Patents

Literature

49results about How to "Pure steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

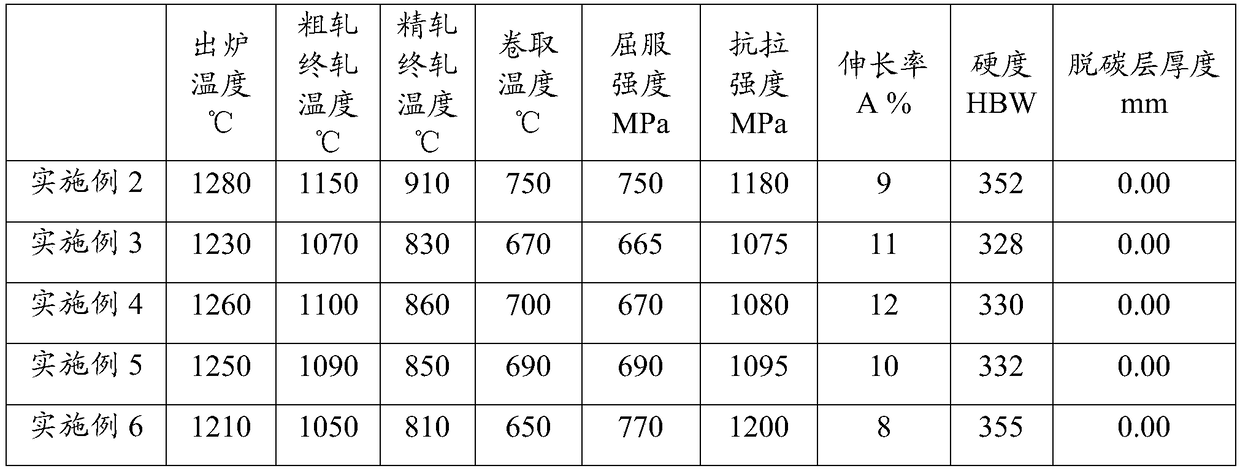

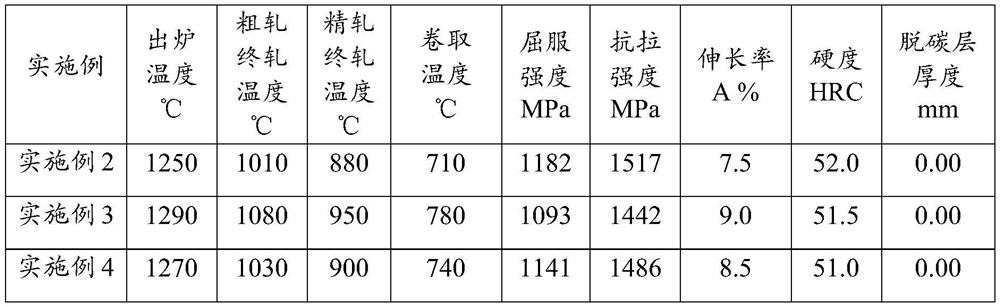

High-strength hot rolled steel plate and manufacturing method thereof

ActiveCN101280390APure steelImprove performanceTemperature control deviceManufacturing convertersManganeseUltimate tensile strength

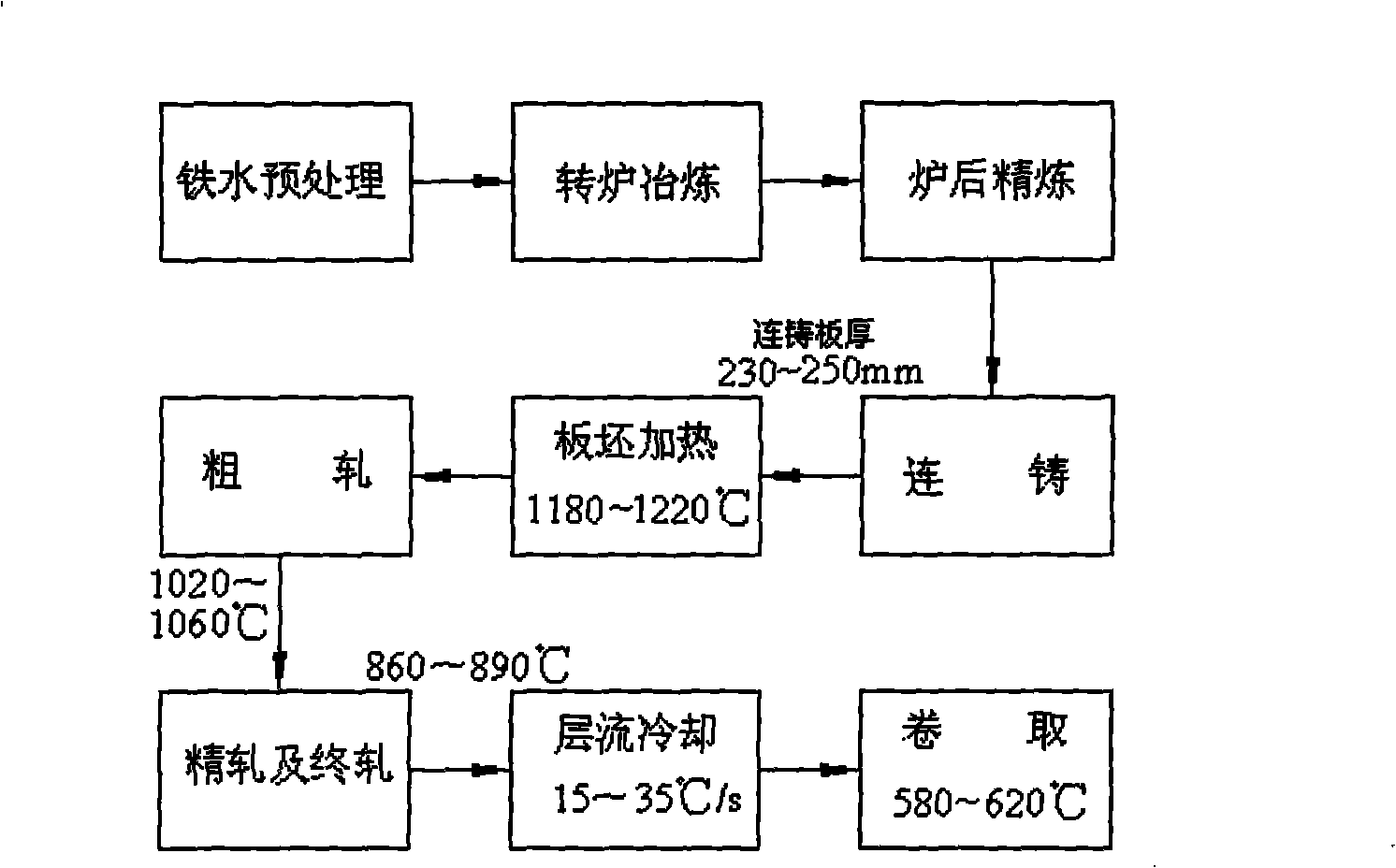

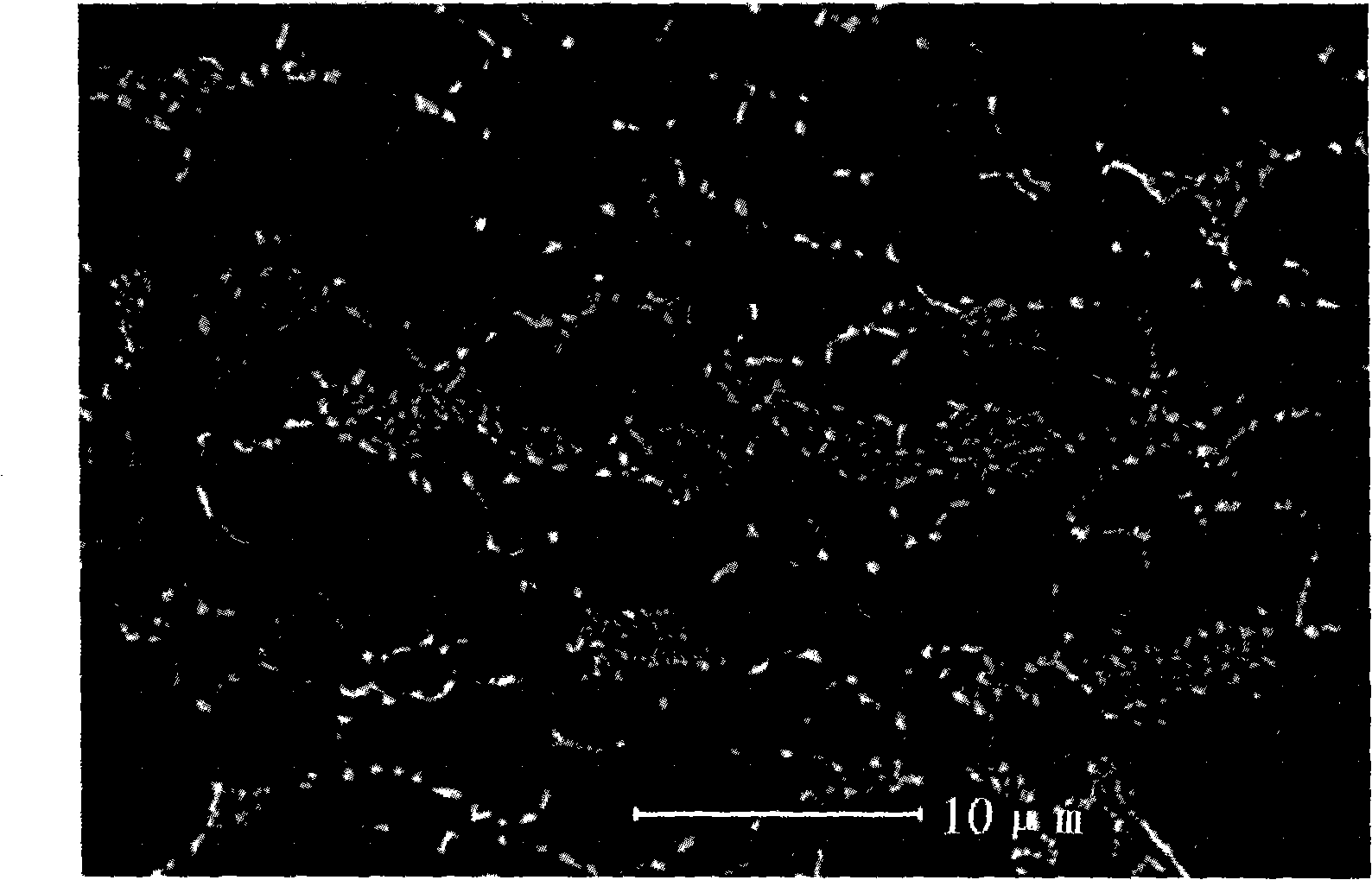

The invention discloses a high strength hot rolled structure steel plate, which belongs to the technical field of the metal structure material. In the invention, an Nb microalloying element is added into low carbon and high manganese clean steel, and also Ca in minute quantities is added. Simultaneously, the invention also discloses the manufacturing method of the steel plate, the manufacturing method comprises the steps that the converter smelting and refining, continuous caster protecting casting, and rolling control and cooling control process is adopted, through the thinning strengthening and precipitation strengthening of the crystal grain, the hot tandem rolled coiled sheet with pure steel quality, good combined property and uniform and fine grain size can be obtained, the steel plate not only has high strength, but also has very high toughness and superior cold forming performance, and the structure requirement of the vehicle can be met.

