Patents

Literature

563results about How to "Refined grain size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

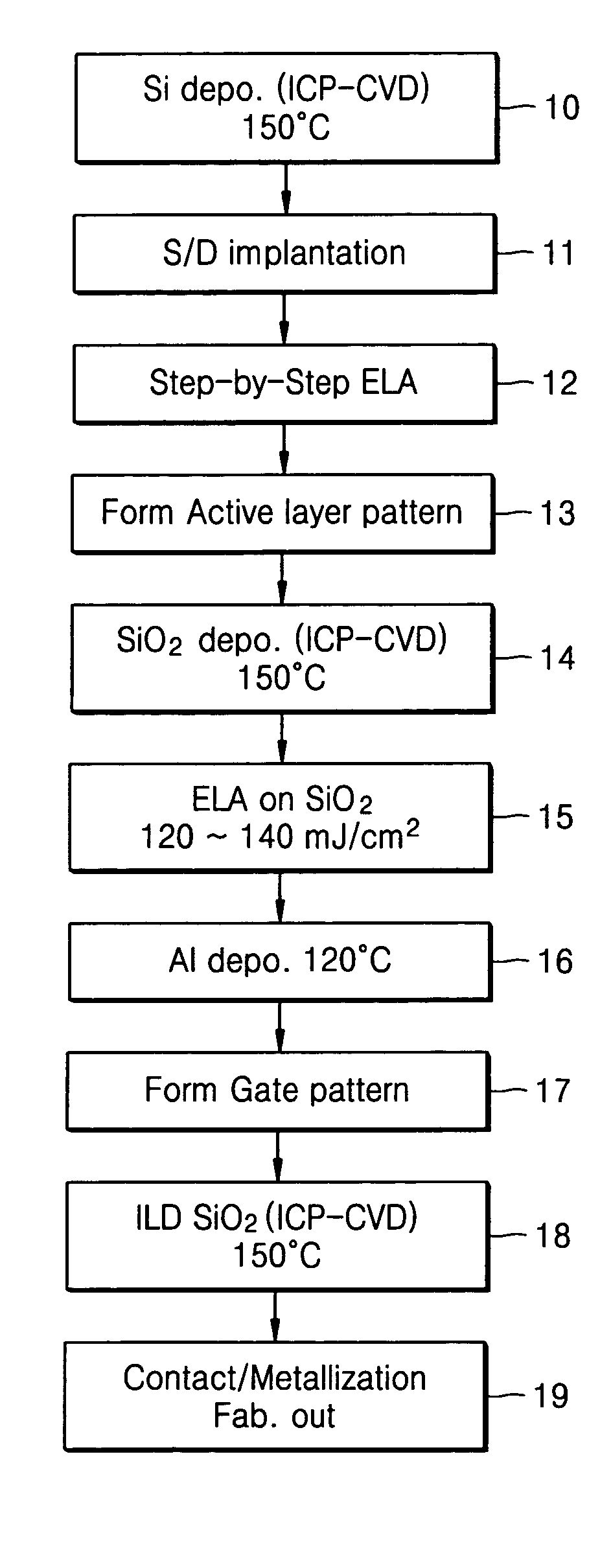

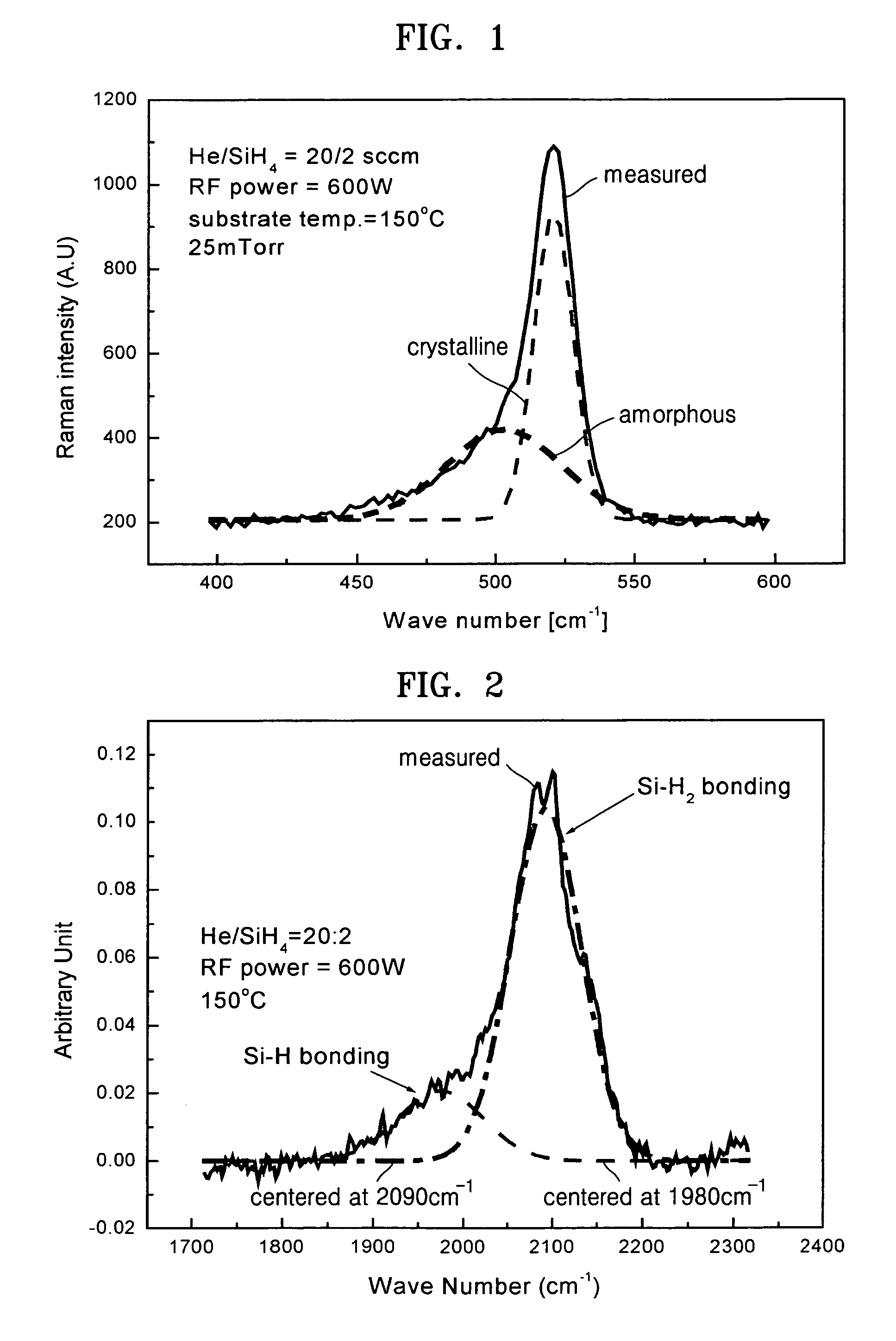

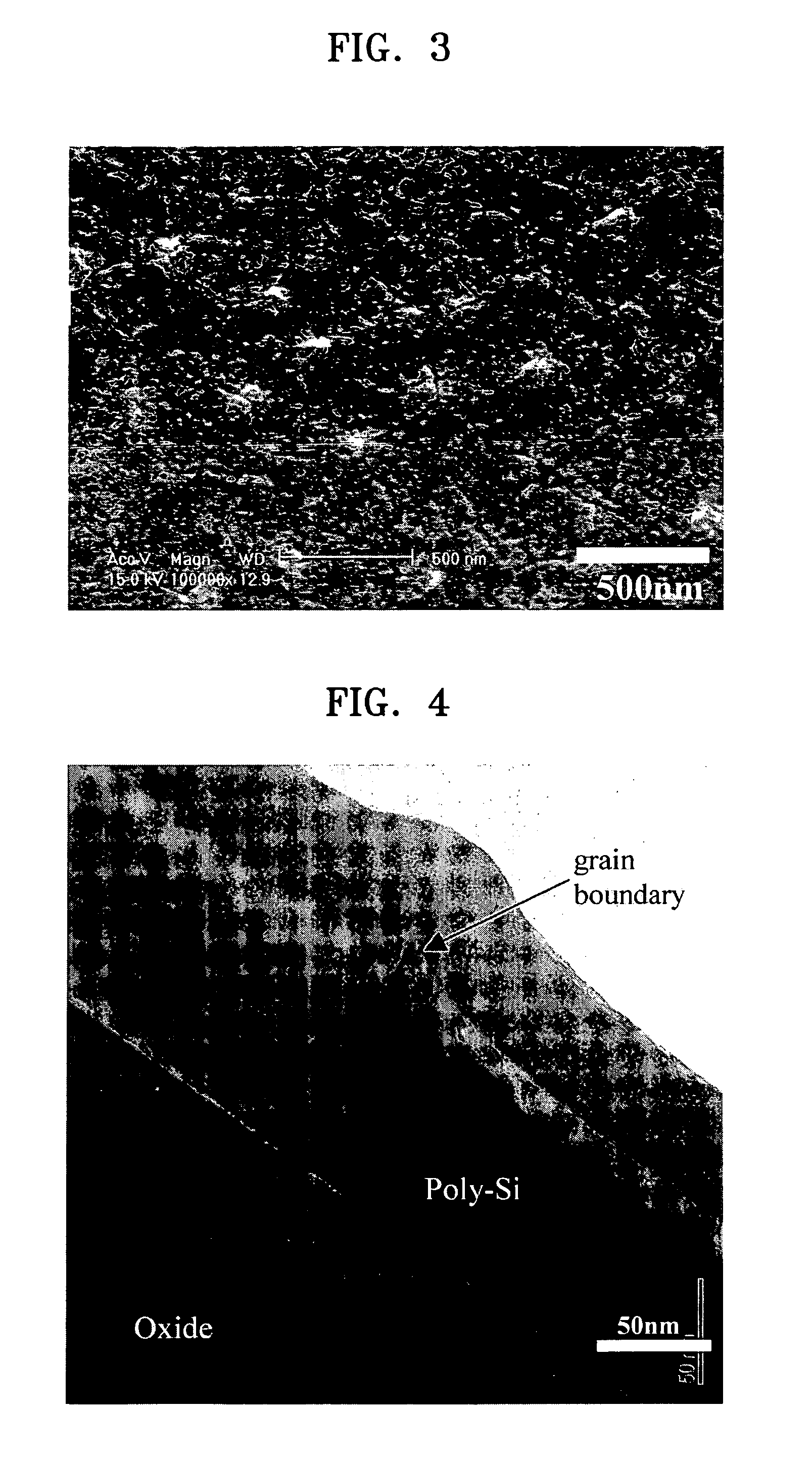

Method of fabricating poly-crystalline silicon thin film and method of fabricating transistor using the same

InactiveUS7563659B2Refined grain sizeHigh energyTransistorSemiconductor/solid-state device manufacturingInductively coupled plasmaSilicon thin film

A method of fabricating a poly-Si thin film and a method of fabricating a poly-Si TFT using the same are provided. The poly-Si thin film is formed at a low temperature using inductively coupled plasma chemical vapor deposition (ICP-CVD). After the ICP-CVD, excimer laser annealing (ELA) is performed while increasing energy by predetermined steps. A poly-Si active layer and a SiO2 gate insulating layer are deposited at a temperature of about 150° C. using ICP-CVD. The poly-Si has a large grain size of about 3000 Å or more. An interface trap density of the SiO2 can be as high as 1011 / cm2. A transistor having good electrical characteristics can be fabricated at a low temperature and thus can be formed on a heat tolerant plastic substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

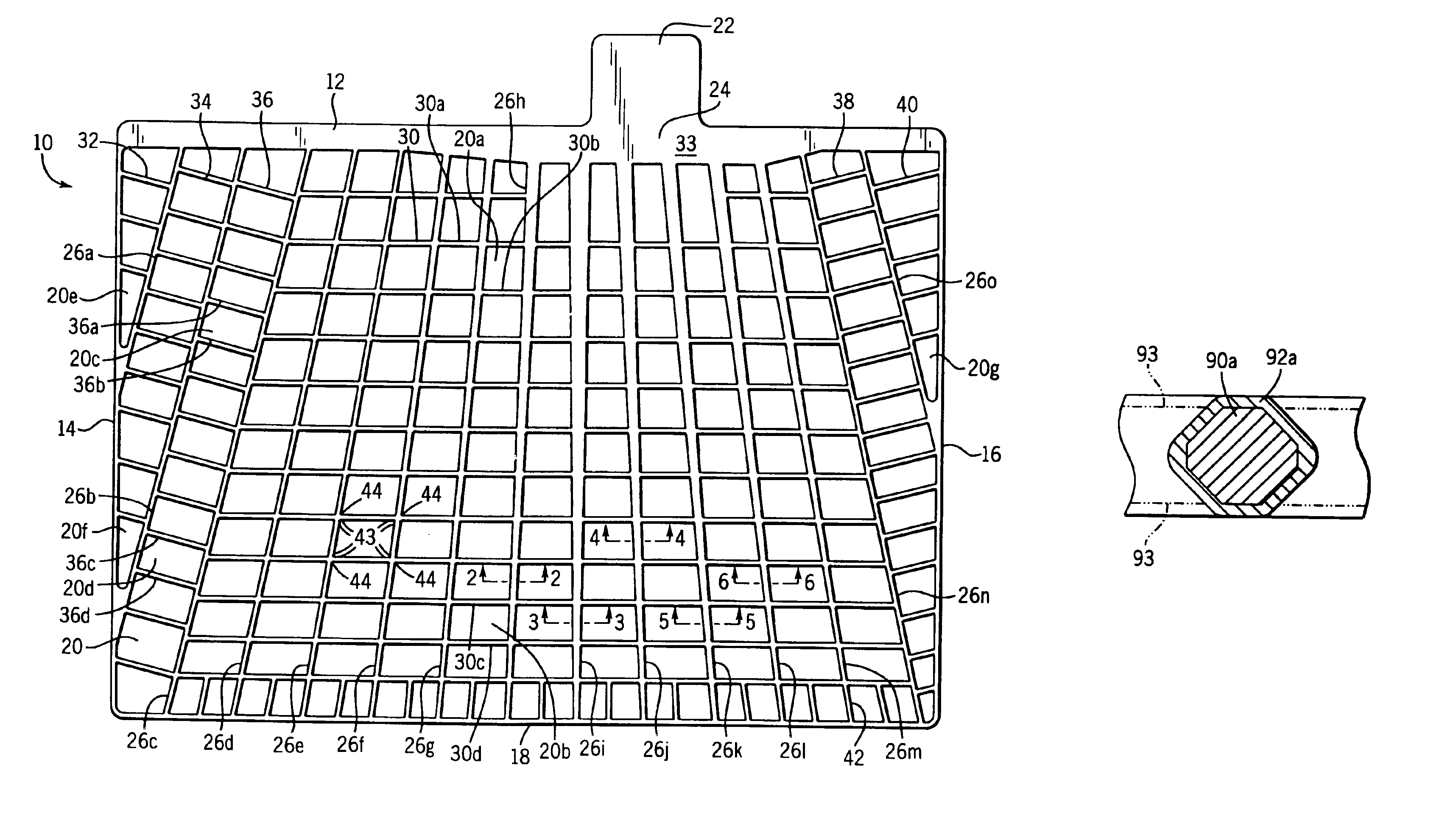

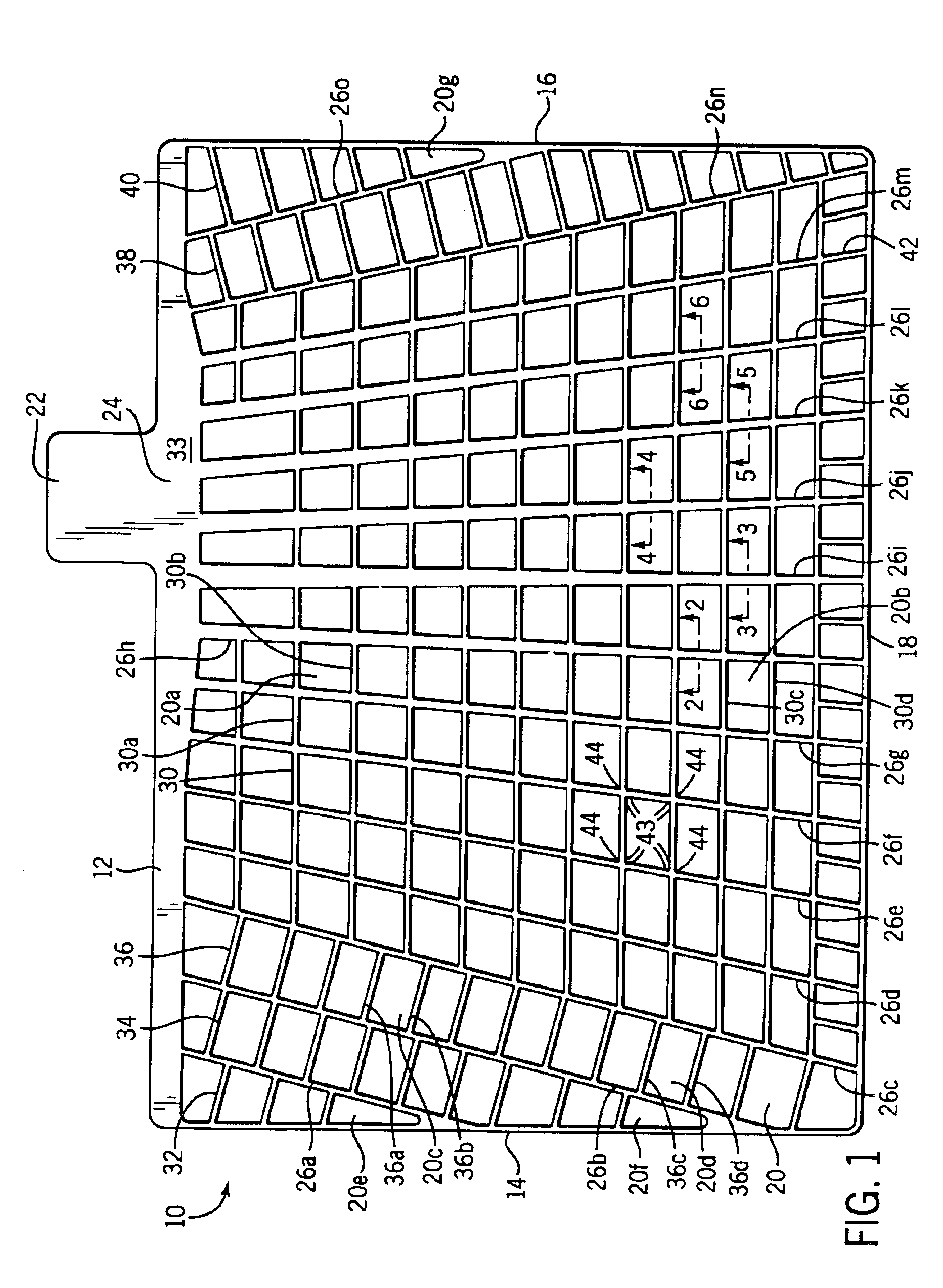

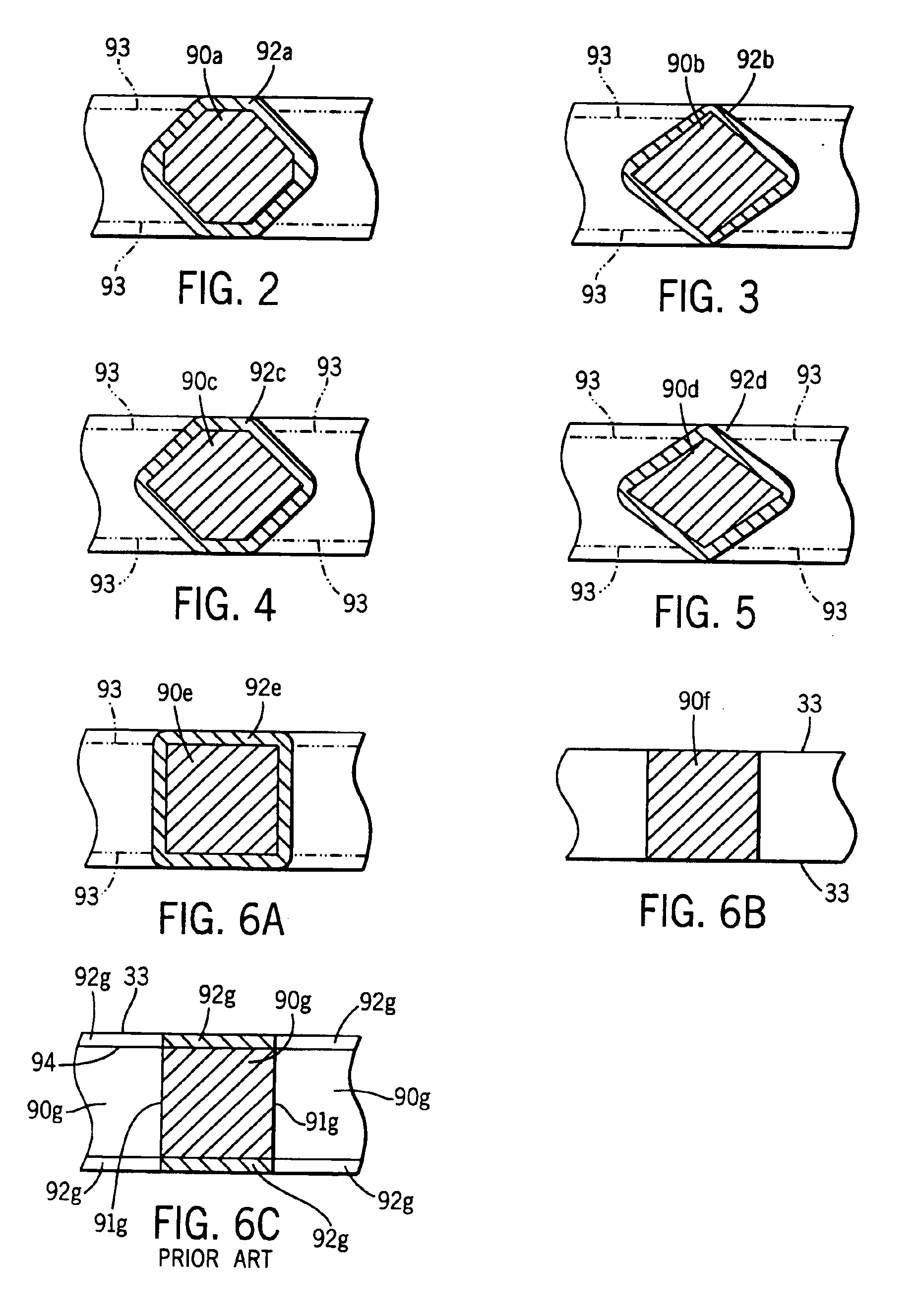

Battery grid

InactiveUS6953641B2Extend battery lifeImprove adhesionElectrode carriers/collectorsLead-acid accumulator electrodesPunchingEngineering

A method of forming battery grids or plates that includes the step of applying a lead alloy coating to a continuous strip of interconnected battery grids formed from a lead alloy grid material is disclosed. The battery grids may be formed by a continuous battery grid making process such as strip expansion, strip punching, or continuous grid casting. In one version of the method, the grid wires of a continuous strip of battery grids produced by a punching process are immersed in a melt of the lead alloy coating. In another version of the method, the grid wires of a continuous strip of battery grids produced by a punching process are deformed such that the grid wires have a cross-section other than the rectangular cross-section produced by the punching process and the strip of interconnected grids is immersed in a melt of the lead alloy coating. The method increases the cycle life of a battery.

Owner:CPS TECH HLDG LLC

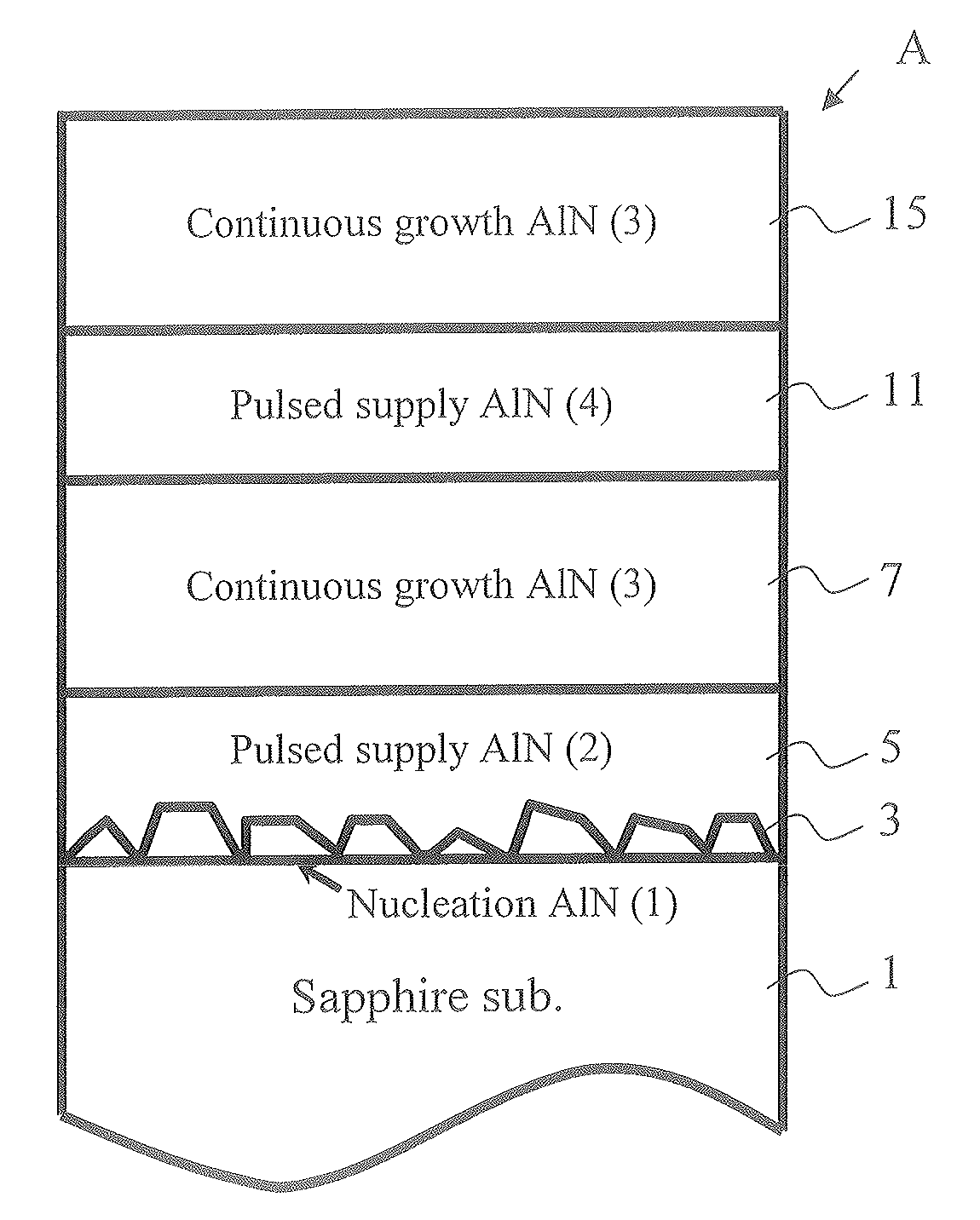

Optical semiconductor device and method for manufacturing the same

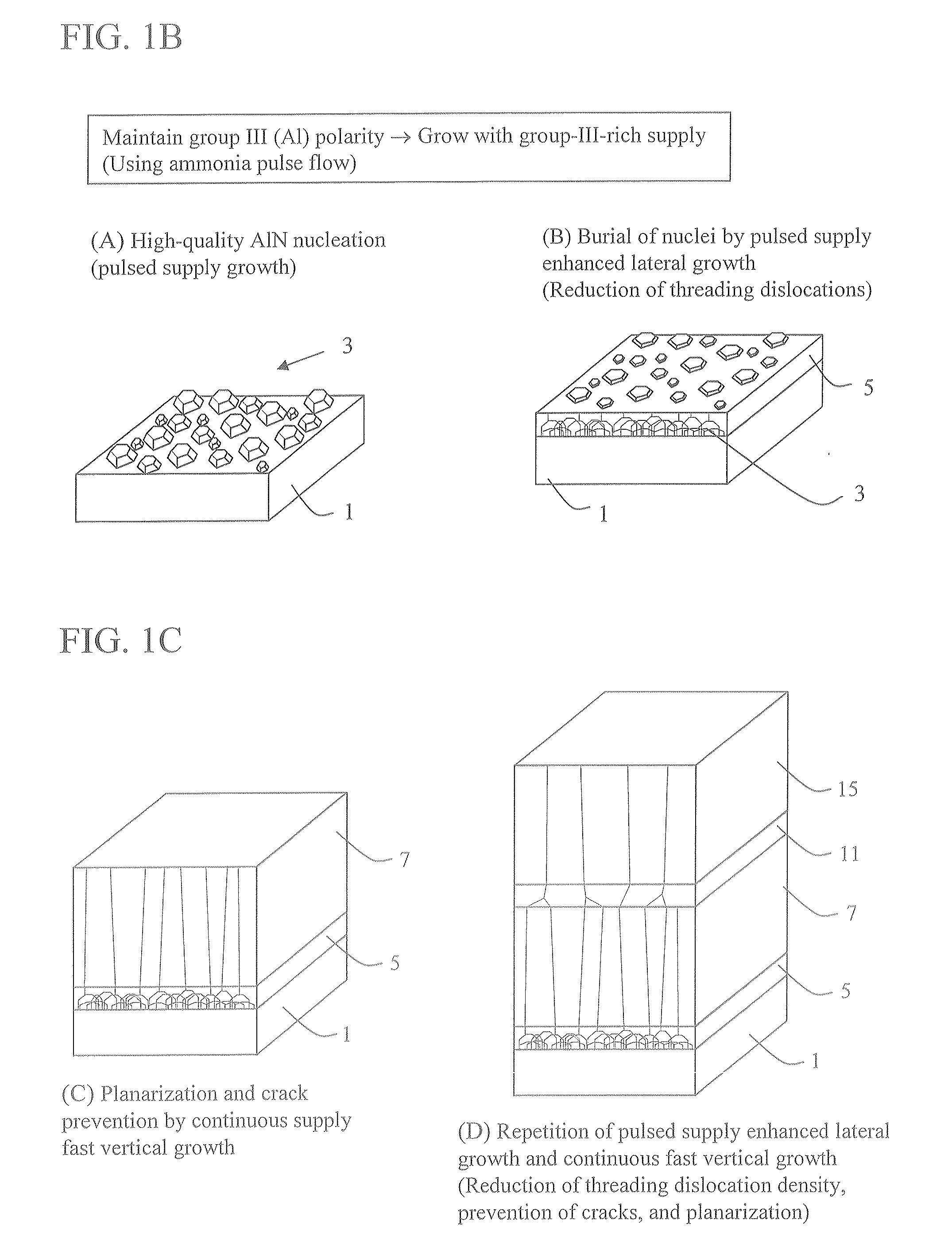

InactiveUS20090057646A1Improve luminous efficiencySuppress gas phase reactionSemiconductor/solid-state device manufacturingSemiconductor devicesLattice mismatchNucleation mode

