Patents

Literature

8372 results about "Strip steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strip Steel or cold rolled strip is a steel product that is produced from a hot rolled strip that has been pickled. The coil is then reduced by a single stand cold roll steel mill straight away or reversing mill or in a tandem mill consisting of several single stands in a series. The strip is reduced to approximately final thickness by cold-rolling directly, or with the inclusion of an annealing operation at some intermediate thickness to facilitate further cold reduction or to obtain mechanical properties desired in the finished product. High carbon strip steel requires additional annealing and cold reduction operations. The coil is then slit to the desired width through the process of roll slitting.

Method for controlling planeness of cold-rolling strip steel

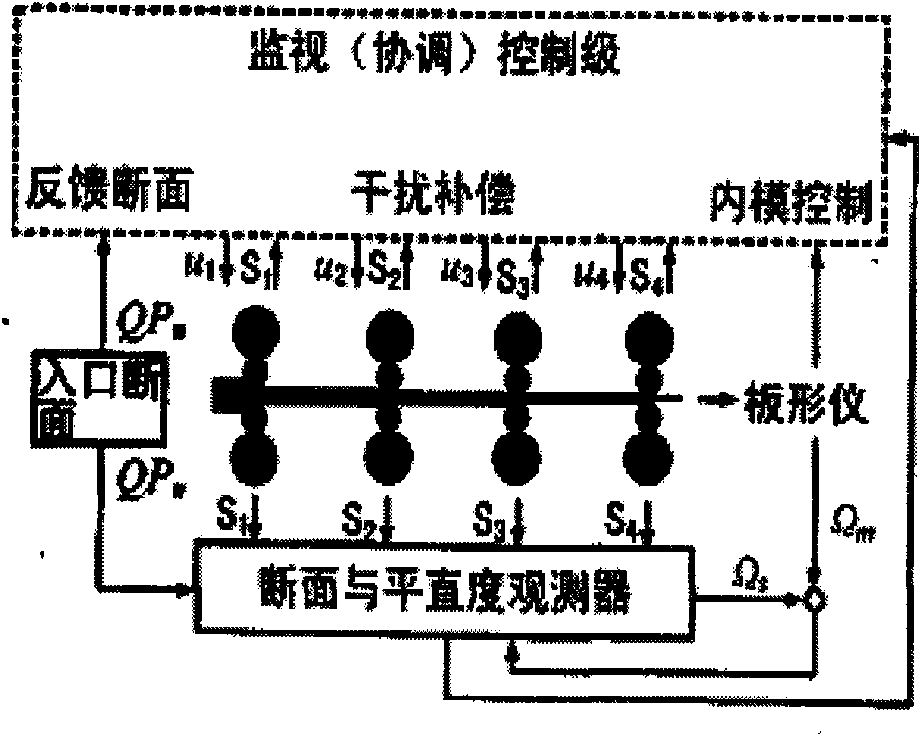

ActiveCN101618402ARealize coordinated controlAccurate detectionRare end control deviceTemperature control deviceAutomatic controlEngineering

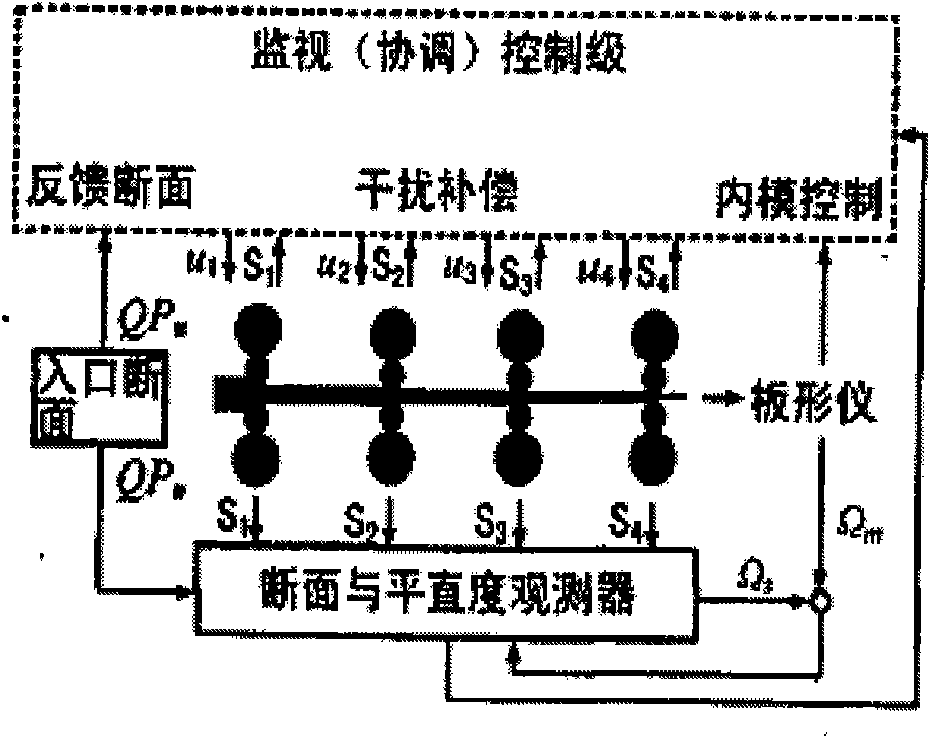

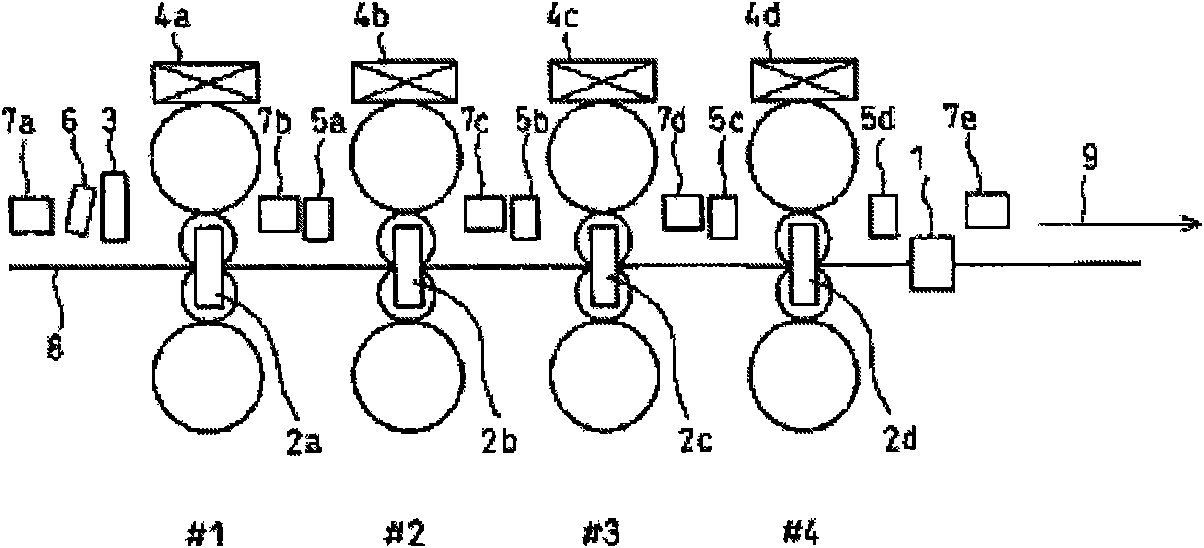

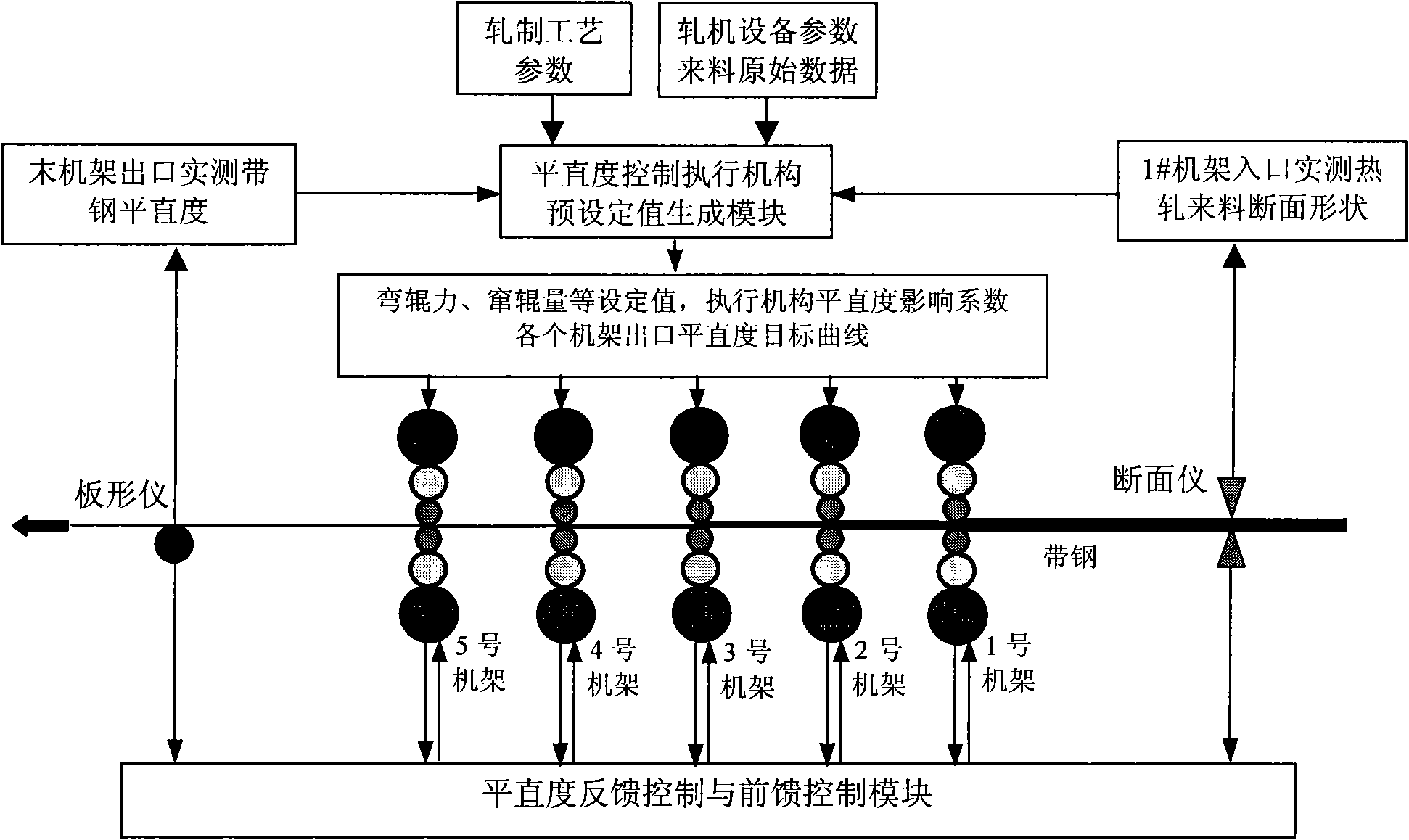

The invention discloses a method for controlling the planeness of cold-rolling strip steel, which comprises the following steps of: carrying out planeness feed-forward control, planeness feedback control and coordination control between both; detecting the cross-section shape and the planeness of a hot rolling incoming material, and actually-measured rolling technological parameters of each frame in real time based on a profiler configured on a No. 1 frame inlet, wherein the parameters comprise rolling force actually-measured values and plate shape adjusting mechanism actually-measured values, and carrying out the feed-forward control on the planeness of each frame outlet; and actually measuring the planeness of the cold-rolling strip steel based on a plate shape roller configured on an outlet of a cold rolling mill, and intensively carrying out the feedback control on the planeness of a final frame outlet. The method can eliminate the influences of the cross-section shape and the planeness of the hot rolling incoming material and fluctuations of the rolling technological parameters on the planeness of the final frame outlet to improve the planeness quality of the cold-rolling strip steel on the one hand, and can automatically control the planeness of each frame outlet, reduce incidence of abnormal conditions, such as fracture surfaces, deviation and the like, and improve the stability in the production process of tandem cold strip rolling on the other hand.

Owner:BAOSHAN IRON & STEEL CO LTD

Integrated control method of cold-rolling strip steel flatness and lateral thickness difference

ActiveCN101683659AImprove stabilityGuaranteed stabilityMetal rolling arrangementsProfile control deviceStrip steelFeedback control

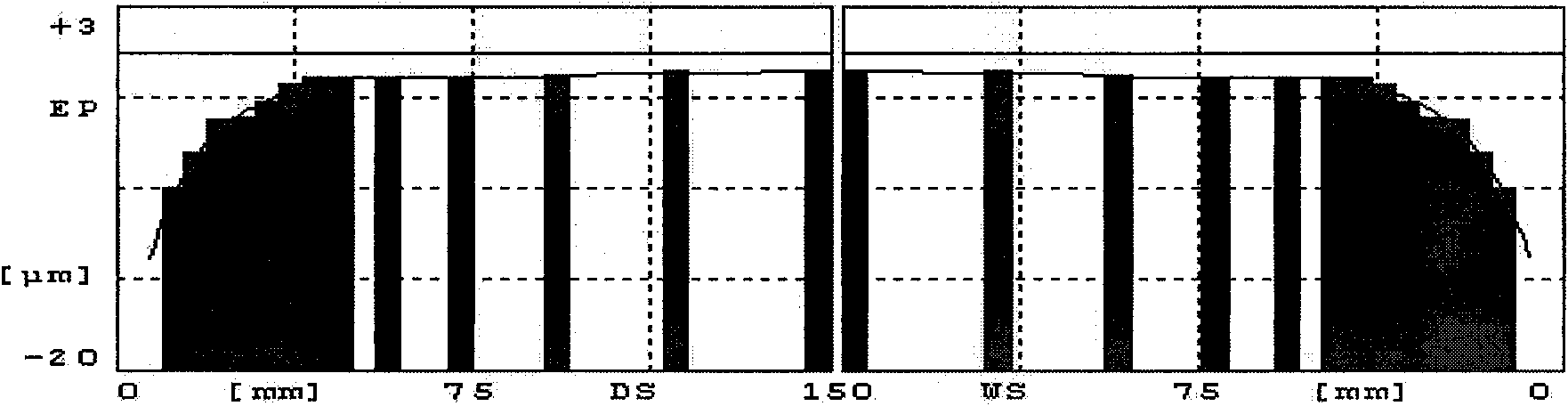

The invention discloses an integrated control method of cold-rolling strip steel flatness and lateral thickness difference, comprising: moderately and mainly controlling the shape of the strip steel section on the upstream rack of a cold-rolling mill, and mainly controlling strip steel flatness on the downstream rack; based on a profiler configured on a No.1 rack inlet of the cold-rolling mill, actually measuring and hot rolling incoming material section shape and flatness and rolling technological parameter measured values of each rack, wherein the rolling technological parameter measured values comprise rolling force and a plate shape regulating mechanism measured value; actually measuring the cold-rolling strip steel flatness on the basis of a shape meter configured on the cold-rollingmill outlet; performing feed-forward control to the shape of the strip steel section by taking the upstream rack, in particular the No. 1 rack as a key point; and performing feedback control to the strip steel flatness by taking the downstream rack, in particular an end rack as a key point to realize integrated control to the cold-rolling strip steel flatness and lateral thickness difference. Theinvention performs integrated coordination control by the strip steel flatness and section shape and reduces cold-rolling strip steel lateral thickness difference on the basis of further improving cold-rolling strip steel flatness quality.

Owner:BAOSHAN IRON & STEEL CO LTD

Surface iron scale control method for middle sheet billet continuous casting and rolling steel plate

InactiveCN101012528AReduce generationGood removal effectTemperature control deviceWork treatment devicesThin slabEnergy conservation

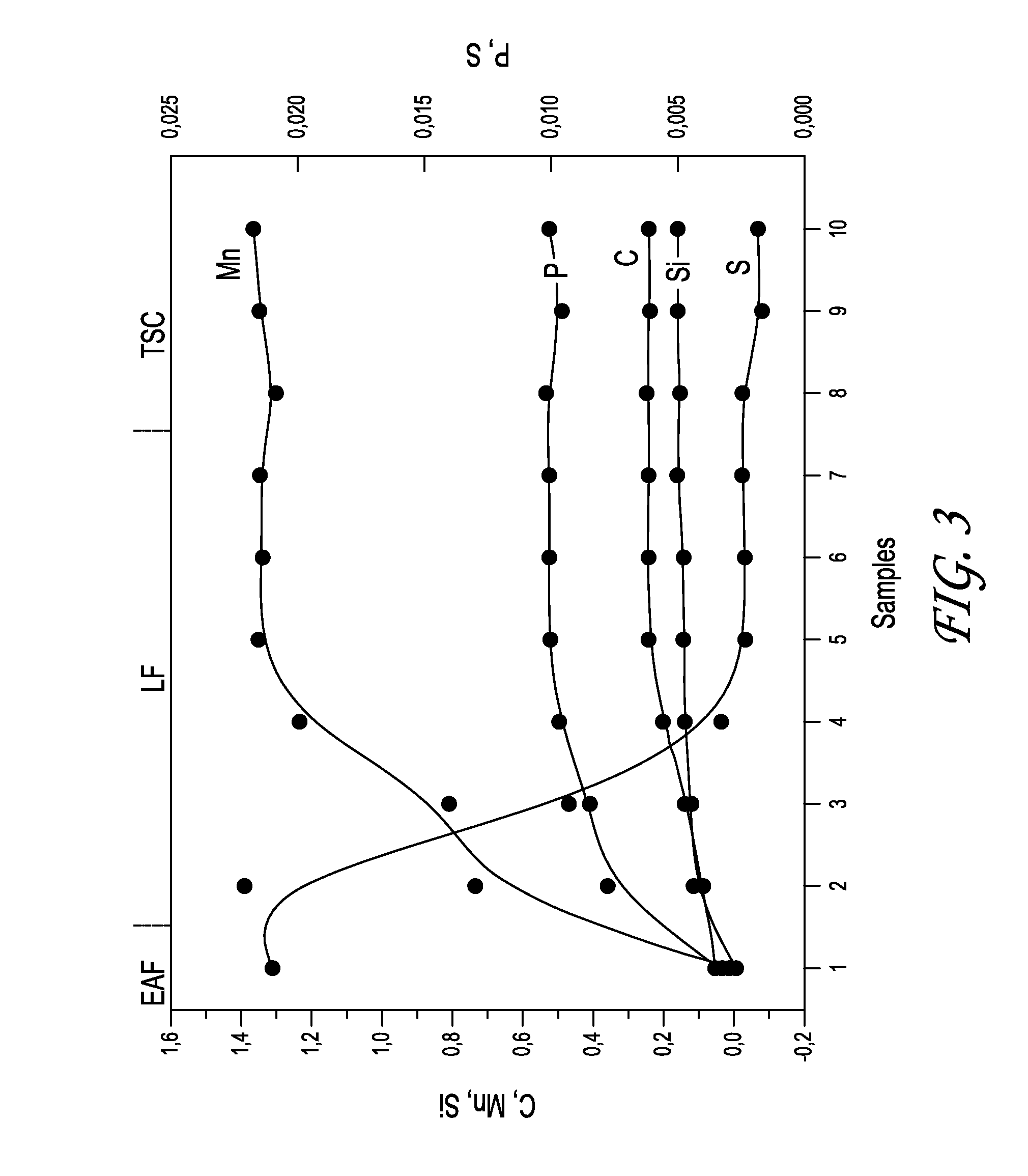

The invention discloses a controlling method of iron oxide sheet of rolled band steel surface of middle-thin board blank, which is characterized by the following: controlling component; proceeding heat load directly; heating to remove phosphor; rolling under high temperature; forcing to cool; controlling Si content in the steel; eliminating red ferric oxide on the surface of heat roll steel; fitting for the steel with not more than 0.18%C, not more than 0.20% Si, not more than 1.50% Mn, not more than 0.015% P, not more than 0.01% S and Nb, V and Ti.

Owner:ANGANG STEEL CO LTD

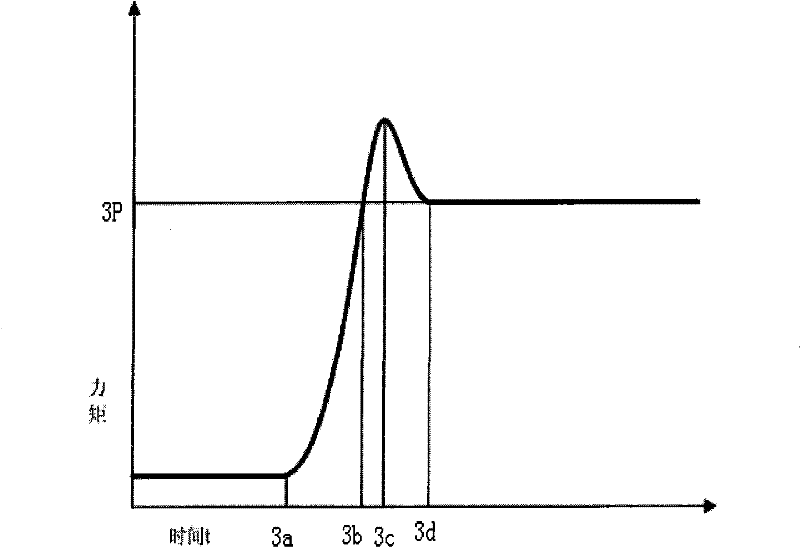

Method for controlling hot rolling coiling tension

ActiveCN102125936ASolve the problem of narrowing the widthAvoid quality problemsTension/compression control deviceEngineeringStrip steel

The invention discloses a method for controlling hot rolling coiling tension. Strip steel coiling is controlled by a two-level tension control method. The method mainly comprises the following steps of: calculating a first level set value and a second level set value; starting first level tension control according to a calculating result when the head part of strip steel enters a coiling machine;when actually measured coil moment reaches the first level moment set value, delaying some time and starting second level tension control until the strip steel is completely coiled; detecting and determining the width and the coiling quality of the strip steel, and adjusting a tension coefficient if the detected width and coiling quality of the strip steel is unqualified; and performing a self-adapting step. The control method overcomes the defects of the prior art and well solves the problem that the width quality and the coiling quality of the strip steel cannot be qualified at the same time, and the width of the strip steel is ensured as well as the coiling quality of the strip steel.

Owner:BAOSHAN IRON & STEEL CO LTD

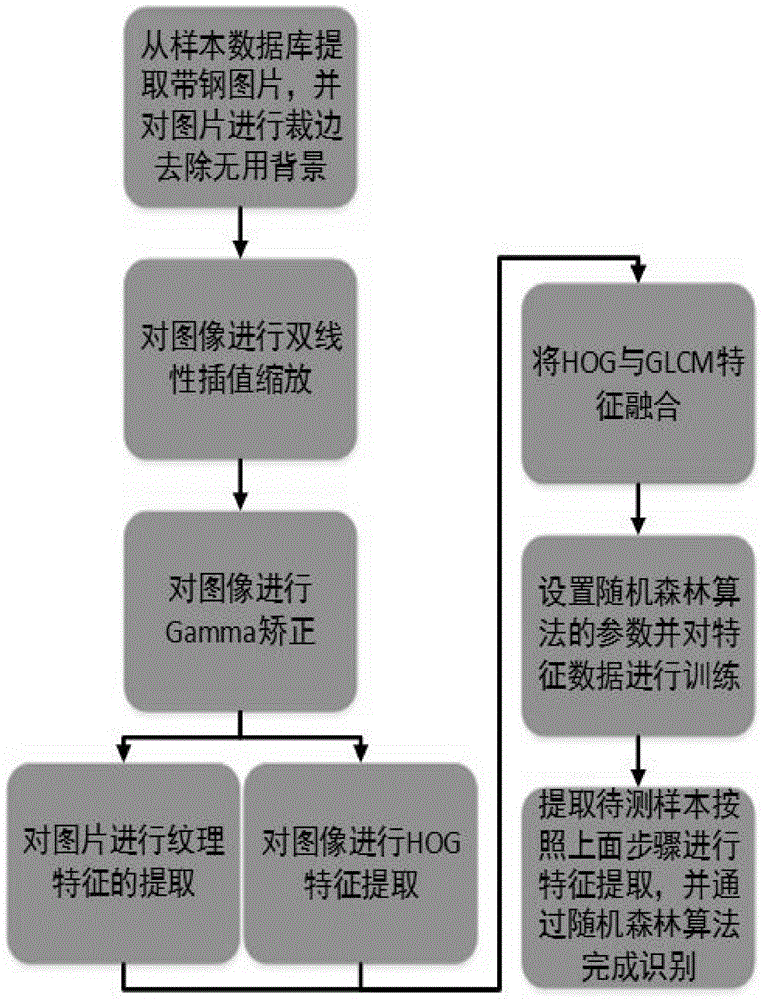

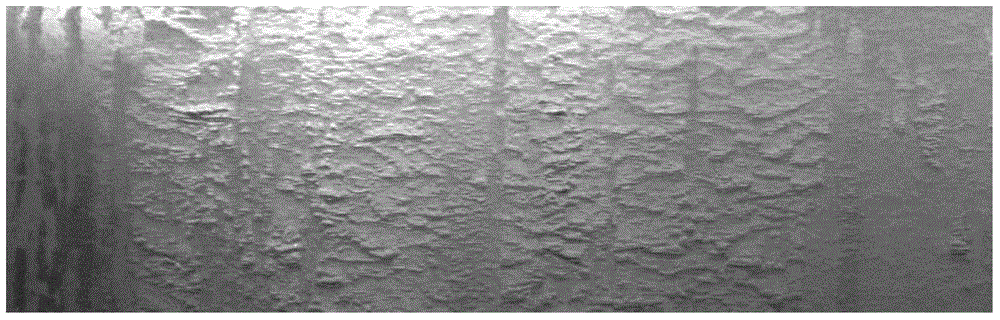

Strip steel surface area type defect identification and classification method

ActiveCN104866862AEasy to handleAccurate identificationCharacter and pattern recognitionFeature setHistogram of oriented gradients

The invention discloses a strip steel surface area type defect identification and classification method which comprises the following steps: extracting strip steel surface pictures in a training sample database, removing useless backgrounds and keeping the category of the pictures to a corresponding label matrix; carrying out bilinear interpolation algorithm zooming on the pictures; carrying out color space normalization on images of the zoomed pictures by adopting a Gamma correction method; carrying out direction gradient histogram feature extraction on the corrected pictures; carrying out textural feature extraction on the corrected pictures by using a gray-level co-occurrence matrix; combining direction gradient histogram features and textural features to form a feature set, which comprises two main kinds of features, as a training database; training the feature data with an improved random forest classification algorithm; carrying out bilinear interpolation algorithm zooming, Gamma correction, direction gradient histogram feature extraction and textural feature extraction on the strip steel defect pictures to be identified in sequence; and then, inputting the feature data into an improved random forest classifier to finish identification.

