Silver nanowire-based transparent conductive thin film and preparation method thereof

A technology of transparent conductive film and silver nanowire, which is applied in the direction of nanostructure manufacturing, conductive layer on insulating carrier, nanotechnology, etc., can solve the limited range of substrate selection, poor adhesion, and conductive layer is easily damaged by sticking And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

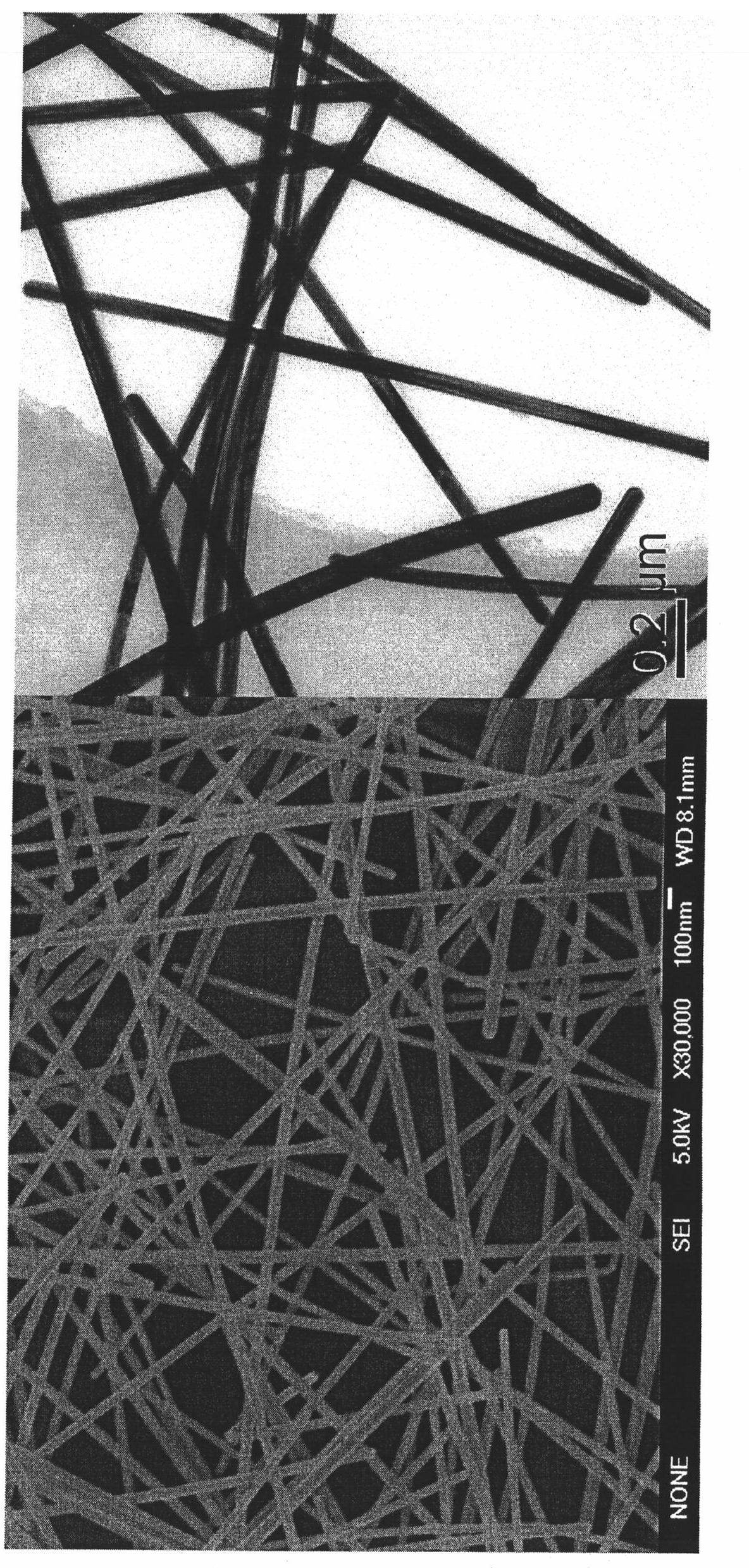

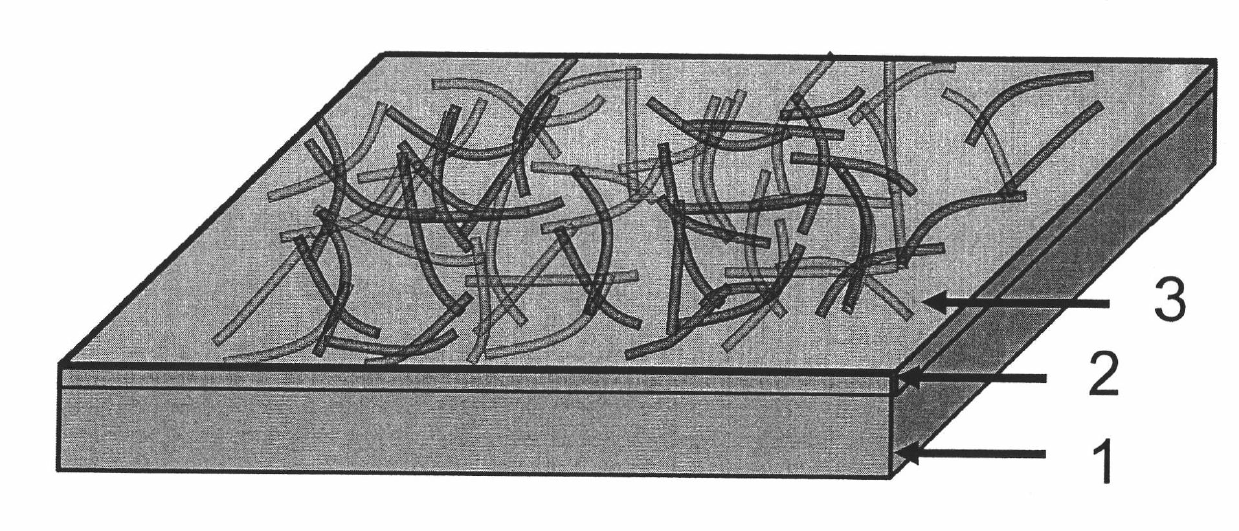

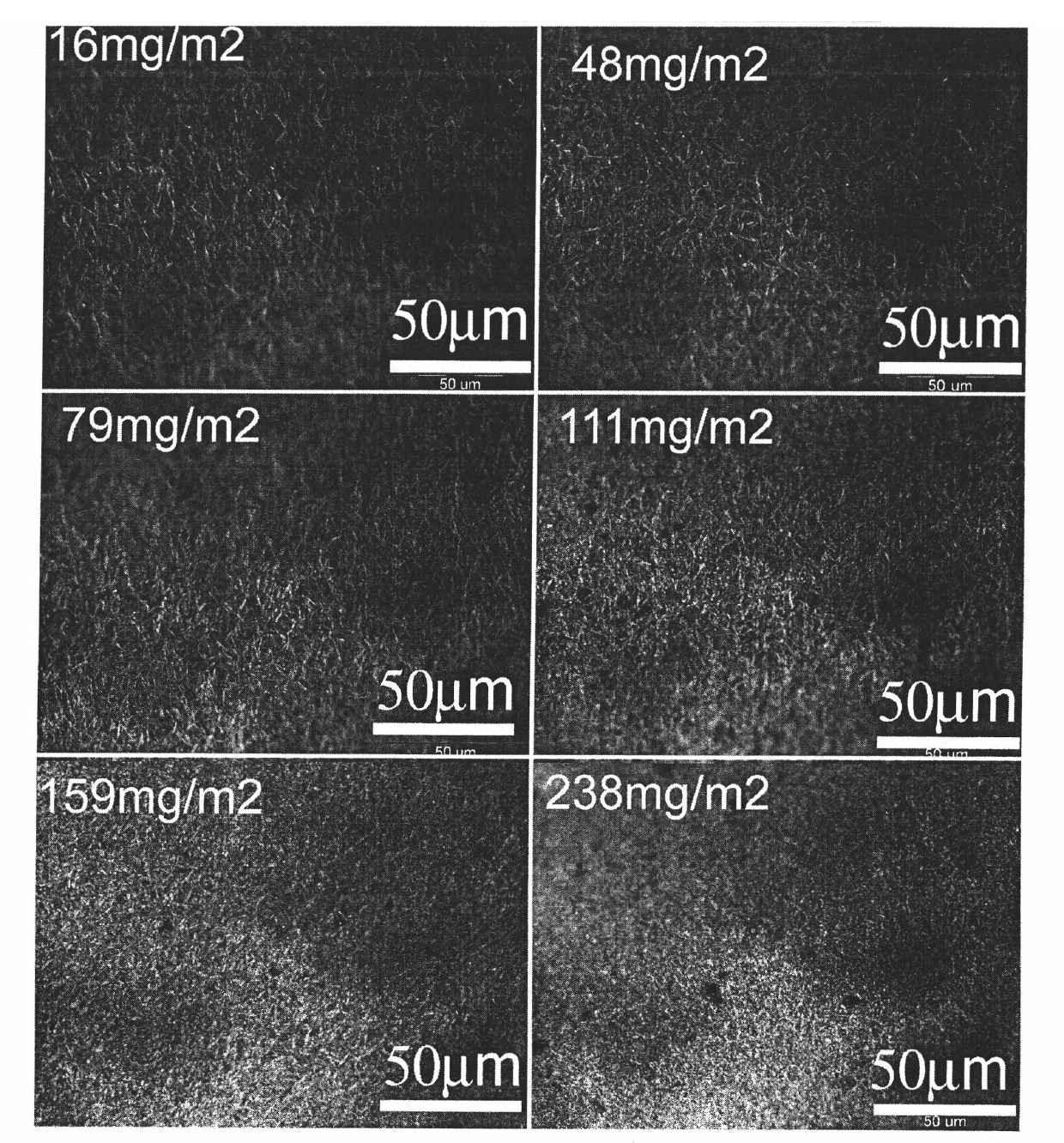

[0022]Use PMMA as a transparent substrate (visible light transmittance 92%), spin-coat a 10% (weight) concentration of polyvinyl alcohol (PVA) aqueous solution on it, and dry it at 70° C. for 2 hours before use. A specific volume of silver nanowire suspension in water is taken and filtered to form a uniform conductive network on the filter membrane. The filter membrane covered with the silver nanowire layer is used as a transfer membrane, which is pressed tightly on the dry PVA film, and the silver nanowire and PVA form a firm bond. The filter membrane is peeled off to obtain a uniform and firm silver nanowire transparent conductive film. Its optical microscope such as image 3 As shown, it can be seen that the silver nanowires formed a uniform conductive network on the PVA adhesion layer.

