Patents

Literature

2922results about "Measuring devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

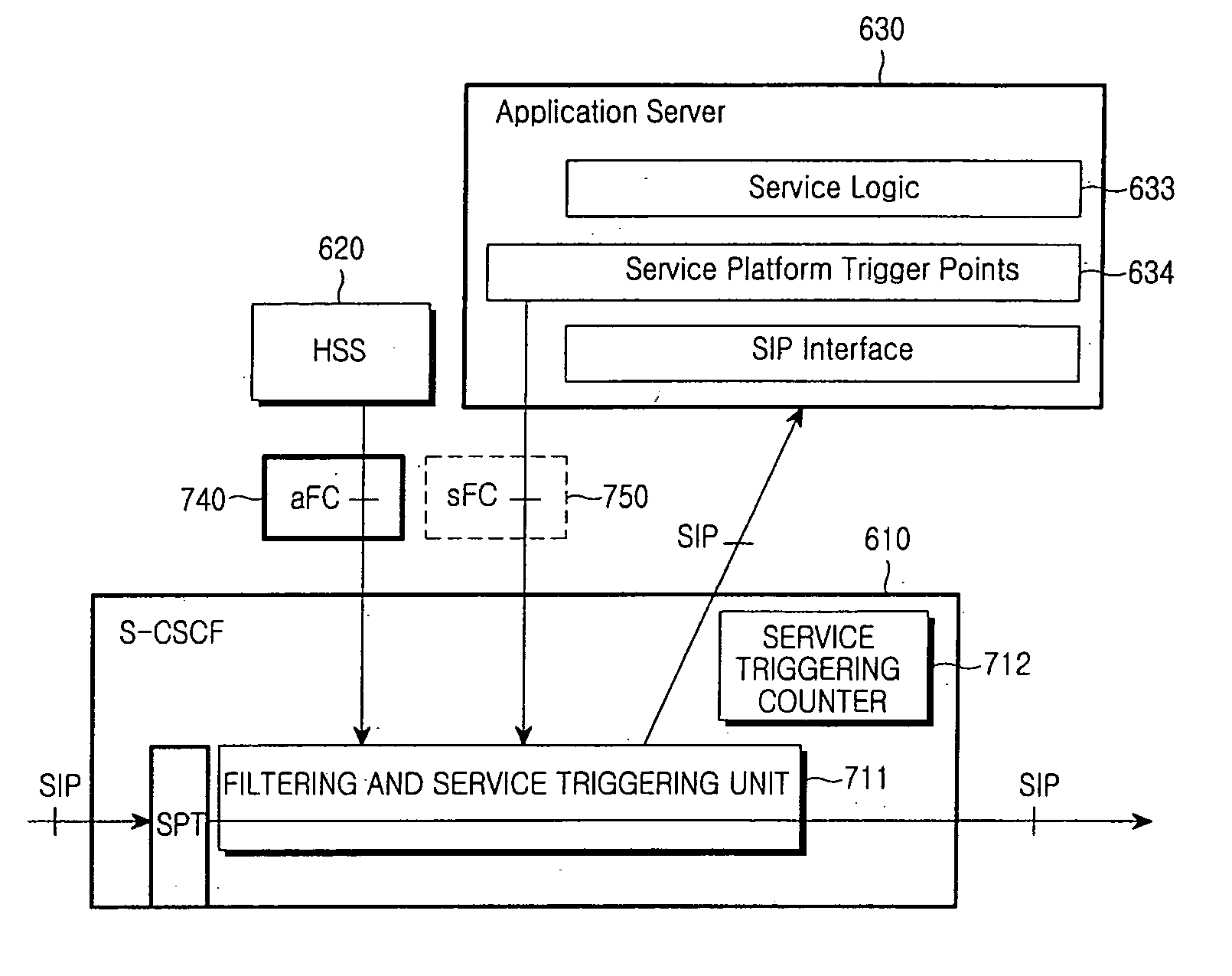

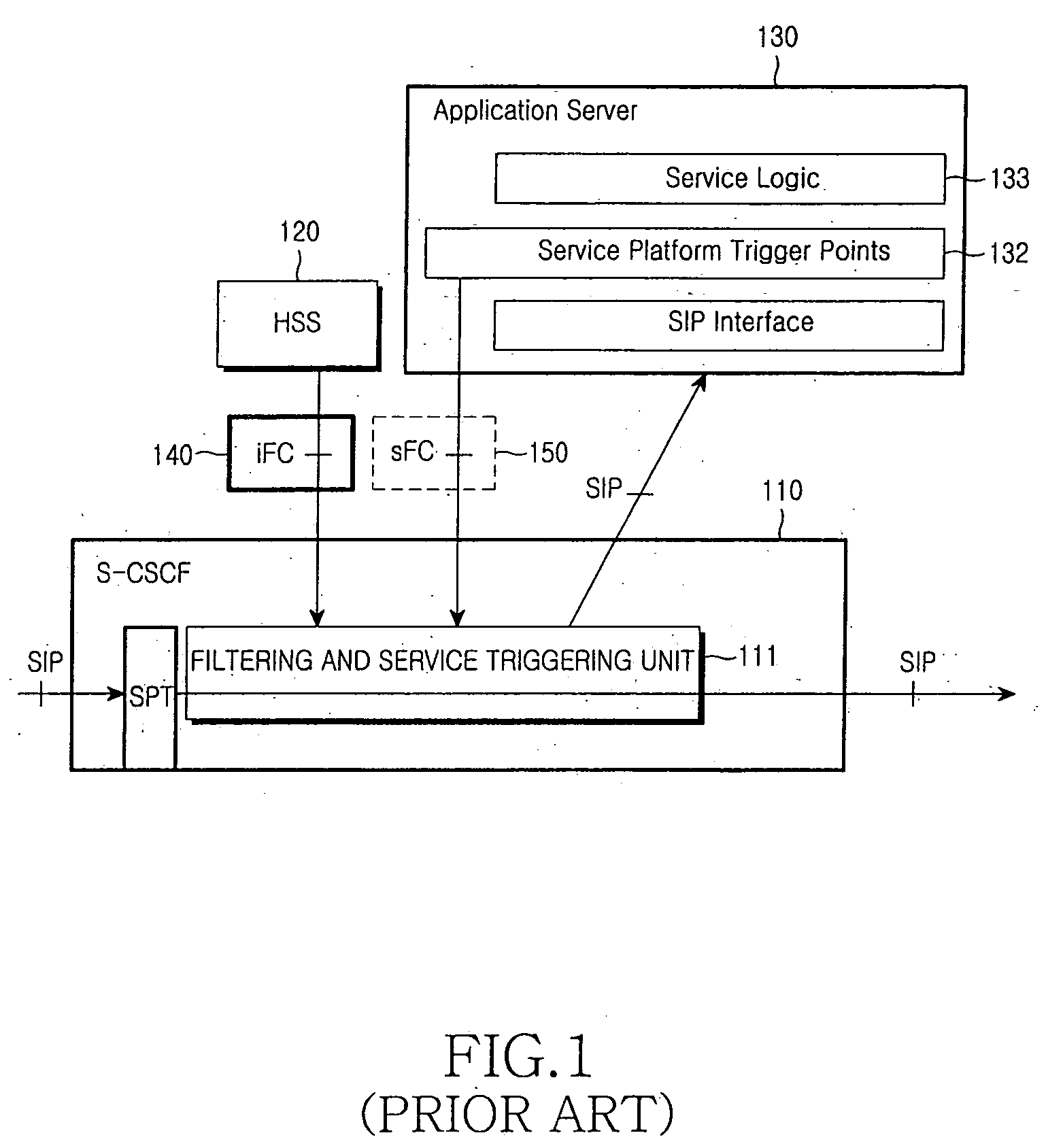

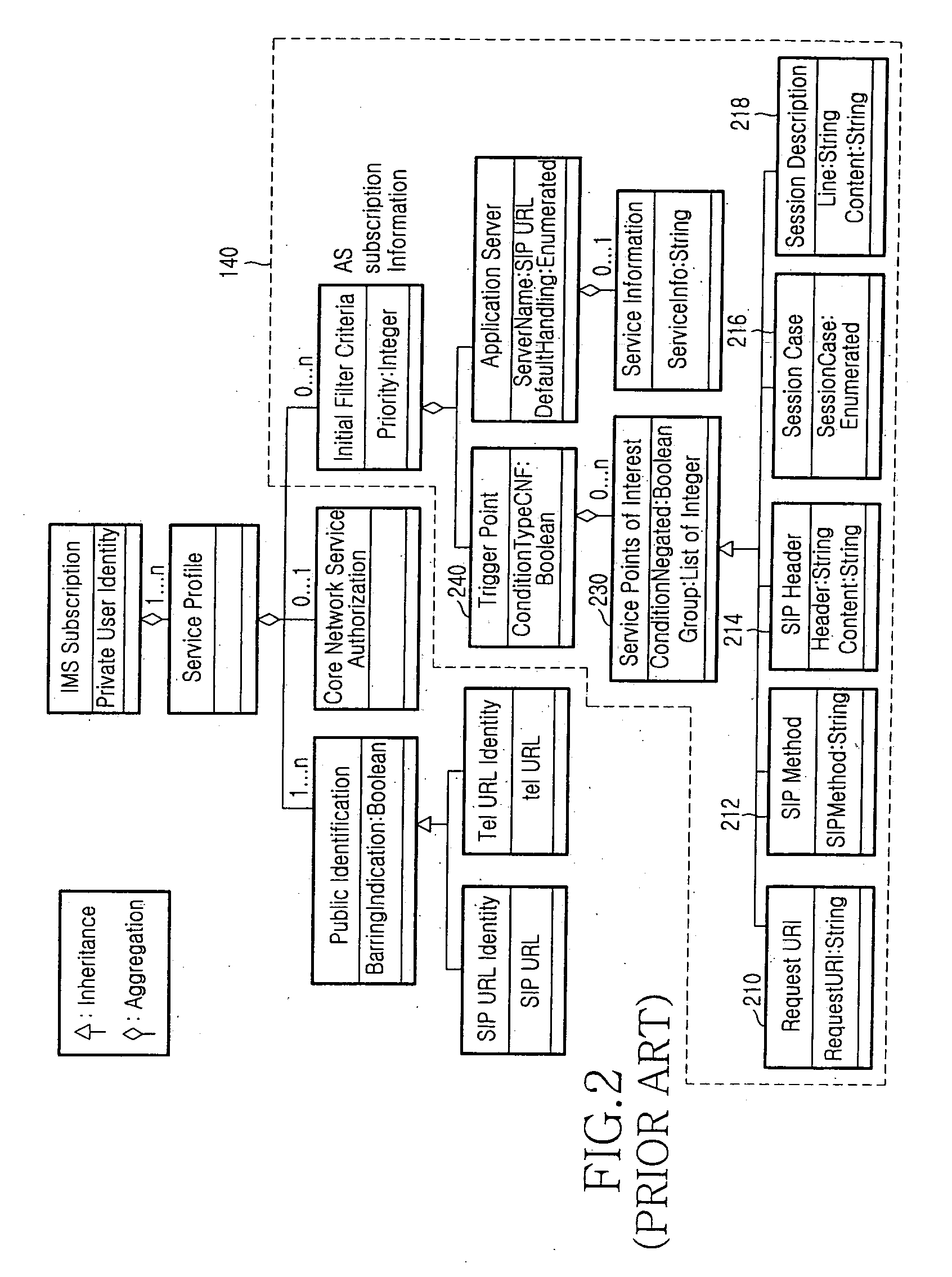

Method and system for processing service triggering in internet protocol multimedia subsystem

A service triggering system and method for performing service triggering in an Internet protocol (IP) multimedia subsystem based on any message upon a call setup request in an IMS network are provided, in which a call session control function (CSCF) processes service triggering based on all messages, to which filter criteria (FC) information required for the service triggering is applied, upon a call setup, a home subscriber server (HSS) provides the filter criteria to the call session control function upon registration of a subscriber, an application server performs a call processing for providing a transcoding service, when an originating user equipment and a terminating user equipment use different codecs, and a media resource function performs a transcoding operation in accordance with different codecs between the originating user equipment and the terminating user equipment.

Owner:SAMSUNG ELECTRONICS CO LTD

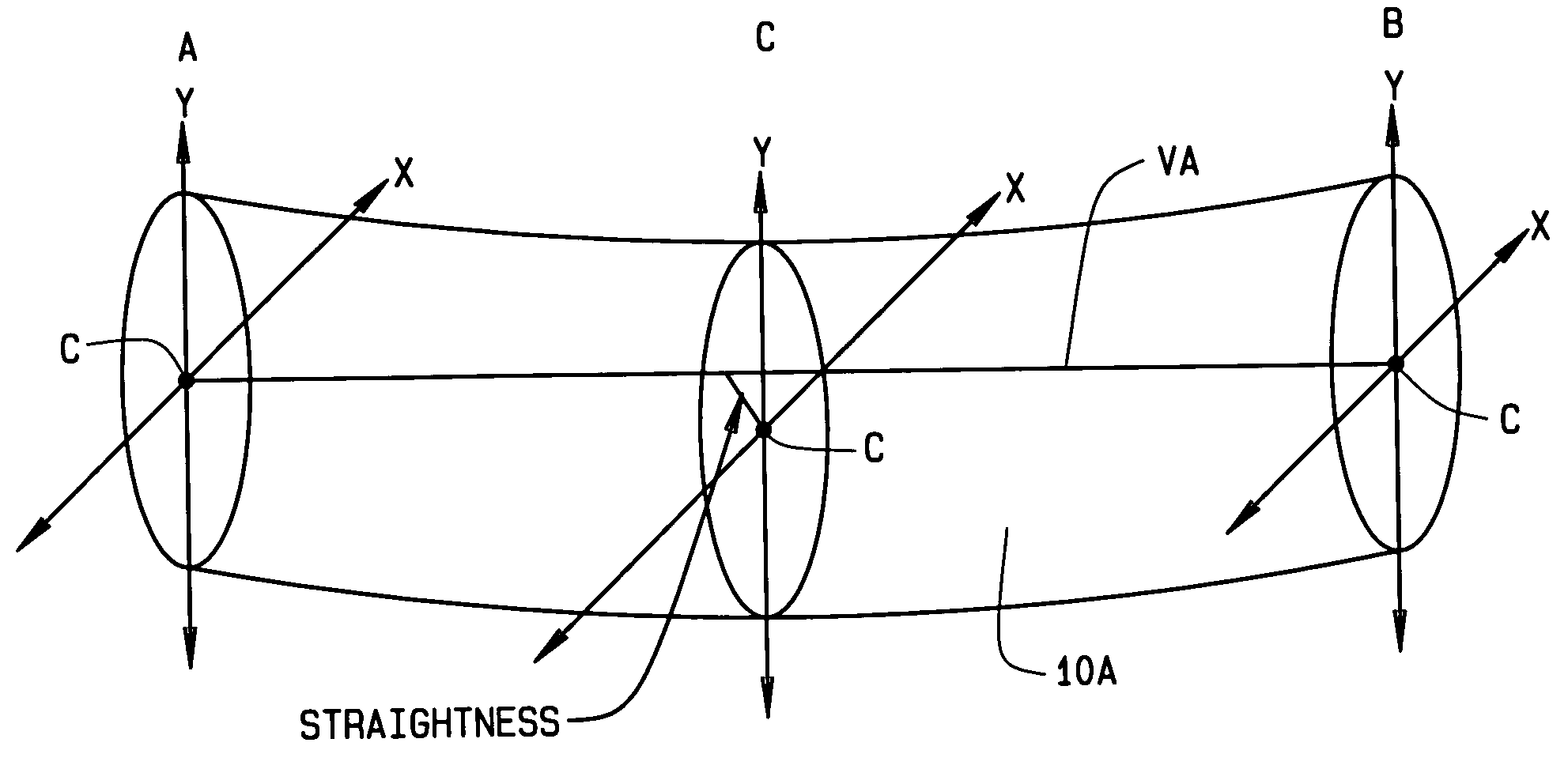

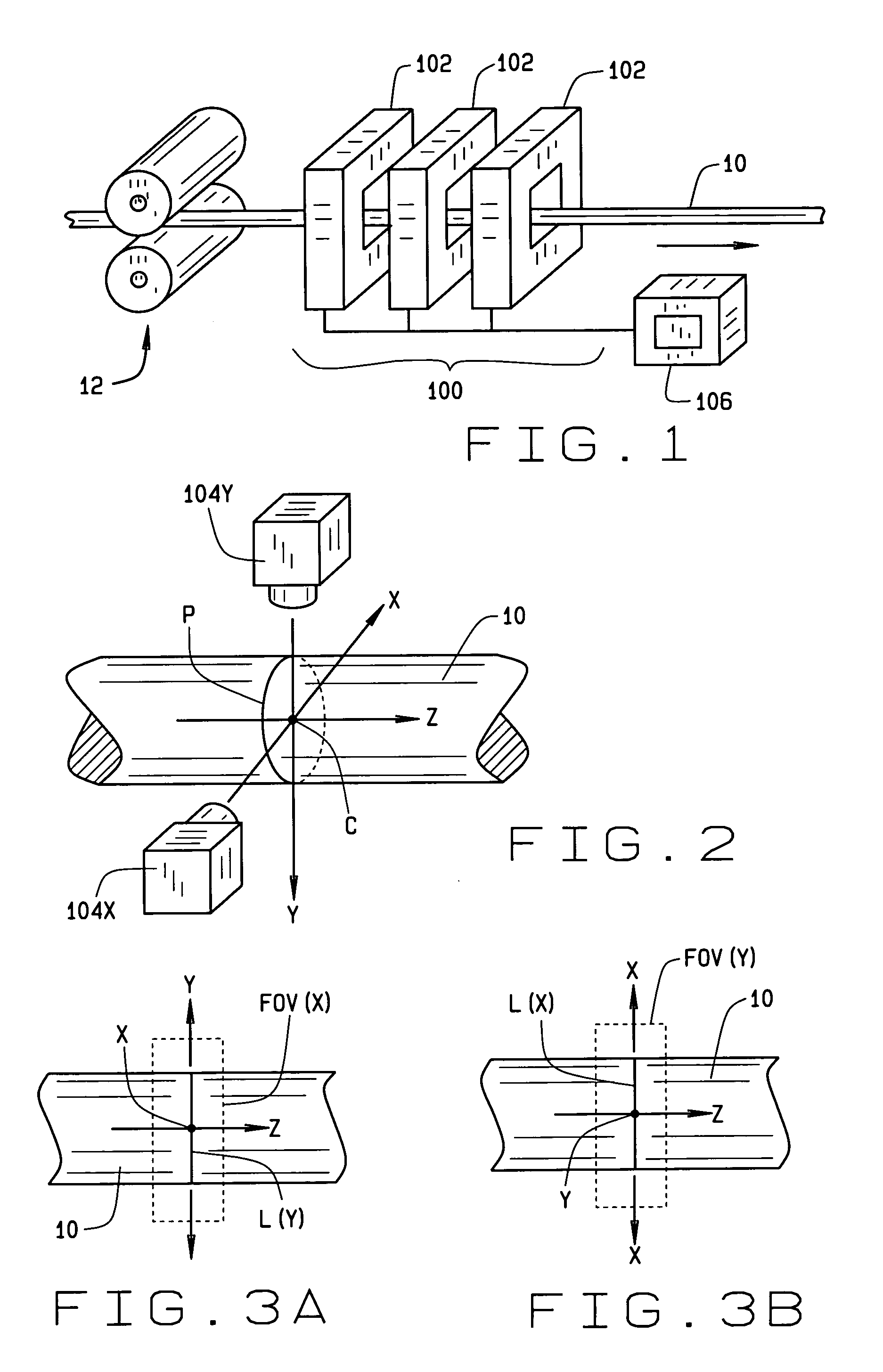

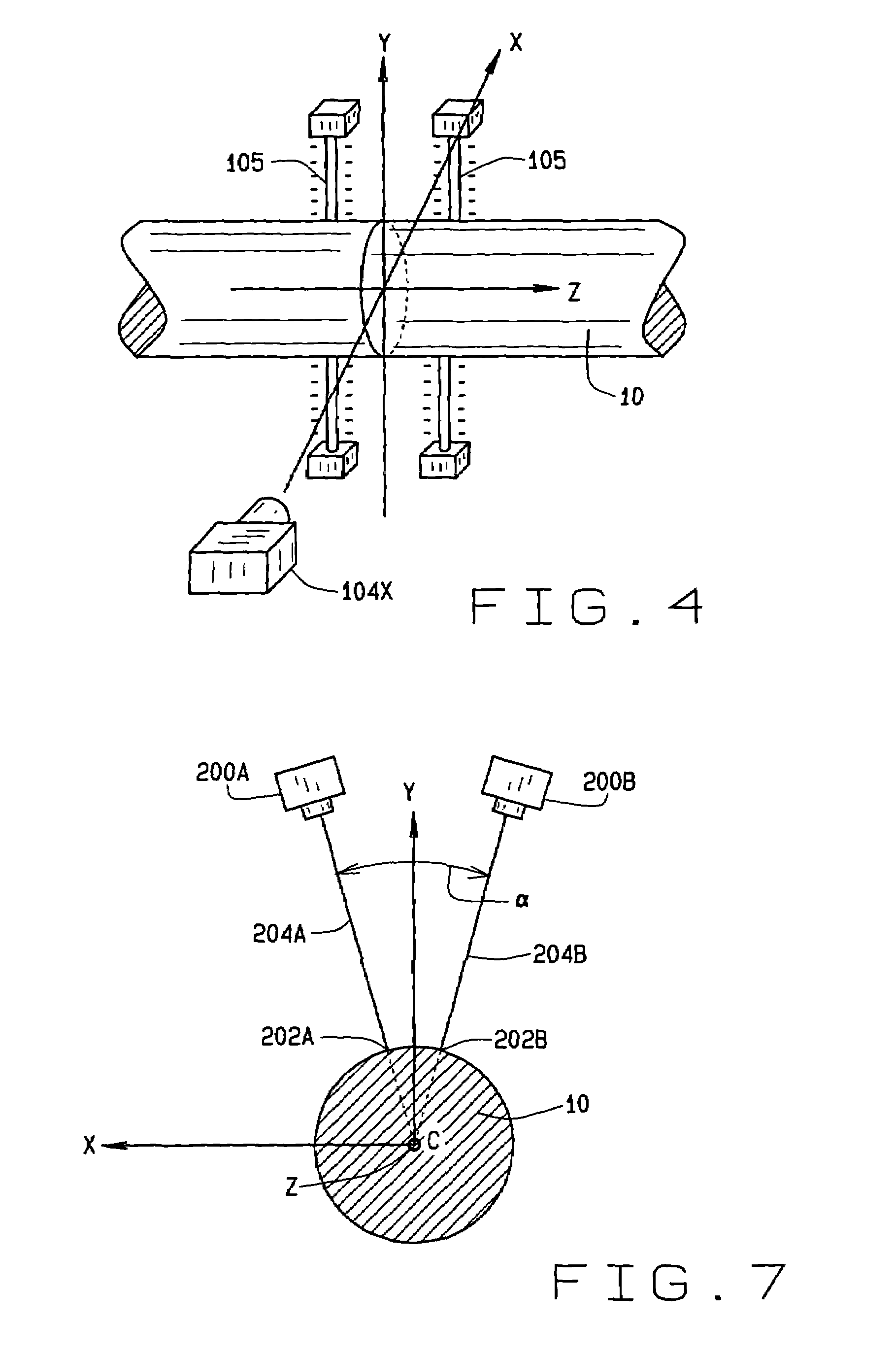

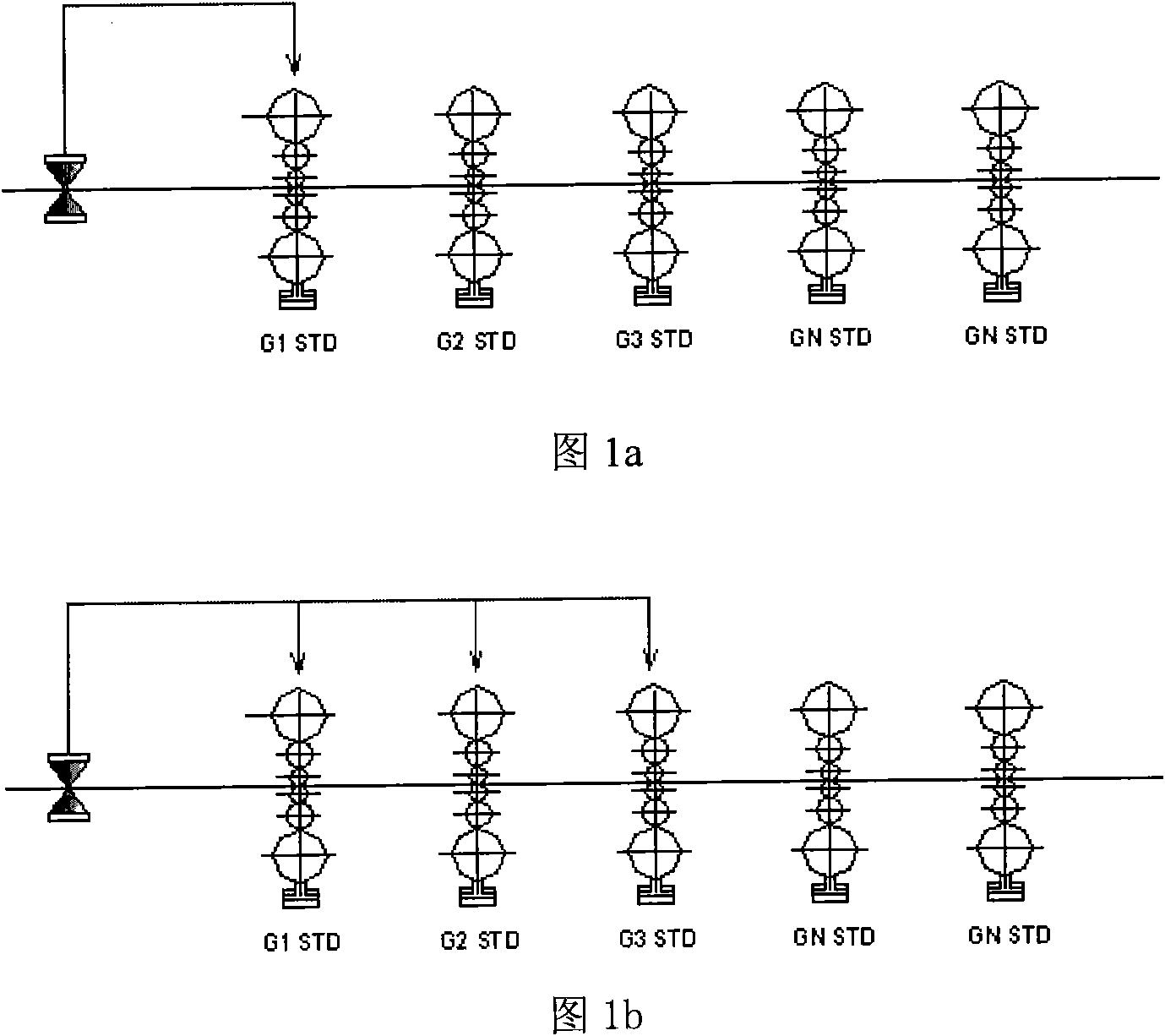

Method and apparatus for determining the straightness of tubes and bars

A method and apparatus for automating the measurement of straightness of linear stock material produced by the operation of a mill. As the linear stock material exits from the mill, sensors acquire a sequence of image or distance measurement pairs associated with the material at discrete longitudinal points over a segment of the material. A processing system utilizes the data pairs to determine a set of centroids for a segment of the material. A virtual axis is identified between centroids associated with the segment, and the processing system determines a measure of deviation of each remaining centroid in a segment from the virtual axis to identify a degree of concavity of the material within the segment, as well as to identify a measure of the angular orientation of the concavity about the virtual axis.

