Patents

Literature

2633results about How to "Improve organization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

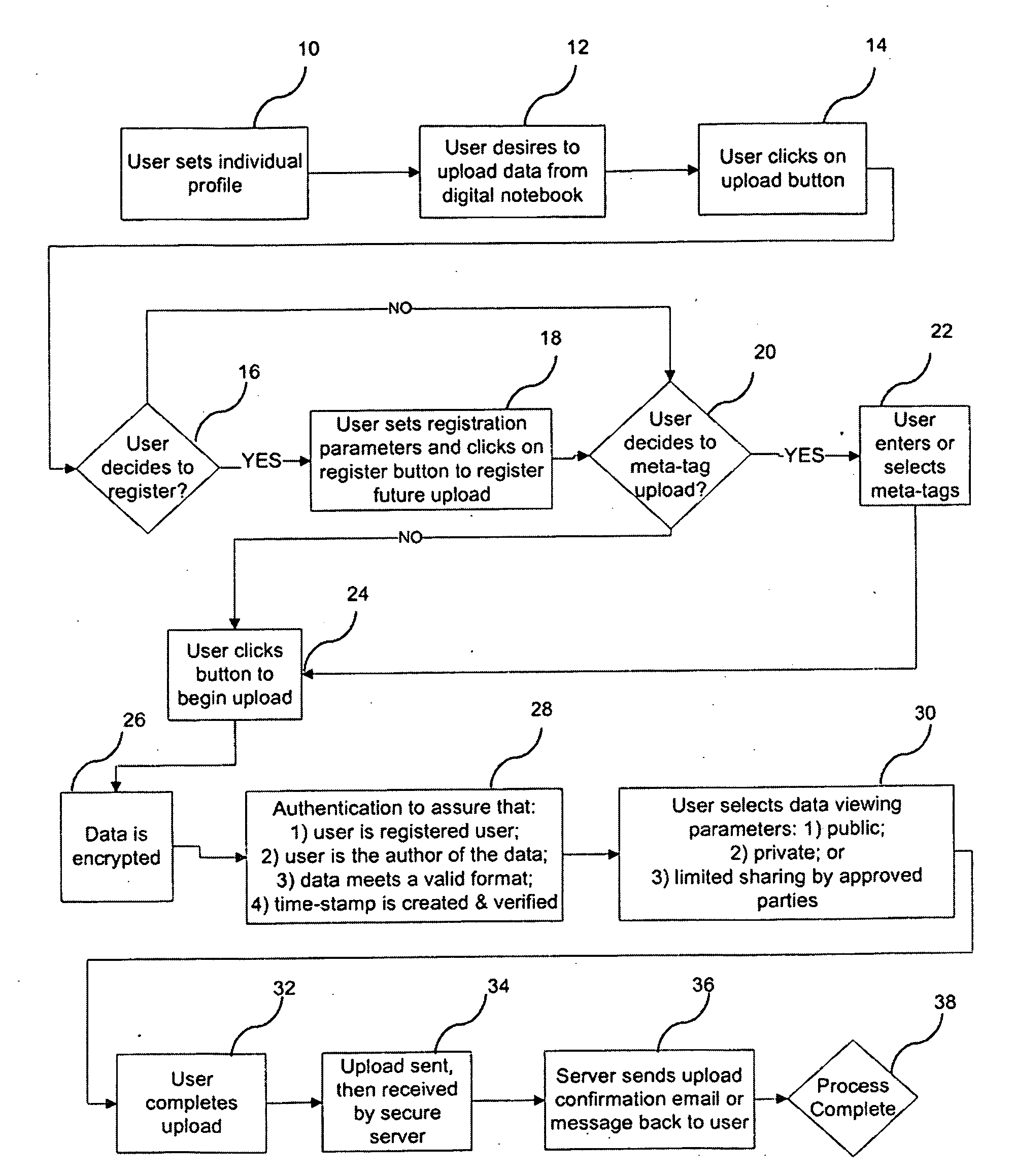

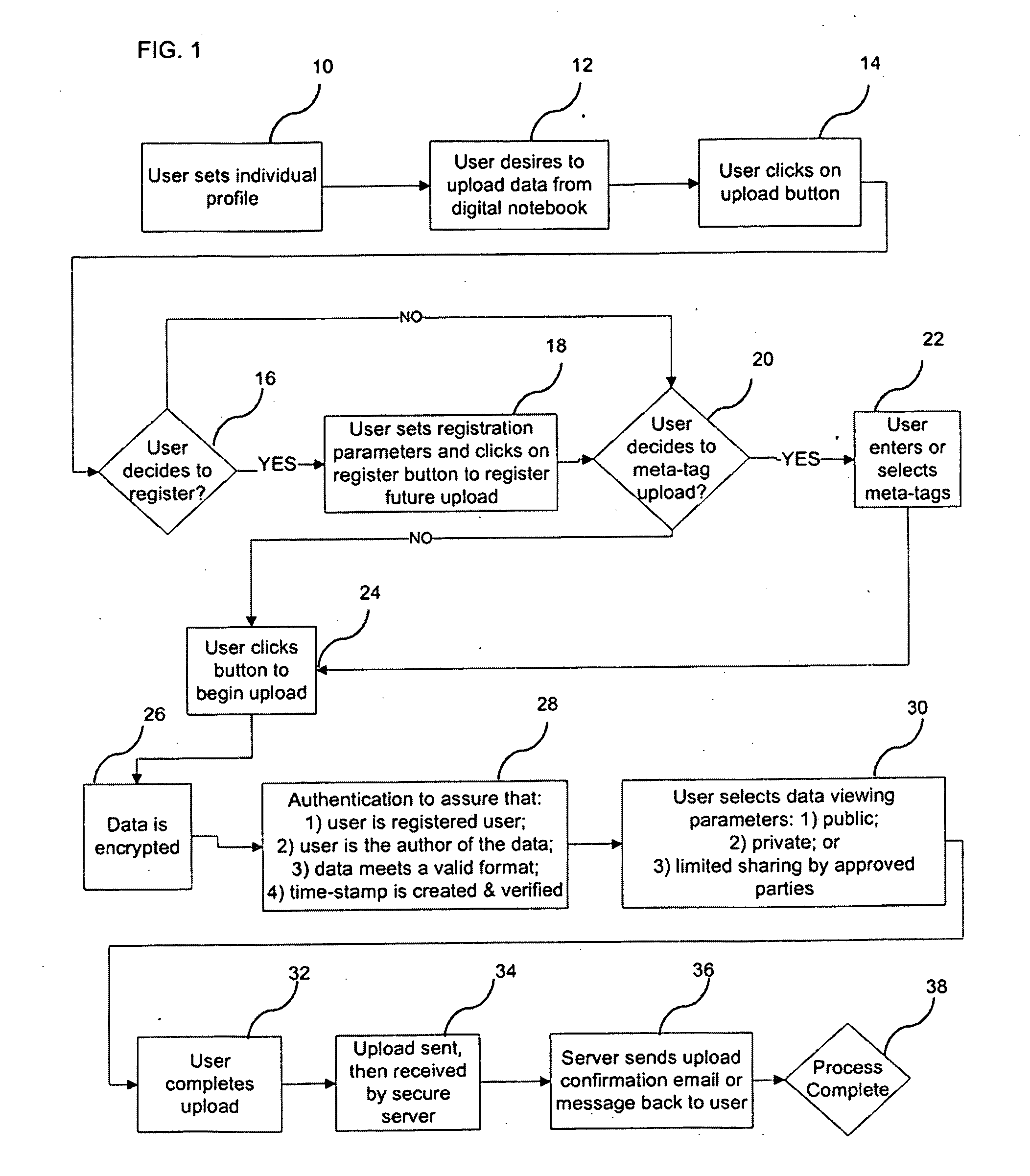

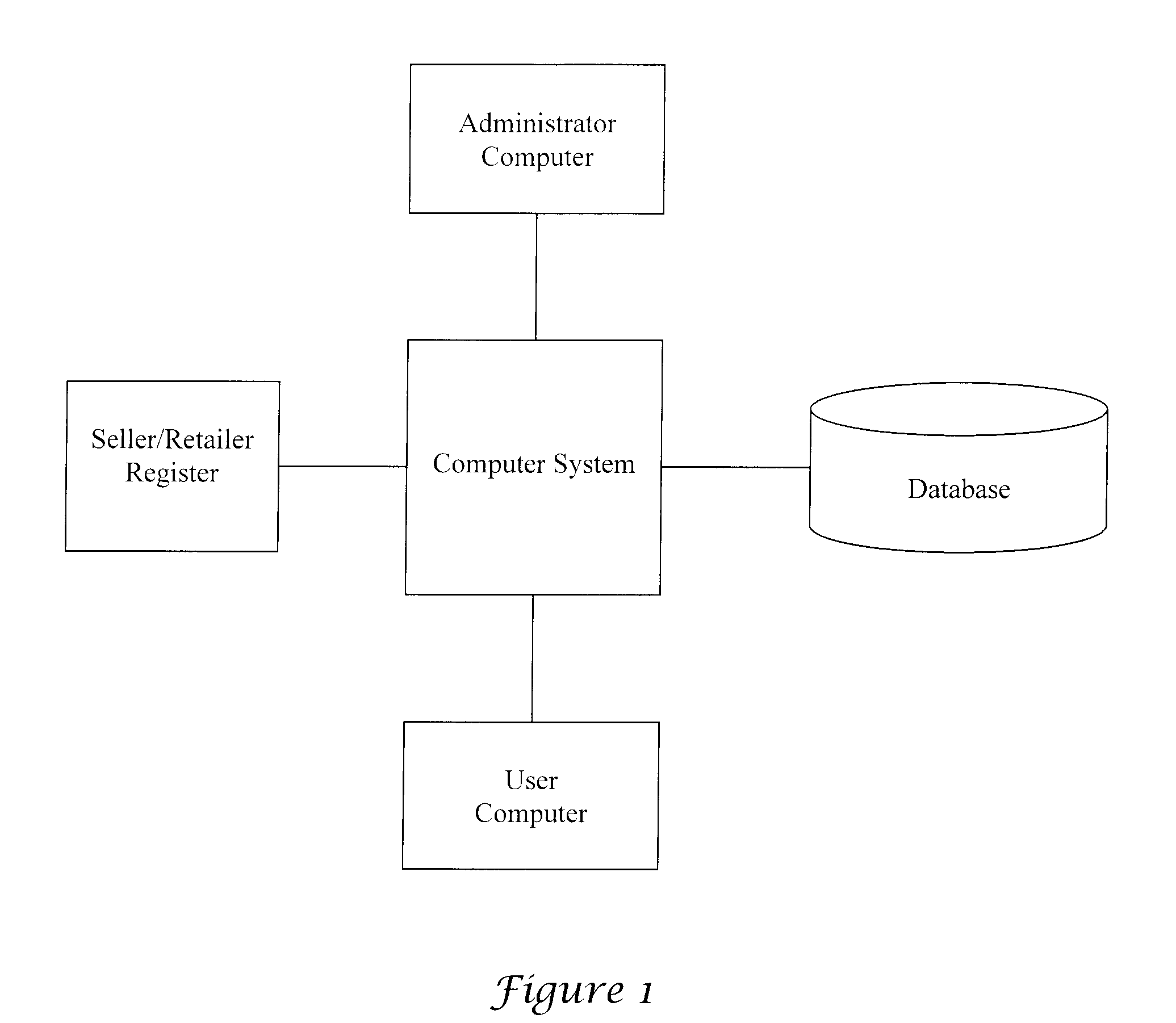

System, method and apparatus for data capture and management

InactiveUS20090012806A1Facilitates multi-input data captureEasy to customizeDigital data processing detailsUser identity/authority verificationPersonalizationThird party

A method and system and apparatus for capturing, accessing, securing, personalizing and organizing data and content. The system includes a plurality of mobile computing devices. Each mobile device preferably includes a personalized interface for multiple input data capture and includes a system for transmitting the content and information to a secure server network, a system for organizing the data and information into personalized modules, and a means for transmitting the content to third parties for authentication and time / date stamping and registration. Said apparatus captures stores, secures, and sends data and information via wireless transmission means and / or networked means, to a mobile device and / or secure server to facilitate discovery and or innovation.

Owner:RICORDI CAMILLO +2

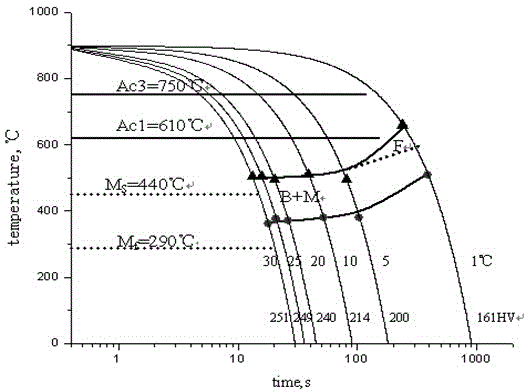

Method for producing 700Mpa V-N microalloyed high-strength air corrosion-resistant steel based on sheet bar continuous casting tandem rolling process

InactiveCN1884608AHigh strengthGood formabilityTemperature control deviceMetal rolling arrangementsSheet steelChemical composition

This invention exposed the producing method of V-N microalloyed high strength weathering steel which produced with near net shape con-casting technology. It is smelted in electric furnace or converter, refined, con-casted, casted, then directly sent into roller hearth furnace or soaking pit, hot-rolled, laminar cooled, coiled. The liquid steel's chemical elements are (Wt.%): C: <=0.08%, Si: 0.25- 0.75%, Mn: 0.8-2.0%, P: 0.070-0.150%, S: <=0.040%, Cu: 0.25-0.60 %, Cr: 0.30-1.25 wt%, Ni: <=0.65%, V: 0.05-0.20%, N: 0.015-0.030%. This invention can get the high intensity, formation, weathering, joining character stably. The alloying cost is relatively low. So it can be used to produce container, carriage, and other industry facility.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

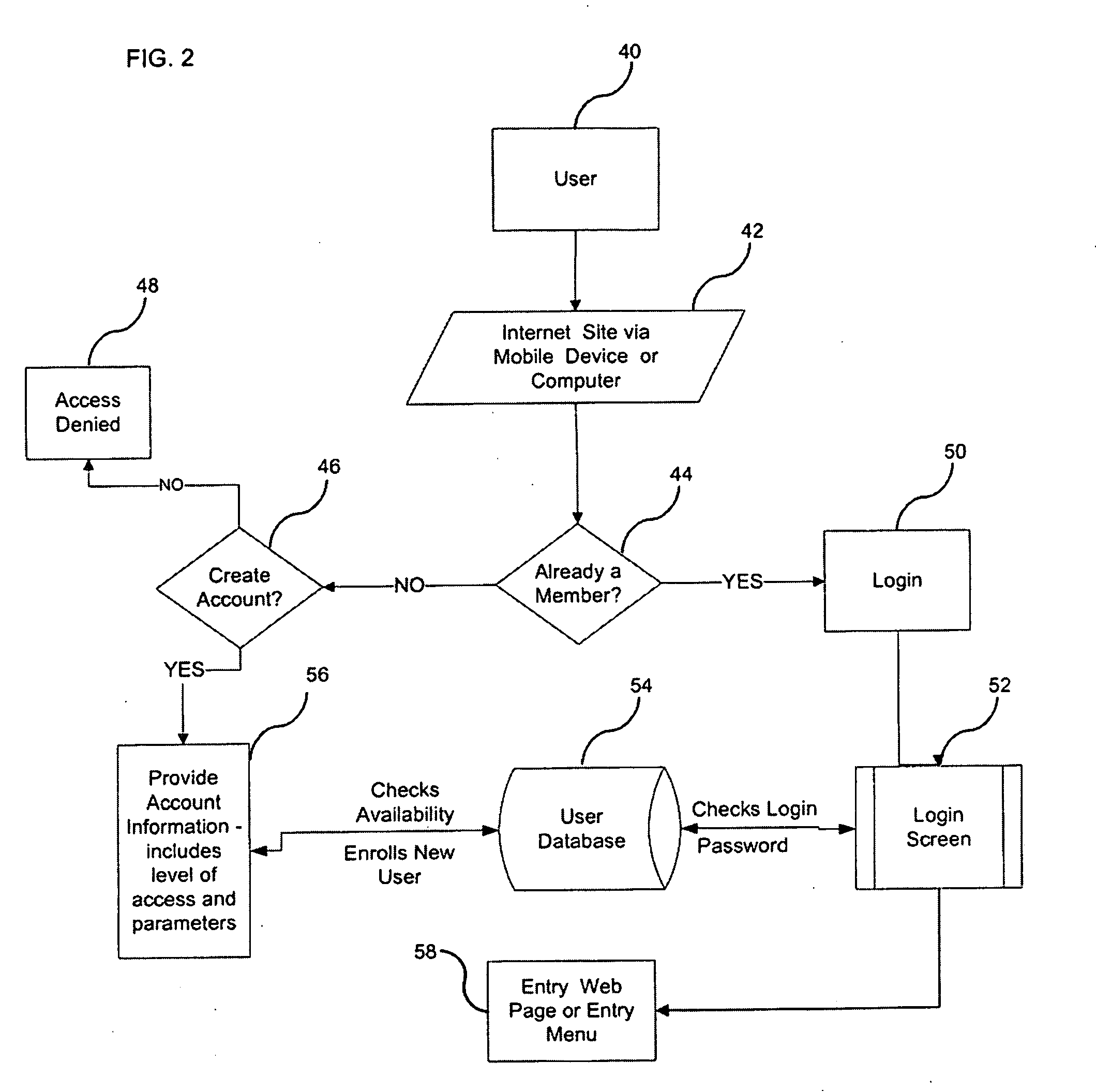

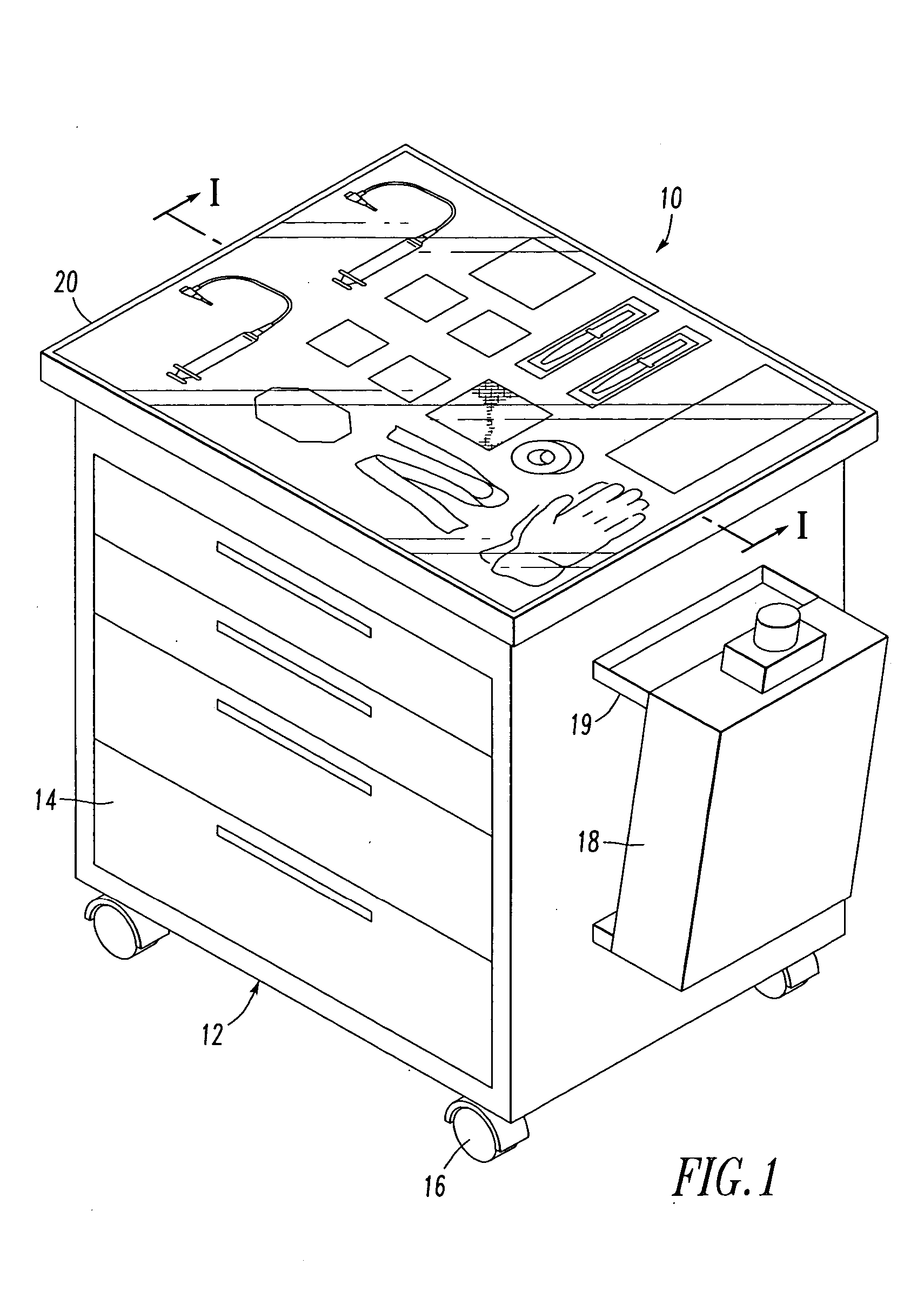

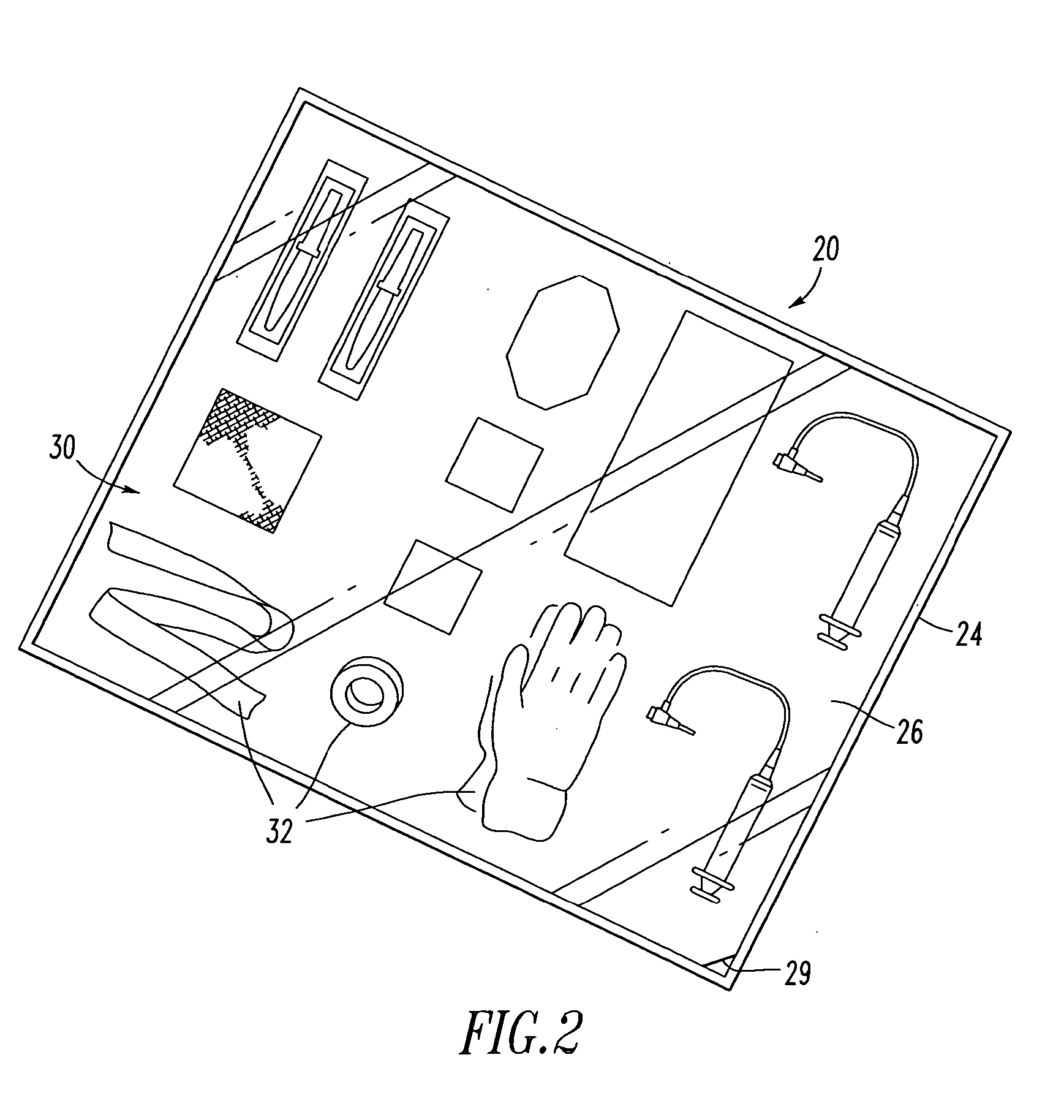

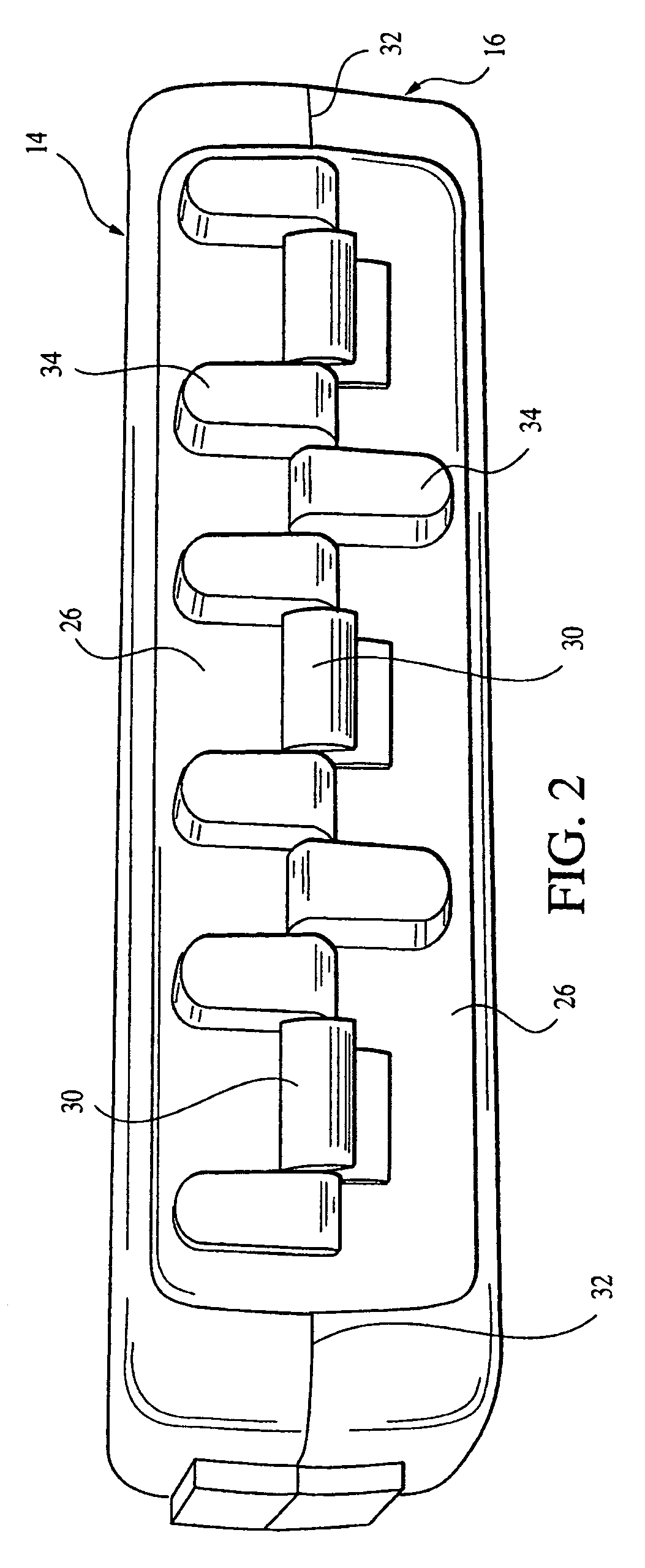

Medical procedure cart and method of customizing the same

InactiveUS20050236940A1Improve organizationReadily availableSurgical furnitureSledgesEquipment OperatorEngineering

A medical procedure cart includes a housing having a working surface disposed on a top thereof. The working surface forms a tray and includes a transparent top removably disposed above the tray. A height adjustment mechanism adjusts the height of the working surface. The template includes a plurality of figures depicting various different materials, instruments and equipment an operator prefers for a particular procedure. The operator can place the instruments, supplies and equipment on the transparent top of the working surface above a corresponding figure to enable the working surface to be stocked for a particular procedure.

