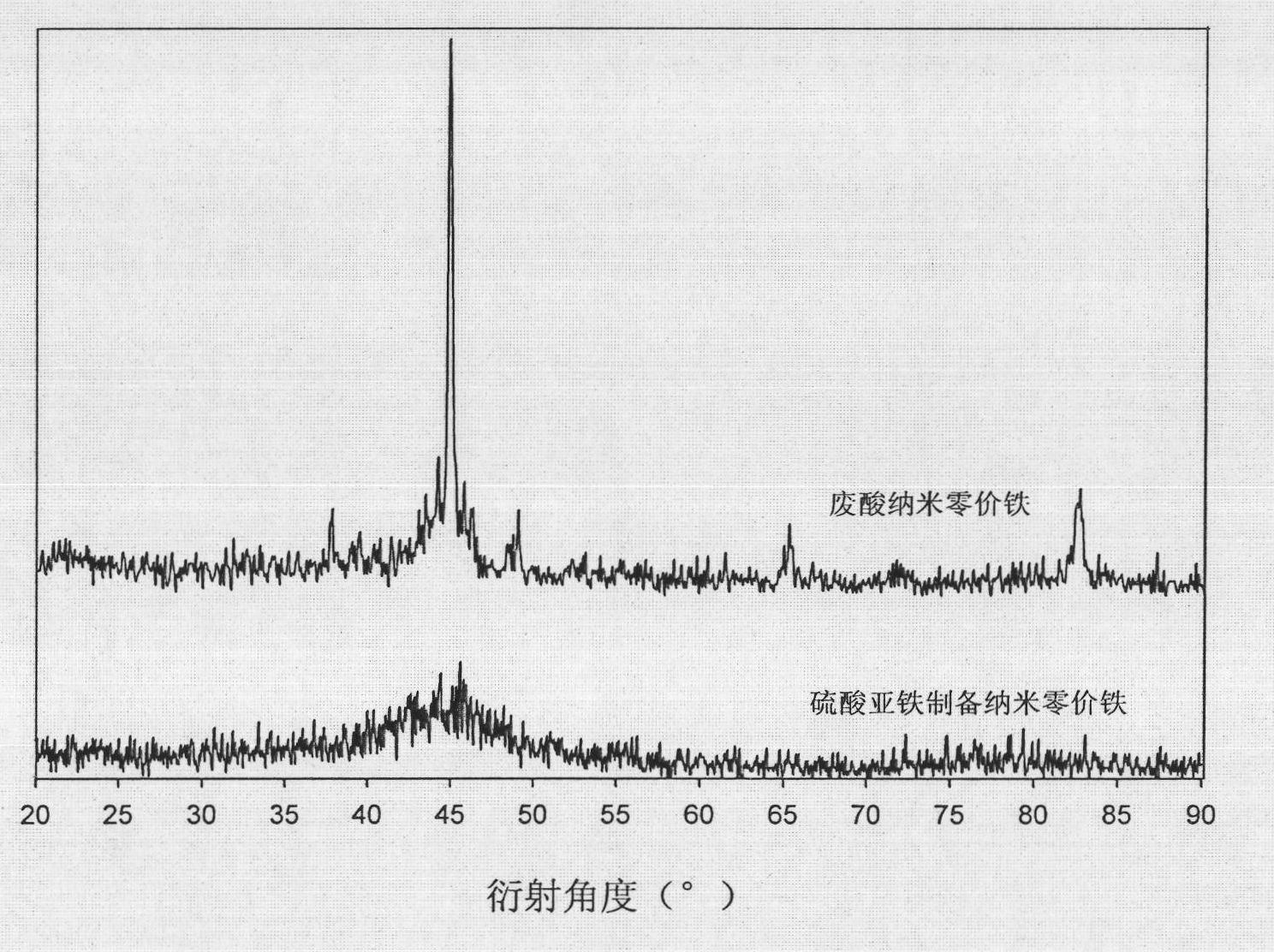

Nano zero-valent iron prepared by using iron and steel acid-cleaning wastewater and preparation method and application thereof

A nano-zero-valent iron and steel pickling technology, which is applied in the direction of protection devices against harmful chemicals, can solve the problems of high operating conditions and equipment requirements, cumbersome operation, etc., and achieve high environmental and economic benefits and enterprise benefits. Time-consuming Short, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Pretreatment of pickling wastewater in the iron and steel industry: the pickling wastewater in the iron and steel industry (taken from Guangzhou Jinlai Cold Rolled Strip Steel Co., Ltd.) without removing iron ions is suction-filtered to filter out solid residues, and then use a concentration of 1.0mol The sodium hydroxide solution of / L regulates the pH value of filtrate to be 4, and plasma inductively coupled emission spectrometry records the content of each element in the waste water, as shown in table 1:

[0042] Table 1

[0043]

[0044] (2) Preparation of sodium borohydride solution: absolute ethanol and water are mixed uniformly at a volume ratio of 3:7; L of sodium borohydride solution.

