Patents

Literature

1390 results about "Bloomery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bloomery is a type of furnace once used widely for smelting iron from its oxides. The bloomery was the earliest form of smelter capable of smelting iron. A bloomery's product is a porous mass of iron and slag called a bloom. This mix of slag and iron in the bloom, termed sponge iron, is usually consolidated and further forged into wrought iron. The bloomery has now largely been superseded by the blast furnace, which produces pig iron.

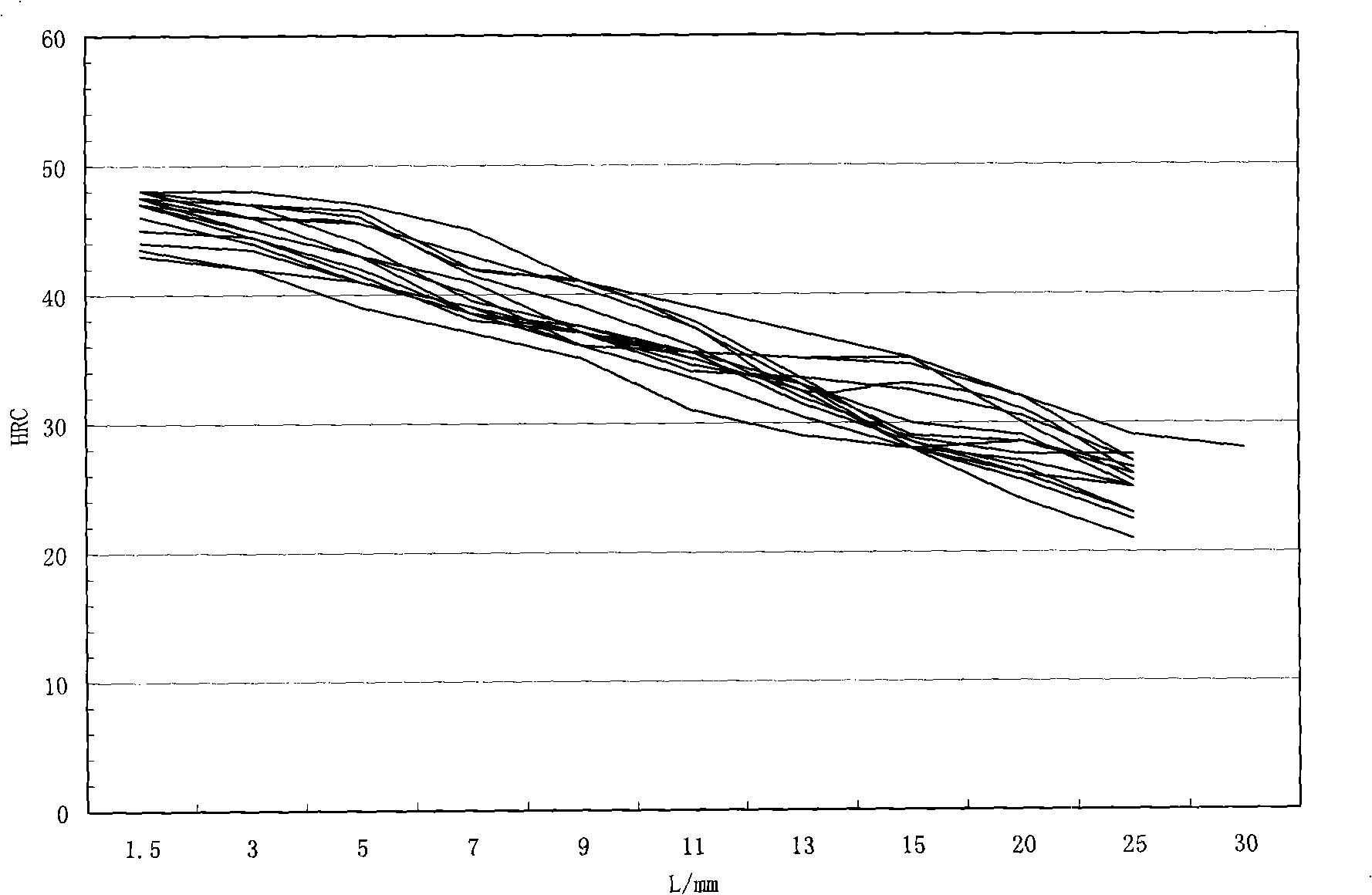

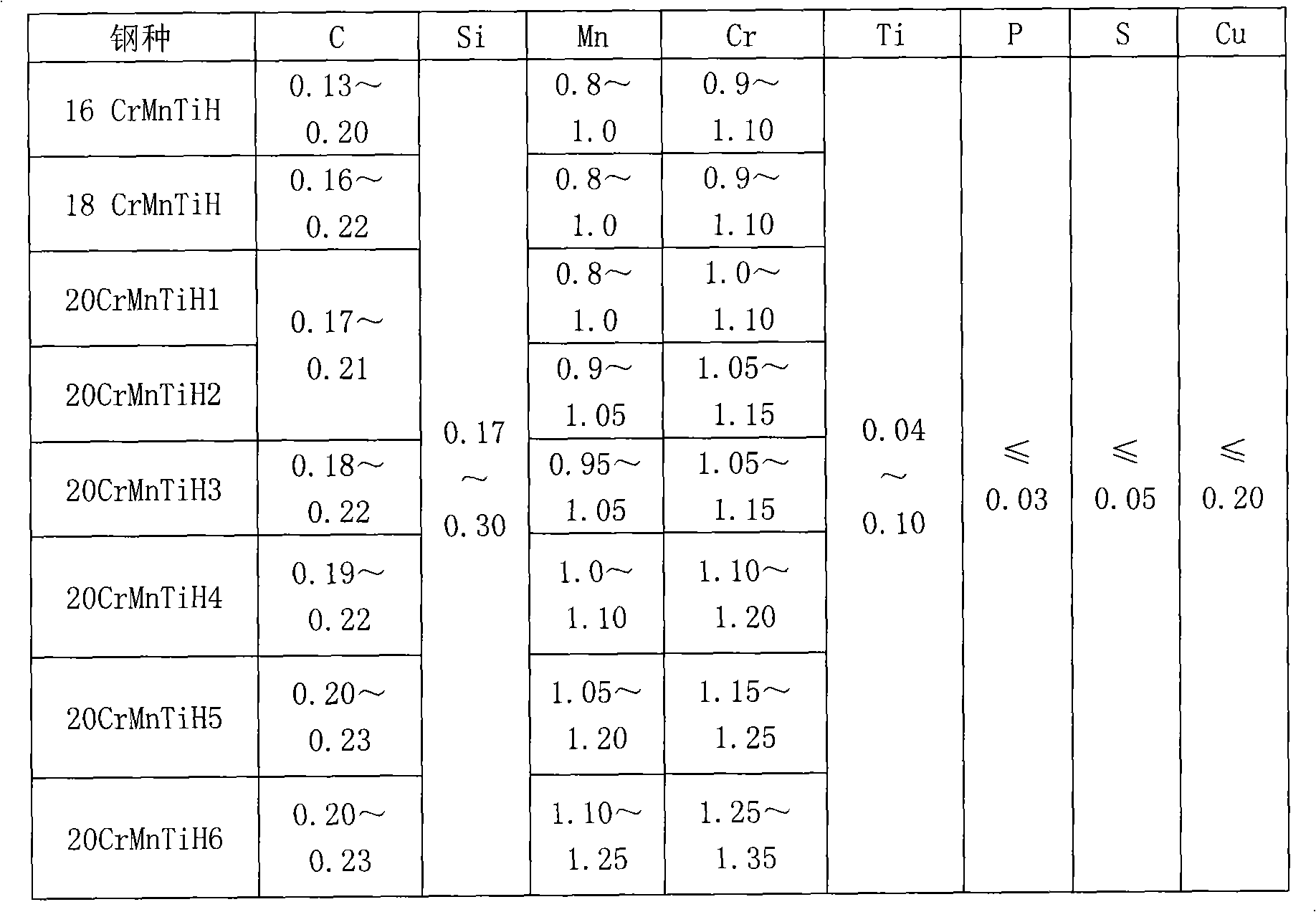

CrMnTi narrow hardenability strip pinion steels and method of manufacture

InactiveCN101289731AGuaranteed narrow hardenability band requirementsTemperature control deviceMetal rolling arrangementsChemical compositionPinion

The invention relates to CrMnTi narrow-hardenability gear steel and a method for manufacturing the same, belonging to the gear steel material and the production process thereof technical field. The chemical composition in percentage by weight of the gear steel is: 0.13-0.23 percent of C, 0.17-0.30 percent of Si, 0.80-1.25 percent of Mn, 0.04-0.10 percent of Ti, 0.90-1.35 percent of Cr, less than or equal to 0.20 percent of Cu, less than or equal to 0.050 percent of S, less than or equal to 0.030 percent of P, less than or equal to 0.05 percent of Mo, less than or equal to 0.25 percent of Ni, [O] less than or equal to 20x10<-6>, [H] less than or equal to 2.5x10<-6>, and the balance being Fe and inevitable impurities. The manufacturing method comprises the following process steps of smelting, continuous casting, rolling and hot rolling, wherein in the step of continuous casting, the superheat degree of a tundish is controlled between 10 and 30 DEG C, and the casting speed is between 0.50 and 0.85 m / min; in the step of rolling, the heating temperature is between 1130 and 1280 DEG C, the start rolling temperature is more than or equal to 1100 DEG C, and the finish rolling temperature is between 850 and 980 DEG C. The gear steel and round steel in the specification between phi 30 and 160 mm can be produced by adopting the manufacturing method. By adopting narrow-composition steel grade design, electric furnace burden structure optimization, electric furnace end point control, grain-refining and banded structure control and other reasonable technological measures, the method effectively realizes hardenability narrowing and other objectives.

Owner:SHANDONG IRON & STEEL CO LTD

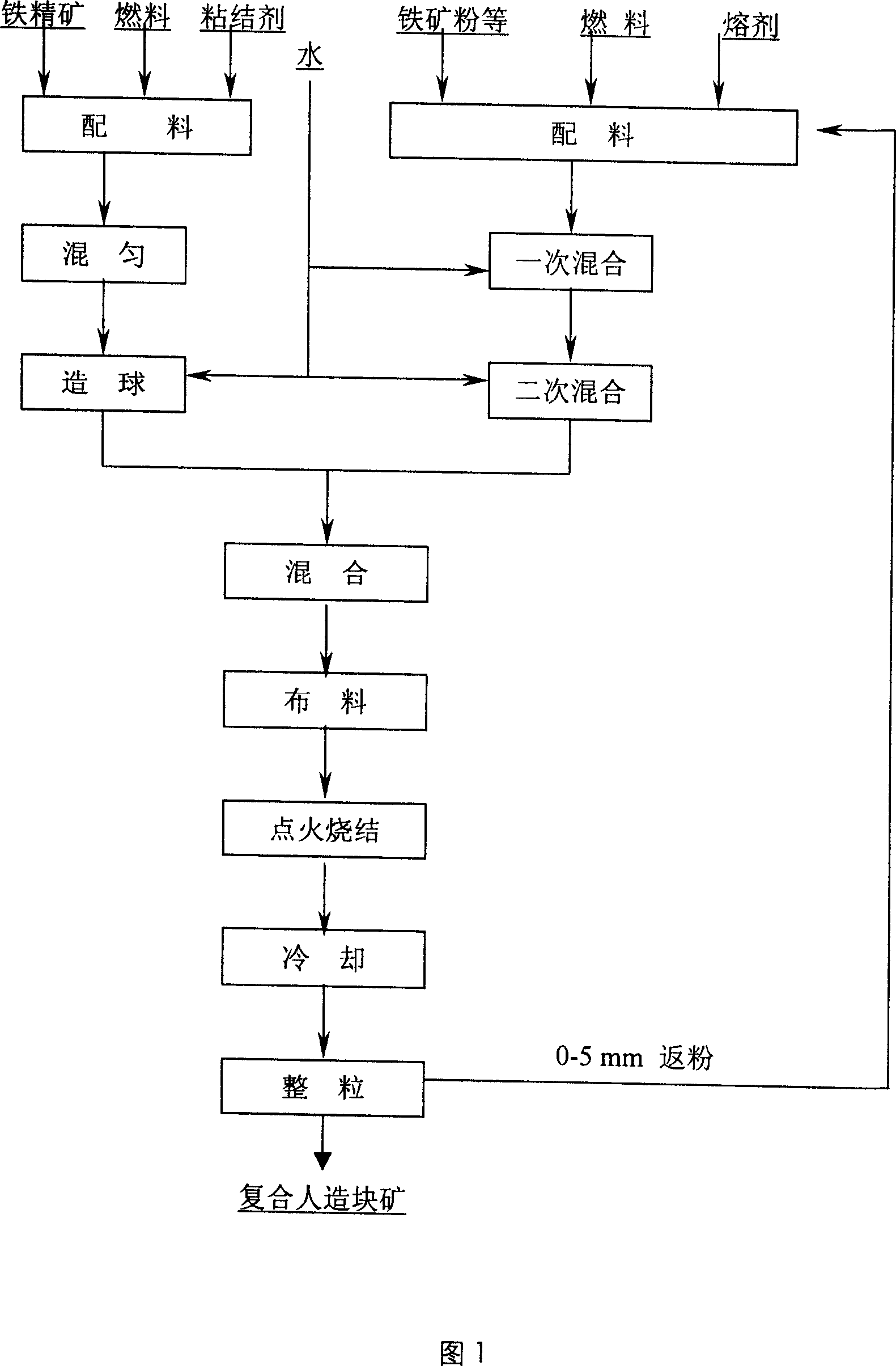

Composite agglomeration technology of iron powdered ore

The invention discloses a ferric powder composite block preparing technology, which is characterized by the following: separating fine ferric ore individually; preparing ball; blending rough particle with ferric powder and other raw materials; paving on the traditional sintering machine; inserting high-alkaline sintering ore of acid ball ore.