Owner:CENT SOUTH UNIV

Carbon steel and stainless steel clad steel plate with toughness performance and production method

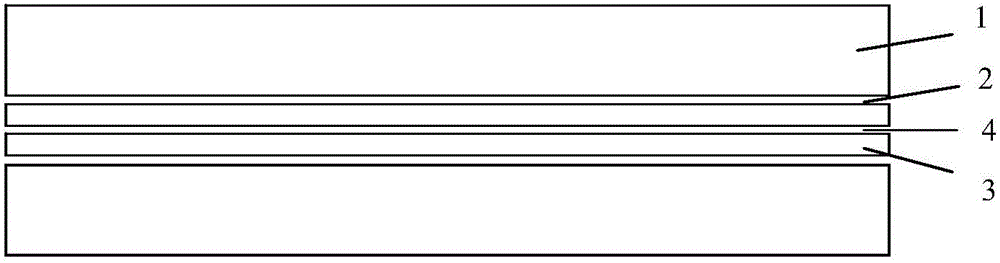

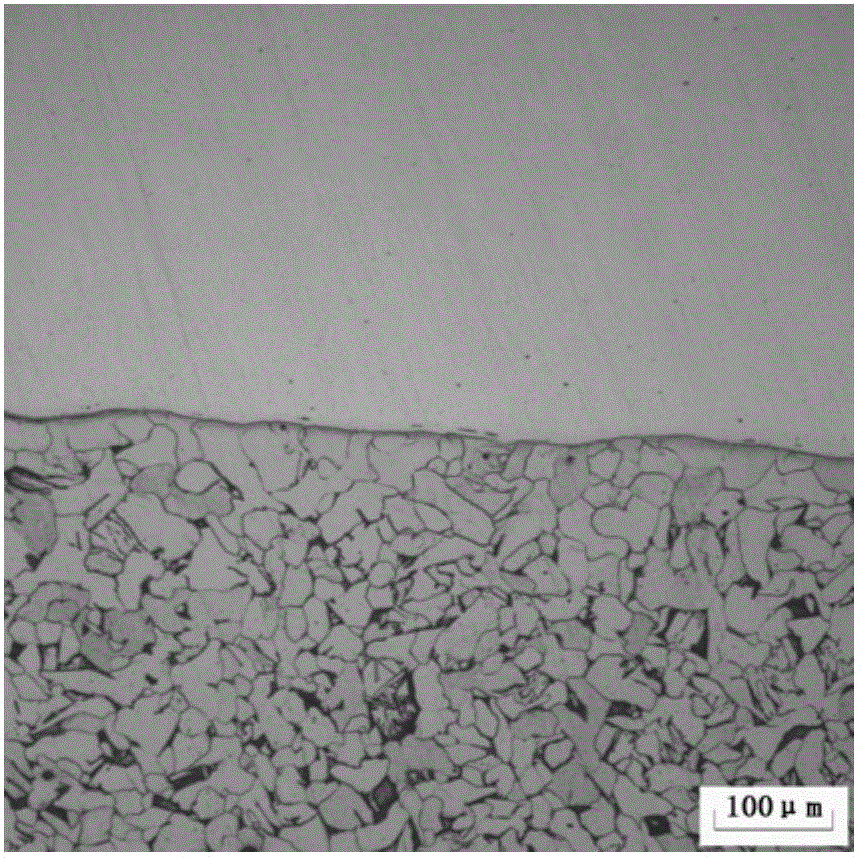

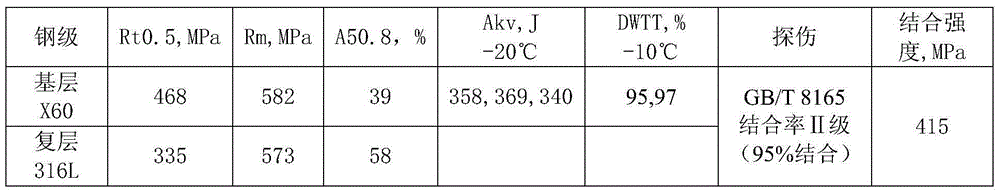

The invention discloses a carbon steel and stainless steel clad steel plate with toughness performance, and belongs to the technical field of production of metal clad plates. Carbon steel is a basal material, and satisfies the requirements of API5L "American Petroleum Pipeline Steel Specification"; 316L stainless steel is a multiple layer, and components satisfy the requirements of ASTM A240M-05 standard "Standard Specification of Chromium and Chromium Nickel Stainless Steel Plate, Sheet and Strip Steel for Pressure Vessels and General Purposes"; flux is BNi brazing filler metal; and solder resist is a mixture of magnesium oxide and aluminum oxide. The process comprises steel blank assembly, heating, rough rolling, finish rolling and heat treatment. The clad steel plate has excellent toughness performance and hydrogen induced cracking resistance, so that the use safety of crude oil conveying pipes is improved.

Owner:QINHUANGDAO SHOUQIN METAL MATERIAL

Cold-rolled sheet rolling emulsified oil containing modified nano copper and preparation method thereof

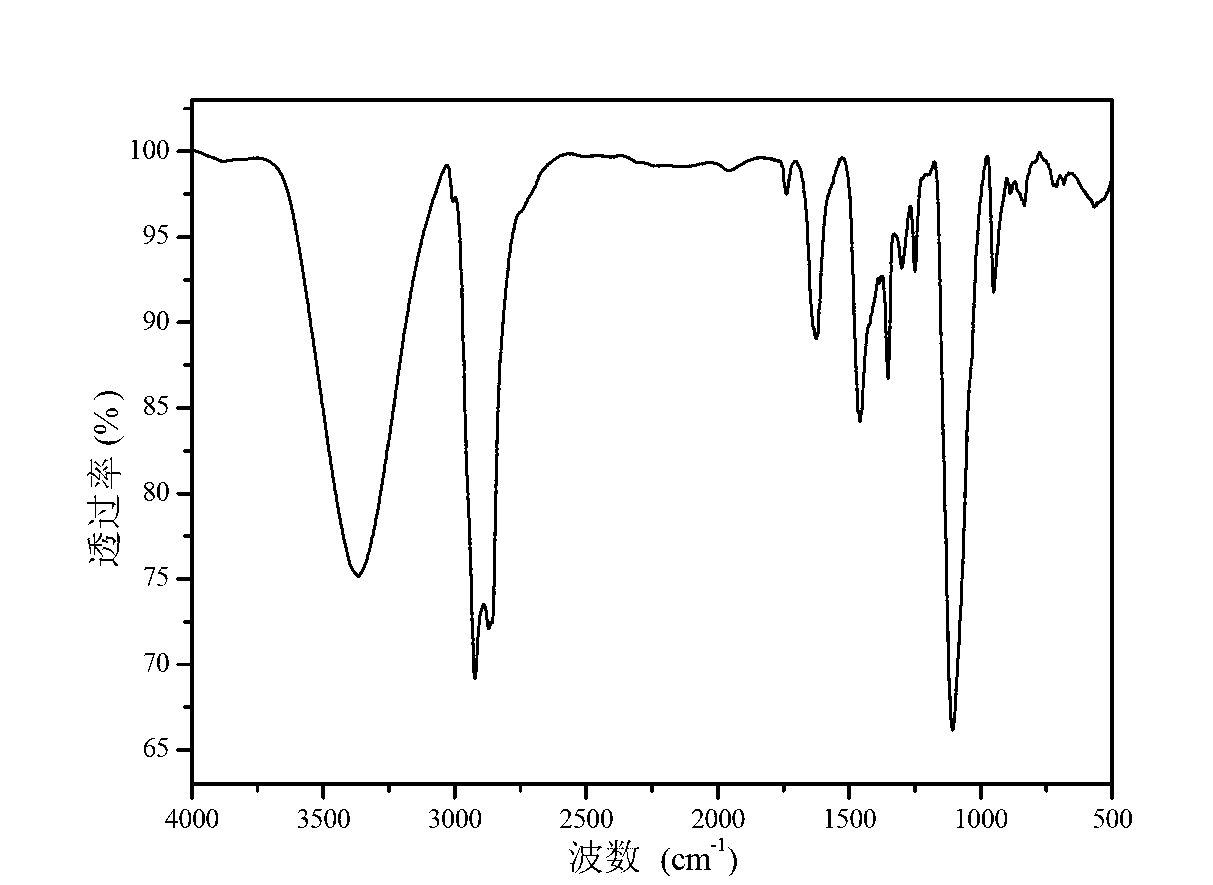

The invention relates to a cold-rolled sheet rolling emulsified oil containing a modified nano copper and preparation method thereof, which belong to the field of organic chemistry. The emulsified oil comprises the following components, in percentage by weight: 54-80% of a base oil, 15-32% of an oiliness agent, 0.1-1% of a modified nano copper particle, 2-4% of an extreme pressure agent, 0.5-2% of an anti-rusting agent, 2-6% of an emulsifier, 0.4-1% of an anti-oxidant, 0.03-0.1% of an anti-foaming agent, and 0.2-0.6% of an anti-mildew agent. The cold-rolled sheet rolling emulsified oil containing the modified nano copper is diluted with water into a 2-6 wt% emulsion, and the emulsion is directly used in the cold rolling process of the strip steel and has very good lubrication, cleaning property of the rolling mill and annealing cleaning property, after annealing, the steel plate not subjected to degreasing has a clean surface without pollutants, so as to satisfy rolling production requirement under high pressure at high speed.

Owner:NORTHEASTERN UNIV

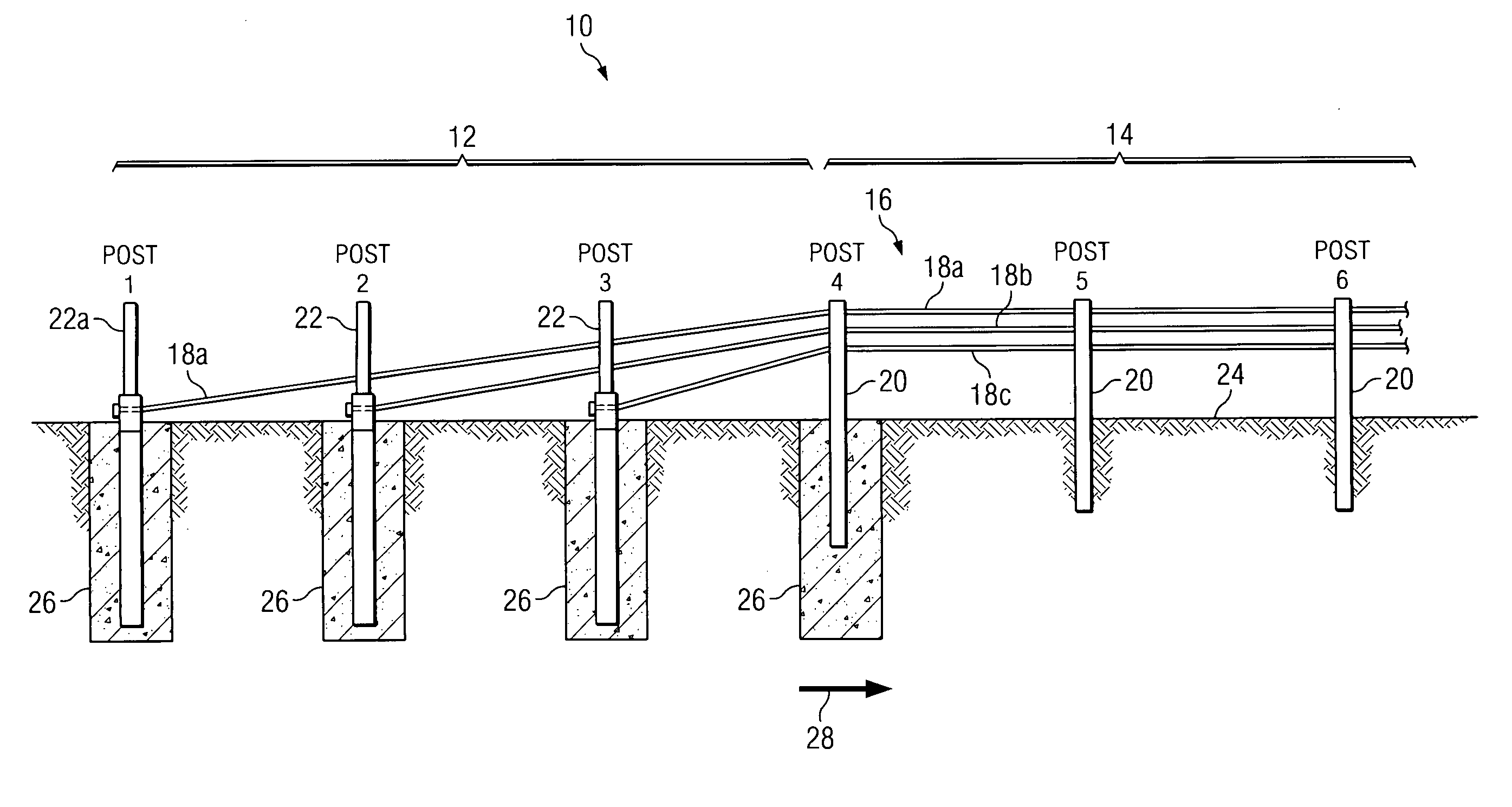

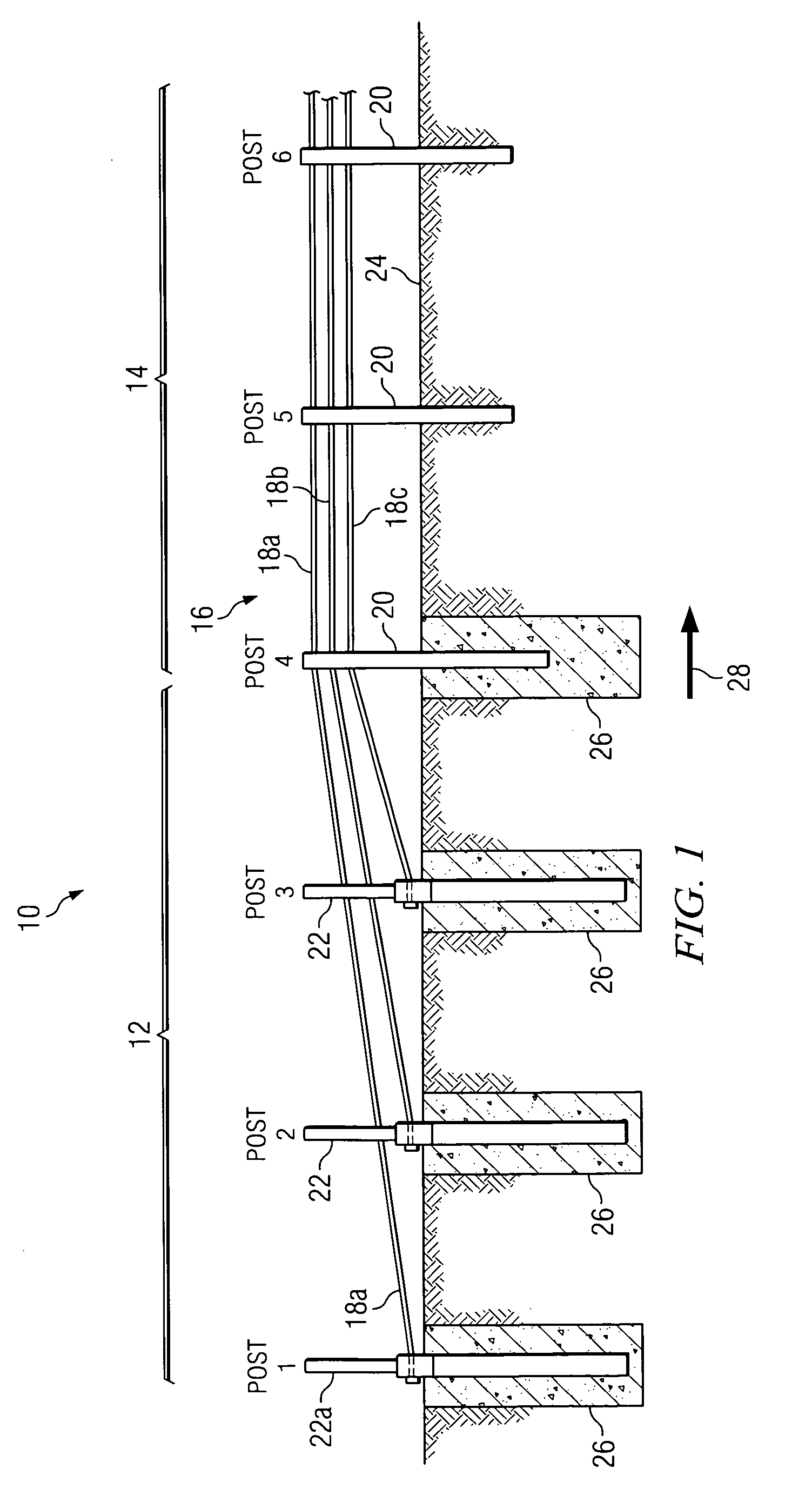

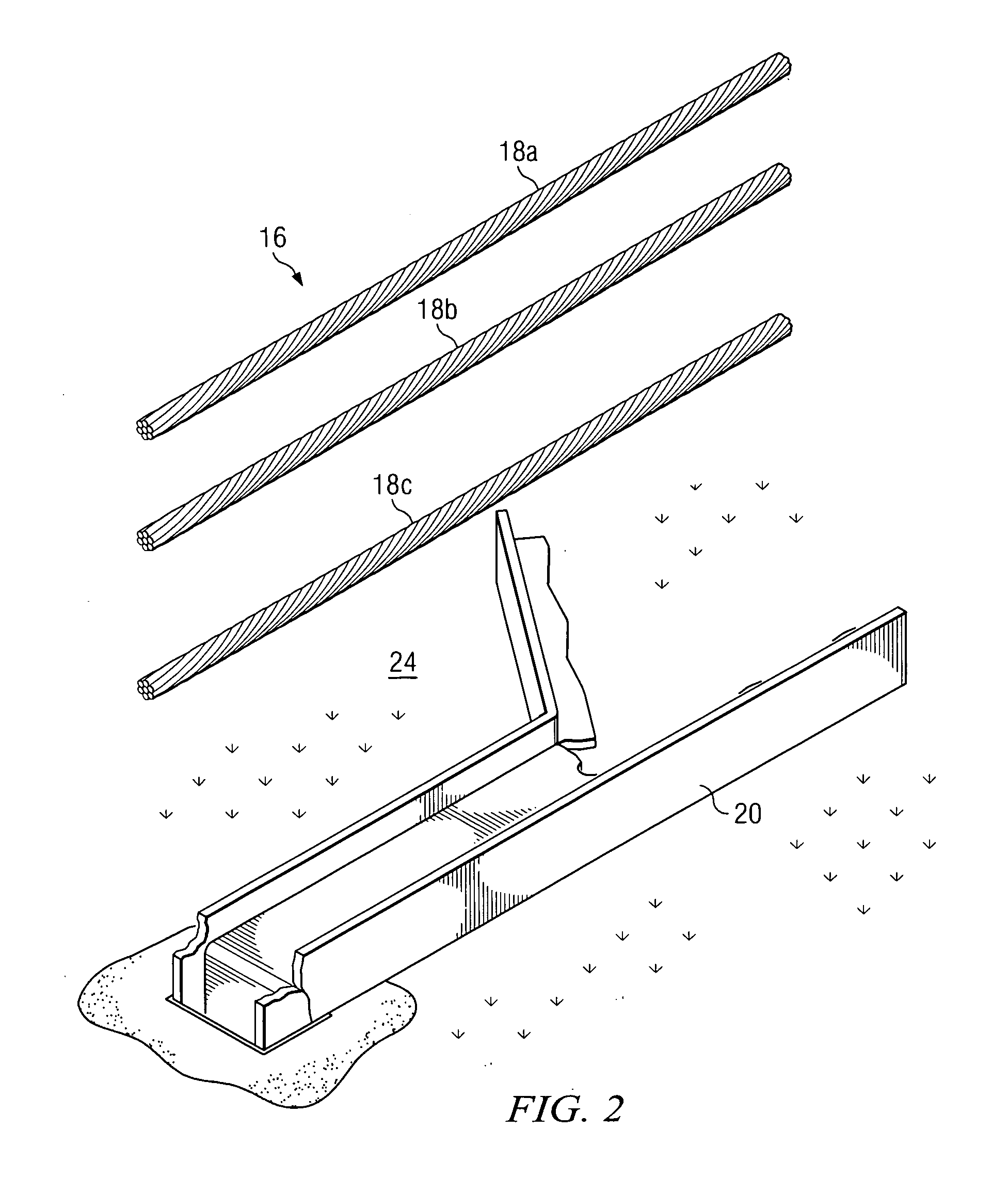

Cable barrier guardrail system with steel yielding support posts

InactiveUS20070102689A1Improve lateral strengthDecreases longitudinal strengthPasturing equipmentRoadway safety arrangementsEngineeringStrip steel

In accordance with a particular embodiment of the present invention, a guardrail system includes at least one cable operable to contain and redirect an errant vehicle. The guardrail system also includes a plurality of guardrail support posts spaced apart in relation to one another. Each support post includes a lower portion, a mid portion, and an upper portion. The lower portion is for installing below grade adjacent the roadway. The mid portion lies substantially adjacent the grade and includes a weakened section operable to weaken the support post about a longitudinal axis. The upper portion is releasably coupled to the at least one cable such that the upper portion is uncoupled from the at least one cable when the support post is displaced.

Owner:TEXAS A&M UNIVERSITY

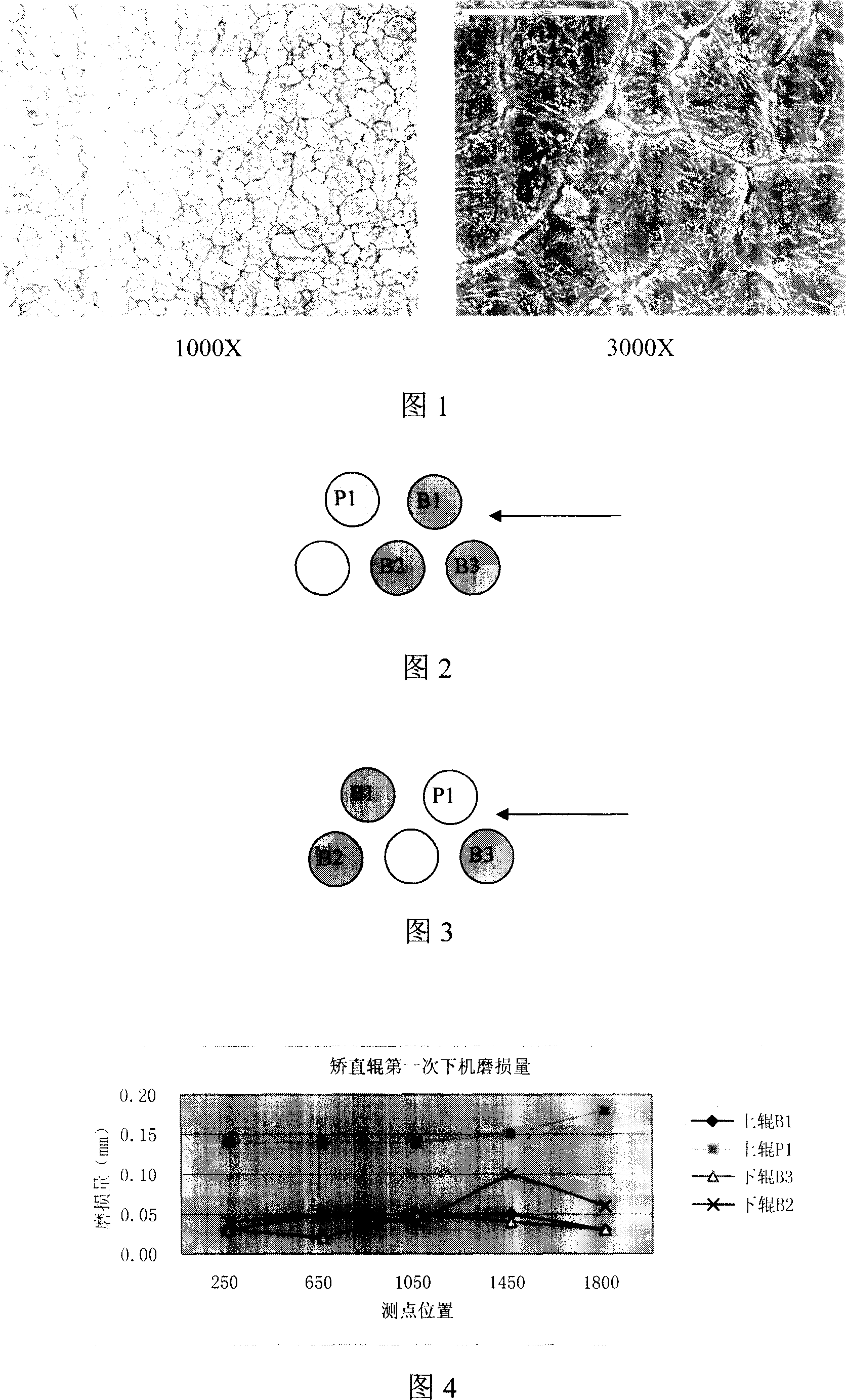

Leveler roll and manufacturing process thereof

ActiveCN101153377AReduce contentChange sizeIncreasing energy efficiencyFurnace typesStrip steelMachining

The invention relates to a straightening roll and the manufacturing process thereof, wherein, the composition of the roll includes 0.60wt percent to 1.10wt percent of C, 0.20wt percent to 1.0wt percent of Si, 0.20wt percent to 0.60wt percent of Mn, 0.20wt percent to 1.00wt percent of Ni, 4.00wt percent to 6.00wt percent of Cr, 0.20wt percent to 1.00wt percent of Mo, 0.10wt percent to 0.50wt percent of V, less than or equal to 0.02wt percent of P, less than or equal to 0.02wt percent of S and the rest, Fe and other inevitable impurities; the manufacturing process of the roll includes: electric furnace smelting to secondary refining to ingot casing to electrode rolling to electrode rough machining to electroslag remelting to ingot casing to hydrogen diffusion annealing to forging to conditioning treatment to ultrasonic flaw detection and microscopic and macroscopic test to rough machining to quenching and tempering heat treatment to semifinishing to final heat treatment to finish machining to finished product. The invention increases the service life of the straightening roll and the surface quality of strip steel and eliminates the bottleneck in straightening high strength plate during production.