Owner:MAANSHAN IRON & STEEL CO LTD

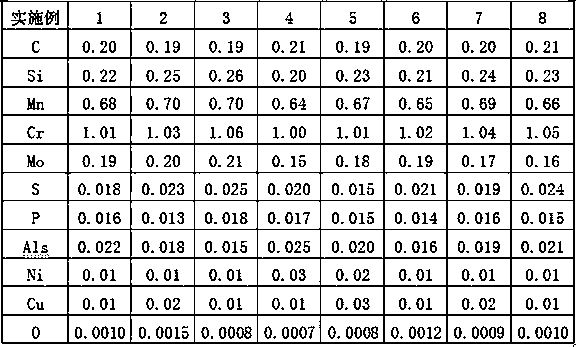

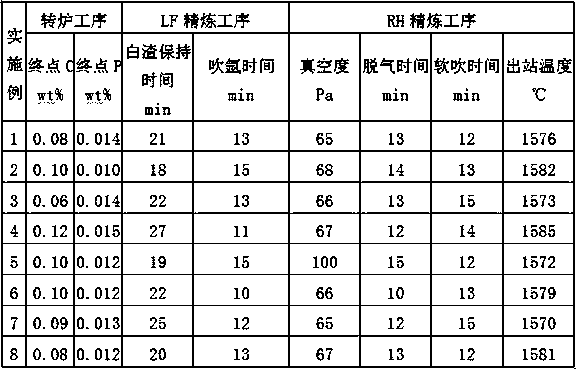

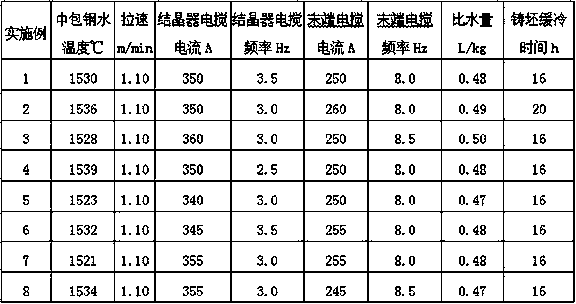

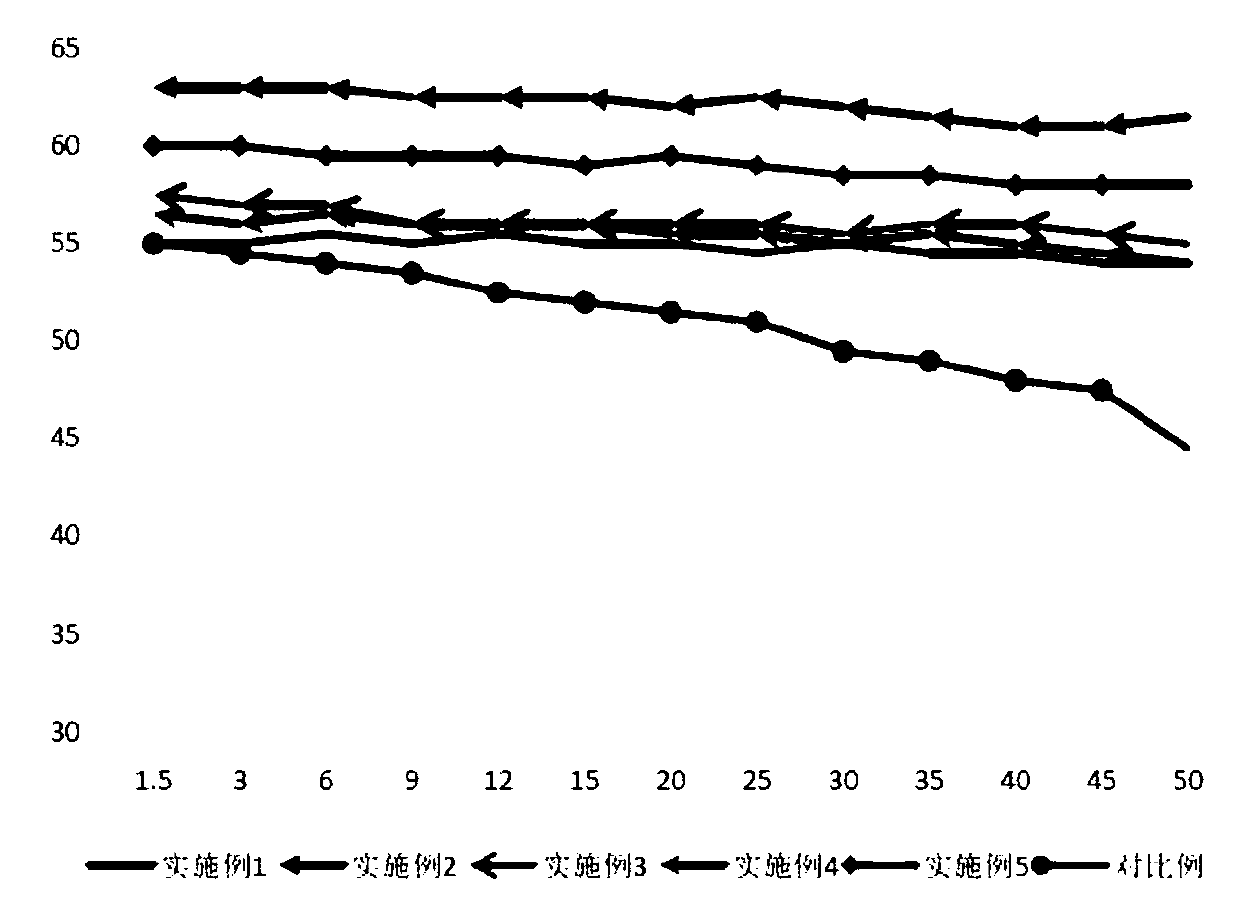

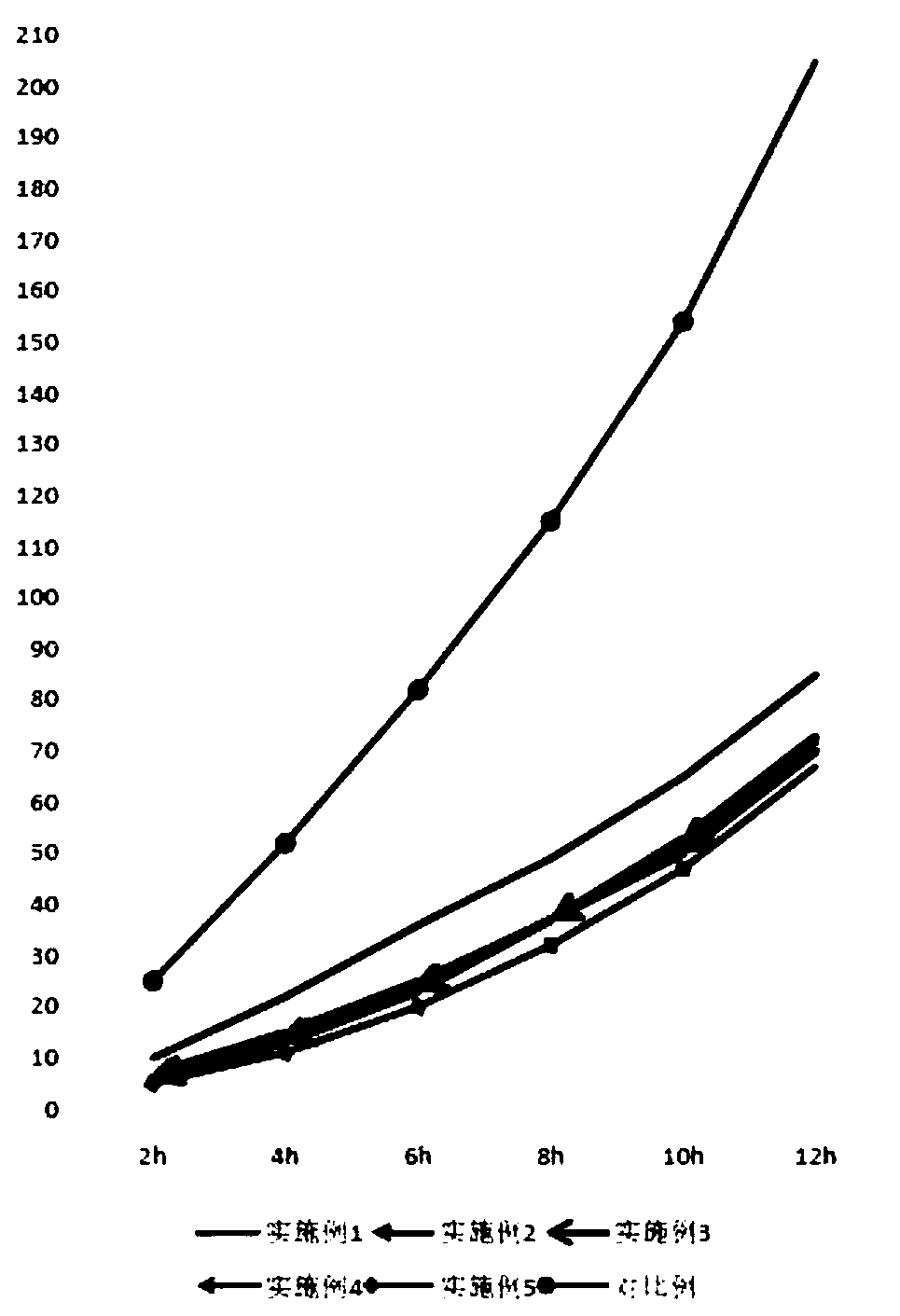

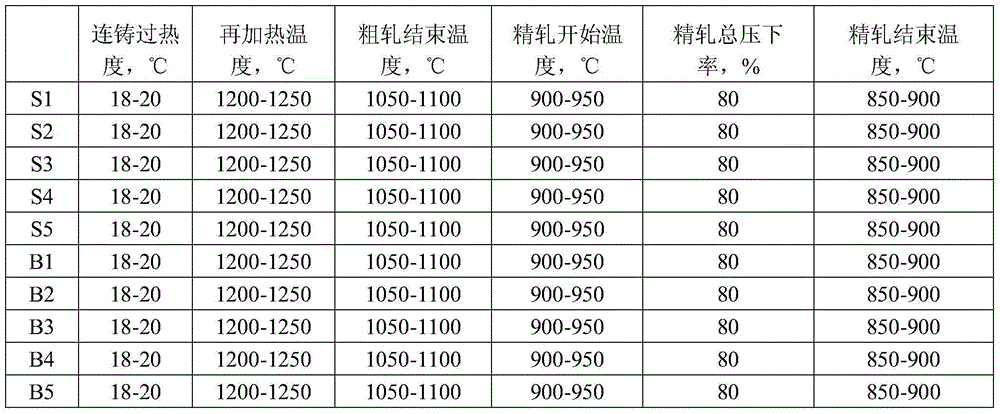

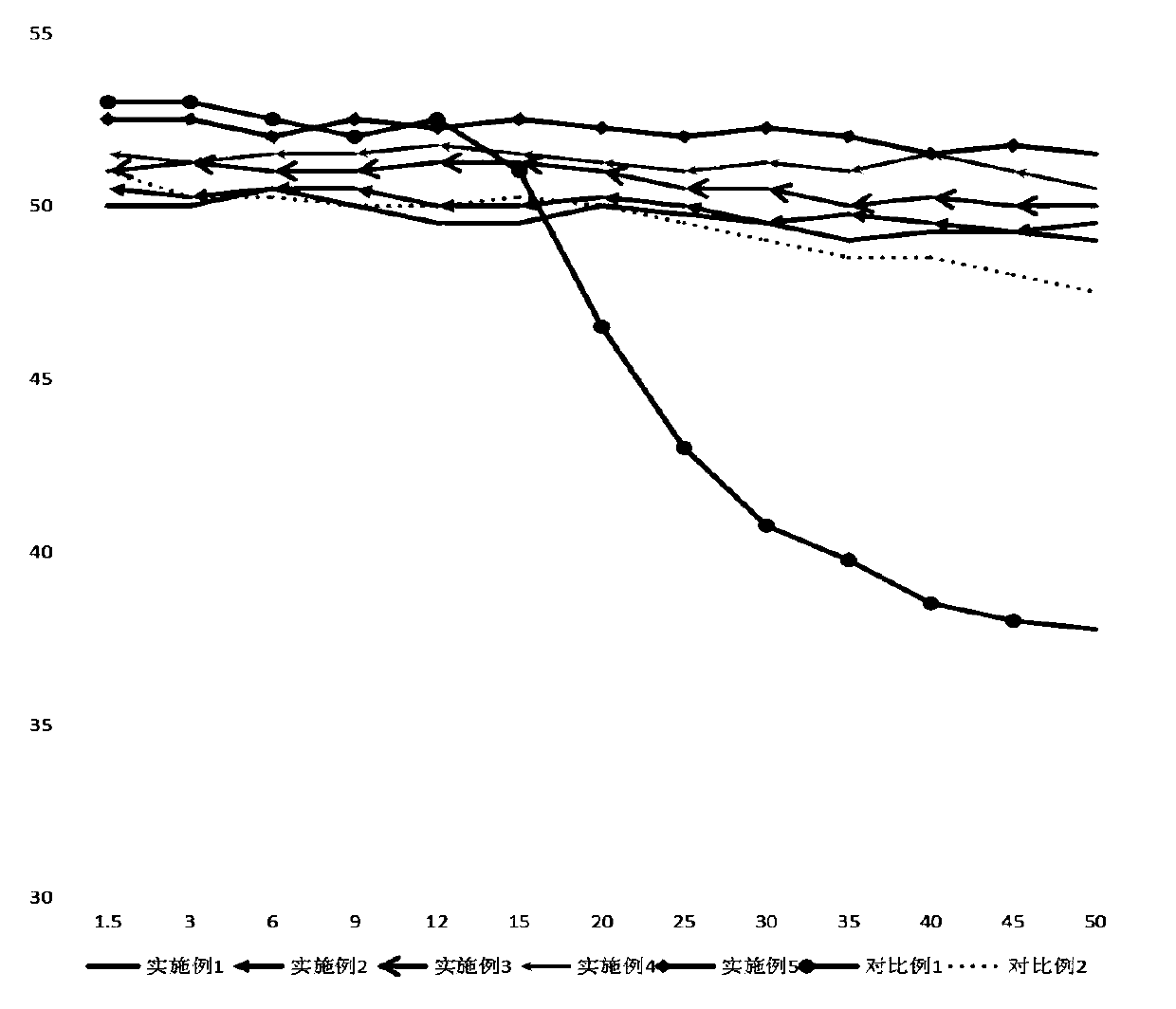

Gear steel 20CrMoSH and technology for improving hardenability stability thereof

The invention discloses gear steel 20CrMoSH and a technology for improving the hardenability stability thereof. The technology comprises the procedures of converter smelting, LF refining, RH refining,continuous casting, heating and rolling. The gear steel is prepared from the chemical components, by weight, 0.19%-0.21% of C, 0.20%-0.26% of Si, 0.64%-0.70% of Mn, 1.00%-1.06% of Cr, 0.15%-0.21% ofMo, 0.015%-0.025% of S, smaller than or equal to 0.018% of P, 0.015%-0.025% of Als, smaller than or equal to 0.03% of Ni, smaller than or equal to 0.03% of Cu, smaller than or equal to 0.0015% of O and the balance Fe and unavoidable impurities. According to the gear steel 20CrMoSH which is produced through the method and has the diameter phi ranging from 28 mm to 50 mm, the hardenability J1.5 ranges from 40 HRC to 45 HRC, the hardenability J5 ranges from 37 HRC to 42 HRC, the hardenability J9 ranges from 28 HRC to 33 HRC, and the maximum discrete value of the hardenability of the steel in thesame furnace is not larger than 3 HRC. The heat-treatment deformation of a gear can be significantly reduced by means of high-stability hardenability, and therefore the meshing precision of the gear is improved. The method is low in cost and high in production efficiency, and the product has the advantages that the hardenability is stable, the gear heat-treatment deformation is small, and the machined gear is high in meshing precision and low in service life.

Owner:HANDAN IRON & STEEL GROUP +1

Mineral high-strength wear-resistant material and preparation method thereof

The invention discloses a mineral high-strength wear-resistant material which is prepared from the following raw materials in percentage by weight: 0.30-0.50% of C, 0.10-0.65% of Si, less than or equal to 1.0% of Mn, 1.0-4.5% of Cr, 0.05-3% of Ni, 0.15-1.5% of Mo, 0.05-0.5% of V, 0.010-0.5% of Nb, 0.01-0.5% of Al, less than or equal to 0.025% of P, less than or equal to 0.015% of S and the balanceof Fe. A chain wheel manufactured from the