Patents

Literature

252 results about "Isothermal forging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Isothermal forging represents a possible alternative to produce near net and net shape forgings.The basic principle of isothermal forging consists of a plastic forming process during which die and work piece temperatures are identical or very similar. Full Name Comment goes here.

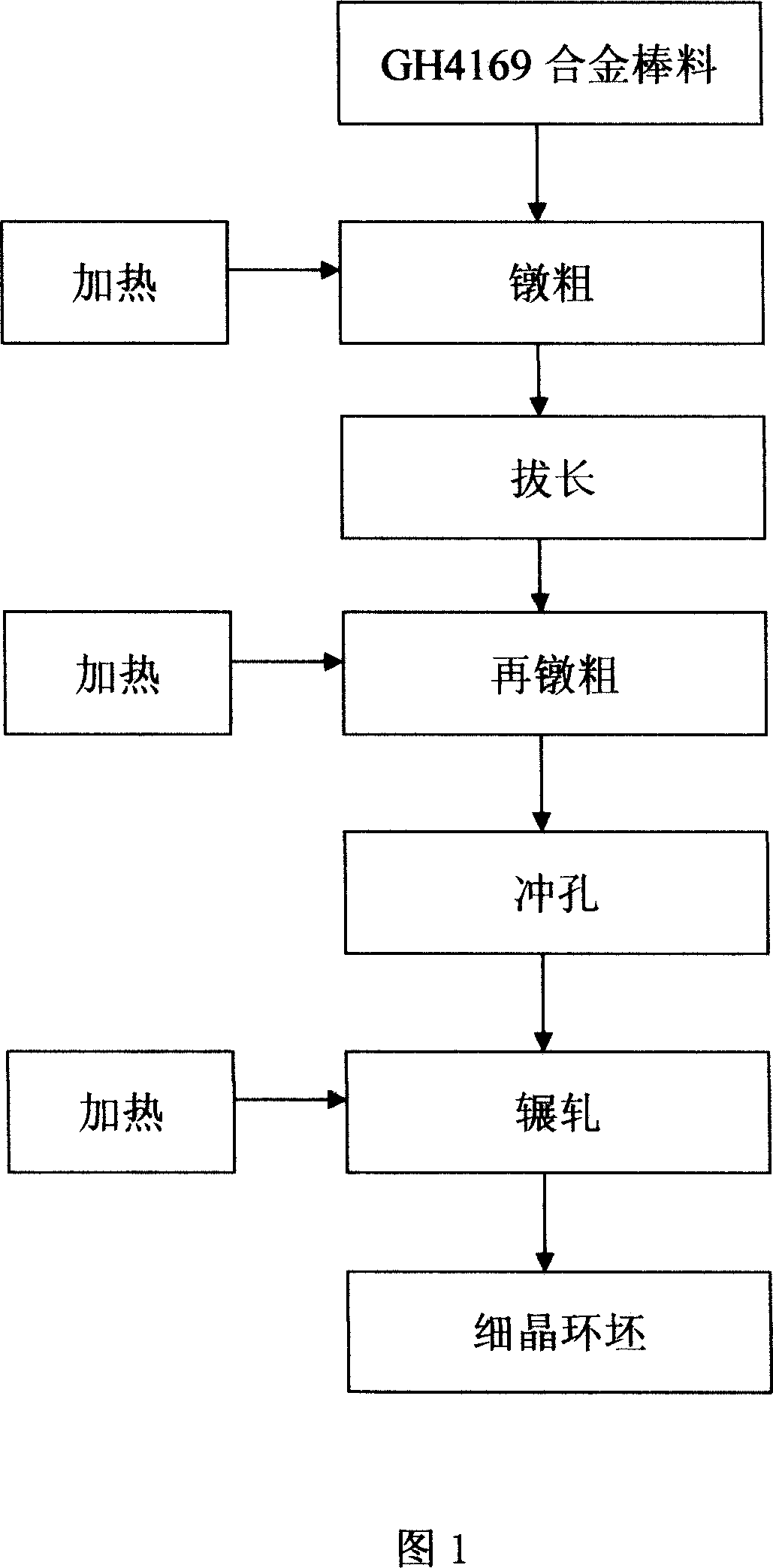

Process of making ring fine crystal blank of GH4169 alloy for near constant temperature forging

The technological process of making ring fine crystal blank of GH4169 alloy for near constant temperature forging includes the following steps: heating the GH4169 alloy rod to 980-1010 deg.c, upsetting into the first cake blank of thickness in 1 / 3-1 / 2 the rod height, drawing the cake blank to secondary rod of original height, heating the secondary rod to 980-1010 deg.c, upsetting into the secondary cake blank of thickness in 1 / 3-1 / 2 the rod height, punching hole in the secondary cake blank, heating the cake blank to 980-1010 deg.c, and rolling to obtain ring fine crystal blank of 35-45 % deformation. The ring fine crystal blank may be near constant temperature forged into forging with fine crystal grains.

Owner:GUIZHOU ANDA AVIATION FORGING

Isothermal forging forming die and method for 7075 aluminum alloy tapered casing

ActiveCN103406482ALow volume productionQuality improvementForging/hammering/pressing machinesGraphite7075 aluminium alloy

The invention discloses an isothermal forging forming die and method for 7075 aluminum alloy tapered casing and relates to an aluminum alloy part forming die and method to solve the problems of folding, streamline disorders, surface coarse grain defects and forming difficulties in manufacturing of 7075 aluminum alloy tapered casing in the prior art. The method comprises main steps of first, blank making, wherein a cylindrical 7075 aluminum alloy blank material is subjected to flat drilling upsetting to be manufactured into a formed blank; second, pre-forging, wherein the blank is placed in a female die of a pre-forging die for pre-forging forming to be produced into a formed pre-forged part; third, primary finish forging, wherein the primary finish forging is performed to manufacture a formed primary finished forged part; fourth, primary cleaning; fifth, damage repairing; sixth, secondary finish forging, wherein the secondary finish forging is performed to manufacture a secondary finished forged part; seventy, secondary cleaning, wherein graphite on the surface is cleared away. The isothermal forging forming die and method are used for manufacturing of 7075 aluminum alloy tapered casing.

Owner:HARBIN INST OF TECH

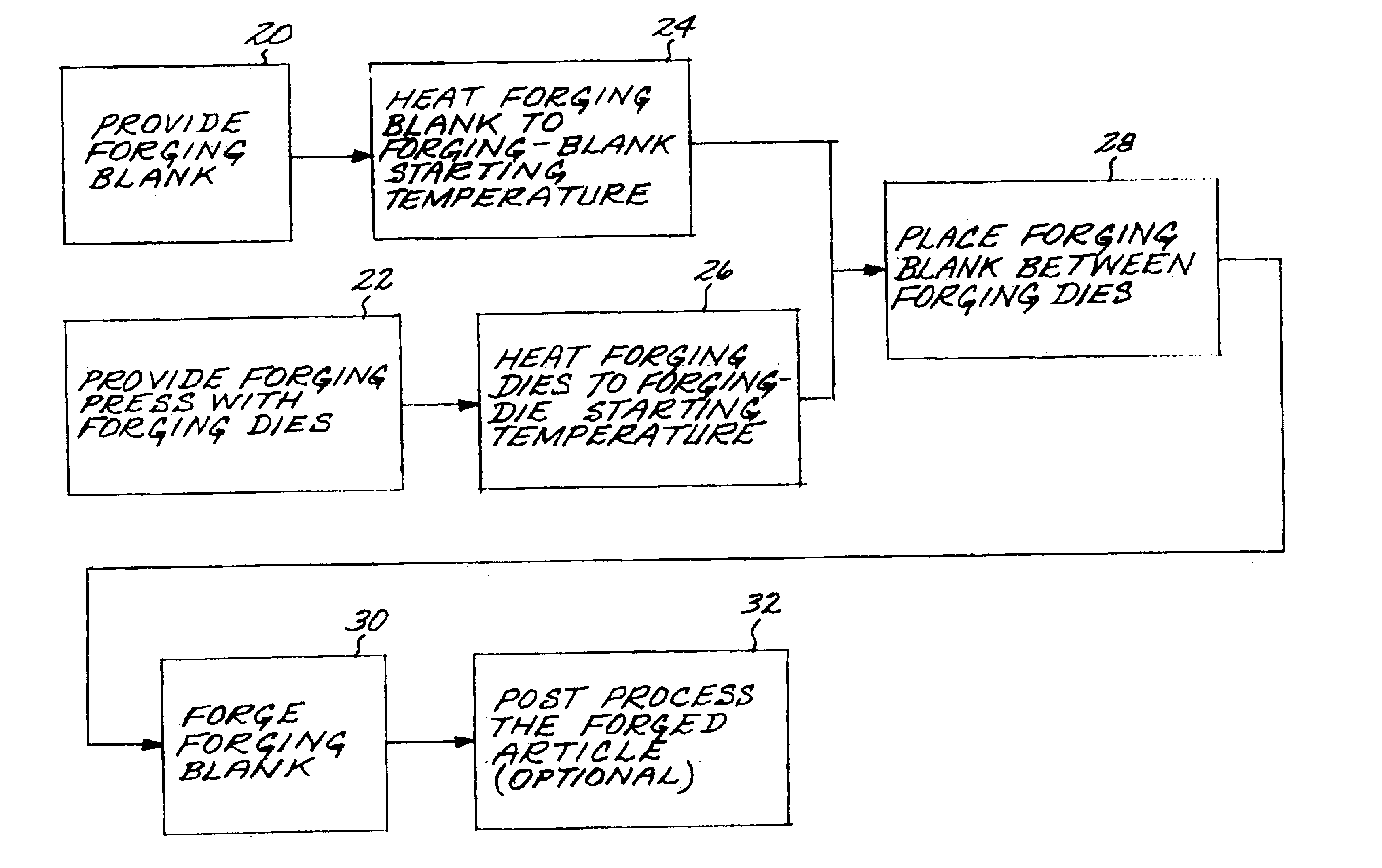

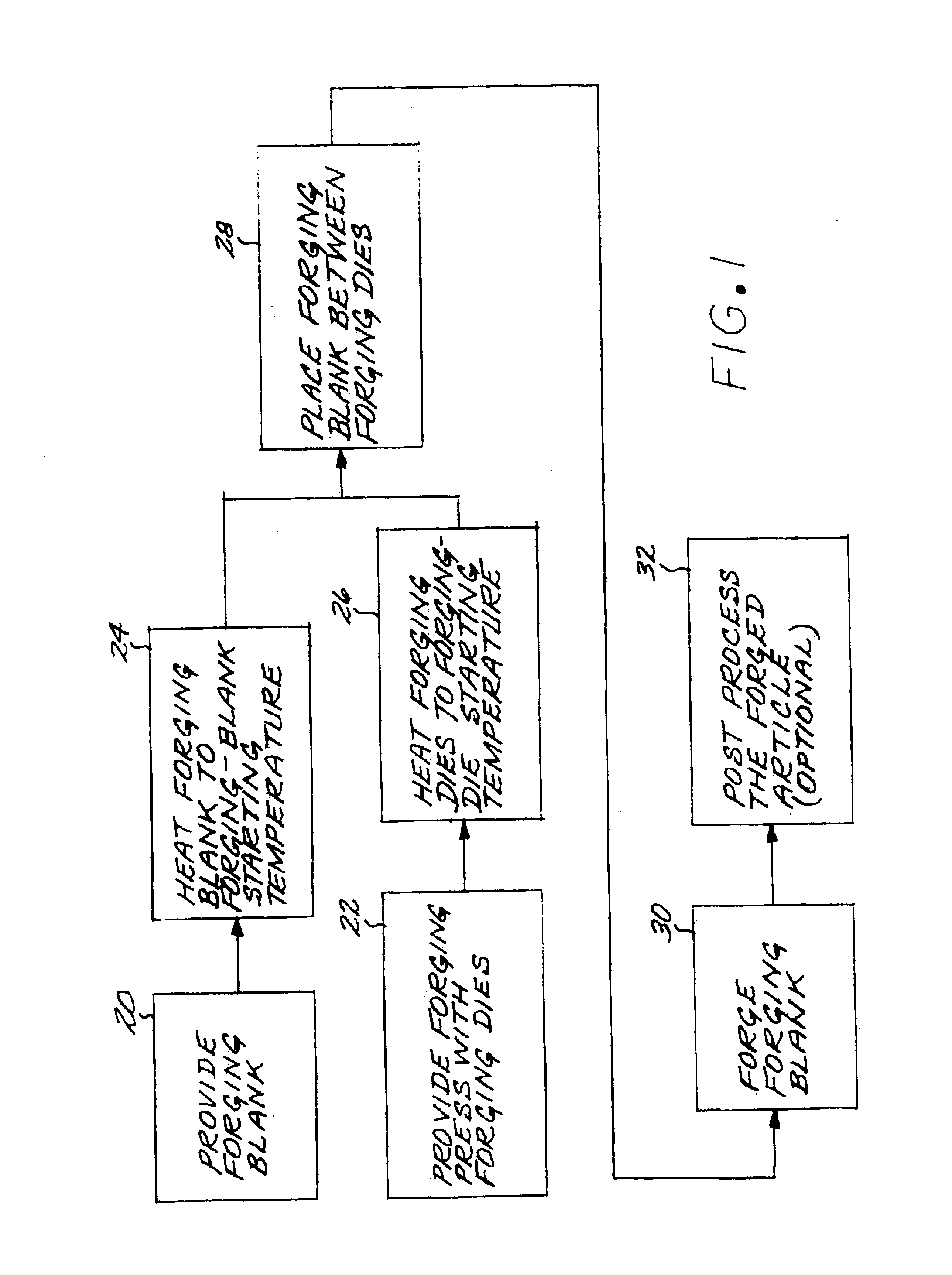

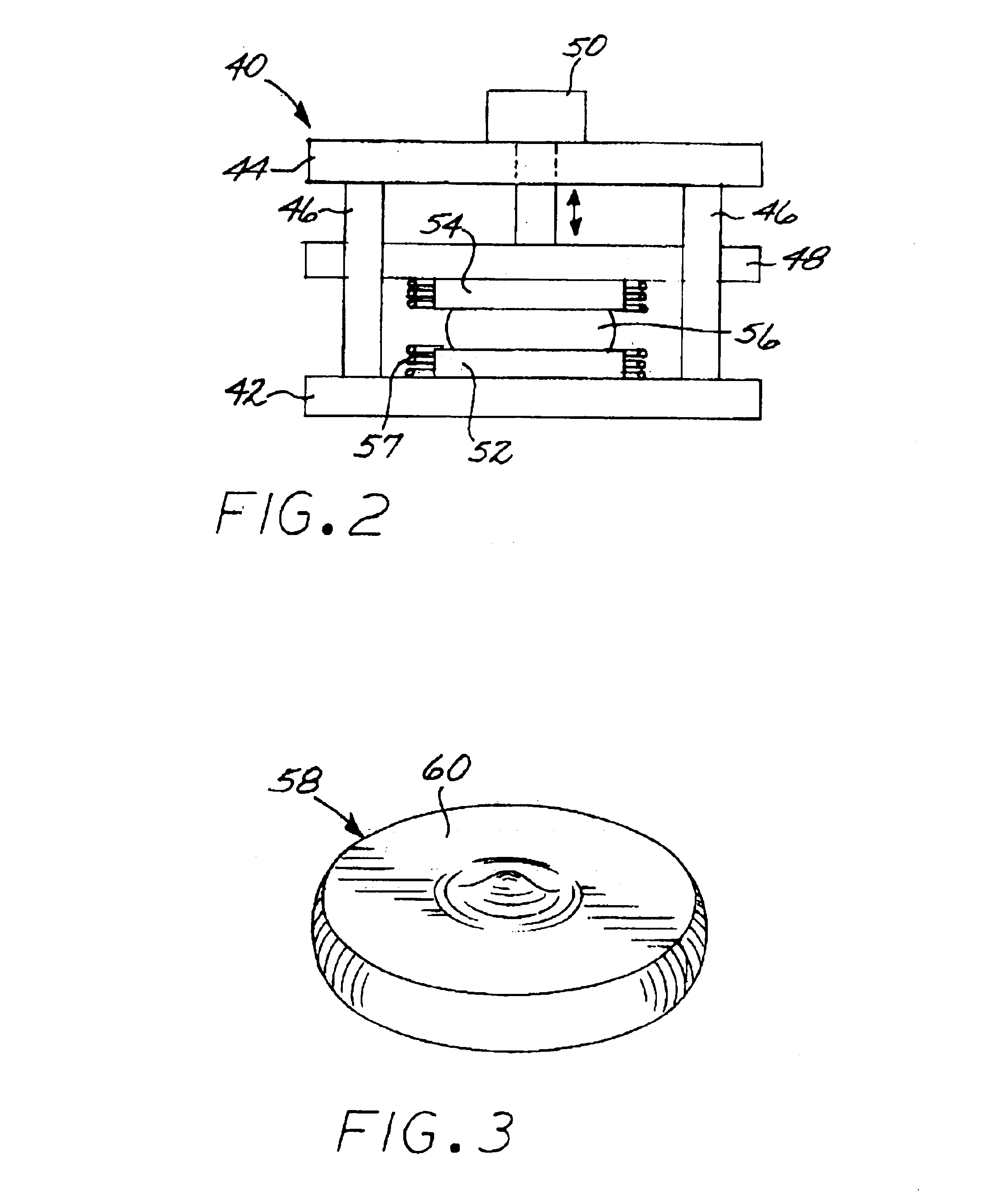

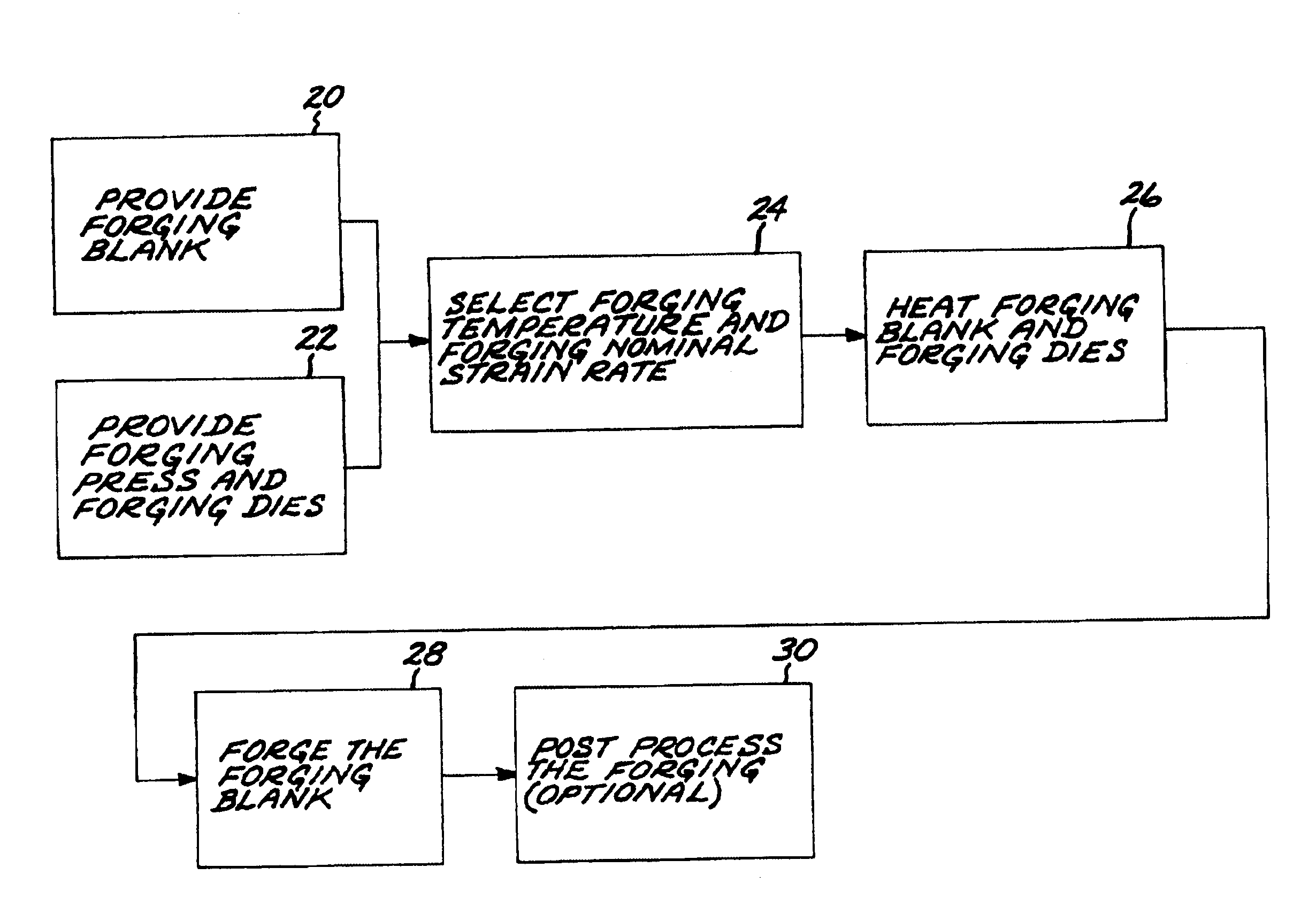

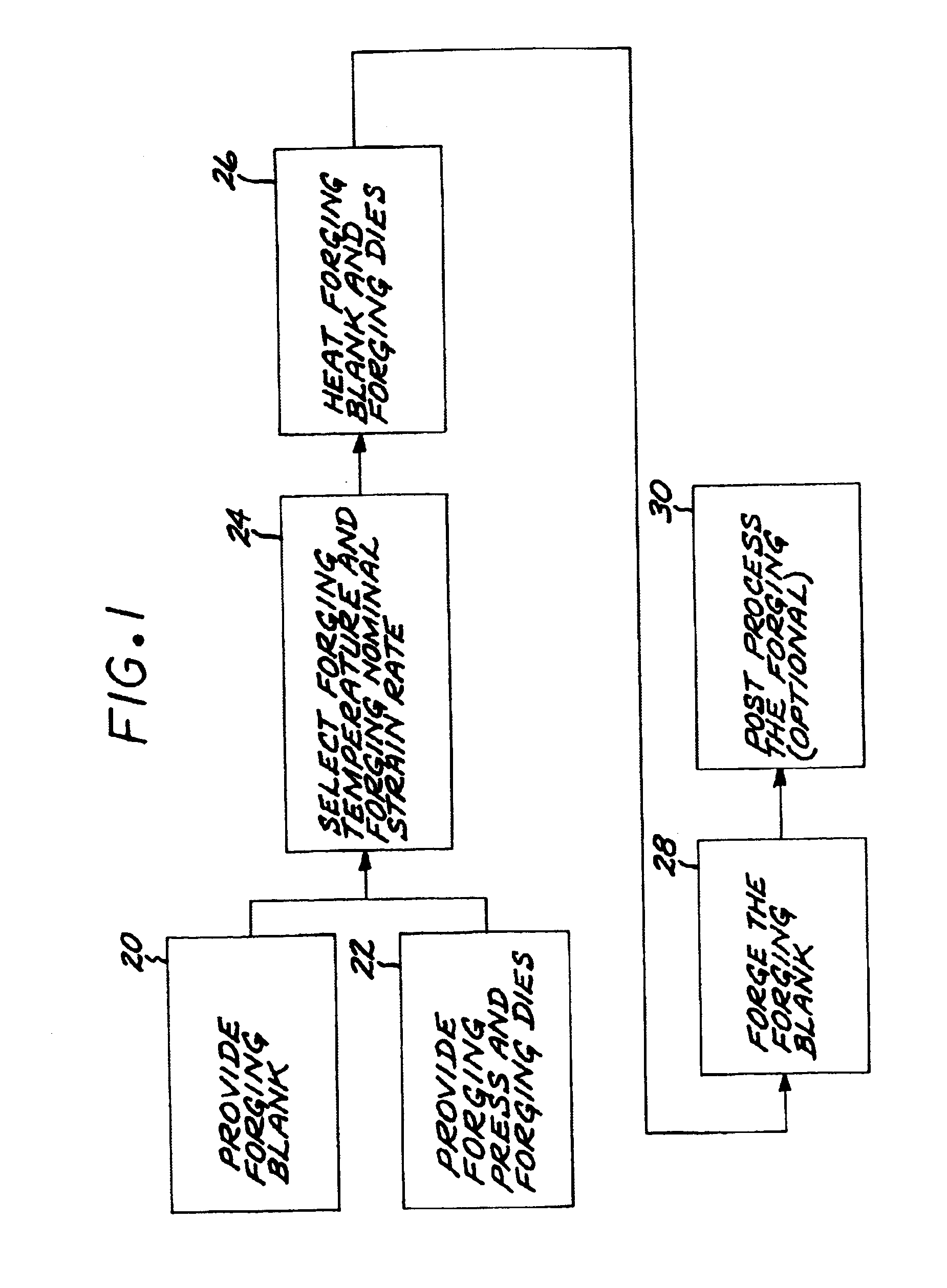

Quasi-isothermal forging of a nickel-base superalloy

InactiveUS6932877B2Reduce the temperatureLow costMetal-working apparatusIsothermal forgingNickel based

A forging blank of a forging nickel-base superalloy is forged in a forging press having forging dies made of a die nickel-base superalloy. The forging is accomplished by heating the forging blank to a forging-blank starting temperature of from about 1850° F. to about 1950° F., heating the forging dies to a forging-die starting temperature of from about 1500° F. to about 1750° F., placing the forging blank into the forging press and between the forging dies, and forging the forging blank at the forging-blank starting temperature using the forging dies at the forging-die starting temperature, to produce a forging.