Owner:BAOSHAN IRON & STEEL CO LTD

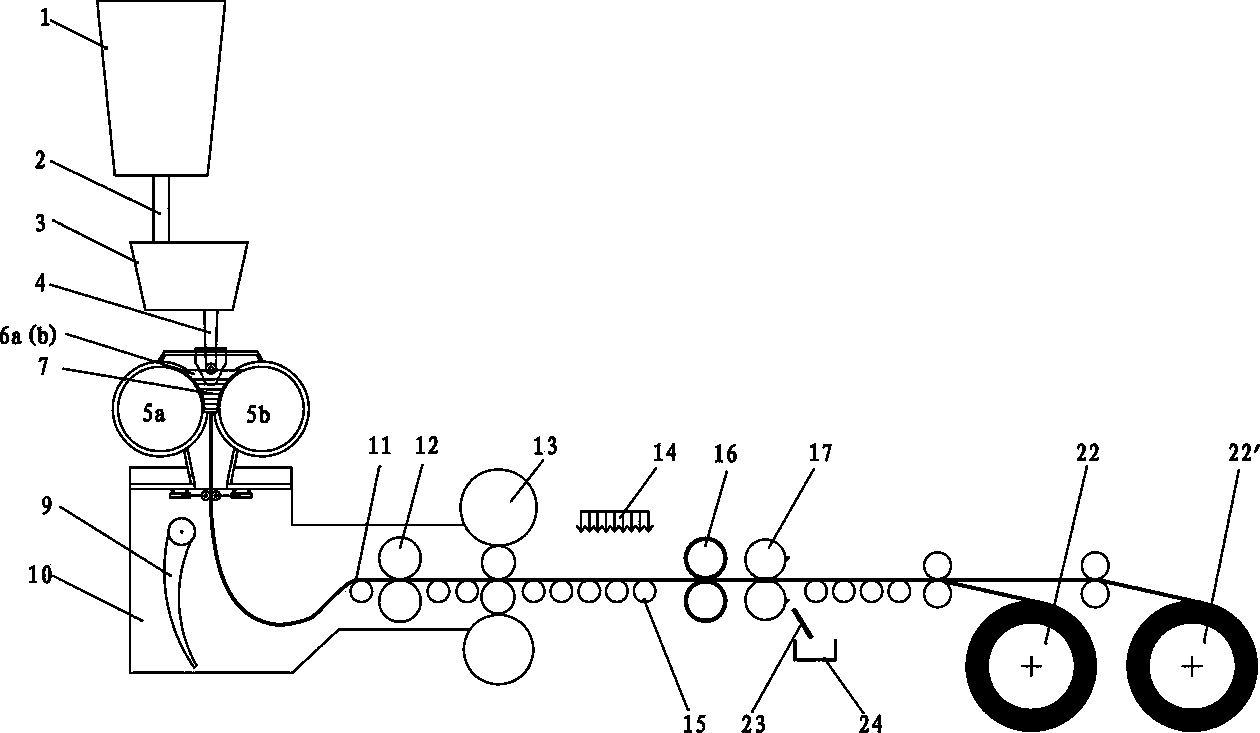

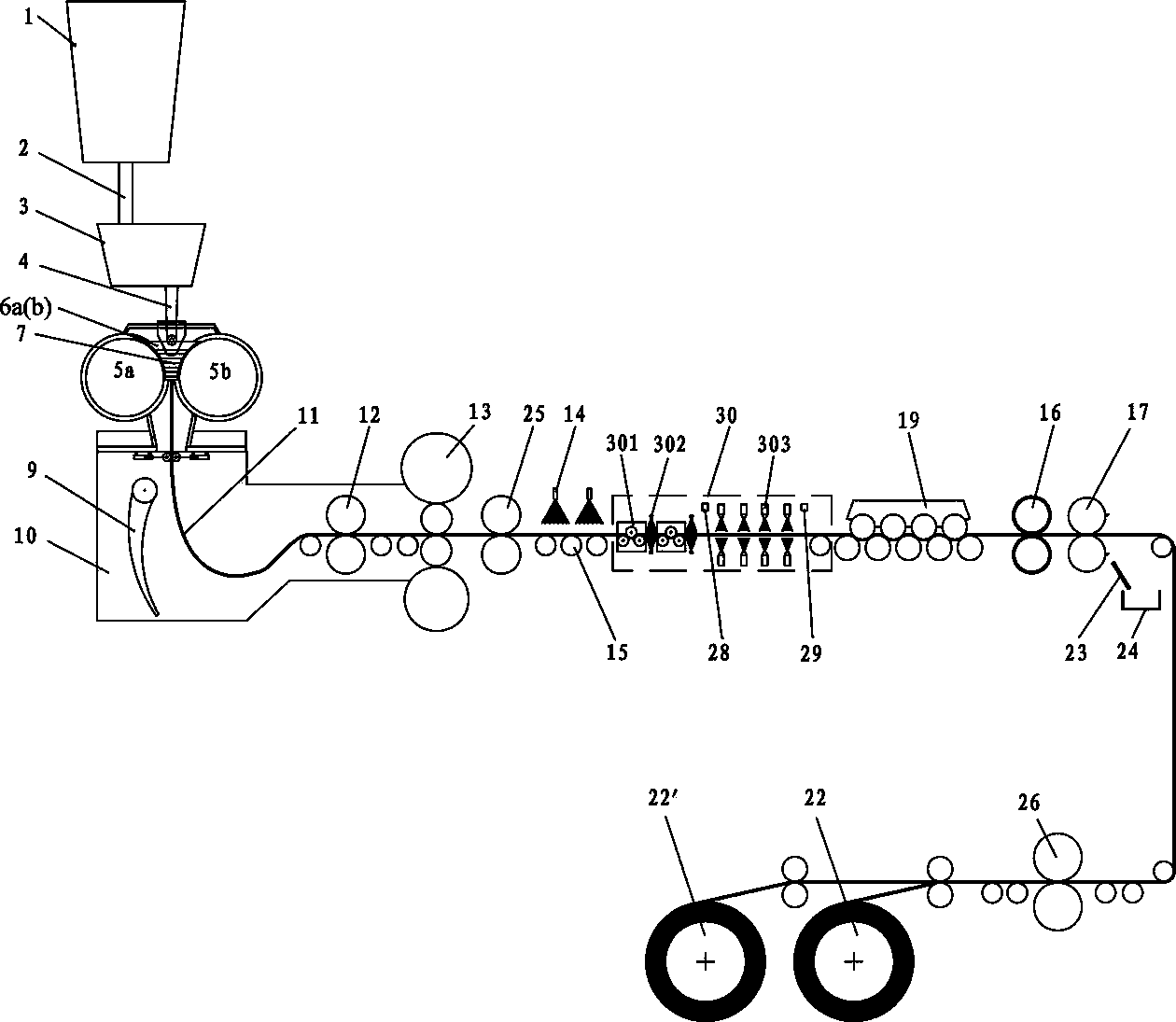

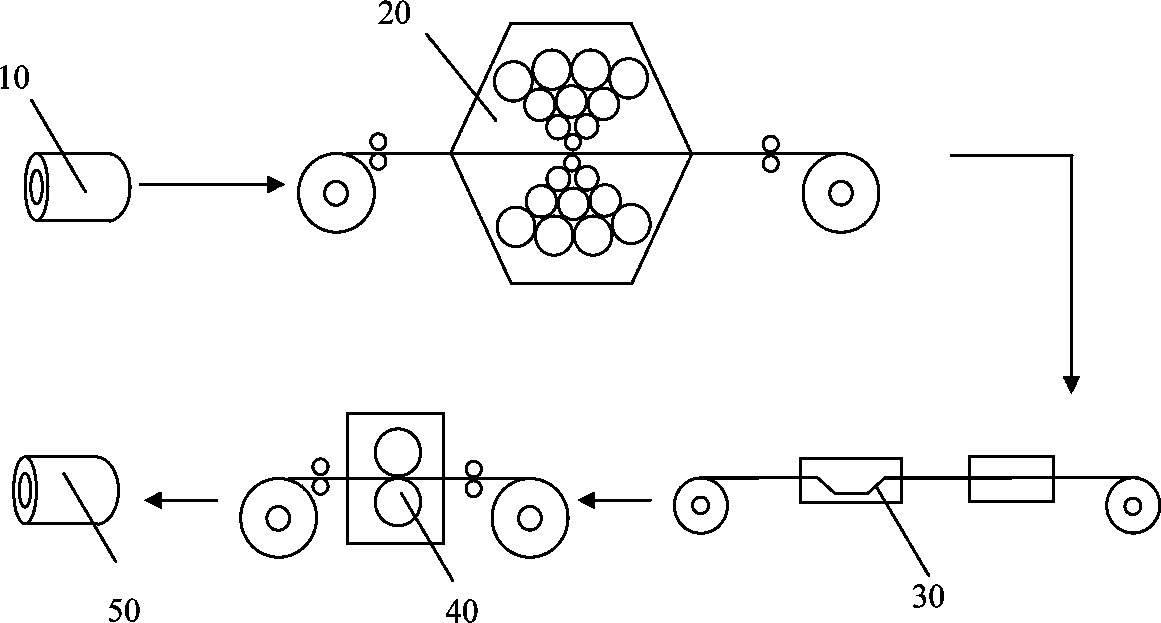

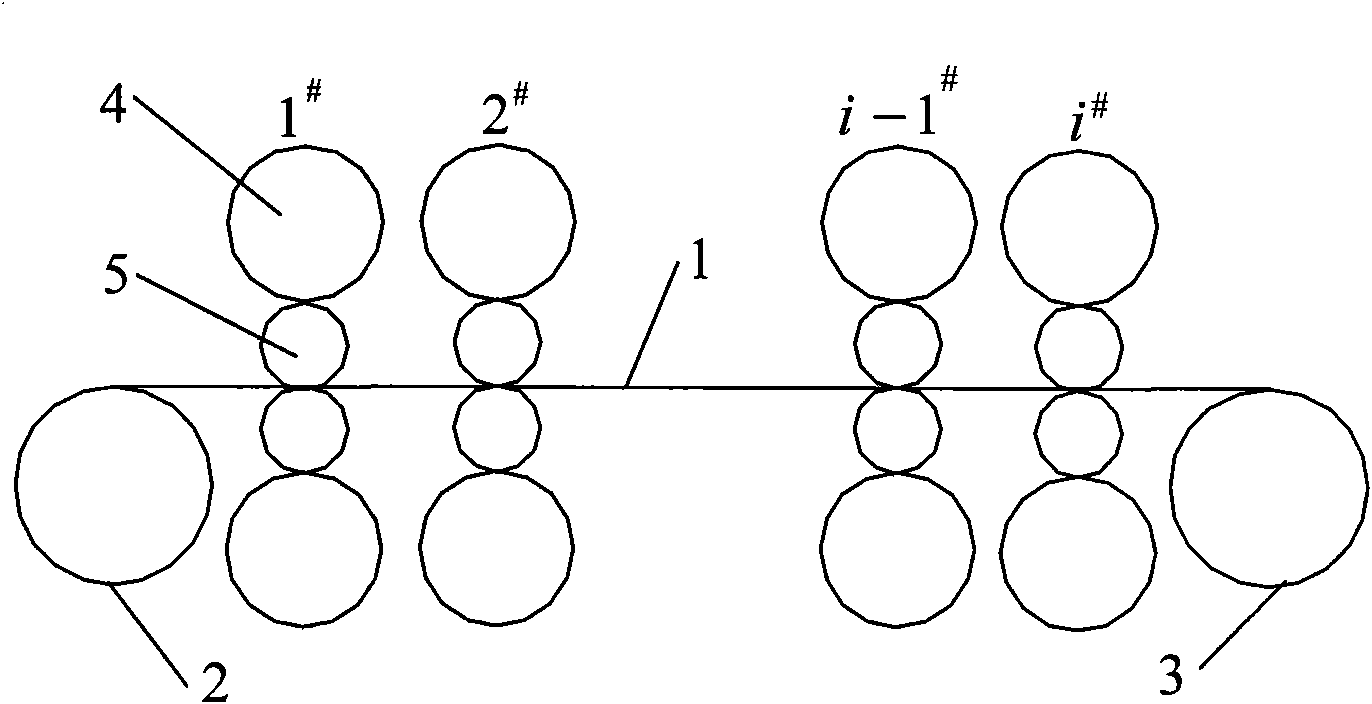

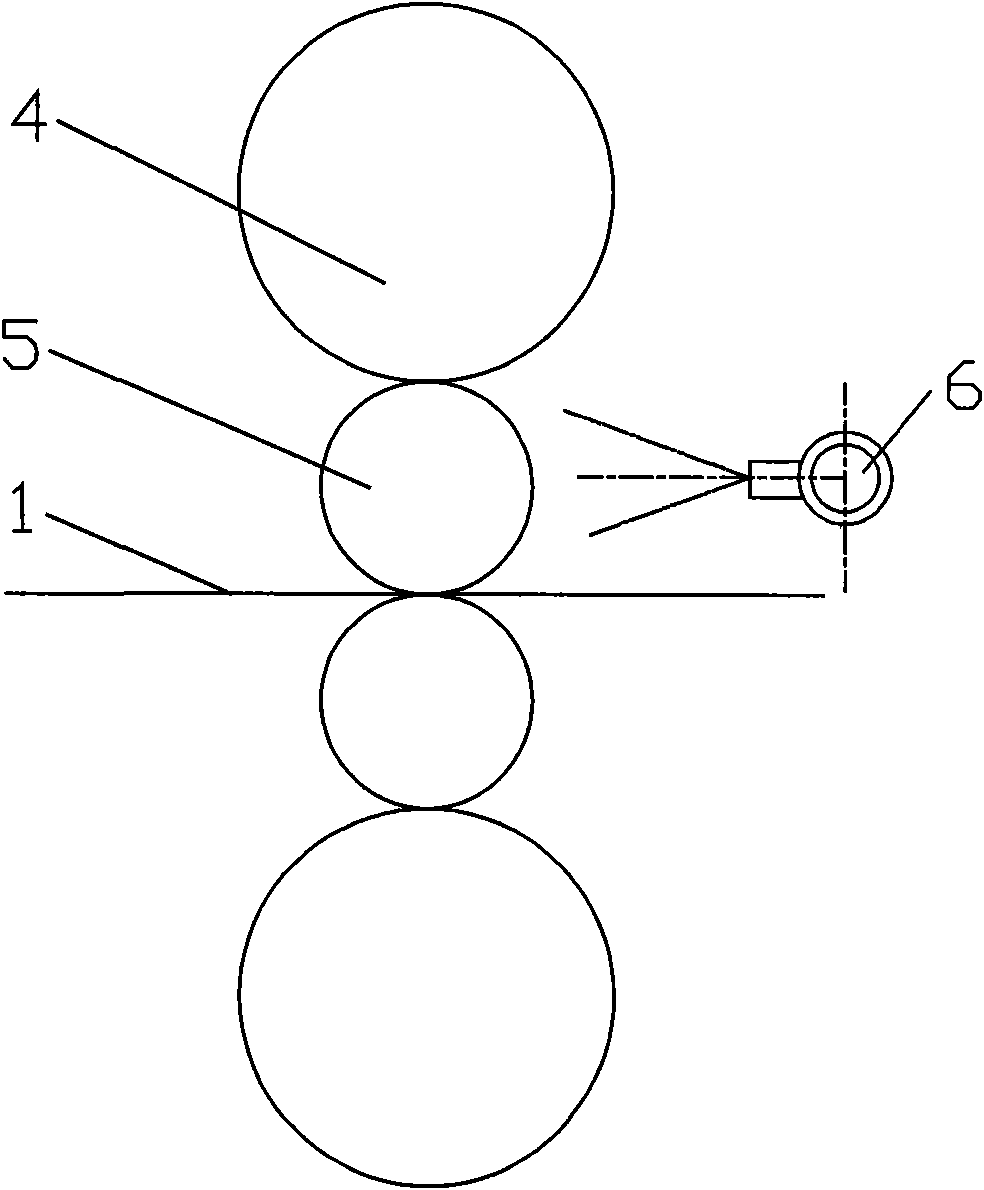

Method of sheet billet continuously casting and rolling to produce thin strip steel coil

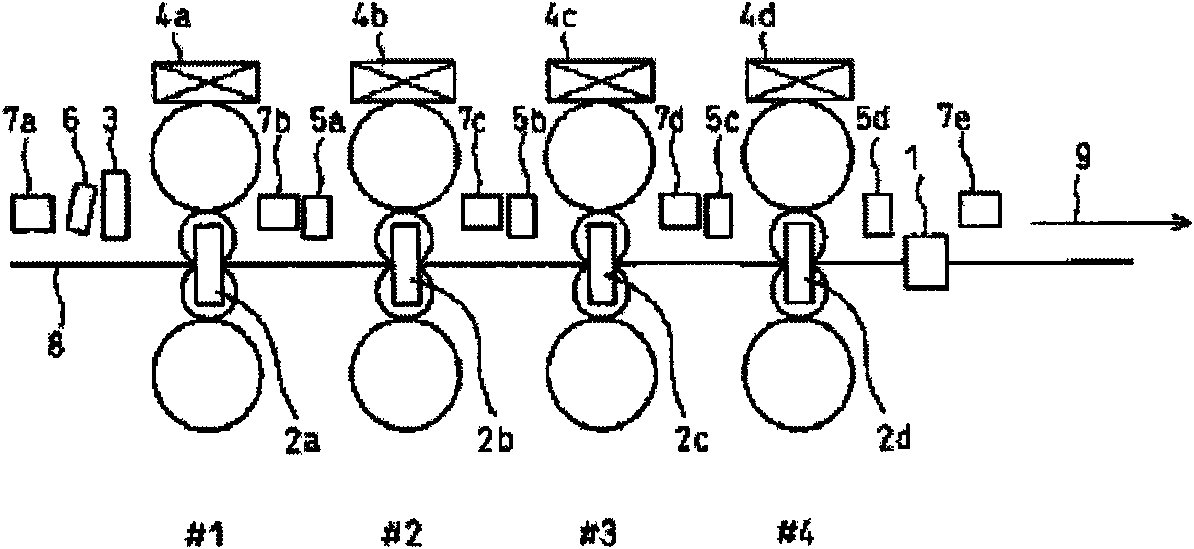

ActiveCN101108394AShort production processSave construction investmentMetal rolling arrangementsProduction lineStrip mill

A method of using thin plate adobe continuous casting and rolling to producing thin band steel coil is provided, which belongs to rolling metal at once after continuous casting, in particular relating to thin standard band steel production method. The invention is characterized in that: a conticaster, a swing shear, a roller-hearth type heating furnace, a scale breaker, a vertical miller, 7 mill groups, laminar flow cooling device and reeling machine are connected to a CSP produce line, the produce line adopts reasonable temperature system, rolling equipment, rolling way and combining with cooling after rolling, the molten steel after continuous casting is a casting adobe of 50 to 70mm thick and 900 to 1300 wide, after cutting, heating, scale breaking, proceed continuous rolling to form a thin band of 1.2 to 1.5mm thick and 900 to 1300 wide, then after cooling to reel steel coil. The production flow is short, the equipment is few, the investment is less and the running expense is low; The technics and equipment is reasonable and high efficient, double locomotive and double flow casting, heating by two furnaces, seven rolling machines roll continuously, the production is smooth and saves energy with high production efficiency; the product performance is even and stable, the board shape is regular with high accuracy and good surface quality.

Owner:MAANSHAN IRON & STEEL CO LTD

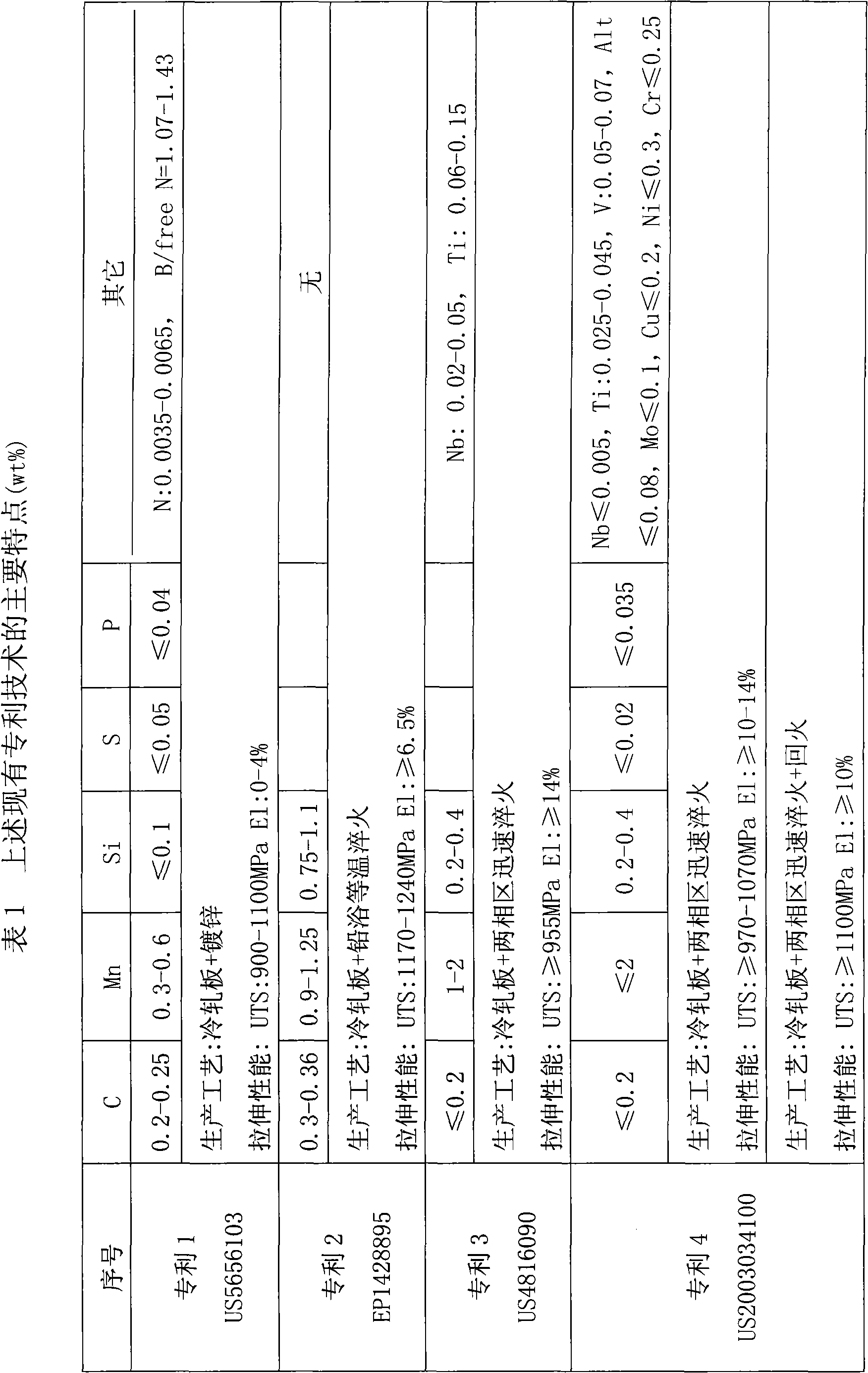

High strength strapping steel with tensile strength over 1,100 MPa and manufacturing method thereof

The invention discloses high strength strapping steel with tensile strength over 1,100 MPa and a manufacturing method thereof. The high strength strapping steel comprises the following components in percentage by weight: 0.25 to 0.35 percent of C, 1.0 to 2.0 percent of Mn, less than or equal to 0.45 percent of Si, less than or equal to 0.04 percent of S, less than or equal to 0.04 percent of P, and the balance of Fe and inevitable impurities. The manufacturing method comprises a steel smelting process, hot rolling process, cold rolling process and ferrite-austenite two-phase region quick quenching and annealing heat treatment process for smelting pure steel while controlling the state of impurities. The method can realize the excellent combination of strength and plasticity, realizes the clean production of the high-strength strapping steel which has a tensile strength over 1,100MPa and an elongation over 10 percent, and has the advantages of easy-to-implement production operation, high production efficiency, low production cost, light environmental pollution. Thus, the method has a good application prospect.

