Patents

Literature

950results about How to "Improve business efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

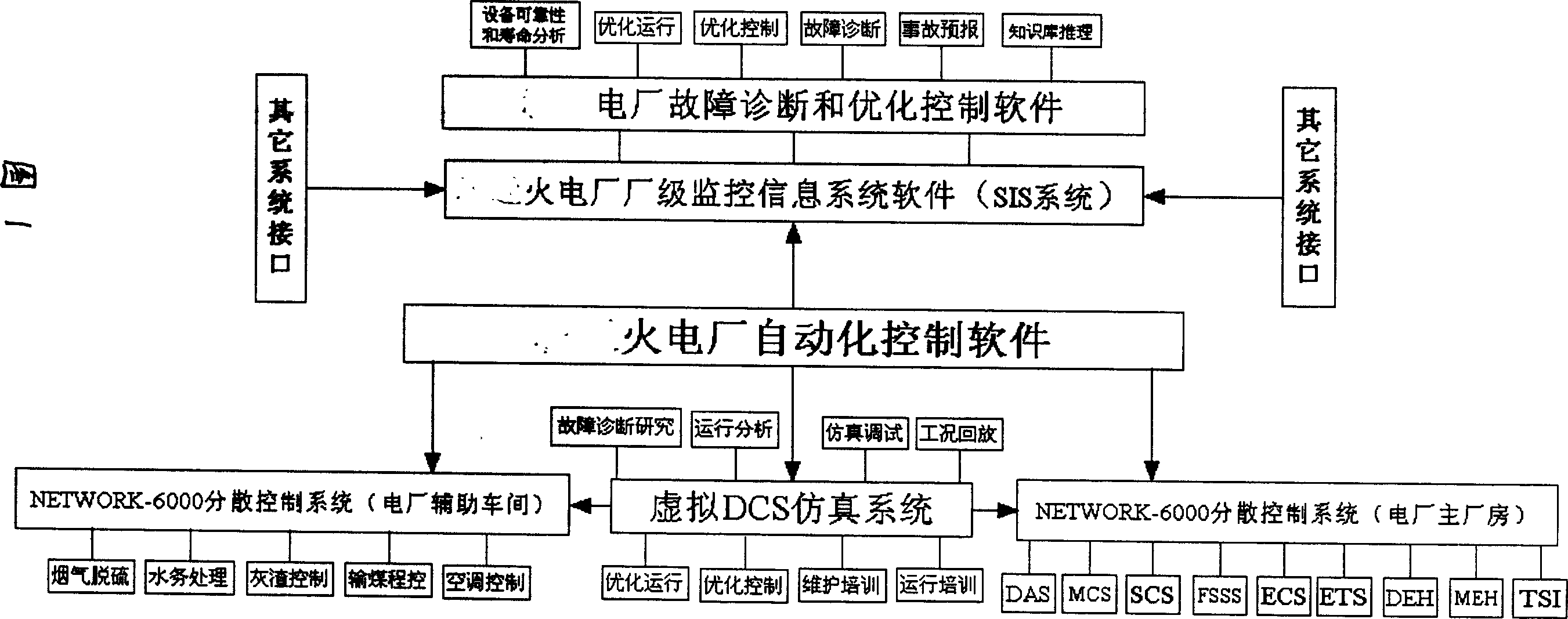

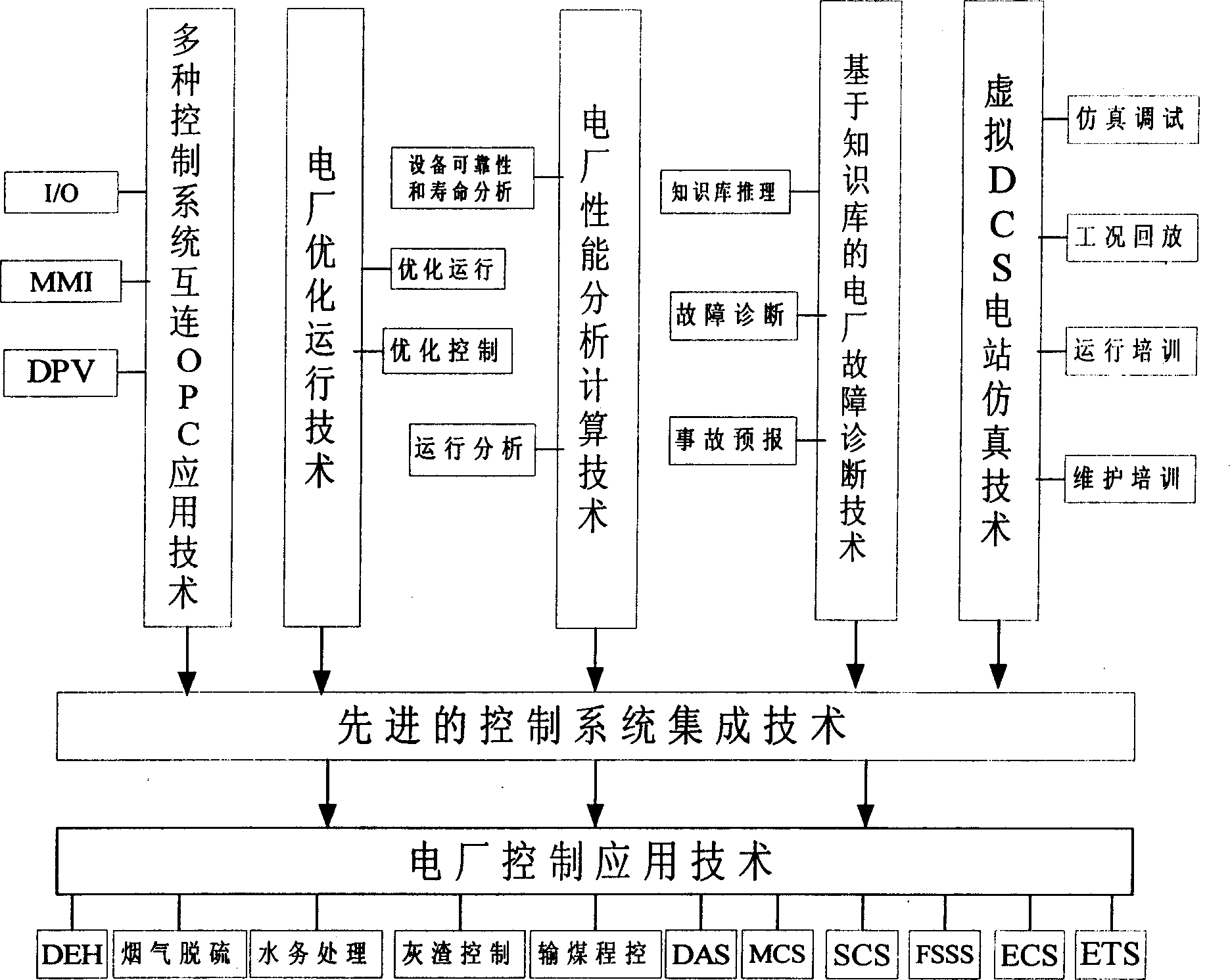

Automatic control system based on artificial intelligence for heat-engine plant

ActiveCN1694025ATake into account maturityGuaranteed growthComputer controlEnergy industryAutomatic controlPower station

The invention discloses a thermoelectric power station automatic control system based on artificial intelligence. It includes dispersible control system, virtual DCS simulation system, program controlling system, monitoring information system and malfunction diagnosing and optimizing controlling system; the dispersible control system is connected with the virtual DCS simulation system and program controlling system; the program controlling system process the operating parameters of every machine group transmitted by dispersible control system, and at the same time transmits data to monitoring information system to display, then transmits malfunction diagnosing and optimizing controlling system to have equipment state monitoring, malfunction diagnosing and forewarns. The invention gathers automatic control, optimizing operation, security monitoring and malfunction diagnosing and forecast. It can improves the automated management level of the thermoelectric power station operation, and enhances enterprises' benefit. It has great economic and applied value in the producing process automatic control of the thermoelectric power station.

Owner:南京科远智慧能源投资有限公司

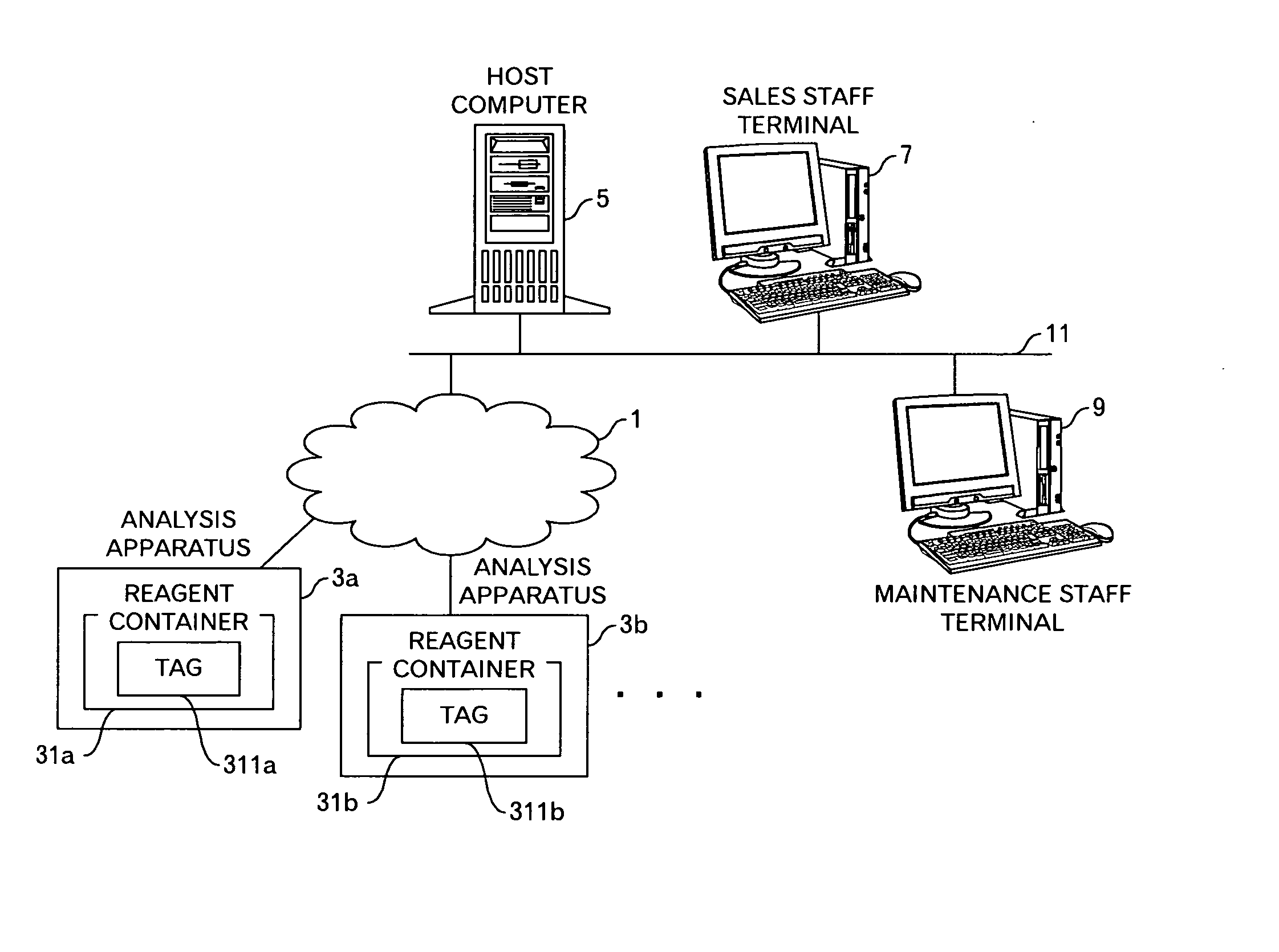

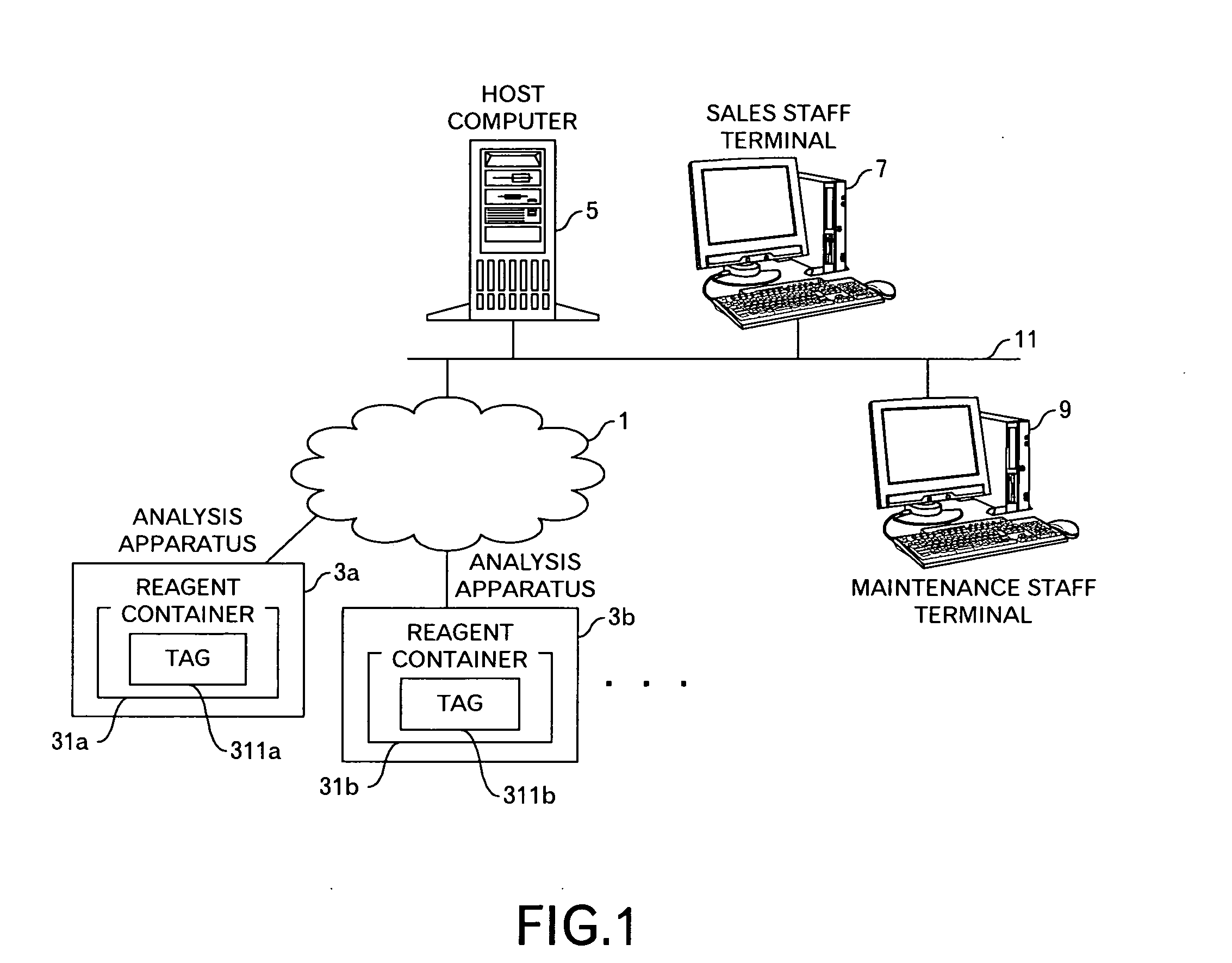

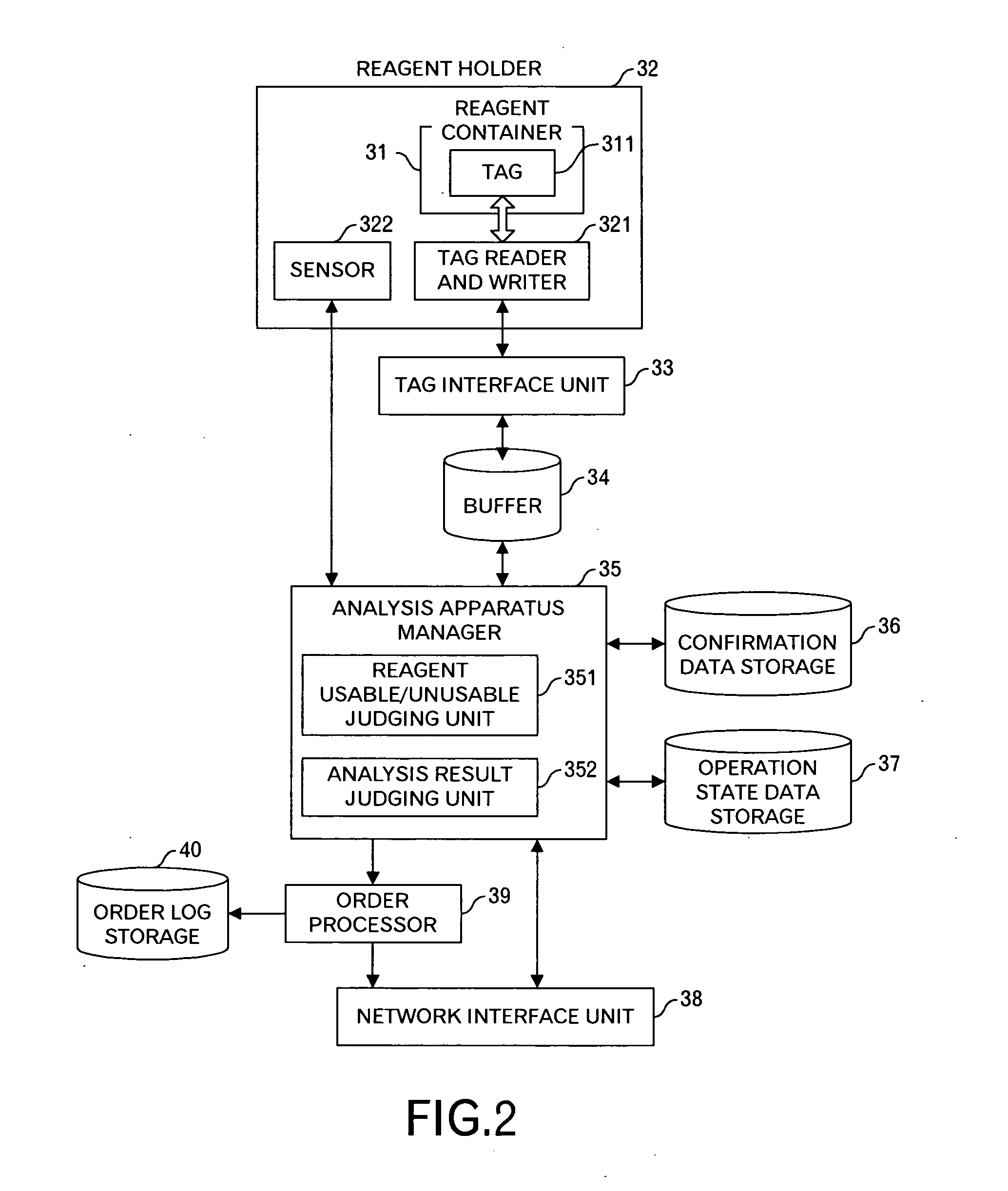

Analysis Assisting Method, Analyzer, Remote Computer, Data Analyzing Method, Program, and Reagent Container

InactiveUS20070255756A1Improve business efficiencyEasy to judgeData processing applicationsPreparing sample for investigationBusiness efficiencyRemote computer

In an analysis system having an analysis apparatus using a reagent container having a memory to store reagent information concerning the reagent in the reagent container and a remote computer, the following steps are executed: reading out the reagent information from the memory of the reagent container; judging, based on the read reagent information, whether or not the reagent in the reagent container is usable; when it is judged that the reagent in the reagent container is unusable, writing data representing the reagent is unusable into the memory of the reagent container; and when it is judged that the reagent in the reagent container is unusable, registering the data representing the reagent is unusable, into a reagent database managed by the remote computer in association with identification information to identify the reagent container. Thus, it is possible to automatically identify the reagent, which should not be used, and to manage the reagent not so as to use it for the analysis. In addition, it is possible to use the data for the enhancement of the business efficiency such as the automatic order of the reagent, the stock management in the manufacturer and the like.

Owner:WAKO PURE CHEMICAL INDUSTRIES

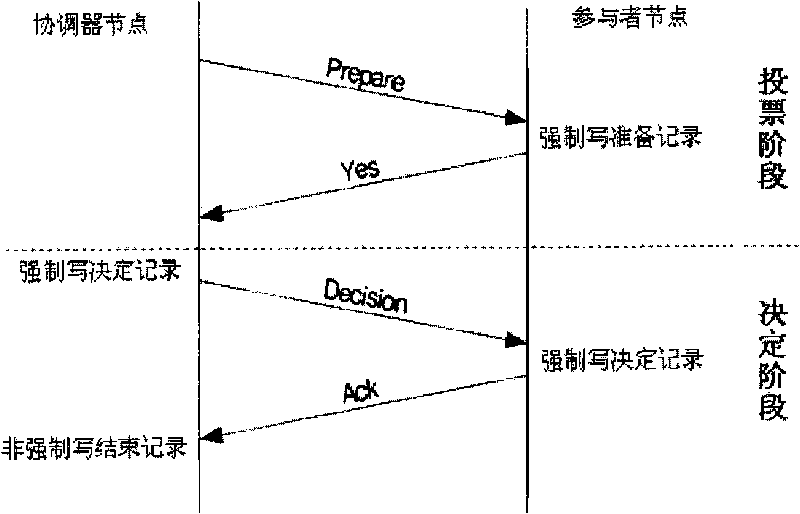

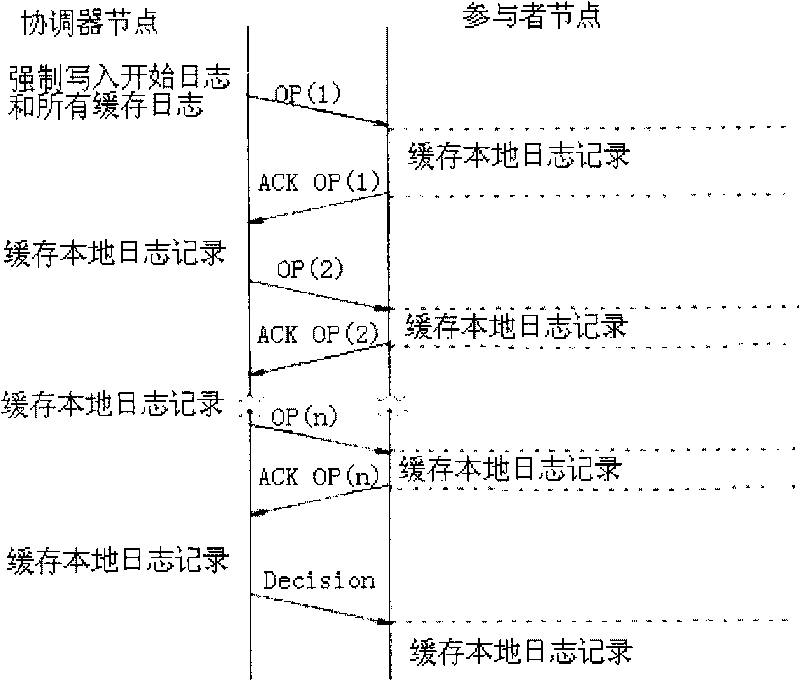

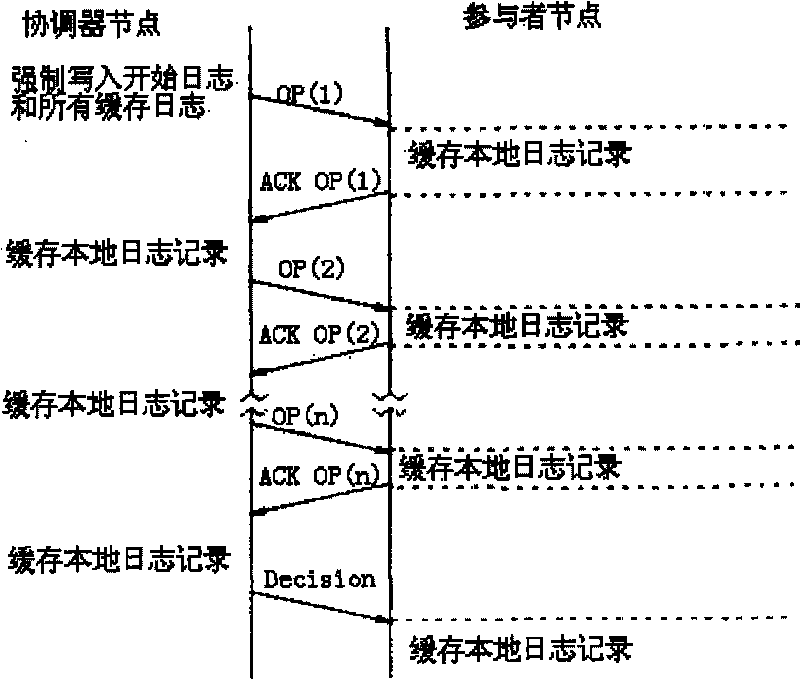

Transaction commit method of distributed database system

InactiveCN101706811AReduce the number of log operationsImprove efficiencySpecial data processing applicationsComputer network technologyHigh availability

The invention discloses a transaction commit method of a distributed database system, belonging to the technical field of computer network. The transaction commit method comprises the following steps: 1) a cache area is respectively allocated in memories of participant nodes and coordinator nodes and used for caching transaction logs; 2) the coordinator nodes determine the participant nodes and establishes connection with the participant nodes according to the transaction content, and simultaneously determines operation request information of the transaction; 3) the coordinator nodes send the one-step operation request messages of the transaction to the participant nodes and simultaneously records the transaction request logs of each operation request; 4) the participant nodes process local logs according to the completion condition of each operation request and send corresponding messages to the coordinator nodes; and 5) the coordinator nodes judge whether the transaction is completed according to the received messages sent by all the participant nodes, and if so, a final decision is given. Compared with the prior art, the transaction commit method greatly reduces the operation times of logs, improves system efficiency and transaction efficiency and has extremely high availability.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

