Patents

Literature

1193 results about "Anthracite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anthracite, often referred to as hard coal, is a hard, compact variety of coal that has a submetallic luster. It has the highest carbon content, the fewest impurities, and the highest energy density of all types of coal and is the highest ranking of coals.

System and method for atmospheric carbon sequestration

ActiveUS20100257775A1Increase carbon emissionsLiquid surface applicatorsSolid waste disposalCarbon sequestrationCoal

This invention relates to systems and methods for converting biomass into highly inert carbon. Specifically, some embodiments densify the carbon into anthracite-style carbon aggregations and store it in geologically stable underground deposits. The use of certain embodiments yield a net effect of removing atmospheric carbon via the process of photosynthesis and converting it into hard coal, which can be stored in underground beds that mimic existing coal deposits which are known to be stable for thousands of years.

Owner:COOL PLANET ENERGY SYST

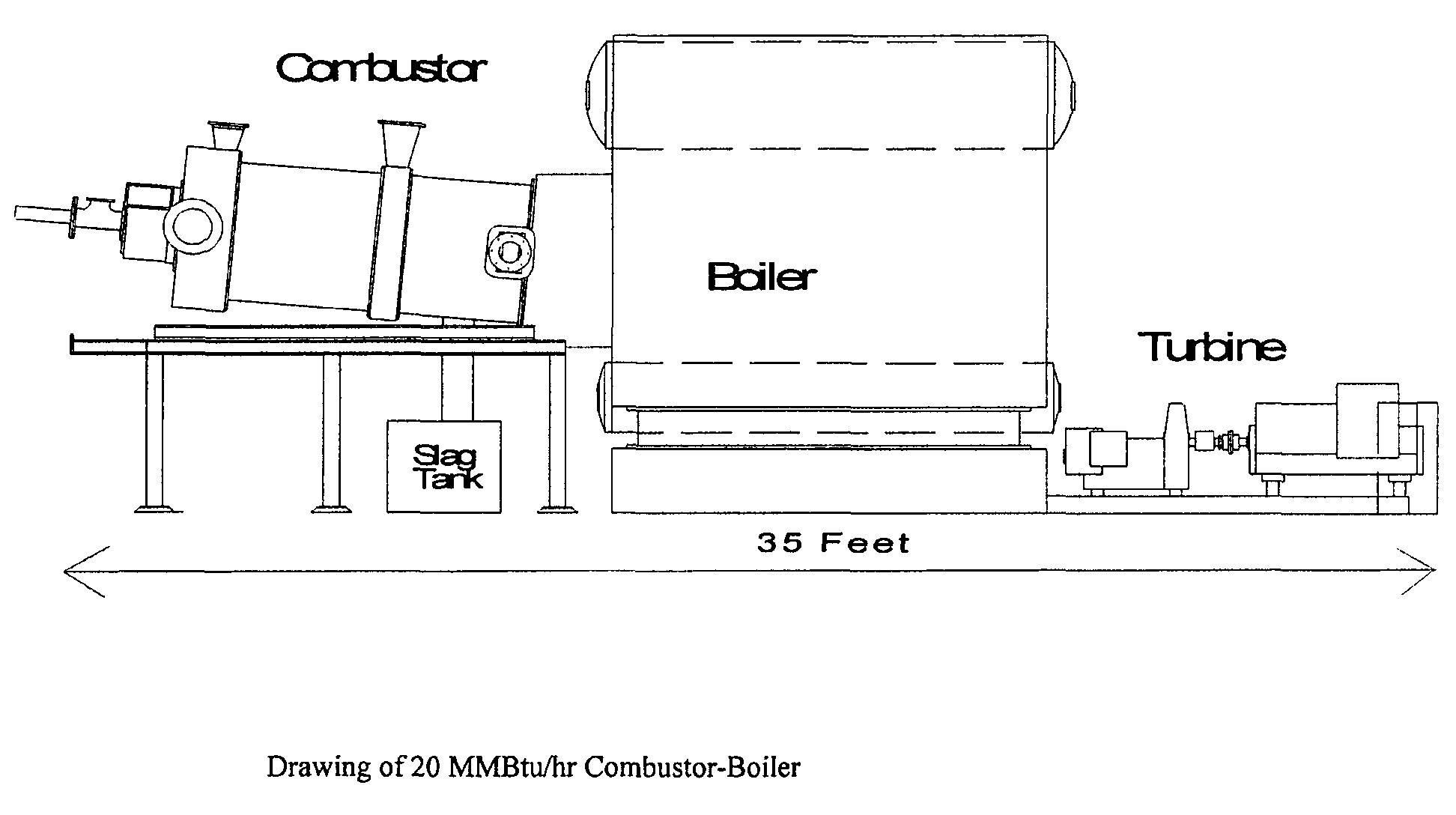

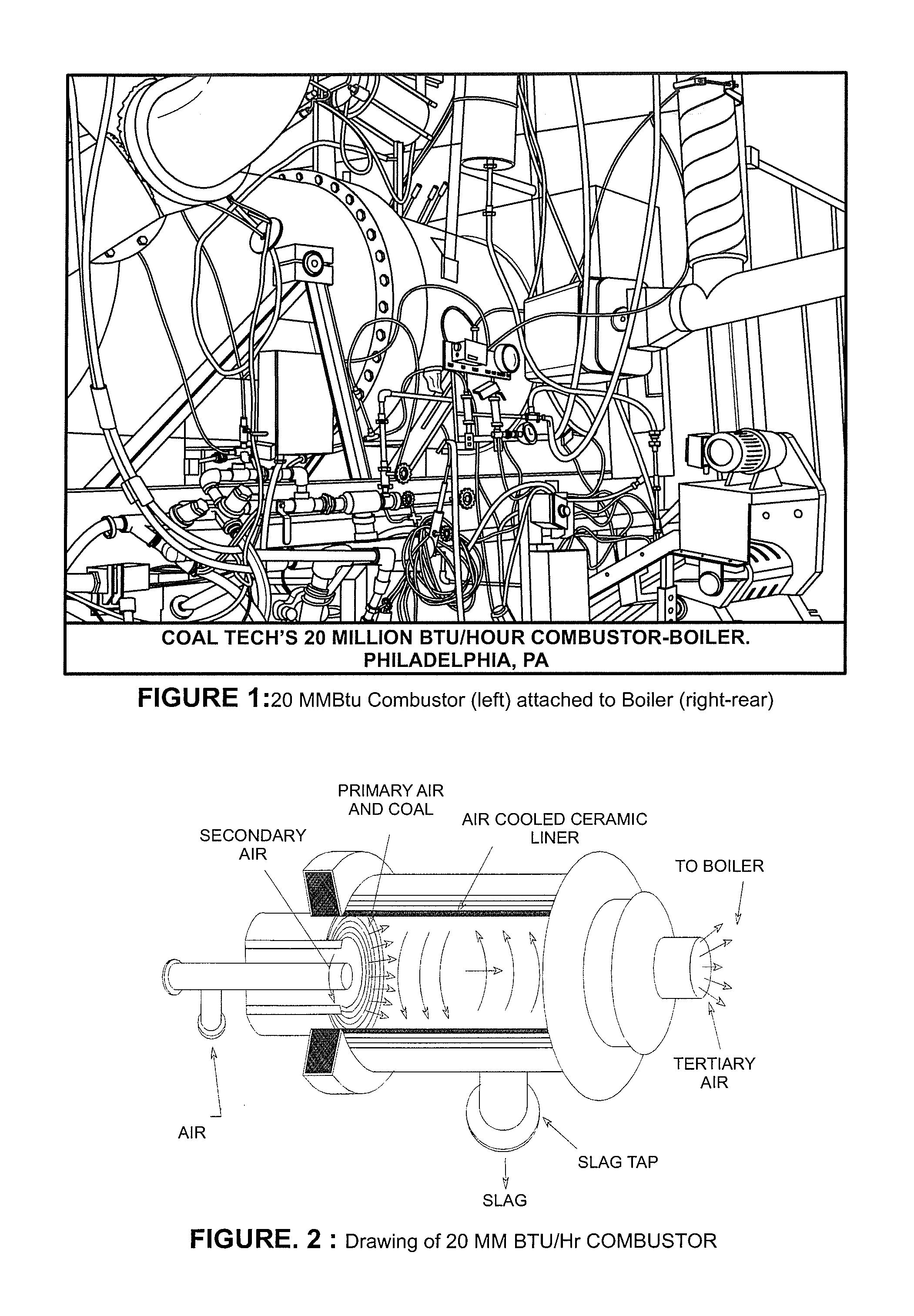

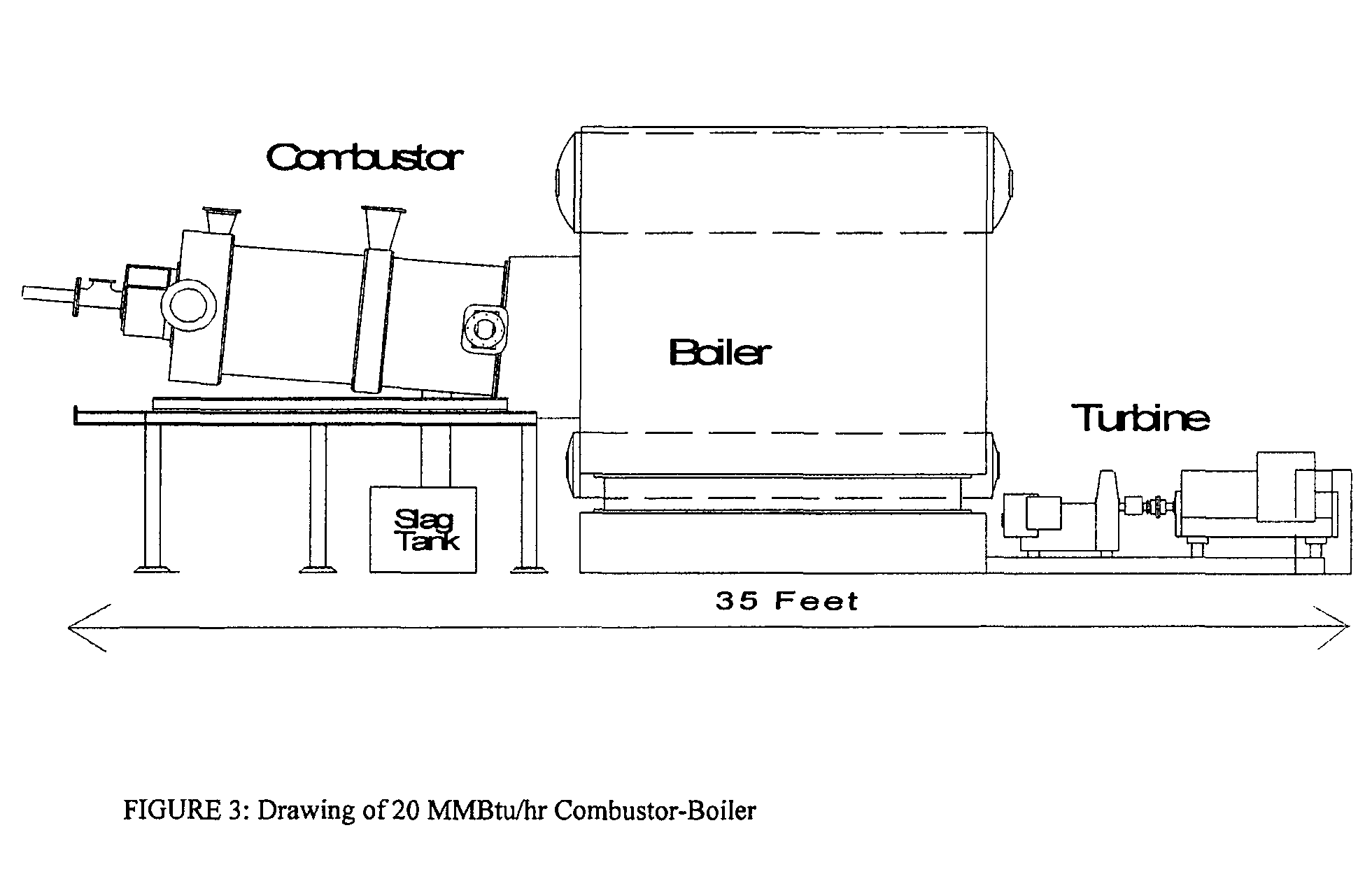

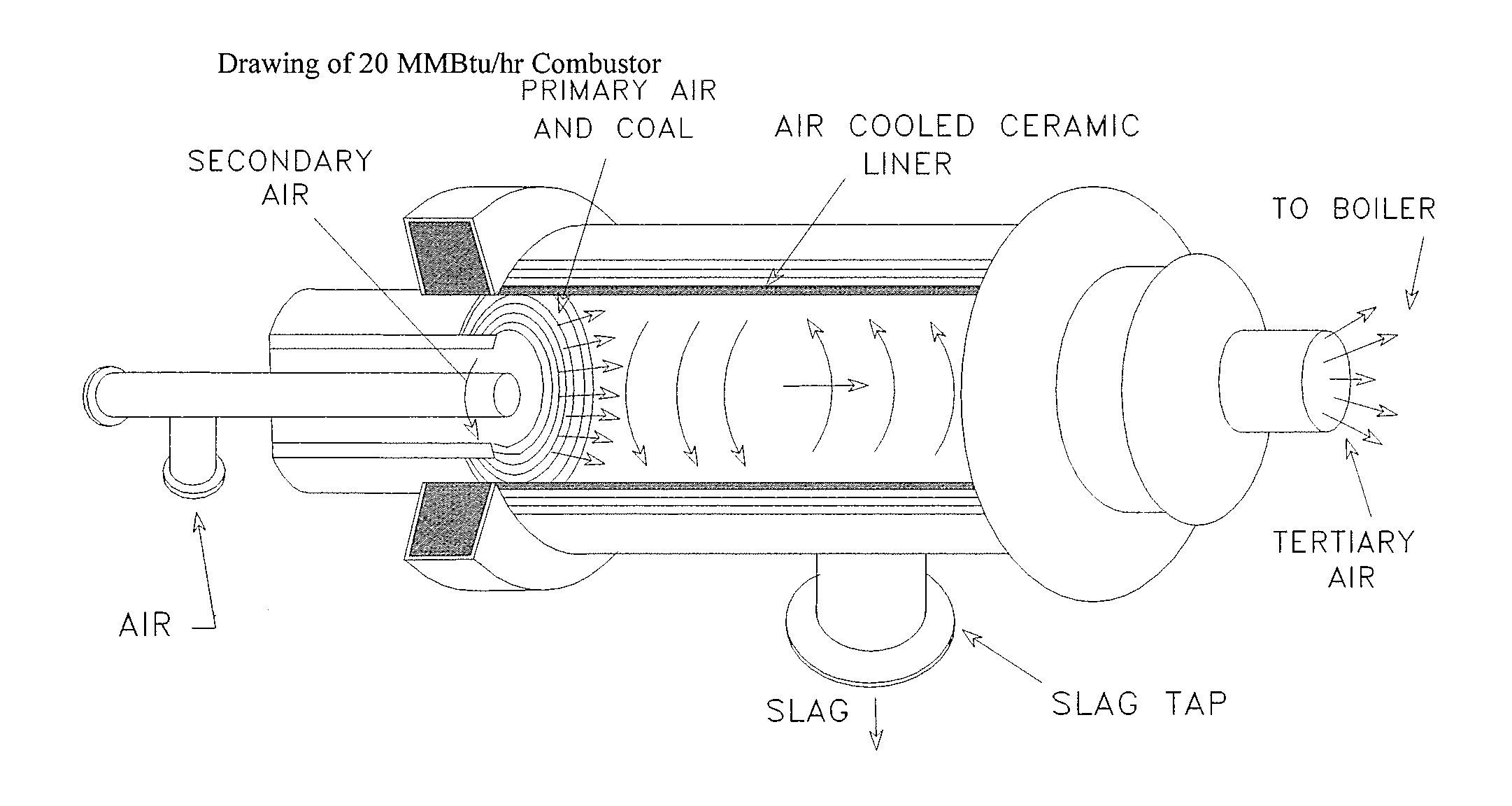

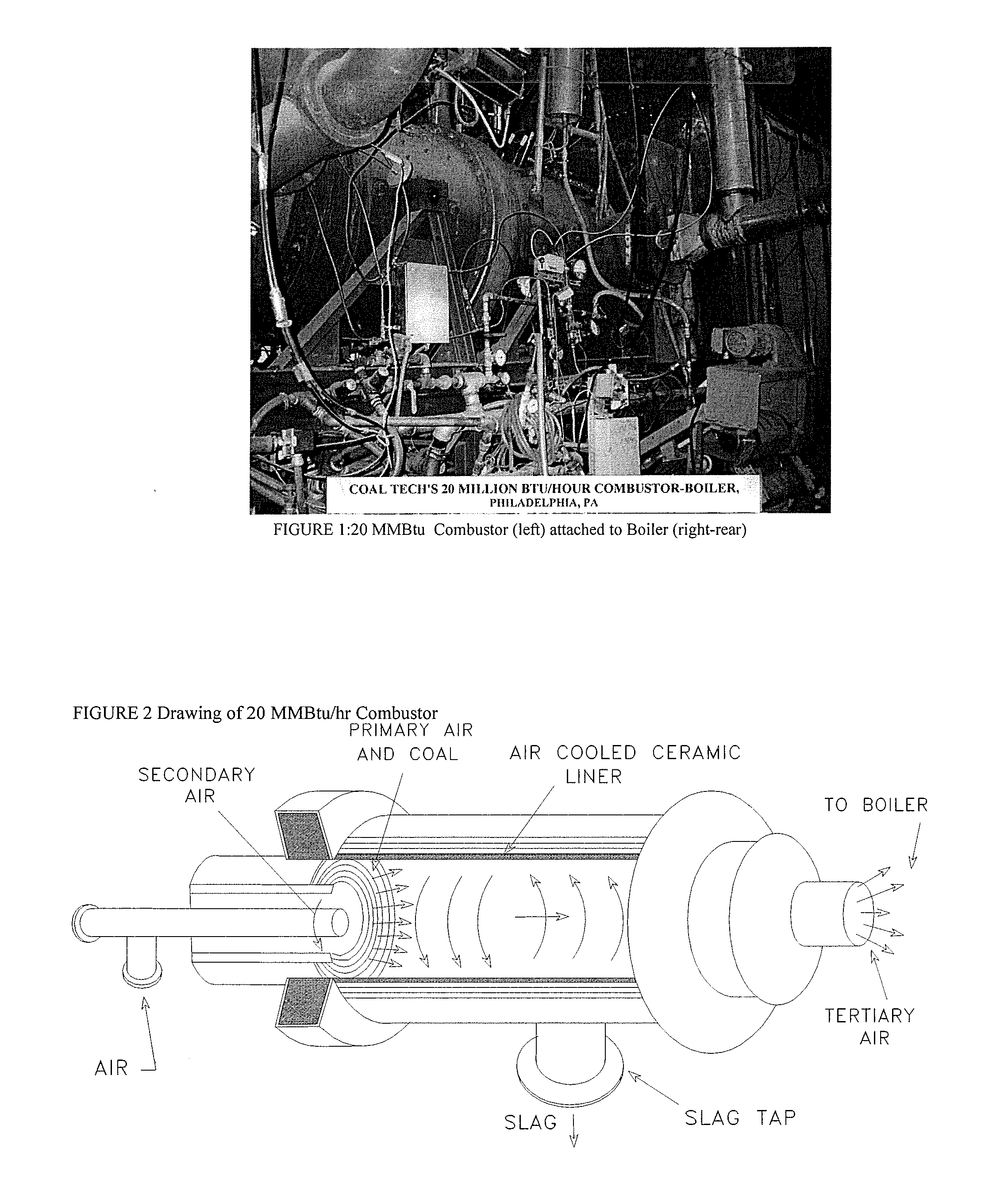

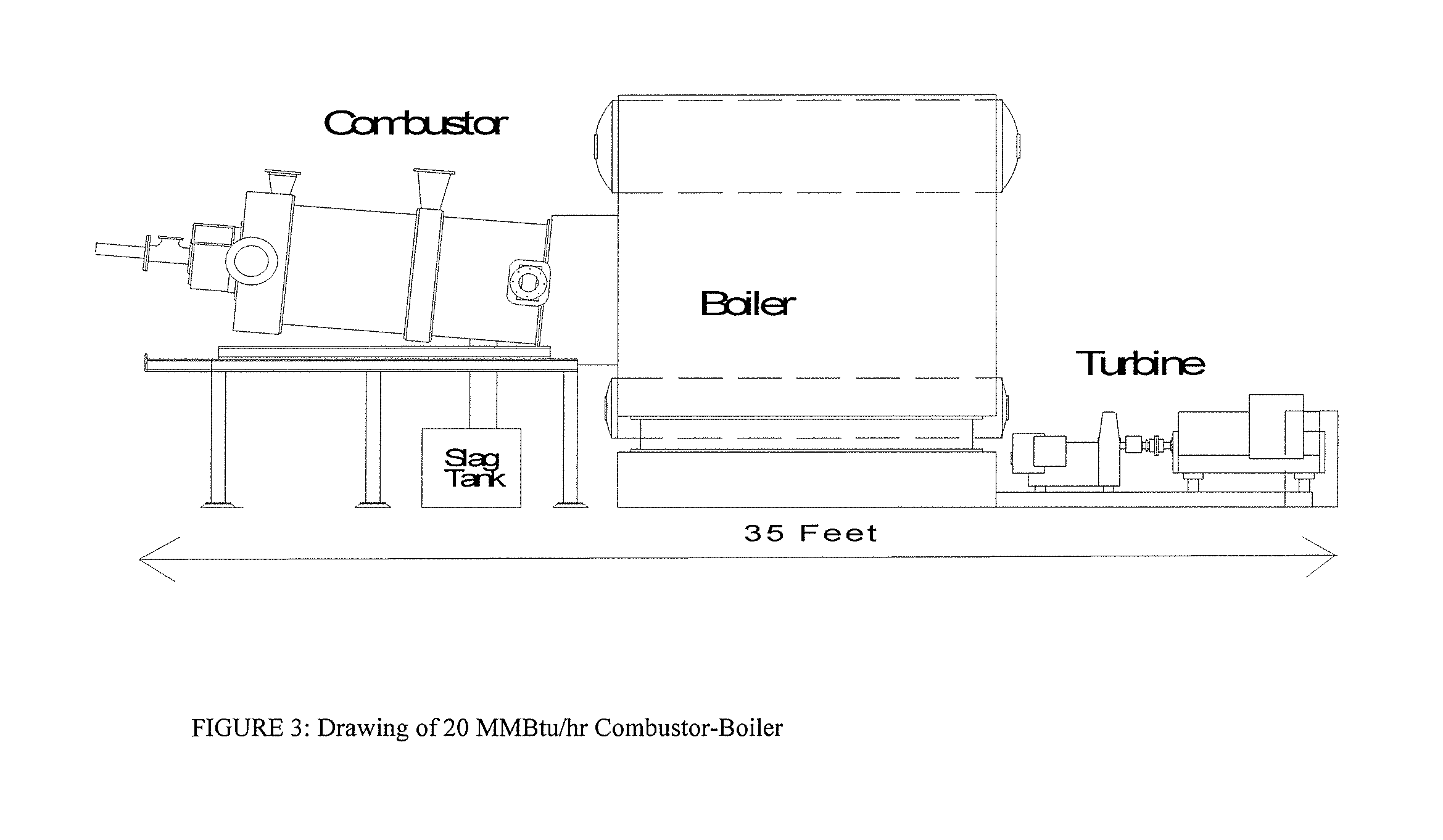

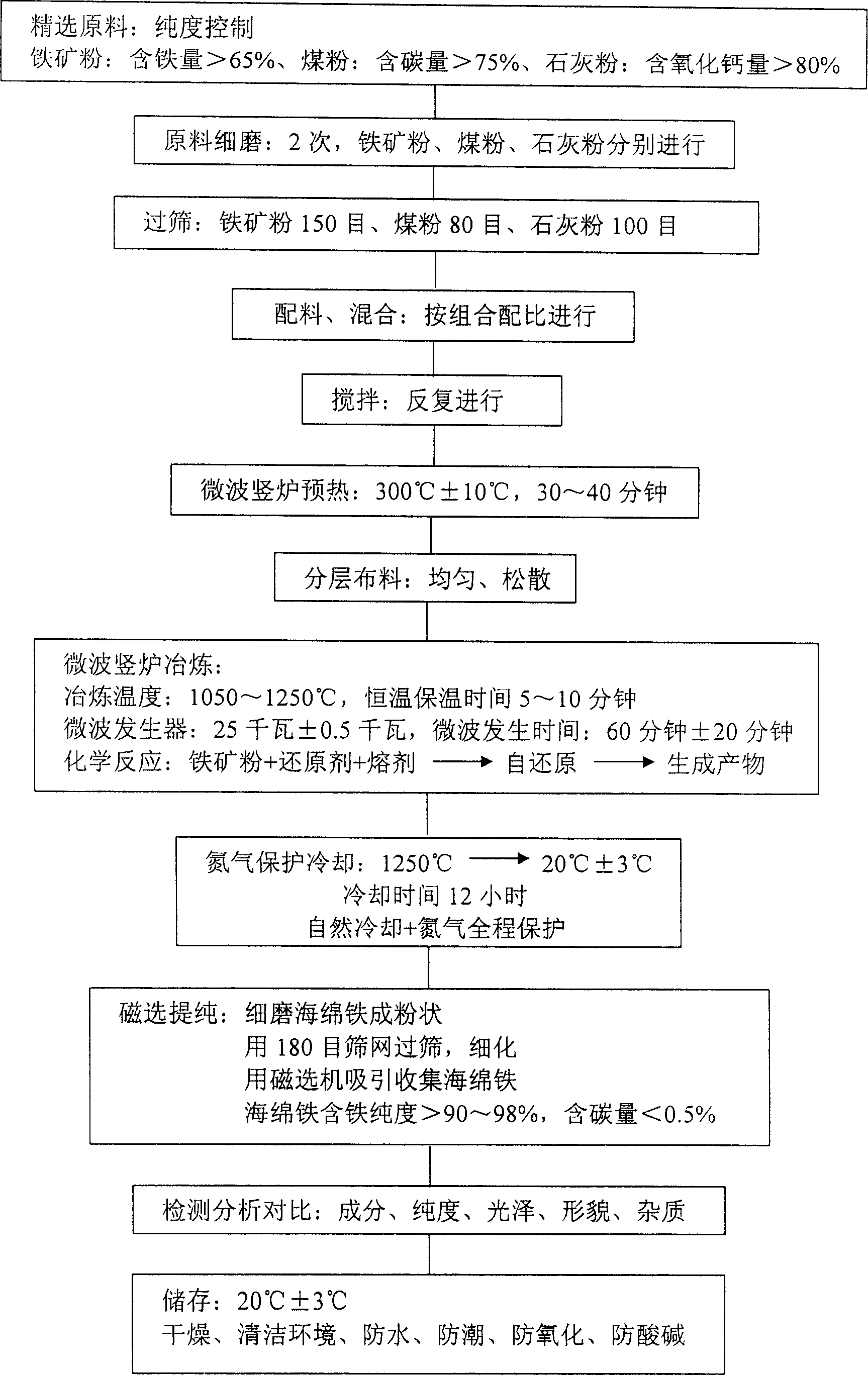

Slagging coal combustor for cementitious slag production, metal oxide reduction, shale gas and oil recovery, enviromental remediation, emission control and CO2 sequestration

InactiveUS8337613B2Reduce transportationMinimize disfiguringNitrogen compoundsSulfur compoundsCombustorEnvironmental remediation

Systems, methods and processes teach by specific examples how the cost of sequestering carbon dioxide (CO2) can be totally offset and turned into profits during coal powered electricity generation from revenue and co-benefits. The process is provided whereby fly ash-carbon mixtures, or de-volatilized coal char, or anthracite coal culm is co-fired in an air-cooled, slagging combustor with limestone or similar slag fluxing materials converts the ash into cementitious slag with properties similar to ground granulated blast furnace slag.