Owner:BAOSHAN IRON & STEEL CO LTD

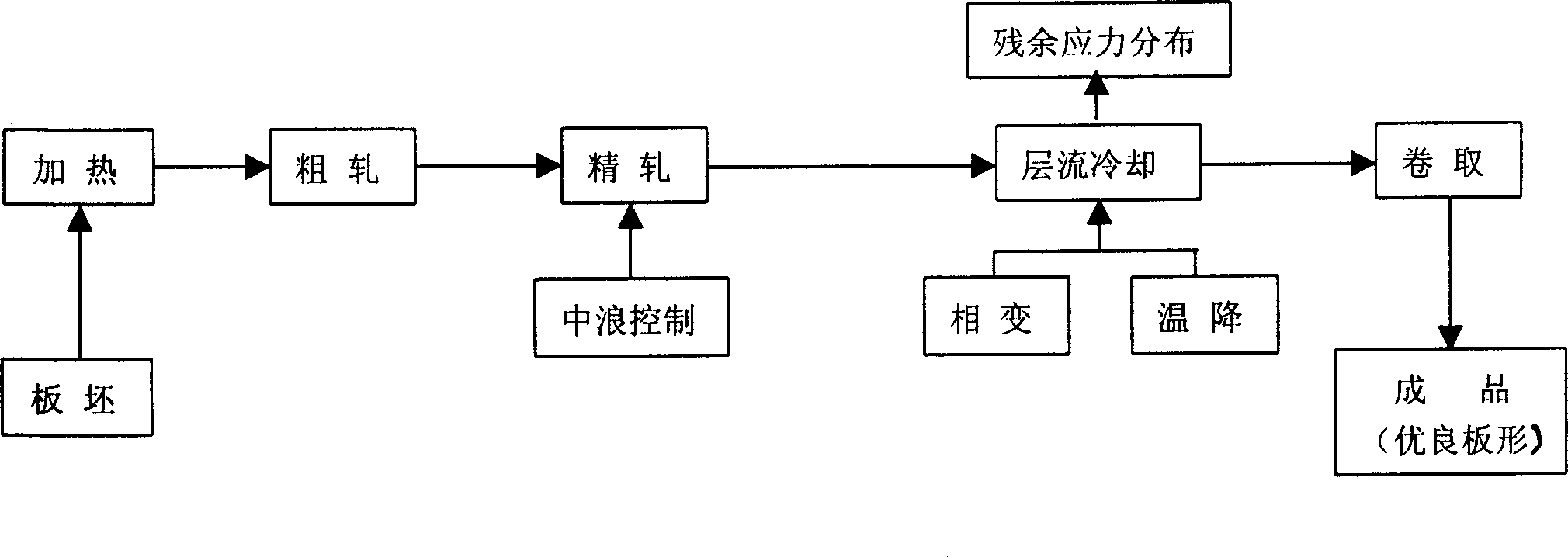

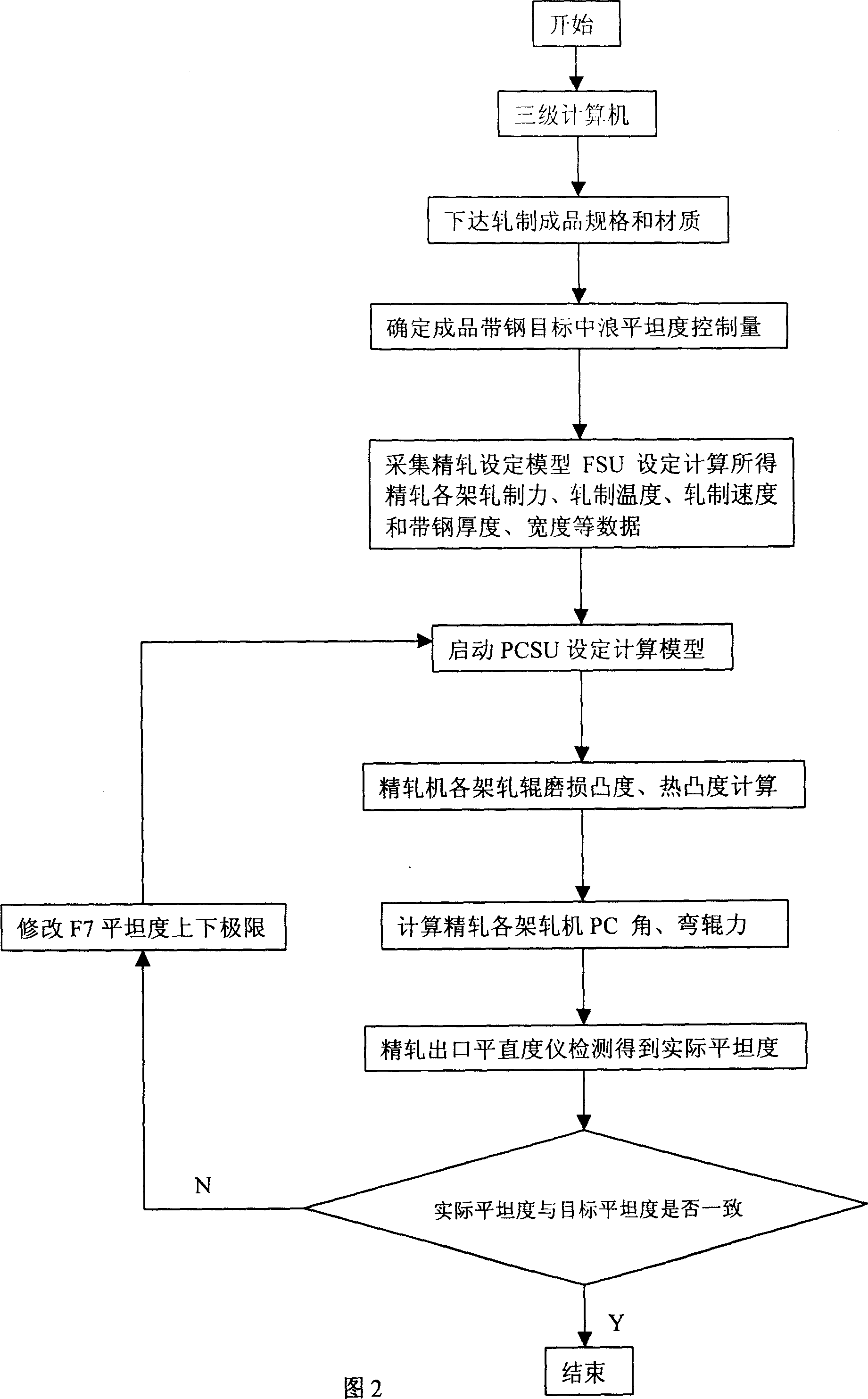

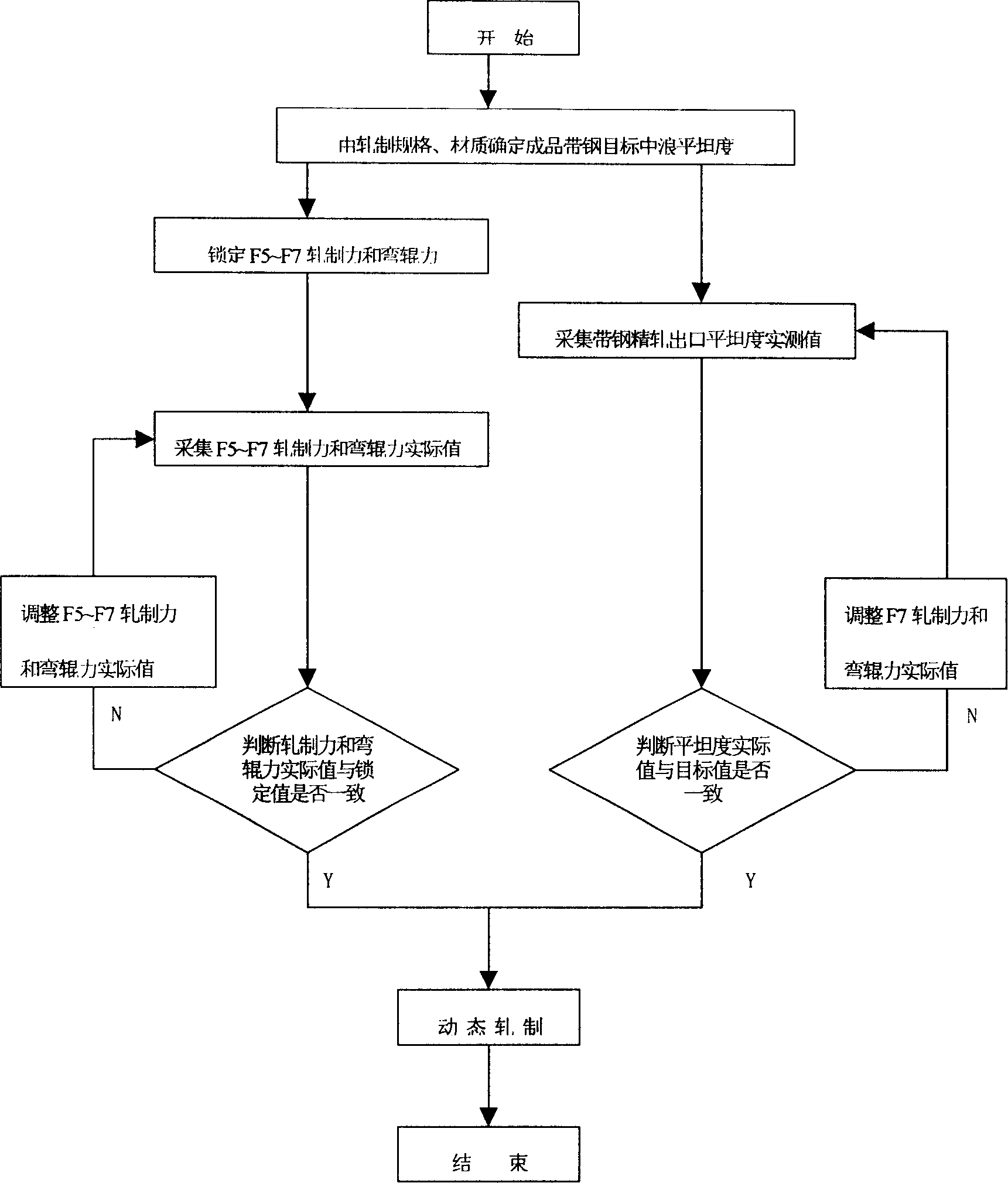

Hot-rolled strip steel moderate sea profile shape controlling method

A method of controlling moderate-sea strip shape of controlling strip steel. The head of strip steel is controlled by moderate-sea PCSU control, that is, PC setting control. The rear of strip steel is controlled by dynamically automatic strip shape moderate-sea control, which is dynamic ASC control. Determining the objective control degree of moderate-sea flatness of strip steel, calculating convexity of finish rolling strip steel, equivalent heat convexity of roller, coefficient of extension and flatness of strip steel. According to kinds, scales of steel, determining factors, constant terms, proportion factors in formulas, making moderate-sea control on flatness of exported finish rolling strip steel. Two-side sea in cooling could be effectively eliminated, which improves the quality ofstrip steel.

Owner:ANGANG STEEL CO LTD

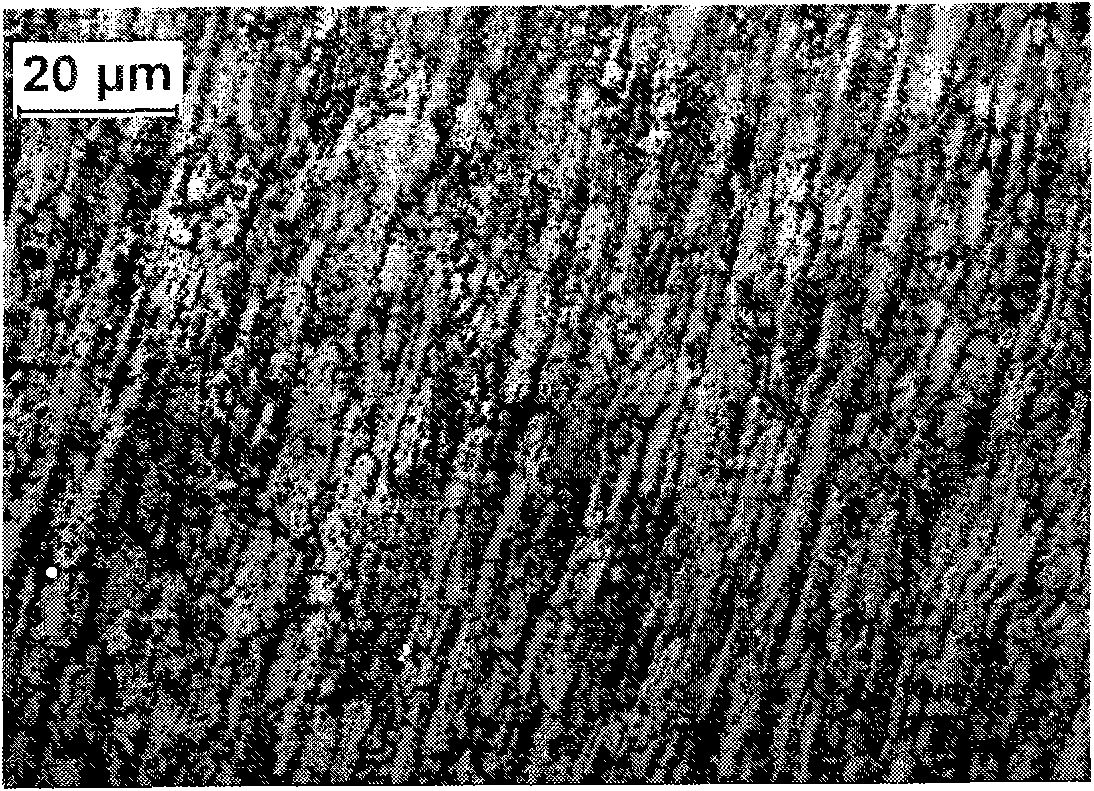

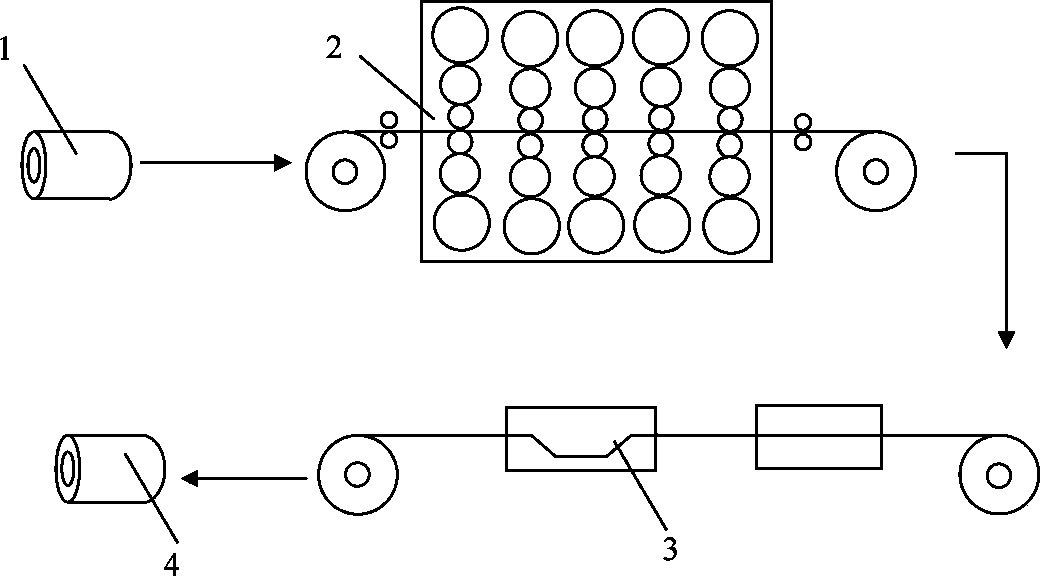

Method for producing high-strength thin strip steel in short process

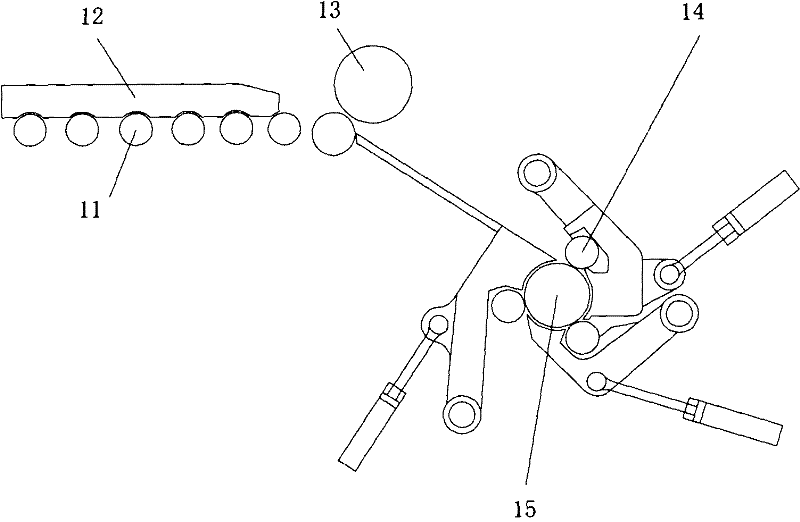

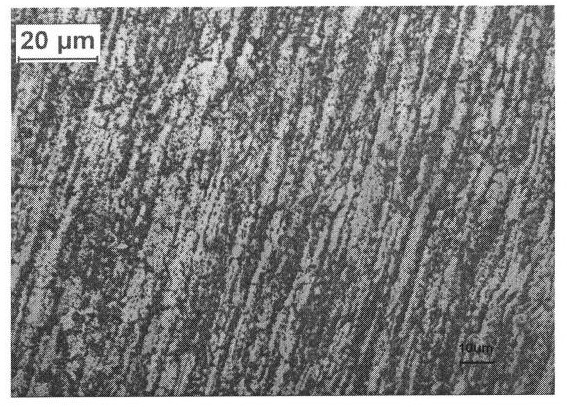

ActiveCN103658178ACost-effectiveShorten the lengthWork treatment devicesMetal rolling arrangementsRare-earth elementMicroscopic scale

The invention relates to a method for producing high-strength thin strip steel in a short process. Twin roll strip casting is adopted for producing an atmospheric-corrosion-resistant steel casting belt containing a rare earth element Re, hot rolling, cooling and anti-oxidation intensive cooling scale removing are performed on the steel casting belt, and then the steel casting belt is reeled up after being straightened, wherein in the hot rolling process of the strip steel, rolling reduction is not smaller than 20%, and finishing rolling temperature is 850-1000 DEG C; then, a staged cooling mode of atomization cooling plus anti-oxidation intensive cooling ( spraying dry ice) is adopted, and intensive cooling is carried out on the high-temperature strip steel, wherein the cooling rate in the atomization cooling process is 50-100 DEG C / s, and the cooling rate in the anti-oxidation intensive cooling process is 100-200 DEG C / s. In this way, through the combined type staged cooling, the uniform steel of a bainite microscopic structure can be obtained, and the bainite structure can remarkably improve the toughness of the steel. The method is especially applicable to atmospheric-corrosion-resistant high-strength thin strip steel with the surface roughness Ra smaller than 2 microns, the thickness of typical strip steel is 0.8-1.6mm, and the strip steel can be supplied in a hot mode instead of a cool mode.

Owner:BAOSHAN IRON & STEEL CO LTD

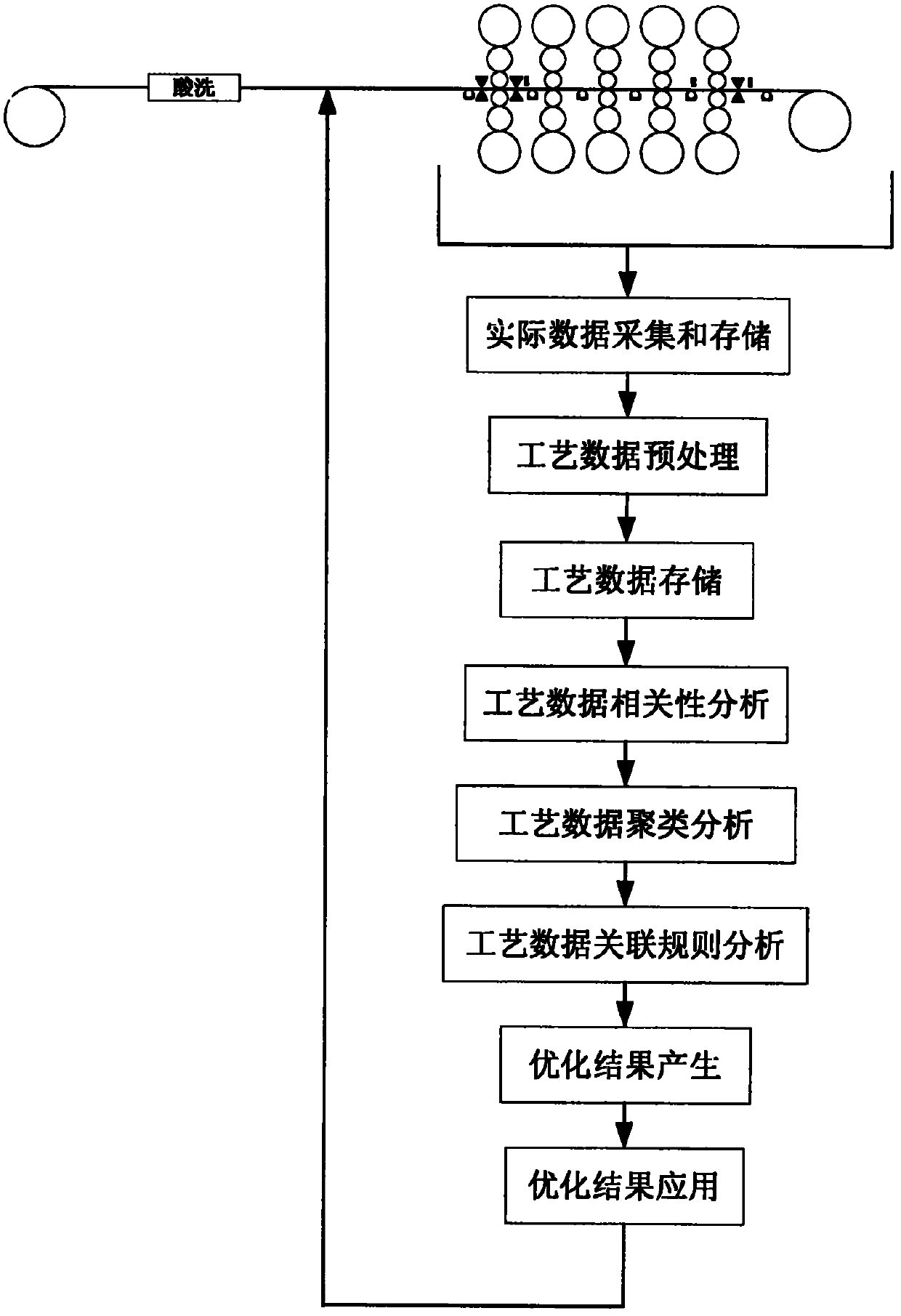

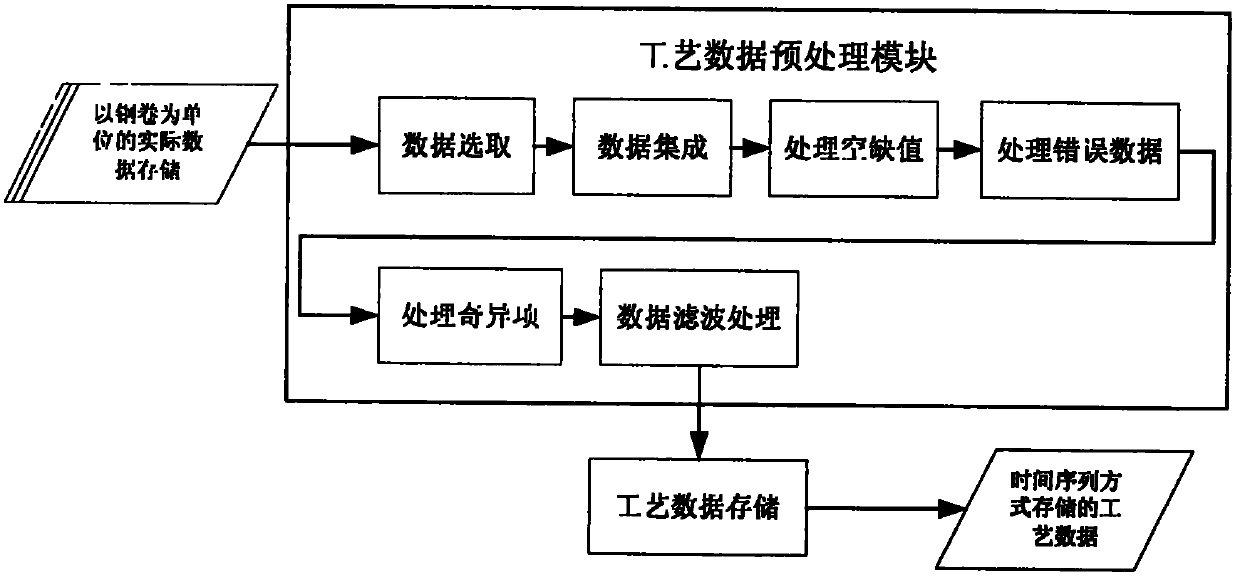

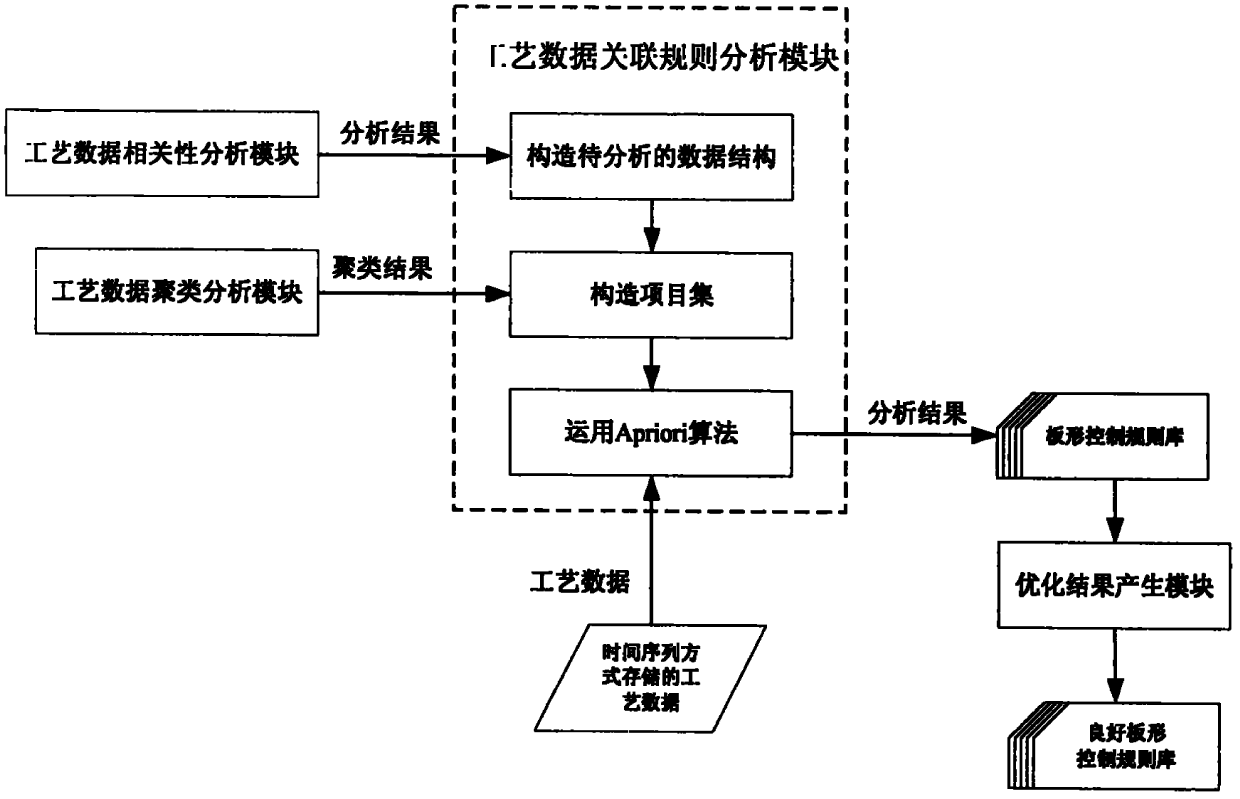

Data mining-based plate shape control key process parameter optimization system

ActiveCN102069094AImprove pass rateImprove the rate of successProfile control deviceAutomatic controlData acquisition

