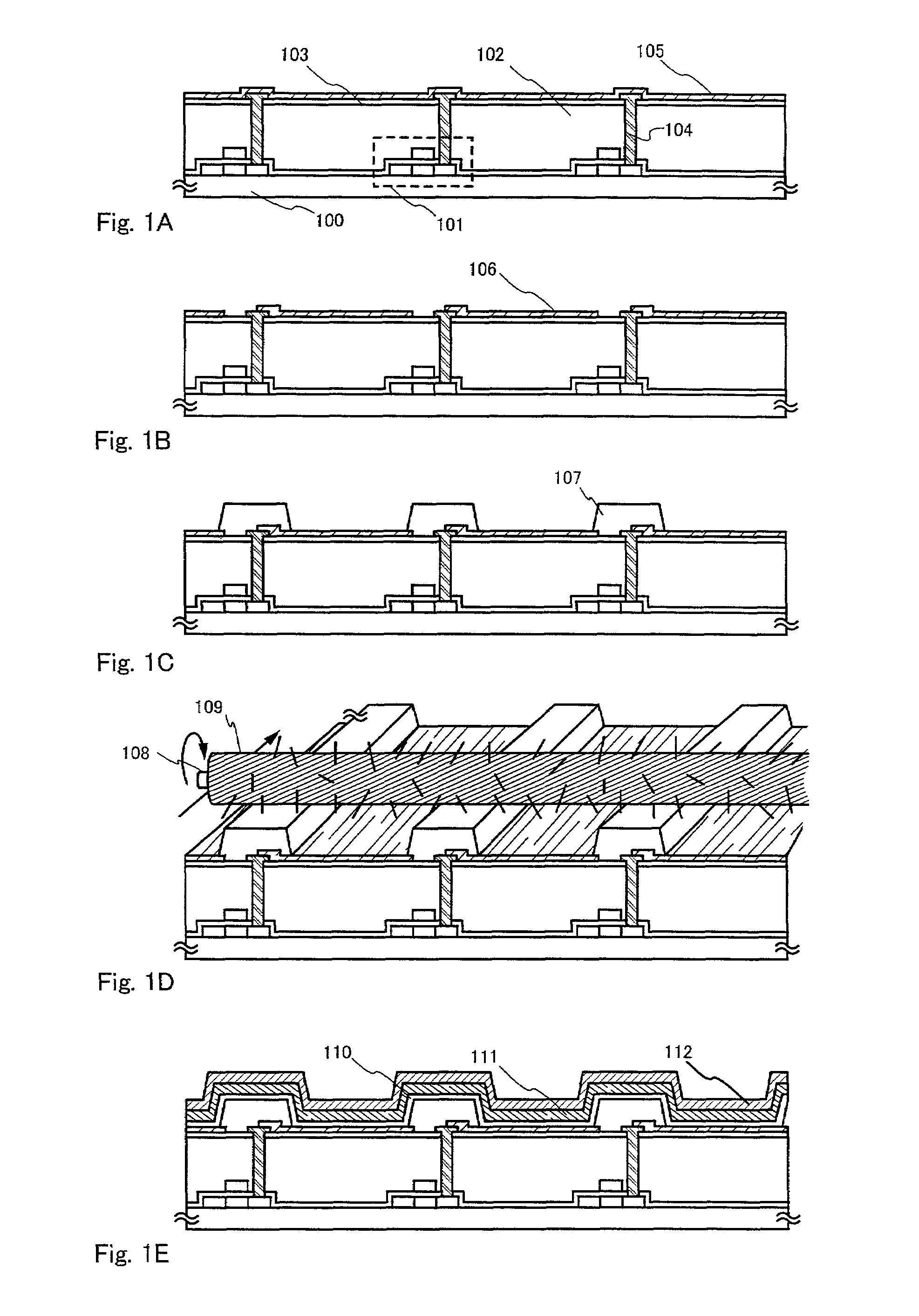

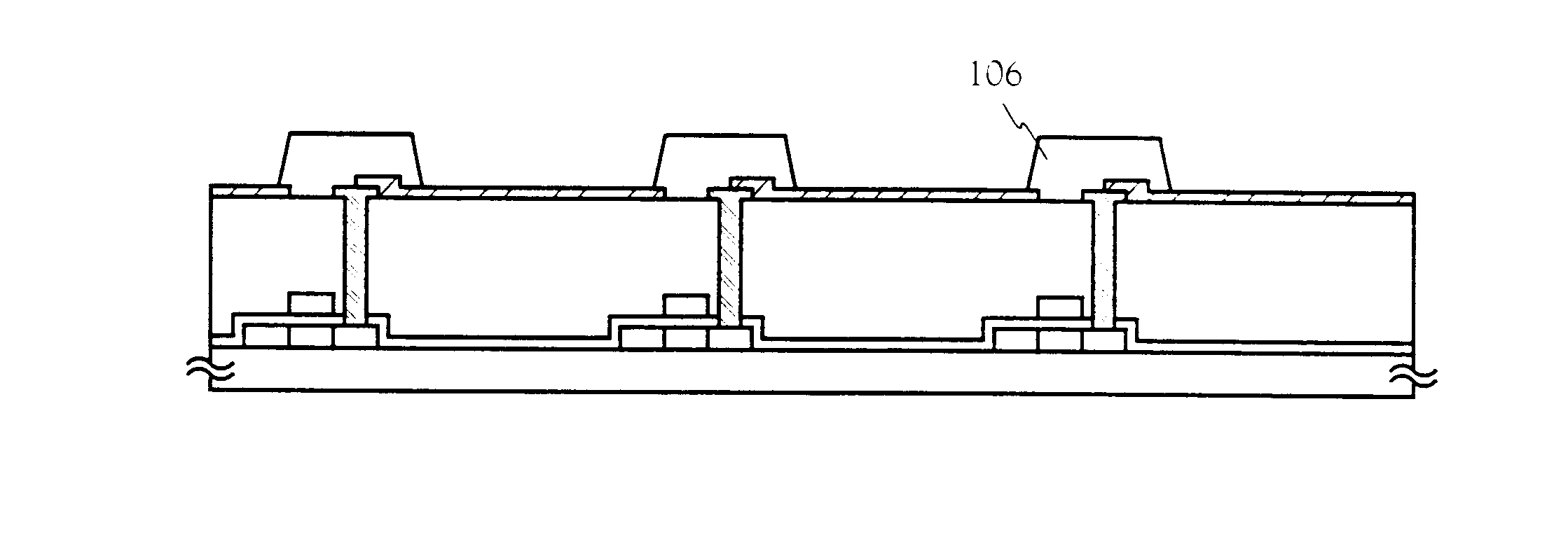

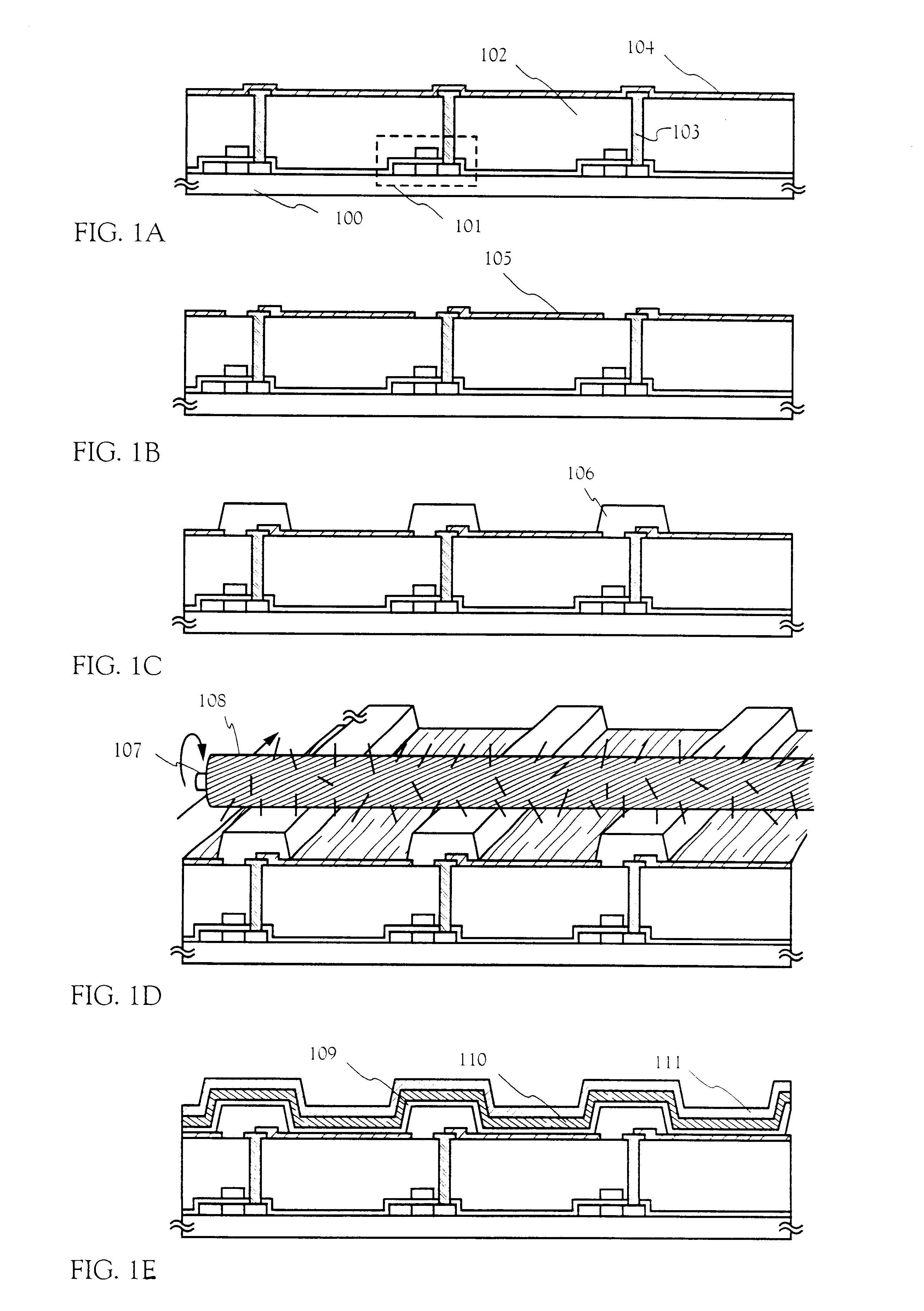

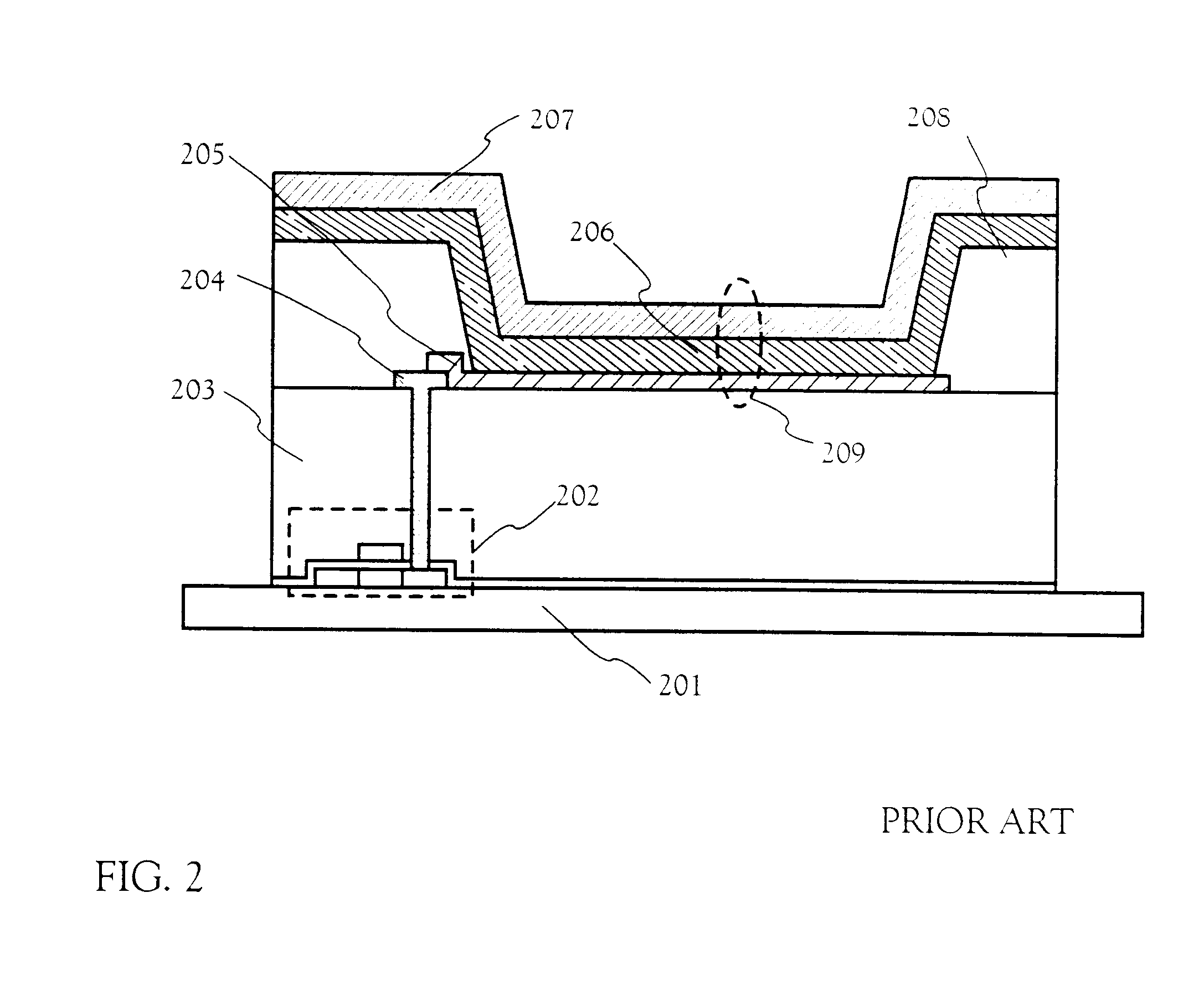

Light emitting device and method of manufacturing the same

InactiveUS20020113248A1Static indicating devicesSemiconductor/solid-state device detailsPolyvinyl alcoholLight emitting device

A high-quality light emitting device is provided which has a long-lasting light emitting element free from the problems of conventional ones because of a structure that allows less degradation, and a method of manufacturing the light emitting device is provided. After a bank is formed, an exposed anode surface is wiped using a PVA (polyvinyl alcohol)-based porous substance or the like to level the surface and remove dusts from the surface. An insulating film is formed between an interlayer insulating film on a TFT and the anode. Alternatively, plasma treatment is performed on the surface of the interlayer insulating film on the TFT for surface modification.

Owner:SEMICON ENERGY LAB CO LTD

Hormone hydrogel rooting film

InactiveCN102599161AExtend the critical periodImprove survival rateBiocidePlant growth regulatorsSocial benefitsPolyvinyl alcohol

The invention discloses a hormone hydrogel rooting film, which is prepared by the steps of: swelling polyvinyl alcohol at normal temperature for 30min, and heating for completely dissolving polyvinyl alcohol to obtain a transparent liquid; cooling, adjusting the pH value of the solution with concentrated hydrochloric acid, adding glycerol and reacting to prepare a hydrogel liquid; and adding hormone to the hydrogel liquid and stirring. When in use, the hormone hydrogel rooting film is spread on the surface of a hard branch cutting shoot, so that a gel film is formed on the surface of the hard branch cutting shoot above the ground so as to achieve the purpose of reducing the moisture of the cutting shoot from dissipation, and a gel film is formed on the surface of the hard branch cutting shoot under the ground so as to keep a moisture state in soil and play a role of slowly releasing hormone to stimulate the rooting of the cutting shoot, thus the rooting critical stage of the hard branch cutting shoot is prolonged and the rooting survival rate of the hard branch cutting shoot is improved. The technical scheme disclosed by the invention is simple and convenient, high in raising seedling survival rate and significant in economic and social benefits, and saves seedling-raising investment by more than 10%.

Owner:濮阳市林业科学院

Poly (vinyl alcohol) - based formaldehyde-free curable aqueous composition

A formaldehyde-free curable aqueous composition containing polyvinyl alcohol, a multi-functional crosslinking agent, and, optionally, a catalyst. The composition may be used as a binder for non-woven products such as fiberglass insulation. The non-woven products are formed by contacting the formaldehyde-free curable aqueous composition with fibrous components and the mixture is cured to form a rigid thermoset polymer providing excellent strength and water resistance of the cured nonwoven product.

Owner:ARCLIN USA

Primer for battery electrode

ActiveUS20100291442A1Electrode carriers/collectorsActive material electrodesPolyvinyl alcoholCrosslinked polymers

Primer arrangements that facilitate electrical conduction and adhesive connection between an electroactive material and a current collector are presented. In some embodiments, primer arrangements described herein include first and second primer layers. The first primer layer may be designed to provide good adhesion to a conductive support. In one particular embodiment, the first primer layer comprises a substantially uncrosslinked polymer having hydroxyl functional groups, e.g., polyvinyl alcohol. The materials used to form the second primer layer may be chosen such that the second primer layer adheres well to both the first primer layer and an electroactive layer. In certain embodiments including combinations of first and second primer layers, one or both of the first and second primer layers comprises less than 30% by weight of a crosslinked polymeric material. A primer including only a single layer of polymeric material is also provided.