Owner:ZAUDERER BERT

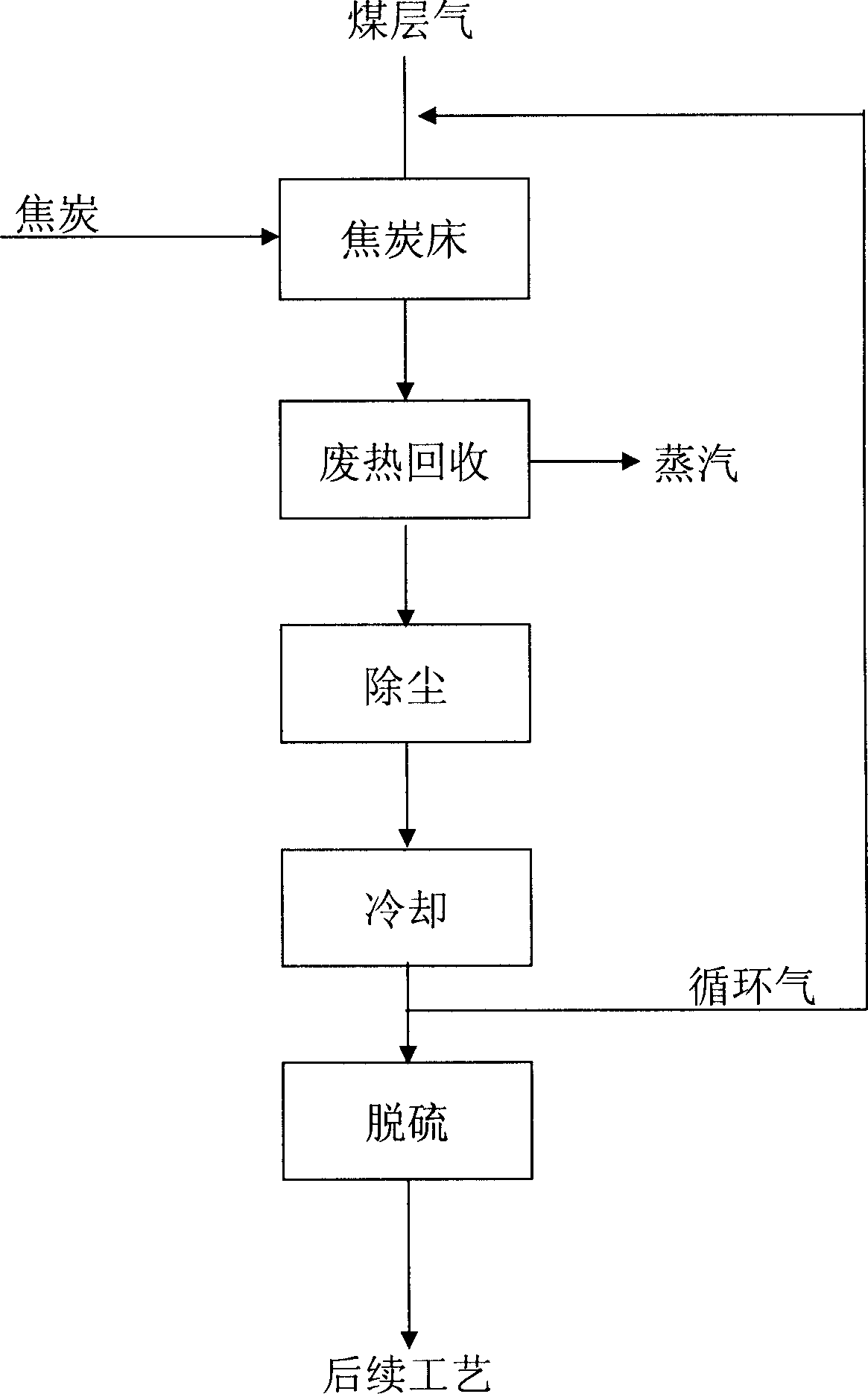

Coal bed gas coke deoxidization technique

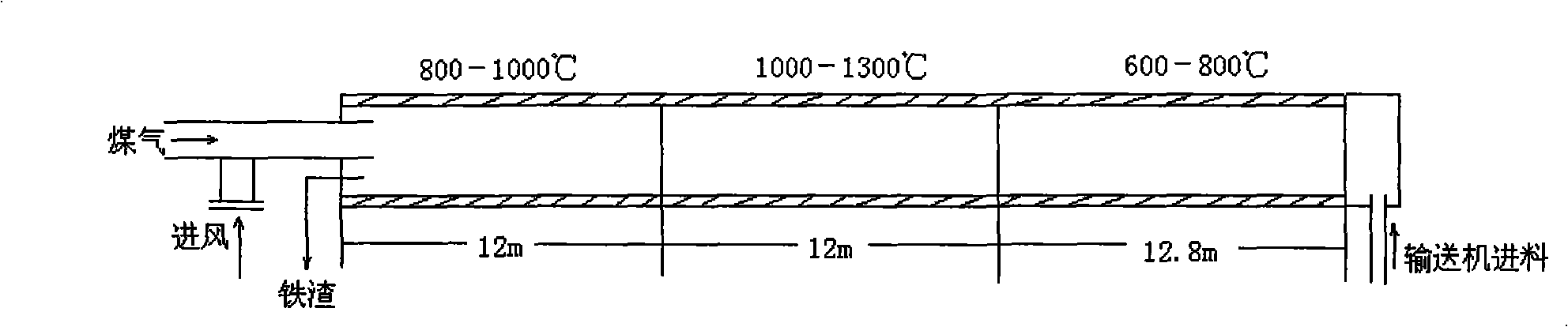

The invention discloses the coal bed gas coke deoxidization technology, comprising the following steps: deoxidizing coal bed gas with coke and anthracite coal, keeping the temperature between 600-1000Deg.C, then dedusting, and cooling; adjusting the oxygen content in deoxidation reactor to 5-9%. The technology can keep reaction temperature, remove oxygen of coal bed gas, reduce methane cracking, and improve safety.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Fuel for firing into rotary kiln cement clinker

A fuel which is used for rotary kiln cement clinker firing is composed of raw materials with the following weight percentage: coal 3-80, straw substances 0-90, forest products wastes 0-95 and food industry by-product residues 0-70. The straw substances refer to rice straws, wheat straws, cotton stalks, sesame stalks, soybean straws, corn stalks, sorghum stalks, rice husks, peanut shells, soybean shells and corn sticks, the forest products wastes refer to defective bamboo, wood, tree branches, leaves, shrubs, faggot straws and sawdust and wood wool corner scrap materials in the bamboo and wood-processing industry, the food industry by-product residues refer to bran, wheat skin, squeezing meal cake, bean dregs and wine lees, and the coal refers to bituminite, anthracite and coke coal powder. The flue raw materials which are used for the rotary kiln cement clinker firing have wide selecting range, simple preparation, convenient use and rapid burning speed and are beneficial for protecting atmosphere circumstances.