The invention relates to a data mining-based plate shape control key process parameter optimization system, and belongs to the technical field of automatic control of cold continuous rolling plate shape. The data mining method is adopted for acquiring key process parameter optimization settings which can meet the good cold continuous rolling plate shape. The system is characterized by comprising the following functional modules: an actual data acquisition and storage module, a process data pre-processing module, a process data storage module, a process data correlation analysis module, a process data clustering analysis module, a process data association rule analysis module, an optimization result generating module and an optimization result application module. The system has the advantage that the good plate shape can be obtained by applying the plate shape control system. The method avoids endless theoretical research on plate shape control and fully utilizes actual plate shape control process data containing successful operation experience of field operators, and the plate shape process parameter settings which can obtain the good plate shape are acquired by data mining, so the plate shape qualification rate and the finished product rate of cold continuous rolled strip steel are improved.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

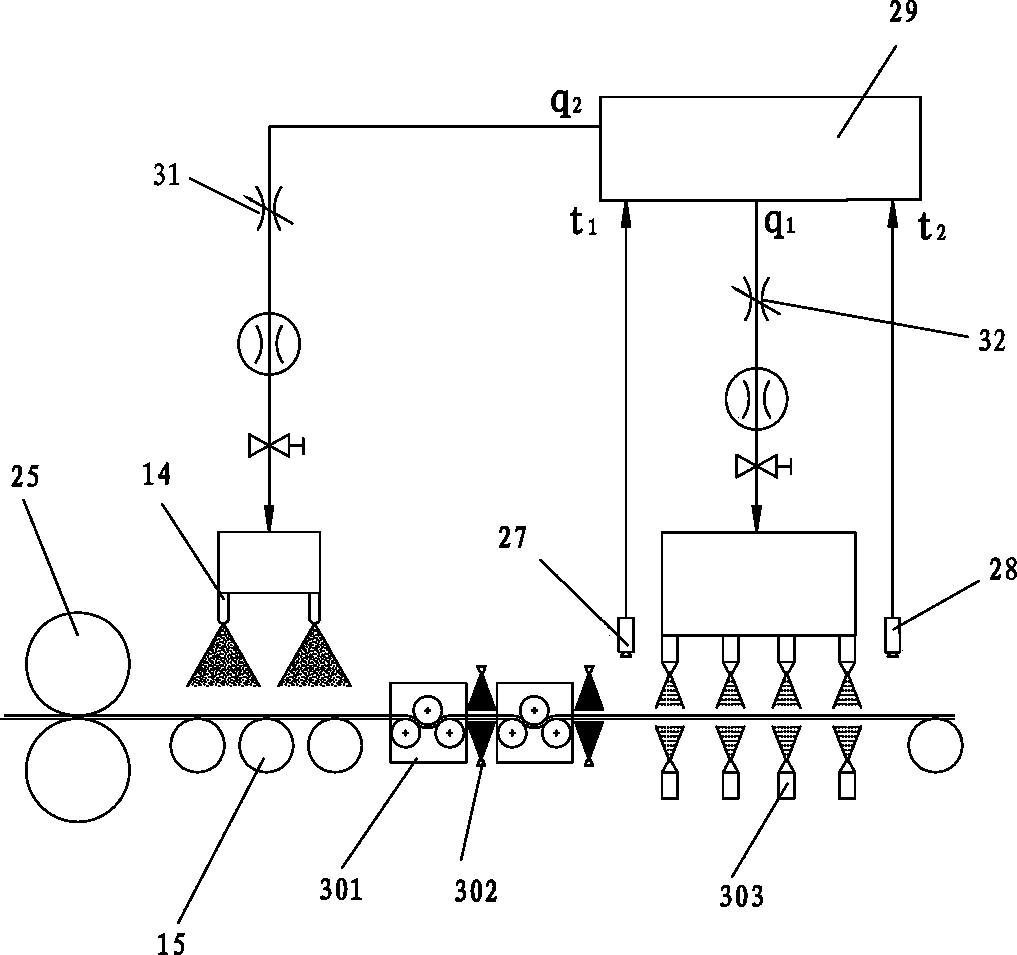

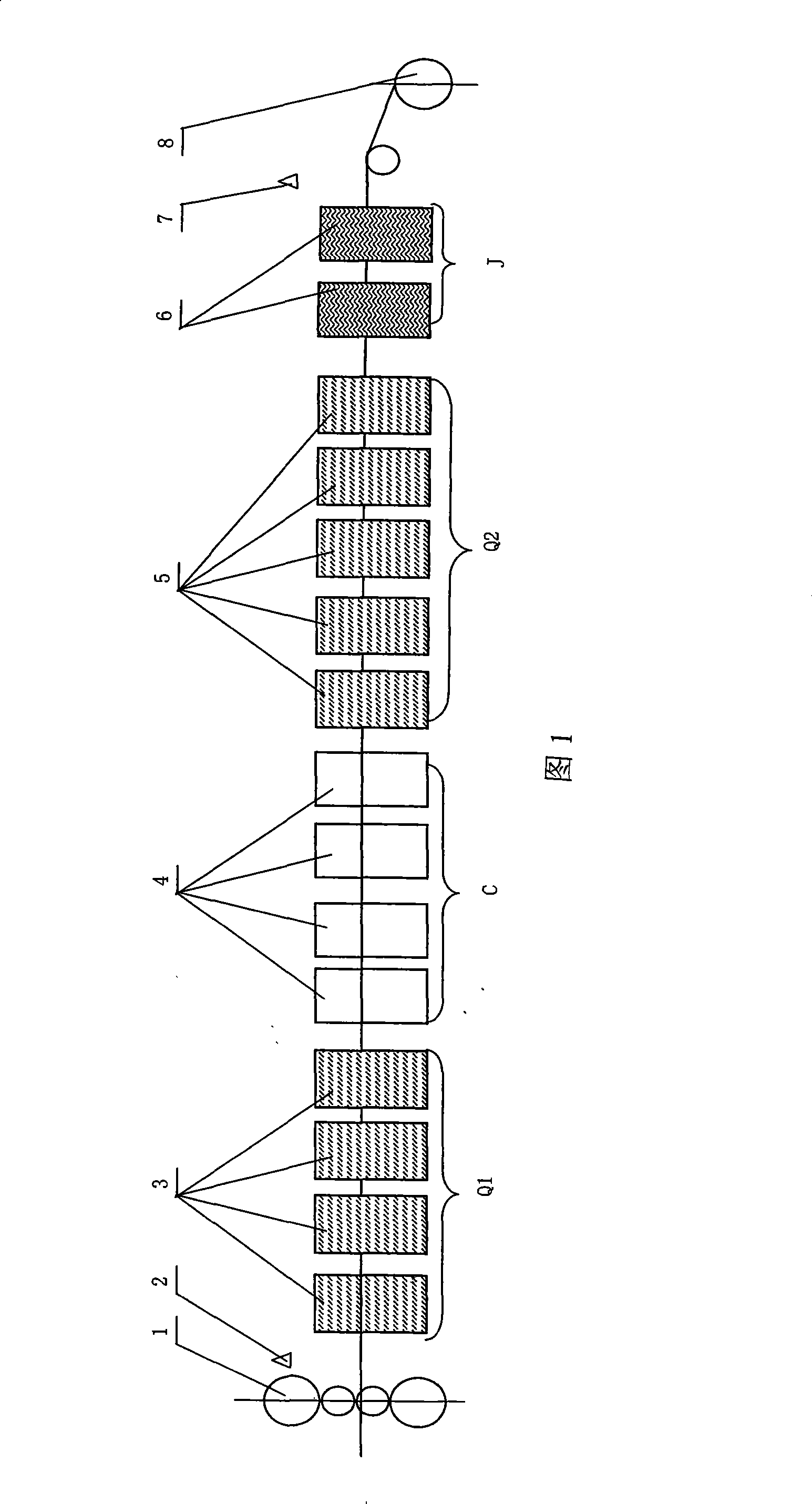

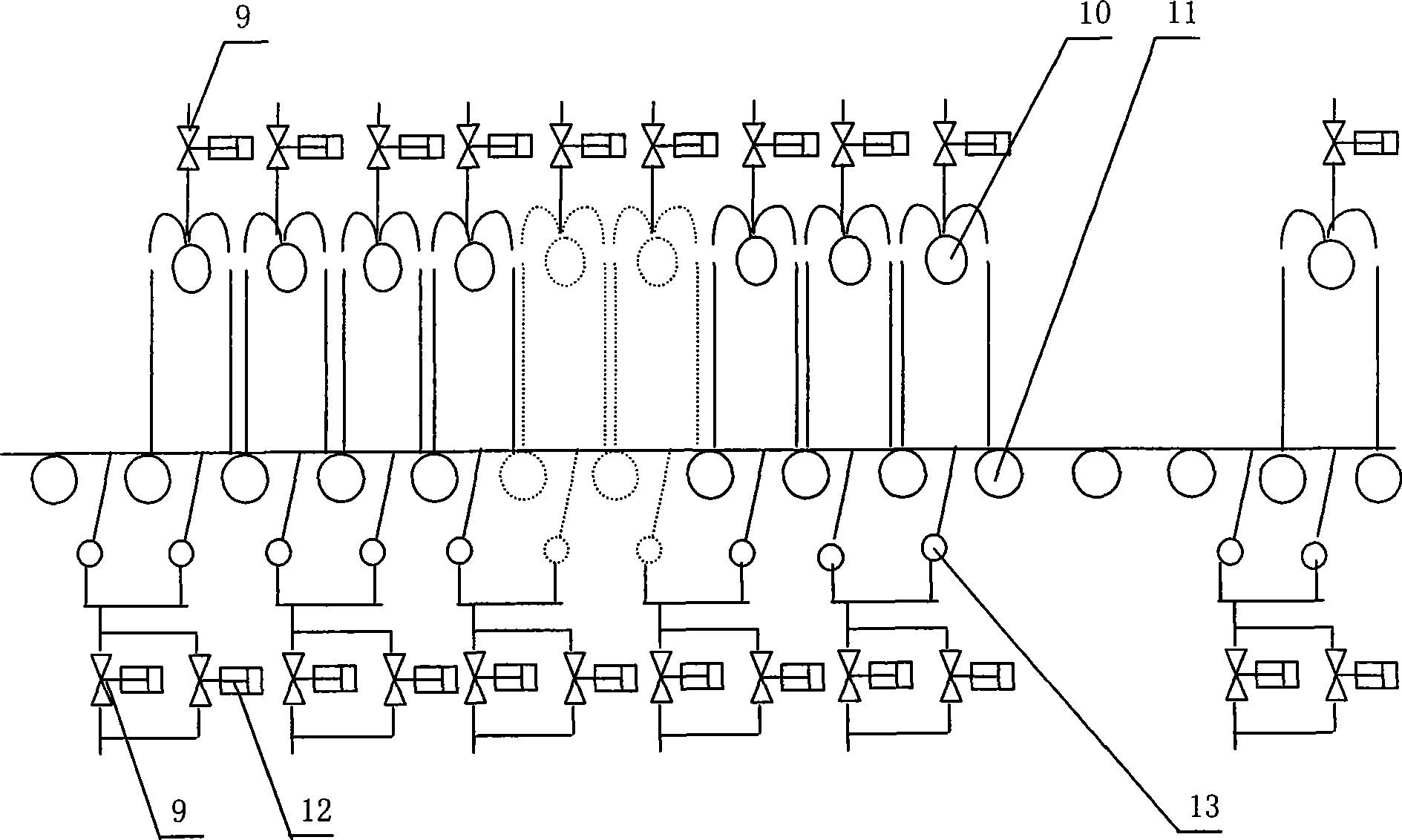

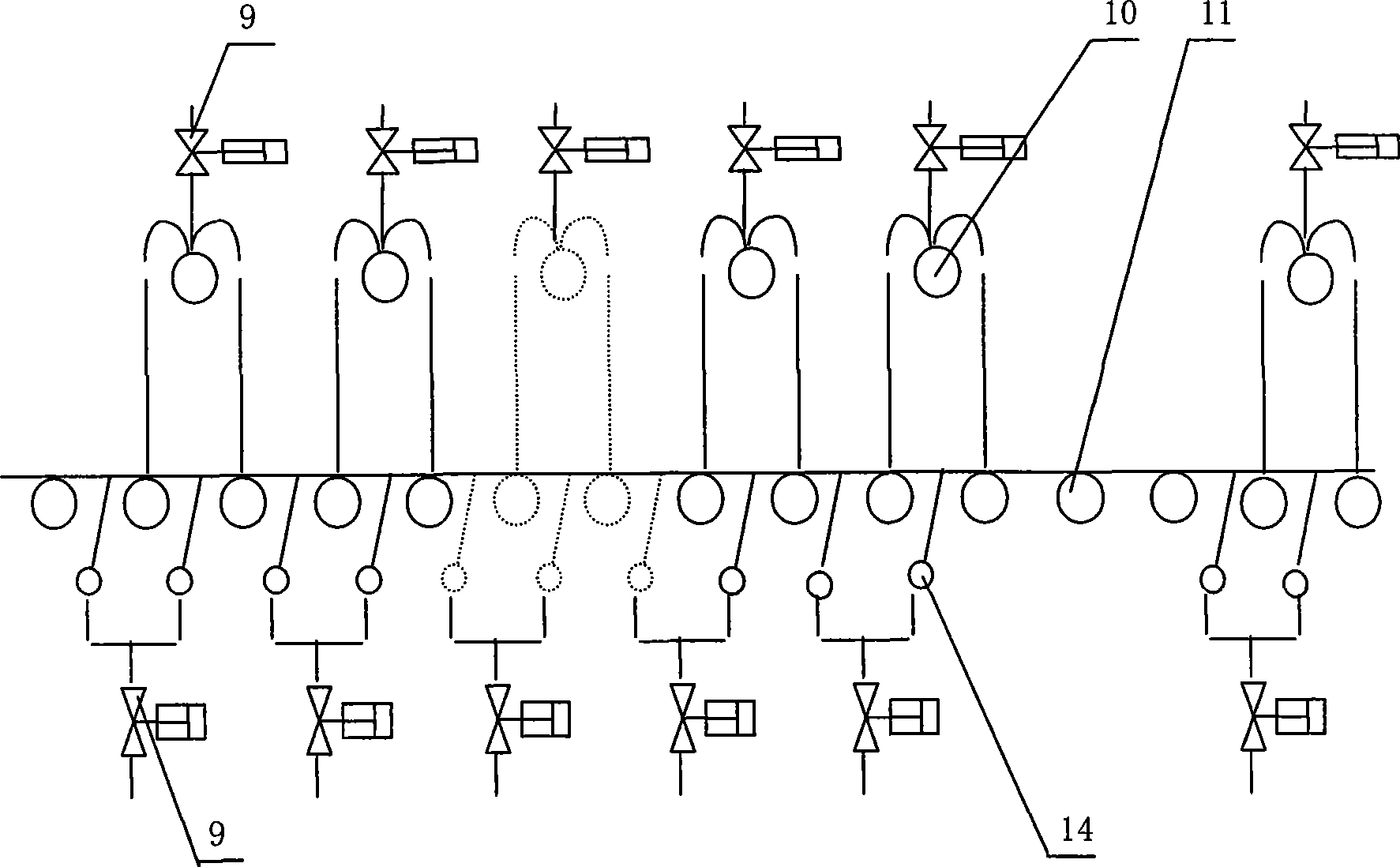

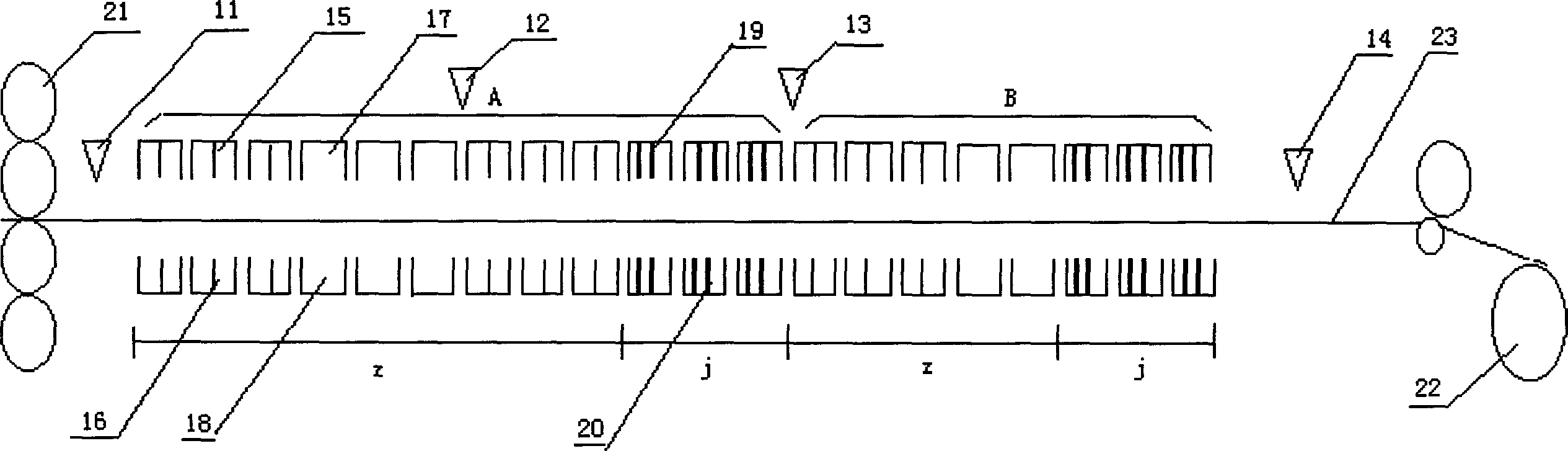

Refrigerating device of belt steel and cooling and controlling method thereof

ActiveCN101381806AHigh control precisionTemperature control deviceFurnace typesComputerized systemStrip steel

The invention belongs to the technical field of metallurgy and in particular relates to a device for cooling strip steel and a cooling control method thereof. The cooling device mainly comprises cooling sections, a strong cooling region Q (Q1, Q2), a rough adjustment cooling region C and an accurate adjustment cooing region J; after manifolds are closed partially, the strong cooling region Q (Q1, Q2) can be used as the rough adjustment cooling region C; each cooling region consists of a plurality of cooling sections; the cooling sections have the same length and consist of laminar flow cooling manifolds on the upper part and spraying manifolds on the lower part; a side spraying device is arranged between the cooling sections so as to remove accumulated water on the surface of the strip steel; and the cooling control method of the device for cooling the strip steel carries out the setting calculation and the feedforward and feedback control through a computer system. The device for cooling the strip steel can flexibly realize the cooling of various modes, has a simple equipment structure, can realize the requirement on cooling control of the multibreed,strip steel, meet the requirements of hot-rolled multiphase steel, ultrafine crystal grain steel and other products and can be widely used for the cooling after rolling of the hot-rolled strip steel.

Owner:CISDI ENG CO LTD

Method for producing ferritic stainless steel bands with roughened surfaces through cold continuous rolling

ActiveCN103372567AExtended rolling kilometersImprove surface qualityWork treatment devicesMetal rolling arrangementsHydrofluoric acidReduction rate

A method for producing ferritic stainless steel bands with roughened surfaces through cold continuous rolling comprises that (1), a five-rack serial type cold continuous rolling is performed, a five-rack serial type cold continuous rolling unit is adopted, the diameter of a working roll of each rolling mill is 300-500mm, and endless rolling is performed; the roughness degrees of the rolls of the first rack to the fourth rack are in a range of 0.5-1.0mum and decrease sequentially; the working roll of the fifth rack is subjected to roughening and chromium plating treatment; an emulsion lubrication rolling mode is adopted, the temperature of an emulsion is 50-60DEG C, the emulsion is sprayed to roll gaps for cooling and lubricating, the temperature of cold-rolled band steel is controlled below 150DEG C; the accumulated reduction rate of the first rack to the fourth rack is larger than 60%, the reduction rate of the fifth rack is in a range of 4-10%, and the roughness of the cold-rolled band steel is controlled in a range of 0.5-1.0mum; (2), the cold-rolled band steel is subjected to annealing acid picking treatment, heating and annealing are performed in a continuous horizontal gas furnace, the annealing temperature is in a range of 800-1000DEG C, and recrystallization of the band steel is finished; finished surfaces are obtained finally through electrolytic picking by Na2SO4 and H2SO4 solutions and soaking picking by a nitric acid and hydrofluoric acid mixed acid solution sequentially after annealing.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

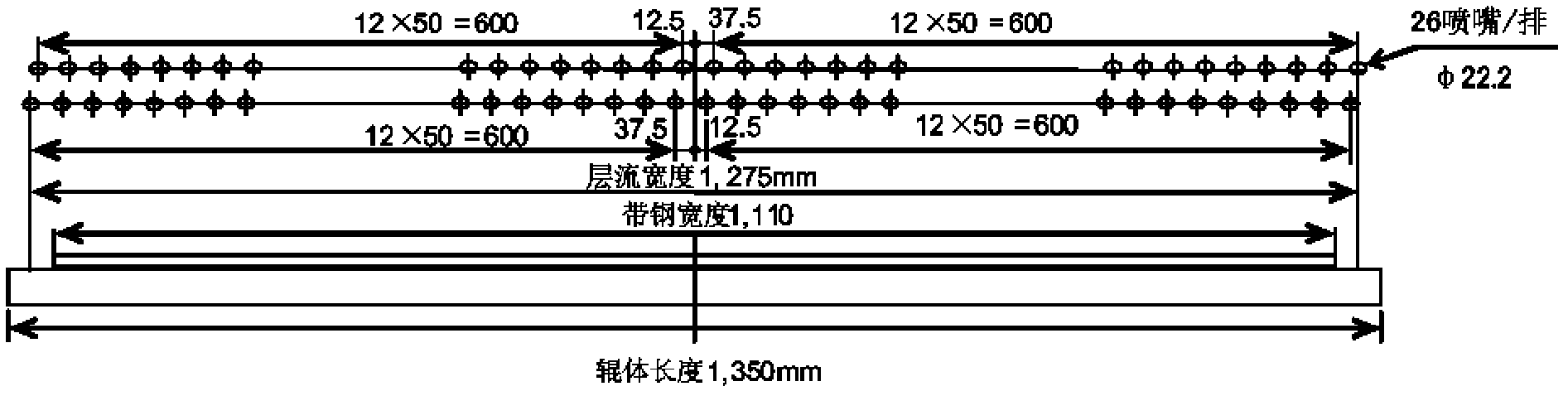

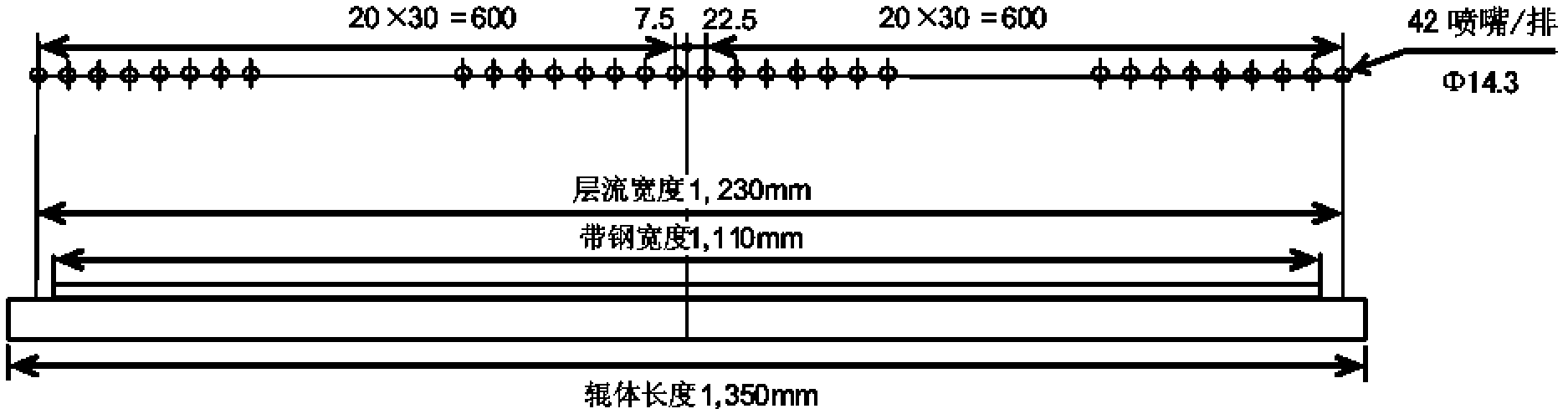

Band-steel laminar-flow cooling device and its cooling control method

InactiveCN1640575ALong cooling areaImprove cooling effectWork treatment devicesMetal rolling arrangementsTemperature controlEngineering

The present invention provides a strip steel laminar flow cooling device which has two cooling zones and has strong cooling function and its controlled cooling method. Said device is formed from cooling zone consisting of upper laminar flow manifold and lower jet manifold, and said cooling zone includes two portions of main cooling section and fine cooling section which are formed from several upper laminar flow manifold groups and correspondent number of lower jet manifold groups. Its controlled cooling method is implemented by using computer to make setting computation, feedback computation and feedforward computation.

