Production method of polysilicon rod

A production method and polysilicon technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of polysilicon growth rate decline, affecting enterprise benefits, etc., to improve surface morphology, improve enterprise benefits, and simple methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

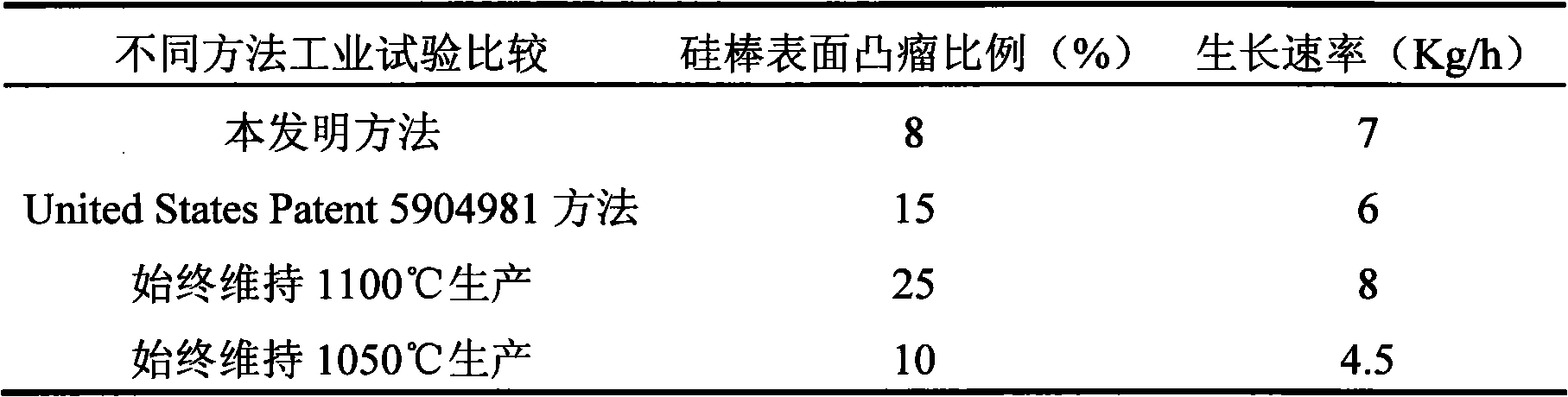

Examples

Embodiment 1

[0031] Polysilicon was grown using silicon cores with a diameter of 5 mm. After the reduction furnace reactor was put into use, the surface reaction temperature was set at 1100°C, and hydrogen gas and trichlorosilane were introduced to react for 35 hours. Trichlorosilane initial flow rate 80Nm 3 / h, in 1Nm 3 / h speed increased to 220Nm at a constant speed 3 / h (about 140h), then keep constant until the reduction reactor is shut down. The initial flow of hydrogen is maintained at 100Nm 3 / h. When the diameter of the silicon rod reaches 50mm, stop applying the current, and at the same time, increase the hydrogen flow rate to 200Nm 3 / h. After 6 hours, when the surface temperature of the silicon rod drops to 1020°C, resume the applied current, and at the same time adjust the hydrogen flow rate to 120Nm 3 / h. Slowly increase the current to increase the surface temperature of the silicon rod, and it takes 45 hours to raise the surface temperature of the silicon rod to about...

Embodiment 2

[0033] Polysilicon was grown using silicon cores with a diameter of 8 mm. After the reduction furnace reactor was put into use, the surface reaction temperature was set at 1180° C., and hydrogen gas and trichlorosilane were introduced to react for 40 hours. The initial flow rate of trichlorosilane is 90Nm 3 / h, in 1Nm 3 / h speed increased to 220Nm at a constant speed 3 / h (about 130h), then keep constant until the reduction reactor is shut down. The initial flow of hydrogen is maintained at 120Nm 3 / h. When the diameter of the silicon rod reaches 50mm, stop applying the current, and at the same time, increase the hydrogen flow rate to 220Nm 3 / h. After 5 hours, when the surface temperature of the silicon rod drops to 1020°C, resume the normal applied current, and at the same time adjust the hydrogen flow rate to 120Nm 3 / h. Slowly increase the current to increase the surface temperature of the silicon rod, and it takes 45 hours to raise the surface temperature of the si...

Embodiment 3

[0035] Polysilicon was grown using silicon cores with a diameter of 6 mm. After the reduction furnace reactor was put into use, the surface reaction temperature was set at 1130° C., and hydrogen gas and trichlorosilane were introduced to react for 37 hours. Trichlorosilane initial flow rate 80Nm 3 / h, at 2Nm 3 / h speed increased to 220Nm at a constant speed 3 / h (about 70h), then keep constant until the reduction reactor is shut down. The initial flow of hydrogen is maintained at 110Nm 3 / h. When the diameter of the silicon rod reaches 50mm, stop applying the current, and at the same time, increase the hydrogen flow rate to 200Nm 3 / h. After 5 hours, when the surface temperature of the silicon rod drops to 1020°C, resume the normal applied current, and at the same time adjust the hydrogen flow rate to 120Nm 3 / h. Slowly increase the current to increase the surface temperature of the silicon rod, and it takes 45 hours to raise the surface temperature of the silicon rod ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com