Owner:SION POWER CORP

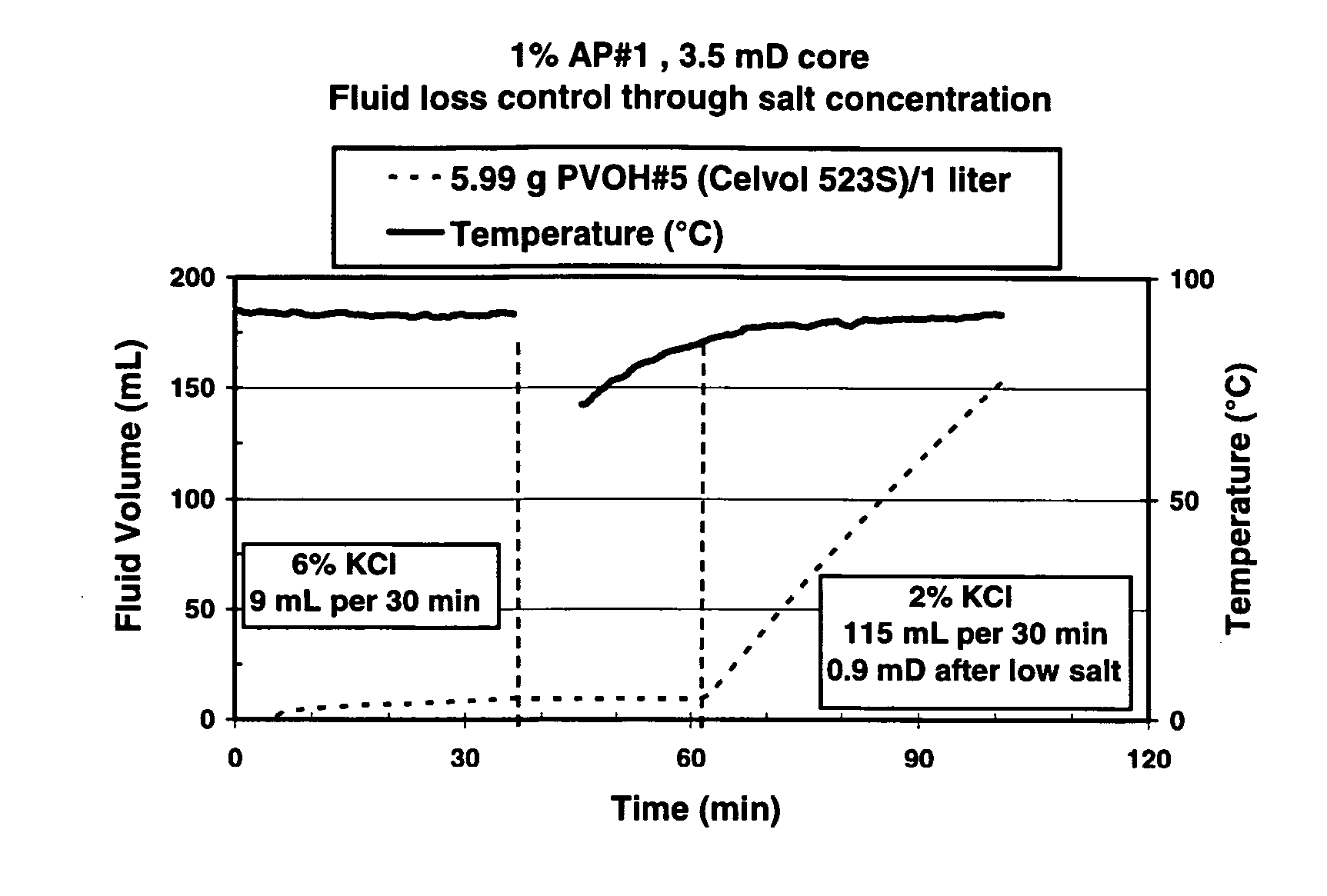

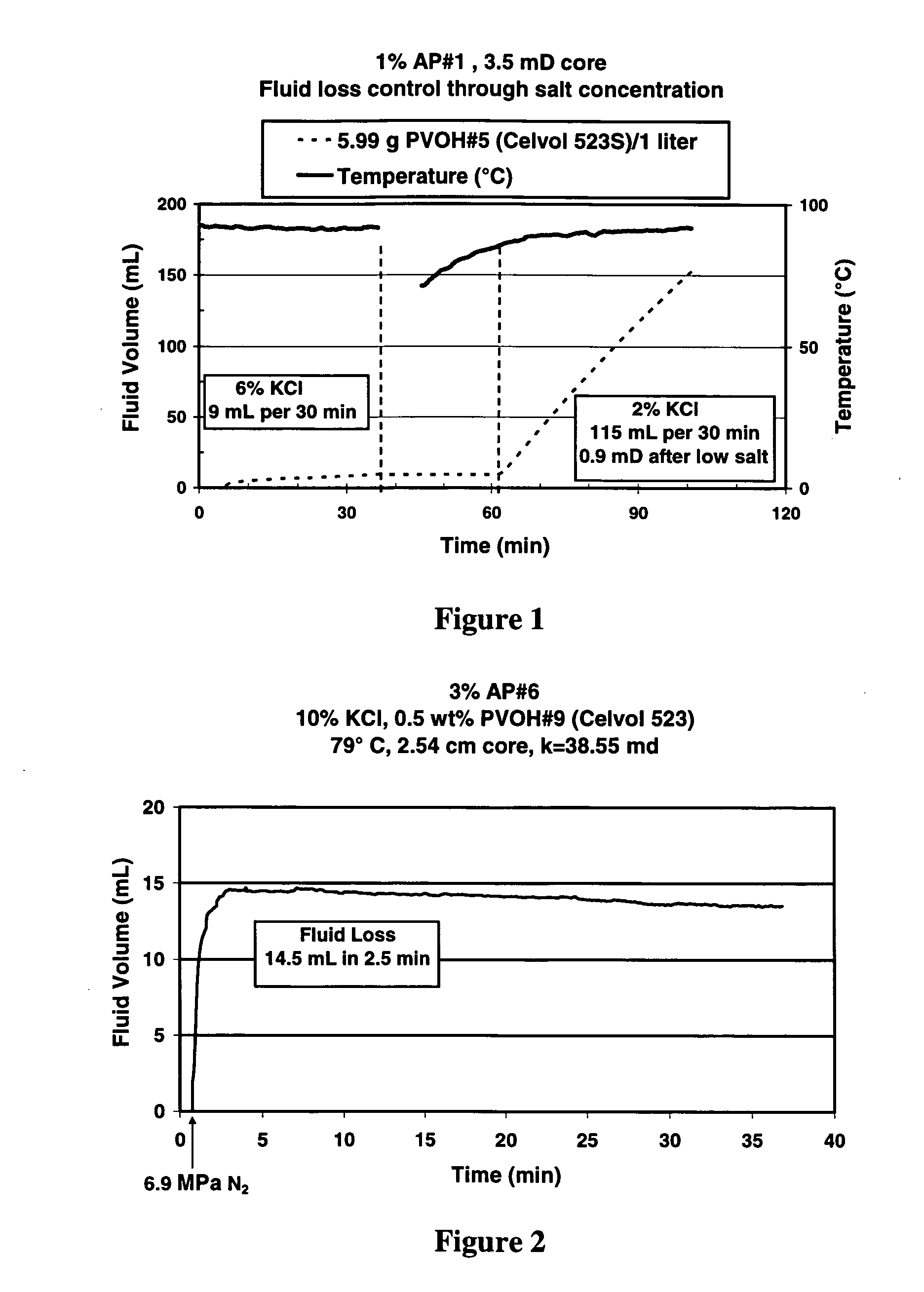

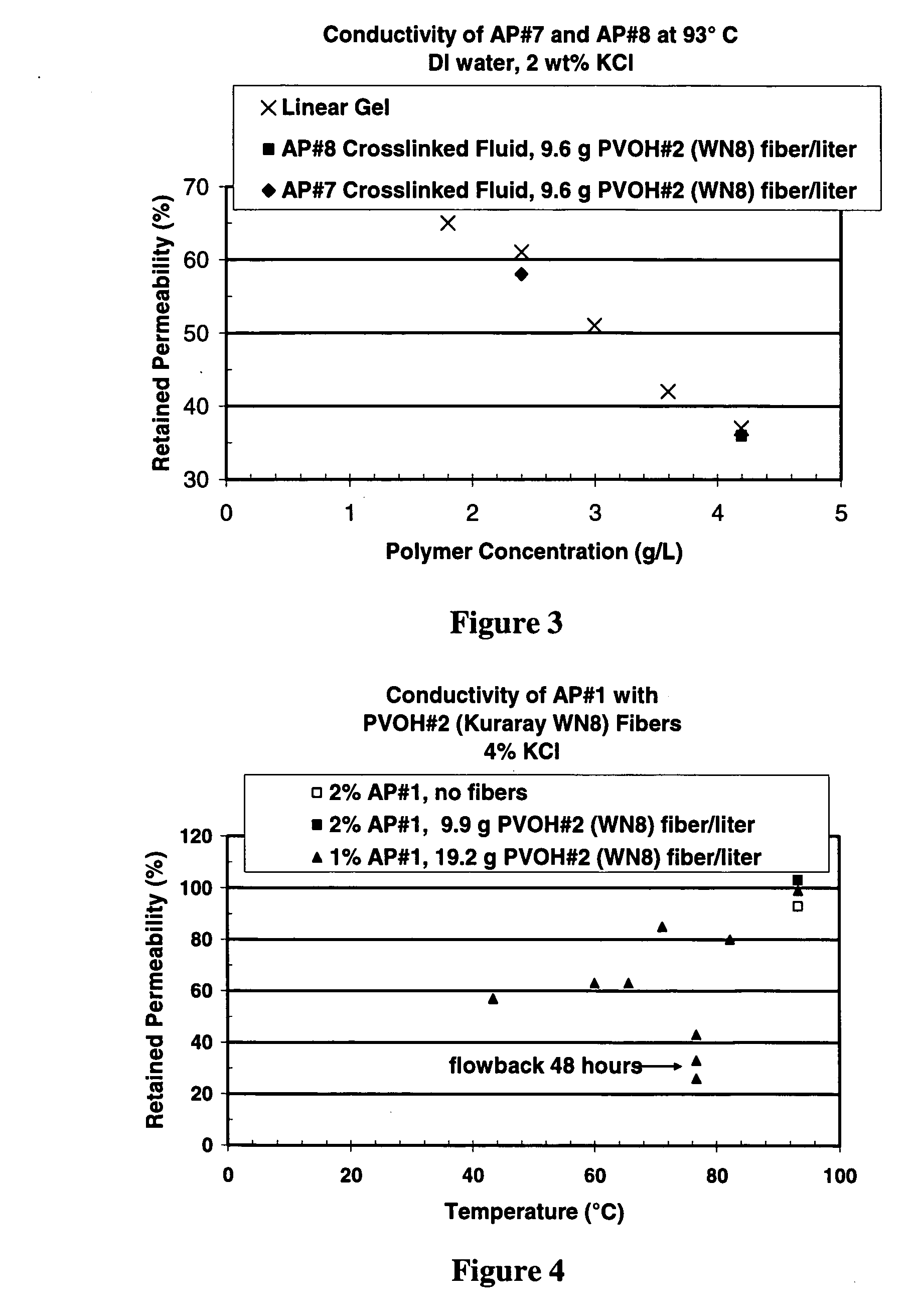

Well treatment with dissolvable polymer

InactiveUS20060157248A1Ease and flexibility for subsequent completion processEasy to processInsulationLiquid/gas jet drillingPolyvinyl alcoholDissolution

Well treatment is disclosed that includes injecting a well treatment fluid with insoluble polyol polymer such as polyvinyl alcohol (PVOH) dispersed therein, depositing the insoluble polymer in the wellbore or an adjacent formation, and thereafter dissolving the polymer by reducing salinity and / or increasing temperature conditions in the environment of the polymer deposit. The method is disclosed for filter cake formation, fluid loss control, drilling, hydraulic fracturing and fiber assisted transport, where removal of the polyol at the end of treatment or after treatment is desired. The method is also disclosed for providing dissolved polyol as a delayed breaker in crosslinked polymer viscosified systems and viscoelastic surfactant systems. Also disclosed are well treatment fluids containing insoluble amorphous or at least partially crystalline polyol, and a PVOH fiber composition wherein the fibers are stabilized from dissolution by salinity.

Owner:SCHLUMBERGER TECH CORP

Multilayer Films Or Plasticizer-Containing Polyvinyl Acetal With Sound-Absorbing Properties

ActiveUS20100028642A1Improve sound absorptionLow costSynthetic resin layered productsConstructions elementsPolyvinyl acetatePolyvinyl alcohol

An interlayer film for laminated glass with sound-absorbing properties contains at least two individual films, wherein the first individual film comprises a polyvinyl acetal with a portion of polyvinyl acetate groups of 0.1 to 11 mol % and a second individual film comprises a polyvinyl acetal with a portion of polyvinyl acetate groups of between 5 and 8 mol %.