Owner:吴飞龙

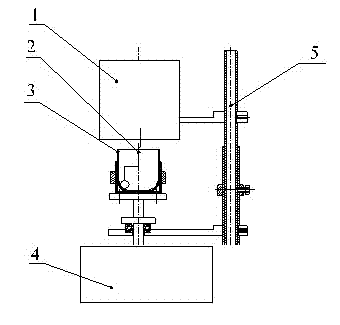

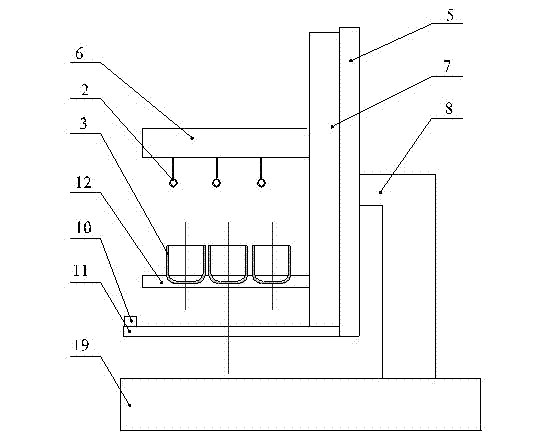

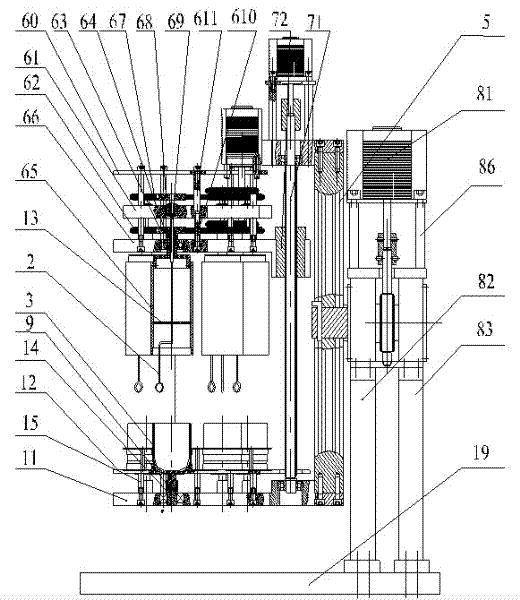

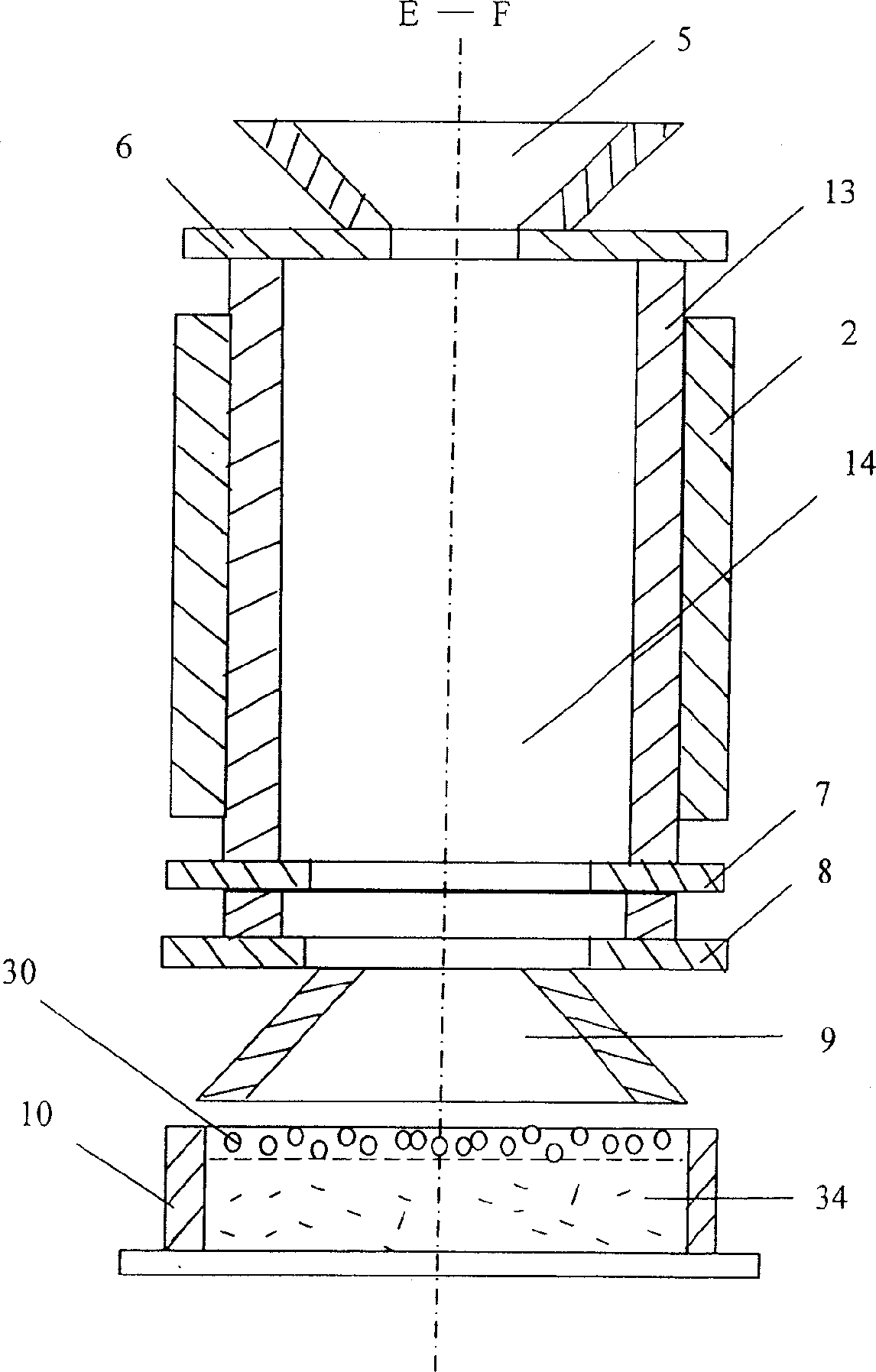

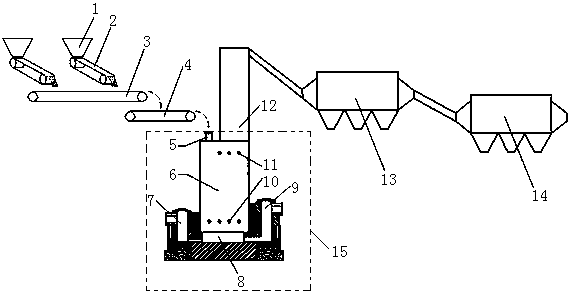

Stirring device with transmission type multi-crucible

ActiveCN102380328AIncrease profitAvoid unstable rotationMixing methodsMixer accessoriesBiochemical engineeringCrucible

The invention discloses a stirring device with a transmission type multi-crucible, which is characterized that a control mechanism is fixed on a bottom plate, a lifting device, an inclination device, a heterodromous rotation device and a crucible tray are fixed on the bottom plate. The transmission driven crucible and the heterodromous rotation device capable of heterodromously rotating a mixing wire are arranged on the upper part of the lifting device, the crucible tray capable of placing the multi-crucible is placed on the lower part of the lifting device, the inclination device fixed on the fixed pedestal is communicated with the heterodromous rotation device. The stirring device of the invention has the advantages of simple and compact structure, and simple operation, and is capable of effectively solving the problem for batch producing anthracite samples, and increasing the production number and the quality of the anthracite caking index samples.

Owner:江苏双星特钢有限公司

Slagging coal combustor for cementitious slag production, metal oxide reduction, shale gas and oil recovery, enviromental remediation, emission control and co2 sequestration

InactiveUS20110173139A1Reduce transportationMinimize disfiguringNitrogen compoundsSulfur compoundsMaterials scienceChar

Systems, methods and processes teach by specific examples how the cost of sequestering carbon dioxide (CO2) can be totally offset and turned into profits during coal powered electricity generation from revenue and co-benefits. The process is provided whereby fly ash-carbon mixtures, or de-volatilized coal char, or anthracite coal culm is co-fired in an air-cooled, slagging combustor with limestone or similar slag fluxing materials converts the ash into cementitious slag with properties similar to ground granulated blast furnace slag.

Owner:ZAUDERER BERT

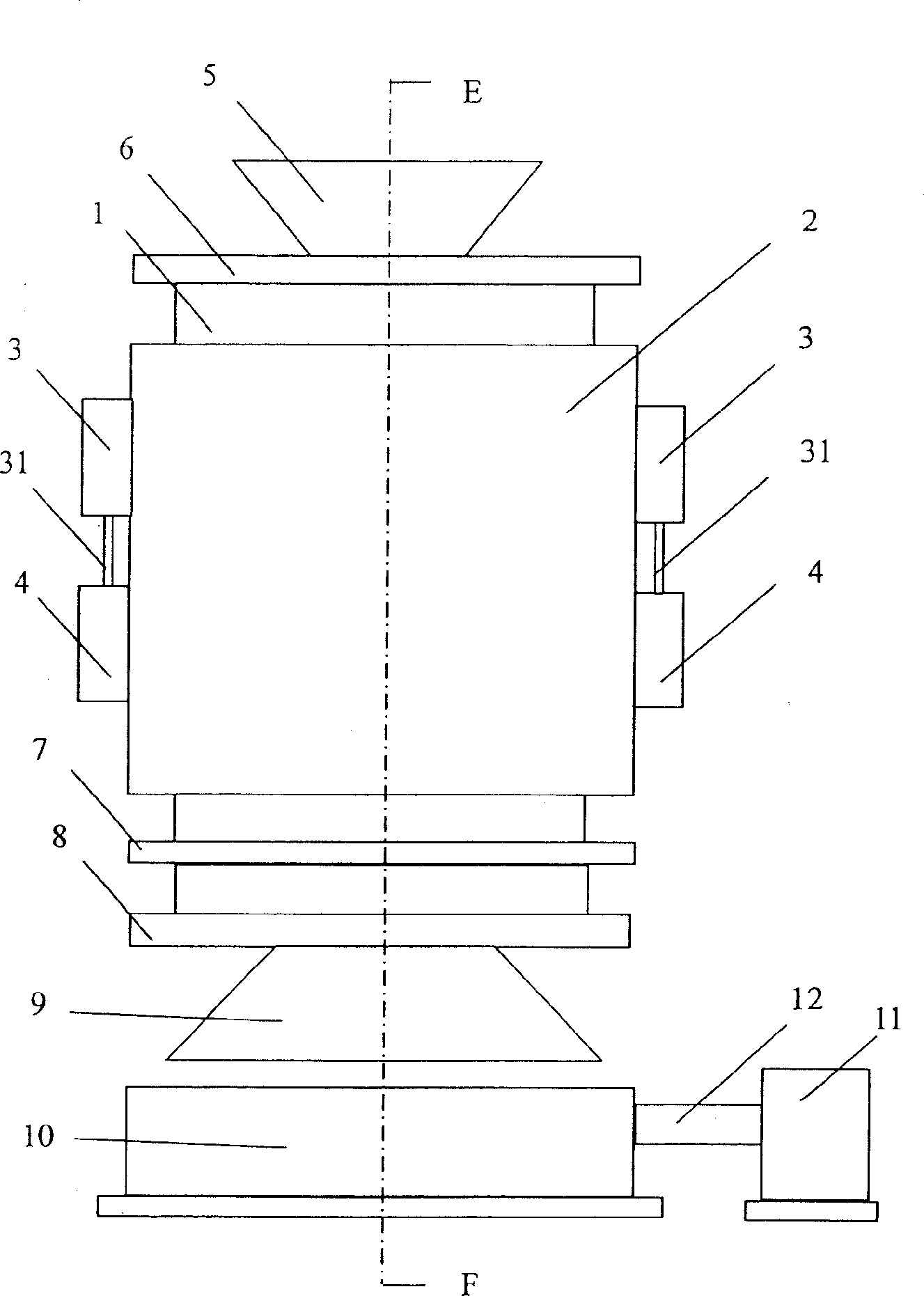

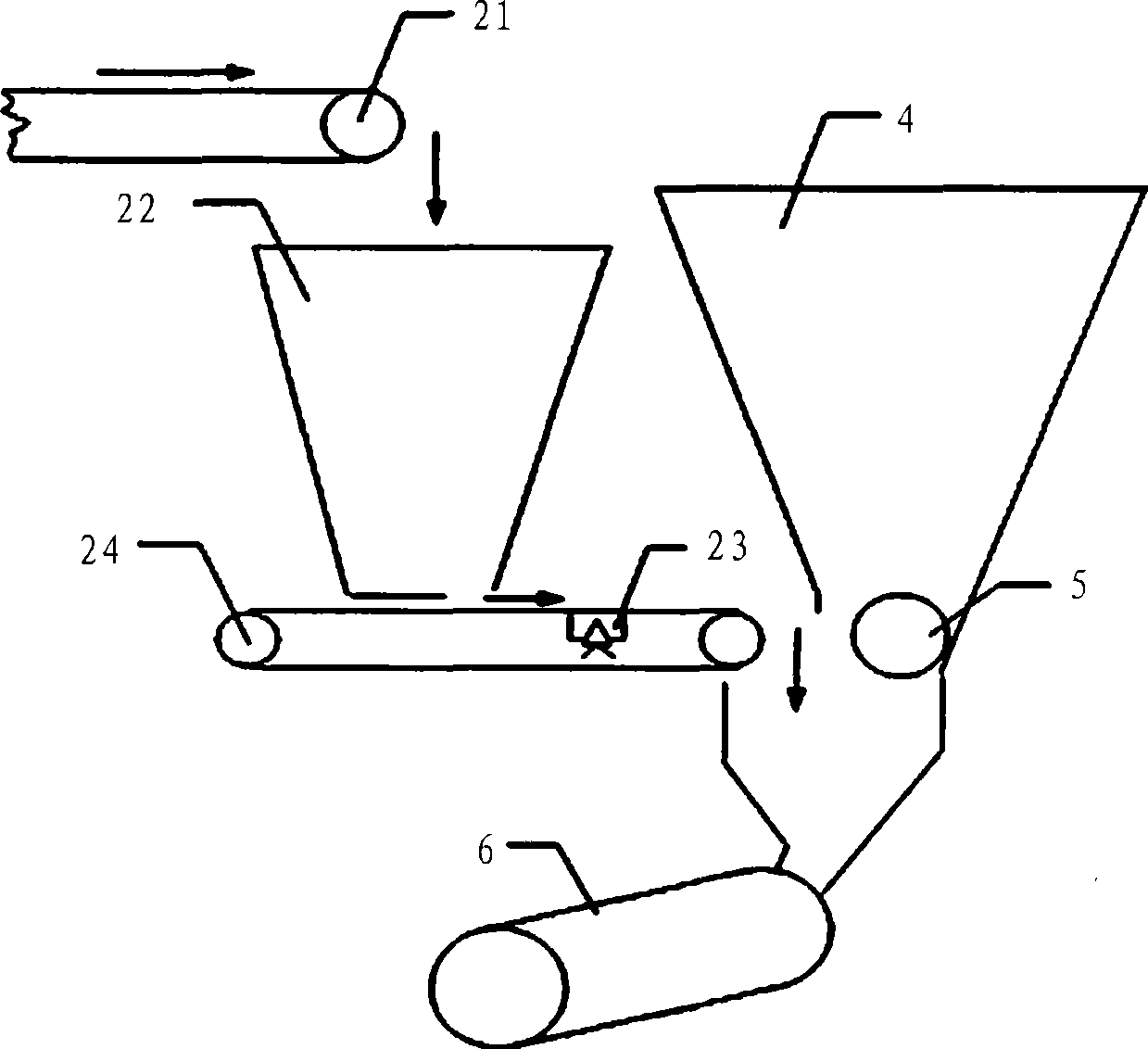

Method of manufacturing low carbon sponge iron using microwave vertical furnace

The invention relates to a method to make low carbon sponge iron by microwave shaft furnace. It adopts iron ore powder as raw material, common soft coal dust or anthracite dust as reducer to gain high quality low carbon sponge. It uses the feature that the iron ore powder, carbon powder, and lime powder has selective absorbing to microwave. Under the condition of sealing and high temperature, and under the effect of microwave generator, heater, and adjustor, it would take carbon heat self-reduction by absorbing the heat produced by microwave generator to gain low carbon sponge iron. The method has simple technology, shortens the reduction time period, saves coking coal and coke resource, and reduces environment pollution. The degree of metallization could reach 90-98%, and the carbon content could be lower than 0.5%. It is the ideal method to make low carbon sponge iron.