Owner:CENT SOUTH UNIV

Production of clean high carbon chromic bearing steel

A method for manufacturing high-cleaning and high carbon complex bearing steel includes: 1) choosing charging mixture 2) first steel making molten steel by is greater than or equal to 30ton electric furnace a. smelting furnace burden b. running out foaming slag and adding lime c. alloying when steel tapping with 92% tap and >90% level 3) refining molten steel by steel ladle furnace a. cleaning steel ladle and furnace cleaning b. through bottom blowing argon mixing with 60 min, earlier stage argon blowing intensity 0.4Mpa and later stage 0.3Mpa, material adding amount is less than or equal to 8Kg / ton steel c. precipitating and deoxidizing by two-stage aluminum feeding method, adding crystallized silicon powder, fluorite(content of calcium is greater than or equal to 98%) into slag face, and dispersing deoxidizing 4) vacuum furnace treating a. bottom blowing argon 0.3Mpa, 25min, vacuum content is less than or equal to 140Pa b. bottom blowing argon mixing 15min, 0.1Mpa without materials after treating 5) molten steel mould casting under inactive gas a. ingot moulding temperature 70deg.C, runner brick coating b. pouring speed 5.1ton steel / min of ingot body and mouth. It achieves high yield.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Method for smelting nickel-based high temperature alloy in vacuum induction furnace

The invention relates to a method for smelting a nickel-based high temperature alloy in a vacuum induction furnace. The method sequentially comprises the following steps of: I, putting alloy raw materials into the furnace in a ratio; II, closing a furnace cover, vacuumizing, and performing power transmission to melt furnace burden; III, melting at the speed of less than or equal to 1 / 2 maximum furnace capacity / hour; IV, after the furnace burden is completely melted, starting performing bottom argon blowing, and refining for 20 to 25 minutes; V, stopping argon blowing, adding Al and Ti, and alloying; VI, after Al and Ti are completely melted, performing bottom argon blowing, and refining; VII, after refining is finished, closing a vacuum pump, and filling argon into the furnace and an ingot mold; VIII, alloying at the finishing point, namely adding B, Zr and a rare earth element, and adding a Ni-Mg alloy; and IX, performing electrified tapping after 3 to 4 minutes, and casting into an alloy ingot. By the method for smelting the nickel-based high temperature alloy in the vacuum induction furnace, refining time is 35 to 40 minutes, and the nickel-based high temperature alloy with very low carbon content can be obtained.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

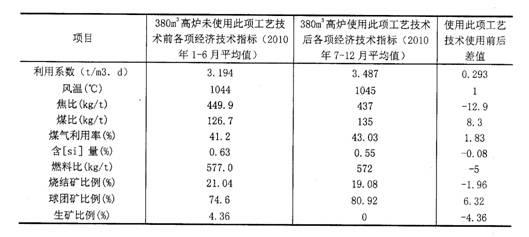

Blast furnace iron-smelting method

InactiveCN101260444AIncrease usage ratioIncrease vanadium contentBlast furnace detailsMagnetiteTitanium

The invention belongs to the blast furnace ironmaking field and particularly relates to a new blast furnace ironmaking method by adopting common iron ore and vanadium titanium magnet to make iron, thereby not only guaranteeing the grade as fired but also lowering the production cost. When sintering ore is prepared by the method, the raw materials are mixed according to the following proportioning by weight: vanadium-titanium magnetite ore concrete of ranging from 35 to 50 percent, common iron ore of ranging from 30 to 45 percent, and fuel and fusing agent of 20 percent; part of the vanadium-titanium magnetite ore concrete is made into pellet ore independently; in the blast furnace ironmaking process, the pellet ore is mixed with the sintering ore and common lump ore to make iron, the blast furnace charging materials are mixed according to the following proportioning by weight: sintering ore of ranging from 60 to 65 percent, vanadium-titanium magnetite pellet ore of ranging from 25 to 35 percent, and common lump ore of ranging from 5 to 10 percent, wherein, the common lump ore contains bixbyite of about 2 percent. The method increases the use ratio of the vanadium-titanium magnetite by optimizing the furnace charging material structure, makes the best of the rich vanadium-titanium magnetite resources, lowers the production cost of the blast furnace ironmaking, and effectively increases the vanadium content in the molten iron, thereby having positive effects.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Melting process for producing synthetic cast iron by utilizing SiC carburizing siliconizing

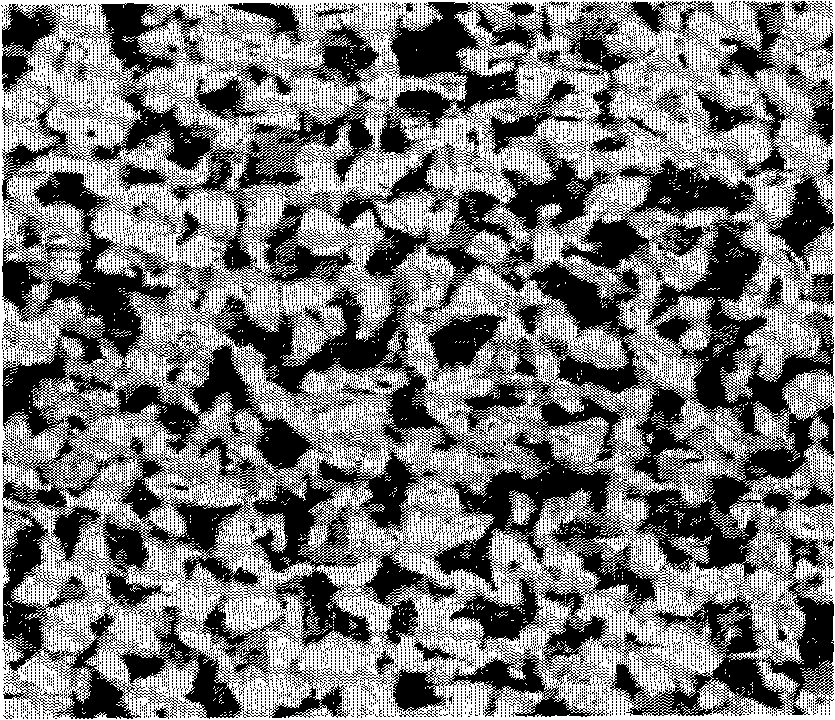

ActiveCN101649369AReduce dosageImprove toughnessProcess efficiency improvementGranularityFerrosilicon

The invention discloses a melting process for producing synthetic cast iron by utilizing SiC carburizing siliconizing, which produces the synthetic cast iron by taking scrap steel, pig iron and cast iron returns or scrap steel and cast iron returns as the main raw materials in an induction furnace by utilizing SiC as an carburizing siliconizing agent, wherein the addition of SiC is 0.5-3%, and thegranularity is 6-20mm; SiC is added to a hearth before melting or is added during the melting process, or the two modes cooperate to be used. The invention utilizes SiC to replace the pig iron and silicon iron carburizing siliconizing to reduce the pig iron and silicon iron so as to reduce the cost, and meanwhile, the tendency of the molten iron chill and the reverse chill of the produced synthetic cast iron is small; the dimensions of graphite pebbles in produced nodular cast iron are small, the sphericity or roundness is high, the content of ferrite is high, and the roughness of the nodularcast iron is improved; the organization of produced grey cast iron is refined, and the mechanical property and the abrasion resistance are obviously improved. The invention can be used for producingvarious trademarks of grey cast iron, nodular cast iron and alloy cast iron.

Owner:河南省金太阳精密铸业股份有限公司

Method for smelting bell-less top blast furnace high proportion pellet ore burden structure

InactiveCN102010920AAvoid thickeningImprove utilization factorBlast furnace detailsAlkalinityCombustion

The invention discloses a method for smelting a bell-less top blast furnace high proportion pellet ore burden structure. Alkalinity of sintering ore is improved to be 2.5-3.5 times or flux with high CaO content is added, the technology that bulk coke is charged at the center and coke is mixed in ore is adopted, a charging method of split charging, ore coke unequal stockline and chute feeder feeding from small angle to high angle is adopted, a tank is reversed regularly, and batch weight of ore is expanded, so that a blast furnace stock column can maintain stable and uniform edge gas flow and strong center gas flow when gas flow passes through; the tuyere theoretical combustion temperature is controlled to be 2200-2300 DEG C; and the operation policy of low silicon and low slag basicity is adopted to smelt. The utilization factor of the blast furnace can be improved by 8-10%; the fuel ratio of the blast furnace can be reduced by 2-3%; and the Si content of pig iron is reduced, the desulphuration capacity is improved, the pig iron quality is improved, the furnace body service life is prolonged to more than eight years, and the blast furnace production stability and the economic benefit are improved. The invention is applicable to the bell-less top blast furnace under the condition that pellet ore in the blast furnace burden structure accounts for 60-100% of the total burden quantity.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

Steel-smelting regulator and preparation thereof

InactiveCN101413043AReduce TFe contentAvoid pollutionManufacturing convertersProcess efficiency improvementSteelmakingHigh calcium

The invention belongs to the ironmaking and steelmaking field, and provides a steelmaking regulator with settled dust as a main material and a method for preparing the same. The invention aims at solving the problem existing in prior art that discharged settled dust causes environmental pollution. The steelmaking regulator is prepared from the following materials in weight percentage: 67 to 73 percent of settled dust, 7 to 13 percent of silicon carbide material, 15 to 20 percent of magnesium material, and bonding agent which accounts for 5 to 10 percent of the total weight of the settled dust, the silicon carbide material and the magnesium material. The steelmaking regulator can completely replace the prior technique of adding modifier and furnace protecting material, has good slag regulating and slag thickening effect, has better slag splashing furnace protection effect compared with the prior product, reducing TFe in slag, obviously lowering production cost of steelmaking, thoroughly eliminating environmental pollution caused by the emission of steelmaking high calcium settled dust and realizing the recovery and the reutilization of resources.

Owner:PANZHIHUA GANGCHENG GROUP

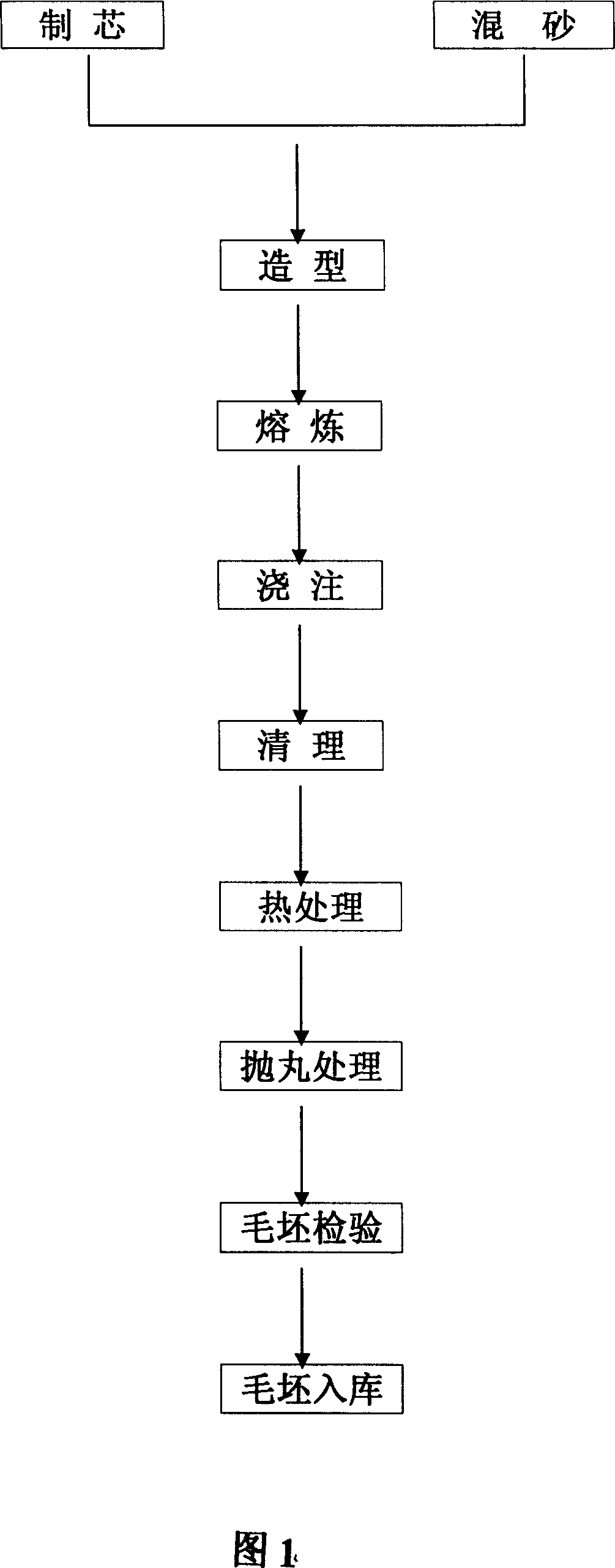

High nickel austenite spheroidal graphite cast-iron gas exhaust branch pipe casting technique

InactiveCN1923412AReduce burning lossImprove the mechanical properties at room temperatureMolten metal pouring equipmentsExhaust apparatusFerrosiliconDuctile iron

The invention relates to a method for casting high-nickel austenite nodular graphite cast iron discharge branch tube. Wherein, the invention comprises preparing core, mixing sand, shaping, smelting, irrigating, thermally processing, machining, dropping, checking, and packing; the smelting comprises mixing material, controlling smelting, balling, and breeding, and the nickel is added at later period; adding chromium at overheated period of iron water; the balling agent is nickel magnesium silicon iron balling agent; the breeding agent is 75 silicon iron; the iron water is irrigated quickly to charge section; the irrigating temperature is 1460-1530Deg. C; the thermally processing increases the casting to 870-1000Deg. C; keeping temperature for 3-6hours, cooling to 620Deg. C, and discharging. The invention has high impact-resistance and worm-anti property, better corrosion-resistance and oxidization resistance.