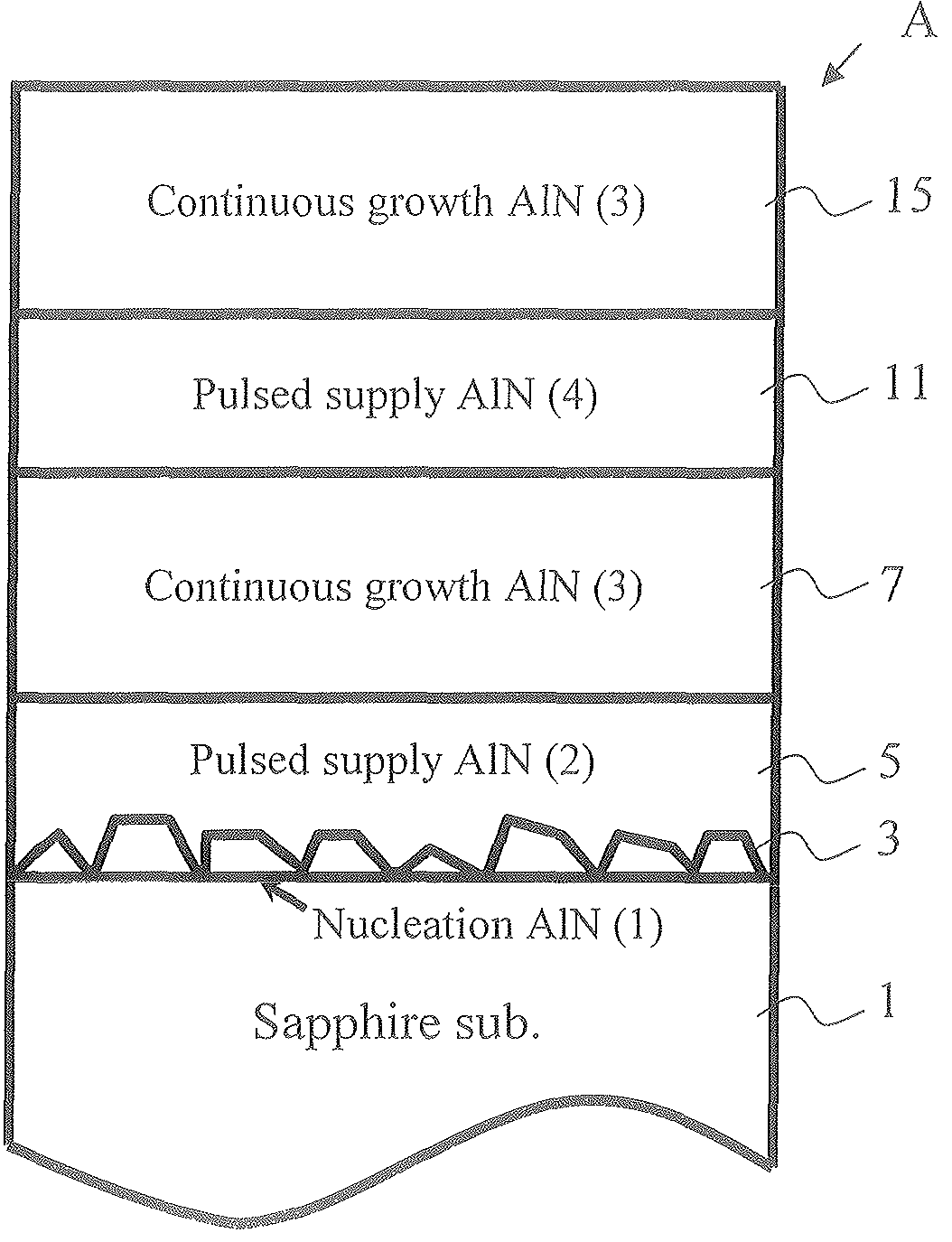

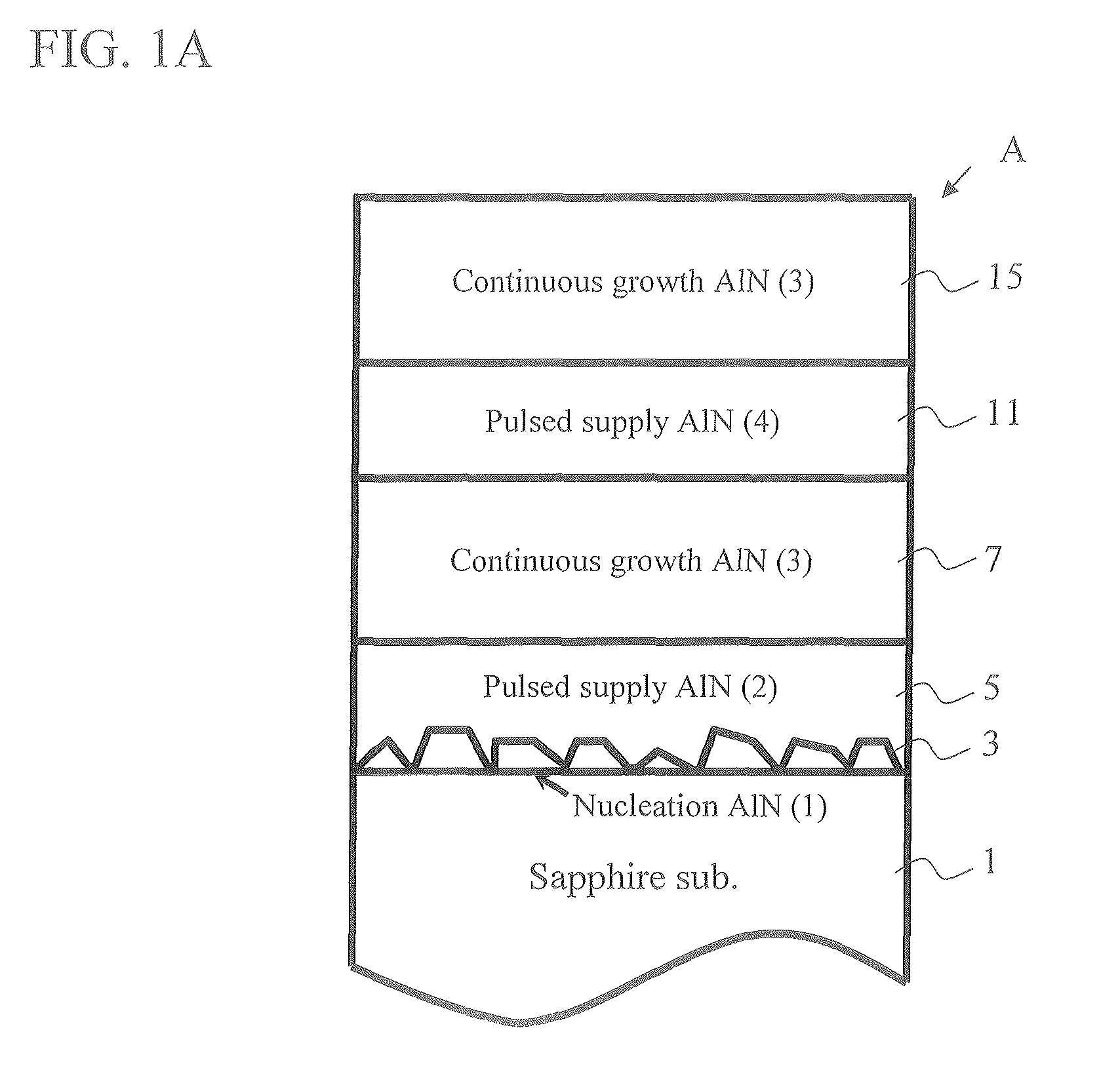

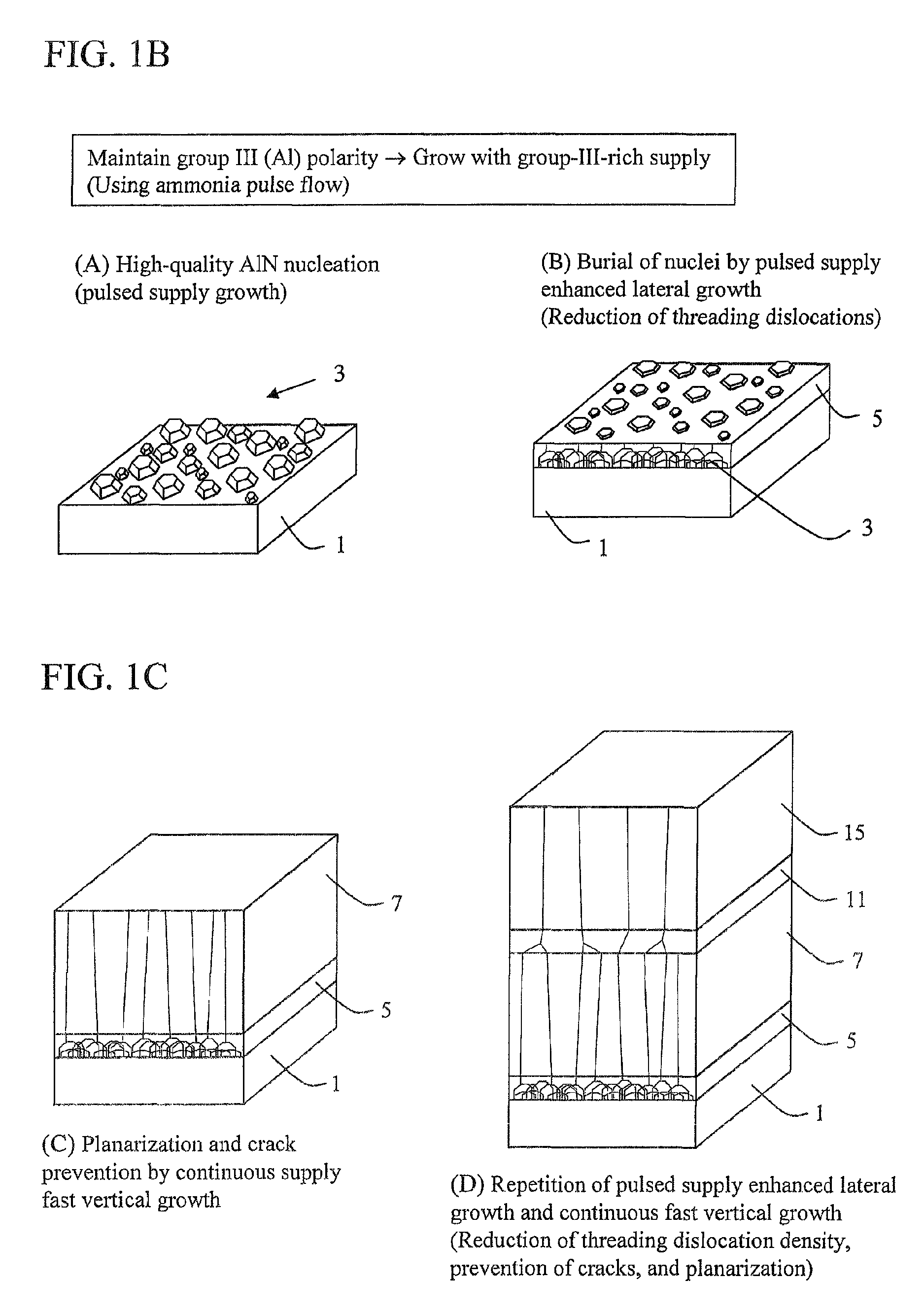

Because of a large lattice mismatch between a sapphire substrate and a group III-V compound semiconductor, a good crystal is difficult to grow. A high-quality AlN buffer growth structure A on a sapphire substrate includes a sapphire (0001) substrate 1, an AlN nucleation layer 3 formed on the sapphire substrate 1, a pulsed supplied AlN layer 5 formed on the AlN nucleation layer 3, and a continuous growth AlN layer 7 formed on the pulsed supplied AlN layer 5. Formed on the continuous growth AlN layer 7 is at least one set of a pulsed supplied AlN layer 11 and a continuous growth AlN layer 15. The AlN layer 3 is grown in an initial nucleation mode which is a first growth mode by using an NH3 pulsed supply method. The pulsed supplied AlN layer 5 is formed by using NH3 pulsed supply in a low growth mode which is a second growth mode that increases a grain size and reduces dislocations and therefore is capable of reducing dislocations and burying the nucleation layer 3. The continuous growth AlN layer 7 is a fast vertical growth mode that improves flatness and suppresses crack occurrences. As examples of the thickness of layers; the pulsed supplied AlN layer 5, 11 is 0.3 μm and the thickness of the continuous growth AlN layer 7, 15 is 1 μm, for example. Characteristics of conditions under which layers are grown are as follows. The AlN layer 3 is grown under a high temperature and a high pressure with a low V-III ratio (less N). The pulsed supplied AlN layer 5 is grown at a low temperature and a low pressure with a high V-III ratio (more N). The continuous AlN layer 7 is grown at a high temperature and a high pressure with a high V-III ratio (Al rich and less N) without using an NH3 pulsed supply AlN growth method.

Owner:RIKEN

All-vapor processing of p-type tellurium-containing II-VI semiconductor and ohmic contacts thereof

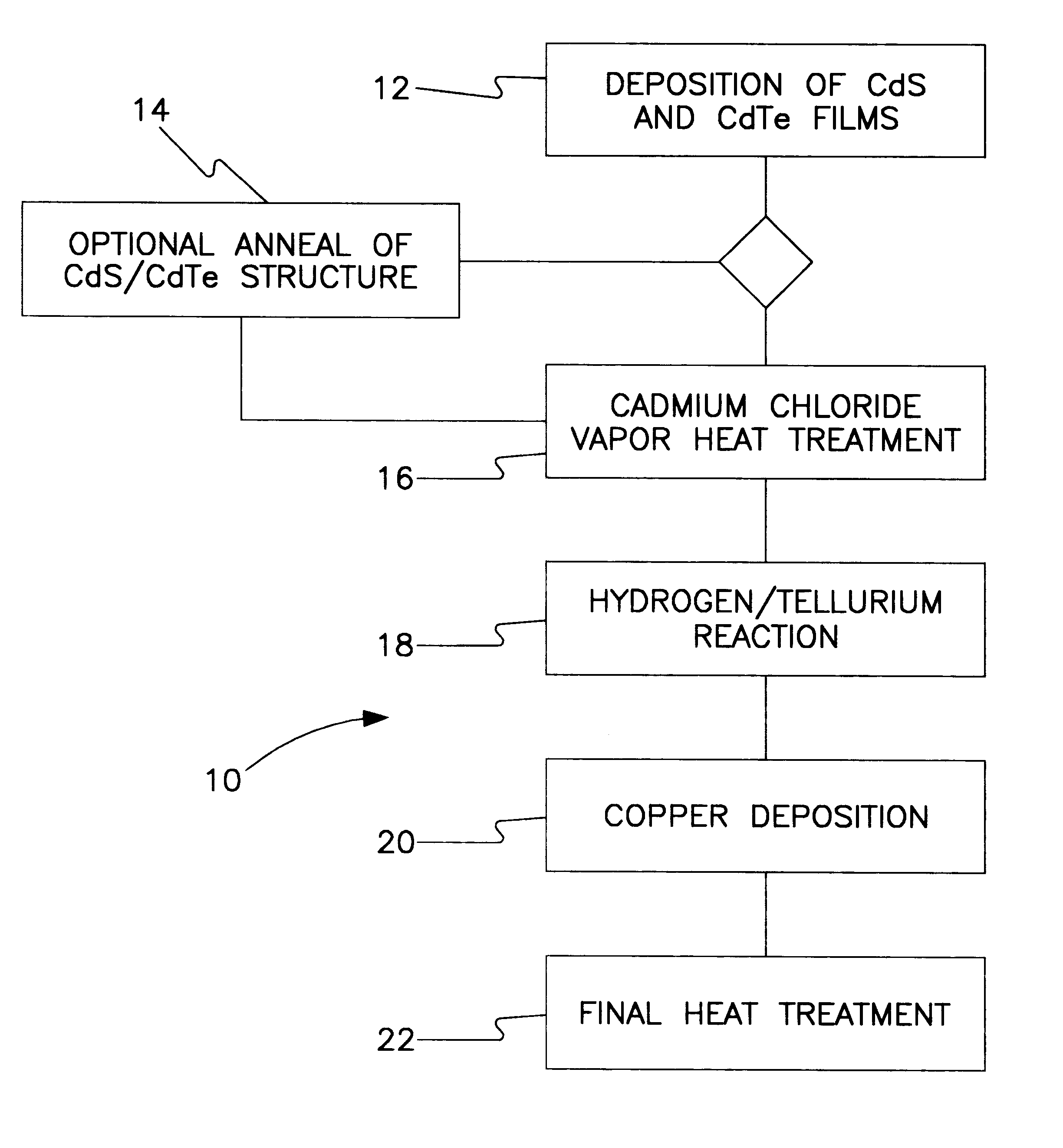

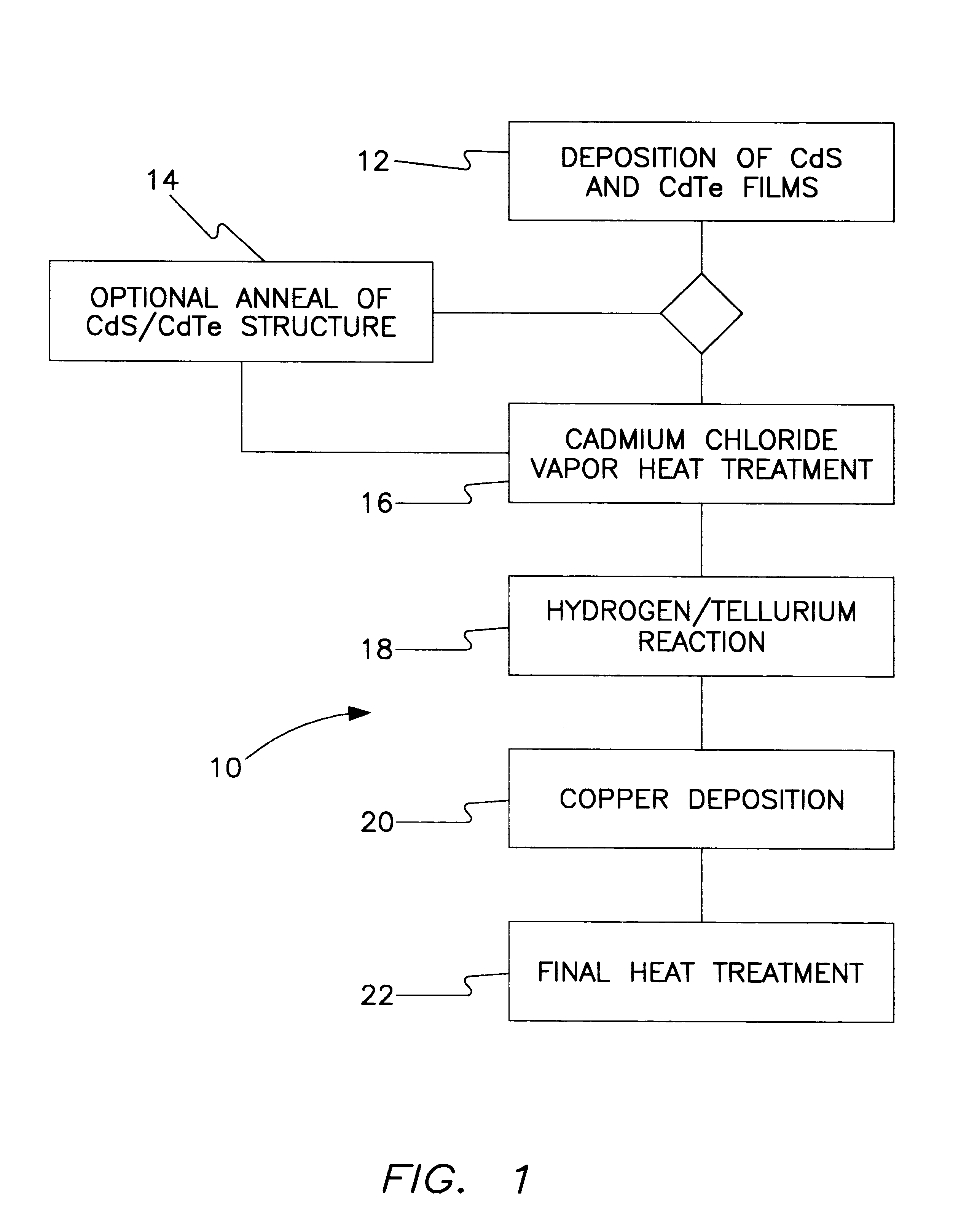

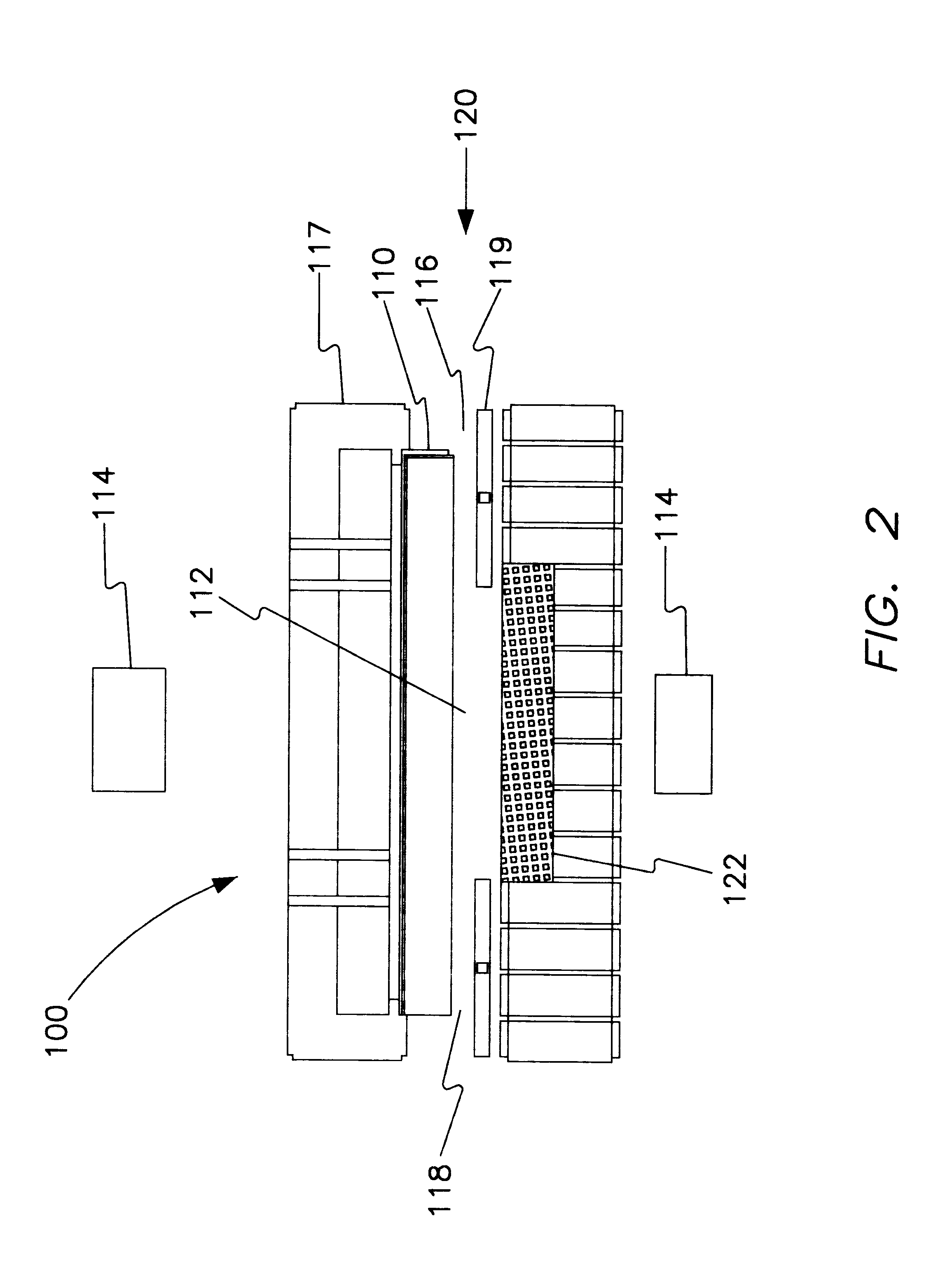

InactiveUS6251701B1Reduce manufacturing costReduce pollutionFinal product manufactureSemiconductor/solid-state device manufacturingOhmic contactTellurium compounds

An all dry method for producing solar cells is provided comprising first heat-annealing a II-VI semiconductor; enhancing the conductivity and grain size of the annealed layer; modifying the surface and depositing a tellurium layer onto the enhanced layer; and then depositing copper onto the tellurium layer so as to produce a copper tellurium compound on the layer.

Owner:U S DEPT OF ENGERGY

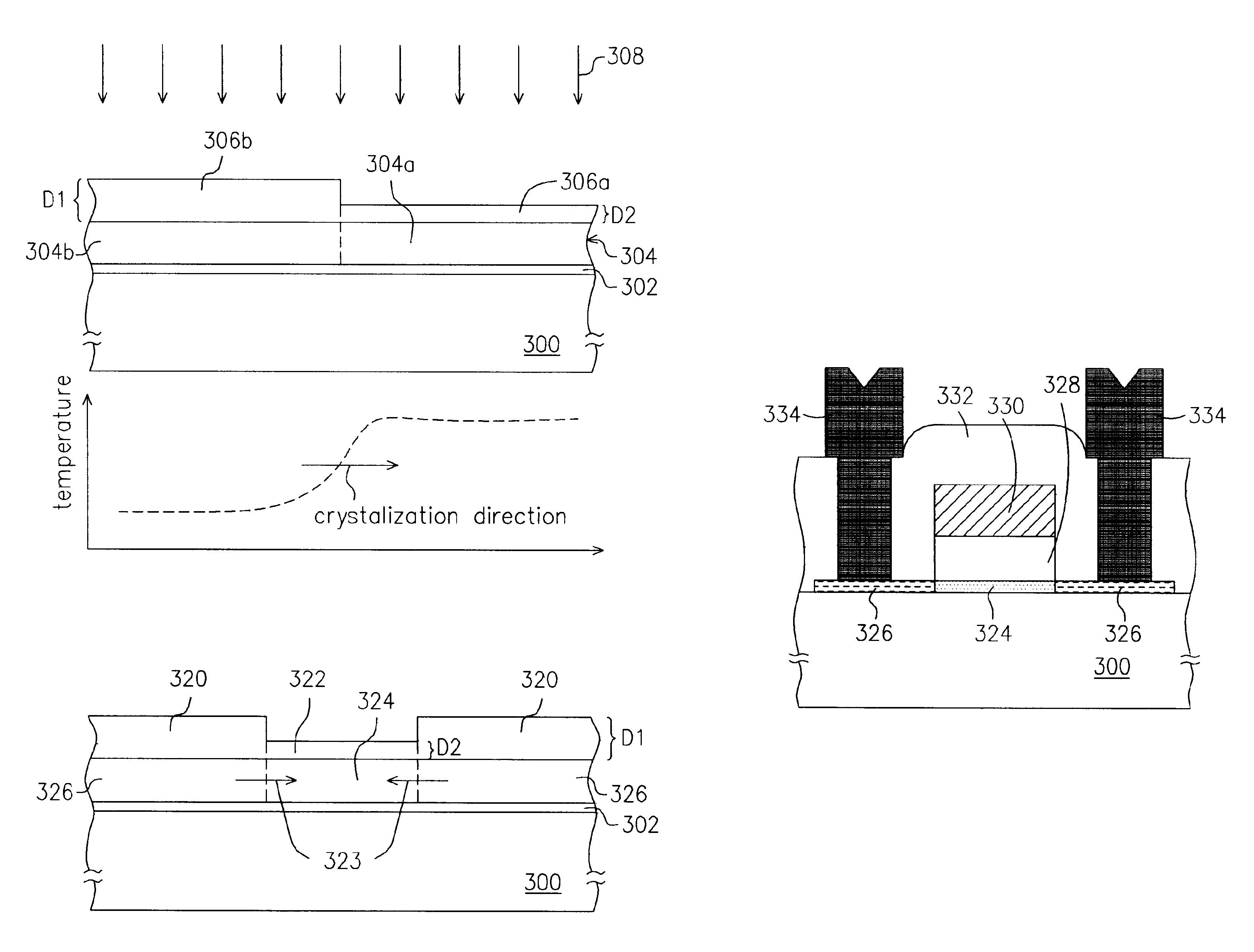

Method of fabricating polysilicon film

InactiveUS6916690B2Increasing lateral temperature gradientInduce lateral crystallizationTransistorSolid-state devicesAmorphous siliconLaser annealing

A method of fabricating polysilicon film is described. An amorphous silicon layer is formed on the substrate, an optical layer is formed on the amorphous silicon layer, wherein the optical has a first region having a first thickness and a second region having a second thickness, and the reflectivity of the first region for an excimer laser is higher than that of the second region. A laser annealing process is then preformed to transform the amorphous silicon layer into a polysilicon film.

Owner:AU OPTRONICS CORP

Translucent alumina sintered body and a process for producing the same

InactiveUS6482761B1Improve corrosion resistanceEasy to provideImpression capsArtificial teethAlkaline earth metalTransmittance

A translucent alumina sintered body wherein the total content of an alkali metal element and an alkaline earth metal element is 50 ppm or less, and the linear transmittance of a light having a wavelength of 600 nm is 40% or more at a thickness of the sintered body of 0.85 mm.

