Patents

Literature

37results about How to "Prevent restacking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

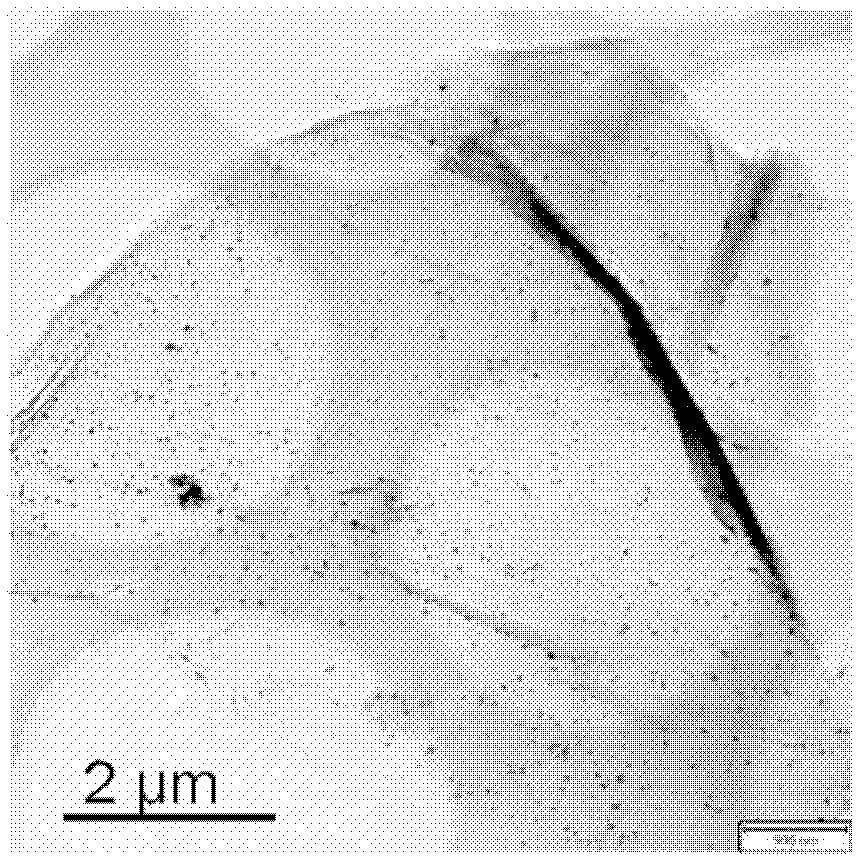

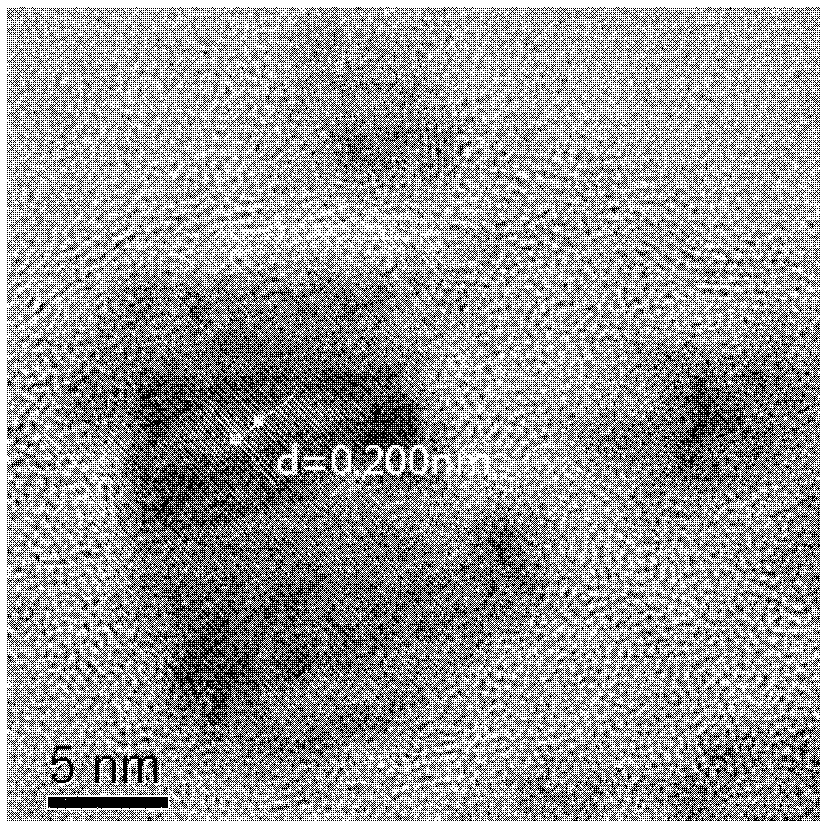

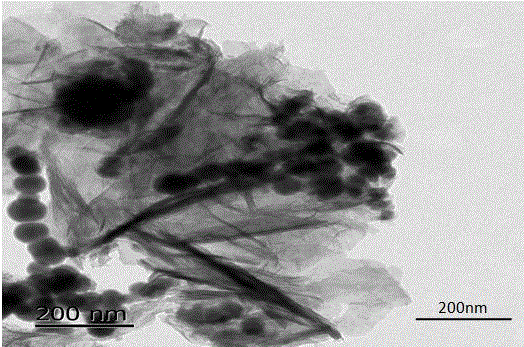

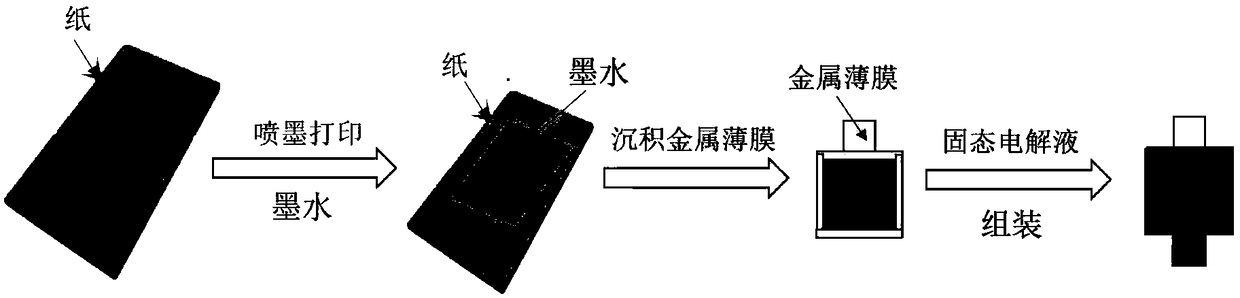

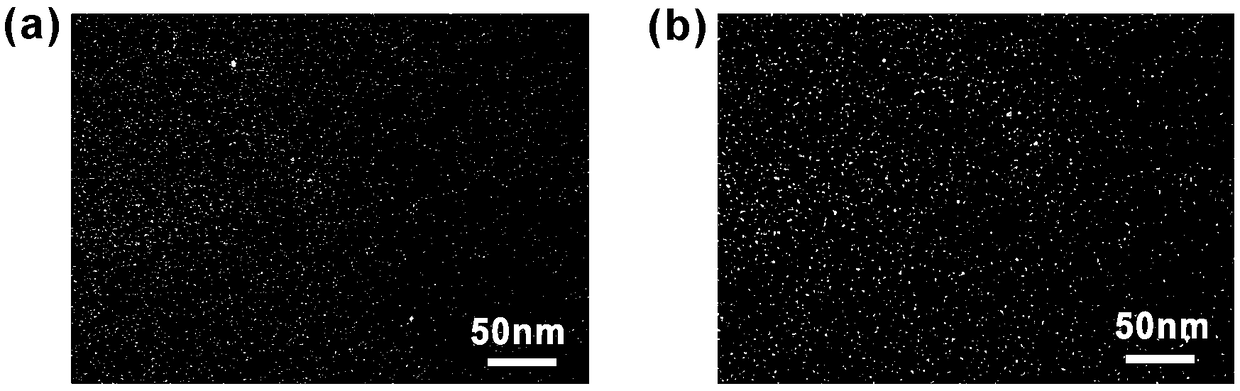

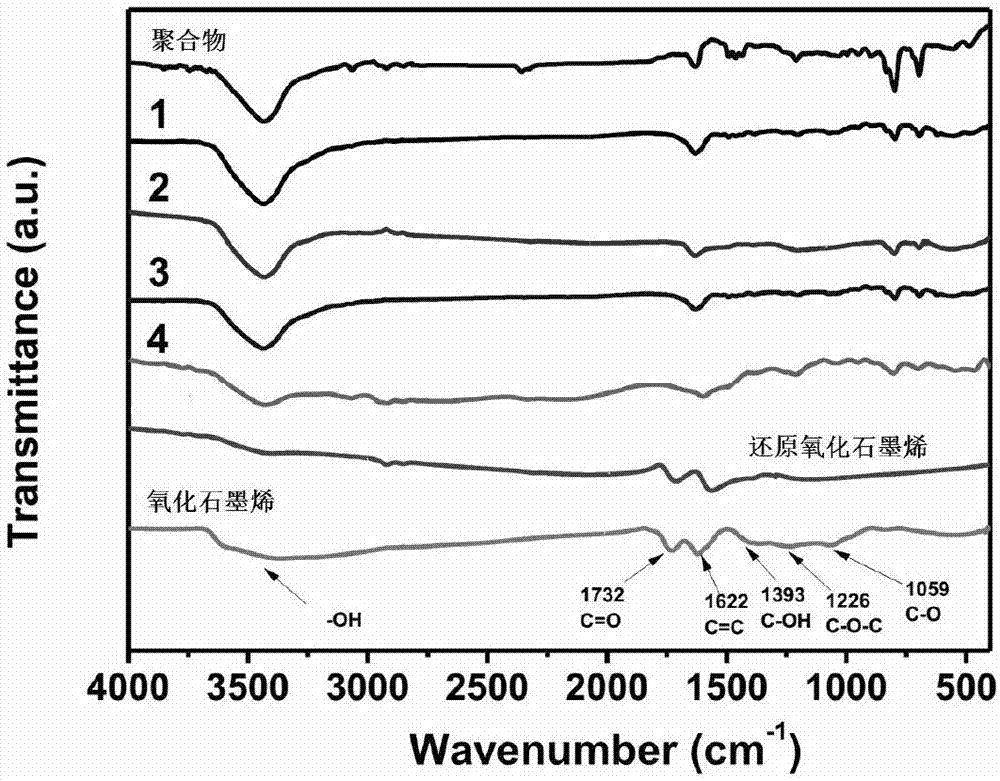

Surface nano-nickel particle modified graphene nano material and preparation method thereof

InactiveCN102583348AGood soft magneticPrevent restackingGrapheneInorganic material magnetismCvd grapheneChemical plating

The invention discloses a surface nano-nickel particle modified graphene nano material and a preparation method of the nano material, belonging to the field of nano material preparation technology. The preparation method can be used for preparing surface nano-nickel particle modified graphene by the steps of preparation of graphite oxide, preparation of graphene oxide and pretreatment. According to the invention, the surface nano-nickel particle modified graphene is prepared by a chemical plating method, so that the particle size and the crystal form of surface nano-nickel particles can be effectively controlled, and the graphene oxide part can be reduced when metal particles are deposited; and graphene sheet layers are prevented from being stacked again by the deposition of nickel particles on the surface of the graphene; and the graphene has excellent soft magnetism so as to be magnetized under the minimal additional magnetic field.