mineral high-strength wear-resistant material is excellent in alloy element proportion, is pure in steel, is uniform in structure, has excellent comprehensive performance, is high in chain gear hardness, is uniform in hardness and is good in wear resistance; and meanwhile, a base body part has good impact toughness and strength. The defects that a commonChinese chain wheel is poor in comprehensive performance and is low in coal passing amount are solved. The mineral high-strength wear-resistant material greatly improves the coal passing amount of the chain wheel, reduces chain wheel use cost, and improves economic benefits.

Owner:YINGKOU SPECIAL STEEL FORGING

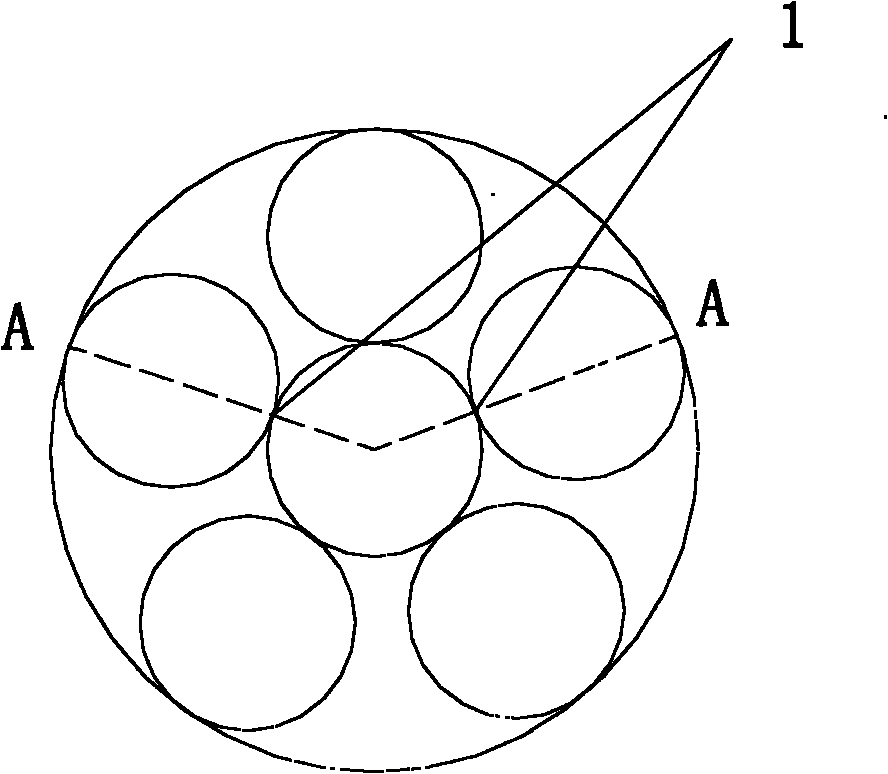

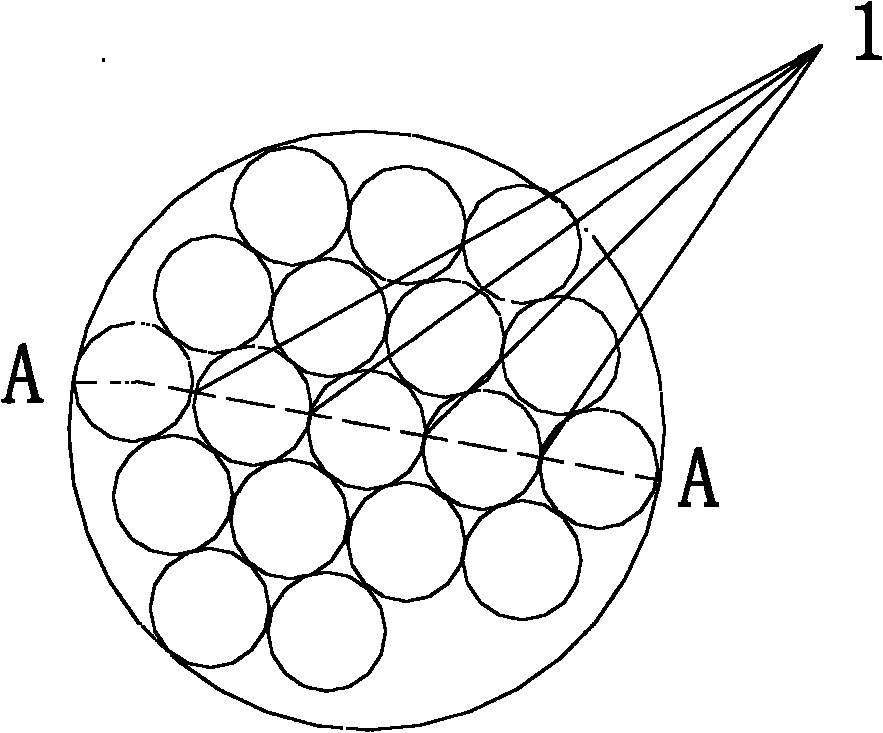

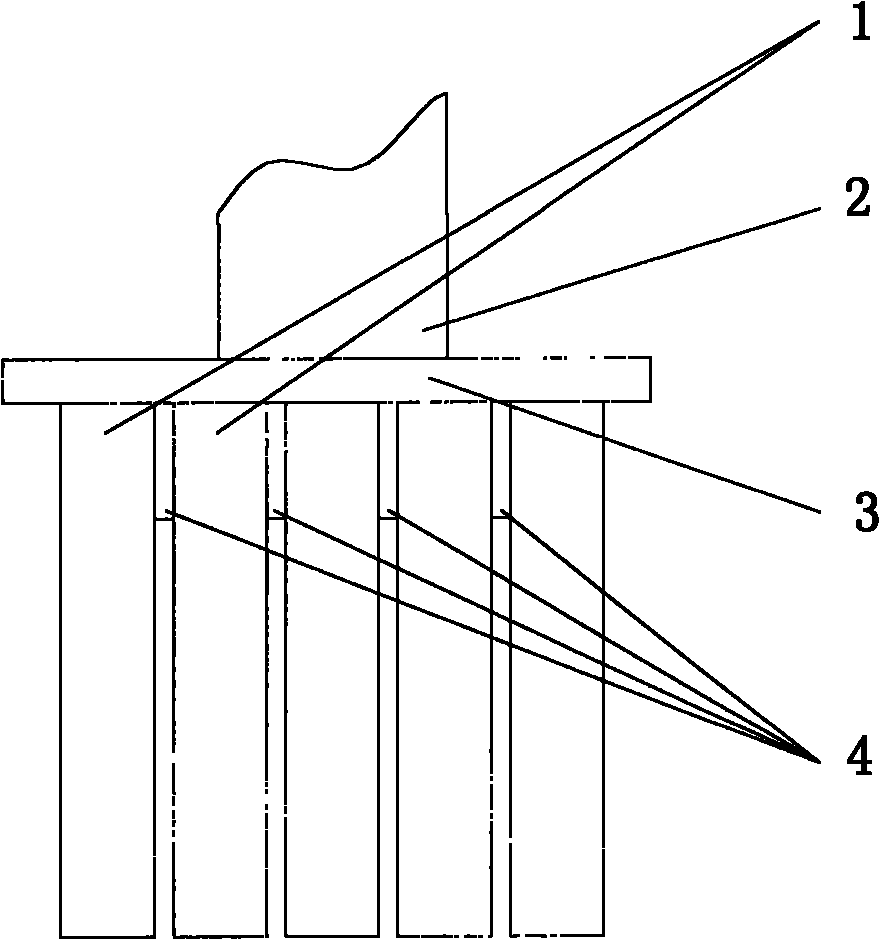

Batch welding electric slag re-melting method for jacking core rods

The patent refers to the field of 'production or refining of metals ; pretreatment of raw materials'. The invention relates to a batch welding electric slag re-melting method for jacking core rods, and belongs to the field of electric slag furnace melting processes. The method comprises the following steps of: welding a connecting plate between the jacking core rods and a pseudo electrode, determining the welding position on the connecting plate according to the number and specification of the jacking core rods, trimming the ends of the jacking core rods, keeping the longitudinal welding bead length between the jacking core rods at 130 to 150 millimeters, and keeping the center of each electrode blank vertical to the end face of the pseudo electrode after batch welding; and according to the filling ratio, slag quantity, inter-electrode distance control and power setting parameters in the electric slag re-melting process, selecting a refining slag system for adding in a weight ratio of CaF2: Al3O2: SiO2 of 66: 28: 6 before re-melting, and adding Al-Mn-Si powder composite deoxidizer at intervals of 10 minutes during re-melting. The method realizes a process of batch welding re-melting of multi-electrode blanks in one furnace and effectively controls the easily oxidized elements from being burnt; the electric slag ingot tissue is compact, and the steel is pure so that the jacking core rods are directly converted into products by electric slag re-melting, and reutilization of materials is realized.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