Owner:西峡县内燃机进排气管有限责任公司

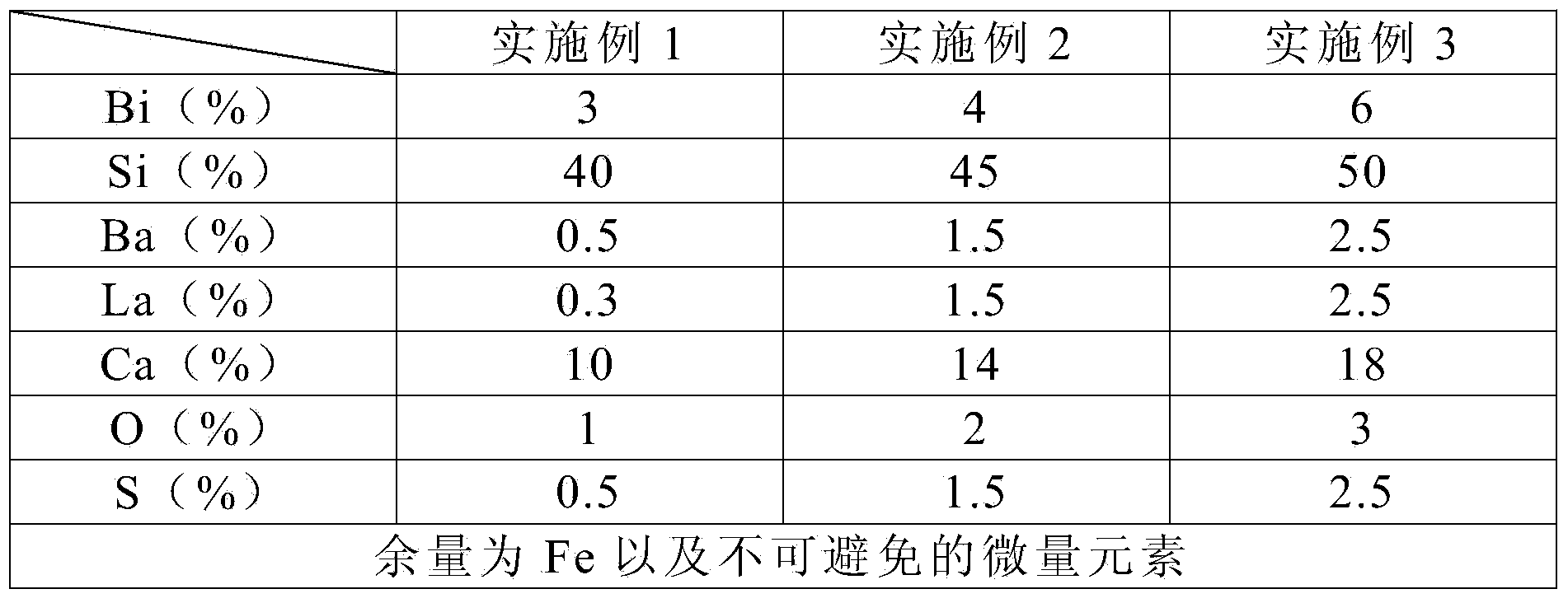

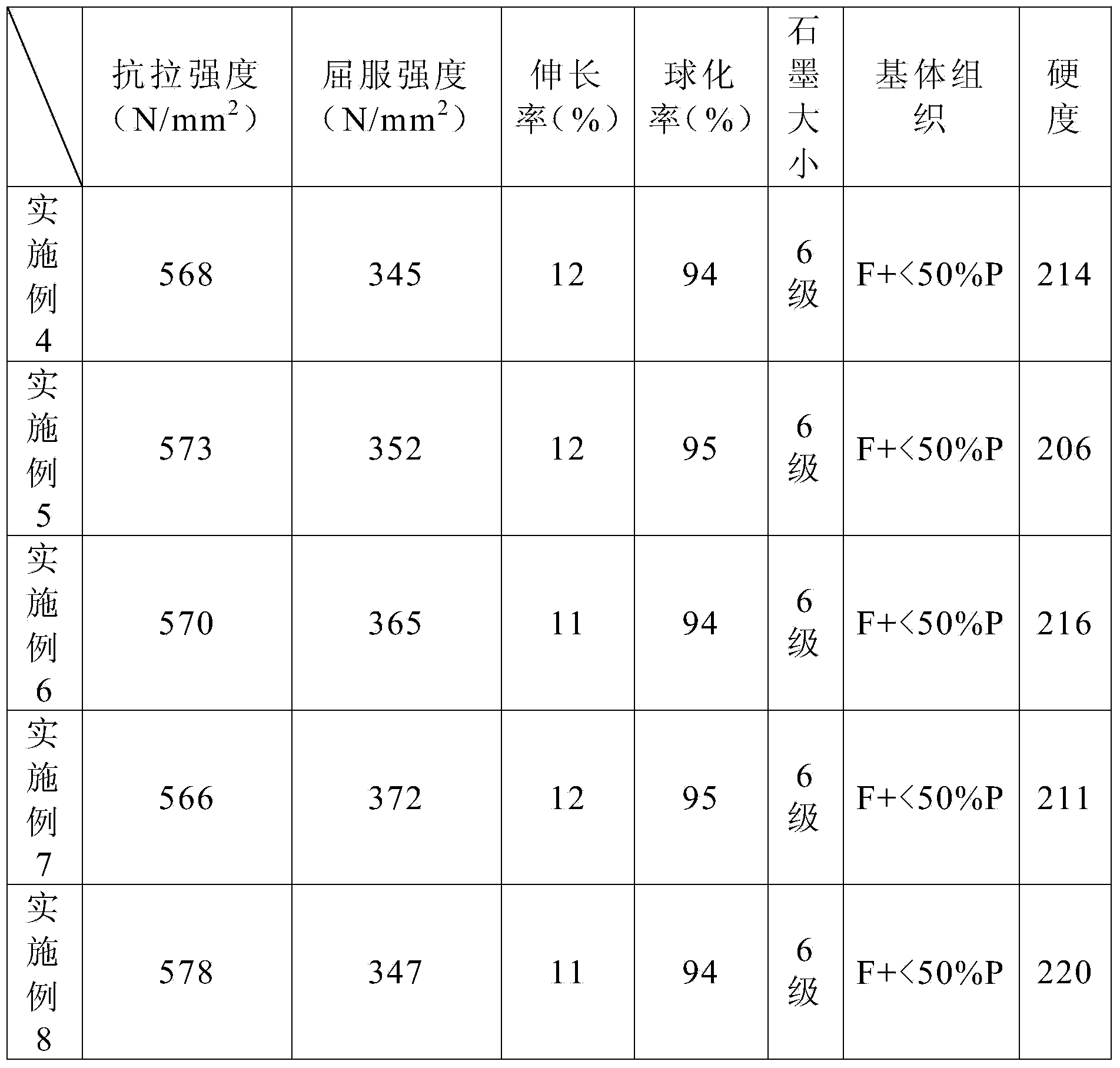

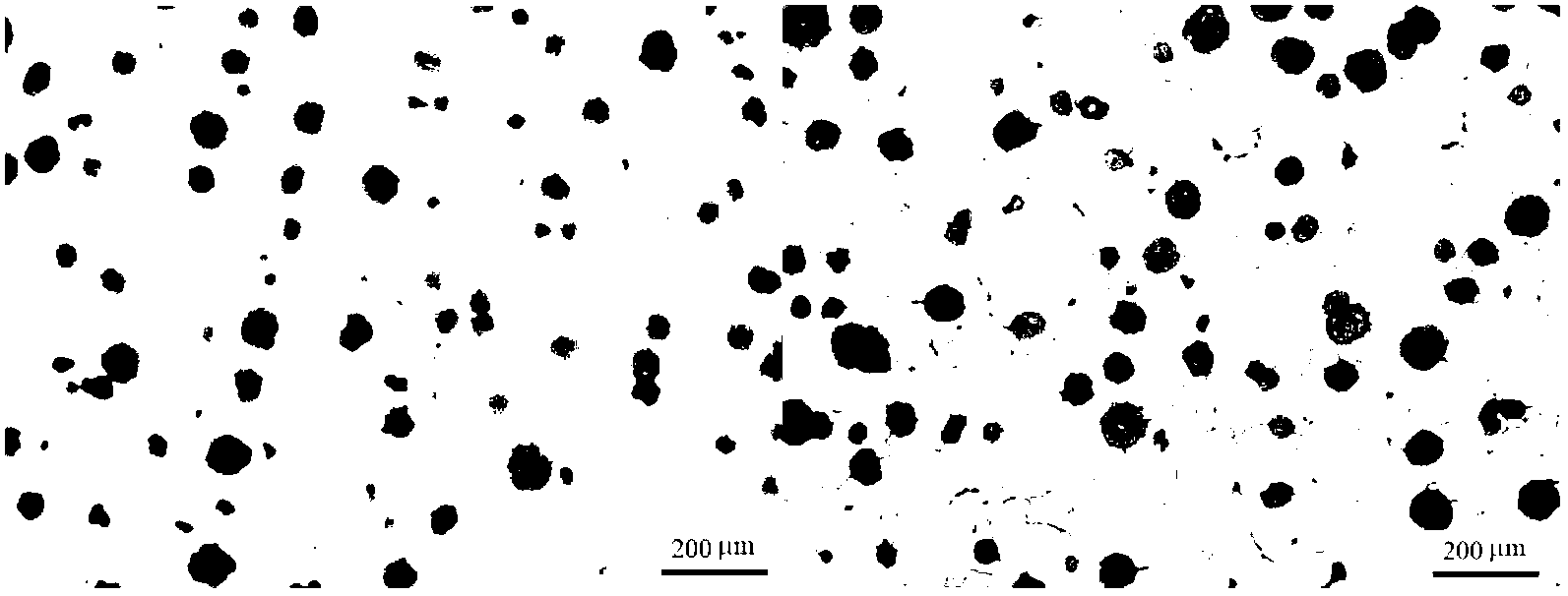

Nodular cast iron inoculant and preparation method thereof and application in smelting nodular cast iron

ActiveCN103484749AIncrease the number of ballsIncrease the number ofTrace element compositionAdhesive

The invention relates to a nodular cast iron inoculant and a preparation method thereof and an application in smelting nodular cast iron. The nodular cast iron inoculant consists of 3-6% of Bi, 40-50% of Si, 0.5-3% of Ba, 0.1-3% of La, 10-18% of Ca, 1-3% of O, 0.5-3% of S and the balance of Fe and unavoidable trace elements. The nodular cast iron inoculant is prepared by the steps of mechanically mixing a metal oxide, a metal sulfide and a silicon iron-based alloy; adding an adhesive into a grinding device, and pressing the mixture into a cluster; breaking the cluster, screening and wrapping with an aluminum foil. In use, when the output molten iron accounts for about 1 / 2 of the lip-pour ladle, the inoculant is added to perform inoculation treatment on the nodular cast iron once or multiple times. The inoculant provided by the invention contains the trace elements such as O, S, Bi and the like and is low-silicon and efficient, and multiple heterogeneous nucleation mass points are formed in the iron liquid, thereby increasing the graphite quantity, improving the shock resistance, mechanical property and yield, increasing the utilization rate of foundry returns, and increasing the economic benefits.

Owner:宁波康发铸造有限公司

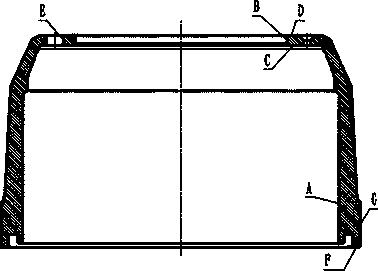

Vanadium titanium cast iron brake drum and preparation method thereof

The invention relates to a manufacturing technique of an automotive vanadium titanium cast iron brake drum with high strength and high abrasive resistance, and particularly relates to a preparation method of a vanadium titanium cast iron brake drum. The preparation method comprises the following steps: melting base iron, namely b y taking vanadium titanium pig iron, steel scrap, foundry returns, a carburant, ferrosilicon, ferromanganese and ferrochrome as furnace charge, adding the carburant to the furnace bottom; smelting the furnace charges by using a medium-frequency induction furnace to prepare the base iron; heating and purifying molten iron in an overheating manner after the molten iron is molten down, and then carrying out heat preservation at 1520-1530 DEG C; and carrying out drossing, adding a slag conglomeration agent to the surface to carry out heat preservation after drossing, and then adding a little of furnace charge, and adjusting the ingredients and the like of the molten iron. A little of furnace charge is added at the later smelting stage to increase the heterogeneous core technology, so that the chilling tendency of the molten iron is relieved, the graphitization ability of the molten iron is improved, and the inoculation effect is improved. A secondary inoculation treatment process of a launder and a pouring cup is adopted, so that the inoculation effect is improved, the graphite form is improved, carbide and ferrite are removed, and the content of pearlite is improved.