Owner:BEIHANG UNIV

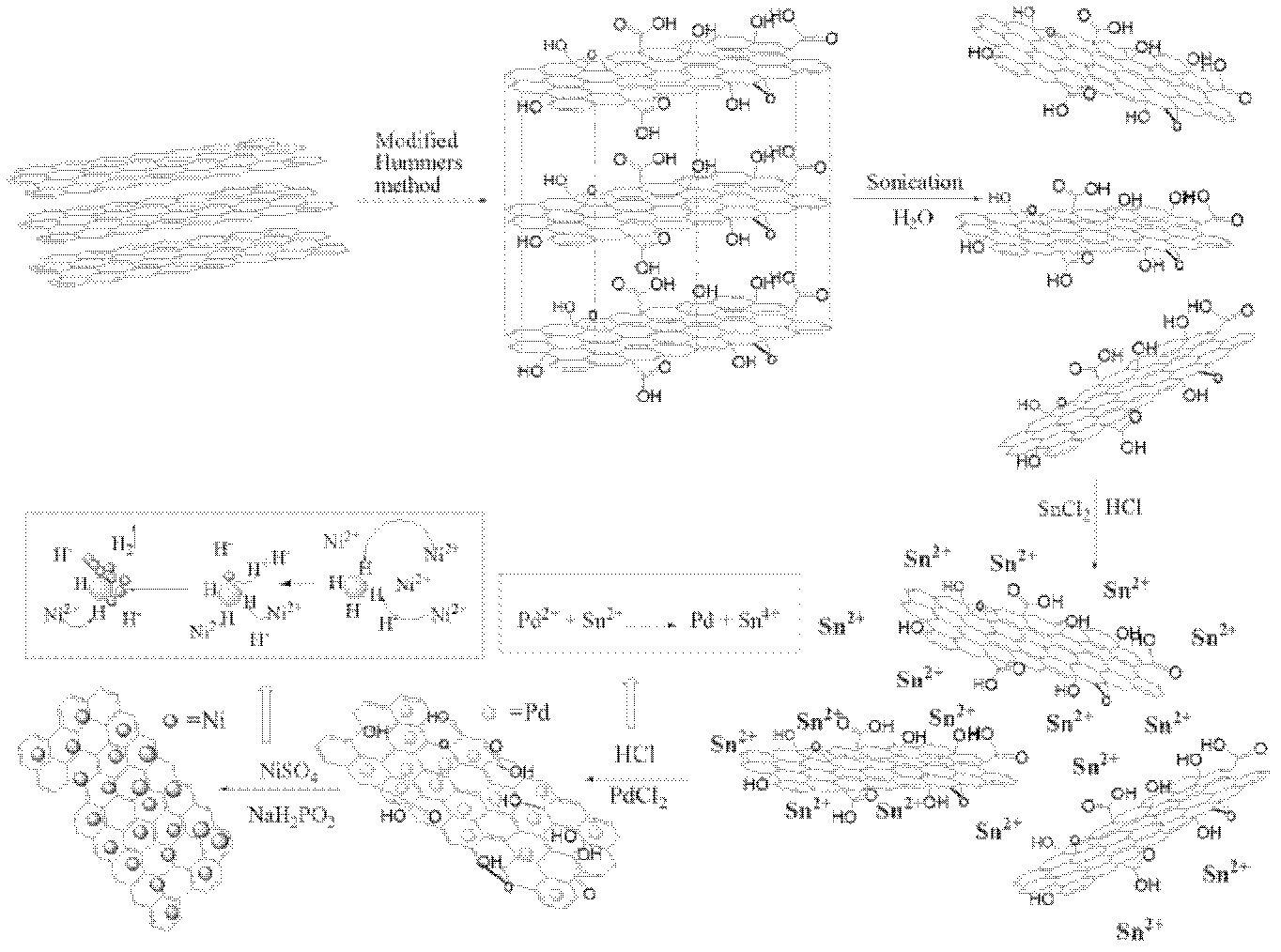

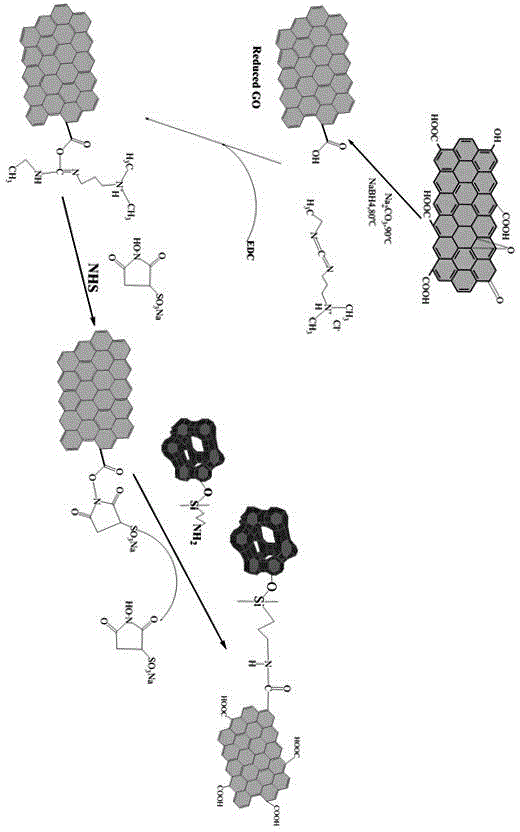

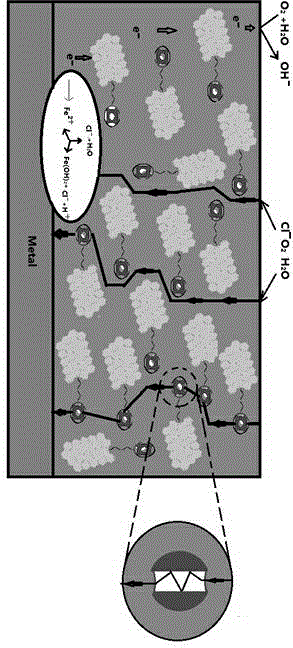

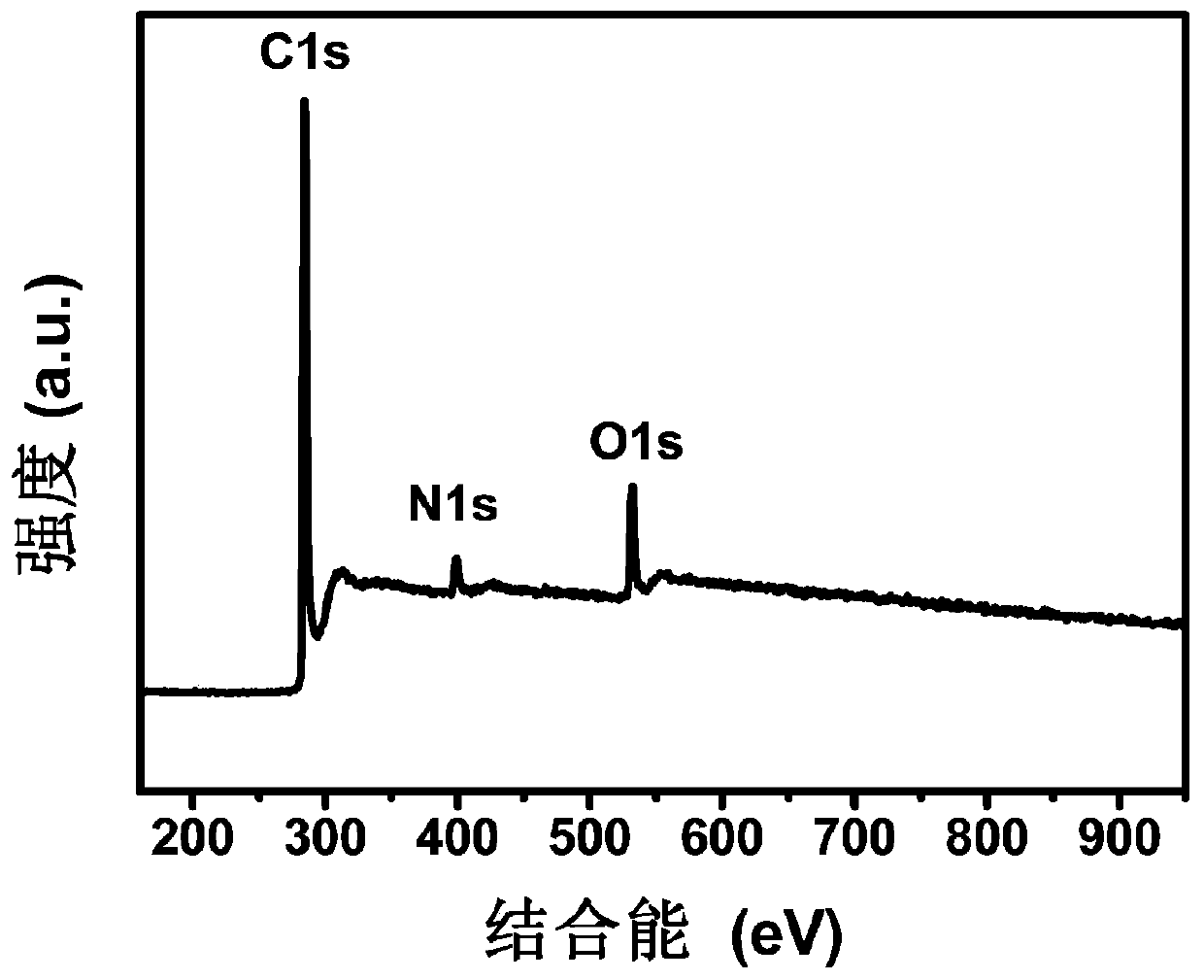

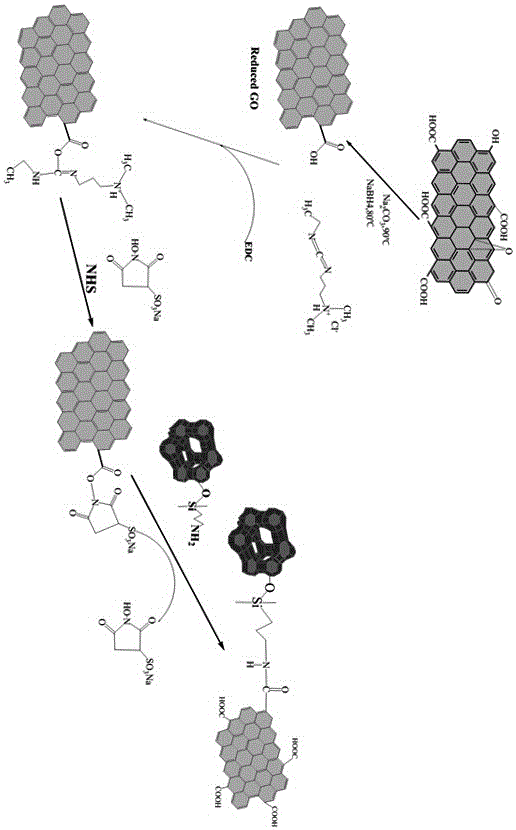

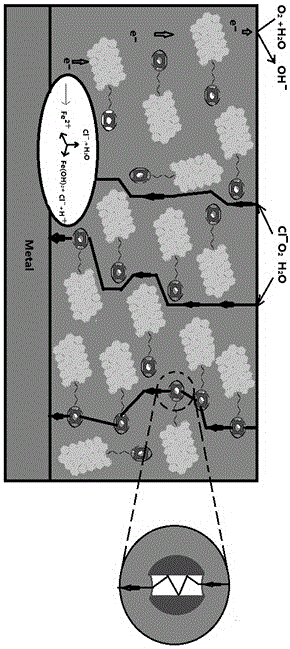

Preparation method of waterborne epoxy composite anticorrosive coating

InactiveCN104877517APrevent restackingAvoid gatheringAnti-corrosive paintsEpoxy resin coatingsEpoxyElectrochemical corrosion

The invention provides a preparation method of a waterborne epoxy composite anticorrosive coating and relates to a preparation method of a composite coating material. The waterborne epoxy composite anticorrosive coating provided by the invention is prepared by adopting carbodiimide (EDC) mediated condensation reaction to integrate zeolite and graphene, and then filling the integrated zeolite and graphene into waterborne epoxy resin. By adopting the method, the characteristics of more pore passages and large specific surface area of zeolite are combined with high strength and electron mobility of graphene; corrosive particles can be blocked from passing through a coating layer to reach a metal matrix and the time for the corrosive particles to pass through the coating layer to reach the metal matrix can be prolonged in the process of anticorrosive application of the coating; and the cathode reaction during corrosion can be transferred to an interface between the coating layer and air by virtue of the electrical conductivity of graphene, thereby slowing down the happening of electrochemical corrosion reaction. By adopting the method, the defects that the current waterborne anticorrosive coating layer is generally poor in barrier property and short in anticorrosion cycle are overcome, and the anticorrosion performance of the waterborne coating layer is greatly improved.