Owner:SUMITOMO CHEM CO LTD

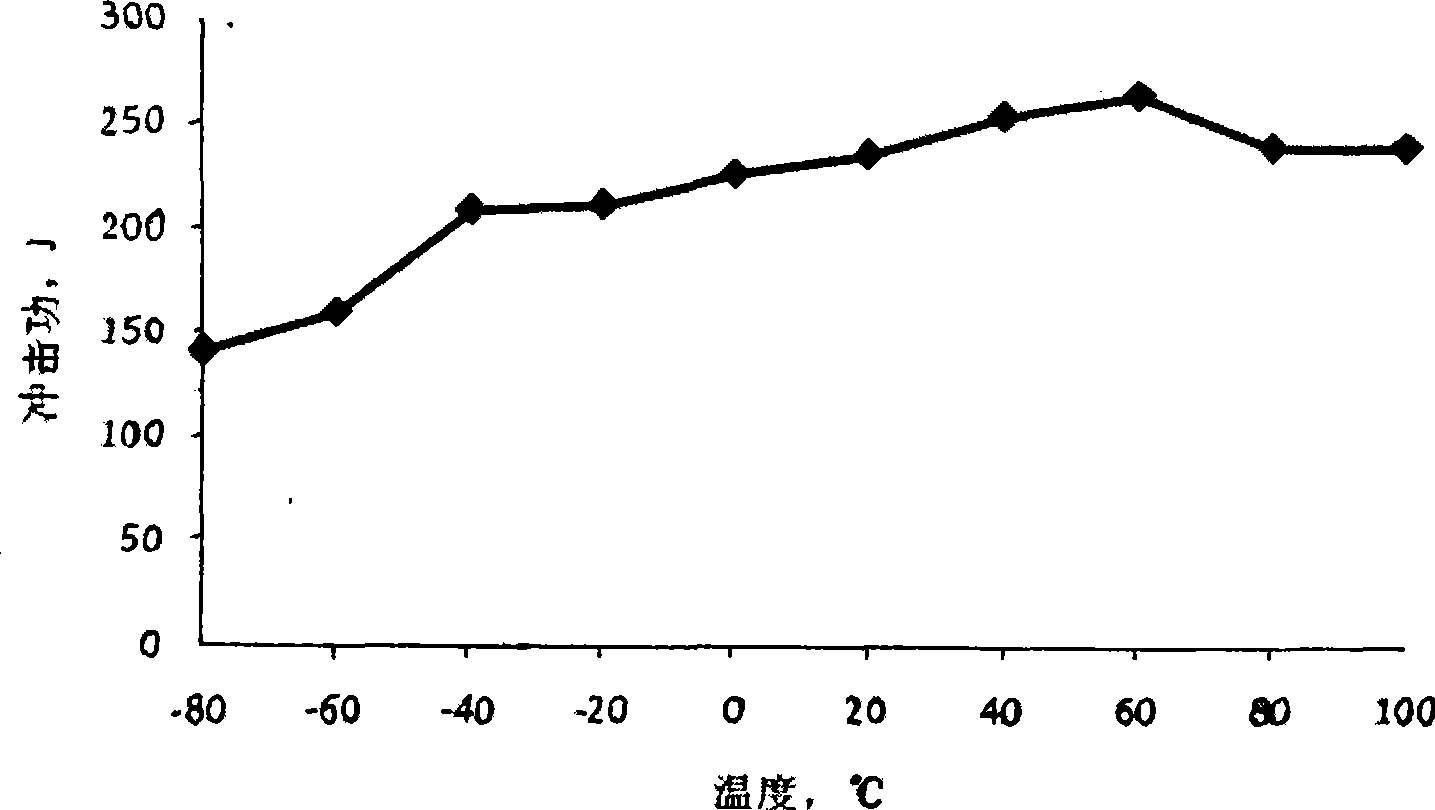

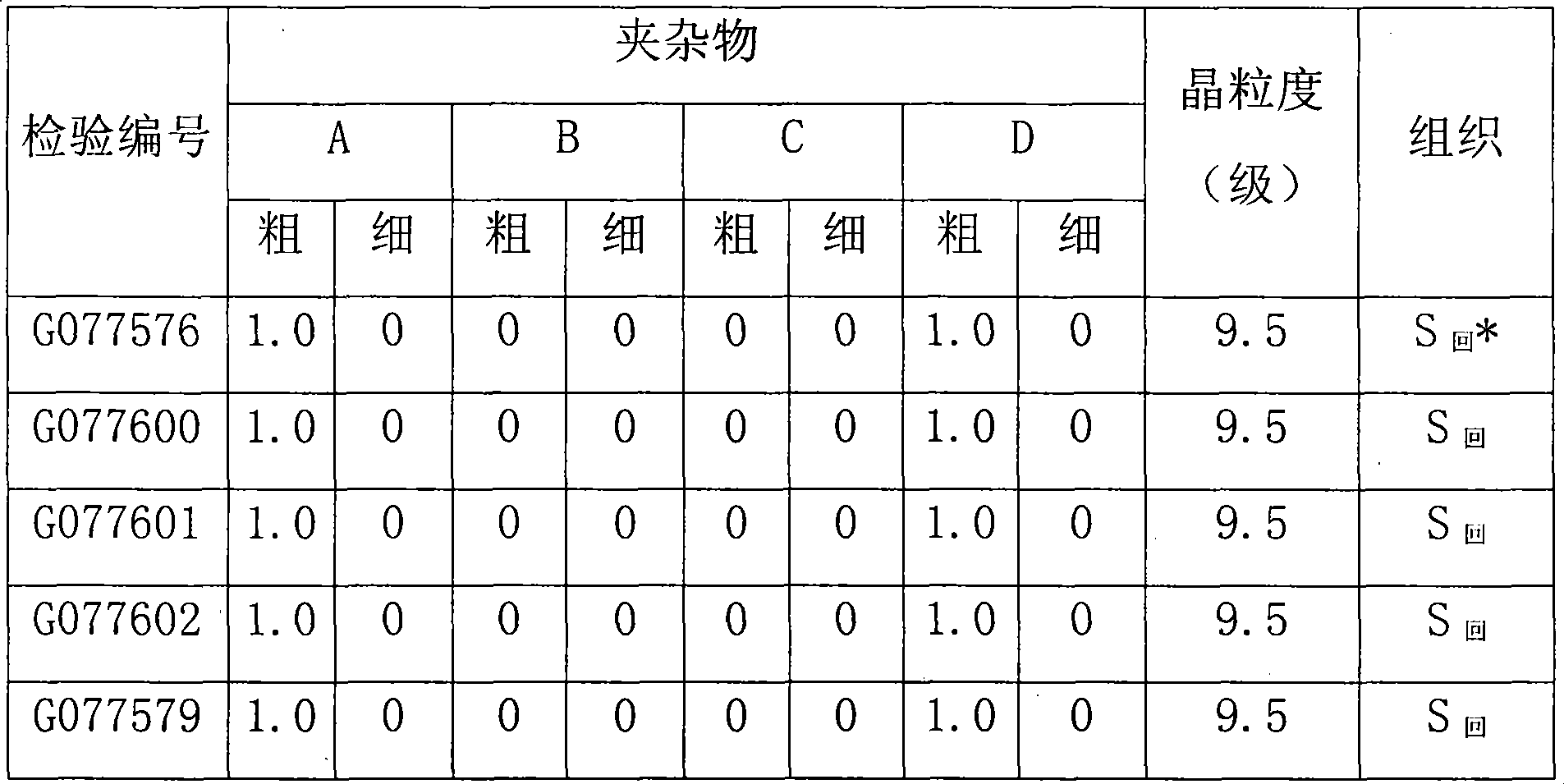

Manufacture method of large caliber high steel grade corrosion proof seamless steel tube in diameter phi 219.0-460.0mm

ActiveCN101417296AReduce adverse effectsImprove mechanical propertiesTemperature control deviceFurnace typesSuperficial massPetroleum

The invention provides a production method of a large caliber high steel-grade corrosion-resistant seamless steel tube with the diameter of phi 219.0-phi460.0mm, which comprises the steps of the techniques of: steel making, tube rolling, thermal treatment and processing of the steel tube, and the like, and produces the large caliber high steel-grade corrosion-resistant seamless steel tube with the diameter of phi 219.0-phi460.0mm. The method has the effects of solving the problem of extremely unfavorable influence of the harmful elements such as P, S, and the like on the corrosion resistance of a petroleum-special tube and obtaining a high-quality round billet, adopts the combination of phi 460 three-roller retained mandrel POF rolling mill with high-end thermal rolling control technique to obtain fine quality tube bodies with different sizes, and obtains pipeline tubes with eligible surface quality and combination property by reasonable thermal treatment technique and the control technique of the residual stress of the steel tube, which not only has high strength and excellent corrosion-resistant property but also has good toughness. The invention has the beneficial effects that the steel tube has good physical-chemical properties, high tube body size precision, and convenience for use as well as being beneficial for the safety of long-distance delivery ducts, and can be widely used for the acid oil-gas fields containing hydrogen sulfide.

Owner:TIANJIN STEEL PIPE MFG CO LTD

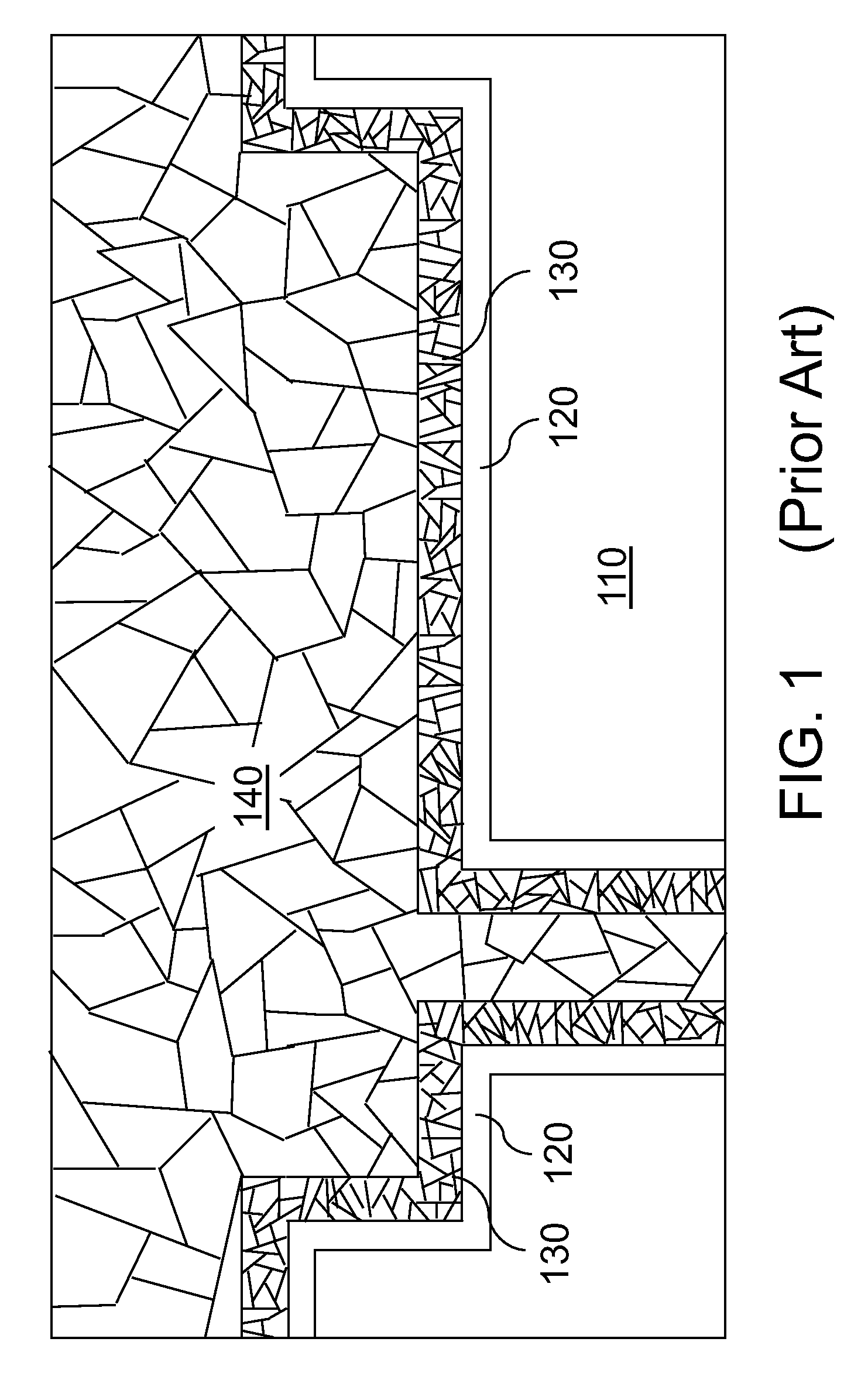

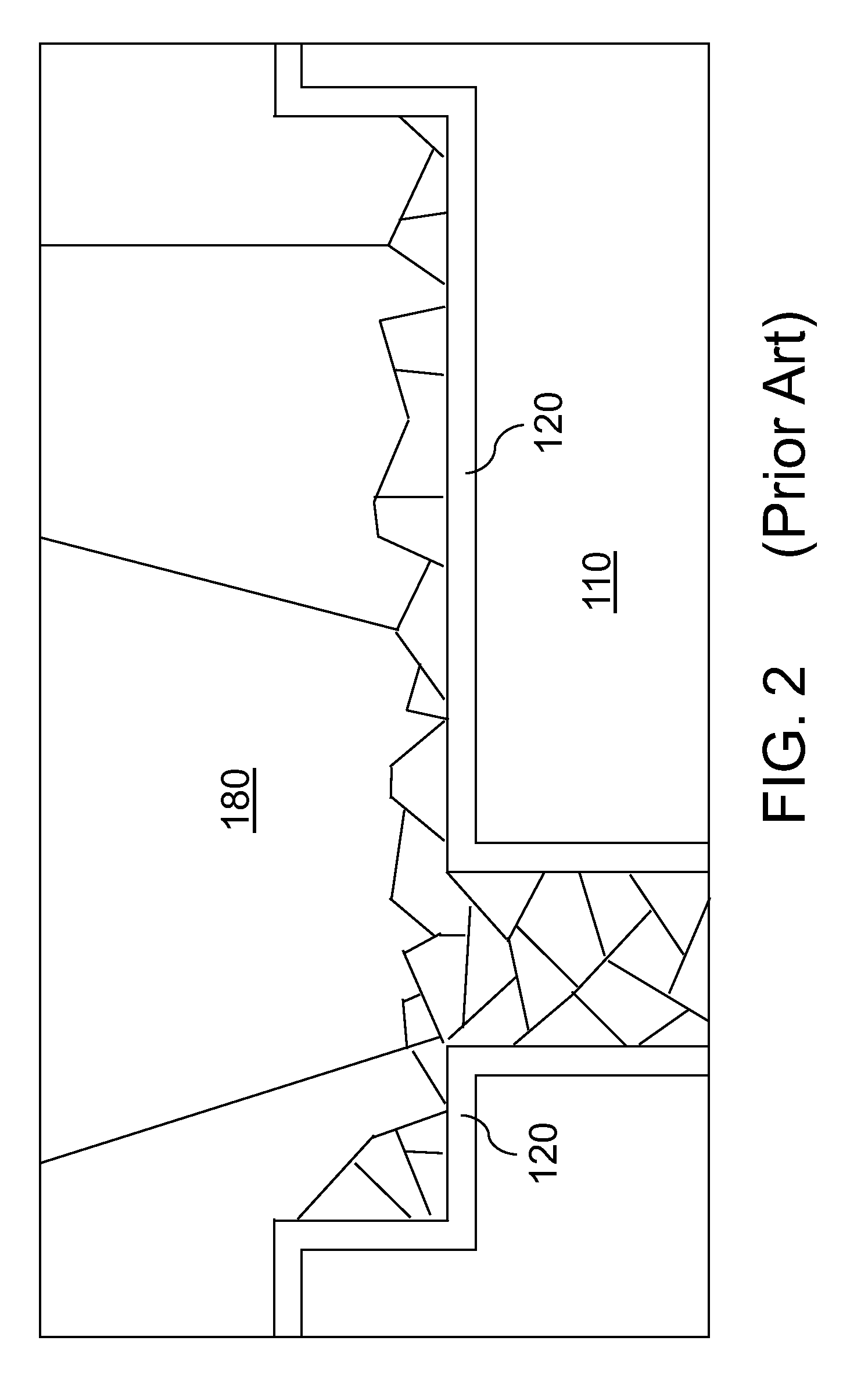

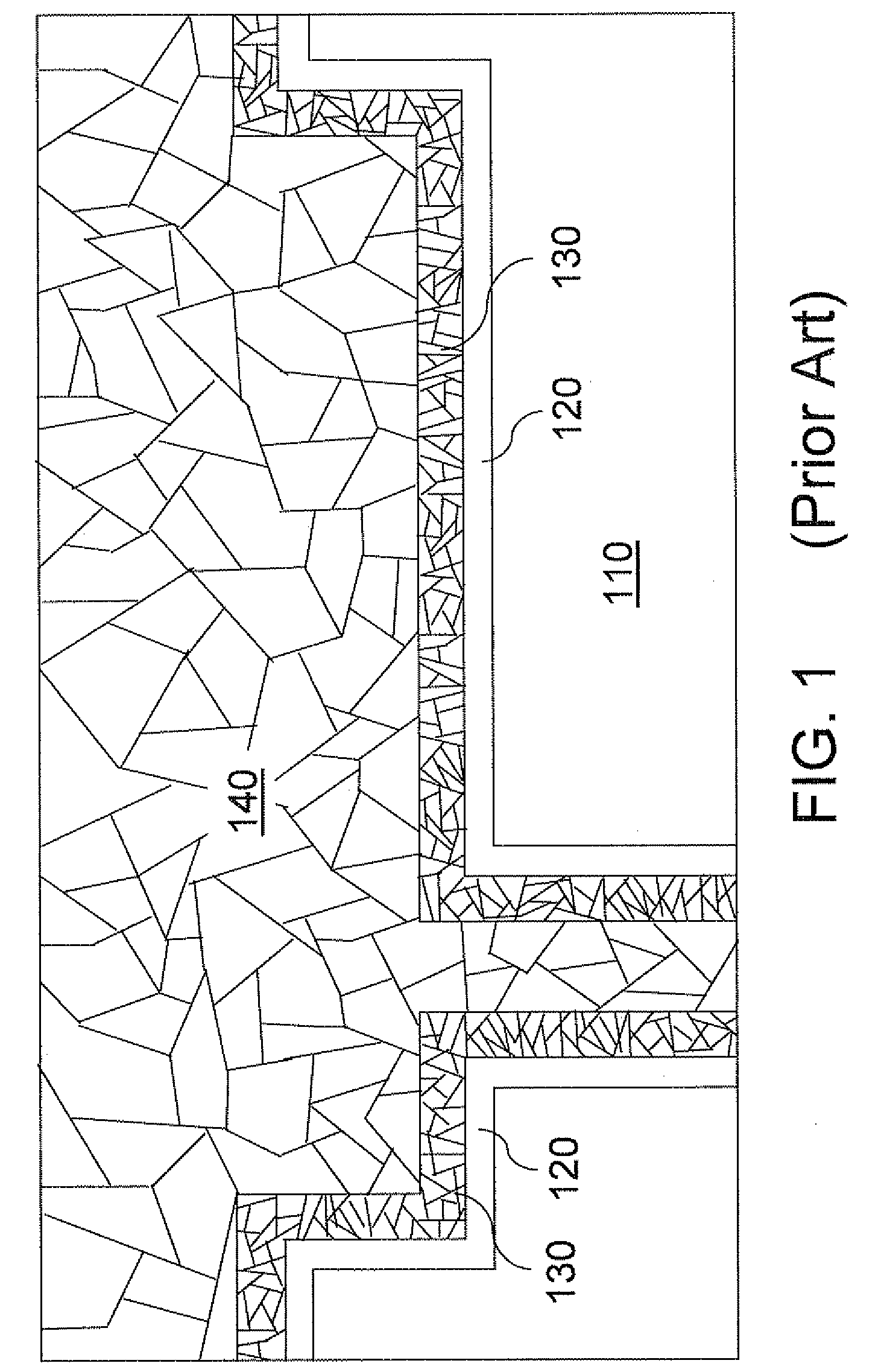

Microstructure modification in copper interconnect structure

ActiveUS20090206484A1Preventing diffusion of copperFaster rateSemiconductor/solid-state device detailsSolid-state devicesCopper platingMetal interconnect

Cobalt is added to a copper seed layer, a copper plating layer, or a copper capping layer in order to modify the microstructure of copper lines and vias. The cobalt can be in the form of a copper-cobalt alloy or as a very thin cobalt layer. The grain boundaries configured in bamboo microstructure in the inventive metal interconnect structure shut down copper grain boundary diffusion. The composition of the metal interconnect structure after grain growth contains from about 1 ppm to about 10% of cobalt in atomic concentration. Grain boundaries extend from a top surface of a copper-cobalt alloy line to a bottom surface of the copper-cobalt alloy line, and are separated from any other grain boundary by a distance greater than a width of the copper-cobalt alloy line.

Owner:TESSERA INC

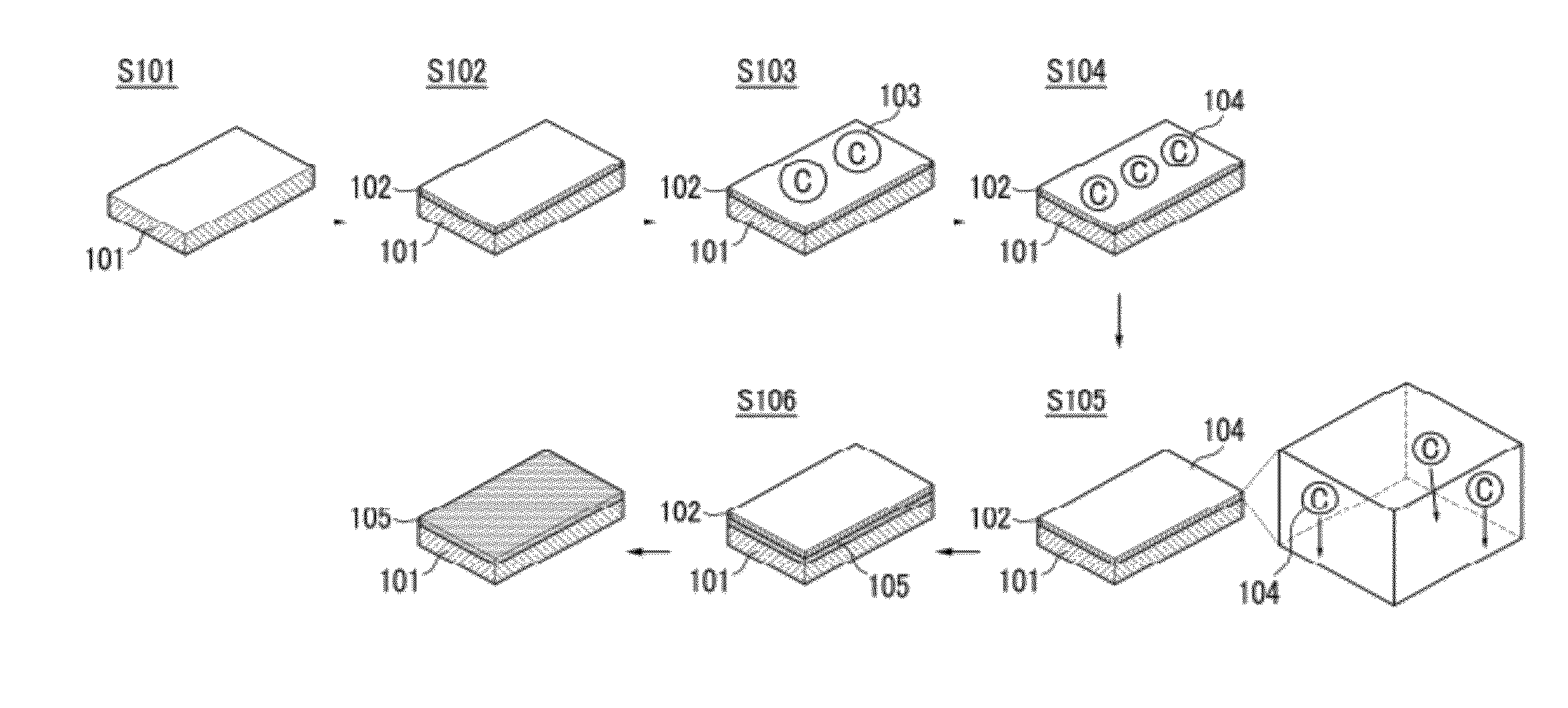

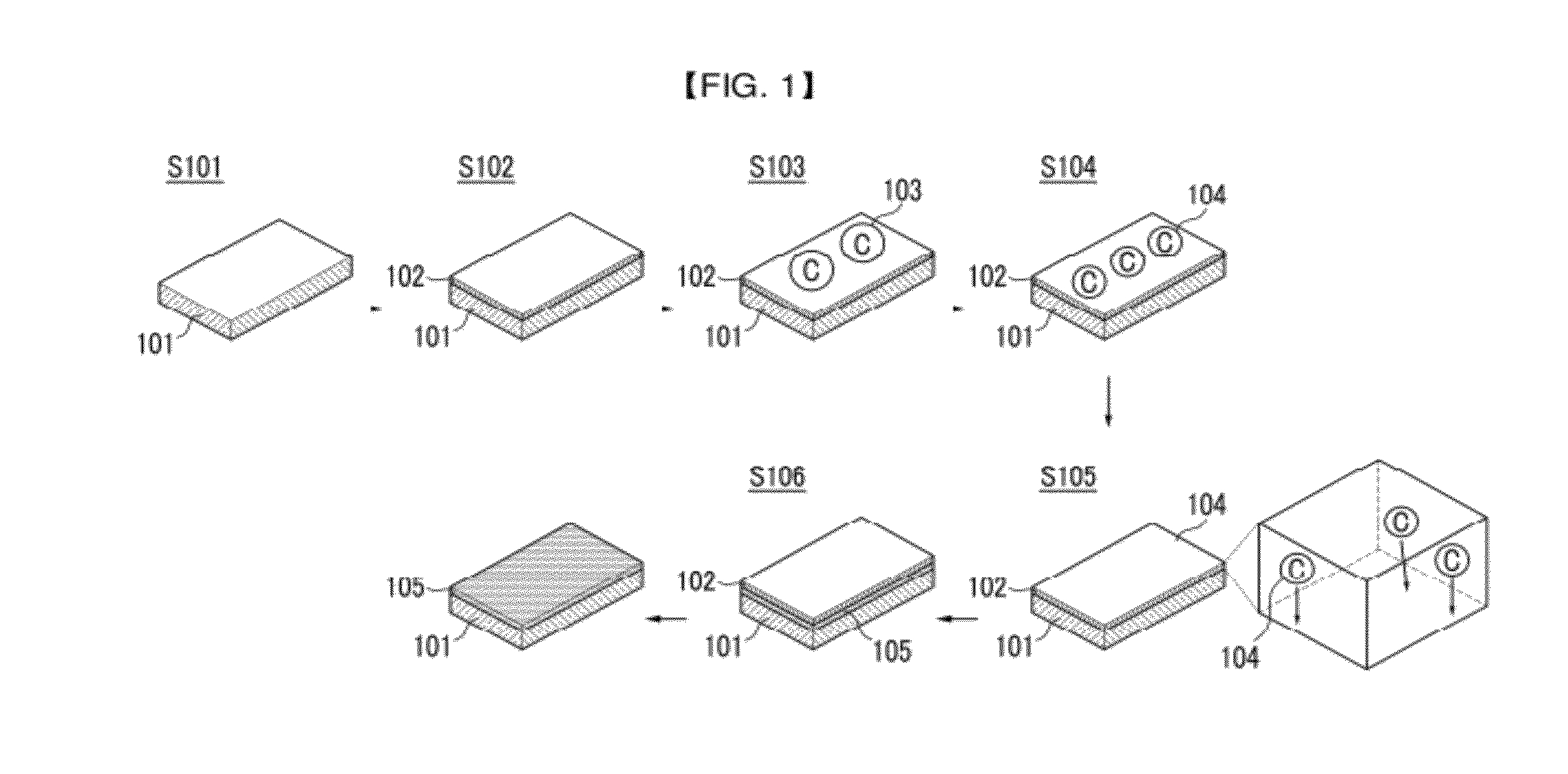

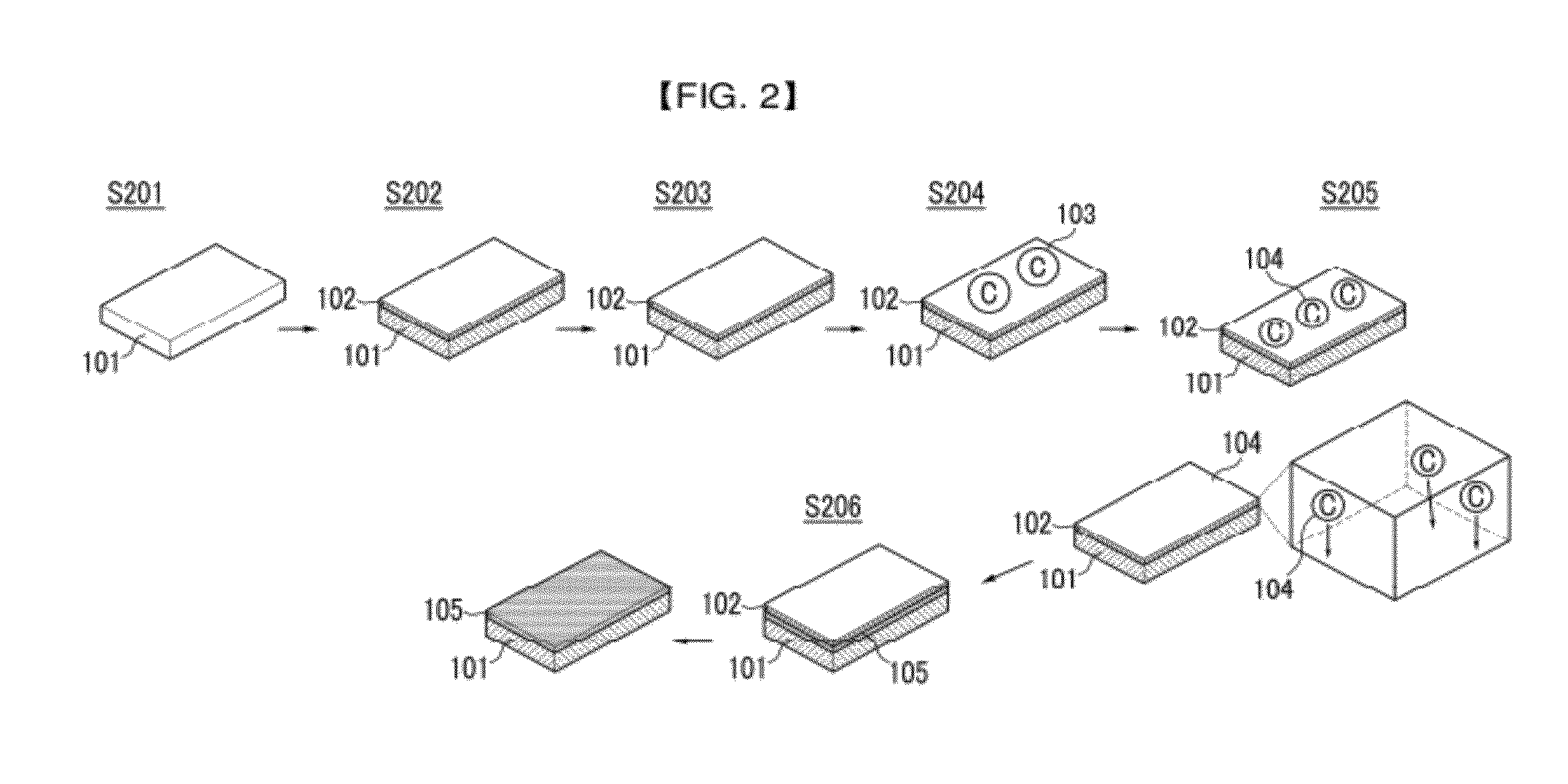

Method for manufacturing graphene, transparent electrode and active layer comprising the same, and display, electronic device, optoelectronic device, battery, solar cell, and dye-sensitized solar cell including the electrode and the active layer

InactiveUS20120328906A1Easy to patternImprove featuresMaterial nanotechnologyFinal product manufactureDisplay deviceSolar cell

Disclosed is a method of manufacturing graphene, a transparent electrode and an active layer including the graphene, and a display, an electronic device, an optoelectronic device, a solar cell, and a dye-sensitized solar cell including the transparent electrode and the active layer. The method of manufacturing graphene includes: (a) preparing a subject substrate; (b) forming a metal thin film on the subject substrate and heat-treating the metal thin film to increase the grain size of the metal thin film; (c) supplying a carbon source material on the metal thin film; (d) heating the supplied carbon source material, the subject substrate, and the metal thin film; (e) diffusing carbon atoms generated from the heated carbon source material due to thermal decomposition into the metal thin film; and (f) forming graphene on the subject substrate by the carbon atoms diffused through the metal thin film.

