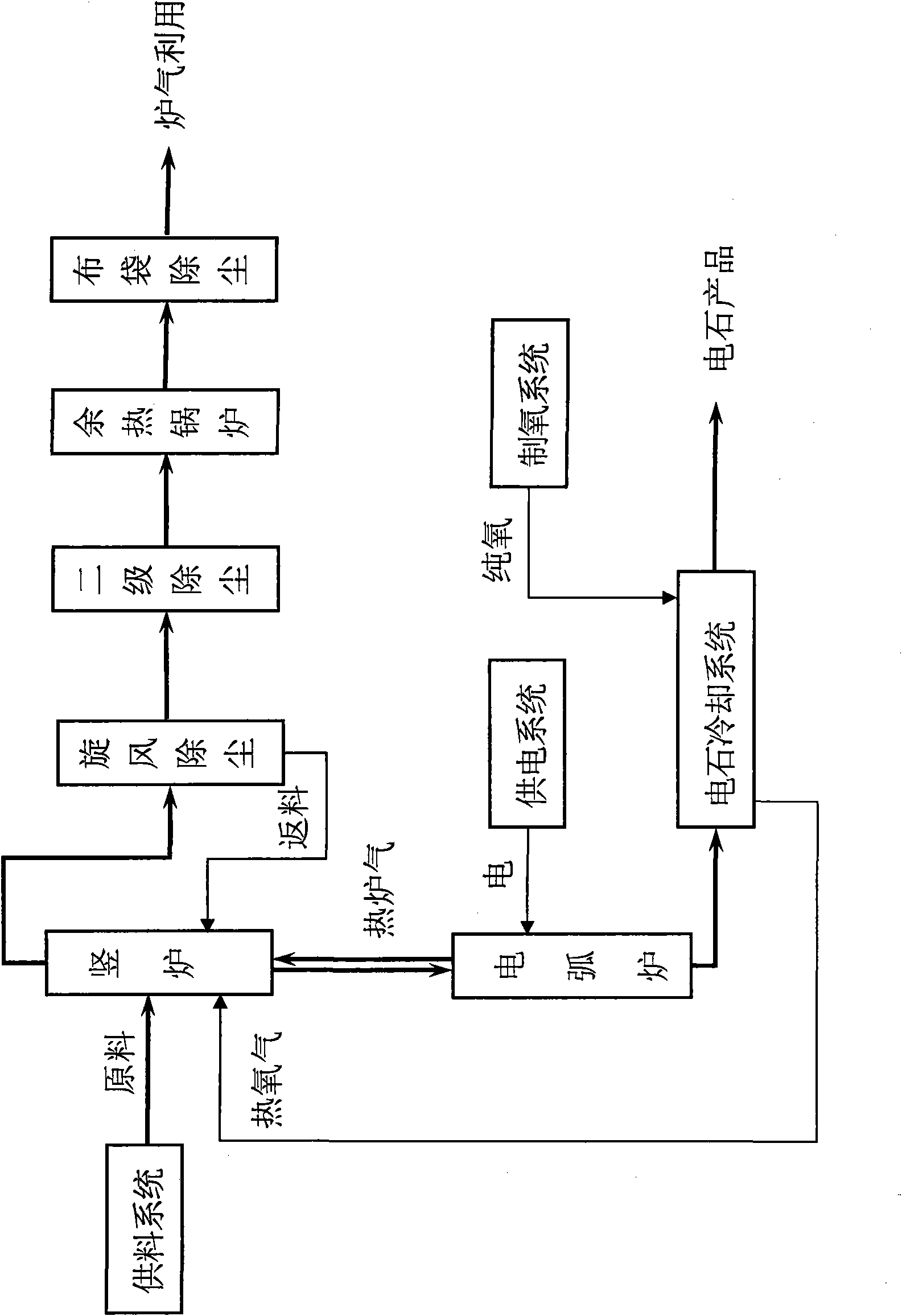

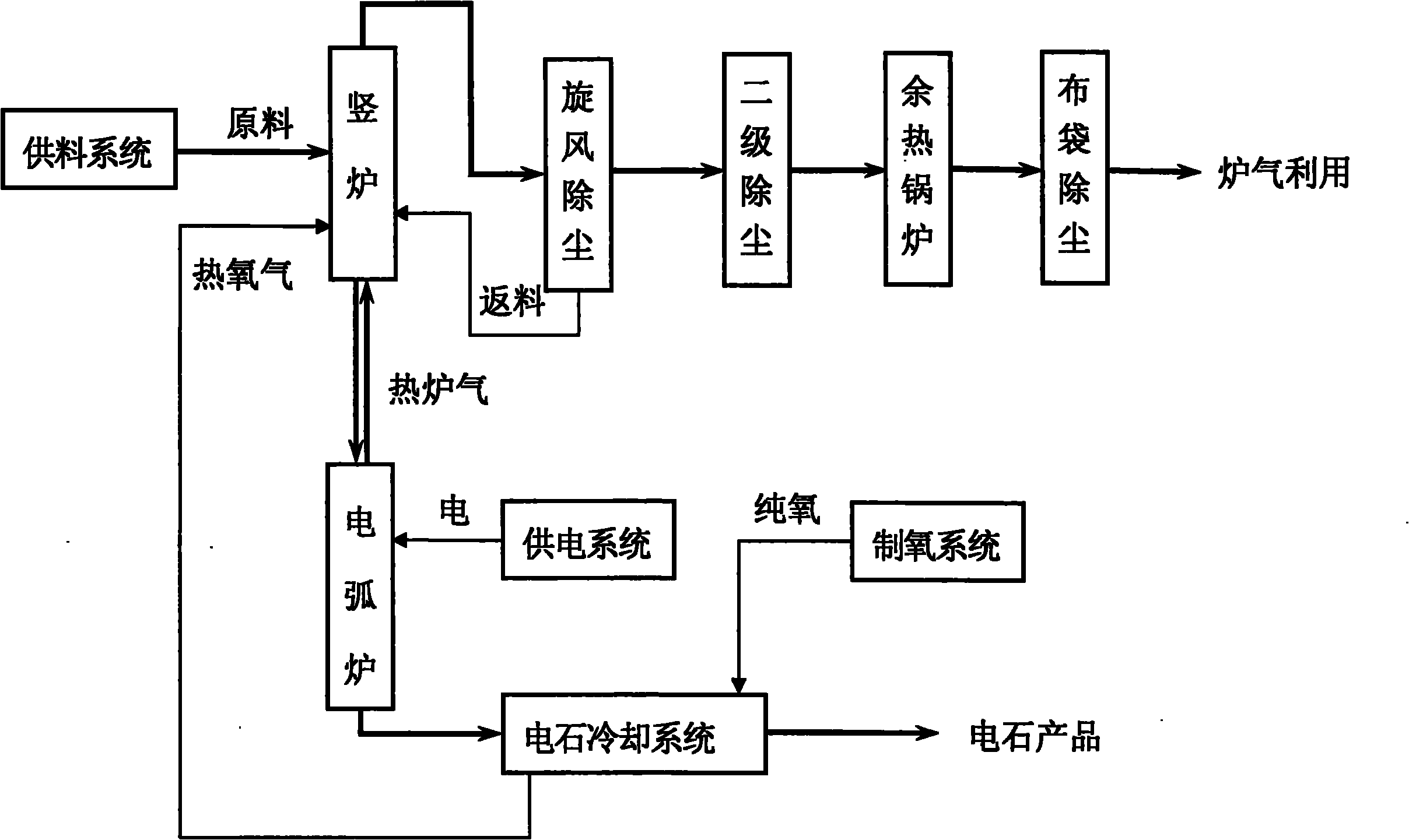

Process and device for producing calcium carbide by using powder raw materials through two-stage method

A two-stage method and raw material technology, applied in the chemical industry, sustainable manufacturing/processing, carbide, etc., can solve the problems of long residence time, slow reaction rate, small production capacity, etc., and achieve fast reaction rate and high utilization rate , the effect of large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