Owner:CHILDRENS MEDICAL CENT CORP

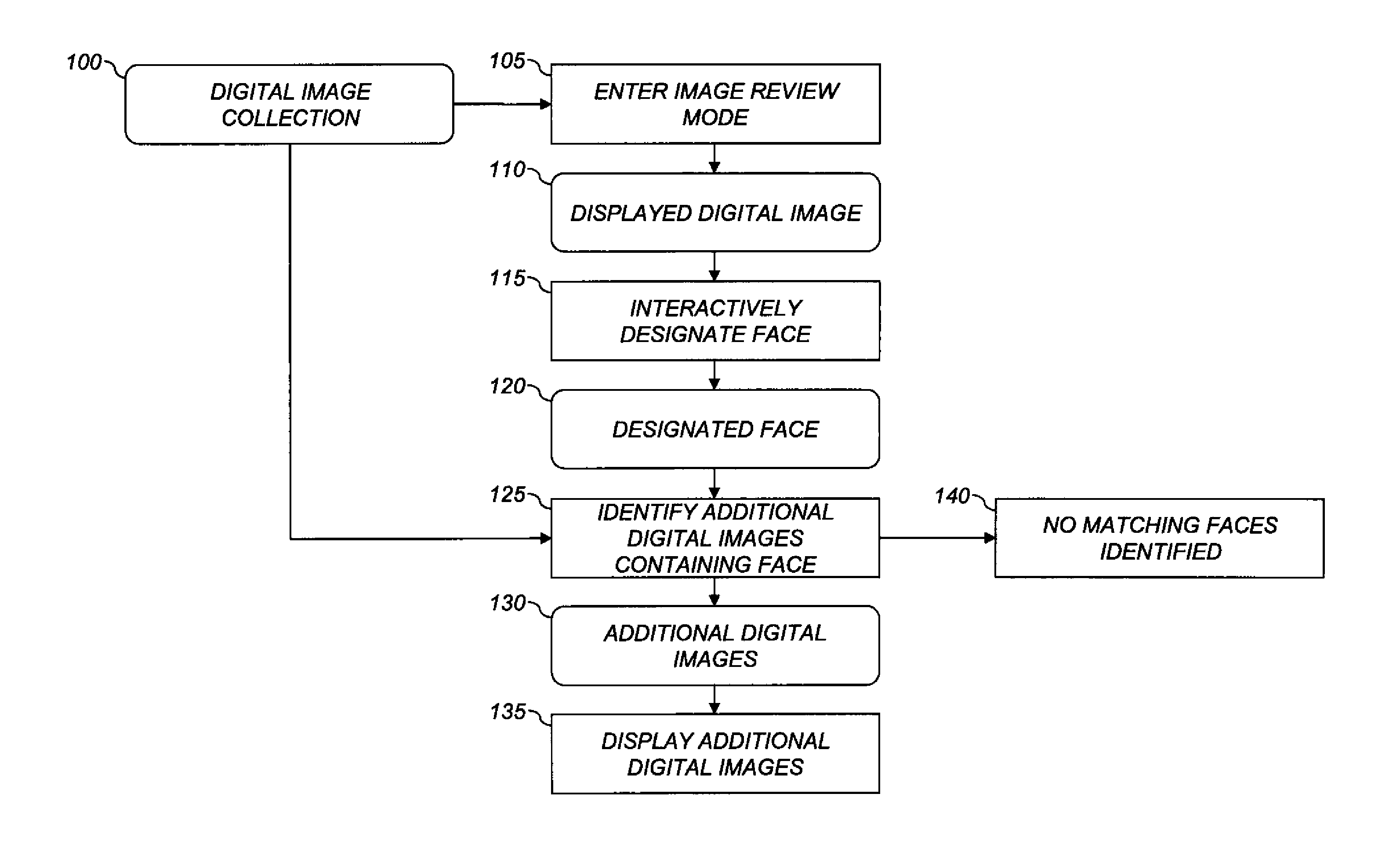

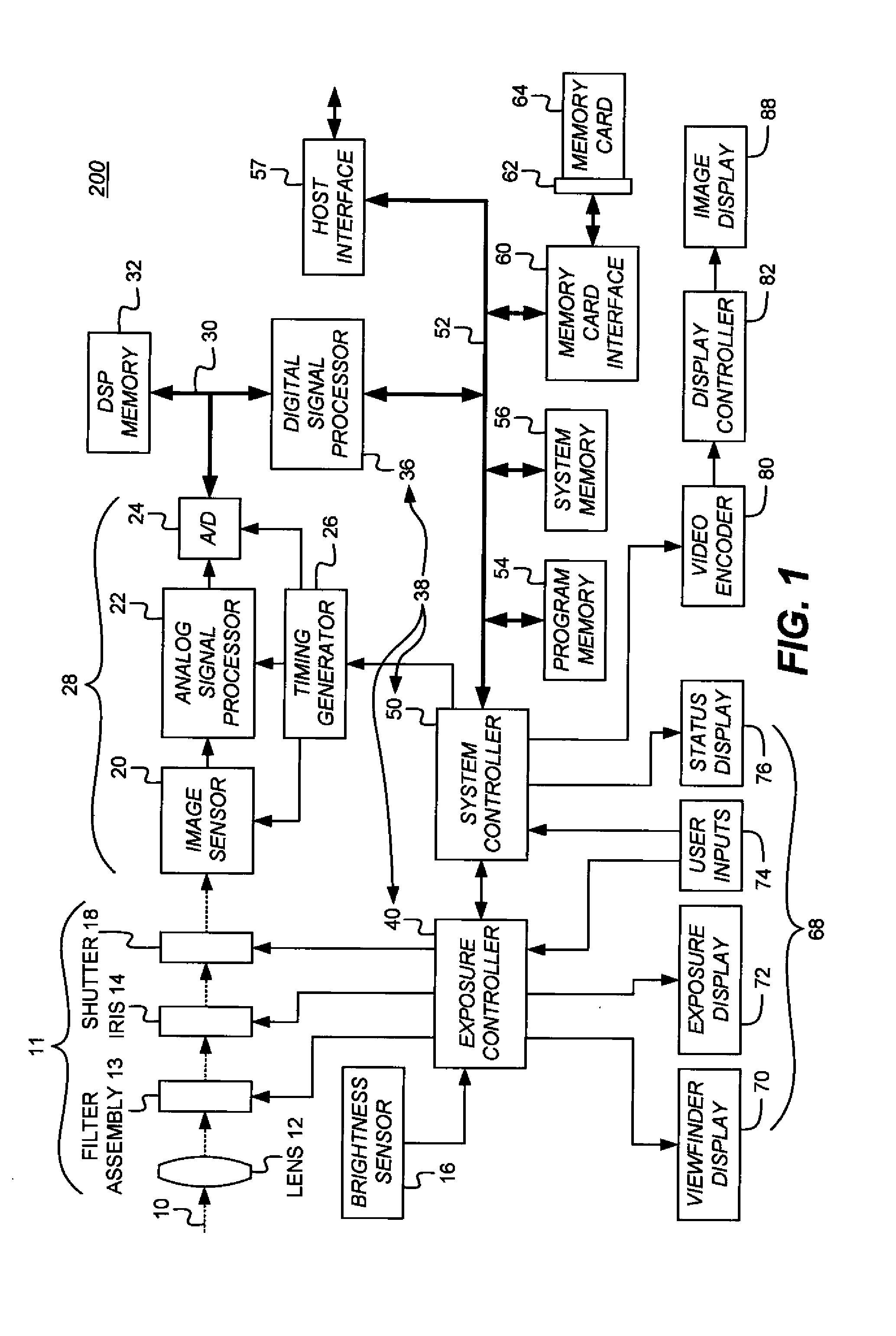

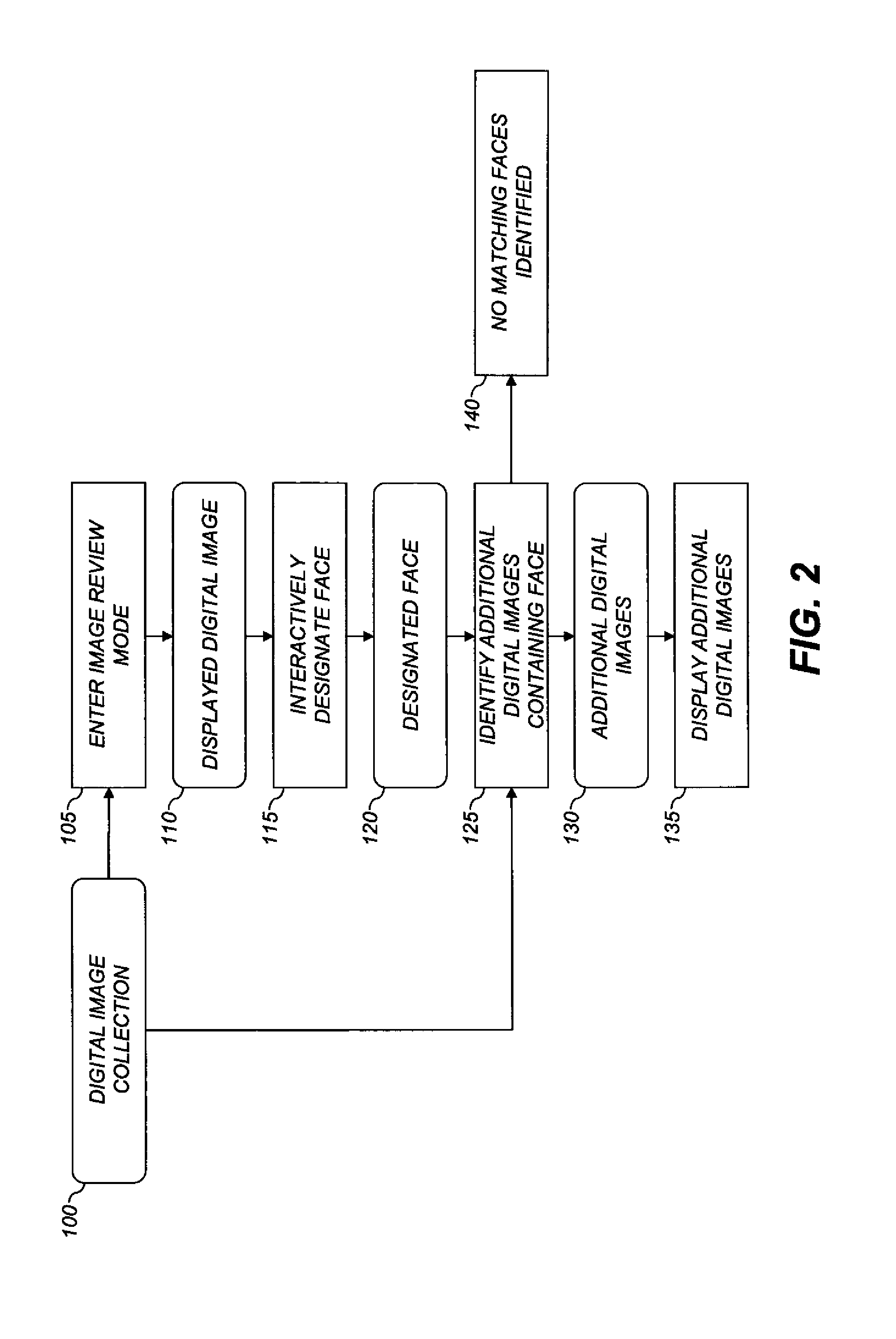

Searching digital image collections using face recognition

InactiveUS20110243397A1Facilitates efficient searchingImprove organizationTelevision system detailsDigital data information retrievalRecognition algorithmDigital image

A method for searching a collection of digital images on a display screen, comprising: entering an image review mode and displaying on the display screen a first digital image from the collection of digital images; designating a face contained in the first digital image by using an interactive user interface to indicate a region of the displayed first digital image containing the face; using a processor to execute an automatic face recognition algorithm to identify one or more additional digital images from the collection of digital images that contain the designated face; and displaying the identified one or more additional digital images on the display screen.

Owner:EASTMAN KODAK CO

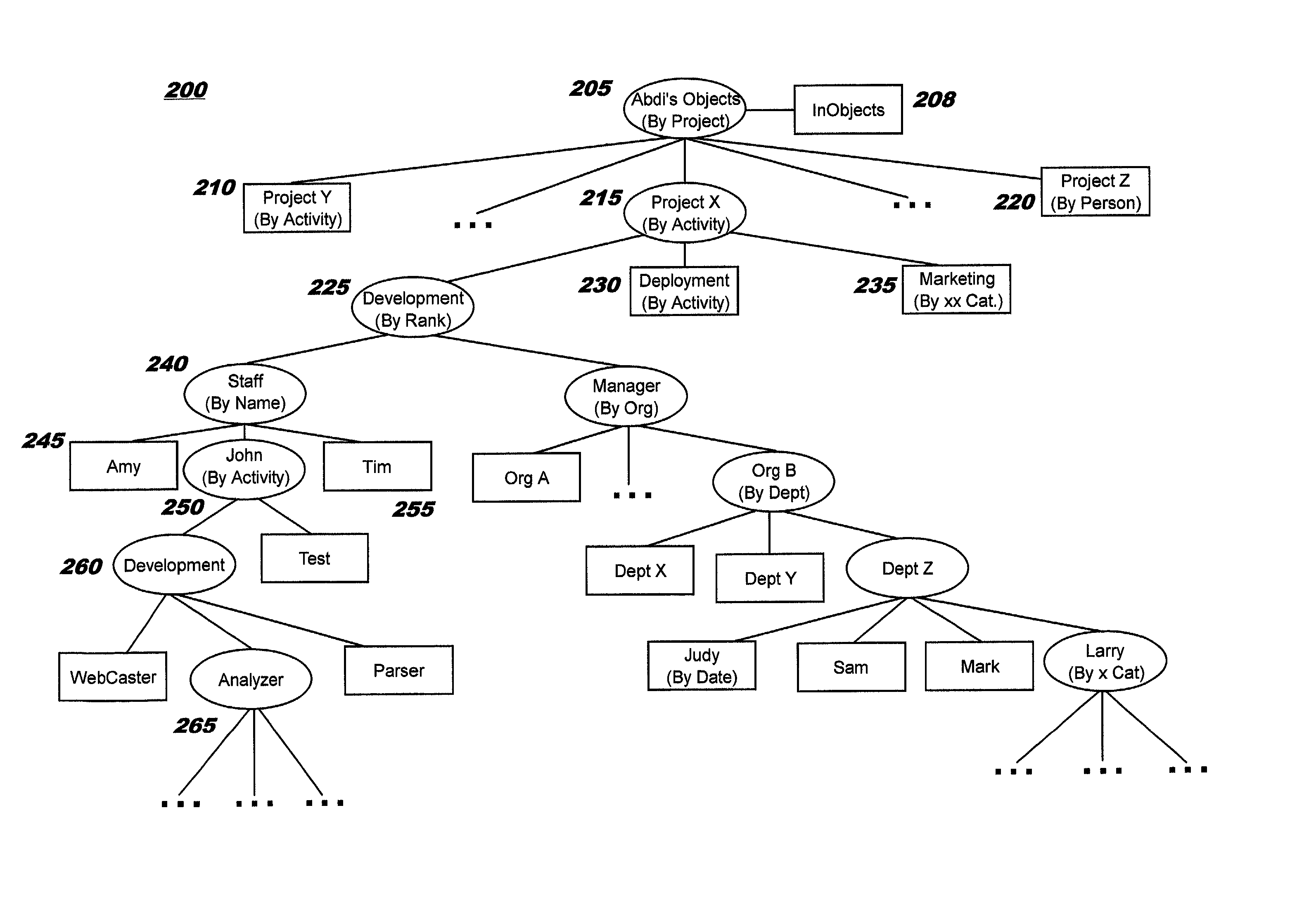

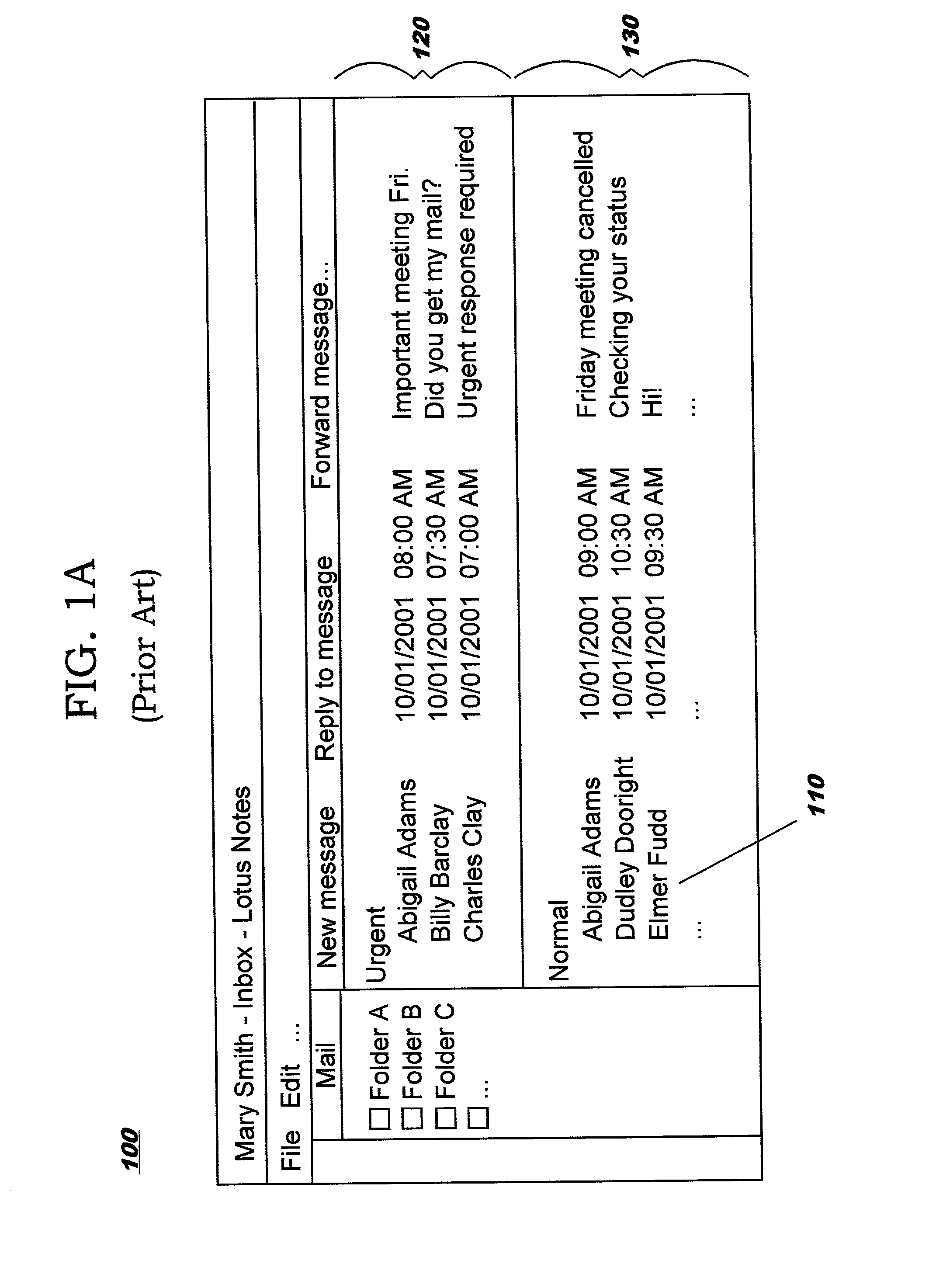

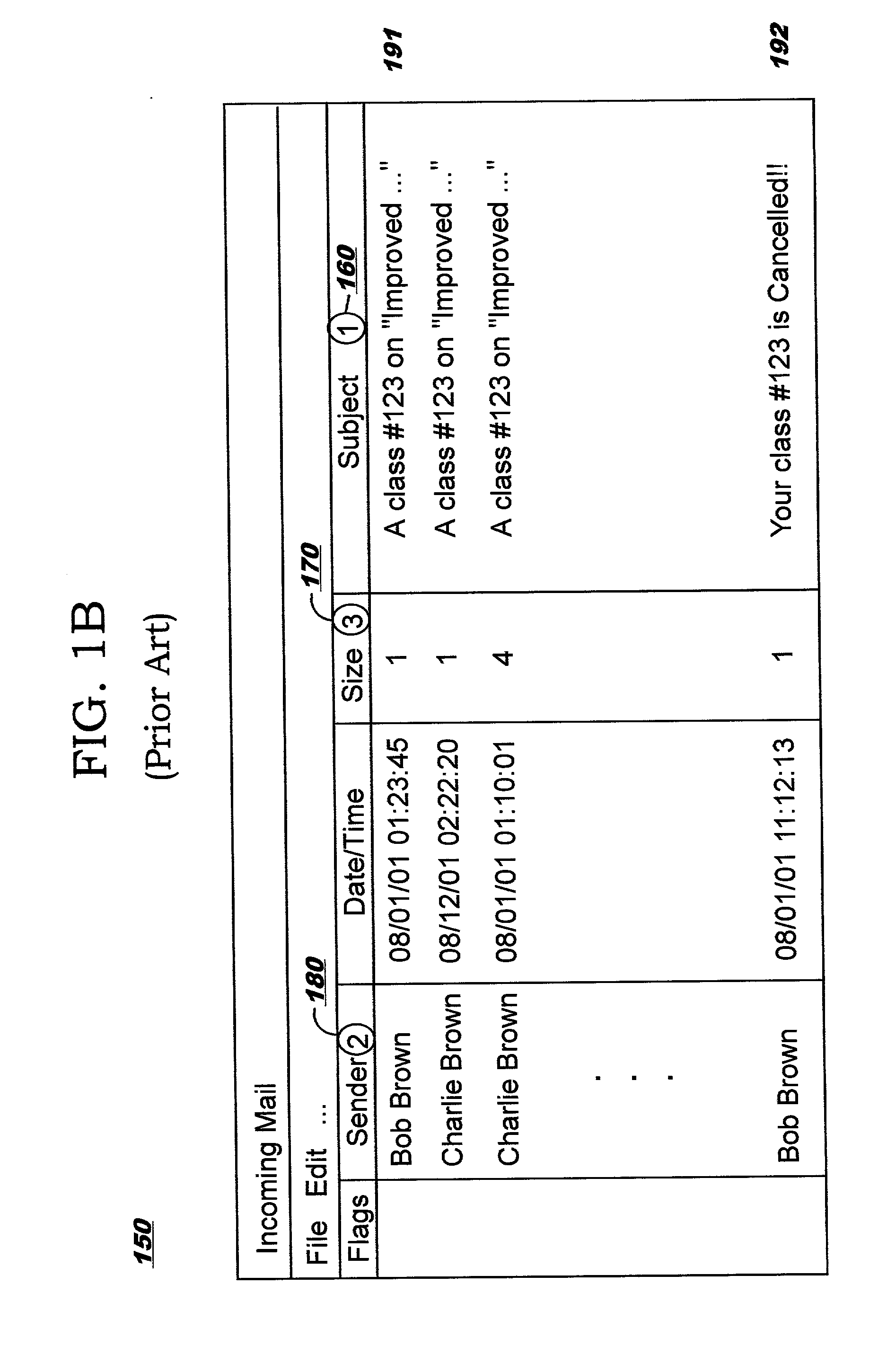

Relational view of electronic objects

InactiveUS20030069892A1Simple technologyImprove organizationDigital data processing detailsSpecial data processing applicationsDocumentationData mining

Methods, systems, and computer program products for organizing and viewing electronic objects (such as incoming electronic mail messages, documents, and so forth) according to relationships among the objects. Objects may be organized according to user-selectable, node-specific criteria These criteria may be dynamically learned, based upon a particular user's behavior, using the disclosed techniques.

Owner:IBM CORP

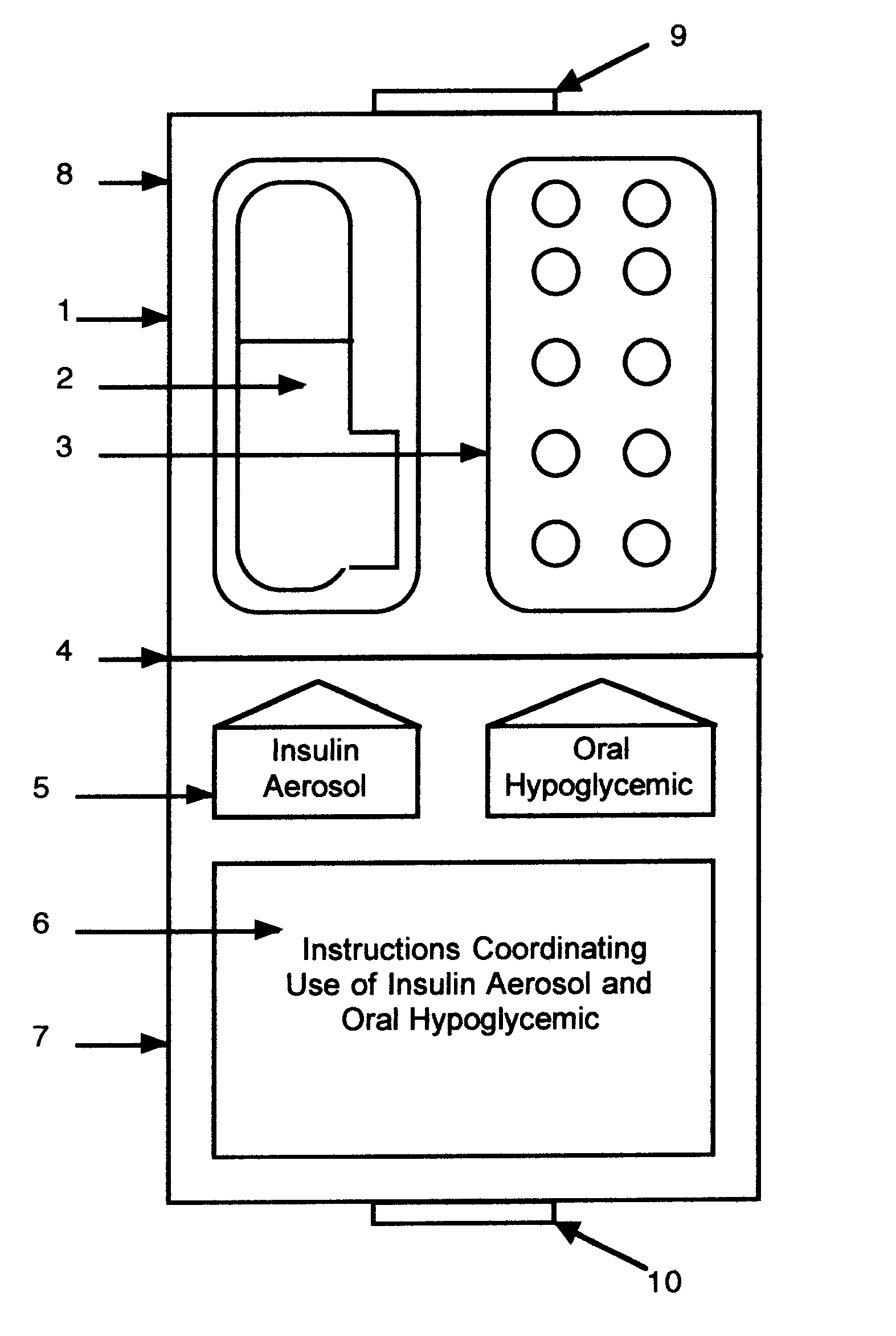

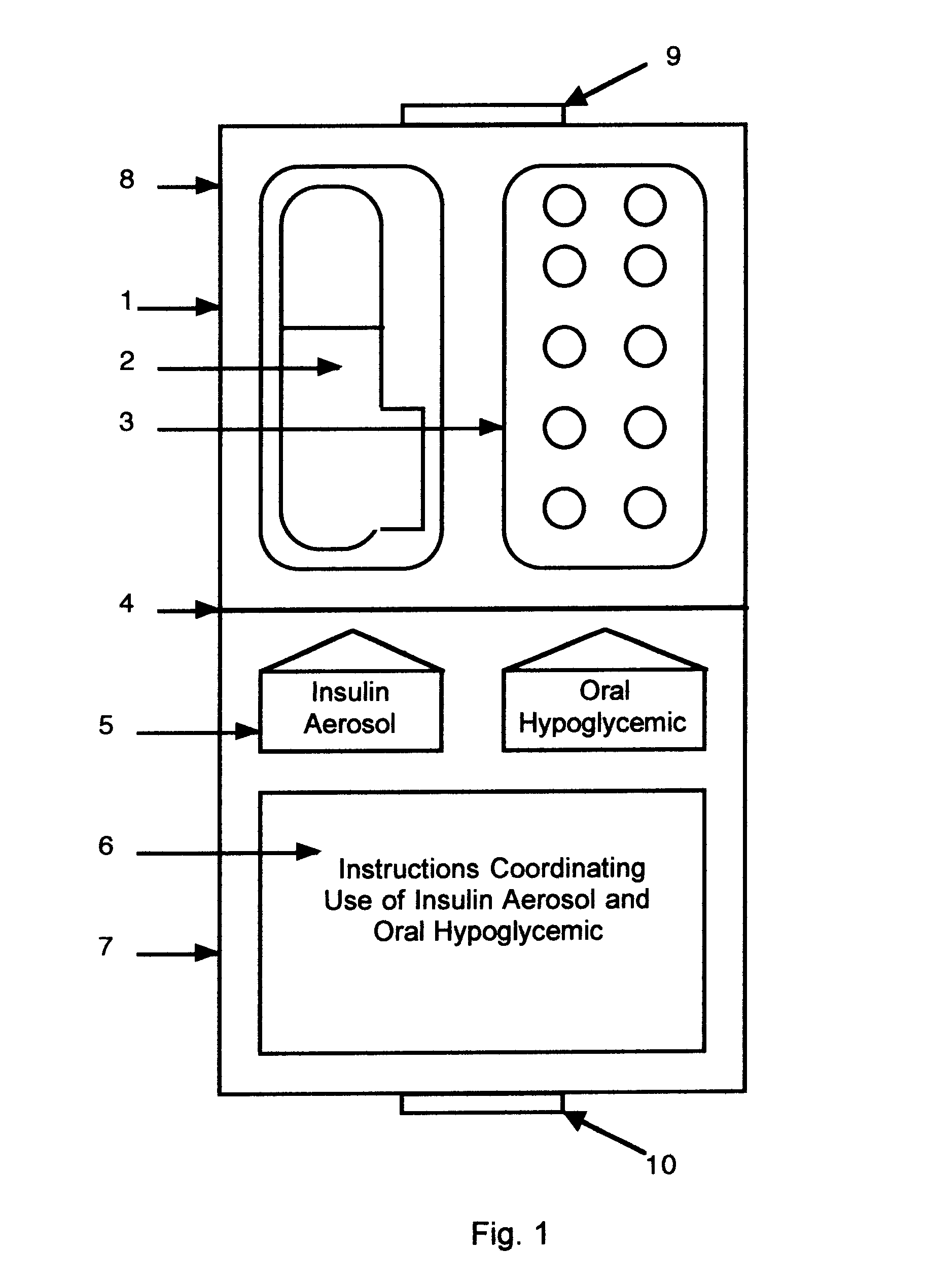

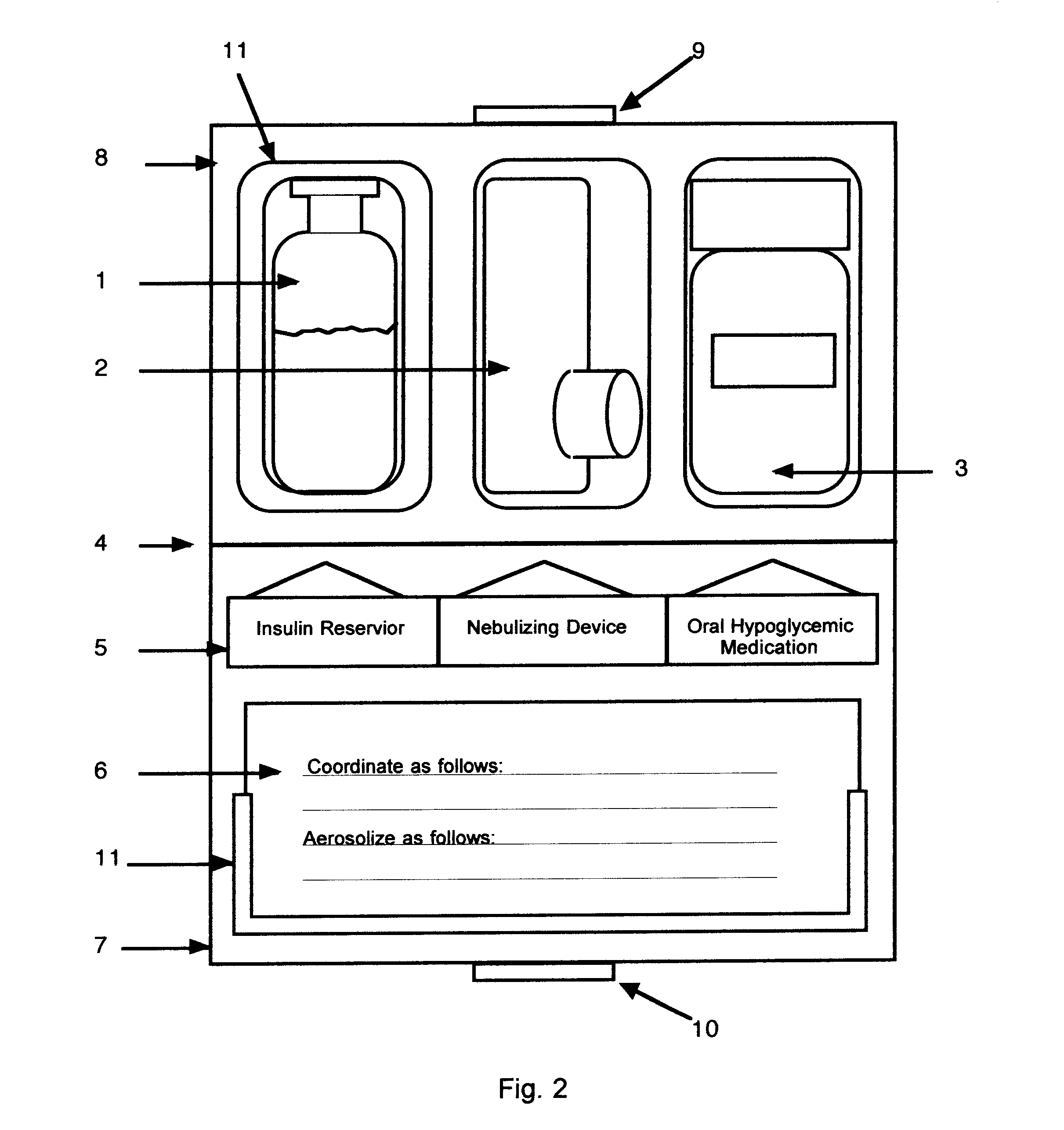

Method and device for facilitating combined aerosol and oral treatments for diabetes mellitus

InactiveUS6187291B1Improve convenienceImprove organizationPowder deliveryAerosol deliveryOral treatmentINSULIN PREPARATIONS

A dispensing container which incorporates an aerosolizable topical insulin preparation, at least one oral hypoglycemic agent, and indicia and instructions for their coordinated use as a single therapeutic regimen for the treatment of diabetes mellitus in a human, and a method for treating diabetes mellitus which employs such a device.