Owner:GENERAL ELECTRIC CO

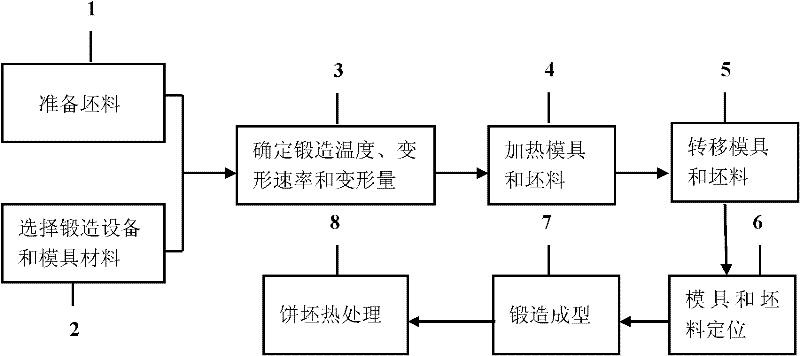

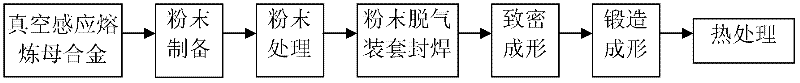

Composite preparation method for fine crystal titanium alloy

InactiveCN102121078AGive full play to high temperature plasticityHigh densityDehydrogenationTitanium alloy

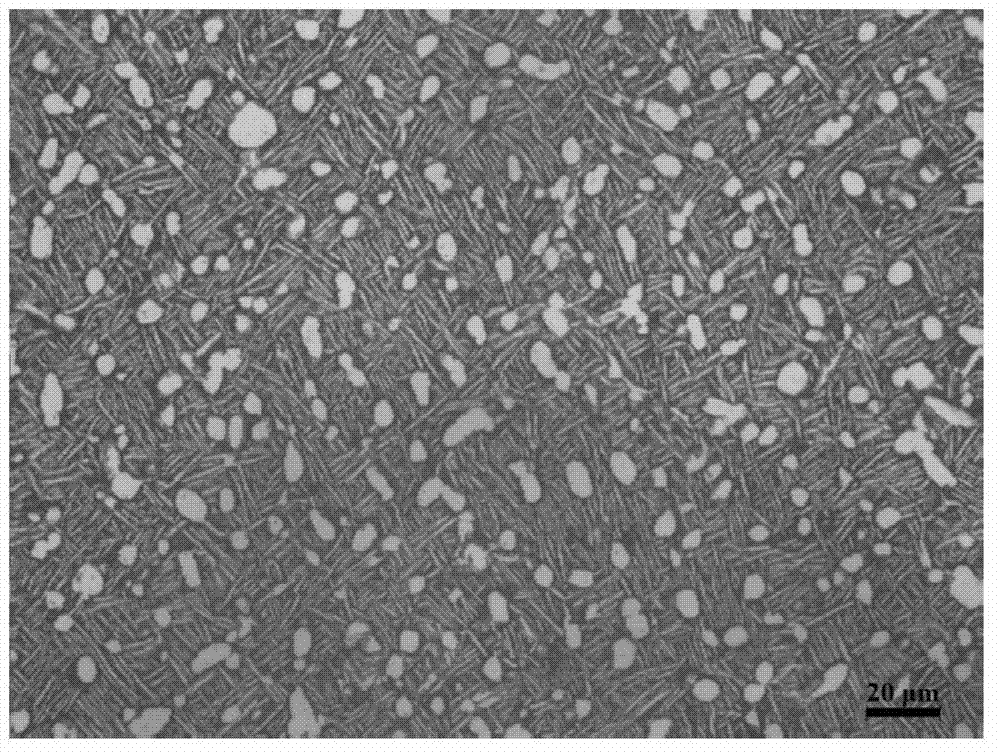

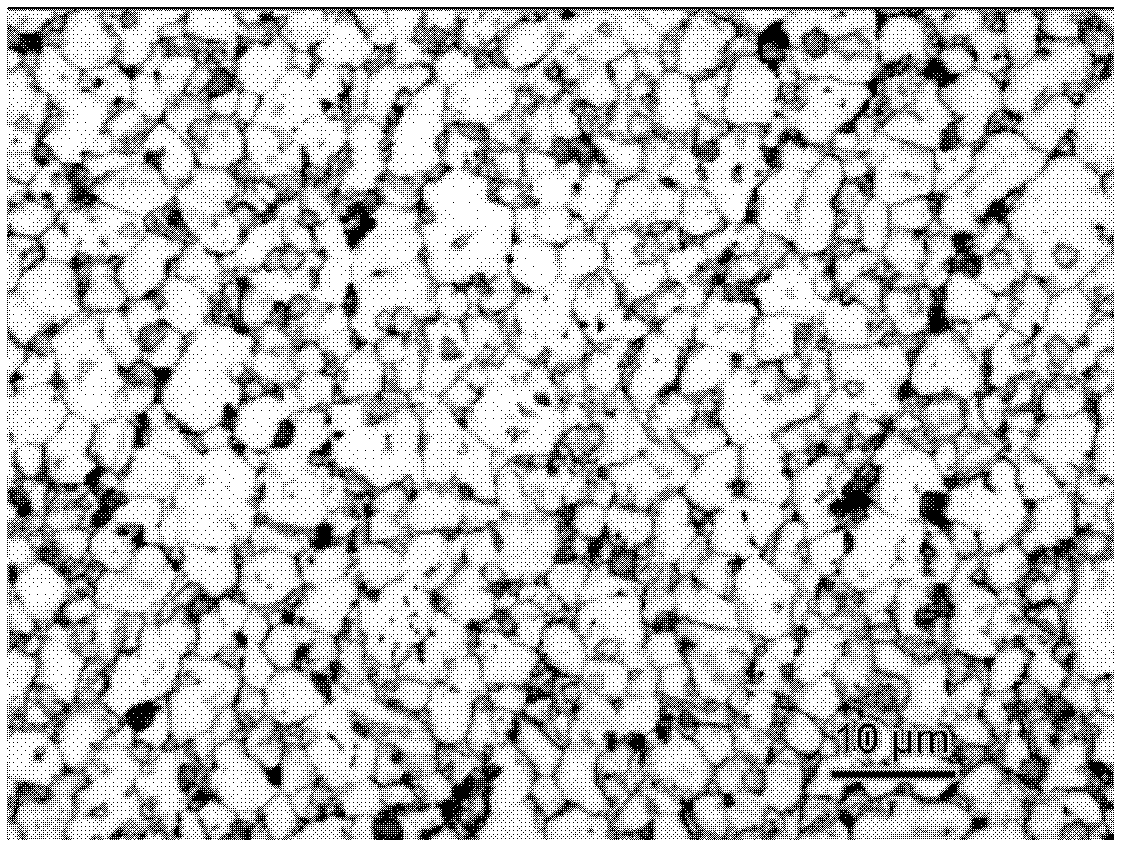

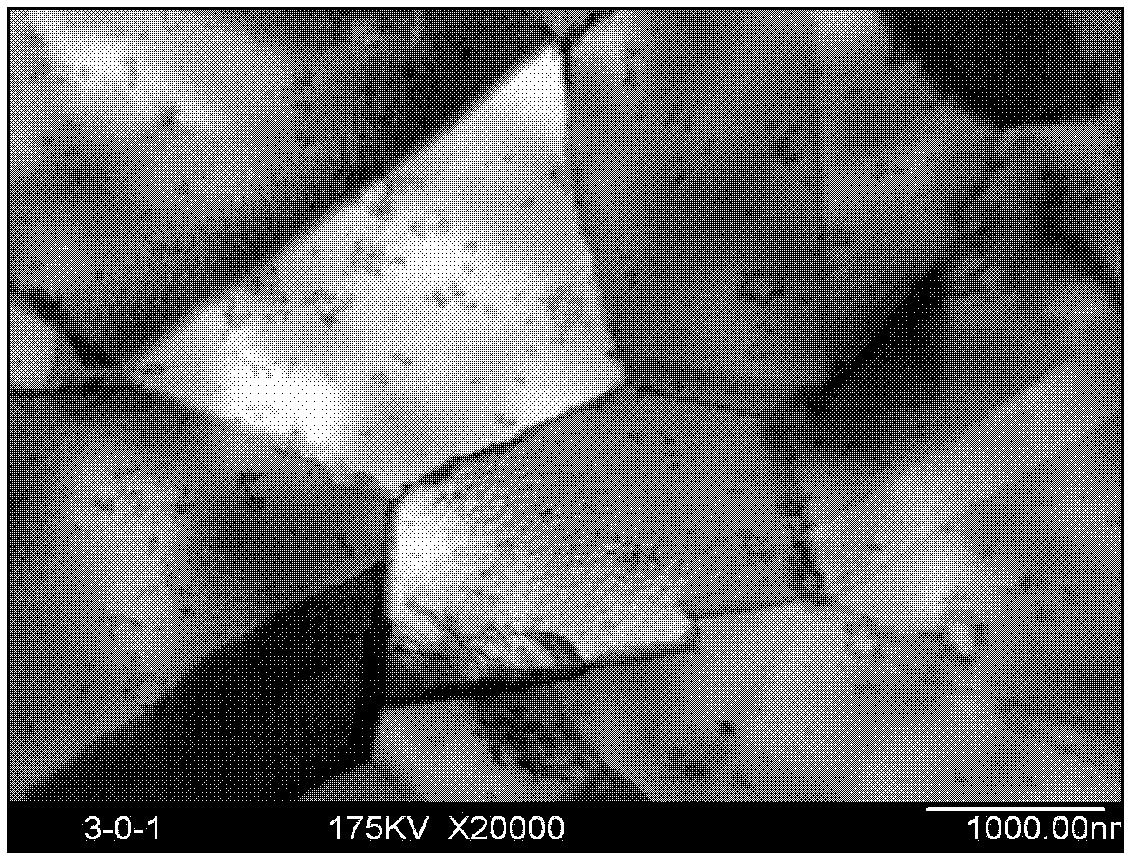

The invention relates to a composite preparation method for a fine crystal titanium alloy, which comprises the following steps of: performing cold isostatic pressing and vacuum sintering on hydrogenated dehydrogenation titanium alloy powder, then performing first heating high-temperature isothermal forging by adopting medium strain rate over a transformation point to close internal holes of the powdery alloy, improve the compactness of the alloy and improve the plasticity of the alloy, performing second heating low-temperature isothermal forging by adopting medium strain rate below the transformation point to further compact and thin the powdery titanium alloy, and finally performing thermal treatment to obtain the high-compactness fine crystal powdery titanium alloy. According to the preparation method, the preparation period of common forged titanium alloy is effectively shortened, the loss of raw materials is reduced, near net shape precision forgings can be simultaneously formed, the prepared powdery titanium alloy has no component segregation, the compactness is more than 99 percent, the equiaxial tissues are uniform and fine, the size of alpha phase is less than 2 microns, and the mechanical property is excellent.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

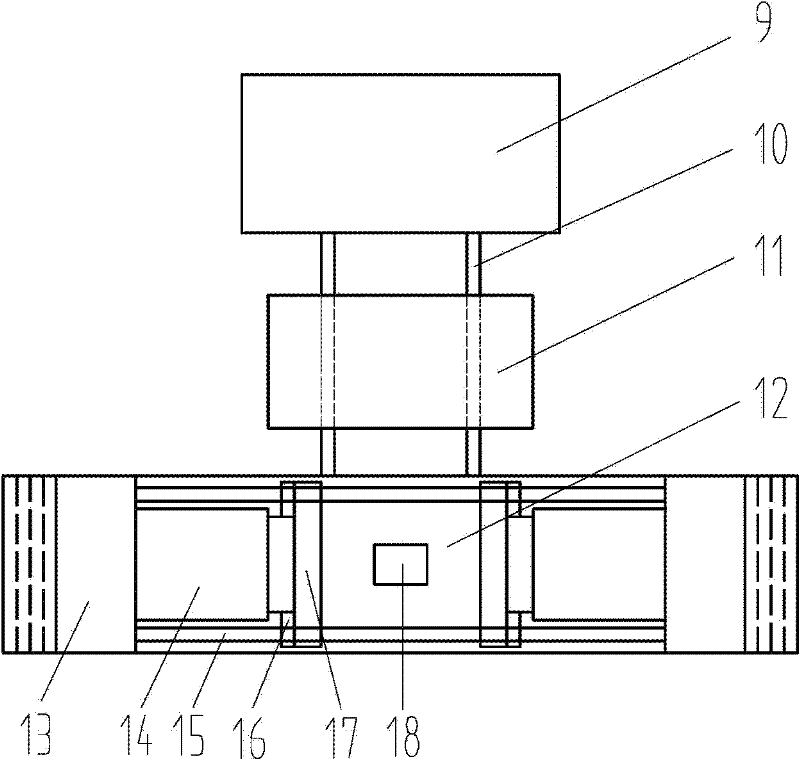

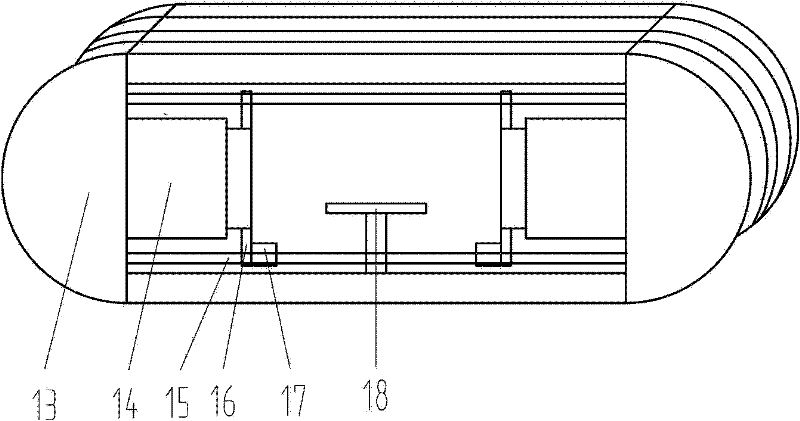

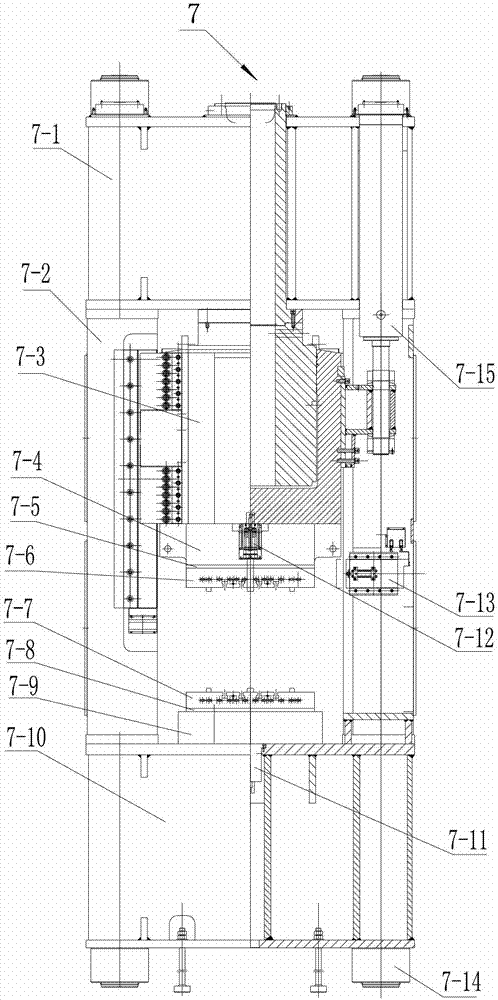

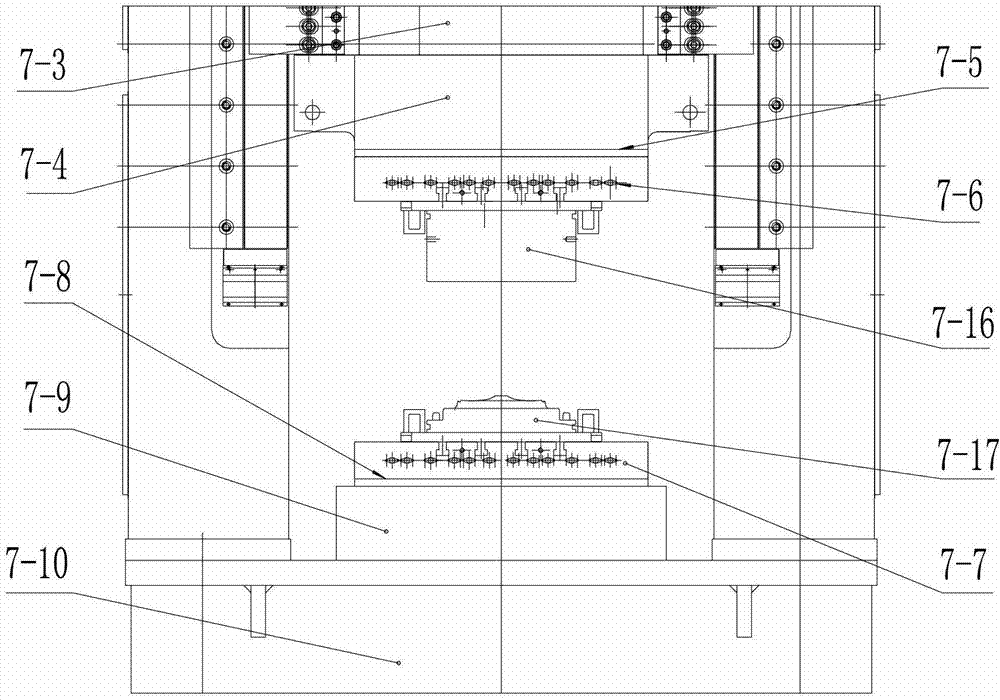

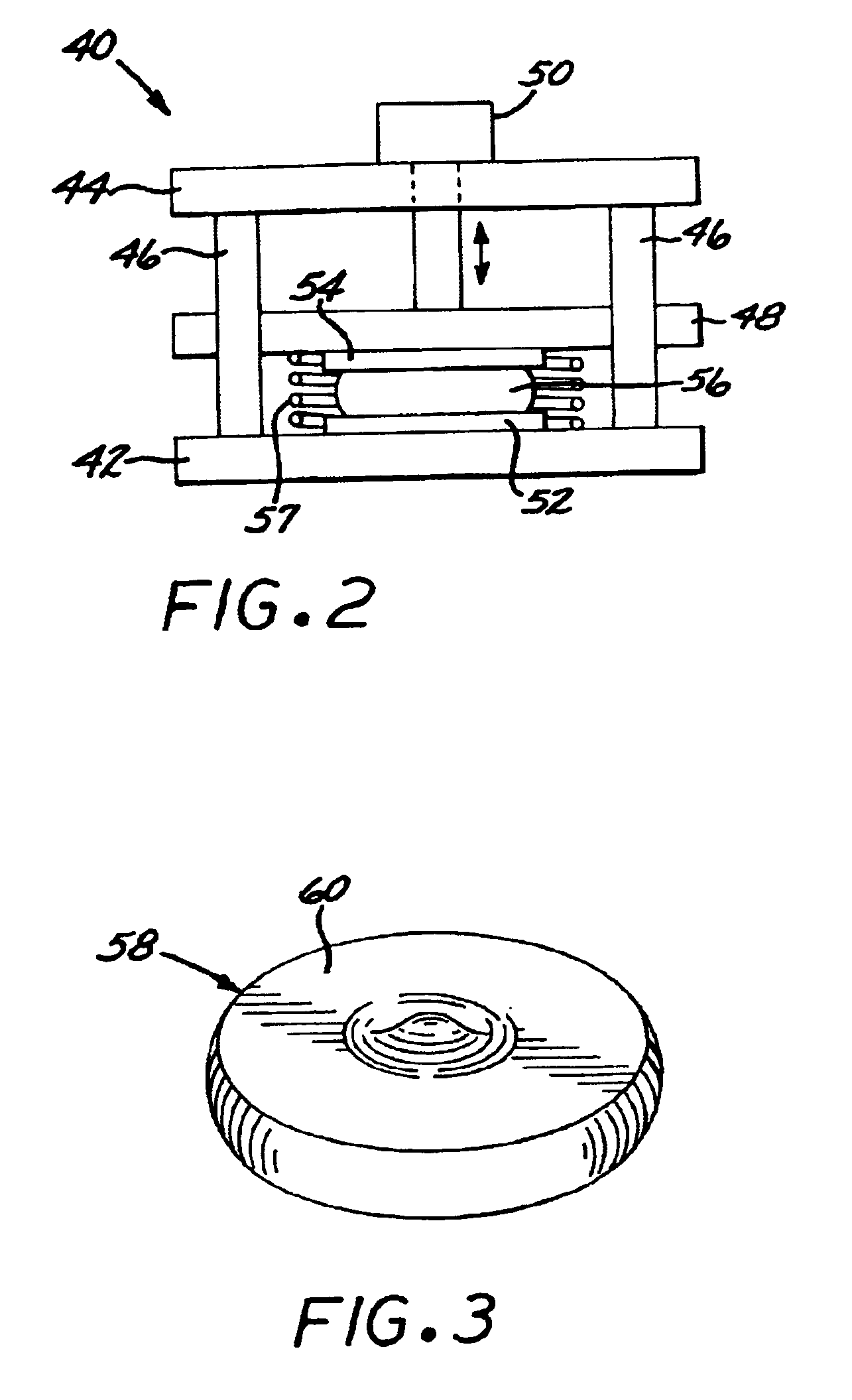

Quick isothermal forging method and device for preparing less-deformable alloy cake blank

ActiveCN102303083AReduce manufacturing costReduce the cost of forging processForging press detailsFlow stressHigh volume manufacturing

The invention discloses a quick isothermal forging method and device for preparing a less-deformable alloy cake blank. The device comprises a heating device, an automatic feeding device, a horizontal hydraulic forging device, a blank positioning device and a flame heating device. A mould material used by the device is a nickel-based alloy with creep strength which is higher than the flow stress of a forged high-temperature alloy under corresponding forging temperature and deformation rate. In the method, a homogenized electroslag remelting continuous directional solidification technology or other processes with maneuverability can be selected for preparing a high-alloyed less-deformable alloy directional solidification billet, as well as a fine grain billet prepared by adopting the processes, such as powder metallurgy and the like. The method and the device have the advantages of short production period, convenience for control and low cost, and are suitable for mass production of large-size high-clean and uniform tissue high-alloying less-deformable alloy cake blanks.

Owner:CENT IRON & STEEL RES INST

Automobile hub isothermal forging and spinning forming process

InactiveCN102814621AReduce consumptionHigh precisionMetal-working apparatusWheelsTemperature controlCasting defect

The invention relates to an automobile hub isothermal forging and spinning forming process which mainly overcomes casting defects of proneness to shrinkage and looseness, low mechanical property and the like of a traditional metal mold casting blank forming method and overcomes the shortcoming that an automobile hub is large in machining allowance, high in production cost and difficult in wide application. The technical scheme includes that the process includes: cutting an aluminum alloy rod to a blank; preheating the blank to the temperature of 460 DEG C to 500 DEG C and then keeping the temperature for 1 hour; forging and pressing the blank for 3-4 times under a forging press to manufacture a pre-forging blank; preheating a die; placing the pre-forging blank into the forging die (controlling the die temperature at 400-450 DEG C) under a 1500t forging press, and performing isothermal forging for 2-3 times again to enable an aluminum alloy hub to be formed primarily; and spinning for precise forming. By the forming process, product manufacturing precision and strength are enhanced, and the forming process belongs to precise forming and is capable of effectively saving production cost and improving mechanical property of the hub.