Owner:陈国

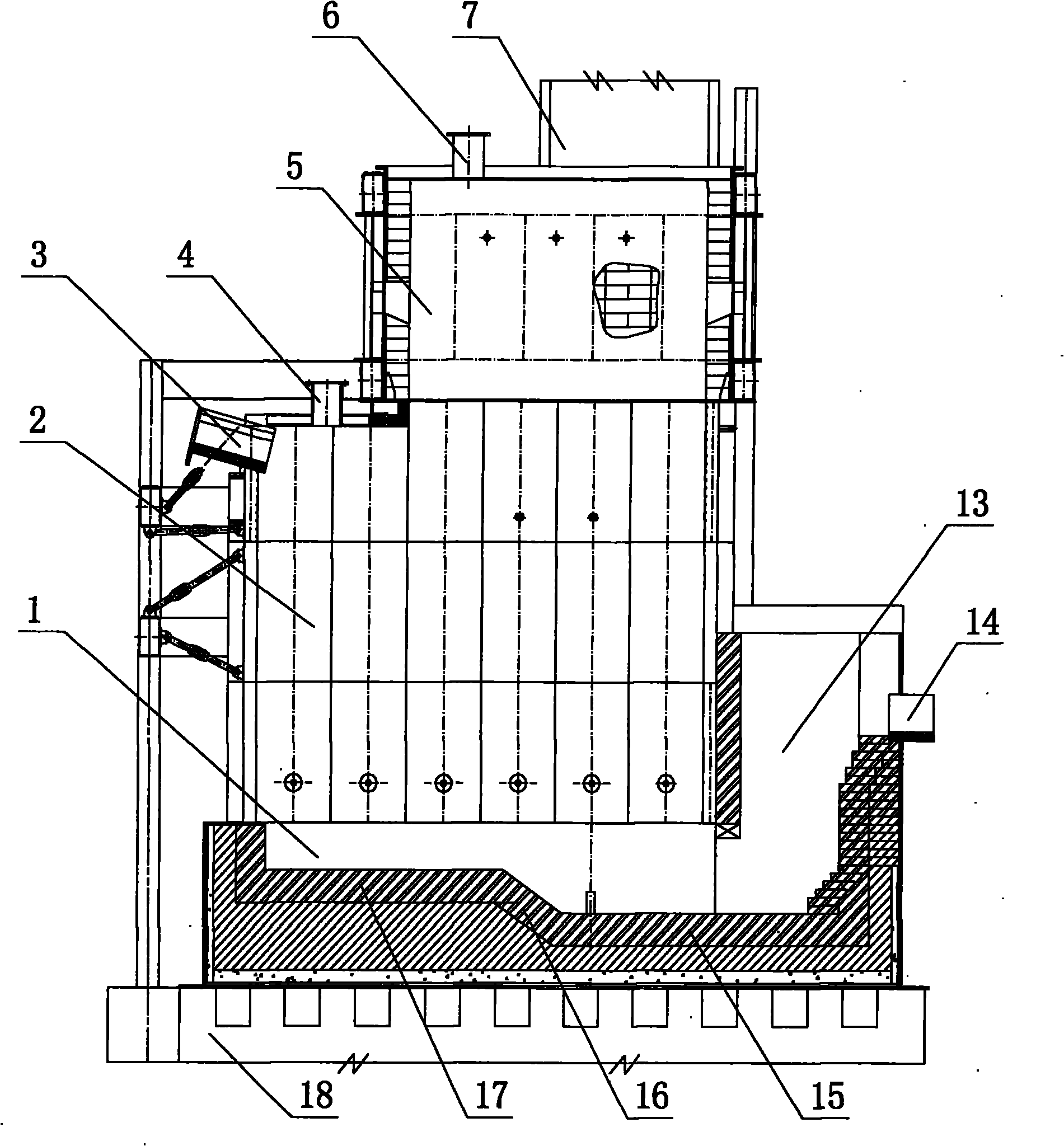

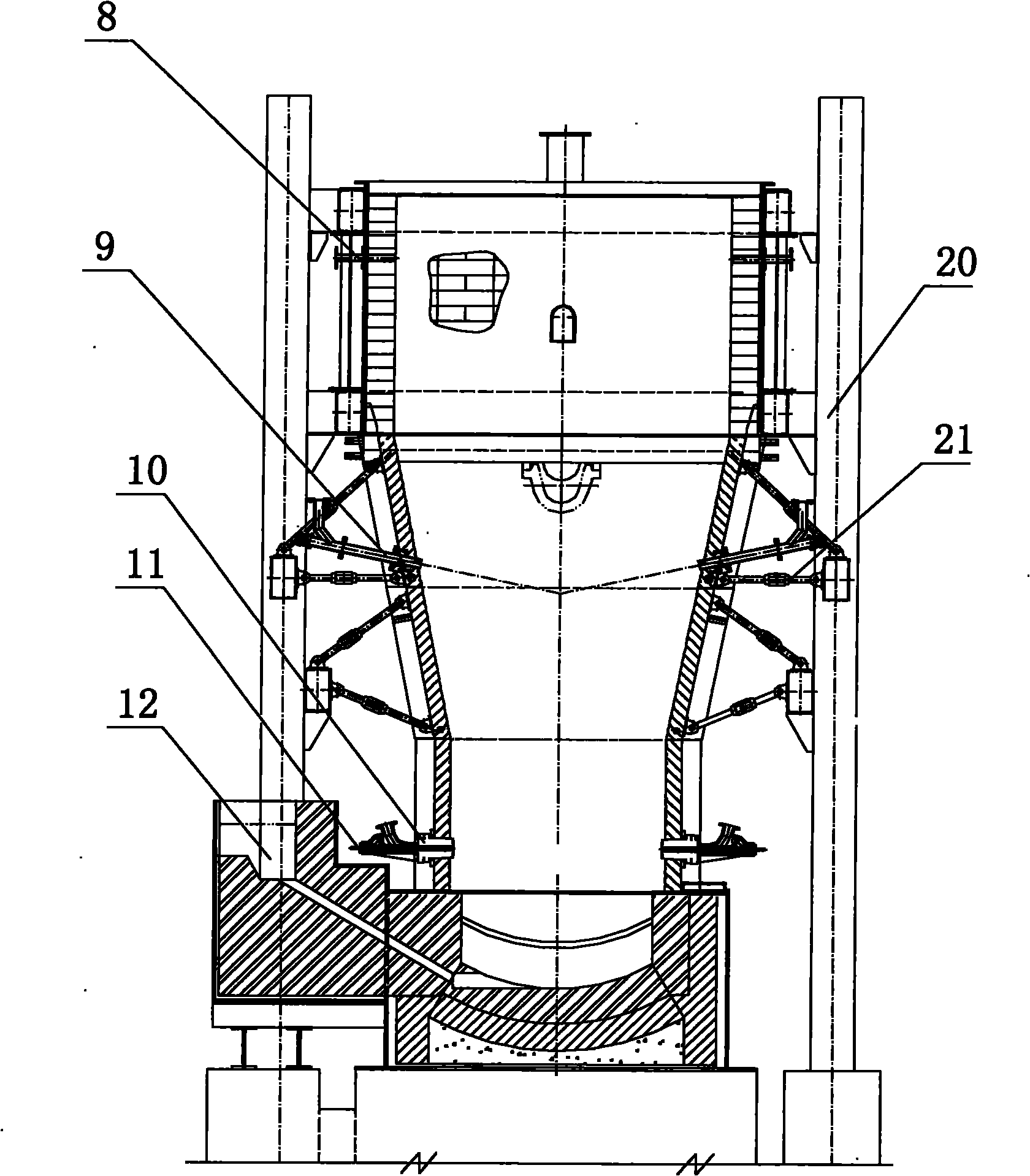

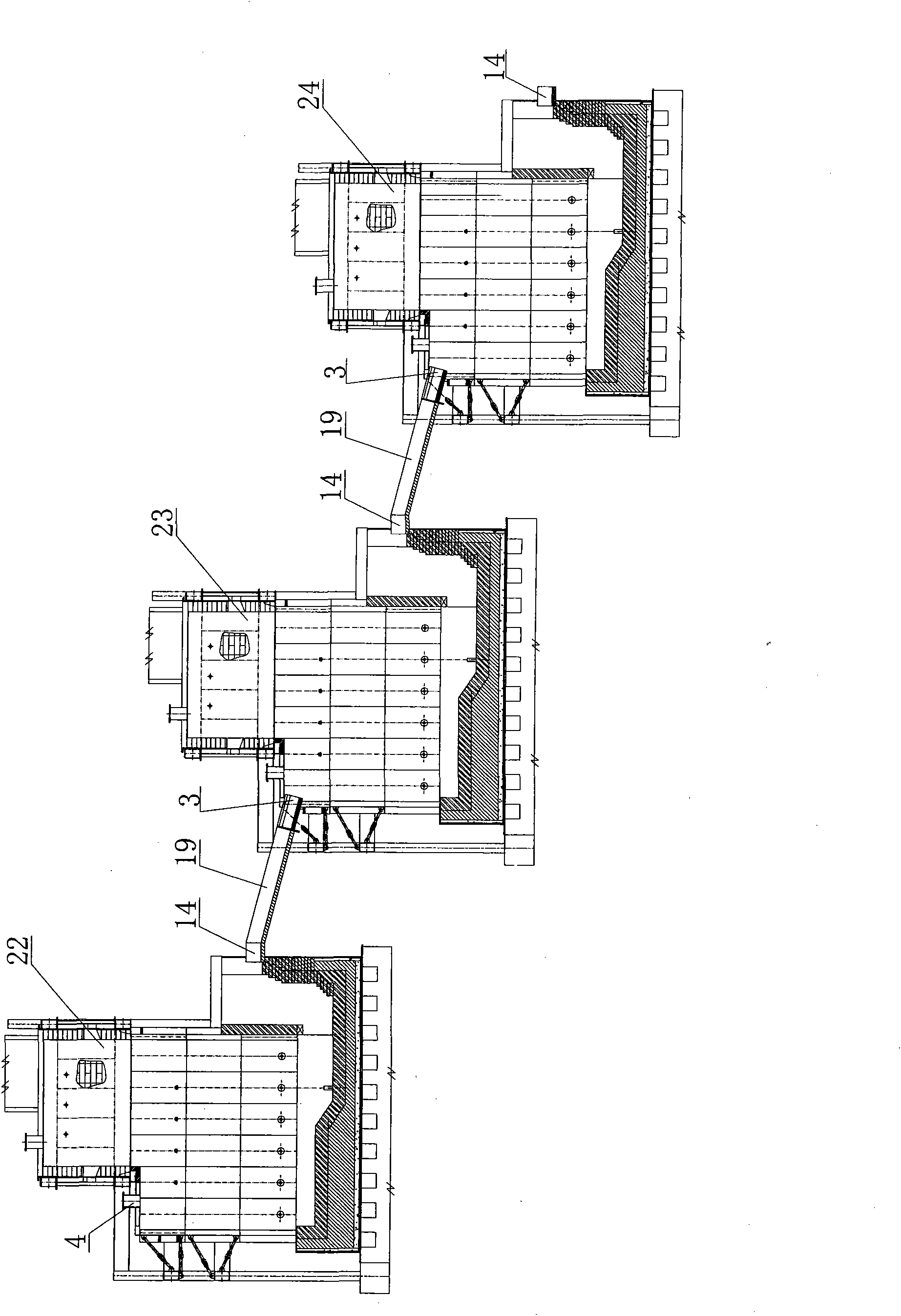

Direct lead-smelting comprehensive metallurgical device and smelting process

The invention relates to an energy-saving high-efficient direct lead-smelting comprehensive metallurgical device, which is formed by serially joining three melting bath smelting furnaces: a first furnace, a second furnace and a third furnace; and the second furnace consists of a furnace cylinder and a furnace body which is arranged on the furnace cylinder. The top part of the upper furnace body is provided with a smoke exhaust port and a standby feeding port; a charge feeding port and a slag feeding port are arranged above the lower furnace body; and the bottom part of the lower furnace body is provided with a slag siphonic water-collecting well. The furnace body is provided with three rows of supply-air outlets. The bottom part of the furnace cylinder is provided with a metal siphonic outlet. Due to the adoption of the direct lead-smelting comprehensive metallurgical device, the heat loss is small, the heat utilization rate is high, sulfuric dioxide smoke with high concentration can be produced, and the requirement for producing the acid can be more favorably satisfied; and molten high-lead thermal slag which is produced through oxidation and smelting directly flows into a reducing furnace, so the heat of the thermal molten slag can be adequately utilized. The land occupied area is small, the investment can be saved, the heat loss is less, the heat utilization rate is high, the heat energy can be adequately utilized, a great amount of energy consumption can be saved, output of smoke is small, the content of harmful ingredients in smoke is low, and the environmental pollution problem can be more effectively solved.

Owner:JIYUAN WANYANG SMELTING GROUP +2

Processing method for preparing phosphate rock powder into pellet yellow phosphorus charge

ActiveCN102701164AIncrease the content of phosphorus pentoxideHigh strengthPhosphorus compoundsPhosphateBall mill

The invention provides a processing method for preparing phosphate rock powder into pellet yellow phosphorus charge. For producing 1000kg of yellow phosphorus pellet charge, 1000kg of the phosphate rock powder, 100kg of humic acid and 20kg of sodium hydroxide are adopted. The preparation method comprises the following steps of: adding the phosphate rock powder (100 meshes) into a binding agent combined by the humic acid and the sodium hydroxide, uniformly stirring, pressing into pellets by a ball press, rolling by a disc pelletizer for ejection, entering an air heating furnace for preliminary drying, entering a vertical kiln for through drying, and then further entering a rotary kiln for performing high-temperature calcination treatment at the temperature of 1100 DEG C-1200 DEG C so as to obtain a yellow phosphorus charge finished product. According to the processing method provided by the invention, the phosphate rock powder is utilized, the 100-mesh phosphate rock powder is finely ground by a ball mill and pressed into the pellet-like yellow phosphorus charge finished product via the binding agent; and compared with lump ore charge, the removal rate of harmful carbonate impurities can be up to 95%, the power consumption per ton of yellow phosphorus is reduced by 35%, the discharge of pollutants is reduced, and the production cost is lowered. The processing method is the excellent processing method for producing yellow phosphorus by utilizing the phosphate rock powder in China at present.

Owner:瓮安烨烨磷化工实业有限公司

Zinc leaching slag treatment method

ActiveCN103421955AShort processShorten the smelting processProcess efficiency improvementLead smeltingMolten bath

A zinc leaching slag treatment method comprises the following steps: 1) The dried zinc leaching slag is evenly mixed with coke powder, and then the mixture is added to a volatilization kiln through a feeding scraper-trough conveyer at the tail of the kiln; 2) under the high-temperature condition of the volatilization kiln, the mixture generates kiln slag and smoke, valuable metals in the zinc leaching slag are deoxidize, as a result, lead and zinc steam is generated and gathered in the smoke, and gold, silver and copper enters to the kiln slag; 3) the kiln slag is delivered to a smelting furnace, furnace burden is added from the top of the smelting furnace, oxygen-enriched air is blown through an oxygen lance, the furnace hearth is stirred, the smelting temperature of the smelting furnace and the ratio of oxygen quantity to kiln slag dry measure are controlled, and slagging smelting is completed; 4) after the slagging smelting carried out in step 3), the valuable metals gold, silver and copper in the kiln slag are gathered in matte, the generated lead steam is gathered in smoke, and the kiln slag is cooled gradually. According to the zinc leaching slag treatment method, the technological process is short, the energy consumption is low, the cost is low, and the valuable metal recovery rate is high.

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

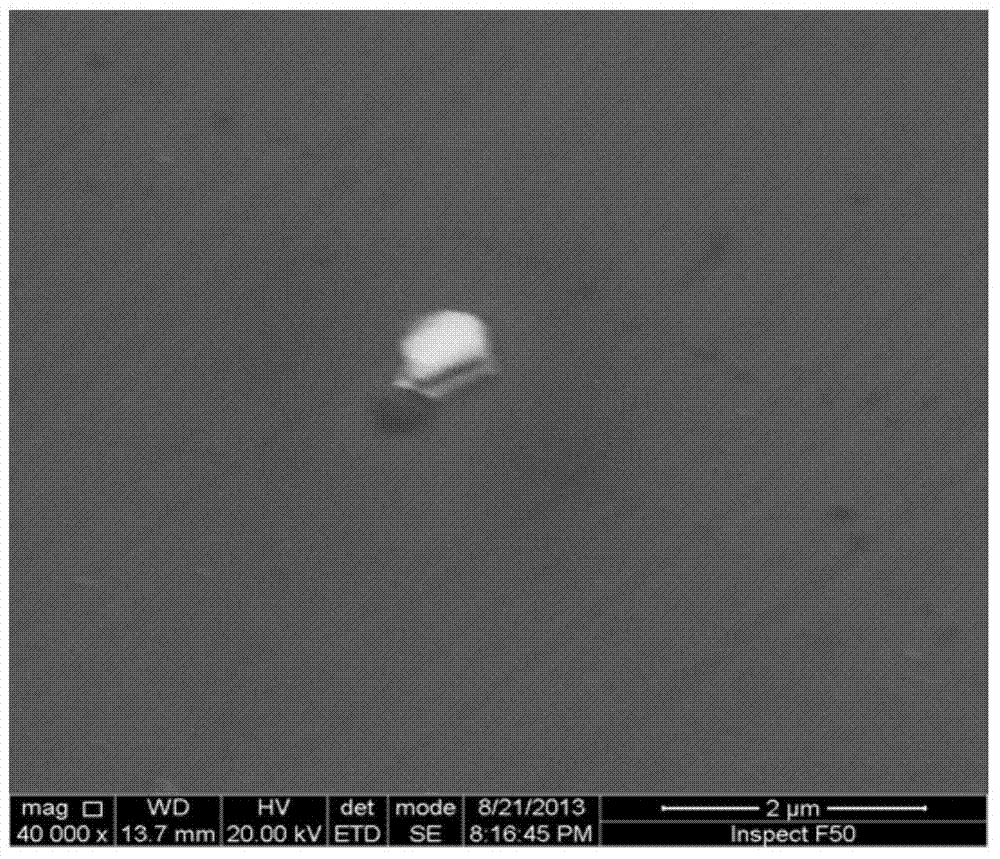

Smelting method of ultra-low oxygen pure steel

The invention relates to the field of smelting and specifically relates to a smelting method of ultra-low oxygen pure steel. A vacuum electric furnace or a vacuum induction furnace is adopted for smelting and vacuum pouring, and the vacuum degree is required to be 0.05-100Pa; after a metal charge is molten, a vacuum state is kept, molten metal is boiled for 5-30min, the oxygen content is reduced by vacuum carbon-oxygen reaction, and no deoxidizer or deoxidization alloy is added. The standing is performed for 20-30min after alloying, and the molten metal is boiled for 5-30min in the vacuum state. When the oxygen content is below 10ppm, 0.5-3kg / t of Si-Ca-Al-Mg-RE composite deoxidizer is added, the standing is performed for 1-10min after adding, then vacuum pouring is performed, and then the pure steel with the total oxygen content of below 4ppm can be obtained. The invention aims at solving the problems that existing steel ingots and cast blanks have more internal inclusions with relatively large sizes, the purity is not high and the channel segregation is serious. Simultaneously, by adopting a rare earth composite additive to perform modification treatment on the inclusions in the steel, the sizes of the inclusions are reduced, and the number of the inclusions in the steel is reduced, thus a new effective way is provided for pure smelting of molten steel.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