Owner:WEINSTEIN ROBERT E +1

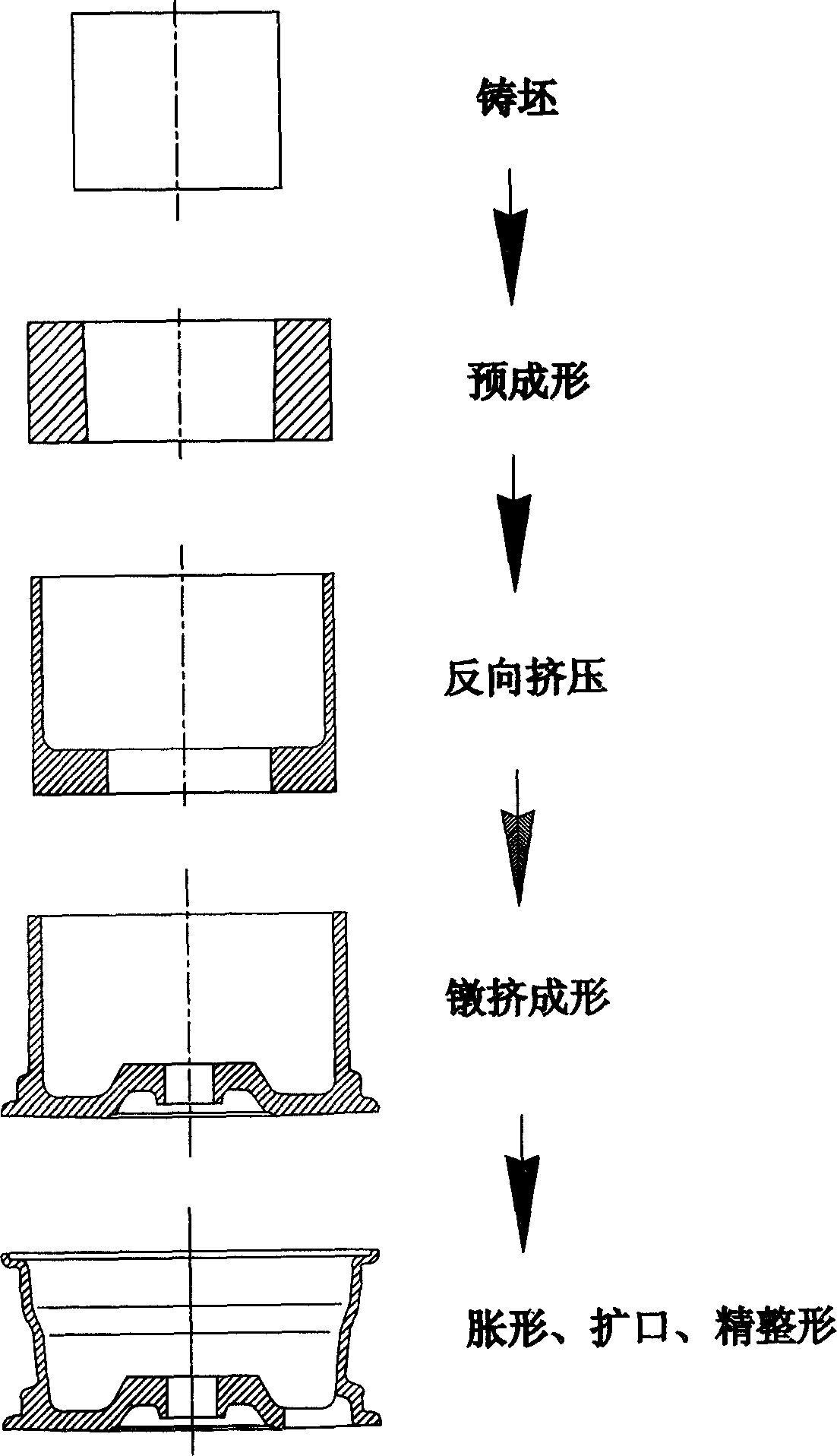

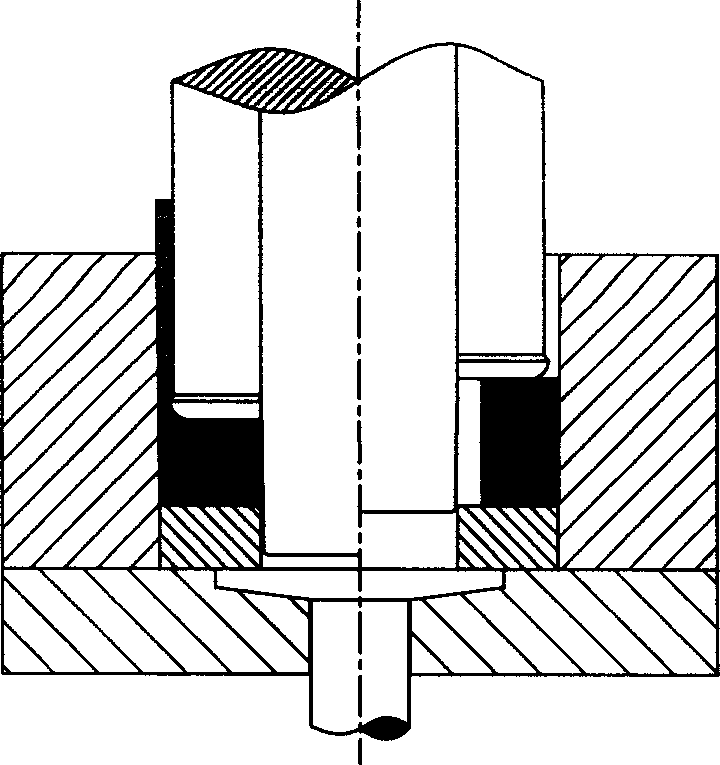

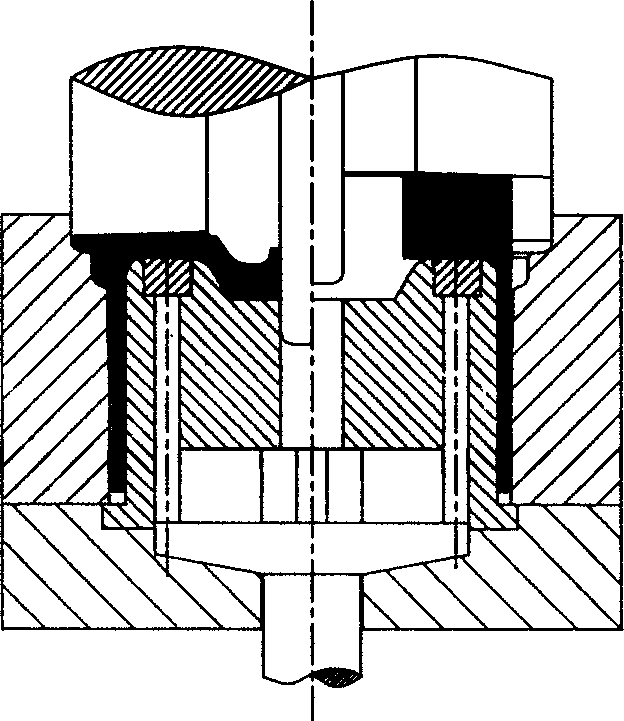

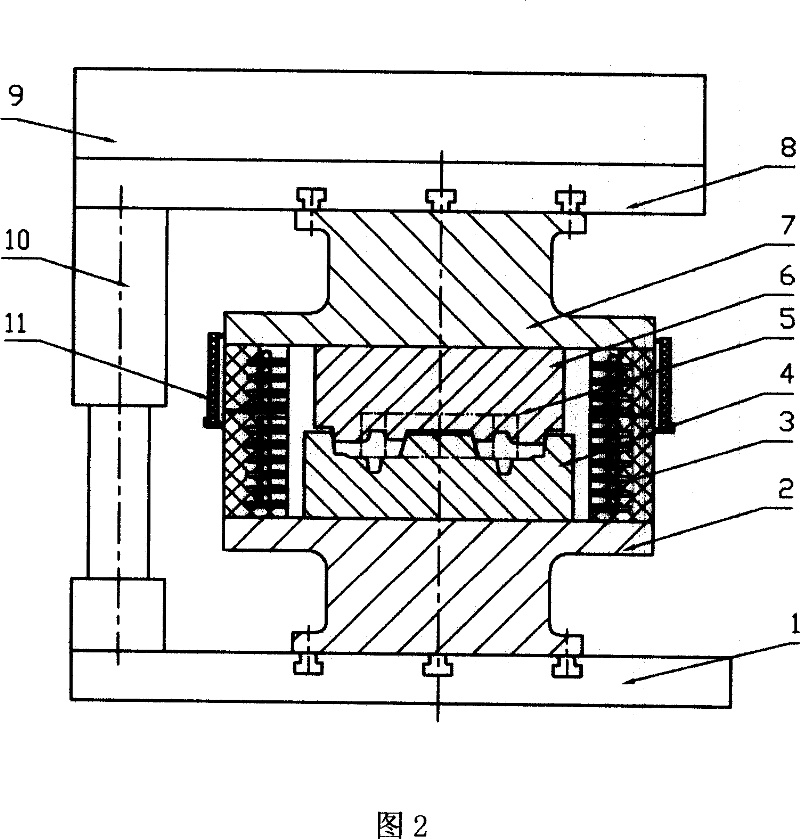

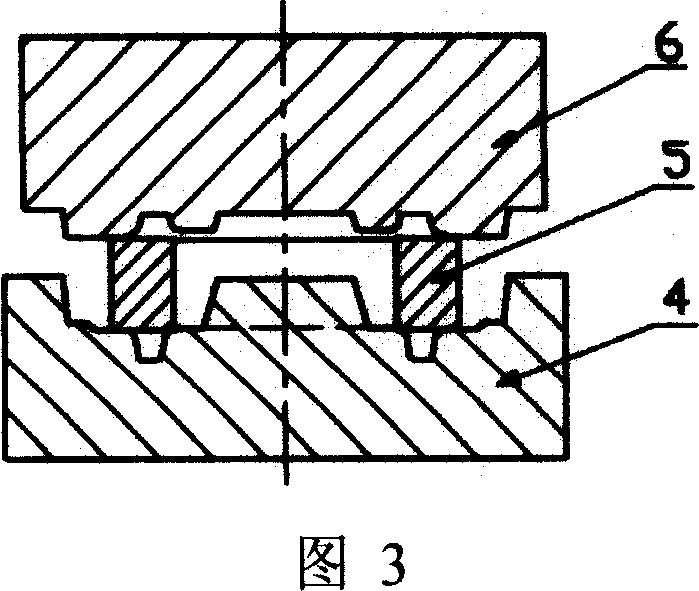

A labor-saving automobile hub forming method and device

InactiveCN1864915AWith substantive technologyReduction toolExtrusion diesExtrusion control devicesEngineeringMechanical engineering

The invention relates to a method for shaping the vehicle hub and relative device. Wherein, it comprises following steps that casting blank; uniform processing; pre-shaping blank; compressing; compressing the front rim; expanding opening and folding the edge at the back rim. The invention is characterized in that: the casting blank via pre-shaping is made into hollow blank; the concave and convex moulds in the compressing step and the compressing front rim step are integrated, while the convex mound contains core axle; the compressing step compresses the hollow blank in the mould via core axle to obtain the cylinder element whose bottom has holes; the step that compressing front rim uses metal diversion to stuff and shape; the step that expanding opening and folding the edge of back rim uses integrated convex mould and separated concave mould to expand opening, fold edge an shape the back rim. The invention can simplify the process, reduce device number, reduce the shaping force, reduce the energy consumption, and reduce the producing cost. The invention is mainly used to produce aluminum and magnesium alloy hub.

Owner:ZHONGBEI UNIV

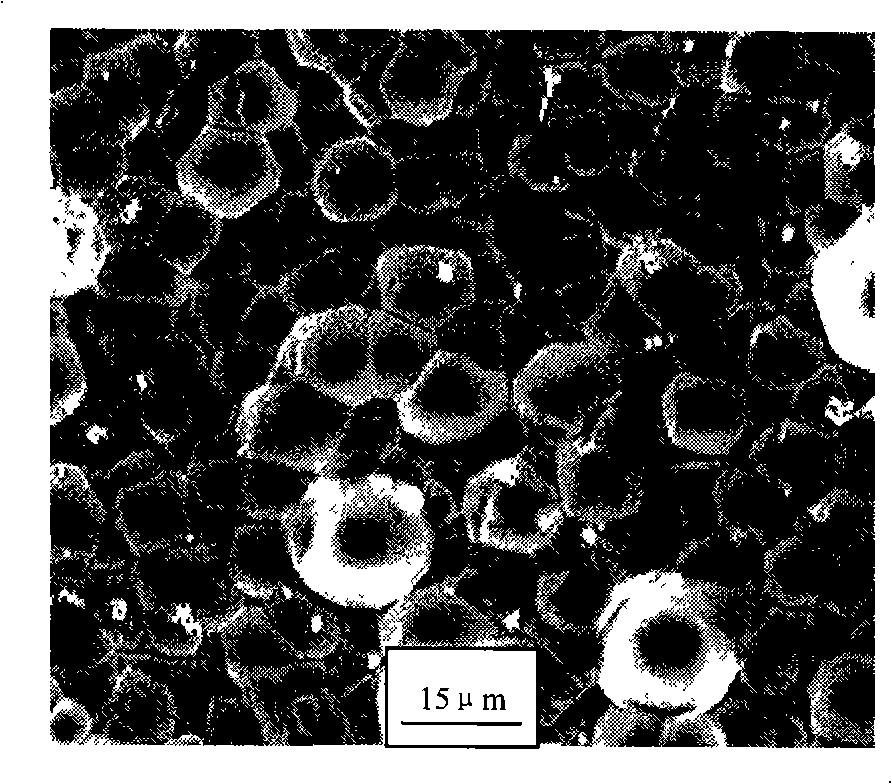

Centrifugal casting high-speed steel composite roll and manufacture method thereof

InactiveCN102615108AGood metallurgical bondHigh strengthRollsMetal rolling arrangementsNiobiumEconomic benefits

The invention relates to a centrifugal casting high-speed steel composite roll and a manufacture method thereof and belongs to the field of casting. The composite roll is composed of outer layer high-speed steel, middle layer graphitic steel and core high-strength nodular cast iron by centrifugal compounding. The centrifugal casting high-speed steel composite roll is based on the conventional high-carbon high-vanadium high-speed steel roll, the content of vanadium is appropriately reduced, niobium is added at the same time, and the Nb / V is controlled to be 0.3 to 0.5 so that Nb and V form complex carbide (V, Nb) C so as to avoid forming segregation under the action of centrifugal force. A roll core of the high-speed steel composite roll adopts high-strength nodular cast iron, and a multivariate graphite steel middle layer is poured between an outer layer and the roll core for preventing interfusing elements of Cr, B, and the like which cause embrittlement when the nodular cast iron is poured to be fused with the outer layer high-speed steel. Microalloying processing for refining the organization is carried out on a roll surface high-speed steel material and the middle layer graphitic steel so as to achieve the purpose of improving the thermal cracking capacity of the roll material. The centrifugal casting high-speed steel composite roll has high overall performance, long service life and good economic benefits.

Owner:BEIJING UNIV OF TECH

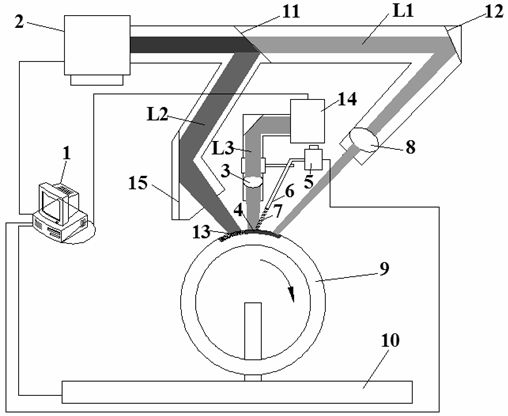

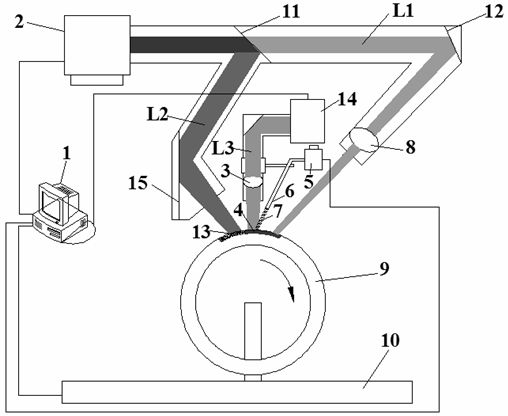

Method with functions of preheating and postheating for forming crack-free coating with high efficiency by three-light-beam laser-cladding technique

InactiveCN102383126ALow and adjustable dilution rateSmall heat affected zoneMetallic material coating processesLaser beam welding apparatusMelting tankHeat-affected zone

The invention discloses a method with functions of preheating and postheating for forming crack-free coating with high efficiency by a three-light-beam laser-cladding technique. The method comprises the following steps of: splitting a laser beam emitted by an Nd: YAG laser into two laser beams by using a laser beam splitter, namely a preheating laser beam for preheating the surface of a base material and a postheating laser beam for postheating the formed coating; then blowing alloy powder into a molten pool which is formed by focusing a laser beam emitted by a CO2 laser and acting the focused laser beam on the surface of the base material by using a powder nozzle, wherein after the CO2 laser beam moves away, a molten layer is cured and crystallized quickly to form the coating; and postheating the formed coating by adopting the postheating laser beam. The method has the advantages that: (1) the dilution rate of the coating is low and adjustable, and the coating is metallurgically combined with the base material, so the base material has a small thermal influence area and is deformation-free and crack-free; (2) residual inner stress in the coating can be eliminated effectively, a tissue can be improved, and the coating has high abrasion resistance, high corrosion resistance, high anti-cracking performance and high thermal shock resistance; and (3) relative to the processing efficiency in the conventional laser cladding technology, the processing efficiency in the method can be improved by 50 times to the maximum extent, so the processing cost is reduced greatly, and a large-scale industrialized application potential is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

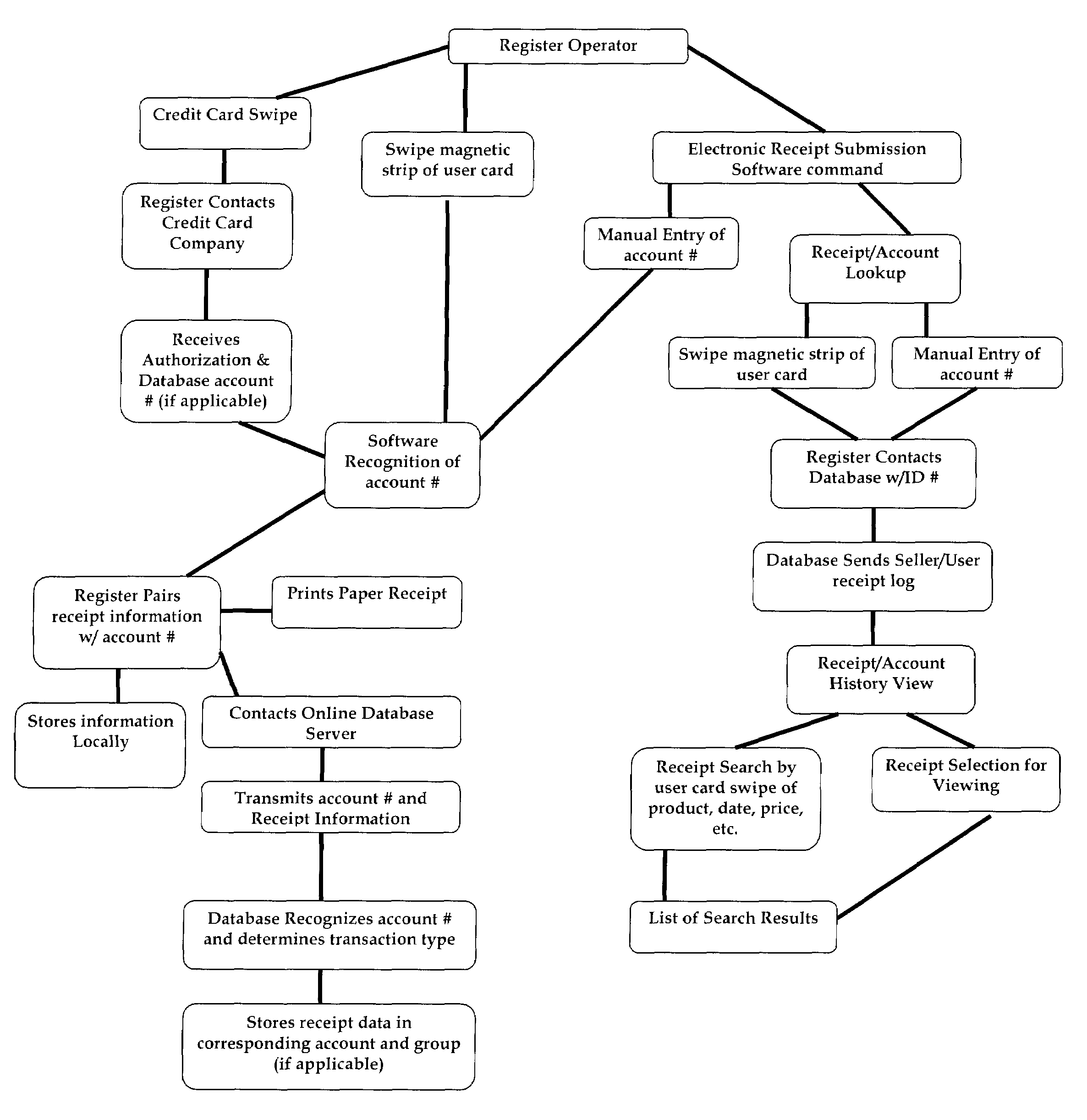

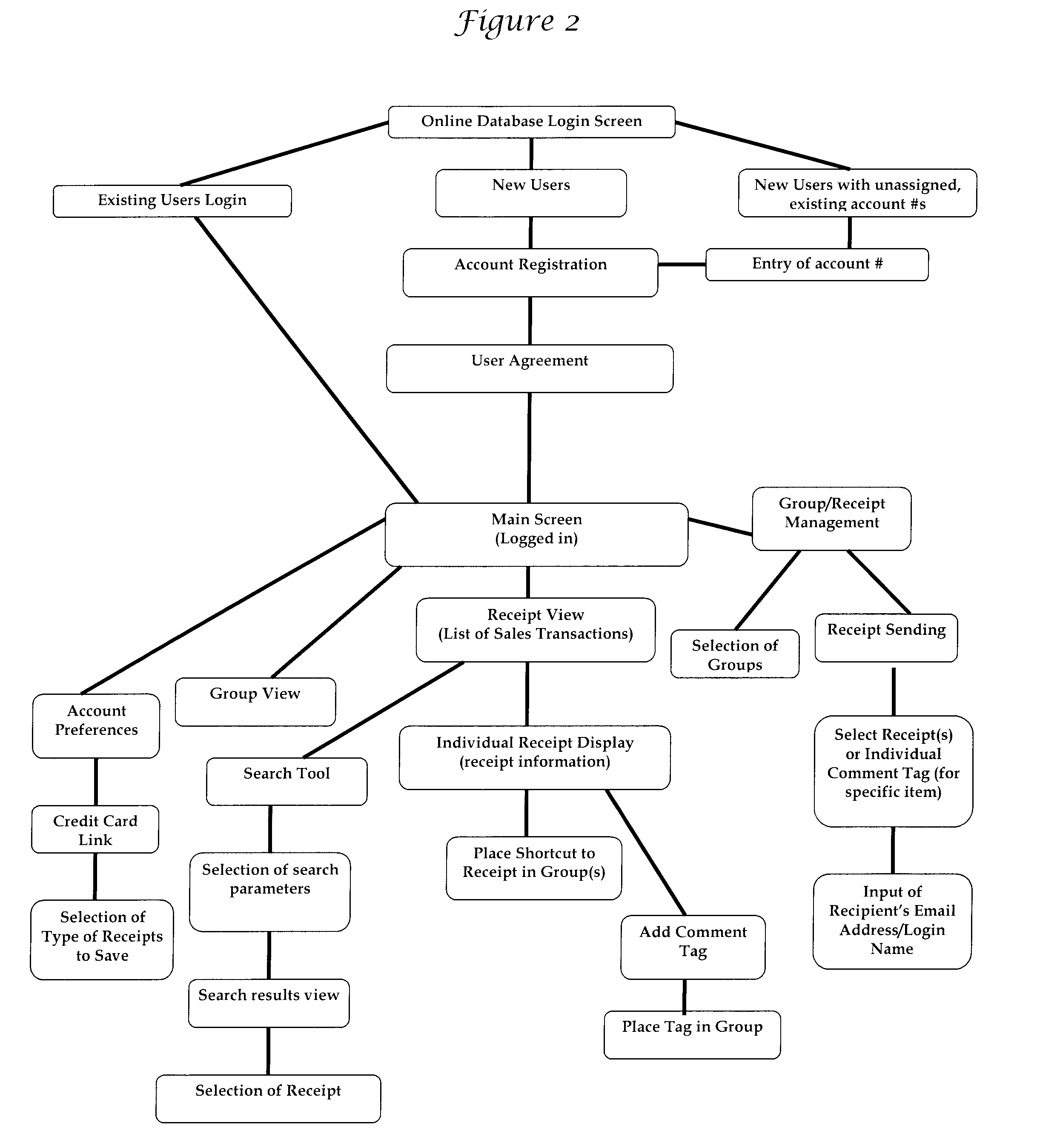

System for online electronic receipt management and method therefor

InactiveUS20070164106A1Gain accessSimple calculationVisual presentationBuying/selling/leasing transactionsReceiptIndividual item

An online electronic receipt management system and method are disclosed. The system and method allow for a centralized online electronic receipt database accessible to a user via the Internet using an email address and password to gain access to the user's unique site. The system and method also allow a user to easily organize entire sales transactions (or individual items from a multiple-item sales transaction) items into categories allow for simple calculation of total expenses relevant to that category. The system and method also allows a user to easily create gift receipts by masking certain portions of the sales transaction prior to transferring it to the recipient.

Owner:MCDEVITT DAVID NEAL +1

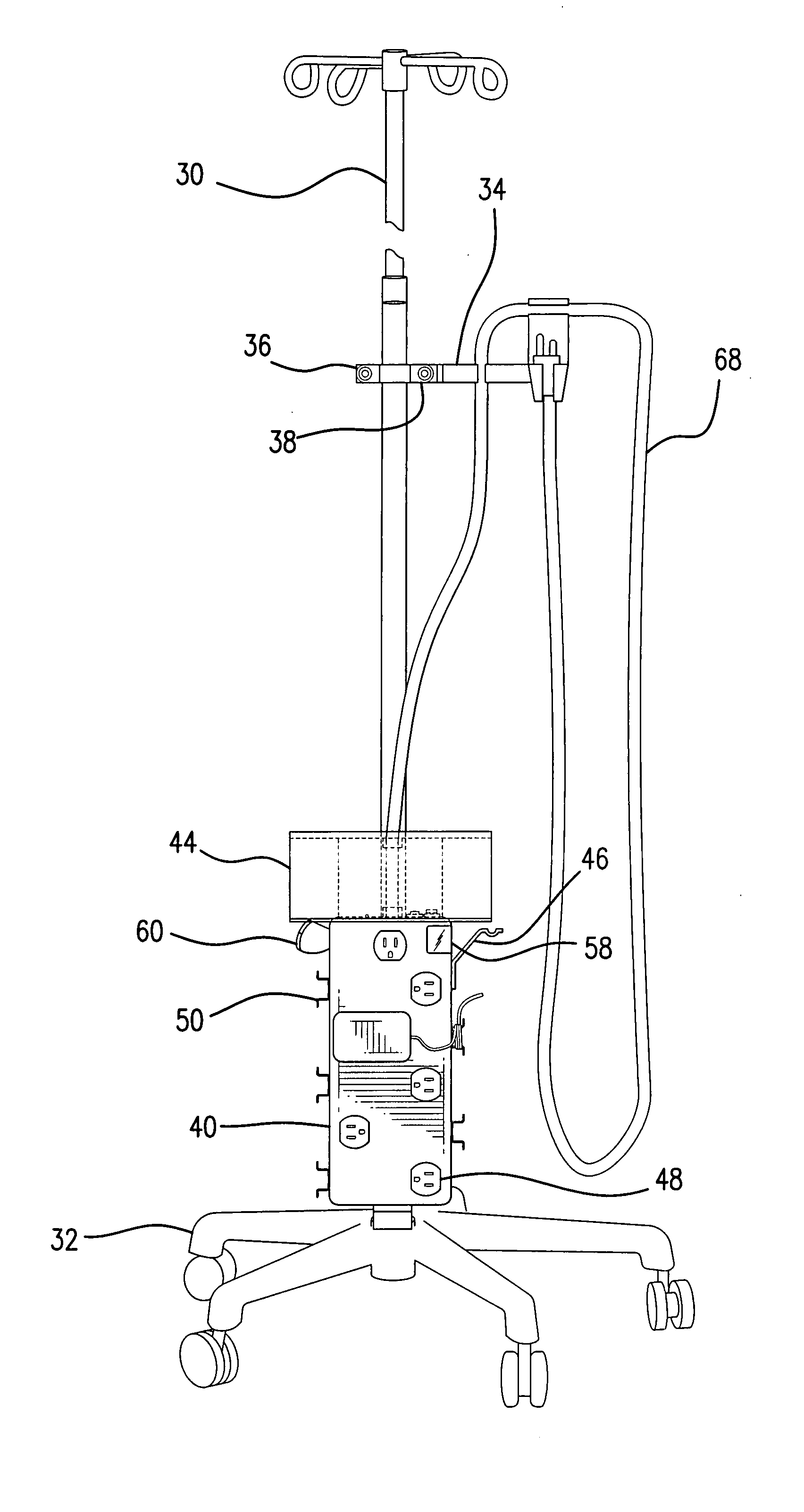

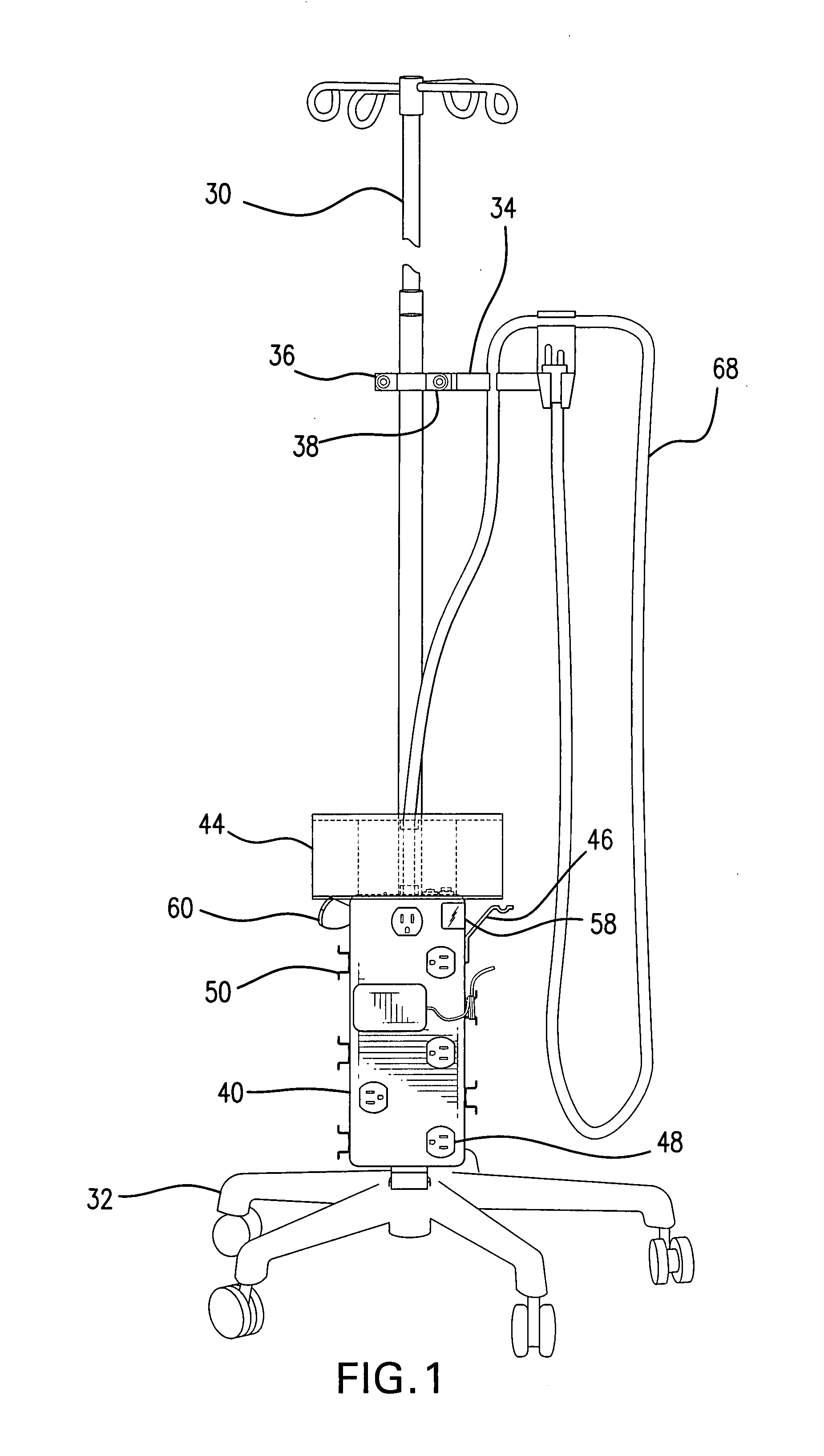

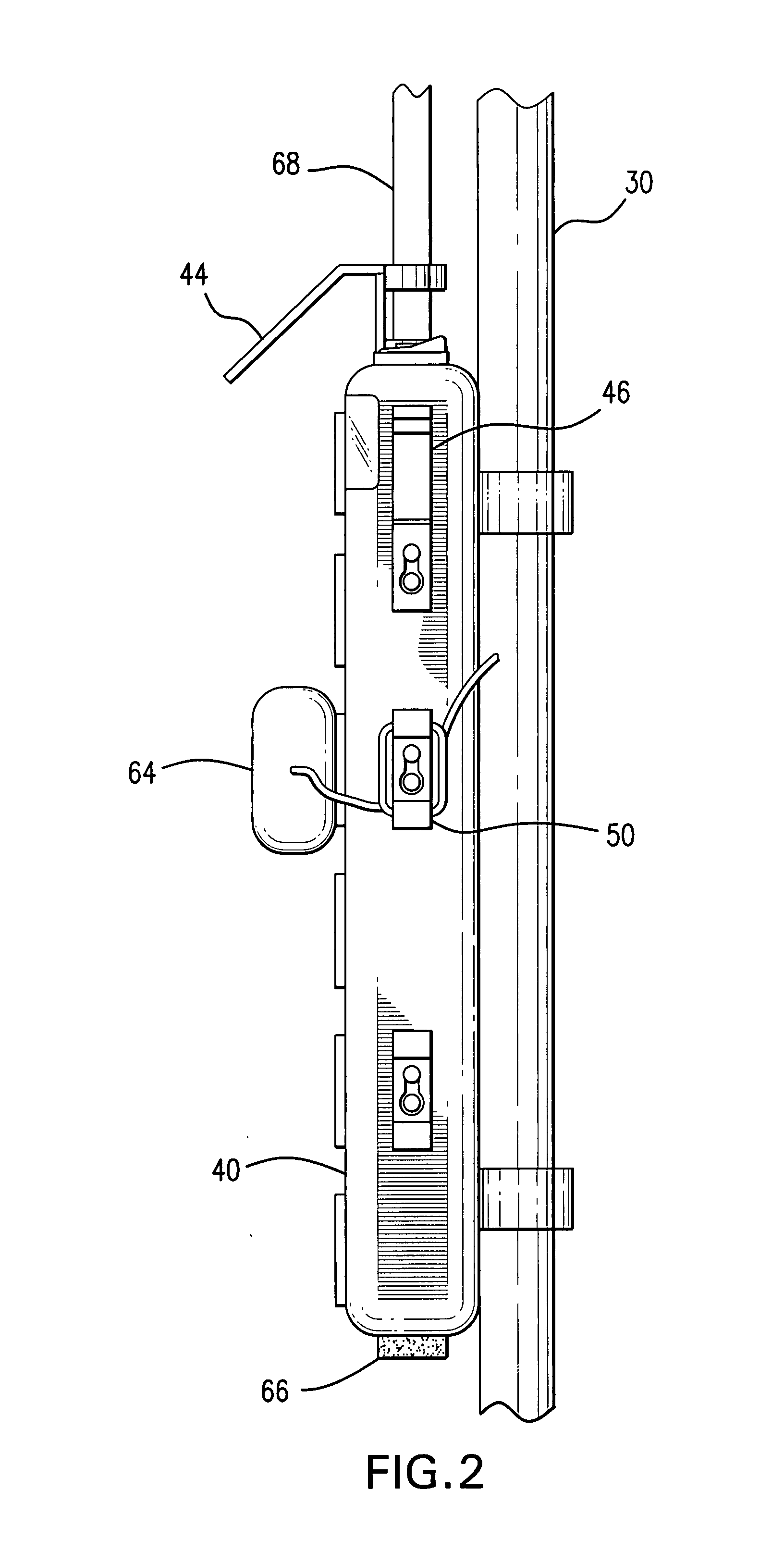

Intravenous pole power organizer (IVPPO)

ActiveUS20080116157A1Improve patient careImprove convenienceWash-standsMedical devicesPatient roomMedicine

The invention provides an apparatus for safely storing and retrieving power cords and electronic wiring associated with a mobile intravenous pole serving patients in intensive care settings wherein a plurality of devices are required and enabling the patient to be mobile without causing power cords and wiring to become tangled and dragging on patient room or hospital floors.