Owner:TAIYUAN UNIV OF TECH

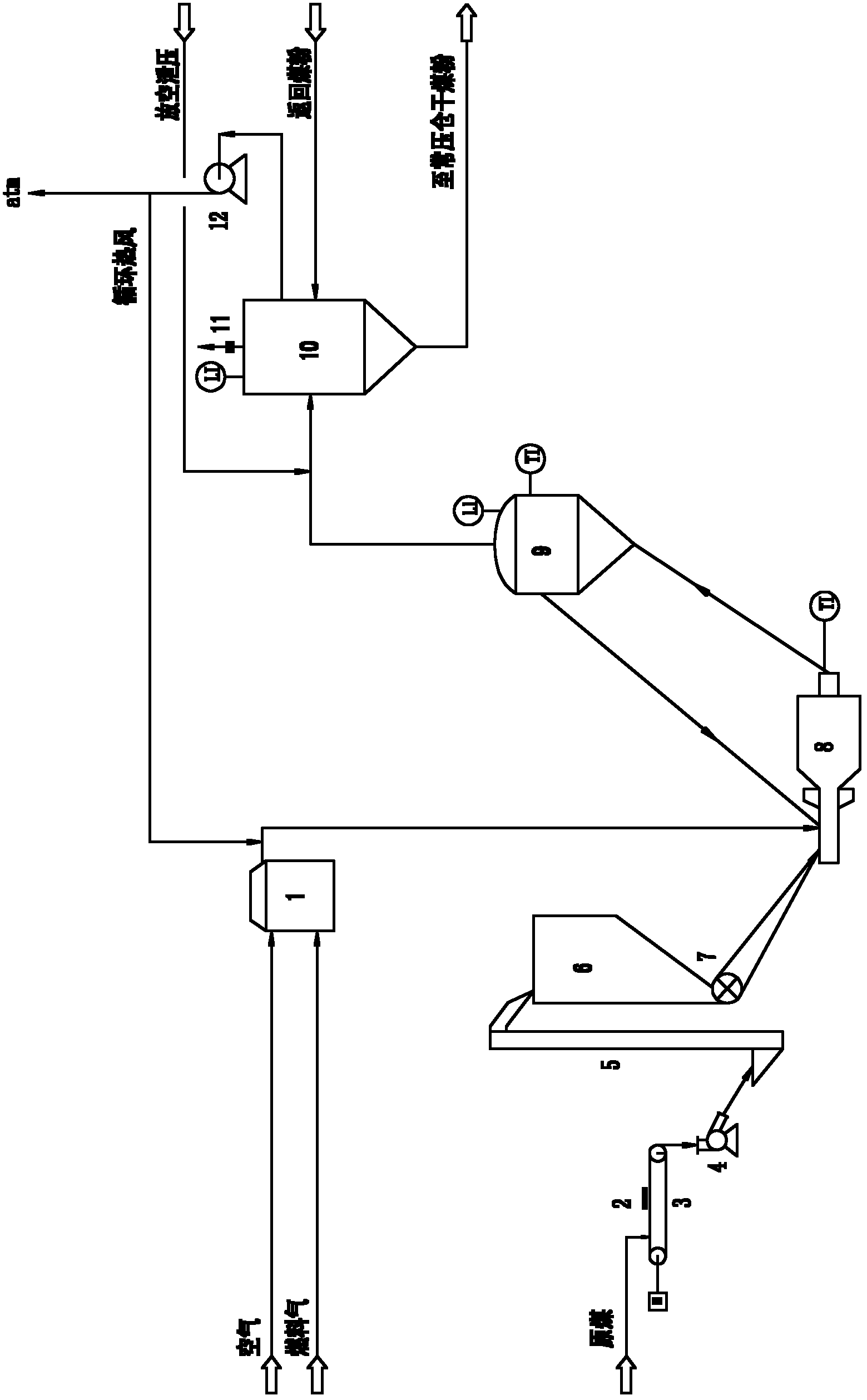

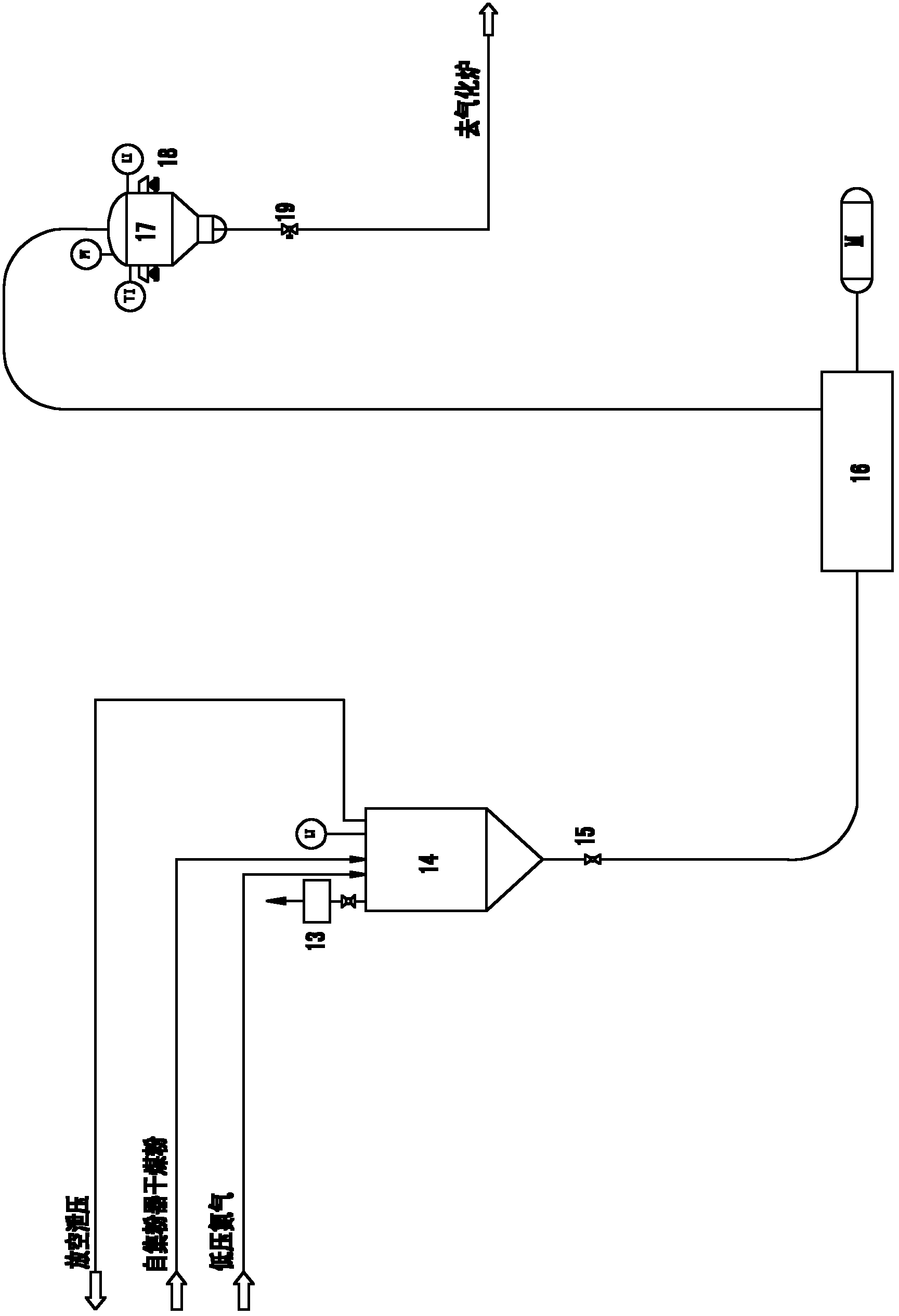

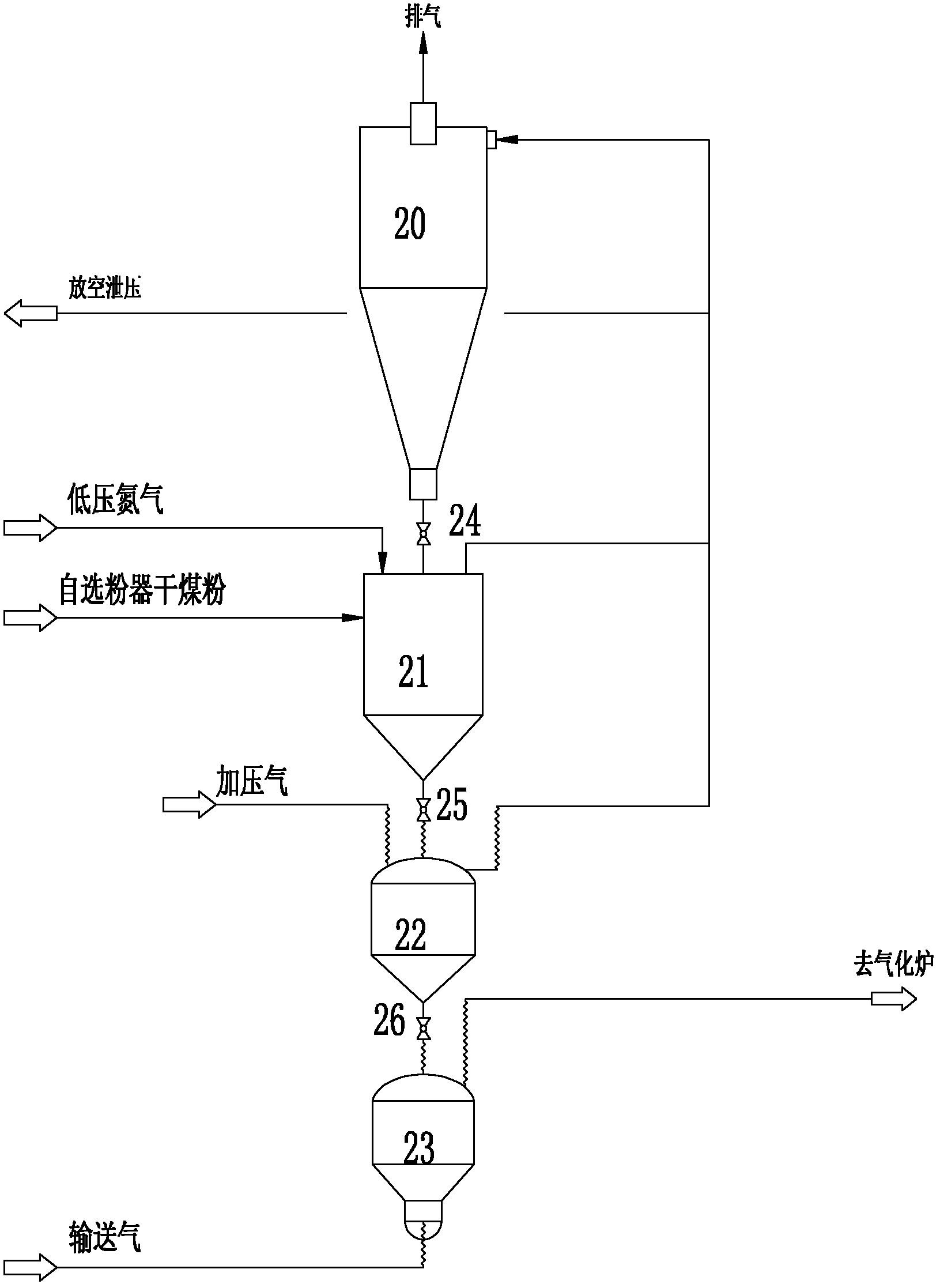

Method for producing synthesis gas by using coal powder as raw material

ActiveCN102352268AImprove utilization efficiencyWon't happenMultistage water/sewage treatmentCombined combustion mitigationProcess configurationAnthracite

The invention discloses a pressurization high temperature gasification method of dry coal powder. The method comprises the following five steps: the preparation of dry coal powder, the pressurization delivery of the dry coal powder, the pressurization and high temperature gasification of the dry coal powder, the cooling of high temperature crude synthesis gas and molten ash and the washing and purifying of the crude synthesis gas, and the treatment of water containing fine ash. The method is suitable for not only the bituminous coal with low ash content and low ash fusion point, but also other types of coal, which widely exist at home and abroad, have different metamorphic degrees and qualities and contain the coal with low ash content and high ash fusion point, the coal with high ash content and low ash fusion point and the anthracite, bituminous coal and lignite with high ash content and high ash fusion point. The method has good gasification index, simple equipment, flexible process configuration, low investment and operation convenience, the large-scale product is easy to realize, and the method has the beneficial effects of wide raw material application range, environmental friendliness and the like.

Owner:THE NORTHWEST RES INST OF CHEM IND

Slag splashing method for converter high-oxidisability furnace residue

InactiveCN101177720AHigh melting temperatureAdjustable viscosityManufacturing convertersComing outSlag

The invention pertains to the metallurgy field and relates to a method of slag splashing for converter maintenance, in particular to a method of the slag splashing for the converter maintenance of converter high oxide slag. After steel come out from a converter, the slag is left inside the converter, a converter top oxygen lance is used for insufflating nitrogen; after the nitrogen is insufflated into the converter through the converter top oxygen lance, a slag modifier compounded by anthracite and magnesia is added into the converter, and the addition quantity of the slag modifier is: 30-100 kilograms slag modifier is added to every ton of the slag. Terminal slag of the converter ironmaking is splashed and bonded on the converter wall to form slag splashing layers. By actualizing the slag splashing for the converter maintenance of the invention, the effect of the slag splashing for the converter maintenance of the converter with high oxidation slag production when smelting the high additional value steel can be obviously improved, and the service life of a converter liner of the converter can be greatly prolonged.