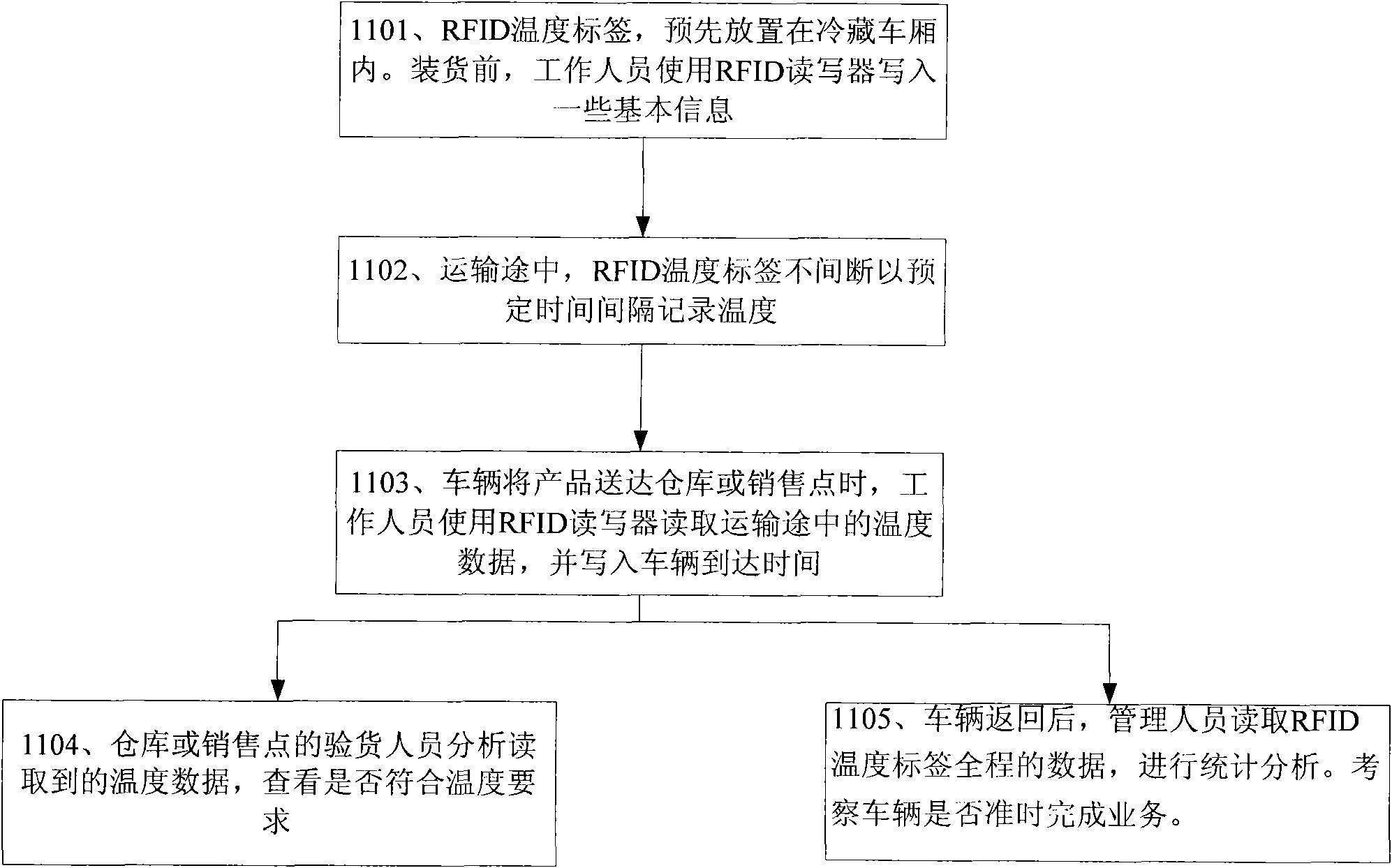

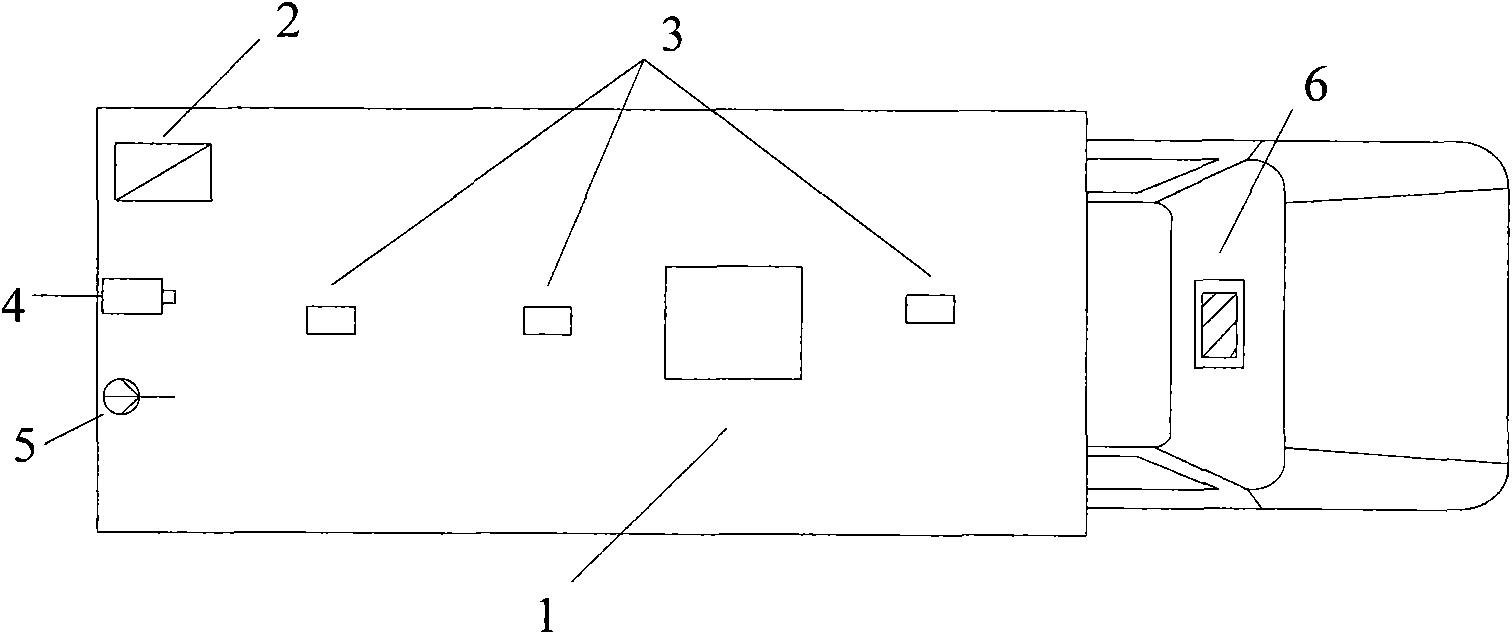

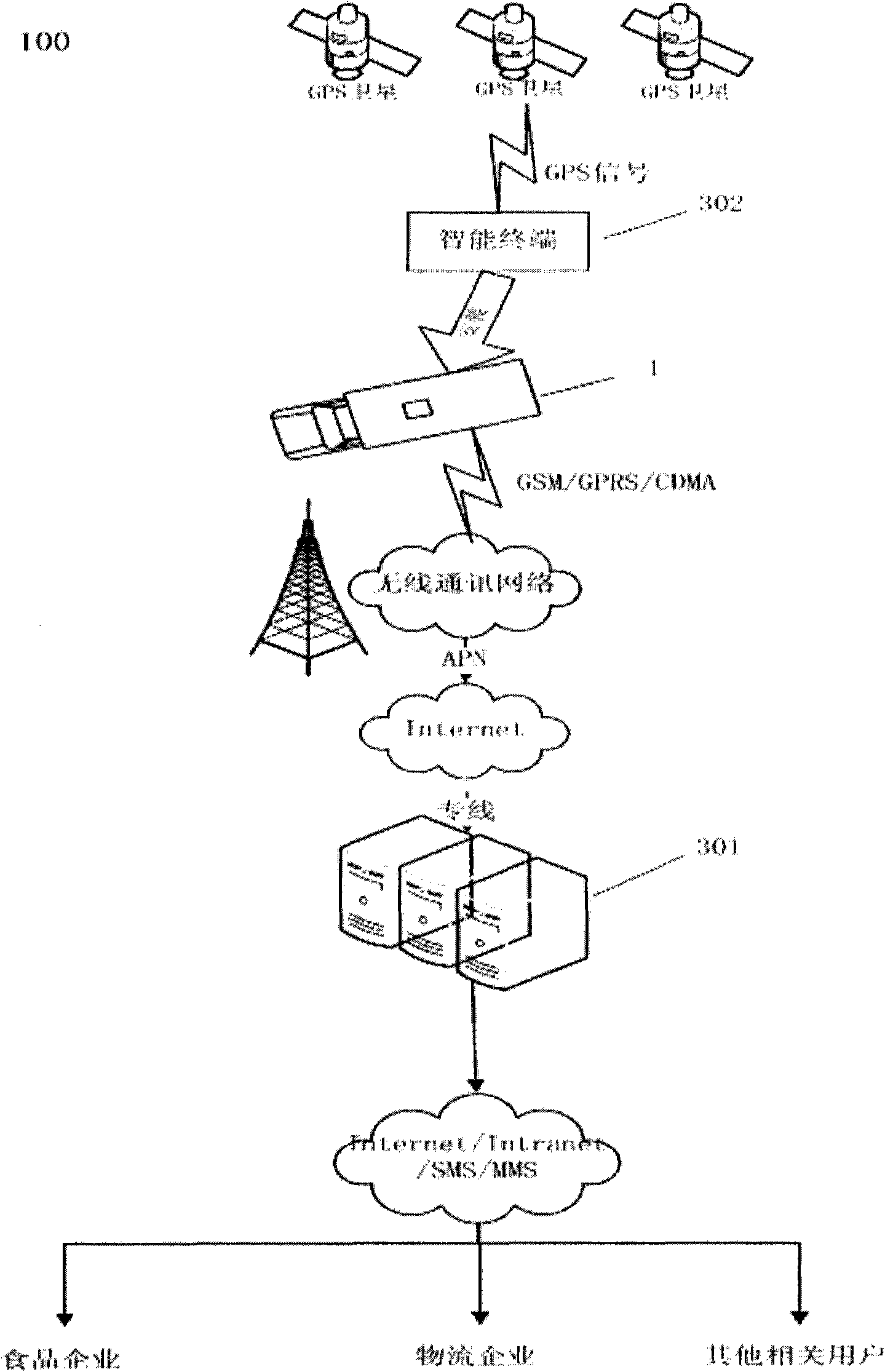

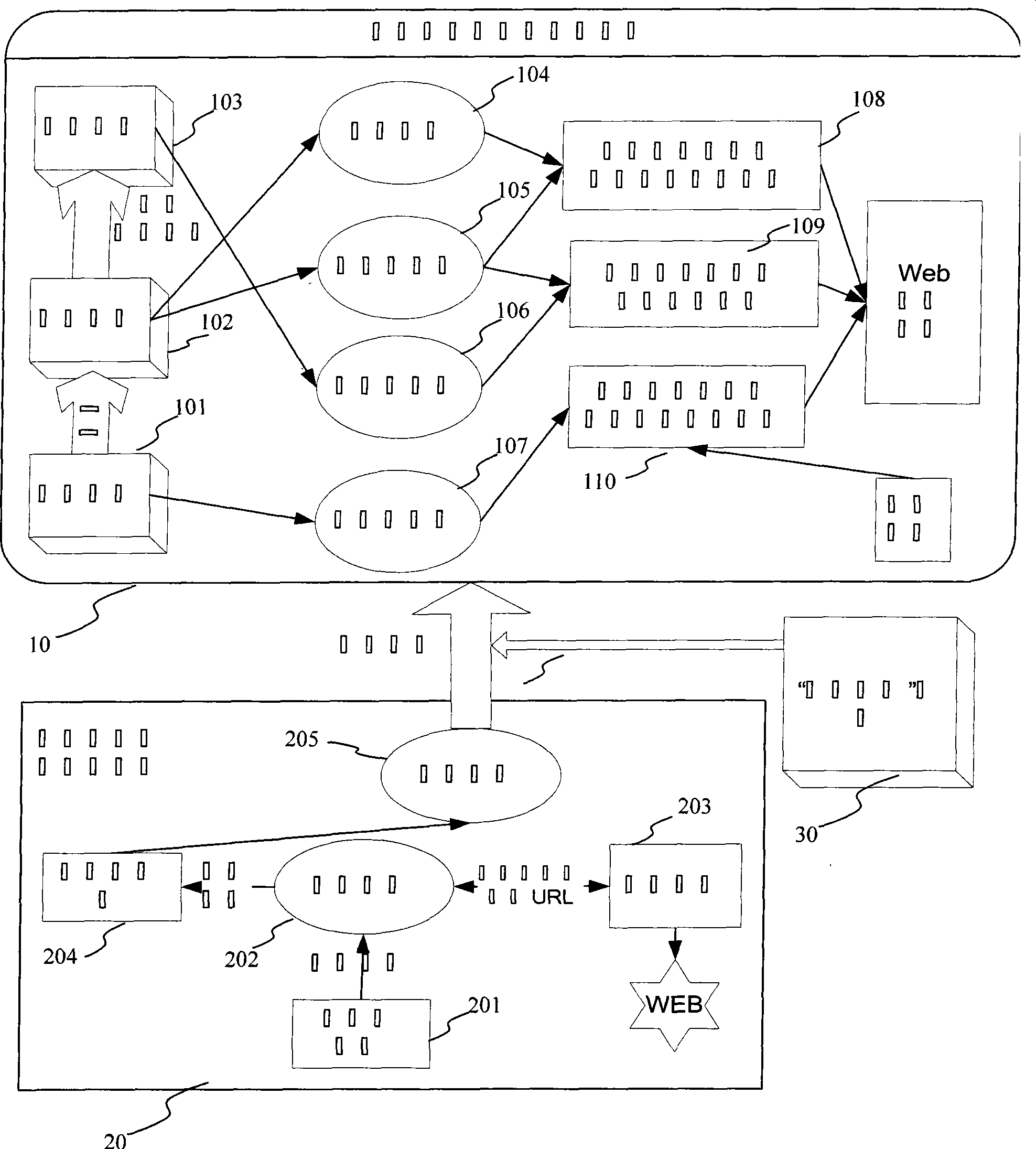

RFID (Radio Frequency Identification Device) based cold-chain logistics management system

InactiveCN101777153APrecise positioningImprove business efficiencyCo-operative working arrangementsLogisticsCode division multiple accessLogistics management

The invention discloses an RFID based cold-chain logistics management system (100) which comprises a monitoring center platform (301) arranged in a monitoring center and intelligent terminals (302) arranged in all cold-chain vehicles. The monitoring center platform (301) receives and saves data uploaded by the intelligent terminals (302) and provides a user operation interface; each intelligent terminal (302) comprises a host machine (2) and a plurality of external devices, the host machine (2) is provided with a GPS (Global Position System) positioning chip, an RFID read module, a wireless communication module, such as GSM (Global System for Mobile Communications ) module or a CDMA (Code Division Multiple Access ) module, and each external device comprises one or more RFID temperature labels (3); the intelligent terminals (302) can carry out real-time communication with the monitoring center platform (301) through a wireless communication network and the Internet, sends temperature data, GPS positioning data and vehicle state data to the monitoring center platform (301), and receives control commands form the monitoring center to control vehicles. The system has the advantages of vehicle optimized dispatch, automated data acquisition, processing and statistic, cost saving and improved efficiency.

Owner:WUHAN WIN WIN INFORMATION TECH

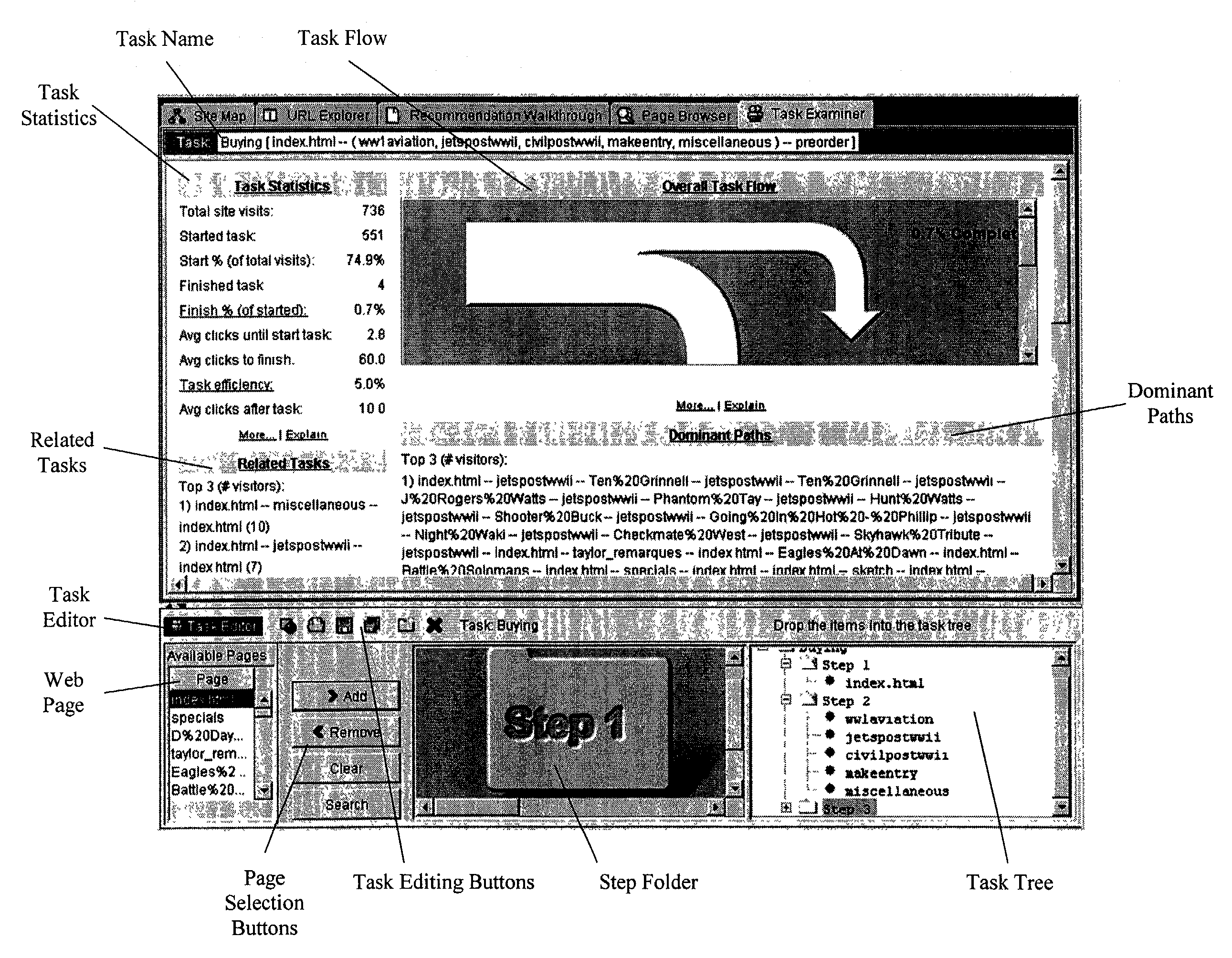

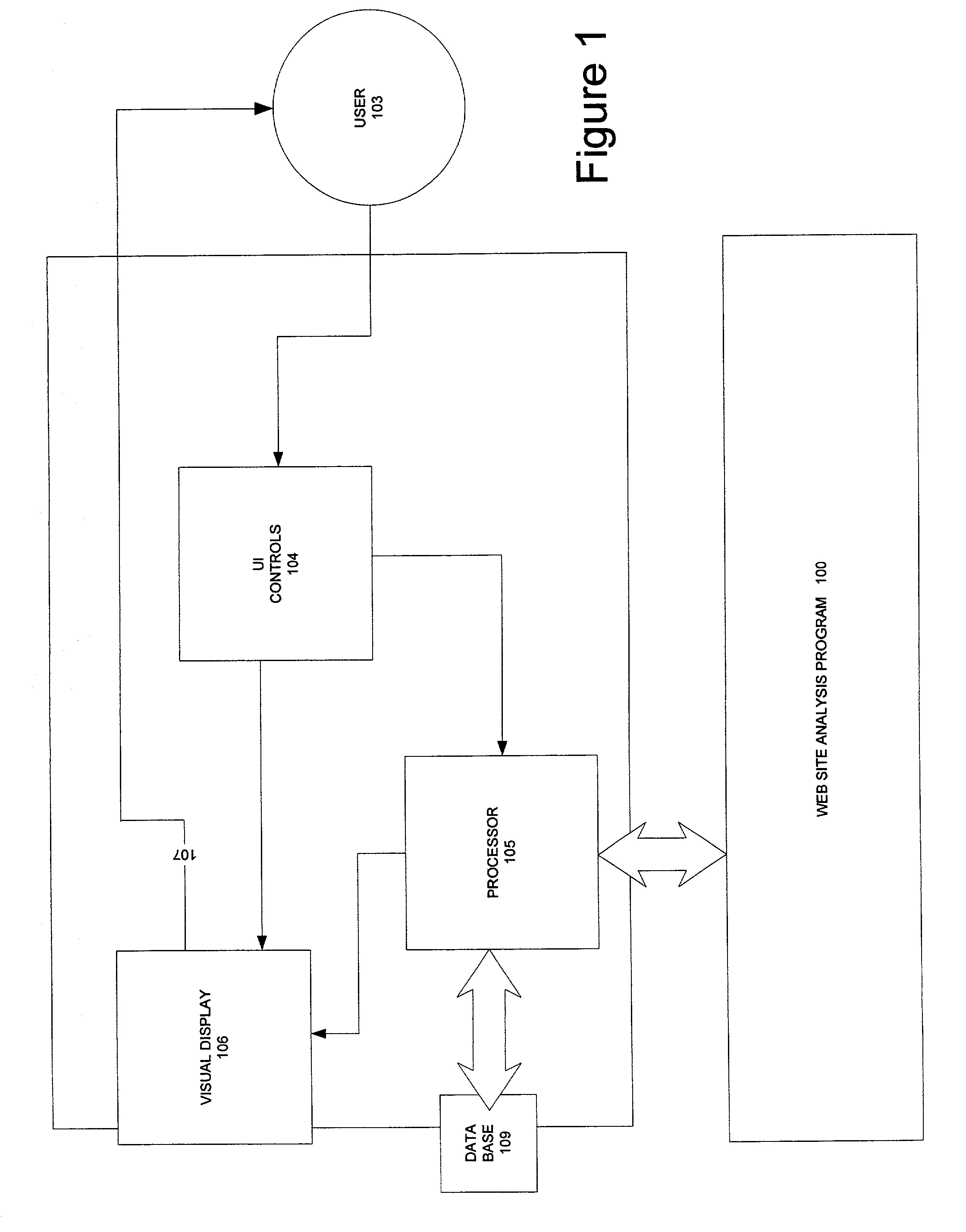

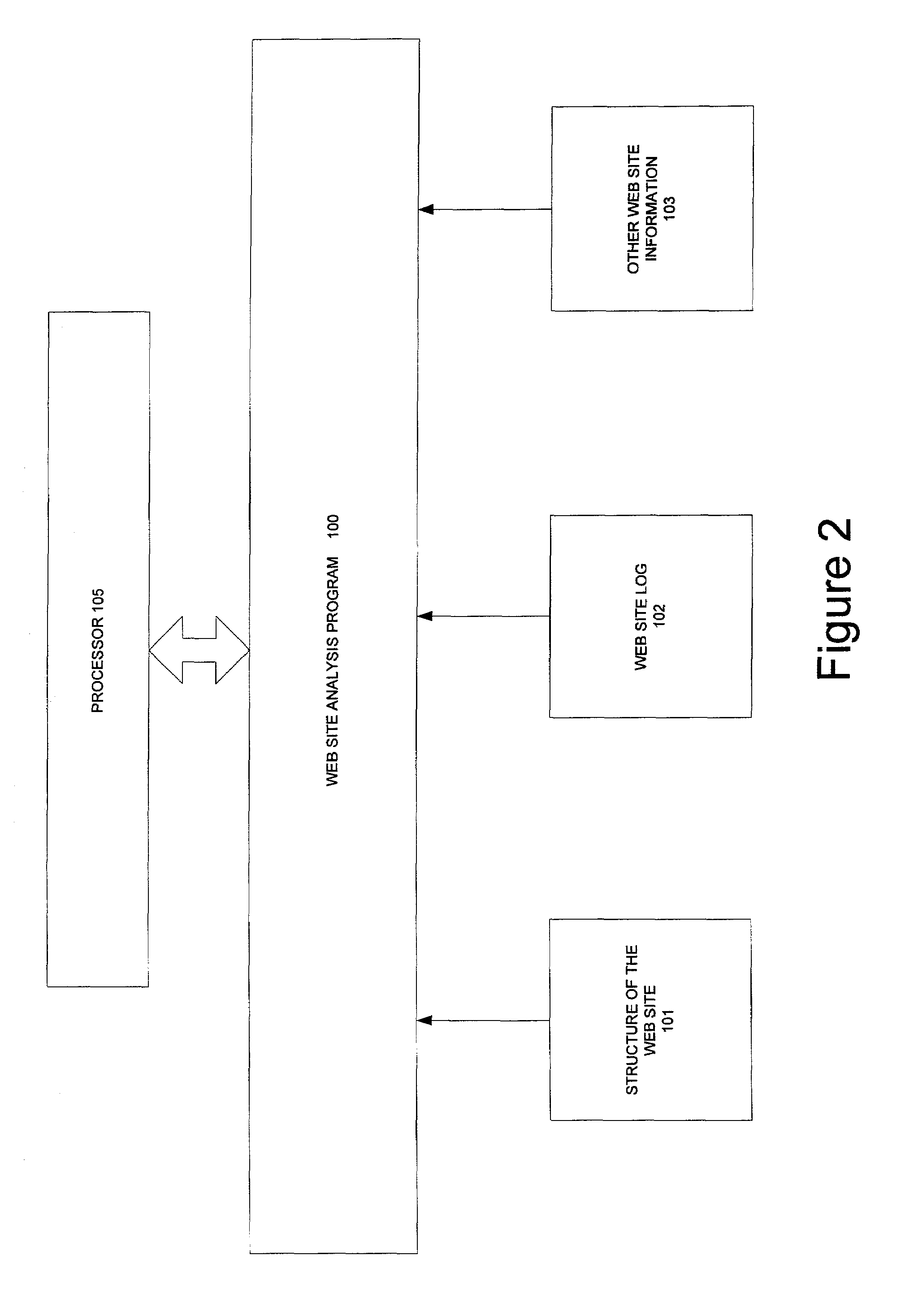

Graphical user interface and web site evaluation tool for customizing web sites

InactiveUS7305622B2Improve recommendationsIncrease success rateDrawing from basic elementsDigital computer detailsWeb siteGraphics

An invention for displaying patterns of utilization of a resource wherein the resource includes a plurality of correlated or uncorrelated objects. The method consists of providing a number of graphical formats from which a format is selected for display of patterns of utilization. Additionally, a query is submitted regarding a particular utilization of the resource. Along with the selected format and query inputs, the invention receives information regarding utilization of the resource from a system. Once the invention receives the inputs and the utilization information from the system, the invention processes the information to a format that conforms with the inputs. The invention then displays the processed information in the selected graphical format. The invention also allows the selection of a second graphical format from the graphical formats for altering the display to show the processed information in the second selected format.