Owner:UNIST ACAD IND RES CORP

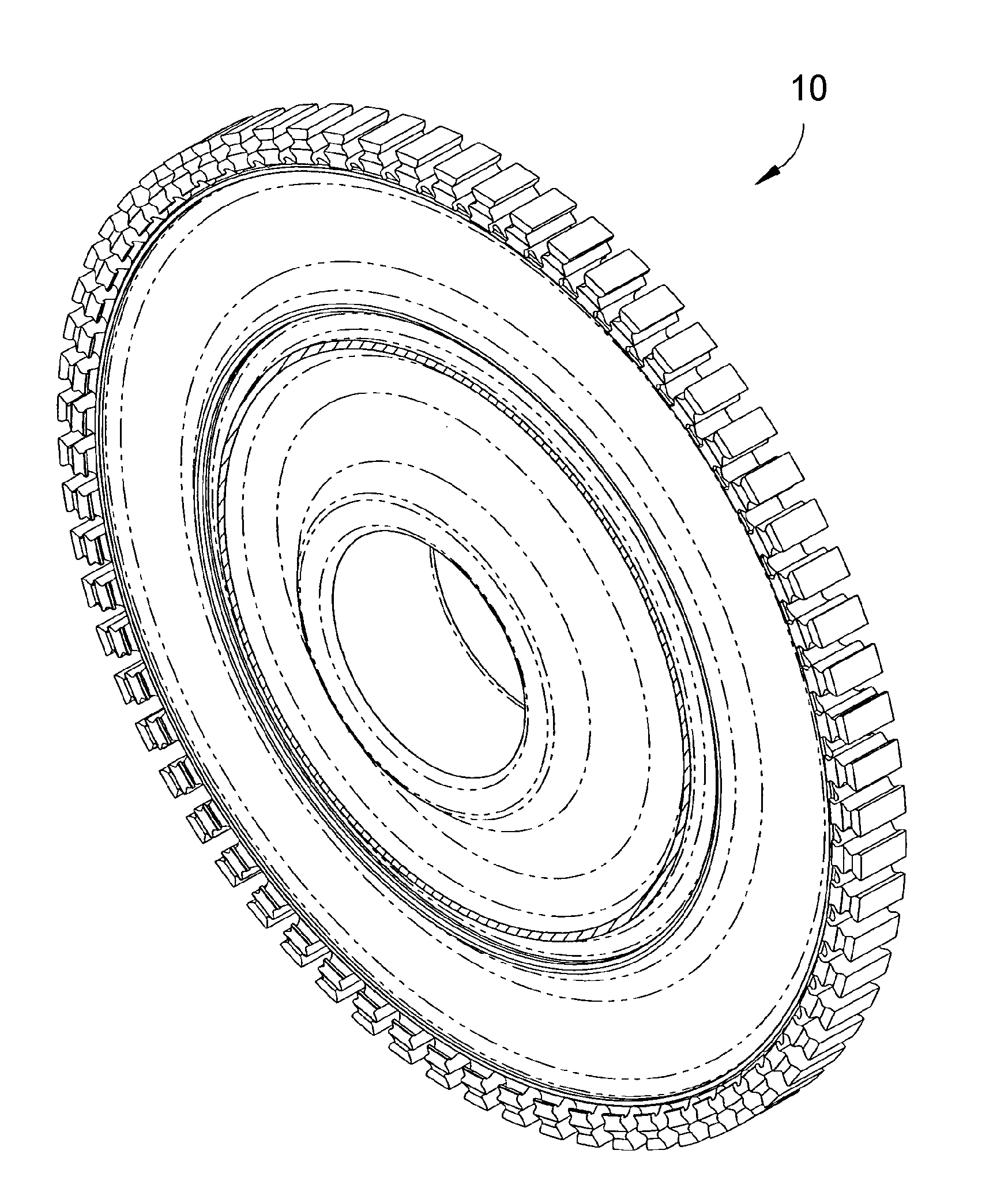

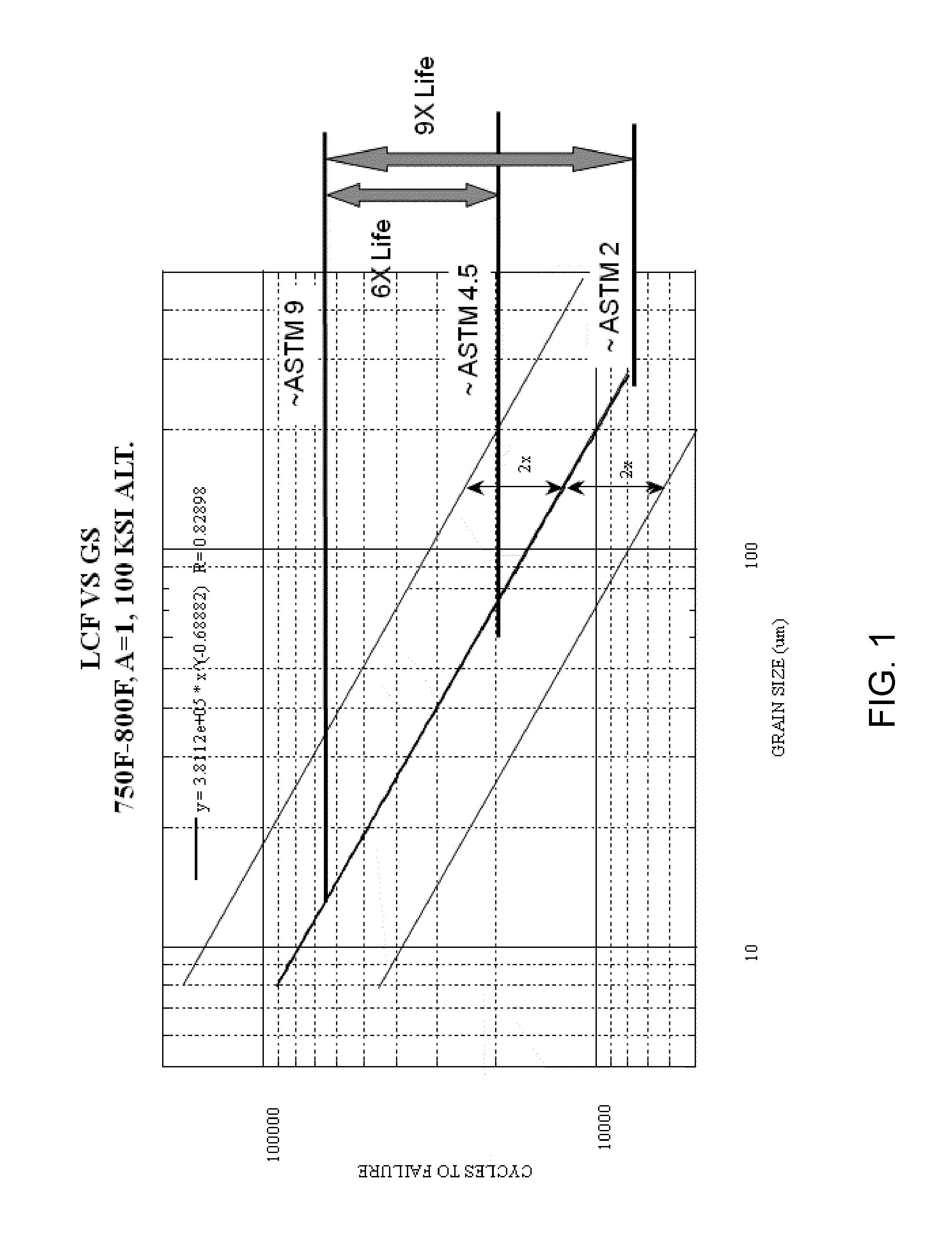

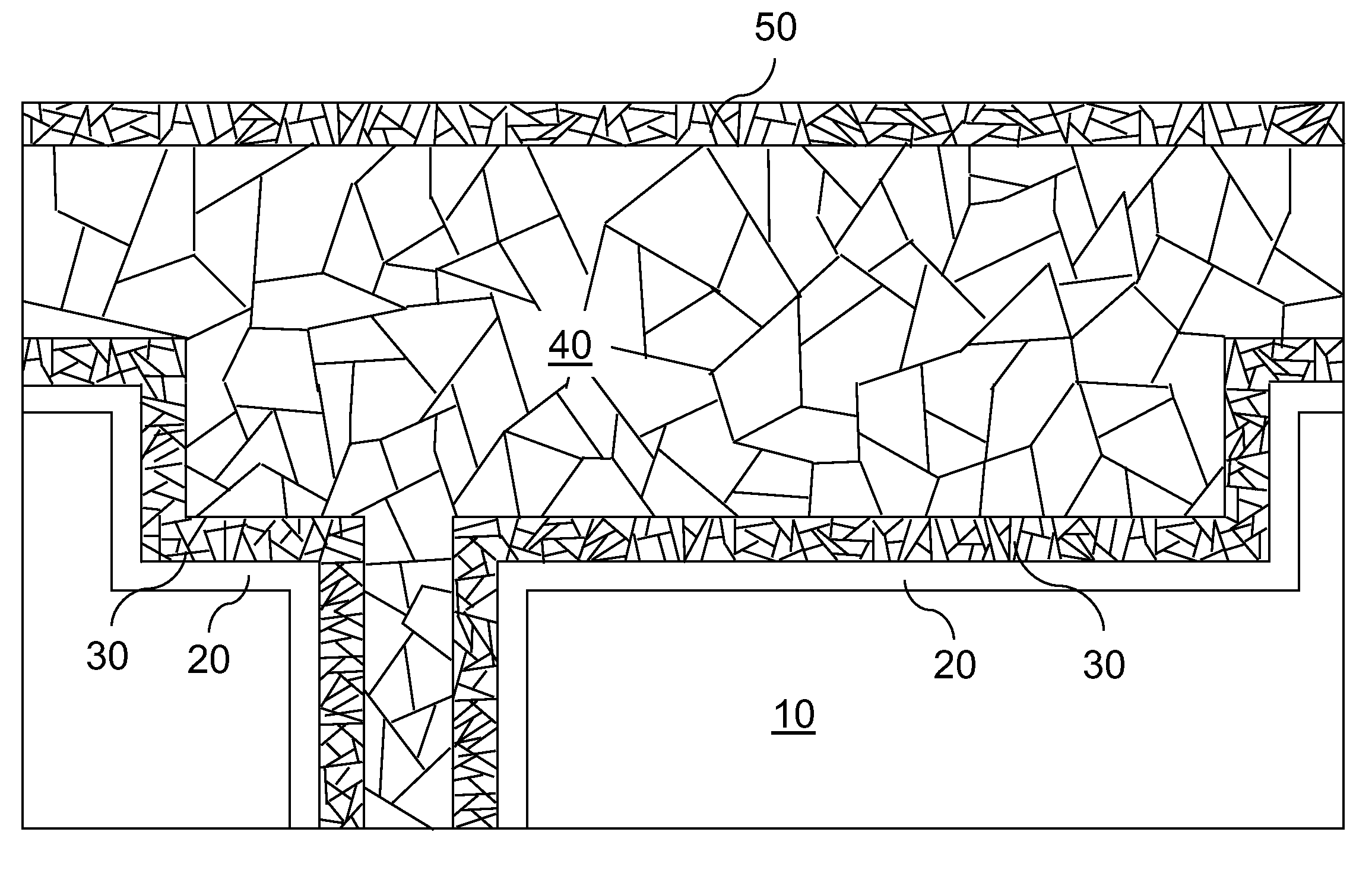

Method of controlling and refining final grain size in supersolvus heat treated nickel-base superalloys

InactiveUS20100329883A1Finer uniform grain sizeImproved low cycle fatigue behaviorPropellersEngine manufactureRheniumNiobium

A gamma prime precipitation-strengthened nickel-base superalloy and method of forging an article from the superalloy to promote a low cycle fatigue resistance and high temperature dwell behavior of the article. The superalloy has a composition of, by weight, 16.0-22.4% cobalt, 6.6-14.3% chromium, 2.6-4.8% aluminum, 2.4-4.6% titanium, 1.4-3.5% tantalum, 0.9-3.0% niobium, 1.9-4.0% tungsten, 1.9-3.9% molybdenum, 0.0-2.5% rhenium, greater than 0.05% carbon, at least 0.1% hafnium, 0.02-0.10% boron, 0.03-0.10% zirconium, the balance nickel and incidental impurities. A billet is formed of the superalloy and worked at a temperature below the gamma prime solvus temperature of the superalloy so as to form a worked article, which is then heat treated above the gamma prime solvus temperature of the superalloy to uniformly coarsen the grains of the article, after which the article is cooled to reprecipitate gamma prime. The article has an average grain size of not coarser than ASTM 7 and is substantially free of critical grain growth.

Owner:GENERAL ELECTRIC CO

Microstructure modification in copper interconnect structure

InactiveUS20100323517A1Inhibited DiffusionFaster rateSemiconductor/solid-state device detailsSolid-state devicesCopper platingMetal interconnect

Cobalt is added to a copper seed layer, a copper plating layer, or a copper capping layer in order to modify the microstructure of copper lines and vias. The cobalt can be in the form of a copper-cobalt alloy or as a very thin cobalt layer. The grain boundaries configured in bamboo microstructure in the inventive metal interconnect structure shut down copper grain boundary diffusion. The composition of the metal interconnect structure after grain growth contains from about 1 ppm to about 10% of cobalt in atomic concentration. Grain boundaries extend from a top surface of a copper-cobalt alloy line to a bottom surface of the copper-cobalt alloy line, and are separated from any other grain boundary by a distance greater than a width of the copper-cobalt alloy line.

Owner:TESSERA INC

Microstructure modification in copper interconnect structure

ActiveUS7843063B2Inhibited DiffusionFaster rateSemiconductor/solid-state device detailsSolid-state devicesMetal interconnectCopper plating

Cobalt is added to a copper seed layer, a copper plating layer, or a copper capping layer in order to modify the microstructure of copper lines and vias. The cobalt can be in the form of a copper-cobalt alloy or as a very thin cobalt layer. The grain boundaries configured in bamboo microstructure in the inventive metal interconnect structure shut down copper grain boundary diffusion. The composition of the metal interconnect structure after grain growth contains from about 1 ppm to about 10% of cobalt in atomic concentration. Grain boundaries extend from a top surface of a copper-cobalt alloy line to a bottom surface of the copper-cobalt alloy line, and are separated from any other grain boundary by a distance greater than a width of the copper-cobalt alloy line.