Owner:蓬莱禄源漆业有限公司

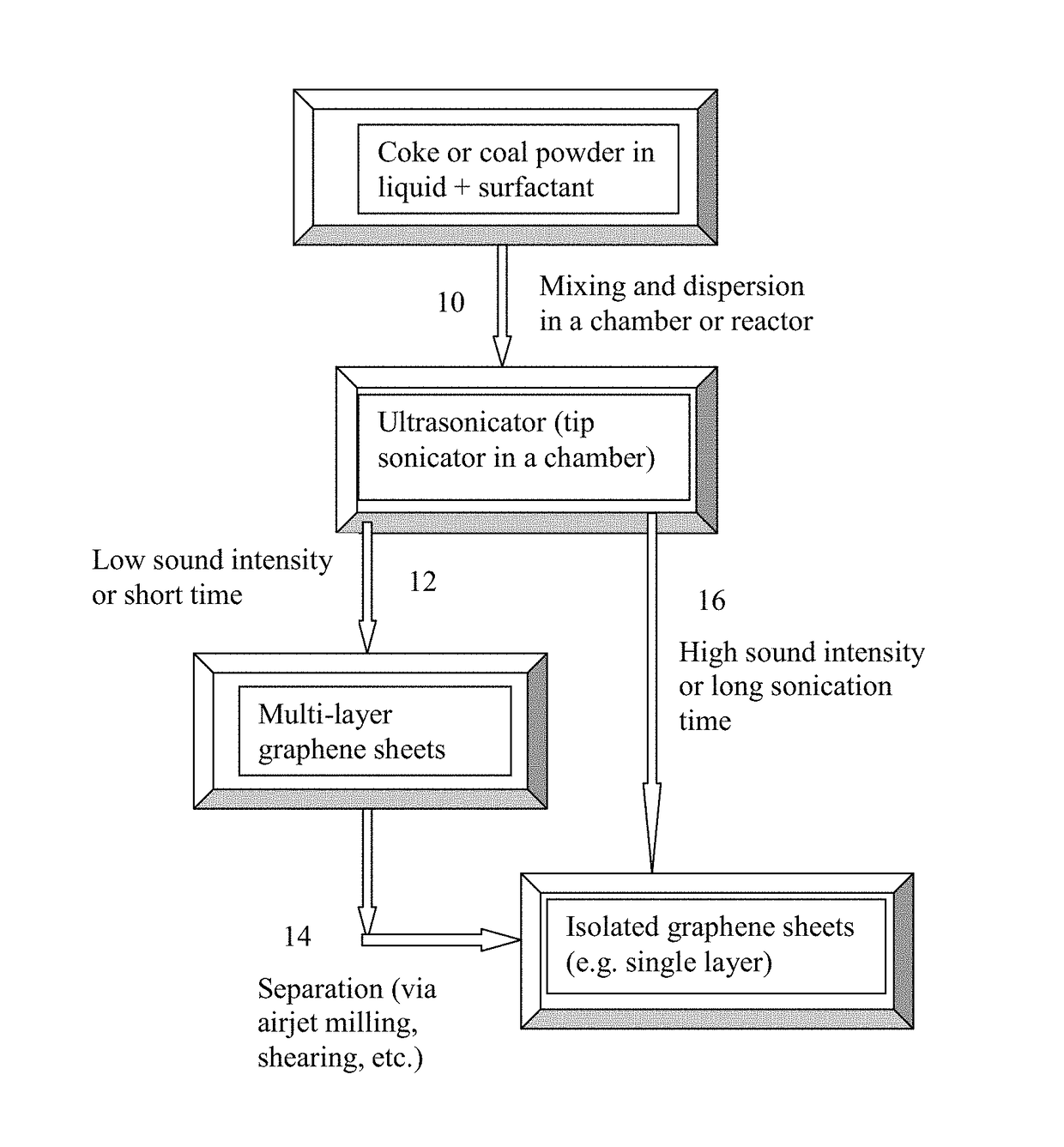

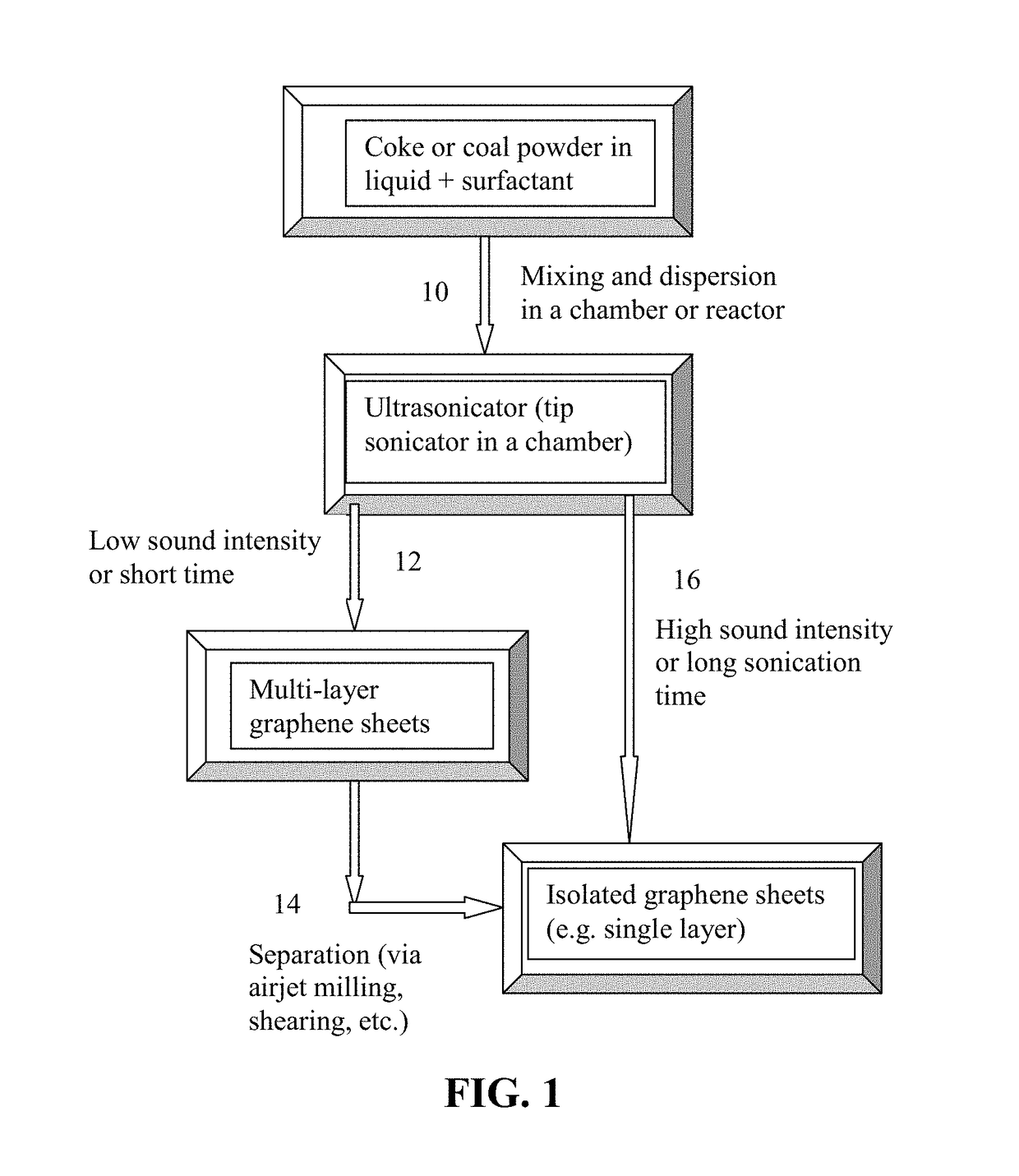

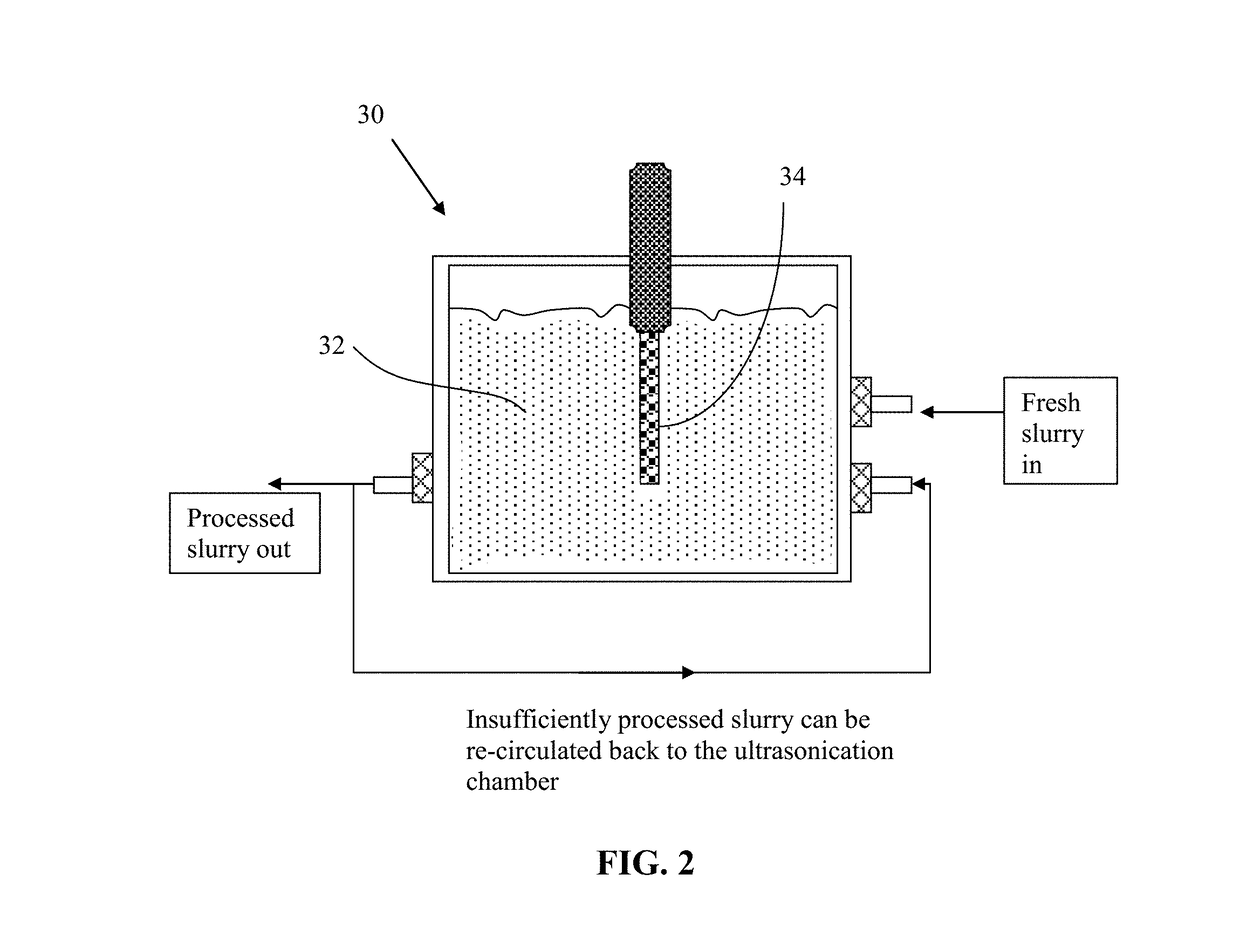

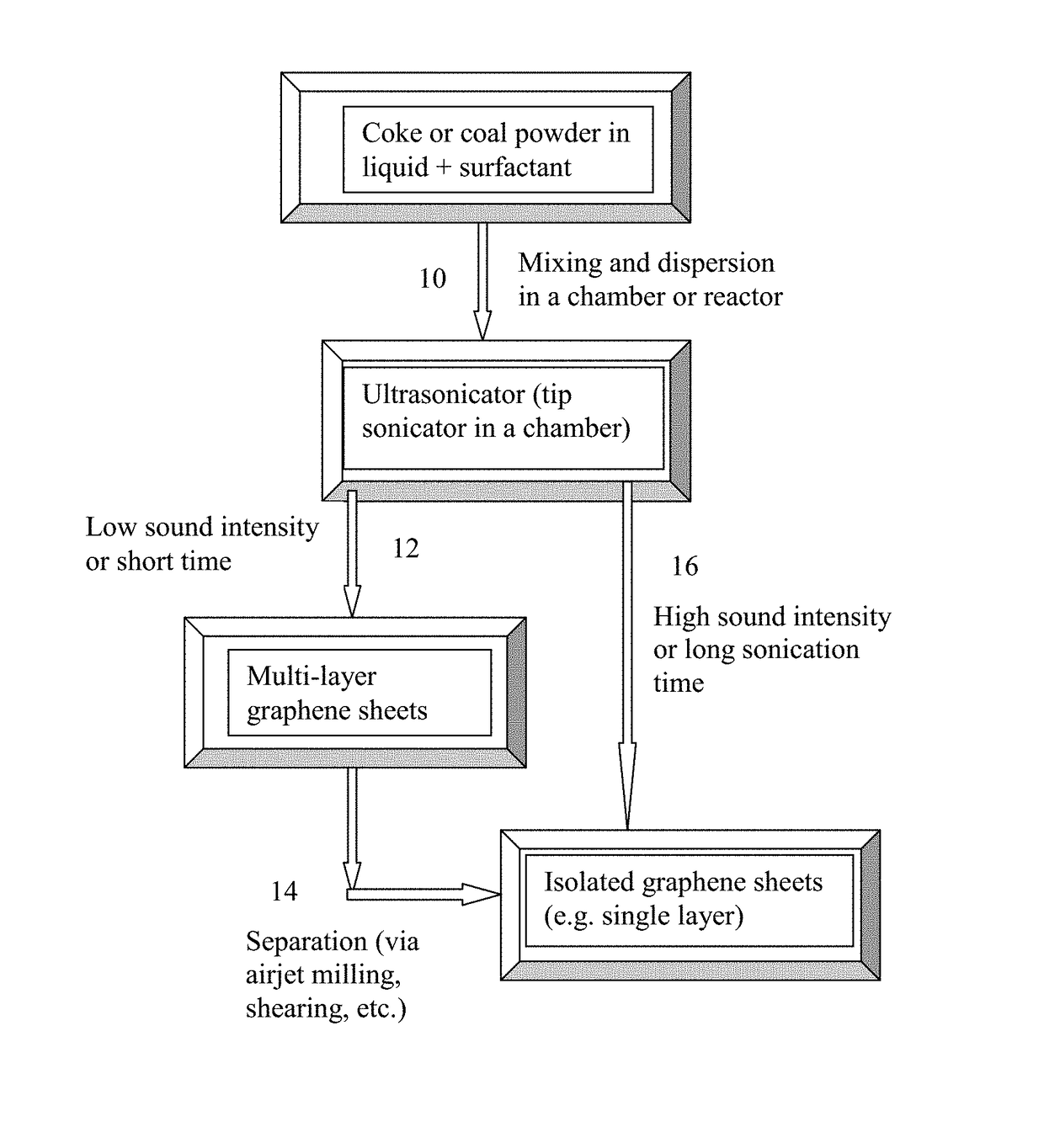

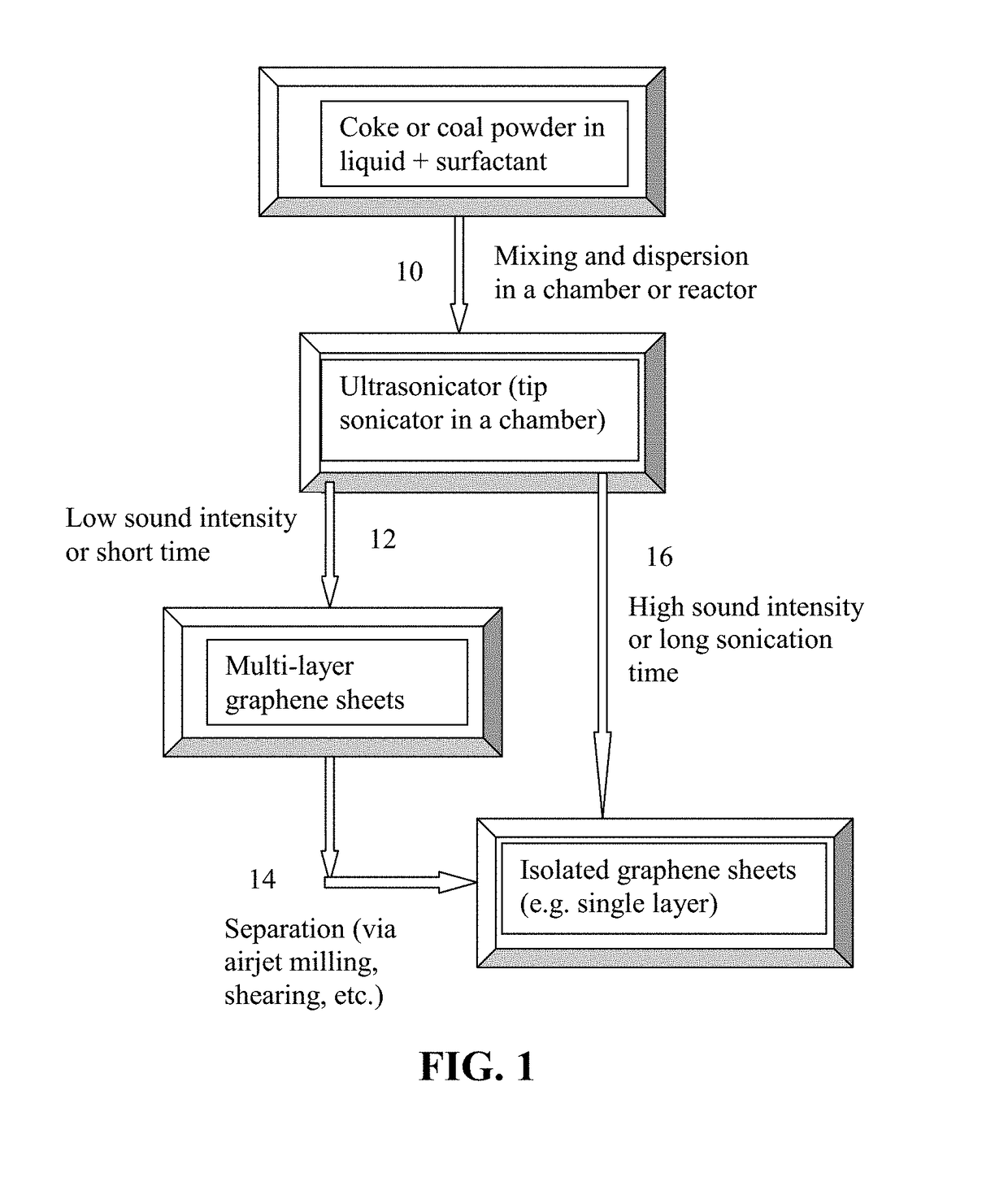

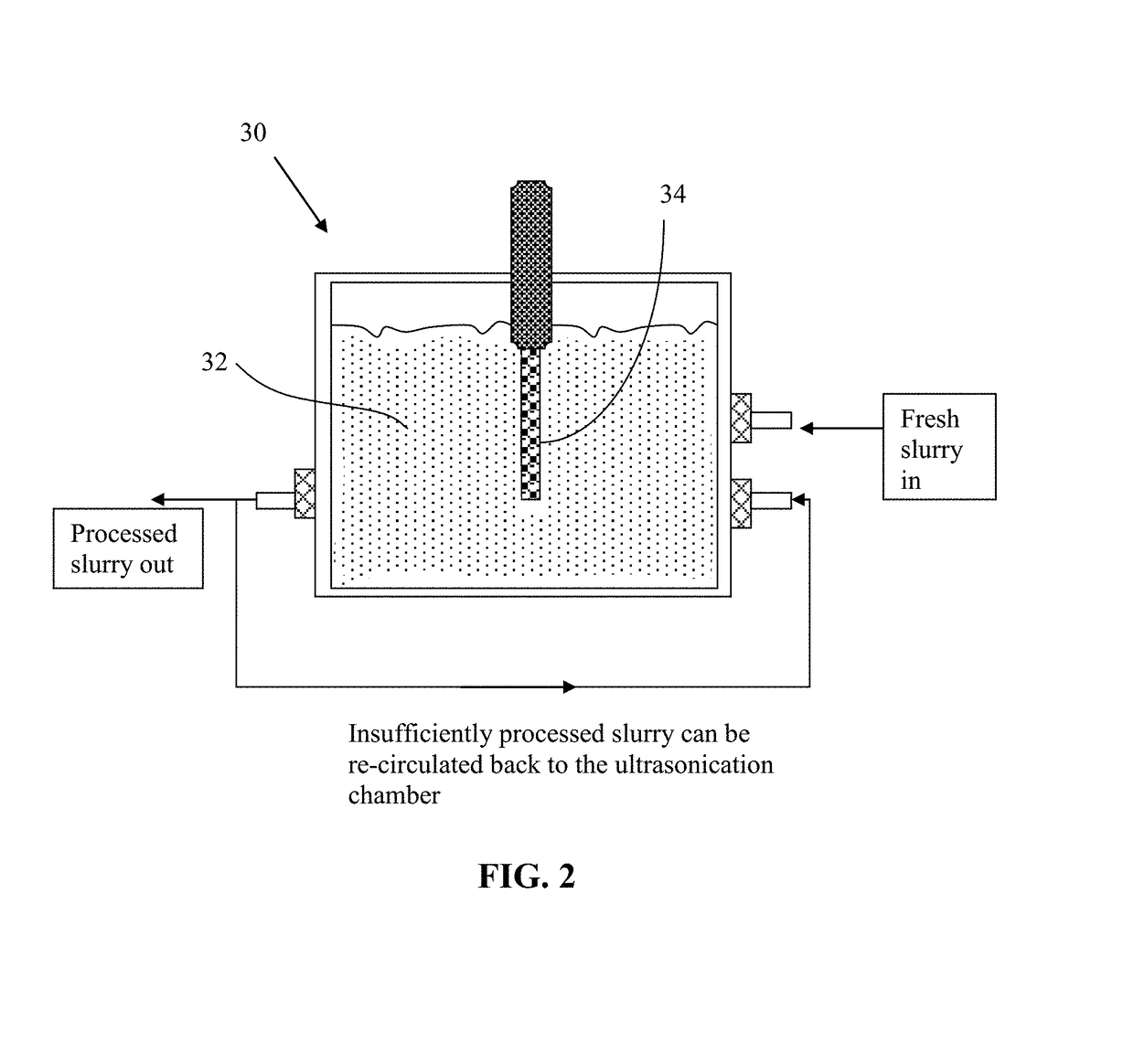

Direct Ultrasonication Production of Graphene Sheets from Coke or Coal

ActiveUS20170369320A1Prevent restackingGuaranteed normal transmissionGrapheneInksLiquid mediumAnthracite

Provided is a method of producing isolated graphene sheets from a supply of coke or coal powder containing therein domains of hexagonal carbon atoms and / or hexagonal carbon atomic interlayers. The method comprises: (a) dispersing particles of the coke or coal powder in a liquid medium containing therein an optional surfactant or dispersing agent to produce a suspension or slurry, wherein the coke or coal powder is selected from petroleum coke, coal-derived coke, meso-phase coke, synthetic coke, leonardite, anthracite, lignite coal, bituminous coal, or natural coal mineral powder, or a combination thereof; and (b) exposing the suspension or slurry to ultrasonication at an energy level for a sufficient length of time to produce the isolated graphene sheets.

Owner:GLOBAL GRAPHENE GRP INC

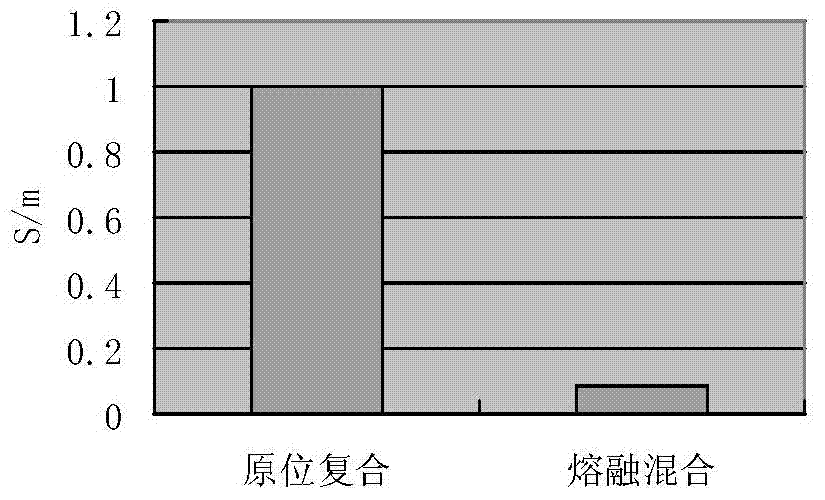

Method for supercritical fluid in-situ preparation of graphene/fluoropolymer composite material

ActiveCN104262516AEasy reunionPrevent restackingBulk chemical productionPolymer scienceHeat conducting

The invention relates to a method for supercritical fluid in-situ preparation of a graphene / fluoropolymer composite material. The method comprises the following steps: dissolving fluoropolymer monomers in a supercritical fluid, simultaneously performing intercalation on graphite by utilizing the supercritical fluid and the polymer monomers, and initiating polymerization reaction by taking the supercritical fluid as a polymerization medium to generate a fluoropolymer so as to promote significant enlargement of spacing intervals between graphite layers, finally and fast strip the graphite after intercalation in a supercritical pressure fast pressure relief process layer by layer and prepare a fluoropolymer conductive and heat-conducting composite material with good dispersion of graphene. Compared with the prior art, according to the graphene / fluoropolymer composite material prepared by the method provided by the invention, due to the wrapping of the fluoropolymer, the re-stacking of graphene layers is avoided, and the problem that graphene is very easy to agglomerate is solved; for the fluoropolymer, by adopting the method, graphene can be uniformly dispersed in a polymer material, and thus a functional novel conductive and heat-conducting composite material is obtained.

Owner:SHANGHAI JIAO TONG UNIV

Graphene/silicon dioxide/nano zero-valent iron composite as well as preparation method and application thereof

ActiveCN105457597ARich reservesLow priceOther chemical processesWater/sewage treatment by sorptionArsenic pollutionSilicic acid

The invention discloses a graphene / silicon dioxide / nano zero-valent iron composite as well as a preparation method and application thereof. The preparation method comprises the following steps: after the graphene oxide is subjected to ultrasonic dispersion, adding tetraethyl orthosilicate, drying after magnetic stirring is carried out completely, introducing nitrogen in a tubular furnace for calcination, adding deionized water into the solids obtained through calcination, after ultrasonic dispersion, introducing nitrogen and adding ferrous sulfate heptahydrate, after uniform stirring, and adding a reducing agent for reducing so as to obtain black flocculent precipitates after complete reaction, washing, carrying out suction filtration, drying, grinding and screening through a sieve so as to obtain the graphene / silicon dioxide / nano zero-valent iron composite. The graphene / silicon dioxide / nano zero-valent iron composite prepared according to the preparation method can be applied to the field of water pollution control as an adsorbent, particularly adsorption removal of arsenic pollutants in waste water, and has the advantages of simple and convenient preparation process, high adsorption speed and the like, and in addition, the required raw materials are wide in source, low in cost and high in practical application value.

