Nichrome steel alloy for smelting stainless steel and producing method thereof

A production method and technology for alloy steel, applied in the field of alloy steel, can solve the problems of high consumption of refractory materials, low production efficiency and high phosphorus content, and achieve the effects of high production efficiency, good quality and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

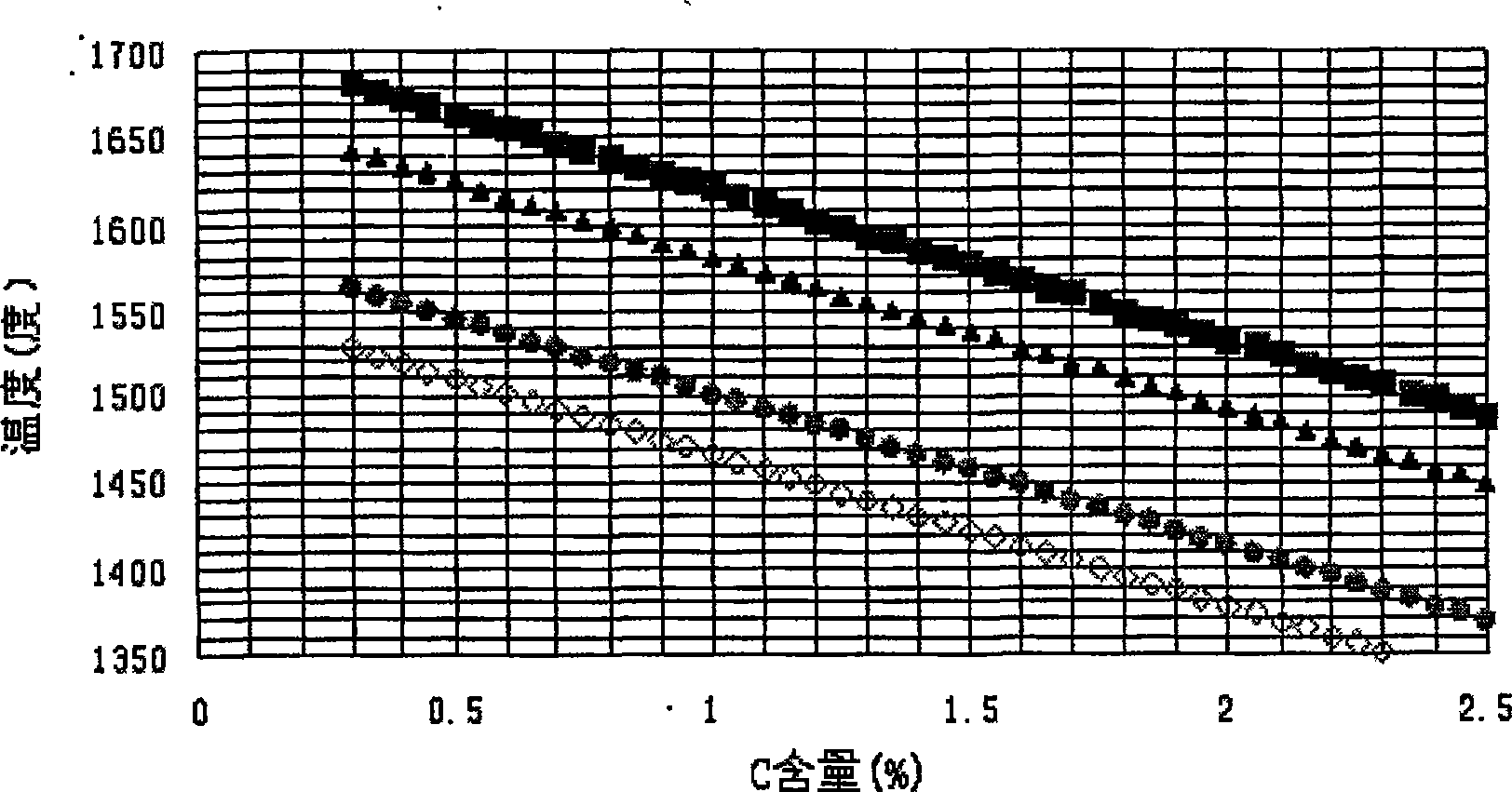

Image

Examples

Embodiment 1

[0030] Embodiment one, the production method of nickel-chromium alloy steel

[0031] (1) Charge preparation:

[0032] Furnace charges are nickel-containing molten iron and nickel-containing iron block, expressed in weight percentage, nickel-containing molten iron is 84.4%, nickel-containing iron block is 15.6%, the charging amount of nickel-containing molten iron is 34.1 tons, nickel-containing iron block, that is, pig iron block, is 6.3 Ton.

[0033] The composition of molten iron is as follows:

[0034] Element C Si mn P S Cr Ni Cu content% 5.25 2.3 0.56 0.086 0.036 3.5 3.77 0.07

[0035] The composition of the nickel-containing iron block is the same as that of the nickel-containing molten iron.

[0036] (2) Oxygen supply: Oxygen top-blown converter is used for smelting, the oxygen pressure used is 0.8-0.9MPa, the oxygen pressure is controlled at 0.85MPa during oxygen supply, and the oxygen flow rate is 8700Nm 3 / h.

[0037] Gun p...

Embodiment 2

[0053] Embodiment two, basically the same as embodiment one, the difference is:

[0054] (1) charge: the nickel-containing molten iron is 80%, the nickel-containing iron block is 20%, the charging amount of the nickel-containing molten iron is 32 tons, and the nickel-containing iron block, that is, the pig iron block, is 8 tons.

[0055] The composition of molten iron is as follows:

[0056] Element C Si mn P S Cr Ni Cu content% 4.13 2.79 0.60 0.092 0.074 3..02 3.64 0.07

[0057] (2) Smelting

[0058] After blowing, the oxygen pressure is 0.80MPa, and the oxygen flow rate is 8600Nm 3 / h, the gun position is 1.2-2.4m, the first time is 7 minutes and 27 seconds, the temperature is 1419℃; the second time is 14 minutes and 10 seconds, the temperature is 1670℃; the third time is 18 minutes and 20 seconds, the temperature is 1710 ℃, the oxygen supply of the whole furnace is 2800m 3 .

Embodiment 3

[0066] Embodiment three, is basically the same as embodiment one, the difference is:

[0067] (1) Furnace charge: 78% of nickel-containing molten iron, 22% of nickel-containing iron block, the composition of molten iron is as follows:

[0068] Element C Si mn P S Cr Ni Cu content% 3.8 2.0 0.45 0.12 0.05 4.0 4.2 0.15

[0069] The composition of nickel-iron block is:

[0070] Element C Si mn P S Cr Ni Cu content% 4.3 2.6 0.34 0.15 0.06 3.7 4.6 0.10

[0071] (2) Smelting

[0072] After blowing, the oxygen pressure is 0.87MPa, and the oxygen flow rate is 8900Nm 3 / h, the gun position is 1.4m, the first time is 9 minutes and 30 seconds, the temperature is 1510°C; the second time is 15 minutes and 10 seconds, the temperature is 1700°C; the third time is 19 minutes and 10 seconds, the temperature is 1700°C, The oxygen supply of the whole furnace is 2900m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com