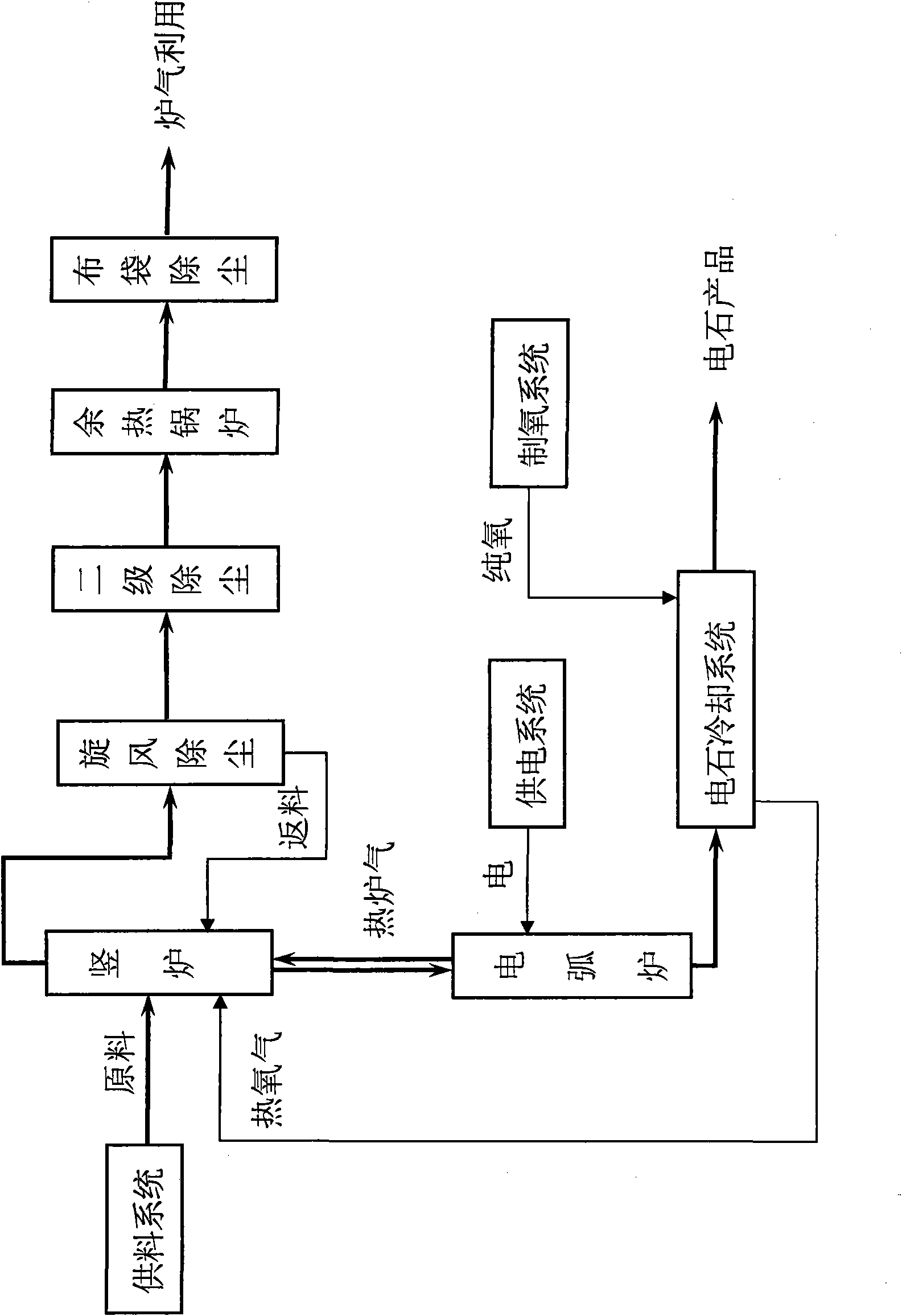

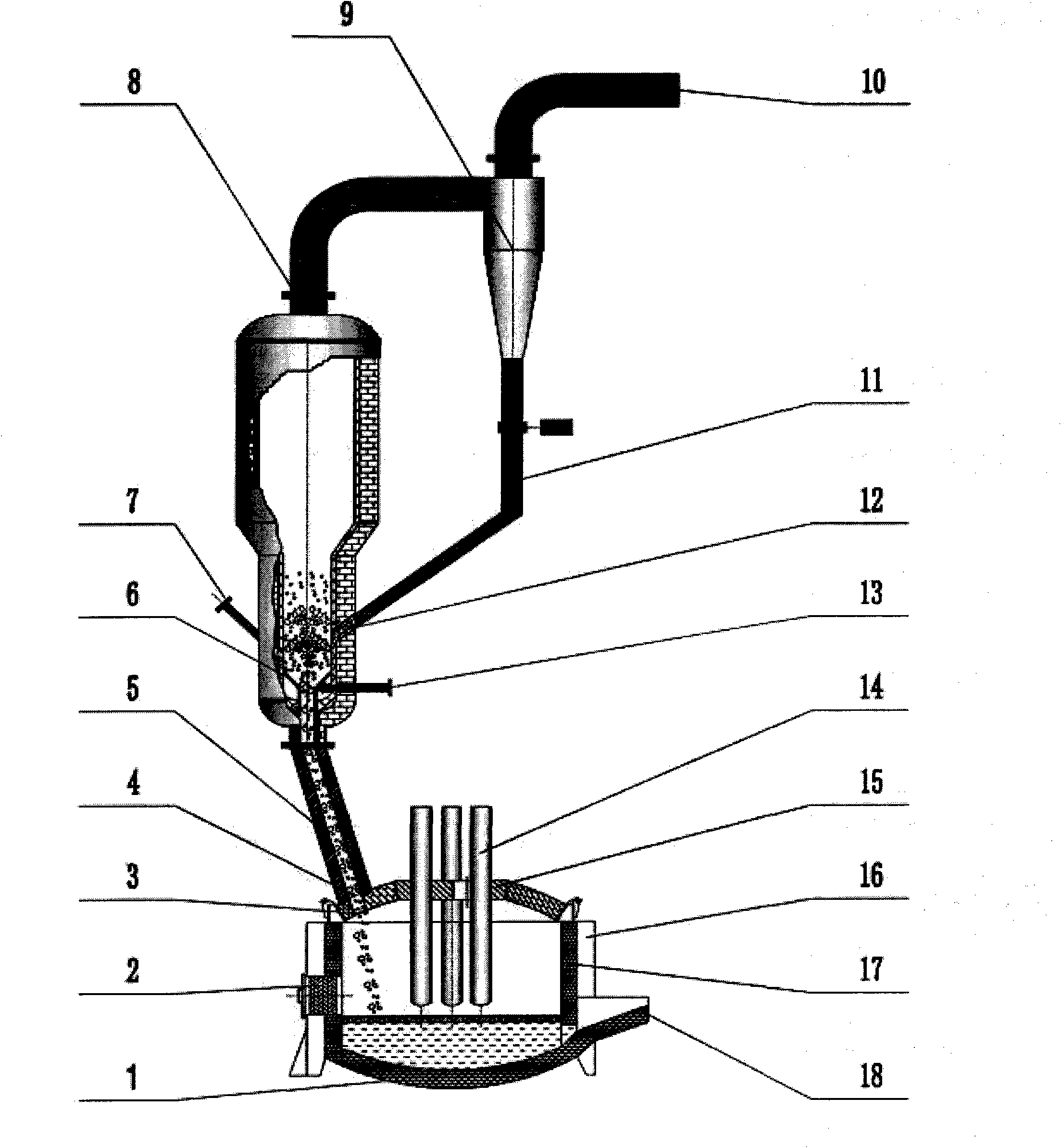

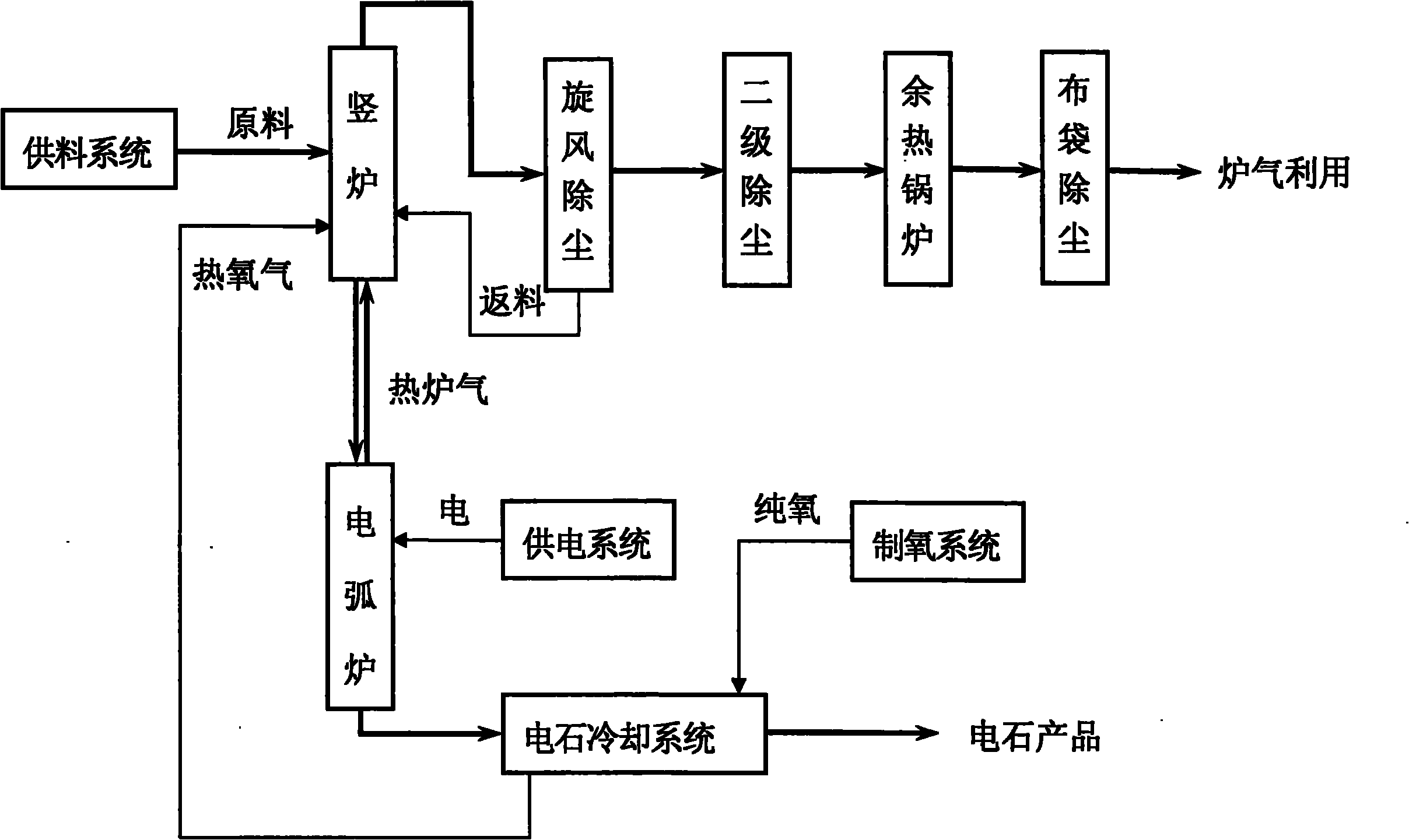

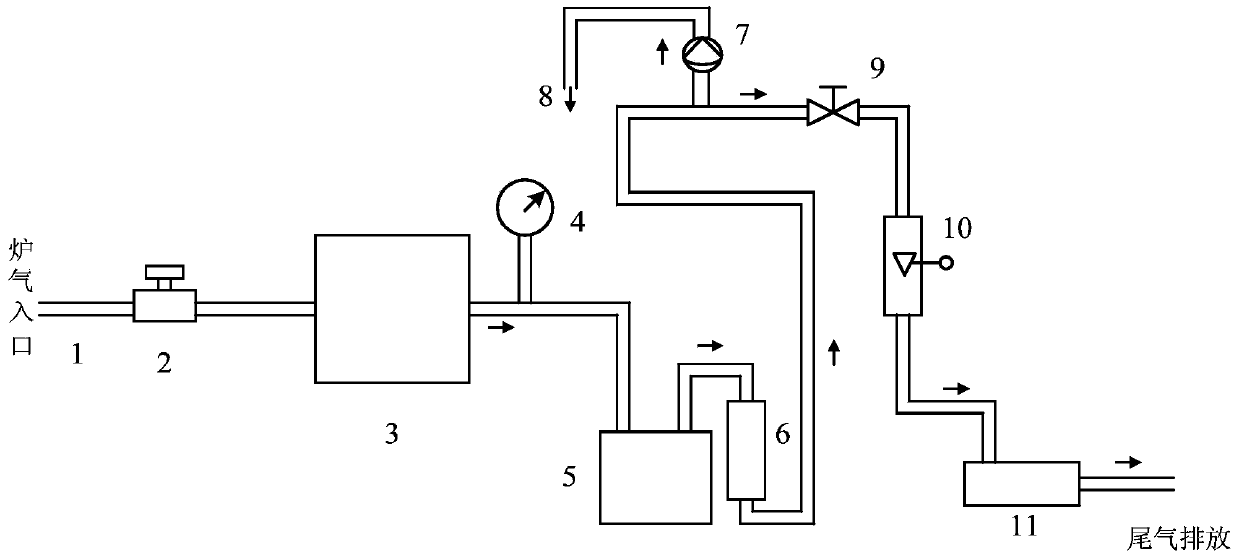

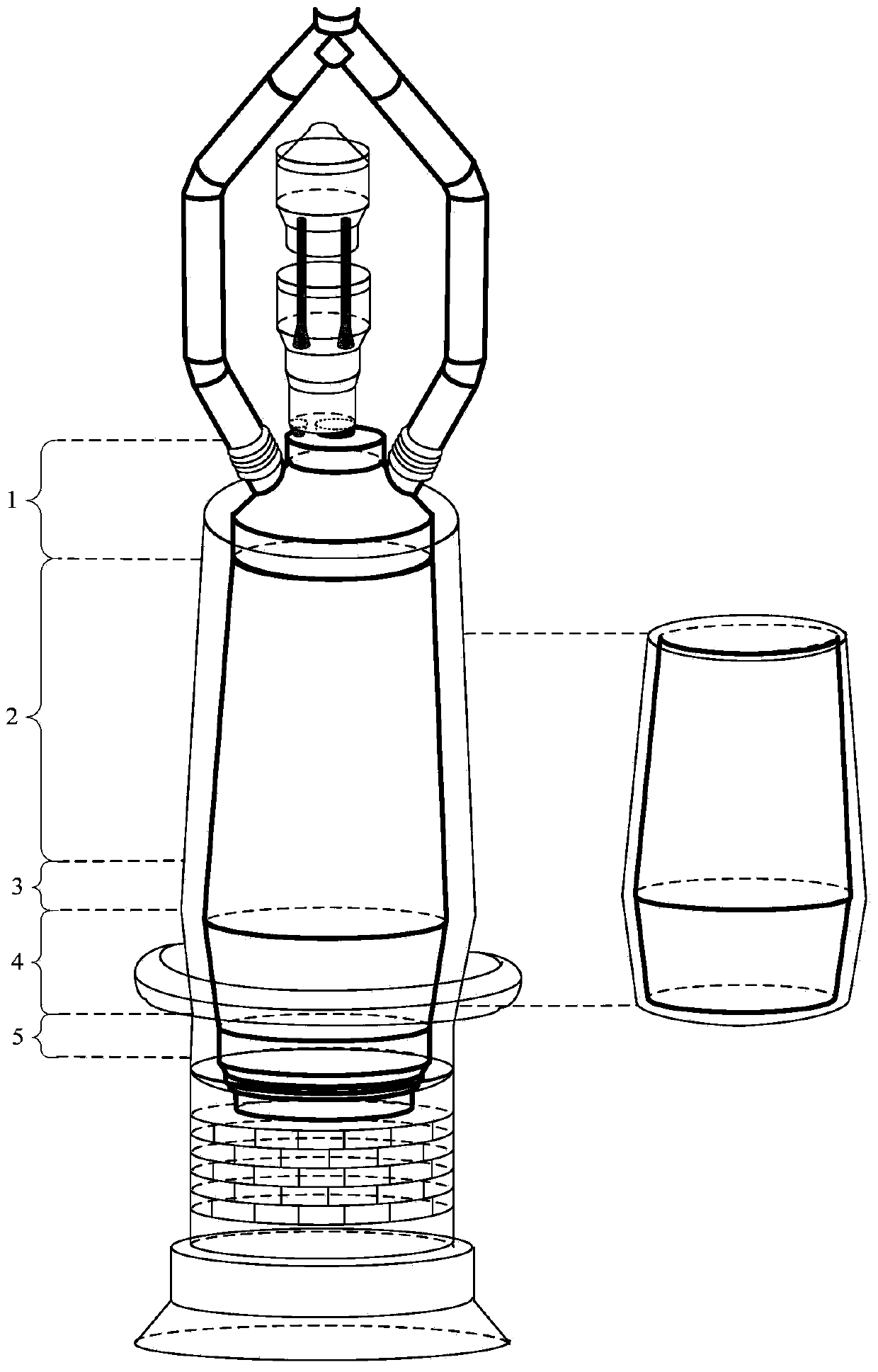

Process and device for producing calcium carbide by using powder raw materials through two-stage method

InactiveCN101817525AWide variety of sourcesIncrease profitEnergy inputCalcium carbideElectric arc furnaceOxygen

The invention relates to a process for producing calcium carbide by using powder raw materials through the two-stage method, which comprises the following steps: leading power carbon-containing material, powder calcium-containing material and oxygen to burn, increasing the temperature of furnace materials in a vertical furnace to above 1300 DEG C, leading the hot furnace materials discharged from the bottom of the vertical furnace to enter into an electric arc furnace, increasing the temperature of the hot furnace materials to 1700-2200 DEG C under the thermal effect of electric arc of an electrode, and carrying out reaction for generating the calcium carbide. Gas containing solids in the vertical furnace is discharged by a furnace gas outlet pipe at the top of the vertical furnace and separated by a cyclone dust collector from, secondary dust collection, residual heat recovery and cloth bag dust collection are carried out on the separated gas to reduce the dust content to below 1-5mg / Nm3, the temperature is reduced to 30-45 DEG C, and then the gas can be recycled as fuel gas or chemical raw material gas. The process has the advantages of powder raw materials, low energy consumption, low cost, continuous production and high grade of the calcium carbide.