Owner:SOUTH CHINA UNIV OF TECH

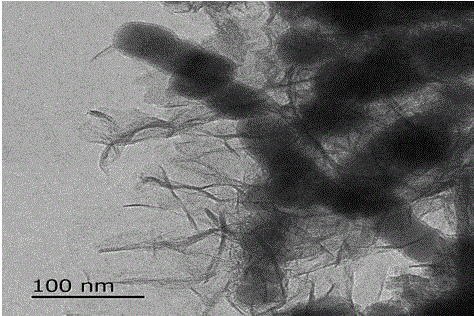

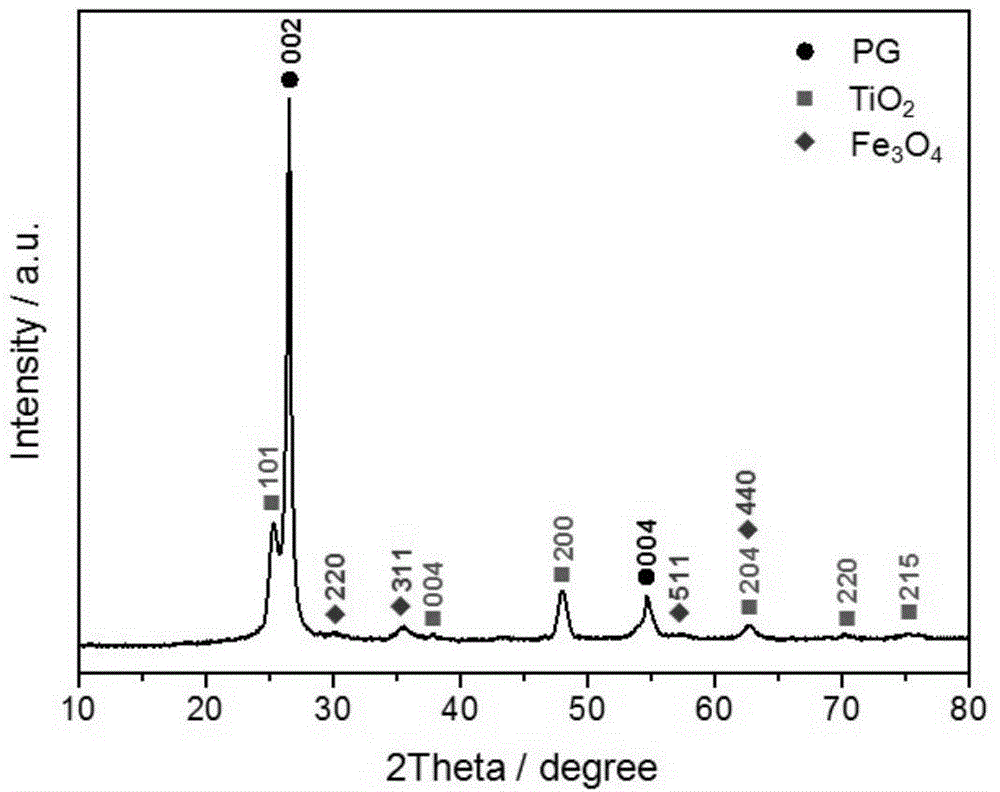

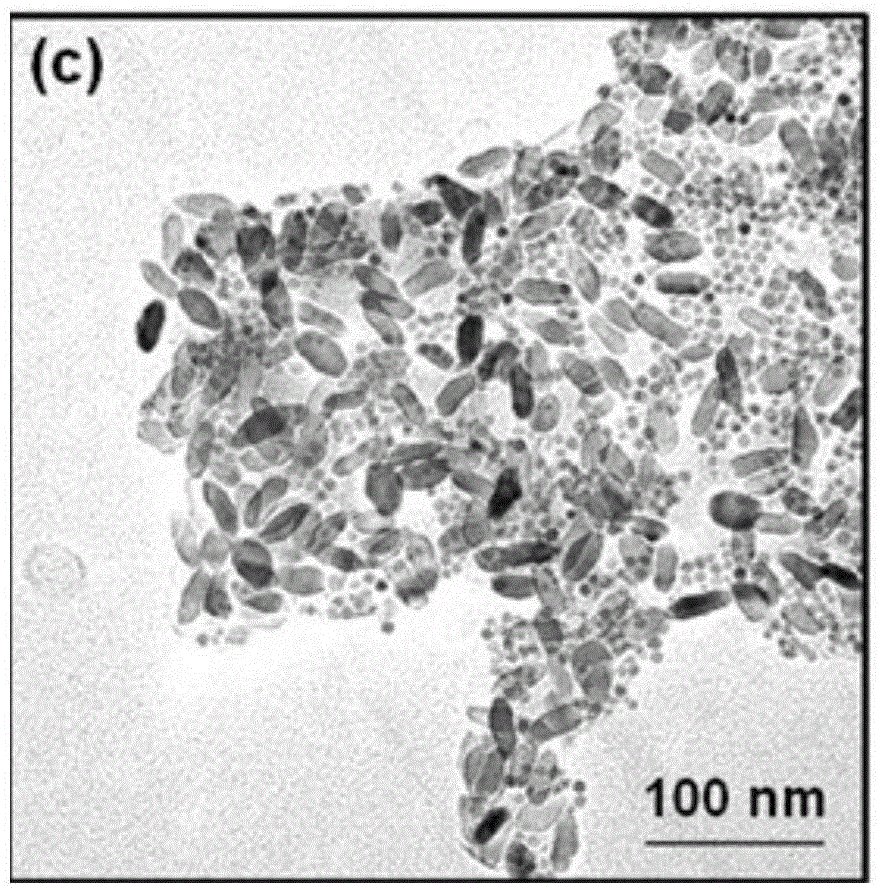

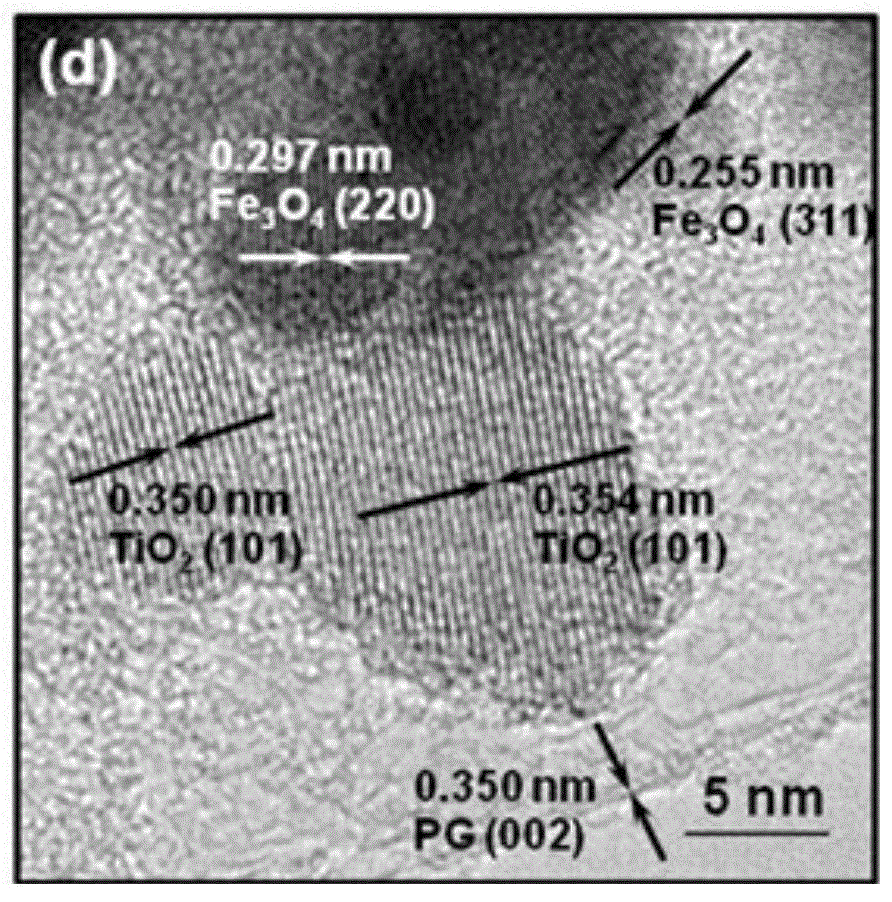

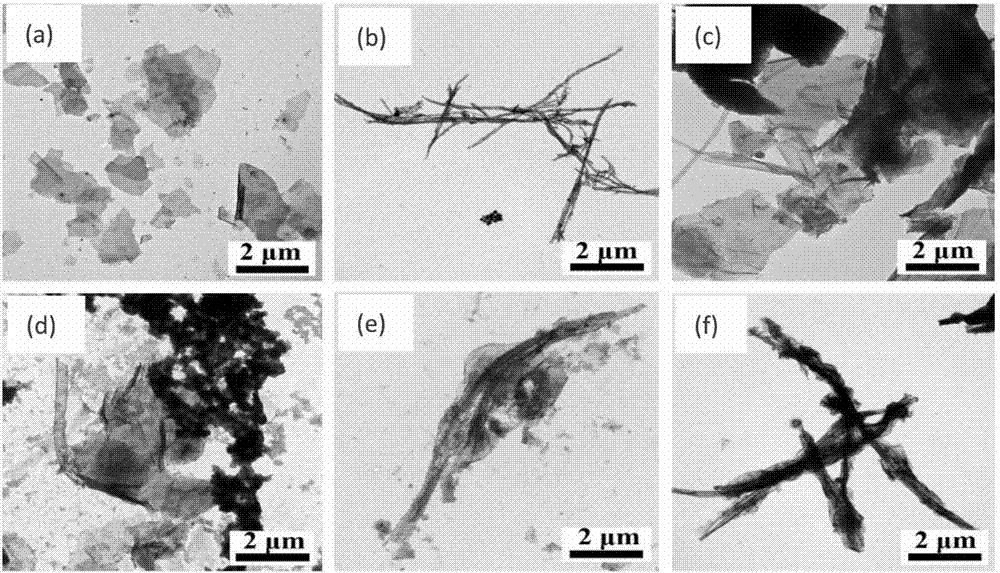

Ternary multilevel multi-dimensional structure composite material and preparation method thereof

ActiveCN104319377AImprove conductivityPromote circulationCell electrodesSecondary cellsNano structuringElectrochemistry

The invention discloses a ternary multilevel multi-dimensional structure composite material and a preparation method thereof. The excellent electrochemical comprehensive performance can be exerted by utilizing the remarkable synergistic effect and unique multilevel multi-dimensional structure. The composite material is formed by TiO2 of a low-dimensional nano structure and second-phase high-specific-capacity metal oxide as well as two-dimensional micrometer (x-y plane direction) high-conductivity plain graphene. Drive force for lowering the total surface free energy of the solution system is utilized to uniformly load and compactly combine TiO2 of the nano structure and high-specific-capacity metal oxide to an exposed surface of the plain graphene nanosheet by virtue of a tetrahydrofuran solution mixing method. The ternary multilevel multi-dimensional structure composite material effectively integrates the remarkable function of each ingredient, including excellent circulating property and outstanding safety of TiO2, high specific capacity of the second-phase metal oxide, and good conductivity of the plain graphene.

Owner:HARBIN INST OF TECH

Method for delaminating/exfoliating layered materials

InactiveUS20110057156A1Improve solubilityImprove mechanical propertiesTungsten halidesPhysical/chemical process catalystsMaterials science

The present invention relates to a method for producing delaminated / exfoliated non-ionic inorganic materials, to such materials and their use as additives.

Owner:DET SELVEJENDE INSTITUT CISMI FOND

Three-dimensional porous structure silicon/graphene composite negative electrode material and preparation method thereof

InactiveCN107317000AImproved magnification performanceImprove conductivityCell electrodesSecondary cellsArgon atmosphereFreeze-drying

The invention discloses a three-dimensional porous structure silicon / graphene composite negative electrode material and a preparation method thereof. The preparation method comprises the following steps: (1) uniformly dispersing nanometer silicon into a mixed solution of ethyl alcohol and water so as to obtain a solution A; (2) adding carboxymethylcellulose and an organic carbon source into the solution A, obtaining a solution B after uniform mixing, and adjusting pH value until the solution B is alkali; (3) mixing the alkali solution B and an oxidized graphene solution, and after ultrasonic dispersion, stirring uniformly to obtain a solution C; (4) after putting the solution C into liquid nitrogen for freezing, and then carrying out freeze drying treatment to obtain solid D; and (5) putting the solid D into an argon atmosphere, and carrying out warming, sintering and cooling to obtain the three-dimensional porous structure silicon / graphene composite negative electrode material. The volume effect of silicon in the charging and discharging process can be effectively accommodated, the electrical conductivity is good, and the material has excellent charging and discharging cycle performance and rate capability and high first columbic efficiency.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

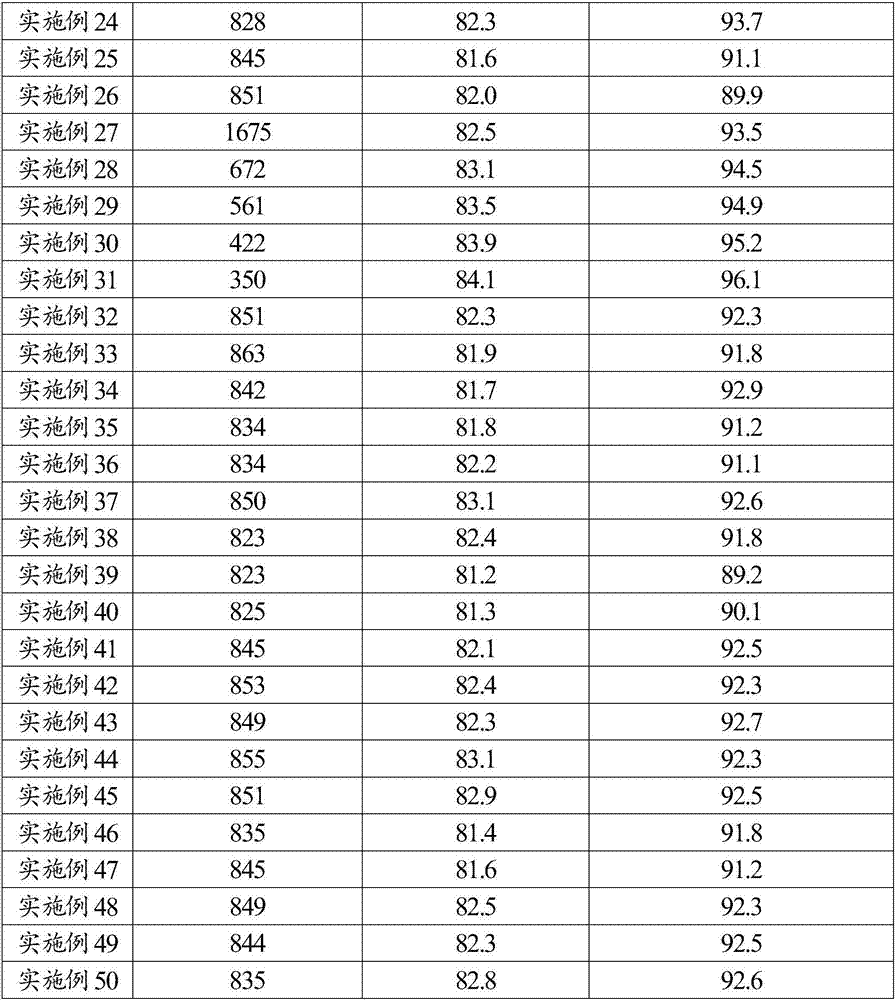

High-performance printable ink, preparation method thereof and application to flexible all-solid-state supercapacitor

InactiveCN108641482AEvenly dispersedSmooth ink flowHybrid capacitor electrodesElectrolytic capacitorsCapacitanceAll solid state

The invention provides high-performance printable ink. The high-performance printable ink is prepared from carbon quantum dots, graphene oxide, a surfactant and a solvent, wherein the carbon quantum dots and graphene oxide have a stronger synergistic effect and can effectively improve overall performance of the material. According to the mixed ink prepared by modifying graphene oxide with the carbon quantum dots, the carbon quantum dots as spacers between graphene oxide layers effectively prevent graphene oxide from stacking again, and meanwhile, the carbon quantum dots generally contain moreoxygen-containing functional groups and open edges and provide more reaction sites for pseudocapacitance, so that a carbon quantum dot / graphene oxide mixed electrode shows better electrochemical capacity and cyclic stability as compared with single carbon quantum dot electrode or single graphene oxide electrode.

Owner:UNIV OF SCI & TECH OF CHINA

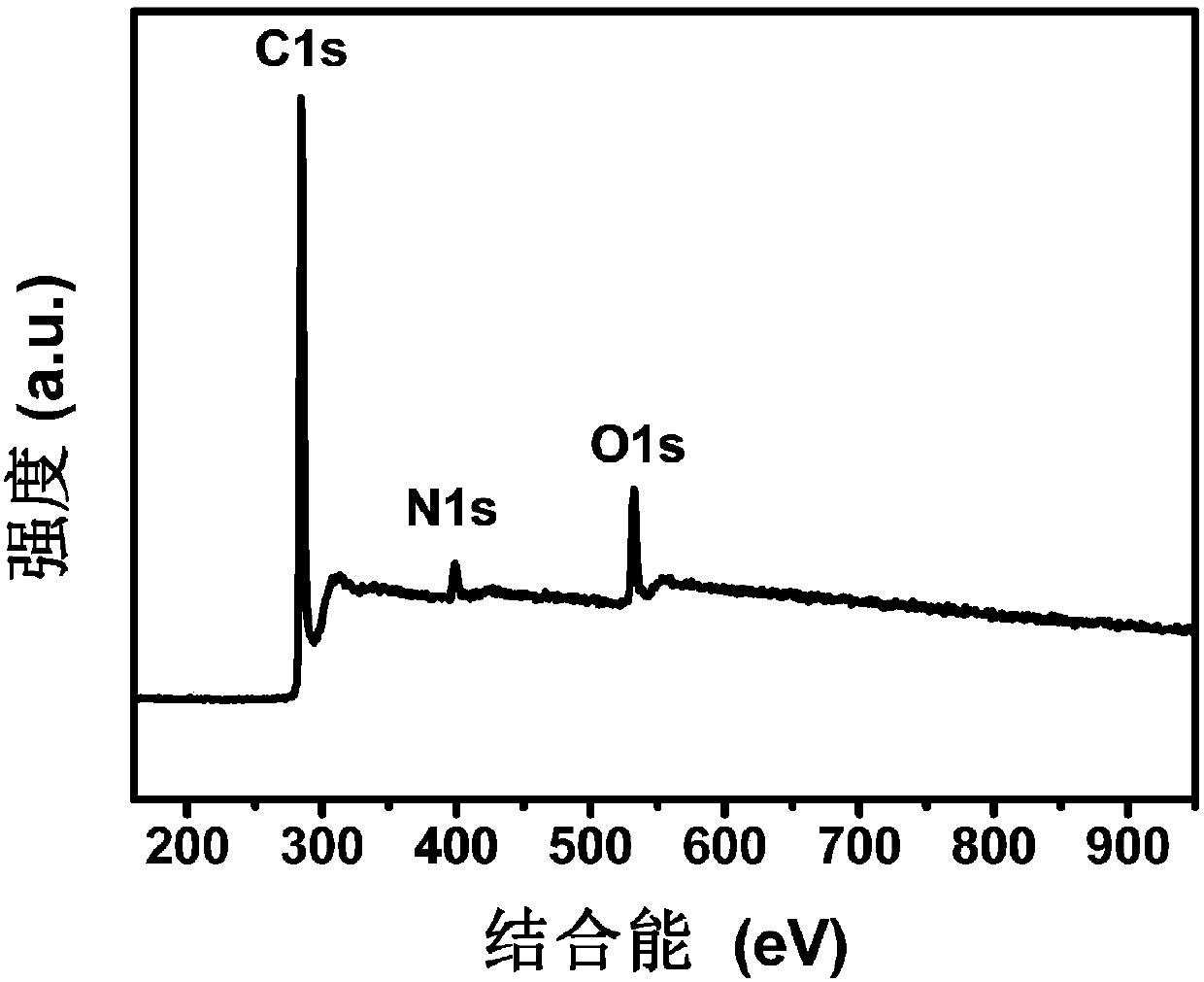

Method for preparing steel structure aqueous corrosion-resistant fireproof coating material

ActiveCN108314951AReduce electron cloud densityNot easily oxidizedFireproof paintsAnti-corrosive paintsAqueous corrosionEpoxy

The invention discloses a method for preparing a steel structure aqueous corrosion-resistant fireproof coating material and relates to a coating preparation method. The method comprises the followingsteps: establishing a melamine and phytic acid flame-retardant layer from molybdenum diselenide (MoSe2) nanosheets by using a layer-by-layer self-assembling method (LBL), and filling an aqueous epoxyresin with the functionalized molybdenum diselenide nanosheets, so as to obtain a steel structure aqueous corrosion-resistant fireproof coating. By adopting the method, the P-N system flame-retardantlayer is prepared, so that the flame retardancy of the aqueous epoxy resin can be improved; the phytic acid in the nano packing has great chelation potential energy, so that the coating can be connected in a relatively intense mode through the phytic acid, and the corrosion resistance and the durability of the coating can be improved; the problem that a nano particle is liable to aggregate becauseof the high surface energy can be also solved.