Owner:韦光东

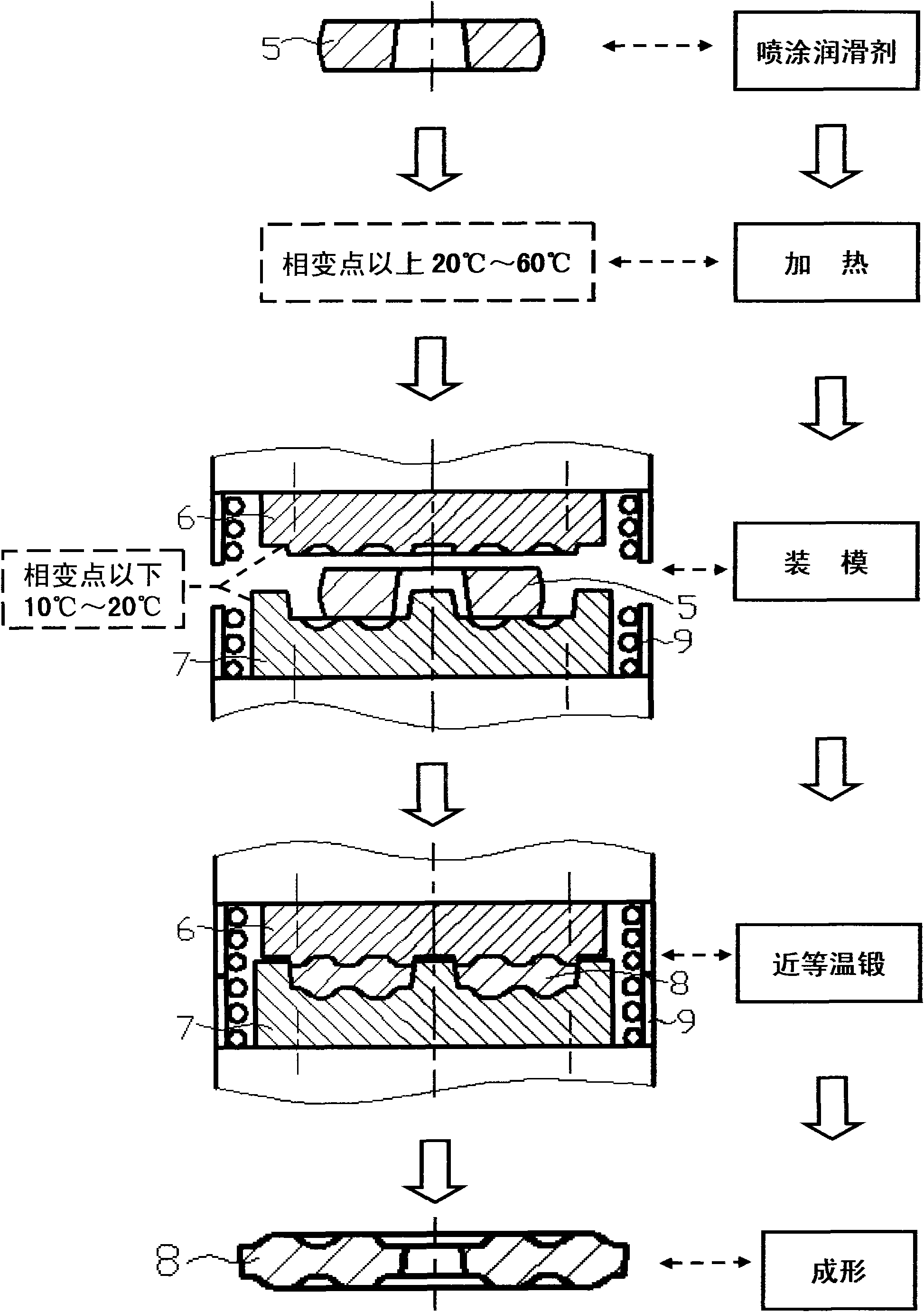

Near-isothermal forging method of TC17 biphase titanium alloy disc forge piece

ActiveCN101804441ASmall and uniform tissueMake up for the phase transition point errorWheelsAviationAir compressor

The invention discloses a near-isothermal forging method of a TC17 biphase titanium alloy disc forge piece, comprising the steps of: heating a TC17 titanium alloy disposable bar ingot to 30-75 DEG C below a phase change point, upsetting the disposable bar ingot into a disposable circular cake; heating the disposable circular cake to 20-60 DEG C over the phase change point, and drawing out the disposable circular cake till the length thereof returns the length of the disposable bar ingot to obtain a secondary bar ingot; heating the secondary bar ingot to 30-75 DEG C below the phase change point, upsetting the secondary bar ingot to form a secondary circular cake, then punching to form an annular blank; and heating the annular blank to 20-60 DEG C over the phase change point, heating an upper forging mold and a lower forging mold to 10-20 DEG C below the phase change point, and forging and stamping the annular blank by the upper forging mold and the lower forging mold under the pressure of 30-60mN to make the deformation degree of the annular blank reach 30-50% in the forging molds at a strain rate of 0.001s-1 to 0.01s-1, and then forming a disc forge piece on fire, wherein the heat treatment after forging is the combination of solution treatment and ageing treatment. The disc forge piece forged by using the method has ideal electrical plating basket structure and high performance and is suitable for manufacturing forge pieces of an air compressor chassis, a turbine disc and the like of an aero-engine.

Owner:GUIZHOU ANDA AVIATION FORGING

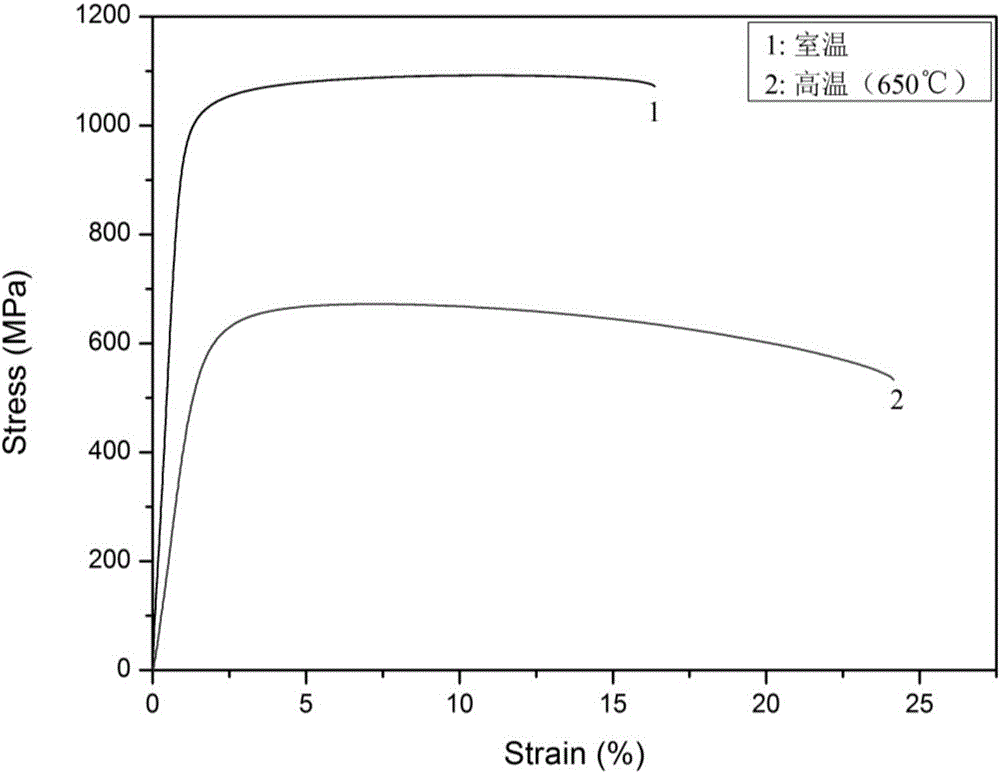

650 DEG C high temperature-resistant titanium alloy material and preparation method thereof

The invention relates to a 650 DEG C high temperature-resistant titanium alloy material and a preparation method thereof, and belongs to the field of titanium alloy materials. The 650 DEG C high temperature-resistant titanium alloy material is prepared from, by mass, 6-7% of Al, 2-3% of Sn, 8-10% of Zr, 0.4-1% of Mo, 0.5-1.2% of Nb, 0.5-1.2% of W, 0.2-0.4% of Si, 0.1-0.3% of Er, and the balance of Ti. The preparation method comprises the following steps: batching, melting, casting and isothermal forging for finally obtaining the novel high temperature titanium alloy material. The tensile strength of the prepared high temperature titanium alloy at 650 DEG C reaches 672.6 MPa, the yield strength of the high temperature titanium alloy at 650 DEG C is 538.9 MPa, the elongation of the high temperature titanium alloy at 650 DEG C is 22.9%, and the high temperature titanium alloy also has excellent room temperature strength and plasticity, excellent service performances and wide application prospect.