Owner:ANGANG STEEL CO LTD

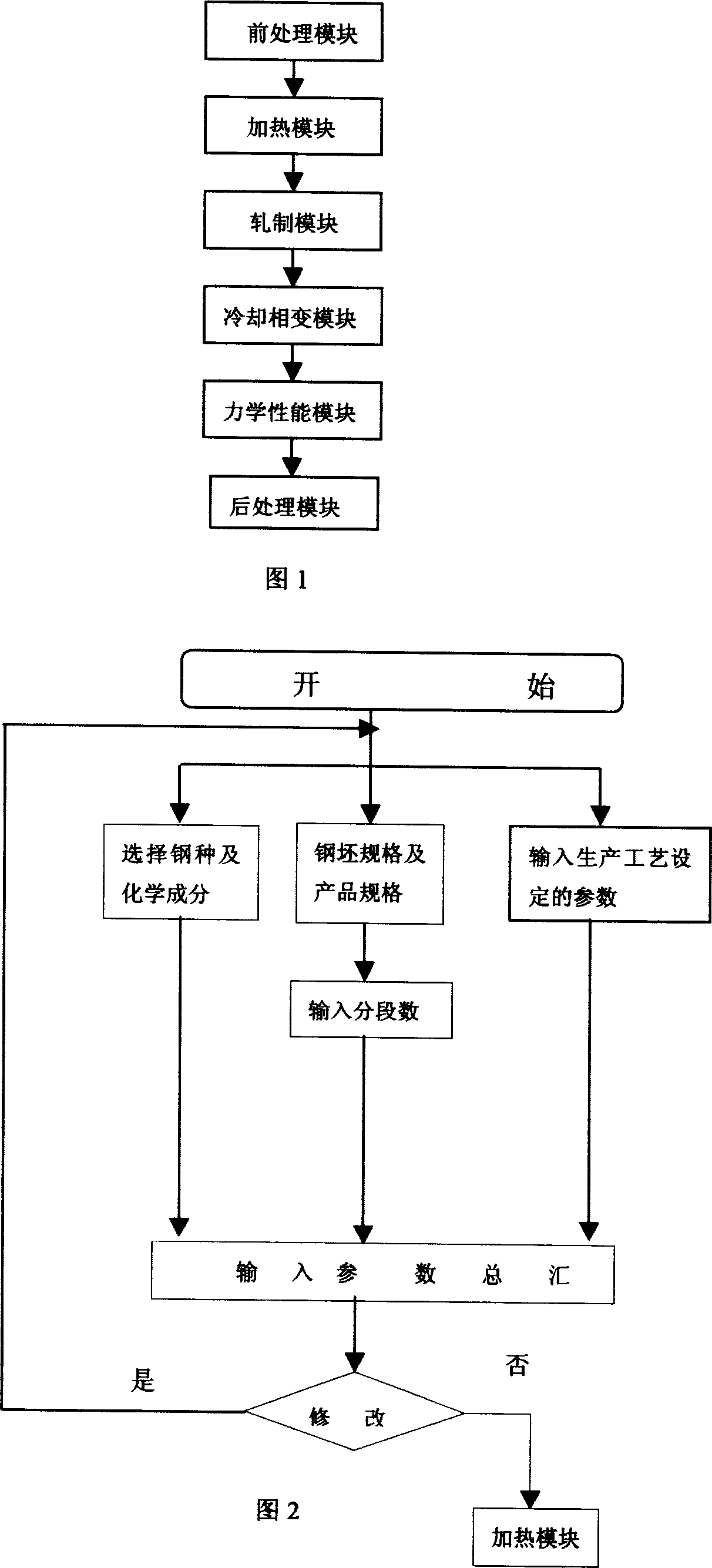

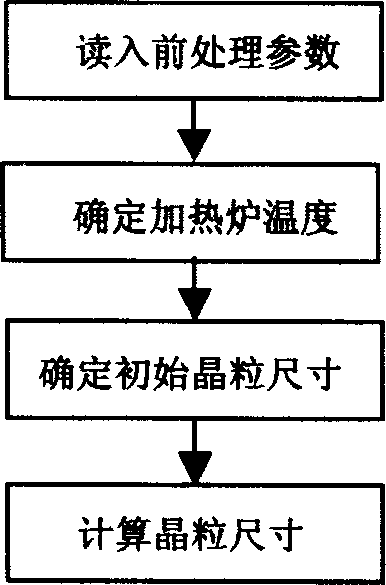

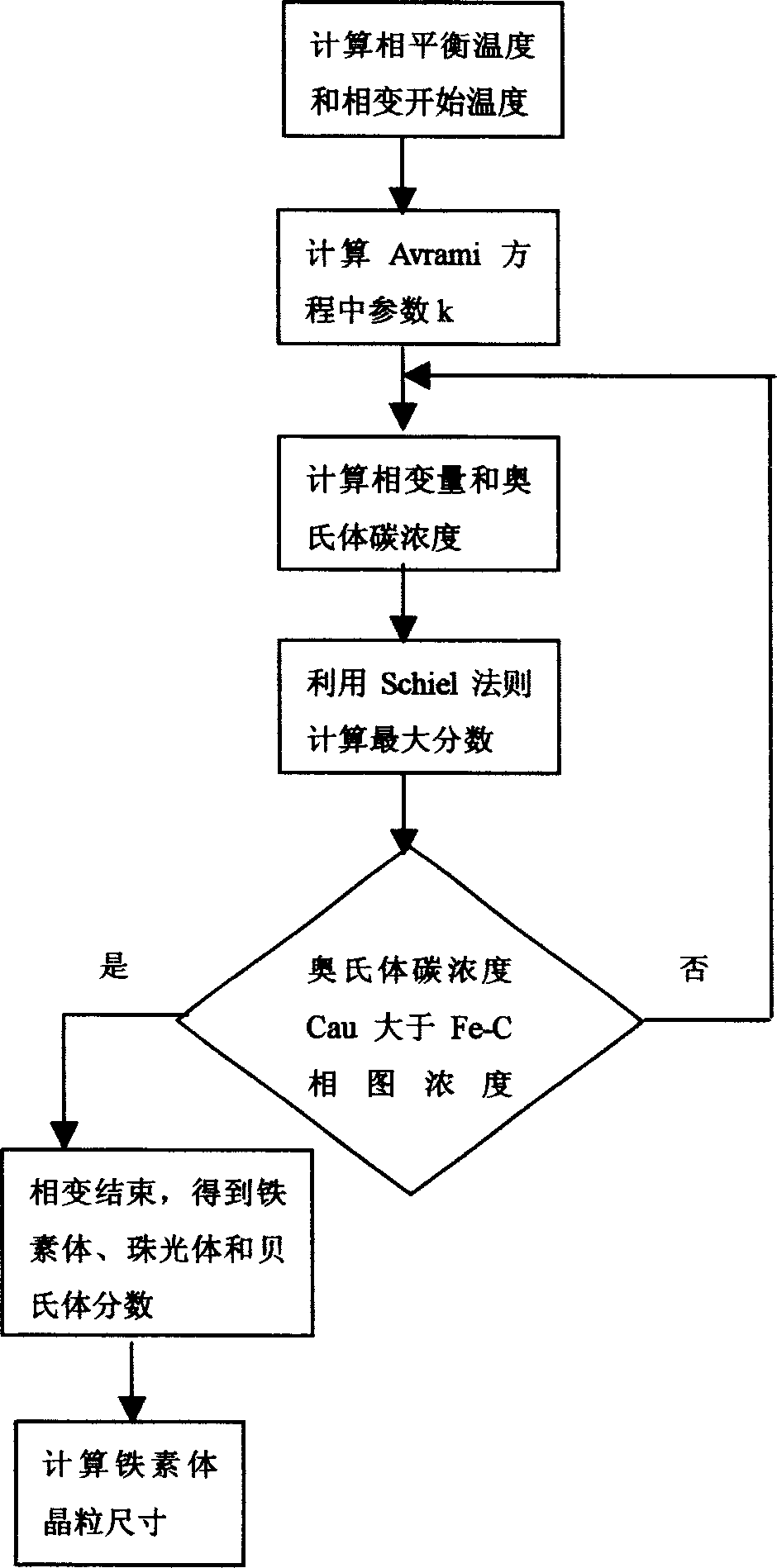

Method for predicting evolvement and performances of structure of strip steels in hot rolled proces

InactiveCN1431060AThe calculation result is accurateCalculations are reliableRoll mill control devicesMetal rolling arrangementsStrip steelPhase change

A method for predicting the structure variation and properties of band steel in hot rolling procedure features that its system is composed of the preprocessing module for reading the technological parameters needed by hot rolling from database, the heating module, rolling module, cooling phase-change module and mechanical performance module for simulating the hot rolling procedure and predicting the final structure performance, and the post-precessing module for displaying the final result.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Control method of tandem cold rolling mill emulsion section cooling

The invention discloses a control method of tandem cold rolling mill emulsion section cooling, comprising the following steps: a. collecting the device parameter of a rolling mill and the key parameter of band steel to be rolled; b. collecting a technological lubrication institution parameter; c. giving emulsion section cooling flow distribution initial value and iteration precision; d. calculating corresponding work roll thermal crown; e. calculating the lateral distribution value of a slipping factor; f. comparing the slipping factor maximum value with a critical value; g. calculating the lateral distribution value of a slip injury index; h. comparing the maximum value of the slip injury index with the critical value; i. calculating the corresponding strip shape distribution value; j. calculating the function value of a strip shape objective function; and k. judging whether Powell condition is available, and obtaining the control curve of the optimal section cooling flow. The controlmethod of the invention combines device section condition with practical flow control precision to set the emulsion flow in sections, reduces problems of slipping, hot slip injury and the like causedby lubrication and ensures the strip shape and the surface quality index of chassis outlet strip steel rolled stock.

Owner:BAOSHAN IRON & STEEL CO LTD

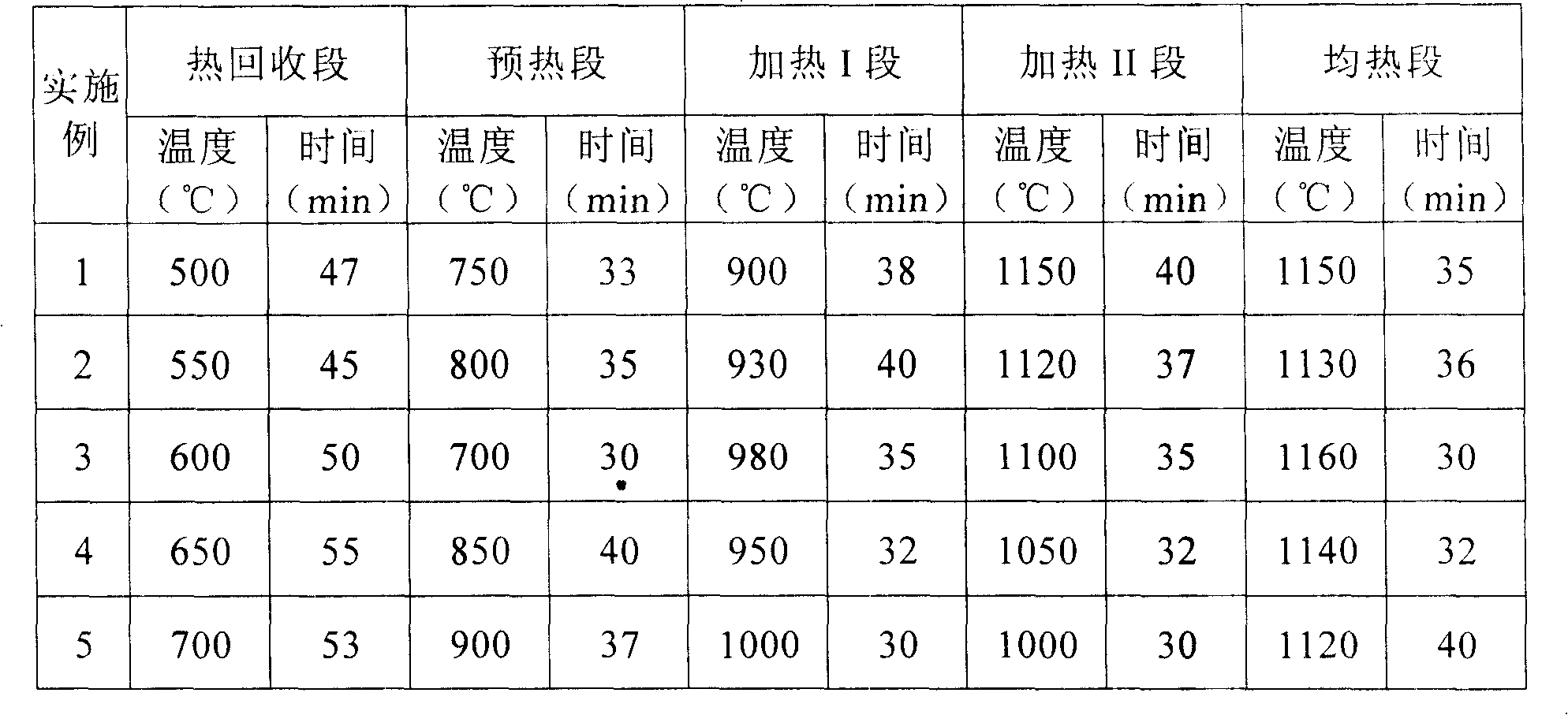

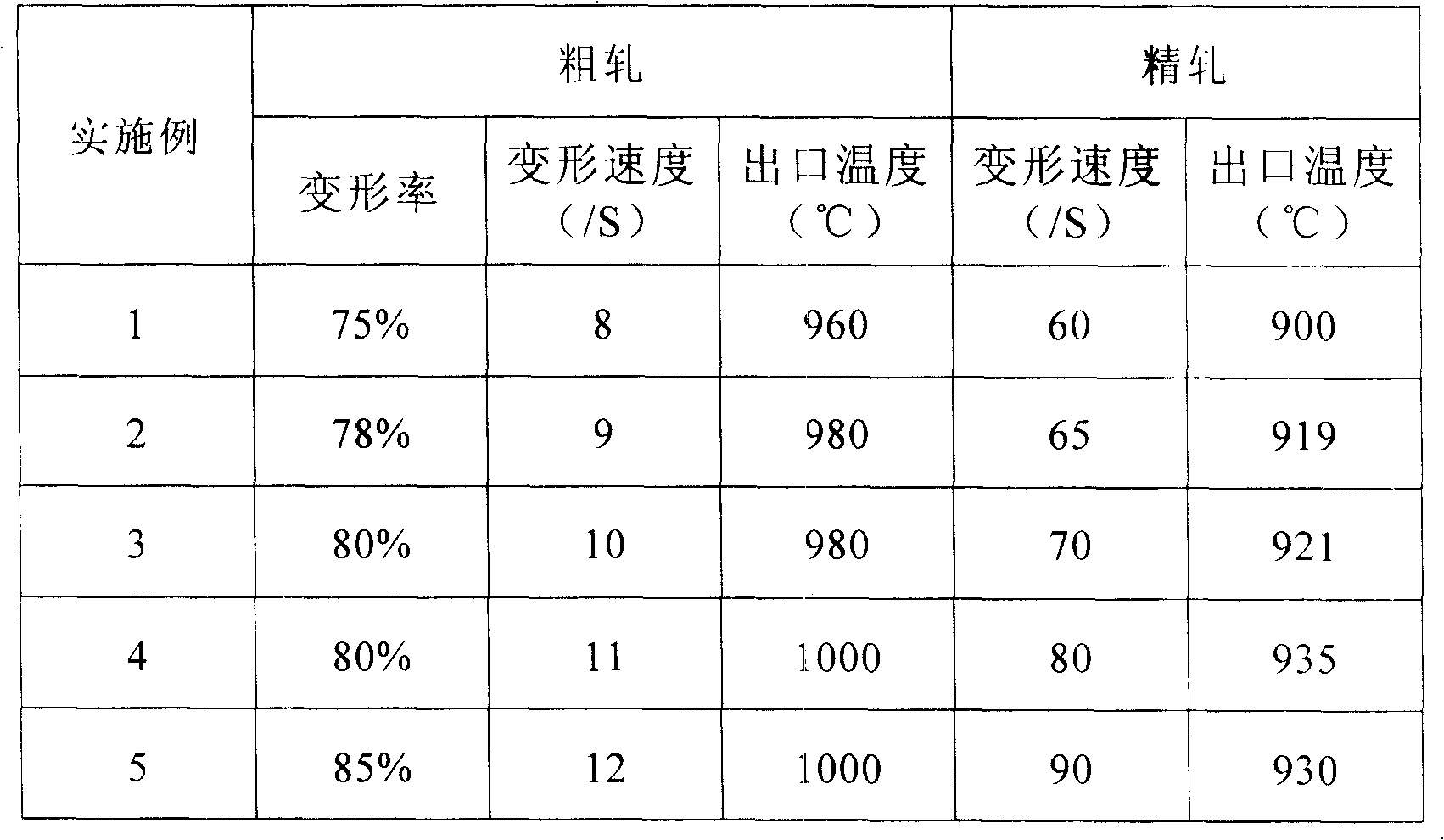

Method for producing hot-rolled ferritic stainless steel strip steel

InactiveCN101245435AFree from common surface defectsNo surface defectsRoll mill control devicesHeat treatment process controlSurface finishChemical composition

The invention discloses a method for producing a hot-rolled ferrite stainless strip steel, which comprises the following steps: 1) the chemical components by weight percentage are: 0.025-0.04 percent of C, less than or equal to 1.00 percent of Si, 0.25-0.4 percent of Mn, less than or equal to 0.030 percent of S, less than or equal to 0.035 of P, 12-12.5 percent of Cr and the rest is Fe; 2) a billet is formed by smelting and casting; 3) heating: the heating temperature zone for heating are divided into a heat recovery section, a preheating section, a I heating section, a II heating section and a holding section; furnace gas is controlled to be neutral atmosphere of non-oxidizing atmosphere; 4) when in heat rolling and rough rolling, the rolling temperature is 1,120 DEG C-1,160 DEG C, and the deforming speed during rolling is 10 / s-12 / s; 5) finish rolling: the deforming speed of the last pass rolling is 60 / s-90 / s, and the outlet temperature of the finish rolling is more than 900 DEG C; 6) cooling is carried out after rolling, and then reeling is carried out. The method of the invention has the advantages that the method guarantees not only the edge quality of the hot-rolled strip steel but also the stamping property of the cold-rolled strip steel, improves the surface finish quality and lowers the production cost, and has high production efficiency and rolling yield, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

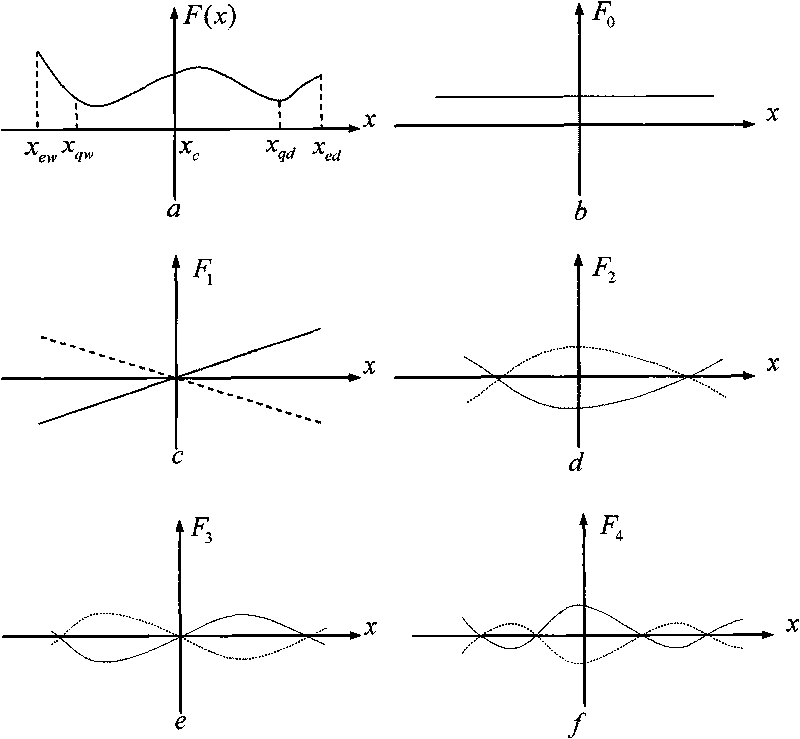

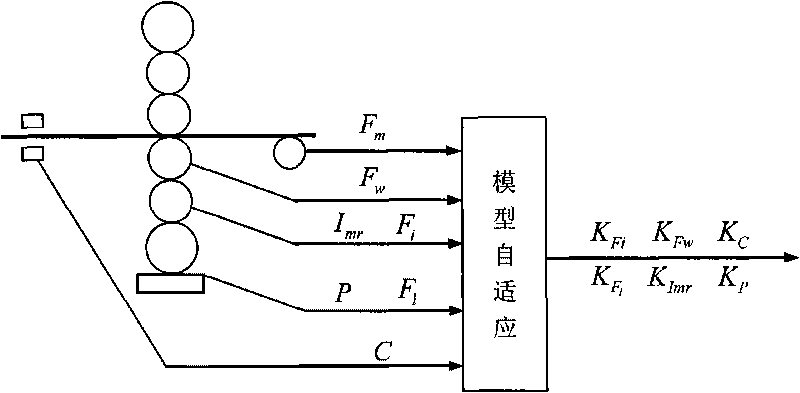

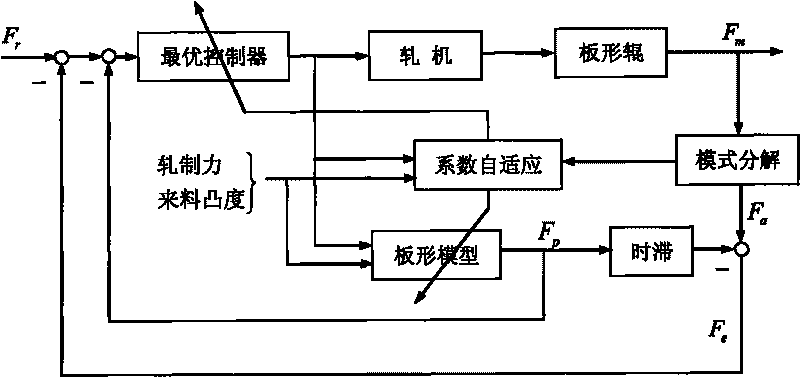

Model self-adapting sheet shape prediction and control method

ActiveCN101758084AEnsure consistencyHigh yieldProfile control deviceAdaptive controlTransmission time delayFeedback controller

The invention relates to a sheet shape control method for strip rolling. A model self-adapting sheet shape prediction and control method comprises the following steps: a sheet shape decomposition method and a sheet shape control model are given, and the input signals of the sheet shape control model include a rolling force and a crown of incoming material; then a sheet shape model which includes executing mechanism characteristics is obtained according to history sheet shape actual output data, the model is dynamically corrected according to real-time rolling parameters and corresponding actual sheet shape values, a correction model is used for accurately predicting the sheet shape and determining the optimal control quantity, and a feedback path, which removes transmission time-delay of strip steel between a frame and a measuring system, is established, thus carrying out regulation of a feedback controller in real time and ensuring rapid and dynamical sheet shape control. As the sheet shape control model is corrected in real time according to actual data, constantly changing actual conditions of the sheet shape model of a rolling mill are satisfied, thus predicting the sheet shape more accurately to increase the control accuracy of the sheet shape.

Owner:BAOSHAN IRON & STEEL CO LTD

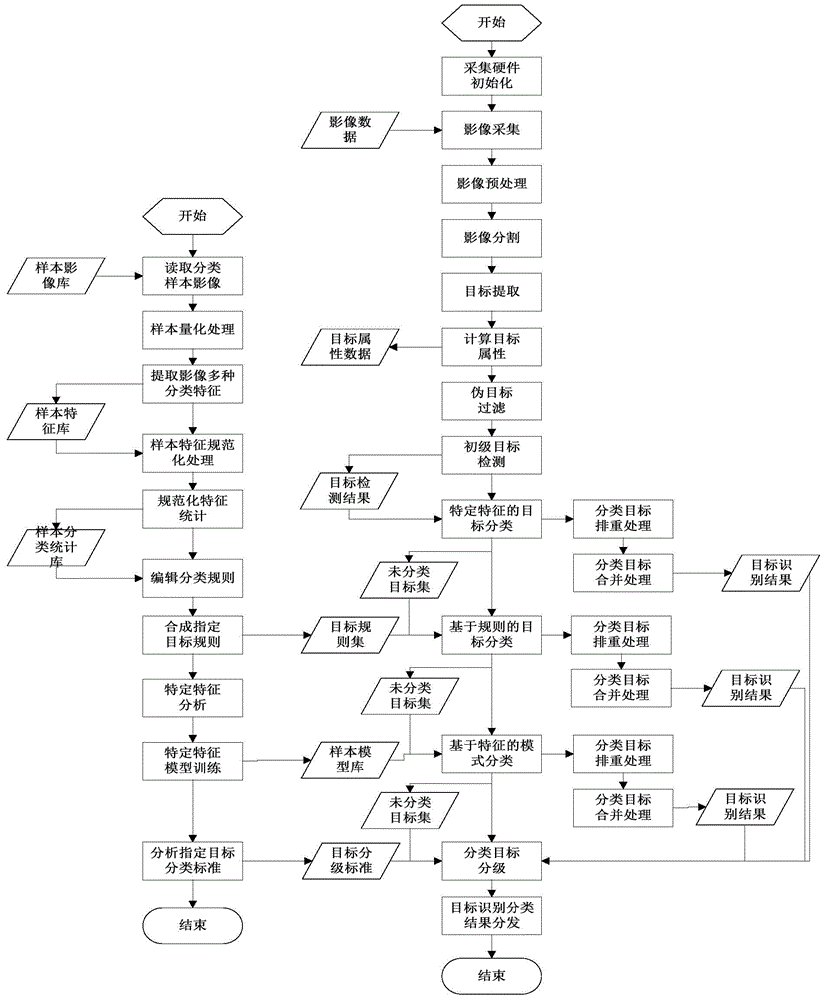

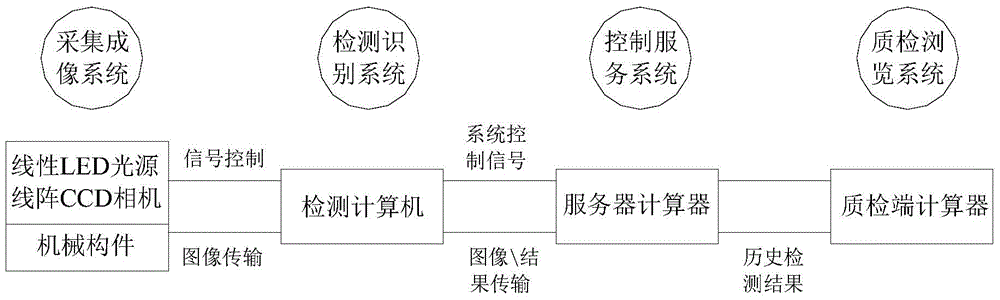

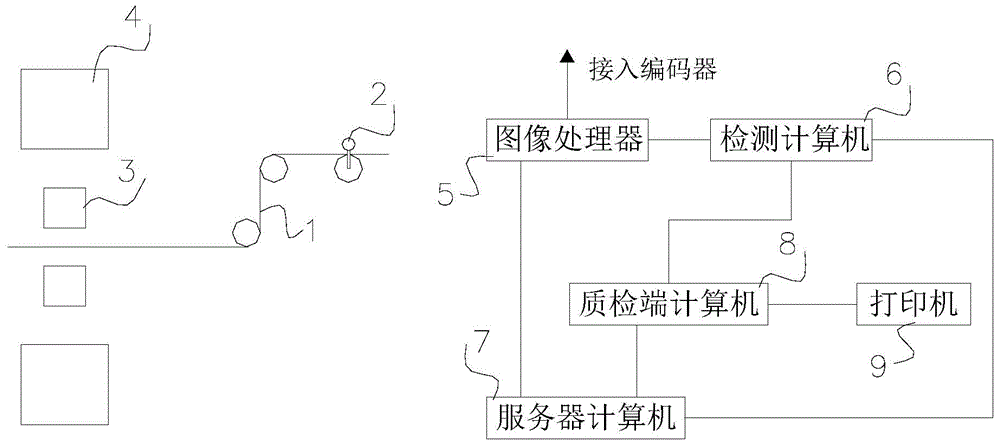

Strip steel surface defect on-line intelligent identification and detection system and detection method

InactiveCN104914111AEasy to collectOptimizing Imaging TechnologyImage analysisOptically investigating flaws/contaminationImaging processingFeature extraction

The invention provides a strip steel surface defect on-line intelligent identification and detection method. The method comprises image acquisition, feature extraction, multistage defect detection and identification, and result output. The invention also provides a strip steel surface defect on-line intelligent identification and detection system. The system comprises an encoder, a linear LED light source, a high speed linear array CCD camera, an image processor, a detection computer, a server computer, a quality inspection terminal computer and a printer. The detection system and detection method optimize a defect image acquisition and imaging technology, can acquire clear and complete defect images, improve a detect image processing technology, and realize complete and effective extraction of image characteristics. The method utilizes the multistage defect detection and identification method comprising primary defect detection and identification, secondary defect detection and identification and SVM identification, solves the problem that the prior art has a single detection method, is suitable for detection of a plurality of types of strip steel defects and has the advantages of real-time detection, accurate classification and high accuracy.