Owner:辽宁麦琪新材料集团有限公司

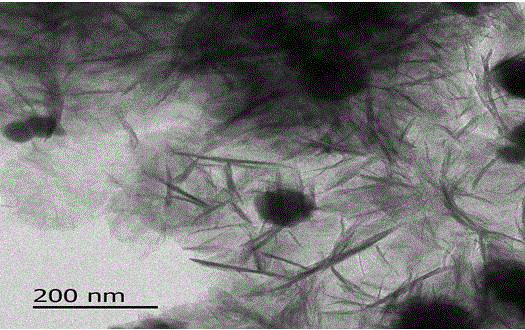

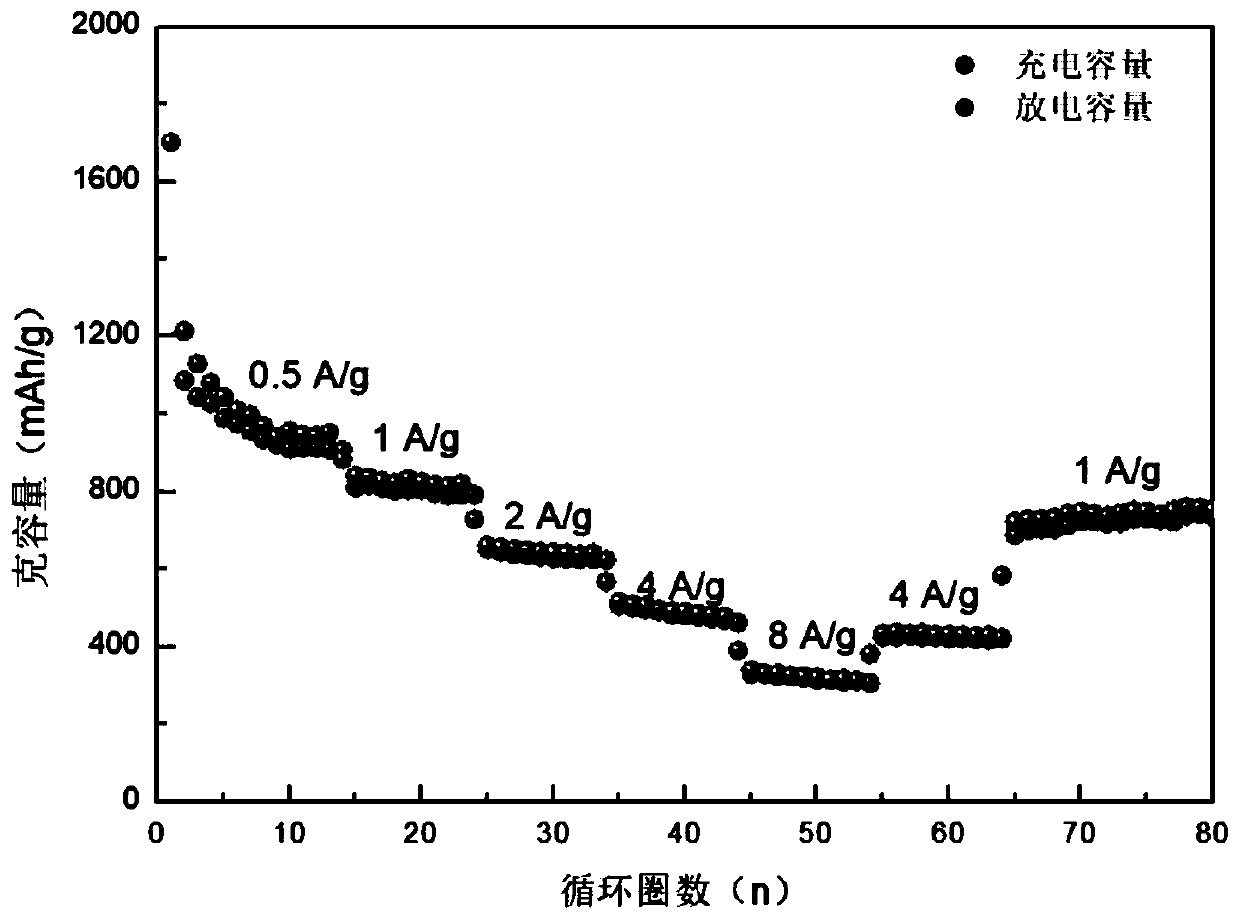

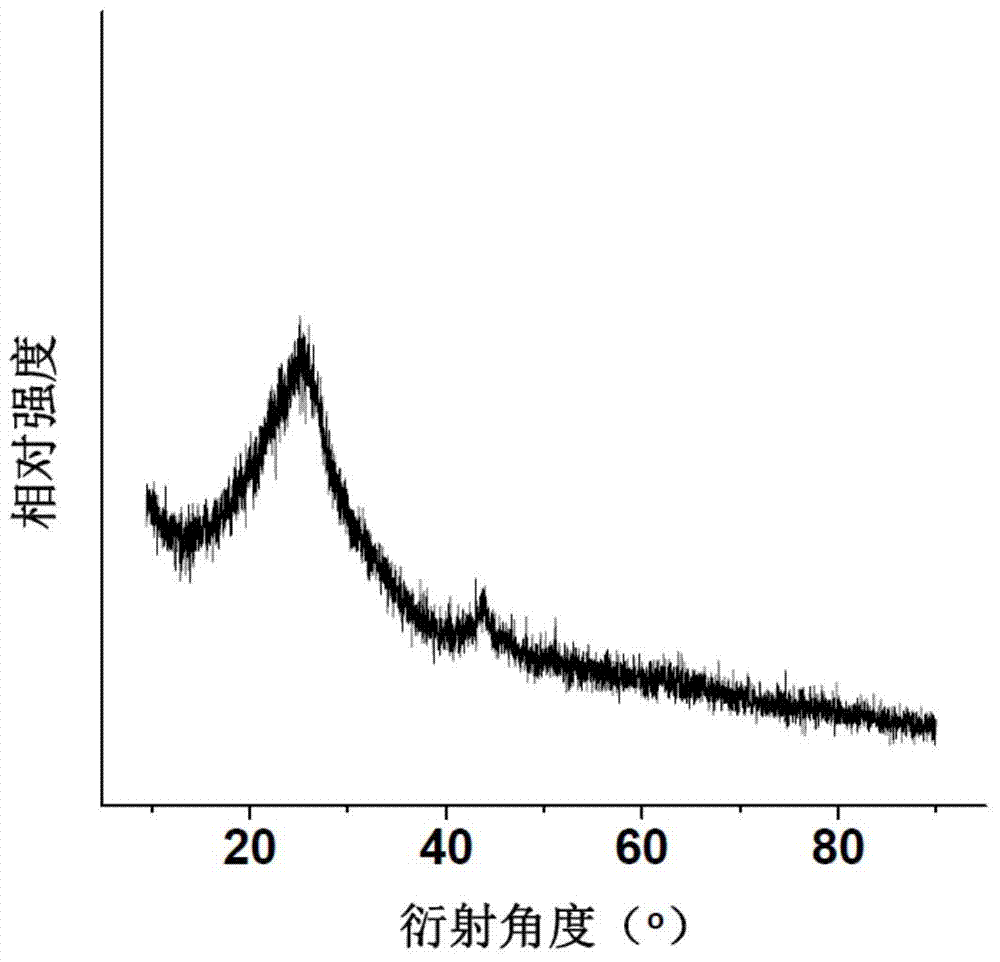

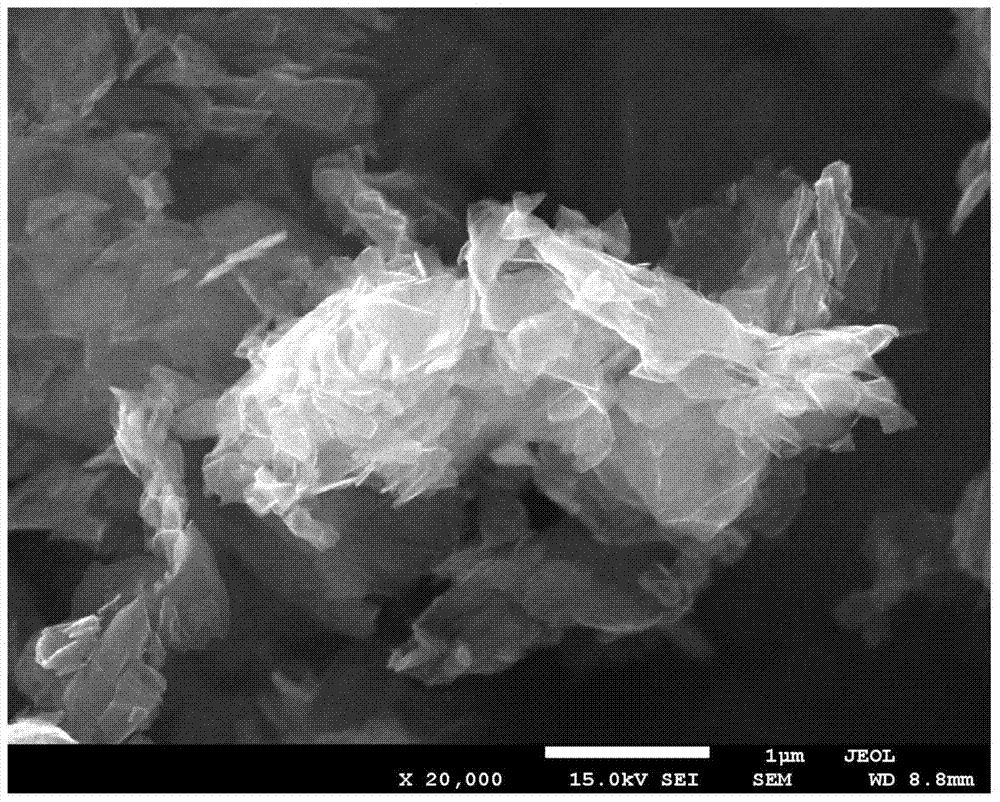

In-situ self-assembled nano-flower-like cobalt disulfide/rGO composite material and preparation method and application thereof

ActiveCN110165171AImproved magnification performanceIncrease gram capacityMaterial nanotechnologySecondary cellsThree dimensional microstructureFreeze-drying

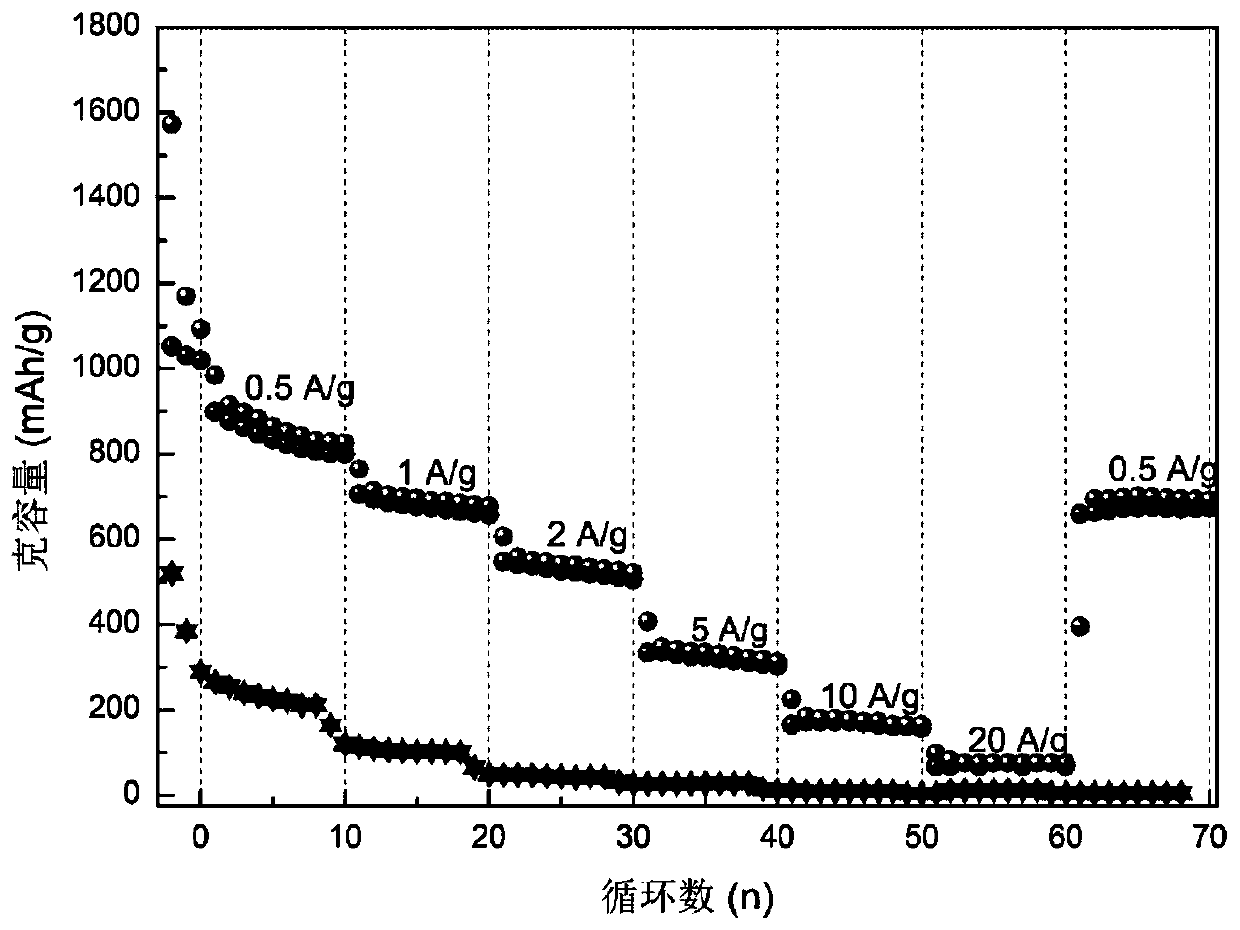

The invention discloses an in-situ self-assembled nano-flower-like cobalt disulfide / rGO composite material and a preparation method and an application thereof. The in-situ self-assembled nano-flower-like cobalt disulfide / rGO composite material is obtained through steps that by adding GO solution to mixed solution of soluble cobalt salt solution and vulcanizing agent solution, and after stirring, ultrasonically, the obtained GO mixed solution is reacted in a stainless steel kettle at 150-280 DEG C, after cooling with the furnace, and the solid is obtained by freezing-drying treatment after suction filtration. The composite material has a nano-flower-like three-dimensional microstructure, nanoflowers are composed of single crystals of cobalt disulfide and grow in situ on a two-dimensional rGO nano sheet substrate, the substrate can effectively accommodate the volume effect of cobalt disulfide during charging and discharging and has good electrical conductivity, moreover, the composite material has excellent charging and discharging cycle performance and rate capability and can be applied in the field of lithium ion battery cathode materials.

