Working roller for wire and bar roughing mill stand and manufacturing method thereof

A manufacturing method and technology of work rolls, which are applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems of large hardness drop, large difference in internal and external performance of the working layer of the roll, and low single-rolling volume, and achieve internal and external hardness. The effect of small drop, reducing the sensitivity of the section, and improving the wear resistance of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

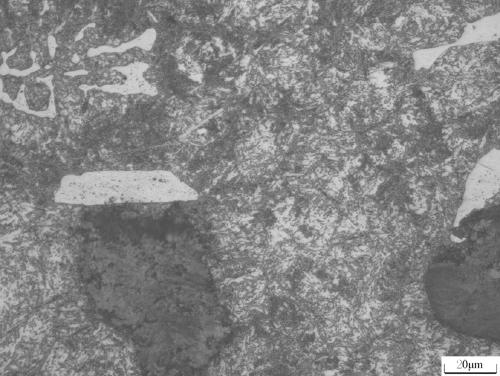

[0040] A work roll for a rough rolling stand of wire and bar, the chemical composition and the weight percentage of each component are: C 2.9-3.6%, Si 1.2-2.0%, Mn 0.3-0.8%, Cr 0.2-1.0%, Ni 1.0~2.0%, Mo 0.2~0.5%, P≤0.15, S≤0.3, the rest is Fe and unavoidable impurities;

[0041] In step b), the smelting temperature is 1440°C, the addition amount of the inoculant is 0.4%, and the addition amount of the nodulizer is 0.8% of the total amount of molten iron;

[0042] In step d): cooling at room temperature to 300°C and opening the box;

[0043] According to the furnace inspection, the chemical composition and the weight percentage of each component of the pearlitic ductile iron blank are: C3.31%, Si 1.52%, Mn 0.55%, Cr 0.31%, Ni 1.3%, Mo 0.3%, P0.15%, S 0.3%, the rest is Fe and unavoidable impurities;

[0044] In step A, the semi-finished work roll is heated to 845°C in an air furnace for heat preservation, the high-temperature quenching and heat preservation time is 12h, and th...

Embodiment 2

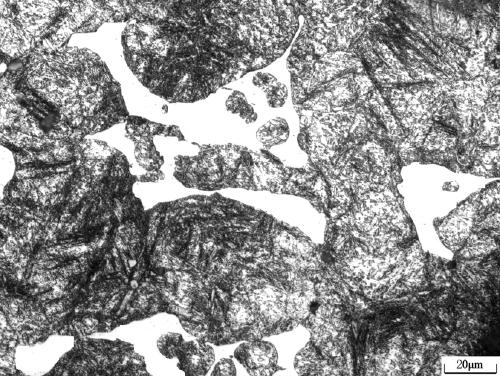

[0054] The process steps in this embodiment are the same as those in Example 1, and the difference from Example 1 is that the smelting temperature in step b) of this embodiment is 1460°C, the amount of inoculant added is 0.6%, and the amount of nodulizer added is molten iron 1.0% of the total amount;

[0055] In step d): cooling at room temperature to 320°C and opening the box;

[0056] According to the furnace inspection, the chemical composition and the weight percentage of each component of the pearlitic ductile iron blank are: C3.1%, Si 1.75%, Mn 0.61%, Cr 0.63%, Ni 2.0%, Mo 0.35%, P 0.04, S≤0.2, the rest are Fe and unavoidable impurities;

[0057] In step A, the semi-finished work roll is heated to 900°C in an air furnace for heat preservation, the high-temperature quenching and heat preservation time is 6h, and the diameter φ of the semi-finished work roll body is 400mm;

[0058] In step B, the water spray pressure is 4.0MPa, and the water spray flow rate is 8.0m 3 / h...

Embodiment 3

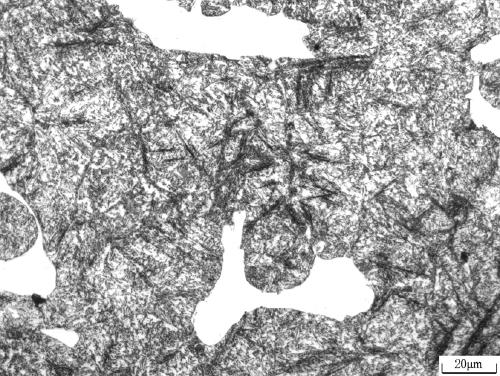

[0067] The process steps in this embodiment are the same as those in Example 1, and the difference from Example 1 is that the smelting temperature in step b) of this embodiment is 1455°C, the amount of inoculant added is 0.8%, and the amount of nodulizer added is molten iron 1.2% of the total amount;

[0068] In step d): cooling at room temperature to 320°C and opening the box;

[0069] According to the furnace inspection, the chemical composition and the weight percentage of each component of the pearlitic ductile iron blank are: C3.4%, Si 1.85%, Mn 0.6%, Cr 0.41%, Ni 1.84%, Mo 0.25%, P 0.04, S≤0.2, the rest are Fe and unavoidable impurities;

[0070] In step A, the semi-finished work roll is heated to 920°C in an air furnace for heat preservation, the high-temperature quenching and heat preservation time is 2h, and the diameter φ of the semi-finished work roll body is 610mm;

[0071] In step B, the water spray pressure is 4.0MPa, and the water spray flow rate is 8.0m 3 / h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com