Electrolytic solution for integrated circuit copper wire laying electrodeposition

An integrated circuit and wiring technology, applied in the field of microelectronics processing, can solve the problem of holes in the deposition surface, and achieve the effects of no hole defects, reduced roughness, and enhanced surface improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Prepare 5000 ml of electrolyte: heat 3000 ml of deionized water to 40 ° C, add 342 g of copper sulfate, stir to dissolve, slowly add 875 g of concentrated sulfuric acid to the above solution, add water to nearly 5000 ml, continue stirring the solution and After it was cooled to room temperature, 300 mg of hydrochloric acid, 400 mg of polyethylene glycol (MW 6000), 75 mg of sodium polydithiodipropane sulfonate and 25 mg of ethylenethiourea were added, and finally 5000 ml of water was added and stirred evenly.

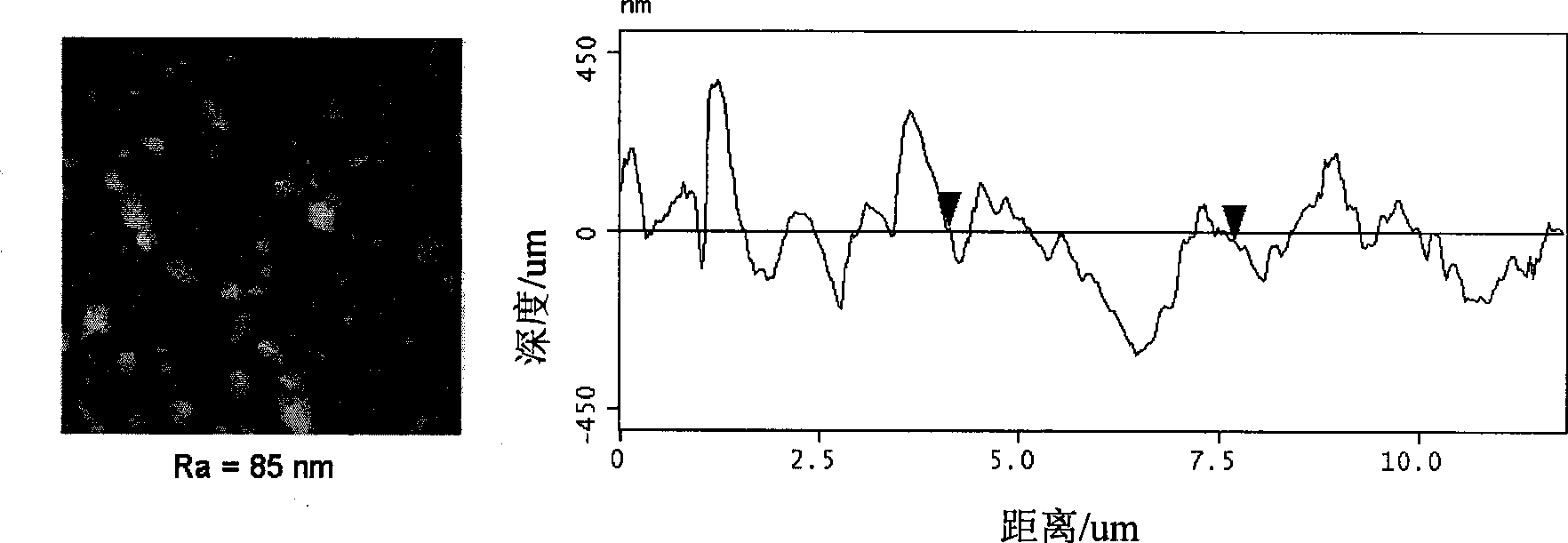

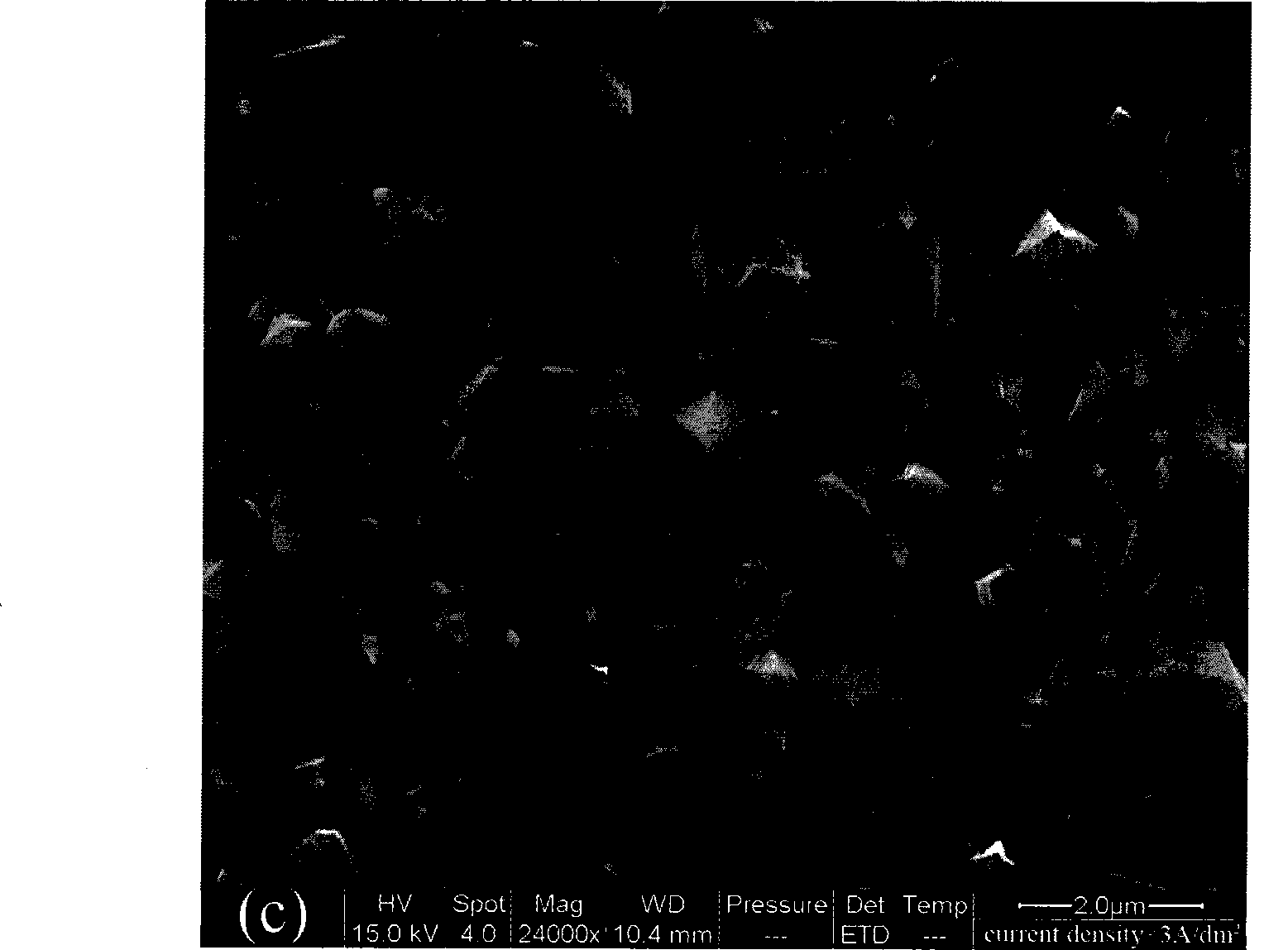

[0040] Electrodeposition experiments were done in the electrolytic tank, the electrodeposition current density was set to 30 mA / cm2, the deposition substrate was a silicon substrate with a 130 nm copper seed layer grown by surface magnetron sputtering, and the scanning electron microscope and atomic force microscope were observed Surface morphology and parameters after deposition such as Pic 4-1 , 4-2 shown.

[0041]It can be seen from the comparison of Compara...

Embodiment 2

[0043] The preparation process is basically the same as in Example 1, except that the components and contents of 1000 milliliters of electrolyte are: 50 grams of copper sulfate, 150 grams of sulfuric acid, 10 milligrams of chloride ions, and 20 grams of polyethylene glycol (MW 8000). mg, the accelerator sodium alcohol thiopropane sulfonate is 30 mg, the leveling agent thiazolethione is 0.5 mg, and the rest is deionized water.

Embodiment 3

[0045] The preparation process is basically the same as in Example 1, except that the composition and content of 1000 milliliters of electrolyte are: 200 grams of copper sulfate, 50 grams of sulfuric acid, 20 milligrams of chloride ions, and 100 milligrams of sodium dodecylsulfonate , Accelerator sodium phenyl polydithiopropane sulfonate is 5 mg, leveling agent ethylene thiourea is 1 mg, and the rest is deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com