Owner:BEIJING UNIV OF TECH

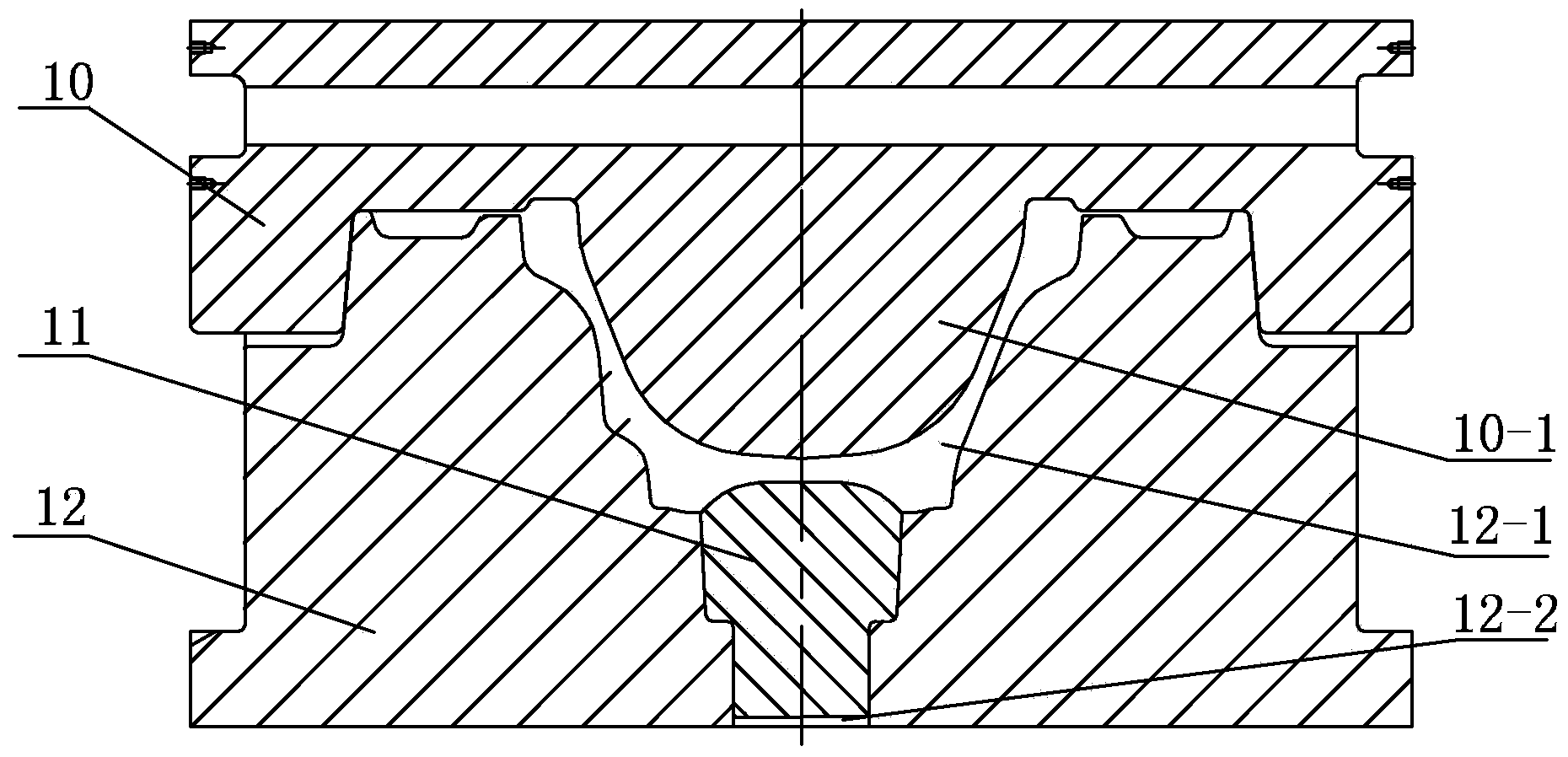

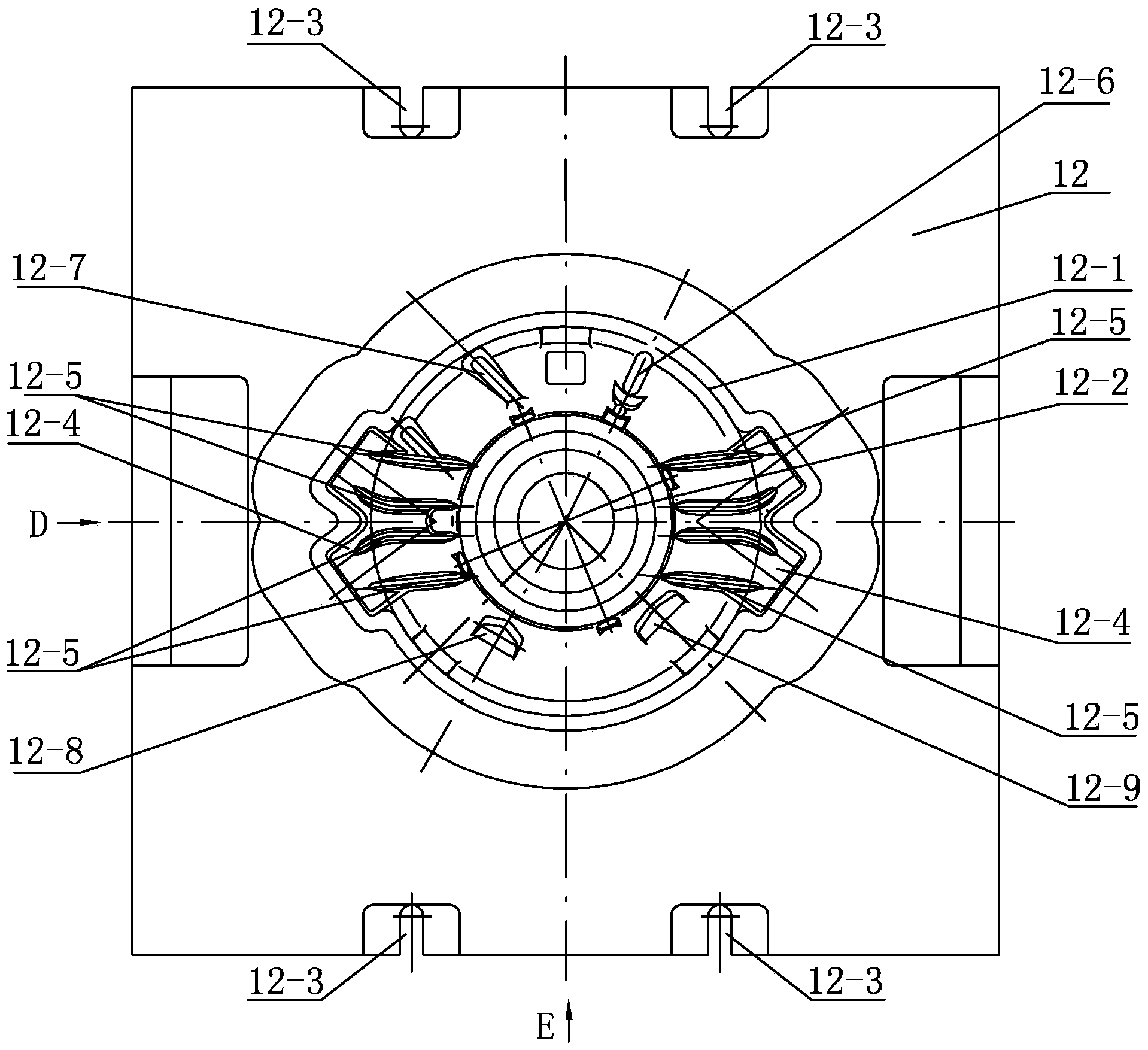

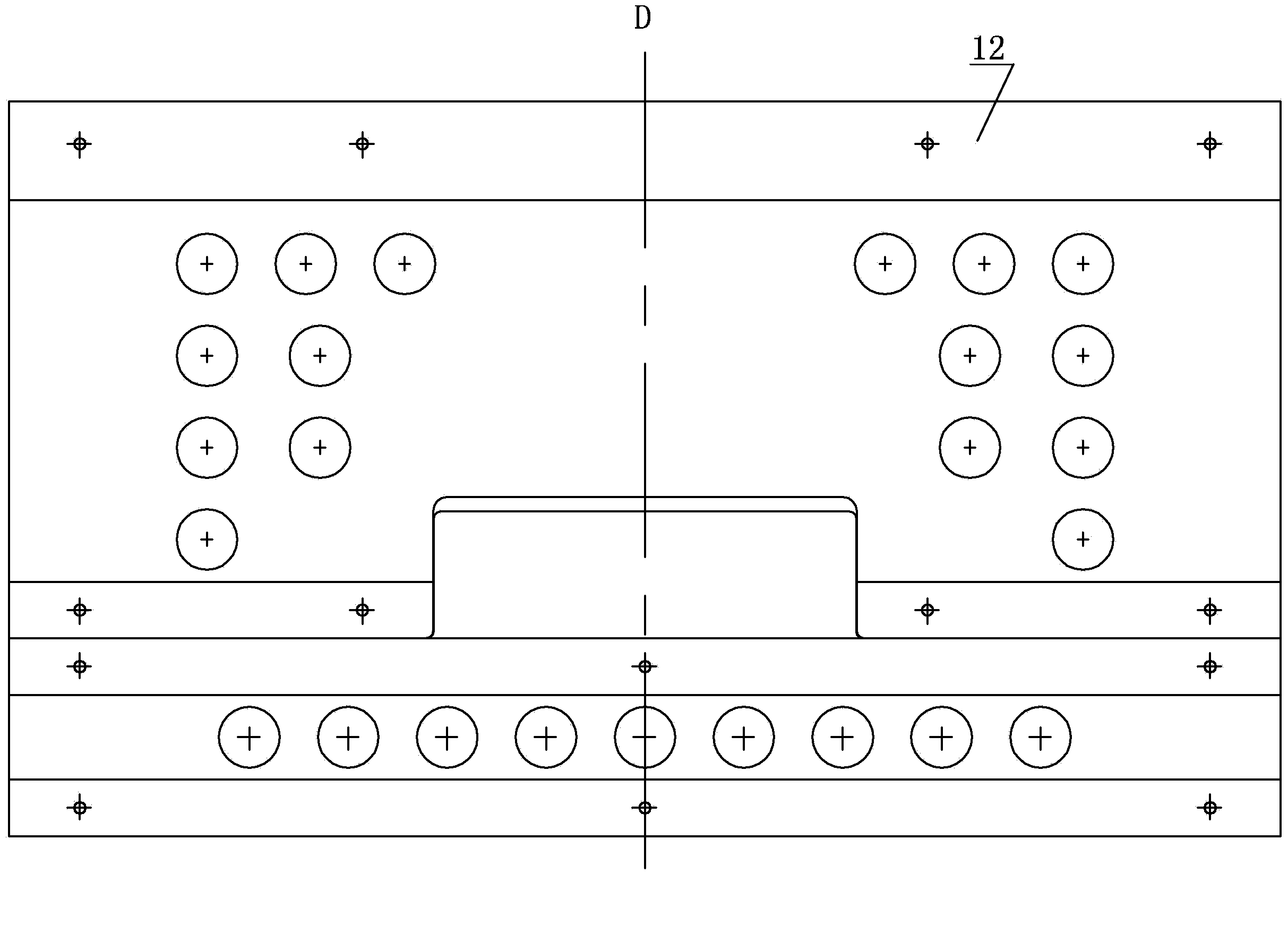

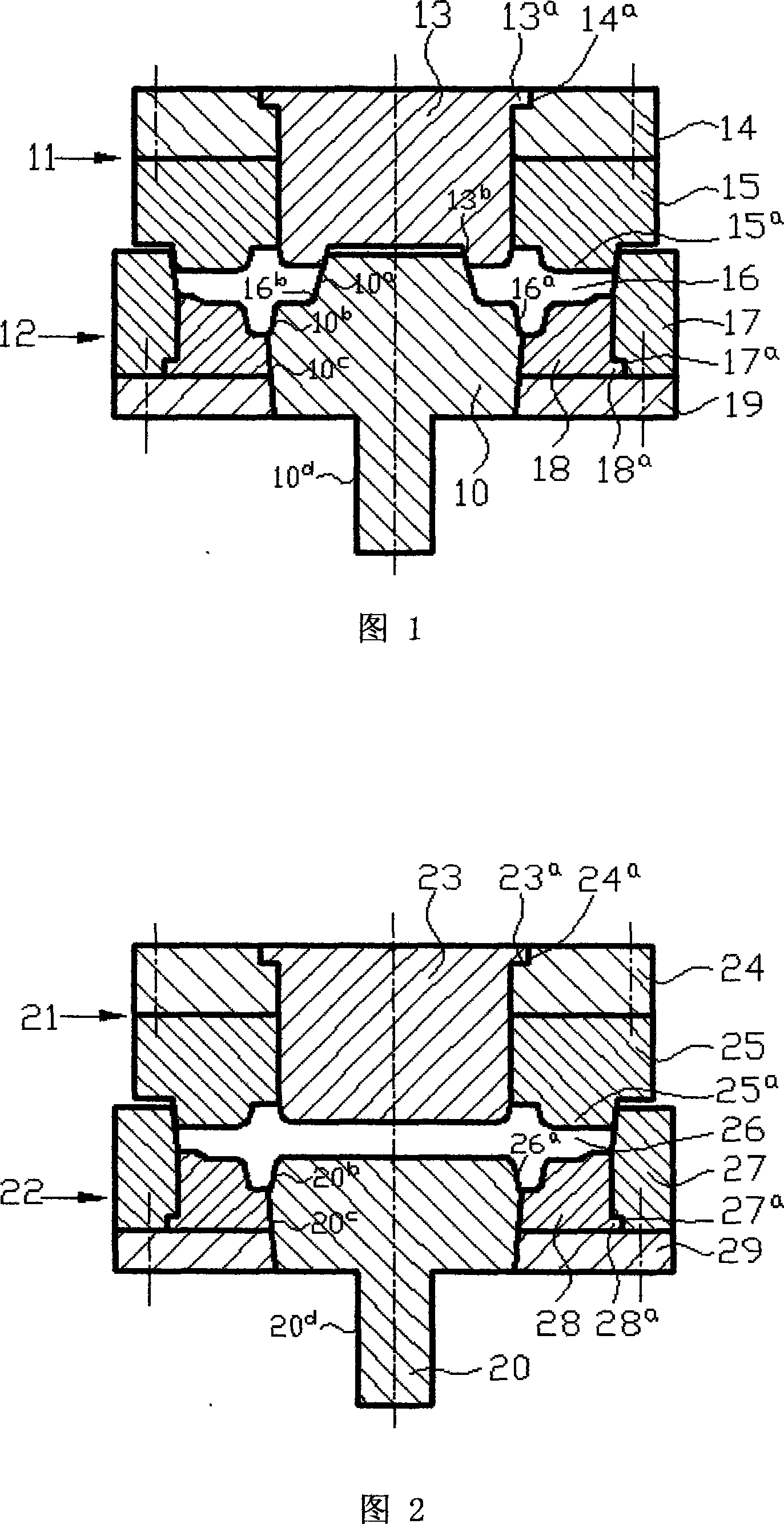

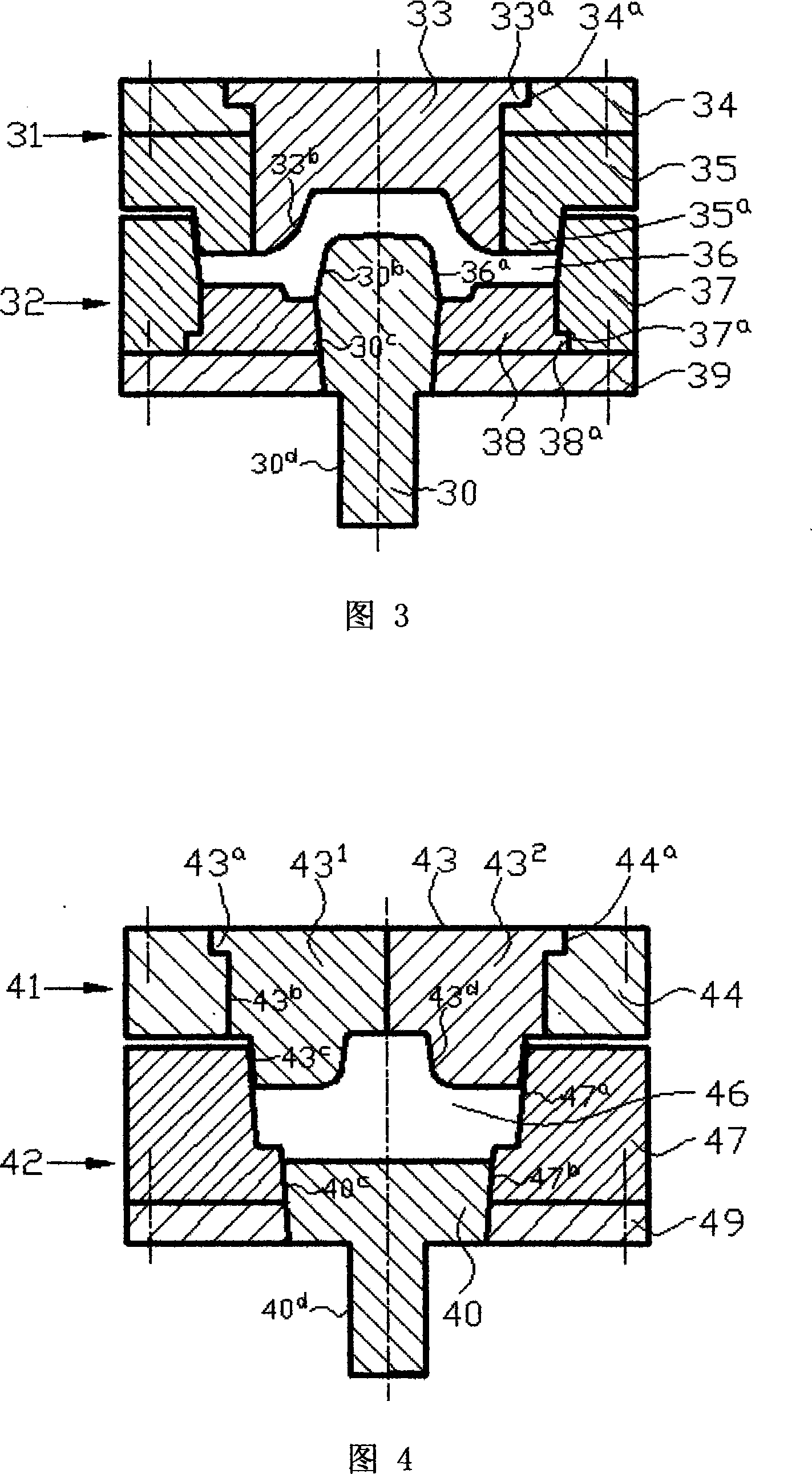

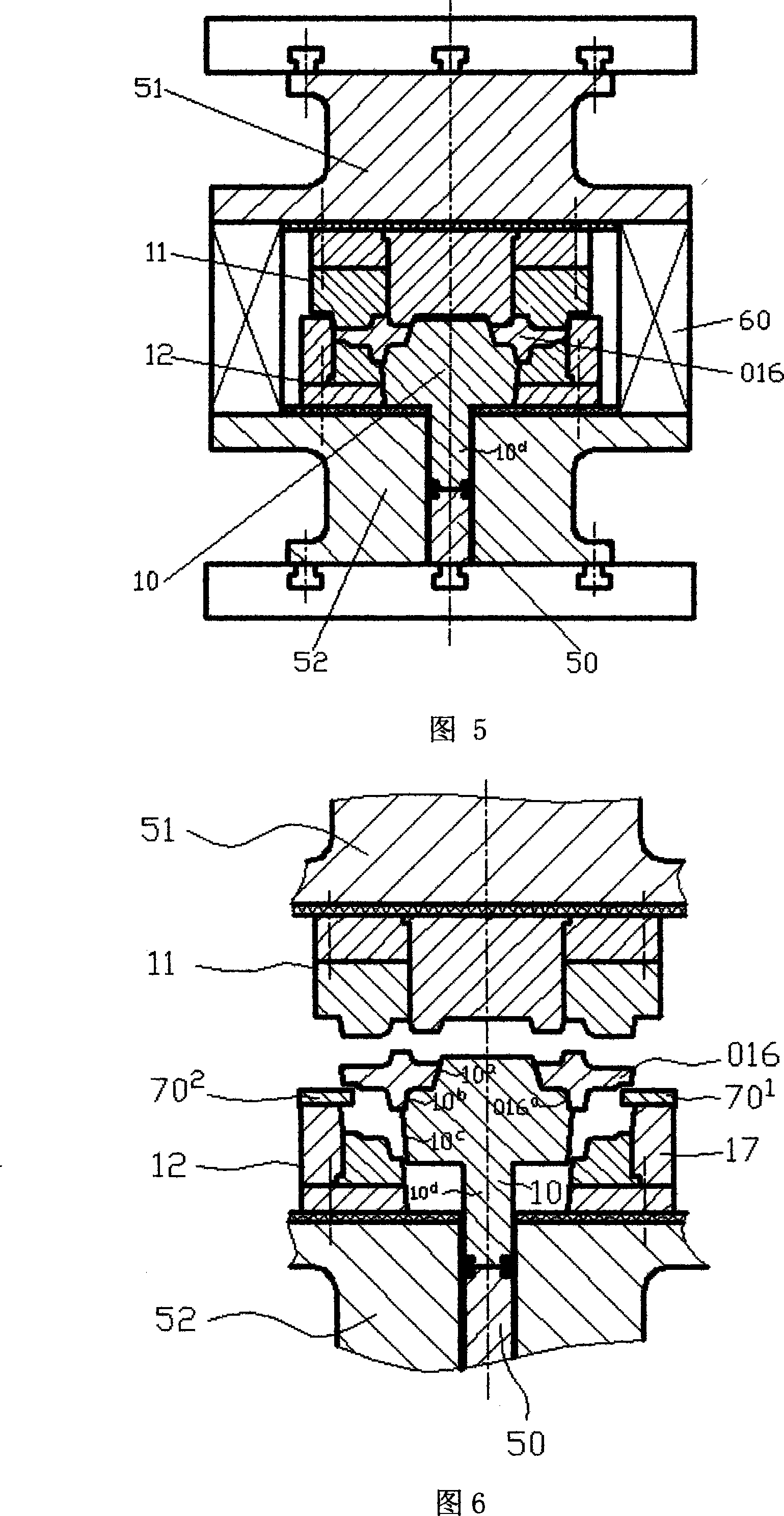

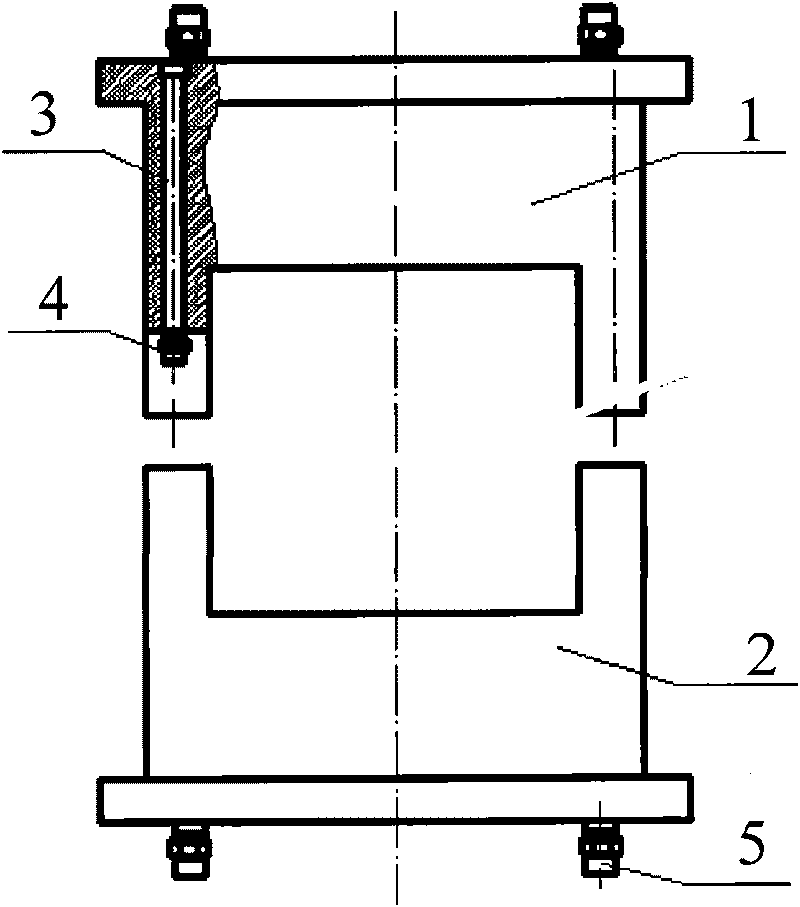

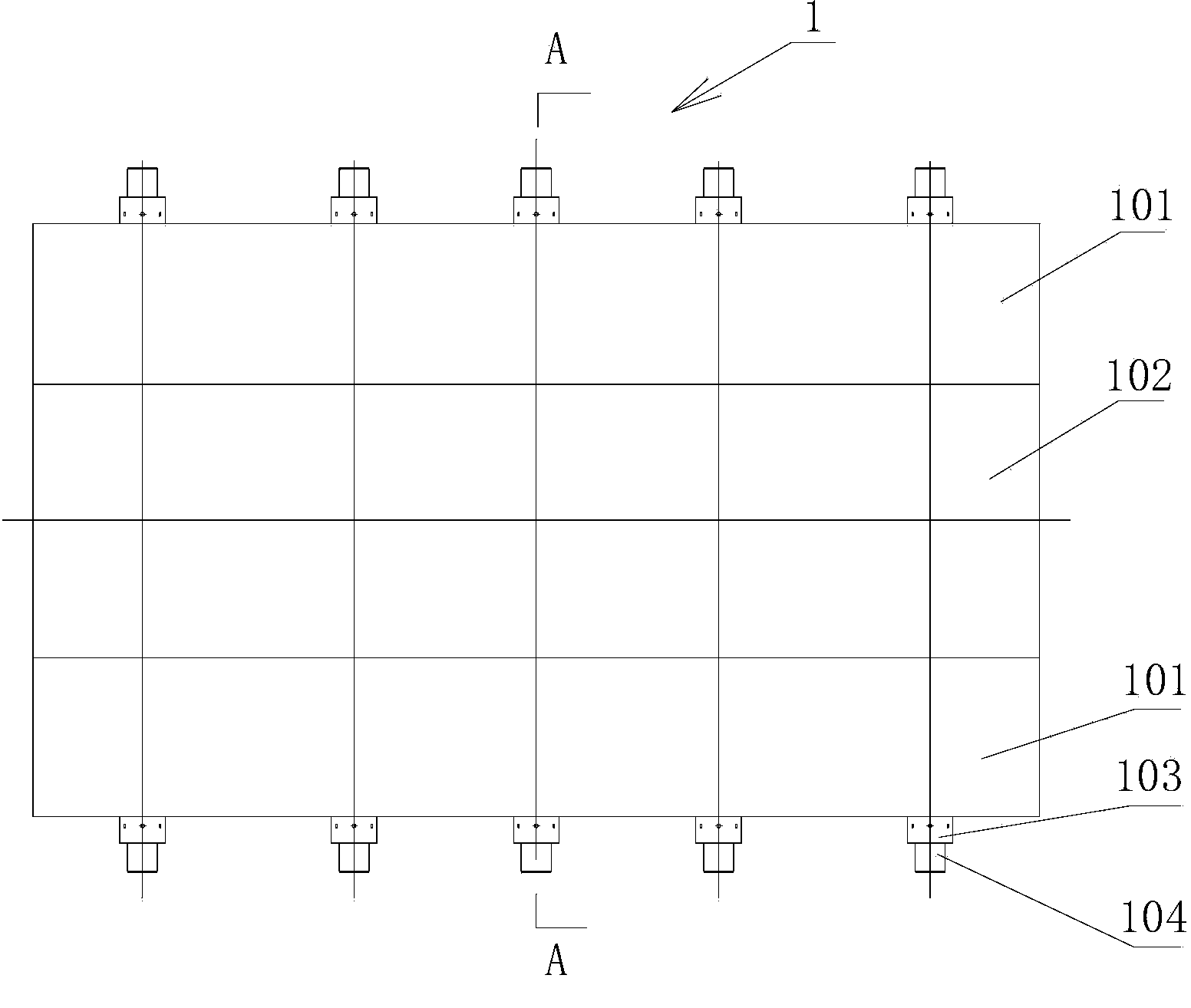

Large-scale forging dies for near-isothermally forging disc forgeable piece

ActiveCN101224484ASuit one's needsReduce manufacturing costForging/hammering/pressing machinesIsothermal forgingHigh heat

The invention discloses a large forging die of a near-isothermal forging disc-shaped forging. The forging die is provided with upper forging dies (11, 21, 31, 41) and lower forging dies (12, 22, 32, 42); the upper forging dies (11, 21, 31, 41) and the lower forging dies (12, 22, 32, 42) have closed forging cavities (16, 26, 36, 46) after being jointed together; in order to lead the forging die to be easy for manufacturing, processing, demoulding and gaining long service life, the upper forging dies (11, 21, 31, 41) and the lower forging dies (12, 22, 32, 42) are dies which consist of a plurality of modules respectively. The forging die is made of a forging high-temperature alloy K403, and mainly used for near-isothermally forging the large solid or hollow disc-shaped forgings with the external diameter more than Phi 800mm.

Owner:GUIZHOU ANDA AVIATION FORGING

Aluminum alloy complex disc part isothermal precision forging process method

InactiveCN101559471AImprove flowEvenly distributedForging/hammering/pressing machinesWheelsIsothermal forgingFine grain

The invention discloses an aluminum alloy complex disc part isothermal precision forging process method, and relates to an aluminum alloy disc part isothermal forging die. The invention solves the problems of streamline turbulence, vortex and percolation of the prior complex disc parts. The process method comprises the following main steps: determining the size of primary fine grain blank; preheating the forging die and the primary fine grain blank; primarily forging isothermal die; performing acid cleaning and mill flashing on primary disc parts; heating the forging die and the primary disc parts; secondarily forging isothermal die; performing acid cleaning, mill flashing and trimming on secondary primary disc parts; heating the forging die and the secondary primary disc parts; tertiarily forging isothermal die; and performing acid cleaning and flash trimming on complex disc parts and performing shape correction. The process method effectively improves the streamlines of forgings, avoids the generation of streamline turbulence, folding, vortex and percolation, streamlines of the formed complex disc parts are distributed along the geometric shapes of the parts, the internals are evenly distributed, and the grain size is even and fine.