Owner:山西亿众公用事业有限公司

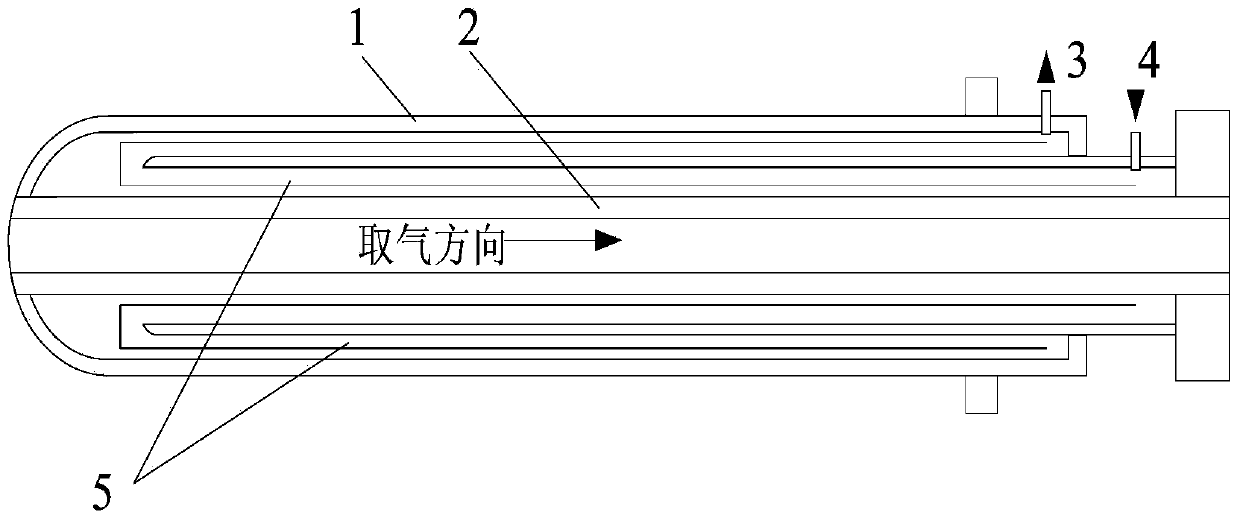

Method for determining position of root of blast furnace cohesive zone through multi-source information fusion

ActiveCN103593540AOvercome huge investmentOvercome the shortcomings of high daily maintenance costsBlast furnace detailsSpecial data processing applicationsThermodynamicsEngineering

The invention provides a method for determining the position of the root of a blast furnace cohesive zone through multi-source information fusion. The method specifically includes the following steps that A gas is taken along the different heights of a blast furnace body, a distribution curve, along the height, of gas utilization rates is drawn, and when the gas utilization rate is zero, the elevation position of the gas utilization rate is obtained through a numerical computation method; B a distribution relation model, in the height direction, of the temperature of the hot surface of a furnace wall of the blast furnace is built, and the area where the temperature of a cooling wall changes obviously is obtained; C the soft melting temperature of a furnace burden corresponding to a furnace burden grade during measurement of A and B is analyzed and determined according to the soft melting temperatures of different furnace burden grades; D the distribution relation model, in the height direction, of the temperature of the hot surface of the furnace wall of the blast furnace is used as main-source information and conclusions of A and C are used as auxiliary information for computing the position of the root of the cohesive zone. By means of the method, according to detectable data, a temperature field distribution model of the hot surface of the furnace wall of the blast furnace, the elevation position where the CO utilization rate is zero and the soft melting temperature of the furnace burden of the blast furnace during data measurement are obtained, the position of the root of the blast furnace cohesive zone is worked out, and the method has the advantages of being small in equipment investment, high in detection precision and the like.

Owner:CENT SOUTH UNIV

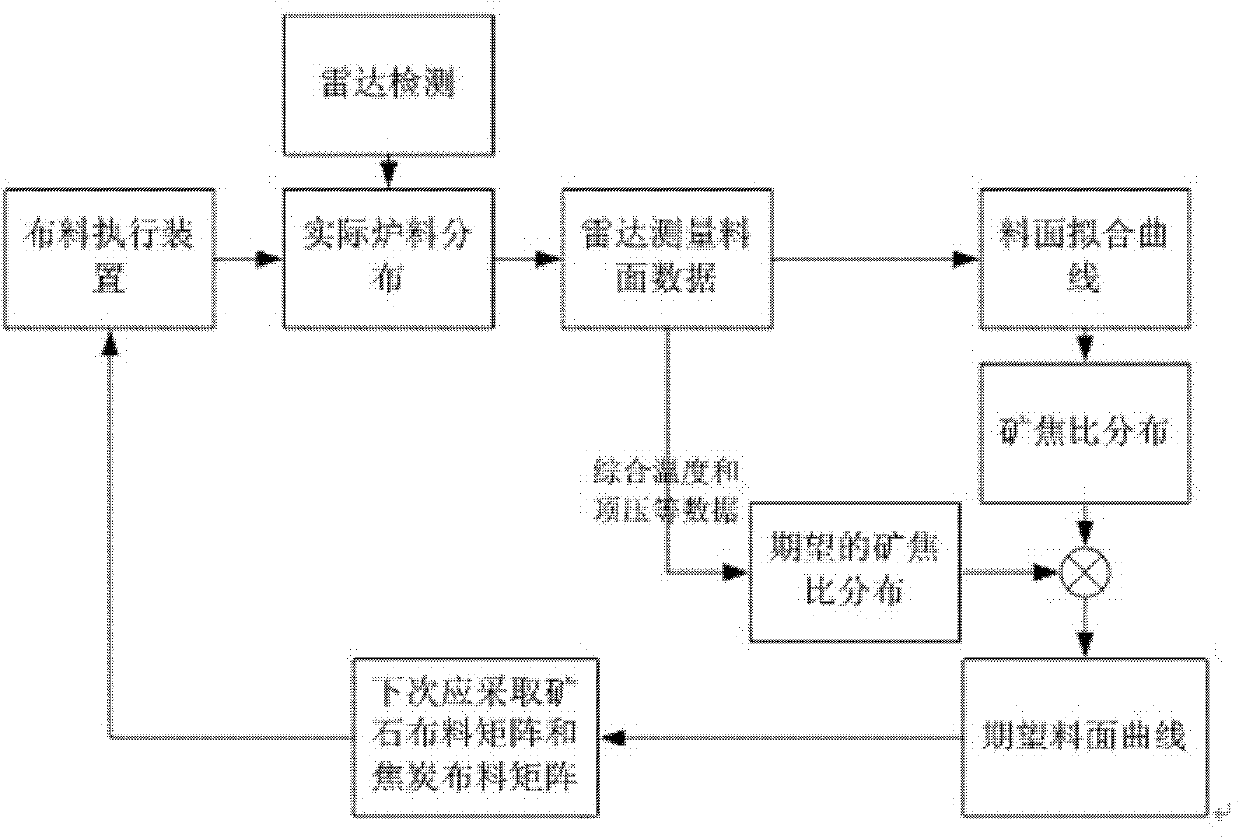

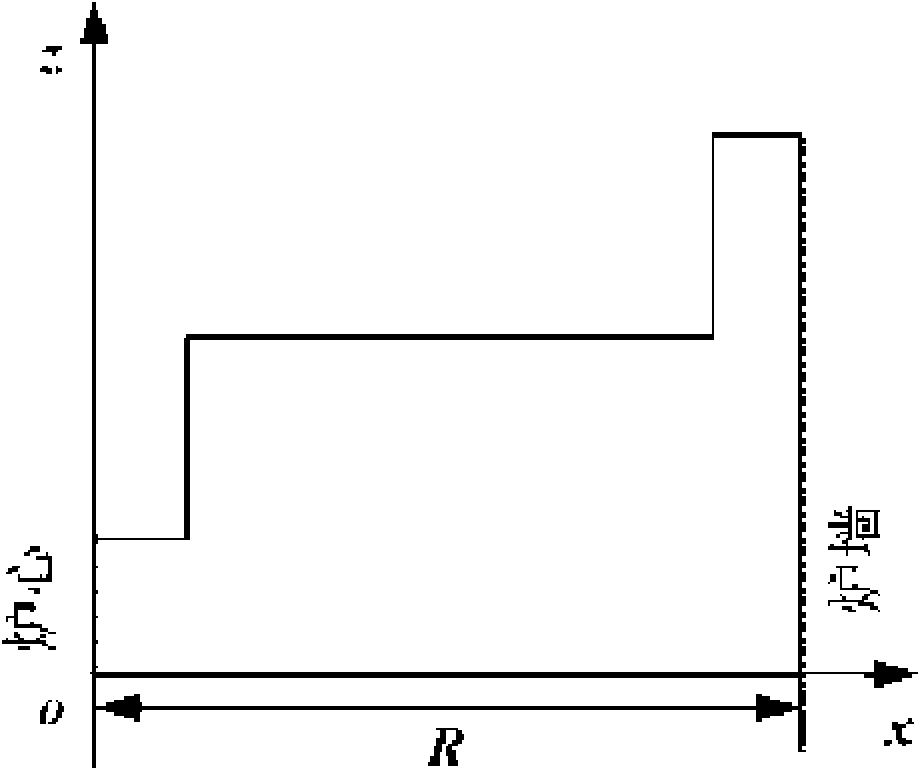

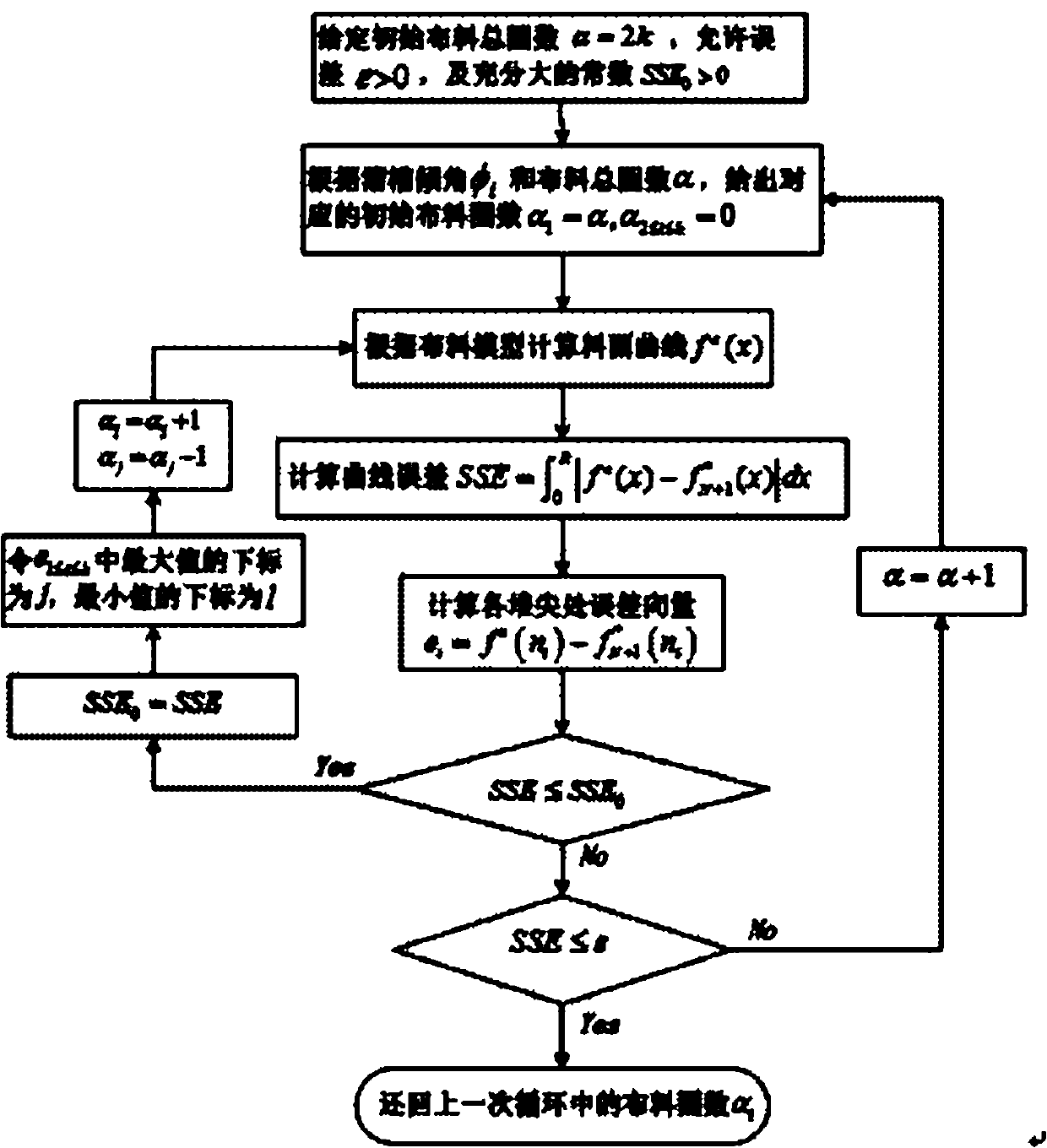

Bell-less blast furnace top distribution closed-loop control method based on multipoint radar data

The invention discloses a bell-less blast furnace top distribution closed-loop control method for calculating furnace charge distribution and ore-coke ratio distribution according to bell-less blast furnace charge surface data measured by multi-point radar and automatically changing a distribution matrix. The method is characterized by comprising the following steps of: accurately estimating a charge level shape by using the multi-point radar data and a distribution model; establishing an ore-coke ratio distribution mathematical model so that the ore-coke ratio distribution can be used for replacing gas flow distribution; establishing an expected ore-coke ratio distribution mathematical model so that expected ore-coke ratio distribution is set according to the furnace condition information; setting an optimal distribution matrix developed on the basis of the radar data so that the ore-coke ratio distribution formed after next distribution reaches the expected distribution; and finally, fulfilling the purposes of closed-loop control and all along reasonable gas flow distribution.

Owner:UNIV OF SCI & TECH BEIJING

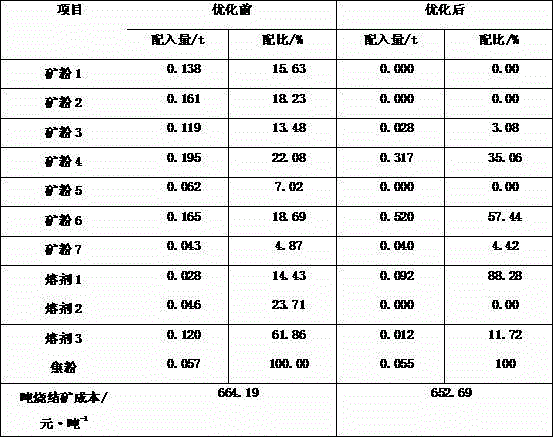

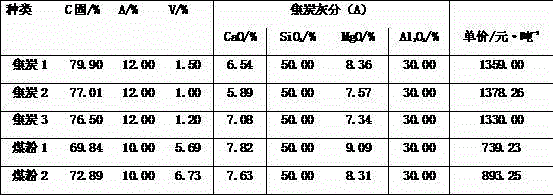

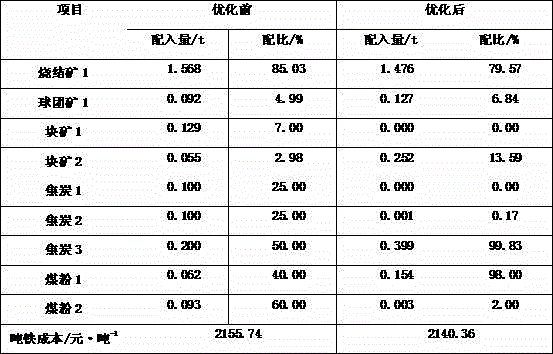

Furnace burden optimization method for iron-making system

ActiveCN104593532AImprovement ingredientsSimple structureBlast furnace detailsSpecial data processing applicationsIndustrial engineeringBlast furnace

The invention relates to a furnace burden optimization method, and particularly relates to a comprehensive proportioning optimization method for sintered ores and blast furnace burdens. The comprehensive proportioning optimization method is a six-in-one furnace burden optimization method for an iron-making system, comprising sintered ore metallurgical performance detection and analysis, sintering process proportioning optimization, sintered ore ingredient predication and analysis, blast furnace burden structure optimization, blast furnace proportioning calculation, iron-making system furnace burden structure multi-target optimization; the optimal proportioning ratios and the optimal ingredients of the various furnace burdens of sintering proportioning and blast furnace proportioning are determined; the problems of limit to a certain procedure of ore blending, sintering and iron-making, high cost and instable quality of the existing iron-making furnace burden optimization method are solved. The furnace burden optimization method disclosed by the invention overall plans the whole iron-making process, highly scientifically analyses, plans and calculates from the whole system, furthest reduces the cost, and finds a furnace burden optimization scheme for an iron-making system, which is low in pig iron production cost, excellent in products and high in yield.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Treatment method for jamesonite and equipment thereof

The present invention is jamesonite treating process and apparatus. The process includes roasting, smelting and fuming. The apparatus has one U-shaped flue connected to collect dust and preserve heat; one spiral feeder with the functions of feeding material stably, mixing materials and dewatering flux and coke; one electric furnace, one multistage continuous fuming furnace and one multistage countercurrent smelting and separating trough connected for continuous operation with high In, Ag, Pb, Zn and Sb recovering rate and low power consumption; one constant temperature condensing rotary drum for collecting In-containing Pb and Zn liquid and solid Sb and separating out As, S and other volatile impurity; and one flue reducing tank to avoid environmental pollution caused by SO2 and As2O3.