Owner:TIMKENSTEEL CORP

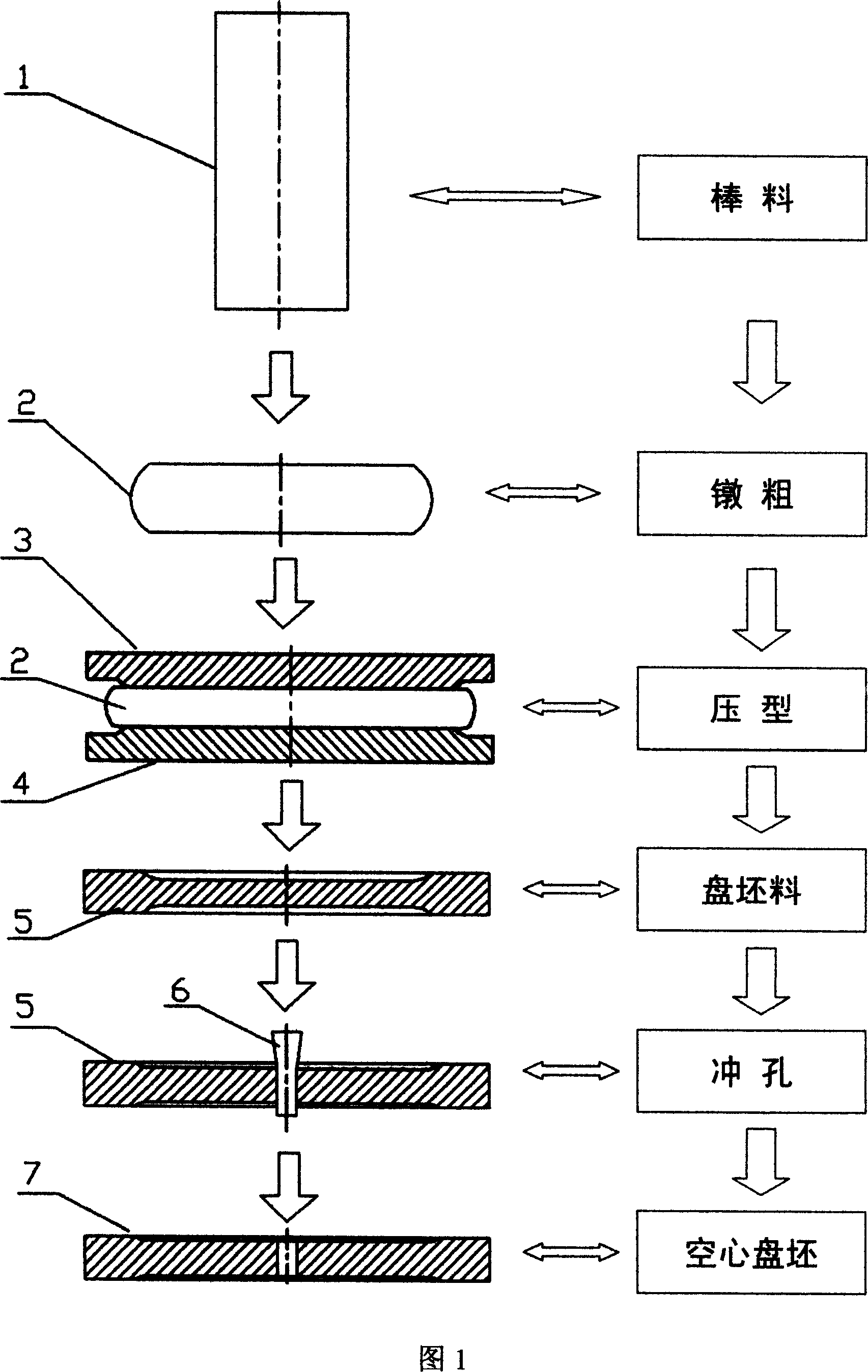

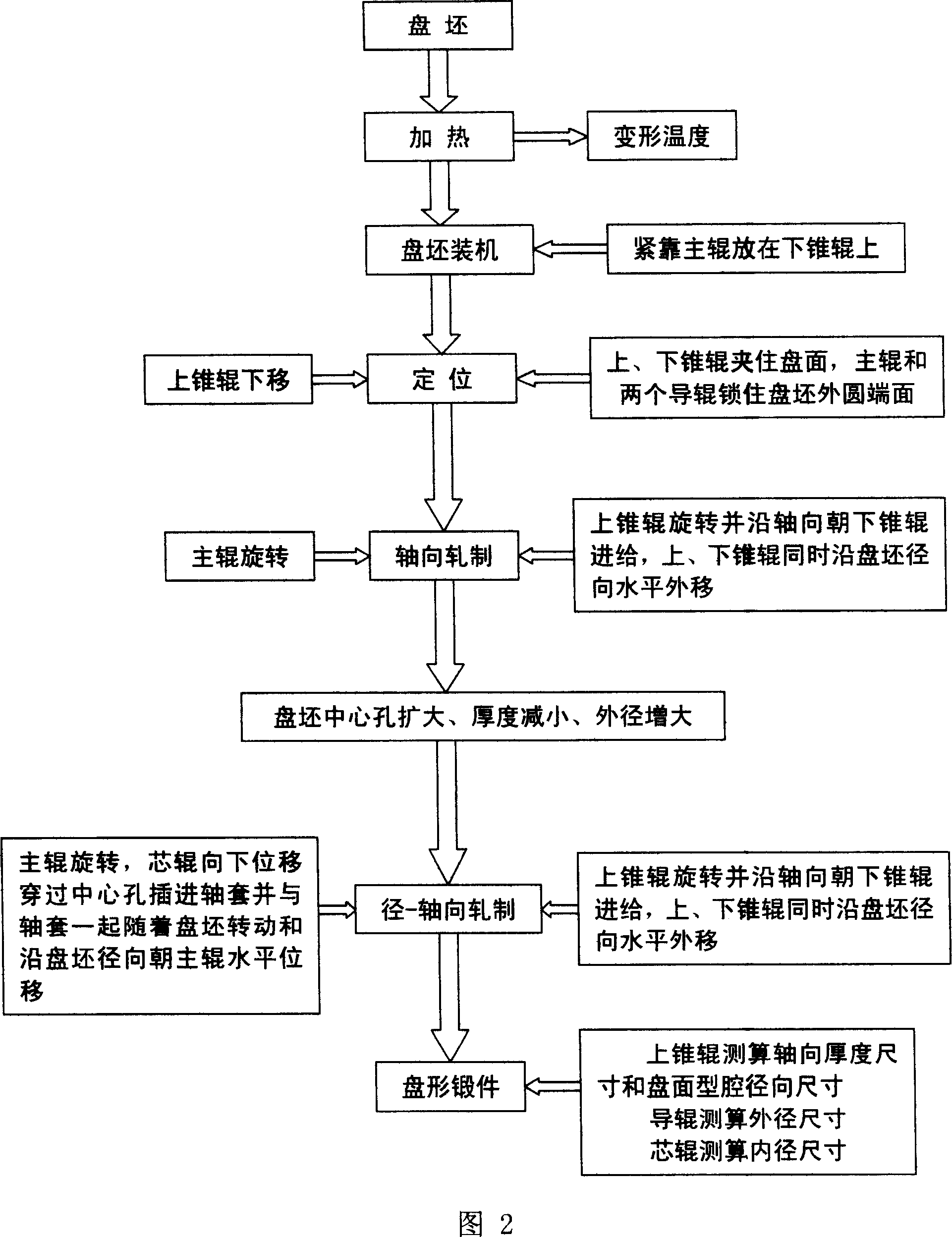

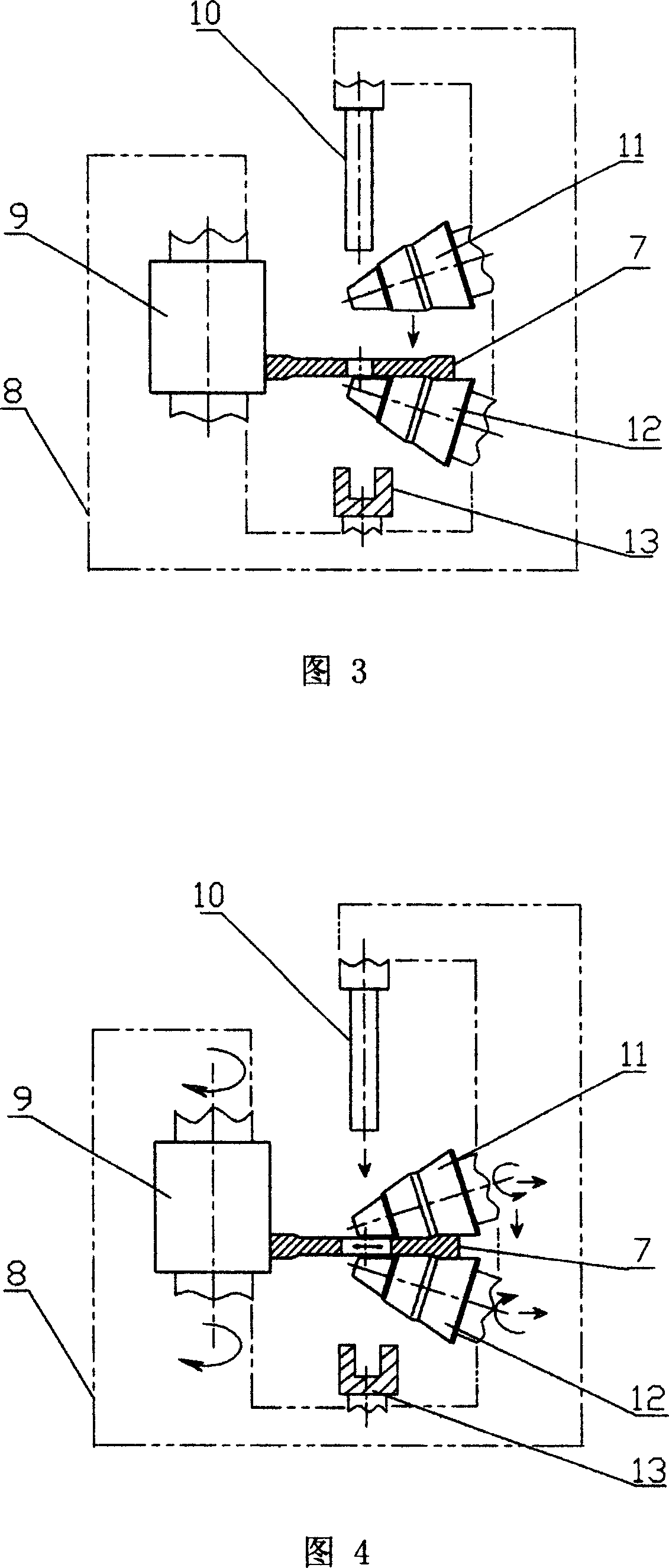

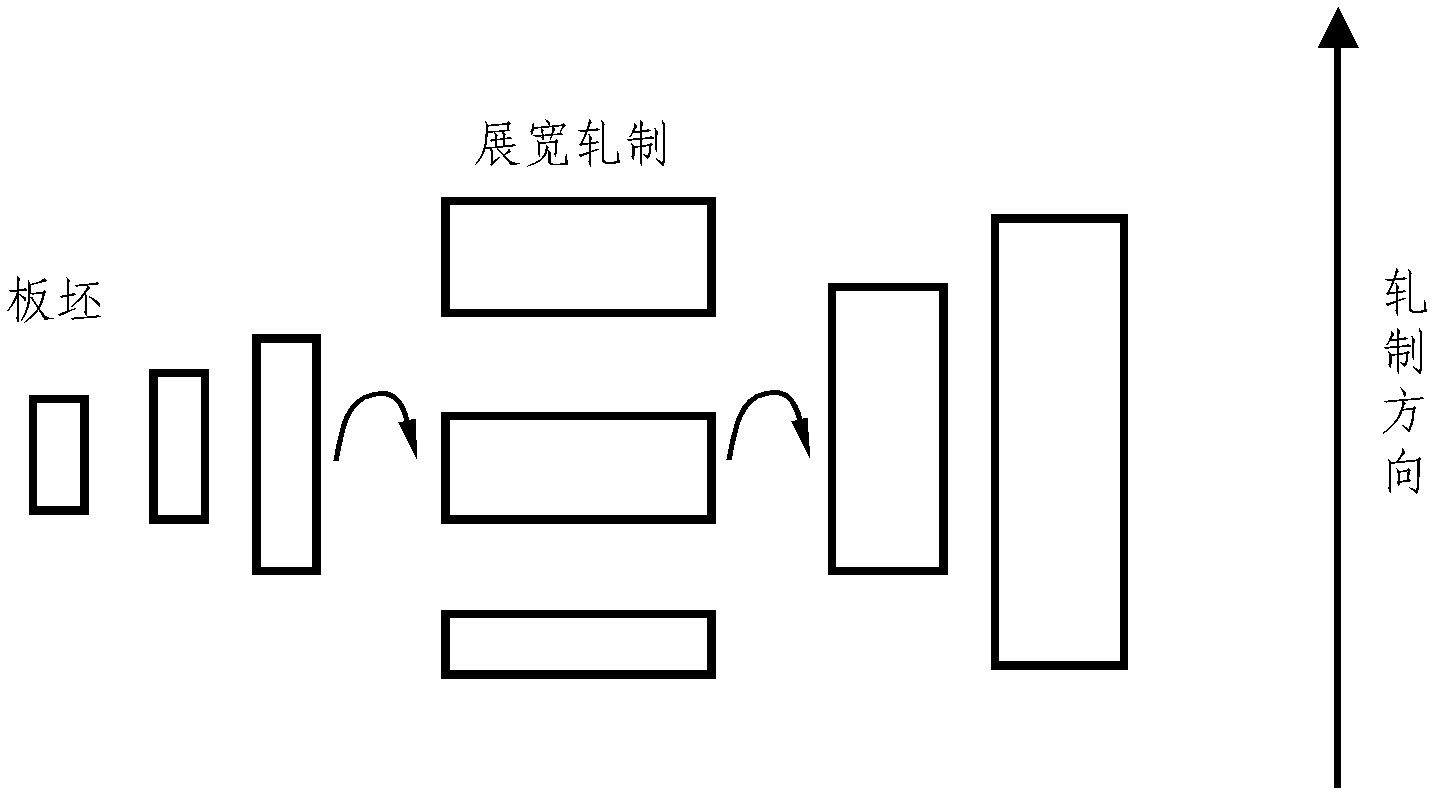

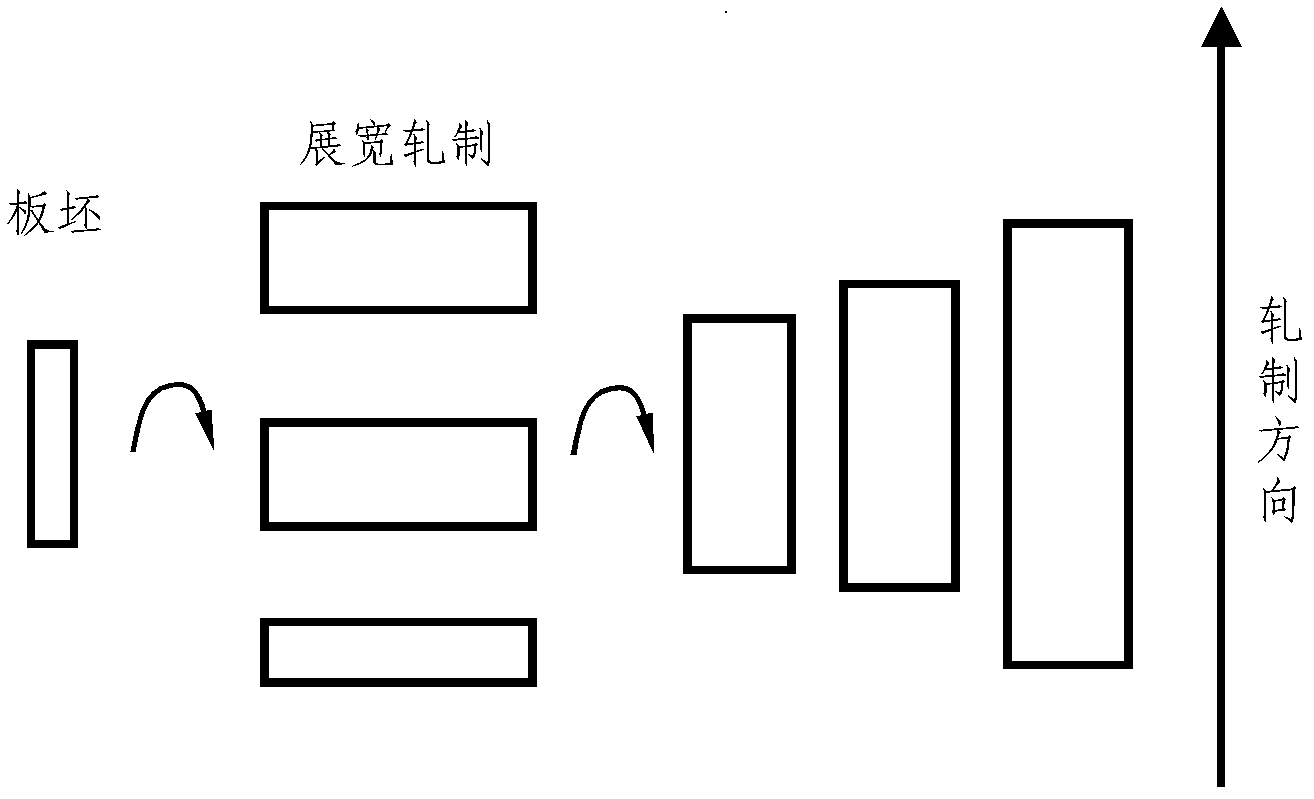

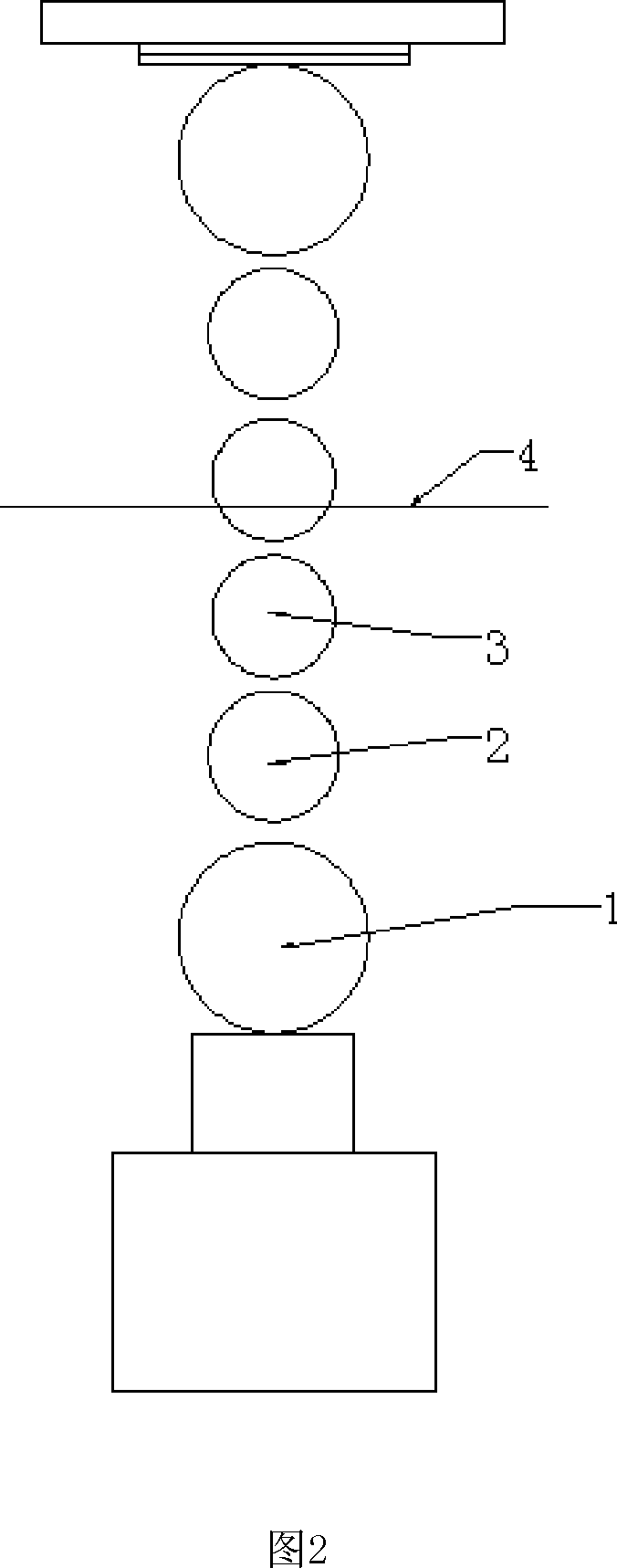

Rolling forming process for large hollow disc forging

ActiveCN101020282ARadial wall thickness reductionReduce axial thicknessRoll force/gap control deviceMeasuring devicesMaterials scienceMetal

The technological process of rolling and forming large hollow disc forging includes the steps of: deforming metal rod material, heating, upsetting to form cake blank, profiling to obtain disc blank, punching hole to obtain hollow disc blank, heating, locating, axial rolling, radial and axial rolling, and measuring size to obtain hollow disc forging. The rolling process has axial rolling force of (2-5)x10<5> kg, radial rolling force of (5-20)x10<4> kg, and broadening speed of 5-15 mm / s. The rolled disc forging has outer diameter of 800-3000 mm, inner diameter of 300-2000 mm and thickness of 30-250 mm. By means of altering the conic size and sizes of the conic roll, disc forgings of different sizes may be rolled. The present invention can form disc forging continuously and form large forging in small apparatus.

Owner:GUIZHOU ANDA AVIATION FORGING

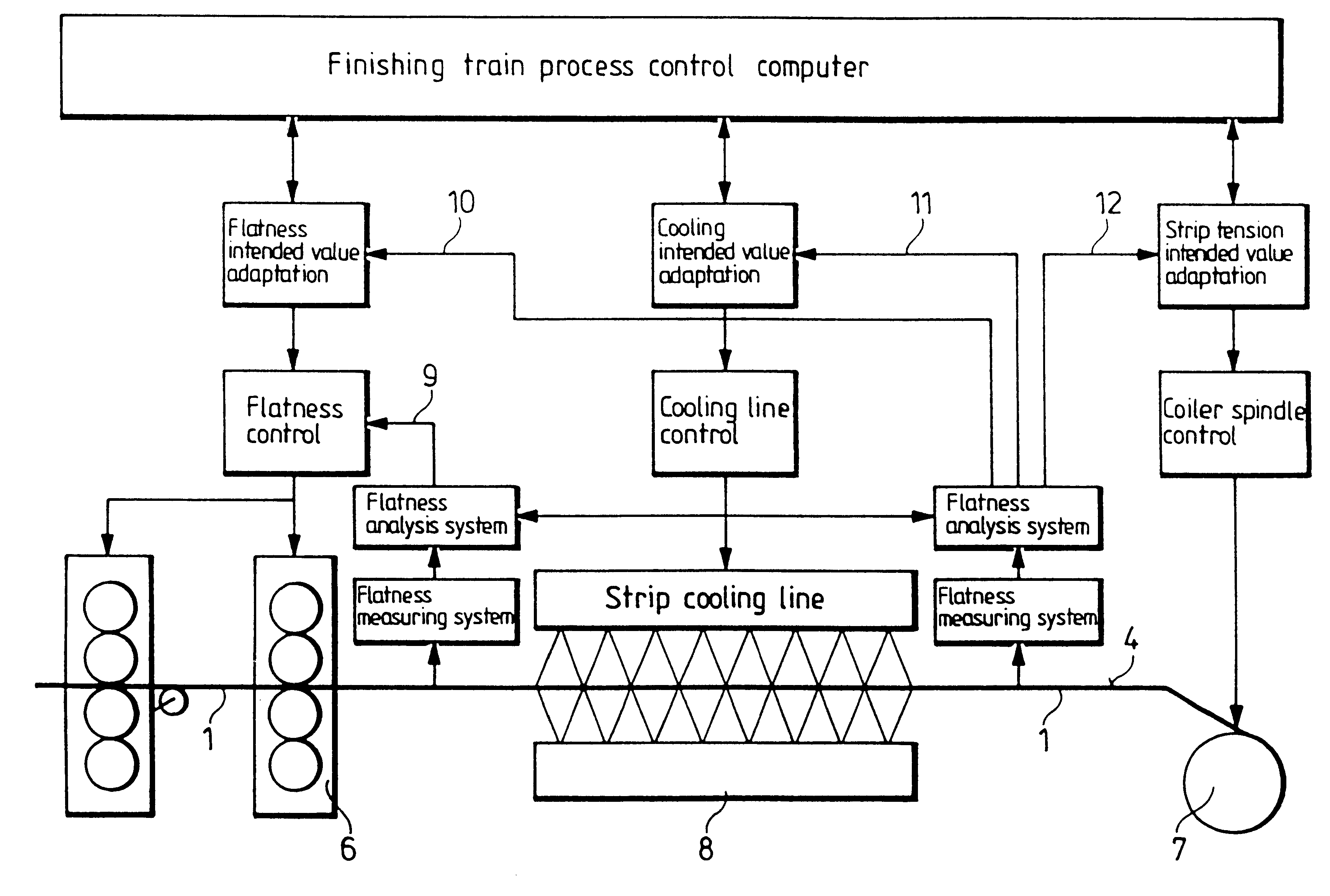

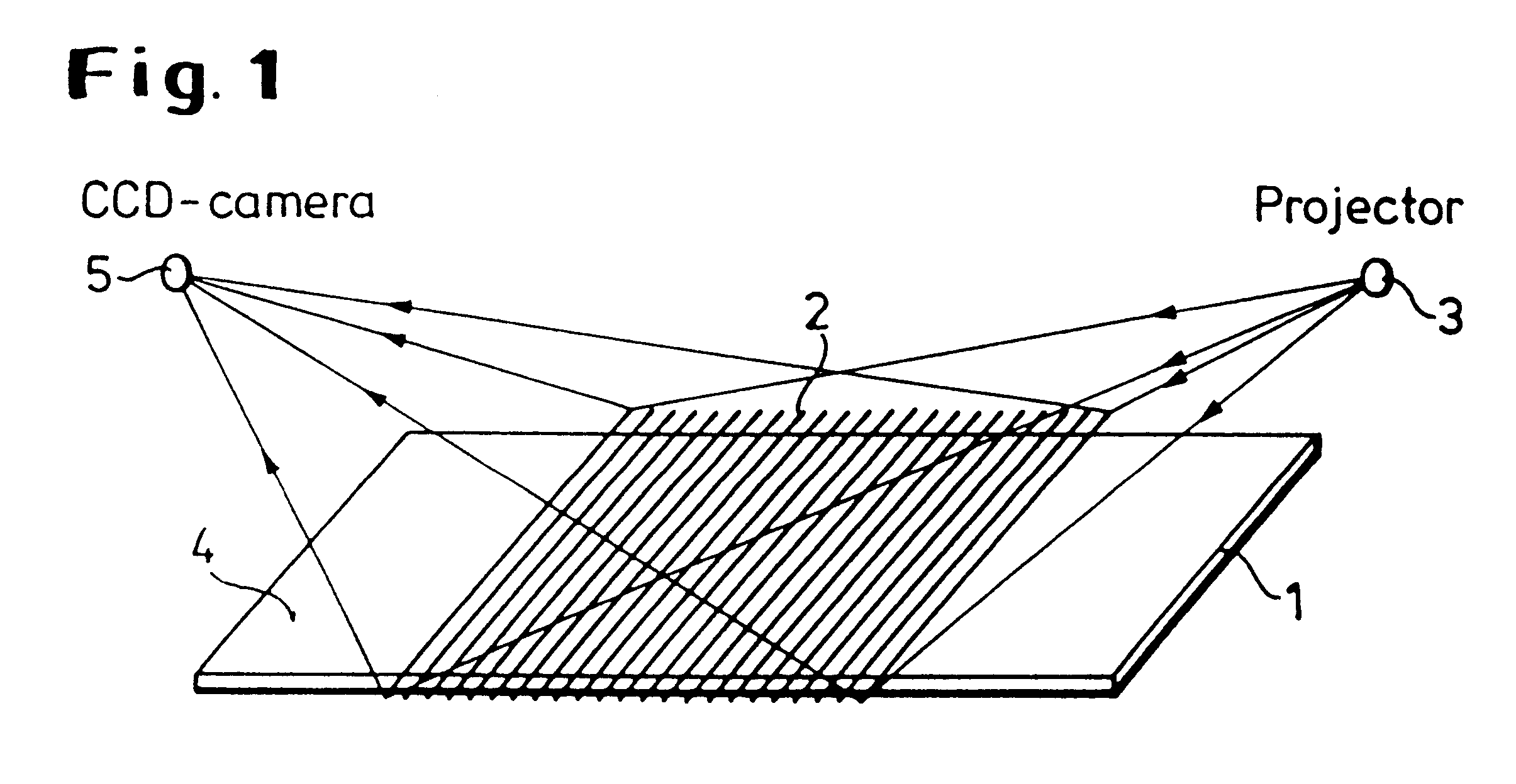

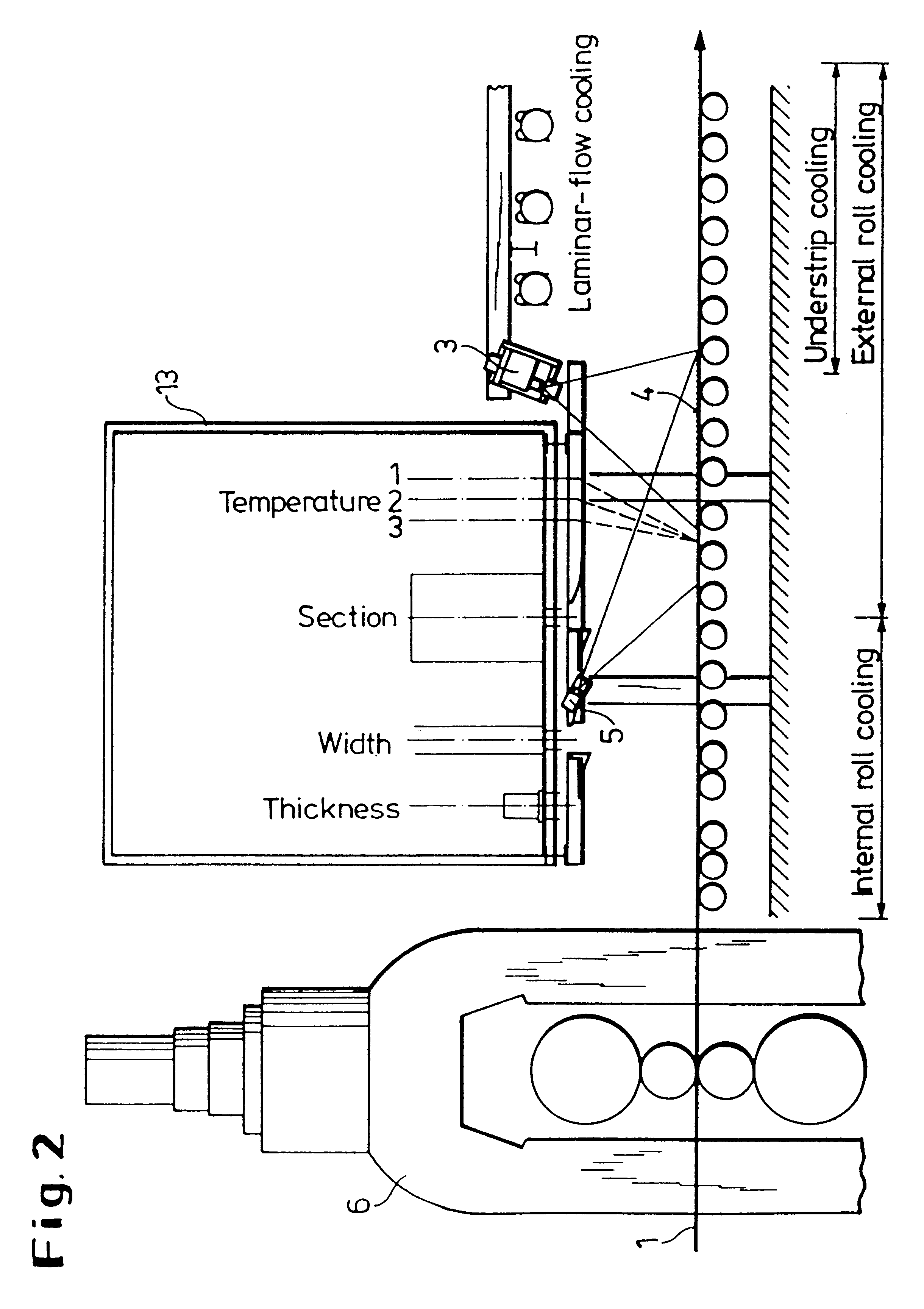

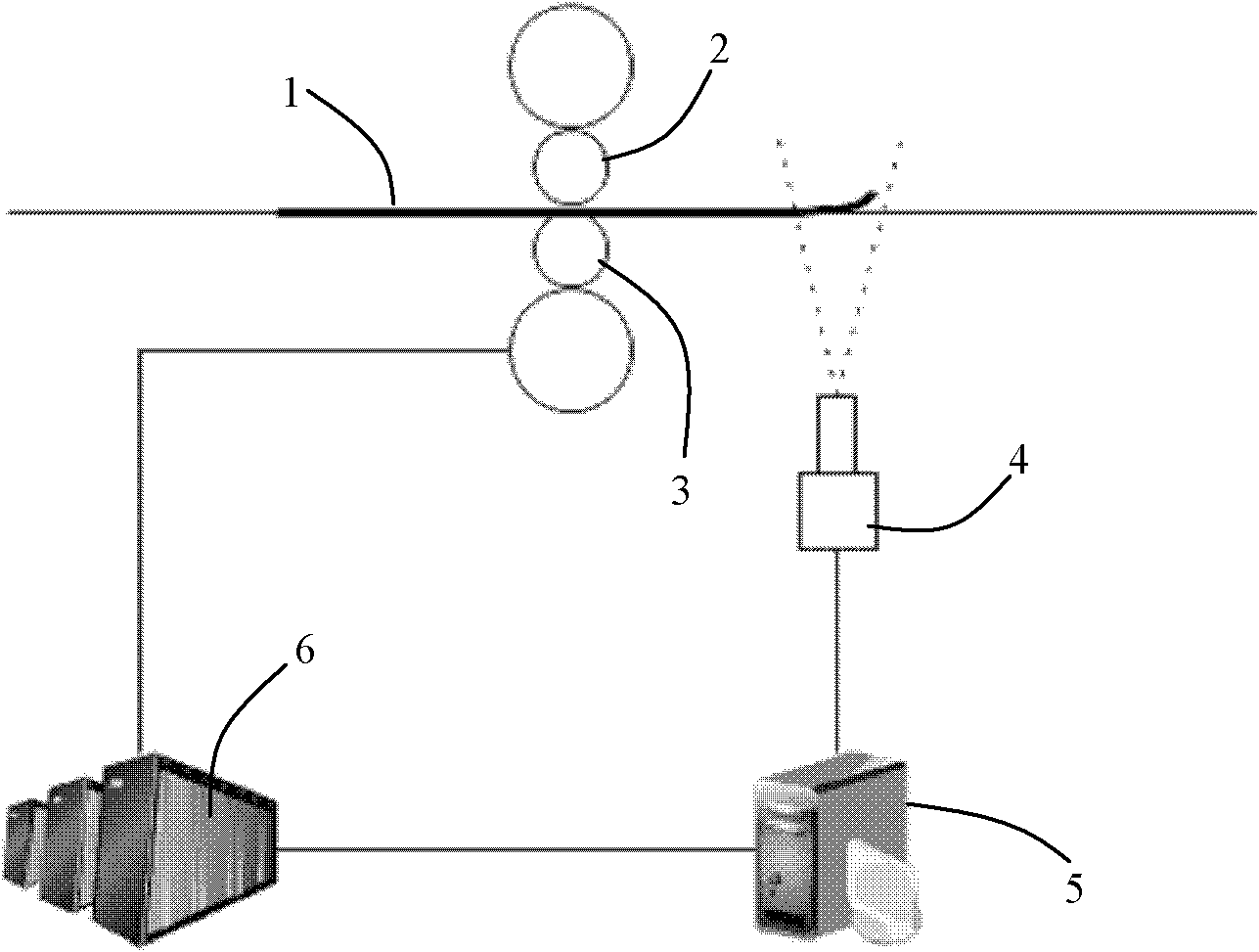

Flatness measurement system for metal strip

InactiveUS6286349B1Easy to measurePermit fine controlTemperature control deviceMeasuring devicesMetal stripsControl system