Thick-specification high-toughness X80 pipe fitting steel plate and manufacturing method

InactiveCN106148846APure steelImprove low temperature toughnessPipe fittingUltimate tensile strength

The invention discloses a thick-specification high-toughness X80 pipe fitting steel plate and a manufacturing method. Low-carbon Nb+Mo+V+Ni+Ti multielement microalloy unique component design is adopted, it is ensured that after heat treatment, thick-specification X80 pipe fitting steel has the excellent strength rich amount and high-toughness performance, a high-clean steel and defect-free continuous casting slab gradual model flexible light reduction technology is utilized, occluded foreign substances in the steel are improved, the level of various kinds of occluded foreign substances in the steel is smaller than or equal to 1.5, crack defects of steel blanks and even steel plates are removed, and by means of the TMCP rolling and whole system destressing technology, the toughness performance of the thick-specification X80 pipe fitting steel plate is improved, and the steel plate shape is improved; by means of the high-temperature tempering heat treatment technology, heat diffusion treatment is achieved, internal stress is released, and the organization structure and toughness of a center line area of the steel plate are improved. The problems that after the heat treatment, the X80 pipe fitting steel plate is low in strength rich amount, poor in toughness plasticity, poor in welding performance, poor in whole plate performance uniformity, poor in plate shape and the like are solved.

Owner:SHANDONG IRON & STEEL CO LTD

SA516Gr70 steel plate meeting high mold welding conditions and production method thereof

The invention discloses a SA516Gr70 steel plate meeting high mold welding conditions and a production method of the SA516Gr70 steel plate meeting the high mold welding conditions. The SA516Gr70 steel plate meeting the high mold welding conditions is composed of the following components including, by weight, 0.18%-0.21% of C, 0.20%-0.40% of Si, 1.10%-1.20% of Mn, not larger than 0.010% of P, not larger than 0.003% of S, 0.020%-1.20% of TAl, 0.015%-0.020% of Nb and the balance Fe and inevitable impurities. The production method comprises the working steps of rolling, water cooling and heat treatment. According to the working step of rolling, the II-type controlled rolling technology is adopted, and rolling is conducted through two stages. The SA516Gr70 steel plate meeting the high mold welding conditions and the production method of the SA516Gr70 steel plate meeting the high mold welding conditions aim to achieve that for different performance requirements and thickness specifications, corresponding internal control components and rolling and heat treatment technologies are determined, the performance yield of the steel plate is improved, the actual performance yield is not higher than 85% at present, and the performance yield is improved to be equal to or higher than 90% through tackling the key problem.

Owner:WUYANG IRON & STEEL

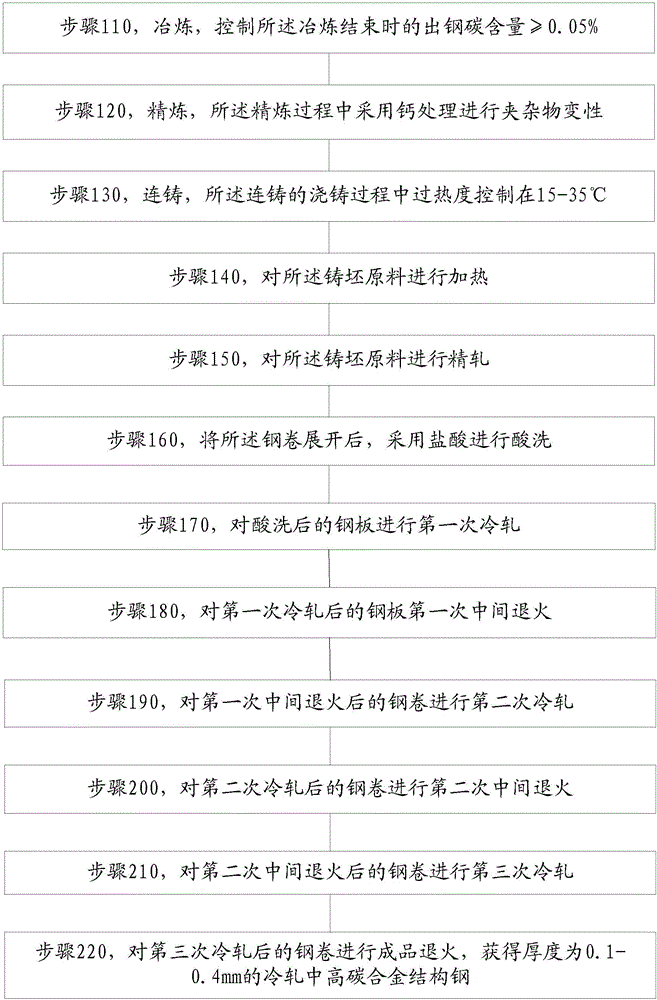

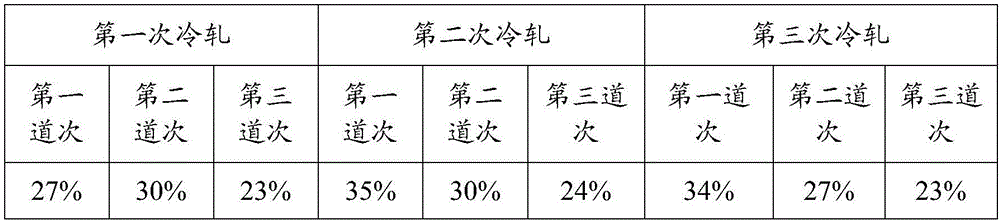

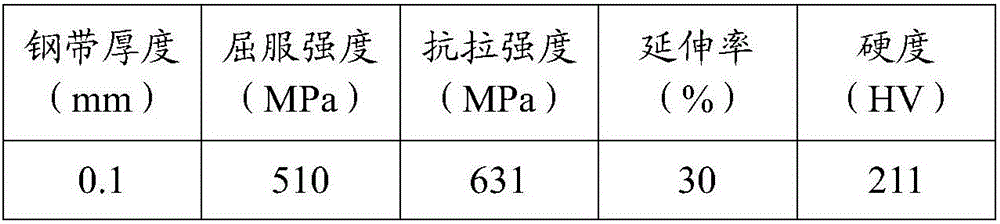

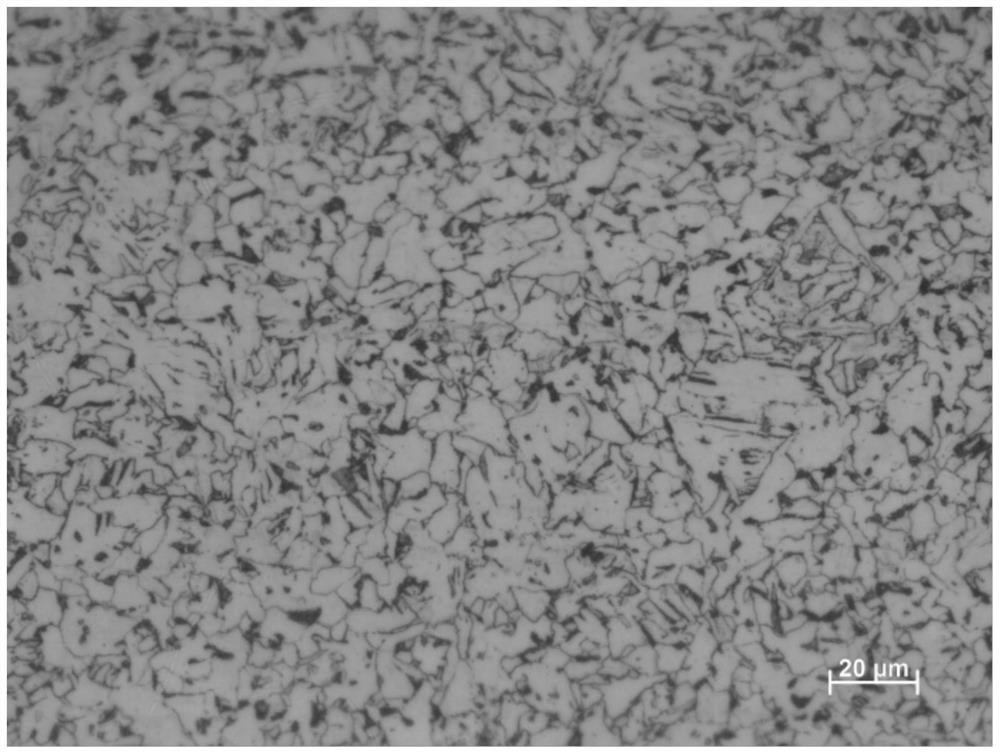

Manufacturing method of cold-rolled medium-high carbon alloy structural steel with thickness ranging from 0.1 mm to 0.4 mm

The invention discloses a manufacturing method of cold-rolled medium-high carbon alloy structural steel with the thickness ranging from 0.1 mm to 0.4 mm. The cold-rolled medium-high carbon alloy structural steel is prepared from components in percentage by weight as follows: 0.25%-0.55% of C, 0.15%-0.35% of Si, 0.10%-2.0% of Mn, 0.10%-2.0% of Cr, 0.010%-0.030% of Alt, less than or equal to 0.015% of P, less than or equal to 0.005% of S, no more than 0.3% of other added alloy elements and the balance of Fe and inevitable impurity elements. The manufacturing method comprises steps as follows: smelting, refining, continuous casting, heating, finish rolling, pickling, cold rolling, intermediate annealing, cold rolling, intermediate annealing, cold rolling and finished product annealing. Through control on inclusions in the steel, three times of cold rolling and three times of annealing, a cold-rolled medium-high carbon alloy structural steel strip with the thickness ranging from 0.1 mm to 0.4 mm is obtained. The total reduction rate of first-time cold rolling and second-time cold rolling is controlled to be larger than or equal to 50%, and the single-pass reduction rate is larger than or equal to 10%, so that lamellar carbide in different areas are crushed, the carbide is evenly separated out in the shape of fine particles through long-time low-temperature intermediate annealing, the strength is further reduced, and the plasticity is further improved.

Owner:武汉钢铁有限公司

Large-thickness 14Cr1MoR steel plate and production method thereof

The invention discloses a large-thickness 14Cr1MoR steel plate and a production method thereof. The large-thickness 14Cr1MoR steel plate comprises the following chemical components in percentage by mass: 0.12-0.14% of C, 0.5-0.6% of Si, 0.40-0.50% of Mn, 0.006-0.007% of P, equal to or less than 0.005% of S, 1.3-1.5% of Cr, 0.58-0.60% of Mo, 0.10-0.20% of Ni, equal to or less than 0.05% of Nb, equal to or less than 0.20% of Cu, equal to or less than 0.003% of Sb, equal to or less than 0.010% of Sn, equal to or less than 0.010% of As and the balance of Fe and unavoidable impurities. The production method comprises the procedures of smelting, continuous casting, heating, rolling and thermal treatment. According to the production method, the two-stage rolling control technology and the thermaltreatment technology of normalizing and tempering are adopted to solve the problems that the crystal particles are thick, non-uniform, lower in impact toughness and higher in hardness, and the head performance and the tail performance of the steel plate differ widely.