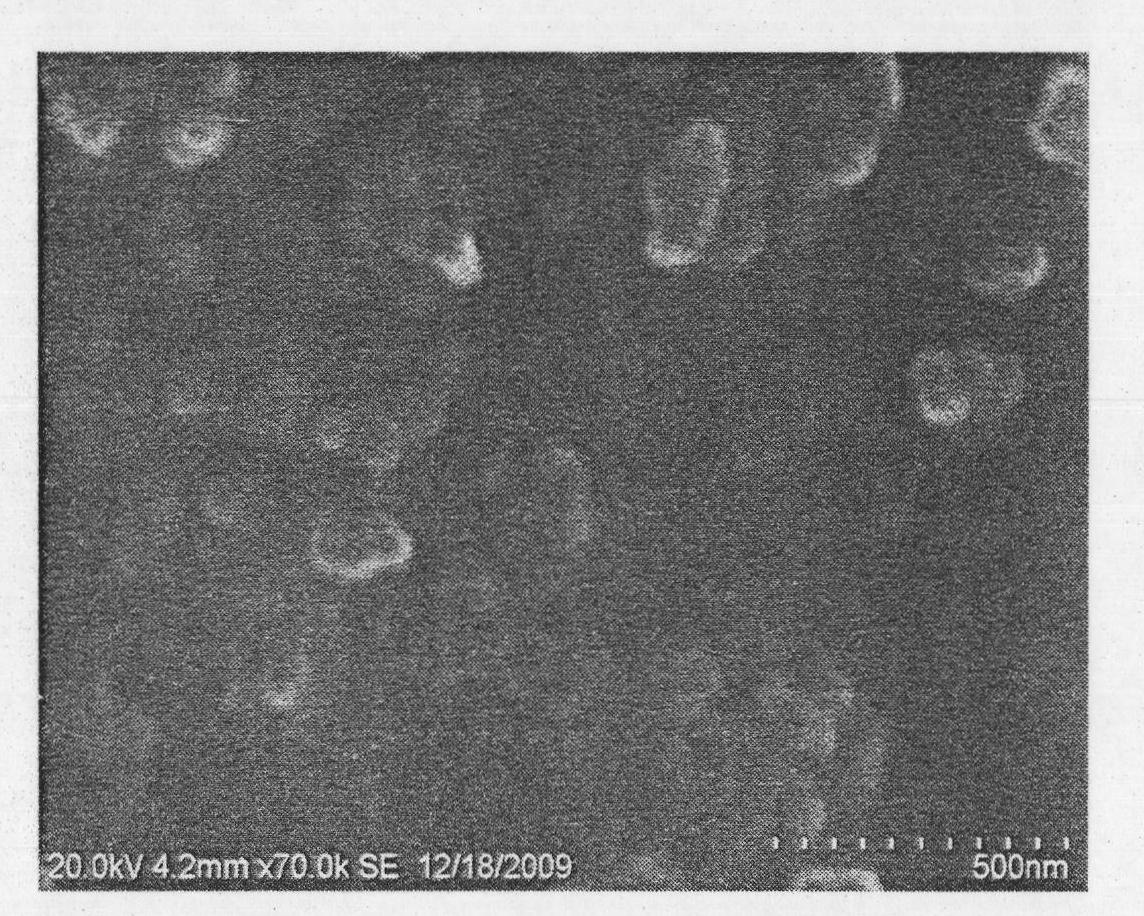

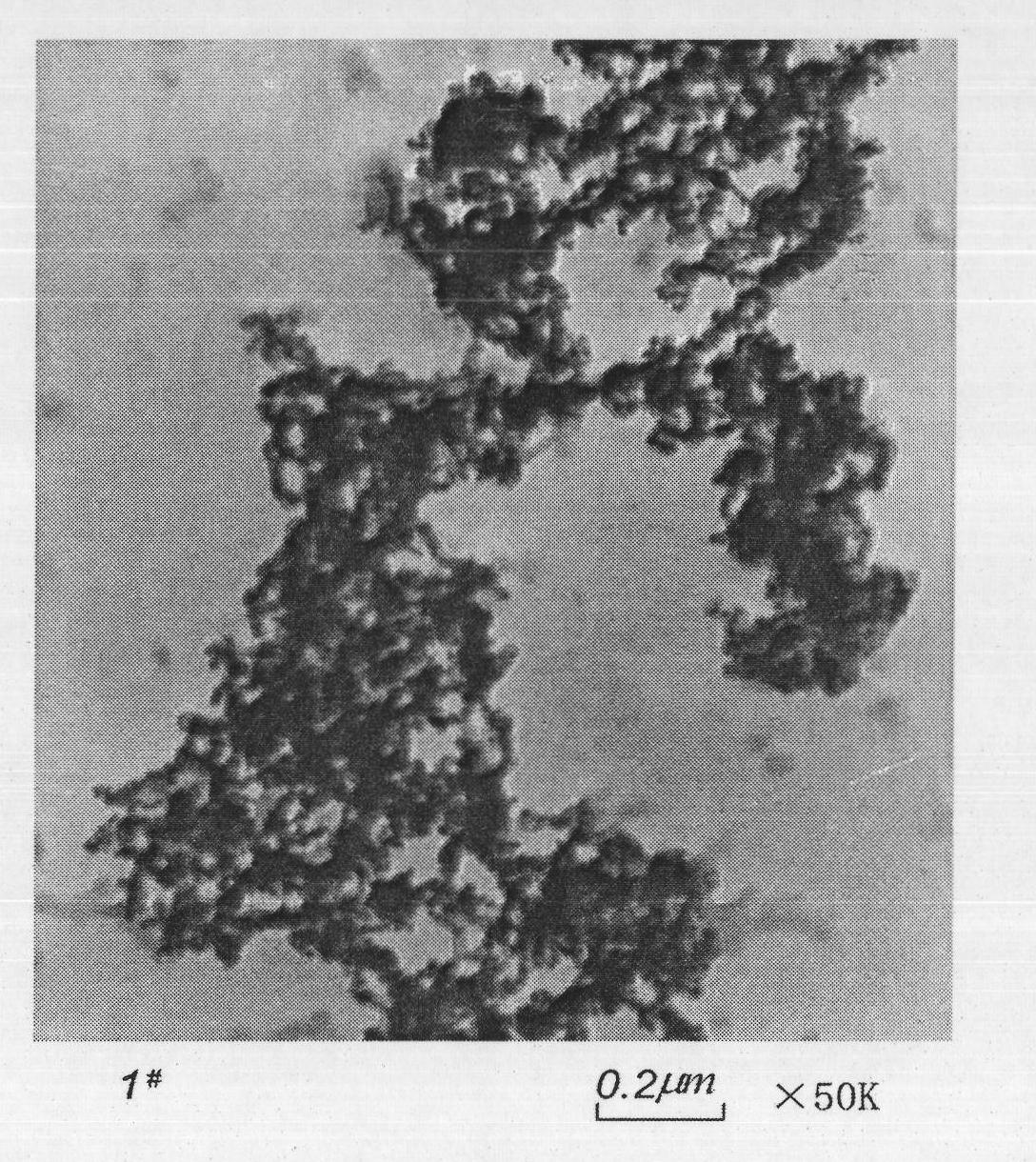

[0045](3) Preparation of nanometer zero-valent iron: at 25°C, get 4.8ml of pickling waste water filtered in step (1), join in 50ml of alcoholic aqueous solution (ethanol: water=3:7), then add 0.58g poly Vinylpyrrolidone, stir to mix. Then add the whole sodium borohydri...

Embodiment 2

[0051] (1) Pretreatment of pickling wastewater in the iron and steel industry: the pickling wastewater in the iron and steel industry (taken from Guangzhou Jinlai Cold Rolled Strip Co., Ltd.) without removing iron ions is suction filtered to filter out solid residues, and then use a concentration of 2.0mol / L of sodium hydroxide solution to adjust the pH value of the filtrate is 6.5, and adopt atomic absorption method to measure the content of total iron ion in the waste water simultaneously, record the content of total iron ion to be 122g / L.

[0052] (2) Preparation of sodium borohydride solution: absolute ethanol and water are mixed uniformly in a volume ratio of 3:7; L of sodium borohydride solution.