Owner:NANJING IRON & STEEL CO LTD +1

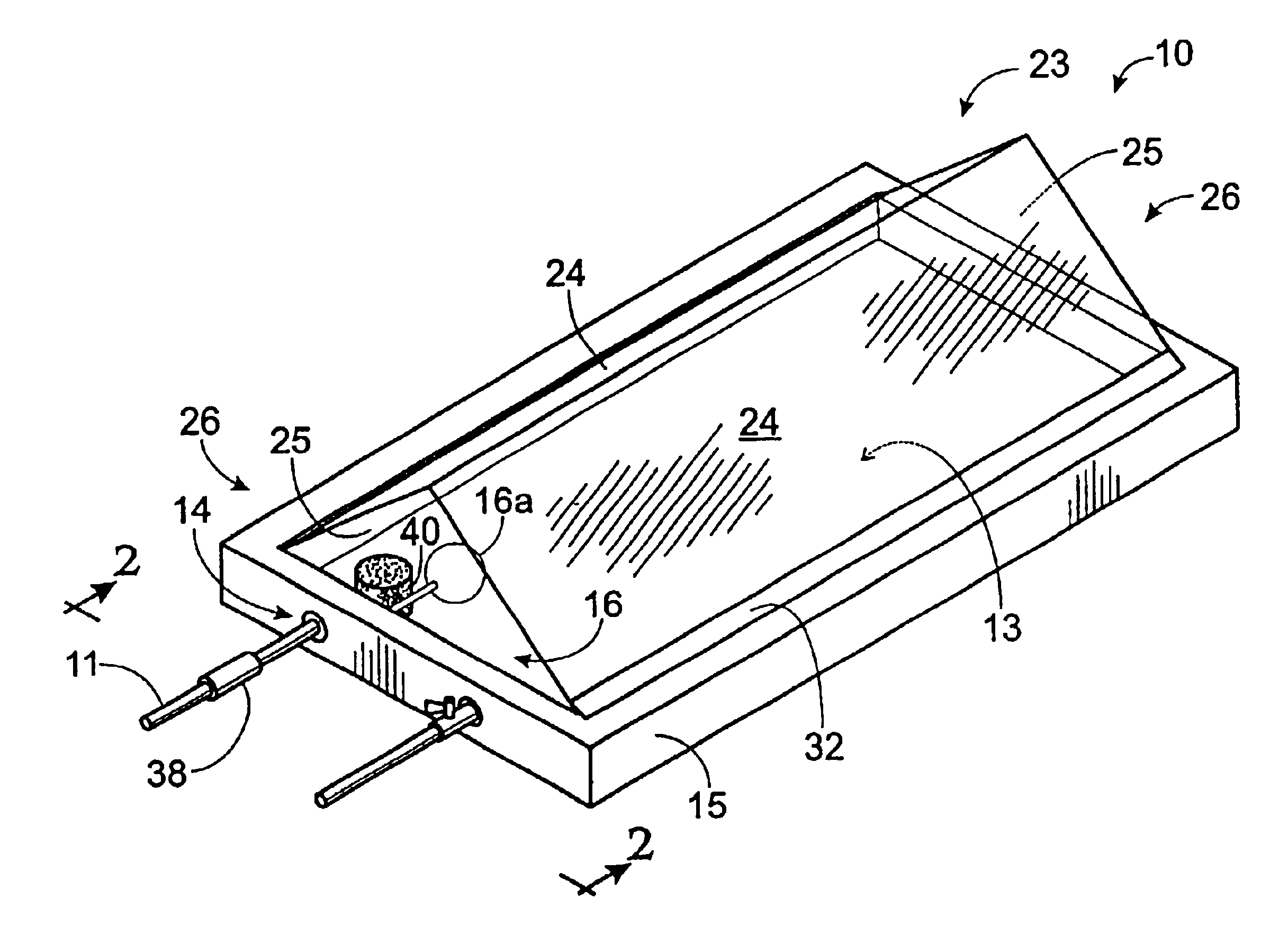

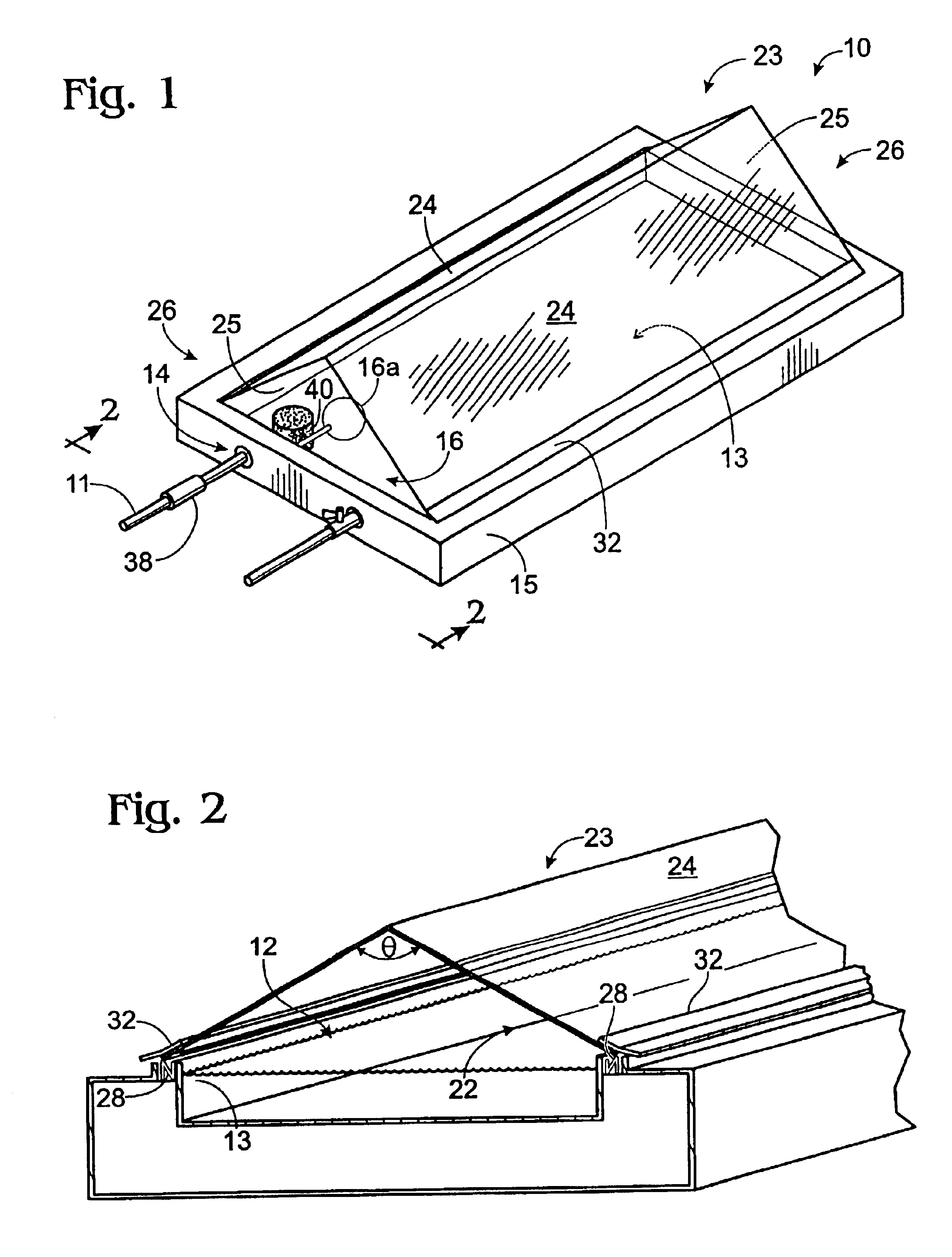

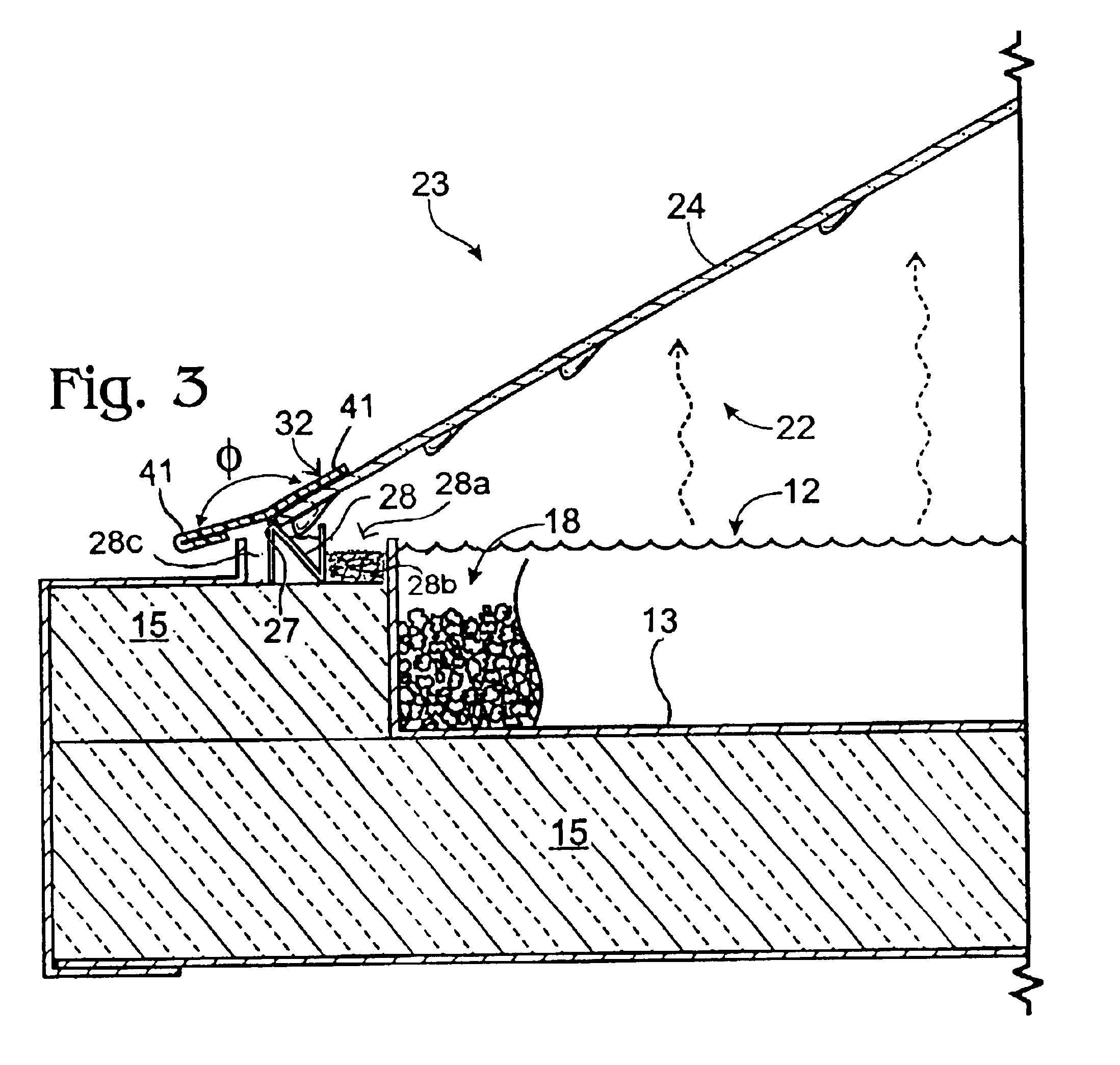

Solar distillation unit

InactiveUS6797124B2Expedited distillationHigh energyWater treatment parameter controlAuxillariesDistillationEvaporation

A solar distilling apparatus employs anthracite coal as a heat-absorbing medium. Greenhouse roof elements rest over a gutter that is isolated from the water-holding container to prevent deposit formation and algae growth from reaching the gutter. Bacterial growth is inhibited by ventilation and the use of titanium-laden magnetite mixed with the anthracite particles. The gutter is also isolated from the exterior of the unit, which prevents contamination from outside sources. The exterior side of the roof elements resting on the gutter are fitted with a metal skirt that provides a heat sink preventing the re-evaporation of condensation flowing toward the gutter.

Owner:LUDWIG DAVID M

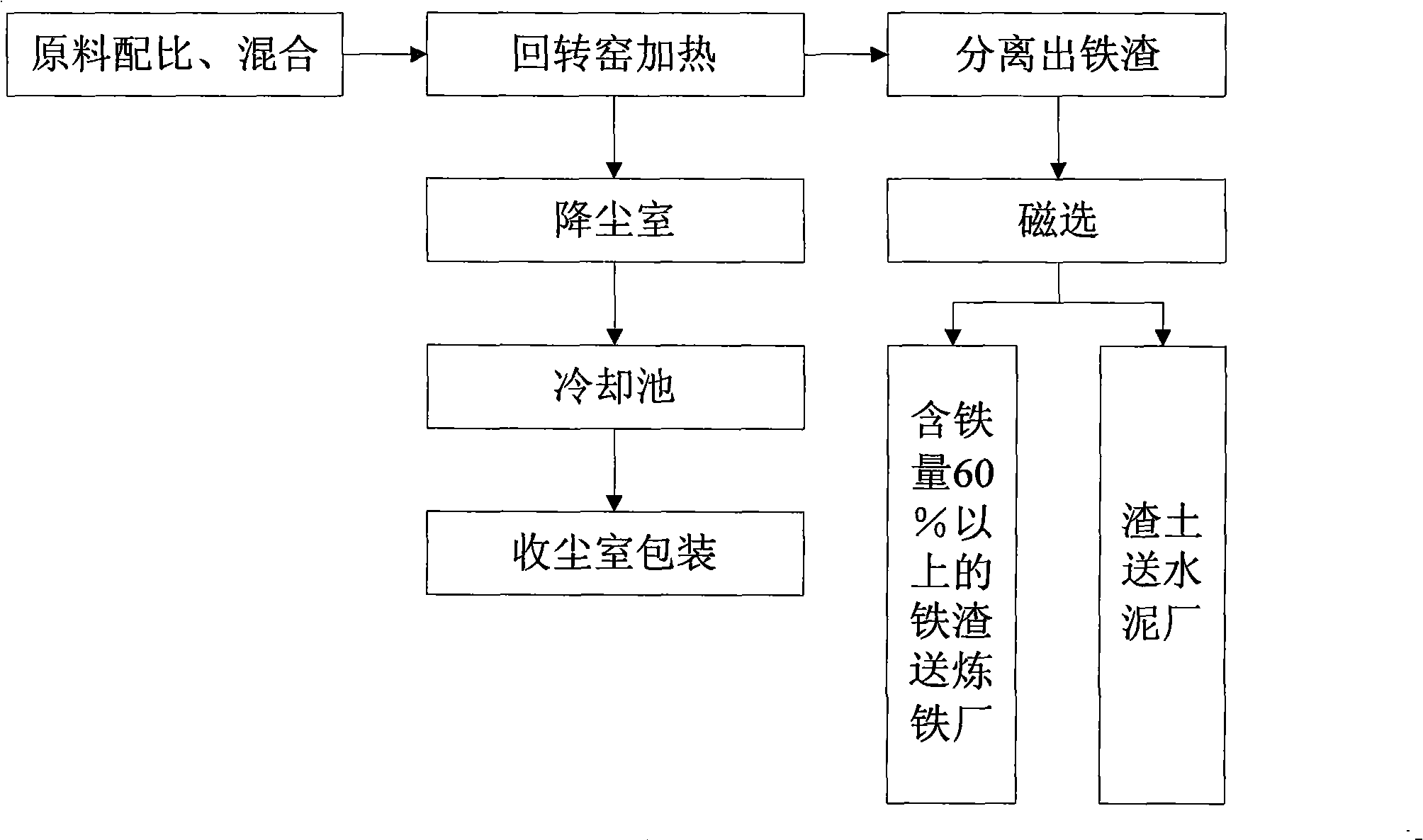

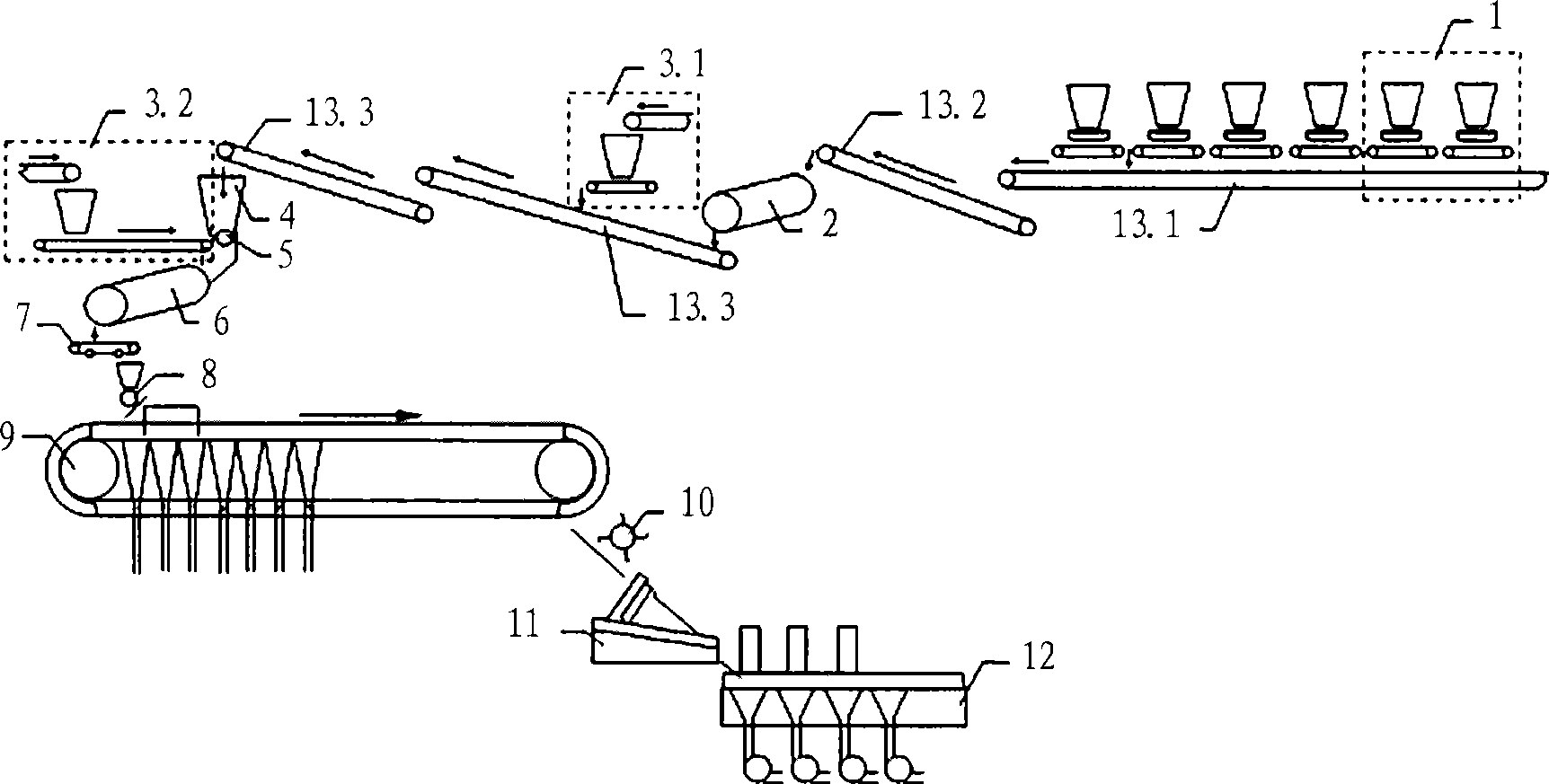

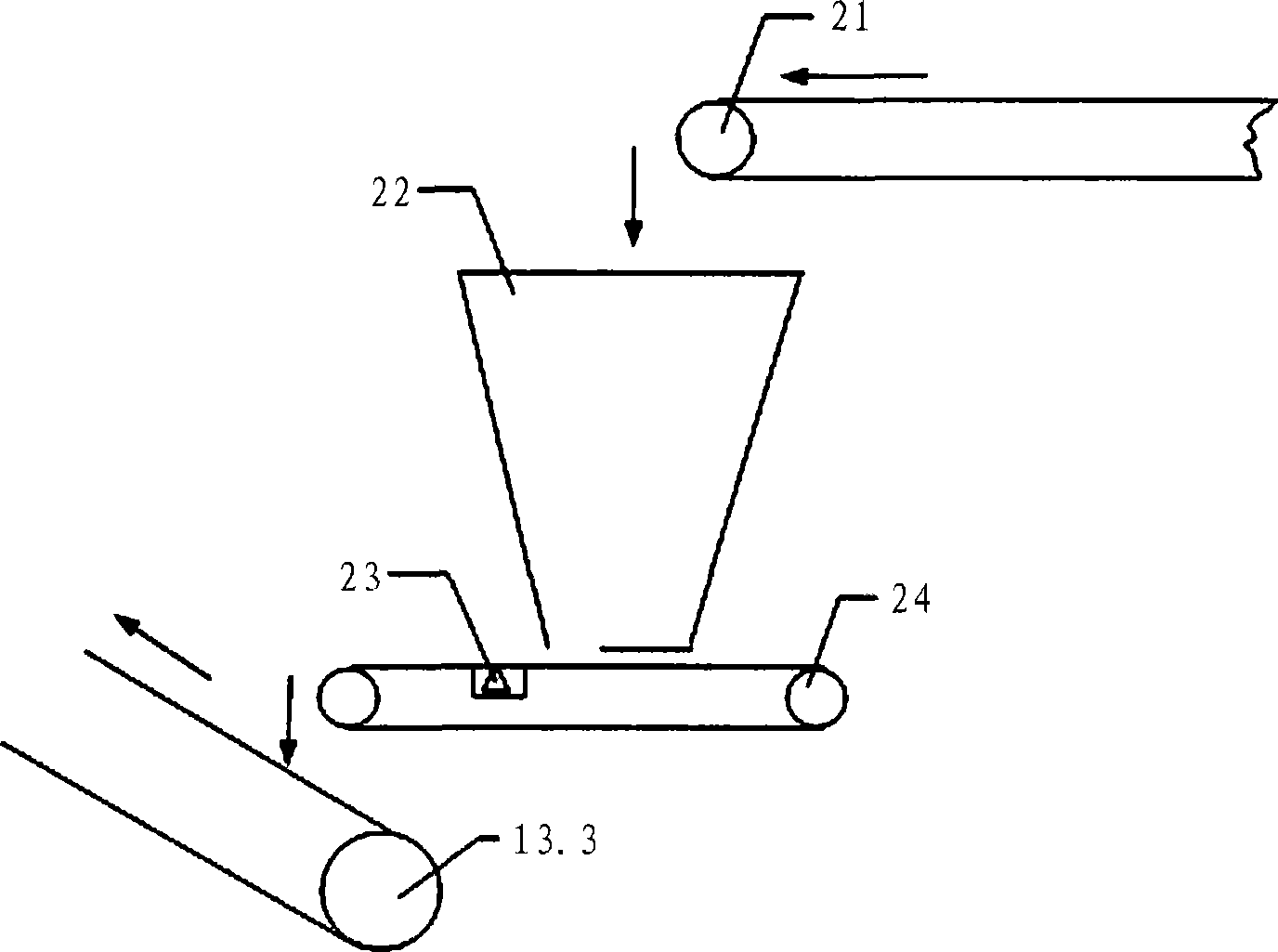

Dust-separation zinc extraction method

InactiveCN101343693ATo achieve the purpose of turning waste into treasureImprove resource utilizationSolid waste managementProcess efficiency improvementResource utilizationWaste material

Disclosed is a dust removal and zinc extraction method. Raw materials are mixed and evenly stirred through a loader according to weight proportion, 30 percent to 40 percent of blast furnace dust removal ashes, 25 percent to 35 percent of power plant dust removal ashes, 25 percent to 35 percent of blast furnace gas slime, 5 percent to 10 percent of anthracite coal are evenly delivered to a rotary kiln to be heated for refining through a conveyor, then are delivered into a dedusting chamber to experience the atomization and separation, the raw materials are delivered into a cooling pond then and zinc oxide powder is forcedly sent into a dust collecting chamber by a suction blower, the dust is collected through a bag and is supplied to a zinc supply smeltery as the raw material. The iron residues separated in the heating and extracting process in the rotary kiln are magnetically separated through a magnet separator, the iron residues with the iron content of 60 percent are delivered to an iron smelting plant, and the residue soil is supplied to a cement plant as the raw material. The invention has the advantages that the iron residues and zinc powder are extracted and separated through adopting the processed waste material dust removal ashes in large-scale smelting enterprises, the purpose of changing wastes into valuables is realized, and the resource utilization rate is enhanced.