Owner:IGNITE ENTERPISE SOFTWARE SOLUTIONS INC

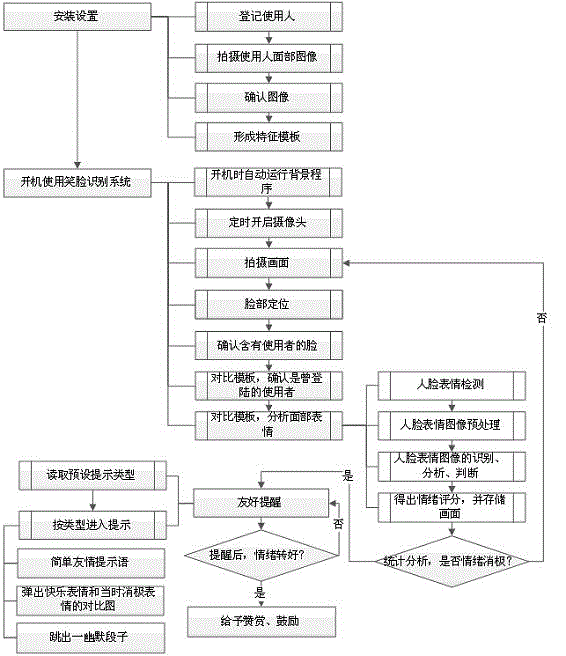

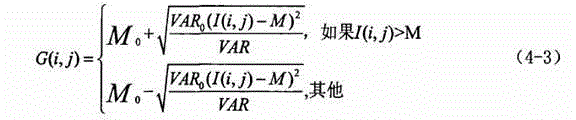

Negative expression recognizing and encouraging system

InactiveCN105354527AGood groomingImprove the quality of workCharacter and pattern recognitionTemplate matchingImaging processing

A negative expression recognizing and encouraging system belongs to the technical fields of image processing and artificial intelligence. The technical points of the invention are that: a computer camera shoots and analyzes the facial expression of a user, and helps the user eliminate the negative feelings; the system pre-acquires basic expression samples of the user being served as a feature template, regularly and automatically starts a video, regularly acquires user face images, pre-treats, recognizes and analyzes the face images, compares the similarities of Euclidean distance differences, geometrical shapes, curvatures, and angle changes of matched critical characteristics of the real-time acquired face images and the expression template, accordingly, determines whether the expression of the user is angry, anxious, tired, or glad, analyzes and determines whether the expression of the user is negative or not in a certain phase by adoption of statistical shape analysis and other statistical methods, and automatically gives a friendly reminder to the negative expression, and the user can be given a praise and an encouragement if the expression of the user can become good after the reminder. The negative expression recognizing and encouraging system has the advantages that: an employee can be encouraged to smile, to be peaceful in work, to discard troubles, and to keep optimistic attitude and good appearance.

Owner:NANJING PERLOVE RADIAL VIDEO EQUIP

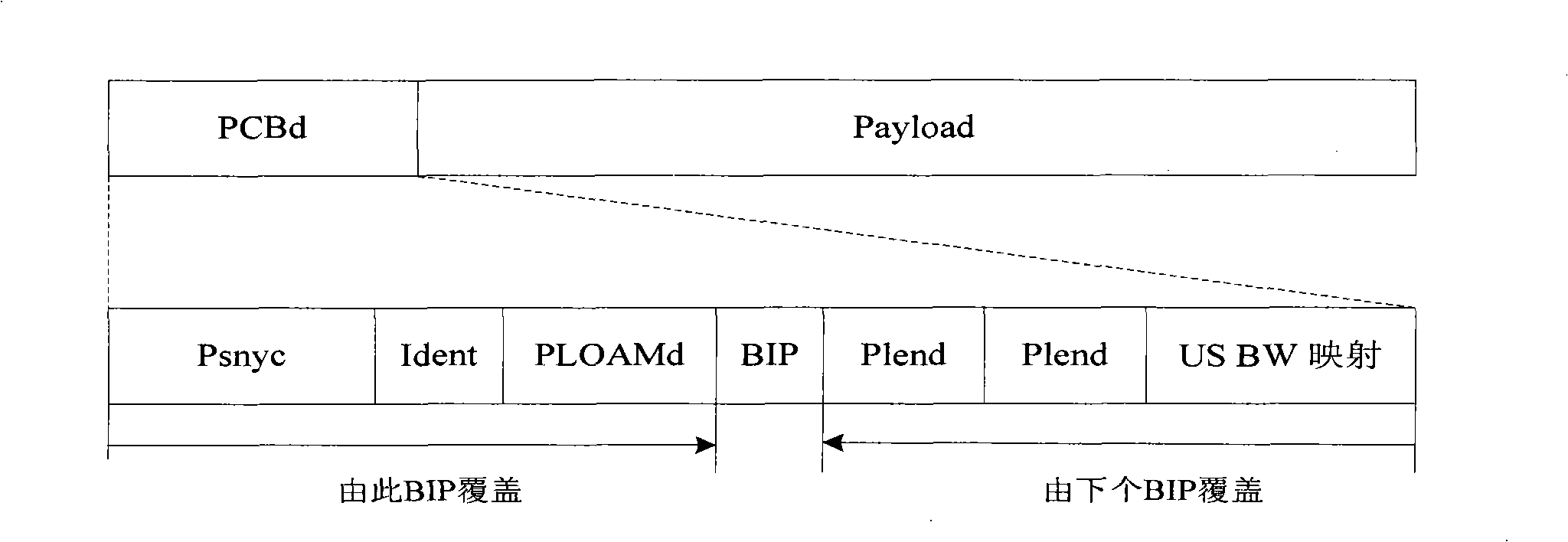

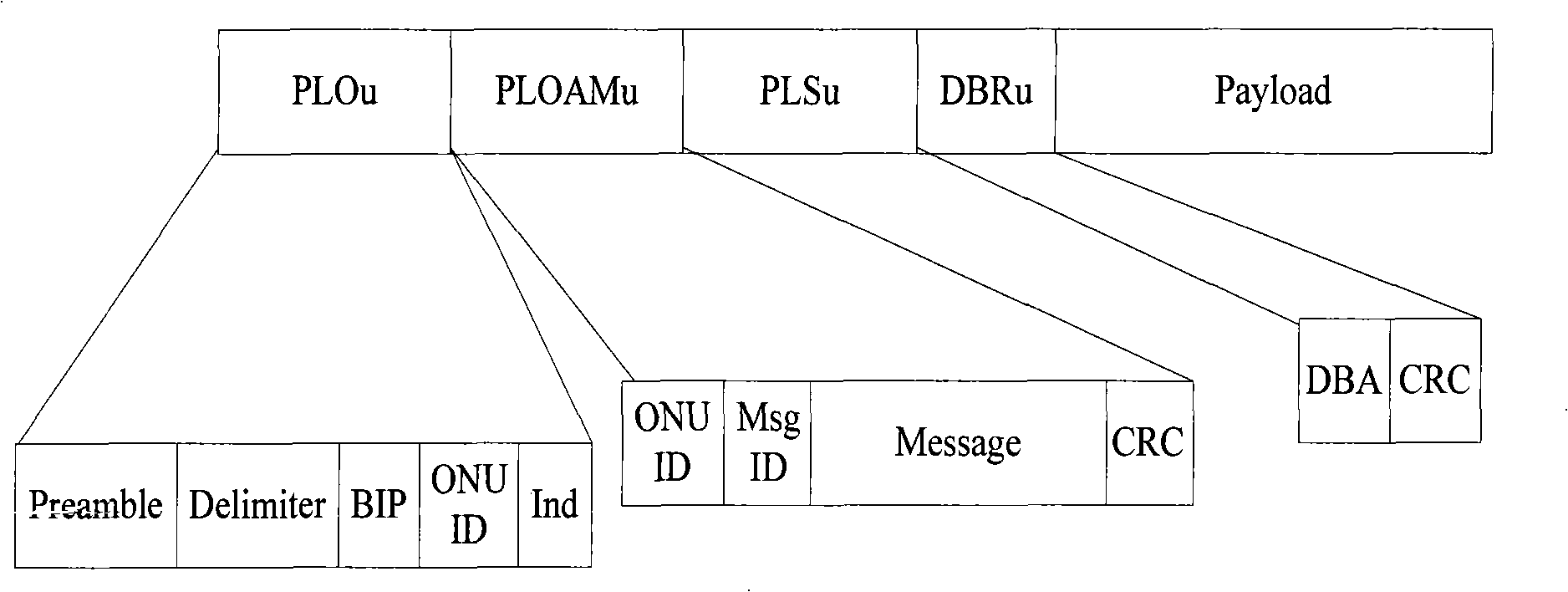

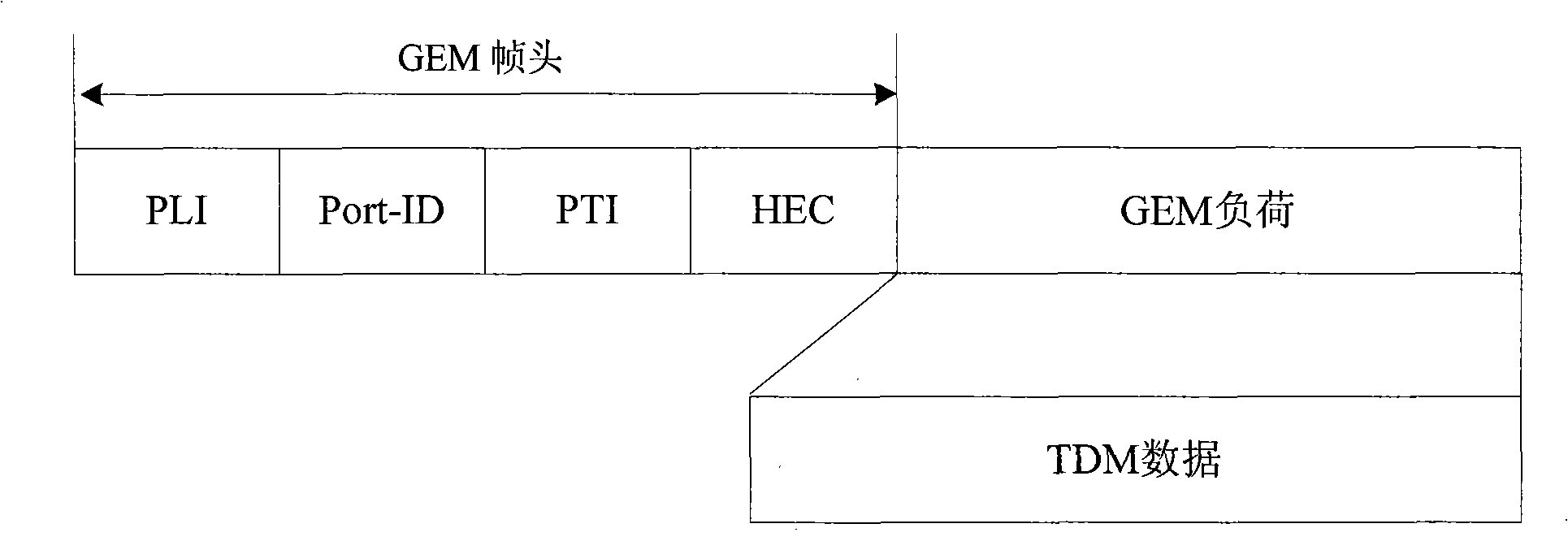

GPON GTC frame-forming sublayer based on FPGA

InactiveCN101409708AImprove business efficiencyHigh bandwidthError preventionData switching networksData streamBusiness efficiency

The invention relates to a GPON GTC framing sub-layer based on FPGA. In the GPON GTC framing sub-layer, a data flow of a GTC framing sub-layer is divided into two paths of uplink and downlink to be treated. The downlink data flow is sent to an ONU by an OLT and is sent to an adaptation layer after the de-framing treatment by a TC layer. In the uplink flow, information required by users is sent to the OLT after the framing treatment of the TC layer in the ONU. The data treatment process is realized in FPGA. The GPON GTC framing sub-layer which has high IP business efficiency and strong TDM business bearing capacity, is based on FPGA, and can provide wider bandwidth for users is provided.

Owner:ZHEJIANG UNIV OF TECH

Method for directly producing high-purity electronic level cobaltous sulfate by using cobalt-containing waste

ActiveCN102061390AMeet high purity requirementsImprove overall recoveryProcess efficiency improvementTotal recoveryGoethite

The invention provides a method for directly producing high-purity electronic level cobaltous sulfate by using cobalt-containing waste, in particular a process for producing cobaltous sulfate by using cobalt-containing waste. The method comprises the steps of: checking and classifying raw materials, wet-milling and size-mixing, acid-decomposing, filtering, washing, separating, and extracting copper sponge. The method is characterized by also comprising the steps of: removing iron with a goethite process, extracting P2O4 and removing impurities, separating nickel from cobalt, extracting N235, purifying, concentrating and crystallizing. The high purity electron level cobaltous sulfate is directly regenerated by using various kinds of cobalt wastes, the requirement of the modern high-technology industry on high purity of the cobaltous sulfate is met; the total recovery of the cobalt is higher than or equal to 98 percent; various usable elements can be comprehensively recycled, and coppersponge, tungsten carbide, iron hydroxide and nickel carbonate can be regenerated while the electronic level cobaltous sulfate as a main product is regenerated. The invention has the advantages of comprehensively utilizing waste cobalt resources, recycling the wastes, improving the enterprise benefit, and being beneficial to the development of energy conservation, emission reduction, environment protection and circular economy.

Owner:HUNAN JINYUAN NEW MATERIALS CO LTD

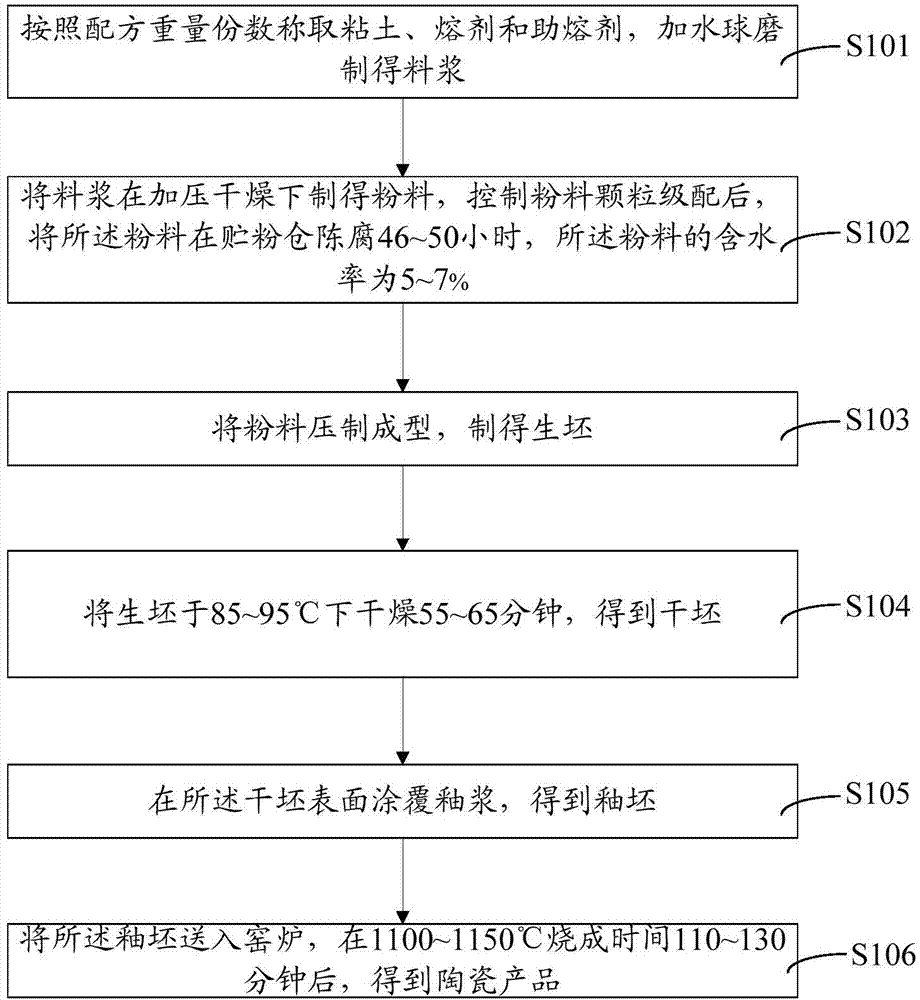

Ceramic formula and preparation method for ceramic product

The invention provides a ceramic formula, comprising, by weight, 55 to 65 parts of clay, 20 to 30 parts of a flux and 15 to 23 parts of a fluxing agent, wherein the clay is a mixture of purple sandshale and china clay mixed according to a weight ratio of 0.67 to 2.0, the flux is shale, and the fluxing agent is one or more selected from the group consisting of limestone, calcite, diopside, wollastonite, dolomite, talcum and industrial waste residue. A preparation method for a ceramic product comprises the following steps: weighing the clay, the flux and the fluxing agent according to the formula, carrying out crushing and screening with a 250-mesh sieve, wherein the weight of screen residue is 1 to 1.5%, adding water, carrying out blending to obtain slurry and then carrying out drying and granulation so as to obtain powder; grading particles and then carrying out molding so as to prepare a green body; carrying out drying so as to prepare a dry body; and carrying out firing so as to prepare a seasonal ceramic body. According to the ceramic formula and the preparation method for the ceramic product in the invention, raw materials are cheap, process is simple, firing temperature is reduced, production cost is decreased, investment for production equipment is lowered down, production efficiency is improved, and energy consumption is reduced.

Owner:怀化市亿智陶瓷有限公司

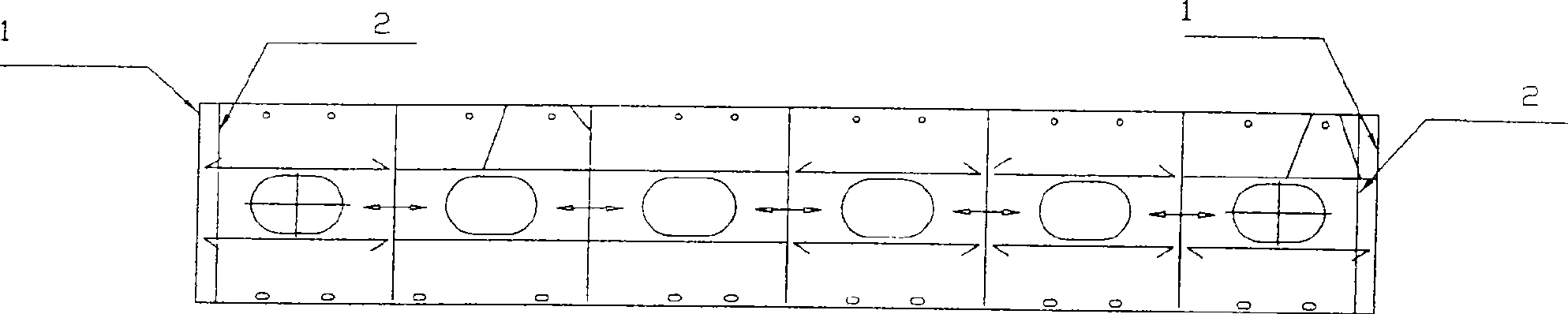

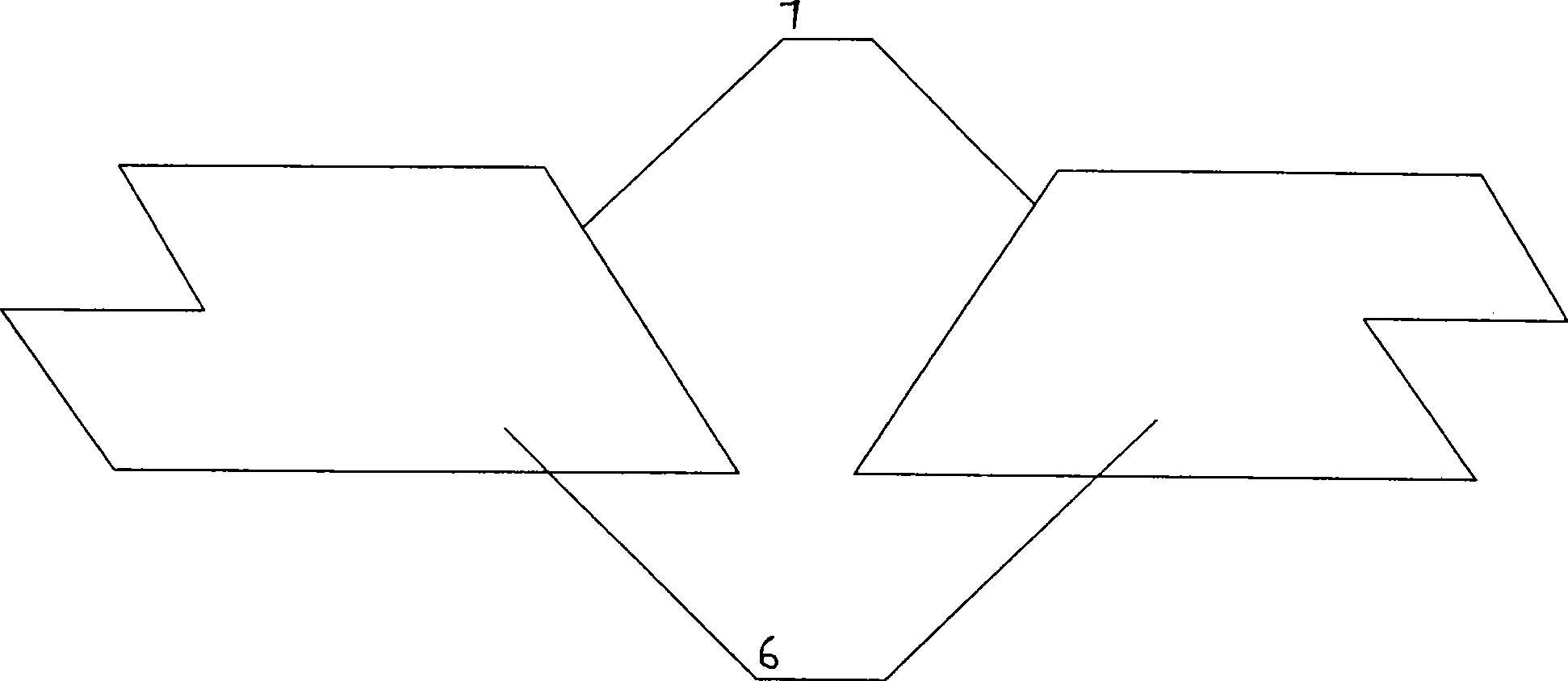

Hull section non-allowance healing accuracy control process

InactiveCN101439754AShorten the construction periodReduce the workload of positioning and trimmingVessel partsMarine engineering

The invention provides a process for controlling hull segmentation non-surplus seaming precision, which comprises the following steps: at the beginning of building, setting each segment of a hull to be in the reverse building state, building an inner bottom plank at the lower part and a bottom board at the upper part; lining out a structural line on the inner bottom plank and drawing surplus cutting lines at two ends thereof simultaneously, and getting 200 millimeters inwards from two ends of a seaming opening as a cross checking line; building the segments of the hull, and turning over the segments of the hull after selection; after turning over the segments of the hull, taking the inner bottom plank as a horizontal plane to adjust levels of four angles, and controlling the planeness of the inner bottom plank in certain range as required; assigning a length direction checking line in the rib direction of the seaming openings at two ends; and punching holes to make marks; lining out a surplus cutting line and a cutting checking line of a segmental annular seaming opening simultaneously; performing cutting, and machining dioxygen divided edges on the adjacent planks of the seaming opening; and after all the segmental cuttings, building a slipway to perform the seaming. Through the non-surplus precision control, the processes of seaming, cutting and secondary seaming are saved, the building cycle of the whole hull is greatly shortened, the labor efficiency is improved, and the enterprise benefit is increased.