Owner:KURARAY EURO GMBH

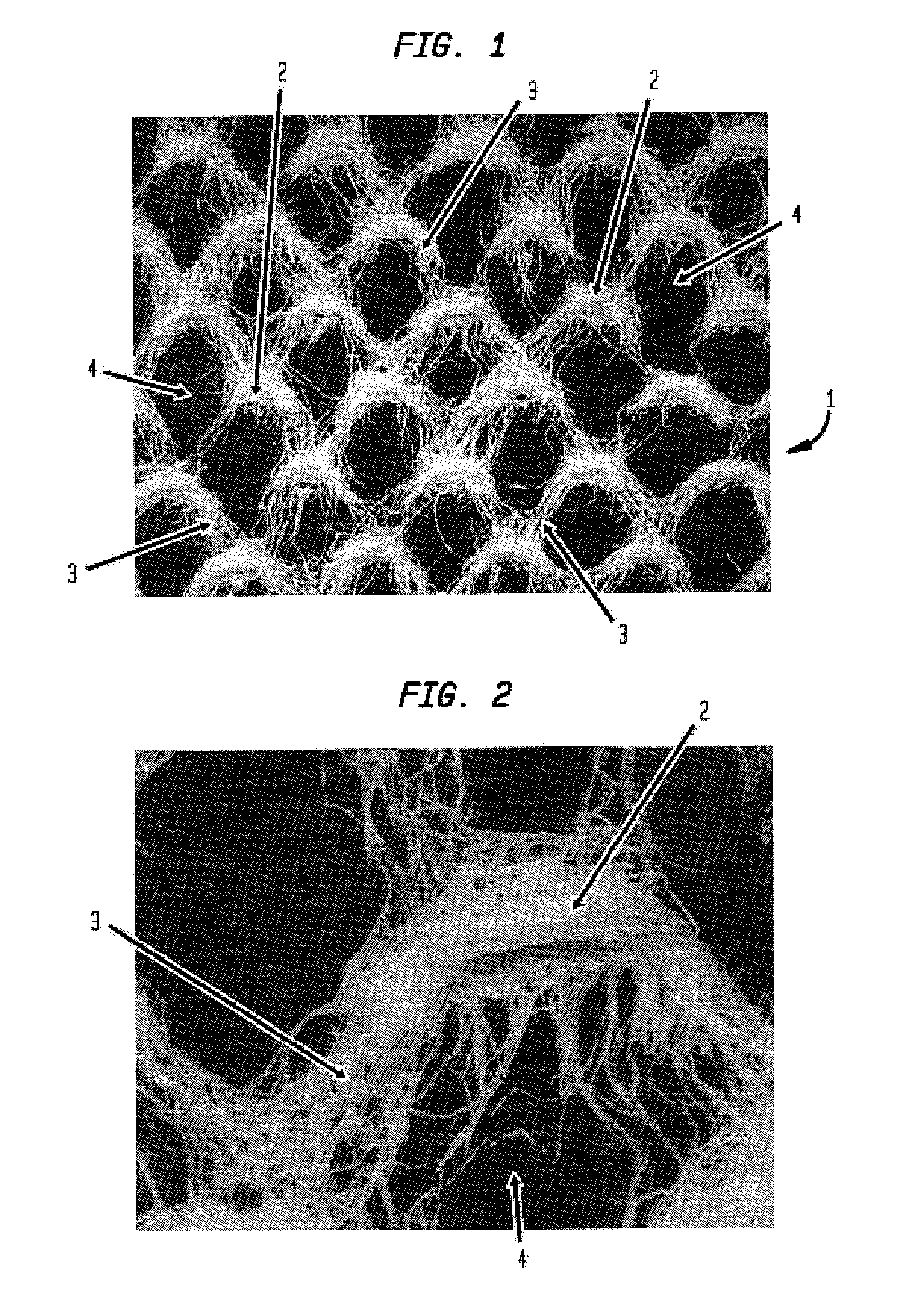

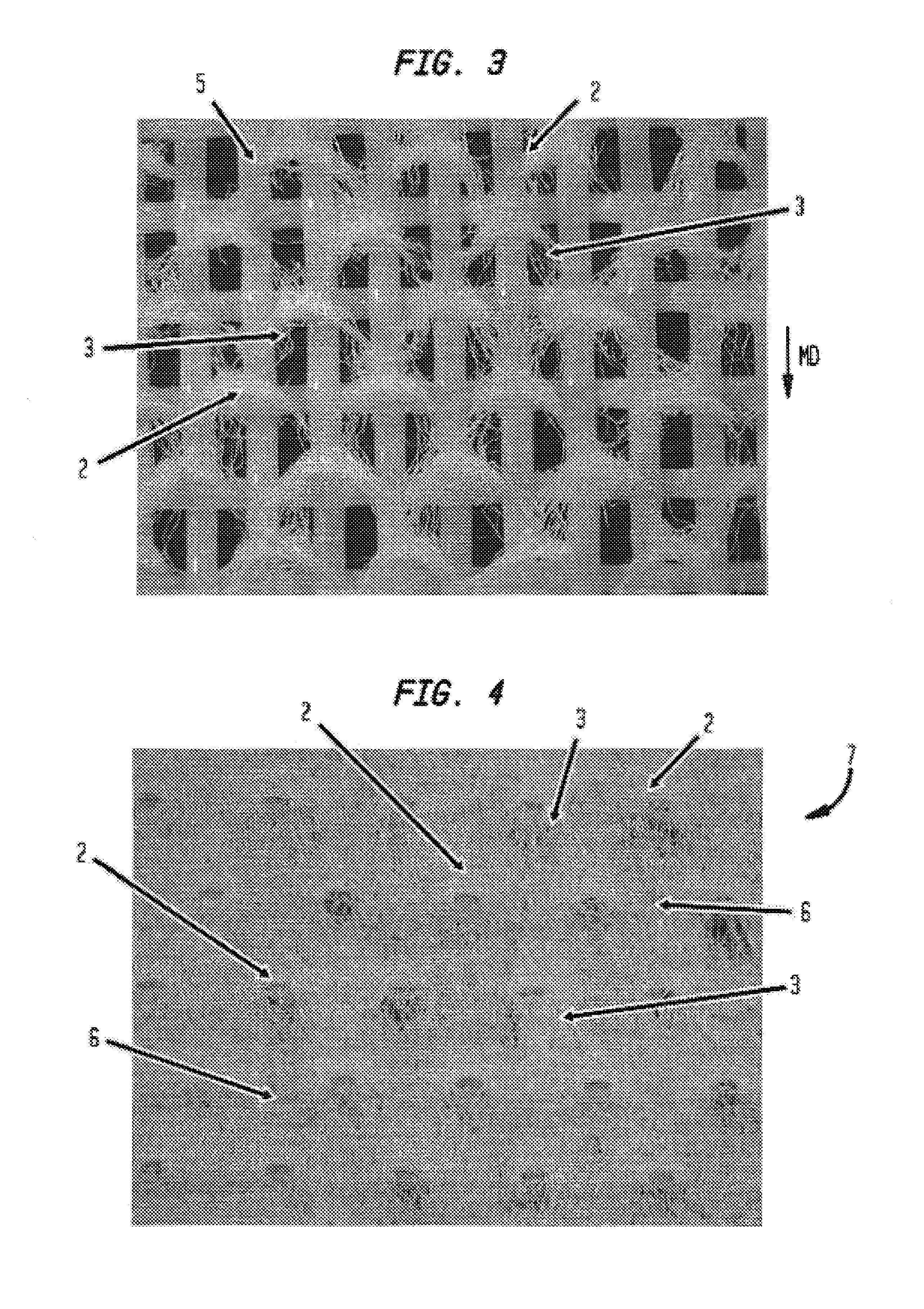

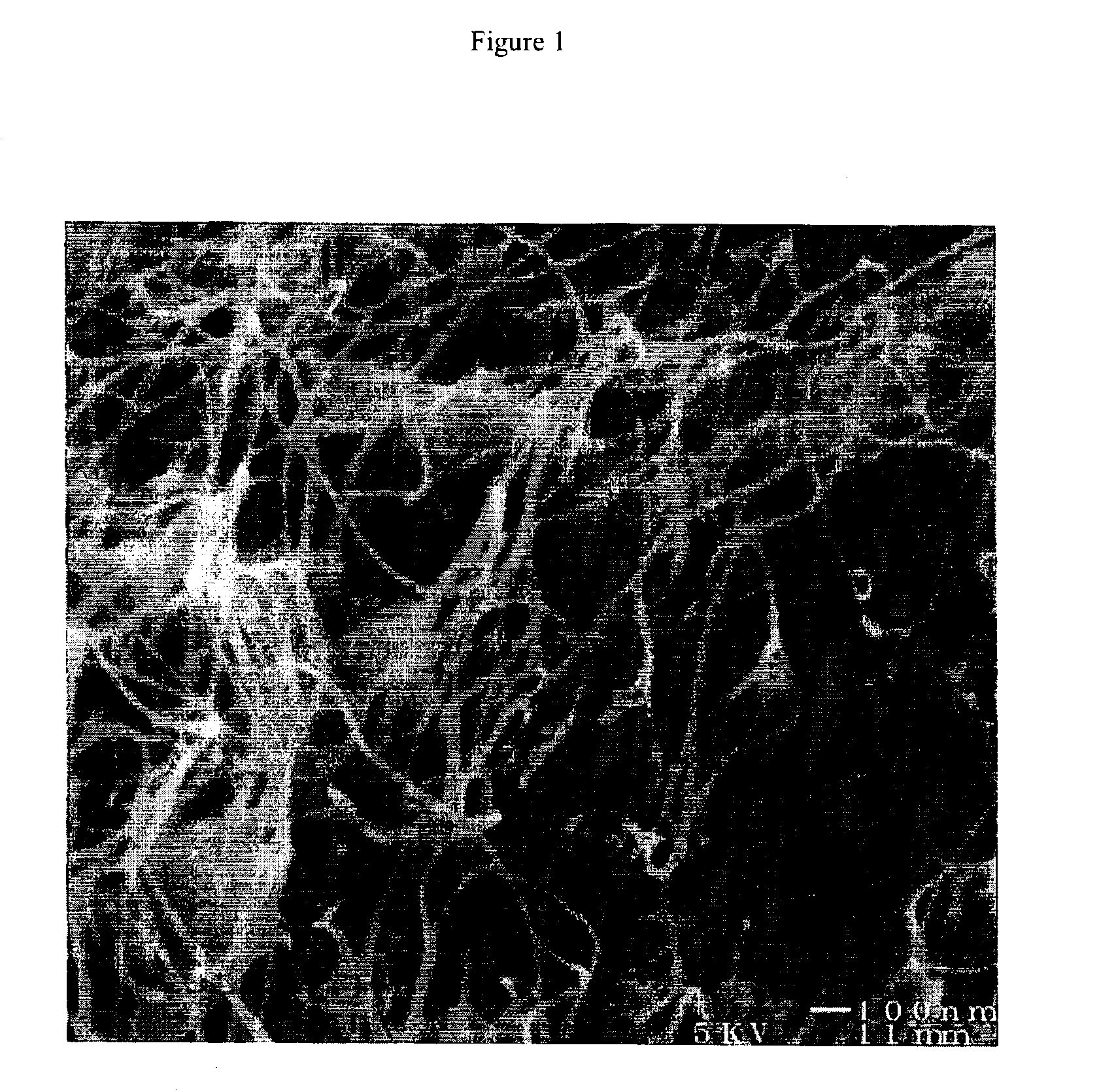

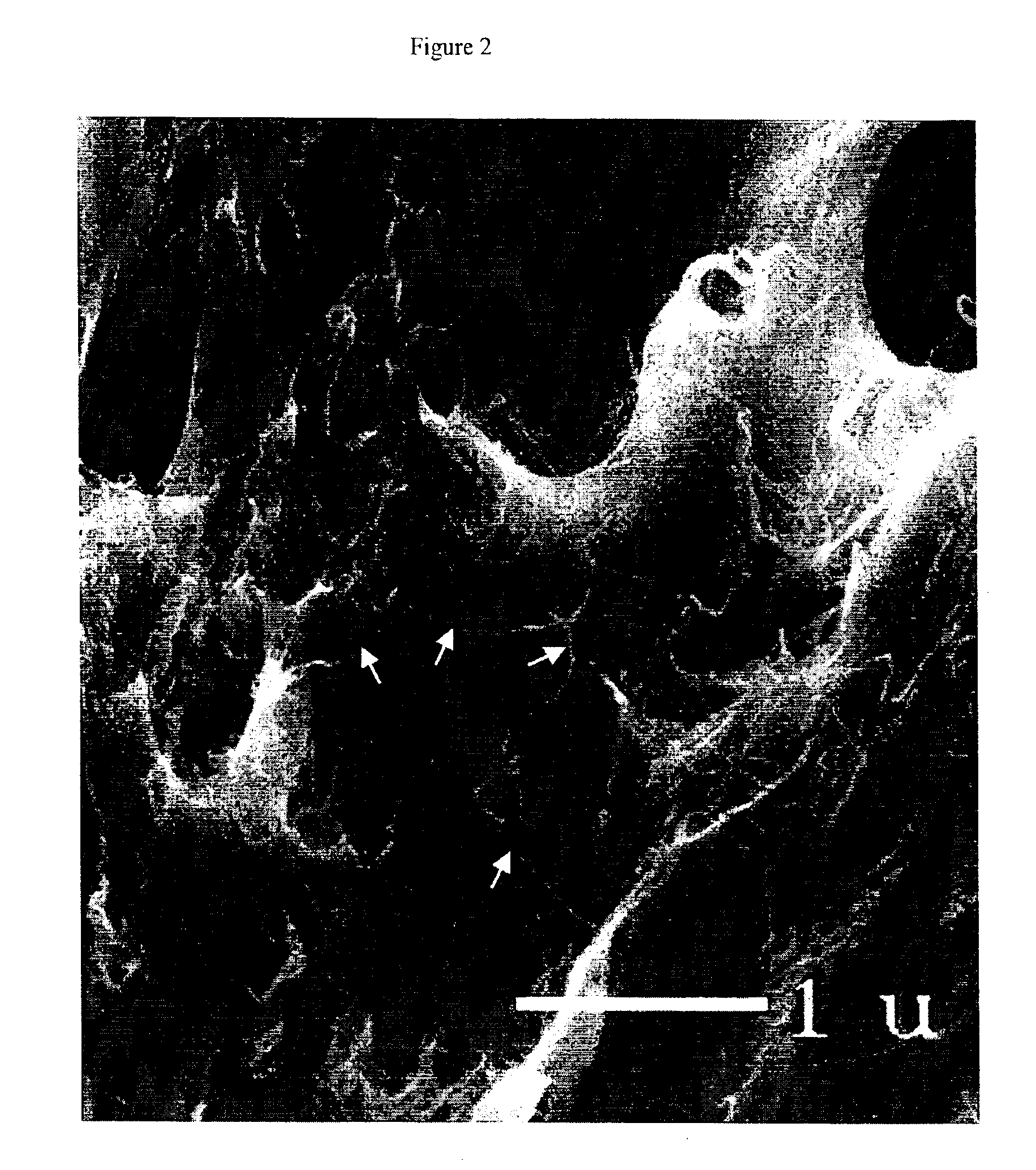

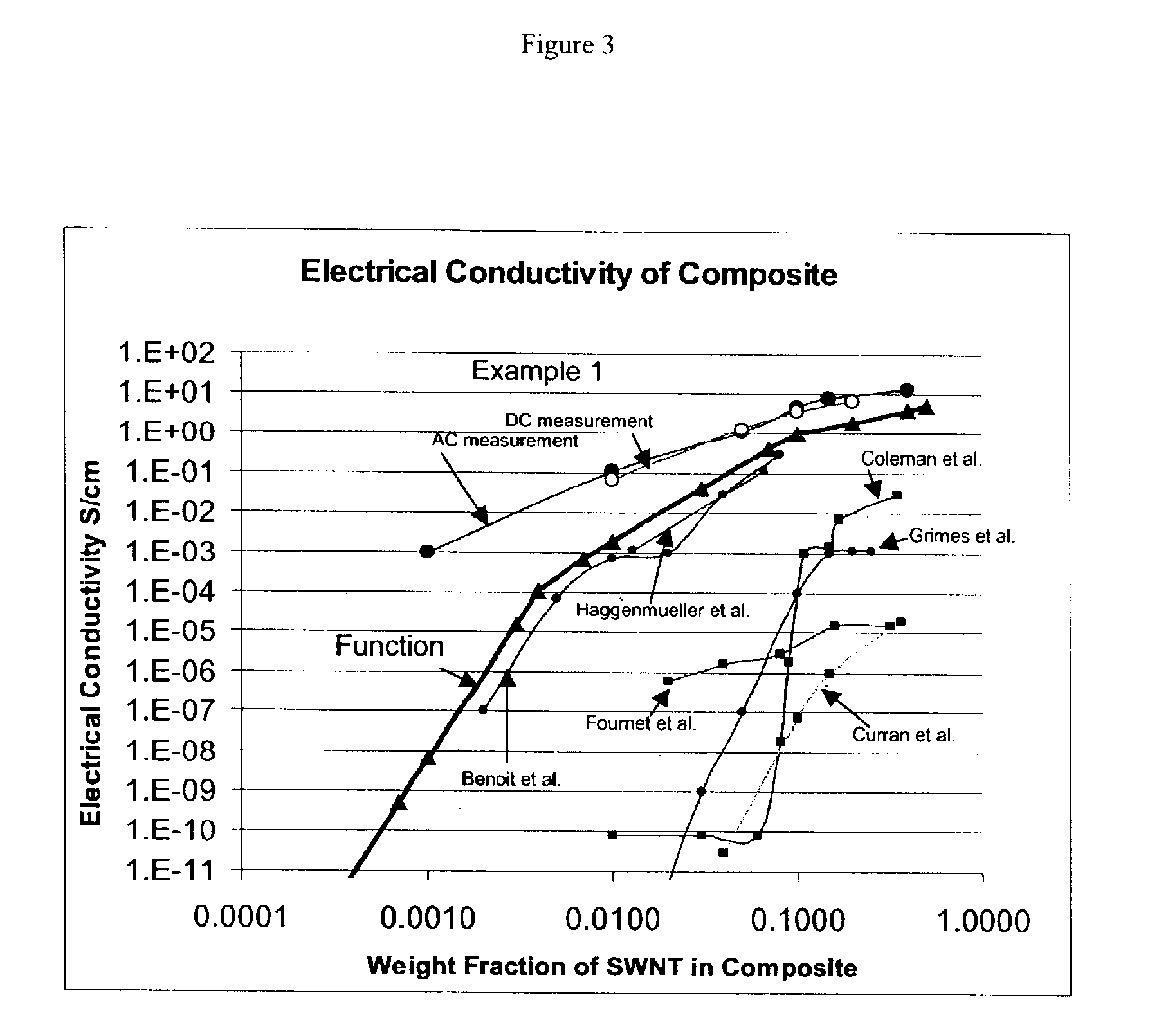

Composite materials comprising polar polymers and single-wall carbon nanotubes

InactiveUS6936653B2Improve conductivityMaterial nanotechnologyIndividual molecule manipulationPolyesterPolymer science

The invention relates to a composite comprising a weight fraction of single-wall carbon nanotubes and at least one polar polymer wherein the composite has an electrical and / or thermal conductivity enhanced over that of the polymer alone. The invention also comprises a method for making this polymer composition. The present application provides composite compositions that, over a wide range of single-wall carbon nanotube loading, have electrical conductivities exceeding those known in the art by more than one order of magnitude. The electrical conductivity enhancement depends on the weight fraction (F) of the single-wall carbon nanotubes in the composite. The electrical conductivity of the composite of this invention is at least 5 Siemens per centimeter (S / cm) at (F) of 0.5 (i.e. where single-wall carbon nanotube loading weight represents half of the total composite weight), at least 1 S / cm at a F of 0.1, at least 1×10−4 S / cm at (F) of 0.004, at least 6×10−9 S / cm at (F) of 0.001 and at least 3×10−16 S / cm (F) plus the intrinsic conductivity of the polymer matrix material at of 0.0001. The thermal conductivity enhancement is in excess of 1 Watt / m-° K. The polar polymer can be polycarbonate, poly(acrylic acid), poly(acrylic acid), poly(methacrylic acid), polyoxide, polysulfide, polysulfone, polyamides, polyester, polyurethane, polyimide, poly(vinyl acetate), poly(vinyl alcohol), poly(vinyl chloride), poly(vinyl pyridine), poly(vinyl pyrrolidone), copolymers thereof and combinations thereof. The composite can further comprise a nonpolar polymer, such as, a polyolefin polymer, polyethylene, polypropylene, polybutene, polyisobutene, polyisoprene, polystyrene, copolymers thereof and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

Composite reverse osmosis membrane having a separation layer with polyvinyl alcohol coating and method of reverse osmotic treatment of water using the same

InactiveUS6177011B1High Salt RejectionPermit practical desalinationGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisZeta potentialWater use

A reverse osmosis composite membrane that has a high salt rejection, a high water permeability, and a high fouling tolerance, and permits practical desalination at a relatively low pressure is provided by coating the surface of a reverse osmosis membrane of aromatic polyamide with polyvinyl alcohol (PVA), for example, and controlling the surface zeta potential of the separation layer within±10 mV at pH 6. This reverse osmosis composite membrane is electrically neutral and controls the electrical adsorption of membrane-fouling substances having a charge group present in water. Therefore, a high separation property can be maintained without fouling the membrane even if water containing a surfactant or a transition metal component is supplied as raw water.

Owner:NITTO DENKO CORP

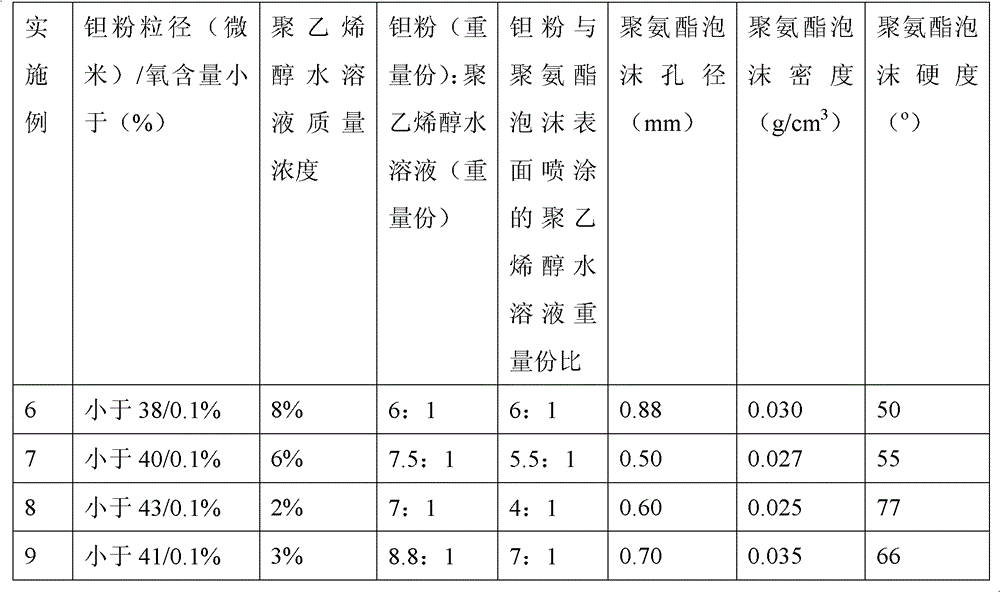

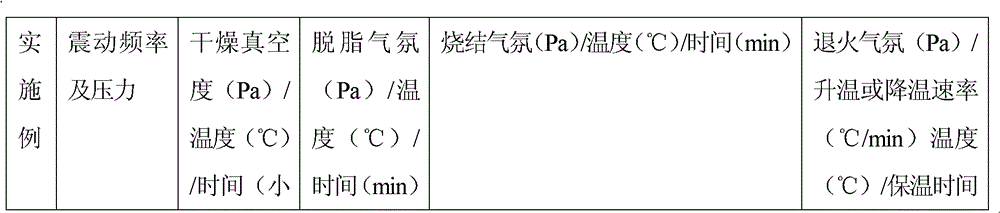

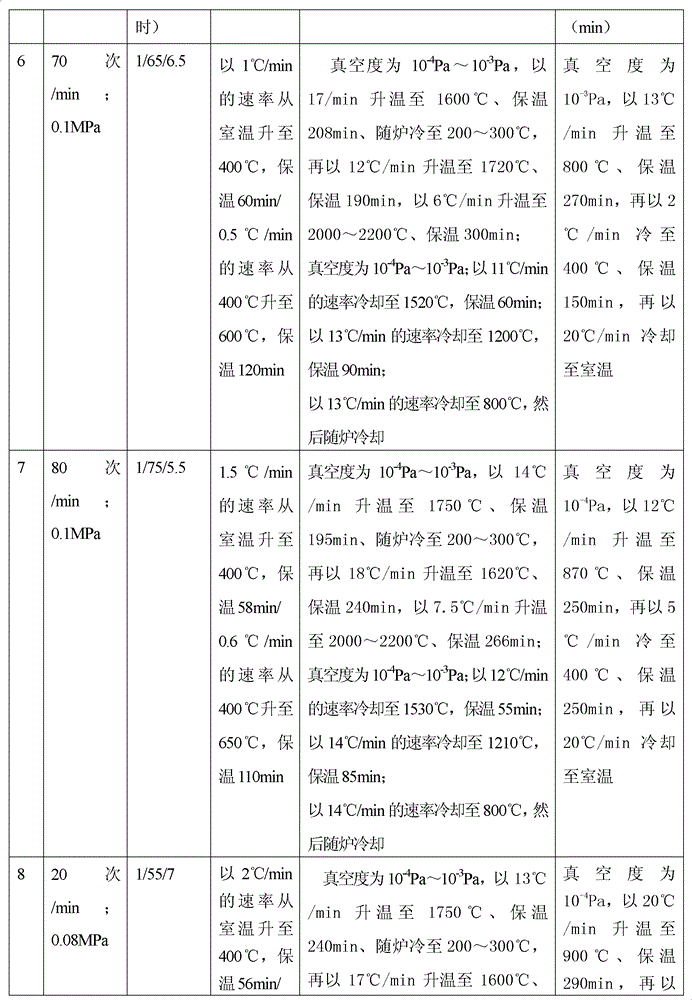

Method for preparing medical porous tantalum implant material

ActiveCN102796894AReduce contentImprove mechanical propertiesProsthesisPolyvinyl alcoholBiocompatibility Testing

The invention discloses a method for preparing a medical porous tantalum material. The method comprises the following steps of: mixing a poly ethanol aqueous solution and tantalum powder to obtain slurry, wherein the mass concentration of the poly ethanol aqueous solution is 2 to 8 percent; injecting the slurry into an organic foam by vibrating and pressurizing, wherein the vibrating frequency is 20 to 80 times / min; drying; degreasing; sintering, namely raising temperature to 1,500 to 1,800 DEG C at the speed of 10 to 20 DEG C / min under the vacuum degree of 10<-4> to 10<-3>Pa, preserving heat for 120 to 240 minutes, cooling to 200 to 300 DEG C along with a furnace, raising temperature to 1,500 to 1,800 DEG C at the speed of 10 to 20 DEG C / min again, preserving heat for 180 to 240 minutes, raising temperature to 2,000 to 2,200 DEG C at the speed of 5 to 10 DEG C / min, and preserving heat for 120 to 360 minutes; cooling; and performing thermal treatment, namely raising temperature to 800 to 900 DEG C at the speed of 10 to 20 DEG C / min under the vacuum degree of 10<-4> to 10<-3> Pa, preserving heat for 240 to 480 minutes, cooling to 400 DGE C at the speed of 2 to 5 DGE C / min, preserving heat for 120 to 300 minutes, and cooling to room temperature along with the furnace. The porous tantalum prepared by the method is very suitable to be used for the medical implant material for replacing bearing bone tissues, and biocompatibility and the mechanical property can be guaranteed simultaneously.