Owner:FULBROOK JASON D +2

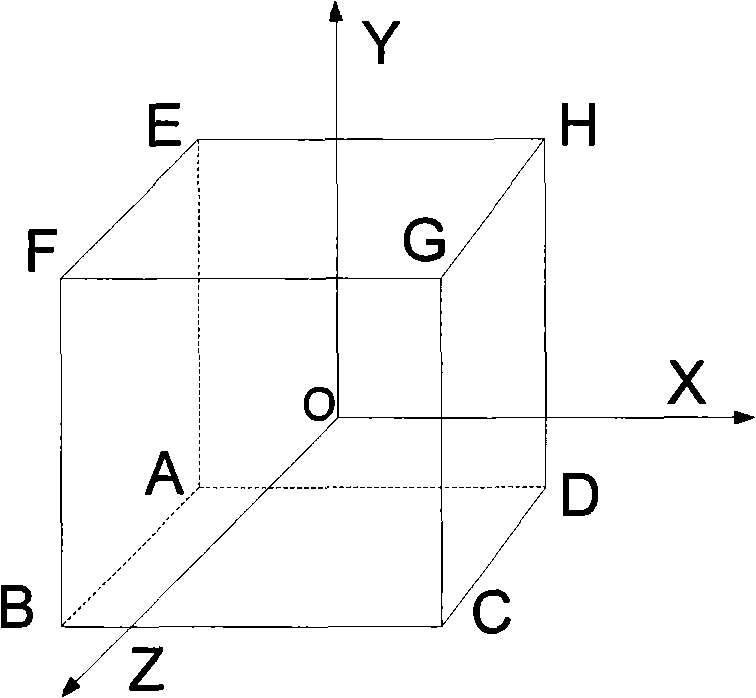

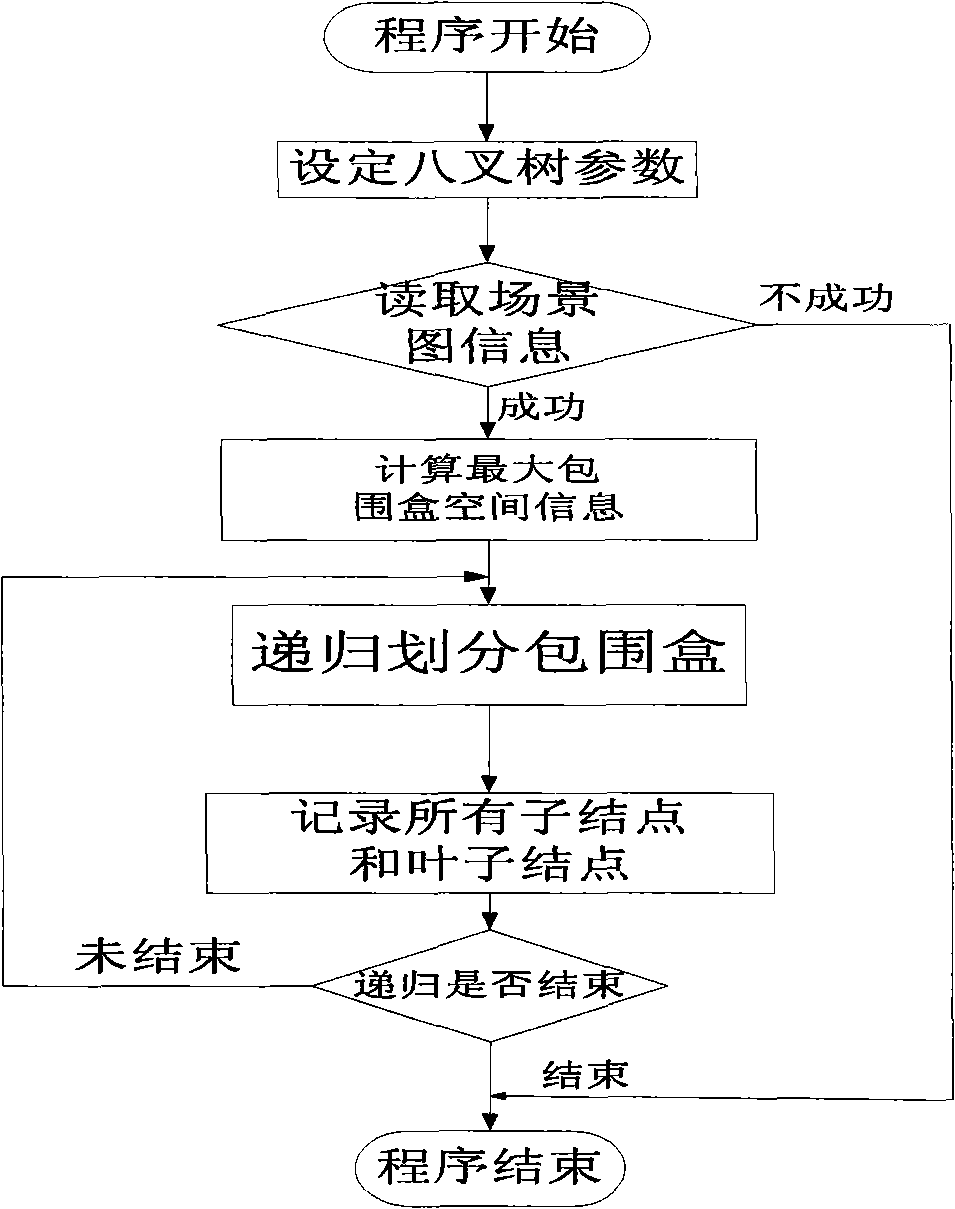

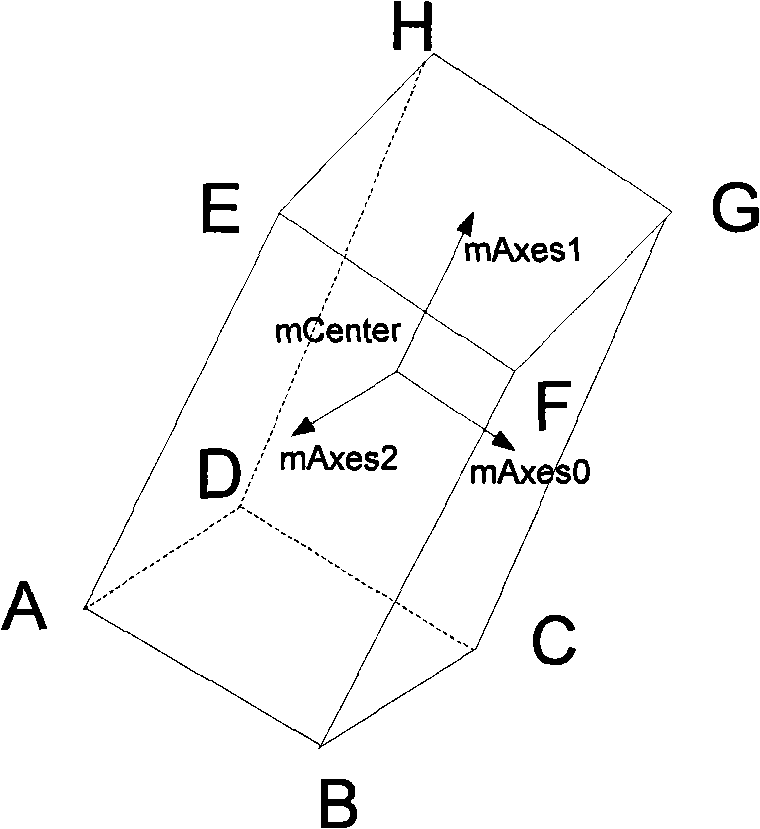

Method for processing cosmically complex three-dimensional scene based on eight-fork tree

InactiveCN101281654AImprove organizationImprove good performanceImage coding3D-image renderingGraphicsComputer graphics

The invention relates to a large scale complex three-dimensional scene processing method based on the octree, belonging to the computer graphics and the virtual reality field, including the steps: (1) loading the large scale three-dimensional scene, organizing all the elements in the scene by the scene drawings; (2) building and generating the octree structure of the scene, recording the related information; (3) using the octree structure, performing the fast sight elimination through the crossing detection algorithm of the retinal cone body and the bounding box; (4) rendering the objects in the retinal cone body. The invention considers the deficiency to render the large scale complex three-dimensional scene when the present drawing renders the engine, uses the octree structure to organize the scene, cuts the geometrical nodes outside the retinal cone body by the space information and the tree structure, fast computes the node sequence required to render, reduces the number of the triangle surfaces transmitted to the rendering channels, thereby effectively advancing the rendering speed, reaching the realtime requirement.

Owner:SHANGHAI UNIV

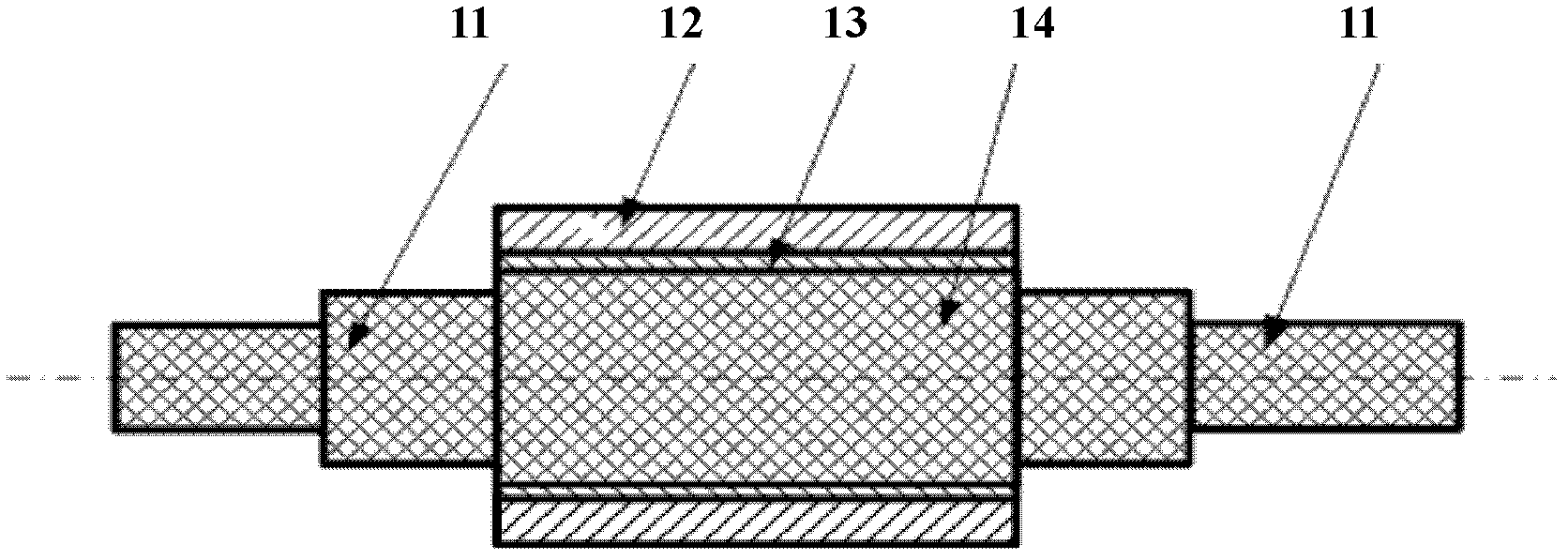

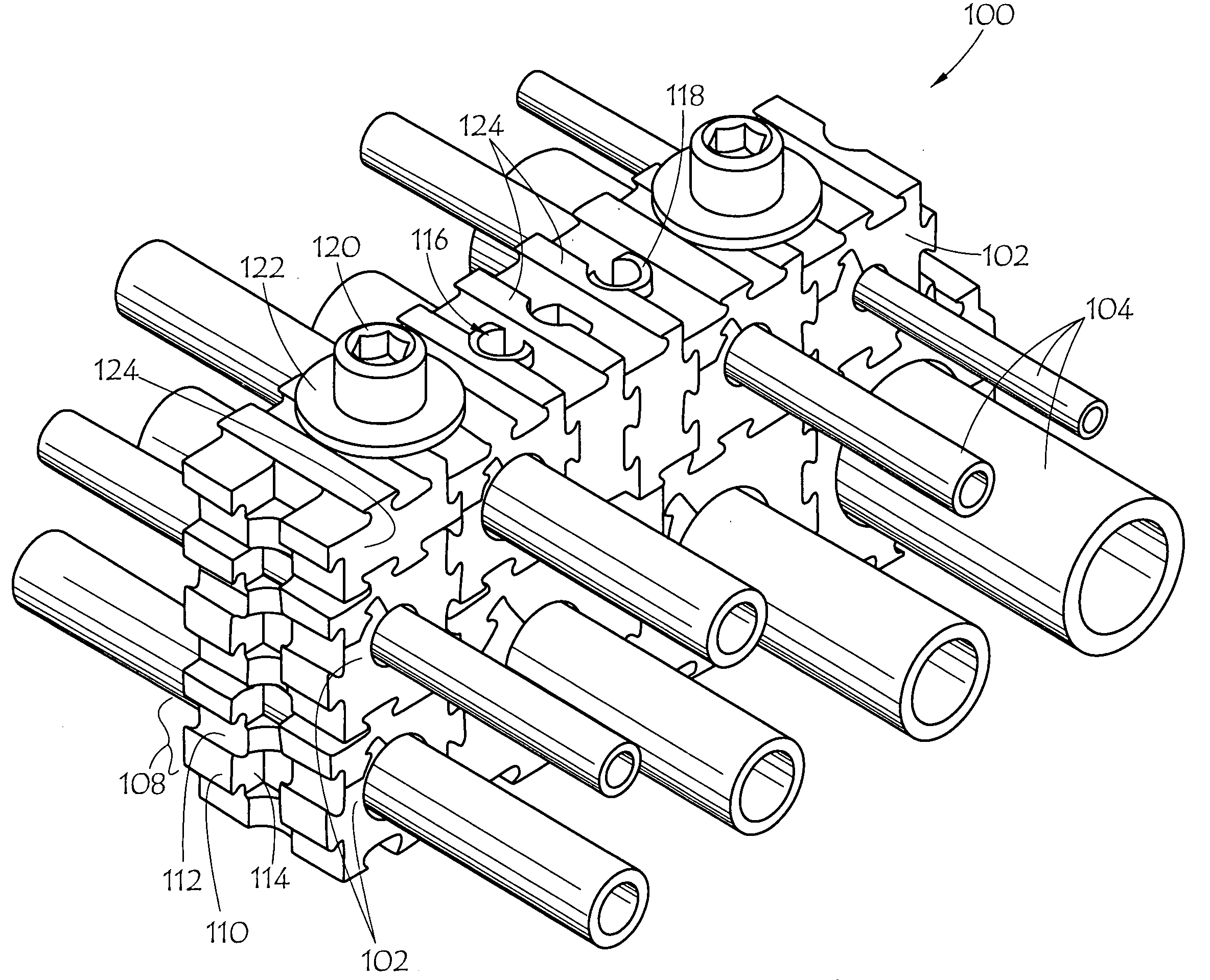

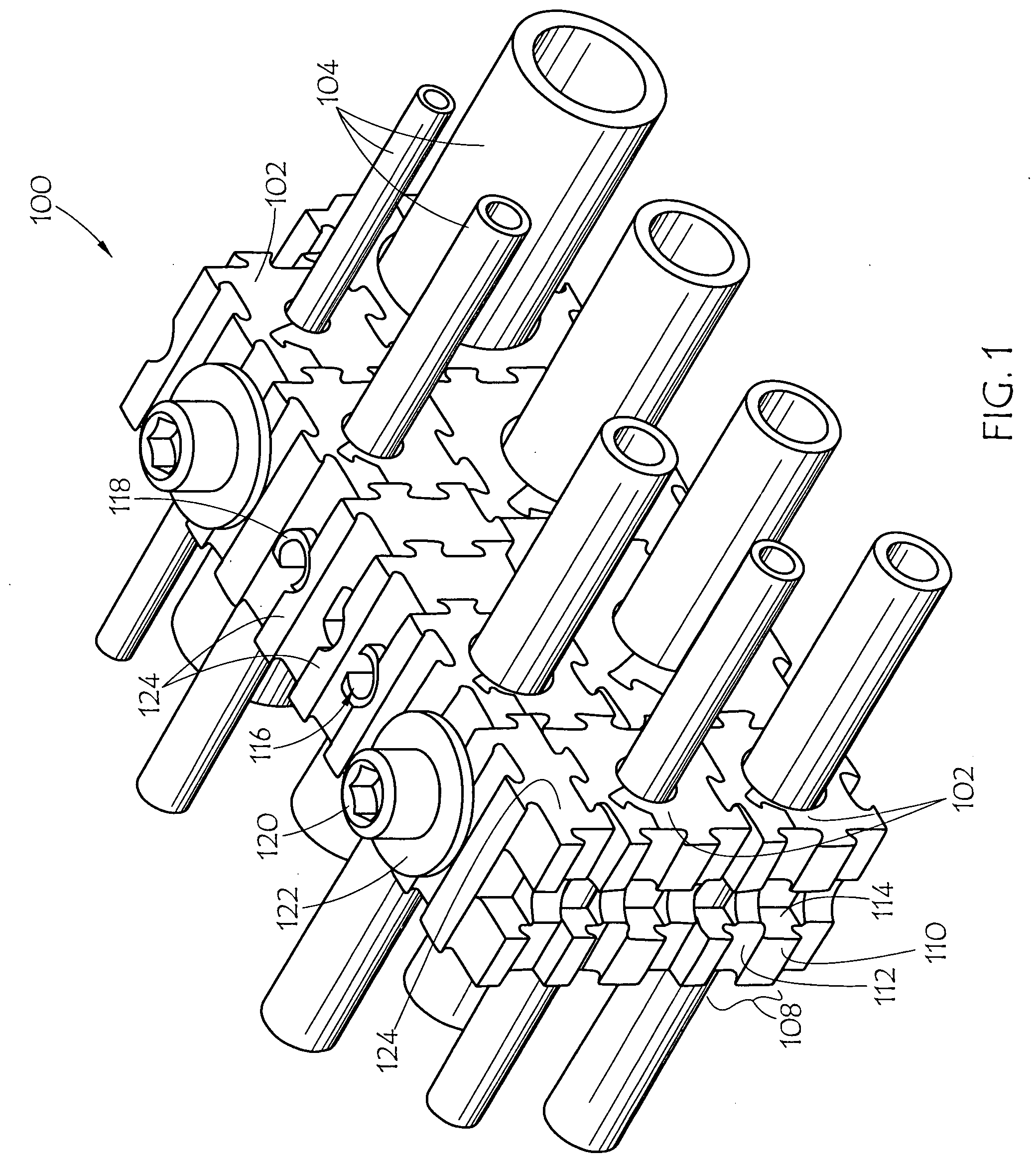

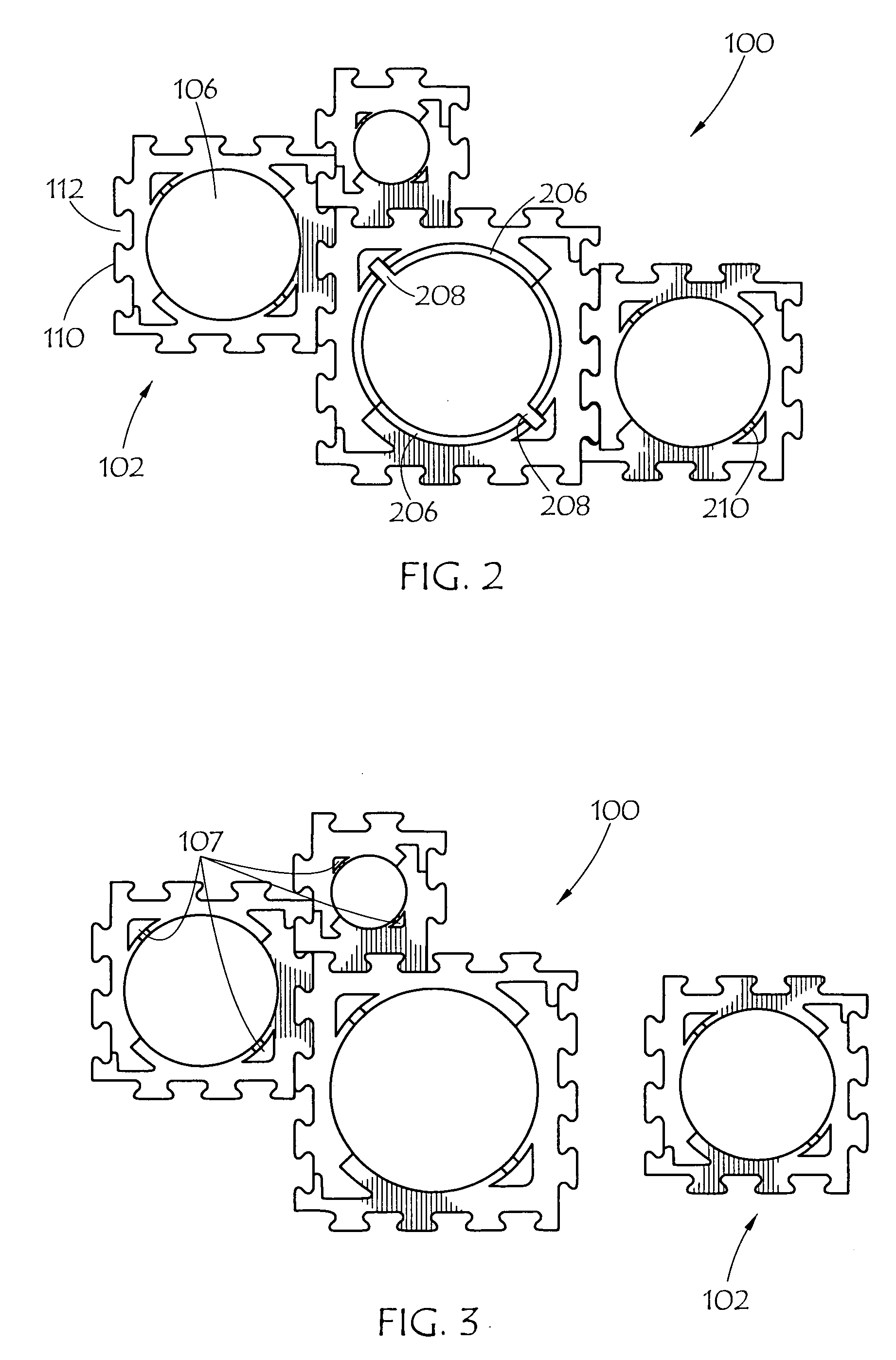

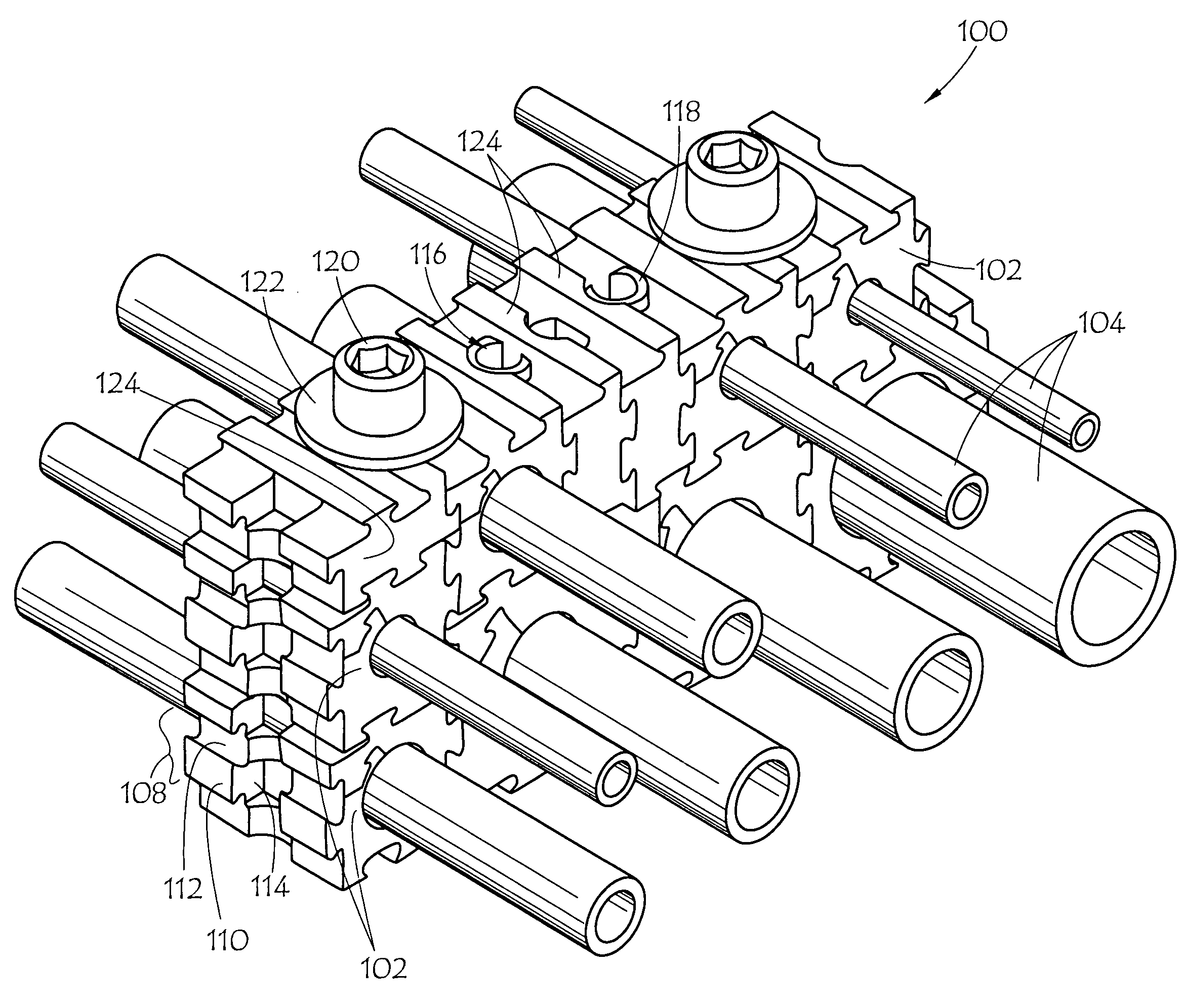

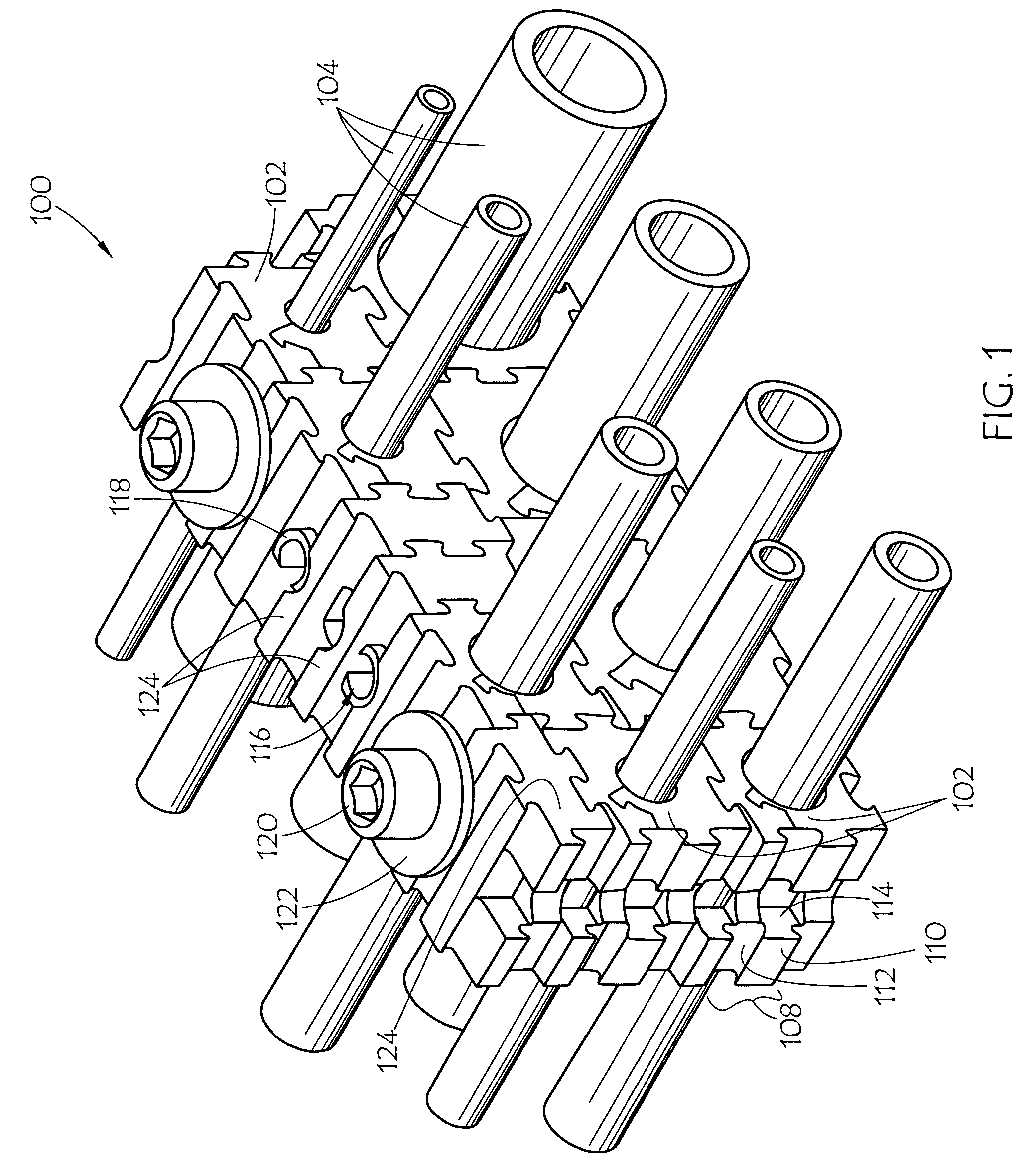

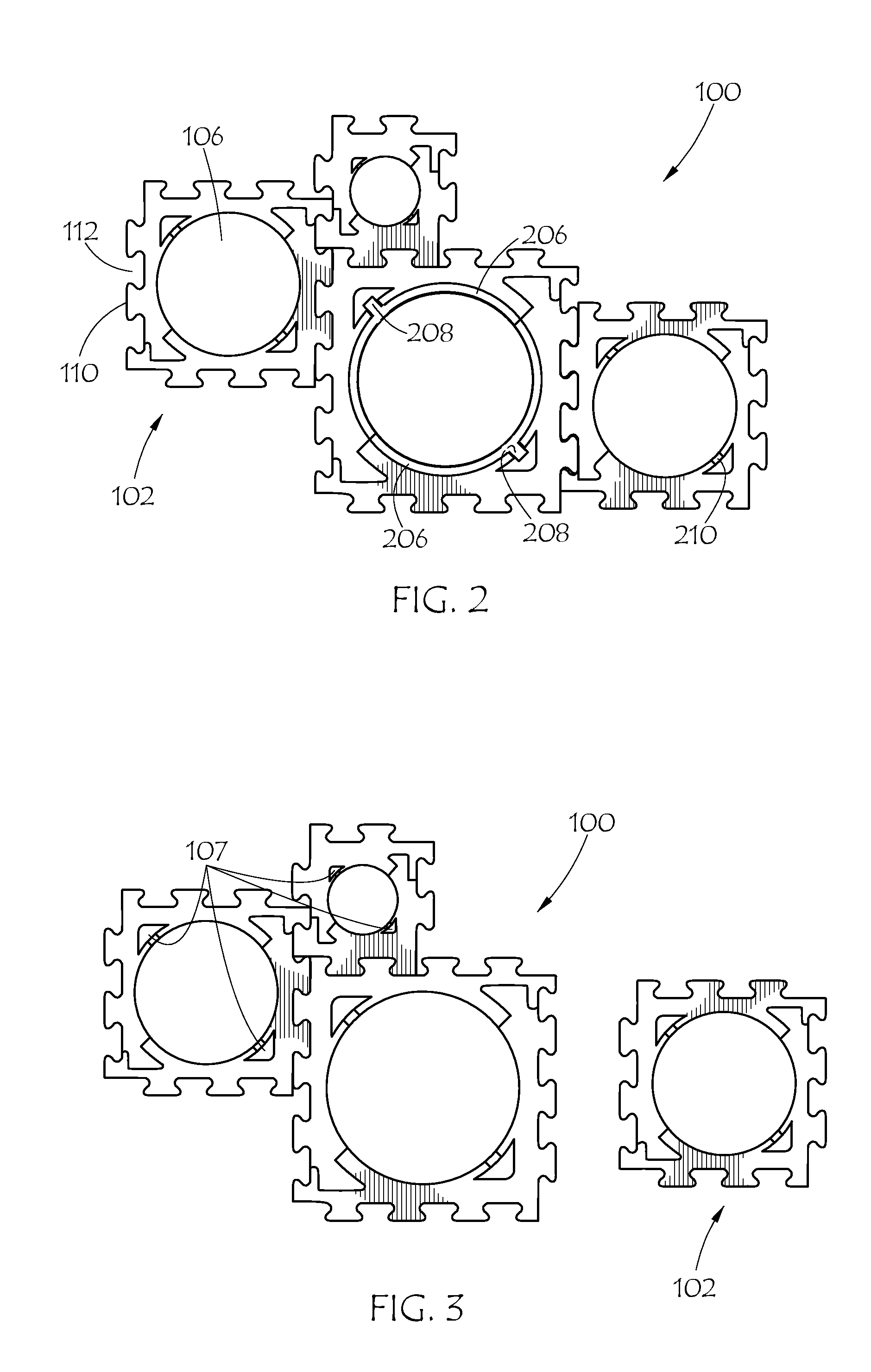

Modular support, assemblies, methods and systems

InactiveUS20090224111A1Reduced part count and costImprove organizationPipe supportsStands/trestlesModularityEngineering

A modular support assembly receives and / or stores elongated objects that may be primarily cylindrical in shape, such as fluid conduits including hydraulic tube, pipe and hose. The modular support assembly includes a plurality of interchangeable modules of differing or similar sizes to create an adjustable assembly whose overall shape and number of modules can change depending upon the intended use of the assembly. The modules comprise sliding engagement portions that are disposed along a periphery of the modules and allow interengageable attachment to other modules. The modules also comprise apertures that can vary in size to accommodate various sizes of objects. The modules can be disassembled by sliding module portion halves apart, facilitating easy assemblage of the modules either before or after the objects retained therein have been positioned, and subsequent removal of individual objects from the assemblage.