Owner:TESSERA INC

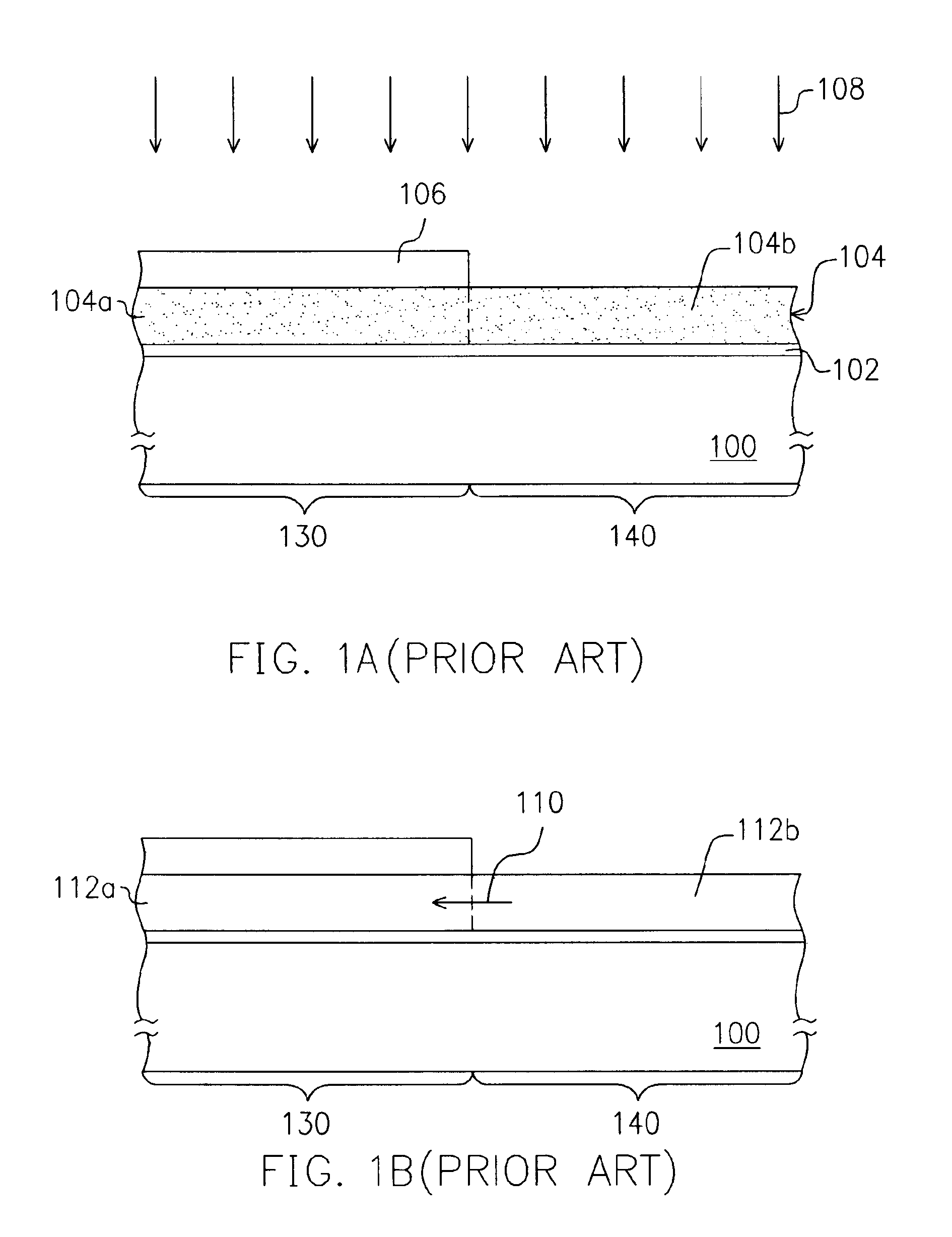

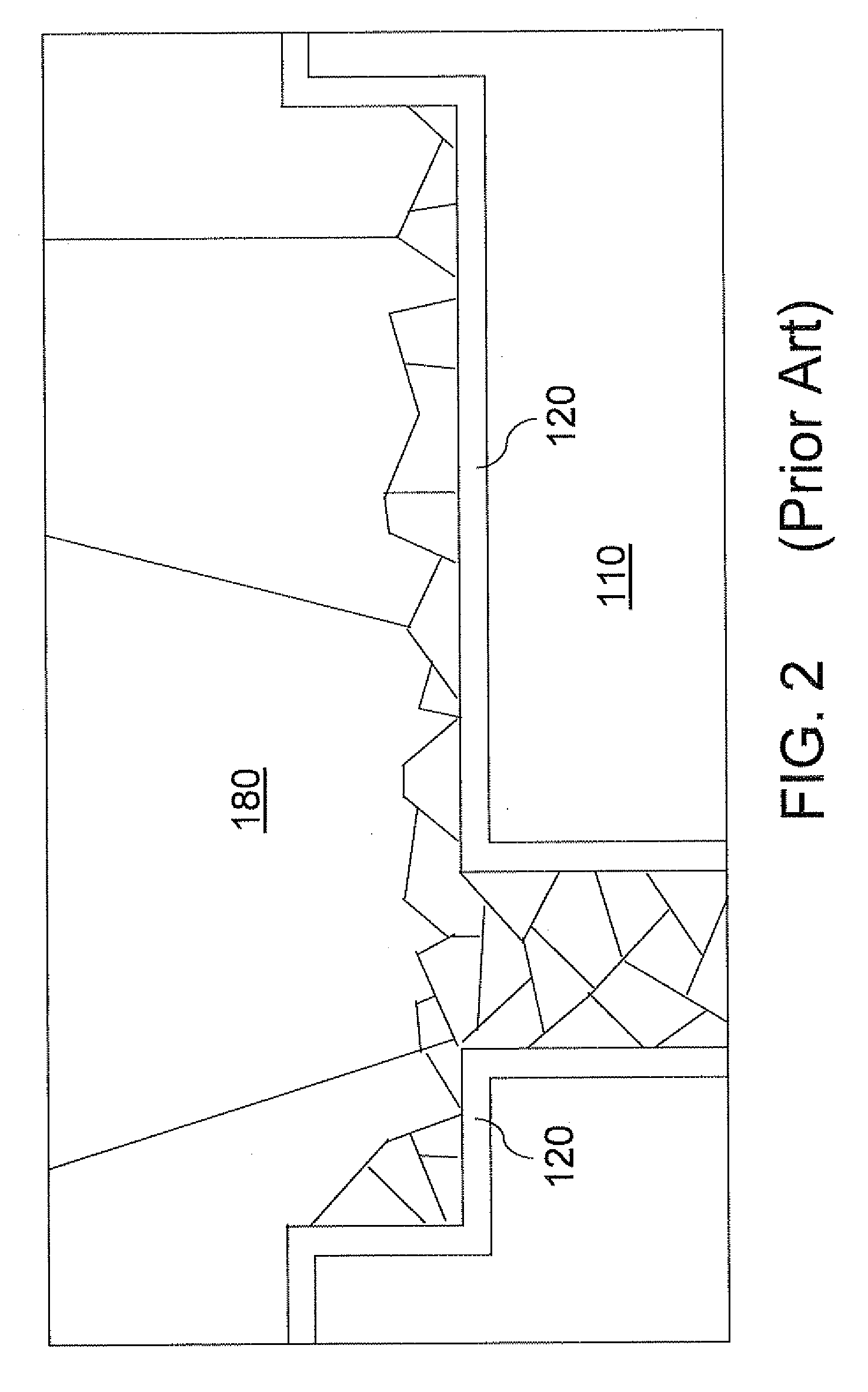

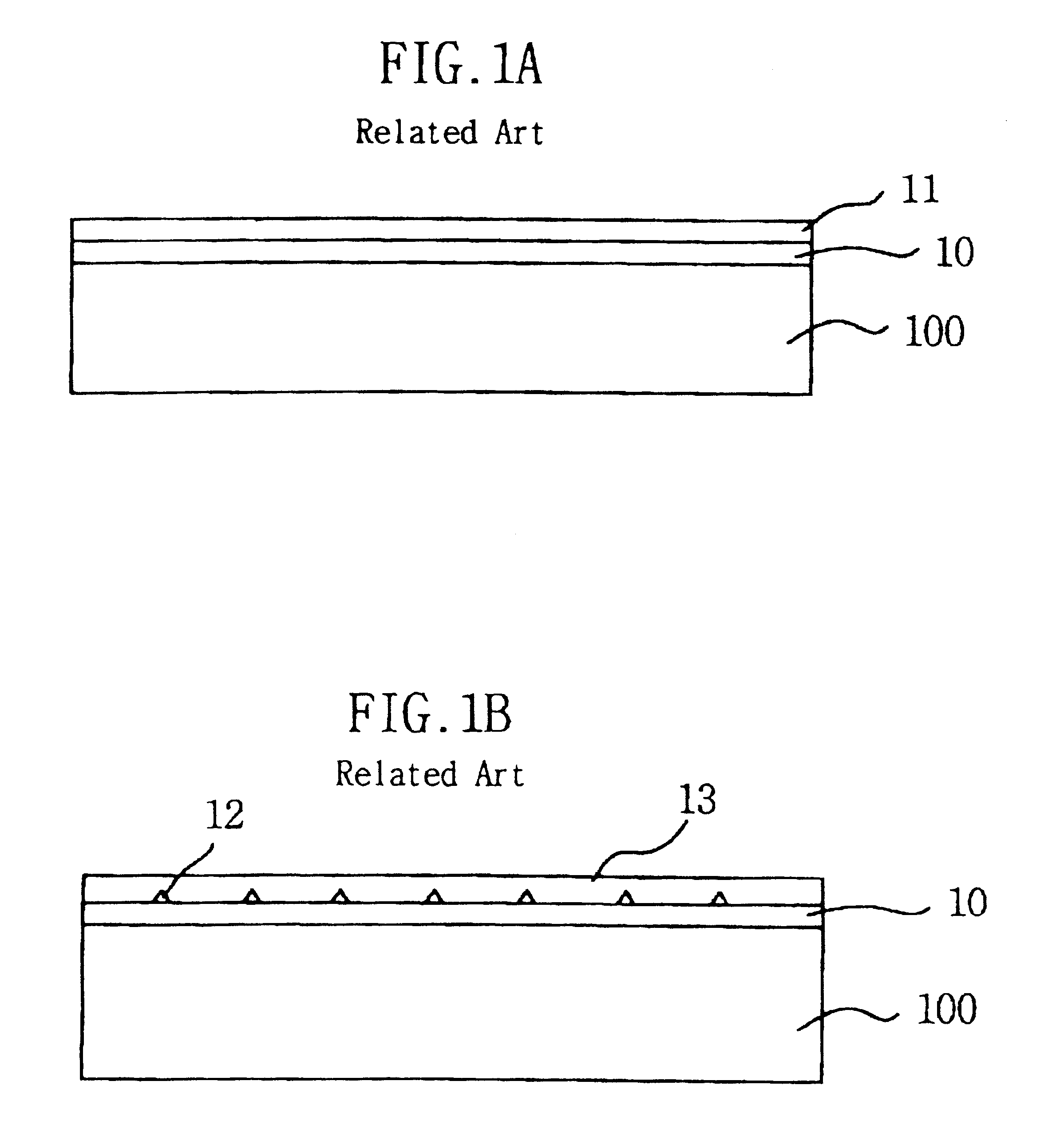

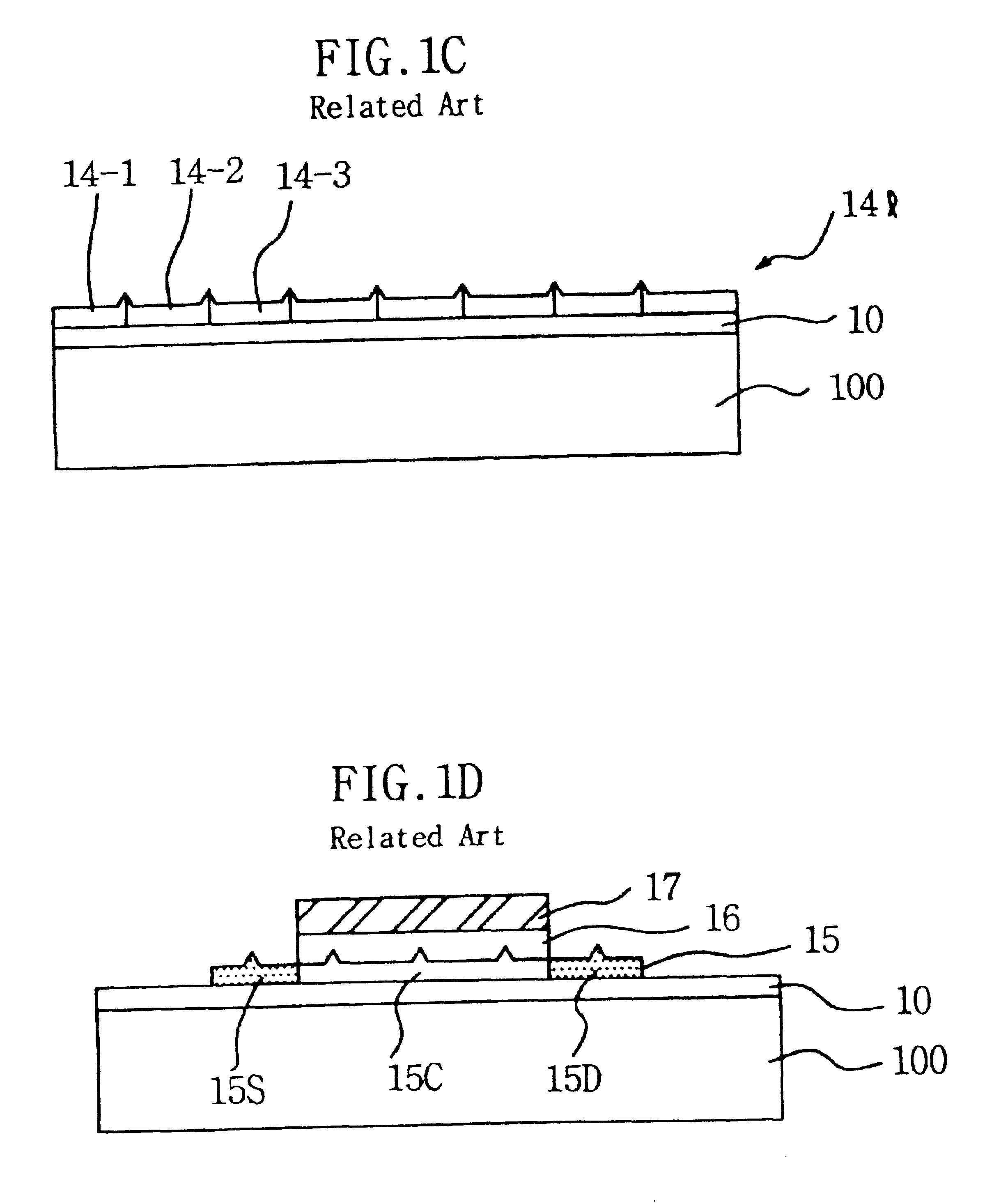

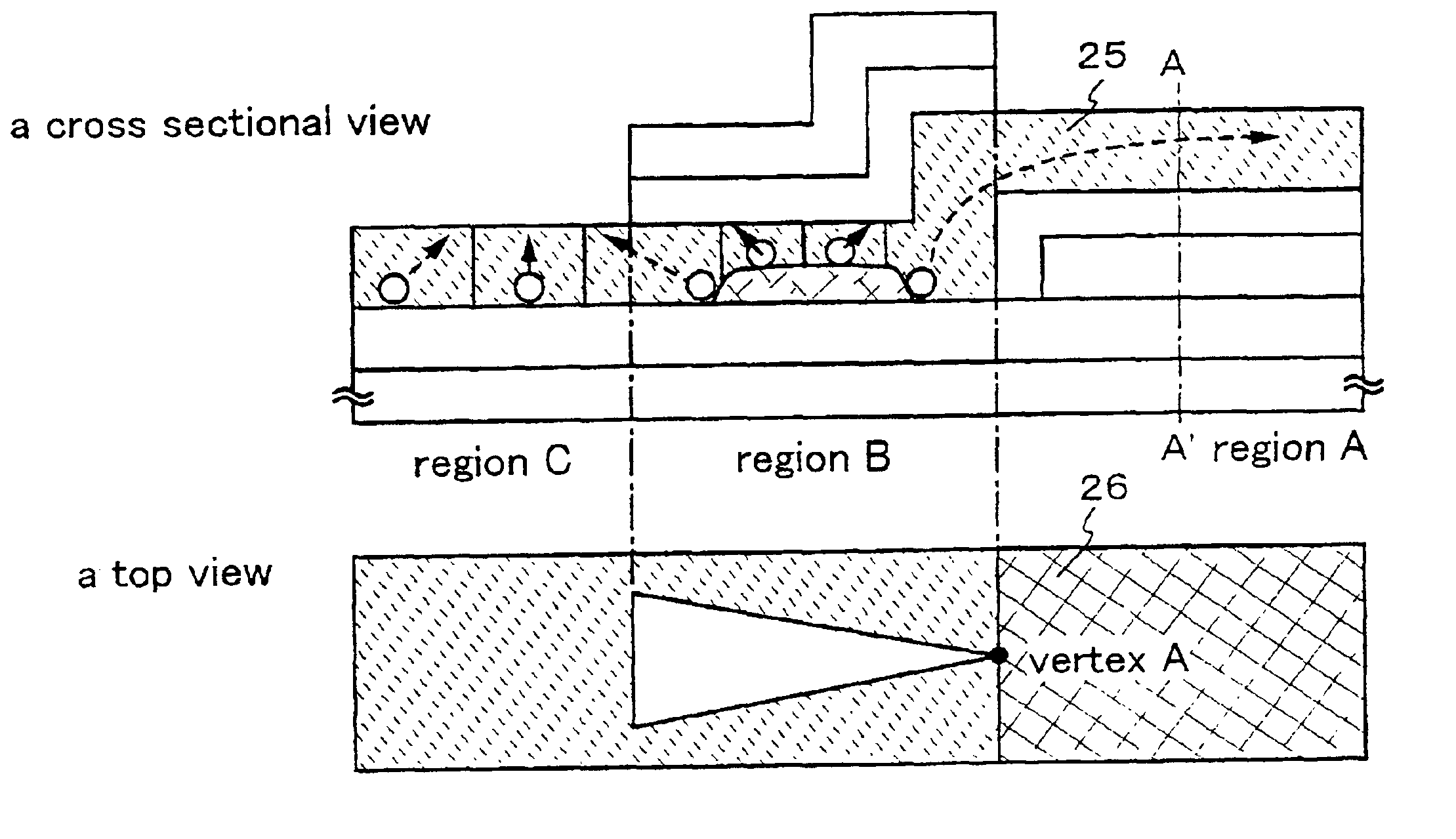

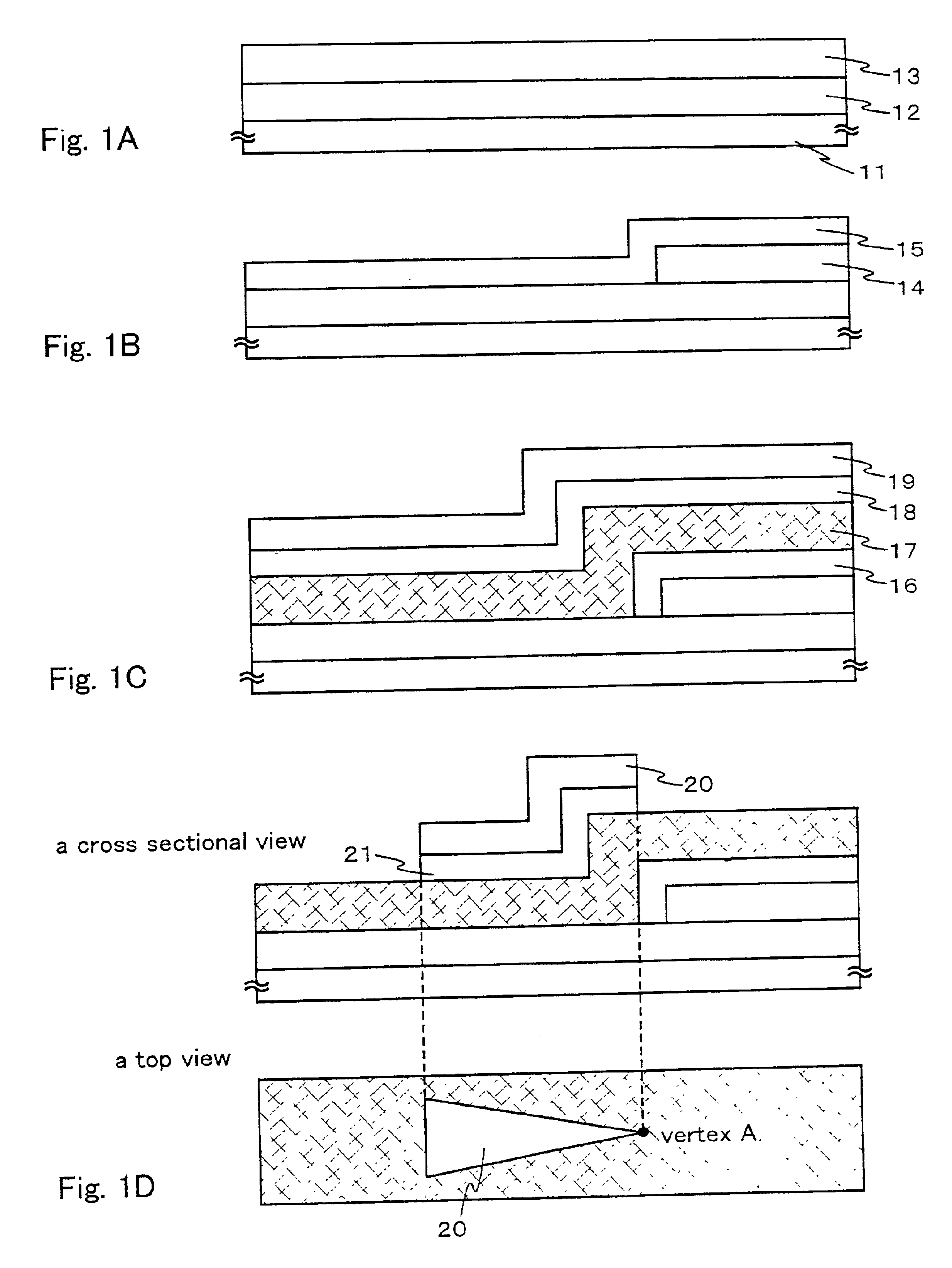

Method of crystallizing a silicon film and thin film transistor and fabricating method thereof using the same

InactiveUS6387779B1Improve featuresIncrease silicon grain sizeTransistorSolid-state devicesCrystalline siliconAmorphous silicon

The present invention relates to a method of crystallizing a silicon film, a thin film transistor, and a fabricating method thereof using the same. More particularly, the present invention relates forming a crystalline silicon film by crystallizing a silicon film using laser energy, and a thin film transistor and a fabricating method thereof using the same. The present invention includes forming a buffer layer on a substrate and forming an amorphous silicon film on the buffer layer wherein the amorphous silicon film includes a first region and second regions connected to both ends of the first region. The buffer layer is etched to a degree by using the amorphous silicon as a mask, wherein a space is formed under the first region and a central part of the second region contacts a remaining portion of the buffer layer. The amorphous silicon film is then crystallized. In another aspect, the present invention includes a method of fabricating a thin film transistor using this method of crystallizing an amorphous silicon film.

Owner:LG DISPLAY CO LTD

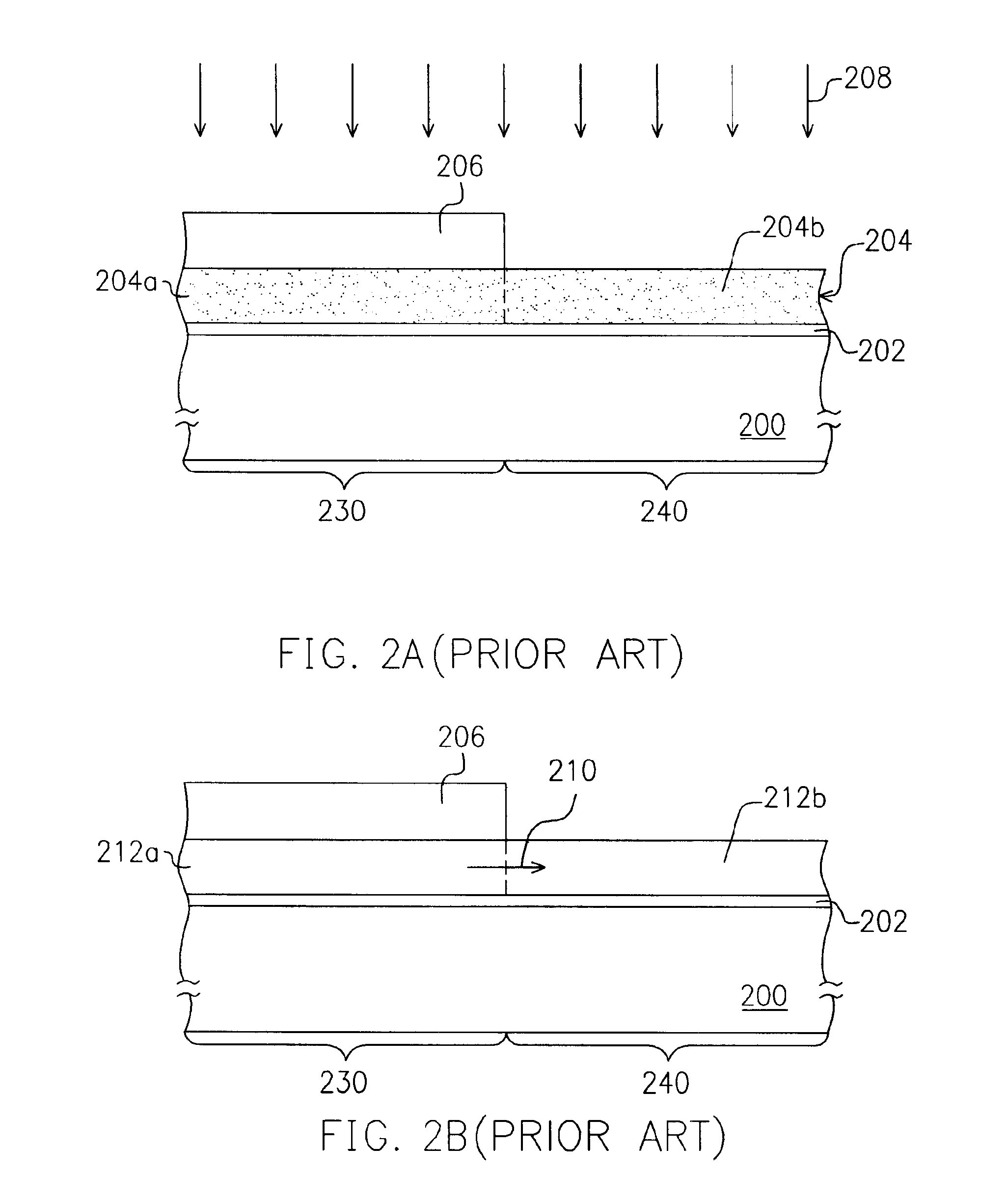

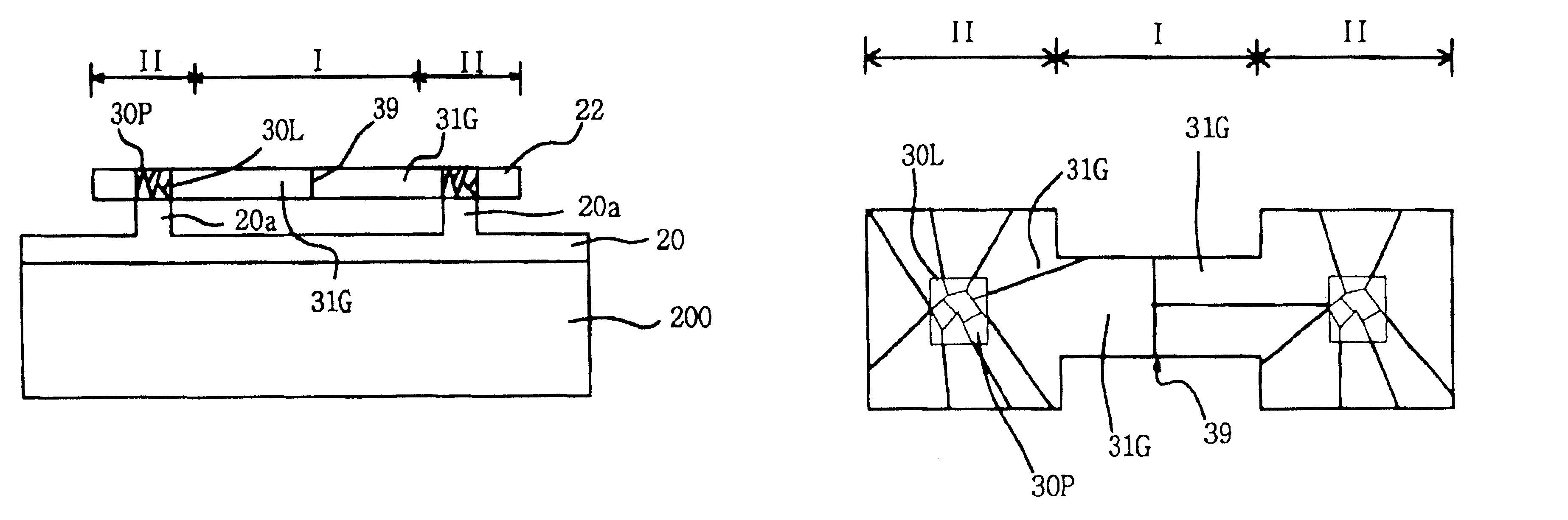

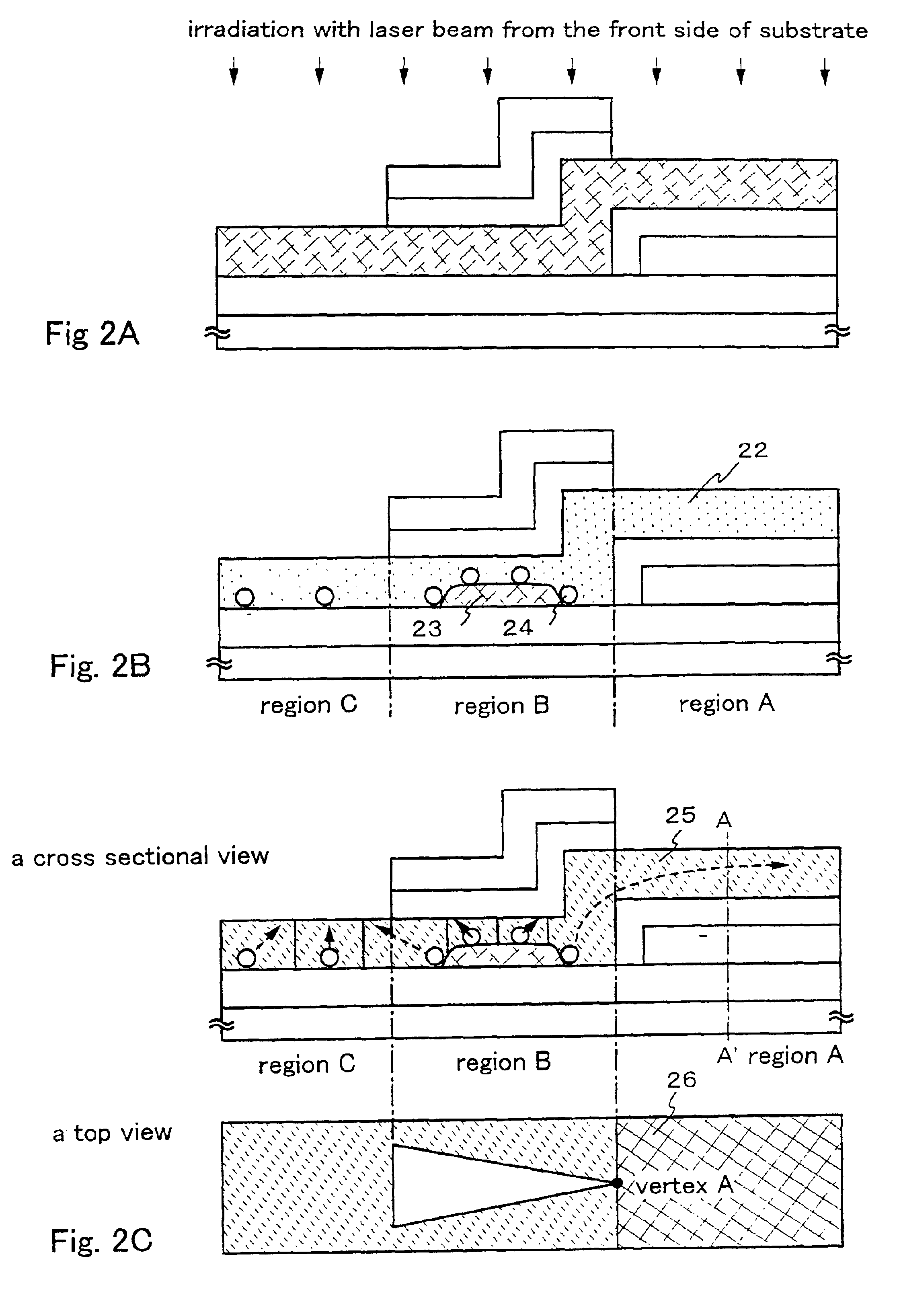

Semiconductor device and method of manufacturing the same

InactiveUS7078321B2Increase speedRun at high speedTransistorSolid-state devicesIrradiationLaser beams

A crystalline semiconductor film in which the position and the size of crystal grains are controlled is provided, and a TFT that can operate at high speed is obtained by forming a channel formation region of the TFT from the crystalline semiconductor film. A heat retaining film is formed on an insulating surface, a semiconductor film is formed to cover the heat retaining film, and a reflective film is formed to partially cover the semiconductor film. The reflective films and the semiconductor film are irradiated with a laser beam. The reflective film creates a distribution in effective irradiation intensity of laser beam on the semiconductor film. The distribution, with the heat retaining effect provided by the heat retaining film, generates a temperature gradient in the semiconductor film. Utilizing these, the position where crystal nuclei are to be generated and the direction in which crystal growth should advance can be controlled and crystal grains having a large grain size can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

Perovskite solar cell and preparation method thereof

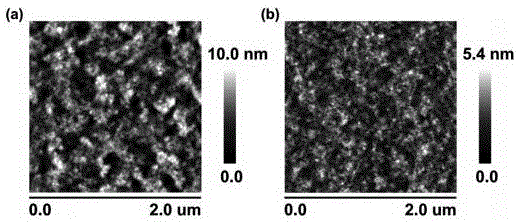

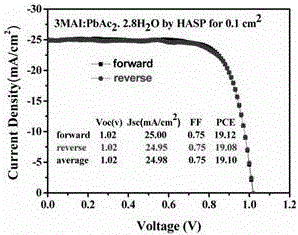

InactiveCN106684247AInhibitory complexImprove photoelectric conversion efficiencySolid-state devicesSemiconductor/solid-state device manufacturingHysteresisSpray coating

The invention discloses a perovskite solar cell and a preparation method thereof. The perovskite solar cell comprises a transparent conductive substrate, a hole transport layer, a decoration layer, a perovskite layer, an electron transport layer, a barrier layer and a metal electrode. The surfaces of PEDOT: PSS, NiOx and the hole transport layer are decorated by ionic liquid based on imidazole, atomic force microscope graphs before and after the decoration are compared, and the decorated surface appearance is more smooth, which is conducive to inhibiting the compounding of dark current. The perovskite layer is a new perovskite material 3MAI: PbAc2.xH2O (x is not smaller than 0 and is not greater than 3), and is prepared by quickly preheating a substrate and heating a perovskite precursor solution, namely instant heating assisted spray coating technology (HASP) at a low temperature (lower than 100 DEG C), which is conducive to increasing the grain size of perovskite and reducing the defects between perovskite grains so as to greatly improve the efficiency of the perovskite battery. The photoelectric conversion efficiency of the final battery device is greater than 19%, the flexible device efficiency is 10.8%, no hysteresis effect is formed, and thus the preparation method has a broad application prospect.

Owner:CENT SOUTH UNIV

Aluminum-scandium alloy target blank and preparation method and application thereof

InactiveCN107841639ALow oxygenMeet the characteristic requirements of sputteringVacuum evaporation coatingSputtering coatingCrystalliteScandium

The invention relates to an aluminum-scandium alloy target blank and a preparation method and application thereof. The aluminum-scandium alloy target blank comprises, by weight part, 0.1-15 parts of scandium and 85-99.9 parts of aluminum, and the oxygen content of the aluminum-scandium alloy target blank is smaller than or equal to 160 ppm. The aluminum-scandium alloy target blank has the beneficial effects that the oxygen content is low, then the prepared target blank cannot generate abnormal discharge or particle splashing scars, and later high-quality film forming can be guaranteed; and inaddition, the aluminum-scandium alloy target blank is even in target blank crystal particle size.