Owner:CHONGQING RUNZE PHARM CO LTD

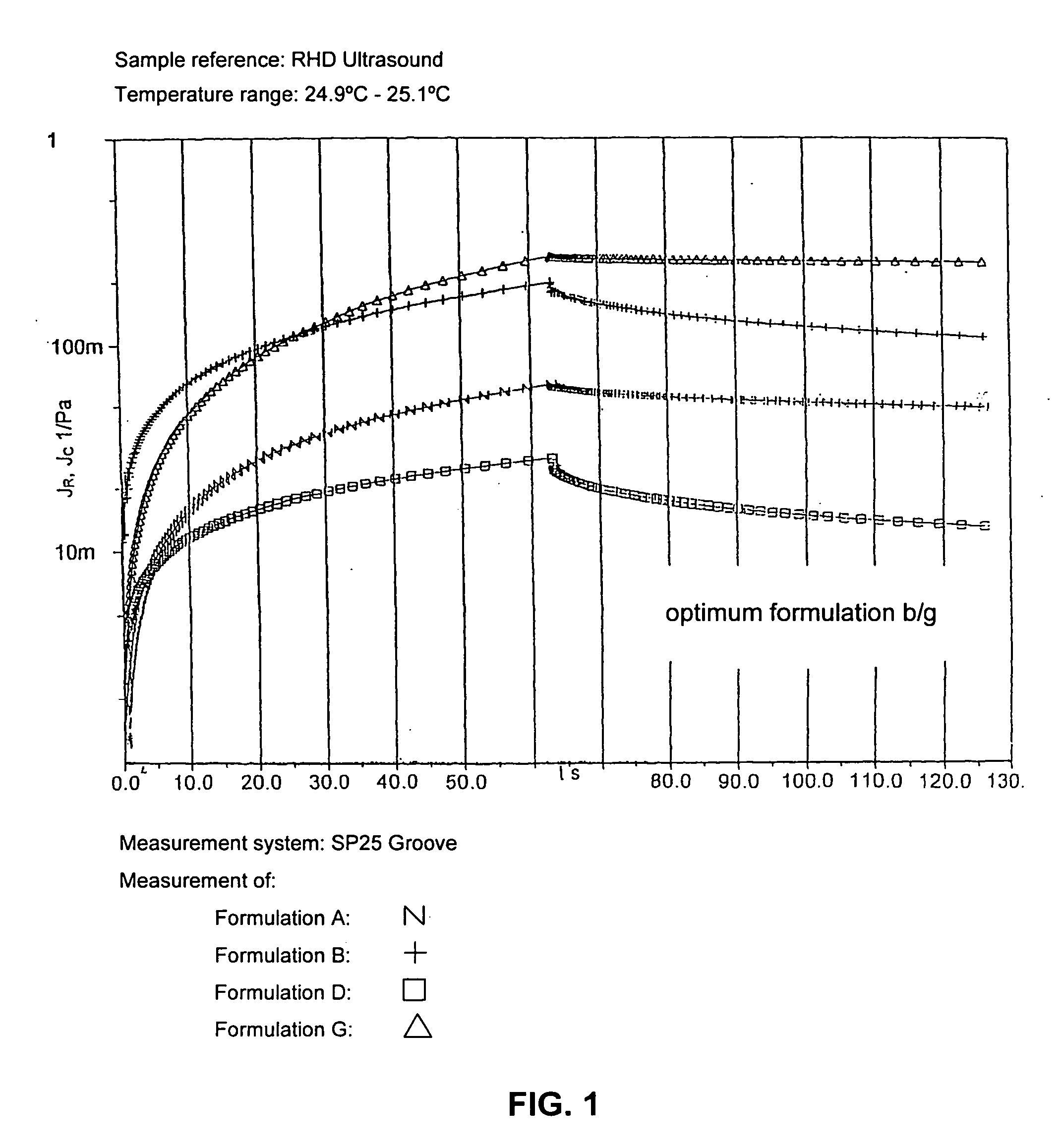

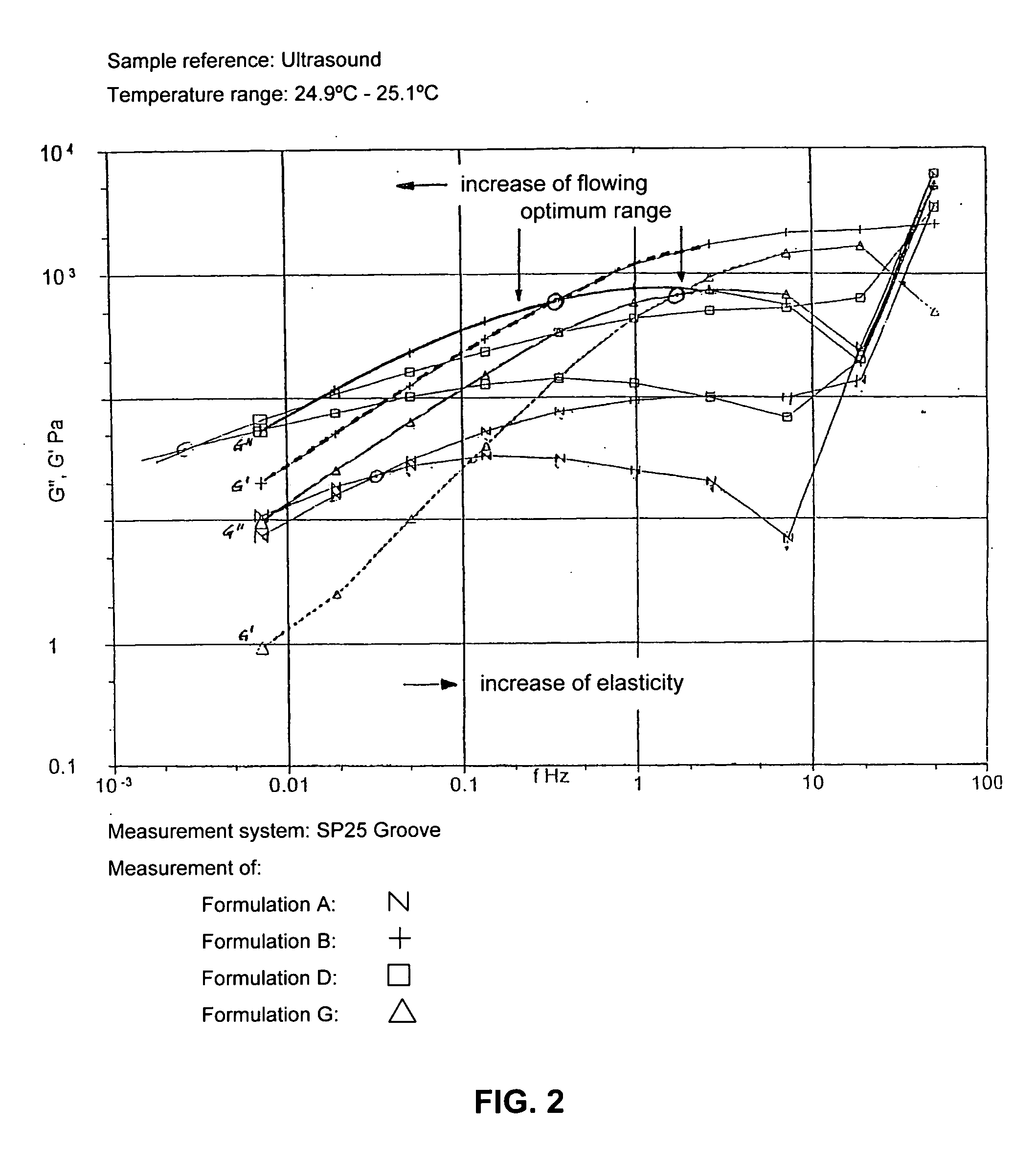

Ultrasound coupling medium for use in medical diagnostics

InactiveUS20070087060A1Avoid pollutionSuitable for usePowder deliveryEchographic/ultrasound-imaging preparationsPolyvinyl alcoholPreservative

A composition of an ultrasound coupling medium is provided. The composition comprises at least 90% water, at least one preservative, and at least one base substance, wherein the composition is extensible into a film with a thickness of up to 1 / 10 mm, wherein the composition can withstand a pressure of up to 30 kp without tearing, wherein the composition can adapt exactly to skin surface without causing any significant air pockets, and wherein the composition can be removed from skin with substantially no residue left behind. The at least one base substance may be a galactomannan, a polyvinyl alcohol (PVA), a complex formation of galactomannan and borate ions, or comninations thereof.

Owner:JOKER AG

Method of manufacturing light emitting device

InactiveUS7264979B2Reduce degradationStatic indicating devicesSolid-state devicesPolyvinyl alcoholLight emitting device

A high-quality light emitting device is provided which has a long-lasting light emitting element free from the problems of conventional ones because of a structure that allows less degradation, and a method of manufacturing the light emitting device is provided. After a bank is formed, an exposed anode surface is wiped using a PVA (polyvinyl alcohol)-based porous substance or the like to level the surface and remove dusts from the surface. An insulating film is formed between an interlayer insulating film on a TFT and the anode. Alternatively, plasma treatment is performed on the surface of the interlayer insulating film on the TFT for surface modification.

Owner:SEMICON ENERGY LAB CO LTD

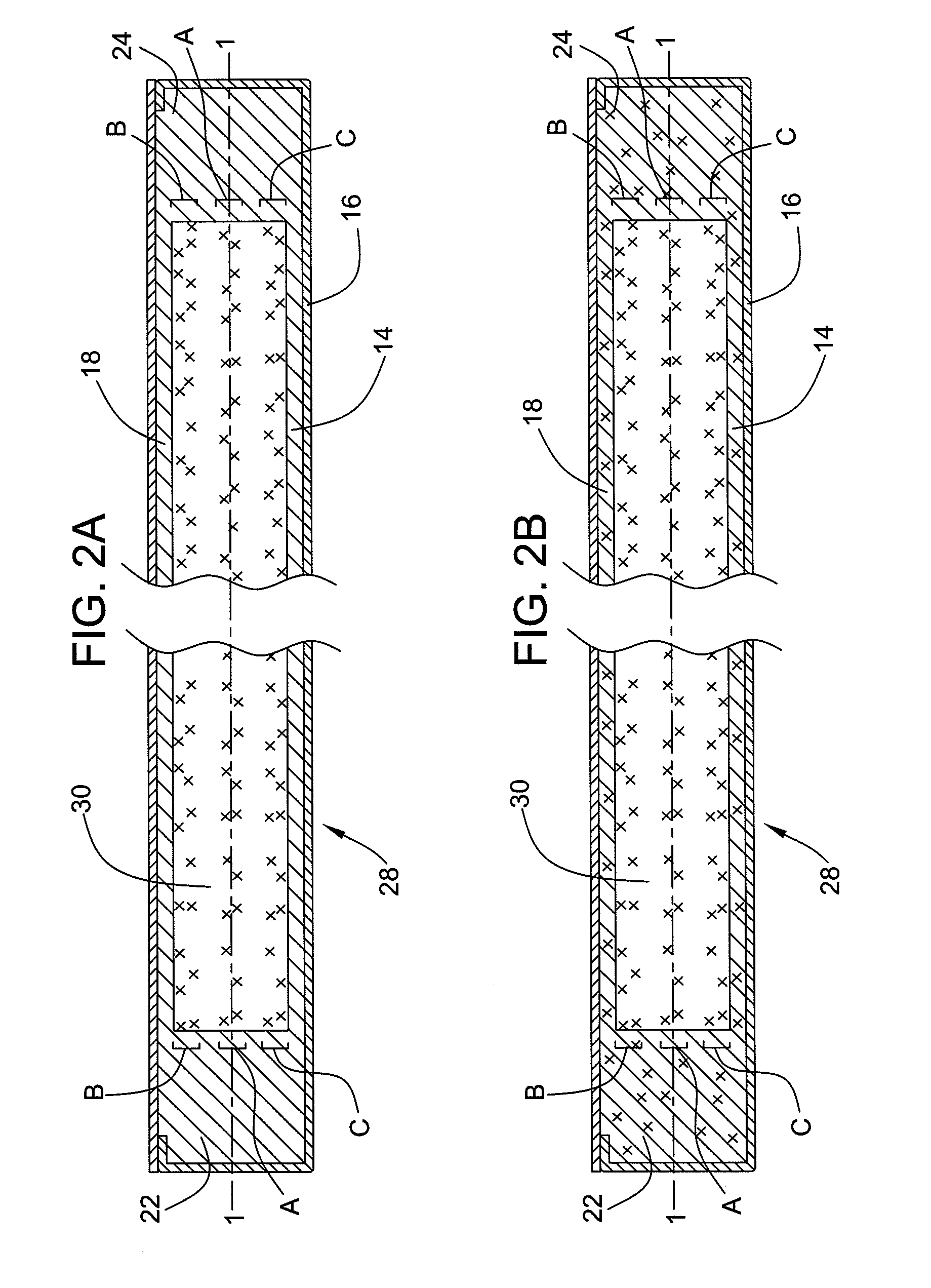

Cementitious article and method for preparing the same

ActiveUS20100247937A1Solid waste managementSynthetic resin layered productsAcetic acidPolymer science

A cementitious article and a method of making a cementitious article are disclosed. The cementitious article comprises a cementitious component that comprises a polyvinyl acetate type polymer, a monobasic phosphate, and optionally boric acid. Cementitious articles, such as board, are prepared such that the polyvinyl acetate type polymer, the monobasic phosphate, and optionally boric acid can be present in the cementitious core, and / or in dense layers if present. The concentration of the polyvinyl acetate type polymer, monobasic phosphate, and optionally boric acid in the cementitious article can increase from a central region A to peripheral regions B and C, respectively. In some embodiments, the polyvinyl acetate type polymer is a polyvinyl alcohol and the monobasic phosphate is monoammonium phosphate.