Owner:HARBIN INST OF TECH

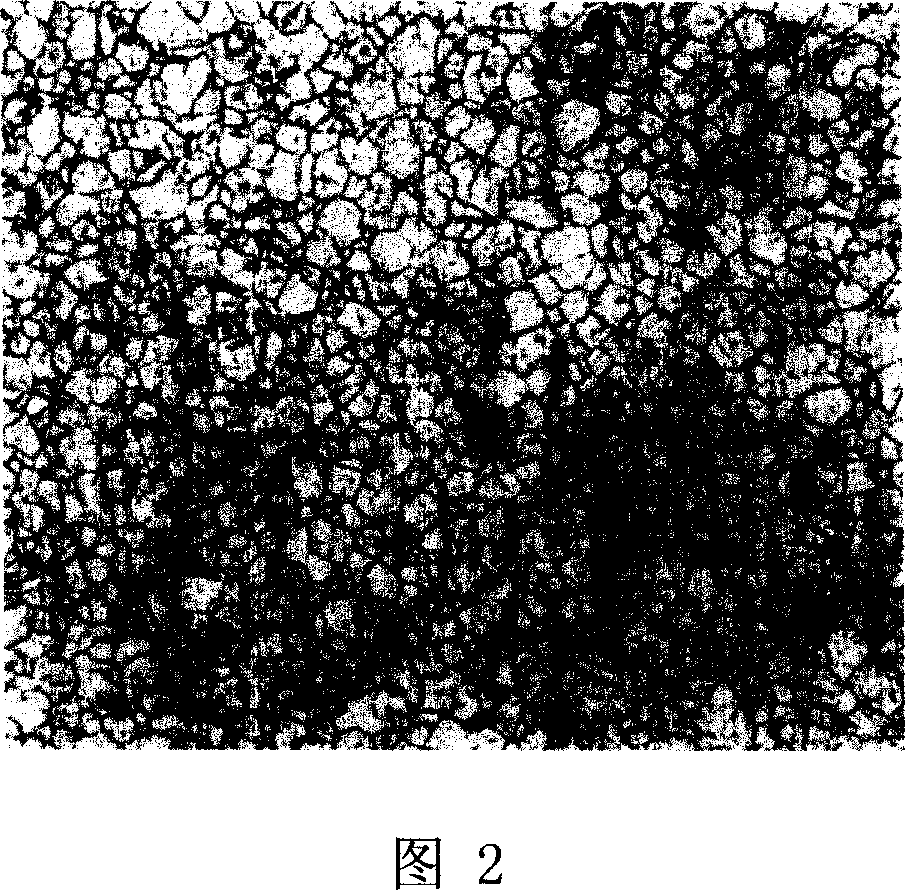

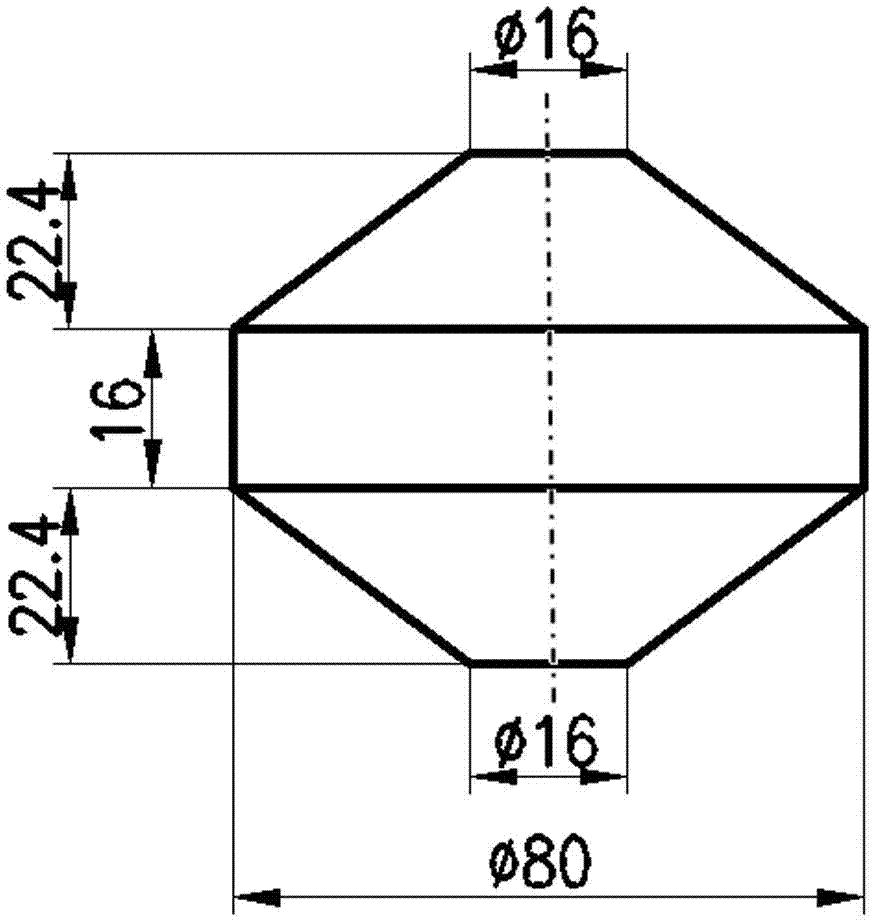

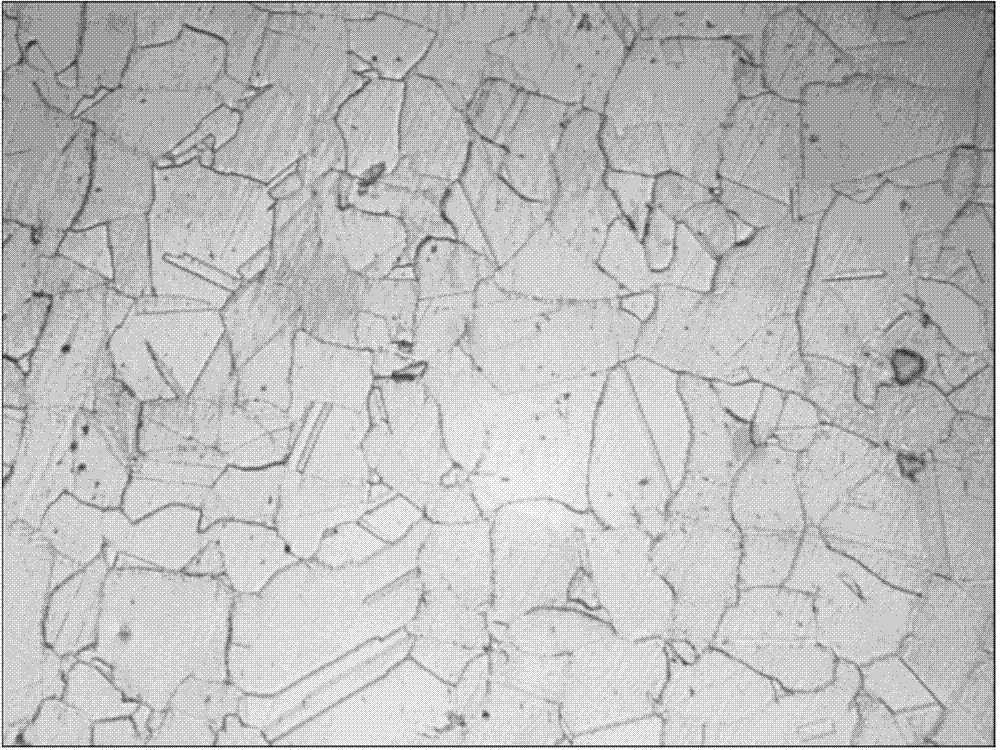

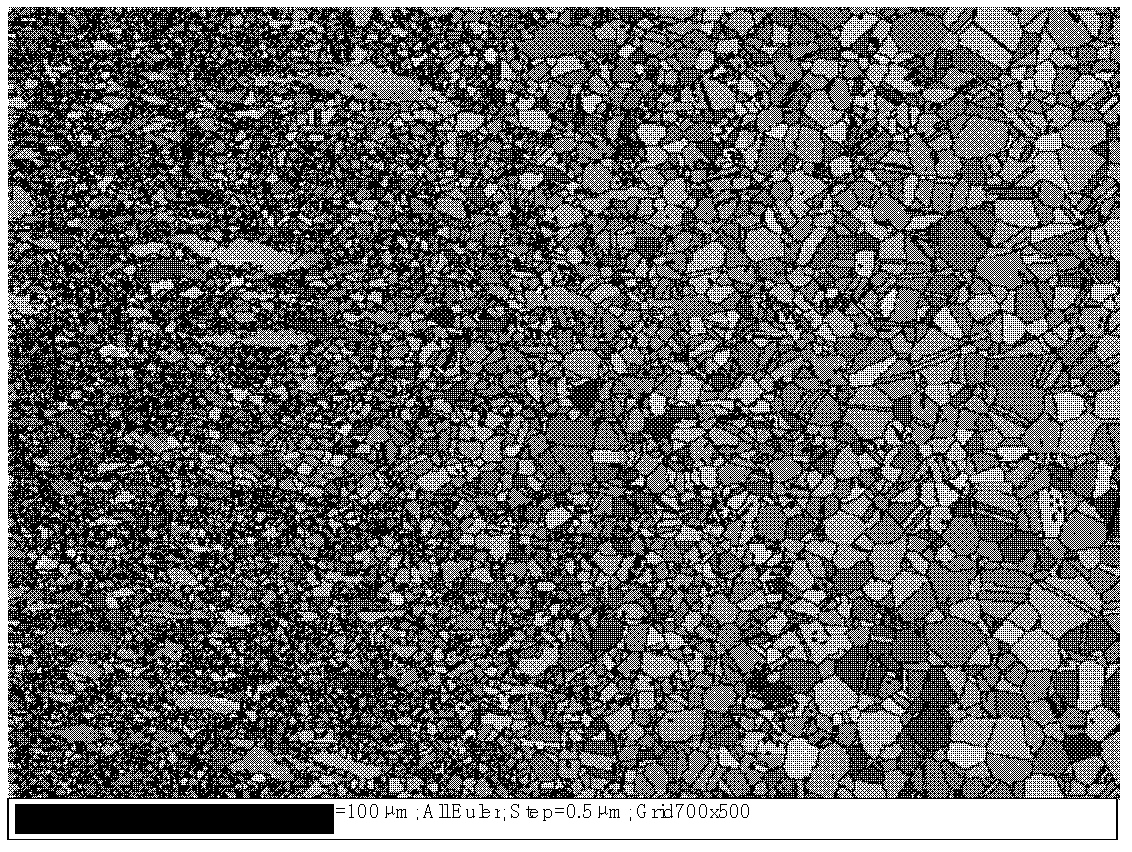

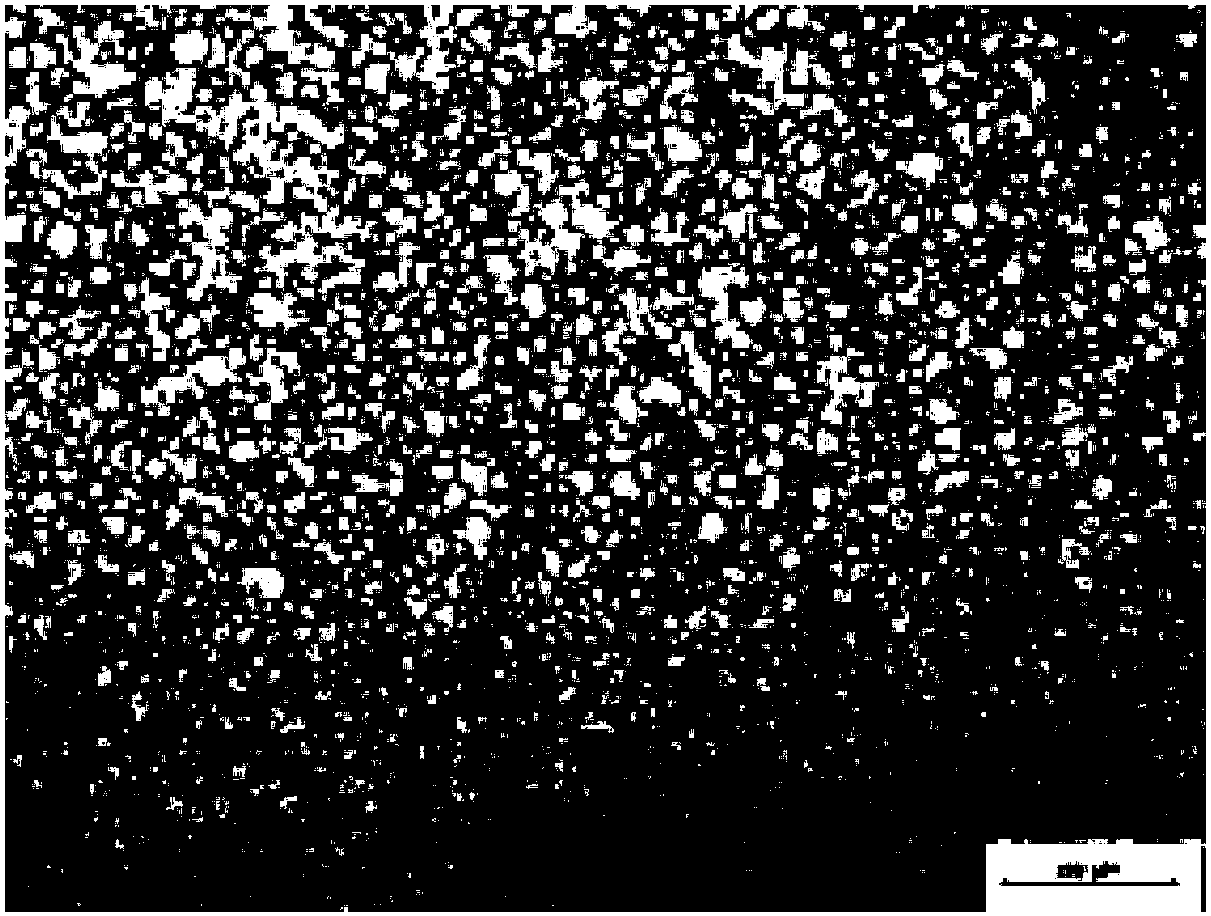

CH4169 alloy forging piece grain size analysis and predication method

The invention relates to the field of high-temperature alloy forging, and particularly relates to a CH4169 alloy forging piece grain size analysis and predication method. The CH4169 alloy forging piece grain size analysis and predication method comprises the following steps: carrying out a near isothermal forging experiment on a CH4169 alloy sub-size double-cone test sample; carrying out finite element simulation on a near isothermal forging experiment process to obtain forging thermal parameters of the test sample; determining the grain size and determining forging thermal parameter values according to a finite element calculation result; drawing a contour map of the relation of the grain size and the forging thermal parameters according to the obtained grain size and forging thermal parameters; carrying out the finite element simulation on an actual production process of a CH4169 alloy forging piece, and counting the forging thermal parameters; and determining the grain size of a part to be analyzed and predicated by utilizing the drawn contour map of the grain size and the forging thermal parameters. According to the CH4169 alloy forging piece grain size analysis and predication method, the established contour map of the relation of the grain size and the CH4169 alloy forging thermal parameters is used for analyzing and predicating the grain size in the CH4169 alloy forging piece, and the method is convenient to use and has the high predication accuracy.

Owner:重庆两航金属材料有限公司

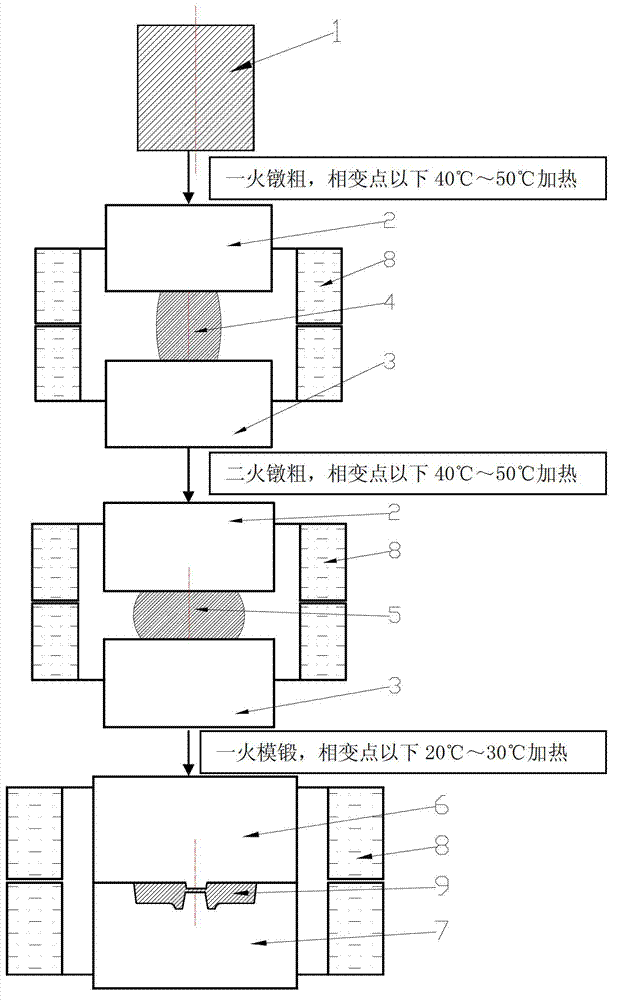

Isothermal forging method of TC17 titanium alloy disc-shaped forge piece

The invention relates to a forging method of a titanium alloy disc-shaped forge piece and particularly relates to an isothermal forging method of a TC17 titanium alloy disc-shaped forge piece. The method includes heating a titanium alloy rod ingot to the temperature which is smaller than a transformation temperature by 40 DEG C-50 DEGC, heating an upper flat die and a lower flat die to a temperature which is smaller than the transformation temperature by 40 DEG C-50 DEGC, and enabling the upper flat die to move downwards so that the rod ingot is subjected to first isothermal upsetting to form a primary biscuit at the strain rate of 0.001s<-1>-0.01s<-1> and then to second isothermal upsetting to form a secondary biscuit at the strain rate of 0.001s<-1>-0.01s<-1>, and the deformation amount is 30%-50%; heating the secondary biscuit to the temperature which is smaller than the transformation temperature by 20 DEG C-30 DEGC, heating an upper cavity die and a lower cavity die to the temperature which is smaller than the transformation temperature by 20 DEG C-30 DEGC, and forging the secondary biscuit by using a pressing machine so that the upper cavity die and the lower cavity die are molded to a forge piece under the conditions that the strain rate is 0.001s<-1>-0.01s<-1> and the deformation amount reaches 30%-50% in the cavity dies; and subjecting the forge piece to heat treatment after forging, wherein the heat treatment includes solid solution treatment and aging treatment. According to the method, the disc-shaped forge piece forged by the method is provided with ideal equiaxed structures and high performances, and the method is suitable for manufacturing forge pieces of compressor disks and turbine disks of aero-engines.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Ultrahigh-strength aluminum alloy material and preparation method of pipe blank for preparing internal cylinder of separator

The invention relates to an ultrahigh-strength aluminum alloy material and a preparation method of a pipe blank for preparing an internal cylinder of a separator, belonging to the technical field of material processing and solving the problems that the traditional aluminum alloy material has lower tensile strength and the internal cylinder of the separator, which is prepared by using the traditional aluminum alloy material, can not meet the requirements on the separator for working for a long time at high rotating speed. The invention puts a technical emphasis on that the ultrahigh-strength aluminum alloy material comprises the following components in percentage by weight: 10.5-13.0wt% of Zn, 2.3-3.2wt% of Mg, 1.2-1.8wt% of Cu, 0.2-0.3wt% of Mn, 0.2-0.3wt% of Cr, 0.1-0.2wt% of Zr, 0.1-0.2wt% of Sc, less than 0.05wt% of Fe, less than 0.05wt% of Si and the balance of Al. The preparation method of the pipe blank comprises the following steps of: melting alloys, and casting into an alloy ingot; carrying out melting, casting transfer, atomized spray and deposition forming on the alloy ingot to prepare a flash set billet; carrying out isothermal forging performing; carrying out hot extrusion forming by adopting an extrusion mould; and carrying out twin-stage solid solution and aging treatment on a preformed pipe blank so as to prepare the pipe blank which can be used for preparing the internal cylinder of the separator. The invention is suitable for preparing the internal cylinder of a centrifugal separator which works for a long time at the rotating speed of 8000-10000 rpm.

Owner:HARBIN INST OF TECH

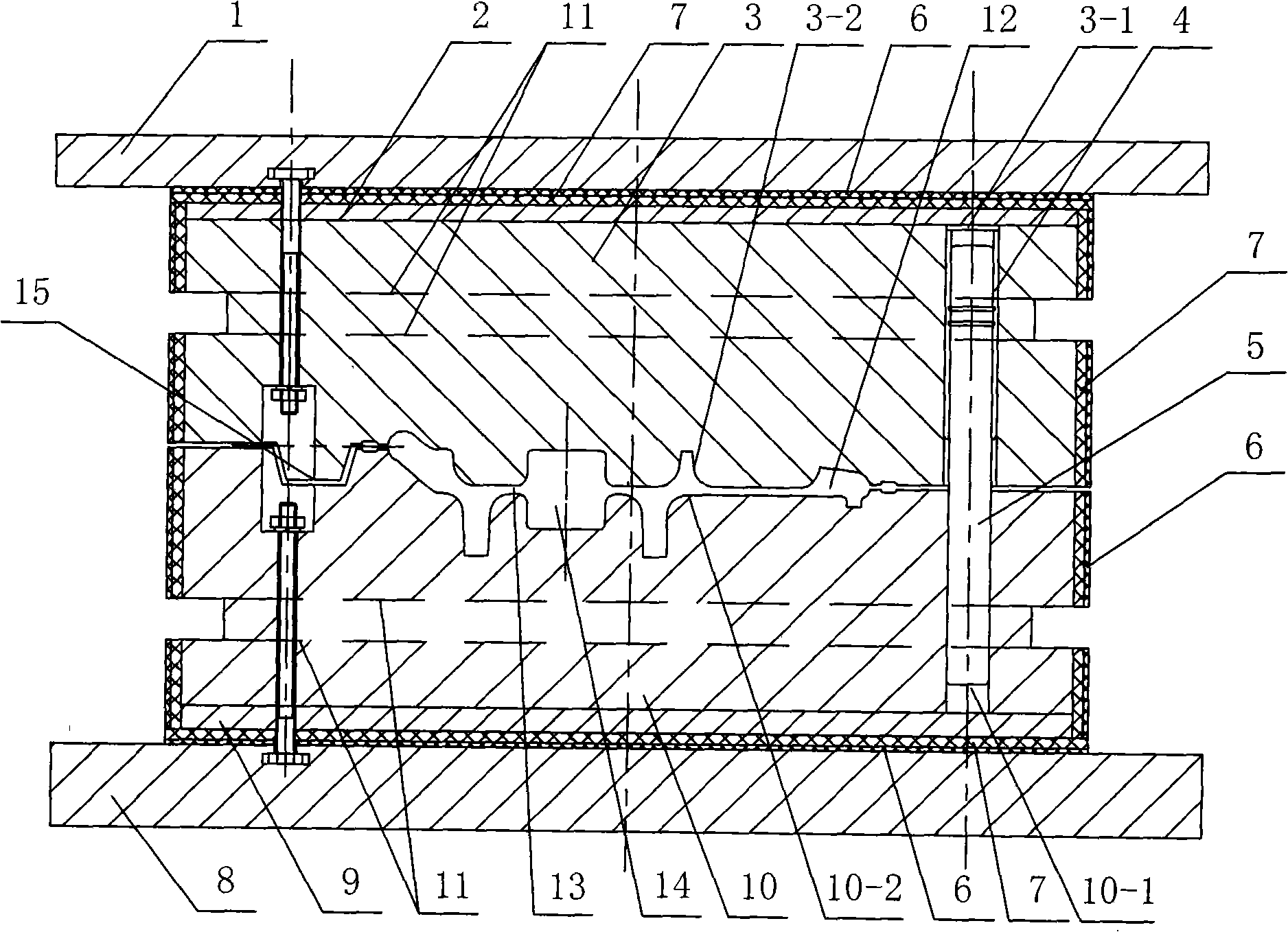

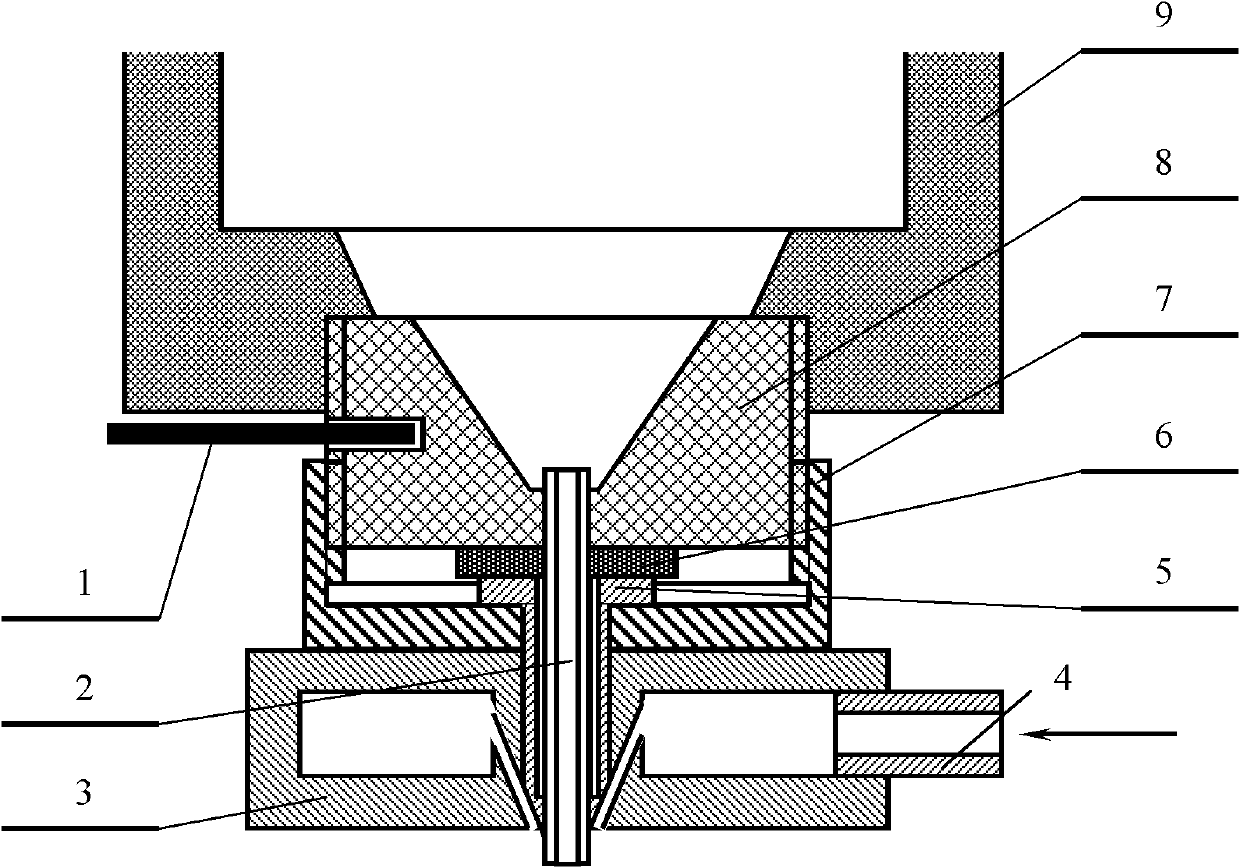

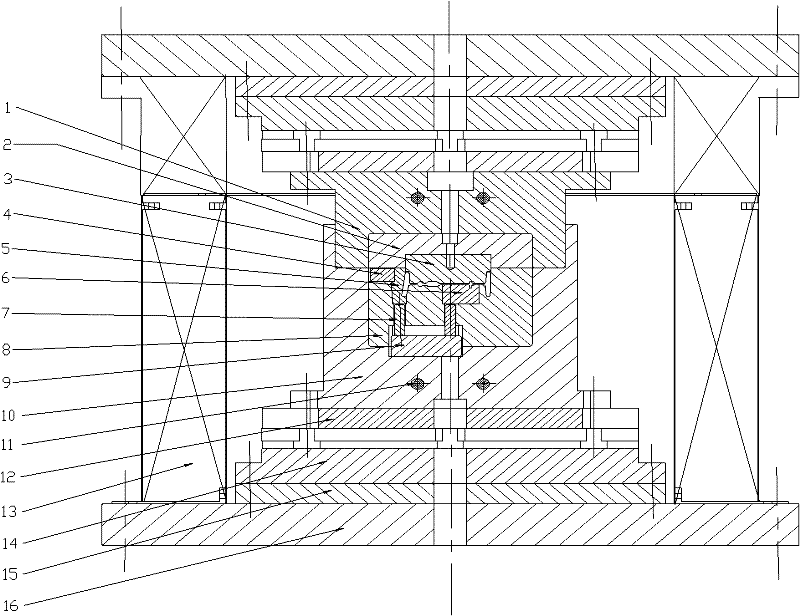

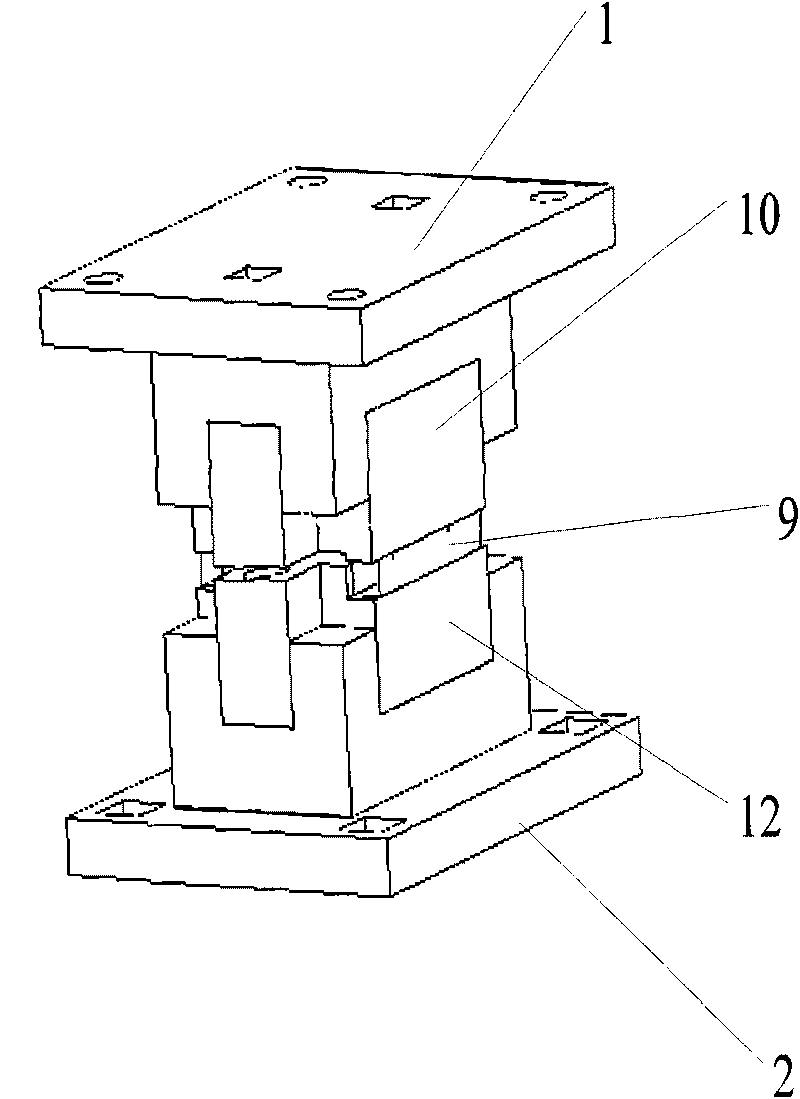

High-strength aluminum alloy isothermal direction-change open die forging method and device

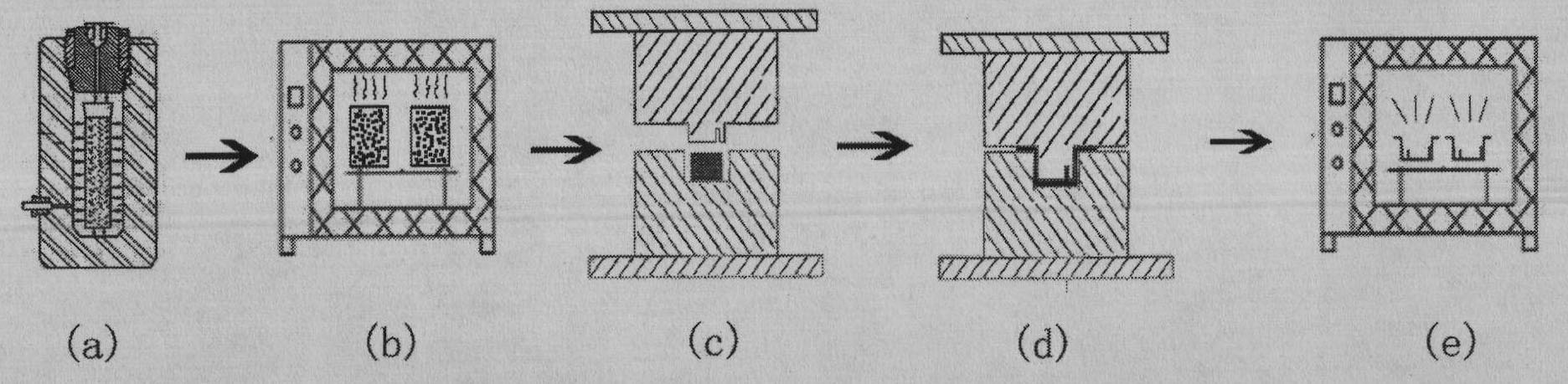

ActiveCN101941039AConstant and uniform temperatureEasy to organizeForge furnacesFurnace temperatureStructure property

The invention relates to a high-strength aluminum alloy isothermal direction-change open die forging method which comprises the following steps: heating preprocessed high-strength aluminum alloy blank in a direction-change isothermal forging heating holding furnace at the temperature of 350-450 DEG C, and keeping the furnace temperature unchanged; and according to the structure property indices required by the blank, repeatedly upsetting and drawing the blank in the direction-change isothermal forging heating holding furnace until the blank reaches the design size of the forge piece. The isothermal direction-change open die forging device comprises a heating furnace and a forging press, wherein the furnace body is installed on the forging platform of the forging press; the forging rammer of the forging press is installed in a through hole in the furnace bottom plate; and the forging head of the forging press is installed in a through hole in the furnace top plate. The invention has the advantages of simple technique, convenient operation, and low tendency to recrystallization, enables the high-strength aluminum alloy to be under isothermal conditions all through the direction-change open die forging process, does not need to heat the blank again in the forging process, improves the quality of the forge piece and enhances the forging efficiency; and the forge piece has the advantages of sufficient structure deformation, uniform deformation at each part, and low tendency of cracking. The forge piece has favorable structure properties, and is suitable for industrial production.