[0023] The transmittance curve is as Figure 4 As shown, the thickness and square resistance of the conductive layer of silver nanowires are as Figure 5 shown. It can be seen that th...

Embodiment 2

[0026] Use PET as a transparent substrate (visible light transmittance 91.3%), spin-coat 10% (weight) concentration of polyvinyl alcohol (PVA) aqueous solution on it, and dry it at 120° C. for 2 hours before use. A specific volume of silver nanowire suspension in water is taken and filtered to form a uniform conductive network on the filter membrane. The filter membrane covered with the silver nanowire layer is used as a transfer membrane, which is pressed tightly on the dry PVA film, and the silver nanowire and PVA form a firm bond. After the filter membrane is peeled off, a uniform and firm silver nanowire transparent conductive film is obtained.

[0027] The transmittance curve is as Figure 8 shown. When the silver nanowire distribution density is 39.8mg / m 2 When the visible light transmittance (525nm) of the PET-PVA-Ag transparent conductive film is 84.6%, the sheet resistance is 137Ω; when the visible light transmittance (525nm) is 77.2%, the sheet resistance is 18.5Ω...

Embodiment 3

[0030] Take float glass (2mm thick) as a transparent substrate, spin-coat a 10% (weight) concentration of polyvinyl alcohol (PVA) aqueous solution on it, rotate at a speed of 1500 rpm, for 15 seconds, and dry it at 120°C for 2 hours. use. Take a specific volume of ethanol suspension solution of silver nanowires, spin-coat at a speed of 1500 rpm for 15 seconds, spin-coat three times, and dry at 120°C for 30 minutes to form a transparent conductive film of silver nanowires. Compared with Example 1 and Example 2, under the same distribution density of silver nanowires, the visible transmittance is similar, but the square resistance value is significantly larger. For example, the distribution density of silver nanowires is 79mg / m 2 , the square resistance is 65Ω. If there is no PVA adhesive layer, after sticking with 3M tape once, the silver nanowires are completely stuck up, and the square resistance becomes infinite; the conductive layer of silver nanowires coated with PVA adh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com