Owner:THE GATES CORP

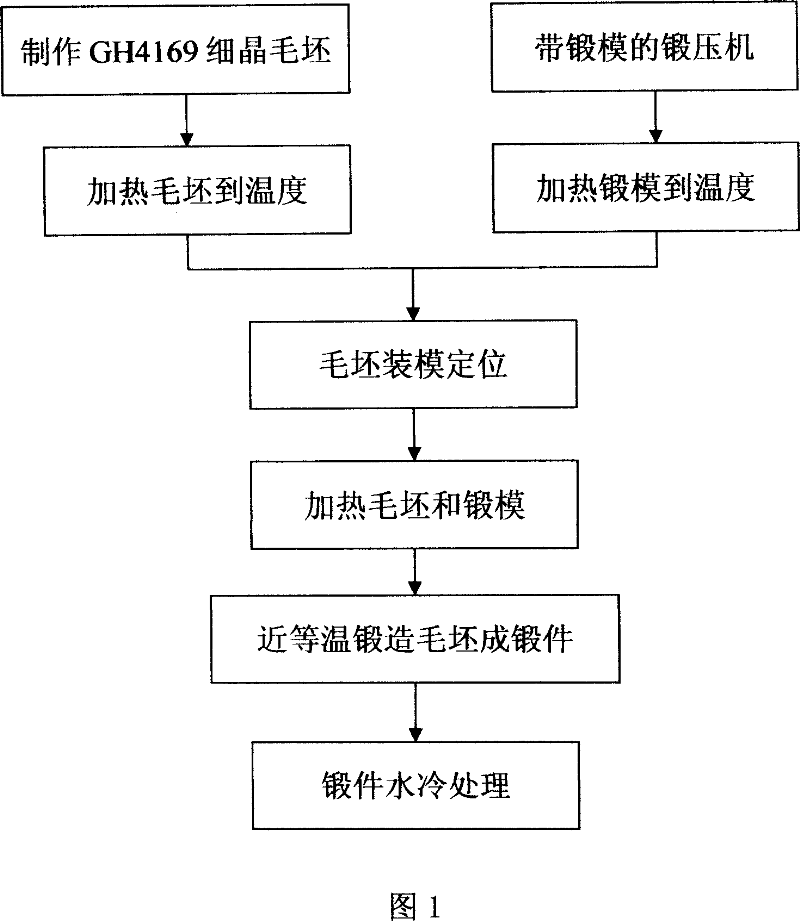

Method for smithing GH4169 alloy plate shaped forgeable piece in air at an approximately equal temperature

ActiveCN101036931AGrain refinementHigh strengthForging/hammering/pressing machinesWheelsRoughcastCrystallite

The invention discloses a close isothermal forging method of GH4169 alloy tray-shaped forging in the air, the technological process is that: making GH4169 finegrain roughcast adopting method of upsetting, punching and rolling after heating GH4169 alloy original rod material to 995-1005 DEG C; respectively heating the finegrain roughcast to 995-1005 DEG C and forging die to 950-965 DEG C; diefilling and positioning the finegrain roughcast; while heating finegrain roughcast and forging die to keep the heating warm humidity; forging die and forging press the finegrain roughcast forming under the 55MN to 65MN forging pressure and 0.01s-1 to 0.05s-1 strain rate; obtaining the tray-shaped forging; water-cool processing the tray-shaped forging. Adopting forging method of the invention can realize forming of the GH4169 alloy material tray-shaped forging difficult to deform and obtain the GH4169 alloy tray-shaped forging with weensy crystal grain, high intensity and complicated shape.

Owner:GUIZHOU ANDA AVIATION FORGING

Modular support, assemblies, methods and systems

A modular support assembly receives and / or stores elongated objects that may be primarily cylindrical in shape, such as fluid conduits including hydraulic tube, pipe and hose. The modular support assembly includes a plurality of interchangeable modules of differing or similar sizes to create an adjustable assembly whose overall shape and number of modules can change depending upon the intended use of the assembly. The modules comprise sliding engagement portions that are disposed along a periphery of the modules and allow interengageable attachment to other modules. The modules also comprise apertures that can vary in size to accommodate various sizes of objects. The modules can be disassembled by sliding module portion halves apart, facilitating easy assemblage of the modules either before or after the objects retained therein have been positioned, and subsequent removal of individual objects from the assemblage.

Owner:THE GATES CORP

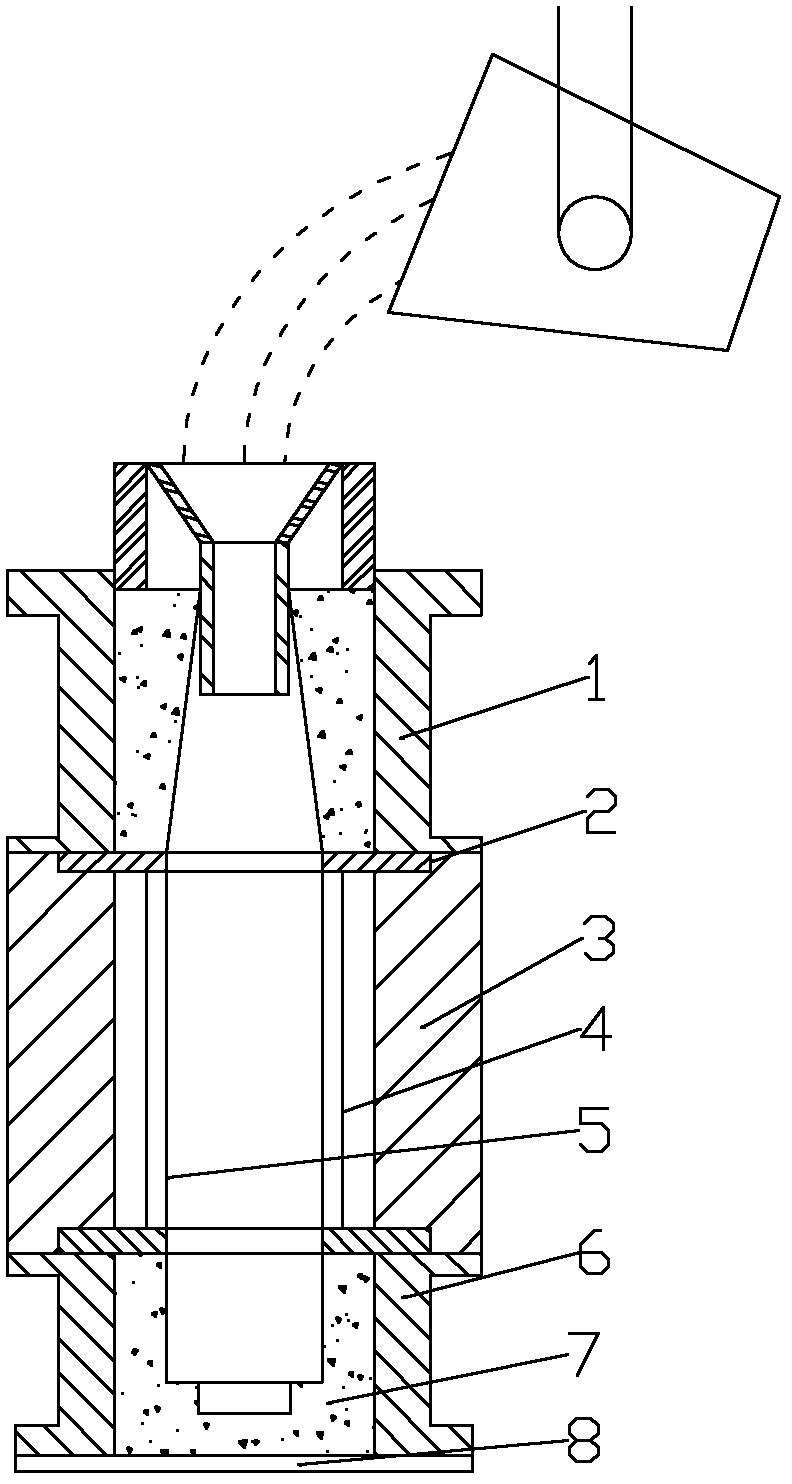

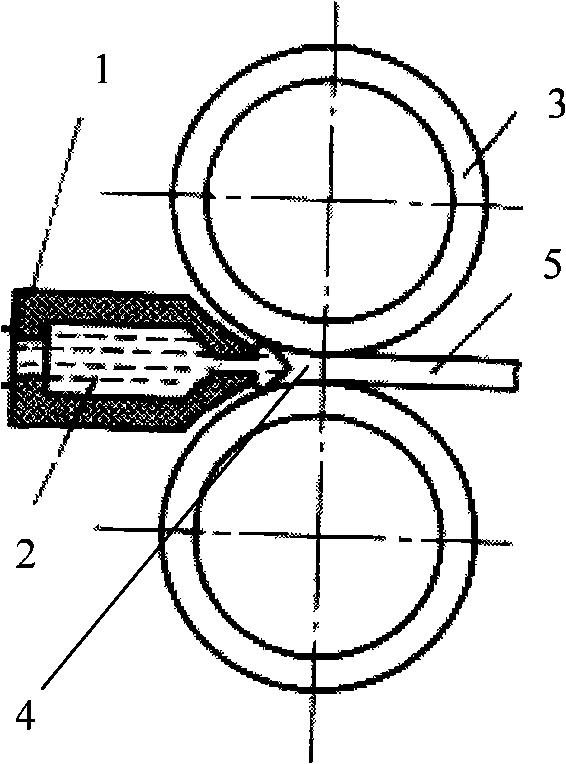

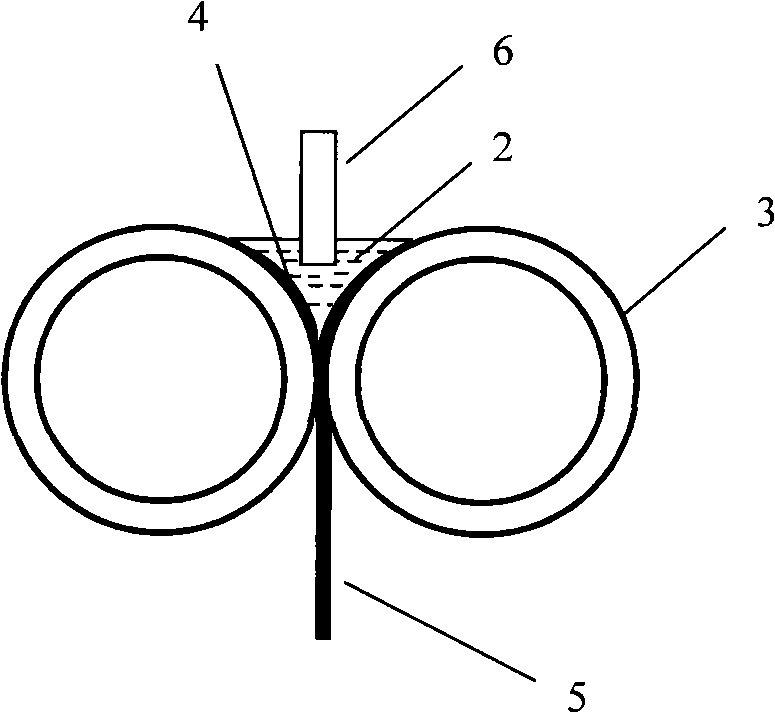

Continuous casting technique for aluminum alloy thin belt blank

InactiveCN101269406AImprove organizationComprehensive mechanical properties of high thin stripIngotMaterials science

The invention discloses a continuous casting process of an aluminum thin billet, which is characterized in that the following steps are included: aluminum alloy ingots are preheated and are melted in a melting furnace in the role of a flux; before casting, a side closure system is preheated to 400-450 DEG C, when the temperature of a melting body ranges from 650 DEG C to 680 DEG C, the aluminum alloy ingots are arranged into a tundish for 15 to 30 minutes in the role of the flux, then through a flux distributing device, the aluminum alloy ingots flow into an equant vertical twin-roll thin strip billet continuous caster, with a left forging seam gap being 0 mm and maintaining the height of a melting pool between 90 mm and 340 mm, the casting is carried out in a sinking way; when in casting, the casting speed of the casting machine ranges from 20 to 120m / min, the thin strip blank is sent into a pinch roll after leaving a casting roller, and the forged aluminum alloy thin strip has a thickness between 1.0 mm and 3.5 mm. The continuous casting process can directly make aluminum alloy thin strip blank from the liquid aluminum alloy, the forged thin strip blank has good quality on the surface, and the internal organizational structure is uniform, thereby being conducive to succeeding rolling processes. The continuous casting process for an aluminum thin blank has short process and low cost.

Owner:CHONGQING UNIV

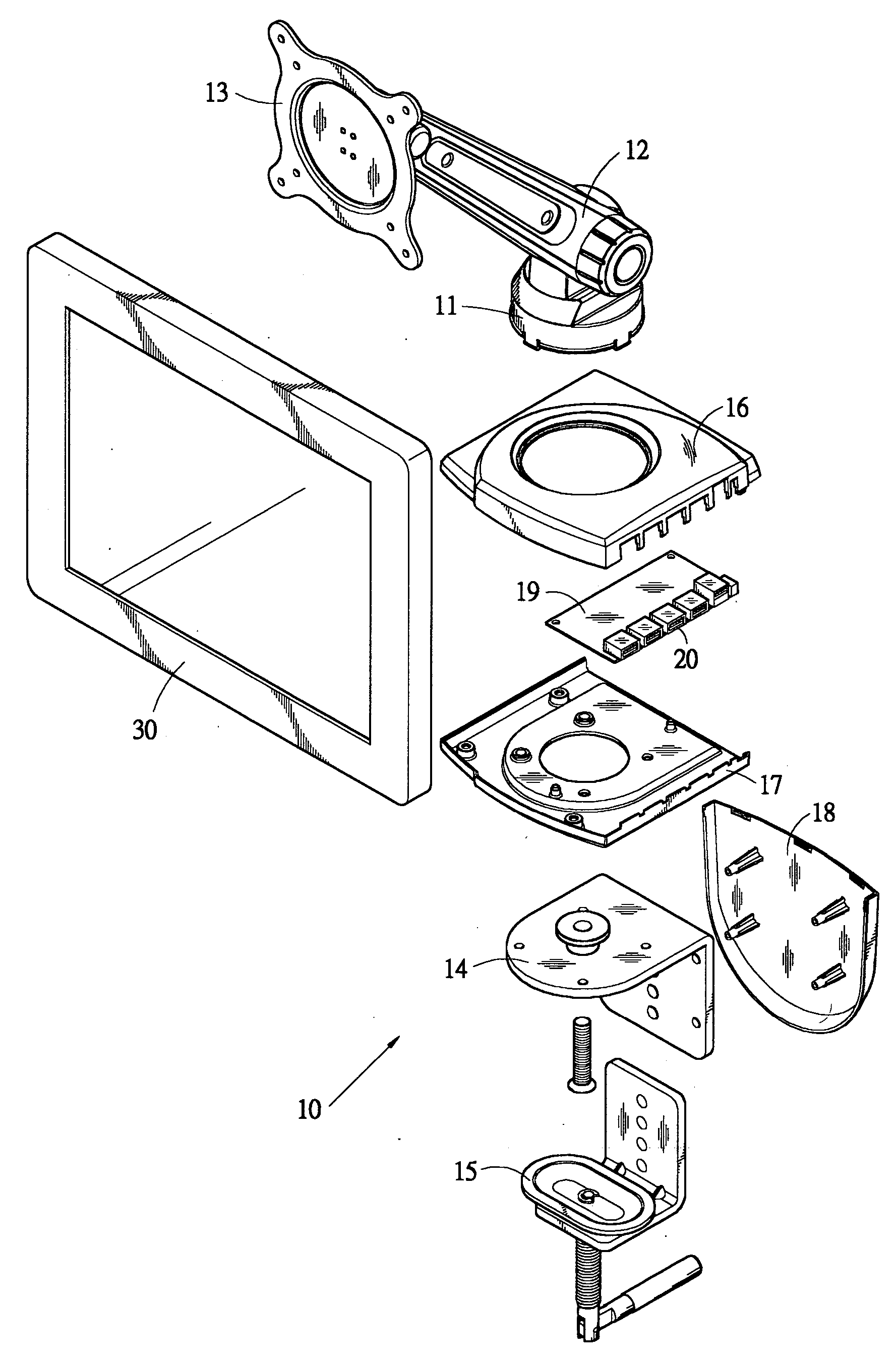

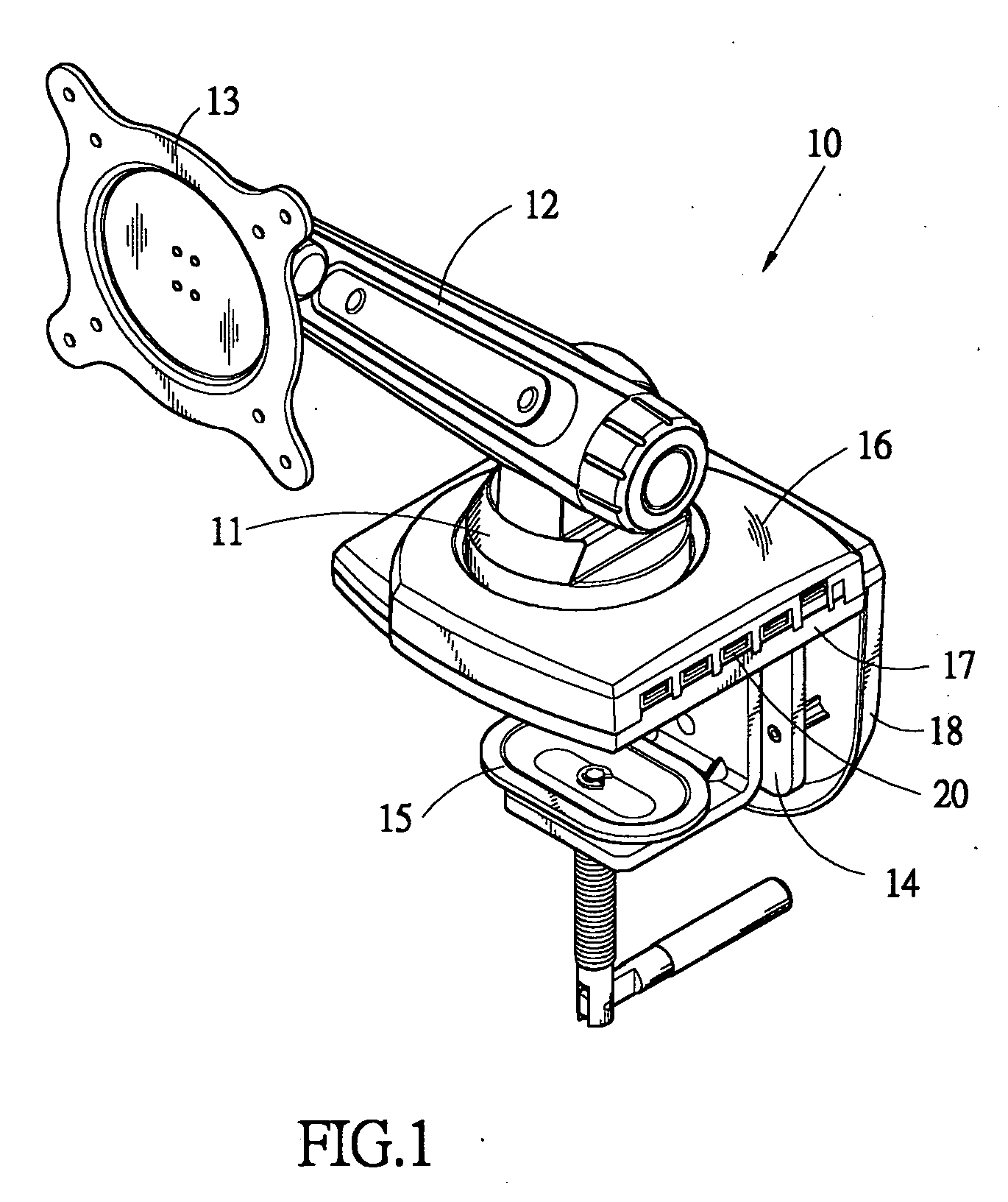

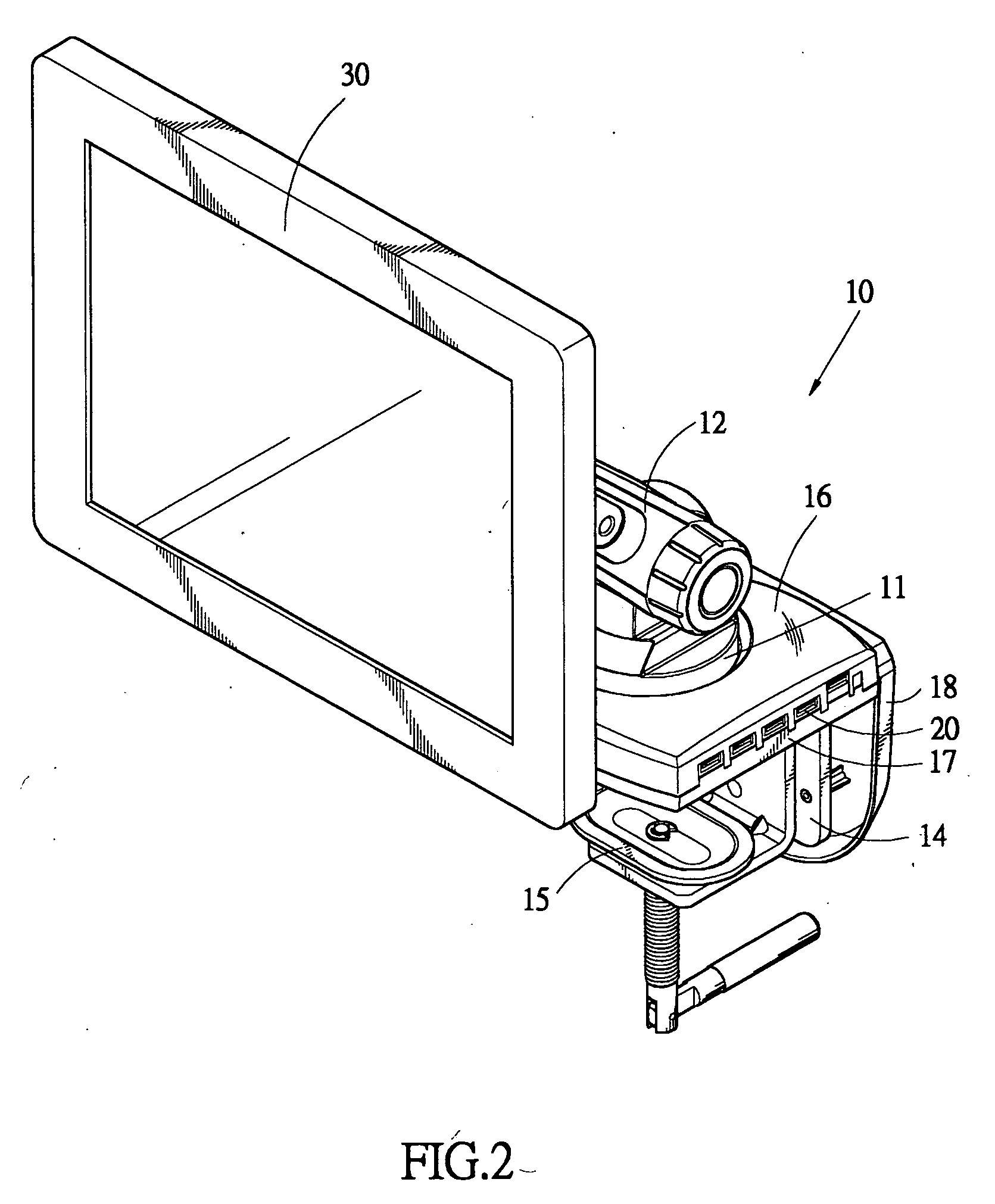

Monitor display carrier

InactiveUS20070139870A1Simplify connection/disconnectionEasy to organizeDigital data processing detailsStands/trestlesInterior spaceDisplay device

A monitor display carrier includes a top base, a bottom mount coupled to the top base, a casing constituted by upper and lower casing members interposed between the top base and the bottom mount, and a USB module encased in the casing. An adjustable arm extends from the top base and supports a monitor display in an orientation- and position-adjustable manner. The bottom mount has a clamp that releasably attaches the carrier to a fixture. The USB module is arranged in the interior space between the upper and lower casing members, which form a unitary device completely covering the USB module with USB sockets of the module exposed to selectively engage corresponding USB ends of connection cables of peripheral devices to provided improved cable organization and easy connection / disconnection of the peripheral devices.

Owner:LIN CHRISTINA

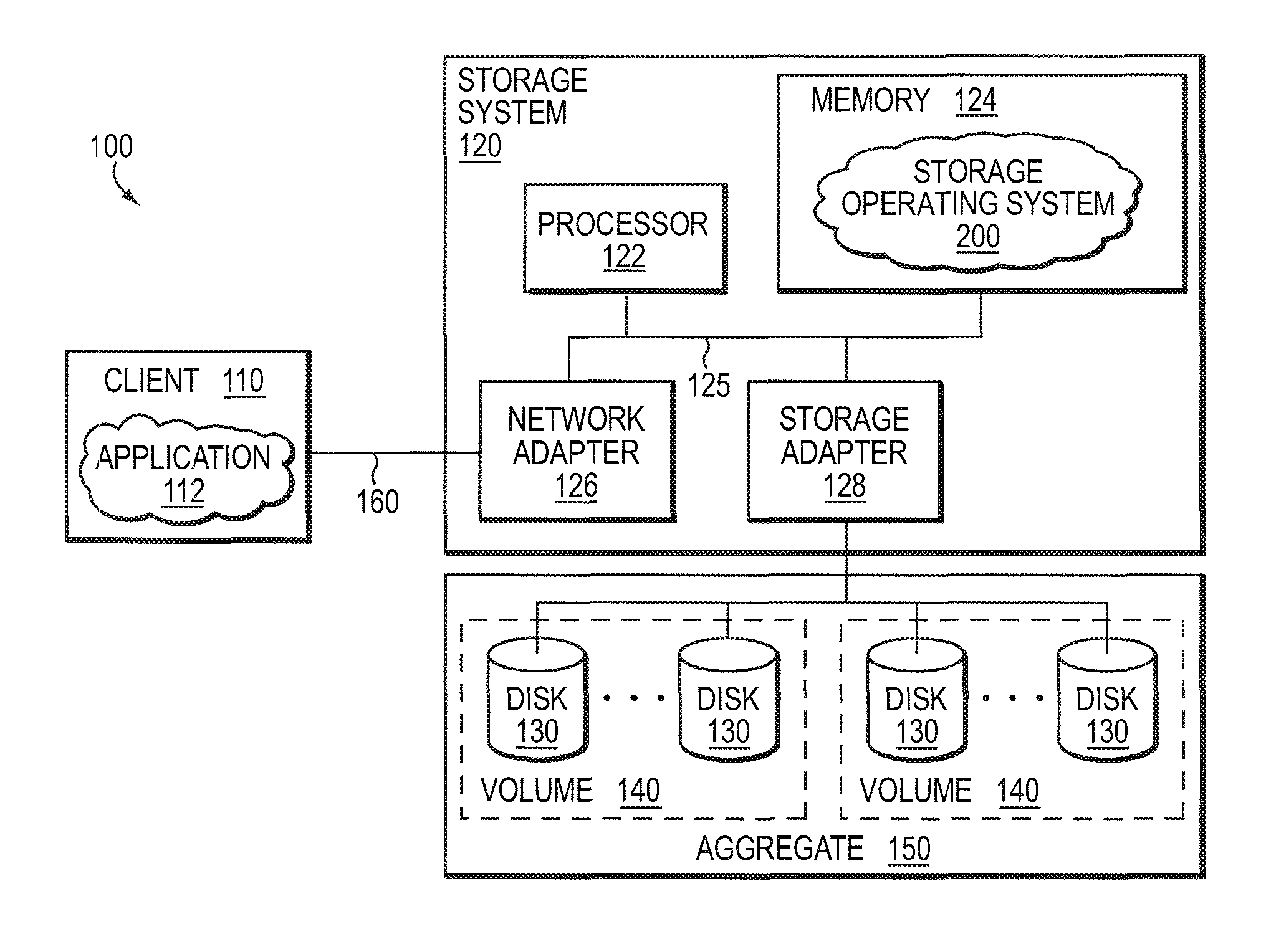

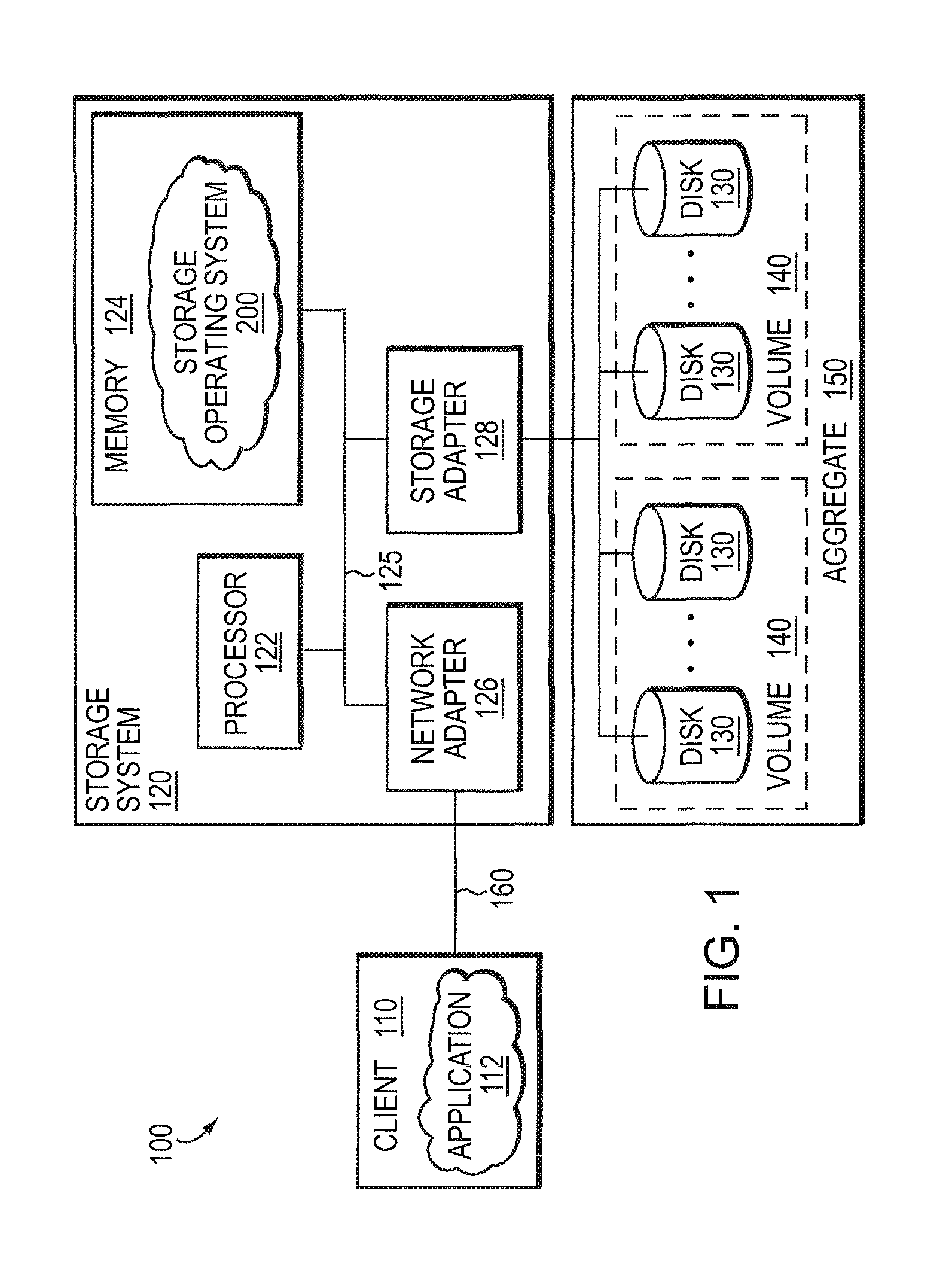

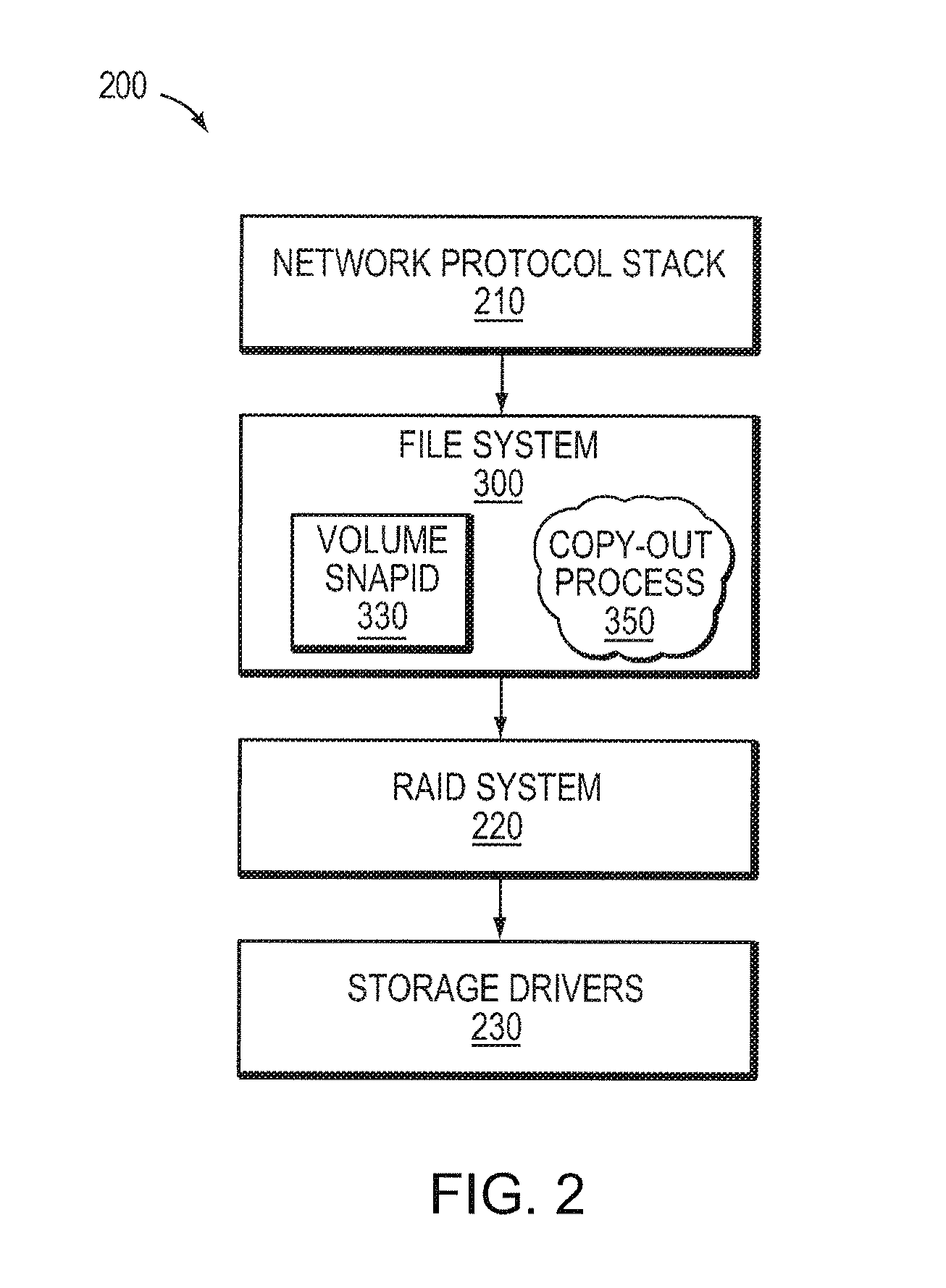

Identifying snapshot membership for blocks based on snapid

ActiveUS7849057B1Efficiently manage and organizeEasy to operateDigital data information retrievalDigital data processing detailsFile systemSelf-balancing binary search tree

An on-disk structure of a file system has the capability to efficiently manage and organize data containers, such as snapshots, stored on a storage system. A multi-bit, monotonically increasing, snapshot identifier (“snapid”) is provided that represents a snapshot and that increases every time a snapshot is generated for a volume of the storage system. The snapid facilitates organization of snapshot metadata within, e.g., a data structure used to organize metadata associated with snapshot data. In the illustrative embodiment, the data structure is a balanced tree structure configured to index the copy-out snapshot data blocks. The snapid is also used to determine which blocks belong to which snapshots. To that end, every block that is used in a snapshot has an associated “valid-to” snapid denoting the newest snapshot for which the block is valid. The oldest snapshot for which the block is valid is one greater than the valid-to field of the next older block at the same file block number.