[0053] (3) Preparation of nanometer zero-valent iron: at 30°C, take 7.2ml of pickling waste water filtered in step (1), join in 50ml of alcoholic aqueous solution (ethanol: water=3:7), then add 0.87g poly Vinylpyrrolidone, stir to mix. Then add the whole sodium borohydride ...

Embodiment 3

[0057] (1) Pretreatment of pickling wastewater in the iron and steel industry: Suction filter the pickling wastewater in the iron and steel industry (taken from Guangzhou Jinlai Cold Rolled Strip Co., Ltd.) without removing iron ions, filter out the solid residue, and then use a concentration of 0.5mol / L of sodium hydroxide solution to adjust the pH value of the filtrate to be 5, and adopt atomic absorption method to measure the content of total iron ions in the waste water simultaneously, record the content of total iron ions to be 122g / L.

[0058] (2) Preparation of sodium borohydride solution: absolute ethanol and water are mixed uniformly at a volume ratio of 3:7; L of sodium borohydride solution.

[0059] (3) Preparation of nanometer zero-valent iron: at 20°C, take 3.6ml of the pickling waste water filtered in step (1), join in 50ml of alcoholic aqueous solution (ethanol: water=3:7), then add 0.44g Polyvinylpyrrolidone, stir to mix. Then add whole sodium borohydride so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com