Owner:GUANGDONG UNIV OF TECH +1

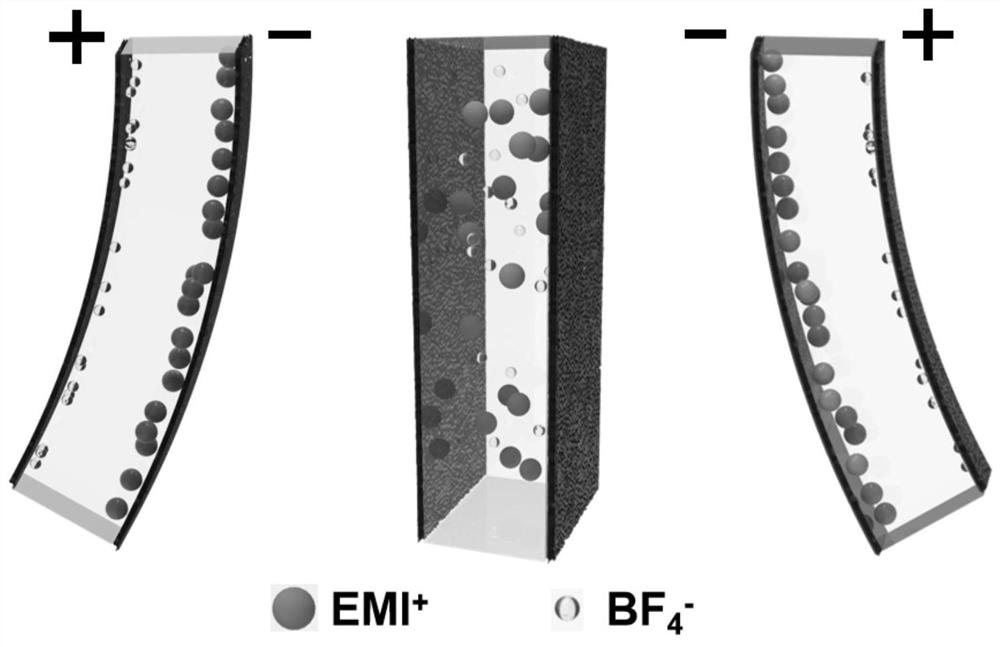

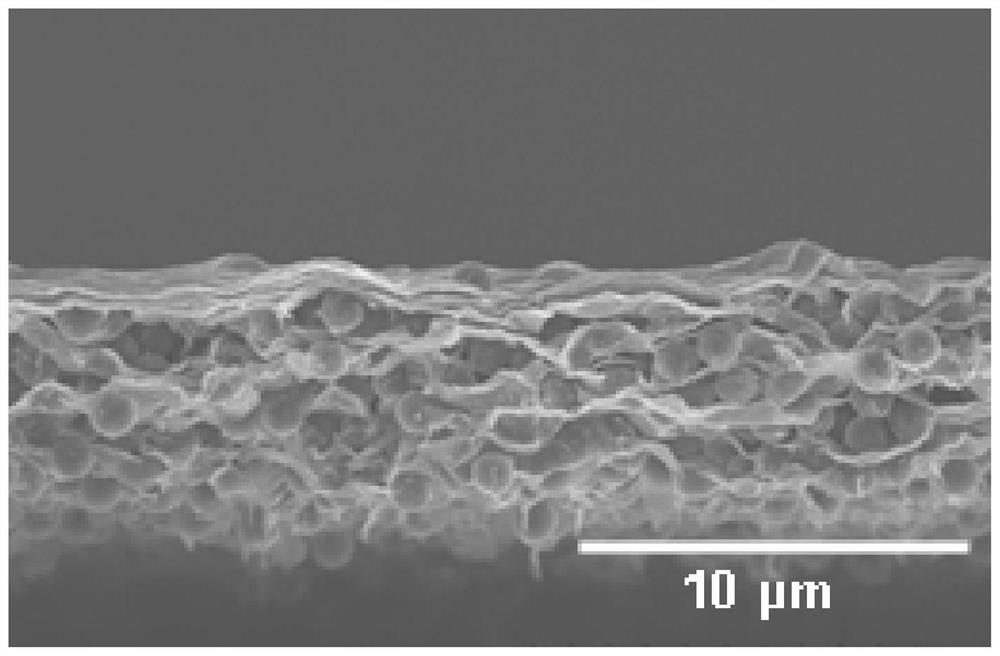

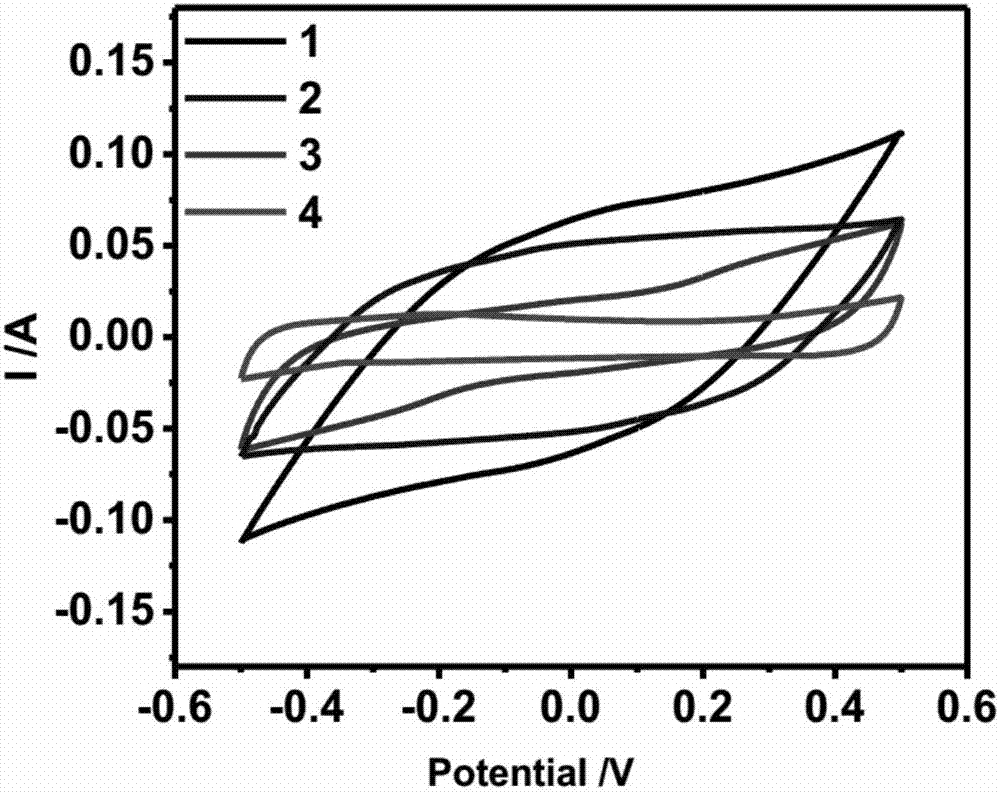

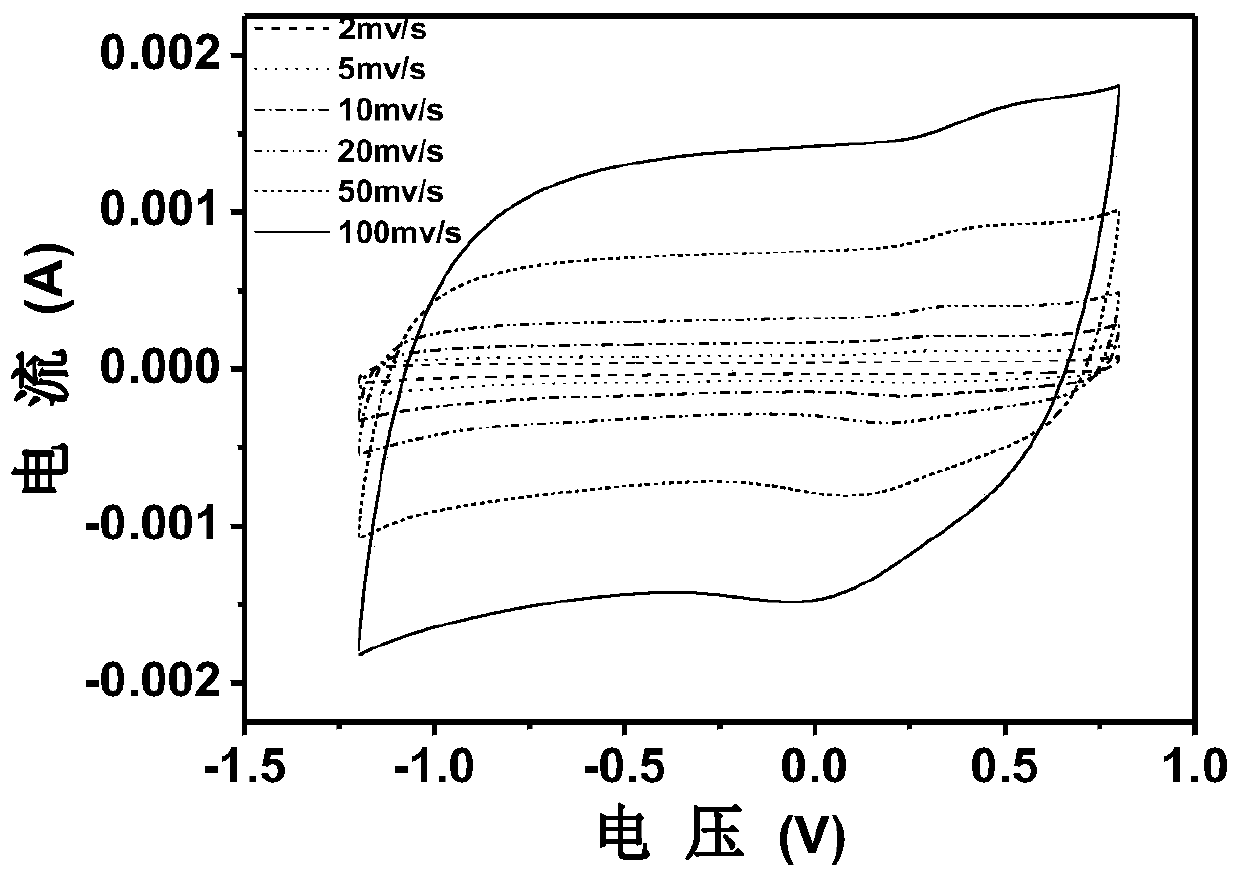

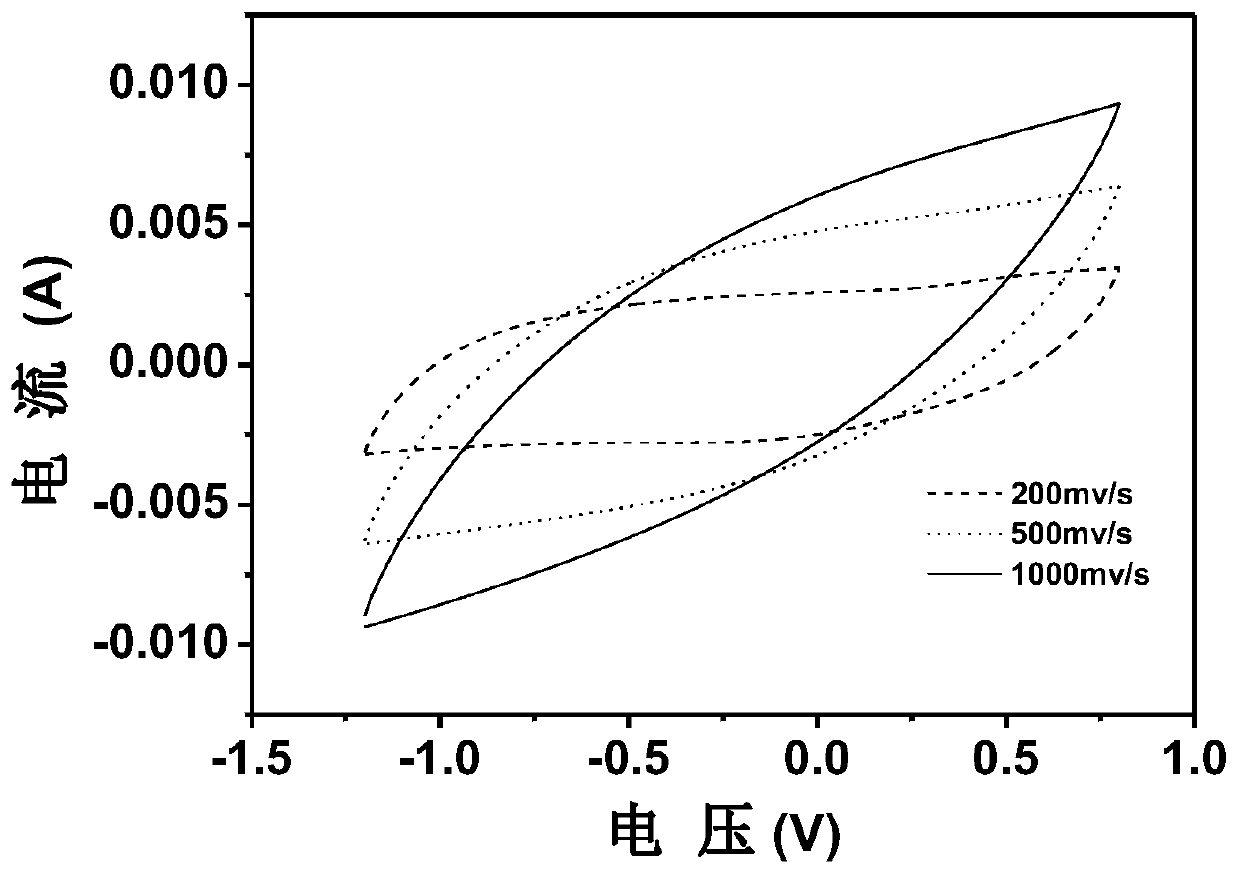

MXene composite material based electrochemical actuator and preparation method and application thereof

PendingCN111740000ALarge bending deformationReduce the driving voltagePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive devicesInsect wingElectrochemistry

The invention relates to an MXene composite material based electrochemical actuator and a preparation method and application thereof. The MXene composite material based electrochemical actuator comprises two electrode layers and an electrolyte layer, wherein the electrolyte layer is clamped between the two electrode layers to form a sandwich structure; the two electrode layers comprise MXene. TheMXene composite material based electrochemical actuator provided by the invention shows excellent actuation performance, and has the characteristics of large bending deformation, low driving voltage,high response speed, good stability, capability of realizing response to frequency and the like; the MXene composite material based electrochemical actuator can be used as bionic equipment, and can beused as a mechanical claw to realize grabbing of articles, imitate vibration of insect wings, swing of leaves, opening and closing of flowers and the like. In addition, the preparation process of theMXene composite material based electrochemical actuator is simple, and complex equipment is not needed.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Electrostatic self-assembly three-dimensional flower-like cobalt disulfide/MXene composite material and preparation method and application thereof

ActiveCN110416508AExcellent rate performanceEffective volume effectMaterial nanotechnologyCell electrodesFreeze-dryingFiltration

The invention discloses an electrostatic self-assembly three-dimensional flower-like cobalt disulfide / MXene composite material and a preparation method and application thereof. The composite materialis prepared by the following steps: stirring a soluble cobalt salt aqueous solution and a vulcanizing agent aqueous solution to obtain a mixed solution, carrying out hydrothermal reaction on the mixedsolution at 150-280 DEG C, performing cooling along with a furnace, carrying out suction filtration, and carrying out drying to obtain a solid A; adding the solid A into a polydiallyldimethylammoniumchloride solution, performing stirring, and performing washing to obtain a solid B; putting the solid B into an MXene aqueous solution, performing stirring, performing standing, carrying out centrifugal washing, and carrying out freeze drying to obtain a solid C; and under the protection of nitrogen, calcining the solid C at 500-700 DEG C to obtain the composite material. The composite material is self-assembled on an MXene nanosheet substrate through electrostatic interaction, the substrate can effectively accommodate the volume effect of cobalt disulfide in the charging and discharging process, and the composite material has excellent charging and discharging cycle performances, rate capability and high initial coulombic efficiency.

Owner:GUANGDONG UNIV OF TECH +1

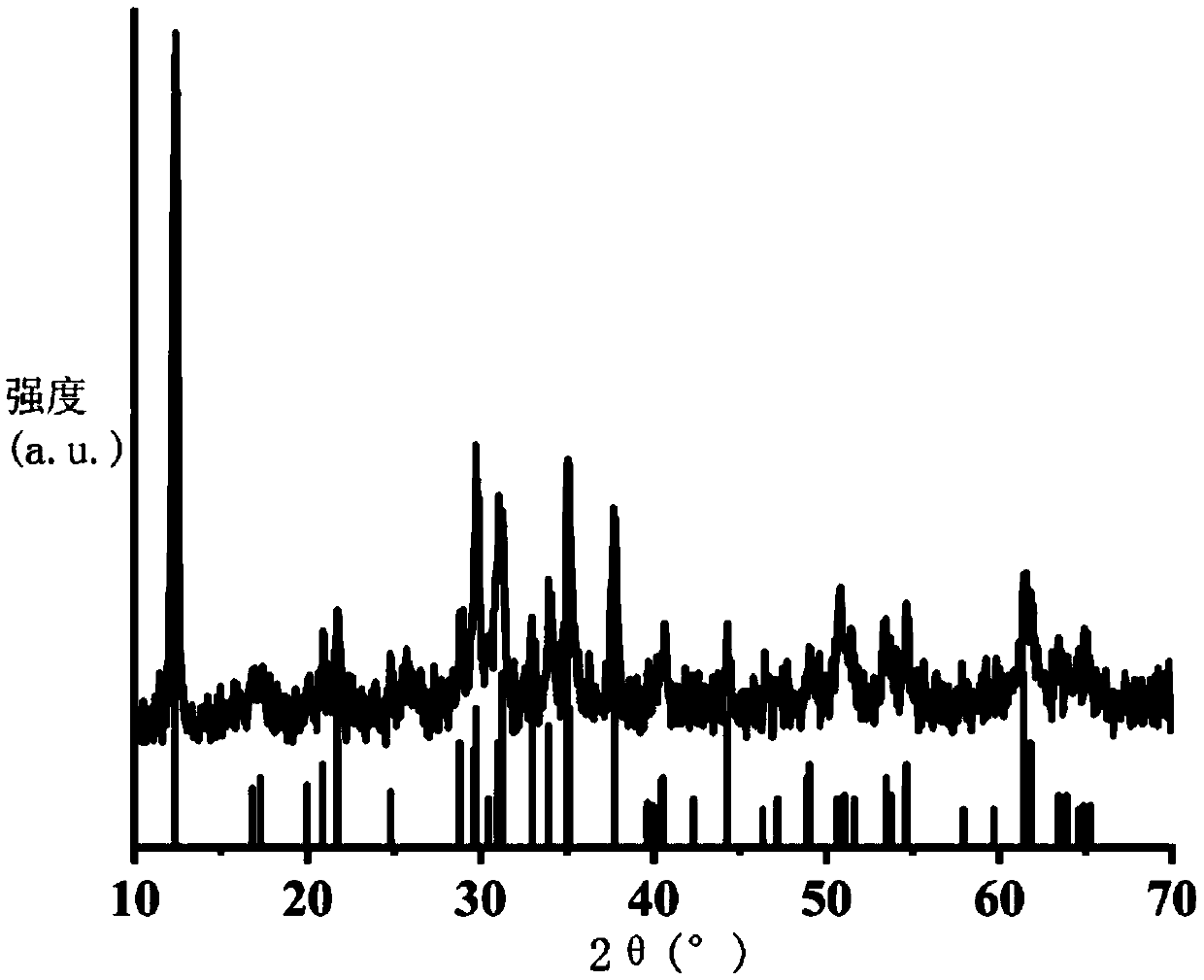

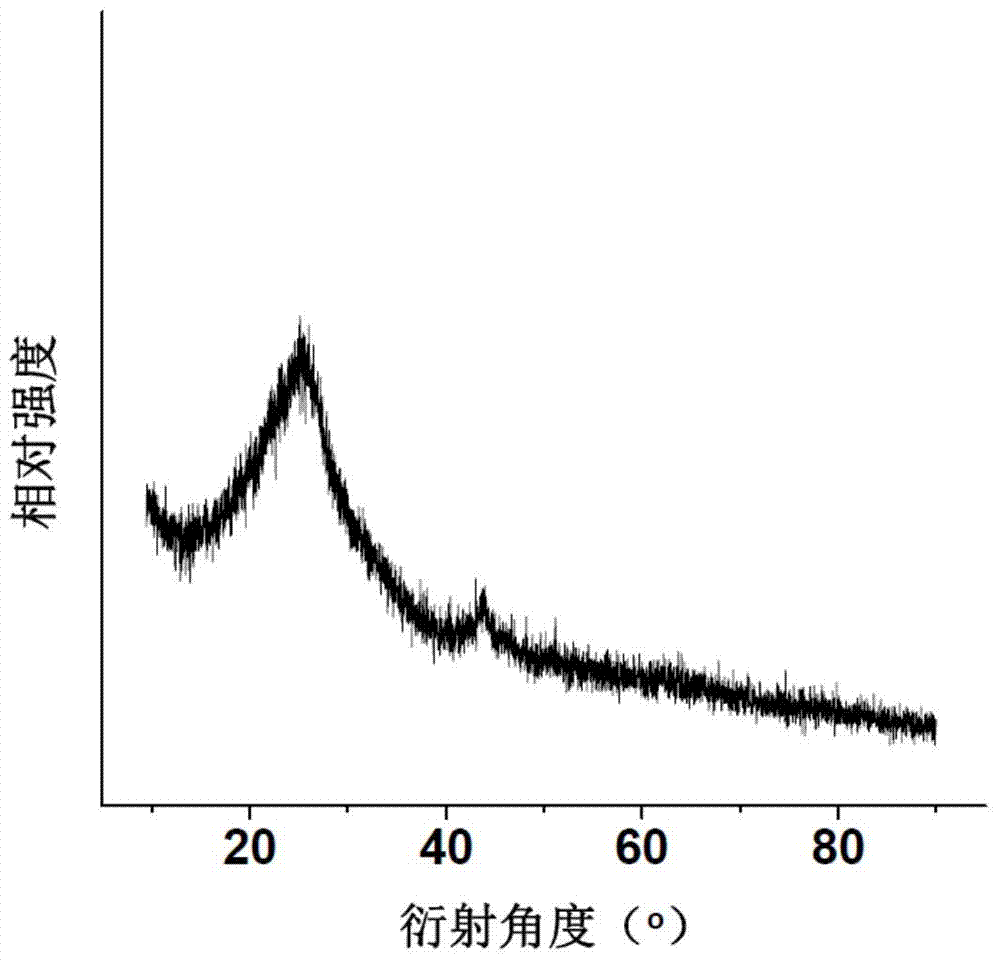

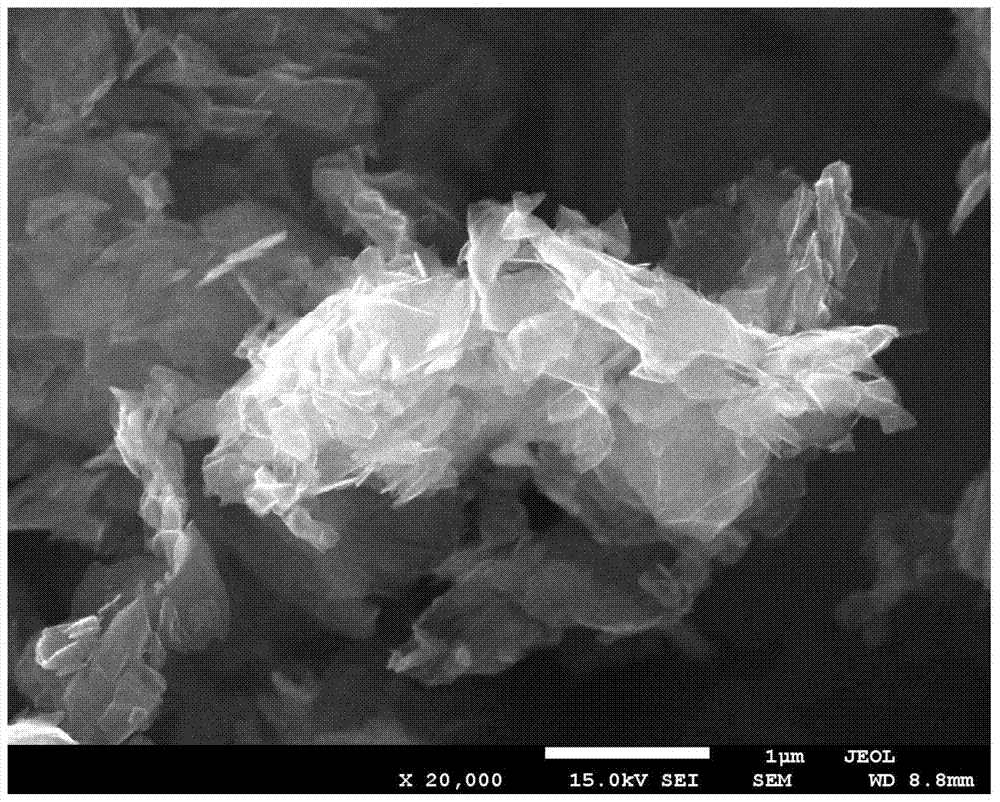

Method for solvothermal peeling preparation of microcrystalline graphene from microcrystalline graphite

The invention relates to a method for solvothermal peeling preparation of microcrystalline graphene from microcrystalline graphite, and belongs to the technical field of graphene material preparation. The method comprises the following steps: uniformly mixing microcrystalline graphite powder with a mixed solution of o-dichlorobenzene and one or more of N-methylpyrrolidone, N,N-dimethylformamide, N,N-dimethyl acetamide and butanolide to the microcrystalline graphite concentration of 1-30mg.mL<-1>; adding the obtained solution into a closed container, heating to 180-210DEG C, and stirring for 24h or more; carrying out continuous ultrasonic treatment at 0-5DEG C under 80-100W for 10min or above; centrifuging, and collecting the obtained precipitate; dispersing the precipitate in methanol or ethanol or isopropanol or n-propanol, centrifuging, and collecting the obtained new precipitate; dispersing the new precipitate in water, centrifuging, and collecting the finally obtained precipitate; and dispersing the finally obtained precipitate, freezing within 10min to form a solid, and carrying out vacuum drying to obtain the microcrystalline graphene. The method has the advantages of low cost, high grade and large reserve of the above raw material, simple preparation, low cost, and realization of amplified production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +2

Copper pyrovanadate/nitrogen-doped graphene composite material and preparation method and application thereof

ActiveCN109103432AImprove conductivityPrevents volume expansion/contraction and aggregationNegative electrodesSecondary cellsCvd grapheneLithium electrode

The invention relates to the technical field of nanometer materials, in particular to a copper pyrovanadate / nitrogen-doped graphene composite material and a preparation method thereof and an application thereof in a lithium ion battery. Graphene oxide, PVP, organic amines, Cu salt and a vanadium source are mixed and dispersed in water in a certain proportion and copper pyrovanadate / nitrogen dopedgraphene composite material with three-dimensional mesoporous structure is synthesized by hydrothermal method in one step. By changing the type and amount of vanadate, the growth of copper pyrovanadate on the surface of graphene oxide is regulated, the composite material not only combines the advantages of graphene and copper pyrovanadate, but also greatly overcomes the respective shortcomings ofgraphene and copper pyrovanadate, effectively improves the conductivity of the composite material, can alleviate the volume change in the charge and discharge process, has good electrochemical performance, and can be used as the negative electrode material of lithium battery. The preparation method of the invention is simple, high efficiency and low cost, and can realize a large number of preparation.