Owner:THYSSEN KRUPP STAHL AG +1

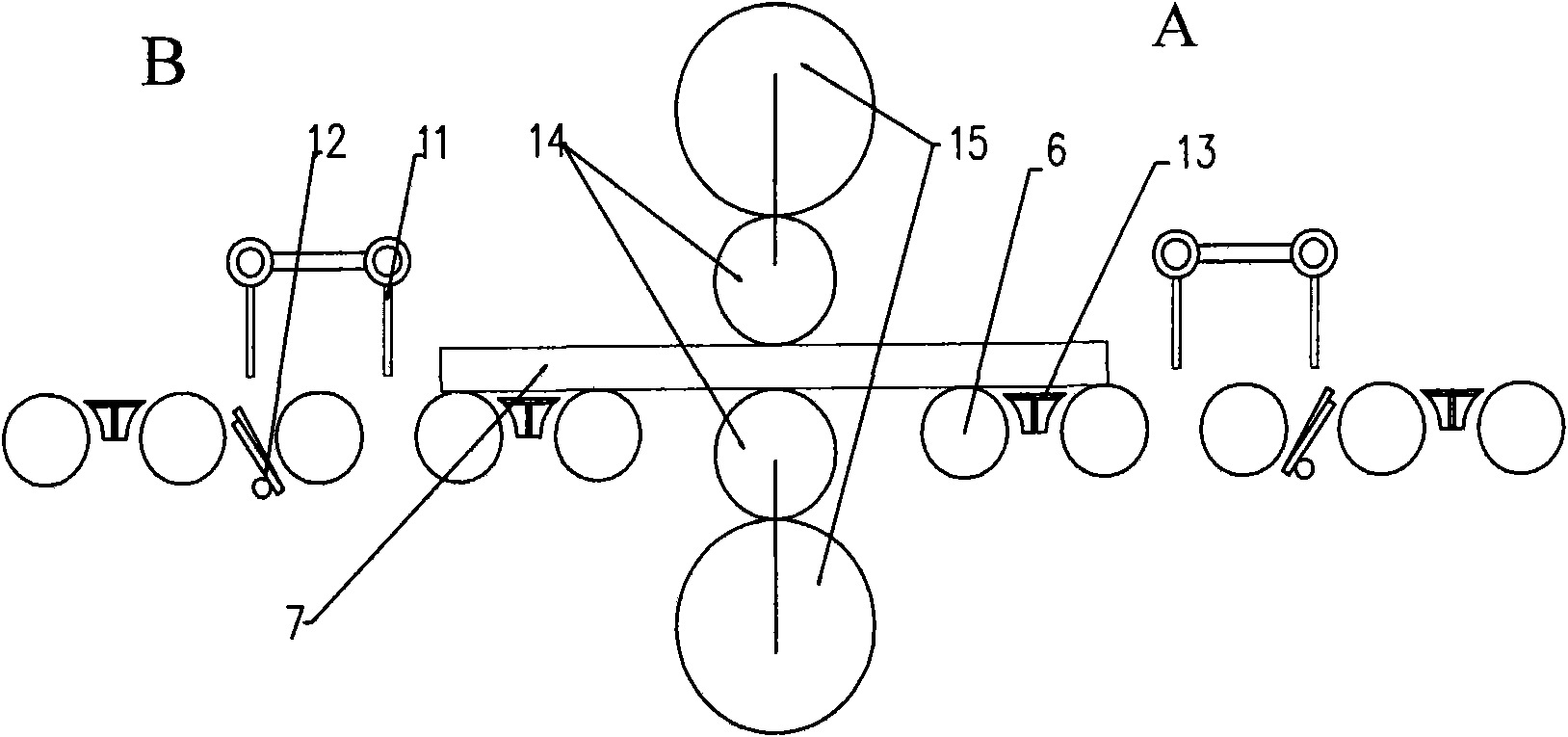

Device and method for detecting and controlling tilting buckle head of band steel in rough rolling process

ActiveCN101920270AImprove rolling qualityImprove operational safetyMeasuring devicesMetal rolling arrangementsSheet steelHead tilting

The invention discloses a device and a method for detecting and controlling the tilting buckle head of band steel in the rough rolling process. The actual head tilting or buckle head condition of the rolled band steel can be detected by using head tilting and buckling detectors arranged above roller beds and between the roller beds and then the rolling speeds of an upper roller and a lower roller for biting the band steel can be automatically adjusted when the next band steel is rolled, so that upper surface band steel and the lower surface band steel consistently extend and the aim of controlling the tilting buckle head of the band steel can be achieved, wherein the control belongs to the feedback control. According to the invention, the rolling speeds of the upper roller and the lower roller can be adjusted by detecting the actual head tilting or buckle head condition of the band steel, and the detection process is not influenced by logged water, fog, the roughness of the rollers, the elevation of a rolling line, the amplitude of rolling reduction, the thickness of the band steel, the rolling speed and other factors, so that the invention has high accuracy of controlling the tilting buckle head, effectively improves the rolling quality of steel plates and the operation safety of operators and reduces the labor intensity.

Owner:BAOSHAN IRON & STEEL CO LTD

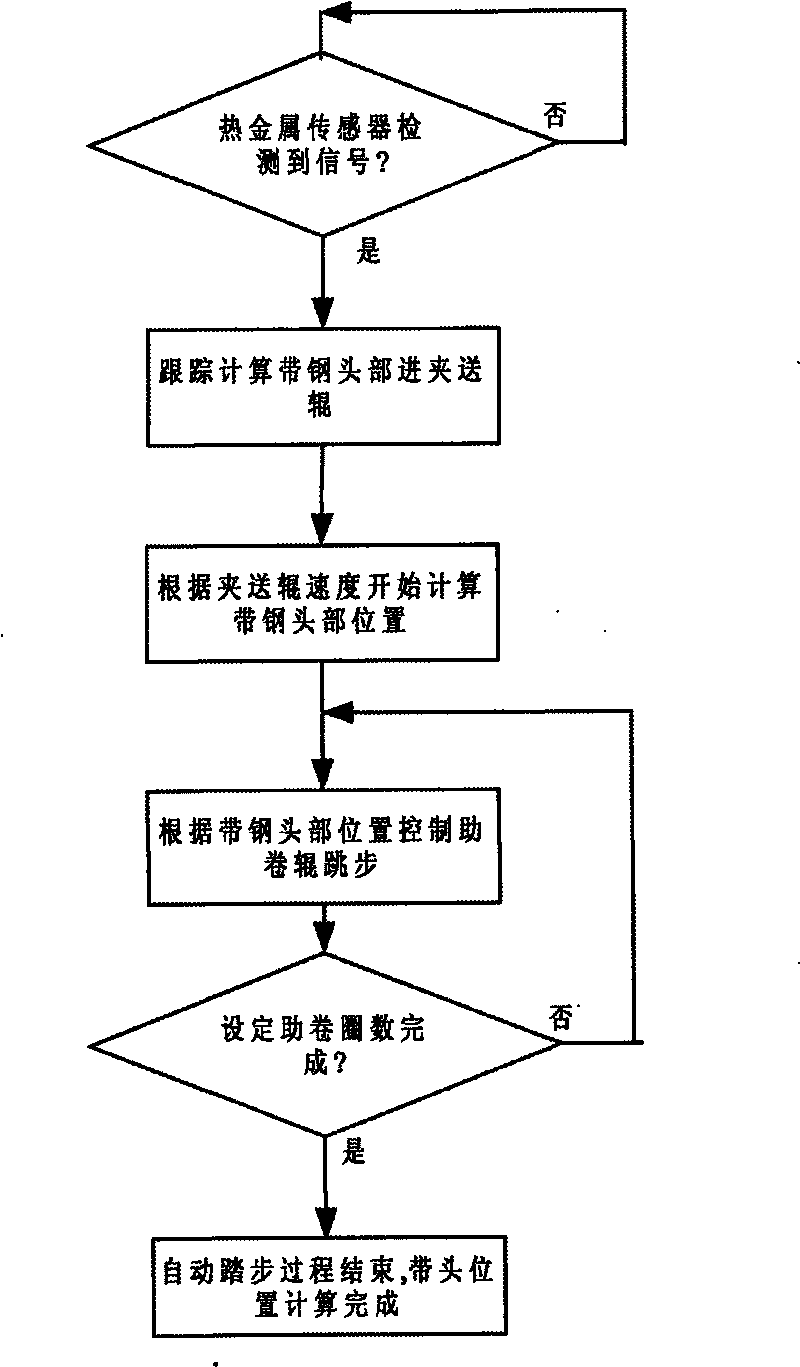

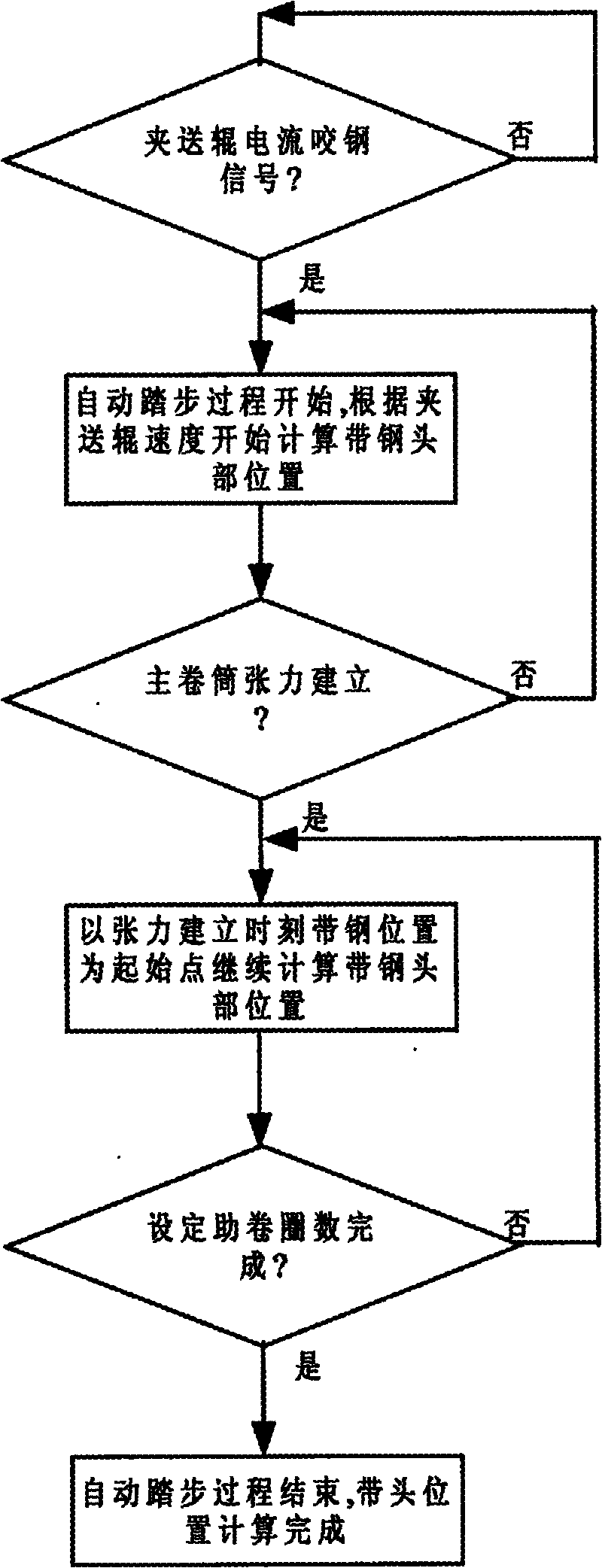

Method for calculating and locating strip steel head of automatic stepping system of hot continuous rolling coiling machine

InactiveCN101722196AOvercome the shortcomings of being susceptible to various interferences on siteHigh degree of automationRoll mill control devicesMeasuring devicesHead positionEngineering

The embodiment of the invention provides a method for calculating and locating the strip steel head of an automatic stepping system of a hot continuous rolling coiling machine, comprising the following steps of: detecting whether the strip steel enters a pinch roll, wherein when the strip steel is detected to enter the pinch roll, the automatic stepping process begins, the head position of the strip steel is calculated according to the speed of a lower pinch roll; detecting the tension of a main drum, if the tension of the main drum is not established, the head position of the strip steel is continuously calculated according to the speed of a lower pinch roll, if the tension of the main drum is established, the head position of the strip steel is continuously calculated by using the momentary position of the strip steel head at the main drum at the tension establishing moment as a start point; detecting whether the set wrapping number of turns is finished, if the set wrapping number of turns is not finished, the head position of the strip steel is continuously calculated by using the head position of the strip steel at the tension establishing moment as a start point; if the set wrapping number of turns is finished, the automatic stepping process stops and the calculation for the head position of the strip steel is finished. The invention can effectively overcome the defects that an on-site hot metal detector and an optoelectronic detecting element are subject to various on-site interferences.

Owner:WUHAN IRON & STEEL (GROUP) CORP

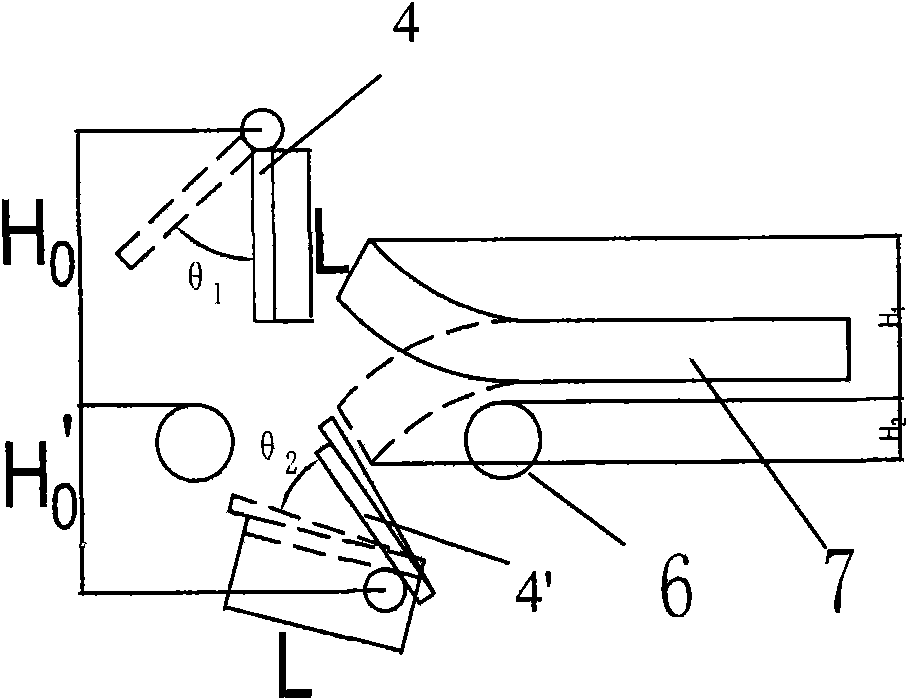

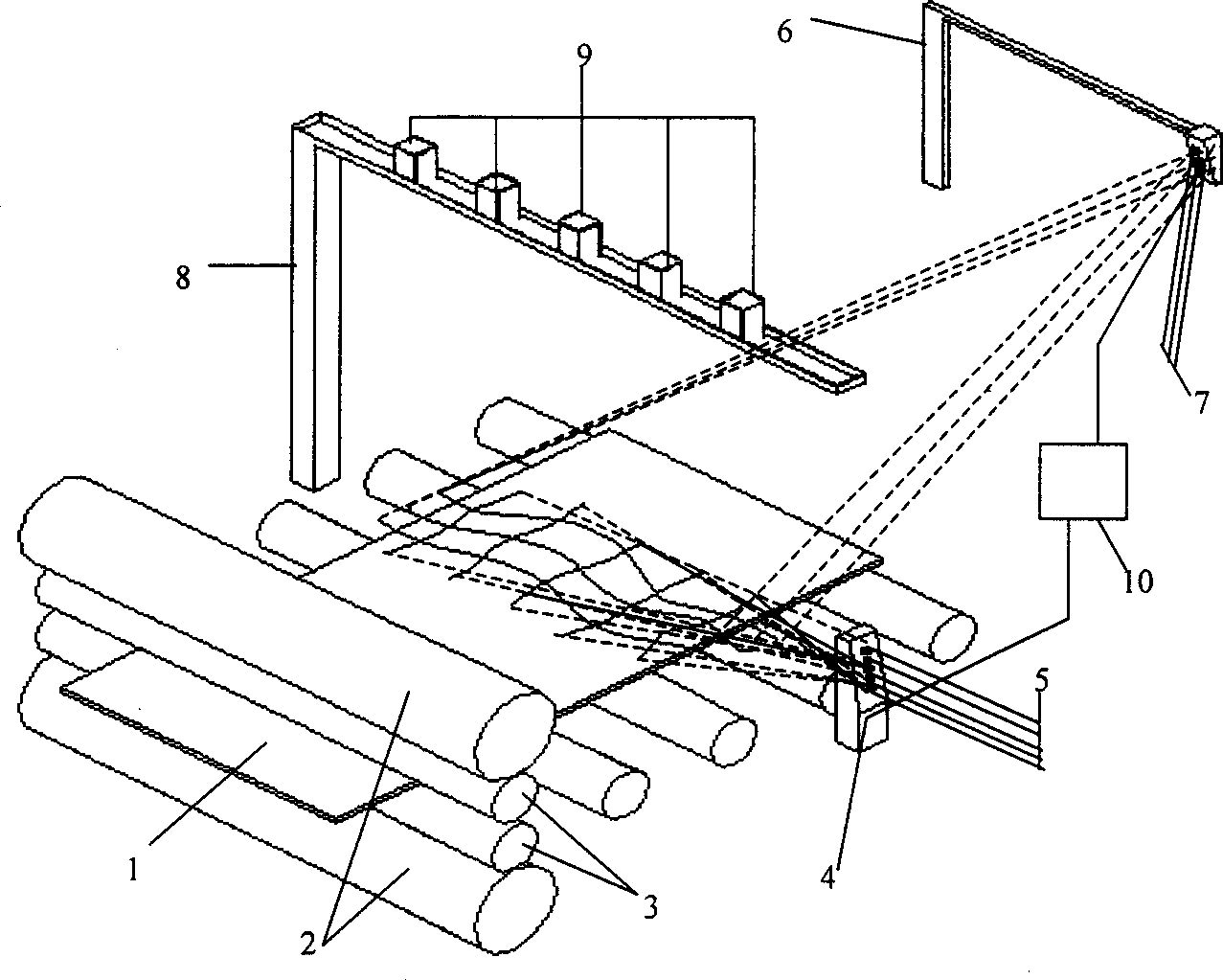

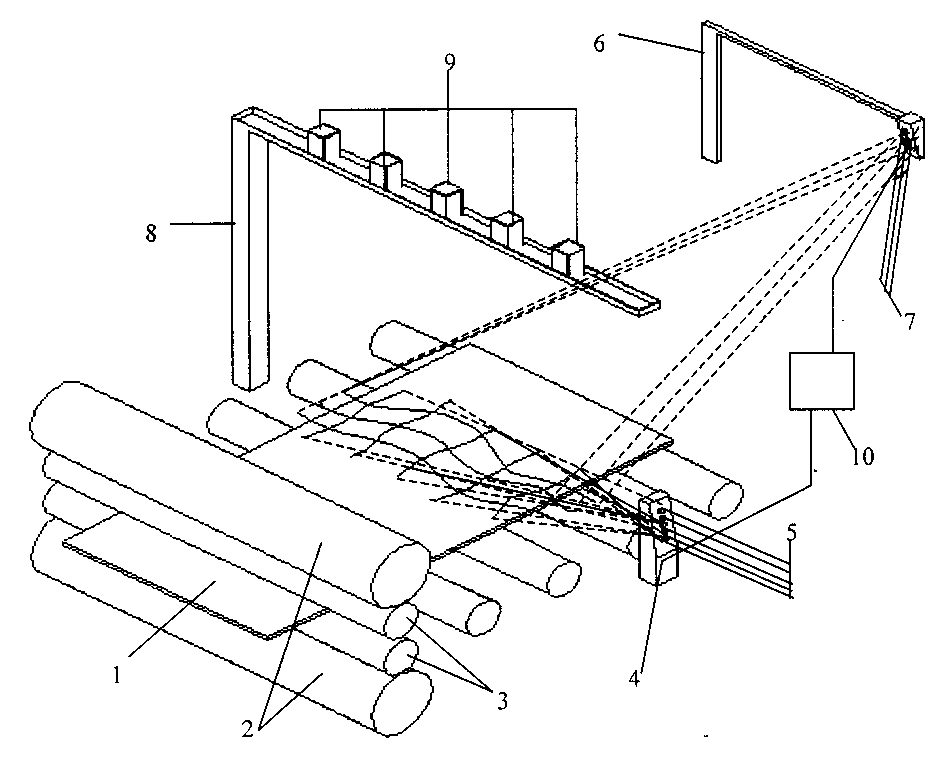

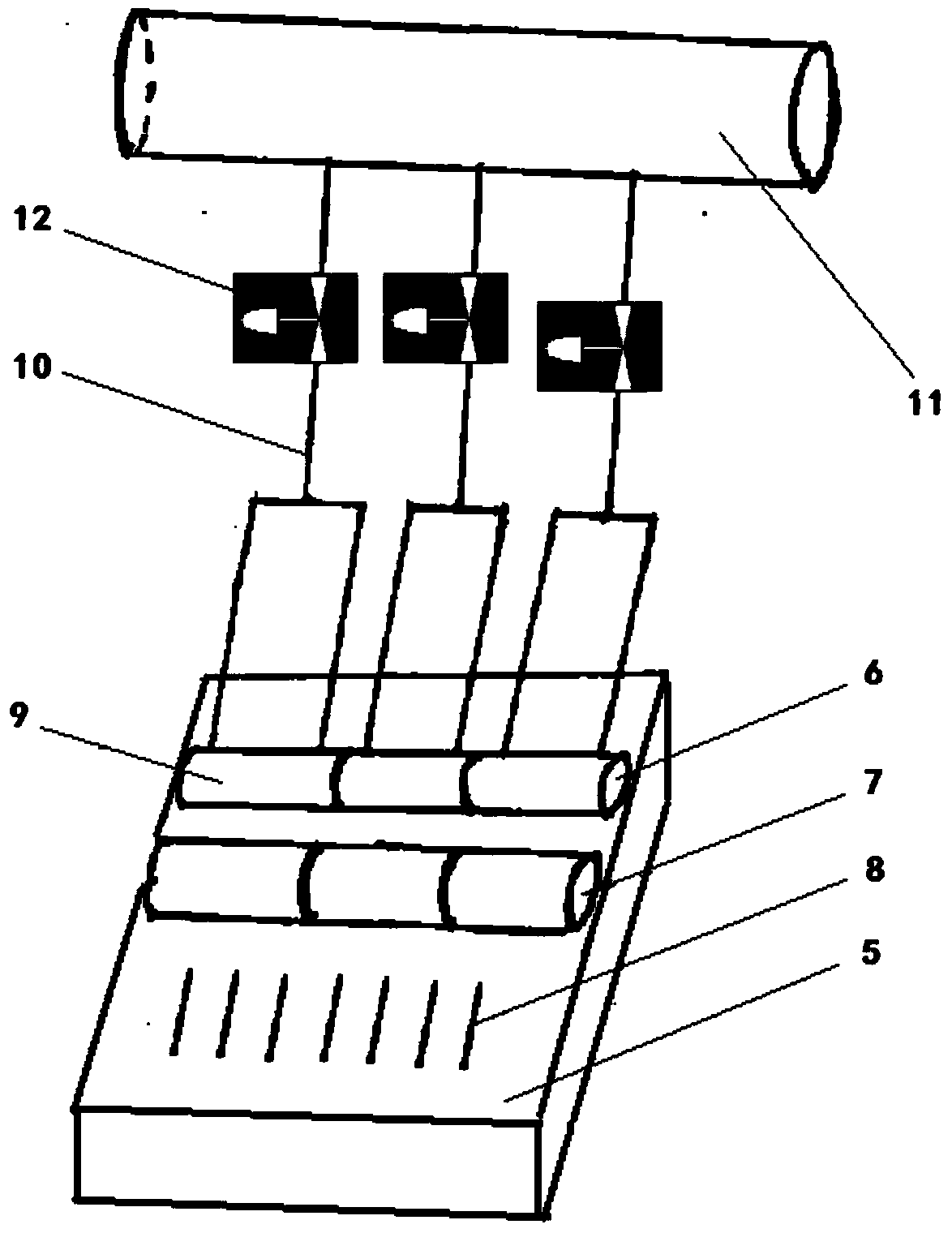

Linearl laser detector of plate shape

InactiveCN1356186ASimple structureEasy to manufactureMeasuring devicesMetal rolling arrangementsPhase detectorStrip steel

A laser detector for in-line measuring the flatness of steel band or plate in its cold rolling, hot rolling or straightening step is composed of steel band, supporting rollers, working rollers, longitudinal linear semiconducto laser device, transverse linear semiconductor laser device, longitudinal laser device supporter and position regulator, transverse laser device supporter and position regulator, camera supporter and position regulator, several planar array CCD cannerals and optical filters, and computer processing system. Its advantages include simple structure, easy operation and high precision.

Owner:UNIV OF SCI & TECH BEIJING

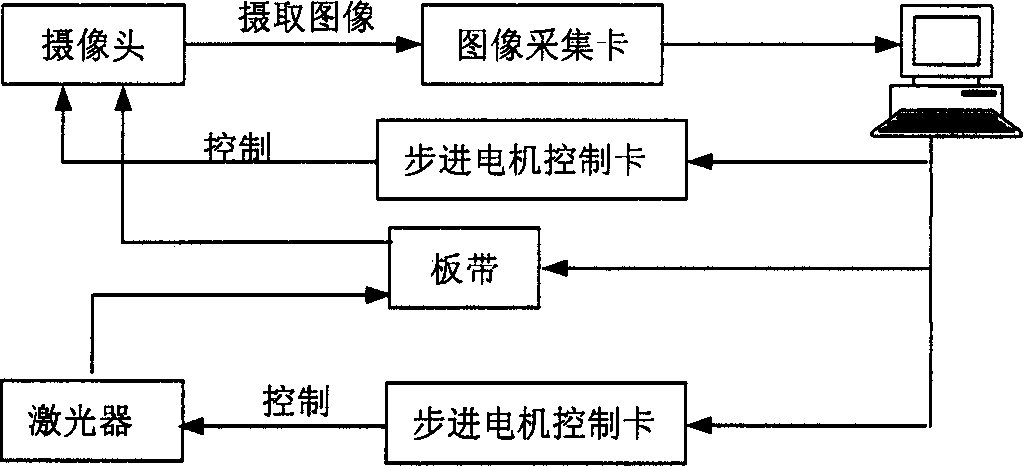

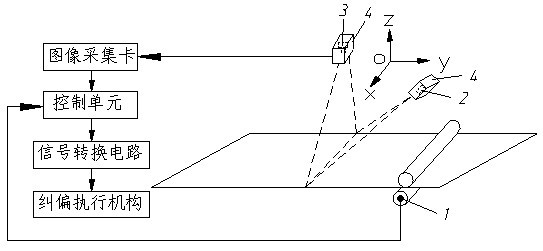

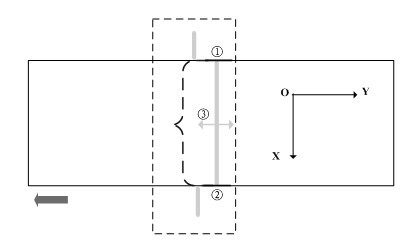

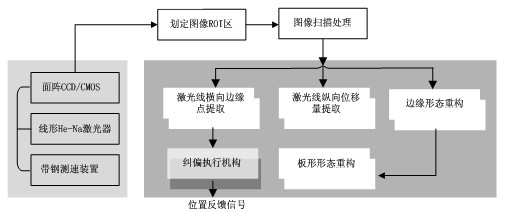

Band steel deflection and floating quantity laser scanning detection method and deflection correction system

InactiveCN102319743AControllable detection accuracyQuick scanRoll mill control devicesMeasuring devicesLaser transmitterAnti jamming

The invention discloses a band steel deflection and floating quantity laser scanning detection method, which comprises the following steps that: 1) a linear laser emitter is used for irradiating the band steel, and a laser linear light beam is formed on the band steel in the width direction; 2) a plane array image sensor arranged above the band steel is used for scanning the laser linear light beam in real time; 3) the scanned laser linear light beam is sent into a computer, and the computer determines the band steel edges according to the laser linear light beam; and 4) the band steel deflection quantity can be calculated according to the band steel edges determined by the computer at different moments, and simultaneously, the upwards and downwards floating quantity of the band steel canbe calculated according to the displacement quantity of the laser linear light beam in the length direction of the band steel. The band steel deflection and floating quantity laser scanning detectionmethod has the advantages that the cost is low, the detection precision is high, the real-time performance and the anti-jamming capability are high, the long-time stable operation can be realized in complicated environment, the band steel deflection automatic detection level is favorably improved, the installation and the maintenance of equipment are convenient, and the technical support is provided for the efficient production of the band steel.