Owner:UNITED STATES GYPSUM CO

Stabilized Glycosaminoglycan Preparations and Related Methods

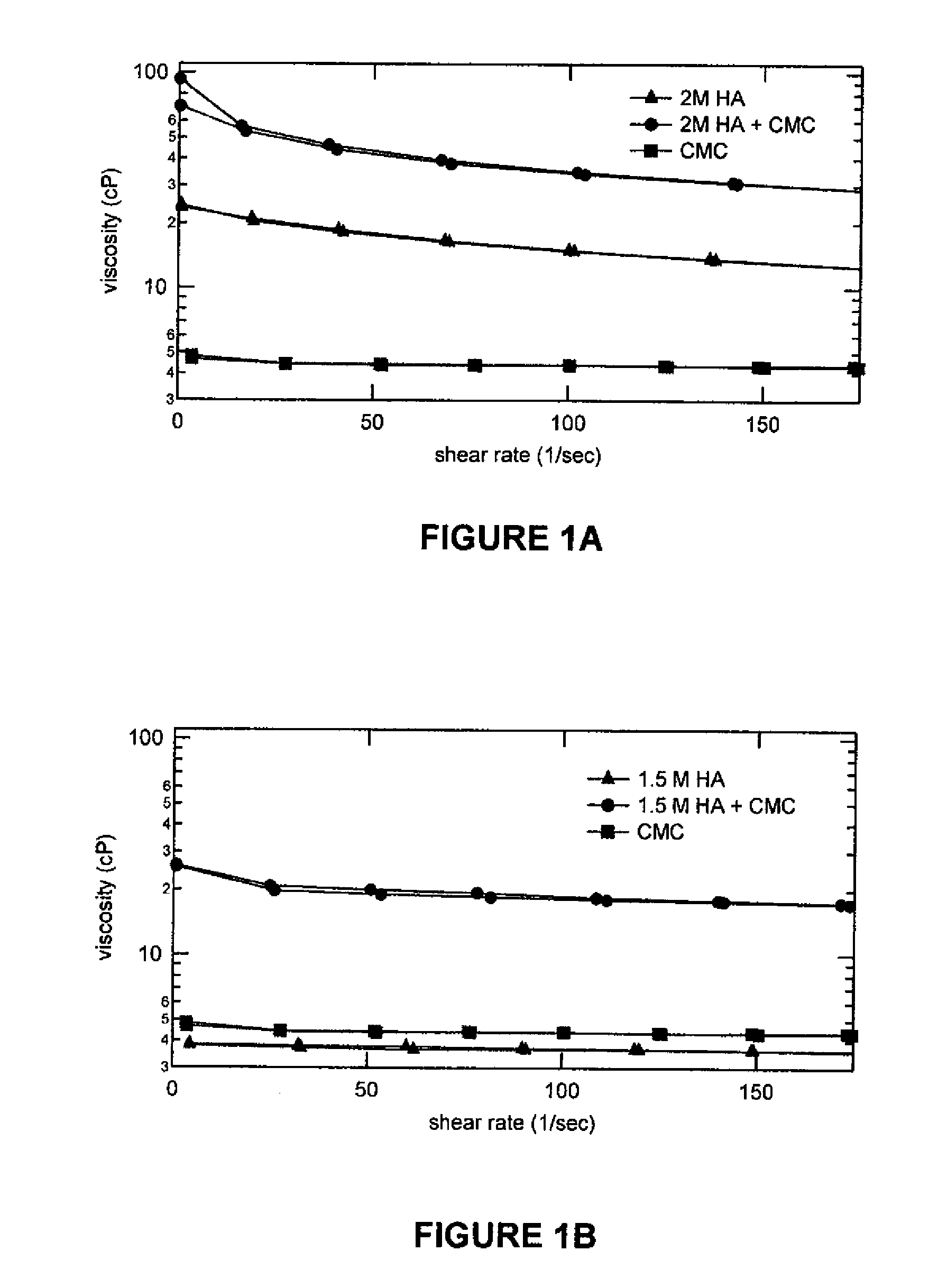

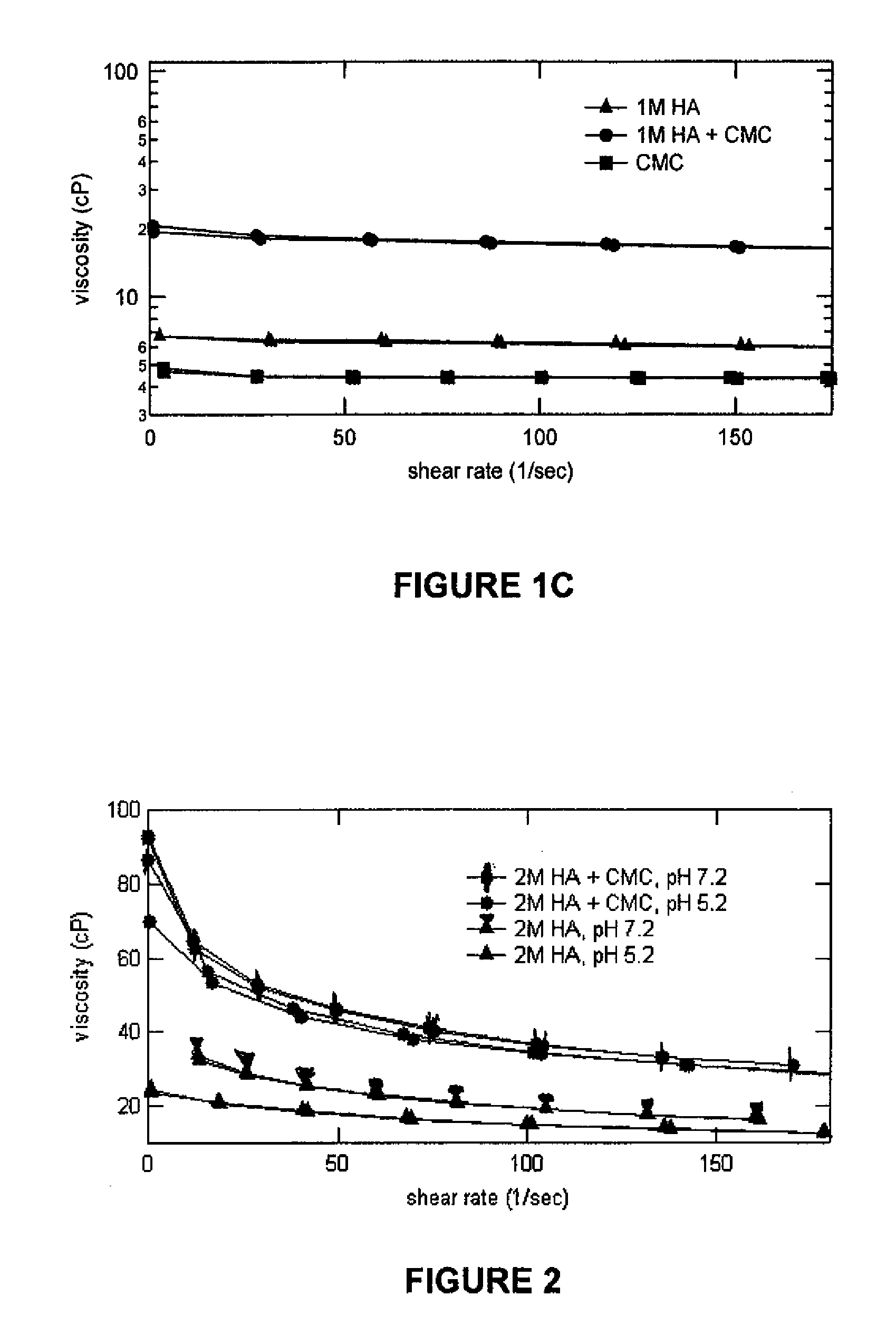

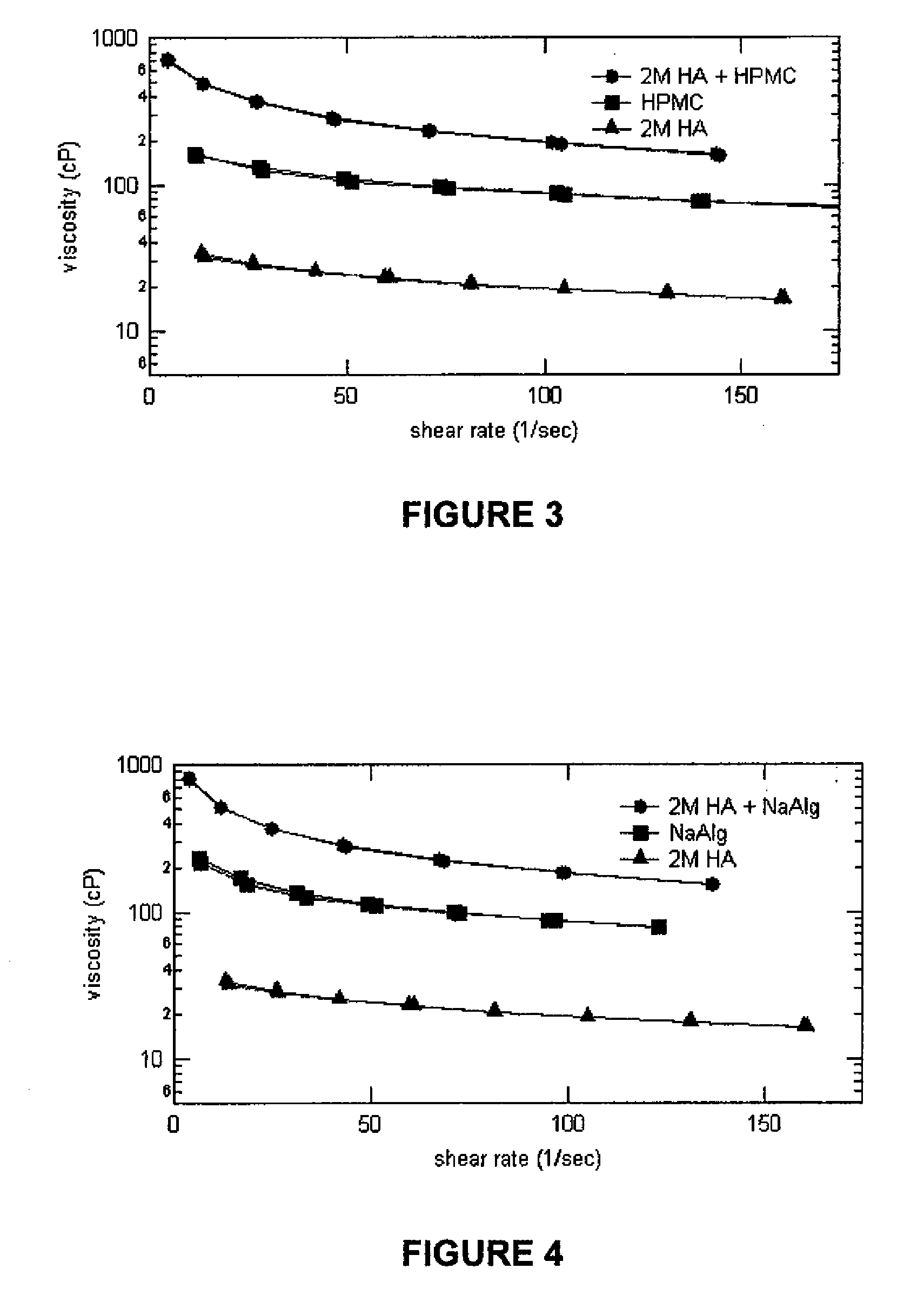

Compositions comprising a glycosaminoglycan (e.g., a hyaluronan, hyaluronic acid, hyaluronate, sodium hyaluronate, dermatan sulfate, karatan sulfate, chondroitin 6-sulfate, heparin, etc.) in combination with at least one component selected from; i) polyglycols (e.g., polyethylene glycol), ii) long chain hydroxy polyanionic polysaccharides (e.g., dextran, sodium alginate, alginic acid, propylene glycol alginate, carboxymethyl cellulose and carboxyethyl cellulose, hydroxyl ethyl starch, hydroxyl propyl methyl cellulose, hydroxy propyl ethyl cellulose, hydroxy propyl cellulose, methyl cellulose, polylysine, polyhistidine, polyhydroxy proline, poly ornithine, polyvinyl pyrolidone, polyvinyl alcohol, chitosan, etc.) and iii) long chain Nitrogen containing polymers (e.g., Polylysine, Polyvinylpyrrolidone, and polyvinyl alcohol). The invention also includes methods for using such compositions (e.g., as substance delivery materials, tissue fillers or bulking agents, as moistening or hydrating agents, etc.)

Owner:S K PHARMA INC

Multipurpose hydrogel compositions and products

InactiveUS20100055153A1Wide range of applicationsHigh mechanical strengthIn-vivo radioactive preparationsOintment deliveryPolyvinyl alcoholPolysaccharide

Disclosed are sterile hydrogel compositions comprising polyvinyl alcohol (“PVA”), polyvinyl pyrrolidone (“PVP”), and a polysaccharide, wherein the combined amount of PVA and PVP present in the hydrogel compositions is from about 2% to about 12% weight by volume, based on the total volume of the composition, and wherein the hydrogel compositions has a gel fraction greater than or equal to 97%. Sterile hydrogel products including such sterile hydrogel compositions, and methods of making such sterile hydrogel compositions and sterile hydrogel products.

Owner:TRANSDERMAL INNOVATIONS

Interlayer films for laminated glazing containing silica with specific refractive index

InactiveUS20100124647A1Improve mechanical propertiesSynthetic resin layered productsAbsorbent padsPolymer sciencePolyvinyl alcohol

Interlayer films useful for laminated glass contain a polyvinyl acetal (A), at least on plasticizer (B), fumed silica (C) and at least one basic compound (D), wherein the difference of refractive index between fumed silica (C) and plasticized polyvinyl acetal (A+B) is 0.015 or less, and the weight ratio of C / (A+B) is 2.7-60 / 100.

Owner:KURARAY EURO GMBH +1

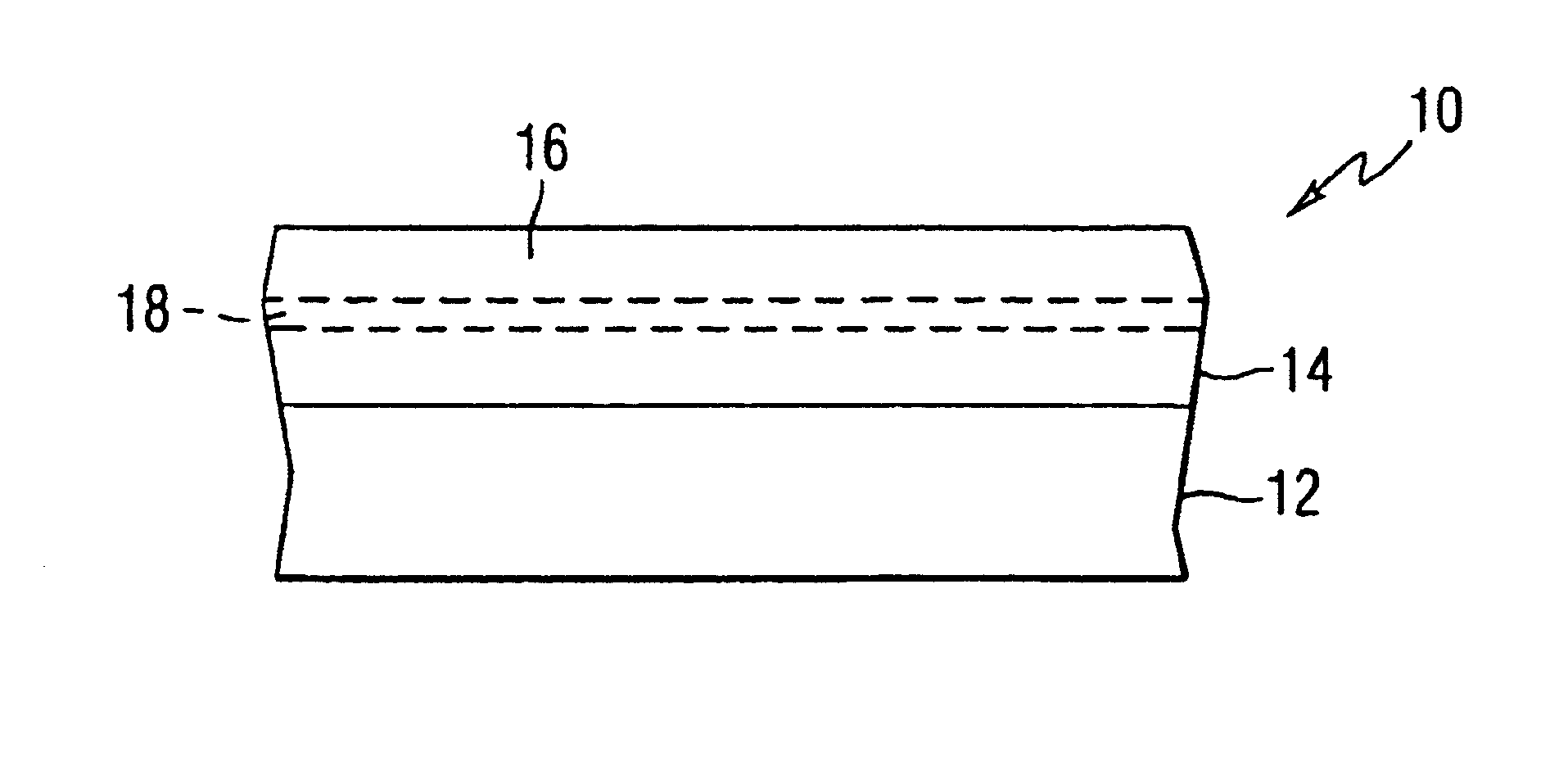

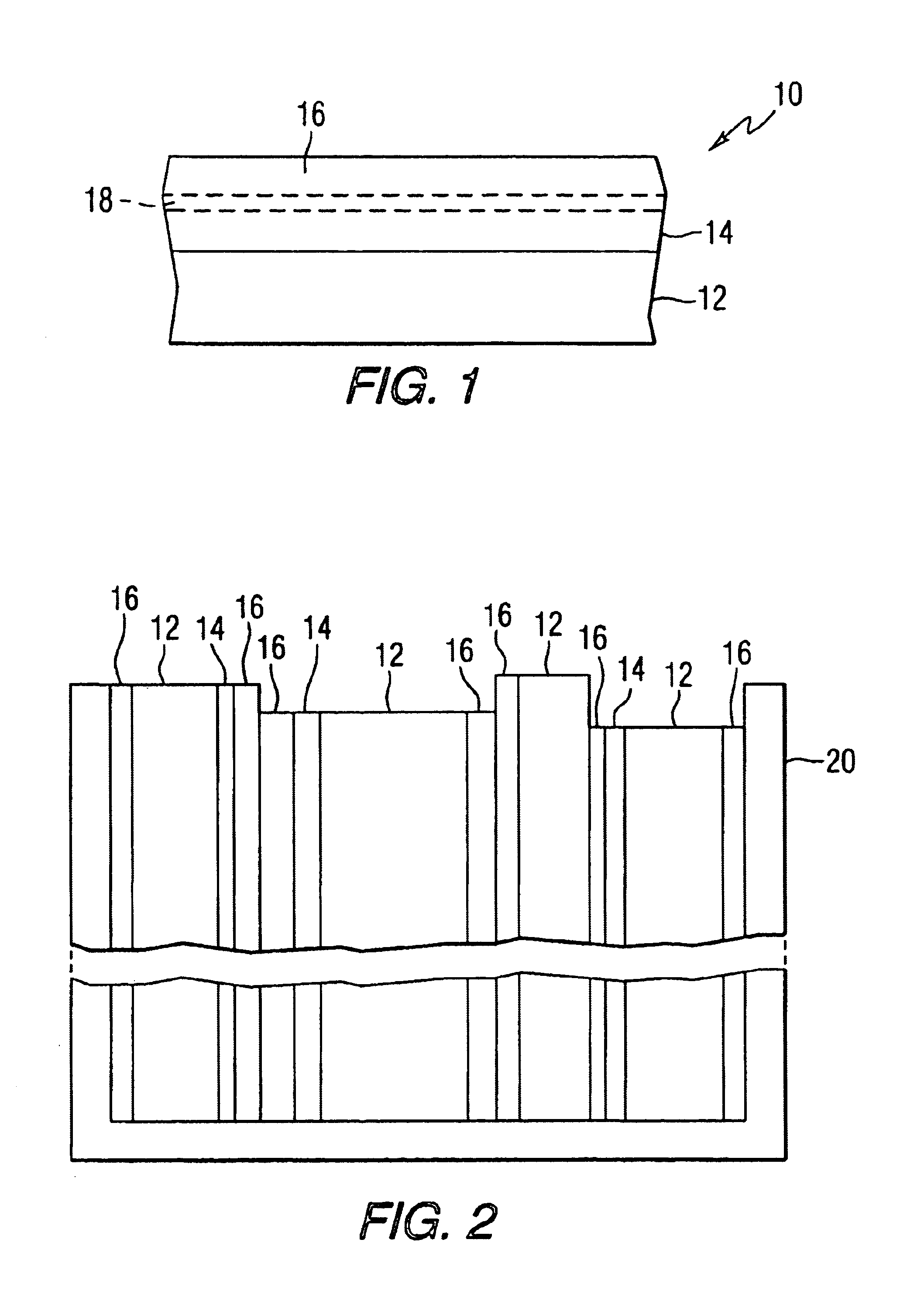

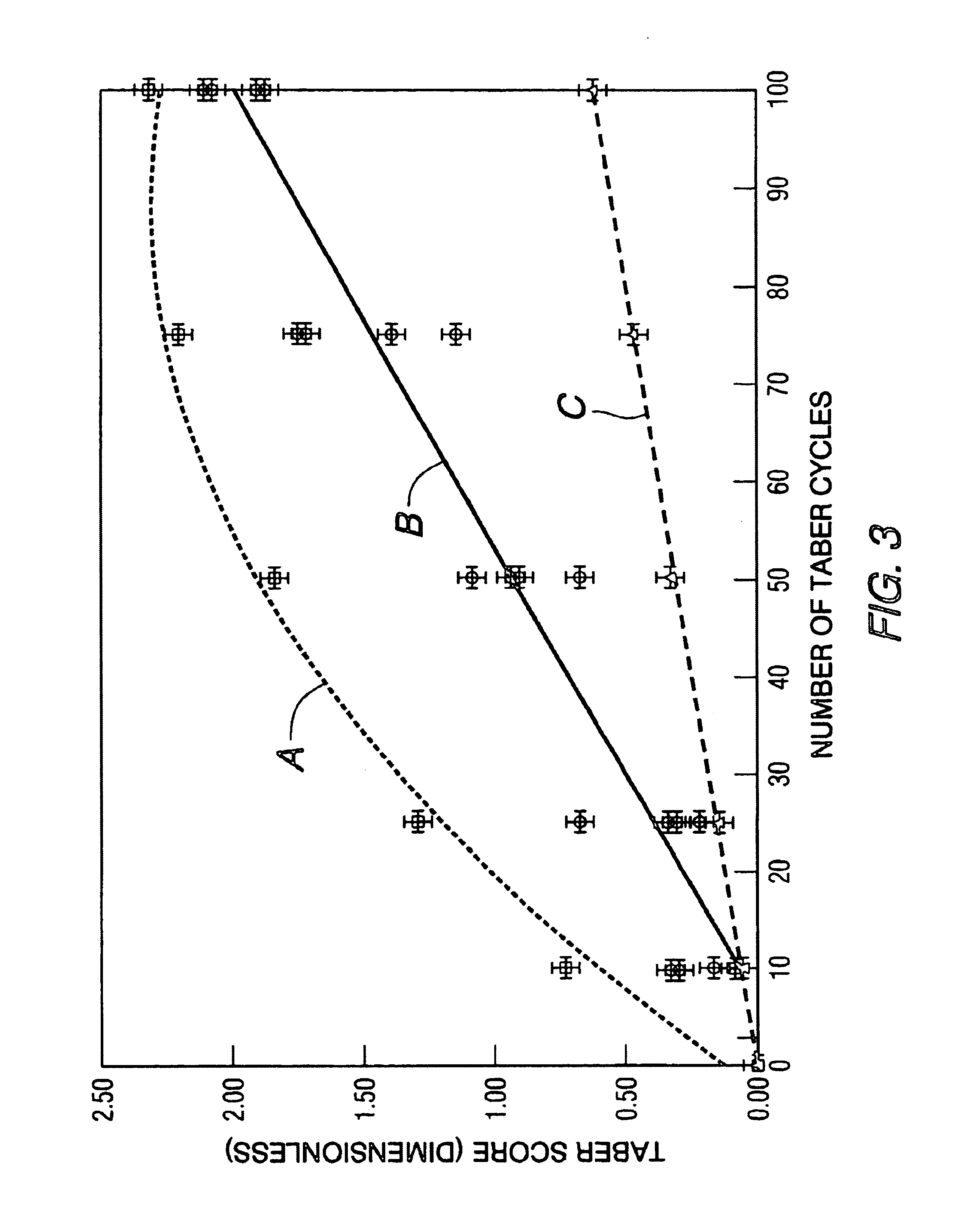

Light-transmitting and/or coated article with removable protective coating and methods of making the same

InactiveUS6849328B1Heating evenlyIncrease heat absorptionSynthetic resin layered productsPaints with biocidesCombustionPolyvinyl alcohol

A method and coating are provided for temporarily protecting a substrate or article during shipping, handling or storage by applying a removable protective coating over at least a portion of the substrate. The substrate may be flat or curved and may have zero, one or more functional coatings. A plurality of substrates with the protective coating of the invention may be arranged in a shipping container so that the protective coating reduces the possibility of damage to the substrate or optional functional coating. In one embodiment, the protective coating is the evaporation or reaction product of an aqueous coating composition containing a polyvinyl alcohol polymer which may be subsequently removed by aqueous washing, thermal decomposition or combustion. In another embodiment, the protective coating is formed by sputtering a substantially carbon coating onto the substrate. The carbon coating is subsequently removed by combustion. The protective coating may have identification materials, such as colorants or fragrance materials, such that different types of substrates and / or functional coatings can be distinguished from each other. Additionally, the temporary protective coating can improve the heating of a functionally coated glass substrate.