Owner:CENT SOUTH UNIV

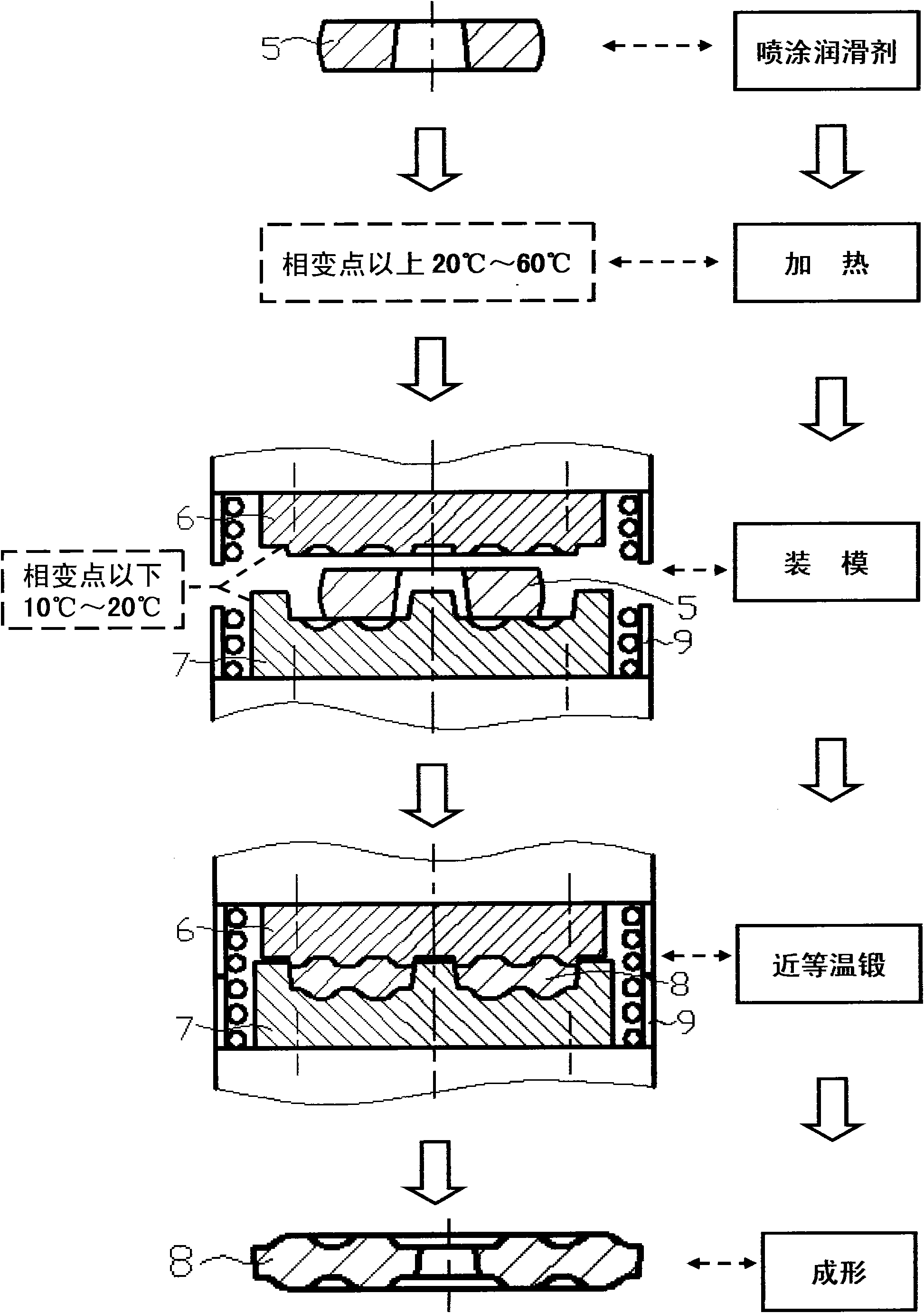

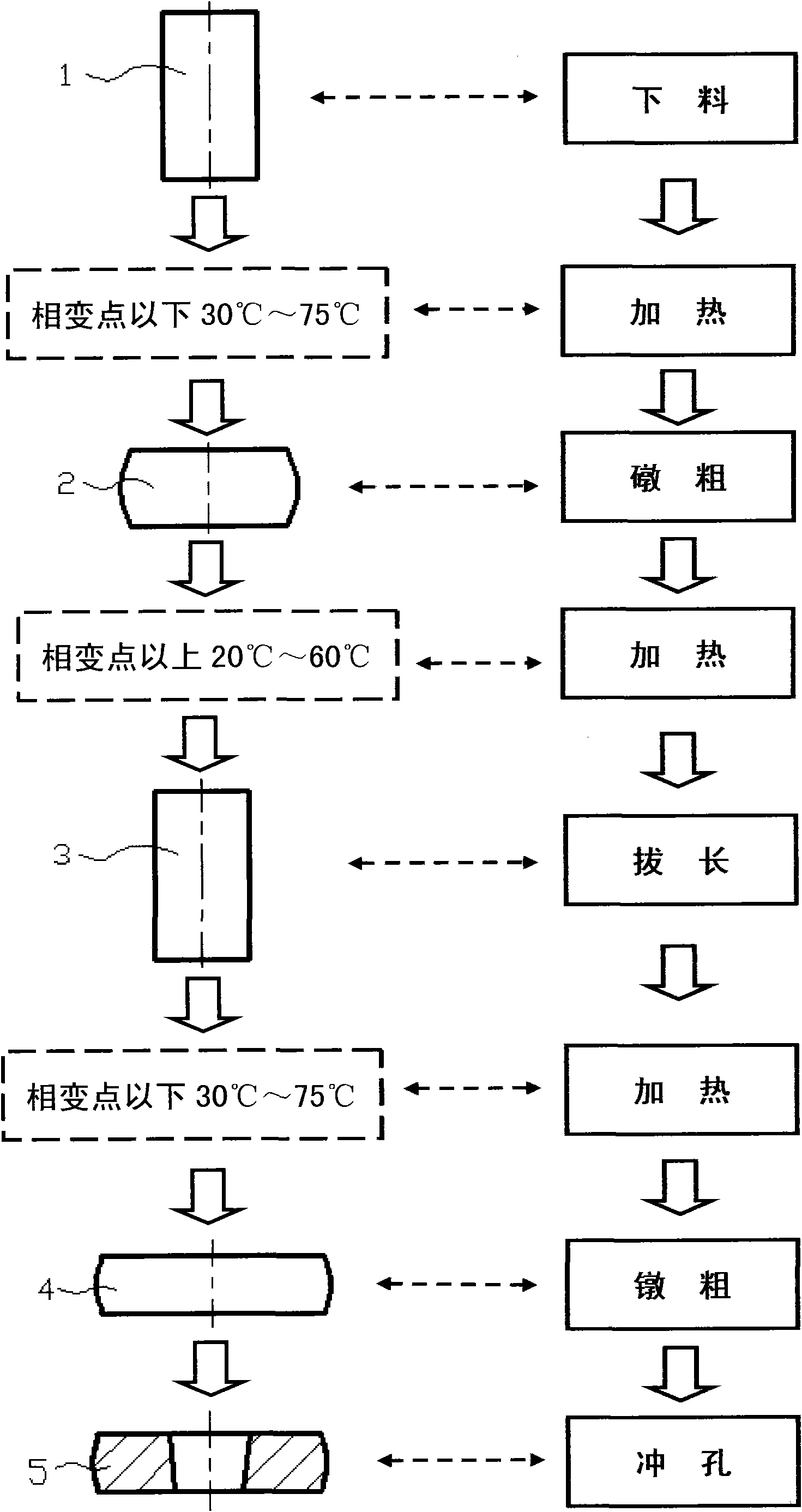

Approximate isothermal forging method of BT25 two-phase titanium alloy disk forge piece

ActiveCN101829749ASmall and uniform tissueMake up for the phase transition point errorMetal-working apparatusFurnace typesIngotTurbine

The invention discloses an approximate isothermal forging method of a BT25 two-phase titanium alloy disk forge piece. The process comprises the following steps of: heating a primary BT25 titanium alloy rod ingot to be below a phase transformation point by 30-75 DEG C and upsetting into a primary cake; heating the primary cake to be above the phase transformation point by 20-60 DEG C and drawing to return to the length of the primary rod ingot to obtain a secondary rod ingot; heating the secondary rod ingot to be below the phase transformation point by 30-75 DEG C, upsetting into a secondary cake and then punching into a ring blank; heating the ring blank to be above the phase transformation point by 20-60 DEG C, heating an upper forging die and a lower forging die to be below the phase transformation point by 10-20 DEG C, wherein the upper forging die and the lower forging die forge the ring blank by using the pressure of 30-60MN to ensure that the deformation of the ring blank in the forging dies reaches 30-50 percent by a strain rate of 0.001s<-1>-0.01s<-1> to form a disk forging piece by once heating, and heat treatment after forging adopts twice annealing treatment. The disk forging piece forged by using the method has better ideal network texture and high property, thus the method is suitable for manufacturing forging pieces such as compressor disks, turbine disks, and the like of aircraft engines.

Owner:GUIZHOU ANDA AVIATION FORGING

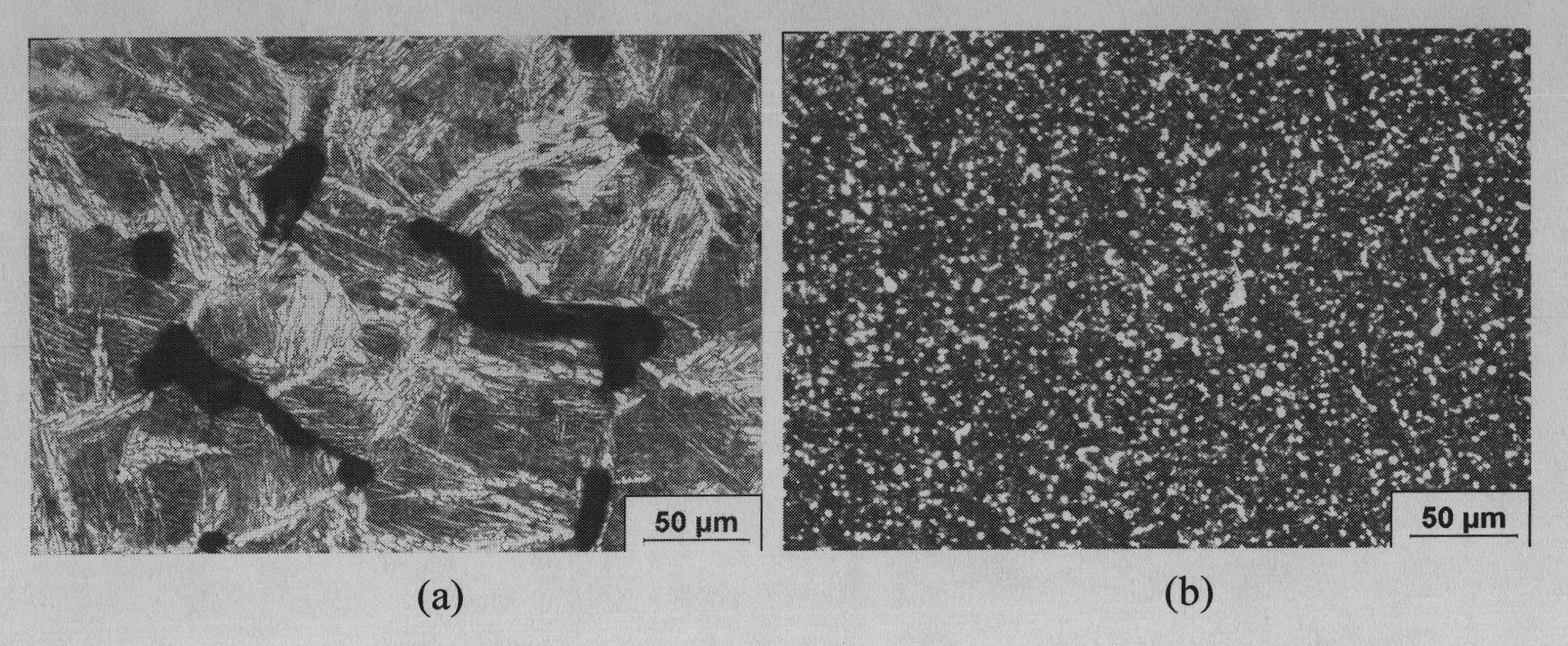

Manufacturing method for double-structure turbine disk

InactiveCN102615284ASatisfy fine grain size requirementsMeet the requirements of coarse grain sizeTechnical literatureSuperalloy

The invention discloses a manufacturing method for a double-structure turbine disk, which is used for solving the technical problems of small grain sizes and small gradients of the conventional disk edges and disk hubs. The technical scheme comprises the following steps of: preparing a powder high-temperature alloy material; encapsulating; performing heat treatment before forging; performing near isothermal forging; performing fine grain heat treatment and gradient heat treatment; and manufacturing the double-structure turbine disk. Due to the heat treatment before forging, the turbine disk has ASTM 13 level of grain sizes, and the requirement on the fine grain sizes of disk center parts is met preferentially; and the grain sizes of the disk edges are obviously increased to the ASTM 3 level of grain sizes after the gradient heat aftertreatment, and the requirement on coarse grain sizes of the disk edge parts is met. Compared with the manufacturing method of the background technical literature 1, the manufacturing method has the advantages that a fine grain heat treatment process is added, the temperature gradients during the gradient heat treatment are increased, and the grain sizes and the gradients of the disk centers and the disk edges are obviously increased.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for forging large-size integral titanium alloy frames

InactiveCN102513487AShorten the forging cycleIncrease productivityMetal-working apparatusTitanium alloyLarge size

The invention belongs to the technical field of forging, and relates to a method for forging large-size integral titanium alloy frames, which includes: the first step, designing a finish forge piece and an isothermal forging die according to materials, shapes and size of parts; the second step, designing a hammer pre-forging piece and a die drawing and keeping the size of a cavity of the pre-forging piece die and the size of a cavity of the isothermal forging die consistent; the third step, selecting pre-forging piece blank and making a finish forging die and a pre-forging die according to the first step and the second step; the fourth step, processing the blank by means of hammer pre-forging including coating protective lubricant, heating by an electric furnace, holding temperature, forging, subsequent process and the like; and the fifth step, processing the pre-forging piece by means of isothermal die-forging. The method realizes organic combination of hammer pre-forging and isothermal forging, so that the forging cycle is shortened and the heating number is reduced from 5-7 to 2 in isothermal forging.

Owner:SHAANXI HONGYUAN AVIATION FORGING

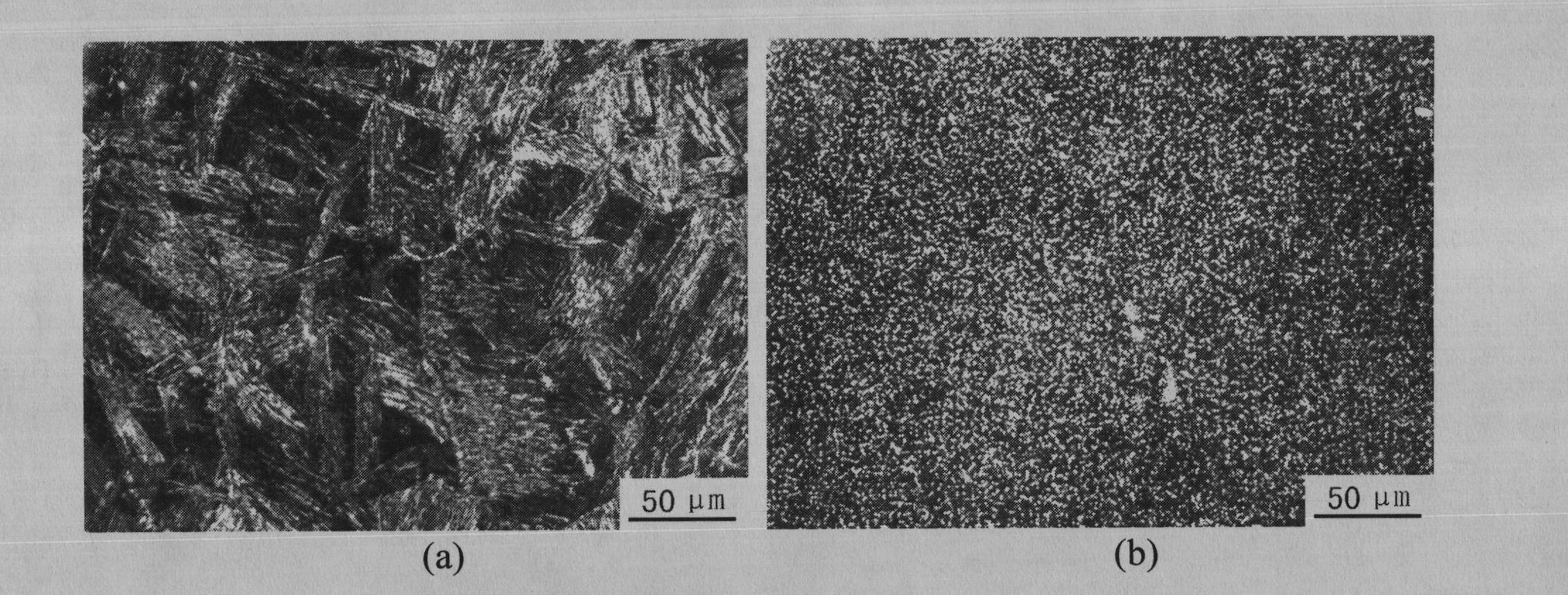

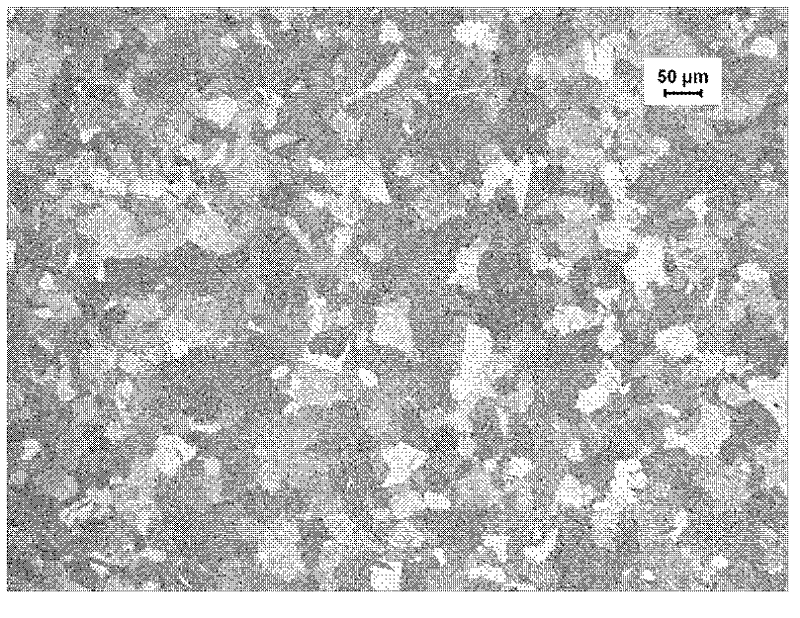

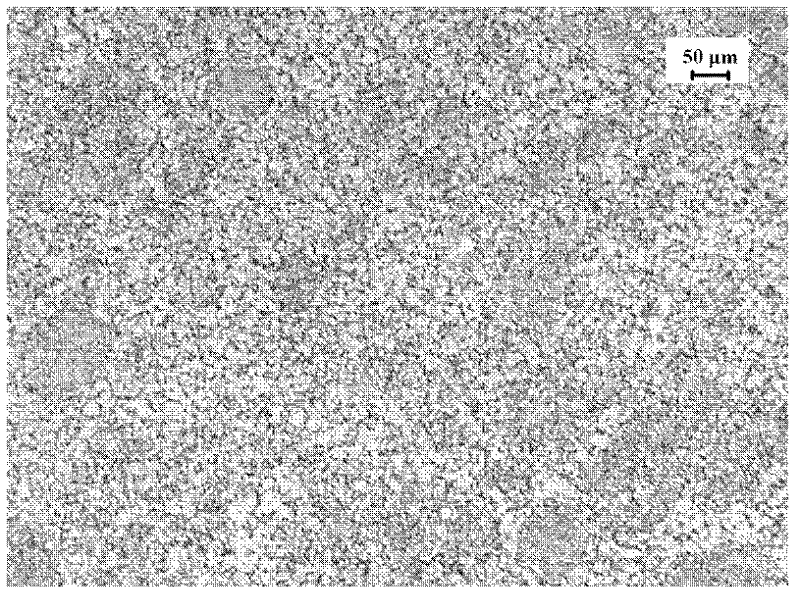

Preparation method of ultrafine grain nickel base powder high temperature alloy

A preparation method of an ultrafine grain nickel base powder high temperature alloy belongs to the technical field of high temperature alloy. Pinning effect of crystal boundary gamma' particle during thermal deformation is utilized; powder high temperature alloy ingot is heated in air to a temperature 40-80 DEG C lower than a complete dissolving temperature of a gamma' hardening constituent thereof, treated with multiple heating quasi isothermal forging to reach a ingot accumulation deflection of higher than 75% and treated with recrystallization annealing to obtain a cake blank with uniform structure and grain size of grade 10-12. The invention has the following advantages: quasi isothermal forging with gross distortion of powder high temperature alloy can be realized to obtain ultrafine grain cake blank; production organization is simple and highly operational, so as to effectively solve a problem of processing powder high temperature alloy into uniform ultrafine grain by hot working; and produced cake blank has large deflection, so as to facilitate elimination of residual dendrite and original particle boundary in an isostatic pressing state tissue; product quality is good; production efficiency is high; and cost is low.