Owner:CHONGQING UNIV

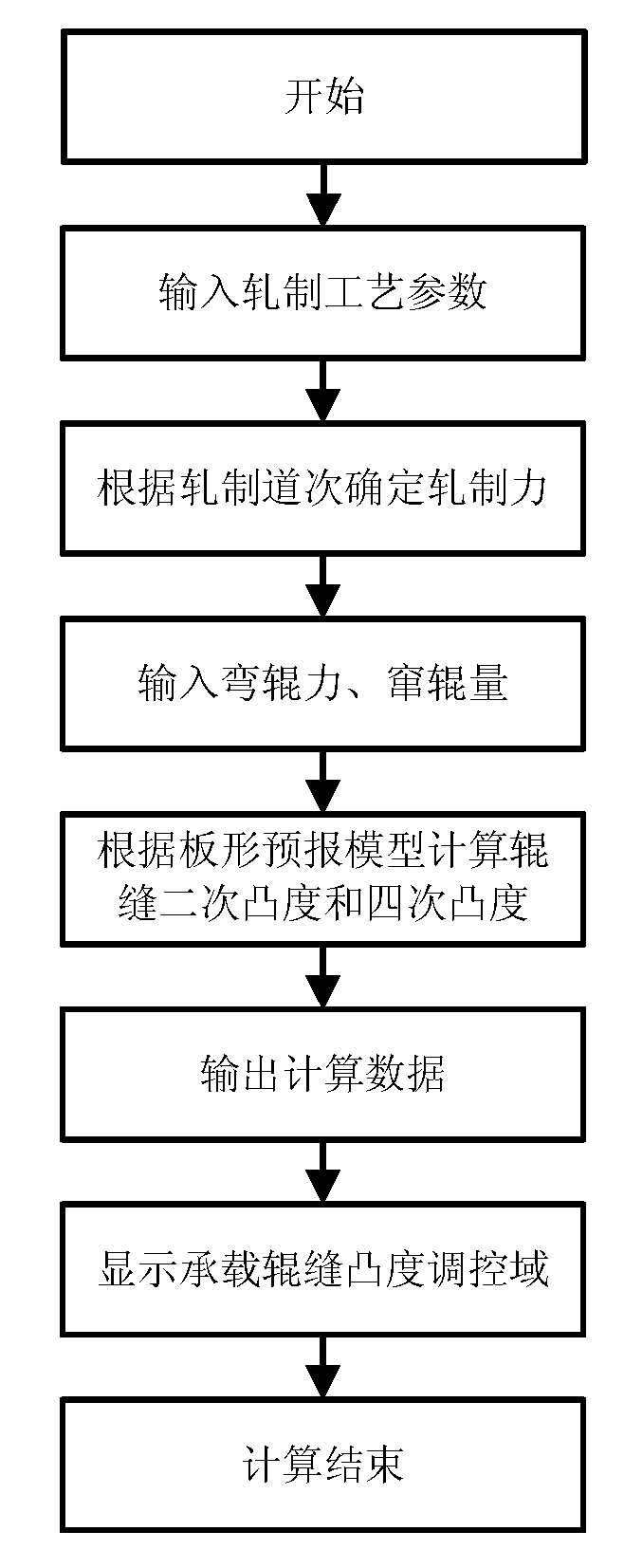

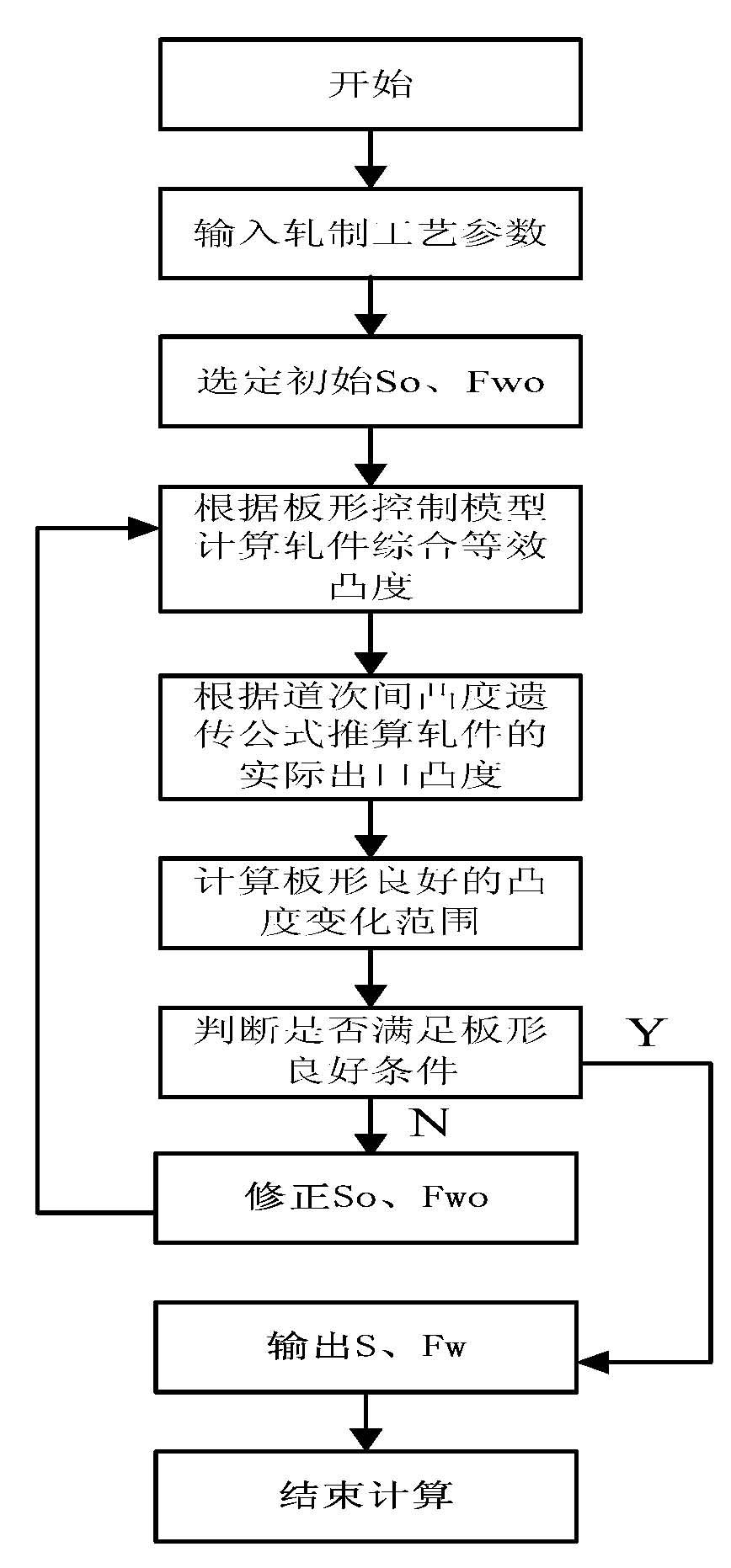

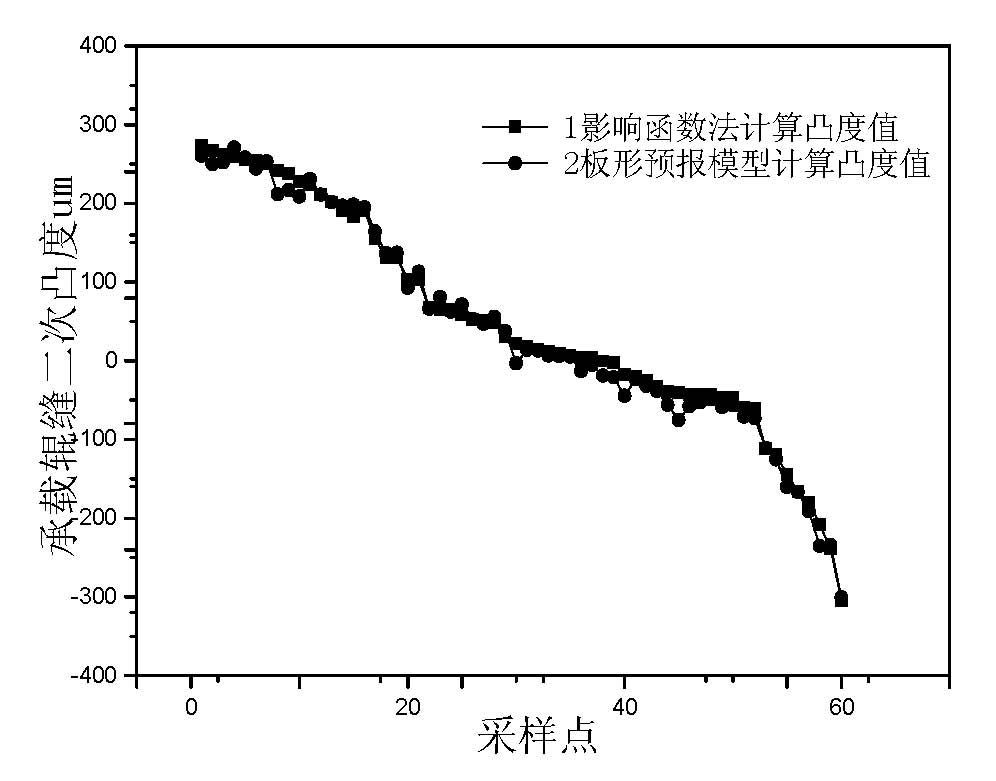

High-precision strip shape control prediction method for CVC (continuously variable crown) four-roll cold rolling mill

InactiveCN102601127AComposite wave in control sideHigh yieldMeasuring devicesProfile control deviceClassical mechanicsWave form

The invention relates to a high-precision strip shape control prediction method for a CVC (continuously variable crown) four-roll cold rolling mill. The high-precision strip shape control prediction method includes the steps: (1) building a strip shape prediction model for the CVC four-roll cold rolling mill; (2) determining parameters of the strip shape prediction model by means of regression; and (3) predicting a crown regulating domain of the CVC four-roll cold rolling mill in an online and real-time manner according to the regulating range of strip steel widths, roll radiuses, roll bending force and traversing positions under the condition of determined rolling force based on the strip shape prediction model. By the aid of the technical scheme, the strip shape prediction model is built, the secondary crown and the quaternary crown of a bearing roll gap can be accurately predicted, and the strip shape regulating capability of the rolling mill can be predicted in an online manner based on the strip shape prediction model. Besides, preset values of the roll bending force and roll shifting of the CVC four-roll cold rolling mill can be optimized, so that double waves or middle waves in a secondary wave form and edge and middle composite waves in a quaternary wave form can be effectively controlled, and the yield of a strip is improved.

Owner:WISDRI ENG & RES INC LTD

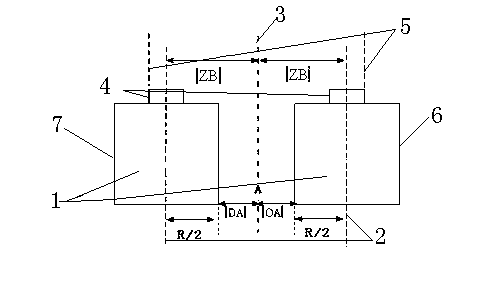

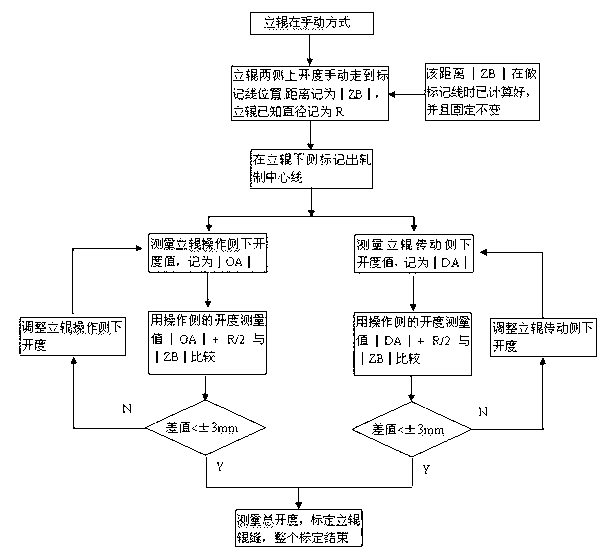

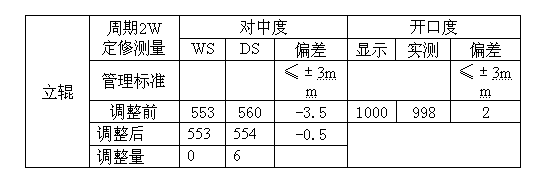

Calibration method for clearance between rolls of hot-rolling vertical rolls

InactiveCN102989792AProtective functionEliminate the problem of abnormal widthMetal rolling stand detailsMeasuring devicesStrip steelEngineering

The invention relates to a calibration method for clearance between rolls of hot-rolling vertical rolls, which mainly solves the technical problem that strip steel is deficient in quality because verticality and alignment to calibration of vertical rolls are not considered in current methods. The technical scheme is that the calibration method for clearance between rolls of hot-rolling vertical rolls comprises the steps of: 1, finding a rolling center line and marking; 2, additionally arranging two position marks on a transverse slipway of a hot-rolling vertical roll device, and marking the distance from the marks to the rolling center line as |ZB|; 3, hitting apertures on both sides of the vertical rolls to marked positions, wherein a roll block is inside a marking line and aligned with the marking line; 4, measuring the distance from the lower ends on both sides of the vertical rolls to the rolling center line, and marking the measuring point as a point A, the radius of the rolls as R / 2 and the distances from A to a vertical roll operating side and from A to a transmission side as |OA| and |DA|; 5, comparing the measured value |OA|+R / 2 on the operating side with |ZB|, wherein if the difference is in a precision range, the verticality is good, and if the difference is not in the precision range, the clearance between rolls on the operating side is adjusted so that the difference is in the precision control range; 6, adjusting the clearance between rolls on the transmission side by the adjusting method in the step 5; and 7, measuring the total aperture of the vertical rolls, inputting the measured values and calibrating the clearance between rolls of vertical rolls after adjusting the verticality and alignment.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

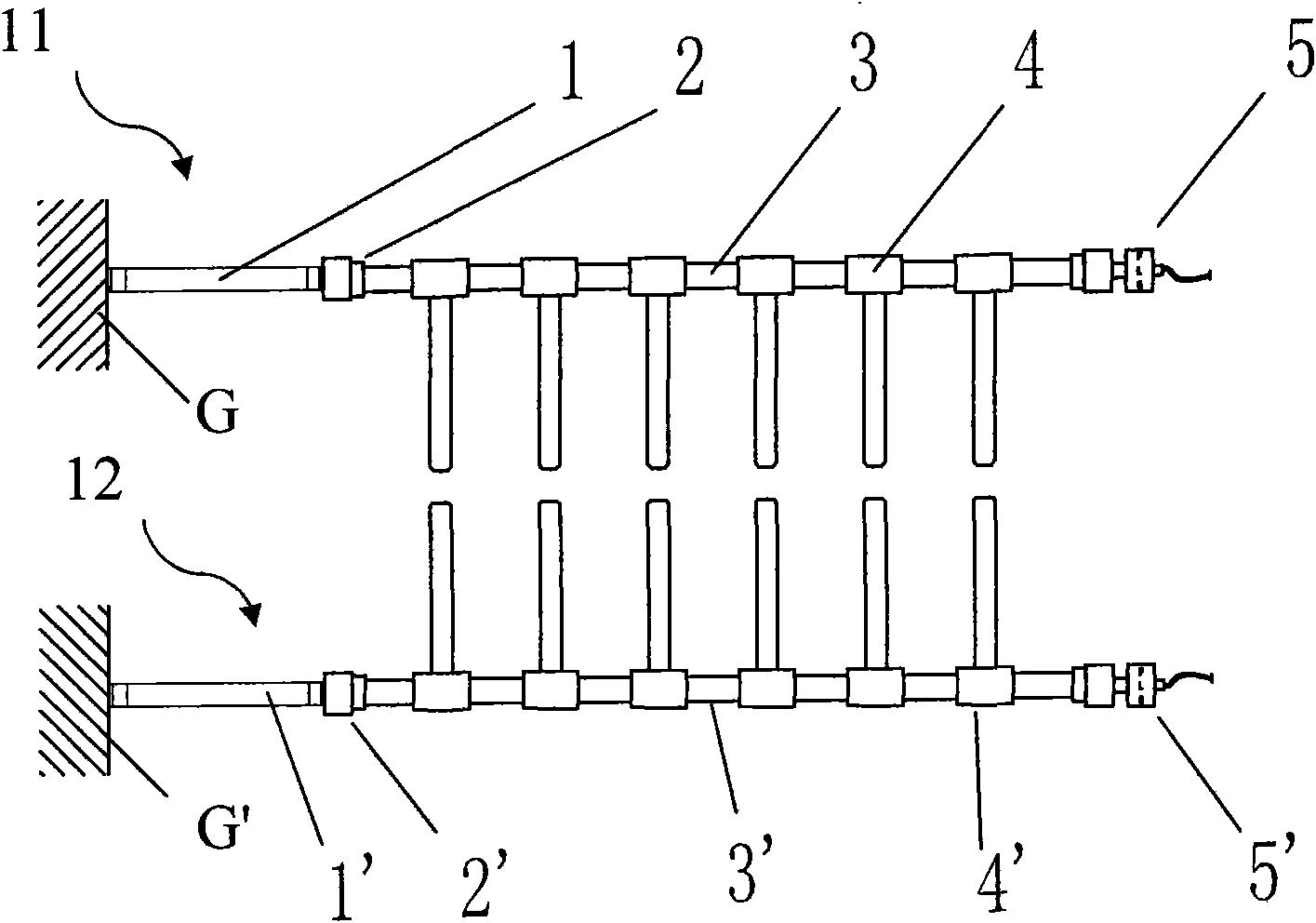

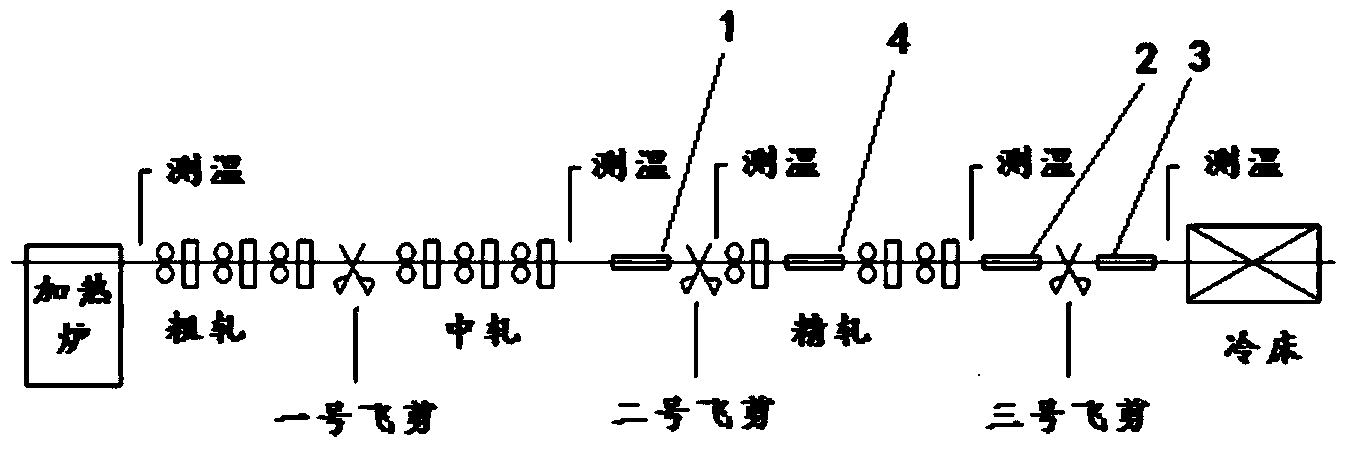

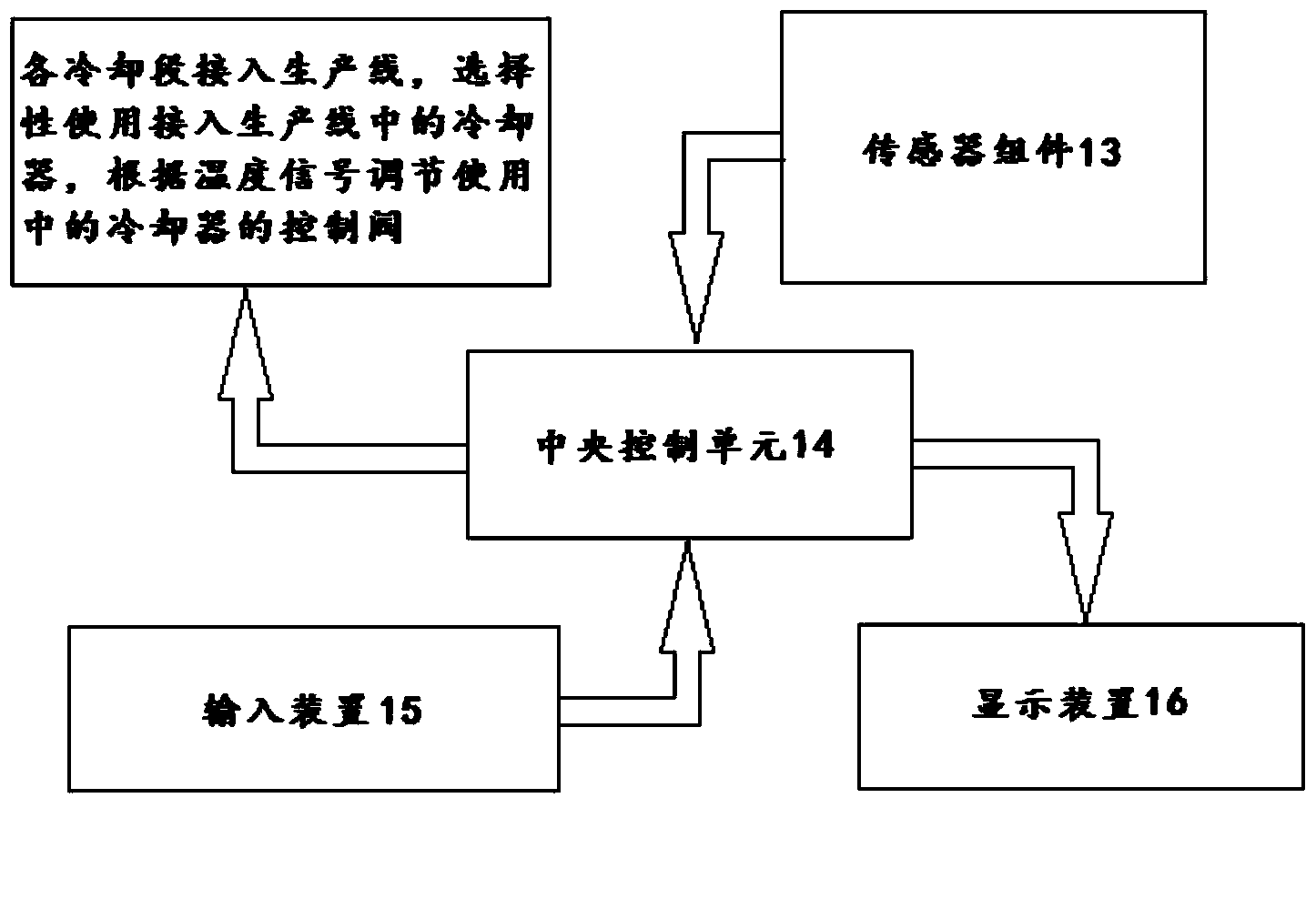

Controlled rolling and controlled cooling system for bars

ActiveCN103551403APrevent "overcooling"Large temperature difference in the axial directionTemperature control deviceWork treatment devicesProduction lineEngineering

A controlled rolling and controlled cooling system for bars comprises a first cooling section at the position of an outlet of an intermediate mill group, a machine cooling section of a finishing mill group, a second cooling section between the finishing mill group and a third flying shear, a third cooling section between the third flying shear and a cooling bed, a sensor module and a central control unit. The first cooling section, the second cooling section and the third cooling section respectively comprise one or a plurality of cooling lines arranged on a horizontal moving trolley and a bypass roll table, one cooling line or the bypass roll table can be selectively connected to a production line by horizontally moving the horizontal moving trolley, and every production line comprises one or a plurality of series connection coolers. Every cooler is connected to a water supply main pipe through one water supply branched pipe, control valves are arranged in the water supply branched pipes, and the coolers connected to the production lines are selected and used by opening and closing of the control valves. According to the controlled rolling and controlled cooling system, a plurality of cooling sections can be selected flexibly, the coolers in every cooling section can also be selectively used simultaneously, and accordingly the system not only is good in applicability, but also improves bar finished product performances.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

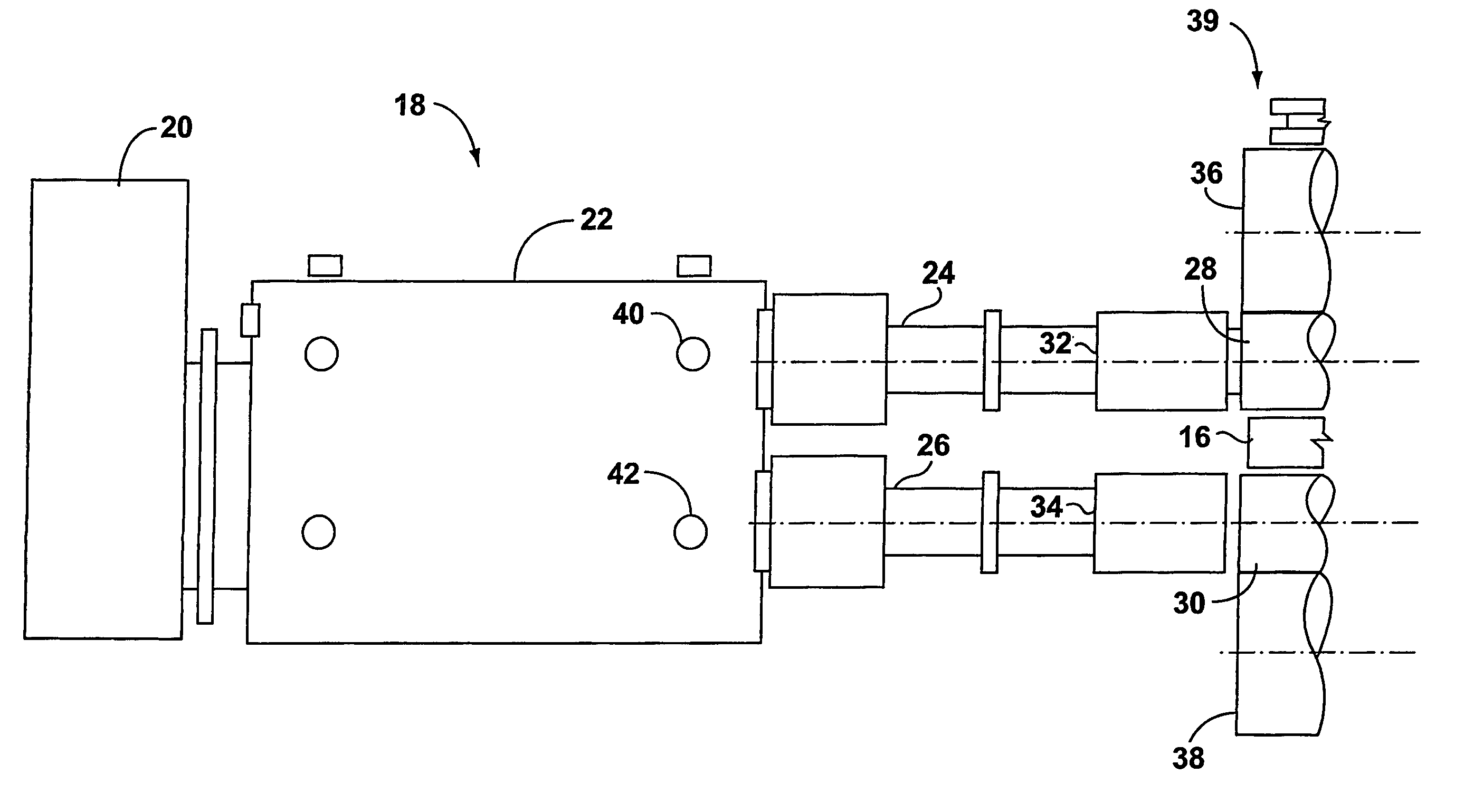

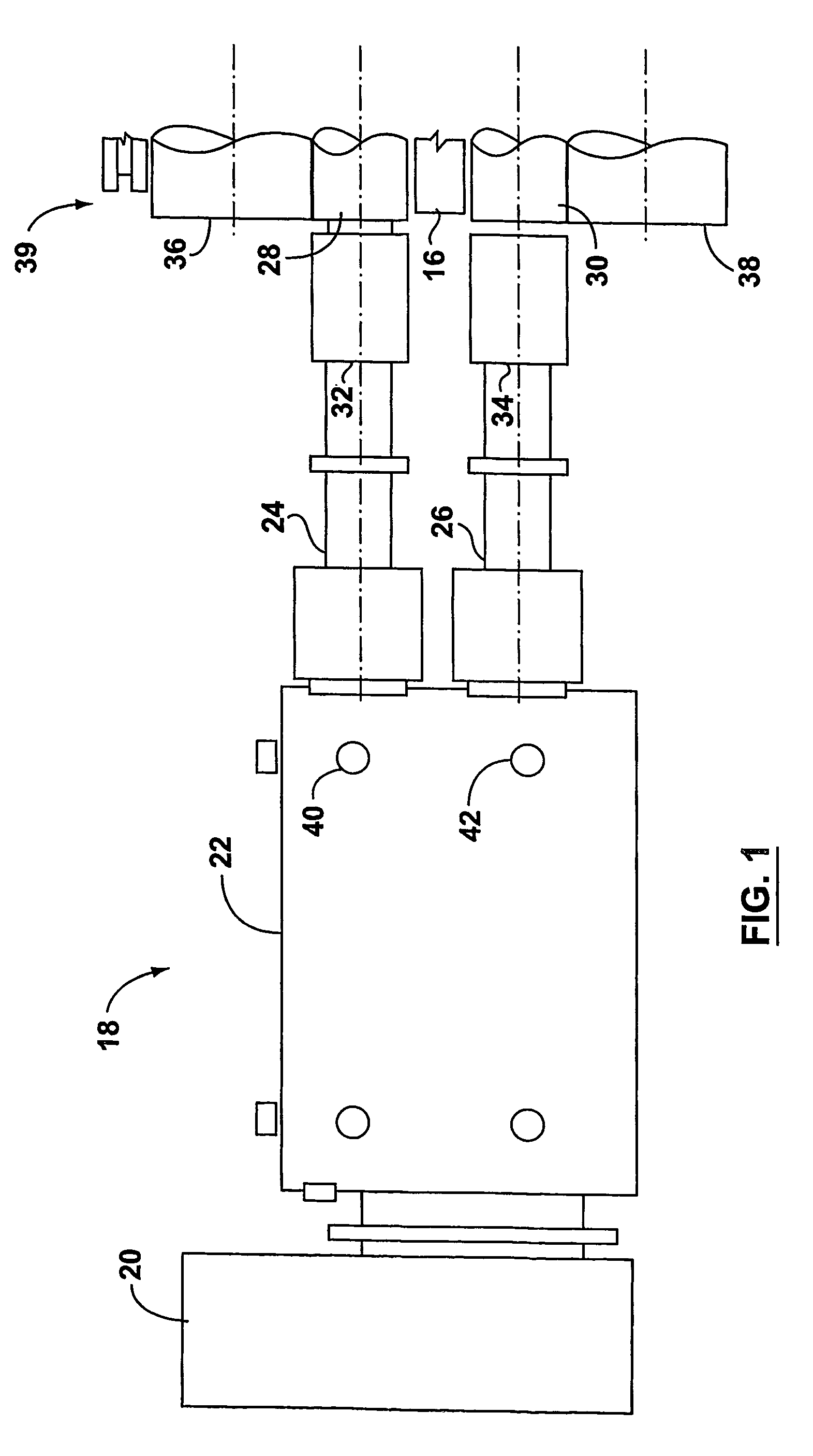

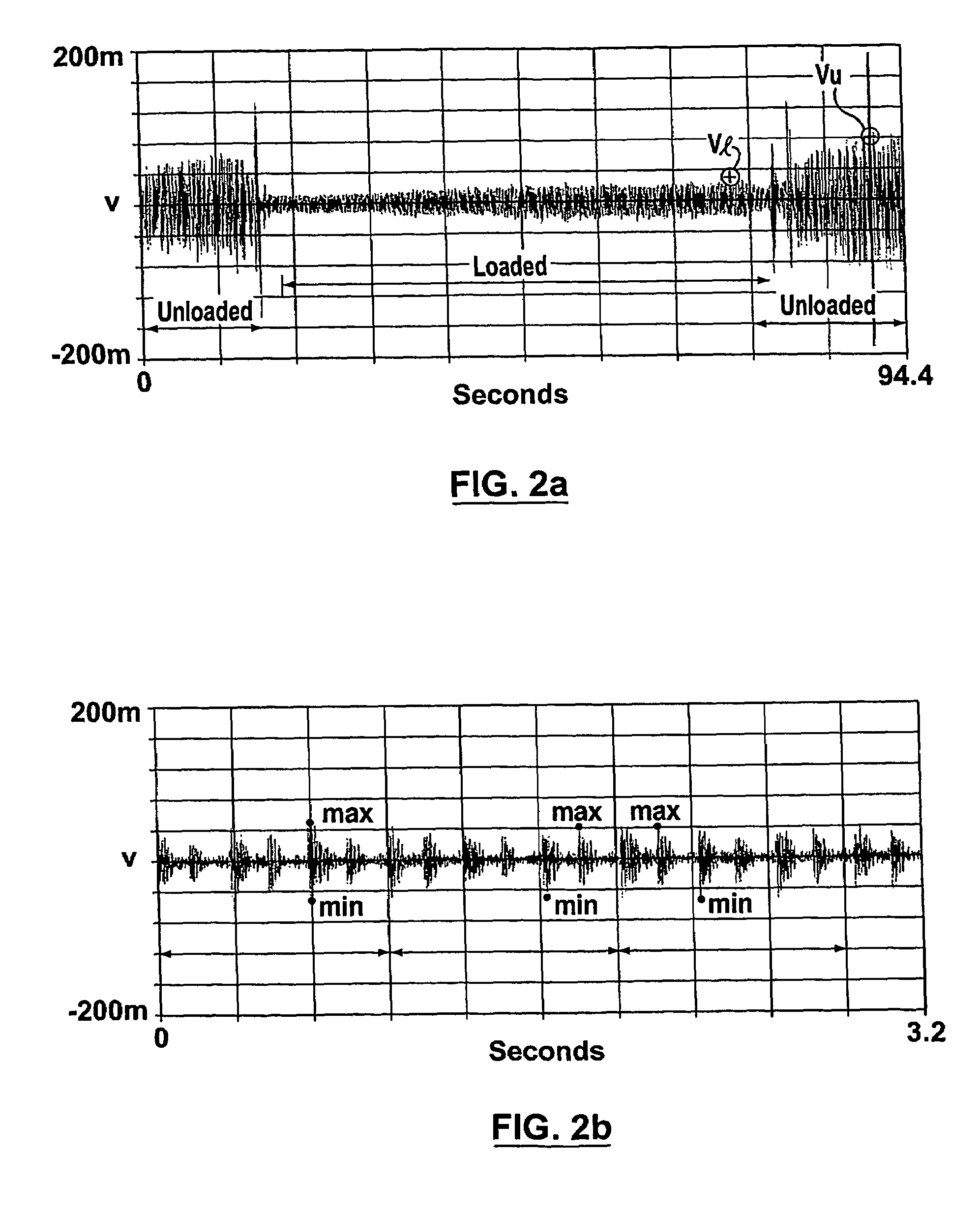

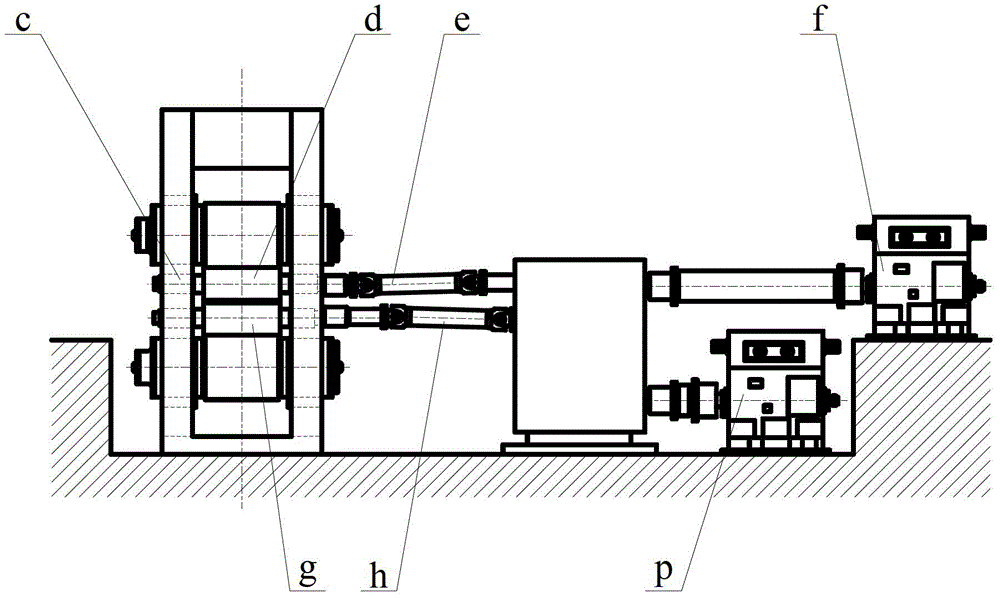

Diagnostic method for predicting maintenance requirements in rotating equipment

ActiveUS7206719B2Vibration measurement in solidsMachine part testingDiagnostic methodsReliability engineering

This invention is a method to determine the condition of rotating equipment, namely drive spindles, to enable the timely maintenance or replacement of same. The method uses an electrical signal from a vibration sensor mounted on part of the drive train to measure the level of vibration energy when the equipment is rotating under loaded and unloaded conditions. The relative vibration under the loaded and unloaded conditions is used as an indicator of equipment condition. Typically there is more vibration under load when the equipment is in good condition. When the level of vibration under the no-load condition matches or exceeds that seen under load, the equipment needs to be serviced or replaced.