Owner:NANJING BANQIAO SLAG

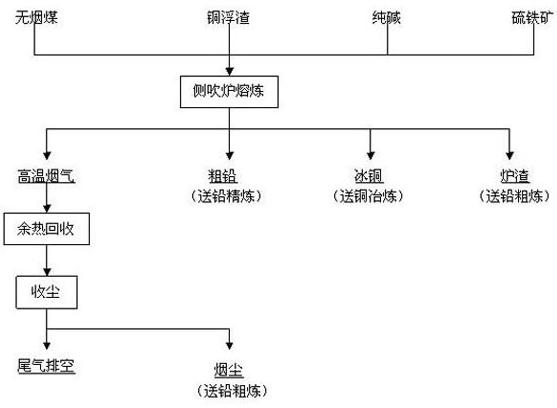

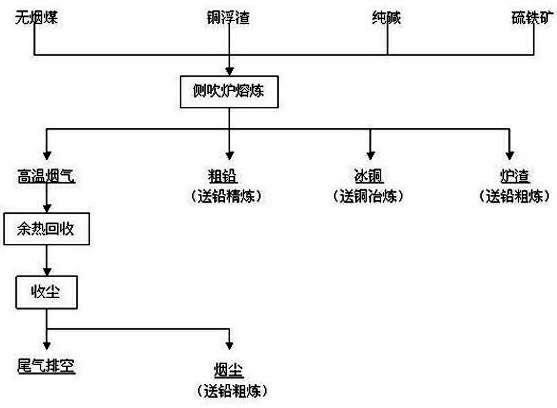

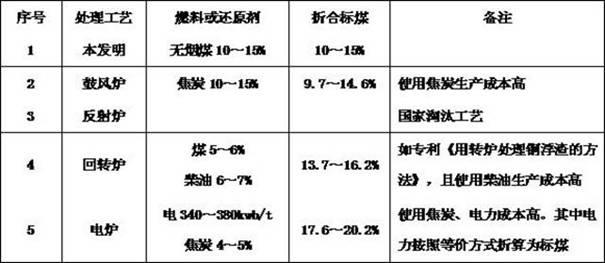

Method for producing lead bullion by means of copper dross side-blown smelting

The invention belongs to the technical field of metallurgy, and relates to a method for producing lead bullion by means of copper dross side-blown smelting. The method comprises the following steps of: 1) burdening copper dross, sodium carbonate and pyrite according to the proportion of 100:(8-10):(6-8), evenly feeding for 1-2 hours, wherein the feeding temperature is 600-800 DEG C, and evenly blowing anthracite by high-pressure wind; 2) smelting for 1-2 hours at the temperature of 600-800 DEG C after feeding, rising the temperature to 1100-1200 DEG C and smelting for 2-3 hours, and smelting the metallic lead and the chemical combination-state lead in the copper dross into the lead bullion; and 3) stopping blowing the anthracite, separating for 0.5-1 hour in a cleaning way, discharging the lead bullion and the copper matte in a siphon way, opening a slag hole to discharge the slag, and carrying out waste heat recovery and dust collection on the high-temperature smoke to be discharged to the air after the high-temperature smoke reaches the standard. The method takes the anthracite as the fuel or the reducing agent, and the other methods use the coke, the diesel oil or the electric energy, so that the method is more economical and suitable for large-scale production.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

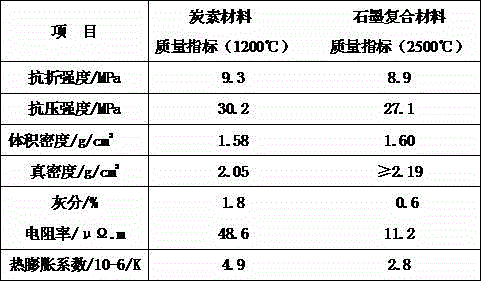

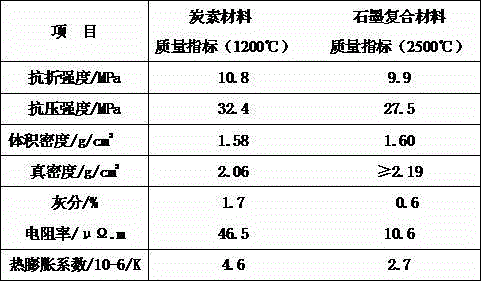

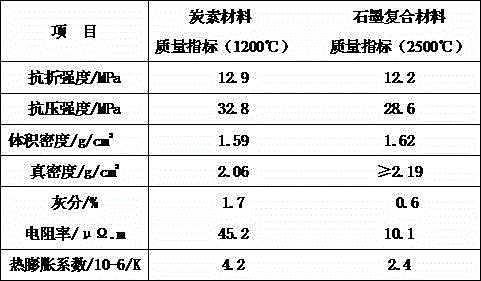

Preparation method of carbon-graphite composite material

The invention relates to a preparation method of a carbon-graphite composite material. The preparation method is characterized in that the carbon-graphite composite material is prepared from the following raw materials in percentage by weight: 1.5-2.5% of carbon black, 5%-8% of graphite with the particle size smaller than or equal to 1mm, 25%-30% of calcined petroleum coke powder with the particle size smaller than or equal to 0.075mm, 15%-20% of calcined petroleum coke with the particle size of 1mm-4mm, 10%-15% of electric calcined anthracite with the particle size of 4mm-10mm, 5%-10% of electric calcined anthracite with the particle size of 10mm-16mm, 5%-15% of calcined pitch coke with the particle size of 10mm-16mm, 18%-20% of coal pitch and short carbon fiber, wherein short carbon fiber is equal to 1%-3% of total weight of the raw materials. The carbon-graphite composite material is prepared by the steps of material preparation, mixed kneading, forming, roasting and graphitization and is excellent in performance, high in breaking strength, relatively good in thermal shock resistance and relatively low in expansion factor; the carbon-graphite composite material does not crack and break and has good stability.

Owner:SHANXI LIANGYU CARBON CO LTD

Method and device for producing crude antimony trioxide by smelting of rich oxygen side-blown volatile molten pool

The invention discloses a method and a device for producing crude antimony trioxide by smelting of a rich oxygen side-blown volatile molten pool. The method comprises the following steps: by taking an antimonial material as a raw material, blind coal or coke or a natural gas or a coal gas and the like as supplement fuel, and iron ore and lime as fluxes, blowing oxygen-enriched air, entering a furnace to react after metering a charging material, so as to produce high-temperature smoke and melt; condensing and dedusting the high-temperature smoke, and then feeding the smoke to an acid making system to prepare an acid, wherein the condensed powder is a crude antimony trioxide product to feed to the next procedure to process; respectively discharging the high-temperature melt after settling and layering in a hearth; quenching the slag to be directly used as a waste slag, and returning a little of produced antimony matte and crude antimony; and feeding noble antimony to the next procedure to process and extract gold. The invention also comprises a device for producing crude antimony trioxide by smelting of a rich oxygen side-blown volatile molten pool. The device has the advantages of being strong in raw material adaptability, low in energy consumption, high in smoke SO2 concentration, high in direct recovery rate and recovery rate of antimony and noble metal, clean and environment-friendly to produce, low in production cost and the like, and the acid can be directly prepared.

Owner:锡矿山闪星锑业有限责任公司 +3

Method for preparing high-specific surface area calcium hydroxide for dry desulphurization

InactiveCN101774620AAdjustable specific surface areaHigh porosityCalcium/strontium/barium oxides/hydroxidesCalcium hydroxidePolyol

The invention relates to a method for preparing high-specific surface area calcium hydroxide for dry desulphurization, which comprises the following steps of: (1) carrying out calcination on lime stone and anthracite to generate calcium oxide; (2) passing through a vibrating screen, breaking by a breaking machine, entering a digesting device and enabling water to act with the calcium oxide in a spraying state; (3) leading calcium hydroxide to pass through the vibrating screen and leading the obtained calcium hydroxide to enter a finished product storing bin; (4) sampling and measuring the specific surface area of a calcium hydroxide finished product on a nitrogen absorbing specific surface area instrument, wherein the digesting water adopted in the step (2) contains smaller than 2.0 percent of organic amine or / and polyalcohol / inorganic sodium salt. The specific surface area of the calcium hydroxide prepared by the method is adjustable, the calcium hydroxide with the specific surface area of 15-30m2 / g is prepared, and the calcium hydroxide with different specific surface area is provided according to the composition of smoke to reach the use requirement of desulphurization; and meanwhile, the production cost is also reduced.

Owner:CHANGSHU DAZHONG CALCIFIC OBJECTS

Active carbon used for adsorbing and removing sulfides in gasoline, and preparation method thereof

ActiveCN102188954AHighly selective adsorptionLow ashOther chemical processesHydrocarbon oils refiningHydration reactionAdhesive

The invention relates to active carbon used for absorbing and removing sulfides in gasoline, and a preparation method thereof. The active carbon is composed of the following components in percentage by weight: 40-70% of petroleum coke, 10-50% of coal, 10-30% of adhesive, 0.1-10% of pore forming agent and 0.1-10% of amodifier, wherein the ash content of the petroleum coke is less than 1%; the coalis anthracite or bituminous coal with volatile content less than 35%; the adhesive is one of or the mixture of coal pitch, coal tar, vacuum residue, coked condensed oil, ethylene cracked residue, catalytic slurry, petroleum pitch and petroleum pitch oxide; the pore forming agent is one of or the mixture of carbon black containing active functional groups and active elements, furfural residue, ferrocene, furfuryl alcohol and potassium; and the modifier is a hydrate nitrate of Cr, Fe, Co, Ni, Mo, Ti, Cu or Zn. The active carbon has the characteristics of low ash content, high strength, high selectivity, excellent adsorption performance and the like.

Owner:PETROCHINA CO LTD

Regeneration treatment method for waste cathode carbon blocks of aluminum electrolytic cell

The invention discloses a regeneration treatment method for waste cathode carbon blocks of an aluminum electrolytic cell and belongs to the technical field of solid waste treatment in the aluminum electrolysis industry. The main treatment process comprises the steps of crushing, screening, toxicity inhibition, batching and pressure-controlled heat treatment. After waste cathode carbon block materials of the aluminum electrolytic cell are crushed and screened, toxic inhibitors of hydrogen peroxide, potassium permanganate, hypochlorite and the like are added, then carbonaceous materials of anthracite, calcined petroleum coke, waste anode carbon blocks, anode scraps and the like are blended to serve as furnace-in raw materials, and the furnace-in raw materials are placed in a resistance furnace to be subjected to heat treatment at the ordinary pressure (1200-1800 DEG C) or the control pressure (1000-1600 DEG C and 0.01-0.5 atm). Fluoride volatilized from flue gas can be used for producingfluoride salt electrolytes after being cooled and crystallized, treated materials do not contain any contaminant, the carbon content is up to 99%, the conductivity is good, the specific surface areais large, the treated materials can be used for producing various carbon products, waste is turned into wealth, and environment-friendly resource application of overhaul of the waste cathode carbon blocks of the aluminum electrolytic cell is achieved.

Owner:UNIV OF SCI & TECH BEIJING

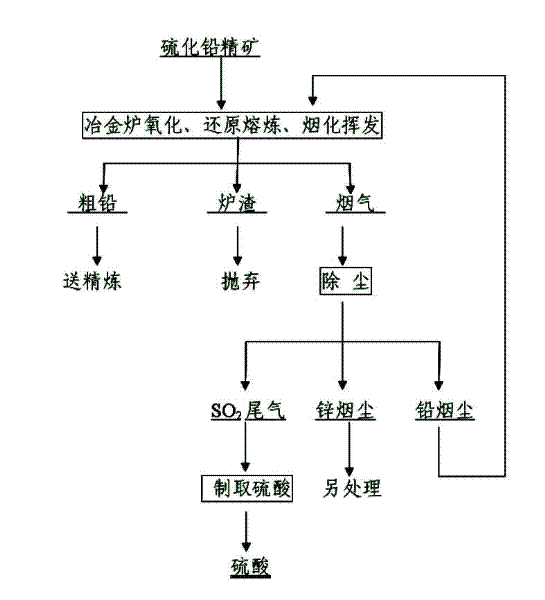

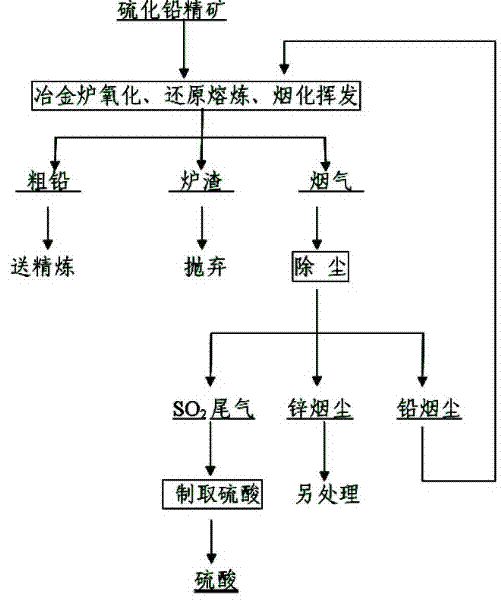

One-step oxidation smelting, reduction smelting and slag fuming and volatilization methods for lead sulfide concentrate

The invention relates to non-ferrous metal metallurgy technology, in particular to the pyrometallurgy technology of lead sulfide concentrate. The process method is to successively carry out three smelting processes of oxidation smelting, reduction smelting and fuming volatilization in the same metallurgical furnace to smelt lead sulfide concentrate, and smelt crude lead, zinc fume and discardable slag in one step. In the oxidation smelting stage, after the feed reaches the set amount, the lead oxide slag is not released, and the high-temperature liquid slag is directly used in the furnace to transfer to the reduction stage of the lead oxide slag, and the smoke generated by oxidation smelting and reduction smelting is returned to the furnace for smelting. After the reduction is completed, all the crude lead is released, and the high-temperature liquid slag remains in the furnace, and it enters the slag fuming stage, and the zinc fume dust from the slag fuming is recovered and enters the next smelting cycle. The heat of the slag in the invention is fully utilized, and the energy-saving effect is obvious. The raw material preparation of the method is simple, the reducing agent only needs ordinary anthracite, and part of the fuel that needs to be supplemented in the reducing section and the fuming section is pulverized coal, which is low in value and easy to obtain.

Owner:YUNNAN TIN GROUP HLDG

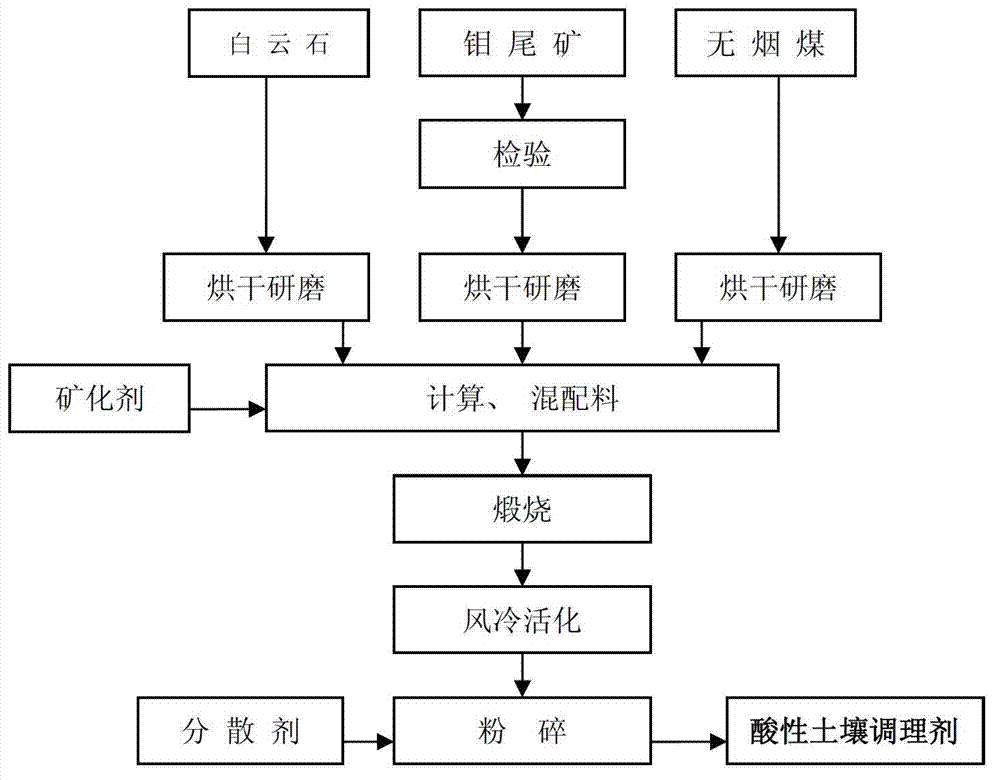

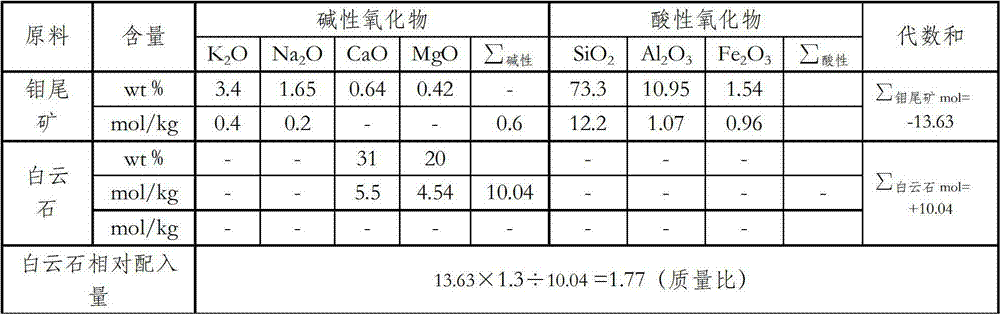

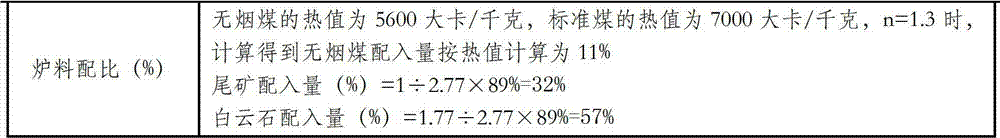

Method for producing multiplex siliceous fertilizer from molybdenum mine tailings

InactiveCN101050140ASolve the problem of polluted groundwaterAchieve reuseCement productionFertilizer mixturesDolomiteQuenching

This invention discloses a method for producing multi-element silicon fertilizer from molybdenum tailing and dolomite or high-magnesium limestone. The method comprises: calculating the equivalents of acidic oxides and alkaline oxides in molybdenum tailing, dolomite or high-magnesium limestone, and anthracite or white coal, calculating the coal amount for greater than or equal to 1200 deg.C kiln temperature, calculating the amounts of molybdenum tailing and dolomite or high-magnesium limestone at an acidic oxides / alkaline oxides weight ratio of 1:2, mixing with coal, adding calcination additive containing 0.2-1% alkali metal ions, grinding to higher than 80 mesh fine powder, adding into a shaft kiln, calcining at 1200-1350 deg.C to obtain silicon fertilizer clinker, or adding into a pelletizer, adding water, palletizing, calcining at 1200 deg.C or higher to obtain silicon fertilizer clinker, quenching and pulverizing to obtain multi-element silicon fertilizer.