Owner:GEMCH MATERIAL TECH SUZHOU

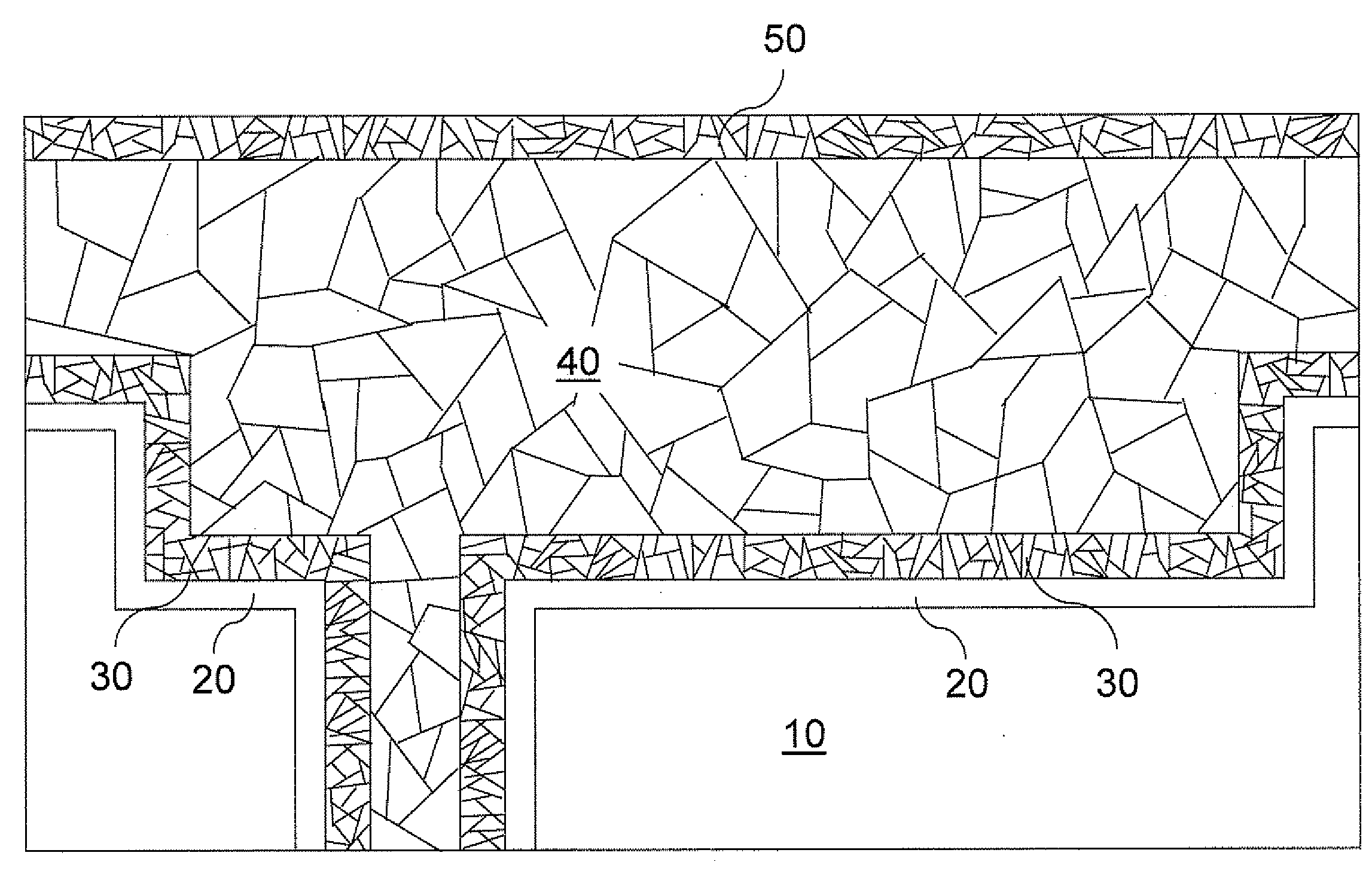

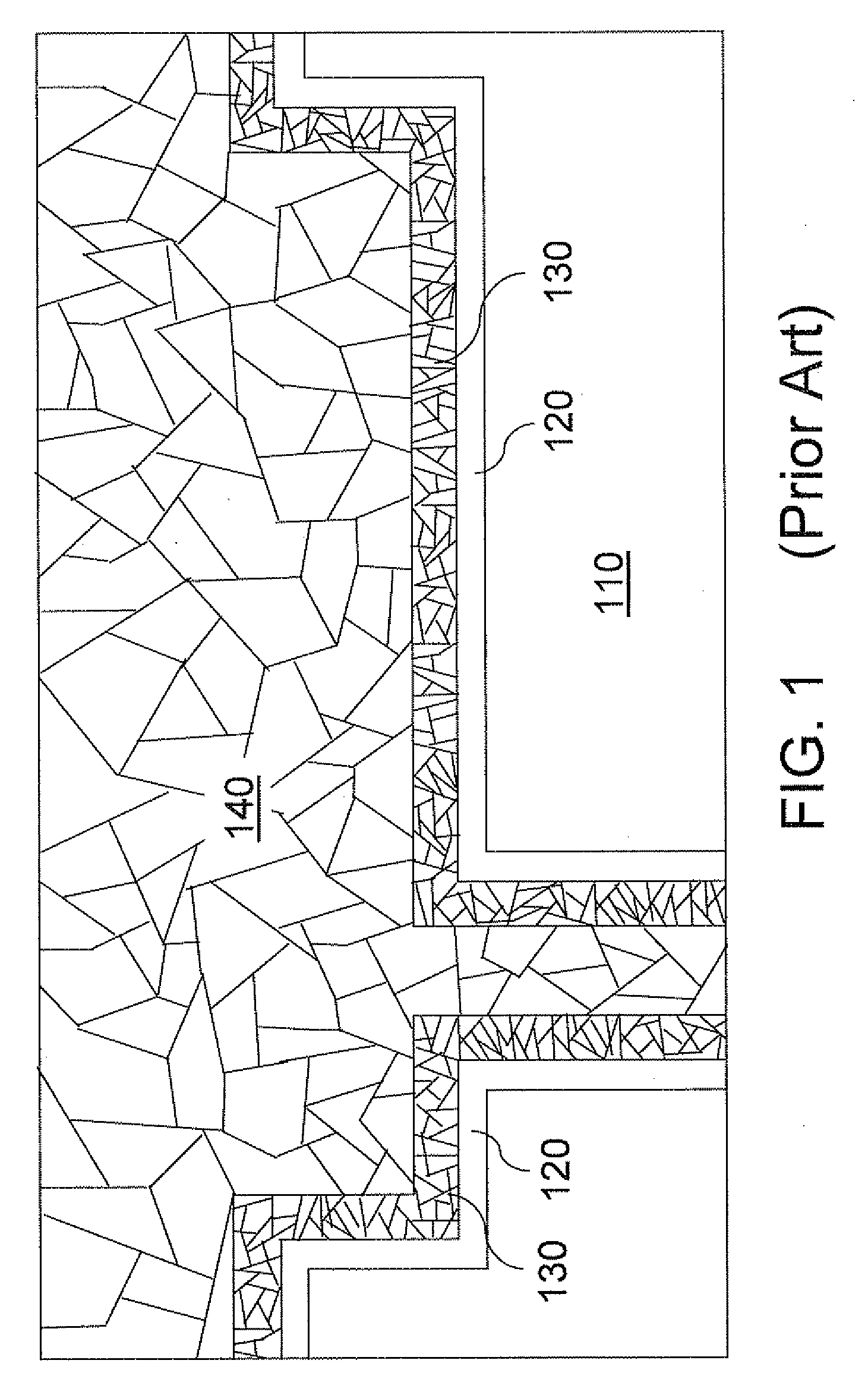

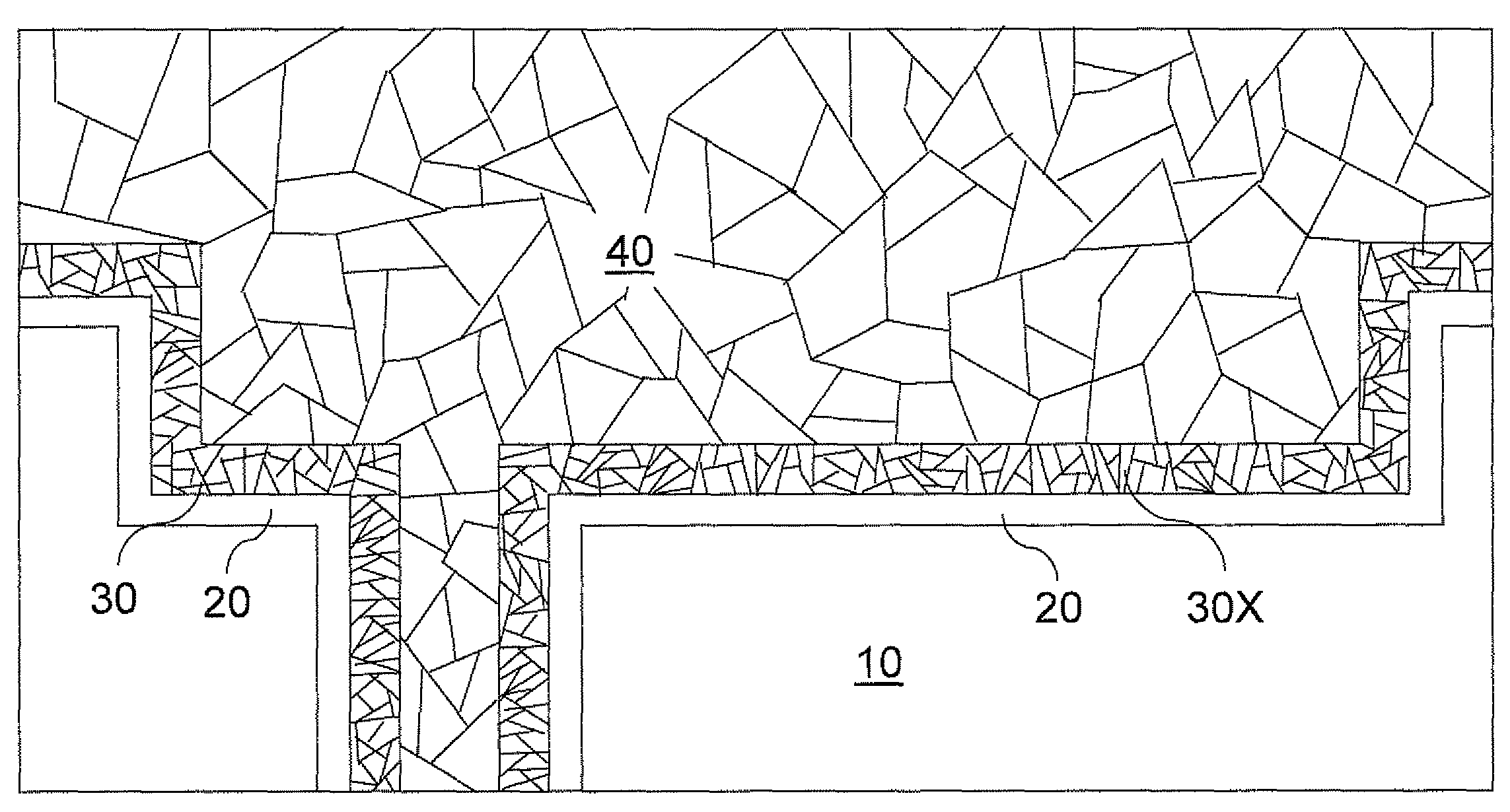

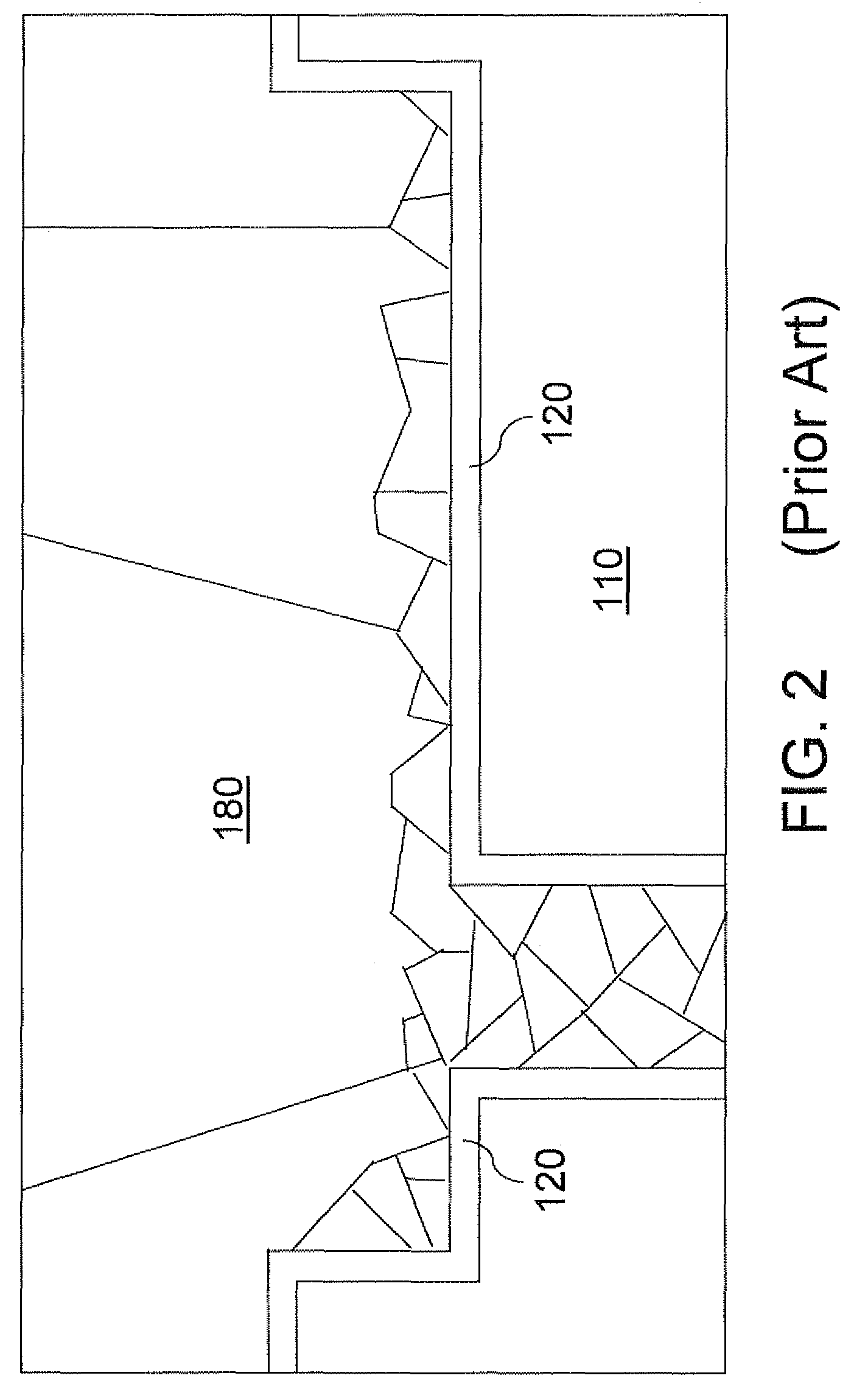

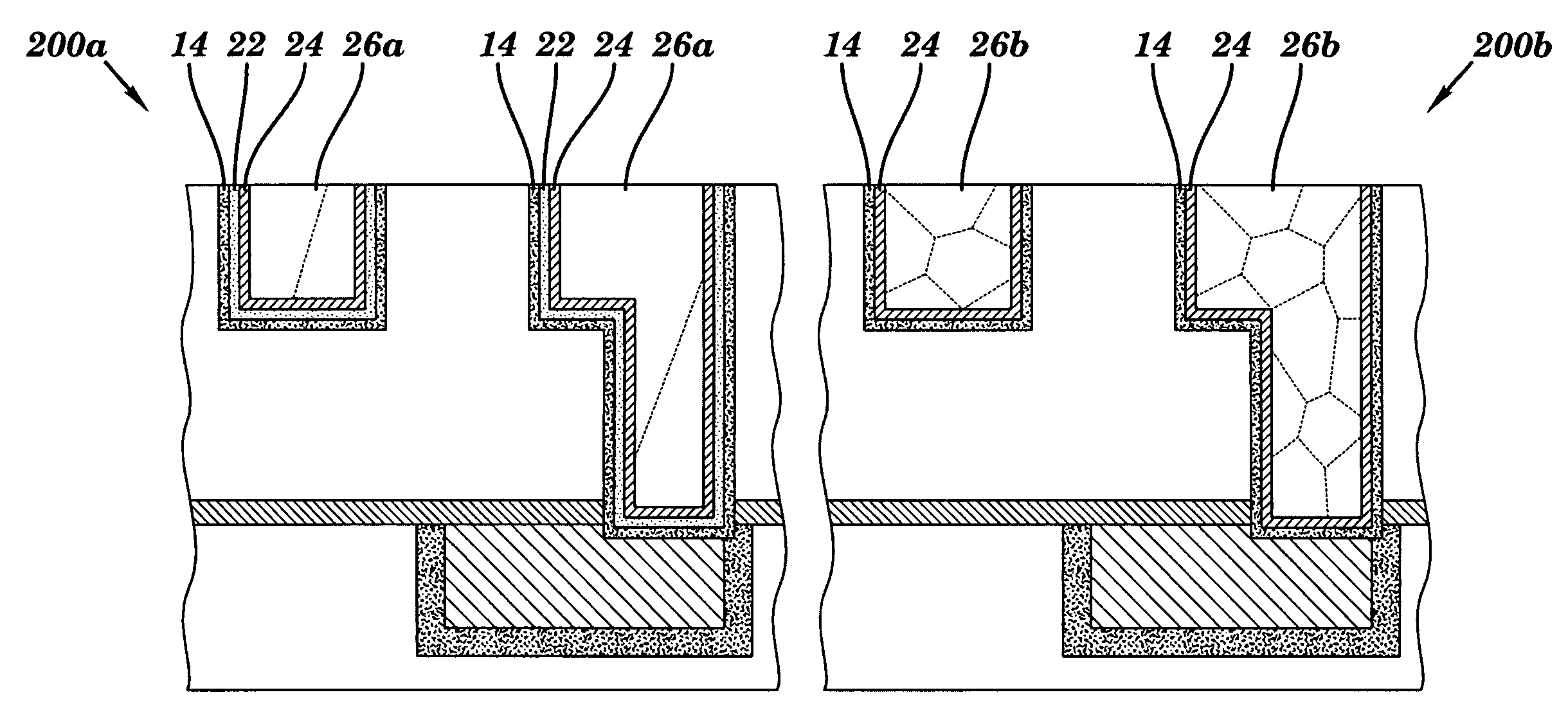

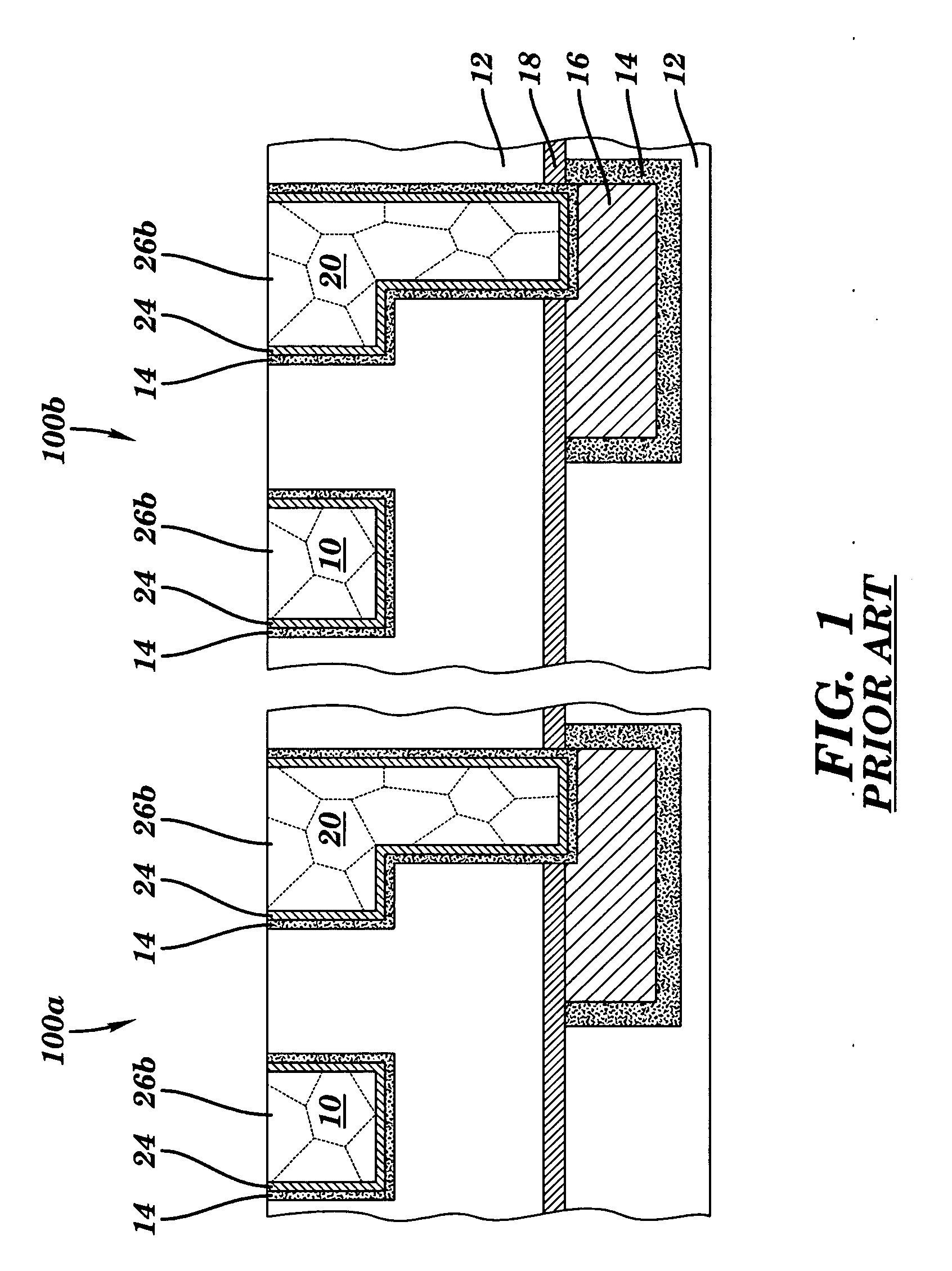

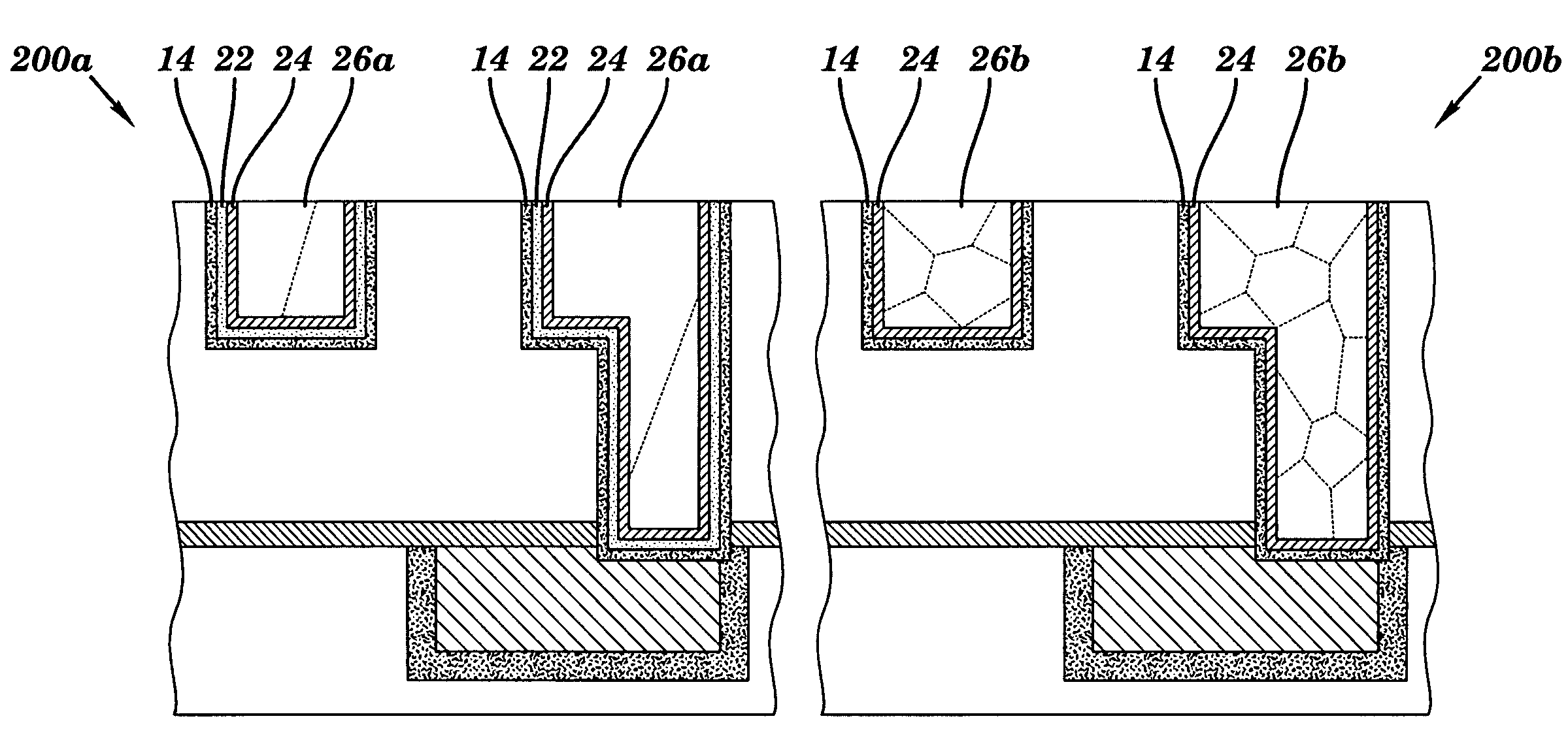

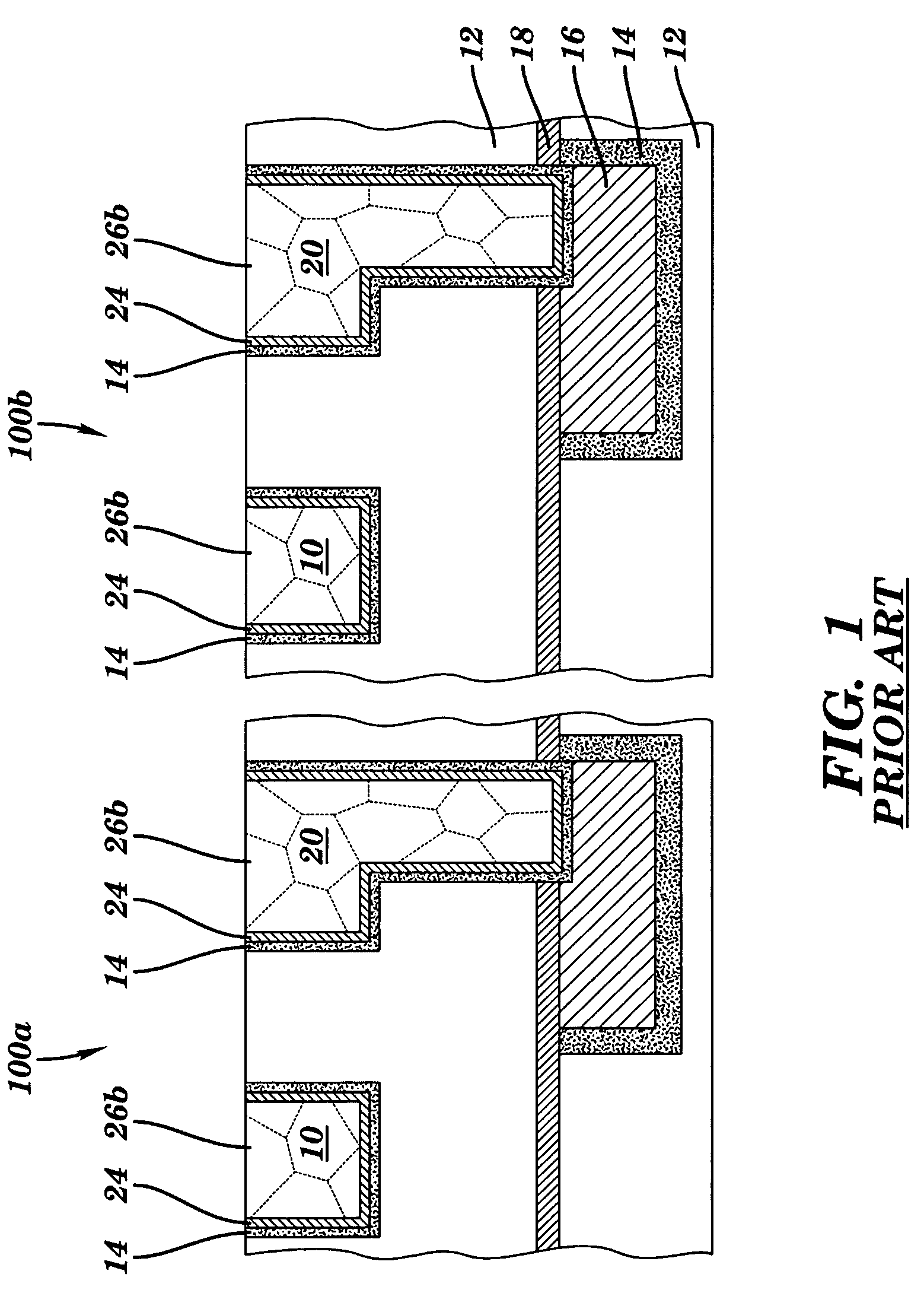

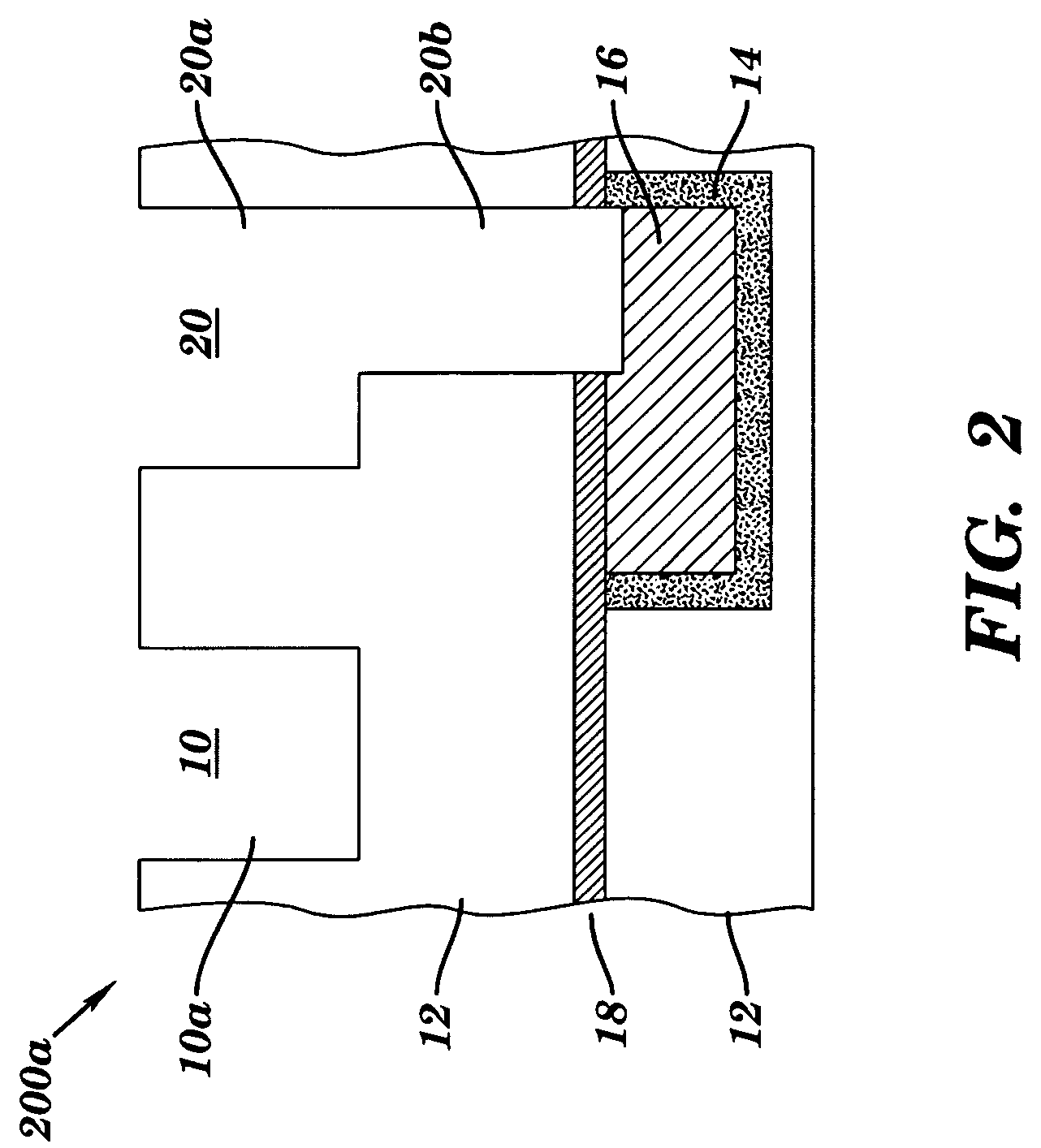

Simultaneous grain modulation for beol applications

InactiveUS20090174075A1Reduce processing stepsEfficient executionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureMaterials science

The invention is directed to an improved semiconductor structure, such that within the same insulating layer, Cu interconnects embedded within the same insulating level layer have a different Cu grain size than other Cu interconnects embedded within the same insulating level layer.

Owner:GLOBALFOUNDRIES INC

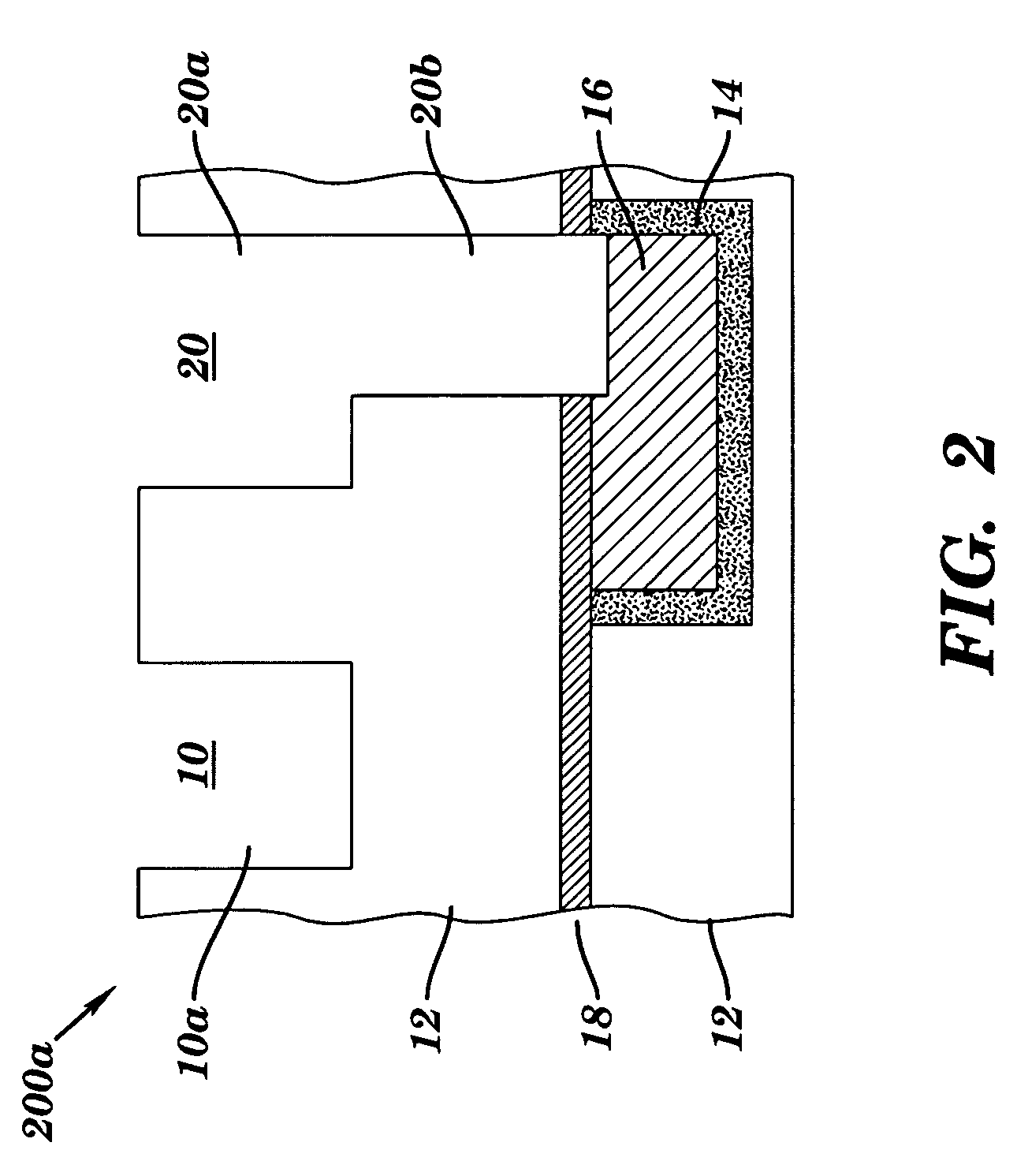

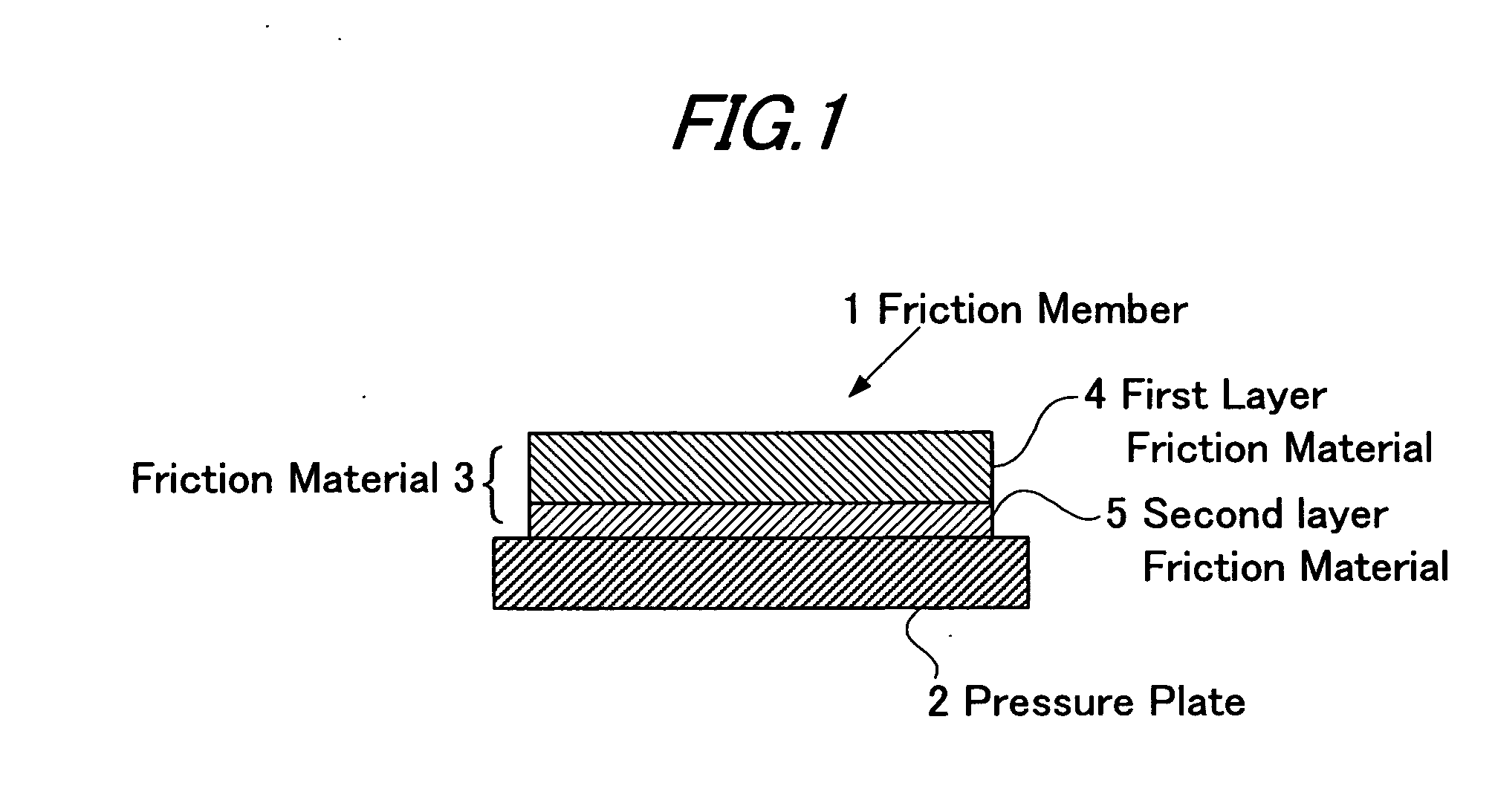

Non-asbestos friction member

A friction material containing a thermosetting resin binder, reinforcing fibers, and a friction modifier are integrally formed with a pressure plate. The friction material has a first layer friction material on a side of a friction surface and a second layer friction material on a side of the pressure plate. A pre-mix containing an elastomer and a cross-linker is blended in the second layer friction material. The premix preferably contains fibers, and the premix preferably contains 10 to 97 vol % of an elastomer blended therewith.