Owner:WUYANG IRON & STEEL

Hot-rolled pickled plate used for hydroformed steel pipe, and manufacturing method thereof

The invention provides a hot-rolled pickled plate used for hydroformed steel pipe, and a manufacturing method thereof. The hot-rolled pickled plate comprises, by weight, 0.05 to 0.2% of C, 0.1 to 1.0% of Si, 0.5 to 1.5% of Mn, 0.001 to 0.02% of Sn, P<=0.015%, S<=0.015%, and the balance Fe and inevitable impurities; and in addition, one or more elements selected from 0.005 to 0.1% of Ti, 0.005 to 0.1% of Nb, and 0.001 to 0.1% of V can be added. According to the manufacturing method, heating temperature is controlled to be 1100 to 1200 DEG C; rough rolling finished rolling temperature is controlled to be higher than 1020 DEG C; precision rolling initial rolling temperature is lower than 1000 DEG C; the temperature of a precision rolling outlet is controlled to be 850 to 910 DEG C by spraying water onto machine frames; laminar cooling is carried out as soon as rolling is finished, and cooling speed is controlled to be 14 to 30 DEG C / s; curl temperature is controlled to be 530 to 600 DEG C; stacking slow-cooling is adopted, and slow cooling speed is controlled to be 0.01 to 0.08 DEG C / s. The obtained hot-rolled pickled plate is pure in steel, and low in alloy amount; strength is high, forming performance is excellent; hydroforming requirements can be satisfied; steel pipe subsequent heating and reducing rolling processes are reduced; cost is low; performance is stable; economic benefit is high; and the hot-rolled pickled plate possesses excellent forming performance and hydraulic expanding performance.

Owner:ANGANG STEEL CO LTD

Composite alloy of Al - Mg - Ca - Fe with lower carbon, silicon, phosphor, and sulfur in use for final steelmaking deoxidizer

This invention relates to a final deoxidizer for steelmaking, which is low-C, low-Si, low-P and low-S Al-Mn-Mg-Ca-F alloy. The alloy can be used as the final deoxidizer for steelmaking with good effect, and does not need further refinery of steel. The alloy comprises: C less than or equal to 0.2 wt.%, Si less than or equal to 1.0 wt.%, P less than or equal to 0.02 wt.%, S less than or equal to 0.02 wt.%, Al 40-50 wt.%, Mn 1.0-10 wt.%, Mg 0.1-10 wt.%, Ca 0.1-10 wt.%, and Fe as balance. This invention adopts main frequency induction furnace smelting to produce the final deoxidizer. The final deoxidizer has such advantages as high specific gravity, low melting point, no pulverization, good deoxidation and desulphurization effects, high yield, high fluidity of deoxidized molten steel, no nodulation, easy suspension of deoxidized product, low inclusion total content, high molten steel purity, good steel quality, fine grains, good mechanical properties, and long service life.

Owner:李兴有

Low-temperature impact resistant angle steel for power transmission iron tower

The invention discloses low-temperature impact resistant angle steel for a power transmission iron tower. The angle steel comprises the following chemical components in percentage by weight: 0.05-0.15% of C, 1.20-1.60% of Mn, 0.01-0.05% of Si, 0.02-0.10% of V, 0.02-0.06% of Ni, 0.001-0.005% of Ca, 0.01-0.20% of Cr, 0.10-0.25% of Cu, 0.01-0.03% of P, 0.20-0.35% of Mo, 0.005-0.02% of S and the balance of Fe. The angle steel disclosed by the invention is pure in steel quality and stable in structure, has excellent low-temperature flexibility and good mechanical properties, and the result of a low-temperature tensile property test performed by a GB / T13239-2006 low-temperature tensile test method shows that the yield strength of the angle steel is greater than 350MPa.

Owner:ANHUI HONGYUAN LINE EQUIP

High-strength steel plate with excellent cold forming property and manufacturing method of high-strength steel plate

ActiveCN104404377AGood welding performanceGood cold forming propertiesProcess efficiency improvementSteel qualityFerrosilicon

The invention discloses a high-strength steel plate with excellent cold forming property and a manufacturing method of the high-strength steel plate. The manufacturing method comprises the following steps: performing converter smelting on molten iron, heating to 1250-1350 DEG C, adding waste steel, adding aluminum by a single slag process for deoxidation and alloying, tapping in which a steel ladle needs to be subjected to bottom argon blowing, blocking slag, performing LF furnace secondary refining on molten steel subjected to converter smelting, adding ferromanganese, ferroniobium, ferrosilicon, ferrochromium and ferromolybdenum, performing RH process vacuum degassing, and adding ferrotitanium; conveying the molten steel to a casting machine for continuous casting; reheating a prepared plate blank; descaling; roughly rolling; finely rolling; cooling; hotly straightening; performing heat treatment; shearing; hardening and tempering; sampling; checking; warehousing the finished steel plate. According to the manufacturing method, the high-strength steel plate with excellent cold forming property is manufactured by adopting a low-carbon component design, properly adding elements capable of improving hardenability, improving steel purity and optimizing heat treatment and hardening and tempering processes.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

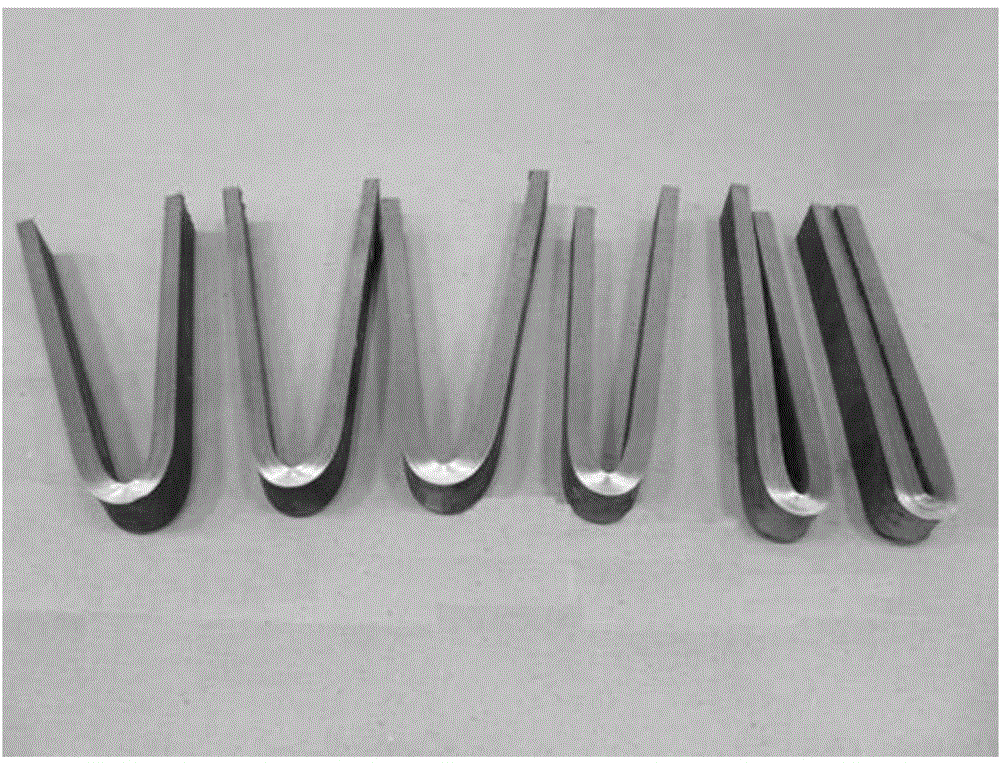

High-strength high-toughness pipe for crane boom and manufacturing method for high-strength high-toughness pipe

The invention provides a high-strength high-toughness pipe for a crane boom. The high-strength high-toughness pipe consists of the following components in percentage by mass: 0.14-0.18% of C, 0.30-0.50% of Si, 1.30-1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.008% of S, 0.35-0.50% of Cr, 0.10-0.20% of Ni, 0.25-0.38% of Mo, 0.07-0.12% of V, less than or equal to 0.05% of Ti, 0.30-0.45% of W, 0.02-0.05% of Al, less than or equal to 0.02% of Cu, less than or equal to 0.05% of Nb, less than or equal to 0.007% of N, and the balance iron and impurities. Ferrotitanium is added 5-8 minutes before ending external refining. A pipe blank heating temperature ranges from 1260 DEG C to 1280 DEG C; a steel pipe quenching temperature ranges from 920 DEG C to 930 DEG C, a tempering temperature ranges from 690 DEG C to 700 DEG C, and thermal insulation time ranges from 40 minutes to 60 minutes. The process is simple and easy to realize; the boom is welded and judged according to the technical requirements of standard Pressure-bearing Equipment Welding Procedure Qualification NB / T47014-2011; bending tests such as a room-temperature tensile test, a lateral bending test, a surface bending test and a back bending test as well as a low-temperature impact test at (-)40 DEG C of the boom are qualified; and moreover, production performances are uniform and stability is good.

Owner:ANGANG STEEL CO LTD

380L vehicle beam black steel and production method thereof

The present invention belongs to the field of steelmaking, and particularly relates to a 380L vehicle beam black steel and a production method thereof, wherein the 380L vehicle beam black steel comprises, by mass, 0.06-0.08% of C, 0.02-0.08% of Si, 0.81-0.93% of Mn, 0.008-0.012% of P, 0.002-0.007% of S, 0.02-0.04% of Als, 0.020-0.033% of Nb, 0.08-0.11% of Cr, 0.0050-0.020% of Ti, and the balance of Fe. The produced 380L vehicle beam hot-rolling black surface steel of the present invention has characteristics of stable chemical component, pure steel, excellent mechanical property, excellent stamping molding performance, and excellent corrosion resistance.

Owner:BENGANG STEEL PLATES

690MPa-grade quenched and tempered high-strength steel plate and production method thereof

InactiveCN108441771ALow costReduce leveling costsElectric furnaceProcess efficiency improvementSheet steelChemical composition

The invention discloses a 690MPa-grade quenched and tempered high-strength steel plate and a production method of the 690MPa-grade quenched and tempered high-strength steel plate. According to the chemical components, the 690MPa-grade quenched and tempered high-strength steel plate comprises, by mass percentage, 0.18%-0.22% of C, 0.20%-0.40% of Si, smaller than or equal to 0.025% of P, smaller than or equal to 0.015% of S, 1.7%-2.2% of Mn, 0.0060%-0.0120% of N, 0.090%-0.12% of V, 0.003%-0.005% of B and the balance Fe and inevitable impurity elements. The production method comprises the steps of a smelting working procedure, a heating working procedure, a rolling working procedure, a cooling working procedure, a slow cooling working procedure and a quenching and tempering thermal treatmentworking procedure, wherein a quenching and tempering technology is adopted by the quenching and tempering thermal treatment working procedure. According to the 690MPa-grade quenched and tempered high-strength steel plate and the production method of the 690MPa-grade quenched and tempered high-strength steel plate, the organization type of the steel plate is tempered sorbite and tempered martensite, the yield strength Rp0.2 of the steel plate is larger than or equal to 670MPa, the tensile strength Rm is larger than or equal to 730MPa, A50 is larger than or equal to 20%, the -20 DEG C transverseimpact energy is larger than or equal to 80J, and the surface hardness HB is larger than or equal to 360.

Owner:WUYANG IRON & STEEL

Low-alloy and high-strength steel plate for anticorrosion, and production method thereof

The invention discloses a low-alloy and high-strength steel plate for anticorrosion, and a production method thereof. The steel plate comprises, by mass, 0.07-0.10% of C, 0.30-0.40% of Si, 0.65-0.85%of Mn, 0.010% or less of P, 0.005% or less of S, 0.30-0.50% of Al, 2.15-2.35% of Cr, 0.35-0.50% of Mo, 0.20% or less of Cu, 0.20% or less of Ni, and the balance of Fe and inevitable impurities. The production method of the steel plate comprises the following processes: smelting, continuous casting, heating, rolling and heat treatment. The steel plate has the characteristics of high density, moderate strength level, moderate hardness, excellent -20 DEG C low temperature impact toughness, excellent hydrogen sulfide corrosion resistance, good comprehensive performances and good welding performance, and meets the requirements of pressure containers for hydrogen sulfide corrosion resistant steel.