Owner:TRUSDA IND

Preparation of graphene/poly(1,3,6,8-tetrathiophenepyrene) nano-scroll composite material

InactiveCN107359056ALarge specific surface areaImprove structural stabilityHybrid capacitor electrodesNanotechnologyCapacitanceSupercapacitor

The invention discloses a preparation method of a graphene / poly(1,3,6,8-tetrathiophenepyrene) nano-scroll composite material. The method comprises the steps: mixing poly(1,3,6,8-tetrathiophenepyrene) and oxidized graphene, and preparing a nano-scroll structure through in-situ reduction, wherein the nano-scroll structure can serve as an electrode material of a supercapacitor. The invention relates to the preparation of the graphene / poly(1,3,6,8-tetrathiophenepyrene) nano-scroll composite material. The material serves as the electrode material of the supercapacitor, so a higher specific capacitance value can be obtained. The method is simple, and the working state is stable and reliable, so the method is worthy of being discloses and protected.

Owner:NANJING UNIV OF POSTS & TELECOMM

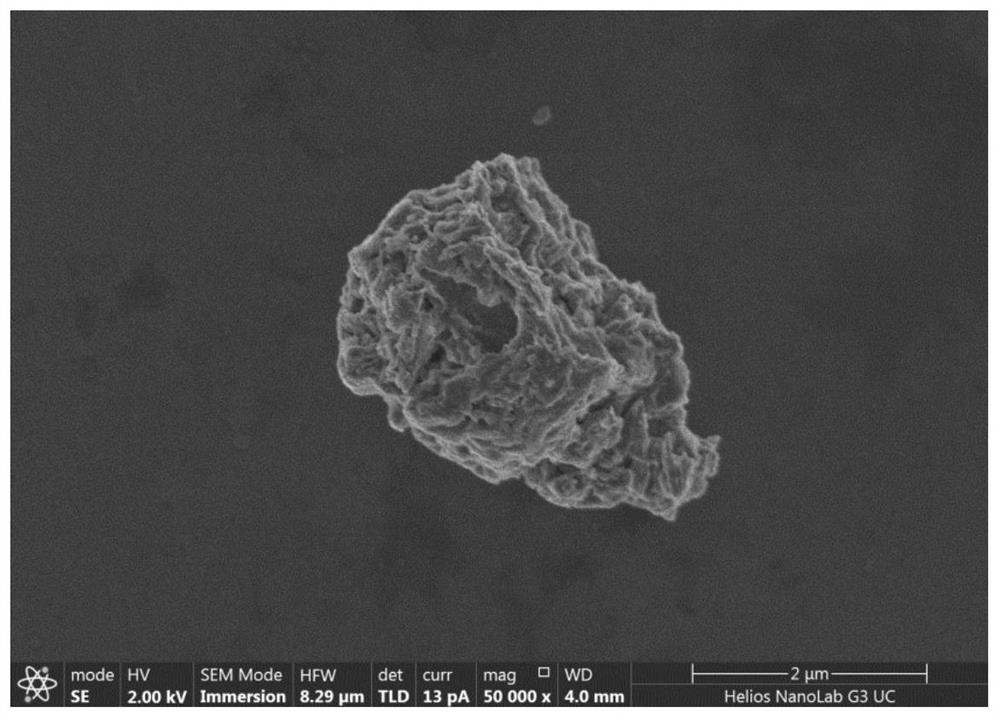

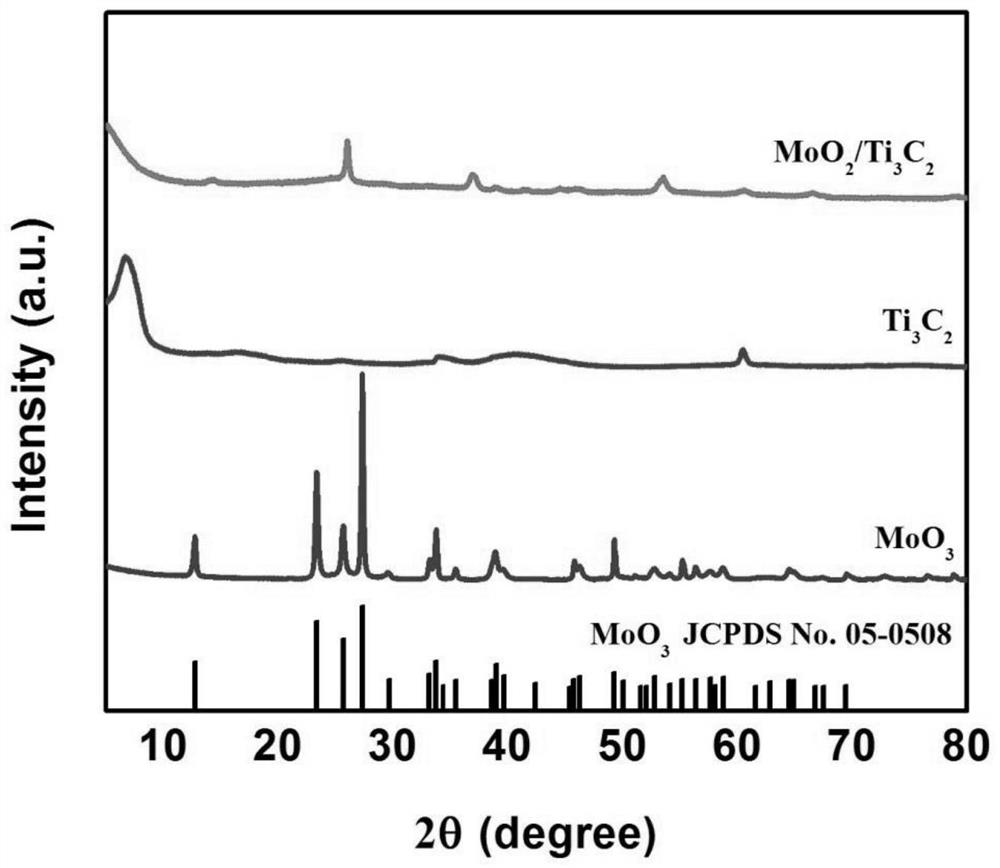

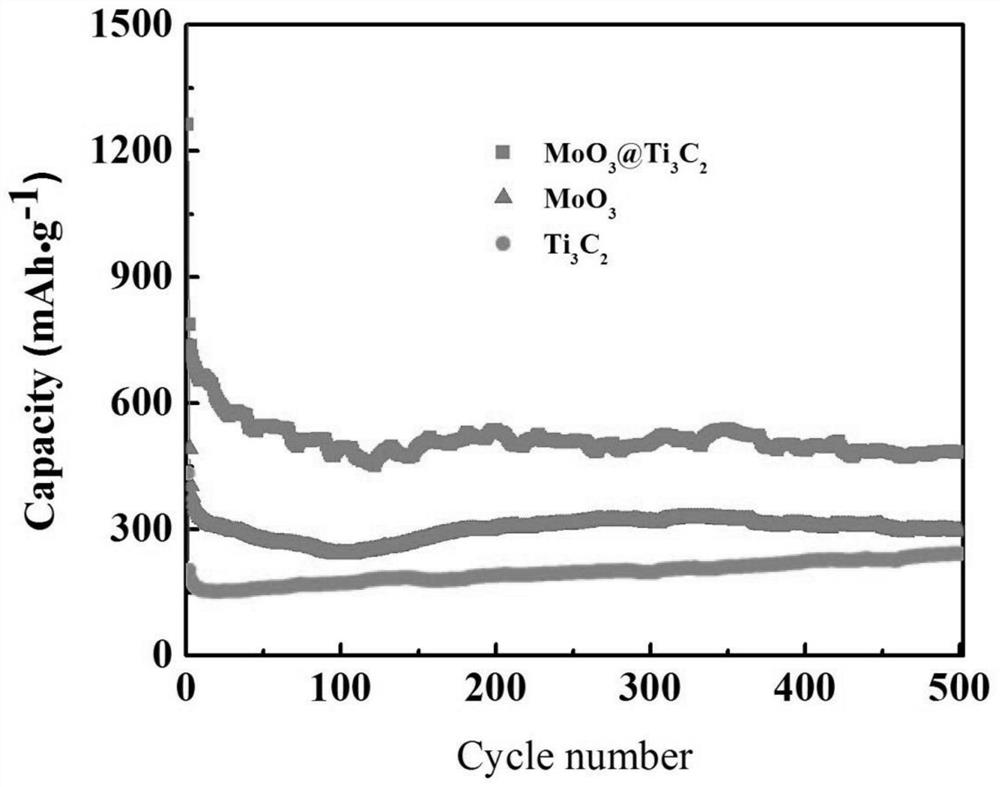

Electrostatic self-assembly spherical molybdenum trioxide/MXene composite material as well as preparation method and application thereof

PendingCN112510187AGood cycle stabilityPrevent collapseMaterial nanotechnologySecondary cellsComposite materialAcetylacetone

The invention discloses an electrostatic self-assembly spherical molybdenum trioxide / MXene composite material as well as a preparation method and application thereof. The composite material is prepared by the following steps: dissolving soluble molybdenum acetylacetonate in ethanol, stirring to obtain a mixed solution, carrying out solvothermal reaction at 150-280 DEG C, cooling along with a furnace, washing, filtering, drying, and calcining at 400-600 DEG C to obtain a solid A; adding the solid A into a polydiallyldimethylammonium chloride solution, stirring, and centrifugally washing to obtain a solid B; dropwise adding an MXene aqueous solution into the solid B aqueous solution, stirring, standing, carrying out centrifugal washing, and carrying out freeze drying to obtain a solid C; andunder the protection of nitrogen, calcining the solid C at 400-600 DEG C to obtain the material. The composite material is self-assembled on an MXene nanosheet matrix through electrostatic interaction, the matrix can effectively accommodate the volume effect of molybdenum trioxide in the charging and discharging process, and the composite material has excellent charging and discharging cycle performance, rate capability and high initial coulombic efficiency.

Owner:CENT SOUTH UNIV

Tannic acid heterogeneous synergistic electro-Fenton method for catalytic degradation of phenol organic wastewater

InactiveCN113044930AFacilitate the reduction reactionEasy transferWater contaminantsWater/sewage treatment by oxidationElectrolysisPhenol

The invention discloses a tannic acid heterogeneous synergistic electro-Fenton method for catalytic degradation of phenol organic wastewater, which comprises the following steps that: tannic acid and soluble electrolyte are added into phenol organic wastewater to obtain a mixed solution A; the mixture A is electrolyzed in an electrolysis mode; and in the electrolysis process, a cathode adopts graphene oxide, ferroferric oxide or a graphene oxide loaded ferroferric oxide modified foam electrode, and an anode adopts an inert electrode. The tannic acid and the soluble electrolyte are added into the phenol organic wastewater, the added soluble electrolyte can provide conductive ions to ensure smooth an electrolysis process, the added tannic acid can form a TA-Fe (III) complex to promote the reduction reaction between Fe < 3 + > and Fe < 2 + >, so that the capability of activating H2O2 to generate. OH by Fe < 3 + > is indirectly enhanced, and the speed of degrading the phenol organic pollutants by the electro-Fenton method is obviously improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Direct ultrasonication production of graphene sheets from coke or coal

Provided is a method of producing isolated graphene sheets from a supply of coke or coal powder containing therein domains of hexagonal carbon atoms and / or hexagonal carbon atomic interlayers. The method comprises: (a) dispersing particles of the coke or coal powder in a liquid medium containing therein an optional surfactant or dispersing agent to produce a suspension or slurry, wherein the coke or coal powder is selected from petroleum coke, coal-derived coke, meso-phase coke, synthetic coke, leonardite, anthracite, lignite coal, bituminous coal, or natural coal mineral powder, or a combination thereof; and (b) exposing the suspension or slurry to ultrasonication at an energy level for a sufficient length of time to produce the isolated graphene sheets.

Owner:GLOBAL GRAPHENE GRP INC

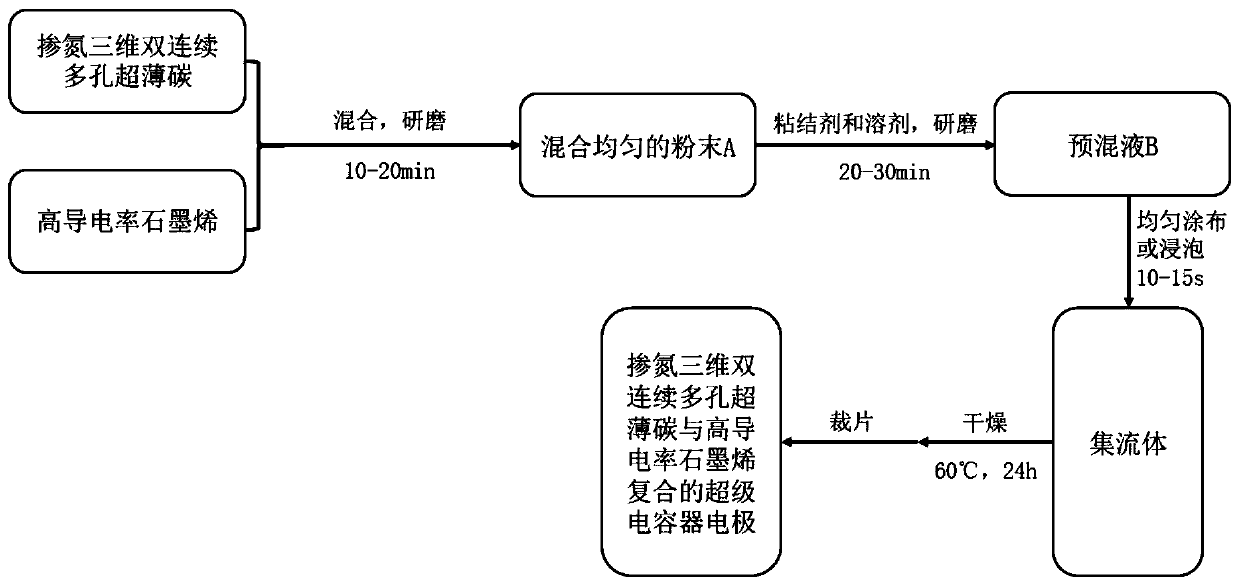

Nitrogen-doped three-dimensional bicontinuous porous carbon and graphene composite electrode as well as preparation and application thereof

InactiveCN111029165AEasy to makeLow costHybrid capacitor electrodesHybrid/EDL manufactureComposite electrodePorous carbon

The invention relates to a nitrogen-doped three-dimensional bicontinuous porous carbon and graphene composite electrode and preparation and application thereof, and belongs to the technical field of capacitor electrodes. The electrode comprises a current collector and a composite material, the composite material is loaded on a surface of the current collector, and the composite material contains nitrogen-doped three-dimensional bicontinuous porous carbon and graphene; nitrogen-doped three-dimensional bicontinuous porous carbon porous carbon particles are used as spacers to avoid re-stacking ofthe graphene and are used for increasing the contact area with the graphene. The preparation method comprises the following steps: mixing the nitrogen-doped three-dimensional bicontinuous porous carbon and the graphene, adding a binder and a solvent, and then coating a current collector, or immersing the current collector in a mixture; and drying to obtain the composite electrode. The electrode of a nitrogen-doped three-dimensional bicontinuous porous ultra-thin carbon and high-conductivity graphene composite super capacitor provided by the invention has excellent conductivity which is higherthan the specific capacity and energy density of a traditional capacitor, good electrochemical cycling stability, simple process, low cost and environmental friendliness.

Owner:HUAZHONG UNIV OF SCI & TECH

Expandable preparation method of high-density N-doped graphite material

ActiveCN107651668ARealize scalable productionPrevent restackingHybrid capacitor electrodesGrapheneHigh densityGraphite

The invention relates to an expandable preparation method of a high-density N-doped graphite material, which includes steps of mixing GO dispersing fluid with PEI solution to obtain GO-PEI composite;drying and roasting the GO-PEI composite. An amino functional group of the PEI can reduce the GO oxygen content on a certain degree and effectively stop the thermal expansion caused by decomposing massive oxygen-containing functional groups to be gas during the process of roasting the samples, so that the material density is greatly reduced. The vibration density of the material and the balance regulation of the surface area can be realized by controlling the PEI addition. The reaction process is free from adding metal salt type pore forming substance or activating reagent; thus the original framework structure of the graphite can be well kept, and the operation step is simple and easy to carry out.

