Aluminum alloy complex disc part isothermal precision forging process method

A disc-like parts, precision forging technology, applied in the field of warm forging technology, can solve the problems of streamline disorder, eddy current and through-flow, etc., and achieve the effect of improving streamline, uniform and fine grain size, and uniform distribution of internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

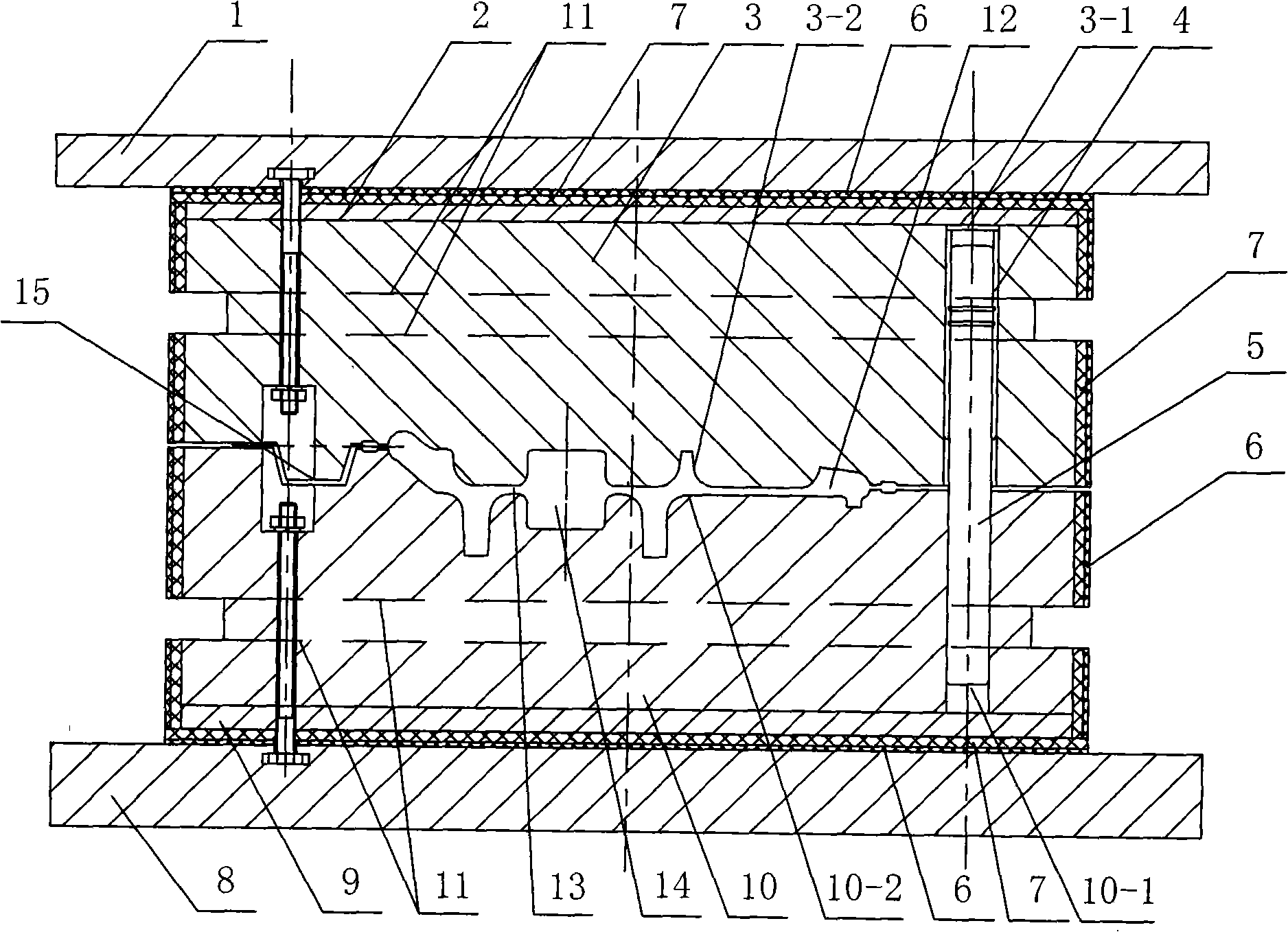

Image

Examples

specific Embodiment approach 1

[0017] Specific implementation mode 1: The steps of a pressure control method for viscoelastic-plastic soft mold forming of an aluminum alloy cover part in this embodiment are as follows: the steps of an isothermal precision forging process for complex aluminum alloy disc parts are:

[0018] Step 1: determining the size of the original fine-grained blank;

[0019] Step 2: Preheating the forging die and the original fine-grained billet: heating the original fine-grained billet to 430±5°C in air, while installing the forging die on the forging press, and heating the forging die to 430±5°C;

[0020] Step 3: The first isothermal die forging forming: Spray the lubricant on the surface of the forging die, and then put the billet heated to the forging temperature into the forging die on the forging press, and use the heating device of the forging die to continue to heat the billet and the forging die Heating, keeping the forging die and the billet within the forging temperature range...

specific Embodiment approach 2

[0029] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the forging pressure provided by the forging press in step 3, step 6 and step 9 of this embodiment is 10000KN~30000KN. The strain rate of the sub-preliminary discs is 9×10 -4 ~1.2×10 -4 . The forming effect is good.

specific Embodiment approach 3

[0030] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the deformation amount of the first isothermal die forging in step three of this embodiment, the deformation amount of the second isothermal die forging in step six and The deformation amount of the third isothermal die forging in step nine is 30%-60%. More effectively prevent forging folding, eddy current and flow through.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com