Owner:WUYANG IRON & STEEL

Hydrogen sulfide corrosion preventing thin steel sheet subjected to long-time simulated post weld heat treatment and production method

ActiveCN107619999AImprove organizationImprove mechanical propertiesChemical compositionSolid solution strengthening

The invention discloses a hydrogen sulfide corrosion preventing thin steel sheet subjected to long-time simulated post weld heat treatment and a production method. The thin steel sheet comprises the chemical components of, by mass, 0.16%-0.19% of C, 0.20%-0.40% of Si, 1.15%-1.30% of Mn, no more than 0.010% of P, no more than 0.005% of S, 0.020%-0.050% of Al and the balance Fe and inevitable impurities. The production method comprises the heating, rolling and heat treatment processes. The rolling process adopts a two-stage rolling technique, and the heat treatment process adopts a quenching andtempering technique. C and Mn solid solution strengthening is adopted; the steel sheet is high in density and strength grade, excellent in -30 DEG C low-temperature impact toughness, moderate in hardness and excellent in hydrogen sulfide corrosion preventing performance, the requirement for hydrogen sulfide corrosion preventing steel, subjected to long-time simulated post weld heat treatment, fora pressure vessel can be met, and good comprehensive performance and welding performance are achieved; the number of banded structures is 0; and the thickness specification of the thin steel sheet is8-20 mm.

Owner:WUYANG IRON & STEEL

SCC-corrosion-resistant pipe steel and manufacturing technology thereof

SCC-corrosion-resistant pipe steel comprises, in percent by mass, Si: 0.15-0.25%, Mn: 1.6-2.0%, Ni: 0.05-0.15%, Cr: 0.65-0.80%, Cu: 0.05-0.12%, Mg: 0.02-0.05%, Ti: 0.015-0.025%, Ca: 0.001-0.003%, W: 0.002-0.005%, Al: 0.025-0.055%, P<=0.012%, S<=0.01%, the balance Fe and unavoidable impurities, wherein 0.05<=C+Ni / 5+Cr / 10-Mg-10W<=0.09. The manufacturing technology of the pipe steel comprises pre-desulphurization of molten iron, converter smelting, LF refining, RH processing, slab continuous casting, slab reheating, rolling and cooling bed cooling. By adding a proper amount of Mg, Ca and W into the pipe steel, reduction of pH value of corrosion front end is inhibited, generation and expansion of corrosion-cracked cracks are effectively inhibited, the content of C, Ni and Cr are controlled at proper scopes, and the pipe steel is guaranteed to have excellent SCC (Stress Corrosion Cracking) corrosion resistance and HIC (Hydrogen Induced Cracking) corrosion resistance.

Owner:RIZHAO STEEL HLDG GROUP

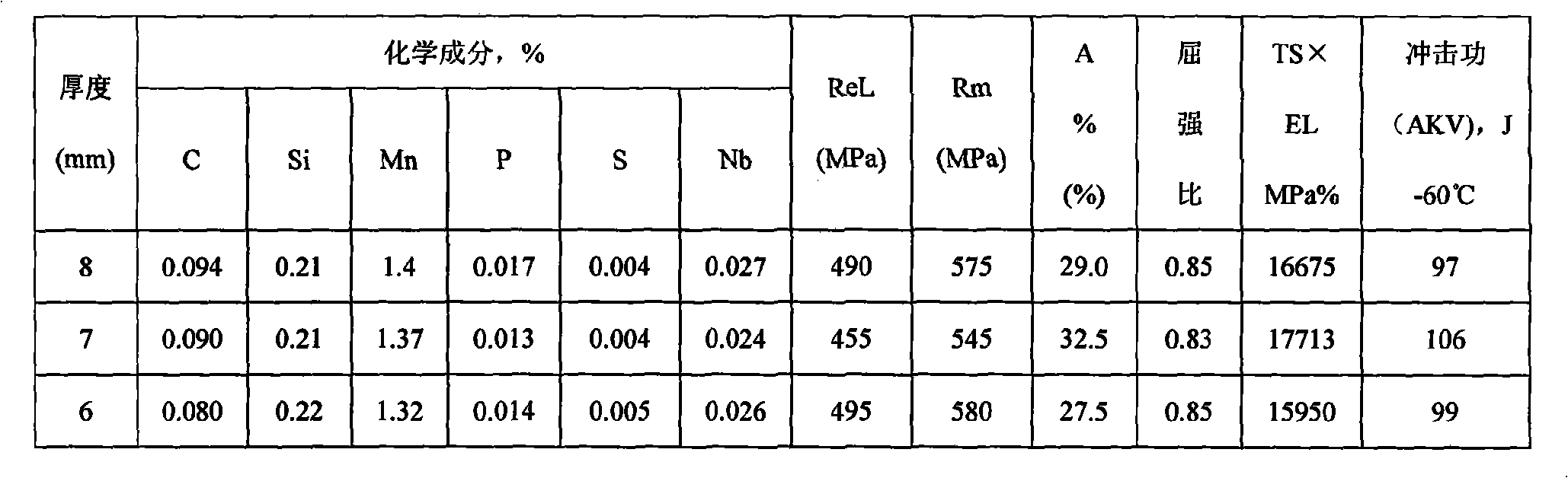

Making method of steel plate for auto girders

The invention discloses a making method of a steel plate for auto girders. The steel plate for auto girders is composed of C, Si, Mn, P, S, Nb, Ca, Al, Ti, Fe and the like. The hot-rolled coiled plate having the advantages of pure steel, excellent comprehensive properties and uniform and fine grain size is obtained through reasonable chemical component blending by adopting converter smelting, refining, protected casting of a continuous caster, and controlled rolling and cooling technologies. The tensile strength, the yield strength and the elongation percentage of the steel plate for auto girders are 585-610MPa, 500-520MPa and 30-35%, and the steel plate for auto girders can satisfy production demands of heavy duty auto girders, and can also be used for producing other high-strength automobile structure members.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

Petroleum drilling high-strength alloy structural steel and preparation method thereof

The invention relates to petroleum drilling high-strength alloy structural steel, which comprises the following components in percentage by weight: 0.28-0.36% of C, less than or equal to 0.50% of Si,less than or equal to 0.80% of Mn, 1.40-2.40% of Cr, 1.0-2.4% of Ni, 0.50-1.00% of Mo, less than or equal to 0.20% of V, less than or equal to 0.050% of Nb, less than or equal to 0.040% of Al, less than or equal to 0.020% of P, less than or equal to 0.010% of S, and the balance of Fe and inevitable impurities. Drill rods and transmission shafts manufactured by adopting the petroleum drilling high-strength alloy structural steel have the advantages of excellent alloy element proportion, pure steel, uniform structure, high strength, good toughness, high fatigue strength and excellent comprehensive performance. The petroleum drilling high-strength alloy structural steel solves the problems of low strength, poor fatigue strength, short service life and high possibility of accidental breakage when encountering a complex geological structure of the conventional commonly-used drill rod and transmission shaft materials in China, the service life of the drill rods and the transmission shafts isgreatly prolonged, accidental breakage is avoided, the production efficiency is improved, and the production cost is saved.

Owner:YINGKOU SPECIAL STEEL FORGING

Low-cost extra-thick wear-resistant steel plate for a marine platform rack and production method thereof

InactiveCN110923544AReasonable designSolid solution strengtheningFurnace typesHeat treatment furnacesTemperingHigh wear resistance

The invention discloses a low-cost extra-thick wear-resistant steel plate for a marine platform rack. The steel plate comprises the following chemical components, in mass percent, 0.30% to 0.40% of C,0.15% to 0.35% of Si, 0.5% to 0.6% of Mn, <=0.012% of P, <=0.002% of S, 0.5% to 0.6% of Ni, 0.8% to 0.9% of Cr, 0.50% to 0.60% of Mo, 0.020% to 0.045% of TAl (all aluminum), and the balance of Fe andinevitable impurities. The steel plate is prepared by electric furnace smelting, vacuum extraction, die-casting, air-temperature rolling, and two different temperature quenching and tempering treatments of an extra-thick quencher, has mechanical properties of high strength and hardness, good wear resistance, and good low-temperature impact toughness, and is low cost due to the low content of precious alloy elements.

Owner:WUYANG IRON & STEEL

22SiMn2B steel plate for construction machine and production method of 22SiMn2B steel plate

The invention discloses a 22SiMn2B steel plate for a construction machine and a production method of the 22SiMn2B steel plate. The steel plate comprises, by mass percentages, 0.19-0.25% of C, 0.70-1.00% of Si, 1.50-1.85% of Mn, not larger than 0.025% of P, 0.010-0.060% of Ti, 0.0005-0.035% of B and the balance Fe and inevitable impurities. The production method comprise the steps of steel making,continuous casting, heating and rolling processes; and an II-type rolling control process is adopted for the rolling process. By the adoption of the method, the Brinell hardness of the surface of thesteel plate produced by the method is less than or equal to 230 HB and the surface roughness is less than or equal to 5 mm / 1 m. The produced steel plate has the beneficial effects of being pure in steel quality, high in density and stable in quality, and the performance of the steel plate meets the requirements. The steel plate produced by the method is low in production cost, and mass productioncan be achieved.

Owner:WUYANG IRON & STEEL

Electroslag-forming tempered hydroelectric steel plate and production method thereof

The invention discloses an electroslag-forming tempered hydroelectric steel plate and a production method thereof. The steel plate comprises the chemical components of, by mass, 0.13-0.18% of C, 0.20-0.50% of Si, 0.90-1.30% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.60-1.25% of Ni, 0.30-0.60% of C, 0.40-0.60% of Mo, 0.02-0.05% of Nb, 0.020-0.050% of Tal, and thebalance Fe and inevitable impurities. The production method comprises the steps of smelting, continuous casting, electroslag remelting, heating, rolling, annealing and heat treatment. The obtained steel plate has excellent isotropy, impact toughness and Z-direction performance, the looseness and segregation level is lower than or equal to level 1.0, the yield is high, and the steel plate meets the requirements of large hydraulic turbine set for low-alloy super-thick steel plates.

Owner:WUYANG IRON & STEEL

Preparation method of low-alloy-cost large-thickness high-low-temperature-toughness 13MnNi6-3 quenched and tempered container steel

InactiveCN113005354AGood mechanical propertiesImprove organizationManufacturing convertersTemperingManganese

The invention belongs to the technical field of metallurgy, and particularly relates to a preparation method of low-alloy-cost large-thickness-specification high-low-temperature-toughness 13MnNi6-3 quenched and tempered container steel. Through the alloying component design of low carbon, low manganese, 0.5% of Ni and 0.030% of Nb, casting blank production is adopted, and the reasonable controlled rolling and controlled cooling, quenching and tempering processes are utilized, so that the low-alloy-cost large-thickness-specification high-low-temperature-toughness 13MnNi6-3 quenched and tempered container steel is produced. The thickness specification of the product produced through the method covers 12-90 mm, and the low-temperature impact absorption energy KV2 of the position where the thickness is 1 / 4 and the core portion (the position where the thickness is 1 / 2) at the temperature of minus 70 DEG C is larger than or equal to 260 J. The preparation method is reasonable in component design, low in alloy cost and simple and easy in process control, the obtained steel has ultrahigh low-temperature toughness, and the preparation method has guiding significance for development of the low-temperature pressure container steel market of large-thickness-specification, low-temperature ultrahigh-impact-toughness and high-welding-performance products produced at low alloy cost.

Owner:SD STEEL RIZHAO CO LTD

Complex ferroalloy of aluminum, nickel, copper with lower carbon and silicon in use for final steelmaking deoxidizer

This invention relates to a final deoxidizer for steelmaking, which is low-C and low-Si Al-Ni-Cu alloy. The alloy comprises: C less than or equal to 0.3 wt.%, Si less than or equal to 1 wt.%, S less than or equal to 0.03 wt.%, Al 5-40 wt.%, Ni 15-65 wt.%, Cu 15-65 wt.%, and Fe as balance. The alloy has such advantages as low melting point, high specific gravity, no pulverization, no impurities, easy operation, good deoxidation effect, high Ni and Cu yields (100%), and high steel qualification rate. The alloy is added into molten steel after discharge from furnace, thus can prevent steel quality deterioration. Besides, adding the alloy after discharge from furnace does not influence normal production time, and is good to furnace body.