Owner:JIANGDONG SHIPYARD CHINA NAT CHANGJIANG SHIPPING COOPERATION

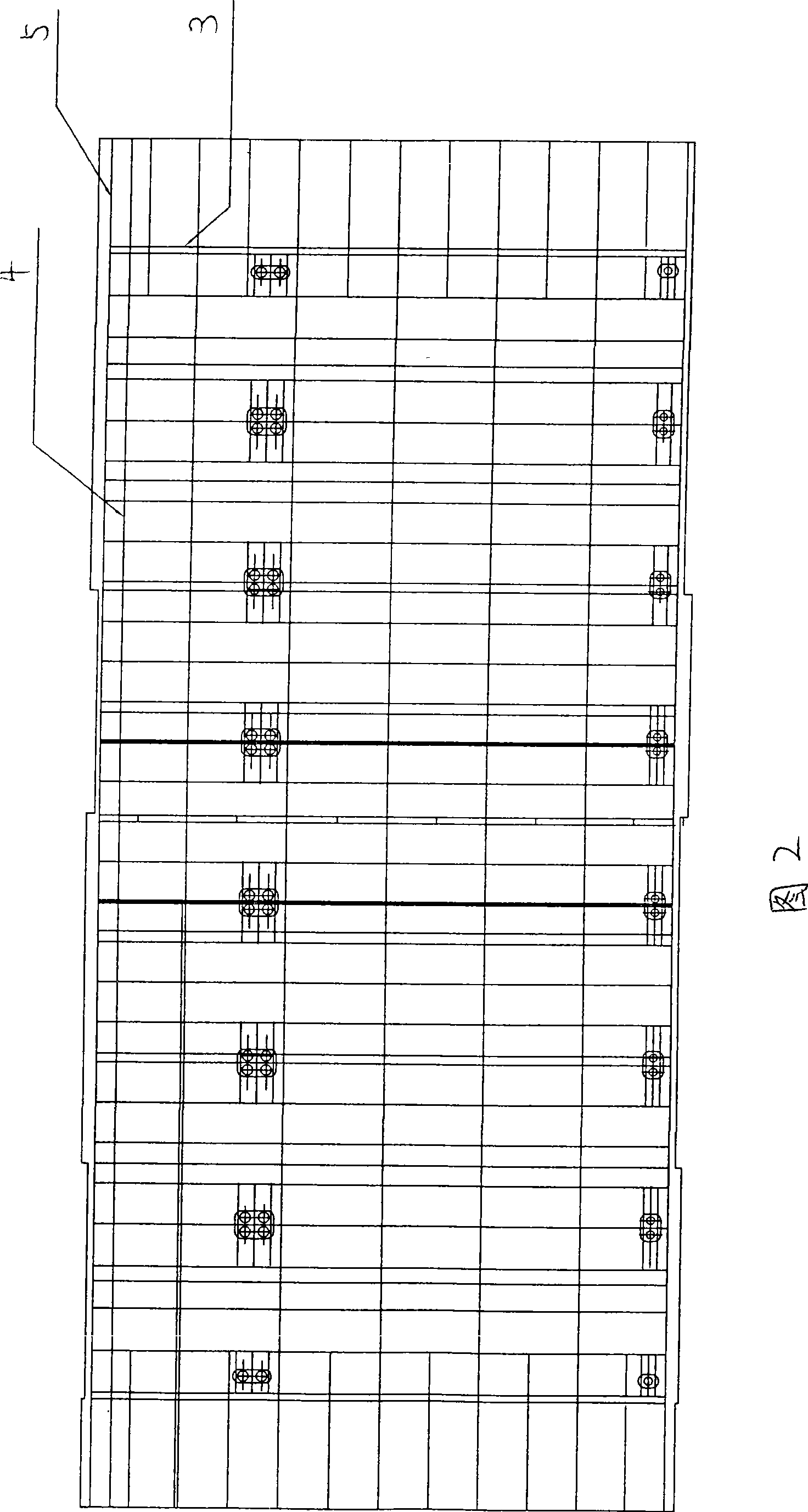

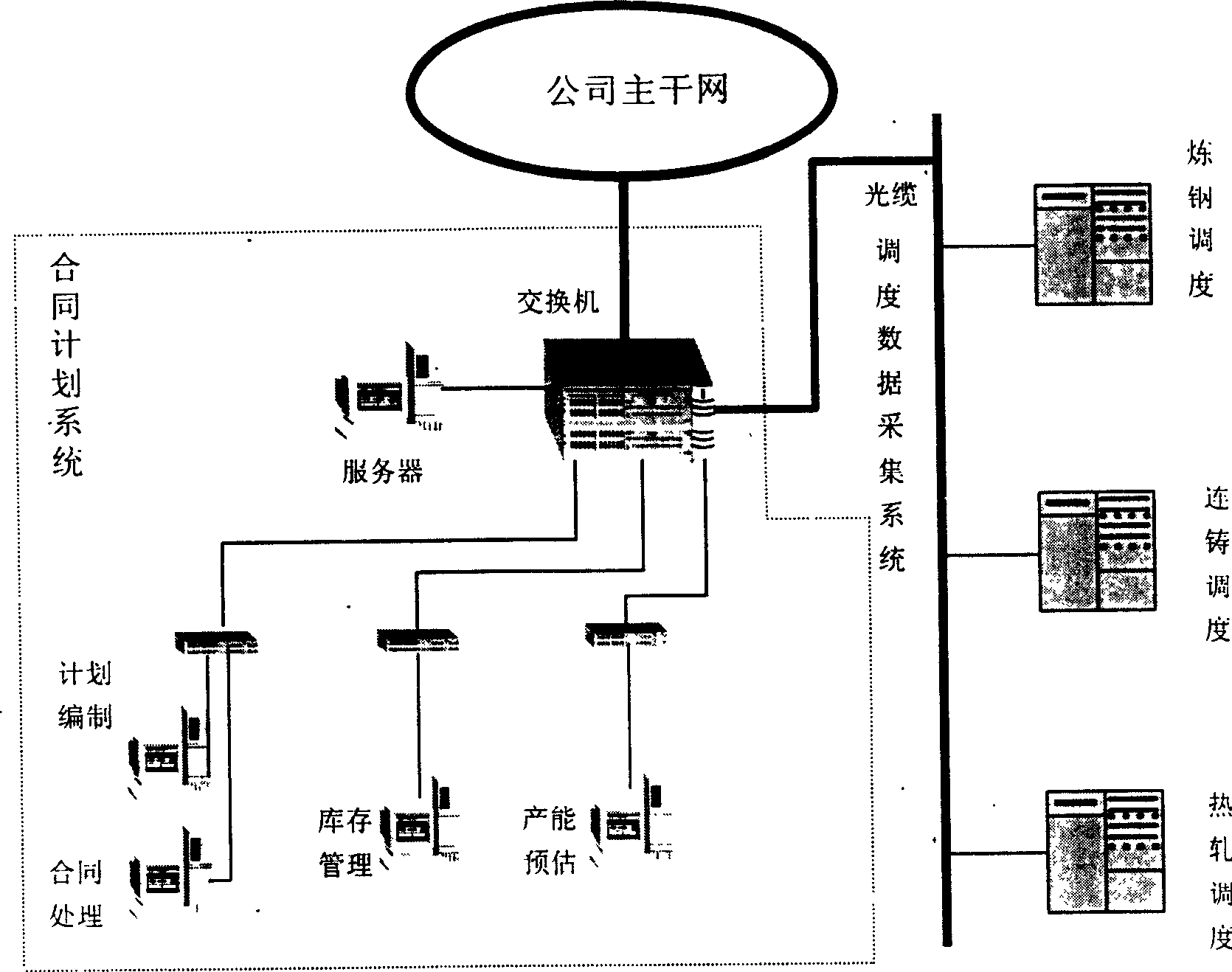

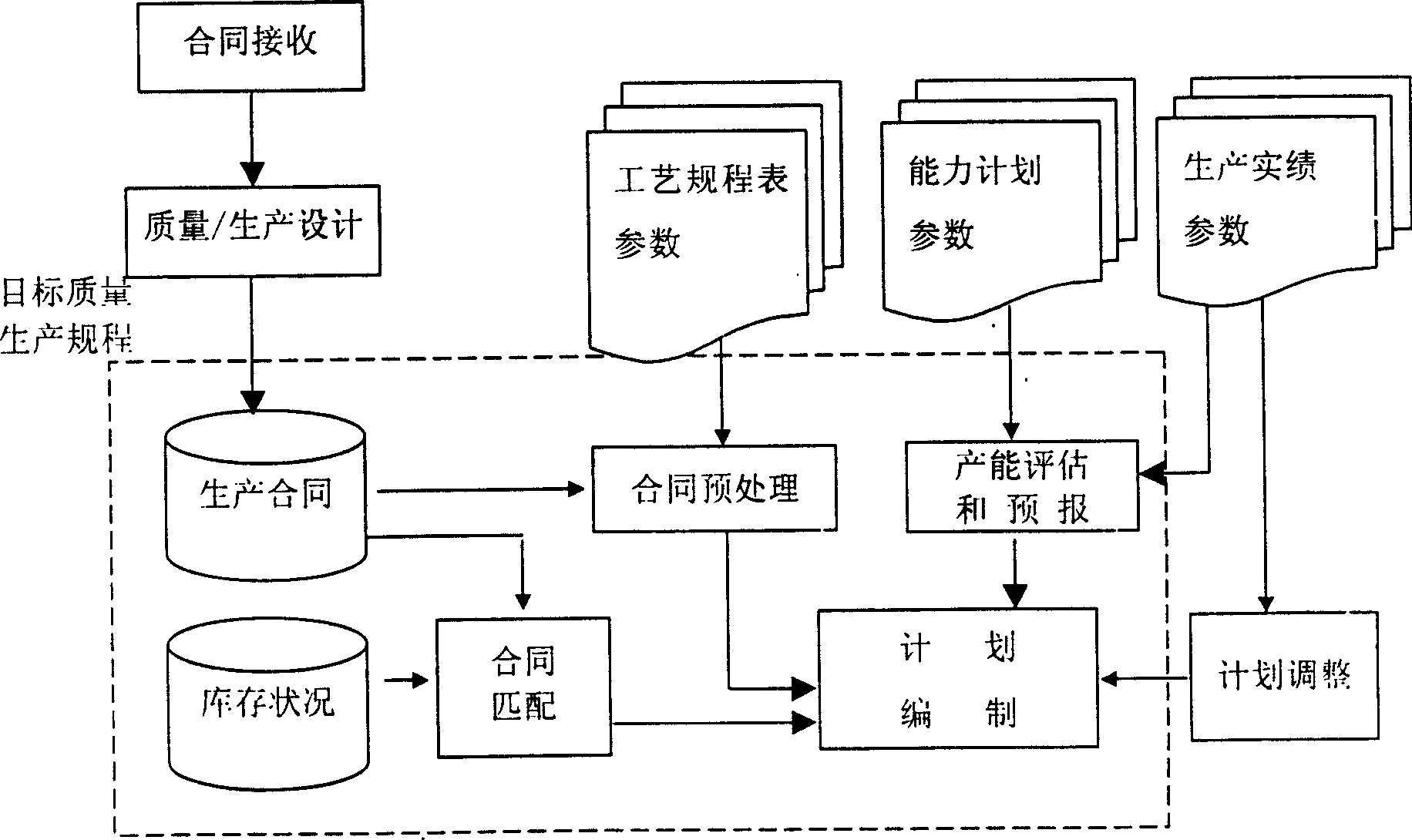

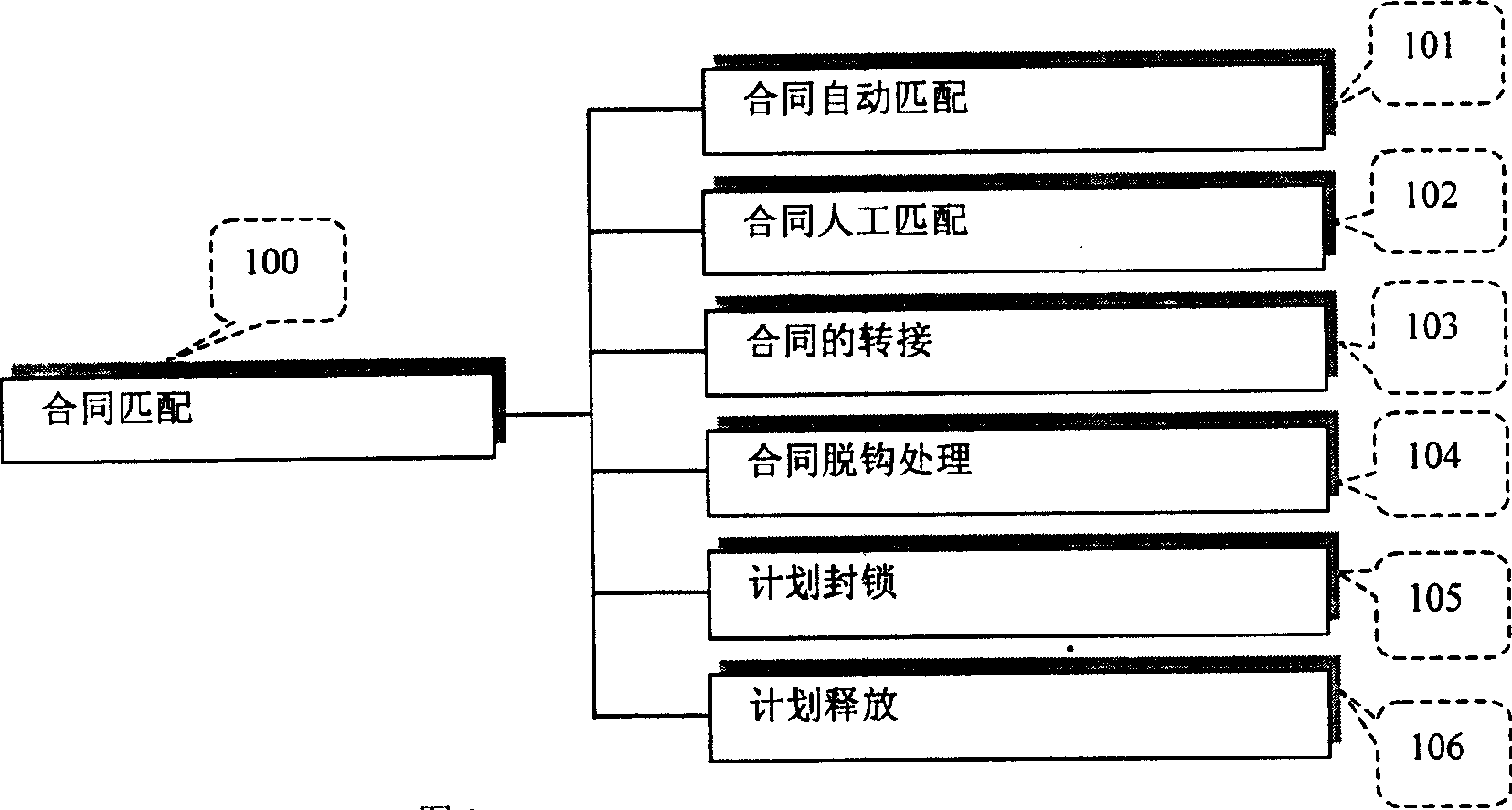

Method of united optimized managing contracts and repertories in plane of steel production

InactiveCN1661609AOptimize production capacity allocationQuick buildSpecial data processing applications

The present invention relates to a computer production management technology field under the network environment, and it is a steel production plan and stock combined optimization management method. Its structure is formed from computer hardware platform and software platform management method, in which the hardware platform uses exchanger as kernel, and is connected with backbone network and dispatching data acquisition system by means of optical cable, at the same time is connected with management terminal by means of server, and the software platform uses plan-making function module as centre, and can implement the management of contract matching, contract preprocessing, production capacity estimation and forecast and plan-making function so as to implement optimize scientific management of stool production.

Owner:何浩然 +1

Temperature optical energy-saving control method for plastic dryer

ActiveCN103399486AHigh precisionMeet energy saving requirementsAdaptive controlNetwork methodOptical transfer function

The invention discloses a temperature optical energy-saving control method for a plastic dryer. According to the method, running characteristics of the plastic dryer under different working conditions are considered, a predictive control strategy on the basis of multi-model switching is adopted to identify dynamic characteristics of an air temperature of the plastic dryer and a switching system model of an object under each typical working condition is established; then an optical target function with constraint is established by utilizing a switching rule and a mixed neural network is formed by a neural network for processing a continuous variable and a neural network for processing a discrete binary variable together; and finally, the switching system is subjected to optimization solution by utilizing the mixed neural network method. According to the invention, a controlled system can be in the optical running state under each typical working condition, so that accuracy of controlling the air temperature of the plastic dryer is improved.

Owner:HANGZHOU DIANZI UNIV

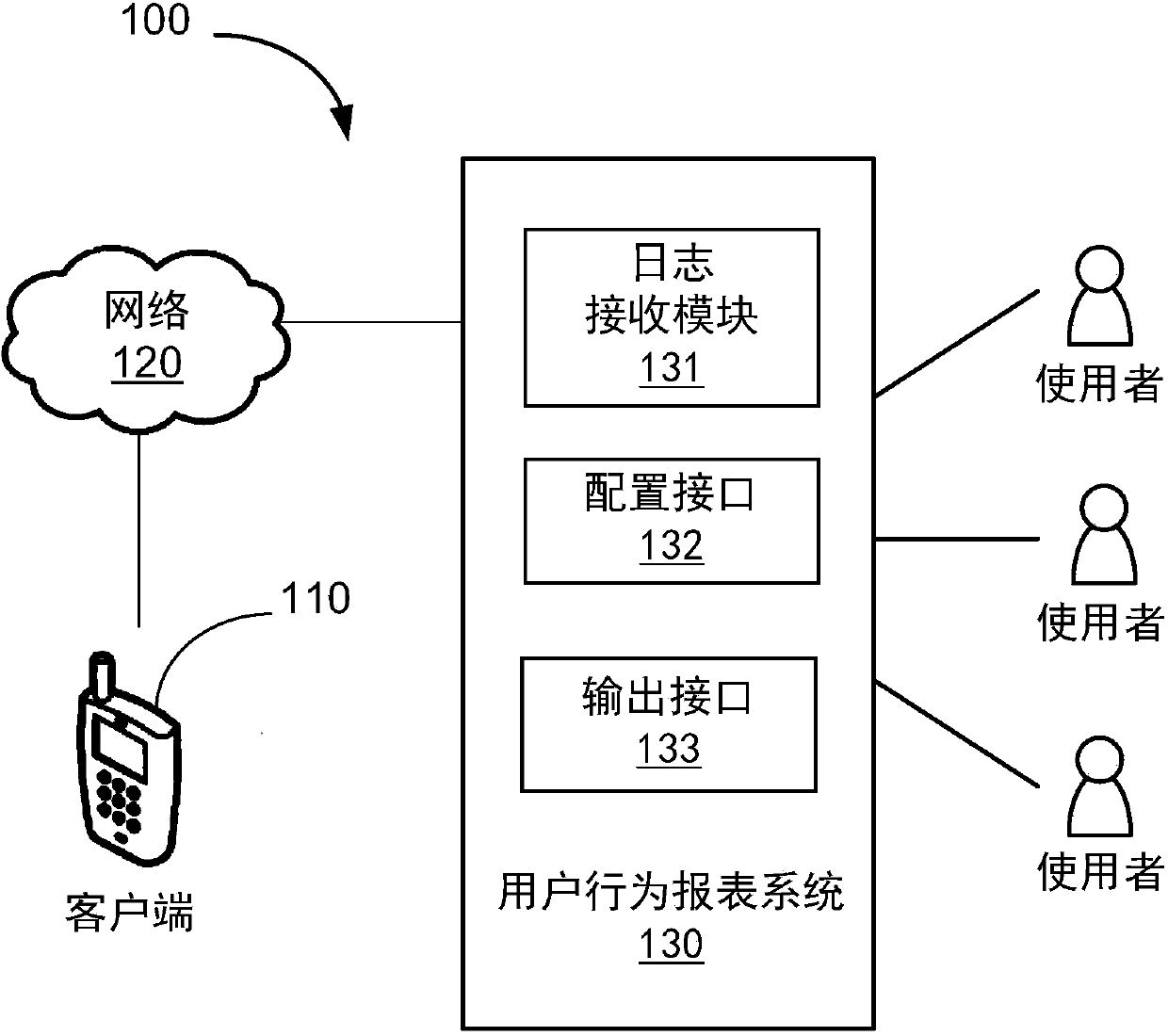

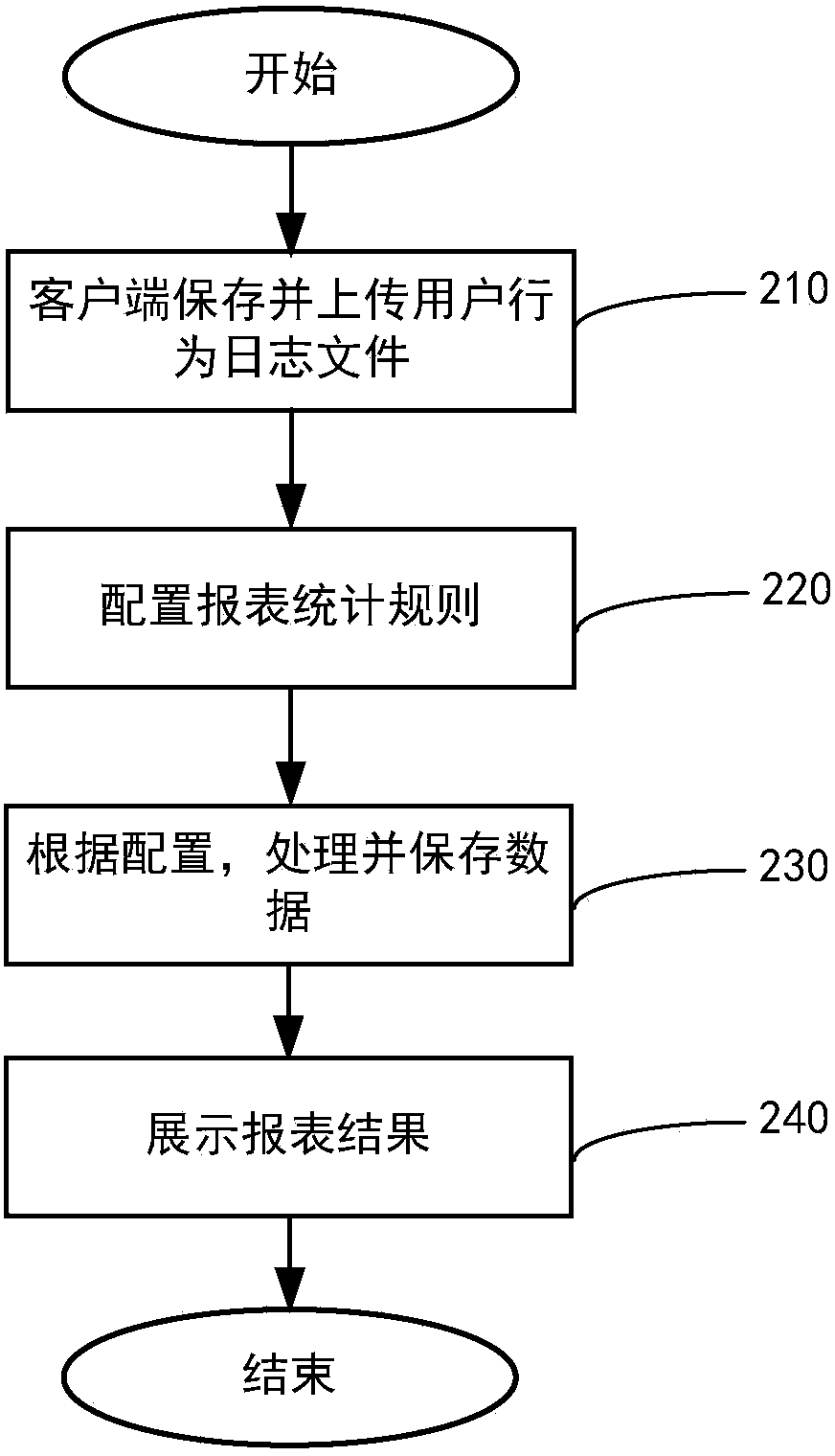

Automatic report analytical method based on user behavior logs

InactiveCN103778244AReduce personnel costsImprove business efficiencyDatabase management systemsError detection/correctionLogfileEngineering

The invention provides an automatic report analytical method based on user behavior logs. A system with the method comprises a user behavior report system and a client, wherein the user behavior report system comprises a log receiving module, a configuration interface and an output interface. The method comprises steps as follows: a), the client stores and uploads a user behavior log file; b), report statistical rules are configured; c), data are processed and stored according to configuration; and d), a report result is shown. According to the automatic report analytical method based on the user behavior logs, a report can be generated automatically simply, conveniently and efficiently, personnel cost is saved for an enterprise, and enterprise revenue is increased.

Owner:BEIJING 58 INFORMATION TECH

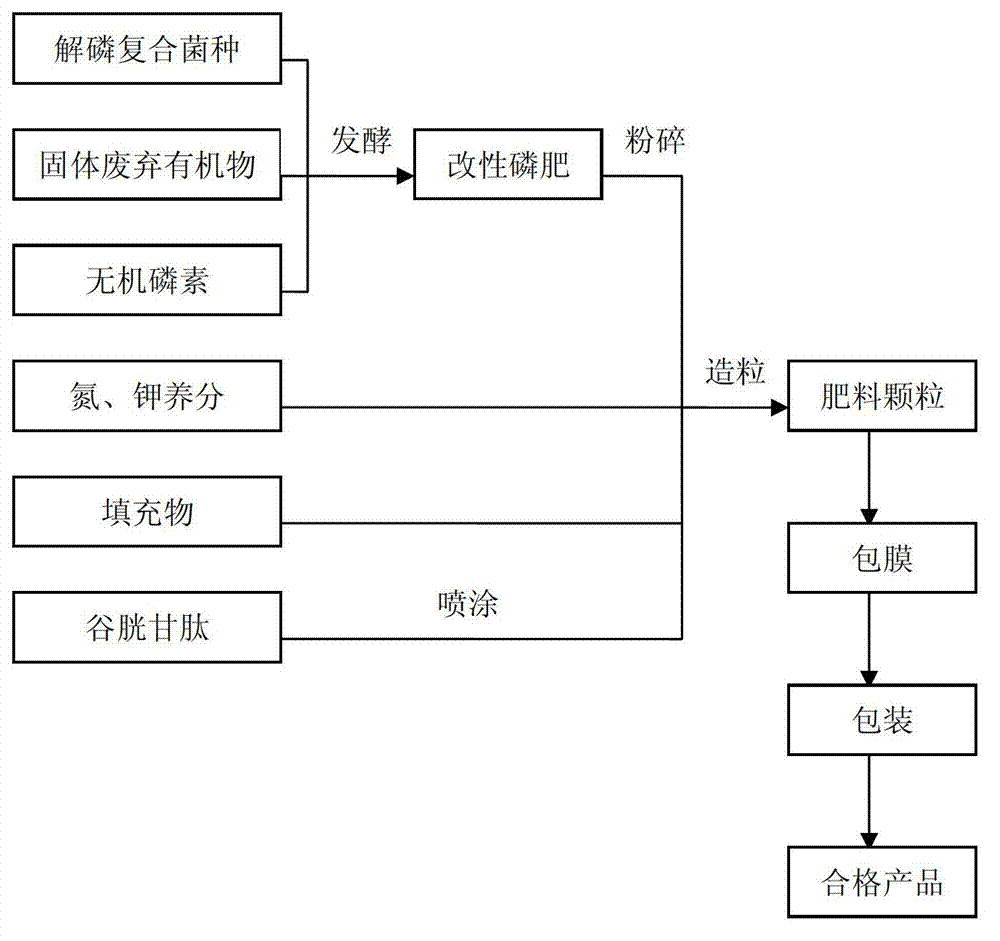

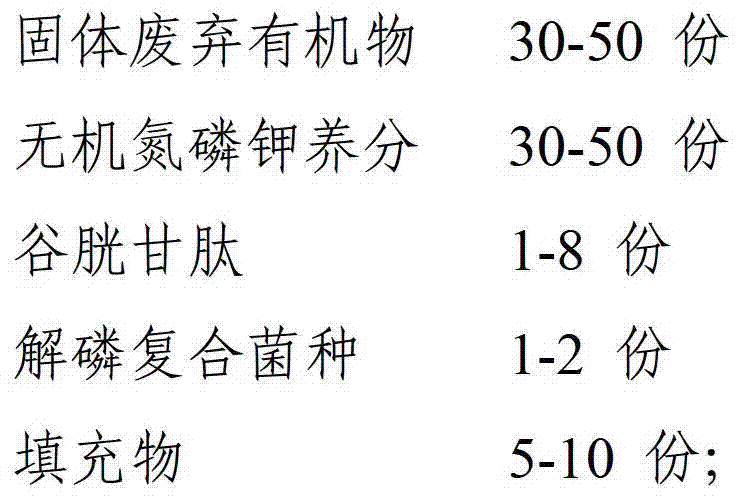

Environment-friendly organic-inorganic compound fertilizer and preparation method thereof

ActiveCN103204744AImprove protectionImprove overall utilizationFertilizer mixturesPotassiumGrossularine-1

The invention provides an environment-friendly organic-inorganic compound fertilizer. The fertilizer comprises the following raw materials in parts by weight: 30-50 parts of solid waste organic, 30-50 parts of inorganic nitrogen phosphorus and potassium nutrient, 1-8 parts of glutathione, 1-2 parts of phosphate-solubilizing compound strain, and 5-10 parts of filler. The organic-matter containing raw material adopted by the fertilizer is from a large amount of solid waste organic from other industries, the byproduct or leftovers are used for providing abundant organic matter so as to produce the organic-inorganic compound fertilizer, the waste is turned into wealth, the environmental protection is realized, the cost is saved, and the enterprise benefit is increased. The detoxication effect of the glutathione is used for producing the organic-inorganic compound fertilizer, so that the blank in China is filled.