Owner:VITRO FLAT GLASS LLC

Water-soluble film

ActiveUS20090291282A1Good water solubilitySynthetic resin layered productsInksPolymer sciencePolyvinyl alcohol

The present invention relates to a water-soluble film, which is a polyvinyl alcohol film comprising a polyvinyl alcohol resin (A), wherein the water-soluble film has a time for dissolution in water at 20° C. of not more than 60 seconds in terms of a film thickness of 76 μm, a b-value of the film is not more than 0.5, and a b-value of the film after leaving at 80° C. for 72 hr is not more than 1.0, preferably a water-soluble film comprising: a polyvinyl alcohol resin (A); at least two kinds of plasticizers (B); and a sulfite salt (C), wherein the content of the plasticizer (B) based on 100 parts by weight of the polyvinyl alcohol resin (A) is 5 to 50 parts by weight and the content ratio of the sulfite salt (C) to the plasticizer (B) (C / B: weight ratio) is more than 0.02 and not more than 0.35. According to the invention, there is provided a water-soluble film comprising a PVA resin as a main component, wherein the film is less likely to cause coloration at the time of film formation and coloration with time even upon contact with a chemical.

Owner:MITSUBISHI CHEM CORP

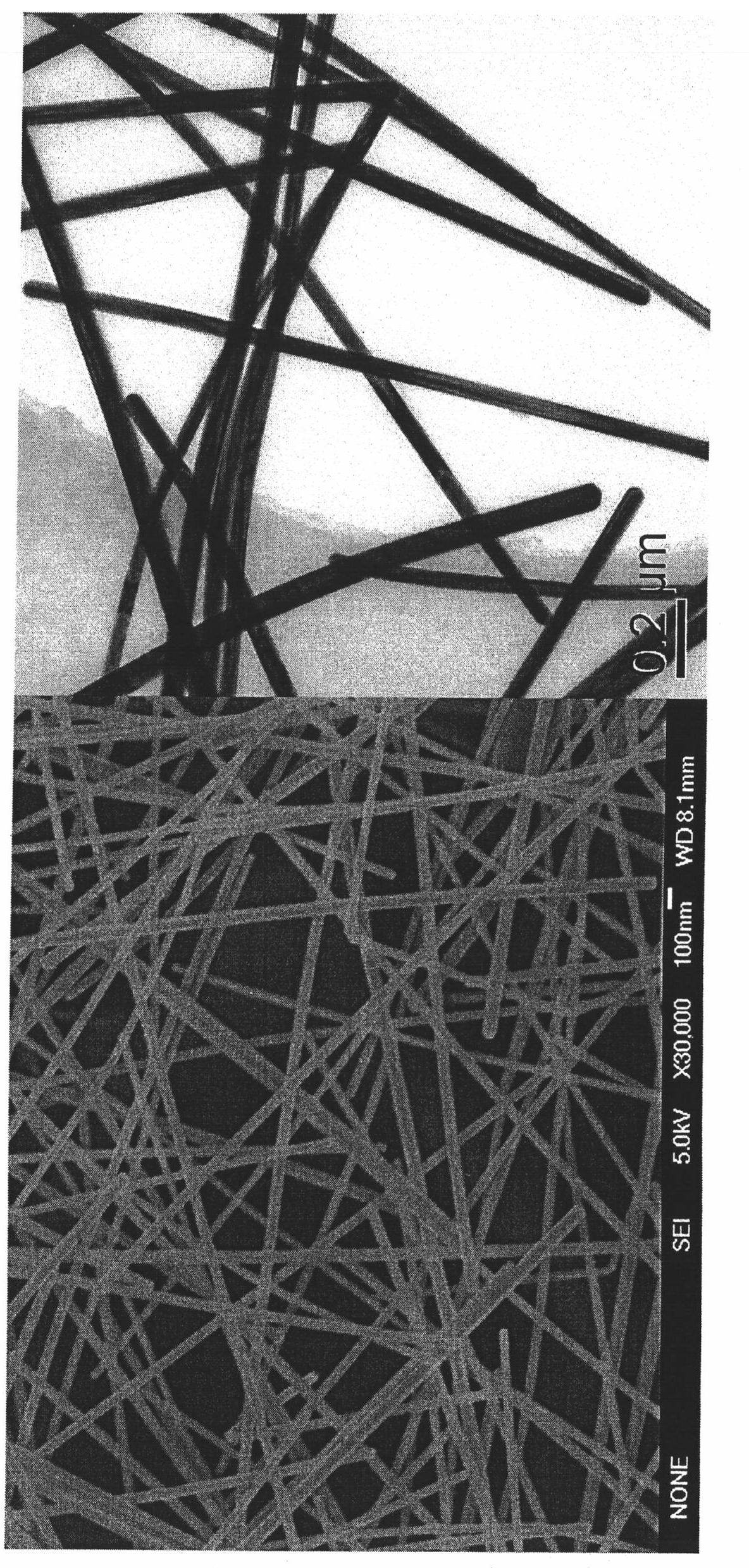

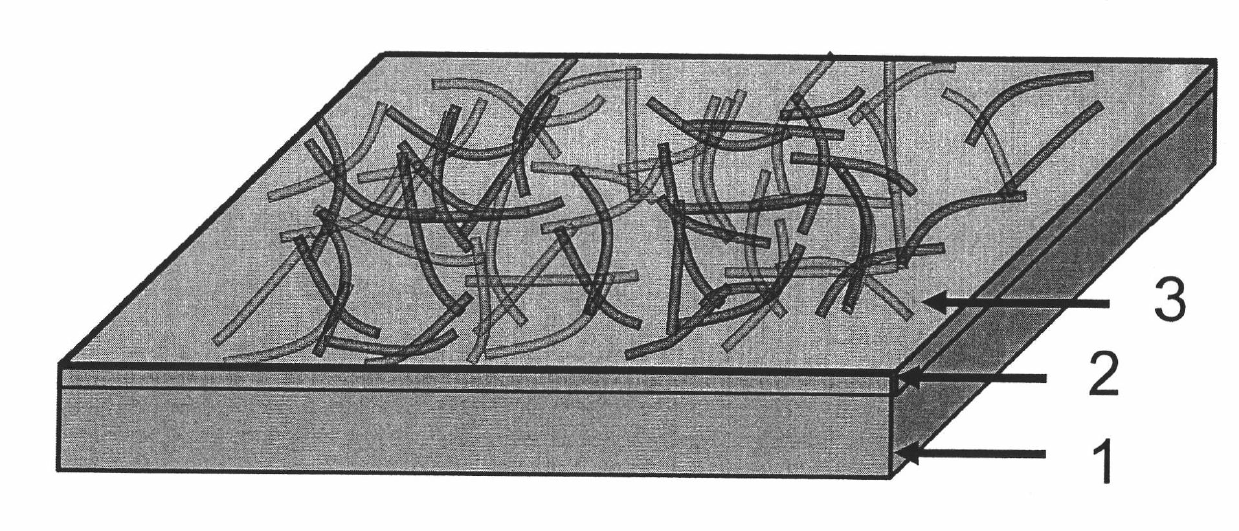

Silver nanowire-based transparent conductive thin film and preparation method thereof

InactiveCN102087886AReduce roughnessReduce transmittanceConductive layers on insulating-supportsIndividual molecule manipulationPolyvinyl alcoholPolymethyl methacrylate

The invention provides a silver nanowire-based transparent conductive thin film and a preparation method thereof. The preparation method is characterized by comprising the following steps of: forming a uniform adhesive layer on a substrate by organic polymer fluid; and forming a silver nanowire conductive layer on the adhesive layer, wherein silver nanowires can be firmly adhered to the adhesive layer. Through the adhesive layer, the firmness and the reliability of the silver nanowire transparent conductive thin film are greatly improved, the problem of easiness of falling of the silver nanowires is solved, and the selection range of the substrate is expanded. If the adhesive layer is formed by polyvinyl alcohol on a polymethyl methacrylate (PMMA) substrate, the visible light transmittance reaches 84 percent when square resistance is 130.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Associating hydrogels for nucleus pulposus replacement in intervertebral discs

A prosthetic nucleus prepared from blends of polyvinylalcohol and polyvinyl pyrollidone or its copolymers for replacement of the nucleus pulposus in intervertebral discs is provided. Also provided are methods of replacing the nucleus pulposus and treating disc degeneration-associated pain in mammals using this prosthetic nucleus.