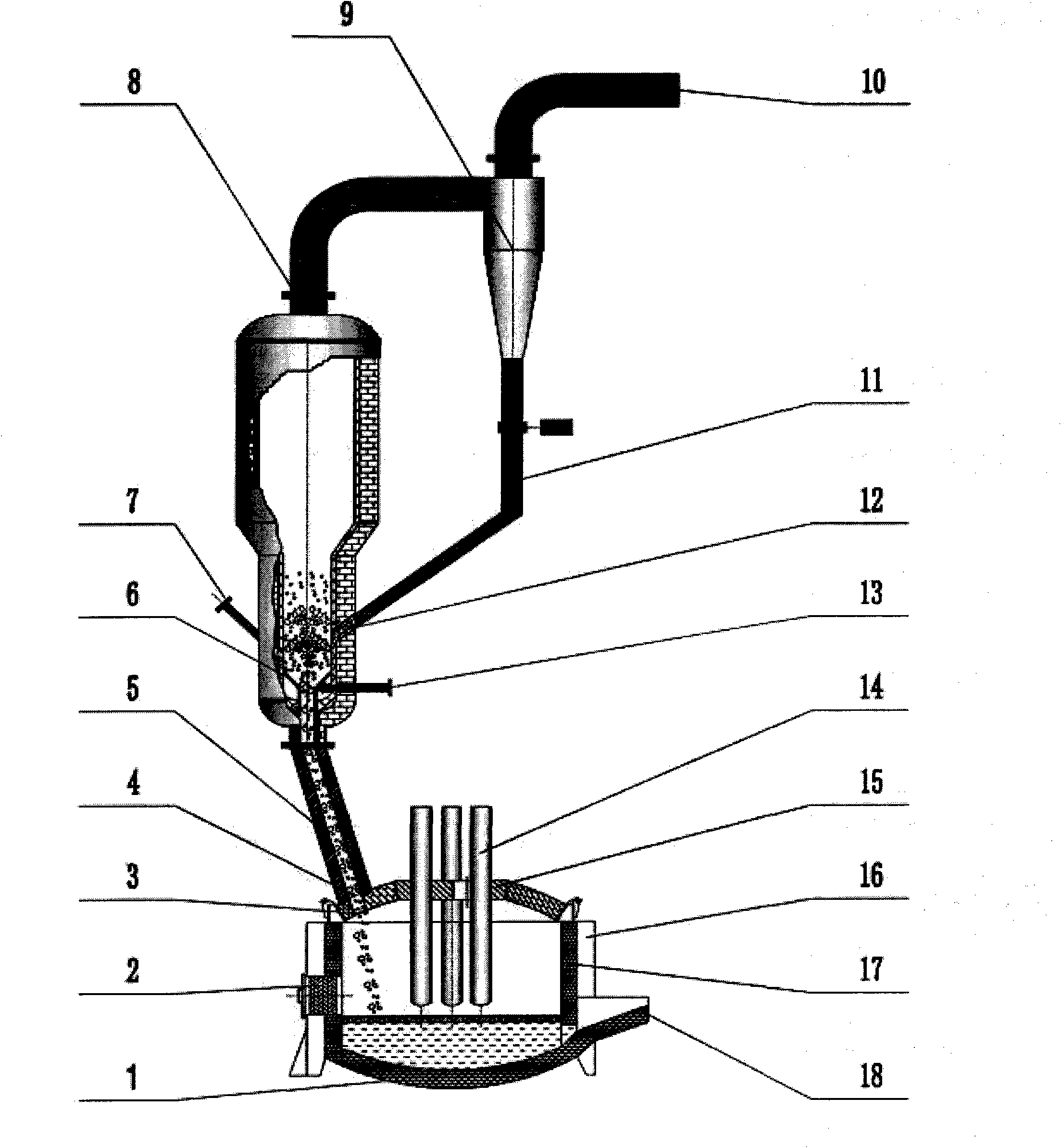

[0026] The device for producing calcium carbide by the two-stage method is composed of an upper shaft furnace, a lower electric arc furnace and a cyclone separator 9. The shaft furnace is a cylindrical structure with an external insulation layer. The lower part of the shaft furnace has a gas distribution plate 6, and the gas distribution plate 6 is There are raw material inlet 7, raw material return port 12, oxygen nozzle 13 under the gas distribution plate 6, furnace gas outlet 8 on the top of the shaft furnace connected to the cyclone dust collector 9, the raw material return pipe 11 on the cyclone dust collector and the raw material return port 12 connections, the bottom of the shaft furnace communicates with the feeding pipe 5, and the lower section of the electric arc furnace consists of a furnace shell 16, a furnace wall 17, a furnace body manhole 2, a furnace cover 3, an electrode 14, an electrode sealing ring 15, a hearth 1, and a calcium carbide liquid row Outlet 18 an...

Embodiment 2

[0032] The vertical furnace aspect ratio of the calcium carbide plant produced by the two-stage method is 5.5, and there are 6 oxygen nozzles. The above-mentioned anthracite and quicklime are crushed and screened until the particle size is less than 8mm, and dried until the moisture content is less than 4wt%. After blending according to the weight ratio—anthracite: quicklime=1.72:1, they are continuously fed at a flow rate of 210kg / h In the vertical furnace, the discharge temperature of the upper shaft furnace is controlled at 1300-1500°C, the temperature of the calcium carbide liquid in the lower section of the electric arc furnace is controlled at about 1900-2100°C, and 64Nm of pure oxygen is injected 3 / h. Discharge calcium carbide liquid every two hours, each discharge is about 170kg, cool it to room temperature, CaC 2 The content is 80.6%, and the gas production is 300L / kg. All the other are with embodiment 1.

Embodiment 3

[0034]The vertical furnace aspect ratio of the calcium carbide plant produced by the two-stage method is 4, and there are 3 oxygen nozzles. The above-mentioned coke and limestone are first crushed and screened until the particle size is less than 8mm, dried until the water content is less than 4wt%, and then mixed according to the weight ratio—coke:limestone=1.47:1, and then fed continuously according to the flow rate of 330kg / h In the vertical furnace, the discharge temperature of the upper section of the shaft furnace is controlled at 1300-1500°C, the temperature of the calcium carbide liquid in the lower section of the electric arc furnace is controlled at 1900-2100°C, and pure oxygen is injected at 110.8Nm 3 / h. Discharge calcium carbide liquid every two hours, each discharge is about 170kg, cool it to room temperature, CaC 2 The content is 80.6%, and the gas production is 300L / kg. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com