Owner:AKEBONO BRAKE IND CO LTD

Preparation process of sputtered rotary molybdenum-sodium-alloy tubular target

ActiveCN103045925AHigh densitySmall grain sizeVacuum evaporation coatingSputtering coatingSodium molybdateNiobium alloy

The invention discloses a preparation process of a sputtered rotary molybdenum-sodium-alloy tubular target. The preparation process comprises the following steps of: (1) preparing materials, wherein used powder comprises molybdenum powder and sodium molybdate powder, the physical property of the powder is as follows: the Mo content of the molybdenum powder is at least 99.95% with the granularity of 3-5 microns, and the sodium molybdate content of the sodium molybdate powder is at least 99.0% with the granularity of 20-40 microns; (2) blending the powder: weighing the molybdenum powder and the sodium molybdate powder proportionately, controlling the mass percentage content of the molybdenum powder to be 90-99% and that of the sodium molybdate powder to be 1-10%; (3) carrying out mechanical alloying: synthesizing nanometer molybdenum-sodium alloy powder; (4) filling into a die; (5) carrying out cold isostatic pressing; (6) sintering; (7) forging; (8) performing vacuum annealing; and (9) mechanically processing to obtain the sputtered rotary molybdenum-sodium-alloy tubular target. A produced molybdenum-niobium-alloy tubular target has characteristics of uniform elements, no segregation, fine grain size and high purity, completely meets requirements of CIGS (Copper Indium Gallium Selenide) photovoltaic cells and increases the use efficiency of the cells.

Owner:LUOYANG SIFON ELECTRONICS

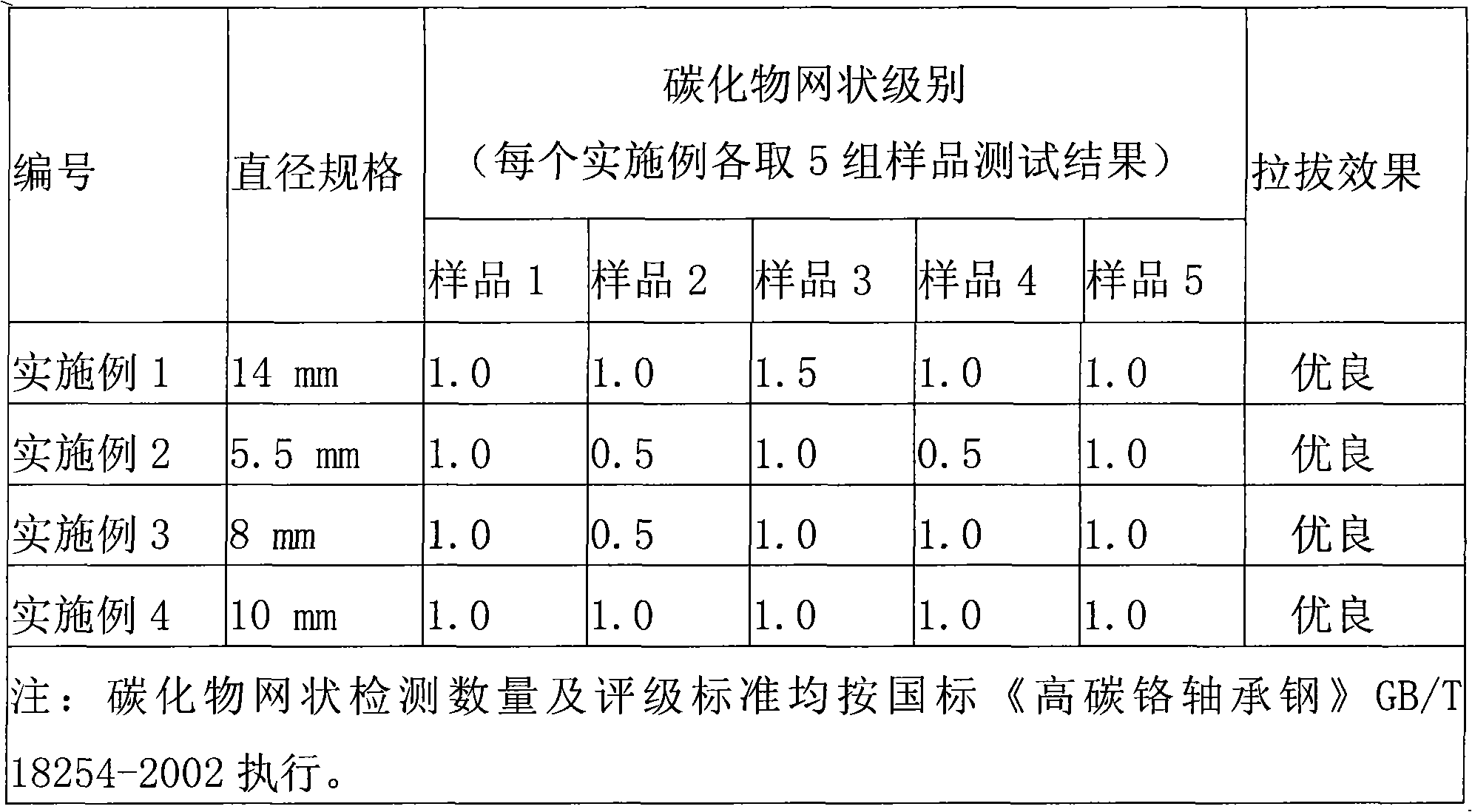

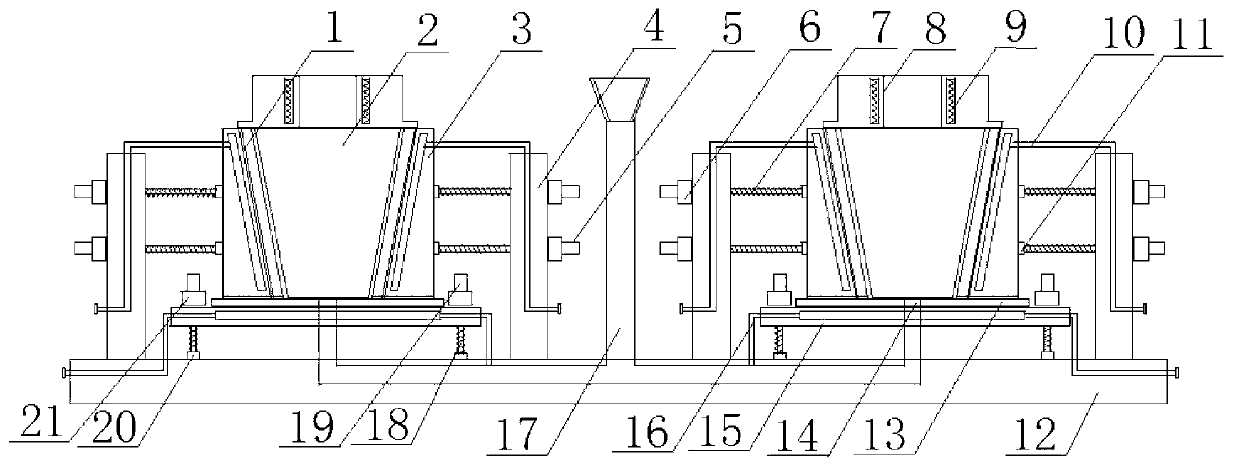

Method for reducing net level of bearing steel wire rod carbide

The invention discloses a method for reducing net level of bearing steel wire rod carbide, including the following steps: firstly, bearing steel continuous casting billet is heated and warmed up, and rough rolling, medium rolling and pre-finishing treatments are carried out at the temperature of 1030 to 1130 DEG C, so that the accumulated elongation percentage n1 of rolled pieces is 65 to 120 times; secondly, pre-hydrocooling treatment of rolled pieces is carried out, the cooling speed is controlled in the range of 10 to 40 DEG C per second, and the cooling time is controlled in the range of 0.8 to 2.2 seconds; then 4 to 10 sub-finishing treatments of rolled pieces are carried out, the start-rolling temperature is controlled in the range of 900 to 950 DEG C, and the final-rolling temperature is controlled in the range of 920 to 990 DEG C; then the rolled pieces are in hydrocooling treatment, the cooling speed is controlled in the range of 50 to 350 DEG C per second, the spinning temperature is controlled in the range of 760 to 820 DEG C, and dispersed rolls are manufactured; finally, the dispersed rolls are in air-cooled treatment, the air-cooled speed is controlled in the range of 2 to 10 DEG C per second, the roll collection temperature when the dispersed rolls come out of air-cooled roller way is controlled in the range of 330 to 450 DEG C, and the dispersed rolls are disposed in environmental air and cooled till room temperature. The products produced by using the method have 95% of carbide whose net level is less than or equal to 1.0 in which the average level is 0.95, thereby being capable of increasing abrasion resistance and service life of steel.

Owner:武钢集团有限公司

Steel plate ingot casting device and method for producing ultra-thick steel plate cast ingot with same

The invention discloses a steel plate ingot casting device, which comprises a pedestal, a fixed framework and an ingot mold, wherein the fixed framework is fixedly connected with the pedestal; the ingot mold is positioned in the fixed framework and consists of two pairs of side templates, i.e., front, rear, left and right side templates, and a bottom template; the outer sides of the side templates and the bottom template are respectively provided with a cooling water box; the side templates are provided with squeezing mechanisms; the bottom template is provided with a lifting mechanism; the side templates and the bottom template are all copper plate products; and the bottom template is provided with a runner port. According to the steel plate ingot casting device, deformation under cold and hot intensity stress can be avoided, and a shrinkage hole is avoided; since the solidification time is greatly shortened, the segregation in a steel ingot can be obviously relieved, thereby greatly improving the internal quality and the performance of a produced ultra-thick plate; and meanwhile, the steel plate ingot casting device has the advantages of freely adjustable ingot mold size, long service life of the ingot mold and the like.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

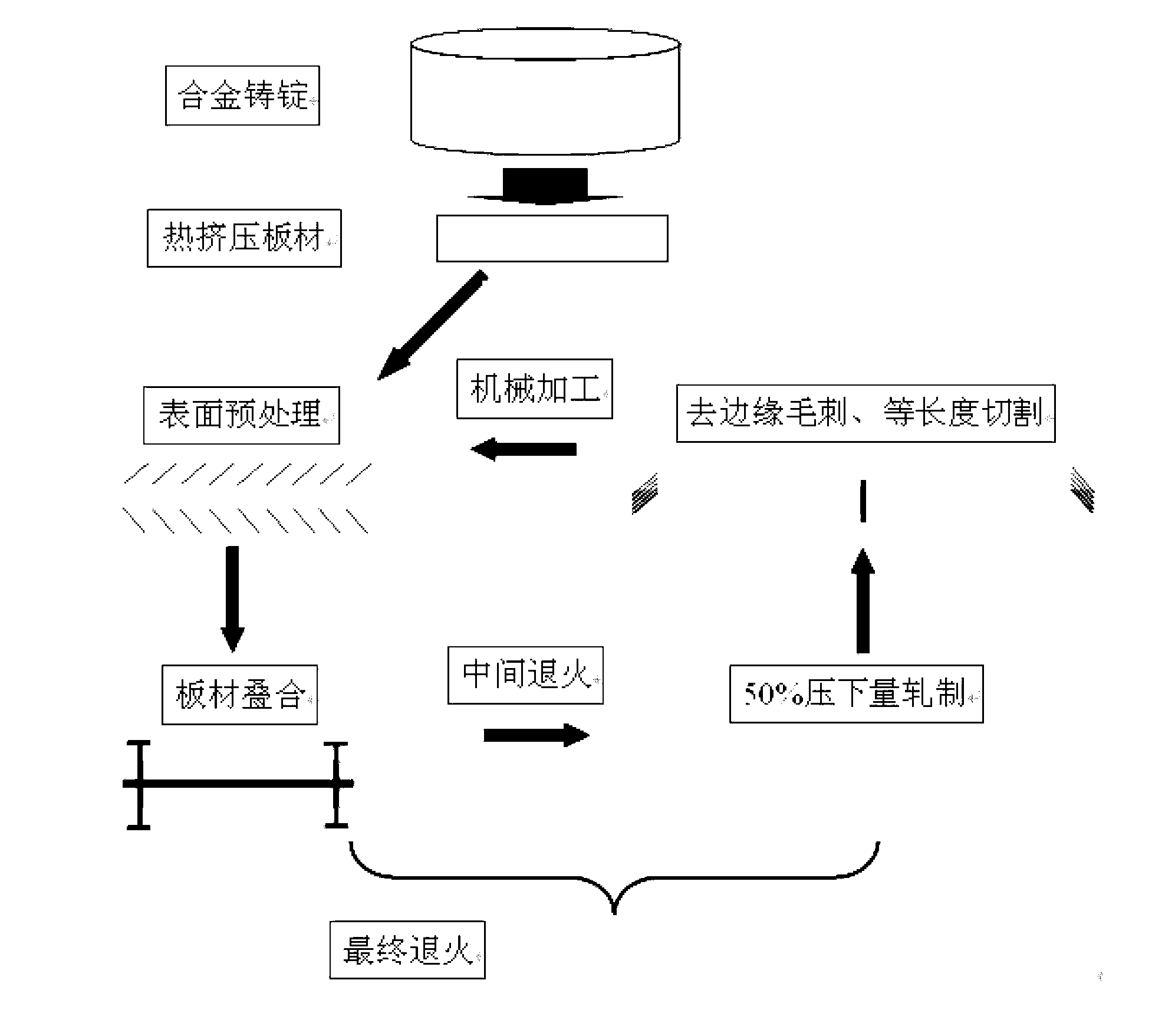

Preparation method of ultrafine grain rare earth magnesium alloy

The invention provides a preparation method of an ultrafine grain rare earth magnesium alloy. The method comprises the following steps of: firstly performing solution treatment on a rare earth magnesium alloy cast ingot to obtain the rare earth magnesium alloy after the solution treatment; then performing heat deformation processing on the obtained rare earth magnesium alloy after the solution treatment to obtain a heat-deformed rare earth magnesium alloy plate, wherein the heat deformation processing temperature is 350 DEG C-450 DEG C; and finally performing accumulative roll bonding with the single-pass rolling reduction of 50% on the obtained heat-deformed rare earth magnesium alloy plate, and annealing to obtain the ultrafine grain rare earth magnesium alloy. According to the preparation method provided by the invention, a heat deformation processing-accumulative roll bonding compound process is firstly adopted to successfully prepare the ultrafine grain rare earth magnesium alloy, and the problem of deterioration of mechanical properties, which is caused by non-uniform distribution of thick and big LPSO (long period stacking ordered) phases in the alloy is effectively solved; and furthermore, the preparation method provided by the invention has the advantages of simple process flow and low equipment cost, and is favorable for further large-scale industrial production.

Owner:XINJIANG TENGXIANG MAGNESIUM PROD CO LTD

Simultaneous grain modulation for BEOL applications

InactiveUS7732922B2Refined grain sizeReduce processing stepsSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureMaterials science

The invention is directed to an improved semiconductor structure, such that within the same insulating layer, Cu interconnects embedded within the same insulating level layer have a different Cu grain size than other Cu interconnects embedded within the same insulating level layer.

Owner:GLOBALFOUNDRIES INC

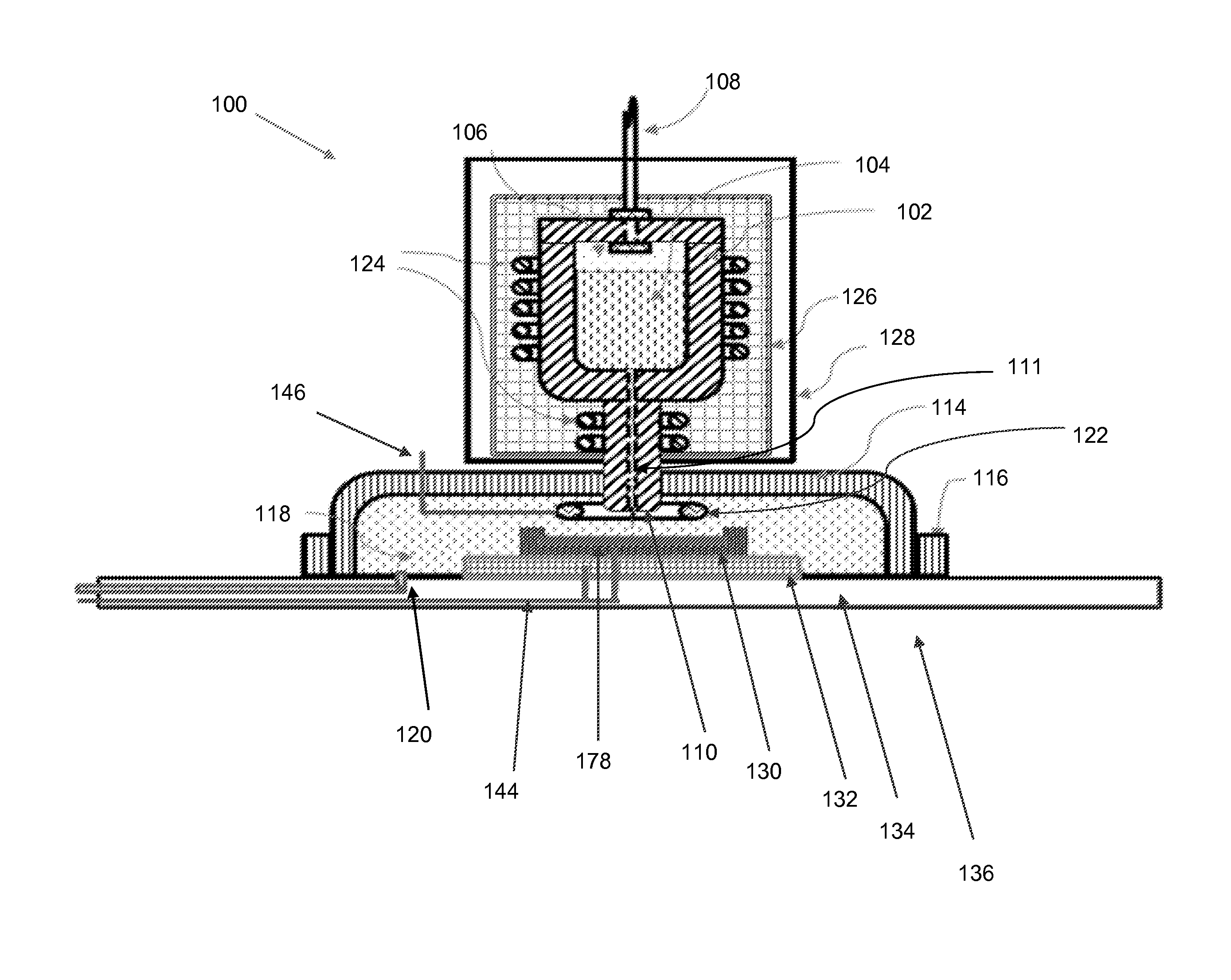

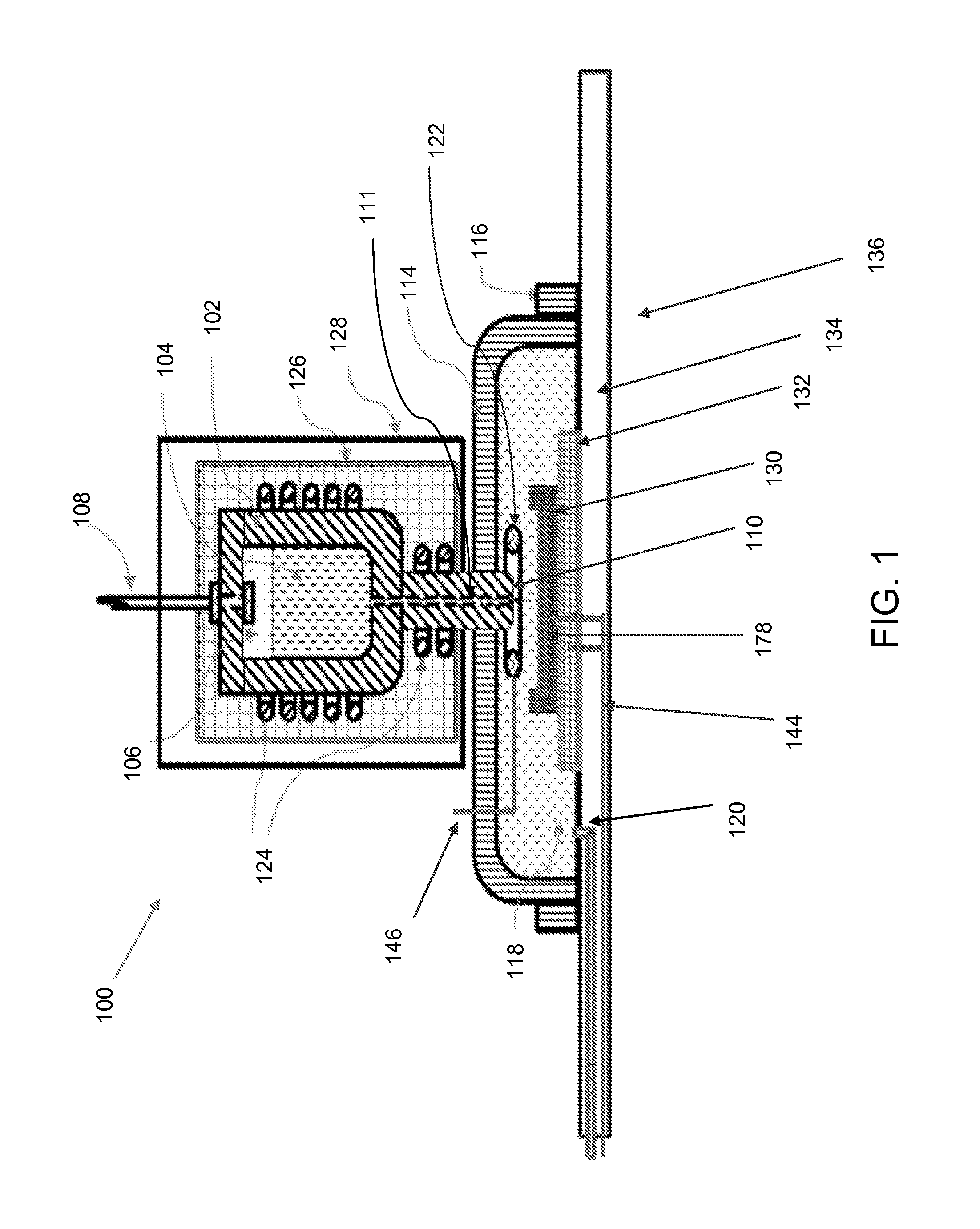

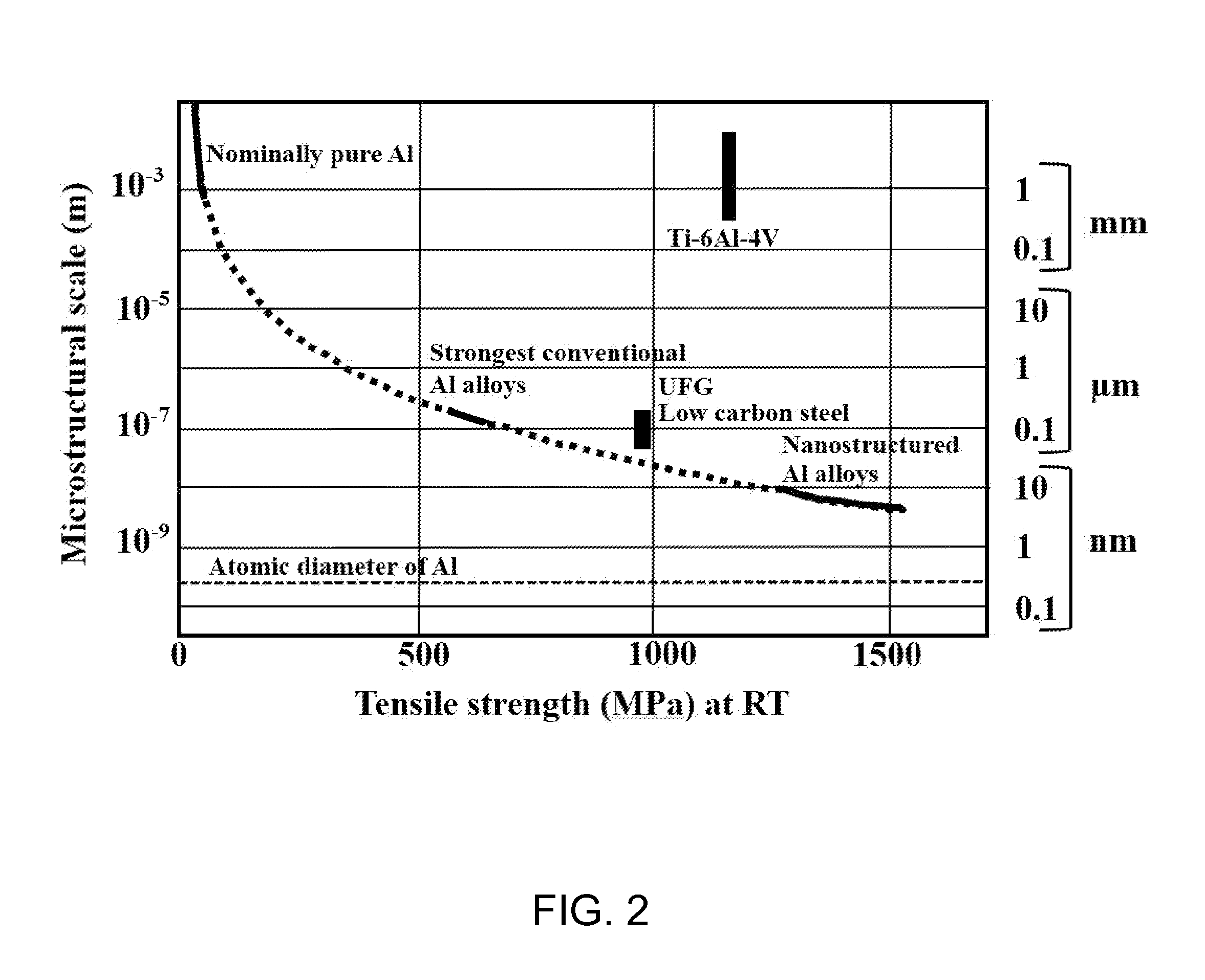

Electrospray pinning of nanograined depositions

ActiveUS20150251213A1Inhibition of recrystallizationEnhanced nucleationLiquid surface applicatorsAdditive manufacturing apparatusGrain growthElectric field

A method and apparatus for fabrication of objects retaining nano-scale characteristics. A composition is provided comprising grain growth inhibitor particles in solution with a binding agent in a molten phase. An electric field and a magnetic field are generated with a combined extraction electrode. The composition is electrosprayed from a nozzle with the electric field to form a stream of droplets. The electric field drives the droplets toward a moving stage holding an object comprising successive deposition layers. The magnetic field limits dispersion of the stream of droplets. The stage is moved laterally as the stream of droplets impacts the object to form a current deposition layer of the object. The stage is moved vertically as necessary to maintain a target stand-off distance between the nozzle and a previous deposition layer of the object, based on profile data of the previous deposition layer.