Owner:NETWORK APPLIANCE INC

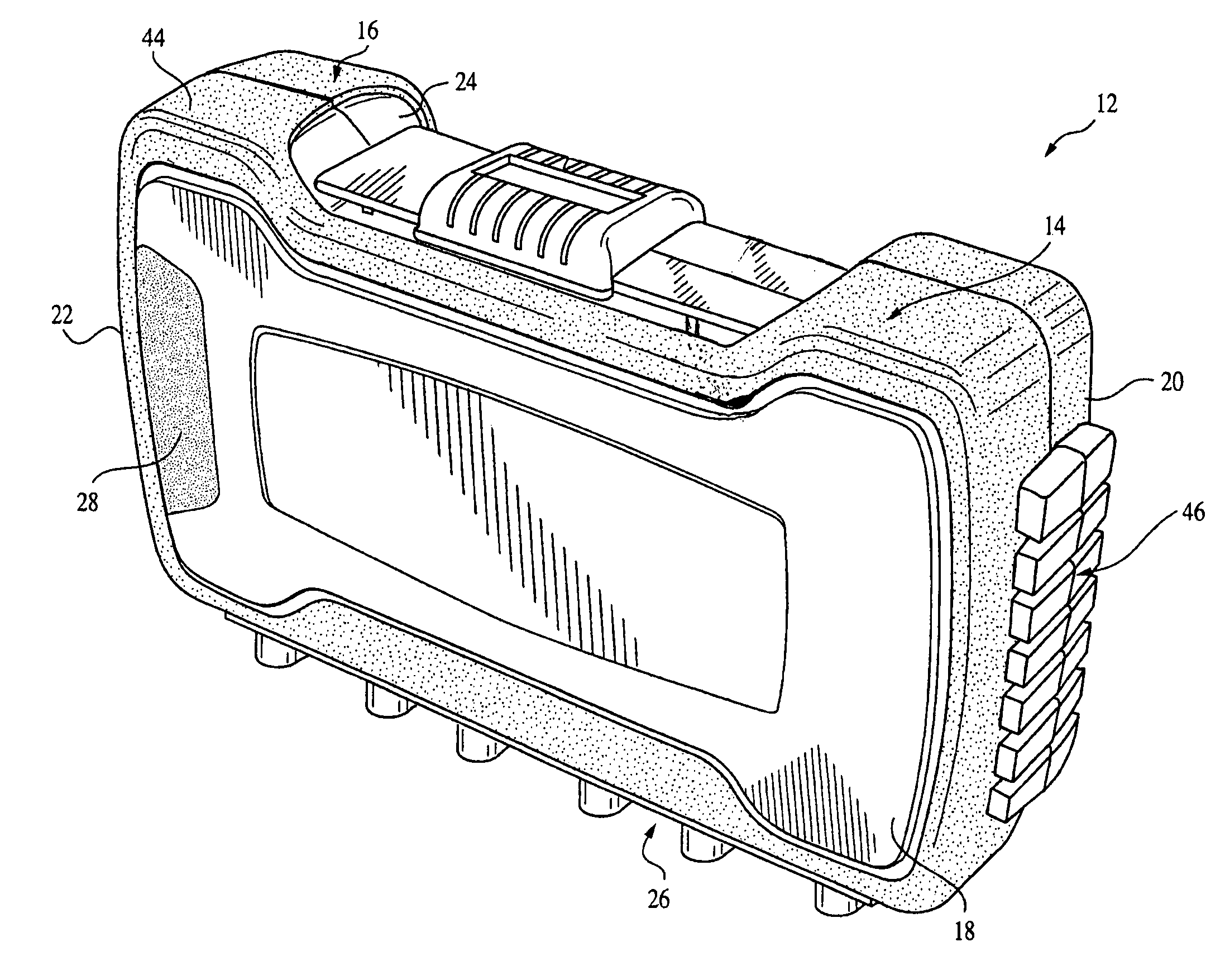

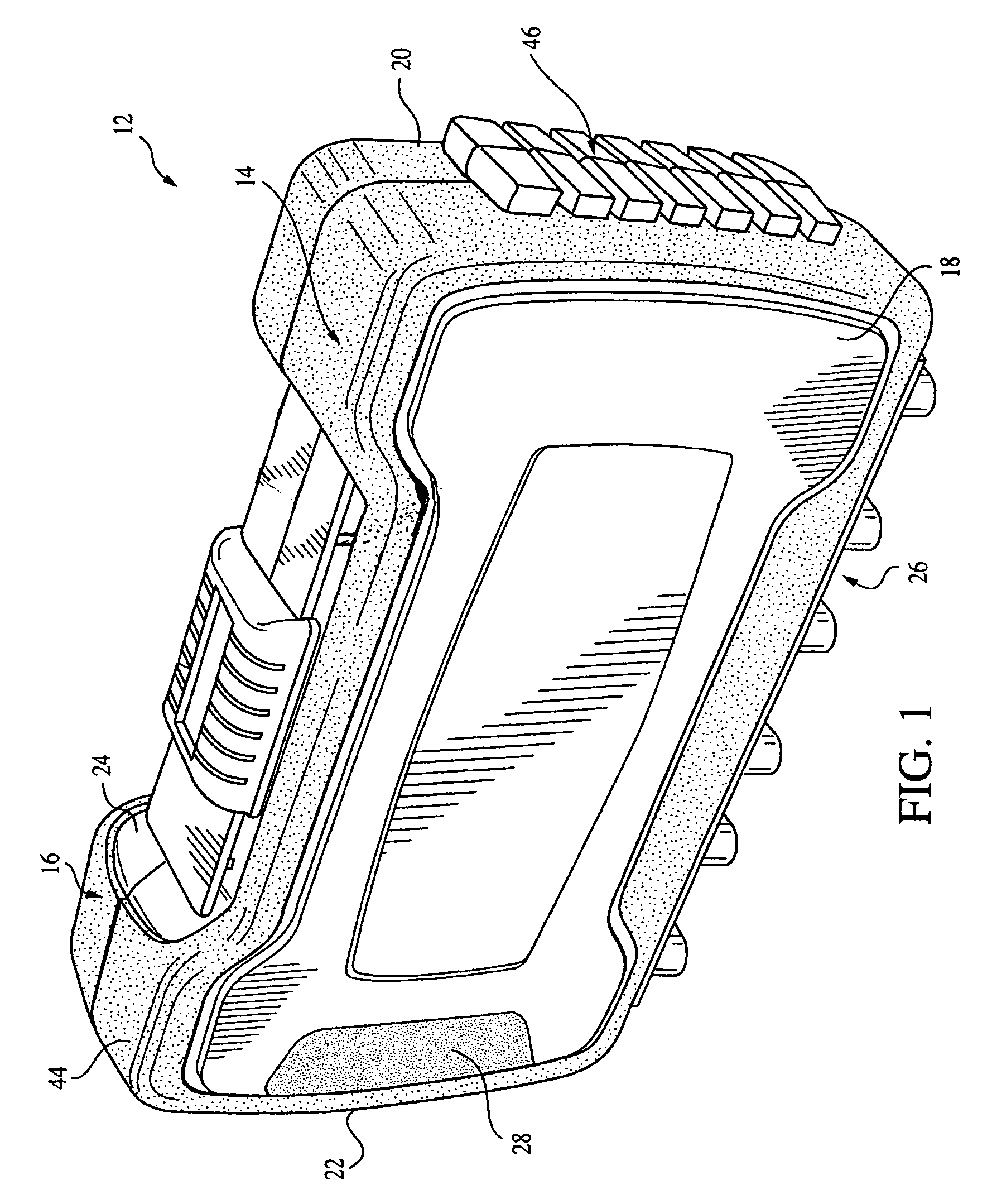

Multi-configured tool bit box

ActiveUS7225923B2Increased durabilityImproved gripping characteristicOther accessoriesContainer/bottle contructionEngineeringTroffer

A tool case for the storage of drill bits and similarly shaped tools includes two housing members that are hingedly attached and which open and close, with respect to one another. The tool case of the present invention includes elastomeric material surrounding the periphery of the tool case and tool trays on the inside of the case that retain inverted drill bits and similarly shaped tools. The tool trays disposed within the two housing members are removably attached to inner recessed cavities in the housing member by snapping male protrusions located on the tray into corresponding female recesses located on the inner surface of the recessed cavities.

Owner:BLACK & DECKER INC

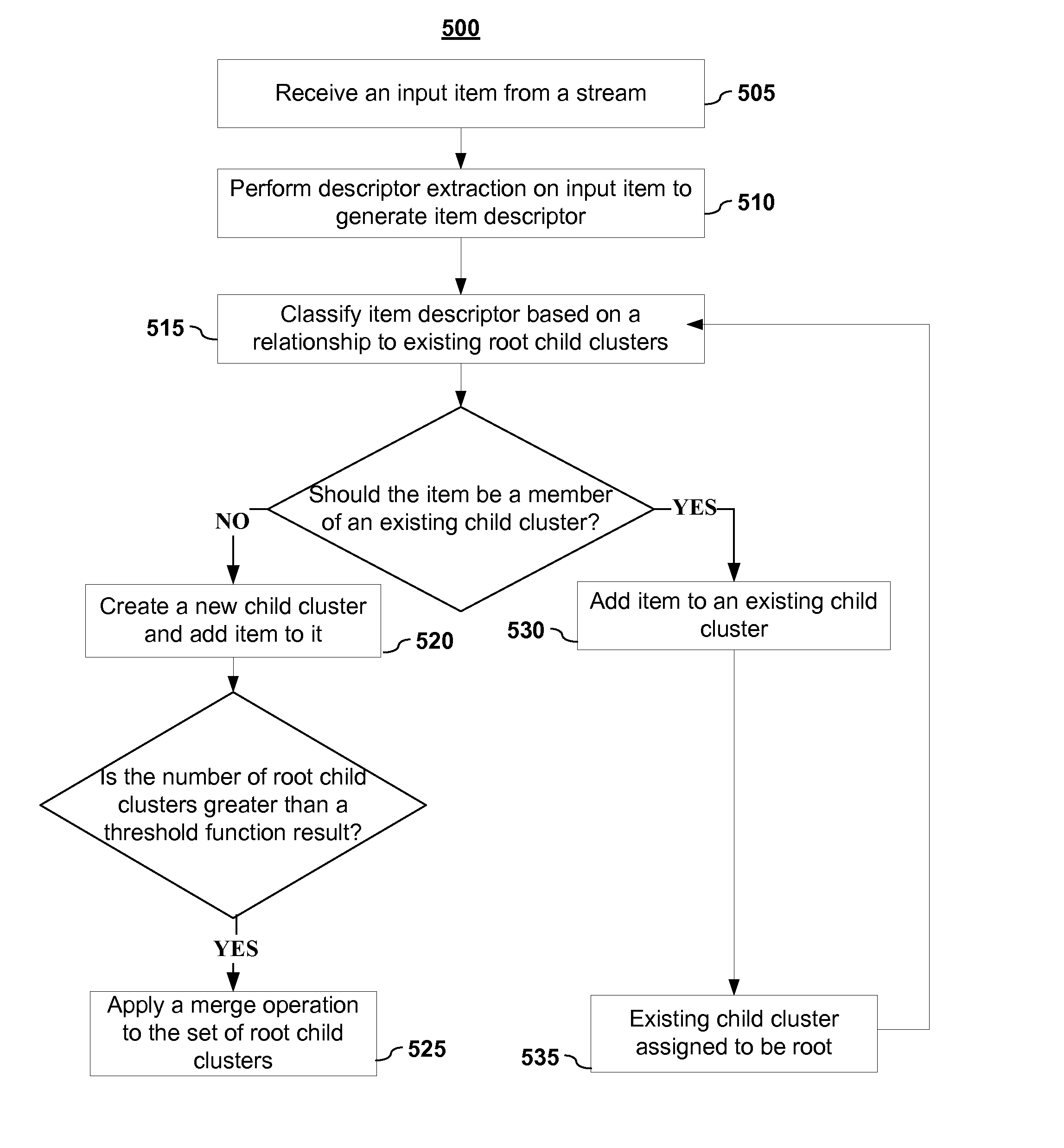

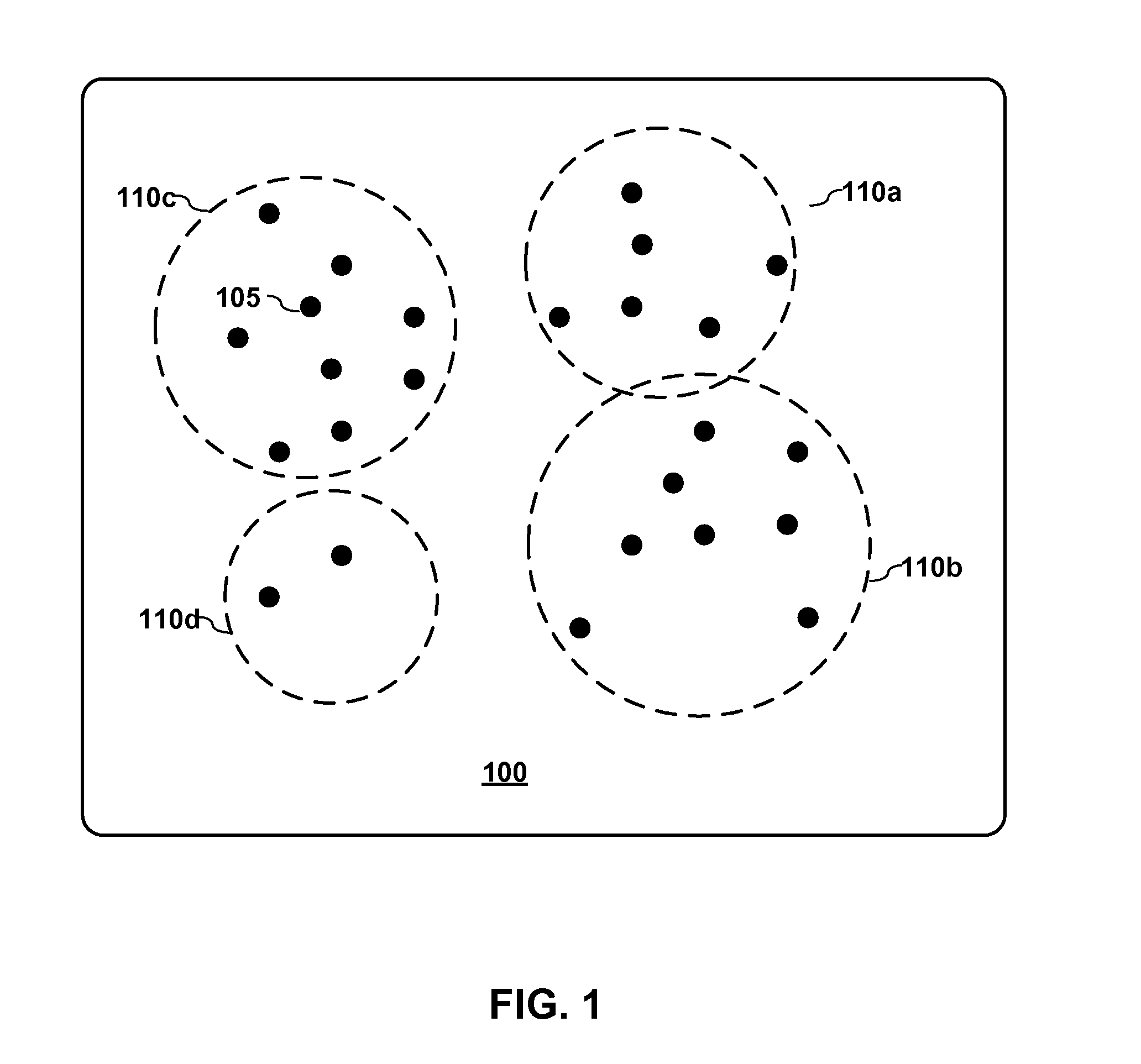

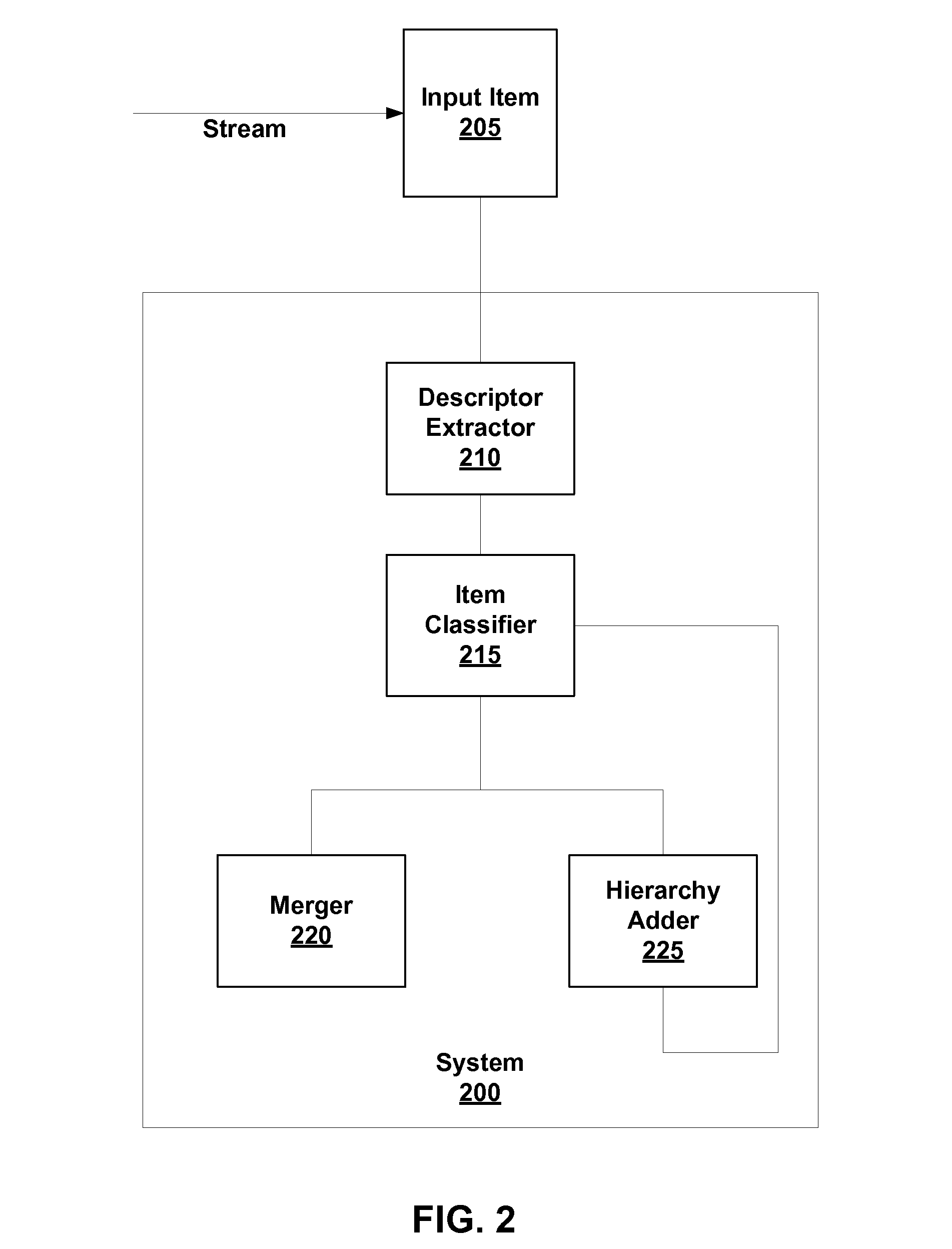

Streaming Hierarchical Clustering

InactiveUS20090037440A1Improve organizationDigital data information retrievalCharacter and pattern recognitionDocument preparationData mining

Systems, apparatuses, and methods are described for incrementally adding items received from an input stream to a cluster hierarchy. An item, such as a document, may be added to a cluster hierarchy by analyzing both the item and its relationship to the existing cluster hierarchy. In response to this analysis, a cluster hierarchy may be adjusted to provide an improved organization of its data, including the newly added item.

Owner:METALINCS CORP

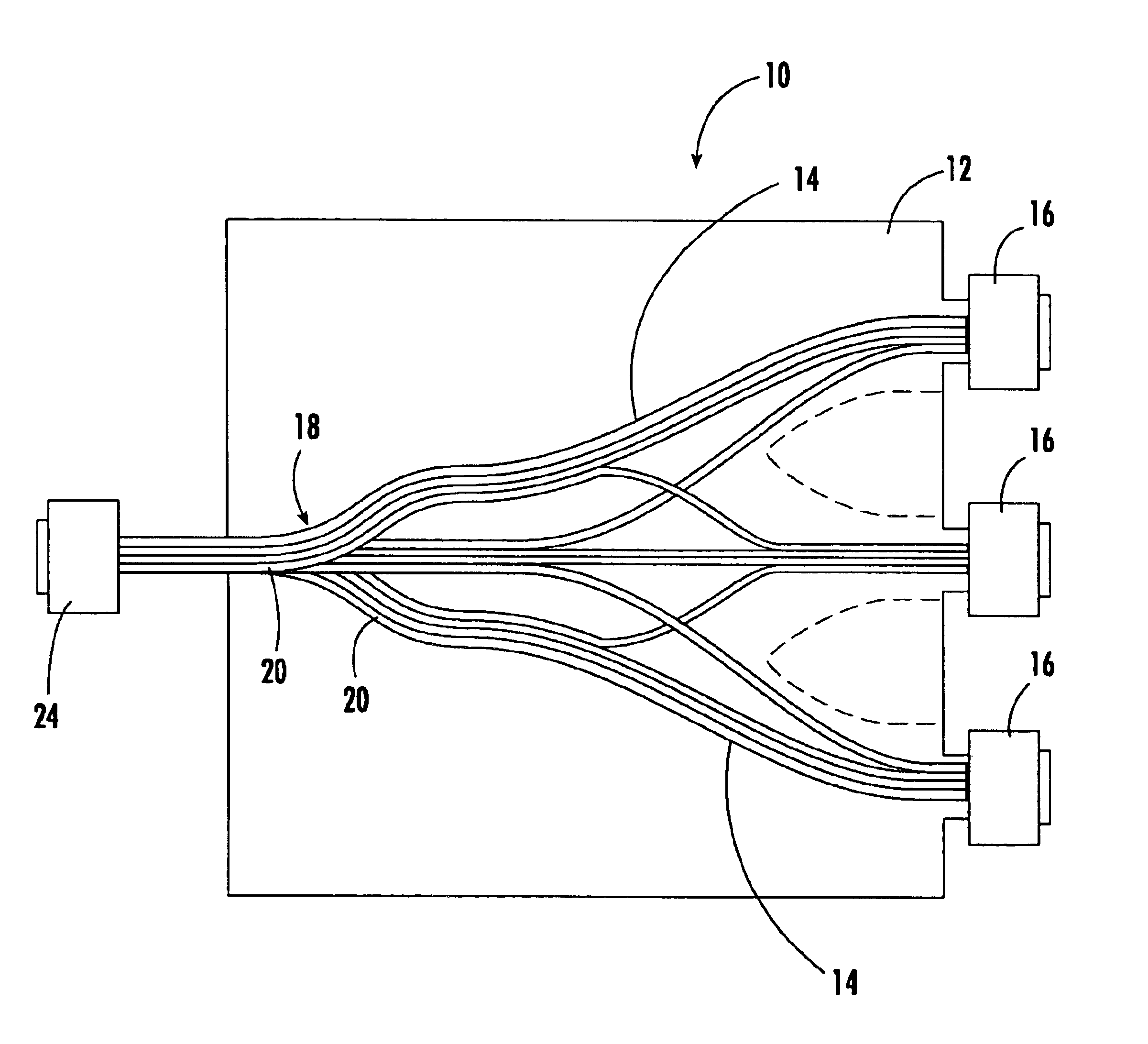

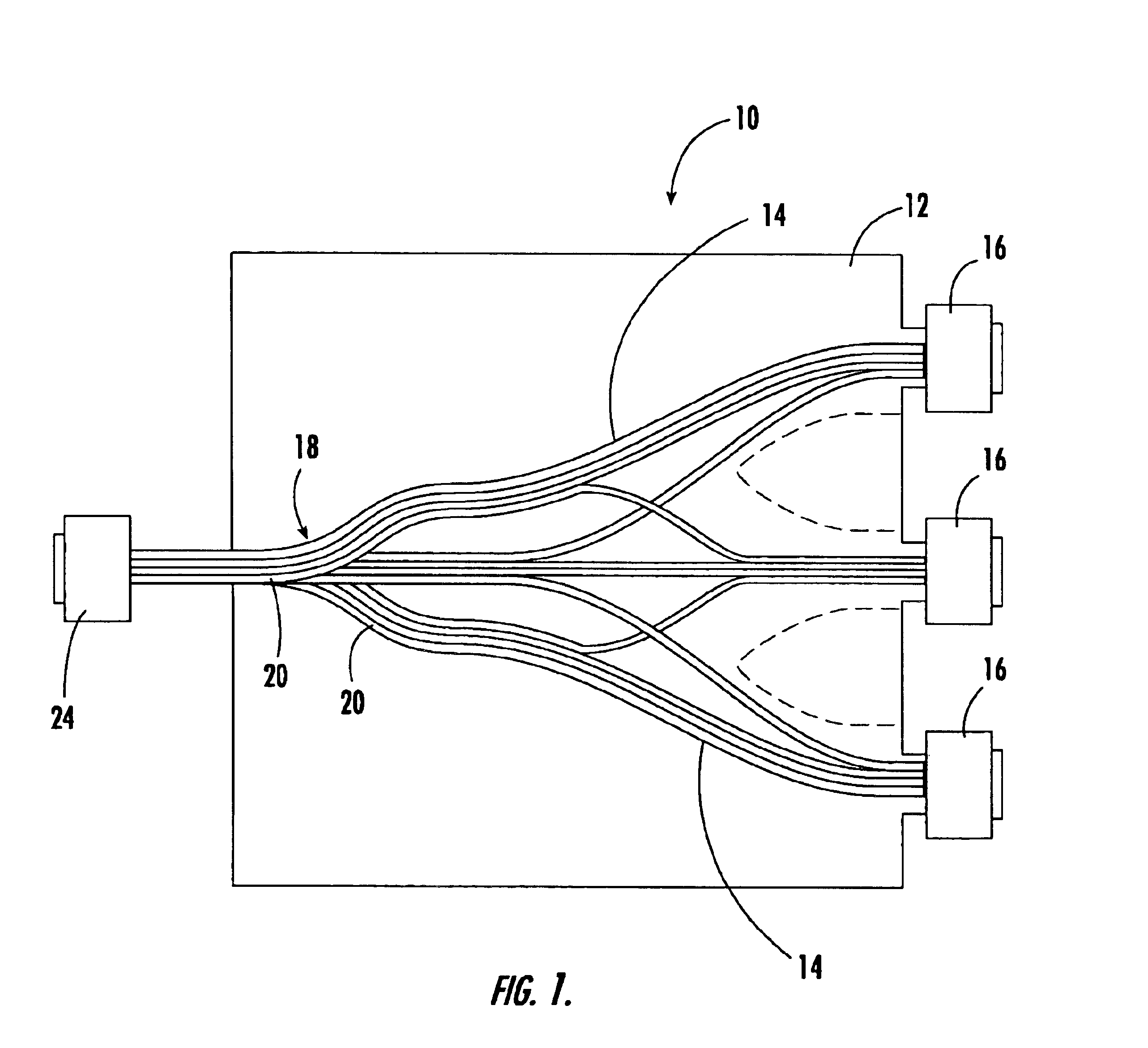

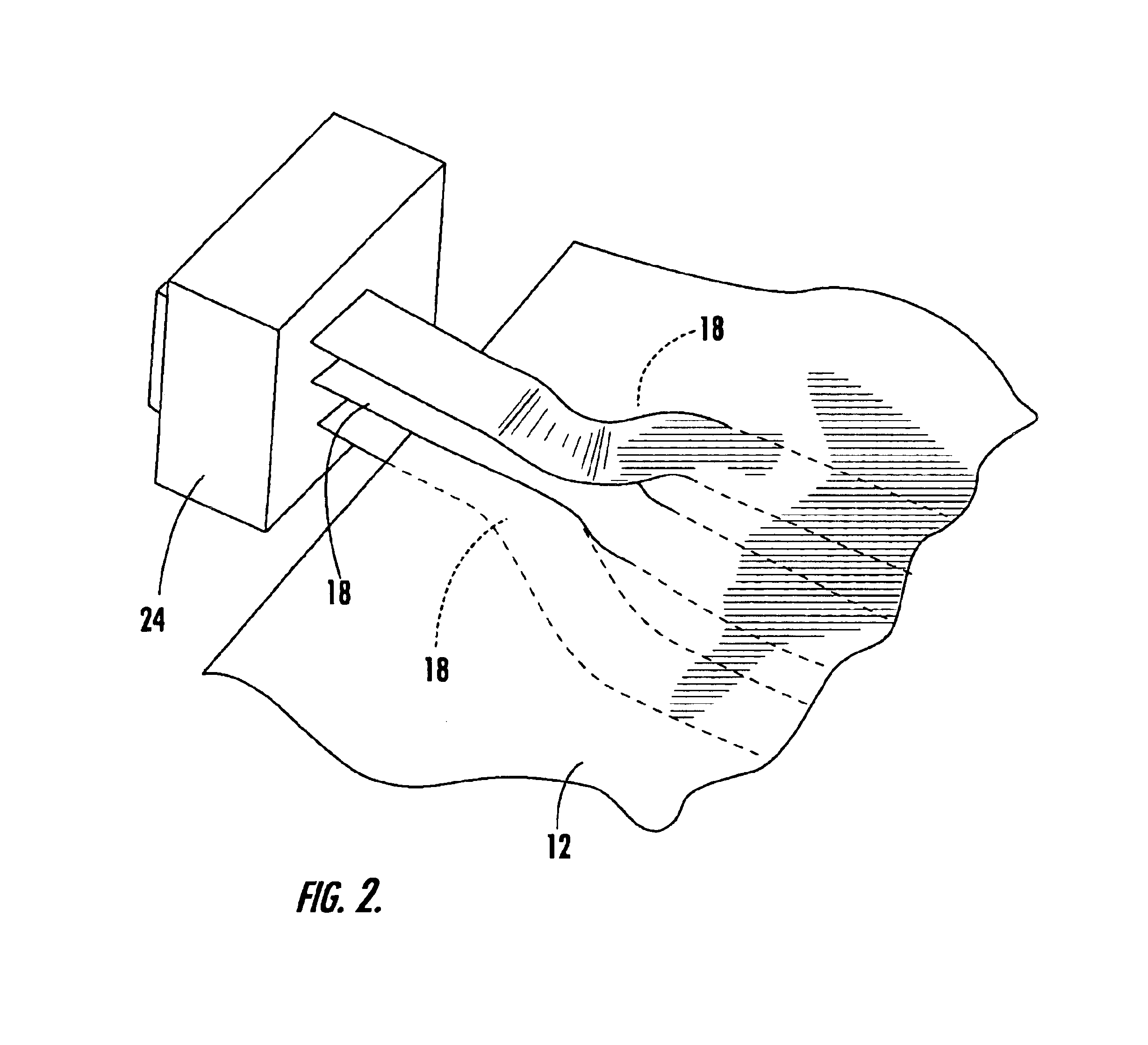

Optical circuit having legs in a stacked configuration and an associated fabrication method

InactiveUS6850671B2Improves fiber managementImprove organizationCoupling light guidesFibre mechanical structuresEngineeringOptical fiber

An optical circuit is provided having a plurality of legs, each of which may have one or more optical fibers bound together by a matrix material, arranged in a stacked configuration in such a manner as to reduce, if not eliminate, the stress to which the optical fibers are subjected. The optical circuit includes a main body having a flexible substrate and a plurality of optical fibers mounted upon the substrate and lying in a common plane. The plurality of legs extend outwardly from an edge of the main body. The legs are disposed in a stacked configuration in which at least one leg overlies another leg. As such, at least one leg lies at least partially outside of the common plane defined by the substrate. A method for fabricating the optical circuit is also provided.