Owner:SHANDONG BAOYUAN BIOTECH CO LTD

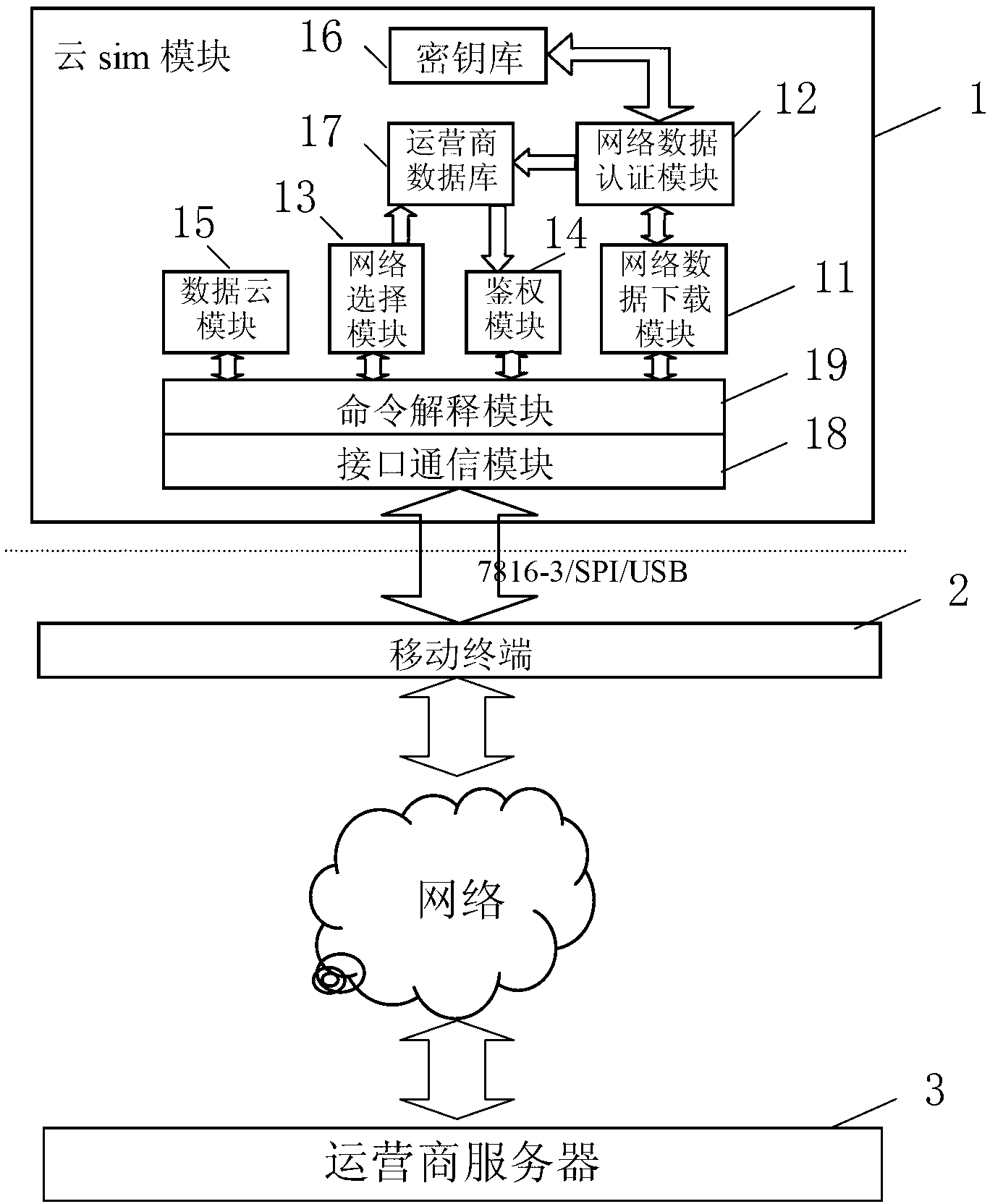

Cloud SIM (subscriber identity module) capable of freely downloading network data

InactiveCN103079193AHigh operating freedomImprove business efficiencySecurity arrangementNetwork data managementNetwork dataSubscriber identity module

The invention discloses a cloud SIM (subscriber identity module) capable of freely downloading network data. The cloud SIM comprises a network data downloading module, a key store, an operator database, a network data authentication module, an authentication module, a network selection module, a command interpretation module and an interface communication module. According to the scheme provided by the invention, subscribers can freely download network authentication data and network configuration data of an operator server, so the subscribers can use different operator networks through the same SIM card, the operation freedom degree of the subscribers is greatly improved, and in addition, the subscribers can download different network authentication data for handling different services, so the service handling efficiency of the subscribers is improved. Therefore, the cloud SIM provided by the invention has the advantages that different operator networks can be replaced for communication, so convenience is brought for users.

Owner:EASTCOMPEACE TECH

Treatment method of carbon black tail gas

InactiveCN102120120AHigh calorific valueHigh thermal efficiencyNitrogen purification/separationDispersed particle separationNitrogen gasMoisture

The invention discloses a treatment method of carbon black tail gas, and the method comprises the steps: (1) washing off the H2O and H2S in the tail gas, collecting a waste liquid and carrying out neutralization treatment; (2) introducing the washed tail gas in a pressure swing adsorption device, drying, and adsorbing the moisture which is not fully dried in the tail gas; (3) introducing the dried tail gas in a temperature swing adsorption device and removing the H2S and SO2 impurities in the tail gas; (4) storing the tail gas in a nitrogen storage tank for application; and (5) introducing the treated carbon black tail gas in a tail gas header pipe for combustion. The method has the following advantages: (1) the energy consumption is reduced, and the benefits of enterprises are improved; (2) the internal capacities of a tail gas combustion furnace and a tail gas boiler are reduced, related supporting facilities are reduced, and the one-time investment is lowered; (3) the pollution of the waste gas to the atmosphere is avoided after tail gas combustion; (4) the generated nitrogen can be used for multiple industries, and new benefit growth points of the carbon black enterprises are created; and (5) the method is applicable to treatment of tail gas generated by various carbon black production methods.

Owner:CHAOYANG BLACK CAT WUXINGQI CARBON BLACK CO LTD

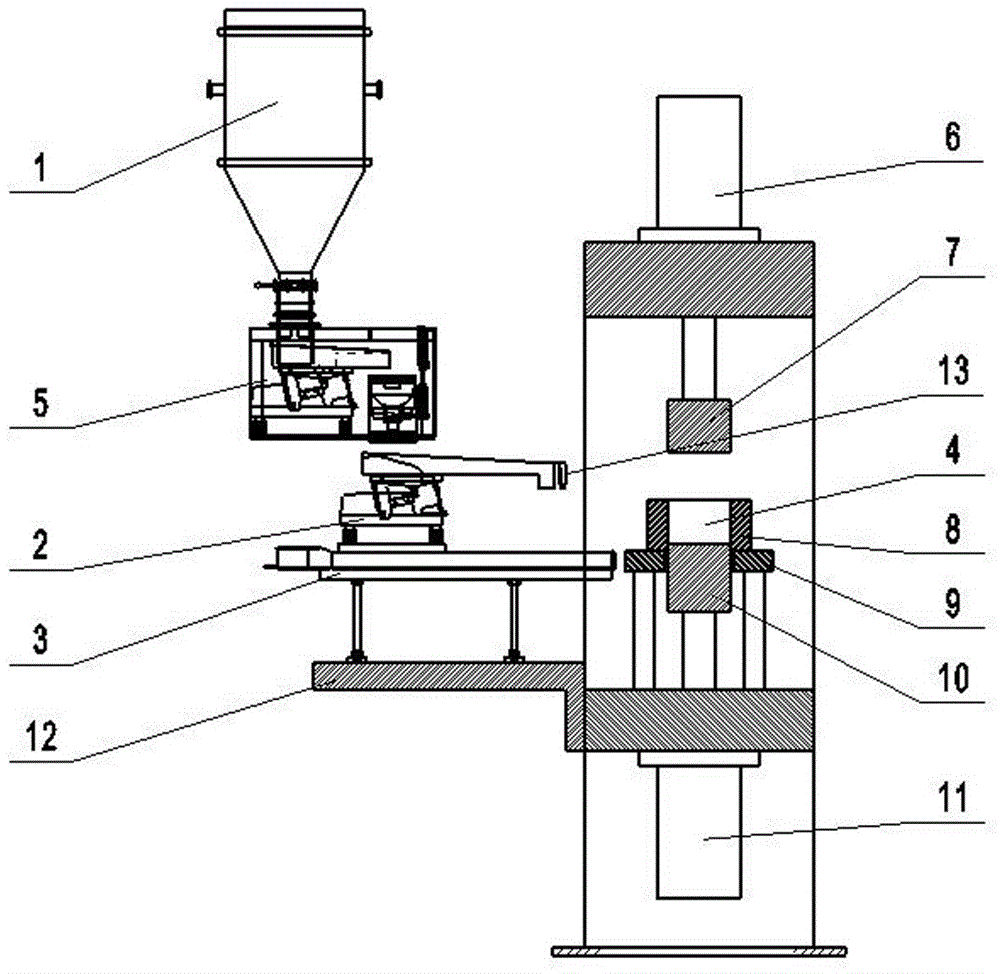

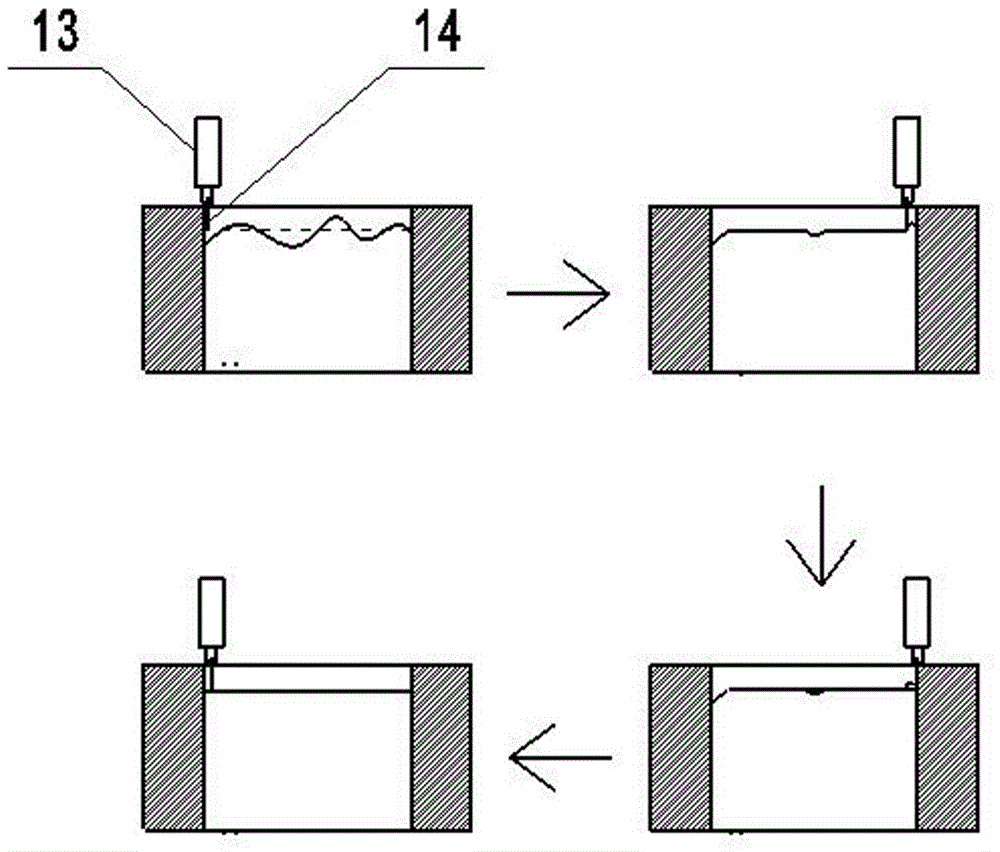

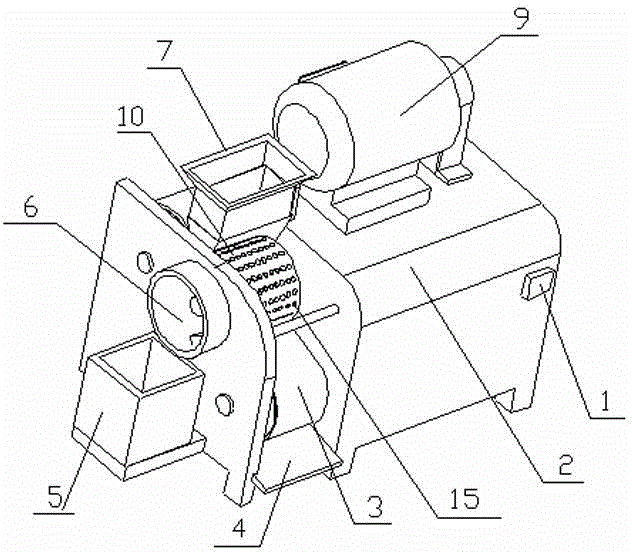

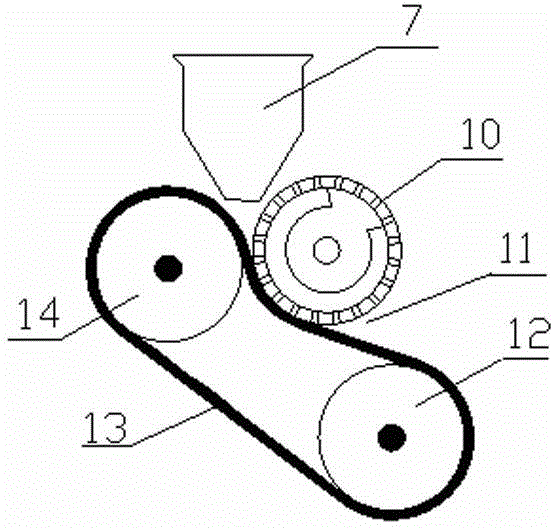

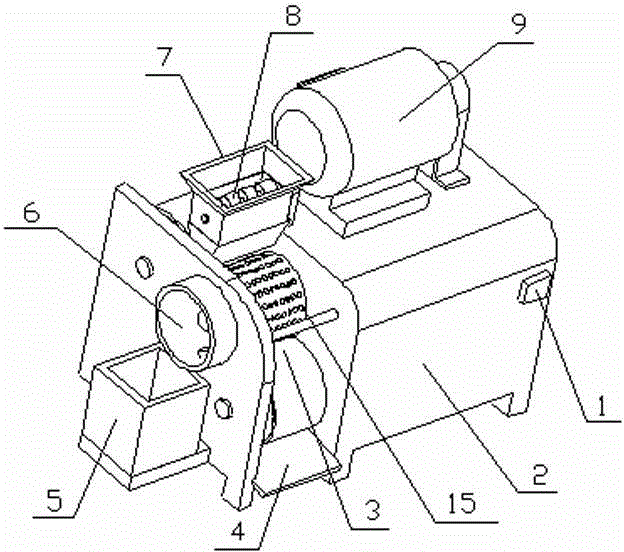

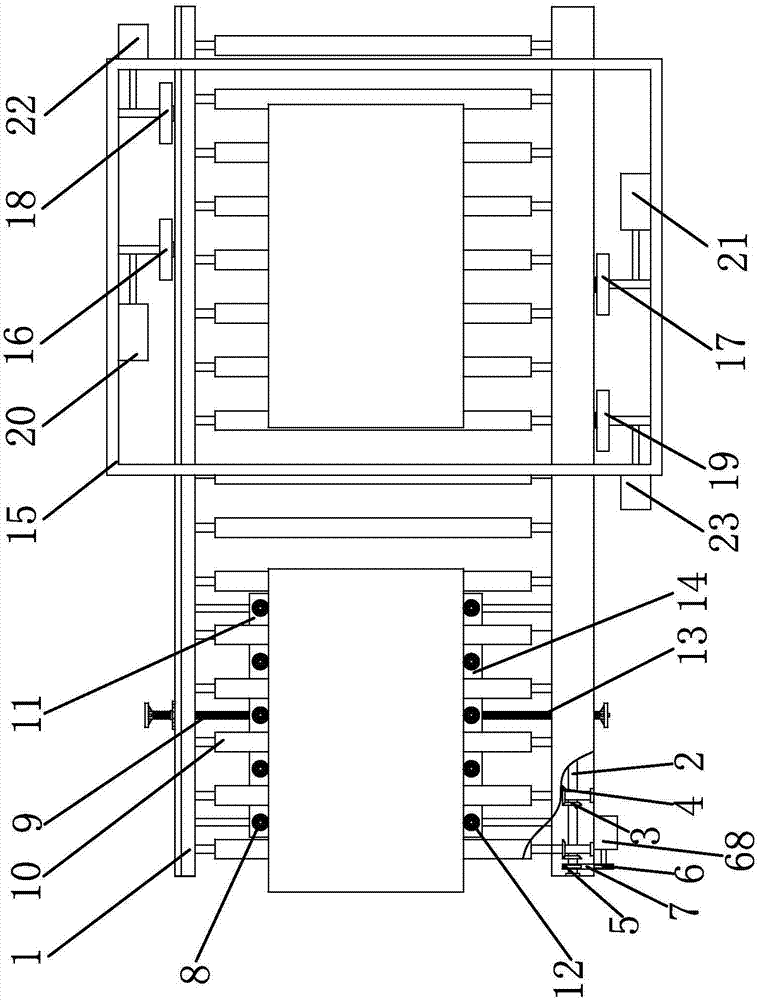

Quantitative powder adding method and device

InactiveCN106079550AEvenly distributedPrevent leakageLoading/unloadingShaping pressReciprocating motionMaterials science

The invention provides a quantitative powder adding method and device. The quantitative powder adding method and device are mainly applied to powder adding. The quantitative powder adding method comprises the steps that powder is weighed through a weighing machine and then poured into a feeder, the feeder is driven to move to the position above a mold by a driving device at the lower end of the feeder, the feeder is started, the powder in the feeder successively falls into a mold cavity of the mold, and the driving device drives the feeder to reciprocate between the two ends of the mold cavity in the process that the powder successively falls into the mold cavity till all the powder is added; and a driving cylinder and a scraping piece are arranged at the front end of the feeder, and the driving cylinder drives the scraping piece to level the powder in the mold cavity after all the powder is added. According to the quantitative powder adding method and device, quantitative powder is stably added into the mold cavity through the feeder and leveled through the scraping piece, so that the powder in the mold cavity is evenly distributed, the defects of powder leakage, caking, bulk specific weight changes and the like in the prior art are overcome, powder waste is reduced, and the benefits of enterprises are increased.

Owner:孔庆虹

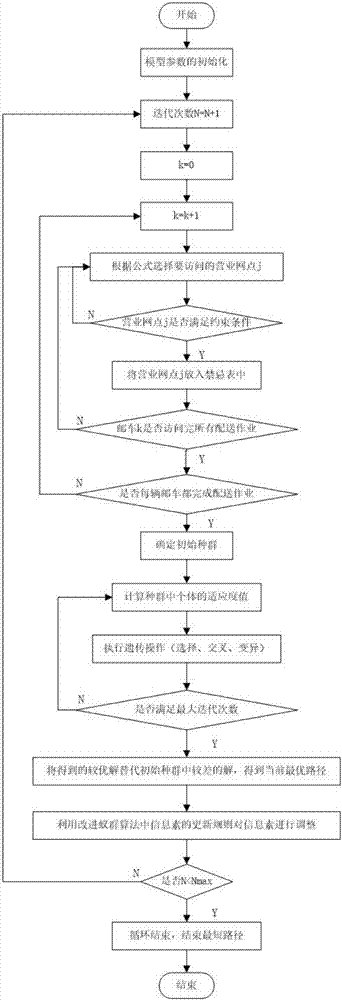

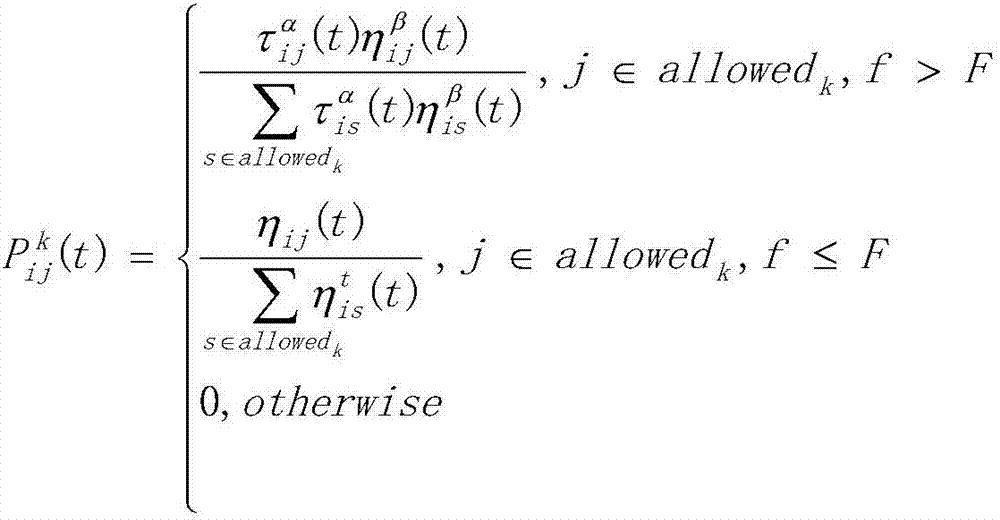

Logistic delivery path planning method

InactiveCN107220731AShorten delivery timeLow costGenetic modelsForecastingGenetic algorithmPlanning approach

The invention relates to a logistic delivery path planning method, aims to improve algorithm performance and global search capability and makes up for defects of an ant colony algorithm and a genetic algorithm. According to the method, crossover and mutation operation of the genetic algorithm are introduced, prematurity and early convergence phenomena in a local search process can be effectively avoided, random search and rapid and global convergence of the genetic algorithm are further utilized to generate an initial solution of a to-be-solved problem, the initial solution is converted into initial pheromone distribution of the ant colony algorithm, and characteristics of the ant colony algorithm including parallelism, the positive feedback mechanism and high solution efficiency are then utilized to seek the optimal solution. The method is advantaged in that a problem of insufficient initial pheromone of the ant colony algorithm is solved, and relatively good time efficiency and solution efficiency are realized.