Owner:锦州沈宏集团股份有限公司

Method for charging iron ore sintering fuel

The invention discloses a method for charging iron ore sintering fuel which includes steps as follows: mixing sintering-waited material with a first adding fuel into a mixer for mixing; mixing the once mixed material with a second adding fuel into a second mixer for mixing; adding the twice mixed material into a sintering machine, wherein, the second adding fuel position locates on a random position after once mixing and before twice mixing, the fuel is a mixture of once coke powder and second coke powder, or once smokeless coal and twice coke powder. The method is suitable for all kinds iron ore sintering containing vanadium titano-magnetite.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

Method for preparing active semicoking H2S desulphurizer

InactiveCN1621498AWide variety of sourcesLow pricePhysical/chemical process catalystsOther chemical processesSorbentCoking plant

The present invention discloses the preparation process of active semi-coke H2S desulfurizer. The active semi-coke H2S desulfurizer is prepared with lignite semi-coke, anthracite or soft coal semi-coke and other carbon containing material and through first pressurized hydrothermal chemical modification, subsequent soaking with cuprammonia, CuSO4 solution or K2CO3 solution, drying and high temperature calcining. The present invention has the features of wide material source, low cost, repeated use of the adsorbent product, final use in waste water treatment and as fuel and no secondary pollution. The present invention may be used widely in purifying gas in various plants and environment protecting industry.

Owner:OCEAN UNIV OF CHINA

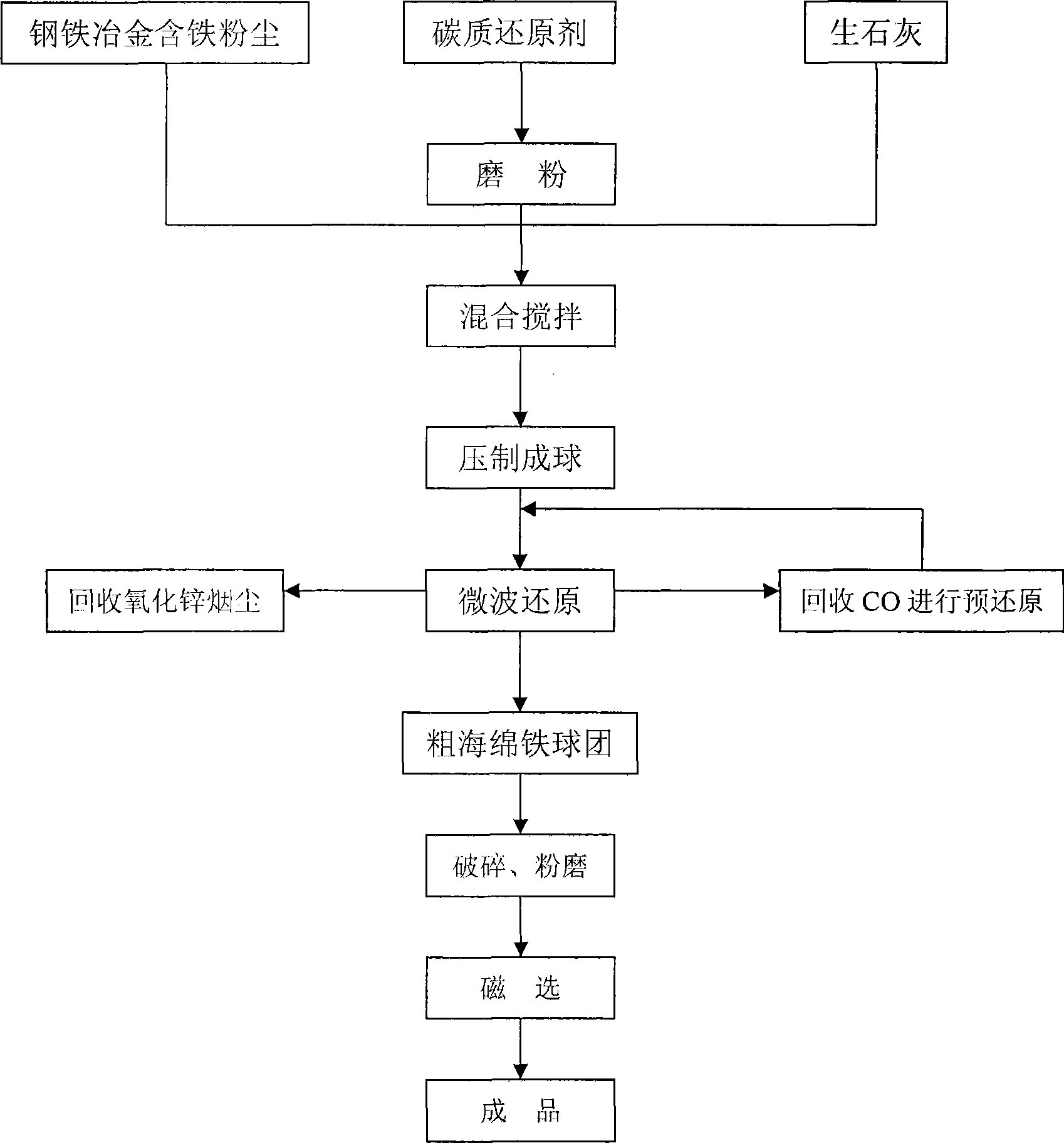

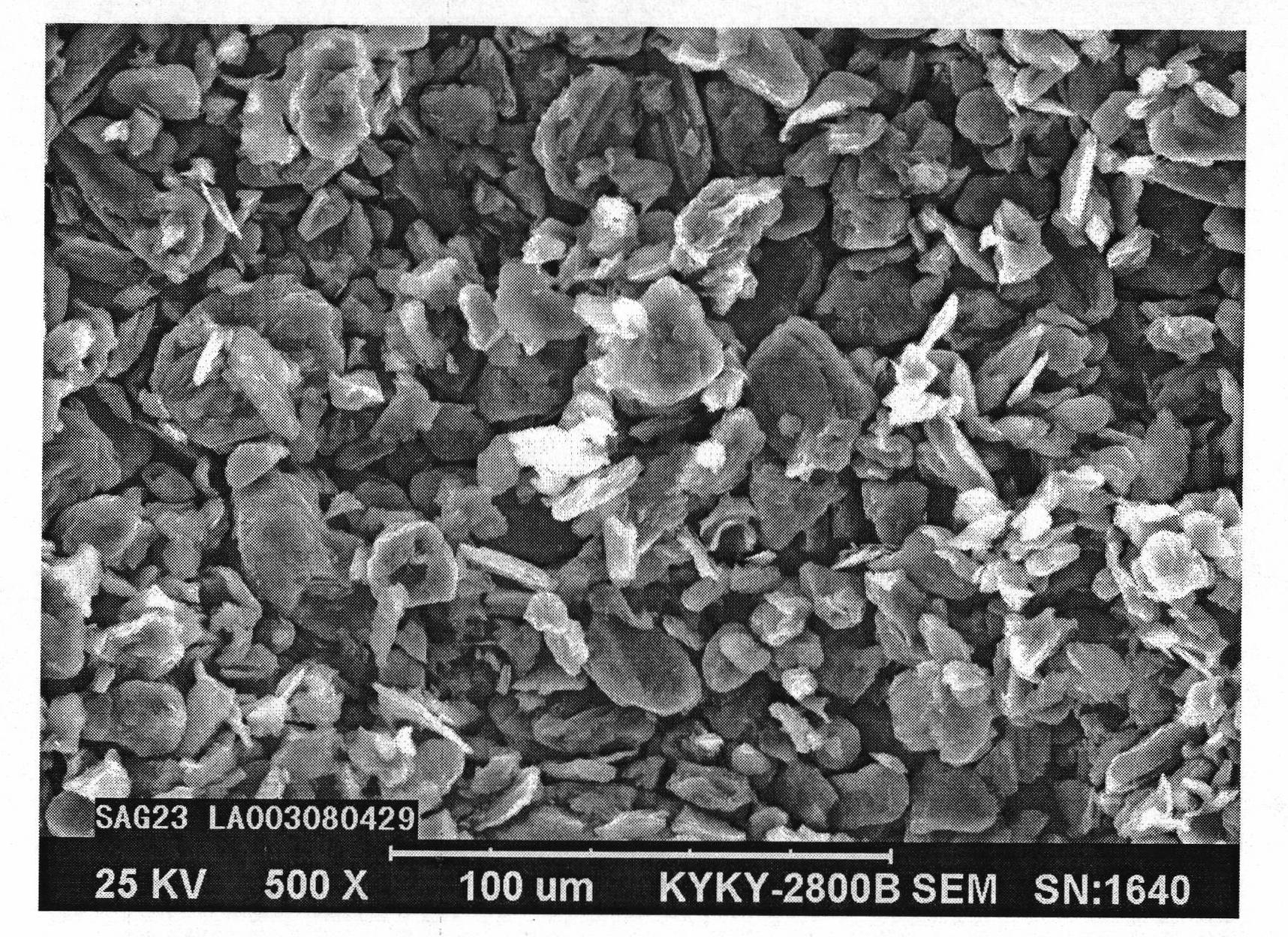

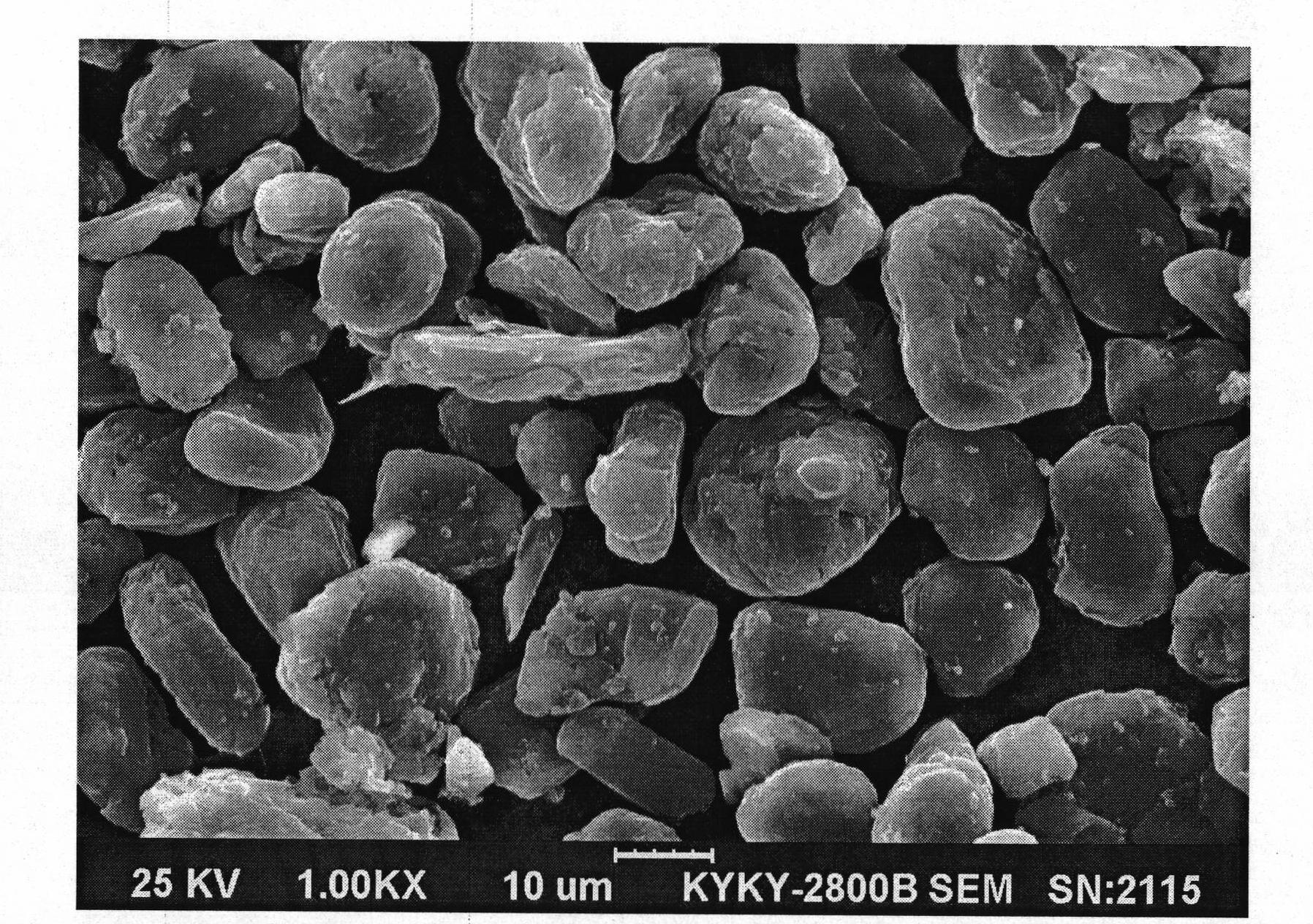

Process for directly producing sponge iron by microwave carbothermal reduction steel metallurgical iron-bearing dust

InactiveCN101457269AReduce consumptionHeating up fastFluidised-bed furnacesChemical reactionMicrowave

The invention discloses a process for directly producing sponge iron by microwave carbothermal reduction of ferrous metallurgical iron-containing dust. Anthracite coal is added to the ferrous metallurgical iron-containing dust, the weight of the ferrous metallurgical iron-containing dust accounts for 20-80% of the total weight, that of the anthracite coal accounts for 10-60%, and 1-20% of calcium lime is added to be taken as an additive; an obtained mixture is pressed into a 2mm-100mm ball after mixing and drying treatment, the heating temperature is between 800 DEG C to 1300 DEG C by adopting a microwave heating mode, the mixture reacts in a microwave reducing furnace to obtain a semi-finished raw sponge ball; and the ball is crushed and ground into fine powder less than 80 meshes, and finally a sponge iron product consistent with the requirement is obtained by a magnetic separation process. The process has the advantages of having selective heating characteristic, being capable of directly heating fine materials, having rapid temperature rise, having even heating, reducing energy consumption, lowering chemical reaction activation energy, and being capable of causing atoms and molecules of the materials to generate high-speed rotation. The process does not produce any pollution, which is beneficial to the environmental protection.

Owner:重庆科健冶金材料有限公司

Low-cost carbon anode for aluminum electrolysis, and preparation method thereof

The invention relates to a low-cost carbon anode for aluminum electrolysis, and a preparation method thereof. Raw materials of the carbon anode comprise 80-85wt% of aggregate and 15-20wt% of a binder, the aggregate comprises 50-60wt% of carbonized rice husk having a granularity of 2-6mm and subjected to acid and alkali ash removal, 15-20wt% of anthracite having a granularity of 0-1mm, 12-16wt% of petroleum coke and 12-16wt% of artificial graphite having a granularity of 0-1mm, and the binder comprises 60-70wt% of a modified phenolic resin and 30-40wt% of modified asphalt. The preparation method comprises the following steps: preprocessing the aggregate, mixing with the binder, carrying out compression molding, roasting and cooling to prepare the carbon anode. The preparation method, which uses the carbonized rice husk and the anthracite to substitute the petroleum coke as a main aggregate, can mitigate Chinese petroleum import pressure and alleviate the petroleum scarcity crisis caused by the rapid industrial development to realize the effective utilization of byproducts of agricultural products and the reduction of the aluminum electrolysis cost.

Owner:HENAN UNIV OF SCI & TECH

Method for extracting iron from copper smelting waste residue

The invention relates to a method for extracting iron from copper smelting waste residue. The method comprises the following steps: pulverizing copper slag, a reductant which is a mixture comprising one or more of anthracite, graphite, petroleum coke and coke, calcium oxide or calcium carbonate into a certain granularity, fully mixing the materials, carrying out mineralogical reconstruction and carbothermal reduction under high temperature to convert fayalite in the residue into iron oxide and then reduce the iron oxide into iron, and recovering the iron by magnetic separation, wherein, nonmagnetic products can be taken as raw materials for burning cement.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing activated carbon with large specific surface area through rapid activation

The invention relates to a method for preparing activated carbon with a large specific surface area through rapid activation. The activated carbon with a large specific surface area is prepared through rapidly activating high-carbon raw materials, such as anthracite, petroleum coke and the like, by auxiliaries and alkali together. The method comprises the steps of uniformly mixing the high-carbon raw materials, the activating auxiliaries and KOH, so as to obtain an alkali-carbon mixture, and heating the alkali-carbon mixture under the protection of an inert atmosphere, so as to obtain an activation product; quickly cooling the activation product to room temperature under the protection of the inert atmosphere; washing the activation product with water, and drying, thereby preparing the activated carbon with a large specific surface area. According to the method, the activation temperature is low, the activation time is short, a relatively high yield of activated carbon with a large specific surface area is obtained under the condition of a lower alkali / carbon ratio, the utilization ratio of alkali, carbon and energy is increased, the production cost is reduced, and the pollution is reduced.

Owner:DALIAN UNIV

Biomass particle fuel

InactiveCN101955830AAvoid or reduce flowHigh calorific valueBiofuelsSolid fuelsEngineeringAnthracite

The invention discloses a biomass particle fuel. The biomass particle fuel comprises the following components in percentage by weight: 50 to 60 percent of plant straw, 2 to 5 percent of anthracite, 15 to 20 percent of coal slime, 2 to 5 percent of yellow mud, 2 to 5 percent of waste grease, 8 to 12 percent of food wastes, 8 to 12 percent of water and 10 to 15 percent of large animal manure. The fuel has the characteristics that: firstly, heat value is increased remarkably and unit heat value is up to 5,000 kilocalories; secondly, burning point is lowered greatly; thirdly, due to the addition of supporting materials such as the yellow mud and the like, air permeability is improved and heat utilization ratio is increased; fourthly, combustion time can be prolonged from 1.5 hours of a pure biomass fuel on average to over 3 hours; fifthly, a large number of food wastes are consumed, so that drainage oil and garbage pigs are reduced and prevented from being sold on the market; and sixthly, the pollution of the large animal manure on the environment is reduced.

Owner:王德明

Lithium ion battery cathode material and preparation method thereof

The invention relates to a lithium ion battery cathode material and a preparation method thereof, belonging to the field of preparation of lithium ion battery cathode materials. The invention is characterized in that the material has a graphite or carbon core shell structure, graphitized high-quality anthracite is used in a core material and amorphous carbon is used in a shell material. The graphitized high-quality anthracite is treated at a temperature of 2800 to 3100 DEG C, a graphitization degree is greater than 80%, the content of fixed carbon is greater than 99.9%, and the granularity of the anthracite is in a range of 5 mu m to 50 mu m; the amorphous carbon is prepared from a precursor which comprises asphalt, emulsified bitumen, phenolic resin, furfural resin, epoxy resin or resin materials. The lithium ion battery cathode material prepared in the invention is characterized in that initial efficiency is greater than 90%, initial discharge capacity is greater than 350 mAh / g and a capacity retention rate is greater than 90% after 200 cycles.