Owner:US CONEC

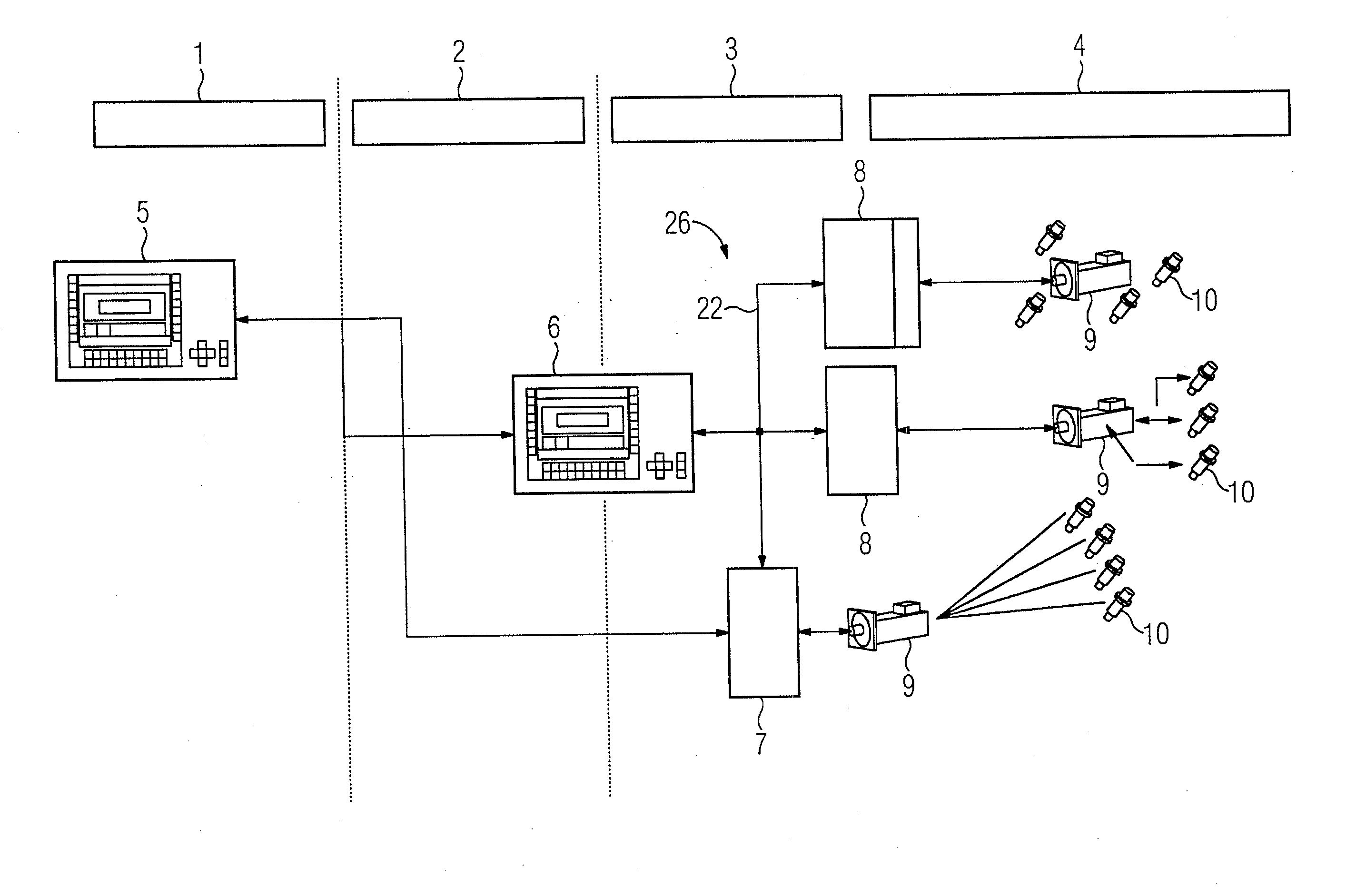

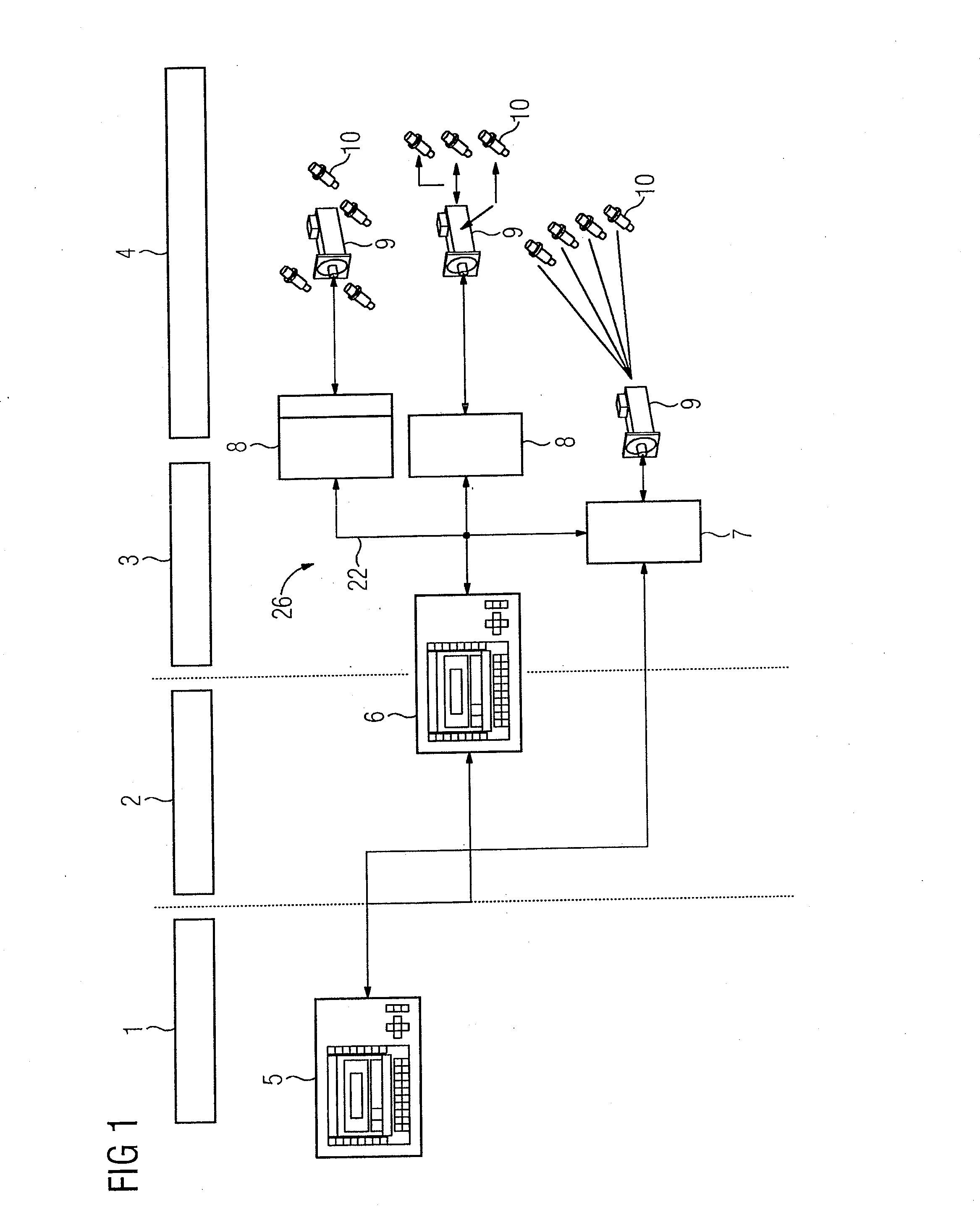

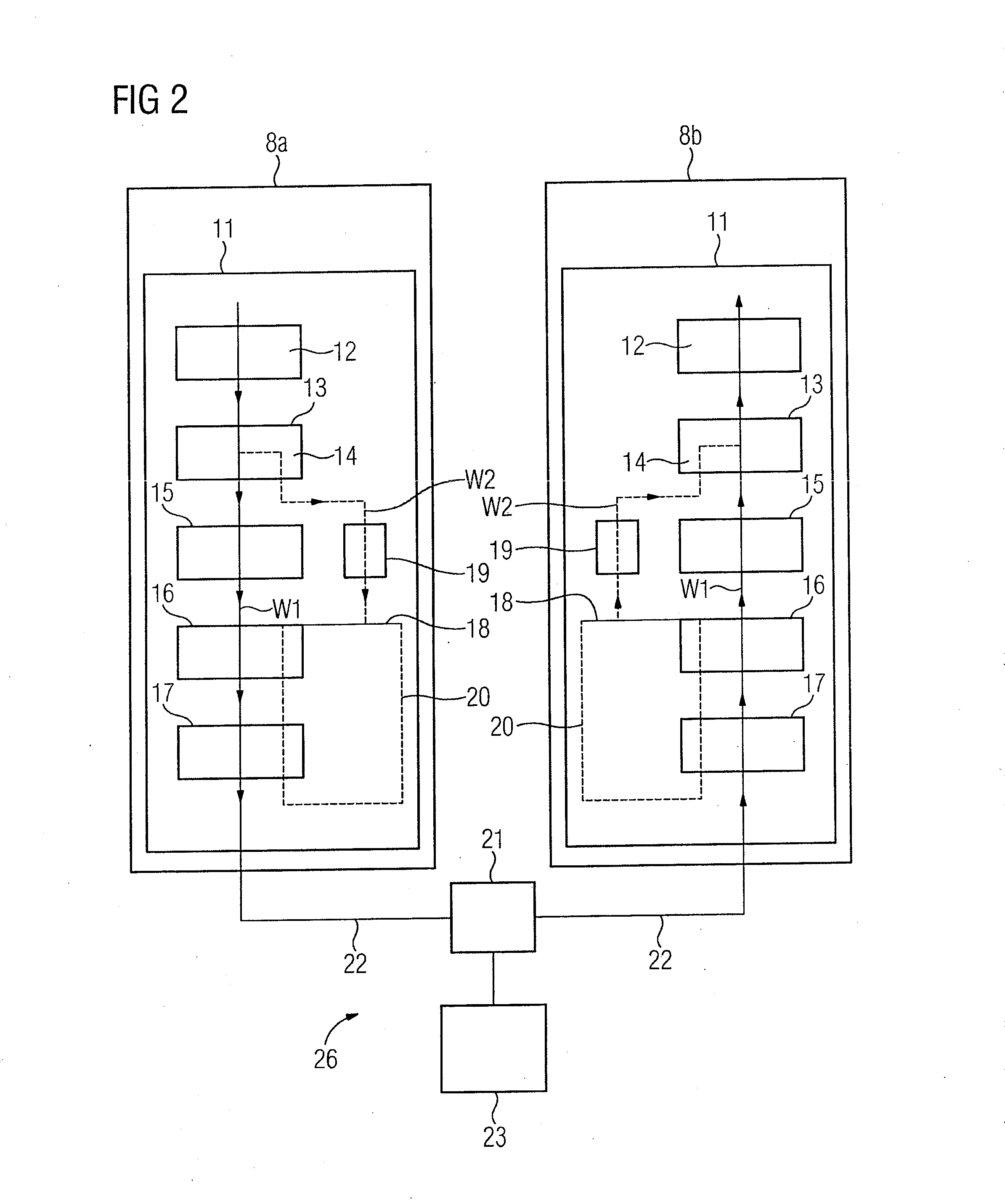

Method and Apparatus for Interchanging Data, and Network

InactiveUS20130070788A1Highly integratedHigh degreeTime-division multiplexTransmissionComputer hardwareNetwork Communication Protocols

A method for interchanging data between two devices in a network which utilizes a communication protocol with an interface based on the OPC-UA standard to interchange the data, wherein the communication protocol comprises an interface based on the stream reservation protocol standard or an interface based on the multiple stream registration protocol standard in accordance with IEEE standard 802.1Qat, such that the data is interchangeable between the two devices using both interfaces in a prescribed period of time.

Owner:SIEMENS AG

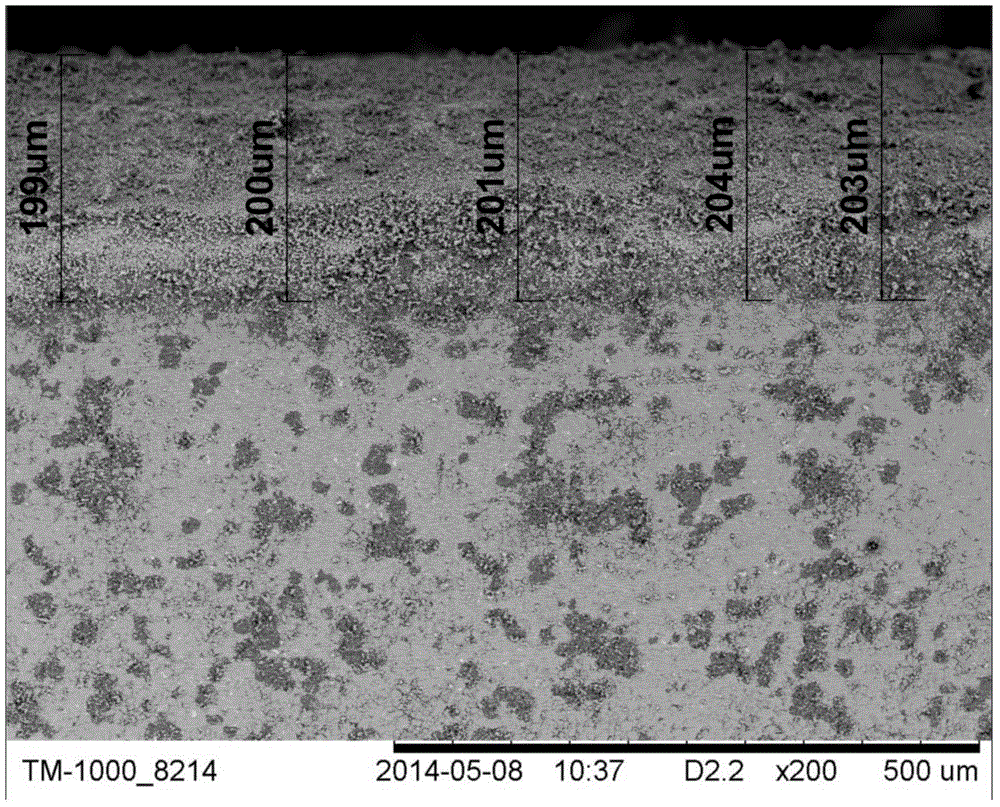

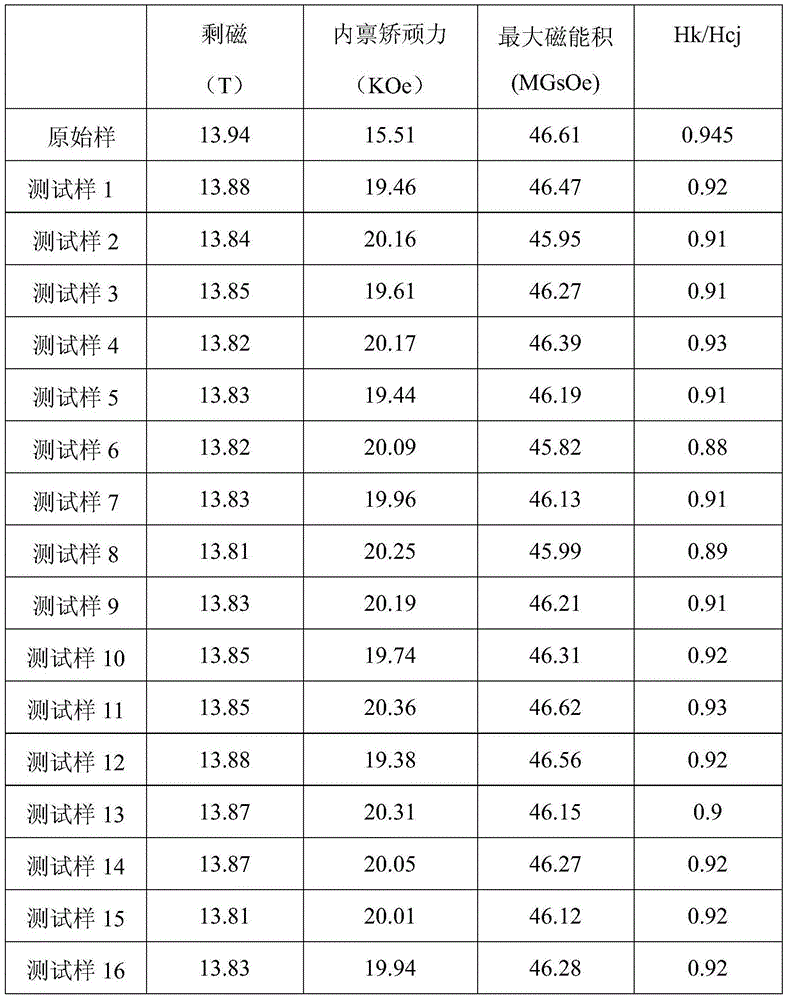

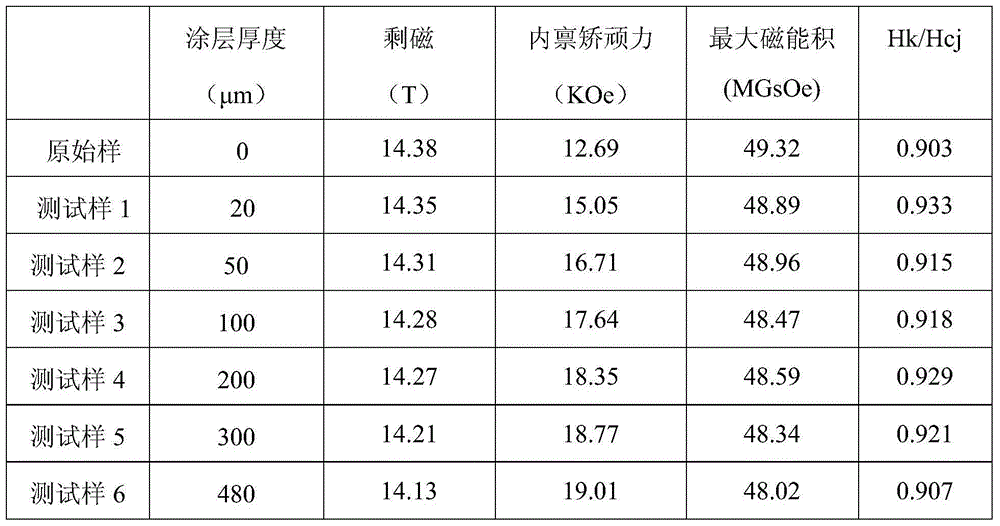

Method for improving the magnetic property of sintered NdFeB flaky magnets

ActiveCN104134528AImprove magnetic propertiesImprove organizationInorganic material magnetismSolid state diffusion coatingRare-earth elementMetallurgy

The invention discloses a method for improving the magnetic property of sintered NdFeB flaky magnets. First, suspension liquid containing heavy rare earth elements and having the viscosity of 0.1 to 500 mpa.s in the conditions of normal temperature and pressure is sprayed onto the surface of a sintered NdFeB flaky magnet uniformly. Second, the sintered NdFeB flaky magnet is dried, and then a coating containing heavy rare earth elements is obtained on the surface of the sintered NdFeB flaky magnet. Finally, the diffusion treatment and the ageing treatment are carried out on the dried sintered NdFeB flaky magnet in the environment of inert gas. The method has the advantages that the spraying technology can be applied to the grain boundary diffusion technique successfully, more specifically, a coating with high distribution uniformity and thickness distribution can be obtained on the surface of sintered NdFeB flaky magnets, and the grain boundary diffusion technology can be applied industrially for improving the magnetic property of sintered NdFeB flaky magnets.

Owner:NINGBO YUNSHENG +2

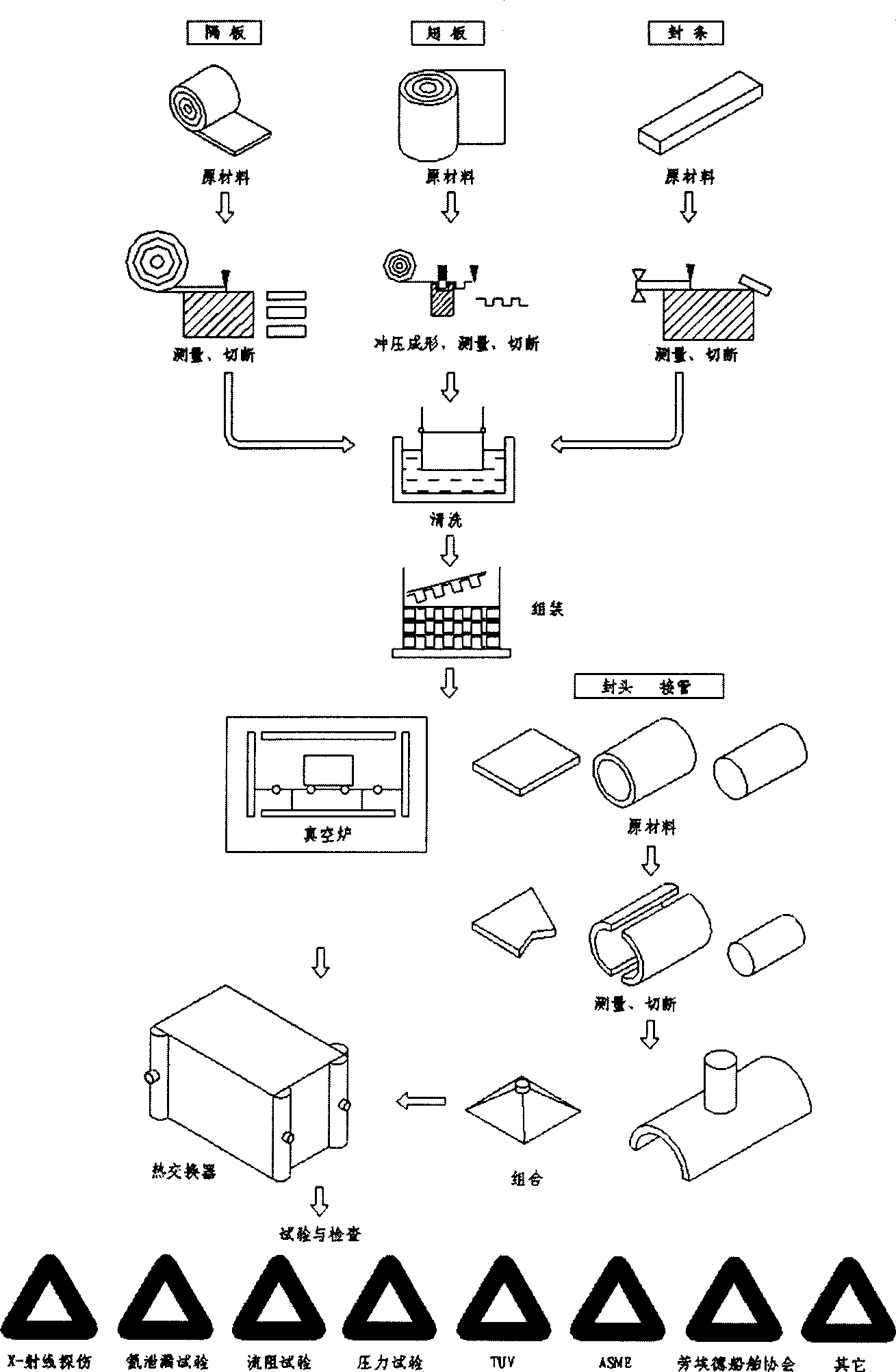

Manufacture of fine-type stainless steel plate heat exchanger

InactiveCN1375374AImprove wettabilityIngredients evenly distributedSoldering apparatusX-rayHigh pressure water

The production method of austenitic stainless steel plate fin heat exchanger includes the following steps: part preparation: partition, sealing strip, fin, sealing head and connecting pipe preparation; cleaning before welding; acid pickling to remove oil, dirt and oxide, and using high-pressure water to wash; element assembling and holding; vacuum braze welding, adopting argon arc welding to weldscaling head and connecting pipe, making general assembly; test and inspection, making x-ray inspection, helium leak detection, flow resistance test, pressure test, TUV, ASME and other test and inspection. Said invented process raise the production quality of said stainless steel plate fin heat exchanger, tensile-strength of connector and its service life.

Owner:NANJING UNIV OF TECH

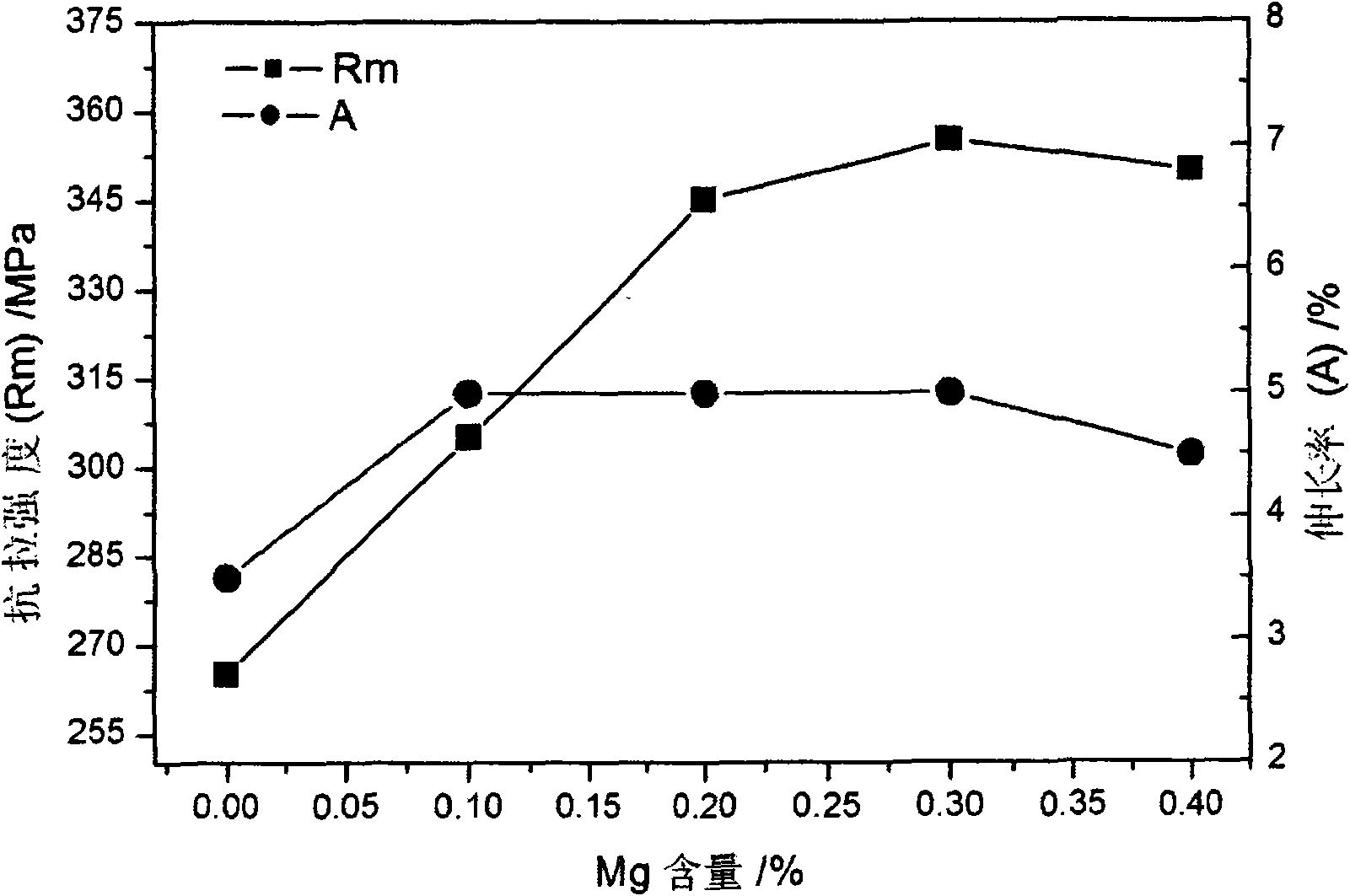

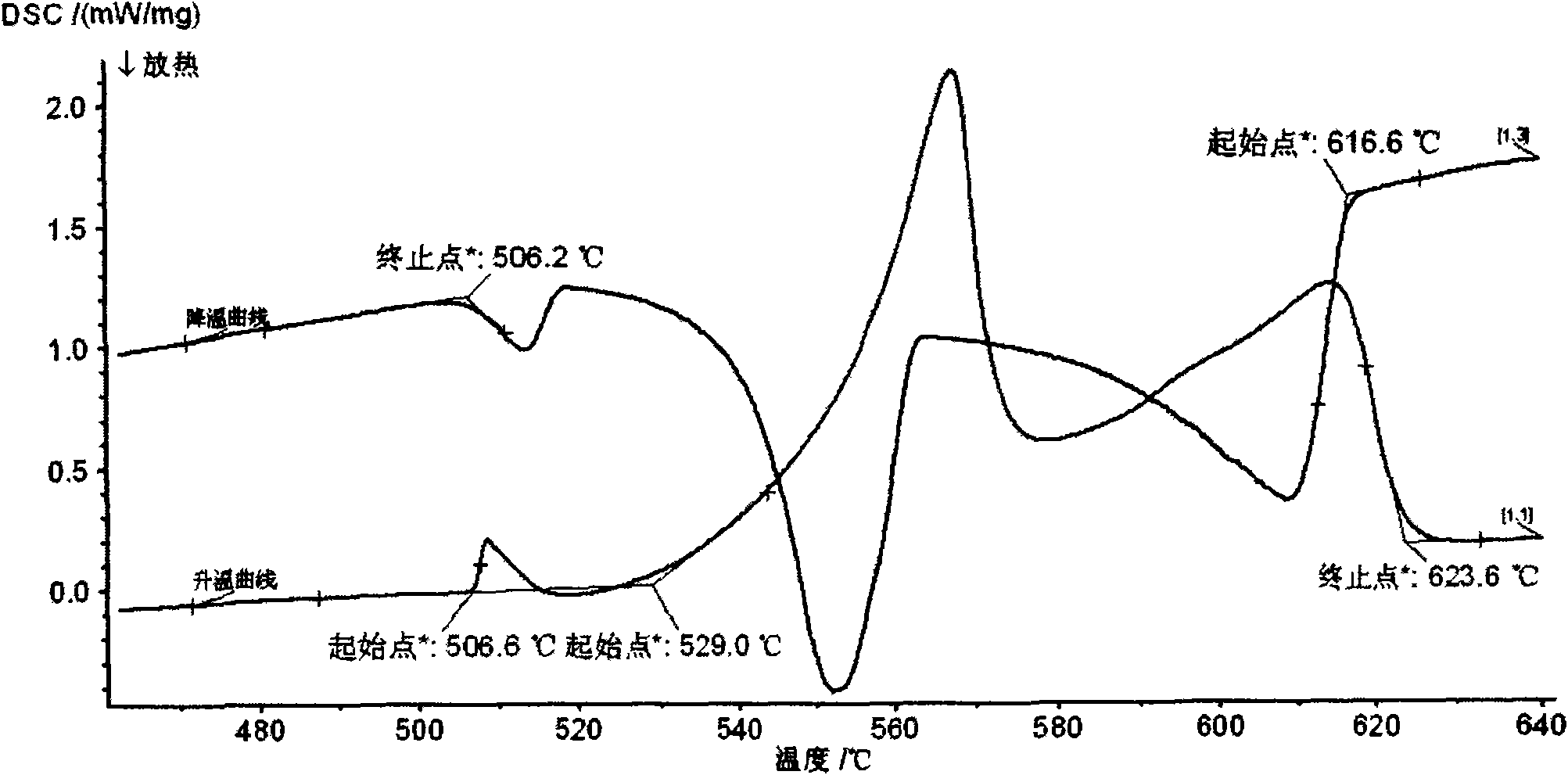

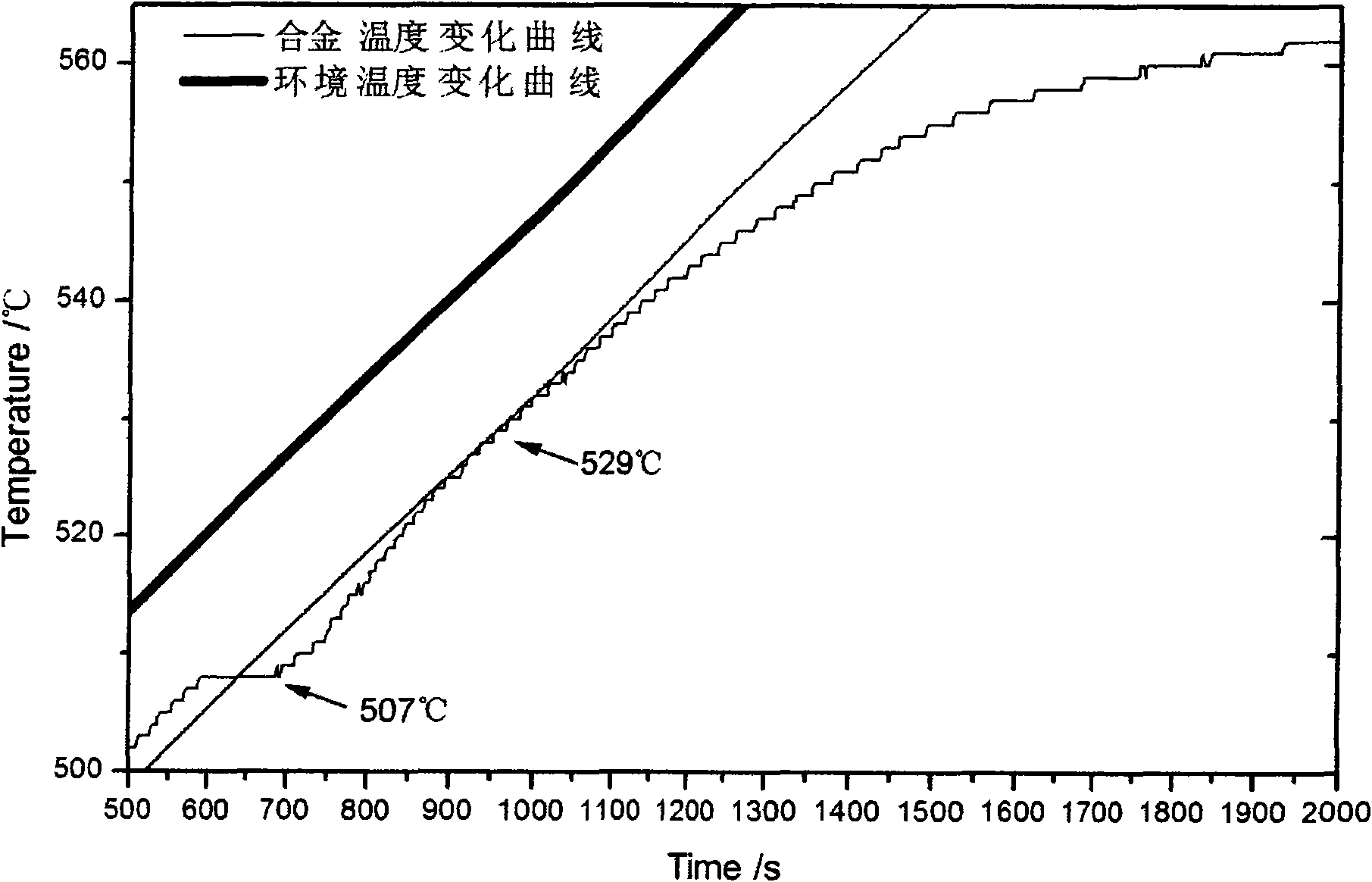

Cast aluminum-silicon alloy for engine cylinder head and heat treatment process

InactiveCN102071341AImprove room temperature performanceHigh tensile strengthChemical compositionSilicon alloy