Owner:李兴有

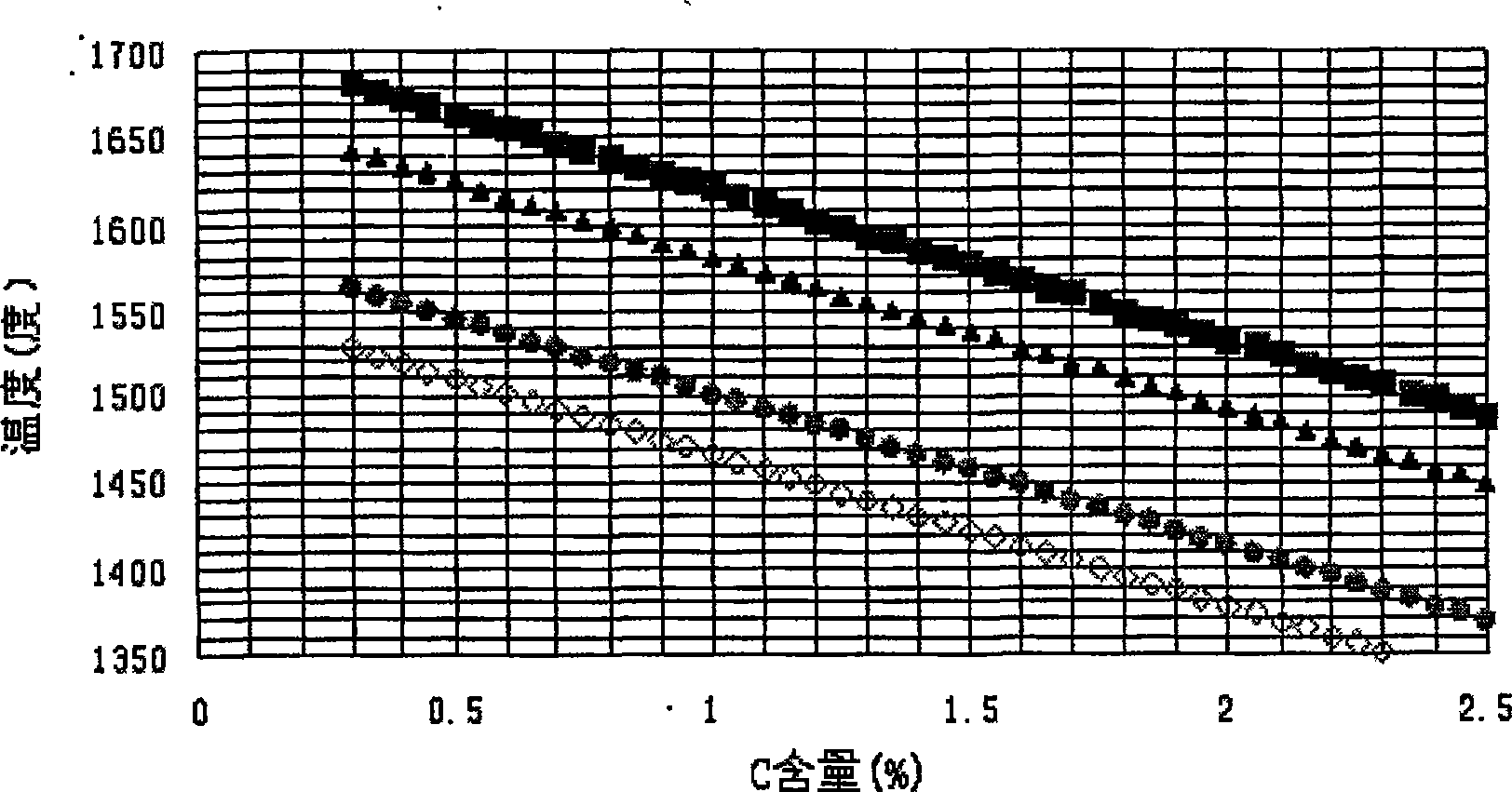

Hot-rolled coiled plate for gardening tool and manufacturing method of hot-rolled coiled plate

The invention provides a hot-rolled coiled plate for a gardening tool. The hot-rolled coiled plate comprises, by weight percent, 0.83%-1.03% of C, 0.12%-0.40% of Si, 0.25%-0.90% of Mn, 0.010%-0.070% of Al, not larger than 0.025% of P, not larger than 0.025% of S, 0.30%-0.80% of Cr, not larger than 0.55% of C and the balance Fe and inevitable impurity elements. The invention further provides a manufacturing method of the hot-rolled coiled plate for the gardening tool. The manufacturing method comprises the steps of molten iron pretreatment, converter smelting, external refining (LF+RH), slab continuous casting, hot conveying and hot charging or slab heat treatment, slab heating, high-pressure water descaling, rolling of roughing rolling unit, high-pressure water descaling, rolling of finishing mill group, cooling after rolling, coiling, cooling after coiling and heat treatment of the hot-rolled coiled plate. The hot-rolled coiled plate for the gardening tool has high hardness and wear resistance and excellent high-temperature mechanical performance and hardenability.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Quenched and tempered water power plant large-thickness low-alloy high-strength steel plate and production method thereof

A quenched and tempered water power plant large-thickness low-alloy high-strength steel plate and a production method thereof are disclosed. The chemical components of the steel plate are as follows in mass percent: C: 0.16 to 0.19%, Si: 0.27 to 0.37 %, Mn: 1.50 to 1.70 %, P <= 0.015 %, S <= 0.005 %, Ni: 0.40 to 0.80 %, Nb: 0.020 to 0.050 %, TAl: 0.020 to 0.050 %, and the balance of Fe and inevitable impurities. The production method comprises the steps of smelting, mold casting, ingot cleaning and stacking slow cooling, heating, rolling, ultrasonic flaw detection and heat treatment. The S460N / Z35 steel plate with the maximum thickness of 260mm has good comprehensive performance, and meets the requirements for a low-alloy extra-thick steel plate of a large-scale hydraulic turbine unit, themethod is simple in process, easy to operate and high in yield, and is suitable for production in all qualified thick plate factories.