Owner:刘强

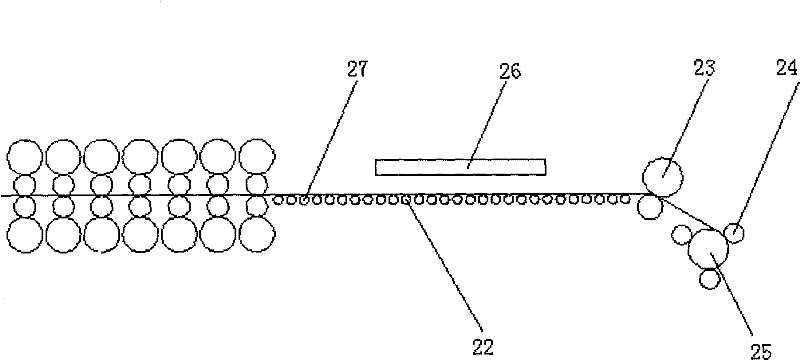

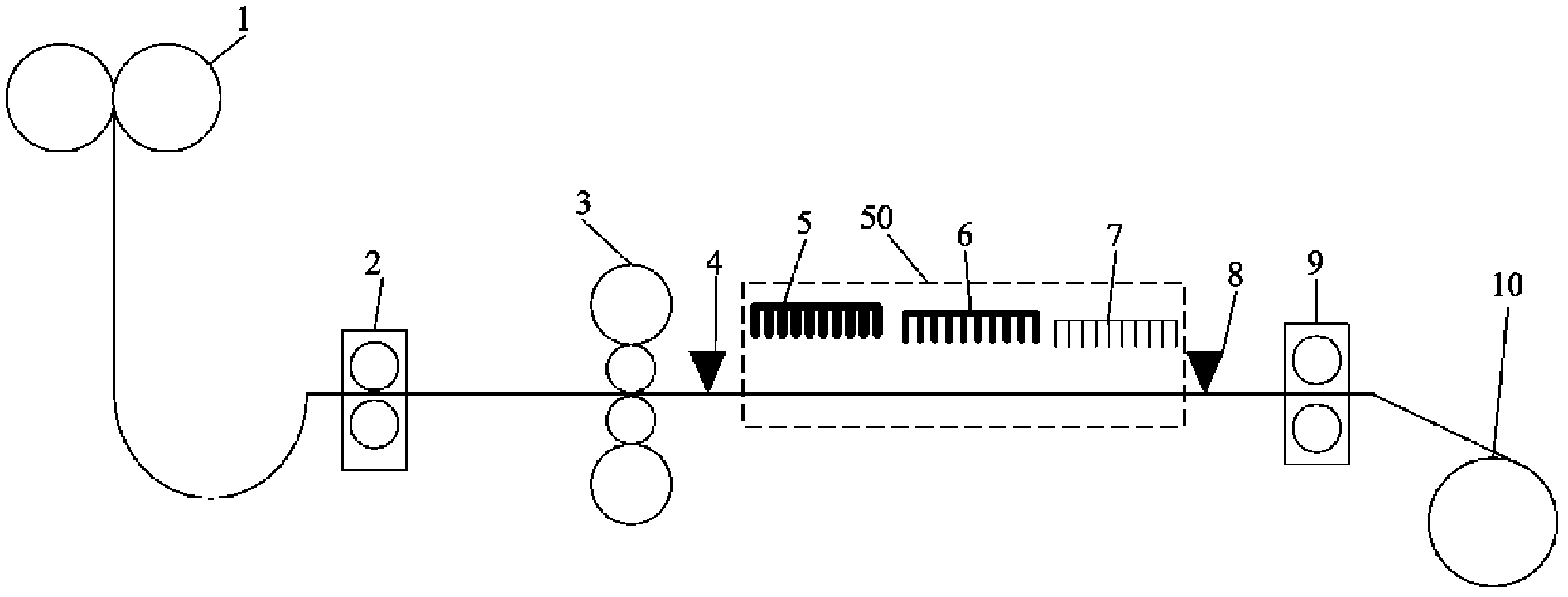

Cooling system for rolled stripe continuously-casting production line and control method thereof

ActiveCN102553950AMeet the temperature dropFulfil requirementsTemperature control deviceWork treatment devicesAdaptive learningLow speed

The invention relates to control devices or methods specially for metal rolling machines and manufacturing products of the metal rolling machines and discloses a cooling system for a rolled stripe continuously-casting production line and a control method of the cooling system. The system comprises a segmented laminar flow cooling device and a cooling control system which are arranged behind an online hot rolling machine, wherein the segmented laminar flow cooling device comprises at least two segmented laminar flow cooling collecting pipe areas, wherein one of the at least two segmented laminar flow cooling pipe collecting areas adopts a nozzle cooling collecting pipe with small pipe diameter, the cooling control system is an online double-closed-loop control system and comprises a double-closed-loop control circuit, the double-closed-loop control circuit comprises a feedforward control module, a precomputation module, a feedback control module, a coiling-ahead temperature measuring module and a self-adaption learning module, the double-closed-loop control circuit selects at least one collecting pipe area of the segmented laminar flow cooling device, the number of open collecting pipes in the selected collecting pipe area can be adjusted by a group of control valves, and the requirements on the accuracy of coiling temperature of steel stripes rolled at a low speed during the variation of speed and thickness in a limited cooling area can be met by the nozzle cooling collecting pipe with the small pipe diameter and the online double-closed-loop control system.

Owner:BAOSHAN IRON & STEEL CO LTD

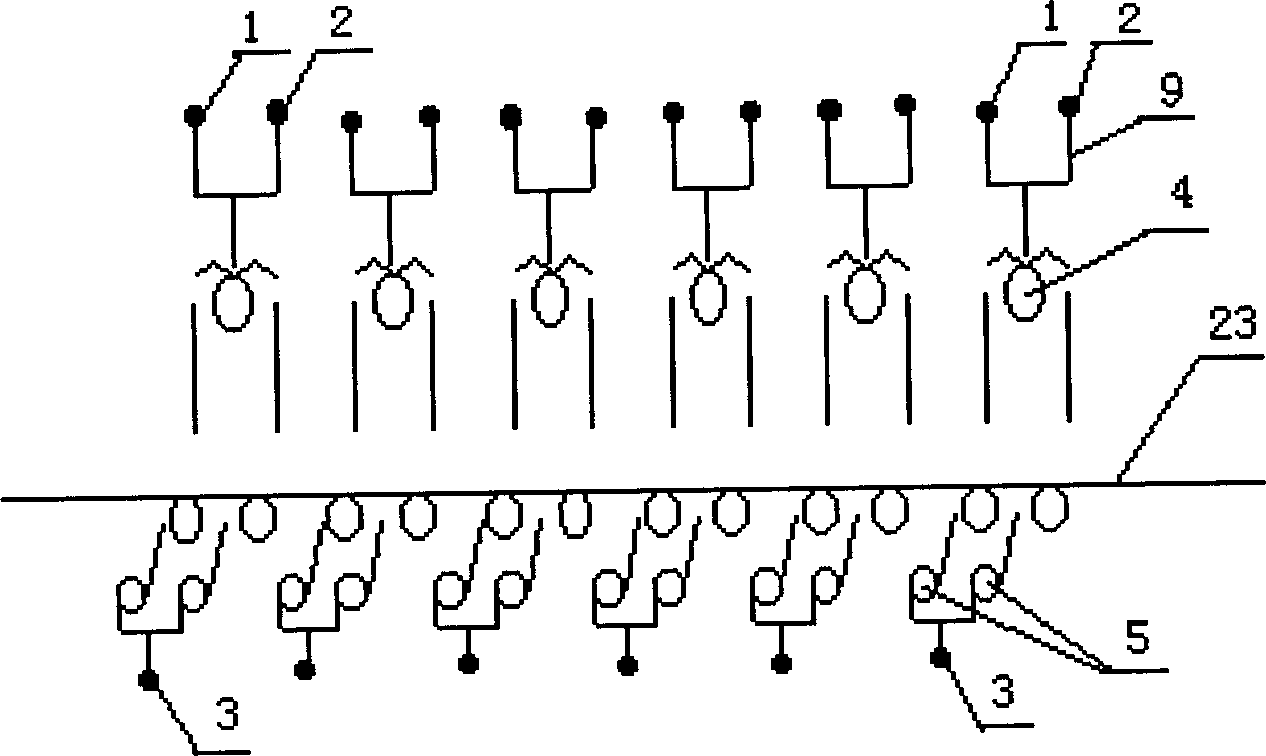

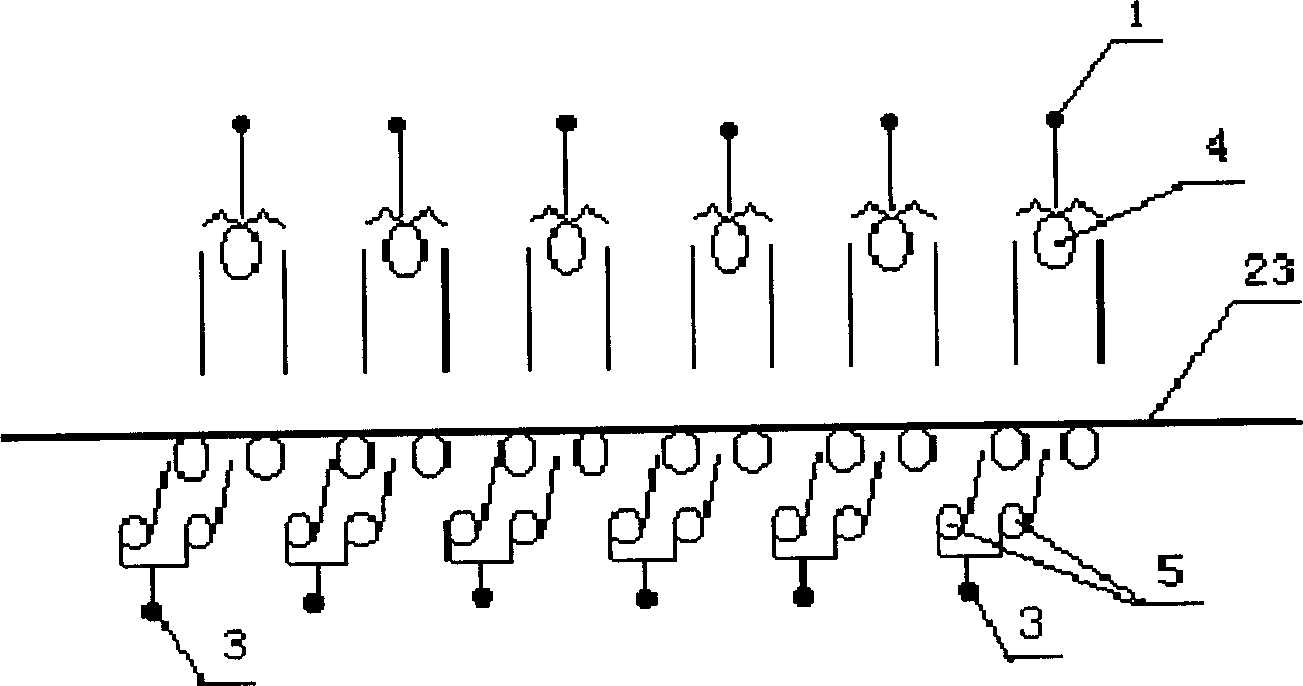

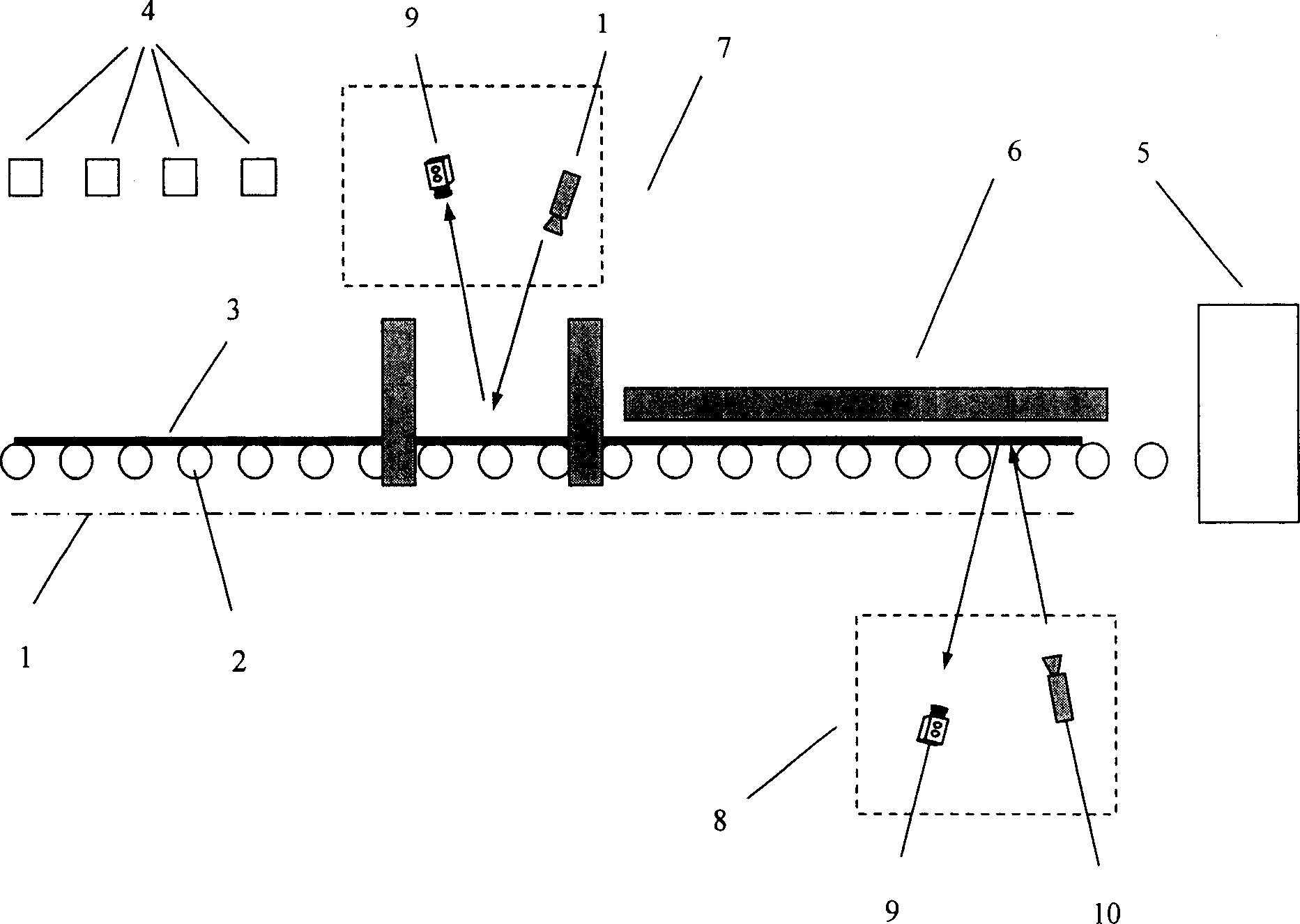

Device and method for detecting and controlling tilting buckle head of band steel in rough rolling process

ActiveCN101920270AImprove rolling qualityImprove operational safetyMeasuring devicesMetal rolling arrangementsSheet steelHead tilting

The invention discloses a device and a method for detecting and controlling the tilting buckle head of band steel in the rough rolling process. The actual head tilting or buckle head condition of the rolled band steel can be detected by using head tilting and buckling detectors arranged above roller beds and between the roller beds and then the rolling speeds of an upper roller and a lower roller for biting the band steel can be automatically adjusted when the next band steel is rolled, so that upper surface band steel and the lower surface band steel consistently extend and the aim of controlling the tilting buckle head of the band steel can be achieved, wherein the control belongs to the feedback control. According to the invention, the rolling speeds of the upper roller and the lower roller can be adjusted by detecting the actual head tilting or buckle head condition of the band steel, and the detection process is not influenced by logged water, fog, the roughness of the rollers, the elevation of a rolling line, the amplitude of rolling reduction, the thickness of the band steel, the rolling speed and other factors, so that the invention has high accuracy of controlling the tilting buckle head, effectively improves the rolling quality of steel plates and the operation safety of operators and reduces the labor intensity.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for continuous casting, continuoccs rolling intermediate and thin sheet blanket

InactiveCN1483521ASmall temperature differenceImprove surface qualityMetal rolling arrangementsAutomatic controlThin slab

The production method of sheet billet conticasting tandem-rolling coil sheet is characterized by that said invention adopts the following technical measures: using conticasting machine and making pulling rate of casting blank low, and making the blank material have reasonable section; compactly arranging conticasting machine and heating furnace, making the conticasting blank output roller conveyer and inlet roller conveyer of heating furnace have double purpose, making inlet temp. of casting blank be above 900 deg.C; adopting double furnace and hating; and adopting small-cross charging and tapping process; two-high reversing rougher for three passes, four-high reversing rougher for one pass; and adopting thermal coiler box process of workpiece so as to raise coil sheet quality and reduce its production cost.