The invention relates to a cast aluminum-silicon alloy for an engine cylinder head and a heat treatment process. The alloy comprises the following chemical ingredients in percentage by weight: 5.0 to 7.0 percent of Si, 3.0 to 4.0 percent of Cu, 0.2 to 0.4 percent of Mg, 0.1 to 0.3 percent of Mn, 0.10 to 0.20 percent of Zr, 0.15 to 0.25 percent of Ti, 0.01 to 0.05 percent of B, 0.02 to 0.09 percent of Sr, 0.1 to 0.3 percent of rare earth (RE), less then 0.3 percent of Fe and the balance Al, wherein the rare earth (RE) adopts mixed rare earth. The heat treatment process comprises the following steps: carrying out primary solution at a temperature between 490 DEG C and 505 DEG C, and carrying out heat insulation for 4 to 6h; carrying out secondary solution at a temperature between 510 DEG C and 525 DEG C, carrying out heat insulation for 6 to 10h, and carrying out quenching by hot water of 60 to 80 DEG C; and carrying out aging treatment with parameters of the aging temperature being 155to 165 DEG C and the heat insulation time being 5 to 9h, and carrying out cooling in the air. All alloy elements of the cast aluminum-silicon alloy provided by the invention are reasonably matched, good mechanical performance is realized, at a normal temperature, the tensile strength reaches 325 to 355MPa, the tensile stretch is 2.5 to 5.5 percent, at a high temperature of 250 DEG C, the tensile strength reaches 240 to 270MPa, and the tensile stretch is 3.0 to 5.5 percent, after the heating processing technology, the heat resistance performance of the alloy is improved, and the casting defect is reduced.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

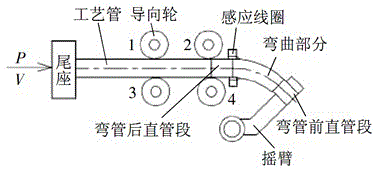

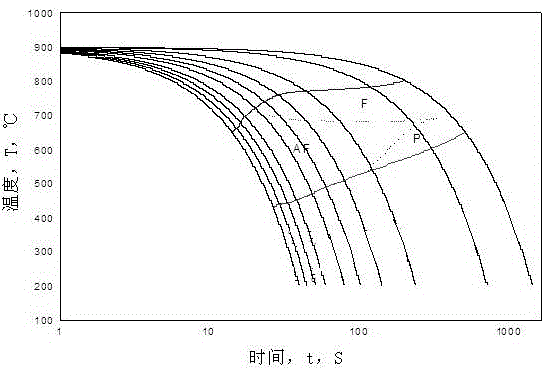

Wide and thick steel plate for hot-bent elbow pipes at X65-X80 levels and manufacturing method of wide and thick steel plate

InactiveCN104404378AGuaranteed StrengthGuaranteed tissue homogeneityLine tubingStructural engineering

The invention relates to a wide and thick steel plate for hot-bent elbow pipes at X65-X80 levels and a manufacturing method of the wide and thick steel plate. Especially, proper ingredients, structures and technologies for the steel plate for the elbow pipes at X65, X70 and X80 levels are designed respectively according to different pipe bending technologies of pipe bending factories, and the pipeline steel performance requirement for reaching the related strength levels after hot bending of the pipes is met. The steel plate is 20-40 mm thick and 2,500-4,000 mm wide, the hot-rolled steel plate with excellent toughness, thermal formability and thermal stability is obtained, a solution is provided for steel plates for high-pressure elbow pipes in long delivery pipeline projects, and the usage security of the high-level pipeline steel plate is improved.

Owner:SHANDONG IRON & STEEL CO LTD

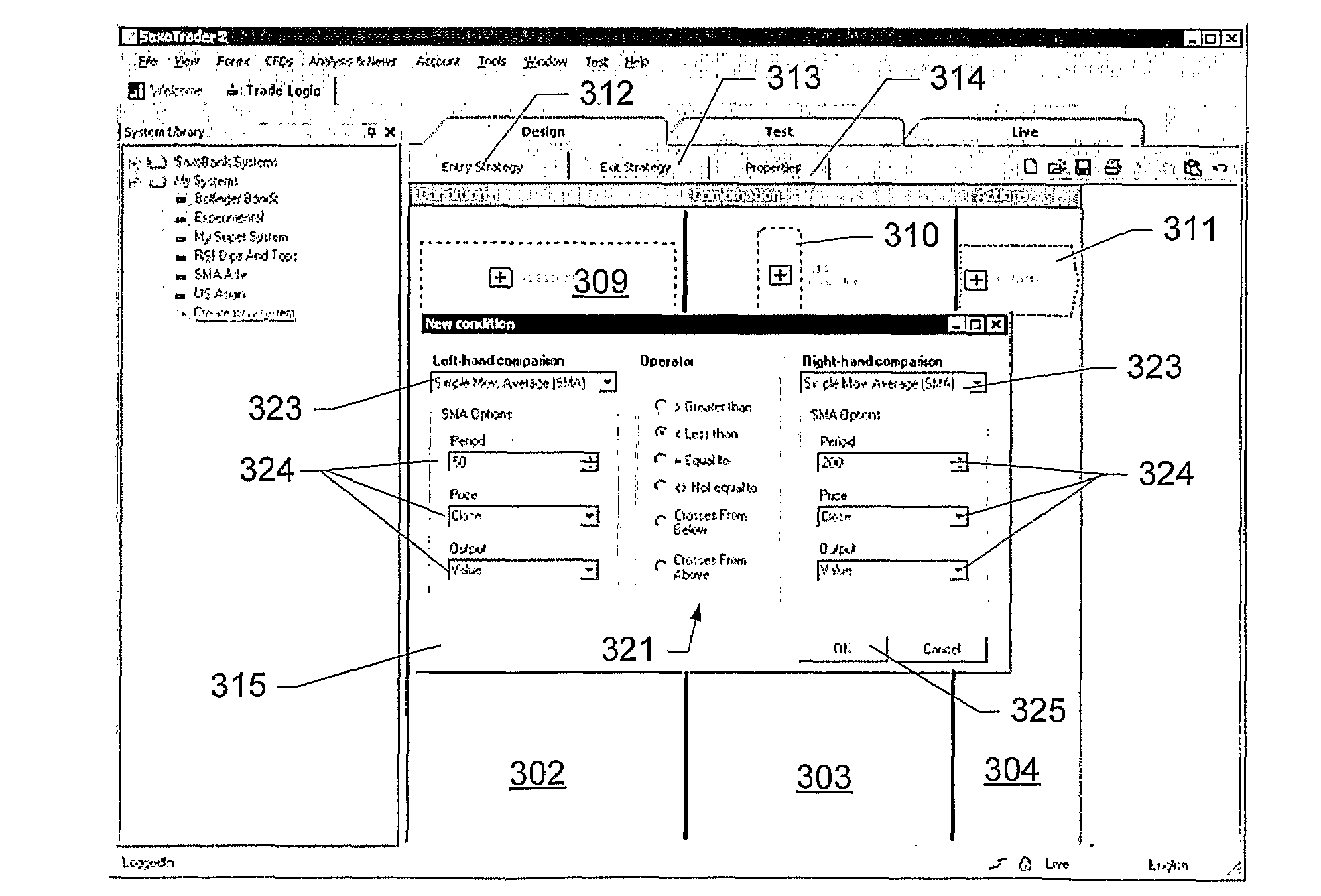

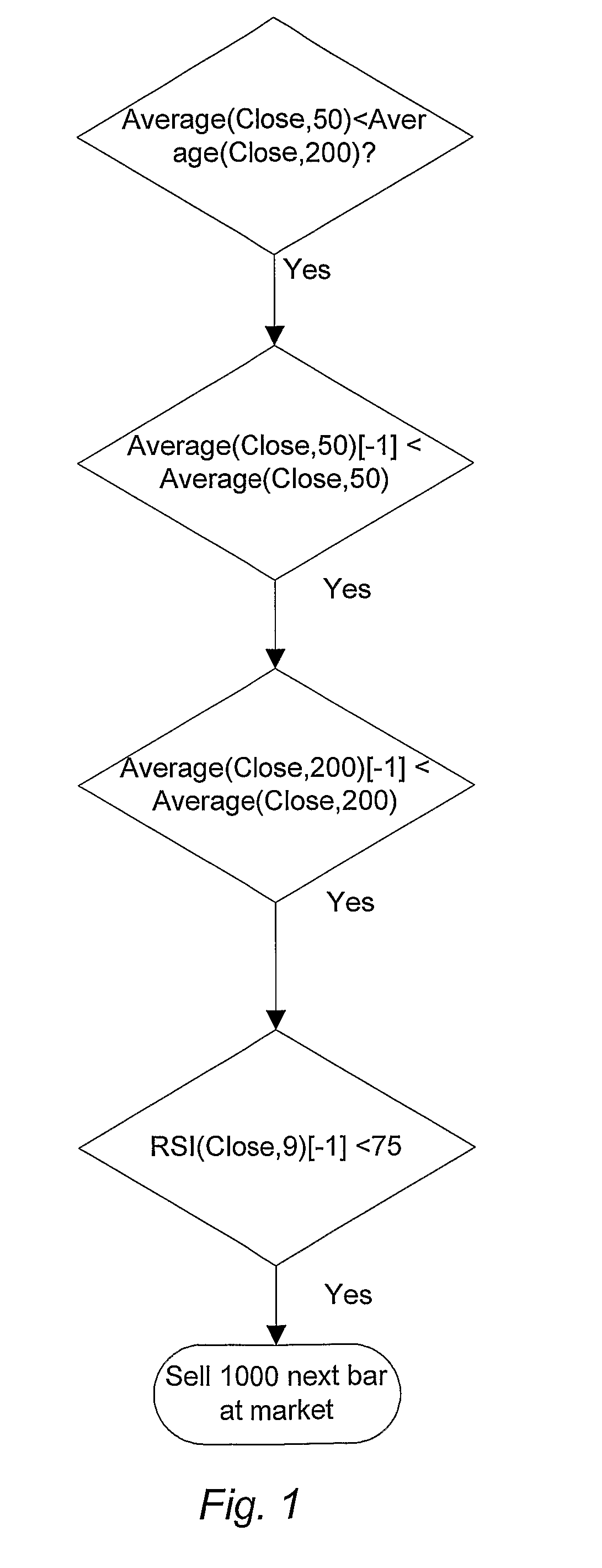

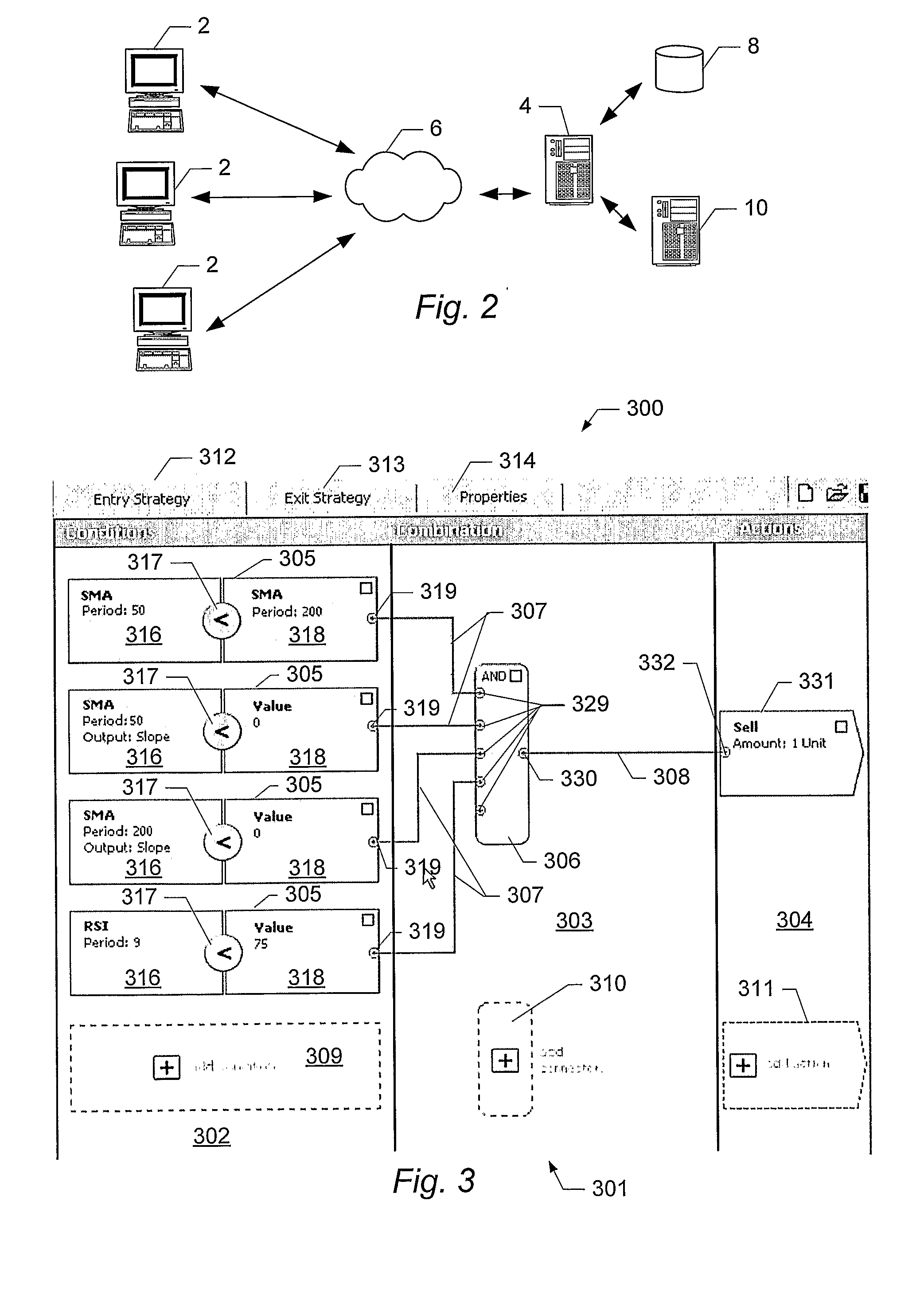

Financial trading system

InactiveUS20100057600A1Improve organizationEasy to useFinanceVisual/graphical programmingGraphicsGraphical user interface

Disclosed is a computer-implemented system for facilitating generation of a computer-executable financial trading strategy, the system being adapted to provide a graphical user interface for defining a financial trading strategy by arranging interconnectable building blocks into a diagram on a drawing pane provided by the graphical user interface, each building block representing a functional system component of the financial trading strategy; wherein the system includes a plurality of types of functional system components, wherein the drawing pane includes a corresponding plurality of sub-panes, and wherein the system is configured to provide functionality for a user-controlled placement of building blocks into the sub-panes corresponding to the respective types of building blocks.

Owner:SAXO BANK

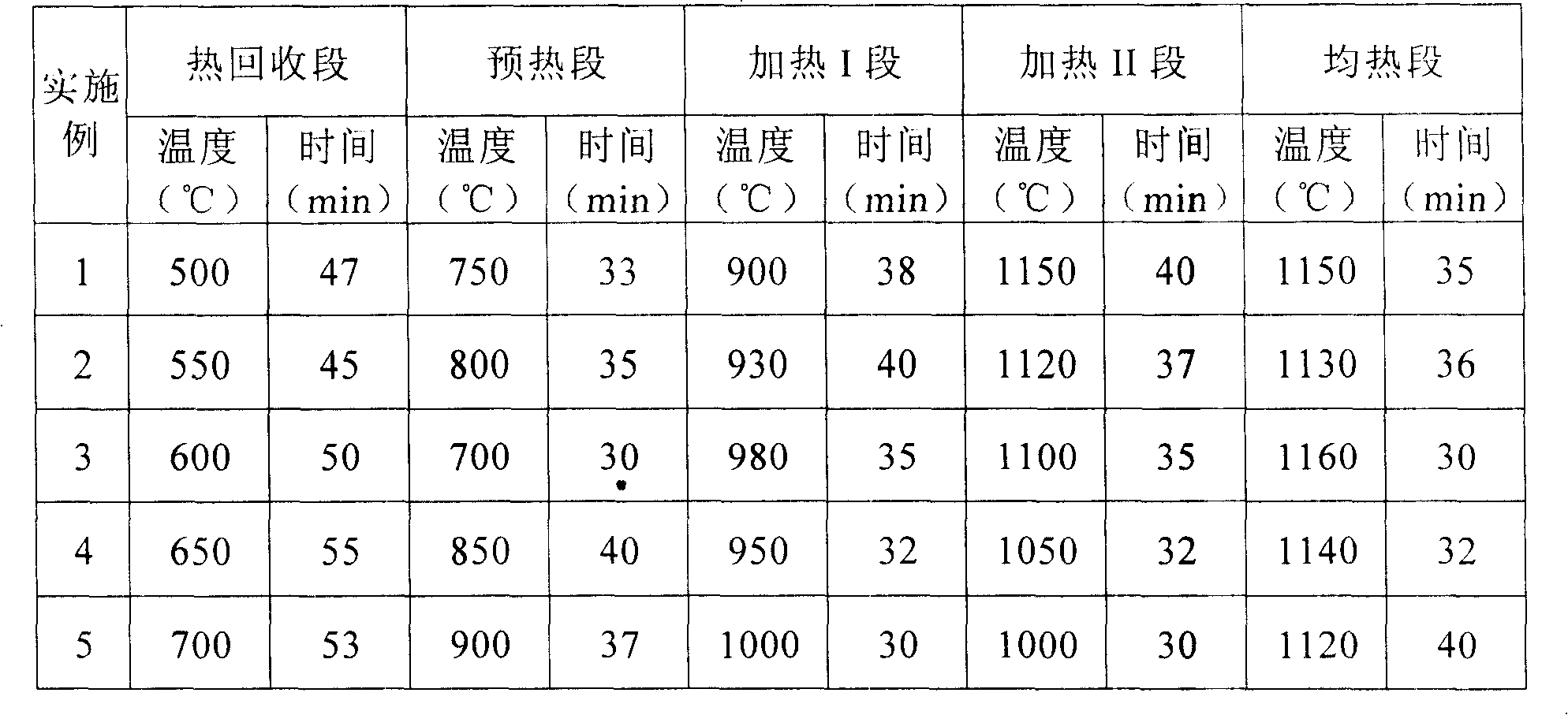

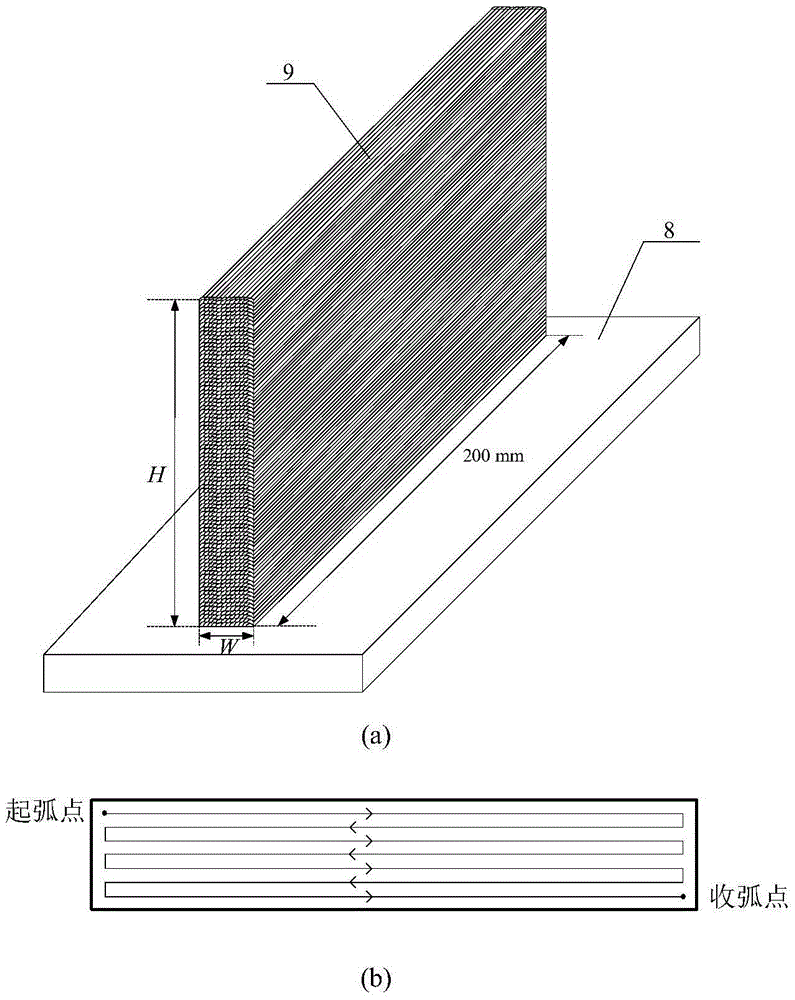

Method for producing hot-rolled ferritic stainless steel strip steel

InactiveCN101245435AFree from common surface defectsNo surface defectsRoll mill control devicesHeat treatment process controlSurface finishChemical composition

The invention discloses a method for producing a hot-rolled ferrite stainless strip steel, which comprises the following steps: 1) the chemical components by weight percentage are: 0.025-0.04 percent of C, less than or equal to 1.00 percent of Si, 0.25-0.4 percent of Mn, less than or equal to 0.030 percent of S, less than or equal to 0.035 of P, 12-12.5 percent of Cr and the rest is Fe; 2) a billet is formed by smelting and casting; 3) heating: the heating temperature zone for heating are divided into a heat recovery section, a preheating section, a I heating section, a II heating section and a holding section; furnace gas is controlled to be neutral atmosphere of non-oxidizing atmosphere; 4) when in heat rolling and rough rolling, the rolling temperature is 1,120 DEG C-1,160 DEG C, and the deforming speed during rolling is 10 / s-12 / s; 5) finish rolling: the deforming speed of the last pass rolling is 60 / s-90 / s, and the outlet temperature of the finish rolling is more than 900 DEG C; 6) cooling is carried out after rolling, and then reeling is carried out. The method of the invention has the advantages that the method guarantees not only the edge quality of the hot-rolled strip steel but also the stamping property of the cold-rolled strip steel, improves the surface finish quality and lowers the production cost, and has high production efficiency and rolling yield, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

Low-pressure casting method of aluminum alloy automobile hub

ActiveCN102366828AOptimization of process parameters and heat treatment parametersImprove performanceHubsThermal treatmentAluminium alloy

The invention discloses a low-pressure casting method of an aluminum alloy automobile hub. In the method, by optimizing alloy component design, adding a proper amount of Al-Ti-B-C refining agent and rare-earth modifying agent, low-pressure casting process parameters and thermal treatment parameters are optimized, so that the prepared automobile hub is provided with a tissue consisting of fine and uniform a dendritic crystal and fine and uniform worm-shaped or spherical silicon, and the performance of the aluminum alloy automobile hub is improved.

Owner:QINHUANGDAO XINGLONG WHEEL HUB

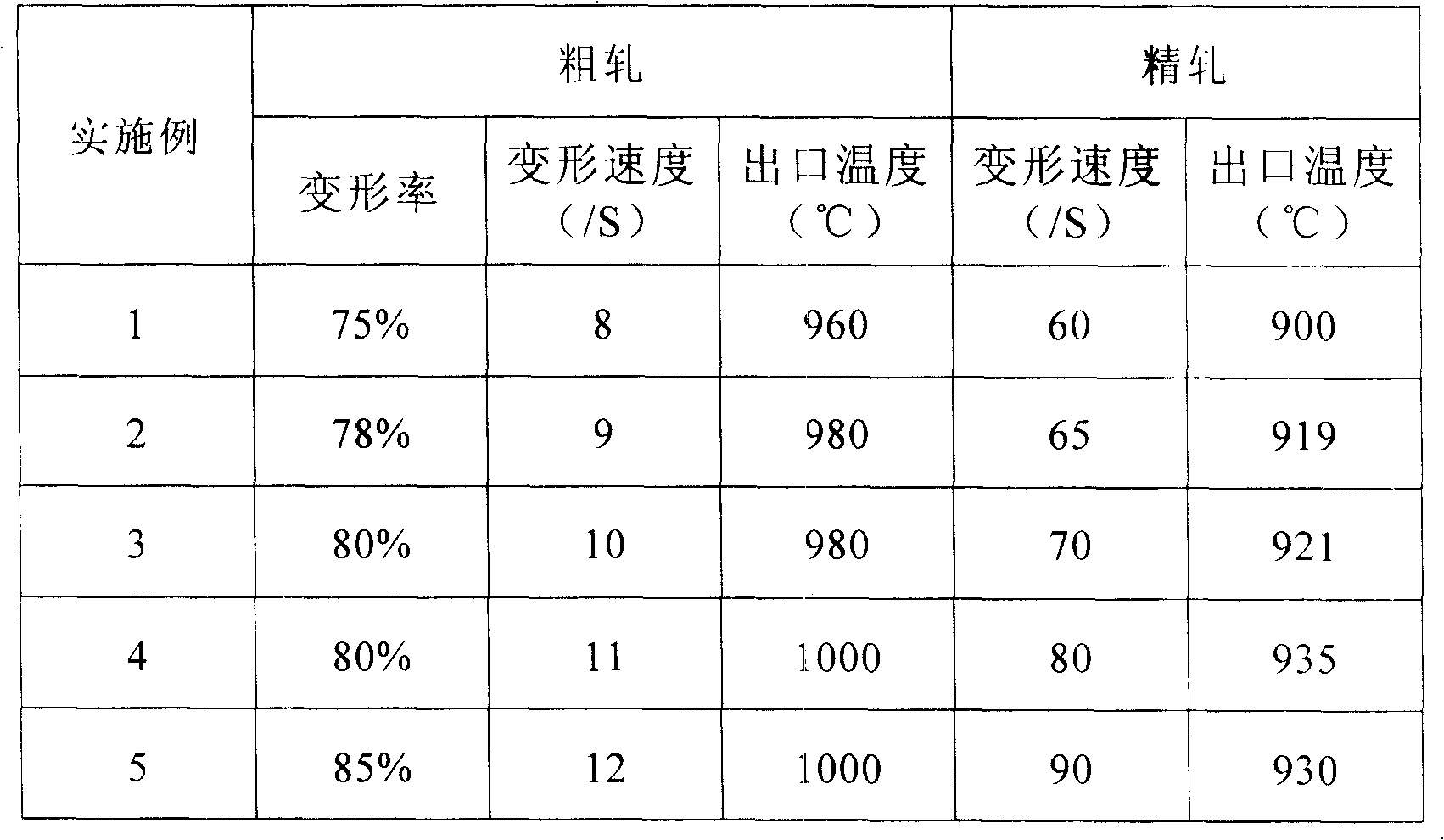

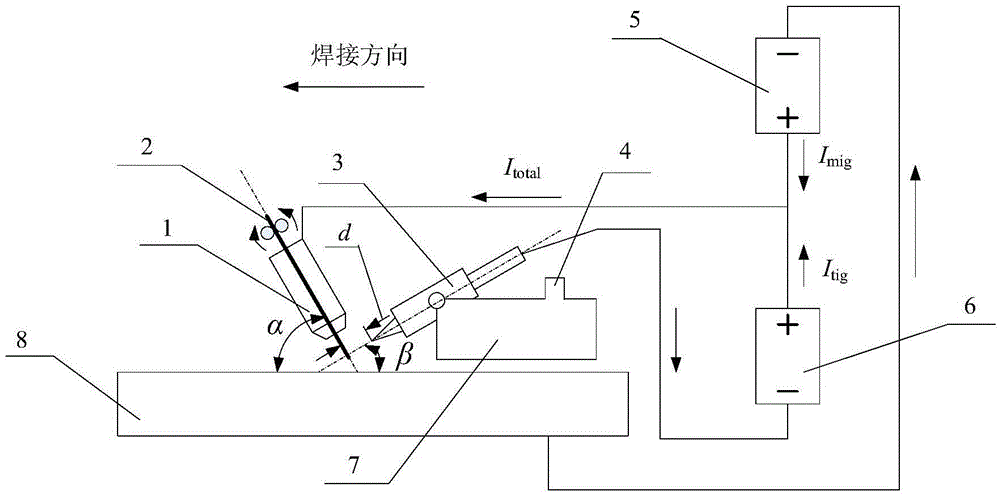

Material increase manufacturing method for titanium alloy shape part by using double-arc hybrid heat source

InactiveCN105458470AImprove deposition rate and welding speedAvoid overheatingArc welding apparatusWelding/soldering/cutting articlesElectric arcPower flow

The invention relates to a material increase manufacturing method for a titanium alloy shape part by using a double-arc hybrid heat source. The method comprises the following steps: MIG welding and TIG welding are originally combed, a welding wire as a melting electrode is sent out by an MIG welding gun and is subjected to surfacing on a base plate; an MIG power anode is connected with a TIG power anode, and an MIG power cathode is connected with the base plate, the MIG welding gun is connected with the MIG power anode, and a TIG welding gun is connected with a TIG power cathode; the MIG welding gun is in the front, and the TIG welding gun is in the back; the current of the welding wire is shunted through a TIG welding circuit, so that the current passing through the welding wire is large, and the current passing through a weldment is small. After the base plate completes a first surfacing layer, a hybrid welding gun is increased by a story height, and a second layer of shape part is welded; the above process is repeated, so that the titanium alloy shape part is formed by overlaying plurality of surfacing layer. The method has the advantages of being high in metal deposition rate, high in welding speed, less in weldment heat input, good in structural and mechanical properties of the shape part and low in cost and solves the problems of lager heat input, low welding speed, poor welding quality and low efficiency during material increase manufacturing of the traditional titanium alloy single TIG arc wire feeding.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com