Owner:广西冶金研究院有限公司

Vanadium iron spraying powder refining technique

InactiveCN101148733AImprove reaction kinetic conditionsHigh recovery rateProcess efficiency improvementAlloyPowder Spray

The present invention discloses one kind of powder spraying ferrovanadium refining process. During electro alumino-thermic process, and after completing alumino-thermic reaction, separating slag from the alloy and stopping heating, reductive powder material is sprayed through the spray gun inserted into the slag layer and the furnace body is rotated so that the sprayed powder material is well mixed to the slag. Then, the electrode is re-inserted for further smelting for one other 20-25 min, so as to make the residual vanadium in the slag reduced to produce ferrovanadium. The present invention has effectively improved reaction dynamic condition of the refined material, complete reaction, high vanadium recovering rate and lowered production cost.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

Method for dephosphorization and desulphurization in process of steel production in induction furnace

The invention provides a method for dephosphorization and desulphurization in the process of steel production in an induction furnace, which is characterized by comprising the following steps of: during the smelting period and the initial period of total meltdown of charging materials, controlling the temperature of molten steel to below 1,450 EDG C, performing dephosphorization treatment on a liquid steel by using a dephosphorizing agent consisting of lime-ferric oxide-boron anhydrous, and controlling the phosphorous content in the liquid steel to below 0.01 percent; after finishing the dephosphorization, absolutely deslagging, then rapidly raising the temperature of the liquid steel to 1, 500 to 1, 600 DEG C; and performing pre-deoxidation and alloying on the liquid steel, and then adding the desulphurizing agent consisting of lime-calcium carbide-aluminum ash, performing the desulphuration on the liquid steel, and reducing the phosphorous content in the liquid steel to below 0.08 percent. The method has the advantages of combining the smelting characteristics of the induction furnace, fully utilizing favorable thermodynamic conditions of dephosphorization and desulphurization, realizing high-efficiency dephosphorization and desulphurization by slagging and greatly improving the quality of the liquid steel; and meanwhile, the method also has the advantages of low cost, less equipment investment, simple operation, easy implementation, and obvious economic benefits and social benefits.