Owner:DOFASCO INC

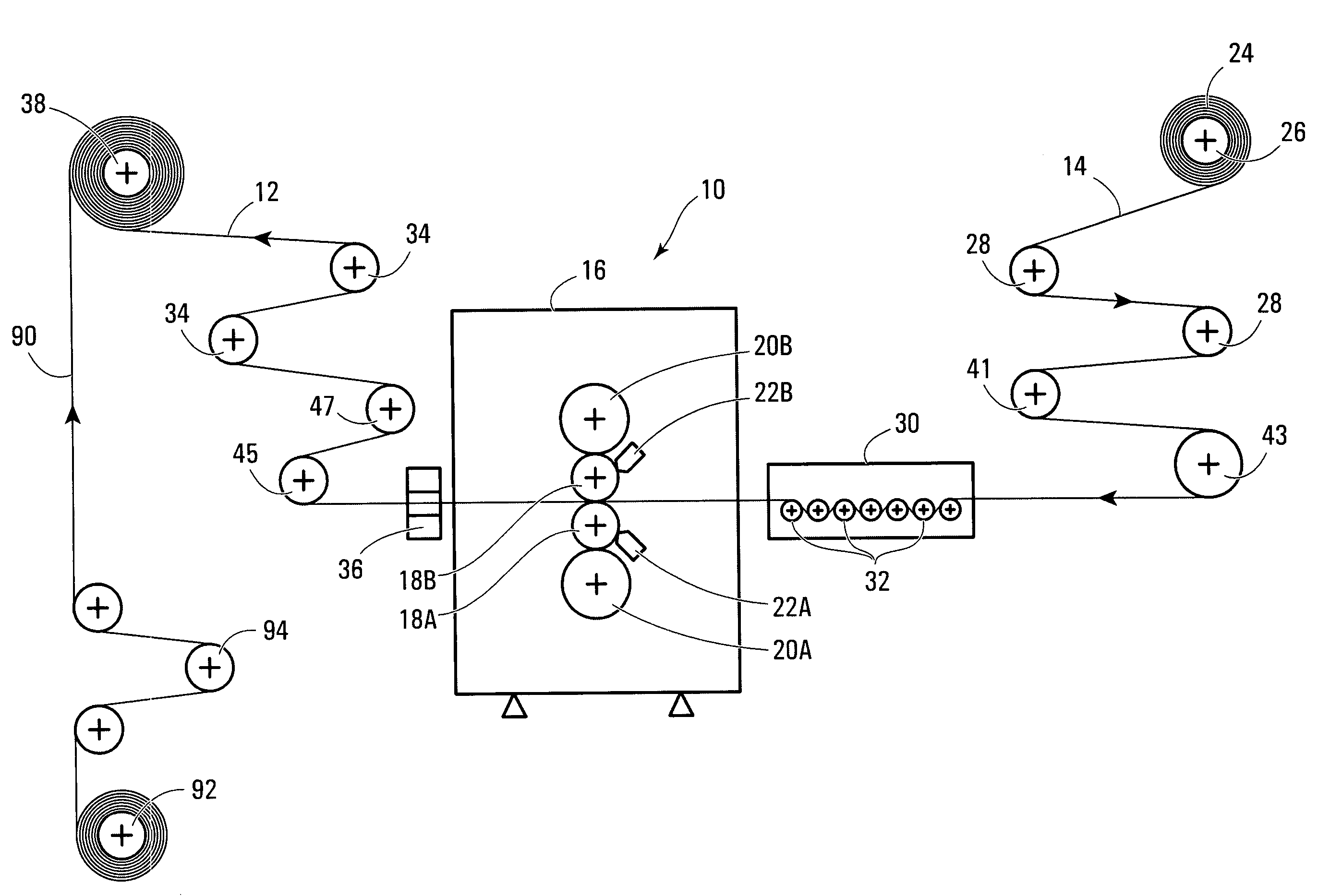

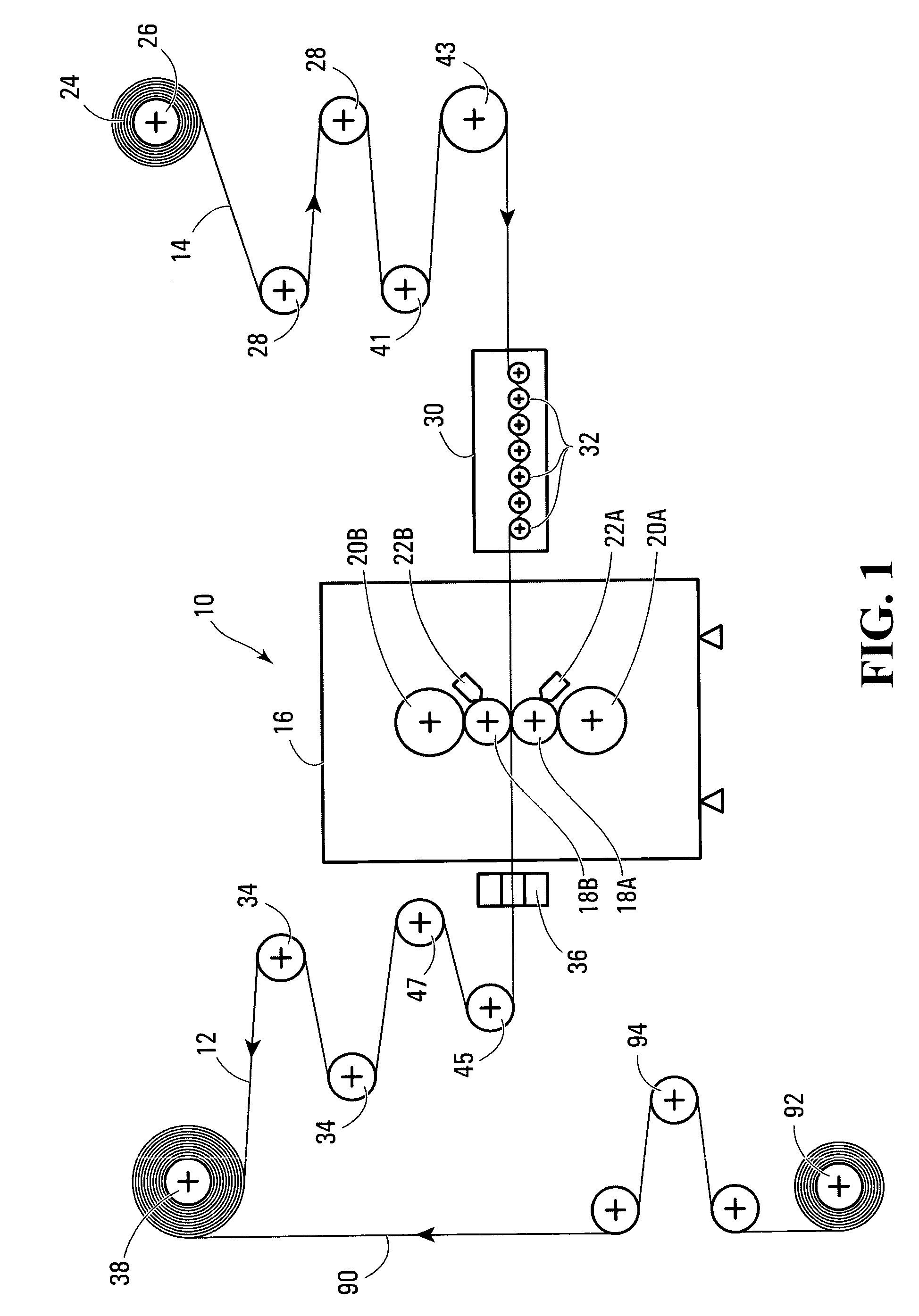

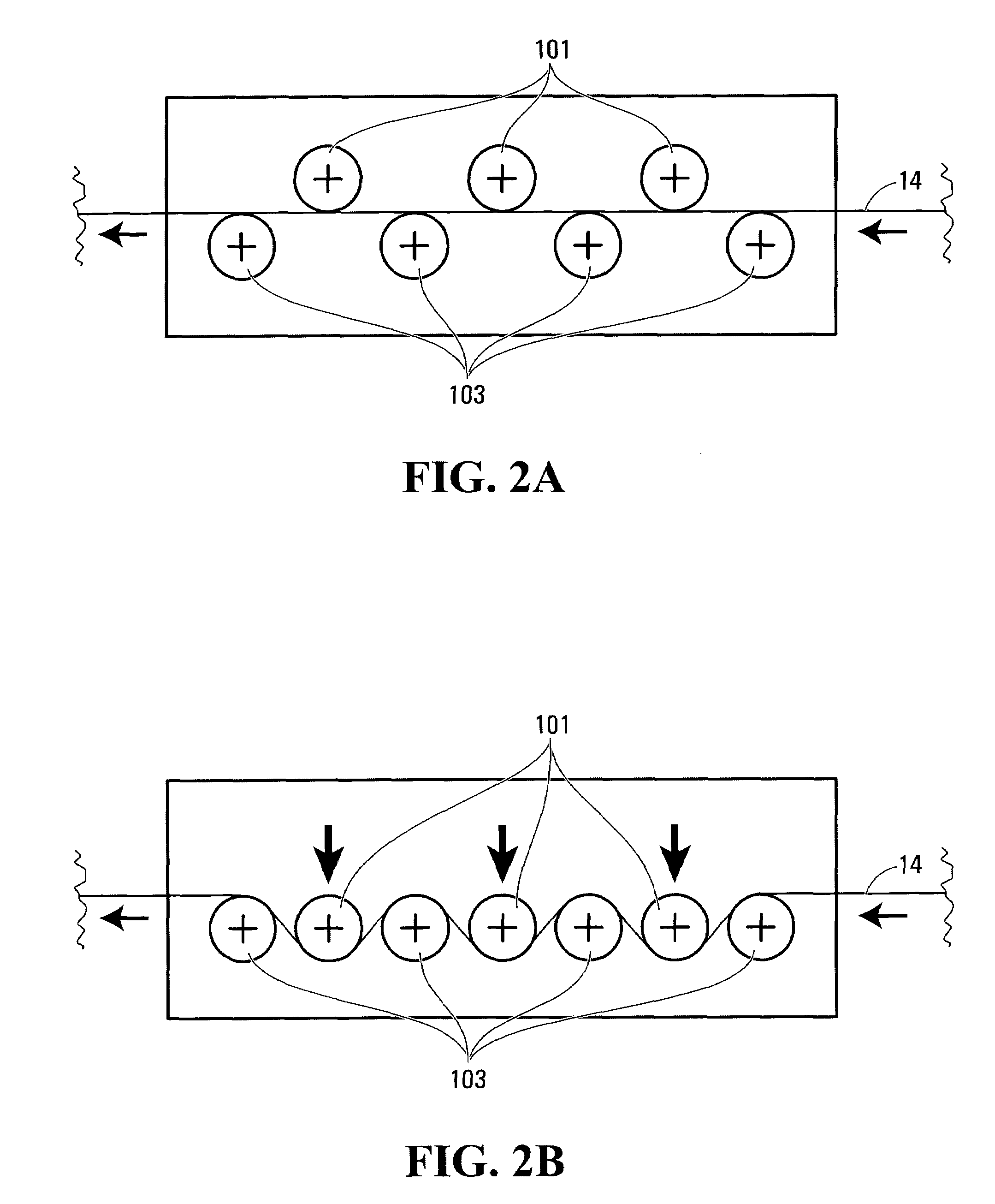

Lamination process and apparatus for alkali metals or alloys thereof

ActiveUS7513136B2Reduce thicknessElectrode rolling/calenderingRoll force/gap control deviceLithiumElectrical battery

An apparatus for and method of manufacturing lithium or lithium alloy anodes for electrochemical cells by a lamination process wherein a lithium or lithium alloy sheet is reduced into a thin lithium or lithium alloy film. The method and apparatus provide adjustments of the profile defined by the meeting surfaces of a pair of working rollers to compensate for thermal dilation of the working rollers or to compensate for irregular thickness of the lithium or lithium alloy sheet to control the shape and profile of the lithium or lithium alloy film being laminated.

Owner:BATHIUM CANADA

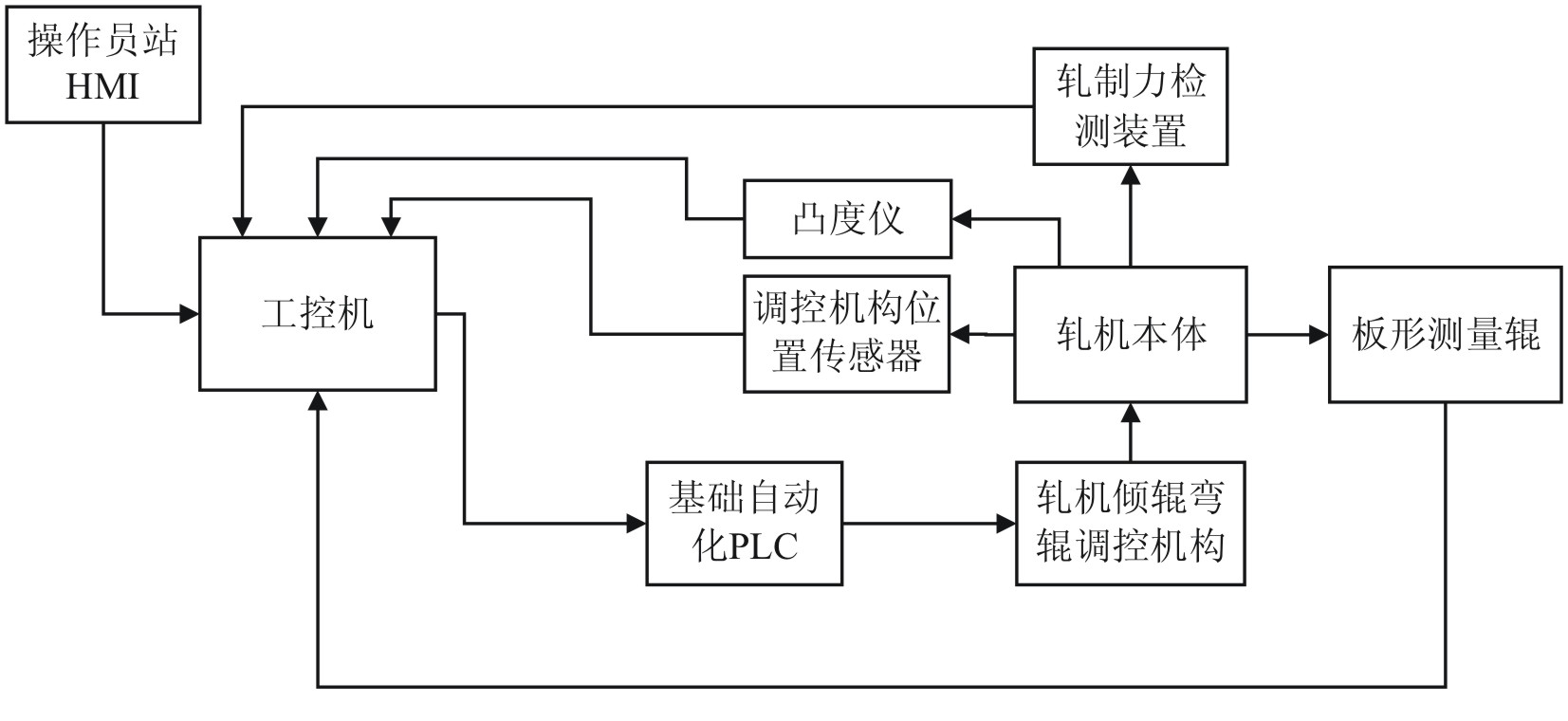

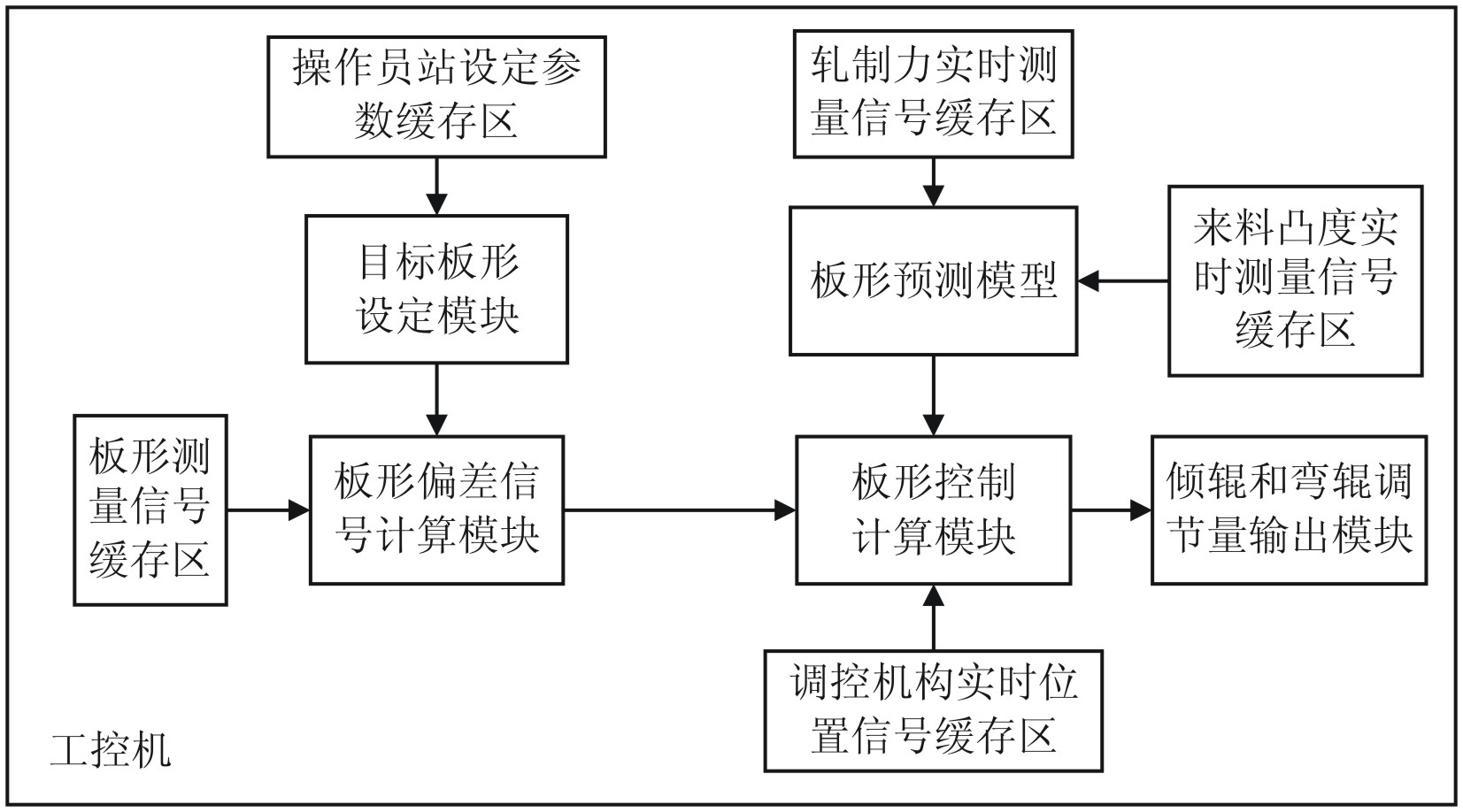

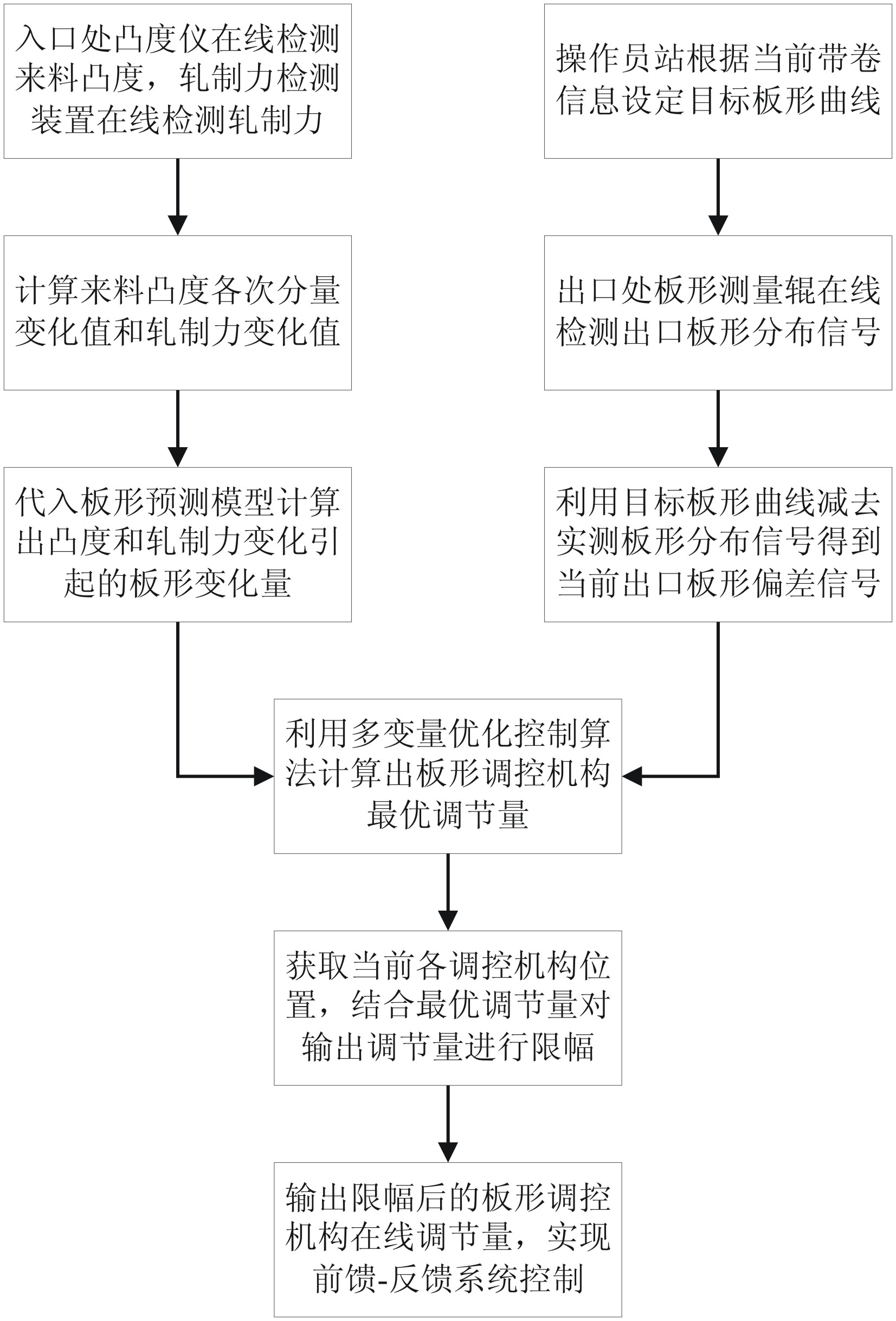

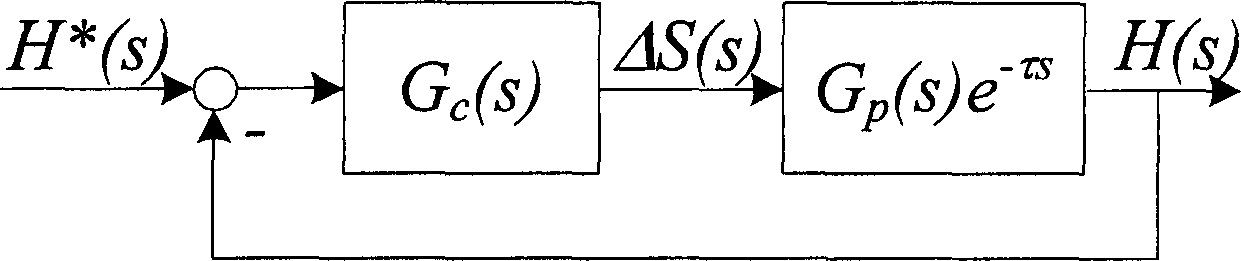

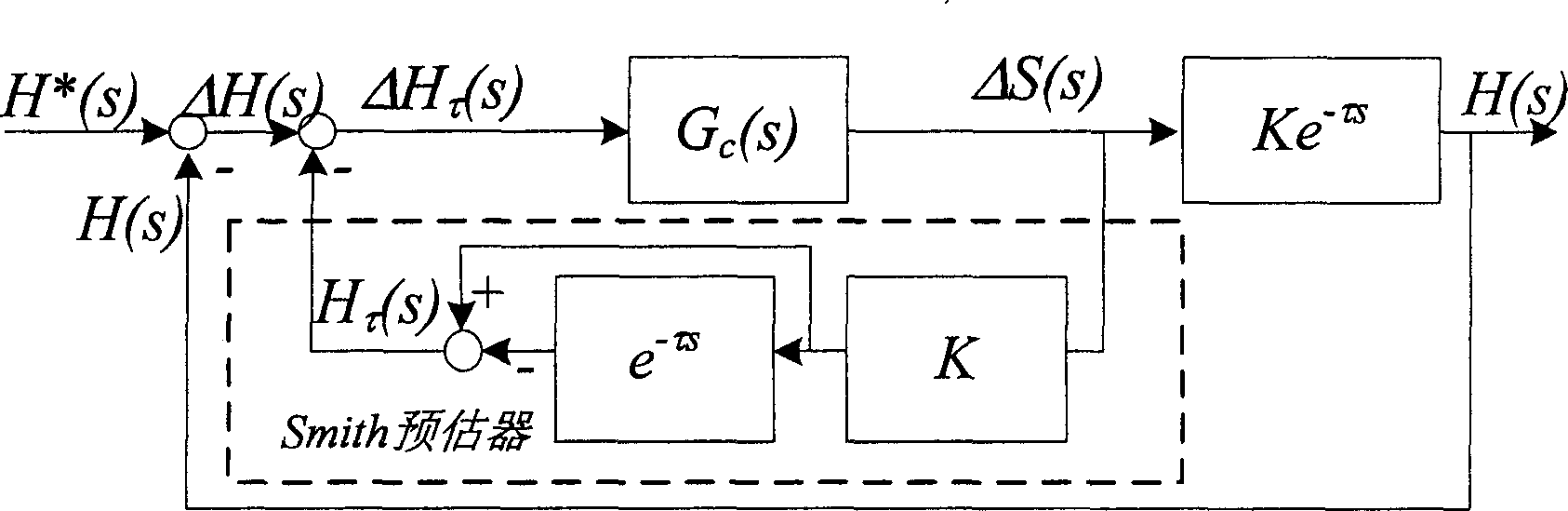

Cold-rolled strip steel plate shape control system and method

ActiveCN102632085AEliminate technical issues that degrade qualityEliminate shape defectsMeasuring devicesProfile control deviceAutomatic controlTime delays

The invention discloses a cold-rolled strip steel plate shape control system and method. An advanced feedforward-feedback cooperative control architecture is adopted and after a plate shape automatic control system is put into on-line operation, plate shape variation and outlet plate shape real-time deflection caused by changes of convexity and rolling force are jointly calculated out by calculating links of the plate shape variation and the outlet plate shape real-time deflection which are caused by the changes of the convexity and the rolling force; and then an on-line regulation variable for control of a cold-rolled strip steel plate shape is calculated out at an optimal regulation variable calculating and amplitude limit processing link of a plate shape control mechanism. The time-delay influence of strip steel in transmission between a rolling mill and a plate shape gauge is eliminated and the precision for estimating the plate shape is ensured; and the technical problem of outlet plate shape quality variation caused by practical factors such as the convexity change and the rolling force fluctuation of supplied materials during the rolling process can be solved, so that the quality of cold-rolled strip steel products is enhanced remarkably.