Owner:BEIJING CISRI GAONA TECH

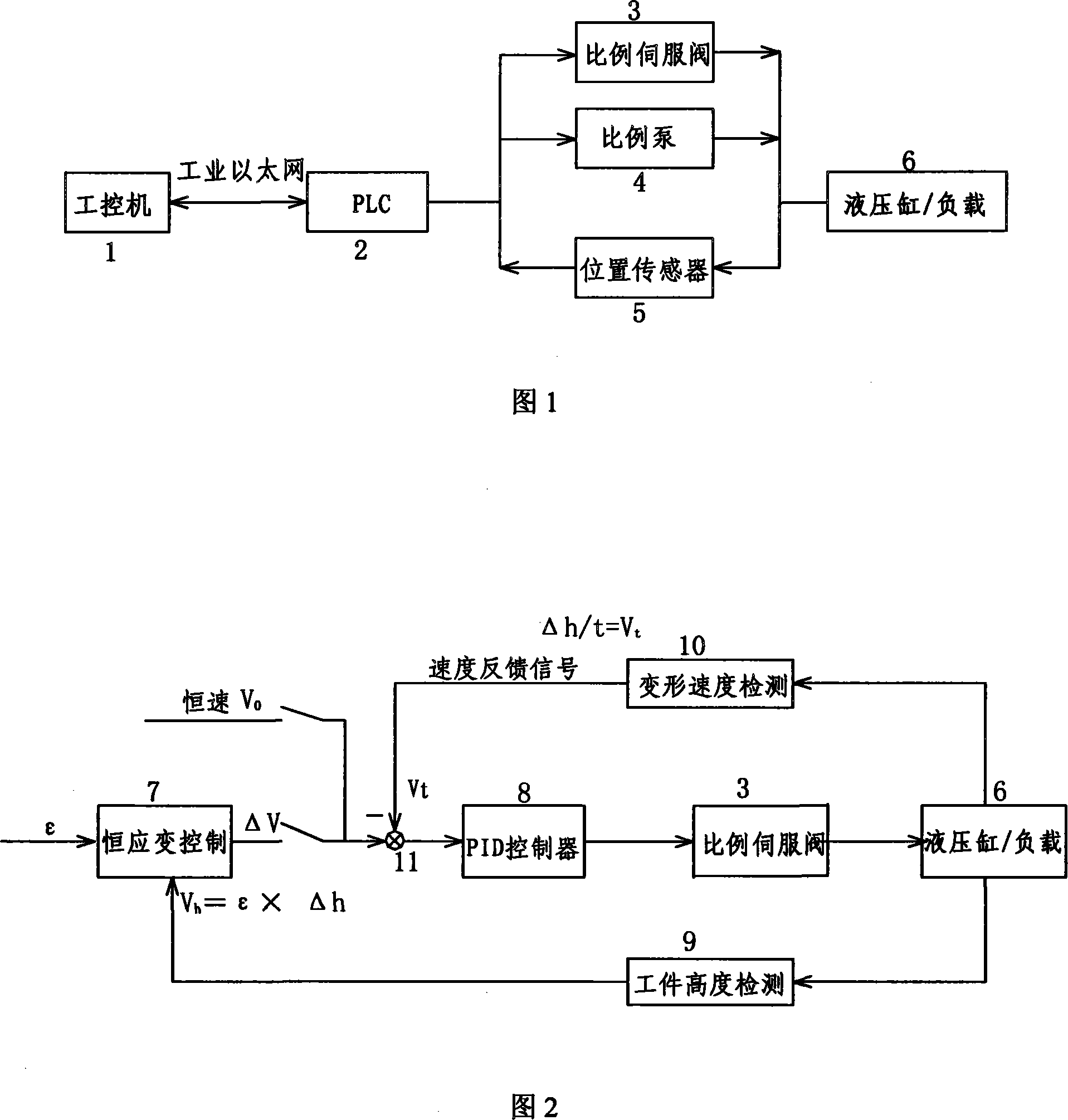

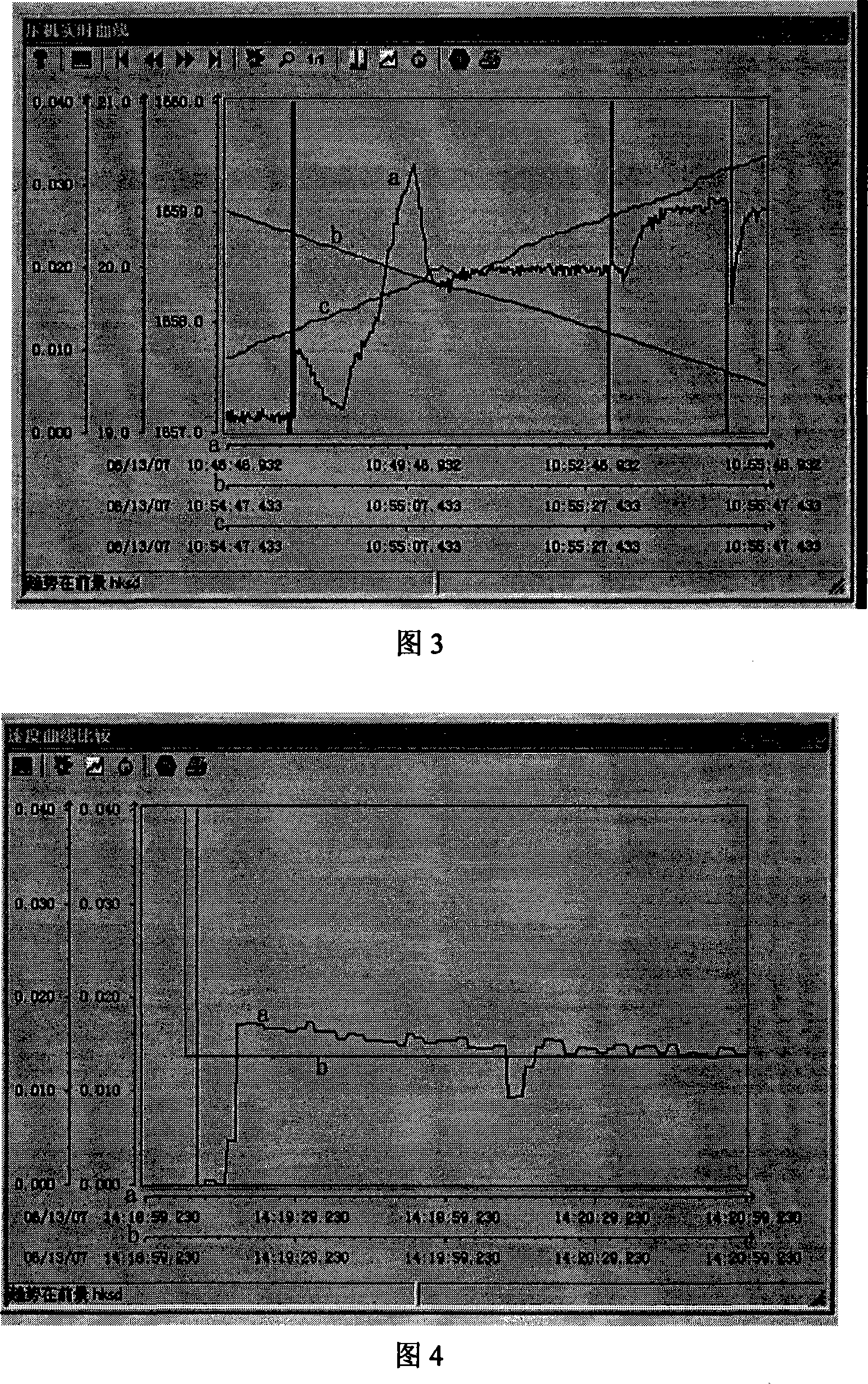

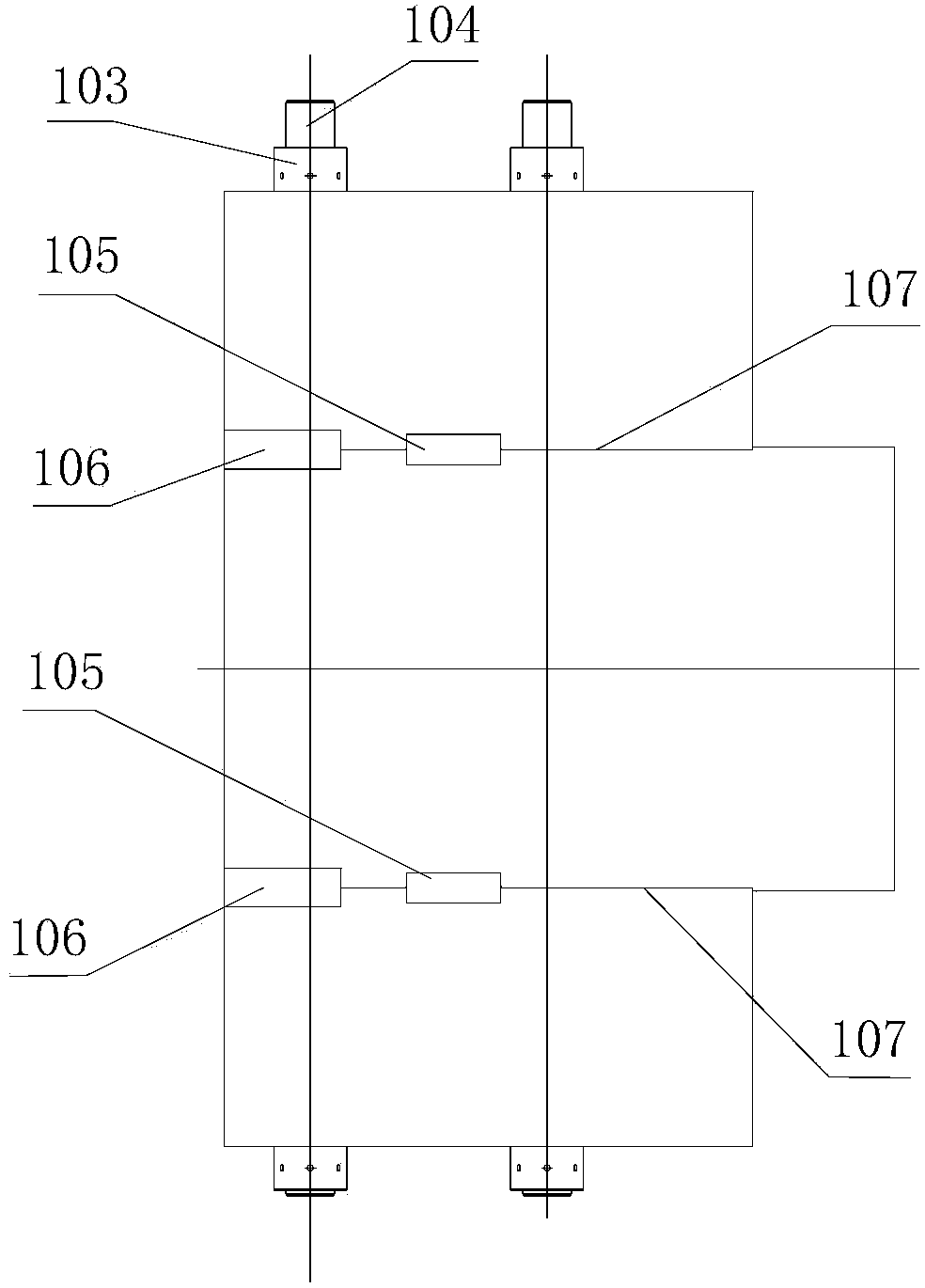

Ultramicro-speed closed loop controlling structure for hydraulic forming machine

InactiveCN101125352AWith constant strain control functionSimple control structureForging press drivesTotal factory controlHydraulic cylinderIndustrial Ethernet

The invention discloses a super dead slow speed closed loop control mechanism for a forging hydrodynamic press, which comprises an industrial computer, a principal controller PLC that controls the forging hydrodynamic press and is connected with the industrial computer through an industrial Ethernet. The principal controller PLC is connected with one end of the proportional servovalve unit and one end of the proportional pump unit that is controlled by the principal controller PLC; another end of the proportional servovalve unit and the proportional pump unit is connected with a hydraulic cylinder of the forging hydrodynamic press which is driven by the proportional sevovalve unit and the proportional pump unit. A position sensor which is connected with the principla controller PLC and feeds signals of the position of the hydraulic cylinder back to the principal controller PLC is arranged on the hydraulic cylinder. The position sensor is connected with a position input module inside the principal controller PLC. The proportional servovalve is connected with an anolog variable output module inside the principal controller PLC. The invention comes in simple control structure, stable control effect, high automation, high accuracy, high real time and high reliability, with a control effect of a super dead slow speed and constant strain, realizing freewill adjustment when the speed is between 0.002 to 12mm / s in the isothermal forging art work, and has constant strain control capability when the speed is between 0.002mm / s to 0.03mm / s, and 0.04 to 0.06mm / s.

Owner:TIANJIN TIANDUAN PRESS CO LTD

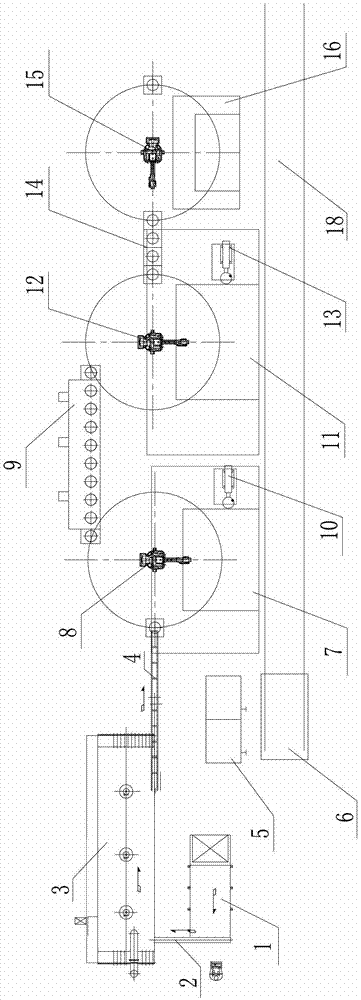

Large-scale aluminum alloy hub isothermal forging production line

ActiveCN102873253ASimplify the pressing processRealize visual operationShaping safety devicesForging/hammering/pressing machinesProduction lineHeating furnace

The invention relates to a large-scale aluminum alloy hub isothermal forging production line. The large-scale aluminum alloy hub isothermal forging production line is characterized by comprising a bar cutting machine, a bar heating furnace, a plurality of delivery manipulators, a pre-forging hydraulic press, a hub finish-forging hydraulic press, an aluminum alloy hub broaching and trimming hydraulic press and a pressing die. A cold material conveying roller table is arranged between the bar cutting machine and the bar heating furnace, a hot material conveying roller table is arranged between the other end of the bar heating furnace and the delivery manipulators, a die heating furnace, a die change trolley and a change trolley rail are arranged on one side of the pre-forging hydraulic press, a pre-forging lubrication spraying device is arranged on the other side of the pre-forging hydraulic press, a middle heating furnace or a delivery roller table is arranged between each two manipulators, and a finish-forging lubrication spraying device is arranged on one side of the hub finish-forging hydraulic press. The large-scale aluminum alloy hub isothermal forging production line has the advantages that by means of structural and technical combination of hot die forging, broaching and trimming, one-time pressing of aluminum alloy hubs can be realized, the pressing process of the aluminum alloy hubs is simplified, cost, time and labor for later-stage secondary processing and shaping can be greatly saved, and production efficiency is improved.

Owner:TIANJIN TIANDUAN PRESS CO LTD

Isothermal forging of nickel-base superalloys in air

A superalloy made of a forging nickel-base superalloy such as Rene™ 88DT or ME3 is forged in a forging press having forging dies made of a die nickel-base superalloy. The forging is accomplished by heating to a forging temperature of from about 1700° F. to about 1850° F., and forging at that forging temperature and at a nominal strain rate. The die nickel-base superalloy is selected to have a creep strength of not less than a flow stress of the forging nickel-base superalloy at the forging temperature and strain rate.

Owner:GENERAL ELECTRIC CO

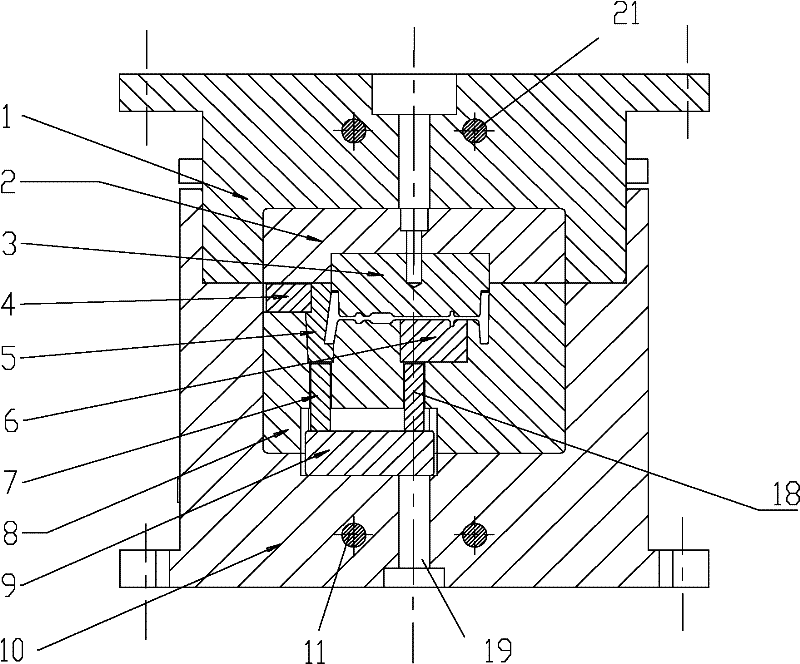

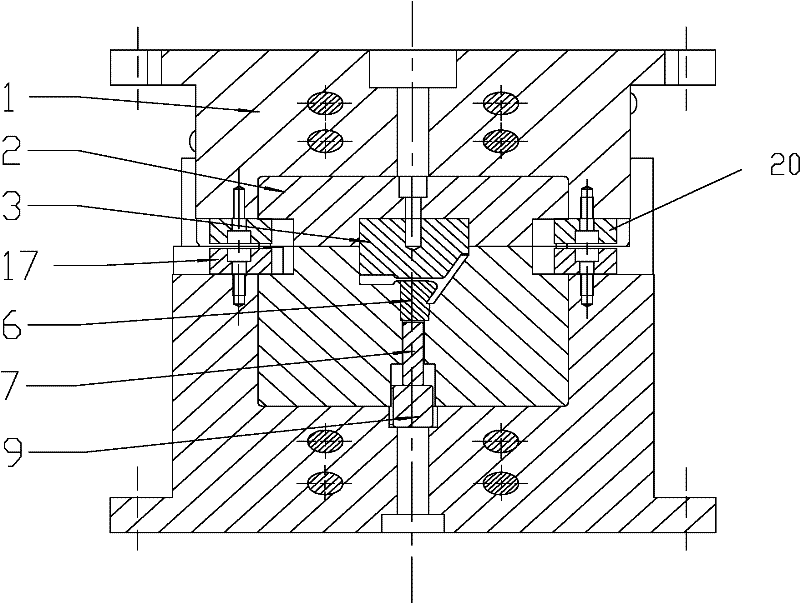

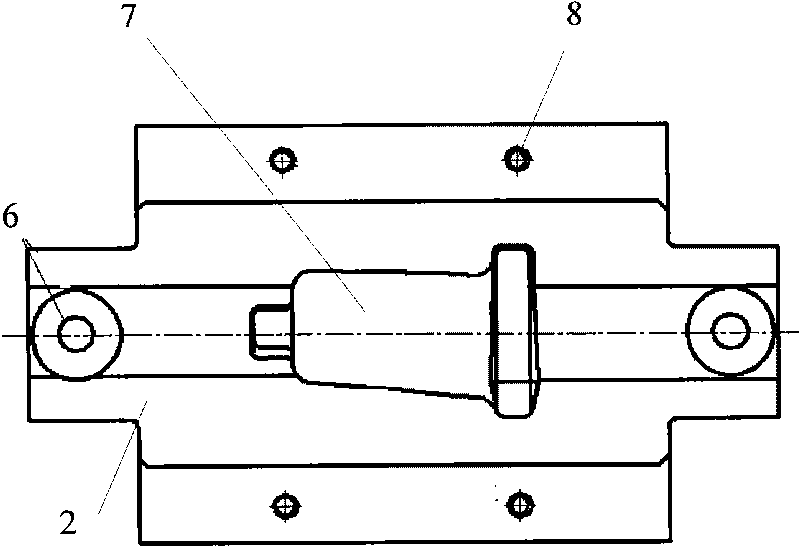

Precision isothermal forging combined die for complex aerospace die forged pieces

InactiveCN102179466AFully formedFull demouldingForging/hammering/pressing machinesEngineeringIsothermal forging

The invention discloses a precision isothermal forging combined die for complex aerospace die forged pieces, which comprises an upper die and a lower die, wherein the upper die comprises an upper die seat (1), an upper die inner sleeve (2) and an upper die insert block (3); and the lower die comprises a side surface insert block pressure plate (4), a side surface insert block (5), a bottom surface insert block (6), a first ejector rod (7), a second ejector rod (18), a lower die inner sleeve (8), an ejector rod tray (9) and a lower die seat (10). The upper die insert block (3) constitutes the die surface of the upper die; and the side surface insert block (5), the bottom surface insert block (6) and the lower die inner sleeve (8) constitute the die surface of the lower die together. The invention provides the combined die, which can realize complete filling, smooth streamline, no folding, easiness in die release and strong universality for aerospace type complex members, such as aerospace joint type parts.

Owner:CENT SOUTH UNIV

Isothermal forging method for titanium alloy blade

InactiveCN101733348ALower deformation temperatureImprove surface qualityForging/hammering/pressing machinesTitanium alloyMechanical property

The invention discloses an isothermal forging method for titanium alloy blade, which is implemented by the following steps: (1) coating lubricant on the surface of pre-forged titanium alloy blade blank; pre-heating with an electrothermal furnace to the deformation temperature of the blade blank; (2) fixing a lower die holder in an isothermal molding heater, and respectively fixing the upper die and the lower die on the upper die holder and lower die holder; (3) fixing the isothermal molding heater on a hydraulic press, heating to 900-930 DEG C and maintaining the temperature for at least 3h; (4) taking the blade blank out of the electrothermal furnace, putting into the upper die and the lower die in the isothermal molding heater, forging by the hydraulic press, and controlling the hydraulic press to perform return stroke operation when the dimension of the blade blank satisfies the requirement. The titanium alloy blade blank obtained by the inventive method has a preciseness satisfying technical requirement and obviously improved mechanical property.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Calcium-containing rare earth magnesium alloy plate with high room temperature forming property and preparation method

ActiveCN108300918AImprove mechanical propertiesImprove performanceRollsMetal rolling arrangementsRare earthMechanical property

The invention discloses a calcium-containing rare earth magnesium alloy plate with a high room temperature forming property and a preparation method of the calcium-containing rare earth magnesium alloy plate. The calcium-containing rare earth magnesium alloy plate with the high room temperature forming property comprises the following specific chemical components: 1-3 wt% of Zn, 1-3 wt% of Al, 0.1-0.4 wt% of Ca, 0.1-0.4 wt% of Gd, 0.1-0.4 wt% of Y, 0-0.2 wt% of Mn and the balance of Mg. The preparation method comprises the following steps: carrying out casting (semi-continuous water-cooling orsolid die casting) and solution treatment (insulating for 12-24 hours at the temperature of 300-450 DEG C and then air-cooling to the room temperature) on magnesium alloy in the component range; thenpreparing a plate with a certain thickness by processes including common rolling or extruding and then rolling or isothermal forging and then rolling and the like; and finally annealing for 30-60 minutes at the temperature of 300-350 DEG C. The magnesium alloy plate prepared by the preparation method has high room temperature forming property, and good comprehensive mechanical property, heat resistance and corrosion resistance.

Owner:UNIV OF SCI & TECH BEIJING +1

Heavy-duty isothermal forging hydraulic press

ActiveCN103447434AReduce manufacturing costHigh leveling accuracyForging/hammering/pressing machinesForging press detailsAviationLeveling effect

The invention relates to a heavy-duty isothermal forging hydraulic press, which comprises an upper transverse beam, a lower transverse beam, upright posts, a main cylinder, side cylinders and a slide block, wherein an upper baseplate is fixed on the lower plane of the slide block; and a movable workbench is arranged on the lower transverse beam. The heavy-duty isothermal forging hydraulic press is characterized in that the upper transverse beam and the lower transverse beam form a combined beam body structure; leveling cylinders are fixed on the four corners of the upper end of the upper transverse beam and the upper end of the lower transverse beam; each leveling cylinder is provided with an independent leveling control system; an upper knock-out device is arranged on the slide block; movable workbench positioning mechanisms are arranged on the lower part of the movable workbench body and in the lower transverse beam; and the movable workbench body is further provided with a movable workbench clamping device. The heavy-duty isothermal forging hydraulic press is characterized in that a combined transverse beam is light in weight and is convenient to transport and produce, and the manufacturing cost can be reduced; a leveling effect is achieved via the leveling cylinders, the leveling response time is shortened, and energy is saved greatly; through the upper knock-out device, successful demolding of workpieces can be realized, and the workpiece forging and pressing quality is ensured; and accurate positioning and stable running of a press workbench can be realized, and the production requirement of forging equipment for heavy-duty aviation forgings is met.