Owner:ANGANG STEEL CO LTD

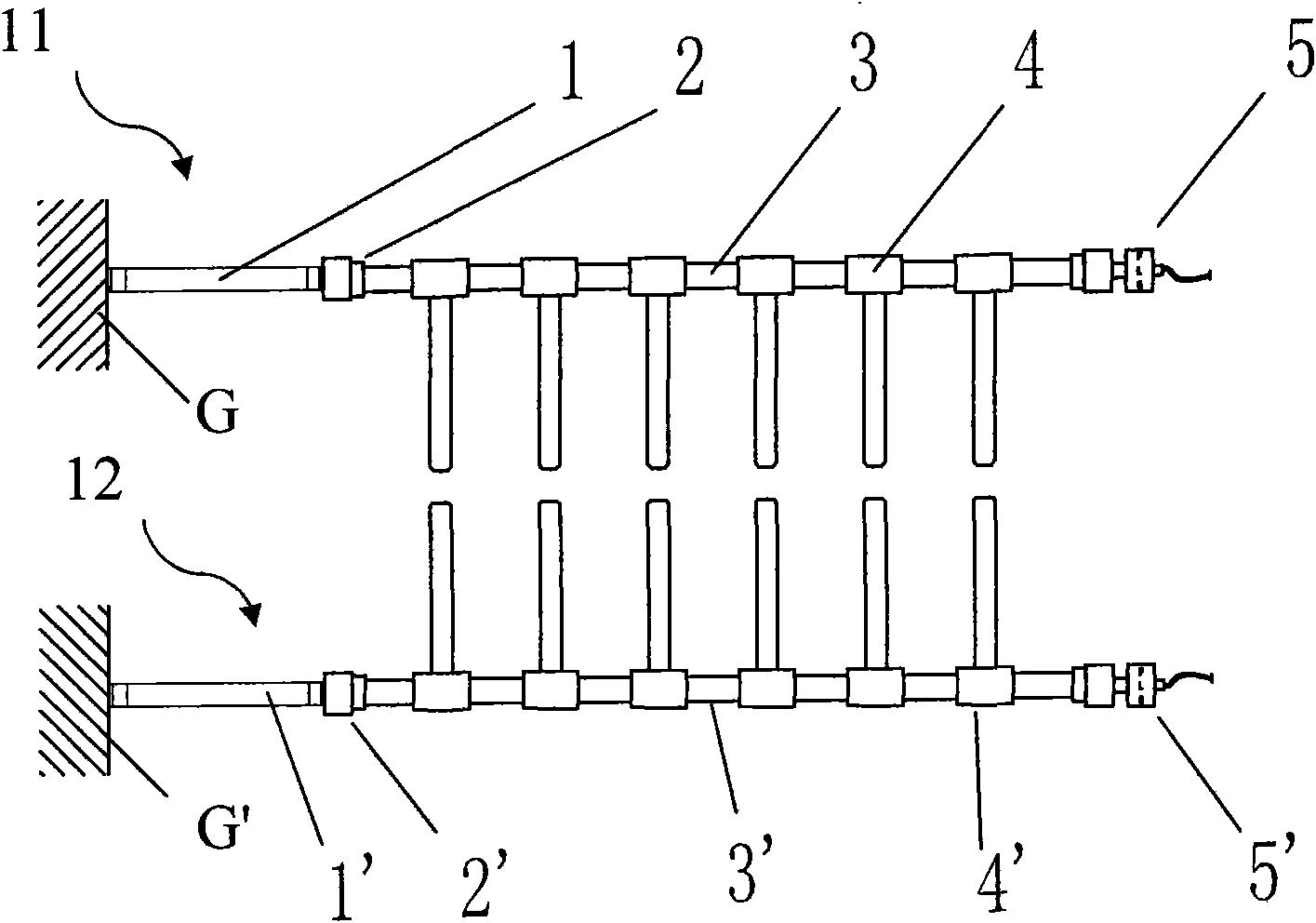

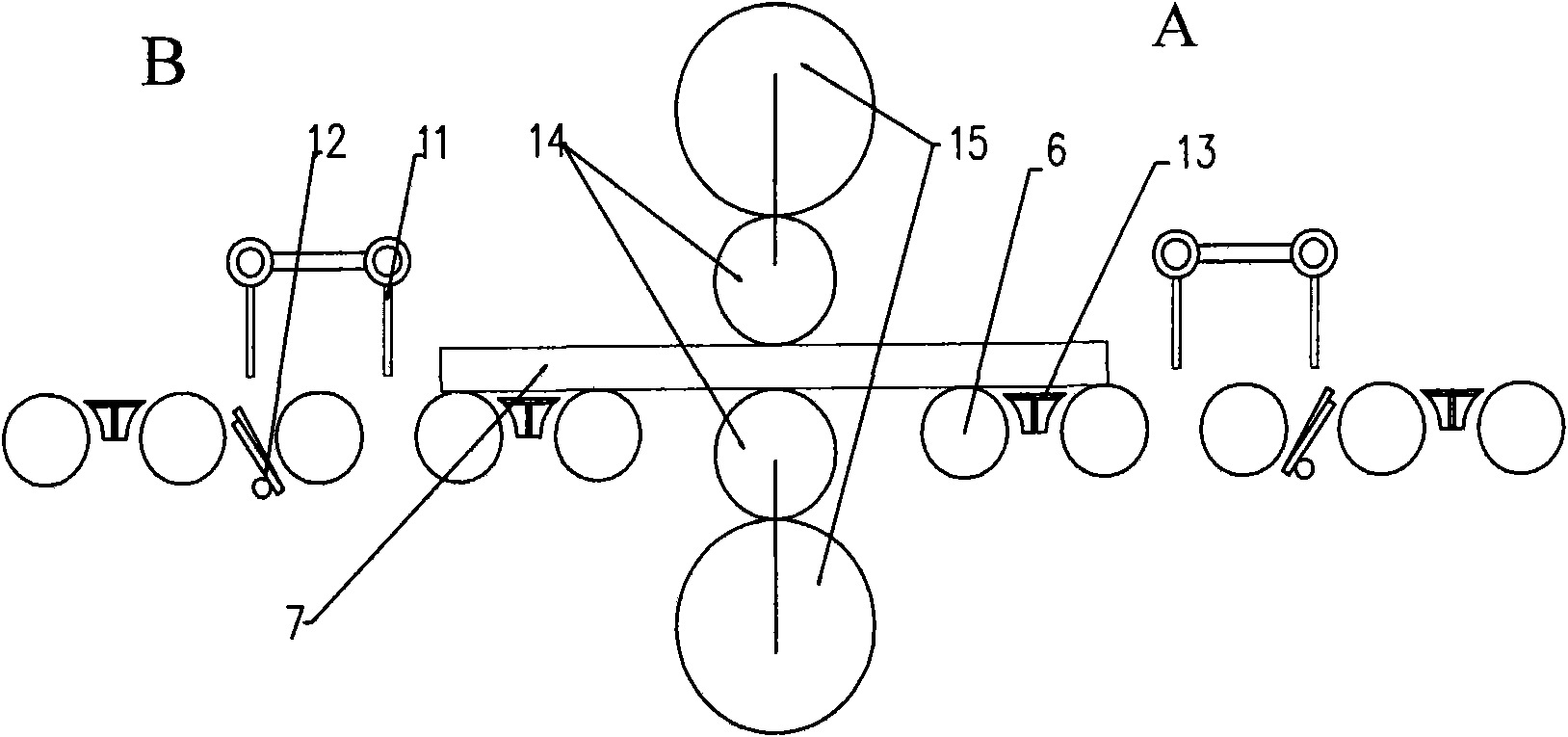

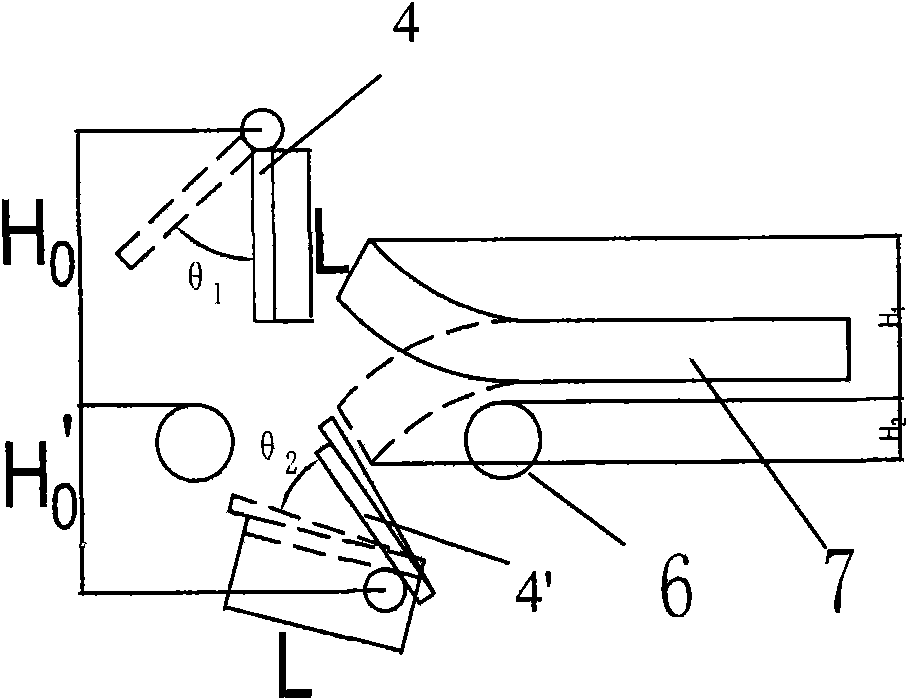

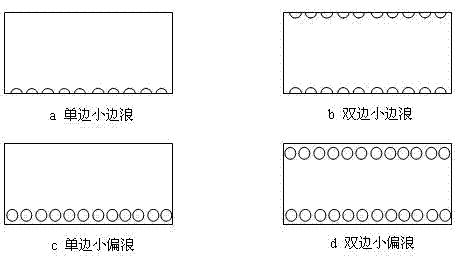

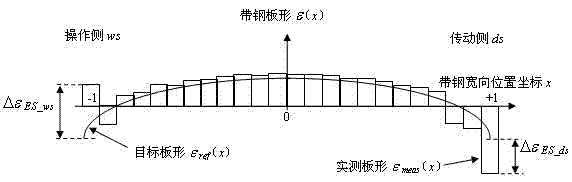

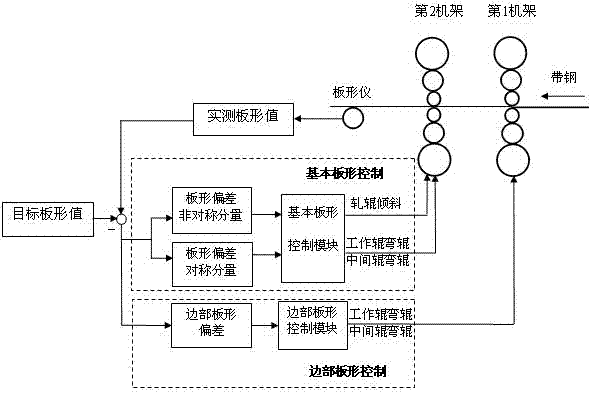

Control method of edge portion strip shape of cold rolling strip steel

The invention relates to a rolling method of cold rolling strip steel, in particular to a control method of edge portion strip shape of thin strip steel rolled by a cold continuous rolling mill or a two-stand temper mill. In a strip shape feedback control system centered on a last stand and on the basis of fundamental strip shape control function of major control for conventional edge waves and center waves, the method identifies the state of the edge portion strip shape of the strip steel based on the difference between the actual measured strip shape of strip steel edge portion together with the adjacent areas at the exit of last stand and an objective strip shape, and adjusts the corresponding strip shape executive mechanisms of the last stand and the rest stands according to the state of the edge portion strip shape to realize effective control for the edge portion strip shape of the strip steel, such as small edge waves and small side waves, thereby further improving the quality of the strip steel after cold rolling or temper rolling.

Owner:BAOSHAN IRON & STEEL CO LTD

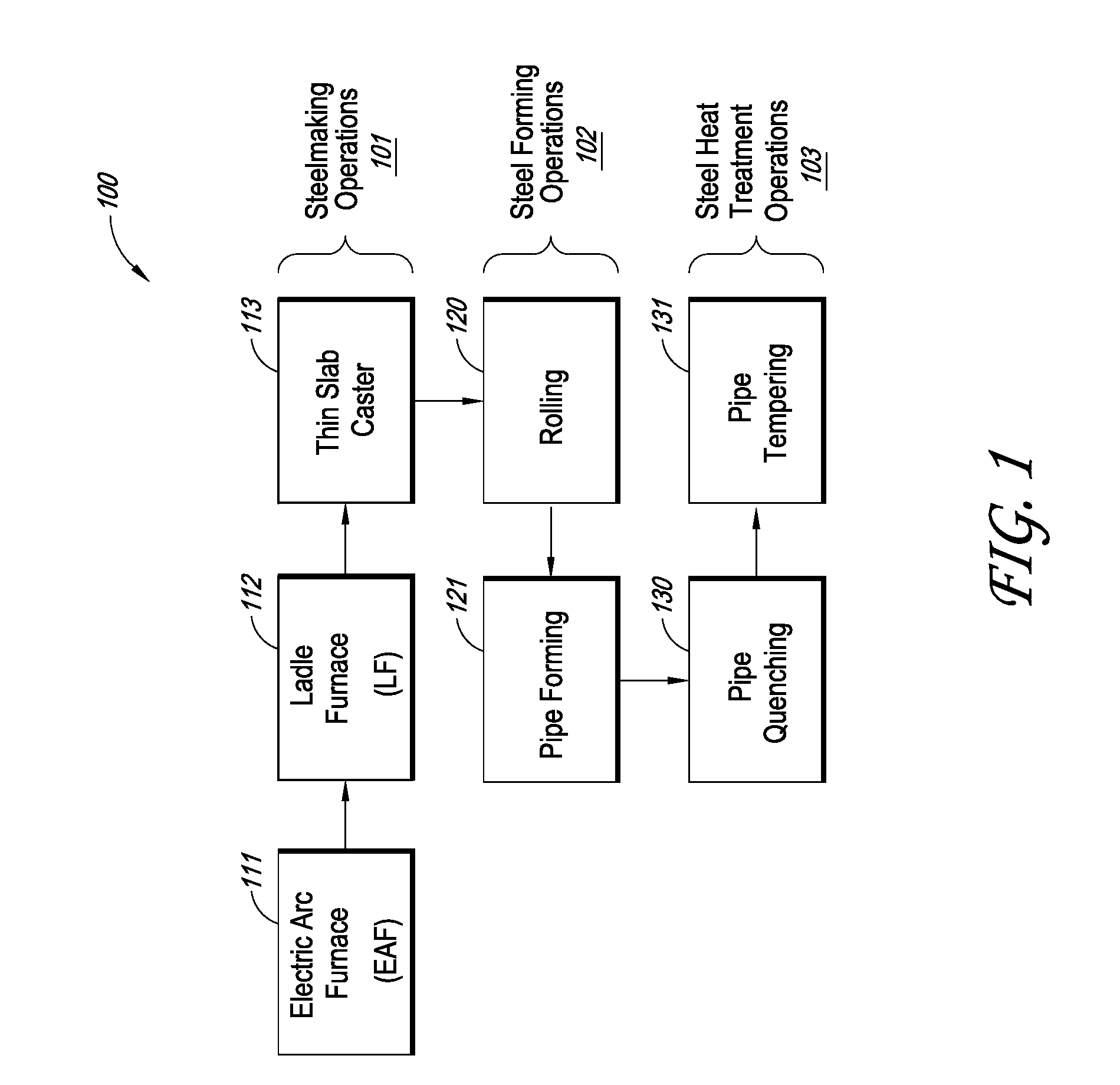

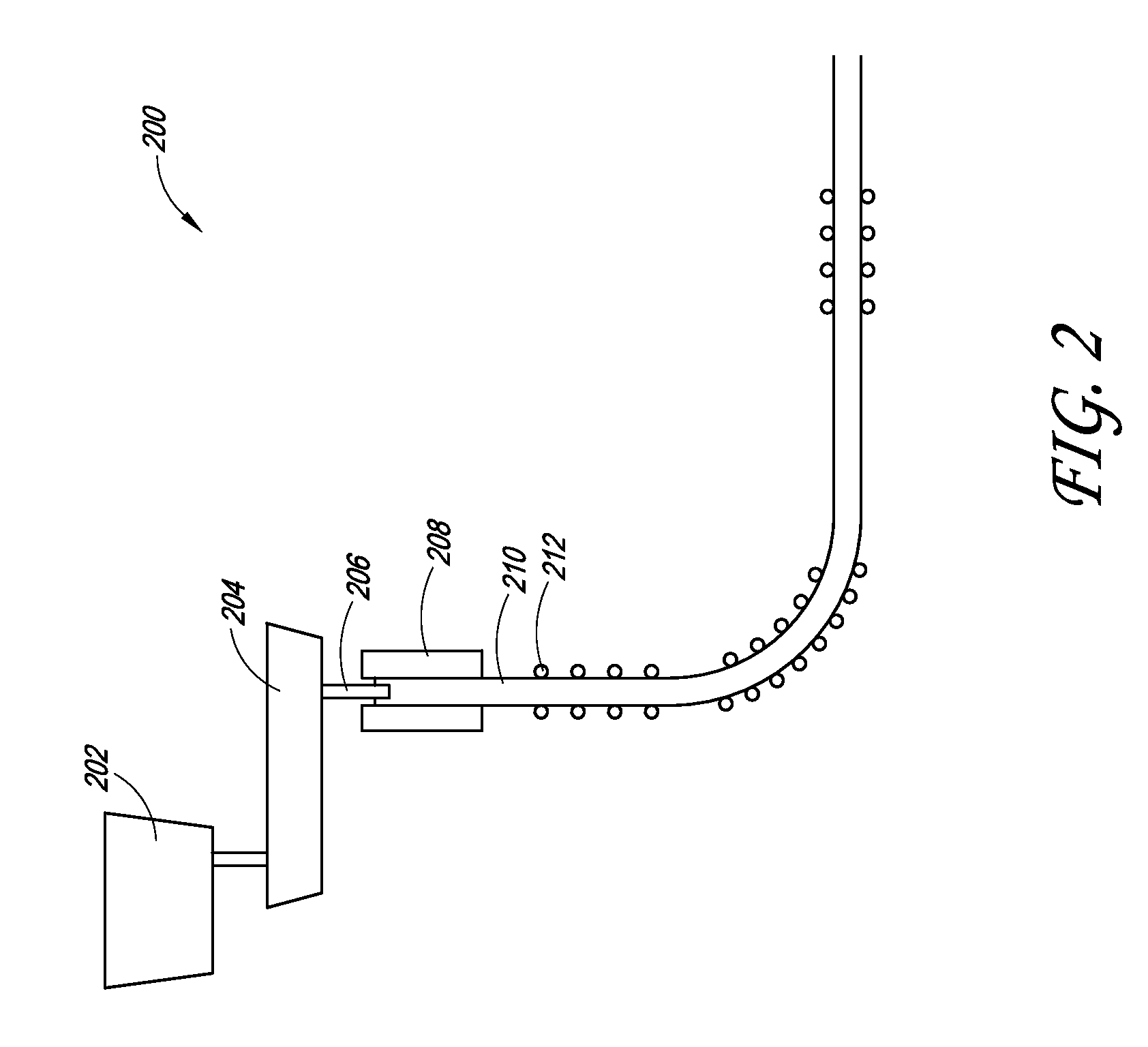

Compact strip or thin slab processing of boron/titanium steels

A method for casting medium carbon, B / Ti steel product using compact strip processing or thin slab casting. The method can include providing a steel composition including boron and titanium and casting the steel composition into a slab having a thickness between about 25 and 150 mm. The slab can have a cast composition including about 0.23 to 0.30 wt. % carbon, about 0.0010 to 0.0050 wt. % boron, about 0.010 to 0.050 wt. % titanium, about 1.15 to 1.50 wt. % manganese, less than 0.35 wt. % silicon and a Ti / N ratio greater than 2.9. The amount of each element is provided based upon the total weight of the steel composition. The steel slab can be free from cracks and significant defects. Furthermore, the steel slab can be used for electric resistance welded (ERW) products.

Owner:MAVERICK TUBE +1

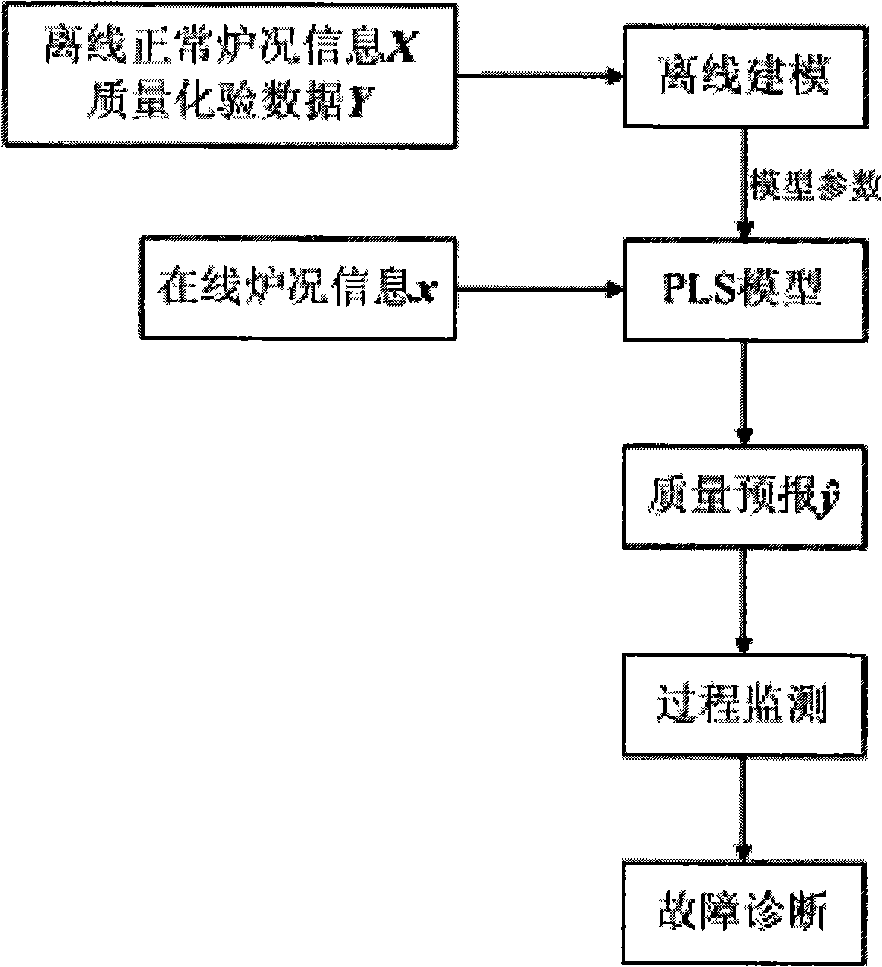

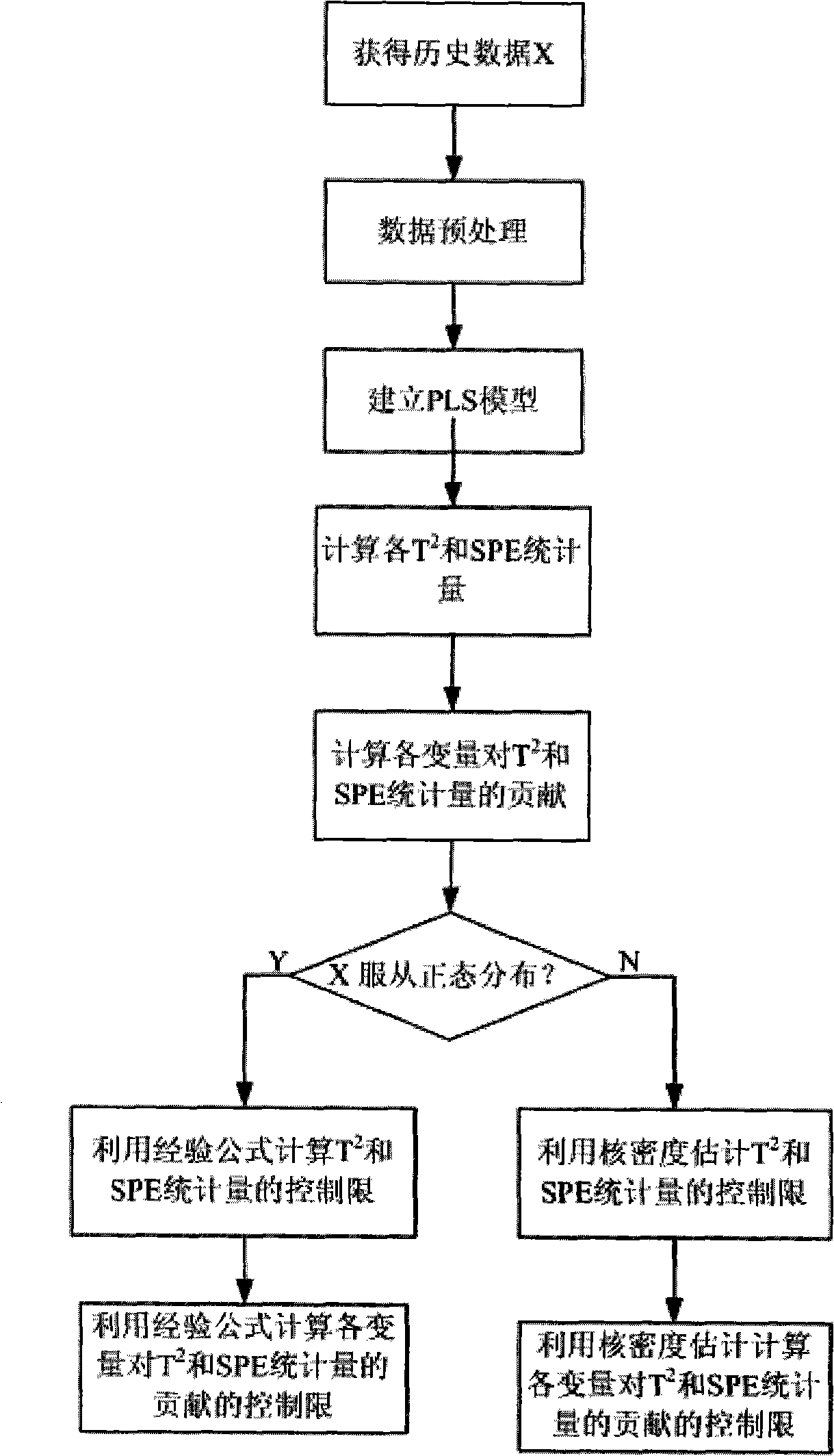

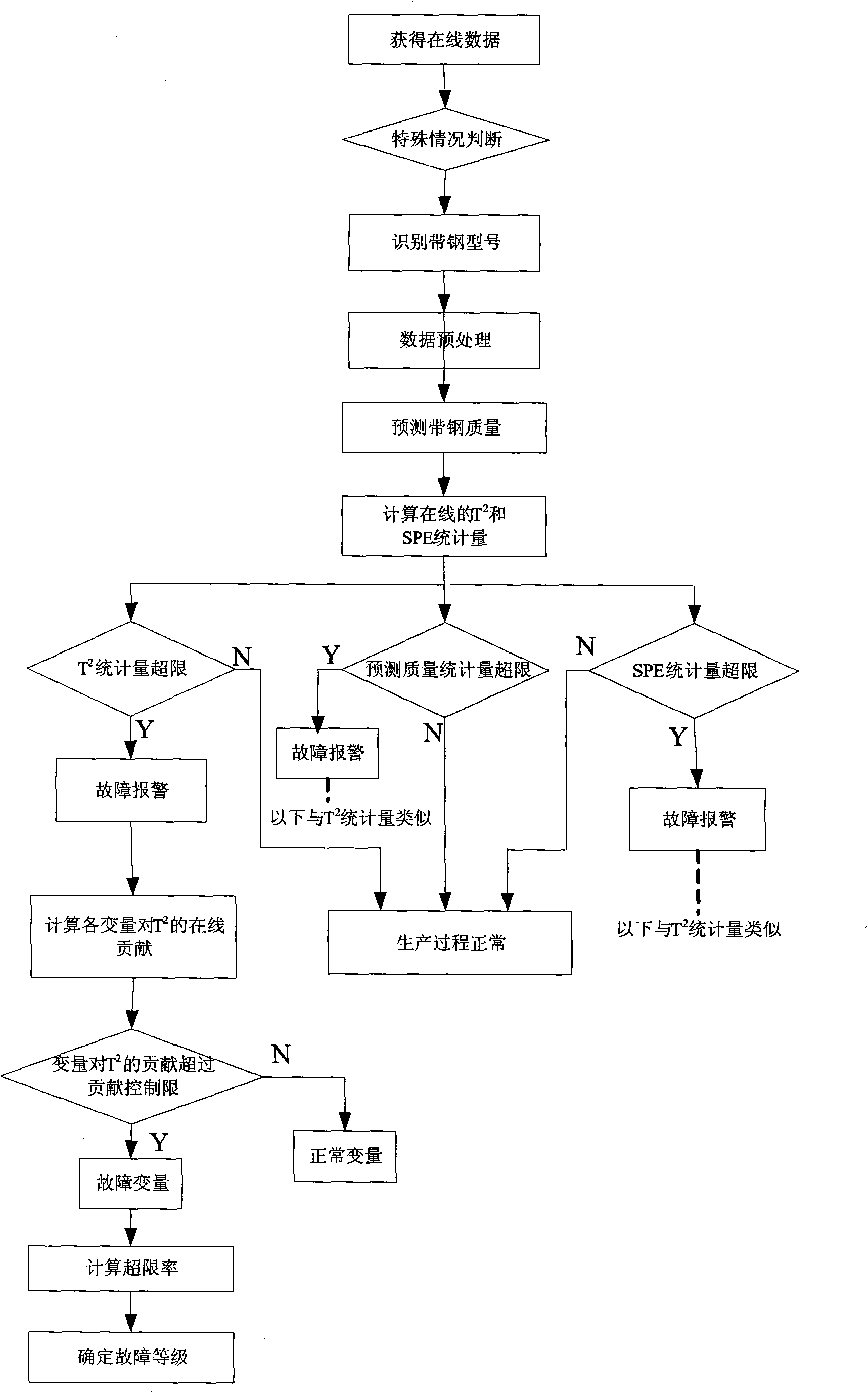

Strip steel quality forecasting, furnace condition early-warning and fault diagnosis method based on partial least square

ActiveCN102033523AClear structureClear relationshipFurnace typesHeat treatment furnacesModel selectionData pre-processing

The invention relates to a strip steel quality forecasting, furnace condition early-warning and fault diagnosis method, in particular to a strip steel quality forecasting, furnace condition early-warning and fault diagnosis method based on partial least square, comprising the following steps: model selection: multiple models are adopted to describe the process characteristics of corresponding steel types; data preprocessing: data alignment based on the model is carried out, synchronization relation of process input and quality output is built and data dimensionless treatment is carried out to eliminate effect of process data on modeling precision owning to non-unity of physical units; an off-line model building; a PLS (partial least square) model for strip steel quality and process variable is built by utilizing a great amount of historical data in normal working conditions; determining control limit of an monitor-control index; determining variable quantity control limit; and on-line forecasting and on-line detection and fault diagnosis. In the invention, the model for the strip steel quality and the process variable is built by PLS algorithm, so as to realize real-time quality forecasting, process monitoring and fault diagnosis.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE +1

Novel repair and reconstruction technique for defect treatment of strip coiler hollow axle

InactiveCN101397663AAddressing selection limitationsImprove corrosion resistanceMetallic material coating processesThermal deformationAlloy

Owner:岳阳大陆激光技术有限公司 +2

Online detecting method and device for hot rolling strip surface fault based on laser line light source

InactiveCN1900701AImprove spotlight effectGood monochromaticityOptically investigating flaws/contaminationLaser lightGreen laser

Using laser line in high brightness emitted from linear light source of green laser in great power irradiates surface of hot rolling strip steel. Linear array CCD camera collects laser light reflected from surface of strip steel online so as to obtain image on surface of strip steel. Based on different properties of light reflectivity between defect area and no defect area on surface of strip steel, the invention carries out process and analysis for image on surface of strip steel collected by camera, so as to determine whether there are defects on surface of strip steel and sort the defects. The invention does not need of unpacking roller, installing baffle, uses fewer light sources so as to lower cost of hardware, and maintenance cost. Since laser light possesses good condensation performance and monochromaticity, images on surface of strip steel collected by camera are in good quality. Thus, tiny defect can be detected.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com