Owner:DREXEL UNIV

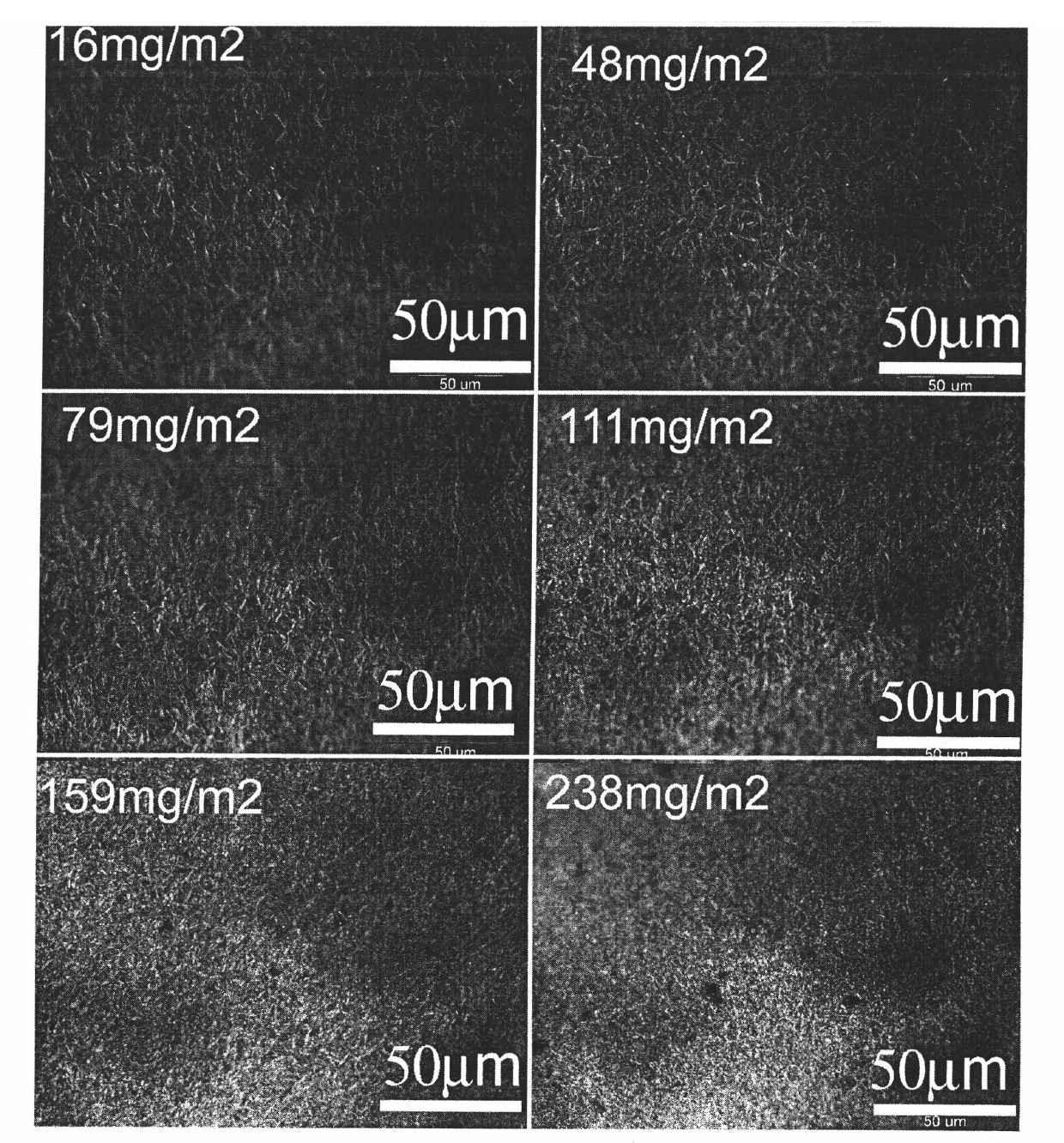

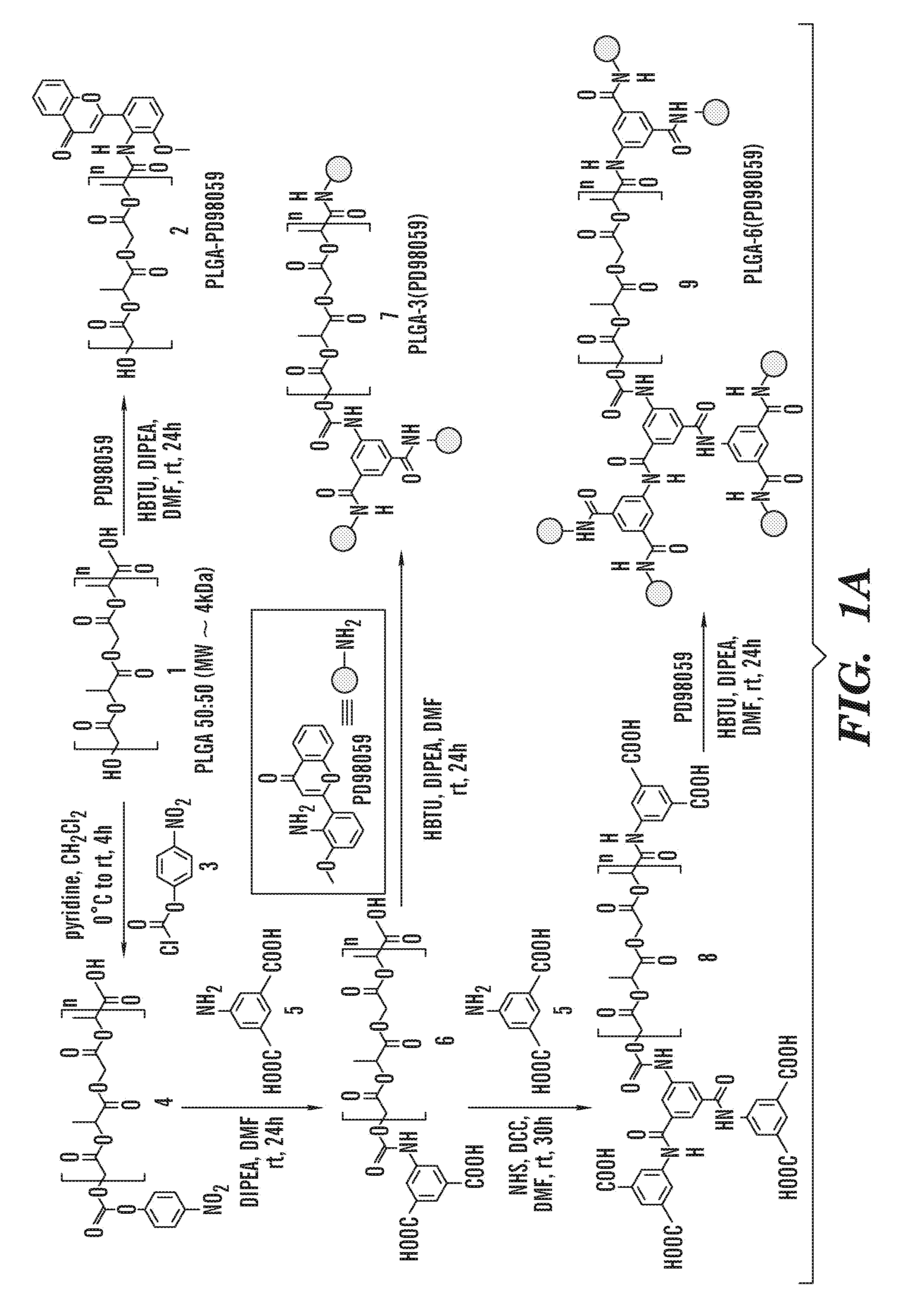

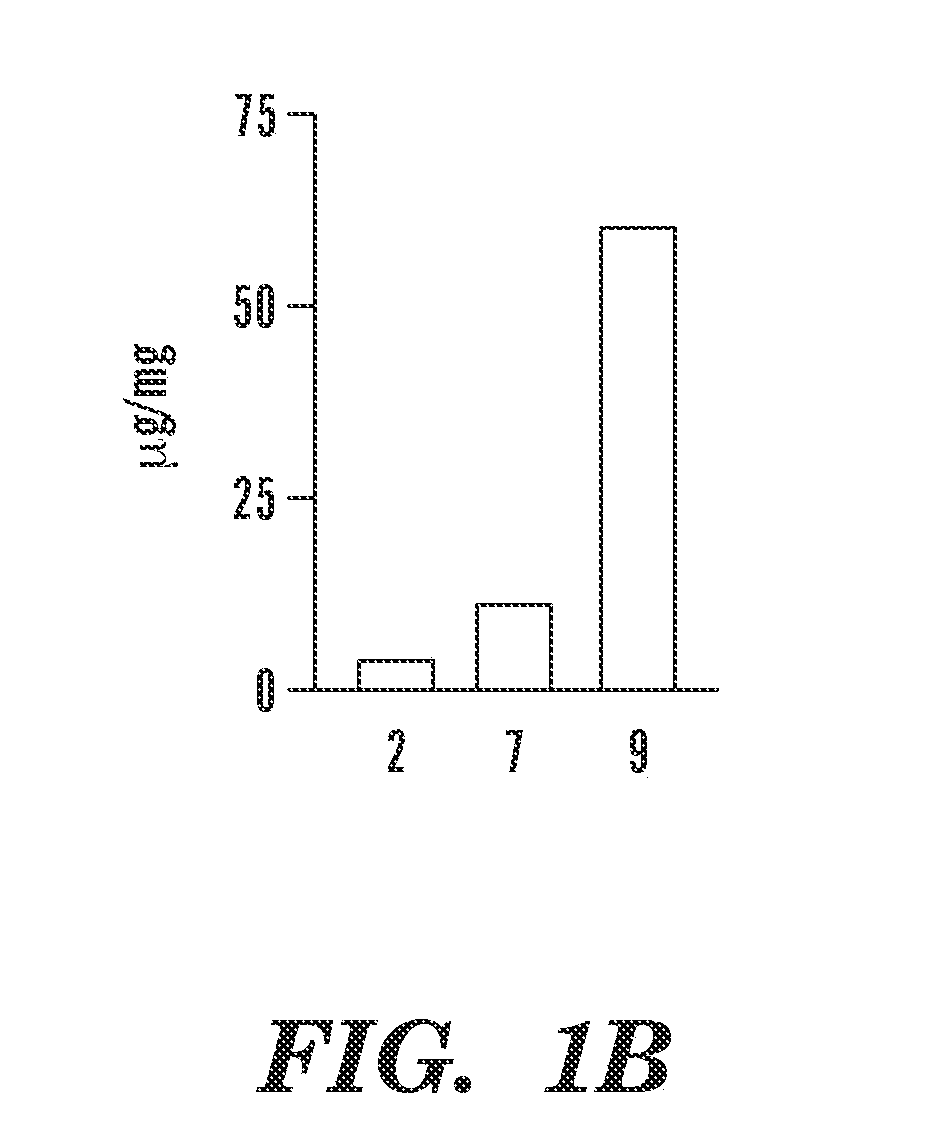

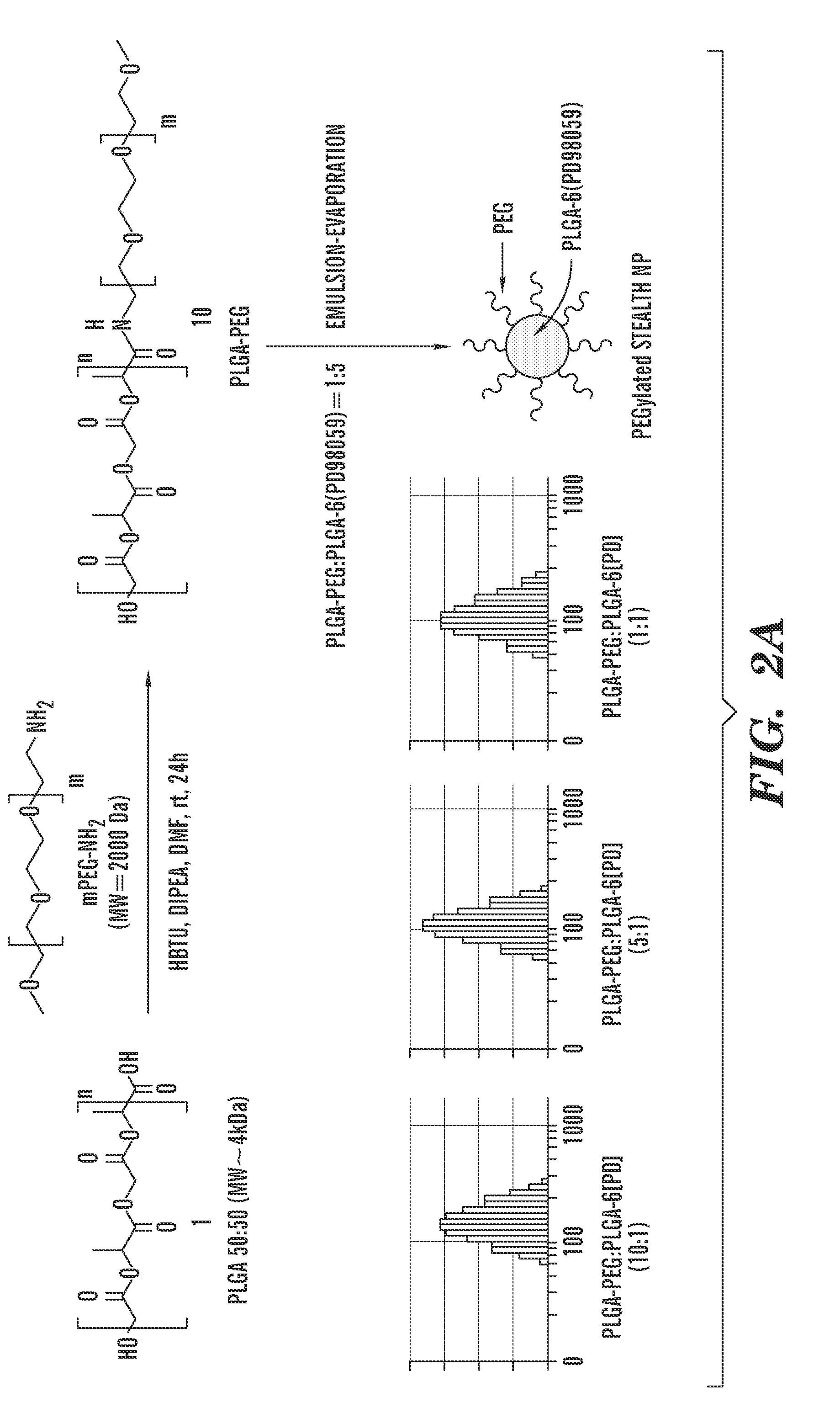

Polymeric nanoparticles with enhanced drug-loading and methods of use thereof

The invention is directed to modified polymers with increased drug-loading including compounds of formula (I): wherein Z is a poly(lactic-co-glycolic acid) (PLGA) polymer having molecular weight from 1-15 kDa and where the ratio of lactide to glycolide in the PLGA polymer is from 1:10 to 10:1; formula (II) R1 are independently H, R2, OH, O-alkyl, —O—R2, NH—R2, -linker-R2, or -and R2 are independently one or more therapeutic agents. The invention is also directed to nanoparticle drug delivery systems including a PLGA-b-PEG block copolymer; and a stabilizer and to drug delivery systems including PLGA-b-PEG block copolymer polyvinyl alcohol (PVA) nanoparticle; and the modified polymer substantially as described herein.

Owner:THE BRIGHAM & WOMEN S HOSPITAL INC

Polyvinyl alcohol-containing compositions and methods for dermal delivery of drugs

InactiveUS20070196323A1Easily peelableEasily removablePharmaceutical non-active ingredientsSynthetic polymeric active ingredientsPropanolAlcohol

The present invention is drawn to adhesive solidifying formulations, and methods for dermal delivery of a drug. The formulation can include a drug, a solvent vehicle, and a polyvinyl alcohol. The solvent vehicle can include a volatile solvent system including water and an alcohol solvent, e.g., ethanol, propanol, and / or isopropanol, and a non-volatile solvent system including at least one non-volatile solvent which is compatible with polyvinyl alcohol. The formulation is formulated such that the water to polyvinyl alcohol weight ratio is in the range of from about 4:1 to about 1:1, and water to alcohol solvent weight ratio in the range of from about 0.33:1 to about 6:1.

Owner:ZARS INC

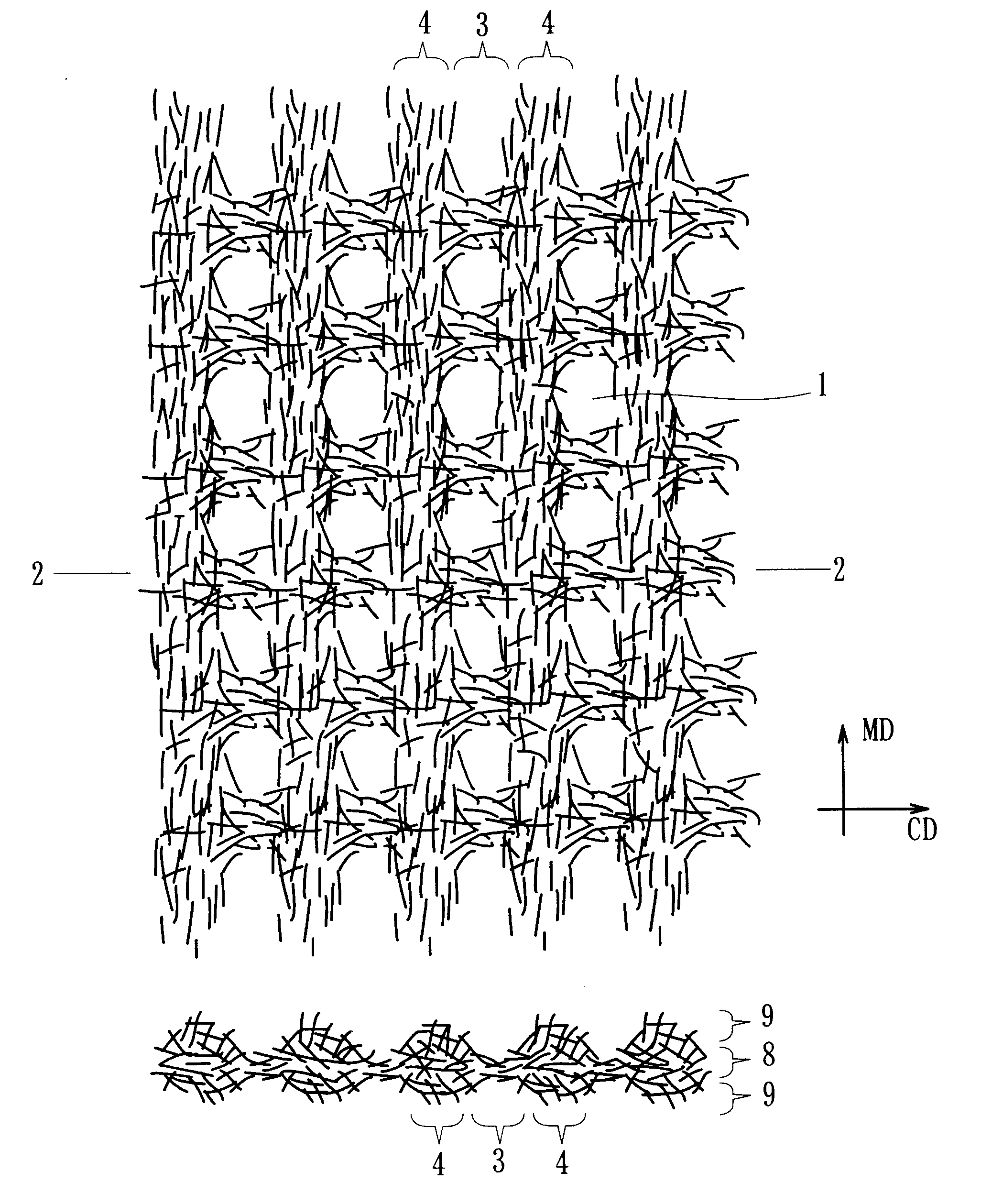

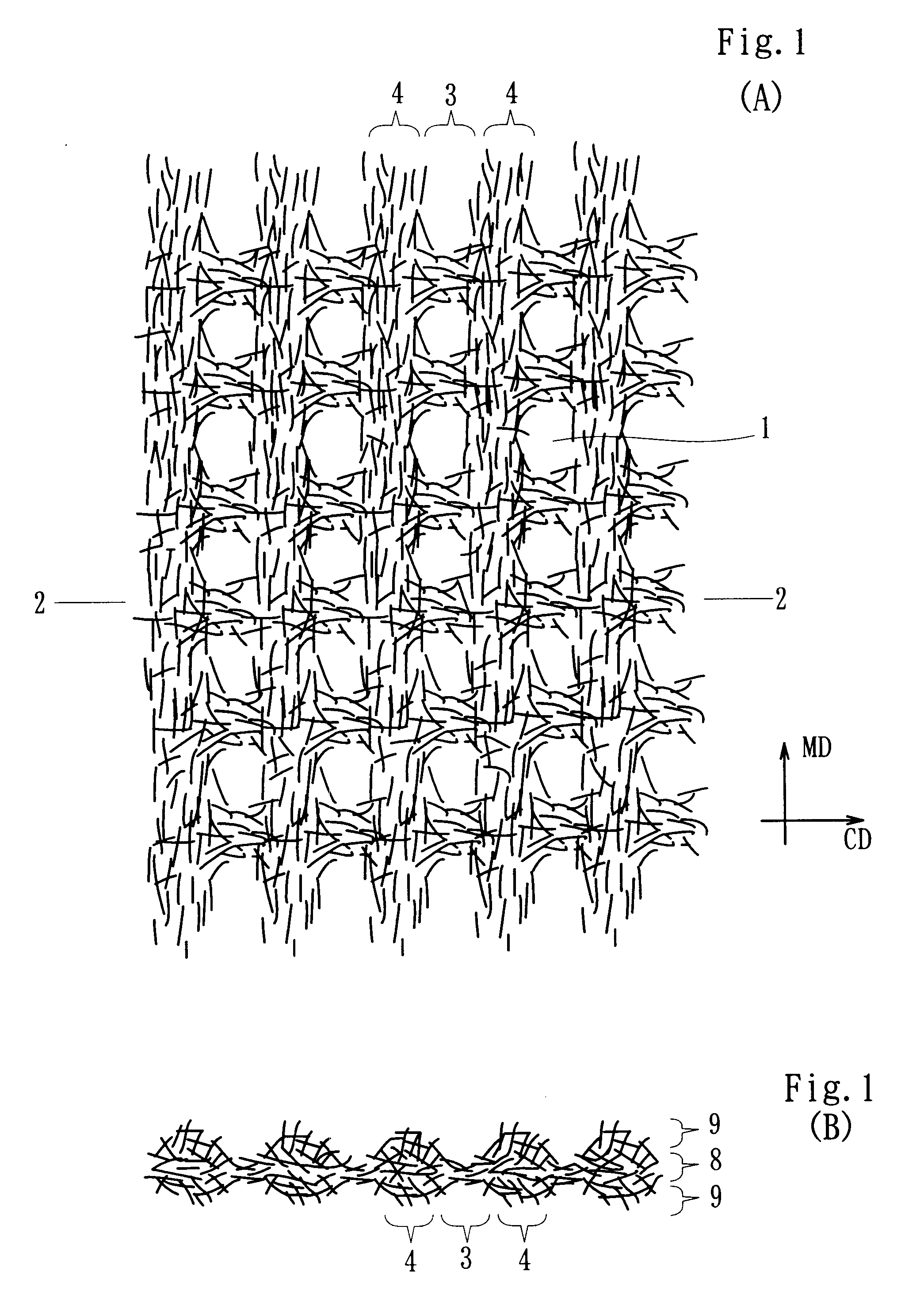

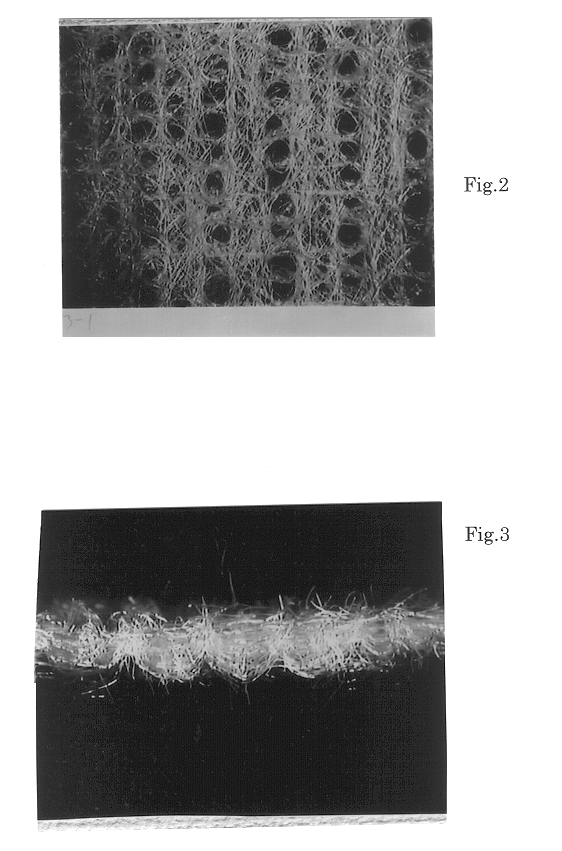

Method of manufacturing a water disintegratable non-woven fabric and the water disintegratable non-woven fabric

InactiveUS6451718B1Improve wiping effectNon-fibrous pulp additionSynthetic resin layered productsFiberCarboxymethyl cellulose

A water disintegratable non-woven fabric having excellent water disintegratability and high wet strength can be obtained by a step of forming a fiber web from fibers having a fiber length of 10 mm or less, a step of applying a water jet treatment to the fiber web to obtain a fiber sheet having wet strength of less than 100 g / 25 mm in MD and CD, the wet strength being defined by tensile strength at break of the fiber sheet, as measured by using a tensilon tester with a chuck distance of 100 mm, at a tensile speed of 100 mm / min to the fiber sheet which is cut into 25 mm width and 150 mm length and impregnated with water in an amount 2.5 times the weight of the fiber sheet, and a step of adding at least one binder selected from the group consisting of carboxymethyl cellulose, alkylcellulose, polyvinyl alcohol and modified polyvinyl alcohol to the fiber sheet. The water disintegratable non-woven fabric is sufficiently bulky and has an excellent wiping effect.

Owner:UNI CHARM CORP

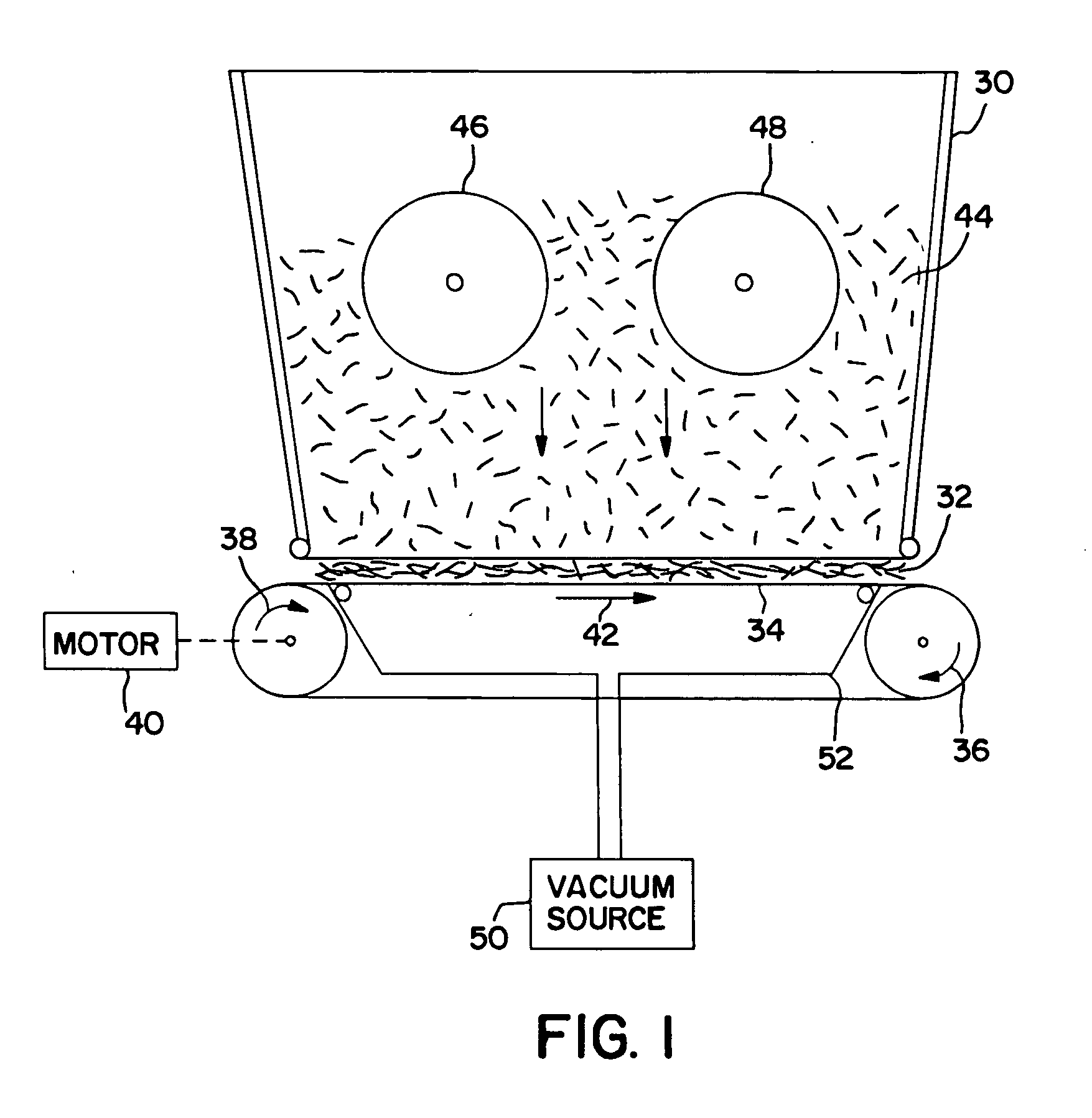

Water dispersible, pre-saturated wiping products

A water dispersible nonwoven web is disclosed. The nonwoven web is produced in an airlaying process and contains pulp fibers mixed with water soluble fibers. The water soluble fibers may be, for instance, polyvinyl alcohol fibers. The nonwoven web may be pre-saturated with a cleaning solution. Once pre-saturated with a cleaning solution, the wiping product is particularly well suited to cleaning and / or disinfecting surfaces, such as toilet seats prior to use. Because the nonwoven web is water dispersible, the wiper may be disposed of by being flushed down a toilet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Light emitting device and manufacturing method thereof

InactiveUS6720198B2Solid-state devicesSemiconductor/solid-state device manufacturingPolyvinyl alcoholPorous medium

A method of manufacturing a high quality light emitting device is provided, in which light emitting elements having long life are manufactured by using light emitting elements having a structure that deteriorates less easily than conventional structures. After forming a bank, an exposed anode surface is wiped using a PVA (polyvinyl alcohol)-based porous medium, performing leveling and removal of debris. An insulating film is formed covering the bank and the anode, unevenness on the anode surface is covered, and the balance between the amount of holes and electrons injected into an organic compound layer can be regulated.