Owner:NANJING UNIV OF POSTS & TELECOMM

Automatic assembly method and system of three-dimensional models

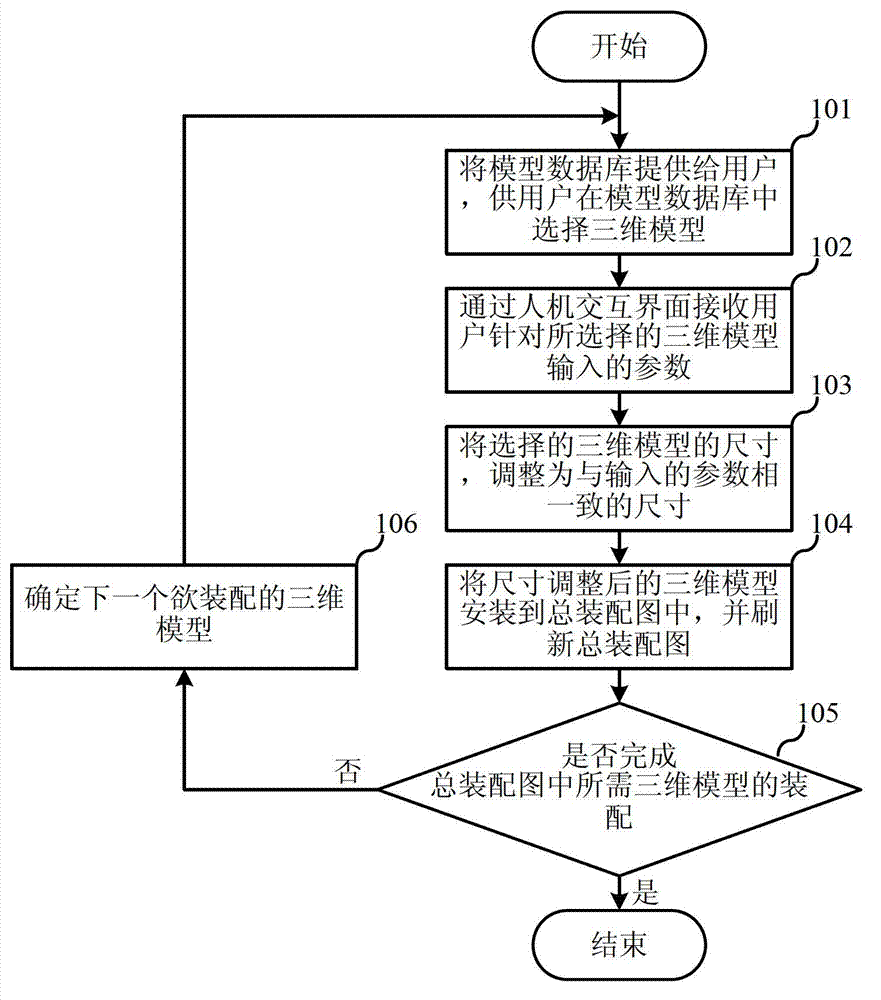

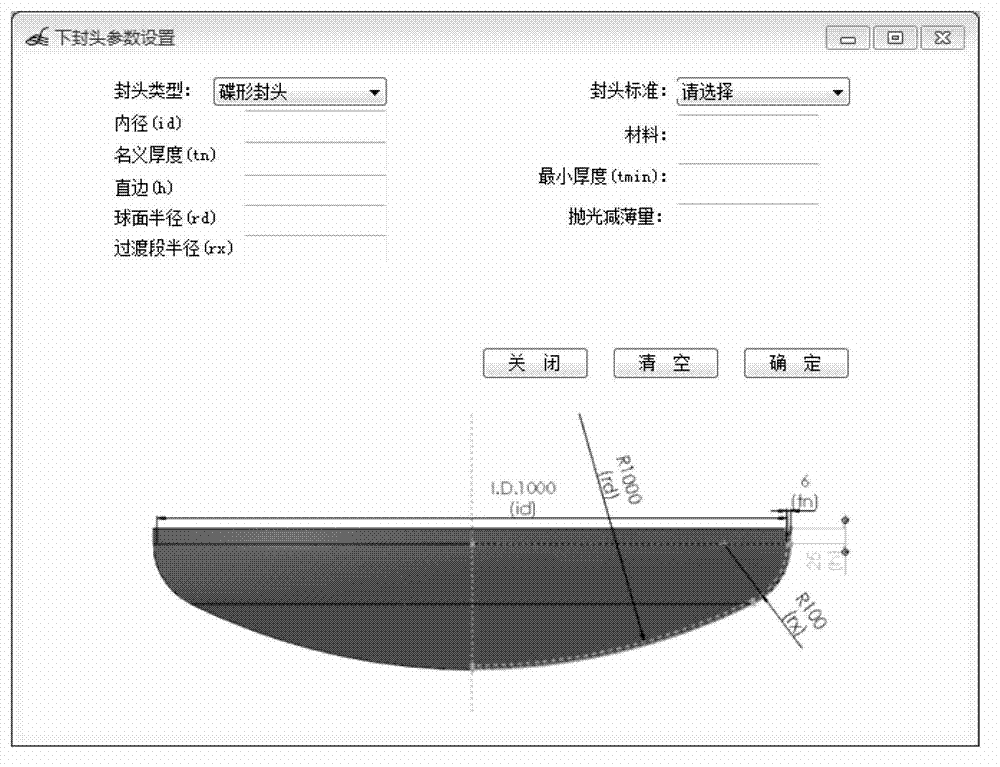

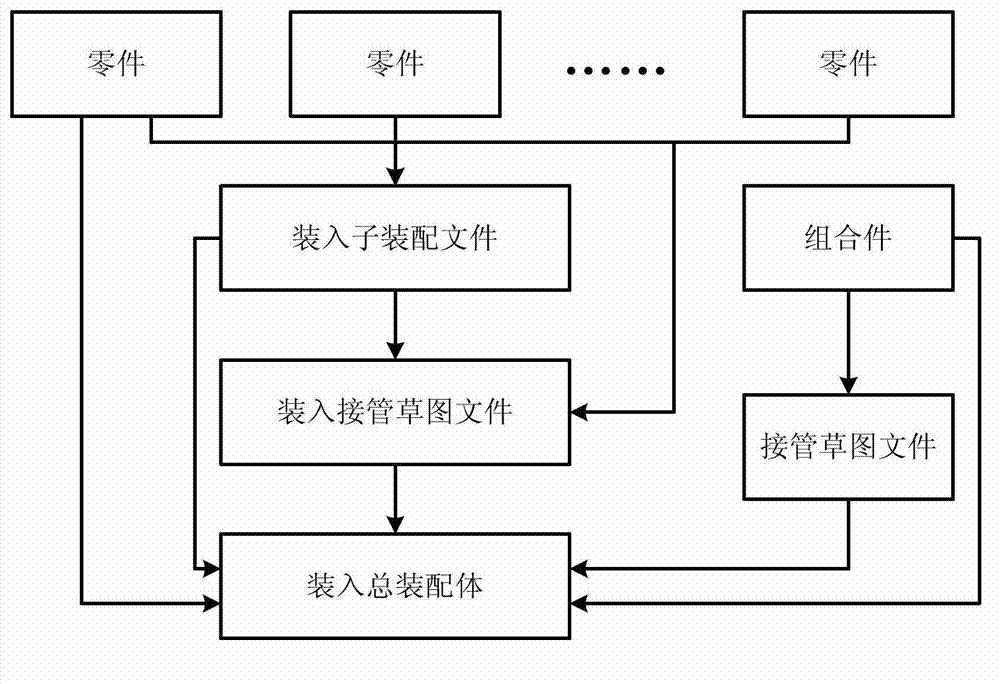

InactiveCN102819629AEliminate complex operationsImprove efficiencySpecial data processing applicationsThree dimensional modelComputer-aided

The invention relates to the field of computer aided designs and discloses an automatic assembly method and an automatic assembly system of three-dimensional models. The method comprises the following steps: selecting three-dimensional models from pre-drawn three-dimensional models stored in a model database; adjusting to enable the dimensions of the three-dimensional model to be same as input parameters in accordance with parameters of a three-dimensional model input by a user; installing the three-dimensional models with the adjusted dimensions in a general assembly drawing, and refreshing the general assembly drawing; and repeating the processes of the three-dimensional model including selection, parameter acquisition, model adjustment and assembly until the assembly of three-dimensional model required in the general assembly drawing is completed, thus realizing automatic parameterized assembly of the three-dimensional model. The method is used to eliminate complicated operations of designers and improve the efficiency.

Owner:上海美弛腾流体技术有限公司

Aluminum-chromium-zirconium composite air bricks and manufacturing method thereof

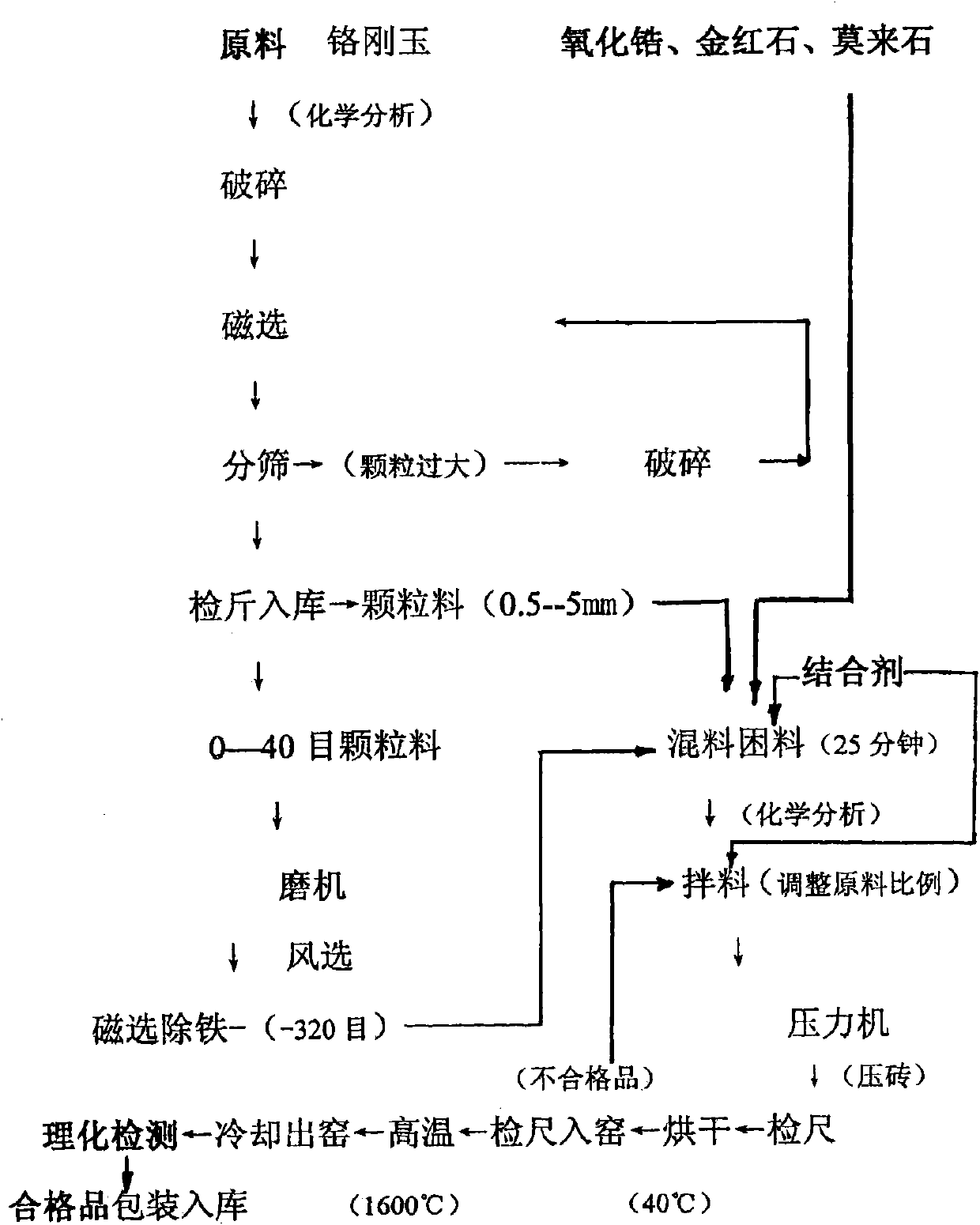

ActiveCN101792323ASmall coefficient of thermal expansionImprove mechanical propertiesMelt-holding vesselsFurnace componentsBrickMullite

The invention discloses aluminum-chromium-zirconium composite air bricks and a manufacturing method thereof, and relates to industrial bricks and a manufacturing method thereof. Each brick comprises the following chemical components in percentage by weight: more than or equal to 72 percent of Al2O3, more than or equal to 15 percent of Cr2O3, more than or equal to 4 percent of ZrO2, more than or equal to 5 percent of mullite, more than or equal to 3 percent of TiO2, and more than or equal to 1 percent of Fe2O3. The aluminum-chromium-zirconium composite air brick comprises the following processsteps: crushing a raw material chrome corundum until the largest granule has the grain size of less than or equal to 5mm; performing deironization, magnetic separation and sieving, and feeding granules with the grain size of 0.5 to 5mm into a blender mixer to mix the granules and zirconium oxide, rutile, mullite and a binding agent; grinding granules with 0 to 40 meshes into granules of -320 meshes, performing magnetic separation and deferrization on the granules, mixing the granules and the zirconium oxide, rutile, mullite and the binding agent, standing for 25 minutes and performing brick-pressing operation; and drying the bricks at the temperature of 40 DEG C, and firing the bricks in a high-temperature kiln at the temperature of between 1,600 and 1,800 DEG C. The aluminum-chromium-zirconium composite air bricks are applied to an airheater in oil field, a scrap metal incinerator and a copper converter, and the service life of the furnaces is improved.

Owner:锦州大隆特种耐火材料有限公司

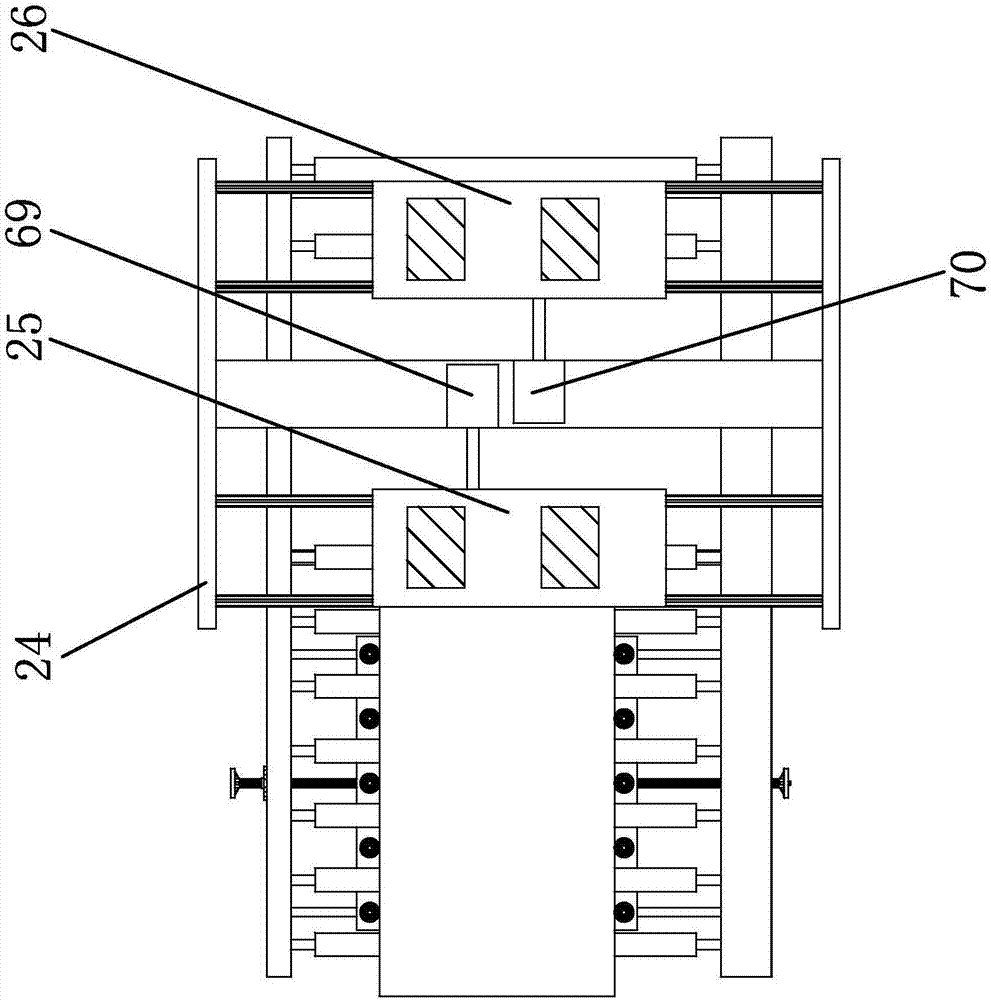

Shrimp-crab meat collecting method and shrimp-crab meat collecting equipment

ActiveCN104082391AEasy to separateImprove business efficiencyBivalves processingShrimpElectric machinery

The invention relates to a shrimp-crab meat collecting method and meat collecting equipment. The shrimp-crab meat collecting method comprises the following steps of adding water to shrimps and crabs, carrying out extrusion crushing, and removing shells. The shrimp-crab meat collecting method is characterized in that the extrusion crushing process is finished by virtue of an extrusion device, wherein the extrusion device comprises a material hopper, a grinding wheel set, a shell discharging hole, a meat storing bucket and an electric motor, the shrimps and crabs are fed into slits of the grinding wheel set, the grinding wheel set is driven by the electric motor to extrude the shrimps and crabs so as to separate meat from shells, the shells enter the shell discharging hole, and the meat enters the meat storing bucket; the shells are removed by virtue of shell-meat separation equipment, wherein the shell-meat separation equipment comprises a vibrating mechanism, an outer bucket and an inner bucket, sieving holes are formed in the inner bucket, the inner bucket is arranged in the outer bucket, in a use process of the shell-meat separation equipment, the extruded shrimp meat and crab meat are put in the inner bucket, a high-speed motor is started, and the inner bucket is vibrated by a cam and a spring commonly, so that the shrimp meat, the crab meat and the fine shrimp and crab shells enter the outer bucket through the sieving holes in the inner bucket.

Owner:ZHEJIANG OCEAN UNIV

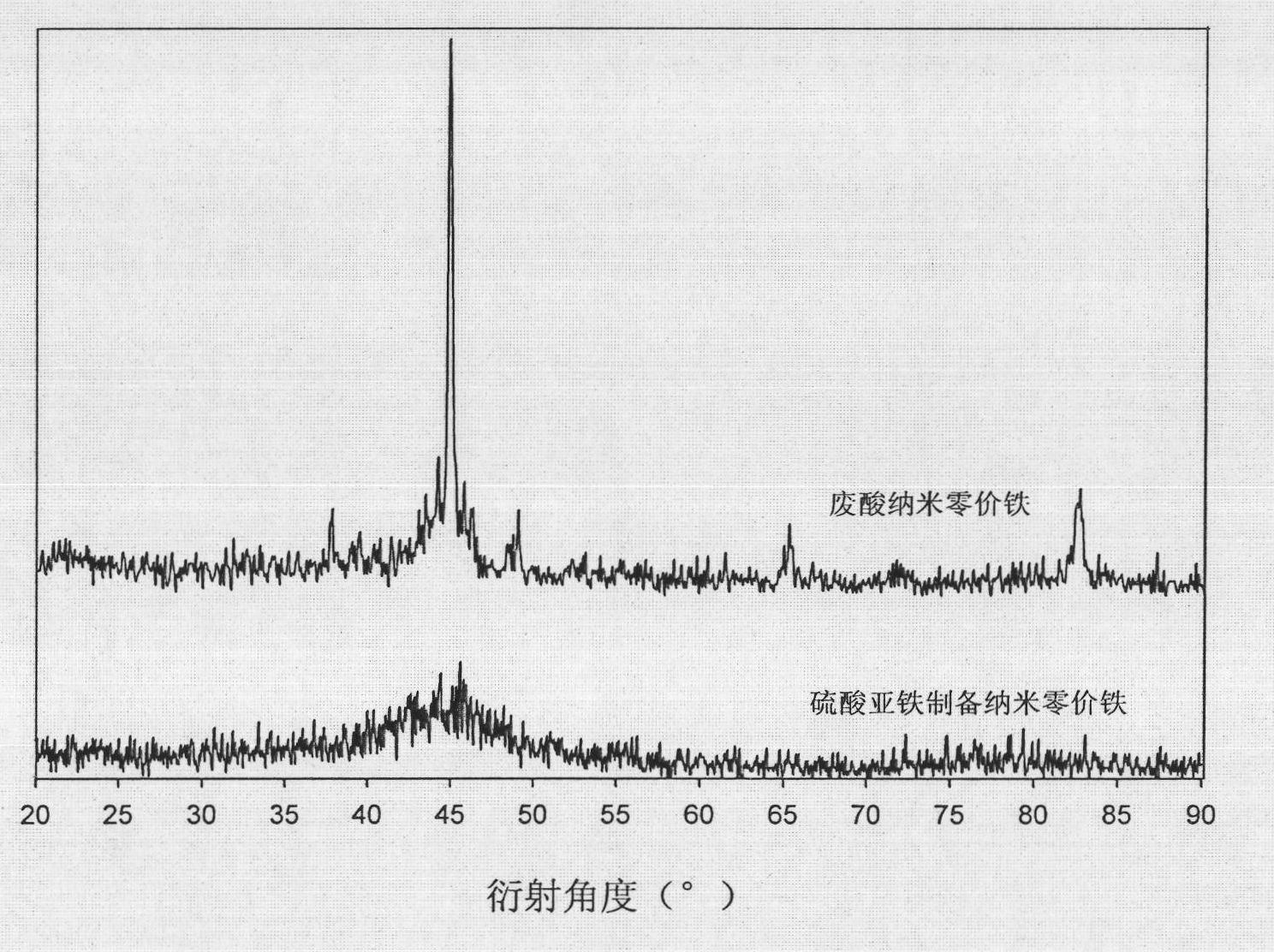

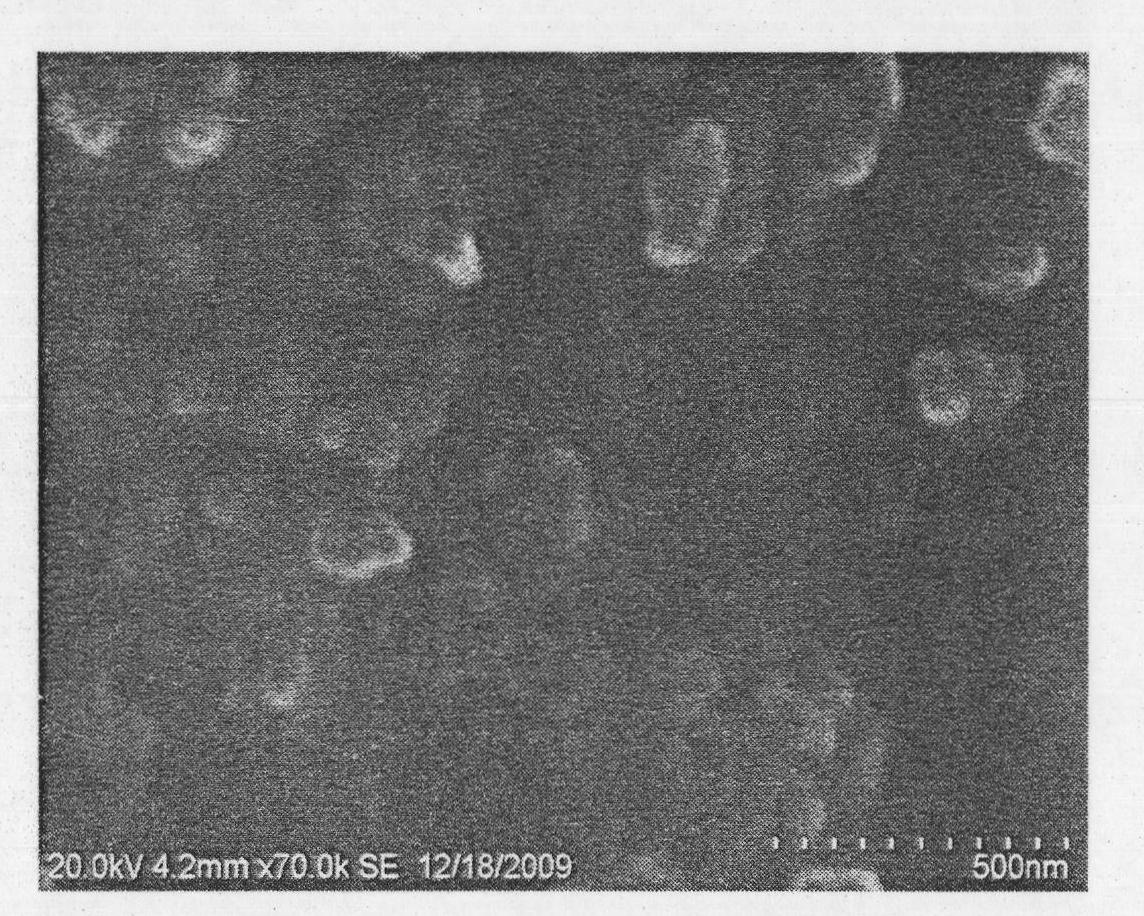

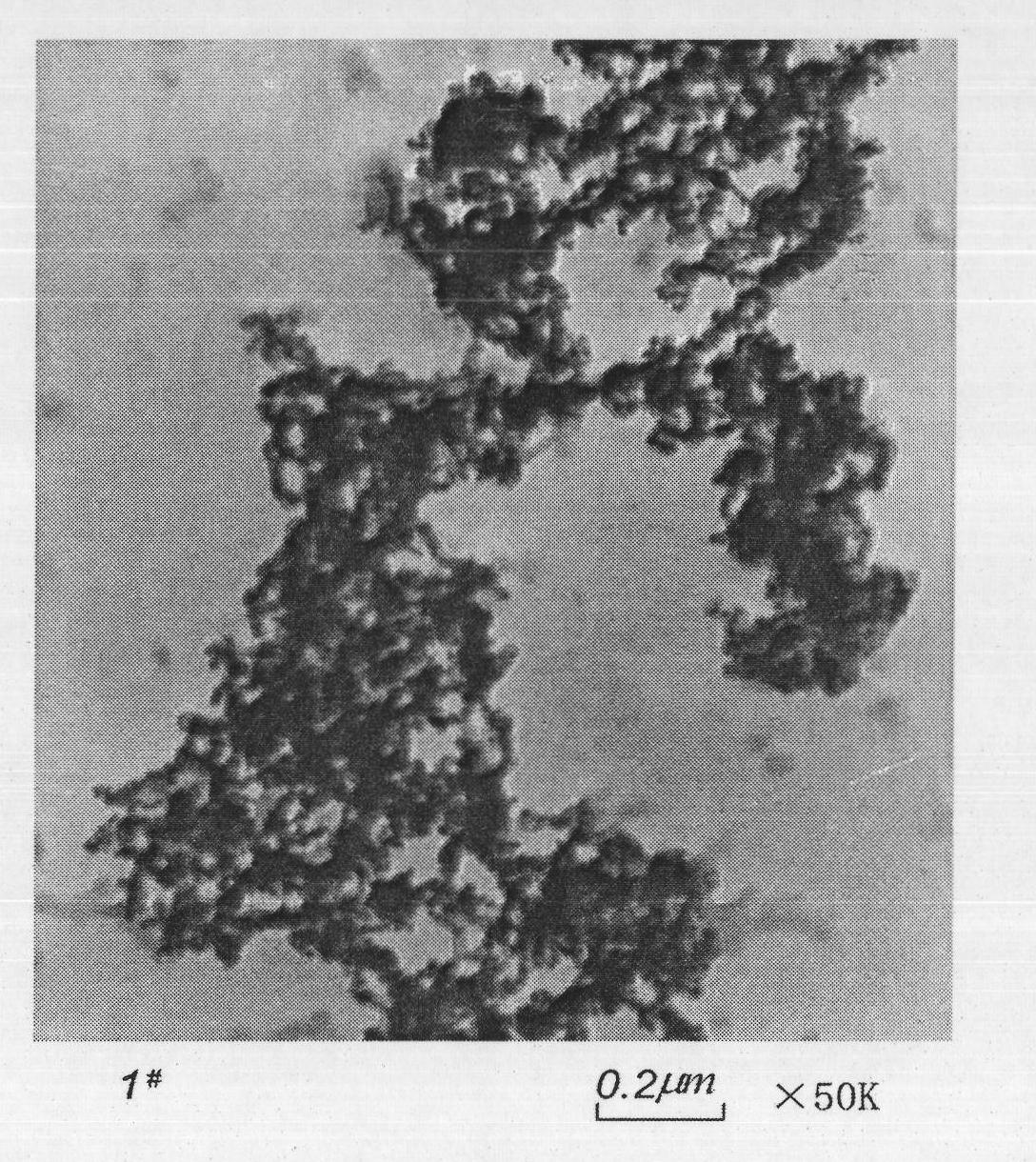

Nano zero-valent iron prepared by using iron and steel acid-cleaning wastewater and preparation method and application thereof

ActiveCN101844230AEfficient conversionEasy to operateChemical protectionMaterials sciencePolyvinylpyrrolidone

The invention discloses nano zero-valent iron prepared by using iron and steel acid-cleaning wastewater and a preparation method and application thereof. The preparation method comprises the following steps: filtering acid-cleaning wastewater without removing iron ions in the iron and steel industry; regulating pH value of filtrate; successively adding ethanol solution and polyvinylpyrrolidone; adding sodium borohydride, absolute ethanol and water to prepare into sodium borohydride solution; stirring under protection of inert gas for reaction; and carrying solid-liquid separation, collecting, washing and drying solid to obtain the nano zero-valent iron. In the invention, addition of polyvinylpyrrolidone is equivalent to the mass of total iron ions in a reaction system; and the mole number of sodium borohydride is as at least three times as that of the iron ions in the total reaction system. The method can effectively convert the iron ions in the acid-cleaning wastewater in the iron and steel industry into the nano zero-valent irons, and the conversion rate reaches up to over 99%; sizes of the nano zero-valent iron particles prepared by the method are between 50-80 nm; and the nano zero-valent iron particles are spherical particles, and have good crystal forms and strong capability of degrading polybrominated diphenyl ethers.