Owner:TSINGHUA UNIV

Anode material for lithium-ion battery prepared by anthracite and preparation method thereof

The invention discloses an anode material for a lithium-ion battery prepared by anthracite, the particle size distribution D10 is 6-10 mu m, D50 is 17-20 mu m and D90 is 28-50 mu m, the tap density is 0.8-1.6g / cm3, the carbon content is 93.0-99.99%, and the graphitization degree is 85-97%. The anode material for the lithium-ion battery prepared by the anthracite has the characteristics of high gram specific capacity, strong intermolecular bonding force, low thermal expansion coefficient, good high and low temperature resistance, long cycle life, high compacted density of pole pieces and the like.

Owner:LUOYANG YUEXING NEW ENERGY TECH

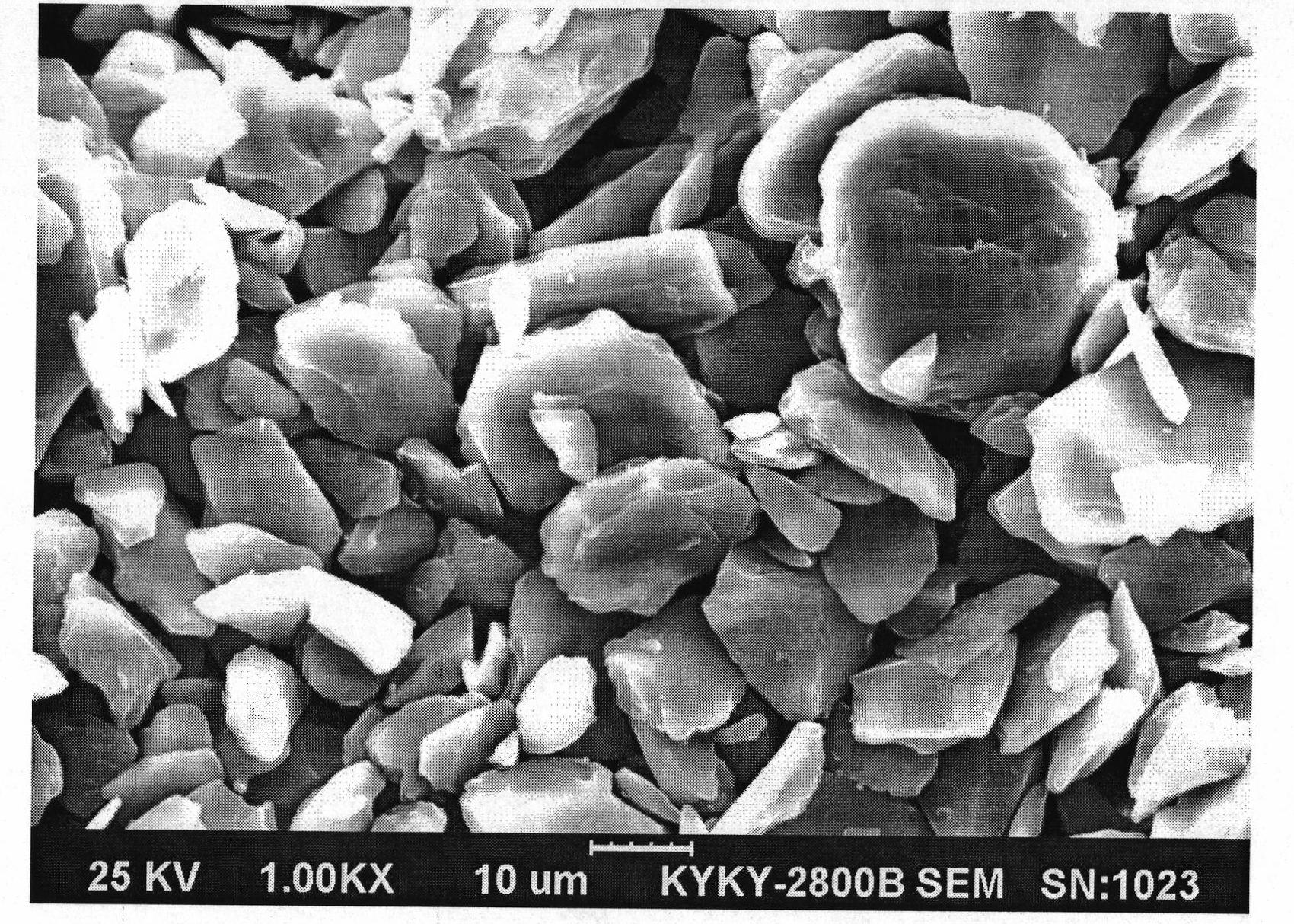

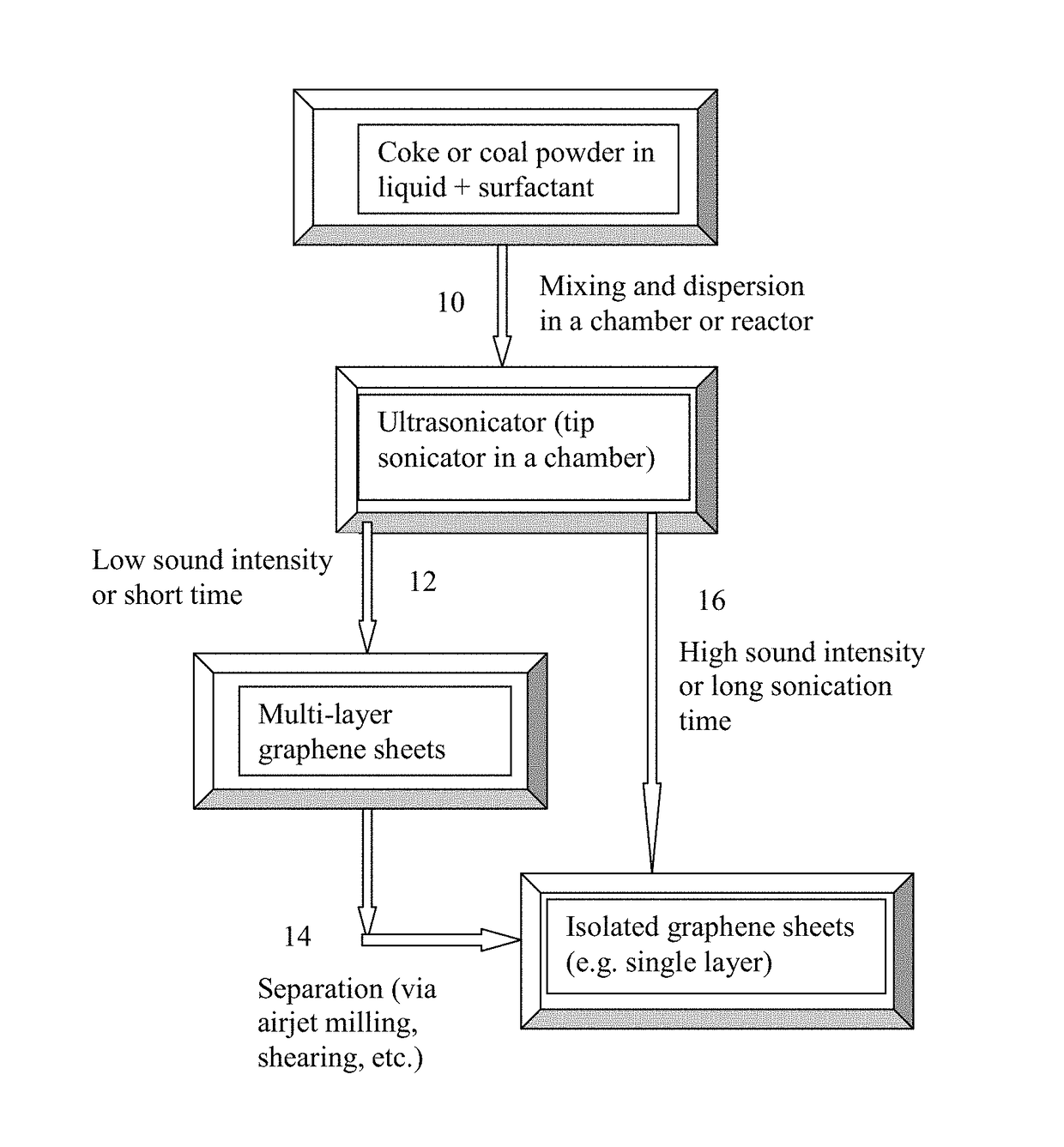

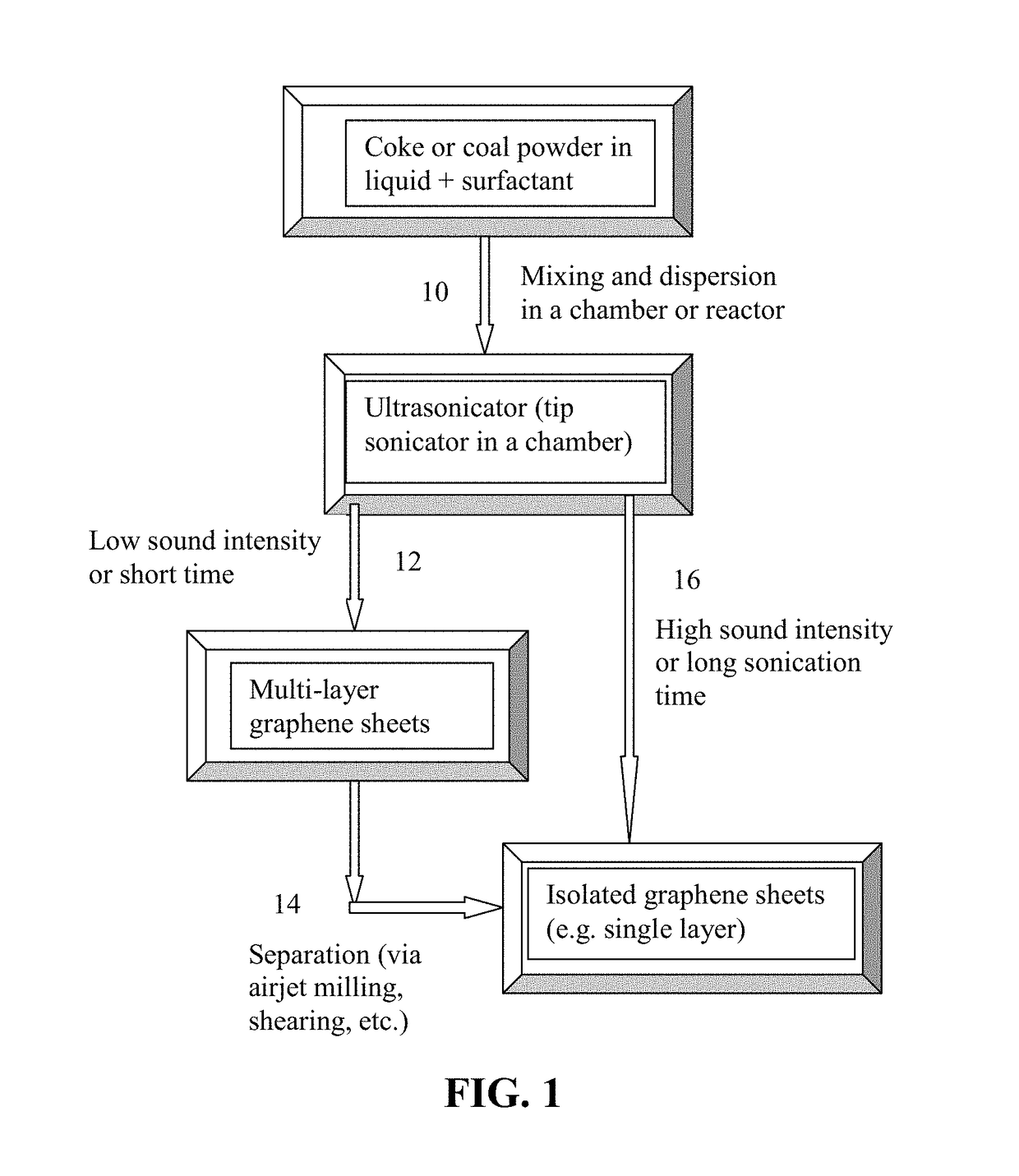

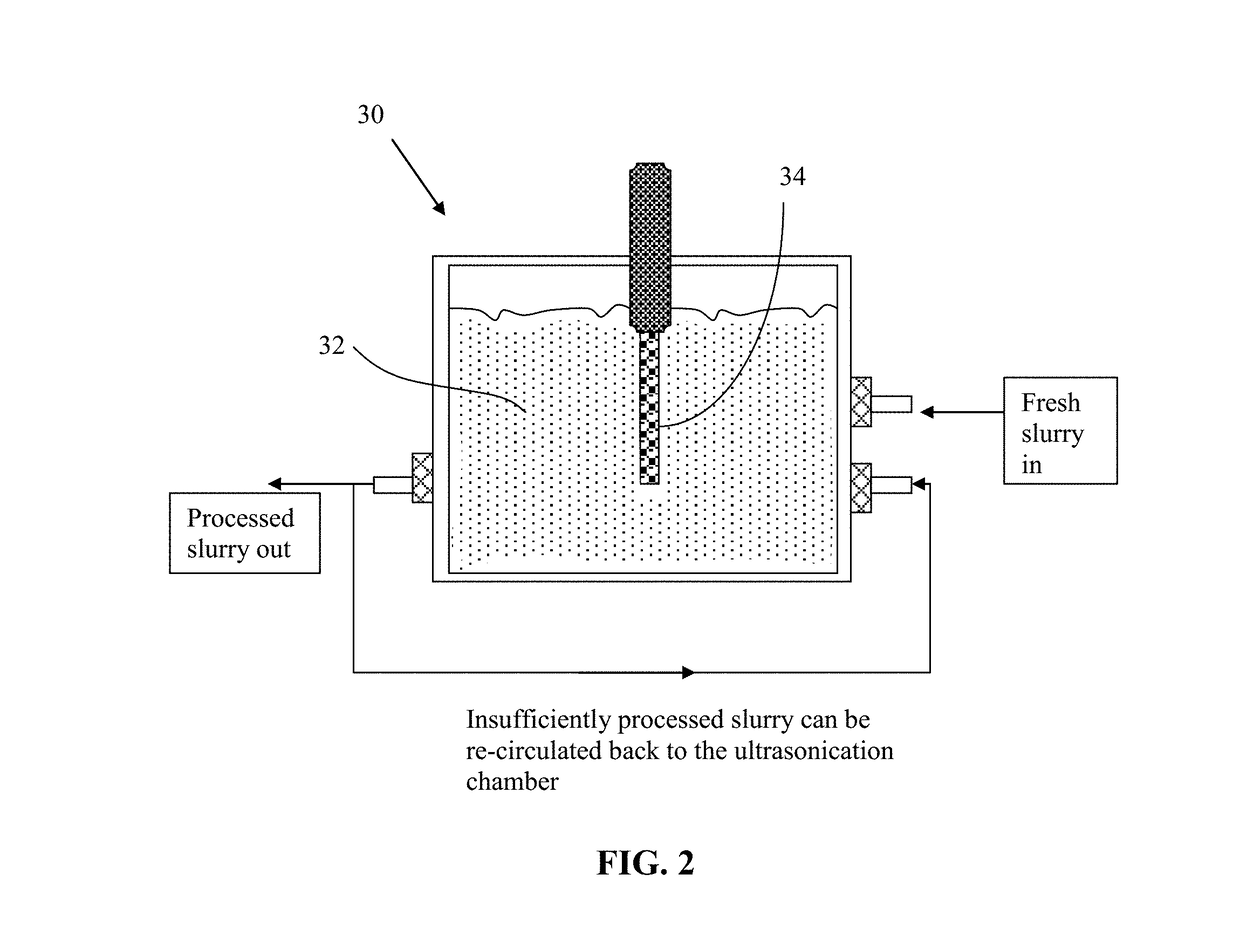

Direct Ultrasonication Production of Graphene Sheets from Coke or Coal

ActiveUS20170369320A1Prevent restackingGuaranteed normal transmissionGrapheneInksLiquid mediumAnthracite

Provided is a method of producing isolated graphene sheets from a supply of coke or coal powder containing therein domains of hexagonal carbon atoms and / or hexagonal carbon atomic interlayers. The method comprises: (a) dispersing particles of the coke or coal powder in a liquid medium containing therein an optional surfactant or dispersing agent to produce a suspension or slurry, wherein the coke or coal powder is selected from petroleum coke, coal-derived coke, meso-phase coke, synthetic coke, leonardite, anthracite, lignite coal, bituminous coal, or natural coal mineral powder, or a combination thereof; and (b) exposing the suspension or slurry to ultrasonication at an energy level for a sufficient length of time to produce the isolated graphene sheets.

Owner:GLOBAL GRAPHENE GRP INC

Molybdenum tailings acid soil conditioner and production process thereof

ActiveCN102826926AAchieve reductionEfficient improvementFertilizer mixturesAnthraciteSoil conditioner

The invention discloses a molybdenum tailings acid soil conditioner and a production process for the molybdenum tailings acid soil conditioner. The molybdenum tailings acid soil conditioner comprises clinkers and dispersing agents, the clinkers use molybdenum tailings, dolomites and anthracite to serve as raw materials, activated clinkers are obtained through inspection, grinding, material mixing, burning at the temperature of 1150-1350 DEG C and activating, and then the dispersing agents are added to be smashed to be the acid soil conditioner. The molybdenum tailings acid soil conditioner can efficiently, stably and enduringly improve acid soil, simultaneously provides microelement mineral nutrition for weak acid soil, and has advantages of low energy consumption, low cost and low price and the like, wherein the microelement mineral nutrition can be absorbed by crops in balance and are not easy to run off. The production process for the molybdenum tailings acid soil conditioner can sufficiently use valuable resources in molybdenum tailings, achieves decrement discharge of the tailings, lowers environment stress and reduces potential safety hazards.

Owner:广东万山环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com