Owner:TIANJIN TIANDUAN PRESS CO LTD

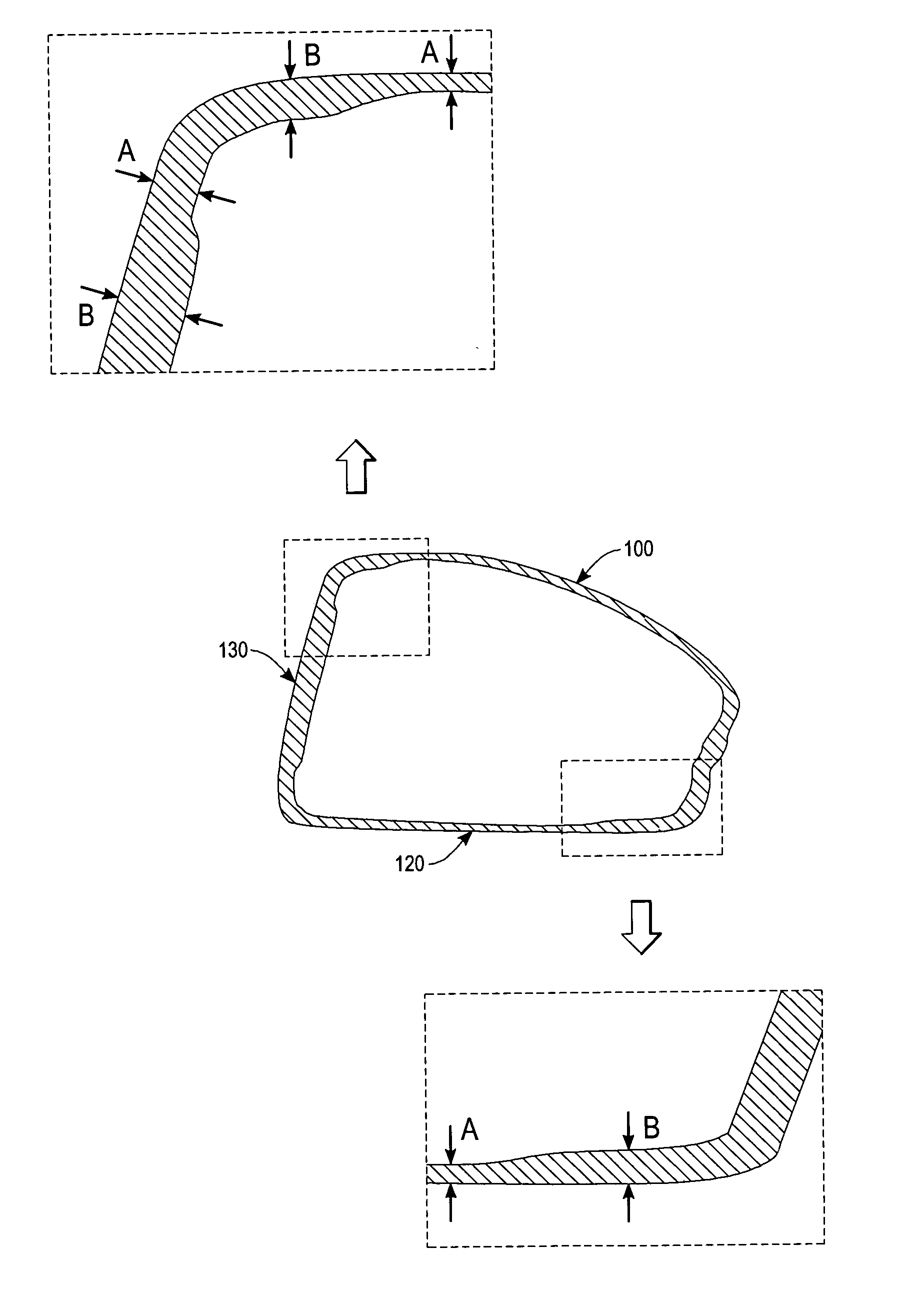

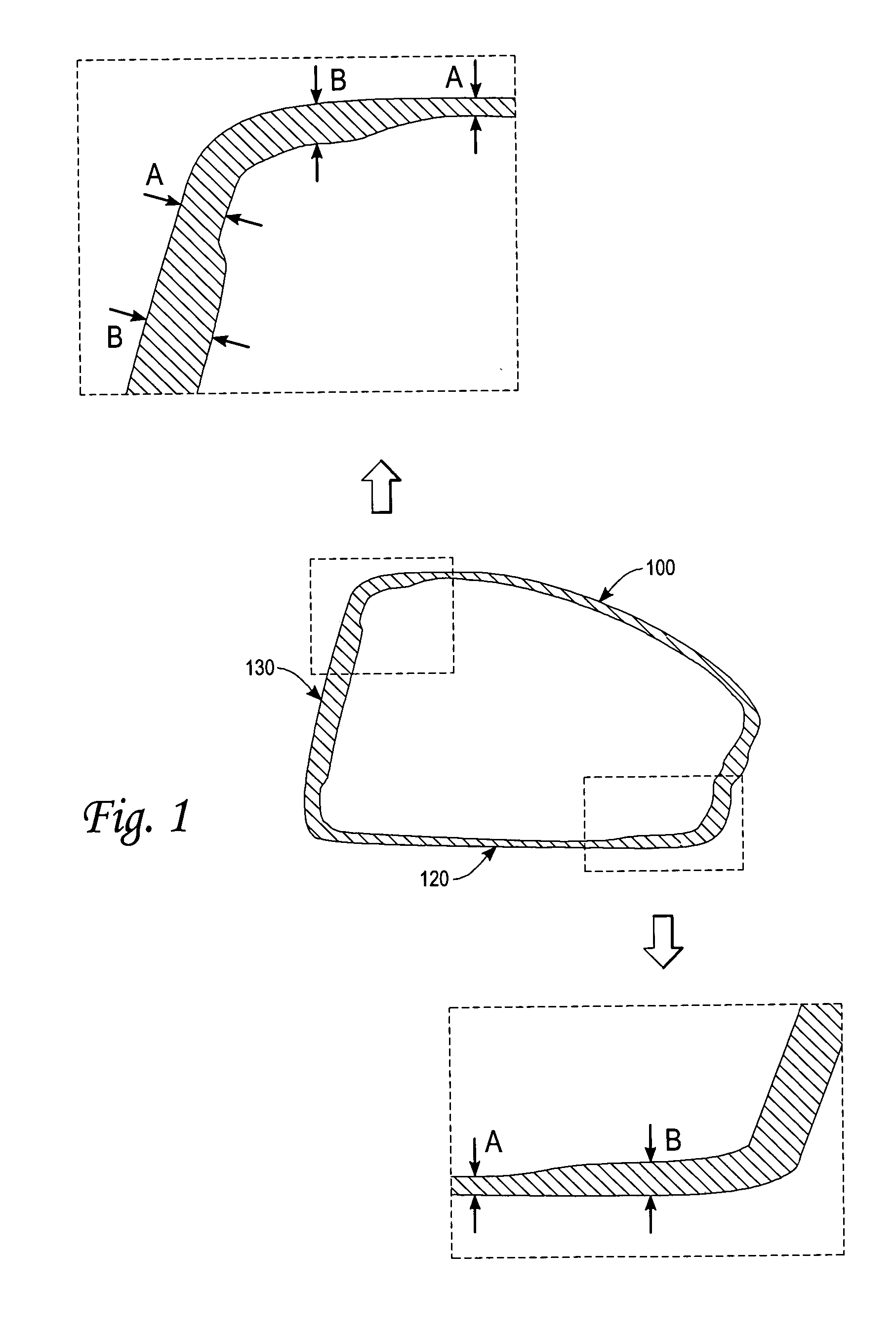

Method of making a golf club head

InactiveUS20050023329A1Good lookingFunction increaseHigh frequency current welding apparatusWelding/cutting media/materialsCelsius DegreeTitanium

A method of making a titanium golf club head includes steps. One adopts Ti-4-6 Titanium alloy as SPDF material under isothermal forging conditions, sets the SPDF temperature at between 870-970 degrees Celsius, while heating the molds and workpieces simultaneously in a high frequency stove. One also moves the molds and workpieces from the stove to the forging machine, adjusting the forging machine reacting speed rate within the range of 10−2 / s to 10−4 / s.

Owner:SONG YUAN LIN

Isothermal forging method of TiAl alloy

InactiveCN102312181AUniform tissue sizeOvercome defects such as high hardness, high brittleness, and difficult processingMetal-working apparatusIngot castingSurface oxidation

The invention discloses an isothermal forging method of TiAl alloy. The method comprises steps that: scale and crack defects visible to naked eye on a surface of a melted alloy ingot casting are lathed and a supersonic wave flaw detection is conducted; a holding furnace with a heater is arranged on a press, and a die temperature is controlled at 850-900 DEG C, especially during a forging process;defect-free TiAl alloy is coated with a high temperature oxidation resistant coating on the surface thereof, and dried naturally; the surface treated TiAl alloy is heated in the holding furnace and insulated at 1150-1250 DEG C for 2-2.5 h; the heated TiAl alloy is treated with the isothermal forging along a material height direction, with an initial deflection controlled within 5%, compacted for 2 times, heated in the holding furnace again, and insulated at 1150-1250 DEG C for 0.5-1h; and the above forging process is repeated until the TiAl alloy plate with a preset thickness is obtained. Thetechnology of the invention is simple, at low costs, and capable of preparing a high quality and defect-free TiAl alloy target material.

Owner:浙江嘉钛金属科技有限公司

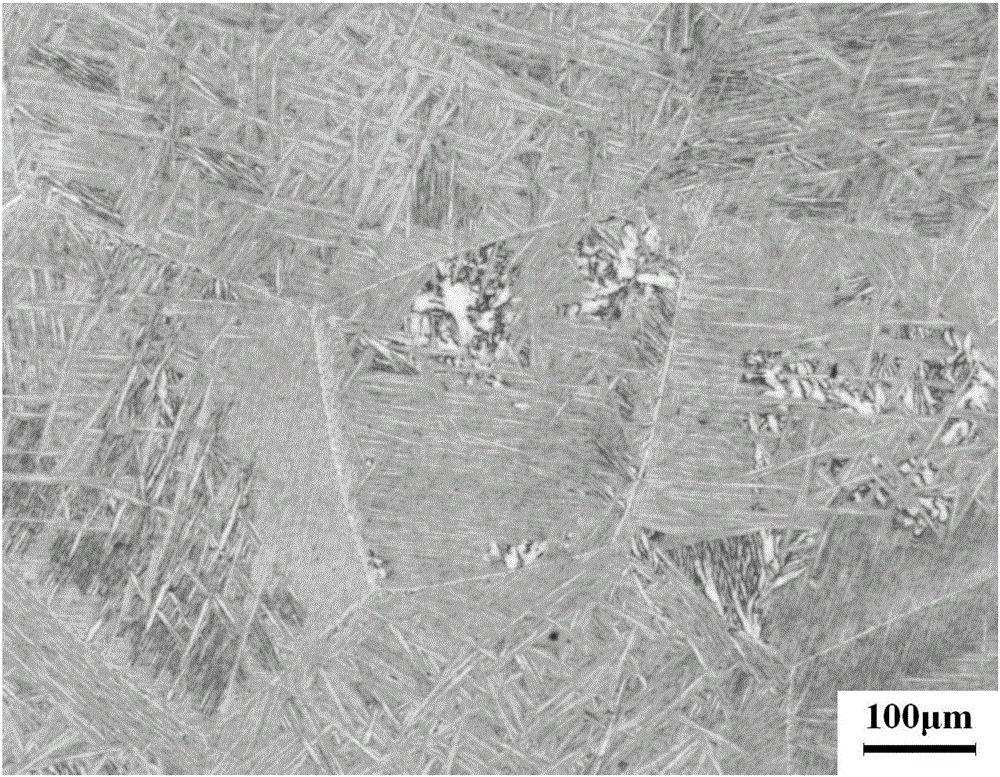

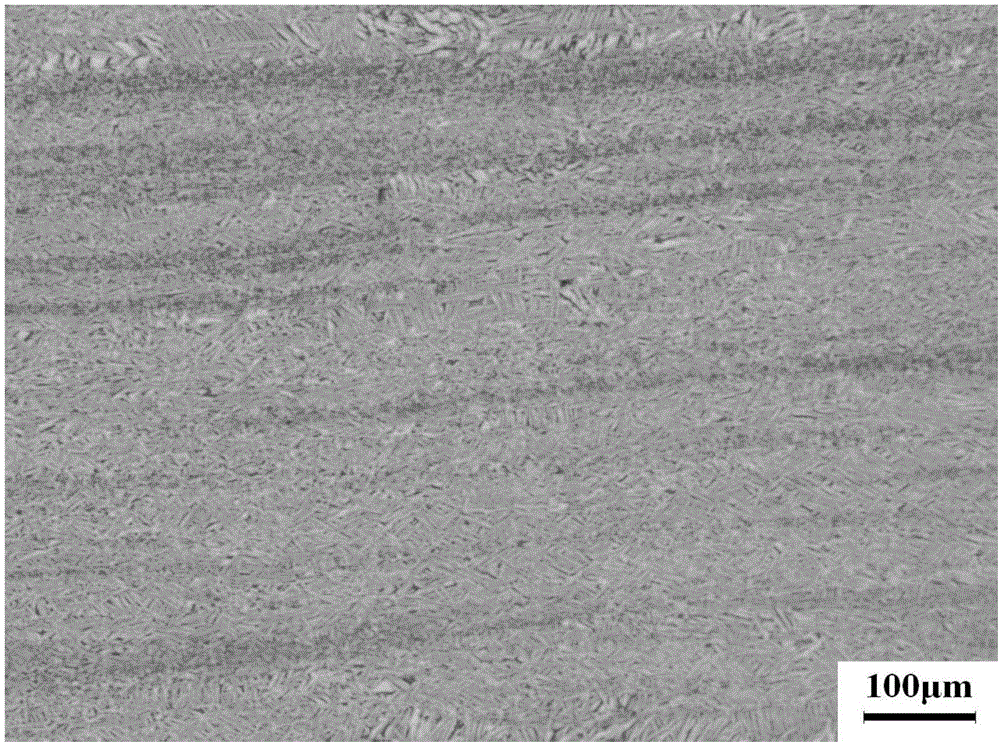

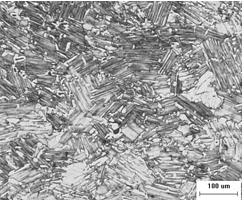

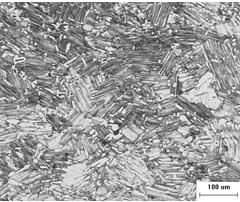

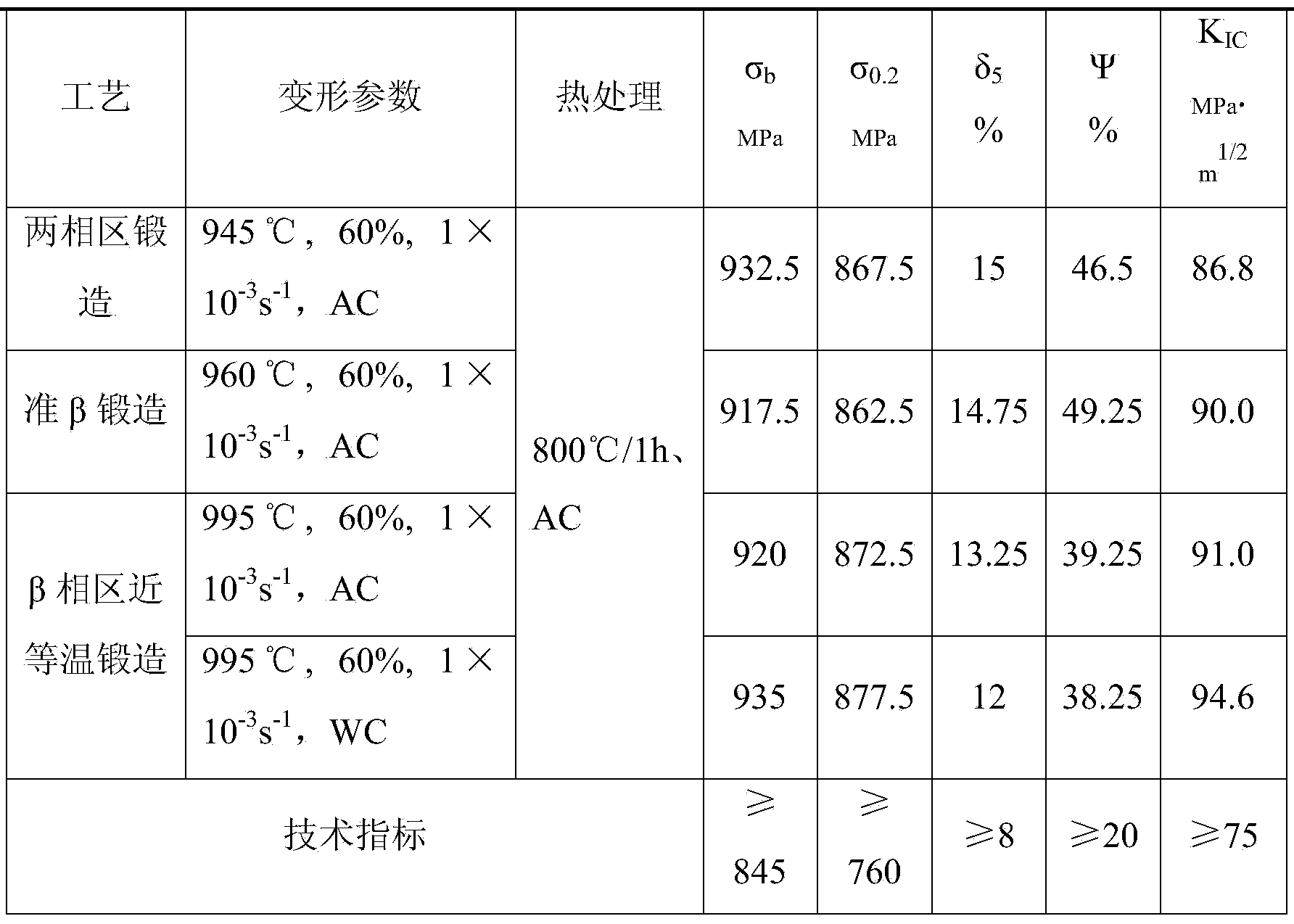

Beta phase nearly isothermal forging of high-damage tolerant titanium alloy TC4-DT

InactiveCN103966535AImprove fracture toughnessImprove performanceMetal-working apparatusBeta phaseControl system

The invention relates to a beta phase nearly isothermal forging method for a high-damage tolerant titanium alloy TC4-DT. After a sample is heated to a certain temperature above T beta and preserved at the temperature for a certain time, deformation parameters, such as deformation degree and deformation speed and the heating temperature of a die during deformation are set in an isothermal forging control system of a hydraulic press so as to deform the sample, air cooling or water cooling is carried out after forging, and then, common annealing treatment is carried out on the deformed sample to ensure the stability of texture. The method belongs to a beta phase nearly isothermal forging technology which not only improves the fracture toughness of the TC4-DT alloy, but also can improve the tenacity. A flaky texture with high plasticity is obtained, the flaky tissue not only has the plasticity of a basket-weave structure, but also has the inherent excellent properties of the flaky texture, damage design requirements can be met, and the stable and reliable performance of components in actual application is ensured.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Process for forming moderately-strong heat-resisting magnesium alloy die-forged piece

ActiveCN103786031AUniform tissueSpeed up the flowOther manufacturing equipments/toolsHeating/cooling devicesIngotUltimate tensile strength

The invention relates to a process for forming a moderately-strong heat-resisting magnesium alloy die-forged piece. Magnesium alloy comprises, by mass, 7.5%-9.0% of Al, 0.02%-0.80% of Ag, 0.35%-0.55% of Zn, 0.05%-0.20% of Mn, 0.1%-0.10% of RE and 0.001%-0.020% of Ca, the balance of Mg and impurity elements which can not be removed. The method includes the steps that an alloy ingot is formed through semicontinuous casting; the ingot is subjected to double-stage homogenizing annealing; the ingot is subjected to multidirectional variable-temperature forging at the temperature ranging from 350 DEG C to 410 DEG C after being subjected to annealing, and the annealing temperature is reduced by 10 DEG C to 20 DEG C after each time of annealing deformation; the ingot is subjected to isothermal forging at the temperature ranging from 350 DEG C to 400 DEG C after being subjected to multidirectional variable-temperature forging; aging of the die-forged piece is carried out and lasts for 20 hours to 30 hours at the temperature ranging from 170 DEG C to 200 DEG C. The magnesium alloy die-forged piece manufactured through the method is larger than or equal to 360 MPa in tensile strength, larger than or equal to 255 MPa in yield strength and larger than or equal to 7% in elongation percentage at an indoor temperature after the aging process.

Owner:CENT SOUTH UNIV +1

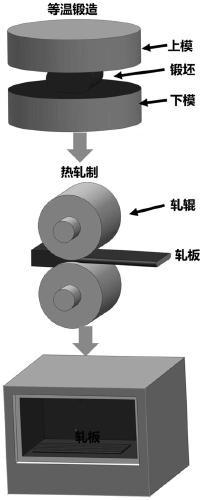

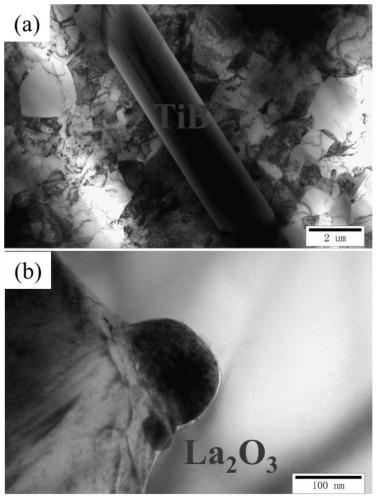

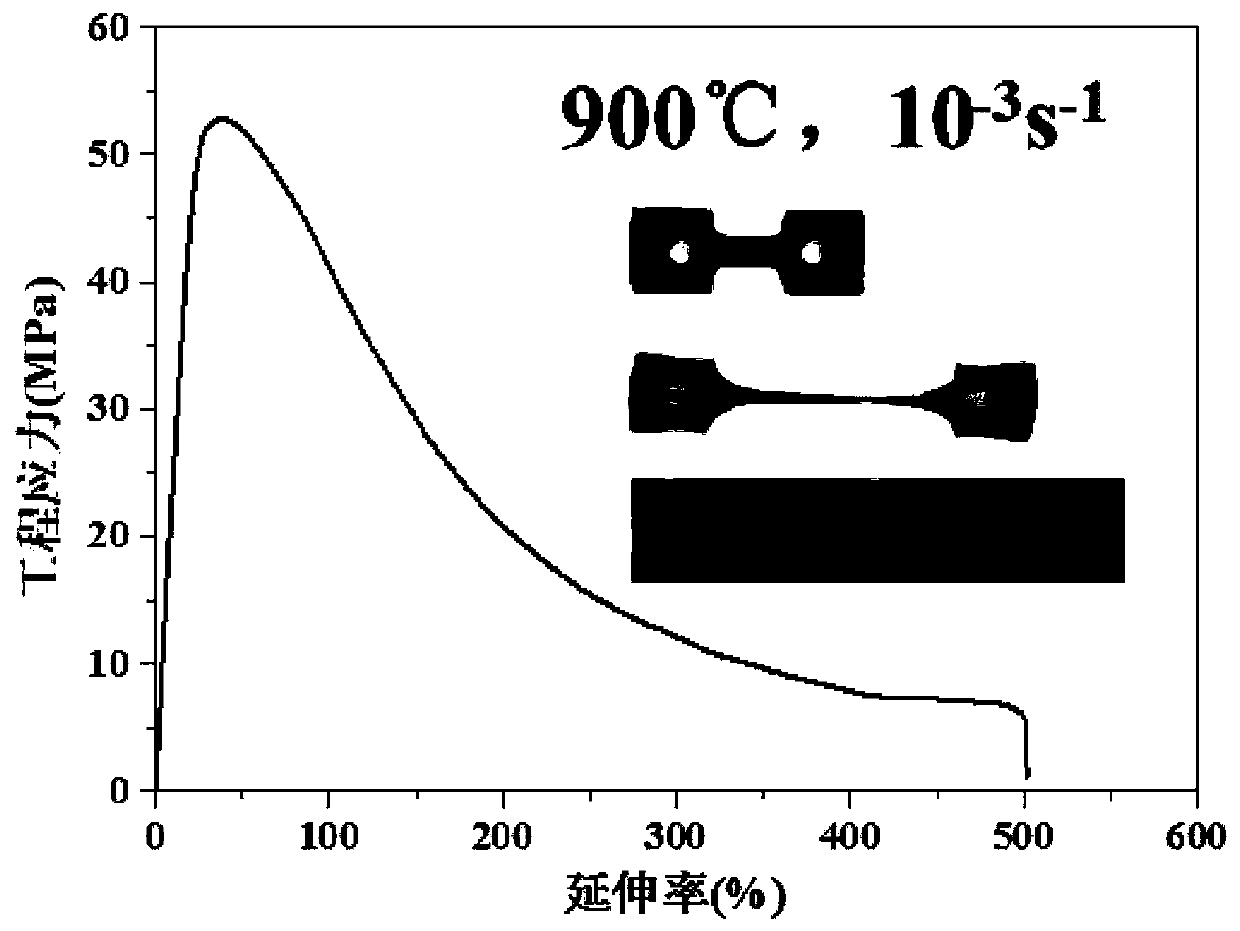

Isothermal superplastic deformation method for micro/nano particulate reinforced titanium matrix composite

The invention discloses an isothermal superplastic deformation method for a micro / nano particulate reinforced titanium matrix composite. The method comprises the following steps of A, preparing a titanium boride and rare earth oxide micro / nano particulate hybrid reinforced titanium matrix composite by utilizing an in-situ synthesis technique, and performing vacuum consumable electrode arc melting on the composite for more than two times; B, performing cogging forging on the composite in a Beta single-phase region, wherein deformation amount is greater than or equal to 50 %; performing isothermal forging on the composite in an (Alpha + Beta) two-phase region to obtain a titanium matrix composite forging blank, wherein deformation amount is greater than or equal to 60 %; and C, performing hot rolling on the titanium matrix composite forging blank in a near Beta phase region, wherein deformation amount is greater than or equal to 80 %, and performing annealing treatment to obtain the micro / nano particulate reinforced titanium matrix composite. The micro / nano particulate reinforced titanium matrix composite is formed by the isothermal forging technology and hot rolling, and thus, the matrix structure can be effectively refined, and the material forming rate is increased; and a plate has good superplasticity within the deformation process range of 800-1000 DEG C and 5 x 10<-3>-10<-4>s<-1>.

Owner:上海交通大学包头材料研究院 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com