Owner:SOUTH CHINA NORMAL UNIVERSITY

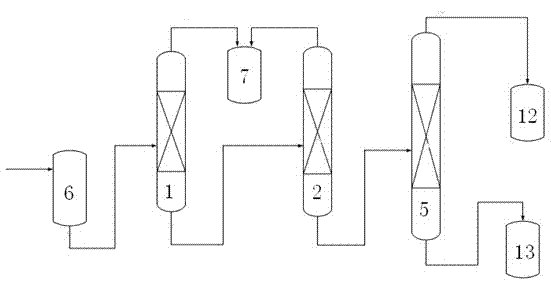

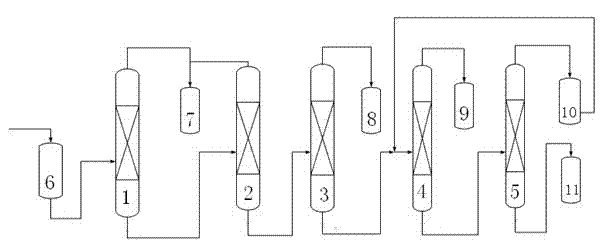

Ethylene glycol rectification device system and rectification technique in industry of producing ethylene glycol by synthesis gas

ActiveCN103193595AIncrease productionIncrease incomeOrganic compound preparationHydroxy compound preparationHydrogenation reactionProcess engineering

The invention discloses an ethylene glycol rectification device system in industry of producing ethylene glycol by synthesis gas. The ethylene glycol rectification device system comprises a primary dealcoholization tower, a secondary dealcoholization tower, an ethylene glycol refining tower, wherein the primary dealcoholization tower is connected with a hydrogenation reaction product tank by a pipeline, the secondary dealcoholization tower is connected with the primary dealcoholization tower by a pipeline, the ethylene glycol refining tower is connected with the secondary dealcoholization tower, an ethanol removal tower and a butylenes glycol removal tower which are connected by a pipeline are arranged on the pipeline between the secondary dealcoholization tower and the ethylene glycol refining tower, the top of the ethanol removal tower is connected with an ethanol tank, and the top of the butylenes glycol removal tower is connected with the butylenes glycol tank. The invention further discloses a rectification technique in industry of producing ethylene glycol by synthesis gas. According to the ethylene glycol rectification device system in industry of producing ethylene glycol by synthesis gas, the steam consumption can be reduced, the energy consumption can be saved, the purity of the methanol can be improved, the output of premium grade products can be increased, the production cost can be greatly lowered, and the enterprise benefits can be increased.

Owner:PUJING CHEM IND SHA

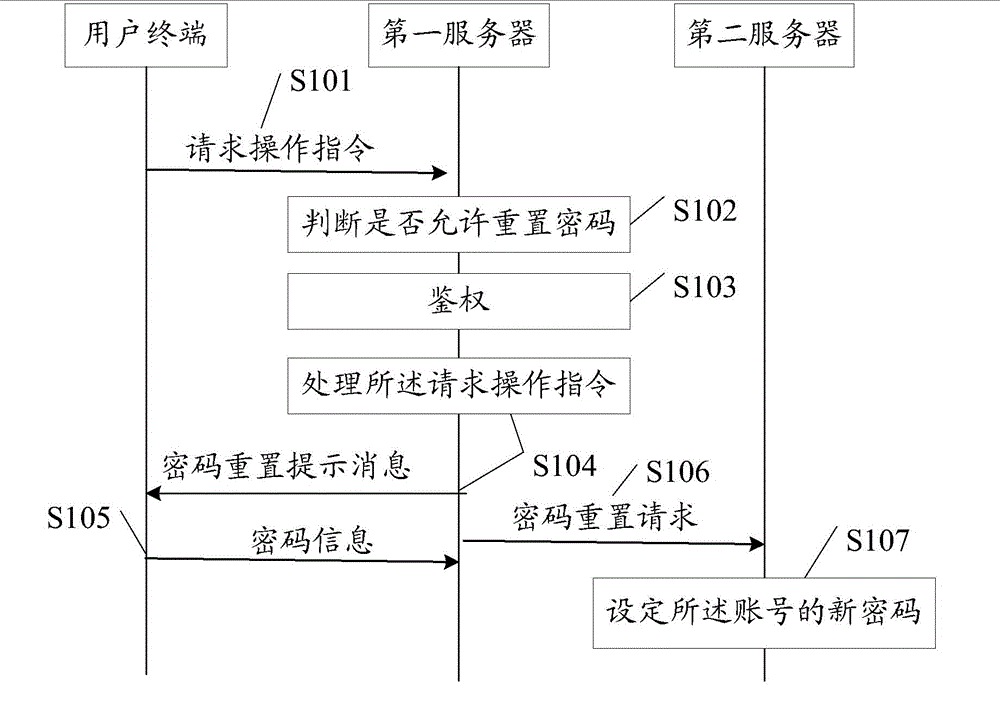

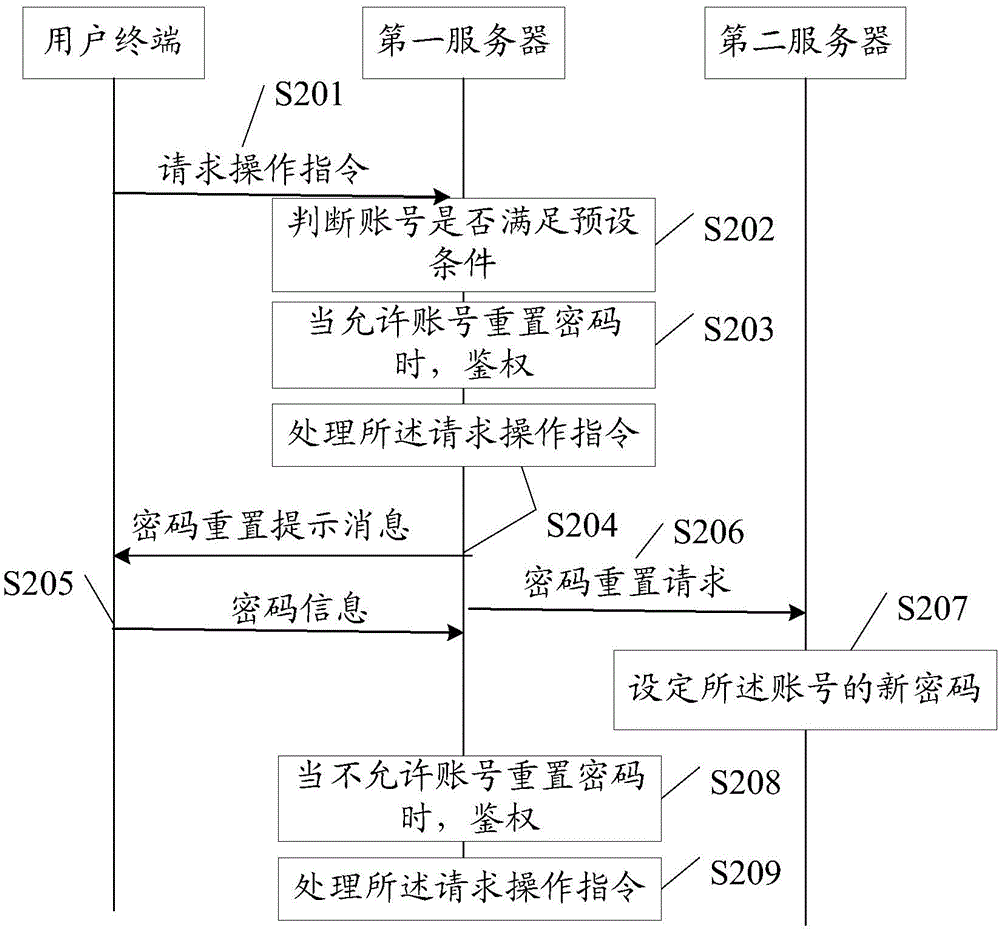

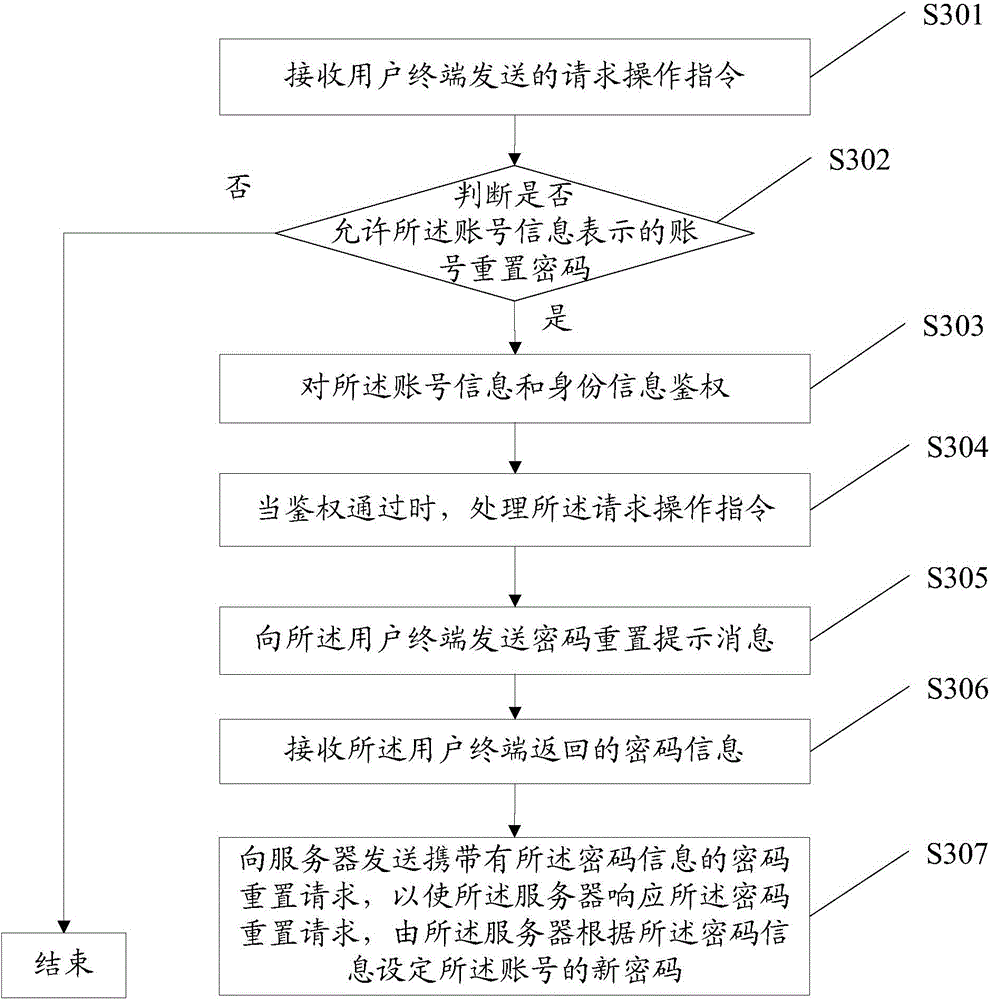

Method, device and system for password reset

ActiveCN104618314AImprove securityImprove business efficiencyPayment architectureTransmissionPasswordAuthentication

The embodiment of the invention discloses a method, a device and a system for password reset. The method comprises the steps that a first server receives a request operation order sent by a user terminal, wherein the request operation order comprises account information and identity information; the first server judges whether to allow an account represented by the account information to reset a password; if the account is allowed to reset the password, the first server authenticates the account information and the identity information; if the authentication succeeds, the request operation order is processed, and a password reset prompt message is sent to the user terminal; the user terminal receives the password reset prompt message and sends password information set by a user responding to the password reset prompt message to the first server; the first server sends a password reset request with the password information to a second server; and the second server responds to the password reset request and sets a new password of the account according to the password information. The method can improve the safety of the reset password, and also can improve service processing efficiency of equipment.

Owner:TENCENT TECH (SHENZHEN) CO LTD

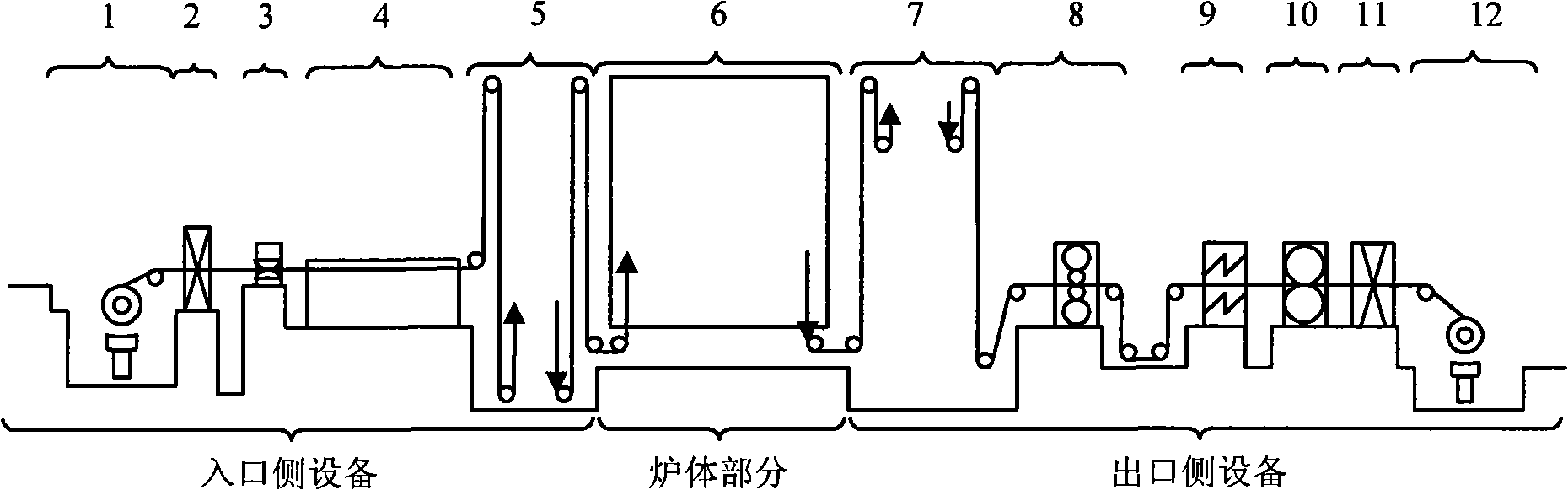

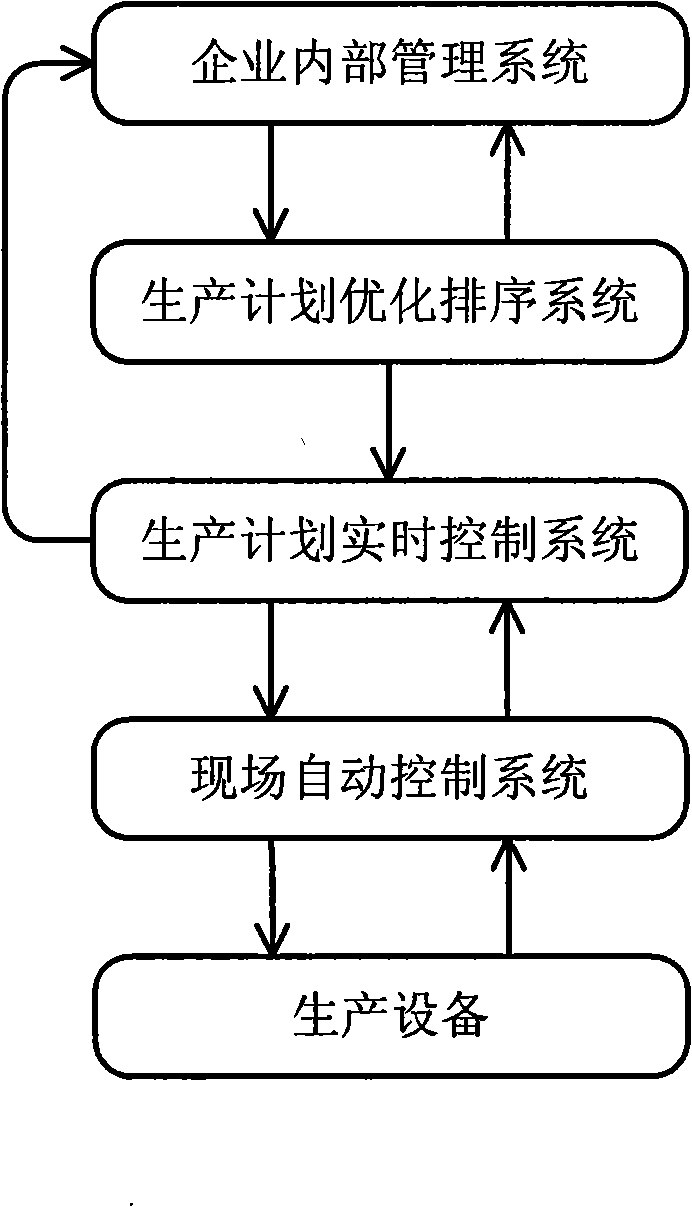

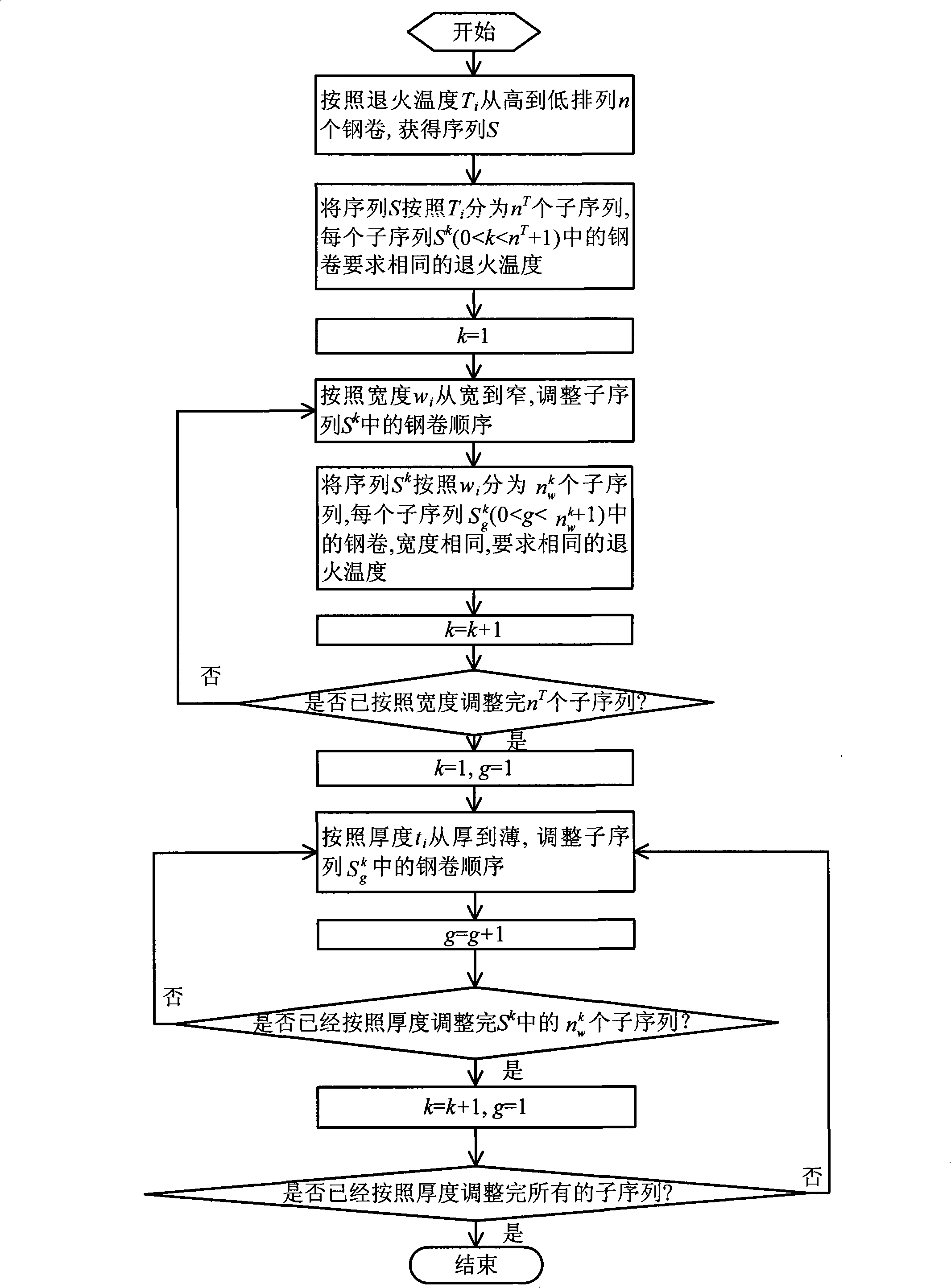

Cold rolling continuous annealing units steel coil optimizing ordering method and its system

ActiveCN101334660AReduce adjustmentSmooth execution of the planTotal factory controlProgramme total factory controlNeighborhood searchMetallic materials

The invention provides an optimum cold rolling continuous annealing unit steel coil sorting method and a system thereof, belonging to the field of metal material processing information technique; the optimum method comprises the steps as follows: 1: the candidate steel coil is respectively sorted from highness to lowness and from lowness to highness according to the annealing temperature so as to form two initial sorting proposal; each initial sorting proposal is optimized by adopting width preference sorting or thickness preference sorting so as to obtain a plurality of groups of initial feasible sorting proposals; 2: the sorting proposal with the minimum optimum object value is selected out of the initial steel coil sorting proposals so as to be taken as the initial feasible production plan; 3: the initial feasible production plan is adjusted by using exchanging neighborhood tabu searching and alternative path conversion neighborhood searching and by taking the minimum optimum sorting model object value as the object. The corresponding system is provided on the basis of the method of the invention; therefore, switching during the execution process of the production plan is reduced, the transition is smooth, the product quality is improved and the yield is improved.