Owner:SHANDONG UNIV

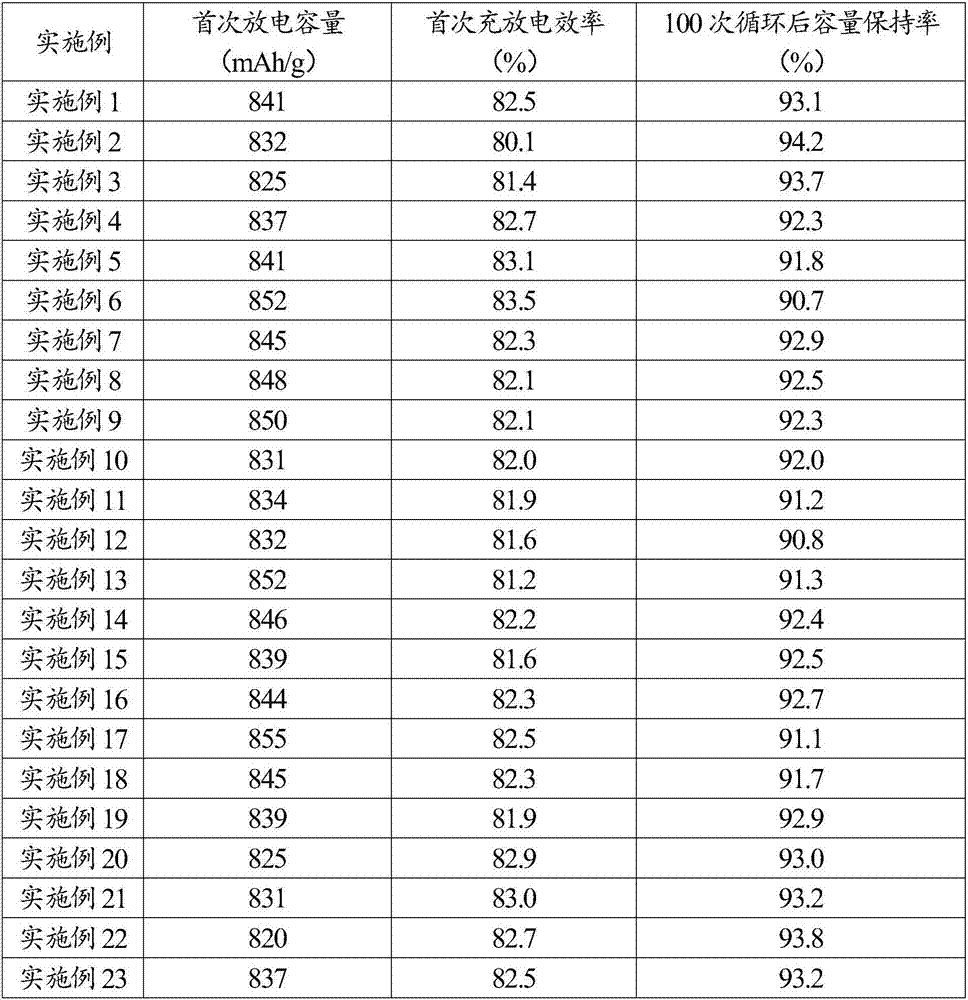

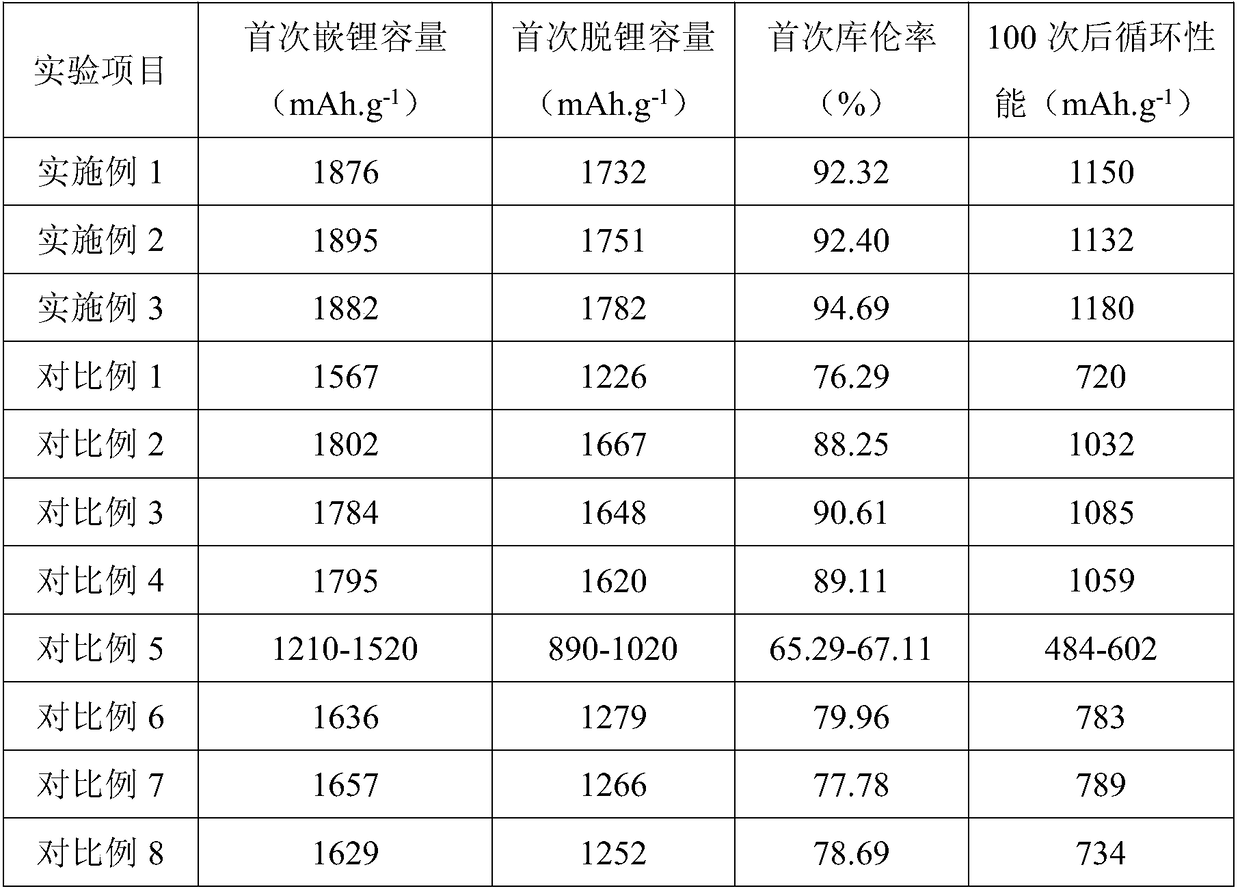

Alumina-modified graphene lithium ion battery anode material and preparation method thereof

ActiveCN108365209AThe first lithium intercalation capacity is highHigh delithiation capacity for the first timeNegative electrodesSecondary cellsFiberCarbon fibers

The invention discloses an alumina-modified graphene lithium ion battery anode material and a preparation method thereof, which belong to the technical field of lithium ion battery anode materials. The alumina-modified graphene lithium ion battery anode material consists of the following raw materials: nano-silicon powder, carbon fibers, graphene, carbon nanotubes, ethylene carbonate, alumina andpolyacrylic acid; and the lithium ion battery anode material is prepared by steps such as ultrasonic treatment, magnetic stirring, microwave treatment and high-temperature calcination. According to the invention, by means of a reinforcing system composed of ethylene carbonate, alumina and polyacrylic acid, the lithium intercalation capacity, lithium deintercalation capacity, initial coulombic efficiency and cycle performance of the alumina-modified graphene lithium ion battery anode material are increased.

Owner:山东信开源科技创新发展有限责任公司

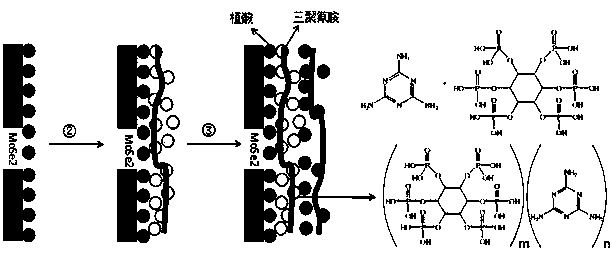

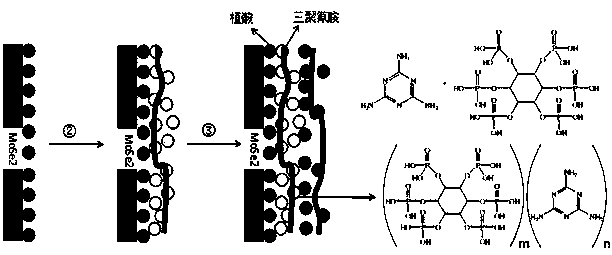

Preparation method of graphene/graphite lithium ion battery anode material

ActiveCN109411723APrevent restackingImprove absorbing performanceCell electrodesSecondary cellsImpurityGraphite oxide

The invention provides a preparation method of a graphene / graphite lithium ion battery anode material. The preparation method is characterized by comprising the following steps: (1) adding graphite oxide into deionized water, and performing ultrasonic treatment for 20-60 min; centrifuging obtained suspension for 20-60 min at the condition of 1,500-3,000 rpm; after the centrifugation, removing supernatant with impurities not stripped at the bottom to obtain graphene oxide colloid; (2) mixing a graphene oxide colloid solution obtained in the step (1) with an expanding agent, adding a graphite electrode material, and stirring and drying to obtain a graphene oxide / graphite material; (3) performing microwave heating on the graphene oxide / graphite material obtained in the step (2) in an inert atmosphere to obtain the graphene / graphite lithium ion battery anode material. The preparation method provided by the invention has the advantages of simple technology, short path and low cost; the obtained lithium battery anode material has great specific capacity and high cyclic stability.

Owner:SHANGHAI INST OF TECH

Preparation method of water-based anti-corrosion and fire-proof coating material for steel structure

ActiveCN108314951BReduce electron cloud densityNot easily oxidizedFireproof paintsAnti-corrosive paintsEpoxyPhytic acid

Owner:辽宁麦琪新材料集团有限公司

Method for preparing microcrystalline graphene by solvent thermal exfoliation of microcrystalline graphite

The invention relates to a method for preparing microcrystalline graphene by solvent thermal exfoliation of microcrystalline graphite, and belongs to the technical field of graphene material preparation. The method is: mixing microcrystalline graphite powder with more than one of N-methylpyrrolidone, N,N-dimethylformamide, N,N-dimethylacetamide and butyrolactone and o-dichlorobenzene Mix the solution evenly, the concentration of microcrystalline graphite is 1-30mg mL-1; put it into a closed container and heat it to 180-210°C and stir for ≥24h; continue to treat it with 80-100W ultrasonic at 0-5°C for ≥10min; centrifuge to collect the precipitate Disperse in methanol, ethanol, isopropanol or n-propanol, and collect the precipitate by centrifugation; disperse in water, collect the precipitate by centrifugation; disperse in water, freeze into a solid within ≤10min, and dry in vacuum to obtain microcrystalline graphene. The method has the advantages of low raw material cost, high grade, large reserve, simple preparation, low cost, and scalable production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +2

A kind of graphene/silicon dioxide/nano zero-valent iron composite material and its preparation method and application

ActiveCN105457597BRich reservesLow priceOther chemical processesWater/sewage treatment by sorptionHydration reactionArsenic pollution

The invention discloses a graphene / silicon dioxide / nano zero-valent iron composite as well as a preparation method and application thereof. The preparation method comprises the following steps: after the graphene oxide is subjected to ultrasonic dispersion, adding tetraethyl orthosilicate, drying after magnetic stirring is carried out completely, introducing nitrogen in a tubular furnace for calcination, adding deionized water into the solids obtained through calcination, after ultrasonic dispersion, introducing nitrogen and adding ferrous sulfate heptahydrate, after uniform stirring, and adding a reducing agent for reducing so as to obtain black flocculent precipitates after complete reaction, washing, carrying out suction filtration, drying, grinding and screening through a sieve so as to obtain the graphene / silicon dioxide / nano zero-valent iron composite. The graphene / silicon dioxide / nano zero-valent iron composite prepared according to the preparation method can be applied to the field of water pollution control as an adsorbent, particularly adsorption removal of arsenic pollutants in waste water, and has the advantages of simple and convenient preparation process, high adsorption speed and the like, and in addition, the required raw materials are wide in source, low in cost and high in practical application value.

Owner:SOUTH CHINA UNIV OF TECH

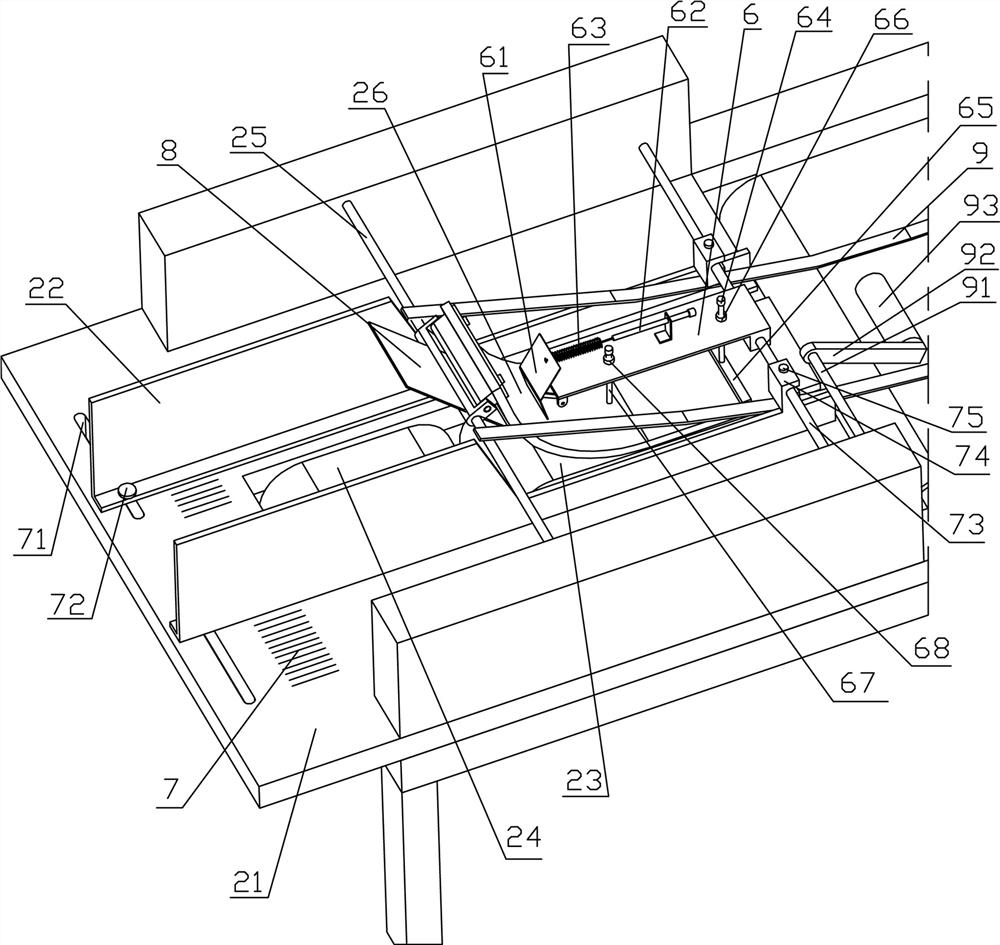

Automatic piece separating device for mask packaging bag

PendingCN112141442APrevent restackingImprove reliabilityWrapper twisting/gatheringArticle feedersMachineLeather belt

The invention discloses an automatic piece separating device for a mask packaging bag. The automatic piece separating device comprises a rack, wherein a piece separating machine and a transfer conveying belt are arranged on the rack; the piece separating machine is structurally characterized in that a mounting table is arranged on the rack; two guide plates are arranged on the mounting table; a rear piece separating conveying belt and a front piece separating conveying belt are arranged between the two guide plates; a mounting rod and a piece separating elastic belt are arranged above the rearpiece separating conveying belt; the mounting rod can rotate on the rack; the front end of the piece separating elastic belt is upwards tilted and can be hinged with a rod body of the mounting rod ina manner of swinging up and down; the rear part of the piece separating elastic belt is placed on the rear piece separating conveying belt; a mounting frame is arranged above the piece separating elastic belt; a front pressing mechanism and a rear pressing mechanism are arranged on the mounting frame; convex points are arranged on a belt of the rear piece separating conveying belt; two pressing strips are placed on the transfer conveying belt; a cross rod is arranged on the rack; a swing rod is mounted at the end part of the cross rod; and a roller is mounted on the swing rod; and a torsionalspring is mounted between the end part of the swing rod and the end part of the cross rod. The automatic piece separating device is high in piece separating reliability.

Owner:SUZHOU LOTTE PROTECTIVE EQUIP CO LTD

A scalable method for the fabrication of high-density n-doped graphene materials

ActiveCN107651668BRealize scalable productionPrevent restackingHybrid capacitor electrodesGrapheneThermal dilatationDoped graphene

The invention relates to an expandable preparation method of a high-density N-doped graphite material, which includes steps of mixing GO dispersing fluid with PEI solution to obtain GO-PEI composite;drying and roasting the GO-PEI composite. An amino functional group of the PEI can reduce the GO oxygen content on a certain degree and effectively stop the thermal expansion caused by decomposing massive oxygen-containing functional groups to be gas during the process of roasting the samples, so that the material density is greatly reduced. The vibration density of the material and the balance regulation of the surface area can be realized by controlling the PEI addition. The reaction process is free from adding metal salt type pore forming substance or activating reagent; thus the original framework structure of the graphite can be well kept, and the operation step is simple and easy to carry out.

Owner:SHANDONG UNIV

Preparation method of aluminum oxide modified graphene lithium ion battery negative electrode material

ActiveCN108365209BThe first lithium intercalation capacity is highHigh delithiation capacity for the first timeSecondary cellsNegative electrodesCarbon fibersCarbon nanotube

The invention discloses an alumina-modified graphene lithium ion battery anode material and a preparation method thereof, which belong to the technical field of lithium ion battery anode materials. The alumina-modified graphene lithium ion battery anode material consists of the following raw materials: nano-silicon powder, carbon fibers, graphene, carbon nanotubes, ethylene carbonate, alumina andpolyacrylic acid; and the lithium ion battery anode material is prepared by steps such as ultrasonic treatment, magnetic stirring, microwave treatment and high-temperature calcination. According to the invention, by means of a reinforcing system composed of ethylene carbonate, alumina and polyacrylic acid, the lithium intercalation capacity, lithium deintercalation capacity, initial coulombic efficiency and cycle performance of the alumina-modified graphene lithium ion battery anode material are increased.

Owner:山东信开源科技创新发展有限责任公司

A kind of preparation method of waterborne epoxy composite anticorrosion coating

InactiveCN104877517BPrevent restackingAvoid gatheringAnti-corrosive paintsEpoxy resin coatingsEpoxyElectrochemical corrosion

The invention provides a preparation method of a waterborne epoxy composite anticorrosive coating and relates to a preparation method of a composite coating material. The waterborne epoxy composite anticorrosive coating provided by the invention is prepared by adopting carbodiimide (EDC) mediated condensation reaction to integrate zeolite and graphene, and then filling the integrated zeolite and graphene into waterborne epoxy resin. By adopting the method, the characteristics of more pore passages and large specific surface area of zeolite are combined with high strength and electron mobility of graphene; corrosive particles can be blocked from passing through a coating layer to reach a metal matrix and the time for the corrosive particles to pass through the coating layer to reach the metal matrix can be prolonged in the process of anticorrosive application of the coating; and the cathode reaction during corrosion can be transferred to an interface between the coating layer and air by virtue of the electrical conductivity of graphene, thereby slowing down the happening of electrochemical corrosion reaction. By adopting the method, the defects that the current waterborne anticorrosive coating layer is generally poor in barrier property and short in anticorrosion cycle are overcome, and the anticorrosion performance of the waterborne coating layer is greatly improved.

Owner:蓬莱禄源漆业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com