Device and method for detecting and controlling tilting buckle head of band steel in rough rolling process

A rolling process, detection and control technology, applied in the direction of rolling mill control devices, length measuring devices, metal rolling, etc., can solve the problems of too much influence, the increase of strip warping, and the proneness of strip buckling, etc., to achieve accuracy High, the effect of improving rolling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

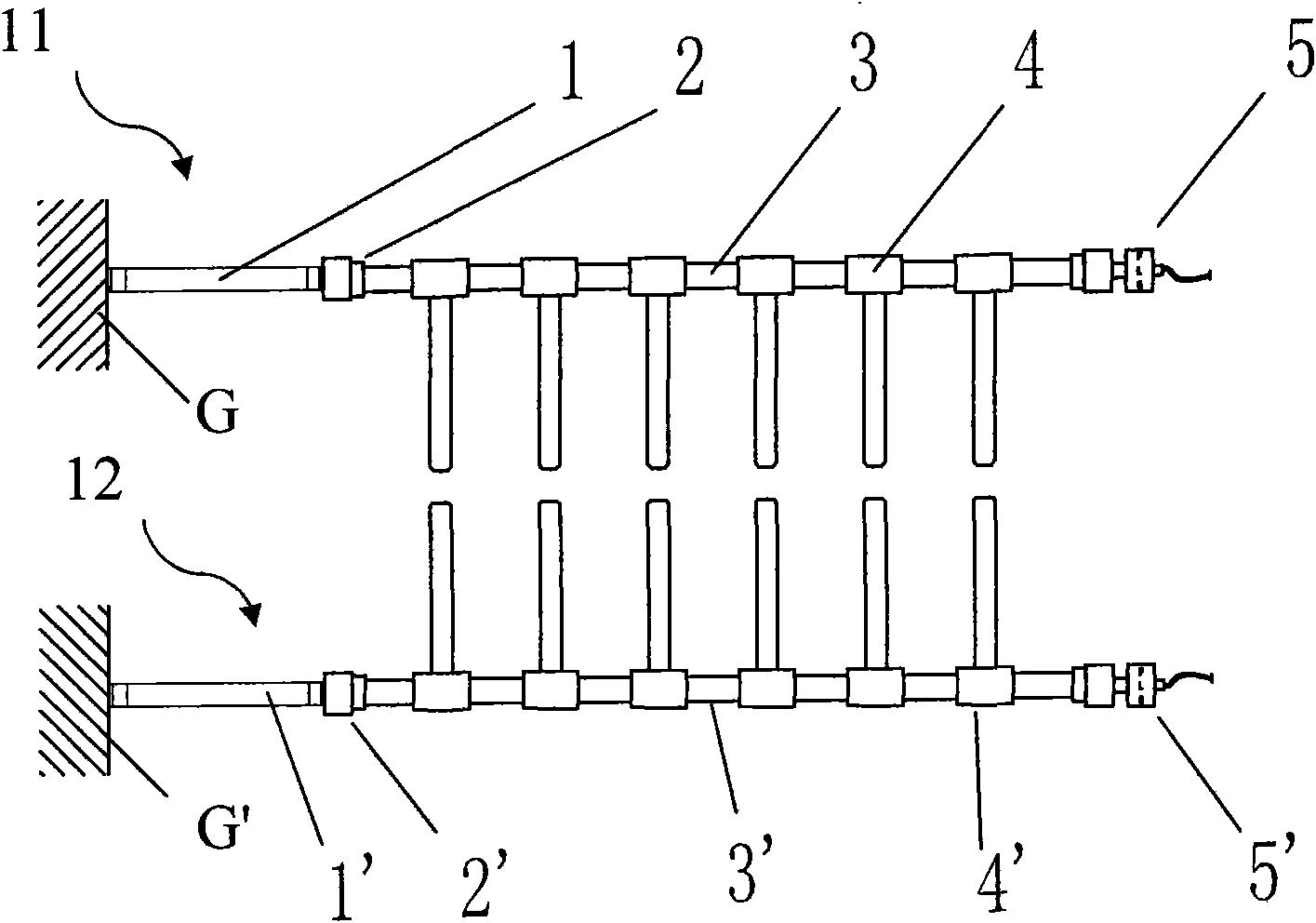

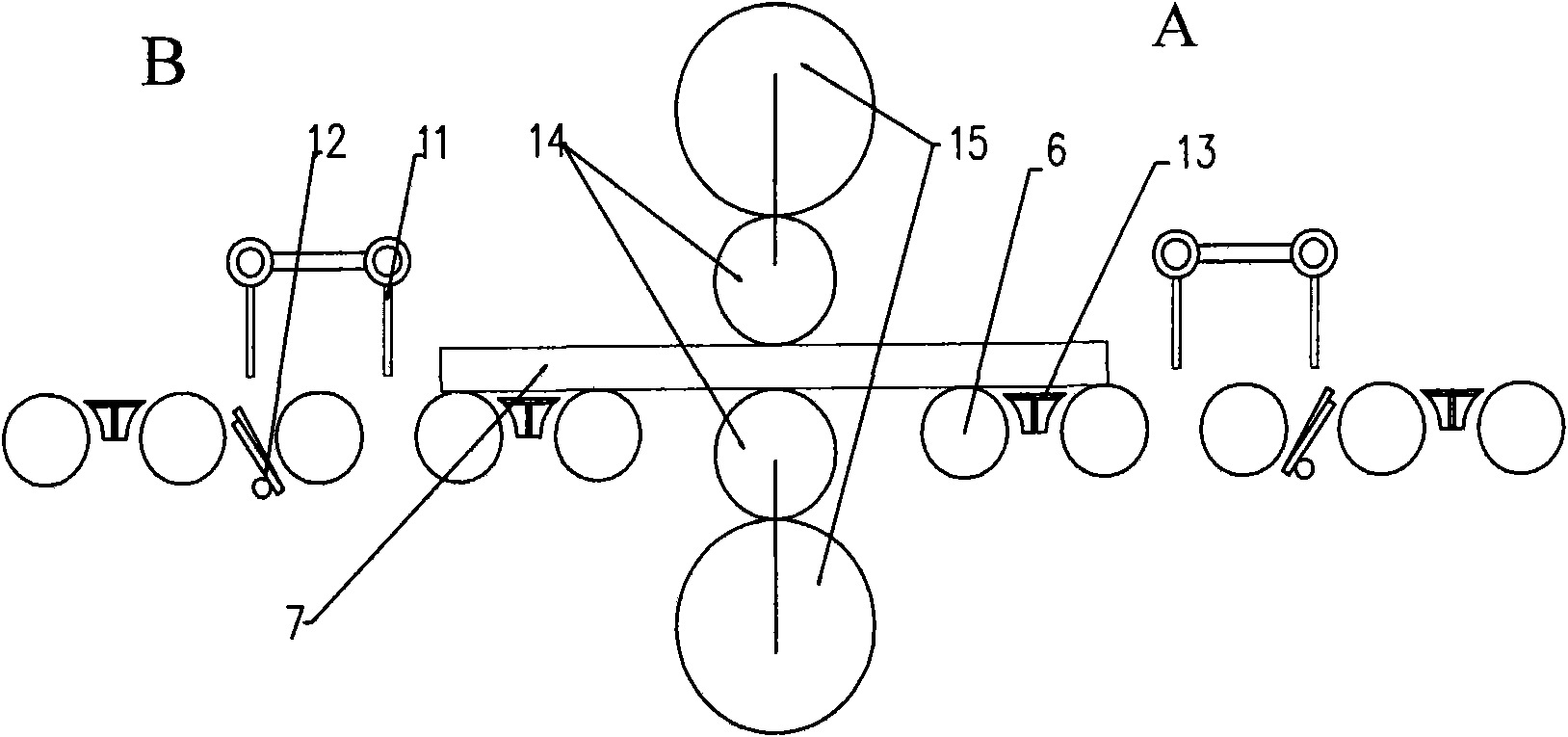

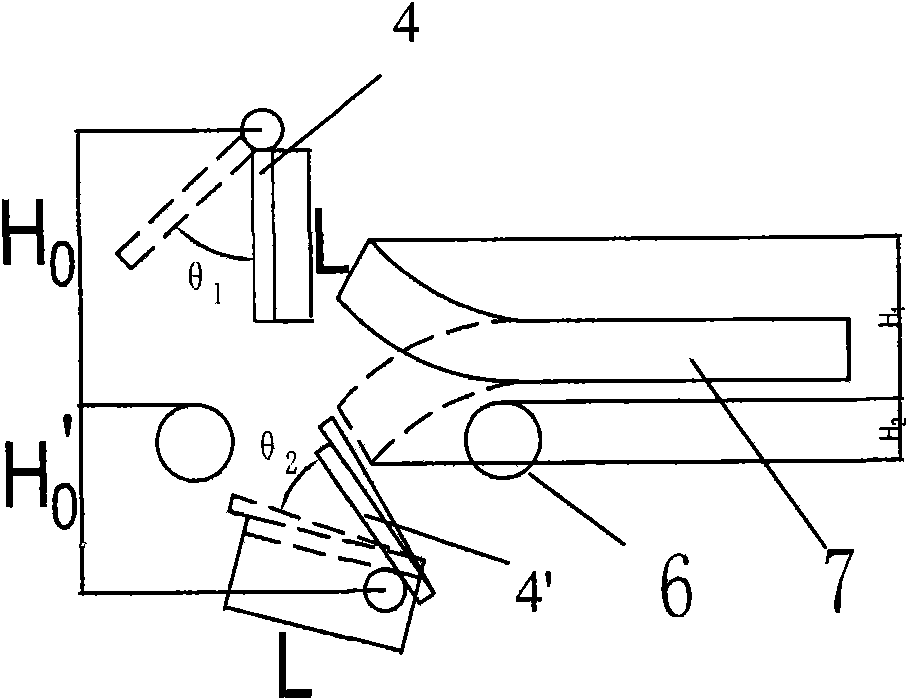

[0044] The specific implementation of the device and method for detecting and controlling strip buckle during the rough rolling process of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

[0045] The method of the present invention is to use the buckle head detector arranged above and between the roller tables to detect the actual buckle head or buckle head condition after strip rolling, and then automatically adjust the upper and lower The roll speed when the roll bites the steel can achieve the purpose of controlling the buckle head of the strip steel, which belongs to the feedback control. For example, when it is detected that the strip steel that is being rolled is warped, it will increase the speed of the upper roll when the next piece of strip steel is rolled, and the extension of the upper and lower surface steel strips will be consistent by forcing the extension of the upper surface of the strip s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com