Owner:SEMICON ENERGY LAB CO LTD

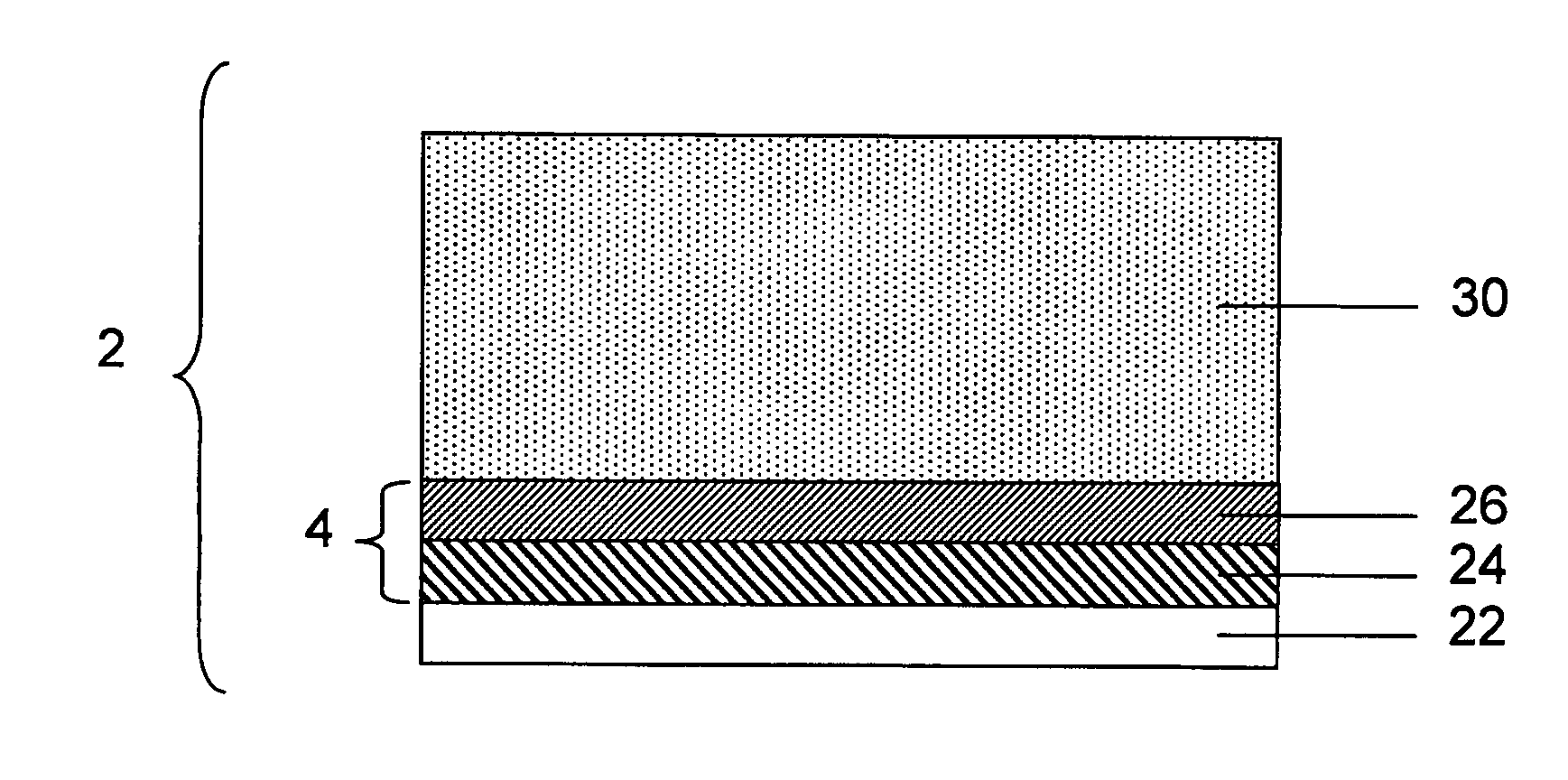

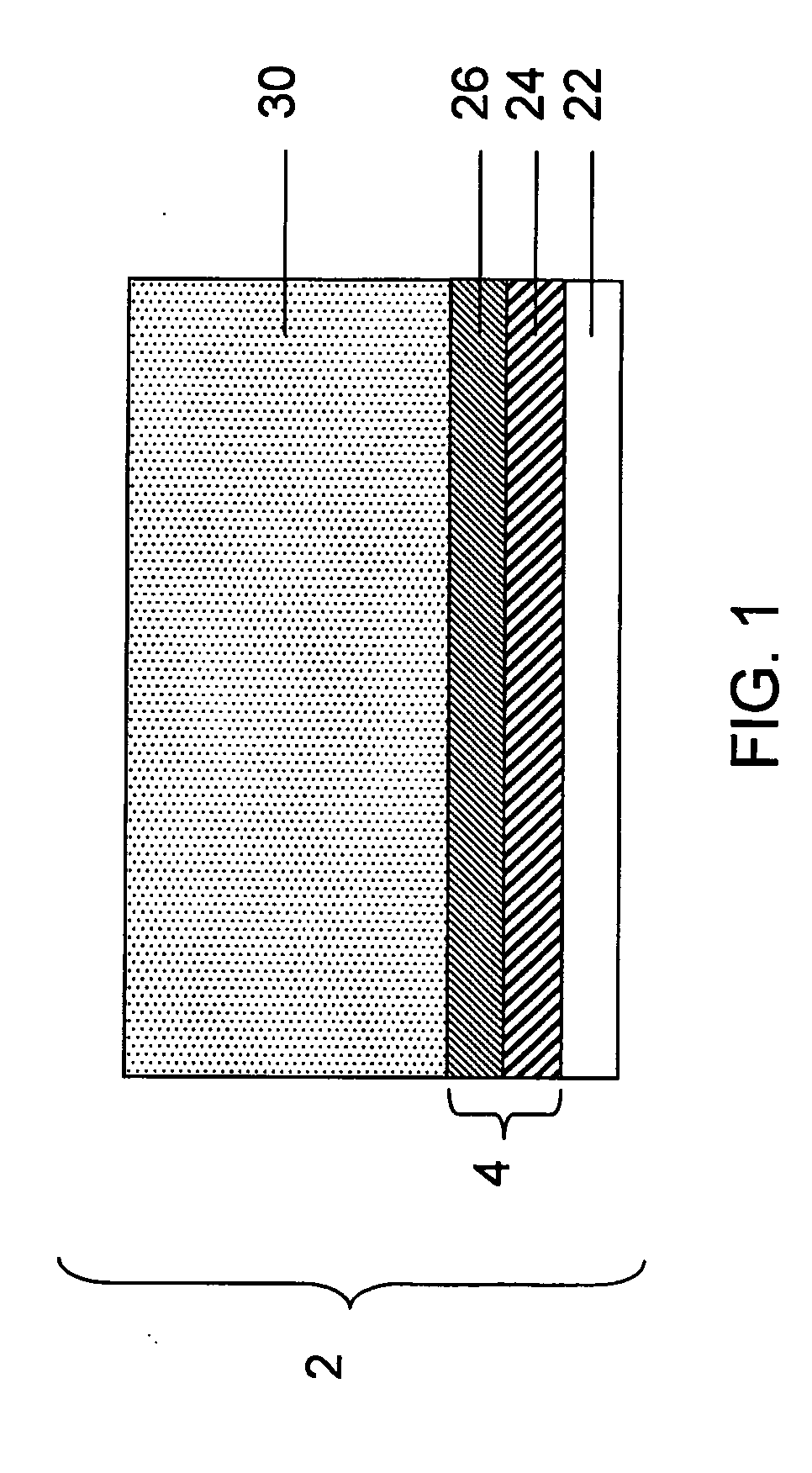

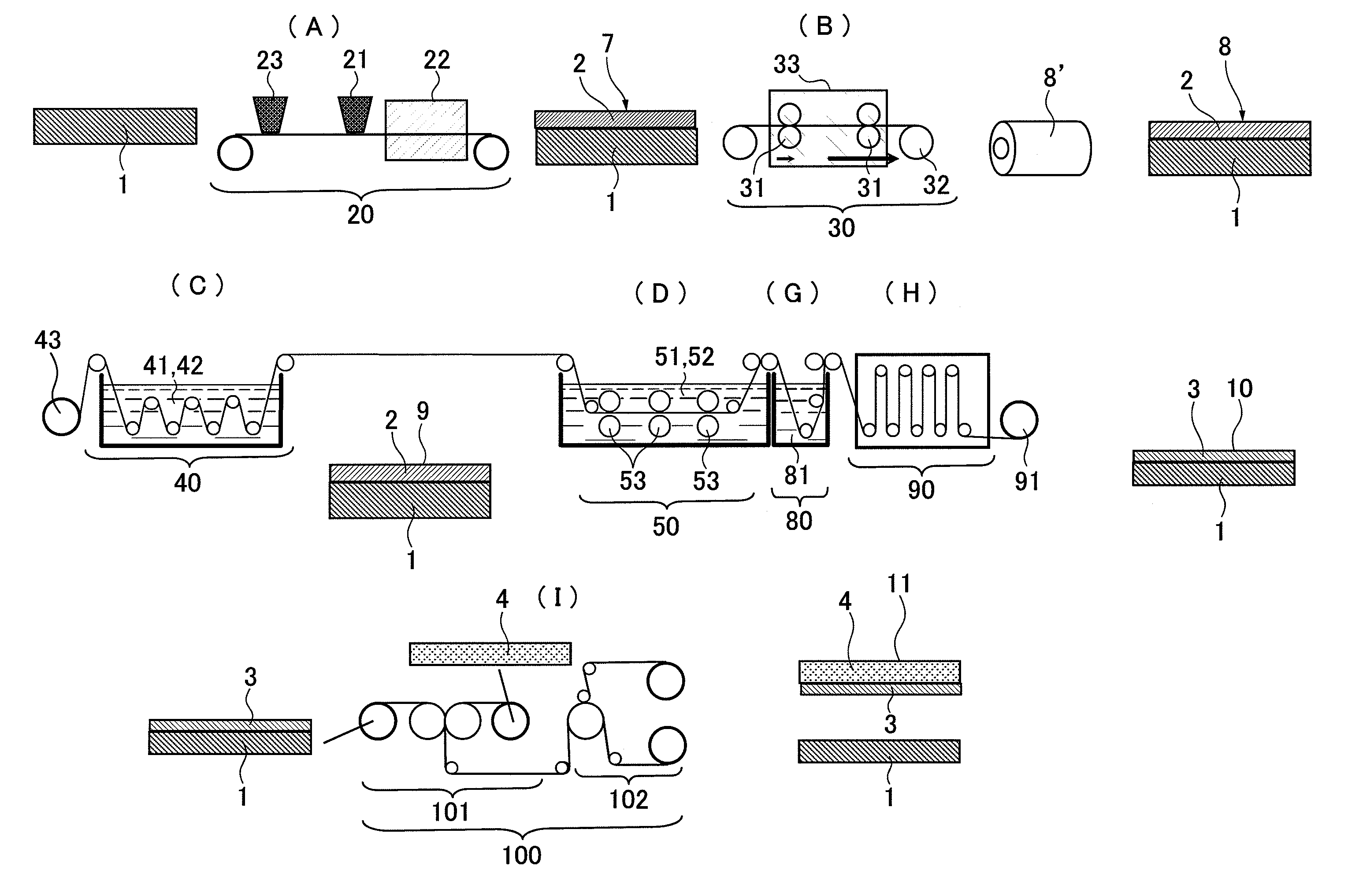

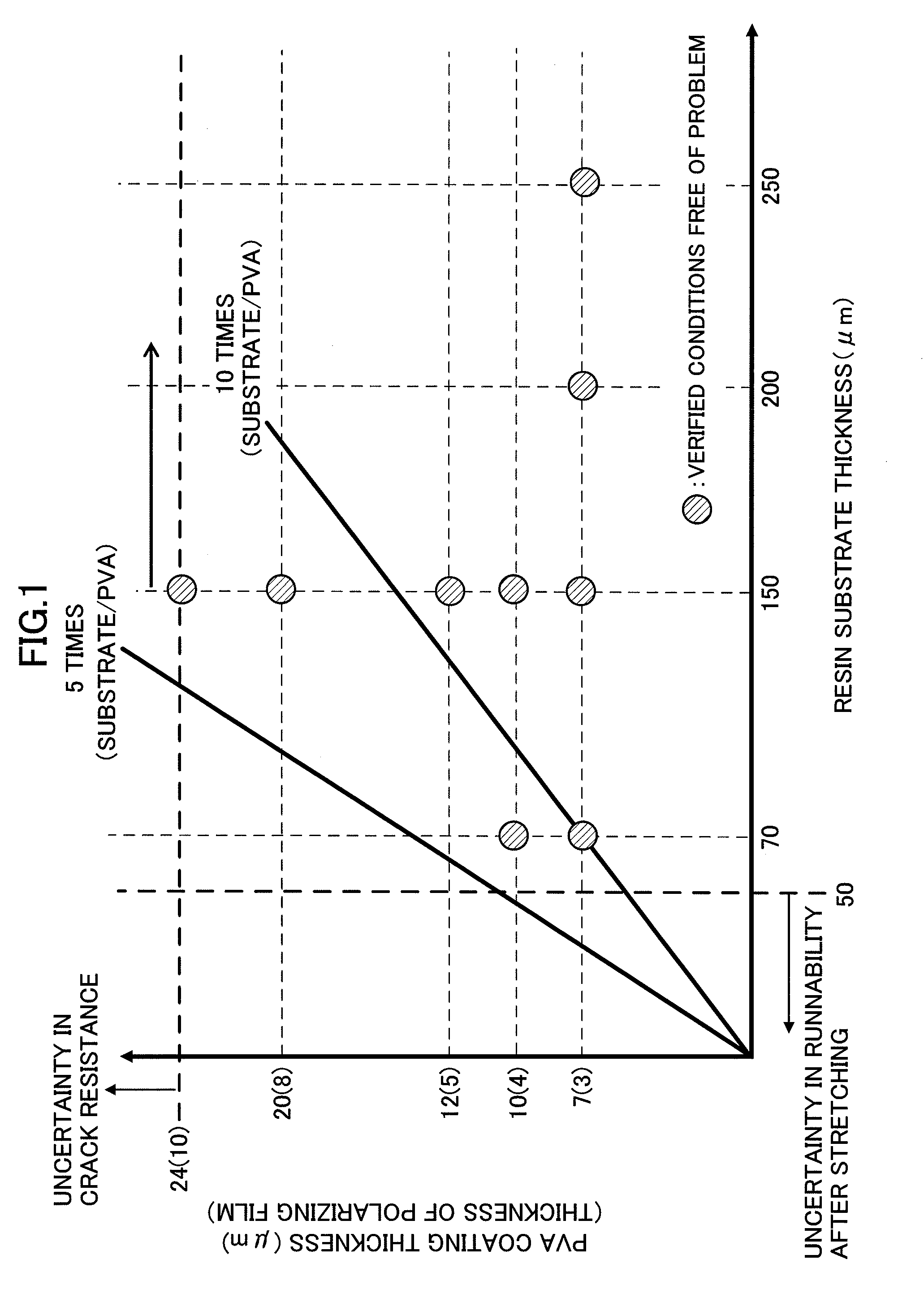

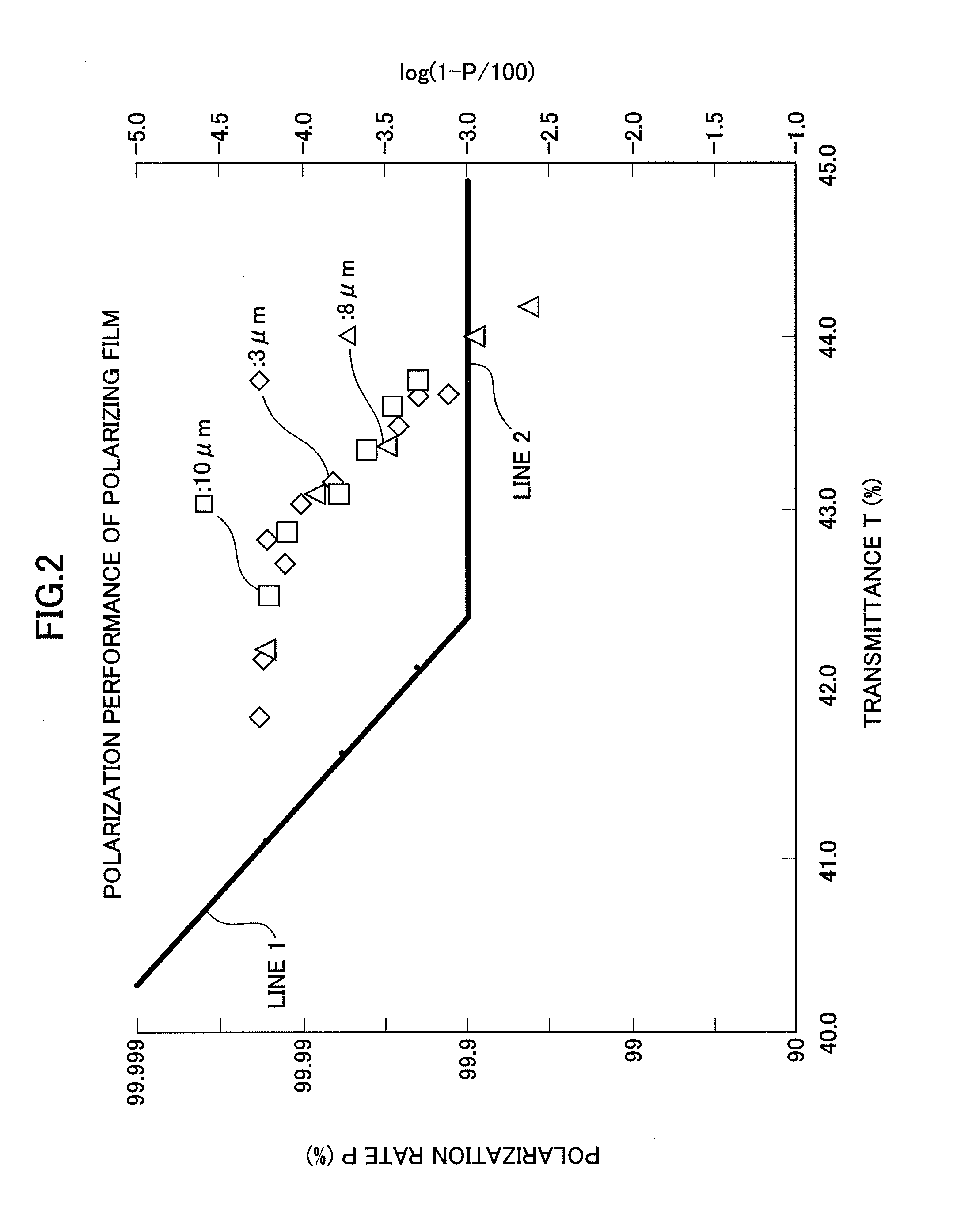

Method of producing roll of laminate strip with polarizing film

ActiveUS20120056340A1Thin thicknessControlling laminationOptical articlesPolyvinyl alcoholBoric acid

A method of producing a roll of an optical film laminate strip including a polarizing film includes the steps of: forming a continuous web of optical film laminate including a polarizing film which consists of a polyvinyl alcohol type resin layer and has a thickness of 10 μm or less, wherein the polarizing film is formed by performing an stretching sub-step of subjecting a laminate comprising a continuous web of thermoplastic resin substrate and a polyvinyl alcohol type resin layer formed on the substrate, to a uniaxial stretching in a lengthwise direction of the laminate based on 2-stage stretching consisting of preliminary in-air stretching and in-boric-acid-solution stretching; cutting the continuous web of optical film laminate along a direction parallel to the length direction to form at least one continuous web of laminate strip having a given width; and winding the continuous web of laminate strip having the given width into a roll.

Owner:NITTO DENKO CORP

Acidified attapulgite clay

Owner:XUYI BOTU ATTAPULGITE CLAY HIGH TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com