Owner:惠州市南钢金属压延有限公司

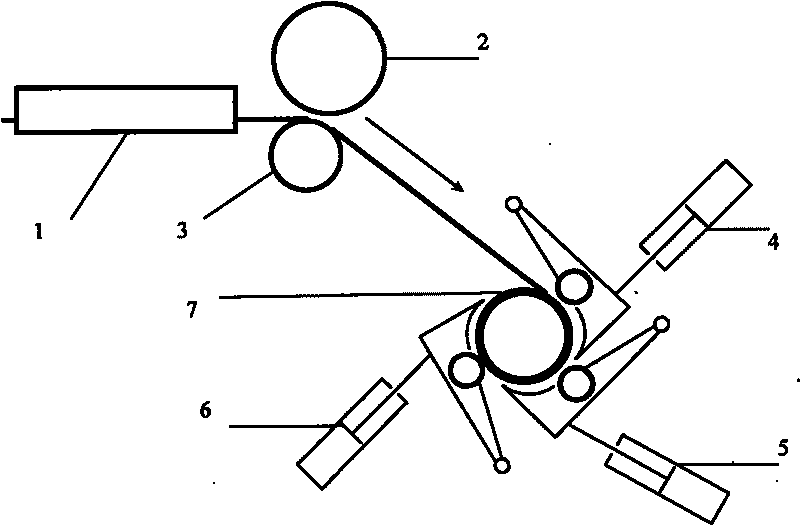

Rolling device for preparing high-toughness high-formability magnesium alloy sheet strip coil

ActiveCN102240676ARealize continuous temperature-controlled rollingImprove mechanical propertiesMeasuring devicesTension/compression control deviceMetallic materialsFeedback control

The invention relates to a rolling device for preparing a high-toughness high-formability magnesium alloy sheet strip coil and belongs to the field of metal material rolling. The rolling device provided by the invention comprises a rolling machine, an uncoiling machine, a left-right recoiling machine, a front online heating insulating device of the roll machine, a rear online heating insulating device of the roll machine, a straightening machine, a bending rectifying machine, a thickness measuring device, a steering tension roll, a guide roll, a roller heating and lubricating device and the like. In the invention, an online continuous heating device and an advanced PLC (programmable logic control) feedback control system are adopted, and continuous temperature control rolling on the magnesium alloy strip coil is realized. The rolling device provided by the invention has the advantages of uniform heating temperature, high heating efficiency and high temperature control accuracy, and high-quality thin wrought magnesium alloy strip coils are efficiently produced by virtue of a roller preheating insulating system, a technical lubricating system, a strip shape control system and a tension straightening device, thus the geometric quality and structure properties of rolled metal can meet operating requirements.

Owner:江苏永良镁业科技有限公司

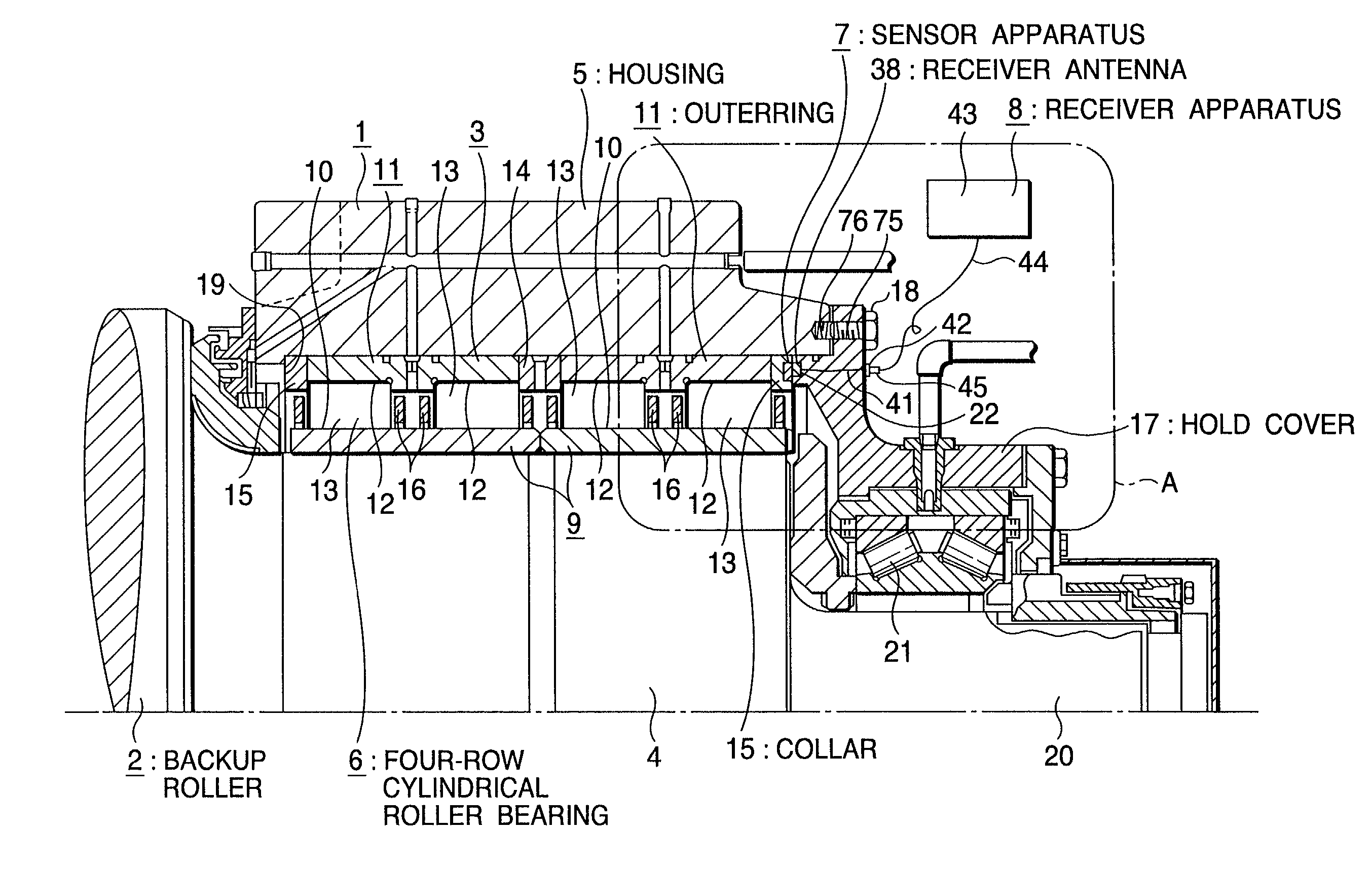

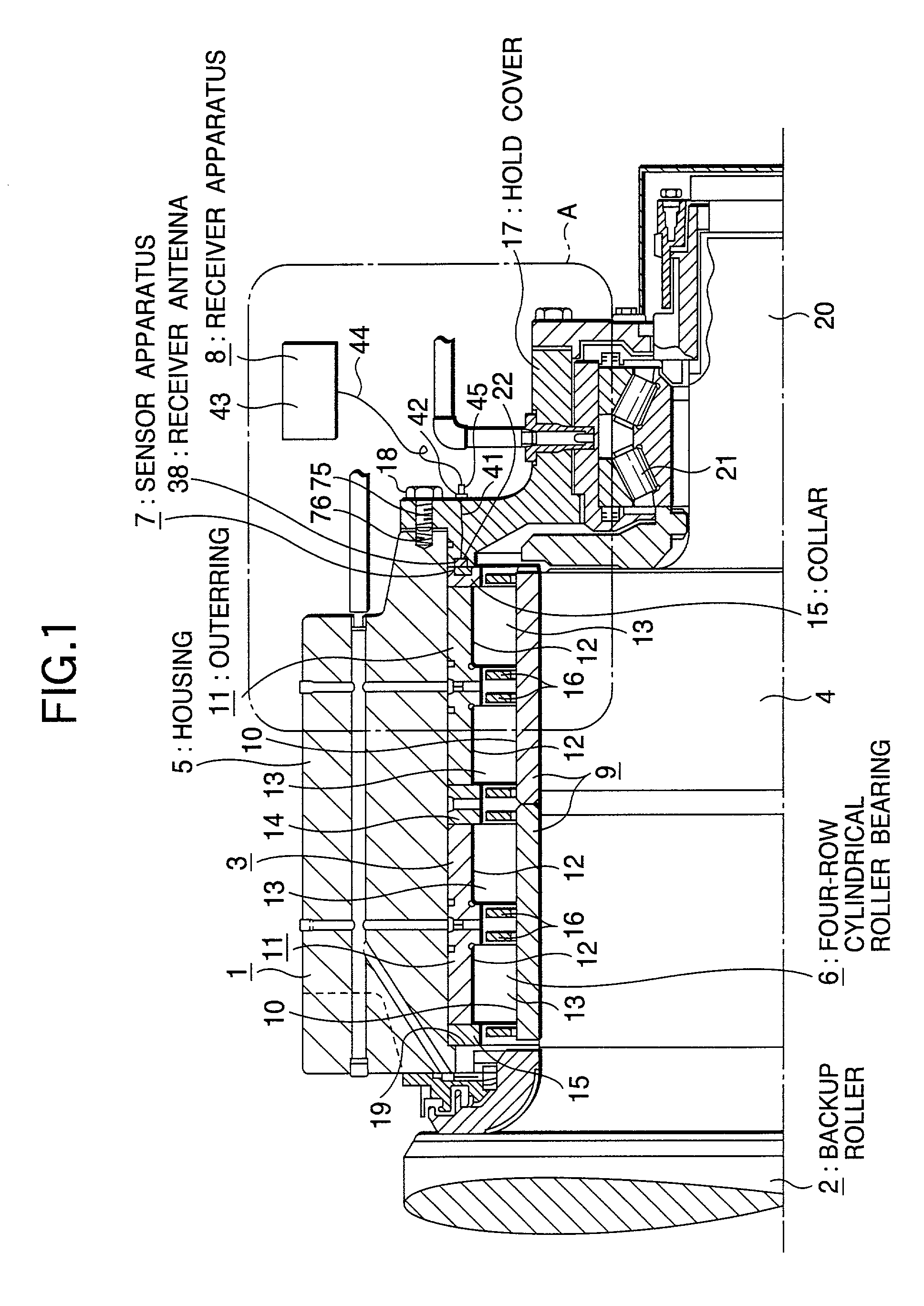

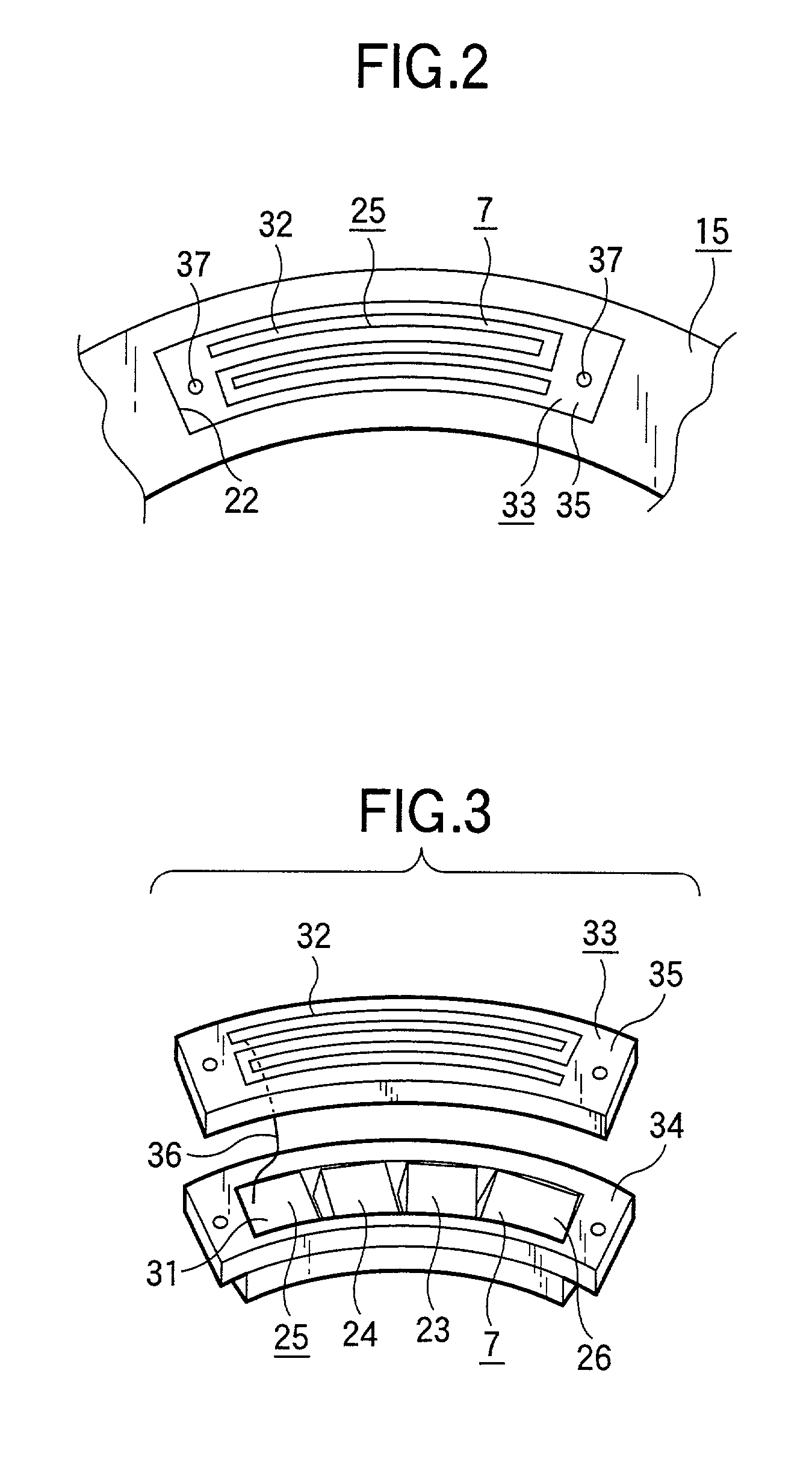

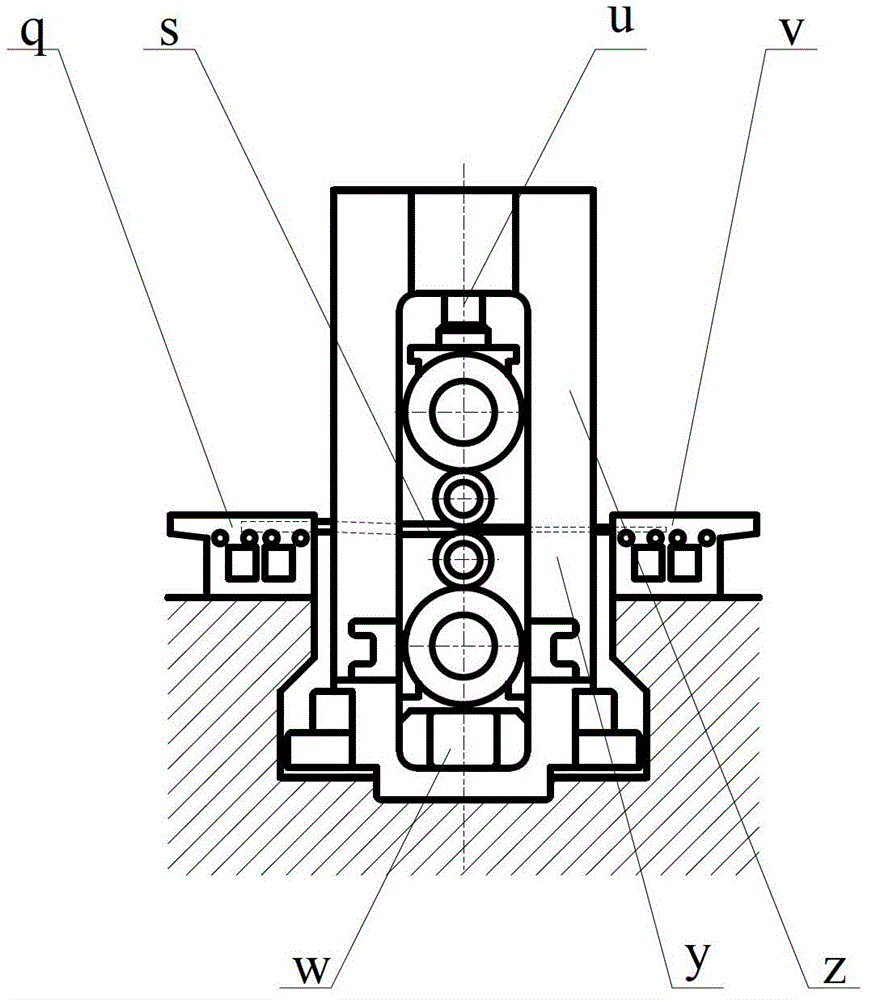

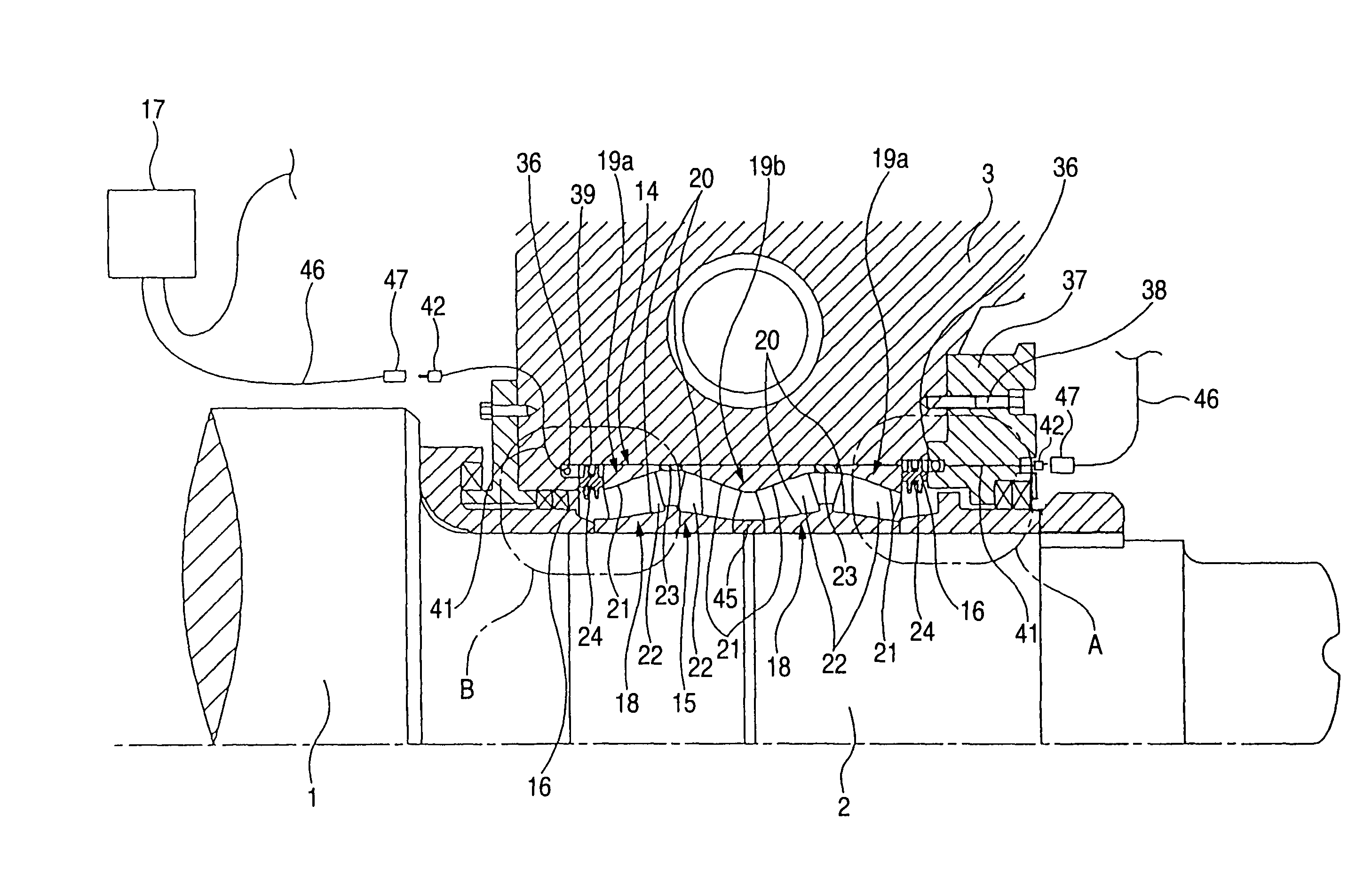

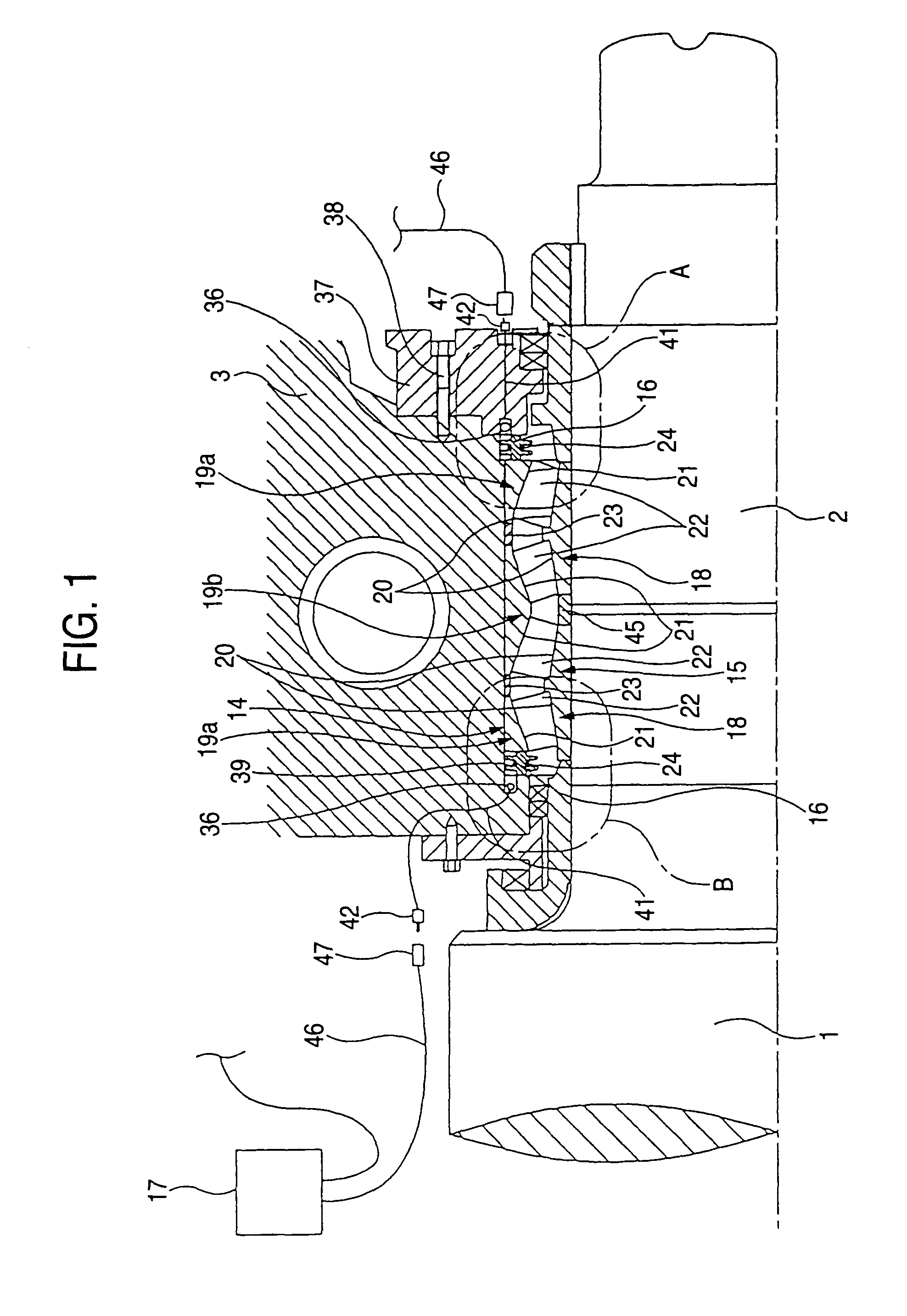

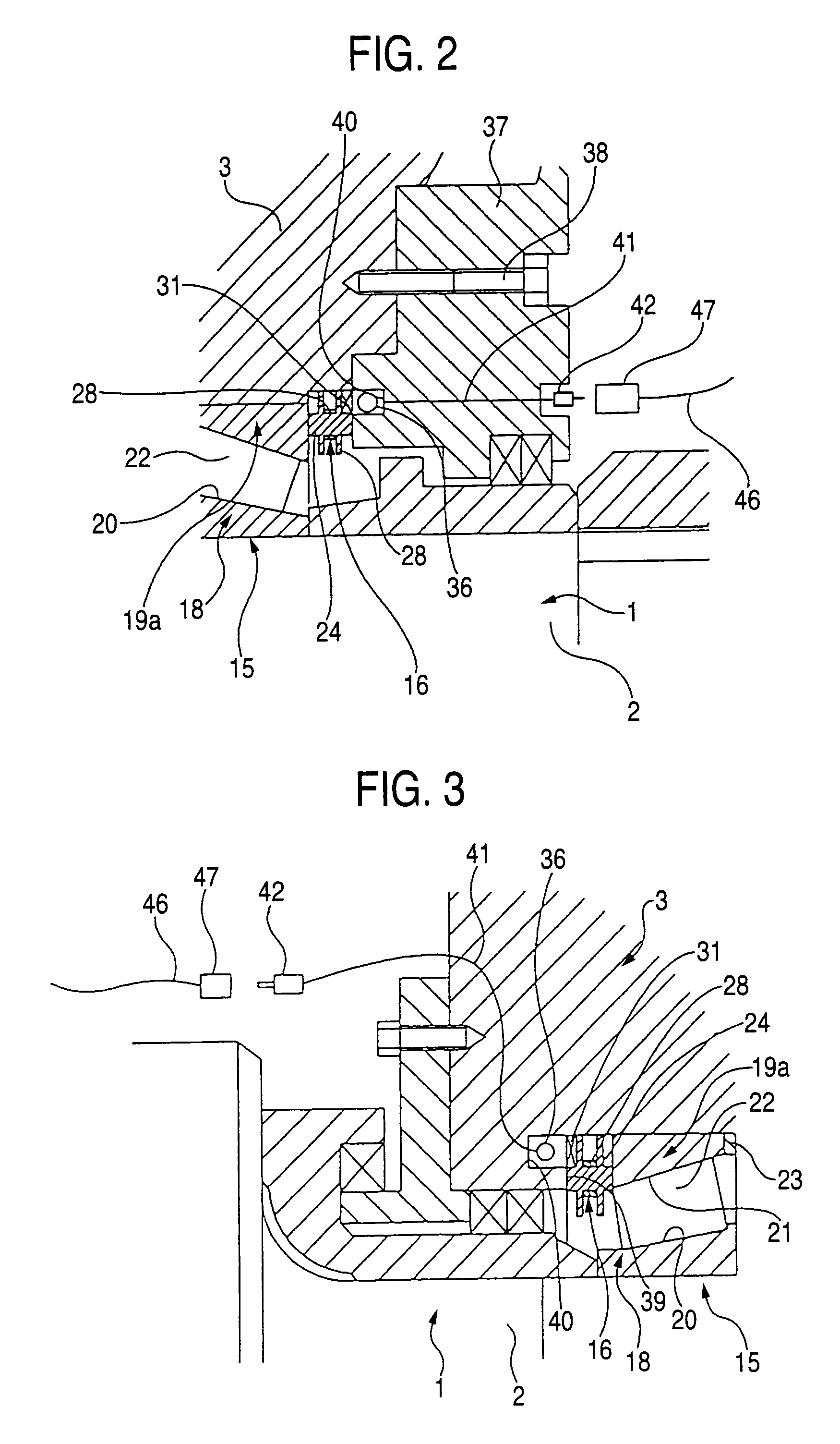

Rolling bearing unit with sensor

InactiveUS20030048962A1Easy to replaceEasy to confirmVibration measurement in solidsRotary bearingsRolling-element bearingEngineering

A four-row cylindrical roller bearing is incorporated into between the inner peripheral surface of a housing and the outer peripheral surface of a backup roller. A sensor unit 7 is held in a portion of a collar disposed in the axial-direction end portion of the four-row cylindrical roller bearing. The sensor unit comprises a detect part for detecting temperatures and vibrations and a transmitter device for transmitting signals, which are obtained after output signals taken out from the detect part are processed, as radio signals. On a portion of a hold cover which is a separate member from the collar, there is disposed a receive antenna which is part of a receiver apparatus for receiving the radio signals transmitted by the transmitter device.

Owner:NSK LTD

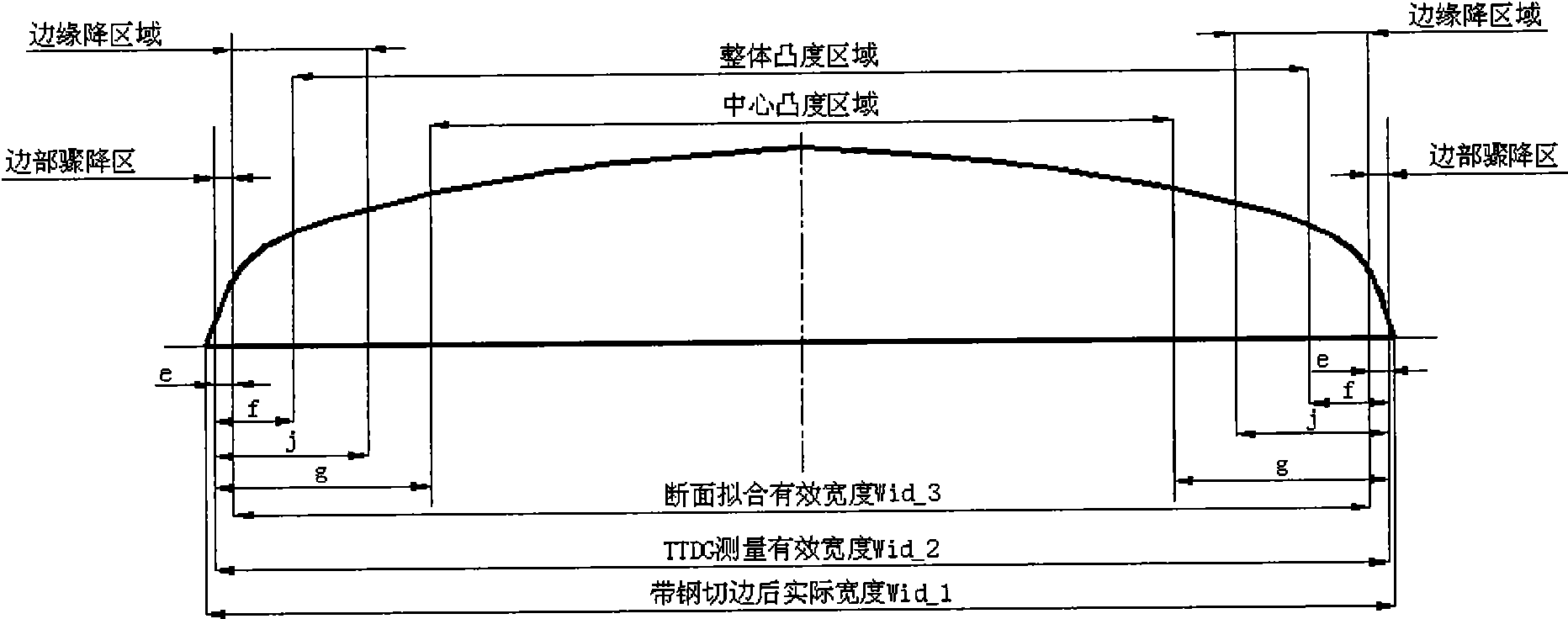

Control method of lateral thick difference of cold-rolling strip steels

ActiveCN102029294AReal-time acquisition of lateral thickness fluctuationsTimely responseRoll force/gap control deviceMeasuring devicesStrip steelEngineering

The invention discloses a control method of the lateral thick difference of cold-rolling strip steels, which realizes the feedforward control of the lateral thick difference of the cold-rolling strip steels by detecting the shapes of the profiles of hot-rolling supplied materials in real time on the basis of a profiler configured on an inlet of a No.1 rack. The control method mainly comprises thefollowing steps of: (1) configuring a strip steel profile shape detector on the inlet of the No.1 rack of a cold-rolling mill, and detecting the shapes of the profiles of the hot-rolling supplied materials in real time; (2) calculating to obtain the characteristic value vectors of the profiles of the cold-rolling strip steels positioned on the inlet of the No.1 rack through the measured values ofthe shapes of the profiles of the hot-rolling supplied materials; (3) respectively determining the compensation amount of a working bending roll, an intermediate bending roll, a supporting tilting roll, an upper shifting roll, a lower shifting roll and an intermediate shifting roll of the No.1 rack according to the difference of the actual values of the characteristic vectors of the profiles of the cold-rolling strip steels positioned on the inlet of the No.1 rack and the target values of the characteristic vectors; and (4) when the lateral thick difference is output in a controlling way, adopting the actual distribution of the flatness of a roll gap outlet as a constraint condition. The invention can further enhance the quality of the cold-rolling strip steels of cold-rolling mill products and ensure the stability of a cold-rolling production process.