Owner:JIANGSU UNIV

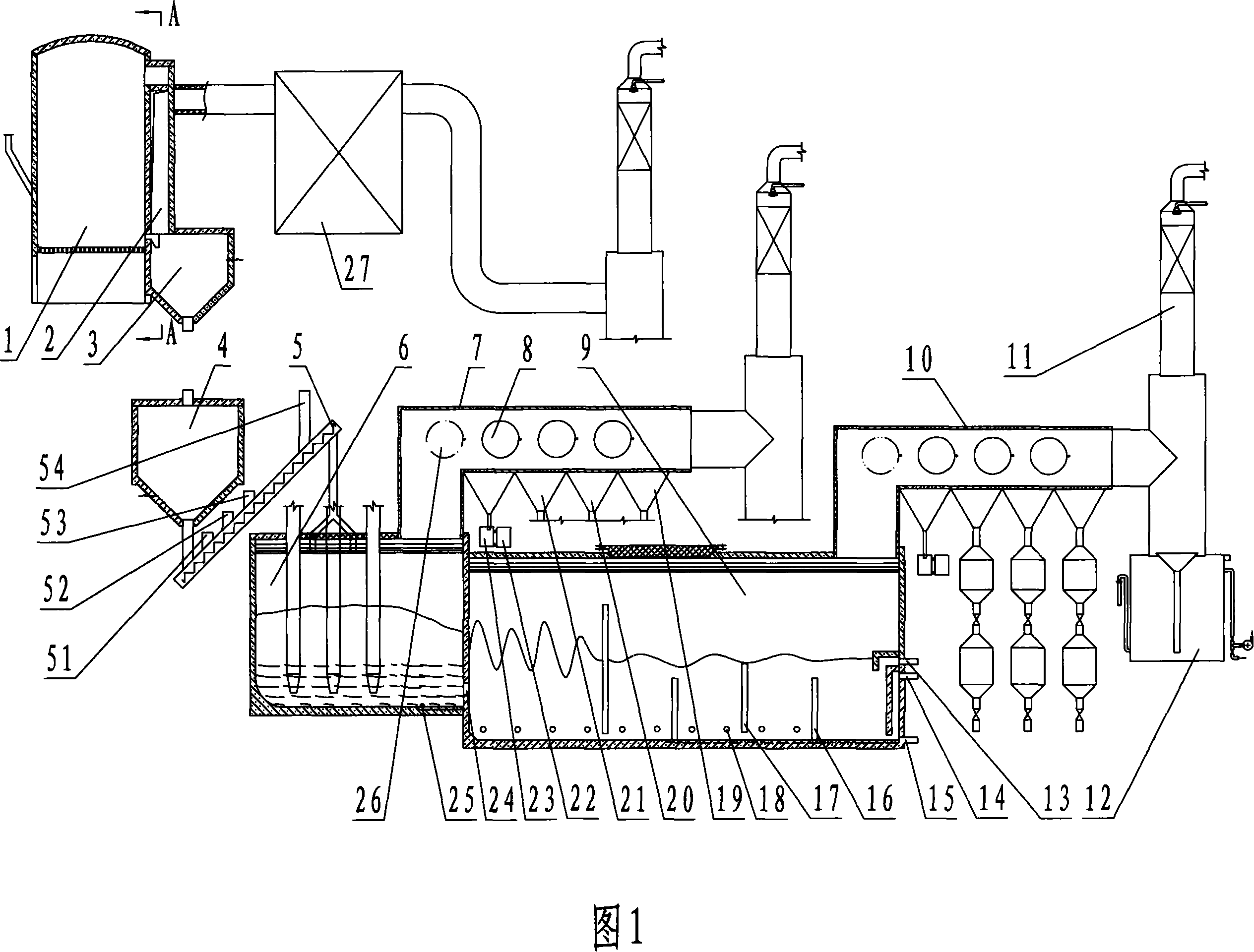

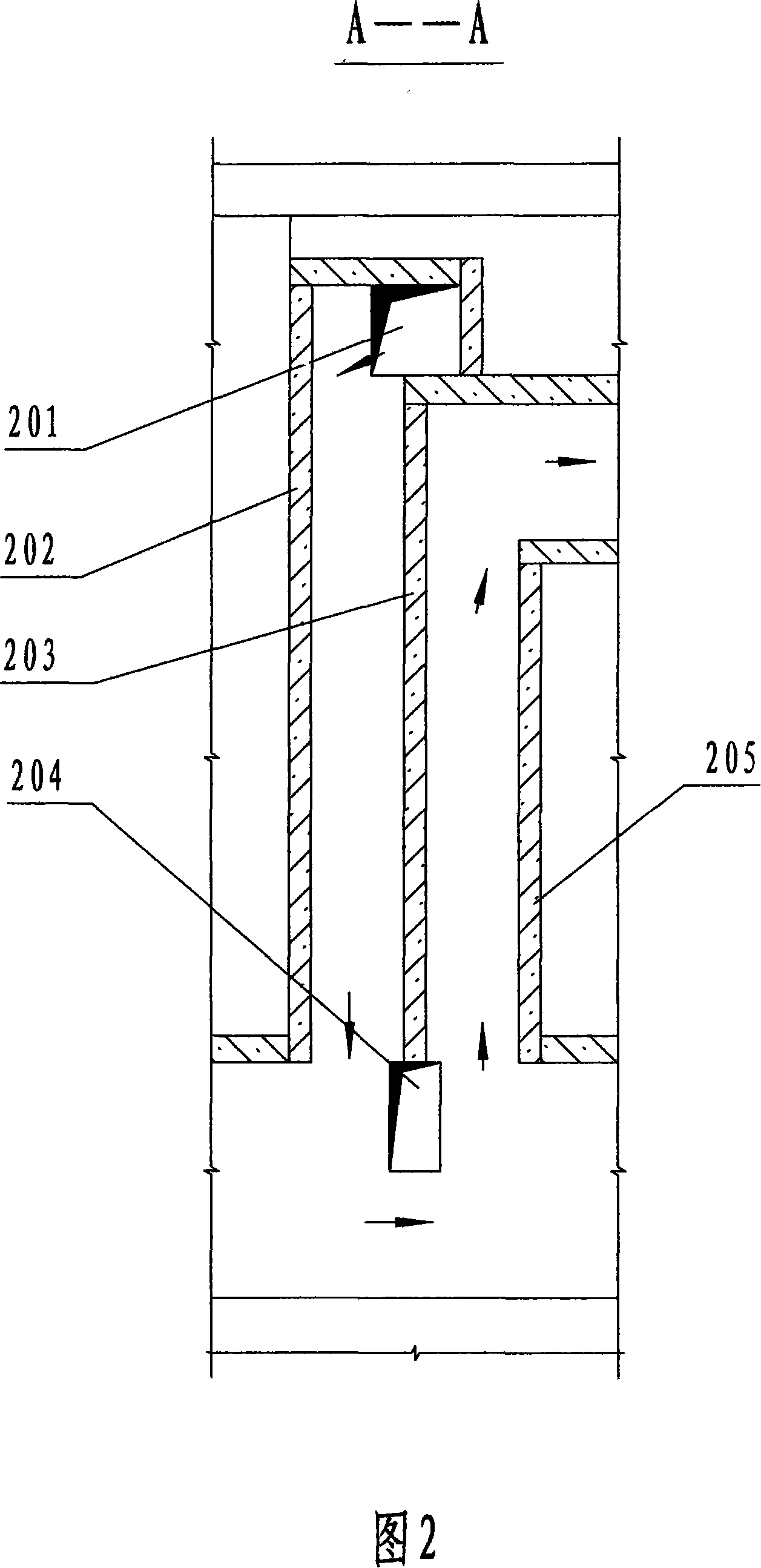

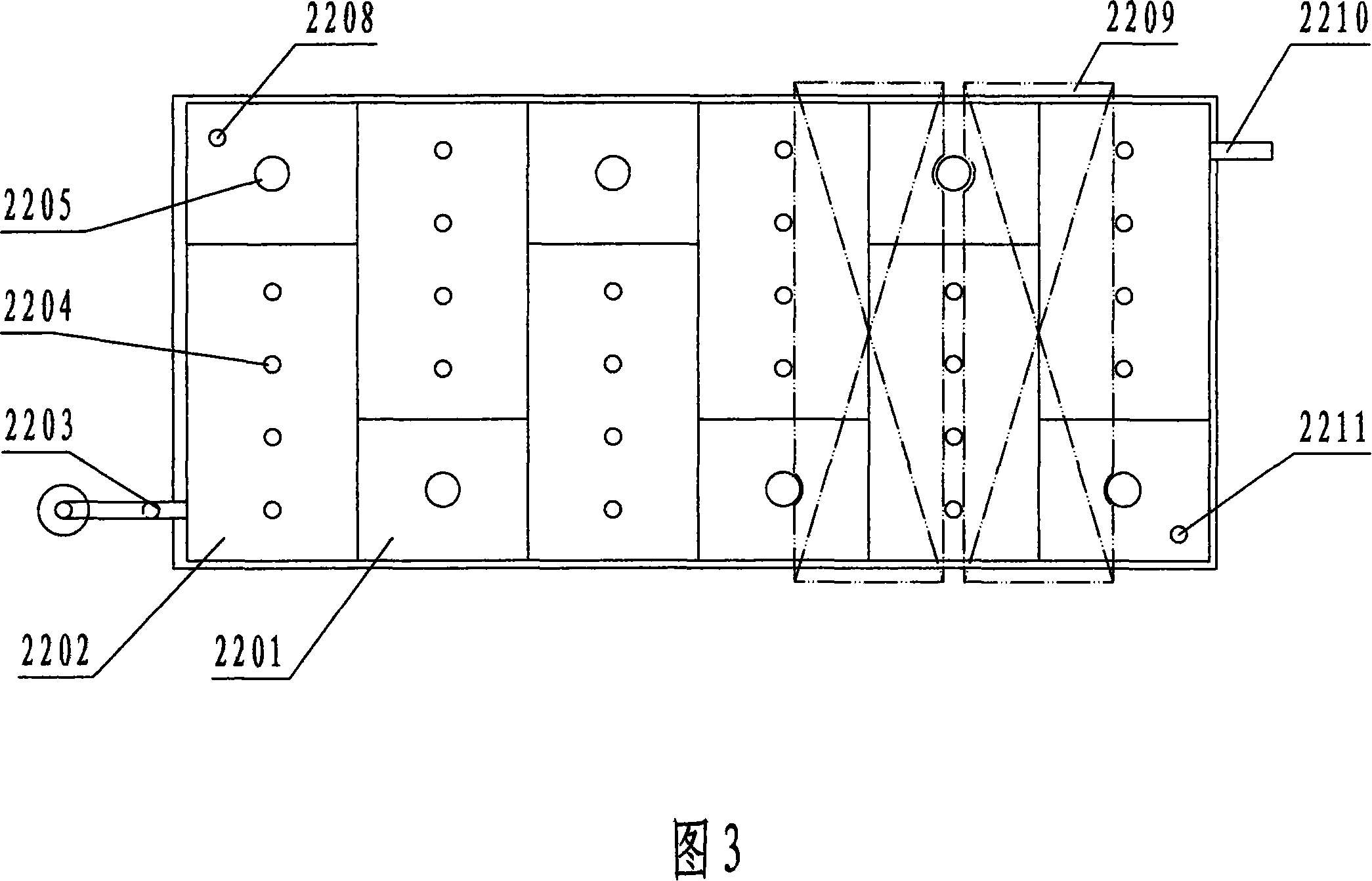

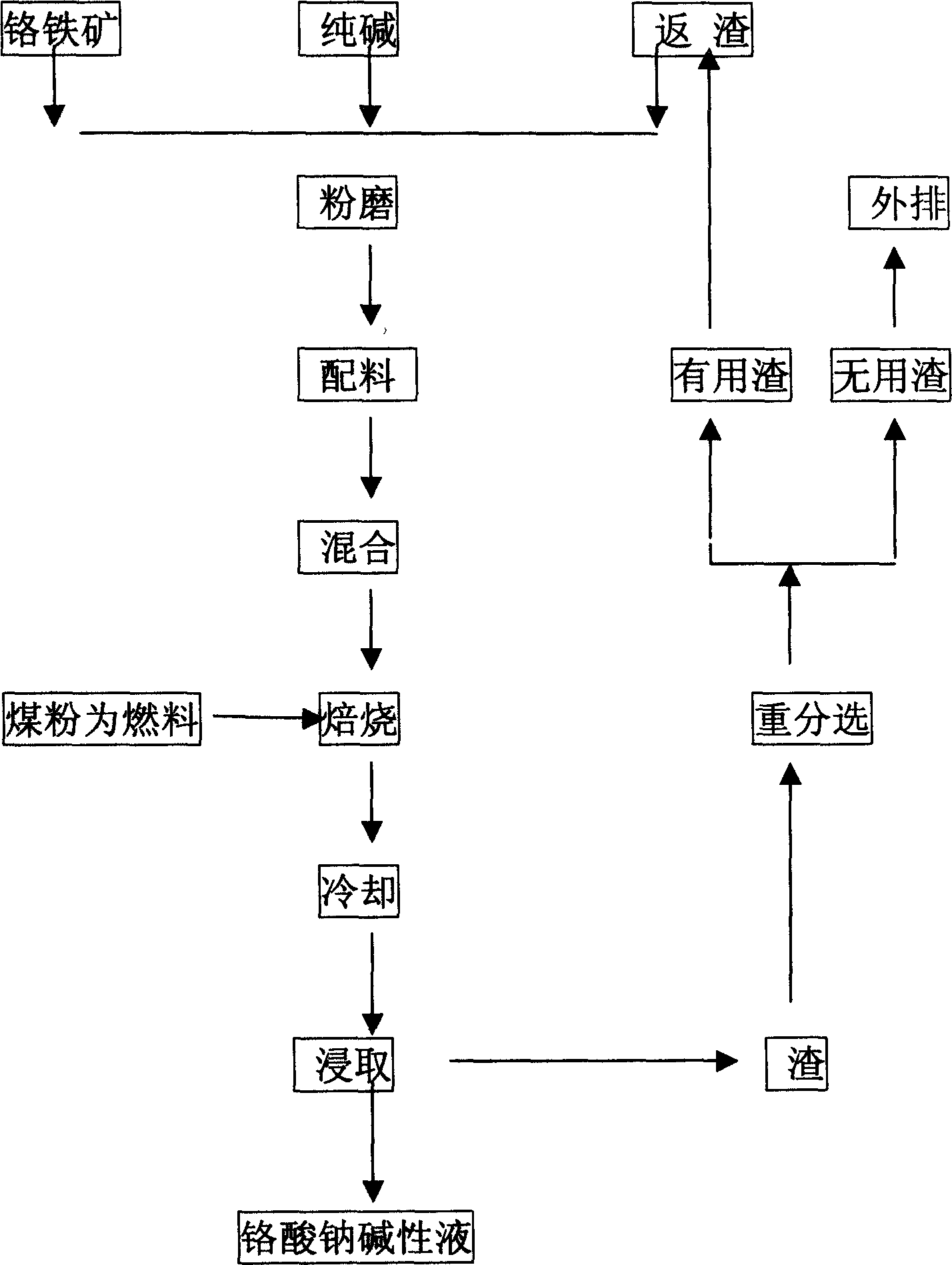

Process for producing sodium chromate by calcium-free calcination

The invention relates to a method to manufacture sodium chromate. It adopts non- calcium roasting technics to realize industrialized production. With chromite, soda and chrome dregs without calcium as charging after mixing evenly, coal dust as fuel, the steps are as follows: coal injection baking in burner, leaching clinker, gravity sorting chrome dregs without calcium and recycling useful dregs as filling. It is the first time that fillings are composed with iron ore, chromite and soda after baking. With shortening technics route and reducing equipment investment, the invention can reduce production cost. Without segregation and adhibiting wall, roasting heat is easy to control.

Owner:TIANJIN CHEM RES & DESIGN INST +1

Smelting process of steel for high-titanium alloy welding wire

ActiveCN102586685AGood deoxygenationImprove purityElectric furnaceProcess efficiency improvementFerrosiliconTitanium alloy

The invention relates to a production process of steel, in particular to a smelting process of steel for a high-titanium alloy welding wire. The smelting process comprises the following steps of: in an electric furnace smelting step, adding molten iron and waste steel and tapping molten steel, wherein the molten iron accounts for 50-60% the total amount of the furnace charge, and the tapping temperature is not lower than 1630 DEG C; in a refining furnace refining step, adding silicon-aluminum-calcium deoxidant in a refining furnace for manufacturing white slag through diffusion deoxidization, and adding low-carbon ferromanganese and ferrosilicon according to steel grade component requirements and sampling component analysis to regulate components of the molten steel so as to reach temperature of 1630-1650 DEG C matching vacuum treatment; in a vacuum furnace degassing step, keeping the temperature for 10-15min under a low vacuum degree of 1 millibar, and carrying out secondary refining after vacuum breakage; and in a secondary refining step, adding low-aluminum ferrotitanium to regulate titanium content at the refining temperature of 1585-1600 DEG C, stirring for 1-2min, adding iron sulfide, stirring for 1-2min, taking a lollipop sample to analyze, continuously keeping static stirring, carrying out soft argon blowing for 15-40min after all components are qualified and carrying out continuous casting when the temperature is up to 1565-1585 DEG C. The smelting process disclosed by the invention can effectively control purification degree of the molten steel, ensures stability of titanium in the molten steel and improves the surface quality of a cast blank.

Owner:NANJING IRON & STEEL CO LTD

Method for adjusting furnace charge structure before damping-down period of blast furnace for smelting high-titanium schreyerite

ActiveCN104694682AGuaranteed viscosityFast air supplyBlast furnace detailsAir volumeBlast furnace smelting

The invention belongs to the technical field of schreyerite blast furnace smelting, and particularly relates to a method for adjusting a furnace charge structure before a long damping-down period (the damping-down period is longer than five hours and shorter than five days) of a blast furnace for smelting high-titanium schreyerite. The method for adjusting the furnace charge structure before the damping-down period of the blast furnace for smelting the high-titanium schreyerite includes the step that in the smelting period before the damping-down period of the blast furnace, the furnace charge structure is adjusted to enable slag newly generated in the damping-down period of the blast furnace to meet the conditions that the content of TiO2 ranges from 1% to 20%, the binary alkalinity (CaO / SiO2) of the slag ranges from 1.00 to 1.03, the content of CaF2 ranges from 0.50% to 2.0%, and the content of MnO2 ranges from 1.0% to 4%. By means of the method, after damping-down overhauling is completed, the air volume can be rapidly (a period with the length 1 time to 1.5 times that of the damping-down period is needed) recovered to the air volume required by normal production.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

Method for manufacturing high-elongation nodular cast iron QT700-7 by using steel scraps

InactiveCN104313233ASimple production processLow costProcess efficiency improvementFoundryForeign technology

The invention discloses a method for manufacturing high-elongation nodular cast iron QT700-7 by using steel scraps. Furnace burden comprises 60-85% of steel scrap Q235 and 15-40% of ductile cast iron foundry returns according to weight percentage; the method comprises the following steps: wire feeding type spheroidizing treatment, first wire feeding type inoculation treatment, second pour-over inoculation treatment and third stream inoculation treatment are carried out through alloying base iron in a furnace; casting, cooling, cleaning, tensile test and elongation rate calculation are carried out. Through the adoption of the method disclosed by the invention, as the steel scraps are adopted for production, the elongation rate reaches more than 7% while the tensile strength of the QT700 reaches more than 700 MPa; the problem that the elongation rate of the traditional nodular cast iron QT700-2 is low is solved; the requirement of high strength and high elongation rate of the nodular cast iron QT700 required for a high-requirement product is satisfied; a gap of the domestic and foreign technologies for manufacturing the high elongation nodular cast iron QT700-7 is filled; the cost is low; the economic benefits of manufacturing enterprises are obviously increased.

Owner:罗建华

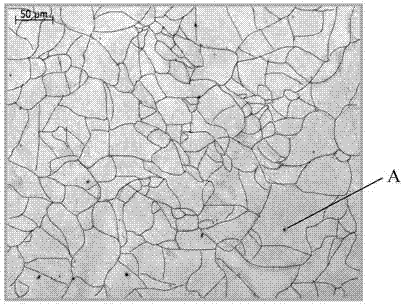

Control method of as-cast condition heavy section ferrite-based nodular iron casting graphite nodule and matrix structure

ActiveCN103014219ASuitable for productionAbnormal graphite does not appearProcess efficiency improvementFerrosiliconDuctile iron

The invention discloses a control method of an as-cast condition heavy section ferrite-based nodular iron casting graphite nodule and a matrix structure. The control method comprises the following steps of: manufacturing a weight panel according to the shape of a spheroidizing packet; selecting pig iron, foundry returns, scrap steels and silicon irons to prepare materials; scaling the spheroidizing packet by using smelted molten iron more than or equal to 1500 DEG C; adding a spheroidizing agent, a nucleating agent, scrap iron, the weight panel, pig iron and Sb into a packet pit in sequence to carry out spheroidizing; adding an inoculation agent which accounts for 0.1-0.2% of molten iron by weight into the surface of the molten iron after the spheroidizing; stirring and scattering slag removers on the surface of the molten iron; after the spheroidizing, pouring the molten iron into a phenolic sand molded sand box which is prepared in advance so as to be cast and molded, wherein the molten iron needs to be breaded along with the flow, the breading quantity is 0.2% of the weight of a cast piece, and the box is opened after being molded and cooled to be less than 300 DEG C. The mechanical performance of the central part of a body of the material under the cast mode is as follows: the extension strength sigma b is not less than 380MPa, the surrendering strength sigma 0.2 is not less than 230Pa, and the cut-off ductility delta is not less than 20%.

Owner:JIANGSU HONGDE SPECIAL PARTS CO LTD +1

Production method of low-impurity vanadium-aluminium alloy

The invention provides a production method of low-impurity vanadium-aluminium alloy. The production method comprises the following steps: uniformly mixing vanadium pentoxide, metallic aluminium and a coolant which are used as furnace burden and putting the mixture into an open reacting furnace, and igniting and smelting to obtain vanadium-aluminium alloy and slag, wherein the weight ratio of vanadium pentoxide to metallic aluminium is 1.15-1.8:1; granularity of the coolant is vanadium-aluminium alloy particles with granularity being less than 0.25mm; the addition amount of the coolant can guarantee that calorific value per furnace burden is controlled within 3300-3500 kJ / kg; and the calorific value per furnace burden equals to the ratio of heat generated by a reaction between vanadium pentoxide and metallic aluminium to the total addition amount of vanadium pentoxide, metallic aluminium and the coolant. The content of V in the vanadium-aluminium alloy produced by the method provided by the invention is 62.9-87.13wt%, the content of Al is 12.6-36.8wt%, the content of Fe is no greater than 0.16wt%, and the content of Si is no greater than 0.19wt%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

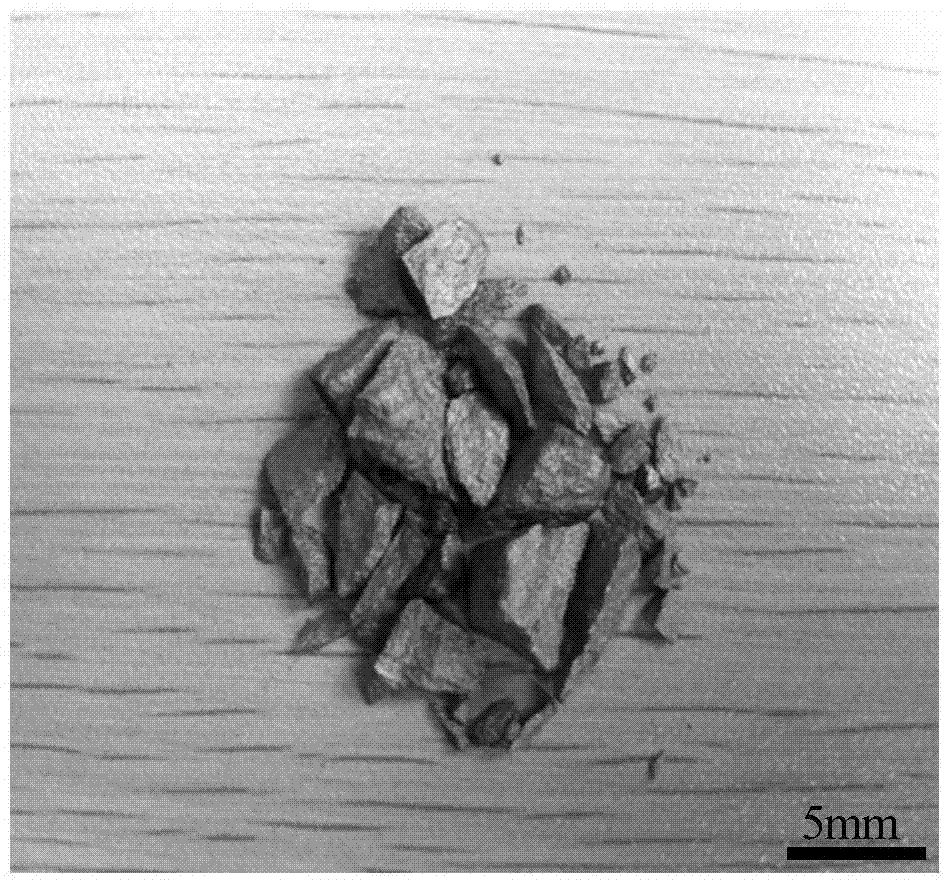

Method for preparing sigma-phase FeV50

The invention belongs to the field of metallurgy and relates to a method for preparing sigma-phase FeV50. The technical problem to the solved of the invention is to provide a method for preparing the sigma-phase FeV50 which has good apparent mass and is easy to break. In the adopted technical scheme, the sigma-phase FeV50 is obtained by uniformly mixing vanadium oxide, aluminum, iron and lime serving as raw materials, feeding the mixture into a furnace and smelting the mixture in an electric arc furnace by an electro-aluminothermic process. The method comprises the following steps of: a, adding excess aluminum into the raw materials while proportioning so as to reduce the vanadium oxide, melting a furnace charge down, depleting slag until vanadium content is low and removing lean slag; and b, adding an appropriate amount of vanadium oxide into alloy liquor from which the slag is removed to remove the excess aluminum, discharging and casting when the temperature and aluminum content ofthe alloy liquor meet requirements and cooling so as to obtain a product, namely, the sigma-phase FeV50. The crush strength of the sigma-phase FeV50 produced by the process is less than 510 MPa and convenience can be brought to vanadium iron manufacturers and customers in the crushing, sampling and using processes of vanadium iron.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

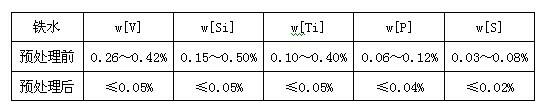

Multistage combined pretreatment method for vanadium-bearing molten iron

The invention relates to a multistage combined pretreatment method for vanadium-bearing molten iron, in particular to a molten iron pretreatment process for realizing desulfurization, dephosphorization and vanadium extraction on the vanadium-bearing molten iron, belonging to the technical field of refinement of pig iron. According to the technical scheme, converter vanadium extraction is performed on the vanadium-bearing molten iron to obtain semisteel, and then converter steelmaking is performed on the semisteel. The technical scheme is characterized in that vanadium-bearing molten iron obtained by iron tapping of more than one blast furnace is collected, and the molten iron is pretreated in a three-stage combined mode, wherein at the first stage, granulated magnesium is singly blown in a ladle for desulfurization; at the second stage, vanadium extraction, desilicification and titanium removal are performed by a converter; and at the third stage, dephosphorization is performed in the semisteel tapping process of the vanadium extraction converter. The multistage combined pretreatment method for vanadium-bearing molten iron combines a common molten iron pretreatment process with a special converter vanadium extraction process, thus effectively reducing the costly desulfurization burden of a blast furnace, realizing low coke-ratio operation, and further improving and optimizing the furnace charge structure; and in addition, the multistage combined pretreatment method is favorable for high-speed converting of a steelmaking furnace, and also can provide favorable conditions for intelligent control of the steelmaking furnace by a computer.

Owner:HEBEI IRON AND STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com