Owner:NORTHEASTERN UNIV

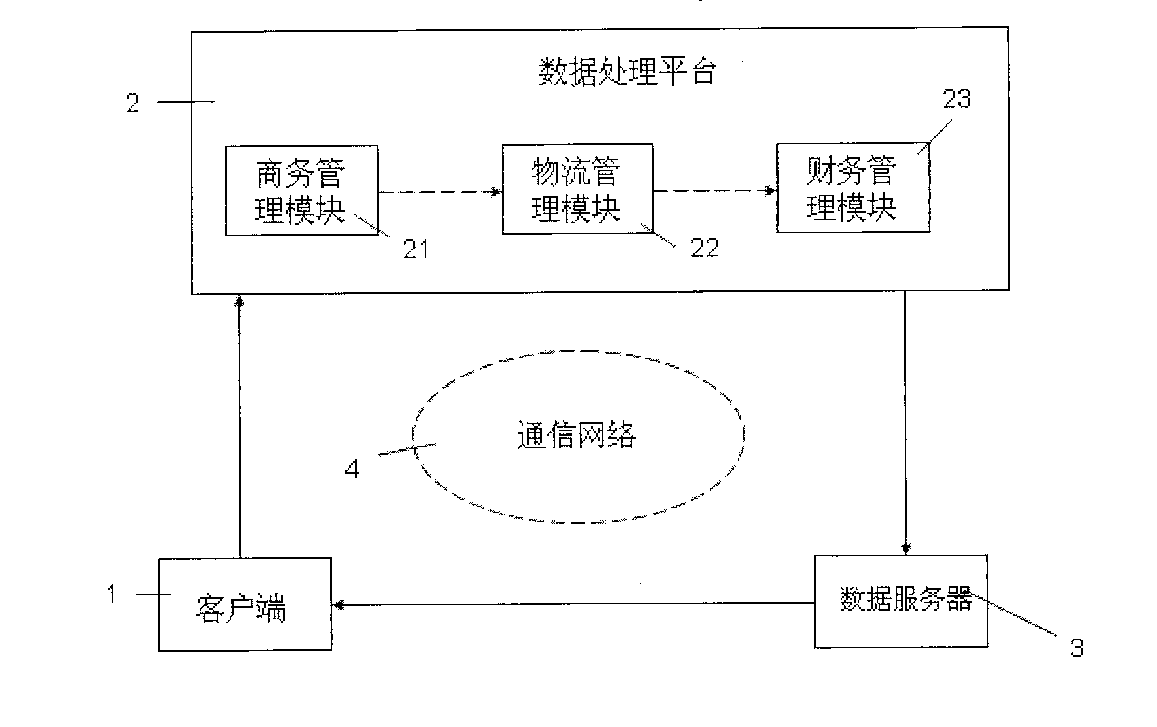

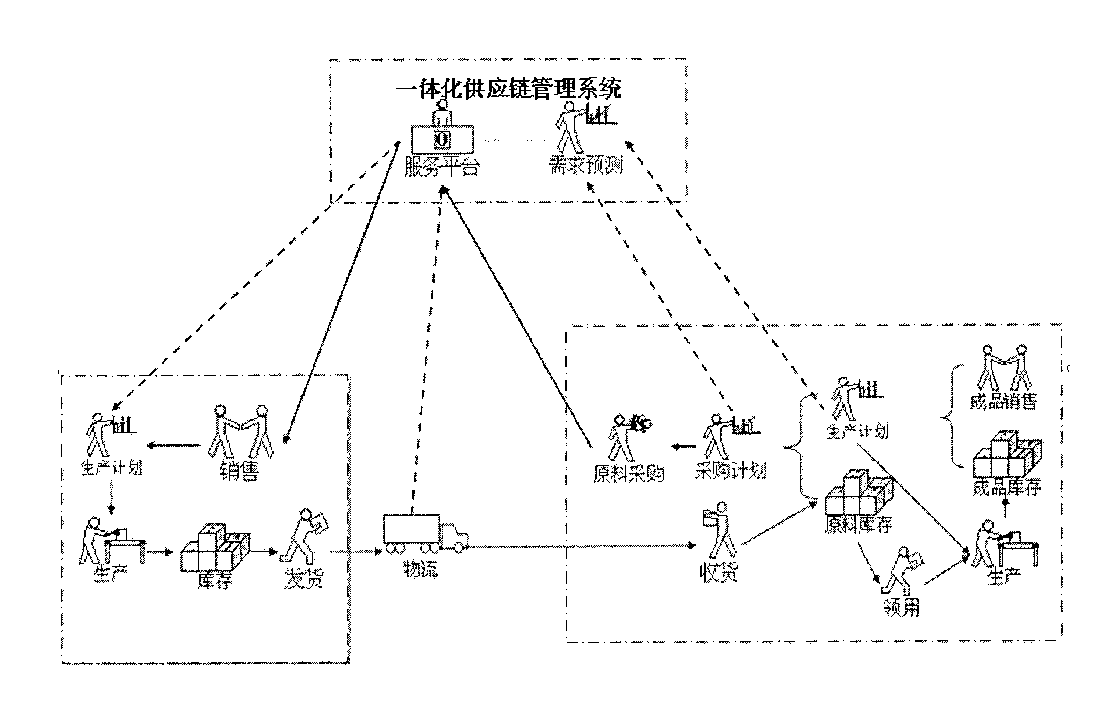

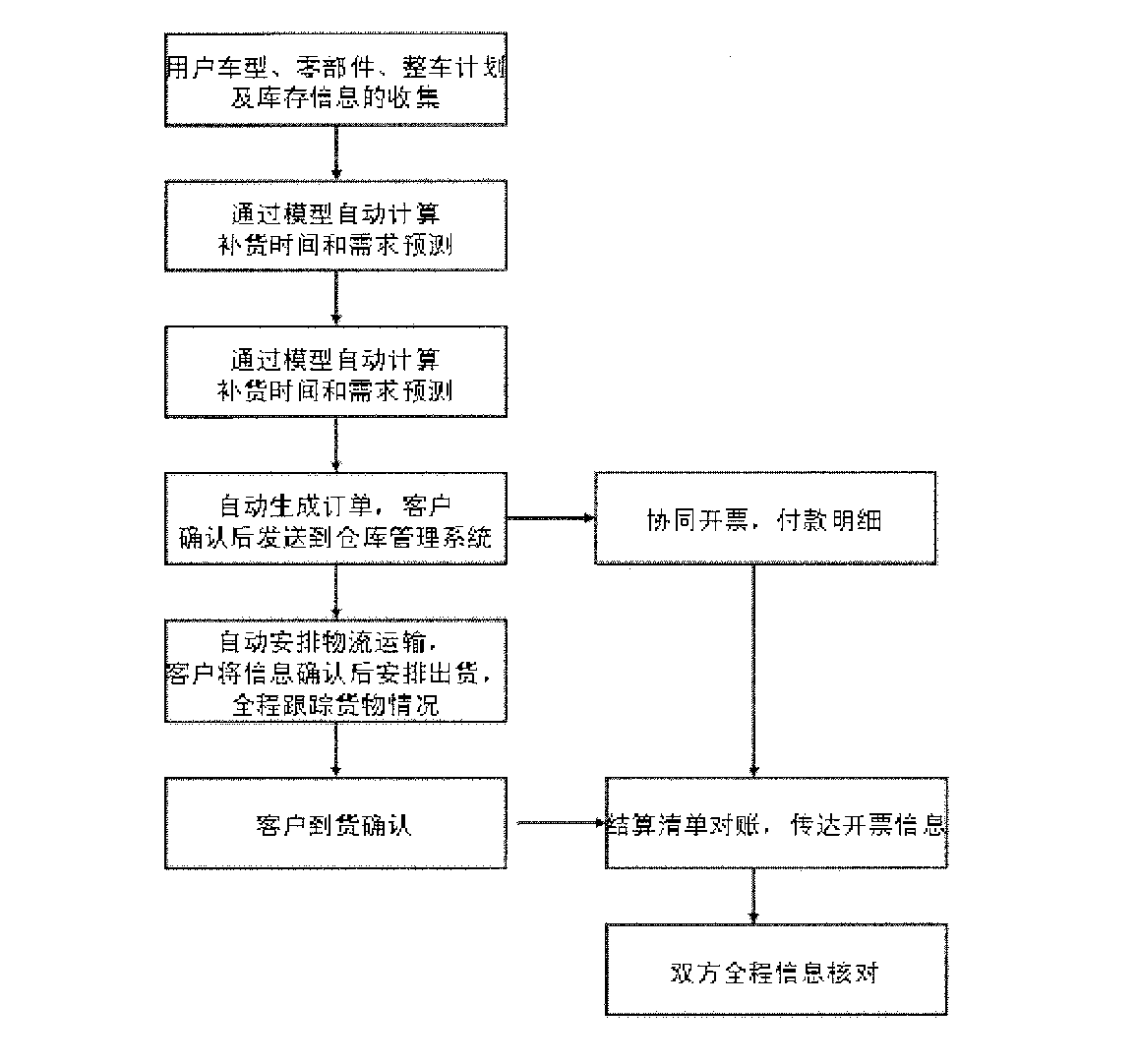

Integral supply chain management system in steel industry and implementing method

The invention discloses an integral supply chain management system in the steel industry and an implementing method. The system comprises a client side, a data processing platform, a data server and a communication network. The client side is an operating platform of the system, the data processing platform comprises a commercial management module, a logistic management module and a financial management module, and the data server is used to store and inquire data. A user can assist clients through the data processing platform to formulate an accurate and accessible demand plan as well as demand prediction of the clients, so as to guide production management of enterprises, formulate reasonable production plans and arrange production scientifically. Meanwhile, client information is immediately stored to the data server of the integral supply chain management system. In addition, from the aspect of managing the supply chain by the user, the system further provide multi-azimuth information support for purchasing management, logistic transportation, financial settlement, cost optimization and the like for the user. Both parts are interacted with each other immediately, so that common benefit of the enterprisers and the clients is realized.

Owner:长春宝钢钢材贸易有限公司

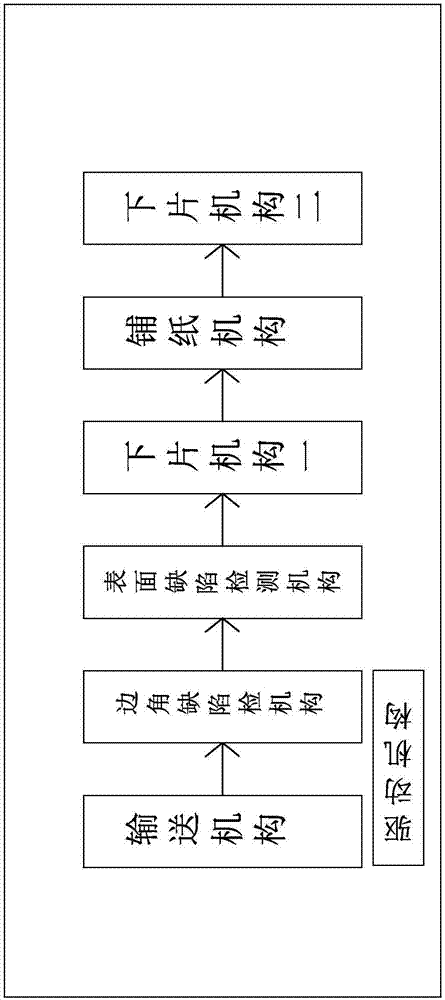

Fully-automatic assembly line after glass toughening

ActiveCN106890796AGuaranteed production speedIncrease productivitySortingGlass productionOff TreatmentEngineering

The invention provides a fully-automatic assembly line after glass toughening, belongs to the technical field of machinery, and solves the problem of low production efficiency in the prior art. The fully-automatic assembly line after glass toughening comprises a rack, wherein a strip-shaped guide rail is fixed to the rack; a conveying mechanism capable of automatically conveying glass to move forwards is arranged on the guide rail; the conveying mechanism comprises a plurality of conveying rolls; the conveying rolls are arranged on the guide rail in a manner of circumferentially rotating and being axially fixed; a drive mechanism enabling the conveying rolls to synchronously rotate is arranged at one side of the rack; the guide rail is provided with an inlet end and an outlet end; and an anti-deflection mechanism for preventing the glass from deflection, a corner defect detection mechanism capable of carrying out corner defect detection on the glass, a surface defect detection mechanism capable of carrying out surface defect detection on the glass, a batch-off mechanism I capable of carrying out batch-off treatment on glass defective products, and a paper laying mechanism capable of carrying out online automatic paper laying on qualified glass are sequentially arranged from the inlet end to the outlet end. The fully-automatic assembly line after glass toughening has the advantage of being efficient.

Owner:FLAT GLASS GROUP CO LTD

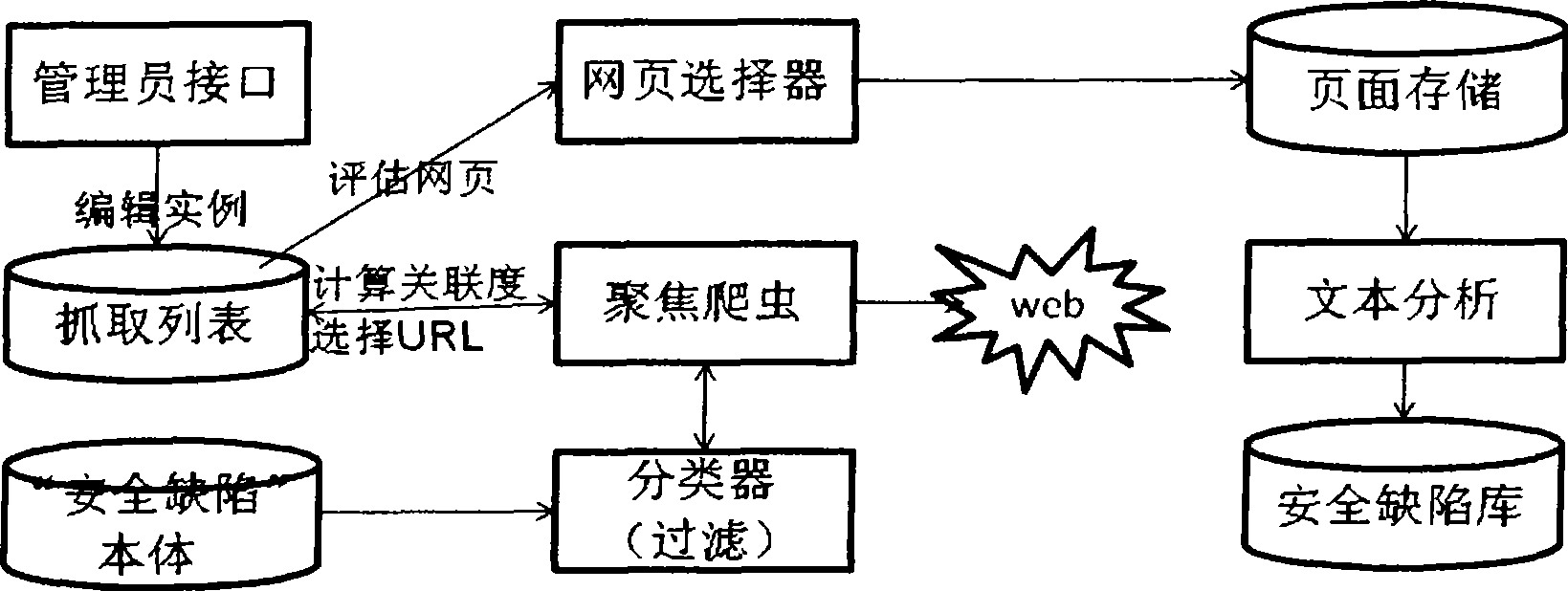

Software safety defect library system based on attack mode and management method thereof

ActiveCN101452469AQuality improvementReduced security flawsDigital data protectionSpecial data processing applicationsManagement unitSubject matter

The invention discloses a software security defect database system based on an attack mode, which comprises a construction unit of a security defect database, a management unit of the security defect database, and a security defect body. The software security defect database system is characterized in that the construction unit of the security defect database comprises the steps of establishing a mapping from the attack mode to a software defect structure, establishing a mapping from the attack mode to a security defect and a mapping from the security defect to a corresponding alleviation proposal, and constructing the two mappings into a unified model; and the management unit of the security defect database comprises a security defect information acquisition module and a security defect information classification module, wherein information acquisition is based on WEB subject mining technology, and defect classification is based on body technology. The software security defect database system simultaneously combines external attack mode analysis and a security-oriented software development cycle to construct a security defect database model, so as to reduce security defects of software products and improve the quality of software, thereby the software security defect database system meets different demands on software security defect examples in different stages and can be used for supporting the data service of the security defect model.

Owner:江苏永达电力电信安装工程有限公司

Process for recycling copper through electrodeposition by treating scrap copper materials by adopting cyclone electrolysis technology

ActiveCN102534656ATo achieve the purpose of high efficiency and environmental protectionImprove leaching efficiencyPhotography auxillary processesProcess efficiency improvementHigh current densityCyclone

The invention provides a process for recycling copper through electrodeposition by treating scrap copper materials by adopting a cyclone electrolysis technology, belonging to the technical field of recycling copper from wastes containing copper. The process is characterized by taking various purchased wastes containing copper as raw materials, preliminarily screening and grinding the wastes, adding the materials to a dissolved copper leaching bath device to undergo continuous copper dissolving to obtain a copper sulfate solution, then filtering the solution with precision filter equipment, decoppering the obtained filtrate through cyclone electrolysis, scalding an obtained copper pipe with weak acid and then feeding the copper pipe into a product processing unit to process a standard copper plate. The process has the following beneficial effects: through portable or module assembly, the cyclone electrolysis bath and support equipment are convenient to install, dismantle and move; the solution circulates in a closed loop, thus avoiding emission of harmful gases; electrolytic deposition is carried out on the metals selectively and the copper can be better purified by applying the cyclone electrolysis technology; higher current density and current efficiency are ensured, fewer reagents are consumed, the production cost is lowered and the enterprise revenue is improved; and high efficiency and high purity electrolytic extraction is carried out on the solution, the recycled copper is the standard cathode copper and the total recycling rate is above 96%.

Owner:浙江科菲科技股份有限公司

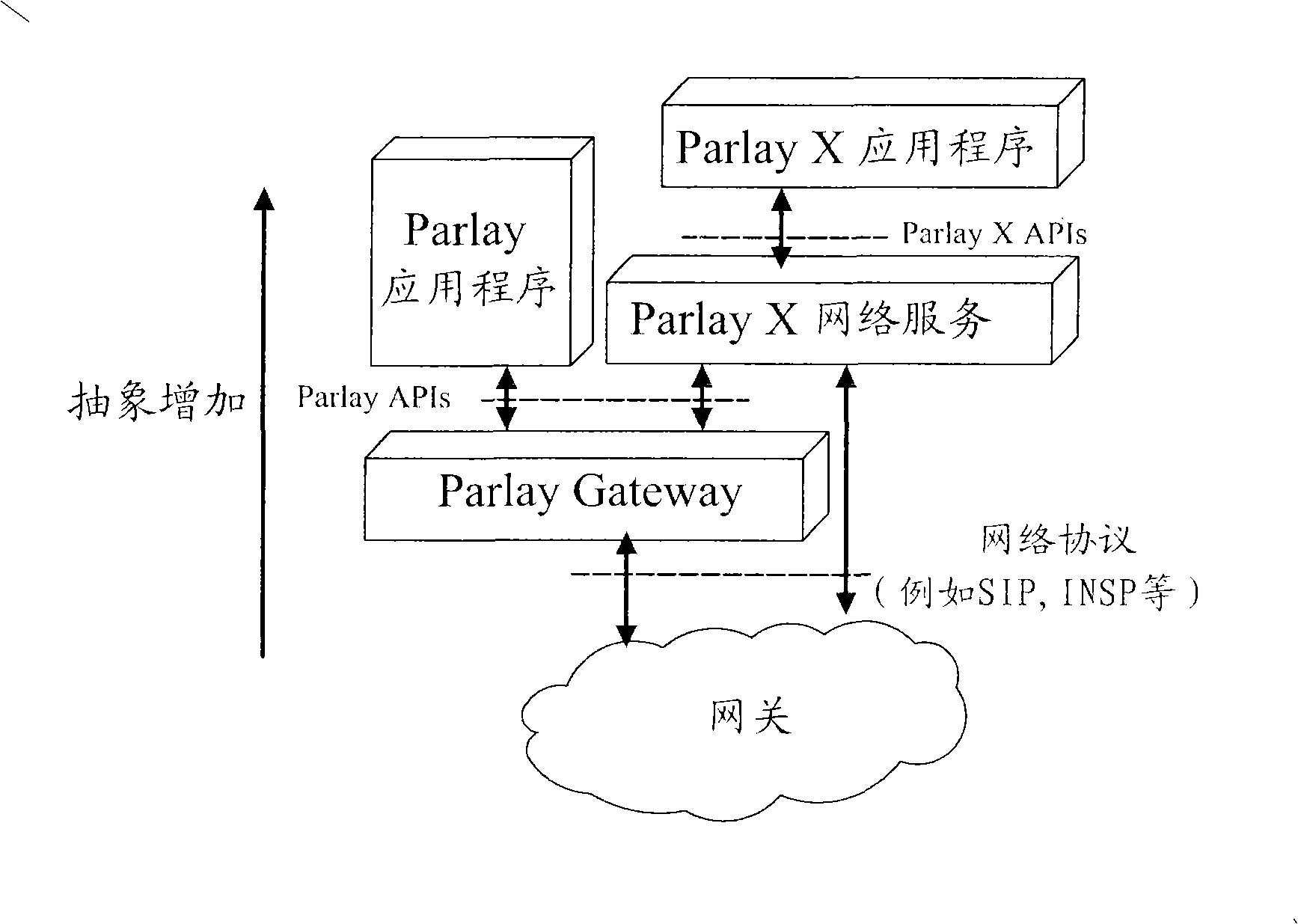

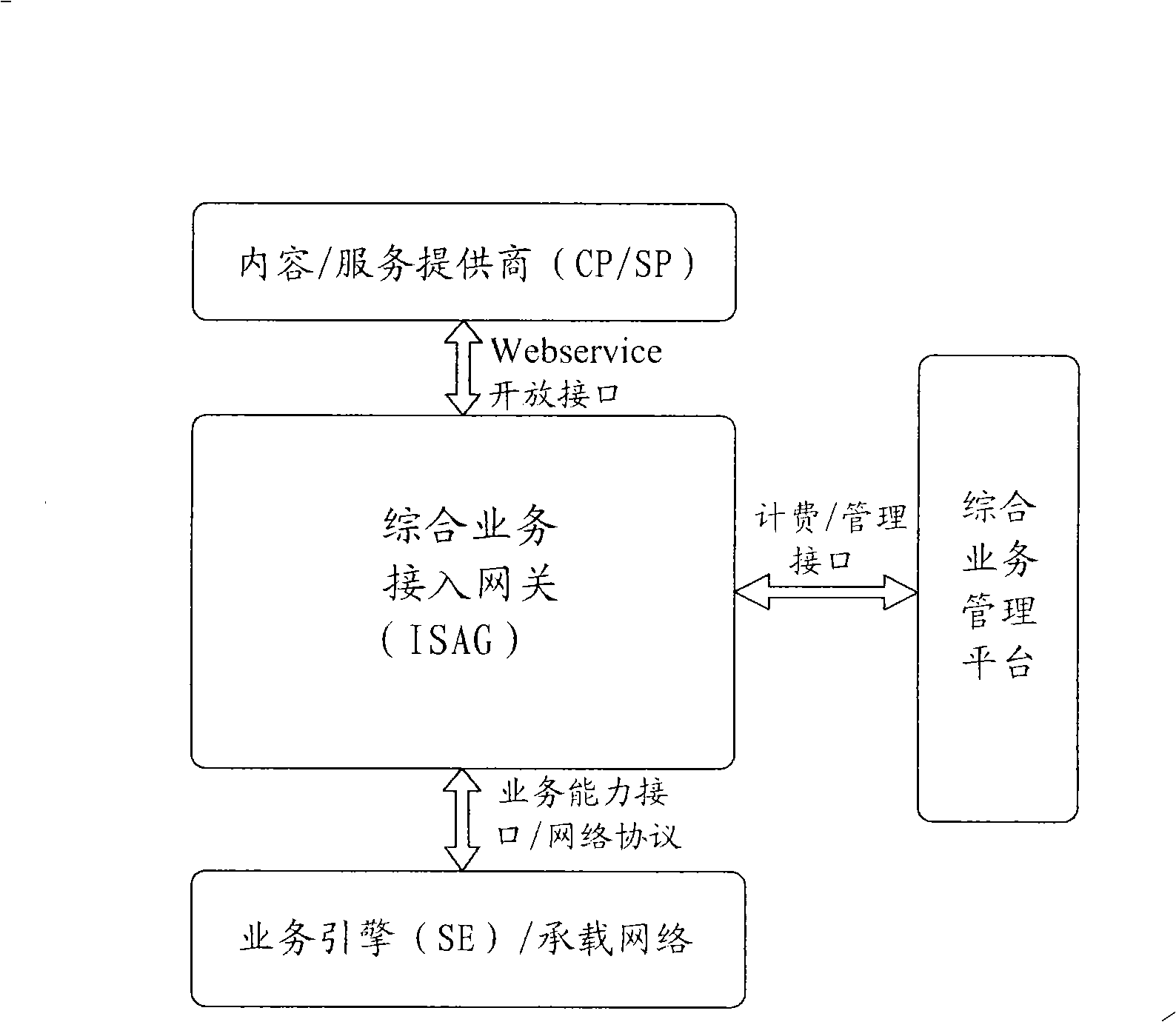

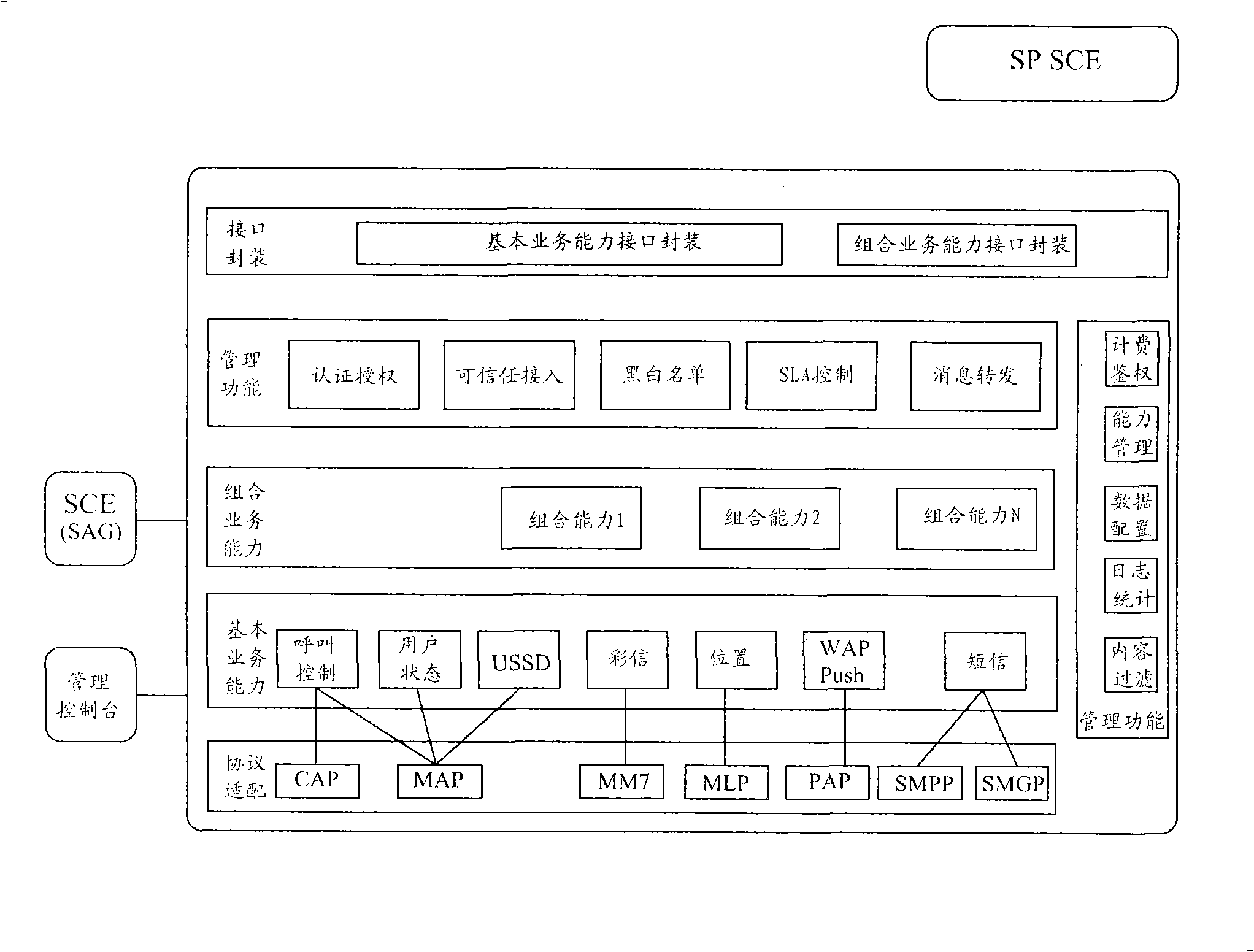

Platform implementing mechanism supporting development and operation of combined value added service capability

ActiveCN101291449AMasking complexityRich varietyRadio/inductive link selection arrangementsComposite servicesOpen platform

The invention relates to an integrated service access gateway (ISAG) used as a telecommunication value-added service opening platform, wherein, a monitoring management module, an authentication charging interface module and a composite service module are arranged on the basis of the prior Parlay / ParlayX system. The ISAG inherits the advantages of cross-network and uniform openness of a plurality of abilities of a Parlay / ParlayX gateway, can perform real-time inspection and control on an SP and an SP service and avoid molestation and bamboozlement of the SP on users, and simultaneously flexibly realizes development, package and openness of composite service abilities and meets numerous requirements of the SP.

Owner:CHINA TELECOM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com