Owner:BAOSHAN IRON & STEEL CO LTD

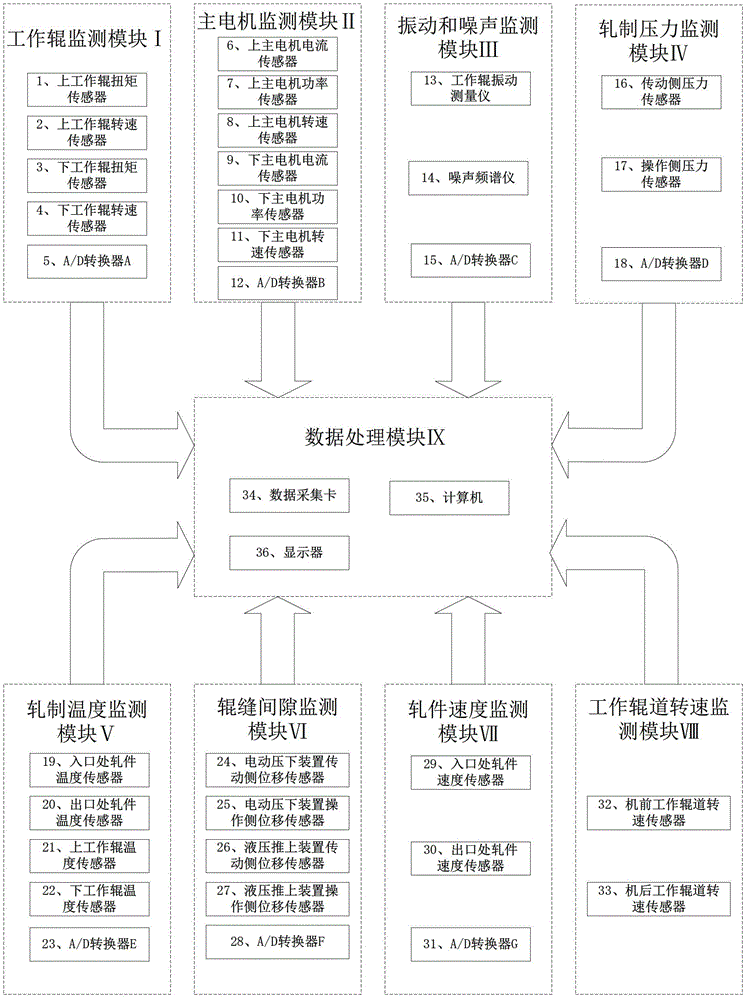

Magnesium alloy plate rolling parameter monitoring and fault diagnosing system and method

InactiveCN103331310AGuaranteed operational reliabilityHigh industrial applicabilityMeasuring devicesMetal rolling arrangementsNoise monitoringWork roll

The invention discloses a magnesium alloy plate rolling parameter monitoring and fault diagnosing system and method. The system is composed of a work roll monitoring module, a main motor monitoring module, a vibration and noise monitoring module, a rolling pressure monitoring module, a rolling temperature monitoring module, a roll gap interval monitoring module, a piece rolling speed monitoring module, a work roll way revolving speed monitoring module, a data processing module and a rolling mill, technological parameters such as rolling force and the rolling temperature and equipment parameters such as the motor current are monitored at the same time, the operating state of equipment is provided according to the parameters, and temperature prediction and fault diagnosis are conducted. Operating data of the equipment are recorded, a temperature monitoring model and a fault diagnosis model are completed, and an intelligent monitoring and diagnosing system with self-learning capacity is set up. A basis is provided for the design of the magnesium alloy rolling equipment, and the magnesium alloy plate rolling parameter monitoring and fault diagnosing system and method has guiding significance for the design of rolling equipment. The magnesium alloy plate rolling parameter monitoring and fault diagnosing system and method is strong in industrial applicability and has very good application prospects.

Owner:JILIN UNIV

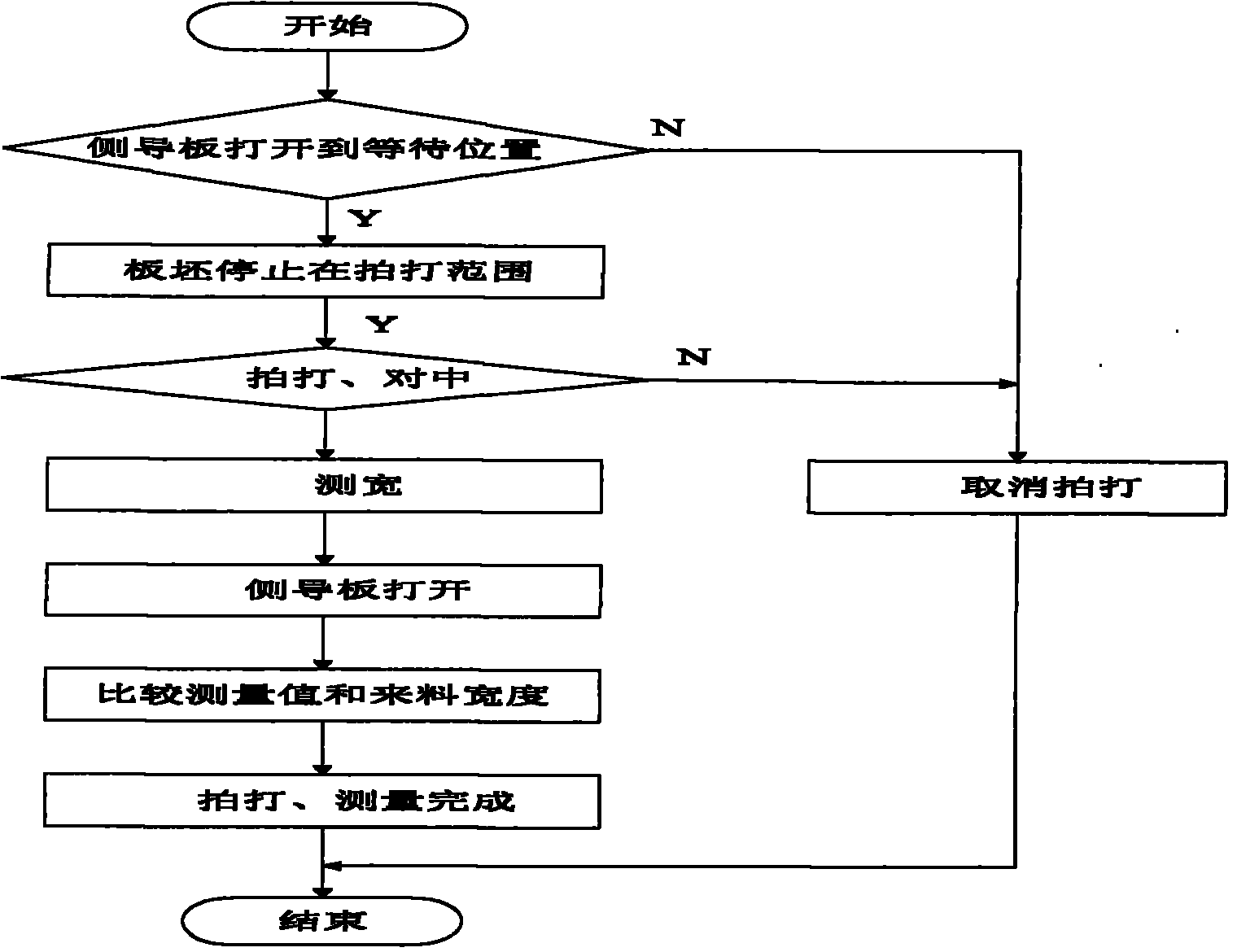

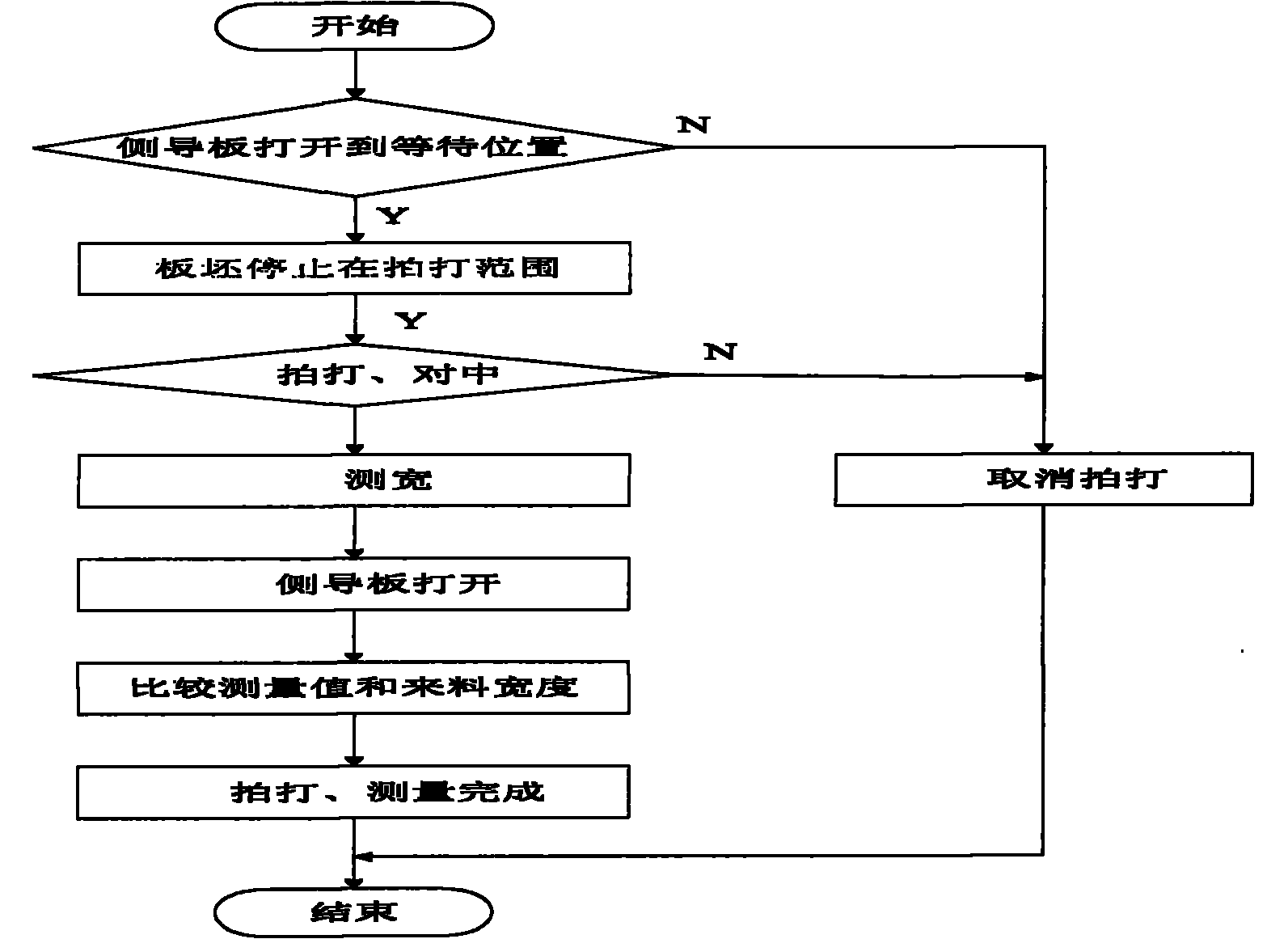

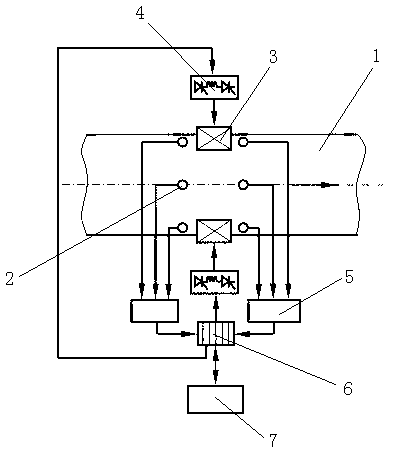

Method for setting vertical roll gap by centering side guide plates, measuring width and correcting

ActiveCN102825072AMeasure quicklyPrevent rolling abnormalitiesMetal rolling stand detailsMeasuring devicesControl systemRolling mill

Owner:BAOSHAN IRON & STEEL CO LTD

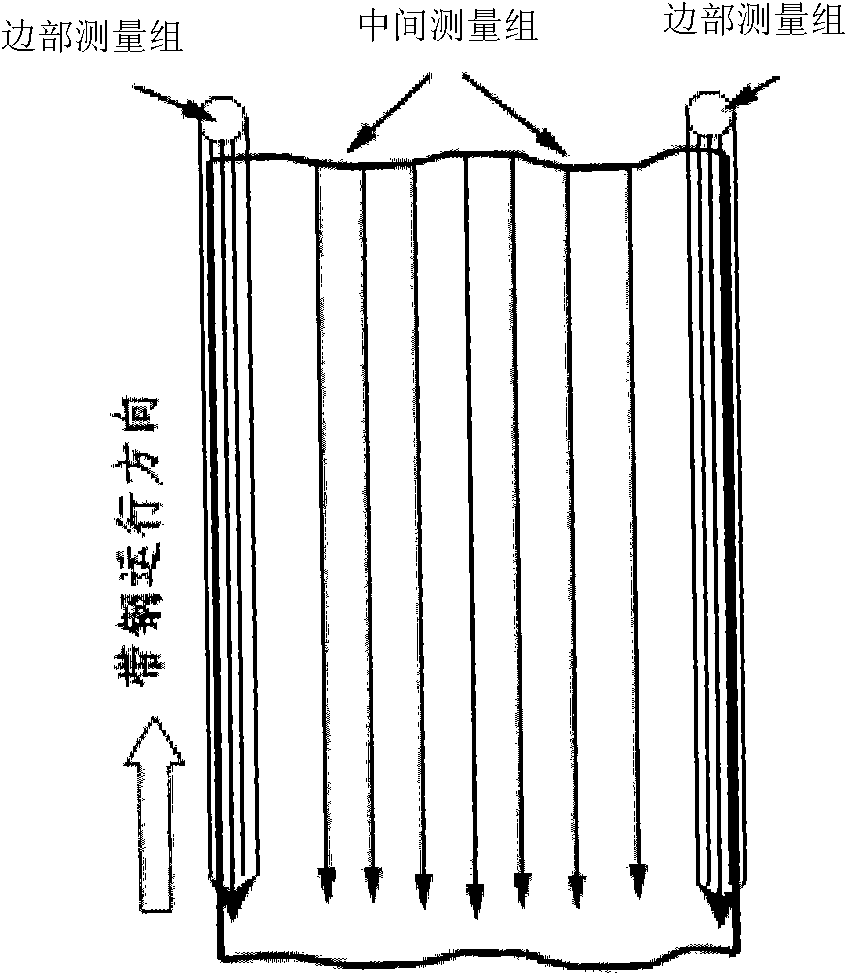

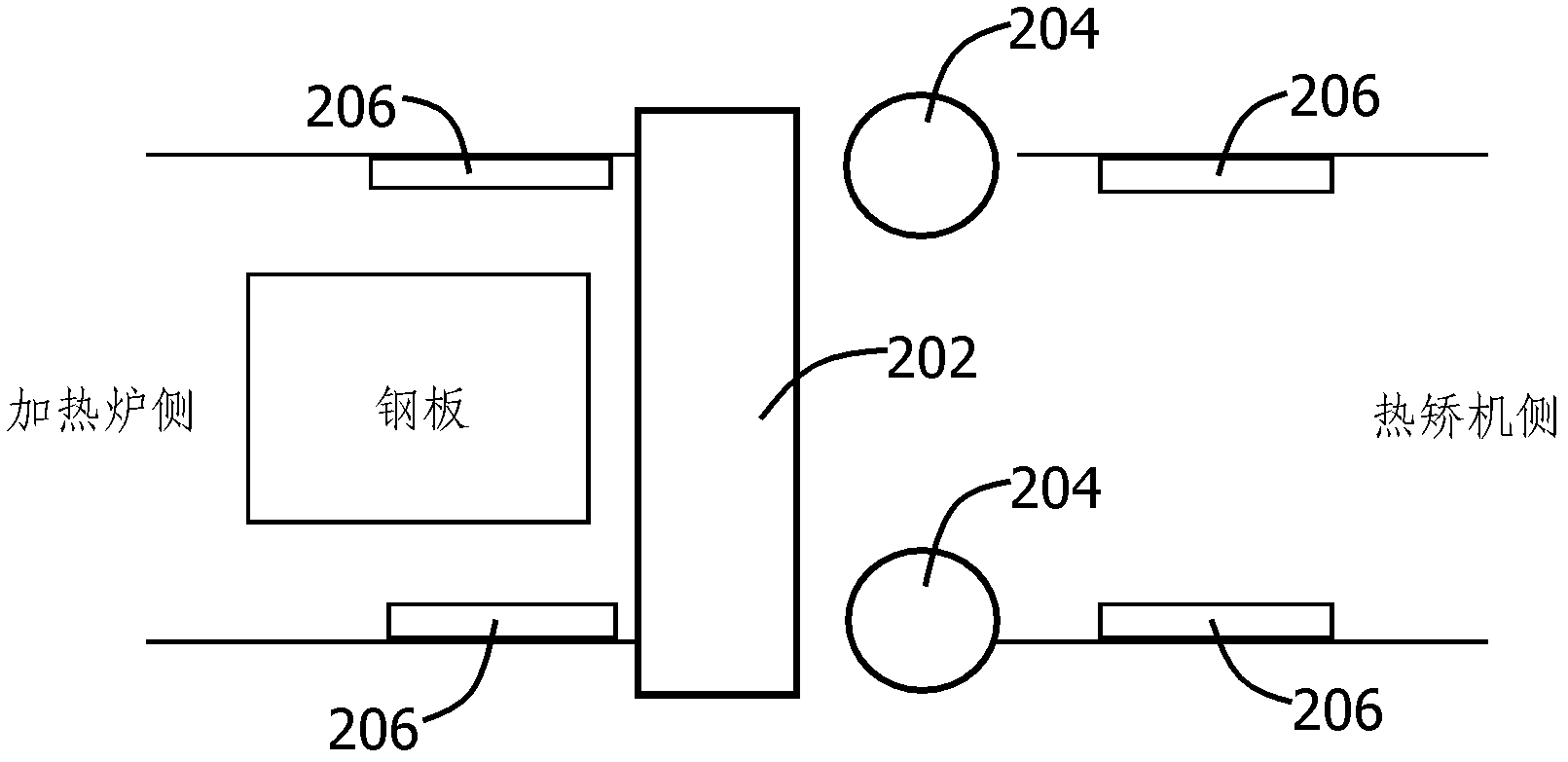

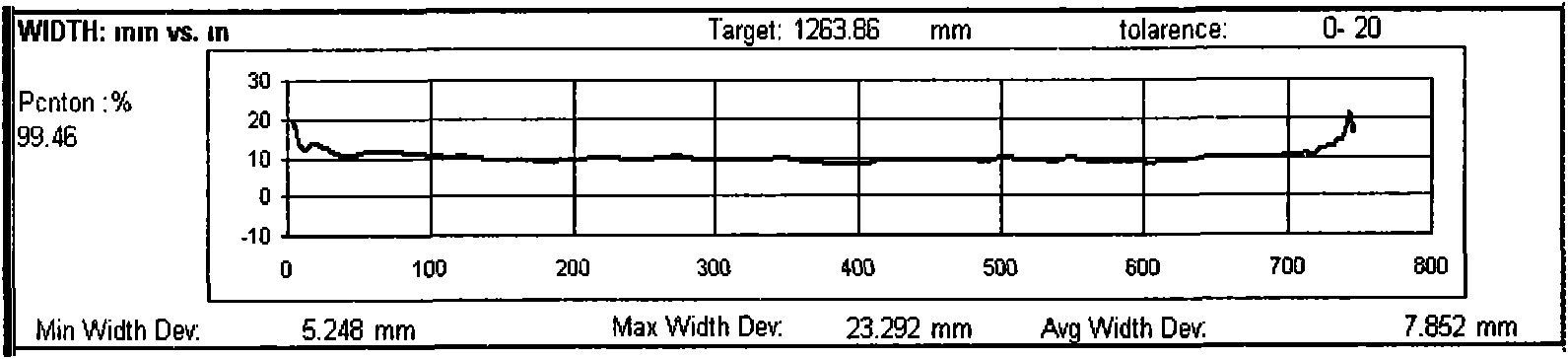

Method suitable for width measurement and centering of rough rolling slab in hot rolling mill

InactiveCN101811140AAccurately measure the actual widthAvoid misuseGuiding/positioning/aligning arrangementsRoll mill control devicesContact pressureEngineering

The invention relates to a method suitable for width measurement and centering of a rough rolling slab in a hot rolling mill, which belongs to the technical filed of steeling rolling computer control. The method mainly comprises the following steps of: 1, controlling a left guide plate and a right guide plate to arrive holding positions; 2, controlling the left guide plate and the right guide plate to move towards the direction of a rolling central line synchronously until contacting and patting a blank plate; 3, when the contact pressures of the left guide plate and the right guide plate, and the blank plate reach a predetermined value; recording the distance between the left guide plate and the right guide plate and the blank plate; 4, taking the recorded distance value as an actual width measurement value of the blank plate which is used for performing on-line control on rolling parts including a vertical roller; and 5, controlling the left guide plate and the right guide plate to return to guide positions. By adopting the method of the invention, original side plates which only have a guiding effect can play a role in patting the blank plate and ensuring the blank plate to be centered, and can be used as a detection device for measuring the actual width of the blank plate accurately, so that an error action caused by data error is avoided and the performance of equipment is remarkably enhanced without adding equipment investment hardly.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

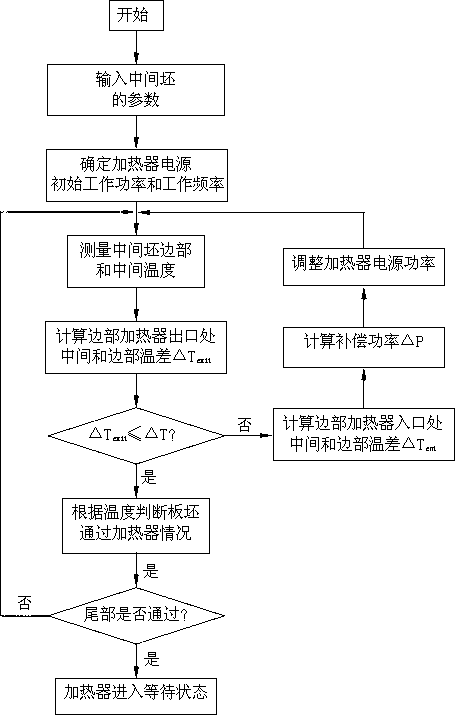

System and method for measuring and controlling heating temperature of edge of hot rolling slab

ActiveCN103286143AEnsure consistencyEliminate errorsTemperature control deviceMeasuring devicesObservational errorPower compensation

The invention relates to the field of edge heating of a hot rolling slab, in particular to a system and a method for measuring and controlling the heating temperature of an edge of a hot rolling slab. The system for measuring and controlling the heating temperature of the edge of the hot rolling slab comprises a temperature sensor group, an edge heating induction head, a heater power source, a data collector, a PLC (programmable logic controller) and an industrial control computer. The method for measuring and controlling the heating temperature of the edge of the hot rolling slab comprises the steps as follows: calculating and setting heating frequency and initial work power according to a parameter of an intermediate slab of an incoming material, and setting a target control temperature difference delta T of an intermediate blank at an induction head outlet; comparing the target temperature difference with an actually-measured outlet temperature difference, and judging whether power compensation is needed; and obtaining a power compensation value in combination of induction head inlet temperature difference data, adjusting output power of the heater power source, and completing control. According to the temperature differences of the edge and the middle of the intermediate blank before and after heating, the output power is controlled in real time, and measurement errors caused by outlet and inlet environments of the edge heater are eliminated, so that the control accuracy is improved greatly, and the product quality is increased.

Owner:BAOSHAN IRON & STEEL CO LTD

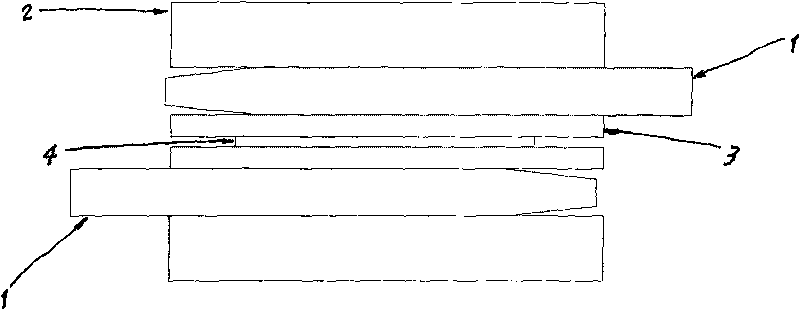

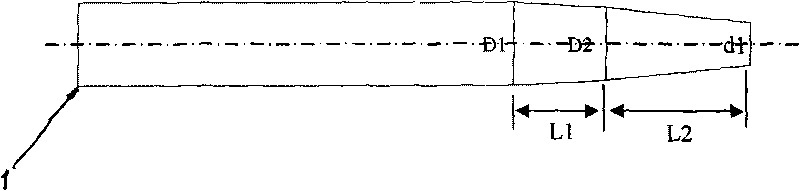

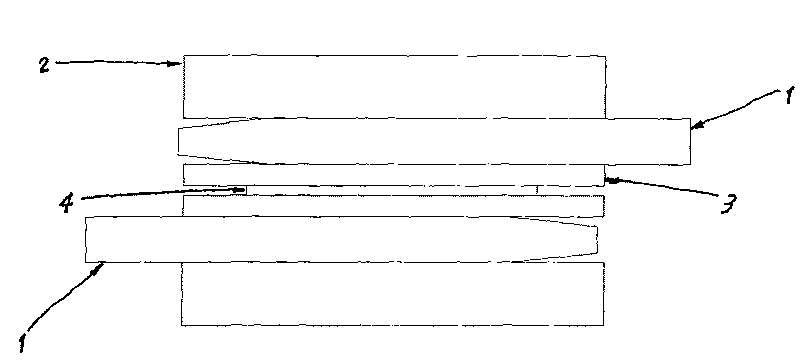

A high-performance cooper-coated aluminum rectangle section compound conductive bus bar and its making technology

ActiveCN101241778AMeet the requirements of multiple specificationsGreat widthSingle bars/rods/wires/strips conductorsMeasuring devicesCopperAluminum composites

The present invention provides a high-performance copper-clad aluminum cross section composite conductive bus-bar and the preparing technique thereof, and the invention relates to a rectangle-cross section bimetal composite material and the preparation thereof. The copper-clad aluminum rectangular cross section composite conductive bus-bar is compounded by the core-part aluminum and the coating layer copper. The area proportion of the coating copper layer is 15to 50 The technique comprises the following procedures: Adopting horizontal continuous casting for directly compounding and forming the copper-clad aluminum composite blank. Commonly flat-roller rolling and finish drawing-pulling the copper-clad aluminum blank according to requirement or rolling with the flat roller provided with a vertical roller, the range of the rolling speed is 3-50m / min, and the single-pass relative reduction is between 15and 40 The speed range of finish drawing-pulling is 1-20m / min and the single-pass cross section scalage is 10%. When the multiple-pass relative reduction is up to 70%, the low-temperature intermediate annealing is executed to the copper-clad aluminum composite conductive bus-bar. The annealing temperature is between 250 and 450 DEG C and the annealing time is between 0.5 and 3h. The annealed composite conductive bus-bar is executed with hole-form rolling or drawing. The invention not only can produce the high-performance copper-clad aluminum cross section composite conductive bus-bar, but also has the advantages of short process flow and high efficiency of the producing method.

Owner:UNIV OF SCI & TECH BEIJING

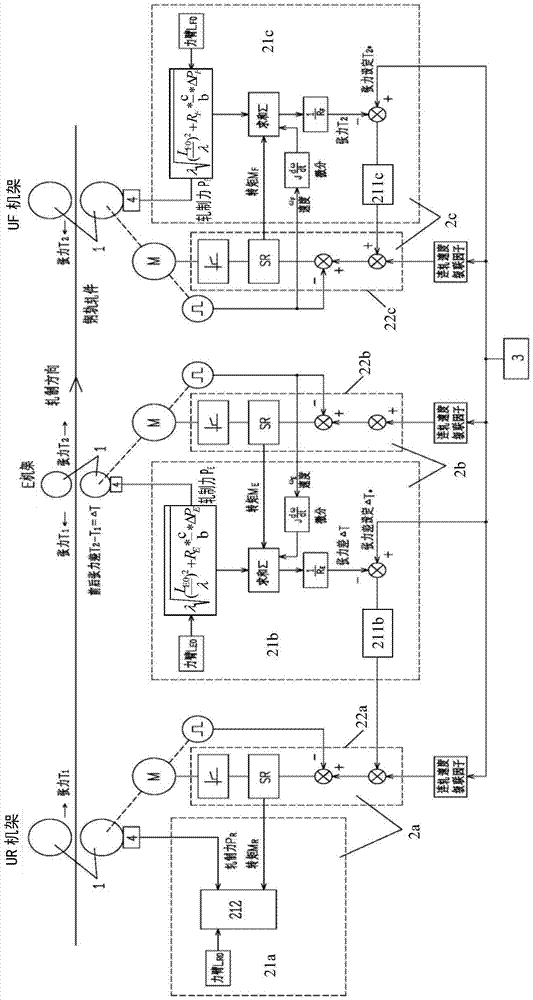

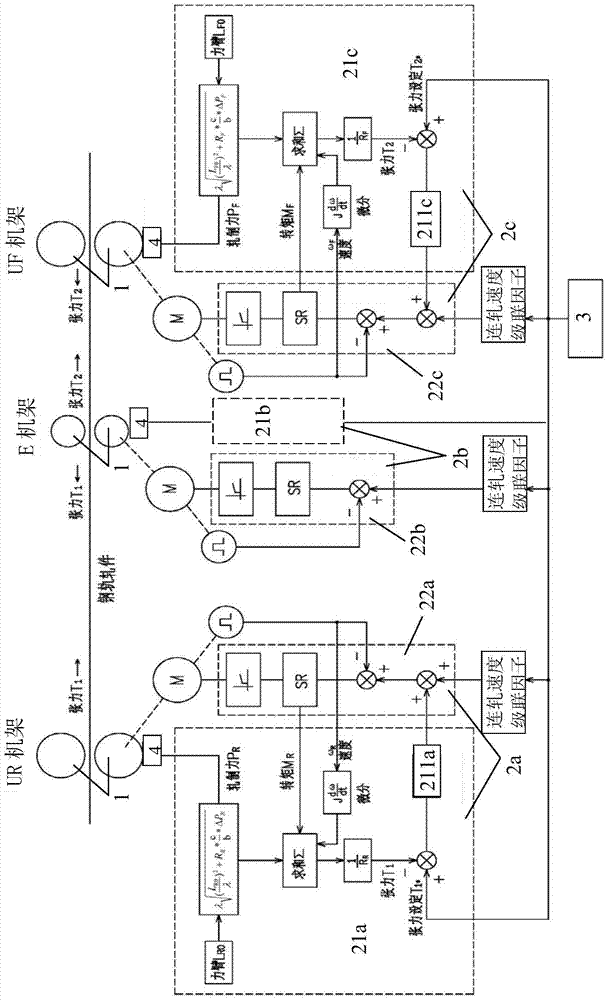

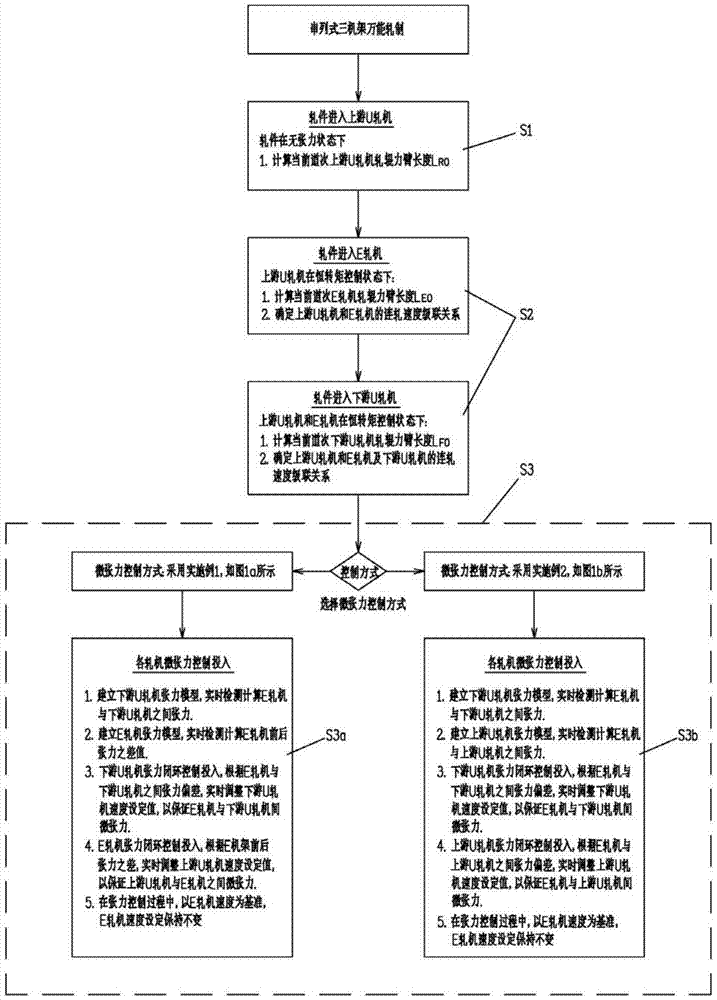

Micro-tension control system and method

ActiveCN103567230AGuaranteed tension control accuracyGeometry out-of-tolerance reductionMeasuring devicesTension/compression control deviceLoop controlClosed loop

The invention discloses a micro-tension control system and method. In the hot continuous rolling process, when a rolled piece enters a current machine frame and is stably bitten, the current machine frame is kept under speed control, speed control of main motors of machine frames on the upstream of the current machine frame is switched to constant torque control, on the basis, the torque and the rolling force of a main motor of the current machine frame are sampled to calculate the initial length of a rolling force arm, and the tension measurement calculating accuracy is improved. Each machine frame is provided with a pressure measuring head device to directly detect the rolling force, and consideration is given to the situation that the length of the rolling force arm is changed along with changes of the rolling force. Tension between the machine frames is obtained in real time through tension calculating models to form micro-tension closed-loop control to adjust the speeds of the machine frames so as to correct the tension deviations between the machine frames. As for a serial type universal rolling mill, the speed of the E machine frame serves as a standard, the rolling speed of the E machine frame is kept unchanged while speed set values of the other machine frames are adjusted, and real-time control is carried out on dynamic instantaneous values of the tension difference of the E machine frame before and after the adjustment process to guarantee micro-tension rolling of series universal rolling.