Owner:WUYANG IRON & STEEL

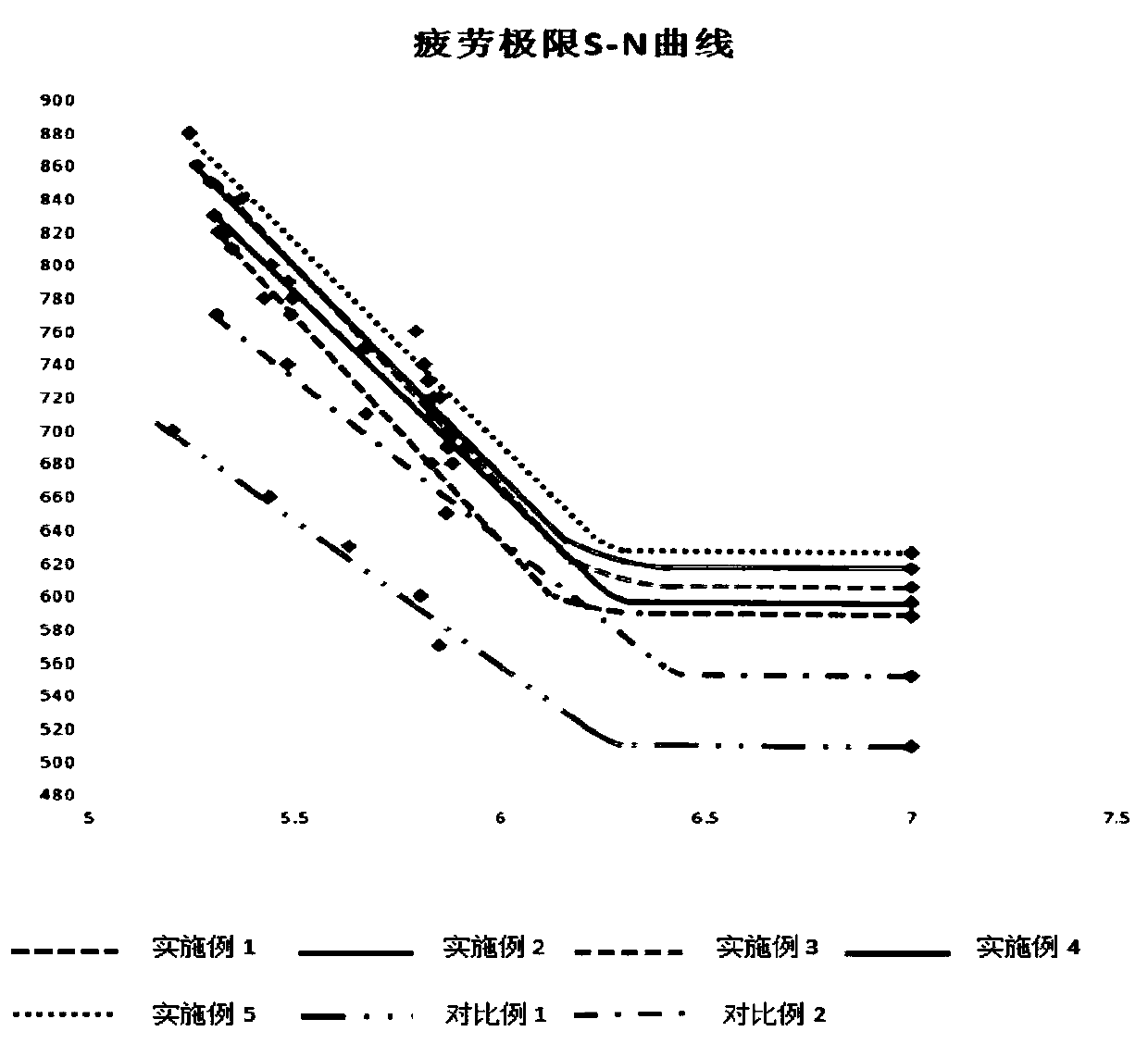

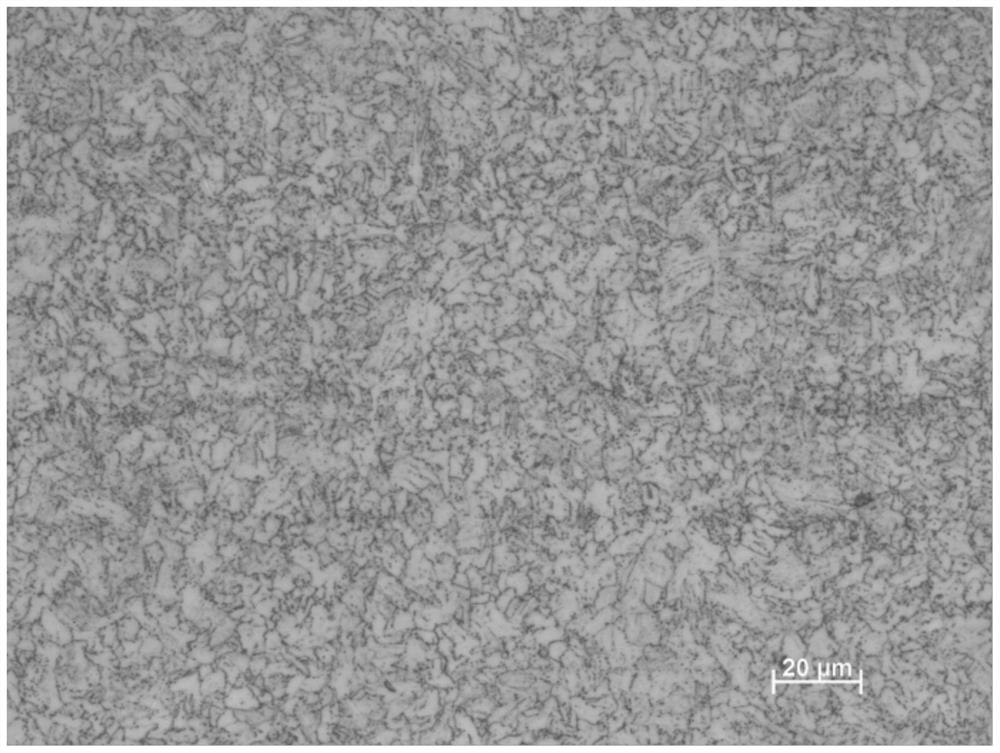

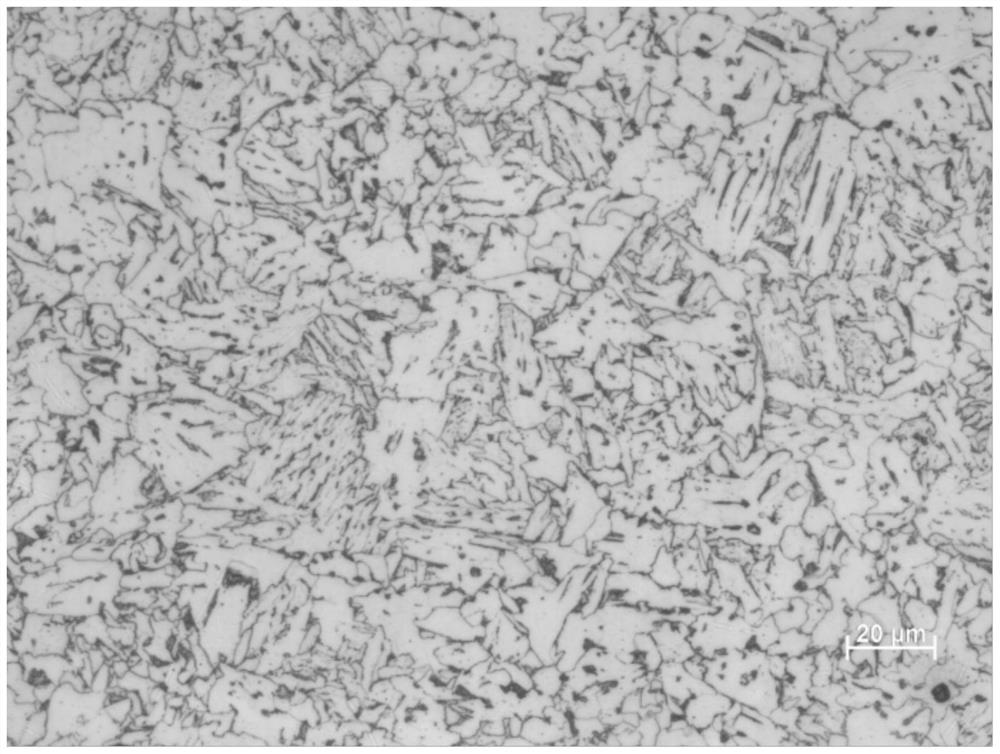

Hot-rolled steel strip, preparation method thereof and application of hot-rolled steel strip in double-metal band saw back material

The invention belongs to the technical field of medium-carbon high-alloy steel, and relates to a hot-rolled steel strip, a preparation method thereof and application of the hot-rolled steel strip in a double-metal band saw back material. The hot rolled steel strip provided by the invention comprises the following components in percentage by weight: 0.28%-0.40% of C, 0.10%-0.50% of Si, 0.40%-1.20% of Mn, 0.01%-0.10% of Al, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 2.80%-4.10% of Cr, 1.50%-2.60% of Mo, 0.60%-1.40% of Ni, 0.10%-0.60% of V, 0.01%-0.12% of Nb, less than or equal to 0.02% of Cu, less than or equal to 120 ppm of N, less than or equal to 18 ppm of O, less than or equal to 2.4 ppm of H and the balance of Fe and inevitable impurity elements. The hot rolled steel strip for the double-metal band saw back material has high finished product anti-fatigue performance, the idling fatigue test life of the hot rolled steel strip is larger than or equal to 70000 weeks, the fatigue life is prolonged by 30-60% compared with that of traditional saw back steel X32, and the use requirement of the high-fatigue-performance double-metal band saw back material is met.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Nichrome steel alloy for smelting stainless steel and producing method thereof

The invention discloses nickel-chrome alloy steel used for smelting stainless steel, and the production method thereof. The nickel-chrome alloy steel comprises the following components: carbon is 0.3to 2.0, silicon is lower than or equal to 1.0, manganese is lower than or equal to 0.5, phosphorus is lower than or equal to 0.03, sulfur is lower than or equal to 0.04, chromium is 0.6 to 2.5, nickel is 3.5 to 7.0, copper is lower than or equal to 0.2, and the residual is iron. The production process comprises charging material preparation, oxygen supply, slag forming, end point control, deoxidization alloying and nitrogen flush processing, etc., charging material comprises nickel including molten iron and nickel including iron blocks, being expressed according the weight percentage, nickel including molten iron occupies 75 to 90 percent, the nickel including iron blocks occupy 10 to 25 percent; an oxygen top-blow converter is adopted to smelt, the double slag method is used to form the slag, the end point alkalinity is larger than 2.5, the carbon content C is larger than or equal to 0.30. The nickel-chrome alloy steel of the invention includes lower phosphorus and sulfur which can be directly used as raw materials for smelting the stainless steel, the output and the quality of the stainless steel can be improved, and the production cost is reduced.

Owner:河南昌泰不锈钢板有限公司

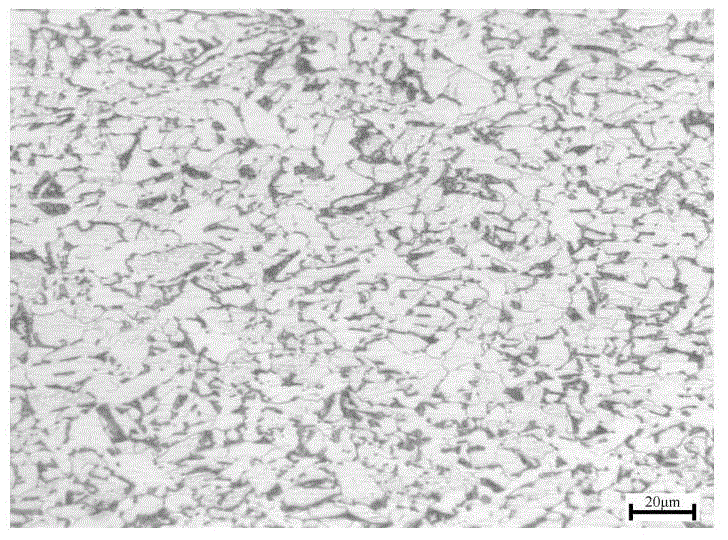

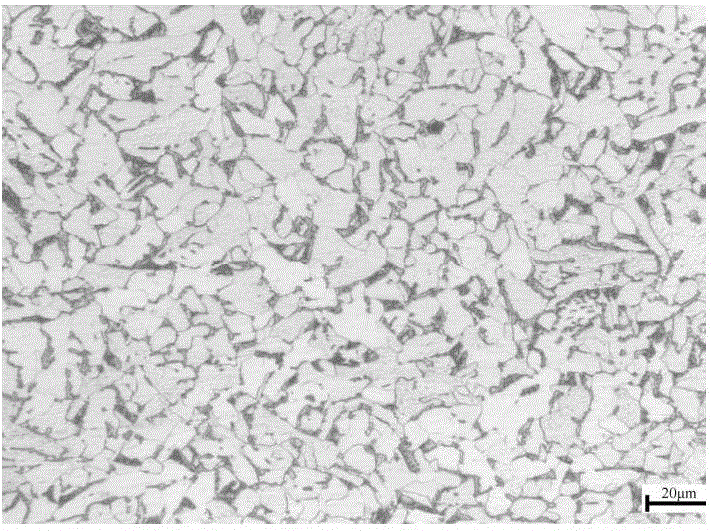

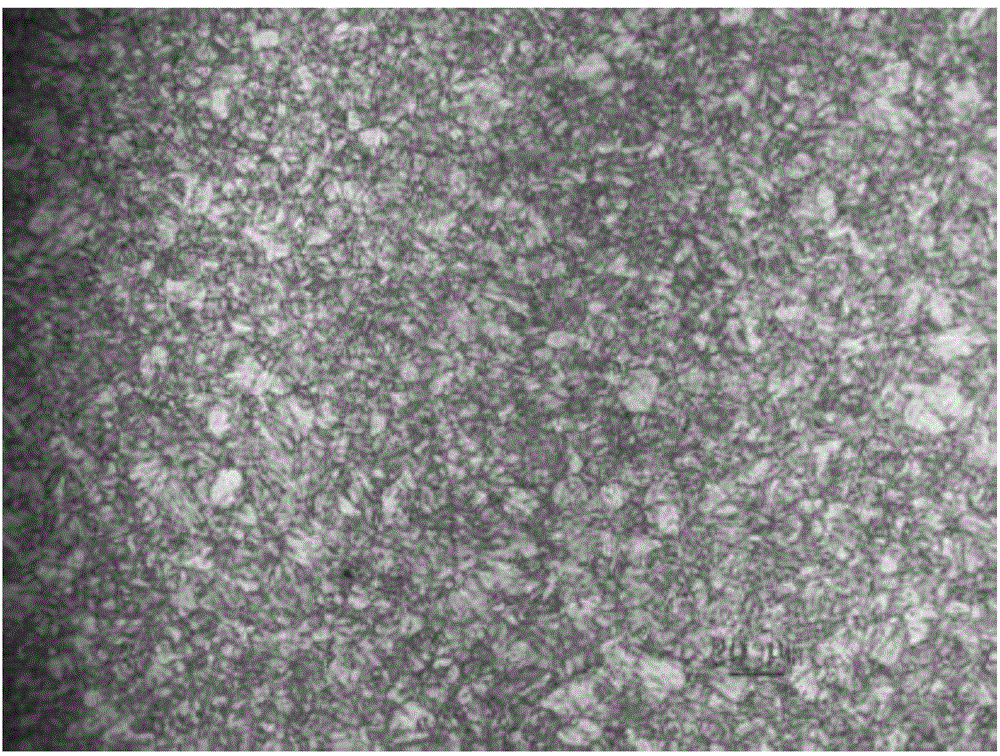

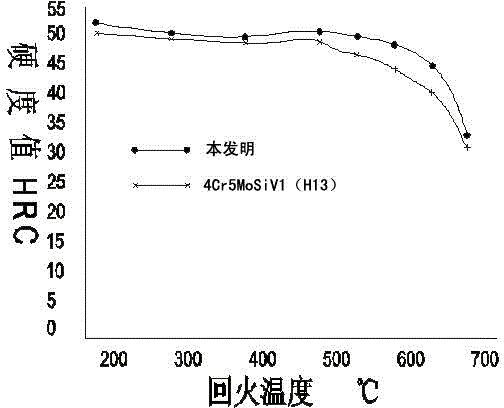

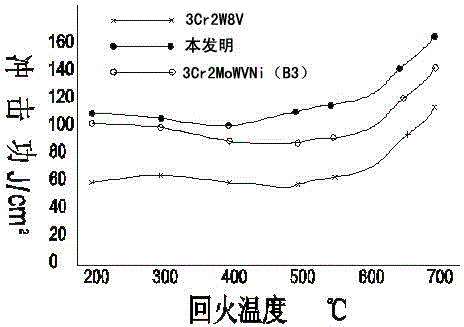

B3R hot work die steel with high strength and toughness and resistance to tempering, and preparation process thereof

The invention provides 4Cr3MoWVNi (B3R) hot work die steel with high strength and toughness and resistance to tempering, and a preparation process thereof. Raw materials for preparing the B3R hot work die steel comprise, by weight, C 0.35 to 0.42%, Si 0.15 to 0.35%, Mn 0.3 to 0.5%, Cr 2.50 to 3.50%, Mo 1.00 to 1.50%, W 0.50 to 0.80%, V 0.50 to 0.80%, Ni 1.45 to 1.85%, S 0.003 to 0.010% and P 0.008 to 0.018%, with the balance being Fe. The preparation process comprises the following steps: smelting at intermediate frequency--remelting (refining) of electroslag-diffusion hydrogen of electroslagingots, annealing treatment of electroslag ingots--forging--annealing of forging stocks--rough machining--vacuum heat treatment, and secondary tempering so as to obtain the novel product of die steel. The hot work die steel prepared in the invention has high Rockwell hardness, excellent impact toughness and tempering (thermal fatigue) resistance, and the advantages of optimized collocation of components, pure steel quality, a uniform structure, high strength, strong toughness, good tempering resistance, etc.

Owner:SHANDONG YUANDA MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com