Owner:Q21 CORPORATION +1

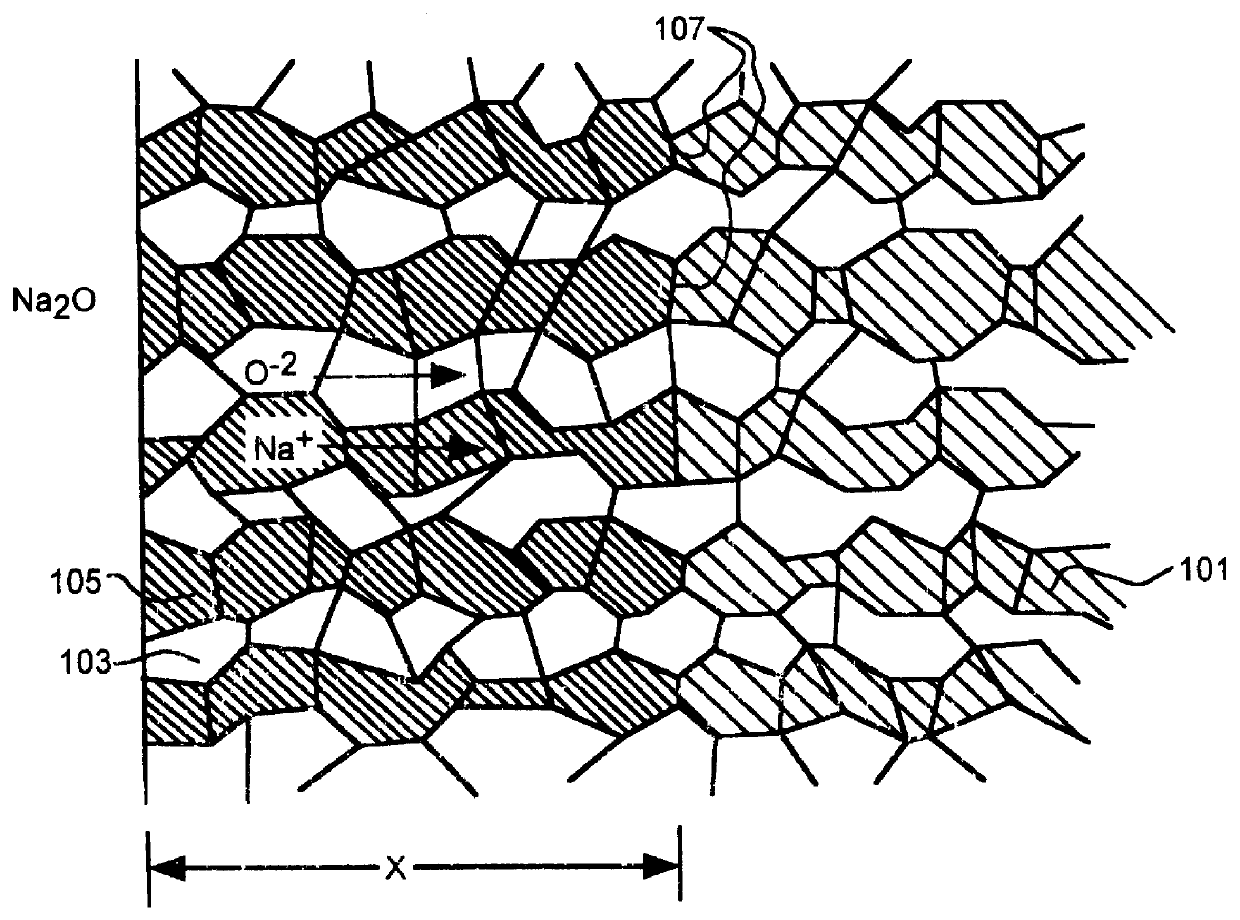

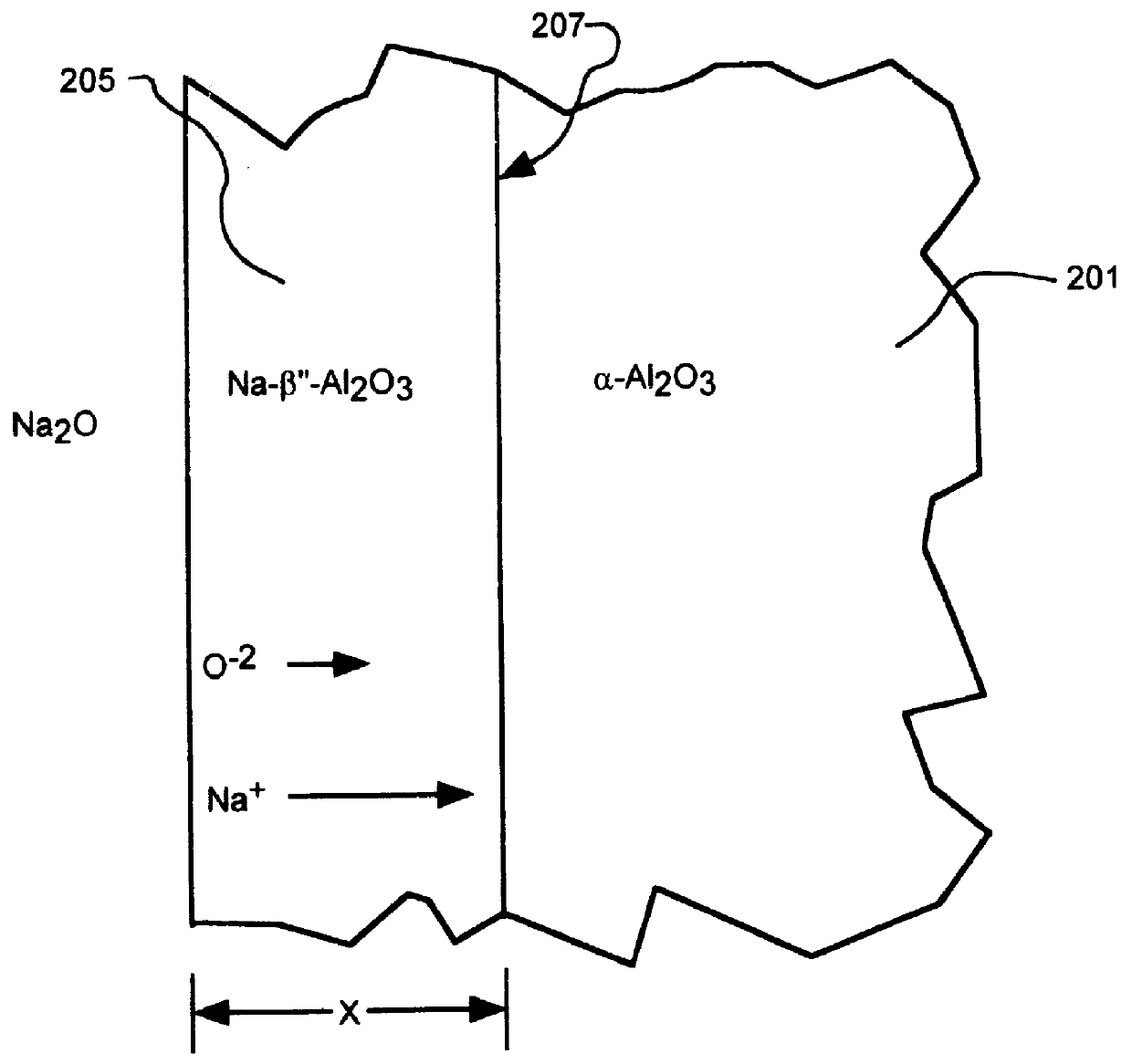

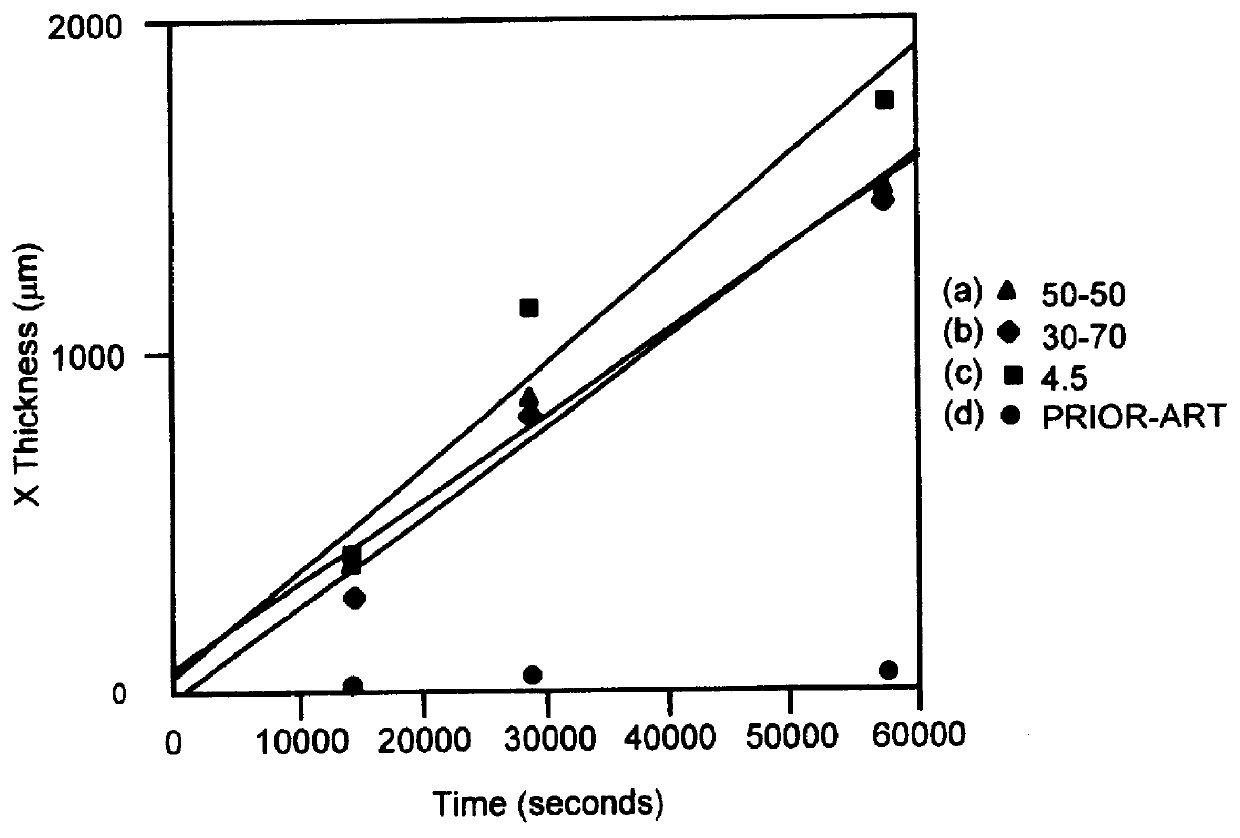

Alkali-metal- beta - and beta ''-alumina and gallate polycrystalline ceramics and fabrication by a vapor phase method

InactiveUS6117807ARefined grain sizeInhibition formationMaterial analysis by electric/magnetic meansSolid electrolyte cellsReaction frontElectrical conductor

A ceramic composite containing alkali-metal- beta - or beta ''-alumina and an oxygen-ion conductor is fabricated by converting alpha -alumina to alkali-metal- beta - or beta ''-alumina. A ceramic composite with continuous phases of alpha -alumina and the oxygen-ion conducting ceramic, such as zirconia, is exposed to a vapor containing an alkali-metal oxide, such as an oxide of sodium or potassium. Alkali metal ions diffuse through alkali-metal- beta - or beta ''-alumina converted from alpha -alumina and oxygen ions diffuse through the oxygen-ion conducting ceramic to a reaction front where alpha -alumina is converted to alkali-metal- beta - or beta ''-alumina. A stabilizer for alkali-metal- beta ''-alumina is preferably introduced into the alpha -alumina / oxygen-ion conductor composite or introduced into the vapor used to convert the alpha -alumina to an alkali-metal- beta ''-alumina.

Owner:MATERIALS & SYST RES

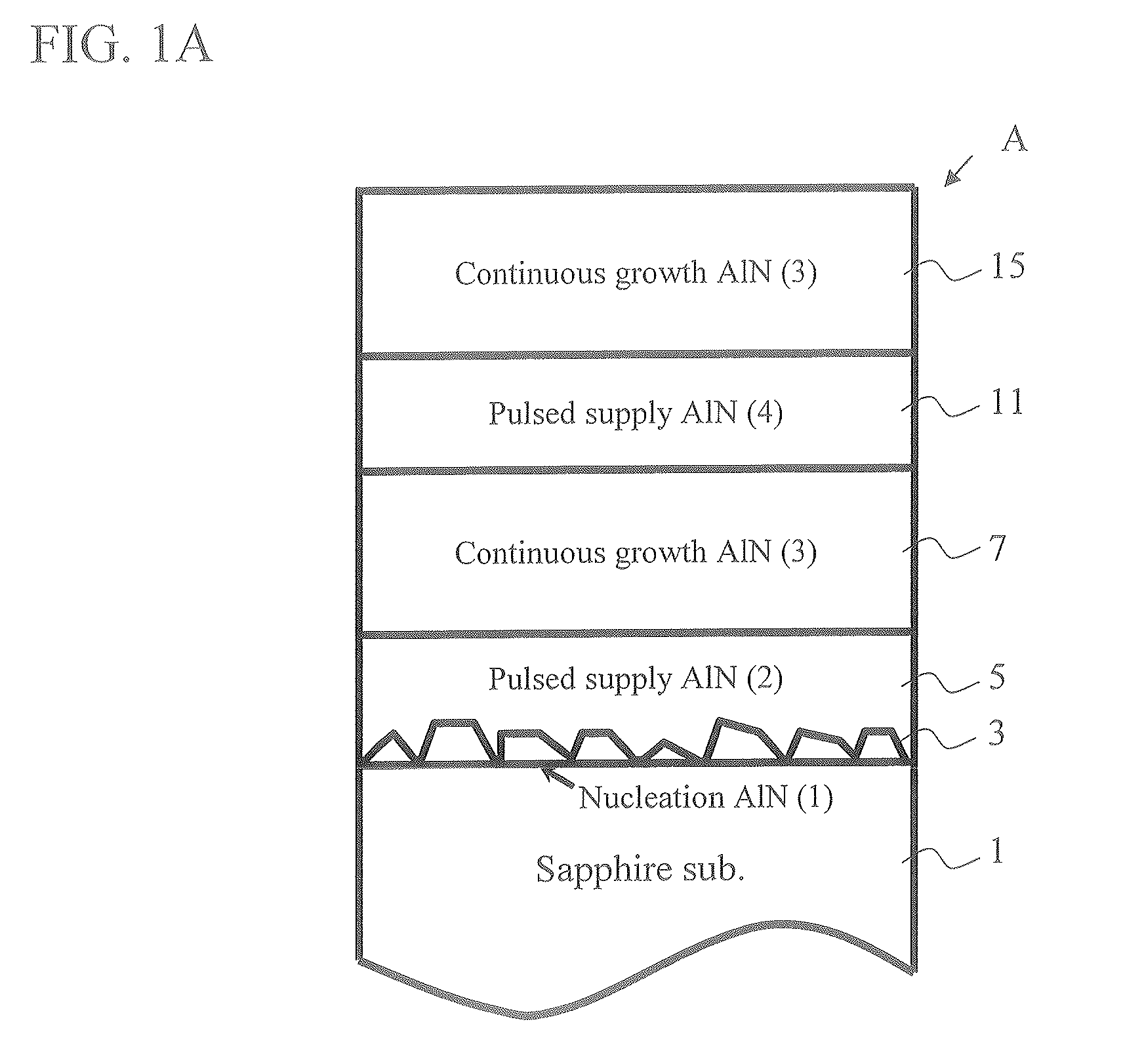

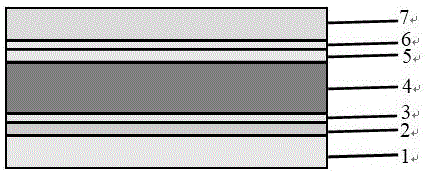

Optical semiconductor device and method for manufacturing the same

InactiveUS7811847B2Suppress gas phase reactionPromote migrationSemiconductor/solid-state device manufacturingSemiconductor devicesLattice mismatchNucleation mode

Because of a large lattice mismatch between a sapphire substrate and a group III-V compound semiconductor, a good crystal is difficult to grow. A high-quality AlN buffer growth structure A on a sapphire substrate includes a sapphire (0001) substrate 1, an AlN nucleation layer 3 formed on the sapphire substrate 1, a pulsed supplied AlN layer 5 formed on the AlN nucleation layer 3, and a continuous growth AlN layer 7 formed on the pulsed supplied AlN layer 5. Formed on the continuous growth AlN layer 7 is at least one set of a pulsed supplied AlN layer 11 and a continuous growth AlN layer 15. The AlN layer 3 is grown in an initial nucleation mode which is a first growth mode by using an NH3 pulsed supply method. The pulsed supplied AlN layer 5 is formed by using NH3 pulsed supply in a low growth mode which is a second growth mode that increases a grain size and reduces dislocations and therefore is capable of reducing dislocations and burying the nucleation layer 3. The continuous growth AlN layer 7 is a fast vertical growth mode that improves flatness and suppresses crack occurrences. As examples of the thickness of layers; the pulsed supplied AlN layer 5, 11 is 0.3 μm and the thickness of the continuous growth AlN layer 7, 15 is 1 μm, for example. Characteristics of conditions under which layers are grown are as follows. The AlN layer 3 is grown under a high temperature and a high pressure with a low V-III ratio (less N). The pulsed supplied AlN layer 5 is grown at a low temperature and a low pressure with a high V-III ratio (more N). The continuous AlN layer 7 is grown at a high temperature and a high pressure with a high V-III ratio (Al rich and less N) without using an NH3 pulsed supply AlN growth method.

Owner:RIKEN

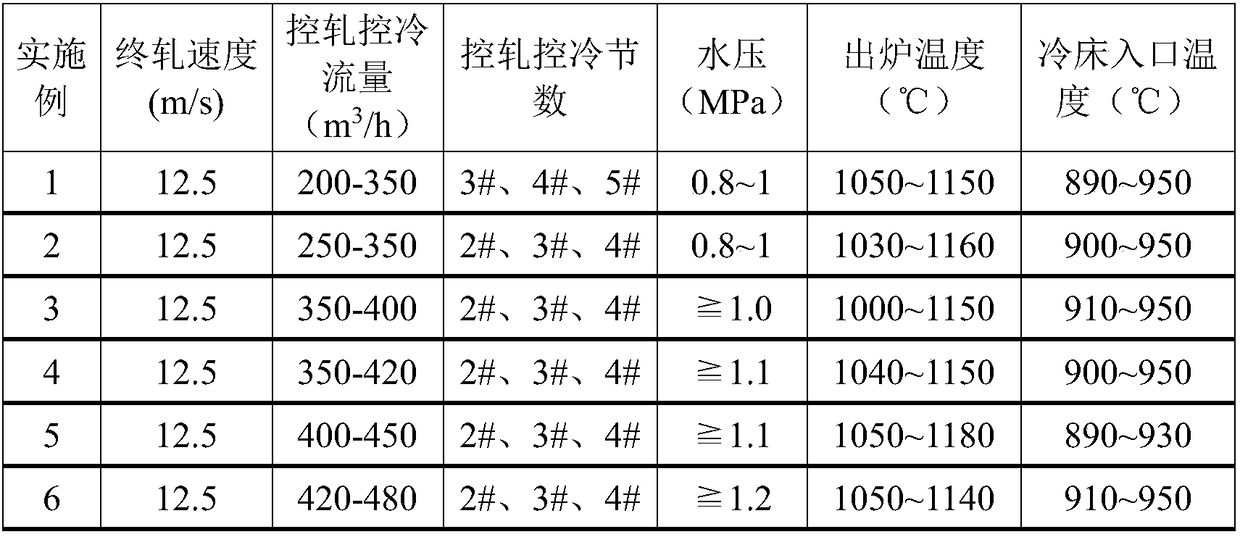

Low-temperature rolling production method of high-performance 20CrMnTi gear steel

ActiveCN108906884AOptimizing the heating process systemReduce heating energy consumptionTemperature control deviceWork treatment devicesHeating furnaceMechanical property

The invention belongs to the field of special steel production machining of metallurgical industries and particularly relates to a low-temperature rolling production method of high-performance 20CrMnTi gear steel. With 20CrMnTi continuous casting slabs as raw materials, the method comprises the following working processes of heating, descaling, rough rolling, continuous rolling, water penetrationand cold rolling, finish rolling of a rod material sizing reduction unit and cooling through a cold bed in sequence, and finally a finished product rod material is obtained. According to the low-temperature rolling production method of the high-performance 20CrMnTi gear steel, the heating technical system of a heating furnace is optimized, the heating energy consumption is reduced, the productioncost is reduced, and the environment is protected; the high-performance 20CrMnTi gear steel is obtained, grain size control, rigidity control and mechanical property control over the high-performance20CrMnTi gear steel are superior than control in a common rolling technology, the metallographic structure of the high-performance 20CrMnTi gear steel is ferrite and pearlite, the rigidity is generally 170-220 HBW, the grain size of the high-performance 20CrMnTi gear steel is small and even, the grain size of the rolled round steel at least reaches 9.0 grade, and the comprehensive mechanical properties of the high-performance 20CrMnTi gear steel are superior than those of the common rolling technology.

Owner:DAYE SPECIAL STEEL CO LTD

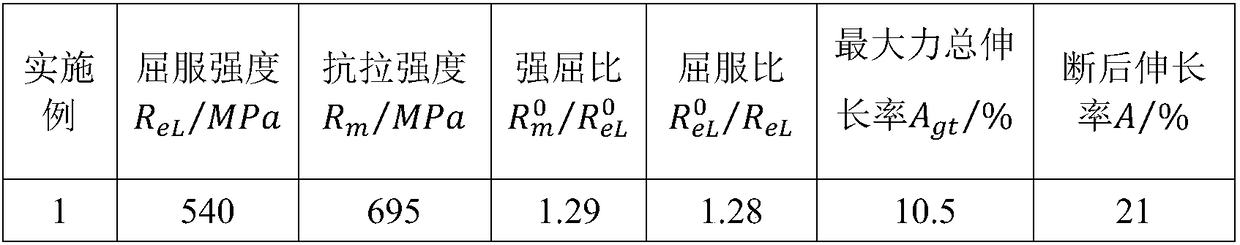

Steel bar with high weather resistance, low cost and seawater corrosion resistance and production process

ActiveCN108251746AGood weather resistanceLow costProcess efficiency improvementWeather resistanceRebar

The invention provides a steel bar with high weather resistance, low cost and seawater corrosion resistance and a production process. The steel bar comprises the following elementary compositions of,by weight, 0.04%-0.10% of C, 0.10%-0.50% of Si, 0.5%-1.6% of Mn, 0.03% or less of P, 0.02% or less of S, 2%-4% of Cr, 0.3%-0.5% of Cu, 0.2%-0.6% of Ni, and the balance Fe and inevitable impurities. According to the steel bar, the mechanical property meets the requirement of the steel bar for corrosion resistance, the aging strain is low, and the corrosion rate is lower than 70% that of common steel bars. The technical path of the process comprises a 70-ton ultrahigh-power electric furnace, LF ladle refining, deoxidation and alloying after steel discharging, argon blowing, continuous casting of165 square billets at four streams by four machines, a heat accumulating type stepping heating furnace, 18 non-twist tandem mills, controlled-rolling and controlled-cold cooling, finishing, packagingand storage.

Owner:福建三宝钢铁有限公司

Ceramic particle reinforced aluminum-based gradient composite material and preparation method thereof and jetting precipitation device for preparing material

The invention belongs to the field of aluminum-based composite material and preparation technology thereof and in particular discloses a ceramic particle reinforced aluminum-based gradient composite material, a preparation method thereof and a device used by the method. The composite material uses aluminum alloy as a matrix; the volume fractions of ceramic particles serving as a reinforcement material in the surface layer and the bottom layer are between 30 and 40 percent and between 0 and 5 percent respectively; the ceramic particles perform continuous gradient variation from the surface layer to the bottom layer; and the preparation method comprises the following steps: introducing the ceramic reinforced particles to a high-pressure airflow channel by a discharge amount regulation device to form a solid phase flow and a gas phase flow; atomizing molten aluminum alloy liquid, mixing the molten aluminum alloy liquid and the ceramic particles of the solid phase flow and the gas phase flow, and precipitating the mixture on a deposition matrix to prepare a deposition billet; and controlling the discharge amount regulation device and output air pressure through a programmable logic controller according to the height information of the deposition billet to obtain the ceramic particle reinforced aluminum-based gradient composite material. The preparation method of the invention has convenient operation and high automation degree; and the prepared composite material has the advantages of light weight, high wear resistance and anticorrosion of the surface and the like.

Owner:HUNAN UNIV

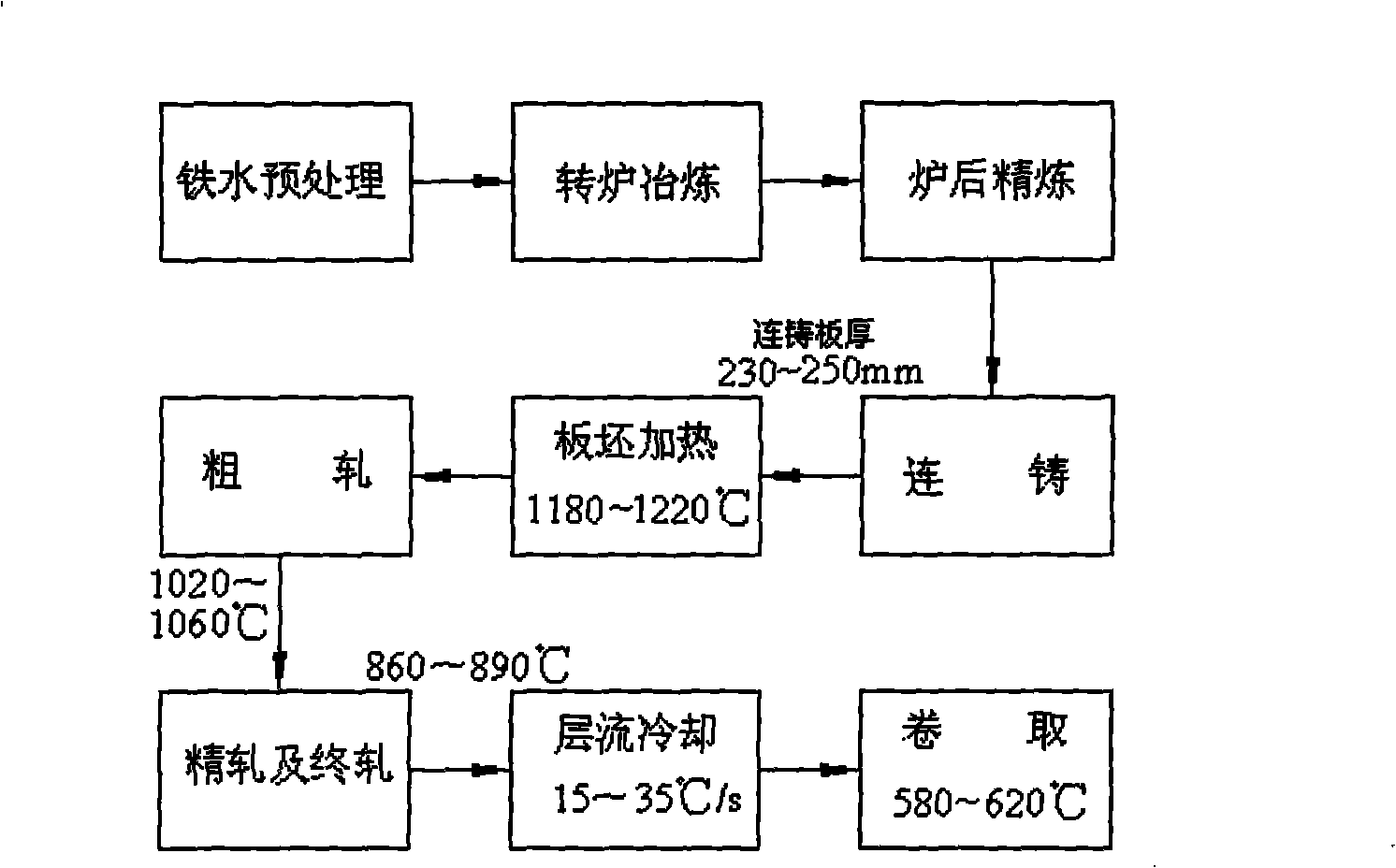

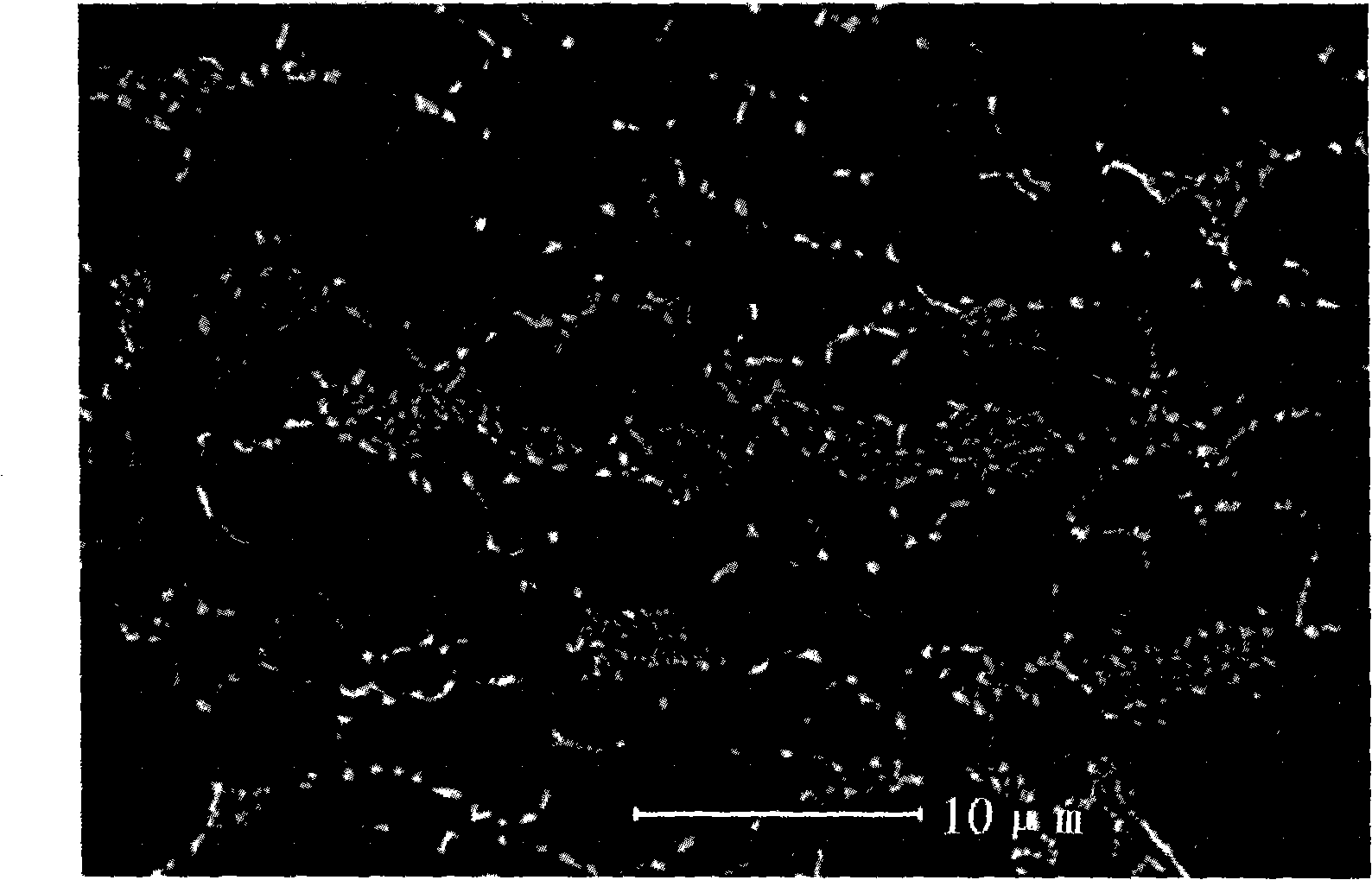

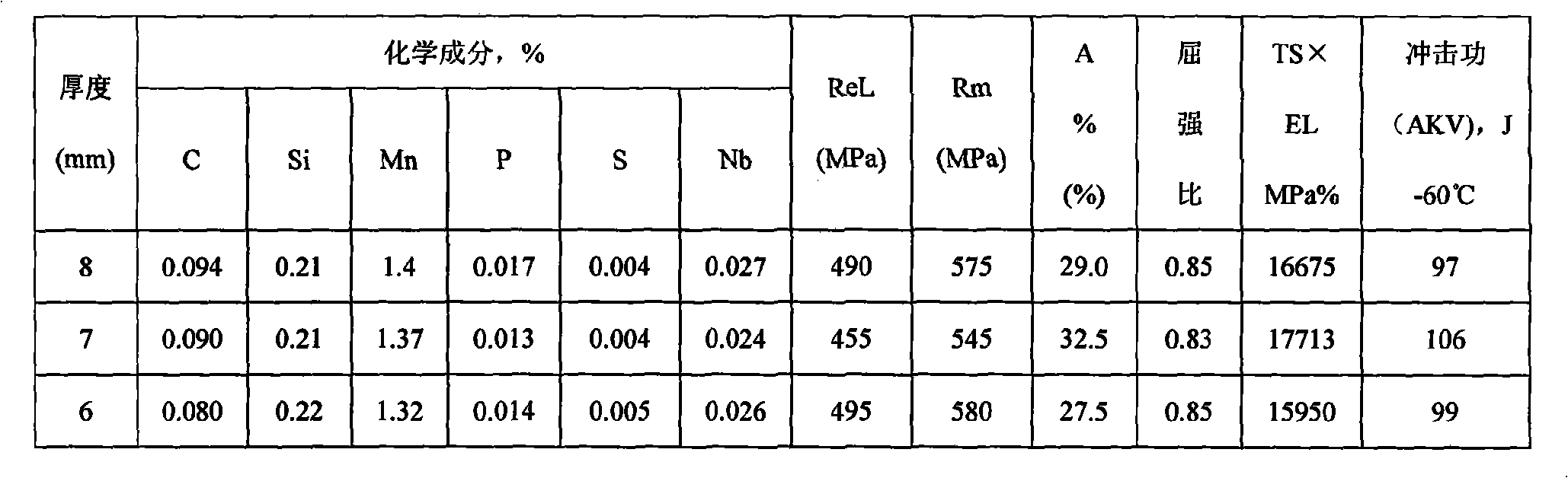

High-strength hot rolled steel plate and manufacturing method thereof

ActiveCN101280390APure steelImprove performanceTemperature control deviceManufacturing convertersManganeseUltimate tensile strength

The invention discloses a high strength hot rolled structure steel plate, which belongs to the technical field of the metal structure material. In the invention, an Nb microalloying element is added into low carbon and high manganese clean steel, and also Ca in minute quantities is added. Simultaneously, the invention also discloses the manufacturing method of the steel plate, the manufacturing method comprises the steps that the converter smelting and refining, continuous caster protecting casting, and rolling control and cooling control process is adopted, through the thinning strengthening and precipitation strengthening of the crystal grain, the hot tandem rolled coiled sheet with pure steel quality, good combined property and uniform and fine grain size can be obtained, the steel plate not only has high strength, but also has very high toughness and superior cold forming performance, and the structure requirement of the vehicle can be met.

Owner:MAANSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com