Owner:BERIS ENG & RES CORP

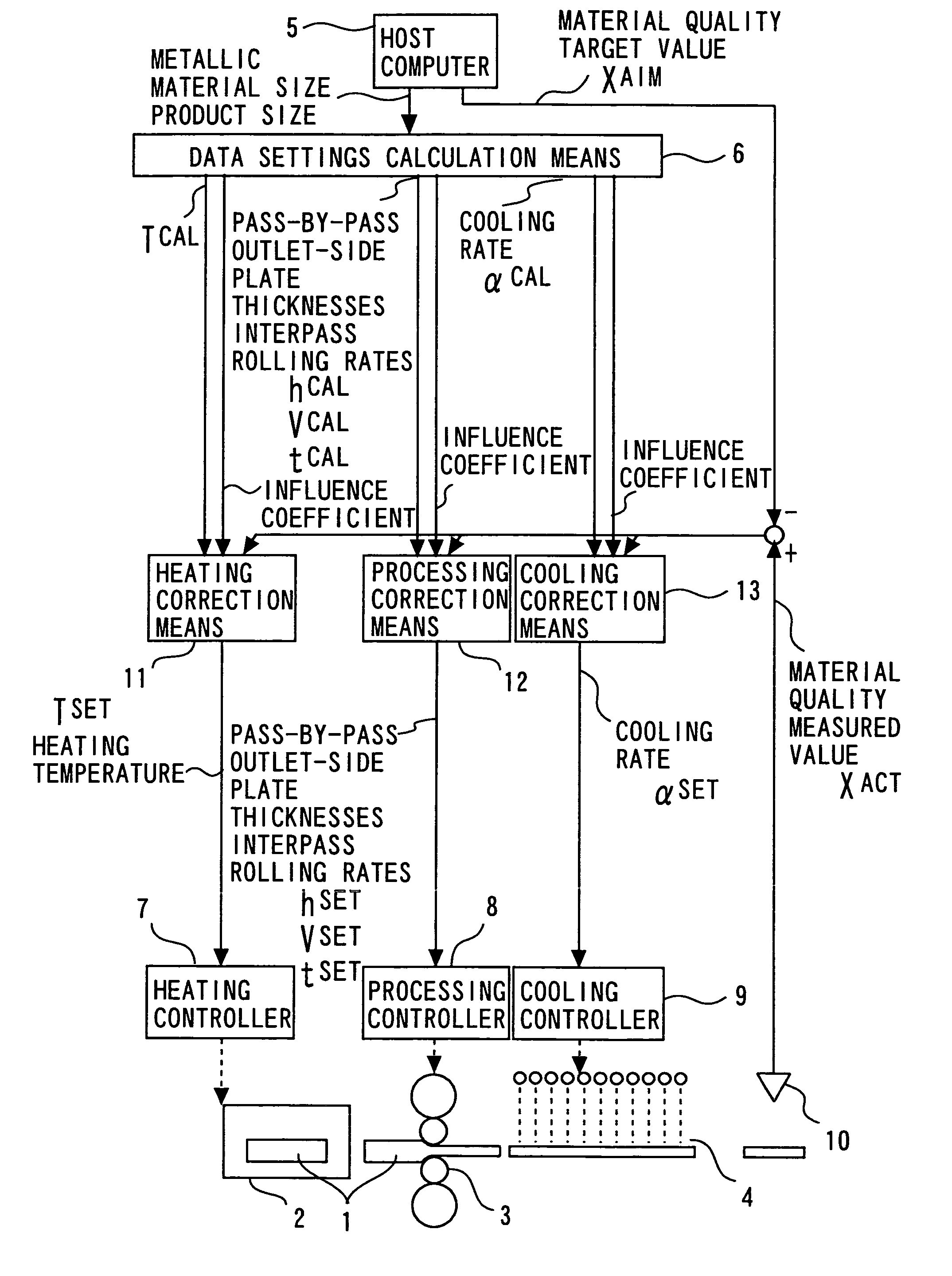

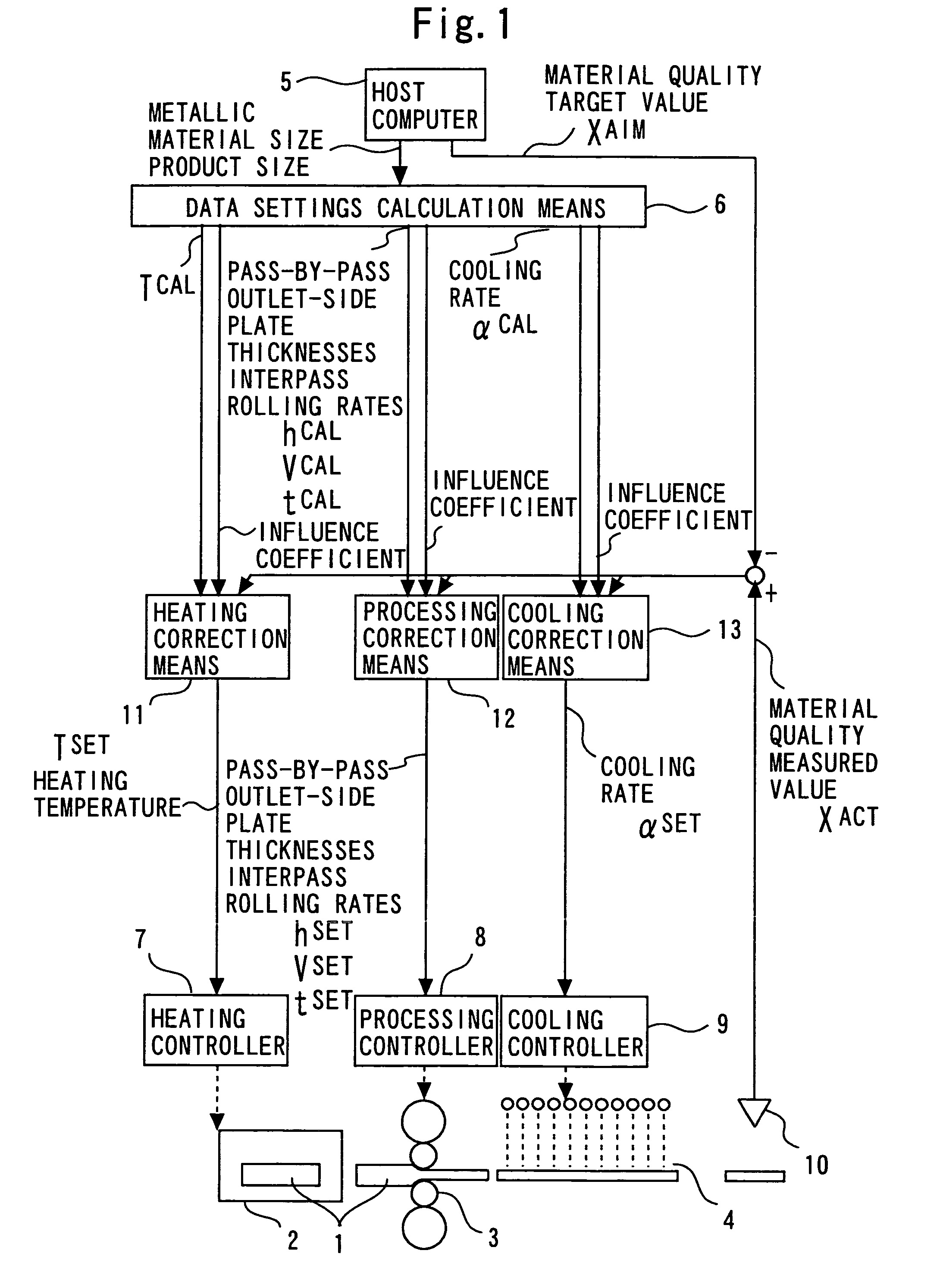

Method and apparatus for controlling materials quality in rolling, forging, or leveling process

ActiveUS20070151635A1Avoid it happening againConstant material qualityShaping toolsEnvelopes/bags making machineryManufacturing lineMaterial quality

The invention matches the material quality of a product to target data, even when a materials quality model is insufficient in prediction accuracy. Heating a metallic material, rolling, forging, or leveling the metallic material, and cooling the metallic material are each conducted at least once. Prior to manufacture of a metallic product of a desired size and shape, qualitative data of the metallic material are measured at a position by materials, quality sensor in a manufacturing line, and modifications based on measured data are made to heating, processing, or cooling conditions in at least one of the steps, upstream of the materials measured data sensor so that the quality of the metallic material at the measuring position agrees with target data.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

Method for plotting roll gap for changing roller under condition of on-line strip steel in rolling mill

InactiveCN101091967AAvoid influenceIncrease flexibilityRoll force/gap control deviceMeasuring devicesEngineeringStrip steel

The invention discloses a cold-rolling mill HC rolling mill strip steel online roll changing and roll gap demarcating method that includes the following steps: a. according to request, haulling out old roller and installing new roller; starting new / old roller diameter bias compensating function; starting roll gap demarcating function; until rolling load is less than 50t, finishing demarcating. The invention has the advantages of simple technology, high reliability, and could save the time of changing roller. It also improves the reliability and practicability of online roller-changing.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

Method for rolling precision stainless steel strips with Sendzimir rolling mill

InactiveCN101690940ALow investment costLow costRoll force/gap control deviceCounter-pressure devicesComputerized systemStrip steel

The invention discloses a method for rolling precision stainless steel strips with a Sendzimir rolling mill, which belongs to the field of stainless steel technology and steel rolling. In the method, a process regulation of rolling a strip with the thickness less than 0.3 mm is added on the basis of the prior rolling process regulations of a twenty high rolling mill; a computer system is adopted to perform control and rational roll system configuration so as to rationally assign the deformation rate of each pass and prevent the problems that strings of edge waves of the steel strip are drawn, or tension sides are ripped and broken, and string drawing easily occurs when the rolling mill is started; checking apparatuses, such as a thickness gauge, a plate shape gauge and the like, are corrected; and the surface conditions and the like of the rolled steel strip are checked in advance of two passes so as to comprehensively meet the requirements of producing the precision stainless steel strips of less than 0.3 mm. The method not only expands the rolling range of the twenty high Sendzimir rolling mill, but also can produce products with high value added and reduce investment cost of new precision rolling mills, and is good for producing and rolling the precision stainless steel strips with short time, higher speed and lower cost, and has great application and popularization values in the manufacturing industry.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

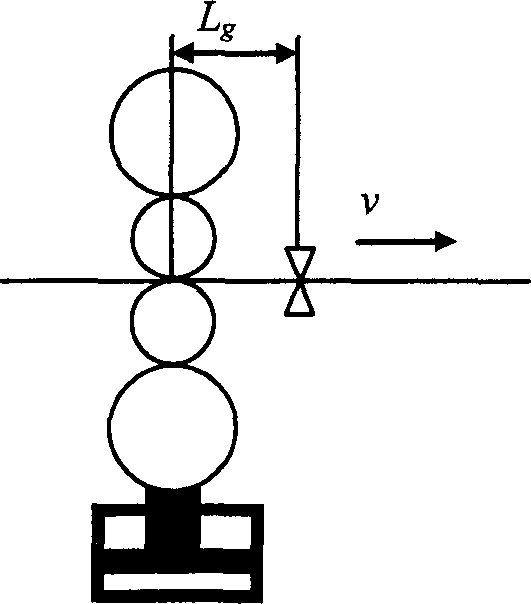

Method for automatic controlling thickness in fast high precision plate strip rolling process

InactiveCN1820863ASolve the problem that lag time varies with rolling speedThickness Error EliminationRoll mill control devicesMeasuring devicesAutomatic controlMeasuring instrument

The fast high precision plate and strip rolling AGC monitoring process includes the following steps: 1. inputting rolling system and steel strip data, including rolling machine rigidity coeffiecient M, steel strip plasticity coefficient Q and the distance Lg between the thickness measuring instrument and the roller axis; 2. determining the proportion coefficient K=M / M+Q of the thickness controlling target; 3. setting sample tracking length Ls=Ls / n; 4. taking the eliminating rate a of the integration regulator; 5. acquiring the measured thickness values and average thickness difference in the time i with the thickness measuring instrument and computer; and 6. calculating the addition value of the roll gap and the control rate at time i based on the recursive formula of the present invention. The present invention has high response speed, and high static control precision superior to 1 %.

Owner:NORTHEASTERN UNIV

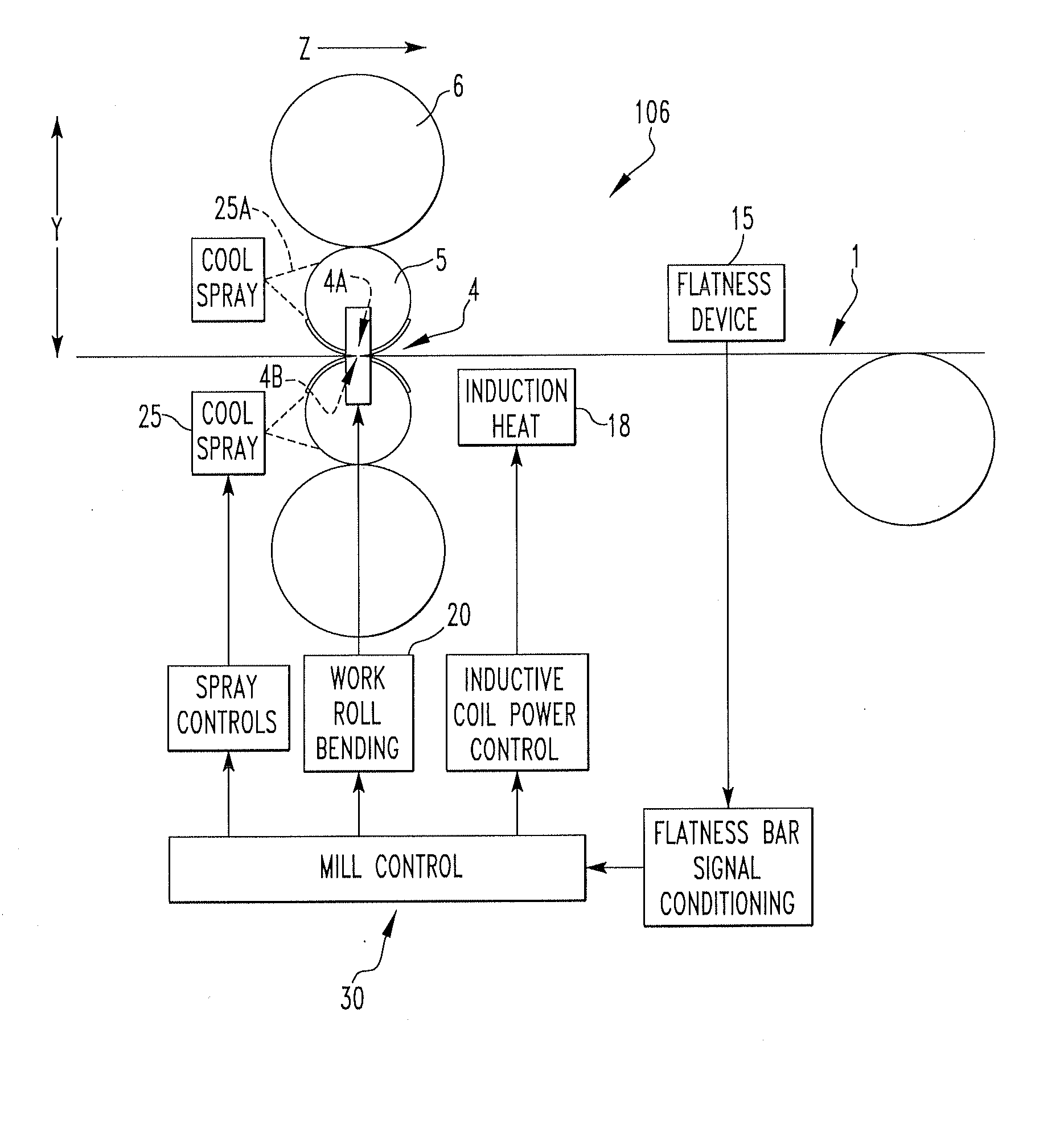

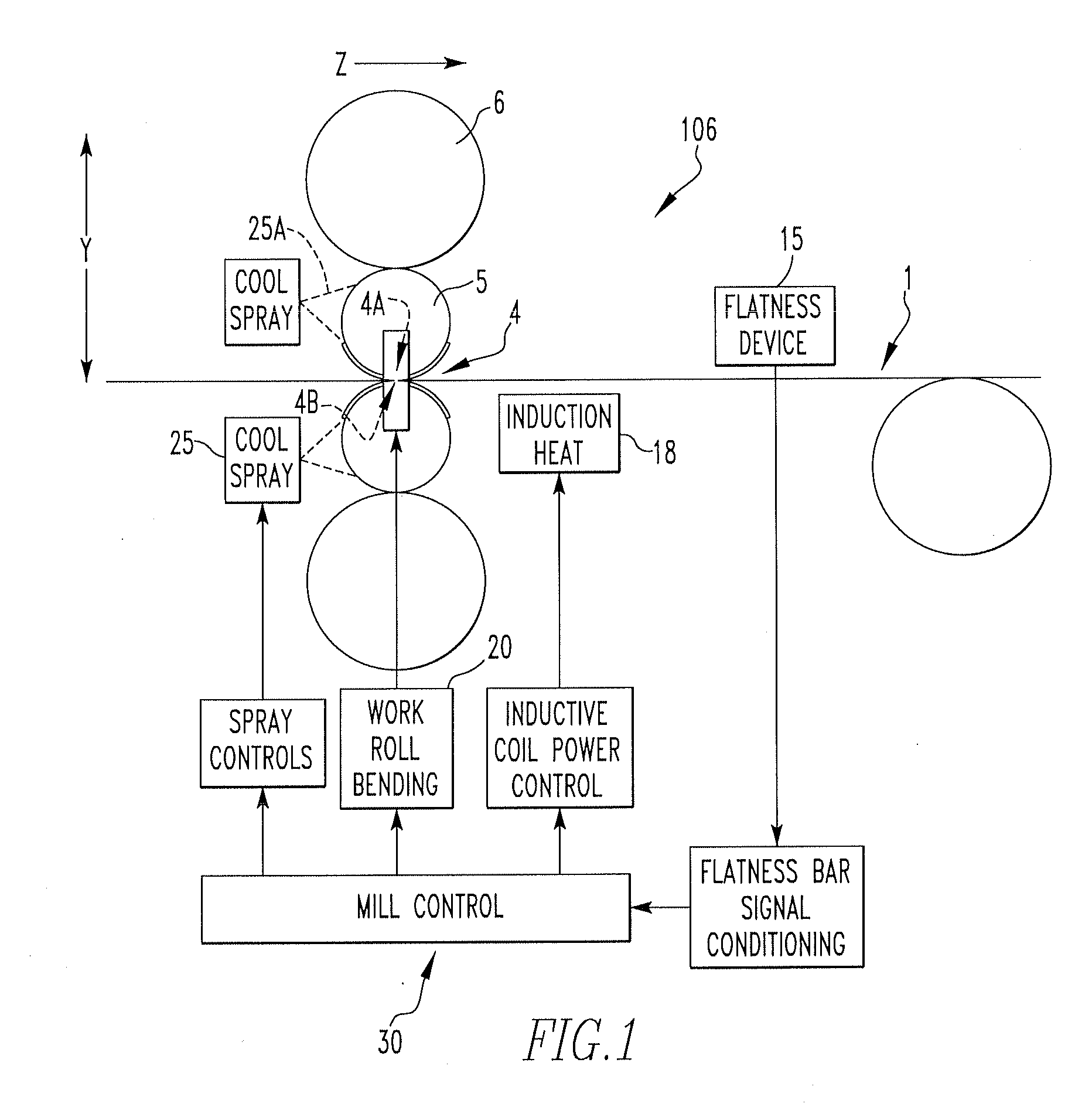

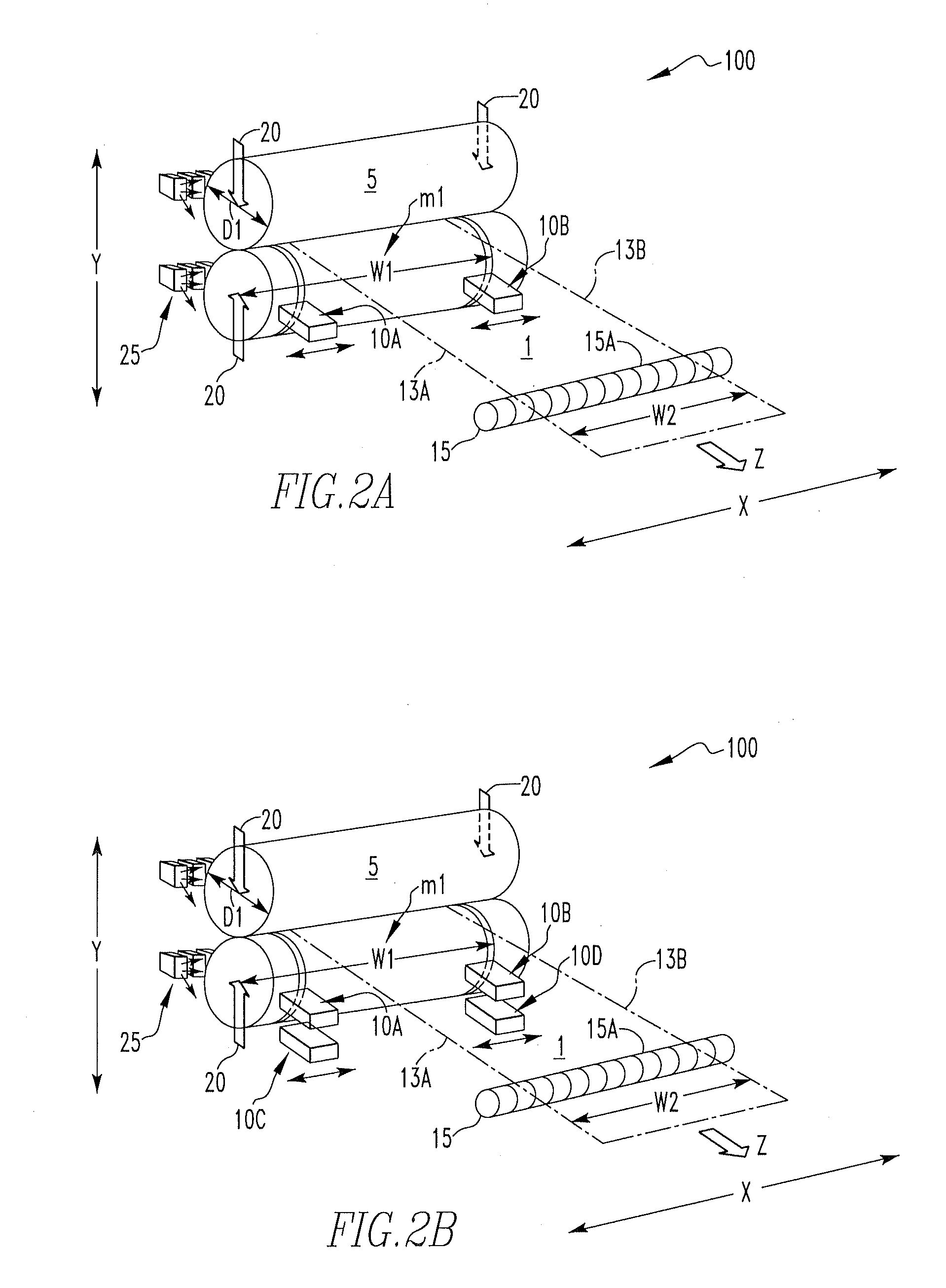

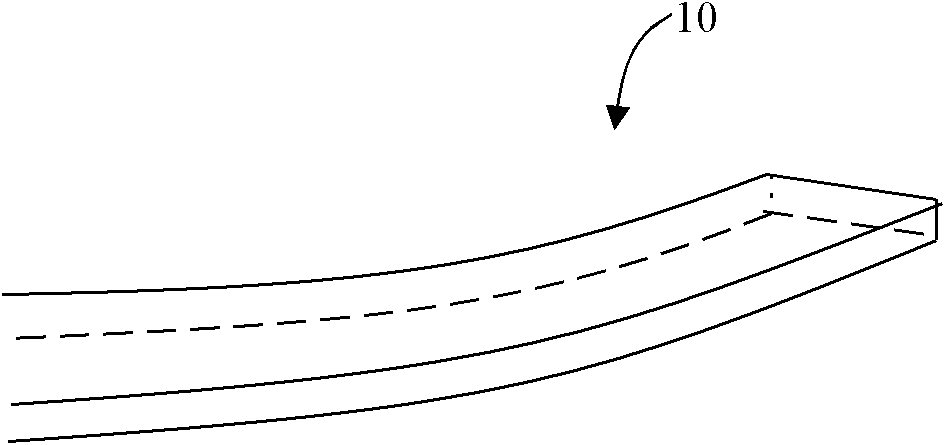

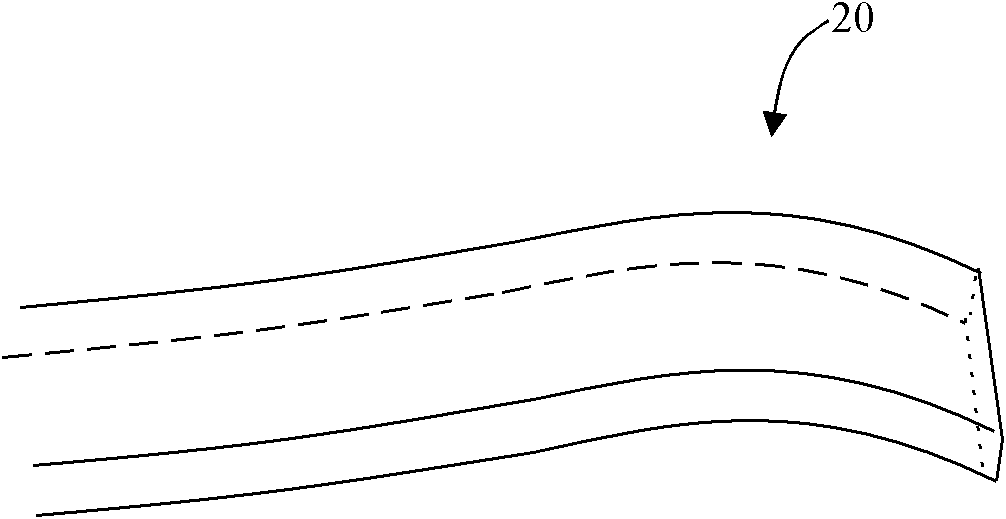

Application of induction heating to control sheet flatness in cold rolling mills

A system for rolling metal sheet having a substantially uniform flatness including a rolling mill including a pair of work rollers for reducing the thickness of a metal sheet, an induction heating apparatus in close proximity to at least one roller, bending jacks corresponding to each of the rollers, and a cooling spray system in proximity to rollers; a flatness measuring device positioned to measure a differential in flatness of the metal sheet; and an mill control interface connected between the flatness measuring device and the rolling mill's actuators, in which the mill control interface is configured to actuate the induction heating apparatus, the bending jacks and the cooling spray system to substantially eliminate flatness differentials is the metal sheet's flatness. The induction coil heating apparatus is configured to eliminate high tension on the strip edges caused by the temperature gradients in the work rolls at the edges of the metal strip.

Owner:ARCONIC INC

Control method for upward and downward head bending of plate blank

ActiveCN102836883AImprove straightnessHigh measurement accuracyRoll mill control devicesMeasuring devicesEngineeringHead shape

The invention discloses a control method for upward and downward head bending of a plate blank, and the control method comprises the steps that a head shape curve of the plate blank and a plurality of sampling sites are collected by CCD (charge coupled device) camera equipment; a cubic polynomial curve is used for fitting according to the sampling sites; the maximum monotone interval of the curve close to the head of the plate blank is obtained to judge the upward or downward head bending; and quantification is conducted; the arc length deviation value of the upper and lower surfaces between the head end point and the tail end point of the plate blank is calculated; a speed difference adjustment value of upper and lower rolls in the pass is calculated; and a new speed difference is decided according to the speed difference adjustment value. The control method for the upward and downward head bending of the plate blank is high in measurement accuracy and easy to maintain, a set value of the speed difference can be adjusted automatically according to the buckling condition of the rolled plate blank, and the straightness of the rolled plate blank can be improved greatly.

Owner:BAOSHAN IRON & STEEL CO LTD

Rolling bearing unit

InactiveUS6971799B2Prolong lifeReduce signalingElectric signal transmission systemsRoller bearingsRolling-element bearingDistortion

A four-row tapered roller bearing is incorporated in the clearance between the inner surface of a housing and the outer surface of a rolling roller. A pair of supporting members supporting sensor devices are fitted in and supported by a part of the inner surface of the housing in such a manner that they are opposed to the ends of outer rings of the four-row tapered roller bearing disposed close to the both axial ends thereof. The sensor devices each comprise a distortion gauge as a detecting portion and a first coil for transmitting as a wireless signal a signal obtained by processing an output signal outputted from the distortion gauge. A second coil for receiving the wireless signal transmitted by the first coil is retained on a part of a member other than the supporting members.

Owner:NSK LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com